Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

85results about How to "Reduce hydrogen sulfide content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for separating hydrocarbon compounds

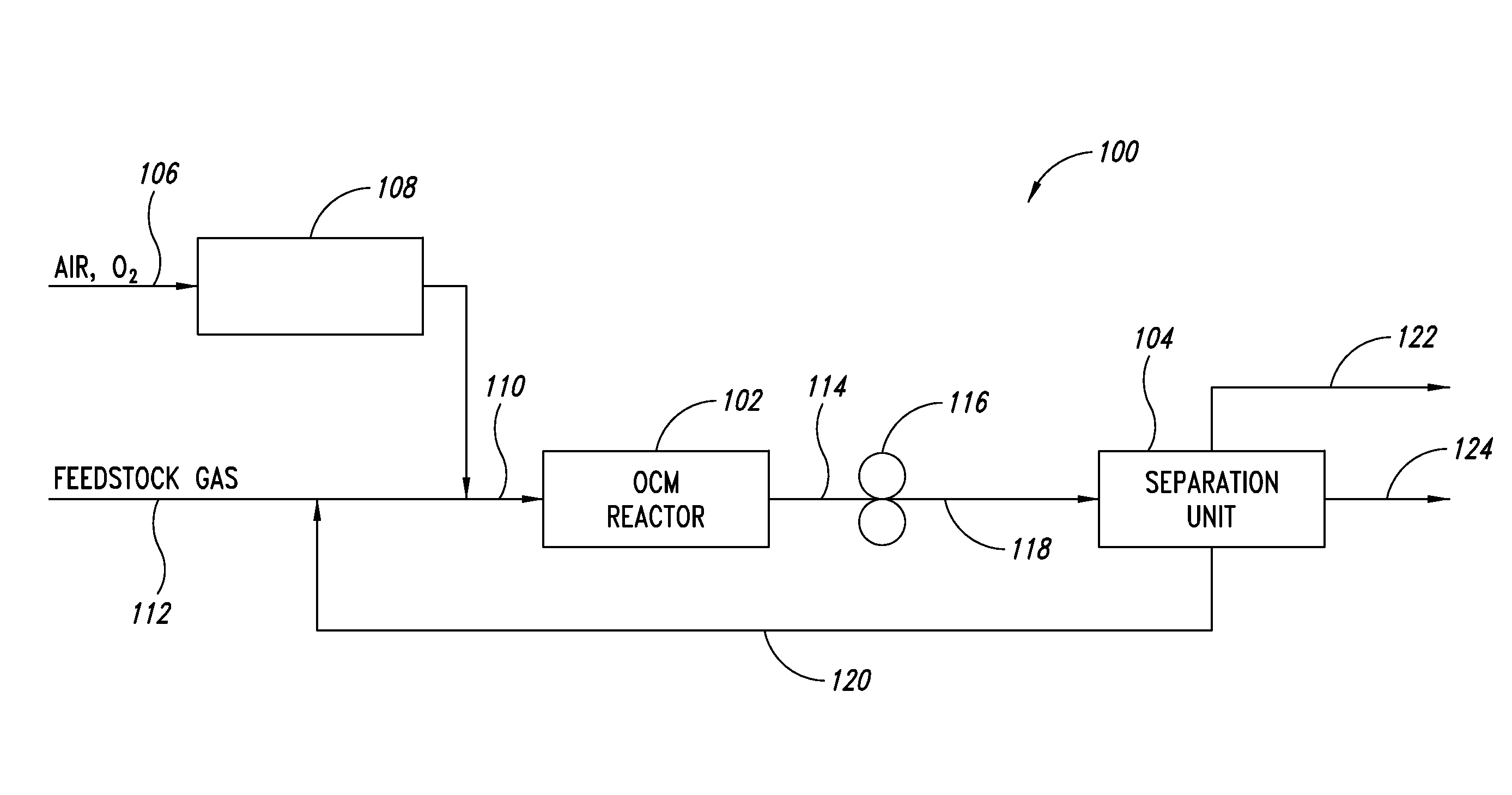

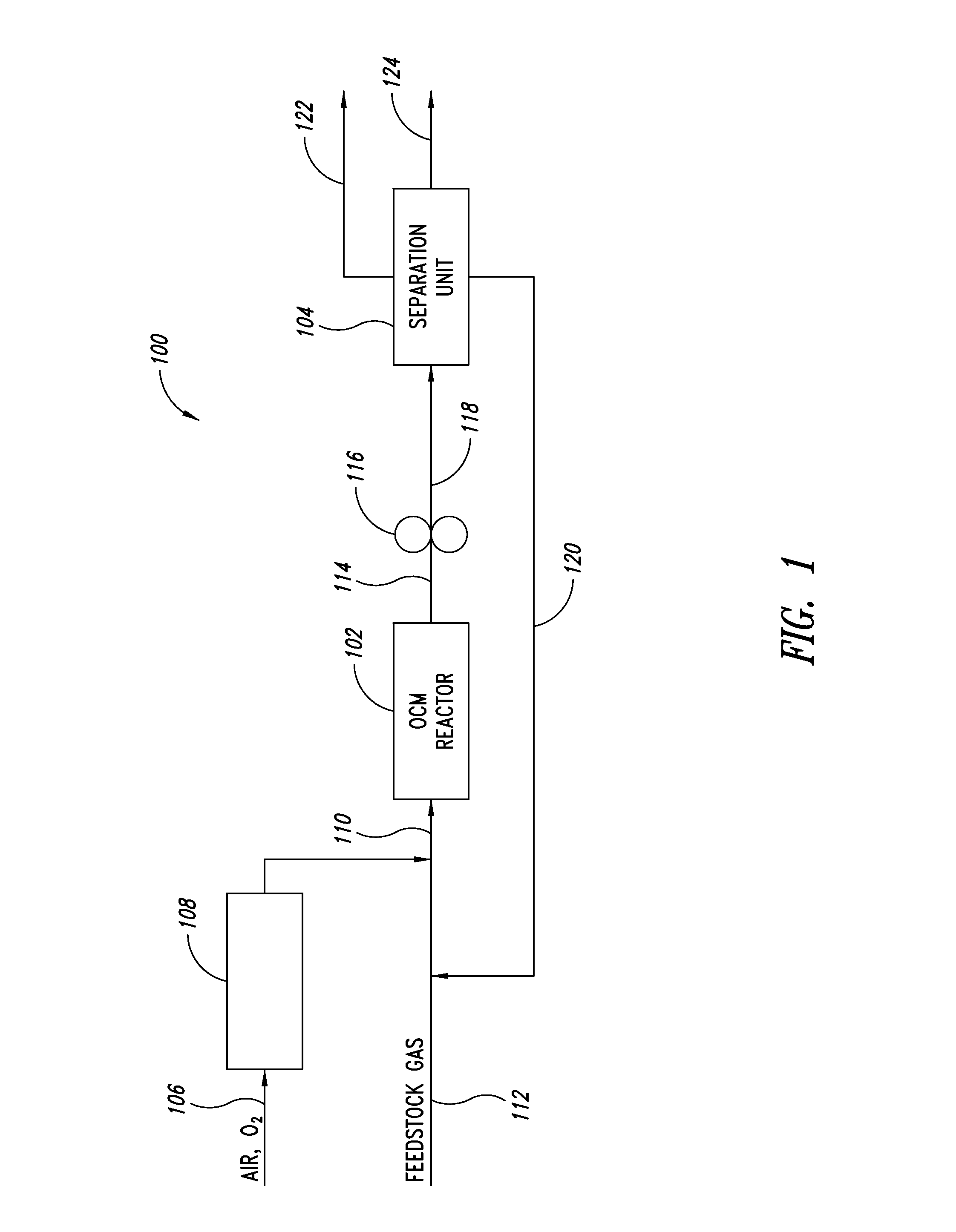

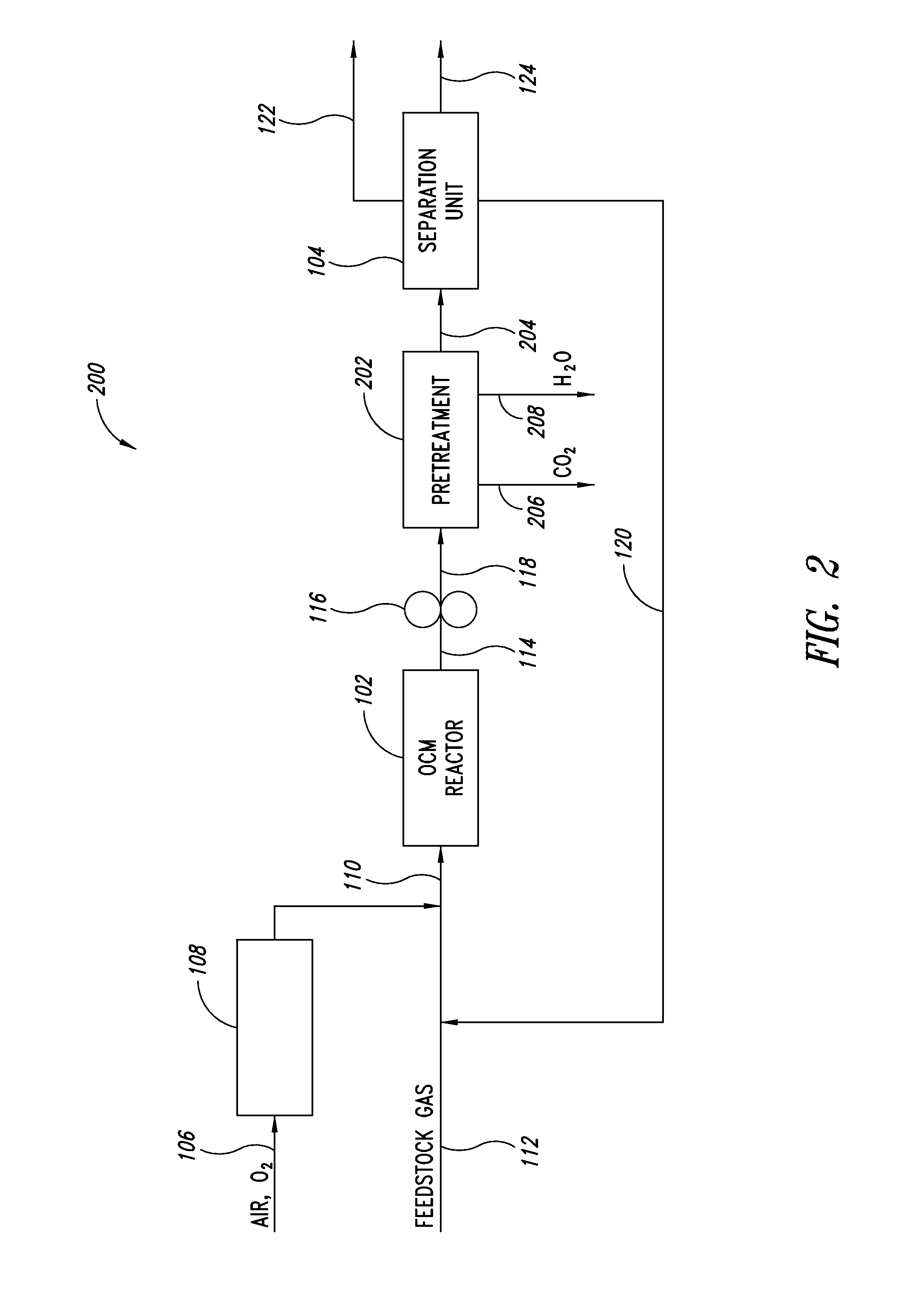

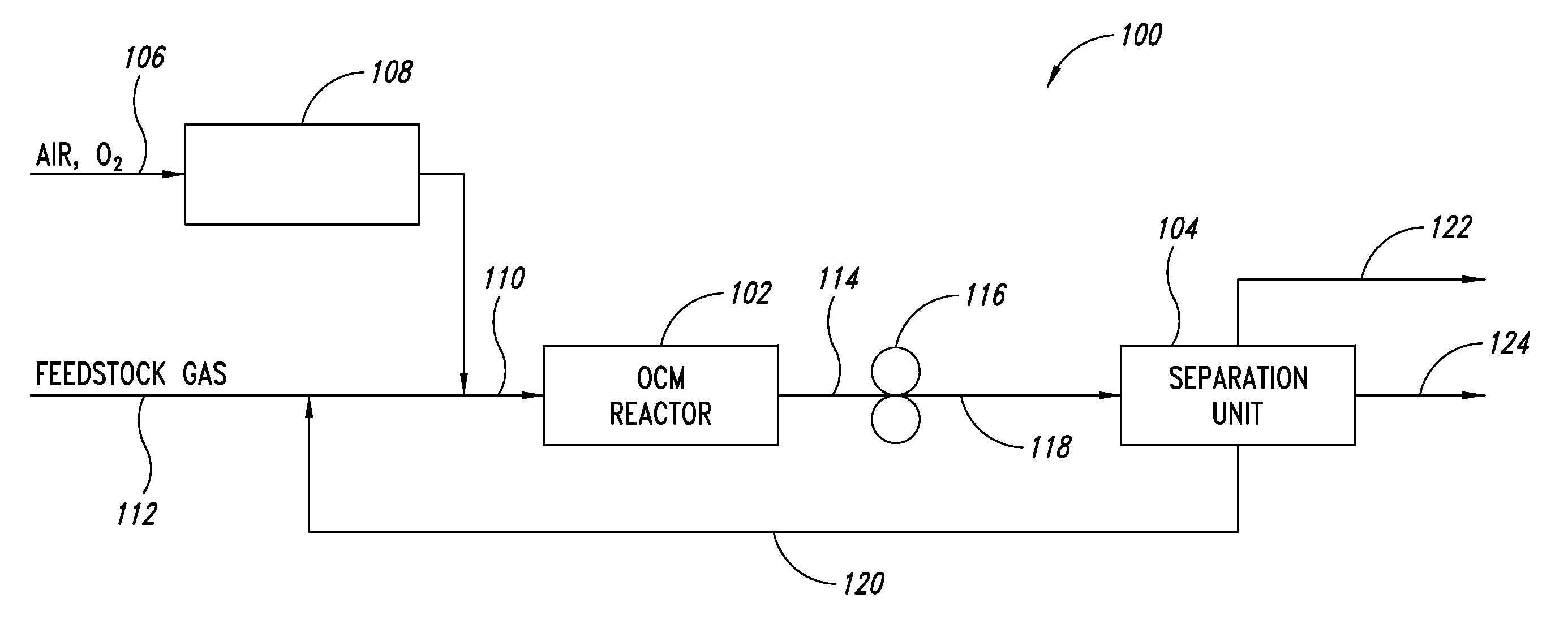

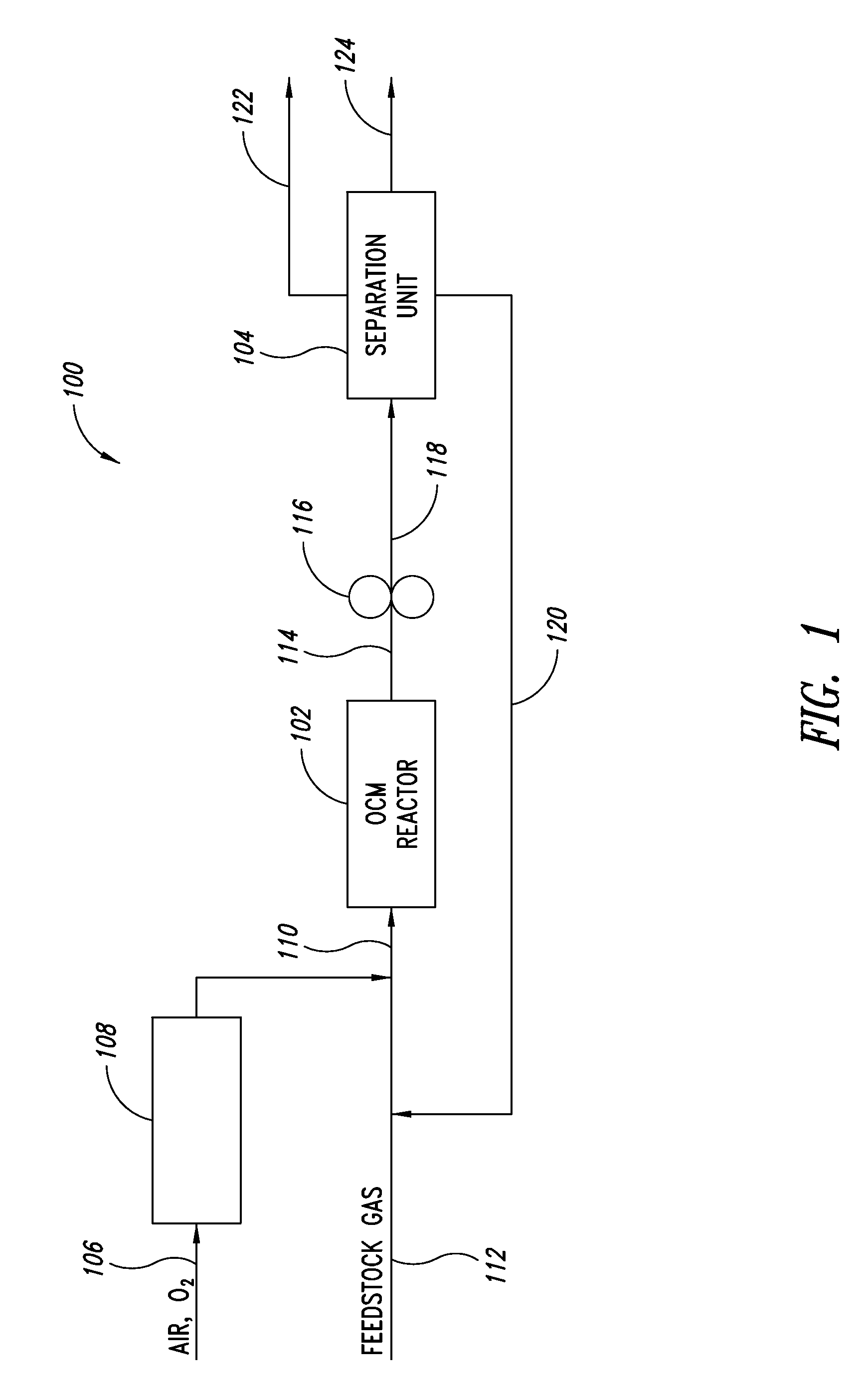

ActiveUS20130225884A1Reduced water contentReduce carbon dioxide contentSolidificationLiquefactionChemistryProduct gas

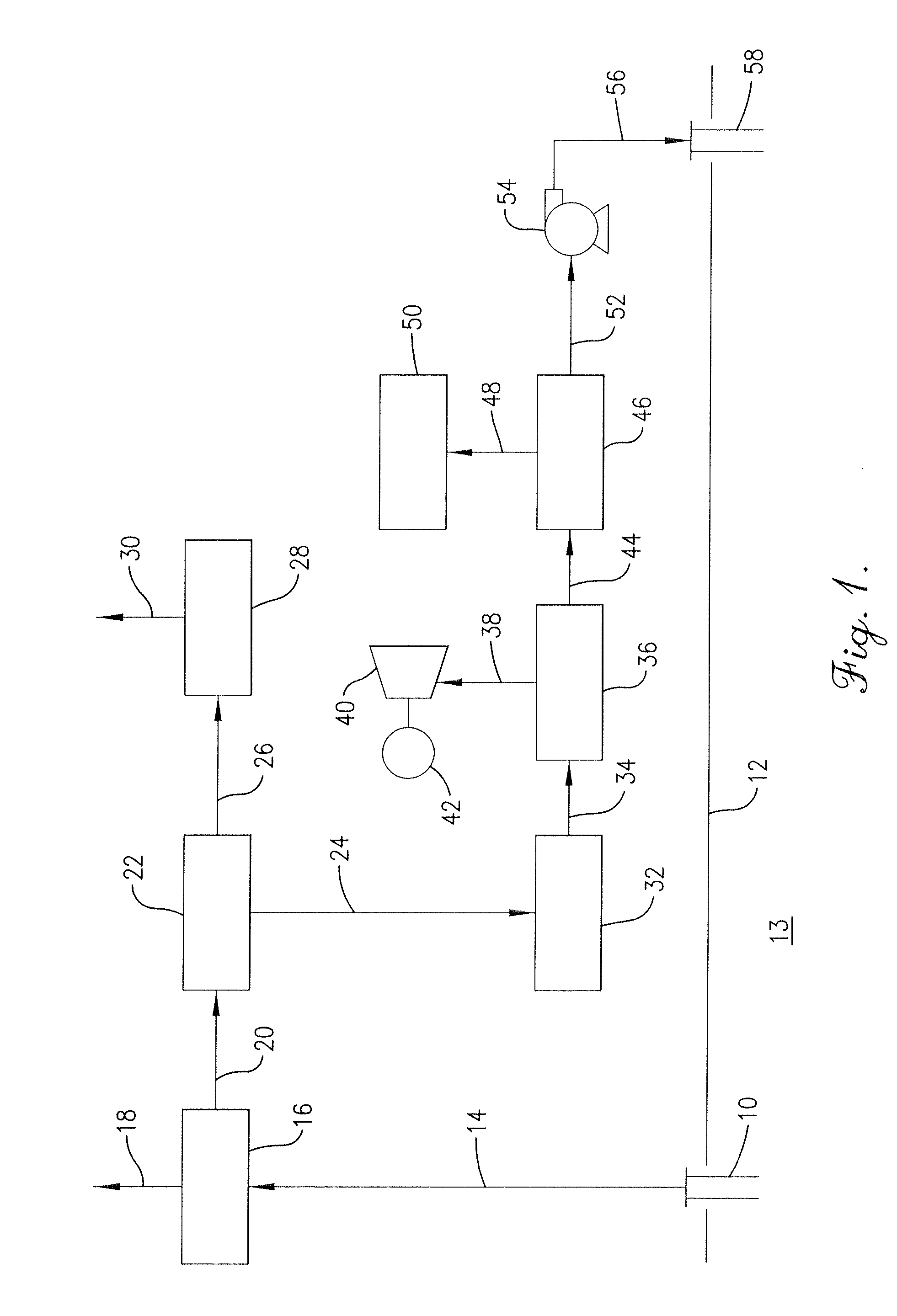

Disclosed herein are processes for producing and separating ethane and ethylene. In some embodiments, an oxidative coupling of methane (OCM) product gas comprising ethane and ethylene is introduced to a separation unit comprising two separators. Within the separation unit, the OCM product gas is separated to provide a C2-rich effluent, a methane-rich effluent, and a nitrogen-rich effluent. Advantageously, in some embodiments the separation is achieved with little or no external refrigeration requirement.

Owner:LUMMUS TECH LLC

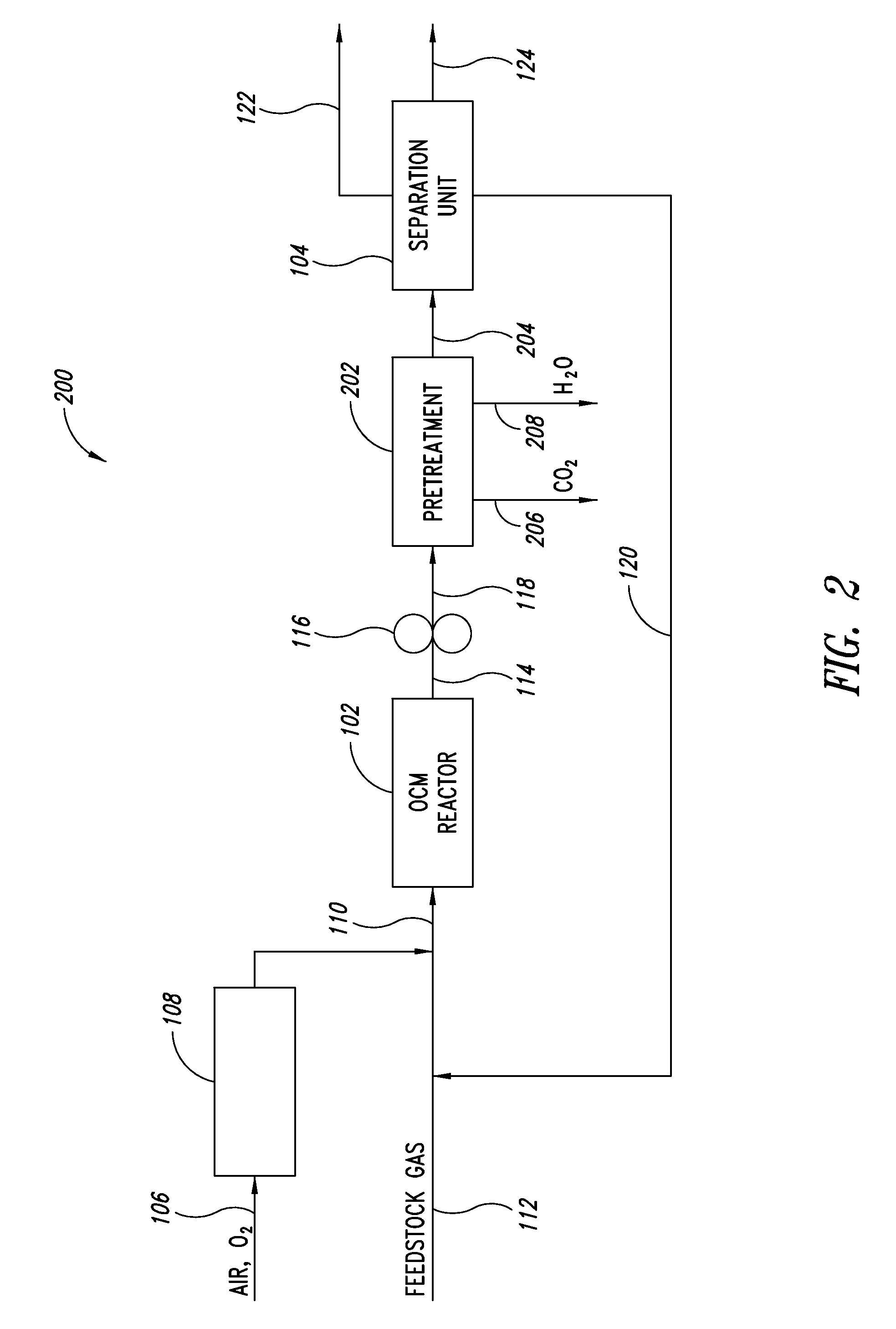

Process for separating hydrocarbon compounds

ActiveUS20150368167A1Reduce moistureReduce hydrogen sulfide contentSolidificationLiquefactionHydrocotyle bowlesioidesOxidative coupling of methane

Disclosed herein are processes for producing and separating ethane and ethylene. In some embodiments, an oxidative coupling of methane (OCM) product gas comprising ethane and ethylene is introduced to a separation unit comprising two separators. Within the separation unit, the OCM product gas is separated to provide a C2-rich effluent, a methane-rich effluent, and a nitrogen-rich effluent. Advantageously, in some embodiments the separation is achieved with little or no external refrigeration requirement.

Owner:LUMMUS TECH LLC

Process for separating hydrocarbon compounds

Disclosed herein are processes for producing and separating ethane and ethylene. In some embodiments, an oxidative coupling of methane (OCM) product gas comprising ethane and ethylene is introduced to a separation unit comprising two separators. Within the separation unit, the OCM product gas is separated to provide a C2-rich effluent, a methane-rich effluent, and a nitrogen-rich effluent. Advantageously, in some embodiments the separation is achieved with little or no external refrigeration requirement.

Owner:LUMMUS TECH LLC

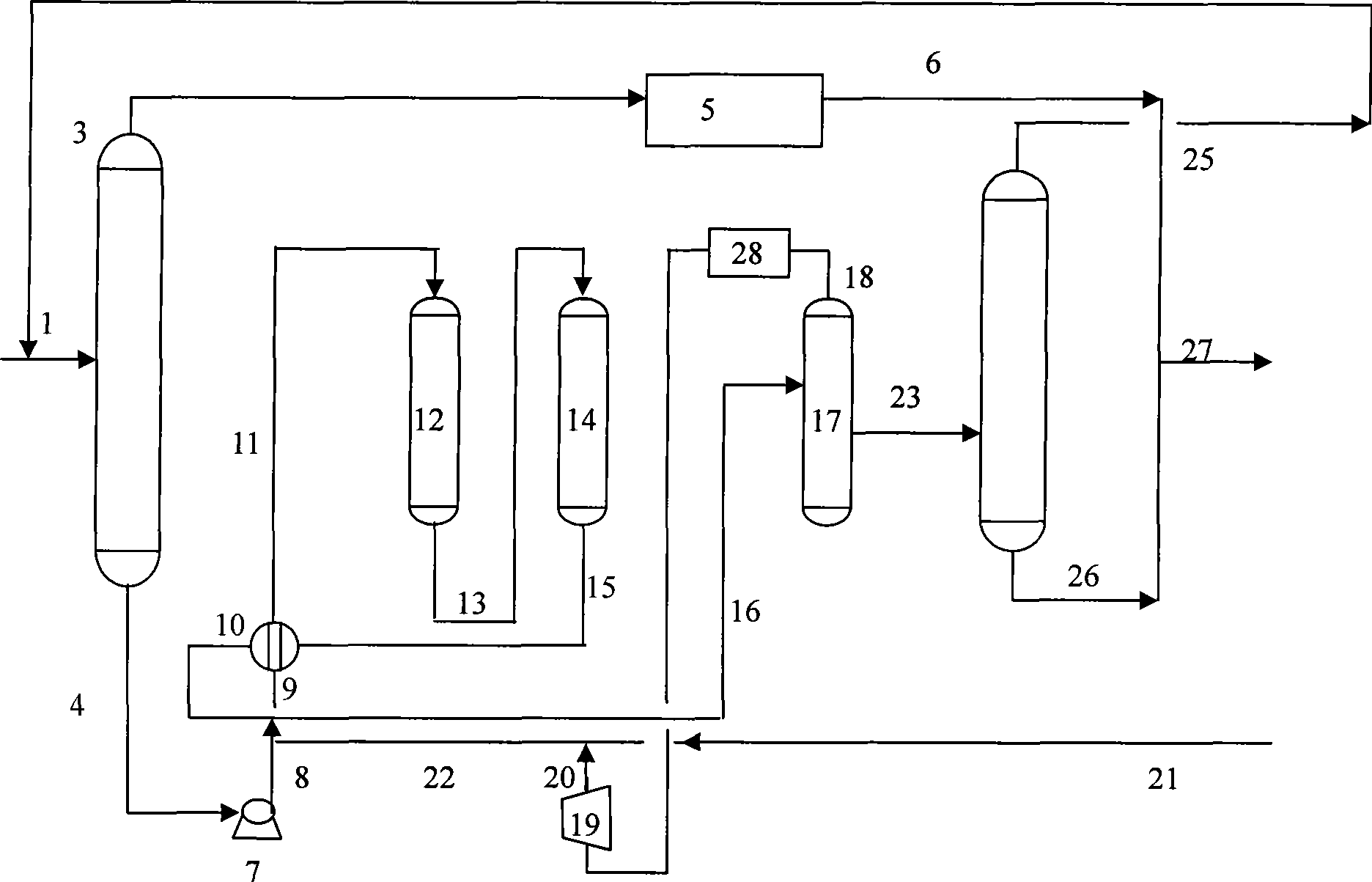

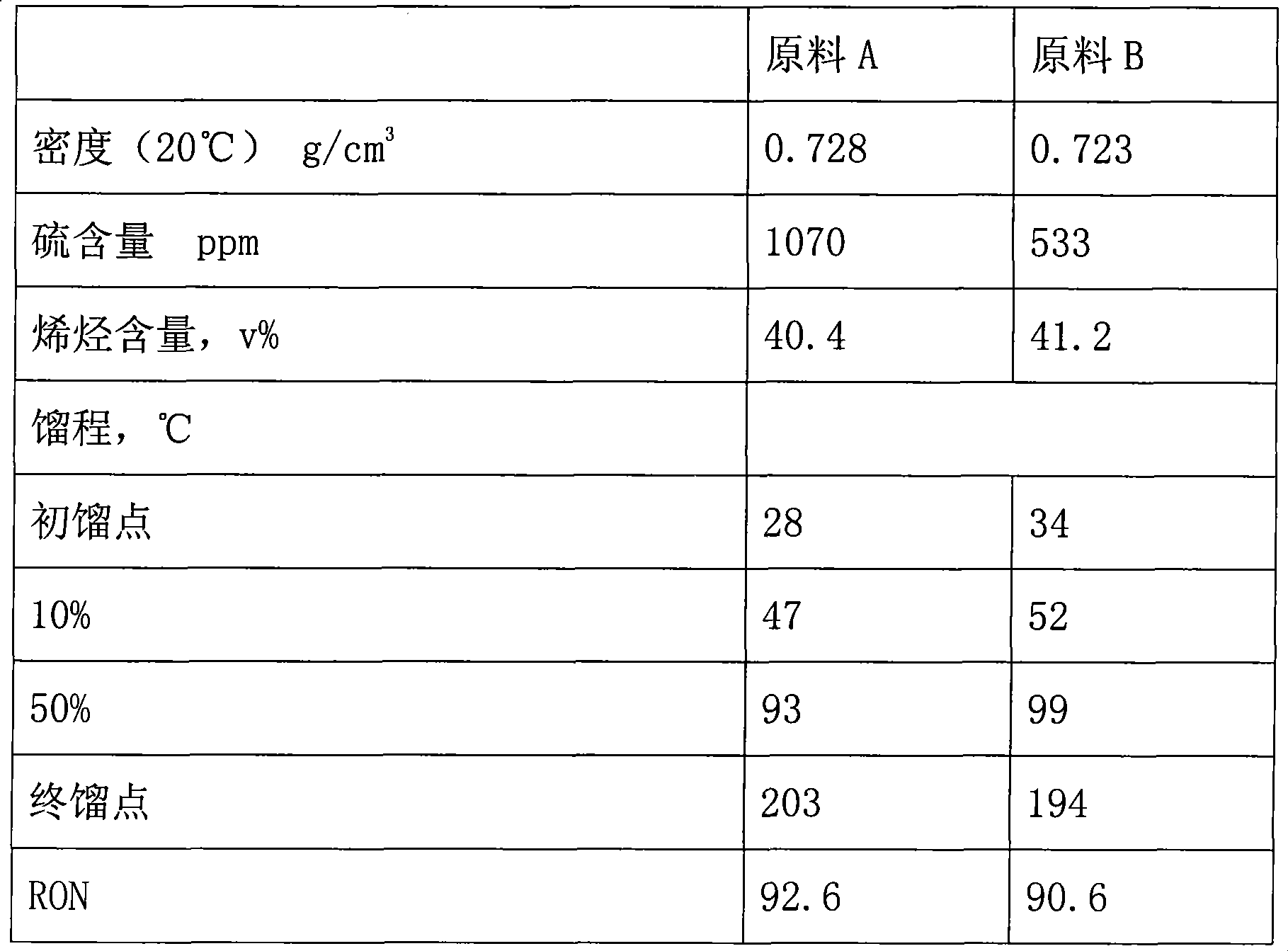

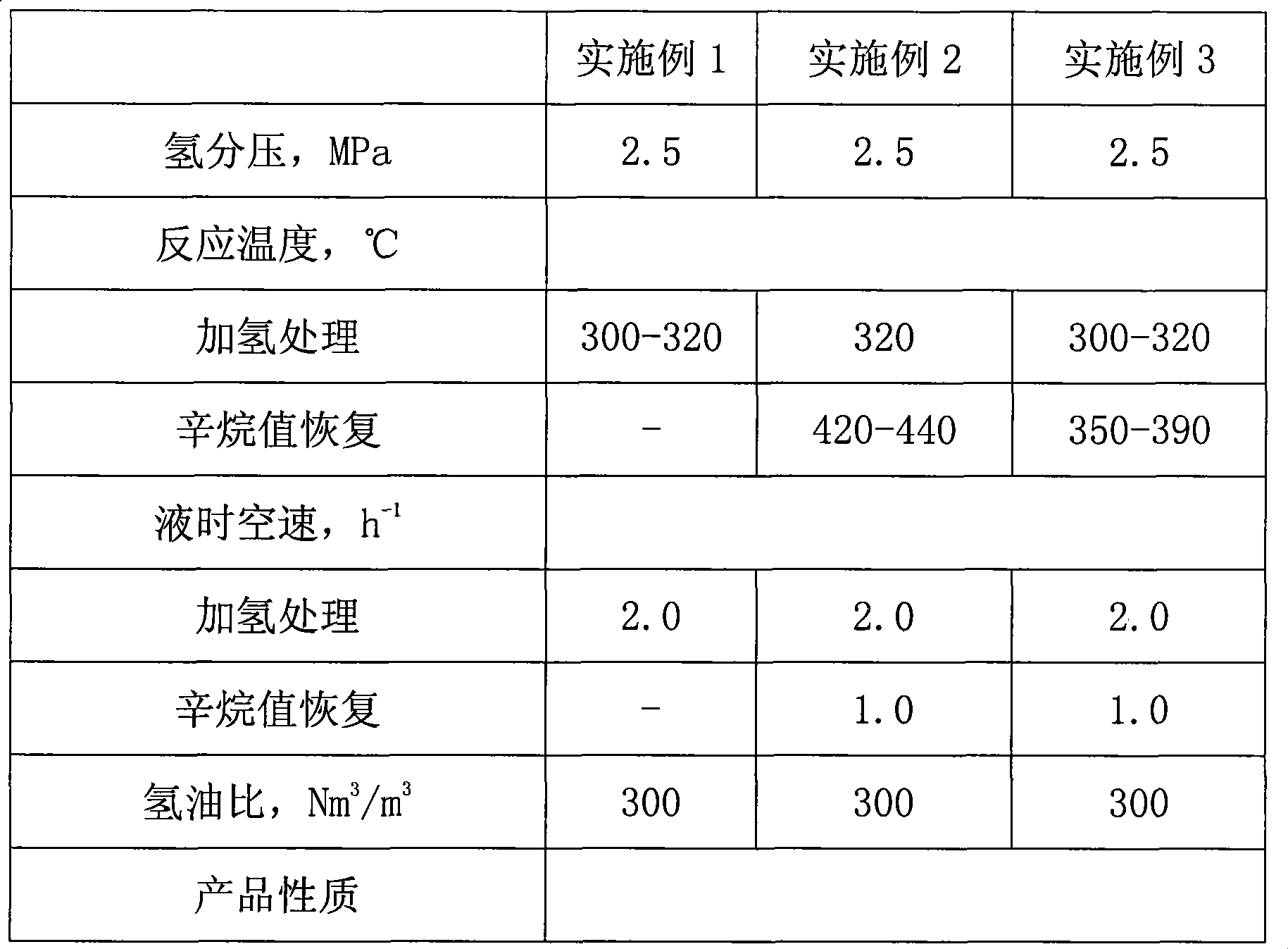

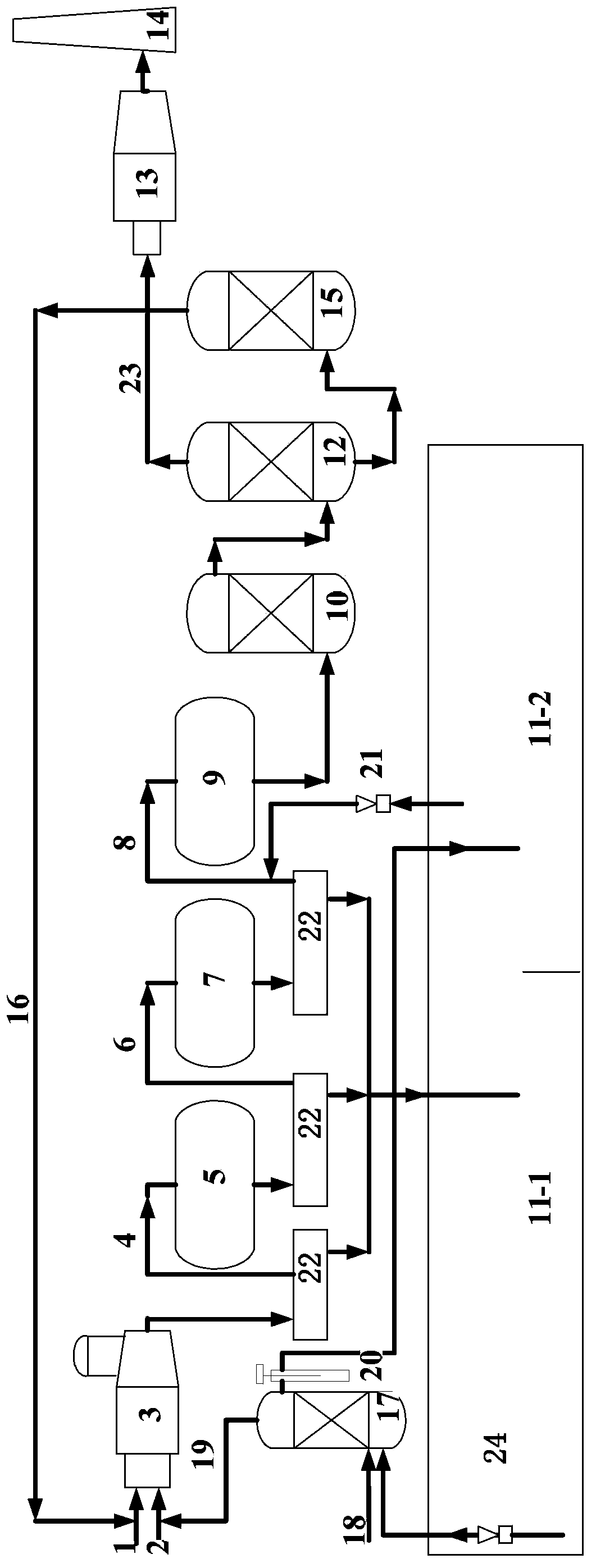

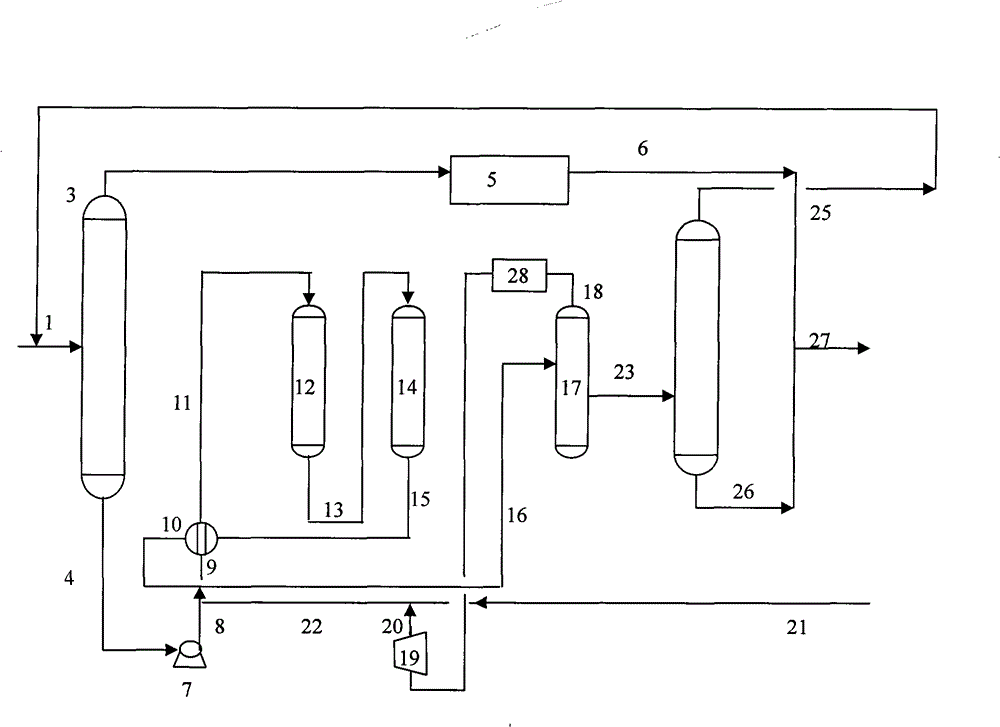

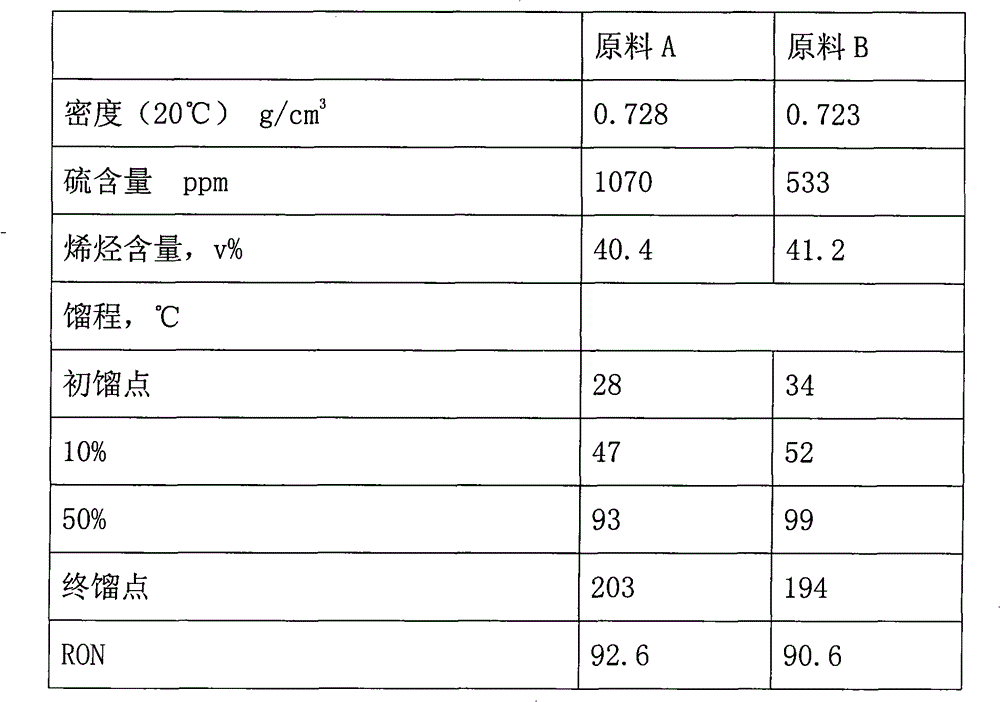

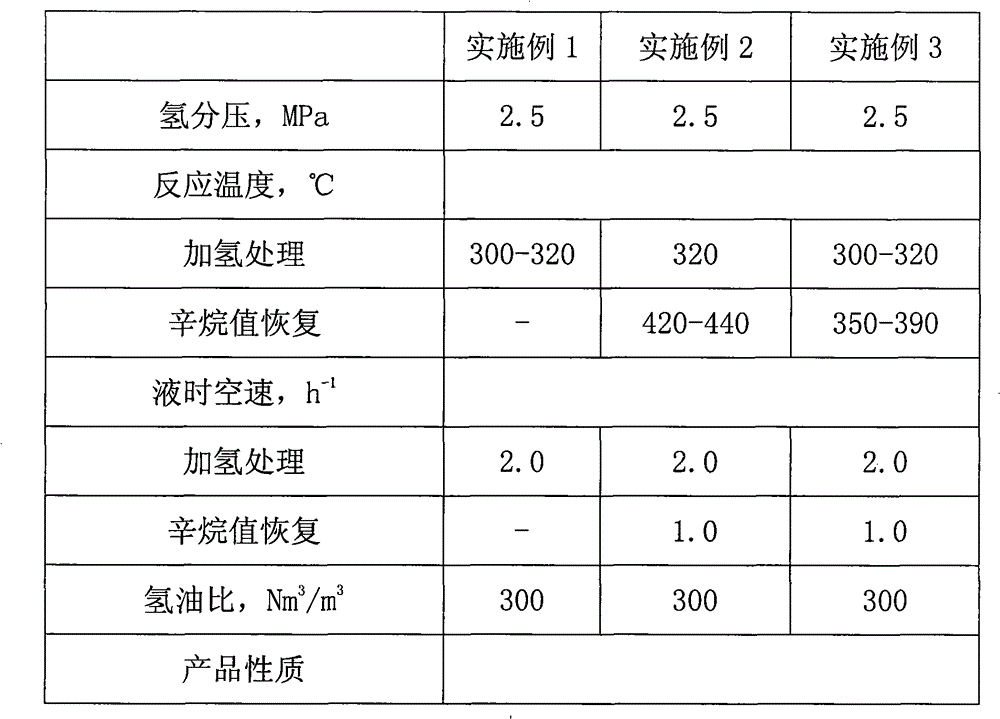

Hydrogenation modification method for catalytically cracked gasoline

ActiveCN101368111ANo change in octaneReduce hydrogen sulfide contentGasoline stabilisationRefining to eliminate hetero atomsIsomerizationHydrodesulfurization

The invention relates to a hydro-upgrading method for catalytic cracking gasoline; the method comprises the following steps: gasoline whole fraction is cut into light fraction and heavy fraction; the cutting point is 60 DEG C to 80 DEG C; mercaptan in the light gasoline fraction is removed through mercaptan removal alkali washing; the heavy gasoline fraction and hydrogen gas have catalytic hydrodesulfurization, denitrogenation and olefin saturated reaction; reactor effluent or the reactor effluent after removing hydrogen sulfide is contacted with octane value restore catalyzer, and isomerization, aromatizatian and building up reaction are implemented, hydrogenated oil is separated and lighter hydrocarbon gasoline fraction is obtained, hydrogen-rich gas at the top of a high partial tank is circularly used through hydrogen sulfide removal, and lighter hydrocarbon at the top of a stabilizer tower is feedback to a fractionation tank to be fractionated again; the condition of the hydrotreating reaction is that hydrogen partial pressure is 1.5 to 3.0 MPa; the reaction temperature is 250 to 320 DEG C; the liquid hourly space velocity is 3.0 to 5.0 h<-1>, and the hydrogen-oil ratio is 200 to 500 Nm<3> / m<3>; the sulfur content of the gasoline product is smaller than 100 ppm, the octane value is unchanged, and the yield of gasoline reaches 98.5 weight percent.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

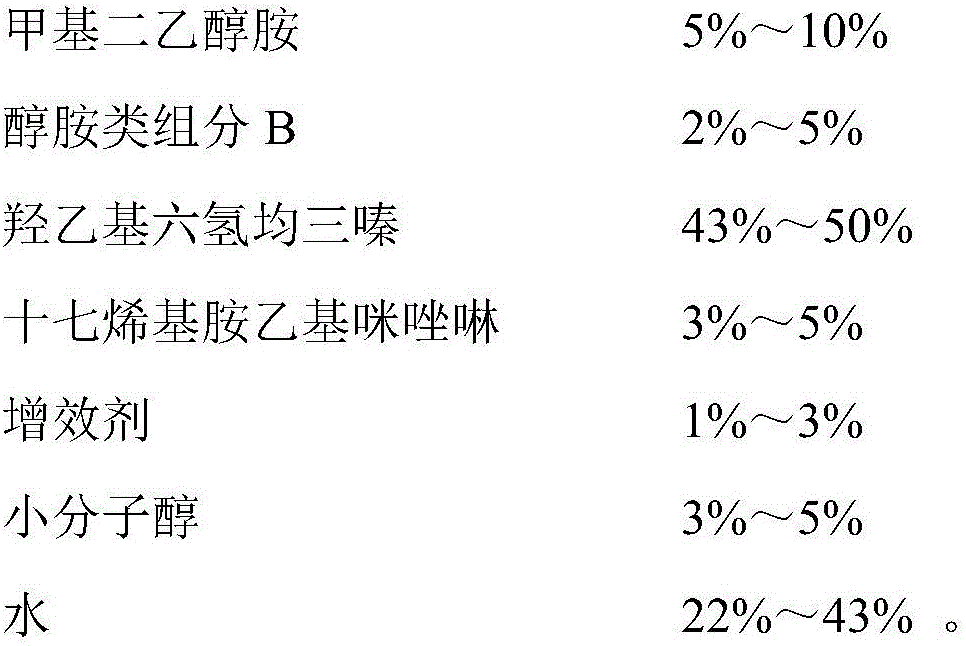

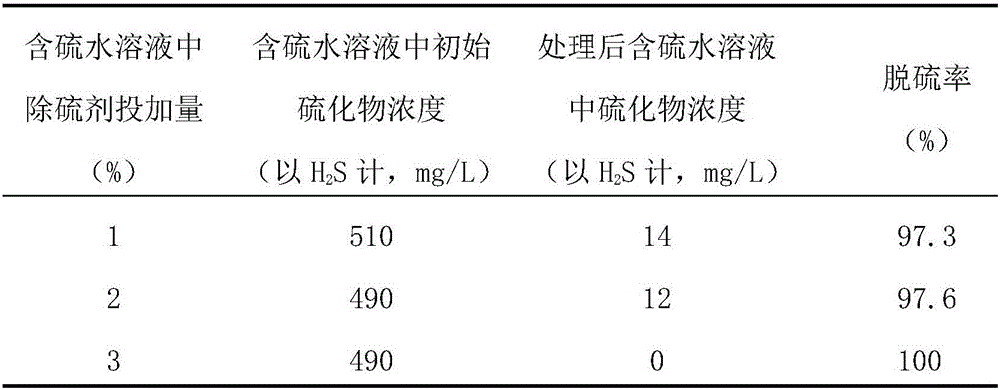

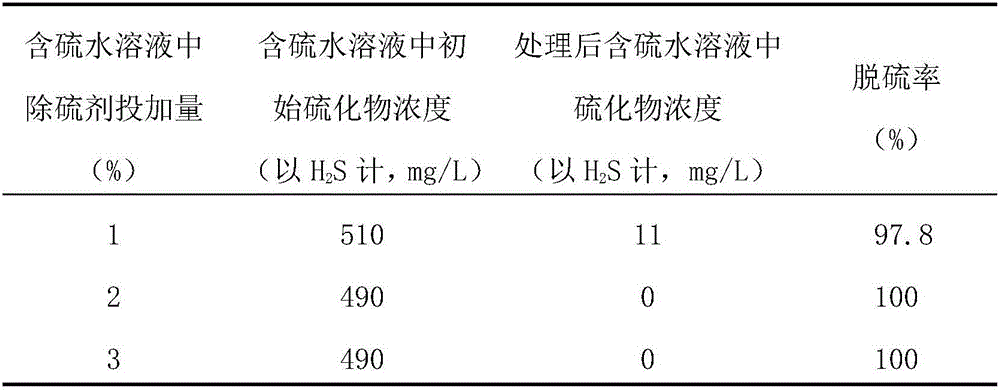

Organic composite efficient sulfur removal agent for oil-gas field and preparation method and application of organic composite efficient sulfur removal agent

ActiveCN106479468AEfficient removalReduce contentGaseous fuelsDrilling compositionDecompositionGlycerol

The invention discloses an organic composite efficient sulfur removal agent for oil-gas field and preparation method and application of the organic composite efficient sulfur removal agent. The sulfur removal agent is characterized in that water serves a solvent and comprises an alcohol amine component A, an alcohol amine component B, a triazine derivative, inhibiter, synergist and low-molecular mass alcohols; the alcohol amine component A refers to methyldiethanolamine, the alcohol amine component B refers to one of triethanolamine and diethanolamine or a mixture of triethanolamine and diethanolamine; triazine derivative refers to hexahydro-1,3,5-tris-s-triazine; the inhibiter refers to seventeen alkenyl amide ethyl imidazoline; the synergist refers to sulfolane; the low-molecular mass alcohols refer to one of ethylene glycol and glycerol or a mixture of ethylene glycol and glycerol. The sulfur removal agent has the advantages of good selectivity on sulfuretted hydrogen, small dosage, quick effect, high sulfur removal efficiency, no corrosion of steel, stable product performance, difficulty in heating decomposition, capability of being biodegradable and the like; sulfide like sulfuretted hydrogen existing in extraction of an oil-gas well can be effectively removed or reduced to safety threshold value range in content, corrosion of sulfide on pipelines and equipment is inhibited, and safety on the equipment and operation personnel is guaranteed.

Owner:陕西森瑞石油技术开发有限公司

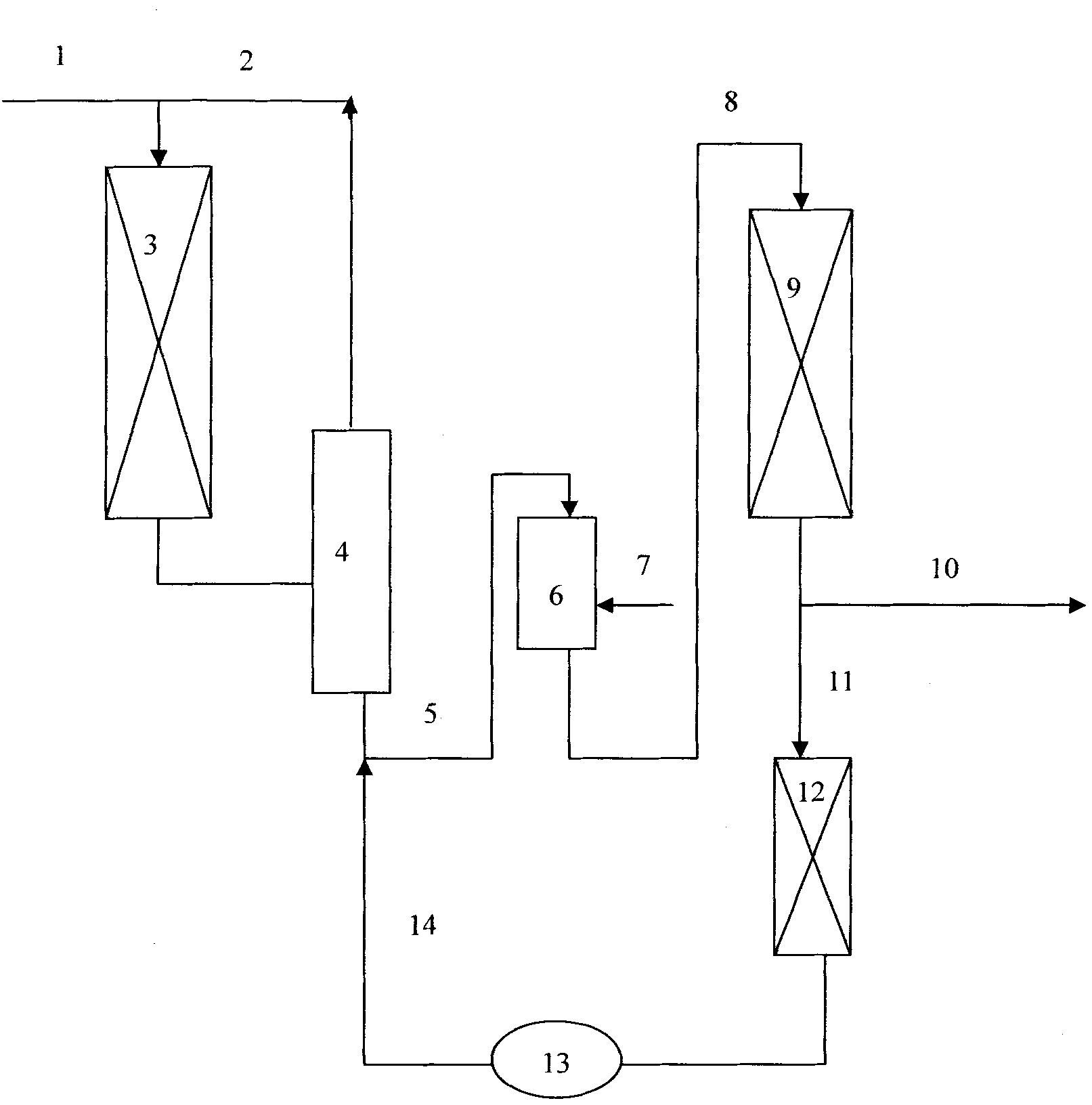

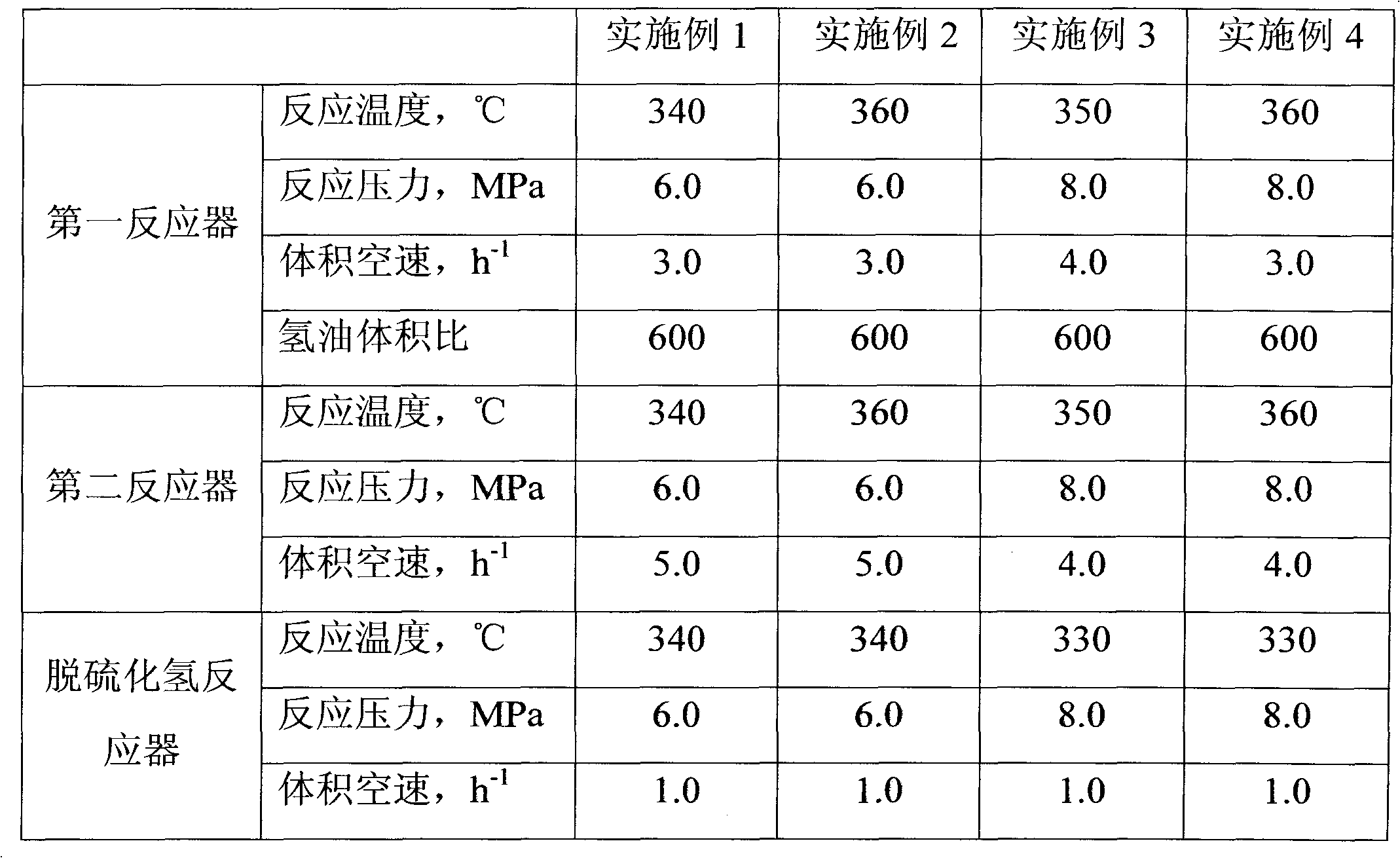

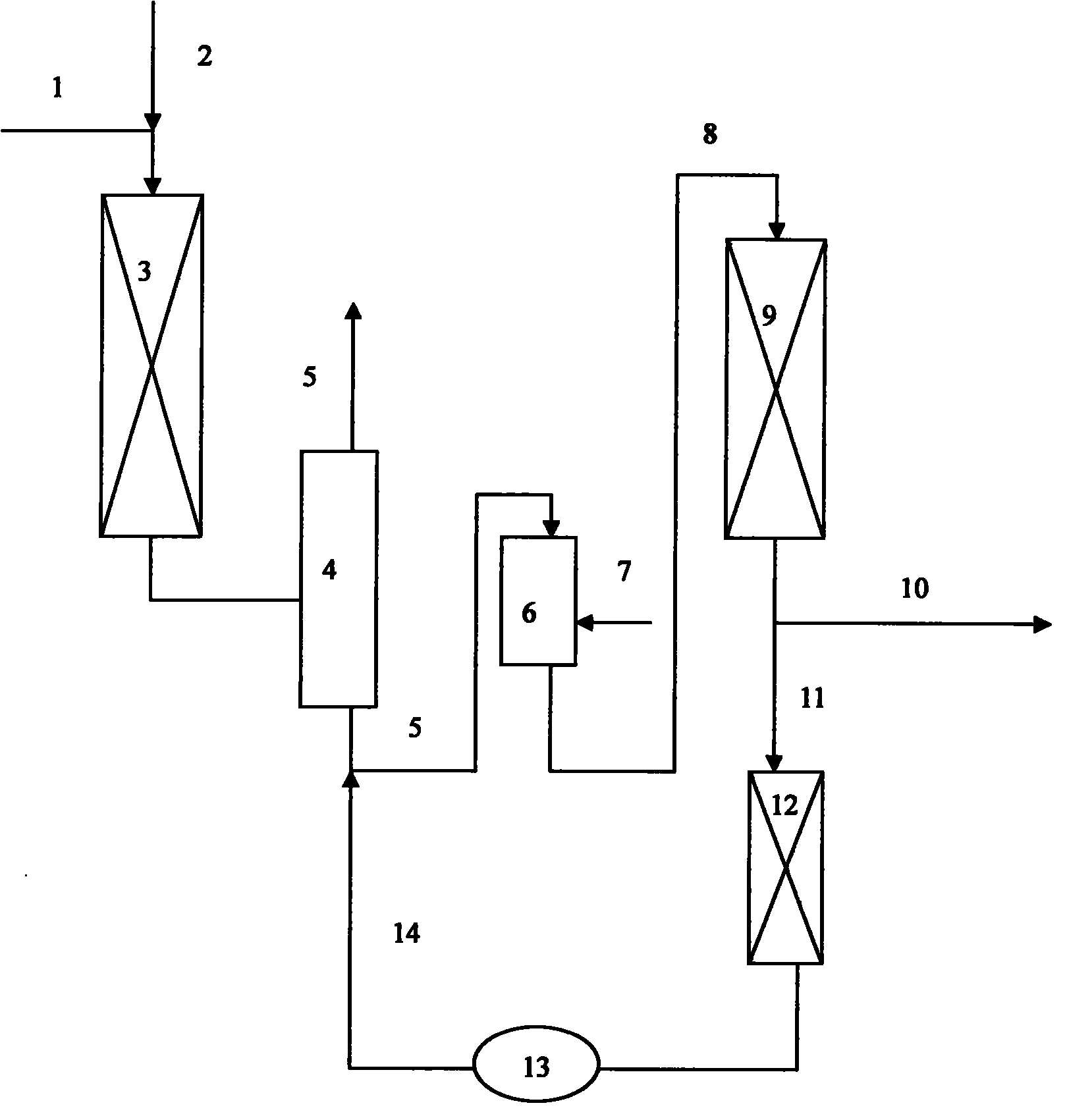

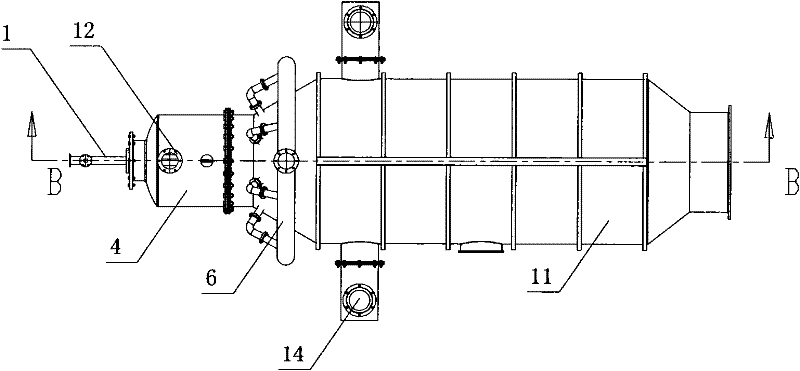

Diesel hydrogenation method

ActiveCN102311794AReduce hydrogen sulfide contentQuality improvementTreatment with hydrotreatment processesGas phaseHydrogenation reaction

The invention discloses a diesel hydrogenation method, which comprises: reacting a diesel raw material in a conventional liquid-phase circulating hydrogenation reactor, and subjecting the efflux to gas-liquid separation; after hydrogen dissolved in a liquid phase is saturated, delivering the liquid phase to a liquid phase circulating hydrogenation reactor for reaction; and after liquid-phase circulating oil passes through a hydrogen sulfide removal reactor, circulating the liquid-phase circulating oil to the entrance of a liquid phase hydrogenation reactor. In the method, the raw material oil is pretreated by gas-phase circulating hydrogenation, the sulfur content in the generated oil is reduced to 500 mu g / g; and after a liquid-phase hydrogenation reaction, the hydrogen sulfide removal content in the circulating oil is reduced; and after hydrogen sulfide is removed from the circulating oil by absorption, the hydrogen sulfide content can be reduced to below 100 mu g / g, a sulfur-containing environment required by a catalyst is maintained, the activity of the catalyst is not inhibited, and thus, smooth deep removal of aromatics and deep desulfuration reaction in the liquid-phase hydrogenation reactor are promoted.

Owner:CHINA PETROLEUM & CHEM CORP +1

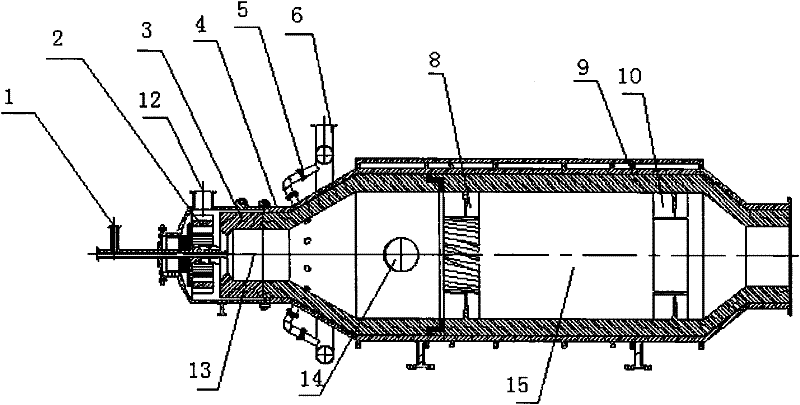

Compulsory mixed tail gas furnace

ActiveCN102192515AIncrease the degree of mixingImprove flame stabilityIncinerator apparatusCombustorCombustion chamber

The invention relates to a compulsory mixed tail gas furnace. An igniter is communicated with a burner inner pipe; a composite air distribution blade is positioned at the other end of a burner, and is communicated with a combustor; a primary air inlet is arranged on a shell of the combustor; a vortex guide vane is positioned in an air chamber between the primary air inlet and the composite air distribution blade; the combustor is sequentially communicated with an air cavity and a tail gas cavity; a secondary air inlet is arranged out of the shell of the combustor at the air cavity, and the air cavity is communicated with the combustor; a vortex mixing blade is installed at the connecting end of the combustion chamber and the tail gas cavity; and an inner shunting and accelerating mixing blade and an outer shunting and accelerating mixing blade are installed at a tapered end of the combustion chamber, and are fixed at the inner surface of a fire-proof lining of the combustion chamber. The structure has the characteristics that the fuel gas and air are mixed fully, the combustion is complete, the heat energy utilization is full, and the like; and the hydrogen sulfide content in the tail gas is reduced obviously, which plays an active role in pushing the integral performance and environment protection of a tail gas burning device.

Owner:PETROCHINA CO LTD

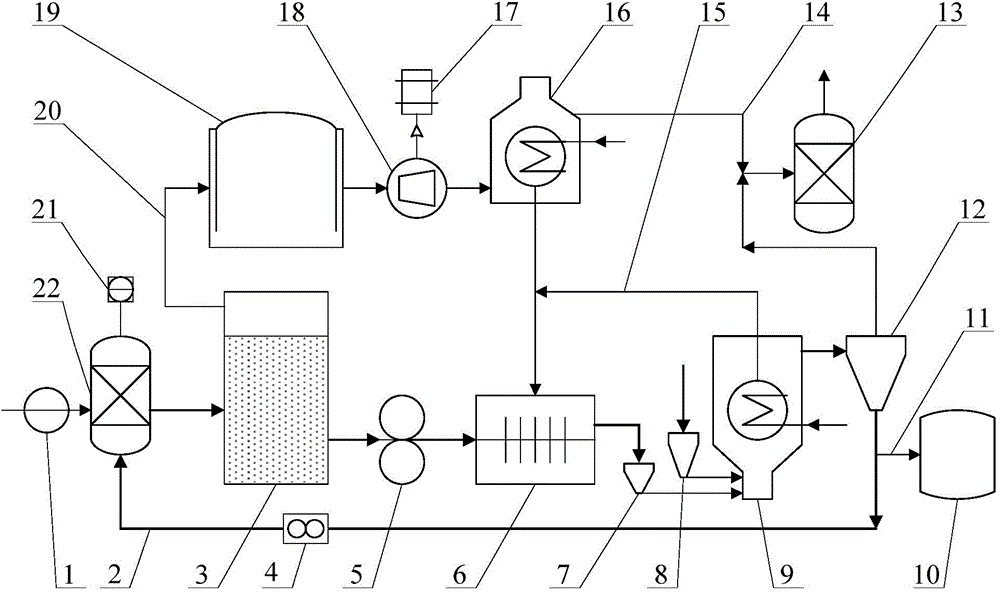

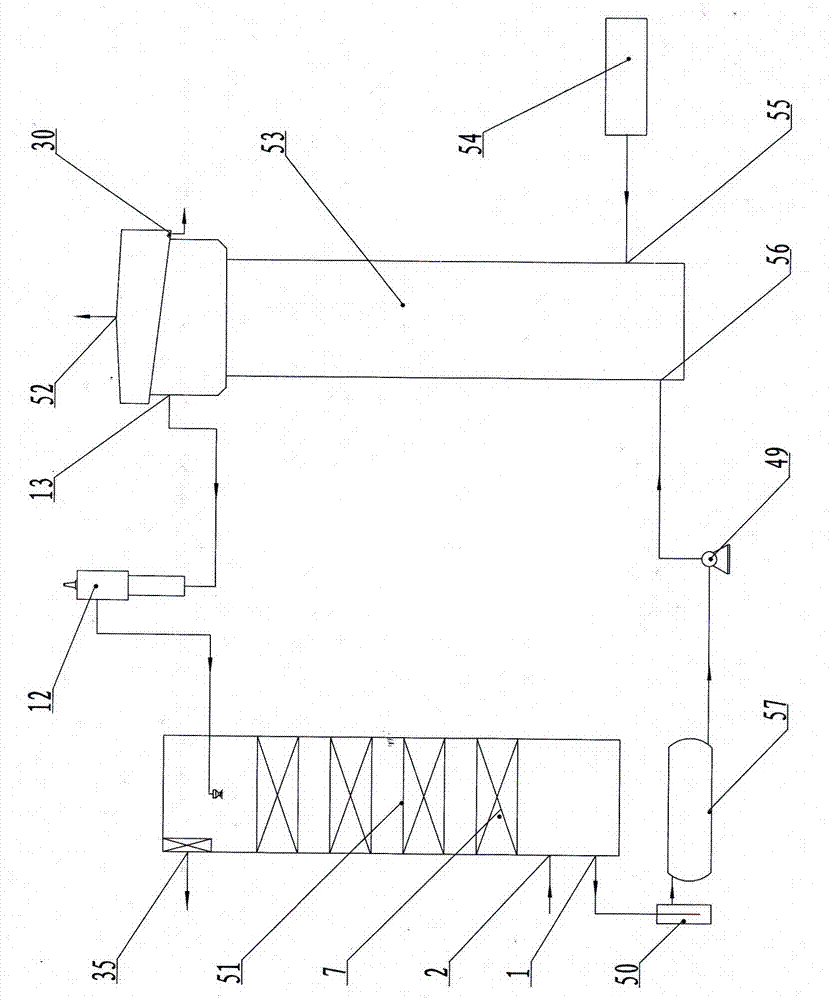

Sludge resource utilization system and method

ActiveCN104154546AReduce moisture contentLow costIncinerator apparatusCombined combustion mitigationSludgeResource utilization

The invention relates to a sludge resource utilization system and method. Surplus calcium oxide is used as agents of a whole sludge treatment process. The system and method have the advantages of being harmless and stable in sludge processing, reduction is achieved, reutilization is achieved, desulfurizing agent consumption is small, and the reutilization rate is high. According to the technical scheme, the system comprises a preprocessor for sludge organic matter decomposing, an outlet of the preprocessor is communicated with an anaerobic fermentation tank, a methane outlet of the anaerobic fermentation tank is connected with a methane tank, a sludge outlet of the anaerobic fermentation tank is connected with a dehydrator and a dryer in sequence, a sludge outlet of the dryer and an inlet of an incinerator are communicated, a smoke outlet of the incinerator is connected with a dust collector, a flying ash outlet of the dust collector is divided into two ways which are connected with a flying ash inlet of the preprocessor and an ash storeroom respectively, an outlet of the methane tank is communicated with an electricity generating fuel machine, a smoke outlet of the fuel machine is connected with a waste heat boiler, and the incinerator and the waste heat boiler provide heat for the dryer through heat supplying pipes.

Owner:凤阳县经济发展投资有限公司

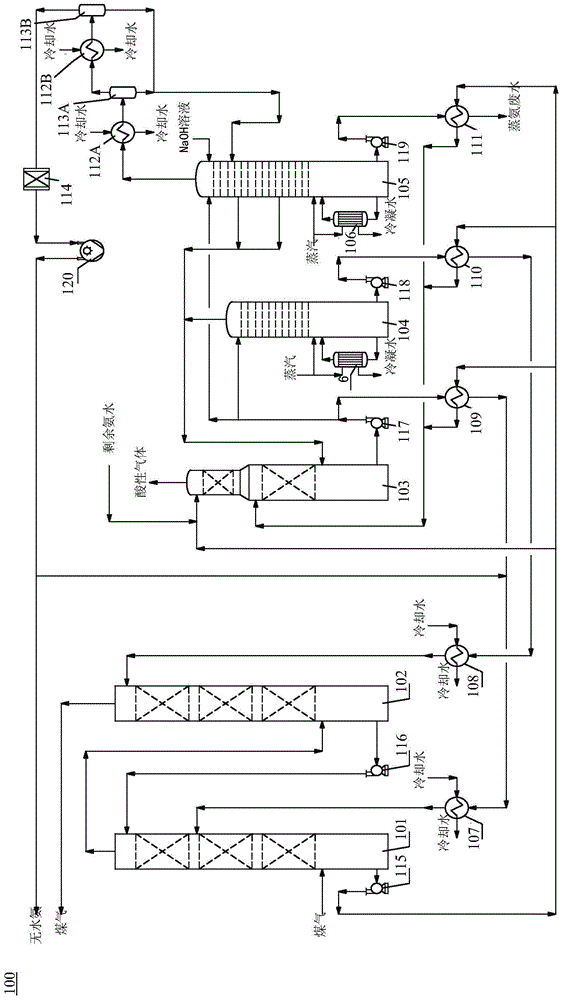

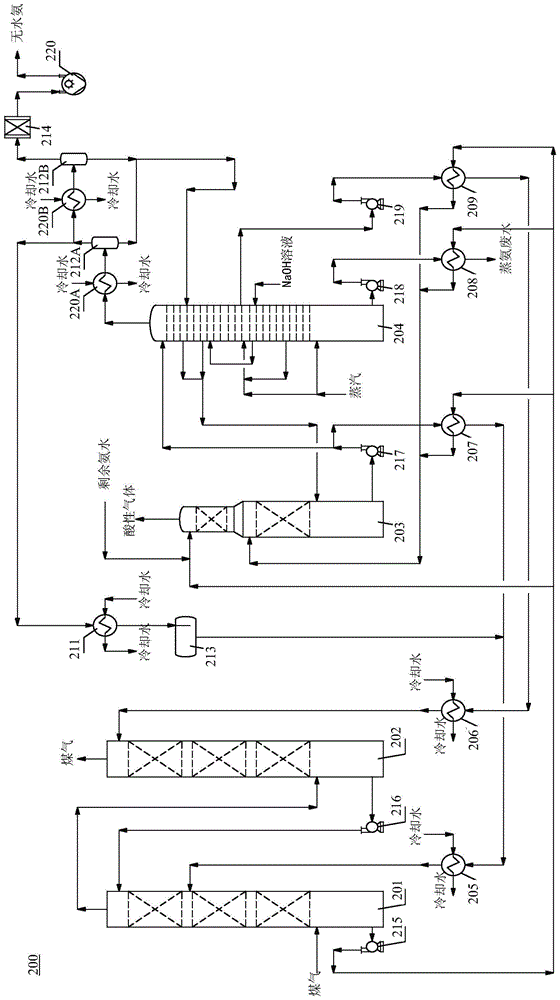

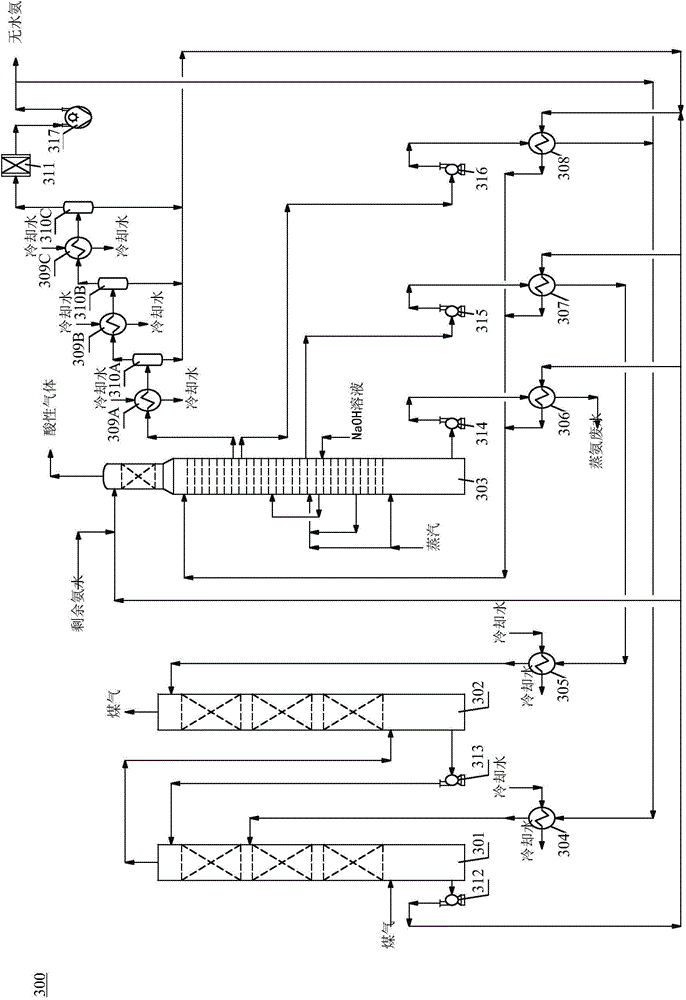

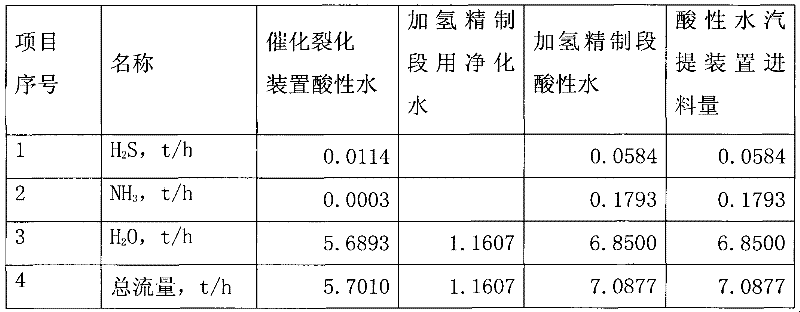

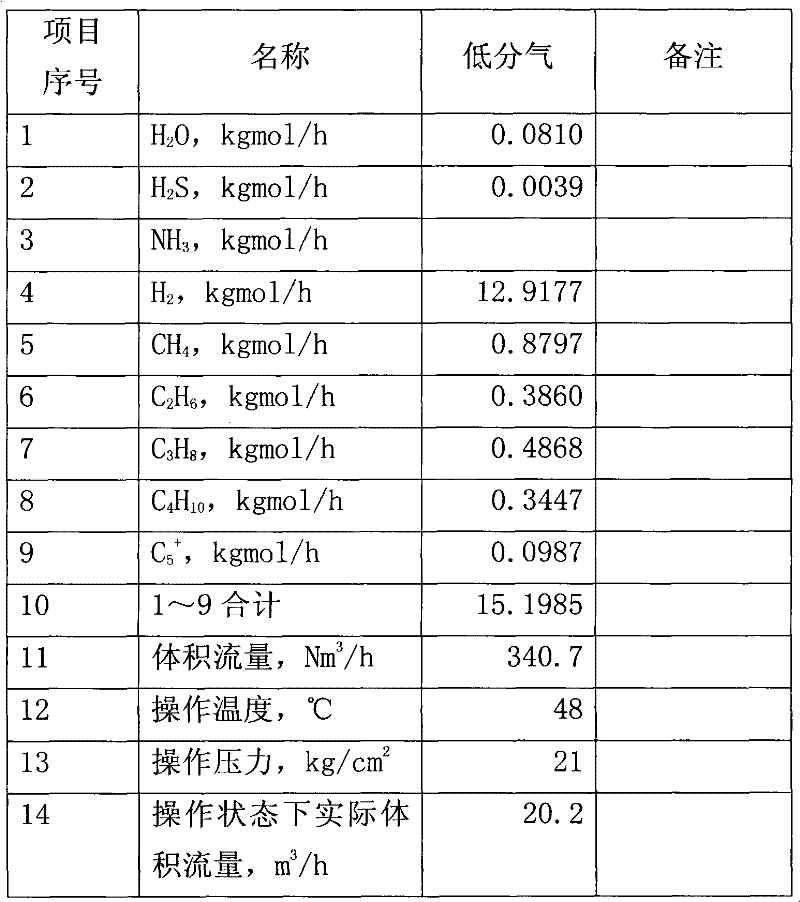

Process for producing anhydrous ammonia by ammonia distillation and deacidification

ActiveCN105984886AReduce hydrogen sulfide contentEmission reductionCombustible gas purificationAmmonia preparation/separationDistillationAmmonia

Owner:薛斌

Method for using process water as flushing water of reaction effluent in hydrocarbon hydrogenation process

InactiveCN102373083AReduce in quantityReduce the amount requiredTreatment with hydrotreatment processesWater sourceWater treatment

The invention relates to a method for using process water as flushing water of reaction effluent in a hydrocarbon hydrogenation process. The process water containing hydrogen sulfide and / or ammonia and / or hydrocarbon oil is used as the flushing water of the reaction effluent in the hydrocarbon hydrogenation process, so the total quantity of raw material water of water treatment devices such as an oily sewage treatment device or an acidulous water steam stripping device is reduced. In order to enlarging the process water source or reducing the influence of the process water on the quality of oil generated through hydrogenation in the hydrocarbon hydrogenation process, a process water deoiling process is added, oil obtained in the deoiling process can be reused as raw material oil in the hydrocarbon hydrogenation process or to enter hydrocarbon products of a process water generating device. The method is particularly suitable for the design or modification of the hydrogenation process of high-nitrogen-content hydrocarbon oil such as coal tar or shale oil.

Owner:何巨堂

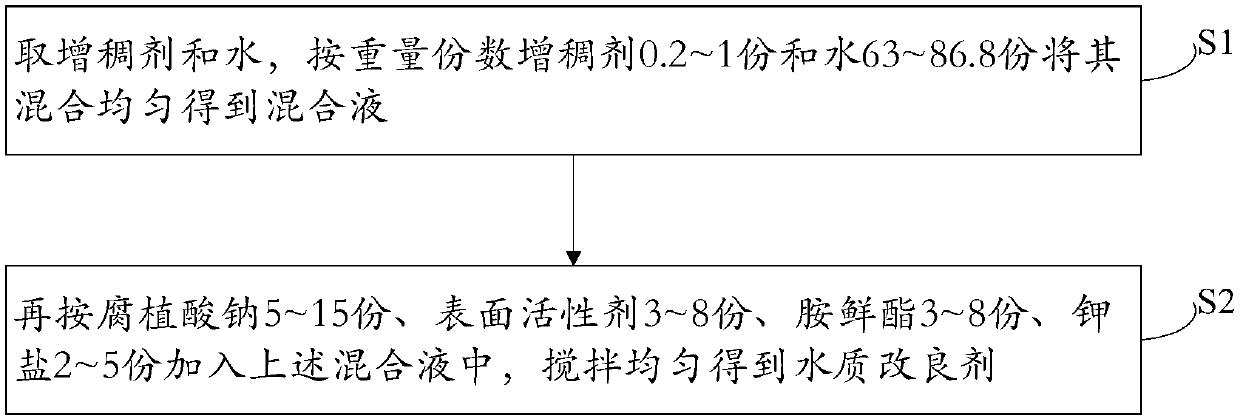

Water quality improver and preparation method thereof

InactiveCN108033497ASurface tensionReduce surface tensionWaste water treatment from animal husbandryWater/sewage treatment by flocculation/precipitationWater sourceWater quality

The invention discloses a water quality improver and a preparation method thereof. The water quality improver comprises the following components calculated in parts by weight: 5-15 parts of sodium humate, 3-8 parts of a surfactant, 3-8 parts of diethyl aminoethyl hexanoate, 2-5 parts of potassium salt, 0.2-1 part of a thickening agent and 63-86.8 parts of water. The water quality improver disclosed by the invention has the benefits that through the sodium humate, the effects of rapidly complexing heavy metal ions and harmful elements in water and reducing the contents of heavy metal ions, ammonia nitrogen, nitrite, hydrogen sulfide in the aquaculture water are realized, and the purpose of purifying a water source is achieved, so that an excellent growth environment and baits are provided for farmed animals, and the healthy growth of the farmed animals is promoted.

Owner:CHANGSHA BEST BIOLOGICAL TECH INST

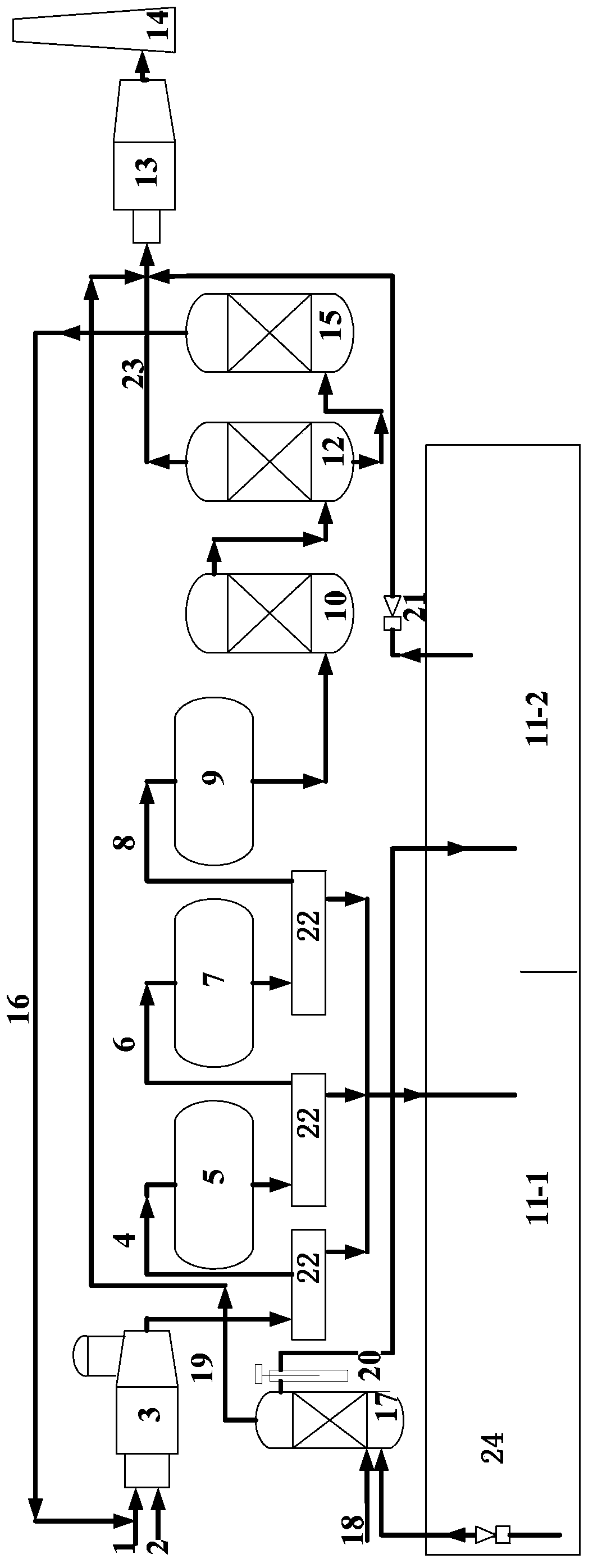

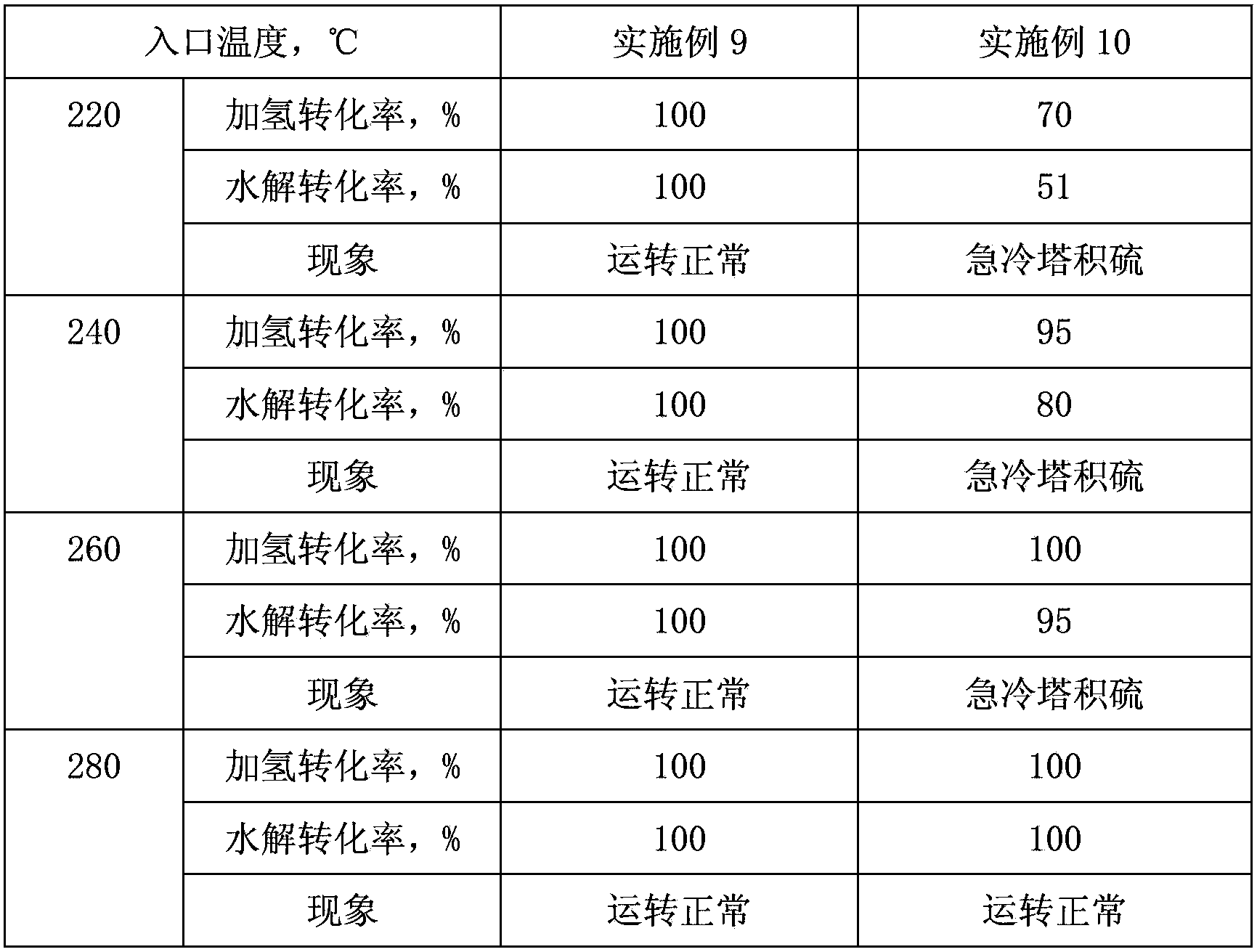

Treatment method for liquid sulfur degassing in sulfur recovery process

ActiveCN104249994AReduce hydrogen sulfide contentChemical industrySulfur preparation/purificationExhaust gasChemistry

Belonging to the technical field of sulfur recovery, the invention specifically relates to a treatment method for liquid sulfur degassing. The method includes a liquid sulfur degassing treatment stage: pressurizing undegassed liquid sulfur collected in an undegassed compartment of a liquid sulfur pool, then subjecting the pressurized undegassed liquid sulfur and compressed air to catalytic reaction together, removing H2S dissolved in liquid sulfur, mixing the degassed exhaust gas with air, then leading the mixture into a sulfur production furnace, returning the mixture to the thermal reaction stage again for further recovery of elemental sulfur; and recovery and storage of degassed liquid sulfur. The treatment method for liquid sulfur degassing provided by the invention is efficient, energy-saving and economical, and can greatly lower the SO2 emission concentration and H2S content.

Owner:CHINA PETROLEUM & CHEM CORP

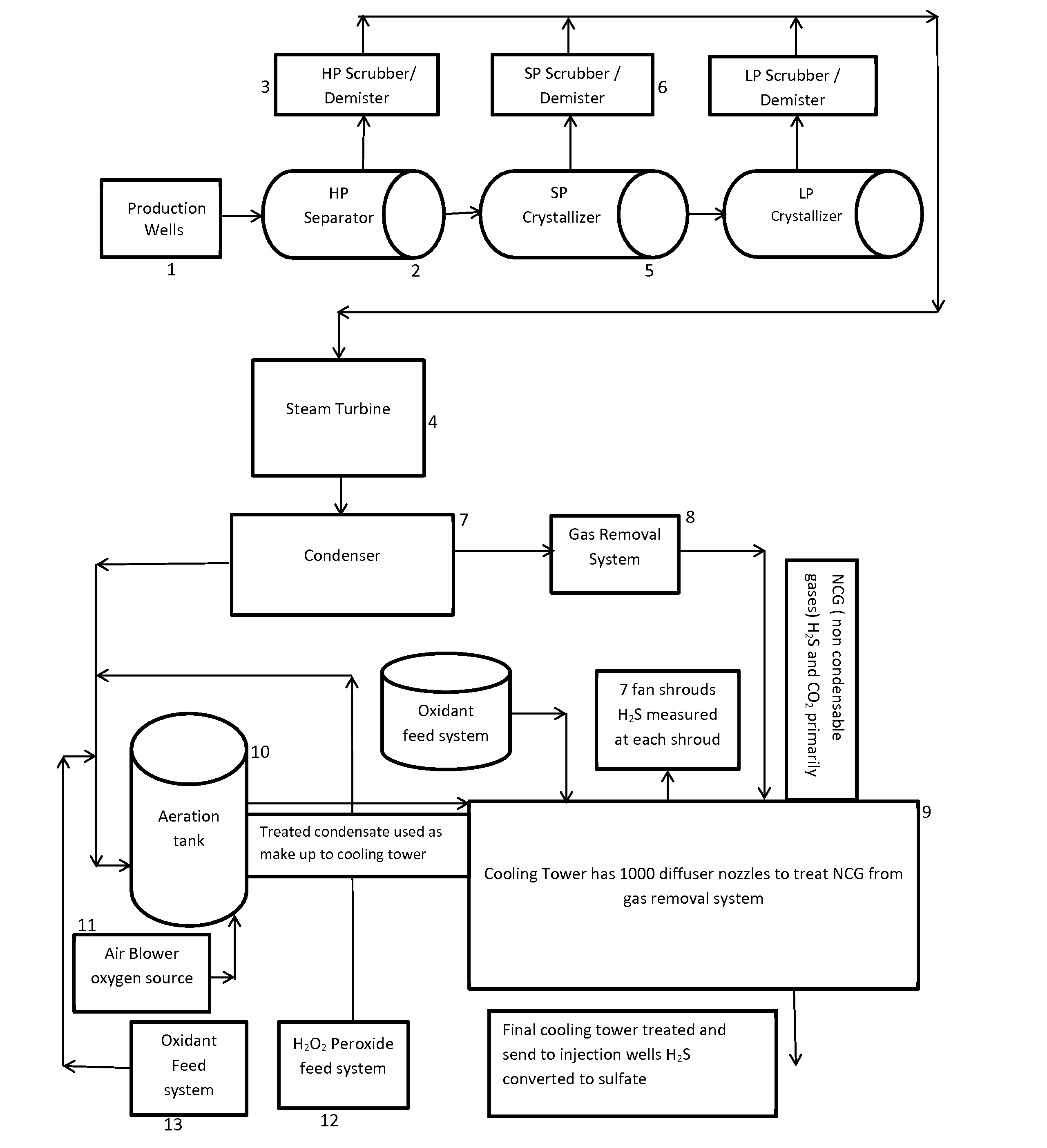

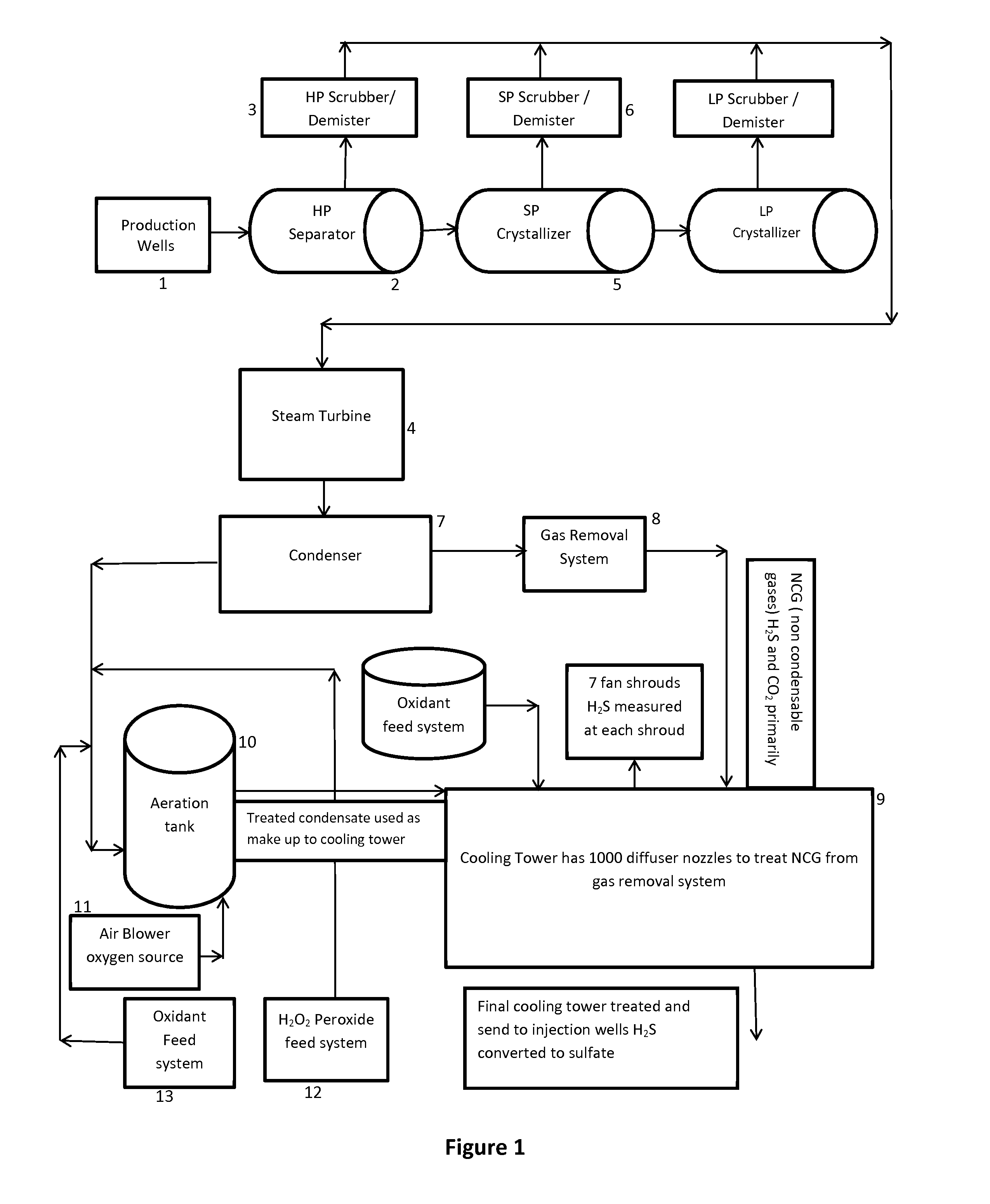

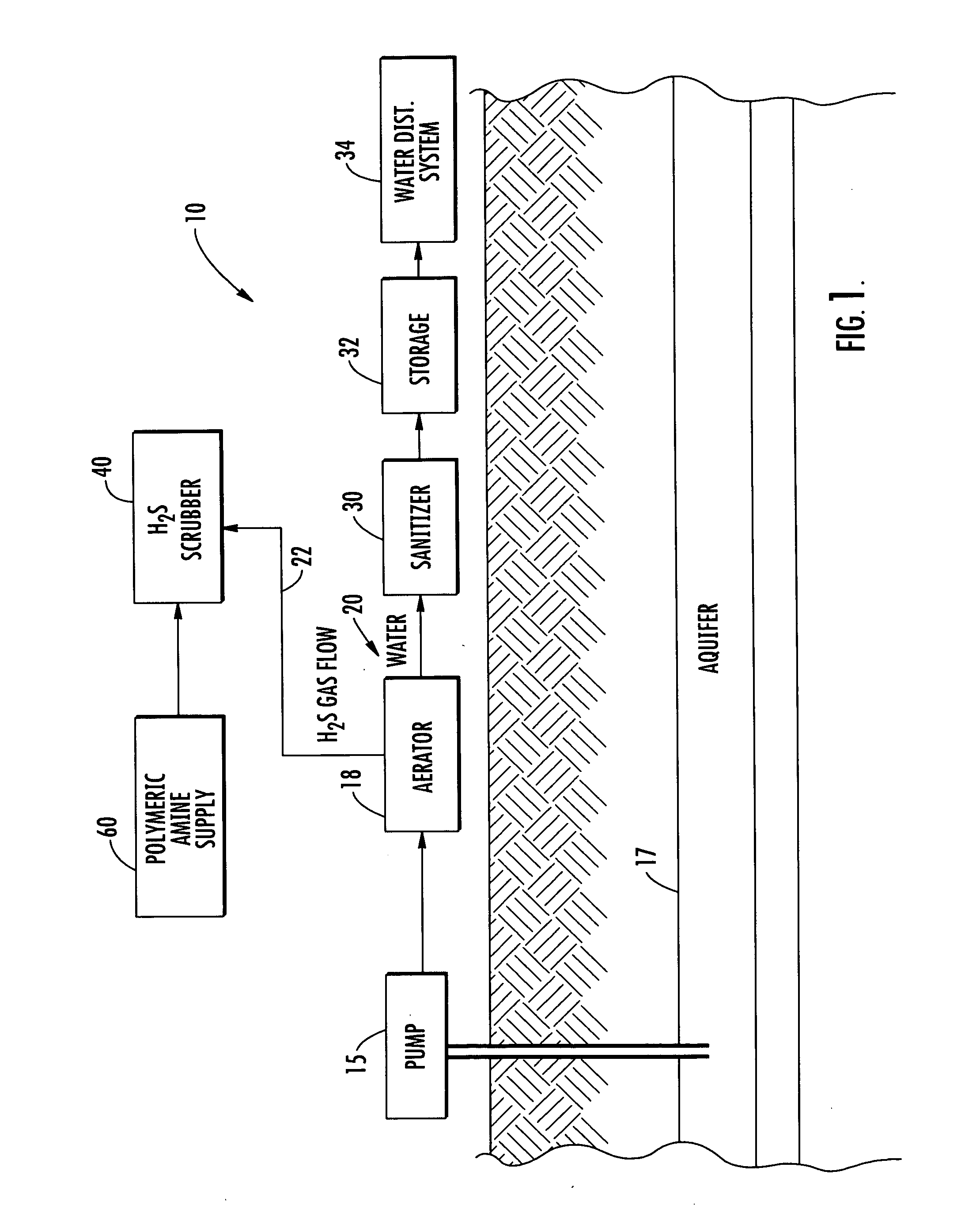

Hydrogen sulfide abatement in geothermal facilities

ActiveUS20160023927A1Reduce hydrogen sulfide contentWater treatment compoundsWater contaminantsSulfateNuclear chemistry

A method of reducing hydrogen sulfide content in a medium is disclosed. The method may include the steps of contacting a medium containing hydrogen sulfide with an effective amount of hydrogen peroxide, contacting the medium with an oxidizing agent, converting the hydrogen sulfide to sulfate, and reducing the hydrogen sulfide content in the medium. The medium may be a gas or a liquid.

Owner:ECOLAB USA INC

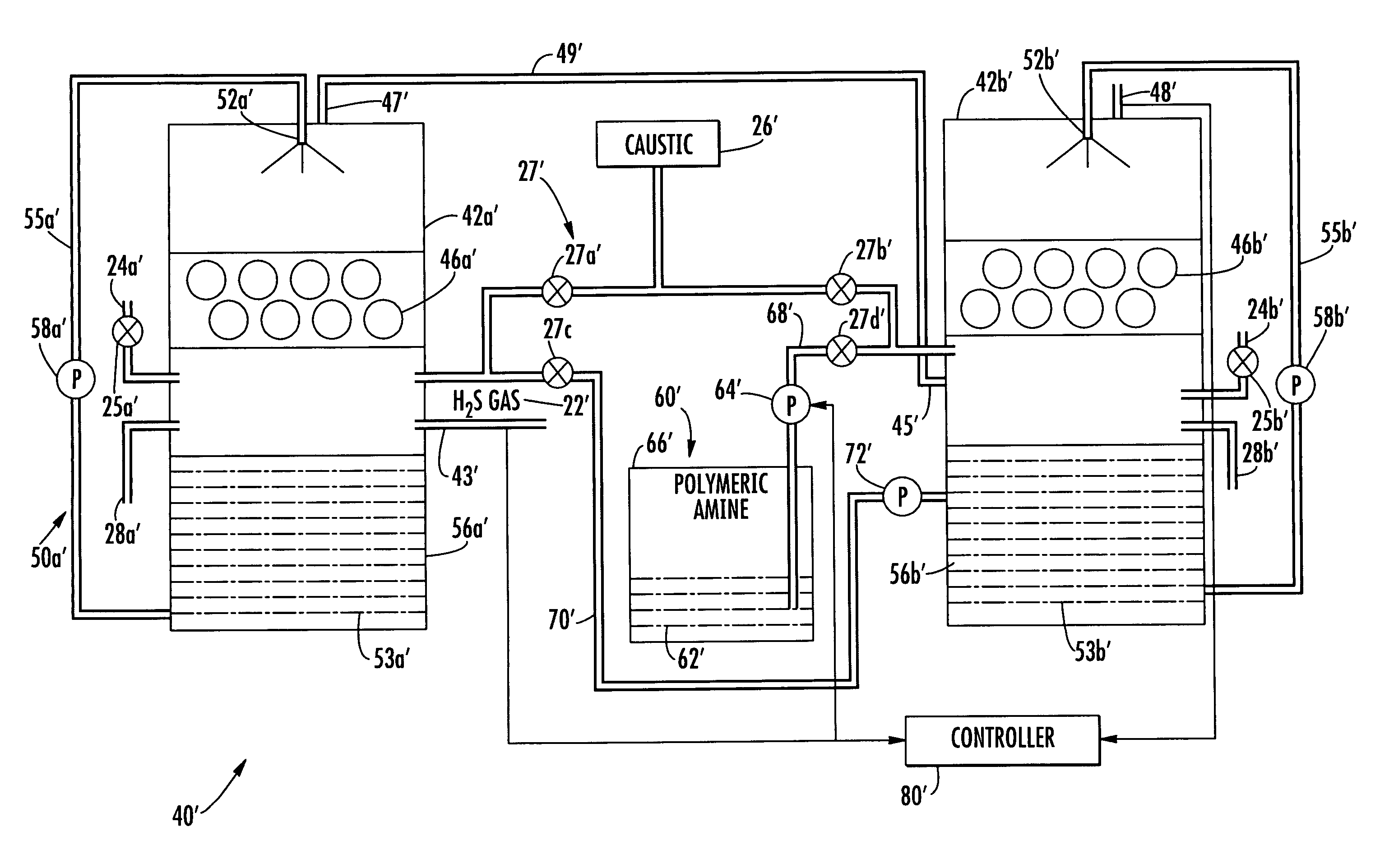

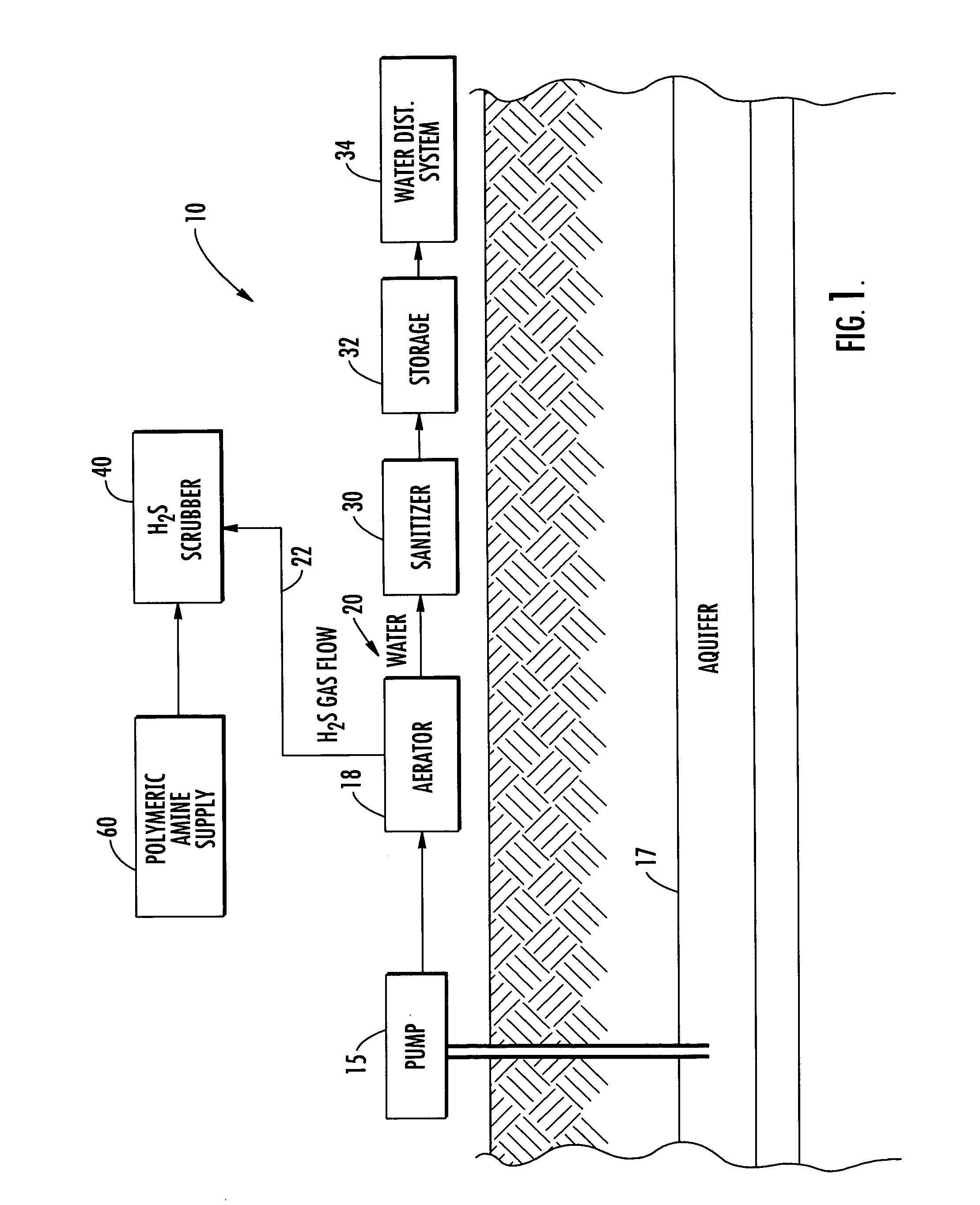

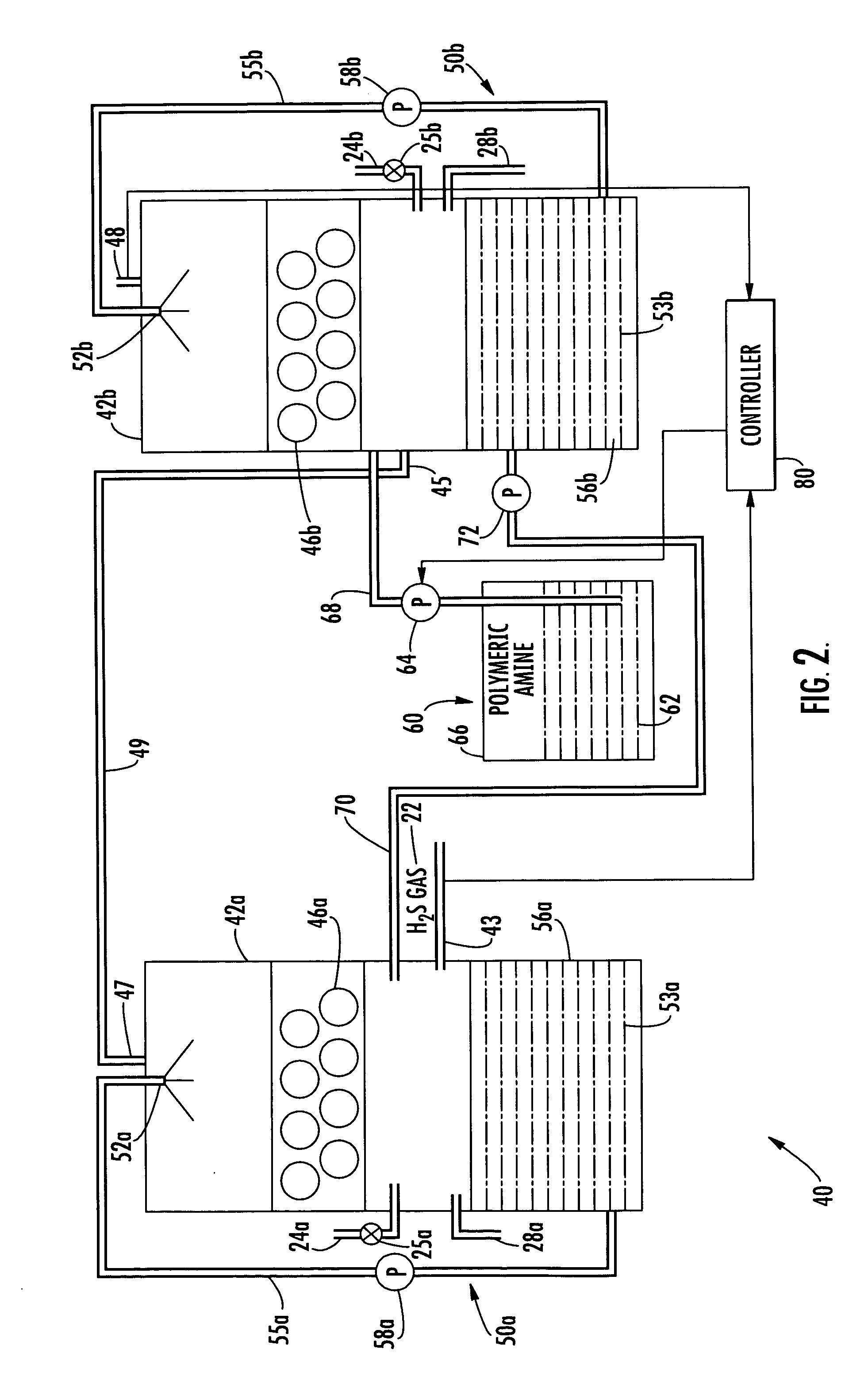

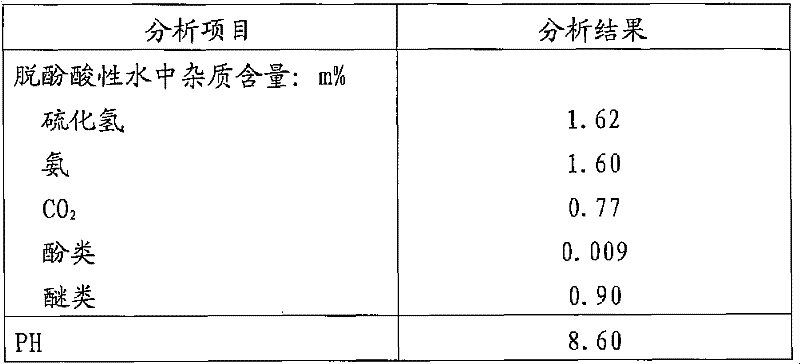

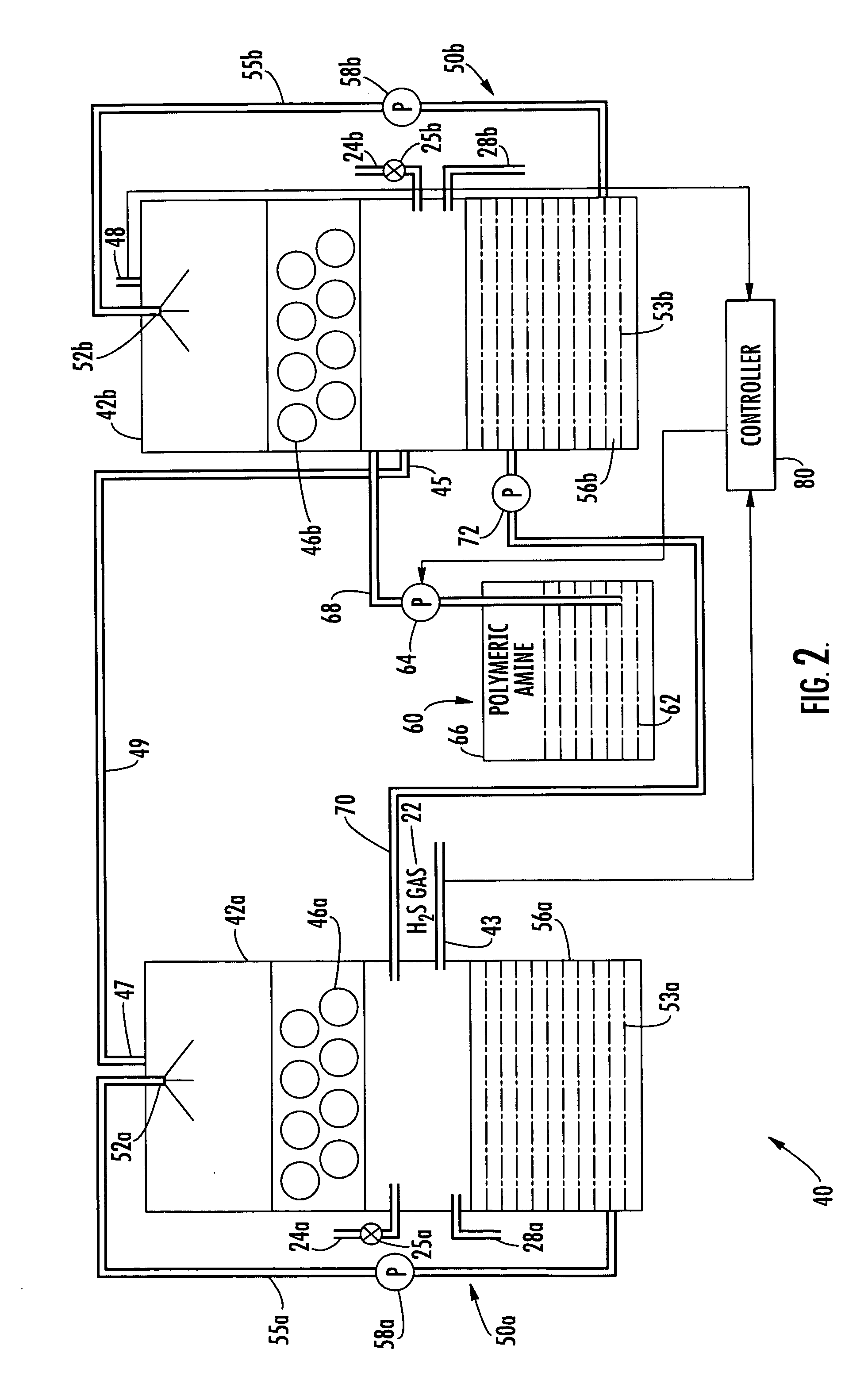

Hydrogen sulfide scrubber using polymeric amine and associated methods

ActiveUS7077884B2Reduce needCost effectiveDispersed particle filtrationUsing liquid separation agentEngineeringCirculating pump

A hydrogen sulfide scrubber includes first and second scrubber tanks with scrubber media contained therein. Scrubbing solution circulators each include a dispenser for dispensing scrubbing solution into contact with the scrubber media, a sump for collecting the scrubbing solution after contact with the scrubber media, and a circulating pump for circulating the scrubbing solution from the sump back to the dispenser after contact with the scrubber media. A polymeric amine supply is provided for supplying a polymeric amine to the scrubbing solution in the second tank. The scrubbing solution in the first tank may be charged with the polymeric amine by a charging line extending from the second tank to the first tank. In other embodiments, a regenerative blower and associated nozzle may be used to generate a scrubbing solution mist in the space beneath the scrubber media and above the sump.

Owner:Q2 TECH

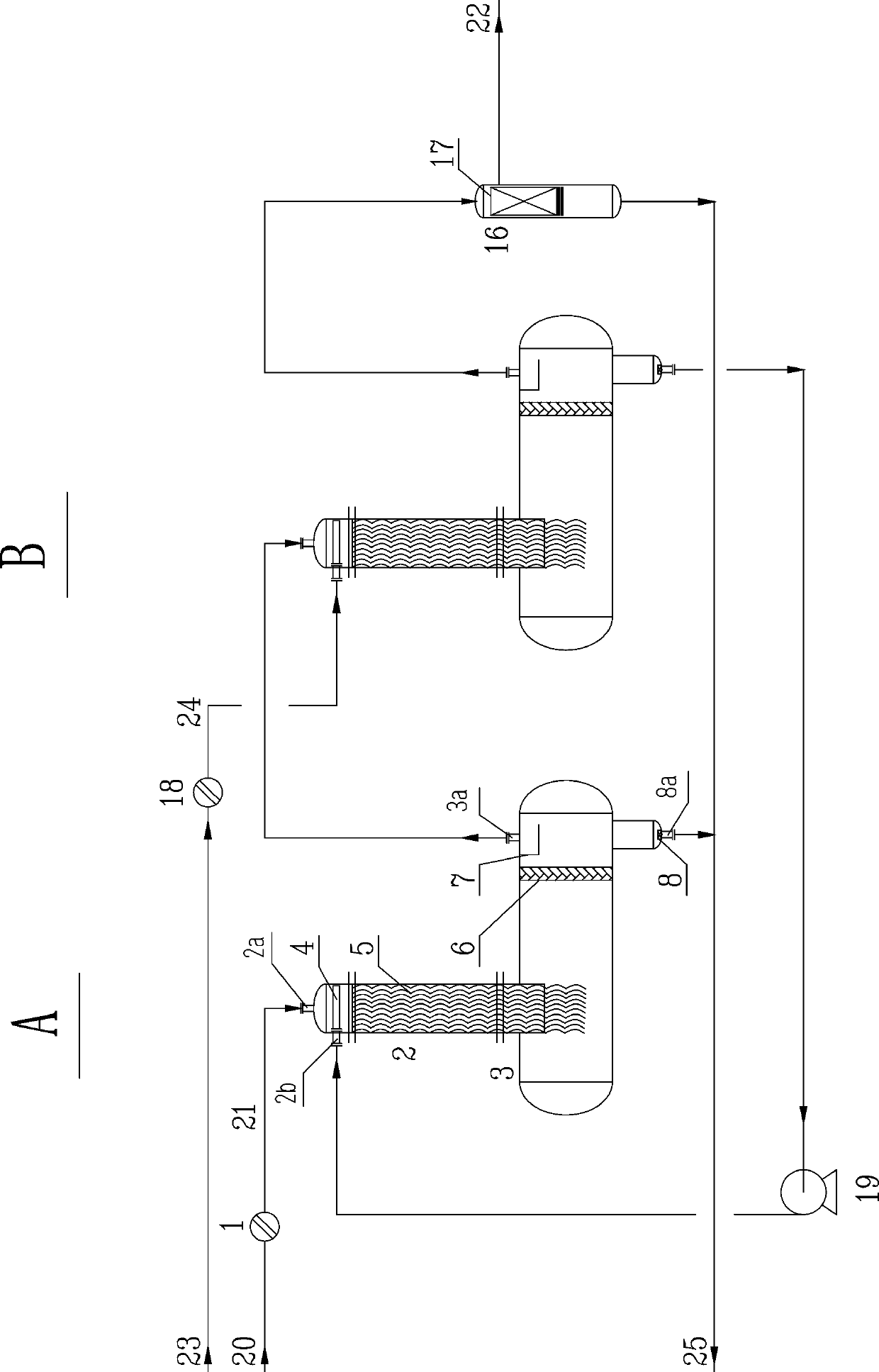

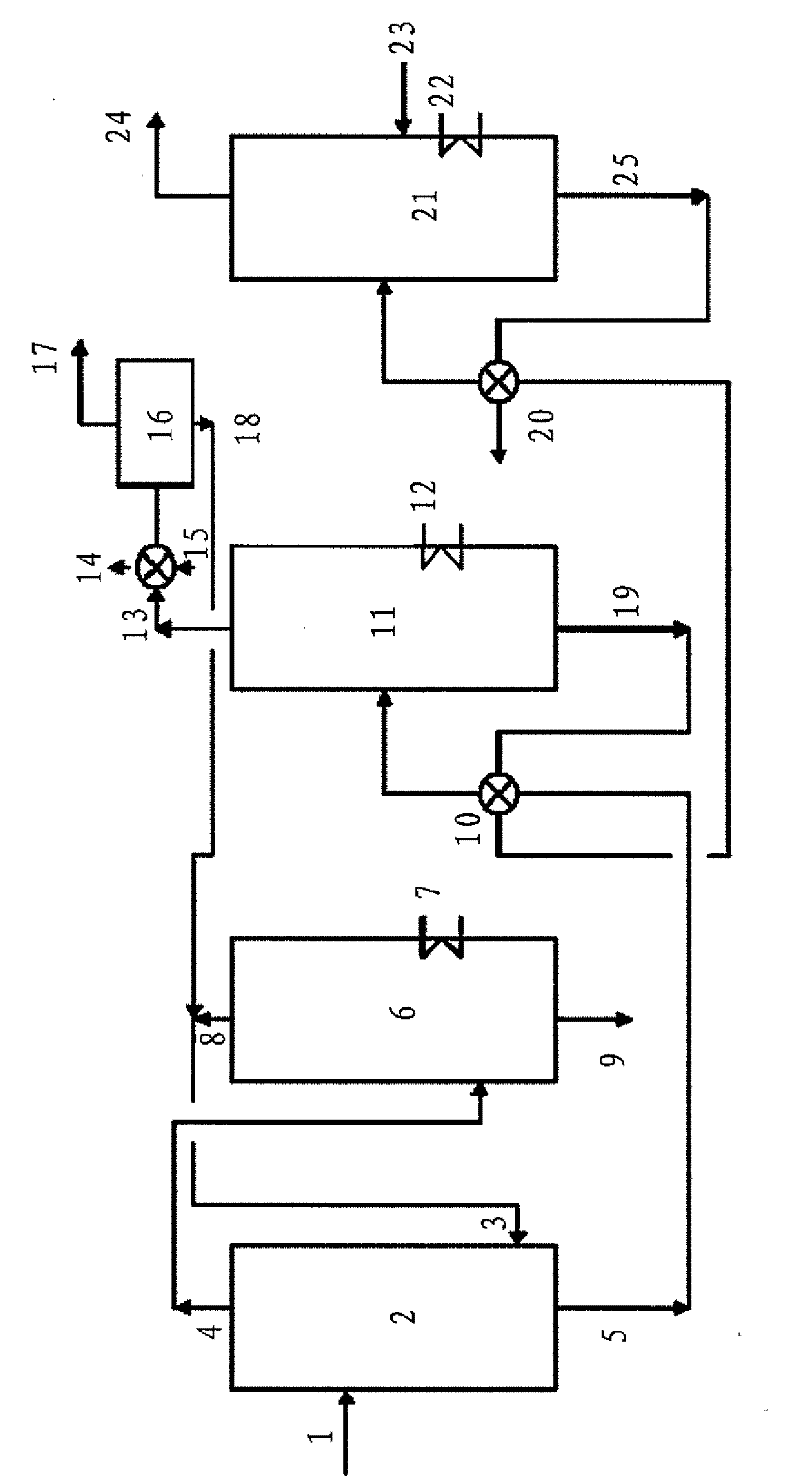

Method and apparatus for separating hydrogen sulfide, and hydrogen production system using same

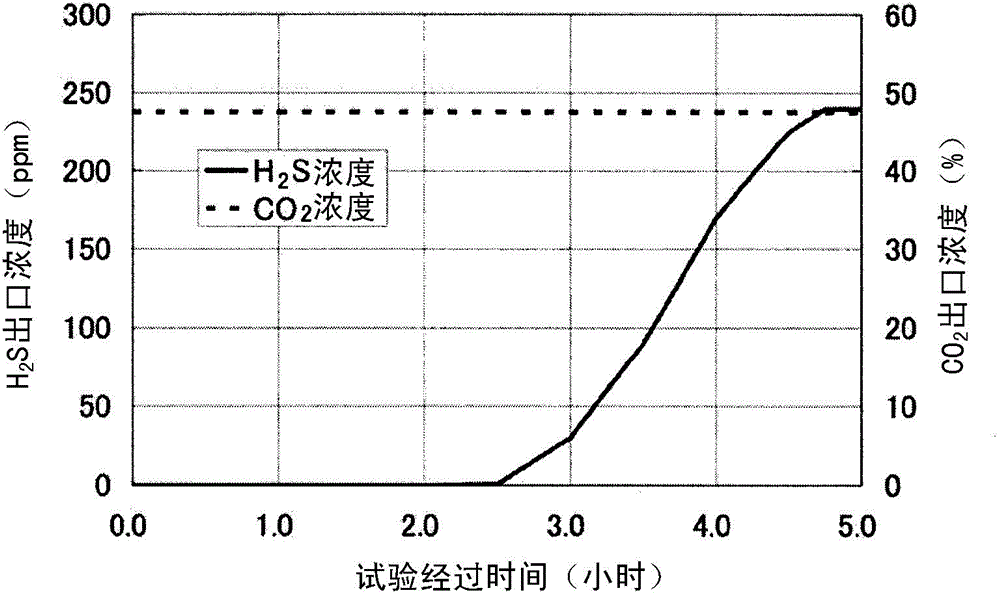

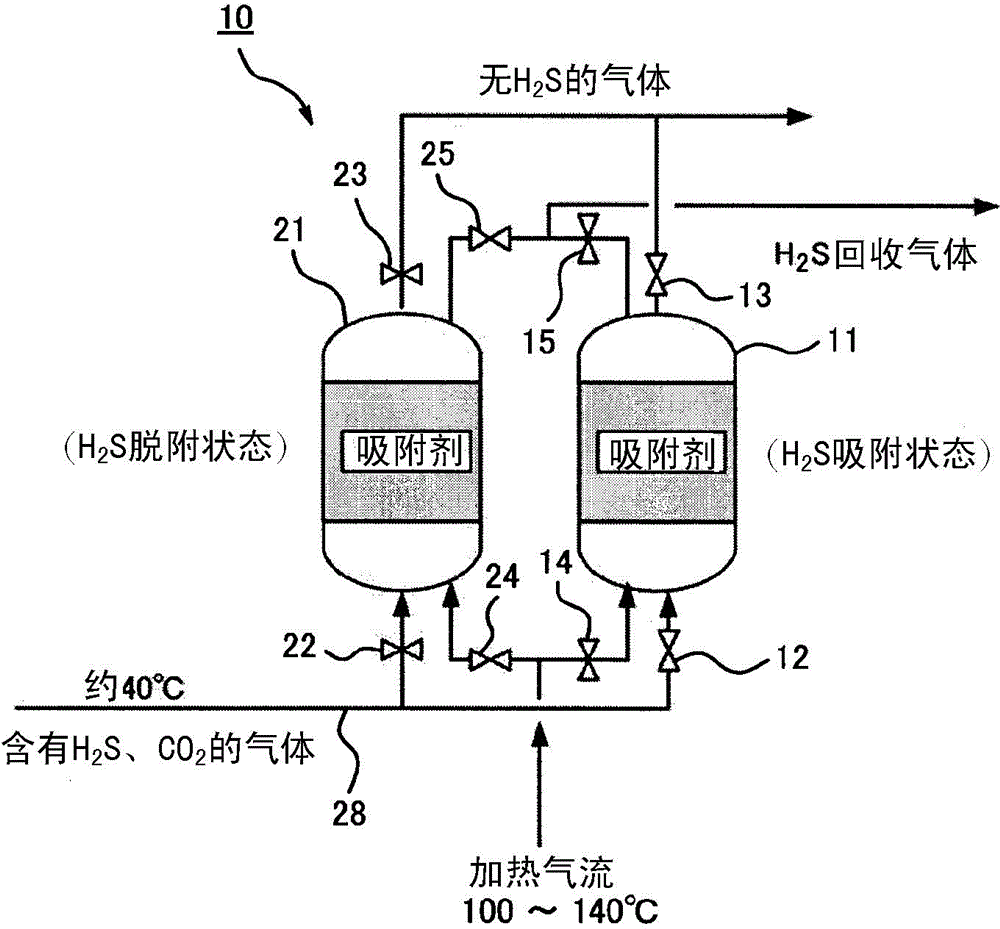

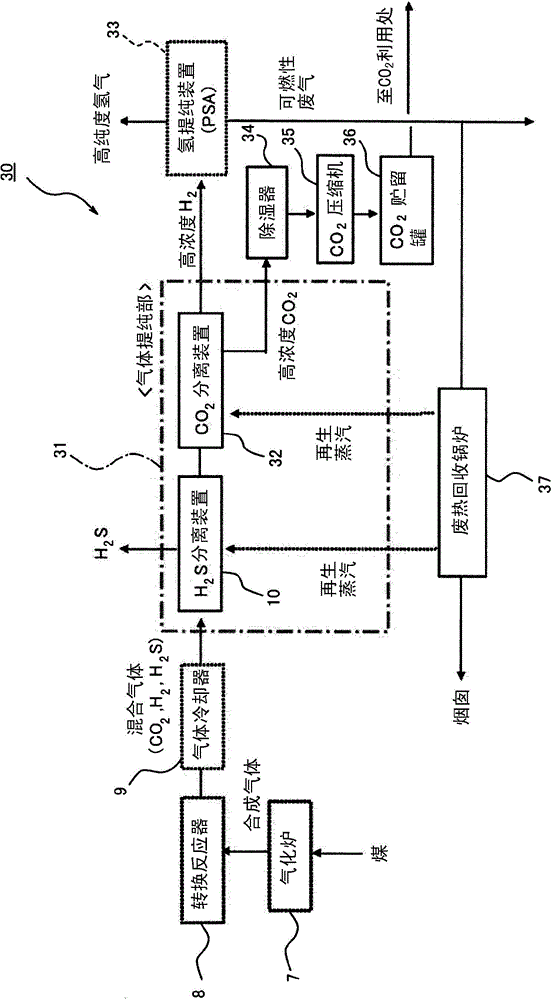

ActiveCN103958029AReduce hydrogen sulfide contentHydrogen separation by selective and reversible uptakeGas treatmentActivated carbonProduct gas

The purpose of the present invention is to provide: a method and an apparatus for separating H2S, each of which is capable of selectively separating only H2S from a gas to be processed, said gas containing CO2 and H2S; and a hydrogen production system which uses this apparatus for separating H2S. A hydrogen production system of the present invention is provided with adsorbent filled towers (11, 21) which are filled with an H2S adsorbent that is obtained by having an activated carbon support triethanolamine, and a mixed gas at about 40 DEG C is supplied thereto via a line (28), said mixed gas containing CO2 and H2S and derived from a synthetic gas. While holding valves (12, 13) open, valves (22, 23) closed, valves (14, 15) closed and valves (24, 25) open, H2S is adsorbed from a gas to be processed in a dry state in the adsorbent filled tower (11) and H2S is desorbed in the adsorbent filled tower (21). In cases where H2S is adsorbed from the gas to be processed in the adsorbent filled tower (21) and H2S is desorbed in the adsorbent filled tower (11), the valves (12, 13, 24, 25) are held closed and the valves (22, 23, 14, 15) are held open.

Owner:KAWASAKI HEAVY IND LTD

Method for reducing the H2S content of an H2S-containing subterranean formation

InactiveUS20100108315A1Reduce hydrogen sulfide contentFluid removalDrilling compositionSulfur dioxideHydrogen sulfide

Owner:BLACK & VEATCH CORP

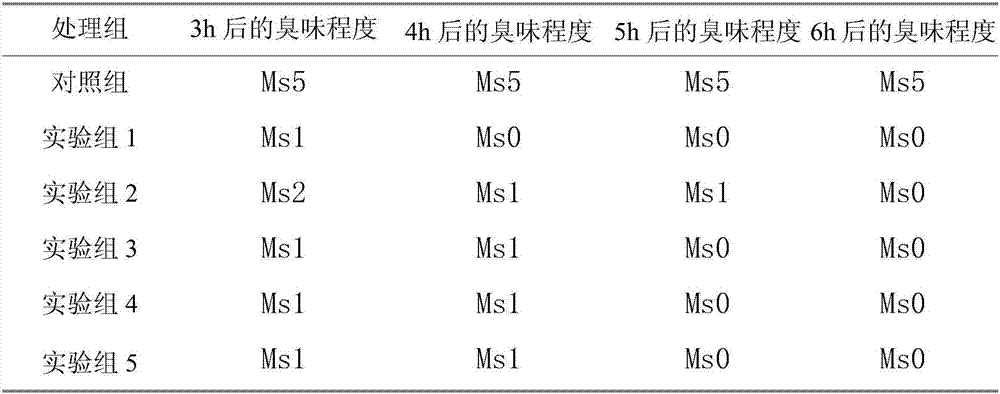

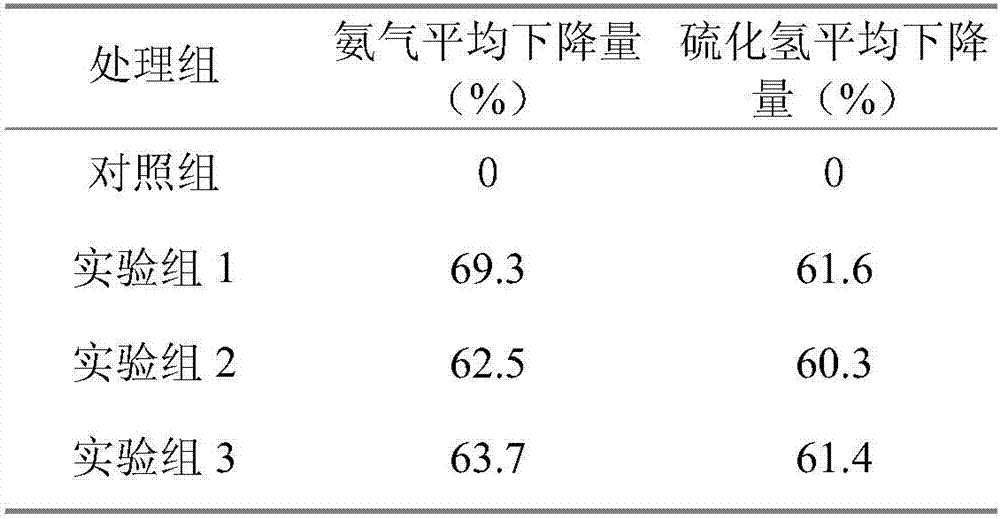

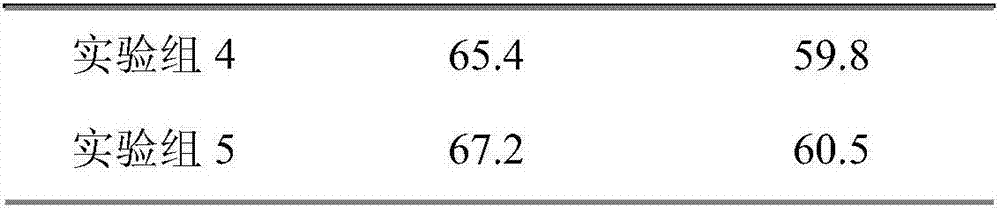

Pig farm manure pollution plant-derived deodorant, preparation method and applications thereof

The present invention relates to a pig farm manure pollution plant-derived deodorant, and further provides a preparation method of the pig farm manure pollution plant-derived deodorant, and applications of the pig farm manure pollution plant-derived deodorant in production of an organic fertilizer for crops. According to the present invention, the pig farm manure pollution plant-derived deodorant is prepared from the following components: acorus calamus l, mulberry leaf, lotus leaf, enteromorpha powder, sea lettuce powder, grapefruit skin, folium artemisiae argyi, green tea and zeolite powder; and the prepared pig farm manure pollution plant-derived deodorant can rapidly and effectively remove pig manure odor, has significant deodorizing effect, can effectively reduce the impact of pig manure odor on the environment, can inhibit the generation of hydrogen sulfide, ammonia and other harmful gases, and can reduce the pollution of pig manure on the environment.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI +1

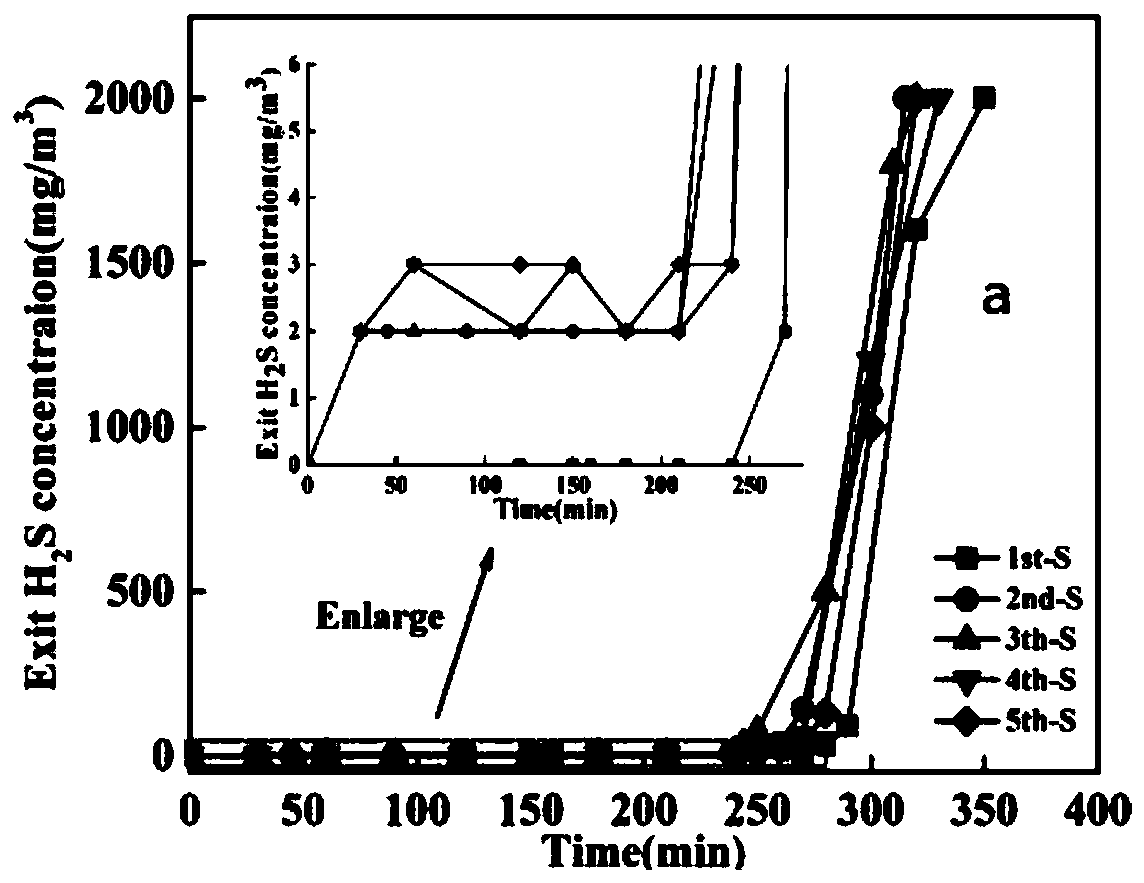

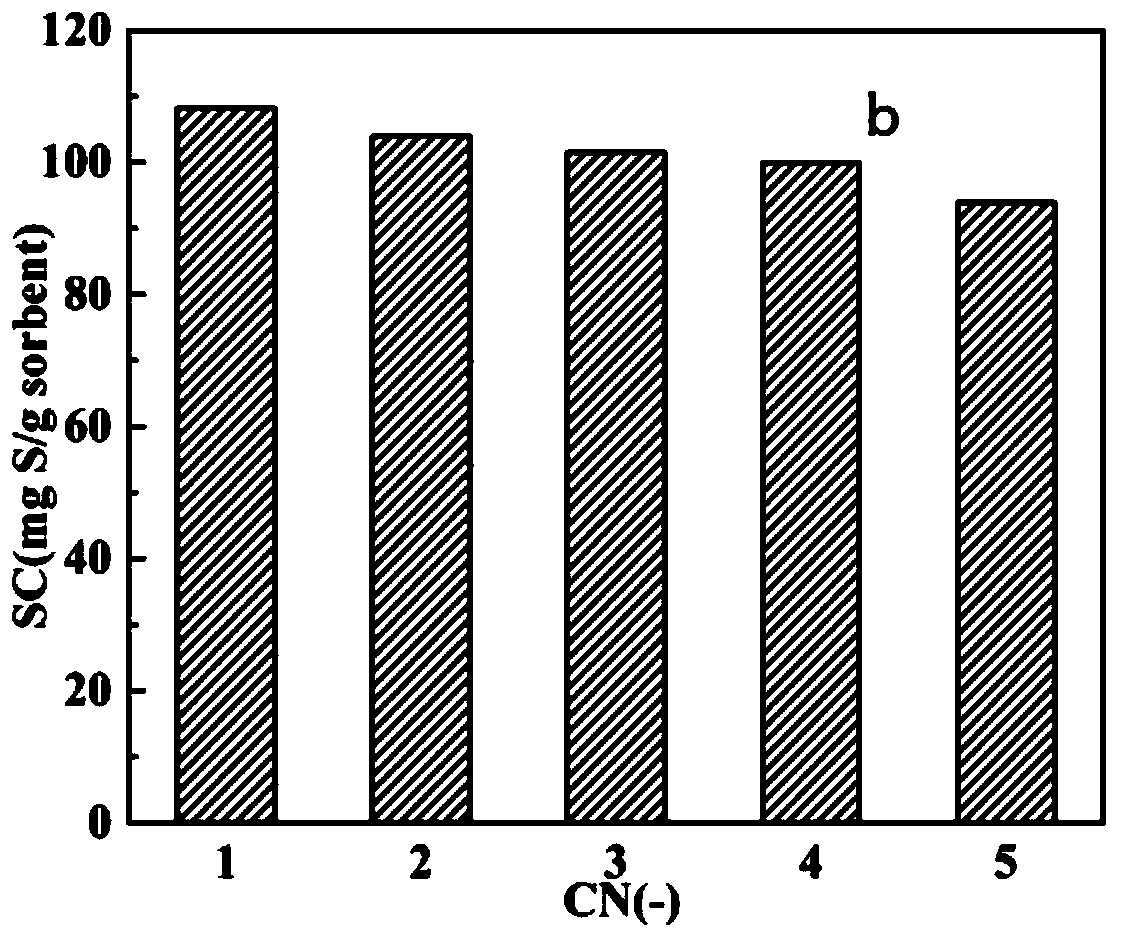

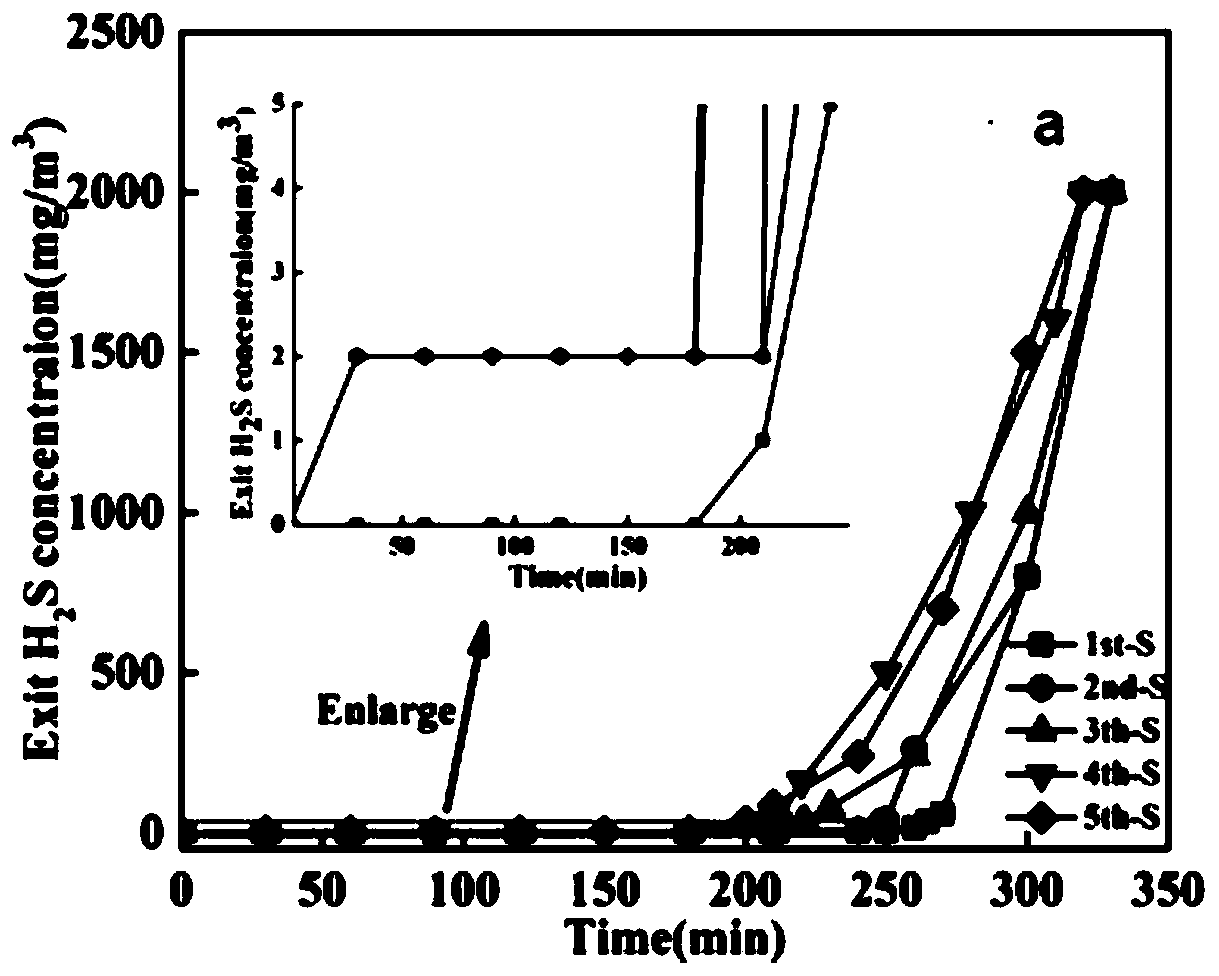

Composite adsorbent for removing hydrogen sulfide at high temperature, and preparation method and application thereof

ActiveCN110801821AImprove desulfurization effectReduce hydrogen sulfide contentGas treatmentOther chemical processesReducing atmosphereManganese oxide

The invention belongs to the technical field of desulfurization adsorbents, and particularly relates to a composite adsorbent for removing hydrogen sulfide at a high temperature, and a preparation method and application thereof. The composite adsorbent for removing hydrogen sulfide provided by the invention comprises the following components in percentage by weight: 10%-50% of manganese oxide, 30%-40% of alumina, and 2%-15% of an auxiliary agent, wherein the auxiliary agent is selected from a mixture of at least two of lanthanum oxide, cerium oxide, barium oxide or nickel oxide. The compositeadsorbent for removing hydrogen sulfide can work normally at 800 DEG C or more, and has the following advantages: 1) the desulfurization effect of the fresh adsorbent is good, in the simulated reducing atmosphere desulfurization experiment, a removal rate of hydrogen sulfide is close to 100%, and the content of hydrogen sulfide in a tail gas is less than 1 mg / m<3>; 2) the desulfurization performance of the adsorbent is stable during the desulfurization-regeneration cycle process, the breakthrough sulfur capacity and desulfurization efficiency are both kept stable, and the hydrogen sulfide content in the tail gas is less than 3 mg / m<3> during the desulfurization process; and 3) the adsorbent is in a dry state, no aqueous solution is required during use, and thereby the water consumption isreduced.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Compound powder of anti-stress agent for aquaculture and preparation method thereof

InactiveCN104983793AClear ingredientsStable effectOrganic active ingredientsImmunological disordersGlucose powderIndividual animal

Owner:FRESHWATER FISHERIES RES CENT OF CHINESE ACAD OF FISHERY SCI

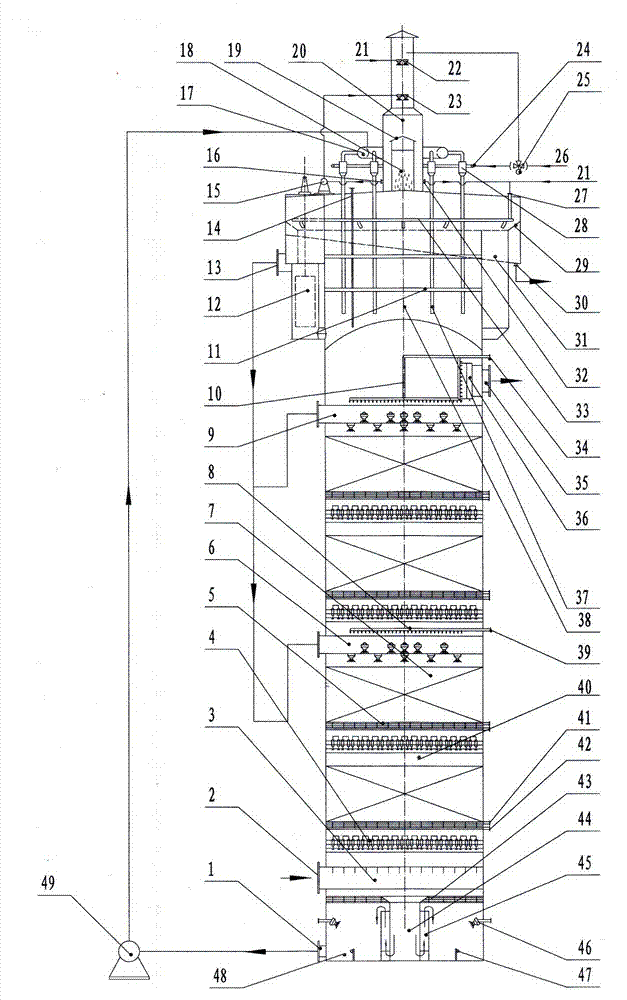

Coking gas desulfuration-regeneration integrated column having multilayer spray structure

InactiveCN104762110AImprove desulfurization efficiencySolve the incomplete desulfurization effectGas contaminants removalExhaust gasFilling materials

A coking gas desulfuration-regeneration integrated column having multilayer spray structure. In the invention, a conventional desulfuration technology device in the prior art is changed into an integrated column-type structure design in which a regenerated tail gas washing unit, a regenerating unit, a desulfuration unit and a desulfurated rich solution storage and reaction unit are optimized. In addition, in the four layers of filling material supports in the desulfuration unit are provided with corresponding coil-type re-cooling apparatuses and a two-layered spray structure is arranged at the upper part and the middle part of the desulfuration unit, so that the content of hydrogen sulfide in desulfurated coking gas is low. The regenerated tail gas washing unit installed on the top of the regenerating unit, wherein a tail gas washing process includes two parts: (1) feeding fresh water or a desulfuration solution, which satisfies circulation water equilibrium, to the upper part of interior of the tail gas washing unit; and (2) performing tail gas desulfuration to sprayed fresh water or desulfuration solution to form a washing solution, feeding the washing solution to the upper part of interior of the tail gas washing unit again through a circulation pump, jetting the fresh water or the desulfuration solution or jetting the washing solution by a high-pressure atomization spray gun to perform double tail gas desulfuration washing. By such a process, the operation of integrated column-type desulfuration and regeneration of coking gas is achieved.

Owner:辽宁圣赫机械制造成套设备有限公司

A fiber liquid film contactor amine washing desulphurization device and an amine washing desulphurization method

InactiveCN105505464AReduce hydrogen sulfide contentNo entrainmentGas treatmentDispersed particle separationFiberEngineering

The invention discloses a fiber liquid film contactor amine washing desulphurization device. The device comprises a first fiber liquid film mass-transfer contactor subassembly. The first fiber liquid film mass-transfer contactor subassembly comprises a fiber liquid film contactor, a settlement separating tank and a stream dividing pack. The vertical fiber liquid film contactor is mounted on one end of the horizontally disposed settlement separating tank through a flange. The device is advantageous in that when the hydrogen sulfide content of liquefied gas produced by an oil refinery is lower than 5000 mg / m3, the hydrogen sulfide content of the liquefied gas hydrogen sulfide in which is removed can be ensured to be lower than 1 mg / m3 by adopting amine washing with a primary fiber liquid film contactor and amine removing with a coalescer, and the liquefied gas after removal is free of entrainment of free amine liquids.

Owner:NINGBO ZHANGFU ENERGY TECH CO LTD

Hydrogenation modification method for catalytically cracked gasoline

ActiveCN101368111BNo change in octaneReduce hydrogen sulfide contentGasoline stabilisationRefining to eliminate hetero atomsIsomerizationHydrodesulfurization

The invention relates to a hydro-upgrading method for catalytic cracking gasoline; the method comprises the following steps: gasoline whole fraction is cut into light fraction and heavy fraction; the cutting point is 60 DEG C to 80 DEG C; mercaptan in the light gasoline fraction is removed through mercaptan removal alkali washing; the heavy gasoline fraction and hydrogen gas have catalytic hydrodesulfurization, denitrogenation and olefin saturated reaction; reactor effluent or the reactor effluent after removing hydrogen sulfide is contacted with octane value restore catalyzer, and isomerization, aromatizatian and building up reaction are implemented, hydrogenated oil is separated and lighter hydrocarbon gasoline fraction is obtained, hydrogen-rich gas at the top of a high partial tank is circularly used through hydrogen sulfide removal, and lighter hydrocarbon at the top of a stabilizer tower is feedback to a fractionation tank to be fractionated again; the condition of the hydrotreating reaction is that hydrogen partial pressure is 1.5 to 3.0 MPa; the reaction temperature is 250 to 320 DEG C; the liquid hourly space velocity is 3.0 to 5.0 h<-1>, and the hydrogen-oil ratio is 200 to 500 Nm<3> / m<3>; the sulfur content of the gasoline product is smaller than 100 ppm, the octane value is unchanged, and the yield of gasoline reaches 98.5 weight percent.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

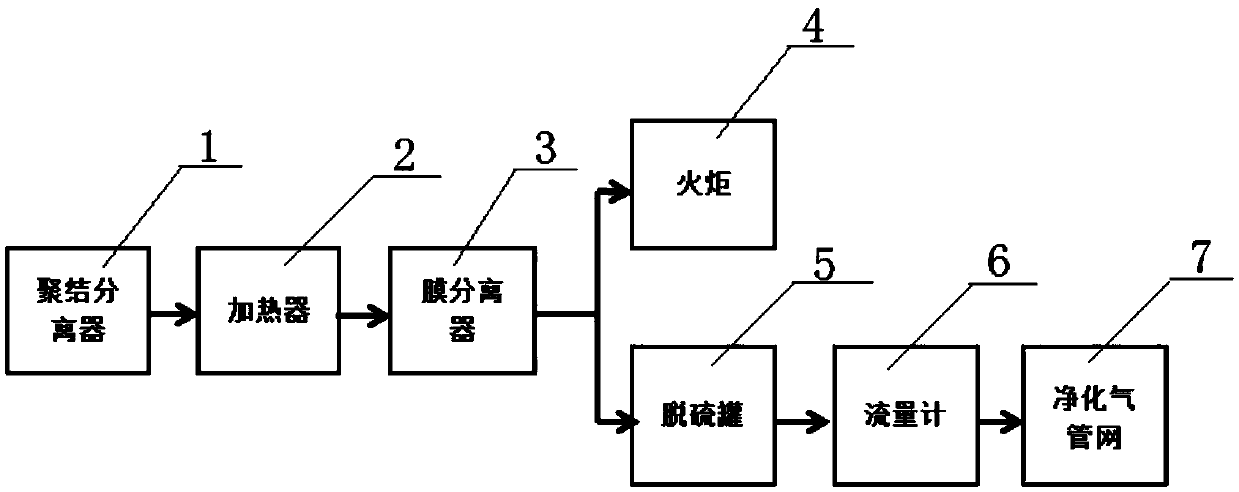

Novel skid-mounted equipment for removing hydrogen sulfide in natural gas

InactiveCN105505497ASimple processConvenient transportation and relocationGaseous fuelsIntensive treatmentCombustion

The invention provides novel skid-mounted equipment for removing hydrogen sulfide in natural gas. The equipment comprises a coalescing separator used for separating droplets and solids which are 5mu m or over, a heater used for realizing complex heating on natural gas to guarantee that the gas temperature is higher than dew point temperatures of water and hydrocarbon, a membrane separator used for crudely separating hydrogen sulfide in natural gas, a torch used for conducting vent combustion or intensive treatment on high-sulfur-content gas, a desulfurization tank used for re-adsorbing and removing remained small amount of hydrogen sulfide in the natural gas, a flowmeter used for monitoring throughput of the treated natural gas and a purified gas pipe network used for delivering standard natural gas, wherein a differential pressure gauge is arranged on the coalescing separator; and a dust filter is arranged at the natural gas outlet in the bottom of the desulfurization tank. The novel skid-mounted equipment has the advantages of highly integrated skid mounting, simplified process, convenience in transportation and removal, operation cost reduction and monitoring function availability.

Owner:TIANJIN PETROCHINA MODERN PETROLEUM EQUIP CO LTD

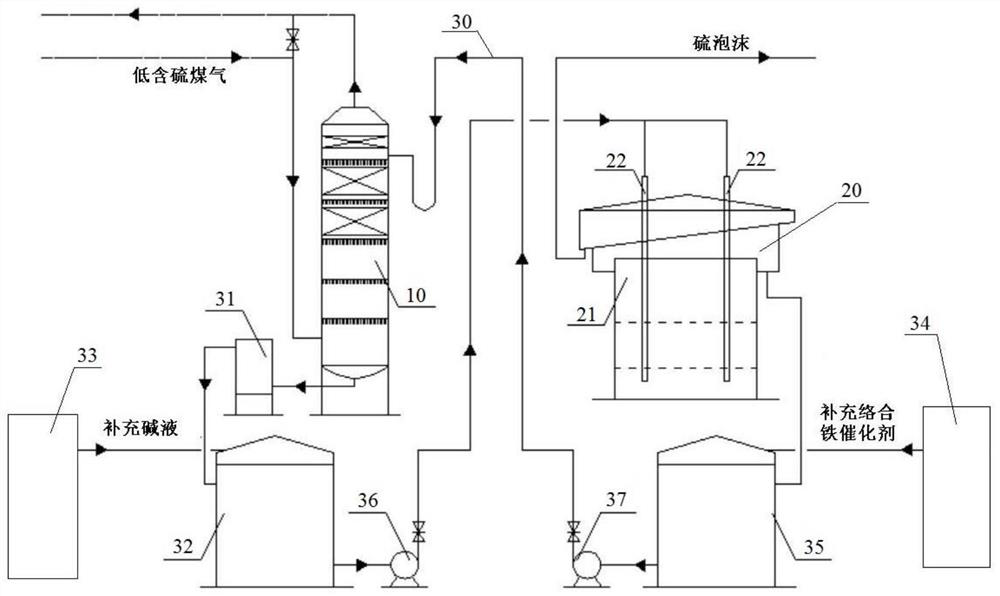

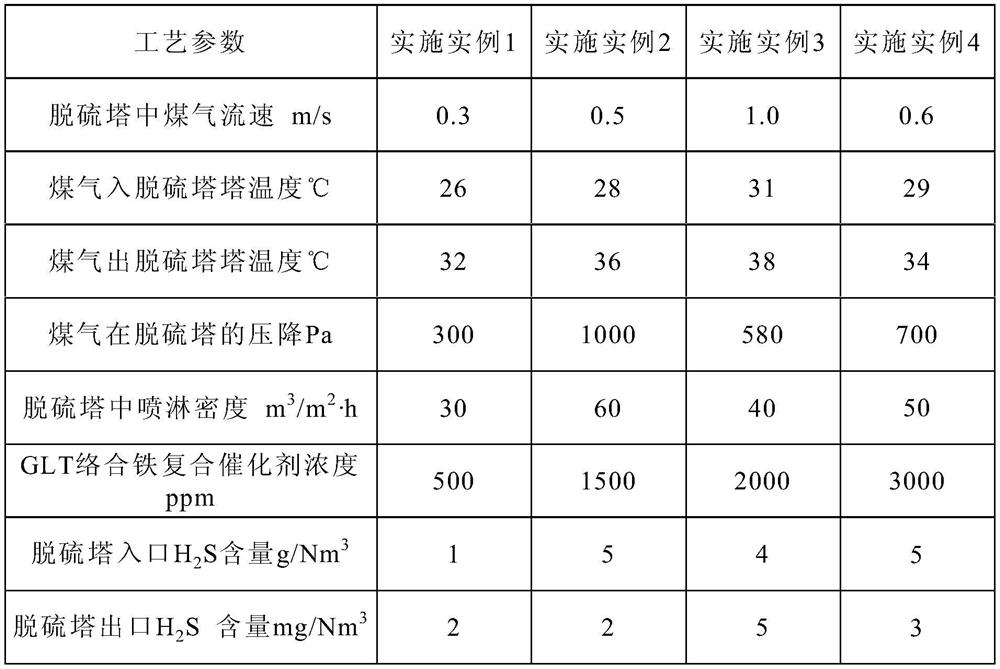

Single-tower desulfurization device and process for low-sulfur coal gas based on complex iron catalyst

InactiveCN112410082AReduce hydrogen sulfide contentImprove desulfurization efficiencyGas purification by liquid washingGas contaminants removalPtru catalystPhysical chemistry

The invention relates to the technical field of desulfurization, in particular to a single-tower desulfurization device and process for low-sulfur coal gas based on a complex iron catalyst. The single-tower desulfurization device for low-sulfur coal gas based on a complex iron catalyst comprises a desulfurization unit, a regeneration unit and a desulfurization liquid circulation unit. The desulfurization unit comprises a desulfurization tower, the desulfurization tower comprises a tower body, a spraying device is arranged at the upper part in the tower body, two packing layers and four layersof liquid distributors are further arranged in the tower body, the four layers of liquid distributors are arranged between a coal gas inlet and the spraying device at equal intervals from top to bottom, a first packing layer is arranged between the spraying device and a first liquid distributor, and a second packing layer is arranged between the first liquid distributor and a second liquid distributor. The desulfurization tower comprises two packing sections and two air spraying sections, and the two packing desulfurization sections and the two spraying desulfurization sections are combined, so that the desulfurization efficiency can be improved, and the hydrogen sulfide content of the low-sulfur coal gas is reduced to 5mg / Nm<3> or below.

Owner:WUHAN GLT ENERGY & ENVIRONMENTAL TECH CO LTD

Egg white hydrolysate and production method therefor

InactiveUS20130251851A1Reduced sulfur smellReduce hydrogen sulfide contentAnimal feeding stuffFood ingredientsHydrolysateProtease

An egg white hydrolysate having a reduced sulfur smell characteristic to egg white and a production method therefor are provided. An egg white hydrolysate having a low hydrogen sulfide content and a reduced sulfur smell can be obtained through a pretreatment step of denaturing egg white by thermally treating a diluted egg white solution under conditions of a pH of 9 to 12 and a temperature of 55° C. to 90° C., the diluted egg white solution having been prepared by diluting 1 part of liquid egg white with 0.4 to 3 parts of water, and a step of performing hydrolysis with a protease.

Owner:Q P CORP

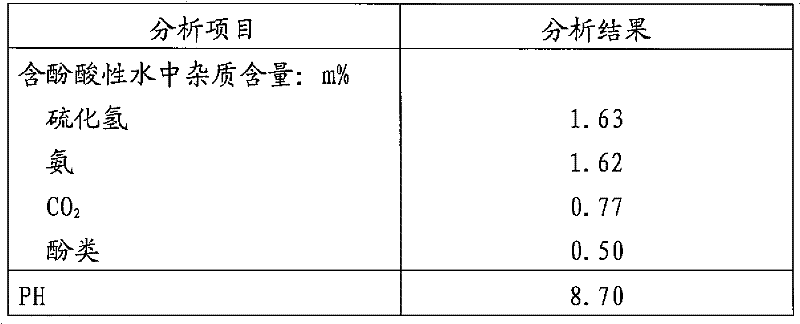

Method and system for treating phenol-containing acidic water by direct liquefaction with coal

ActiveCN102351358AAchieve recyclingEfficient recyclingMultistage water/sewage treatmentWater/sewage treatment by extractionDistillationGas phase

The invention relates to a method and system for treating phenol-containing acidic water by direct liquefaction with coal. The method comprises steps as follows: (1) phenol-containing acidic water enters an extraction tower to be in counterflow contact with an ether solvent, the phenol-containing ether solvent flows out of the tower top, and the dephenolized water flows out of the tower bottom; (2) the phenol-containing ether solvent from the extraction tower top enters an extract distillation tower after heat exchange, the ether solvent flowing out of the distillation tower top is cooled forcyclic use, and crude phenols are led out of the tower bottom; (3) the water from the extraction tower bottom enters a hydrogen sulfide stripping tower after heat exchange, ethers and hydrogen sulfide flows out of the tower top, the ethers is cooled for cyclic use, and the acidic gas containing rich hydrogen sulfide enters a sulfur recovery device; and (4) the water extracted from the hydrogen sulfide stripping tower bottom enters an ammonia stripping tower after heat exchange, caustic alkali is added into a liquid phase on the tower bottom, a gas phase containing rich ammonia flows out of the tower top, and purified water flows out of the tower bottom. The purified water obtained by using the invention can be directly used as influent water for biochemical treatment.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Hydrogen sulfide scrubber using polymeric amine and associated methods

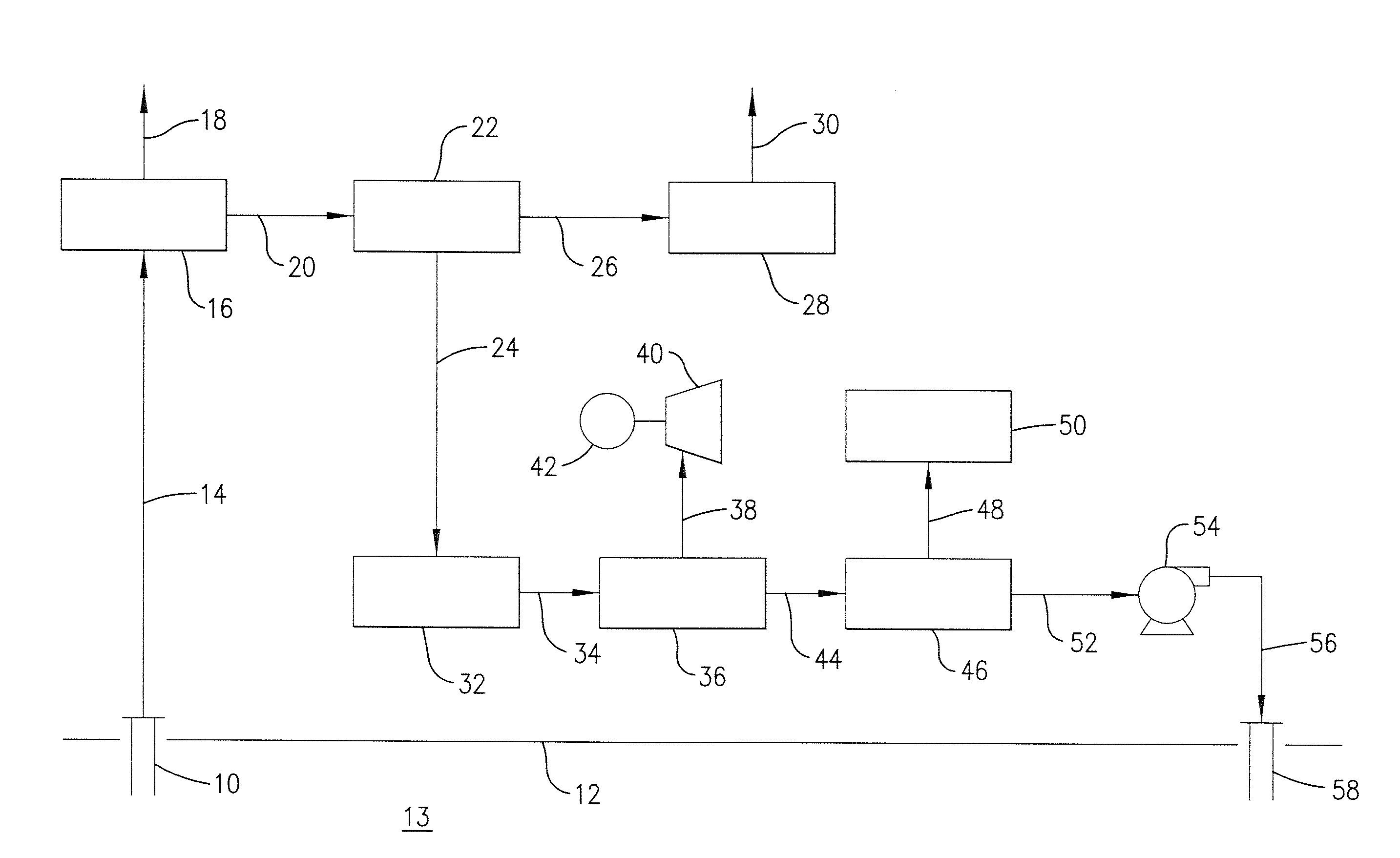

ActiveUS20050274256A1Reduce needCost effectiveDispersed particle filtrationUsing liquid separation agentEngineeringCirculating pump

A hydrogen sulfide scrubber includes first and second scrubber tanks with scrubber media contained therein. Scrubbing solution circulators each include a dispenser for dispensing scrubbing solution into contact with the scrubber media, a sump for collecting the scrubbing solution after contact with the scrubber media, and a circulating pump for circulating the scrubbing solution from the sump back to the dispenser after contact with the scrubber media. A polymeric amine supply is provided for supplying a polymeric amine to the scrubbing solution in the second tank. The scrubbing solution in the first tank may be charged with the polymeric amine by a charging line extending from the second tank to the first tank. In other embodiments, a regenerative blower and associated nozzle may be used to generate a scrubbing solution mist in the space beneath the scrubber media and above the sump.

Owner:Q2 TECH

Desulphurisation process

ActiveUS8702974B2Reduce hydrogen sulfide contentHydrogenGas treatmentOrganosulphur compoundPtru catalyst

A process for desulphurizing hydrocarbons includes passing a mixture of hydrocarbon and hydrogen over a hydrodesulphurization catalyst to convert organosulphur compounds present in the hydrocarbon to hydrogen sulphide, passing the resulting mixture over a hydrogen sulphide sorbent including zinc oxide to reduce the hydrogen sulphide content of the mixture, and passing the hydrogen sulphide-depleted mixture over a further desulphurization material. The further desulphurization material includes one or more nickel compounds, a zinc oxide support material, and optionally one or more promoter metal compounds of iron, cobalt, copper and precious metals. The desulphurization material has a nickel content in the range 0.3 to 20% by weight and a promoter metal compound content in the range 0 to 10% by weight.

Owner:JOHNSON MATTHEY PLC

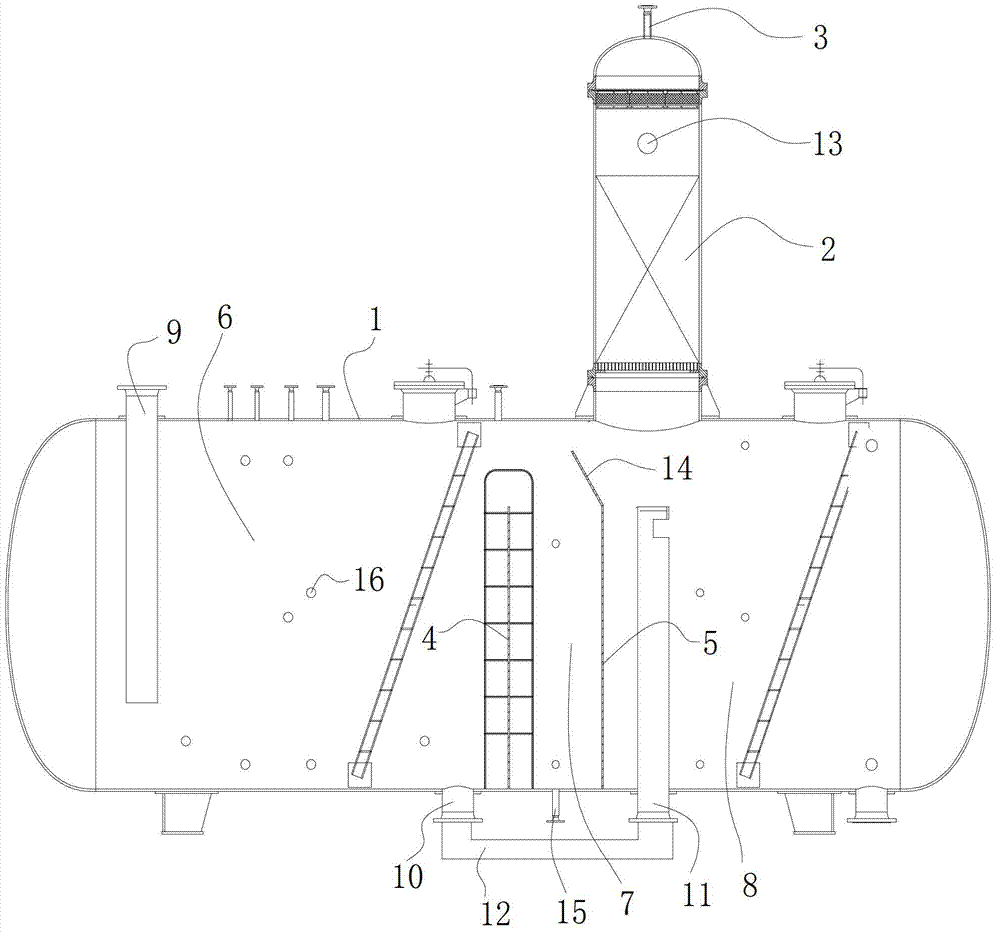

Flash evaporation dealkylation tank for desulfurating pregnant solution

InactiveCN102728087AAvoid Tower Dash AccidentsRemove completelyDispersed particle separationGaseous fuelsEngineeringFlash evaporation

The invention discloses a flash evaporation dealkylation tank for desulfurating pregnant solution, which can thoroughly remove hydrocarbons in pregnant solution. The flash evaporation dealkylation tank comprises a tank body, wherein the top of the tank body is provided with a gas dividing bag, a gas outlet is arranged on the gas dividing bag, the tank body is internally provided with a first clapboard and a second clapboard, the inner cavity of the tank body is divided into a pregnant solution flash evaporation chamber, an oil skimming chamber and a dealkylated pregnant solution storing chamber by the first clapboard and the second clapboard, the upper part of the pregnant solution flash evaporation chamber is communicated with the gas dividing bag, the upper part of the oil skimming chamber is communicated with the upper part of the dealkylated pregnant solution storing chamber, a pregnant solution inlet and a dealkylated pregnant solution outlet are arranged on the pregnant solution flash evaporation chamber, and a dealkylated pregnant solution inlet is arranged on the dealkylated pregnant solution storing chamber. According to the flash evaporation dealkylation tank with the structure, firstly, the light hydrocarbon components in the pregnant solution can be removed by the pregnant solution flash evaporation chamber by means of flash evaporation, and secondly, the heavy hydrocarbon components in the pregnant solution can be removed by the dealkylated pregnant solution storing chamber in a stewing way, so that the hydrocarbons contained in the pregnant solution can be thoroughly removed. The flash evaporation dealkylation tank can be popularized and applied in the field of purifying equipment.

Owner:CHENGDU DEMEI ENG TECH

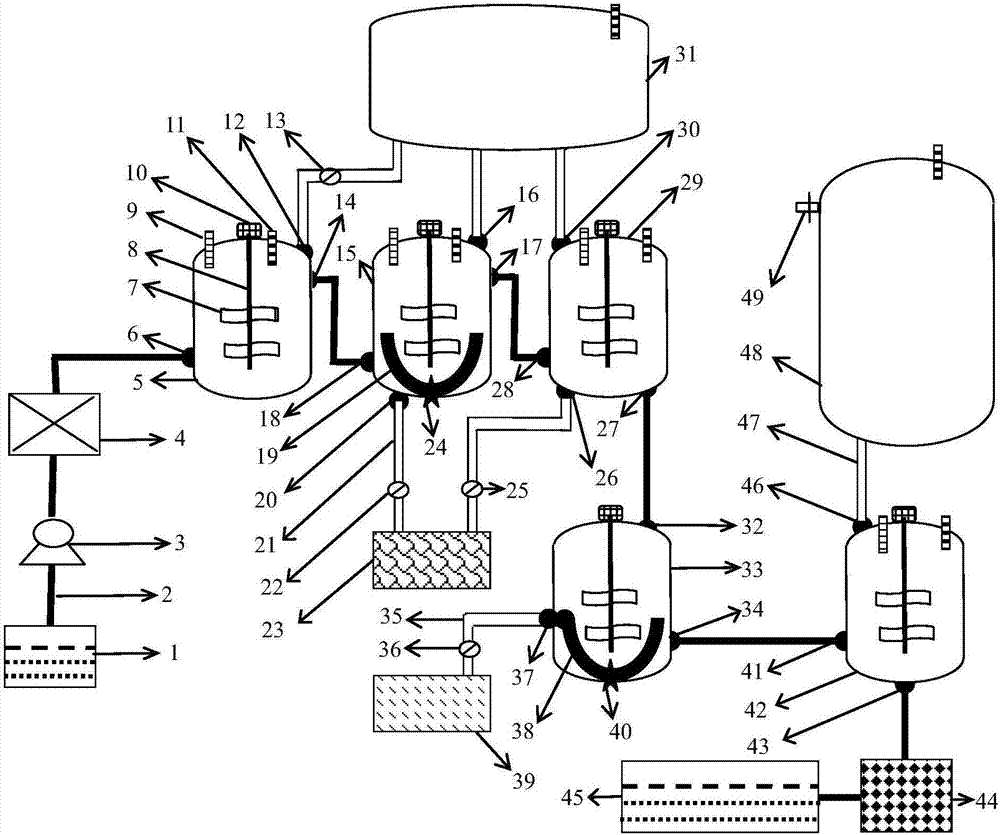

Sludge thermal hydrolysis and anaerobic digestion integrated treatment process system

PendingCN107879583AEasy to dehydrateReduce productionSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationProcess systemsAerobic digestion

The invention discloses a sludge thermal hydrolysis and anaerobic digestion integrated treatment process system. The process system comprises a sludge feed pond, a sludge pipe, a sludge feed pump, a sludge concentrator, a pulping tank, an agitation blade, an agitation shaft, a temperature sensor, an agitation motor, a pressure sensor, a thermal hydrolysis reaction tank, a thermal hydrolysis catalyzing pipe filled with a nickel-based catalyst, a vapor generator, a decompression tank, a vapor storage tank, an advanced oxidation reaction tank, an ozone pipe, an ozone catalyzing pipe filled with atitanium-based catalyst, an ozone generator, a digestion tank, a plate-and-frame filter press, a sludge discharge pond, a methane gas connecting pipe and a methane gas storage tank. The sludge thermal hydrolysis and anaerobic digestion integrated treatment process system has the advantages of low energy consumption, strong bacterium killing capability, good sludge dehydration performance, small dry sludge output, high content of methane gas in biogas, low content of hydrogen sulfide and the like when being applied to sludge treatment.

Owner:北京达源环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com