Method of preparing polypropylene graft polymer

A polypropylene grafting and polymer technology is applied in the field of polypropylene grafting polymer and solid-phase free radical grafting polymerization of polypropylene, which can solve the problems of increasing interfacial adhesion, reducing interfacial tension and poor compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

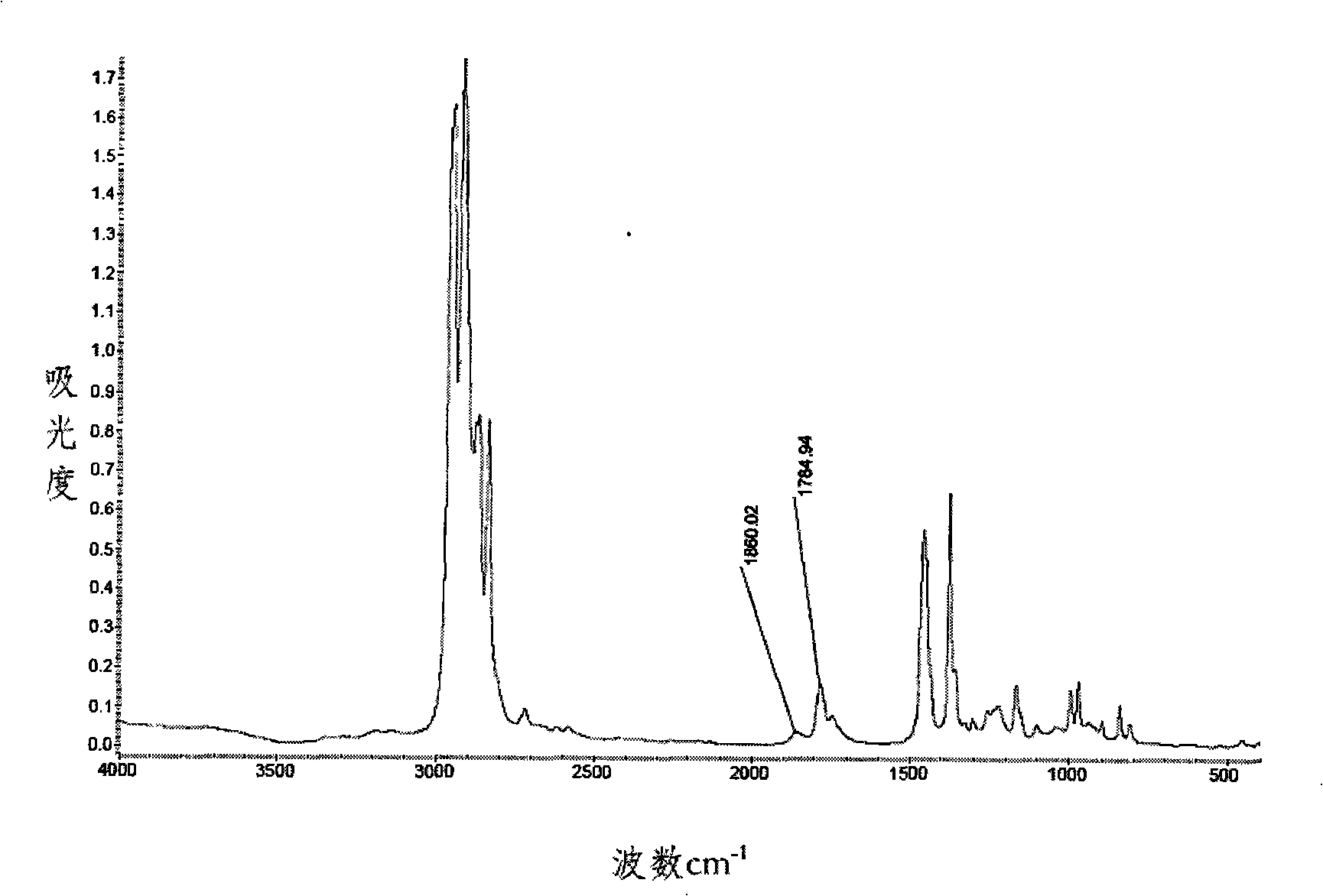

[0031] The polypropylene used in the present invention is a homopolymer of propylene, and the measured melt index is 3.25g (230° C., 10 minutes). Get a 500ml single-necked glass flask, and mix 100 grams of polypropylene, 4.62 grams of maleic anhydride, 5.5 grams of styrene and 0.4 grams of dibenzoyl peroxide in the flask. Then put the glass flask into an oven with a temperature of 90° C. to react for 4 hours. After cooling, the material in the flask is poured into a glass petri dish, put into a vacuum oven, and dried to a constant weight at a temperature of 80-85°C to obtain 109.68 grams of the product, and the conversion rate of the grafted monomer is 99.5%. The melt index is 1.85. It shows that the conversion rate of the grafted monomer in the method of the present invention is high, and the degradation reaction of polypropylene in the graft polymerization process is effectively simulated. Accurately weigh 5.004 grams of the grafted product, extract it with acetone for 24 ...

Embodiment 2

[0033] Take a 500ml single-necked glass flask, add 100 grams of polypropylene, 4.62 grams of maleic anhydride, 5.05 grams of vinyl acetate and 0.4 grams of dibenzoyl peroxide, and mix well. Then put the glass flask into a water bath with a temperature of 90° C., and react for 6 hours. After cooling, the material in the flask was poured into a glass petri dish, put into a vacuum oven, and dried to a constant weight at a temperature of 80-85°C to obtain 108.60 grams of the product, and the conversion rate of the grafted monomer was 99%. The melt index is 5.1. Accurately weigh 5.003 grams of the grafted product, extract it with acetone for 24 hours in a Soxhlet fat extractor, then dry it to constant weight in a vacuum oven at a temperature of 80-85 ° C, and the weight of the remaining product is 4.7741 grams. 56.5% of the monomers were converted to graft copolymers.

Embodiment 3

[0035] Take a 500ml three-neck glass flask equipped with mechanical stirring and put it into a water bath, add 100 grams of polypropylene, 2.31 grams of maleic anhydride, 3.0 grams of styrene and 0.2 grams of dibenzoyl peroxide, start stirring and mixing for 20 minutes . Set the temperature of the water bath to 90° C., and react for 6 hours. After cooling, the material in the flask is poured into a glass petri dish, put into a vacuum oven, and dried to a constant weight at a temperature of 80-85° C. to obtain 105.1 grams of the product, and the conversion rate of the grafted monomer is 99.8%. The melt index is 5.49. Accurately weigh 5.0024 grams of the grafted product, extract it with acetone for 24 hours in a Soxhlet fat extractor, then dry it to constant weight in a vacuum oven at a temperature of 80-85 ° C, and the weight of the remaining product is 4.8999 grams. 65.3% of the monomers were converted to graft copolymers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com