Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2980 results about "Wollastonite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

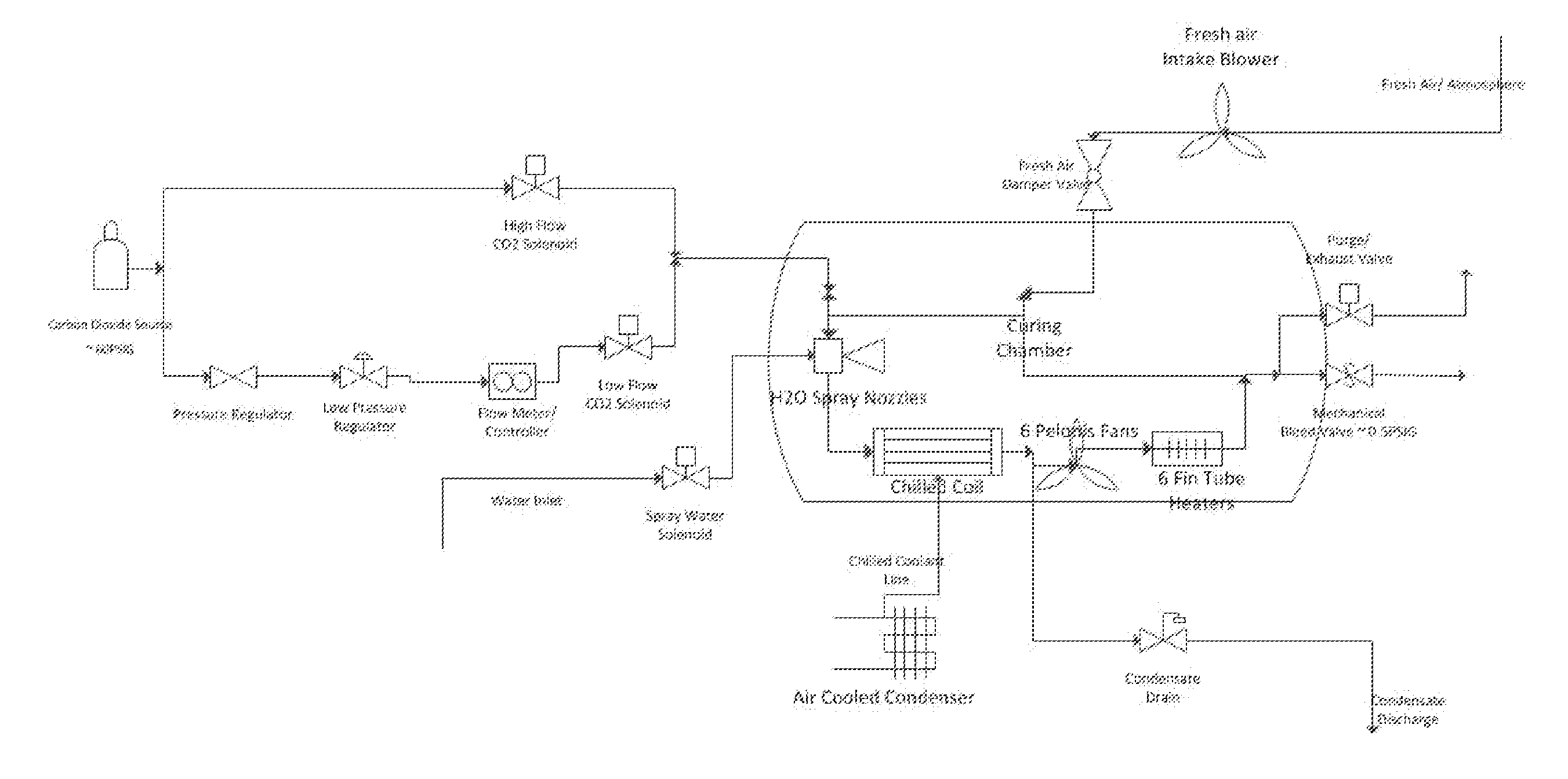

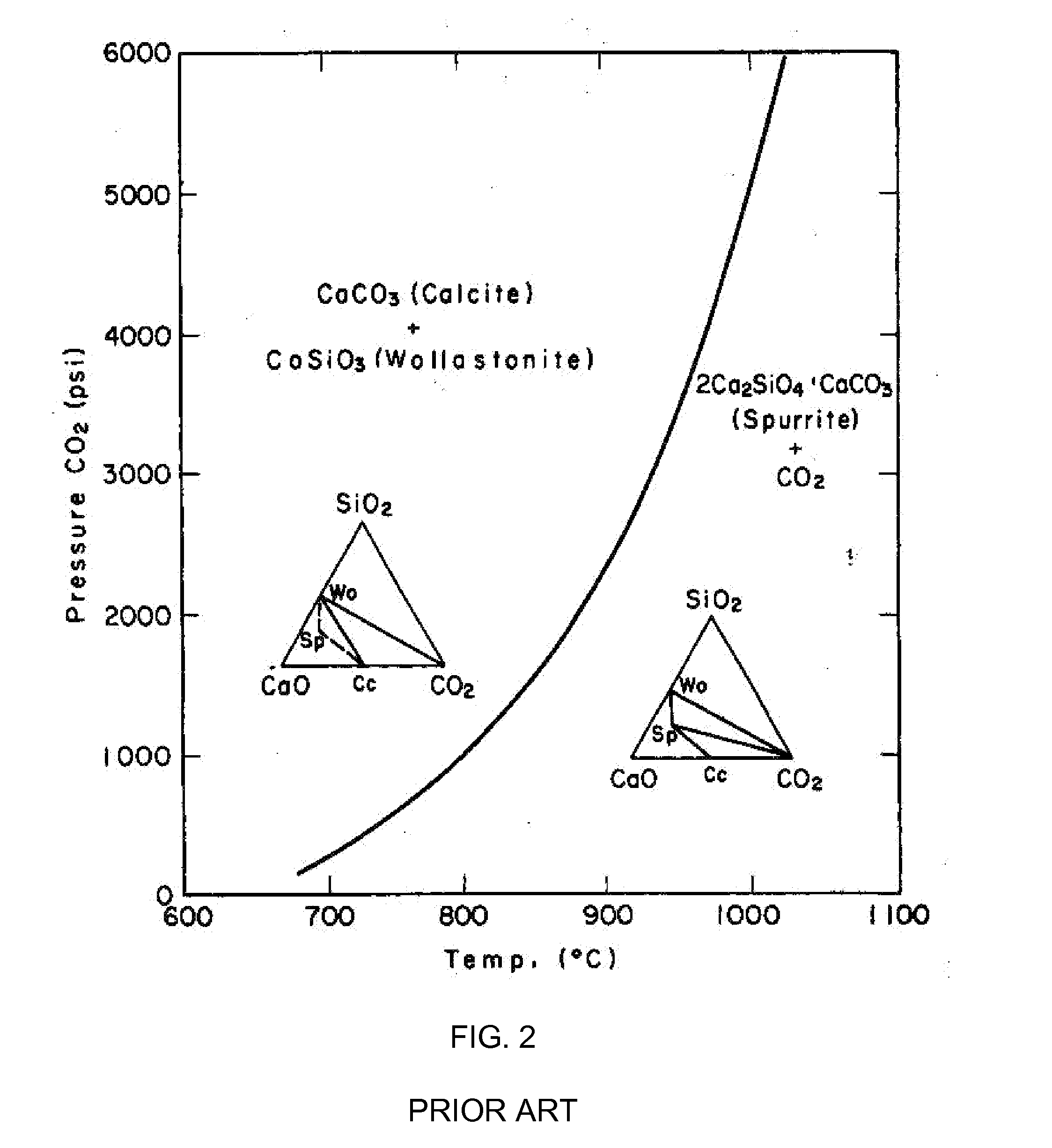

Wollastonite is a calcium inosilicate mineral (CaSiO₃) that may contain small amounts of iron, magnesium, and manganese substituting for calcium. It is usually white. It forms when impure limestone or dolomite is subjected to high temperature and pressure, which sometimes occurs in the presence of silica-bearing fluids as in skarns or in contact with metamorphic rocks. Associated minerals include garnets, vesuvianite, diopside, tremolite, epidote, plagioclase feldspar, pyroxene and calcite. It is named after the English chemist and mineralogist William Hyde Wollaston (1766–1828).

Marble-like composite materials and methods of preparation thereof

InactiveUS20140127450A1Low costIncrease consumptionLayered productsCoatingsCalcium silicateFlexural strength

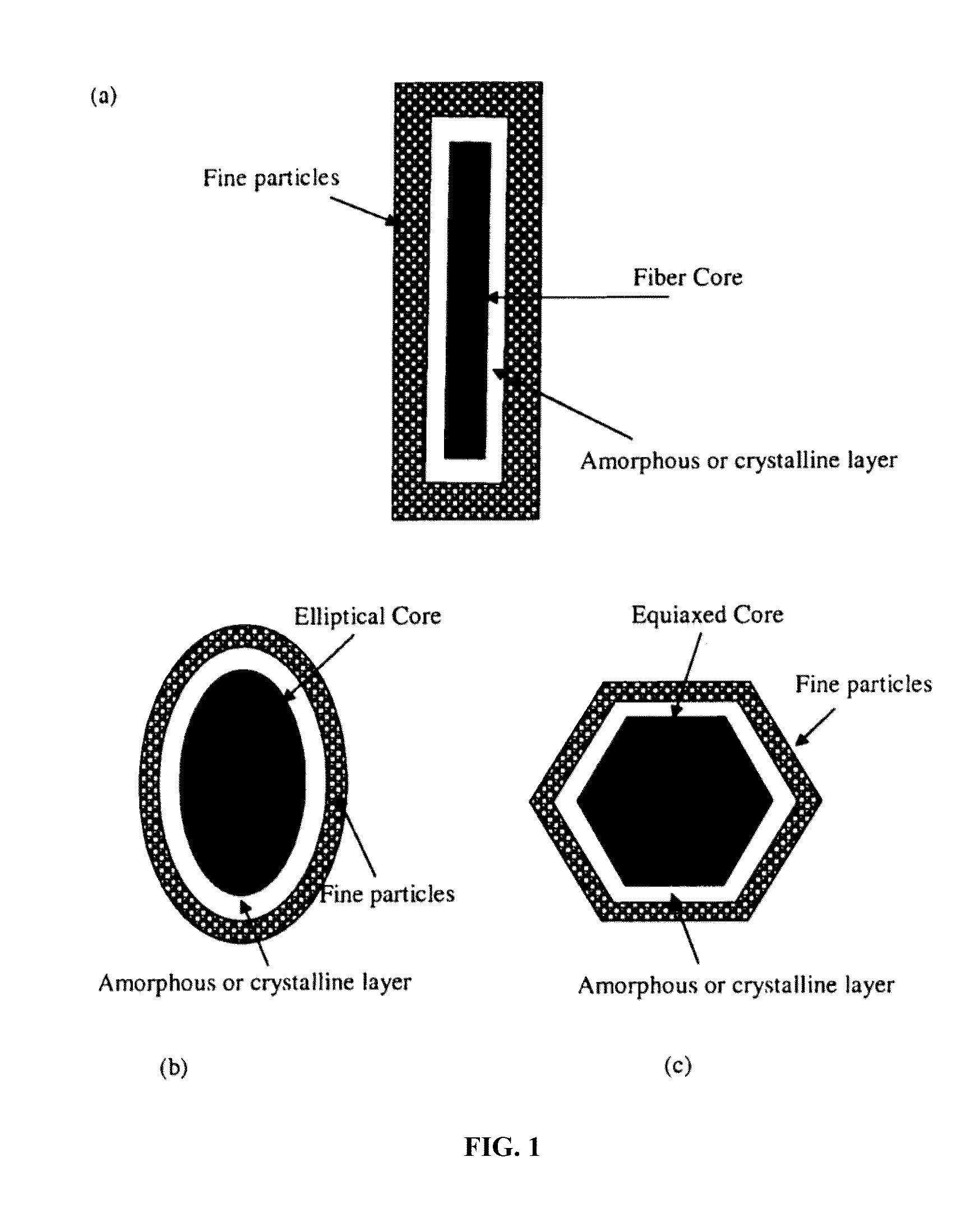

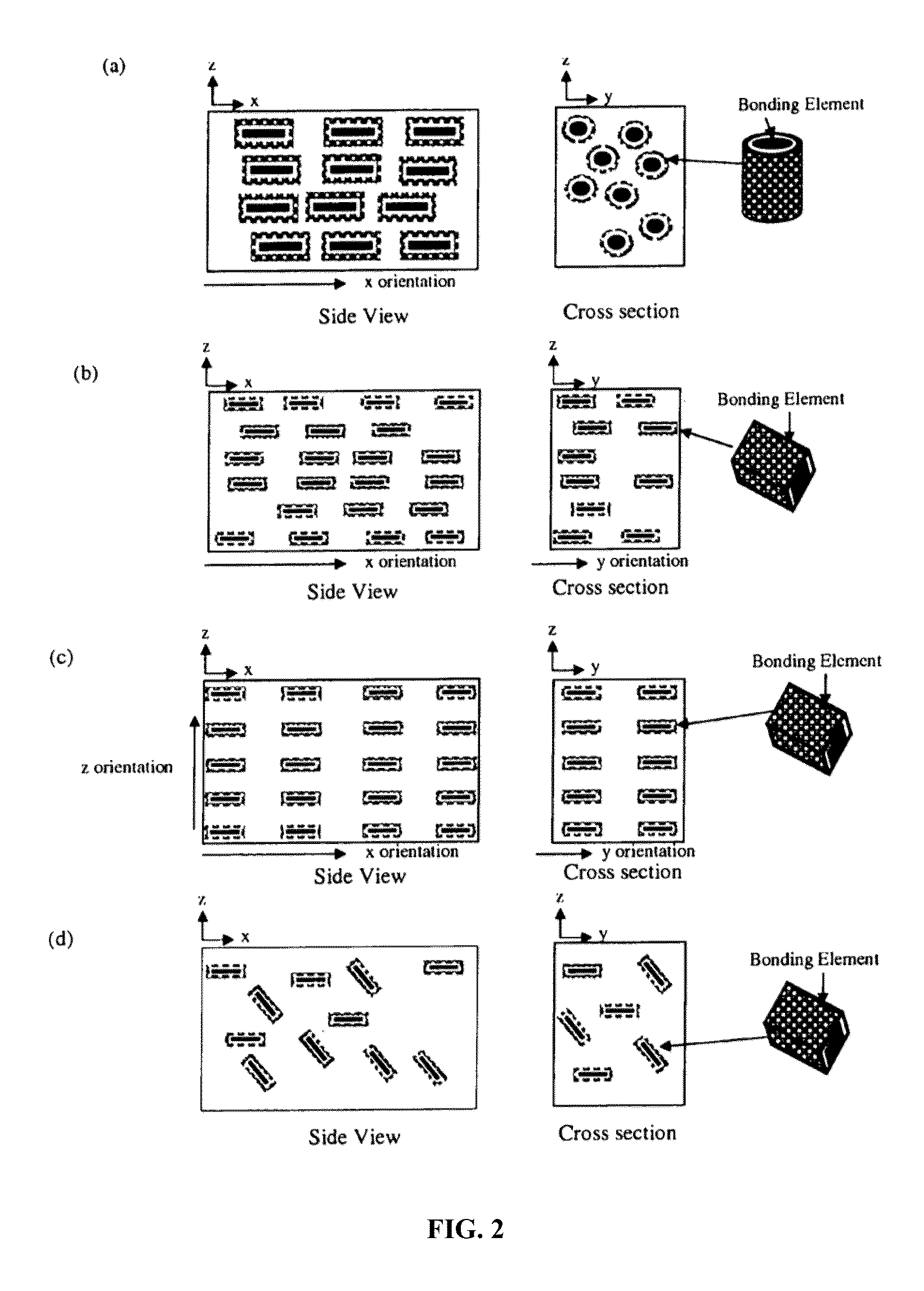

The invention provides novel marble-like composite materials and methods for preparation thereof. The marble-like composite materials can be readily produced from widely available, low cost raw materials by a process suitable for large-scale production. The precursor materials include calcium silicate and calcium carbonate rich materials, for example, wollastonite and limestone. Various additives can be used to fine-tune the physical appearance and mechanical properties of the composite material, such as pigments (e.g., black iron oxide, cobalt oxide and chromium oxide) and minerals (e.g., quartz, mica and feldspar). These marble-like composite materials exhibit veins, swirls and / or waves unique to marble as well as display compressive strength, flexural strength and water absorption similar to that of marble.

Owner:RIMAN RICHARD E +1

Water-borne acrylic type water-proof heat-insulating paint

The invention provides water-borne acrylic water-proof heat insulating paint, which belongs to the field of building materials and can be applied to surfaces of building roofs, metal sheets, ceramic tiles, glazed bricks, decorative tiles and other materials. The invention provides the water-borne acrylic type water-proof heat-insulating paint by using copolymer latex which is cool mixed by elastic acrylic copolymer emulsion, VAE emulsion and an organic silicon water-proof material as a base material, and hollow glass beads in low heat conductivity, hollow ceramic beads and other heat insulating materials, titanium powder, zinc oxide, ultrafine mica and other reflecting materials, and corrosion-resistance blanc fixe, wollastonite and the like as pigments. In the paint, the solar reflectivity is more than or equal to 0.83, the semi-sphere reflectivity is more than or equal to 0.85, weather resistance aging time is 100 hours without fading or pulverizing, and water-proof performance, such as water tightness, low temperature flexibility, tensile strength and the like, can achieve II type product index requirement of JC / T864-2008. Besides the function of decorating materials, the paint has the functions of water proofing and heat insulation.

Owner:CHINA BUILDING MATERIALS ACAD

Process for producing a wollastonite containing polyester and products and articles produced therefrom

InactiveUS20060036012A1Excellent abrasion resistanceHigh strengthSynthetic resin layered productsDomestic containersPolyesterPolymer science

The present invention provides a process for producing a polyester from a polyester composition comprising at least about 1 wt. % wollastonite, based on the total weight of the polyester composition, wherein the wollastonite is added at a temperature of about 240° C. or less. The present invention further provides a process for producing a polyester from a polyester composition comprising at least about 1 wt. % wollastonite, based on the total weight of the polyester composition, and about 0.01 wt. % other filler, based on total weight of the polyester composition, wherein the wollastonite is added at a temperature of about 240° C. or less. The invention is further directed to polyester products produced by said process and the shaped articles formed therefrom.

Owner:EI DU PONT DE NEMOURS & CO

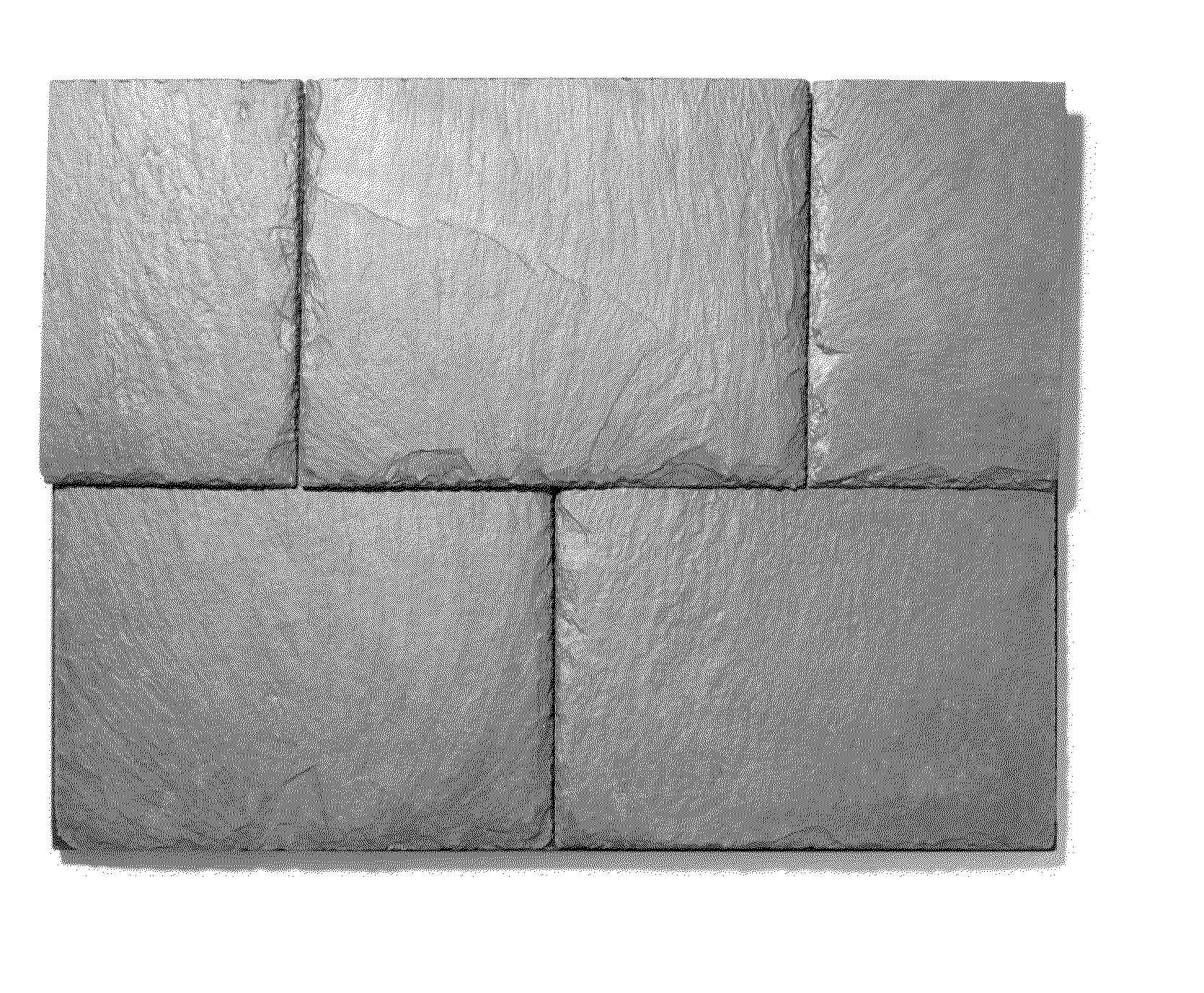

Slate-like composite materials and methods of preparation thereof

InactiveUS20140127458A1Low costIncrease consumptionRoof covering using tiles/slatesRecord information storageCalcium silicateFlexural strength

The invention provides novel slate-like composite materials and methods for preparation thereof. The slate-like composite materials can be readily produced from widely available, low cost precursor materials by a process suitable for large-scale production. The precursor materials include calcium silicate, for example, wollastonite, and particulate filler materials which comprise silicon dioxide-rich materials such as quartz, mica, feldspar, sand and glass. Additives can include calcium carbonate-rich and magnesium carbonate-rich materials. Various additives can be used to fine-tune the physical appearance and mechanical properties of the composite material, such as colorants such as particles of colored materials, such as colored glass, colored sand, and colored quartz particles, and pigments (e.g., black iron oxide, cobalt oxide and chromium oxide). These slate-like composite materials exhibit visual patterns unique to slate as well as display compressive strength, flexural strength and water absorption similar to that of slate.

Owner:ZAMBRZYCKI DAWID +6

Foaming type inorganic heat insulation plate, preparation method thereof and heat insulation layer thereof

InactiveCN101798850ALow thermal conductivityImprove insulation effectSolid waste managementCeramic shaping apparatusFiberCellulose

The invention relates to a foaming type inorganic heat insulation plate, a preparation method thereof and a heat insulation layer thereof, which belongs to the technical field of a heat insulation plate and a heat insulation layer, and provides a foaming type inorganic heat insulation plate with high efficiency and energy saving, a preparation method thereof and a heat insulation layer thereof. The heat insulation plate is prepared from the following raw materials in parts by weight: 10-55 parts of composite light weight admixture, 10-55 parts of cement, 5-30 parts of lime, 3-20 parts of plaster, 1-10 parts of wollastonite, 10-55 parts of water glass, 10-60 parts of foam body which is foamed by a foaming machine through a foaming agent, 3-20 parts of fly ash, 0.1-3 parts of gel powder, 0.05-2 parts of cellulose ether, 0.01-2 parts of glauber salt, 0.1-3 parts of water reducing agent, 0.1-2 parts of hydrophobic agent, 0.01-1 part of mekarlon, 1-10 parts of bone glue, 5-30 parts of emulsion, 4-12 parts of waste slag, 1-45 parts of water and 0.02-1 part of aluminum powder. The invention is applied to the technical field of heat insulation materials.

Owner:太原思科达科技发展有限公司

Machine-made sand self-compacting concrete

A self-compacting concrete with high affinity, strength and durability is proportionally prepared from cement, powdered coal ash, wollastonite, other mineral additives, polycarboxylic acid type water-reducing agent, viscosity increaser, defoaming agent, mechanically prepared sand and broken stone.

Owner:GUIZHOU HIGHWAY ENG GRP

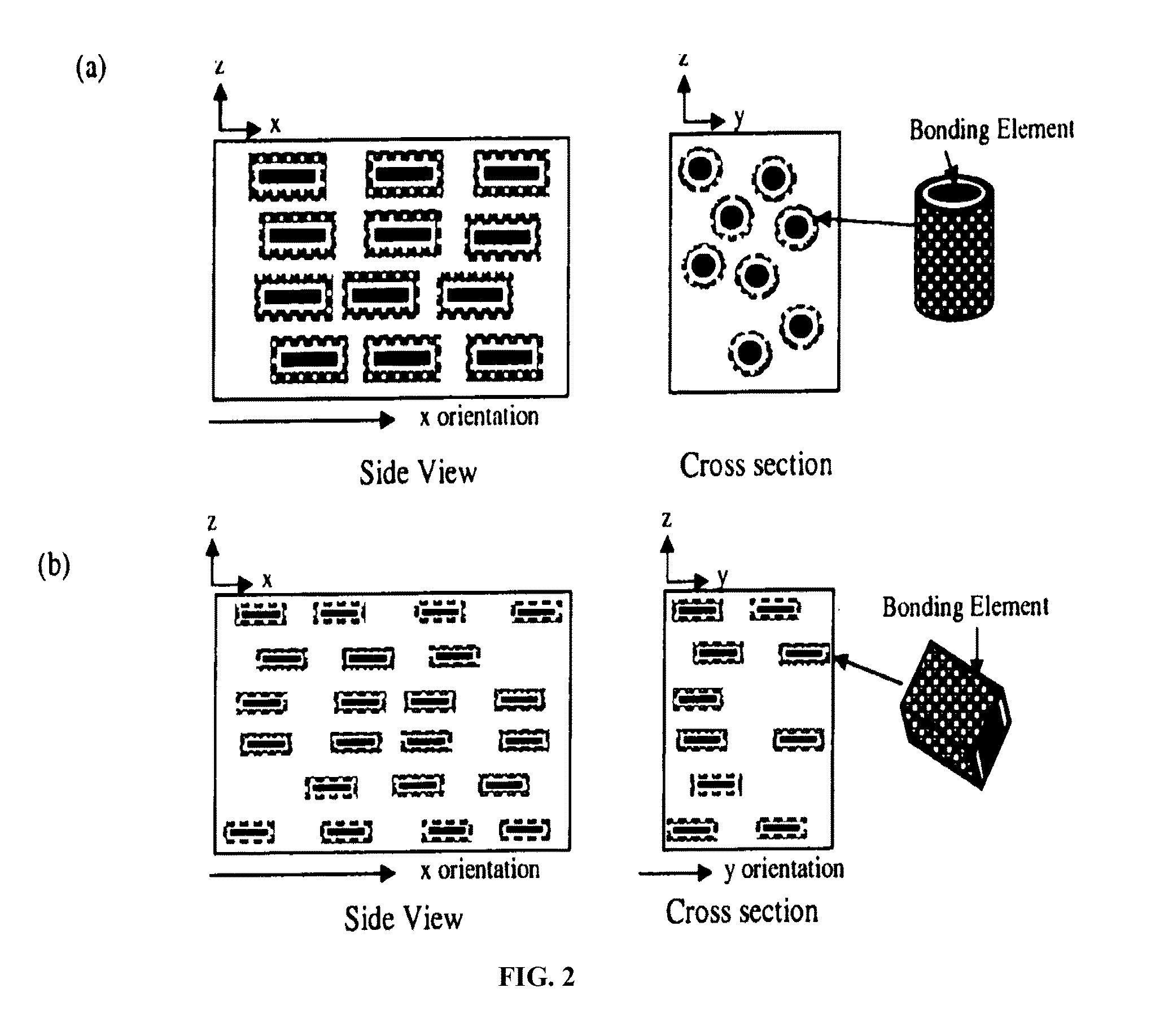

Pavers and block composite materials and methods of preparation thereof

ActiveUS20140314990A1Acceptable compressive strengthLow costRecord information storageCeramic shaping apparatusCalcium silicateCOLORED MATERIAL

The invention provides novel paving stones and construction block composite materials and methods for preparation thereof. The paving stones and construction block composite materials can be readily produced from widely available, low cost precursor materials by a production process that involves compacting in a mold that is suitable for large-scale production. The precursor materials include calcium silicate, for example, wollastonite, and particulate filler materials which can comprise silicon dioxide-rich materials. Additives can include calcium carbonate-rich and magnesium carbonate-rich materials. Various additives can be used to fine-tune the physical appearance and mechanical properties of the composite material, such as colorants such as particles of colored materials, such as, and pigments (e.g., black iron oxide, cobalt oxide and chromium oxide). These paving stones and construction block composite materials exhibit visual patterns similar to stone as well as display compressive strength and water absorption equal to or better than that of stone.

Owner:SOLIDIA TECH

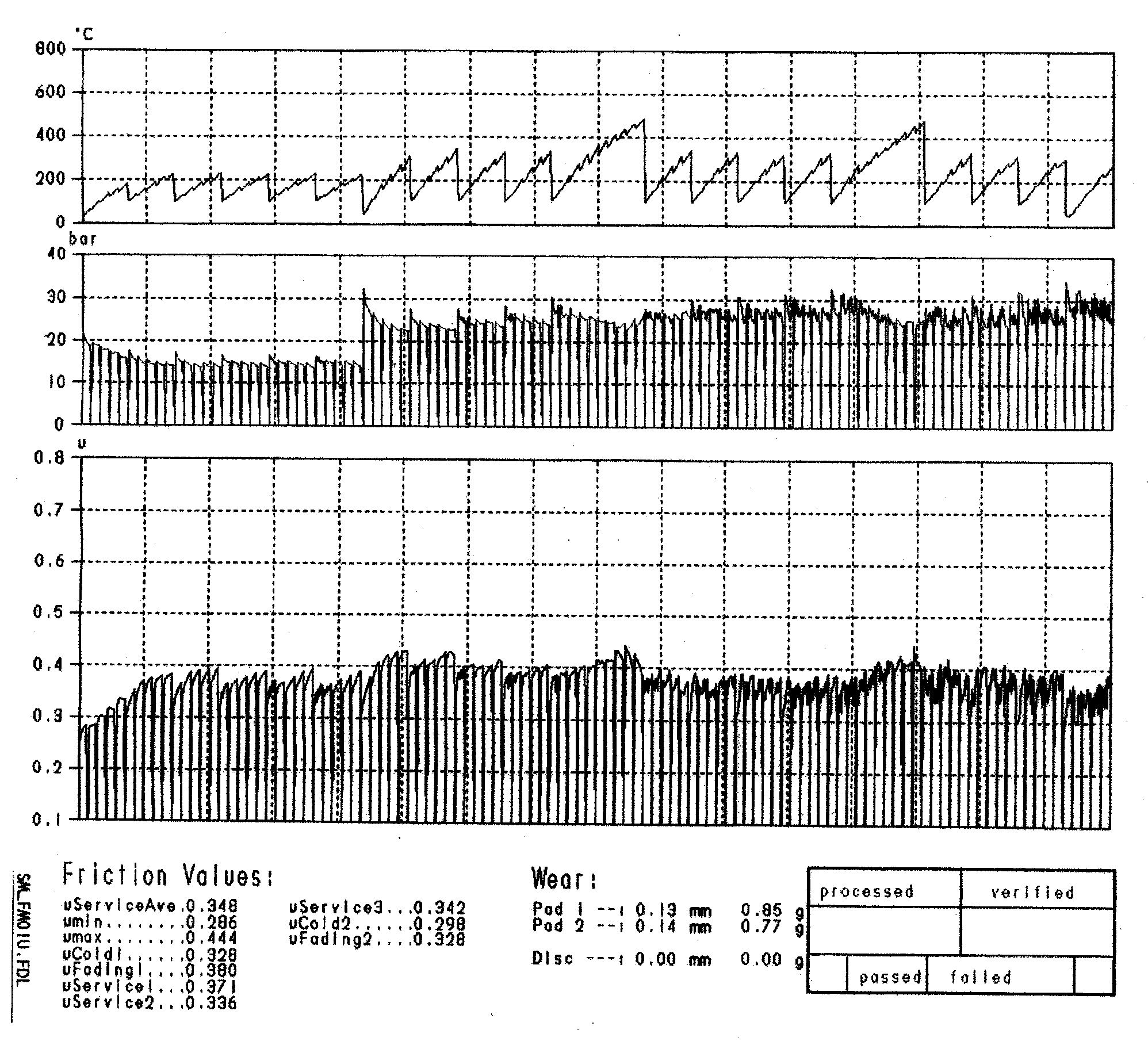

Ceramic base/NAO composite friction material and preparation method thereof

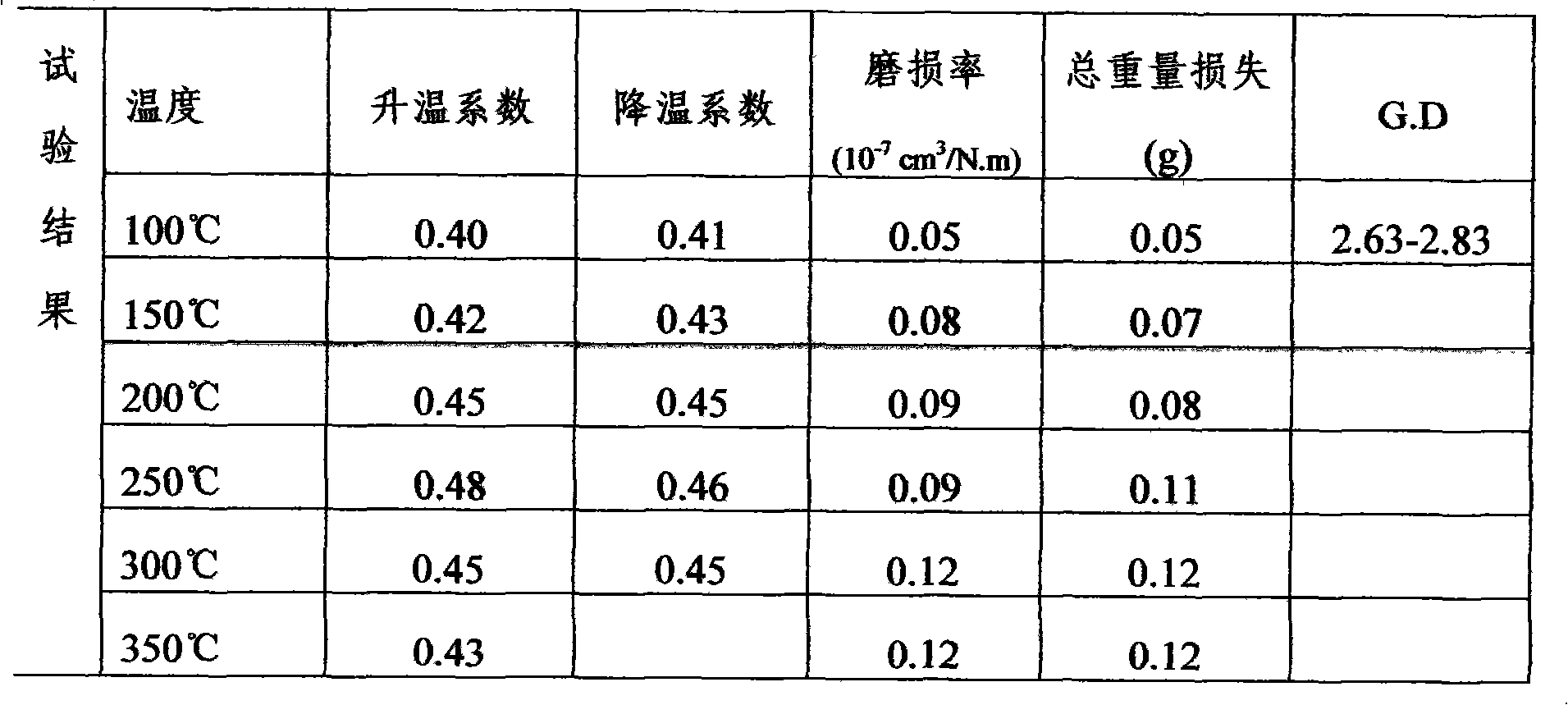

The invention relates to an oxide ceramic base / NAO composite friction material used in a brake of a medium or high-grade car and a preparation method thereof. In the composite friction material, mixed fibers comprise aramid fibers, potassium titanate fibers and silicon, magnesium and calcium oxide ceramic fibers; aedelforsite or mineral fibers and copper fibers are used as the enhancement and conduction fibers; phenolic resin is used as the organic bonding agent; pure oxide ceramics, such as Al2O3, ZrO2, MgO, CaO and the like, are used as the abrasives; solid lubricant, sulfide, graphite coke and the like are used as the abrasion resistant lubricants; and sodium bicarbonate is used as the blowing agent and pairing antioxidant, and barium sulfate inorganic filler is used as the function and toughening filler. The ceramic base / NAO organic friction material mainly maintains the unique performance of the asbestos friction material, remakably lowers the noise, reduces the abrasion possibility, and is beneficial to prolonging the service life of a brake disc, there by being a novel green (less-dust) low-noise environmentally-friendly friction material.

Owner:HUBEI CHIBI SALFER FRICTION MATERIAL

Rapid curing of thin composite material sections

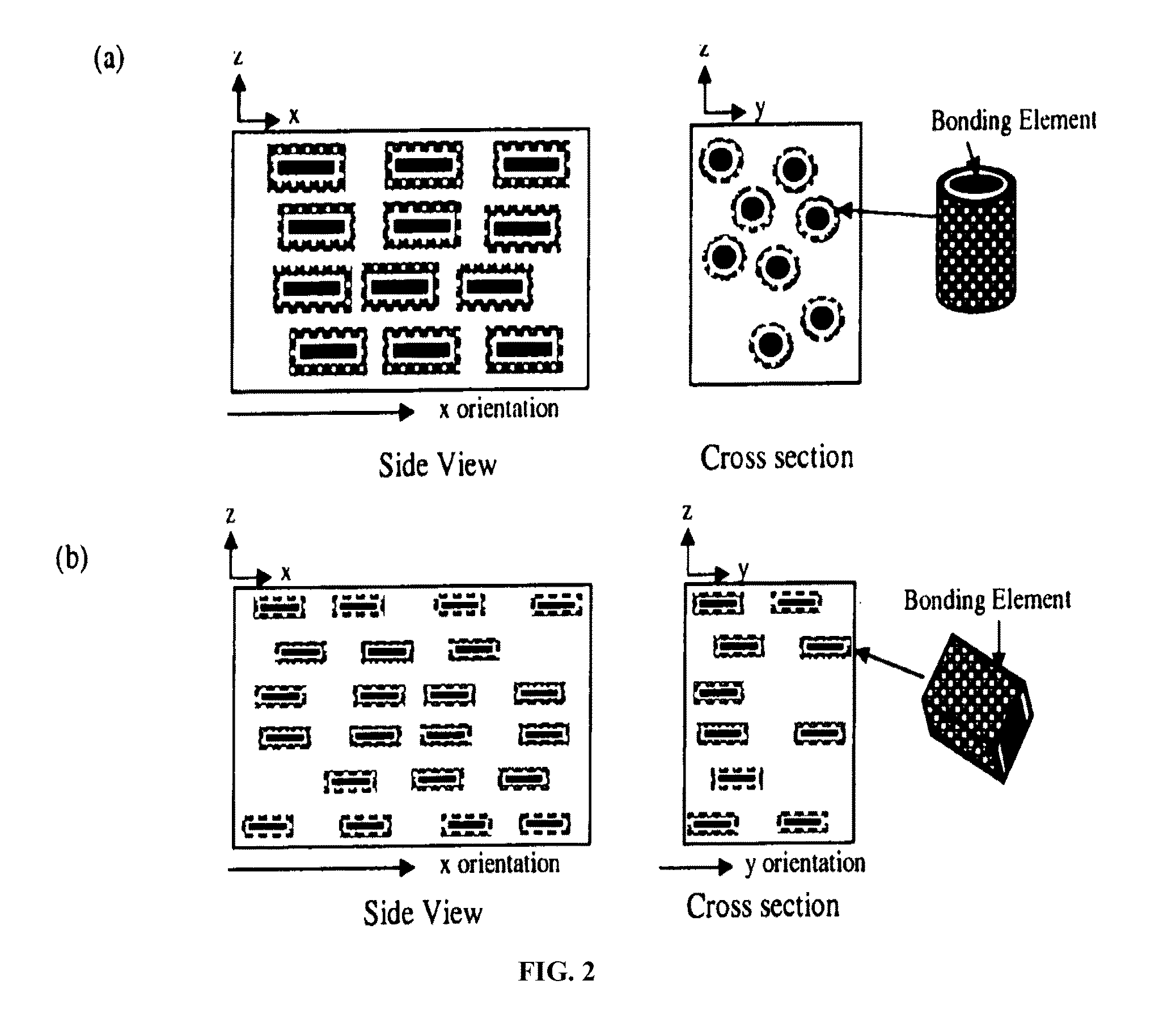

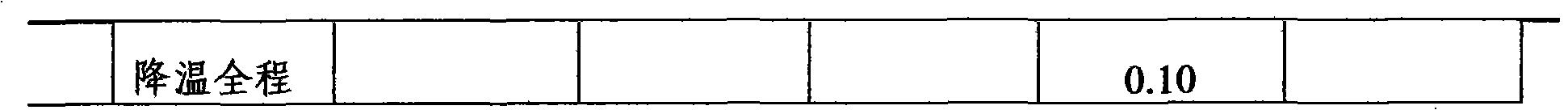

A method of preparing and rapidly curing a composite material having a thin cross section. The composite material includes a mixture of solid particles, at least some of which are a material that reacts with CO2, such as a silicate, for example Wollastonite. The green material is prepared by mixing the solid components with a liquid such as water to form a slurry, and forming green bodies by placing the slurry in forms. The green bodies are reacted with CO2 to form cured composite materials having thin sections, in the range of 10 to 15 mm. Curing in periods of 6 hours has been demonstrated.

Owner:SOLIDIA TECH

Wood-like composite materials and methods of preparation thereof

InactiveUS20140342124A1High compressive strengthLow water absorptionConstruction materialNatural patternsCalcium silicateFlexural strength

The invention provides novel wood-like composite materials and methods for preparation thereof. The wood-like composite materials can be readily produced from widely available, low cost precursor materials by a production process that involves casting in a mold that is suitable for large-scale production. The precursor materials include calcium silicate, for example, wollastonite, and particulate filler materials which comprise silicon dioxide-rich materials such as quartz, mica, feldspar, sand and glass. Additives can include calcium carbonate-rich and magnesium carbonate-rich materials. Various additives can be used to fine-tune the physical appearance and mechanical properties of the composite material, such as colorants such as particles of colored materials, such as, and pigments (e.g., black iron oxide, cobalt oxide and chromium oxide). These wood-like composite materials exhibit visual patterns unique to wood as well as display compressive strength, flexural strength and water absorption superior to that of wood.

Owner:ZAMBRZYCKI DAWID +4

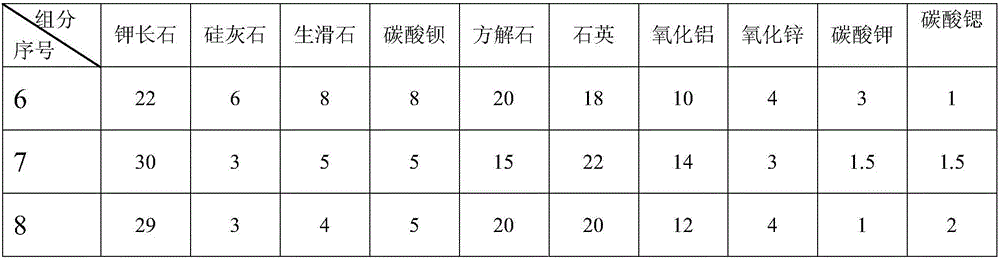

Wear-resistant transparent glaze and method for preparing glazed tile by utilizing same

The invention provides a wear-resistant transparent glaze and a method for preparing a glazed tile by utilizing the same. According to the components of the wear-resistant transparent glaze, spodumene, frit, potash feldspar, calcinedtalc, barium carbonate and zinc oxide are adopted as a fluxing agent, and the Si / Al ratio is adopted by utilizing wollastonite and kaolin. Meanwhile, the wear-resistant performance of the glaze is improved by adopting white corundum and zirconium oxide as a wear-resistant agent. The weight percentage of zirconia relative to the total weight of the raw materials of the wear-resistant transparent glaze is smaller than or equal to 0.2%. The above wear-resistant transparent glaze is applied onto the surface of a green body, and then the green body is polished after being sintered in a furnace to obtain a glazed tile product. Compared with the prior art, the wear-resistant transparent glaze is excellent in wear resistance, and can be used for preparing ceramic tiles with thin glaze layers. The decorative properties and the anti-pollution characteristics of obtained products are greatly improved. Meanwhile, the manufacturing cost of products is lower.

Owner:FOSHAN DONGPENG CERAMIC +3

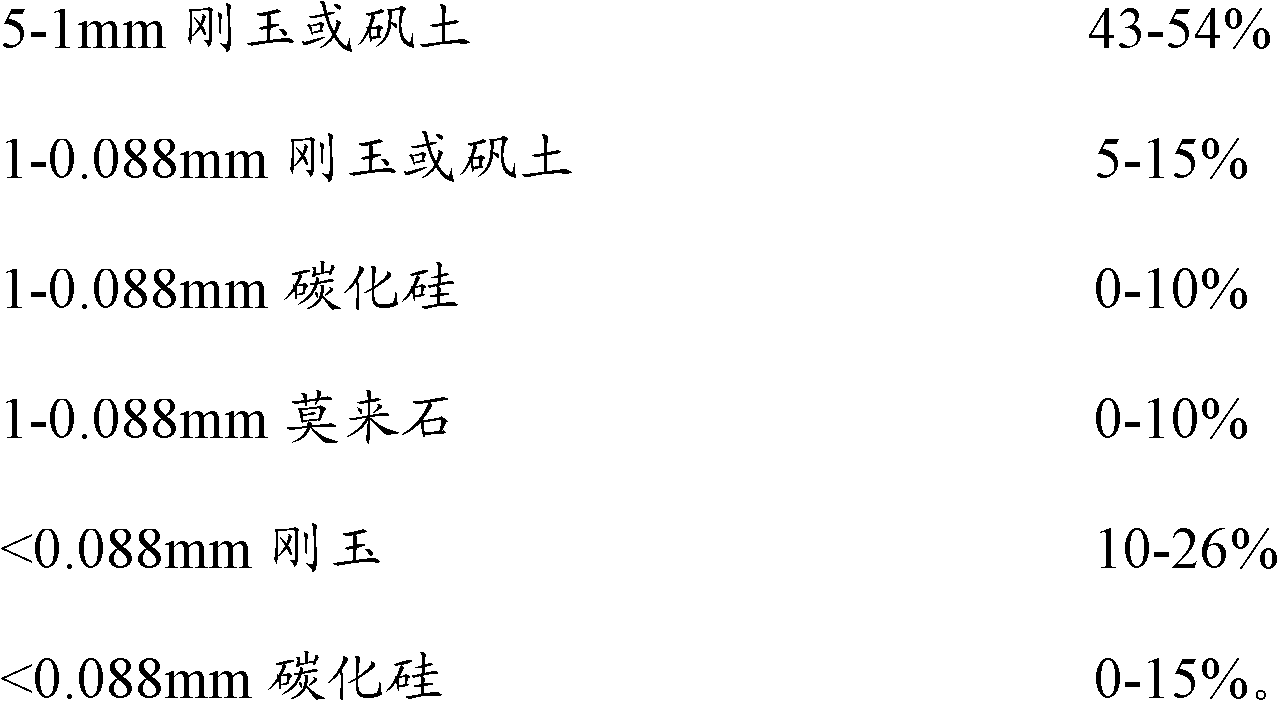

Composite bonding low-temperature constructional castable refractory

The invention relates to a composite bonding low-temperature constructional castable refractory, which can be used for high-temperature kiln engineering. According to the castable refractory, corundum, alumina, mullite and silicon carbide are used as an aggregate, silica sol is used as a bonding agent, aluminate cement is used as a curing agent and a bonding aid, and alumina micro powder, wollastonite, a deflocculant, a retarder, water and the like are added. The composite bonding low-temperature constructional castable refractory has high low-temperature constructional performance, high performance of high-temperature resistance, erosion resistance, thermal shock resistance and high mechanical performance, and meets the requirements of overhauling in winter on the premise that the service life of the castable refractory is not influenced.

Owner:ANHUI RUITAI NEW MATERIALS TECH

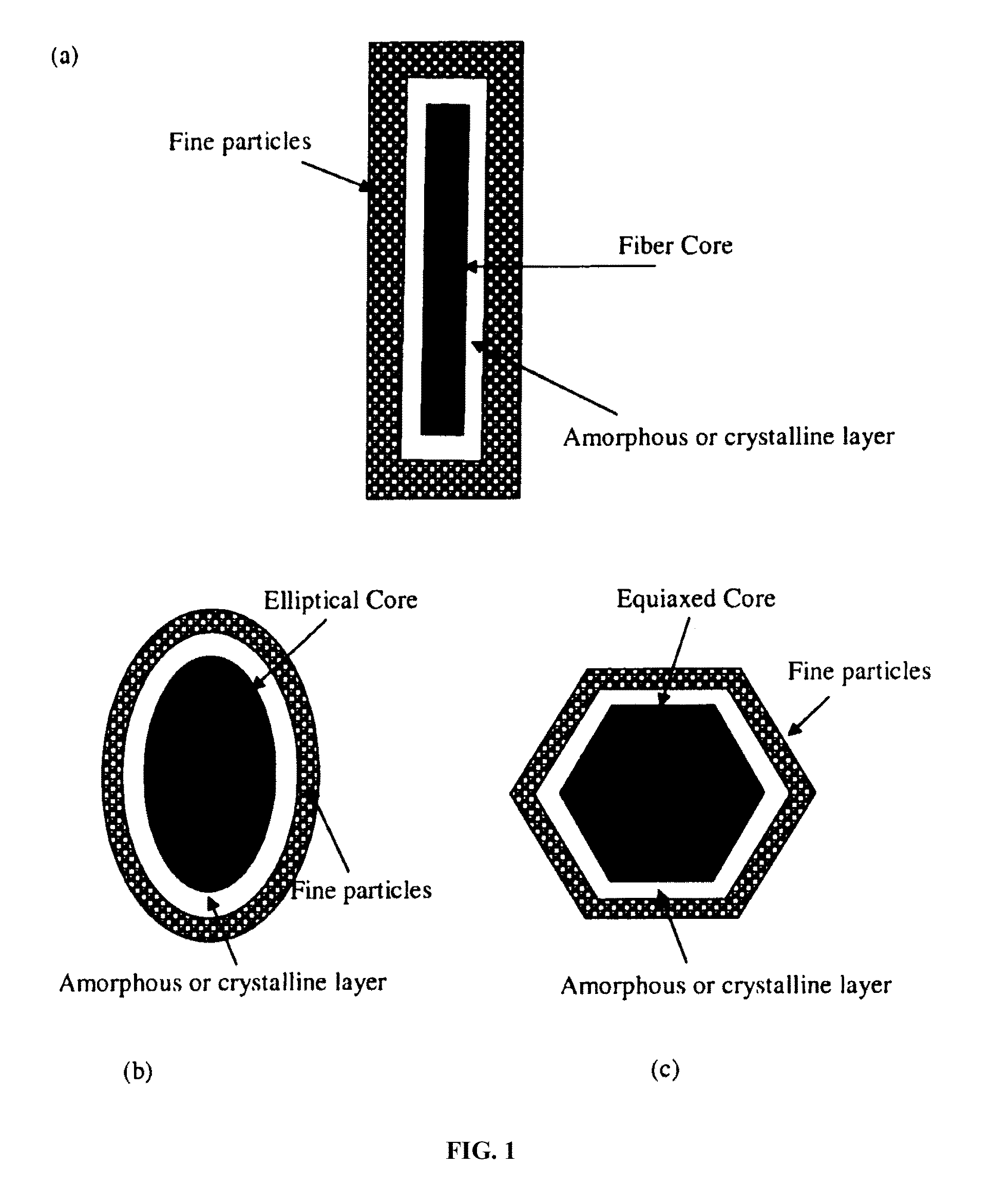

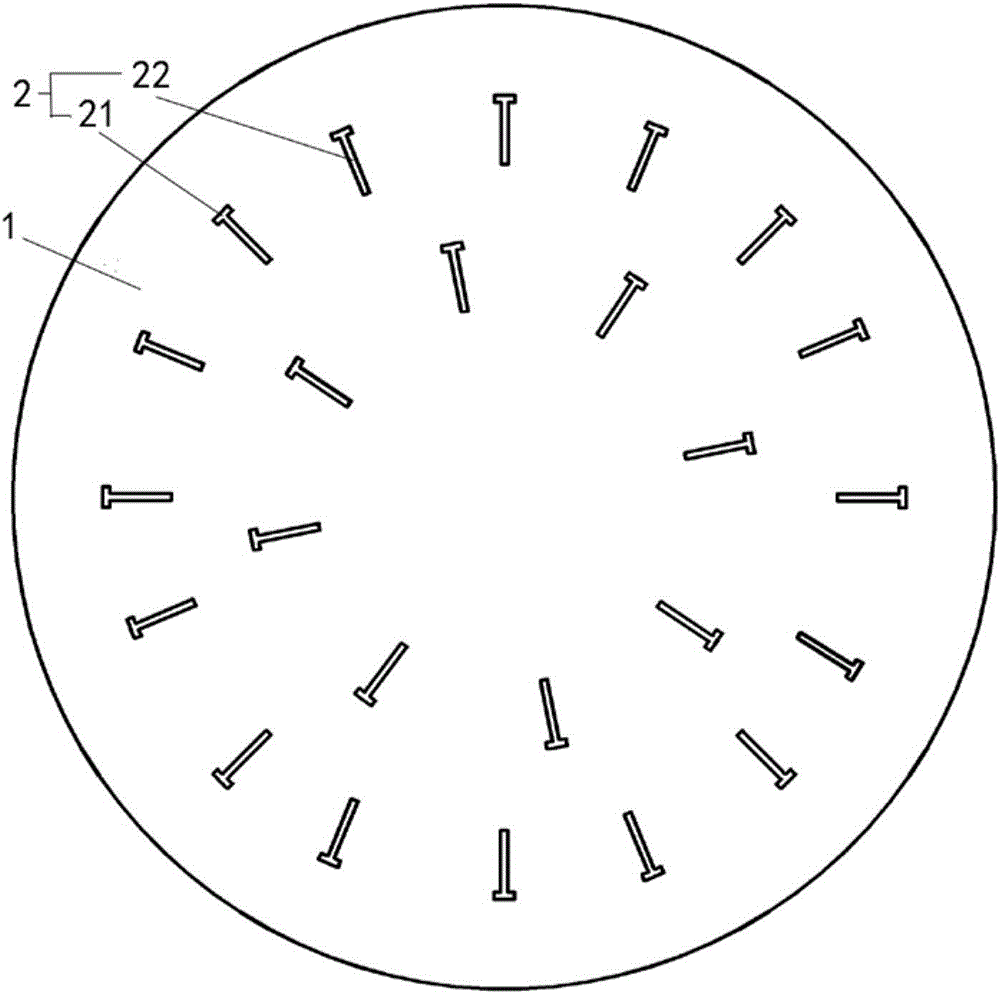

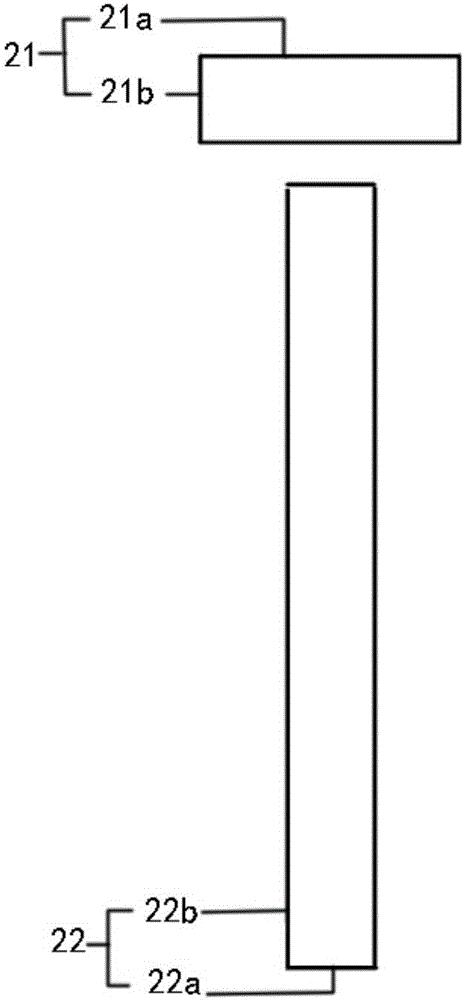

Preparation method of lodging-resistant multi-difference polyester low-elastic filament

ActiveCN106400179AImprove heat resistanceEasy to processMelt spinning methodsMonocomponent polyesters artificial filamentFiberPolyethylene glycol

The invention relates to a preparation method of a lodging-resistant multi-difference polyester low elastic filament. The preparation method comprises the following steps: firstly, mixing nano sepiolite fibers, organic magnesium hydroxide whisker, organic barium sulfate nano powder, ethylene glycol, propylene glycol, p-hydroxybenzoic acid and sodium germanate to obtain a high-modulus composite alcohol solution; secondly, mixing organic wollastonite nano needle-like fibers, mica powder, polyethylene glycol, the propylene glycol, an antioxidant 1010, ethylene glycol antimony and protonated agent phosphoric acid to obtain a high-modulus composite promoter; thirdly, co-polycondensing the high-modulus composite multifunctional alcohol solution and the high-modulus composite promoter with purified terephthalic acid and the ethylene glycol to obtain high-modulus modified polyester; a melt of the high-modulus modified polyester is sprayed from a T-shaped spinneret orifice in a spinneret plate; the lodging-resistant multi-difference polyester low elastic filament is prepared by a special cooling mode and a low-temperature texturing process. The fiber prepared by the preparation method has multiple different properties of different crystallization, different orientation and different shrinkage; after different shrinkage, the appearance is good, and a brushed fabric prepared from the lodging-resistant multi-difference polyester low elastic filament is not easy to lodge.

Owner:荣翔化纤有限公司

Glass-ceramic seals for use in solid oxide fuel cells

The invention is directed to highly crystalline, frit-sintered glass-ceramic materials and seals made using them that are suitable for solid oxide fuel cell applications. The seals have a coefficient of thermal expansion in the range of 70-130×10−7° C., preferably 85-115×10−7° C. The glass-ceramic materials have a crystalline component and a glass component, the crystalline component being >50% of the glass-ceramic and the glass component being <50%. In one preferred embodiment the crystalline component is >75%. Regarding the crystalline component only, >50% of the crystals in the crystalline component of the glass-ceramic has a structure selected from the structural groups represented by walstromite, cyclowollastonite, μ-(Ca,Sr)SiO3, kalsilite, kaliophilite and wollastonite (the primary crystalline phase) and the remaining <50% of the crystalline component is at least one secondary crystalline phase. Generally, the glass-ceramics of the invention are useful as metal-to-metal, metal-to-ceramic and ceramic-to-ceramic sealing agents.

Owner:CORNING INC

Composite bonding wear-resistant castable refractory

The invention relates to a composite bonding wear-resistant castable refractory, which can be used for high-temperature kiln engineering. The amorphous castable refractory which is normal in coagulation, quick in hardening, low in porosity, high in strength and high in abrasive resistance is prepared from silica sol serving as a bonding agent, aluminate cement serving as a curing agent, alumina micro powder and wollastonite which serve as a compact agent, heat resistant steel filters serving as a reinforcing agent and corundum and alumina which serve as an aggregate. The composite bonding wear-resistant castable refractory is suitable for positions such as air pipeline elbows for the cogeneration of cement kilns, cyclone cones and linings for triple air pipe gates which are easy to wear in high-temperature kilns.

Owner:ANHUI RUITAI NEW MATERIALS TECH

Nanocomposite diatom ooze material and construction method thereof

The invention discloses a nanocomposite diatom ooze material and a construction method thereof. The material consists of a diatom ooze powder material and nano-titanium dioxide dispersion liquid, wherein the diatom ooze powder material consists of calcined diatomite, quartz sand, gray calcium powder, bentonite, wollastonite, seaweed gel, cellulose ether and negative ion powder. The construction method comprises the following steps of: mixing the diatom ooze powder material and water according to the weight ratio of 1:0.9 in the field; after stirring for 15 minutes by using an electric stirrer, performing batch-scraping coating texture modeling construction; uniformly spraying the nano-titanium dioxide dispersion liquid, namely photocatalyst solution to a construction surface by using a spraying gun after the surface is dried; and drying for 48 hours. By using the construction method, the problems that nano-titanium dioxide powder is difficult to disperse and easy to agglomerate, and has large additive amount, the production cost is high, and a nano-titanium dioxide material is wasted in the preparation process of the diatom ooze are solved, the functionality of the diatom ooze for purifying and decomposing harmful gases is improved, and the overall cost of the product is reduced.

Owner:JILIN PROVINCE LANSHE DIATOM NEW MATERIALS

Low-luster polypropylene composite material and preparation method thereof

The invention discloses a low-luster polypropylene composite material and a preparation method thereof, belonging to the field of polymer modifying and processing. The low-luster polypropylene composite material is prepared by the following raw materials with the weight percent in brackets: polypropylene (58 to 86%), wollastonite (13 to 30%), other inorganic padding (0 to 12%), flexibilizer POE (0 to 15%), antioxidant (0.1 to 2%), and other assistants (0 to 5%). The wollastonite (the inorganic padding) which can effectively lower the surface luster of a product is added to the basis formula of the polypropylene composite material, so as to prepare the low-luster polypropylene composite material with excellent performance.

Owner:SHANGHAI PRET COMPOSITES

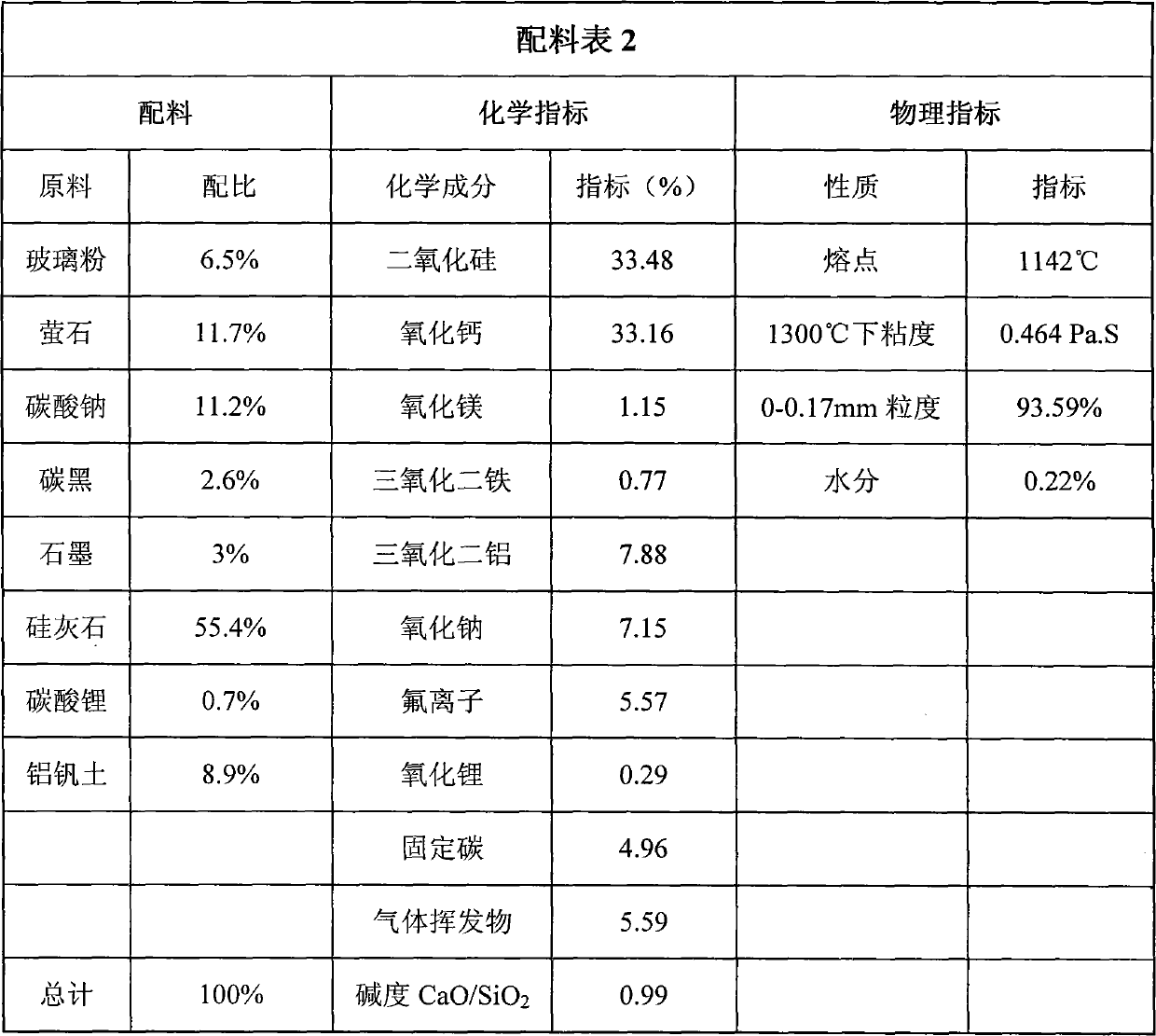

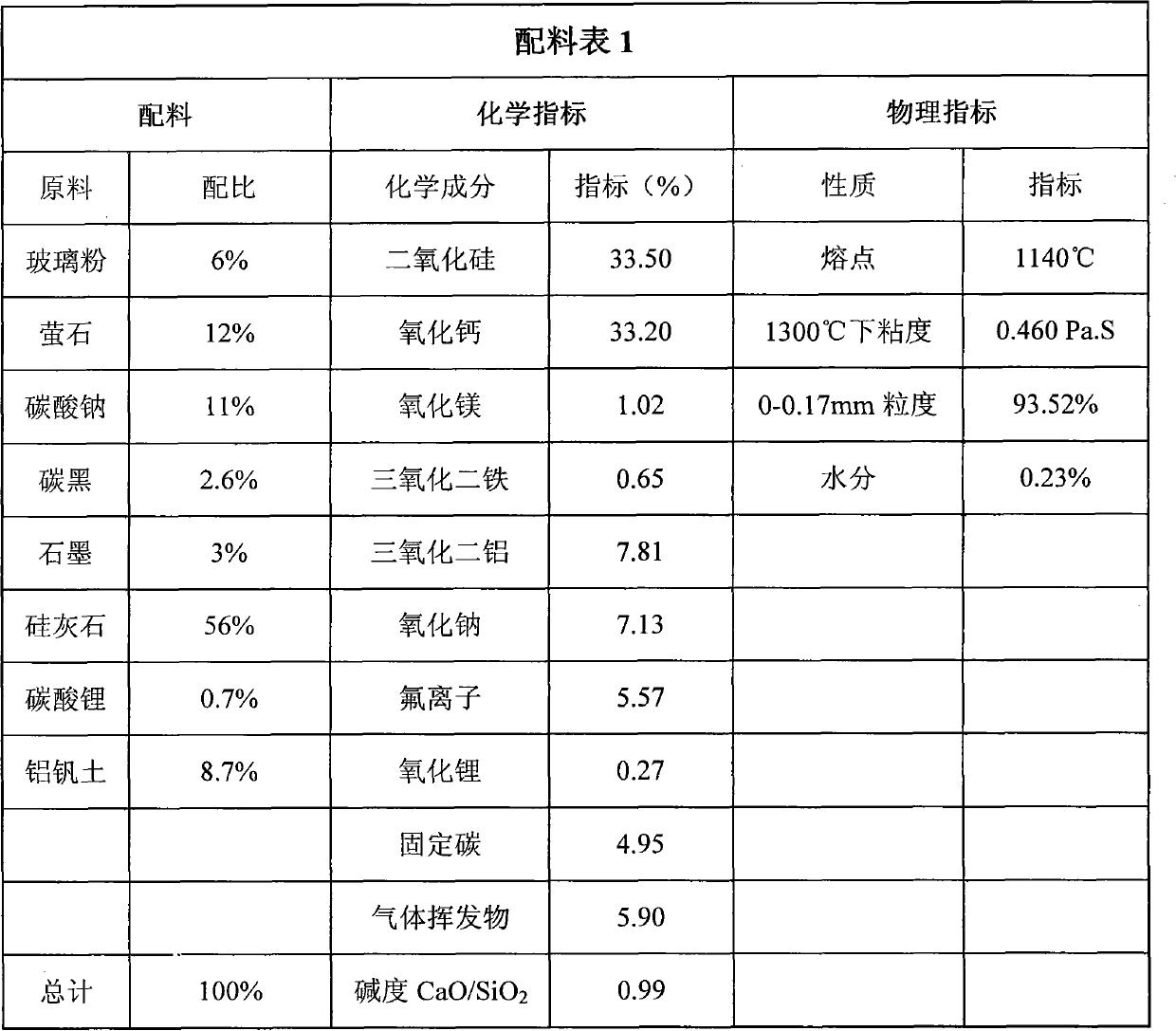

High-manganese high-nitrogen low-nickel stainless steel plate blank continuous casting crystallizer covering slag and preparation method thereof

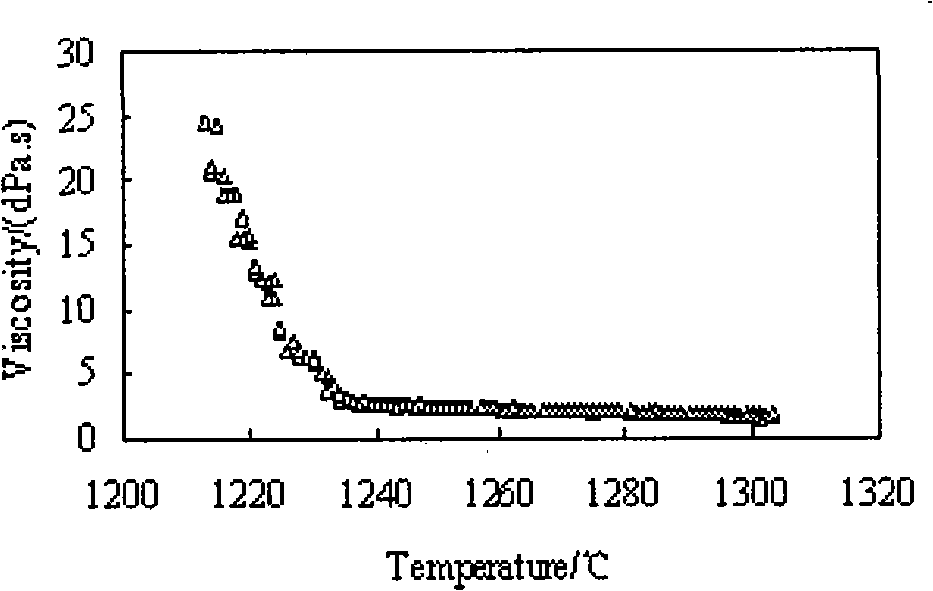

The invention discloses high-manganese high-nitrogen low-nickel stainless steel plate blank continuous casting crystallizer covering slag which comprises the following components in percentage by weight: 54-57% of wollastonite, 9-13% of fluorite, 9-13% of sodium carbonate, 0-1% of lithium carbonate, 5-7% of glass dust, 8-12% of vanadine soil, 2.5-2.7% of soot carbon and 3-3.5% of graphite, and comprises the chemical components in percentage by weight: 31.9-34.9% of calcium oxide, 32.1-35.1% of silicon dioxide, 7.3-8.3% of aluminium oxide, 0.5-1.5% of magnesium oxide, 0.5-1.4% of iron sesquioxide, 4.4-6.4% of fluorion, 6.5-7.5% of sodium oxide, 0-0.39% of lithium oxide, 4.5-6.0% of fixed carbon and 4-7% of gas volatile matters. The alkalinity of the covering slag, namely the ratio of CaO to SiO2, is 0.91 to 1.00, the melting point of the covering slag is 1100 DEG C to 1160 DEG C, and the viscosity of the covering slag is 0.3 to 0.6 Pa.s at 1300 DEG C. The invention can solve the problems of easy crusting, slag entrainment, slag inclusion, slag sticking on casting blank surfaces, bubbles under skins, cracks, deep chatter mark, felting, bleed-out, and the like of the covering slag in the crystallizer during high-manganese high-nitrogen low-nickel stainless steel plate blank continuous casting, and has the advantages of uniform and stable slagging in the crystallizer, good casting blank quality, difficult felting and bleed-out, and the like.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

Novel fireproof coating exclusively for tunnel

The invention relates to the fireproof coating technology, in particular to a novel fireproof coating exclusively for tunnel. A high performance tunnel fireproof coating which conforms the requirements of the I type tunnel fire-resistant experimental test of Chinese GB50016-2006 Code for Fire Protection Regulations of Building Design and the tunnel RABT fire-resistant experimental test of GA / T714-2007 Rapid heating Fire-resistant Test Methods of Fire Protection Materials for Structural Elements for protecting a tunnel fire in China are lacked. The invention reaches the above two standards, comprising the following compositions by weight percentage: 30-40% of high alumina cement and Portland cement, 17-26% of expanded vermiculite, 7-13% of expanded perlite, 4.5-8% of mica, 4-10% of meerschaum, 4-10% of wollastonite in powder, 3.5-4.5% of glass microspheres, 3.5-5.8% of aluminum hydroxide, 5-6.2% of magnesium hydroxide, 0.2-0.4% of polypropylene staple, 0.2-0.3% of a high efficiency water reducing agent and 4-10% of redispersible latex powder.

Owner:JIANGXI LONGZHENG SCI & TECH DEV

Polypropylene material filled with inorganic mineral powder, and its preparation method and application

InactiveCN102206376AExcellent resistance to folding fatigueImprove cold resistanceFlexural modulusMicrosphere

The invention discloses a polypropylene material filled with inorganic mineral powder, and its preparation method and application. The polypropylene material comprises, by weight, 43 to 90% of polypropylene, 0 to 1% of a heat stabilizer, 0 to 1% of a lubricant, 0 to 15% of a flexibilizer and 10 to 40% of an inorganic mineral powder filler, wherein the inorganic mineral powder filler is one selected from the group consisting of calcium carbonate, powdered steatile, kaolin, mica, wollastonite, glass microballoons, ceramic microspheres and barium sulfate or a mixture of the above-mentioned materials. When used as a material for hinges, the polypropylene material filled with inorganic mineral powder in the invention has excellent folding resistance which is similar to that of a pure polypropylene material, good fatigue durability and comprehensive mechanical properties, outstanding cold resistance and high thermal deformation temperature, wherein tensile strength is no less than 30 MPa, flexural modulus is no less than 2000 MPa, the thermal deformation temperature is no less than 110 DEG C; the material can be used for a long time at a temperature of from -35 to 85 DEG C and can be used to prepare hinge materials which have requirements for high heat resistance and cold resistance.

Owner:SHANGHAI KINGFA SCI & TECH

External wall flexible waterproof putty powder and preparation method thereof

The invention relates to external wall flexible waterproof putty powder and a preparation method thereof. The flexible waterproof putty powder consists of the following components according to weight percentage: 22% of cement, 20.5% of heavy calcium carbonate, 15% of quartz powder, 8% of diatomite, 8% of talcum powder, 5% of kaolin, 5% of ash calcium, 3% of ethylene oxide, 2% of a retarder, 0.3% of HPMC, 3% of latex powder, 2% of wollastonite powder, 2% of a catalyst, 0.4% of a dehydrating agent, 0.5% of wood fiber, 0.3% of starch ether and 3% of other fillers, wherein the particle size of the heavy calcium carbonate powder is controlled as follows: d97 is smaller than 10 microns, d50 is 1.5 microns, the whiteness is greater than 95%, and the CaCO3 content is greater than or equal to 98%; the quartz powder with 1-3 microns accounts for 57%, 5-8 microns for 22%, 9-15 microns for 13%, and 15-18 microns for 8%; the diatomite is 260-300 mesh; for kaolin, d97 is about 15 microns, d50 is about 2 microns, and the whiteness is greater than 92%; the retarder includes 72% of a citric acid retarder and 28% of a sodium polyphosphate retarder; the length-diameter ratio of wollastonite powder is greater than 10; HPMC adopts hydroxypropyl methyl cellulose with the viscosity of 100,000. The external wall flexible waterproof putty powder has the characteristics of being white, fine and smooth, good in construction workability, high in strength, good in water resistance and anti-cracking.

Owner:杭州正博新型建筑材料有限公司

Chemical industrial gypsum building materials and method for manufacturing same

InactiveCN101139198AImprove protectionSimple production processSolid waste managementSlurryQuenching

The present invention relates to a chemical gesso building material, which consists of the following components according to weight ratio: 30-60 percent of waste gesso, 15-25 percent of powder coal; 20-30 percent of scoria and 5-20 percent of cement material. The chemical waste stone includes titanium gesso and phosphor gesso. The scoria includes titanium scoria, steel residue, water quenching residue and silicon powder stone. The chemical gesso also includes an assistant agent with the weight ratio of 0-5 percent. The preparation method for the chemical gesso building material includes the following steps: the raw materials are to be prepared according to the corresponding weight ratio for each component; the components are mixed and grinded to prepare the material slurry, and then is to be pressed into a mould; the mould is kept for more than 7 days. The present invention uses the chemical waste residue as the main materials and adopts simple process and equipments; without any calcining, the chemical gesso building products with much better physical force performance can be manufactured. The present invention is with much greater economical benefit and social benefit.

Owner:深圳清研创业投资有限公司

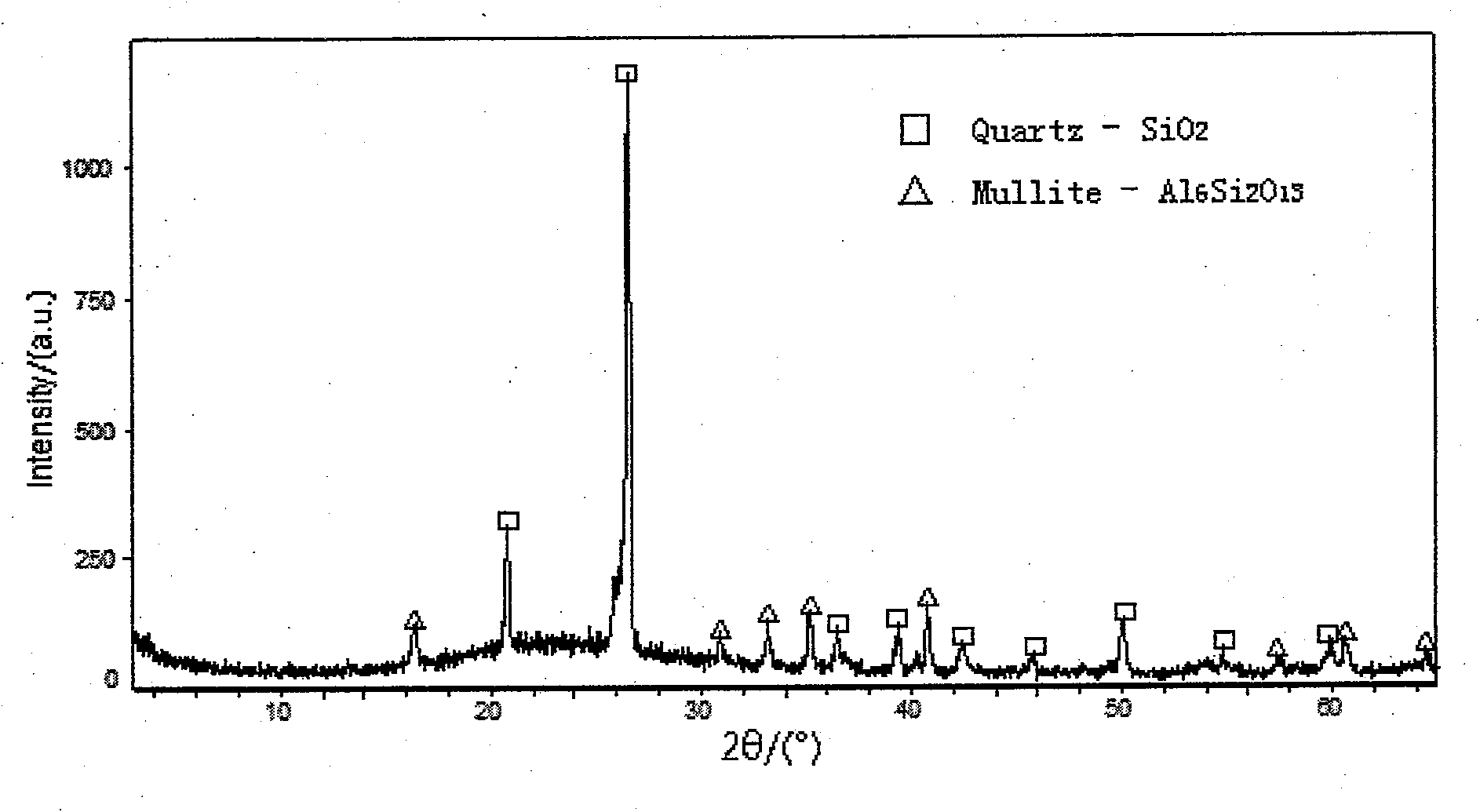

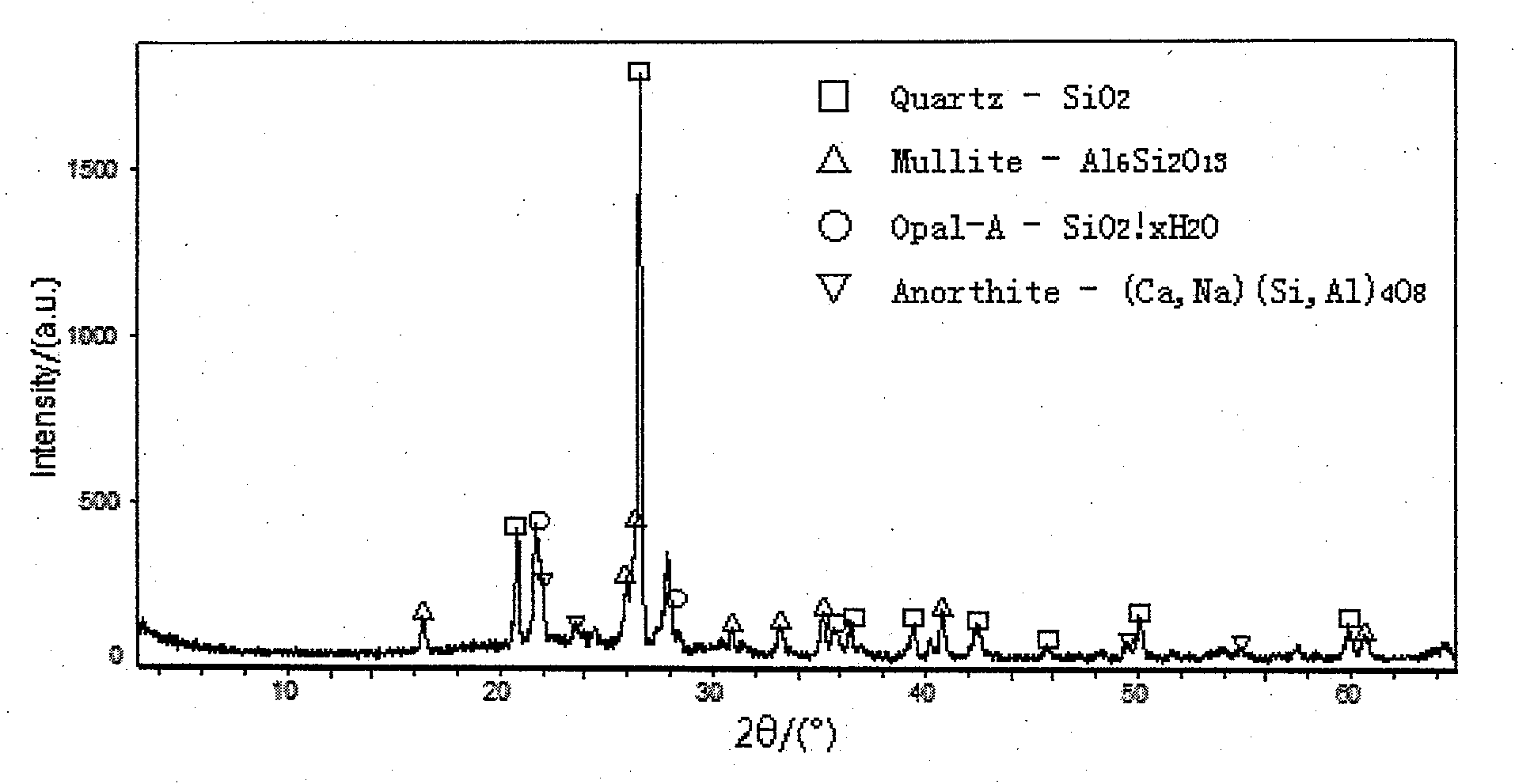

Fine-pottery sanitary ceramic body and manufacturing method thereof

ActiveCN101811858AReduce hygroscopic swellingHigh coefficient of thermal expansionClaywaresGranularityMullite

The invention relates to a fine-pottery sanitary ceramic body and a manufacturing method thereof and belongs to the technical field of ceramic products, which is used for reducing the deformation of a sanitary ceramic product and improving the quality of glaze. The fine-pottery sanitary ceramic body is characterized in that a body raw material comprises the following components in part by mass: 10 to 30 parts of ball clay, 30 to 60 parts of kaoline, 5 to 15 parts of porcelain clay, 5 to 15 parts of quartz and 5 to 15 parts of wollastonite, wherein the kaoline comprises 10 to 25 calcined kaoline. In the manufacturing method, the raw materials and the adding proportion of the fine-pottery body are preferably selected, the crystal phase content of mullite, quartz and the like is controlled, and the glass phase content and the high-temperature plastic deformation are reduced so as to fulfill the aim of reducing the deformation of fine-pottery sanitary ceramics; while reducing the hygroscopic expansion of the body, the manufacturing method improve thermal expansion coefficient of the body at the temperature of 200 DEG C to make the glaze bear high compressive stress, thereby improving the anti-cracking performance of products and ensuring enough long service life. Through the refinement of slurry granularity, the method remarkably reduces the occurrence of disadvantage of glaze pinholes, does not need to reduce the pinholes by using engobe, simplifies a production process, and improves the production efficiency and the qualification rate of the products.

Owner:HUIDA SANITARY WARE

Imitated-marble whole-body ceramic tile and preparation method thereof

The invention discloses an imitated-marble whole-body ceramic tile comprising a whole-body green tile layer and an overglaze layer distributed on the whole-body green tile layer; the whole-body green tile layer comprises the raw materials in percentage by weight: 22-40% of potassium sand, 15-30% of sodium potassium feldspar, 10-20% of potassium feldspar, 10-22% of black clay, 2-10% of kaoline, 2-6% of bentonite, 1-4% of raw talcum and 2-10% of pigment; and the overglaze layer comprises the raw materials in percentage by weight: 30-60% of sodium potassium feldspar, 15-30% of kaoline, 5-10% of wollastonite, 5-10% of aluminum oxide, 2-8% of talcum, 2-10% of zinc oxide and 10-20% of calcium carbonate. By using the imitated-marble whole-body ceramic tile, the problem that the whole-body ceramic tile is difficult to oxidize in a firing process is solved, the whole-body ceramic tile of which the thickness is larger than 1cm can be prepared, the whole-body ceramic tile is good in oxidization performance, and pinholes, black lines, air bubbles and the like are not easy to produce in an intermediate layer; and meanwhile, due to the regulation of components and proportion of an overglaze, the problem that the texture of the overglaze of the whole-body ceramic tile cannot reach the surface texture of natural marble is solved, and the surface texture of the whole-body ceramic tile is closer to that of the natural marble.

Owner:广东金牌陶瓷有限公司

Cement-based penetrable crystallized waterproof paint, preparation method and construction method thereof

The invention relates to a cement-based penetrable crystallized waterproof paint, a preparation method and a construction method thereof. The cement-based penetrable crystallized waterproof paint is prepared from the following raw materials in percentage by weight: 65 to 70 percent of cement, 3 to 10 percent of modified bentonite, 2 to 5 percent of modified sodium silicate, 1 to 5 percent of diffusant, 0.5 to 1 percent of penetrant, 2 to 10 percent of wollastonite and 15 to 25 percent of quartz sand. The waterproof paint can recover minute cracks on concrete interfaces and inhibit the water seepage and damp of base interfaces effectively. In addition, the waterproof paint is high in capacity of freezing resistance, high-temperature resistance, chloridion resistance and acid and alkali resistance, and has a long waterproof effect. According to the cement-based penetrable crystallized waterproof paint, leveling layers on the concrete interfaces are saved, and protective layers are savedafter the concrete interfaces are coated, so the waterproof construction is simple. The cement-based penetrable crystallized waterproof paint is suitable for constructional engineering such as underground engineering, subway tunnels, civil air-defense construction, water ponds, oil sumps, sewage tanks, barns, bathrooms, roof squares, parking platforms, high-grade roadways and the like, and is used for processing defects of cracks, honeycomb pitted surfaces and the like of the concrete interfaces.

Owner:姜哲 +1

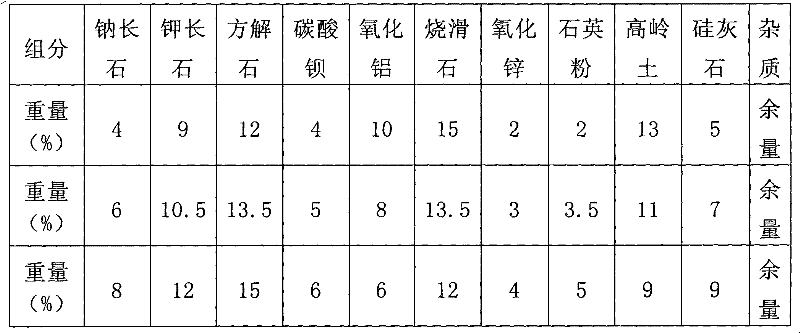

Complete polishing glaze archaizing brick overglaze and preparation method thereof

The invention relates to a complete polishing glaze archaizing brick overglaze and a preparation method thereof. The complete polishing glaze archaizing brick overglaze is prepared from the following raw materials by weight percent: 4-8% of albite, 9-12% of potassium feldspar, 12-15% of calcite, 4-6% of barium carbonate, 6-10% of alumina, 12-15% of burnt talcum, 2-4% of zinc oxide, 2-5% of quartz powder, 9-13% of kaolin, 5-9% of wollastonite and the balance of impurities. The preparation method comprises the following steps: carrying out ball milling in a ratio of weighed raw material to ballstone to ethylene glycol to squeegee oil of 1: (1.8-2): 0.25: 0.3, and simultaneously controlling the fineness degree as follows: the screenings of 325-mesh sieve is 0.3-0.4%; printing on ground glaze and fancy glaze layers through 100-mesh silk screen by using a continuous printing process; and finally, firing through a liquefied gas raceway kiln firing system. According to the invention, the purposes of improving the stability of the process and the quality of the product, reducing glaze material loss in production process, reducing cost and simultaneously avoiding the generation of a screen sticking problem in production are achieved.

Owner:霍镰泉

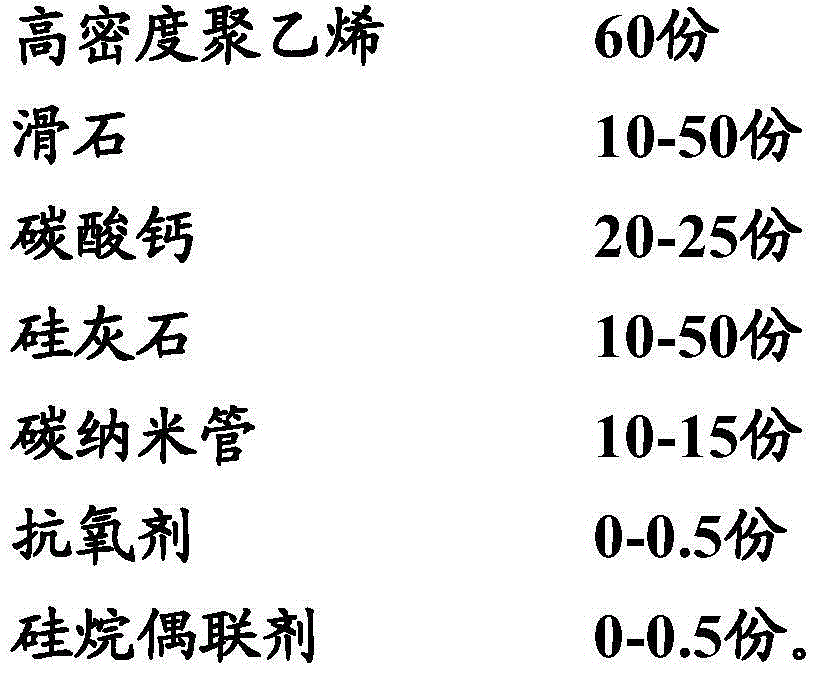

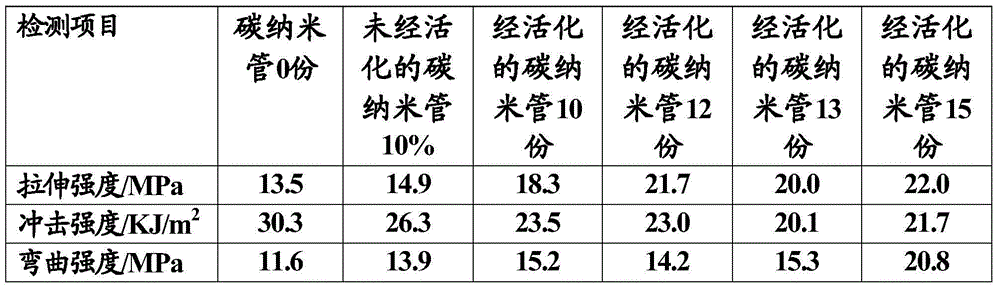

Modified high density polyethylene 3D printing moulding material and preparation method

ActiveCN103980593AHigh tensile strengthImprove impact toughnessLow-density polyethyleneCarbon nanotube

The invention discloses a modified high density polyethylene 3D printing moulding material with toughness. The modified high density polyethylene 3D printing moulding material comprises the following components, by weight, 60 parts of high density polyethylene, 10-50 parts of powdered steatile, 20-25 parts of calcium carbonate, 10-50 parts of wollastonite, 10-15 parts of carbon nanotube, 0.1-0.5 part of an antioxidant and 0.1-0.5 part of a silane coupling agent. The modified high density polyethylene material has high tensile strength and good impact toughness. Application value of high density polyethylane can be raised and its application field can be widened. The high density polyethylene material is more in line with characteristics of a 3D printing material. The material provided by the invention is environmentally friendly, has low cost and has important industrial application value.

Owner:INST OF CHEM CHINESE ACAD OF SCI

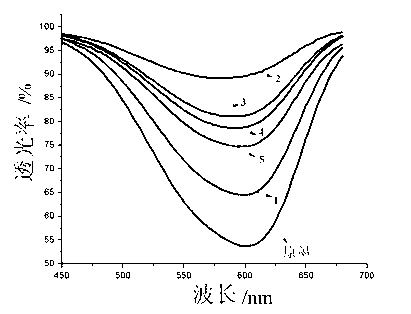

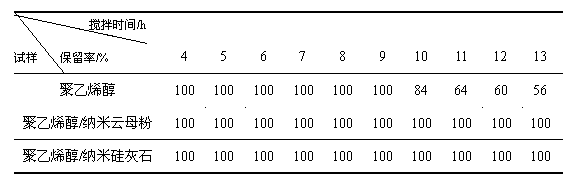

Polyvinyl alcohol/ inorganic nanocomposite hydrogel and preparation method thereof

The invention discloses polyvinyl alcohol / inorganic nanocomposite hydrogel, which is characterized by being formed by the following components: 30-90 parts by weight of polyvinyl alcohol and 0.1-20 parts by weight of inorganic nanocomposite particles through a chemical crosslinking gel method, wherein the inorganic nanocomposite particles comprise nano clay, nano mica powder, a nano molecular sieve, nano wollastonite, nano graphite, nanosilicon dioxide or a carbon nano tube. With the adoption of the polyvinyl alcohol / inorganic nanocomposite hydrogel, the mechanical strength of polyvinyl alcohol hydrogel is enhanced on the basis of not influencing the moisture of the hydrogel, the service life is prolonged, the permeability of the polyvinyl alcohol hydrogel is improved, and a channel is reserved for transmission of matters. As the selection of the materials, the production cost is controlled, and the better economic benefit is brought. The invention also discloses a preparation method of the polyvinyl alcohol / inorganic nanocomposite hydrogel. The preparation method is simple and feasible to operate and good in mechanical strength, and can be produced industrially.

Owner:CHINA PETROCHEMICAL CORP +2

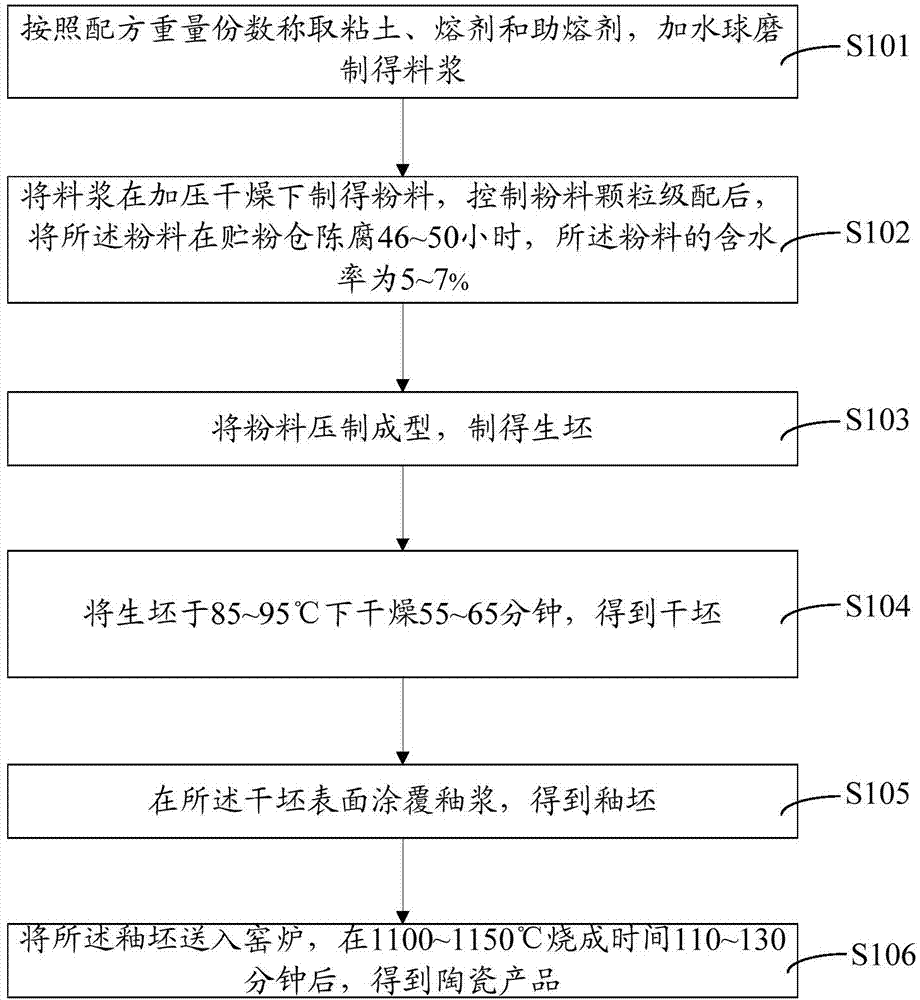

Ceramic formula and preparation method for ceramic product

The invention provides a ceramic formula, comprising, by weight, 55 to 65 parts of clay, 20 to 30 parts of a flux and 15 to 23 parts of a fluxing agent, wherein the clay is a mixture of purple sandshale and china clay mixed according to a weight ratio of 0.67 to 2.0, the flux is shale, and the fluxing agent is one or more selected from the group consisting of limestone, calcite, diopside, wollastonite, dolomite, talcum and industrial waste residue. A preparation method for a ceramic product comprises the following steps: weighing the clay, the flux and the fluxing agent according to the formula, carrying out crushing and screening with a 250-mesh sieve, wherein the weight of screen residue is 1 to 1.5%, adding water, carrying out blending to obtain slurry and then carrying out drying and granulation so as to obtain powder; grading particles and then carrying out molding so as to prepare a green body; carrying out drying so as to prepare a dry body; and carrying out firing so as to prepare a seasonal ceramic body. According to the ceramic formula and the preparation method for the ceramic product in the invention, raw materials are cheap, process is simple, firing temperature is reduced, production cost is decreased, investment for production equipment is lowered down, production efficiency is improved, and energy consumption is reduced.

Owner:怀化市亿智陶瓷有限公司

High-sodium low-fluorine continuous casting mould fluxes and preparation method thereof

The invention relates to high-sodium low-fluorine covering slag, which is prepared from raw materials of wollastonite, limestone, quartz sand, fluorite, bauxite, manganese carbonate, magnesia, hydrous borax, industrial soda, lithium carbonate, and carbonaceous materials, and the chemical components of the covering slag meets the following weight percentage: more than 30 and less than 34 percent of CaO, more than 30 and less than 38 percent of SiO2, more than 12 and less than 25 percent of Na2O, less than 4 percent of MgO, less than 8 percent of MnO, less than 4 percent of B2O3, less than 1.5 percent of Li2O, less than 4 percent of Al2O3, less than 2 percent of F, more than 4 percent and less than 10 percent of C, and the balance being impurities. In the covering slag, the ratio of sigma CaO to the SiO2 is controlled to between 0.8 and 1.15 to ensure that the fused mass of the covering slag does not separate out crystals at high temperature and liquid slag in a slag film can lubricate a casting blank. Aiming at that the content of fluorine has adverse influence on environment and equipment, the invention adopts high-sodium low-fluorine continuous casting covering slag which not only can meet the requirement of coordinated control of heat transfer and lubrification of a continuous casting covering slag for crack sensitive steel to cast casting blank with good surface quality, but also can reduce the fluorine content in air and secondary cooling water, thus the air pollution is reduced and the corrosion of fluorine-contained water to equipment is reduced.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com