Highly-elastic waterproof coating used for metal roof and preparation method thereof

A technology for waterproof coatings and metal roofs, applied in the direction of reflection/signal coatings, coatings, etc., can solve problems that affect the service life of buildings and affect the use of buildings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

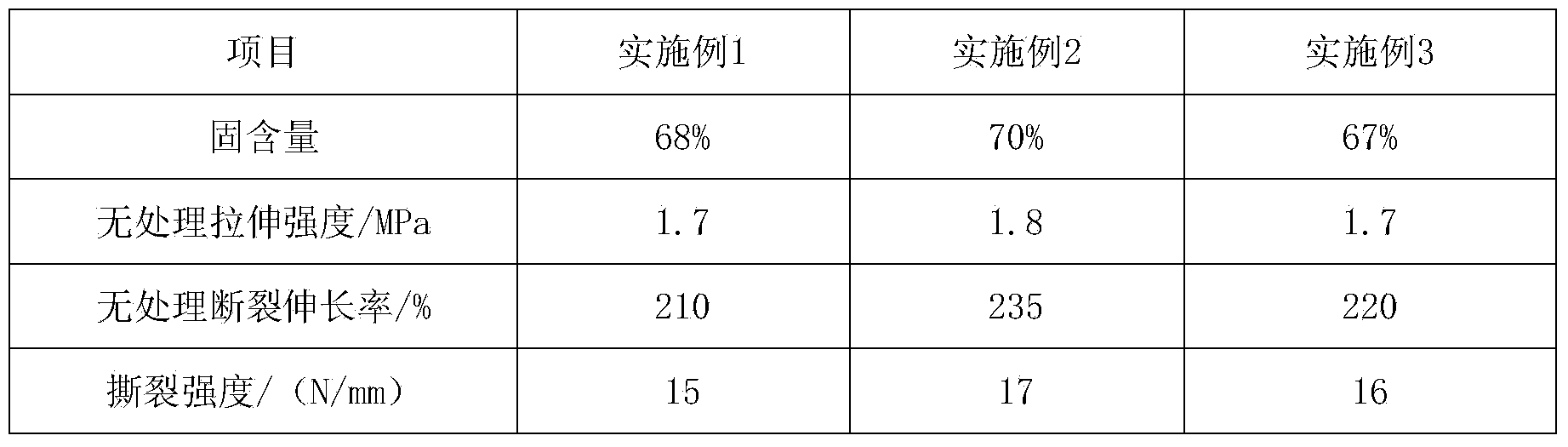

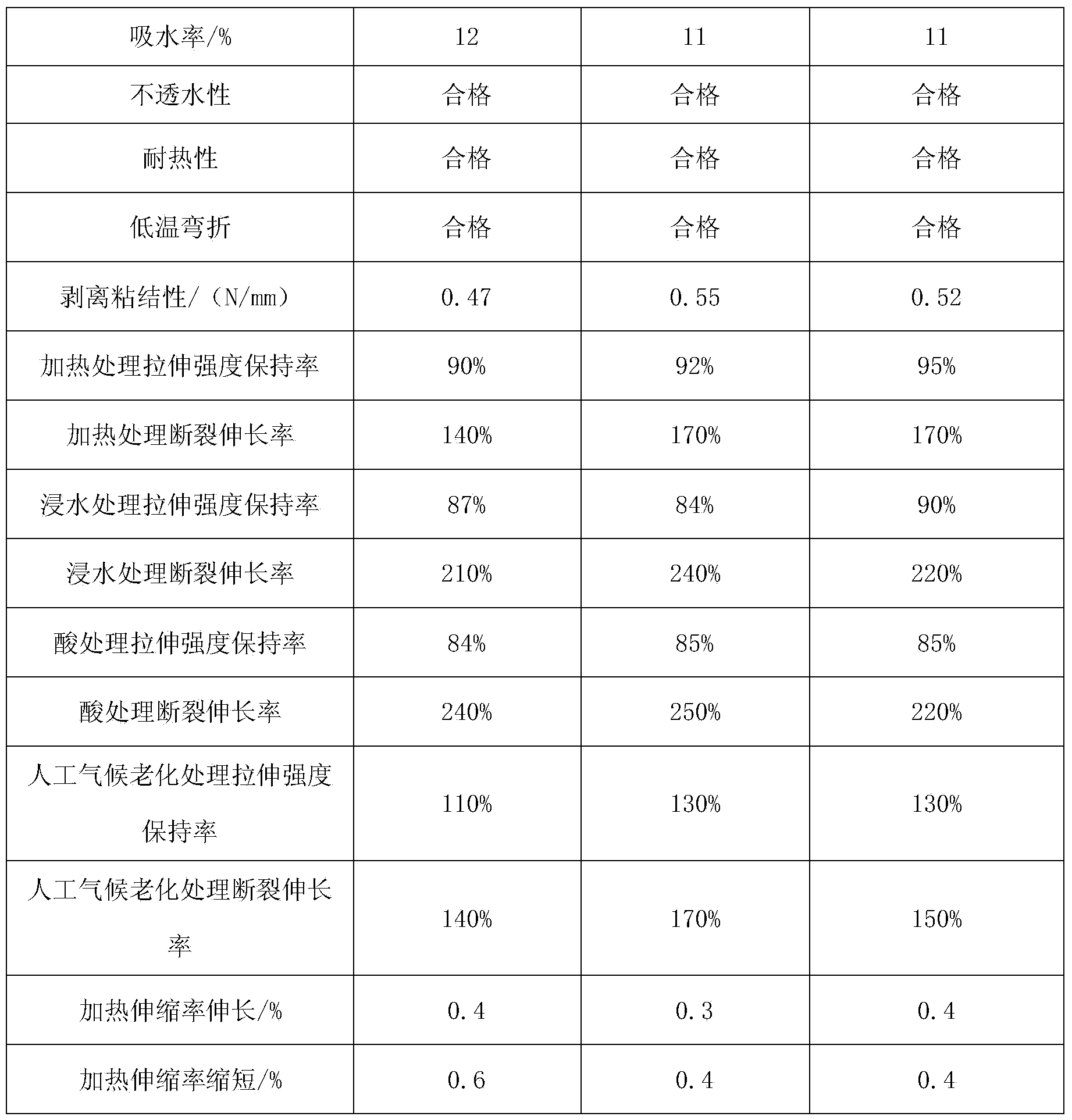

Embodiment 1

[0026] A kind of high-elastic waterproof coating for metal roof, its formula is (weight percentage):

[0027] Table 1: The coating composition of embodiment 1

[0028] composition

Dosage

water

20-25

Dispersant

0.5-1.5

0.1-0.5

0.1-0.5

preservatives

0.1-0.5

antifungal agent

0.1-0.5

pH regulator

0.1-0.5

1-1.5

thickener

0.1-0.3

2468

35-50

15-30

Titanium dioxide

15-30

Coalescent

0.5-1

Vapor SiO 2

0.5-2

[0029] The preparation method is:

[0030] Add water into the reaction kettle, and add dispersant, wetting agent, defoamer, preservative, and antifungal agent respectively while stirring. After stirring evenly, add heavy calcium powder, titanium dioxide, and fumed silica to speed up the stirring speed. until the powder is uniform into a slurry. Red...

Embodiment 2

[0032] A kind of high-elastic waterproof coating for metal roof, its formula is (weight percentage):

[0033] Table 2: The coating composition of embodiment 2

[0034] composition

Dosage

water

15-20

Dispersant

0.5-1.5

0.1-0.5

0.1-0.5

preservatives

0.1-0.5

antifungal agent

0.1-0.5

pH regulator

0.05-0.3

0.5-1.5

thickener

0.1-0.3

AE960

35-55

heavy calcium powder

10-30

Titanium dioxide

10-30

10-30

Coalescent

0.5-1.5

ZnO

1-3

[0035] The preparation method is:

[0036] Add water to the reaction kettle, and add dispersant, wetting agent, defoamer, preservative, and antifungal agent respectively while stirring. After stirring evenly, add heavy calcium powder, titanium dioxide, wollastonite, and zinc oxide to speed up the process. Stir until the powde...

Embodiment 3

[0038] A kind of high-elastic waterproof coating for metal roof, its formula is (weight percentage):

[0039] Table 3: The coating composition of embodiment 3

[0040] composition

Dosage

water

15-25

Dispersant

0.5-1.5

0.1-0.5

0.1-0.5

preservatives

0.1-0.5

antifungal agent

0.1-0.5

pH regulator

0.1-0.5

0.5-1.5

thickener

0.1-0.5

9468

35-50

heavy calcium powder

10-30

Titanium dioxide

5-15

Talc powder

15-30

Coalescent

0.5-1.5

Quartz powder

1-3

[0041] The preparation method is:

[0042] Add water to the reaction kettle, and add dispersant, wetting agent, defoamer, preservative, and antifungal agent respectively while stirring. After stirring evenly, add heavy calcium powder, titanium dioxide, talcum powder, and quartz powder to speed up the stirring. Speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com