Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36644results about How to "Suitable for industrial production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

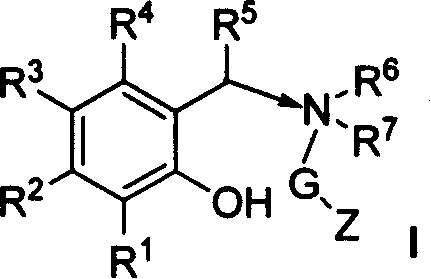

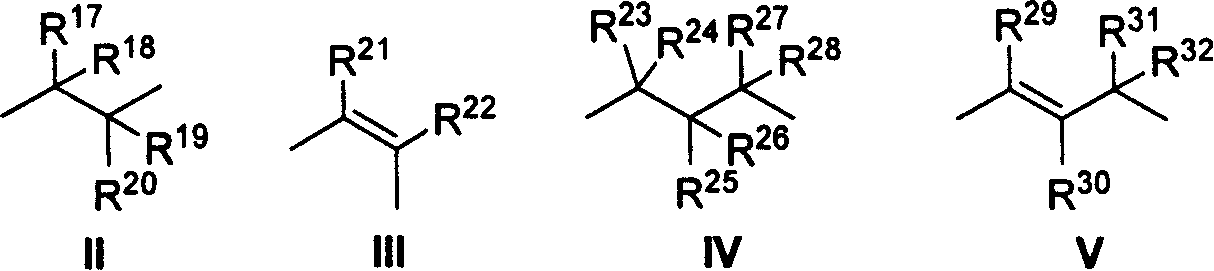

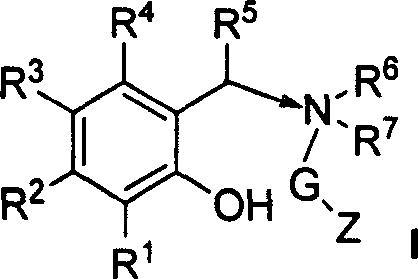

Mono-active center Ziegler-Natta catalyst for olefinic polymerization

The invention relates to a new catalyst for single active central Ziegler-Natta alkene polymerization. Said catalyst takes salicylal containing dentate or substituted salicylal derivatives as electrons, and is prepared by adding pretreated carrier, metallic compound and electrons into magnesium compound / tetrahydrofuran solution. The catalyst can produce ethane homopolymer and copolymer with narrow molecular weight distribution (1.6-3.8) and even comonomer distribution, with high activity and under action of adjuvant catalyst of alkyl aluminium and alkyl aluminoxanes. The ethane polymerization, homopolymerization or combined polymerization of ethane and 1- olefin, ring olefin and polar monomer through slurry method or gas phase method by using said catalyst can be realized.

Owner:SHANGHAI INST OF ORGANIC CHEMISTRY - CHINESE ACAD OF SCI

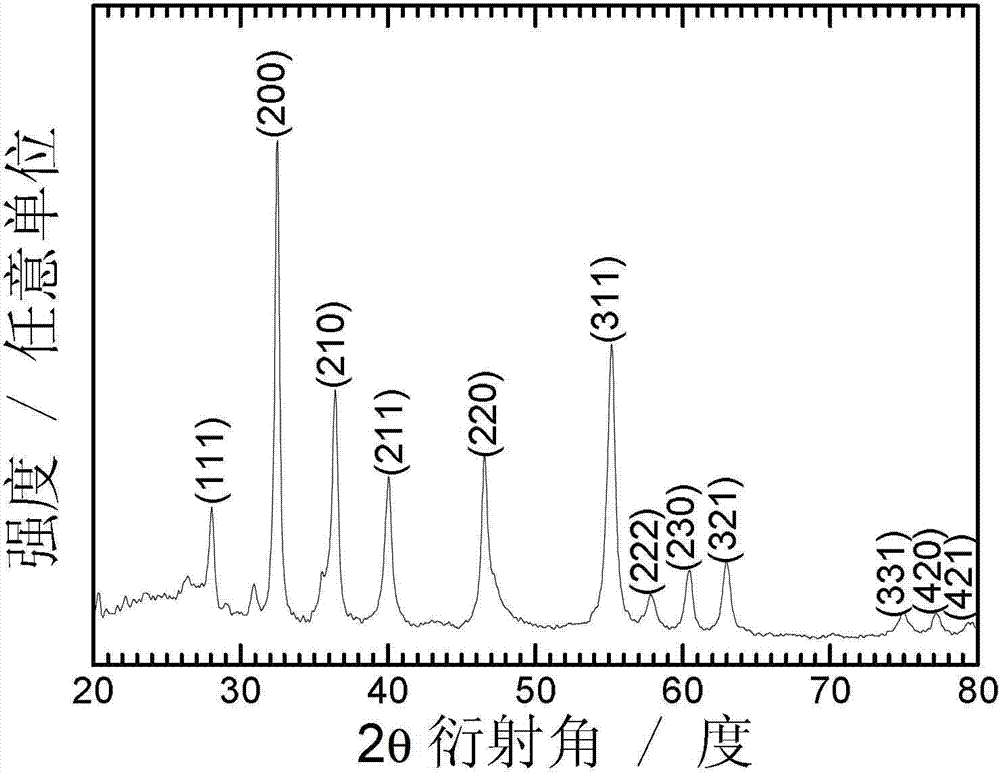

Perovskite/polymer composite luminescent material and preparation method thereof

ActiveCN104861958ASimple and fast operationLow costNanoopticsLuminescent compositionsPhotoluminescenceStructural formula

The invention relates to a perovskite / polymer composite luminescent material and a preparation method thereof, which belong to the technical field of composite materials and luminescent materials, wherein the structural formula of the perovskite is R1NH3AB3 or (R2NH3)2AB4, A and B form a ligand octahedral structure, R1NH3 or R2NH3 are filled into gaps of the ligand octahedral structure which is formed through the A and the B, R1 is methyl, R2 is a long-chain organic molecular group, the A is any one of metal Ge, Sn, Pb, Cu, Mn, Sb and Bi, the B is any one of Cl, Br and I. The perovskite / polymer composite luminescent material which is made through the preparation method is high in luminescent intensity, high in luminescent color purity, excellent in light and thermal stability and excellent chemical resistant property and mechanical property, and lays the foundation for theory research and application of the perovskite / polymer composite luminescent material in high-performance photoluminescence devices, flexible display, lasers, nonlinear optical devices. The preparation method can obtain composite materials which can cover a whole visible region through luminescent wavelengths, and has wide application prospect in the fields of wide gamut light emitting diode (LED) and high performance displays and the like.

Owner:ZHIJING NANOTECH CO LTD

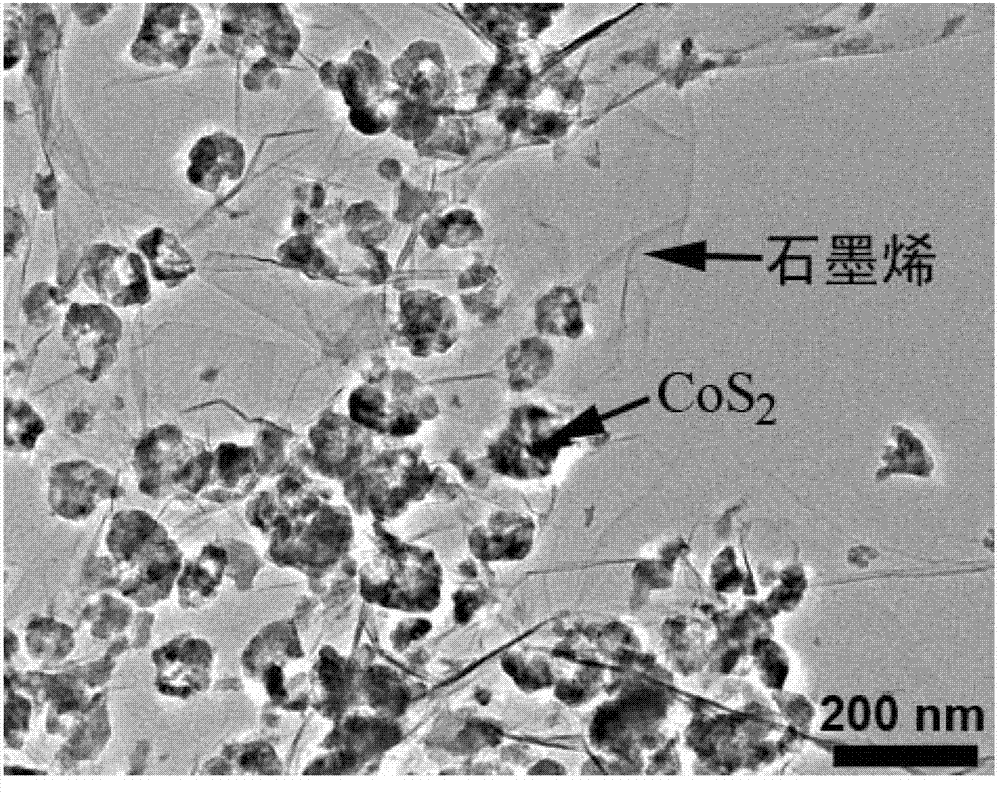

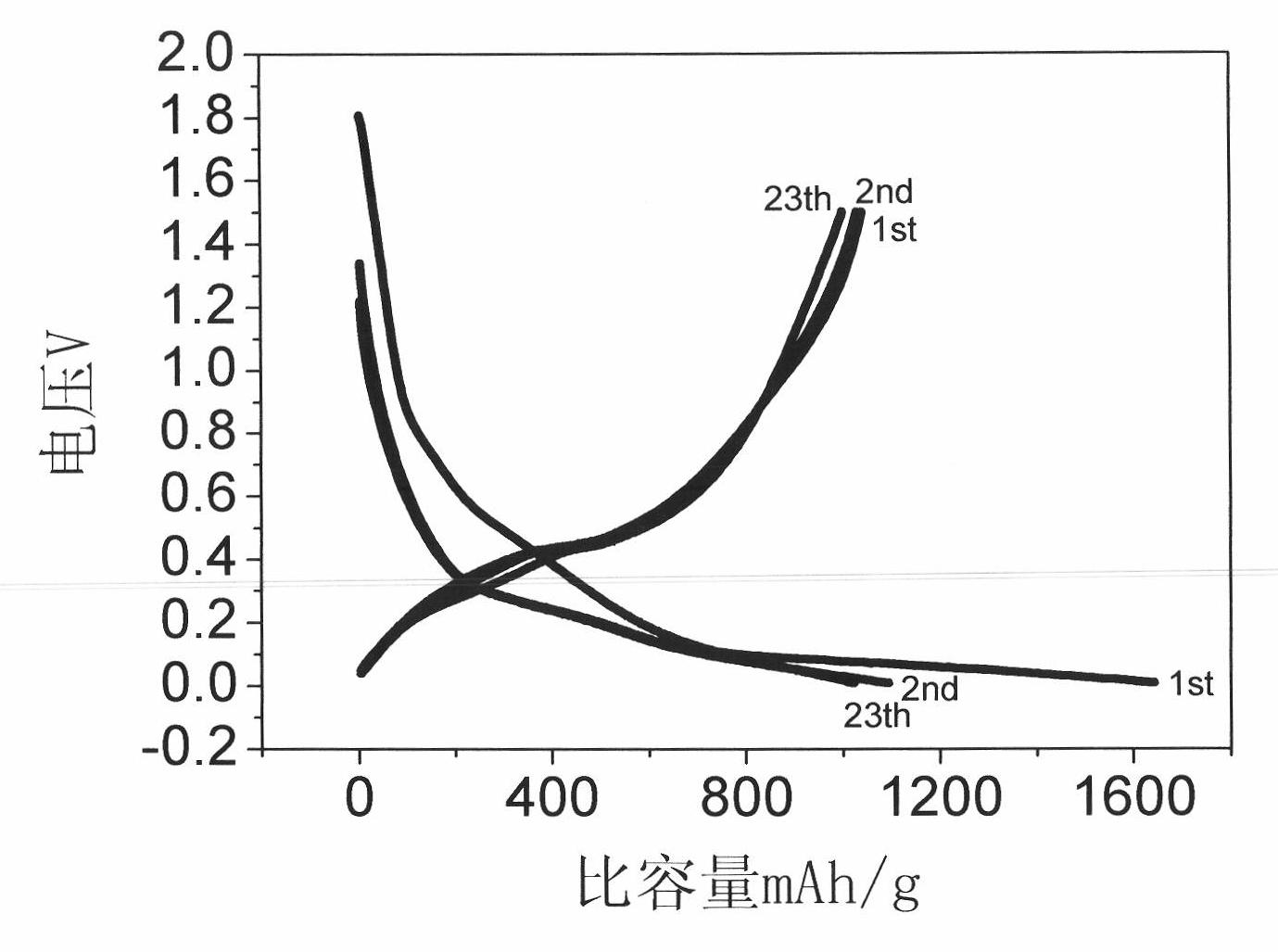

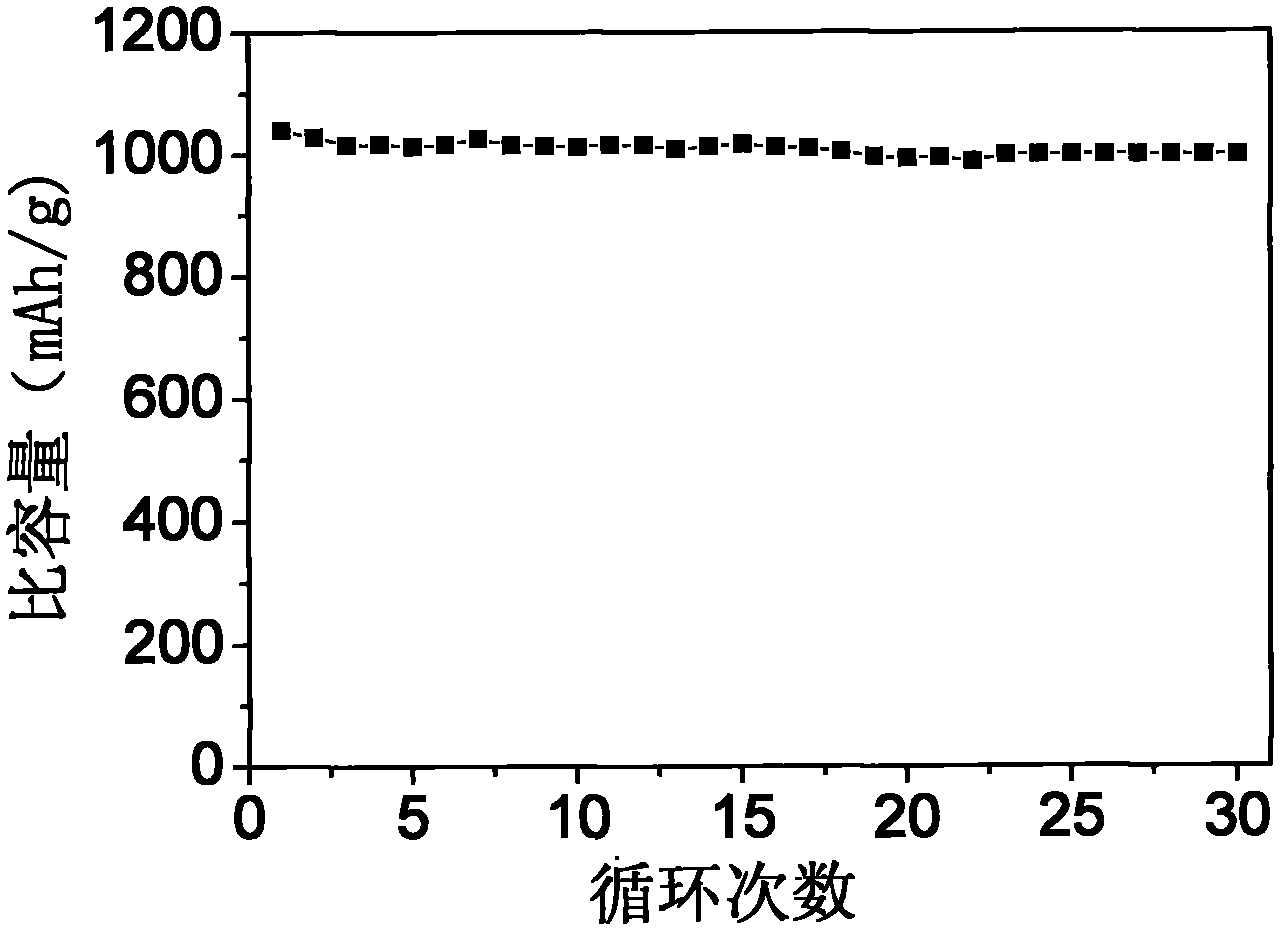

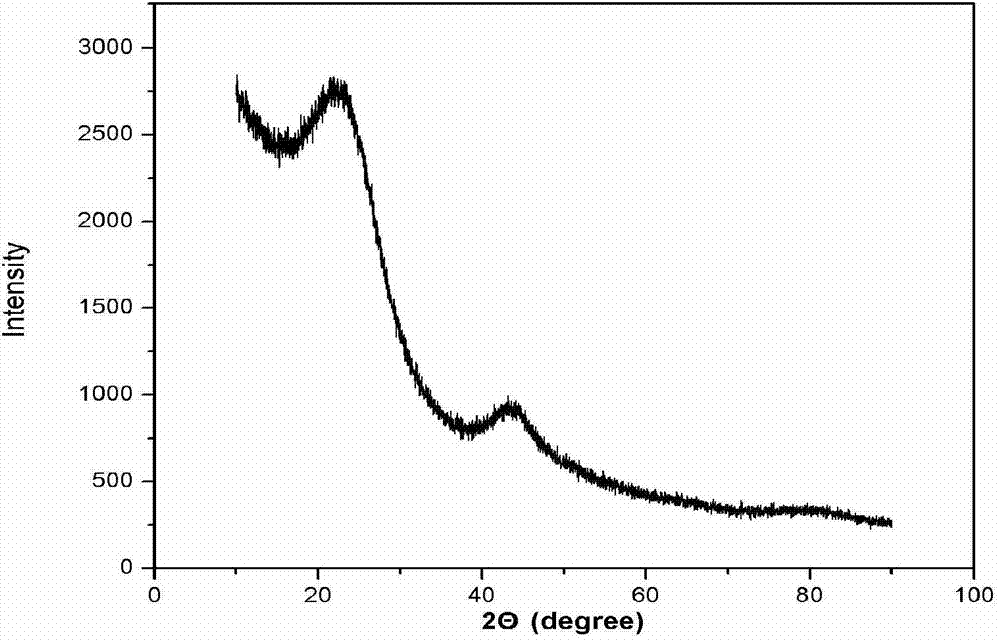

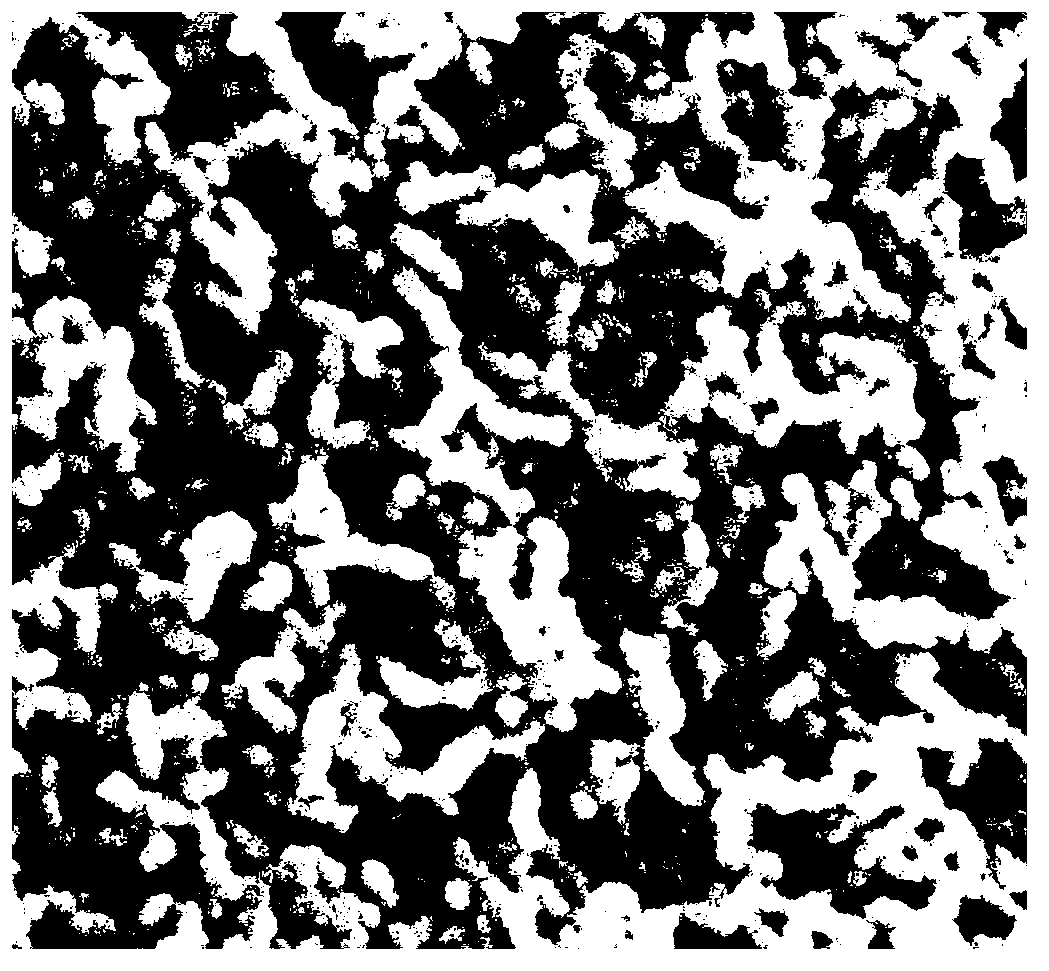

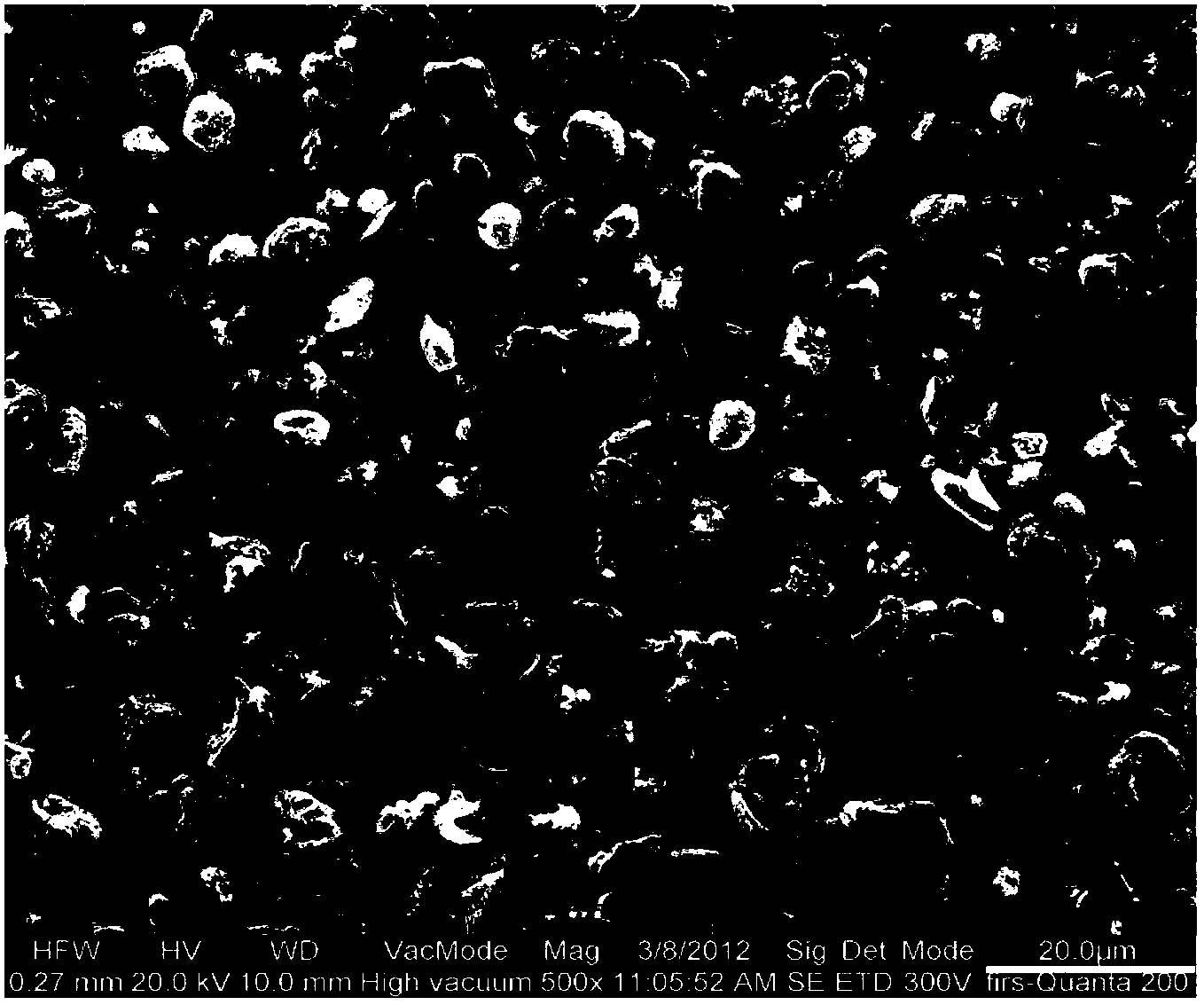

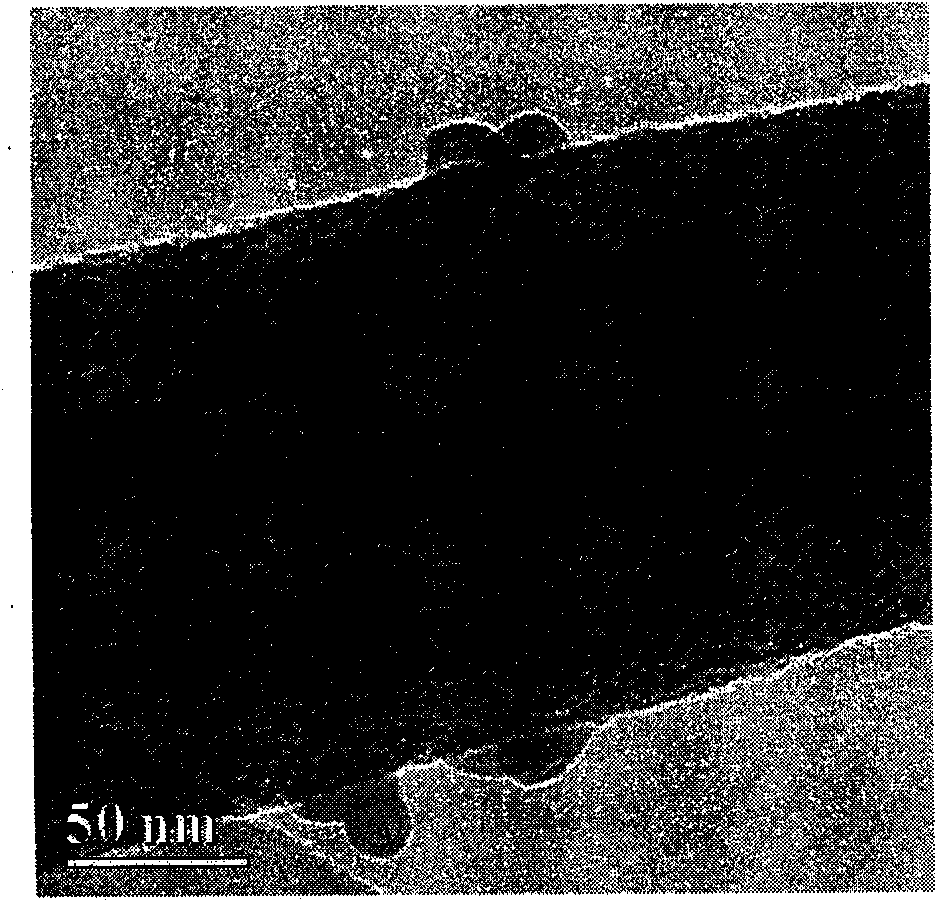

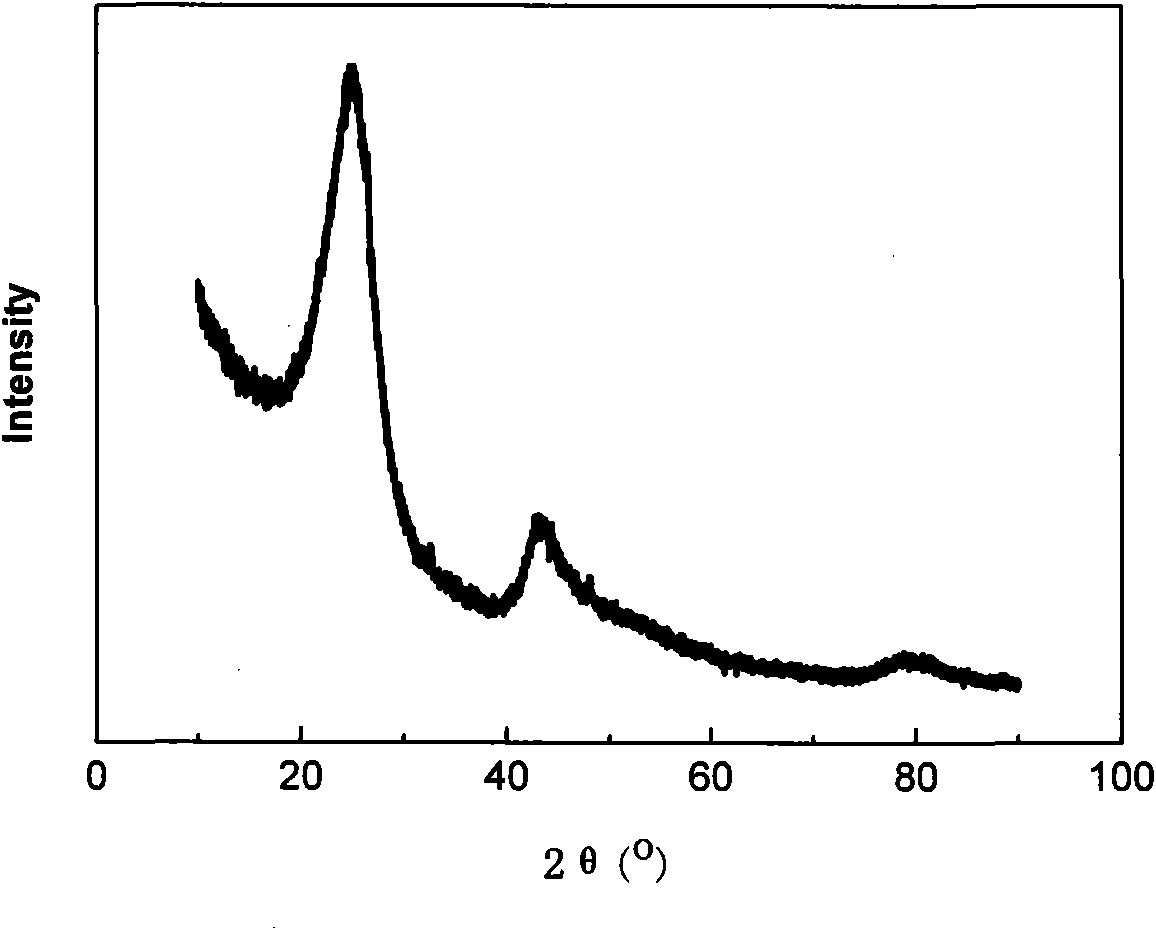

Transition metal sulfide/graphene composite material, and preparation method and application thereof

The invention discloses a transition metal sulfide / graphene composite material which is composed of a nano transition metal sulfide and graphene, wherein the transition metal sulfide is Ni2S3, NiS, FeS, FeS2, CoS, CoS2, CuS2, CuS, MnS or MnS2. Under the dispersion and loading actions of the graphene, the transition metal sulfide can be uniformly distributed and have small particle size, the stability and loop stability of the transition metal sulfide in the charging and discharging process can be effectively enhanced, and the composite material can be used as a lithium ion battery negative pole material. The invention also discloses a one-step low-temperature preparation method of the composite material, which has the advantages of simple technique, low cost, short cycle, low energy consumption and the like and is suitable for large-scale industrial production.

Owner:ZHEJIANG UNIV

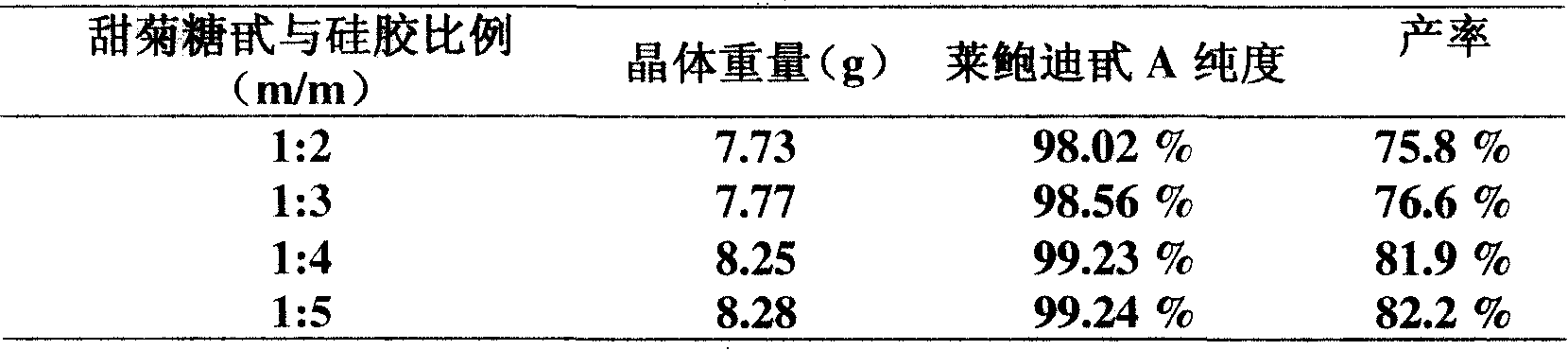

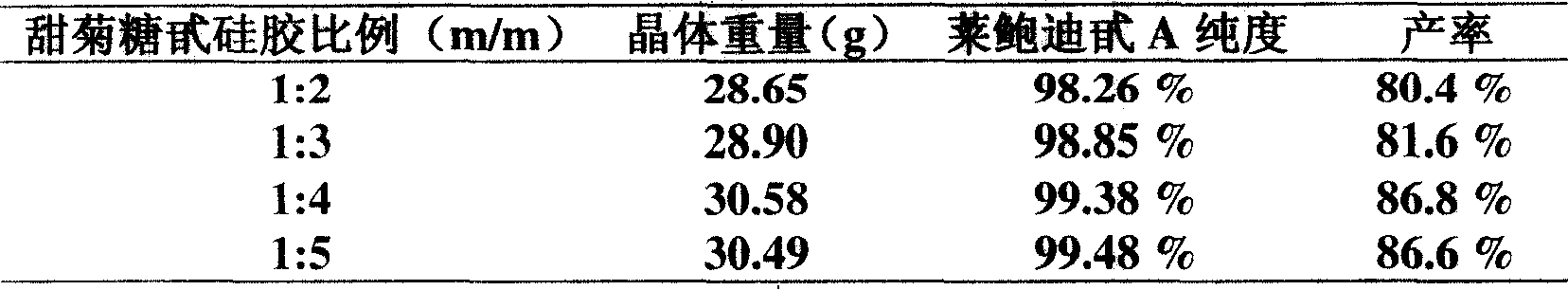

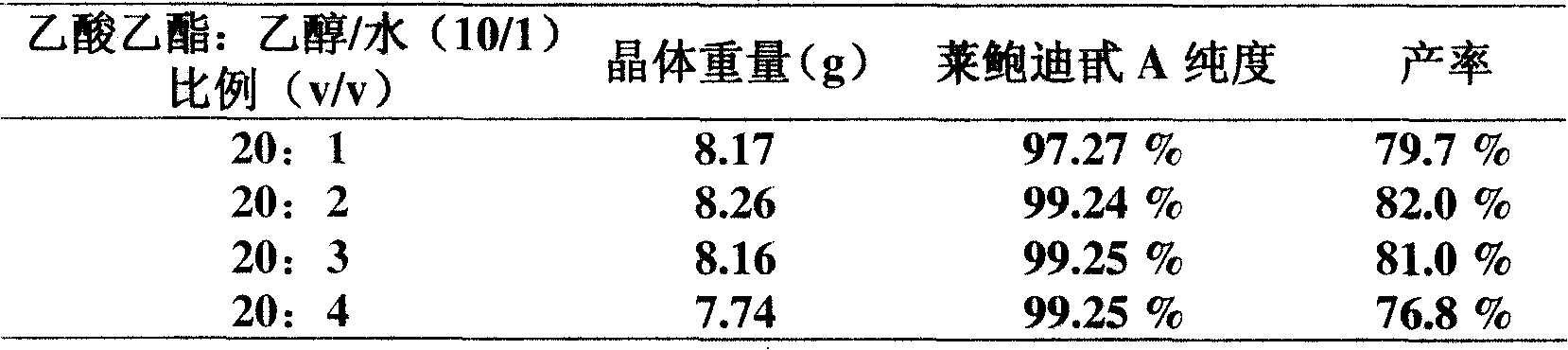

Rebaudioside A and extraction method thereof

InactiveCN101200480ALarge amount of processingLow costSugar derivativesSugar derivatives preparationExtraction methodsChemistry

Owner:CHENGDU WAGOTT RUITIAN TECH CO LTD

Salvia minium phenolic acid A and process of preparing preparation and use

InactiveCN100999470AImprove conversion rateGood repeatabilityOrganic active ingredientsOrganic chemistryMedicineCurative effect

This invention concerns the method of extracting salvianolic acid A from Chinese crude drug: danshen root, and the quality control methods and drug combinations, and the application of this drug. It can be used in the preparation of the prevention drugs for cardiovascular disease, liver damage, liver fibrosis, pulmonary fibrosis and other.

Owner:PHARMA RES INST OF BENCAO TIANYUAN OF BEIJING

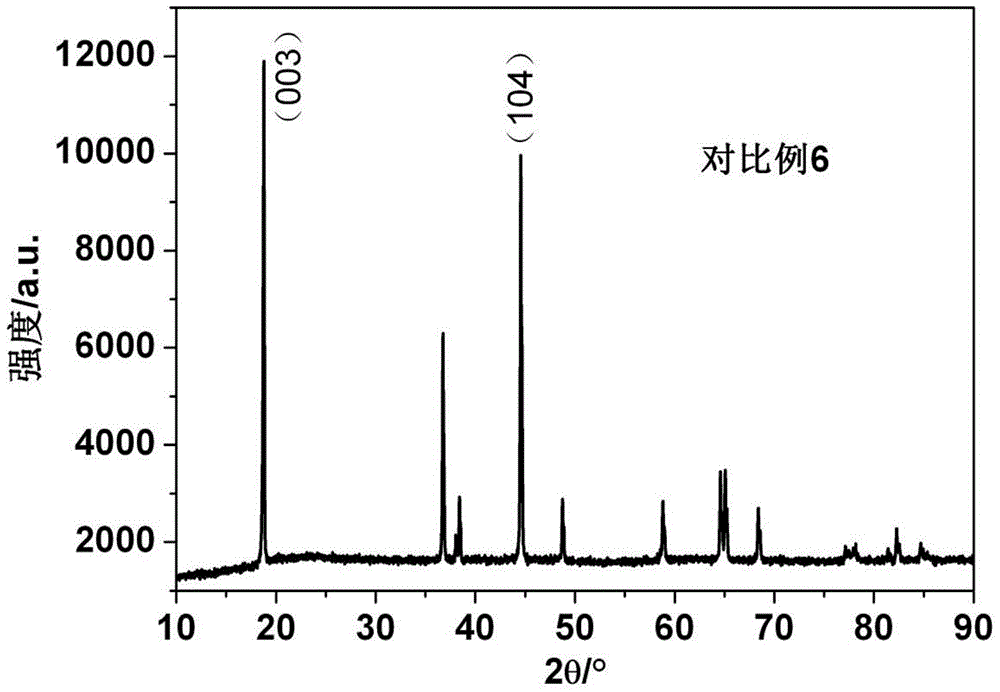

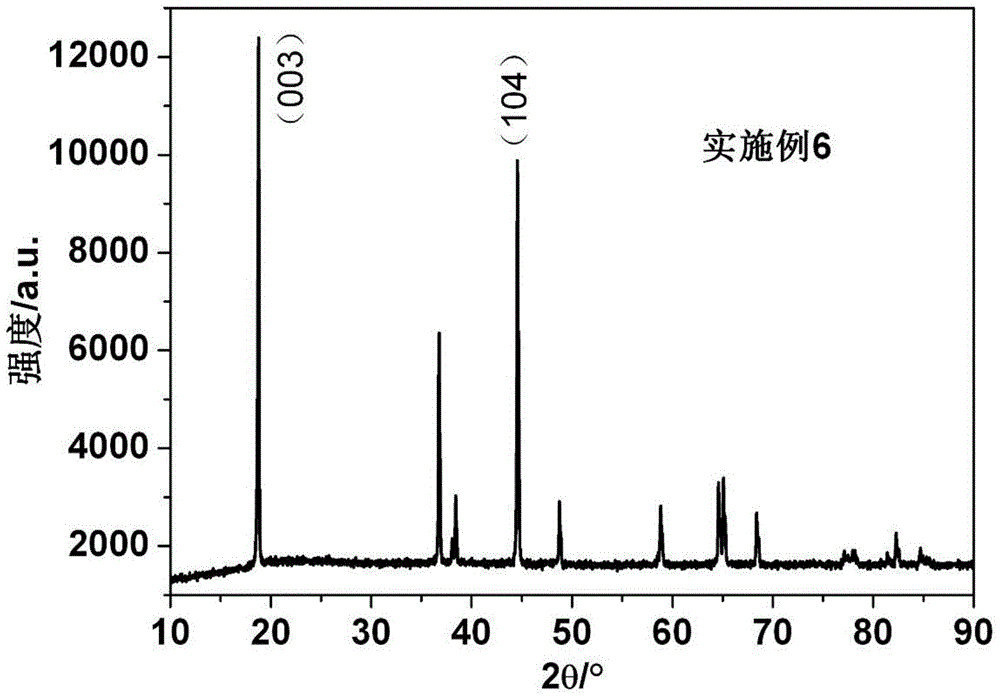

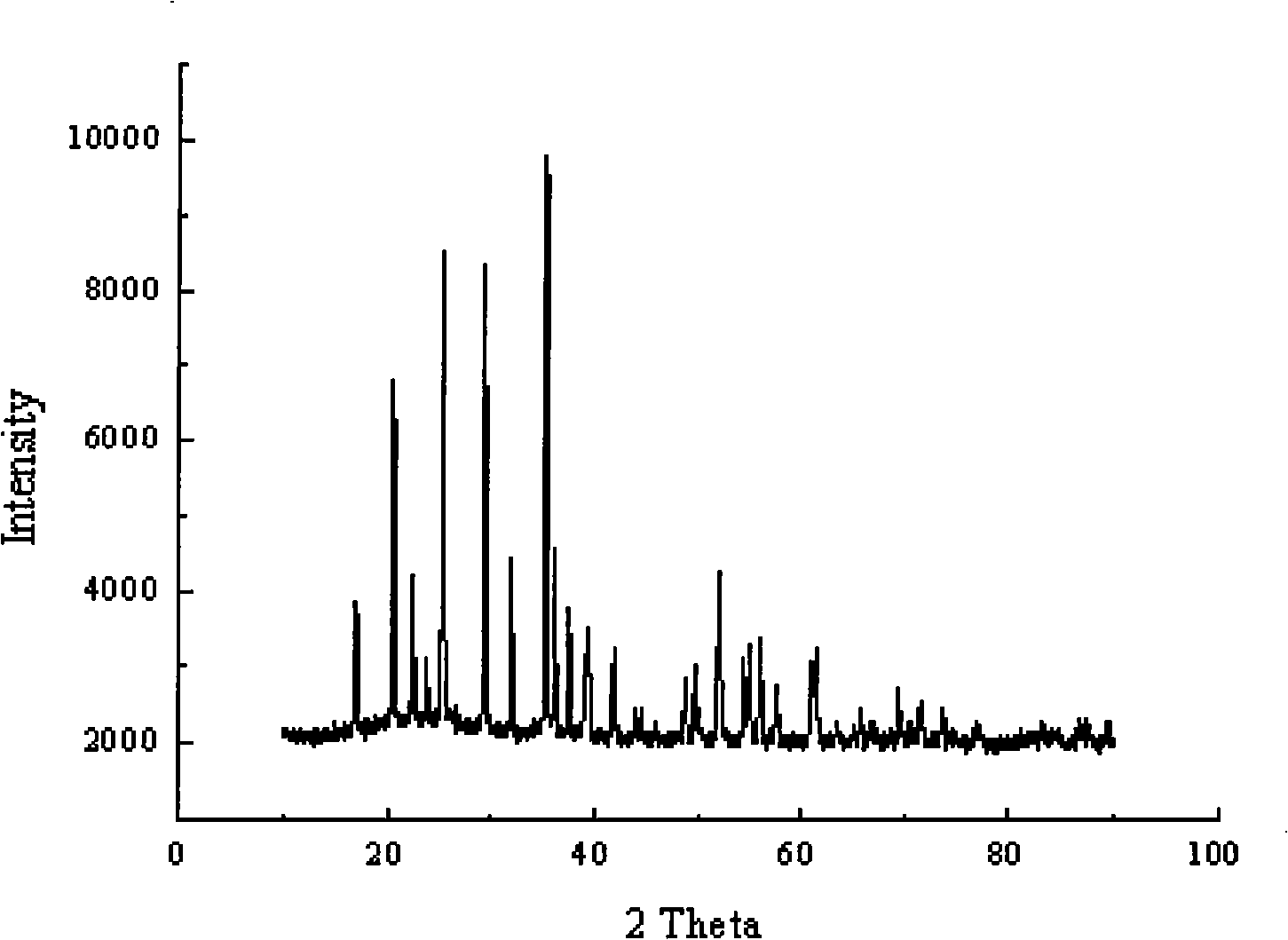

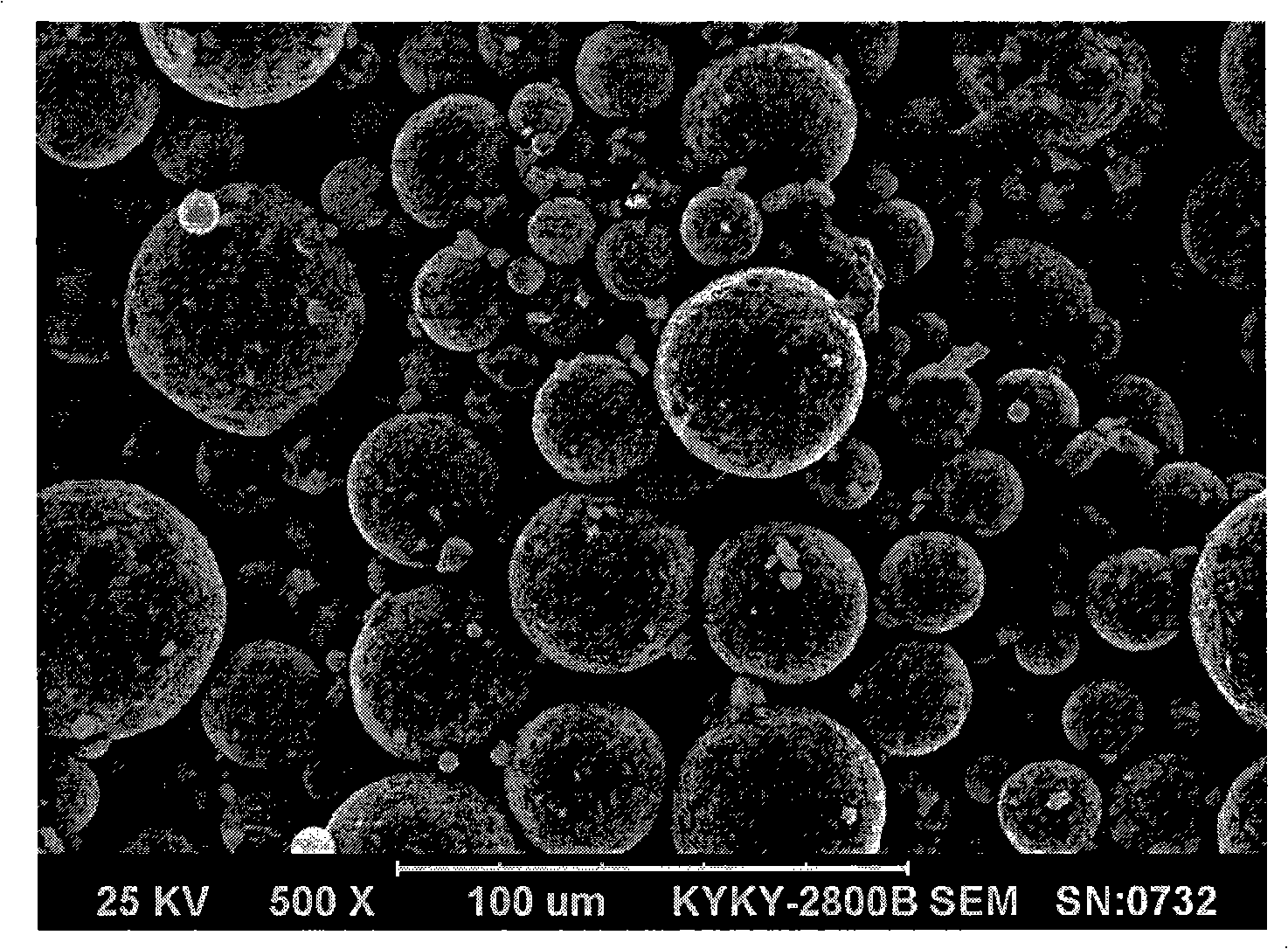

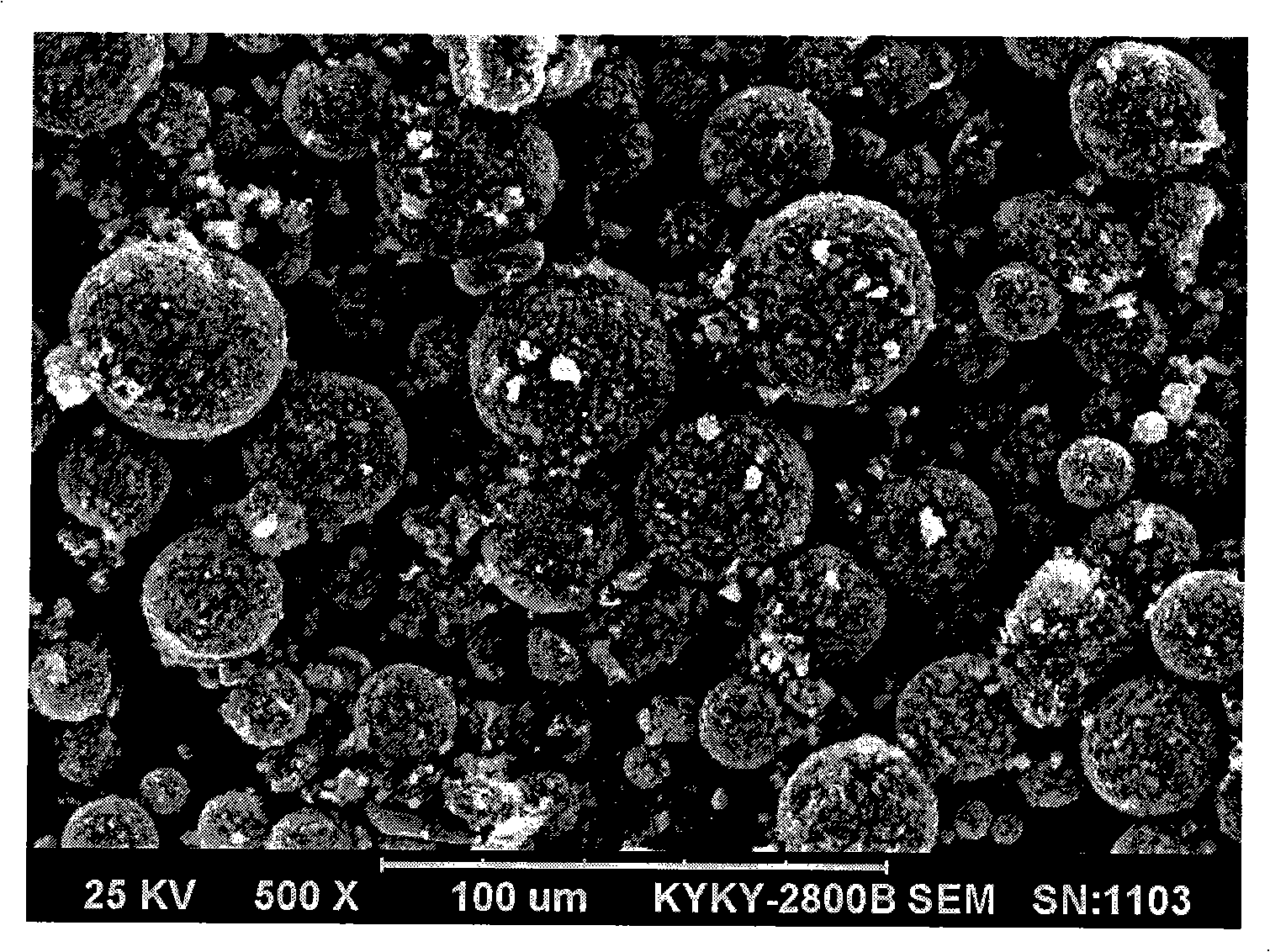

Preparation method for nickel-manganese-cobalt anode material of lithium ion battery

InactiveCN102306765AImprove discharge capacityImprove cycle performanceCell electrodesManganeseLithium compound

The present invention relates to a preparation method for a nickel-manganese-cobalt anode material of a lithium ion battery. According to the present invention, in the presence of nitrogen atmosphere, a mixed solution containing nickel iron, manganese iron and cobalt ion reacts with a precipitating agent, then processes of aging, washing, drying and the like are performed to obtain a nickel-manganese-cobalt hydroxide precursor, the synthesized precursor material has spherical morphology, ideal particle size distribution and high tap density; the precursor, a lithium compound and a doped compound are mixed, then the sintering processing is performed for twice to prepare the nickel-manganese-cobalt three-element composite anode material. The method has characteristics of simple synthesis process, easy process controlling, low energy consumption, high efficiency and low cost, and is applicable for the industrial production; the prepared precursor material has characteristics of spherical morphology, uniform particle distribution and high tap density; the discharge capacity of the battery is improved through doping the metals; the cycle performance of the battery is stable.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

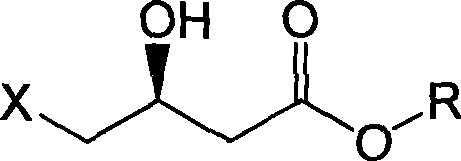

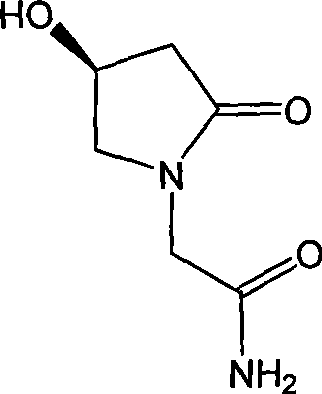

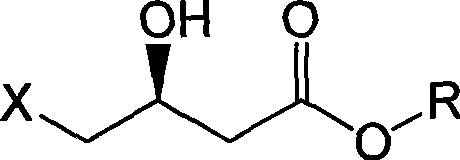

Preparation method for (S)-4-hydroxyl-2-oxo-1-pyrrolidine ethanamide

The present invention provides a preparation method of (S)-4-hydroxyl-2-oxo-1-pyrrolidine acetamide. The preparation method comprises: (S)-4-halogen-3-hydroxyl butyric ester as a raw material reacts under the conditions with polar solvent and alkalinity to prepare the crude product of (S)-4-hydroxyl-2-oxo-1-pyrrolidine acetamide; and the crude product is purified. The preparation method is characterized in that inorganic alkali is added for a plurality of times in the reaction process under the condition with alkalinity so as to control the pH value in the reaction to be less than or equal to 8.5. A large quantity of repeated tests are completed to determine that the optimum pH value of the reaction under the condition with alkalinity is less than or equal to 8.5, and the alkali is added in batches to strictly control the pH value of the whole reaction process, so that the alkali conditions required in the reaction can be satisfied and the reaction can be performed completely, and the target product (S)-oxiracetam is prevented from being damaged in the alkaline solution, thereby improving the yield rate of the target product (S)-oxiracetam and reducing the cost.

Owner:CHONGQING RUNZE PHARM CO LTD

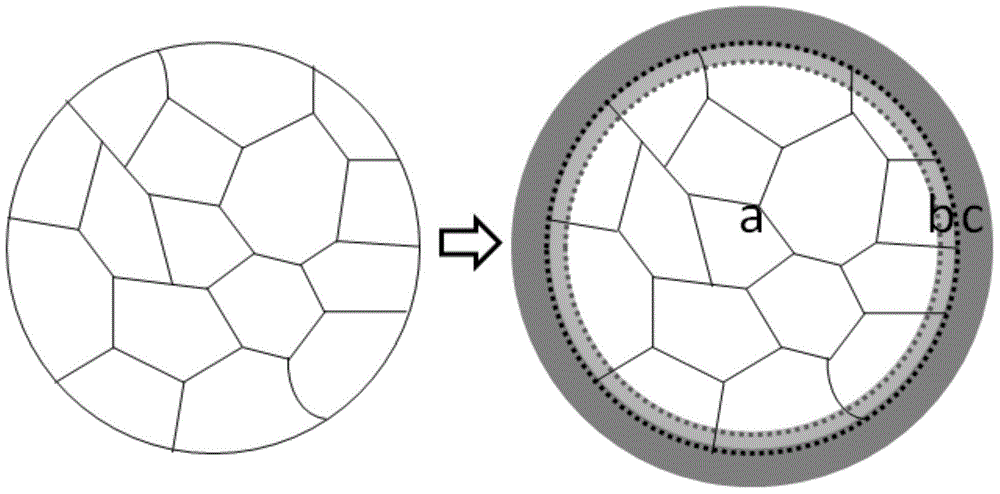

Anode material for nickel-base lithium ion battery and preparation method of anode material

ActiveCN104409700AEasy to operateSuitable for industrial productionCell electrodesSecondary cellsOptoelectronicsOxygen

The invention provides an anode material for a nickel-base lithium ion battery and a preparation method of the anode material. The anode material comprises an inner core, a doping layer and a cladding layer, wherein the chemical formula of the inner core is LiaNixCoyMzO2; the doping layer is another inner core containing M'; at least M' and oxygen elements are contained in the cladding layer; the anode material is of a core-shell structure, and comprises the inner core, the doping layer and the cladding layer from inside to outside. The anode material for the nickel-base lithium ion battery provided by the invention is little in lithium-nickel mixing, and the cycling stability of the material is obviously improved.

Owner:BTR NEW MATERIAL GRP CO LTD

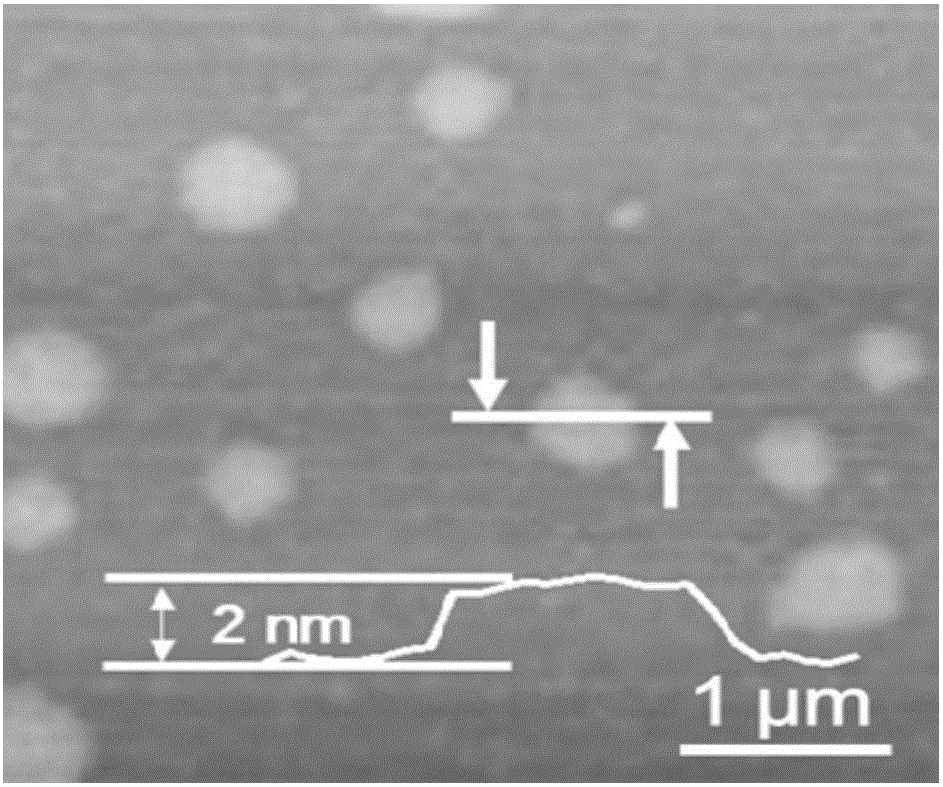

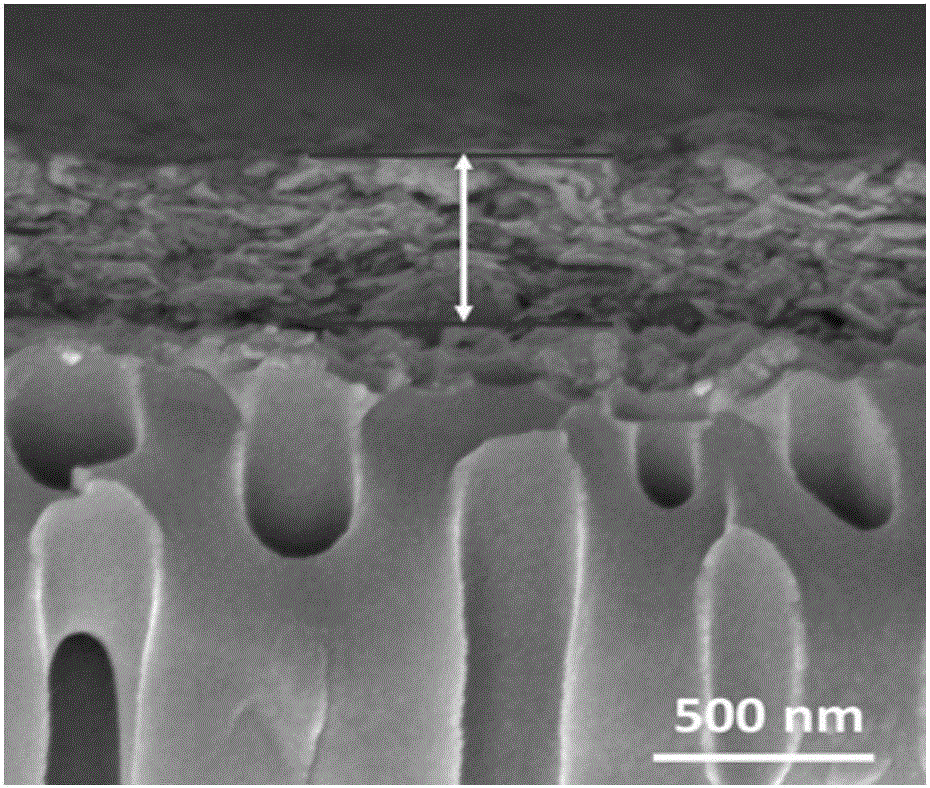

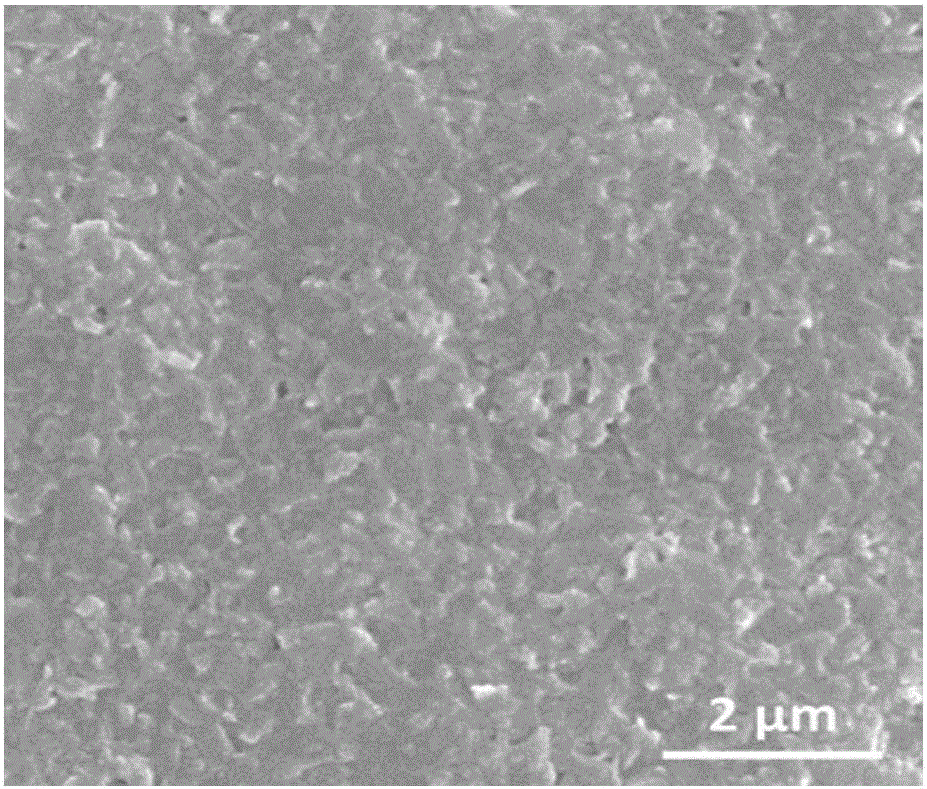

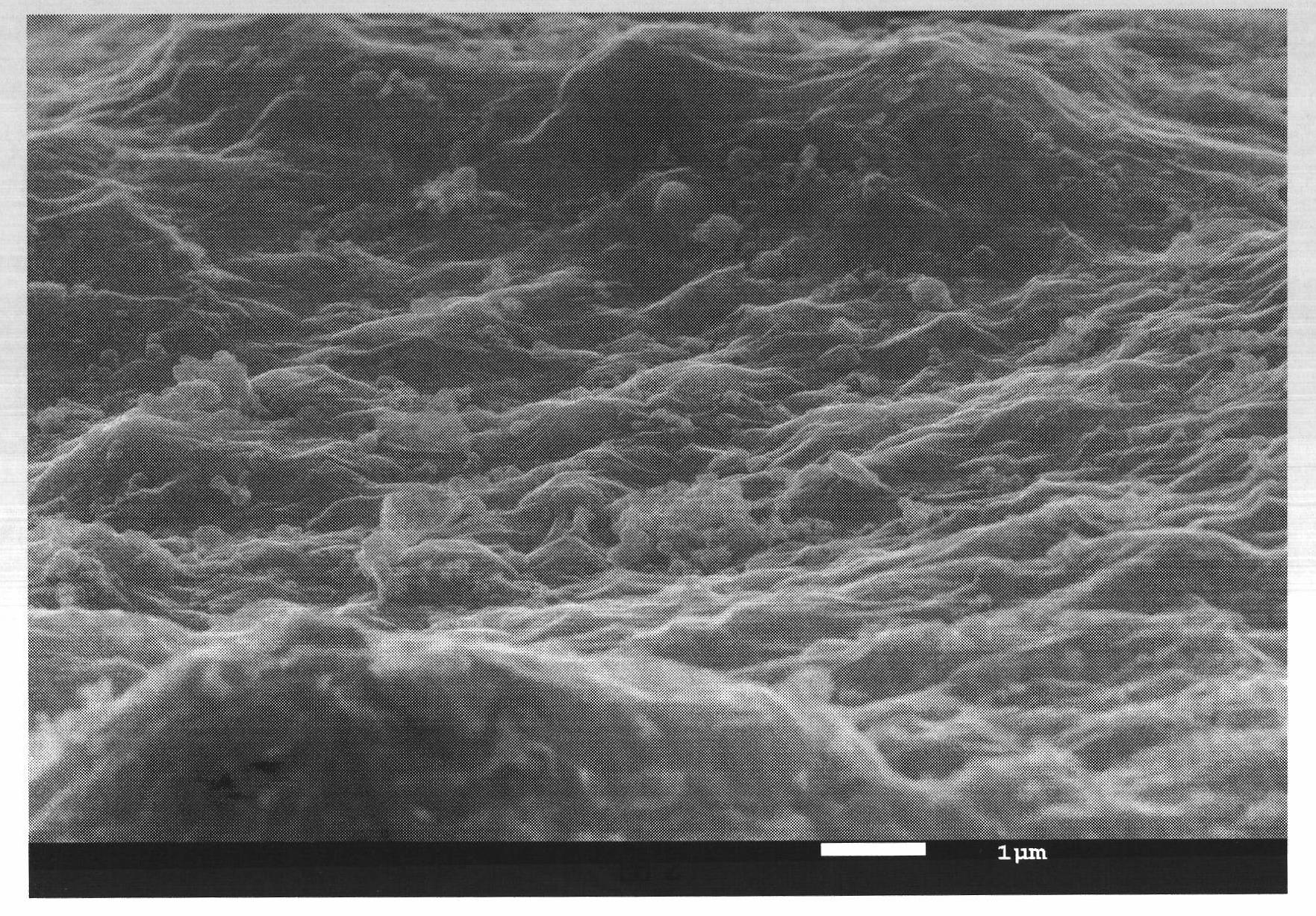

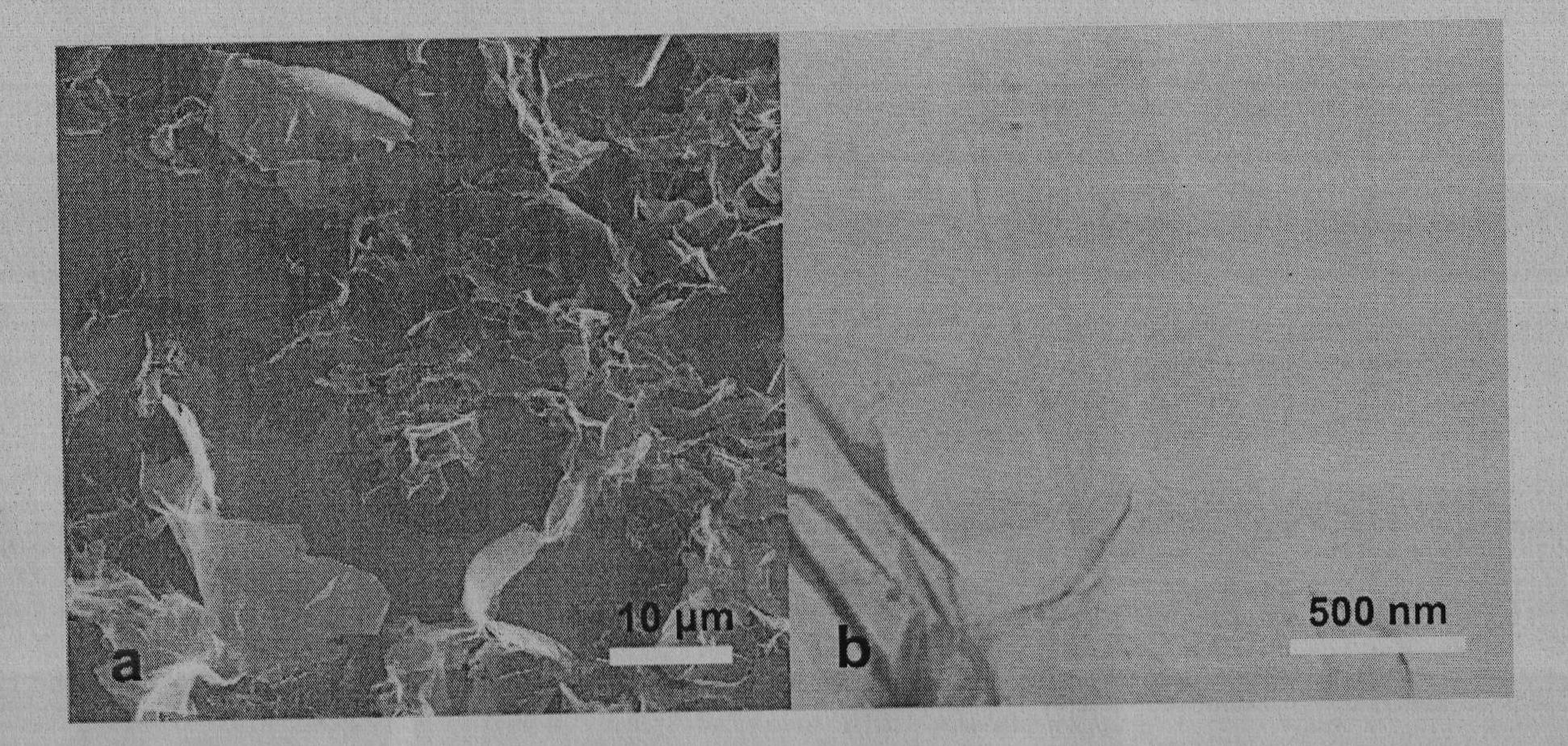

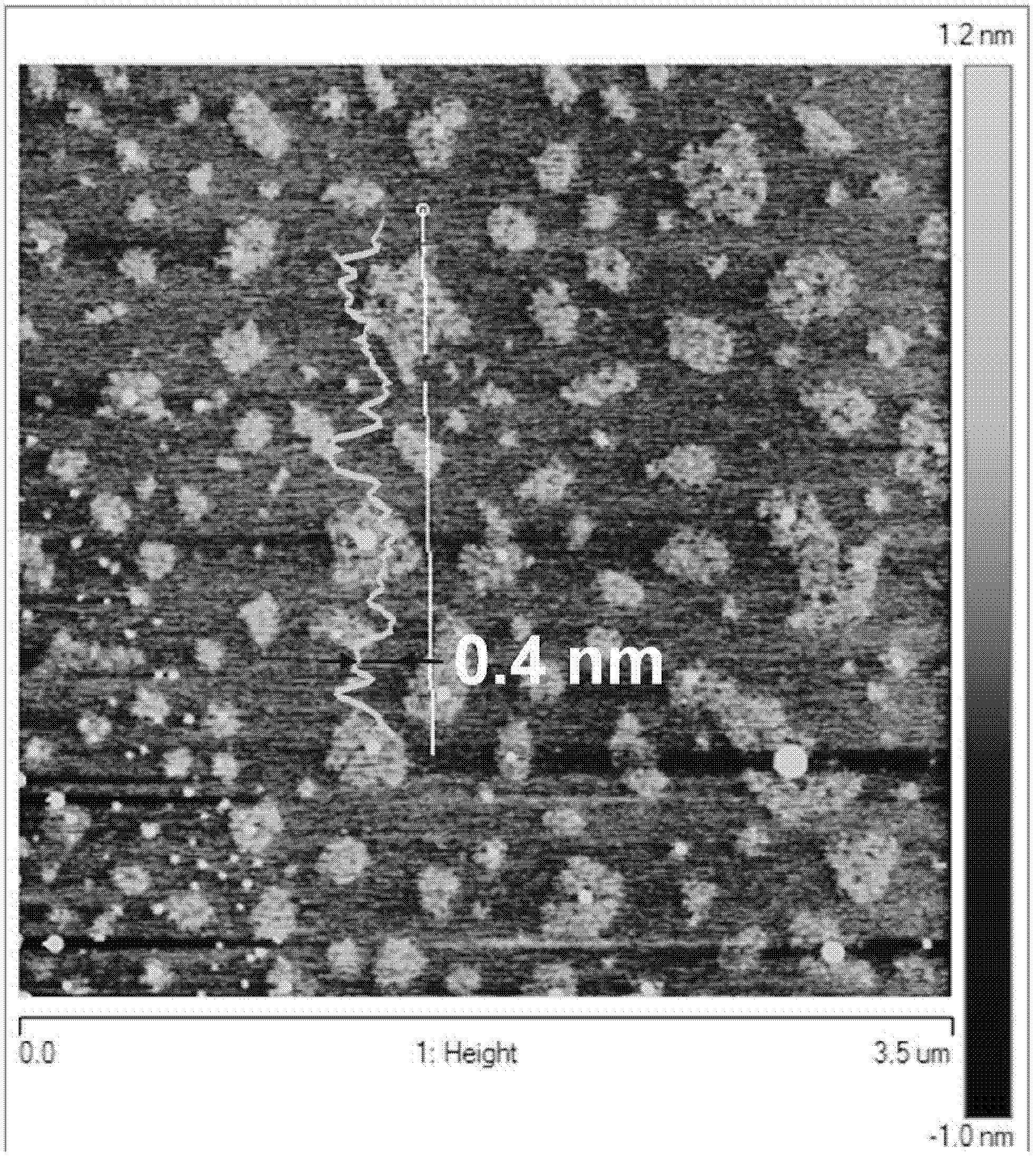

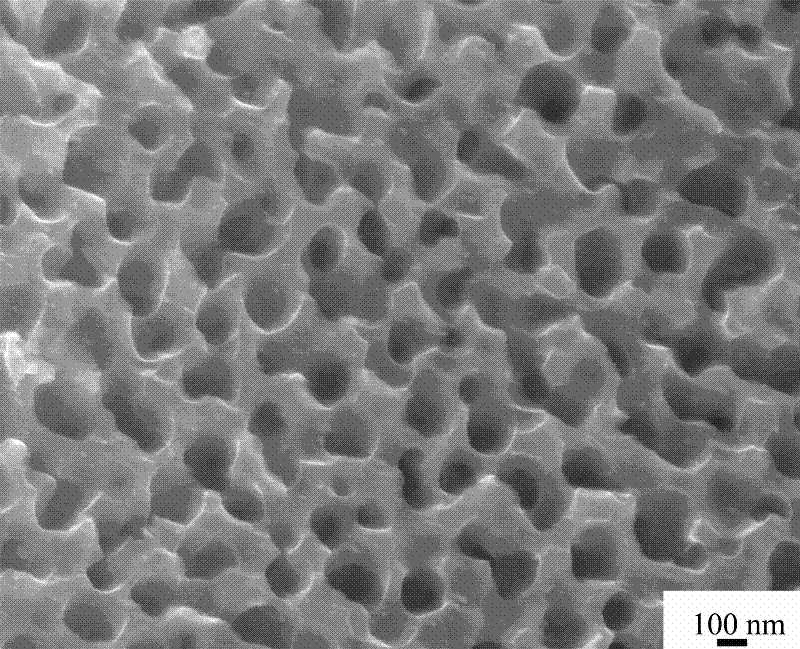

High-performance two-dimensional layered Ti3C2-MXene membrane, preparation method thereof and application of membrane in water treatment

ActiveCN106178979AIncrease water fluxHigh selectivitySemi-permeable membranesWater/sewage treatment bu osmosis/dialysisPorous substrateCentrifugation

The invention belongs to the technical field of membrane preparation and water purification and discloses a high-performance two-dimensional layered Ti3C2-MXene membrane, a preparation method thereof and an application of the Ti3C2-MXene membrane in water treatment. The method comprises steps as follows: (1), Ti3AlC2 powder and an HF solution are mixed, stirred for a reaction, centrifugally washed and dried, and Ti3C2 powder is obtained; (2), the Ti3C2 powder and a solvent are mixed, stirred for the reaction, washed and dried, and treated powder is obtained; (3), the treated powder is dissolved in the solvent and subjected to ultrasonic treatment and centrifugation, a liquid supernatant is taken and dried, and a two-dimensional nanosheet is obtained; (4), a solution is prepared from the two-dimensional nanosheet and deposited on a porous substrate with a nano self-assembly technology, and the high-performance two-dimensional layered Ti3C2-MXene membrane is obtained. The membrane has ultrahigh water flux, higher selectivity and good mechanical property and stability; the method is simple, low in energy consumption and cost, good in repeatability and wide in applicability.

Owner:SOUTH CHINA UNIV OF TECH

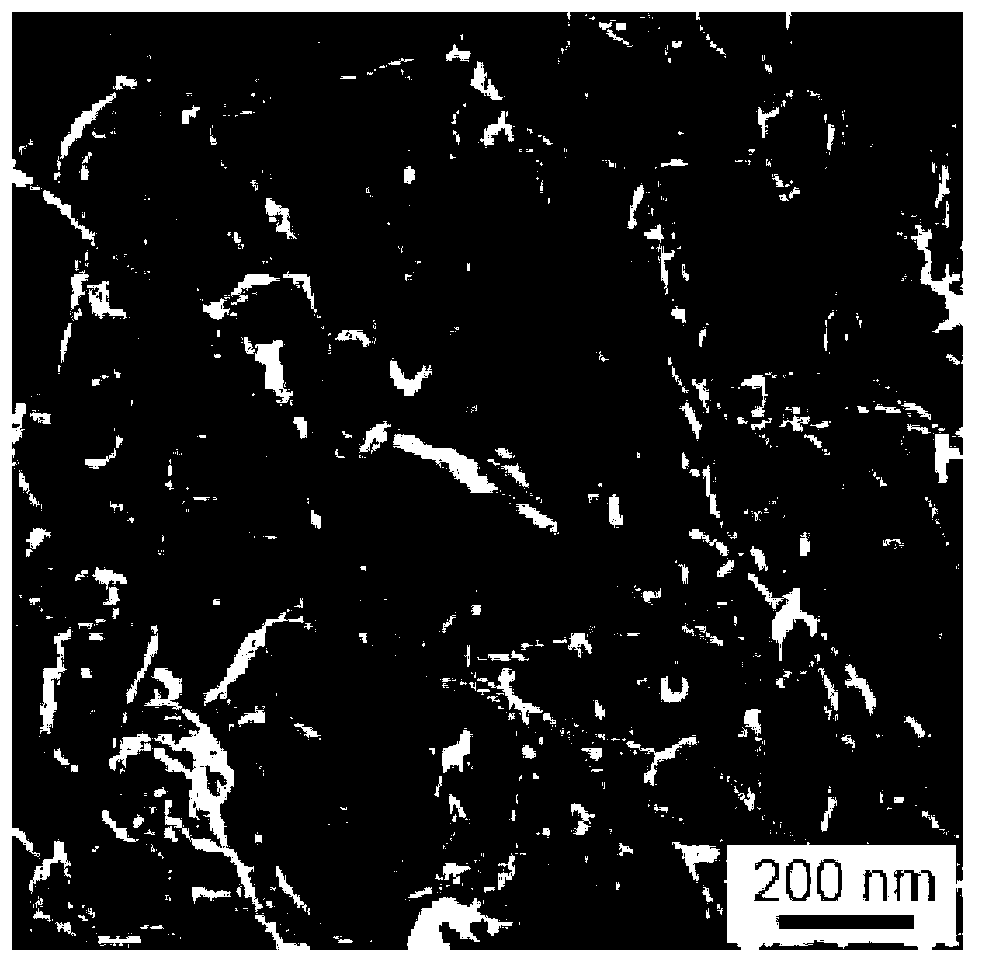

Graphene/silicon lithium ion battery cathode material and preparation method thereof

InactiveCN101924211AHigh specific capacityImprove cycle stabilityCell electrodesComposite filmNew energy

The invention discloses a grapheme / silicon composite material for a lithium ion battery cathode material and a preparation method thereof, belonging to the fields of electrochemistry and new energy materials. The method comprises the following steps of: using graphite as a raw material; oxidizing the graphite into oxidized graphite by adopting oxidants of concentrated sulfuric acid and potassium permanganate; then, ultrasonically stripping the oxidized graphite to prepare oxidized graphene; mixing oxidized graphene in different proportions with nano silicon powder; ultrasonically dispersing, filtering or directly drying into a cake / film; and roasting under a reduction atmosphere to prepare self-support graphene / silicon composite film materials in different proportions. Proved by electrochemistry tests, the graphene / silicon composite film material prepared by the method has higher specific capacity and cycle stability, simple preparation method and easy mass production and consequently is an ideal high-energy lithium ion battery cathode material.

Owner:UNIV OF SCI & TECH BEIJING +1

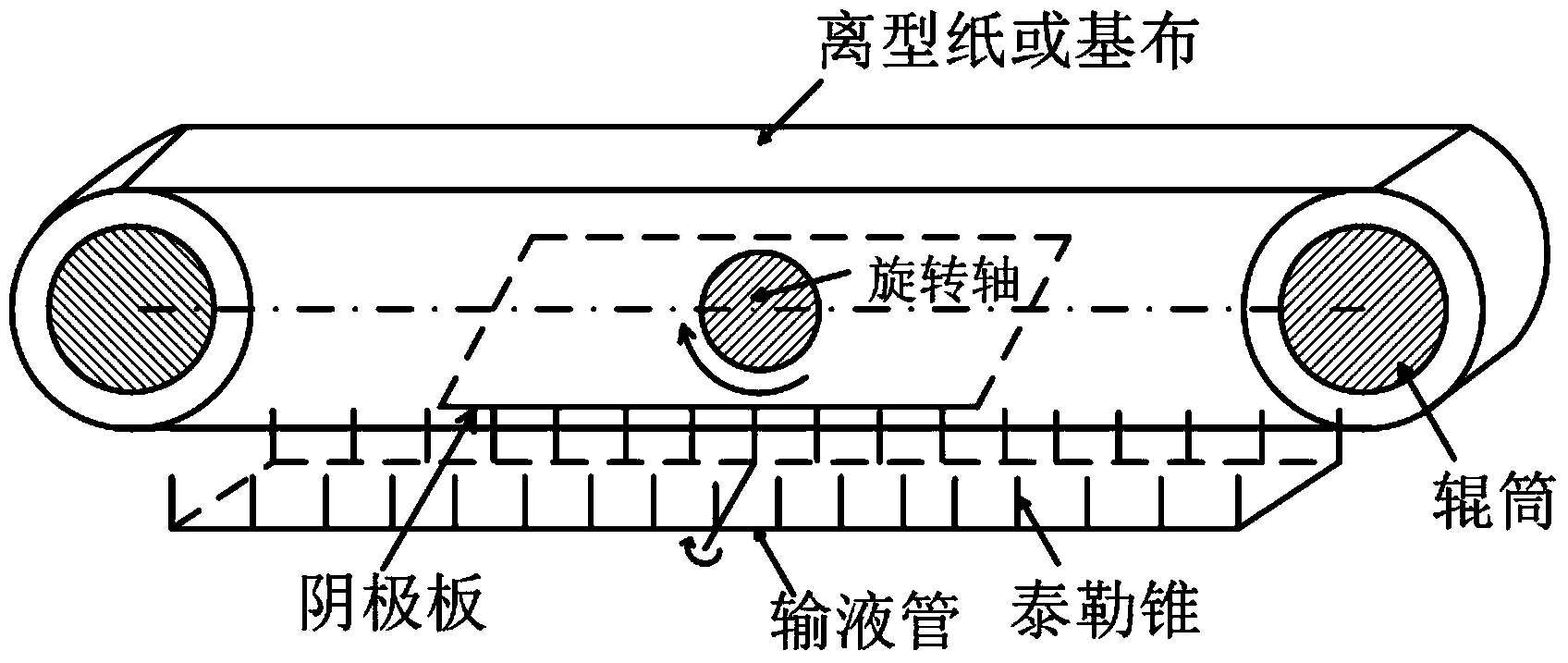

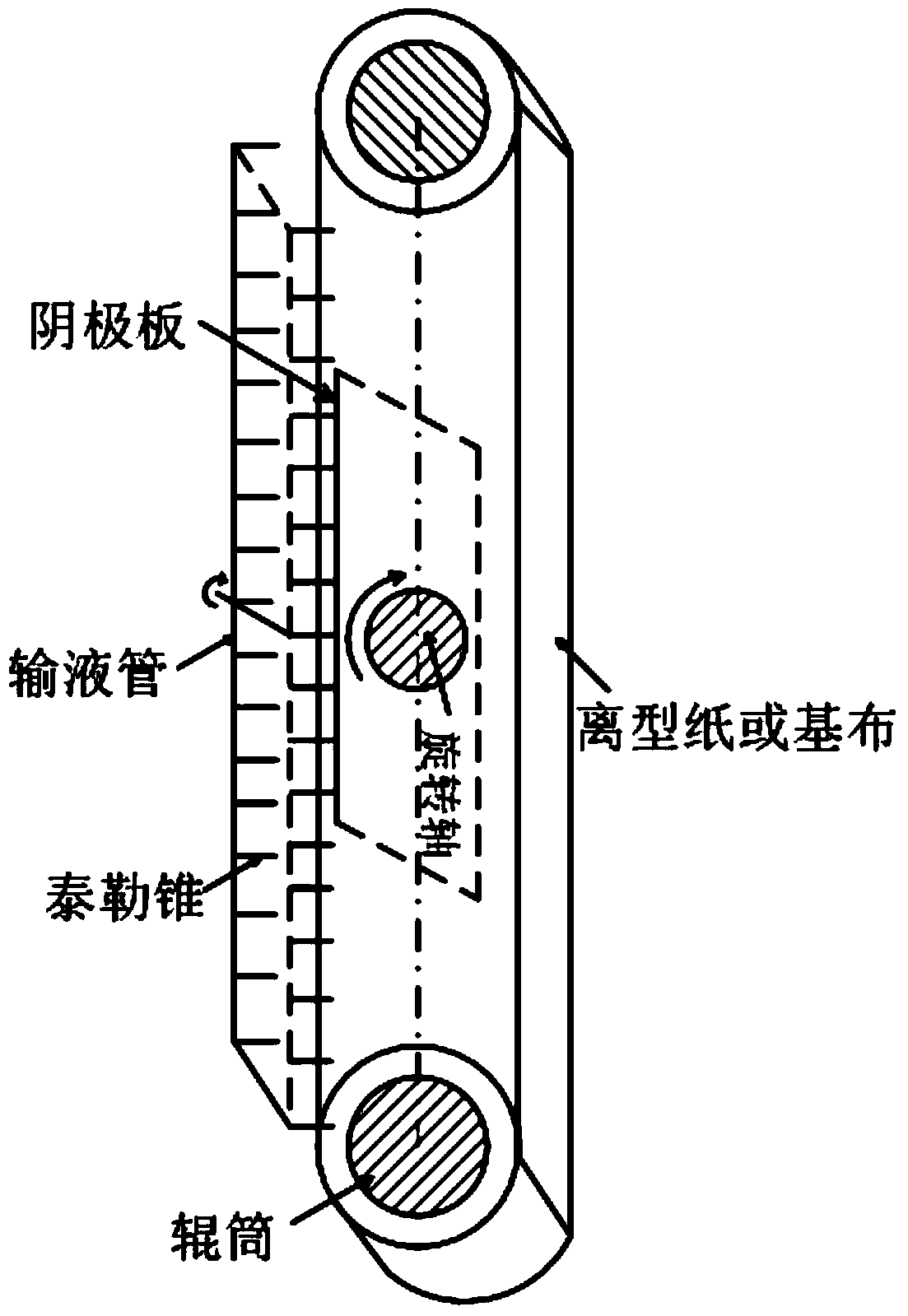

Electrostatic spinning nanofiber membrane as well as preparation method thereof

InactiveCN103437071AIncrease productivityReduce energy consumptionNon-woven fabricsChemical industryFiber

The invention provides an electrostatic spinning nanofiber membrane as well as a preparation method thereof. The electrostatic spinning nanofiber membrane provided by the invention comprises a fiber membrane obtained by electrostatically spinning a high-melting-point polymer and a fiber membrane obtained by electrostatically spinning a low-melting-point polymer, wherein the difference on the melting points of the high-melting-point polymer and the low-melting-point polymer is not less than 10 DEG C. The electrostatic spinning nanofiber membrane provided by the invention is multipurpose and can be applied to the fields such as biomedicines, energy and chemical industry, gas and liquid filtration, waterproofness and windproofness, windproofness and heat insulation, moisture permeability and ventilation, environmental management and semiconductor sensors. According to the electrostatic spinning nanofiber membrane provided by the invention, electrostatic spinning is respectively carried out on the high-melting-point polymer and the low-melting-point polymer, and the high-melting-point polymer fiber membrane and the low-melting-point polymer fiber membrane obtained are composited and hot-pressed to obtain the electrostatic spinning nanofiber membrane. The preparation method provided by the invention is high in production efficiency and low in energy consumption, and is suitable for industrial production.

Owner:ZHEJIANG WEIXING IND DEV

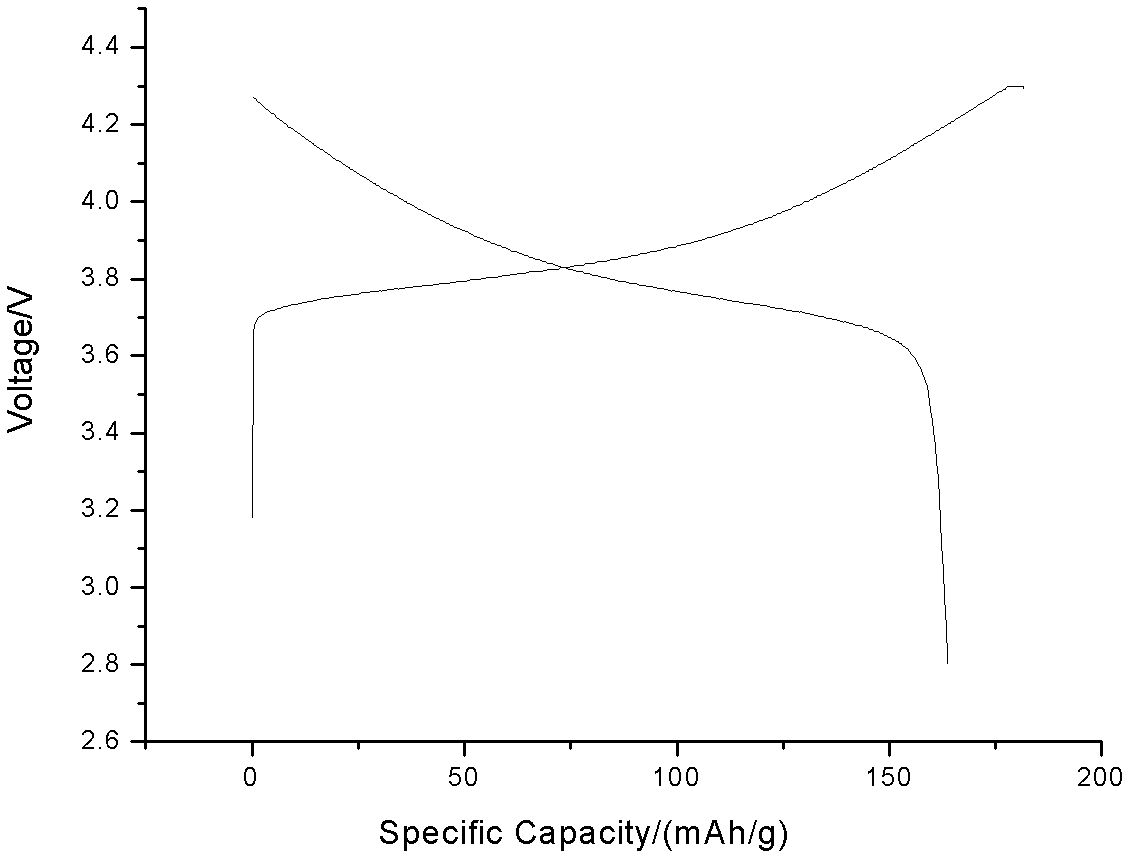

Rare earth doped carbon clad type nanometer anode material iron lithium phosphate and its preparation method

InactiveCN1830764AIncrease capacityImprove cycle lifeCell electrodesPhosphorus compoundsEpoxyRare earth

A carbon-coated RE-doped iron lithium phosphate nano-particle used for positive electrode of battery is prepared from FeC2H4, H2O, Li2CO3, NH4H2PO4, Y2O3, CeO2 and epoxy resin through proportional mixing, ball grinding, baking, sieving, calcining in N2 atmosphere at 350 deg.C and 600-750 deg.C respectively, and keeping the temp for a certain time.

Owner:TSINGHUA UNIV +1

Fruit and vegetable soybean milk drink and preparation method thereof

InactiveCN104997103AGreat tasteRetain nutritional valueFood ingredient functionsOligosaccharide food ingredientsBiotechnologyNutritive values

The present invention discloses a fruit and vegetable soybean milk drink which is prepared from the following raw materials in parts by weight: fruit juice 10-15 parts, vegetable juice 5-10 parts, Chinese red date soybean milk 3-5 parts, white granulated sugar 3-5 parts, high glucose syrup 2-3 parts, xylo-oligosaccharide 1-2 parts, malic acid 2-5 parts, citric acid 0.1-0.2 part, stabilizer 0.1-0.15 part and pure water 77.15-87.3 parts. The preparation method of the fruit and vegetable soybean milk drink comprises the following steps: (1) preparing the fruit juice; (2) preparing the vegetable juice; (3) preparing the Chinese red date soybean milk; (4) blending; (5) homogenizing and degassing; and (6) sterilizing and bottling. The prepared fruit and vegetable soybean milk drink increases the taste, improves the mouthfeel, maintains the nutritional values and increases the nutrients of the soybean milk, not only satisfies the people's pursuit for taste preferences, but also maintains and adds more nutrients, and has higher nutritional values.

Owner:HEILONGJIANG TIANYI AGRI TECH DEV

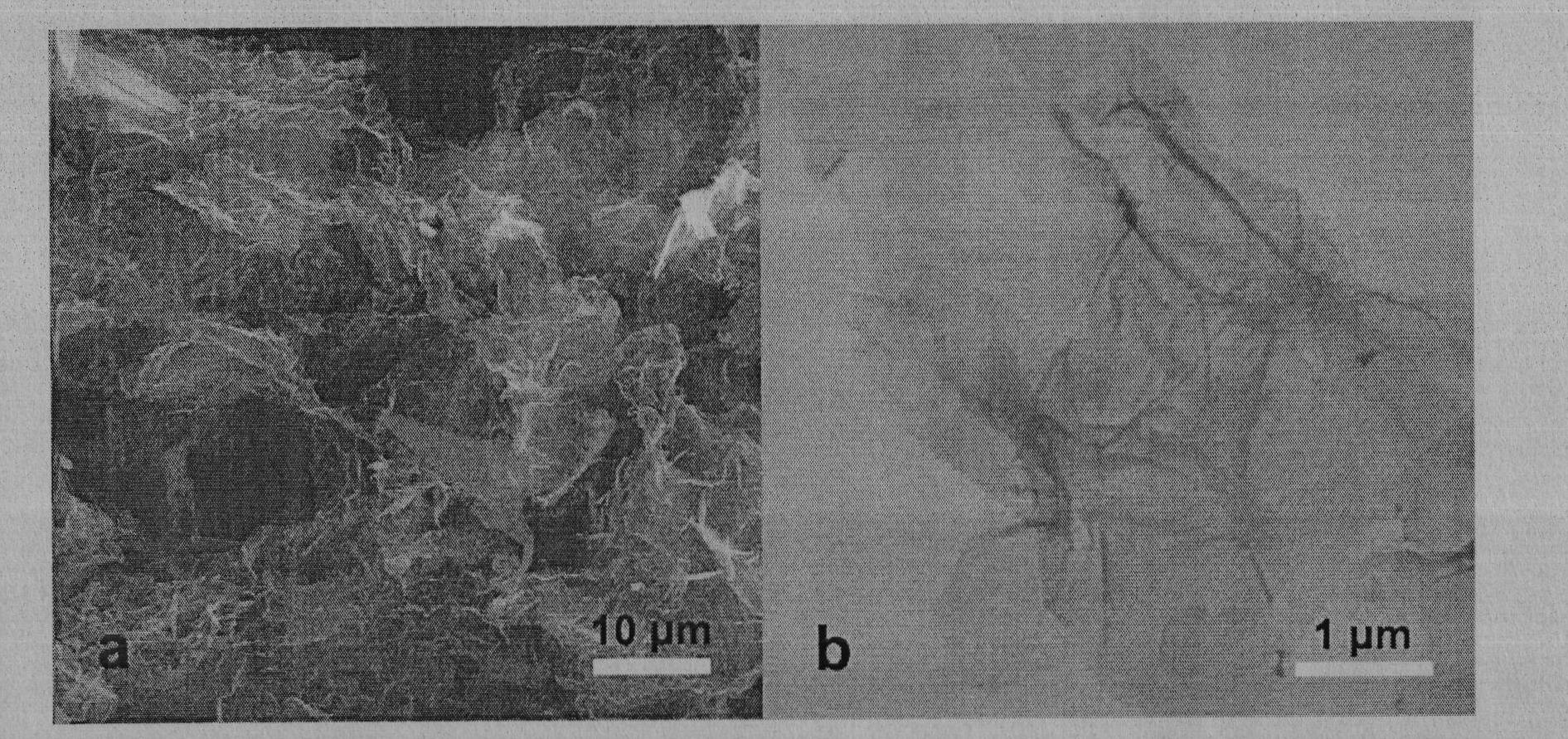

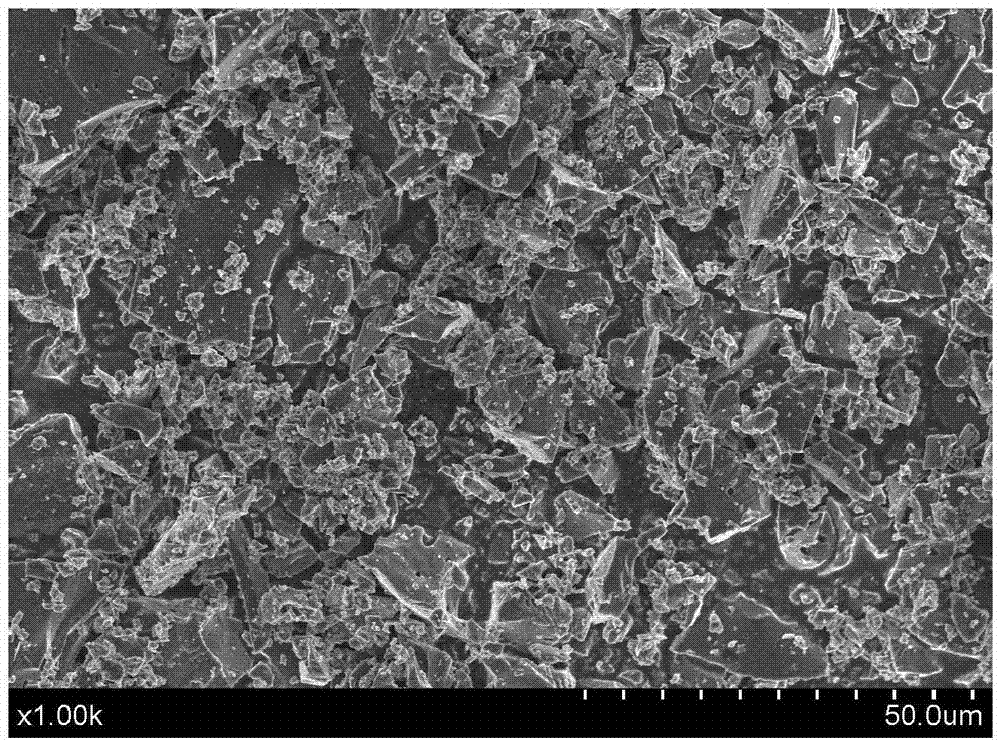

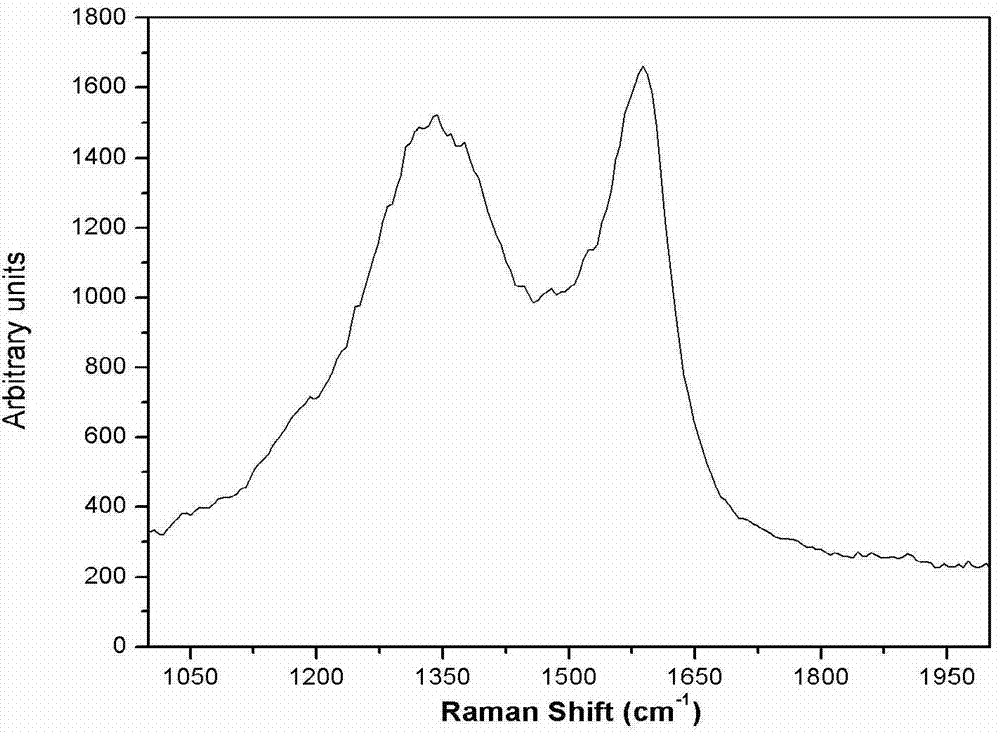

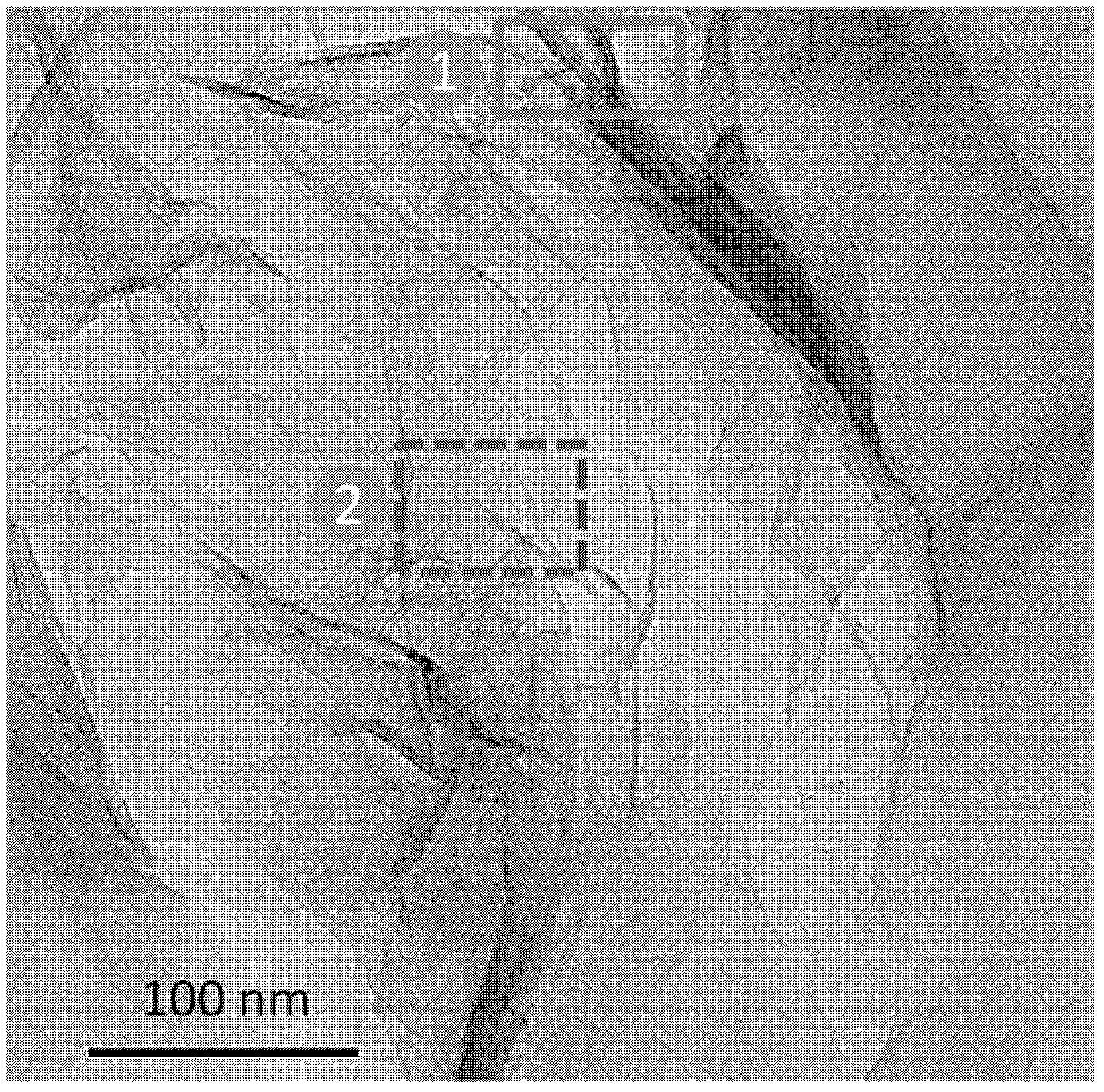

Method for preparing high-quality graphene in large scale by intercalation stripping of graphite by chemical method

The invention discloses a method for preparing high-quality graphene in large scale by intercalation stripping of graphite by chemical method. The main principle and approach are as follows: inserting some reagent into graphite intercalation by chemical method, then adding energy or some reagent to make intercalation material rapidly and violently react to release air and stripping graphite into graphene. The specific embodiment proposal comprises means of liquid phase stripping, solid phase stripping and two-step liquid phase and solid phase combined stripping. The prepared graphene has high single intercalation quality and few detects since it does not go through oxidation and reduction processes. The oxygen content is only 1.63% and is the lowest in known graphene preparation method by graphite. There is no impurity or molecule absorbed on the graphene surface. The invention has low cost, high yield, simple and feasible preparation method and low energy consumption and is suitable for large scale generation.

Owner:深圳市长宜景鑫投资有限公司

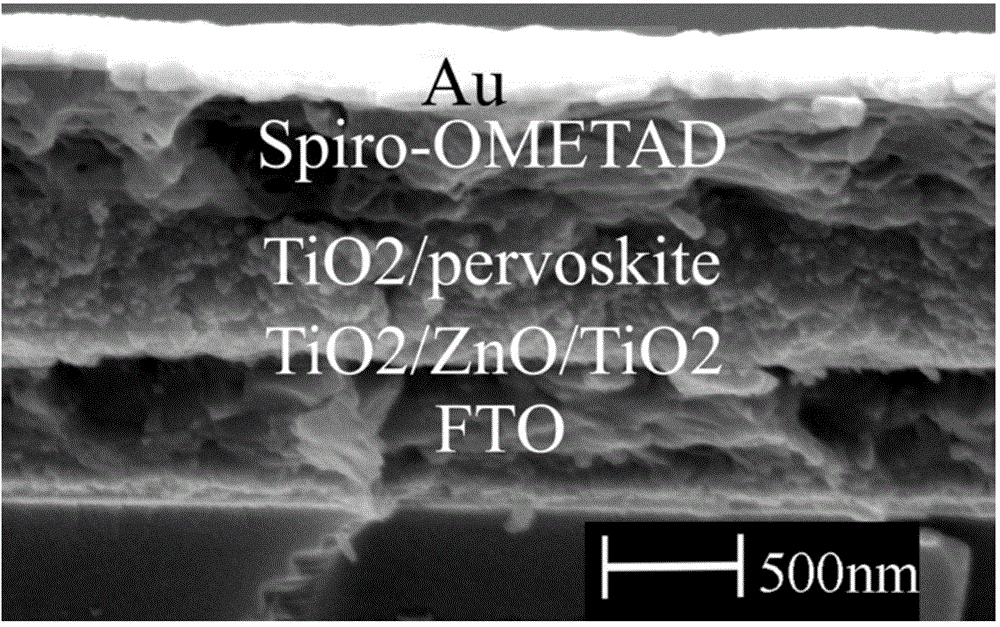

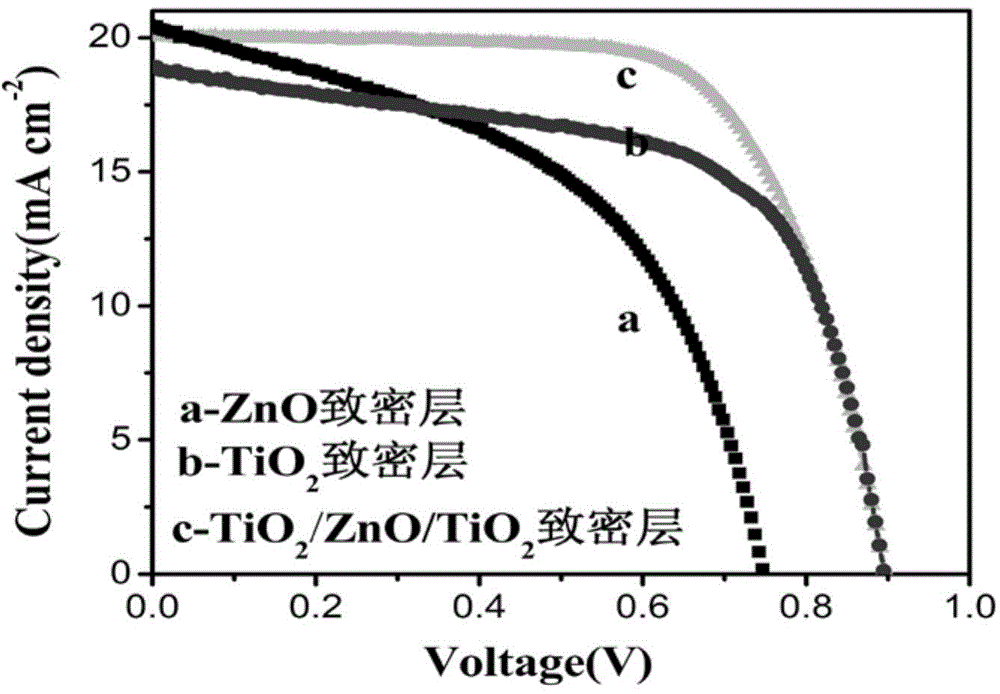

Perovskite solar cell and preparation method thereof

InactiveCN104091888AEasy to prepareControllable parametersSolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellFill factor

The invention relates to a perovskite solar cell and a preparation method thereof. The perovskite solar cell is composed of an FTO glass substrate, a sandwich structure TiO2 / ZnO / TiO2 compact layer, a TiO2 mesoporous / perovskite structure material active light absorption layer, a spiro-OMeTAD hole transferring layer and a gold electrode. Compared with the prior art, the sandwich structure TiO2 / ZnO / TiO2 compact layer combines with the advantages and disadvantages of TiO2 and ZnO, so that fill factors of the perovskite solar cell are improved to 70%, and the photoelectric conversion efficiency reaches 12.6%. Equipment for preparing the perovskite solar cell is simple, the preparing process is simple, control is easy, the cost is low, and the perovskite solar cell has a very good industrial application prospect.

Owner:HUBEI UNIV

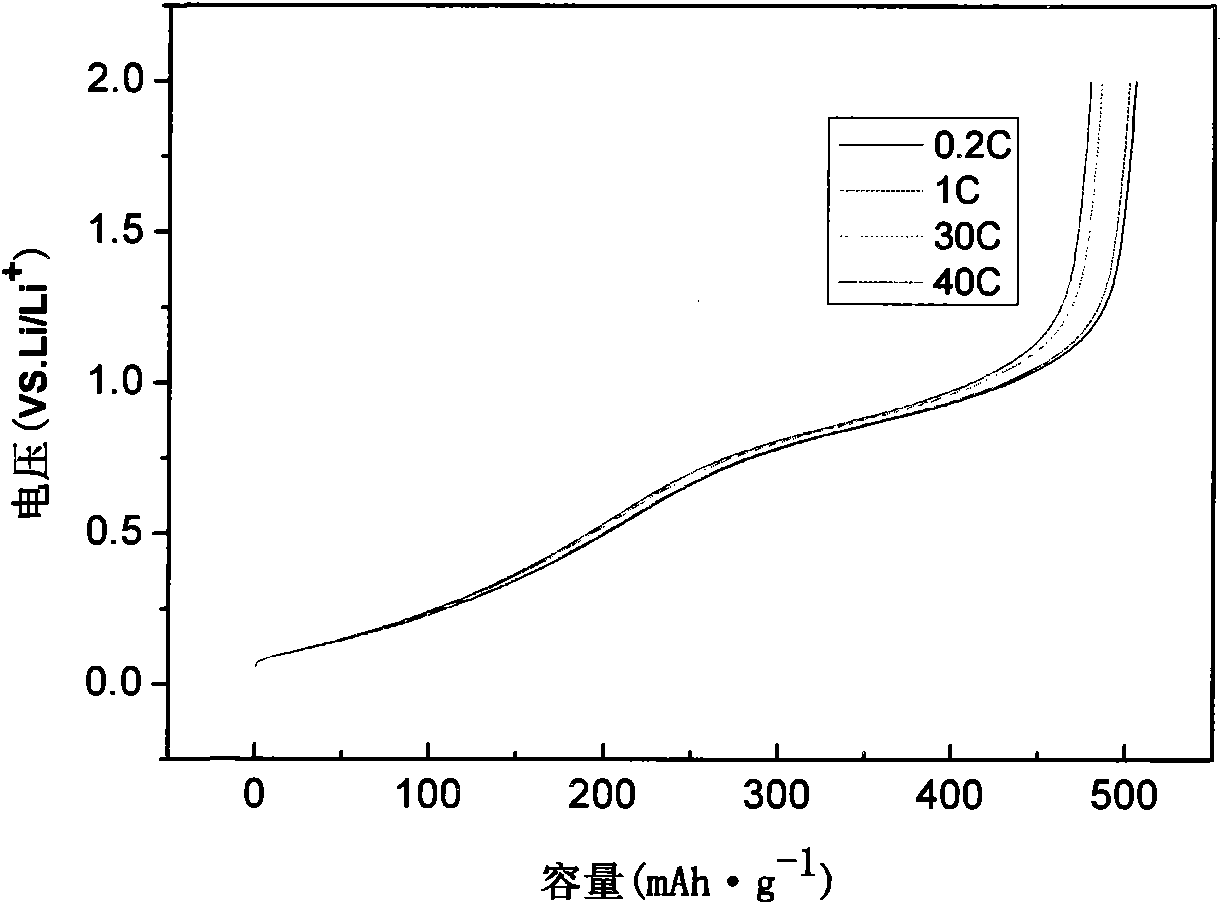

Hard carbon cathode material for lithium ion power and energy storage battery and preparation method of hard carbon cathode material

ActiveCN103094528ALow costImprove cycle performanceCell electrodesCarbon preparation/purificationElectrical batteryEnergy storage

The invention relates to a preparation method of a hard carbon cathode material. The preparation method comprises the step of preparing the hard carbon cathode material by using thermosetting resin or pyrolysis products of a mixture of thermosetting resin and thermoplastic resin as a hard carbon matrix and adopting a carbon material as a coating. In the preparation process of the hard carbon cathode material, a curing agent and a doping matter can be added. The hard carbon cathode material prepared by adopting the preparation method has the characteristics of high capacity, high first-time coulombic efficiency, excellent rate performance, low cost and the like, and is suitable for industrialized production.

Owner:JIXI BTR GRAPHITE IND PARK CO LTD +2

Method for preparing electrodes of super capacitor based on nickel foam and products thereof

InactiveCN103258656AHigh specific capacitanceIncrease energy densityHybrid capacitor electrolytesHybrid capacitor electrodesCapacitanceNon symmetric

The invention discloses a method for preparing electrodes of a dissymmetric super capacitor based on nickel foam. The method comprises the steps: washing the nickel foam, soaking the nickel foam into a graphene oxide aqueous solution to obtain nickel foam in which graphene oxide deposits, serving the nickel foam in which the graphene oxide deposits as precursor materials, and respectively adopting a three-electrode method for preparaing a positive electrode and a negative electrode of the dissymmetric super capacitor, wherein the positive electrode is composed of composite materials of graphene, a carbon nanometer tube and the nickel foam, and the negative electrode is composed of composite materials of graphene, manganese dioxide and the nickel foam. The invention further discloses some other methods for preparing the electrodes of the super capacitor based on the similar principle, and products which correspond to the methods. By means of the methods and the products, respective high-ratio capacitance characteristics of the composite materials are fully played, and energy density of the super capacitor is improved. In addition, usage of various combined reagents can be avoided, and accordingly large-batch industrial production is conducted in a mode of convenient control, low cost and low energy consumption.

Owner:HUAZHONG UNIV OF SCI & TECH

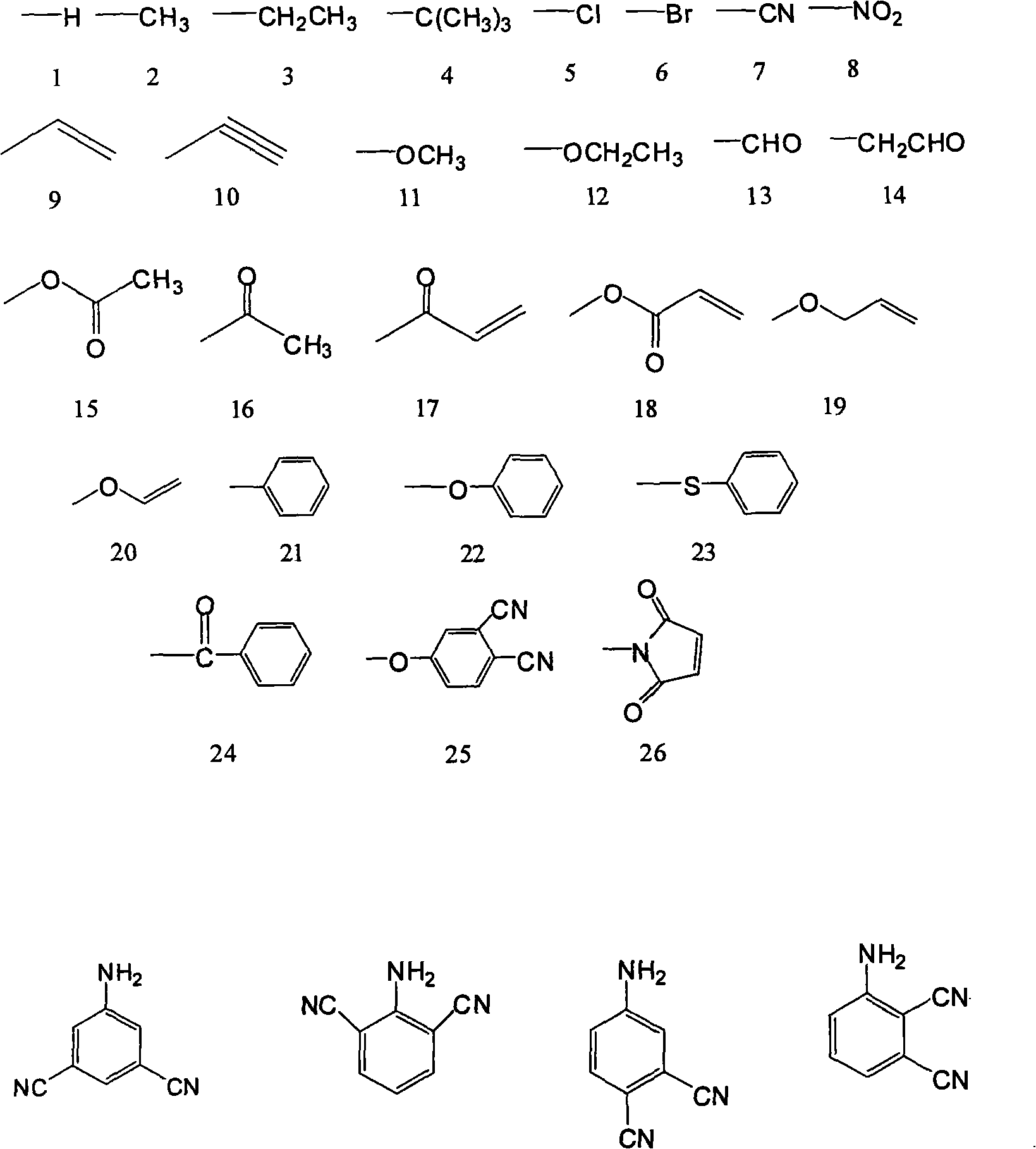

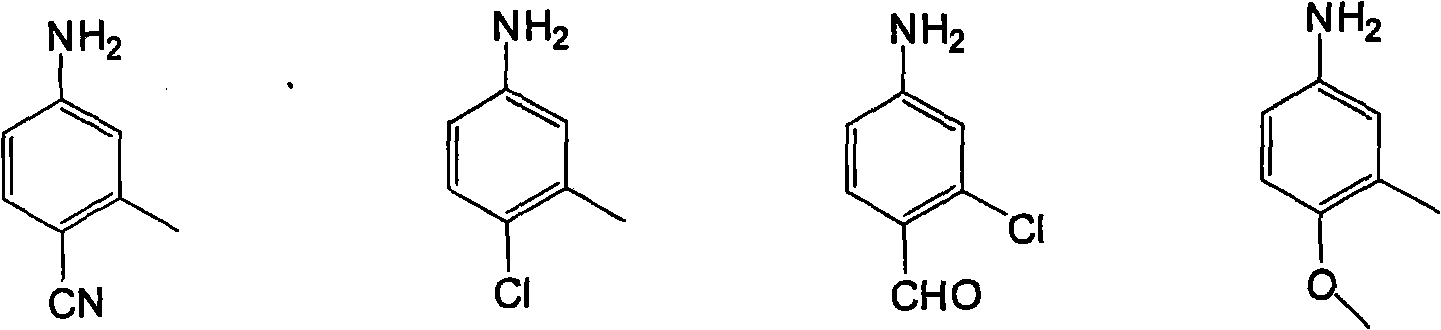

Method for preparing benzoxazine intermediate containing triazine structure

The invention provides a preparation method of triazine structure containing benzoxazine intermediate, which sequentially includes: (1) performing synthetic reaction of aldehyde compound and amine compound at a molar ratio of at least 1:1 which includes adding aldehyde compound and solvent of at least one of clean water, methanol, ethanol, isopropanol, and ethyl acetate into a reactor at the room temperature under the normal pressure to obtain mixed solution with aldehyde mass concentration of no greater than 95%, adding amine compound while stirring, and reacting at 0-100 DEG C under the normal pressure for at least 15 minutes to obtain the reactant liquor; (2) pouring into the cleaning solution, stirring and cleaning, and filtering to collect solid substance, or directly filtering the reactant liquor to collect the solid substance; and (3) drying the solid substance obtained in step (2) at 30-100 DEG C.

Owner:SICHUAN UNIV

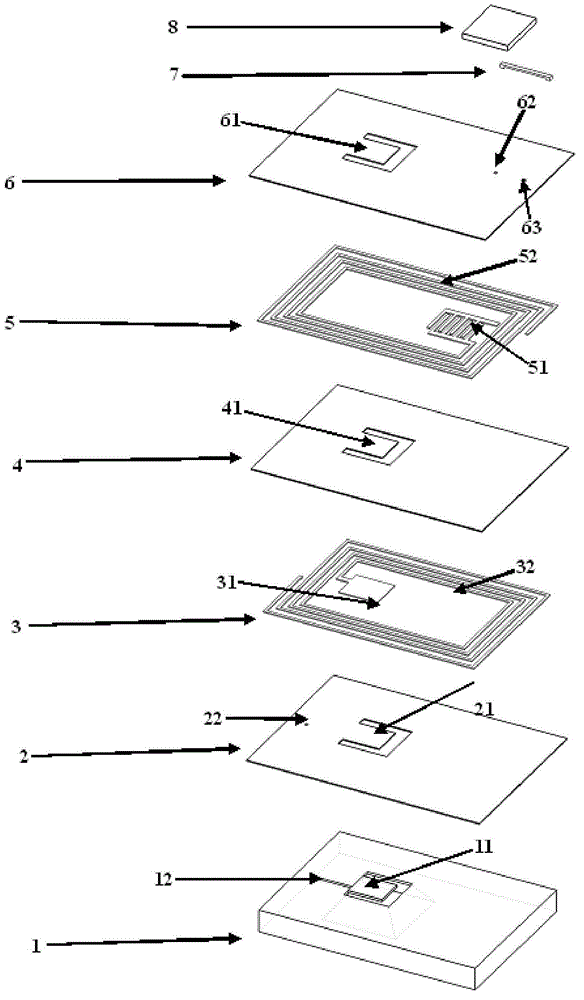

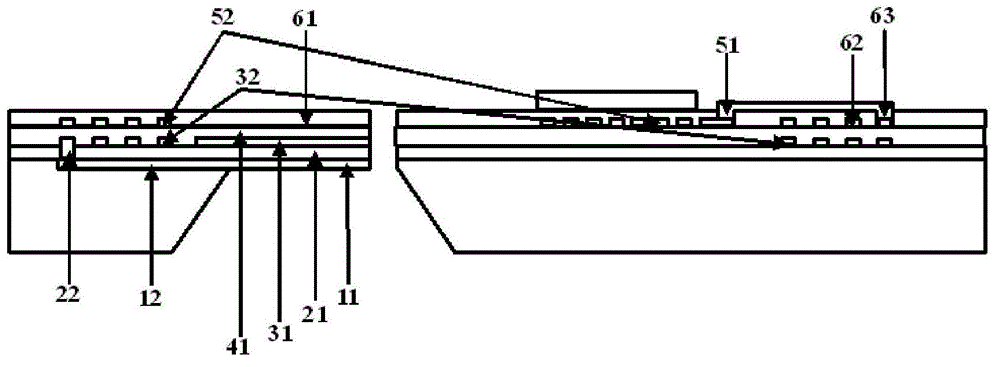

Passive wireless temperature and humidity integrated sensor

ActiveCN102944325AIncrease in sizeIncrease power consumptionThermometers using electric/magnetic elementsUsing electrical meansCapacitanceEngineering

The invention discloses a passive wireless temperature and humidity integrated sensor. A cantilever beam capacitive temperature sensor and an interdigital capacitive humidity sensor are adopted, and the passive wireless temperature and humidity integrated sensor comprises a semiconductor substrate, a lower dielectric layer, a lower metal layer, an intermediate dielectric layer, an intermediate metal layer, an upper dielectric layer, and an upper metal interconnecting line and humidity-sensitive material positioned on the upper surface of the upper dielectric layer. The cantilever beam capacitive temperature sensor, an inductance loop and interdigital capacitive humidity sensor and an inductance loop work in a frequency division mode, the temperature and humidity are wirelessly measured, and the passive wireless temperature and humidity integrated sensor can be applied to measuring and acquiring two parameters, namely the temperature and humidity, in a closed environment or severe conditions. The sensor is manufactured by a complementary metal oxide semiconductor (CMOS) micro-electromechanical system (MEMS) process, and has high performance and low cost.

Owner:SOUTHEAST UNIV

Silicon-carbon composite material, lithium ion battery, and preparation method and application of silicon-carbon composite material

ActiveCN103633295AAlleviate volume expansionAvoid direct contactCell electrodesSecondary cellsCarbon compositesSilicon monoxide

The invention discloses a silicon-carbon composite material, a lithium ion battery, and a preparation method and application of the silicon-carbon composite material. The preparation method of the silicon-carbon composite material comprises the steps: uniformly mixing silicon powder and silicon monoxide powder, then mixing with a solution containing an organic carbon source dispersant, and performing wet-process ball milling to obtain a slurry; uniformly mixing the slurry, graphite and a conductive agent, and performing spray drying to obtain spherical-like particles, wherein graphite is synthetic graphite and / or intermediate-phase graphite; mixing the spherical-like particles and asphalt, performing cladding processing under the inert atmosphere to obtain a cladded material; and then performing carbonizing processing to obtain the silicon-carbon composite material, wherein silicon powder, silicon monoxide powder, graphite and asphalt respectively accounts for 5-15%, 3-10%, 45-75% and 5-40% by weight of the sum of the above materials, and the organic carbon source dispersant and the conductive agent both accounts for 0.1-2% by weight of the sum of silicon powder, silicon monoxide powder and graphite. The silicon-carbon composite material has relatively good cycle performance, and can be directly used as a cathode material of the lithium ion battery. The preparation method is simple in technology, low in cost and applicable to industrial production.

Owner:SHANGHAI SHANSHAN TECH CO LTD

Method for extracting and refining rutin

ActiveCN102718820AReduce pollutionGuaranteed withdrawal rateSugar derivativesSugar derivatives preparationAlkaline waterOrganic solvent

A method for extracting and refining rutin comprises the following steps of (1) extraction: smashing raw materials, adding organic solvent into the smashed raw materials, performing extraction for 2-4 times, mixing extracting solution and concentrating the mixed extracting solution to thick extract with organic solvent content smaller than or equal to 5wt%; (2) alkali dissolution-acid sediment: adding alkaline water into the thick extract, then heating the mixture and stirring, filtering the heated mixture, regulating pH of alkaline filtrate to be 3-4, standing, filtering, drying to obtain a rutin pure product; and (3) mother liquor treatment: enabling obtained acid mother liquor to penetrate through a chromatographic column filled with resin, after the acid mother liquor penetrates through the chromatographic column, firstly using deionized water to wash a column bed until outflow liquid is neutral and colorless, introducing eluent into the chromatographic column and collecting eluate until outflow liquid is colorless, concentrating the eluate to the volume which is 5-10% of the original volume in a pressure reduction mode, cooling the concentrated eluate to achieve crystallization, filtering, using the deionized water to elute a filter cake, and drying the eluted filter cake to obtain a mother liquor rutin product. The prepared rutin is high in yield and purity, and the quality of the rutin reaches the international standard.

Owner:湖南莱崔尔生物科技有限公司

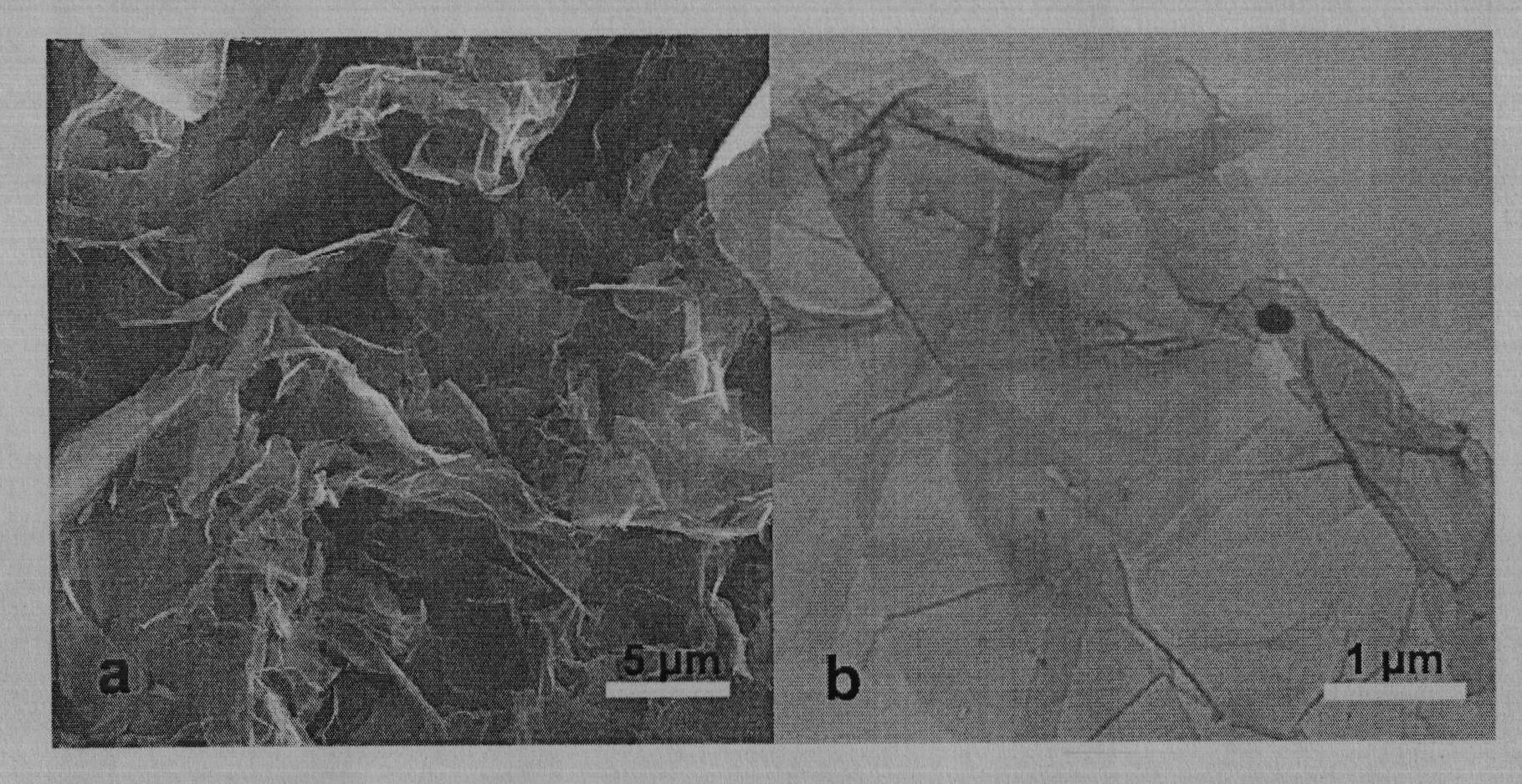

Preparation method of polymer/graphene nano composite material

The invention provides a preparation method of a polymer / graphene nano composite material, comprising the following steps: (a) sufficiently mixing a first mass part of polymer and graphene in organic solvent, and removing the organic solvent to obtain polymer / graphene master batches, wherein the graphene accounts for 1-50% of the total mass of the first mass part of polymer and the grapheme; and (b) melting and blending polymer / graphene master batches and a second mass part of polymer to obtain a polymer / graphene nano composite material. In the invention, firstly, the first mass part of polymer and the graphene are sufficiently mixed in the organic solvent, and the graphene can keep a delamination state in a solvent environment, therefore, the graphene can keep in a single-lamella or less-lamina state and is uniformly dispersed without agglomeration in the first mass part of polymer; and then the polymer / graphene master batches and the second mass part of polymer are melted and blended to obtain the polymer / graphene nano composite material.

Owner:UNIV OF SCI & TECH OF CHINA

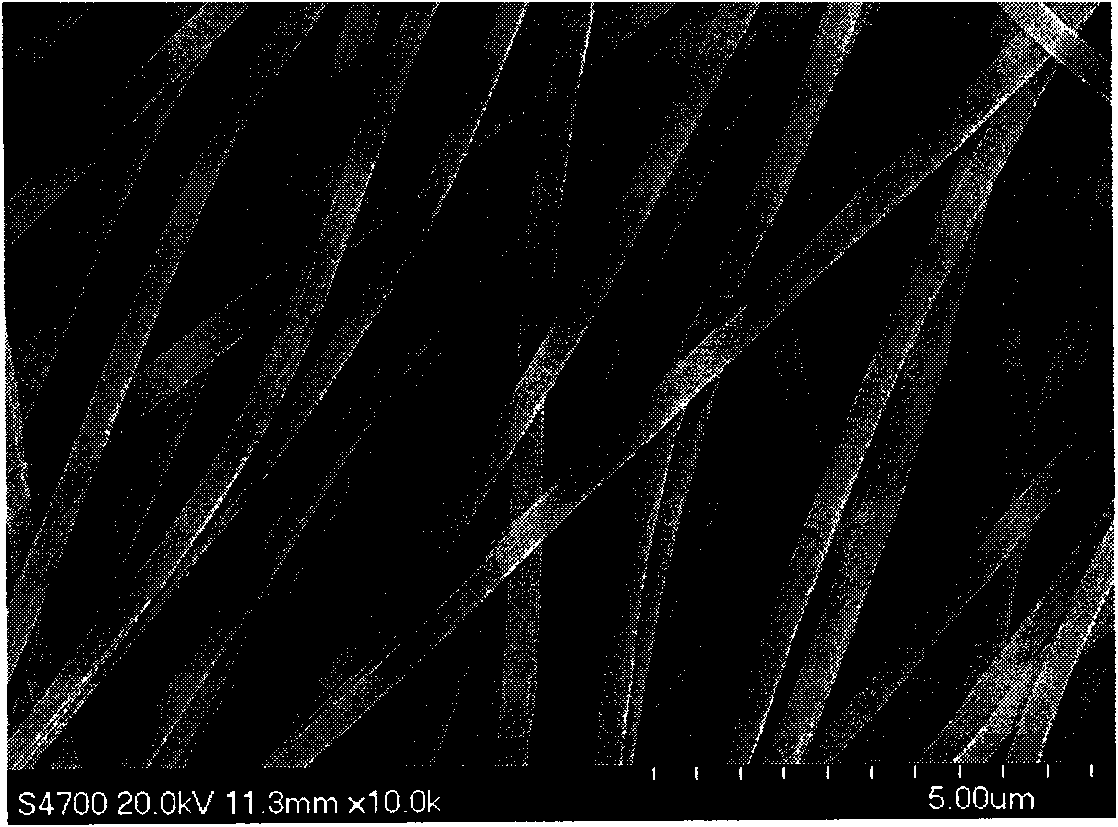

Stannum and carbon composite nano-fiber film negative-electrode material and preparation method thereof

ActiveCN101626075AExcellent discharge performance and charge-discharge cycle stabilitySimple configuration processElectrode manufacturing processesSolventCarbon composites

The invention relates to stannum / carbon nano-fiber composite film material used in the negative electrode of a lithium ion battery and a preparation method thereof and also provides an assembly method of the stannum / carbon nano-fiber composite film material generated according to the preparation method and used as the electrode of the lithium ion battery. The preparation method comprises the following steps: preparing an uniform spinning solution by mixing a stannum precursor compound, a solvent, a precursor polymer of carbon nano-fibers and an organic solvent together; obtaining a polymer nano-fiber film by electro spinning according to a suitable electrostatic spinning technology; and obtaining a stannum / carbon nano-fiber composite film used in the negative electrode of the lithium ion battery through final treatment technologies, such as preoxidation, carbonization, and the like, thereby effectively collaborating the electrochemical performance of stannum / carbon nano-fibers and improving the specific capacity, the first charge-discharge efficiency and the cycle performance of the lithium ion battery.

Owner:BEIJING UNIV OF CHEM TECH

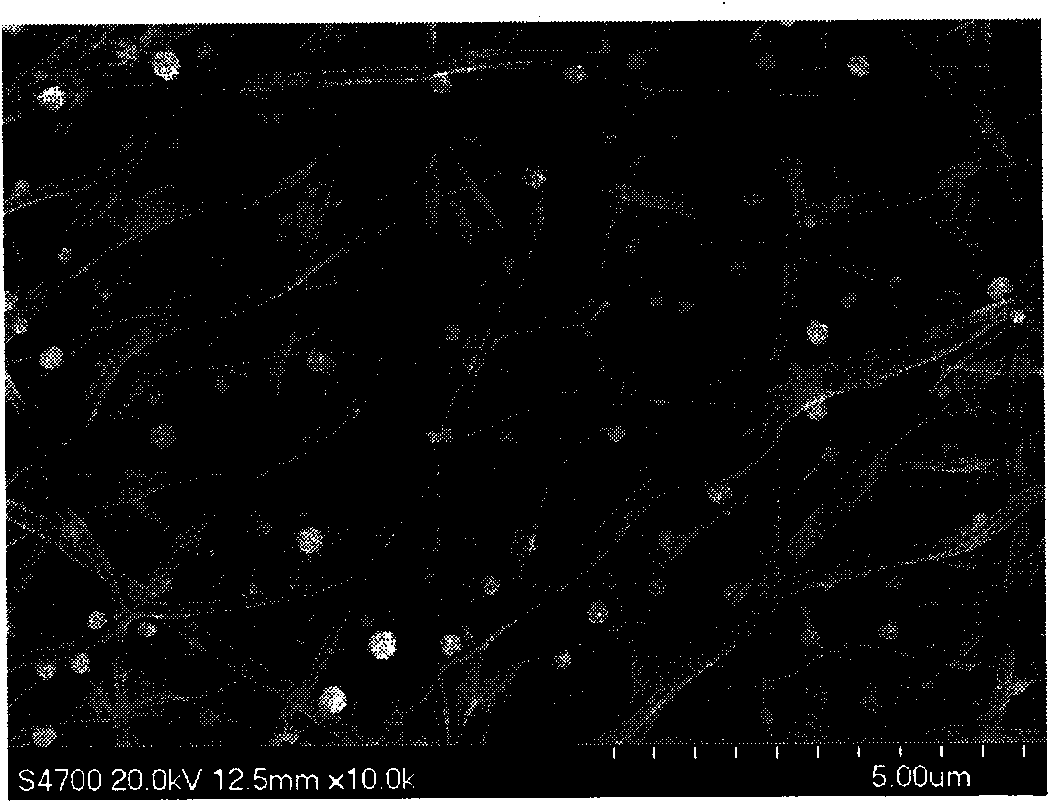

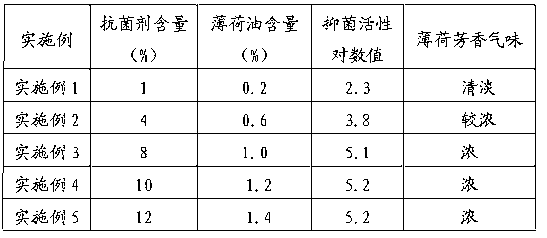

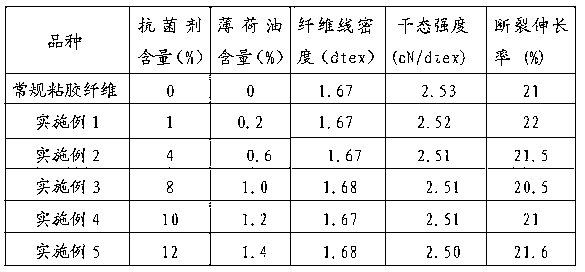

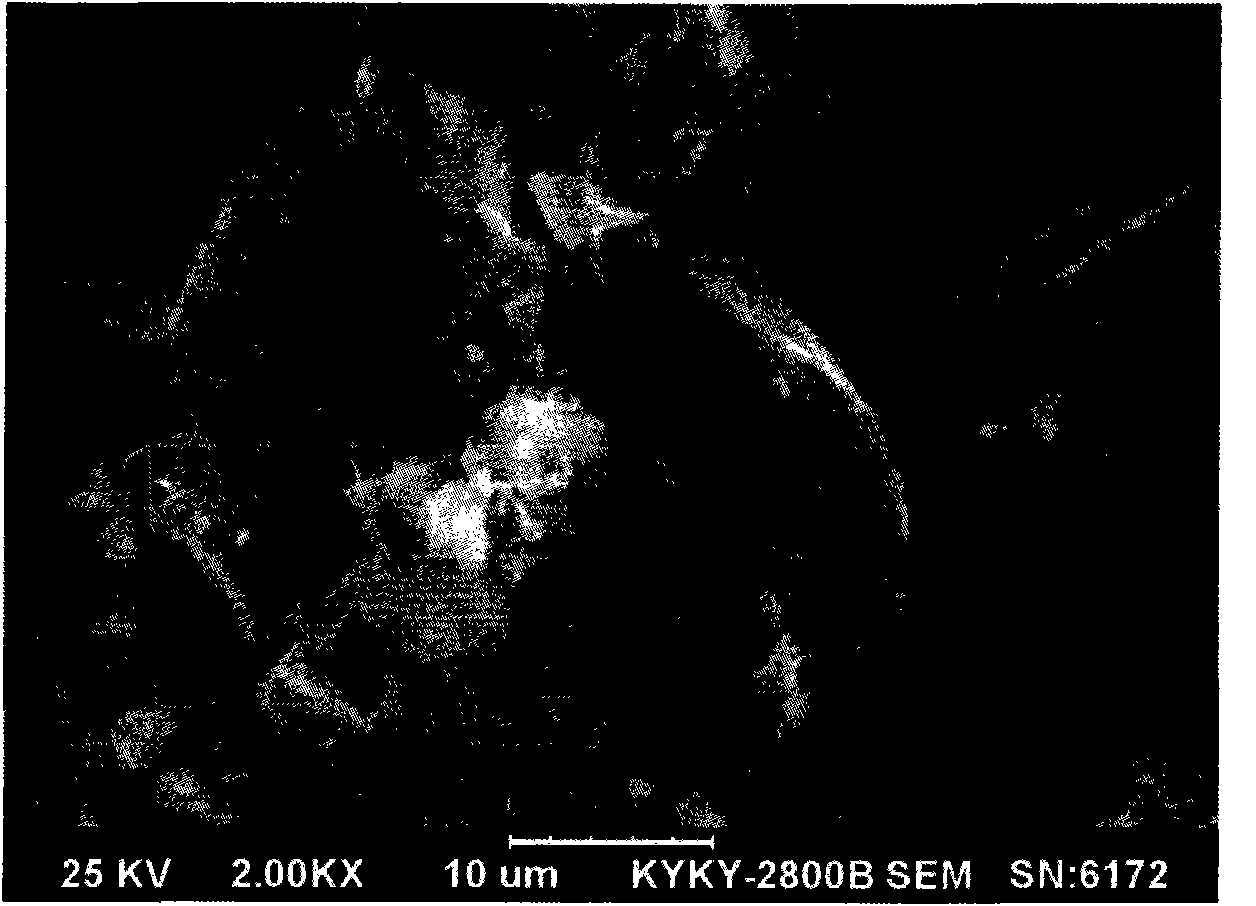

Viscose fiber with plant source anti-bacterial function and aromatic smell, and preparation method thereof

ActiveCN103225123ANo side effectsComfortable to takeArtificial thread manufacturing machinesArtificial filaments from viscoseSide effectMint extract

The invention discloses a viscose fiber with a plant source anti-bacterial function and aromatic smell. The viscose fiber is composed of a viscose spinning solution, an anti-bacterial agent and an aromatic agent, wherein the anti-bacterial agent is mixed powder of a mint extract and a isatis root extract, wherein the weight percentage of the mint extract accounts for 40%-80%; and the weight percentage of the isatis root extract accounts for 60%-20%; the aromatic agent is mint oil coated by microcapsules; the anti-bacterial agent accounts for 1%-8% of the mass of methyl cellulose in the viscose spinning solution; the mint oil accounts for 0.2%-1% of the mass of methyl cellulose in the viscose spinning solution; and the viscose fiber is prepared by adopting a wet spinning method by using the viscose spinning solution, the anti-bacterial agent and the aromatic agent. The plant source extracts and the plant source essential oil are used as the anti-bacterial agent and the aromatic agent; and the anti-bacterial agent and the aromatic agent are uniformly distributed in the fiber, so that the anti-bacterial function and the aromatic smell of the fiber are durable. Since the plant source extracts and the aromatic agent are natural substances extracted from the plants, so that the viscose fiber has no side effect to human body.

Owner:BESTEE MATERIAL (TSINGTAO) CO LTD

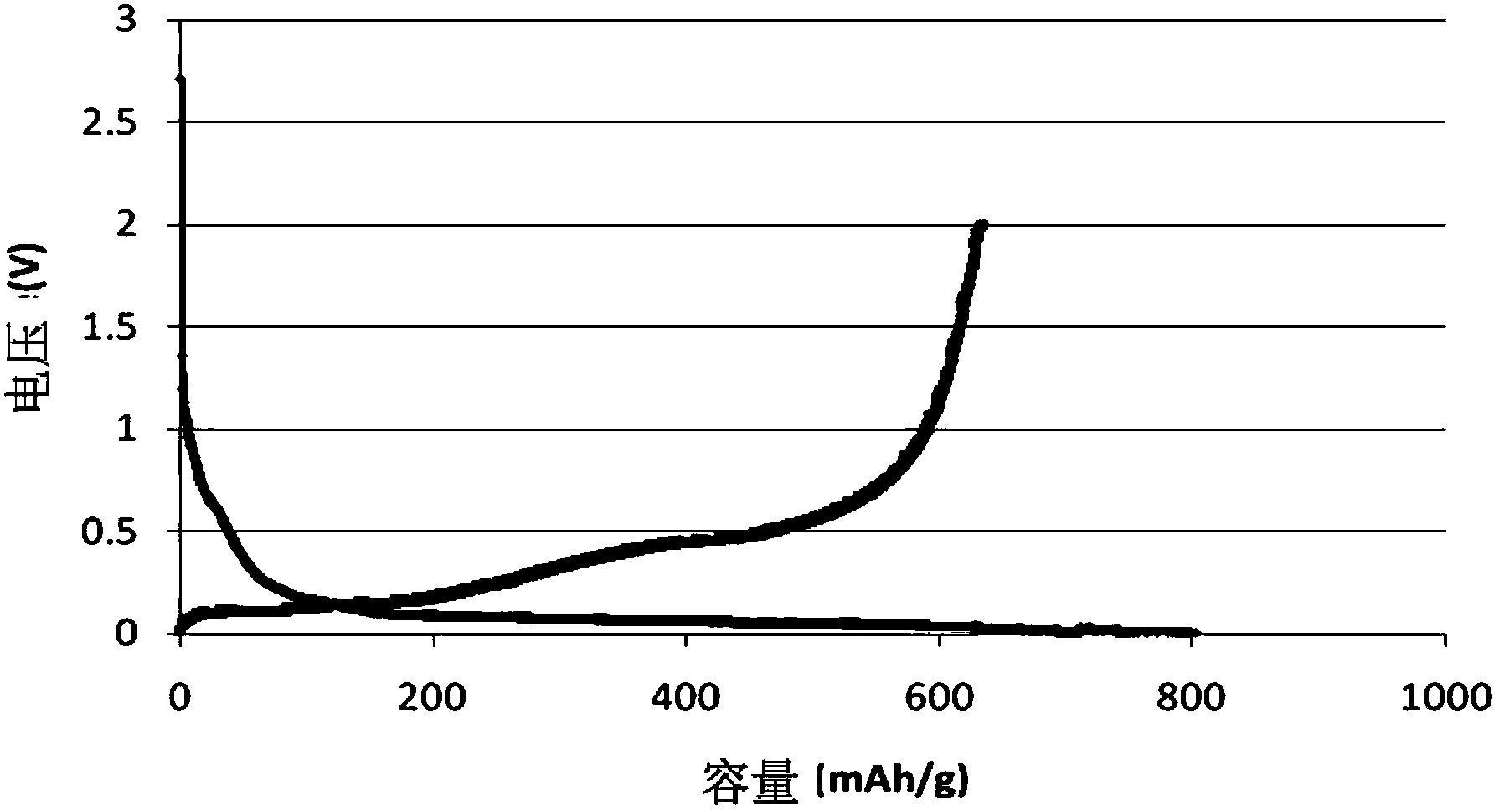

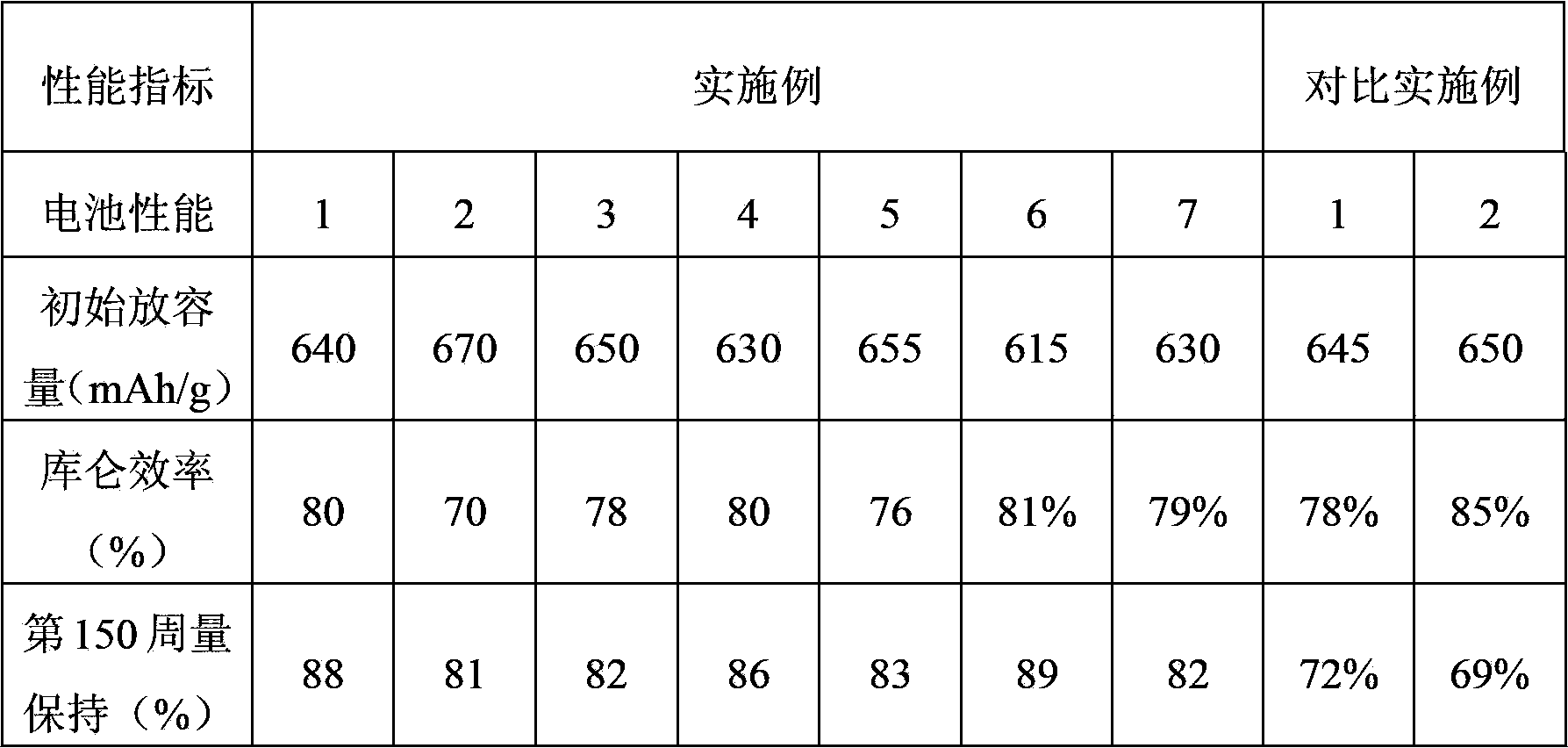

Composite hard carbon cathode material of lithium ion battery and preparation method thereof

ActiveCN101887966AIncrease capacityImprove the first Coulombic efficiencyCell electrodesSodium-ion batteryCharge discharge

The invention discloses a composite hard carbon cathode material of a lithium ion battery and a preparation method thereof, aiming at improving the first coulombic efficiency. In the composite hard carbon cathode material, a coating object is coated outside a hard carbon matrix, a precursor of the hard carbon matrix comprises a thermoplastic resin which forms the hard carbon matrix by pyrolysis, and a precursor of the coating object is an organic matter. The preparation method comprises the steps of curing, pyrolyzing, pulverizing and coating. Compared with the prior art, a curing agent and adopant are added to the resin for curing, the cured mixture is taken as a carbon source, and then the carbon source is pyrolyzed and coated to finally obtain the composite hard carbon cathode material; and the first reversible capacity of the obtained composite hard carbon cathode material is more than 455.2mAh / g and the first coulombic efficiency thereof is more than 79.4% in the case of 0.2C, thus the obtained composite hard carbon cathode material has high capacity and high first coulombic efficiency, meets the requirement of the lithium ion battery with high capacity, high multiplying power and excellent high and low temperature cycle performance on the charge-discharge performances of the cathode material, has low production cost and is suitable for industrial production.

Owner:JIXI BTR GRAPHITE IND PARK CO LTD +2

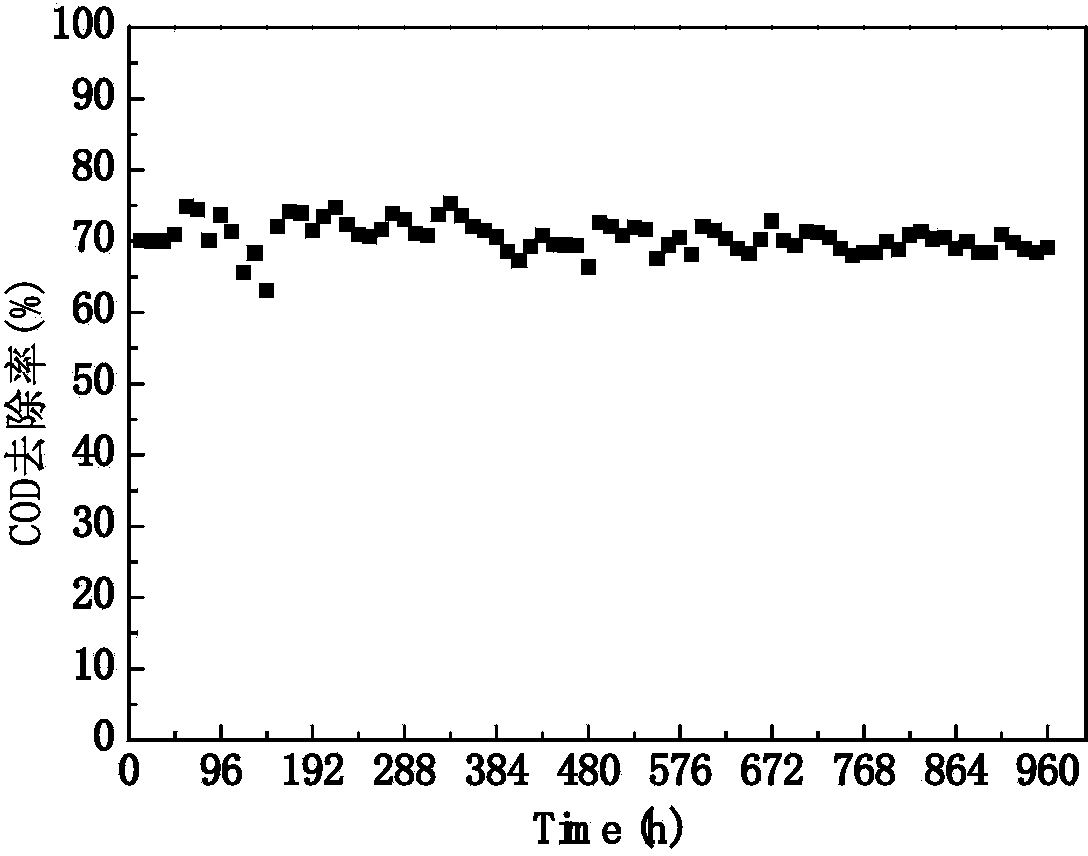

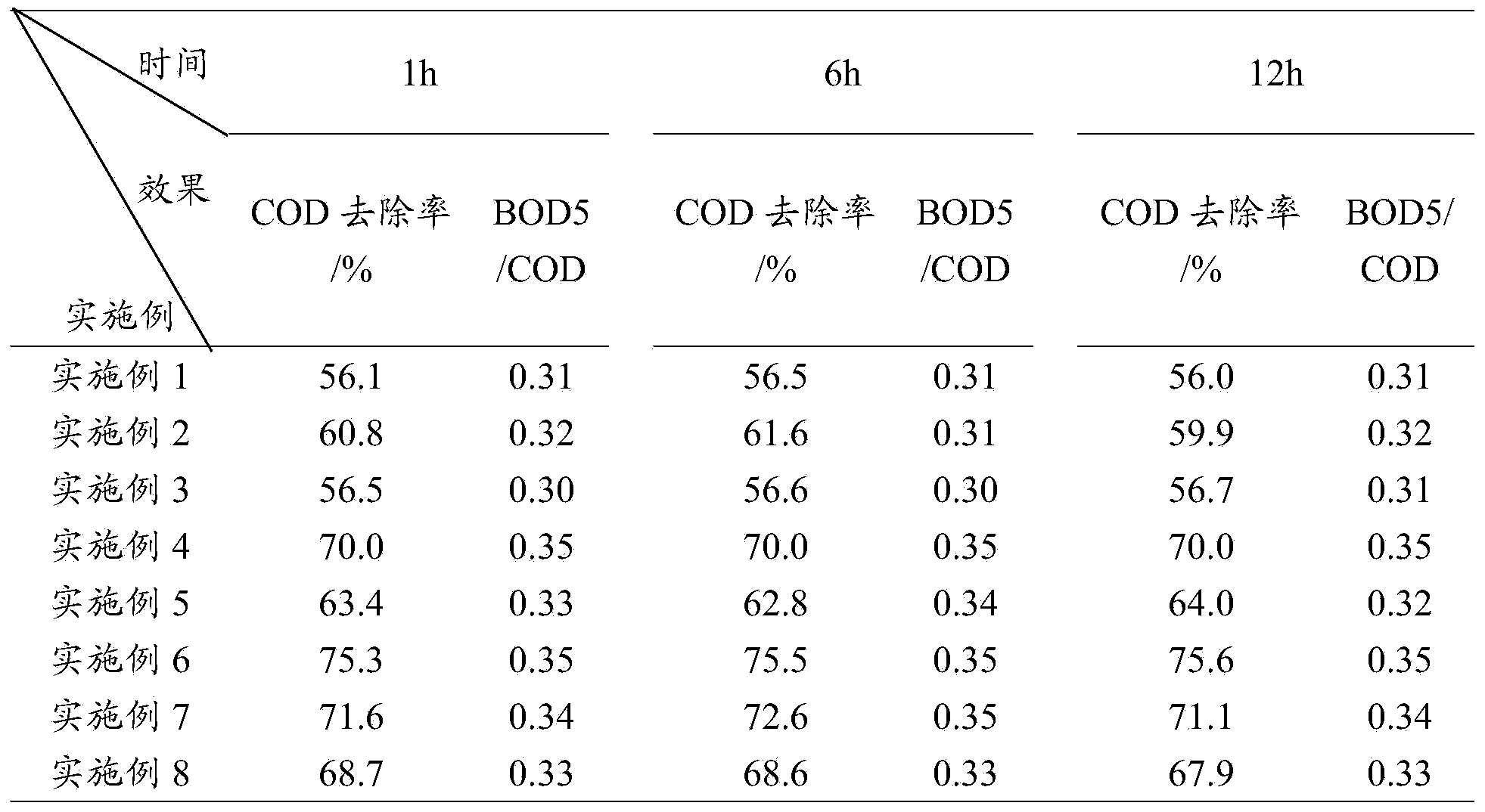

Carbon supported catalyst for ozone oxidation, and preparation method and use thereof

InactiveCN103586026AHigh catalytic activityExtended service lifeWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsActive componentManganese

The invention relates to a carbon supported catalyst for ozone oxidation, and a preparation method and a use thereof. The carbon supported catalyst is composed of an active carbon supported Fe, Cu, Ni or Mg transition metal active component and a Ce, La or K cocatalyst. The catalyst has a very high catalysis activity against non-degradable organic wastewater, allows the COD removal rate to reach above 55% and the biodegradability of the wastewater to be improved to above 0.30, has the advantages of long service life, simple preparation, no secondary pollution, containing of no precious metals, and low production cost, and is very suitable for the use in the industrialized production.

Owner:BEIJING ORIGINWATER TECH CO LTD

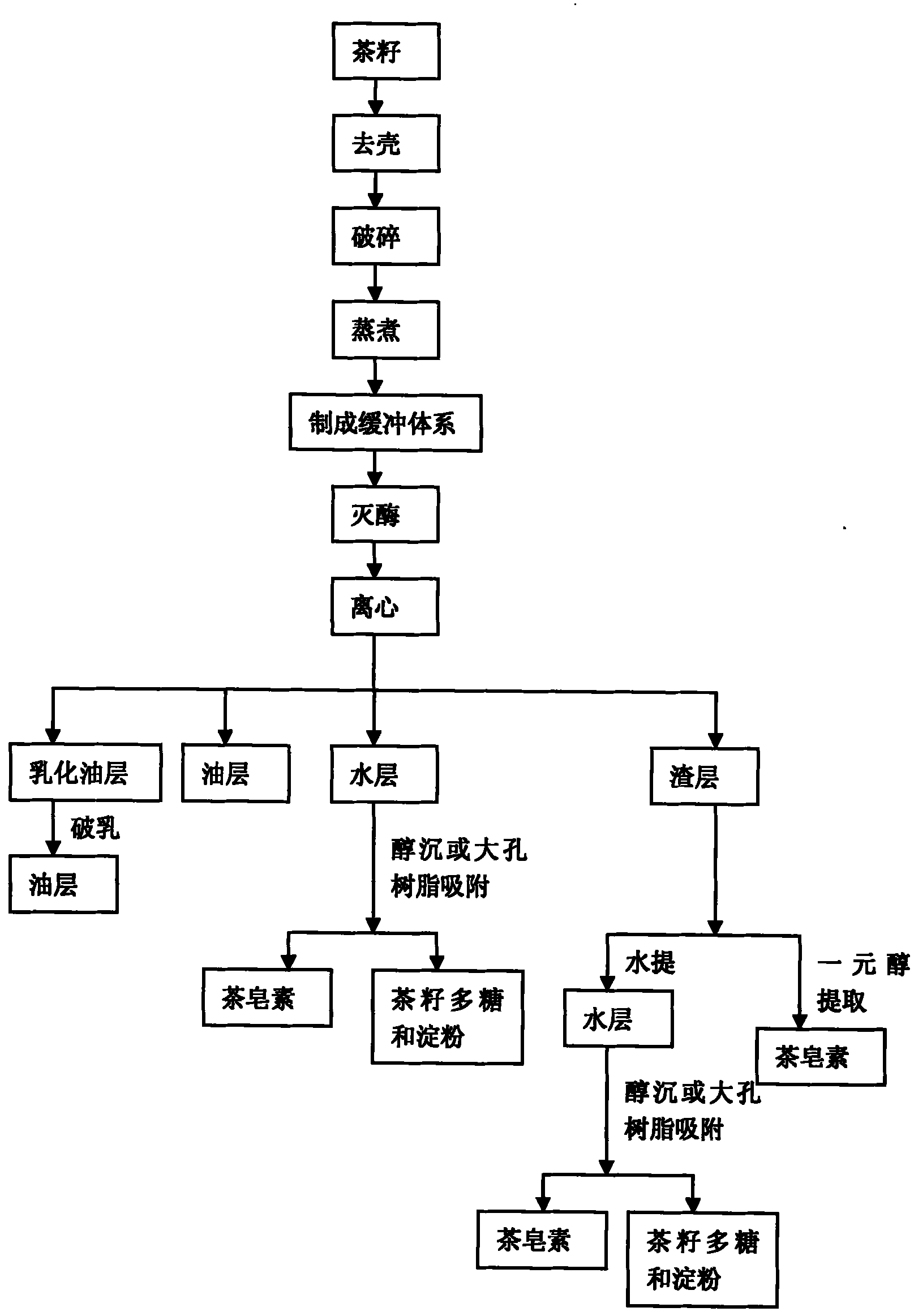

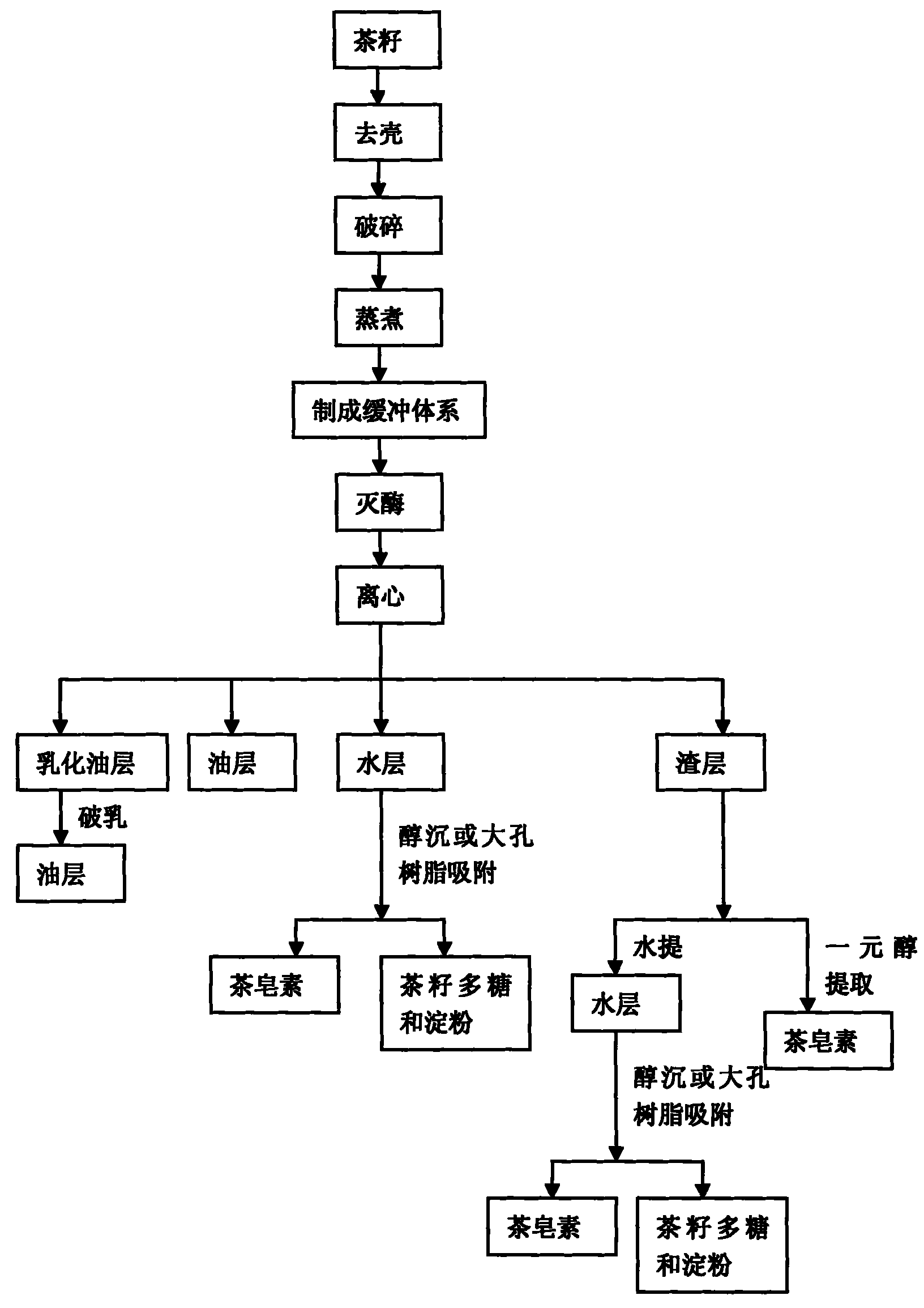

Comprehensive extraction method for extracting tea seed oil, tea saponin and tea seed polysaccharide from tea seeds or camellia seeds

InactiveCN101942355AHigh purityRealize comprehensive utilization and developmentSugar derivativesSteroidsOil processingSlag

The invention discloses a comprehensive extraction method for extracting tea seed oil, tea saponin and tea seed polysaccharide from tea seeds or camellia seeds, belonging to the process fields of grain and oil processing and byproduct extraction. The method comprises the following steps of: with shelled tea seeds as a raw material, firstly, cooking to produce oil; then, adding an exogenous enzyme to obtain a boiled oil layer of a first level an emulsified oil layer, a water layer and a slag layer through zymolysis, blanching and still standing; demulsifying the emulsified oil layer to take boiled oil of a second level; mixing the oil layers of the two levels; centrifugalizing to obtain the tea seed oil; depositing the water layer in alcohol to separate the tea saponin and the tea seed polysaccharide; leaching the slag layer with water or monohydric alcohol to further separate the tea saponin and the tea seed polysaccharide; and purifying a clear solution which is leached with the water or the alcohol with a macroporous absorption resin chromatography column, eluting a resin adsorbate with a base and then an ethanol and collecting an ethanol eluant to obtain high-purity tea saponin. The tea seed oil, the tea saponin and the tea seed polysaccharide are synchronously prepared, thus the invention realizes that a tea seed or camellia seed resource is comprehensively extracted and utilized and has the advantages of simple process, less needed equipment and low cost.

Owner:SHANGHAI NORMAL UNIVERSITY

Lithium ion battery anode material manganese lithium phosphate and preparation method thereof

ActiveCN101320809AImprove electronic conductivityEvenly dispersedElectrode manufacturing processesPhosphorus compoundsCapacitanceLithium iron phosphate

The invention discloses a manganese / lithium phosphate of lithium iron battery positive pole material and a production method thereof, the technical issue to be solved is to improve electrochemical performances of the positive pole material. The material of the invention includes substrates of manganese / lithium phosphate which are covered by a carbon material covering layer, the lithium covering the manganese / lithium phosphate behind the carbon material covering layer is spherical and has microscopic characteristics of being near spherical, rhombic, tapered, tabular, layered or / and block-shaped as well as of having 0.5-30 mum long and short axles. The production method comprises the following steps of: production of nanometer particles, liquid phase mixed reaction, production of precursor, sintering treatment, covering organic substances. Compared with the prior art, the invention improves the electron conductivity of the manganese / lithium phosphate by covering with carbon liquid phase, the carbon sufficiently covers active materials to efficiently prevent particle aggregation, the invention has the characteristics of about 4V of discharge voltage, high discharge and charge capacitance, excellent circulation stability, high safety, simple process, low cost and little influence on the environment.

Owner:SHENZHEN CITY BATTERY NANOMETER TECH

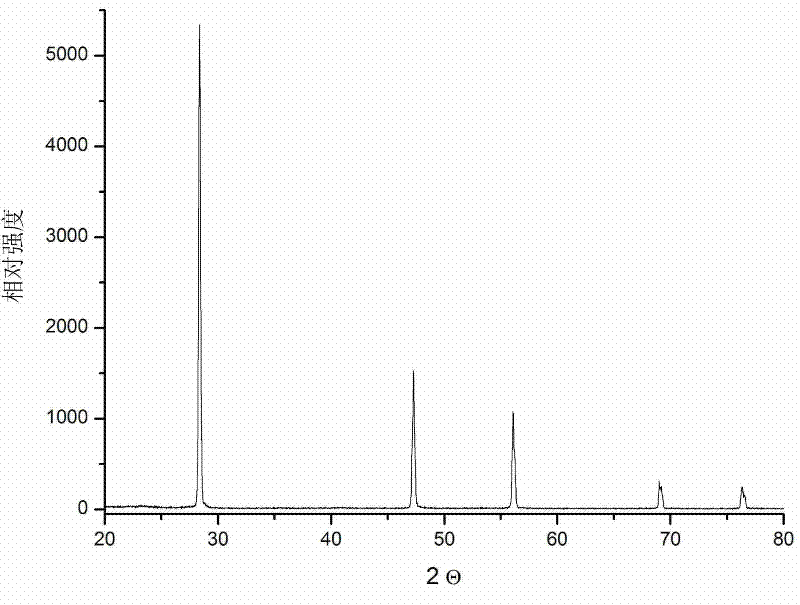

A method for preparing porous silicon by magnesia thermal reduction

InactiveCN102259858AImprove luminous efficiencyStable electrochemical performanceSilicon compoundsMagnesiumOxide

The invention belongs to the synthesis field of porous silicon materials, and particularly relates to a method for preparing porous silicon by magnesiothermic reduction. The method comprises the following steps: carrying out magnesiothermic reduction reaction based on silicon oxide SiOx (x = 0.5-2) as a raw material to generate a mixture of silicon and magnesium oxide; and then selectively dissolving away magnesium oxide with an acid so as to ultimately obtain a self-supported porous silicon material. Compared with the previous conventional electrochemical anodic etching methods, the method provided by the invention has the advantages that the use of expensive monocrystal silicon wafers is avoided, but simple, easily available and low-cost silicon oxide is used as the raw material, thereby not only reducing the cost but also increasing the yield; and the method has the advantages of simple preparation process, environmental friendliness, high preparation efficiency and good repeatability, is more suitable for industrial production, and is expected to be widely applied in the fields of lithium ion secondary batteries, optical materials, biomedical devices, gas-sensitive devices, etc.

Owner:TONGJI UNIV

Polymer/graphene anti-static coating, preparation method and application thereof

InactiveCN104449010AEasy reunionSolving Dispersion ProblemsConjugated diene hydrocarbon coatingsPolyurea/polyurethane coatingsStatic performanceCompound system

The invention discloses a polymer / graphene anti-static coating, a preparation method and application thereof. The coating comprises the following constituents by weight percent: 0.01 portions to 0.5 portions of graphene; 0 portion to 10 portions of conductive additive; 90 portions to 100 portions of polymer; and solvent; the preparation method thereof comprises the following steps: completely and uniformly mixing graphene and conductive additive in advance by various manners; preparing a graphene-conductive additive compound system; using the compound system as a base, adding in conductive additive and polymer along with the solvent, completely and uniformly mixing to obtain the coating. Additionally, an anti-static film can be prepared by using different film forming technologies. The polymer / graphene anti-static coating, the preparation method and application thereof effectively solve the problems that graphene in polymer is easy to agglomerate and difficult to be uniformly dispersed in the preparation process of anti-static coating and film; the anti-static performance and mechanical performance of the coating and the film are greatly increased; meanwhile, the preparation technology is easy to be operated; the production is continuous, and the coating and film are suitable for industrial production.

Owner:苏州格瑞丰纳米科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com