Carbon supported catalyst for ozone oxidation, and preparation method and use thereof

A technology of ozone oxidation and catalyst, applied in the field of water treatment, which can solve the problems of high catalyst cost, cumbersome catalyst preparation method, difficult industrial production and application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

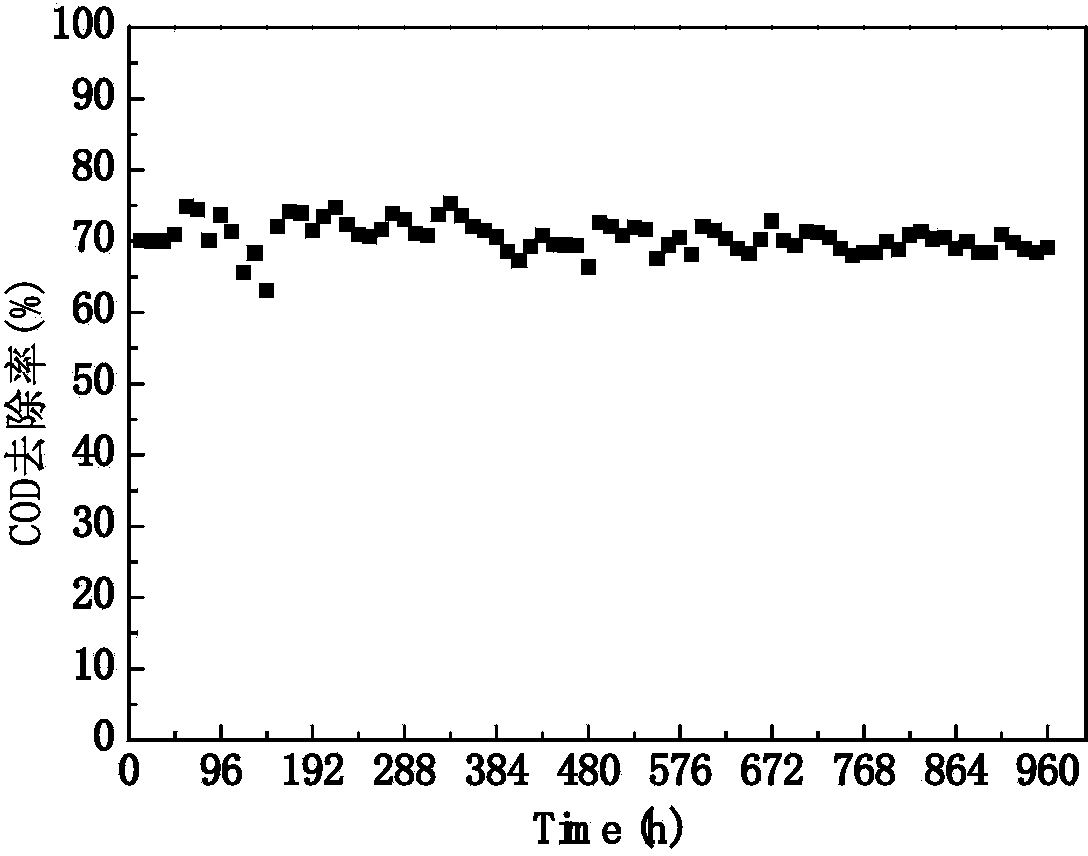

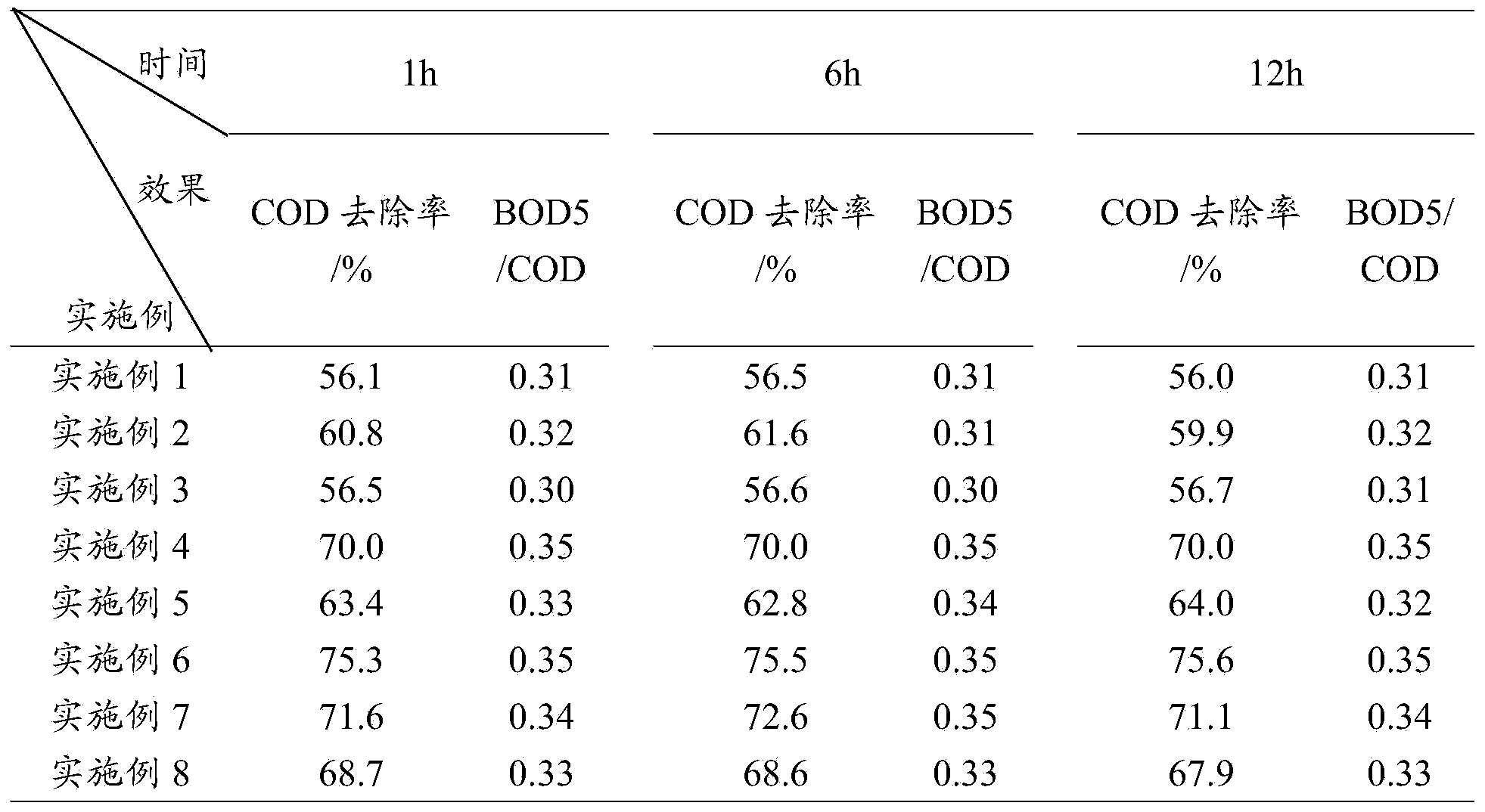

[0108] Example 1: Using the catalyst of the present invention to treat biochemical effluent

[0109] The implementation steps of this embodiment are as follows:

[0110] A. Activated carbon treatment

[0111] The columnar coconut shell activated carbon was first treated with 24% nitric acid aqueous solution by weight for 1.2 days, and then the acid-treated activated carbon was washed with deionized water until the washing water was neutral; then, the acid-treated activated carbon was used for 40 days by weight % sodium hydroxide aqueous solution for 0.5 days, and then use deionized water to rinse the alkali-treated activated carbon until the washing water is neutral; finally dry at a temperature of 110 ° C and an air atmosphere for 3.0 hours;

[0112] B. Preparation of precursor solution

[0113] Dissolving the copper nitrate active component precursor in deionized water to prepare a 0.80mol / L active component precursor solution;

[0114] C. Dipping

[0115] Under the cond...

Embodiment 2

[0119] Example 2: Using the catalyst of the present invention to treat biochemical effluent

[0120] The implementation steps of this embodiment are as follows:

[0121] A. Activated carbon treatment

[0122] The coconut shell activated carbon in sheet form is first treated with 1% nitric acid aqueous solution by weight for 3 days, and then the acid-treated activated carbon is rinsed with deionized water until the washing water is neutral; then, the acid-treated activated carbon is reused by weight. 12% sodium hydroxide aqueous solution for 2 days, and then use deionized water to rinse the alkali-treated activated carbon until the washing water is neutral; finally, dry it for 2.8 hours at a temperature of 98 ° C and an air atmosphere;

[0123] B. Preparation of precursor solution

[0124] Copper nitrate active component precursor and potassium nitrate cocatalyst precursor are dissolved in deionized water to prepare a mixed solution of 0.82mol / L active component precursor and...

Embodiment 3

[0130] Example 3: Using the catalyst of the present invention to treat biochemical effluent

[0131] The implementation steps of this embodiment are as follows:

[0132] A. Activated carbon treatment

[0133] Spherical woody activated carbon was first treated with 8% nitric acid aqueous solution by weight for 2.4 days, and then the acid-treated woody activated carbon was washed with deionized water until the washing water was neutral; then, the acid-treated activated carbon was reused by weight for 1 % sodium hydroxide aqueous solution for 1.5 days, and then use deionized water to rinse the alkali-treated woody activated carbon until the washing water is neutral; finally dry it for 3.0 hours at a temperature of 90°C and in an air atmosphere;

[0134] B. Preparation of precursor solution

[0135] Dissolving manganese nitrate and nickel nitrate active component precursors in deionized water to prepare a mixed solution of 0.94mol / L manganese nitrate and 0.06mol / L nickel nitrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com