Method for using process water as flushing water of reaction effluent in hydrocarbon hydrogenation process

A technology for process and process water, which is applied in the fields of hydrotreating process, petroleum industry, treatment of hydrocarbon oil, etc., and can solve problems such as unreported technical solutions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

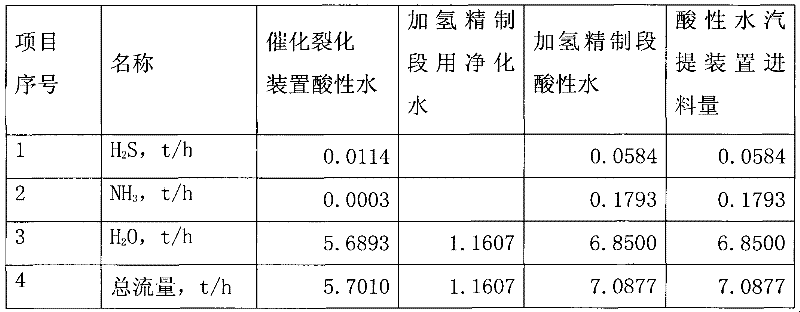

Embodiment 1

[0092] In a certain factory, there is a heavy oil catalytic cracking unit, which produces acidic water of catalytic cracking unit whose properties are shown in Table 2 (discharged from the reflux tank at the top of the catalytic cracking fractionation tower), and another set of medium-temperature coal tar with a conventional boiling range of 120-485 ° C. Hydroconversion unit with oil as raw material, the hydroconversion unit adopts two-stage hydrorefining and hydrocracking process in series, according to the conventional technical scheme, 6.8500t / h of purified water needs to be used as flushing water in the hydrorefining section, The acidic water produced by the hydrogenation unit whose properties are shown in Table 2 (discharged from the high-pressure separator in the hydrorefining section), according to the conventional process, the total amount of acidic water in the two channels is 12.7770t / h after mixing, and all the acidic water enters the acidic water stripping treatment ...

Embodiment 2

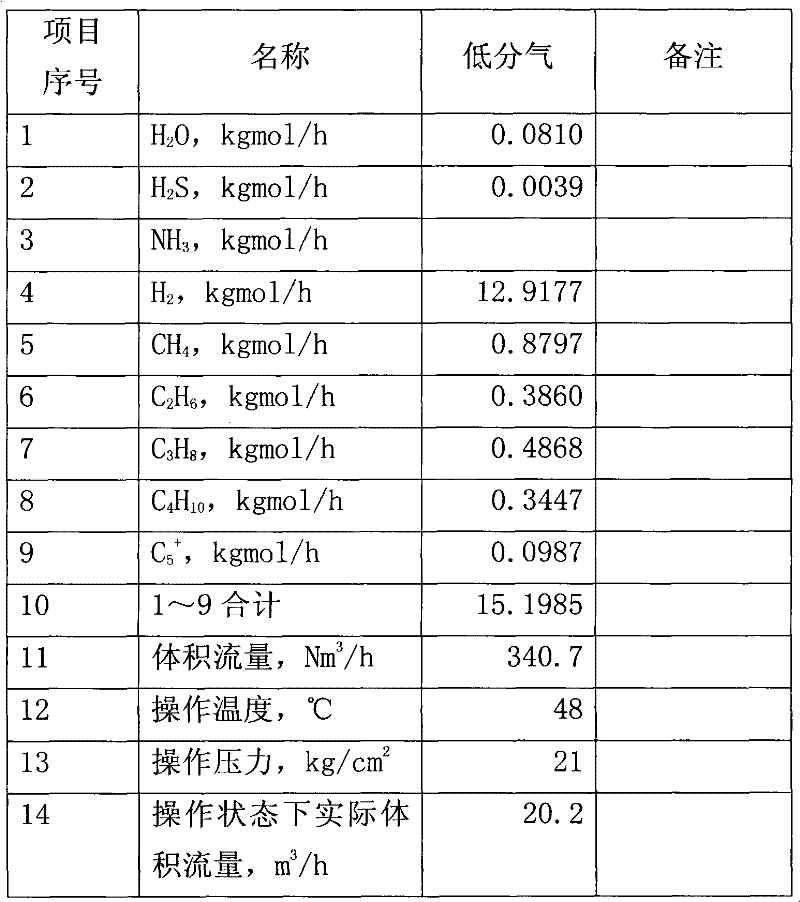

[0102] A set of anthracene oil hydroconversion unit in a factory adopts two-stage processes of hydrofining and hydrocracking. The reaction pressure of the anthracene oil hydrotreating section is 16.8MPa. High-separation gas and hot high-separation oil, the operating pressure of the hot high-pressure separation part is 15.9MPa, and the operating temperature is 280°C. After the hot high-separation gas is cooled to 180°C, it is injected with flushing water, and after further cooling to 48°C, the entry pressure is 15.3MPa and the temperature The cold high-pressure separation at 48°C is partially separated into cold high-separation gas SV, cold high-separation oil SL and cold high-separation water SW.

[0103] Simultaneously the hydrocracking of anthracene oil hydrocracking section produces the property that the low-pressure separator of the fractionation part that produces oil is as table 4 containing hydrogen sulfide low part gas need dehydrogen sulfide, according to the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com