Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1219 results about "Oil processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Statistical determination of historical oilfield data

InactiveUS20090194274A1Optimizing and increasing productionElectric/magnetic detection for well-loggingSurveyProduction optimizationOil processing

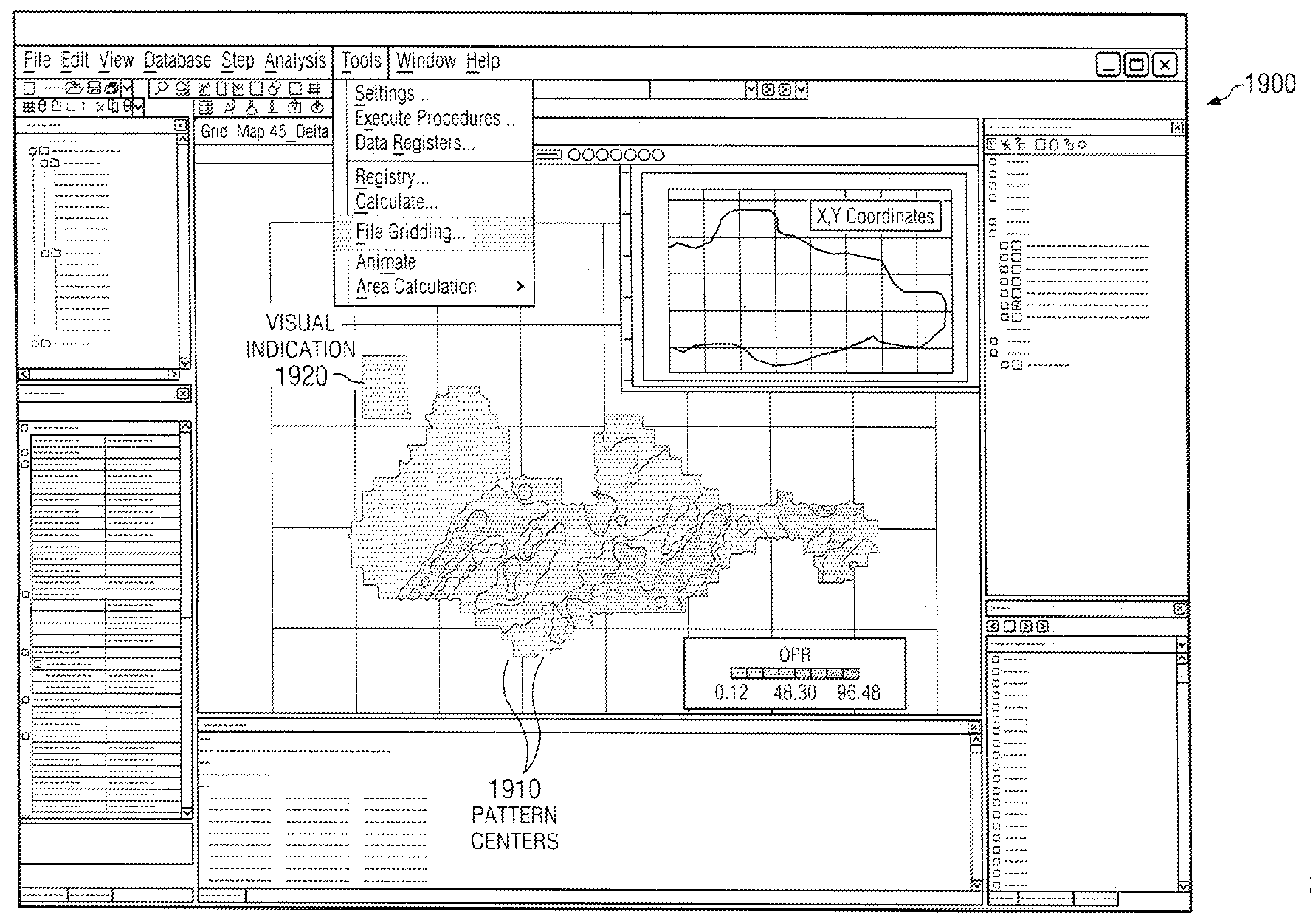

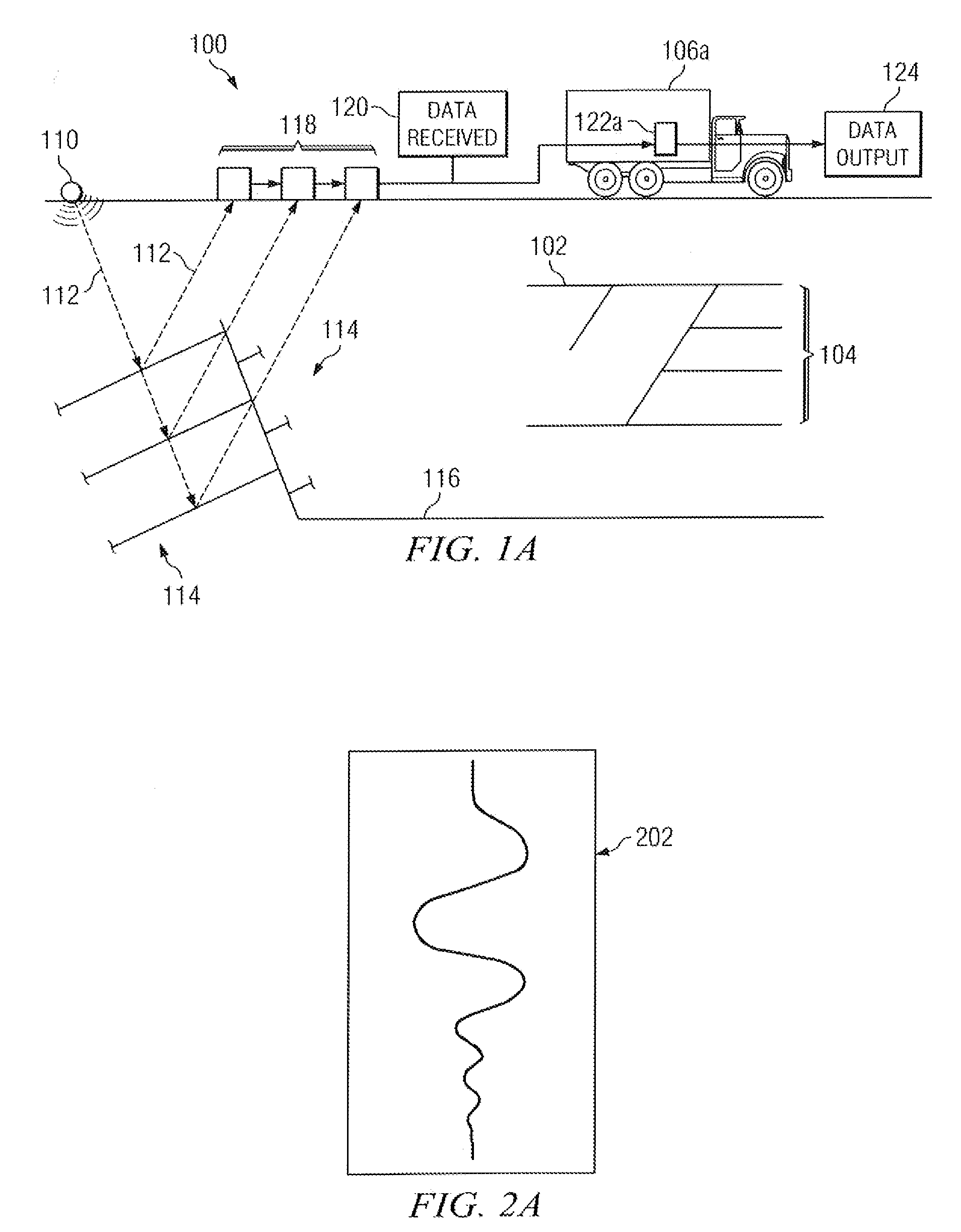

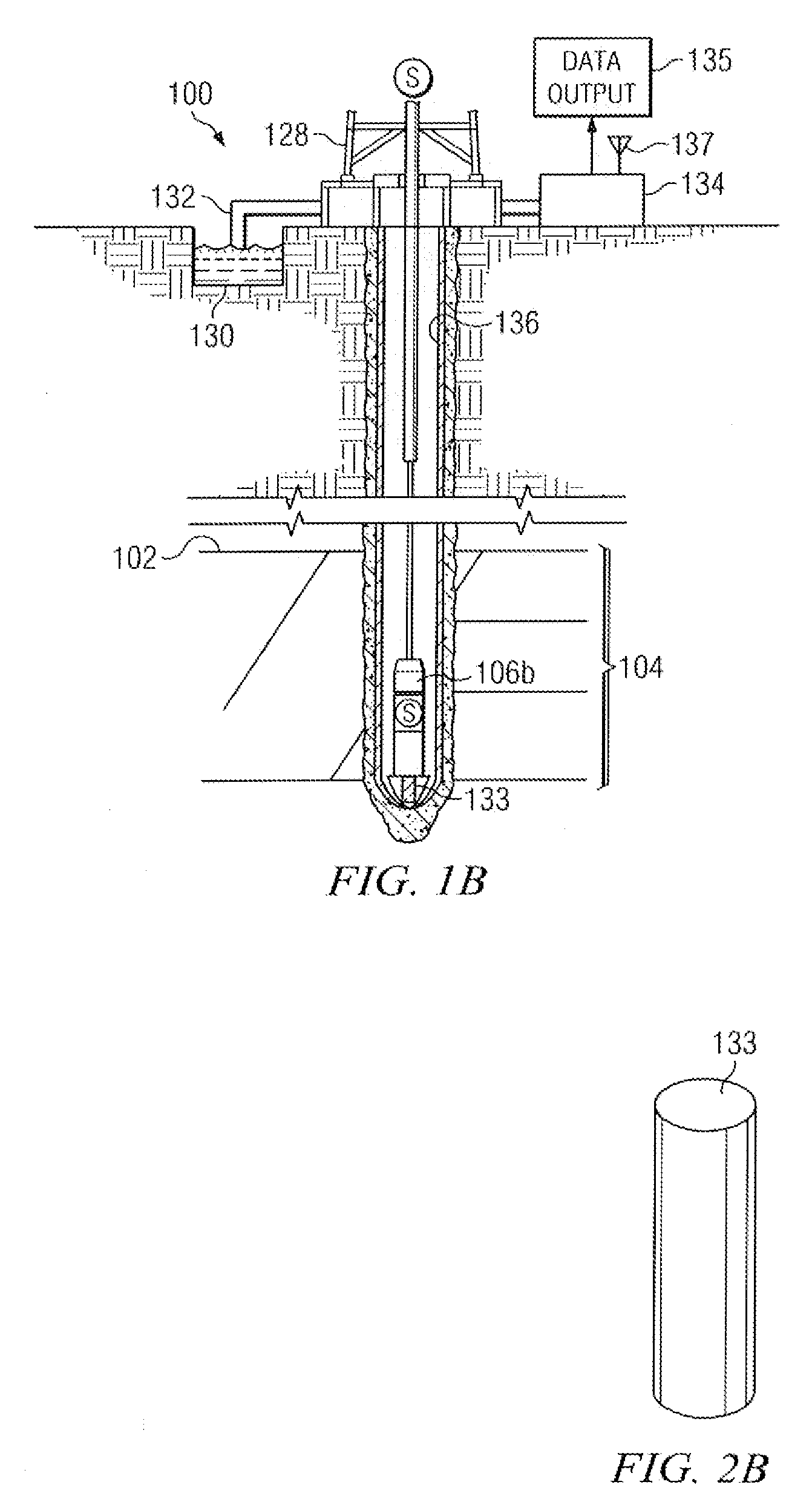

A method, system, and computer program product for performing oilfield surveillance operations. The oilfield has a subterranean formation with geological structures and reservoirs therein. The oilfield is divided into a plurality of patterns, with each pattern comprising a plurality of wells. Historical production / injection data is obtained for the plurality of wells. Two independent statistical treatments are performed to achieve a common objective of production optimization. In the first process, wells and / or patterns are characterized based on Heterogeneity Index results and personalities with the ultimate goal of field production optimization. In the second process, the history of the flood is divided into even time increments. At least two domains for each of the plurality of wells are determined. Each of the at least two domains are centered around each of the plurality wells. A first domain of the at least two domains has a first orientation. A second domain of the at least two domains has a second orientation. An Oil Processing Ratio is determined for each of the at least two domains, then an Oil Processing Ratio Strength Indicator is calculated. At least one Meta Pattern within the field is then identified. An oilfield operation can then be guided based either on the well and / or pattern personality or the at least one Meta Pattern.

Owner:SCHLUMBERGER TECH CORP

Comprehensive extraction method for extracting tea seed oil, tea saponin and tea seed polysaccharide from tea seeds or camellia seeds

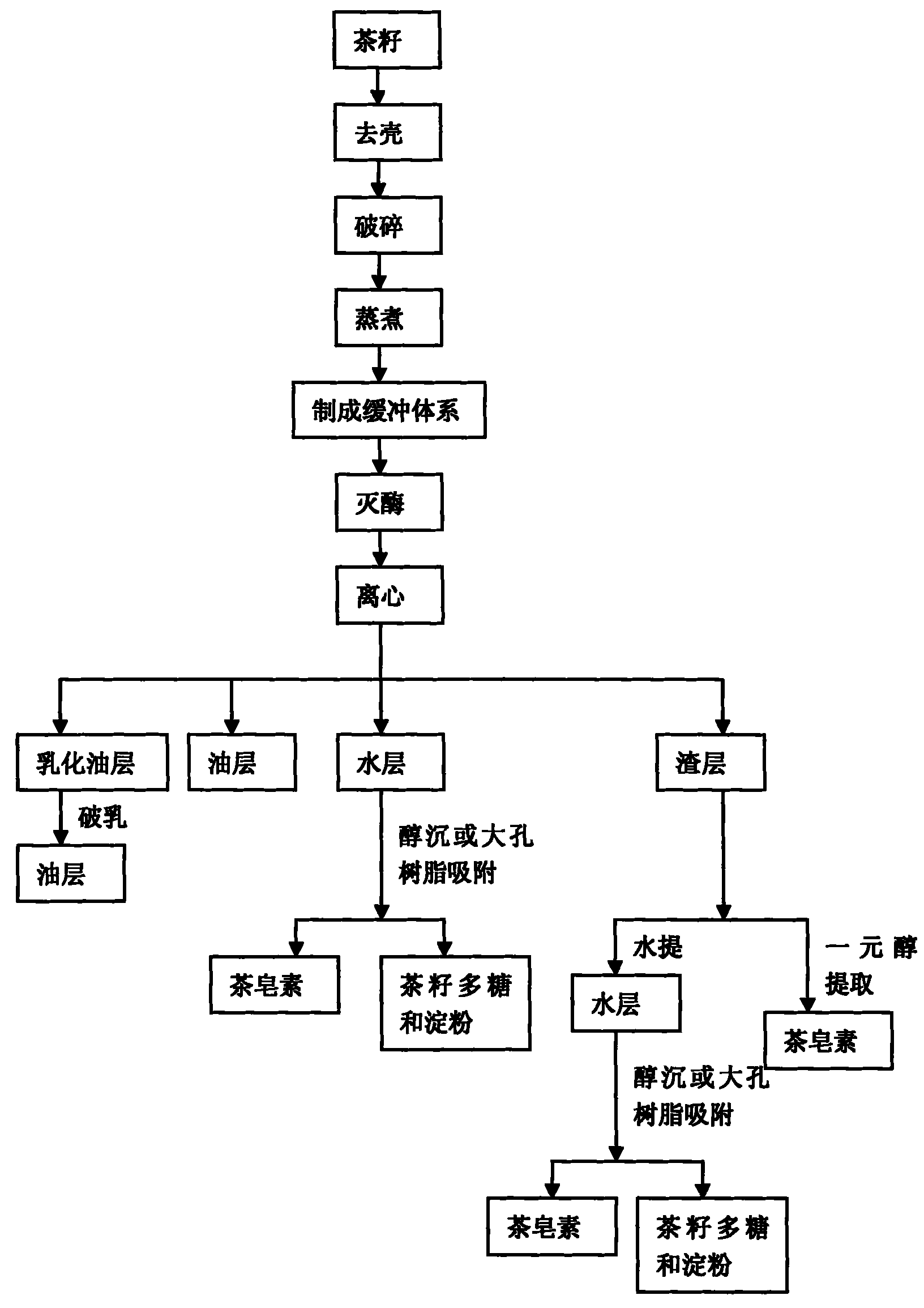

InactiveCN101942355AHigh purityRealize comprehensive utilization and developmentSugar derivativesSteroidsOil processingSlag

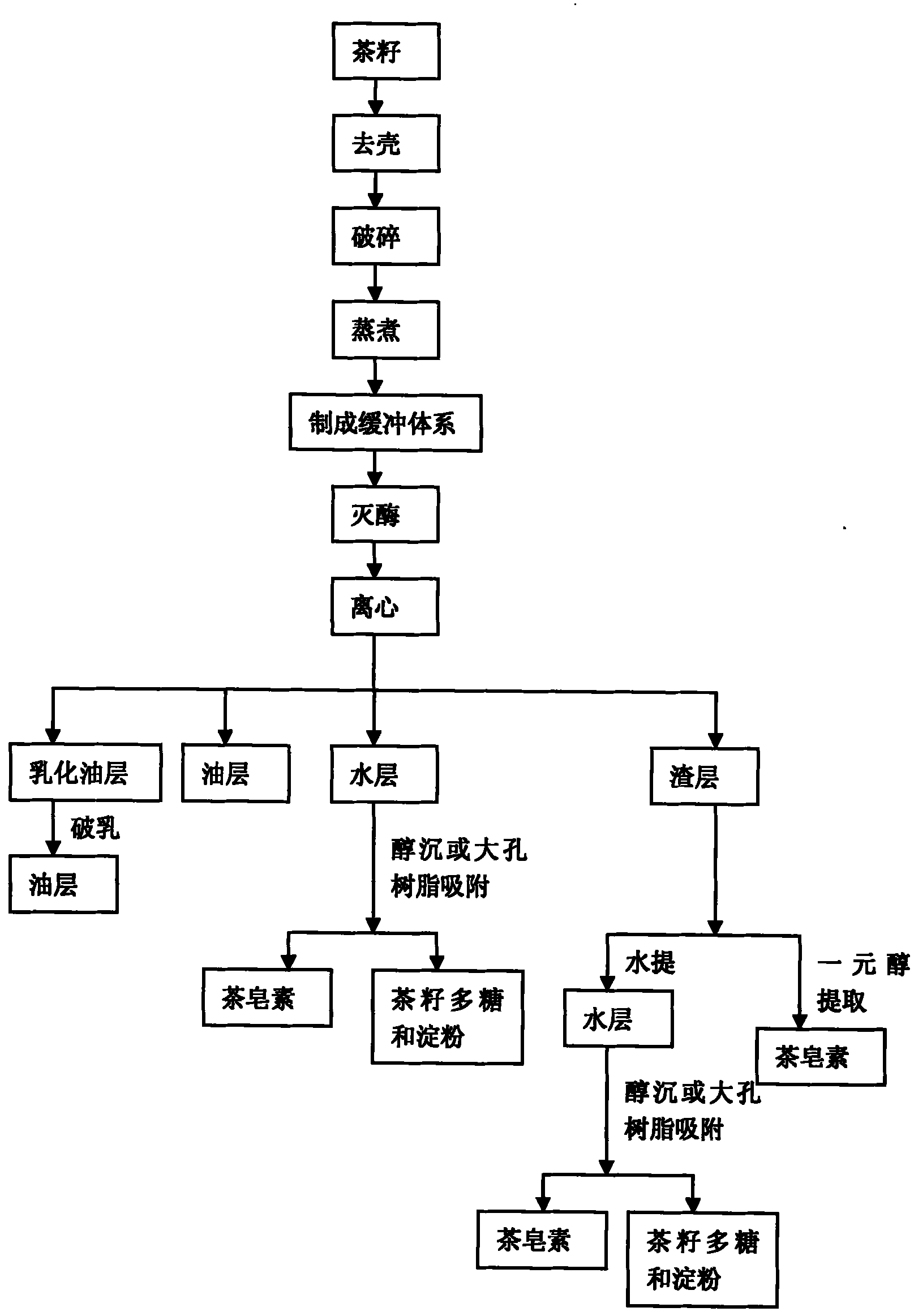

The invention discloses a comprehensive extraction method for extracting tea seed oil, tea saponin and tea seed polysaccharide from tea seeds or camellia seeds, belonging to the process fields of grain and oil processing and byproduct extraction. The method comprises the following steps of: with shelled tea seeds as a raw material, firstly, cooking to produce oil; then, adding an exogenous enzyme to obtain a boiled oil layer of a first level an emulsified oil layer, a water layer and a slag layer through zymolysis, blanching and still standing; demulsifying the emulsified oil layer to take boiled oil of a second level; mixing the oil layers of the two levels; centrifugalizing to obtain the tea seed oil; depositing the water layer in alcohol to separate the tea saponin and the tea seed polysaccharide; leaching the slag layer with water or monohydric alcohol to further separate the tea saponin and the tea seed polysaccharide; and purifying a clear solution which is leached with the water or the alcohol with a macroporous absorption resin chromatography column, eluting a resin adsorbate with a base and then an ethanol and collecting an ethanol eluant to obtain high-purity tea saponin. The tea seed oil, the tea saponin and the tea seed polysaccharide are synchronously prepared, thus the invention realizes that a tea seed or camellia seed resource is comprehensively extracted and utilized and has the advantages of simple process, less needed equipment and low cost.

Owner:SHANGHAI NORMAL UNIVERSITY

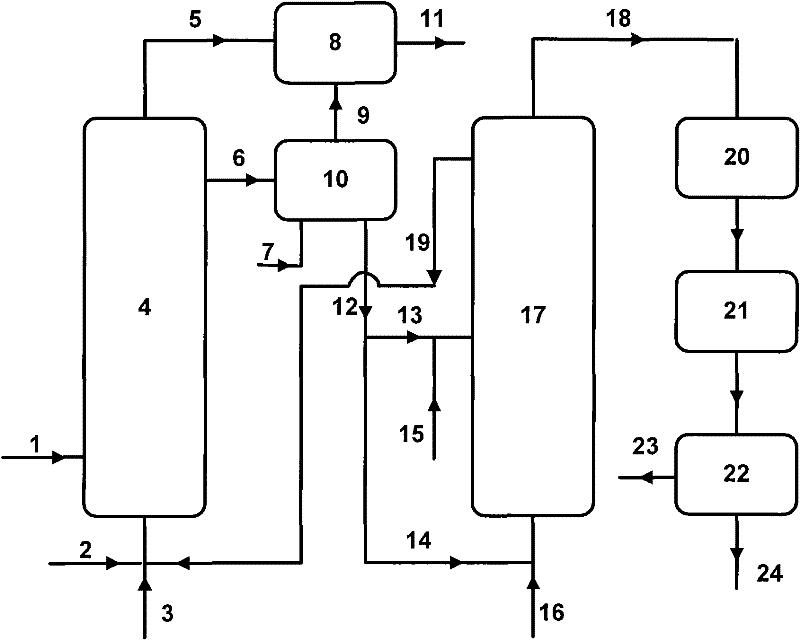

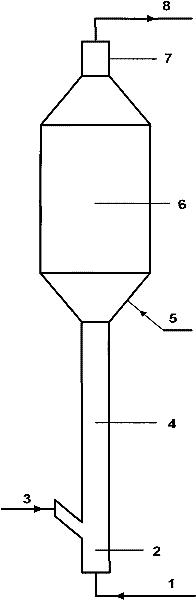

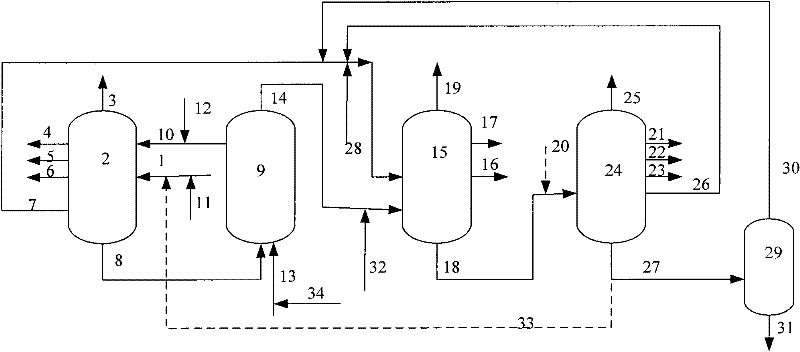

Method for combination processing heavy oil by pyrolysis and gasification

ActiveCN101451073AReasonable useImprove gasification efficiencyThermal non-catalytic crackingCoke ovensOil processingThermal energy

The invention relates to a heavy oil processing method by combining thermal cracking and gasification. A raw material is conducted to a reactor from the bottom of a gas-solid separation region, is dispersed into oil drops through an atomizer; a lightweight component of the oil drop is volatilized to form oil gas in the falling process of the oil drops in a thermal cracking region; a heavy component is condensed to form coke, wherein the oil gas carries out thermal cracking reaction; coke particles drop into a gasification region and carry out gasification reaction at a temperature of between 800 and 1,600 DEG C to generate synthetic gas; one part of residual fine coke particles drop into an ash hopper to form clinker; the other part of the residual fine coke particles and the generated gas flow upwards together, are contacted with the descending liquid drops and carry out heat exchange; gas phase and coke in the gas-solid separation region of the upper part of the rector are separated; the separated fine coke particles re-drop into the thermal cracking region and the gasification region and continuously react; and the separated gas phase flows out of the rector, enters a subsequent separation system and is separated into synthetic gas, dry gas, liquid gas, gasoline, diesel, oil slurry and other products. The method has high gasification efficiency and reasonable utilization of heat energy and reduces energy consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

A biologic organic fertilizer, and preparation method

InactiveCN1872803APromote growthImprove the ecological environmentBio-organic fraction processingClimate change adaptationOil processingPotassium

This invention relates to a method for manufacturing bioorganic fertilizer. The bioorganic fertilizer is manufactured by: mixing sugar industry waste, breeding industry waste, oil-processing waste, phosphoric fertilizer, trace element fertilizer and silicon fertilizer, and performing aerobic fermentation and post fermentation. The effective components of the bioorganic fertilizer are: organic matters (greater than or equal to 30%), N, P and K (greater than or equal to 8%), beneficial microorganisms (greater than or equal to 200,000,000 / g), active silicone (greater than or equal to 5%), magnetic components (0.25%), and Fe, Zn and Mo (0.5-1%). The bioorganic fertilizer has abundant raw material sources, and is environmentally friendly.

Owner:成官文

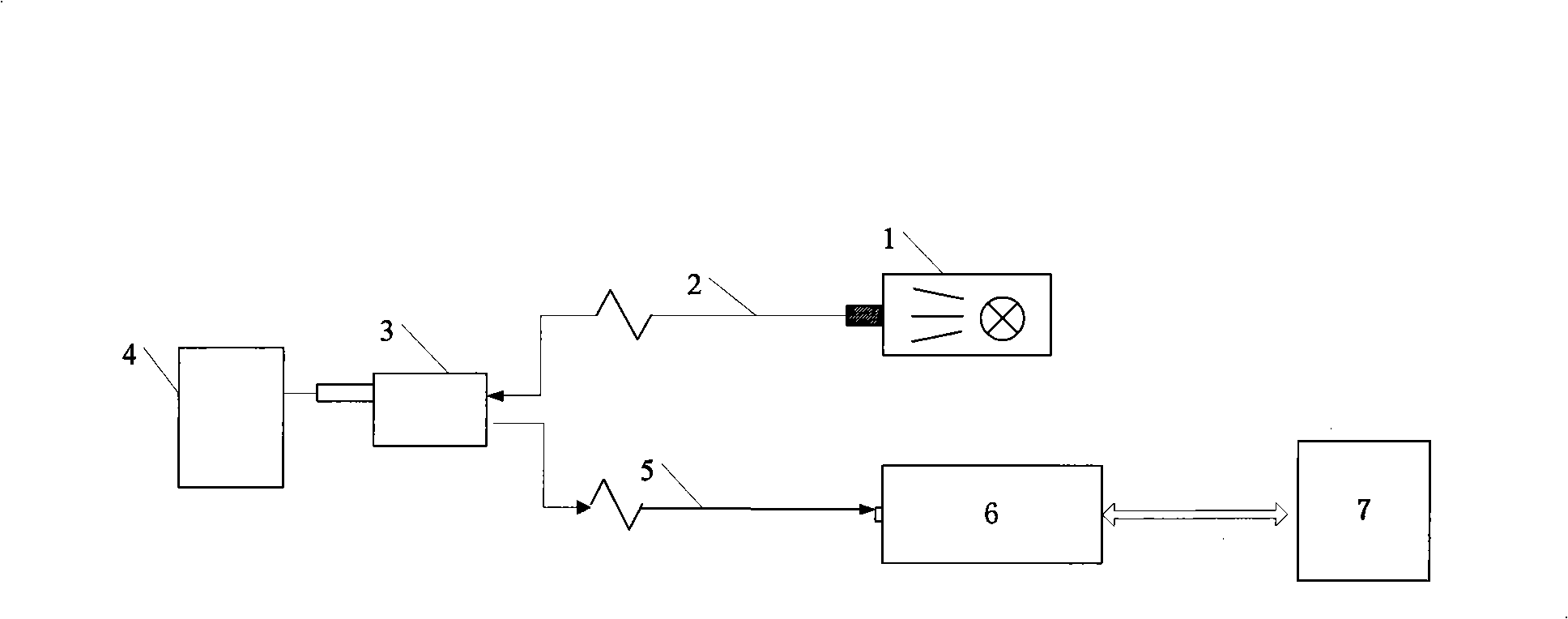

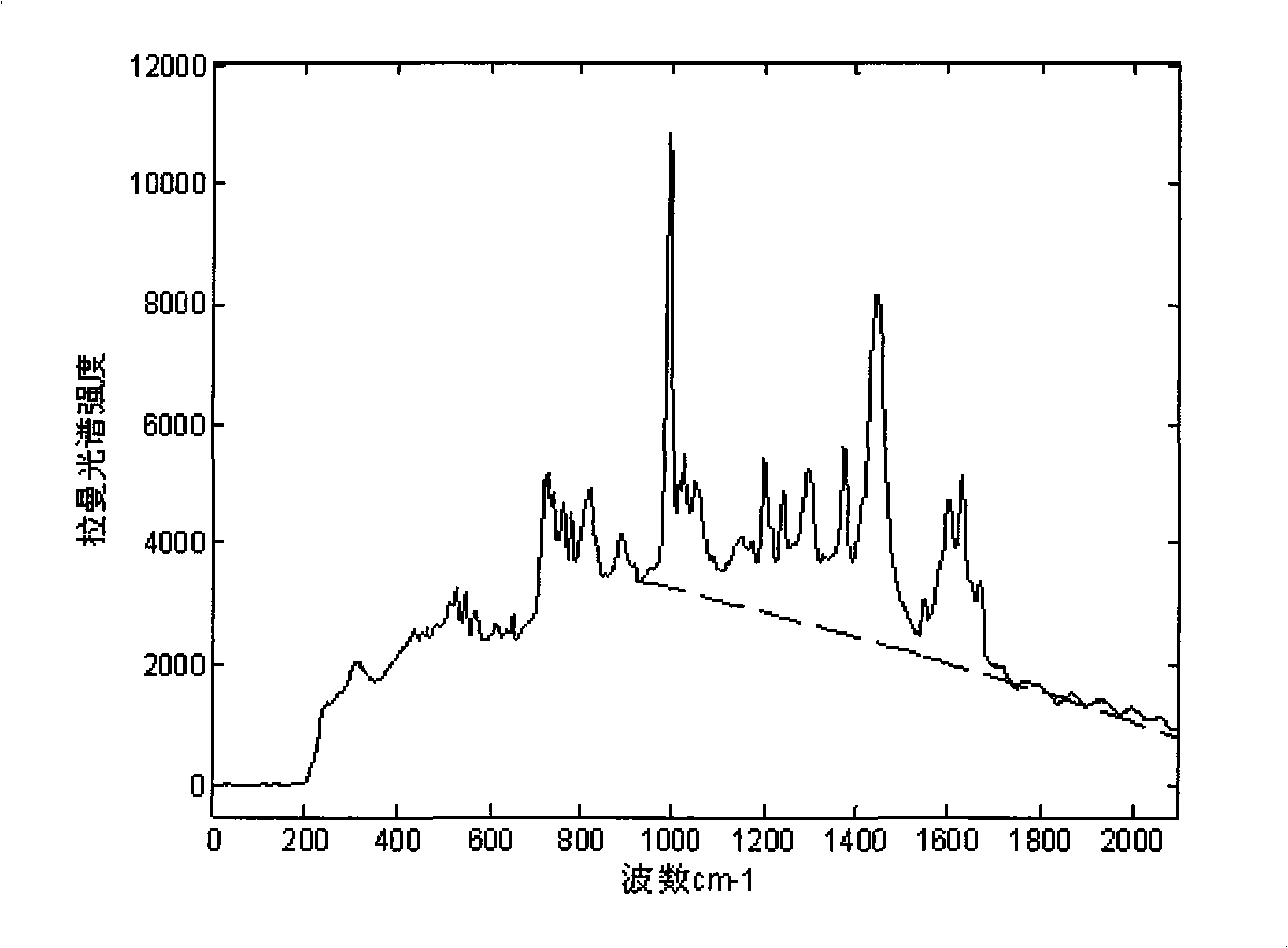

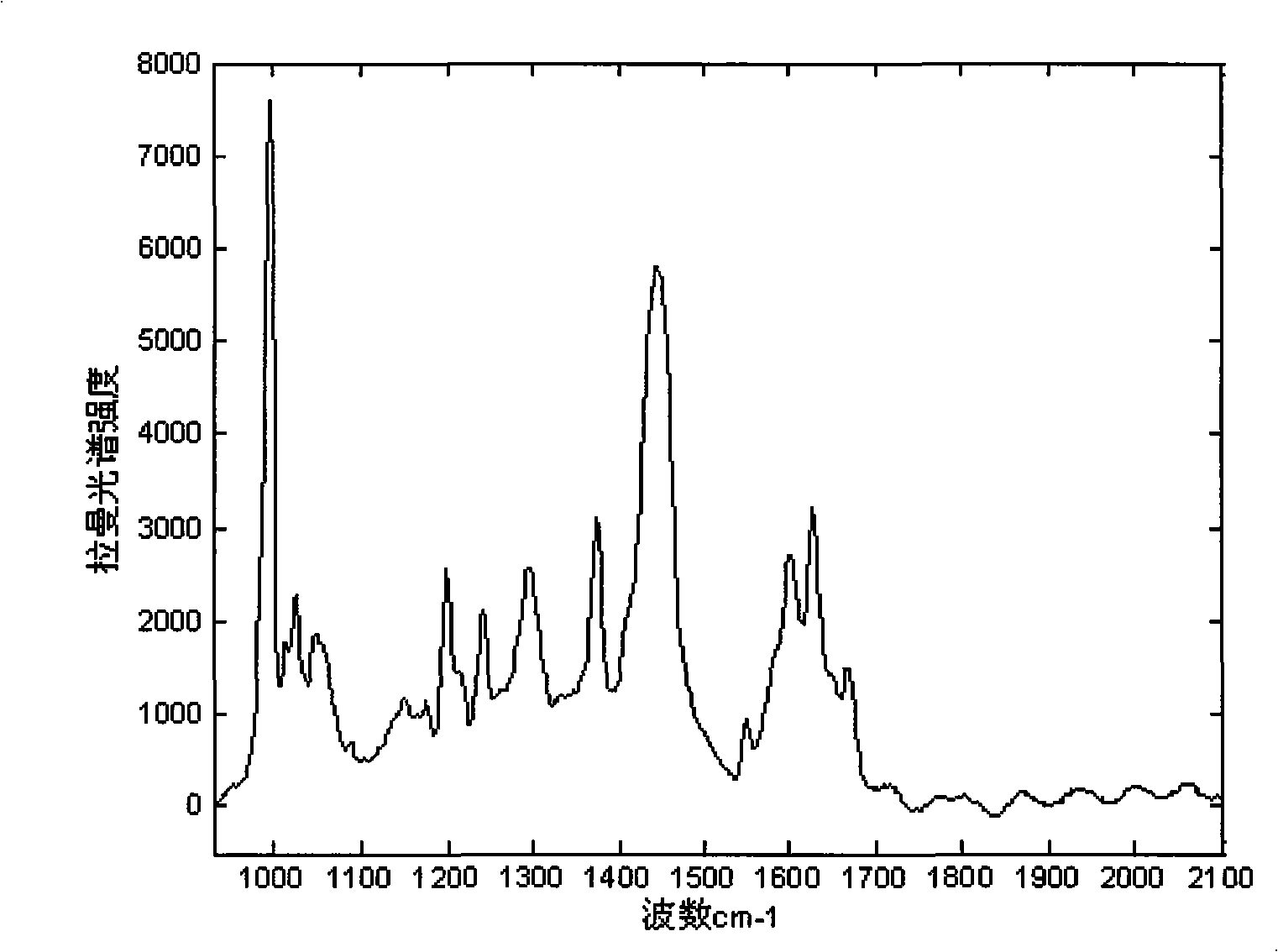

Method for measuring gasoline olefin content based on Raman spectrum

InactiveCN101403696AImprove detection accuracyReduced measurement timeRaman scatteringOil processingFiltration

The invention discloses a method used for measuring the content of gasoline olefin on the basis of Raman spectra, sequentially comprising the steps as follows: the content of olefin in a training sample is measured by a fluorescent indicator adsorption method or a multidimensional gas chromatography; the Raman spectra of the training sample is measured; the measured Raman spectra is preprocessed by smooth filtration, benchmark line correction and standard normalization; a gasoline olefin content correction model is established by applying a least squares support vector machine on the Raman spectra of the preprocessed training sample and the measured olefin content; the Raman spectra of the oil sample to be measured is measured and the Raman spectra is preprocessed by smooth filtration, benchmark line correction and standard normalization; and the olefin content of the oil sample to be measured is calculated according to the correction model. The method combines the Raman spectra with the least squares support vector machine to analyze the content of the olefin in the gasoline, obviously improves the detection precision, greatly shortens the measurement time simultaneously, has no consumption of the sample during the measurement process, and has important significance on the quality control during the oil processing.

Owner:ZHEJIANG UNIV

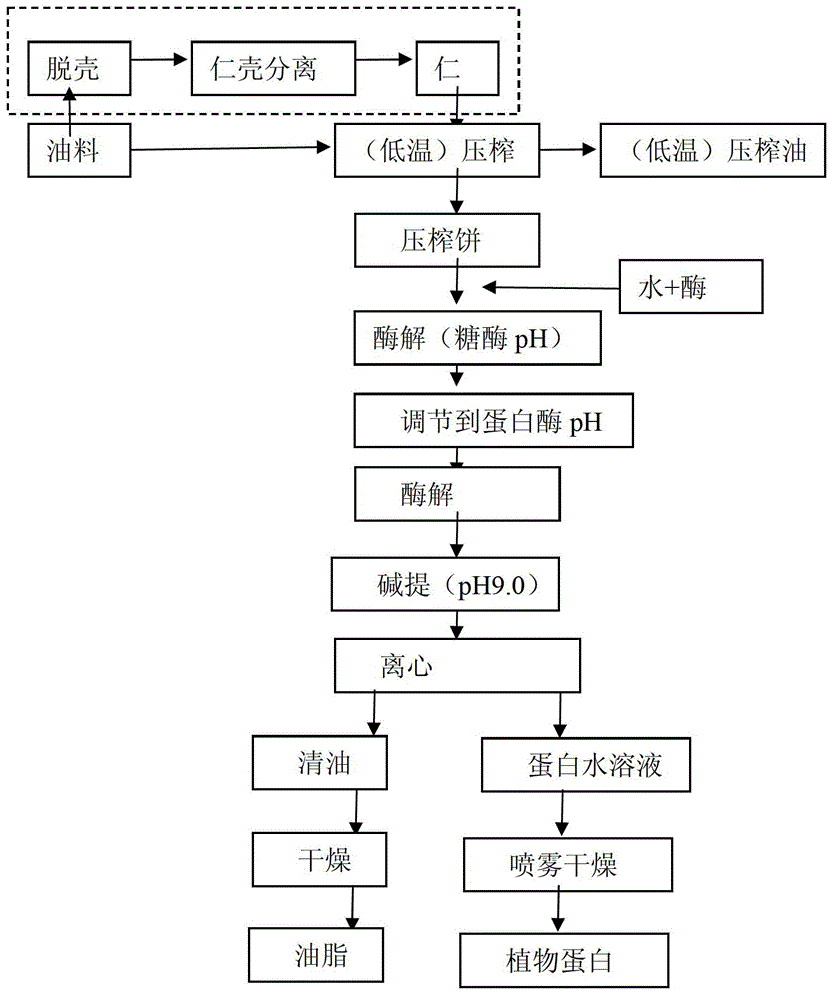

Method for preparing grease and protein from oil seed kernels by aqueous enzymatic method

InactiveCN102746938AQuality improvementHigh priceFatty-oils/fats productionFermentationOil processingOil and grease

The invention relates to a method for preparing grease and protein from oil seed kernels by an aqueous enzymatic method and belongs to the technical field of the application of the biotechnology to the grain and oil food processing. The method for preparing grease and protein from the oil seed kernels by the aqueous enzymatic method is characterized by comprising the following steps of 1) oil preparation through squeezing; 2) crushing; and 3) enzymolysis and drying: water and complex enzyme are added into treated squeezed cakes, the pH is regulated to the pH value and the temperature applicable to carbohydrase, and the enzymolysis is carried out for 15 to 90 minutes; the pH is regulated to the pH value and the temperature applicable to the protease, and the enzymolysis is carried out for 15 to 90 minutes; the pH is regulated to 9.0 after the enzyme reaction, and the stirring alkali extraction is carried out for 10 to 60 minutes at room temperature; boiled oil and protein water solution are separated through centrifugation; and the boiled oil is subjected to vacuum drying at 100 to 120 DEG C, grease products are obtained, the protein water solution is subjected to spraying drying, and plant protein is obtained. The method has the characteristics of high oil yield, low water consumption and low energy consumption, and the additional value of oil processing products can be improved.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

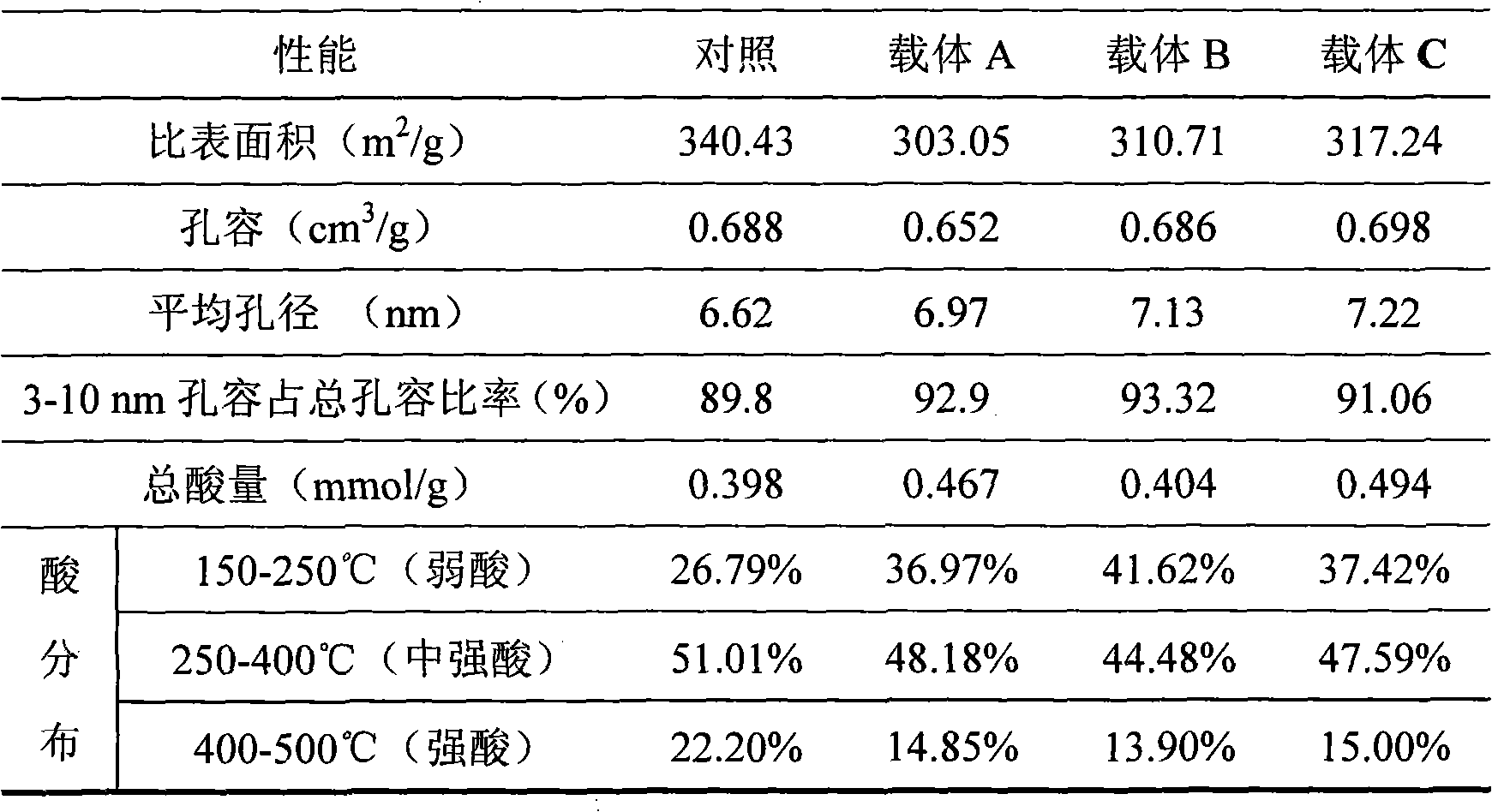

Modified carbon-coated alumina supporter with nucleocapsid structure and preparation method thereof

InactiveCN101327454ALarge specific surface areaLarge hole volumeCatalyst carriersCatalyst activation/preparationOil processingModified carbon

The present invention discloses a modified carbon-covered alumina support with a core-shell structure and a preparation method thereof. The modified carbon-covered alumina support of the present invention is a granule with the core-shell structure. A shell of the core-shell structure is alumina deposited with carbon, and an inner core of the core-shell structure is an industrial alumina support. The modified carbon-covered alumina support of the present invention has the advantages of high specific surface area, large pore volume, high mechanical strength, and the like; the aperture distribution is more concentrated; total acid quantity is increased obviously, and strong acid quantity is reduced; the modified carbon-covered alumina support can be directly used as a catalyst during certain processes and is more applicable to be used as a catalyst support, in particular as a hydrogenation treatment catalyst support during petroleum processing course.

Owner:EAST CHINA UNIV OF SCI & TECH

Alumina support containing silicon and titanium and preparation method thereof

ActiveCN1768945AImprove pore structureLarge specific surface areaCatalyst carriersPore distributionAluminium hydroxide

The invention discloses property-transformation alumina carrier which contains titanium and silica agent and its relative preparing method. Said silica agent is added in the sol process of aluminum hydroxide to improve the specific surface, pore diameter and pore capacity of alumina; after the sol process, individually using acid agent and alkali agent to adjust the pH value of mixed paste solution for several times to make the attained alumina with more centralized pore distribution; the titanium agent is added after the sol process and before the aging process, to improve the surface acid property, surface acid amount and B acid amount of carrier. In addition, the surface of alumina is modified by titanium to decrease the interactive condition between active metal and carrier, which can apply the diffusion of active metal components in the catalyst. The property transformation of said invention can be used as catalysis material when processing oil, especially as the catalyst carrier of hydrogenation treatment and hydrogenation transformation.

Owner:CHINA PETROLEUM & CHEM CORP +1

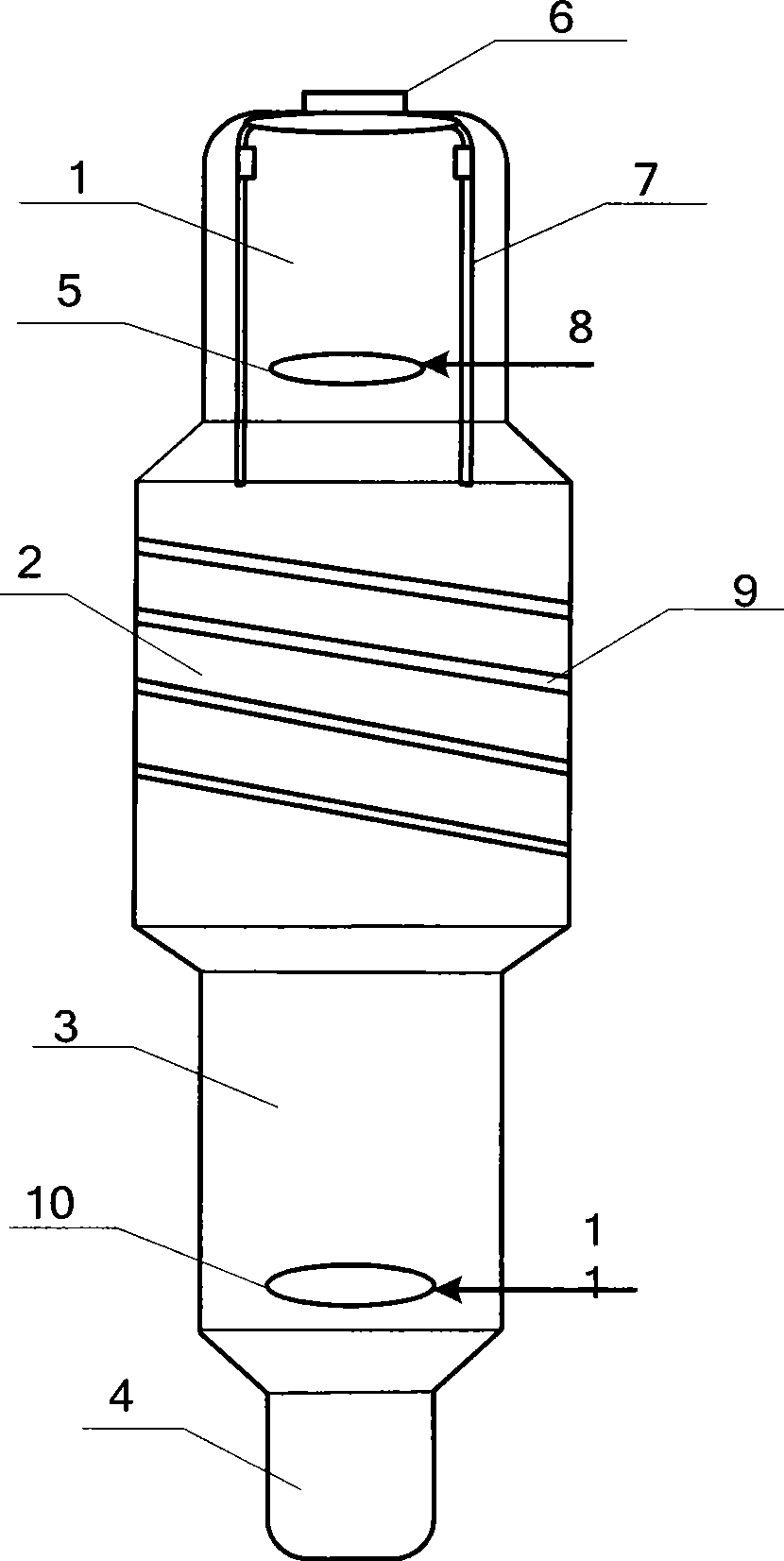

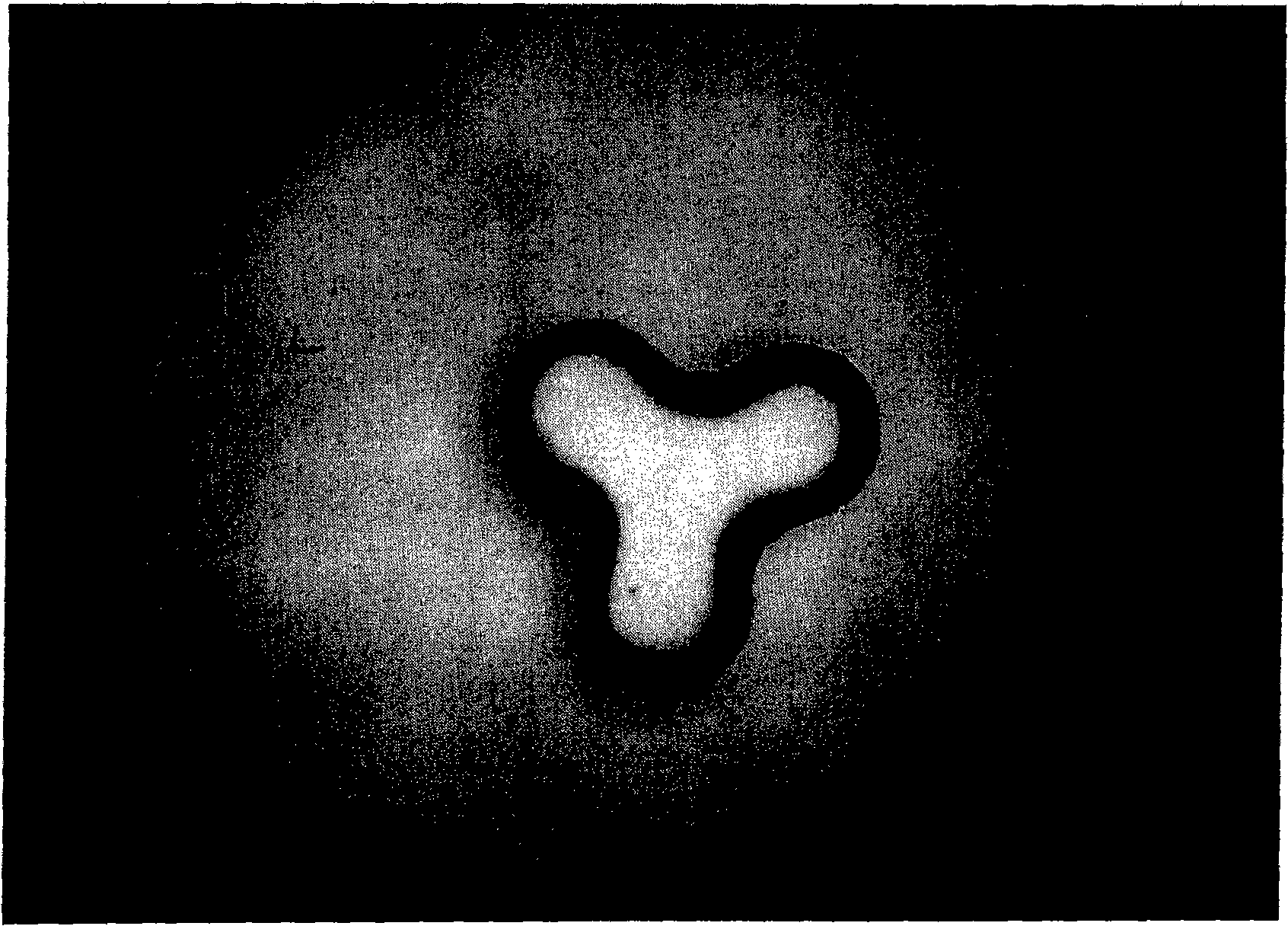

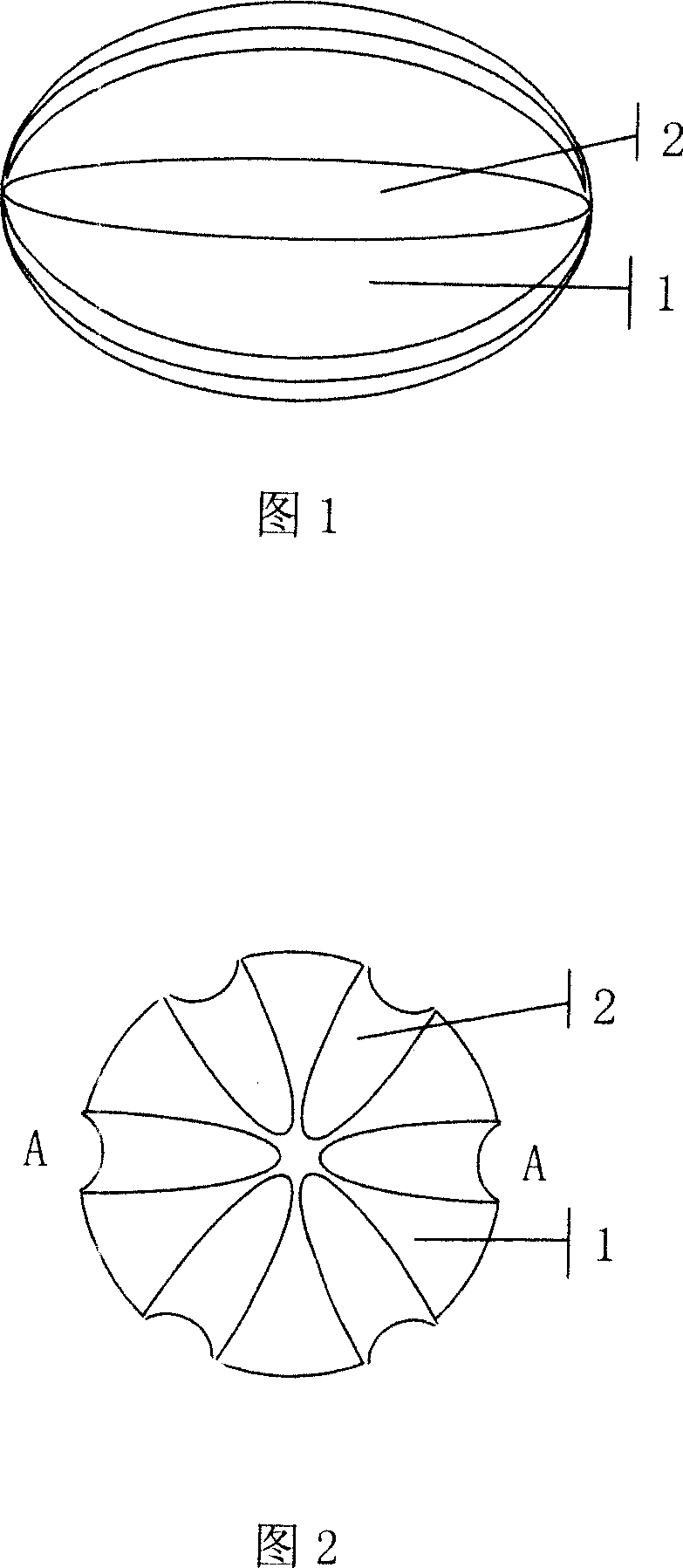

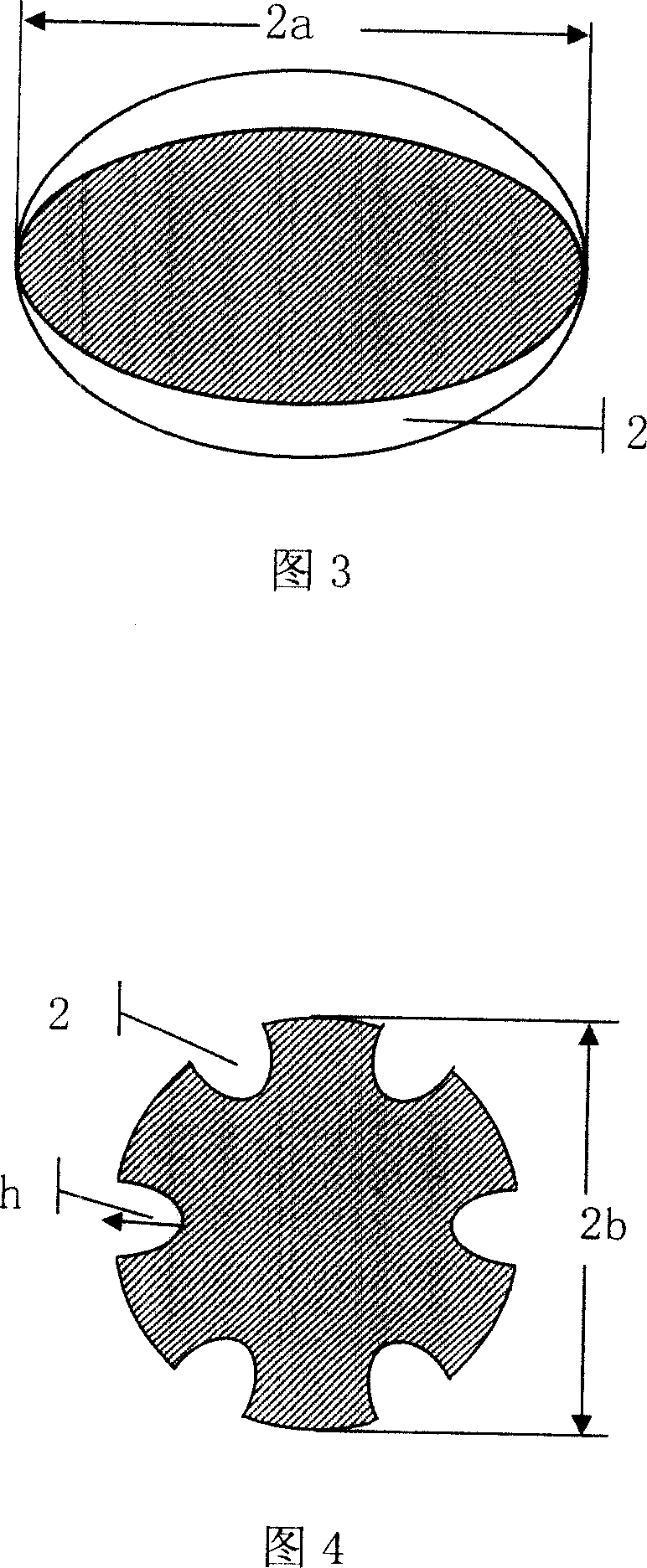

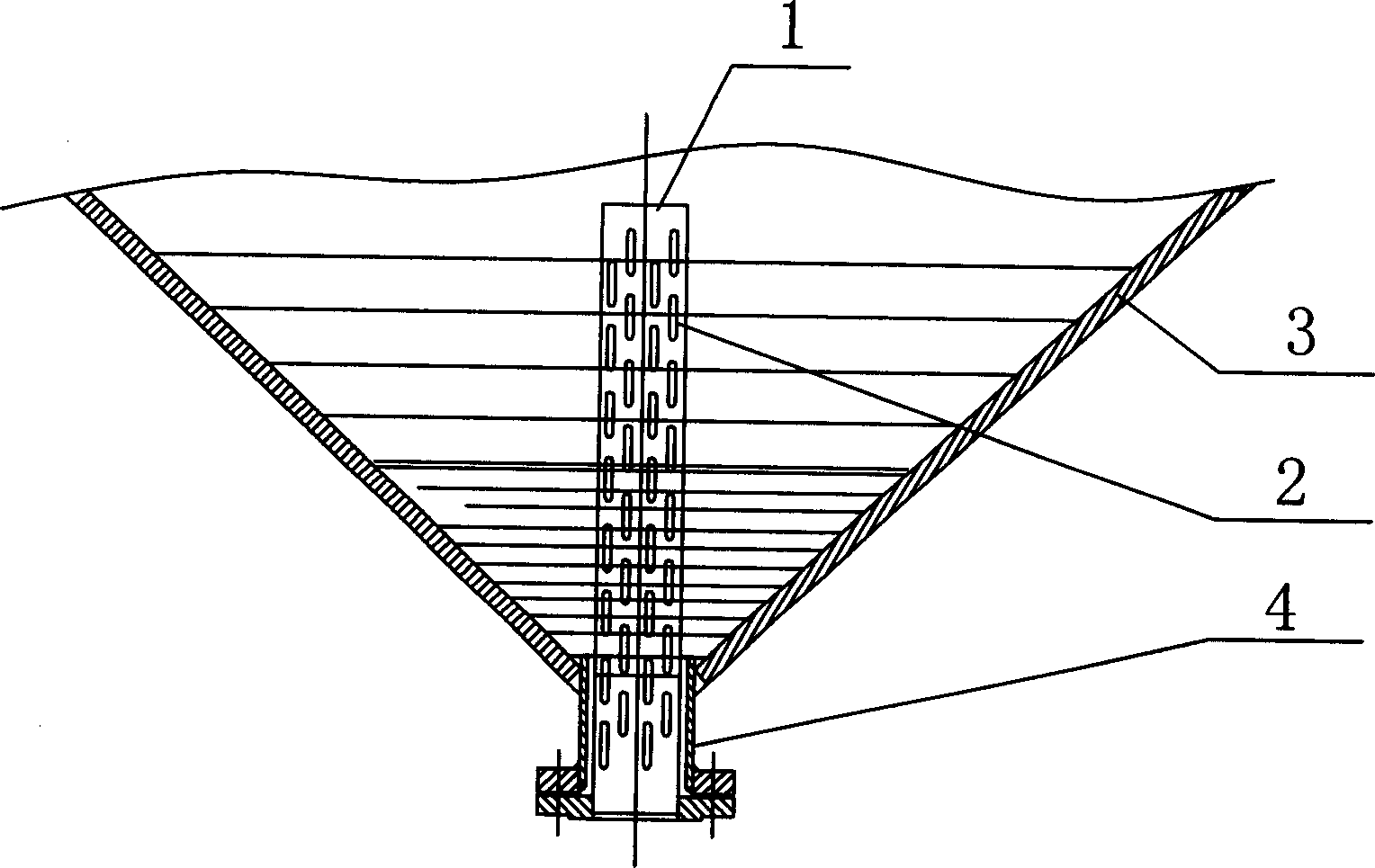

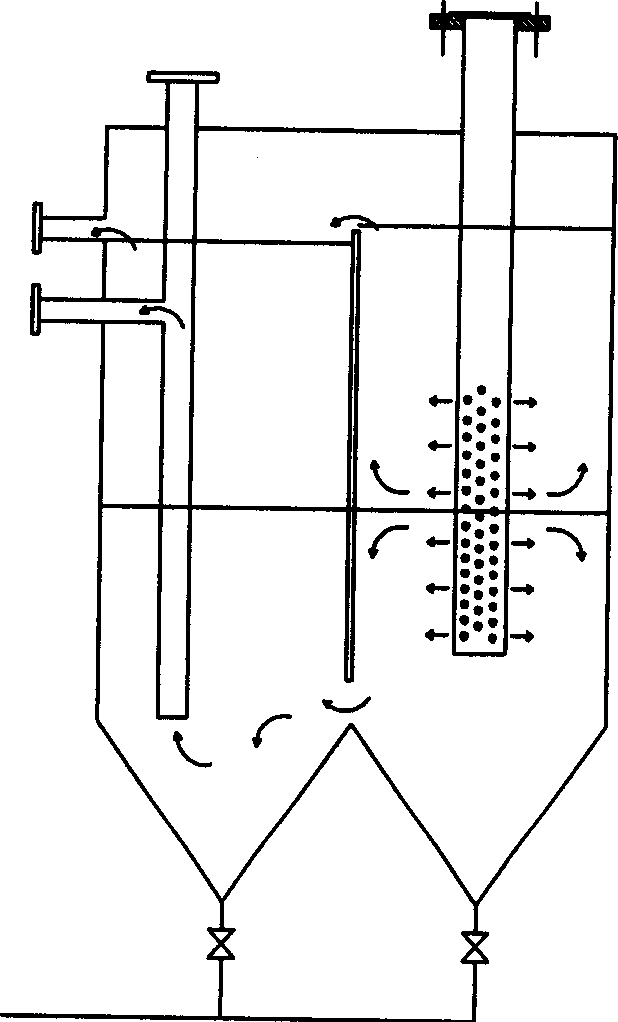

Carrier having a special feature, catalyzer and producing method thereof

ActiveCN101134173AHigh porosityHigh strengthPhysical/chemical process catalystsOil processingSorbent

The present invention is carrier in special shape, catalyst and their preparation process. The carrier is one ellipsoid with the major axis-to-minor axis ratio a / b of 1.05-2.5 and one or several grooves in the major axis direction. The carrier is prepared through pressing the material containing oxide hydrate in a mold to form, and heating the formed matter to convert the oxide hydrate into oxide. The carrier may be applied as adsorbent, catalyst carrier, reactor stuffing, etc. The catalyst prepared with the carrier has relatively great outer surface area and excellent mass transferring process, and may be applied widely in heavy oil processing reaction, etc, especially as hydrogenation activity protectant.

Owner:CHINA PETROLEUM & CHEM CORP +1

Biological organic fertilizer special for organic tobacco leaves and preparation method thereof

InactiveCN102093095ASolve pollutionReduction of Alien HazardsBio-organic fraction processingOrganic fertiliser preparationOil processingBiotechnology

The invention relates to a biological organic fertilizer using grain and oil processing leftovers, excellent animal feces and natural potassium mineral as raw materials and a preparation method thereof. The organic fertilizer comprises the following components in percentage by weight: 10-15 percent of animal feces, 10-15 percent of crop straws, 10-15 percent of natural potassium mineral and the balance of the grain and oil processing leftovers; and in addition, special composite microbial bacteria in an amount which is 0.3-0.5 percent of the total weight of the raw materials are added for the fertilizer. The preparation method has a simple process flow and small floor area and is easy to operate and control; the organic fertilizer has stable quality; peculiar smell is not produced in the production; and the method has no influence on the environment, and is an environmentally-friendly method for treating organic pollution wastes.

Owner:CHINA TOBACCO YUNNAN IND +2

Low-temperature quick deemulsifying agent for water-containing wax-containing erude oil and its preparation method

InactiveCN1537924AFast dehydrationGood demulsification and dehydration effectHydrocarbon oil dewatering/demulsificationEpoxyOil processing

Owner:SHANDONG UNIV

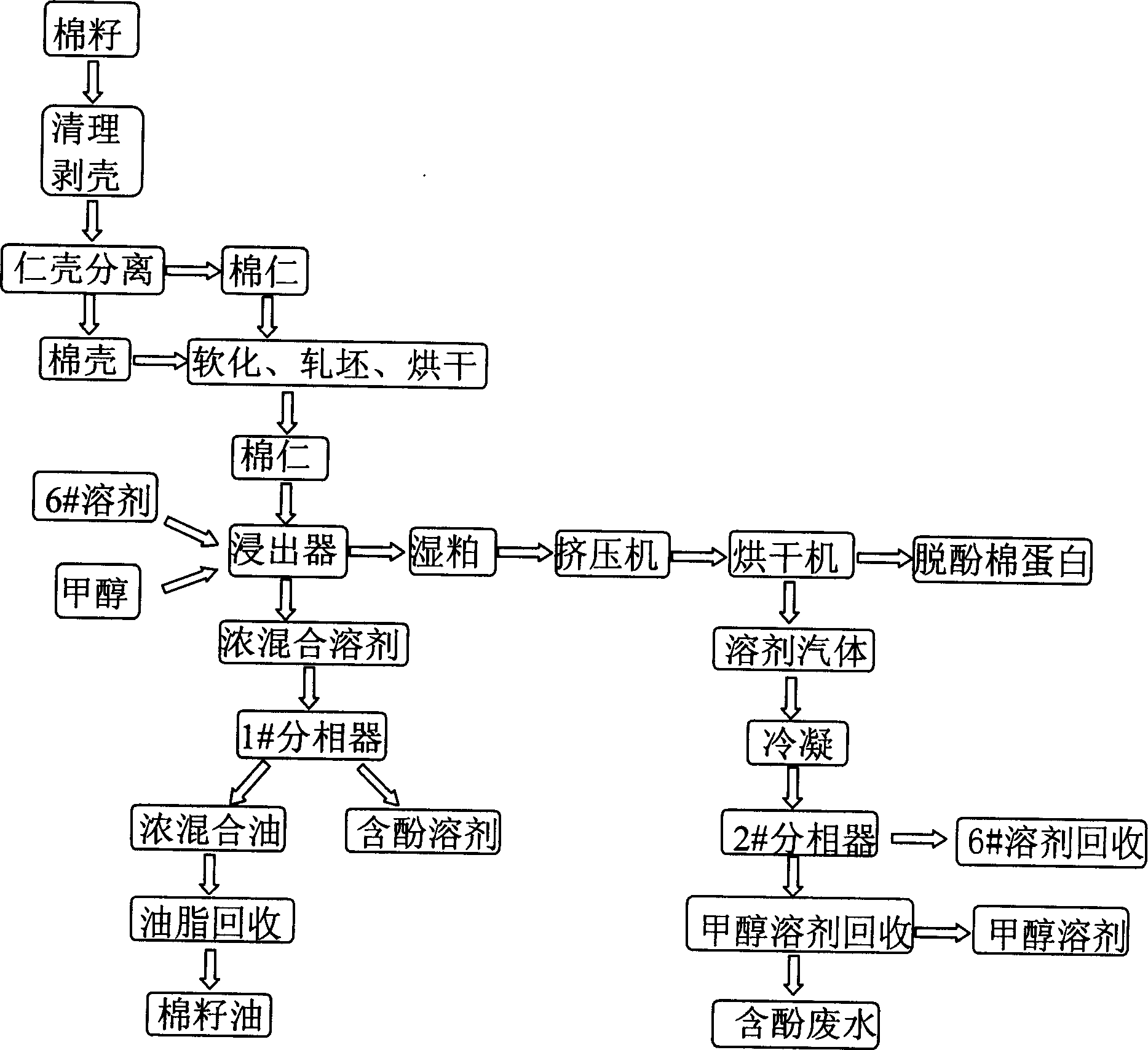

One-step method for producing dephenolized cotton protein

InactiveCN1775061AShort process routeUse less equipmentFatty-oils/fats refiningVegetable proteins working-upOil processingAlcohol

The present invention relates to the field of feed and oil processing technology, in particular, it relates to an one-step method for producing dephenolized cotton protein. It is characterized by that said invention fully utilizes the characteristics of 6# solvent and methyl alcohol mixed solvent, and utilizes the mutual incompatibility of polar solvent and non-polar solvent and simultaneously uses two solvents in one equipment so as to attain the goal of simultaneously extracting gossypol and oil, and can recover 6# solvent, methyl alcohol and oil.

Owner:陕西中恒粮油工程技术有限公司

On-line heat exchanger cleaning method

InactiveUS20060219266A1Reduce operating costsIncrease run lengthDetergent mixture composition preparationHollow article cleaningOil processingSolubility

A method for the on-line cleaning of a heat exchanger used with petroleum process fluids which create coke deposits of asphaltenic origin on the exchanger tubes. The asphaltenes are removed by re-dissolution in a solvent oil of high solubility power for the asphaltenes. Certain asphaltenic crudes are useful as solvents in view of their chemical similarity to the asphaltene coke precursors; also useful are refined petroleum fractions such as gas oils which are also characterized by their solvency for asphaltenes. The solvent oil may be admitted to the heat exchanger following withdrawal of the process fluid and then allowed to soak and dissolve the asphaltene coke precursors after which the resulting solution may be withdrawn and the exchanger returned to use without being at any time disconnected from its associated process unit.

Owner:EXXON RES & ENG CO

Method for processing inferior heavy oil

ActiveCN102234534AHigh economic valueHigh yieldTreatment with plural serial stages onlyGranular/pulverulent flues gasificationSyngasOil processing

A method for processing inferior heavy oil. The method comprises the following steps: allowing a heavy oil raw material to react with a contact agent in a reactor, performing a gasification reaction of the obtained catalyst in a gasifier to generate a syngas-containing gas product and to allow the catalyst to become a semi-regenerant; returning the semi-regenerant to the reactor. The method provided by the invention integrates two aspects of deep processing of inferior heavy oil and reasonable utilization of excess carbonaceous residues, adopts inferior heavy oil as a raw material, performs gasification of surplus coke in a gasifier to generate syngas with the proviso of light oil maximum production, makes reasonable use of residues of heavy oil processing, and produces a product with high economic value.

Owner:CHINA PETROLEUM & CHEM CORP +1

Inferior heavy oil cracking and gasifying catalyst

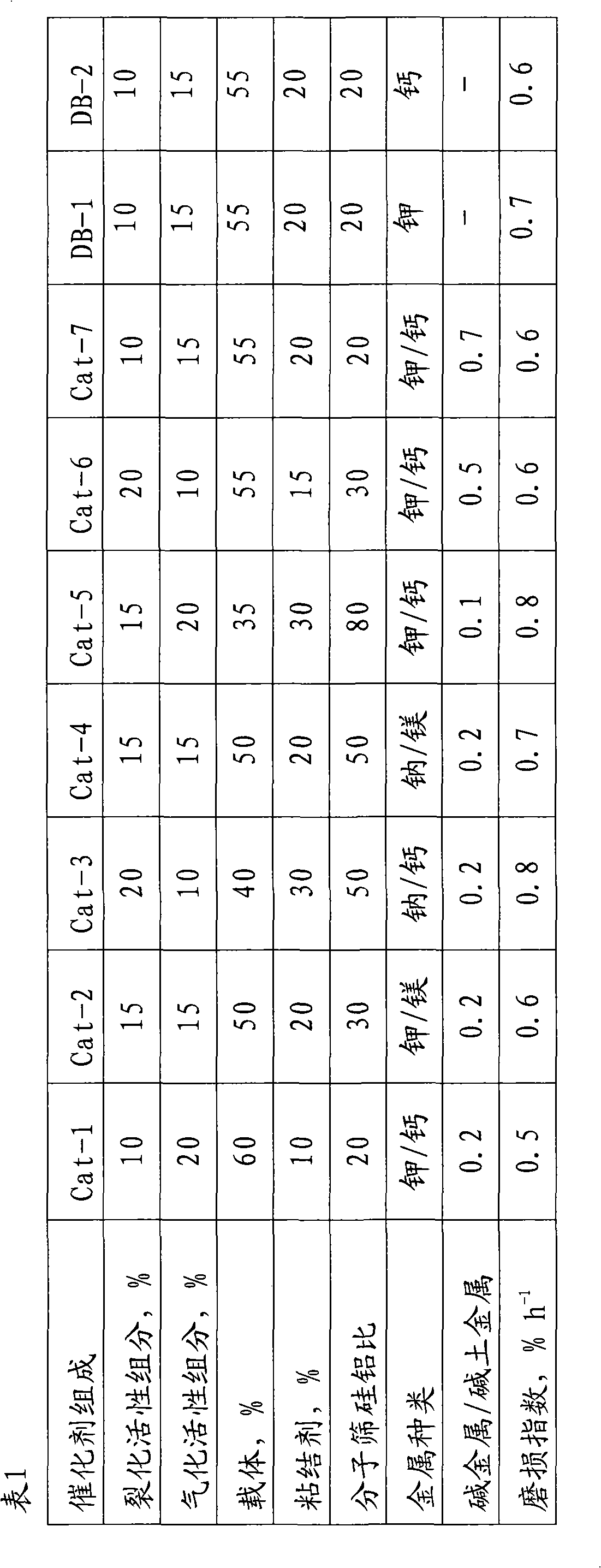

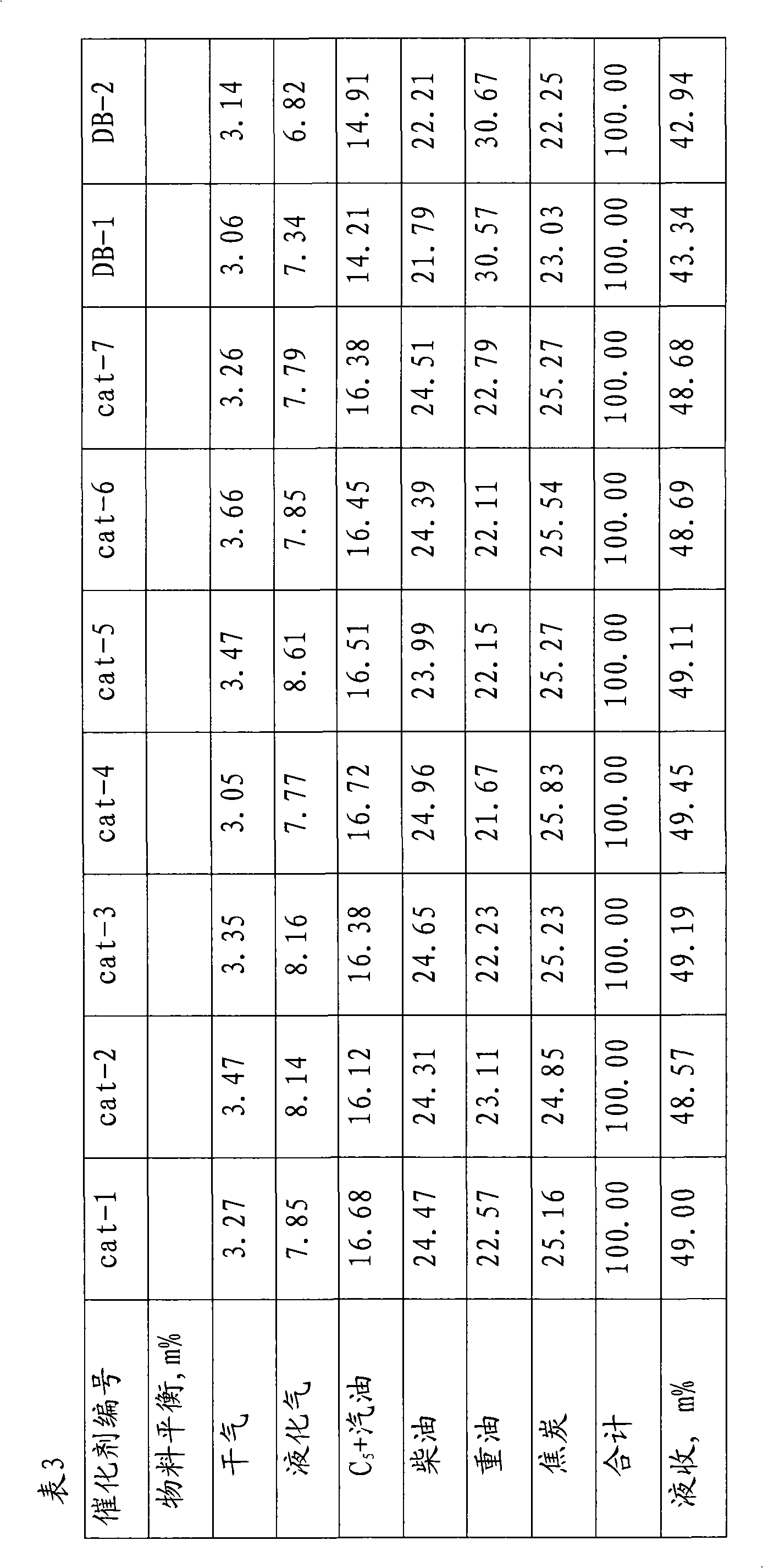

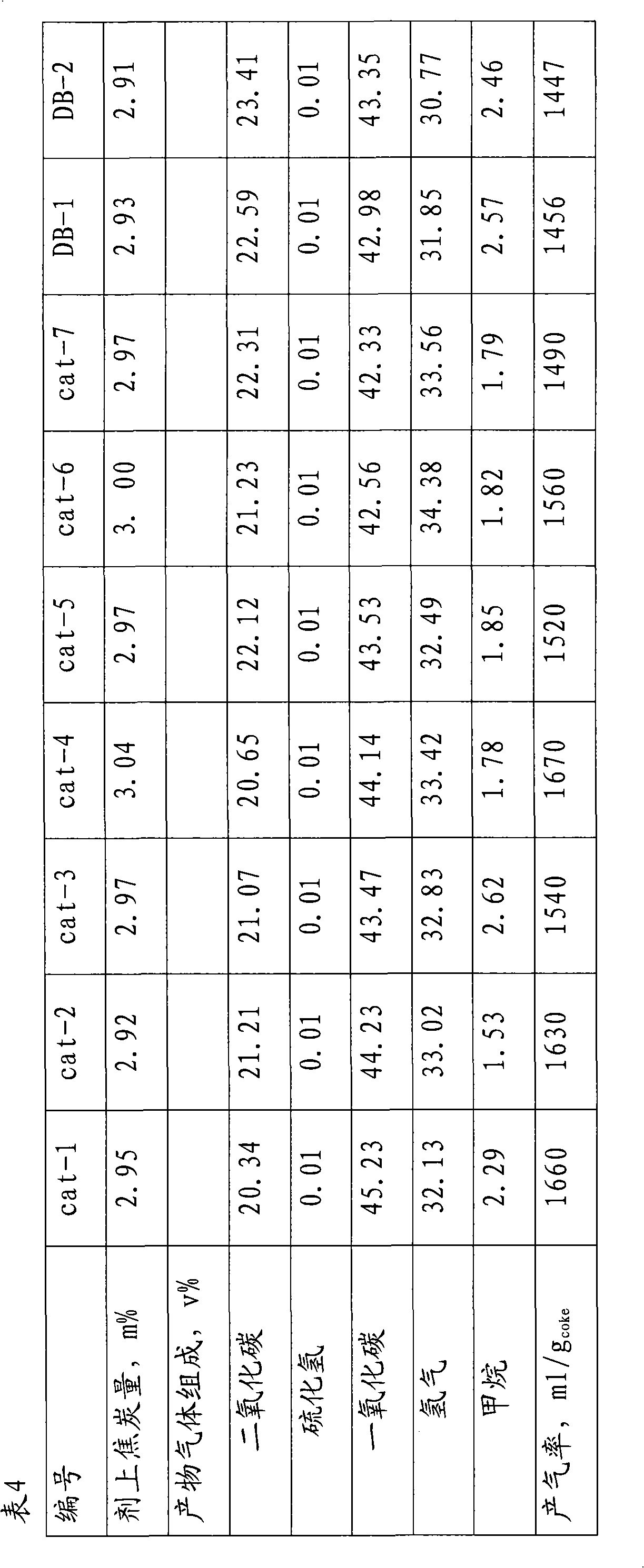

ActiveCN101898143AWeaken the effects of acidityHigh yieldCatalytic crackingMolecular sieve catalystsOil processingAlkaline earth metal

The invention discloses an inferior heavy oil cracking and gasifying catalyst, comprising carrier, binder, gasification active components and cracking active components, wherein the gasification active components are alkali metals and alkaline-earth metals, by taking the catalyst total content as a reference, the oxide content is 2-30%, the atom ratio of the alkali metals to the alkaline-earth metals is (0.05-1.1):1, and the cracking active components are shape selective zeolite with the silica alumina ratio within 20-200. The catalyst aims to the inferior heavy oil processing procedure, considers heavy oil cracking and coke high temperature gasification and improves light oil yield and coke gasification reaction rate obviously.

Owner:CHINA PETROLEUM & CHEM CORP +1

Liquid sol catalyst for hydrogenation of residual oil suspended bed

InactiveCN101011663AImprove hydrogenation activityHigh completeness of vulcanizationPhysical/chemical process catalystsHydrocarbon oil crackingDielectricOil processing

The invention discloses a catalyst of hydrogenated and cracked inferior heavy oil and residual oil suspending bed, which is characterized by the following: adopting 75-98m% water as dispersing dielectric; selecting 2-25m% transition sulfate metal (Fe, Co, Ni, Cr, Cu, Mn, Mo, W) as dispersing phase; controlling grain size between 0.1-100um; hydrogenating and cracking heavy oil into light oil.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Degumming process for edible vegetable oil and application thereof

ActiveCN102533441AImprove degumming effectHigh yieldFatty-oils/fats refiningOil processingOil and grease

The invention relates to a degumming process for edible vegetable oil and the application thereof. The degumming process for edible vegetable oil comprises the following steps: reacting raw oil with an acid to convert non-hydrated phospholipids in the raw oil into hydrated phospholipids, agglomerating micelles by hydration, and performing centrifugal separation to obtain degummed oil. The degumming process for edible vegetable oil can be applied to refining of edible vegetable oil. The invention further discloses a process of refining edible vegetable oil, which can produce RBD oil products by performing the following steps in sequence: degumming process mentioned above, decoloring treatment, deacidifying treatment and deodorizing treatment. The degumming process for edible vegetable oil is suitable for degumming of various edible vegetable oil, particularly seed oil with high phosphorus content (more particularly seed oil with high non-hydrated phospholipids content), and has excellent degumming effect. The degumming process is an innovation in oil and fat degumming aspect, and besides, the improvement on the degumming process promotes the generation of novel physical refining techniques in oil processing.

Owner:SHANGHAI HAOYOU IND EQUIP

Method for preparing metal phosphide hydrogenation refining catalyst by using hydrogen plasma reduction mehtod

InactiveCN101011664AHigh catalytic activityPhysical/chemical process catalystsRefining to eliminate hetero atomsOil processingHydrogen

The invention discloses a solid catalyst in the oil distill hydrogenating course, which comprises the following steps: adopting metal oxide and phosphate salt to make oxide primer; placing the primer in the plasma reactor; aerating hydrogen at 10-600h-1; loading 10-20kV to generate plasma; reducing for 10-180 min; obtaining deep solid as phosphate catalyst.

Owner:DALIAN UNIV OF TECH

Preparation method of saccharose-free functional powdered peony seed oil

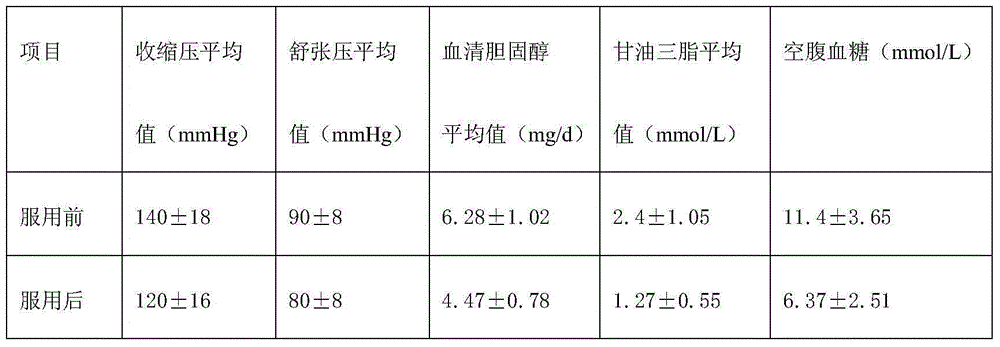

ActiveCN105053276AHigh in alpha-linolenic acidHigh nutritional valueEdible oils/fatsAcute hyperglycaemiaOil processing

The invention belongs to the technical field of oil processing, and particularly relates to a preparation method of saccharose-free functional powdered peony seed oil. The method comprises the following steps: (1) dissolving wall materials with distilled water, and heating and stirring to obtain a solution A; (2) adding food functional factors and an emulsifier into peony seed oil, and mixing and stirring uniformly to obtain an emulsion; (3) shearing and emulsifying the emulsion obtained in the step (2) to obtain an emulsion solution; (4) adding the solution A obtained in the step (3) into the emulsion solution obtained in the step (3), and homogenizing at high pressure to obtain a solution B; and (5) spray-drying the solution B obtained in the step (4), thereby obtaining the powdered peony seed oil. The powdered peony seed oil prepared by the method can be compounded with different nutritive substances according to demands of different groups of special people; as the peony seed oil is high in content of alpha-linolenic acid, the powdered peony seed oil is high in nutritive value; and due to containing no saccharose, the powdered peony seed oil is suitable for patients with hyperglycemia and diabetes to take.

Owner:HEZE YAO & SHUN PEONY BIOTECH

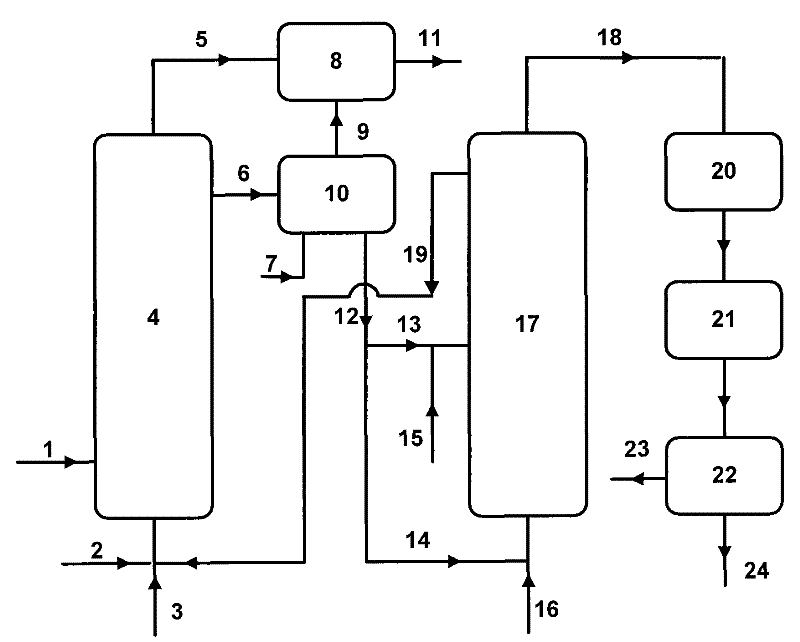

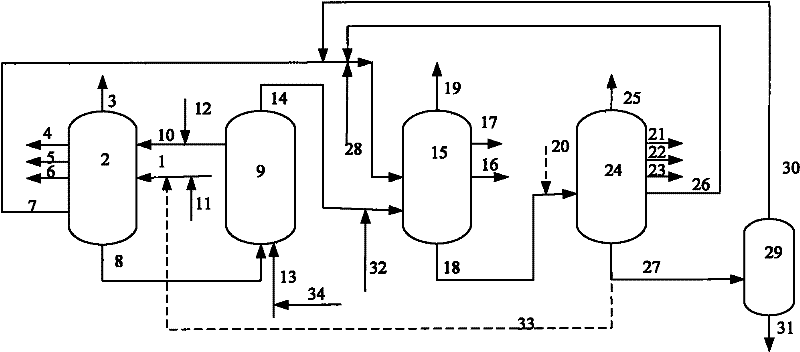

A combined method for processing inferior heavy oil

ActiveCN102260529AAchieve hydrogen balanceEconomic routeHydrogenTreatment with hydrotreatment processesOil processingCombined method

The invention relates to a combined method for processing inferior heavy oil. The method comprises the following steps: a heavy oil raw material is reacted in a contacted cracking unit, an obtained heavy oil fraction I enters into a hydrotreating unit, a contact agent with charcoal enters into a gasification unit for a gasification reaction, the generated hydrogen enters into the hydrotreating unit, a heavy oil fraction II is obtained by a reaction in the hydrotreating unit and enters into a catalytic cracking unit, heavy cycle oil obtained by reacting is returned to the hydrotreating unit, an oil slurry is returned to the contacted cracking unit, regeneration flue gas used as a gasifying agent is returned to the gasification unit. The method of the invention is used for processing inferior heavy oil, and integrates two functions of deep processing of inferior heavy oil and reasonable utilization of excessive carbonaceous residue, so that the hydrogen balance of heavy oil processing can be realized. The combined method of the invention is capable of effectively improving the catalytic cracking raw materials and reasonably utilizing heavy cycle oil, the oil slurry and regeneration flue gas generated by the catalytic cracking apparatus, thereby the treating capacity and economic benefit of the heavy oil catalytic cracking apparatus can be enhanced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for desulfurization of fuel oil by oxidation process with modified titanium silicalite molecular sieve as catalyst

InactiveCN1844321AEasy to useGood catalytic oxidation performanceHydrocarbon oils refiningOil processingCatalytic oxidation

An oxidation sweetening method for fuel oil selecting modified titanium-silicon molecular screen as accelerating agent belongs to technical sphere of petroleum process. The invention provides an accelerating agent of modified titanium-silicon molecular screen which can be used in oxidation sweetening of fuel oil. The charge number of earth silicon in this invention adopting immersion method is 1.0wt%-3.0wt%. The obtained modified titanium-silicon molecular screen is used for catalytic and oxidation desulfurization of fuel oil. The significance effect of this invention is that it improves the repetitive use of accelerating agent in oxidation sweetening reaction. The method includes selecting modified titanium-silicon molecular screen as accelerating agent and removing sulfidization of fuel oil by hydrocarbonylation, which can reduce the sulfur content of fuel oil to 29.7 mu / g from 226.1 mu / g and reach deep desulfuration, and the accelerating agent can be recovered and the catalytic oxidation susceptibility of the recovered accelerating agent is good. The invention is of mild reaction condition, simple equipment and no consumption of hydrogen gas.

Owner:DALIAN UNIV OF TECH

Method for extracting residual oil and tea saponin from tea seed cake after oil extraction

The invention relates to a method for extracting raffinate oil and tea saponin from tea seed cake after oil extraction, which belongs to the field of grain and oil processing and byproduct extracting techniques. The technique of the invention mainly comprises the processes: after the extracted tea seek cake is crashed and dried, the raffinate oil is extracted by using industrial hexane or sherwood oil, the extracted raffinate oil is distilled to remove the solvent so as to obtain crude oil; the distilled solvent can be recycled, the tea seed cake after the raffinate oil is adopted to leach tea saponin by 85 to 95 percent ethanol, the tea saponin is subjected to the water bath heat and reflux for 2 to 3 hours at a temperature of between 70 and 80 DEG C, the tea saponin concentrated solution is obtained after filtering, distilling and concentrating processes, the depigmentation treatment is performed by using active carbon or 35 percent H2O2, and certain mount of acetone is added to the processed solution to keep stand for 1 to 2 hours; and after the tea saponin separates out completely, and the product of tea saponin is obtained by filtering and drying processes.

Owner:SHANGHAI UNIV

Reversed phase micelle nano catalyst for dreg-oil suspension bed hydrogenation cracking and preparing method

InactiveCN101024186AReduce the amount addedHighly uniform dispersionPhysical/chemical process catalystsHydrocarbon oil crackingOil processingNano catalyst

The invention discloses a catalyst for low quality heavy oil or residue suspended bed hydrocracking and preparation method belongs to oil process technology area. The catalyst is a sulfurization form transition metal nm particle that existing in the reversed phase micelle colloidal solution, the disperse medium of reversed phase micelle colloidal solution is organic phase, the disperse phase is a water phase parceled by surface activity, sulfurization form transition metal nm particle steady consist in the water phase. The transition metal active ingredient in disperse phase elect as Cu,Mn,Fe,Co,Ni,Cr,Mo,W,Zn,Sn,Pb elementary sulfurization form particle and so on, the grain size between 1nm-1000um. This catalyst can uniformly dispersed in the low quality heavy oil,residue, and under the certain reaction temperature and hydrogen aura, the low quality heavy oil or residue containing catalyst through suspended bed hydrocracking translated into light oil. On the premise of reducing catalyst enter quantity, the invention effectively controlled the coking products in heavy oil or residue suspended bed hydrocracking process, improved the yield of light oil.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

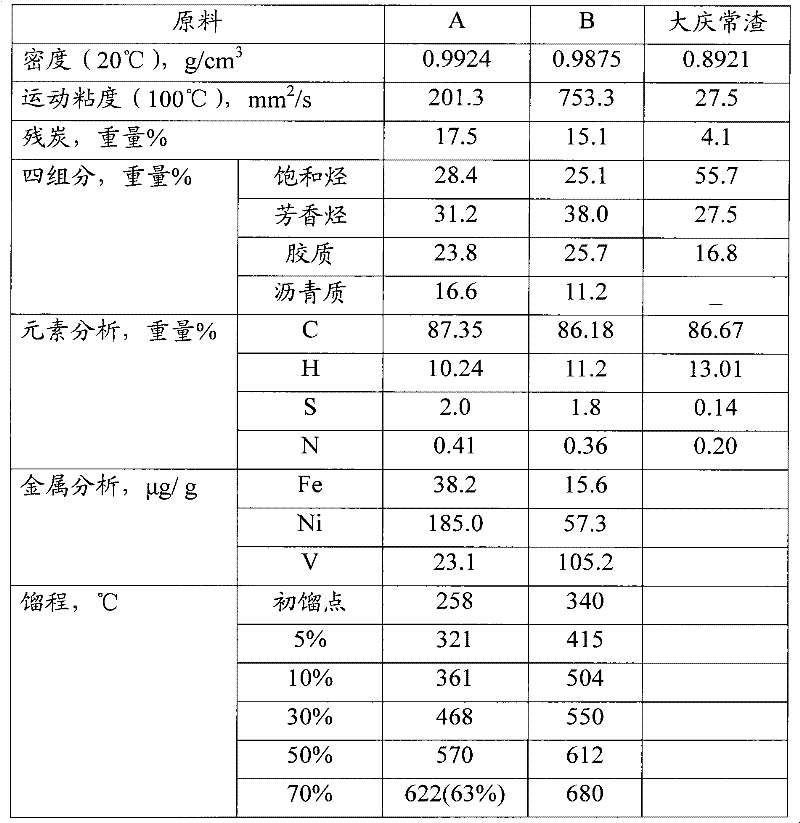

Rapeseed oil processing method

ActiveCN104893813AIncrease vitalityLow in phospholipidsFatty-oils/fats refiningFatty-oils/fats productionActivated carbonOil processing

The invention discloses a rapeseed oil processing method. The rapeseed oil processing method comprises the following steps: 1) preparing crude rapeseed oil; 2) performing ultrasonic assisted phospholipase C degumming treatment on the crude rapeseed oil, and performing centrifugal separation after degumming to obtain degummed rapeseed oil; 3) performing anhydrous long-mixing deacidification treatment on the degummed rapeseed oil to obtain deacidified rapeseed oil; 4) adding spent earth into the deacidified rapeseed oil to perform pre-decolorizing treatment to obtain pre-decolorized rapeseed oil, and adding attapulgite and activated carbon into the pre-decolorized rapeseed oil to perform re-decolorizing treatment to obtain re-decolorized rapeseed oil; 5) performing deodorizing treatment on the re-decolorized rapeseed oil to obtain finished product rapeseed oil. The rapeseed oil processing method has the advantages of good safety and environmental-friendliness, simple process, convenience in operation, low cost and high refining rate, and is applicable to industrial production of rapeseed oil.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Heat Generation Process for Treating Oilfield Deposits

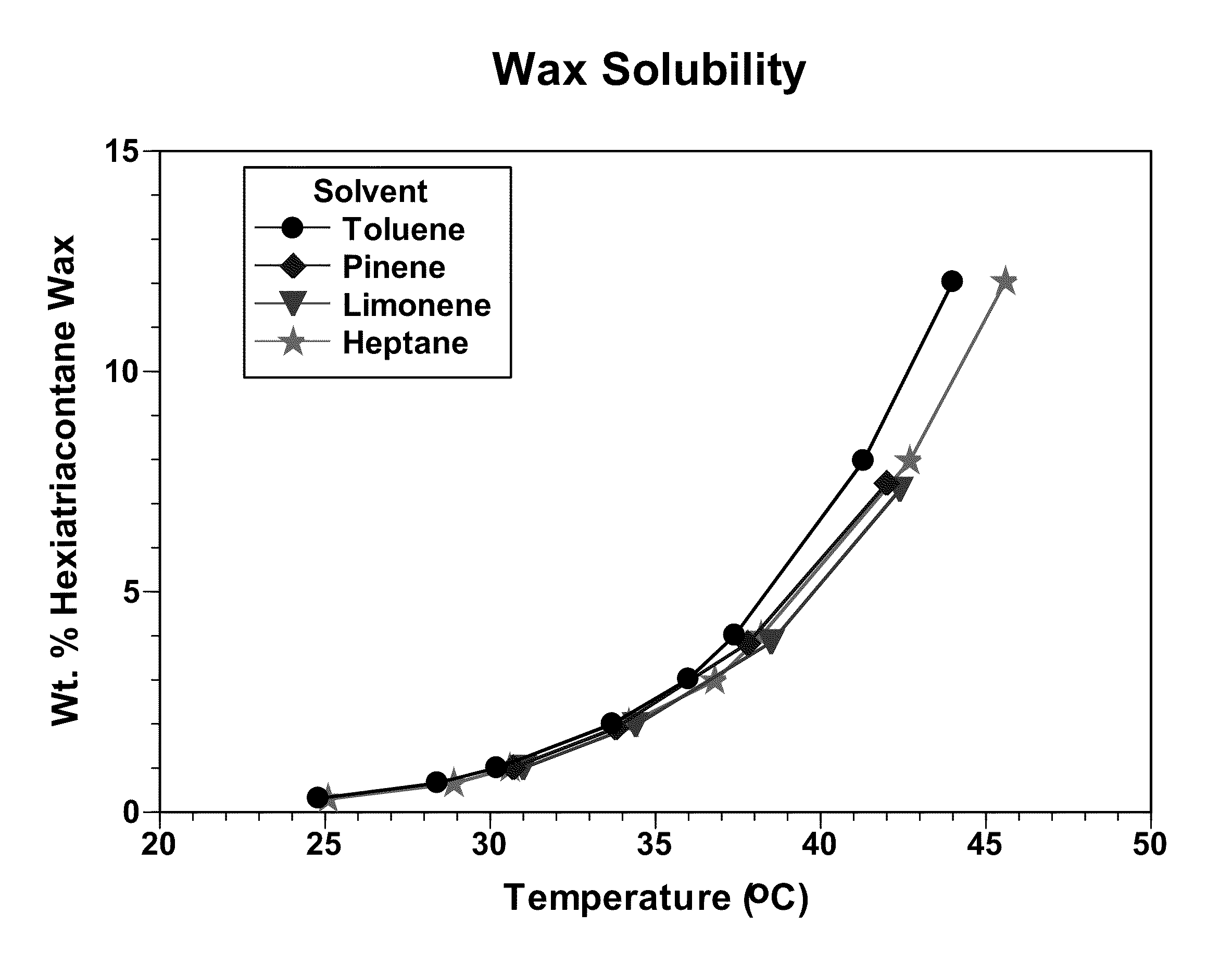

ActiveUS20110114323A1Increase temperatureIncreased deposit solvencyCleaning apparatusHollow article cleaningOil processingFuran

Generating heat within a combination solvent / acid system removes undesirable deposits from petroleum reservoir formations (especially the near well-bore region), oilfield equipment, and petroleum processing equipment. An exothermic reaction occurs between the solvent and the acid and the heat evolved helps remove organic solid deposits. The acids may include organic acid compounds, such as sulfonic acids, sulfuric acid and nitric acid. The solvents may include terpene- and terpene-derivative-containing solvents, including, but not necessarily limited to, limonene, pinene, dipentene, myrcene, turpentines and compounds having at least one double bond, such as methyl furan, dienes, styrene, vinyl acetate and the like. The exothermic reaction produces a great amount of heat, and together with using certain acids and solvents already known as effective to remove paraffin and asphaltene deposition, removing such deposits is improved.

Owner:BAKER HUGHES INC

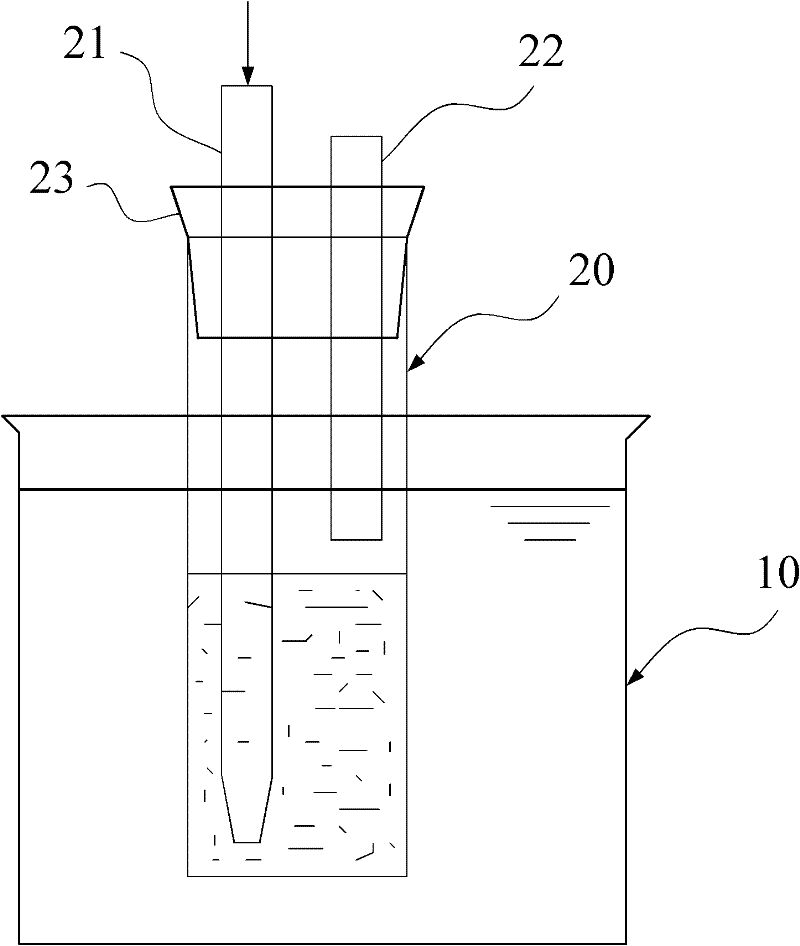

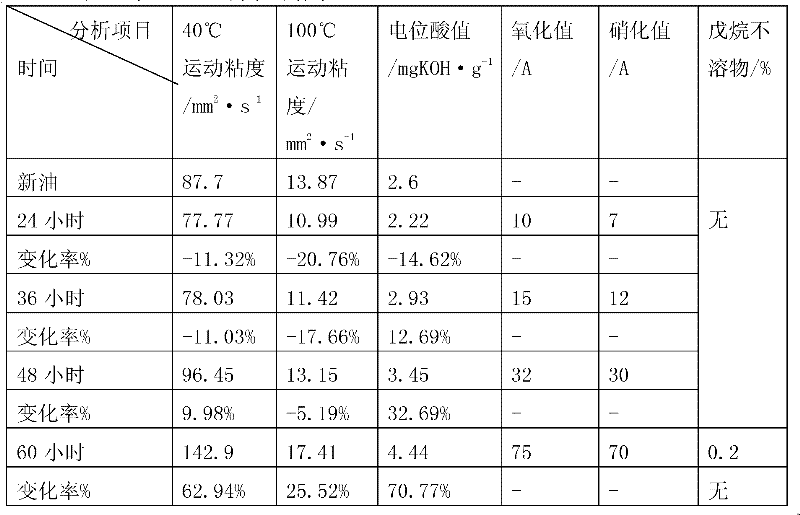

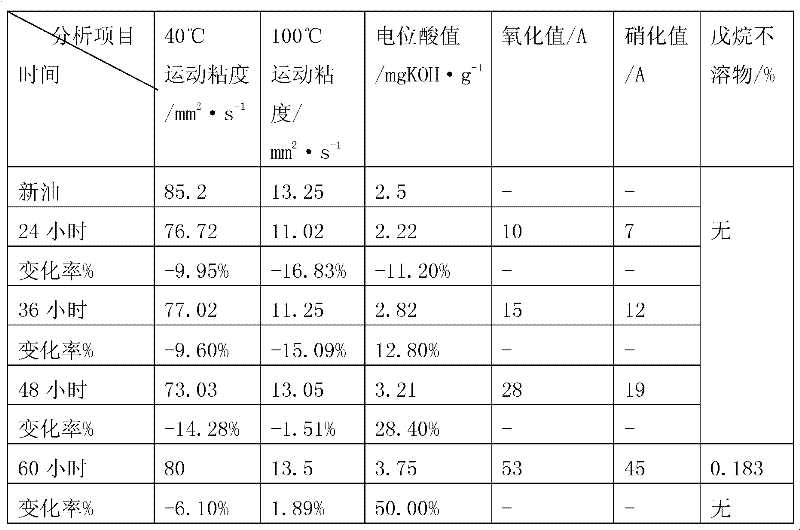

Method for testing oil oxidation stability

ActiveCN102455352AAdjust the test time arbitrarilyComprehensive testMaterial testing goodsOil processingNitration

The invention relates to a method for testing oil oxidation stability. The method comprises the following steps of: supplying an oil processing device which comprises a thermostatic container and an oil container, wherein the oil container is arranged in the thermostatic container and is provided with an air intake pipe and an air outlet pipe; feeding the tested oil and a metal catalyst into the oil container; introducing air into the tested oil via the air intake pipe, wherein the flow of the air is 1 L / H to 20 L / H; measuring the temperature of the tested oil, orderly extracting samples from the tested oil according to a predetermined time sequence after the temperature of the tested oil is up to a set value, and measuring the viscosity, the acid value, the oxidation value and the nitration value of each sample; and measuring the content of an insoluble substance (n-pentane) of the remained oil in the oil container. Through the method, the samples can be sampled by many times during the testing process, so that a performance change trend of the oil is obtained; and the detergent dispersibility and the thermal oxidation stability of the oil can be evaluated.

Owner:CHINA PETROLEUM & CHEM CORP

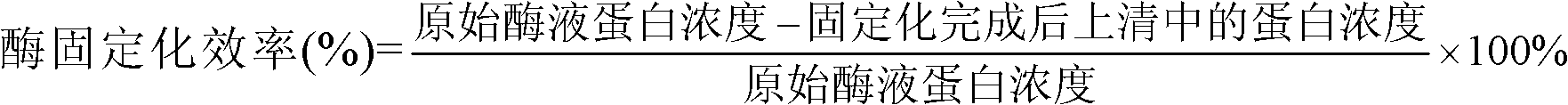

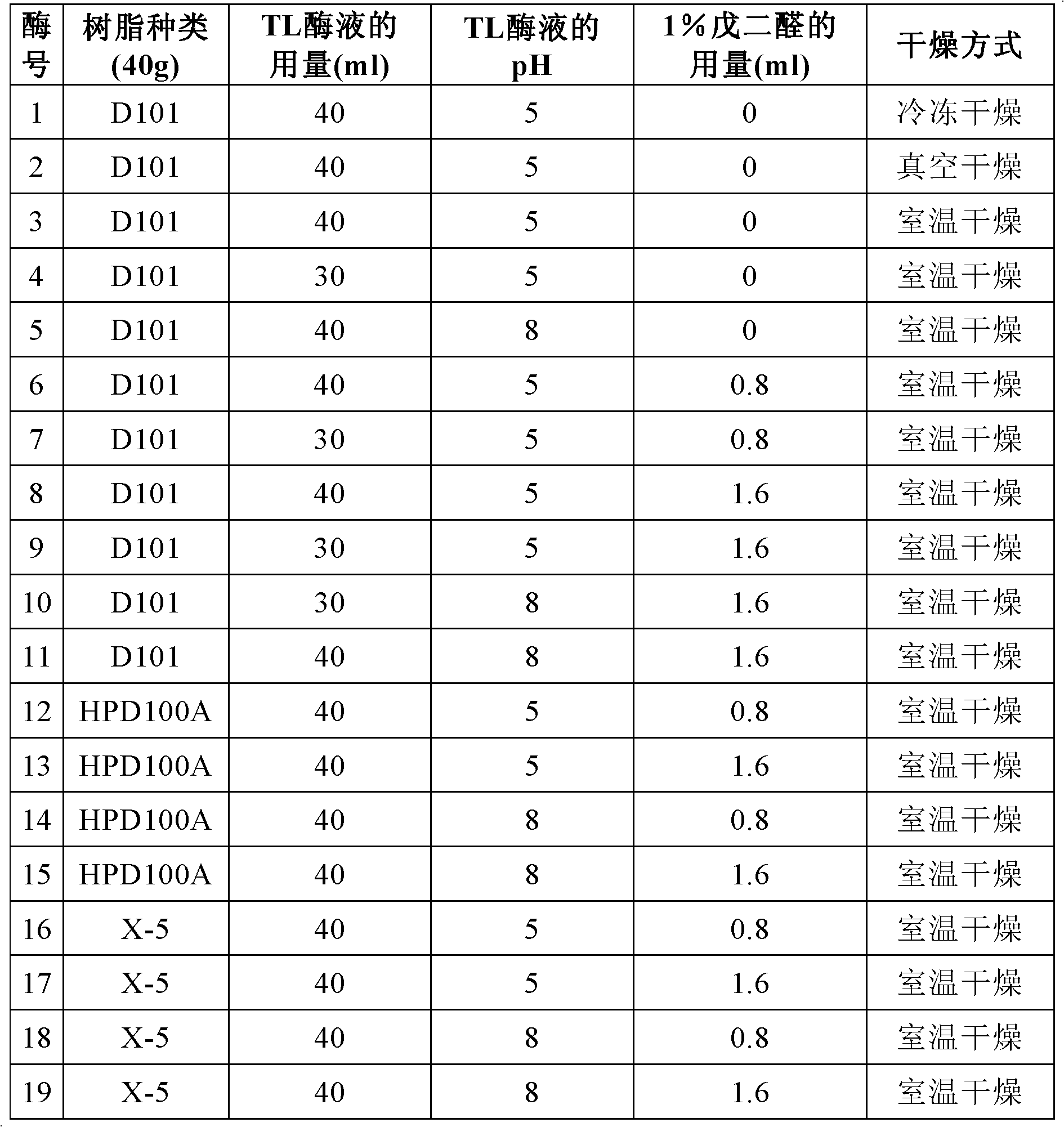

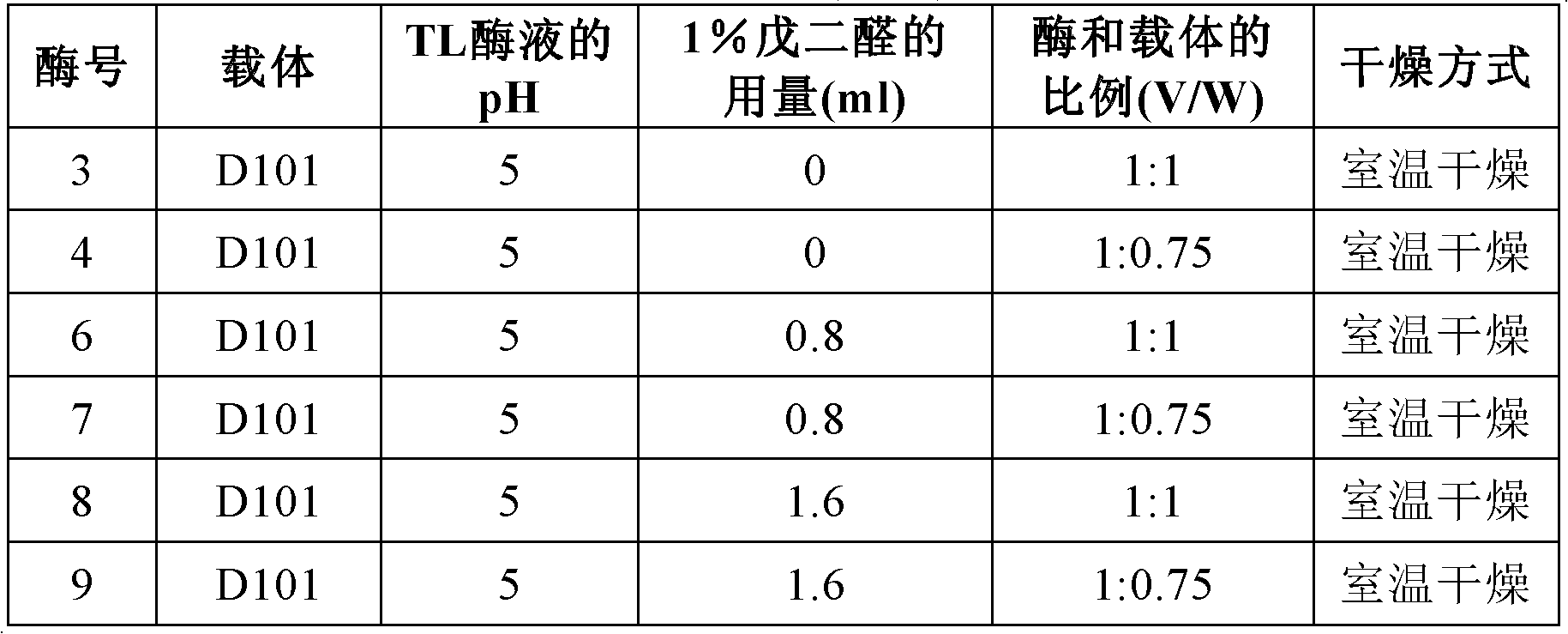

TL immobilization enzyme and application thereof

ActiveCN102839166ASimplify production stepsReduce manufacturing costOn/in organic carrierFermentationOil processingFood industry

The present invention relates to a TL immobilization enzyme and an application thereof. Specifically the present invention provides a preparation method for an immobilization lipase. The method comprises the following steps: a) carrying out a pre-treatment on a carrier, wherein the carrier is selected from an ion exchange resin or a macroporous adsorption resin having a polystyrene skeleton; b) providing a lipase; c) carrying out contact of the pre-treated carrier from the step a) and the lipase provided by the step b), such that the lipase is immobilized on the pre-treated carrier; and d) drying. The present invention further provides the immobilization lipase prepared by using the method of the present invention and an application thereof. According to the present invention, the immobilization enzyme of the present invention has high activity and stability, and does not generate soap during a process of catalysis of an ester exchange reaction in food industry, operation is simple, and oil processing cost is substantially reduced.

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

Preparation method of rapeseed oil

InactiveCN104804866AGuaranteed pureImprove qualityFatty-oils/fats refiningFatty-oils/fats productionOil processingFlavor

The invention discloses a preparation method of rapeseed oil and belongs to the technical field of oil processing. The preparation method comprises the steps as follows: firstly, rapeseed is cleaned, the rapeseed covered with water after cleaning is fried directly in a rapeseed frying process with a sectional type gradual cooling method, and the fried rapeseed is ground to obtain preliminary ground crude oil and rapeseed residues; the granularity and moisture of the rapeseed residues are adjusted, then the rapeseed residues are fed into an agitation tank for leaching, and leached crude oil and rapeseed residues are obtained; the preliminary ground crude oil and the leached crude oil are mixed to obtain mixed crude oil; the mixed crude oil is refined to obtain finished rapeseed oil. The rapeseed oil leaching efficiency is high after processing with the preparation method, the inherent flavor, aroma and nutrient substances of the rapeseed oil are kept, and the prepared rapeseed oil is pure and higher in quality.

Owner:GUIZHOU LIPING QIANXIANGYUAN GREASE CO LTD

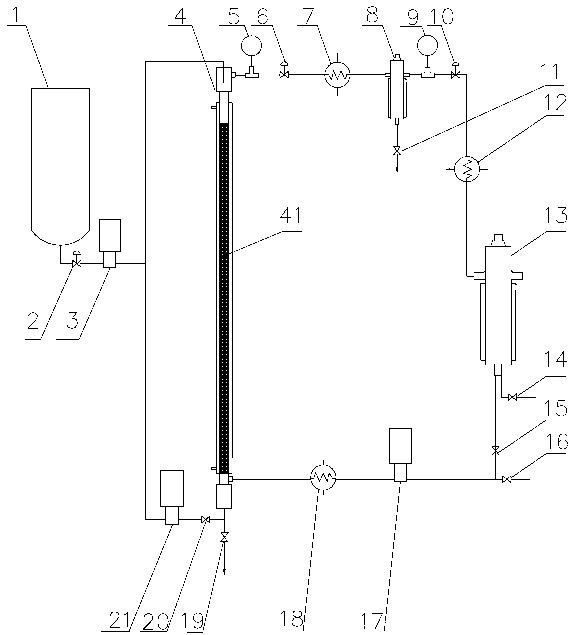

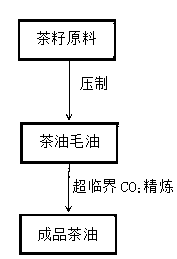

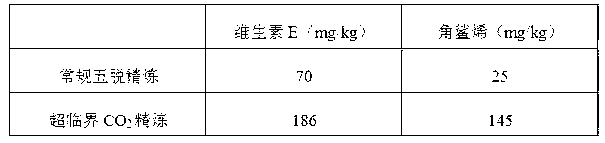

Tea oil processing method and device special for tea oil processing method

InactiveCN103289816AFew stepsEasy to operateFatty-oils/fats refiningFatty-oils/fats productionBiotechnologyOil processing

The invention discloses a tea oil processing method which comprises the following steps of: (1) carrying out pretreatment on raw material: drying tea seeds at low temperature, and then removing shells of the tea seeds; (2) preparing crude oil of the tea oil, and filtering; (3) carrying out supercritical CO2 refining: putting the crude oil of the tea oil into a supercritical CO2 device, extracting under the conditions of 15-25MPa and 30-60 DEG C; removing the impurities in the crude oil of the tea oil to obtain the tea oil finished product. The method adopts supercritical CO2 to remove the impurities of the crude tea oil, thus improving the quality of the tea oil, reducing the refining process, shortening the production cycle, reducing the pollution discharge, reducing the loss of nutritional ingredients of the tea oil in the refining process, increasing the content of active substances such as vitamin E and squalene, and improving the quality and the health care effect of the tea oil. The invention also discloses a device special for the method.

Owner:广州绿和缘生物科技有限公司

Laportea urentissima grease processing technology

InactiveCN101177647AEasy squeezeIncrease oil production rateFatty-oils/fats productionOil processingEngineering

The invention relates to a processing technique of hemp grease. The hemp seed is adopted as raw material, and after the process of dehydration, filter cleaning, peeling, drying, thermal refining, crushing, oil processing and cold-pressed embryos, the fine cold-pressed hemp seed grease which has wide application in basic raw material of health food products, medicines and cosmetics can be obtained.

Owner:广西巴马常春藤生命科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com