Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2902 results about "Polypropylene composites" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite polypropylene material and its preparing method

The composite polypropylene material is prepared with polypropylene 10-100 weight portions, polyethylene 1-50 weight portions, inorganic rigid grain 1-50 weight portions, toughener 1-50 weight portions, coupling agent 0.01-10 weight portions and grafting compatilizer 1-50 weight portions. The composite polypropylene material has high rigidity, high impact strength and balanced rigidity and toughness, and compared with common automobile bumper material, it has 15-30 % higher bending modulus.

Owner:吴永刚

PP composite material of low VOC interior trim parts for automobiles and preparation method thereof

ActiveCN101570612AEfficient decompositionLow VOC contentVehicle componentsPolypropylene compositesAntioxidant

The invention relates to the field of automobiles, and belongs to a PP composite material special for low VOC (volatile organic compounds) high performance automobile interior trim parts and a preparation method thereof. The special material is prepared from the following compositions by mass portion: 60 to 80 portions of polypropylene (PP), 10 to 25 portions of reinforcing filler, 10 to 15 portions of toughening agent, 0.5 to 2 portions of inorganic photocatalyst, 0.2 to 0.5 portion of antioxidant and 0.1 to 0.5 portion of light stabilizer. The prepared polypropylene composite material has TVOC less than 40 mu gC / g, the notch impact strength of a cantilever beam at 23 DEG C between 10 and 42KJ / m, bending modulus between 1,000 and 2,400 MPa, and the melt index at 230 DEG C and 2.16 Kg between 10 and 30g / 10min. The PP composite material of the low VOC interior trim parts for the automobiles has low cost, good stability and the function of self-purification of VOC, and can be widely applied to production of the automobile interior trim parts.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

Scratch-resistant modified polypropylene composite material and preparation method thereof

The invention belongs to the field of modified polypropylene composite materials and relates to a scratch-resistant modified polypropylene composite material which is applicable to manufacturing automotive interior parts and comprises the following components by parts by weight: 60-90 parts of polypropylene, 5-20 parts of plasticizer, 5-20 parts of mineral filler, 0.1-4 parts of wear-resistant agent / scratch-resistant agents and 0.1-3 parts of additives, wherein the wear-resistant agent / scratch-resistant agents can be selected from the mixture of nano-polytetrafluoroethylene superfine micro-powder, organic matter-modified siloxane, modified silicone mixture and reactive modified polysiloxane. The prepared modified polypropylene composite material has high surface gloss and better impact-resistant performance, strength, melt fluidity and mechanical performance; furthermore, due to the use of the various wear-resistant agents / scratch-resistant agents, the scratch-resistant performance of the product is excellent; and the resources of the required raw materials are simultaneously extensive and easy to obtain.

Owner:SUZHOU SUNWAY POLYMER

Non-halogen flame-retardant polypropylene composite material and preparation thereof

InactiveCN101412830AImprove flame retardant performanceImprove mechanical propertiesFlexural modulusAcrylonitrile

The invention provides a halogen-free flame-retardant polypropylene composite material, which is characterized by consisting of the following raw materials in weight portion: 82.5 to 12 portions of polypropylene, 0.3 to 2 portions of heat stabilizer, 0.2 to 1 portion of processing aid, 1 to 10 portions of toughening agent, 10 to 40 portions of flame retardant, 1 to 5 portions of glass fiber compatibilizer and 5 to 30 portions of glass fiber. The invention also provides a method for preparing the material. The material has the flame retardancy up to 1.6mm V0, the tensile strength higher than or equal to 50 MPa, the flexural modulus higher than or equal to 3,000 MPa, the notched impact strength more than or equal to 8KJ / m<2>, the shrinkage between 4 and 6 per thousand, the heat distortion temperature higher than or equal to 140 DEG C, as well as the other technical indexes up to or exceeding the standard of flame-retardant acrylonitrile-butadiene-styrene copolymer materials. As the material uses the phosphorus-nitrogen flame retardant containing no halogen, the flame-retardant effect of the material completely reaches UL94-V0 grade.

Owner:SHANGHAI KINGFA SCI & TECH +1

Cellulosic/polymer composite material

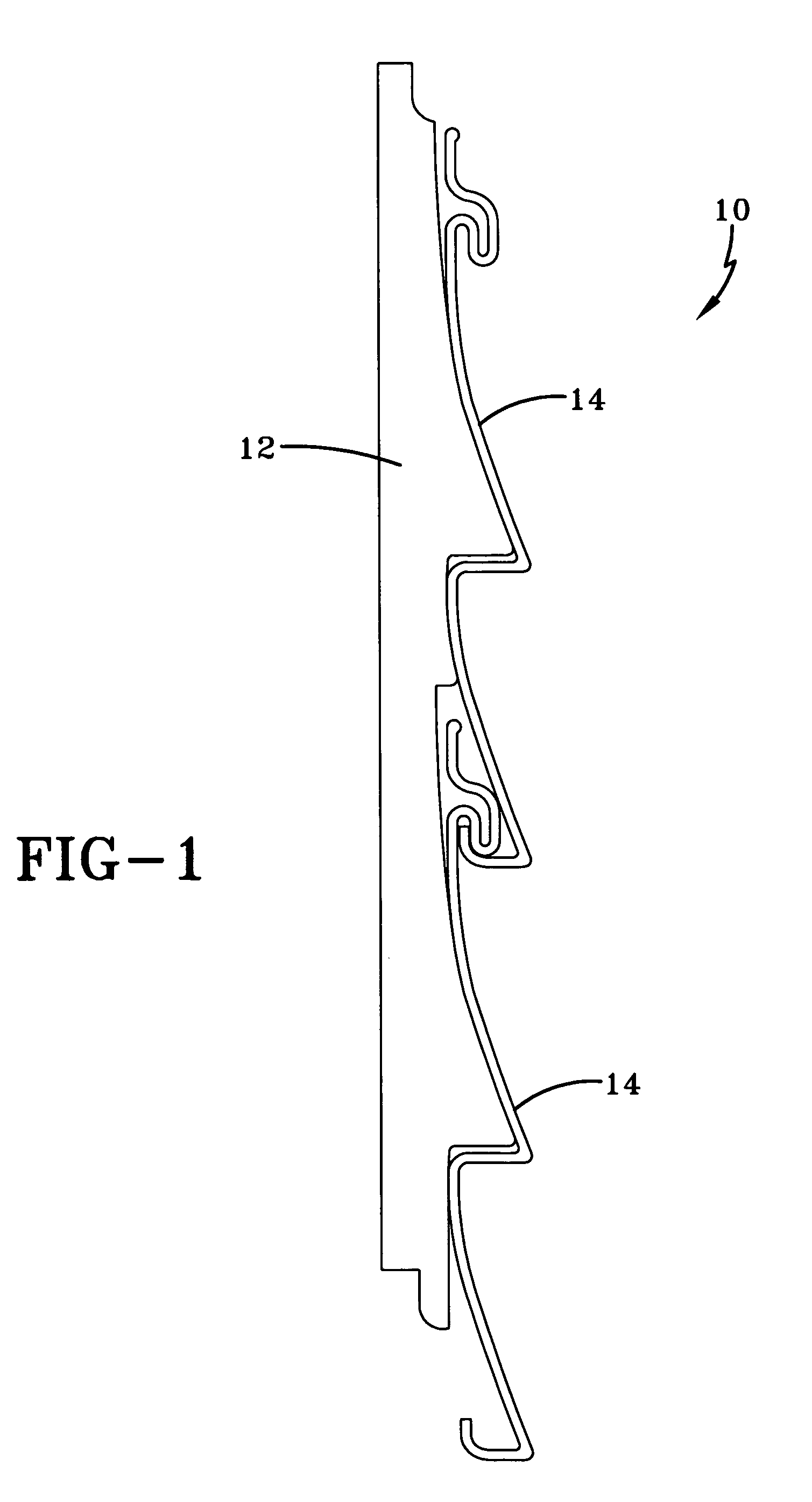

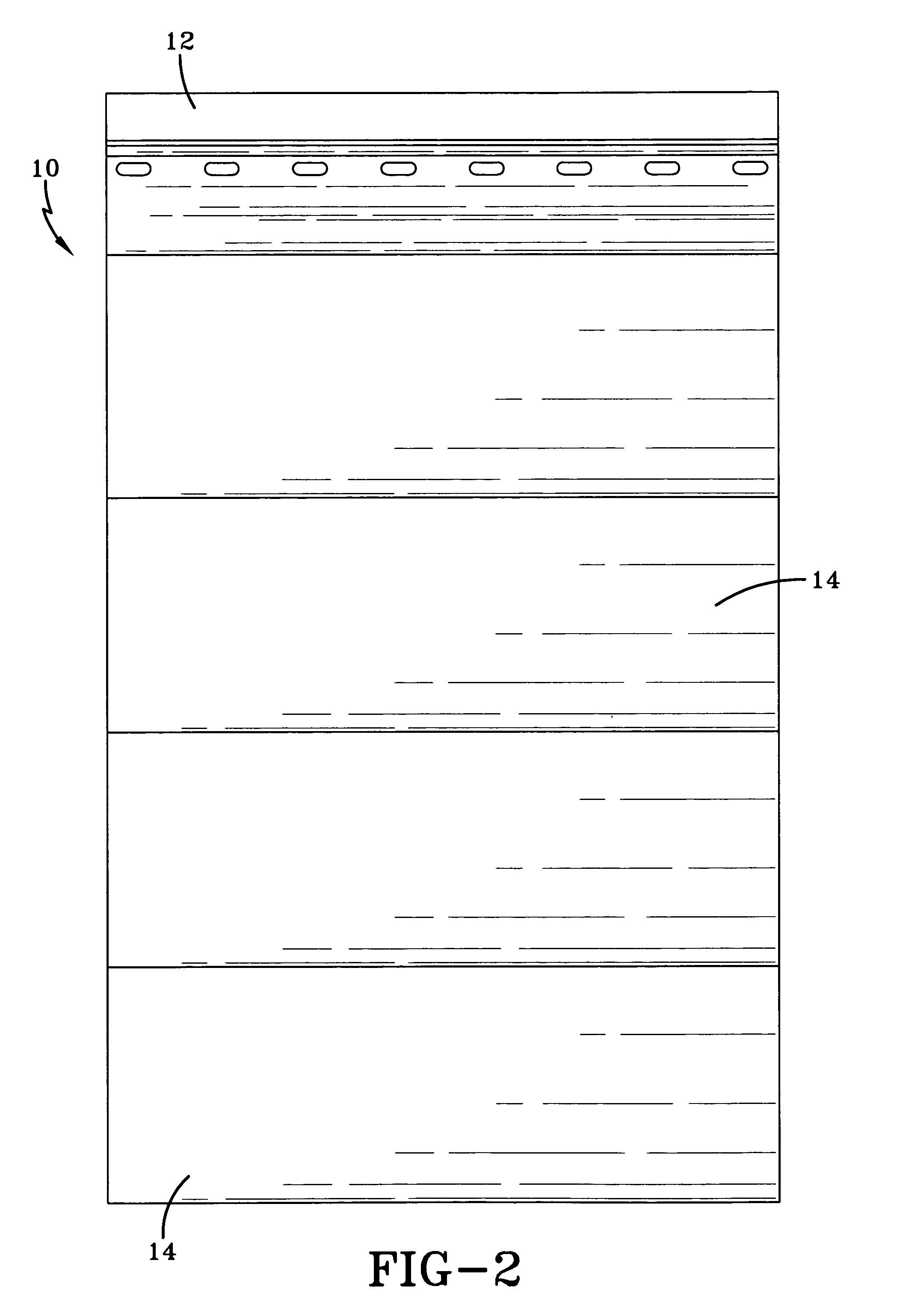

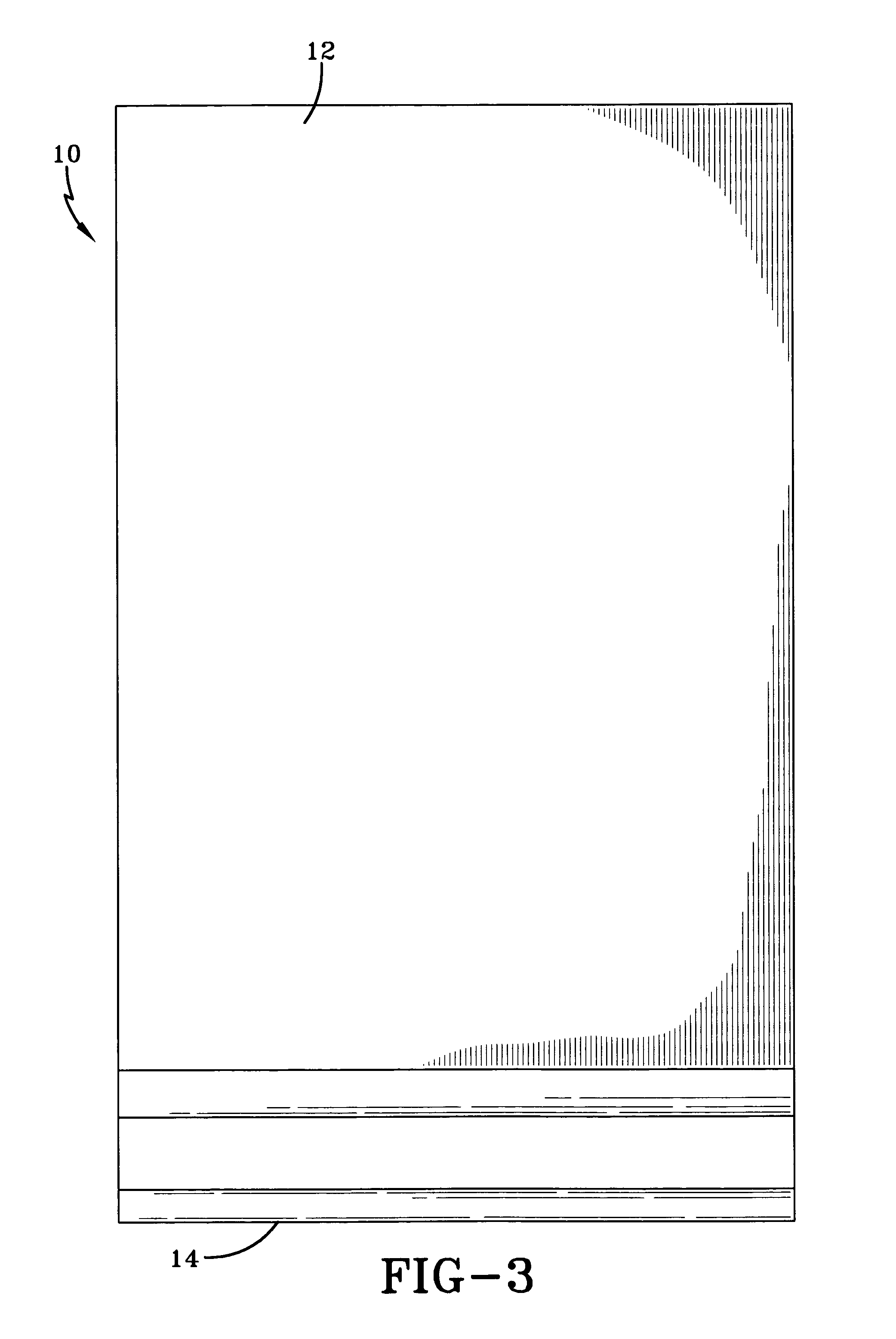

InactiveUS6971211B1Superior resistance to wearGood tearConstruction materialRoof covering using tiles/slatesPolypropylene compositesCellulose

The present invention is a component such as a siding panel that may be comprised of various formulations of cellulosic / polymer composite materials. One embodiment of the present invention is a siding panel that is comprised of a cellulosic / PVC composite material. This composite material may include at least one cellulosic filler in the amount of about 30% to about 60% by weight and a PVC material in the amount of about 40% to about 70% by weight. The PVC material may include about 1 to about 10 parts stabilizer(s) per 100 parts of the PVC resin, about 2 to about 12 parts lubricant(s) per 100 parts of the PVC resin, and about 0.5 to about 8 parts process aid(s) per 100 parts of the PVC resin. Another embodiment of the present invention is a siding panel that may be comprised of a cellulosic / polypropylene composite material. This composite material is comprised of at least one cellulosic filler in an amount of about 30% to about 70% by weight and a polypropylene material in an amount of about 30% to about 70% by weight. The polypropylene material includes at least one lubricant in an amount of about 10 to about 20 parts per 100 parts of a polypropylene resin.

Owner:CPG INT

Natural fiber reinforcement halogen-free flame retardant polypropylene composite material and preparation method thereof

InactiveCN101418099AImprove flame retardant performanceImprove mechanical propertiesGlass fiberHeat deflection temperature

The invention provides a natural fiber reinforced halogen-free flame-retardant polypropylene composite material, which is characterized by consisting of the following raw materials in weight portion: 82.5 to 12 portions of polypropylene, 0.3 to 2 portions of heat stabilizer, 0.2 to 1 portion of processing assistant, 1 to 10 portions of toughening agent, 10 to 40 portions of flame retardant, 1 to 5 portions of compatilizer, and 5 to 30 portions of natural fiber. The invention also provides a method for preparing the material. The composite material has the advantages that the composite material has excellent flame-retardant effect and excellent comprehensive mechanical property; the flame-retardant property of the composite material can reach 1.6mm V0; the tensile strength is more than or equal to 60MPa; the bending modulus is more than or equal to 4,000MPa; the gap impact strength is more than or equal to 10KJ / m<2>; the shrinkage ratio is between 4 and 6 per thousand; the heat distortion temperature is more than or equal to 140 DEG C; and the composite material is a novel environment-friendly material, and has no safety and health problems of glass fibers.

Owner:SHANGHAI KINGFA SCI & TECH +1

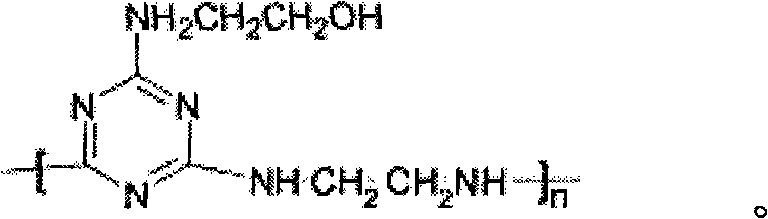

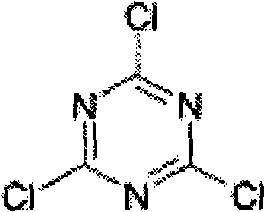

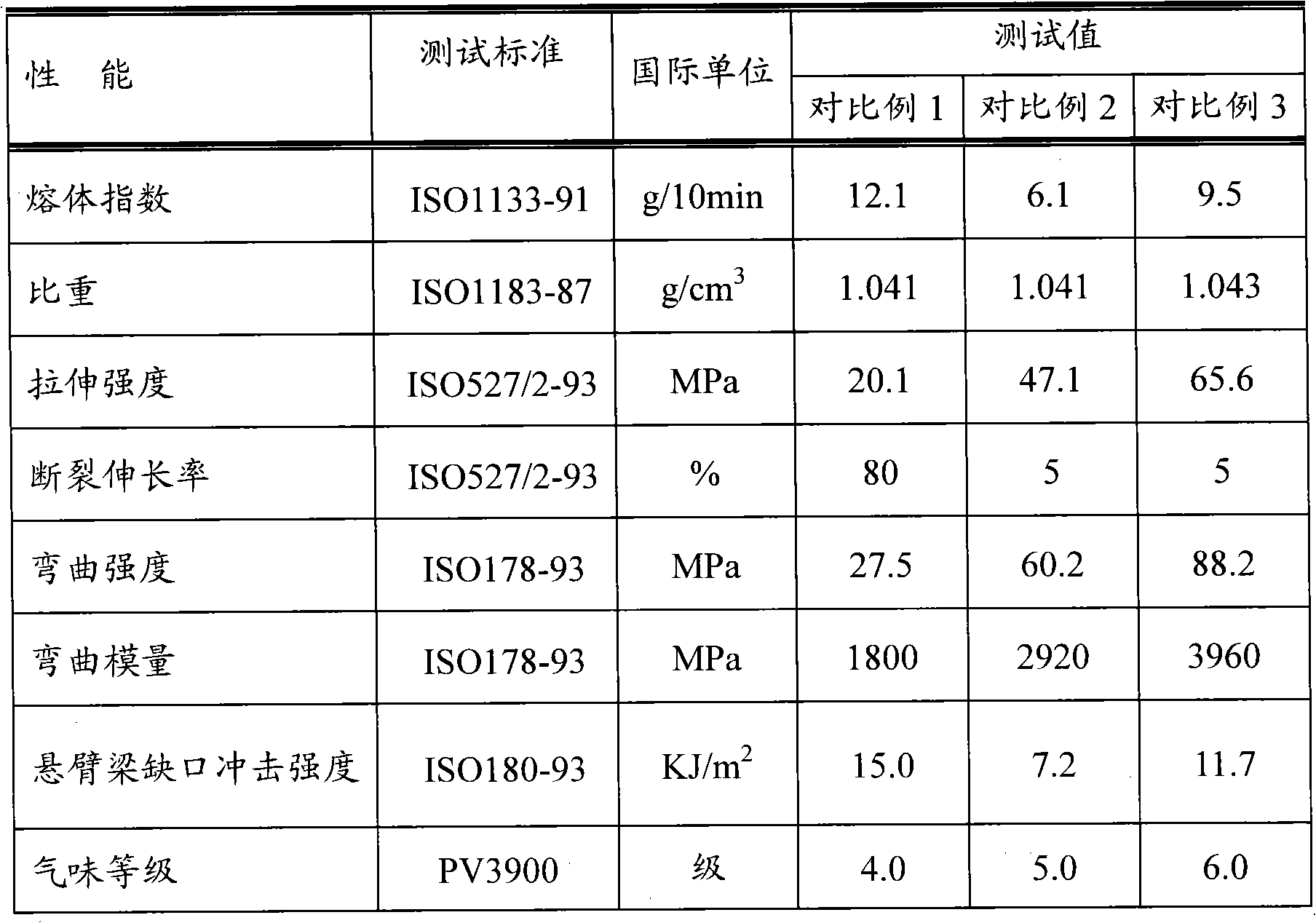

Halogen-free expansion type flame-retardant and preparation thereof

The invention relates to a halogen-free intumescent flame-retardant polypropylene composite and a preparation method thereof. Calculated by weight percentage, the composite comprises 35 to 80 percent of polypropylene, 5 to 30 percent of coated poly-ammonium phosphate, 1 to 20 percent of melamine and the derivatives, 1 to 15 percent of halogen-free macromolecular char forming flame retardant, 0.1 to 5 percent of flame retardant synergist, 1 to 20 percent of rigid inorganic particle, 0.05 to 5 percent of coupling agent, 0.1 to 10 percent of compatilizer, 1 to 20 percent of toughening agent and 0.01 to 4 percent of antioxidant. Compared with the prior art, the material of the invention has good toughness, high strength and environment-protecting flame retardance, and the composite can be widely applied in the fields such as automobile and electronic appliances.

Owner:SHANGHAI RES INST OF CHEM IND +1

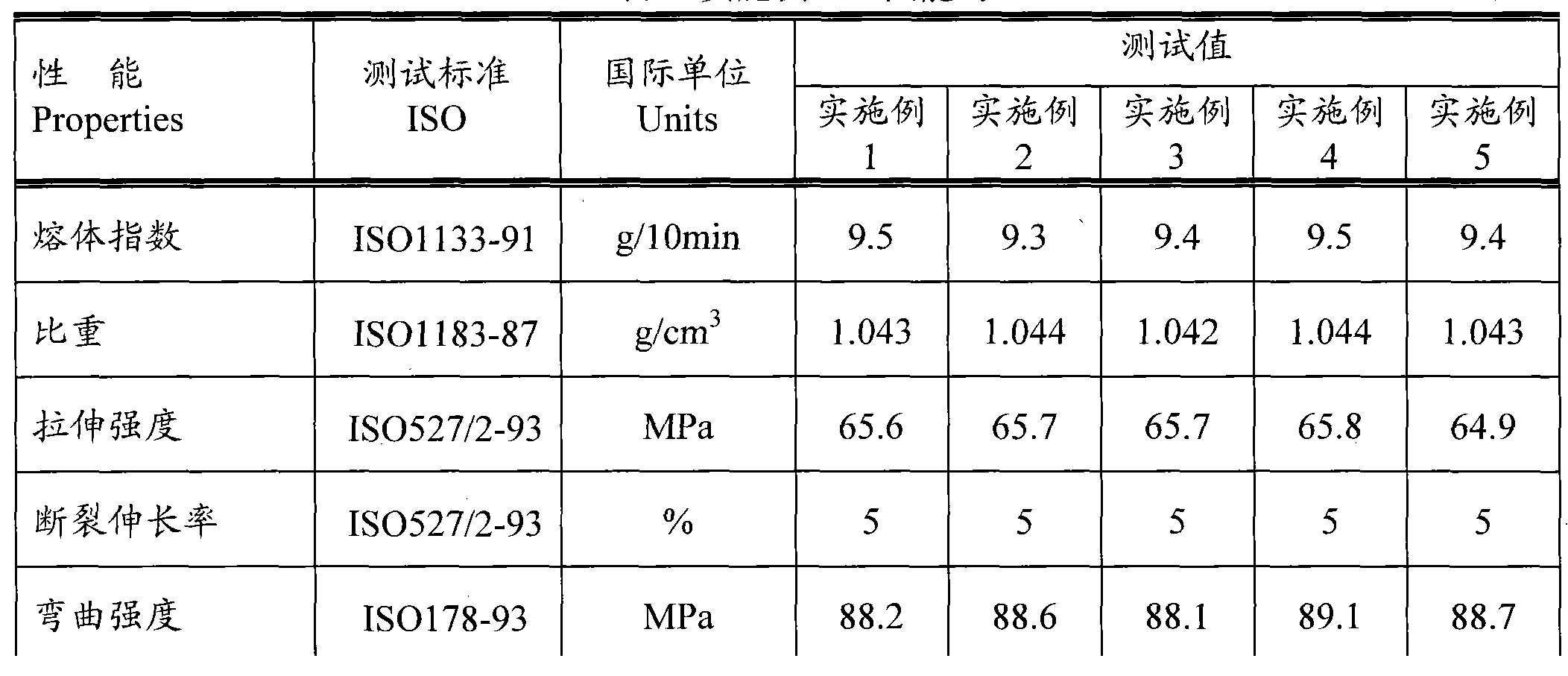

Glass fiber reinforced polypropylene composite material with low odor and preparation method thereof

The invention discloses a glass fiber reinforced polypropylene composite material with low odor and a preparation method thereof. The glass fiber reinforced polypropylene composite material comprises the following components: 32-91% of polypropylene resin, 5-50% of glass fiber, 2-8% of compatilizer, 1-6% of odor inhibitor and 1-4% of other auxiliary agent. The reinforced polypropylene material with low odor is prepared by fusing, extruding and granulating the components through a double screw extruder under the temperature control condition of 220-240 DEG C. The odor inhibitor comprises 30-50% of ricinoleic acid zinc, 20-40% of metal oxide and 10-30% of a clay mineral system. The odor of the glass fiber reinforced polypropylene composite material can be inhibited through combining a physical method and a chemical method. The glass fiber reinforced polypropylene composite material prepared by the method has excellent odor performance; the odor level can be reduced below level 3; the physical property of the glass fiber reinforced polypropylene composite material per se is not influenced after the odor inhibitor is added; and the application field of the glass fiber reinforced polypropylene material in vehicle interior trim parts and a part of home appliance parts can be widened.

Owner:CHENGDU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD +3

PP composite material with low VOC and high performance specially used for automotive upholsteries and preparation method thereof

ActiveCN101691435AAvoid it happening againLow costSuperstructure subunitsPolypropylene compositesFlexural modulus

The invention belongs to a polypropylene (PP) composite material with a low volatile organic compound (VOC) and high performance specially used for automotive upholsteries and a preparation method thereof, relating to the automobile field. The special material is prepared from the following components by mass percent: 60-80% of polypropylene (PP), 10-25% of reinforcing filler, 10-15% of flexibilizer, 0.2-0.5% of antioxidant and 0.1-0.5% of light stabilizer. The total volatile organic compound (TVOC) of the polypropylene composite material obtained in the invention is less than 40 mu gC / g; the notch impact strength of a cantilever beam under 23 DEG C is 15-40kJ / m2; the flexural modulus is 1500-2300MPa; the melt index is more than 10g / 10min at a temperature of 230 DEG C and at a weight of 2.16kg; and the composite material has favorable light and heat stability, low VOC, few components, low cost, good performance, easy preparation and can be widely used in the production of automotive upholsteries.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

Low-diffusion modified polypropylene composite material and preparation method thereof

ActiveCN101817953AHigh surface glossImprove impact resistancePolypropylene compositesMolecular sieve

The invention belongs to the field of modified polypropylene composite materials and relates to a low-odor and low-diffusion modified polypropylene composite material suitable for manufacturing interior decorative parts of automobiles. The composite material comprises the following components in part by weight: 60 to 90 parts of polypropylene, 0 to 40 parts of mineral filler, 1 to 5 parts of odor adsorbent and 0.1 to 1 part of assistant, wherein the odor adsorbent is a mixture of three types of clay, bentonite, porous silicon dioxide, activated aluminum oxide or molecular sieve. The prepared modified polypropylene composite material has the characteristics of high surface glossiness, high shock resistance and intensity, melt flowing property and mechanical property; due to the adoption of various gas adsorbents, the product has low odor diffusion property and a total carbon value of between 13.7 and 24.5 mu gC / g; simultaneously, needed raw materials have wide sources and are readily available.

Owner:SUZHOU SUNWAY POLYMER

Low-luster polypropylene composite material and method for producing the same

InactiveCN101173075AImprove heat aging resistanceImprove performanceElastomerPolypropylene composites

The invention discloses A polypropylene composite material with low luster and a preparation method thereof. The invention is characterized in that the material is formed by following raw materials by weight part: 56.5 to 98 parts of polypropylene, 0.2 to 1.5 parts of heat stabilizer, 0.3 to 1 part of light stabilizer, 0 to 20 parts of elastic bodies, 0.2 to 1 part of processing agent, 0 to 30 parts of inorganic filler, and 0.5 to 5 parts of silicon dioxide. The product of the invention has lower material luster, and the luster for the angle of 60 degrees on a smooth surface is lowered by 10 to 20 degrees than the primary product, thereby satisfying the requirement of low luster for material of people.

Owner:SHANGHAI KINGFA SCI & TECH +1

Low-VOC scratch-resistant modified polypropylene composite material and preparation method thereof

InactiveCN101787159AImprove adsorption capacityFully dispersedMolecular sievePolypropylene composites

The invention belongs to the field of modified polypropylene composite material, and relates to a low-VOC scratch-resistant modified polypropylene composite material which is applicable to manufacturing automobile interior trim parts, and comprises the components based on the parts by weight: 60-90 parts of polypropylene, 5-20 parts of toughening agent, 5-20 parts of mineral filler, 0.1-4 parts of odor adsorbent, 5-15 parts of wear-resistant agent / scratch-resistant agent and 0.1-3 parts of auxiliary agent, wherein the odor adsorbent is a mixture of three selected from clay, bentonite, porous silicon dioxide, activated aluminium oxide or molecular sieve; and the wear-resistant agent / scratch-resistant agent is one or a mixture of two in polytetrafluoroethylene micro powder or reaction-type polyorganosiloxane. The modified polypropylene composite material not only has better impact-resistant performance and strength, but also has excellent scratch-resistant performance and low-VOC diffusion characteristic; and the needed raw materials have wide source and can be conveniently and easily obtained.

Owner:SUZHOU SUNWAY POLYMER

Polypropylene composite material and preparation method thereof

The invention discloses a composite polypropylene material. The composite polypropylene material contains polypropylene resin, glass fiber and an antioxidant, wherein the fiber length of the glass fiber is between 0.4 and 1 millimeter. The invention also discloses a method for preparing the composite polypropylene material. The mechanical properties of the composite polypropylene material such as the tensile strength, the impact strength, the bending strength, the flexural modulus and so on are between the mechanical properties of short glass fiber reinforced polypropylene material and the mechanical properties of long glass fiber reinforced polypropylene material, and the cost of raw materials and the manufacturing cost are low.

Owner:BYD CO LTD

Low-odour polypropylene composite

The invention relates to a low-odour polypropylene compound, the compound comprises (by weight ratio) polypropylene 55-95, talcum powder 0-40, fatty acid ester compound 0.5-3, nano zinc oxide 0.5-3, nano titanium oxide 0.5-3, heat stabilizer DSTP 0.1-1.0, heat stabilizer 3114 0.1-1.0, heat stabilizer 618 0.1-0.5, wherein the fatty acid ester compound being C25-C45 long-chain fatty acid ester, the heat stabilizer DSTP being octadecyl thiodipropionate, the heat stabilizer 3114 being 3,obtaining 5-ditert-butyl-4-hydroxy benzylphosphonate diethylate, the heat stabilizer being dioctadecyl pentaerythritol diphosphite.

Owner:SHANGHAI PRET COMPOSITES +1

Polypropylene composite for automobile bumpers, and preparation method thereof

The invention discloses a polypropylene composite for automobile bumpers, and a preparation method thereof. The polypropylene composite for automobile bumpers comprises 60-80% of polypropylene resin, 10-20% of inorganic filler, 5-15% of thermoplastic elastomer, 5-10% of compatilizer, 0.1-1% of antioxidant, 0-1% of light stabilizer and 0-1% of processing aid. The preparation method of the polypropylene composite for the automobile bumpers comprises the following steps of: firstly, adding the polypropylene resin, the thermoplastic elastomer, the compatilizer and the inorganic filler into a high-speed mixing machine for uniformly mixing, then adding the antioxidant, the light stabilizer and a lubricant to continuously stir and mix at high speed, and finally adding the uniformly mixed material into a double-screw extruder for extruding and forming to obtain the polypropylene composite. Due to the addition of the compatilizer, compared with the prior art, the automobile bumpers made of the polypropylene composite provided by the invention have higher impact resistance and lower cost and can better meet the requirement of customers for an automobile bumper material with high cost performance.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

Polypropylene composite material for 3D (Three Dimensional) printing and preparation method thereof

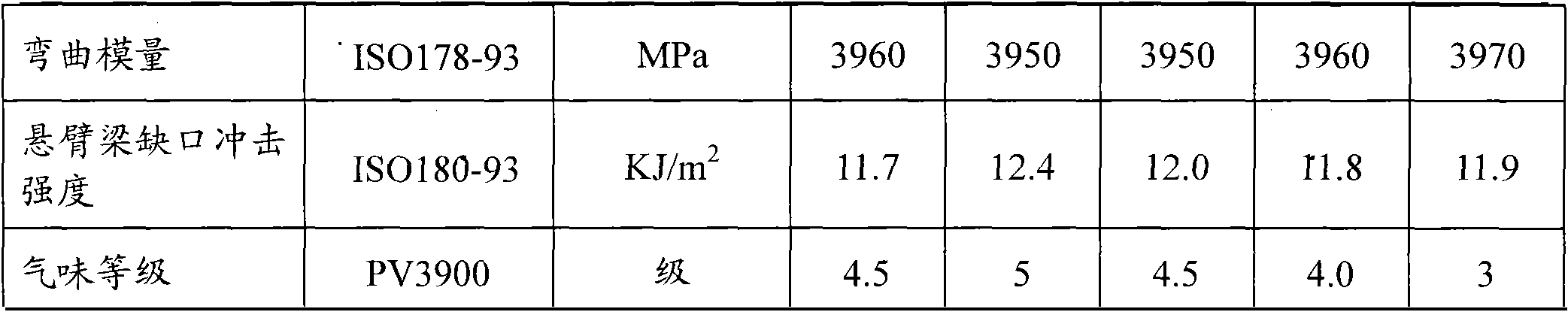

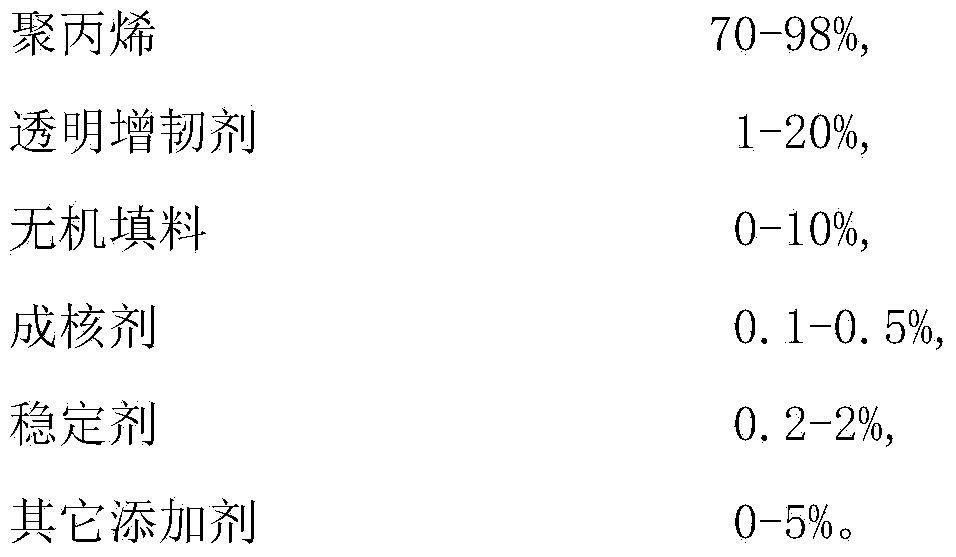

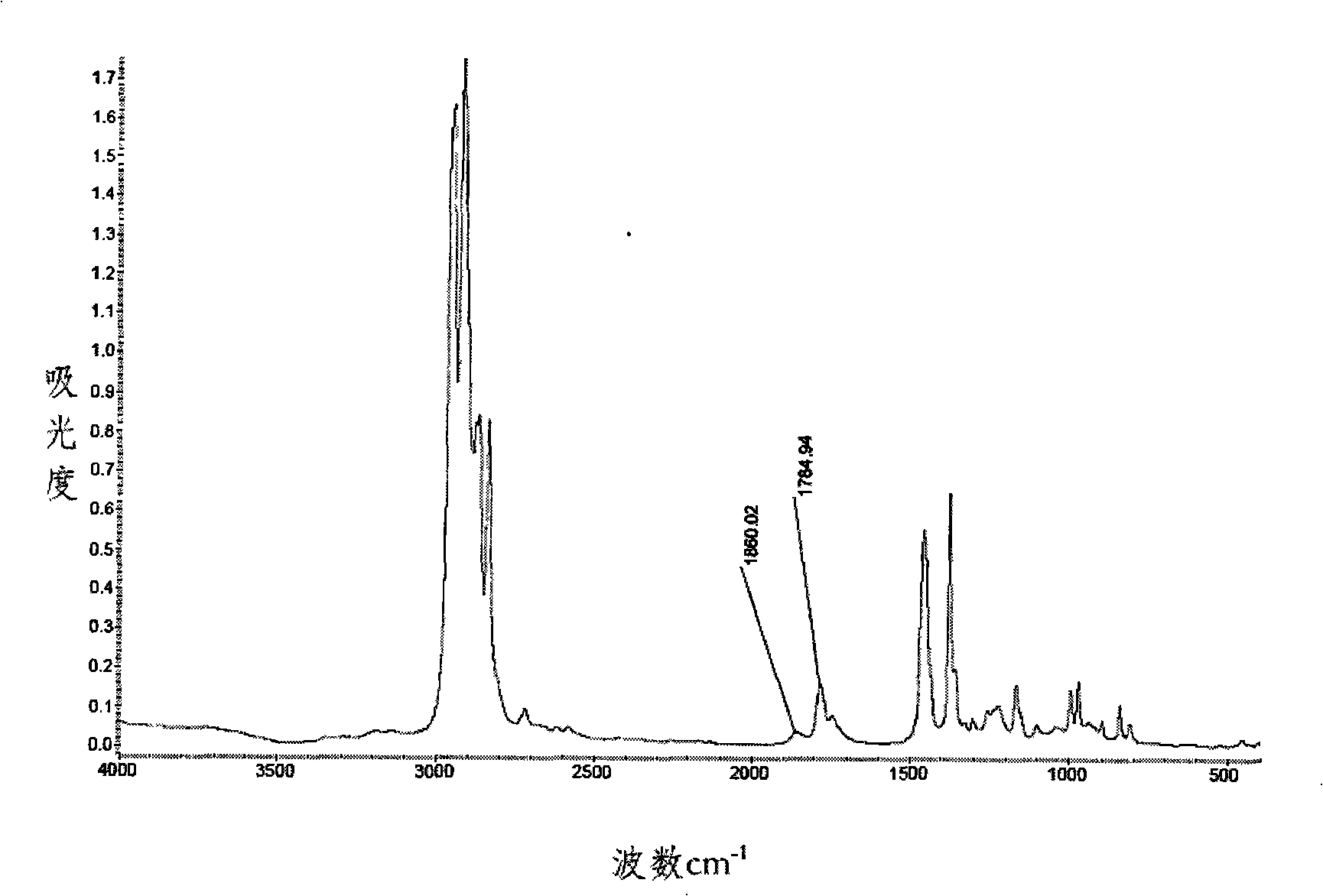

The invention discloses a polypropylene composite material for 3D (Three Dimensional) printing and a preparation method thereof. The polypropylene composite material is composed of following raw materials in percentage by weight: 70%-98% of polypropylene, 1%-20% of a transparent toughening agent, 0-10% of inorganic fillers, 0.1%-0.5% of a nucleating agent, 0.2%-2% of a stabilizing agent and 0-5% of other additives. The polypropylene composite material has the advantages that 1 a propylene-based elastic body is used as the toughening agent for processing polypropylene so that the roughness of materials can be improved and the shrinkage rate of the materials is reduced; the transparency is not greatly influenced; a beta nucleating agent is used for accelerating a crystallization speed; the molding speed is improved, the size of a spherical crystal is thinned and the transparency is improved; the density of a crystal region is reduced and the shrinkage rate is reduced; super-pure and superfine talcum powder or calcium sulfate crystal whiskers with a high mesh number and the like are adopted so that the shrinkage rate is reduced and the good transparency is kept. The polypropylene composite material for the 3D printing has the advantages that 1 the comprehensive performance is good; 2 a manner of wholly feeding from a main feeding opening is adopted so that the dispersion effects of the toughening agent, the talcum powder and the like are improved, and the performance of the composite material is further improved.

Owner:CHONGQNG PRET NEW MATERIAL +2

Carbon nanotube/polypropylene composite materials and process for preparing same

InactiveCN1654528ANo thermal decompositionImprove heat resistancePolypropylene compositesCarbon nanotube

The present invention provides one kind of composite antistatic carbon nanotube / polypropylene material and its preparation process. The composite antistatic carbon nanotube / polypropylene material has carbon nanotube as main antistatic modifying material and polypropylene as main modified target. The composite antistatic carbon nanotube / polypropylene material has both excellent antistatic performance and excellent mechanical performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

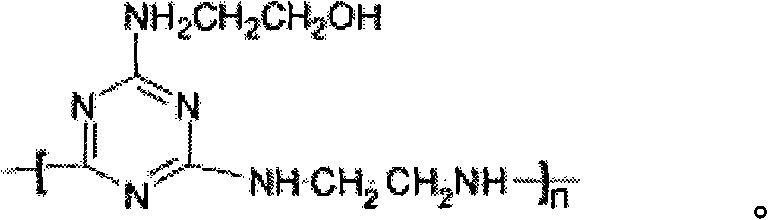

Method of preparing polypropylene graft polymer

The invention relates to a polypropylene graft polymer preparing method which is characterized in that: (a) calculated by weight parts, the polypropylene graft polymer comprises 100 parts of polypropylene, 0.1-20 parts of graft monomer maleic anhydride, 0.1-20 parts of graft monomer styrene monomer or vinyl acetate monomer, 0.01-10 parts of peroxide initiator and 1-20 parts of other vinyl monomers; (b) the graft monomers, the initiator and the polypropylene are evenly mixed; (c) the reactants are heated to reach a temperature of 70-120 DEG C and then react for 1-10 hours; and (d) after the reaction, the polypropylene graft polymer can be obtained through cooling. During the implementation of the method, no solvent, suspending medium or interfacial agent needs to be used, the obtained product can be applied without needing further treatment, for example, a compatilizer for a polypropylene composite material; and the obtained product is particularly used for improving the interfacial compatibility and dispersivity of inorganic filler and polyolefine. The conversion rate of the graft monomers of the invention is greater than 95 percent, and at least 55 percent of the graft monomers form graft polypropylene.

Owner:BEIJING UNIV OF CHEM TECH

Low VOC polypropylene composite material and preparation and application thereof

The invention discloses a low VOC polypropylene composite material and a preparation method and an application thereof. The material is prepared by polypropylene, a filling agent, a smell removing agent, a scraping-proof agent, an antioxygen, a weather-proof agent and a lubricating agent according to part by weight, wherein the smell removing agent is a water-based solution of a polymer surfactant which is adsorbed on a polypropylene carrier; the used smell removing agent is a novel smell removing agent, the melting point of the smell removing agent is 160 DEG C, the boiling point is higher than 100 DEG C; the smell removing agent has the characteristic that the dispersion is uniform, lots of foam of the fused smell removing agent is generated in an extrusion mixing process, the vacuum devolatilization is clean, residue is not generated and the like. The prepared low VOC polypropylene composite material has the characteristics of being UV resistant, scraping resistant, light in smell, less in the VOC residual volume and the like, and is mainly used on automotive trim materials such as an instrument desk, a door plate and a stand column of an automobile.

Owner:ORINKO NEW MATERIAL CO LTD

Polypropylene composite material and preparation method and application thereof

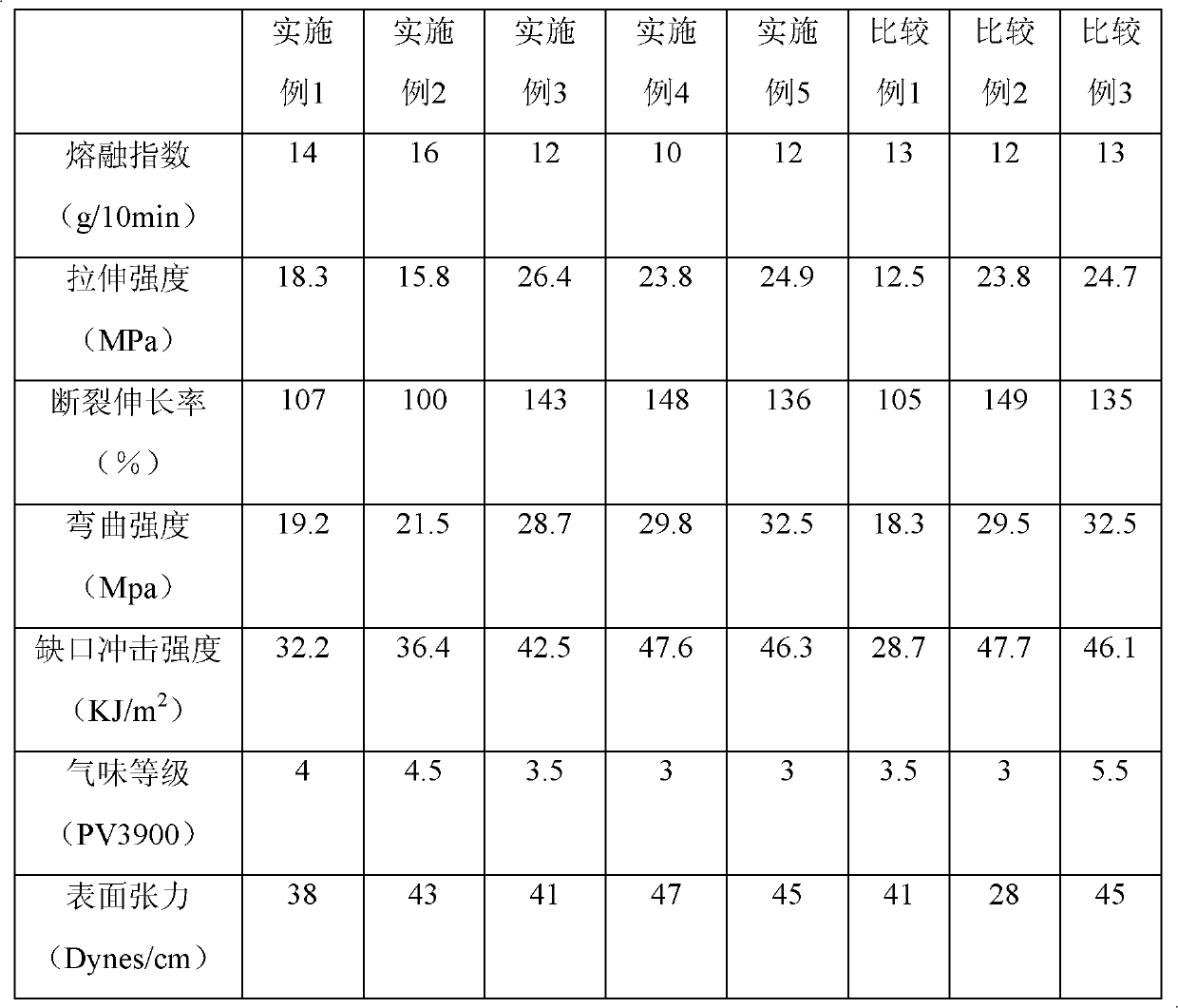

InactiveCN103374180AIncrease surface tensionGood compatibilityPolypropylene compositesHeat resistance

The invention belongs to the technical field of modification and processing of high-molecular materials, and relates to a polypropylene composite material and a preparation method and an application thereof. The polypropylene composite material is prepared from the following components in parts by weight: 100 parts of polypropylene, 20-60 parts of reinforced fibers, 8-20 parts of polar additives, 10-35 parts of toughening agents, 1.5-3.5 parts of antiaging agents, 1.2-4.4 parts of compatilizer, 5-12 parts of inorganic composite fire retardants, 1.5-6.6 parts of smell inhibitors and 0.3-0.8 part of processing auxiliary agents. Compared with the prior art, the prepared polypropylene composite material is high in surface tension, achieves good bonding property with other materials, has the advantages of good rigidity without being lacked of toughness, good heat resistance, ageing resistance and fire retardance, little smell and excellent forming processing property and can be widely used as a special material for inner and outer ornaments of various types of automobiles.

Owner:滁州格美特科技有限公司

Polypropylene composite material and preparation method thereof

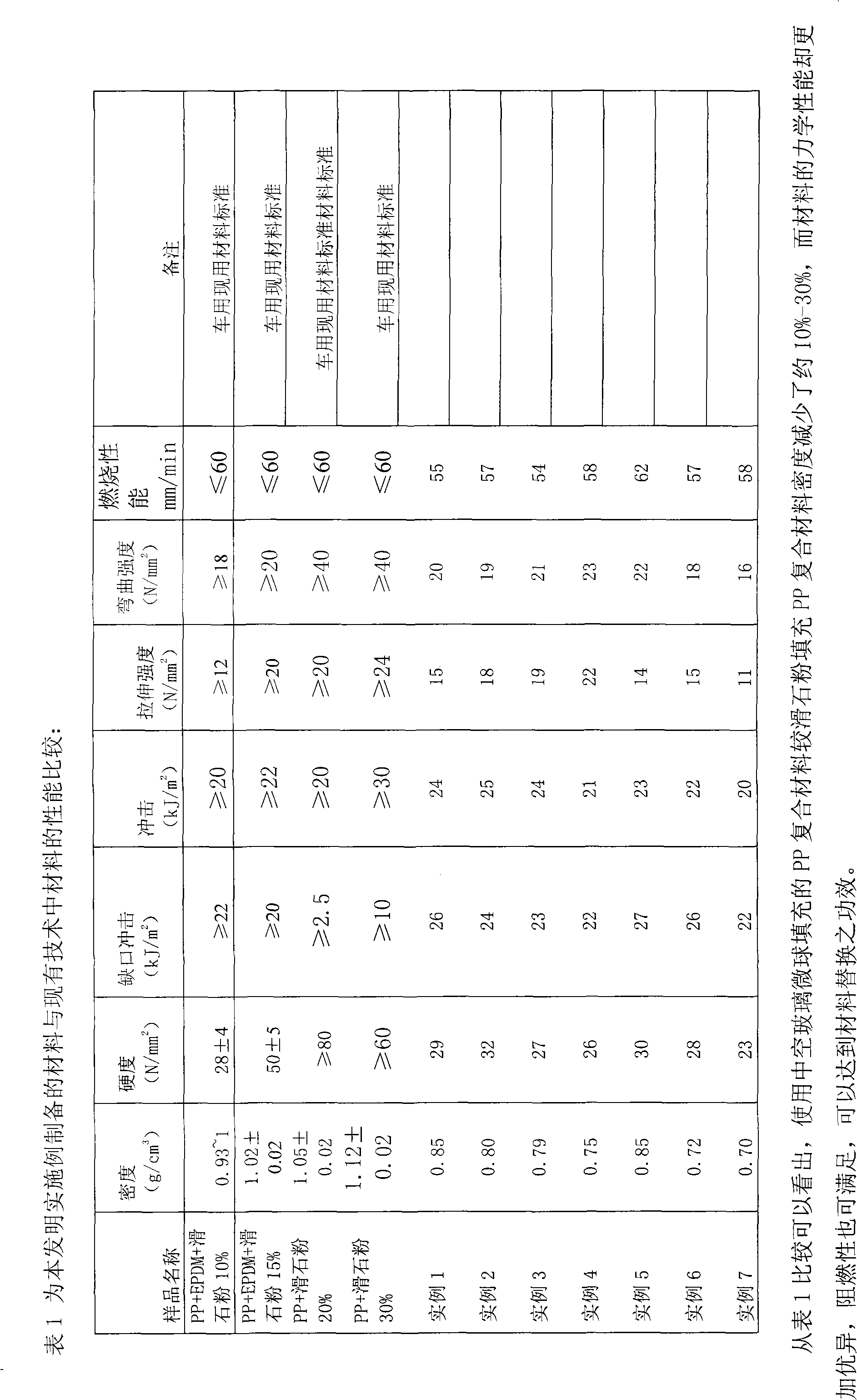

The invention discloses a polypropylene composite material and a preparation method thereof, wherein the formulation of the polypropylene composite material comprises the components by weight percent: 40-70% of polypropylene, 5-30% of toughening agent, 10-40% of hollow glass microspheres, 0.2-5% of photo-thermal stabilizing agent, 0.1-5% of coupling agent, 0.5-5% of compatilizer, 0.1-5% of processing agent and 2-15% of flame retardant agent. The preparation method of the polypropylene composite material comprises the steps that: mixing the raw materials, soaking the hollow glass microspheres in the coupling agent, drying, mixing, pelleting and obtaining the polypropylene composite material. By adding the hollow glass microspheres with high strength, the invention reduces the density of the PP material, improves the strength and the dimensional stability of the PP material, has important significance for reducing the weight of plastics, especially for lightening the weight of automobiles as well as saving energy and reducing emission in the plastic material used for the automobiles.

Owner:CHERY AUTOMOBILE CO LTD

Modified polypropylene composite material of high gloss and low shrinkage and preparation method thereof

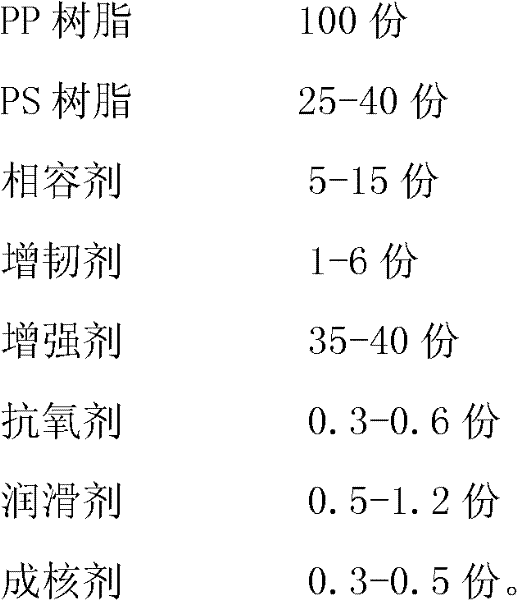

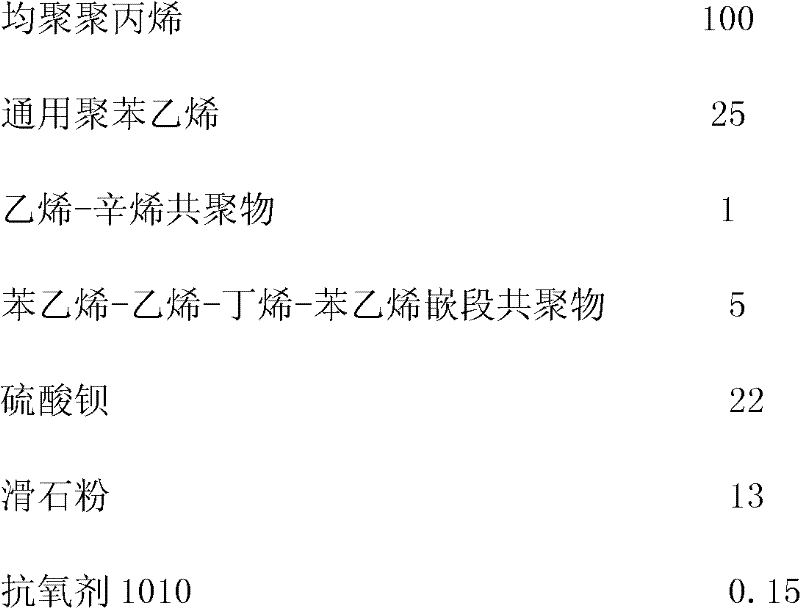

The invention discloses a modified polypropylene composite material of high gloss and low shrinkage and a preparation method thereof. The polypropylene composite material includes the raw materials of by weight: 100 parts of PP (polypropylene) resin, 25-40 parts of PS (polystyrene) resin, 5-15 parts of a compatilizer, 1-6 parts of a flexibilizer, 35-40 parts of a reinforcing agent, 0.3-0.6 parts of an anti-oxidant, 0.5-1.2 parts of a lubricant and 0.3-0.5 parts of a nucleating agent. The preparation method comprises the steps of: mixing the PP resin, the PS resin, the compatilizer, the flexibilizer, the anti-oxidant, the lubricant and the nucleating agent uniformly at a high speed, then adding the reinforcing agent into the mixture and continuing high-speed mixing, adding the obtained mixture into an extruder, conducting extrusion granulation after fusion, thus obtaining the composite material. The modified polypropylene composite material prepared by the method provided in the invention has the characteristics of high gloss and low shrinkage as well as the advantages of good impact strength and high flexural modulus. And the composite material of the invention can be used for material replacement under the precondition of not replacing the original ABS (acrylonitrile butadiene styrene) die and for production of household electrical appliance surface shell products.

Owner:ORINKO NEW MATERIAL CO LTD

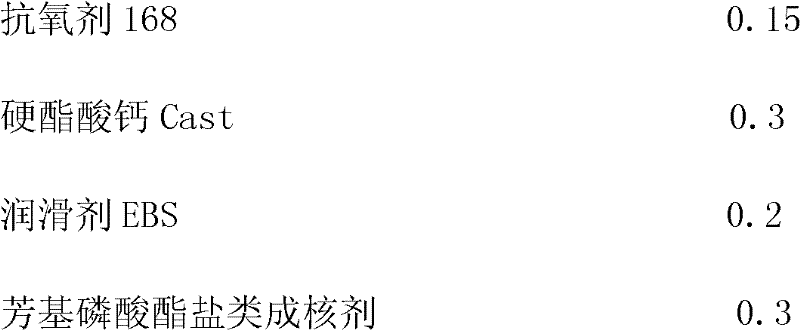

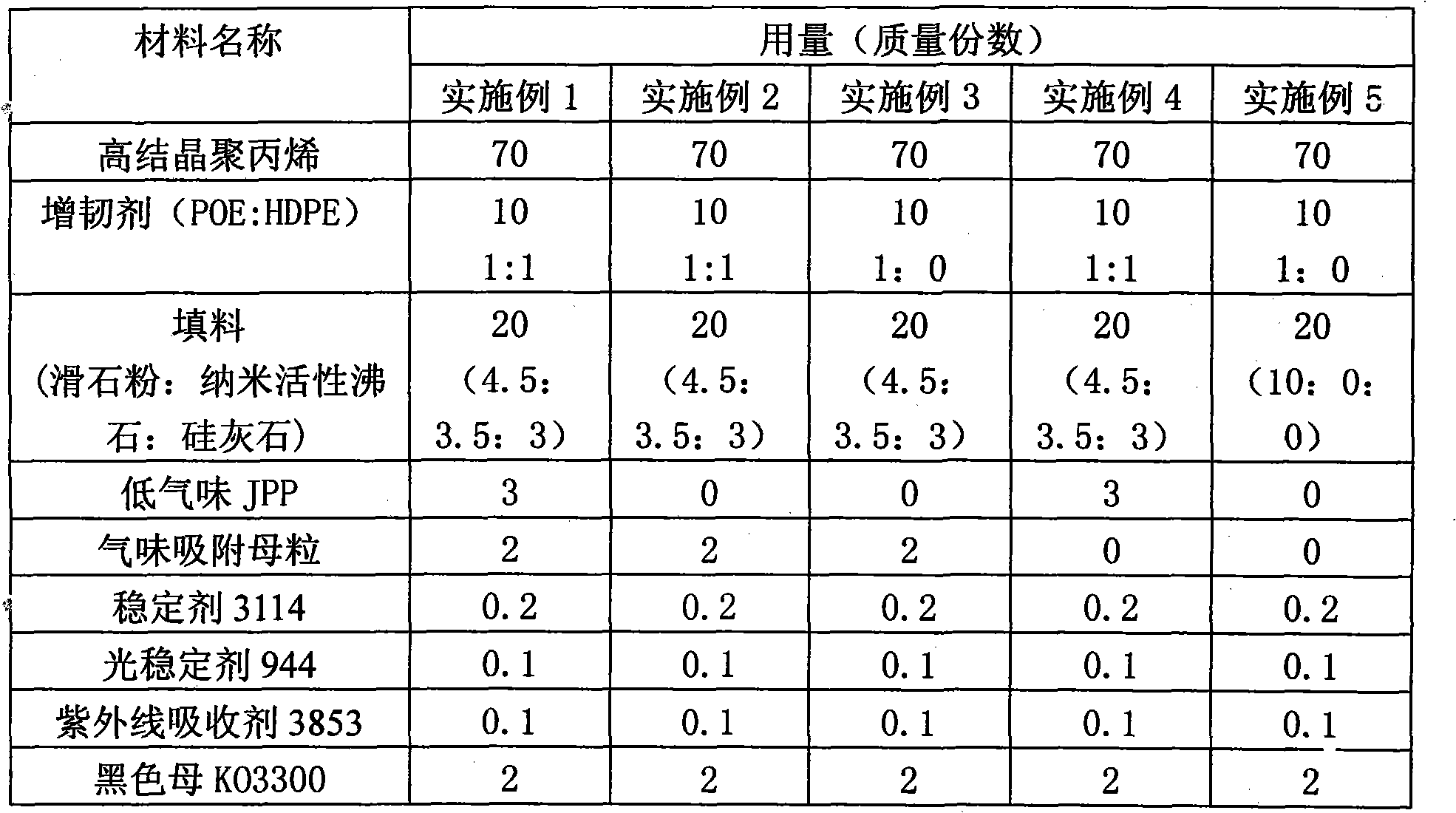

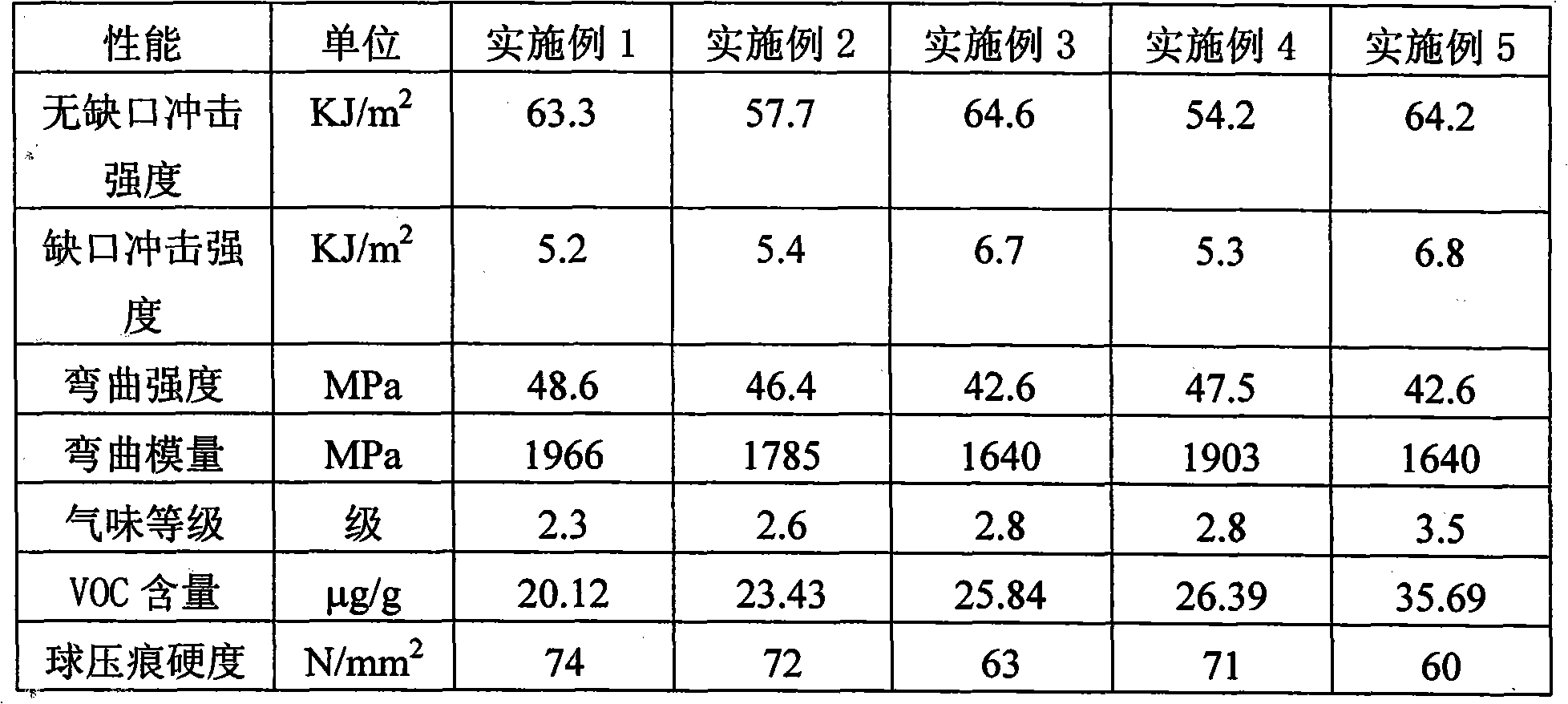

Low-odor, low-volatile organic compound (VOC) and high-performance polypropylene composite material for automotive interior decoration

The invention discloses a low-odor, low-volatile organic compound (VOC) and high-performance polypropylene composite material for automotive interior decoration and a preparation method for the composite material. The composite material is prepared from the following raw materials: 50 to 90 percent of polypropylene, 0 to 40 percent of inorganic filler, 5 to 15 percent of toughening agent, 5 to 10 percent of compatilizer, 0.5 to 5 percent of odor absorption masterbatch, 0.1 to 1.0 percent of antioxidant and 1.0 to 2.5 percent of color masterbatch, wherein a low-odor resin raw material and an additive are preferred; and a multi-component effective odor removal system is involved, and the aluminosilicate odor absorption masterbatch, the low-odor maleic anhydride-grafted polypropylene compatilizer, and an ingredient, namely nanometer activated zeolite in the filler cooperate to remove the odor of materials and reduce the diffusion of organic substances. The composite material has the characteristics of good odor, high surface performance, excellent mechanical properties, low cost and the like.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

Active basic magnesium sulfate whisker modified polypropylene composite material and preparation method thereof

The invention discloses an active basic magnesium sulfate whisker modified polypropylene composite material and a preparation method thereof. The composite material consists of polypropylene, basic magnesium sulfate whiskers, a flexibilizer, a processing agent, a coupling agent, acid dilution and a heat stabilizer. An engineering part made of the composite material disclosed by the invention is developed towards the lightweight; the composite material is beneficial to the reduction of the use quantity of the material and the reduction of the use cost of the material; and moreover, the product is green and environmental-friendly and is suitable to prepare automobile interior parts.

Owner:ORINKO NEW MATERIAL CO LTD

Preparation method of carbon nanotubes/nano ATO (antimony tin oxide)/polypropylene electroconductive fibers

InactiveCN102409421AImprove fill factorImprove electrical performanceElectroconductive/antistatic filament manufactureMonocomponent polyolefin artificial filamentPolypropylene compositesOrganic solvent

The invention discloses a preparation method of carbon nanotubes / nano ATO (antimony tin oxide) / polypropylene electroconductive fibers. The preparation method comprises the following steps of: (1) mixing nano ATO and carbon nanotubes, placing in an organic solvent together with a dispersant, and carrying out surface treatment to obtain a double-component nano electroconductive agent; (2) mixing the double-component nano electroconductive agent with polypropylene slices, and carrying out melt blending and strip preparation and granulation with a screw extruder to obtain double-component nano electroconductive agent / polypropylene composite electroconductive slices; (3) carrying out melt spinning on the composite electroconductive slices to obtain carbon nanotubes / nano ATO / polypropylene nascent electroconductive fibers; and (4) stretching and shaping the carbon nanotubes / nano ATO / polypropylene nascent electroconductive fibers to obtain the carbon nanotubes / nano ATO / polypropylene electroconductive fibers. By using the preparation method, the filling factor of a filler is increased, the content of an electroconductive filler in the material is reduced, the electric conductivity of the material is improved, and the electric performance stability of the material is simultaneously improved; and the preparation method has low price and no special requirement on equipment, has a economicand simple process route, and is suitable for industrial production.

Owner:ZHONGYUAN ENGINEERING COLLEGE

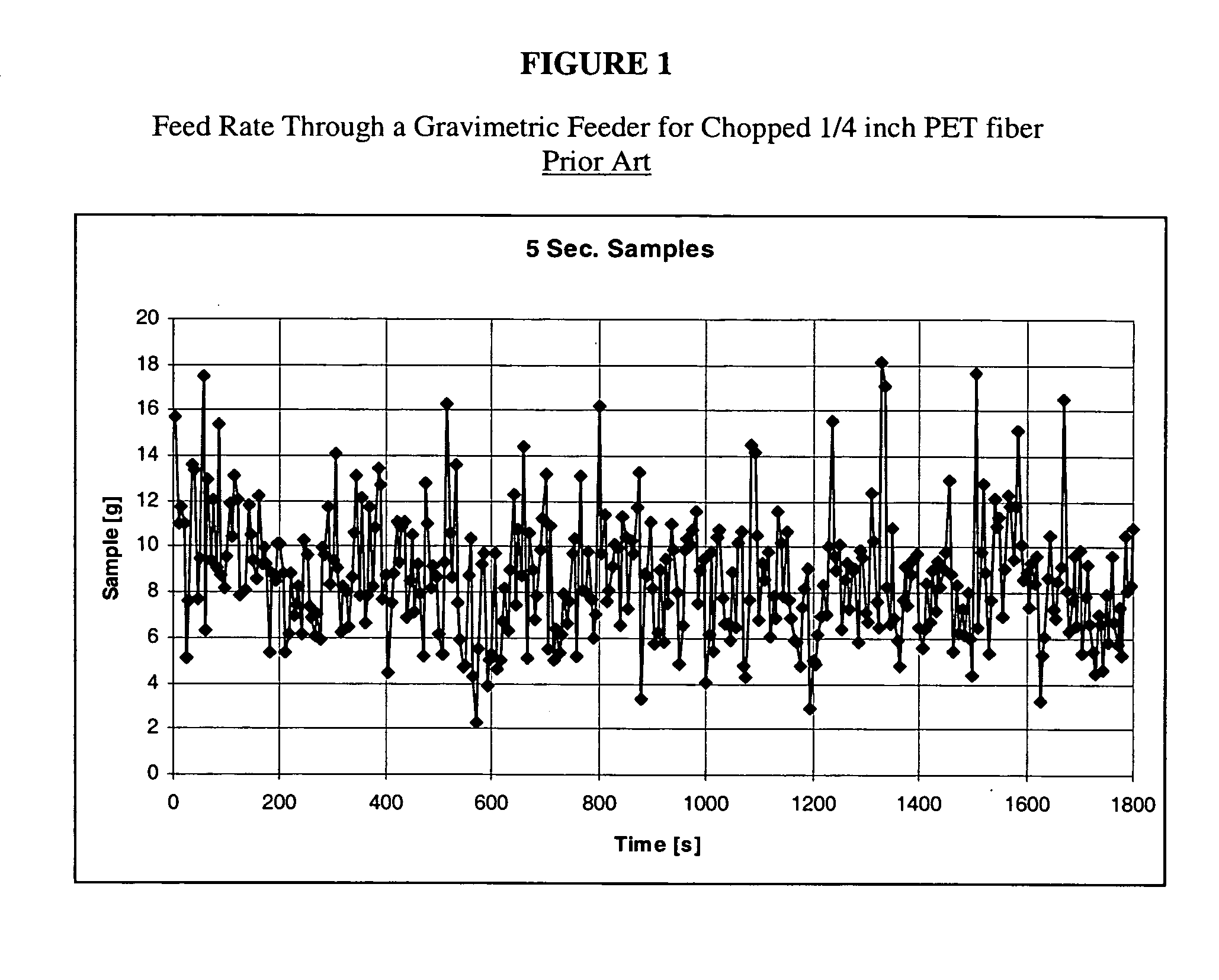

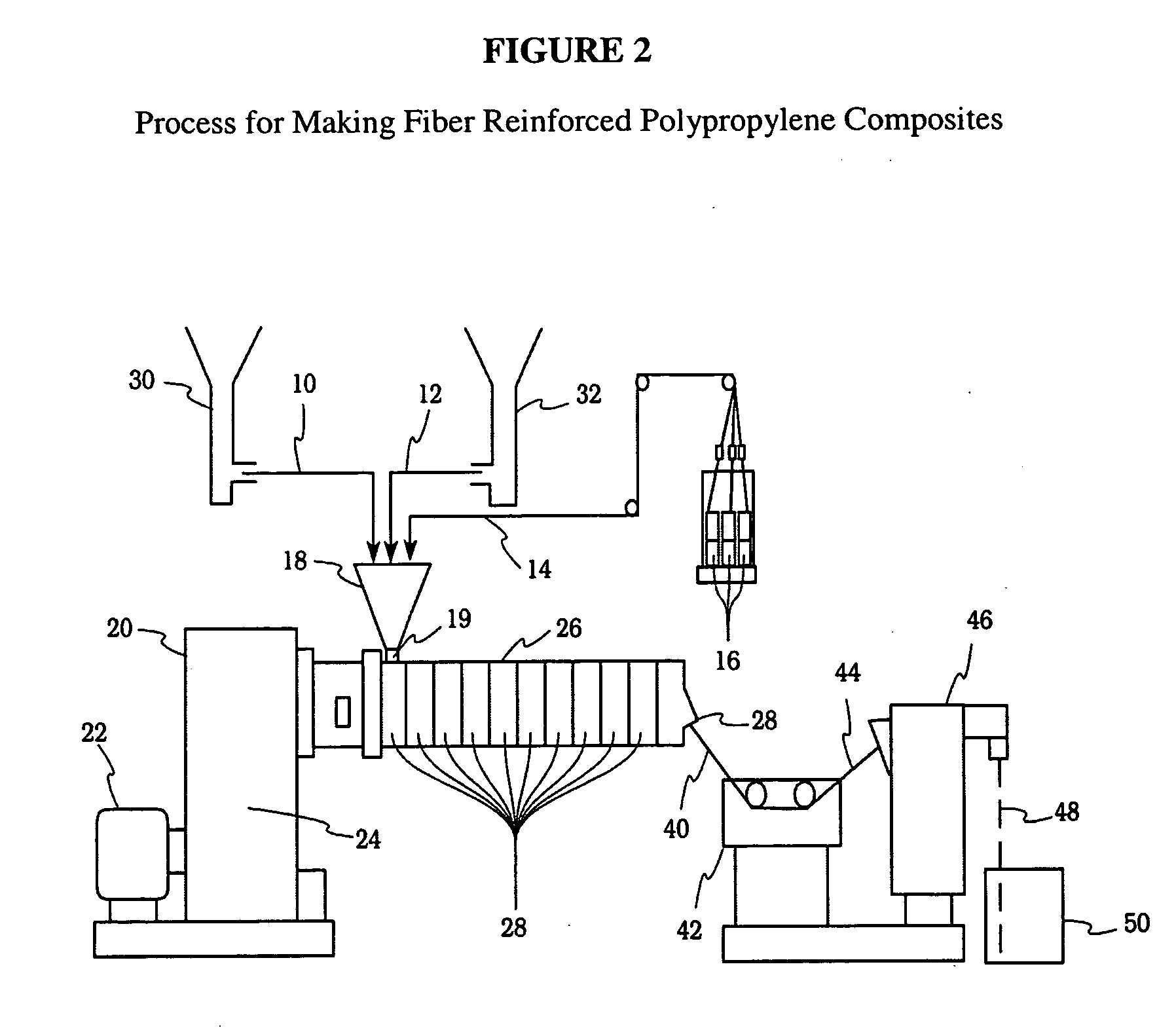

Method for making fiber reinforced polypropylene composites

InactiveUS20060261509A1Improve impact resistanceHigh modulusDomestic articlesArtifical filament manufacturePolypropylene compositesFlexural modulus

The present invention is directed generally to processes for making fiber reinforced polypropylene resins including at least 25 wt % polypropylene based polymer, from 5 to 60 wt % organic fiber, and from 0 to 60 wt % inorganic filler. The process includes extrusion compounding the polypropylene based polymer, the organic fiber, and the inorganic filler to form a fiber reinforced polypropylene resin, which is subsequently molded to form an article with a flexural modulus of at least 300,000 psi, that exhibits ductility during instrumented impact testing (15 mph, −29° C., 25 lbs). Twin screw extruder compounding processes where the organic fiber is continuously fed to the extruder hopper by unwinding from one or more spools, and uniformly dispersed in the fiber reinforced polypropylene resin by twin screws having a combination of conveying and kneading elements are also disclosed.

Owner:LUSTIGER ARNOLD +2

Delustering polypropylene composite material and preparation method thereof

The invention discloses a delustering polypropylene composite material and a preparation method thereof. The dulling polypropylene composite material comprises the following components in mass percent: 60-80% of polypropylene, 2-20% of flexibilizer, 5-20% of compatilizer, 5-25% of organic delustering agent, 0.5-5% of inorganic delustering agent, 0.1-2% of antioxidant and 2-20% of inorganic filler. The dispersion effect of delustering components in the polypropylene is strengthened through preparing master batch, the polypropylene, the delustering agent, the inorganic filler and part of compatilizer are firstly co-blended and then extruded through a dual-screw extruder to prepare the delustering master batch, and then the delustering master batch is co-blended with polypropylene and other components, and then extruded to prepare the delustering polypropylene composite material. The delustering polypropylene composite material is excellent in delustering performance, suitable for injection molding of various delustering products, can be applied to indoor decoration and automotive upholstery and can be used for preventing glare from generating in daily life.

Owner:GUANGDONG KINGFA TECH CO LTD

Polypropylene composite material for automobile bumper and prepn. thereof

InactiveCN1834145AImprove performanceReduce surface defectsBumpersHeat deflection temperaturePolypropylene composites

This invention discloses a kind of polypropylene composite materials for automobile bumpers and its preparation method. This kind of materials comprises 93.3~56.5wt% polypropylene, 0.2~1.5wt% thermo-stabilizers, 0.3~1wt% photo-stabilizers, 0.2~1% auxiliary reagents, 1~20wt% activating and reinforcing masterbatches and 5~20wt% stuffing masterbatches. The product in this invention has high surface activity, low thermo expansion rate and high thermo expansion temperature. The surface tension is 40mN / m, the linear thermo expansion rate is 10 to the power -6 to 10 to the power -7 mm per mm per deg. C, the thermo deformation temperature is 55 deg. C and some other technological indices all reach or exceed current standards for automobile materials. Thanks to the high surface tension and strong paint-adhesion of the bumpers made of this kind of materials, paints can be directly sprayed rather than flame processing. The thermo expansion rate is low, and therefore, loosening due to significant deformation might not occur with large temperature variation. Besides, it also has the advantages of high the thermo resistant temperature, short baking time and high production efficiency.

Owner:SHANGHAI KINGFA SCI & TECH

Low-VOC (Volatile Organic Compound) polypropylene composite material for automotive interior parts and preparation method thereof

Owner:ORINKO NEW MATERIAL CO LTD

Spraying-free scratch-resistant polypropylene composite material used for car exterior trimming parts and preparation method of composite material

InactiveCN104045908AWith metallic luster effectScratch resistantPolypropylene compositesApplication areas

The invention relates to a spraying-free scratch-resistant polypropylene composite material used for car exterior trimming parts and a preparation method of the composite material. The spraying-free scratch-resistant polypropylene composite material is prepared from the following components in parts by weight: 39.6-77.1 parts of polypropylene, 5.0-8.0 parts of high-density polyethylene, 0-15 parts of flexibilizer, 15-25 parts of filler, 0.2-1 part of antioxidant, 1.0-5.0 parts of scratch resistant agent, 0.5-1 part of lubricant, 0.2-0.4 part of light stabilizer, 1.0-5.0 parts of metal toner. According to the spraying-free scratch-resistant polypropylene composite material disclosed by the invention, the metal toner and the scratch resistant agent are adopted, so that the polypropylene composite material has metallic luster effect and scratch resistance, has spraying-free effect and further has scratch resistance at the same time, and therefore, application field of the polypropylene is expanded, and the spraying-free scratch-resistant polypropylene composite material is especially applicable to using on the field of car exterior trimming parts.

Owner:ORINKO NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com