Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

363 results about "Oxidative coupling of methane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

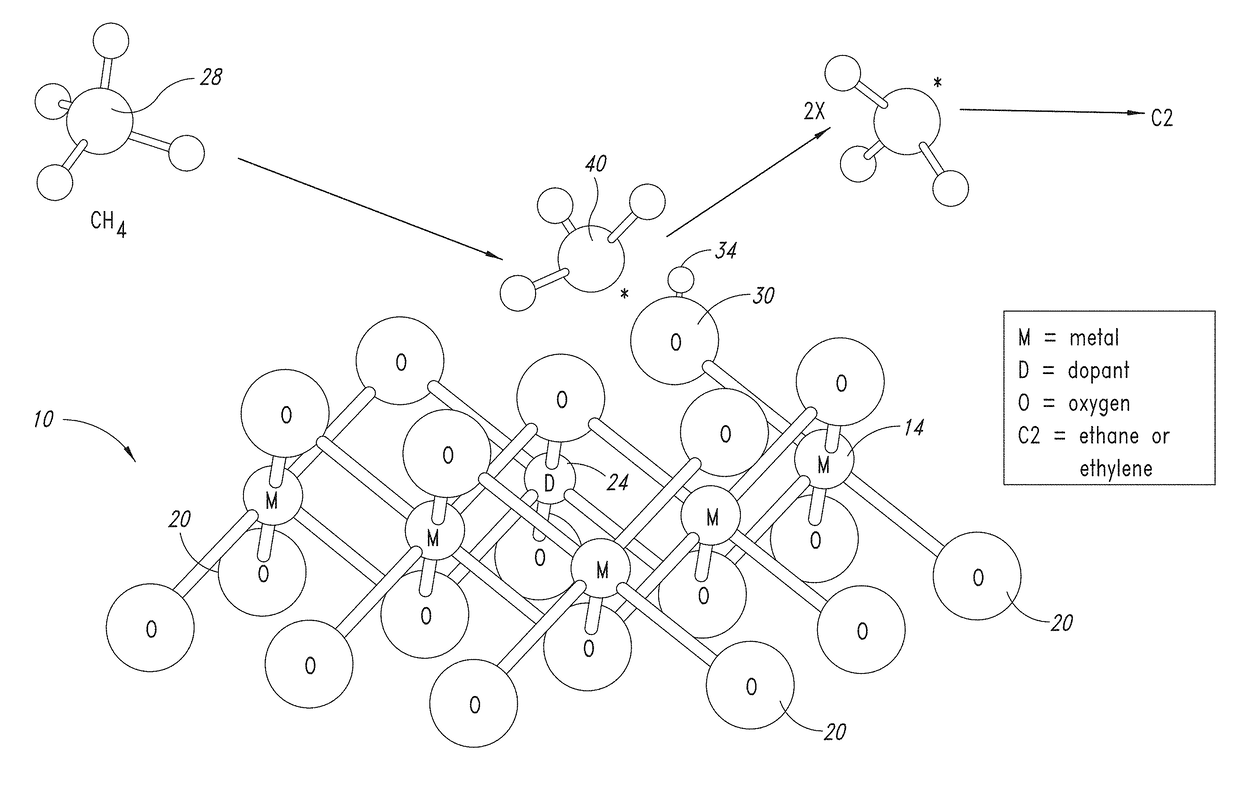

The oxidative coupling of methane (OCM) is a type of chemical reaction discovered in the 1980s for the direct conversion of natural gas, primarily consisting of methane, into value-added chemicals.

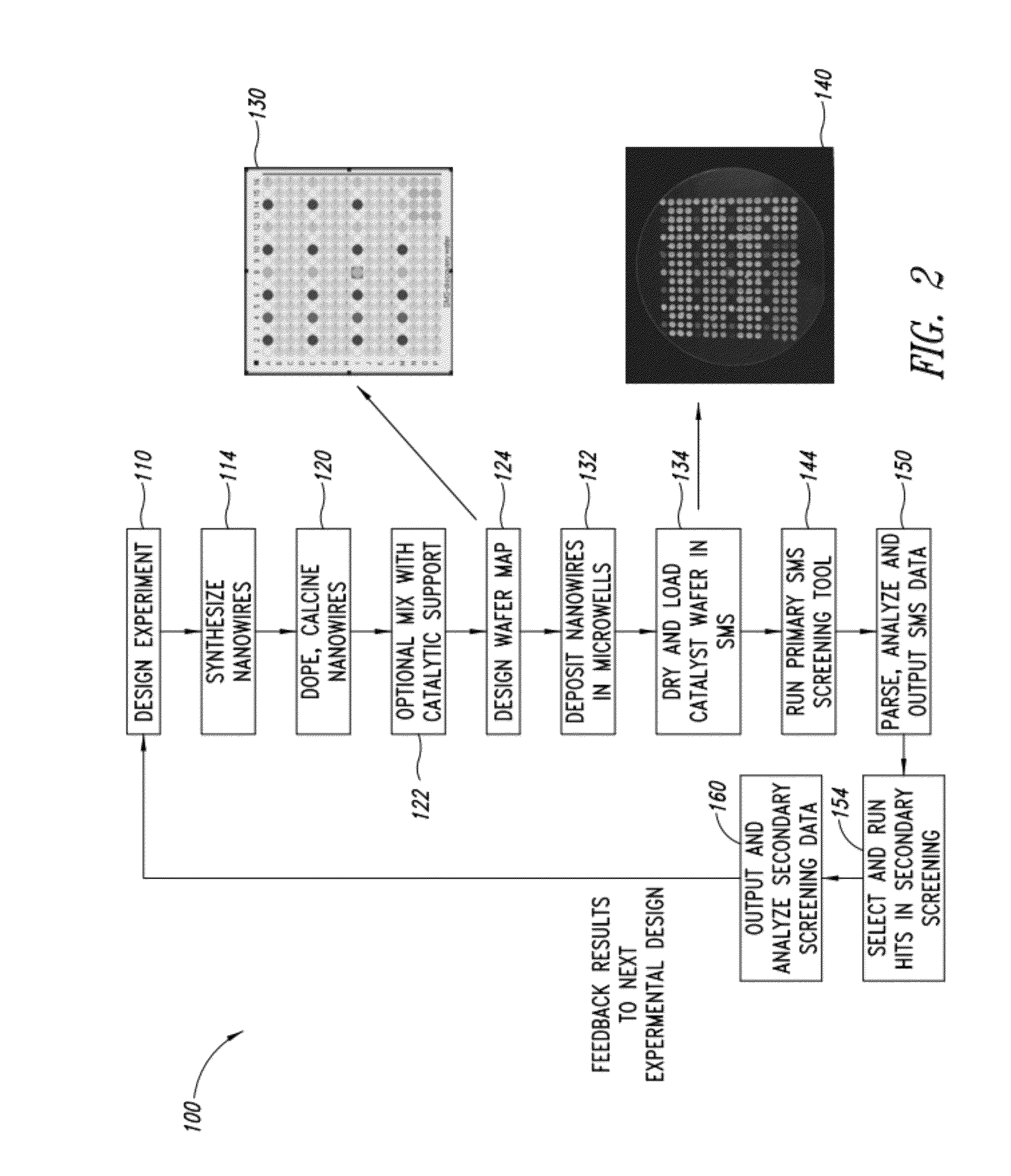

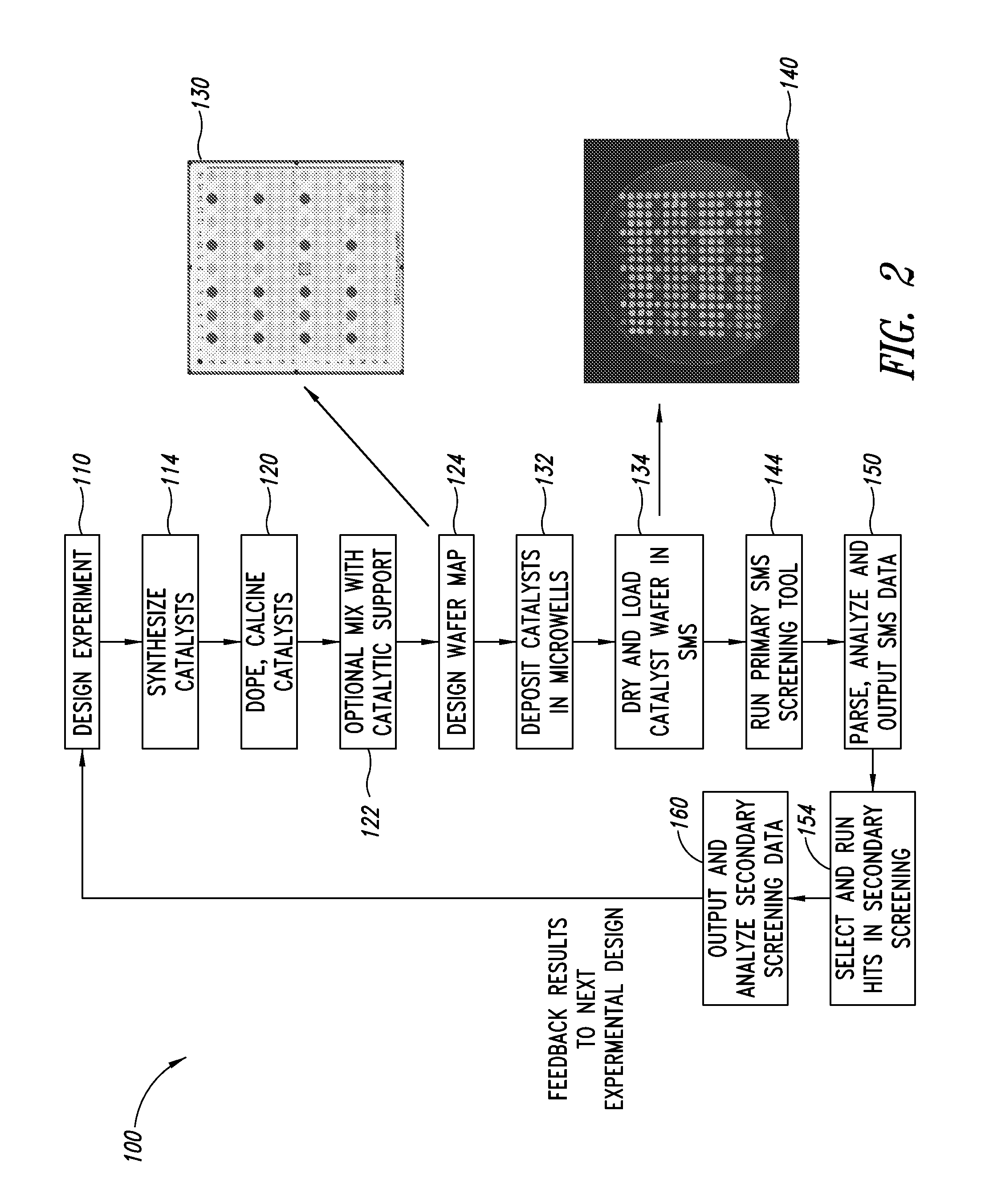

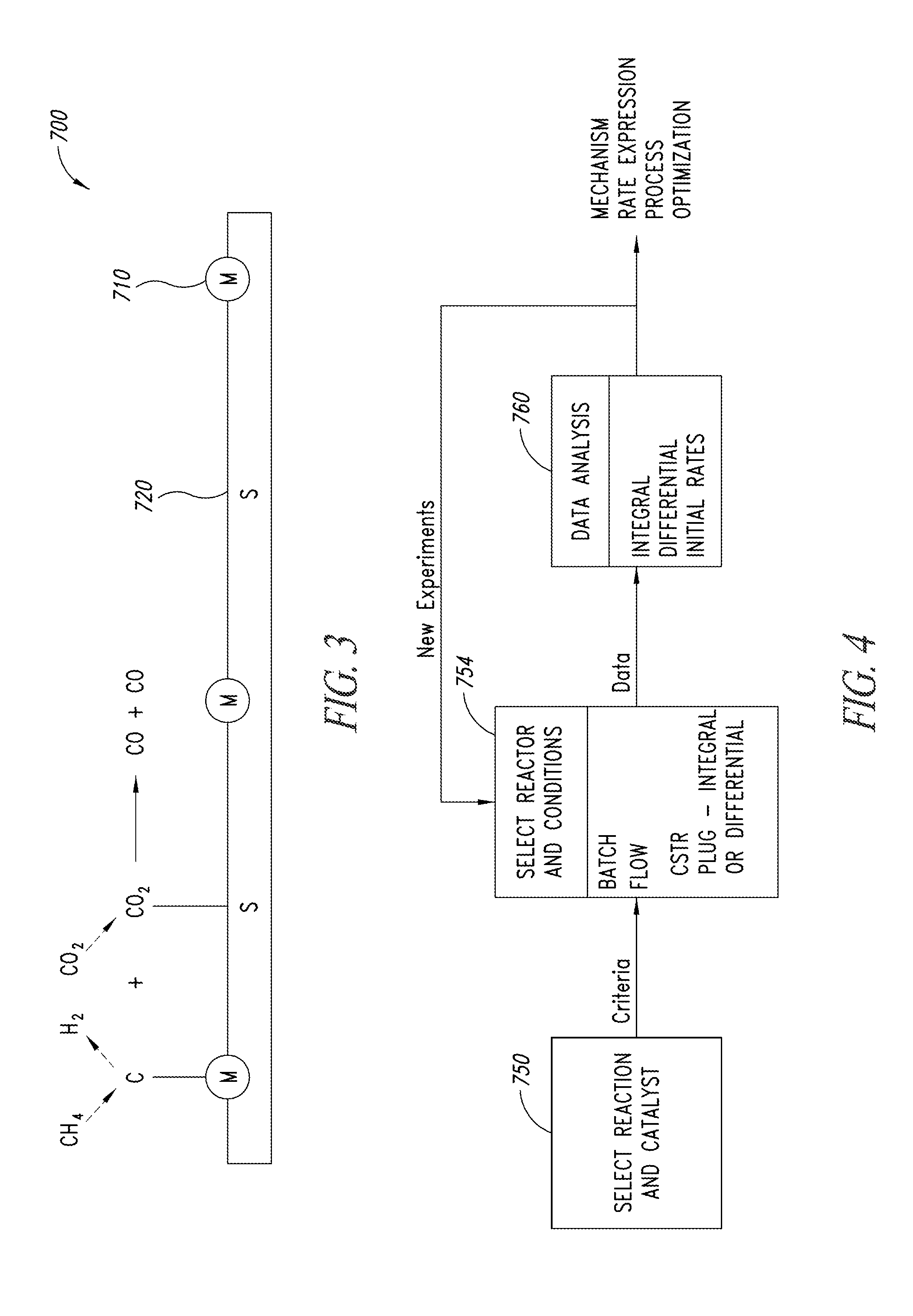

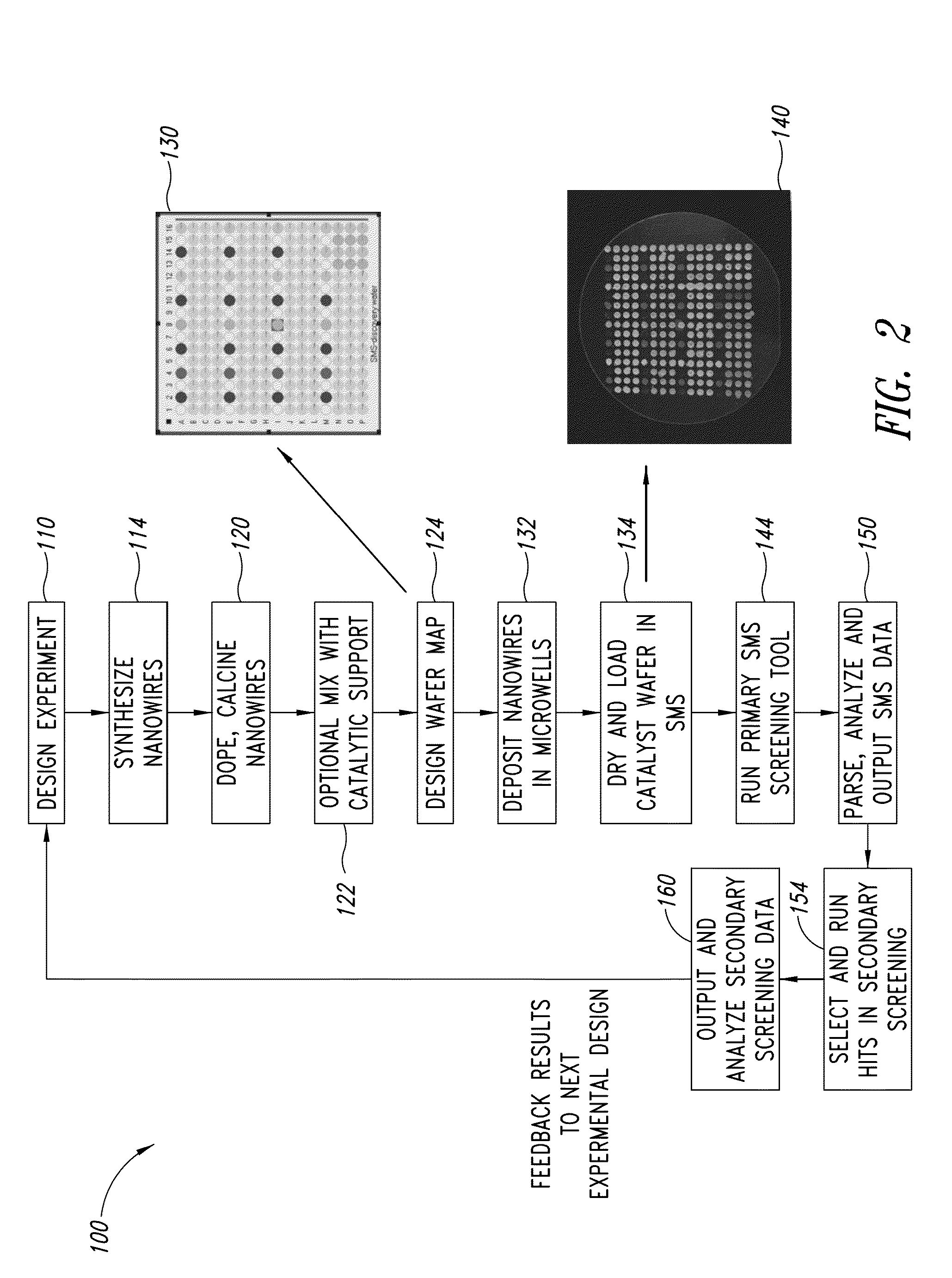

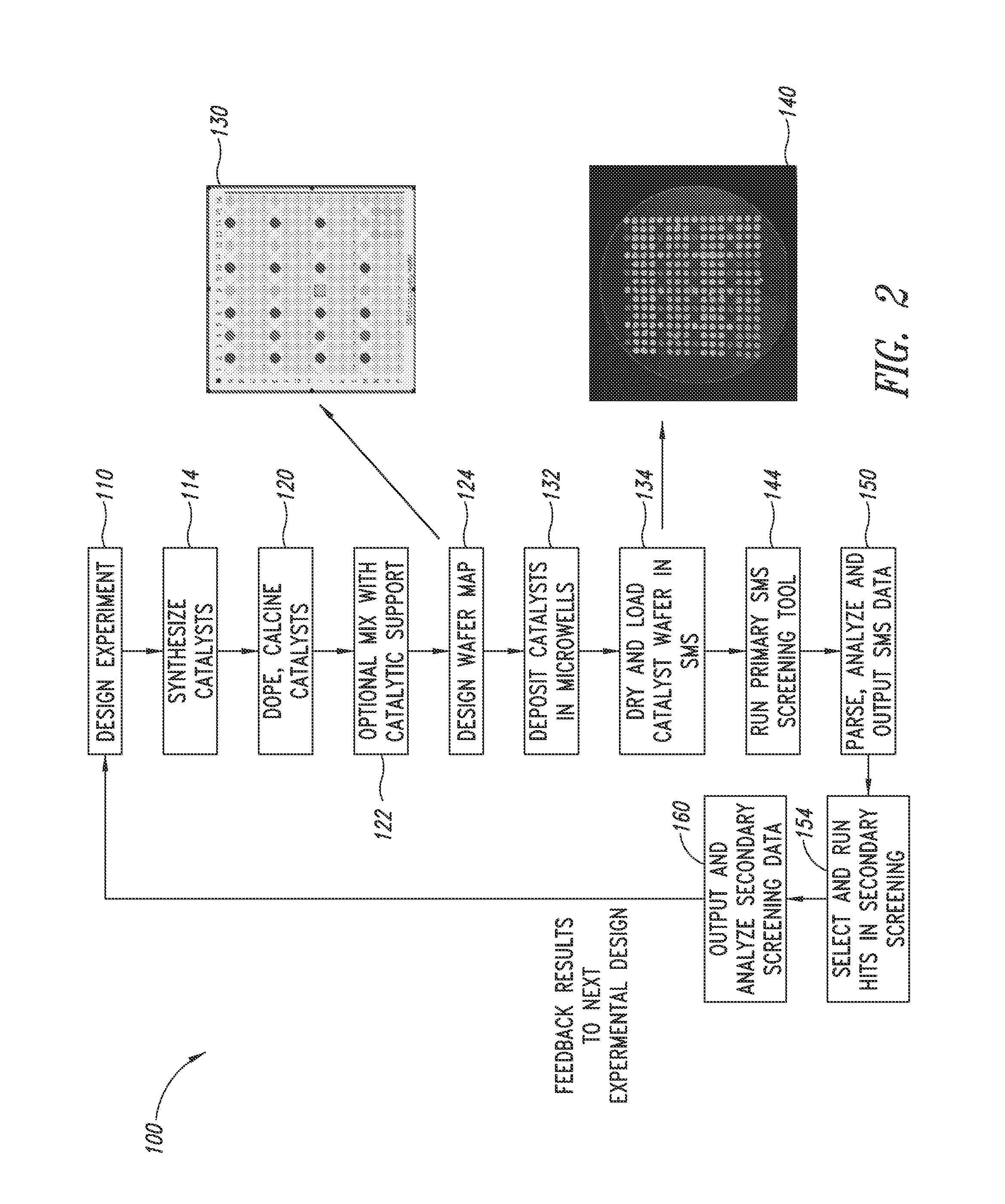

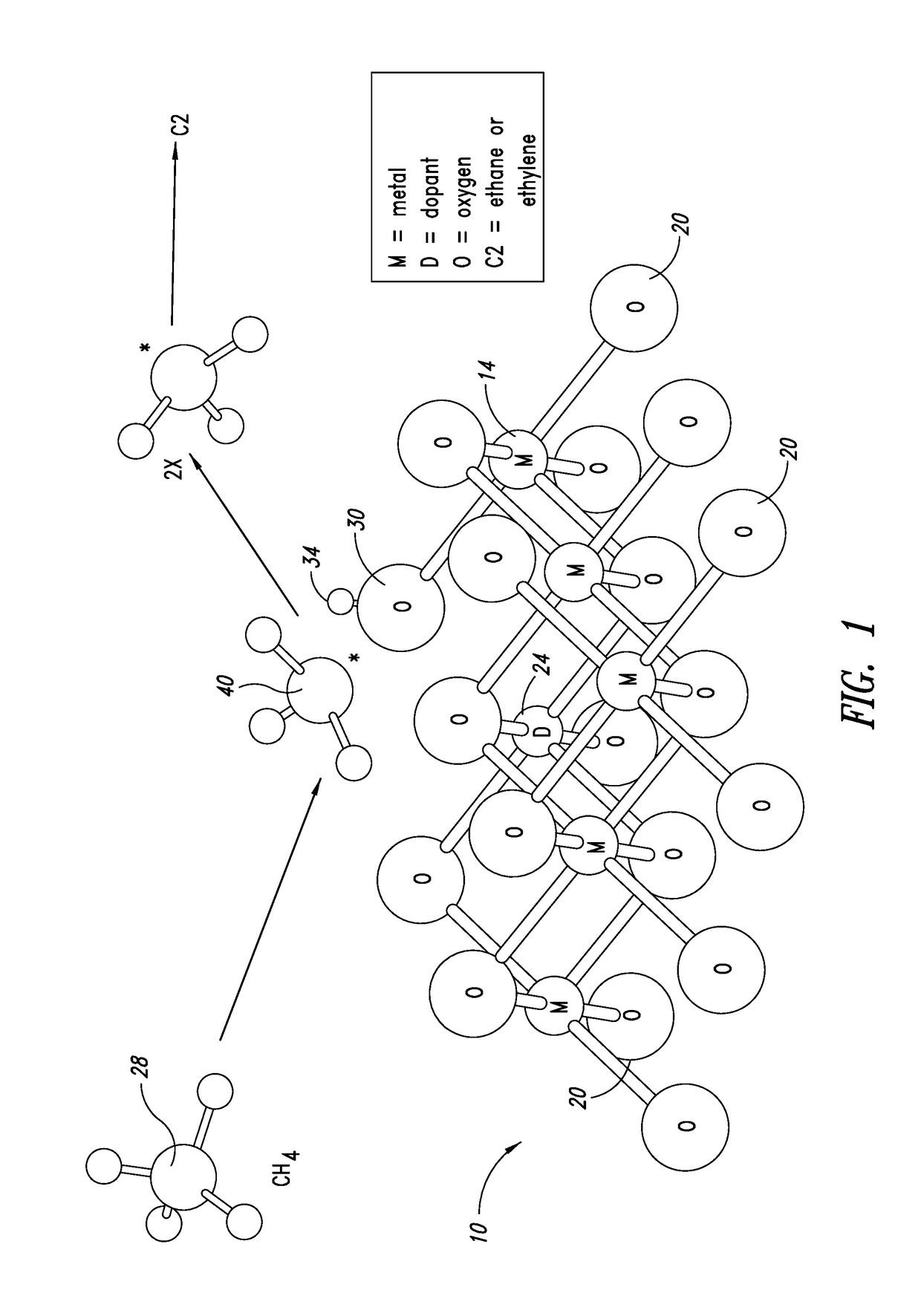

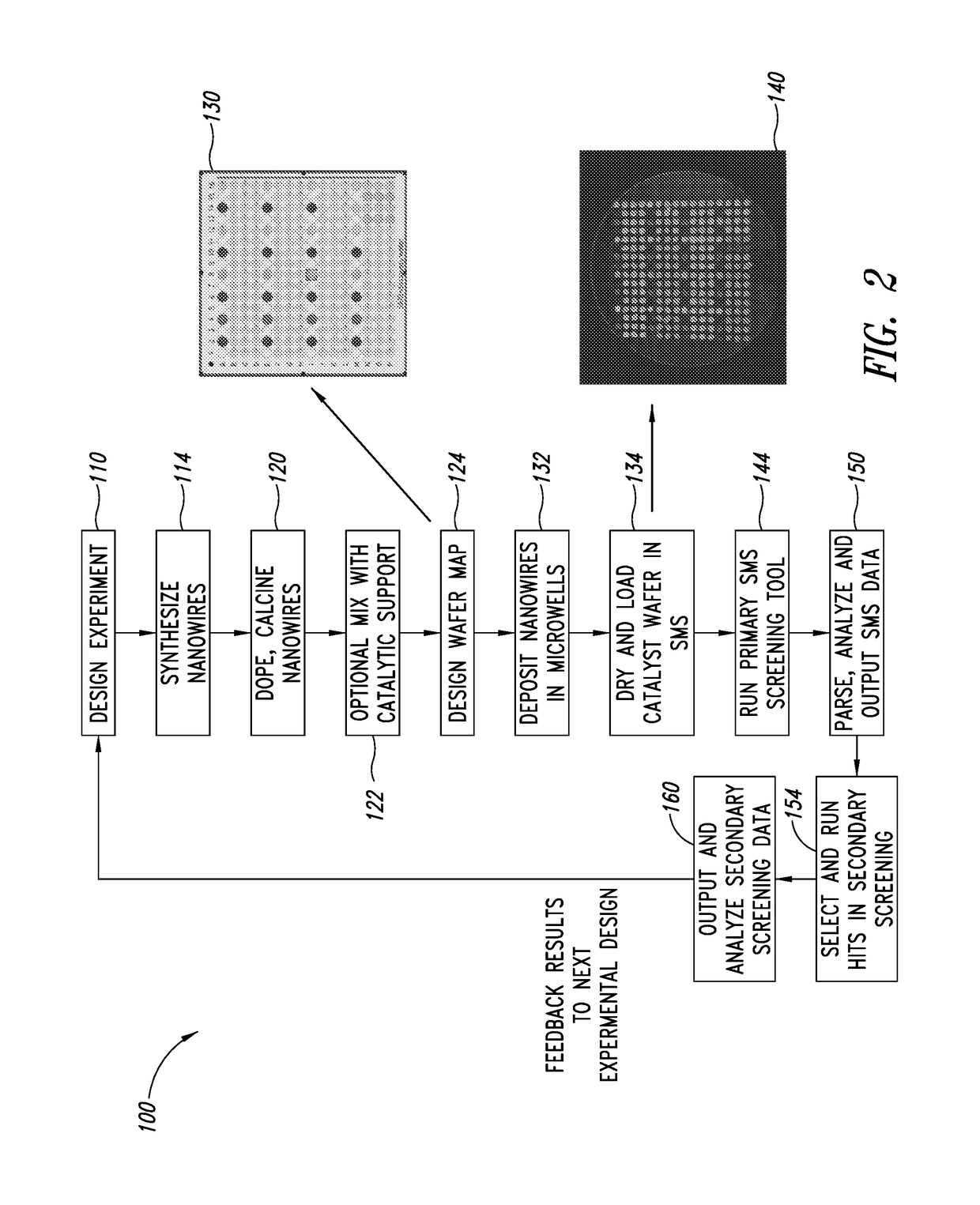

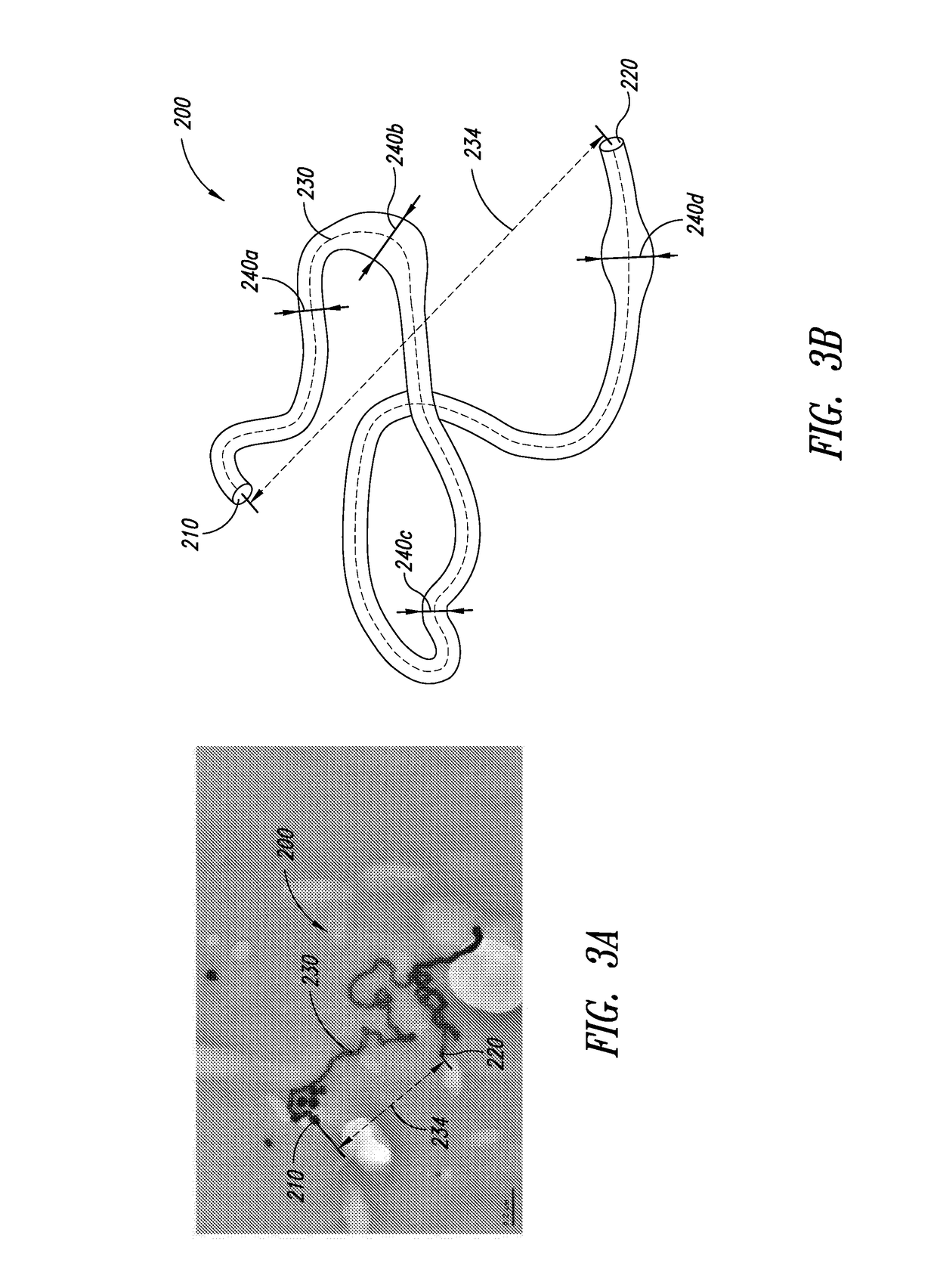

Nanowire catalysts

Nanowires useful as heterogeneous catalysts are provided. The nanowire catalysts are useful in a variety of catalytic reactions, for example, the oxidative coupling of methane to ethylene. Related methods for use and manufacture of the same are also disclosed.

Owner:SILURIA TECH INC

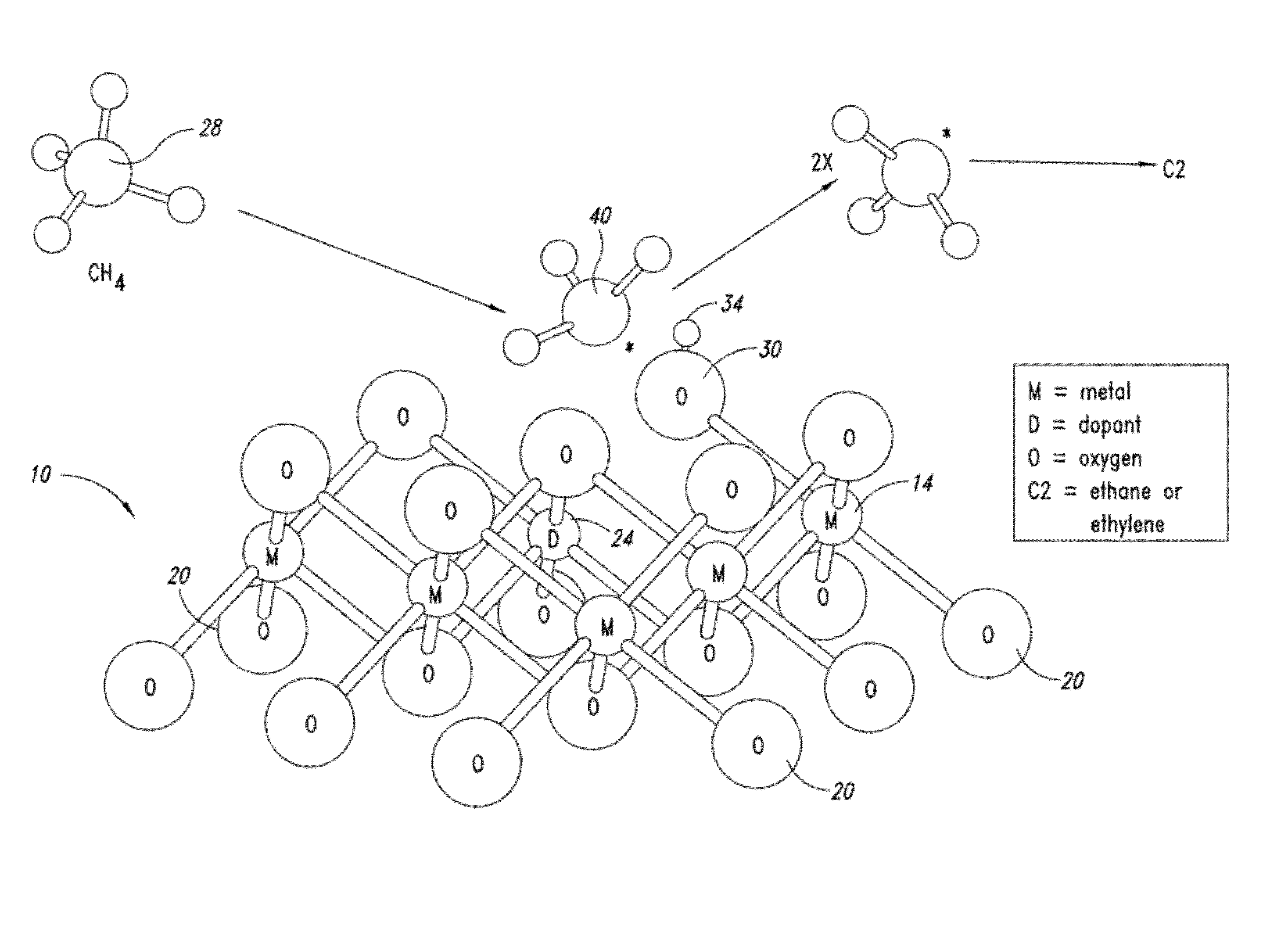

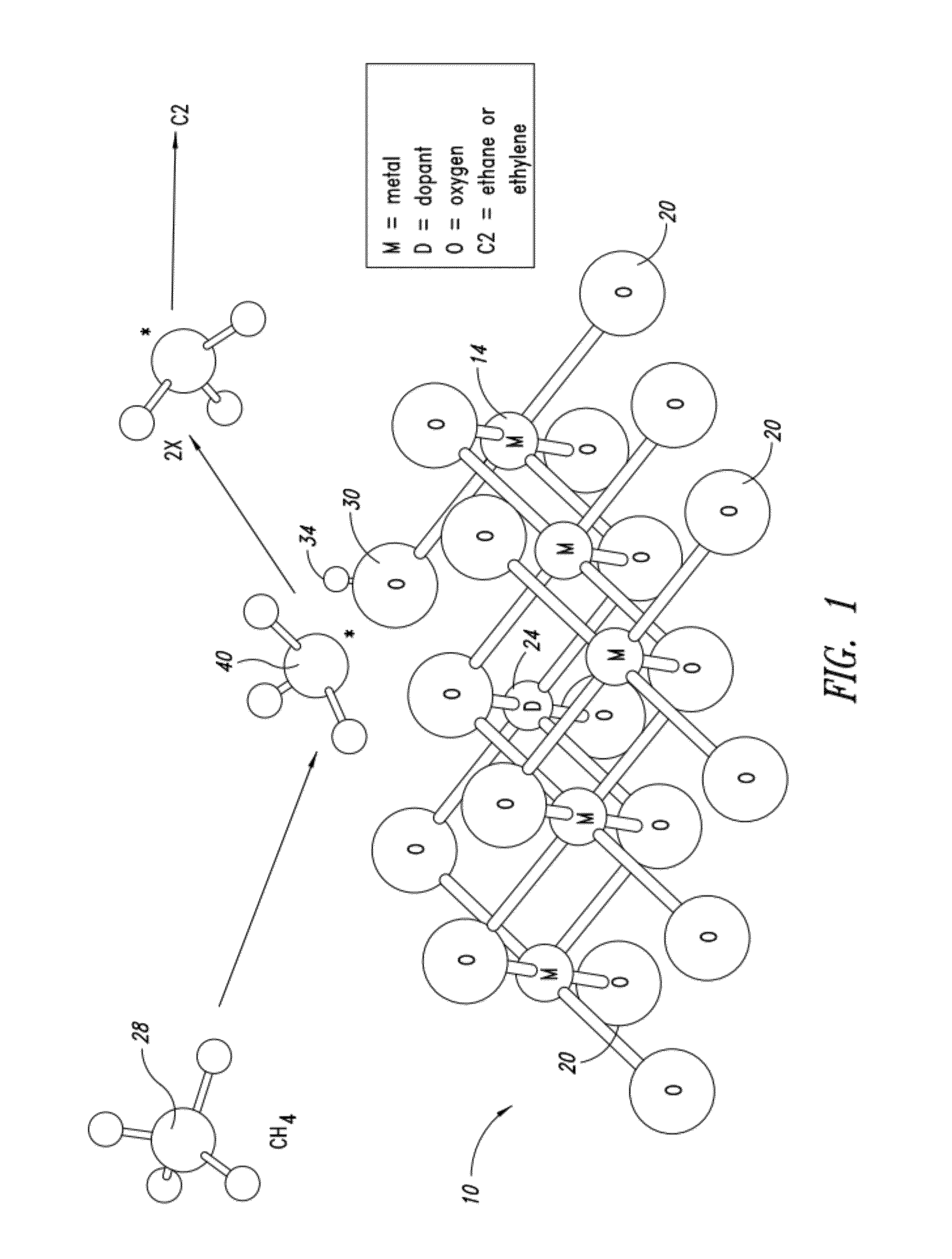

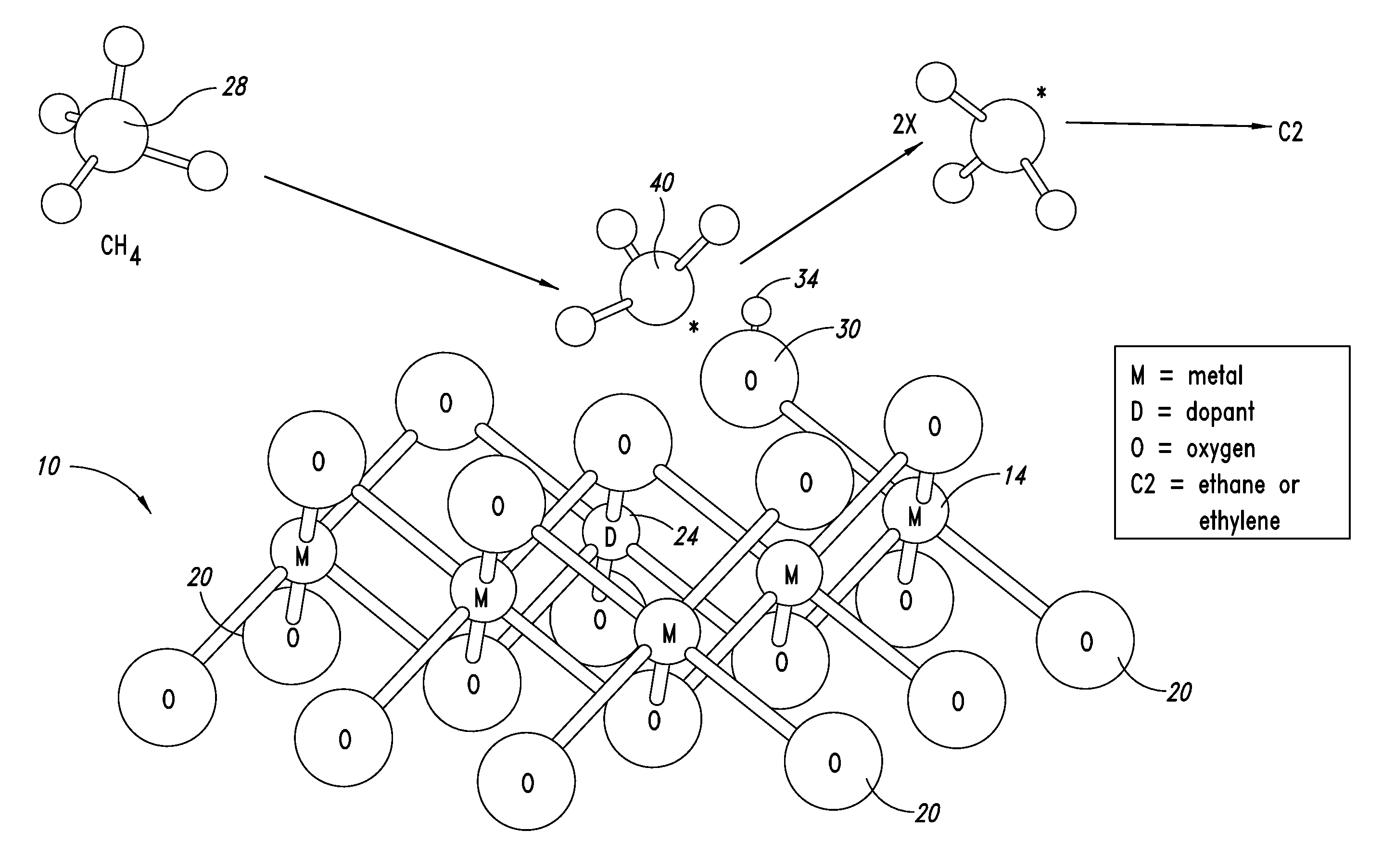

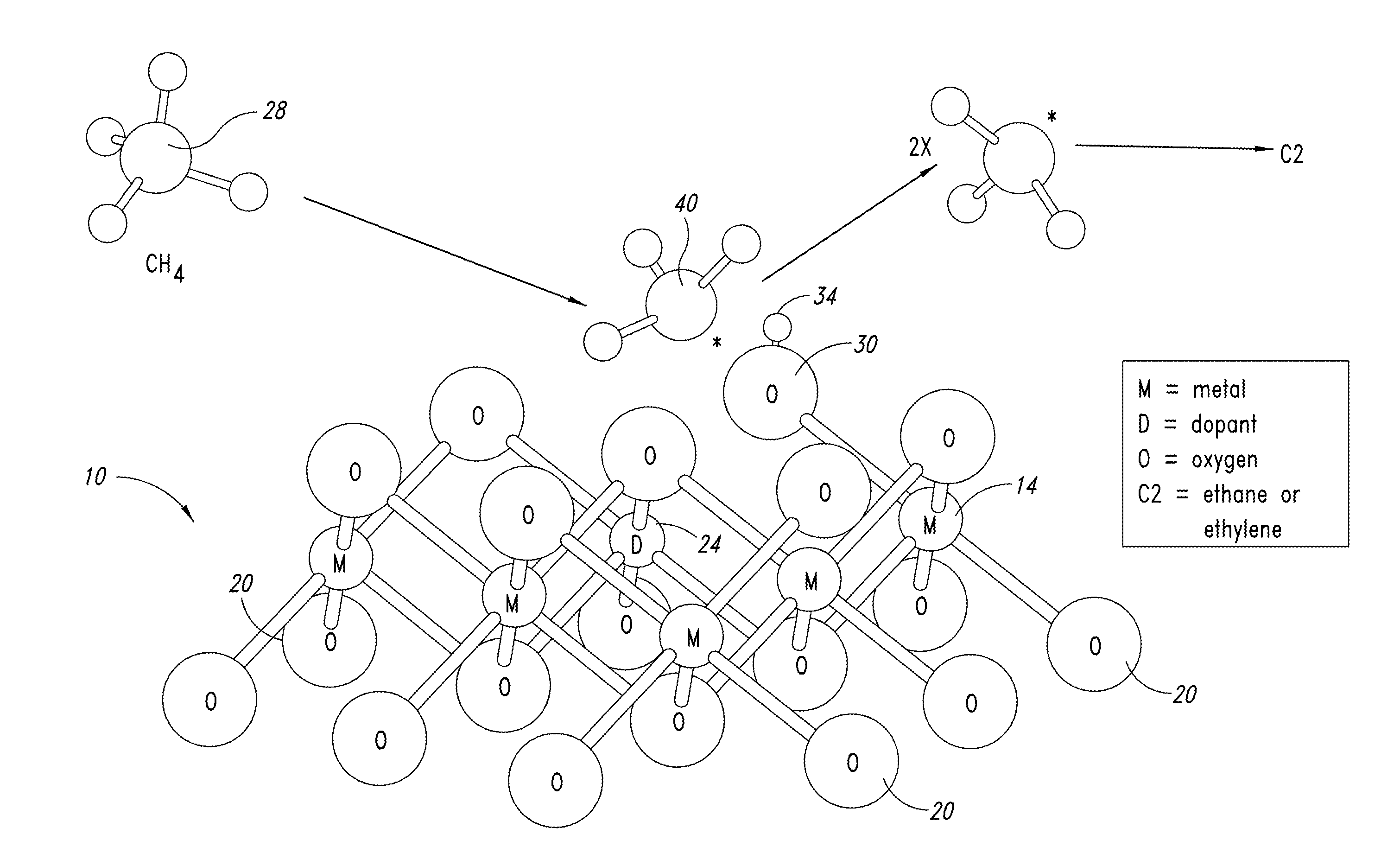

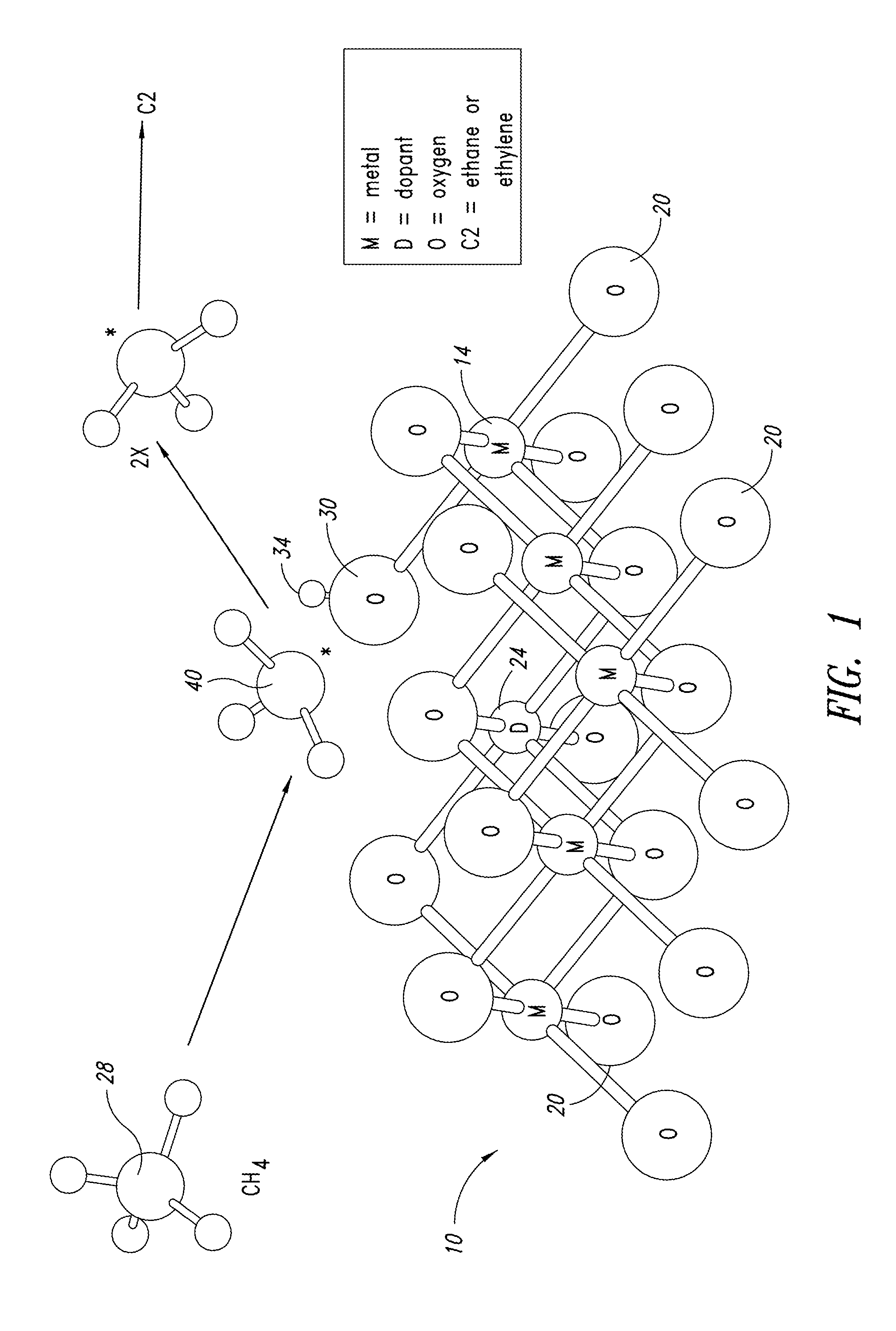

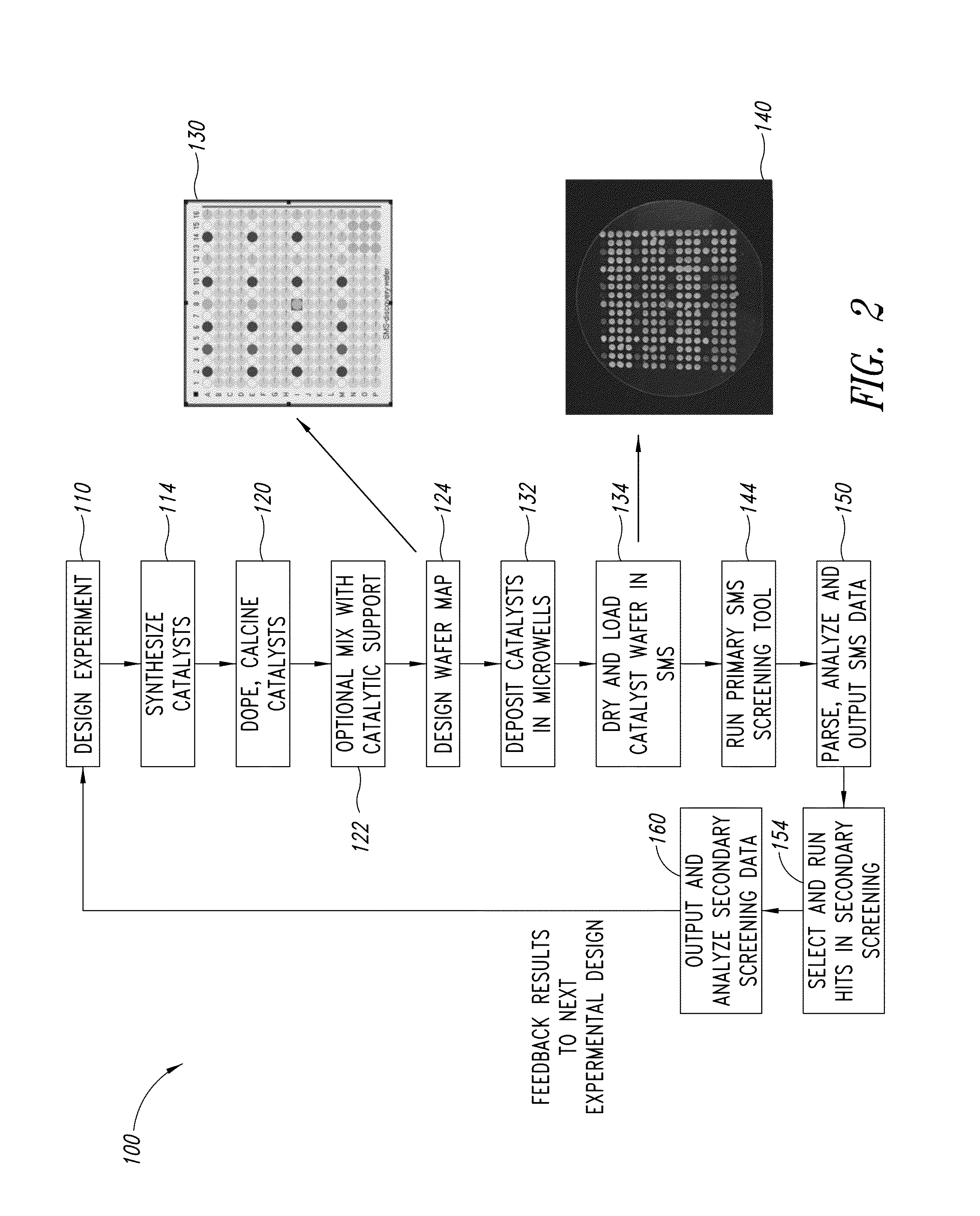

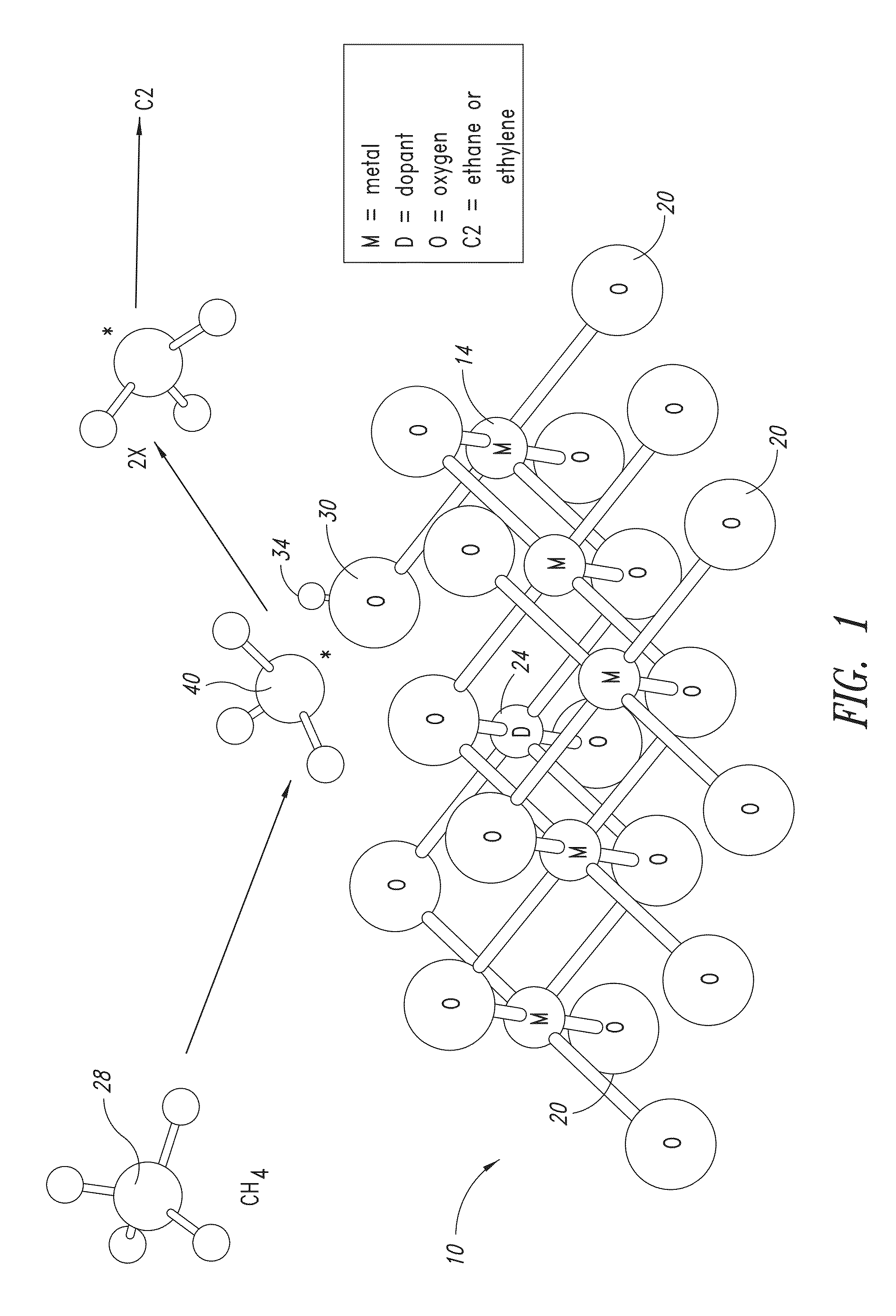

Catalysts for petrochemical catalysis

ActiveUS20130023709A1Sequential/parallel process reactionsManganese oxides/hydroxidesDopantPetrochemical

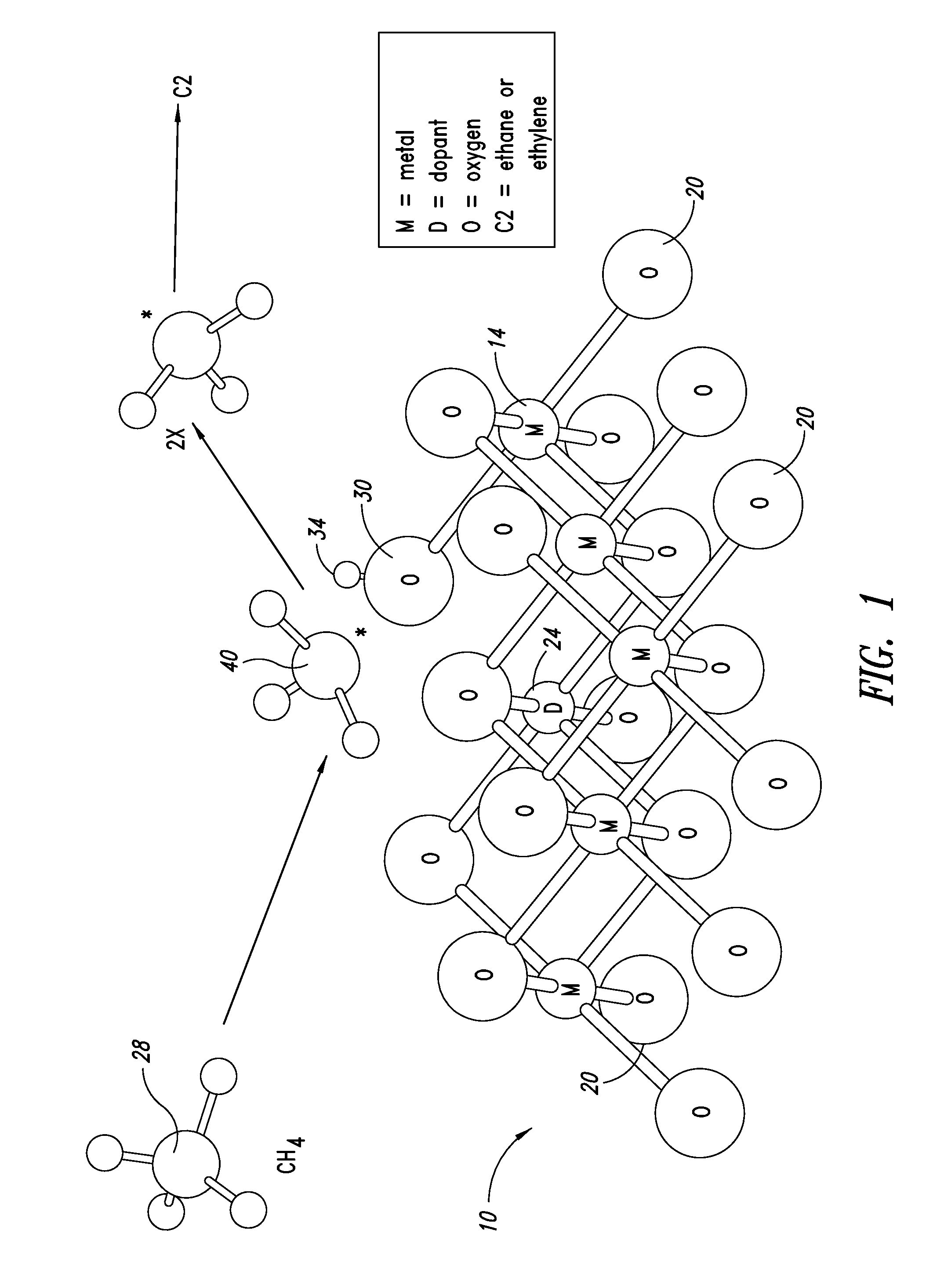

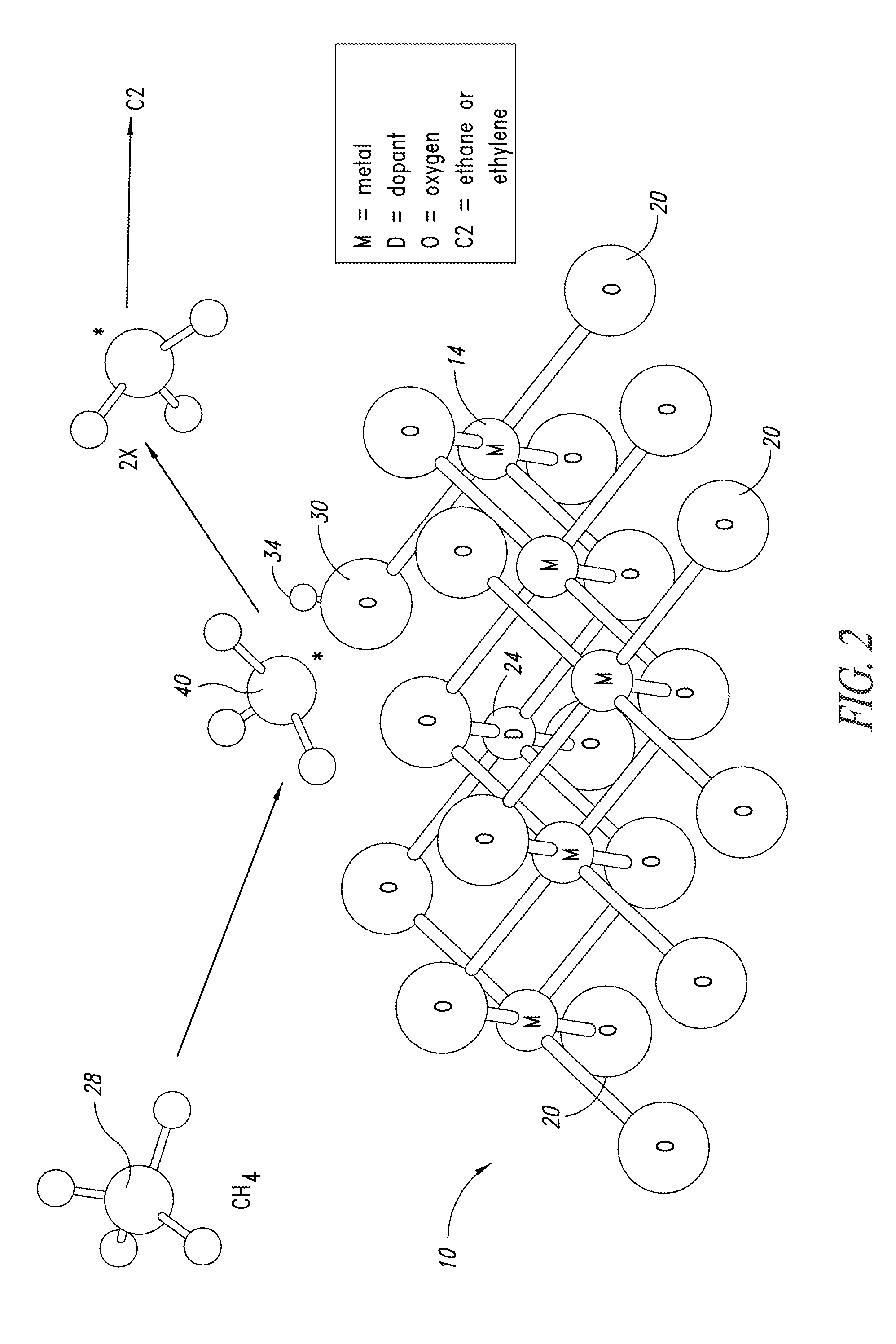

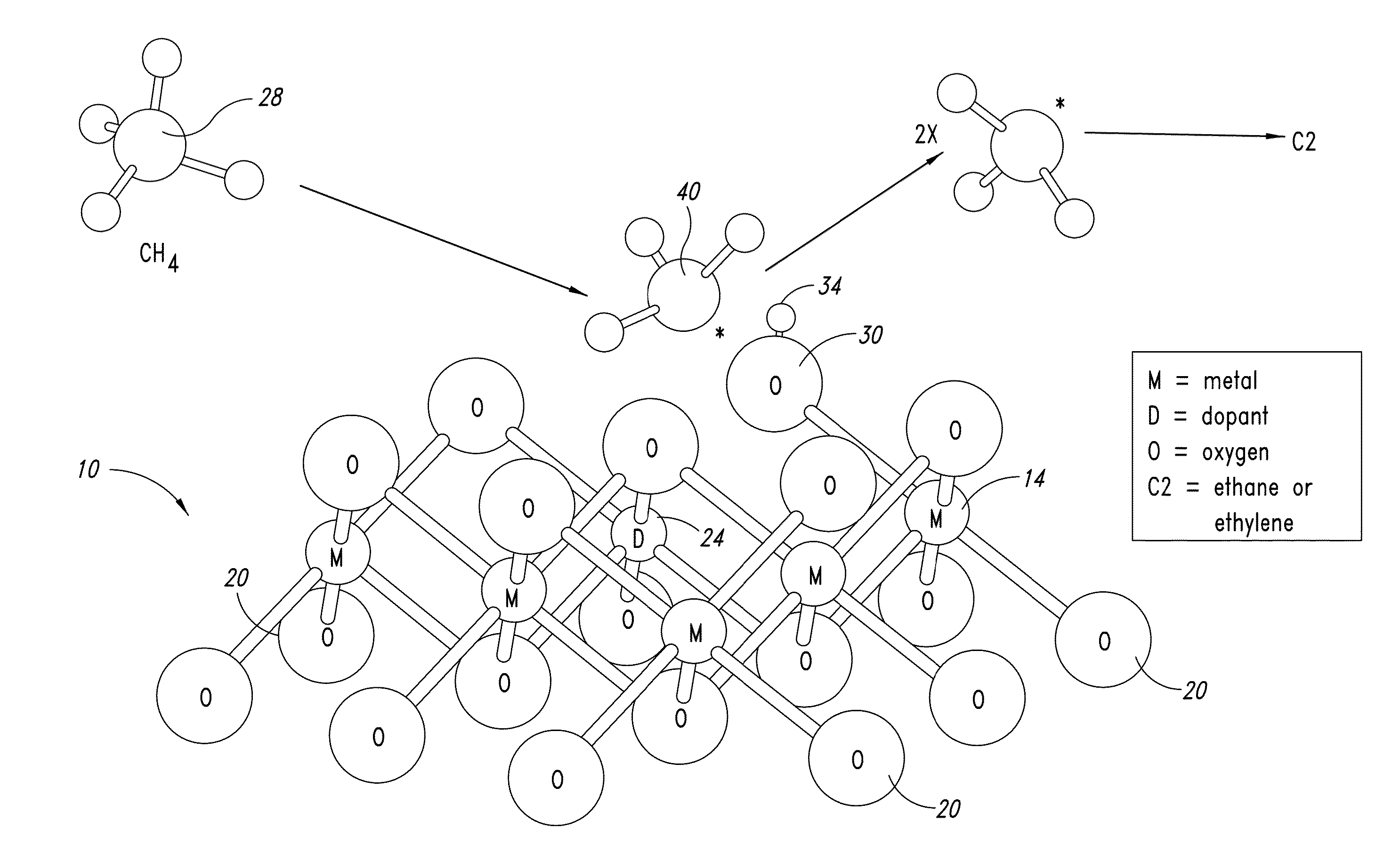

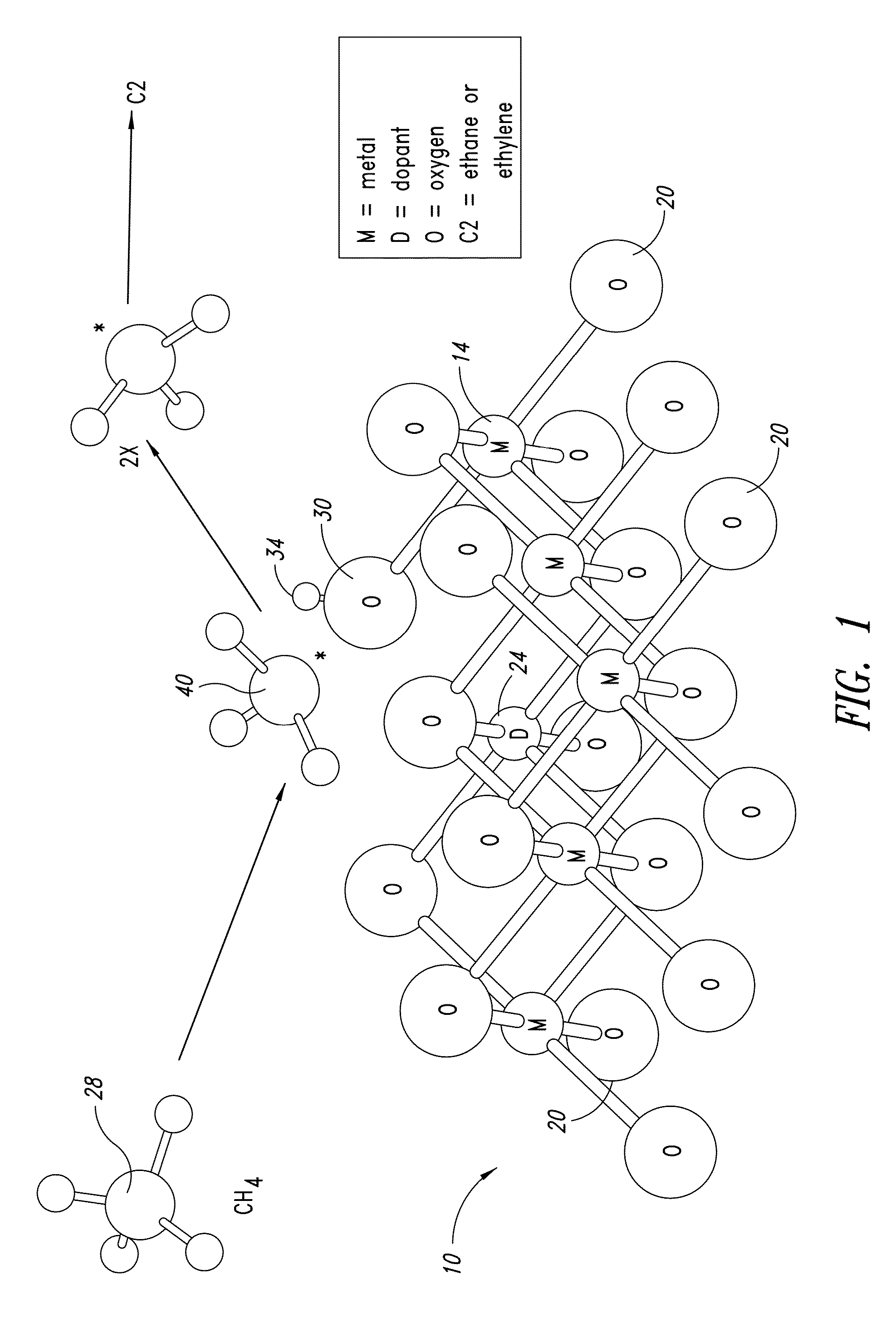

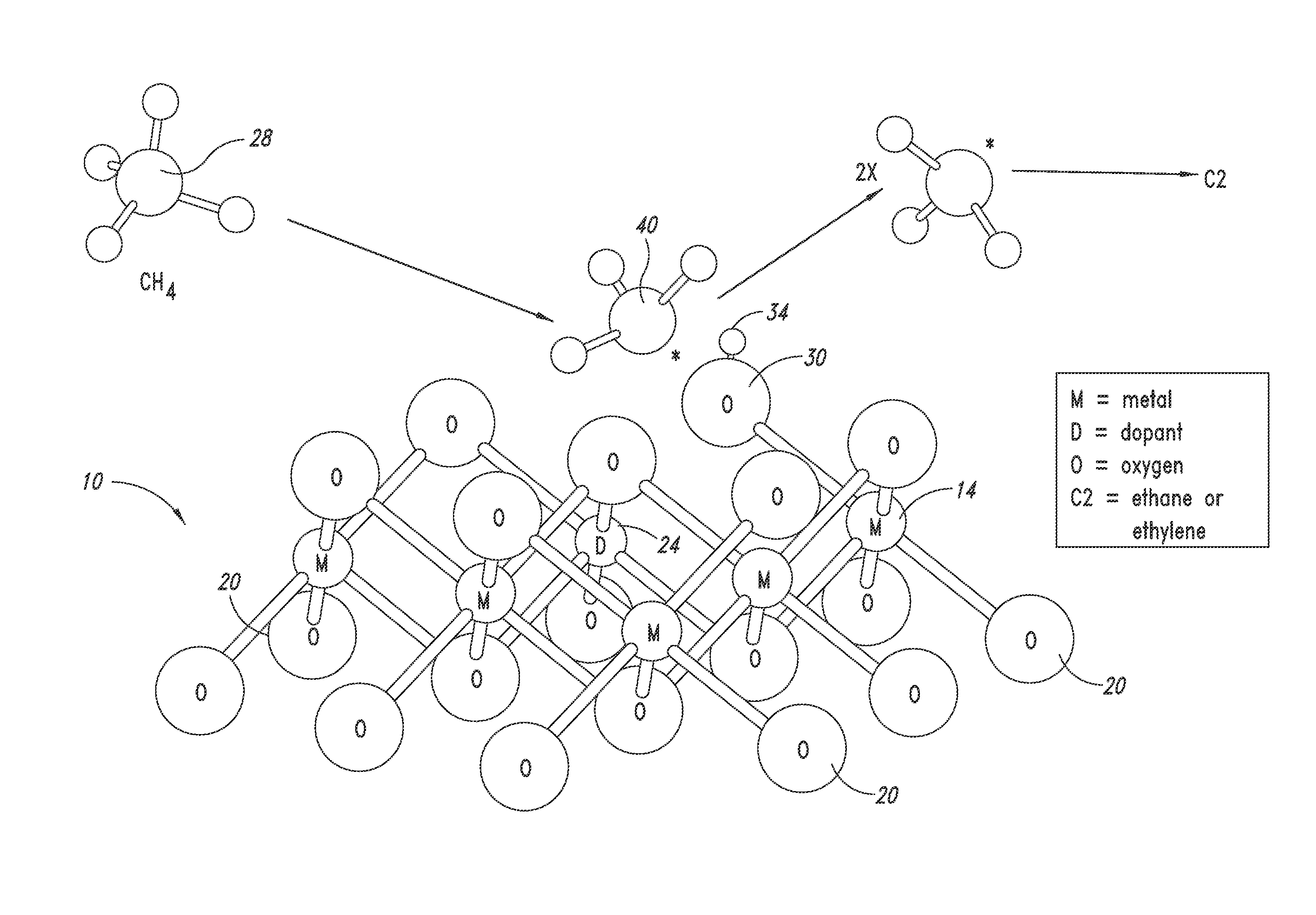

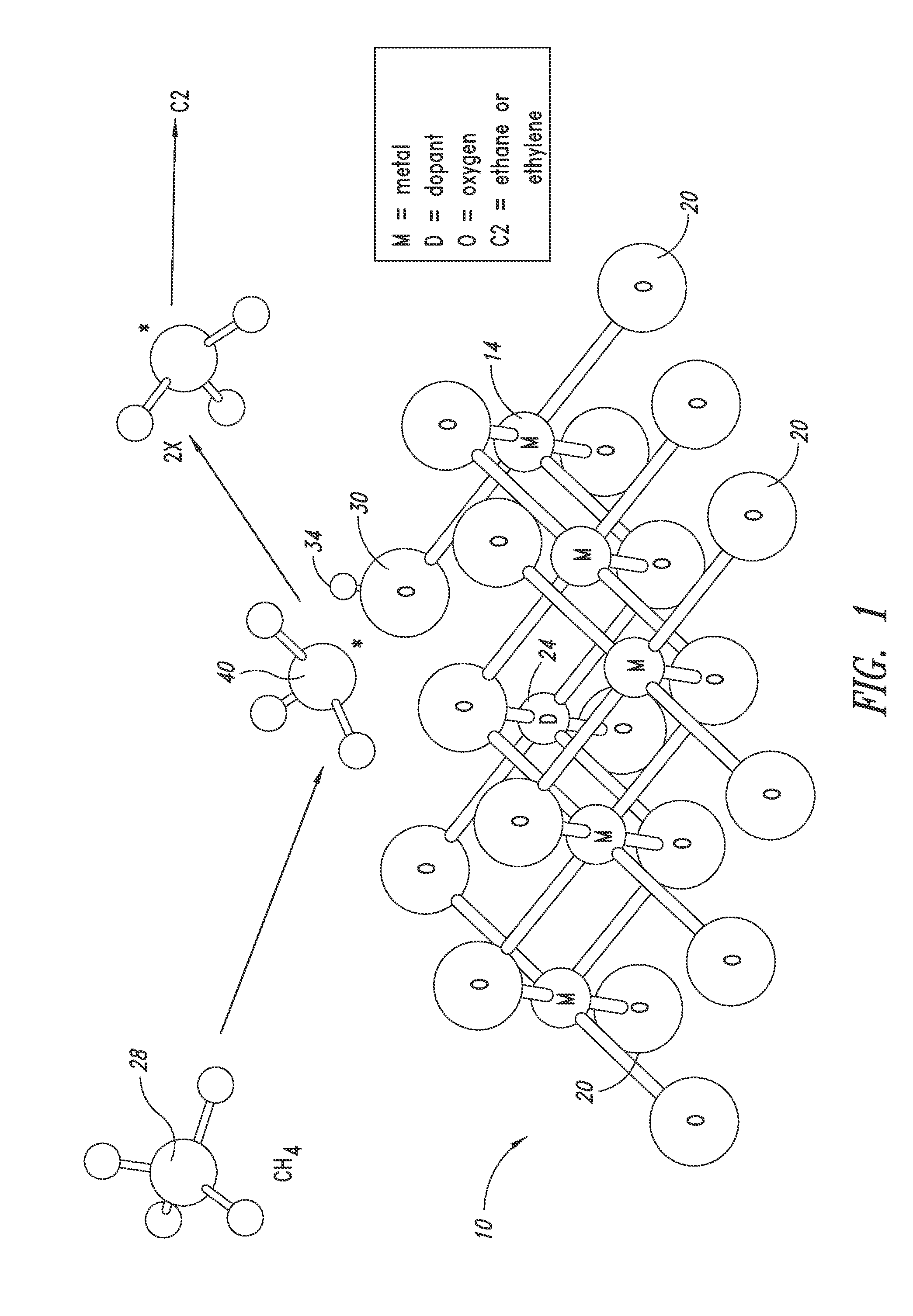

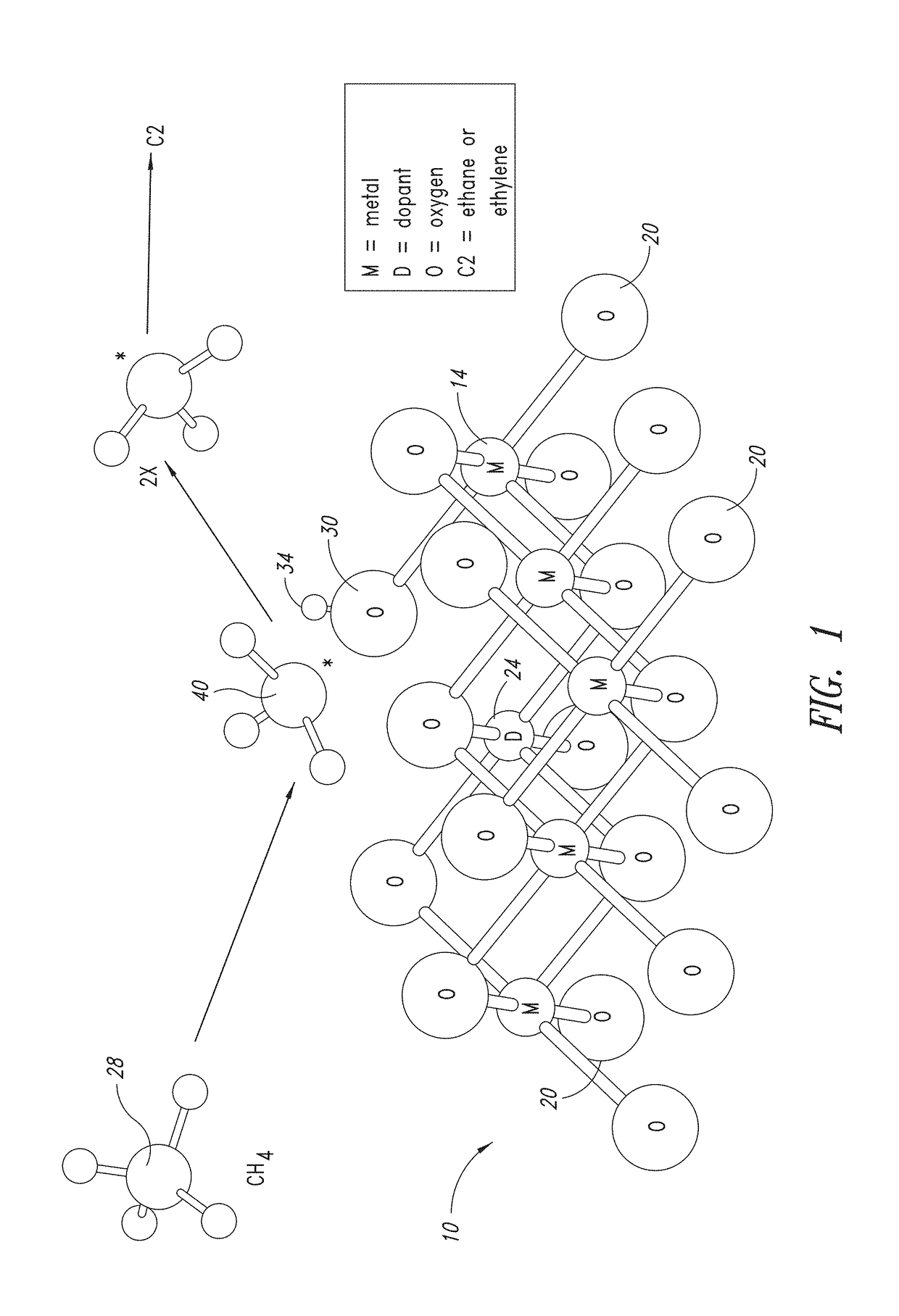

Metal oxide catalysts comprising various dopants are provided. The catalysts are useful as heterogenous catalysts in a variety of catalytic reactions, for example, the oxidative coupling of methane to C2 hydrocarbons such as ethane and ethylene. Related methods for use and manufacture of the same are also disclosed.

Owner:SILURIA TECH INC

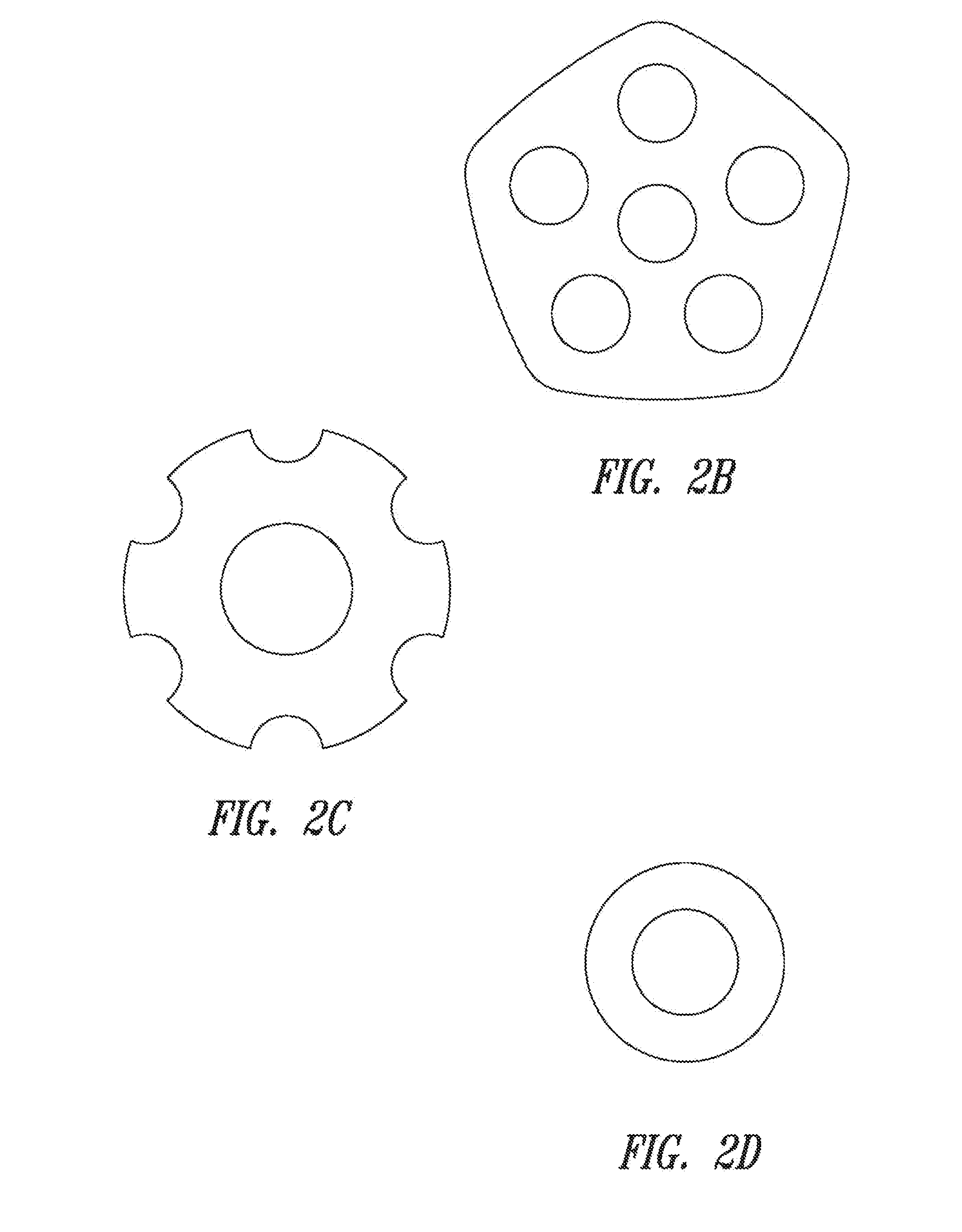

Catalytic forms and formulations

InactiveUS20140121433A1Material nanotechnologyMolecular sieve catalystsOxidative coupling of methaneChemistry

Catalytic forms and formulations are provided. The catalytic forms and formulations are useful in a variety of catalytic reactions, for example, the oxidative coupling of methane. Related methods for use and manufacture of the same are also disclosed.

Owner:SILURIA TECH INC

Nanowire catalysts and methods for their use and preparation

ActiveUS20130165728A1Material nanotechnologyManganese oxides/hydroxidesNanowireOxidative coupling of methane

Nanowires useful as heterogeneous catalysts are provided. The nanowire catalysts are useful in a variety of catalytic reactions, for example, the oxidative coupling of methane to C2 hydrocarbons. Related methods for use and manufacture of the same are also disclosed.

Owner:LUMMUS TECH LLC

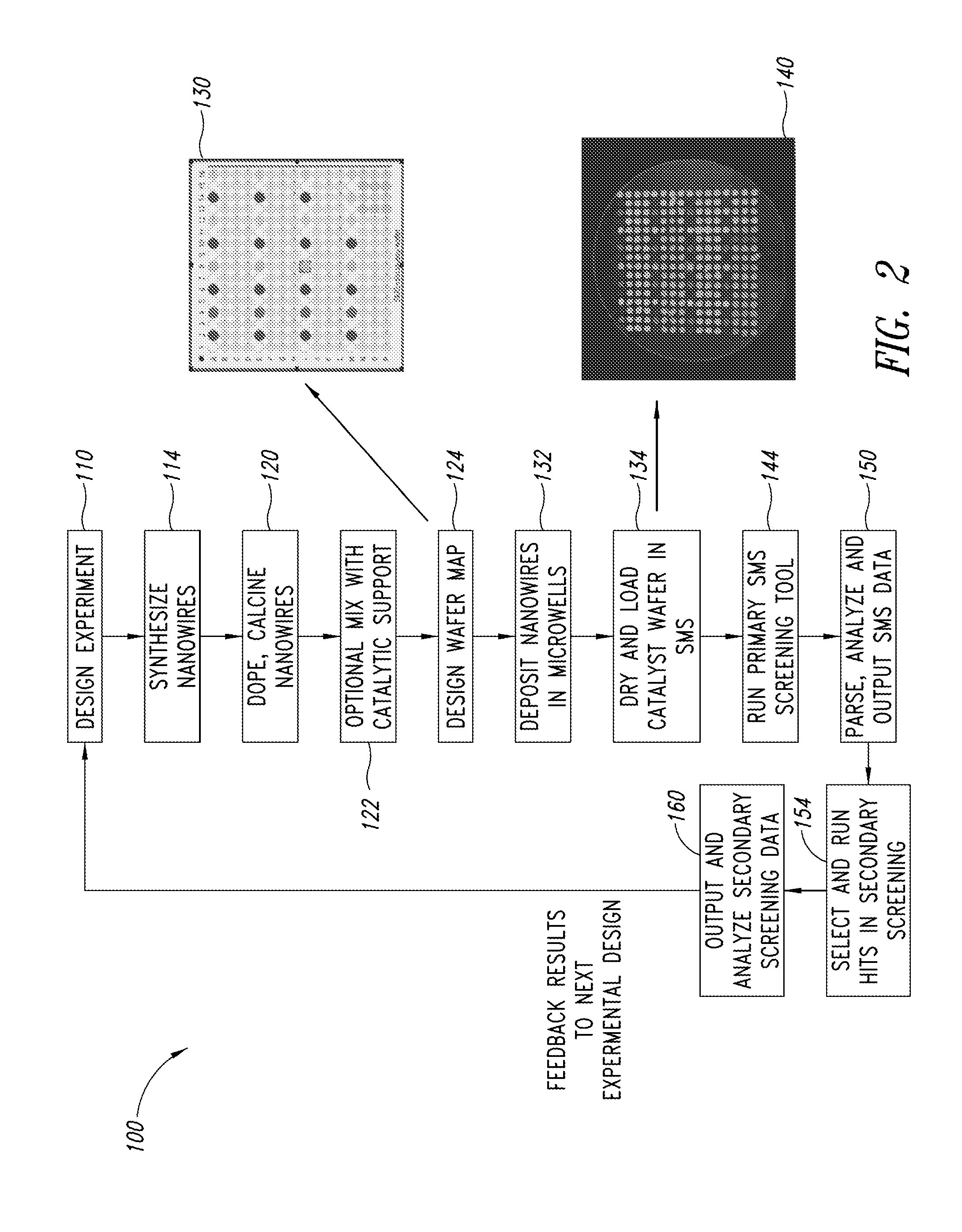

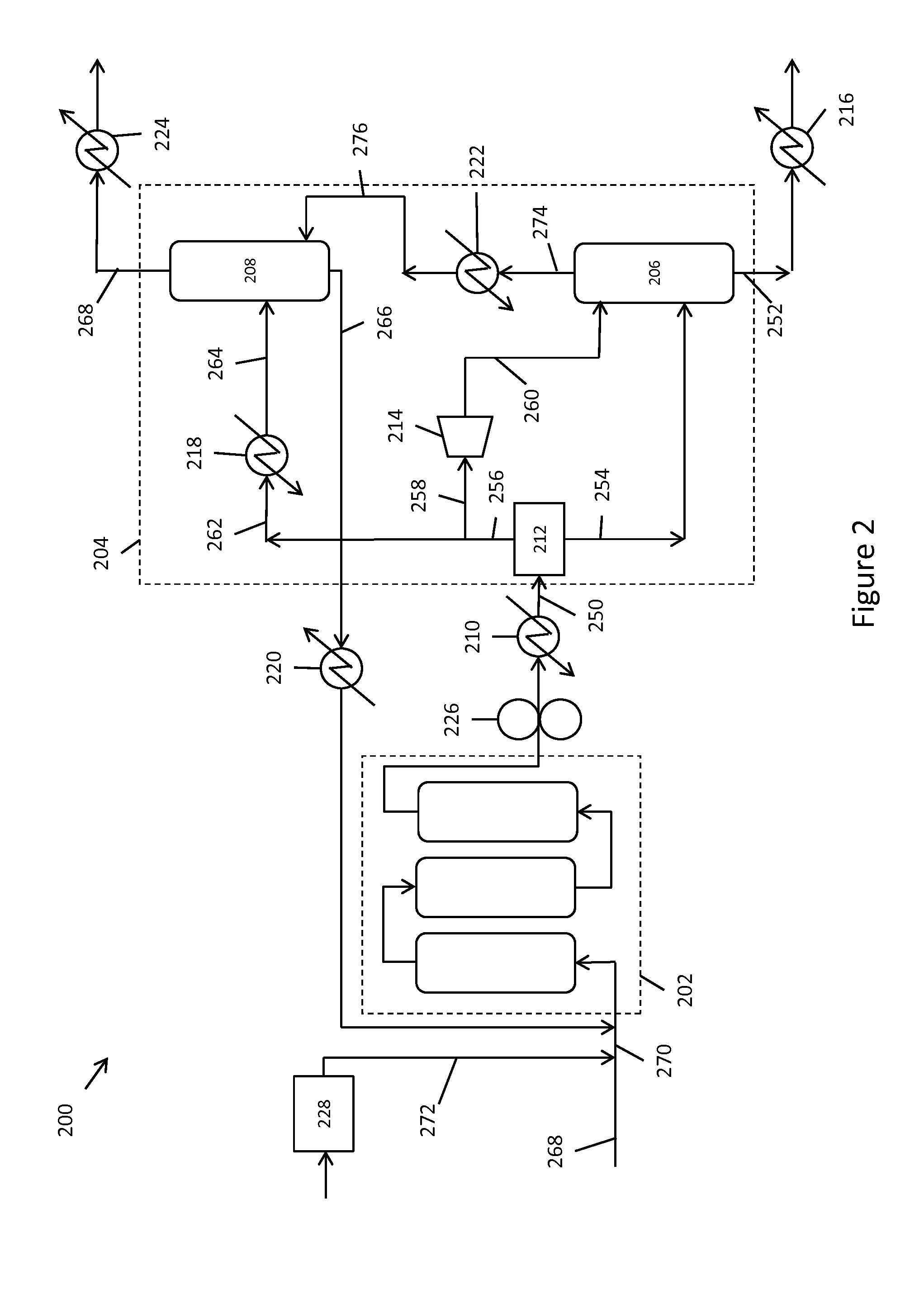

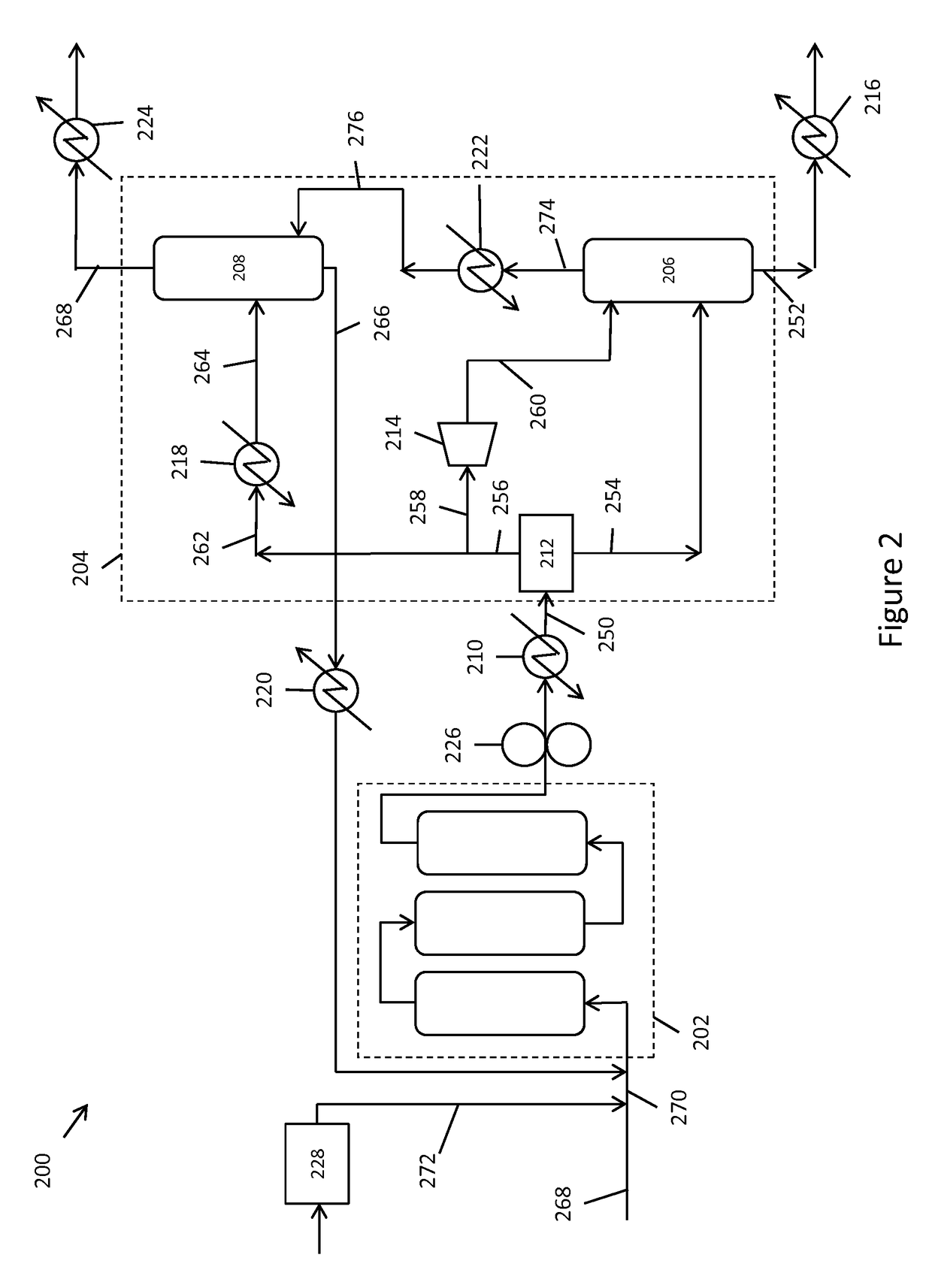

Oxidative coupling of methane systems and methods

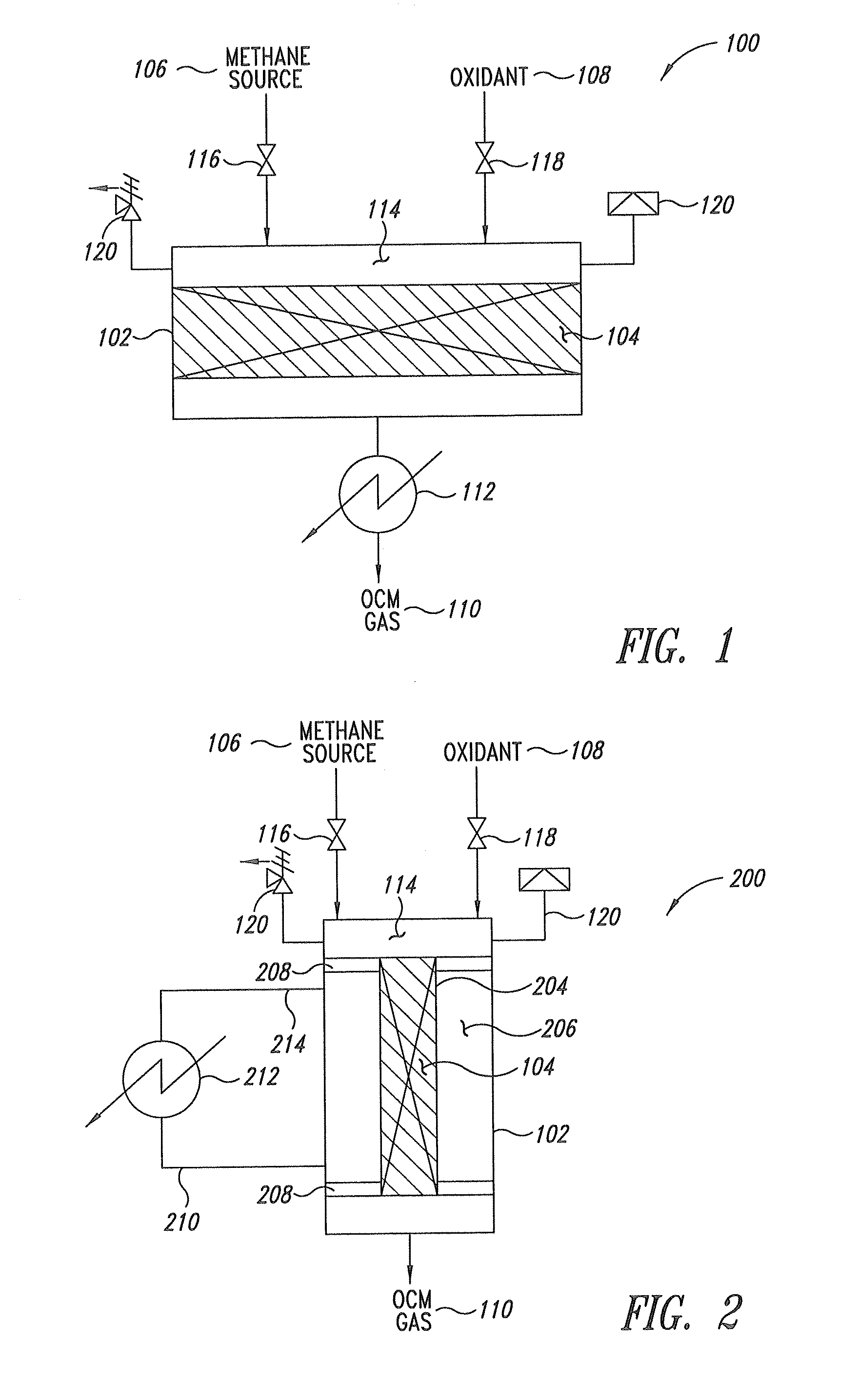

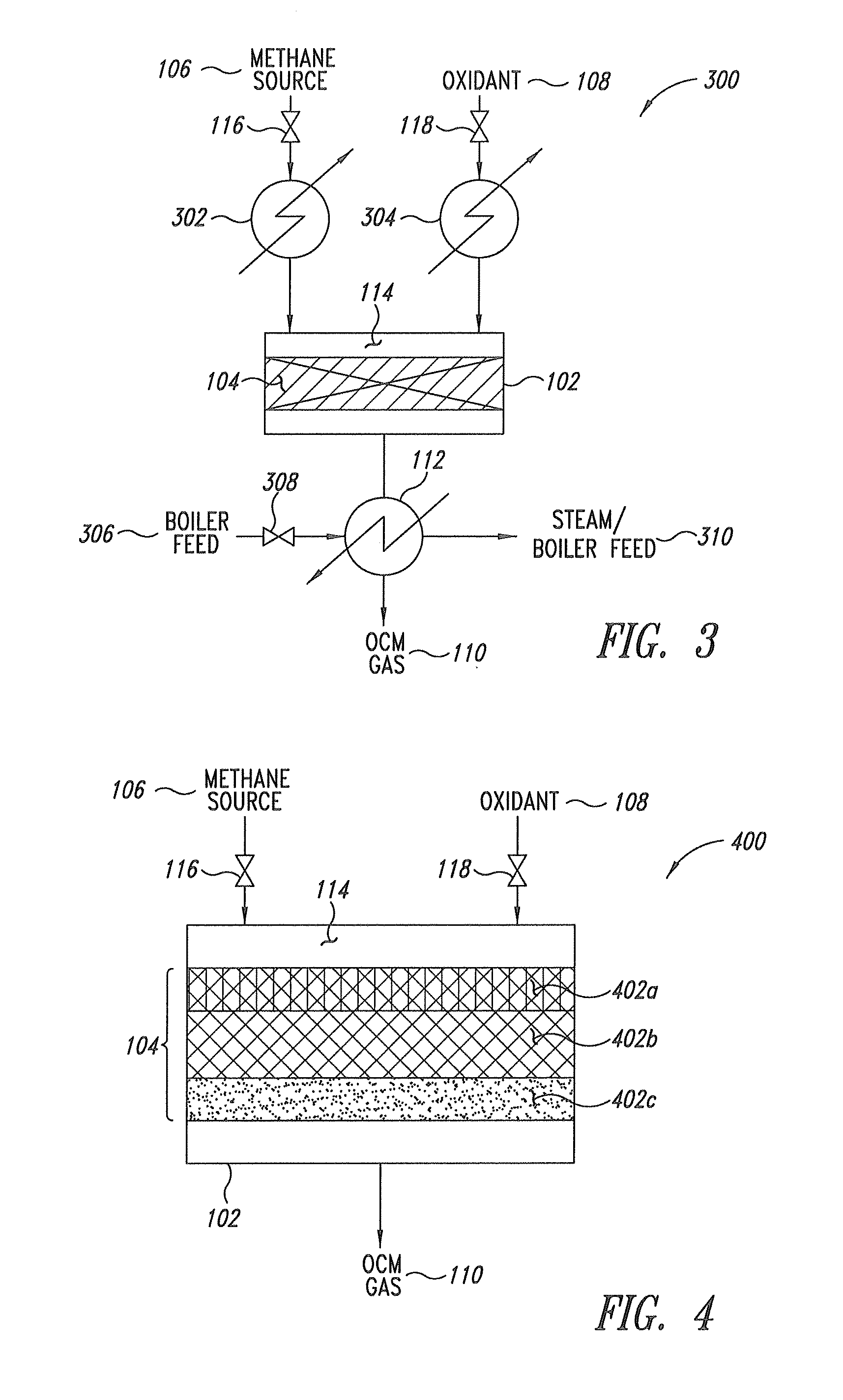

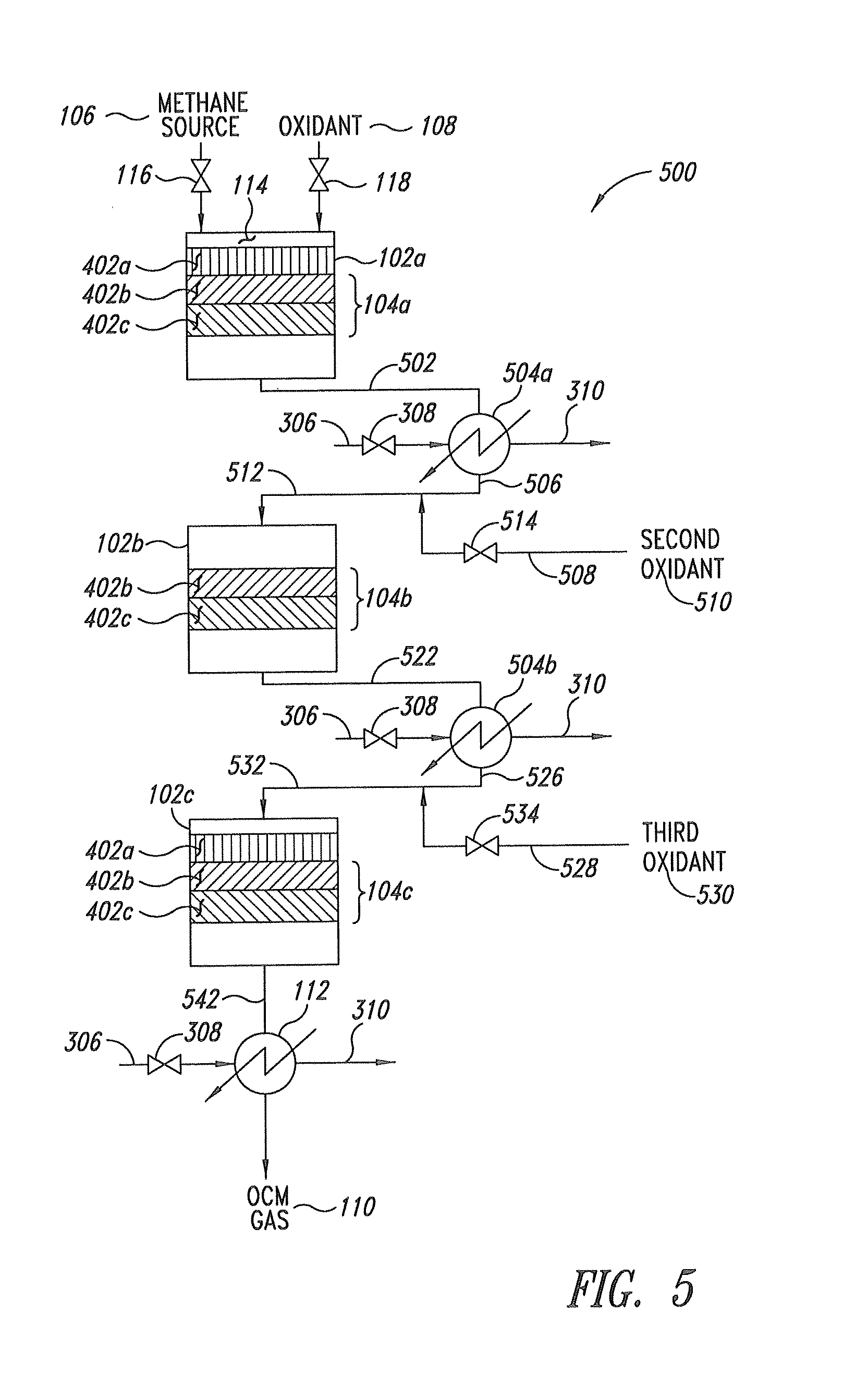

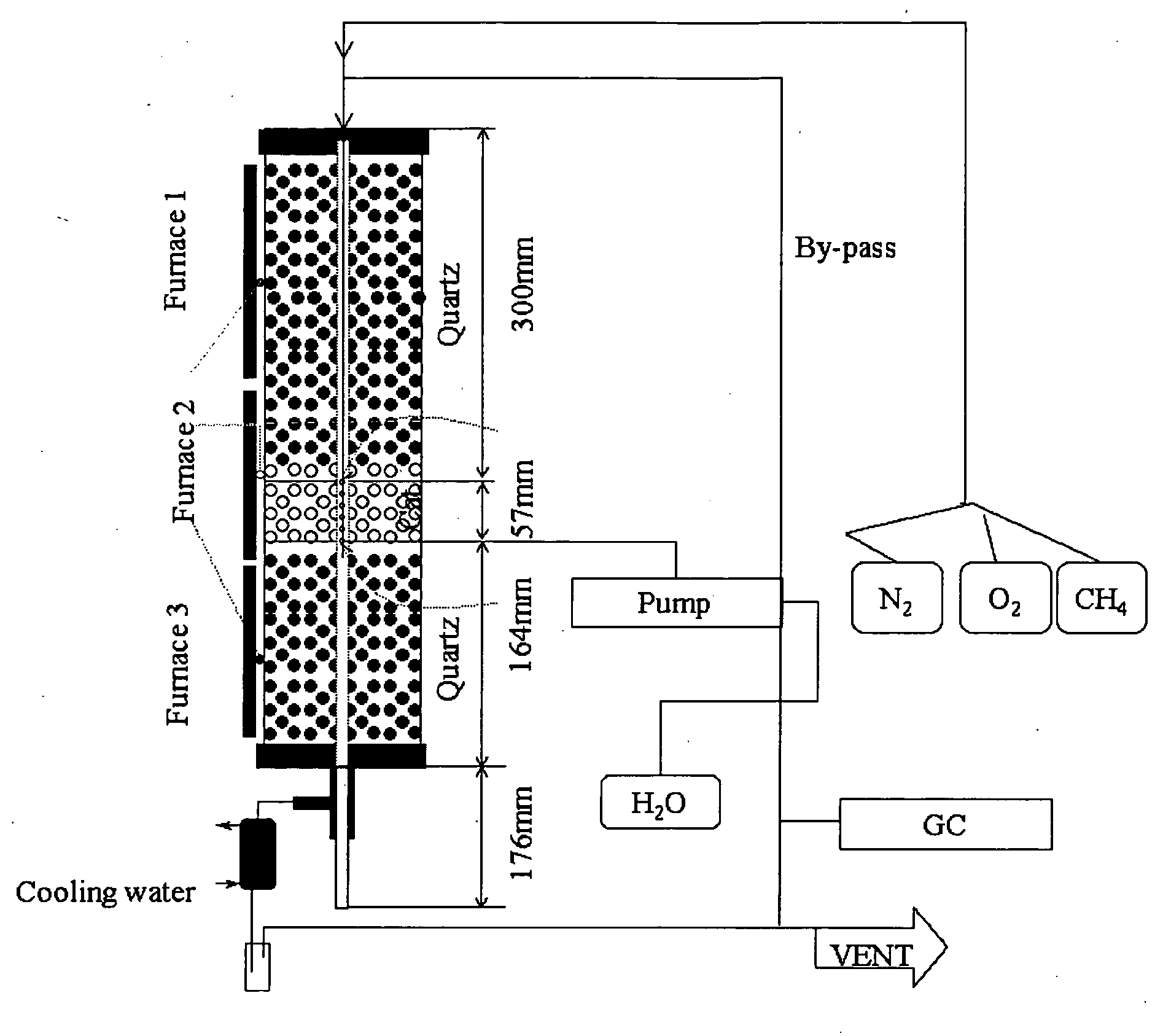

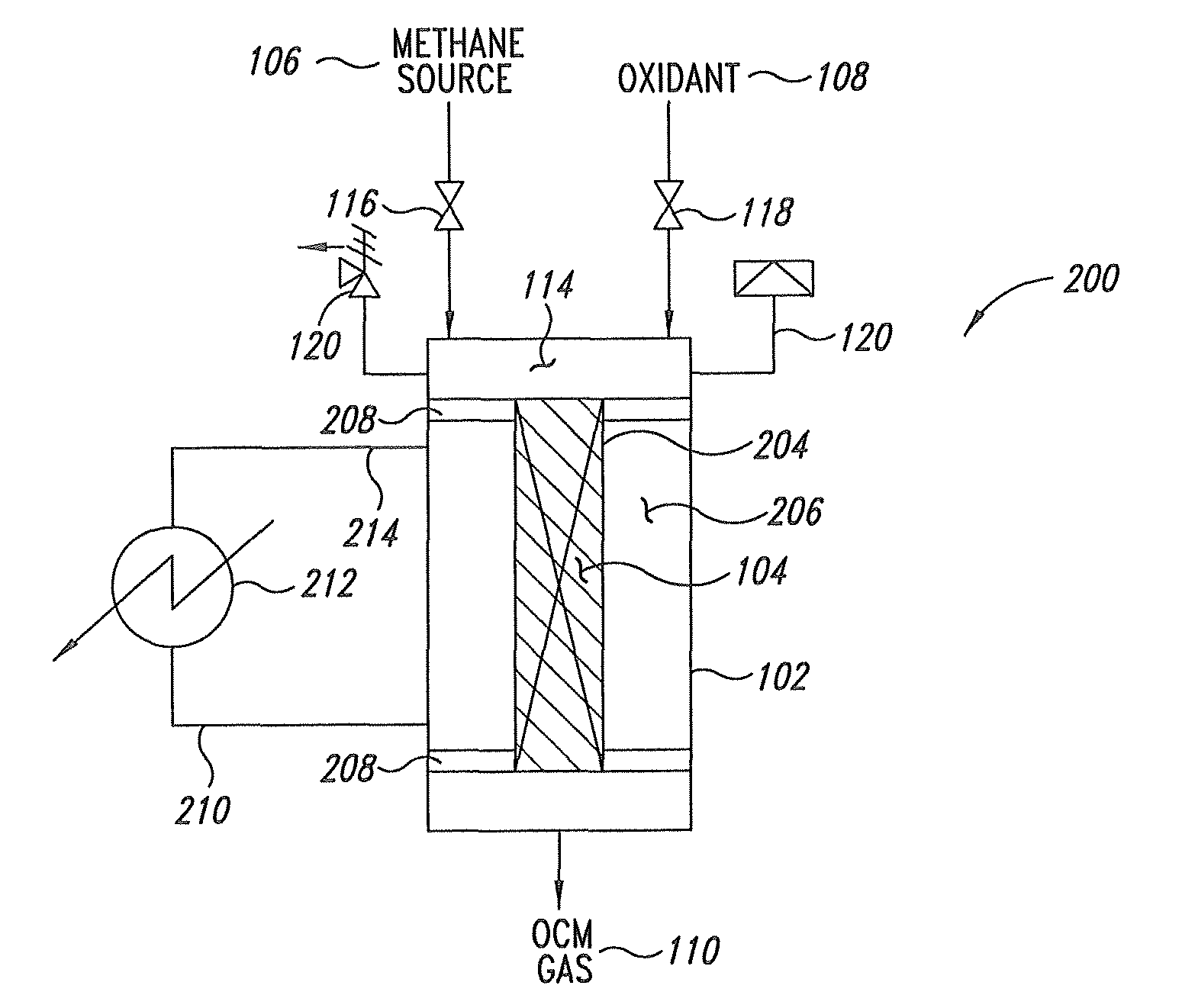

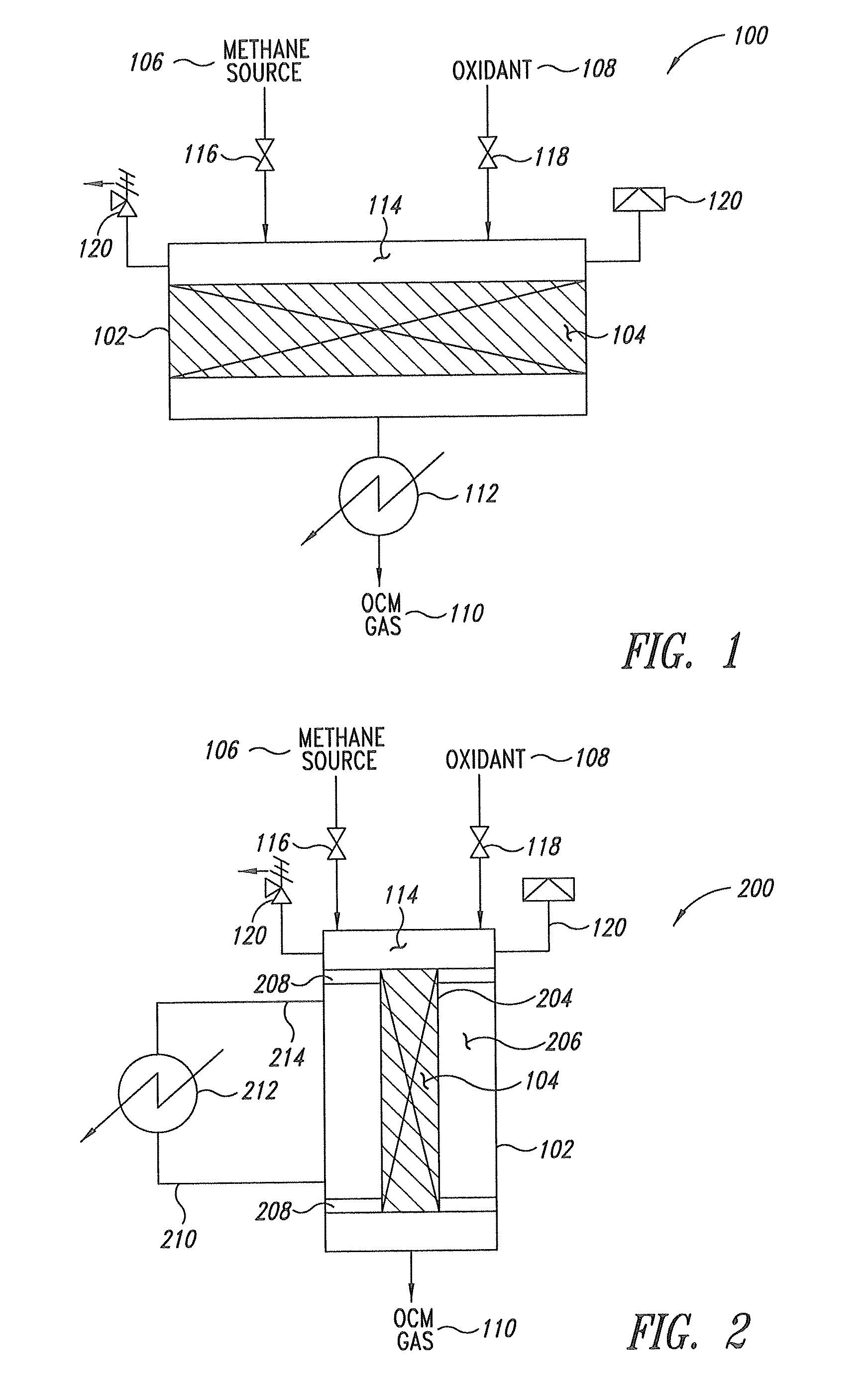

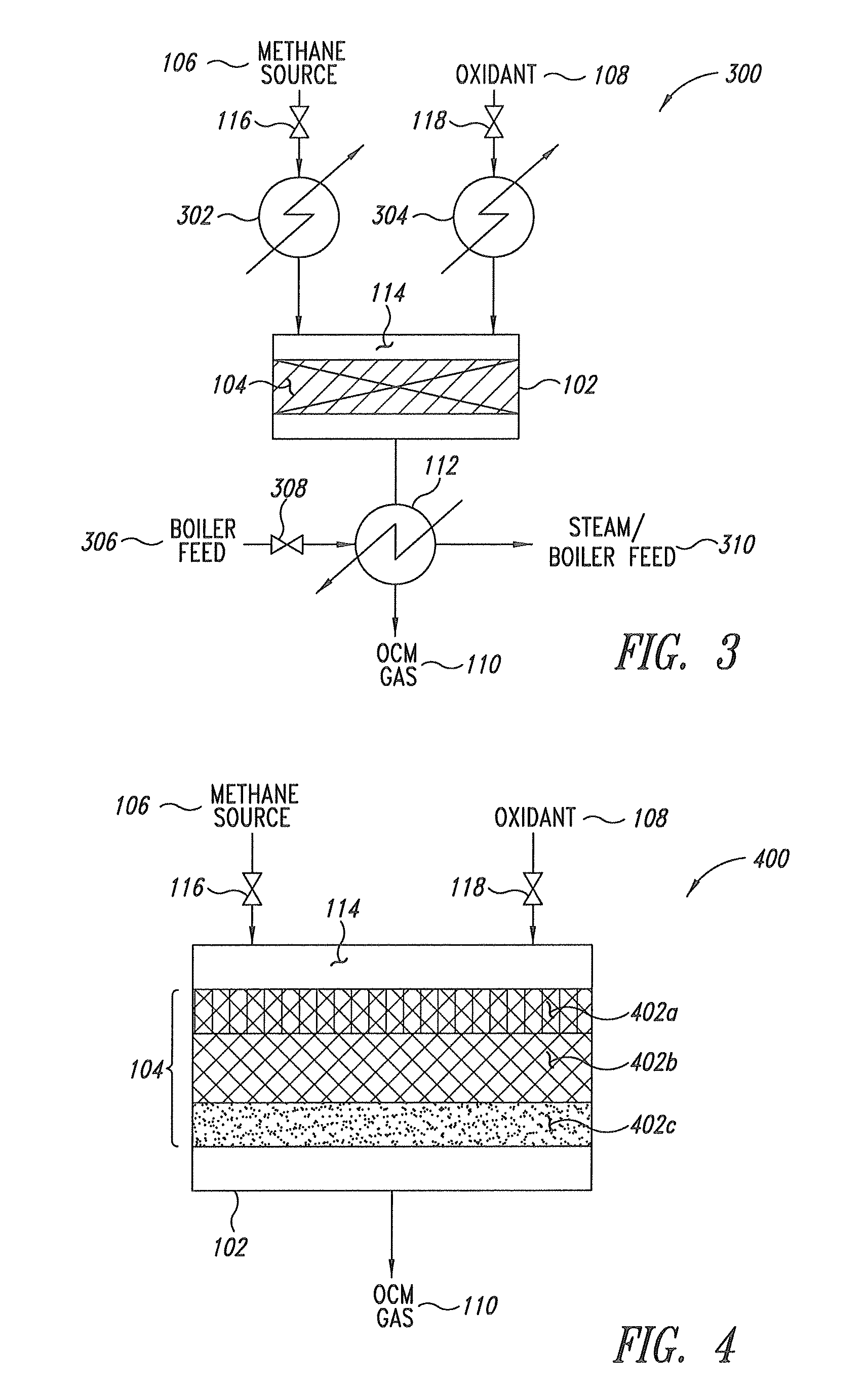

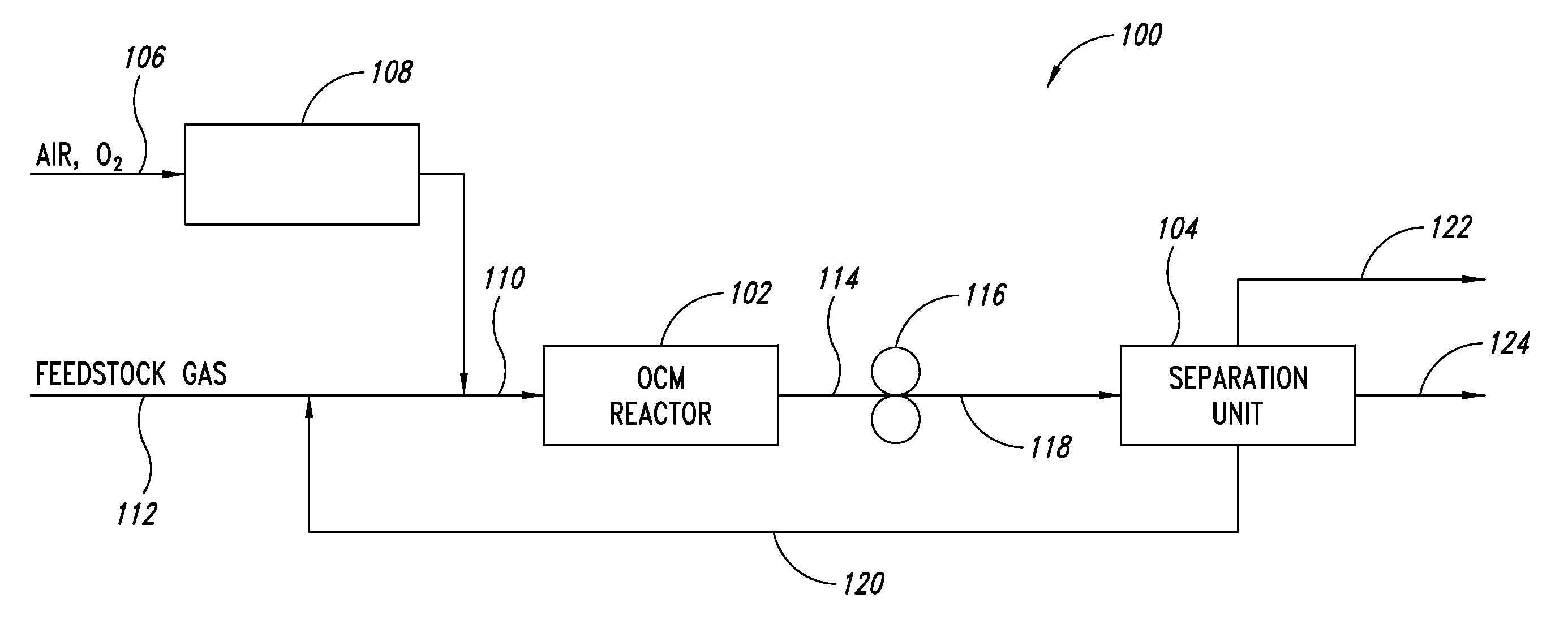

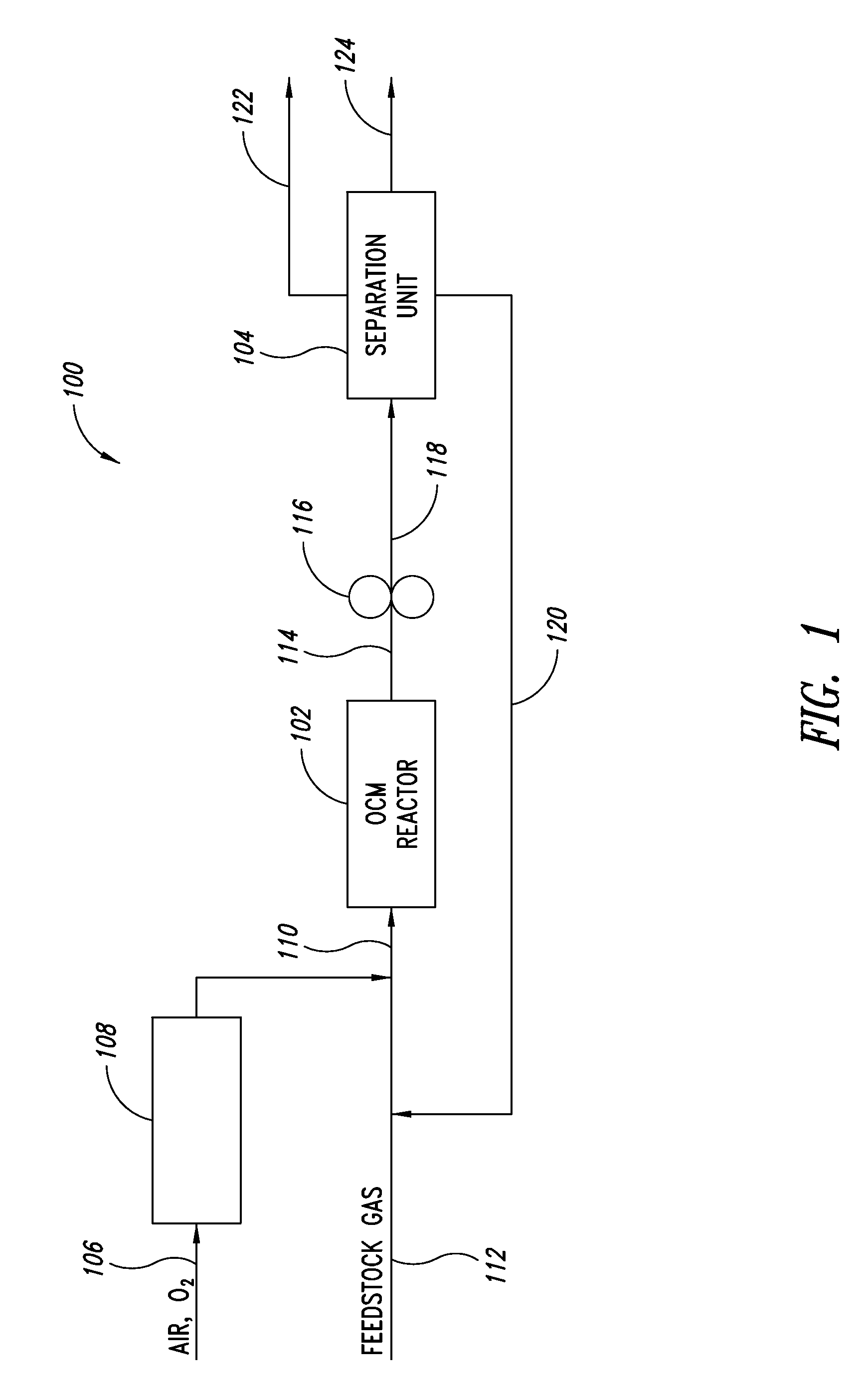

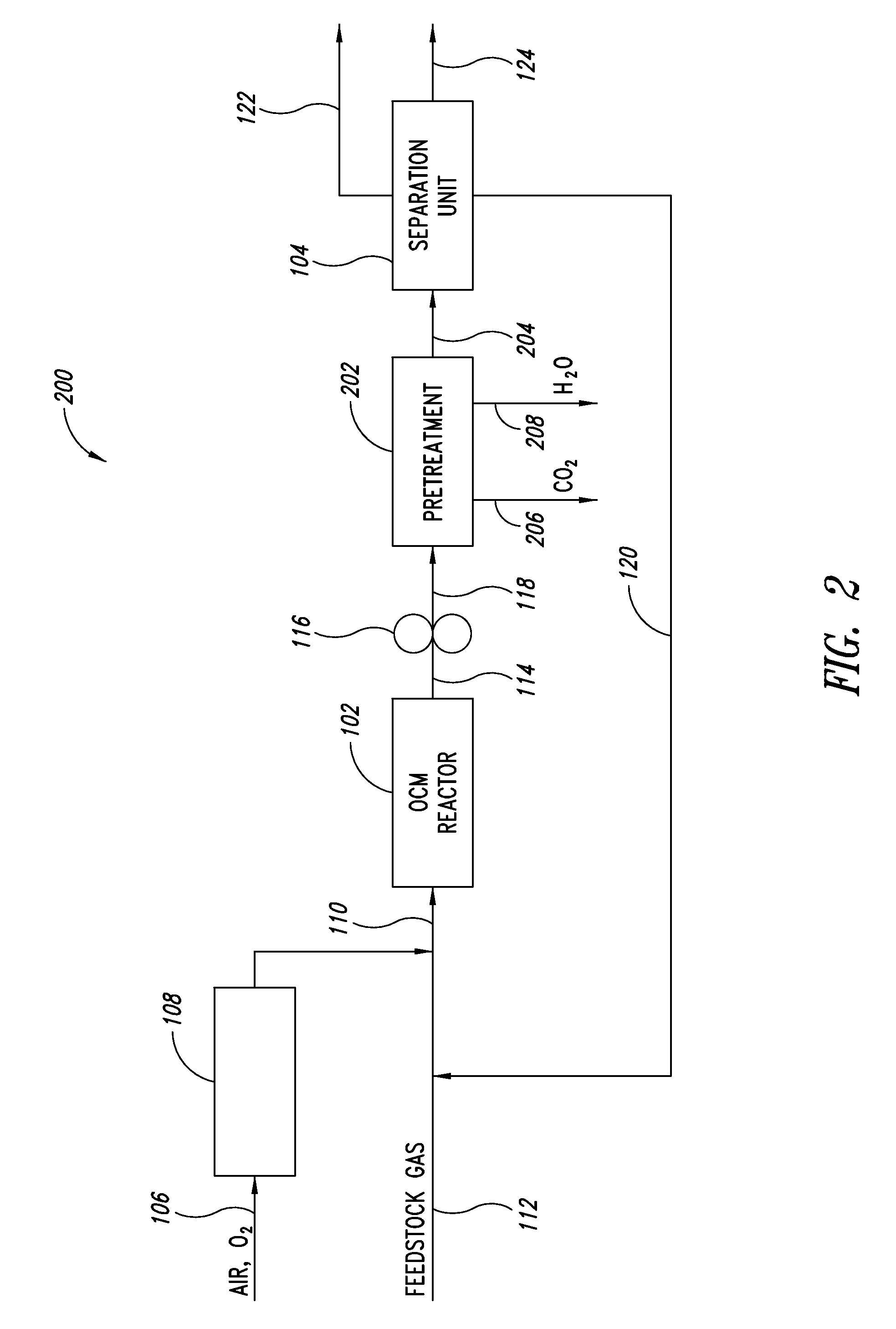

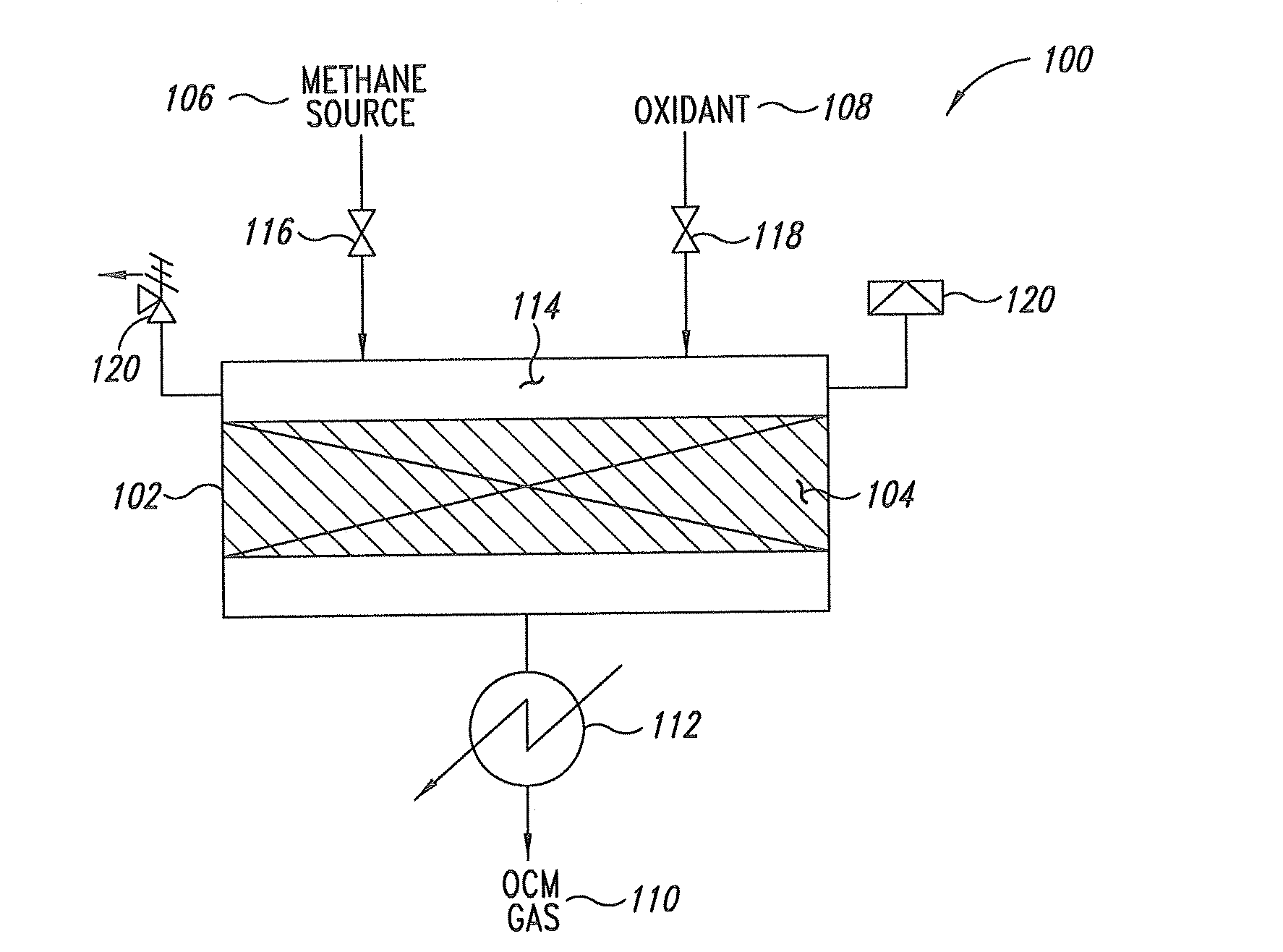

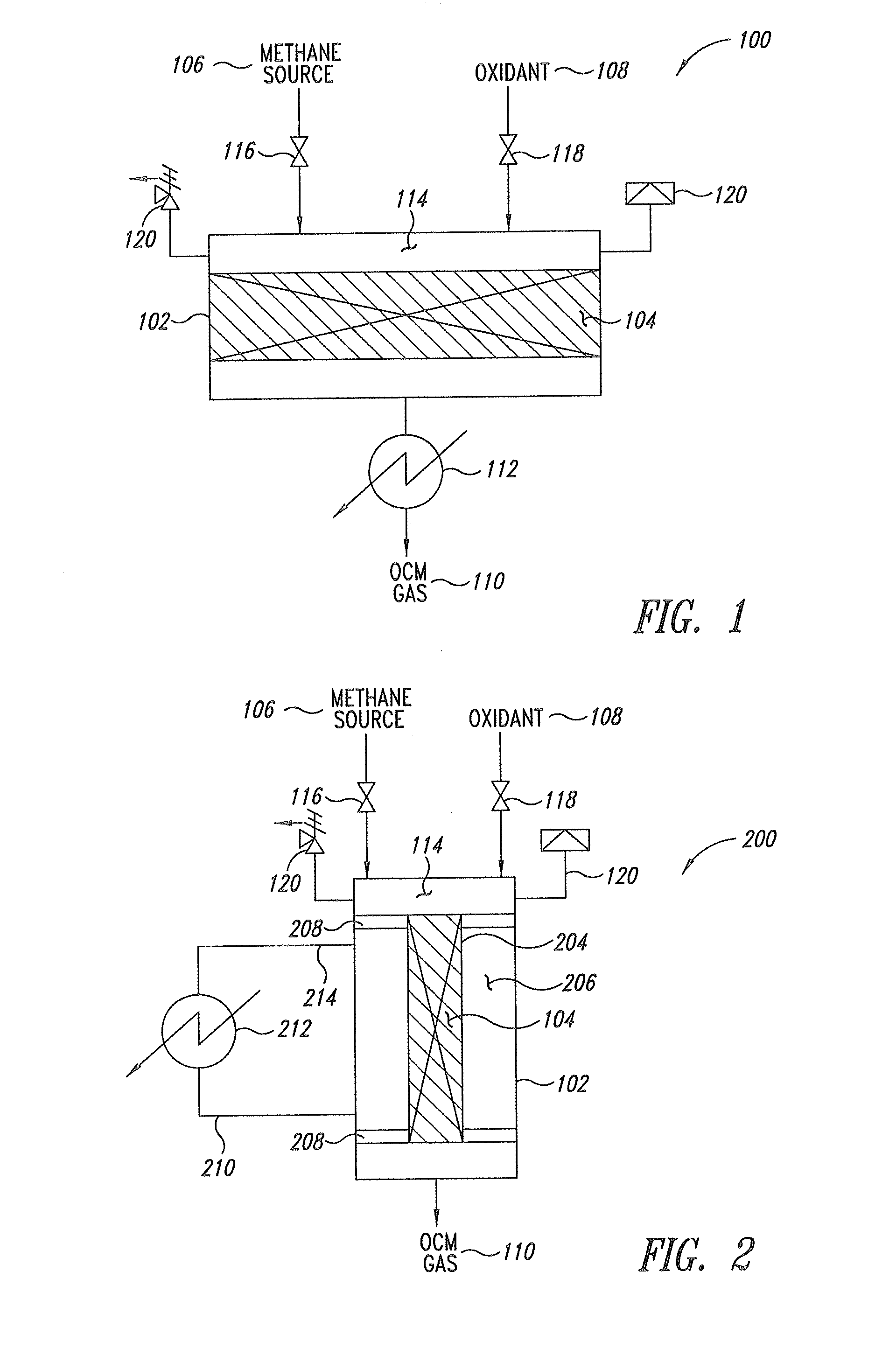

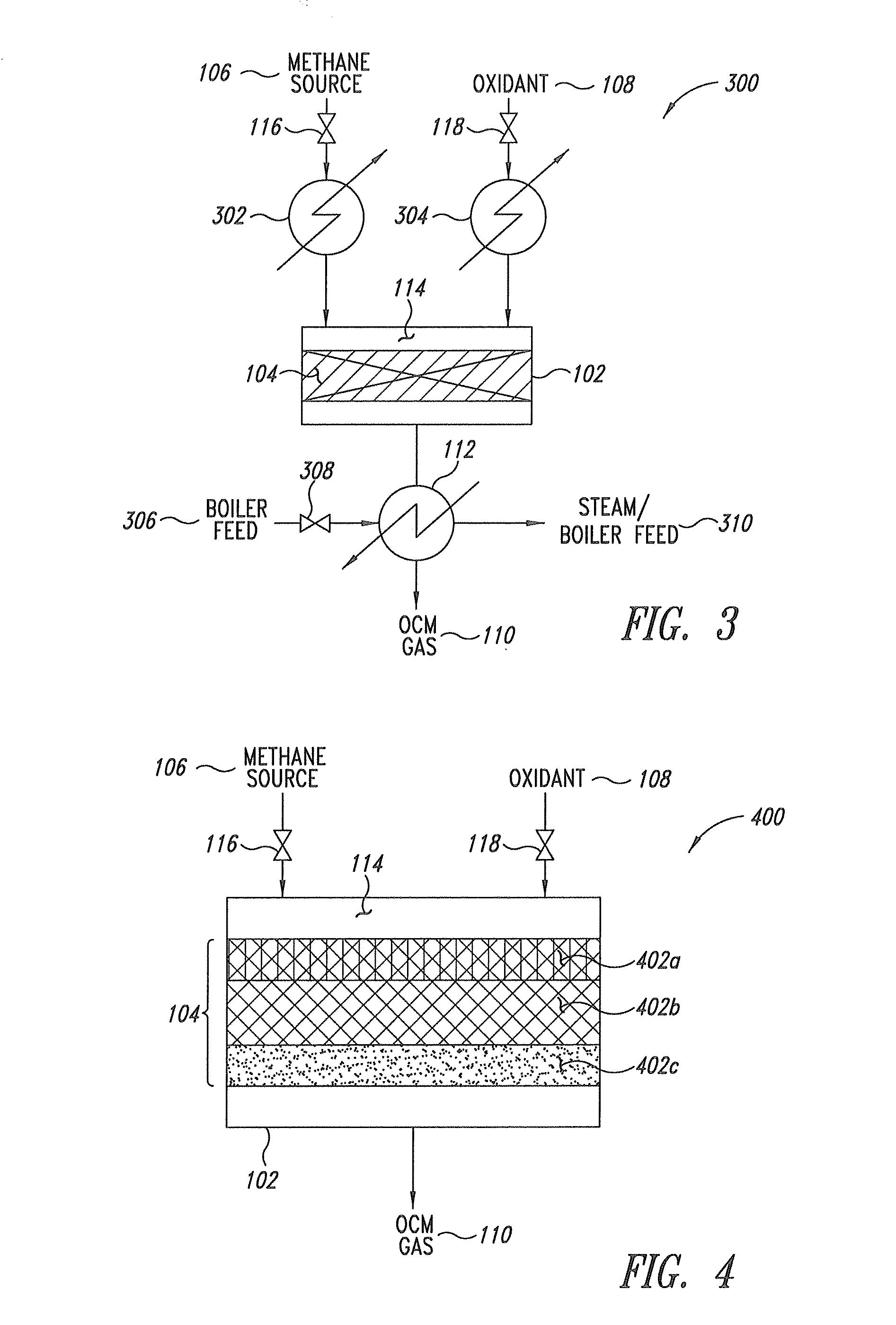

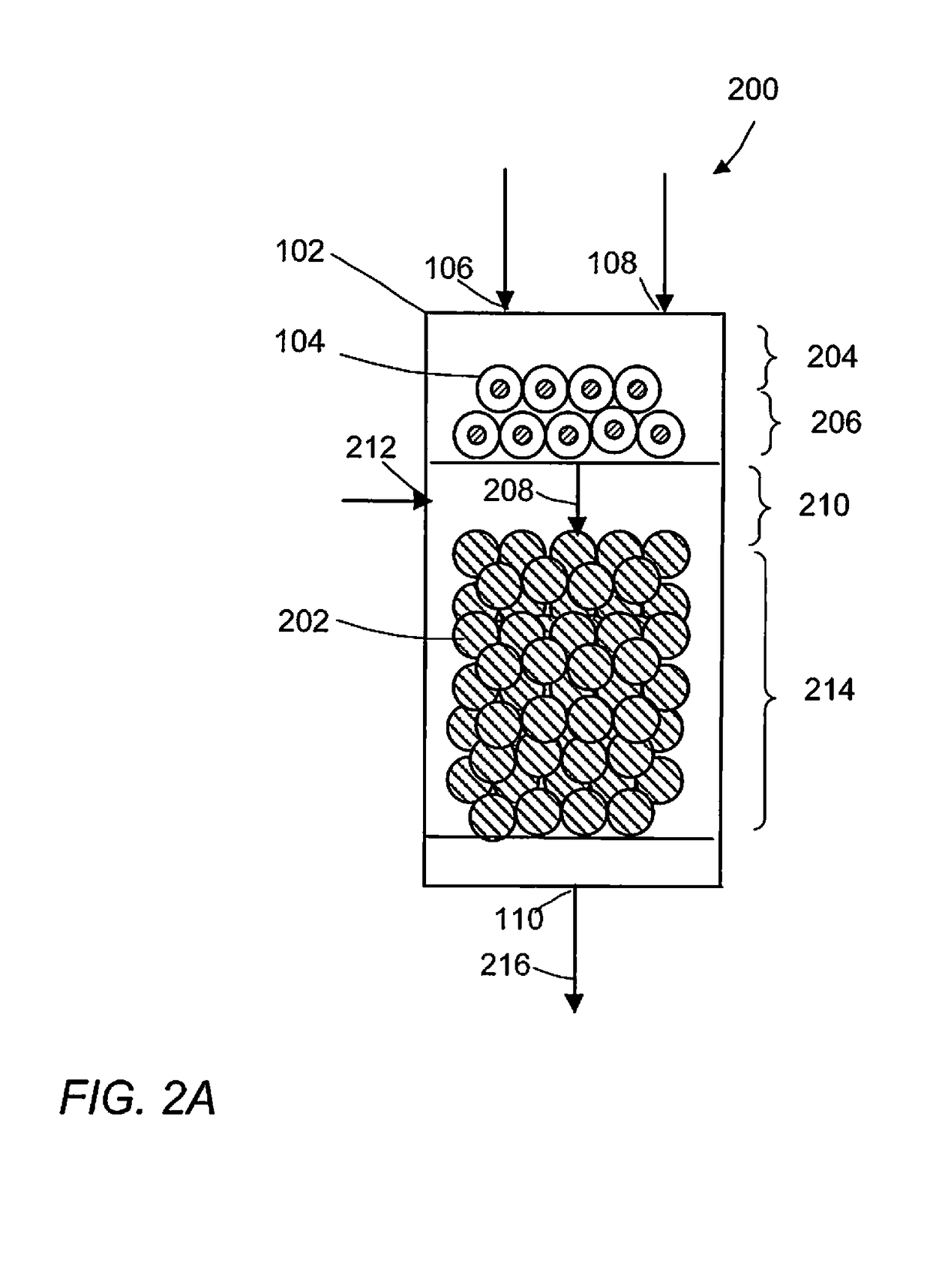

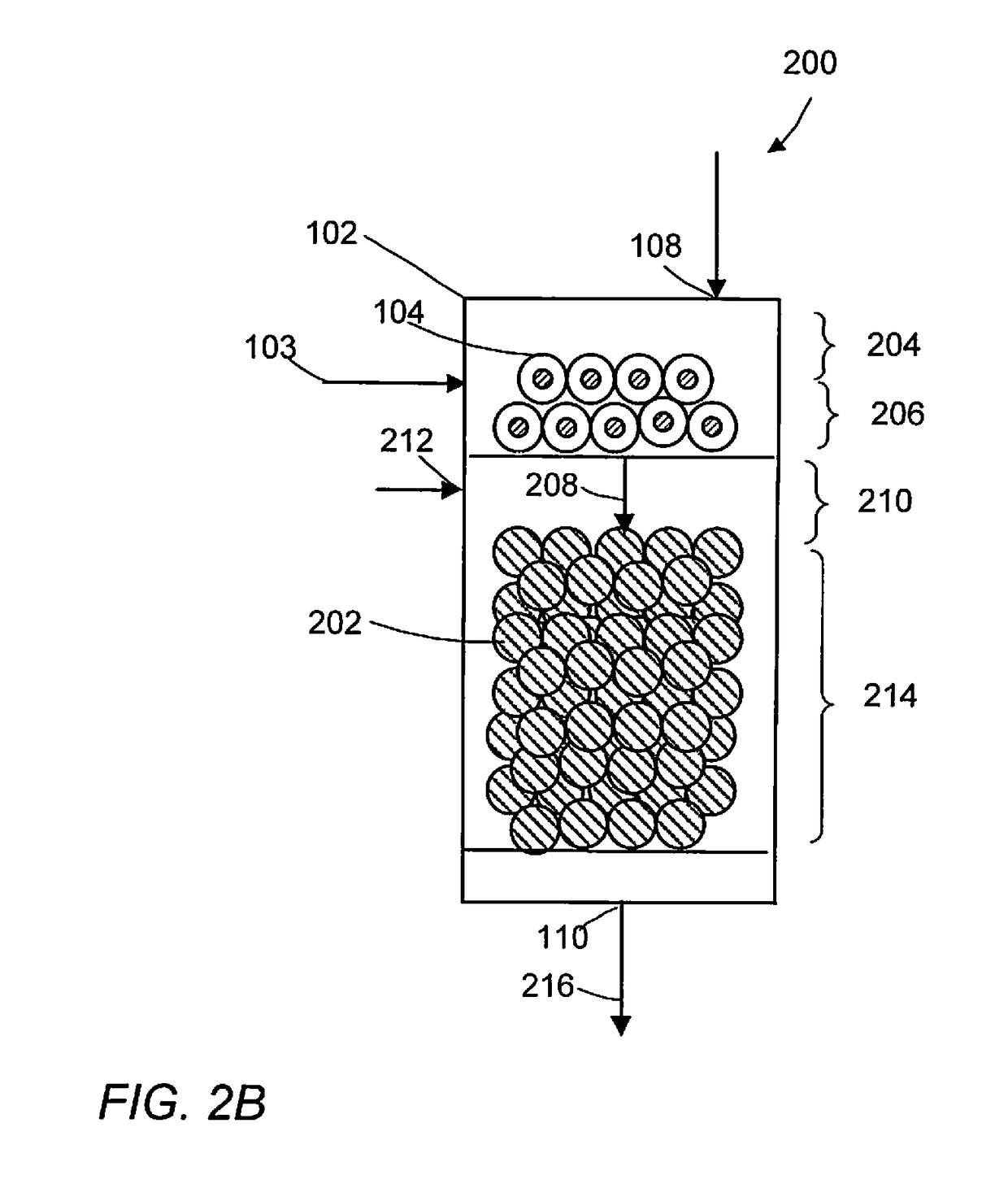

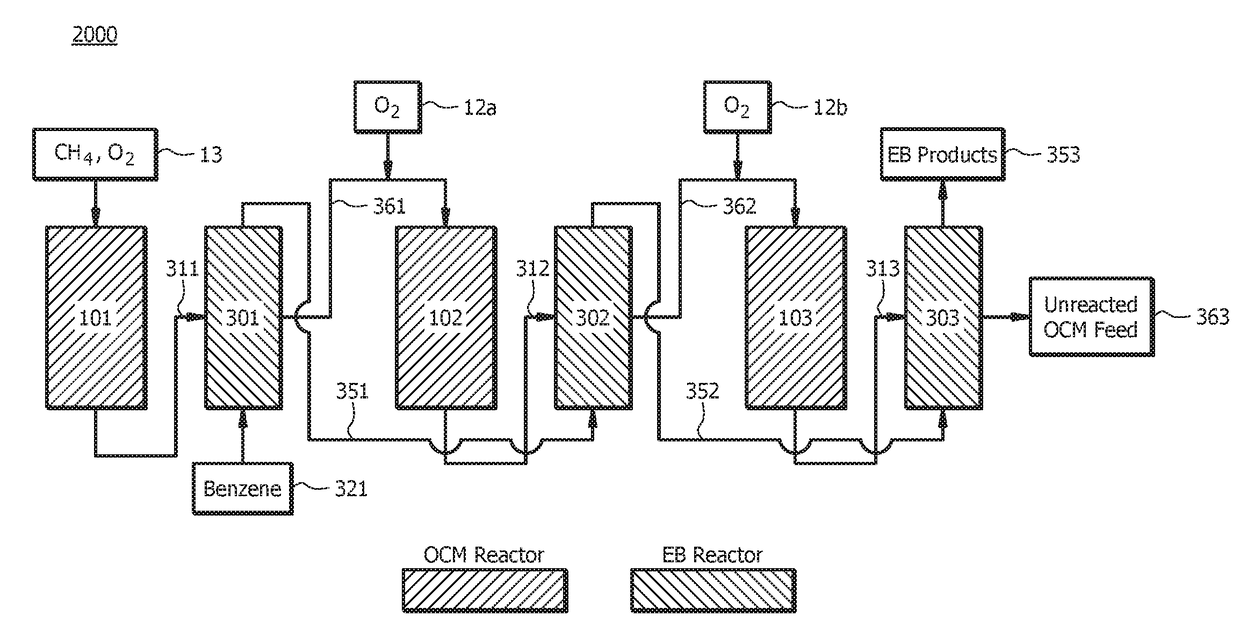

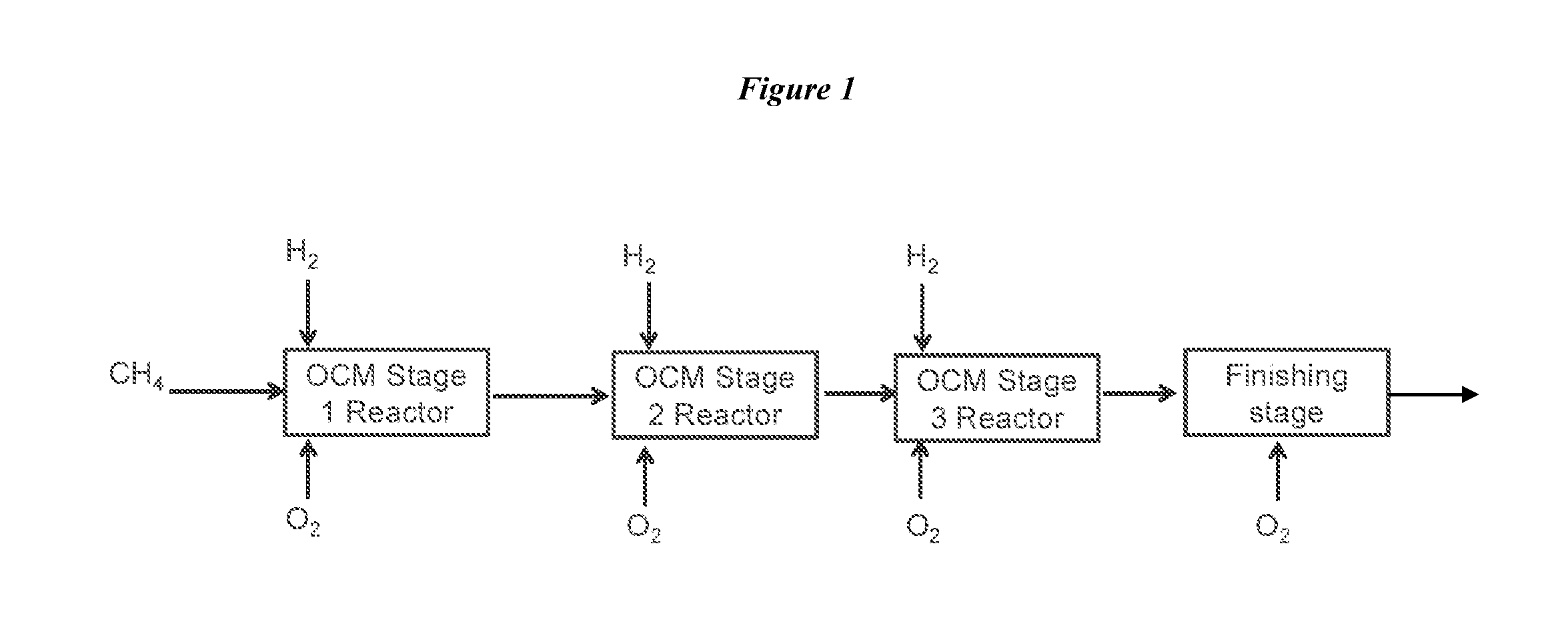

ActiveUS20140107385A1Maintain temperatureTemperatue controlLiquid hydrocarbon mixtures productionChemical compositionPhysical form

Systems and methods conducive to the formation of one or more alkene hydrocarbons using a methane source and an oxidant in an oxidative coupling of methane (OCM) reaction are provided. One or more vessels each containing one or more catalyst beds containing one or more catalysts each having similar or differing chemical composition or physical form may be used. The one or more catalyst beds may be operated under a variety of conditions. At least a portion of the catalyst beds may be operated under substantially adiabatic conditions. At least a portion of the catalyst beds may be operated under substantially isothermal conditions.

Owner:LUMMUS TECH LLC

Polymer templated nanowire catalysts

InactiveUS20130158322A1Improve drawing legibilityMaterial nanotechnologyManganese oxides/hydroxidesNanowirePolymer science

Nanowires useful as heterogeneous catalysts are provided. The nanowire catalysts are prepared by polymer templated methods and are useful in a variety of catalytic reactions, for example, the oxidative coupling of methane to ethane and / or ethylene. Related methods for use and manufacture of the same are also disclosed.

Owner:SILURIA TECH INC

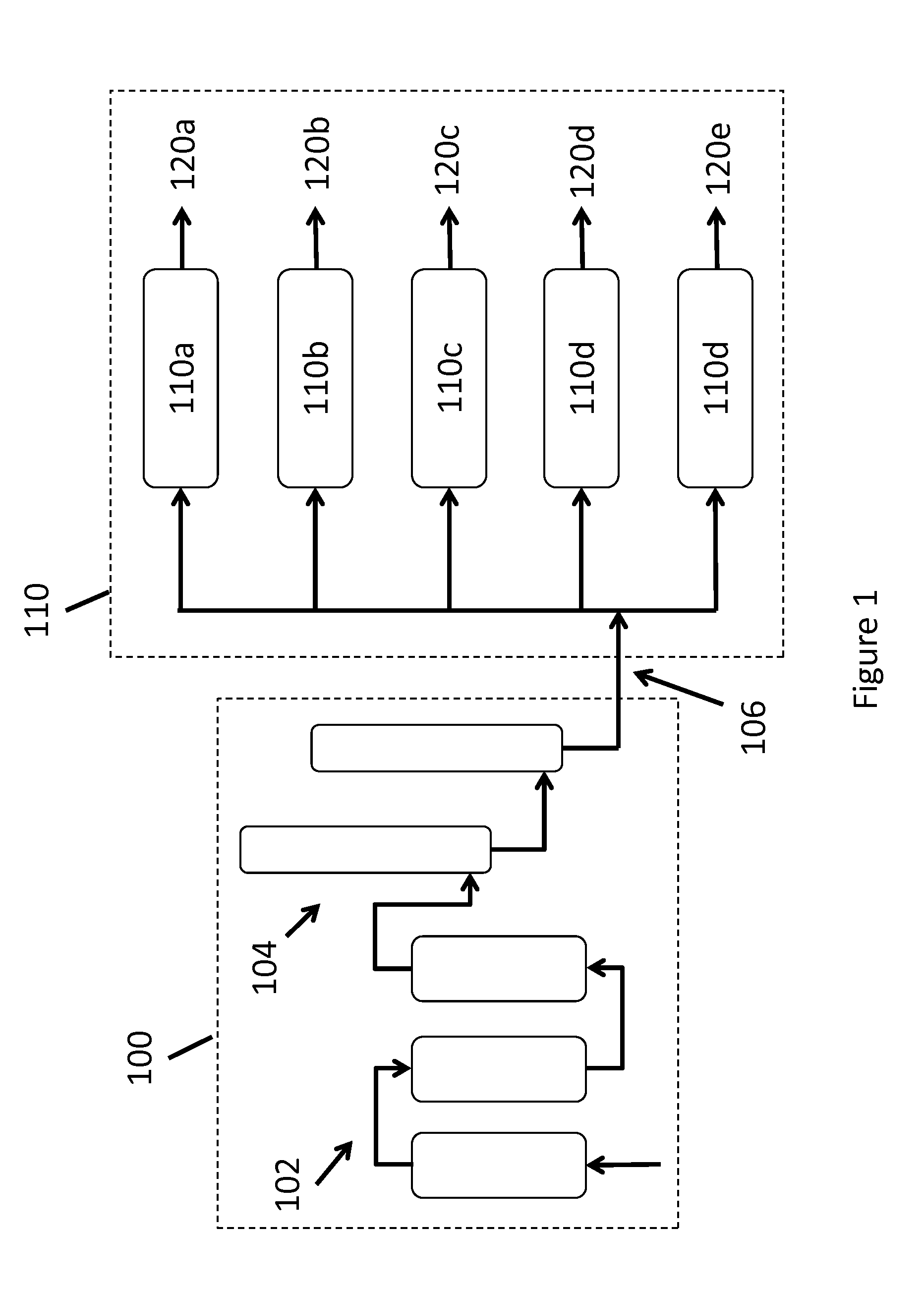

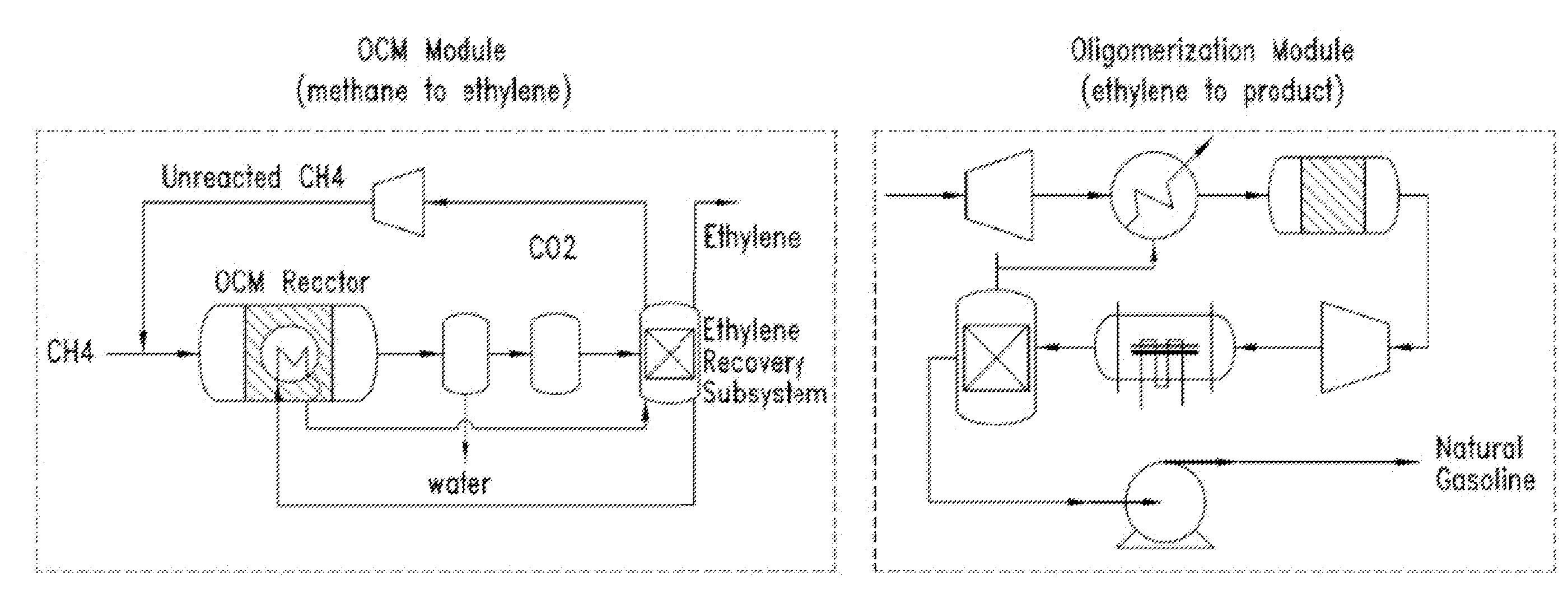

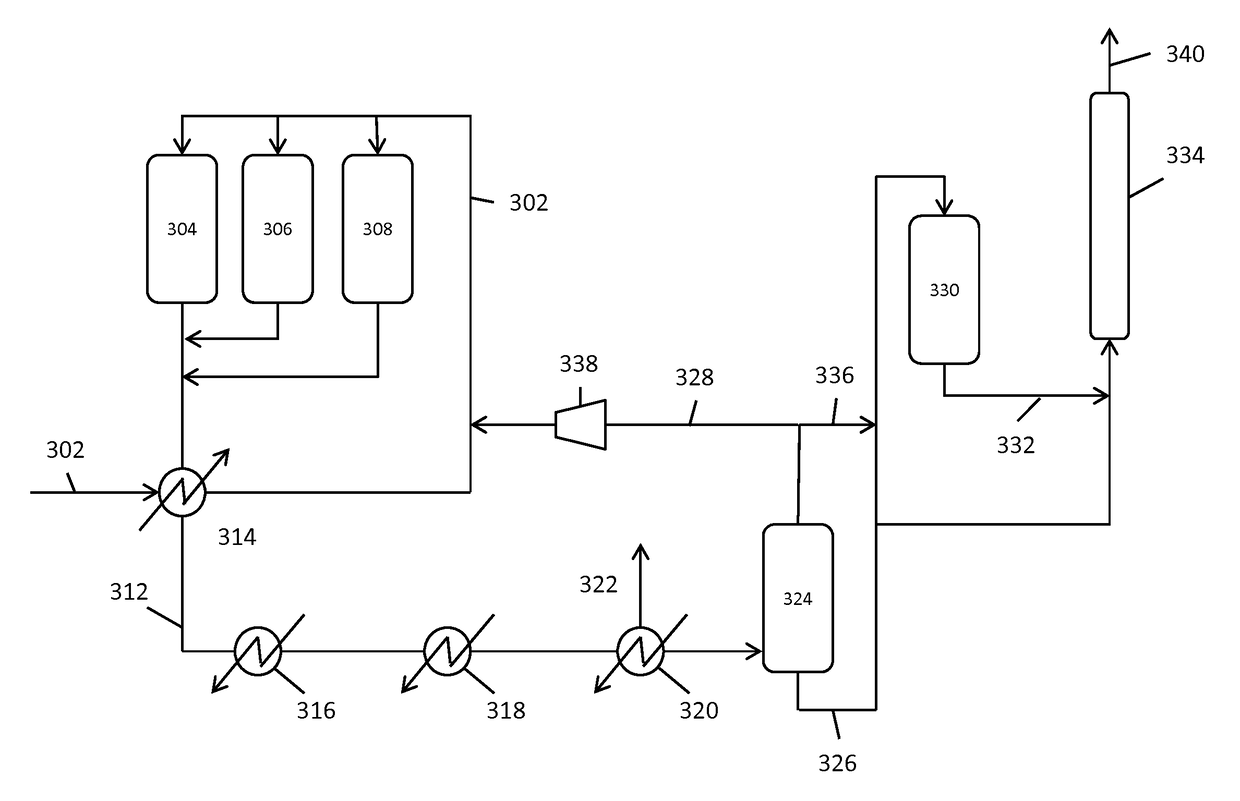

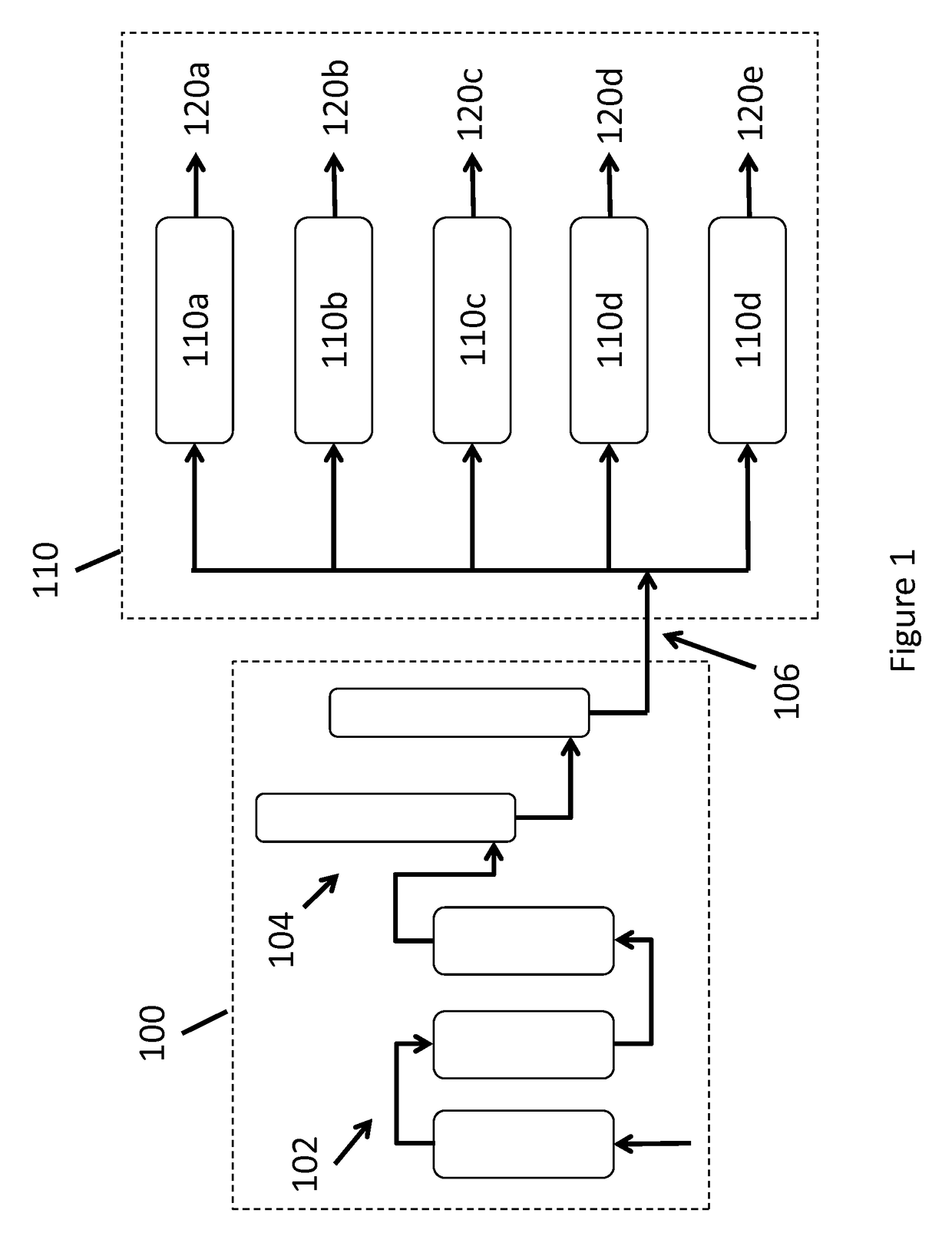

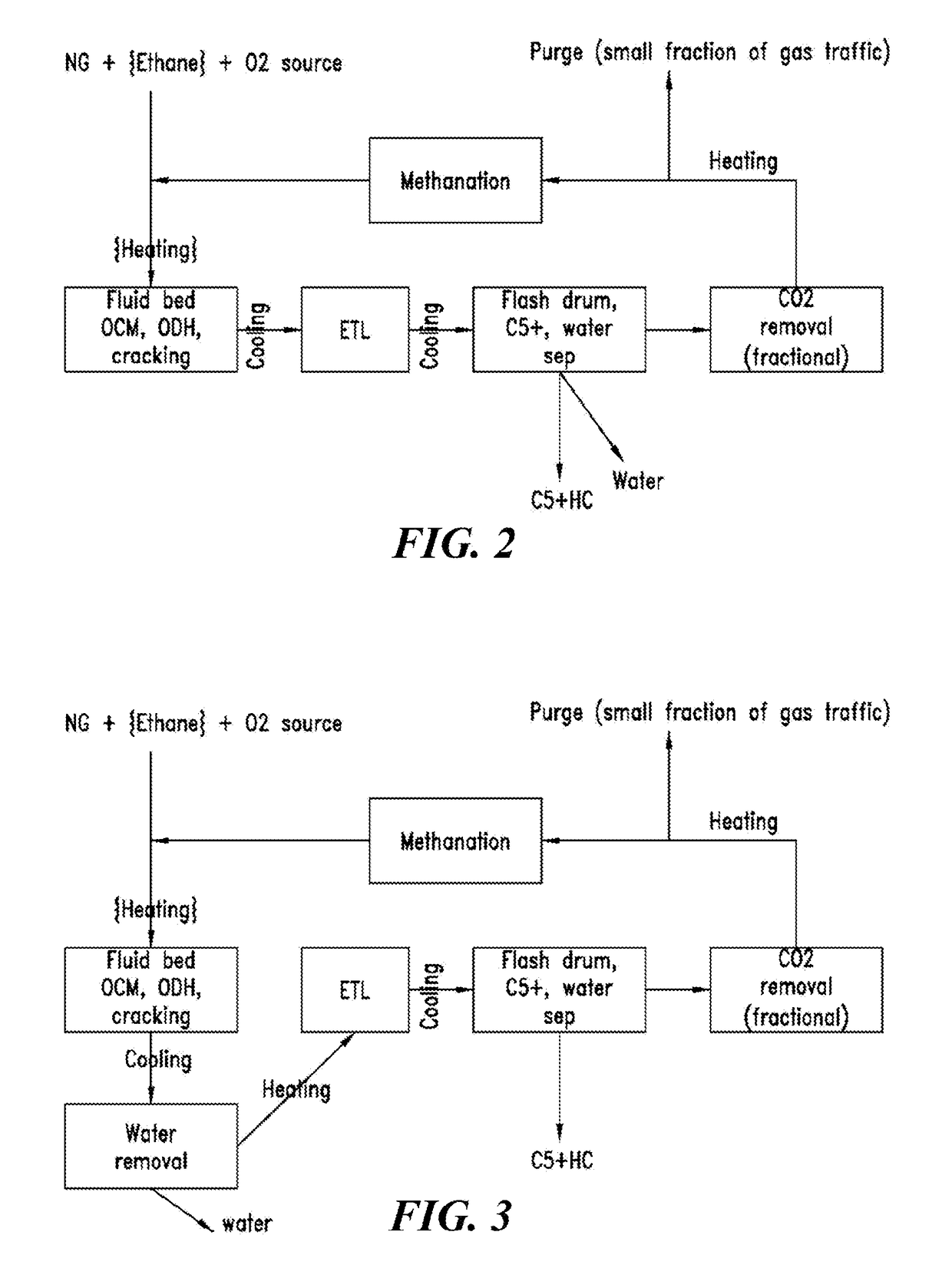

Integrated processes and systems for conversion of methane to multiple higher hydrocarbon products

Integrated systems are provided for the production of higher hydrocarbon compositions, for example liquid hydrocarbon compositions, from methane using an oxidative coupling of methane system to convert methane to ethylene, followed by conversion of ethylene to selectable higher hydrocarbon products. Integrated systems and processes are provided that process methane through to these higher hydrocarbon products.

Owner:LUMMUS TECH LLC

Catalysts for petrochemical catalysis

Metal oxide catalysts comprising various dopants are provided. The catalysts are useful as heterogenous catalysts in a variety of catalytic reactions, for example, the oxidative coupling of methane to C2 hydrocarbons such as ethane and ethylene. Related methods for use and manufacture of the same are also disclosed.

Owner:SILURIA TECH INC

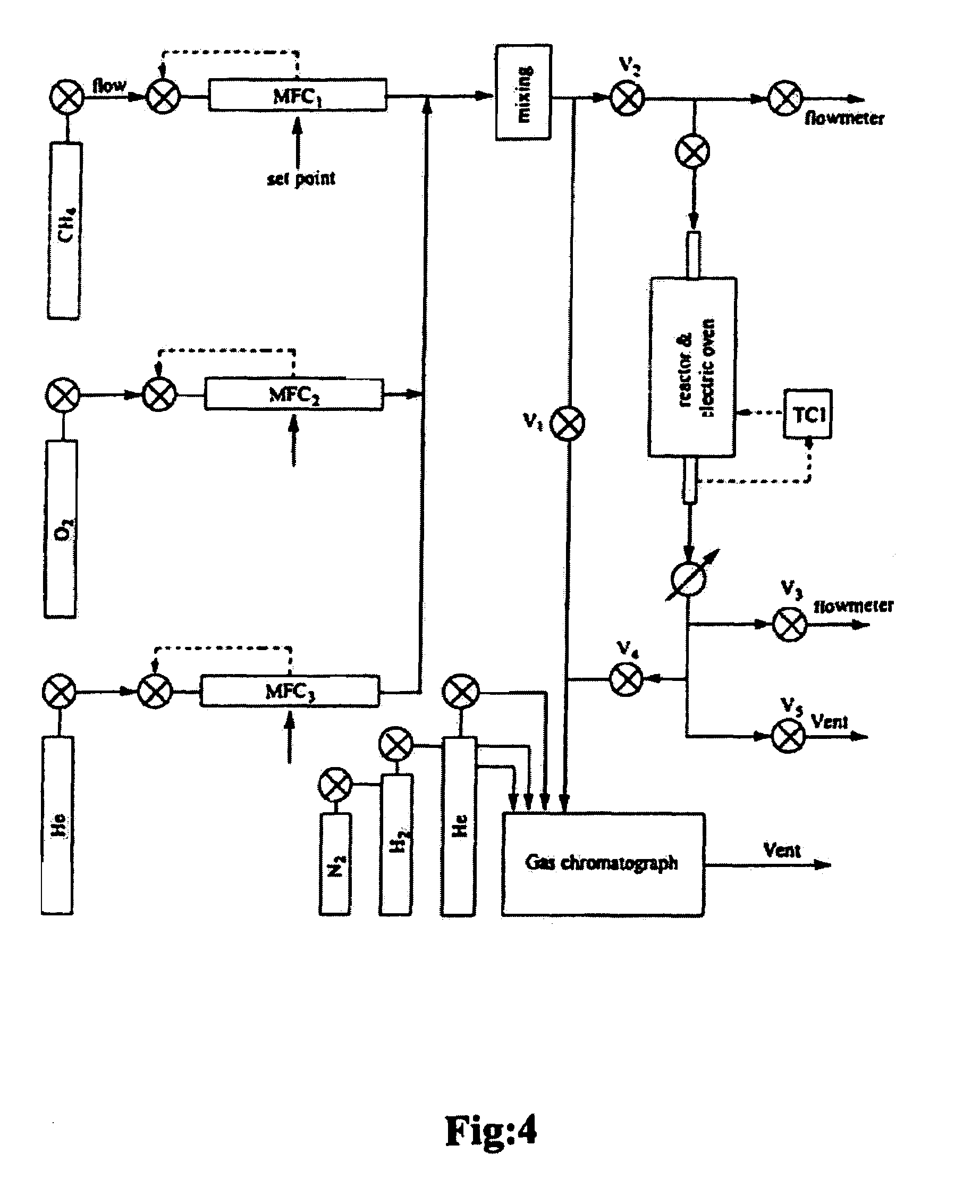

Catalyst and method for converting low molecular weight paraffinic hydrocarbons into alkenes and organic compounds with carbon numbers of 2 or more

InactiveUS20070083073A1Reduce the amount requiredPromotes oxidative couplingHydrogenHeterogenous catalyst chemical elementsCarbon numberOxygen

A catalyst and process for formation of hydrocarbons having carbon numbers of two or greater, the result of both oxidative coupling of methane (“OCM”), and other reforming reactions of OCM end products. An OCM catalyst has a structure represented by formula ABTiO3, wherein A is samarium or tin, B is barium; the reforming catalysts a composition represented by formula XYZ, wherein X is a metal from Group IA, Group IIA or Group VIIIA, or not present, Y a metal from Group VA, Group VIA, Group VIIA or Group VIIIA, Z chosen from oxygen, silica, silicalite and alumina. The inventive catalyst comprises an OCM catalyst and a reforming catalyst blended together; when used in a reactor effects an increased yield of hydrocarbons having a carbon number greater than 2 (in excess of 27%-30%, first pass rate of methane conversion about 50%) than occurs under OCM conditions alone.

Owner:HRD CORP

Catalysts for natural gas processes

Catalysts, catalytic forms and formulations, and catalytic methods are provided. The catalysts and catalytic forms and formulations are useful in a variety of catalytic reactions, for example, the oxidative coupling of methane. Related methods for use and manufacture of the same are also disclosed.

Owner:LUMMUS TECH LLC

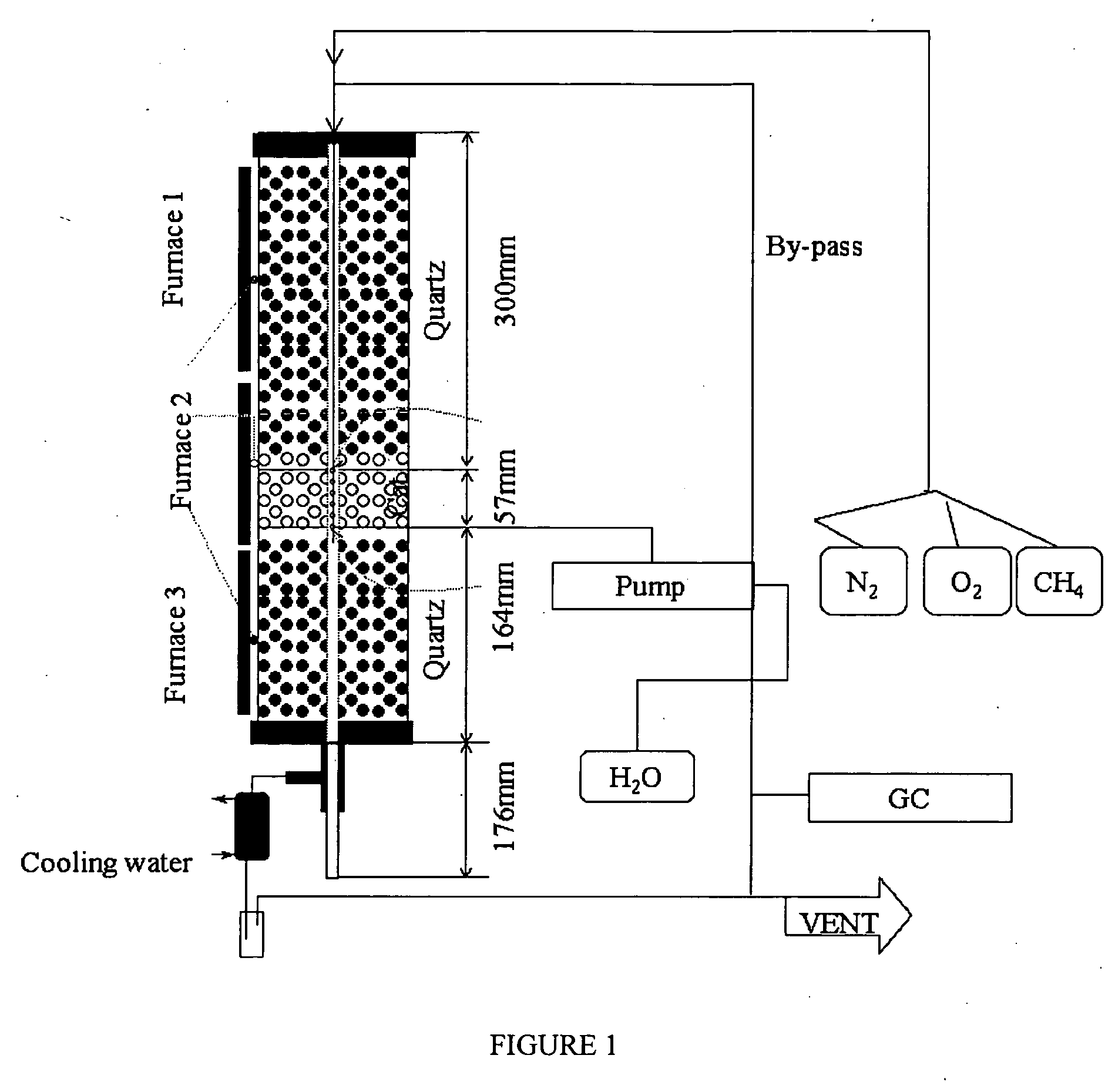

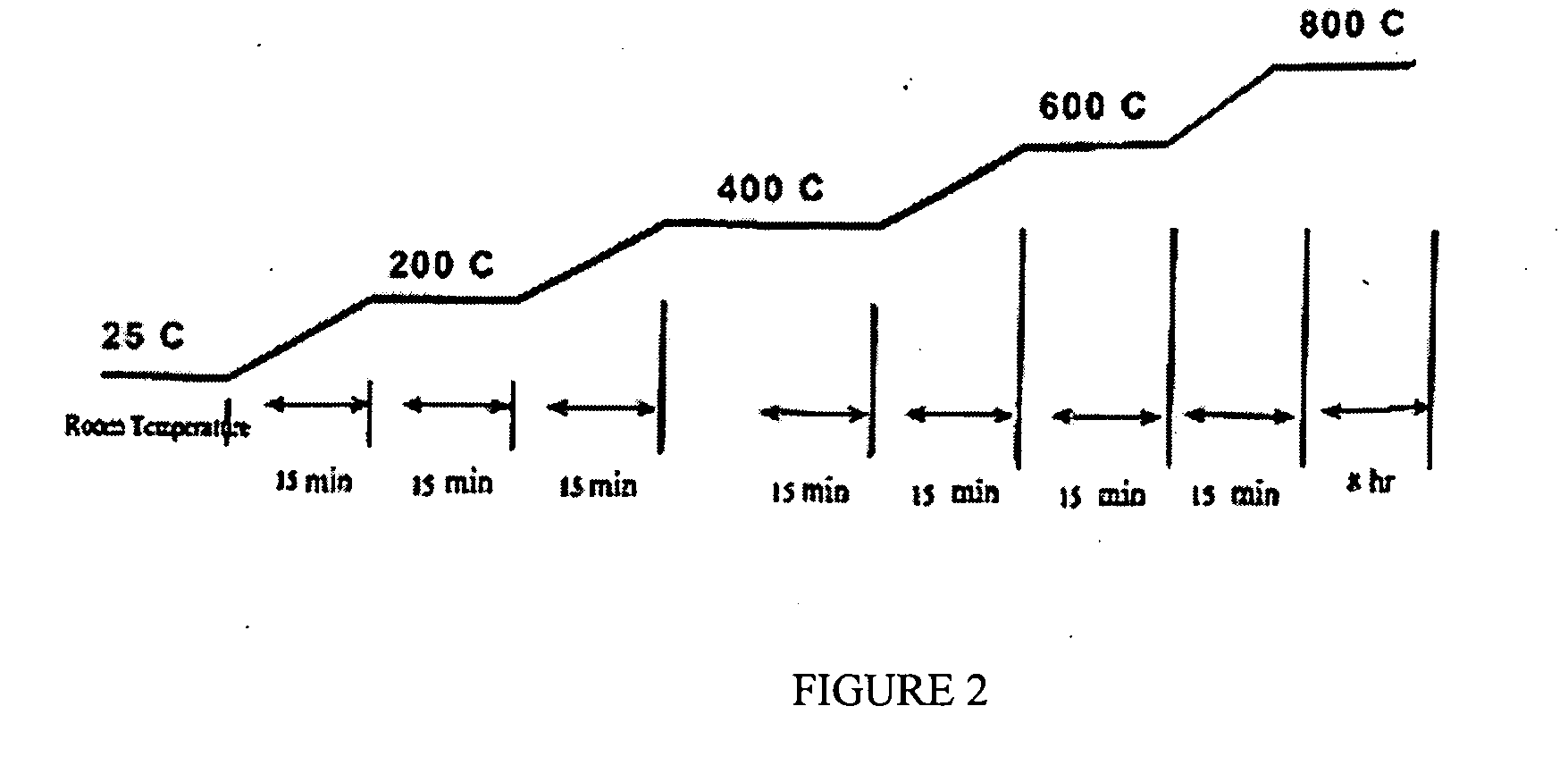

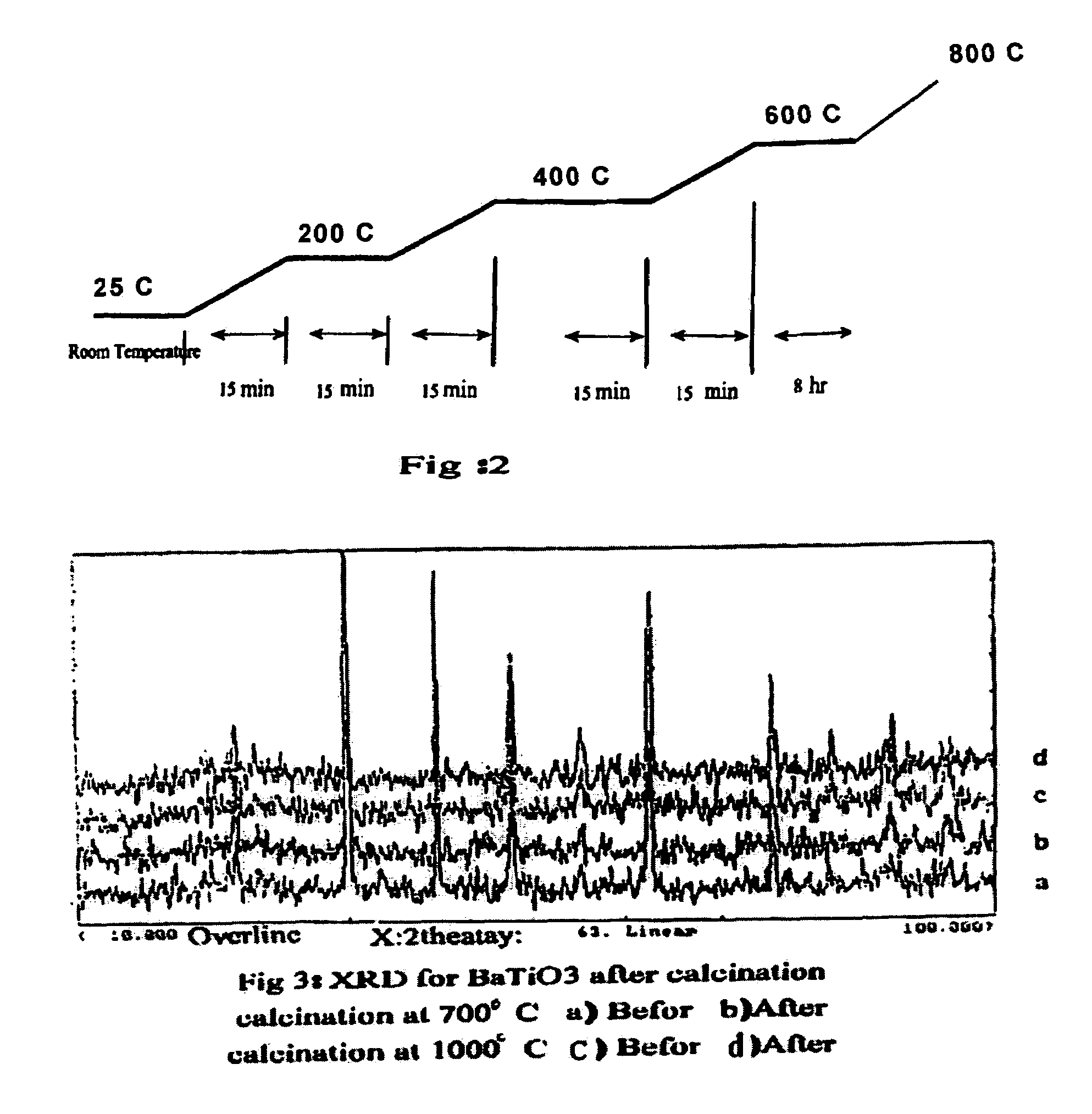

Preparation of catalyst and use for high yield conversion of methane to ethylene

InactiveUS7250543B2Maintain activityAlkaline earth titanatesHydrocarbon by hydrocarbon condensationAlkaline earth metalSlurry

A perovskite catalyst is prepared using a ceramic sol-sol methodology comprising preparing slurry in water of an alkaline earth metal salt, a powdered metal salt and a powdered transition metal oxide, adding a polymeric binder to form a paste, drying and comminuting the paste into a powder and heating the powder with a temperature profile to calcination temperatures. In one embodiment the slurry is formed of titanium oxide with barium carbonate and tin chloride in deionized water, and more specifically by a mixture according to Ba (1-0.05x)+TiO2+SnCl2(0.05x) where x is in moles. The perovskite catalyst is preferably used in a process for oxidative coupling of methane. Catalyst performance is enhanced through the addition of halides to the feed gas in the reaction.

Owner:HRD CORP

Catalysts for petrochemical catalysis

Metal oxide catalysts comprising various dopants are provided. The catalysts are useful as heterogenous catalysts in a variety of catalytic reactions, for example, the oxidative coupling of methane to C2 hydrocarbons such as ethane and ethylene. Related methods for use and manufacture of the same are also disclosed.

Owner:SILURIA TECH INC

Heterogeneous catalysts

ActiveUS20150314267A1High catalytic activityMolecular sieve catalystCatalystsDopantOxidative coupling of methane

Heterogeneous catalysts with optional dopants are provided. The catalysts are useful in a variety of catalytic reactions, for example, the oxidative coupling of methane to C2+ hydrocarbons. Related methods for use and manufacture of the same are also disclosed.

Owner:SILURIA TECH INC

Process for separating hydrocarbon compounds

ActiveUS20150368167A1Reduce moistureReduce hydrogen sulfide contentSolidificationLiquefactionHydrocotyle bowlesioidesOxidative coupling of methane

Disclosed herein are processes for producing and separating ethane and ethylene. In some embodiments, an oxidative coupling of methane (OCM) product gas comprising ethane and ethylene is introduced to a separation unit comprising two separators. Within the separation unit, the OCM product gas is separated to provide a C2-rich effluent, a methane-rich effluent, and a nitrogen-rich effluent. Advantageously, in some embodiments the separation is achieved with little or no external refrigeration requirement.

Owner:LUMMUS TECH LLC

Oxidative coupling of methane systems and methods

ActiveUS9469577B2Maintain temperatureLiquid hydrocarbon mixtures productionEthylene productionChemical compositionPhysical form

Owner:LUMMUS TECH LLC

Process for separating hydrocarbon compounds

Disclosed herein are processes for producing and separating ethane and ethylene. In some embodiments, an oxidative coupling of methane (OCM) product gas comprising ethane and ethylene is introduced to a separation unit comprising two separators. Within the separation unit, the OCM product gas is separated to provide a C2-rich effluent, a methane-rich effluent, and a nitrogen-rich effluent. Advantageously, in some embodiments the separation is achieved with little or no external refrigeration requirement.

Owner:LUMMUS TECH LLC

Catalyst for pressurized oxidative coupling of methane to prepare ethylene and its prepn.

InactiveCN1389293AHigh content of active ingredientsNo diluent requiredHydrocarbon by hydrocarbon condensationMetal/metal-oxides/metal-hydroxide catalystsActive componentSpace velocity

The present invention discloses a catalyst for methane oxidative coupling polymerization to prepare ethylene under the condition of pressurization, and said catalyst uses SiO2 as support, and its active component is formed from Mn2O3, Na2WO4 and SnO2, and its active component content is 10 wt%-20 wt%. Under the condition of no dilution gas, 0.6 MPa and high space velocity it can obtain 33.0% of methane conversion rate and 24.1% of C2 hydrocarbon yield.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Oxidative coupling of methane systems and methods

ActiveUS20150321974A1Maintain temperatureTemperatue controlLiquid hydrocarbon mixtures productionChemical compositionPhysical form

Systems and methods conducive to the formation of one or more alkene hydrocarbons using a methane source and an oxidant in an oxidative coupling of methane (OCM) reaction are provided. One or more vessels each containing one or more catalyst beds containing one or more catalysts each having similar or differing chemical composition or physical form may be used. The one or more catalyst beds may be operated under a variety of conditions. At least a portion of the catalyst beds may be operated under substantially adiabatic conditions. At least a portion of the catalyst beds may be operated under substantially isothermal conditions.

Owner:LUMMUS TECH LLC

Integrated processes and systems for conversion of methane to multiple higher hydrocarbon products

Integrated systems are provided for the production of higher hydrocarbon compositions, for example liquid hydrocarbon compositions, from methane using an oxidative coupling of methane system to convert methane to ethylene, followed by conversion of ethylene to selectable higher hydrocarbon products. Integrated systems and processes are provided that process methane through to these higher hydrocarbon products.

Owner:LUMMUS TECH LLC

Catalysts and methods for natural gas processes

InactiveUS20170267605A1Material nanotechnologyHeterogenous catalyst chemical elementsCatalytic methodOxidative coupling of methane

Catalysts and catalytic methods are provided. The catalysts and methods are useful in a variety of catalytic reactions, for example, the oxidative coupling of methane.

Owner:SILURIA TECH INC

Catalysts for natural gas processes

ActiveUS9751079B2CatalystsHydrocarbon preparation catalystsCatalytic methodOxidative coupling of methane

Catalysts, catalytic forms and formulations, and catalytic methods are provided. The catalysts and catalytic forms and formulations are useful in a variety of catalytic reactions, for example, the oxidative coupling of methane. Related methods for use and manufacture of the same are also disclosed.

Owner:LUMMUS TECH LLC

Heterogeneous catalysts

Heterogeneous catalysts with optional dopants are provided. The catalysts are useful in a variety of catalytic reactions, for example, the oxidative coupling of methane to C2+ hydrocarbons. Related methods for use and manufacture of the same are also disclosed.

Owner:SILURIA TECH INC

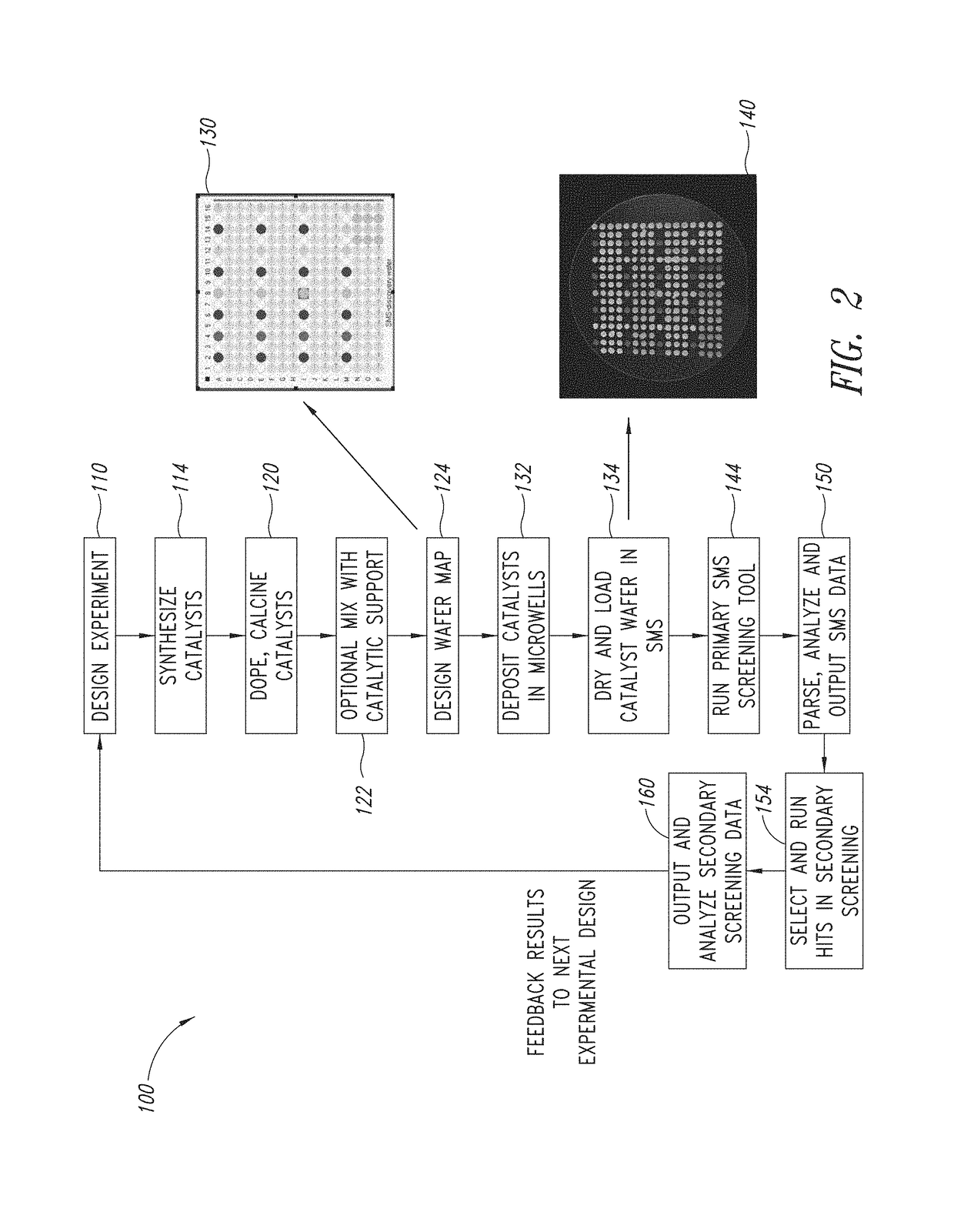

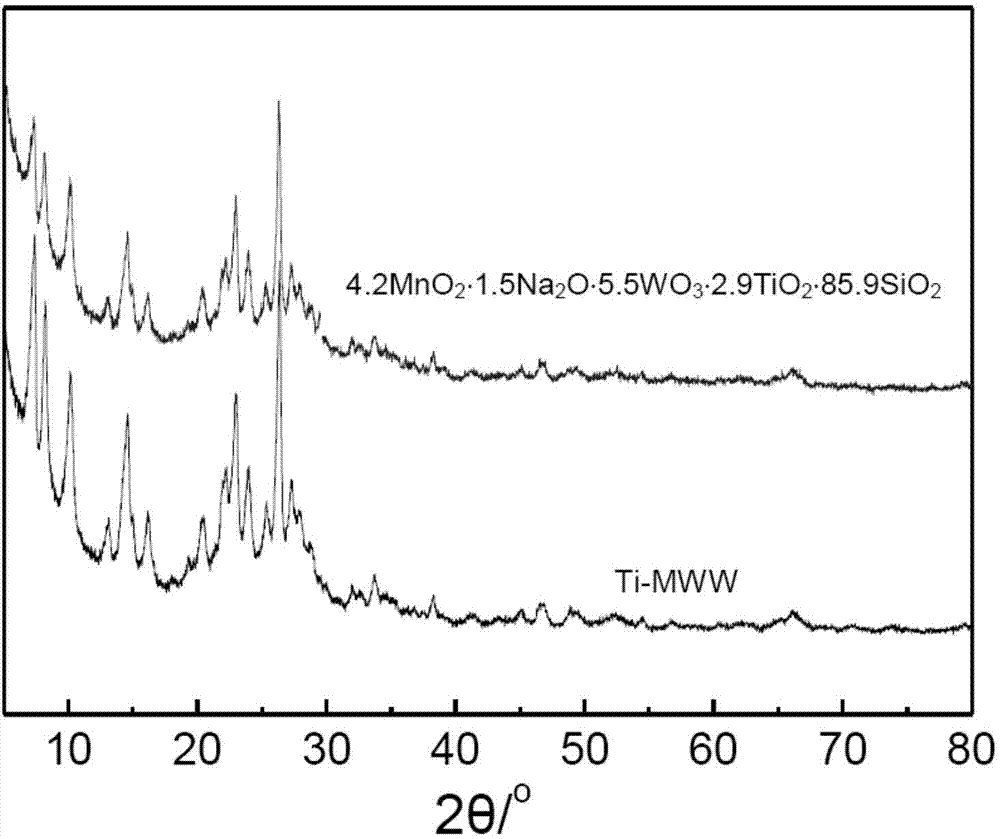

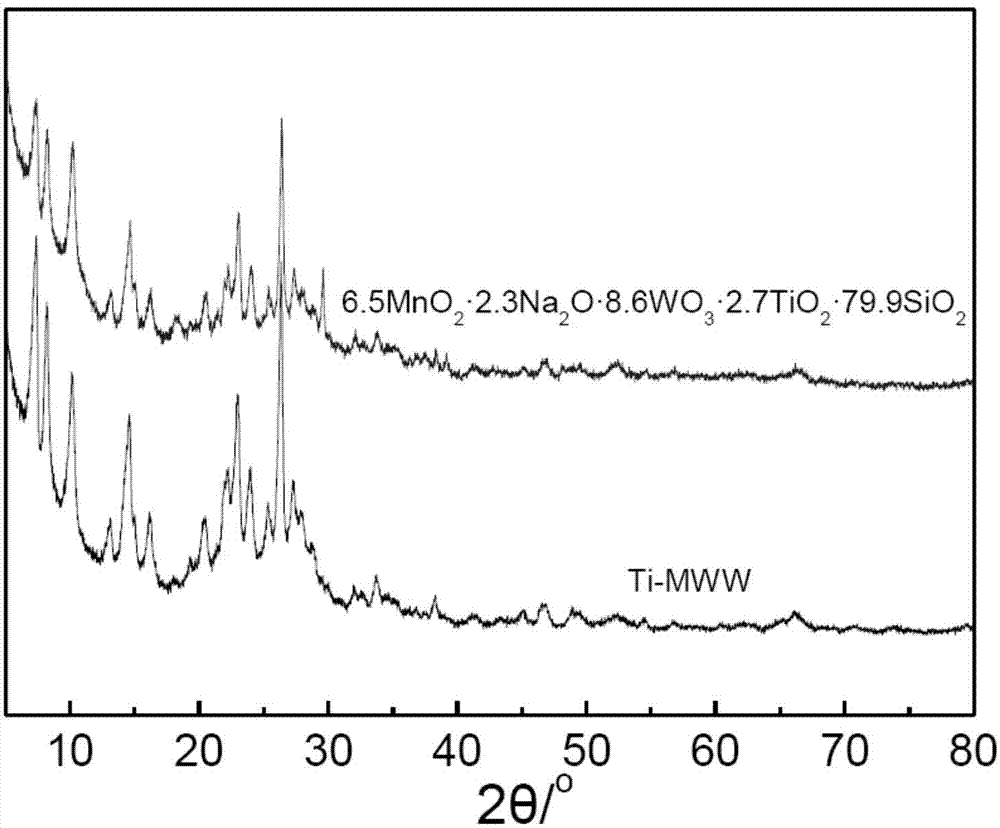

Methane oxidation coupling catalyst and preparation method thereof

ActiveCN104759291AGood activity at low temperatureHigh selectivityMolecular sieve catalystsHeterogenous catalyst chemical elementsManganese oxideStructural formula

The present invention discloses a manganese-sodium-tungsten-silicon composite oxide oxidative coupling of methane catalyst containing or not containing titanium, obtained by loading manganese-sodium-tungsten onto a titanium-silicon molecular sieve or a pure silicon molecular sieve by means of a step-by-step impregnation method and calcination. The manganese-sodium-tungsten-silicon composite oxide catalyst containing or not containing titanium has the following structural formula: vMnO2·xNa2O·yWO3·zTiO2·(100-v-x-y-z)SiO2, the v, x, y, and z respectively representing the fractional quality occupied by metal manganese oxide, sodium oxide, tungsten oxide and titanium oxide, 0.3≤v≤16, 0.1≤x≤5, 0.6≤y≤21, 0.0≤z≤4. The manganese-sodium-tungsten-silicon composite oxide catalyst containing or not containing titanium set forth in the present invention is used for oxidative coupling of methane reactions, having excellent low-temperature catalytic activity and ethylene / propylene selectivity generation and reaction stability.

Owner:ECO ENVIRONMENTAL ENERGY RES INST +1

Production of ethylene with nanowire catalysts

ActiveUS10195603B2Thermal non-catalytic crackingRare earth metal oxides/hydroxidesNanowireOxidative coupling of methane

Nanowires useful as heterogeneous catalysts are provided. The nanowire catalysts are useful in a variety of catalytic reactions, for example, the oxidative coupling of methane to ethylene. Related methods for use and manufacture of the same are also disclosed.

Owner:SILURIA TECH INC

Methane oxidative coupling with la-ce catalysts

ActiveUS20180353940A1More efficient processHigh selectivityHeterogenous catalyst chemical elementsCatalystsCeriumOxygen

A metal oxide catalyst capable of catalyzing an oxidative coupling of methane reaction is described. The metal oxide catalyst includes a lanthanum (La) cerium (Ce) metal oxide and further including a lanthanum hydroxide (La(OH)3) crystalline phase. The catalyst is capable of catalyzing the production of C2+ hydrocarbons from methane and oxygen. Methods and systems of using the metal oxide catalyst to produce C2+ hydrocarbons from a reactant gas are also described.

Owner:SABIC GLOBAL TECH BV

Ethylbenzene Production with Ethylene from Oxidative Coupling of Methane

A method for producing ethylbenzene (EB) comprising introducing to an oxidative coupling of methane (OCM) reactor an OCM reactant mixture comprising CH4 and O2; allowing the OCM reactant mixture to react via OCM reaction to form an OCM product mixture comprising C2H4, C2H6, water, CO, CO2 and unreacted methane; separating the water and optionally CO and / or CO2 from the OCM product mixture to yield an EB reactant mixture comprising C2H4, C2H6, unreacted methane, and optionally CO and / or CO2; (d) introducing benzene and an EB reactant mixture to an EB reactor; allowing benzene to react in a liquid phase with the ethylene of the EB reactant mixture to form EB; recovering from the EB reactor an EB product mixture comprising EB and unreacted benzene, and an unreacted alkanes mixture comprising C2H6 and unreacted methane, and optionally CO and / or CO2; and optionally recycling the unreacted alkanes mixture to the OCM reactor.

Owner:SABIC GLOBAL TECH BV

Method for Producing Hydrocarbons by Oxidative Coupling of Methane without Catalyst

A method for producing olefins and synthesis gas comprising (a) introducing a reactant mixture to a reactor, wherein the reactant mixture comprises methane (CH4) and oxygen (O2), wherein the reactor is characterized by a reaction temperature of from about 700° C. to about 1,100° C.; (b) allowing at least a portion of the reactant mixture to react via an oxidative coupling of CH4 reaction to form a product mixture, wherein the product mixture comprises primary products and unreacted methane, wherein the primary products comprise C2+ hydrocarbons and synthesis gas, wherein the C2+ hydrocarbons comprise olefins, and wherein a selectivity to primary products is from about 70% to about 99%; and (c) recovering at least a portion of the product mixture from the reactor.

Owner:SABIC GLOBAL TECH BV

Process and catalyst for methane conversion to aromatics

ActiveUS9950971B2High Aromatics YieldHigh methane incorporationMolecular sieve catalystsMolecular sieve catalystAromatizationCompound (substance)

A process and catalyst for use therein for the production of aromatics via the oxidative coupling of methane and methane co-aromatization with higher hydrocarbons in a single reaction stage. First, methane is partially converted to ethane and ethylene on an OCM catalyst component, and the OCM intermediate mixture containing methane, ethane and ethylene is subsequently converted into aromatics on an aromatization catalyst component. The reaction may be conducted at 550-850° C. and at about 50 psig. The claimed process and catalyst used therein achieves high methane conversion at lower temperatures (less than 800° C.), higher methane conversion into the aromatic products and significant reductions in production cost when compared to the traditional two (or more) step processes.

Owner:EXXONMOBIL CHEM PAT INC

Low inlet temperature for oxidative coupling of methane

ActiveUS20180162785A1Maximizes energy generatedEnergy efficiencyCatalystsHydrocarbon preparation catalystsReaction zoneOxygen

Disclosed is a process for producing C2+ hydrocarbons, and systems for implementing the process, that includes providing a reactant feed that includes methane and an oxygen containing gas to a first reaction zone, wherein the temperature of the reactant feed is less than 700° C. contacting the reactant feed with a first catalyst capable of catalyzing an oxidative coupling of methane reaction (OCM) to produce a first product stream that includes C2+ hydrocarbons and heat, and contacting the first product stream with a second catalyst capable of catalyzing an OCM reaction to produce a second product stream that includes C2+ hydrocarbons, wherein the produced heat is at least partially used to heat the first product stream prior to or during contact with the second catalyst, wherein the amount of C2+ hydrocarbons in the second product stream is greater than the amount of C2+ hydrocarbons in the first product stream.

Owner:SABIC GLOBAL TECH BV

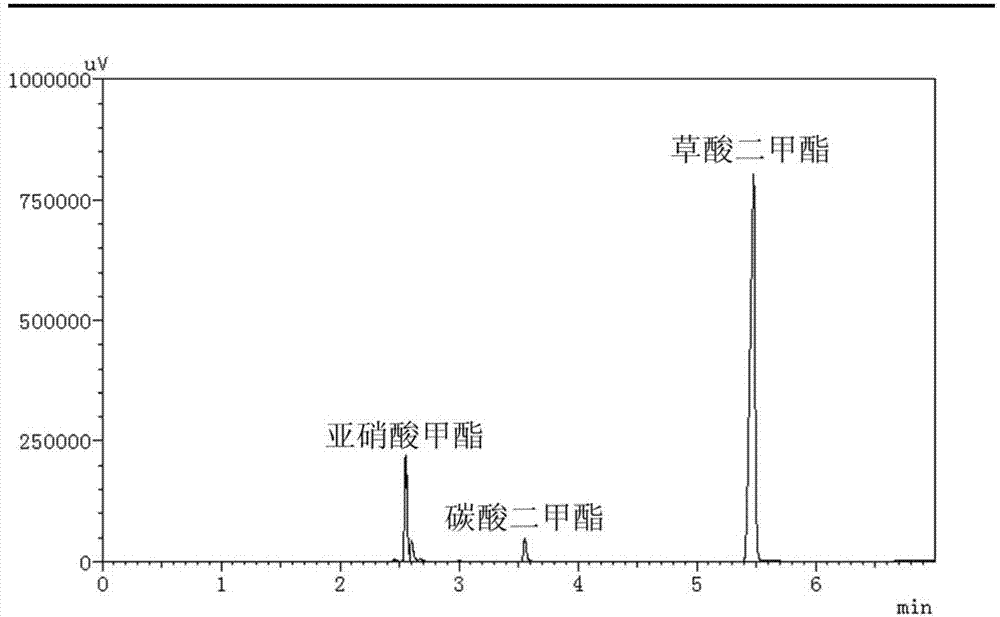

Bimetal nanometer catalyst as well as preparation and application method thereof

ActiveCN103041826AGood dispersionLarge specific surface areaPreparation by carbon monoxide or formate reactionMetal/metal-oxides/metal-hydroxide catalystsDispersityNano catalyst

The invention discloses a bimetal nanometer catalyst used for preparing dimethyl oxalate through CO gas-phase oxidative coupling as well as preparation and an application method of the bimetal nanometer catalyst, and belongs to the technical field of preparation of the dimethyl oxalate. The bimetal nanometer catalyst is characterized in that a catalyst carrier is Alpha-aluminium oxide, an active component is Pd-Cu nanometer grains, the average size of the grain is 2-3nm, the Pd content of the active component is 0.01-2% and Cu content is 0.01-0.04% according to the mass of the catalyst carrier. The catalyst is prepared through a room temperature normal position load method, the preparation method is simple, the energy dissipation is low, the catalyst is suitable for industrial production, the active component Pd-Cu nanometer grains in the catalyst has high dispersity, large specific surface area, small size and uniformity in distribution; the catalyst provided by the invention adopts the Pd-Cu bimetal nanometer grains as the active component, and a bimetal component synergistic effect and a nanometer effect are utilized to reduce the content of the noble metal PD to 0.1% under the premise of keeping the high activity and stability of the catalyst, therefore and the cost of the catalyst is greatly reduced, and the partial substitution of the noble metal is realized.

Owner:贵州鑫醇科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com