Comprehensive extraction method for extracting tea seed oil, tea saponin and tea seed polysaccharide from tea seeds or camellia seeds

A tea seed polysaccharide, comprehensive extraction technology, applied in the direction of chemical instruments and methods, sugar derivatives, sugar derivatives, etc., can solve the problems that did not take into account the industrial production of tea seed polysaccharide, and achieve the effect of low cost and simple extraction equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

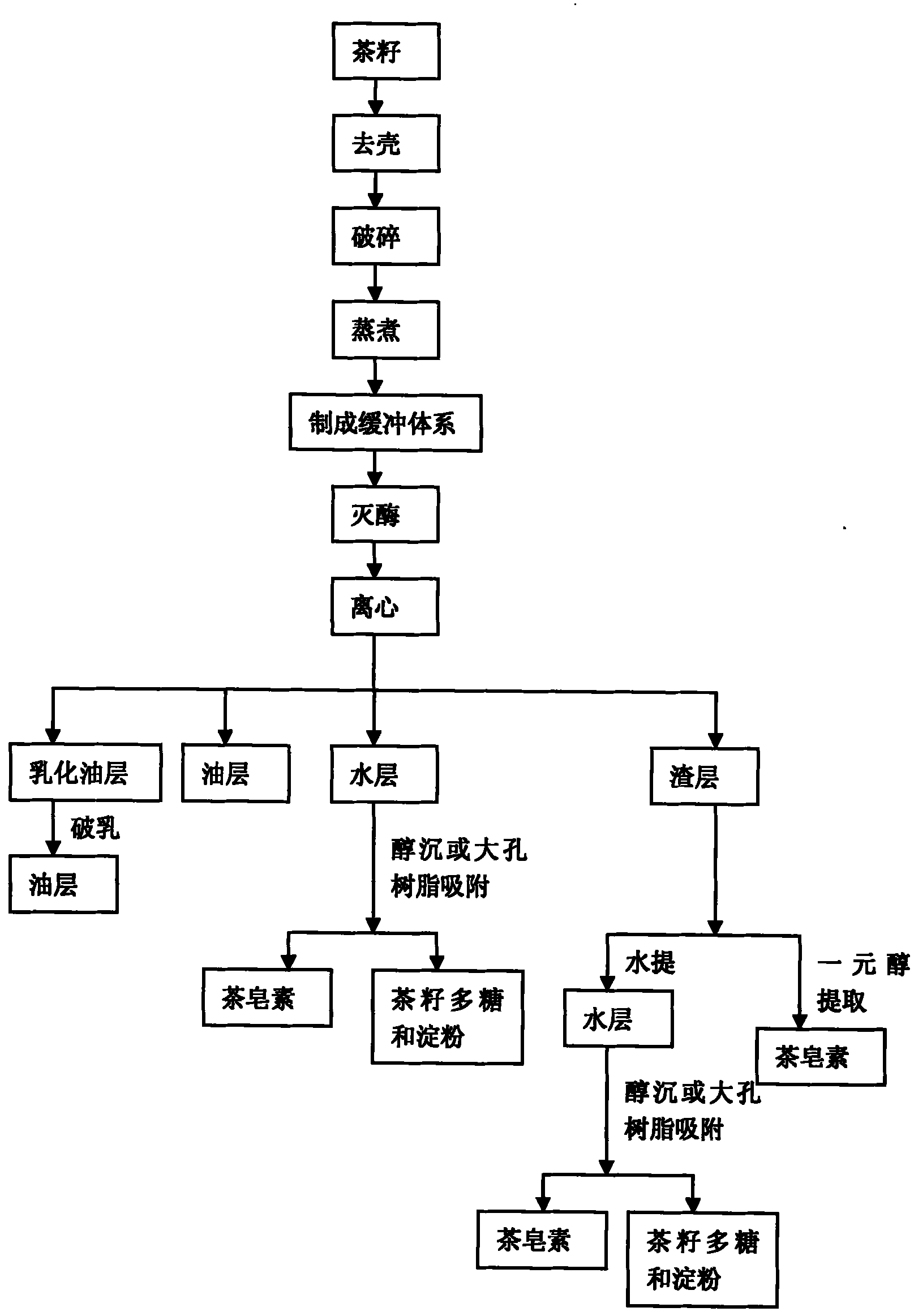

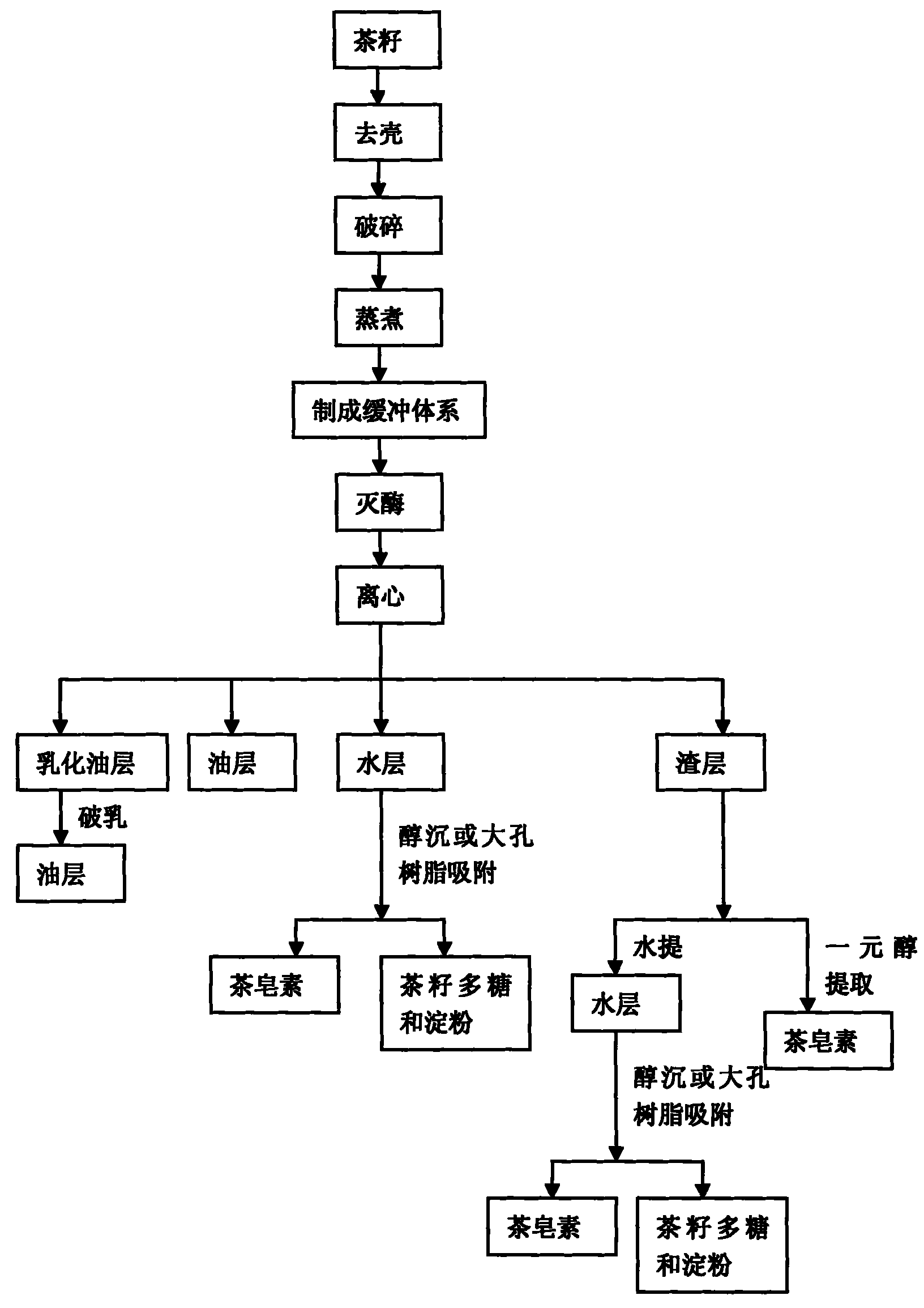

Method used

Image

Examples

Embodiment 1

[0041] Select high-quality Camellia oleifera seeds for shelling and peeling, crush them to 60-80 meshes, treat them with atmospheric pressure steam for 20 minutes, and make a citric acid-sodium citrate buffer solution with pH=5.5 at a solid-liquid ratio of 1:6, at 55°C Add 0.5% of 1:1 cellulase and Neutrase 1.5MG neutral protease under the conditions of the enzymolysis for 6 hours, and keep stirring. Inactivate the enzyme in a water bath at 90°C for 10 min. Centrifuge at 3500r / min to obtain the first-level clear oil layer, emulsified oil layer, water layer and slag layer, heat the emulsified oil layer in a water bath at 70°C for 20 minutes to break the emulsion, take the second-level free clear oil, and combine the two oil layers to obtain crude tea seed oil. The slag layer can be subjected to secondary water extraction, the extraction solid-liquid ratio is 1:4, the extraction temperature is 70°C, and the extraction time is 1.0h. After filtering to remove the slag, the water l...

Embodiment 2

[0043] Select high-quality Camellia oleifera seeds for shelling and peeling, crush them to a size greater than 80 mesh, and treat them with atmospheric pressure steam for 20 minutes, then prepare a citric acid-sodium citrate buffer solution with a solid-to-liquid ratio of 1:5 at a temperature of 55°C. Add 0.5% Neutrase 1.5MG neutral protease under the condition, enzymatic hydrolysis for 6h, and keep stirring. Inactivate the enzyme in a water bath at 90°C for 10 minutes. Centrifuge at 3500r / min. After centrifugation, the system is divided into: first-level clear oil layer, emulsified oil layer, water layer and slag layer. The emulsified oil layer is centrifuged to break the emulsion, and the second-level free clear oil can be taken. The two-stage oil layers are combined to obtain Crude tea seed oil with a yield of 25.8%; the water layer was precipitated with 75% ethanol, and the obtained precipitate was dissolved in water and dried to obtain tea seed polysaccharides with a puri...

Embodiment 3

[0045] After shelling and peeling selected high-quality tea seeds, crush them to 60-80 meshes, treat them with atmospheric pressure steam for 25 minutes, and make a citric acid-sodium citrate buffer solution with pH=4 at a solid-liquid ratio of 1:5, at 55°C Add 0.5% BAN medium-temperature amylase under certain conditions, and perform enzymatic hydrolysis for 6 hours with constant stirring. Inactivate the enzyme in a water bath at 90°C for 10 min. Centrifuge at 3500r / min to obtain the first-level clear oil layer, emulsified oil layer, water layer and slag layer, heat the emulsified oil layer in a water bath at 70°C for 20 minutes to break the emulsion, take the second-level free clear oil, and combine the two oil layers to obtain crude tea seed oil. The extraction rate is 25.3%; the slag layer can be subjected to secondary water extraction, the extraction solid-liquid ratio is 1:4, the extraction temperature is 70°C, and the extraction time is 1.0h. After filtering to remove th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com