Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

136results about How to "High conversion rate of CO" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

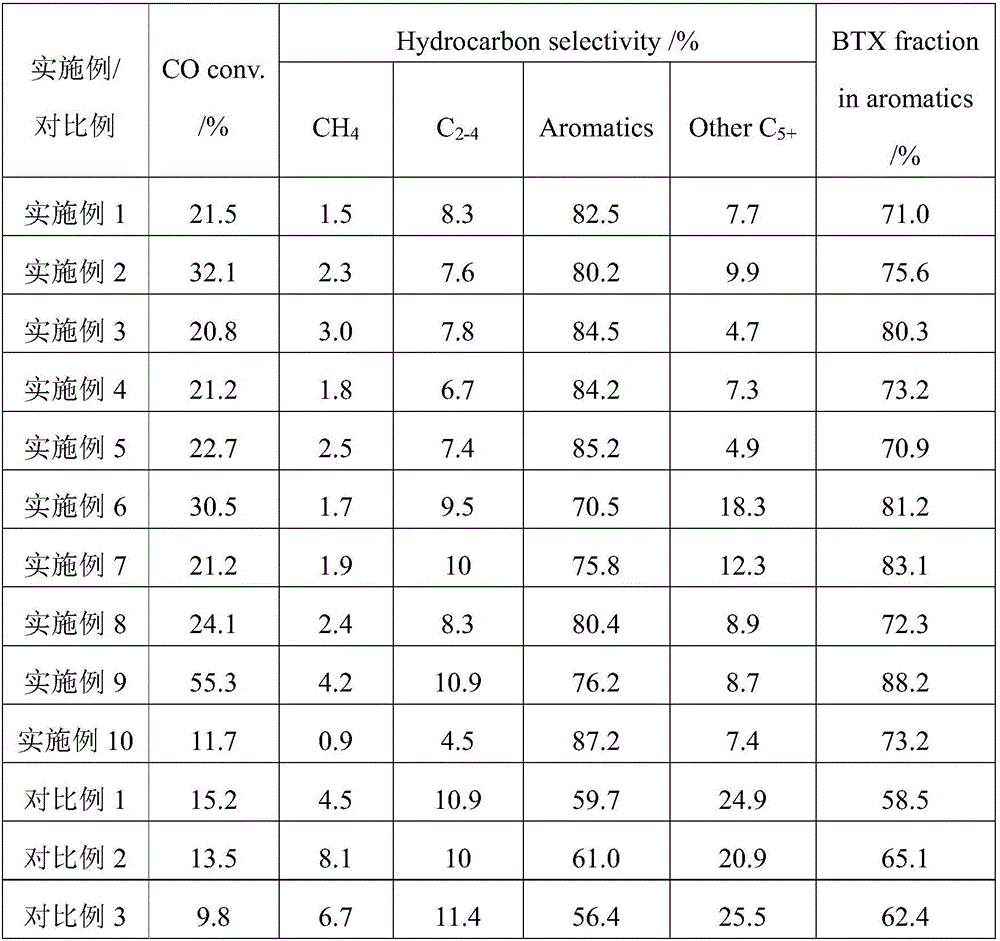

Catalyst for high-selectivity preparation of light aromatic hydrocarbon by using synthesis gas and preparation method thereof

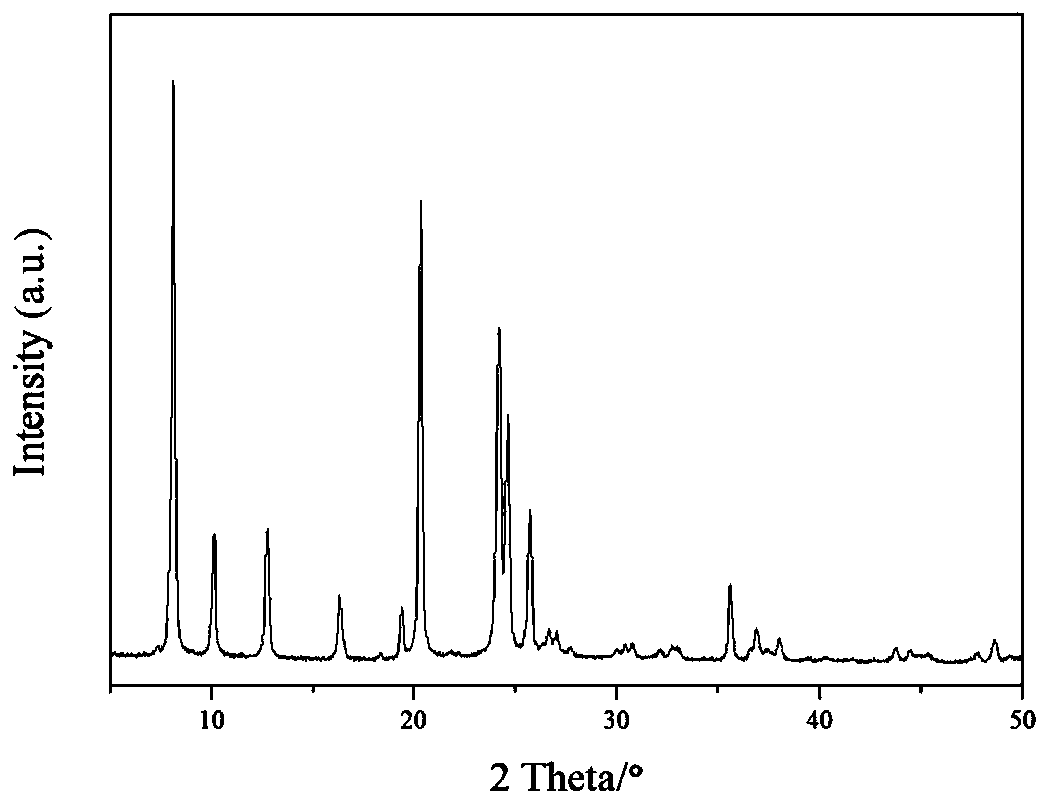

ActiveCN106540740AImprove catalytic performanceHigh conversion rate of COHydrocarbon from carbon oxidesMolecular sieve catalystsPolycyclic aromatic hydrocarbonMolecular sieve

The invention provides a catalyst for high-selectivity preparation of light aromatic hydrocarbon by using synthesis gas and a preparation method thereof and belongs to the field of catalysts. The catalyst is prepared from, by mass, 20%-60% of modified zeolite molecular sieve and 40%-80% of zirconium-containing composite oxide. The preparation method comprises the steps that the zirconium-containing composite oxide is added to a solvent, and ultrasonic dispersion is performed to obtain a solution A; the modified zeolite molecular sieve is added into the solution A; the mixture obtained after ultrasonic dispersion is subjected to suction filtration, and the obtained filter cake after washing is dried; the sample obtained after drying is grinded into powder; the powdery sample is calcinated, and the obtained sample is the catalyst for high-selectivity preparation of the light aromatic hydrocarbon by using synthesis gas. The light aromatic hydrocarbon can be prepared in a high-selectivity mode, and the stability is good. The preparation method of the catalyst for high-selectivity preparation of the light aromatic hydrocarbon by using the synthesis gas is simple and low in cost and has good industrial application prospect.

Owner:XIAMEN UNIV

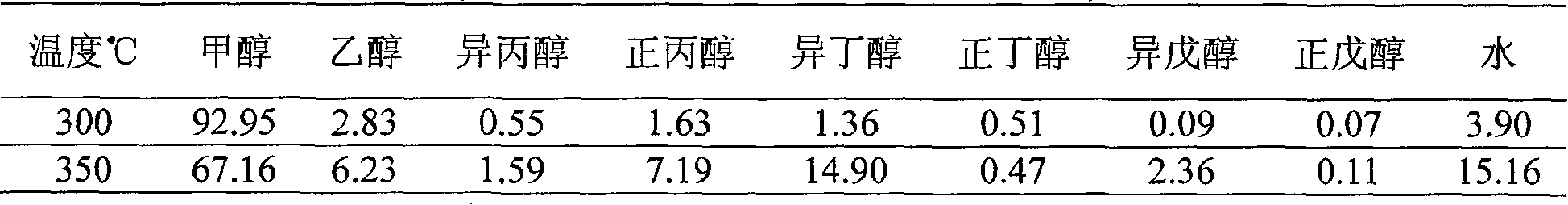

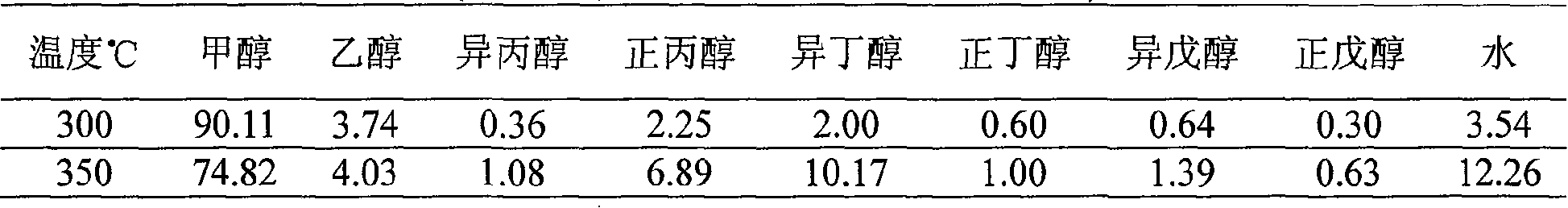

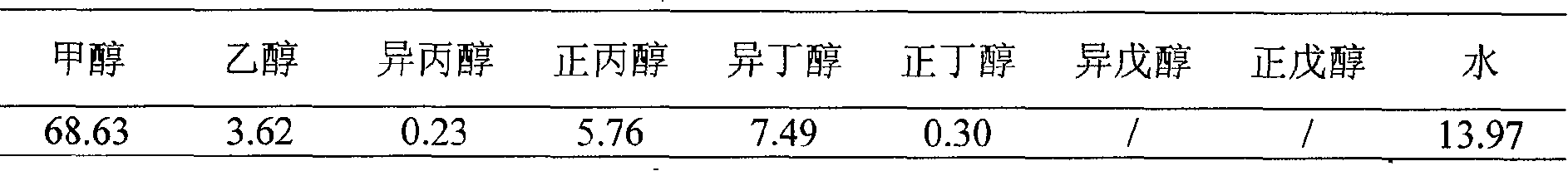

Catalyst for synthesizing low carbon mellow with synthesis gas and preparation method thereof

ActiveCN101185895AHigh conversion rate of COHigh selectivityOrganic compound preparationHydroxy compound preparationIsobutanolPropanol

The invention discloses a catalyst for synthesizing low carbon mixed alcohol with synthetic gas and a preparation method. The main components of the catalyst are copper oxide, zinc oxide, chromium oxide, alumina, and an appropriate amount of other assistants, which are expressed by the general formula Cu(Zn)a(Cr)b(Al)c(M)d(A)e(O)x; the catalyst is prepared by coprecipitation, and the assistant is added by impregnation. Under appropriate conditions, the catalyst can lead CO and hydrogen to react to produce a mixture of oxidation compounds which comprises methanol, ethanol, propanol, isobutanol, pentanol, and a small amount of C5.

Owner:SINOPEC NANJING RES INST OF CHEM IND CO LTD

Methanol synthesizing catalyst and its prepn

InactiveCN1810357AEasy to makeEasy to industrializeOrganic compound preparationHydroxy compound preparationSyngasNitrate

The methanol synthesizing catalyst has the molar ratio of Cu to Zn to Al to Li equal to 6:3:1:0.5, and is prepared through coprecipitation process. The preparation process includes the following steps: 1. dropping mixed solution of nitrate of Cu, Zn, Al and Li in certain molar ratio and Na2CO3 solution into small amount of deionized water while stirring and maintaining the solution pH in 7-8; and 2. ageing for 2 hr after finishing dropping, suction filtering, washing and stoving to obtain the catalyst precursor, and stoving and roasting to obtain the catalyst product. The preparation process is simple and easy to use in industrial production, and the catalyst has activity higher than traditional Cu-Zn-Al catalyst and wide application range for traditional synthetic gas and synthetic gas with relatively high CO and CO2 content.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Nano Pd catalyst used for preparing oxalic ester by CO gas phase oxidation coupling and its preparation method

ActiveCN102513101AHigh selectivityHigh space-time yieldPreparation by carbon monoxide or formate reactionMetal/metal-oxides/metal-hydroxide catalystsGas phaseOxidative coupling of methane

The invention belongs to the oxalic ester preparation technical field, and provides a nano Pd catalyst used for preparing oxalic ester by CO gas phase oxidation coupling in coal glycol, its preparation method and its purpose. According to the invention, the catalyst takes alpha-alumina as a carrier, precious metal Pd nano particles are taken as an active component, by referring the weight of the catalyst carrier, the weight percentage content of the active ingredient Pd is 0.05-2%. The catalyst is prepared by using a nano metal in-situ loading method. The preparation method has the advantages of simple process and low energy consumption, and enables accurate regulation and control on the size and bare crystal face of the Pd nano particles. The catalyst with the bare crystal face of (lll) surface has the advantages of high Pd dispersiveness of active components, small size and narrow distribution, and can catalyze CO gas phase oxidation coupling to oxalic ester with high efficiency under low precious metal load capacity.

Owner:贵州鑫醇科技发展有限公司

Catalyst for synthesizing methyl formate by virtue of gas-phase methanol carbonylation as well as preparation method and application of catalyst

ActiveCN103691451AImprove stabilityLow impurity content requirementPreparation by carbon monoxide or formate reactionMetal/metal-oxides/metal-hydroxide catalystsGas phaseSolvent

The invention discloses a supported nano platinum group metal heterogeneous catalyst for synthesizing methyl formate by virtue of gas-phase methanol carbonylation. The supported nano platinum group metal heterogeneous catalyst is prepared from the following components accounting for the mass of a carrier: 0.01-2 percent of platinum group metal active component, and smaller than or equal to 20% of an optional additive. The invention also discloses a preparation method of the supported nano platinum group metal heterogeneous catalyst for synthesizing the methyl formate by virtue of the gas-phase methanol carbonylation. The preparation method comprises the following steps: optionally immersing the carrier into an aqueous or ethanol solution of an additive precursor, standing, drying, and roasting; then immersing the carrier into an aqueous or ethanol solution of a platinum group metal precursor, and uniformly mixing to enable the carrier to be uniformly dispersed in the platinum group metal precursor solution; carrying out ultrasonic waves treatment under the heating condition until a solvent of the solution volatilizes to be dry, and enabling the platinum group metal precursor to be uniformly adsorbed on the surface of the carrier; drying and roasting an obtained adsorbed sample; then adding a reducing agent, a structure-directing agent and a protective agent to carry out reduction reaction; and then carrying out filtering, washing and vacuum drying to obtain the supported nano platinum group metal heterogeneous catalyst.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

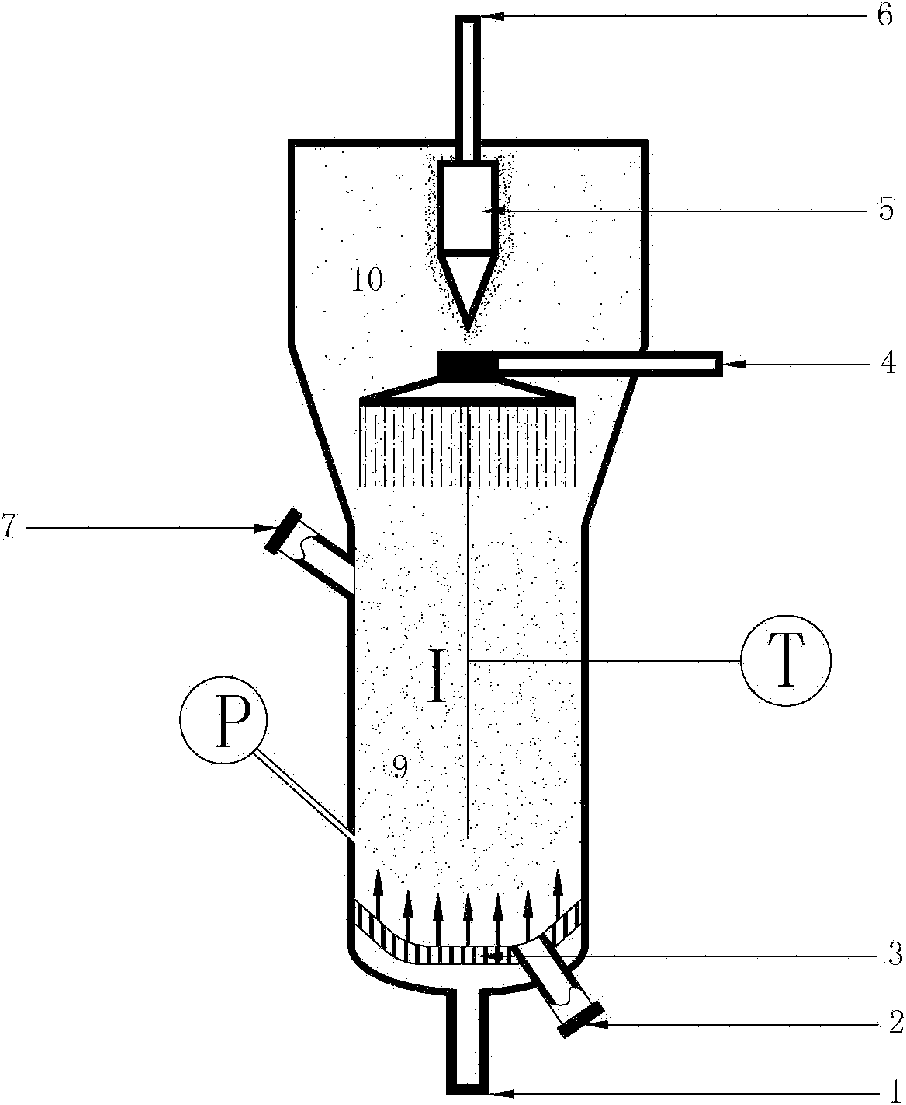

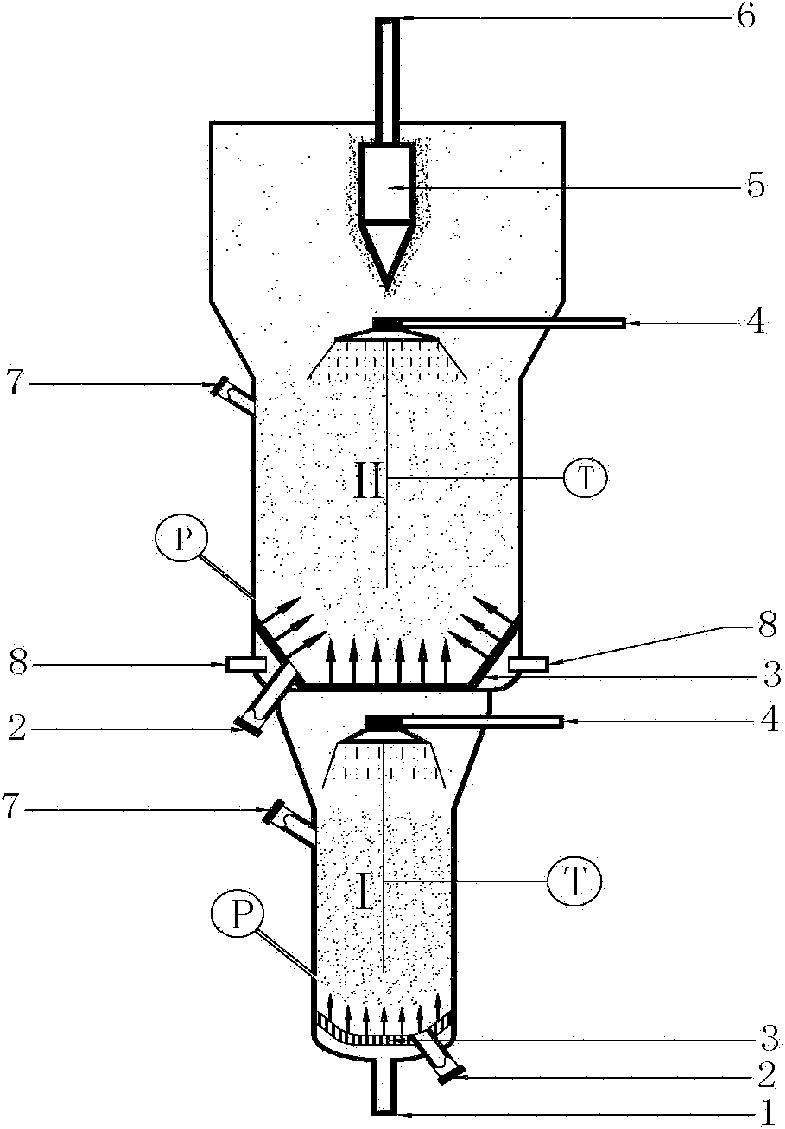

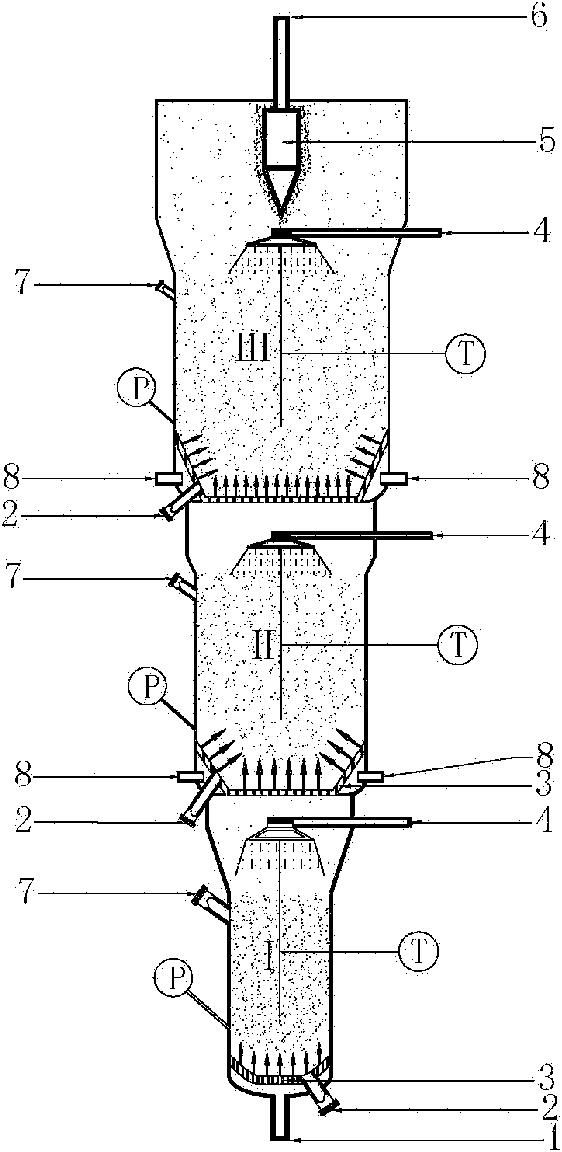

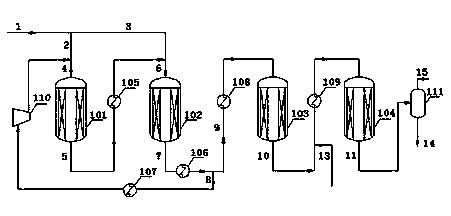

Fluidized bed reactor and method for methanation of gas mixture containing H2 and CO

ActiveCN102600771AReduce the numberExtend your lifeHydrocarbon from carbon oxidesChemical/physical processesGas solidContact high

The invention relates to a fluidized bed reactor and a method for methanation of gas mixture containing H2 and CO. The fluidized bed reactor of the invention comprises a material gas inlet 1, a catalyst outlet 2, a gas-solid separator 5, a product gas outlet 6, a catalyst inlet 7 and a material gas lateral line inlet, wherein one or more gas distribution plate 3 is arranged in the fluidized bed reactor in order to divide the reactor into several fluidized bed layers to form several catalyst dense-phase zones; a cooling water spraying device 4 is arranged above each layer of the catalyst dense-phase zone in order to control temperature of the reactor. Because the circulating cooling water directly contacts high-temperature product gas, the reactor of the invention strengthens heat transfer, is easy to control reaction temperature, reduces heat loss during the heat transfer and improves heat utilization rate during the reaction. The reactor has the advantages of large production flux, big operation elasticity, high CO conversion rate, high selectivity of produced methane, less catalyst dosage, high utilization rate of heat quantity and so on, so that the reactor has good industrial application prospect.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Applications of Ni/SiC catalyst to methane production through syngas conversion

InactiveCN102020525AHigh conversion rate of CONo carbon depositPhysical/chemical process catalystsHydrocarbon from carbon oxidesHigh pressureHigh activity

The invention discloses the applications of a Ni / SiC catalyst to methane production through syngas conversion. Silicon carbide with favorable thermal conductivity and mechanical strength is used as a carrier of a nickel catalyst, wherein the catalyst contains 1-20 percent of nickel metal, and the preparation method is simple and practical. The catalyst can rapidly export a great number of heat generated in a methane production reaction through syngas conversion, avoid congregation of nickel catalyst particles due to partial overheat and inactivation caused by carbon deposition, have the advantages of strong abrasion resistance, high activity, strong carbon deposition resistance, and the like and can be operated at a higher airspeed under high pressure.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Catalyst used for increasing selectivity of higher carbon alcohol production via Fischer-Tropsch synthesis, and preparation method and applications thereof

ActiveCN103586060AHigh selectivityHigh conversion rate of COPhysical/chemical process catalystsLiquid hydrocarbon mixture productionPlasticizerActive component

The invention provides a catalyst used for increasing selectivity of higher carbon alcohol production via Fischer-Tropsch synthesis, and a preparation method and applications thereof, and specifically relates to a catalyst used for increasing selectivity of high carbon primary alcohols (more than 6 carbon atoms) in mixed primary alcohols prepared via hydrogenation of CO, and a preparation method and applications of the catalyst. According to the catalyst, active carbon is taken as a carrier, Co element is taken as an active component, one or more elements selected from Al, B or Ga are taken as auxiliary agents. The catalyst comprises 1 to 30wt% of the active component (based on the content of Co), and 0.01 to 5wt% of the auxiliary agents. The catalyst is capable of increasing selectivity of the high carbon primary alcohols (more than 6 carbon atoms) in the mixed primary alcohols prepared via hydrogenation of CO. The high carbon primary alcohols can be used as main raw materials of washing agents, plasticizers, and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Fischer-Tropsch synthesis cobalt-based catalyst and preparation method thereof

InactiveCN103071481AImprove performanceHigh selectivityLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsKeroseneGroup element

The invention provides a Fischer-Tropsch synthesis cobalt-based catalyst and a preparation method of the Fischer-Tropsch synthesis cobalt-based catalyst. The catalyst contains a silicon aluminum boron composite oxide, cobalt and an assistant, wherein the assistant contains an oxide / oxides of one or two or more VB-group elements, and an oxide / oxides of one or two or more elements of Mn, Ti, Zr, Fe, W, Ce, La and Ni; according to the total amount of the catalyst, the content of cobalt is 1wt%-30wt%, the content of the oxide / oxides of the VB-group elements is 0.02wt%-9wt%, the content of the oxide / oxides of other assistants is 0.01wt%-6wt%, and the balance is the silicon aluminum boron composite oxide. The invention further provides the silicon aluminum boron composite oxide and a preparation method of the load cobalt catalyst. The catalyst is used for the Fischer-Tropsch synthesis reaction, the CO conversion rate and the C5+ selectivity are both higher than 80%, and the selectivity of kerosene and diesel fraction, namely C10-C20, in the C5+ is up to more than 50%.

Owner:WANHUA CHEM GRP CO LTD +1

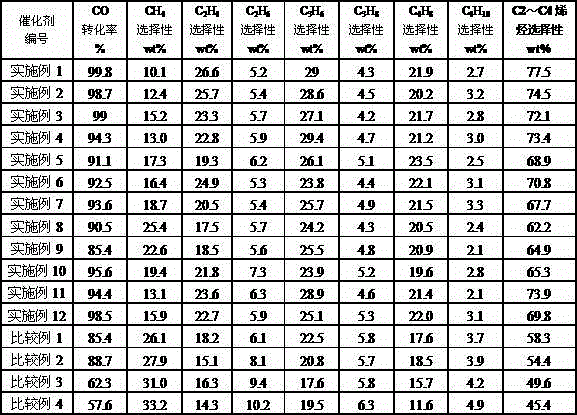

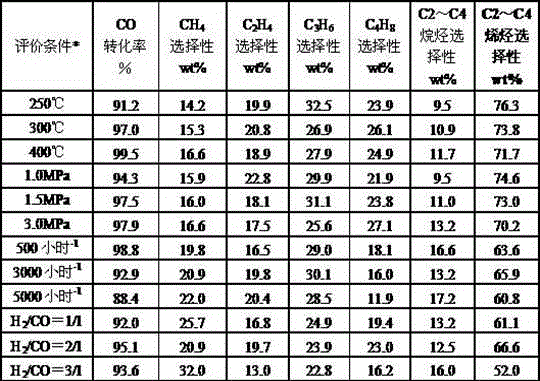

Catalyst for preparing low-carbon olefin from synthesis gas by one-step method, preparation method and application of catalyst

ActiveCN104549325AHighly uniform dispersionIncrease the number ofHydrocarbon from carbon oxidesLiquid hydrocarbon mixture productionSyngasFixed bed

The invention relates to a catalyst for preparing low-carbon olefin from synthesis gas by a one-step method and a preparation method of the catalyst, which are mainly used for solving the problems of low CO conversion rate and low selectivity of low-carbon olefin in the reaction for preparing low-carbon olefin from synthesis gas in the prior art. The catalyst adopted by the invention comprises the following components in percentage by weight: (a) 5-60% of ferrum element or an oxide of the ferrum element; (b) 1-10% of cobalt element or an oxide thereof; (c) 4-20% of at least one element or an oxide thereof selected from strontium or magnesium; (d) 4-20% of at least one element or an oxide thereof selected from molybdenum and zirconium; (e) 1-10% of erbium element or an oxide thereof; and (f) 30-85% of a cocoanut active charcoal carrier. By adopting the technical scheme, the problem is solved well, and the catalyst and the preparation method thereof can be applied to the industrial production for preparing the low-carbon olefin from synthesis gas by using a fixed bed.

Owner:CHINA PETROLEUM & CHEM CORP +1

Synthetic gas-to-oil catalyst using mesoporous molecular sieve SBA-16 as carrier and method for preparing catalyst

InactiveCN102631944ANarrow pore size distributionRegular pore structureMolecular sieve catalystsLiquid hydrocarbon mixture productionMolecular sieveSyngas

The invention discloses a method for preparing a synthetic gas-to-oil (F-T reaction) cobalt-based catalyst by using mesoporous molecular sieve SBA-16 as a carrier, and application of the catalyst to synthetic gas-to-oil reaction. The highly ordered mesoporous structure of the catalyst is kept, and an original cubic symmetric structure of the carrier SBA-16 is also kept. The catalyst prepared by the method has a high active cobalt capacity, so that high activity of the catalyst is ensured, and the catalyst has the advantages of low CH4 selectivity, high C5+ selectivity and fine reaction stability.

Owner:INNER MONGOLIA UNIVERSITY

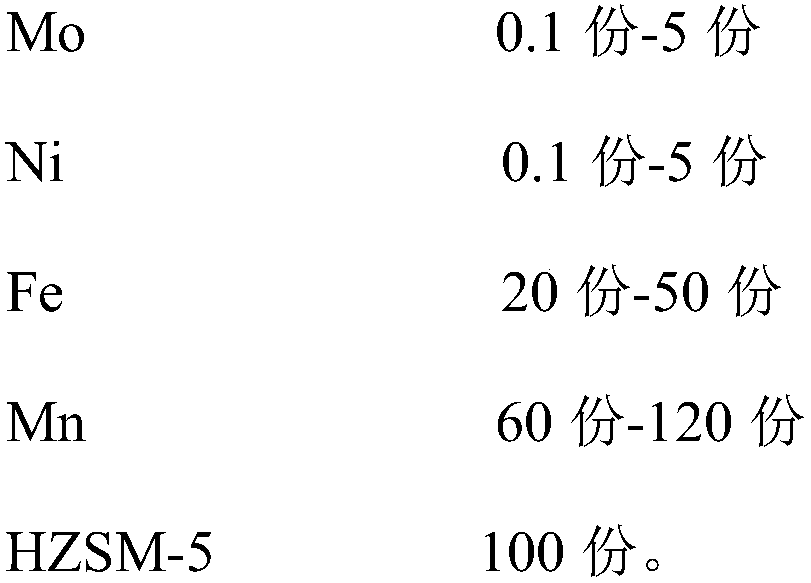

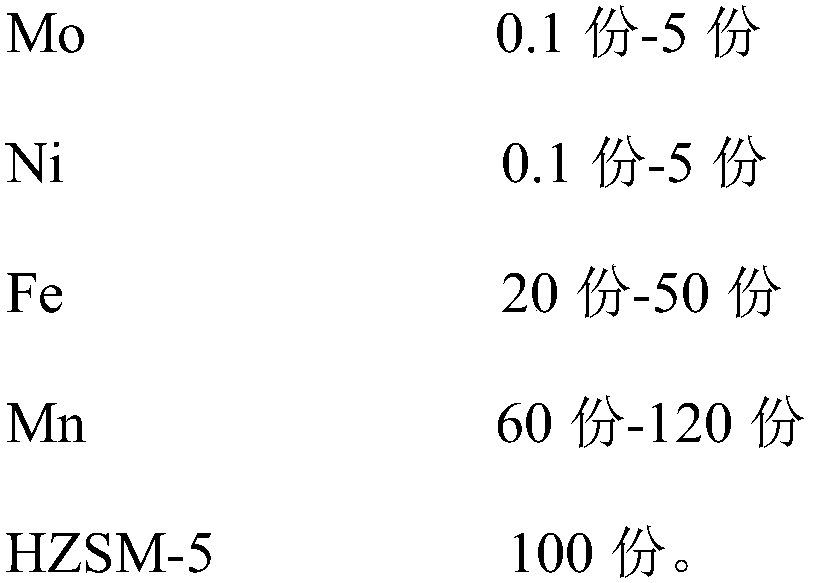

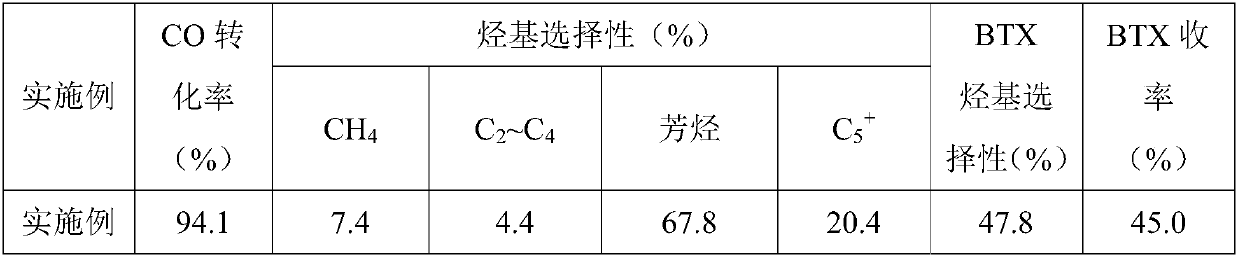

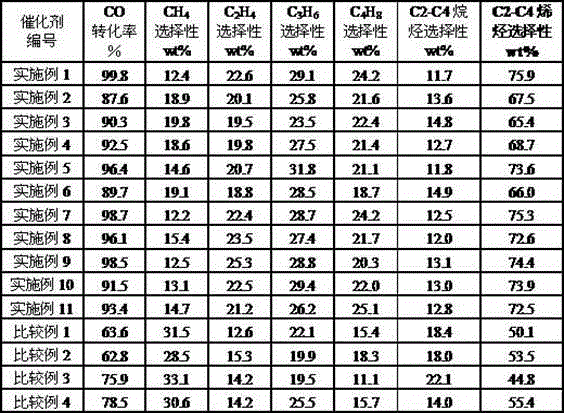

Catalyst for preparing light aromatic hydrocarbon by synthetic gas one-step process, and preparation method and application thereof

InactiveCN107626343AHigh selectivityTroubleshoot Temperature MismatchesMolecular sieve catalystsLiquid hydrocarbon mixture productionBimetalInorganic chemistry

The invention discloses a catalyst for preparing light aromatic hydrocarbon by synthetic gas one-step process, and a preparation method and an application thereof. The catalyst comprises a Fischer-Tropsch synthesis catalyst and an aromatization catalyst, wherein the Fischer-Tropsch synthesis catalyst includes an oxide of Fe and an oxide of Mn, and a composite metal oxide can fully improve the high-temperature Fischer-Tropsch synthesis activity; the aromatization catalyst is a modified molecular sieve with HZSM-5 as a carrier and with Mo and Ni double metals as active components, and the aromatization performance can be significantly improved. Through the combination of the two catalysts, series coupling of a Fischer-Tropsch synthesis reaction and an aromatization reaction is achieved, a one-way conversion rate of CO is increased obviously, and at the same time, a technology route for preparing light aromatic hydrocarbon-benzene, toluene and xylene (BTX) by synthetic gas one-step process is exploited. Experiments verify that the conversion rate of CO reaches up to 98% or more, the selectivity of hydrocarbonyl of aromatic hydrocarbon reaches 73% or more, and the selectivity of hydrocarbyl of BTX reaches 53%. The catalyst for preparing aromatic hydrocarbon by the synthetic gas one-step process has the advantages of relatively good catalytic activity, good stability and simple preparation, and has relatively good industrial application prospects.

Owner:EAST CHINA UNIV OF SCI & TECH

Application of porous ferric oxide/graphene oxide nano-composite material to catalysis of Fischer-Tropsch synthesis

ActiveCN107570155AUniform sizeHigh surface areaMaterial nanotechnologyCatalyst activation/preparationIron saltsNano composites

The invention discloses application of a porous ferric oxide / graphene oxide nano-composite material to catalysis of Fischer-Tropsch synthesis. The porous ferric oxide / graphene oxide nano-composite material can be applied to catalysis of Fischer-Tropsch synthesis. The porous ferric oxide / graphene oxide nano-composite material is prepared according to the following steps: (1) preparing a solution ofinorganic iron salt; (2) adding the solution of the inorganic iron salt into hydrosol of graphene oxide to obtain suspension liquid; and (3) performing hydrothermal reaction on the suspension liquidto obtain a ferric oxide hydrate nano-particle and graphene oxide compound, and drying and calcining sequentially. The porous ferric oxide / graphene oxide nano-composite material can be applied to catalysis of Fischer-Tropsch synthesis. The prepared catalyst has high wear capacity (the wear rate is lower than 2%.h<-1>), high CO conversion rate (90 percent), high heavy hydrocarbon C5+ selectivity (50 percent) and high stability.

Owner:SYNFUELS CHINA TECH CO LTD

Composite carrier-supported cobalt-based Fischer-Tropsch synthesis catalyst, and preparation method and application thereof

ActiveCN104874417AHigh conversion rate of COSuppress generationMolecular sieve catalystsLiquid hydrocarbon mixture productionMolecular sieveActive component

The invention relates to a composite carrier-supported cobalt-based Fischer-Tropsch synthesis catalyst, and a preparation method and an application thereof. The cobalt-based Fischer-Tropsch synthesis catalyst comprises a composite carrier prepared by using zeolite molecular sieve and an ordered meso-porous material, and an active component cobalt and an assistant which are supported on the composite carrier. The preparation method of the catalyst comprises the following steps: preparing the composite carrier composed of the zeolite molecular sieve and the ordered meso-porous material, dipping the active component cobalt and the precursor of the assistant to the composite carrier, drying, and roasting. The cobalt-based Fischer-Tropsch synthesis catalyst using the shape selection and domain restriction of the tunnels of the meso-porous material and the surface acidity of the molecular sieve maintains a high CO conversion rate and high C5-C22 distillate oil selectivity in a wide temperature range, and also has low CH4 and CO2 selectivity.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Catalyst converting synthesis gas into low carbon alkene, preparation method and applications

ActiveCN103418407AEasy to prepareMild conditionsHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsAlkeneMetal

The invention discloses a catalyst converting synthesis gas into low carbon alkene. The catalyst is characterized in that the catalyst contains iron, cobalt and metal M; With Fe2O3 and Co2O3 as counts respectively and the total weight of iron and cobalt in the catalyst as a standard, by weight, the content of iron is 20-80%, and the content of cobalt is 20-80%. With MO as a count, by weight, the content of metal M is 0.1-37% of the total weight of iron and cobalt. The metal M is one or more selected from IA, IIA, IB, IIB, VIIB and VIII metals except iron and cobalt. The invention also provides a preparation method for a catalyst used for converting synthesis gas into low carbon alkene and a prepared catalyst. The invention provides applications of the catalyst in conversion of synthesis gas into low carbon alkene. The catalyst can realize conversion of synthesis gas into low carbon alkene well.

Owner:CHINA PETROLEUM & CHEM CORP +1

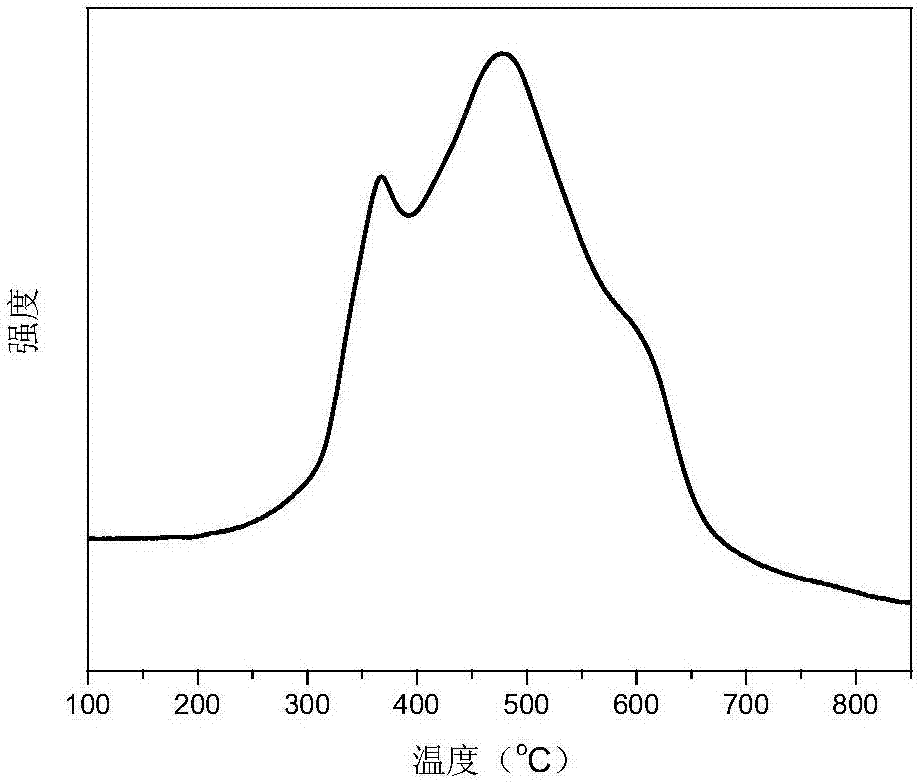

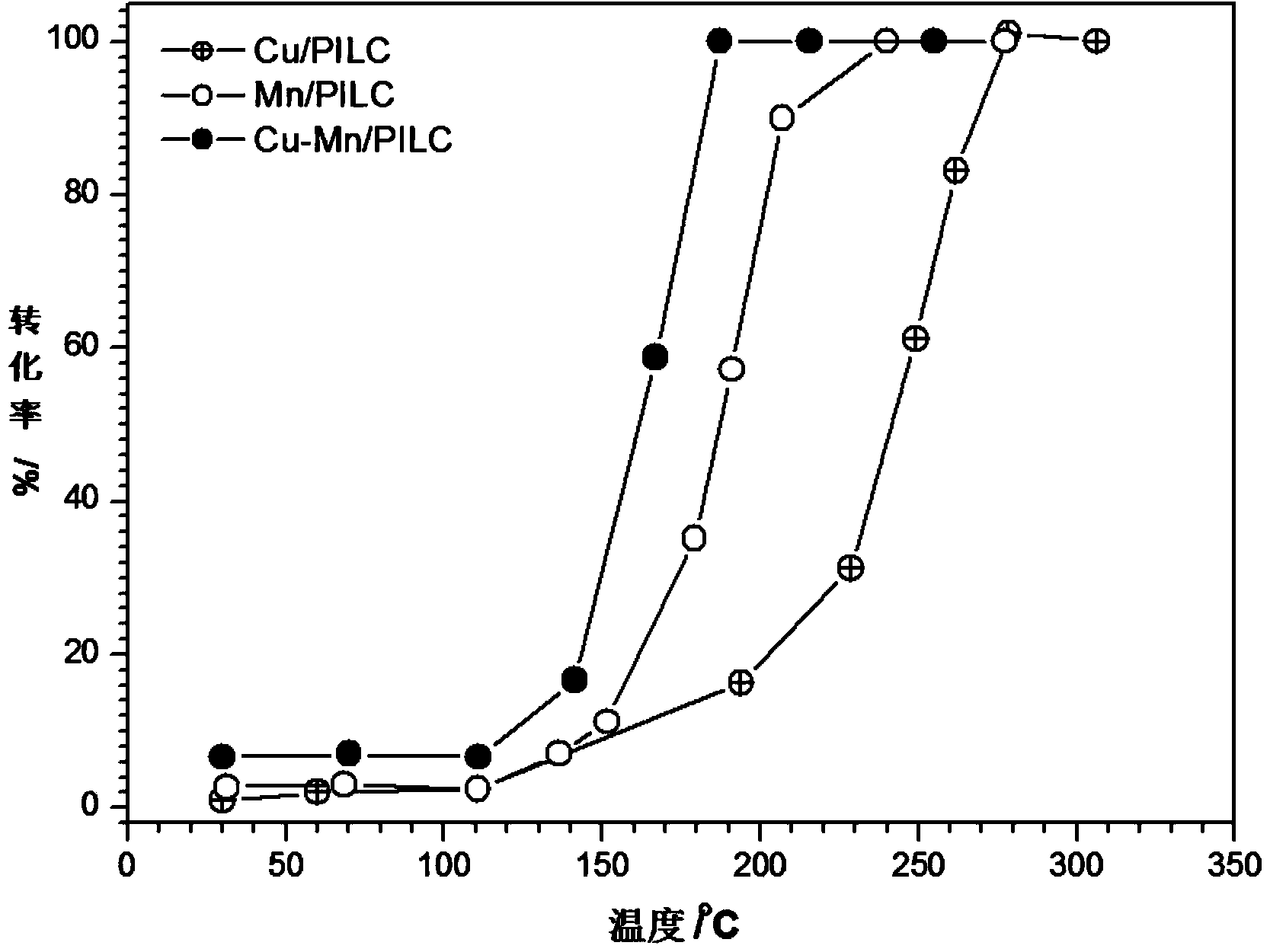

Preparation method and application of Cu-Mn catalyst loaded on aluminum-pillared montmorillonite

InactiveCN103861611AImprove stabilityHigh conversion rate of CODispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCatalytic oxidationMontmorillonite

The invention relates to a preparation method and the application of a Cu-Mn catalyst loaded on aluminium-pillared montmorillonite, belonging to the field of catalytic oxidation of CO. The montmorillonite which is widespread in the natural world is taken as a raw material; the preparation method comprises the steps of modifying the montmorillonite raw ore by sodium treatment and aluminum-pillaring, and loading Cu and Mn onto the aluminum-pillared montmorillonite to prepare the catalyst, wherein the loading amounts of Cu and Mn are respectively 4.8-9wt%. The Cu-Mn catalyst is suitable for the catalytic oxidation of CO with high space velocity (60, 000h<-1>-100, 000h<-1>). After the load-type Cu-Mn catalyst is adopted, CO is completely converted into CO2 (the conversion rate is 100%) at 180 DEG C, and the conversion rate of about 100% of CO can be maintained within 100h at 180 DEG C.

Owner:BEIJING UNIV OF TECH

Iron catalyst for preparing light olefins by use of synthesis gas and preparation method of iron catalyst

ActiveCN104549342AHigh activityActive releaseHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsNiobiumLanthanum

The invention relates to an iron catalyst for preparing light olefins by use of synthesis gas and a preparation method of the iron catalyst, aiming at solving the problems that CO conversion rate is low, the light olefin selectivity is low, and the catalyst has low strength and poor stability under a using condition when the synthesis gas is used for preparing the light olefins in the prior art. The iron catalyst is prepared from the following components in parts by weight: (a) 35-90 parts of iron element or oxide thereof; (b) 5-30 parts of at least one element of titanium and zirconium or oxide of at least one of titanium and zirconium; (c) 5-30 parts of at least one element of molybdenum and tungsten or oxide of at least one of molybdenum and tungsten; (d) 0.1-10 parts of at least one element of vanadium and niobium or oxide of at least one of vanadium and niobium; (e) 0.1-10 parts of at least one element of lanthanum and samarium or oxide of at least one of lanthanum and samarium; and (f) 0.5-5 parts of tin or oxide thereof. The iron catalyst can solve the above problems well and can be used for industrial production for preparing light olefins through Fischer-Tropsch synthesis.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for preparing low carbon olefin by fixed bed, preparation method as well as use thereof

ActiveCN104437532AImprove conversion rateHigh activityHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsFixed bedCerium

The invention relates to a catalyst for preparing low carbon olefin by a fixed bed, a preparation method as well as use thereof, which mainly solves the problem that the CO conversion ratio is low and low carbon olefin selectivity is low in synthesis gas to low carbon reaction in the prior art and the catalyst is poor in intensity and thermal stability under a using condition. By adopting the technical scheme that the catalyst provided by the invention comprises the following components in parts by weight: a) 30-80 parts of iron element and oxides thereof; b) 10-40 parts of at least one element selected from manganese and chromium or oxides thereof; c) 10-40 parts of at least one element selected from copper and zinc or oxides thereof; d) 0.9-20 parts of at least one element selected from potassium and cesium or oxides thereof; e) 0.9-20 parts of at least one element selected from cerium and neodymium or oxides thereof; and f) 0.5-10 parts of an antimony element or oxides thereof, the problem is better solved, and the catalyst can be used for industrial production of Fischer-Tropsch synthesis to prepare low carbon olefin.

Owner:CHINA PETROLEUM & CHEM CORP +1

Iron-based catalyst for Fischer-Tropsch synthesis and preparation method thereof

InactiveCN101537359AHigh conversion rate of COLow CO

<sub>2</sub>

selectivityHydrocarbon from carbon oxidesHeterogenous catalyst chemical elementsNitrateManganese

The invention discloses a preparation method of an iron-based catalyst containing iron, manganese, potassium and copper for Fischer-Tropsch synthesis, which comprises the following steps: mixing an ammonium glycollate solution or an ammonium citrate solution with a nitrate solution of iron and manganese to obtain a sizing agent; drying, physically decomposing and baking the sizing agent; adding auxiliary agents of potassium and copper by dipping treatment; and obtaining the iron-based catalyst for Fischer-Tropsch synthesis by baking, tabletting and crushing treatment. The catalyst prepared by the preparation method of the iron-based catalyst for Fischer-Tropsch synthesis has higher CO conversion rate and lower CO2 selectivity in the application of Fischer-Tropsch synthesis.

Owner:YASHENTECH CORP +1

Catalyst for methanation of CO and H2, and preparation method thereof

ActiveCN102674413ASimple process routeEasy to operateHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsAluminateAcetic acid

The invention relates to the methanation catalysis field, in particular to a catalyst for methanation of CO and H2, and a preparation method thereof. The preparation method of hexa-aluminate comprises the following steps of: 1) dissolving an aluminum salt precursor into water, and adding the obtained water solution into an alcohol solution containing a surface active agent, thus obtaining aluminum salt precursor solution; 2) dissolving an alkaline-earth metal salt precursor into an acetic acid water solution, and adjusting the pH value to be 1, thus obtaining alkaline-earth metal salt precursor solution; 3) adding the alkaline-earth metal salt precursor solution into the aluminum salt precursor solution, and controlling the molar ratio between alkaline-earth metal and aluminum to be 1:(6-12), thus obtaining a precursor mixed solution; and 4) evaporating the precursor mixed solution at the temperature of 20-60 DEG C so as to obtain xerogel, carrying out heat treatment on the xerogel at 800-1200 DEG C in the high-purity inert atmosphere for 2-6 hours, and calcining for 2-6 hours at the same temperature, and finally pickling to obtain a hexa-aluminate carrier. The catalyst is high in catalytic activity, anti-carbon and strong in sintering resistance.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Catalyst for producing light olefins by fixed bed and preparation method for catalyst for producing light olefins by fixed bed

ActiveCN104437511AHigh selectivityHigh conversion rate of COHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsPtru catalystFixed bed

The invention relates to a catalyst for producing light olefins by a fixed bed and a preparation method for the catalyst for producing light olefins by the fixed bed, mainly solving the problems of low CO conversion rate and low selectivity of light olefins during reaction of preparation of light olefins with synthetic gases in the prior art. The catalyst comprises the following components in part by weight: (a) 10-40 parts of iron elements or oxides thereof, (b) 1-10 parts of zinc elements or oxides thereof, (c) 0.5-10 parts of at least one element selected from lanthanum or cerium or oxides thereof, and (d) 30-80 parts composite carriers formed by high-temperature sintering of kaliophilite, calcium carbonate and alpha-aluminum oxide. According to the technical scheme, the catalyst for producing light olefins by the fixed bed and the preparation method can be used for well solving the problems, and can be used for industrial production of light olefins with synthetic gases based on a fixed bed.

Owner:CHINA PETROLEUM & CHEM CORP +1

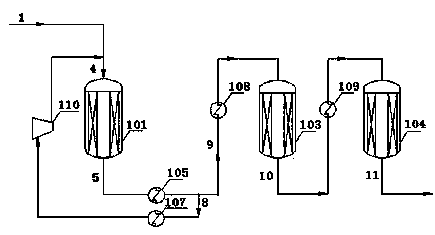

Method of producing substitute natural gas by methanation of synthesis gas

The invention relates to a method of producing substitute natural gas by methanation of synthesis gas, mainly solving problems, namely large using amount of recycle gas and high energy consumption of compressors, of high-temperature methanation reactions in the prior art. According to the technical scheme adopted by the method, the method comprises: a) a step of providing a high-temperature methanation reaction zone including n-stage series-connected reactors, with the n being not less than 2; b) a step of dividing the synthesis gas raw materials containing H2, CO, CO2 and H2O into n sections and respectively feeding the n sections of the synthesis gas raw materials into inlets of the reactors at all stages in the high-temperature methanation reaction zone, wherein a stream flowing out of an outlet of each of the reactors except the reactor at the final stage enters the inlet of the reactor at the next stage, the stream Vn flowing out from the reactor at the final stage is divided into Vn' and Vn'', and the stream Vn' is condensed and circulated to the inlet of the reactor at the first stage; c) a step of providing a low-temperature methanation reaction zone including m-stage series-connected reactors, with the m being not less than 2; and d) a step of feeding the stream Vn'' into the low-temperature methanation reaction zone, and substitute natural gas is obtained after the reaction. By the technical scheme, the problems are solved well and the method can be used in industrial production of the substitute natural gas from the synthesis gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for producing low carbon olefin from synthesis gas and use method of catalyst

ActiveCN104549352AHighly uniform dispersionIncrease the number ofHydrocarbon from carbon oxidesLiquid hydrocarbon mixture productionSyngasPotassium oxide

The invention relates to a catalyst for producing low carbon olefin from synthesis gas and a use method of the catalyst for producing the low carbon olefin from the synthesis gas. According to the catalyst and the use method, the problems of low CO conversion rate and low carbon olefin selectivity in reaction for preparing low carbon olefin from the synthesis gas in the prior art are mainly solved. The catalyst for producing low carbon olefin from the synthesis gas comprises the following components in percentage by weight: (a) 5%-50% of an iron element or oxides of the iron element, (b) 4%-20% of at least one element selected from manganese and zirconium or oxides of the element, (c) 1%-10% of a bismuth element or oxides of the bismuth element and (d) 25%-90% of a carrier, wherein the carrier comprises the following components in parts by weight: (1) 15-40 parts of alpha-aluminum oxide, (2) 1-45 parts of calcium oxide, (3) 1-5 parts of titanium dioxide and (4) 1-20 parts of potassium oxide. According to the technical scheme, the problems are well solved; the catalyst can be applied to the industrial production for producing low carbon olefin from the synthesis gas by virtue of a fixed bed.

Owner:CHINA PETROLEUM & CHEM CORP +1

Iron-based catalyst for preparing low-carbon alkane as well as preparation method and using method of iron-based catalyst for preparing low-carbon alkane

ActiveCN104437524AHigh activityActive releaseHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsAlkanePtru catalyst

The invention relates to an iron-based catalyst for preparing low-carbon alkane as well as a preparation method and a using method of the iron-based catalyst for preparing the low-carbon alkane. The iron-based catalyst for preparing the low-carbon alkane is mainly used for solving the problems that the reaction of preparing low-carbon alkane from a synthesis gas in the prior art is low in CO conversion rate and low in low-carbon alkane selectivity, and the catalyst is poor in strength and thermal stability under a using condition. The problems are solved very well by adopting a technical scheme that the catalyst comprises the following components in parts by weight: a) 20-80 parts of an iron element or oxides thereof; b) 1-15 parts of a cobalt element and oxides thereof; c) 10-30 parts of at least one element selected from molybdenum and vanadium or oxides thereof; d) 5-20 parts of at least one element selected from magnesium and barium or oxides thereof; e) 5-20 parts of at least one element selected from tin and aluminum or oxides thereof; and f) 0.5-10 parts of a scandium element or oxides thereof. The catalyst can be used for industrial production of preparing low-carbon alkane from the synthesis gas by virtue of a one-step process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst used for synthesized gas directly preparing dimethy ether

ActiveCN101121143AHigh activityFine particleMolecular sieve catalystsEther preparationSyngasReaction temperature

The present invention relates to a catalyst for a syngas to directly prepare for dimethl ether and mainly solves the problems in the prior art that a reaction temperature of the catalyst is high; a carbon monoxide transformation rate and / or a selectivity of the dimethl ether are not high. The present invention solves the problem well by adopting a technical proposal that the catalyst comprises an oxide of cuprum, zinc, aluminium and zirconium and a ZSM-5 molecular sieve, which effectively translates the syngas into the dimethl ether by one step. The present invention can be used for the industrial production that the syngas directly prepares for the dimethl ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

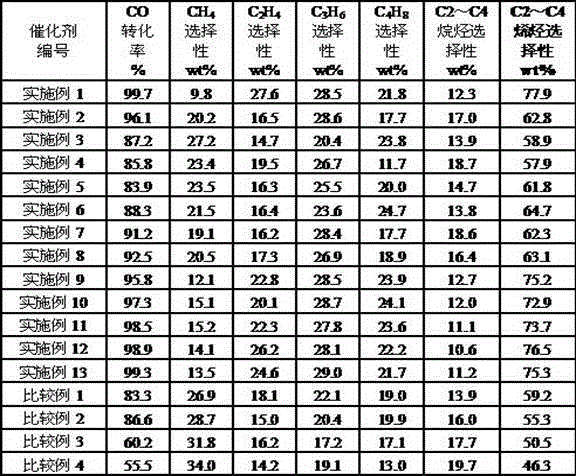

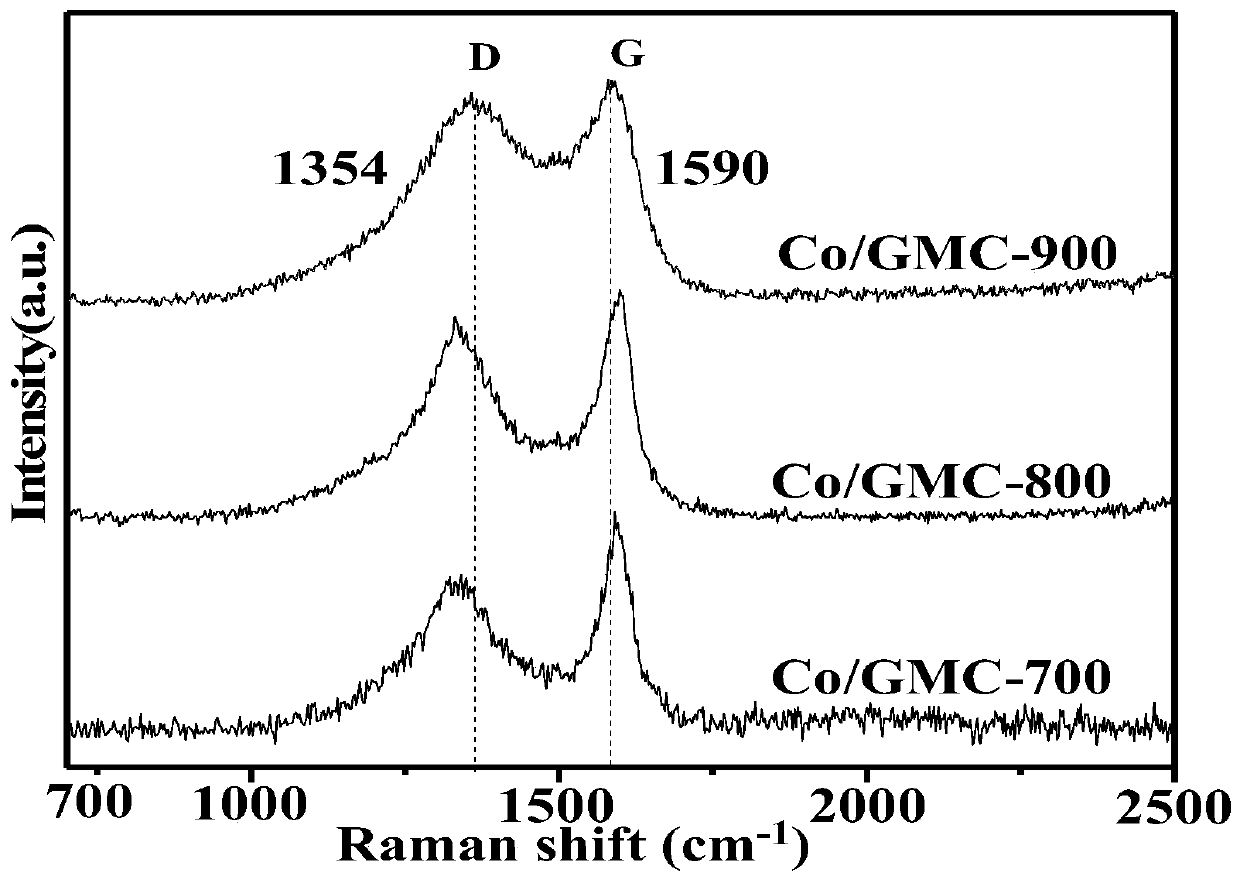

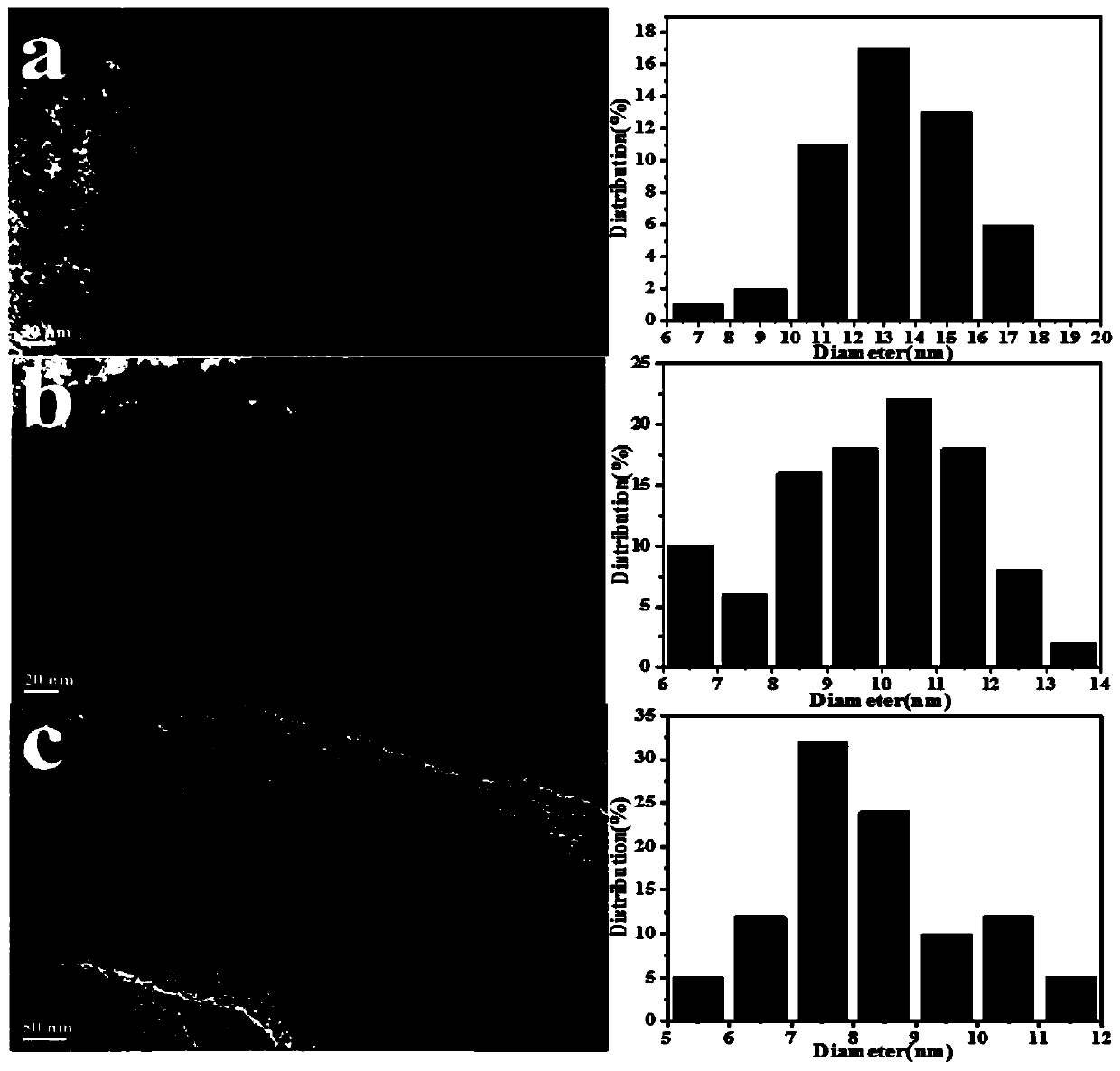

Mesoporous carbon material loaded cobalt-based catalyst and preparation method thereof

InactiveCN110975871AEasy to prepareRegular and orderly structureEnergy inputCatalyst activation/preparationPtru catalystAlcohol

The invention discloses a mesoporous carbon material loaded cobalt-based catalyst and a preparation method thereof, and belongs to the technical field of metal catalysts. The preparation method of thecobalt-based catalyst comprises the steps: (1) dissolving Co(NO3)2.6H2O in an absolute ethyl alcohol solution; (2) immersing a mesoporous carbon material GMC into the solution obtained in the step (1), and evaporating in a rotary evaporator to obtain a mixture; and (3) putting the mixture obtained in the step (2) into a drying oven, and drying; and calcining to obtain the catalyst. The catalyst provided by the invention is higher in graphitization degree, more uniform in CoO particle dispersion, higher in CO conversion rate, lower in CO2 generation rate and better in C5+ selectivity.

Owner:CHANGZHOU INST OF TECH

Method of producing substitute natural gas by methanation of synthesis gas

The invention relates to a method of producing substitute natural gas by methanation of synthesis gas, mainly solving problems, namely large using amount of recycle gas, high energy consumption of compressors, and excess of the H2 component or the CO2 component in substitute natural gas products, of high-temperature methanation reactions in the prior art. According to the technical scheme adopted by the method, the method comprises: a) a step of providing a high-temperature methanation reaction zone including n-stage series-connected reactors; b) a step of dividing the synthesis gas raw materials into n sections and respectively feeding the n sections of the synthesis gas raw materials into inlets of the reactors at all stages in the high-temperature methanation reaction zone, wherein the stream Vn flowing out from the reactor at the final stage is divided into Vn' and Vn'' and the stream Vn' is condensed and circulated to the inlet of the reactor at the first stage; c) a step of providing a low-temperature methanation reaction zone including m-stage series-connected reactors; and d) a step of supplementing a stream I containing CO2 to a reactor at any stage in the low-temperature methanation reaction zone, and a substitute natural gas product is obtained after the reaction. By the technical scheme, the problems are solved well and the method can be used in industrial production of the substitute natural gas from the synthesis gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fe-based catalyst, preparation method thereof and application thereof for preparing aromatic hydrocarbons through one-step method by synthesis gas

InactiveCN110368984AHigh selectivityLow selectivityMolecular sieve catalystsLiquid hydrocarbon mixture productionStructural stabilityFe based

The invention discloses an Fe-based catalyst for preparing aromatic hydrocarbons through a one-step method by synthesis gas and a preparation method of the Fe-based catalyst. The Fe-based catalyst isprepared from a Fe-based spinel material, molecular sieve zeolite and a metal oxide auxiliary agent, wherein the content of the Fe-based spinel material is 9.95%-79.95%, the zeolite molecular sieve is20%-90%, and the oxide auxiliary agent is 0.05-20%. The Fe-based catalyst couples preparation of olefin by the synthesis gas with aromatization reaction of the olefin, and because the spinel materialhas high structural stability and Fe dispersibility in catalytic reaction and high reactivity, light aromatics selectivity and stability are maintained during the 1000h synthesis gas catalytic conversion process, the technical problems of low aromatics selectivity, poor catalyst stability and high content of polycyclic aromatic hydrocarbons in the process preparing the aromatic hydrocarbon from the synthesis gas are solved; and the catalyst synthesis cost is low, the operation is simple, and the Fe-based catalyst and the preparation method are suitable for large-scale industrial production ofthe aromatic hydrocarbons from the synthetic gas.

Owner:SYNFUELS CHINA TECH CO LTD

Method for producing substitute natural gas

The invention relates to a method for producing substitute natural gas. The problems of large using amount of high-temperature methanation reaction circulating gas, high energy consumption of a compressor and excess of an H2 or CO2 component in a substitute natural gas product in the prior art are mainly solved. According to the technical scheme, the method comprises the following steps: (a) proving a high-temperature methanation reaction area, wherein the high-temperature methanation reaction area comprises an n stages of cascaded reactors; (b) dividing synthesis gas raw materials into n sections, causing the n sections of synthesis gas raw materials to enter an inlet of a reactor in each stage in the high-temperature methanation reaction area, dividing a material flow Vn flowing out of an outlet of the reactor in a final stage into Vn' and Vn', and compressing and circulating the material flow Vn to an inlet of the reactor in the first stage; (c) providing a low-temperature methanation reaction area, wherein the low-temperature methanation reaction area comprises m stages of reactors which are connected in series; (d) supplementing an H2-containing material flow I into the reactor in any stage of a low-temperature methanation unit, and performing reaction to obtain the substitute natural gas product. According to the method, the problems are well solved; the method can be used for industrial production of preparing the substitute natural gas with synthesis gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fischer-Tropsch synthesis method

ActiveCN105087042AOvercoming the disadvantage of low selectivityHigh selectivityLiquid hydrocarbon mixture productionAlkaneSynthesis methods

The present invention provides a Fischer-Tropsch synthesis method. The method comprises: under Fischer-Tropsch synthesis conditions and in the presence of a Fischer-Tropsch synthesis catalyst, reacting synthesis gas in a supercritical medium. The supercritical medium is at least one medium selected from C3-C10 alkane, C3-C10 olefin, C6-C10 aromatic hydrocarbon and light oil produced by Fischer-Tropsch synthesis. By using the Fischer-Tropsch synthesis method provided by the present invention, a higher conversion rate of CO and higher C5+ selectivity can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com