Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2571 results about "Porous silicon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Porous silicon (abbreviated as "PS" or "pSi") is a form of the chemical element silicon that has introduced nanopores in its microstructure, rendering a large surface to volume ratio in the order of 500 m²/cm³.

CVD nanoporous silica low dielectric constant films

InactiveUS6171945B1Semiconductor/solid-state device detailsSolid-state devicesSilicon oxideGradual increase

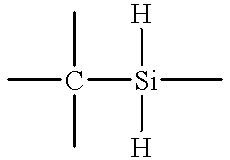

A method and apparatus for depositing nano-porous low dielectric constant films by reaction of a silicon hydride containing compound or mixture optionally having thermally labile organic groups with a peroxide compound on the surface of a substrate. The deposited silicon oxide based film is annealed to form dispersed microscopic voids that remain in a nano-porous silicon oxide based film having a foam structure. The nano-porous silicon oxide based films are useful for filling gaps between metal lines with or without liner or cap layers. The nano-porous silicon oxide based films may also be used as an intermetal dielectric layer for fabricating dual damascene structures. Preferred nano-porous silicon oxide based films are produced by reaction of 1,3,5-trisilanacyclohexane, bis(formyloxysilano)methane, or bis(glyoxylylsilano)methane and hydrogen peroxide followed by a cure / anneal that includes a gradual increase in temperature.

Owner:APPLIED MATERIALS INC

Porous silicon particulates for lithium batteries

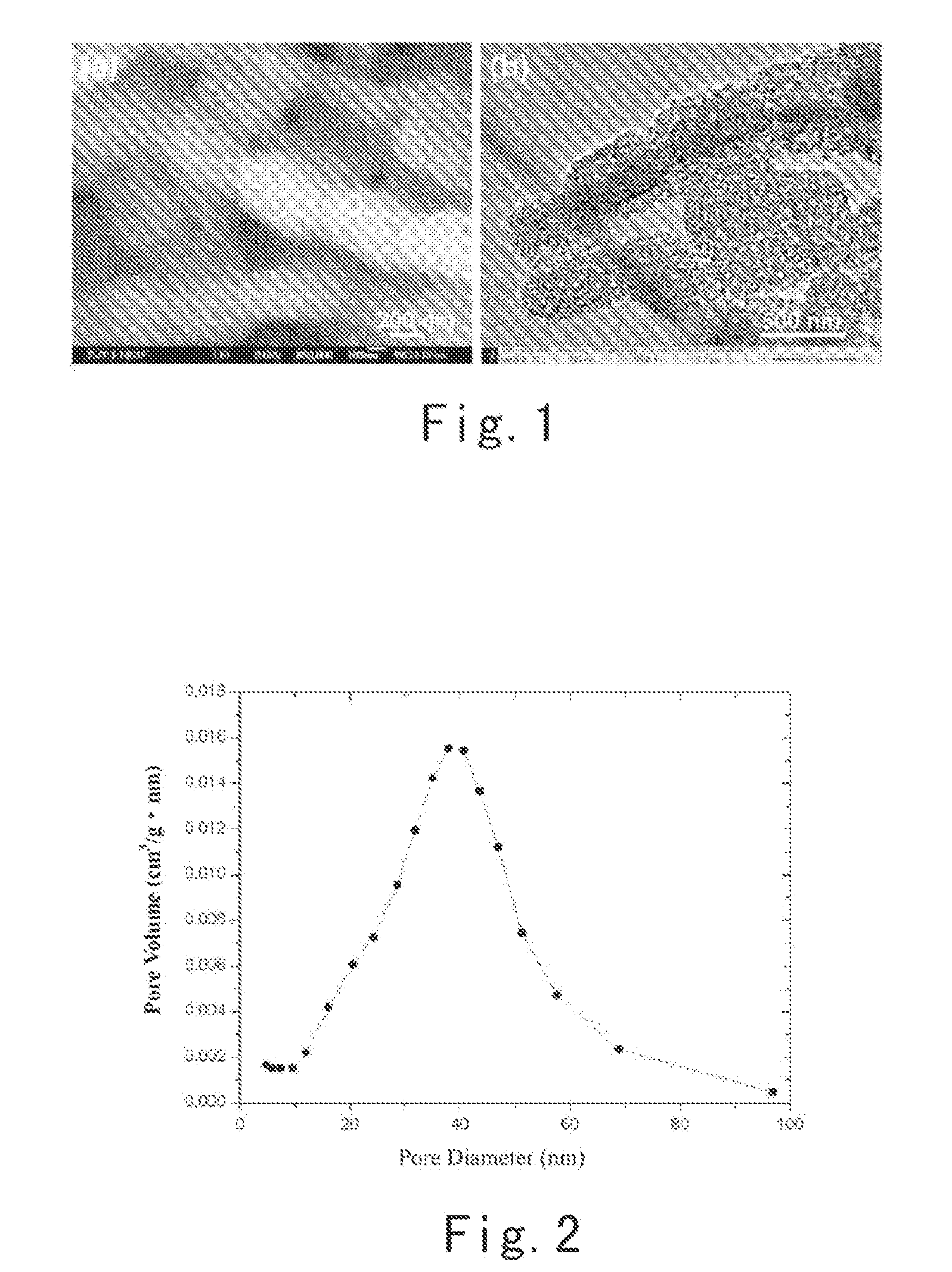

An anode structure for lithium batteries includes nanofeatured silicon particulates dispersed in a conductive network. The particulates are preferably made from metallurgical grade silicon powder via HF / HNO3 acid treatment, yielding crystallite sizes from about 1 to 20 nm and pore sizes from about 1 to 100 nm. Surfaces of the particles may be terminated with selected chemical species to further modify the anode performance characteristics. The conductive network is preferably a carbonaceous material or composite, but it may alternatively contain conductive ceramics such as TiN or B4C. The anode structure may further contain a current collector of copper or nickel mesh or foil.

Owner:TIEGS TERRY N

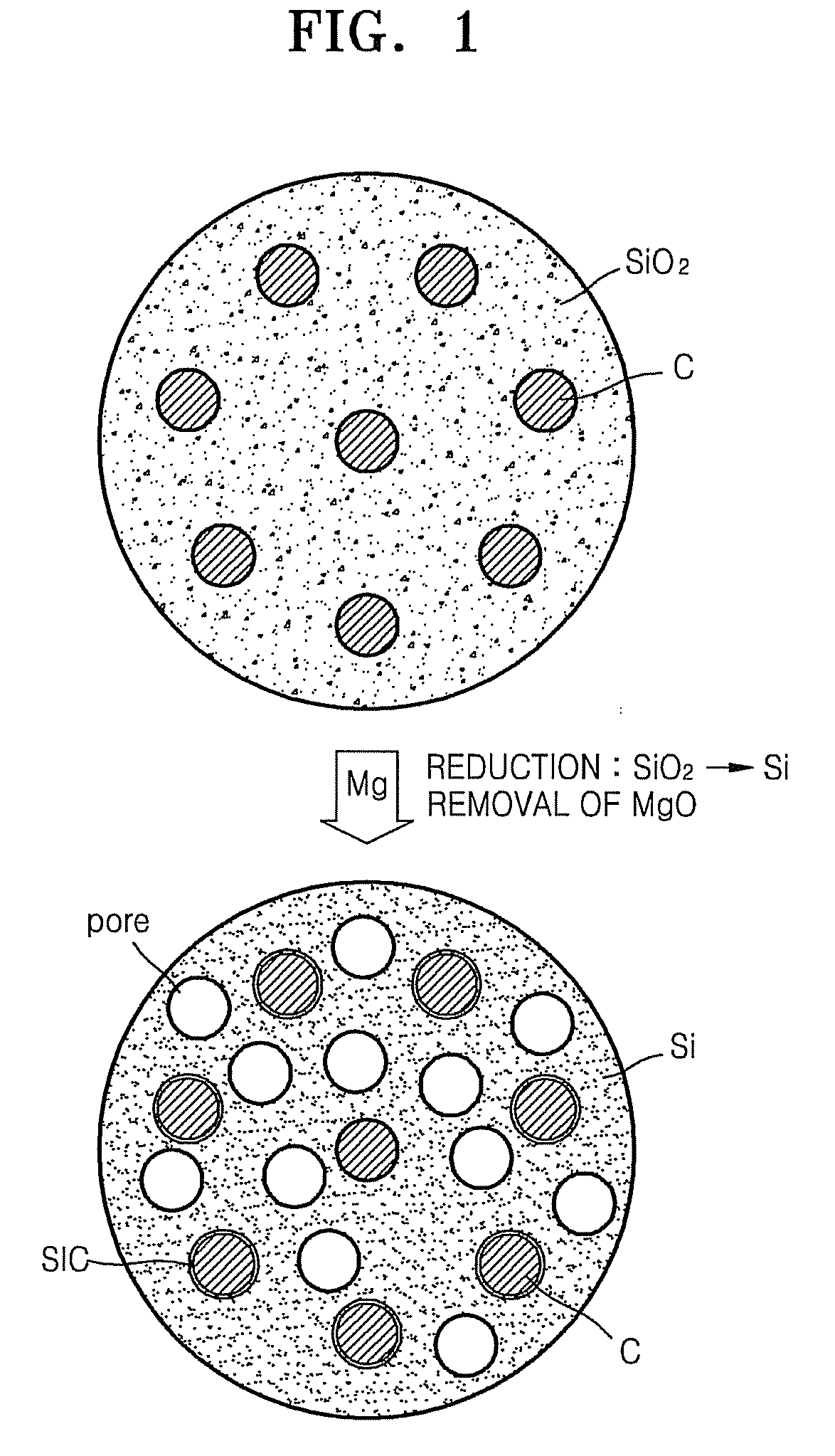

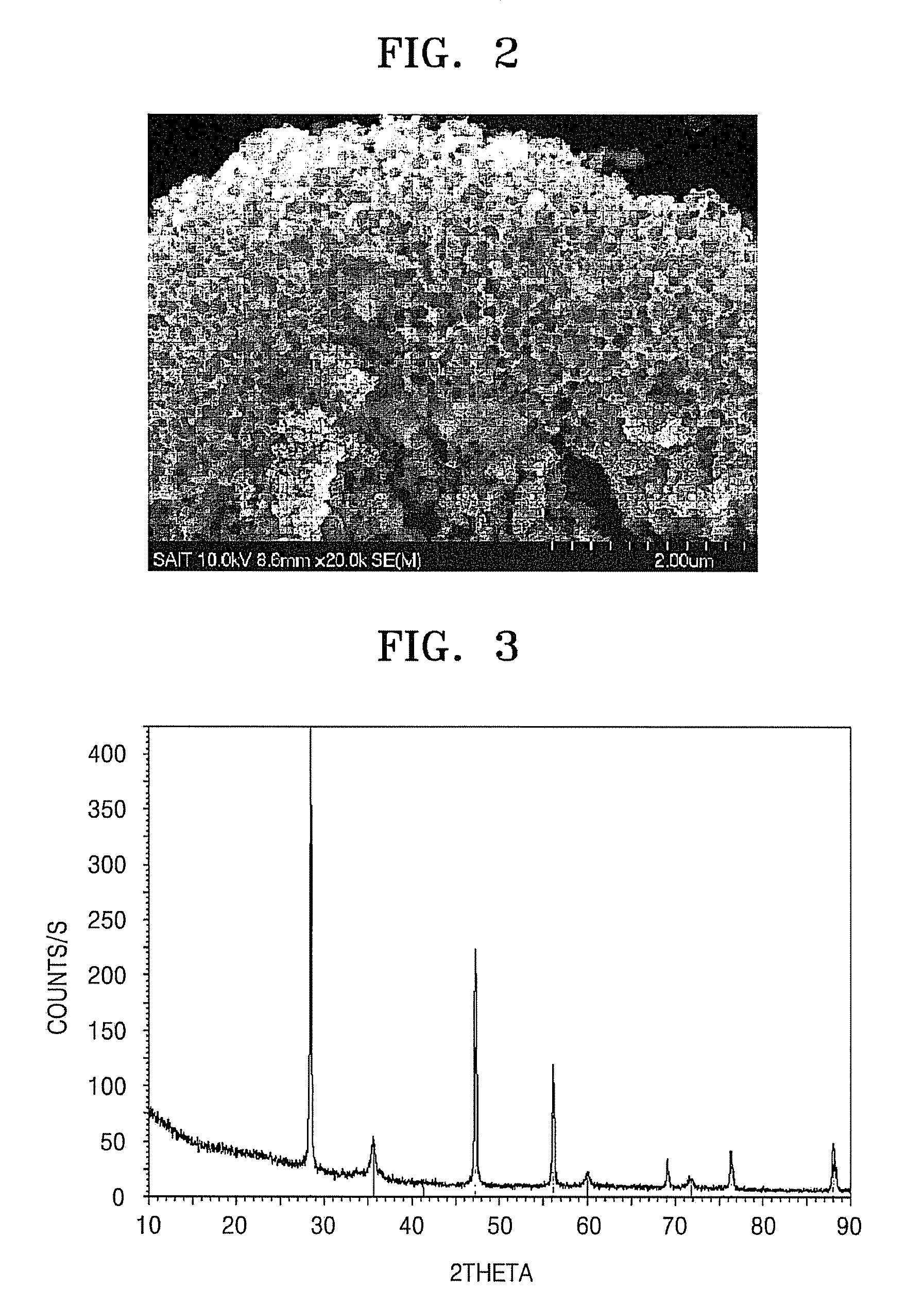

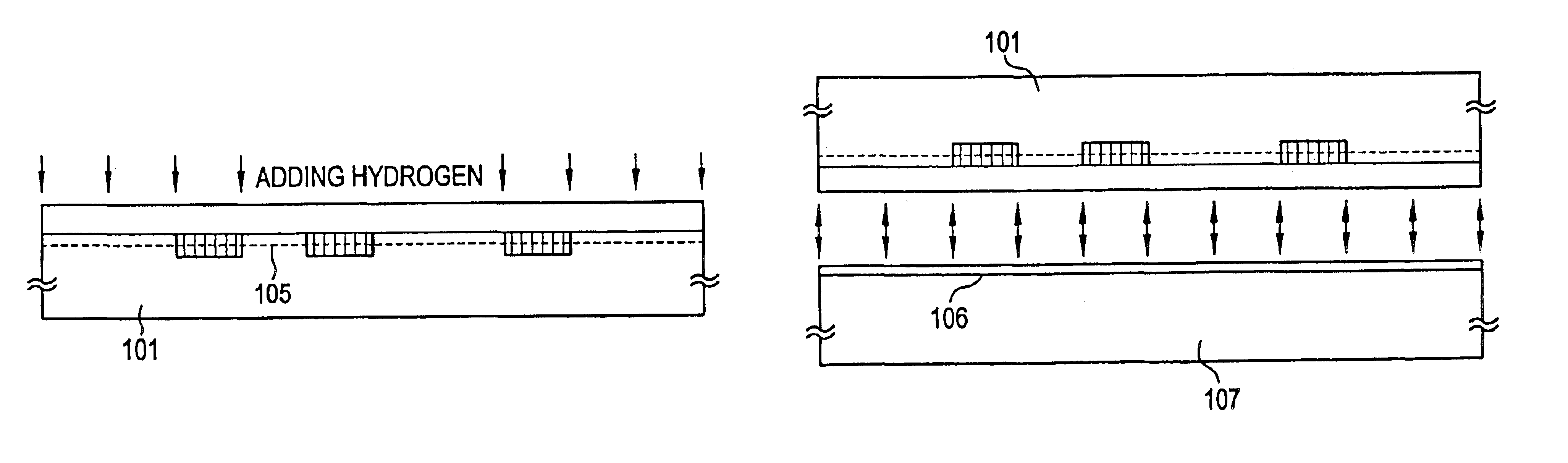

Si/c composite, anode active materials, and lithium battery including the same

ActiveUS20090029256A1Improve initial Coulombic efficiencyGood capacity retentionLiquid surface applicatorsElectrode manufacturing processesLithium-ion batteryPorous silicon

An Si / C composite includes carbon (C) dispersed in porous silicon (Si) particles. The Si / C composite may be used to form an anode active material to provide a lithium battery having a high capacity and excellent capacity retention.

Owner:SAMSUNG SDI CO LTD

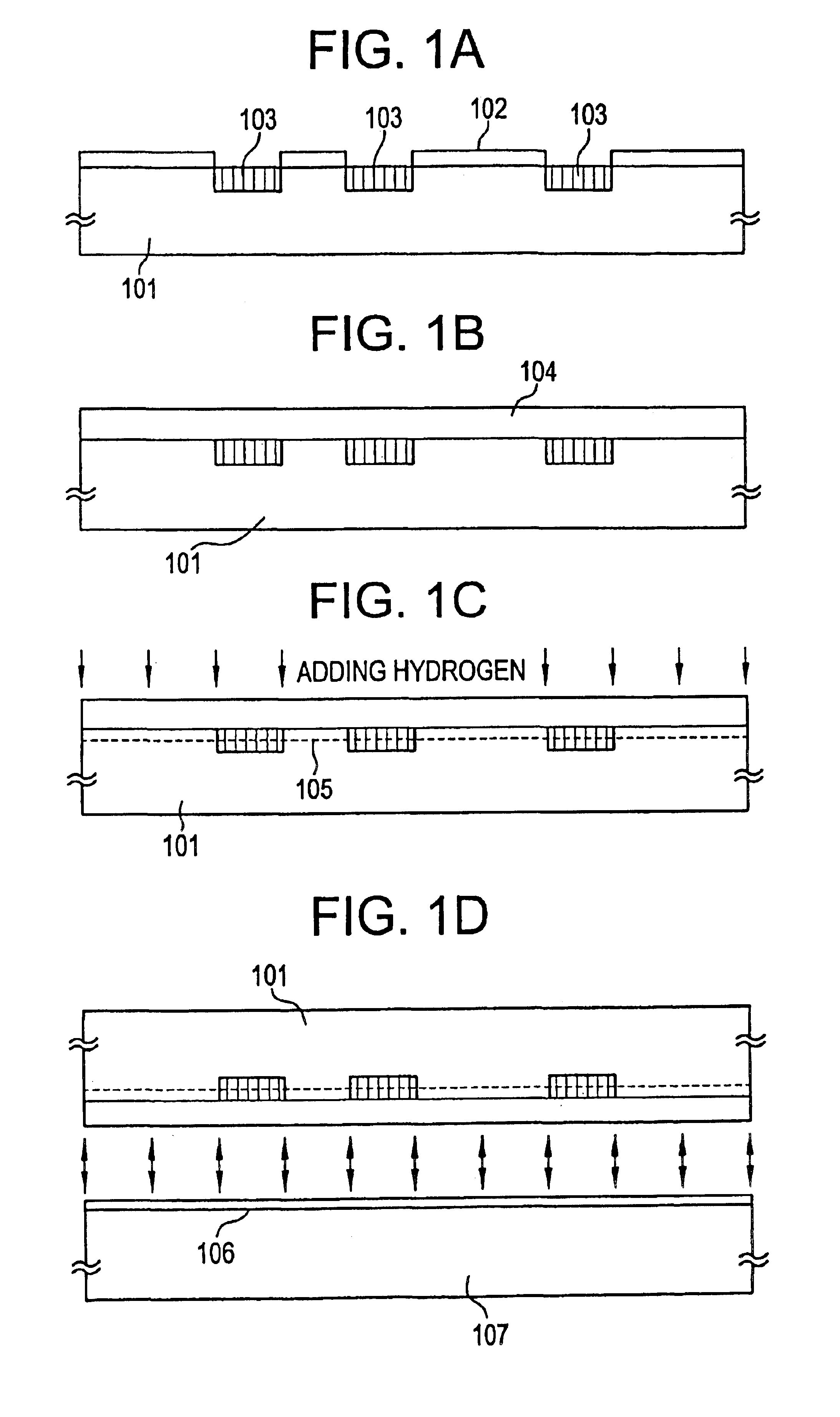

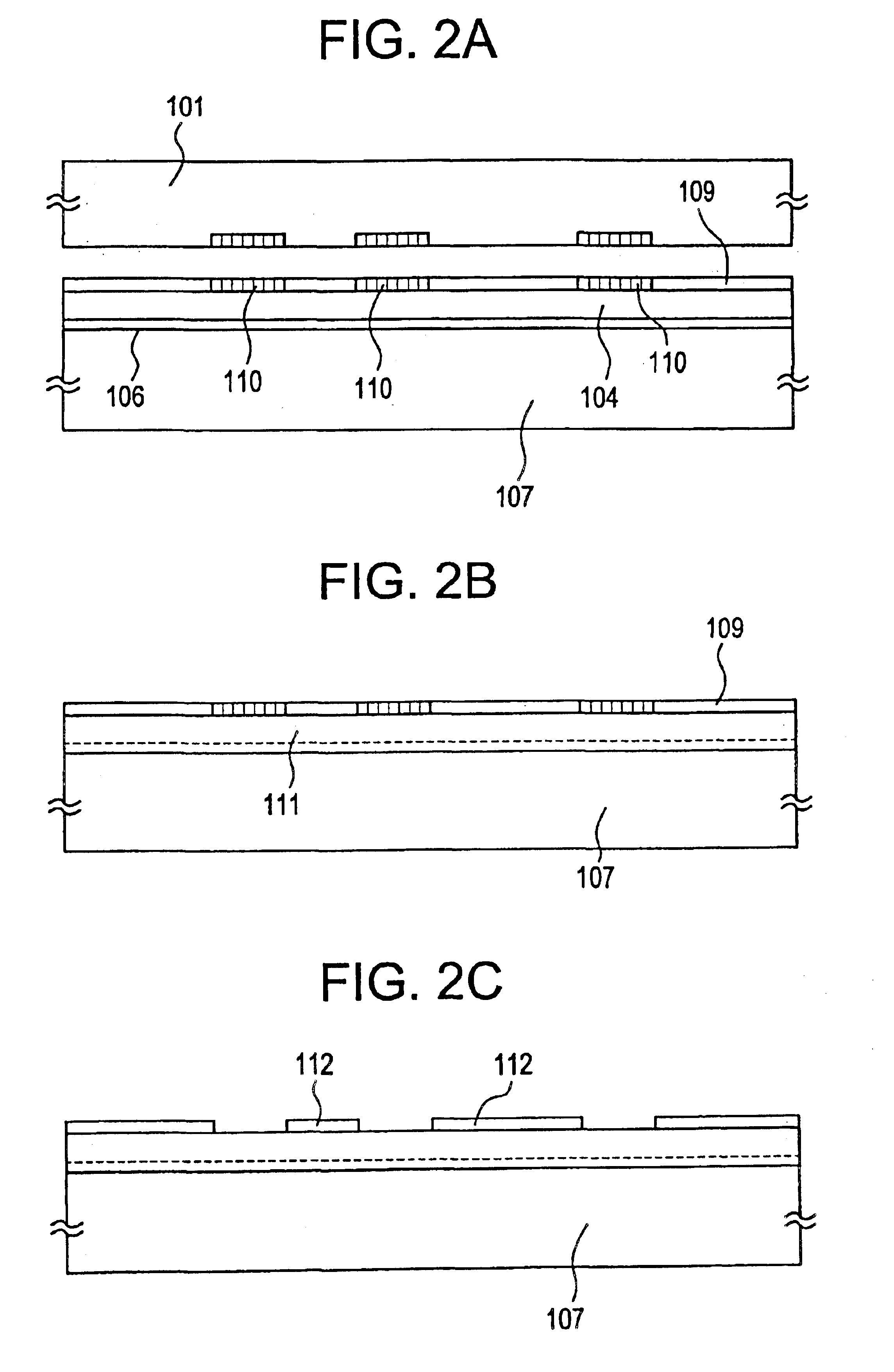

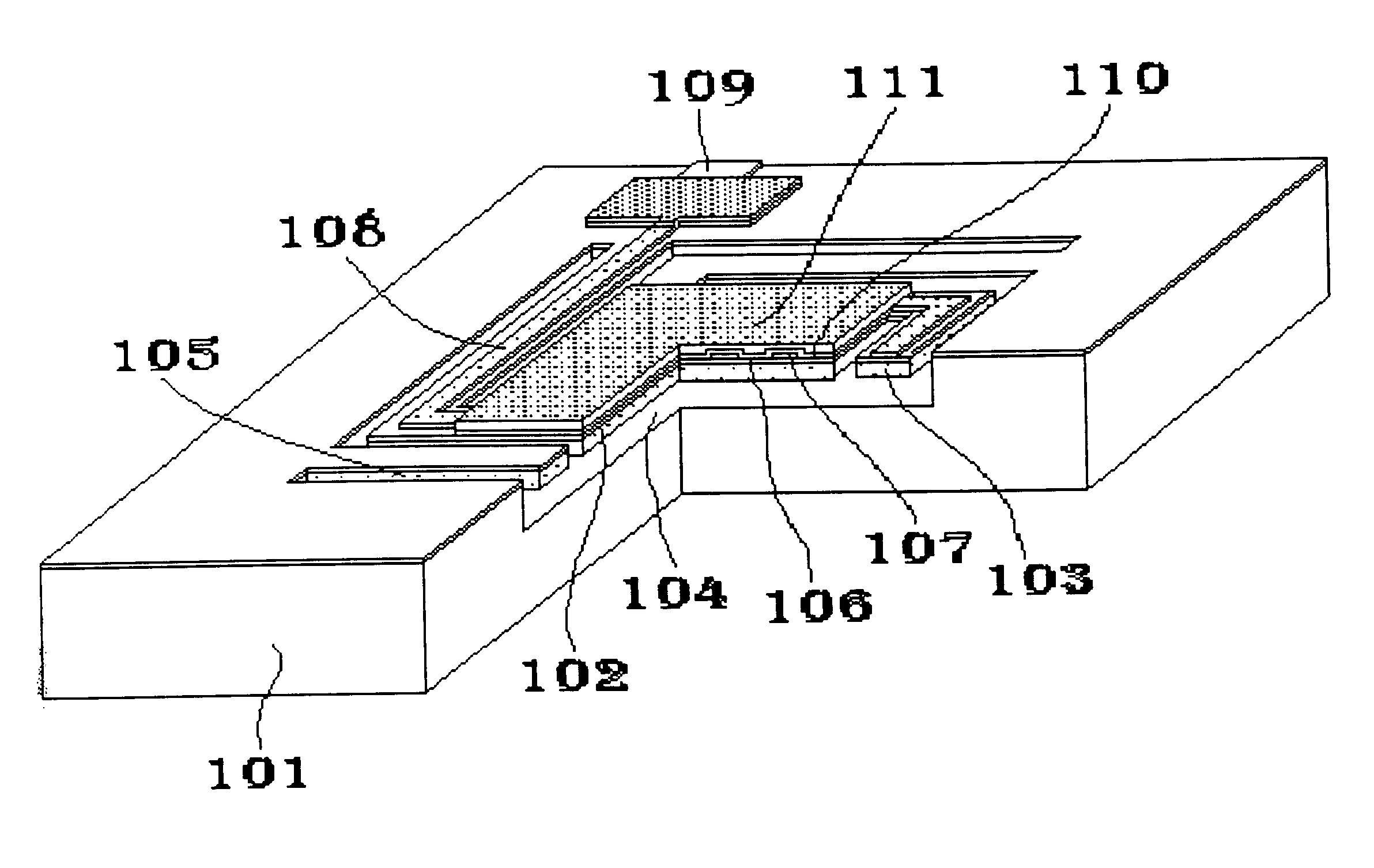

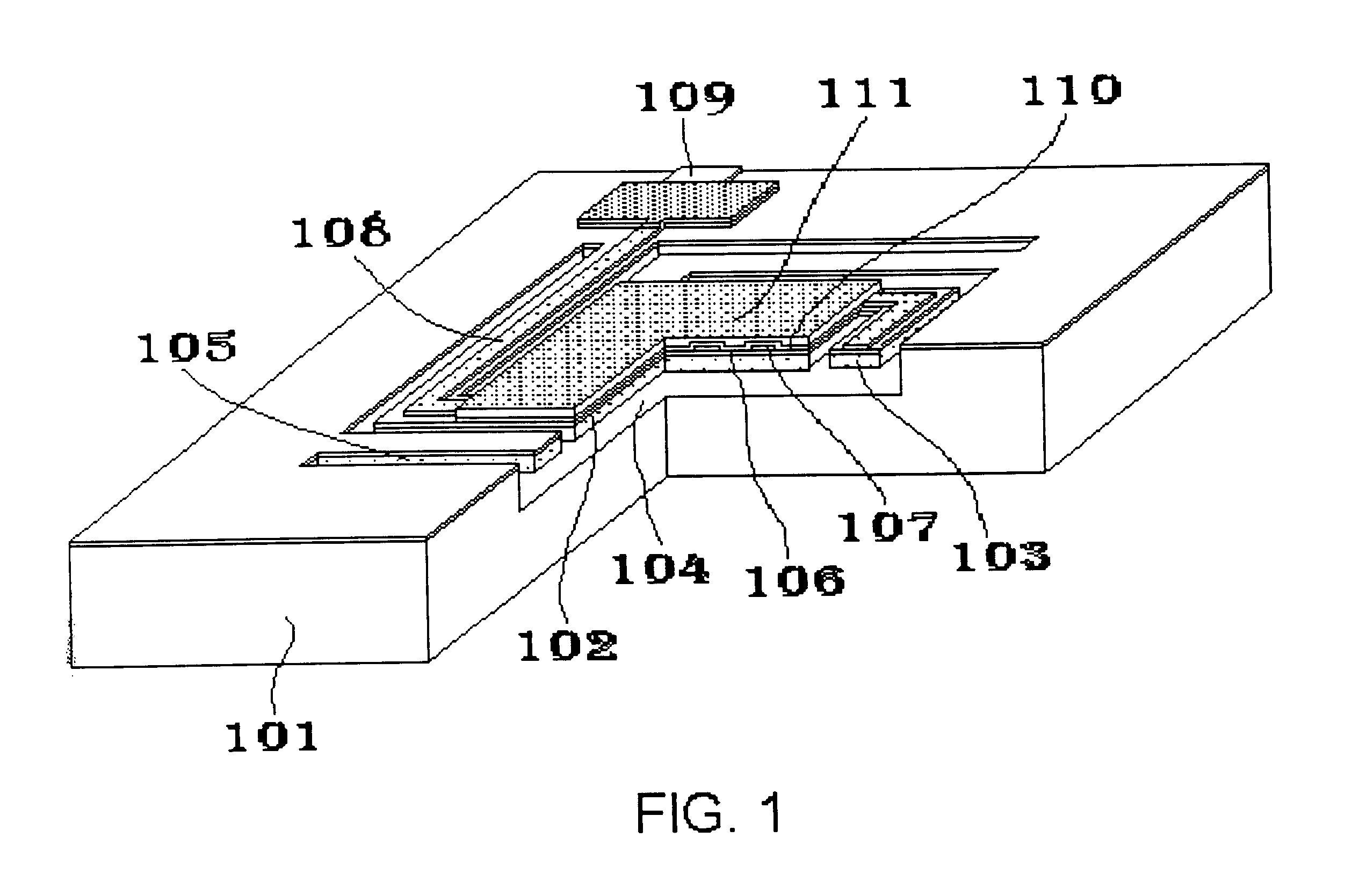

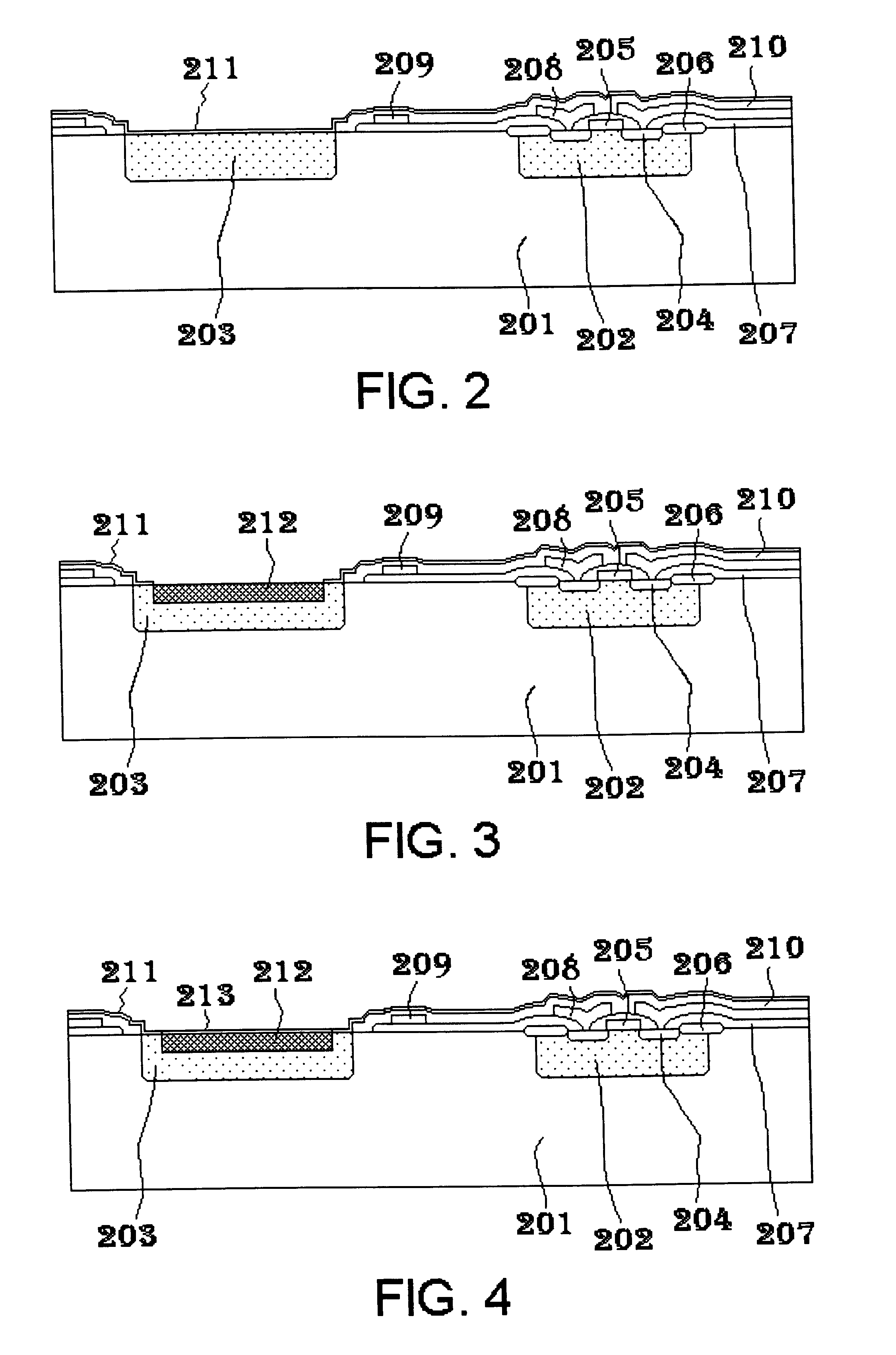

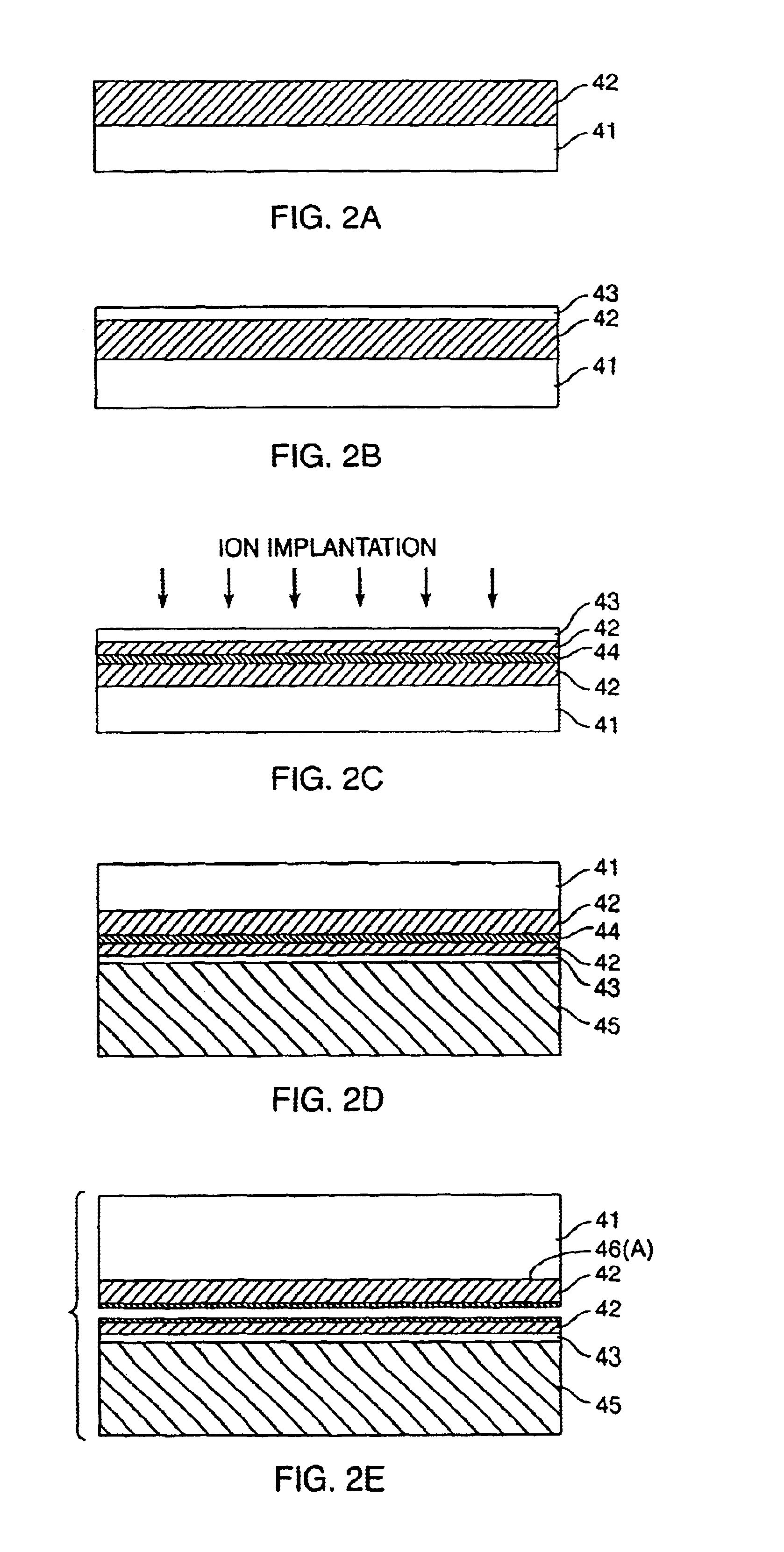

Process for production of SOI substrate and process for production of semiconductor device

A process for producing an adhered SOI substrate without causing cracking and peeling of a single-crystal silicon thin film. The process consists of selectively forming a porous silicon layer in a single-crystal semiconductor substrate, adding hydrogen into the single-crystal semiconductor substrate to form a hydrogen-added layer, adhering the single-crystal semiconductor substrate to a supporting substrate, separating the single-crystal semiconductor substrate at the hydrogen-added layer by thermal annealing, performing thermal annealing again to stabilize the adhering interface, and selectively removing the porous silicon layer to give single-crystal silicon layer divided into islands.

Owner:SEMICON ENERGY LAB CO LTD

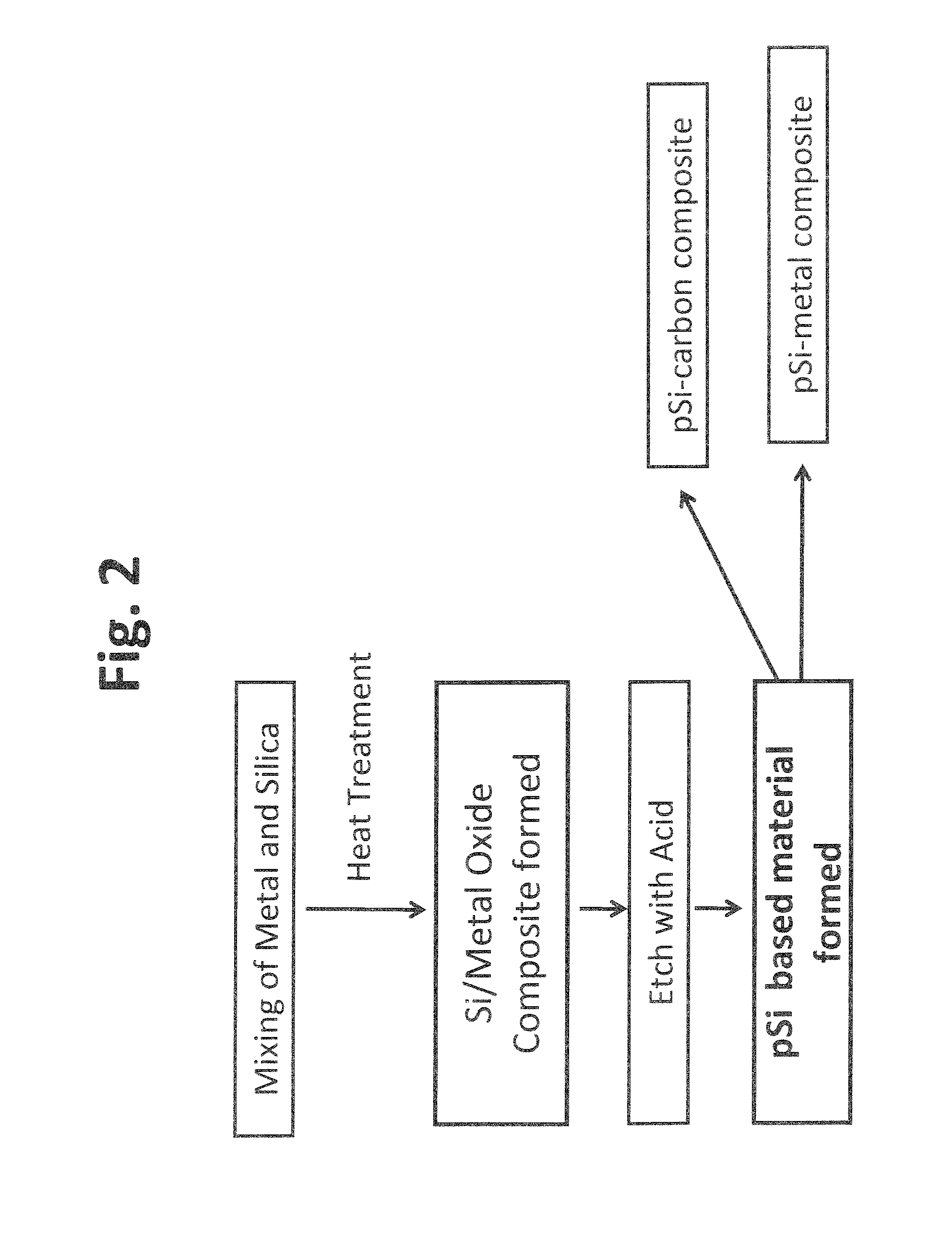

Porous silicon based anode material formed using metal reduction

A porous silicon based material comprising porous crystalline elemental silicon formed by reducing silicon dioxide with a reducing metal in a heating process followed by acid etching is used to construct negative electrode used in lithium ion batteries. Gradual temperature heating ramp(s) with optional temperature steps can be used to perform the heating process. The porous silicon formed has a high surface area from about 10 m2 / g to about 200 m2 / g and is substantially free of carbon. The negative electrode formed can have a discharge specific capacity of at least 1800 mAh / g at rate of C / 3 discharged from 1.5V to 0.005V against lithium with in some embodiments loading levels ranging from about 1.4 mg / cm2 to about 3.5 mg / cm2. In some embodiments, the porous silicon can be coated with a carbon coating or blended with carbon nanofibers or other conductive carbon material.

Owner:IONBLOX INC

Microbolometer infrared sensors

InactiveUS6359276B1High mechanical strengthReduce residual stressSolid-state devicesMaterial analysis by optical meansThermal isolationMicrobolometer

A microbolometer infrared sensor utilizes a porous silicon bridge as its thermal isolating and mechanical supporting structure. Porous silicon formed from single crystal silicon on lightly doped p-type silicon has a thermal conductivity lower than silicon dioxide and silicon nitride, and, therefore, when used as a mechanical supporting structure, can offer better thermal isolation performance. The porous silicon layer can be fabricated much thicker than silicon dioxide and silicon nitride membranes since there is almost no residual stress therein. A thicker porous silicon bridge has higher mechanical support strength. The porous silicon process is a low temperature process. It facilitates a fabrication strategy of microelectronics first and micromechanics last.

Owner:TU XIANG ZHENG

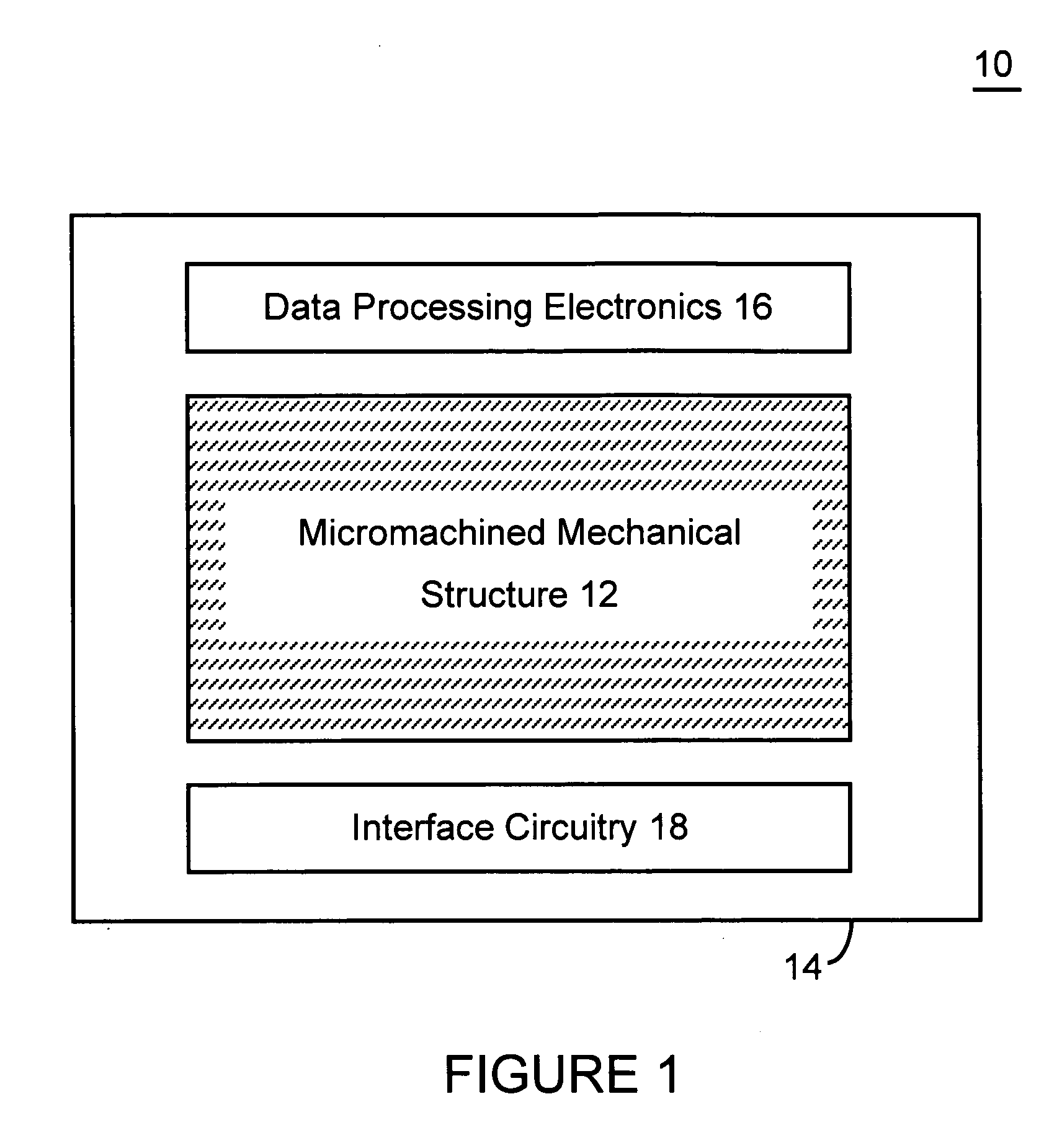

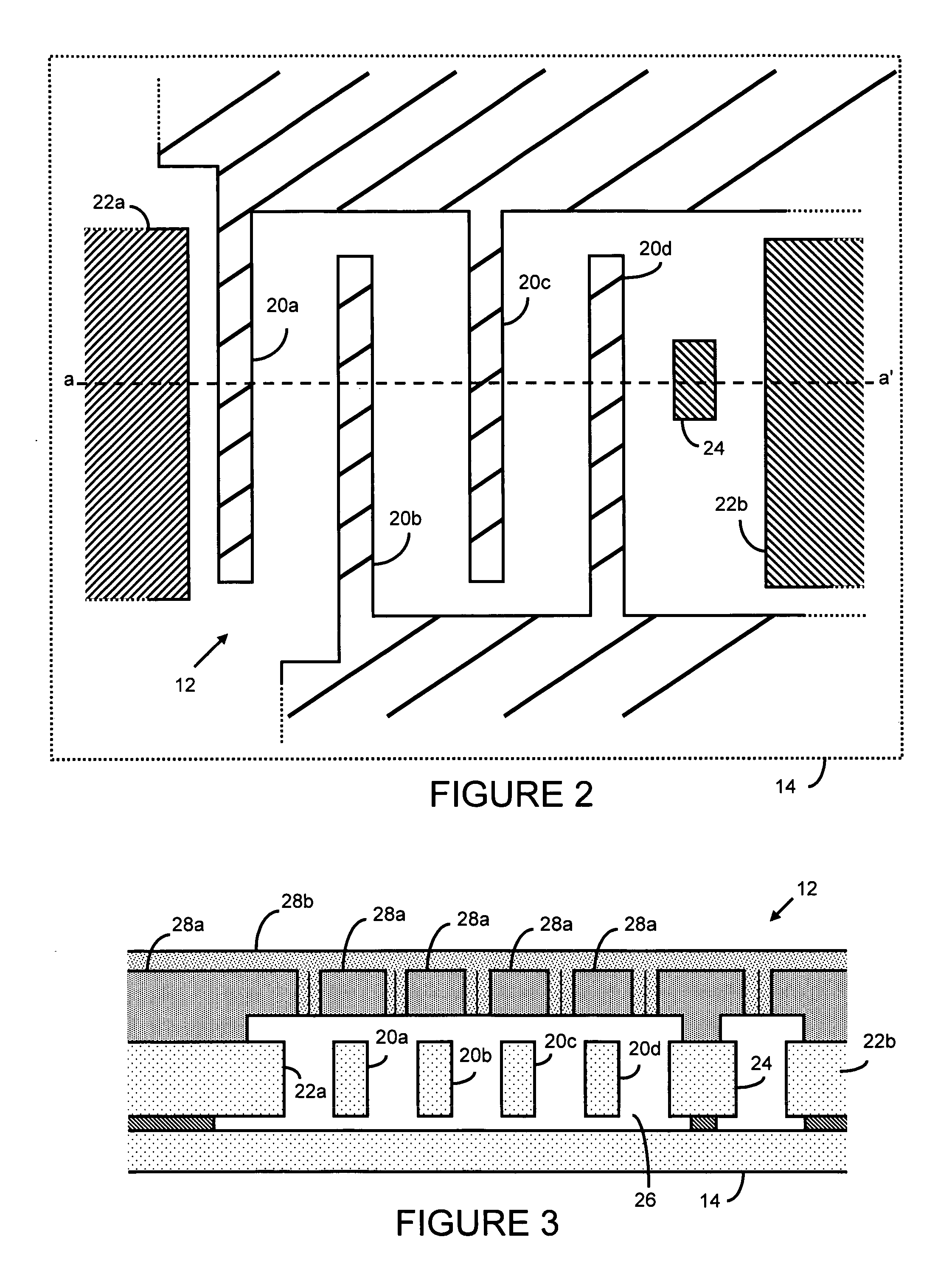

Microelectromechanical systems, and methods for encapsulating and fabricating same

ActiveUS20060108652A1Acceleration measurement using interia forcesSemiconductor/solid-state device detailsIntegrated circuitEngineering

There are many inventions described and illustrated herein. In one aspect, the present invention is directed to a MEMS device, and technique of fabricating or manufacturing a MEMS device, having mechanical structures encapsulated in a chamber prior to final packaging. The material that encapsulates the mechanical structures, when deposited, includes one or more of the following attributes: low tensile stress, good step coverage, maintains its integrity when subjected to subsequent processing, does not significantly and / or adversely impact the performance characteristics of the mechanical structures in the chamber (if coated with the material during deposition), and / or facilitates integration with high-performance integrated circuits. In one embodiment, the material that encapsulates the mechanical structures is, for example, silicon (polycrystalline, amorphous or porous, whether doped or undoped), silicon carbide, silicon-germanium, germanium, or gallium-arsenide.

Owner:ROBERT BOSCH GMBH

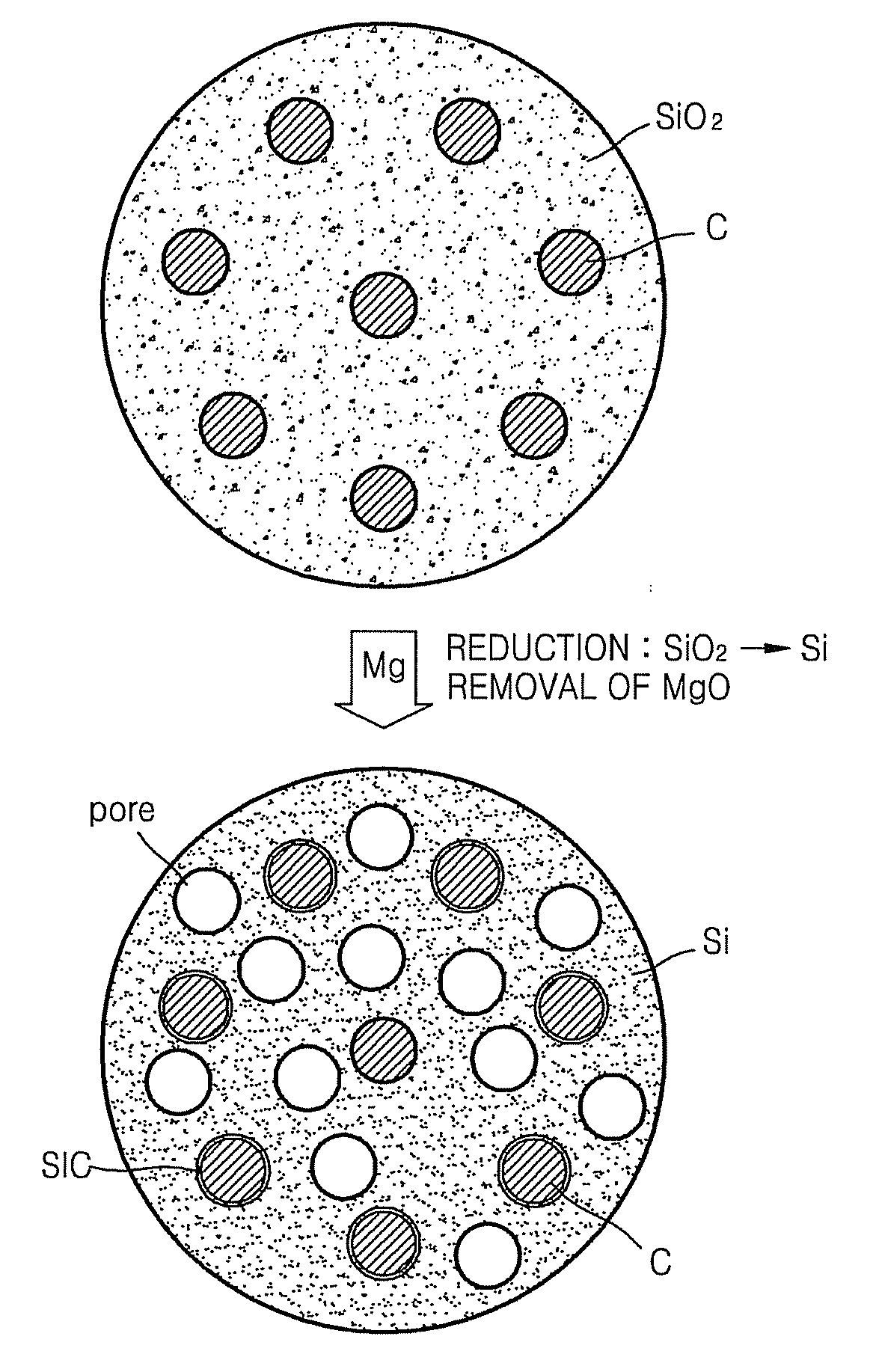

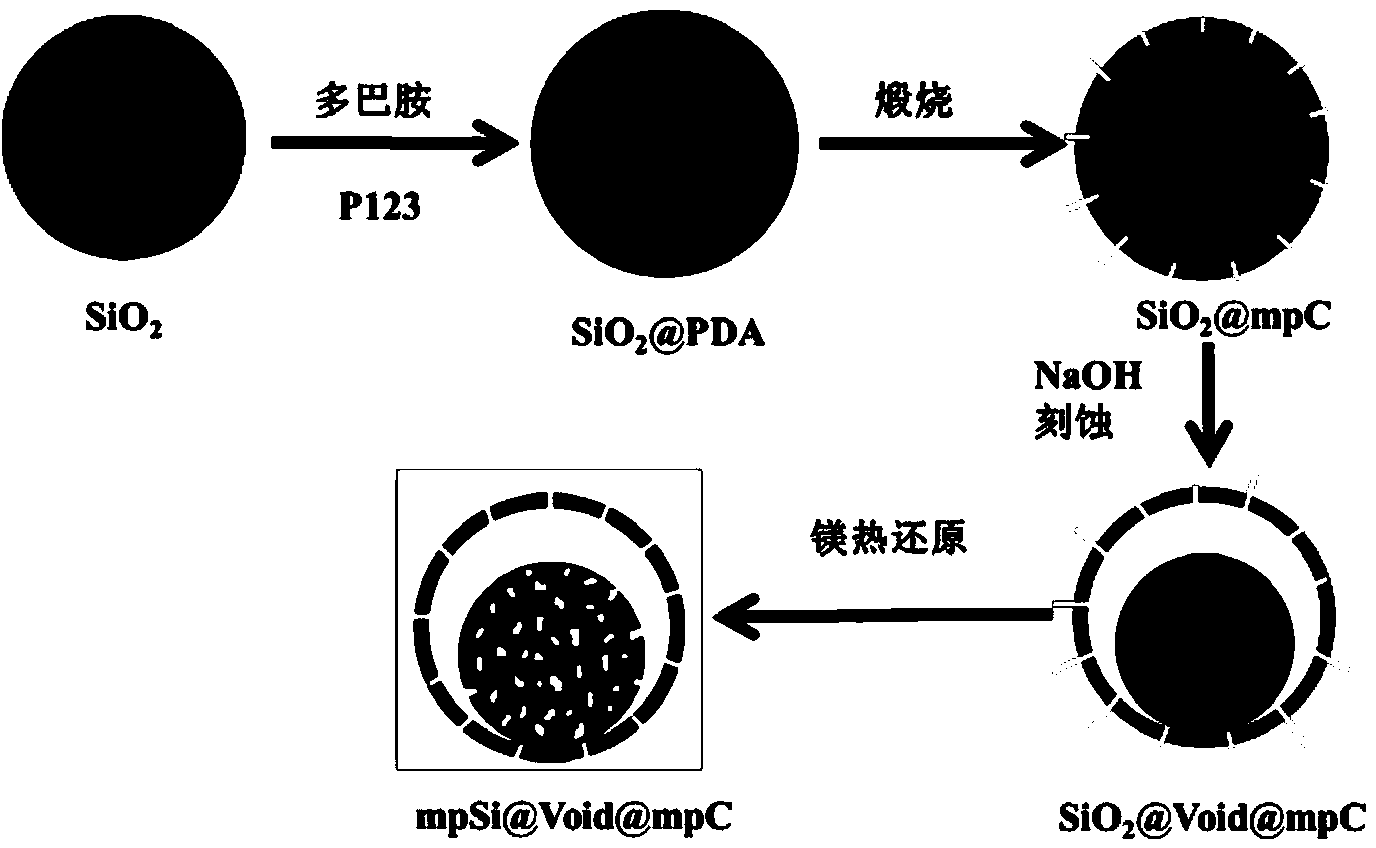

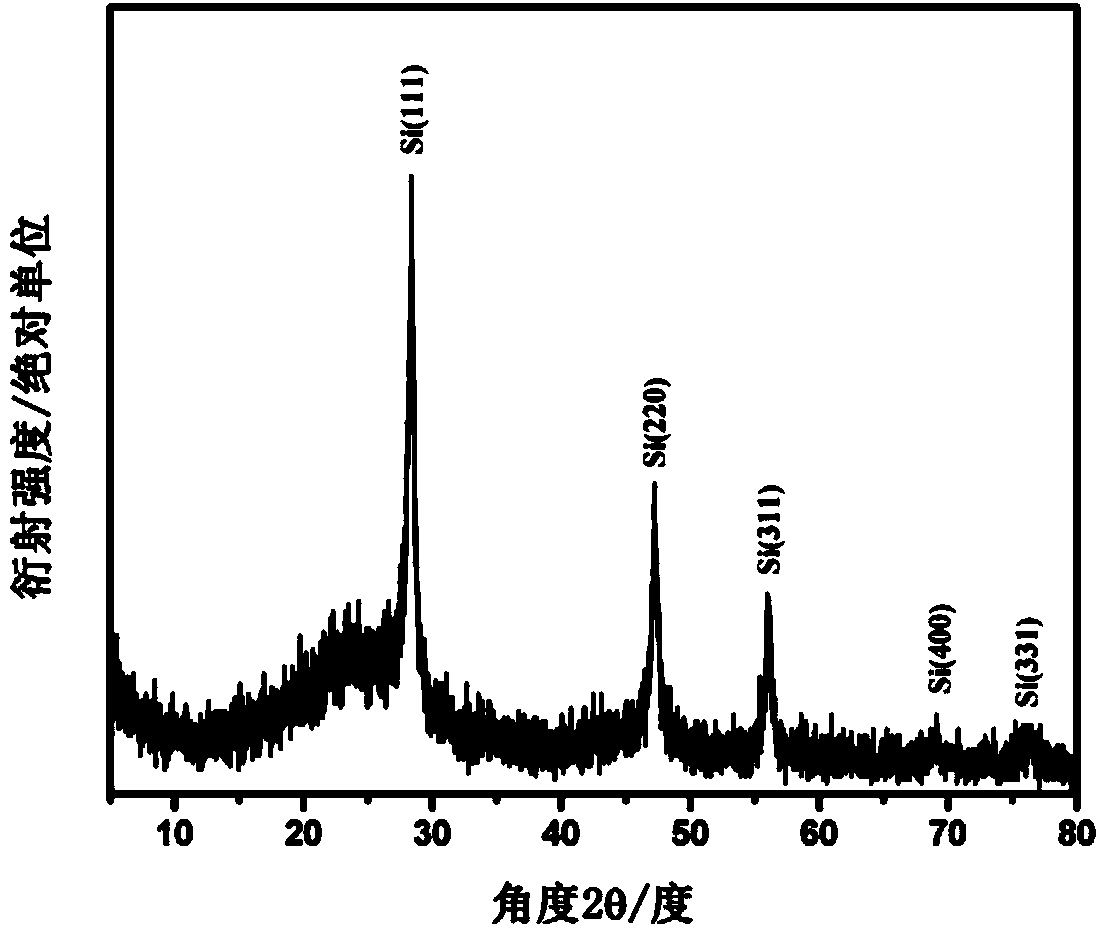

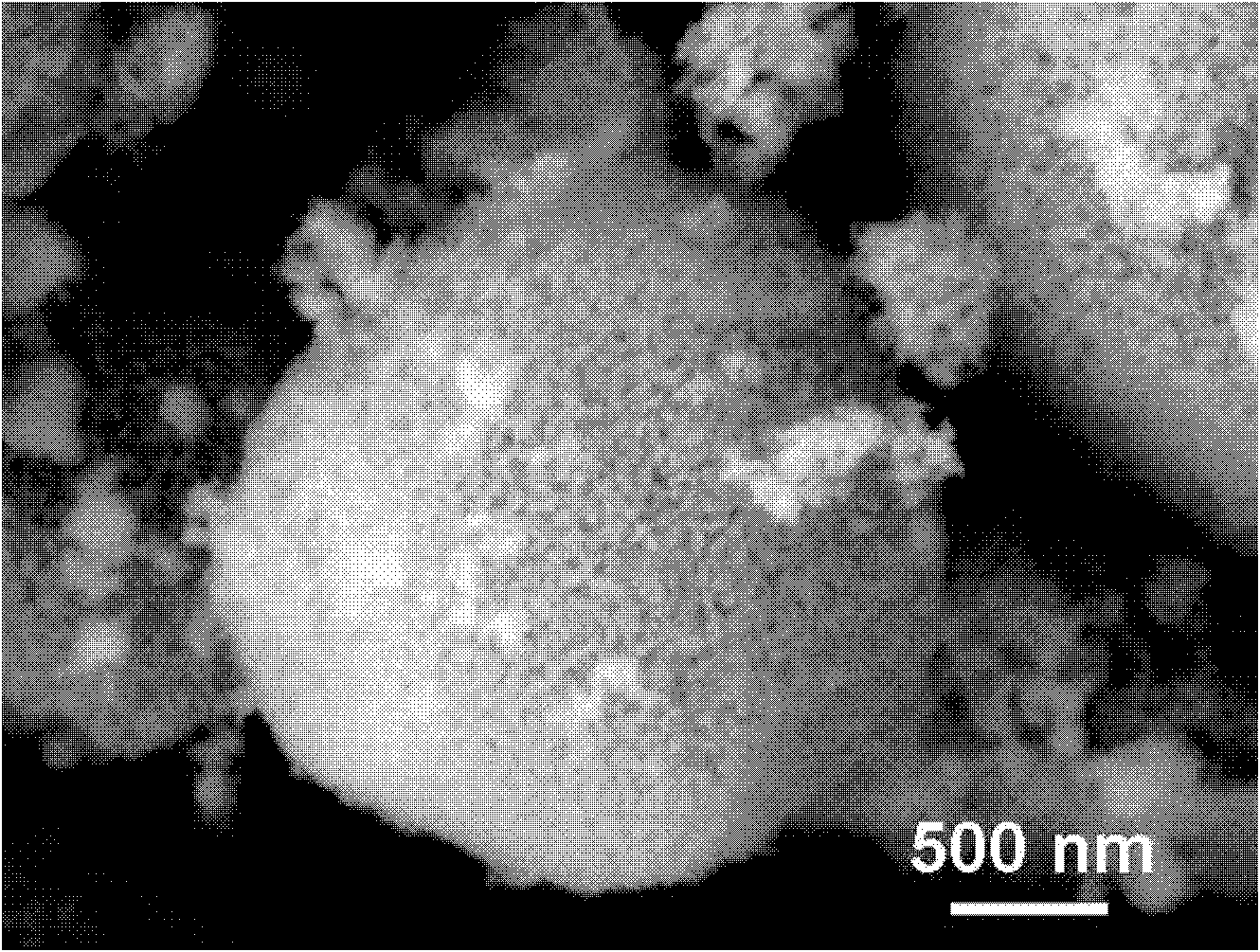

Porous silicon carbon composite microsphere with yolk-eggshell structure and preparation method therefor

InactiveCN103531760AEase of mass productionPromote infiltrationMaterial nanotechnologyCell electrodesCarbon compositesYolk

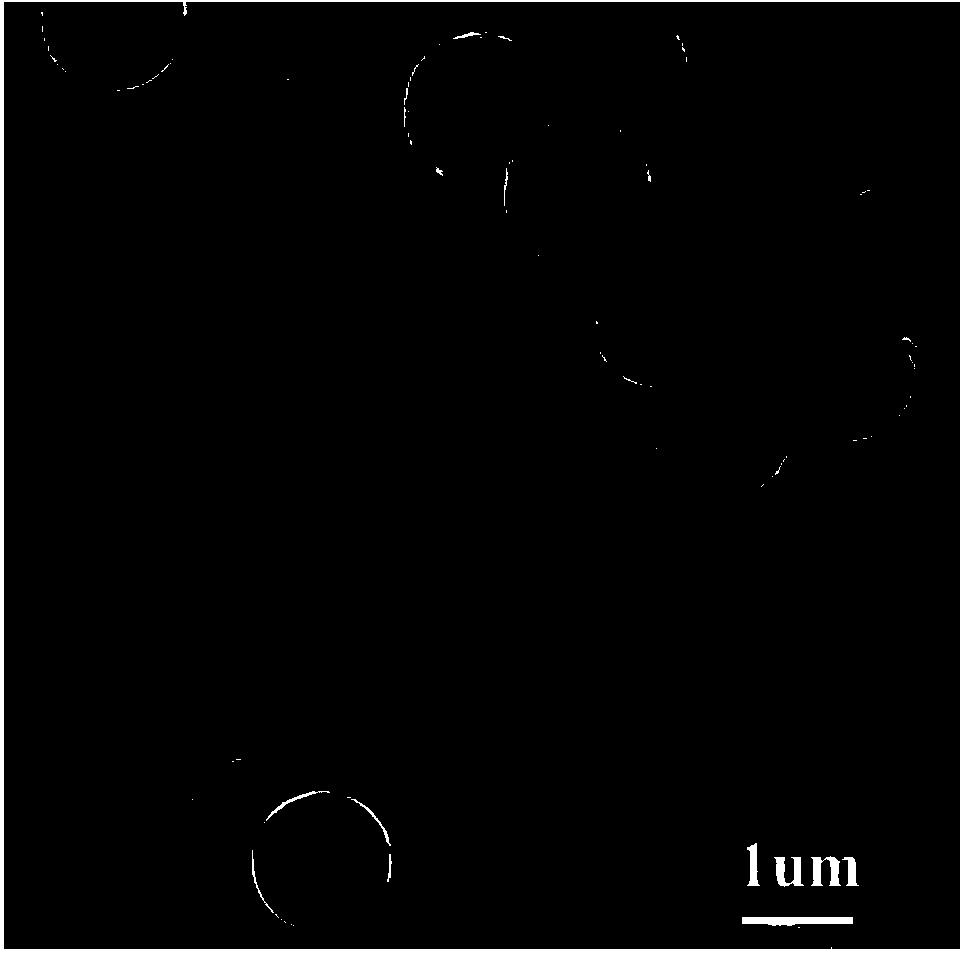

The invention provides a porous silicon carbon composite microsphere with a yolk-eggshell structure and a preparation method therefor, and belongs to the lithium ion battery electrode material technology field. The porous silicon carbon composite microsphere takes a porous submicron silicon sphere mpSi as a core with a diameter of 400-900 nm, and takes porous carbon mpC as a shell with a thickness of 10-60 nm. The inner diameter of a cavity Void is 800-1400 nm. The composition of the silicon carbon composite microsphere can be described as mpSi@Void@mpC. In addition, In the preparation method, cheap silicon dioxide is taken as a silicon source, silicon dioxide is conversed into silicon materials with electrochemical activities through a magnesiothermic reduction method. The size of gaps can be regulated and controlled through control of etching conditions. The preparation method is advantaged in that the material structure can be controlled, the cost is low, the process is simple, and the composite microsphere is convenient for large-scale production.

Owner:BEIJING UNIV OF CHEM TECH

Self-oriented bundles of carbon nanotubes and method of making same

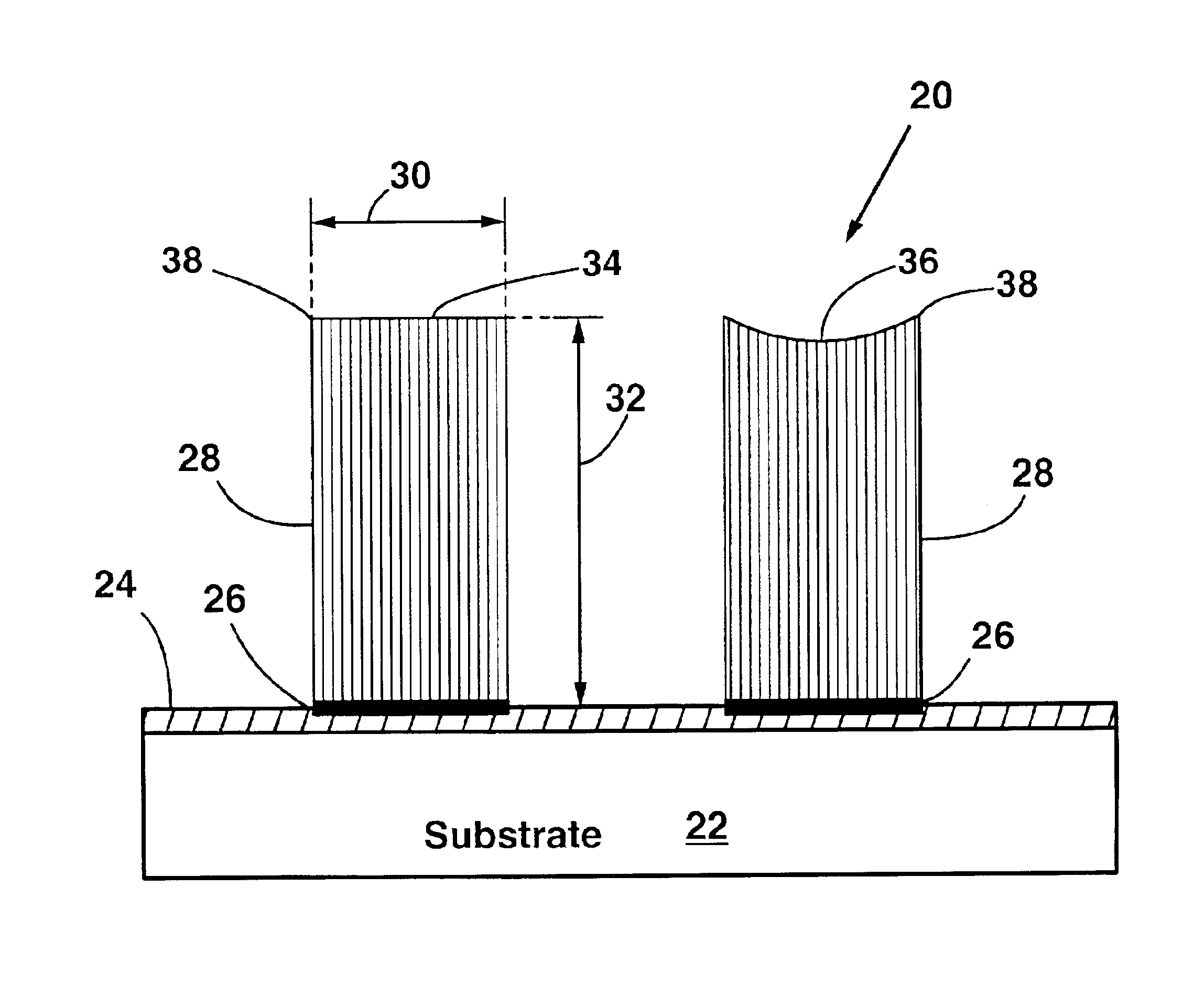

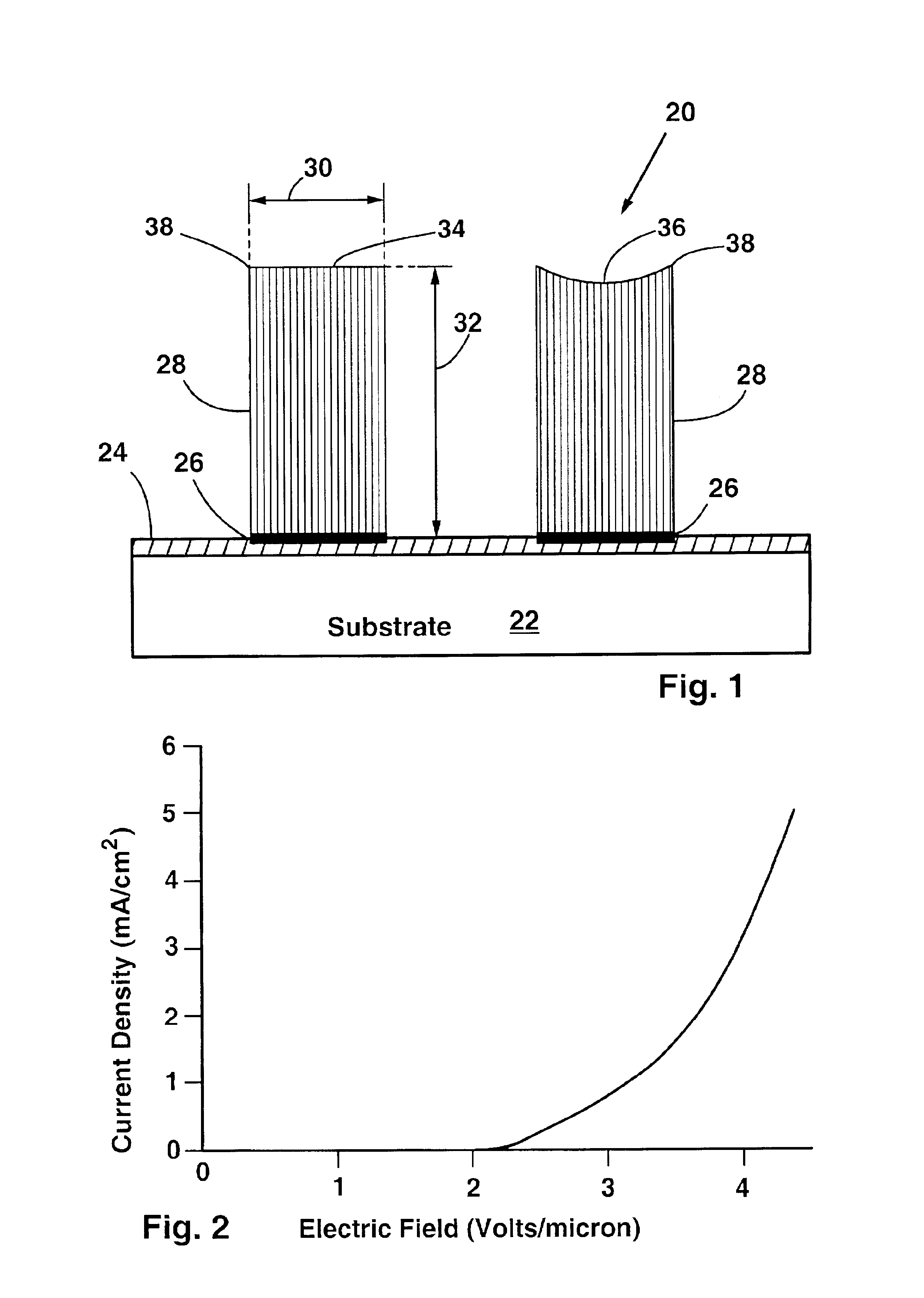

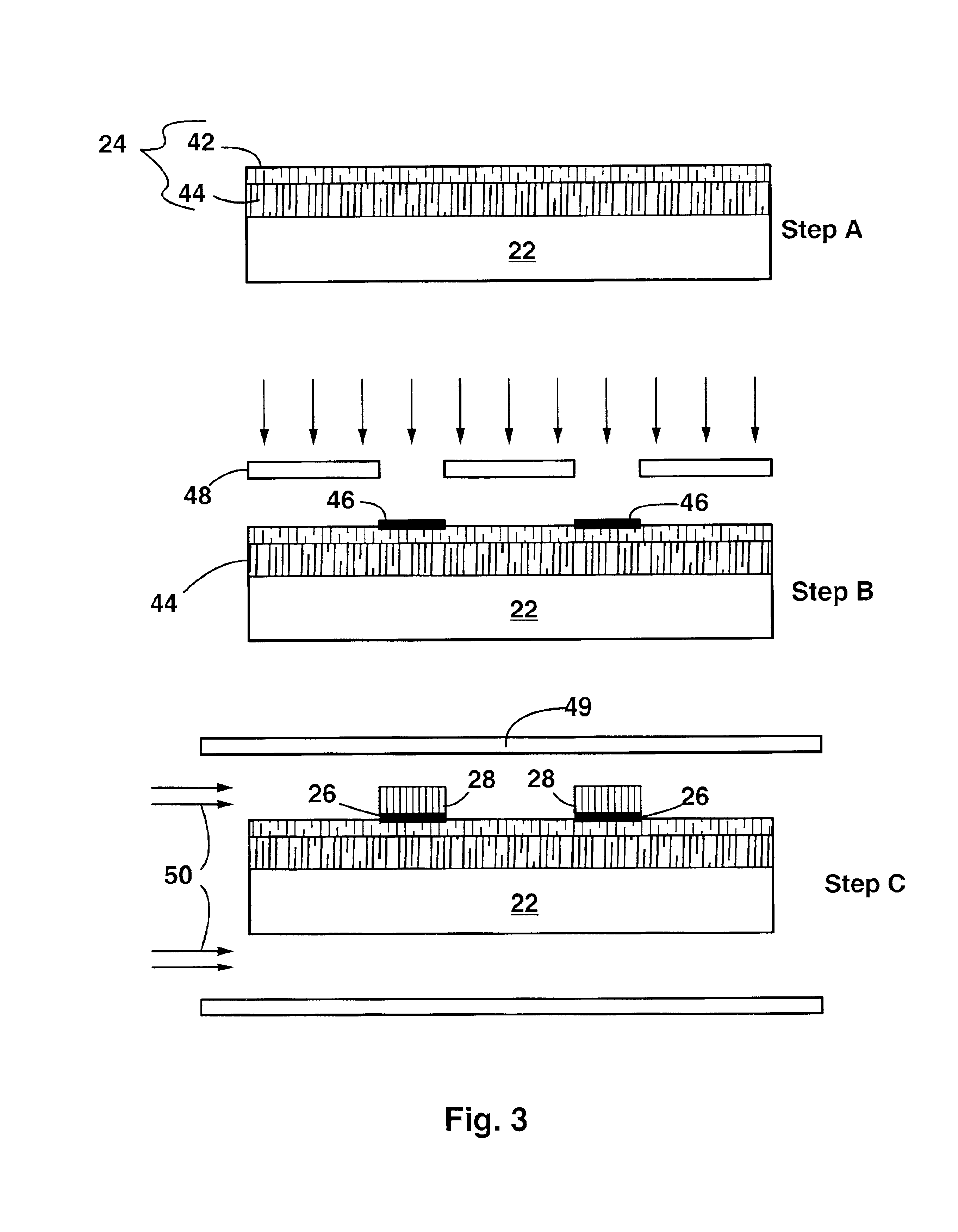

A field emission device having bundles of aligned parallel carbon nanotubes on a substrate. The carbon nanotubes are oriented perpendicular to the substrate. The carbon nanotube bundles may be up to 300 microns tall, for example. The bundles of carbon nanotubes extend only from regions of the substrate patterned with a catalyst material. Preferably, the catalyst material is iron oxide. The substrate is preferably porous silicon, as this produces the highest quality, most well-aligned nanotubes. Smooth, nonporous silicon or quartz can also be used as the substrate. The method of the invention starts with forming a porous layer on a silicon substrate by electrochemical etching. Then, a thin layer of iron is deposited on the porous layer in patterned regions. The iron is then oxidized into iron oxide, and then the substrate is exposed to ethylene gas at elevated temperature. The iron oxide catalyzes the formation of bundles of aligned parallel carbon nanotubes which grow perpendicular to the substrate surface. The height of the nanotube bundles above the substrate is determined by the duration of the catalysis step. The nanotube bundles only grow from the patterned regions.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

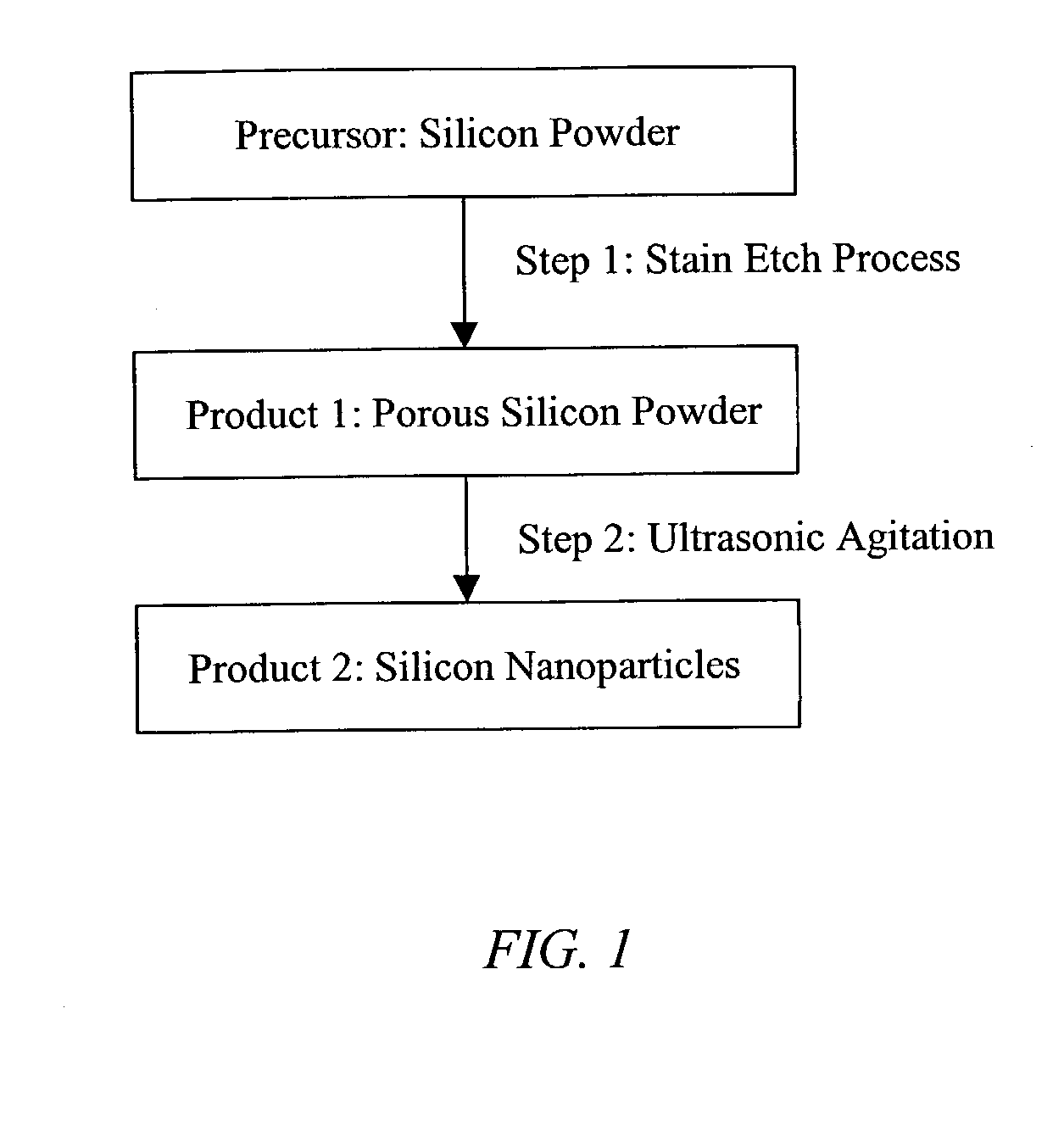

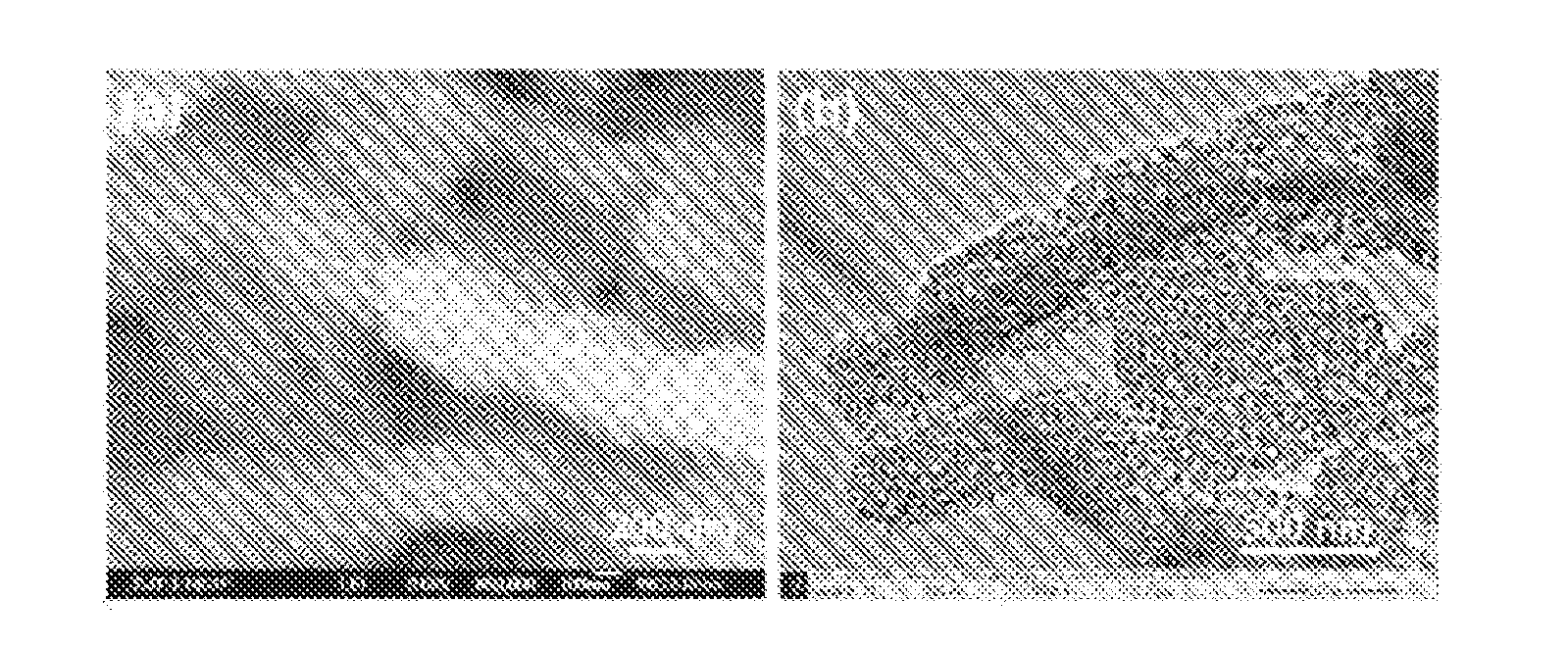

Method of producing silicon nanoparticles from stain-etched silicon powder

The present invention is for a porous silicon powder comprising silicon particles wherein the outermost layers of said particles are porous. The present invention is also directed to a method of making this porous silicon powder using a stain etch method. The present invention is also directed to a method of making silicon nanoparticles from the porous silicon powders using a process of ultrasonic agitation. The present invention also includes methods of processing these silicon nanoparticles for use in a variety of applications.

Owner:SI DIAMOND TECH

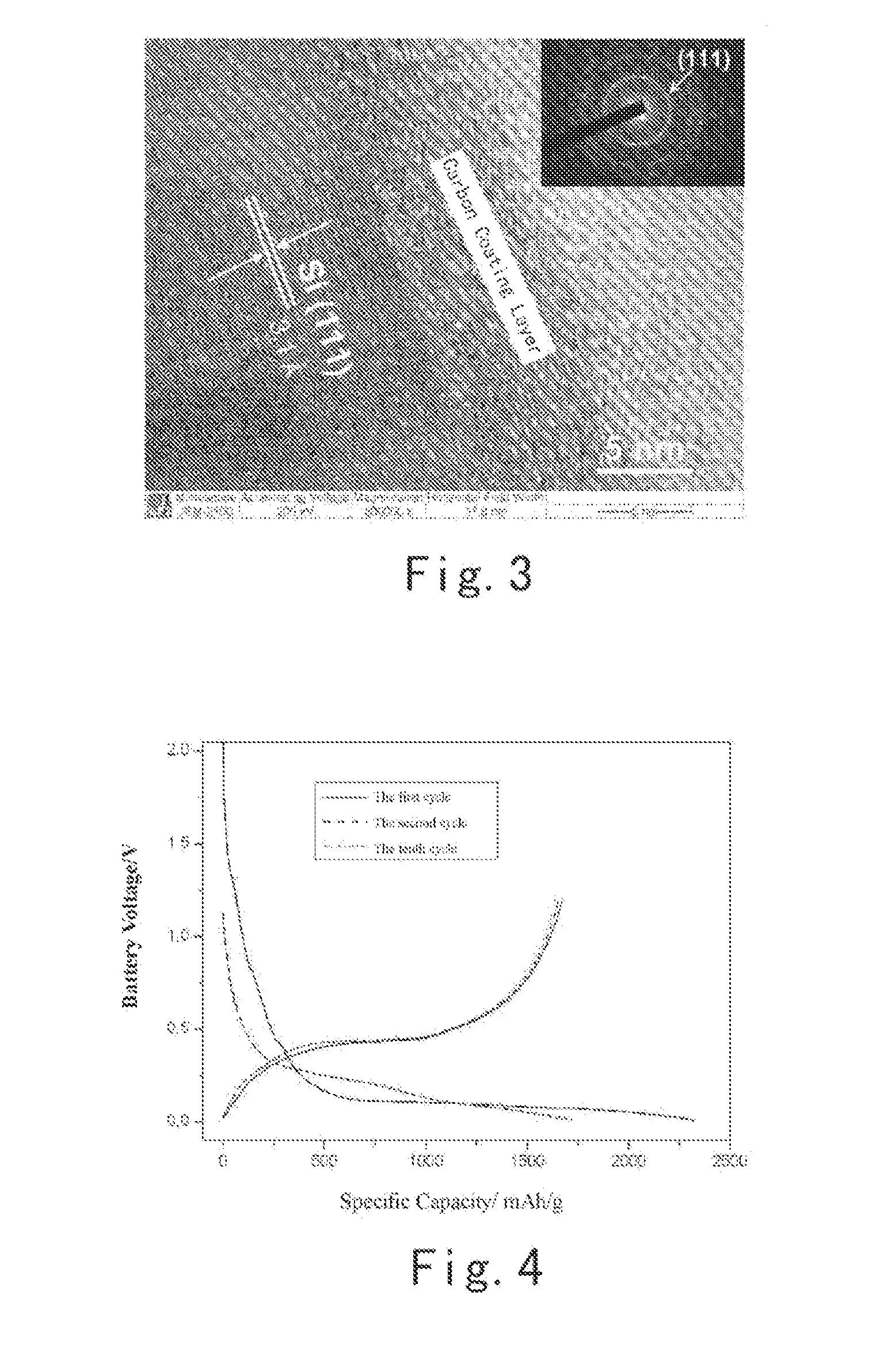

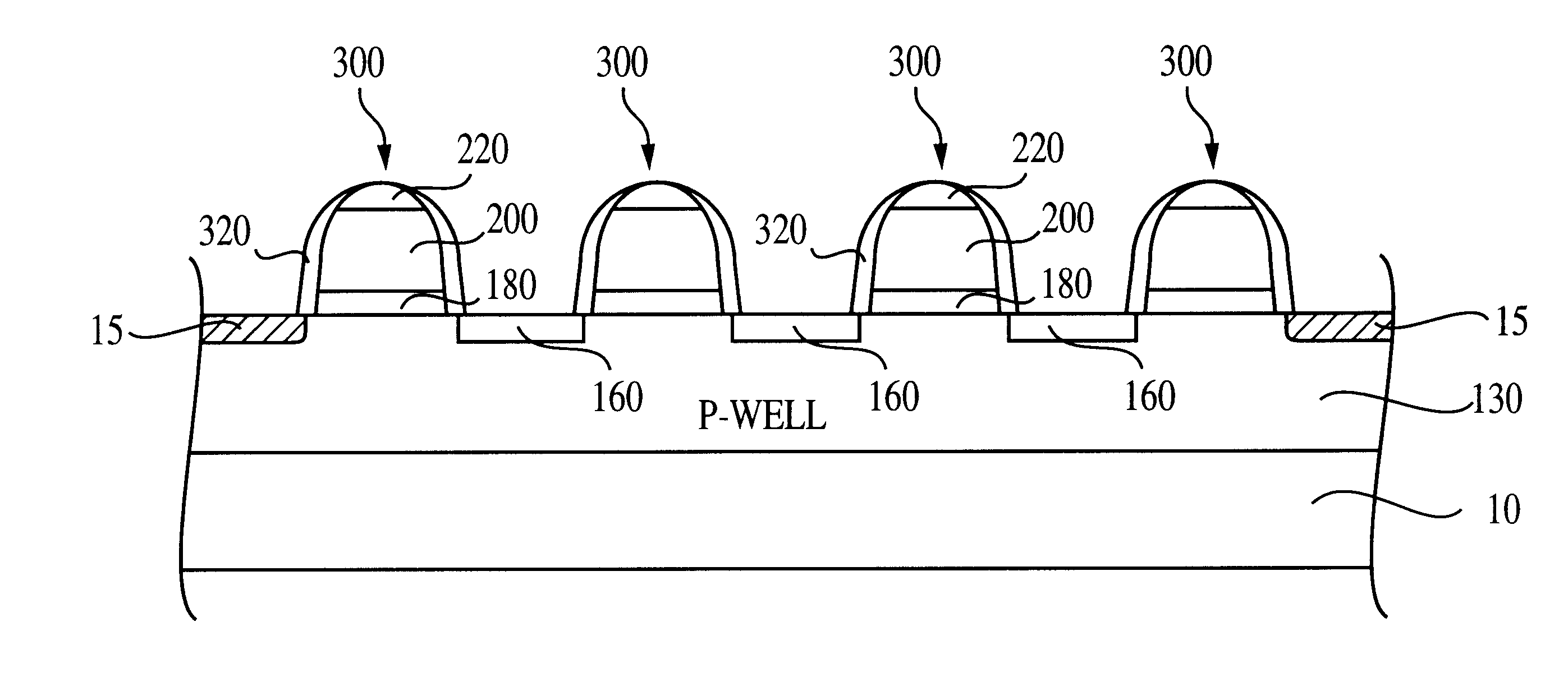

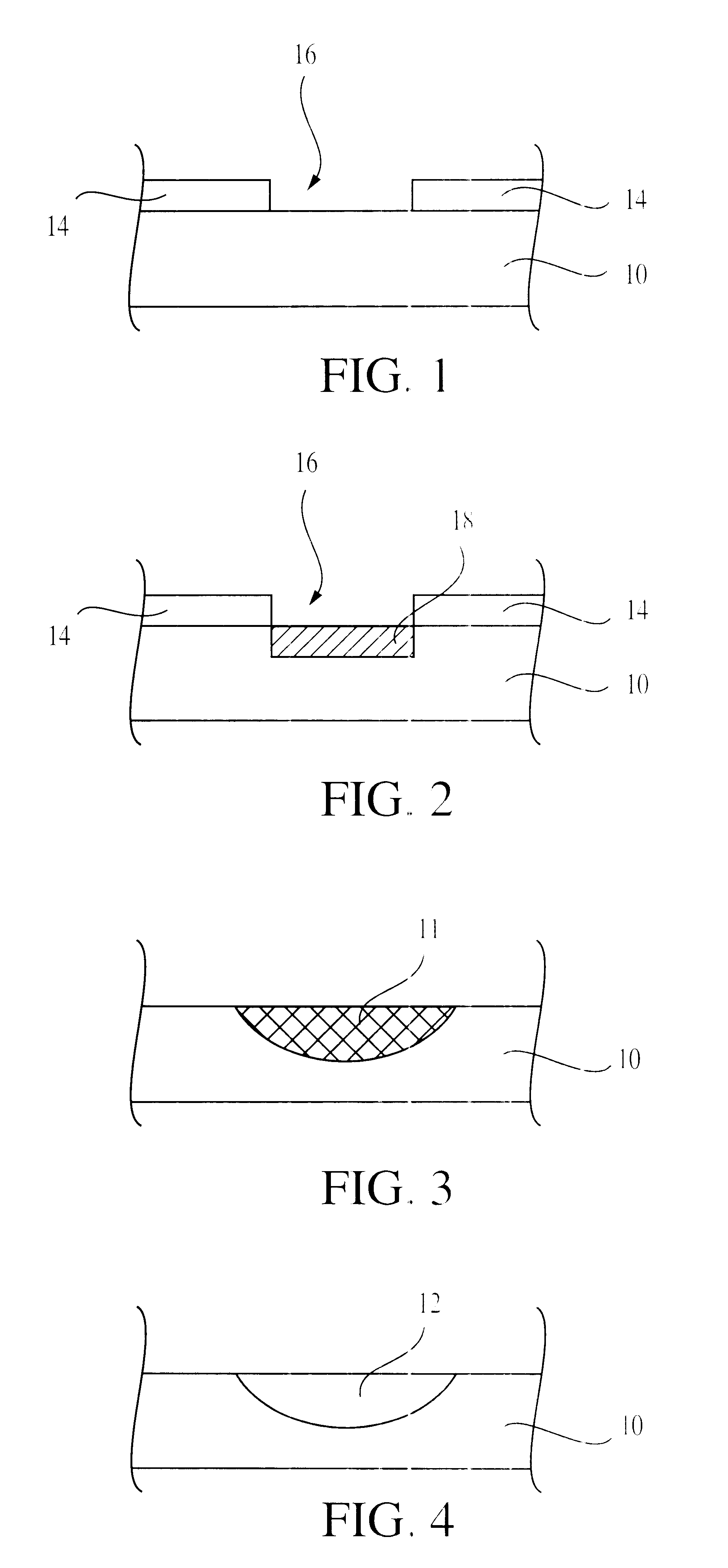

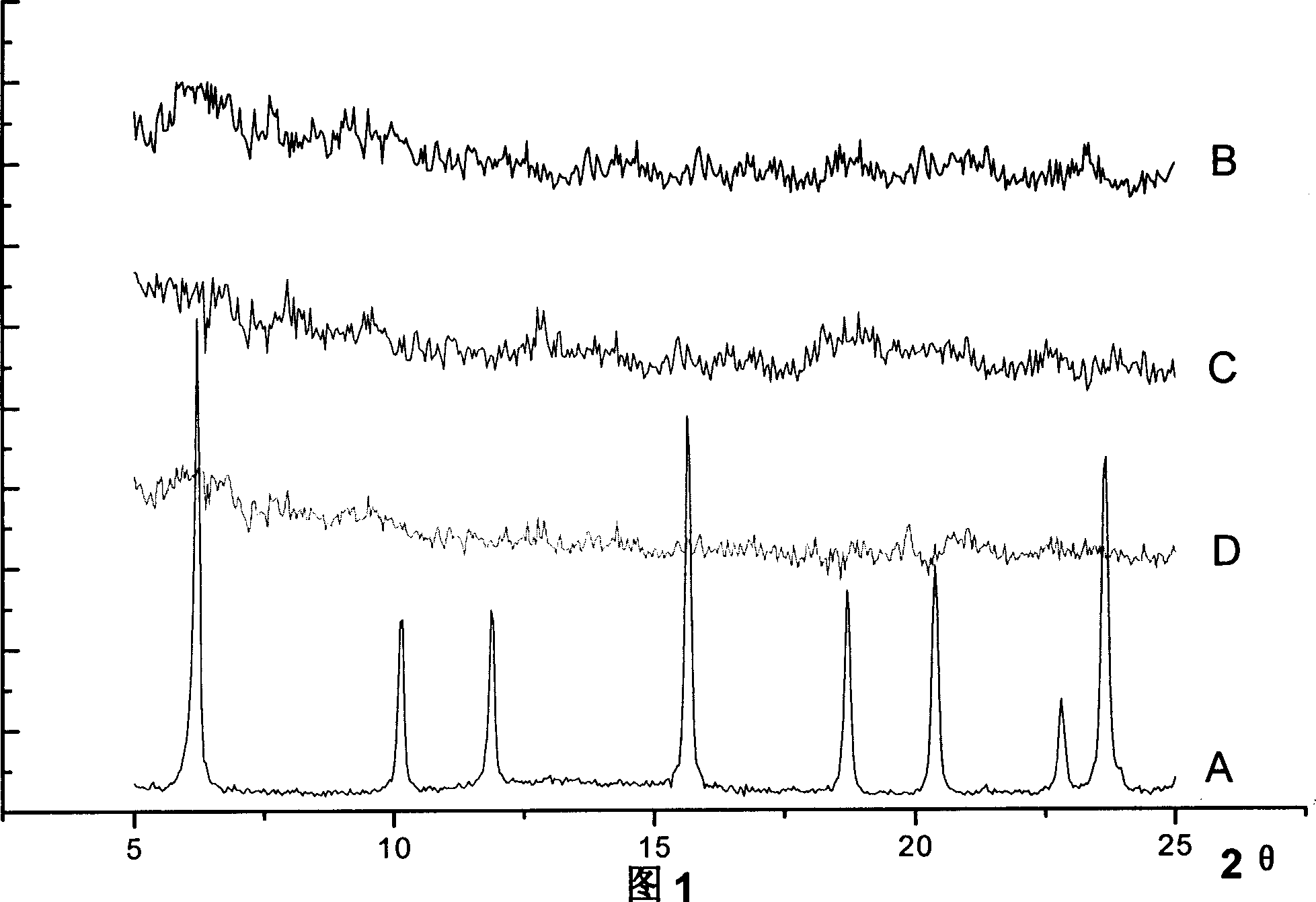

Silicon-carbon Composite Anode Material for Lithium Ion Batteries and A Preparation Method Thereof

ActiveUS20140147751A1Large capacityImprove cycle stability performanceMechanical vibrations separationLiquid/solution decomposition chemical coatingCarbon compositesCarbon coating

Disclosed in the invention are a silicon-carbon composite anode material for lithium ion batteries and a preparation method thereof The material consists of a porous silicon substrate and a carbon coating layer. The preparation method of the material comprises preparing a porous silicon substrate and a carbon coating layer. The silicon-carbon composite anode material for lithium ion batteries has the advantages of high reversible capacity, good cycle performance and good rate performance. The material respectively shows reversible capacities of 1,556 mAh, 1,290 mAh, 877 mAh and 474 mAh / g at 0.2 C, 1 C, 4 C and 15 C rates; the specific capacity remains above 1,500 mAh after 40 cycles at the rate of 0.2 C and the reversible capacity retention rate is up to 90 percent.

Owner:BOSCH CHINA INVESTMENT

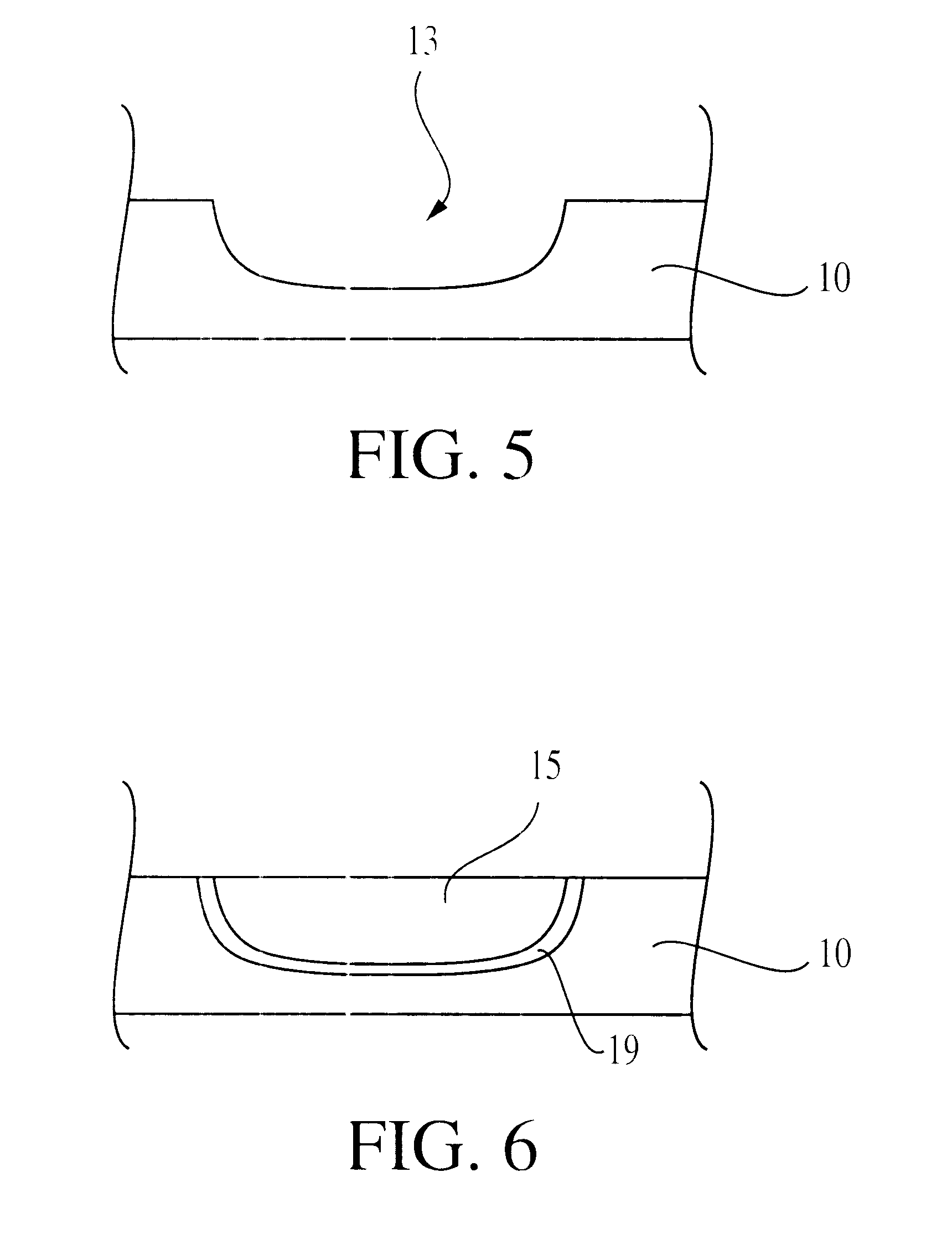

Method for making shallow trenches for isolation

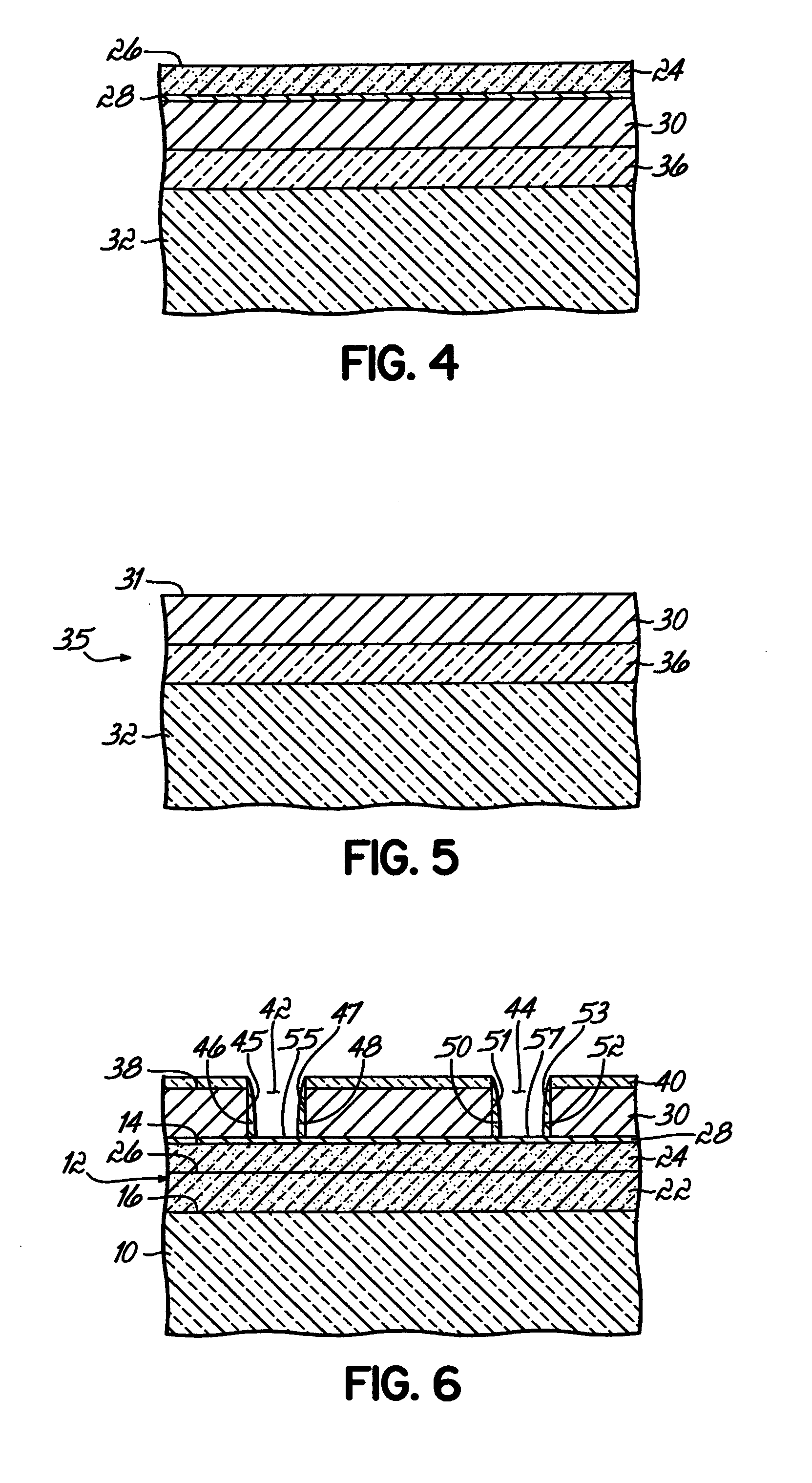

InactiveUS6437417B1Reduce mechanical stressSimple methodSemiconductor/solid-state device manufacturingSemiconductor devicesDielectricEngineering

An improved method for forming shallow trench isolation structures having reduced stress and allowing for greater control over shape, size and characteristics of the shallow trench isolation structures is disclosed. The isolation trench is defined by implanting a substrate through a patterned mask to create heavily doped regions. These heavily doped regions are anodized to form porous silicon and then oxidized. The oxidized porous silicon is removed, leaving behind a trench having rounded corners which is filled with an isolation dielectric.

Owner:APTINA IMAGING CORP

Method for preparing porous silicon/carbon composite material by using diatomite as raw material and application

The invention provides a method for preparing a porous silicon / carbon composite material by using diatomite as the raw material, which is characterized by comprising the following steps of: with the diatomite as the raw material, performing simple refinement and purification processing to obtain silicon with a porous structure by means of metallothermic reduction; performing mechanical ball-milling with the carbon materials and / or precursors of carbon, hydro-thermal carbonization, pyrolytic carbonization or chemical vapor deposition to prepare the porous silicon / carbon composite material. Thecomposite material can be directly used as the cathode of the lithium ion battery, or can be mixed with other cathode materials to be used as the cathode materials of the lithium ion battery. Compared with a pure silicon material as the cathode material of the lithium ion battery, the porous silicon / carbon composite material has the advantages that the first reversible capacity and the circulation stability of the material are greatly improved. In the method, the inexpensive and accessible natural minerals are used as the raw materials, thus the cost is low and the preparation method is simple.

Owner:UNIV OF SCI & TECH BEIJING

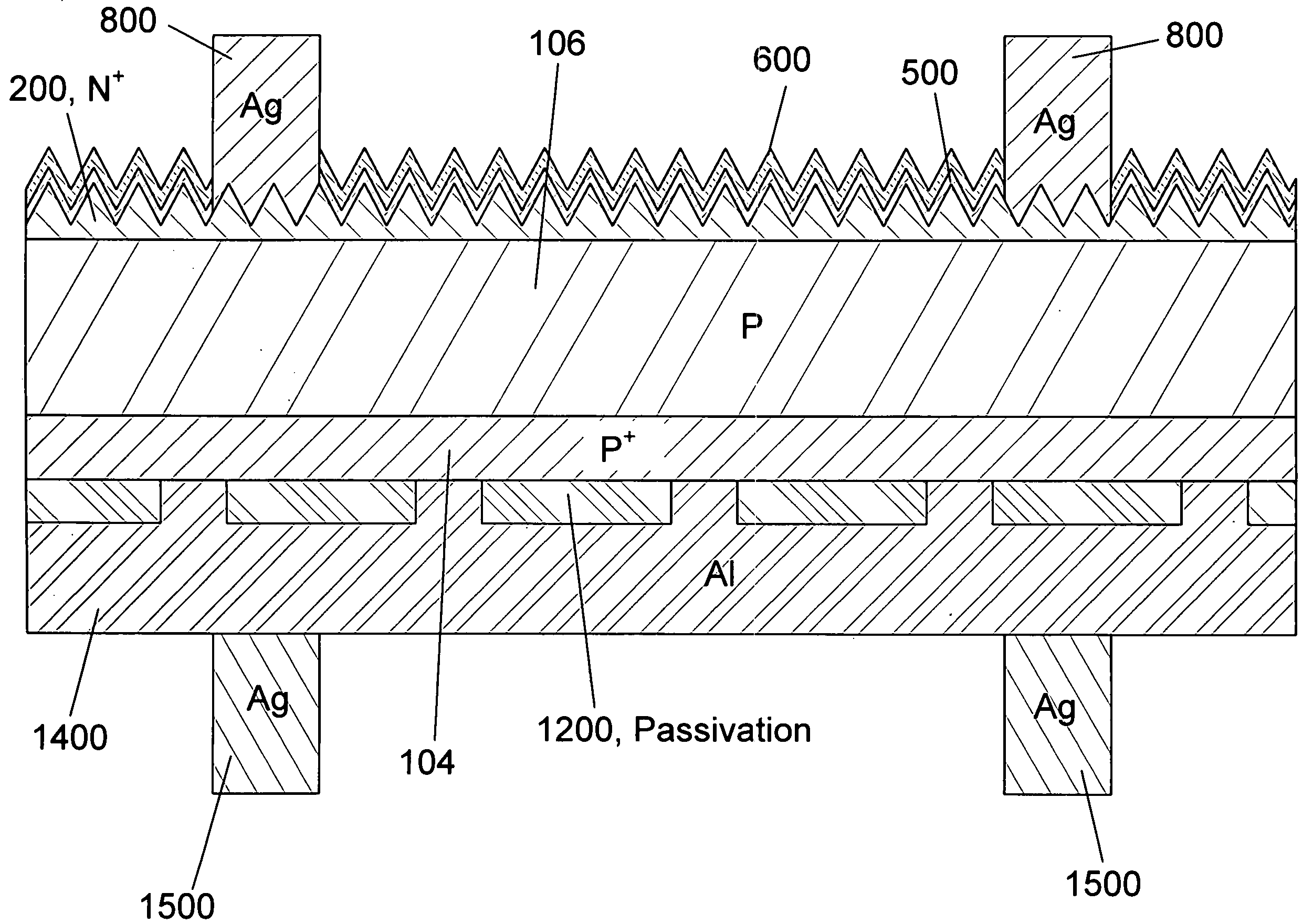

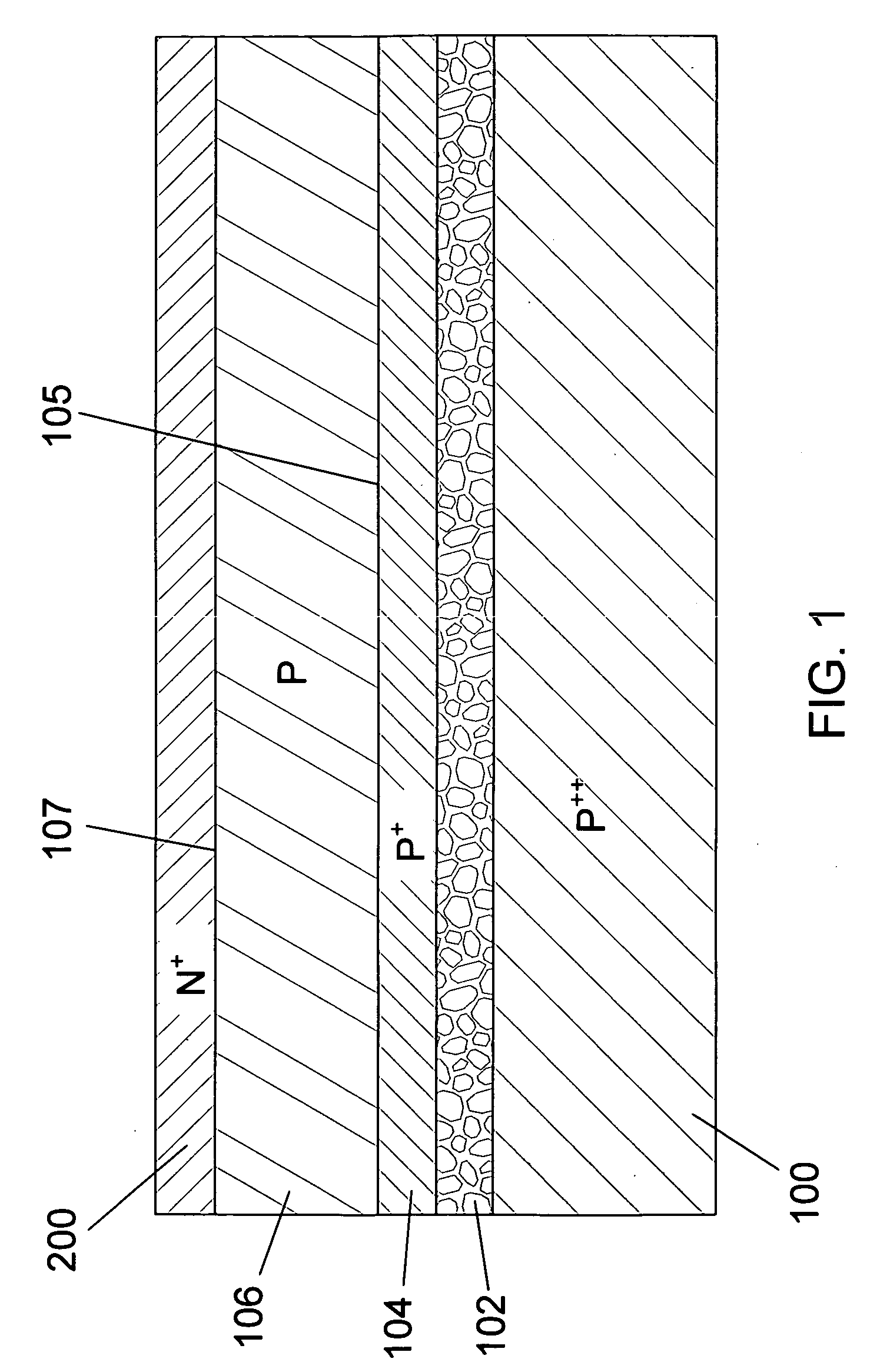

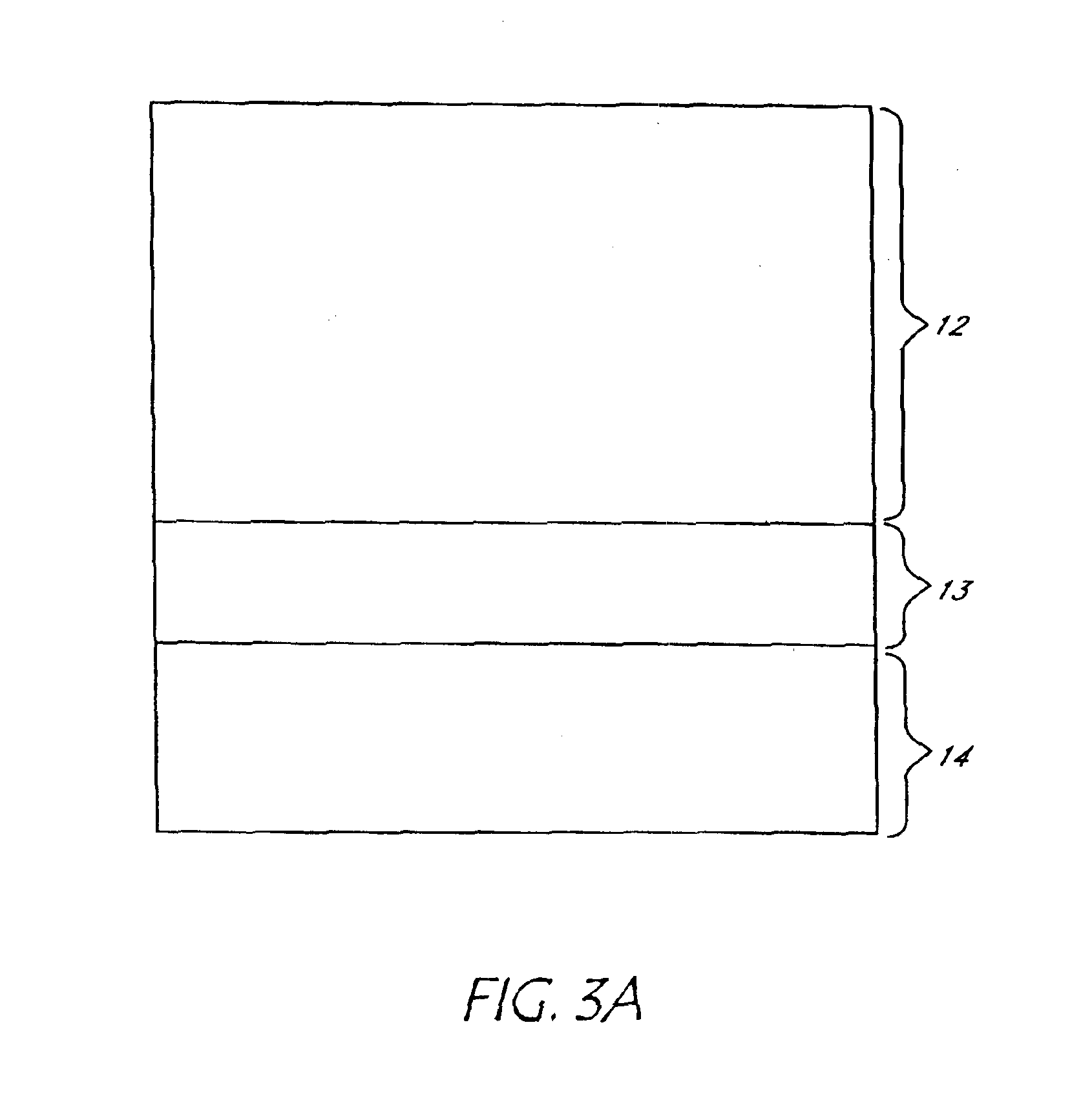

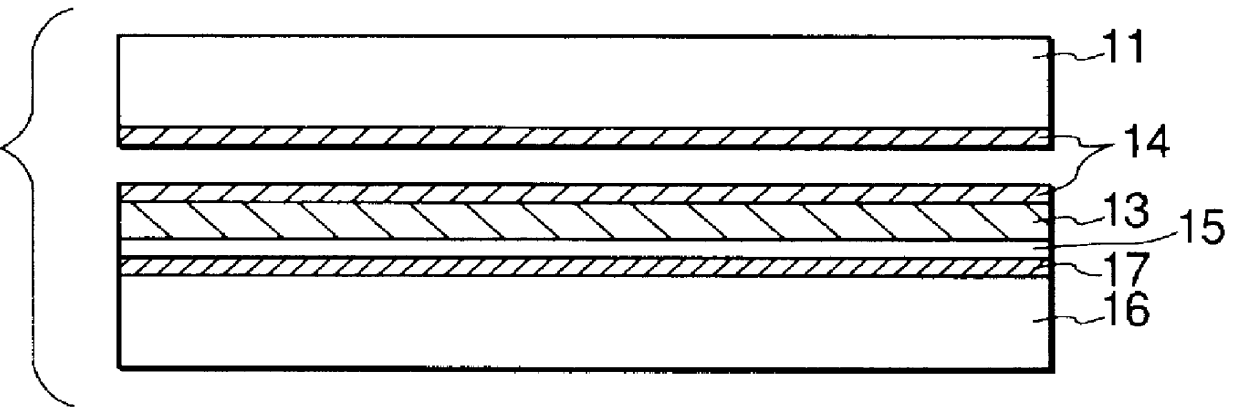

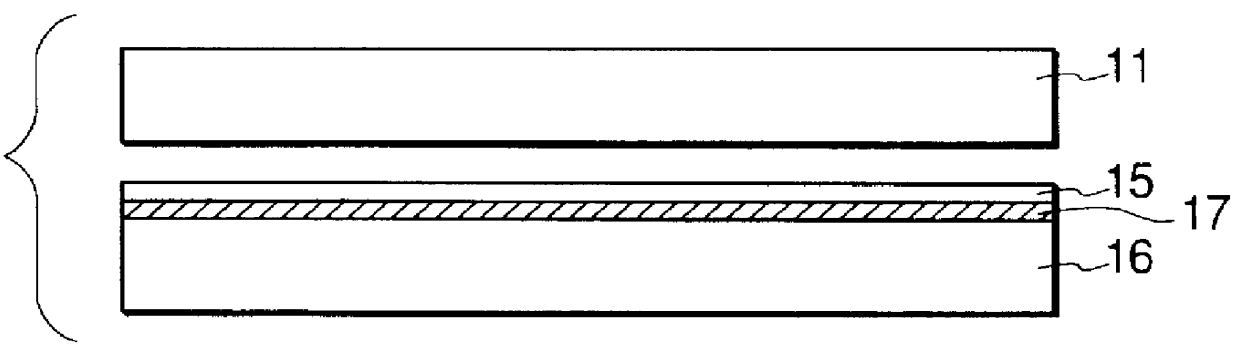

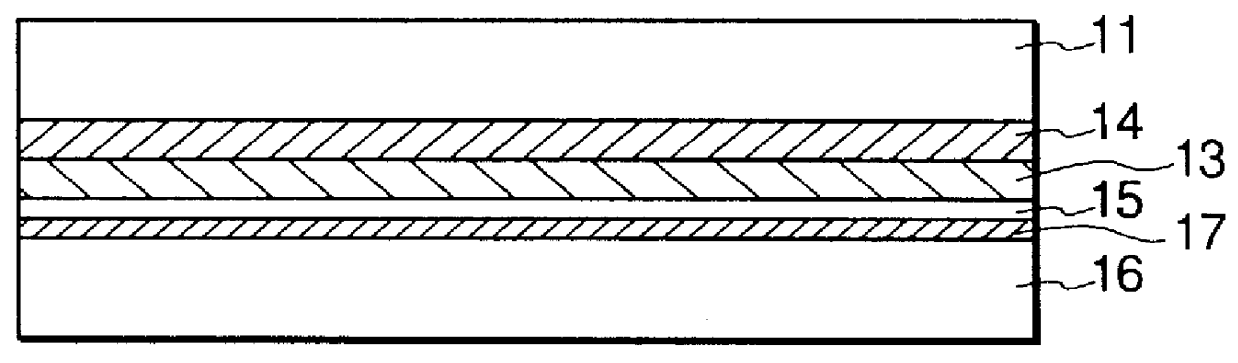

Thin two sided single crystal solar cell and manufacturing process thereof

InactiveUS20100108134A1High quality epitaxial growthImprove material qualitySemiconductor/solid-state device manufacturingPhotovoltaic energy generationAnti-reflective coatingPorous layer

A design and manufacturing method for a photovoltaic (PV) solar cell less than 100 μm thick are disclosed. A porous silicon layer is formed on a wafer substrate. Portions of the PV cell are then formed using diffusion, epitaxy and autodoping from the substrate. All front side processing of the solar cell (junctions, passivation layer, anti-reflective coating, contacts to the N+-type layer) is performed while the thin epitaxial layer is attached to the porous layer and substrate. The wafer is then clamped and exfoliated. The back side of the PV cell is completed from the region of the wafer near the exfoliation fracture layer, with subsequent removal of the porous layer, passivation, patterning of contacts, deposition of a conductive coating, and contacts to the P+-type layer. During manufacturing, the cell is always supported by either the bulk wafer or a wafer chuck, with no processing of bare thin PV cell

Owner:CRYSTAL SOLAR INC

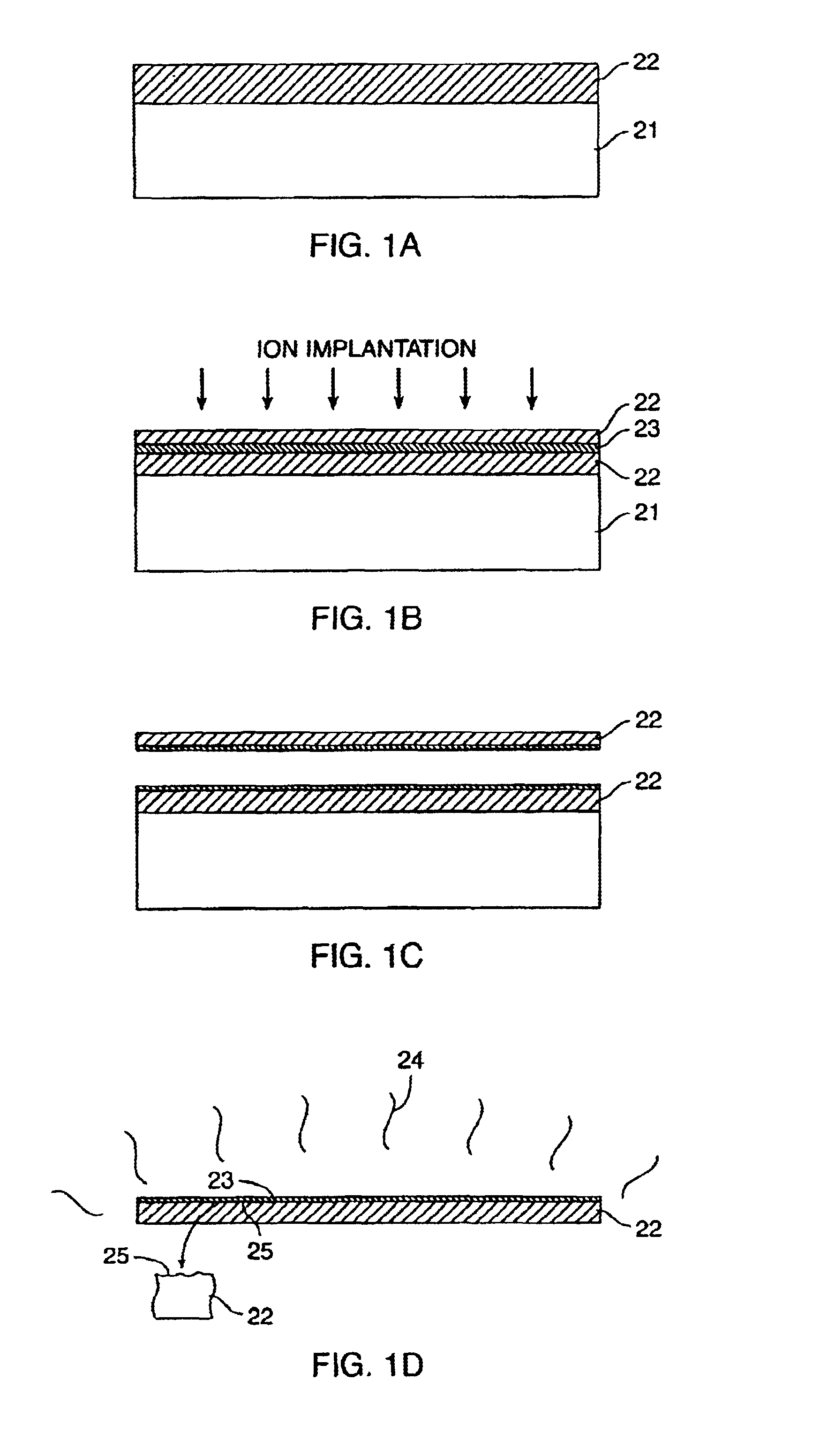

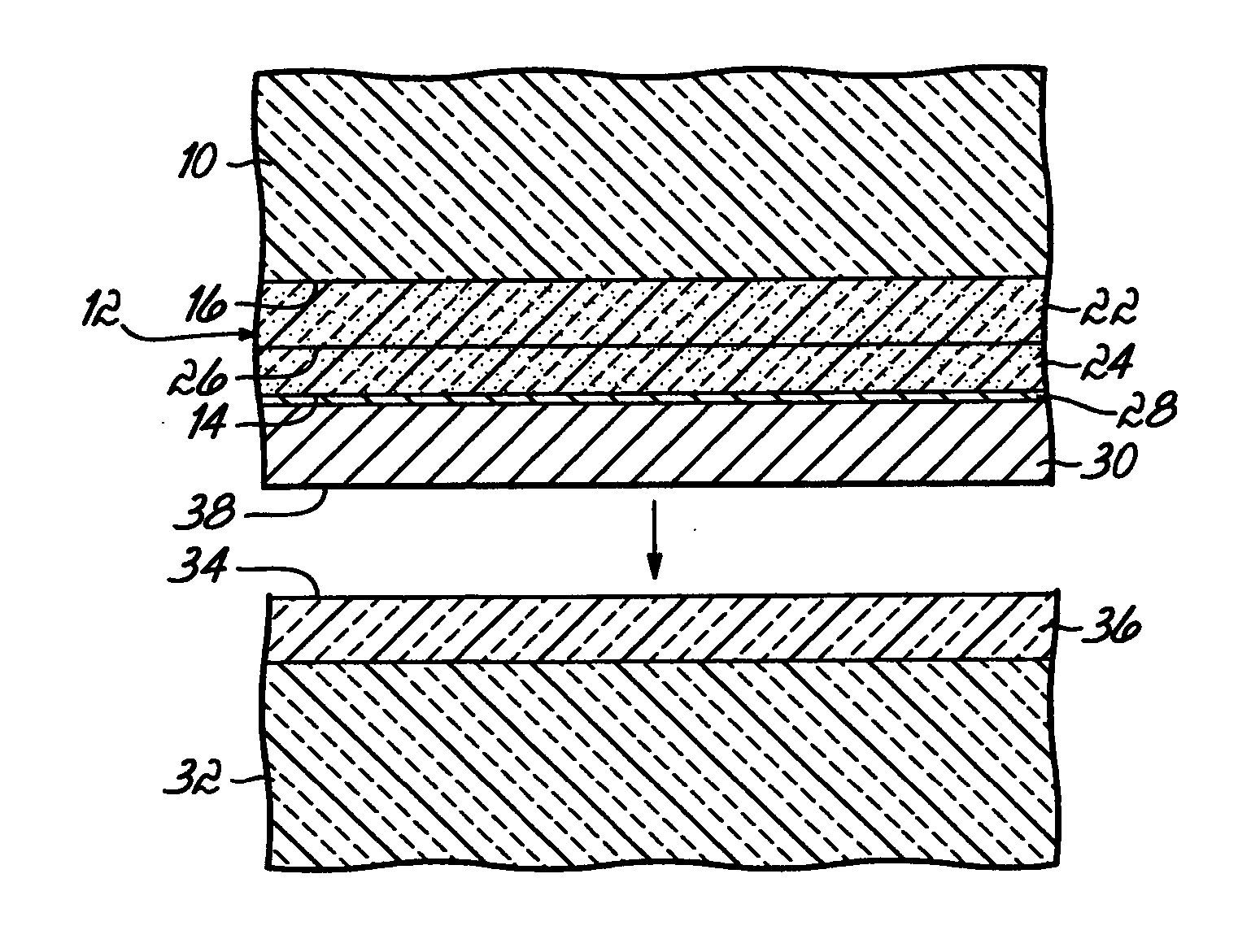

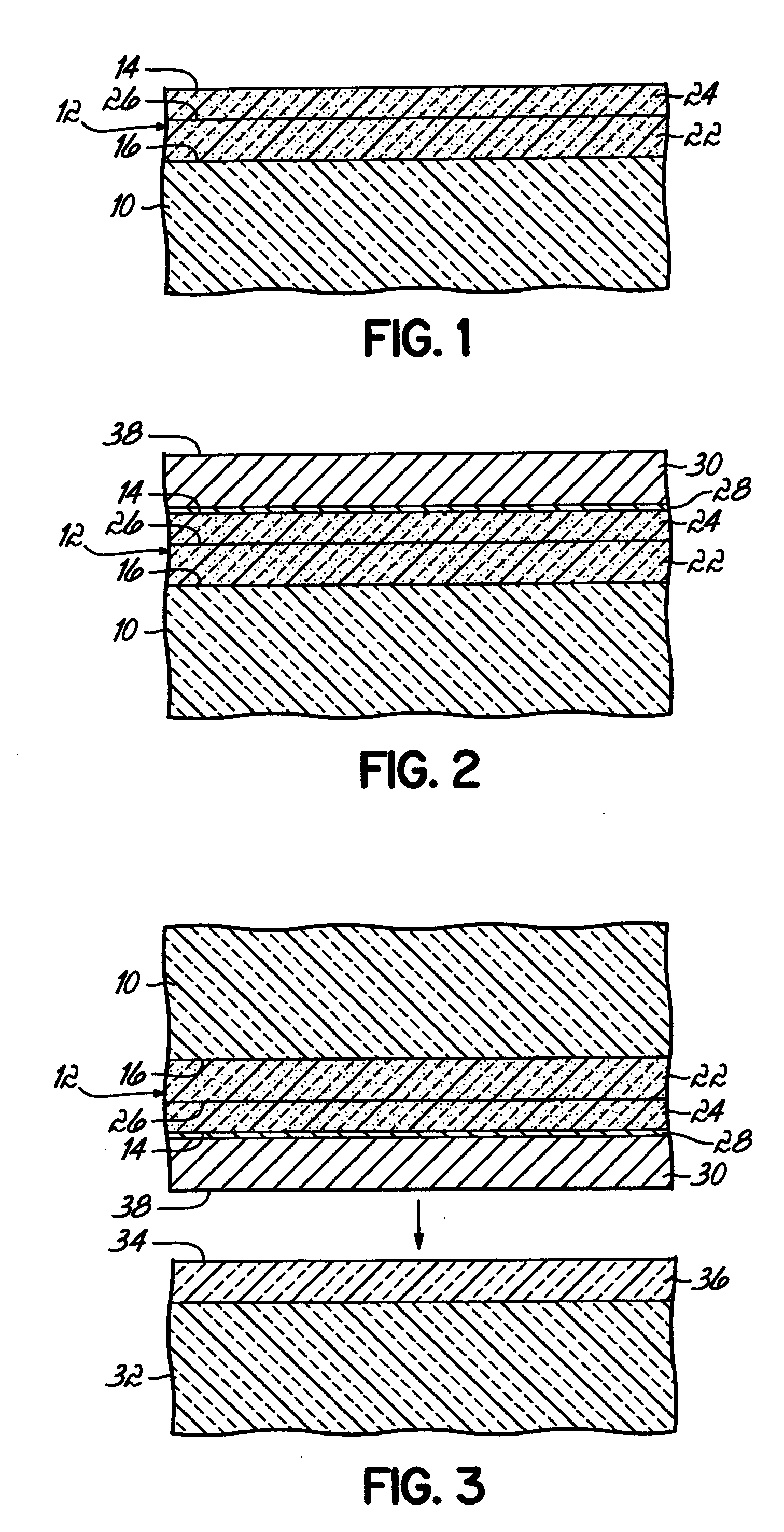

Smoothing method for cleaved films made using a release layer

InactiveUS6881644B2Improve crystal structureReduce defectsPaper/cardboard articlesDecorative surface effectsPorous siliconMaterials science

A method for treating a film of material, which can be defined on a substrate, e.g., silicon. The method includes providing a substrate comprising a cleaved surface, which had a porous silicon layer thereon. The substrate may have a distribution of hydrogen bearing particles defined from the cleaved surface to a region underlying said cleaved surface. The method also includes increasing a temperature of the cleaved surface to greater than about 1,000 Degrees Celsius while maintaining the cleaved surface in a etchant bearing environment to reduce a surface roughness value by about fifty percent and greater. Preferably, the value can be reduced by about eighty or ninety percent and greater, depending upon the embodiment.

Owner:SILICON GENERAL CORPORATION

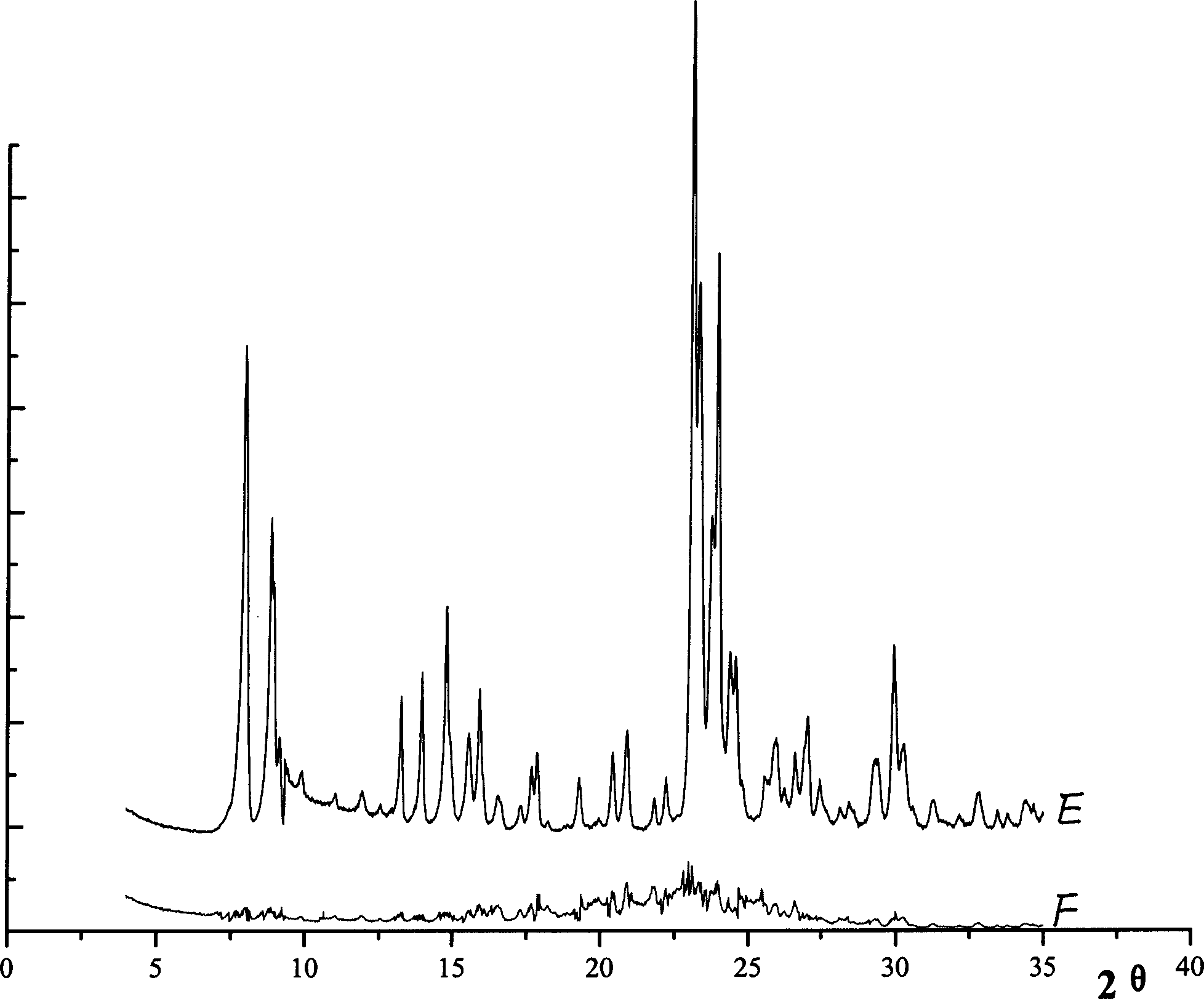

Porous silicon/carbon composite material and preparation method thereof

ActiveCN102208634AHigh specific capacityImprove cycle stabilityCell electrodesCarbon compositesNew energy

The invention discloses a porous silicon / carbon composite material and a preparation method thereof, and belongs to the fields of electrochemistry and new energy materials. The method comprises the following steps of: preparing porous silicon dioxide by using ethyl orthosilicate, silicon tetrachloride, methyl silicone oil and sodium silicide as raw materials, reducing the porous silicon dioxide into porous silicon, coating the porous silicon by adopting an organic carbon source, and performing thermal treatment under an inert atmosphere to prepare the porous silicon / carbon composite material. The material can be directly used as the lithium ion battery cathode material, the first discharge specific capacity of the material can reach 1,245mAh / g, the specific capacity can also reach 1,230mAh / g after 30 cycles, and the material has excellent charge / discharge performance.

Owner:SUZHOU QINGTAO NEW ENERGY TECH CO LTD

Metal aromatic hydrosaturation catalyst

InactiveCN1510112AImprove performanceGood preparation and operabilityRefining by aromatic hydrocarbon hydrogenationHigh resistanceSulfur

A metal-type catalyst for hydrosaturating arylhydrocarbon is composed of the carrier containing porous silicon oxide-aluminium oxide and the hydrogenating active components. Said porous silicon oxide-aluminium oxide has the crystal type chosen from gamma, etc, theta, delta and X ones of aluminium oxide. Its advantages are easy preparing, high resistance to sulfur, and high hydrogenating activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Methods for forming germanium-on-insulator semiconductor structures using a porous layer and semiconductor structures formed by these methods

InactiveUS20070093036A1Minimize nucleationRelaxation stressSemiconductor/solid-state device manufacturingSemiconductor devicesPorous layerSemiconductor structure

A semiconductor structure that includes a monocrystalline germanium-containing layer, preferably substantially pure germanium, a substrate, and a buried insulator layer separating the germanium-containing layer from the substrate. A porous layer, which may be porous silicon, is formed on a substrate and a germanium-containing layer is formed on the porous silicon layer. The porous layer may be converted to a layer of oxide, which provides the buried insulator layer. Alternatively, the germanium-containing layer may be transferred from the porous layer to an insulating layer on another substrate. After the transfer, the insulating layer is buried between the latter substrate and the germanium-containing layer.

Owner:GLOBALFOUNDRIES INC

Implants for administering substances and methods of producing implants

InactiveUS7763277B1Ensure safetyPowder deliveryHydrocarbon active ingredientsAdministered substanceControl manner

A porous silicon implant (42; 60) impregnated with a beneficial substance, such as a micromineral required for healthy physiology, is implanted subcutaneously and is entirely corroded away over the following months / year to release the micromineral in a controlled manner. In a second embodiment the implant (62) may have a large number of holes (72) which contain beneficial substance and which are closed by bio-errodable doors (76, 78) of different thickness so as to stagger the release of the beneficial substance over time as the doors are breached.

Owner:PSIMEDICA

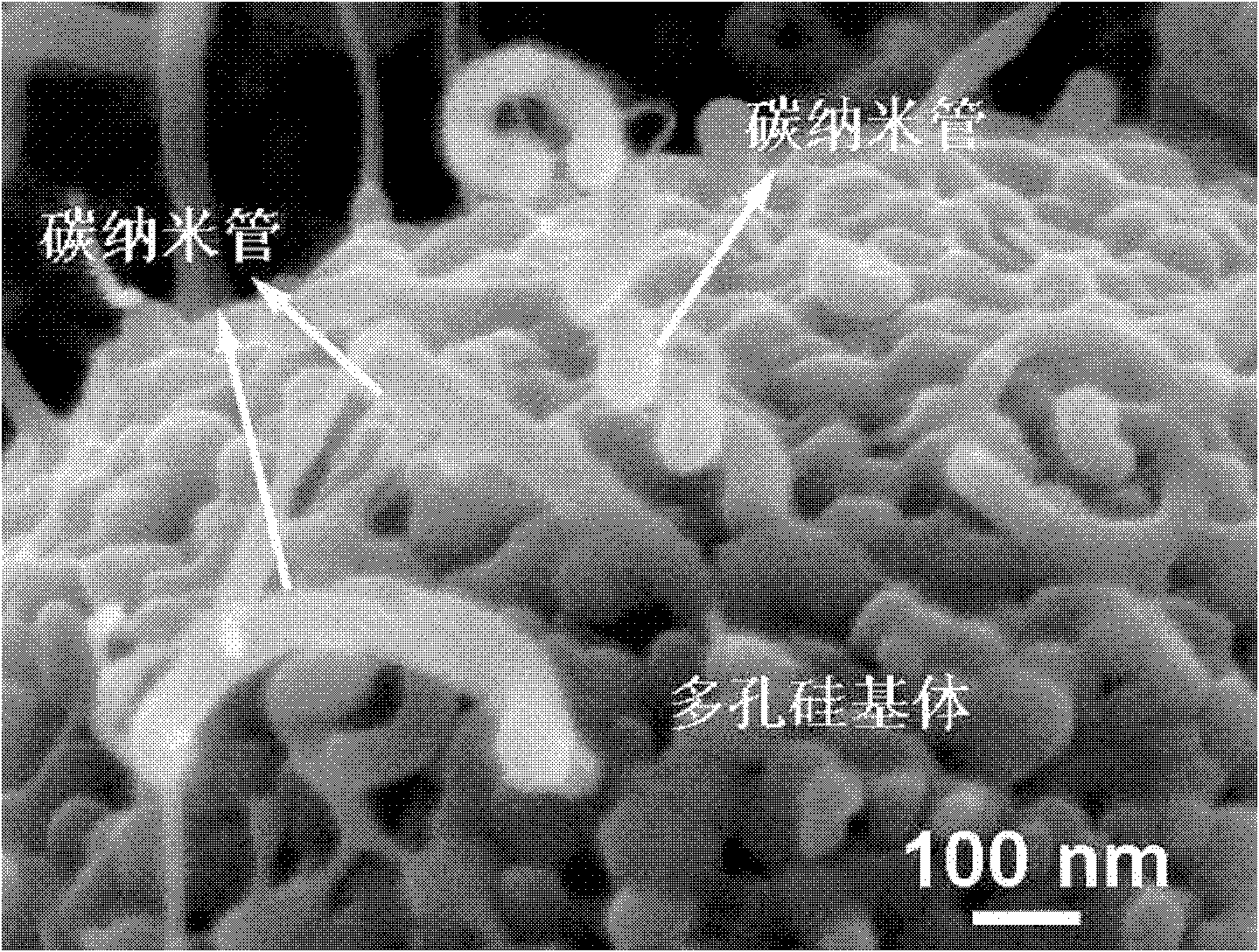

Silicon carbon composite material and preparation method thereof

ActiveCN102185128AIncrease productivityReduce manufacturing costCell electrodesFiberCarbon composites

The invention discloses a silicon carbon composite material and a preparation method thereof. The material disclosed by the invention comprises a porous silicon substrate, a one-dimensional carbon nano material and amorphous carbon, wherein the one-dimensional carbon nano material is a carbon nano tube or carbon nano fiber. The preparation method disclosed by the invention comprises the following steps: preparing the porous silicon substrate; loading a catalyst precursor; and carrying out the chemical vapor deposition. The one-dimensional carbon nano material directly grows on the porous silicon substrate, and the one-dimensional carbon nano material and the porous silicon substrate are coated with the amorphous carbon. The silicon carbon composite material provided by the invention is suitable for the cathode material of a lithium ion battery, and has the advantages of high capacity and stable circulation performance. A constant-current charge and discharge test is carried out under the 300mA / g current density, and the silicon carbon composite material disclosed by the invention has the characteristics that the first reversible capacity is 1149mAh / g; the reversible capacity is 1087mAh / g after the circulation is carried out for 100 times; and the capacity conservation rate is up to 95%.

Owner:DONGGUAN KAIJIN NEW ENERGY TECH

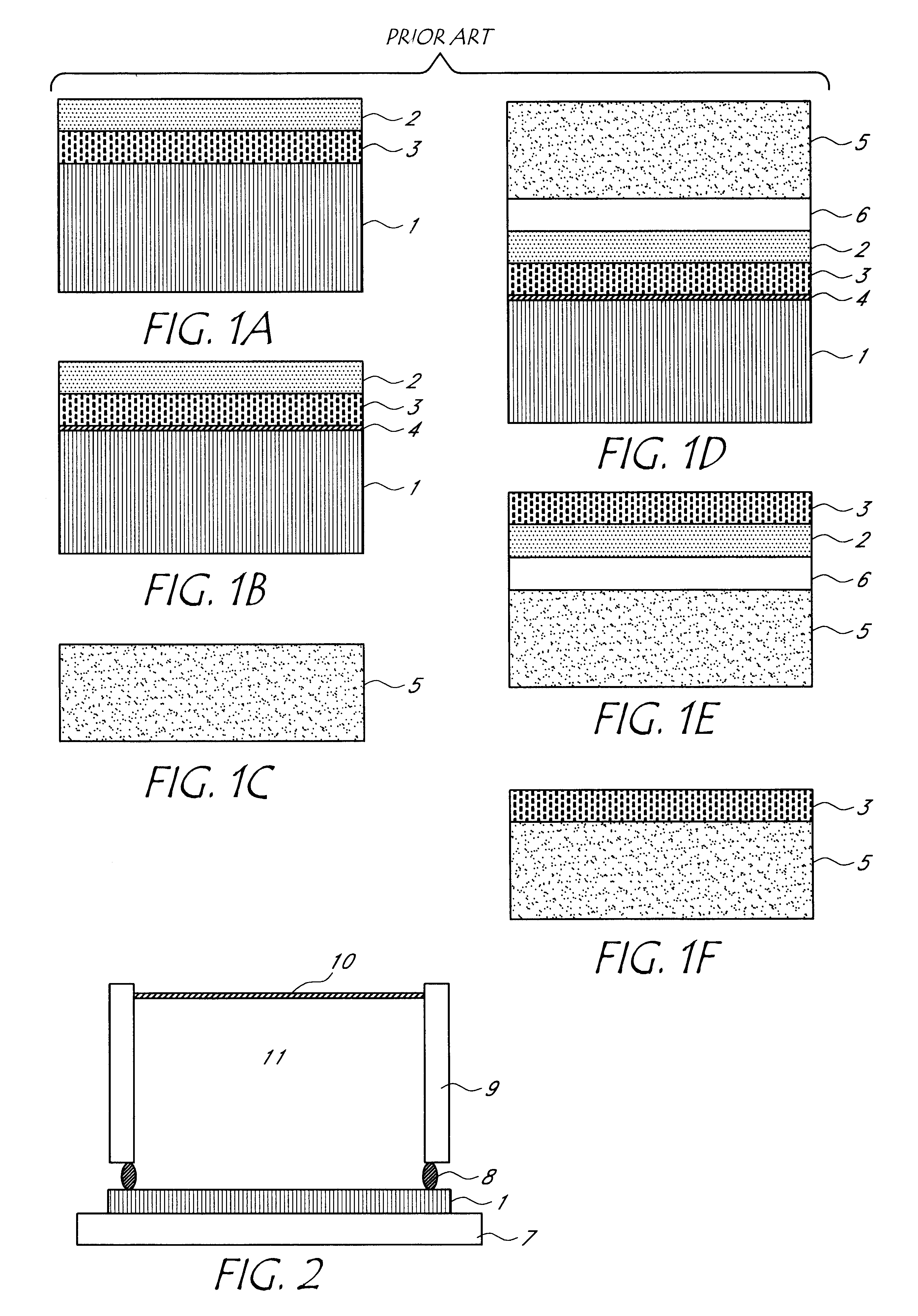

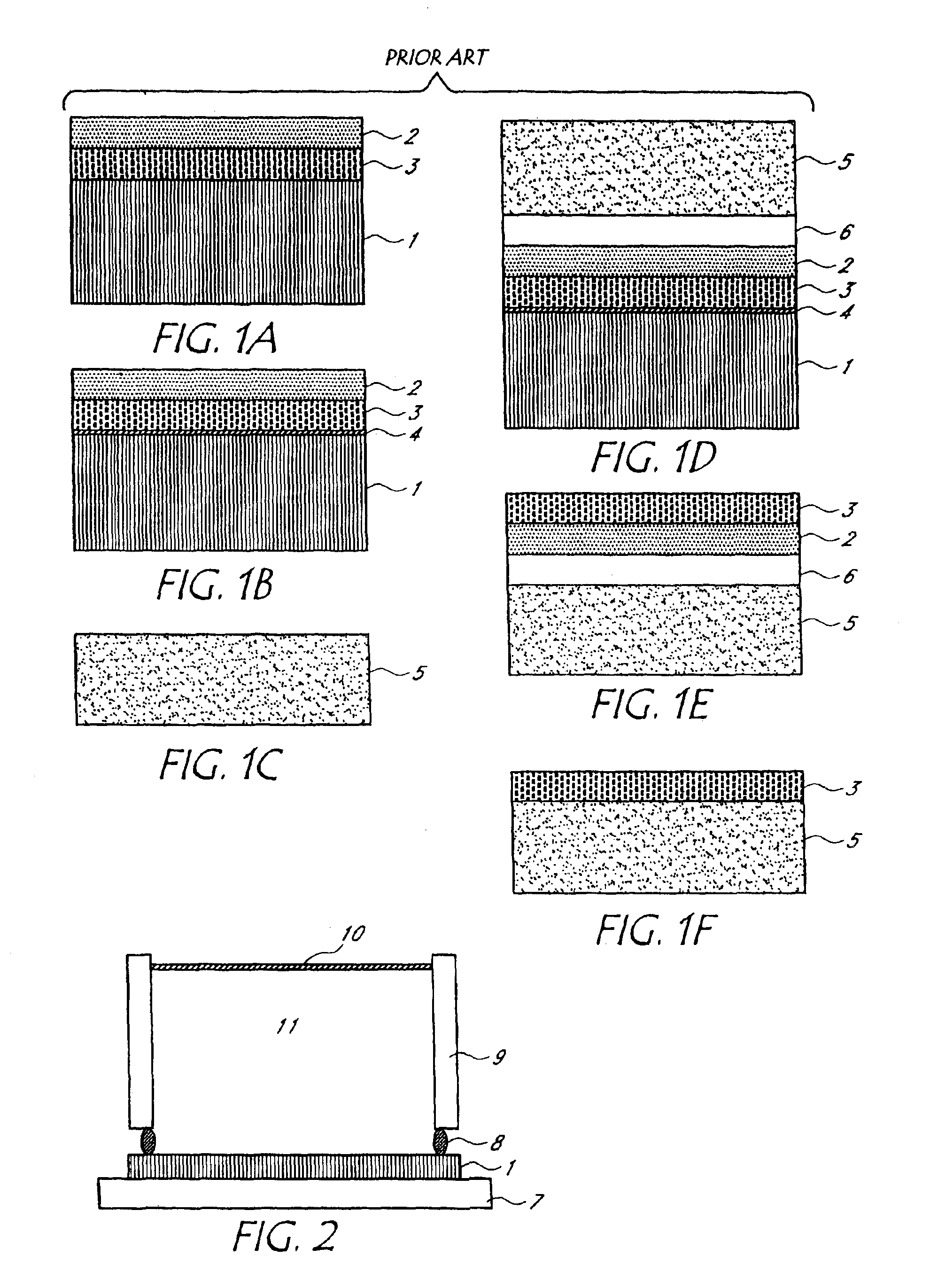

Method for the formation and lift-off of porous silicon layers

InactiveUS6649485B2Easy to controlIncreasing the thicknessSemiconductor/solid-state device manufacturingSemiconductor devicesPorous layerOptoelectronics

A method for the manufacture, formation, and removal of porous layers in a semiconductor substrate having at least a surface acting as a cathode. The method comprises applying a solution comprising negative Fluorine (F<->) ions between the surface of the semiconductor substrate and an anode. The method further comprises applying a predetermined current between the anode and the cathode. The method further comprises maintaining the predetermined current at substantially the same current value for a sufficient amount of time to obtain a low porosity layer at said surface. A high porosity layer positioned under the low porosity layer is also obtained by the method of the invention.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW)

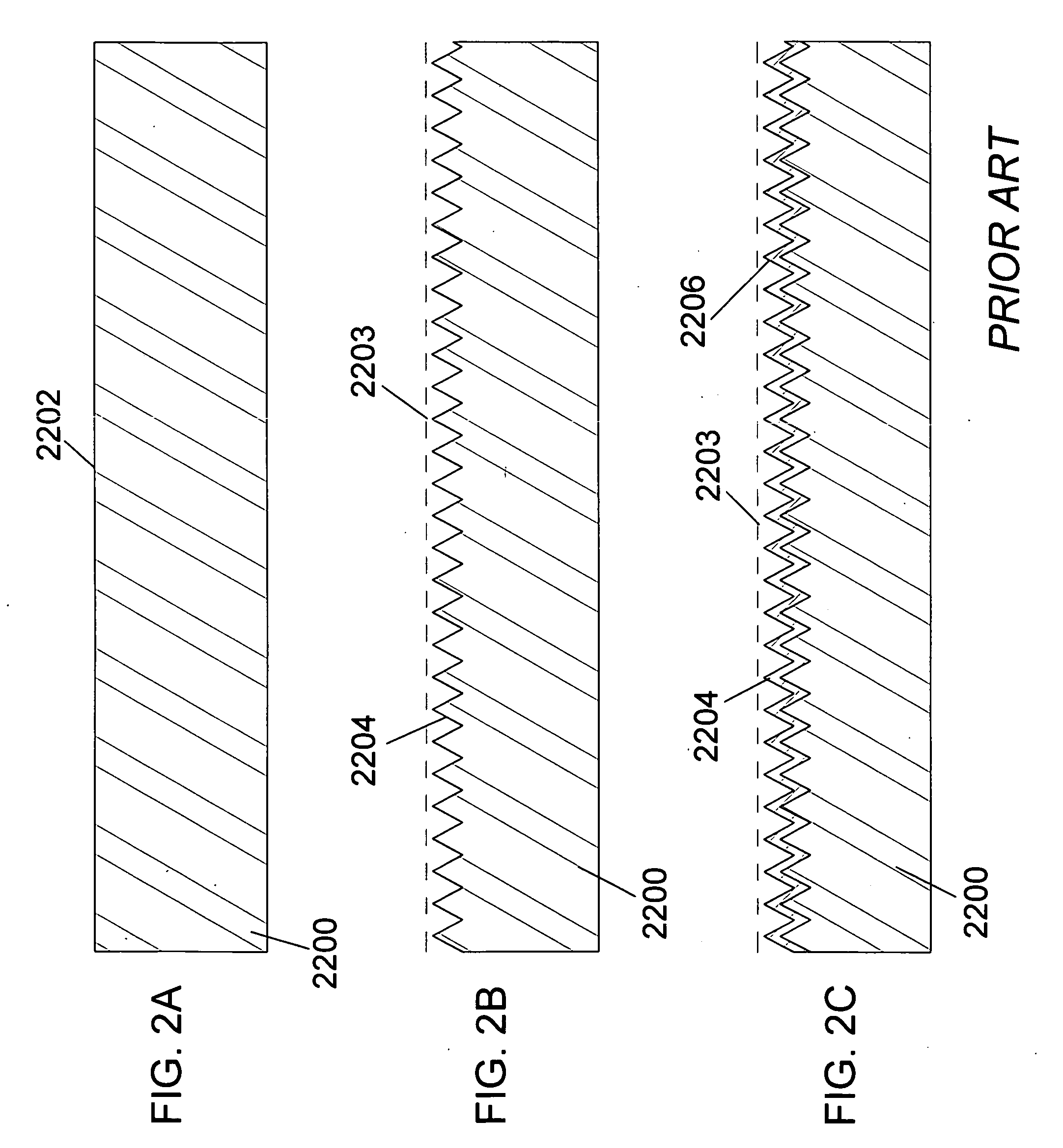

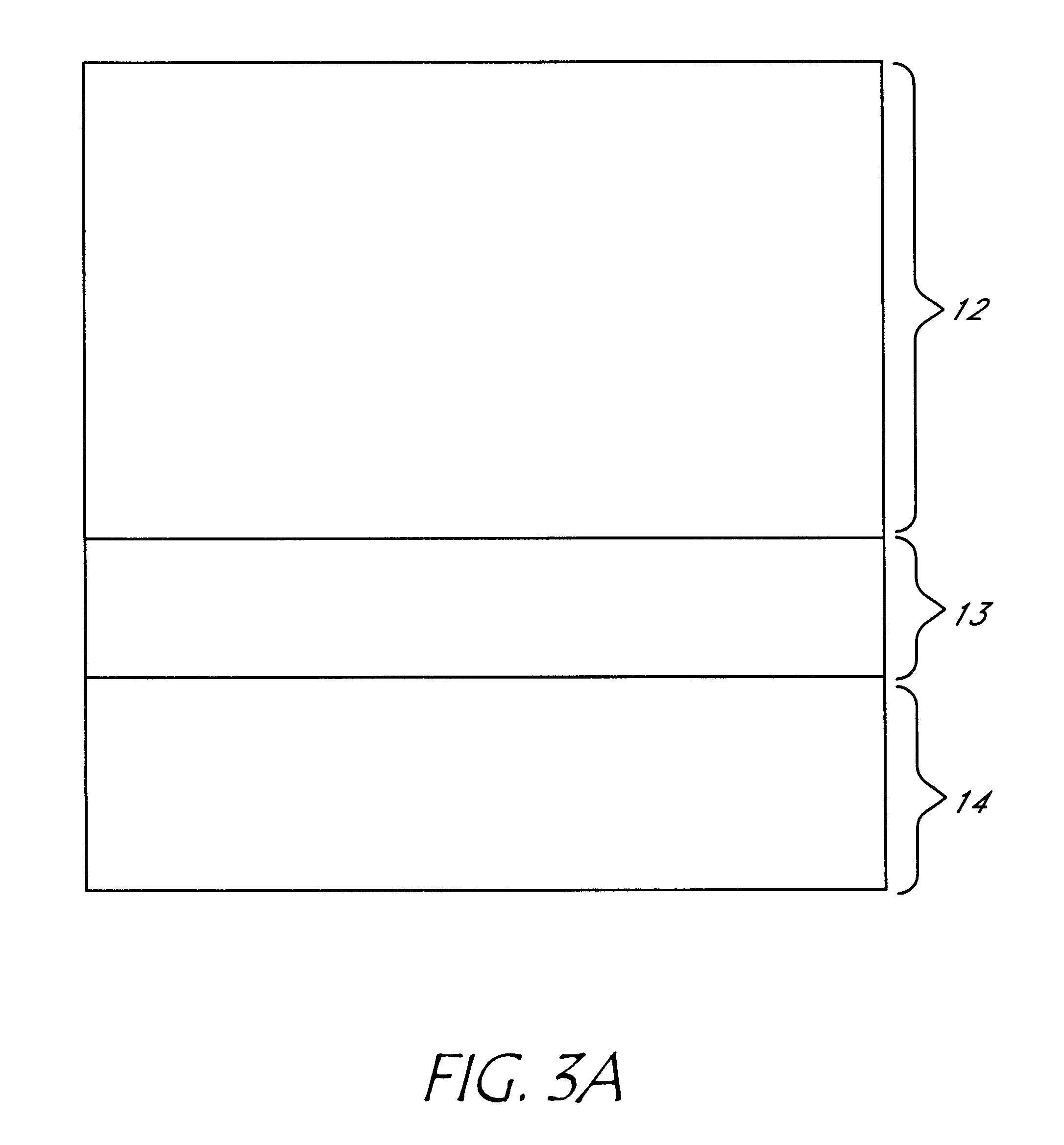

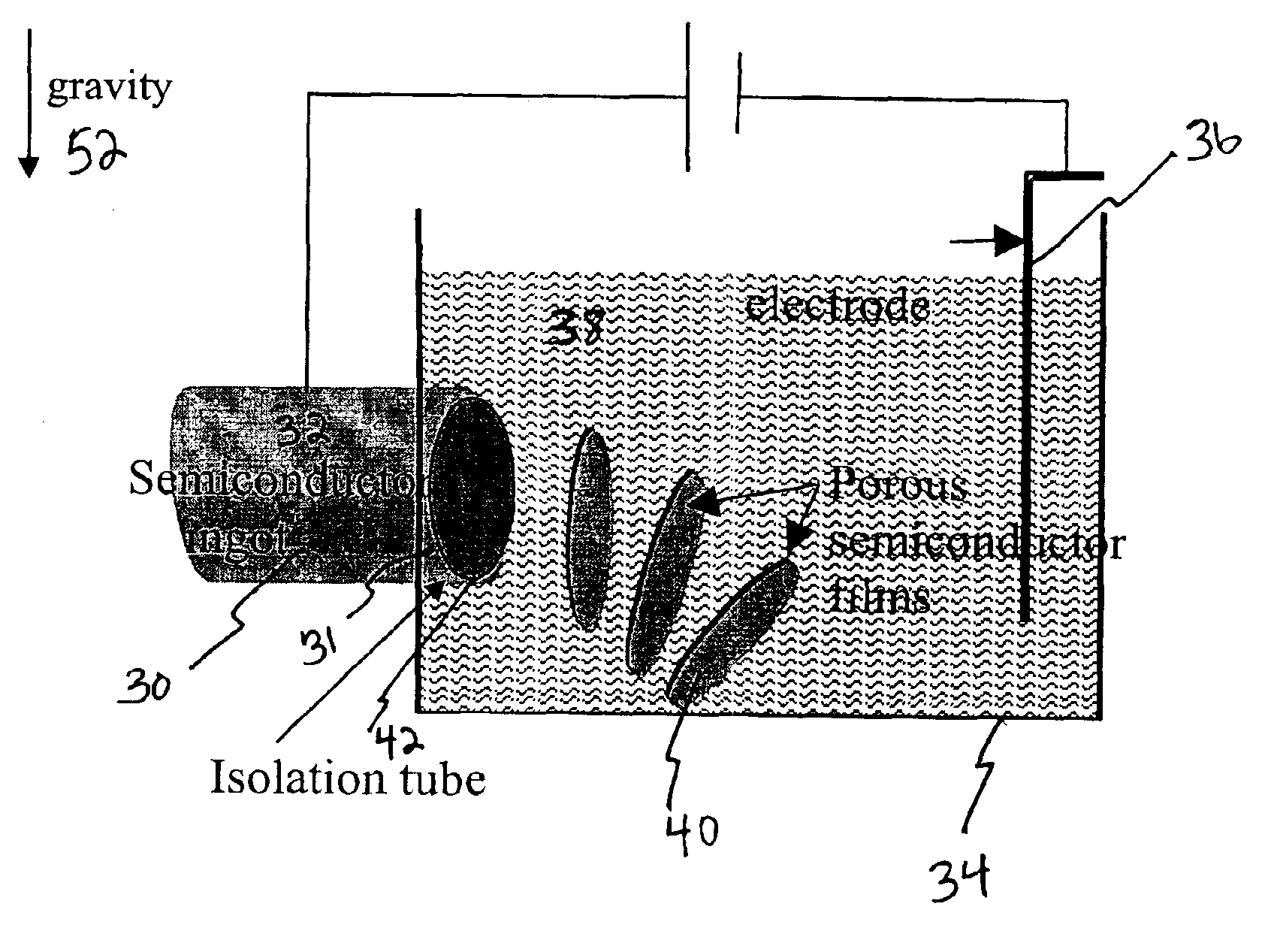

Method and apparatus for continuous formation and lift-off of porous silicon layers

A method and apparatus for slicing a semiconductor substrate. In one embodiment, the invention allows repetitive etching of a surface of the semiconductor substrate with a time dependent concentration of fluorine ions and a time dependent current I, such that multiple porous layers are obtained. The porous layer is released, and the released porous layer is removed from the surface of the substrate. The surface roughness of the porous layer is maintained within an acceptable or desired level of roughness value. The invention also provides an apparatus including a container having an etching solution. The semiconductor substrate may be protected by a tube covering at least a potion of said semiconductor substrate from said etching solution. The rate of insertion of said semiconductor substrate into the container is controlled to synchronize the lift-off with the insertion of the correct thickness of the semiconductor substrate. The anodising current is provided between two electrodes during operation.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW)

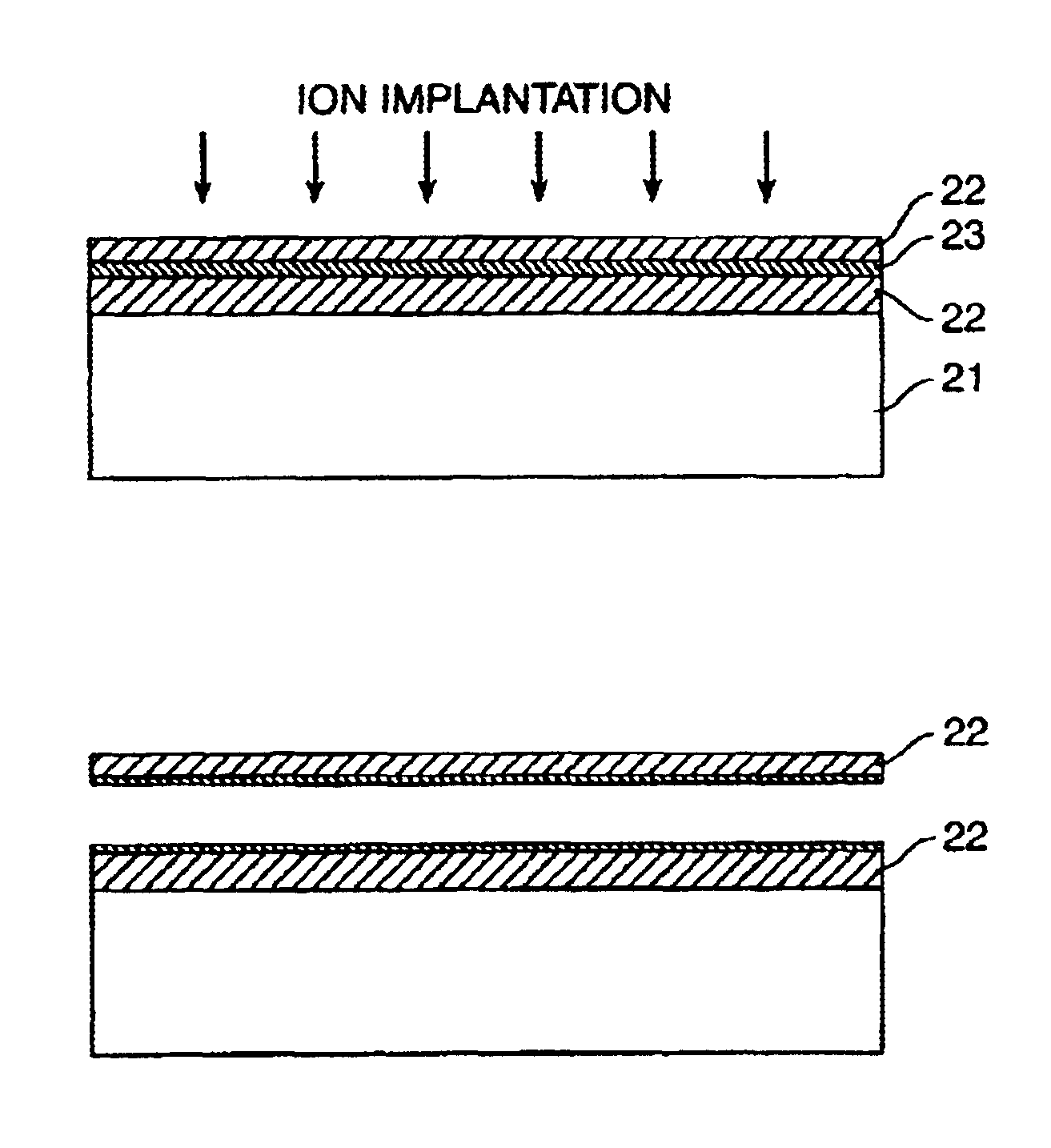

Method of manufacturing semiconductor article

InactiveUS6100165AExpensive to replaceLess costlySolid-state devicesSemiconductor/solid-state device manufacturingPorous siliconConduction type

A method of manufacturing a semiconductor article comprises steps of forming a diffusion region at least on the surface of one of the sides of a silicon substrate by diffusing an element capable of controlling the conduction type, forming a porous silicon layer in a region including the diffusion region, preparing a first substrate by forming a nonporous semiconductor layer on the porous silicon layer, bonding the first substrate and a second substrate together to produce a multilayer structure with the nonporous semiconductor layer located inside, splitting the multilayer structure along the porous silicon layer but not along the diffusion region and removing the porous silicon layer remaining on the split second substrate.

Owner:CANON KK

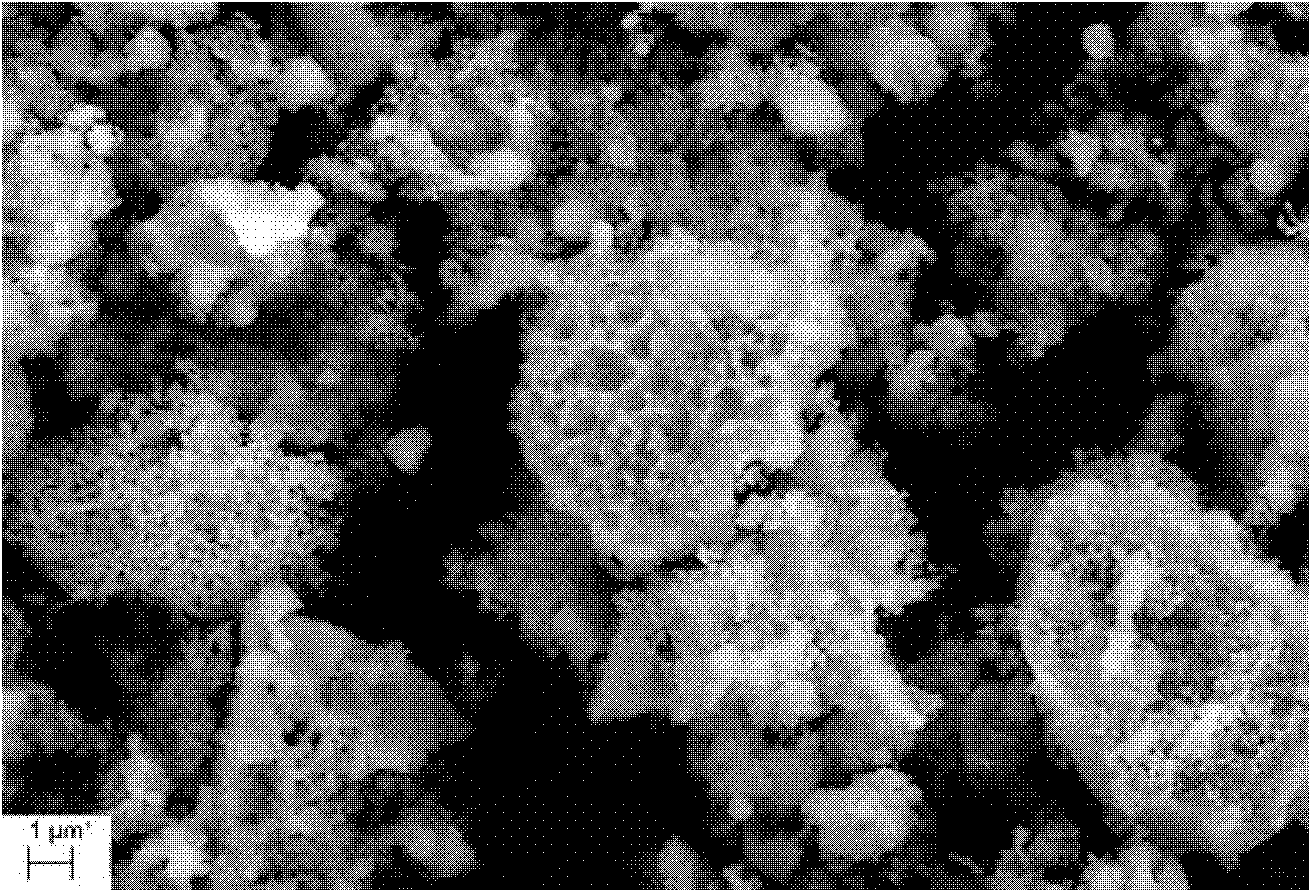

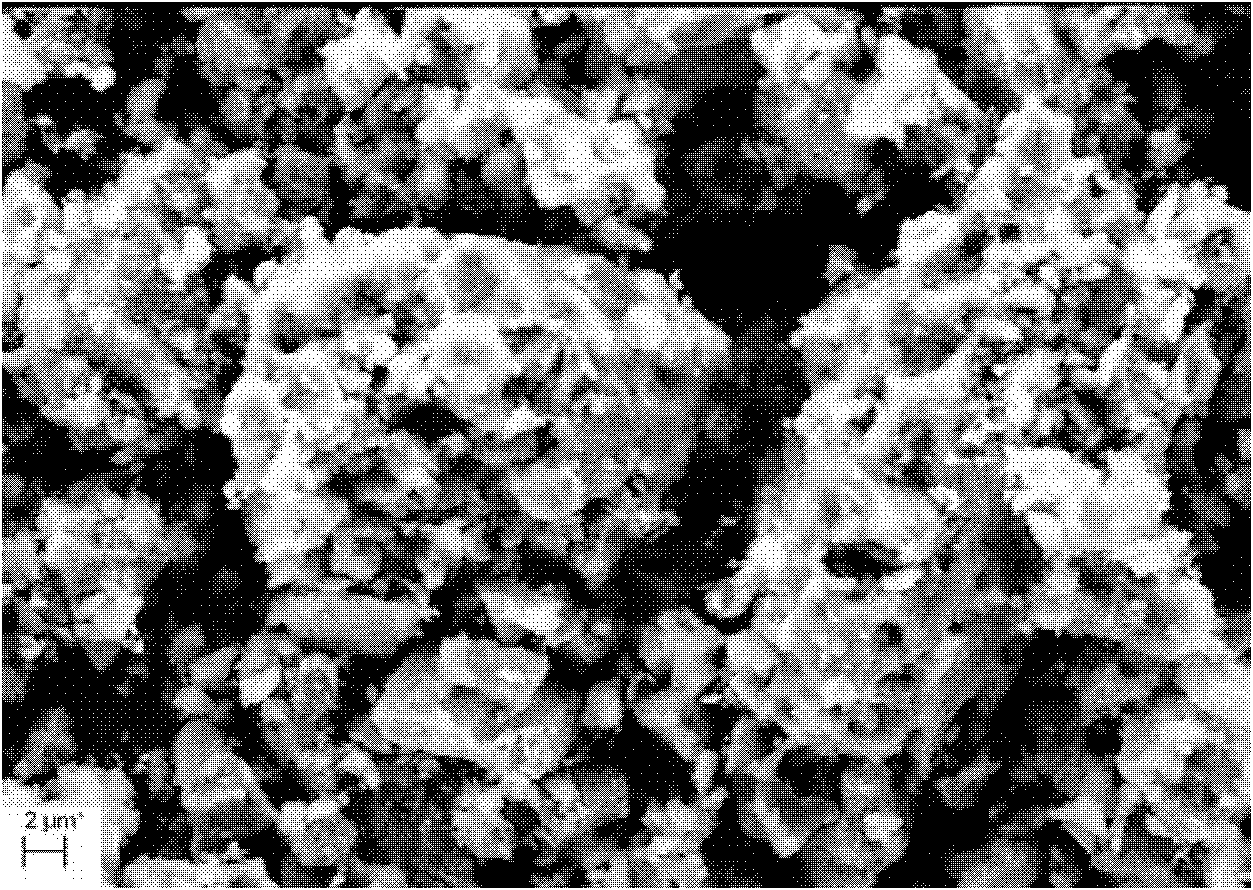

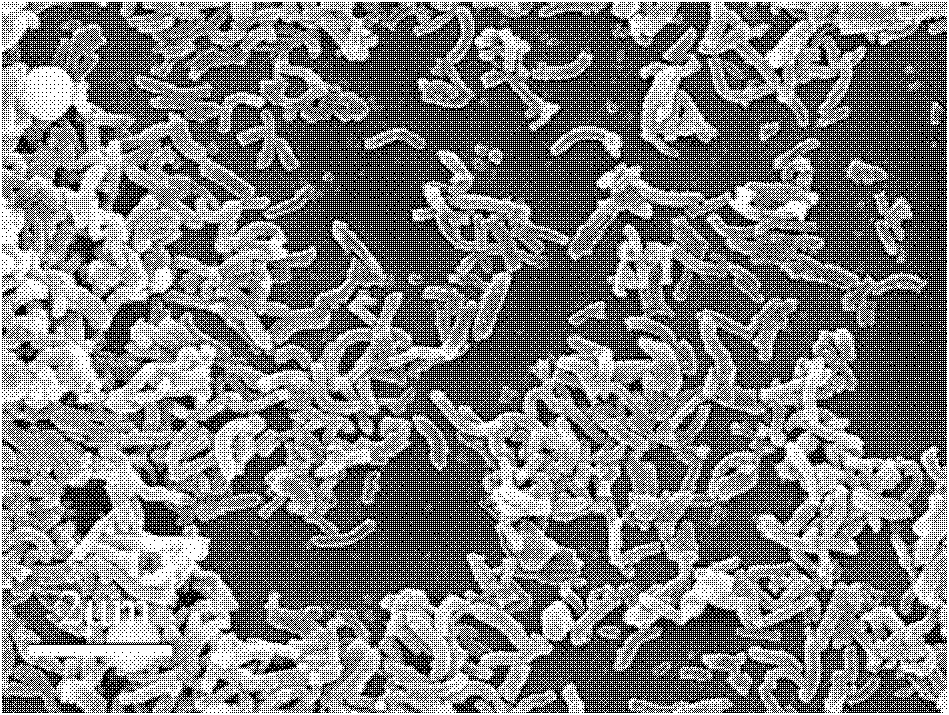

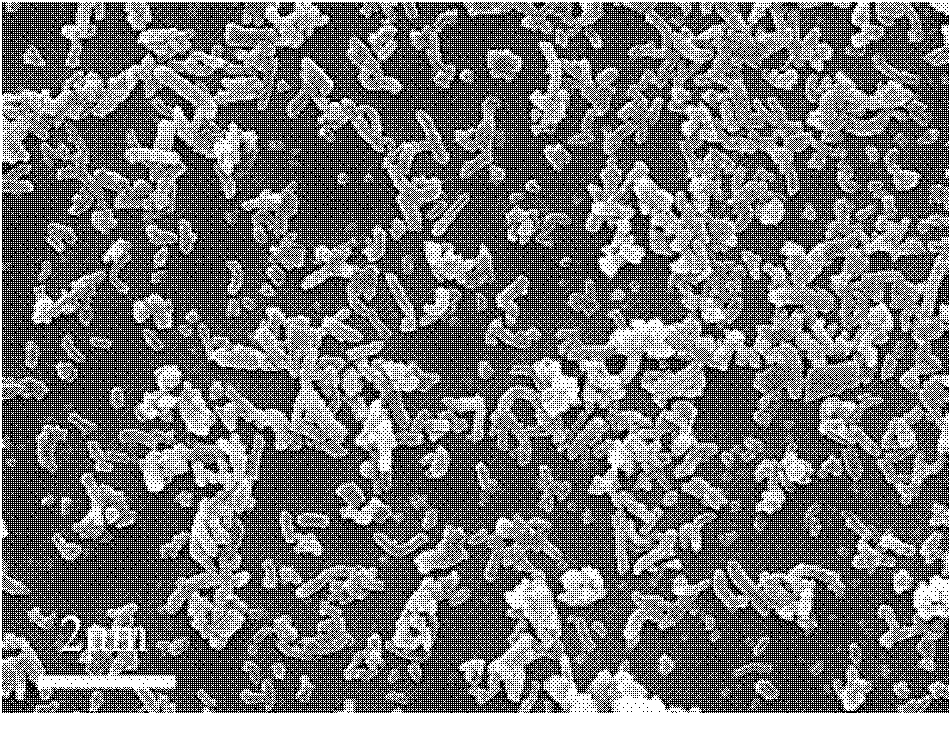

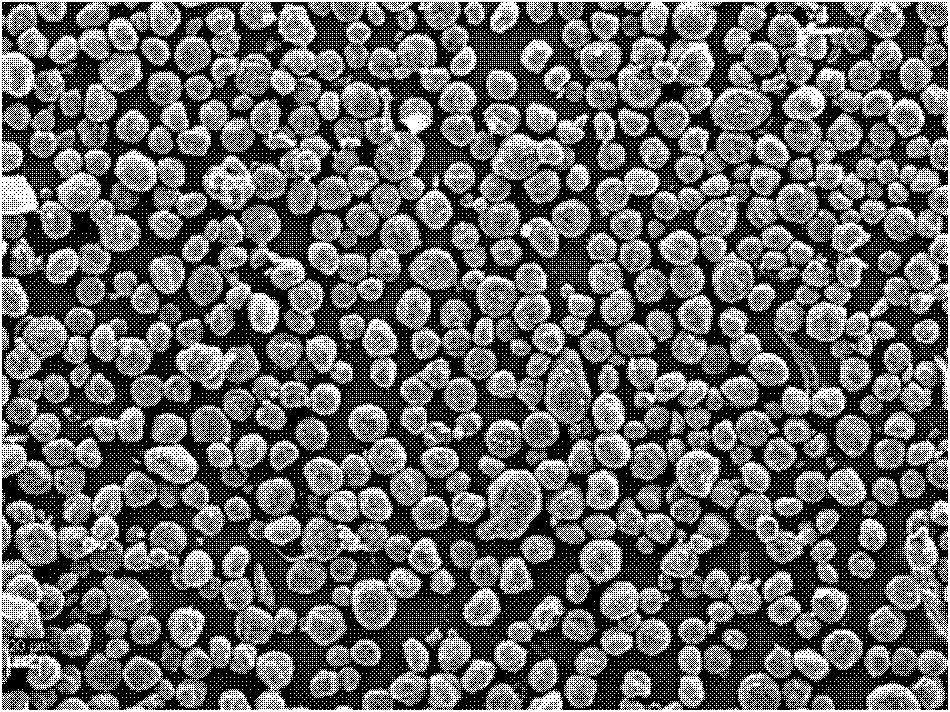

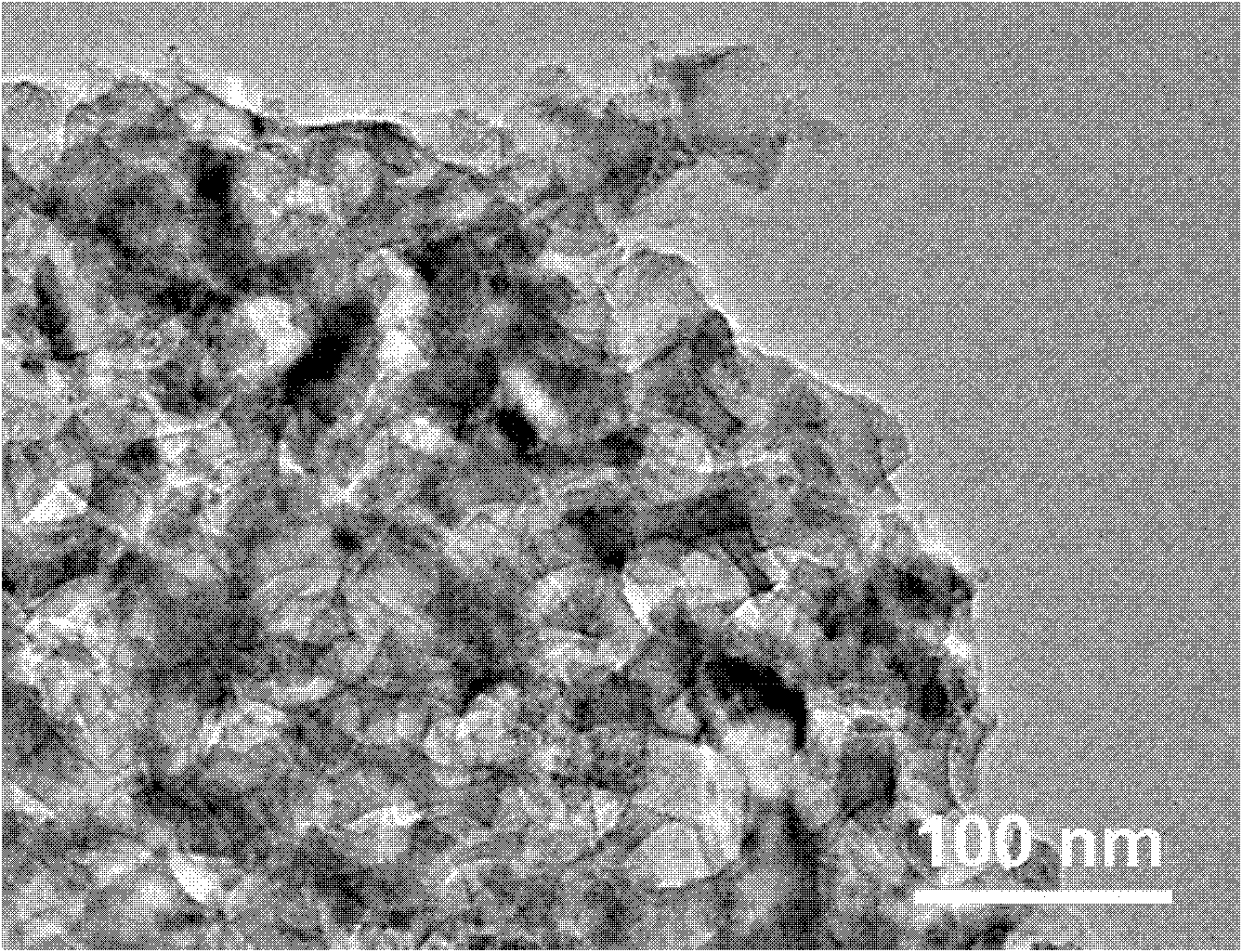

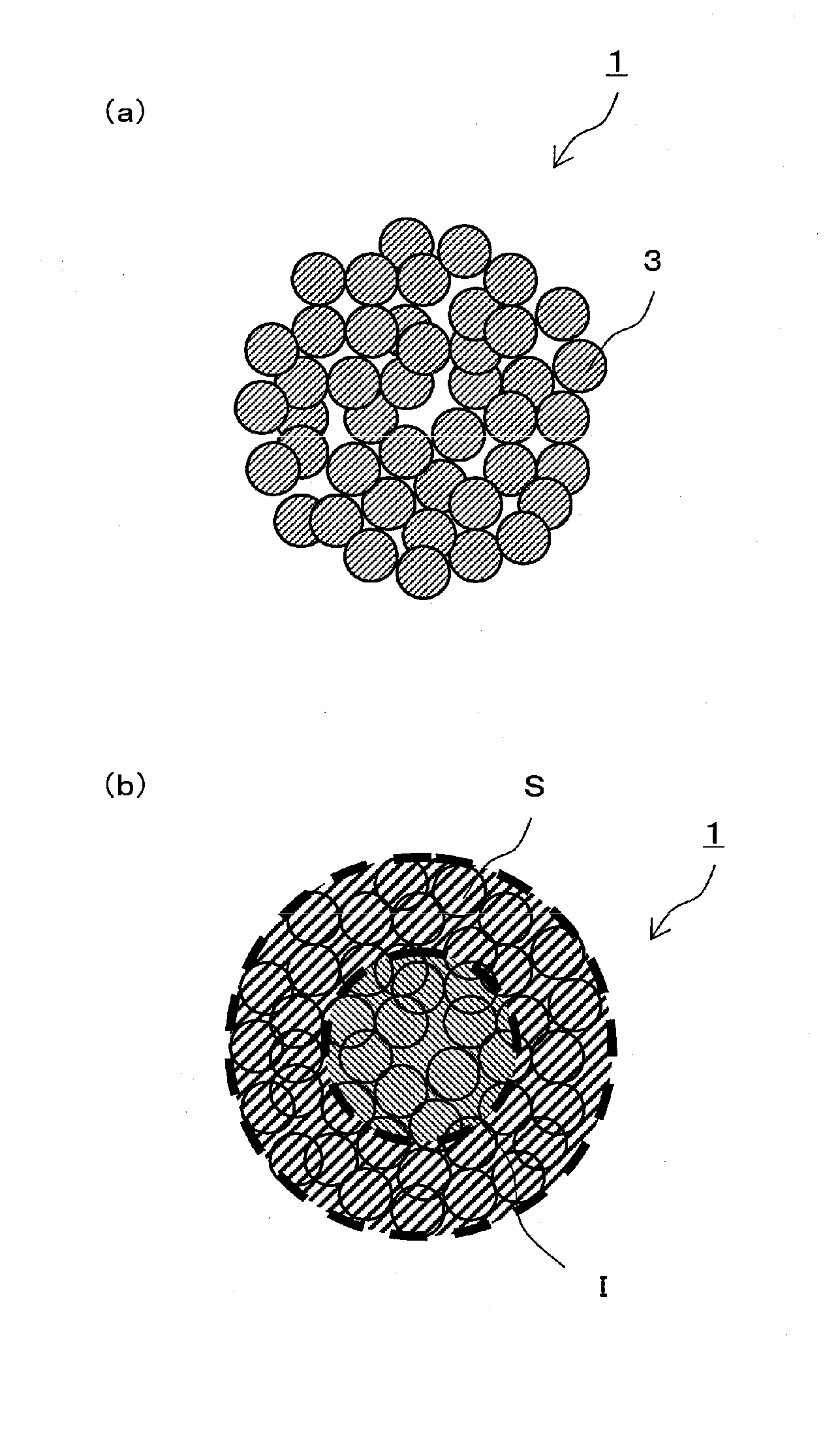

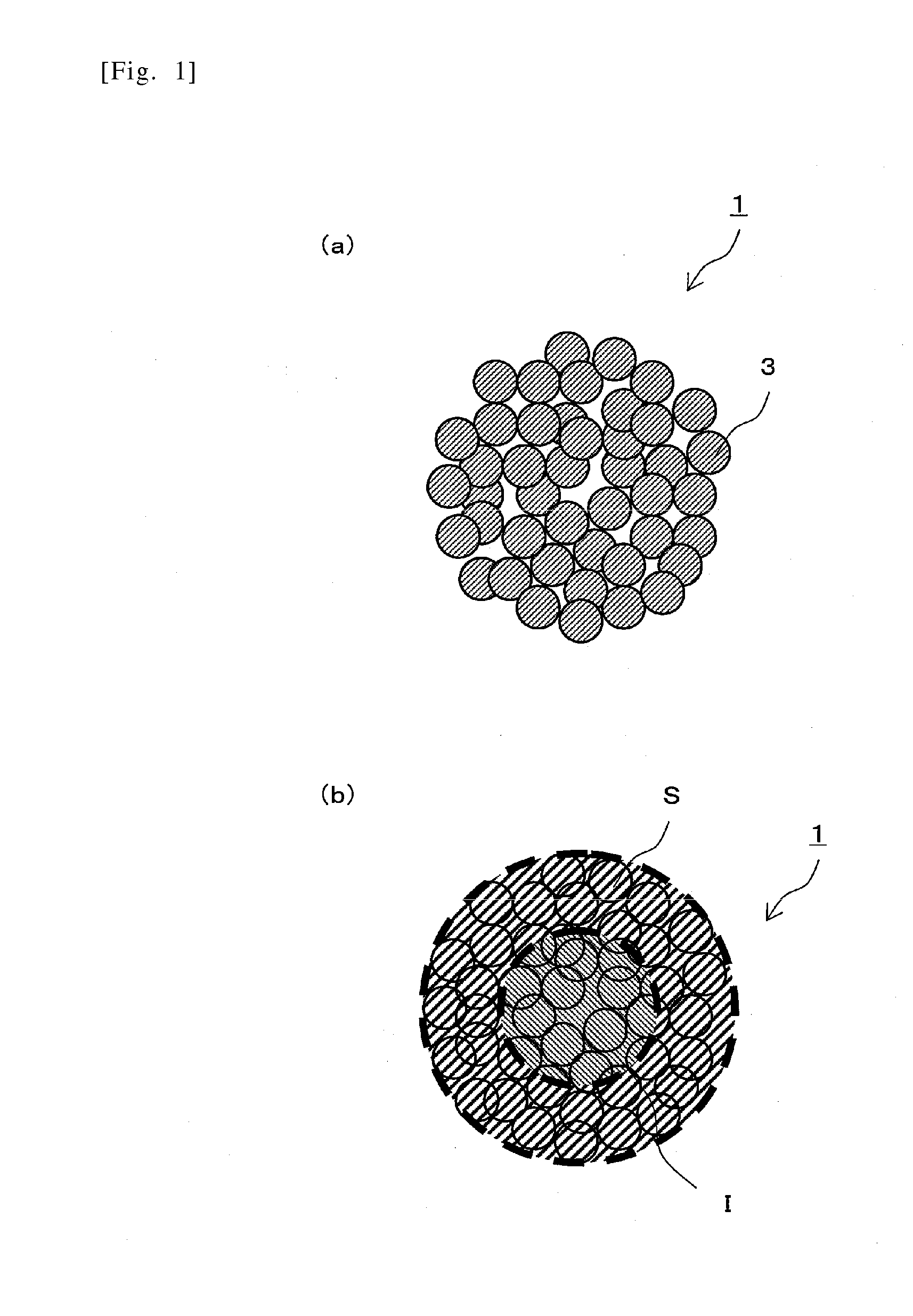

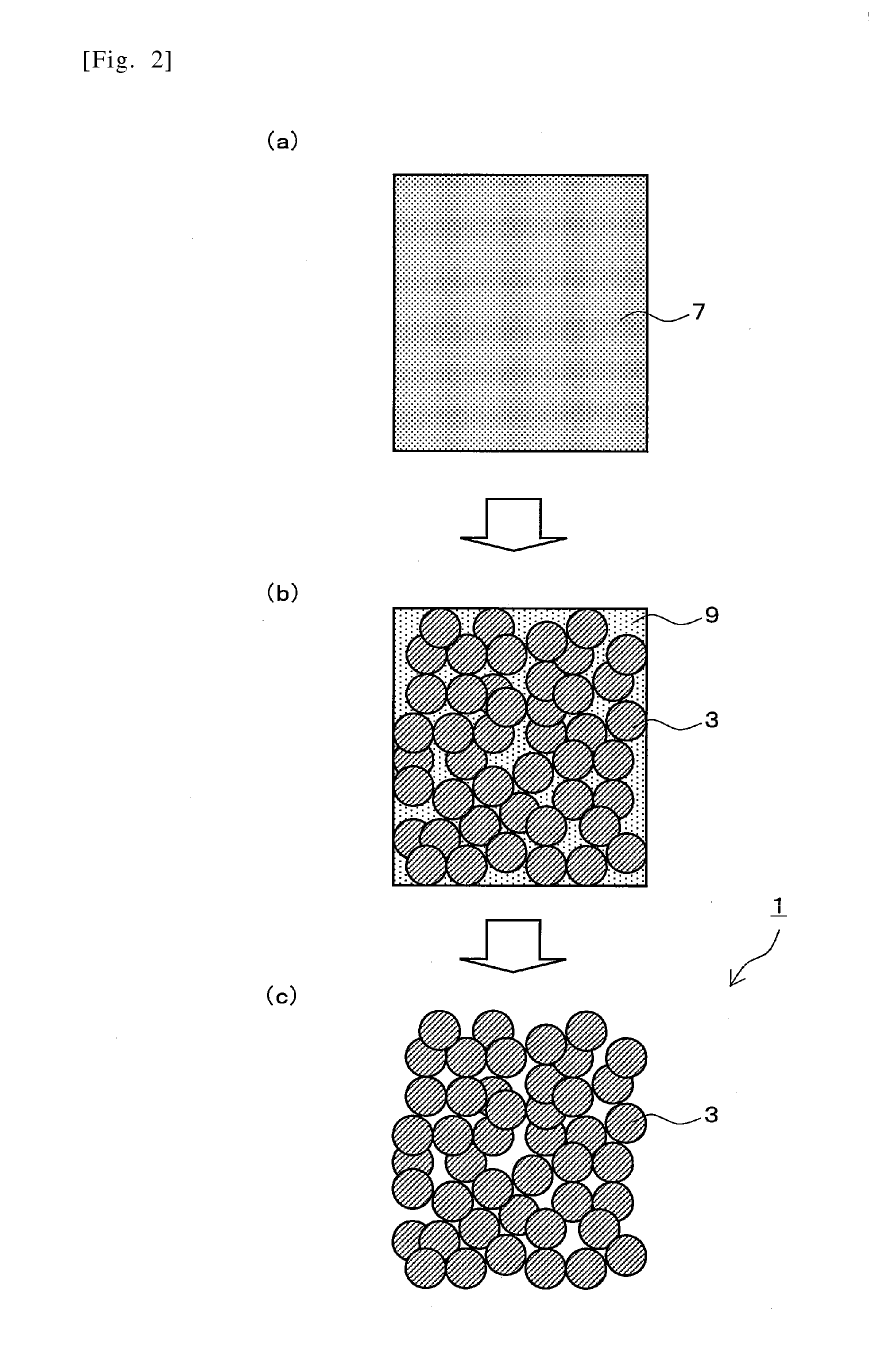

Porous silicon particles and complex porous silicon particles, and method for producing both

ActiveUS20130196158A1Large capacityImprove featuresElectrode manufacturing processesSiliconNetwork structureMicroparticle

Porous silicon particles and complex porous silicon particles suitable for negative electrode materials etc. for lithium-ion batteries, which achieve high capacity and good cycling characteristics, are provided. Porous silicon particles formed by the joining of a plurality of silicon microparticles, and having an average particle diameter of 0.1 μm to 1000 μm, a three-dimensional network structure having continuous gaps, an average porosity of 15 to 93%, and a structure in which the particles of a whole particle are uniform. Complex porous silicon particles formed by the joining of a plurality of silicon microparticles and a plurality of silicon compound particles, and characterized by containing a compound of silicon and composite elements, having an average particle diameter of 0.1 μm to 1000 μm, and having a three-dimensional network structure having continuous gaps.

Owner:FURUKAWA ELECTRIC CO LTD +1

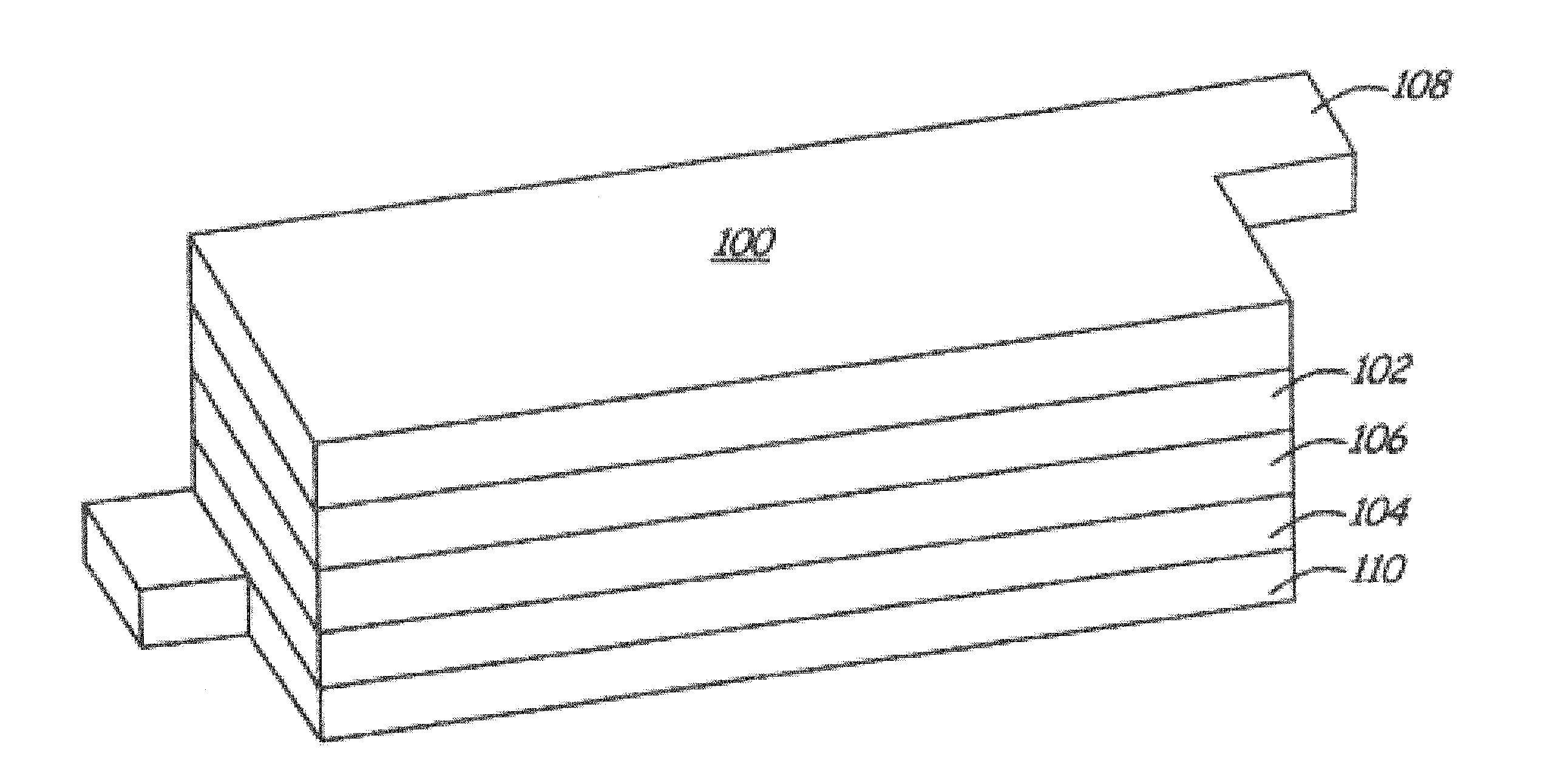

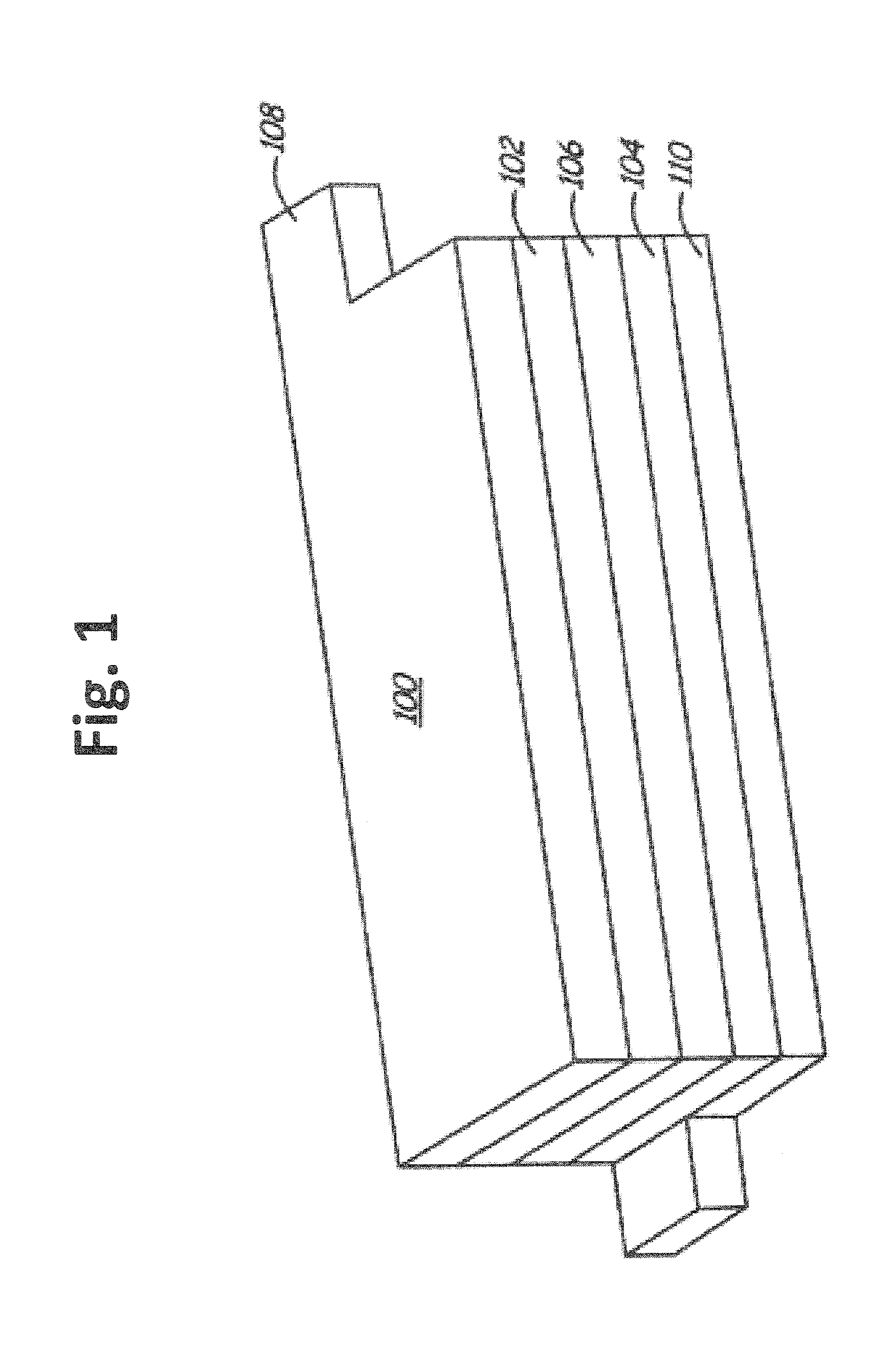

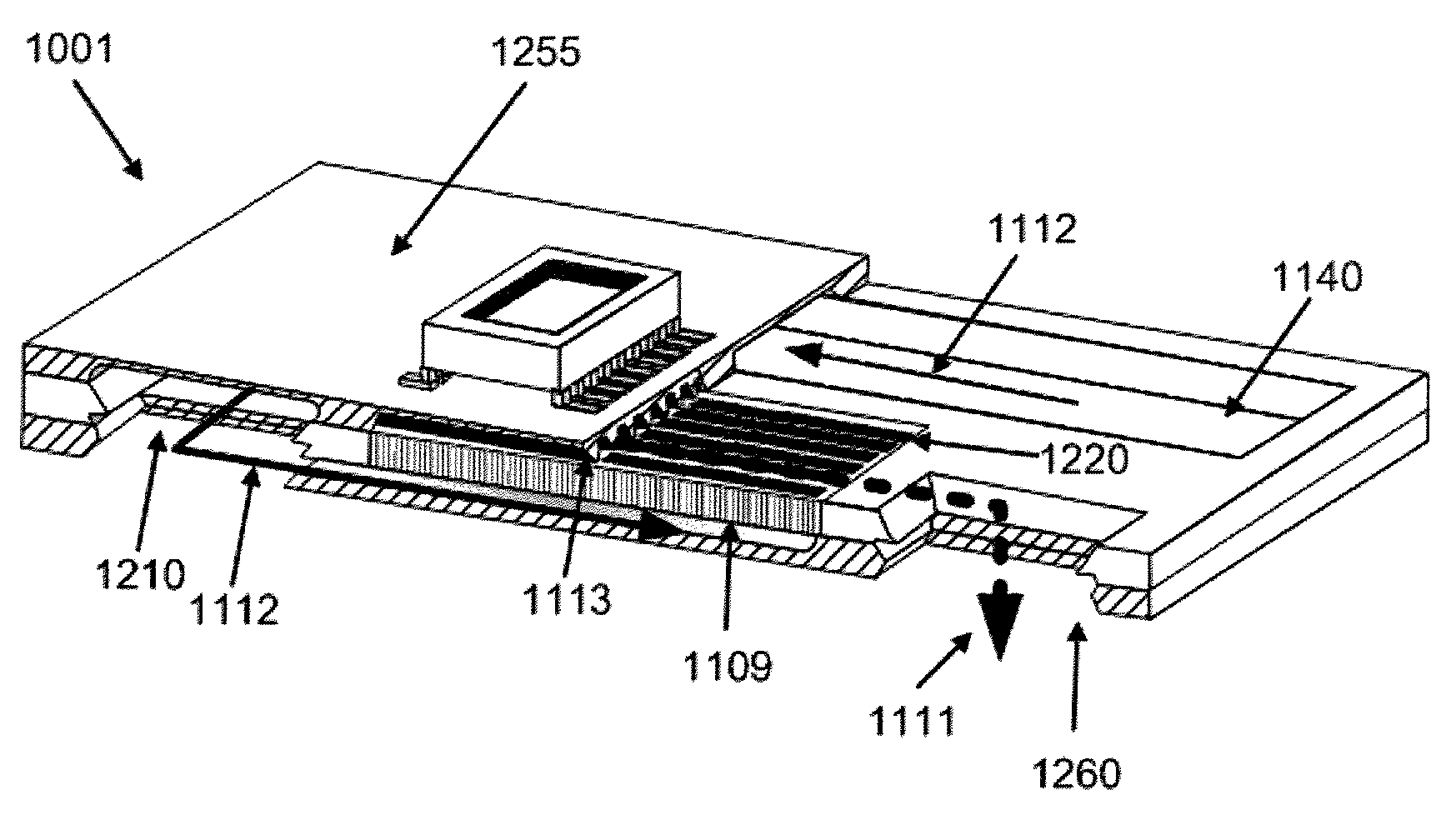

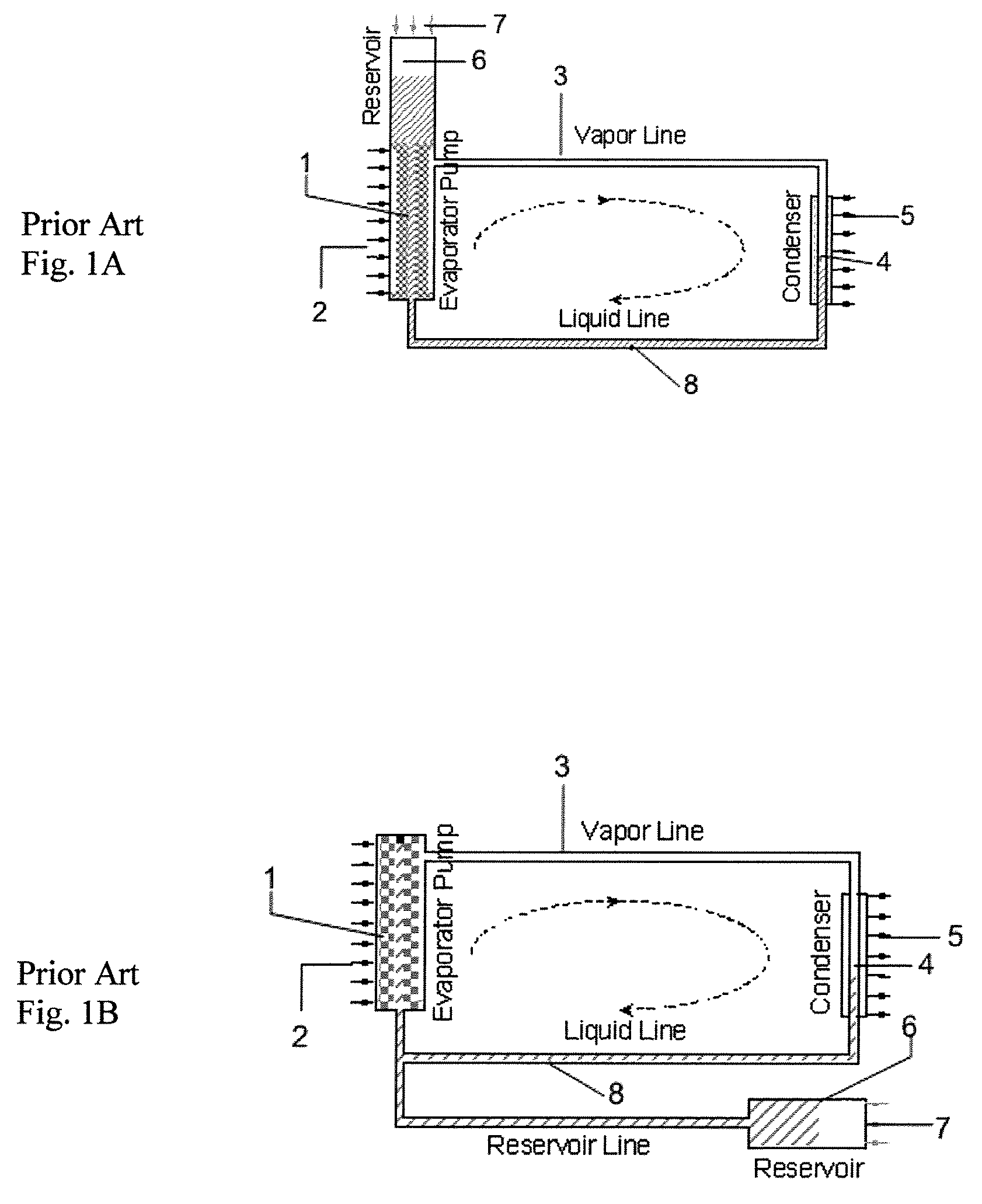

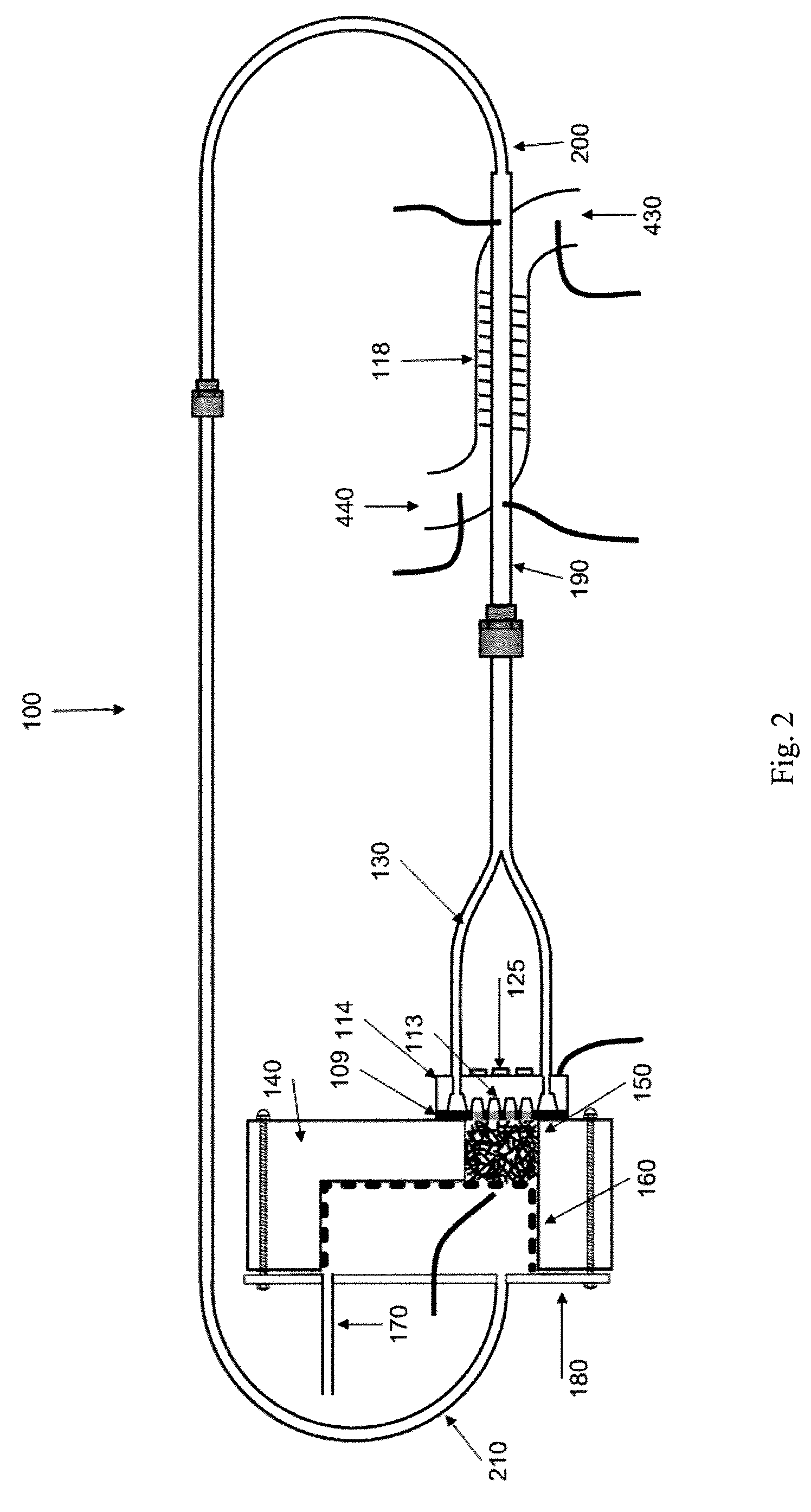

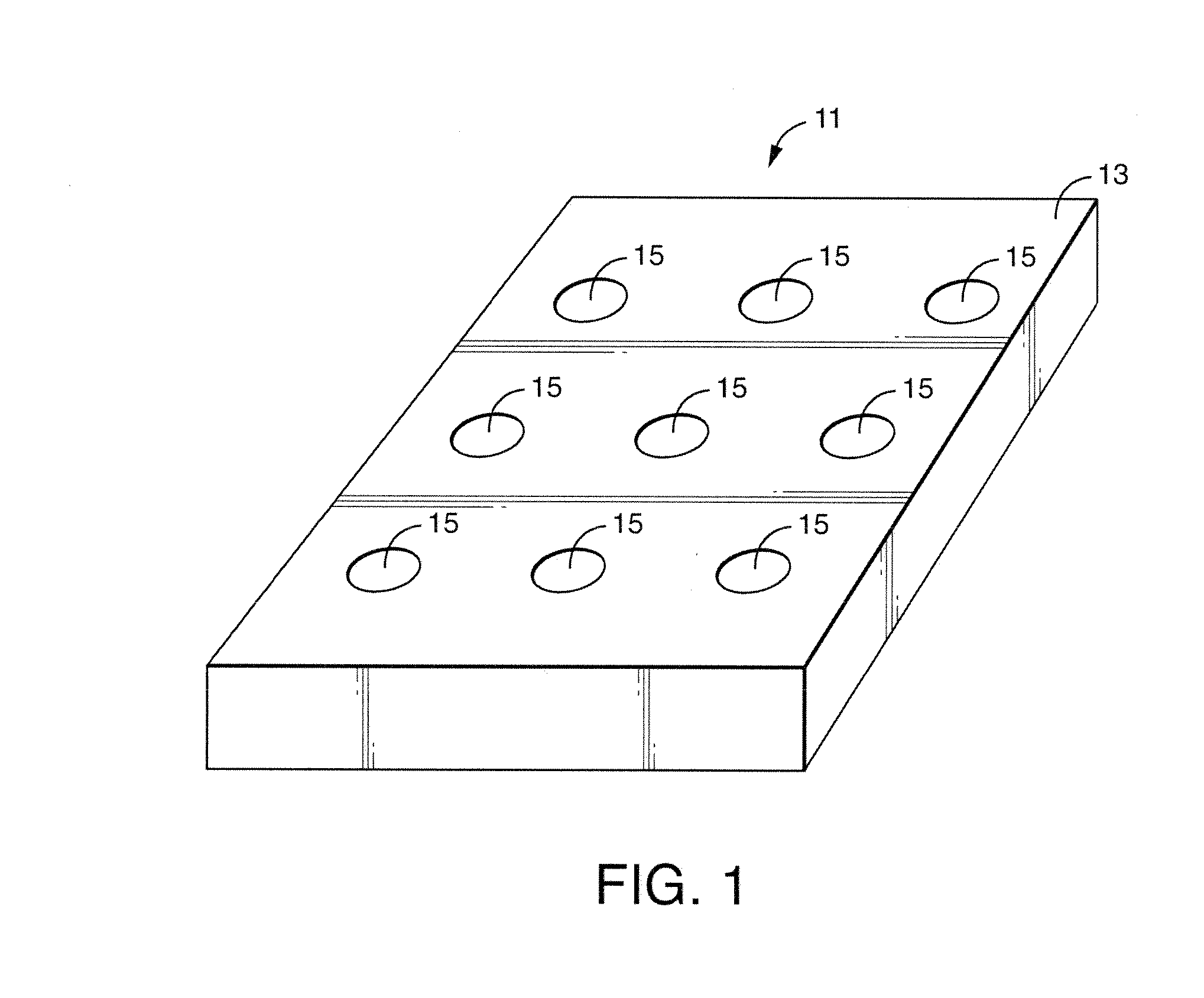

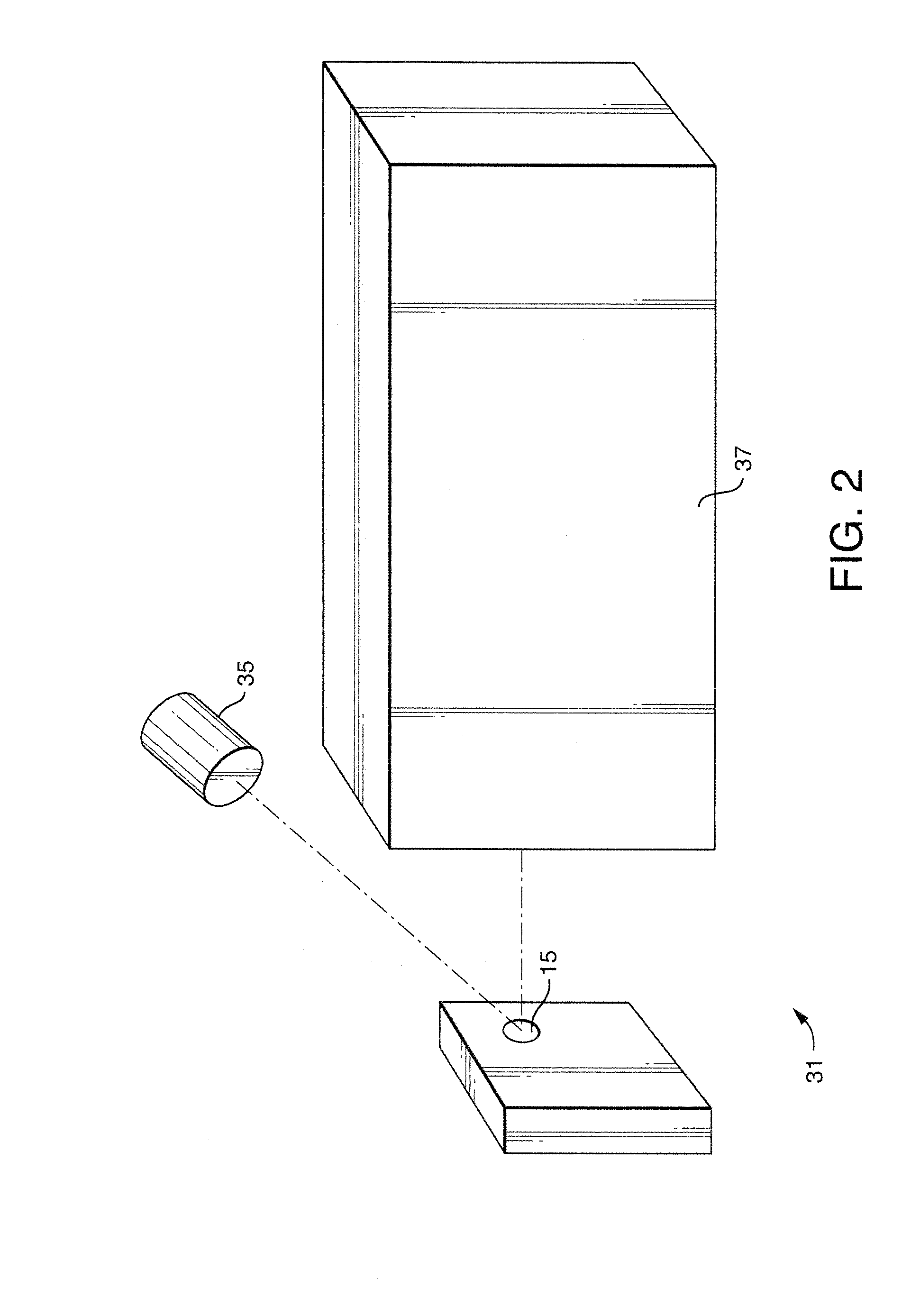

Silicon MEMS based two-phase heat transfer device

InactiveUS20070095507A1Semiconductor/solid-state device detailsSolid-state devicesMicron scaleVolumetric Mass Density

The present invention is a MEMS-based two-phase LHP (loop heat pipe) and CPL (capillary pumped loop) using semiconductor grade silicon and microlithographic / anisotrophic etching techniques to achieve a planar configuration. The principal working material is silicon (and compatible borosilicate glass where necessary), particularly compatible with the cooling needs for electronic and computer chips and package cooling. The microloop heat pipes (μLHP™) utilize cutting edge microfabrication techniques. The device has no pump or moving parts, and is capable of moving heat at high power densities, using revolutionary coherent porous silicon (CPS) wicks. The CPS wicks minimize packaging thermal mismatch stress and improves strength-to-weight ratio. Also burst-through pressures can be controlled as the diameter of the coherent pores can be controlled on a sub-micron scale. The two phase planar operation provides extremely low specific thermal resistance (20-60W / cm2). The operation is dependent upon a unique micropatterened CPS wick which contains up to millions per square centimeter of stacked uniform micro-through-capillaries in semiconductor-grade silicon, which serve as the capillary “engine,” as opposed to the stochastic distribution of pores in the typical heat pipe wick. As with all heat pipes, cooling occurs by virtue of the extraction of heat by the latent heat of phase change of the operating fluid into vapor. In the cooling of a laptop computer processor the device could be attached to the processor during laptop assembly. Consistent with efforts to miniaturize electronics components, the current invention can be directly integrated with a unpackaged chip. For applications requiring larger cooling surface areas, the planar evaporators can be spread out in a matrix and integrally connected through properly sized manifold systems.

Owner:UNIVERSITY OF CINCINNATI

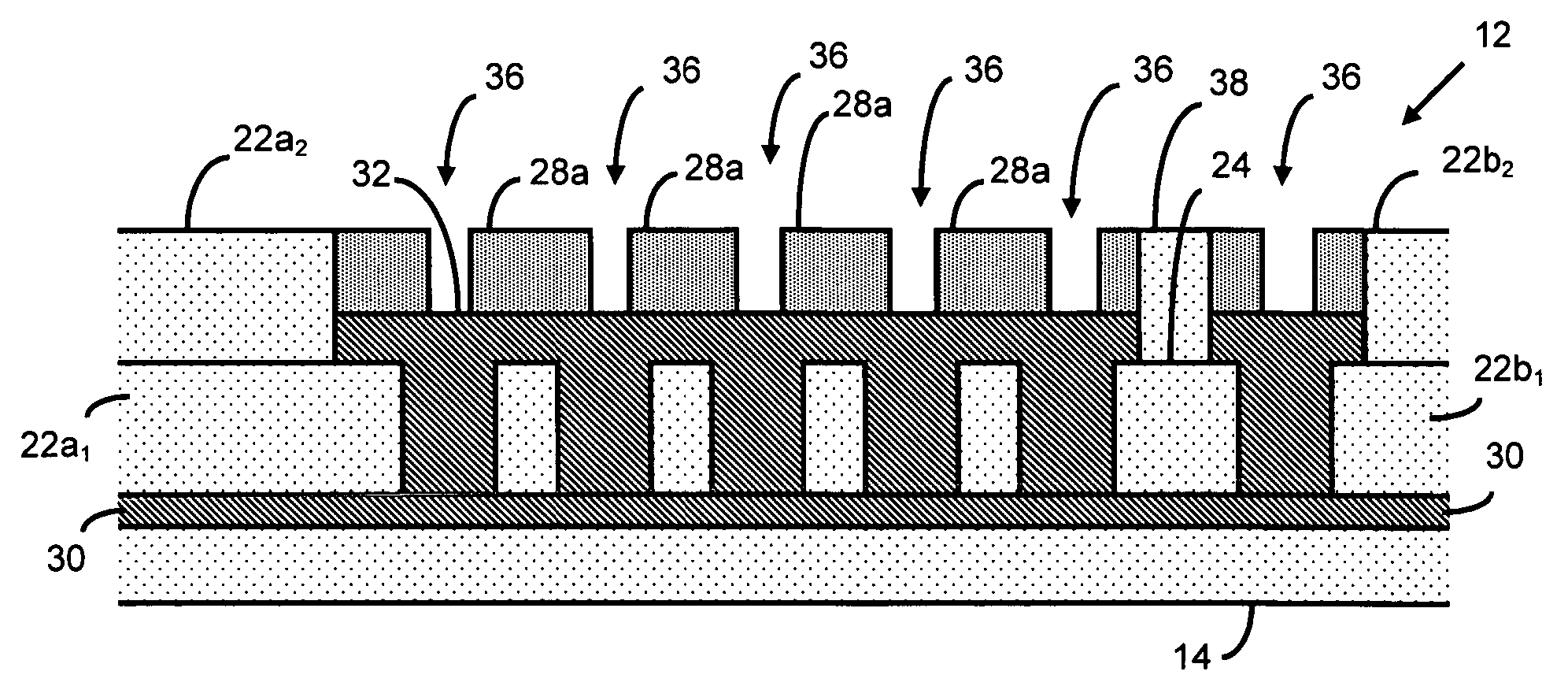

Porous silicon dielectric

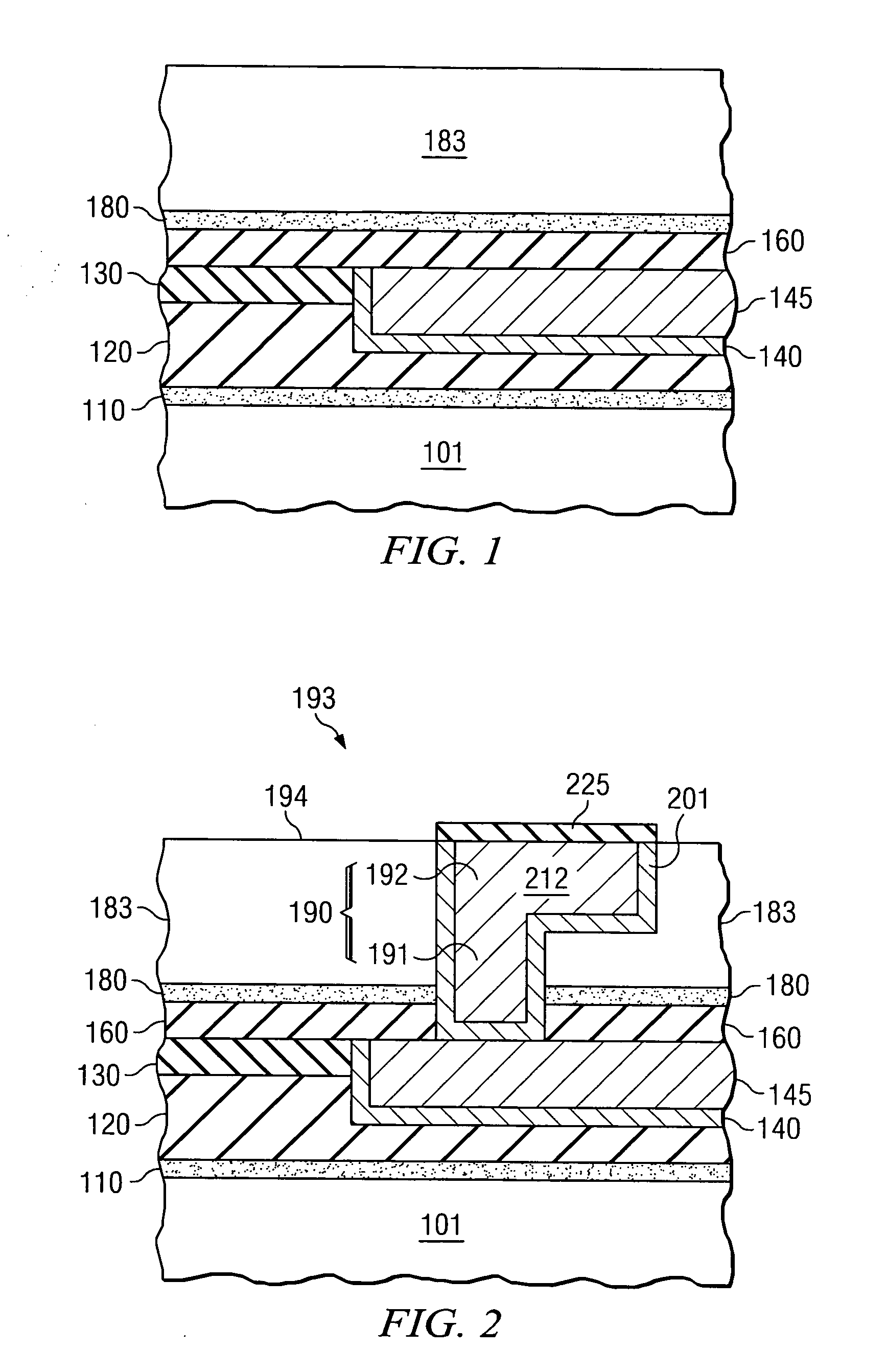

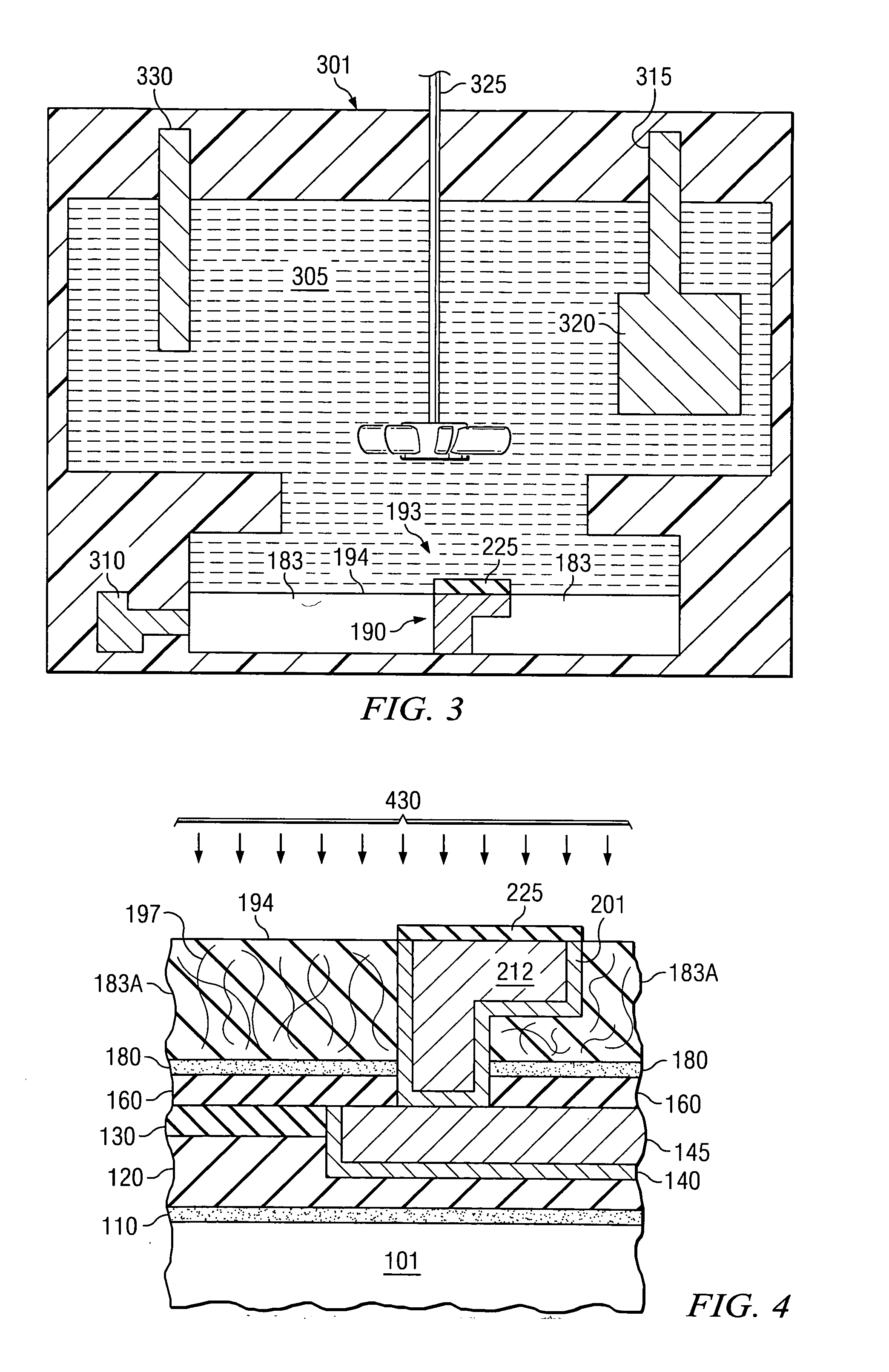

ActiveUS20070173073A1Semiconductor/solid-state device detailsSolid-state devicesDielectricElectrical conductor

Embodiments of the invention provide a semiconductor device having dielectric material and its method of manufacture. A manufacturing method comprises forming a layer of silicon over a substrate, forming an opening through the layer of silicon, filling the opening with a conductor; and anodically etching the layer of silicon so as to form porous silicon. Embodiments may further include passivating the porous silicon such as by treating its surface with an organometallic compound. Other embodiments of the invention provide a semiconductor device comprising a layer comprising functional devices; and an interconnect structure over the layer, wherein the interconnect structure comprises a porous silicon dielectric. In an embodiment of the invention, the interconnect structure comprises a dual damascene interconnect structure. Other embodiments may include a passivation step after the step of oxidizing the porous silicon.

Owner:INFINEON TECH AG

Light emitting photonic crystals

InactiveUS20030148088A1Increase brightnessUniform lightFrom gel statePolycrystalline material growthPhotonic bandgapCrystal orientation

The invention relates to processes for the synthesis of 2-D and 3-D periodic porous silicon structures and composites with improved properties having the advantages of porous silicon and photonic bandgap materials. Photonic crystals comprise a two dimensionally periodic or three dimensionally periodic microporous structural matrix of interconnecting, crystallographically oriented, monodispersed members having voids between adjacent members, and said members additionally having randomly nanoporous surface porosity. The silicon nanofoam material shows enhanced and spectrally controlled / tunable photoluminescence and electroluminesce and finds use as transparent electrodes, high-lumonosity light emitting diodes (LEDs), wavelength division multiplexors, high-active-area catalyst supports, photonic bandgap lasers, silicon-based UV detectors, displays, gas sensors, and the like.

Owner:HONEYWELL INT INC

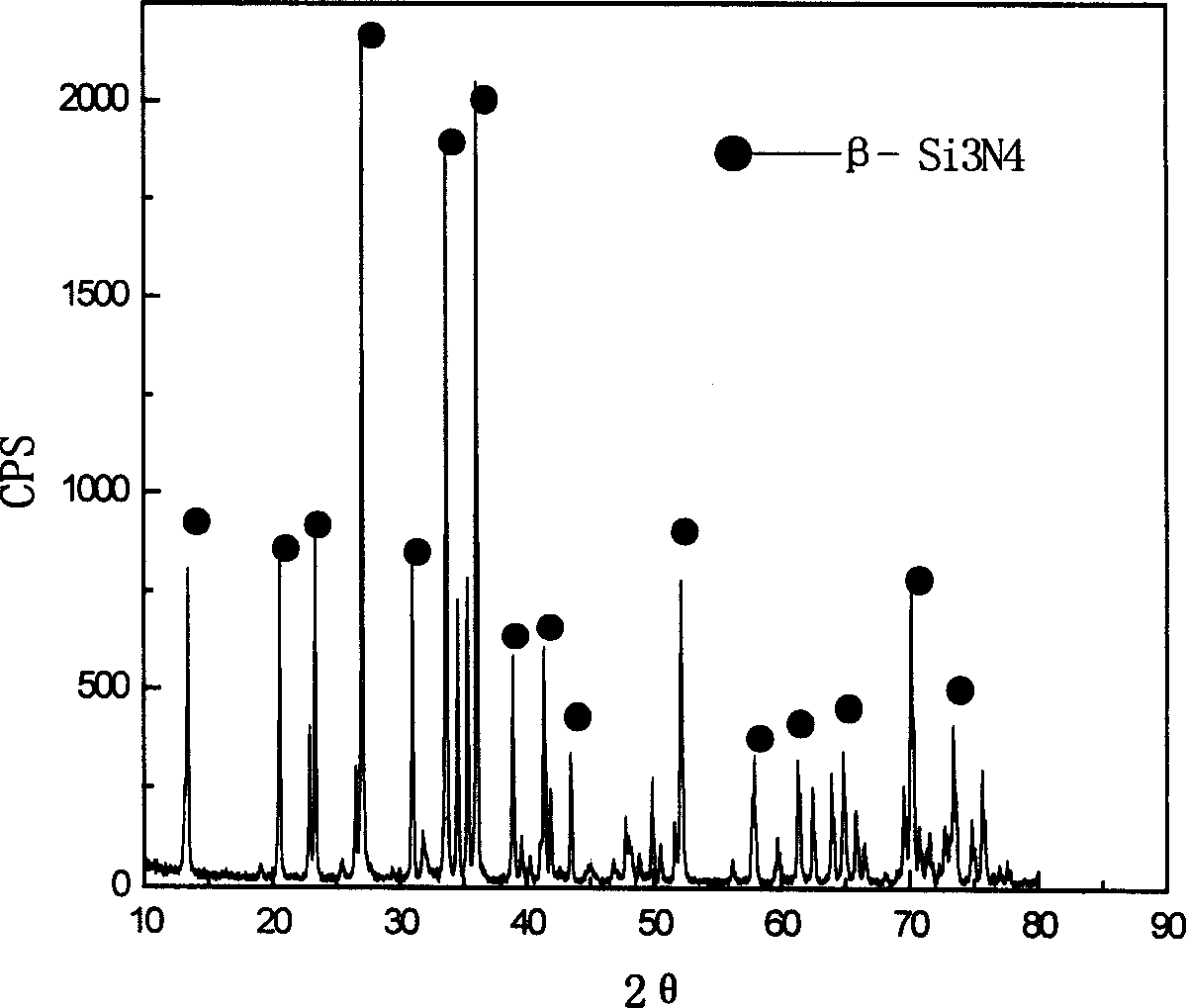

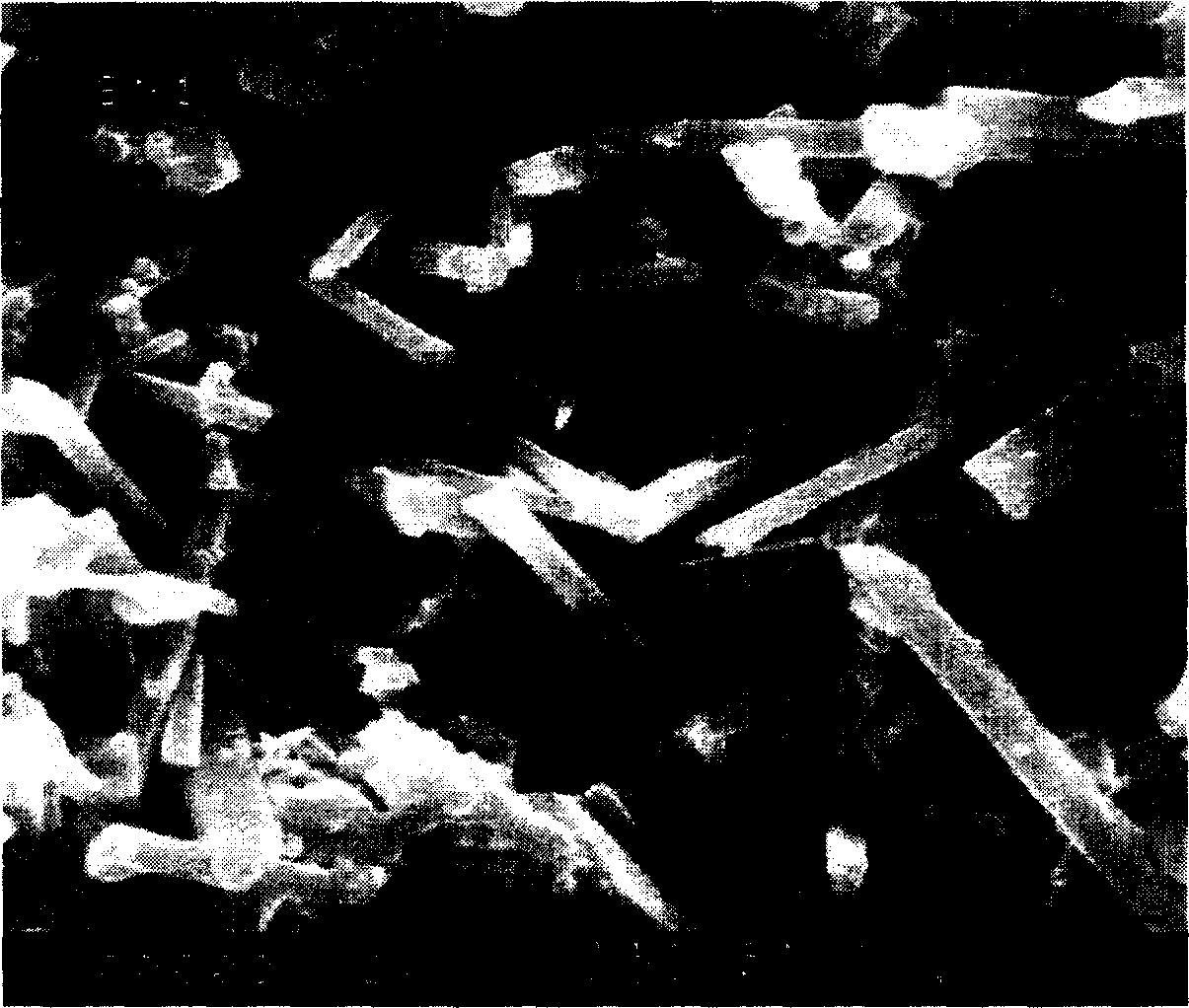

Method for preparing silicon nitride/silicon carbide porous ceramic

The present invention belongs to the field of porous ceramic material technology, and is the preparation process of one low cost and high performance porous silicon nitride / silicon carbide ceramic. The preparation process includes compounding material, forming and sintering as the conventional ceramic material preparing steps. It features that phenolic resin used as pore creating agent and carbon source is in-situ produced into SiC phase through the carbon hot reduction during sintering; and that Si3N4, Al2O3, Y2O3 and phenolic resin in certain proportion are produced into slurry through adding anhydrous alcohol and mixing for 12-24 hr and stoved into powder; and that the ceramic powder is processed through formation, cracking to eliminate glue, carbon hot reduction and sintering to produce the porous ceramic material with porosity of 40-70 %, strength of 70-160 MPa and low cost.

Owner:XI AN JIAOTONG UNIV

Low-diffusion modified polypropylene composite material and preparation method thereof

ActiveCN101817953AHigh surface glossImprove impact resistancePolypropylene compositesMolecular sieve

The invention belongs to the field of modified polypropylene composite materials and relates to a low-odor and low-diffusion modified polypropylene composite material suitable for manufacturing interior decorative parts of automobiles. The composite material comprises the following components in part by weight: 60 to 90 parts of polypropylene, 0 to 40 parts of mineral filler, 1 to 5 parts of odor adsorbent and 0.1 to 1 part of assistant, wherein the odor adsorbent is a mixture of three types of clay, bentonite, porous silicon dioxide, activated aluminum oxide or molecular sieve. The prepared modified polypropylene composite material has the characteristics of high surface glossiness, high shock resistance and intensity, melt flowing property and mechanical property; due to the adoption of various gas adsorbents, the product has low odor diffusion property and a total carbon value of between 13.7 and 24.5 mu gC / g; simultaneously, needed raw materials have wide sources and are readily available.

Owner:SUZHOU SUNWAY POLYMER

Methods, compositions and devices for performing ionization desorption on silicon derivatives

InactiveUS20080073512A1Consistent resultSilicon organic compoundsPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesHydrogenAlcohol

Embodiments of the present invention are directed to a substrate for performing ionization desorption on porous silicon, methods for performing such ionization desorption and methods of making substrates. One embodiment directed to a substrate for performing ionization desorption on silicon comprises a substrate having a surface having a formula of: As used above, X is H or Y, where at least at least twenty five mole percent of X is Y and Y is hydroxyl, or —O—R1, or O—SiR1, R2, R3 wherein R1, R2, and R3 are selected from the group consisting of alkyl, alkenyl, alkynyl, aromatic, amino alkyl, amino alkenyl, amino alkynyl, pyridinyl, pyrridonyl, and carbonyl, alcohol and carboxylic acid derivatives thereof having one to twenty five atoms, and hydroxyl, amino, amide, carboxyl, ester, carbonyl, sulfhydryl, sulfonyl, phosphoral, bromo, iodo, chloro and fluoro derivatives. The letter “n” represents an integer from 1 to infinity and any vacant valences are silicon atoms, hydrogen or impurities.

Owner:WATERS TECH CORP

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com