Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2133 results about "Chromium oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalyst and method for reducing nitrogen oxides in exhaust streams with hydrocarbons or alcohols

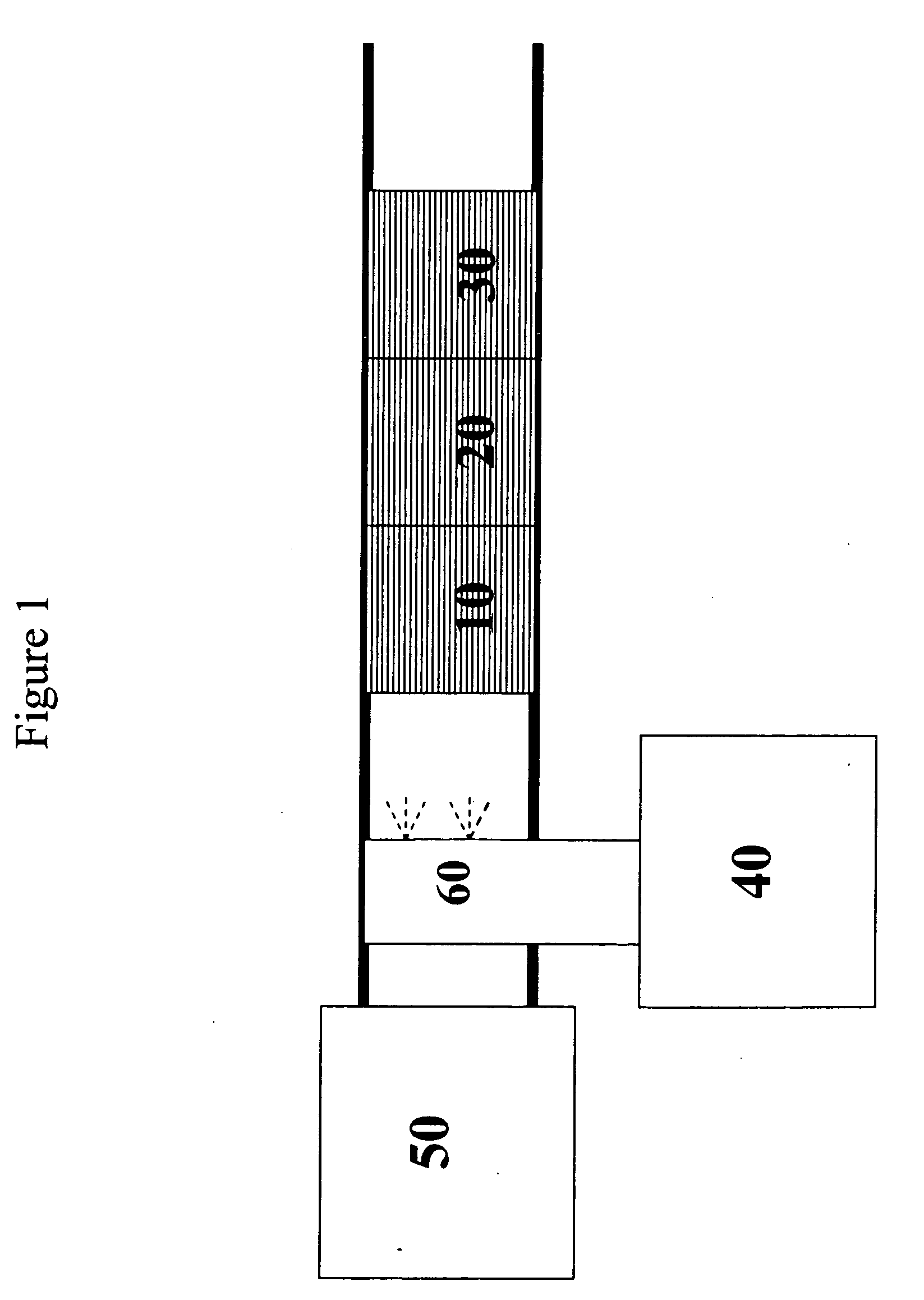

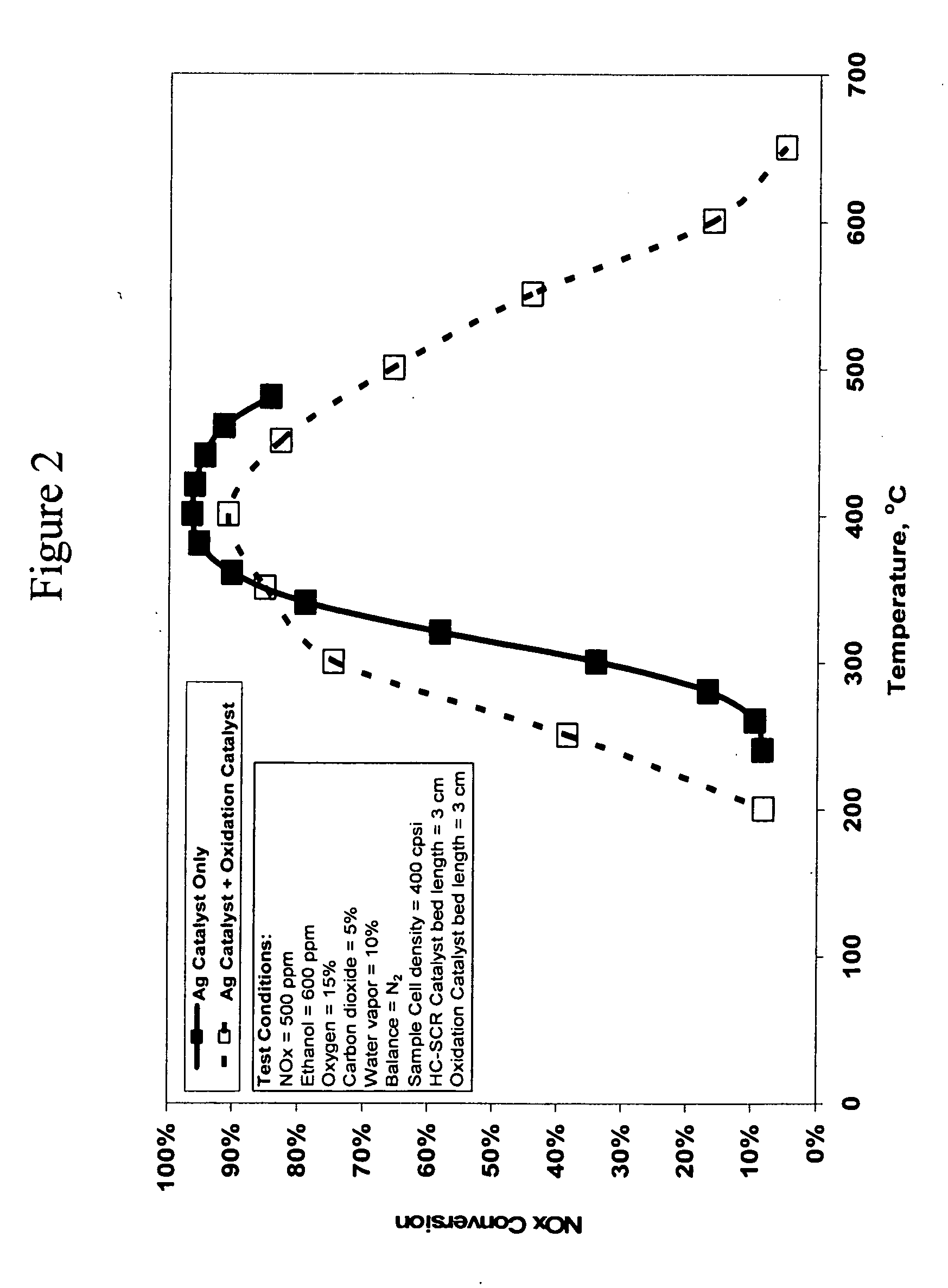

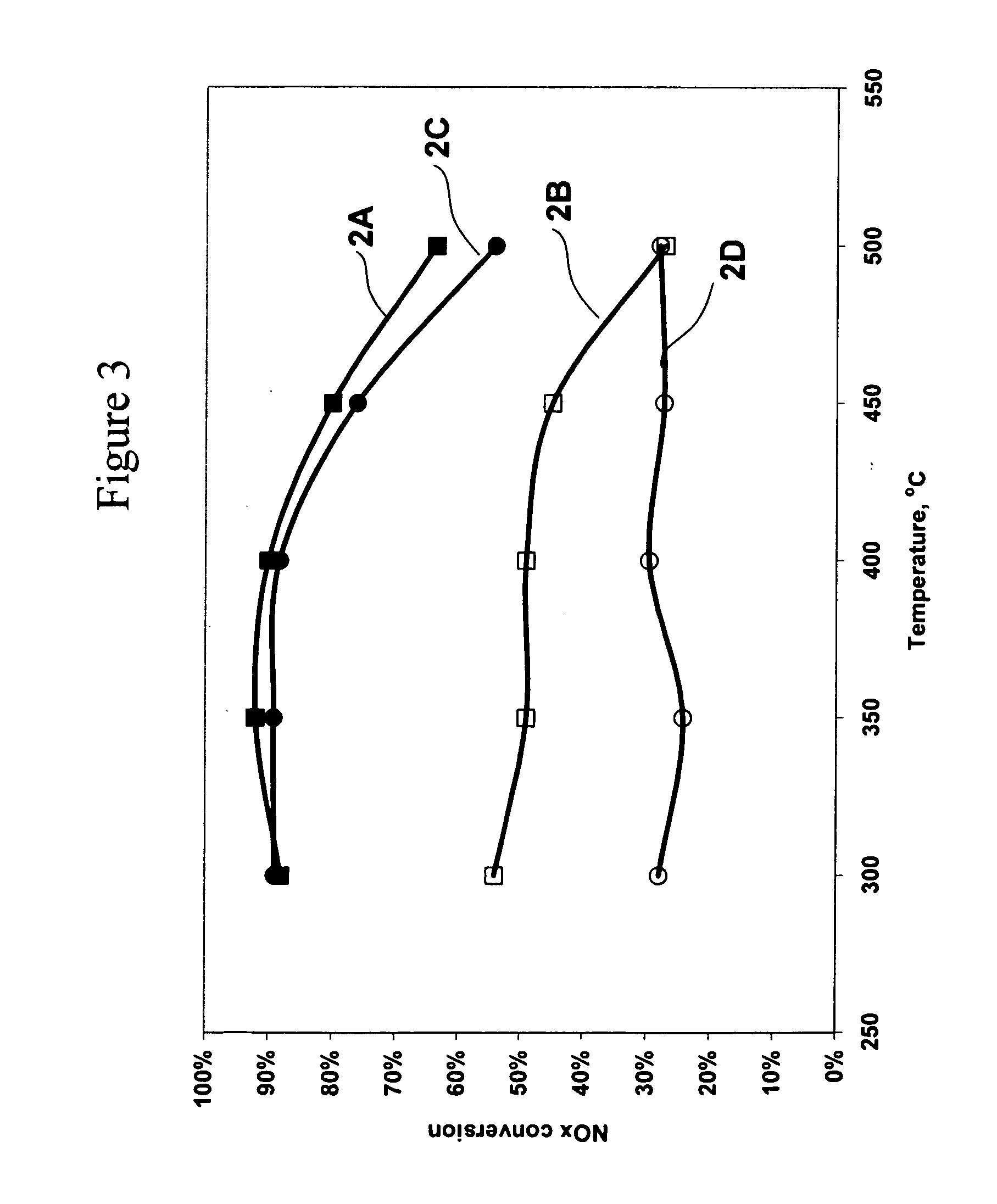

A catalyst system and a method for reducing nitrogen oxides in an exhaust gas by reduction with a hydrocarbon or oxygen-containing organic compound reducing agent are provided. The catalyst system contains a silver catalyst and a modifier catalyst, where the modifier catalyst contains a modifier oxide, where the modifier oxide is selected from the group consisting of iron oxide, cerium oxide, copper oxide, manganese oxide, chromium oxide, a lanthanide oxide, an actinide oxide, molybdenum oxide, tin oxide, indium oxide, rhenium oxide, tantalum oxide, osmium oxide, barium oxide, calcium oxide, strontium oxide, potassium oxide, vanadium oxide, nickel oxide, tungsten oxide, and mixtures thereof. The modifier oxide is supported on an inorganic oxide support or supports, where at least one of the inorganic oxide supports is an acidic support. The catalyst system of the silver catalyst and the modifier catalyst provides higher NOx conversion than either the silver catalyst or the modifier catalyst alone.

Owner:CATALYTIC SOLUTIONS INC

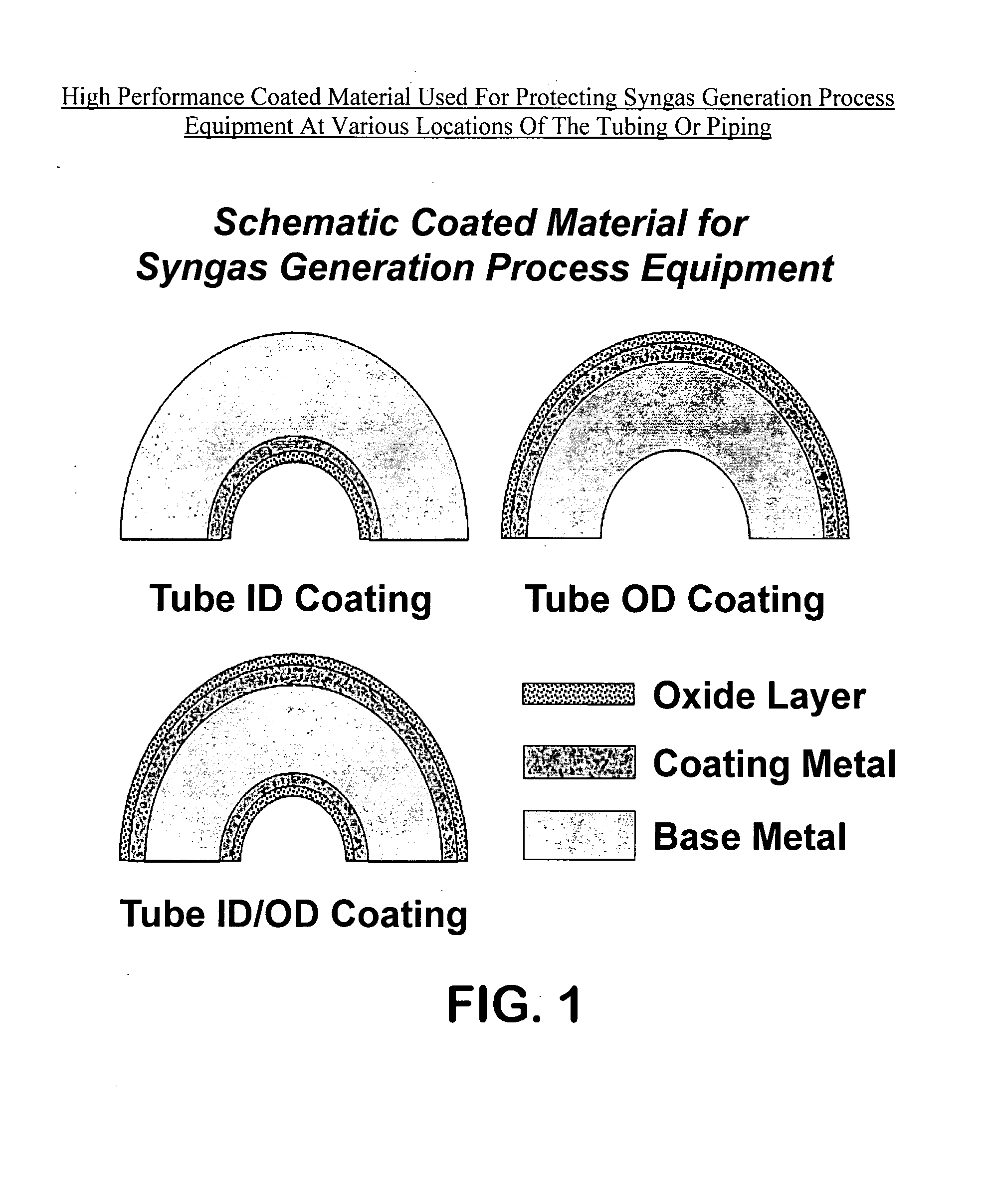

Marble-like composite materials and methods of preparation thereof

InactiveUS20140127450A1Low costIncrease consumptionLayered productsCoatingsCalcium silicateFlexural strength

The invention provides novel marble-like composite materials and methods for preparation thereof. The marble-like composite materials can be readily produced from widely available, low cost raw materials by a process suitable for large-scale production. The precursor materials include calcium silicate and calcium carbonate rich materials, for example, wollastonite and limestone. Various additives can be used to fine-tune the physical appearance and mechanical properties of the composite material, such as pigments (e.g., black iron oxide, cobalt oxide and chromium oxide) and minerals (e.g., quartz, mica and feldspar). These marble-like composite materials exhibit veins, swirls and / or waves unique to marble as well as display compressive strength, flexural strength and water absorption similar to that of marble.

Owner:RIMAN RICHARD E +1

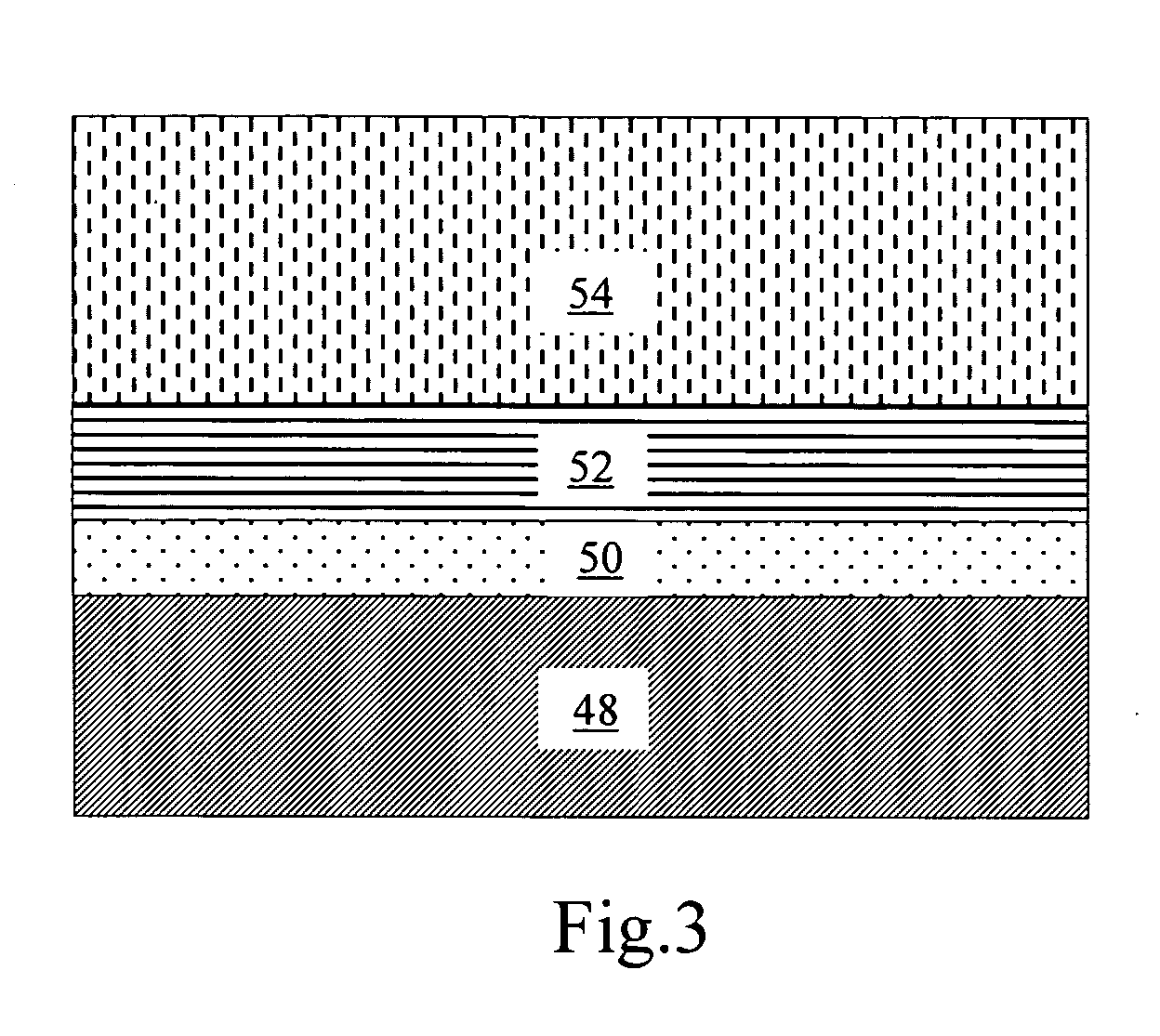

Light-emitting element and light-emitting device using the same

InactiveUS20050116633A1Luminous stabilityEfficient emissionsDischarge tube luminescnet screensElectroluminescent light sourcesEngineeringCopper oxide

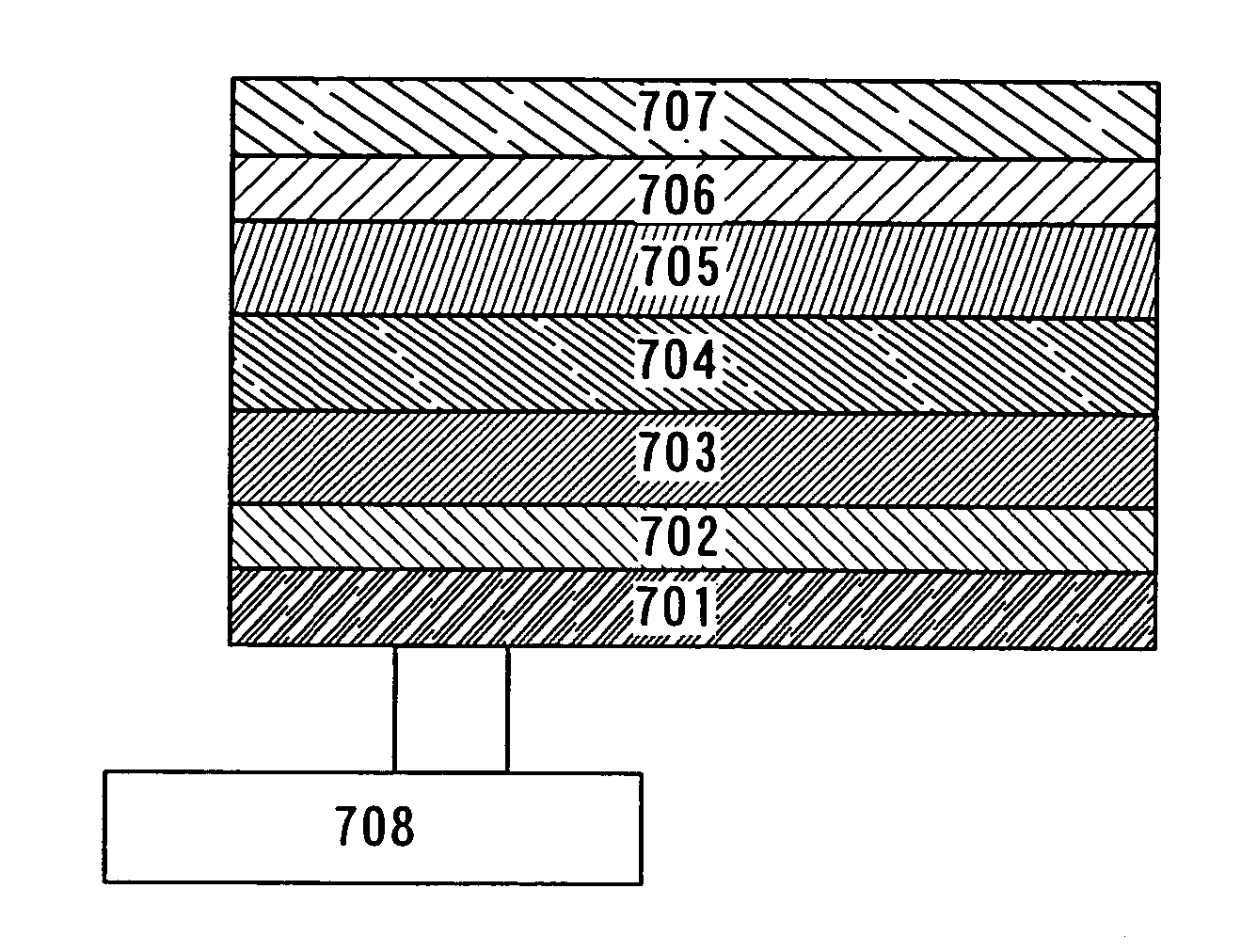

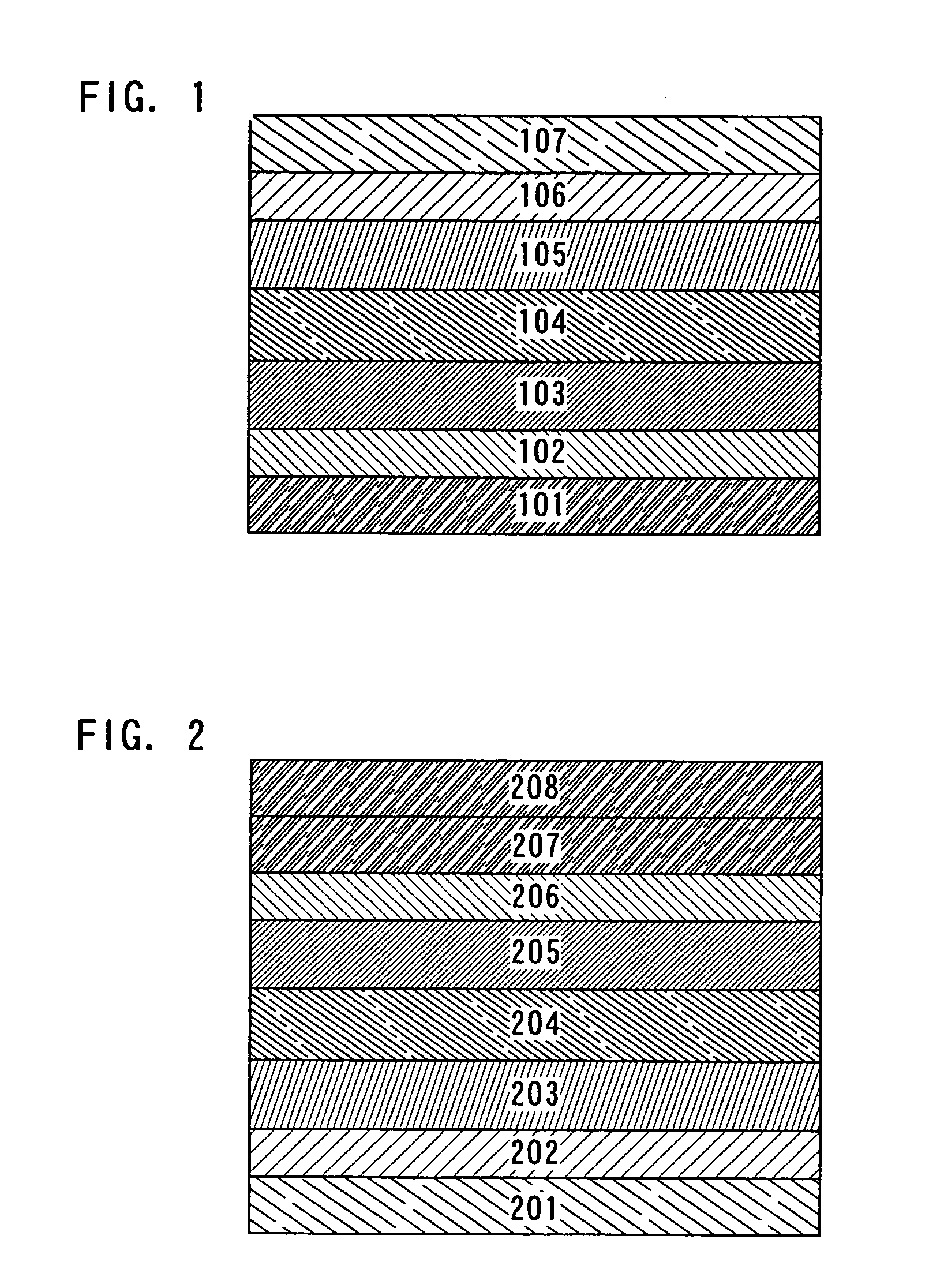

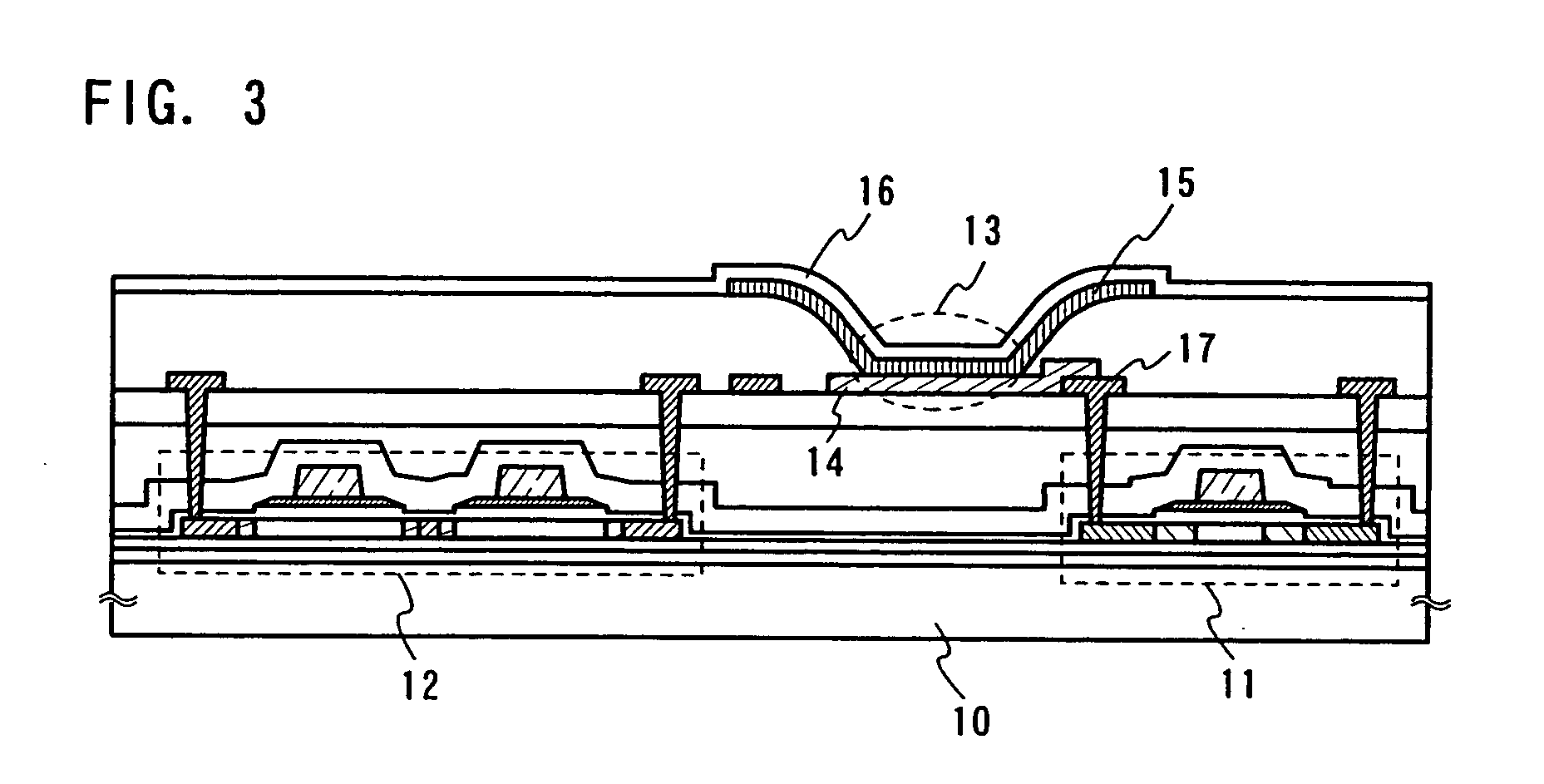

It is an object of the invention is to provide a light-emitting element in which failure of the light-emitting element due to separation can be controlled and stable luminescence can be obtained with high-efficiency and for a long stretch of time by controlling separation of layers constituting the light-emitting element. According to one aspect of a light-emitting element of the invention, the light-emitting element sandwiches a plurality of layers between a pair of electrodes, wherein at least one layer of the plurality of layers is a layer containing a substance selected from bismuth oxide, cobalt oxide, chromium oxide, copper oxide, nickel oxide, and titanium oxide, or at least one layer of layers different from a light-emitting layer among the plurality of layers is a mixed region of one substance selected from bismuth oxide, cobalt oxide, copper oxide, magnesium oxide, nickel oxide, zinc oxide, and titanium oxide and an organic compound.

Owner:SEMICON ENERGY LAB CO LTD

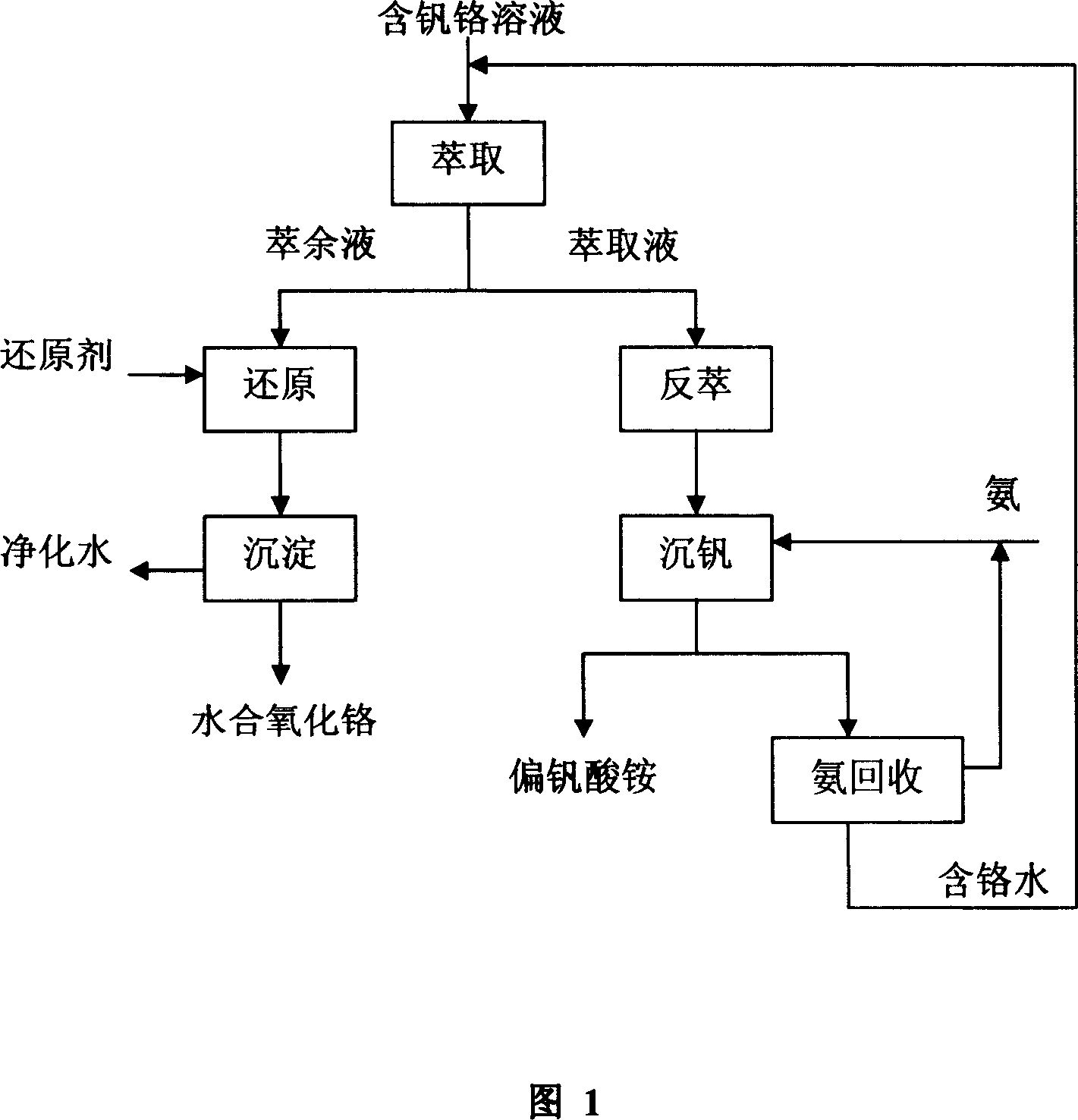

Method for separating and reclaiming vanadium and chromium from solution containing vanadium and chromium

ActiveCN101121962ALow costSimple processProcess efficiency improvementHydration reactionDistillation

This invention relates to an entirely new technology of completely recovering chromium and vanadium from vanadium-chromium miscible liquid. The main procedures include: first a primary-secondary compound amine extracting agent contacts the vanadium-chromium miscible liquid by means of countercurrent contact and extract, so as to extract most of vanadium and a small amount of chromium into a organic phase while most of chromium stays into a aqueous phase; and a reduction reaction is conducted with pH of acid adjustable faffinate (aqueous phase) and a certain amount of a reducing agent; the sodium hydroxide is used for adjusting pH value of the solution and filter, and finally the product is hydrous chromium oxide; at that time, the lye is used as a stripping agent; the vanadium is stripped from the vanadium-rich organic phase into water in the manner of countercurrent contact; and the vanadium is separated from the solution witthe method of ammonium precipitation and in the form of ammonium metavanadate; and finally the supernatant clear solution of the one is processed with deposited vanadium with a high-efficient distillation technology, and the strong aqua ammonia is left in the tower top and deamidization solution is left in the tower bottom until the extraction process is reached. The invention uses the primary-secondary compound amine as the extracting agent, extracts and separates vanadium and chromium selectively at a low temperature. The invention not only has a simple process flow, but also is low-cost, quite applicable in large-scale industrial production. In addition, the invention also provides high-purity ammonium metavanadate and 16 percentage strong aqua ammonia, and makes sure the vanadium and chromium can be completely recovered through re-use of the solution.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

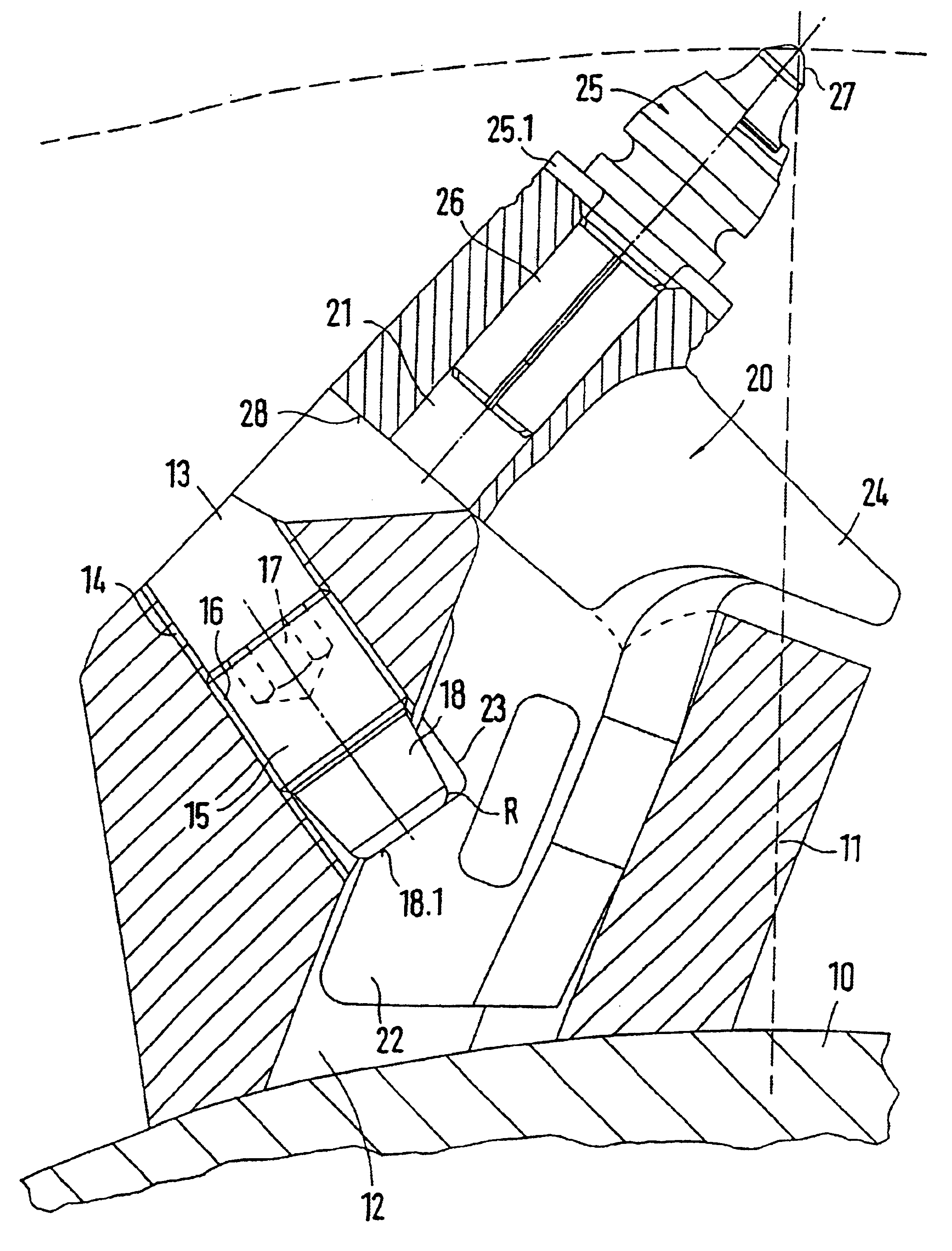

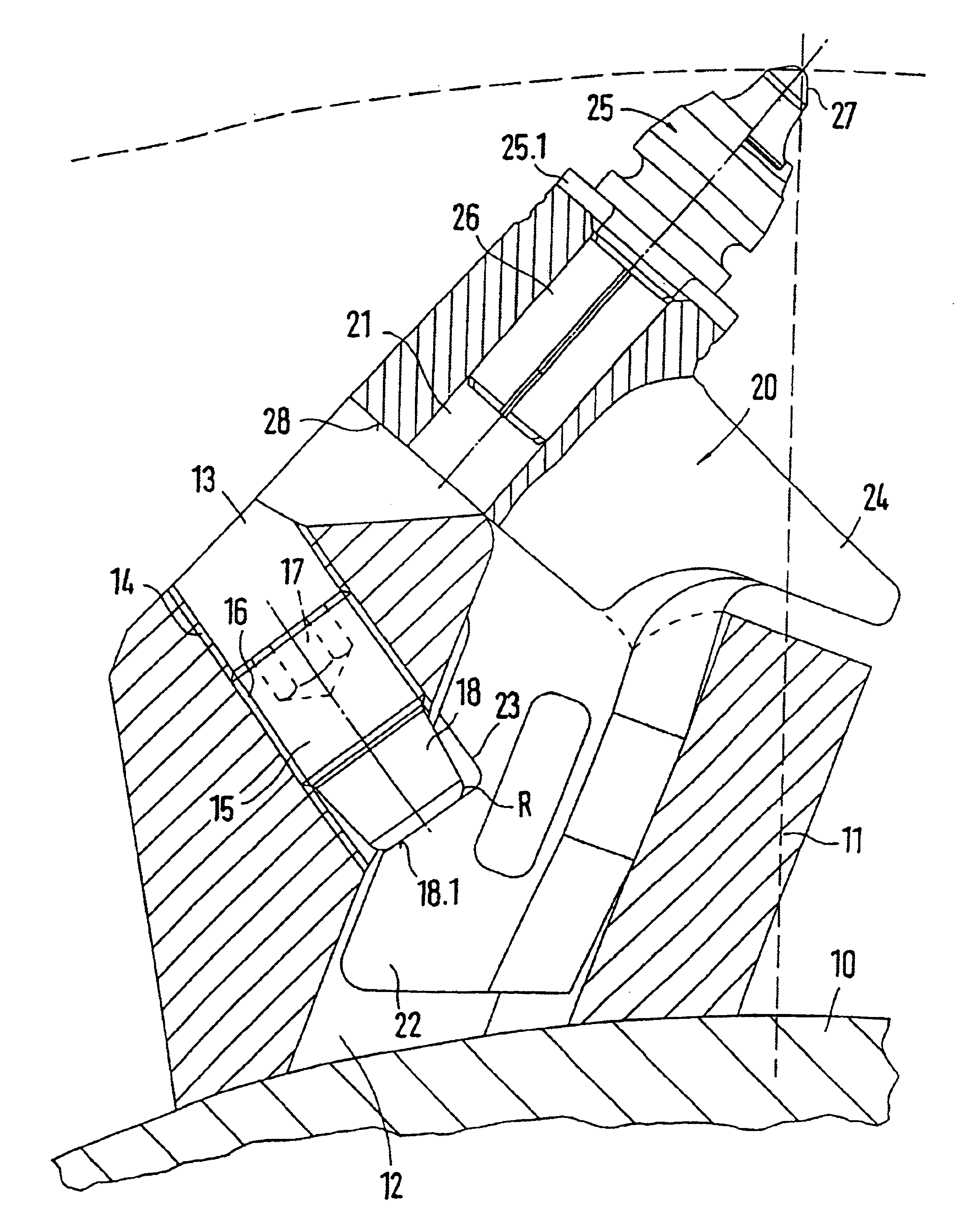

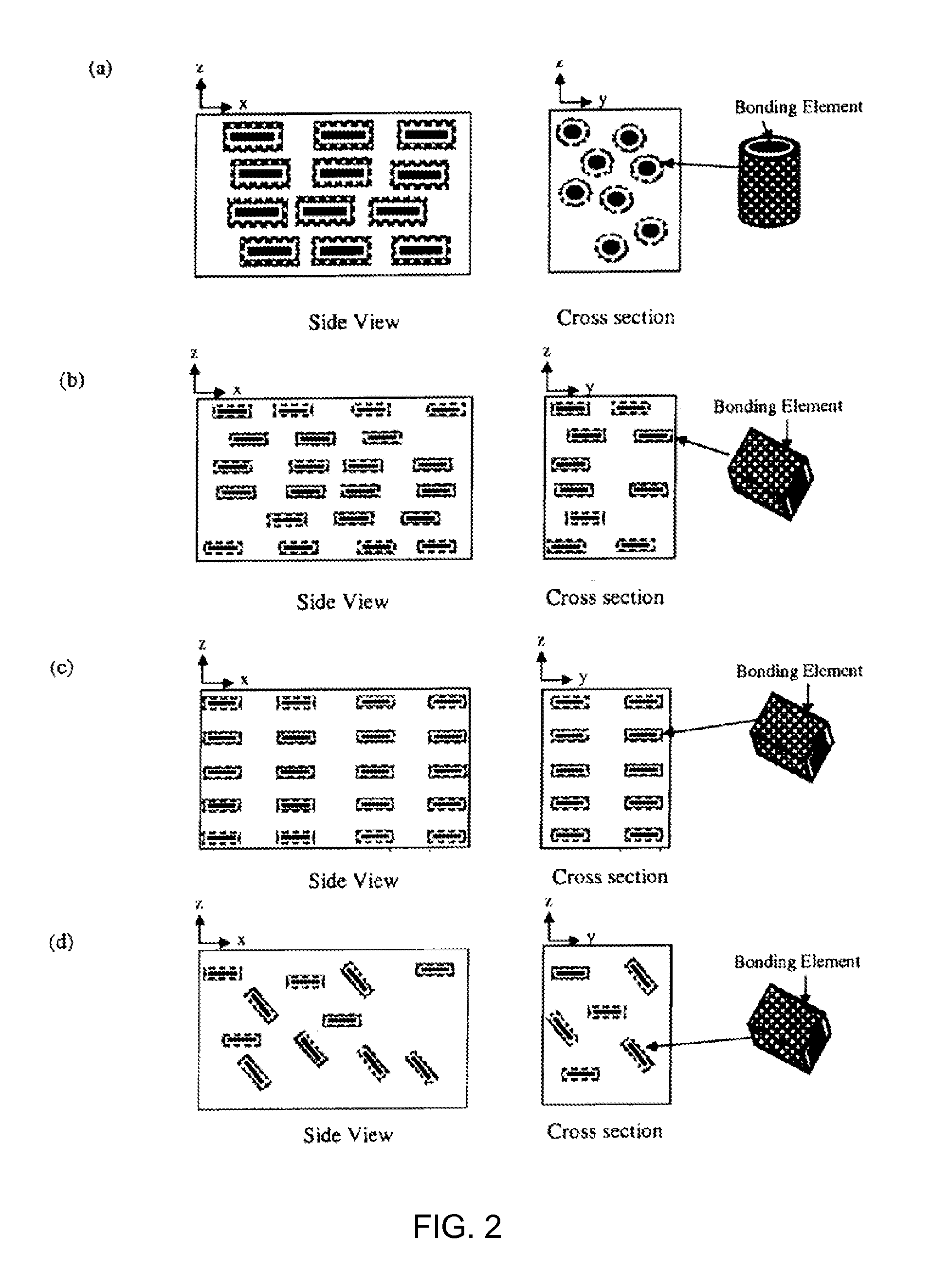

Chisel holder changing system with chisel holder receivers

A chisel holder changing system having a base element with a chisel holder receiver, into which a chisel holder equipped with a chisel can be inserted, wherein the chisel holder is inserted with a holder shaft into the chisel holder receivers and is maintained therein with the aid of bracing screws. Bracing screws can be screwed into a threaded receiver of the base element and during this are supported under tension in a bracing receiver of the holder shaft of the chisel holder. If in a chisel holder changing system in accordance with this invention the surfaces of the outer screw thread of the bracing screw and / or of the inner screw thread of the threaded receivers of the chisel holder receivers have a metallic layer of zinc and aluminum lamellas and a mineral chromium oxide bonding agent, which is burned in after the application, the screw connections are improved so that larger prestressing forces / tightening torques can be transmitted without damage to the screw connections.

Owner:WIRTGEN GMBH

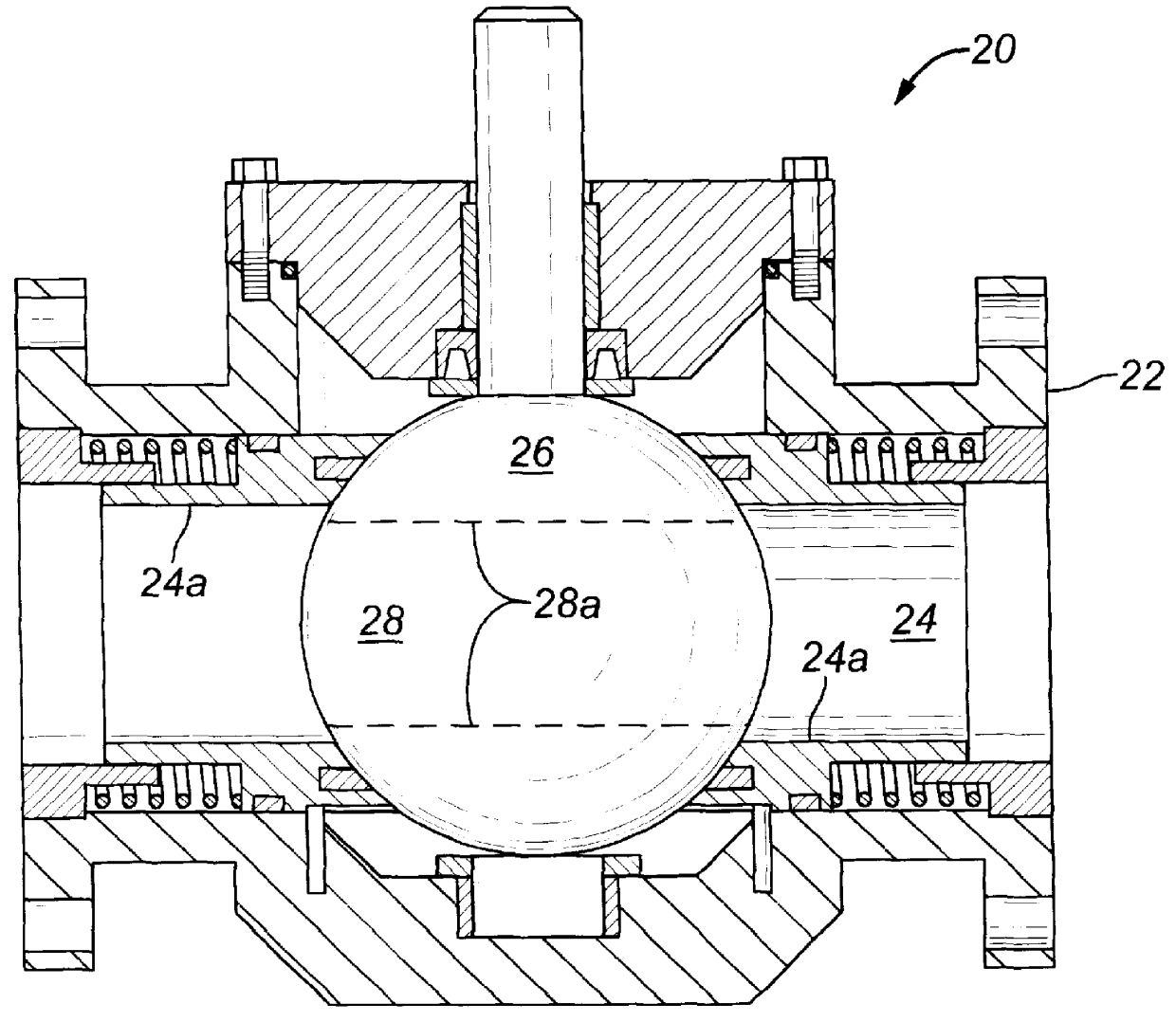

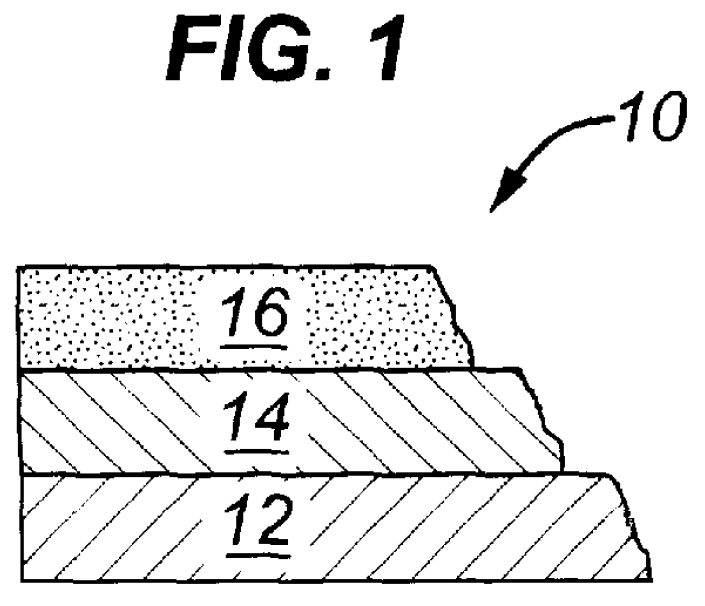

Metal element having a laminated coating

A laminated coating protects a metal substrate in a highly corrosive and highly erosive environment. A coating of a noble metal, such as gold, is bonded to the metal substrate, such as by electroplating or by flame spray. The noble-metal coating protects the metal substrate from the corrosive effects of a process fluid. A ceramic material, such as chromium oxide or titanium dioxide, is bonded to the noble-metal coating. Ceramic materials resist abrasion very well, which protects the underlying noble-metal coating from the erosive / abrasive effects of the process solution, which may contain suspended solids that are highly abrasive. However, the ceramic material is somewhat porous, which allows some seepage of the process fluid. The metal substrate is protected from the corrosive effects of the process fluid by the noble-metal coating.

Owner:WATSON GRINDING & MFG

Thermal protective coating

ActiveUS7105047B2Extended shelf lifeReduce weightAlkali metal silicate coatingsPretreated surfacesCalcium silicateSodium Bentonite

A coating, method of coating and substrates coated thereby, wherein the coating contains an inorganic adhesive such as an alkali / alkaline earth metal silicate such as sodium silicate, potassium silicate, calcium silicate, and magnesium silicate; a filler such as a metal oxide for example silicon dioxide, aluminum oxide, titanium dioxide, magnesium oxide, calcium oxide and boron oxide; and one or more emissivity agents such as silicon hexaboride, carbon tetraboride, silicon tetraboride, silicon carbide, molybdenum disilicide, tungsten disilicide, zirconium diboride, cupric chromite, or metallic oxides such as iron oxides, magnesium oxides, manganese oxides, chromium oxides and copper chromium oxides, and derivatives thereof. In a coating solution, an admixture of the coating contains water. A stabilizer such as bentonite, kaolin, magnesium alumina silicon clay, tabular alumina and stabilized zirconium oxide may be added.

Owner:WESSEX

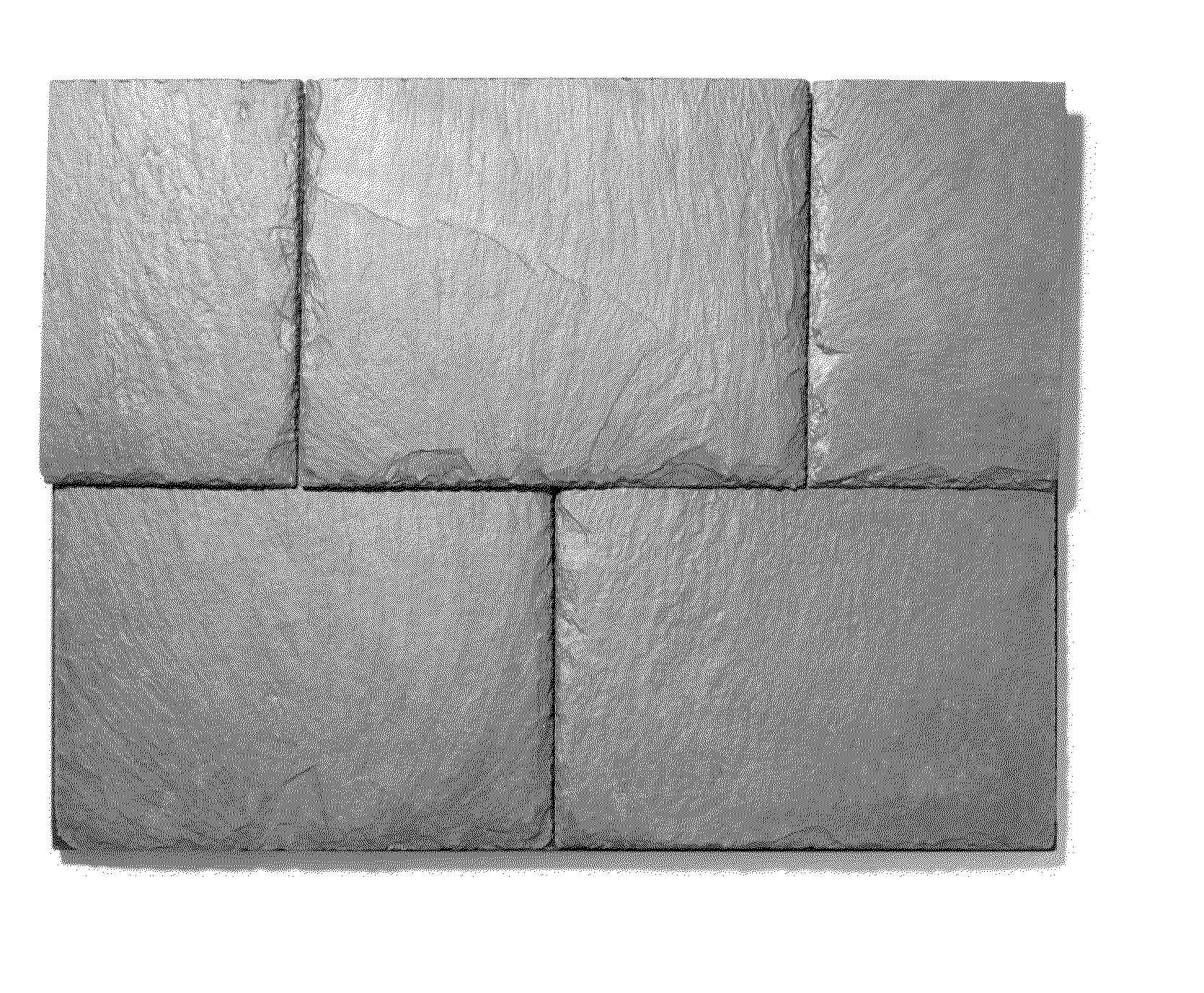

Slate-like composite materials and methods of preparation thereof

InactiveUS20140127458A1Low costIncrease consumptionRoof covering using tiles/slatesRecord information storageCalcium silicateFlexural strength

The invention provides novel slate-like composite materials and methods for preparation thereof. The slate-like composite materials can be readily produced from widely available, low cost precursor materials by a process suitable for large-scale production. The precursor materials include calcium silicate, for example, wollastonite, and particulate filler materials which comprise silicon dioxide-rich materials such as quartz, mica, feldspar, sand and glass. Additives can include calcium carbonate-rich and magnesium carbonate-rich materials. Various additives can be used to fine-tune the physical appearance and mechanical properties of the composite material, such as colorants such as particles of colored materials, such as colored glass, colored sand, and colored quartz particles, and pigments (e.g., black iron oxide, cobalt oxide and chromium oxide). These slate-like composite materials exhibit visual patterns unique to slate as well as display compressive strength, flexural strength and water absorption similar to that of slate.

Owner:ZAMBRZYCKI DAWID +6

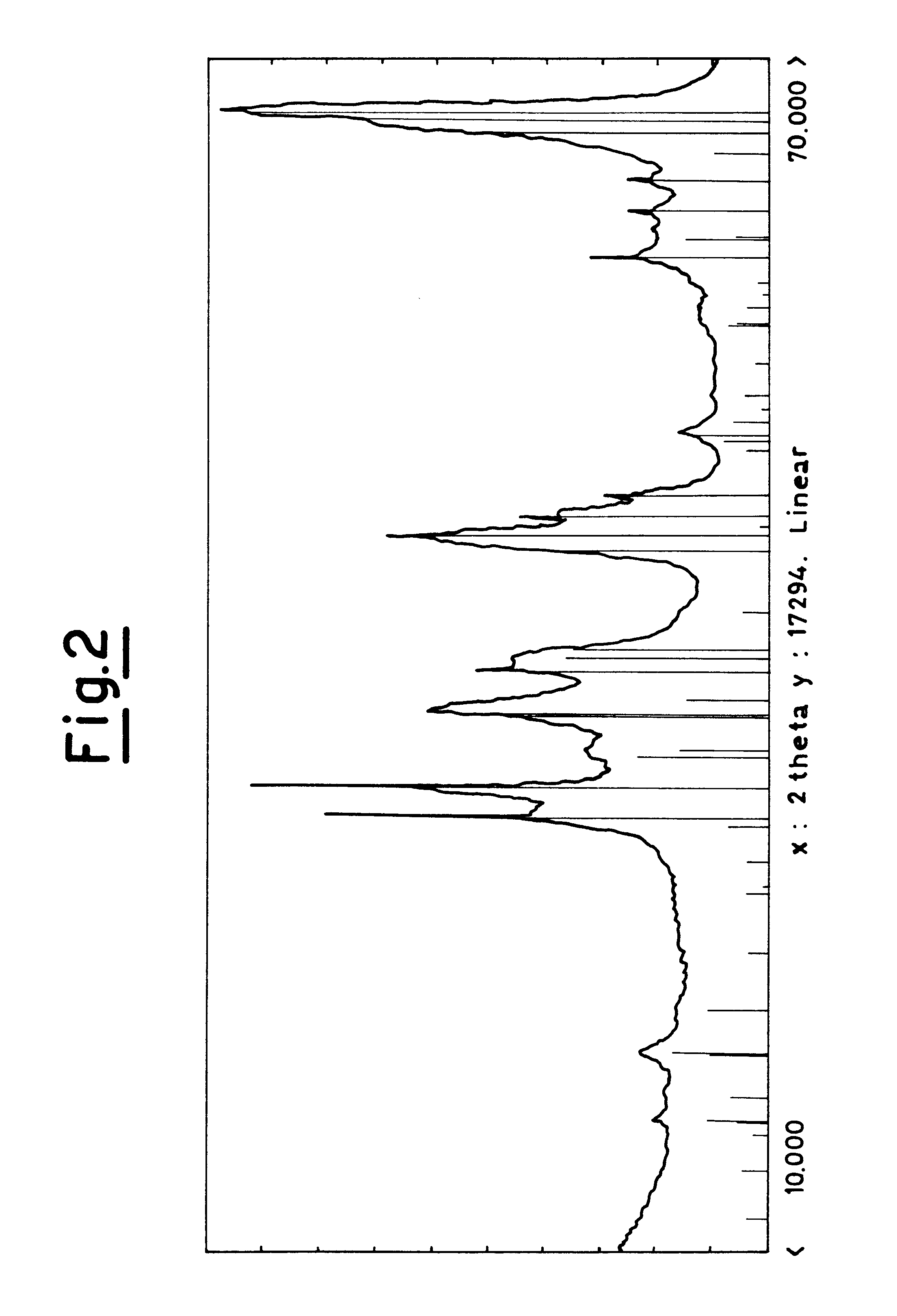

Compositions containing chromium, oxygen, and at least two modifier metals selected the group consisting of gold, silver, and palladium, their preparation, and their use as catalysts and catalyst precursors

InactiveUS20080207962A1Preparation by dehalogenationPreparation by hydrogen halide split-offNitrateAmmonium hydroxide

A catalyst composition is disclosed that includes chromium, oxygen, and at least two of gold, silver, and palladium as essential constituent elements. The amount of modifier metals (gold, silver, and / or palladium) in the composition is from about 0.05 atom % to about 10 atom % based on the total amount of chromium and modifier metals. Also disclosed is a process for changing the fluorine distribution (i.e., content and / or arrangement) in a hydrocarbon or halogenated hydrocarbon in the presence of the catalyst composition; and methods for preparing said catalyst composition. One preparation method involves (a) co-precipitating a solid by adding ammonium hydroxide (aqueous ammonia) to an aqueous solution of soluble salts of modifier metals and a soluble chromium salt that contains at least three moles of nitrate per mole of chromium in the solution and has a modifier metal content of from about 0.05 atom % to about 10 atom % of the total content of modifier metals and chromium in the solution to form an aqueous mixture containing co-precipitated solid; (b) drying the co-precipitated solid formed in (a); and (c) calcining the dried solid formed in (b) in an atmosphere containing at least 10% oxygen by volume. Another preparation method involves (a) impregnating solid chromium oxide with a solution of a soluble modifier metal salts; (b) drying the impregnated chromium oxide prepared in (a); and optionally; (c) calcining the dried solid. Yet another preparation method involves mixing multiple compositions, each comprising chromium, oxygen, and at least one modifier metal.

Owner:EI DU PONT DE NEMOURS & CO

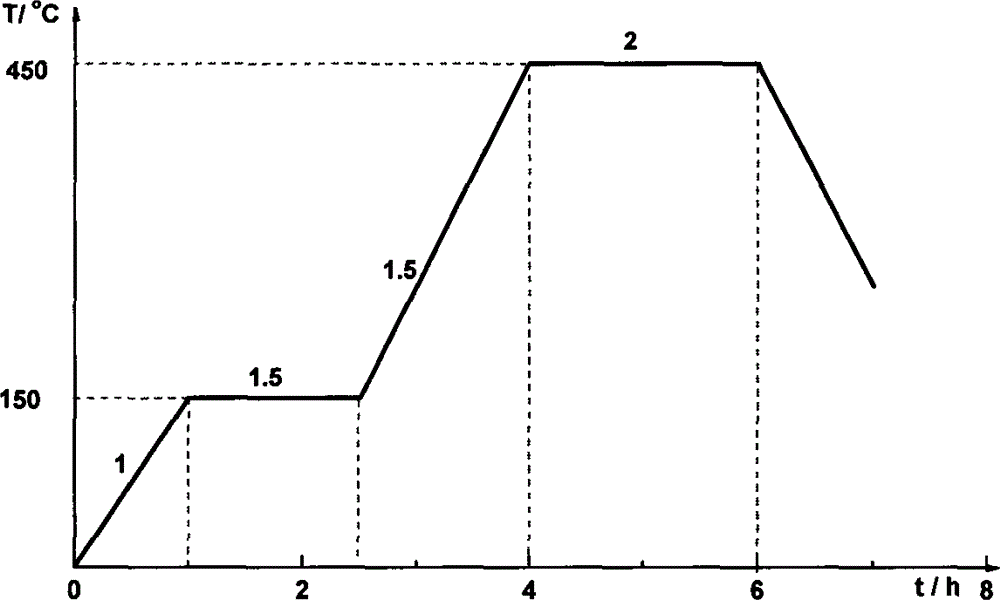

Propane dehydrogenation to propylene catalyst and preparation and applications thereof

InactiveCN102019178ALow costSimple methodCatalyst activation/preparationHydrocarbonsAir atmosphereAlkaline earth metal

The invention relates to a propane dehydrogenation to propylene catalyst and preparation and applications thereof. The propane dehydrogenation to propylene catalyst is characterized by being a composition prepared from Gamma-Al2O3, a kind or many kinds of chromium oxides, a kind or many kinds of rare earth oxides and a kind or many kinds of alkali metal oxides, wherein the Gamma-Al2O3 accounts for 30-95%, the chromium oxides account for 1-50%, the rare earth oxides account for 0-30%, and the alkali metal oxides account for 0-10%. The preparation process comprises the following steps of: adding active components, such as chromium, rare earth, alkali metal and the like into aluminum oxide grout, regulating the pH value of 1-5 to form gelatum with concentrated nitric acid, and spraying and drying to form microballoons; then roasting for 0-5 hours at 250-750 DEG C in a nitrogen atmosphere; and roasting for 0.1-20 hours at 250-1000 DEG C in an air atmosphere. The obtained catalyst is in a fluid bed reactor, and reaction conditions comprise 400-700 DEG C of temperature, 0.01-3MPa of absolute pressure and 10-10000 h-1 of volume hourly space velocity.

Owner:卓润生

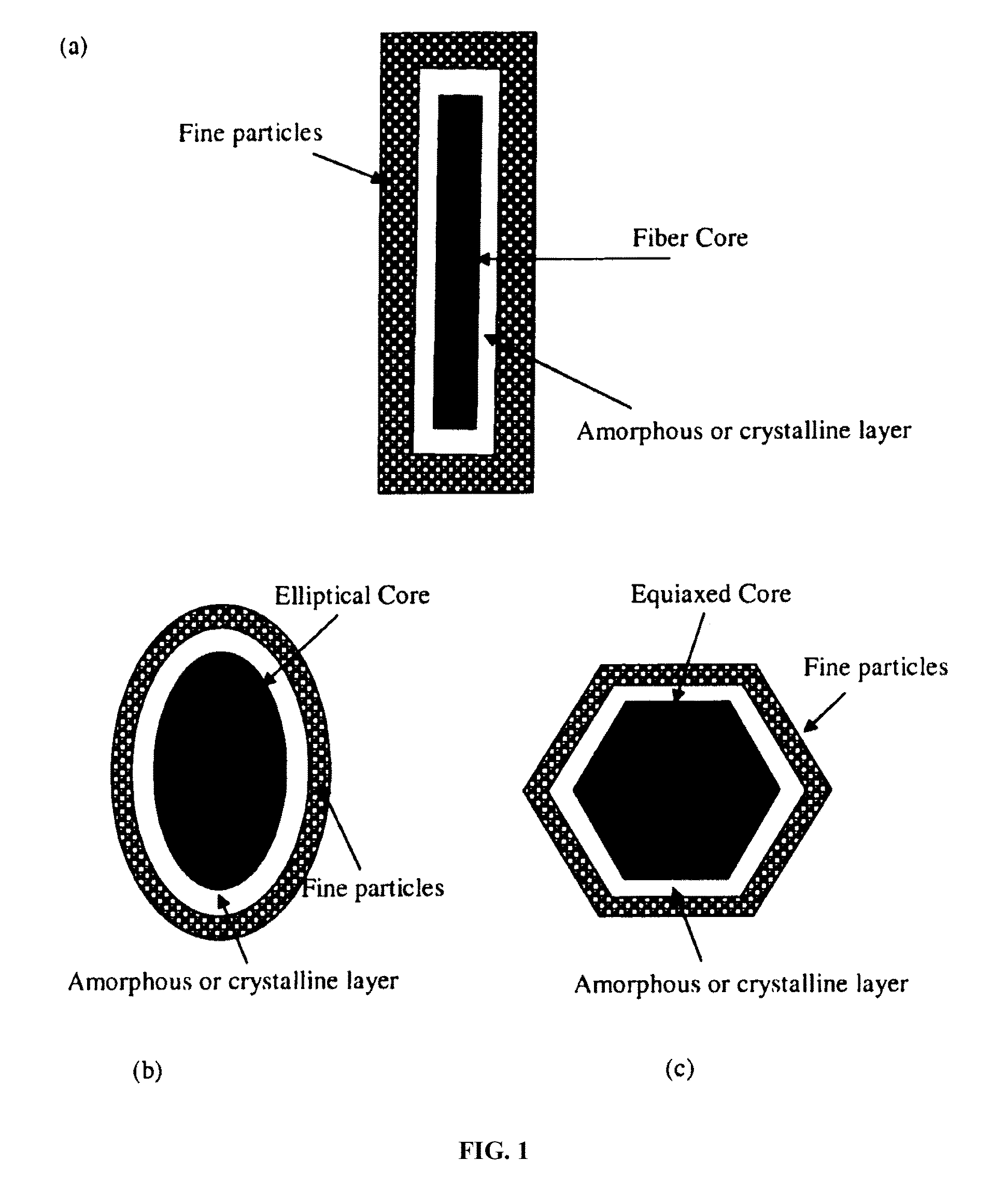

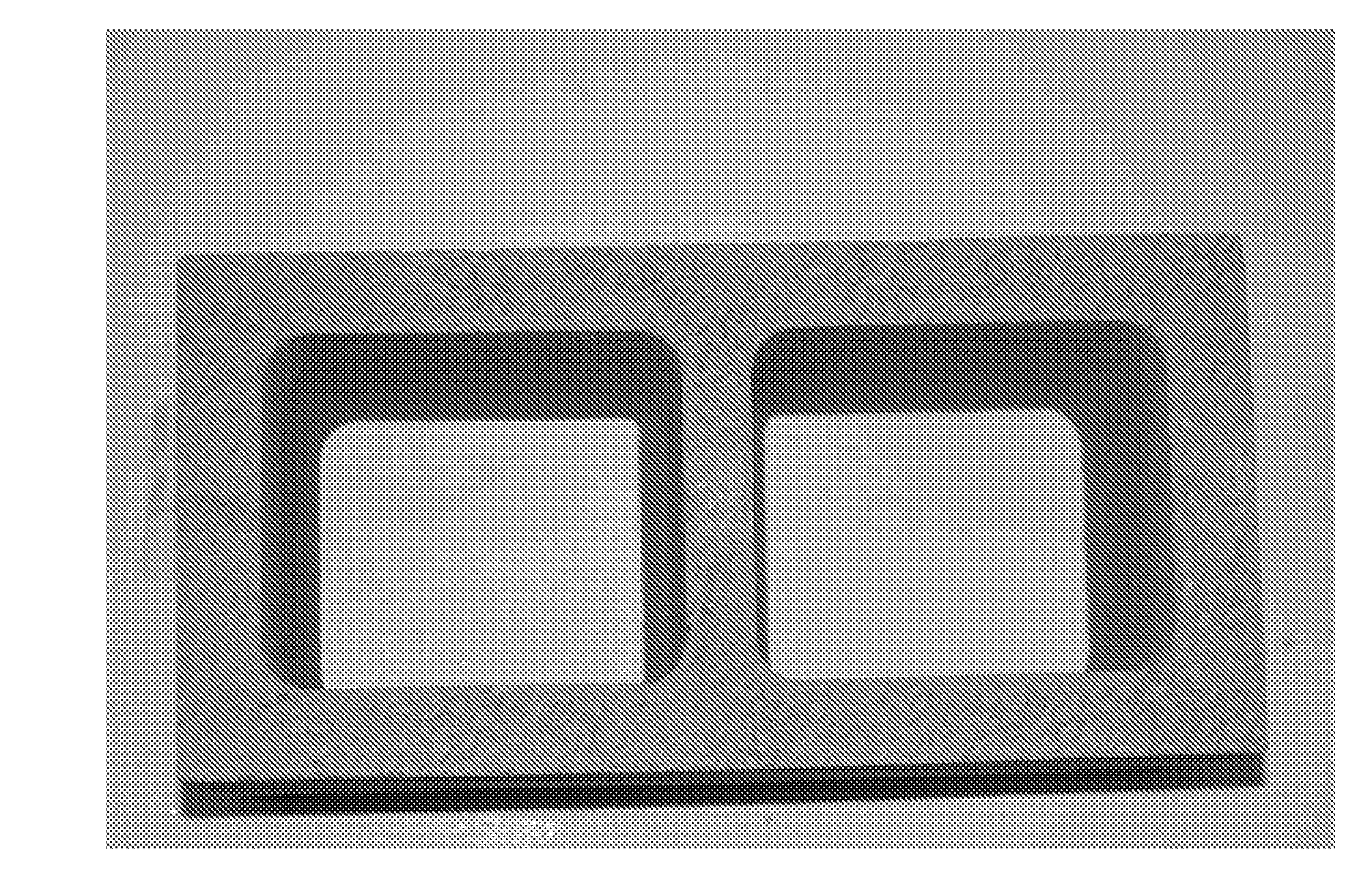

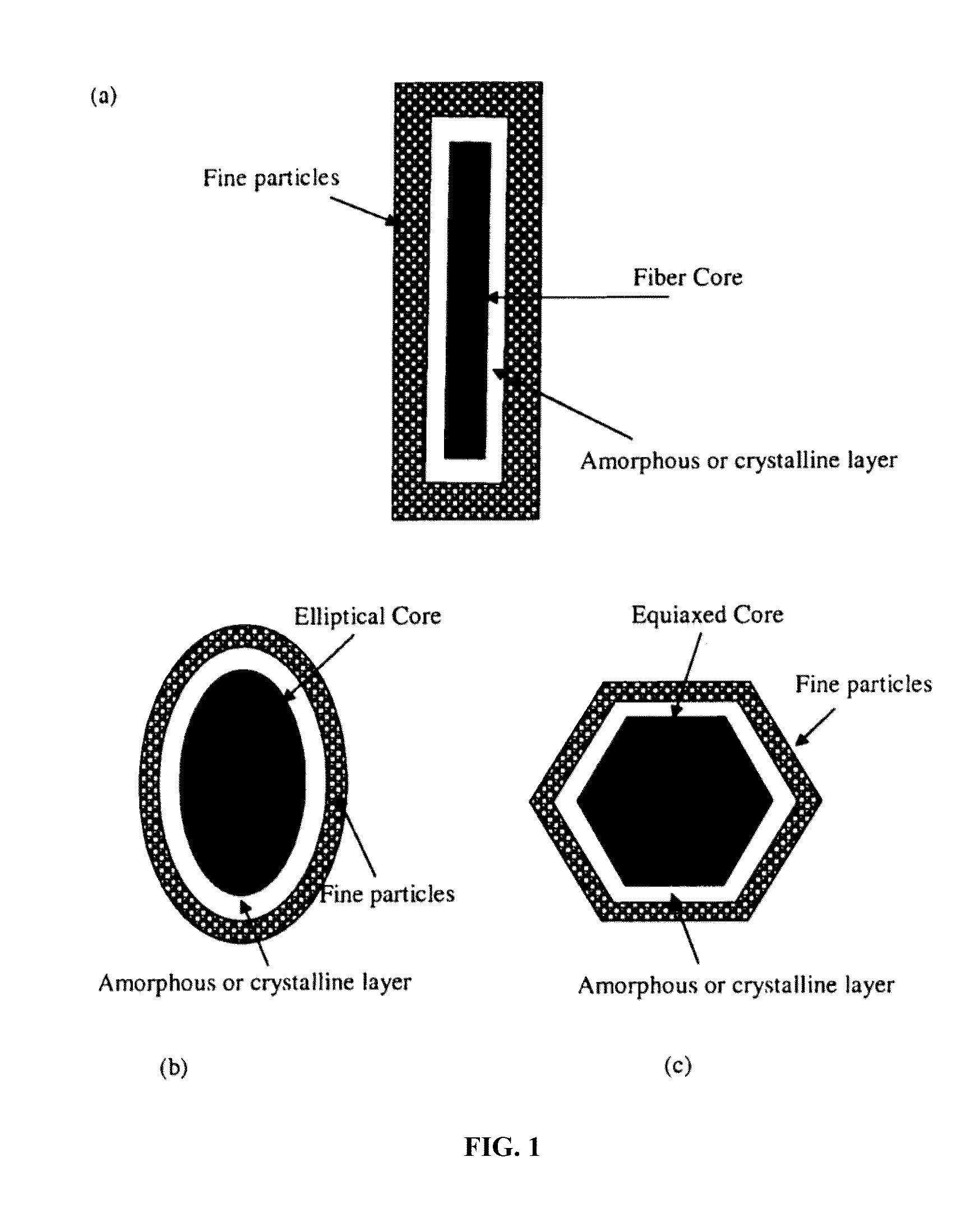

High capacity electrode and methods for its fabrication and use

InactiveUS20070099084A1Improve cycle lifeMinimised mechanical strainElectrode manufacturing processesSecondary cellsAlloyBuffering agent

A battery electrode comprises an electrically conductive substrate having an electrochemically active electrode composition supported thereupon. The composition includes an active material capable of reversibly alloying with lithium, which material shows a volume change upon such reversible alloying. The composition includes a buffering agent which accommodates the volume change in the active material and minimizes mechanical strain in the composition. The active composition may further include materials such as carbon. The active material may comprise silicon, aluminum, antimony, antimony oxides, bismuth, bismuth oxides, tin, tin oxides, chromium, chromium oxides, tungsten, and tungsten oxides or lithium alloys of the foregoing. The buffering agent may comprise a metal or a metal oxide or lithium alloys of the foregoing. Also disclosed are batteries which incorporate these electrodes, methods for the fabrication of the electrodes and methods for the fabrication and operation of the batteries.

Owner:A123 SYSTEMS LLC

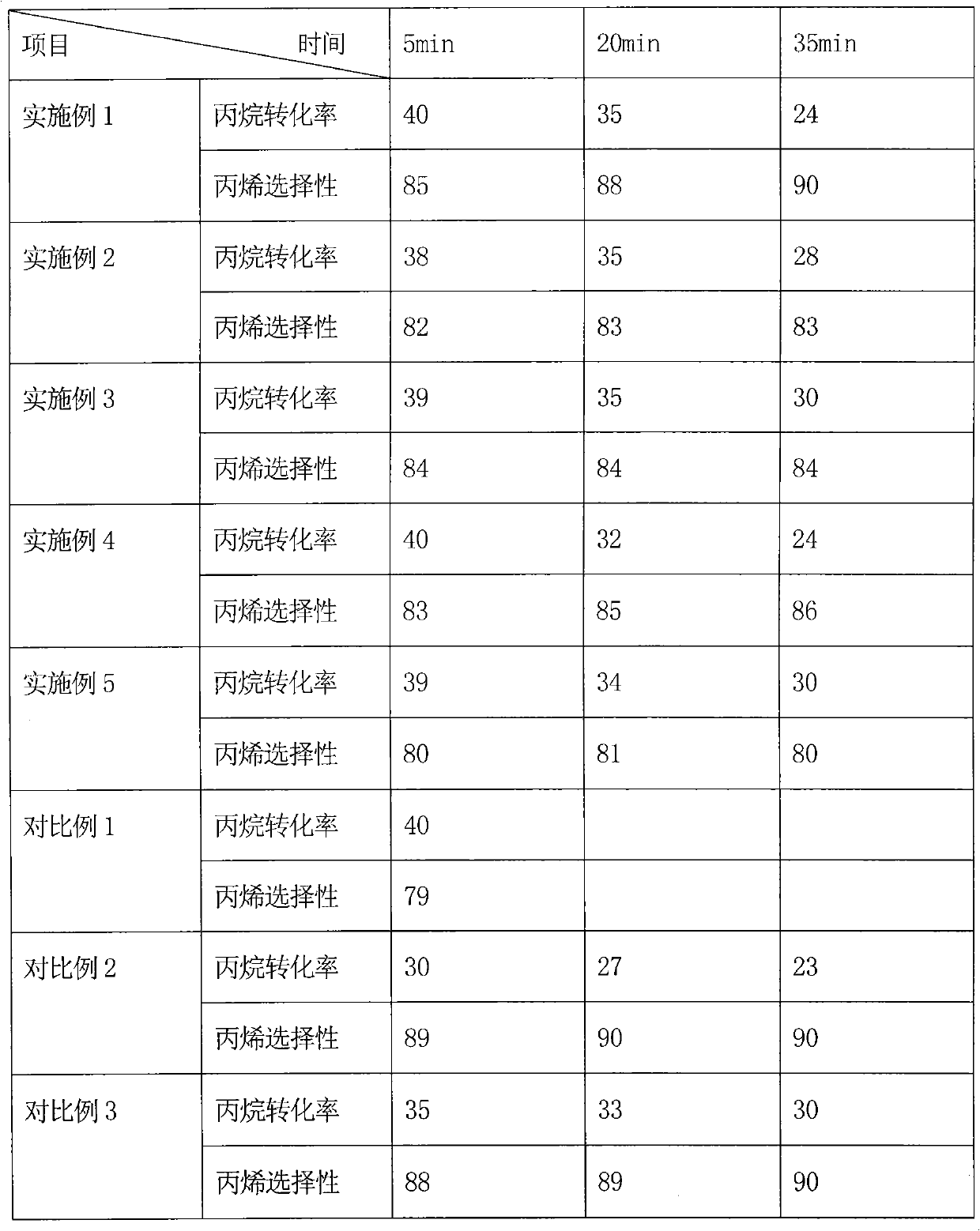

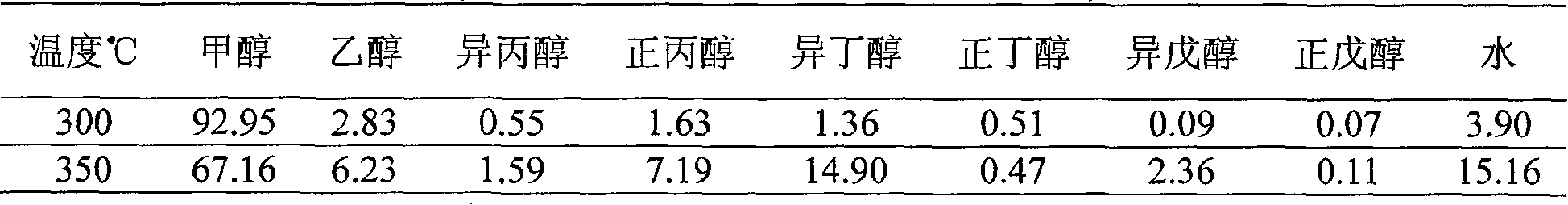

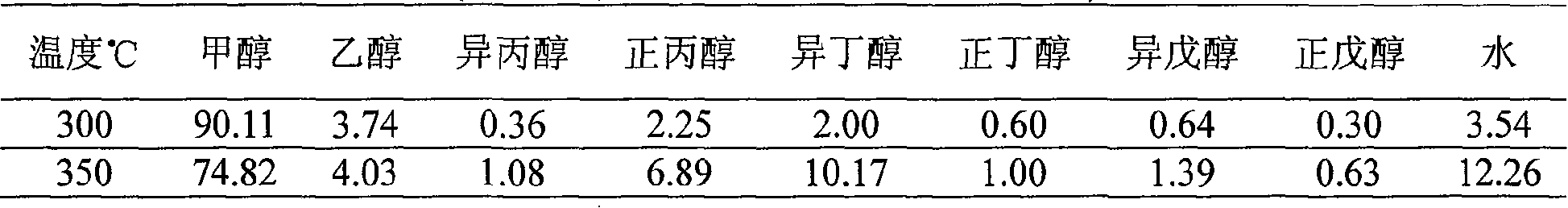

Catalyst for synthesizing low carbon mellow with synthesis gas and preparation method thereof

ActiveCN101185895AHigh conversion rate of COHigh selectivityOrganic compound preparationHydroxy compound preparationIsobutanolPropanol

The invention discloses a catalyst for synthesizing low carbon mixed alcohol with synthetic gas and a preparation method. The main components of the catalyst are copper oxide, zinc oxide, chromium oxide, alumina, and an appropriate amount of other assistants, which are expressed by the general formula Cu(Zn)a(Cr)b(Al)c(M)d(A)e(O)x; the catalyst is prepared by coprecipitation, and the assistant is added by impregnation. Under appropriate conditions, the catalyst can lead CO and hydrogen to react to produce a mixture of oxidation compounds which comprises methanol, ethanol, propanol, isobutanol, pentanol, and a small amount of C5.

Owner:SINOPEC NANJING RES INST OF CHEM IND CO LTD

Pavers and block composite materials and methods of preparation thereof

ActiveUS20140314990A1Acceptable compressive strengthLow costRecord information storageCeramic shaping apparatusCalcium silicateCOLORED MATERIAL

The invention provides novel paving stones and construction block composite materials and methods for preparation thereof. The paving stones and construction block composite materials can be readily produced from widely available, low cost precursor materials by a production process that involves compacting in a mold that is suitable for large-scale production. The precursor materials include calcium silicate, for example, wollastonite, and particulate filler materials which can comprise silicon dioxide-rich materials. Additives can include calcium carbonate-rich and magnesium carbonate-rich materials. Various additives can be used to fine-tune the physical appearance and mechanical properties of the composite material, such as colorants such as particles of colored materials, such as, and pigments (e.g., black iron oxide, cobalt oxide and chromium oxide). These paving stones and construction block composite materials exhibit visual patterns similar to stone as well as display compressive strength and water absorption equal to or better than that of stone.

Owner:SOLIDIA TECH

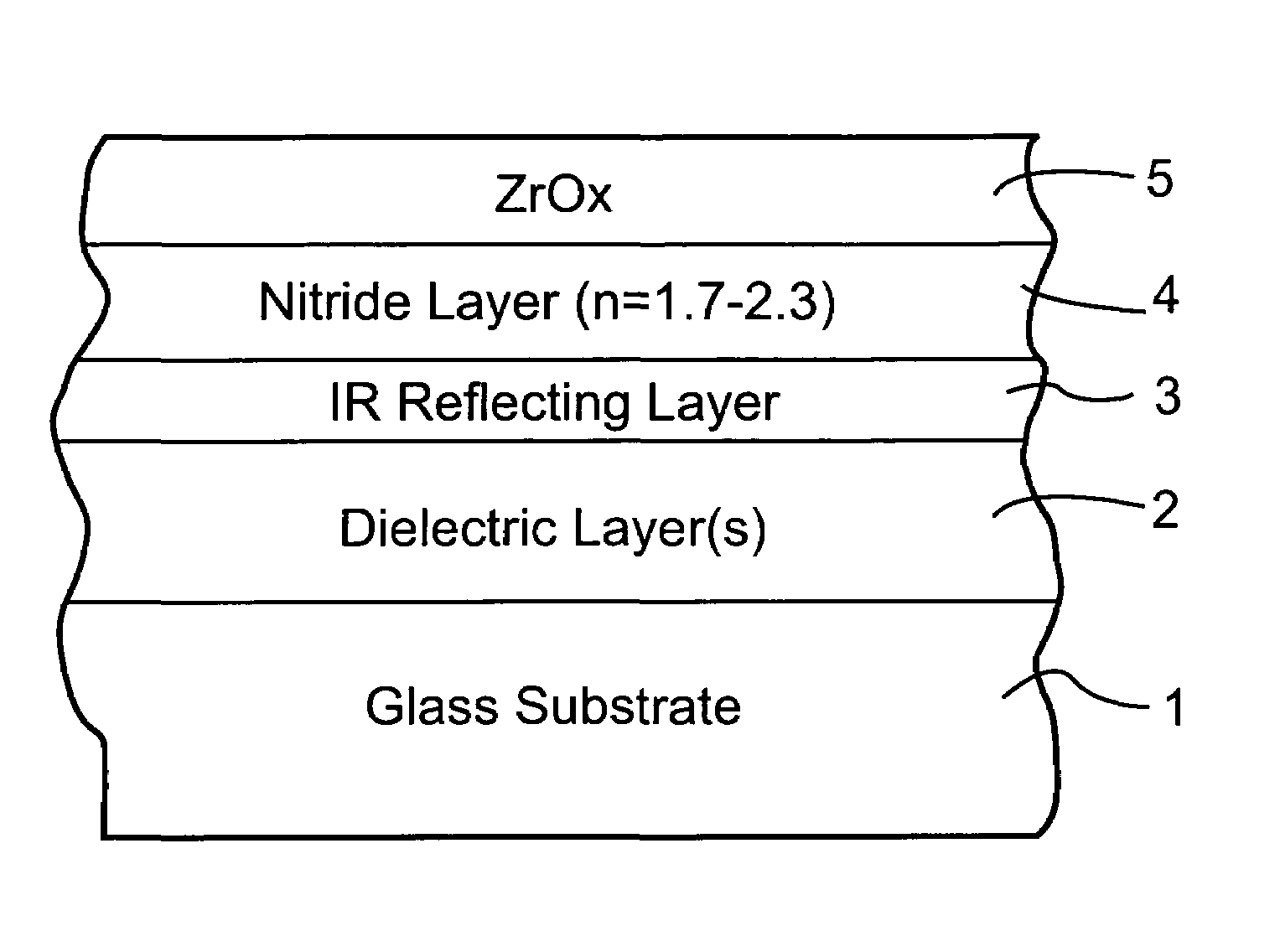

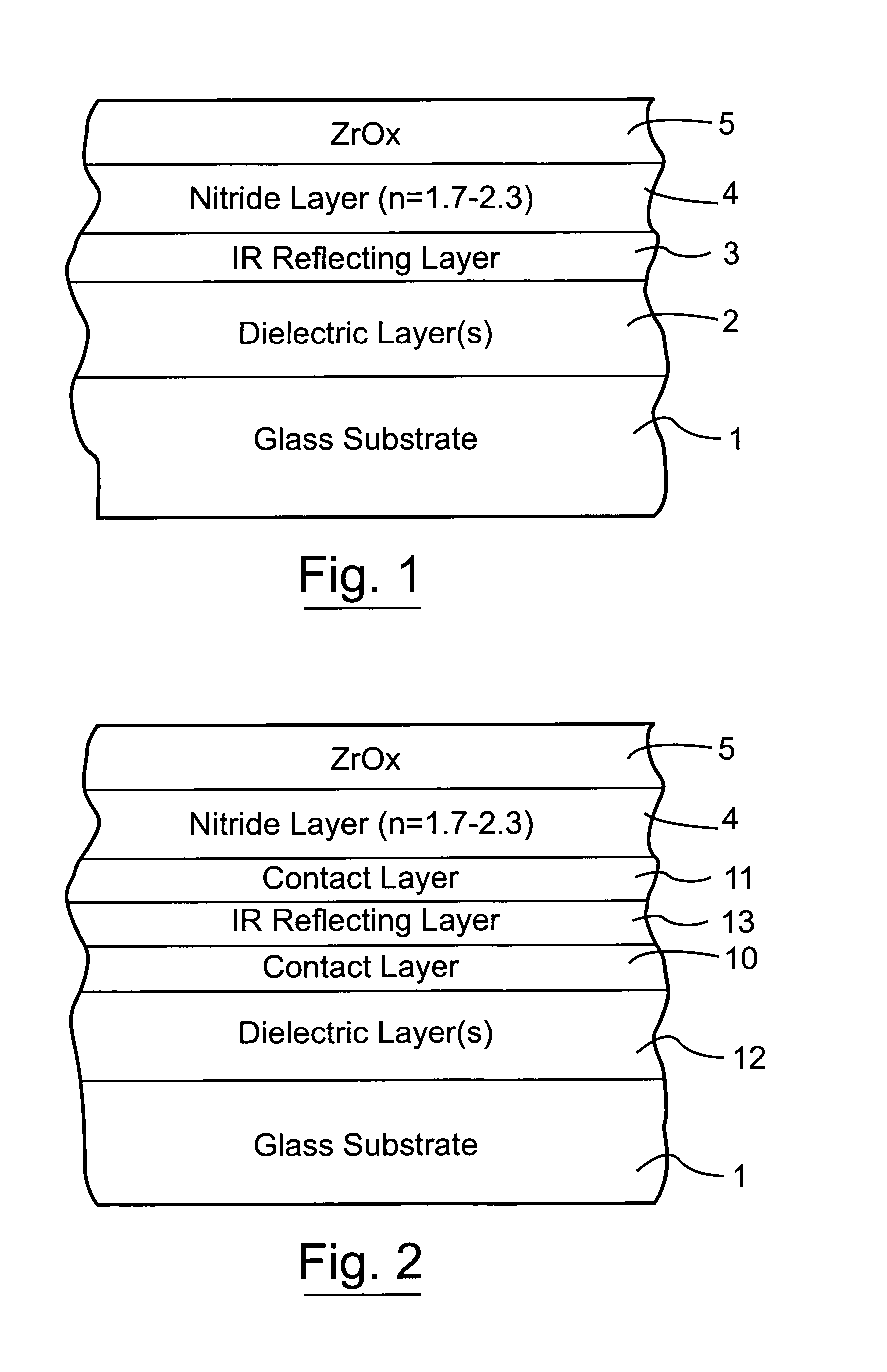

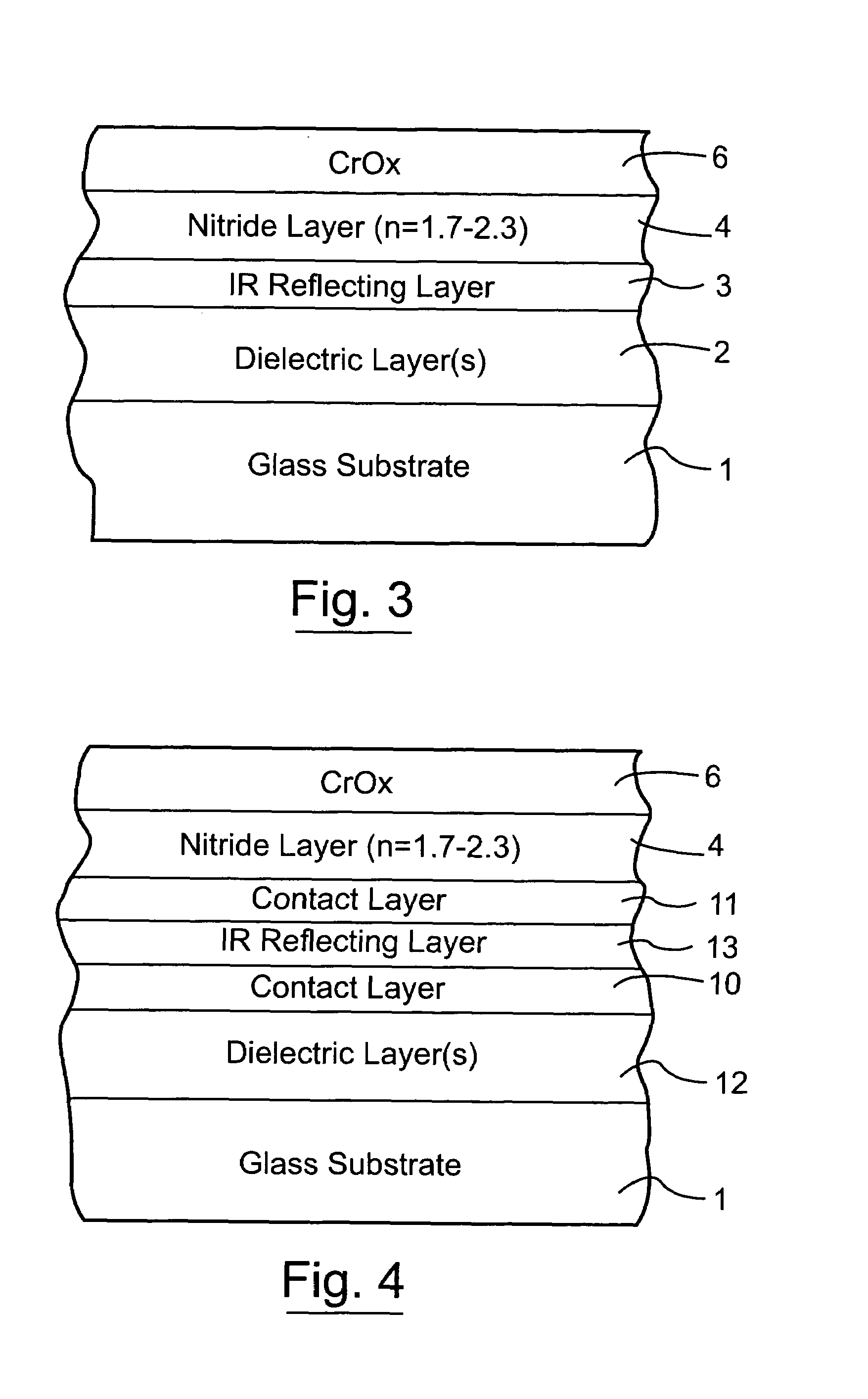

Coated article with dual-layer protective overcoat of nitride and zirconium or chromium oxide

InactiveUS7147924B2Inhibited DiffusionAcceptable optical propertyGlass/slag layered productsCoatingsNitrideZirconium oxide

A coated article is provided so as to include an overcoat including zirconium oxide or chromium oxide. In certain example embodiments, the overcoat includes a dual layer overcoat including a nitride inclusive layer which supports a zirconium oxide (ZrOX) layer. In certain example embodiments, the overcoat may be of chromium oxide, with or without such a nitride inclusive layer.

Owner:GUARDIAN GLASS LLC

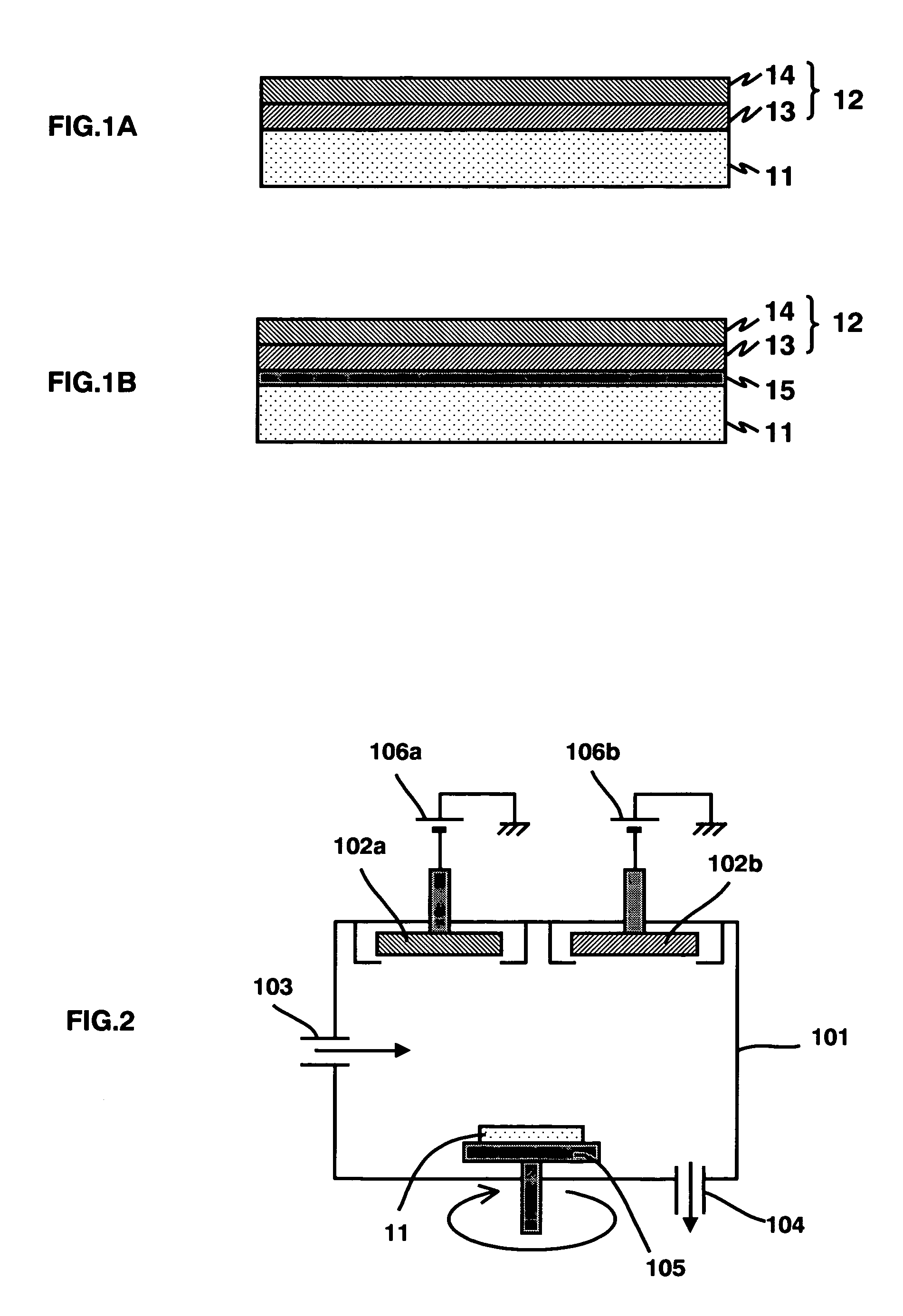

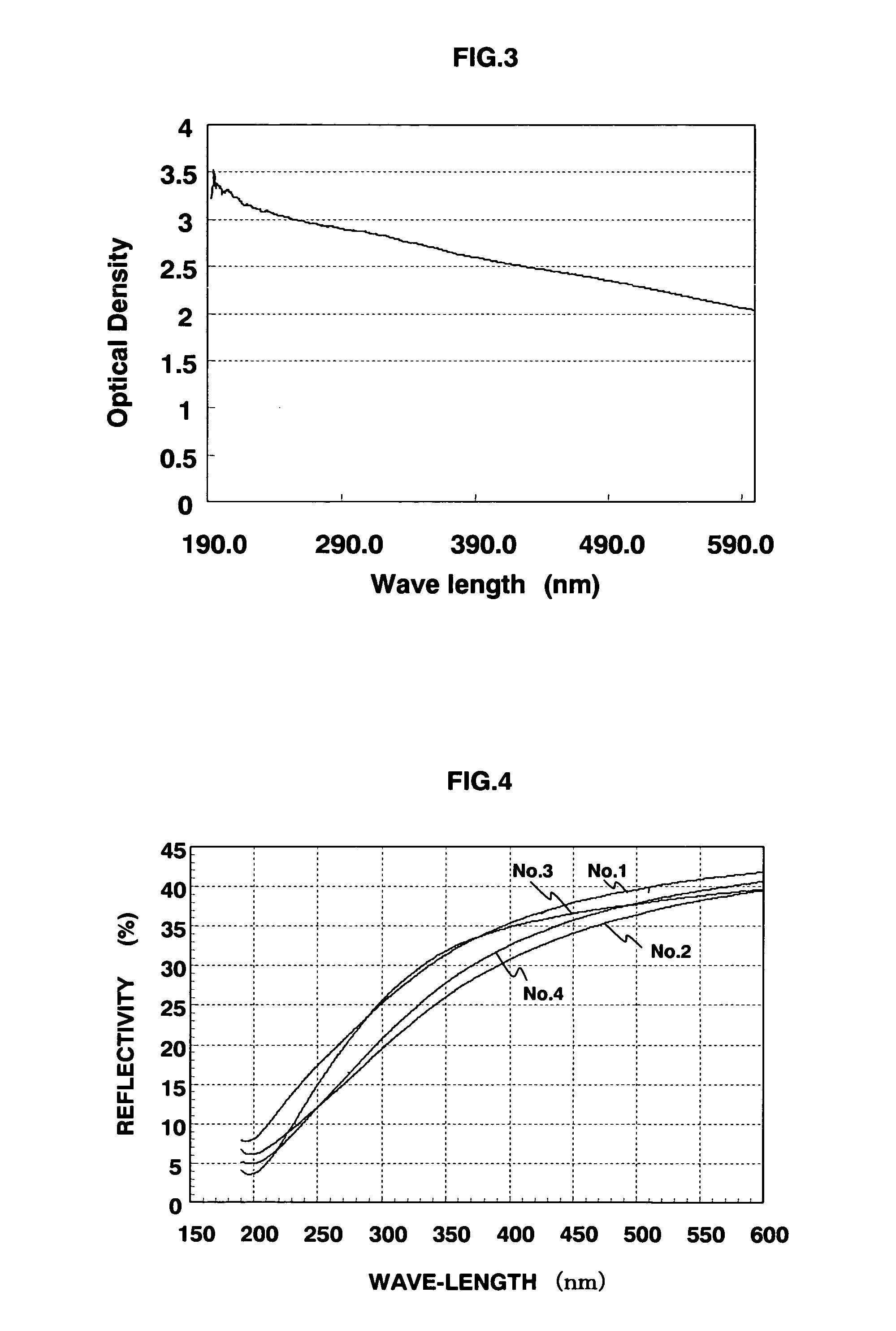

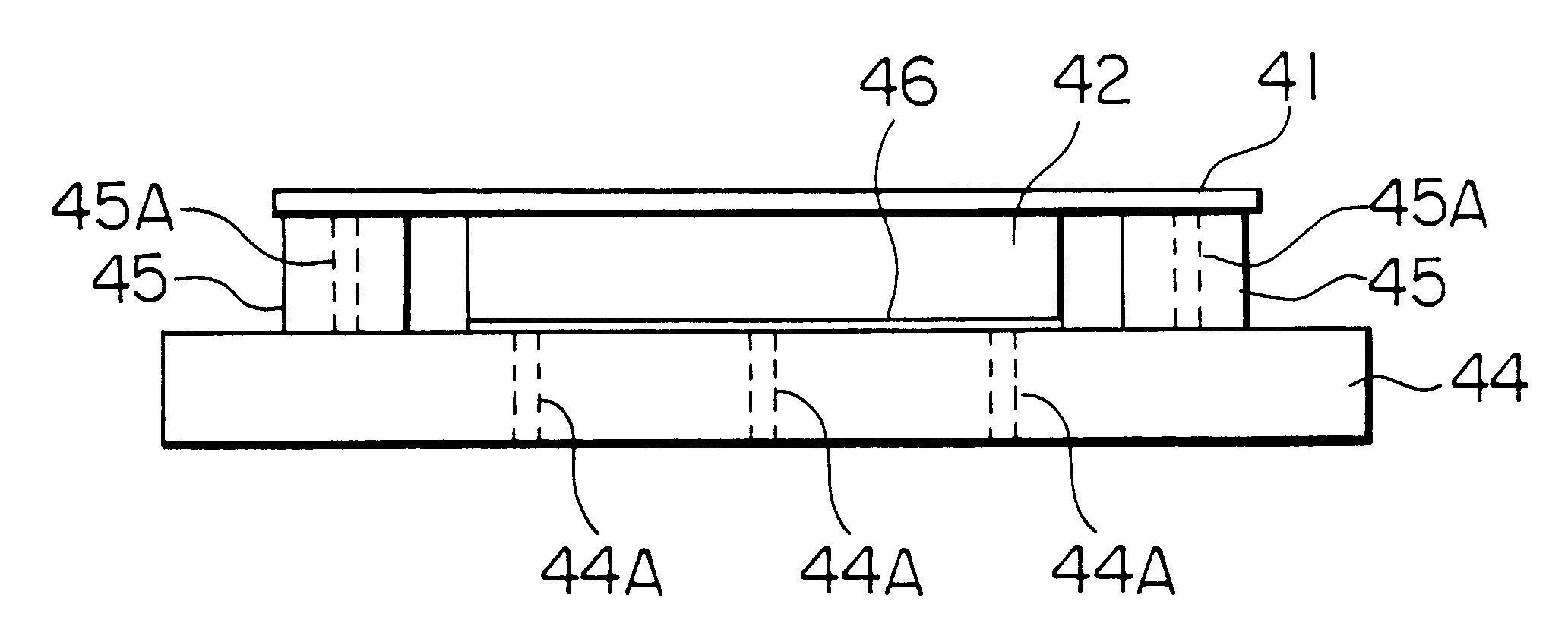

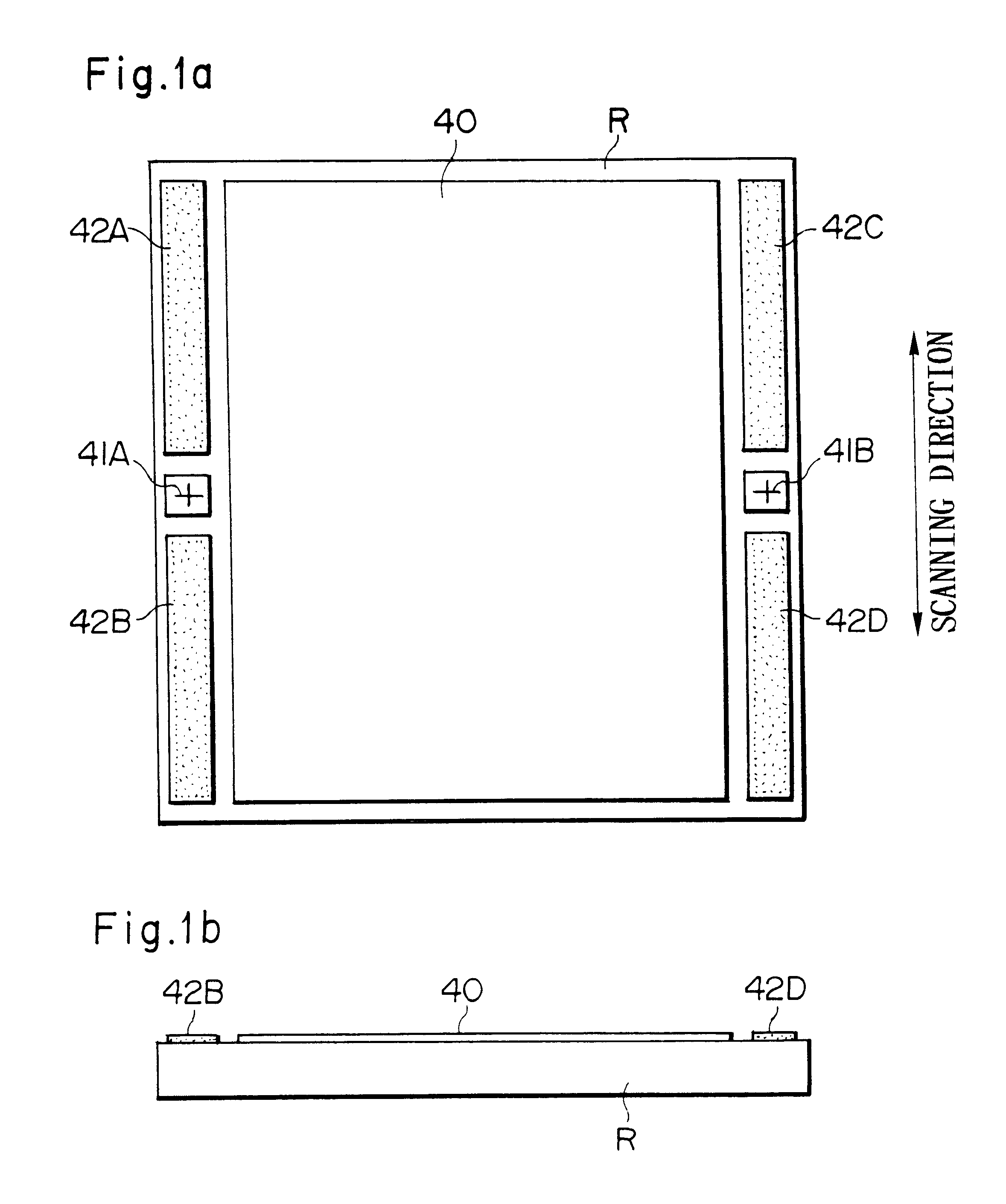

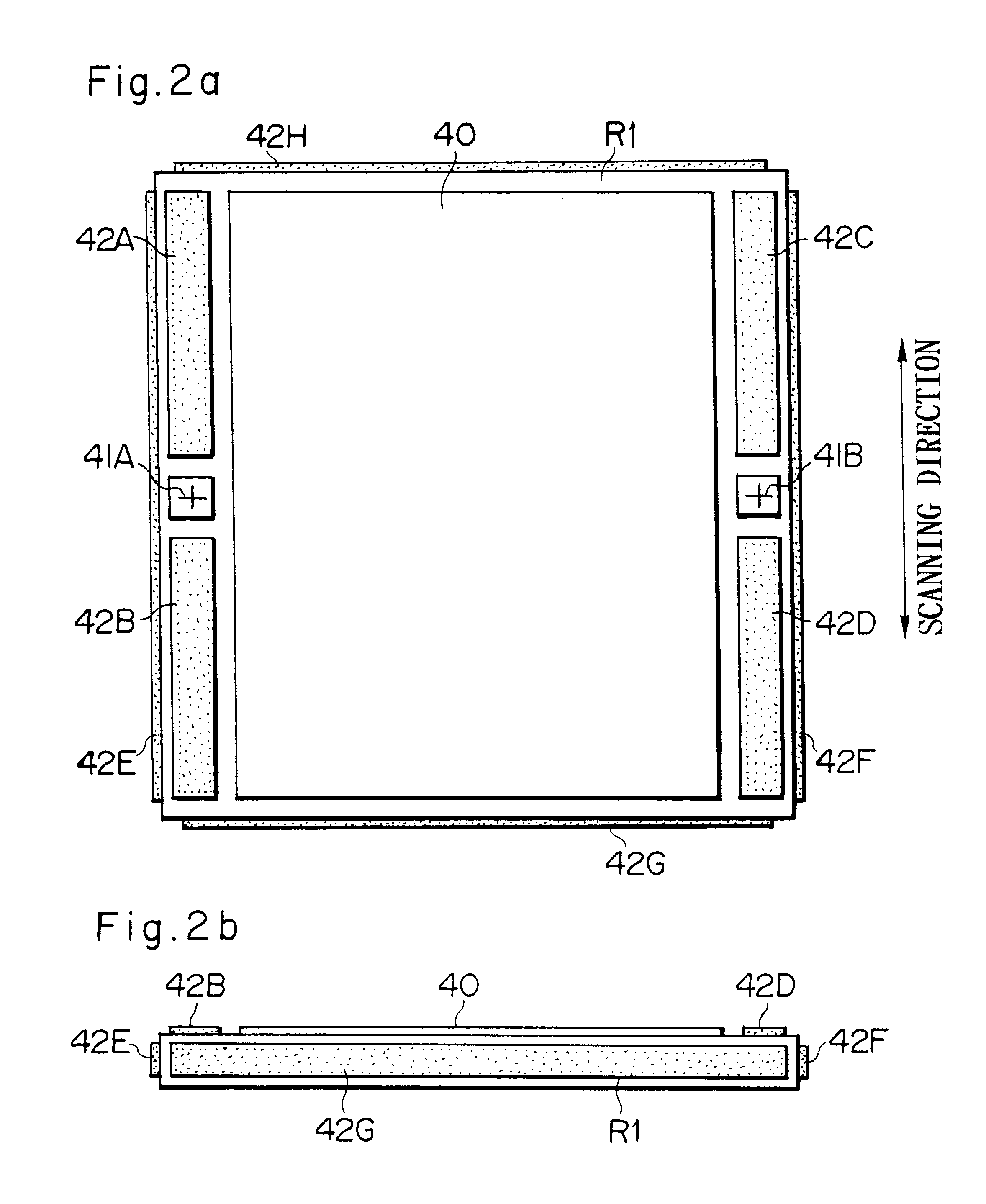

Photomask blank, photomask and fabrication method thereof

ActiveUS20060088774A1Reduce the burden onImprove accuracyDecorative surface effectsSemiconductor/solid-state device manufacturingSilicon oxideChromium nitride

Owner:TOPPAN PHOTOMASK CO LTD +1

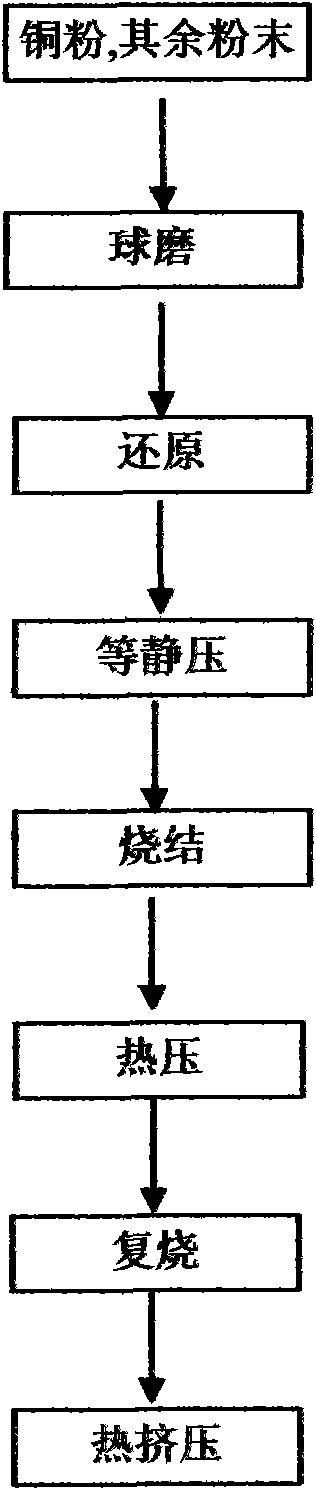

Multiple dispersion strengthening copper-base composite material prepared in situ and preparation method thereof

InactiveCN101613816APromote generationImprove organizational structureTitanium carbideSelf generation

The invention discloses a multiple dispersion strengthening copper-base composite material produced in situ and a preparation method thereof; the reinforced phase comprises at least three of the following substances: titanium carbide, zirconium carbide, alumina, titanium boride, aluminum carbide, chromium oxide, zirconia, graphite and copper; wherein, the contents of titanium carbide, zirconium carbide, alumina, titanium boride, chromium oxide and zirconia are not less than 0.3% and not more than 5%, the content of aluminum carbide is not less than 0.1% and not more than 5%, the content of graphite is not less than 0.1% and not more than 1% and the balance is copper. The particle size of the reinforced phase is between 10nm to 10mu m. The preparation method adopts ball milling; pressing, sintering and squeezing processes and the technological parameters are optimized and controlled properly to obtain the multiple dispersion strengthening copper-base composite material. Because the in situ self-generation technology is adopted and various reinforced phase methods are combined, the material of the invention has higher high-temperature strength and better electroconductibility and anti-creep property compared with the traditional ceramic particle strengthening copper-base composite material.

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

Wood-like composite materials and methods of preparation thereof

InactiveUS20140342124A1High compressive strengthLow water absorptionConstruction materialNatural patternsCalcium silicateFlexural strength

The invention provides novel wood-like composite materials and methods for preparation thereof. The wood-like composite materials can be readily produced from widely available, low cost precursor materials by a production process that involves casting in a mold that is suitable for large-scale production. The precursor materials include calcium silicate, for example, wollastonite, and particulate filler materials which comprise silicon dioxide-rich materials such as quartz, mica, feldspar, sand and glass. Additives can include calcium carbonate-rich and magnesium carbonate-rich materials. Various additives can be used to fine-tune the physical appearance and mechanical properties of the composite material, such as colorants such as particles of colored materials, such as, and pigments (e.g., black iron oxide, cobalt oxide and chromium oxide). These wood-like composite materials exhibit visual patterns unique to wood as well as display compressive strength, flexural strength and water absorption superior to that of wood.

Owner:ZAMBRZYCKI DAWID +4

Low carbon alkane dehydrogenation catalyst and its preparation method and application

ActiveCN103769079AHigh activityHigh selectivityHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsAlkaneActive component

The invention discloses a low carbon alkane dehydrogenation catalyst and its preparation method and application. The low carbon alkane dehydrogenation catalyst uses La-containing alumina as a carrier, and chromium as an active component, taking the weight content of oxides as a reference, the lanthanum oxide content in the final catalyst is 0.1 to 5.0%, the chromium oxide content is 5.0% to 20.0%, and La in the La-containing alumina carrier is introduced in during gelatinizing in the alumina preparation process. The preparation method of the low carbon alkane dehydrogenation catalyst comprises the following steps: preparation of the La-containing Al2O3 carrier and a process of loading active component chromium by an impregnation method. The low carbon alkane dehydrogenation catalyst can be used in production of propylene by dehydrogenation of propane. The low carbon alkane dehydrogenation catalyst prepared by the method does not contain alkaline oxides to avoid strong interaction between the alkaline oxides and the active component, and the activity, stability and propylene selectivity of the low carbon alkane dehydrogenation catalyst are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low carbon alkane dehydrogenation catalyst for alkene production and its preparation method and application

ActiveCN103769078AGood dispersionIncrease loadHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsAlkali metal oxideActive component

The invention discloses a low carbon alkane dehydrogenation catalyst for alkene production and its preparation method and application. The catalyst uses Al2O3 (alumina) as a carrier, chromium as an active component, and an alkali metal as an assistant catalyst component, taking to the final catalyst weight as the base, the chromium oxide content is 10.0%-30.0%, the alkali metal oxide content is 0.5%-3.0%, and the rest is the alumina. The active component chromium is stepwise impregnated onto the alumina carrier before and after impregnation of the alkali metal assistant catalyst component. The low carbon alkane dehydrogenation catalyst for alkene production is used in dehydrogenation of propane to produce propylene. The low carbon alkane dehydrogenation catalyst for alkene production has high activity stability and propylene selectivity, and the preparation method is simple, and is suitable for industrial applications.

Owner:CHINA PETROLEUM & CHEM CORP +1

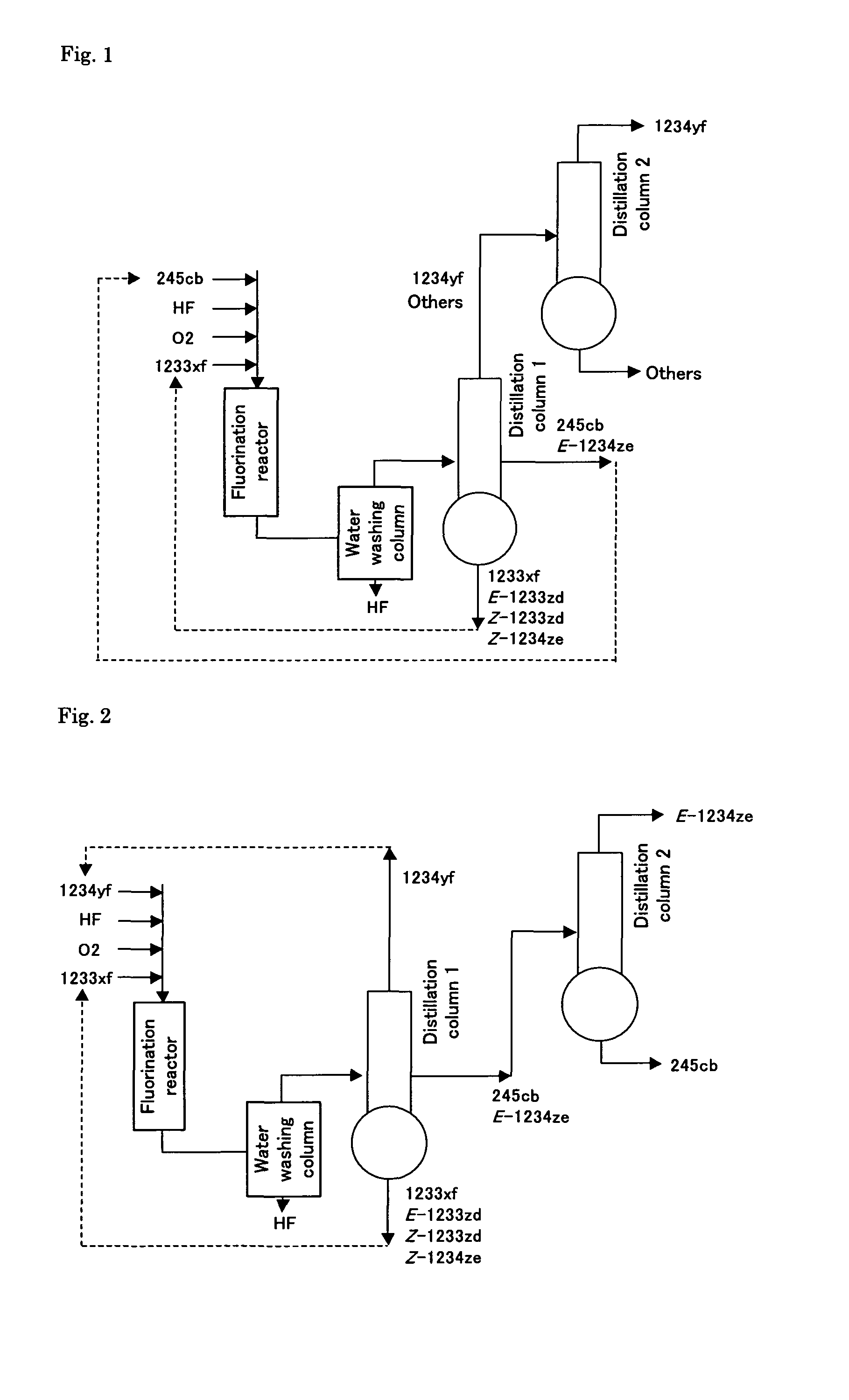

Process for preparation of 2,3,3,3-tetrafluoropropene

ActiveUS8614361B2Efficient productionPreparation by hydrogen halide split-offPreparation by halogen halide additionHydrogen fluorideOxygen

The present invention provides an effective, selective, and industrially applicable process for producing 2,3,3,3-tetrafluoropropene. Specifically, the present invention provides a process for producing 2,3,3,3-tetrafluoropropene including reacting 2-chloro-3,3,3-trifluoropropene with hydrogen fluoride in the presence of oxygen and a catalyst comprising chromium oxide represented by the composition formula: CrOm (1.5<m<3), or fluorinated chromium oxide obtained by fluorinating the chromium oxide.

Owner:DAIKIN IND LTD

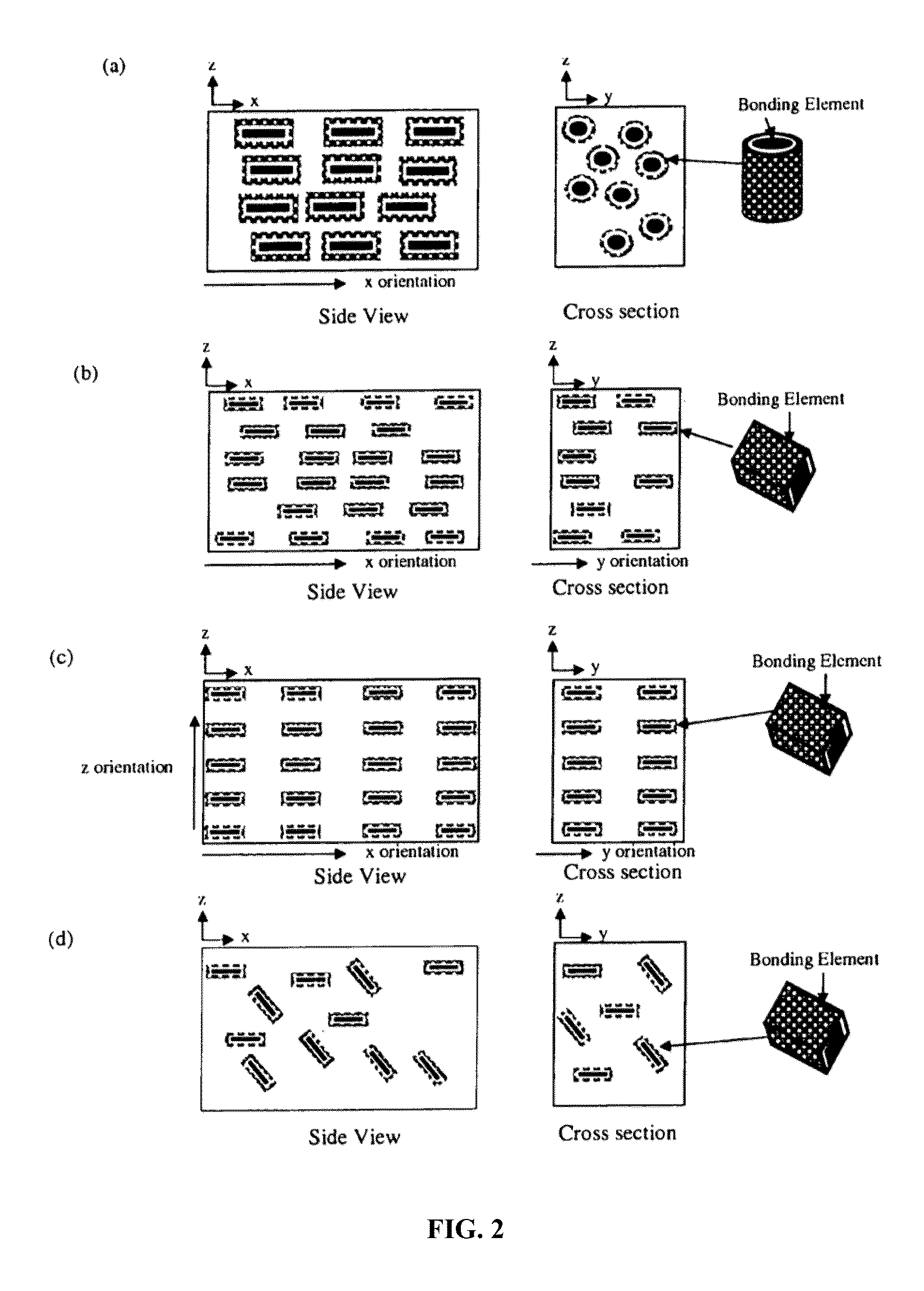

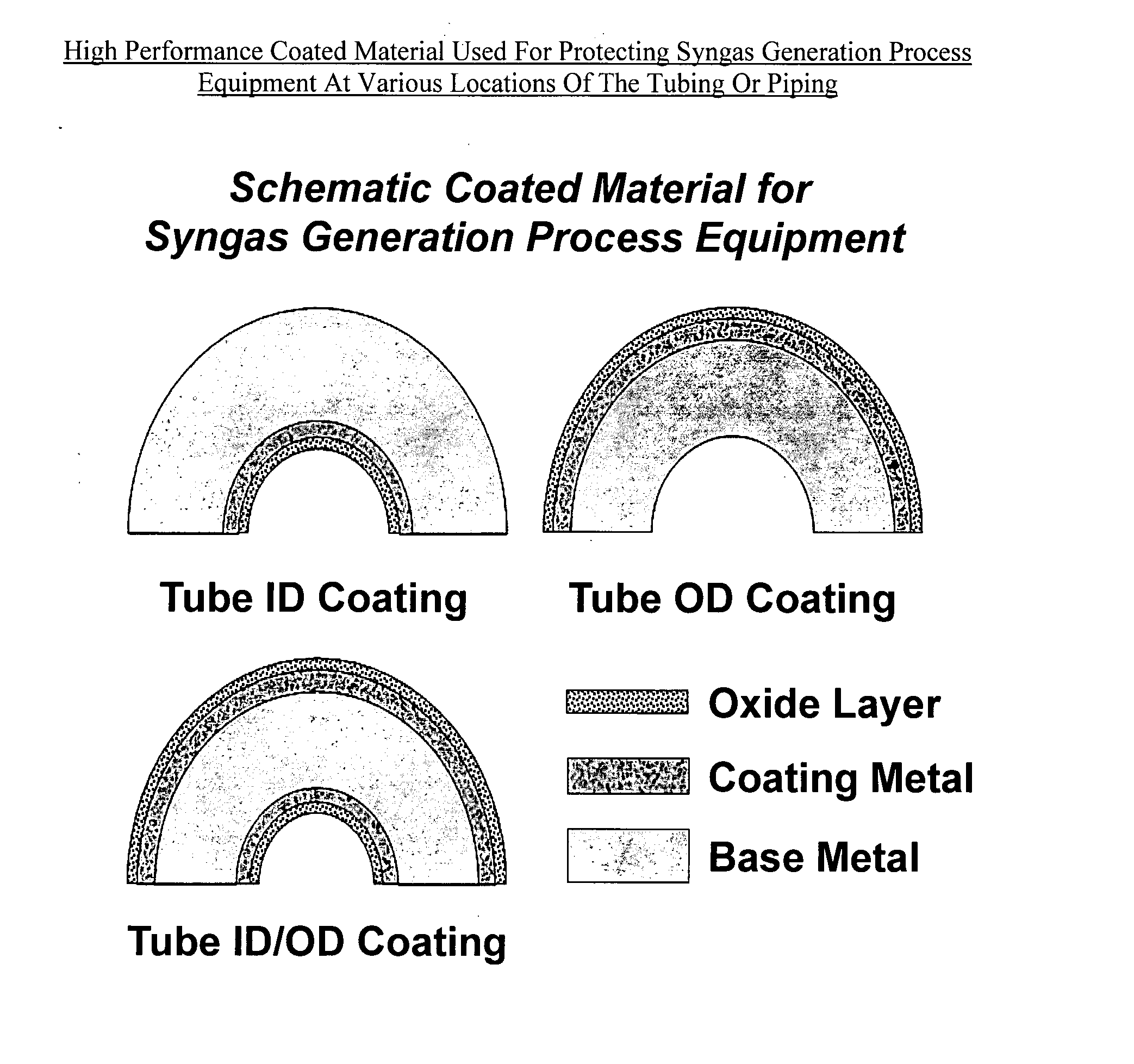

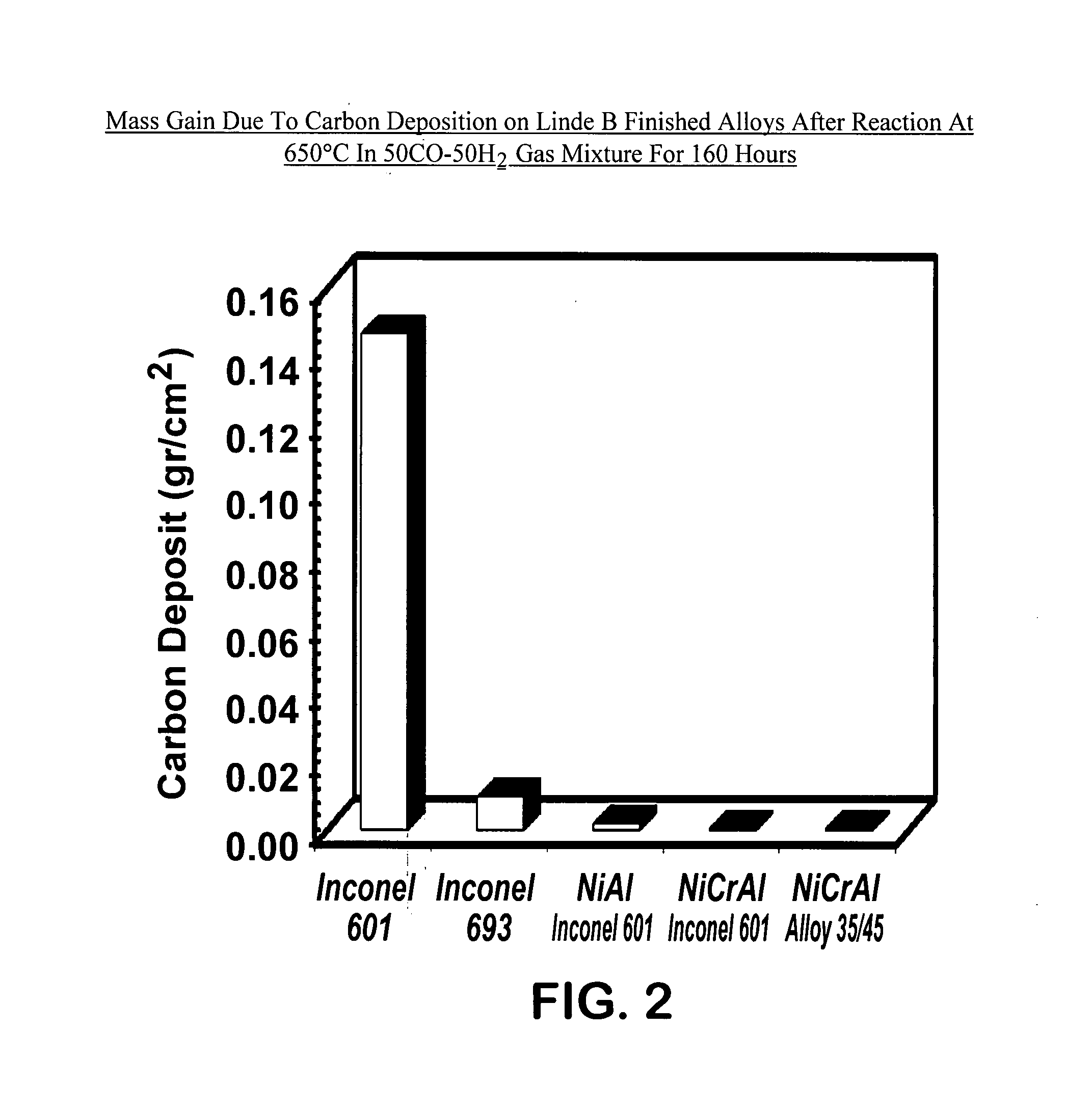

High performance coated material with improved metal dusting corrosion resistance

InactiveUS20080020216A1Improve the immunityReduce carbon depositionAnodisationLiquid surface applicatorsMulliteInconel

High performance coated metal compositions resistant to metal dusting corrosion and methods of providing such compositions are provided by the present invention. The coated metal compositions are represented by the structure (PQR), wherein P is an oxide layer at the surface of (PQR), Q is a coating metal layer interposed between P and R, and R is a base metal. P includes alumina, chromia, silica, mullite or mixtures thereof. Q includes Ni and Al, and at least one element selected from the group consisting of Cr, Si, Mn, Fe, Co, B, C, N, P, Ga, Ge, As, In, Sn, Sb, Pb, Sc, La, Y, Ce, Ti, Zr, Hf, V, Nb, Ta, Mo, W, Ru, Rh, Ir, Pd, Pt, Cu, Ag, Au and mixtures thereof. R is selected from the group consisting of carbon steels, low chromium steels, ferritic stainless steels, austenetic stainless steels, duplex stainless steels, Inconel alloys, Incoloy alloys, Fe—Ni based alloys, Ni-based alloys and Co-based alloys. Advantages exhibited by the disclosed coated metal compositions include improved metal dusting corrosion resistance at high temperatures in carbon-supersaturated environments having relatively low oxygen partial pressures. The coated metal compositions are suitable for use in syngas generation process equipment.

Owner:EXXON RES & ENG CO

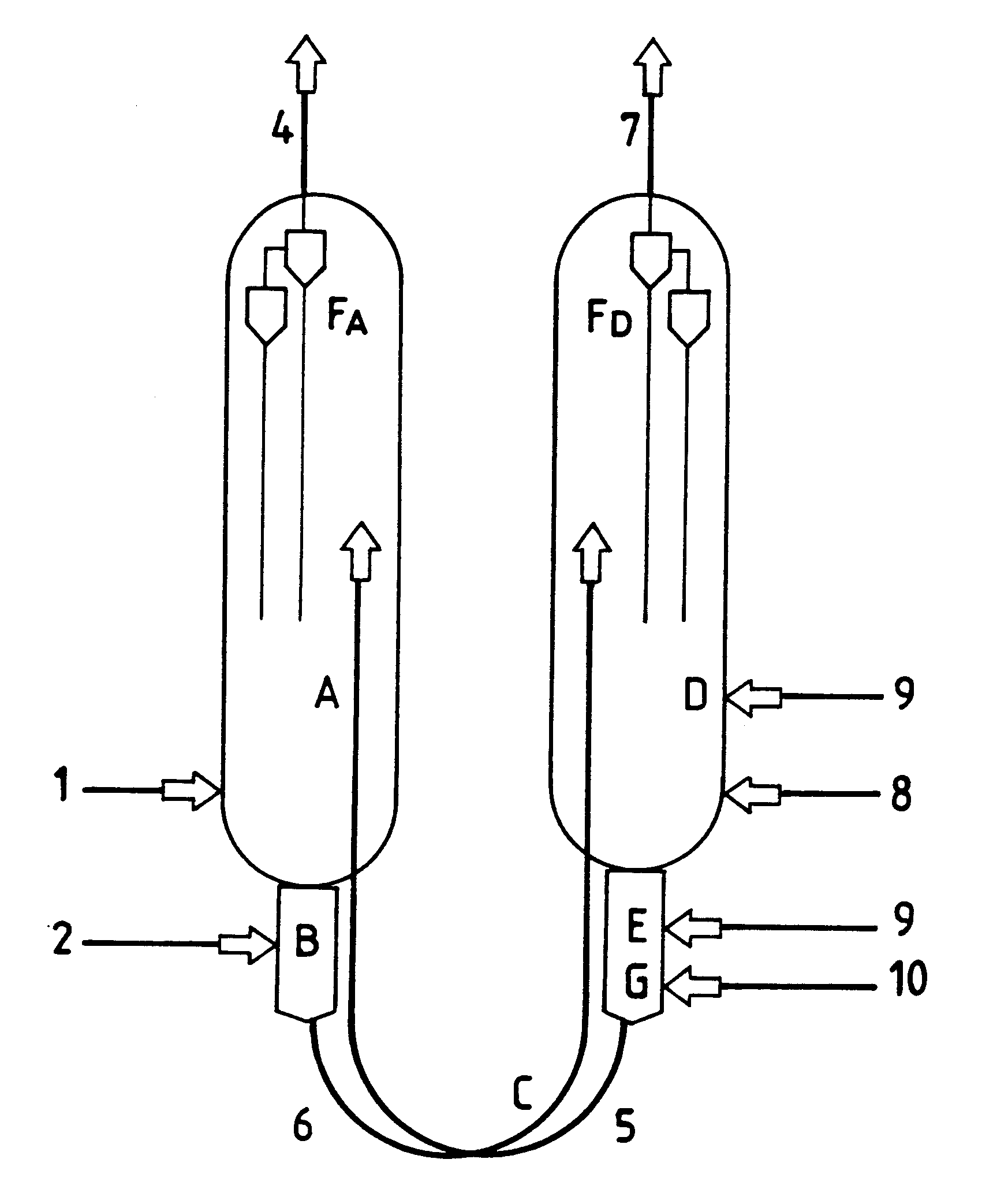

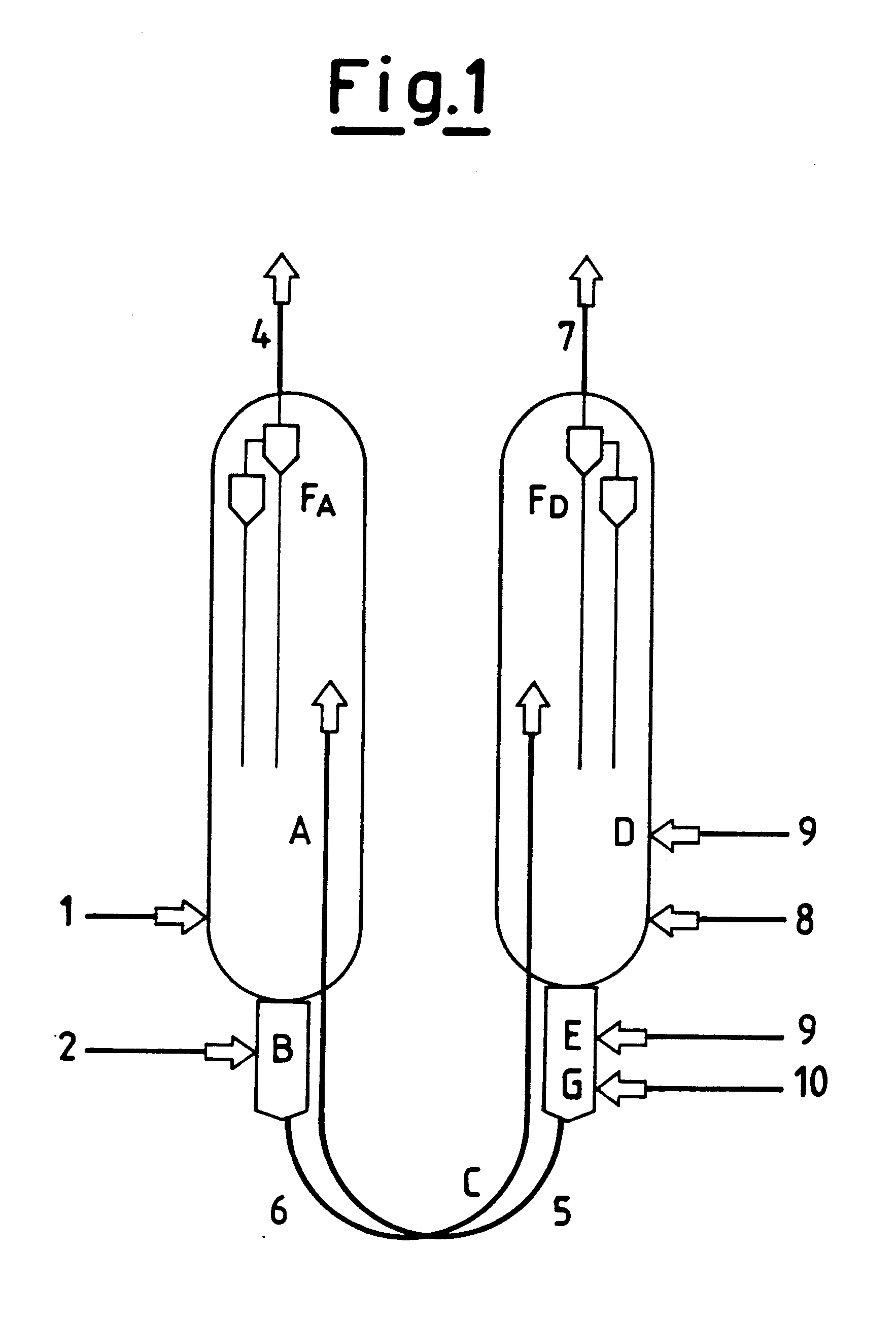

Process for obtaining light olefins by the dehydrogenation of the corresponding paraffins

A process for obtaining light olefins by the dehydrogenation of corresponding paraffins, by reacting the paraffins with a catalytic system containing chromium oxide, tin oxide, at least one alkali metal oxide, and an alumina-silica carrier, and then regenerating the catalytic system in a regenerator by burning coke deposited on its surface at a temperature higher than the average temperature of the reactor.

Owner:SNAMPROGETTI SPA +1

Dehydrogenation catalyst and preparation method and application thereof

ActiveCN103769156AReduce acid contentReduce acid strengthHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsManganeseDehydrogenation

The invention discloses a dehydrogenation catalyst and a preparation method and application thereof. The dehydrogenation catalyst uses ammonia processed alumina as a carrier, chrome as an active component, and one or a plurality of potassium, manganese, cobalt, iron, nickel, copper and zinc as an additive, the additive is loaded onto the carrier by a co-impregnation method, and taking oxide weight content in the final catalyst as a reference, the catalyst comprises 2%-6% of chromium oxide, and 0.1-5% of the additive. The preparation method of the hydrocarbon dehydrogenation catalyst comprises the following processes: using ammonia to preprocess an alumina carrier, using the co-impregnation method to load one or a plurality of potassium, manganese, cobalt, iron, nickel, copper and zinc, and loading the active component chrome. The dehydrogenation catalyst can be used in dehydrogenation of propane for preparation of propylene. The low carbon alkane dehydrogenation catalyst prepared by the preparation method has the advantages of low active component chromium oxide content, good propylene selectivity, high activity and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for ester production and process for producing ester

InactiveUS7091155B2Organic compound preparationCarboxylic acid esters preparationGas phaseSilicon oxide

A catalyst for ester production which comprises zirconium oxide, copper, and at least one oxide selected from the group consisting of zinc oxide, chromium oxide, aluminum oxide and silicon oxide, and is obtainable by reducing with hydrogen a catalyst precursor prepared by the reaction of a salt containing at least one of metals constituting the oxides, a zirconium salt and a copper salt with an alkali hydroxide; and a process for producing an ester which comprises bringing either an alcohol or an alcohol and an aldehyde into contact with this catalyst in a gas phase.

Owner:JNC CORP

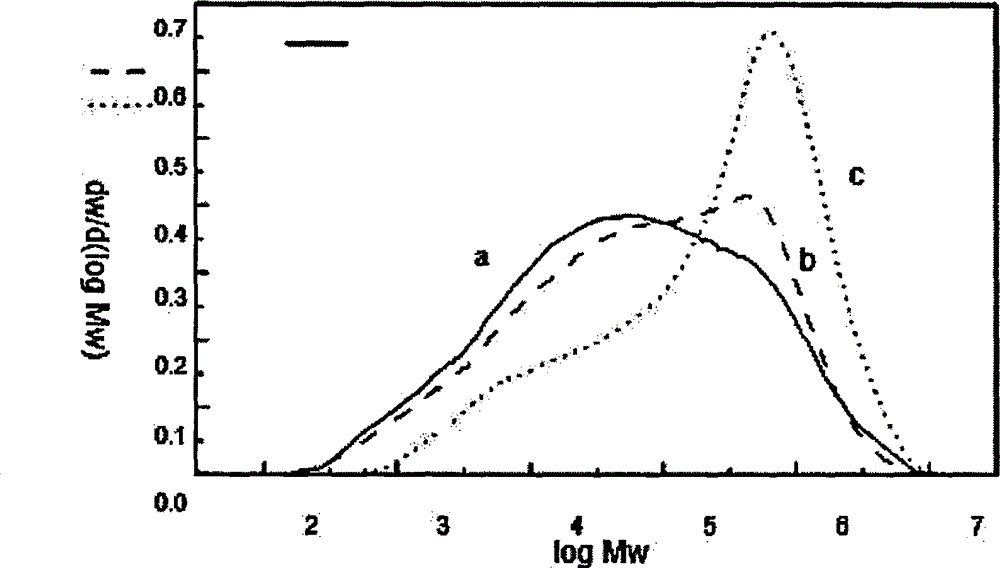

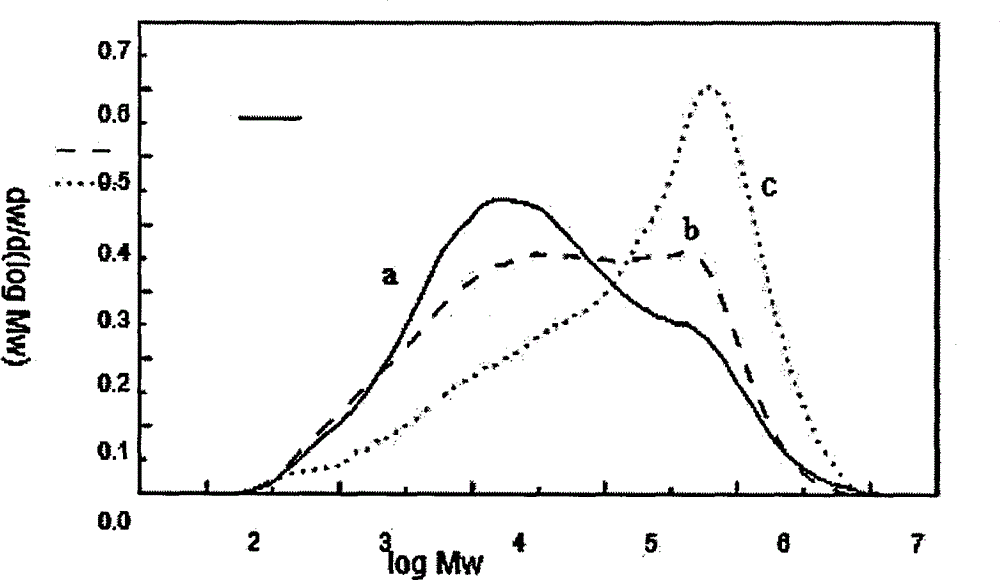

Supported metal oxide double-active center ethylene-polymerization catalyst and its preparation method and use

The invention discloses a supported metal oxide double-active center ethylene-polymerization catalyst and its preparation method and use. The supported metal oxide double-active center ethylene-polymerization catalyst is characterized in that a supported vanadium active ingredient is introduced to a Phillips chromium-based catalyst; and the supported metal oxide double-active center ethylene-polymerization catalyst comprises the two active ingredients and an inorganic carrier, wherein the two active ingredients comprise a chromium oxide and a vanadium oxide. The preparation method of the supported metal oxide double-active center ethylene-polymerization catalyst comprises the following steps of coating a chromium salt and a vanadium salt on the inorganic carrier according to a certain ratio by a stepwise dipping or co-dipping method, carrying out drying, and carrying out high-temperature calcination. The supported metal oxide double-active center ethylene-polymerization catalyst is a catalyst for high-efficiency preparation of polyethylene, and can be used for preparation of an ethylene homopolymer or an ethylene-alpha olefin copolymer. The supported metal oxide double-active center ethylene-polymerization catalyst has high polymerization activity. Through the supported metal oxide double-active center ethylene-polymerization catalyst, polyethylene product molecular weight distribution is wide, wherein molecular weights of a part of polyethylene products are distributed in a double-peak way; hydrogen regulation sensibility and copolymerization performances are good; and the existing equipment utilizing a Phillips catalyst to realize preparation of polyethylene can be popularized and used without reforming.

Owner:EAST CHINA UNIV OF SCI & TECH

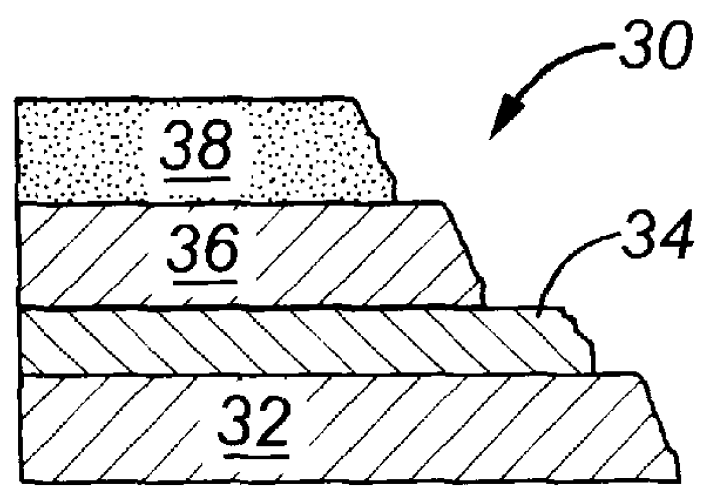

Process for depositing composite coating on a surface

InactiveUS20050136656A1Simple methodVacuum evaporation coatingSputtering coatingCoated surfaceReactive gas

A method for coating a substrate surface where different types of powers are applied to the substrate and different targets. The method involves the formation of a layered structure in the coating where a metal layer is first formed, on top of which is an intermediate layer followed by a top functional layer which is chromium oxide composite. One of the power types is radio frequency power, used particularly for enhancing the efficiency of ionisation and decomposition of the reactive gases in the system. Another type of power, current that is controlled in a pulsed manner, is applied to substrate to improve the alignment of the deposited ions and atoms on the coating surface.

Owner:AGENCY FOR SCI TECH & RES

Photomask, aberration correction plate, exposure apparatus, and process of production of microdevice

InactiveUS6653024B1High light transmittanceImproves UV resistancePhotomechanical exposure apparatusMicrolithography exposure apparatusSilicon oxidePhotomask

A photomask including a substrate comprised of fluorite (calcium fluoride (CaF2)) and protective films comprised of chrome (Cr), chromium oxide (Cro), silicon oxide (SiO2 or SiO), etc. and formed at regions, other than the pattern region where the pattern to be transferred is formed, which contact other members when transporting the photomask or using it for exposure.

Owner:NIKON CORP

Paraffin dehydrogenation catalyst

ActiveUS7012038B2High activityRobust hydrothermal stabilityHydrocarbon by dehydrogenationCatalystsLithium oxideDehydrogenation

One aspect of the invention relates to a dehydrogenation catalyst composite containing alumina, chromium oxide, lithium oxide, and sodium oxide. The invention also relates to methods of making the dehydrogenation catalyst composite. Another aspect of the invention relates to method of dehydrogenating a dehydrogenatable hydrocarbon involving contacting the dehydrogenatable hydrocarbon with a dehydrogenation catalyst composite containing alumina, chromium oxide, lithium oxide, and sodium oxide to provide a dehydrogenated hydrocarbon, such as an olefin.

Owner:TEXAS PETROCHEM +1

Probe needle material, probe needle and probe card each using the same, and inspection process

ActiveUS20100194415A1Maintain contact stabilityNot abraded heavilyElectrical measurement instrument detailsElectrical testingProbe cardHafnium

Disclosed is a probe needle material used for producing a probe needle which is used in contact with an inspection object to inspect electrical characteristics of the inspection object, comprising not less than 0.1% by volume but not more than 3.5% by volume of at least one compound selected from the group consisting of titanium boride, zirconium boride, hafnium boride, niobium boride, tantalum boride, chromium boride, titanium carbide, zirconium carbide, hafnium carbide, vanadium carbide, niobium carbide, tantalum carbide, zirconium oxide, hafnium oxide and chromium oxide and the balance of a tungsten alloy mainly consisting of tungsten.

Owner:KK TOSHIBA +1

Thermal protective coating

ActiveUS20060156958A1Extended shelf lifeExcellent optical propertiesAlkali metal silicate coatingsPretreated surfacesCalcium silicateSodium Bentonite

A coating, method of coating and substrates coated thereby, wherein the coating contains an inorganic adhesive such as an alkali / alkaline earth metal silicate such as sodium silicate, potassium silicate, calcium silicate, and magnesium silicate; a filler such as a metal oxide for example silicon dioxide, aluminum oxide, titanium dioxide, magnesium oxide, calcium oxide and boron oxide; and one or more emissivity agents such as silicon hexaboride, carbon tetraboride, silicon tetraboride, silicon carbide, molybdenum disilicide, tungsten disilicide, zirconium diboride, cupric chromite, or metallic oxides such as iron oxides, magnesium oxides, manganese oxides, chromium oxides and copper chromium oxides, and derivatives thereof. In a coating solution, an admixture of the coating contains water. A stabilizer such as bentonite, kaolin, magnesium alumina silicon clay, tabular alumina and stabilized zirconium oxide may be added.

Owner:WESSEX

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com