Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1396 results about "Styrene Monomer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Styrene is one of the most important monomers produced by the chemical industry today. Styrene monomer is a basic building block of the plastics industry. The conventional method of producing styrene involves the alkylation of benzene with ethylene to produce ethylbenzene, followed by dehydrogenation of ethylbenzene to styrene.

Sulfonated block copolymers, method for making same, and various uses for such block copolymers

ActiveUS7737224B2Reduced responseHigh propertySemi-permeable membranesNegative electrodesMethacrylatePolymer science

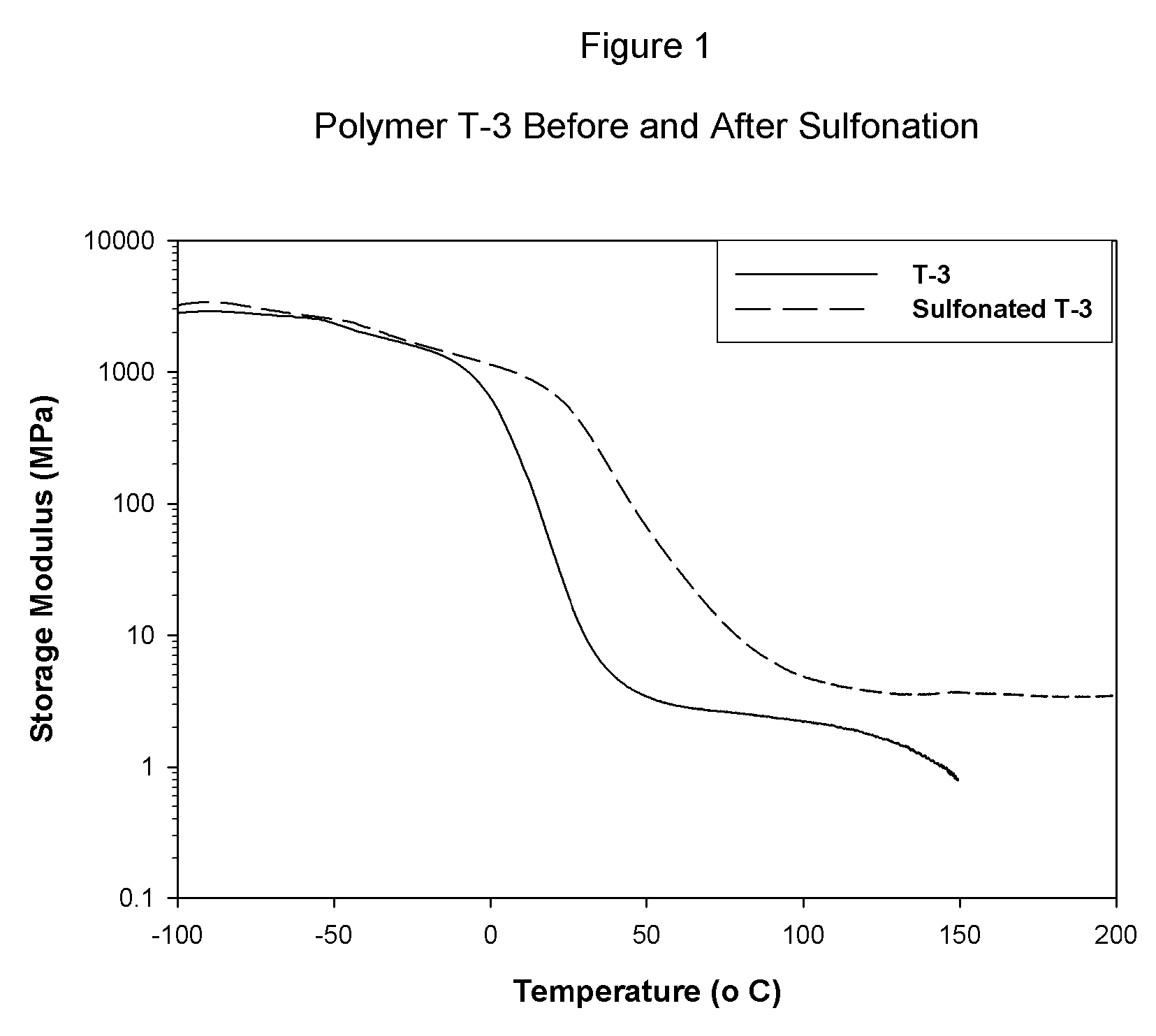

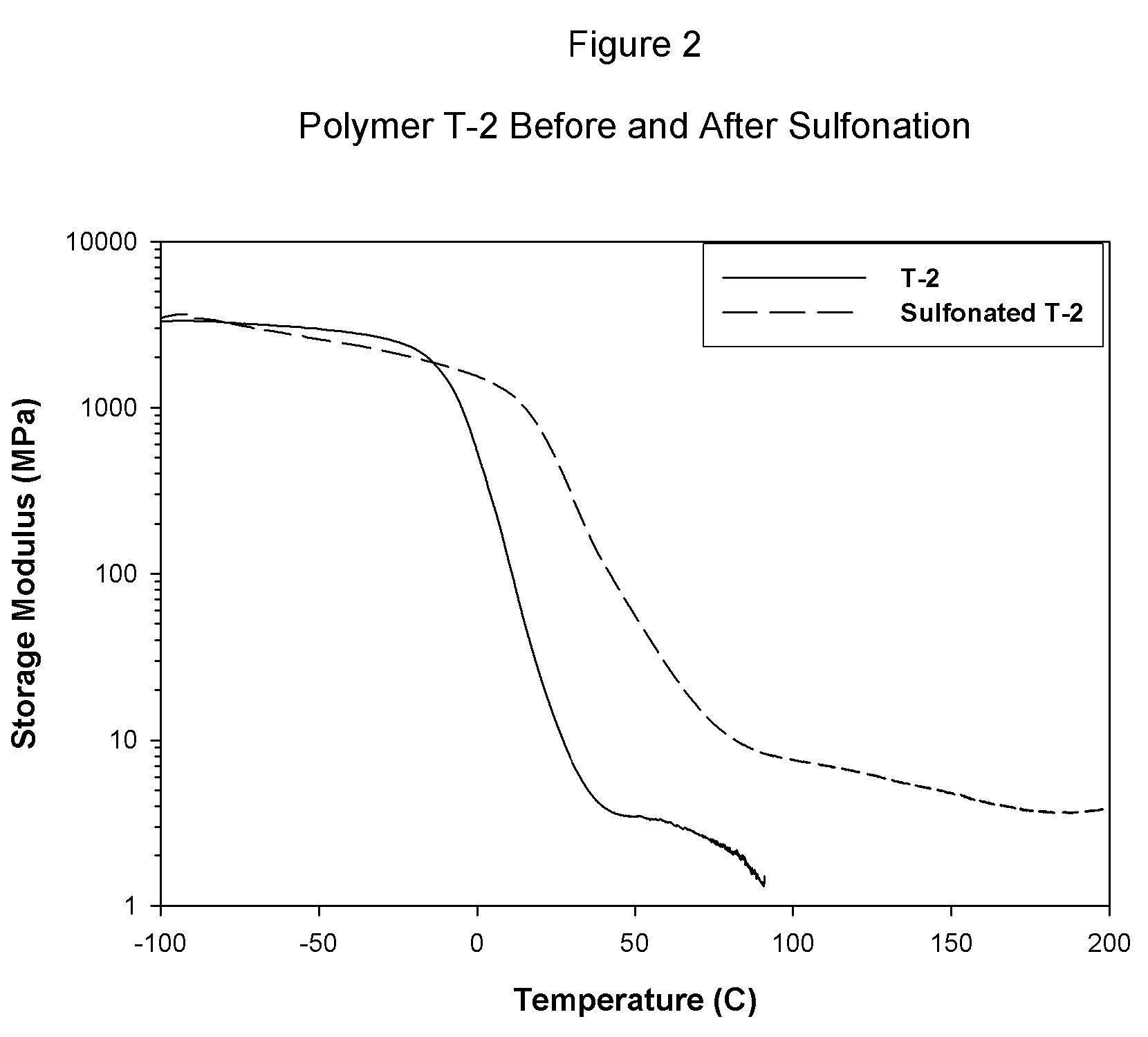

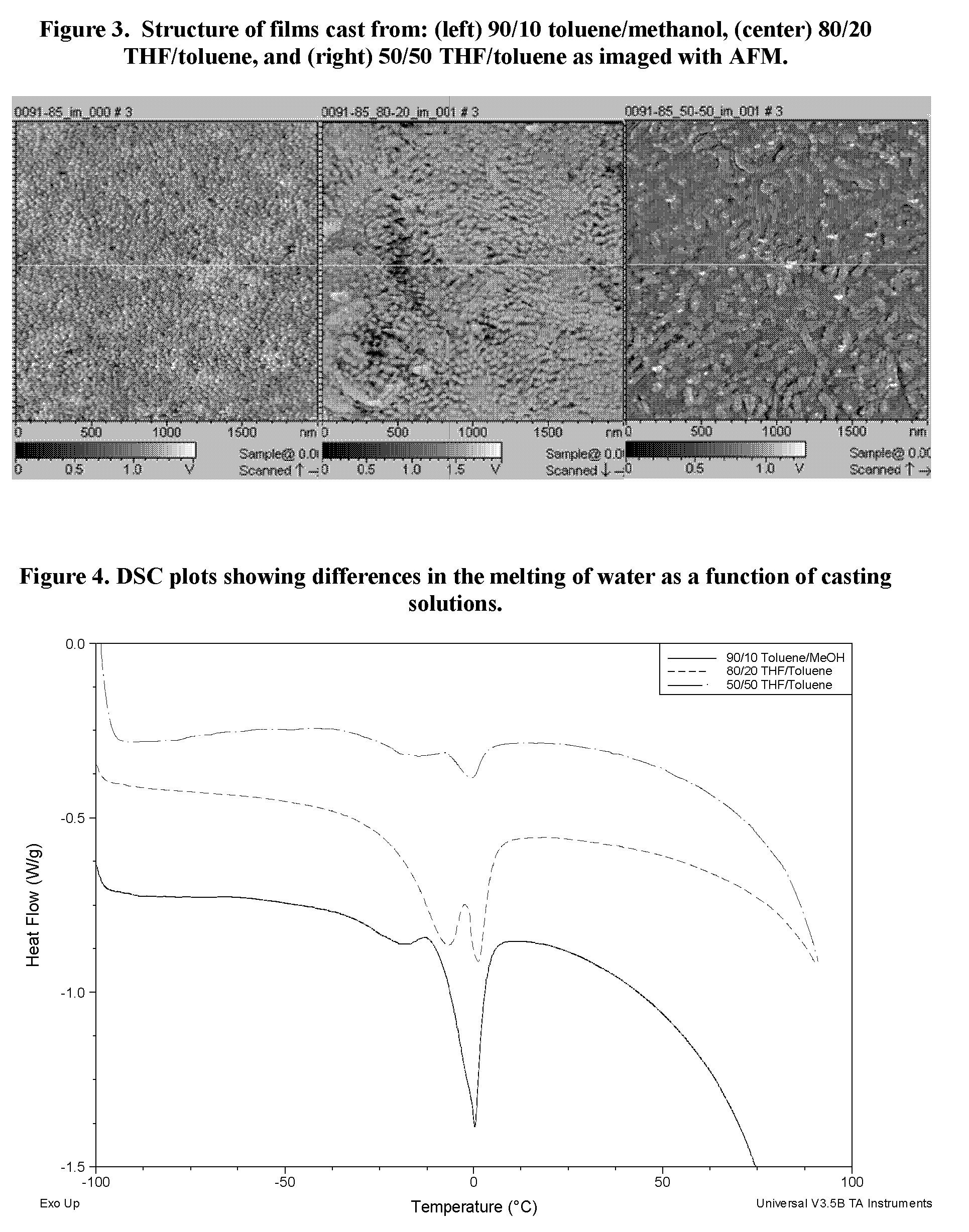

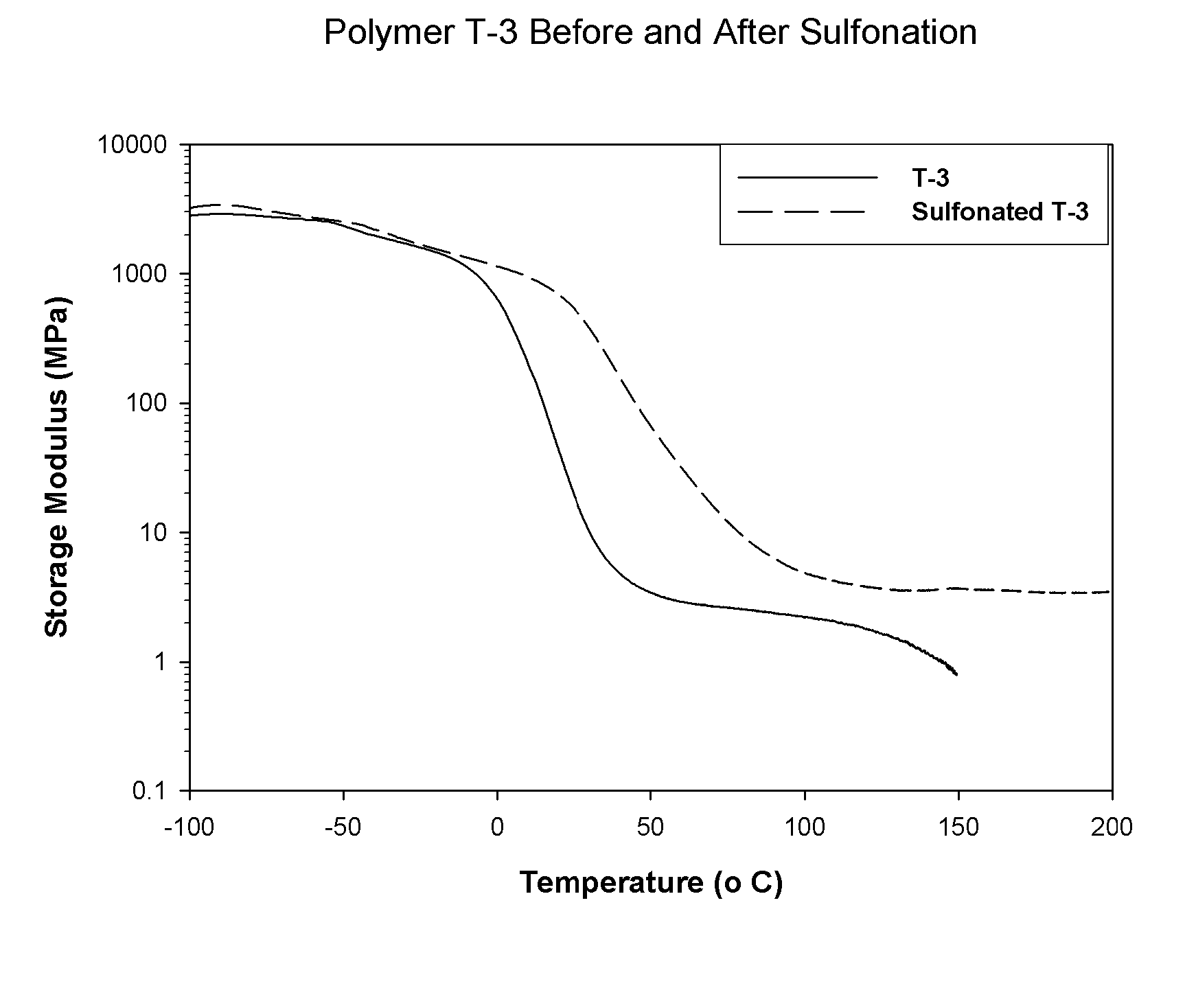

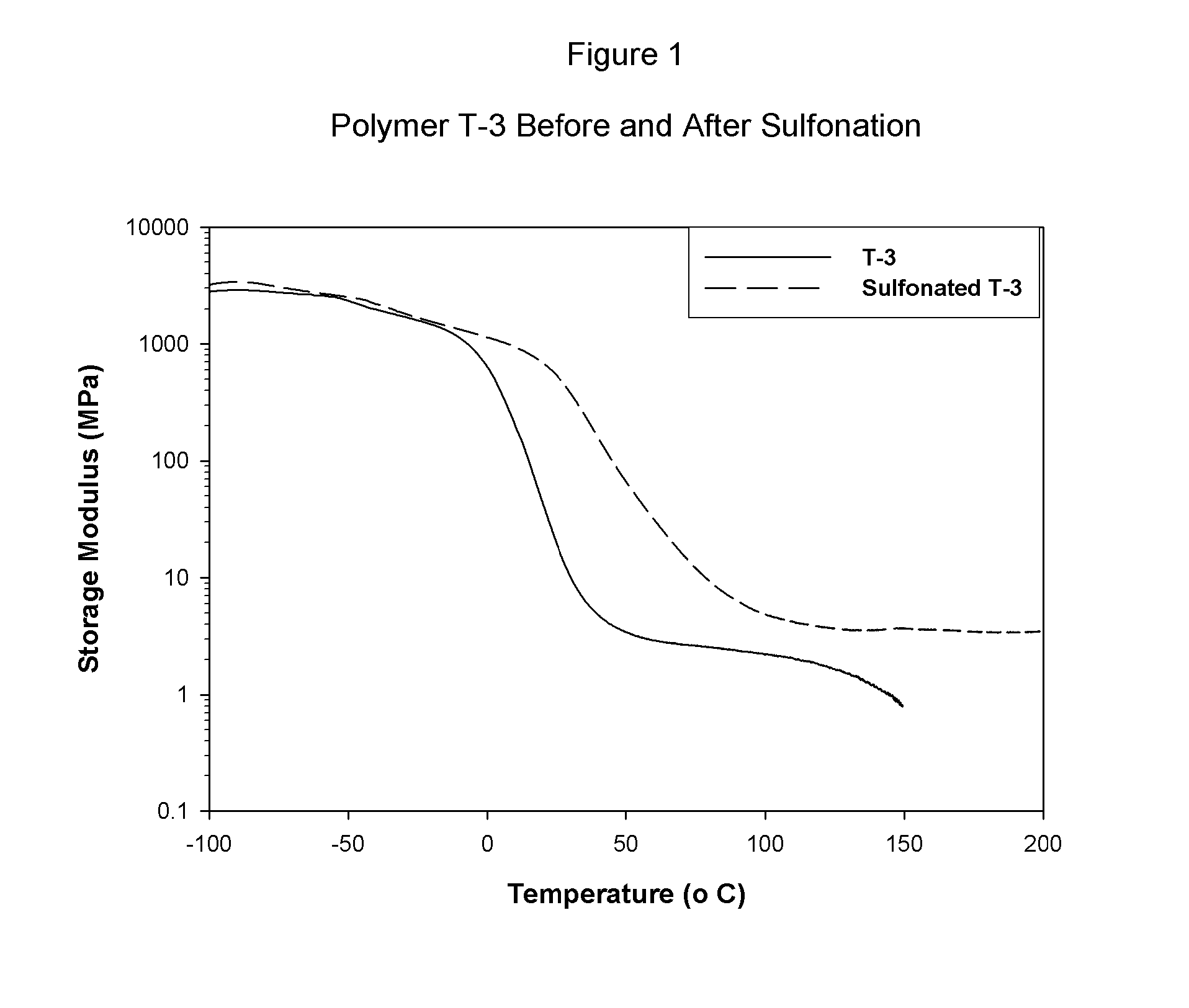

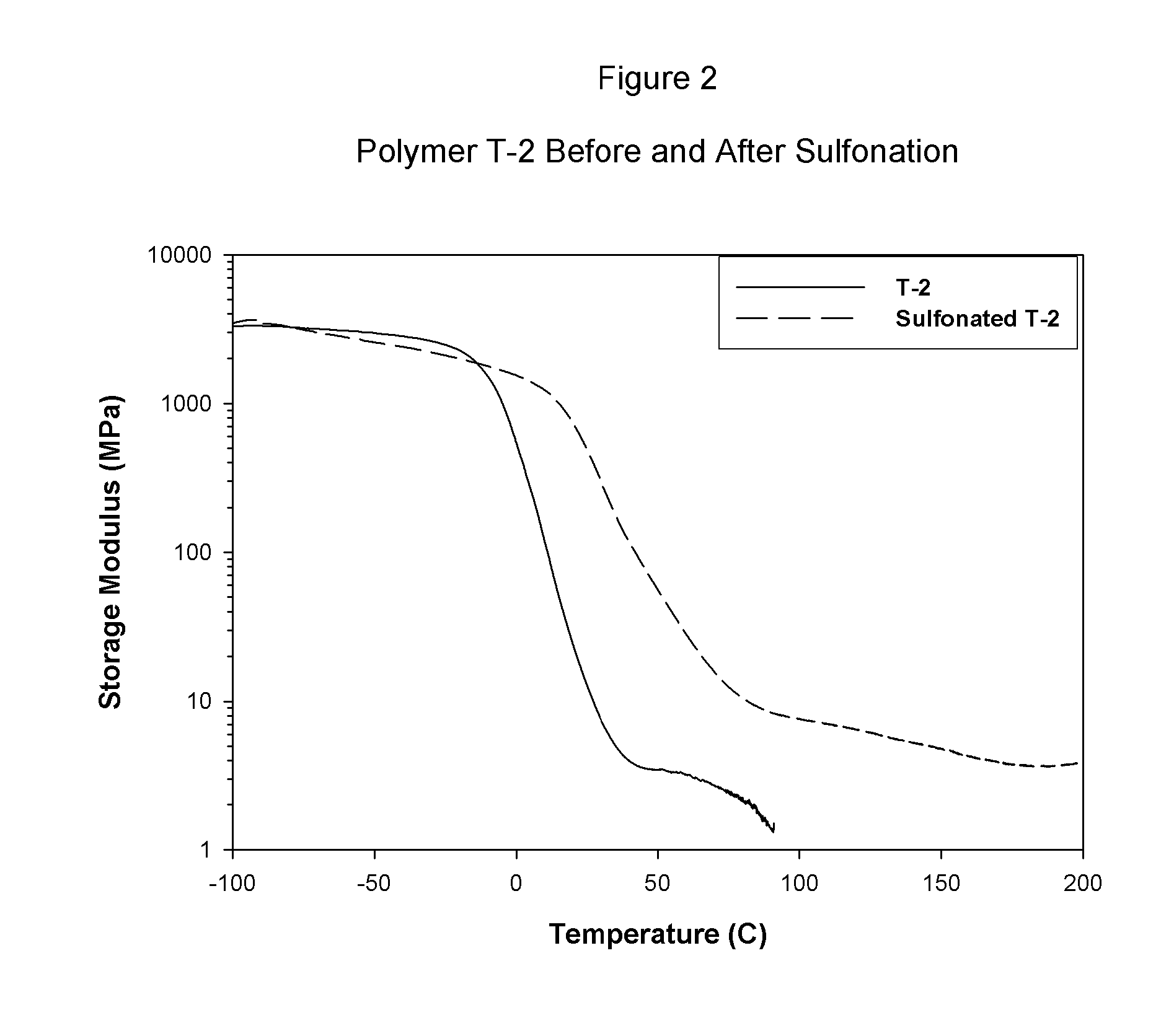

The present invention is a, solid block copolymer comprising at least two polymer end blocks A and at least one polymer interior block B wherein each A block is a polymer block resistant to sulfonation and each B block is a polymer block susceptible to sulfonation, and wherein said A and B blocks do not contain any significant levels of olefinic unsaturation. Preferably, each A block comprising one or more segments selected from polymerized (i) para-substituted styrene monomers, (ii) ethylene, (iii) alpha olefins of 3 to 18 carbon atoms; (iv) hydrogenated 1,3-cyclodiene monomers, (v) hydrogenated monomers of conjugated dienes having a vinyl content less than 35 mol percent prior to hydrogenation, (vi) acrylic esters, (vii) methacrylic esters, and (viii) mixtures thereof; and each B block comprising segments of one or more polymerized vinyl aromatic monomers selected from (i) unsubstituted styrene monomers, (ii) ortho-substituted styrene monomers, (iii) meta-substituted styrene monomers, (iv) alpha-methylstyrene, (v) 1,1-diphenylethylene, (vi) 1,2-diphenylethylene and (vii) mixtures thereof. Also claimed are processes for making such block copolymers, and the various end uses and applications for such block copolymers.

Owner:KRATON POLYMERS US LLC

Sulfonated block copolymers, method for making same, and various uses for such block copolymers

ActiveUS20070021569A1High water transport propertyImprove wet strengthSemi-permeable membranesNegative electrodesMethacrylatePolymer science

The present invention is a, solid block copolymer comprising at least two polymer end blocks A and at least one polymer interior block B wherein each A block is a polymer block resistant to sulfonation and each B block is a polymer block susceptible to sulfonation, and wherein said A and B blocks do not contain any significant levels of olefinic unsaturation. Preferably, each A block comprising one or more segments selected from polymerized (i) para-substituted styrene monomers, (ii) ethylene, (iii) alpha olefins of 3 to 18 carbon atoms; (iv) hydrogenated 1,3-cyclodiene monomers, (v) hydrogenated monomers of conjugated dienes having a vinyl content less than 35 mol percent prior to hydrogenation, (vi) acrylic esters, (vii) methacrylic esters, and (viii) mixtures thereof; and each B block comprising segments of one or more polymerized vinyl aromatic monomers selected from (i) unsubstituted styrene monomers, (ii) ortho-substituted styrene monomers, (iii) meta-substituted styrene monomers, (iv) alpha-methylstyrene, (v) 1,1-diphenylethylene, (vi) 1,2-diphenylethylene and (vii) mixtures thereof. Also claimed are processes for making such block copolymers, and the various end uses and applications for such block copolymers.

Owner:KRATON POLYMERS US LLC

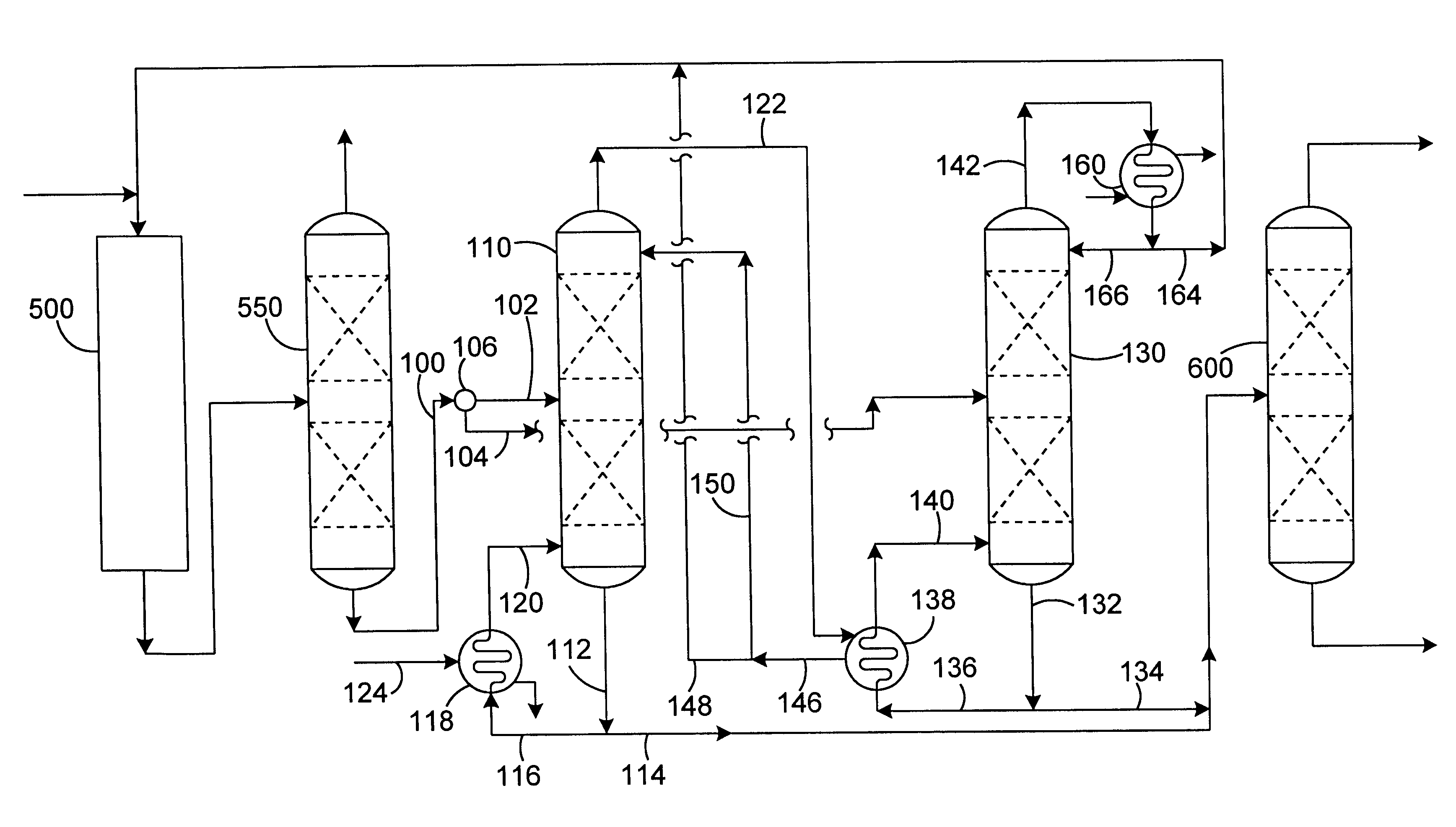

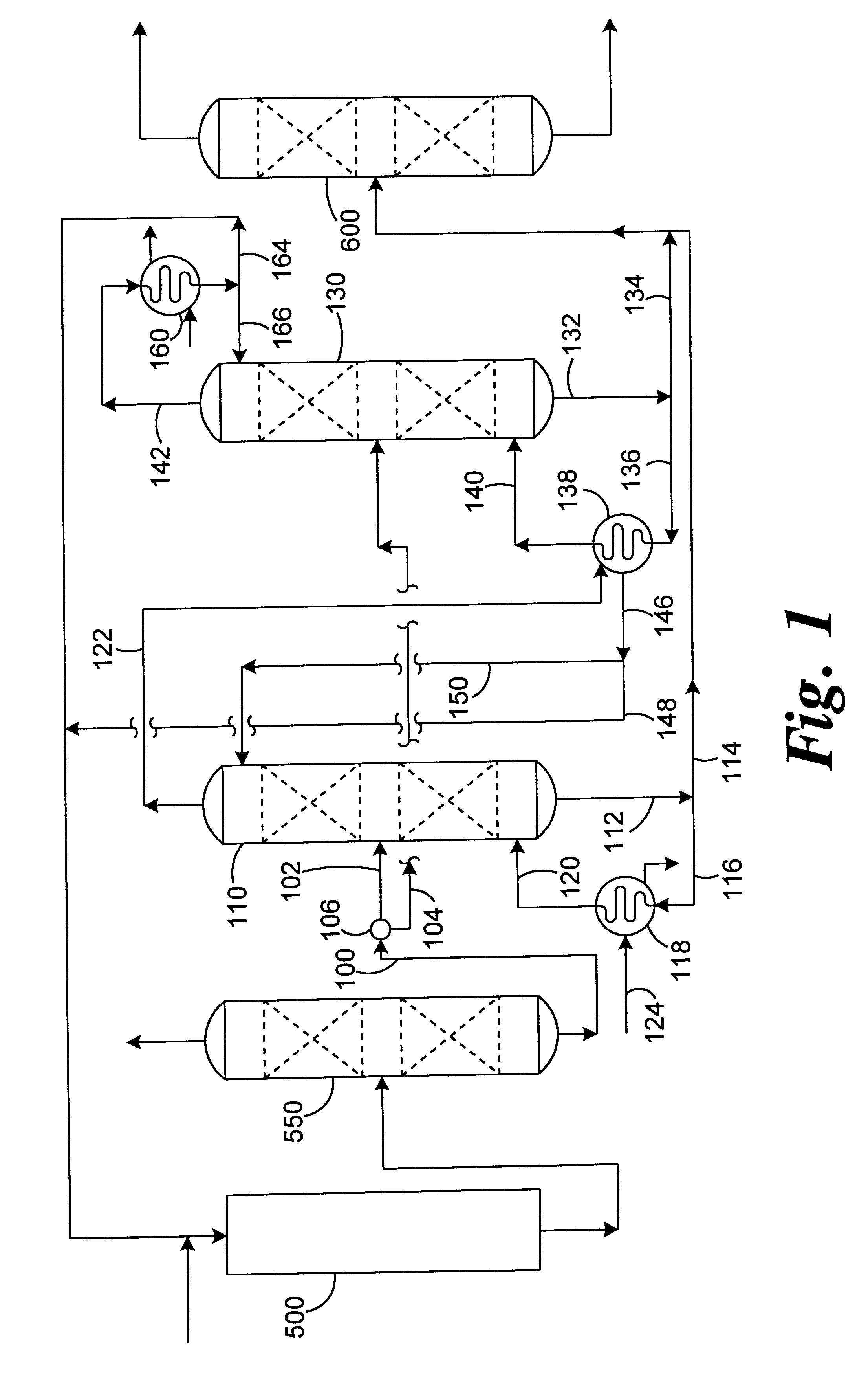

Cascade reboiling of ethylbenzene/styrene columns

InactiveUS6171449B1Reduce use costEfficient and economical approachDistillation regulation/controlDistillation in boilers/stillsCascadeEngineering

Apparatus and process are disclosed for the distillation separation of styrene monomer from ethylbenzene utilizing a split feed to two distillation columns in conjunction with cascade reboiling utilizing thermal energy from the overhead of one column to supply heat to the second.

Owner:STONE & WEBSTER PROCESS TECH

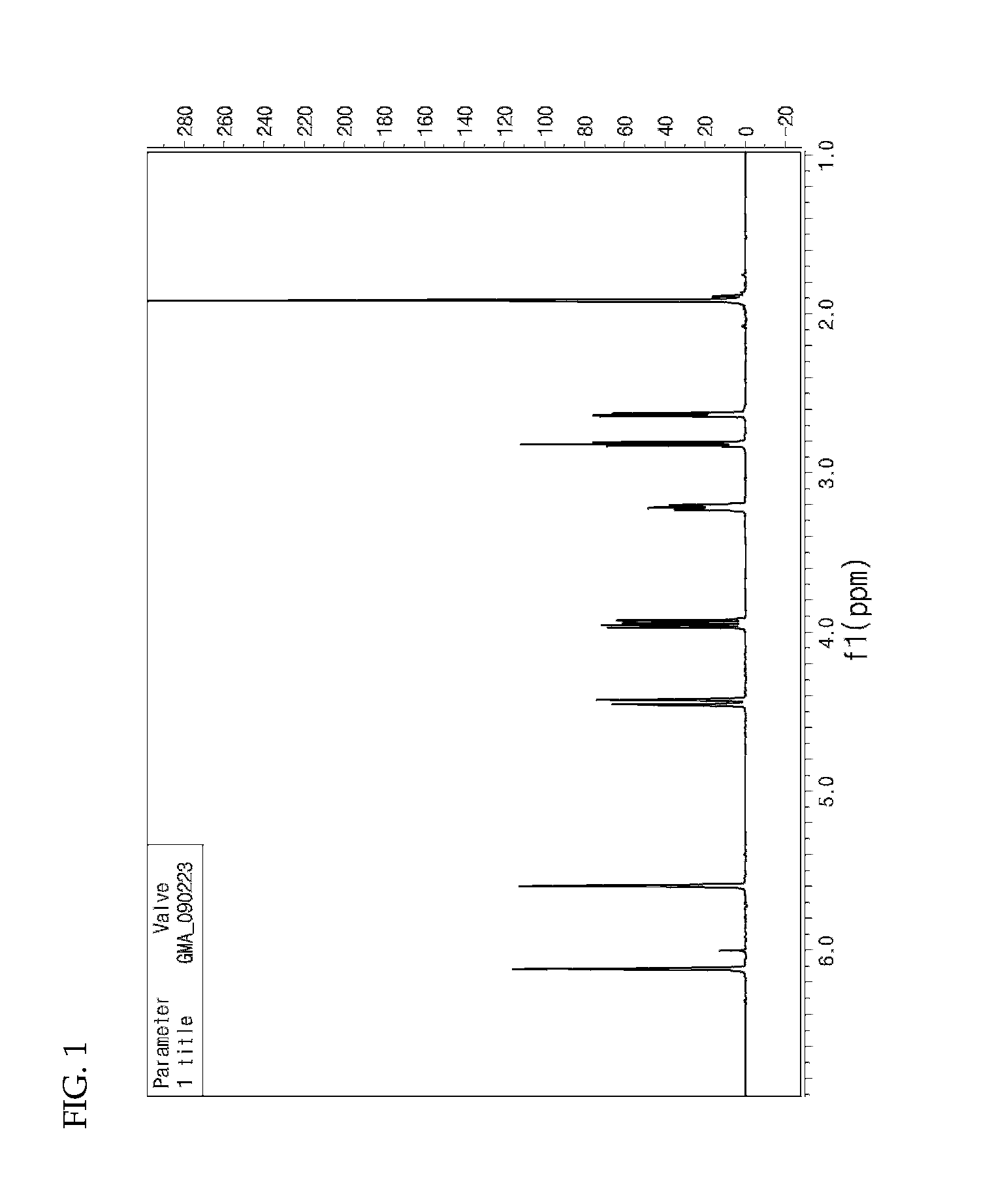

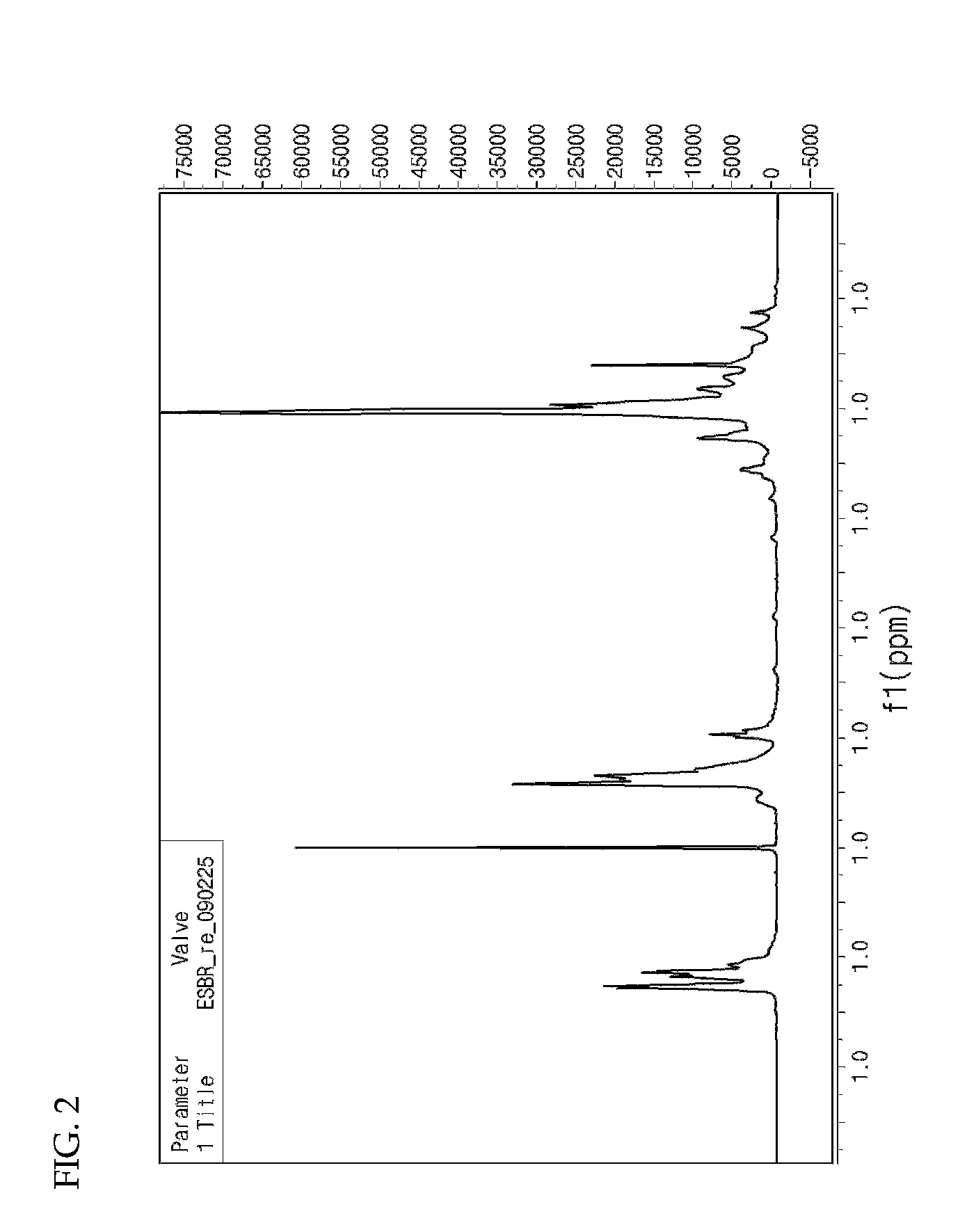

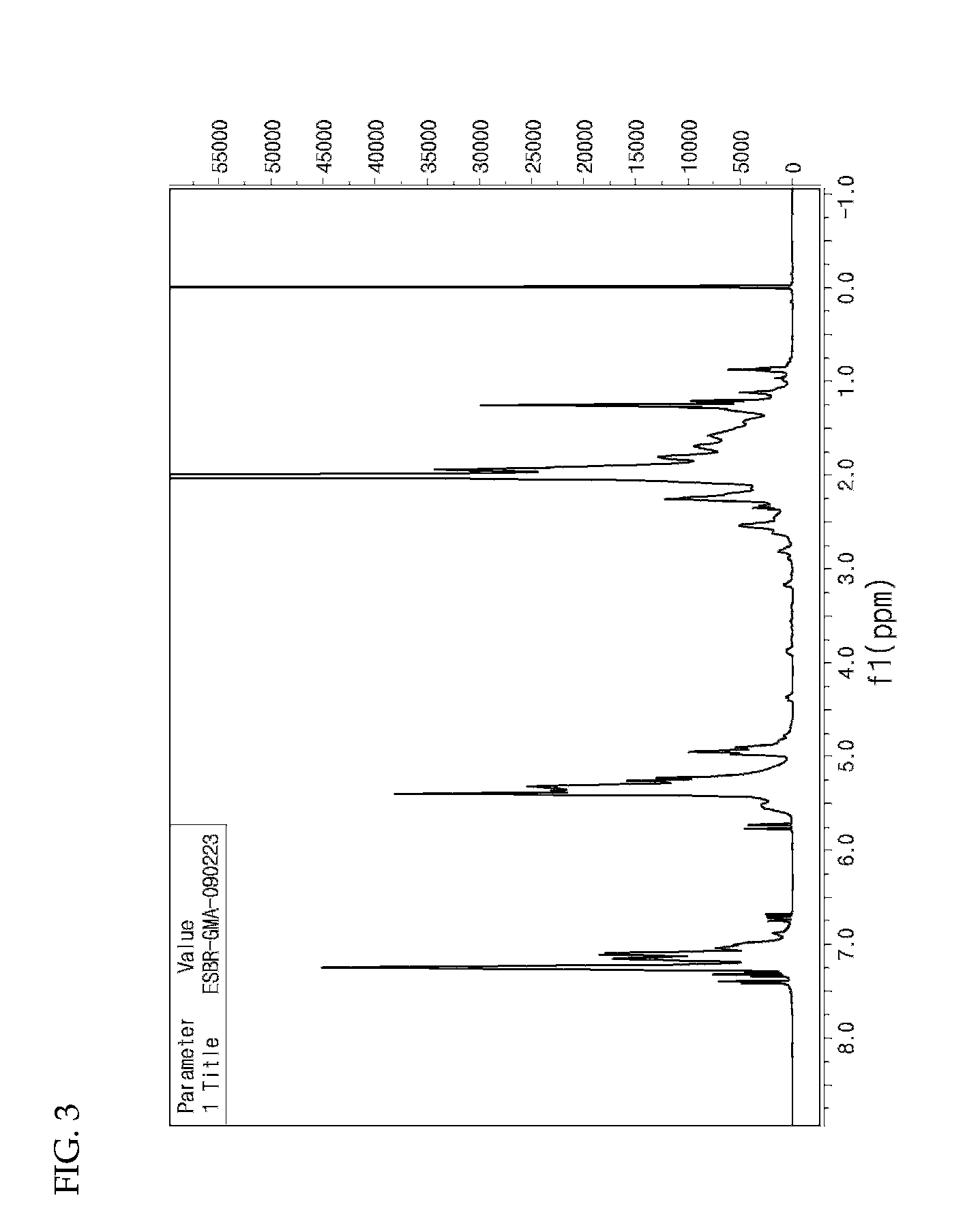

Functional styrene-butadiene copolymer

A functional styrene-butadiene copolymer is disclosed. More specifically, the copolymer is prepared by radical polymerization of a styrene monomer, a butadiene monomer and an epoxy acrylate monomer in an emulsion state and ring-opening of the resultant styrene-butadiene-epoxy acrylate copolymer. When blended with silica, the disclosed copolymer provides excellent wet stopping performance and superior wear resistance. Therefore, it can be usefully applied for industrial materials including fuel-efficient tires, snow tires, belts, hoses, etc.

Owner:KOREA KUMHO PETROCHEMICAL CO LTD

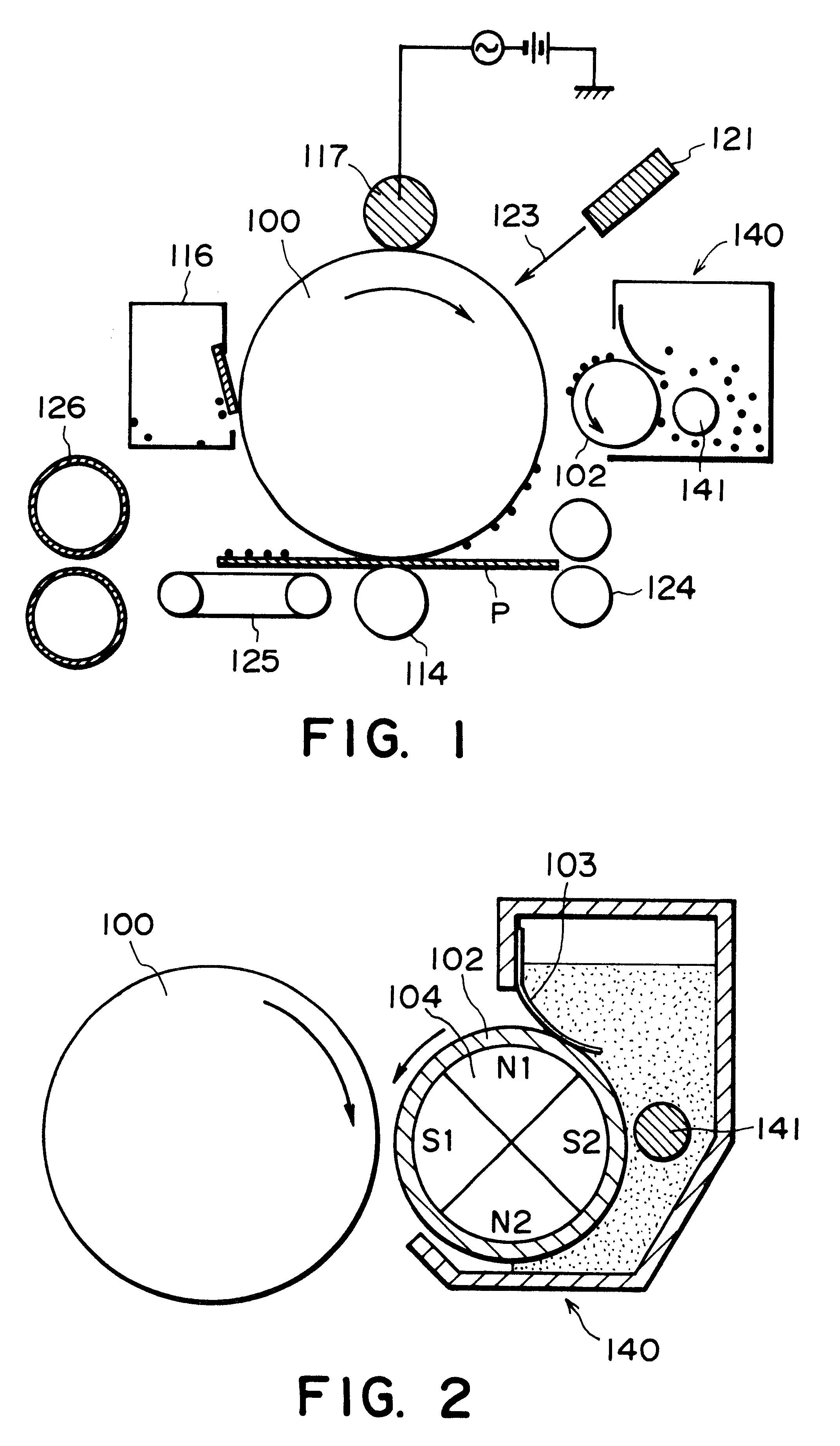

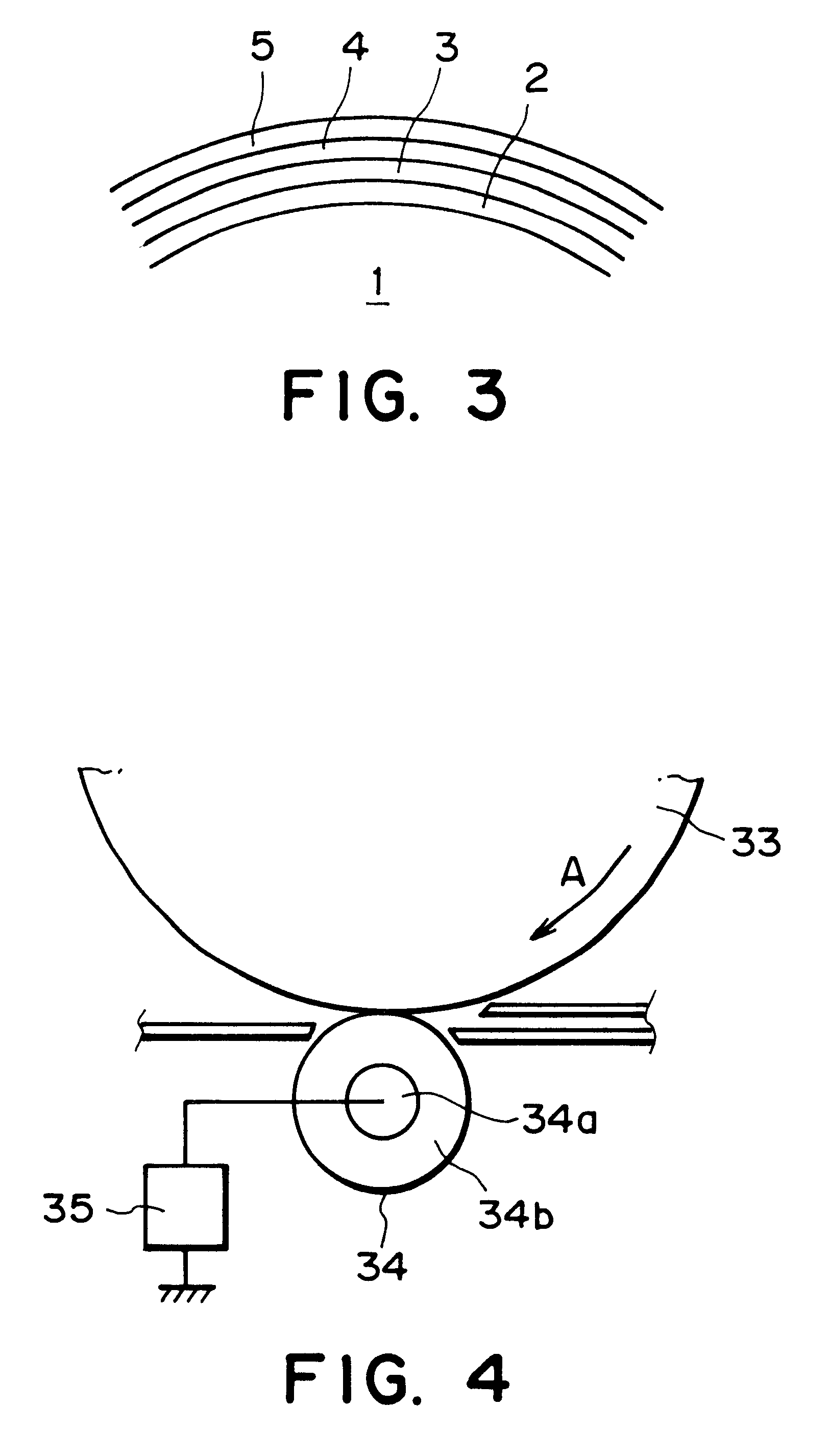

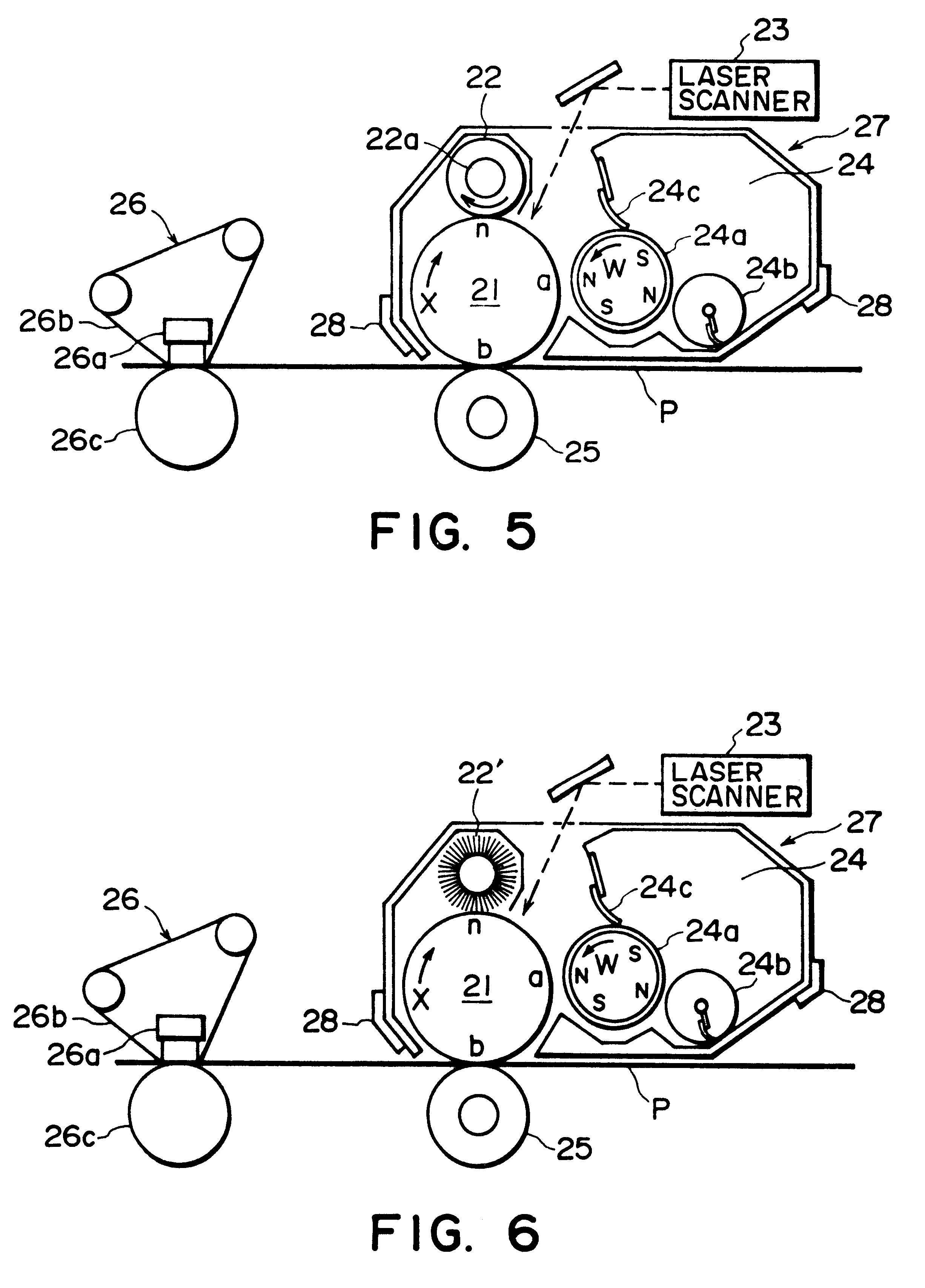

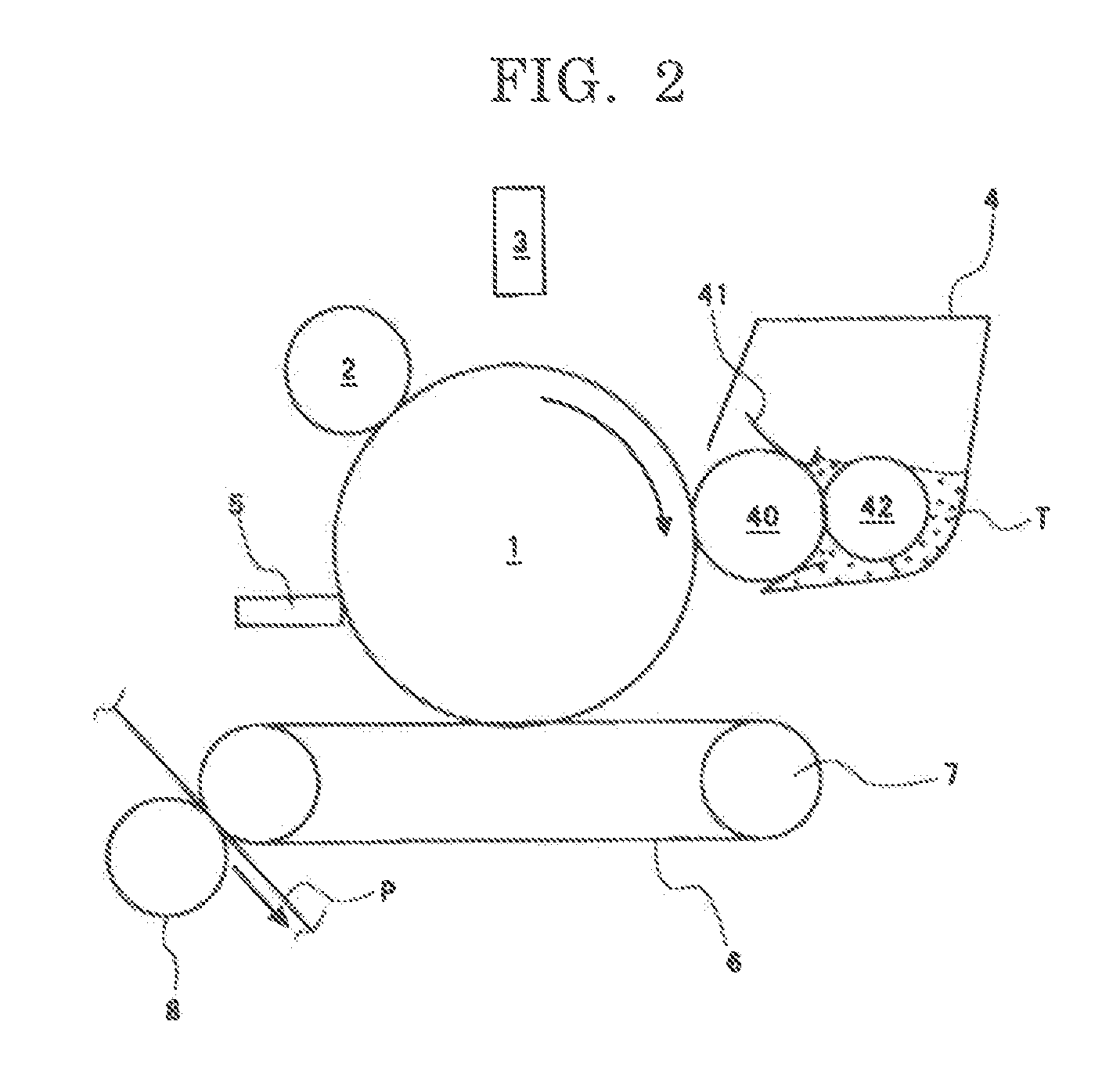

Magnetic toner, process for production thereof, and image forming method, apparatus and process cartridge using the toner

InactiveUS6465144B2Reduce wastePerformance and recoveryDevelopersElectrographic process apparatusMagnetizationX-ray

A magnetic toner includes: magnetic toner particles each comprising at least a binder resin and magnetic toner, and inorganic fine powder. The magnetic toner has an average circularity of at least 0.970, and a magnetization of 10-50 Am2 / kg at a magnetic field of 79.6 kA / m. The magnetic powder comprises at least magnetic iron oxide. The magnetic toner particles retain carbon in an amount of A and iron in an amount of B at surfaces thereof as measured by X-ray photoelectron spectroscopy, satisfying: B / A<0.001. The binder resin comprises a resin formed by polymerization of a monomer comprising at least styrene monomer. The magnetic toner has a residual styrene monomer content of less than 300 ppm, and contains at least 50% by number of toner particles satisfying a relationship of: D / C<=0.02, wherein C represents a volume-average particle size of the magnetic toner, and D represents a minimum distance between the surface of a magnetic toner particle and magnetic powder particles contained in the magnetic toner particle. Owing to the above features, the magnetic toner can exhibit good electrohotographic performances, including excellent chargeability and little transfer-residual toner, even in a cleanerless-mode image forming system.

Owner:CANON KK

Water acrylic resin and preparing method thereof

The utility model relates to a water-based acrylic resin paintand the manufacturing method. The basic ray materials comprise acrylic monomer, styrene monomer, initiator, cosolvent, and active solvent. The utility model is characterized in that the acrylic monomer comprises acrylic derivative with hydroxyl; the cosolvent is ether alcohol solvent; the active solvent is butyl carbonate ethylene derivative active solvent; the initiator is peroxide initiator; and the neutralizer is Amine neutralizer. The resin is manufactured through two-step process. In the first step, water-based acrylic resin prepolymer is manufactured and is then manufactured into resin latex through inner emulsification on the second step. The product is of long storage time and is of no added emulsifier. Under the room temperature, the product can cross-link with water-based isocyanate curing agent to form membrane. The utility model is of excellent membrane, good water resistance, anti-scrubbing property, chemical resistance and sullying resistance.

Owner:上海市涂料研究所有限公司

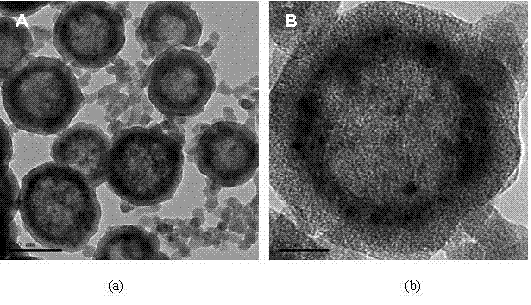

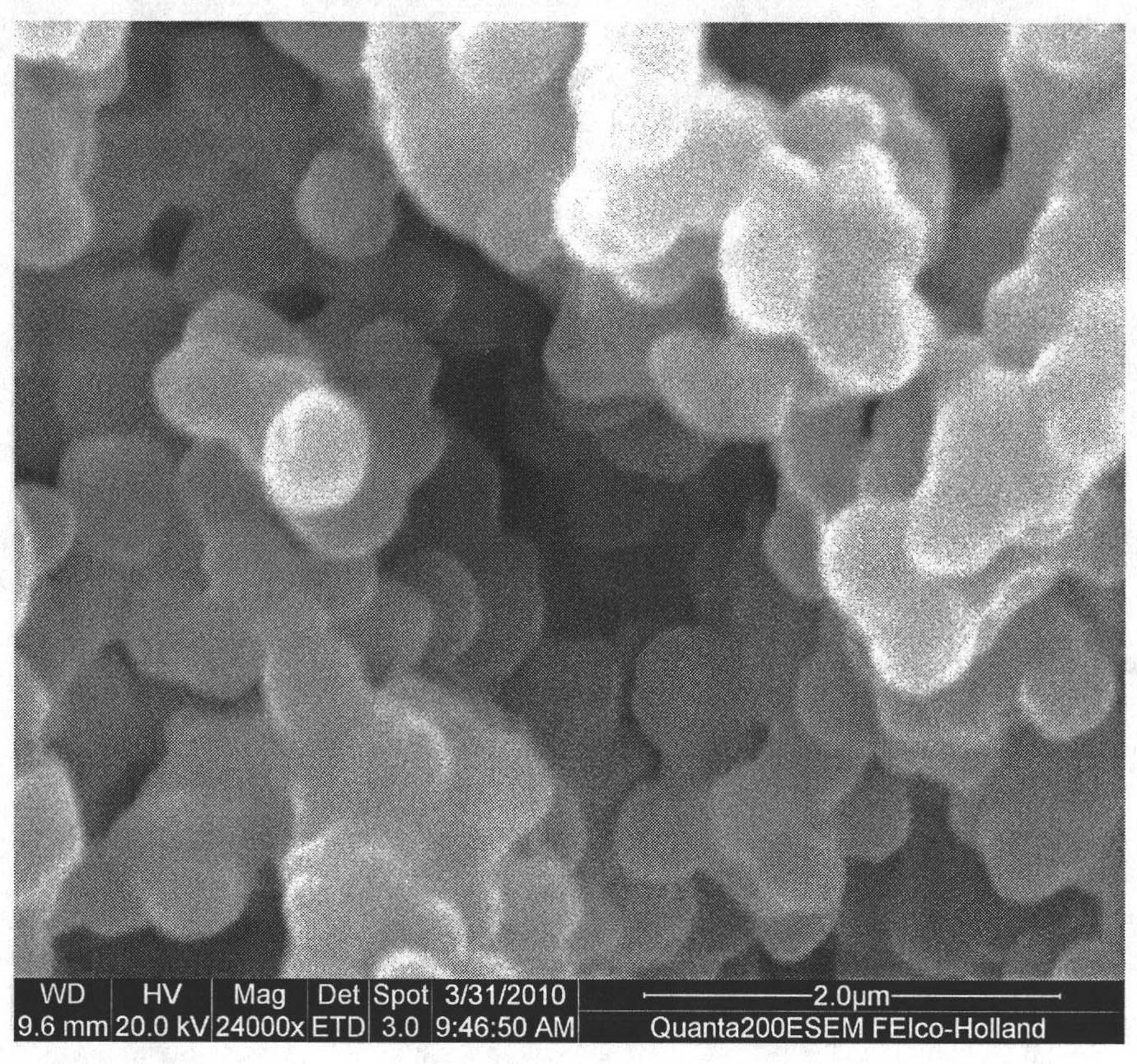

Method for preparing functional composite microsphere with multi-layer core-shell structure and application thereof

InactiveCN101735413ADifferent Surface ElectricityWith strengthDrilling compositionPolymer scienceMicrosphere

The invention discloses a method for preparing functional composite microsphere with a multi-layer core-shell structure and application thereof, and relates to the technical fields of functional macromolecular microsphere preparation and petroleum exploitation, in particular to the technical field of deep profile control water shutoff during high water-cut period of petroleum exploitation. The functional composite microsphere is prepared by a dispersion polymerization method which comprises the following steps: forming a core part by polymerization of a styrene monomer, and forming a cation shell part by copolymerization of acrylamide, the cation monomer and a crosslinking agent; and forming an anion shell part by copolymerization of acrylamide, anion monomer and the crosslinking agent. The functional composite microsphere is characterized in that the size of the microsphere is between 1,500 and 2,000nm and the microsphere is white solid powder or polymer emulsion; the expansion multiplying power of the microsphere is improved by 20 to 50 times after 5-day hydration; and therefore, the functional composite microsphere can be used for effective plugging at the pore throat of a bottom high permeability zone during high water-cut period of the petroleum exploitation.

Owner:JIANGNAN UNIV

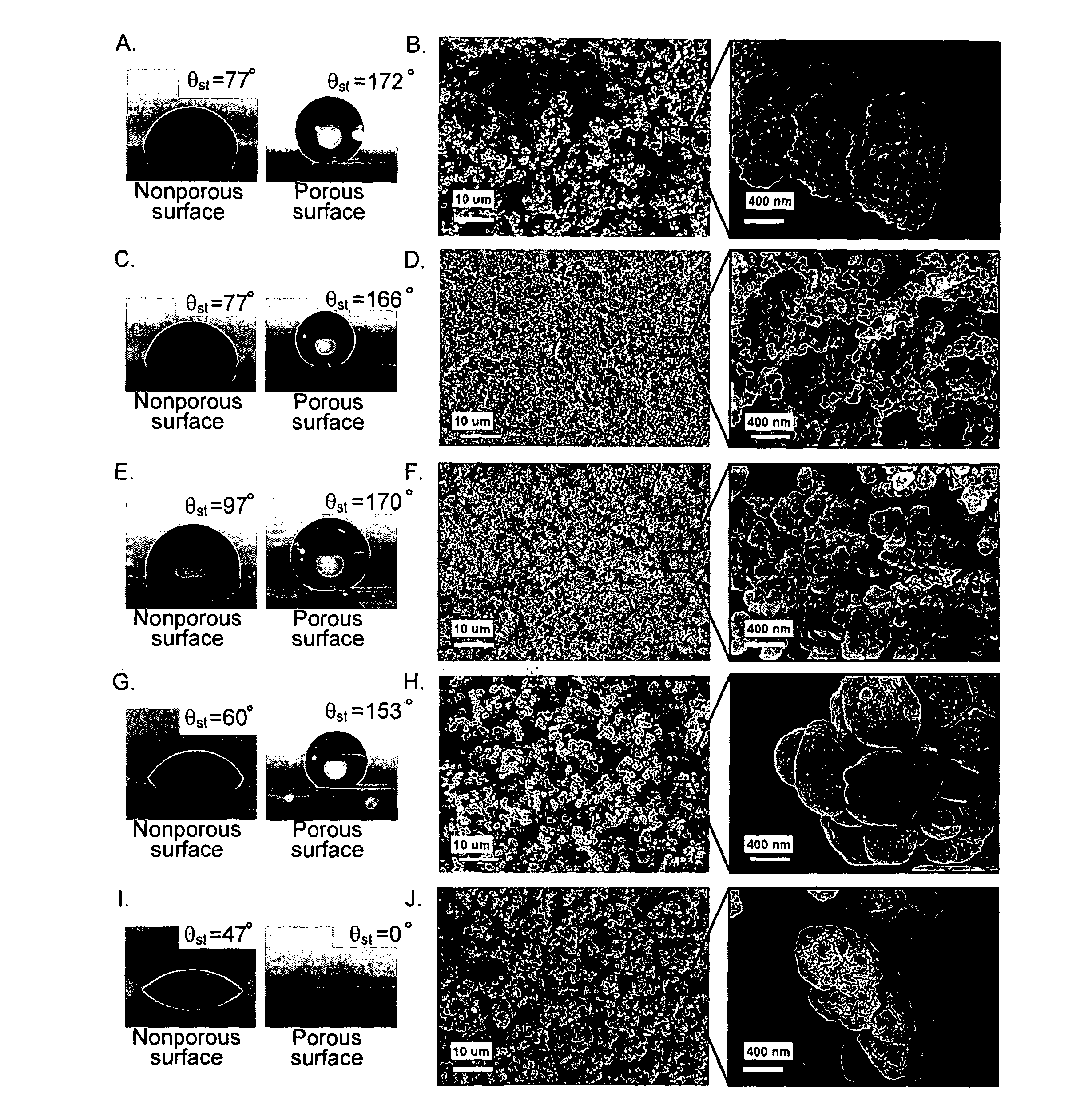

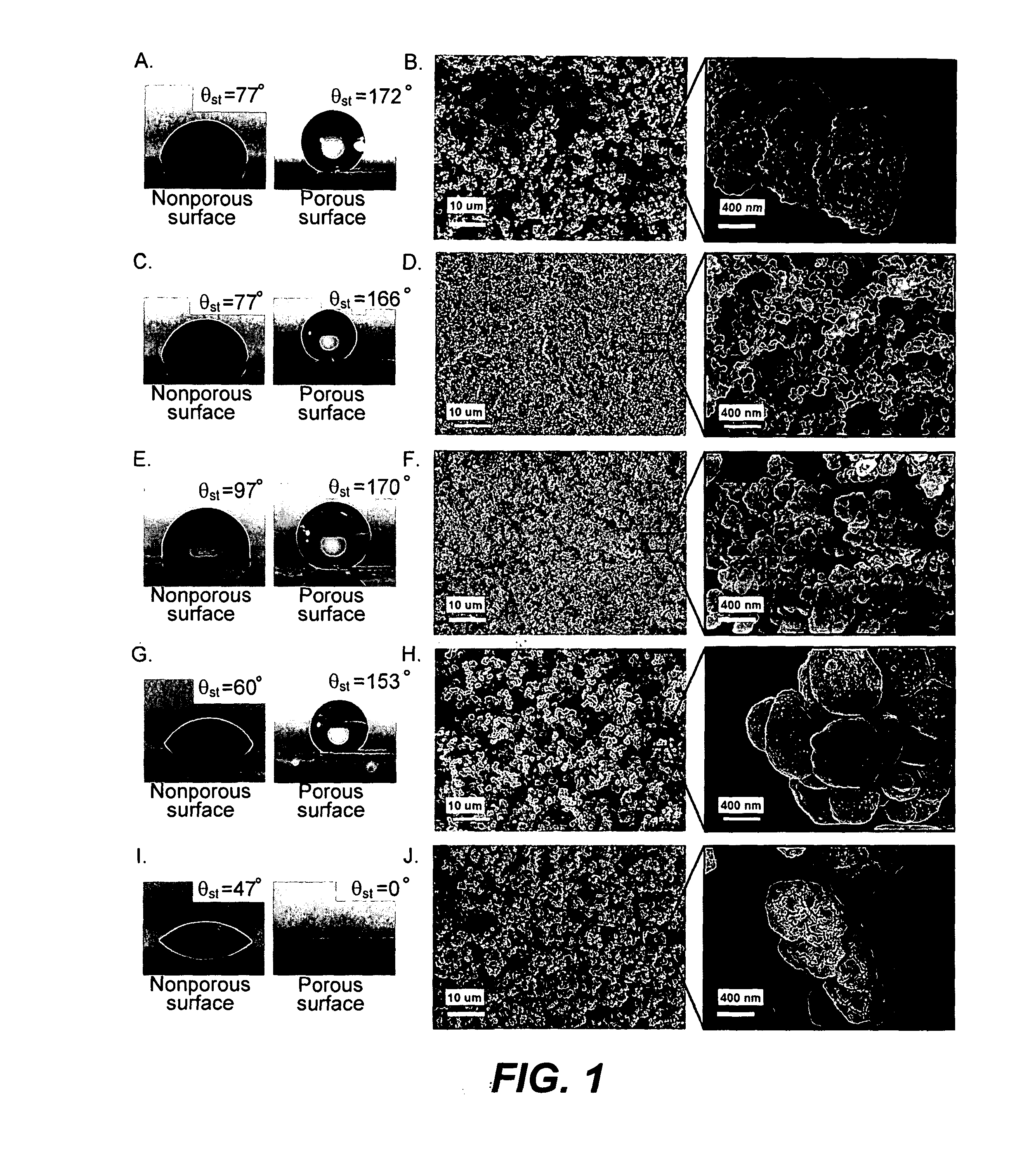

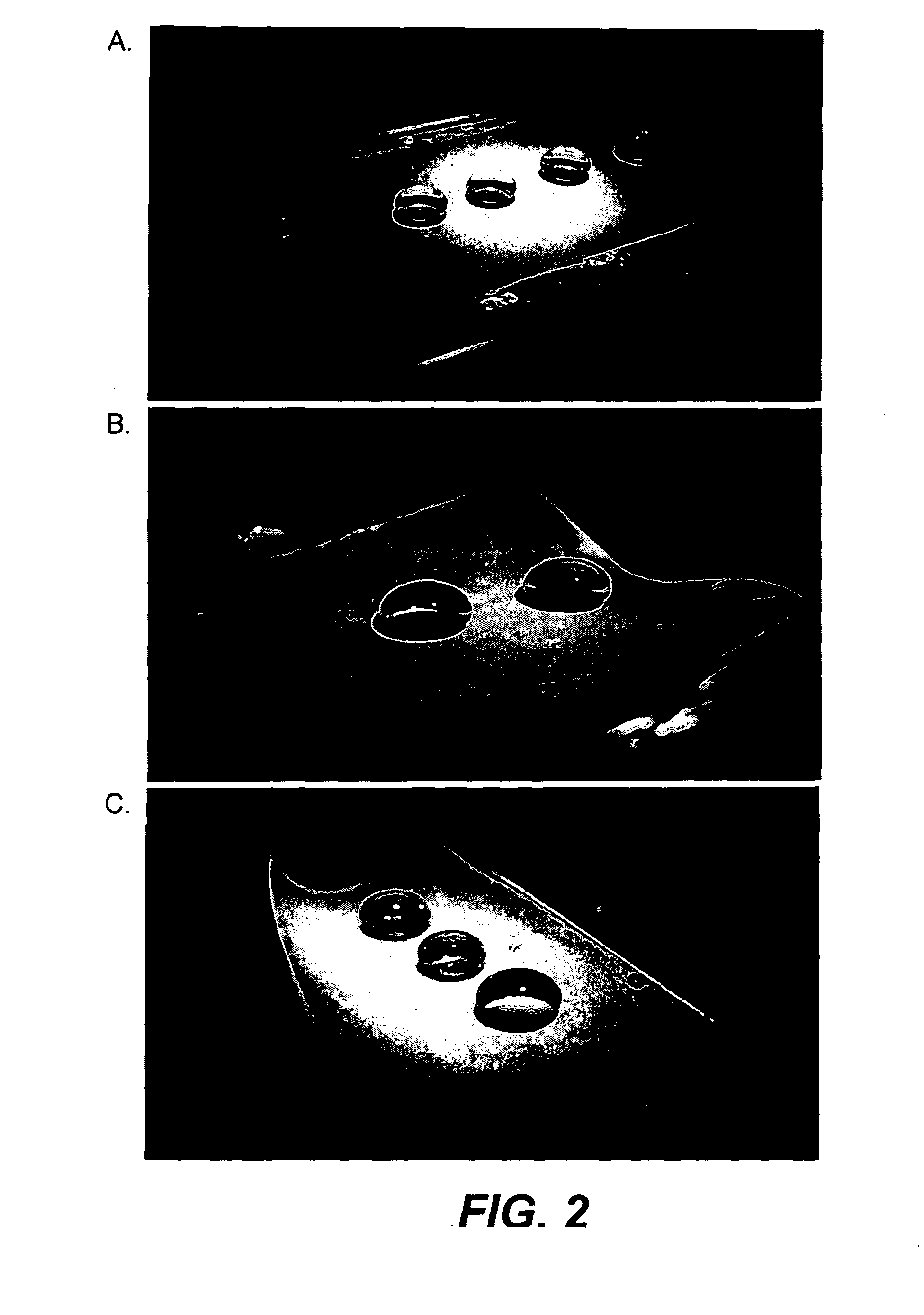

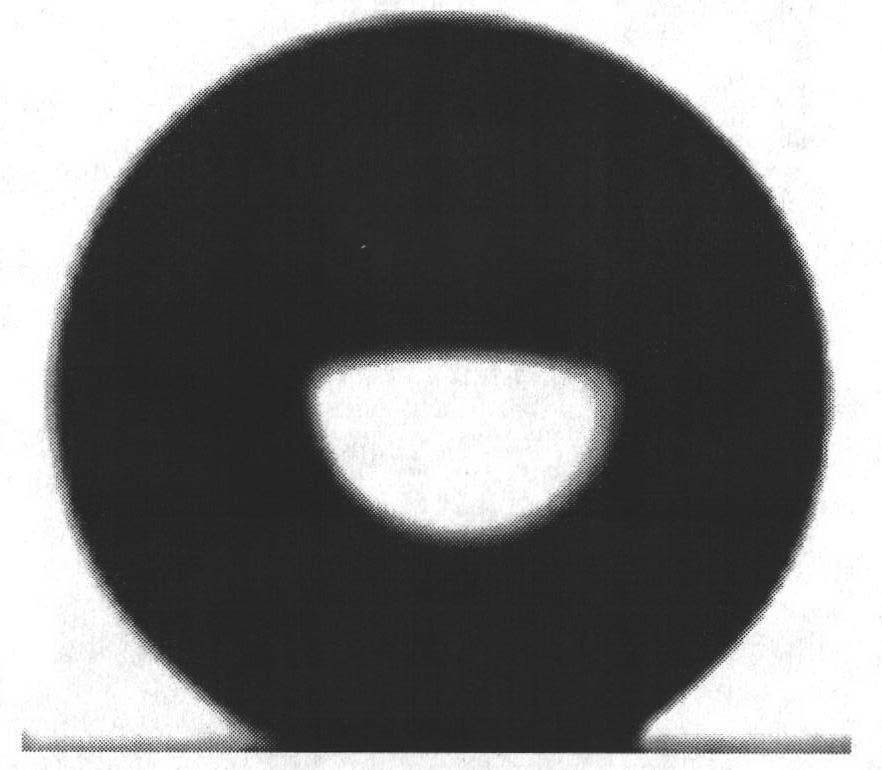

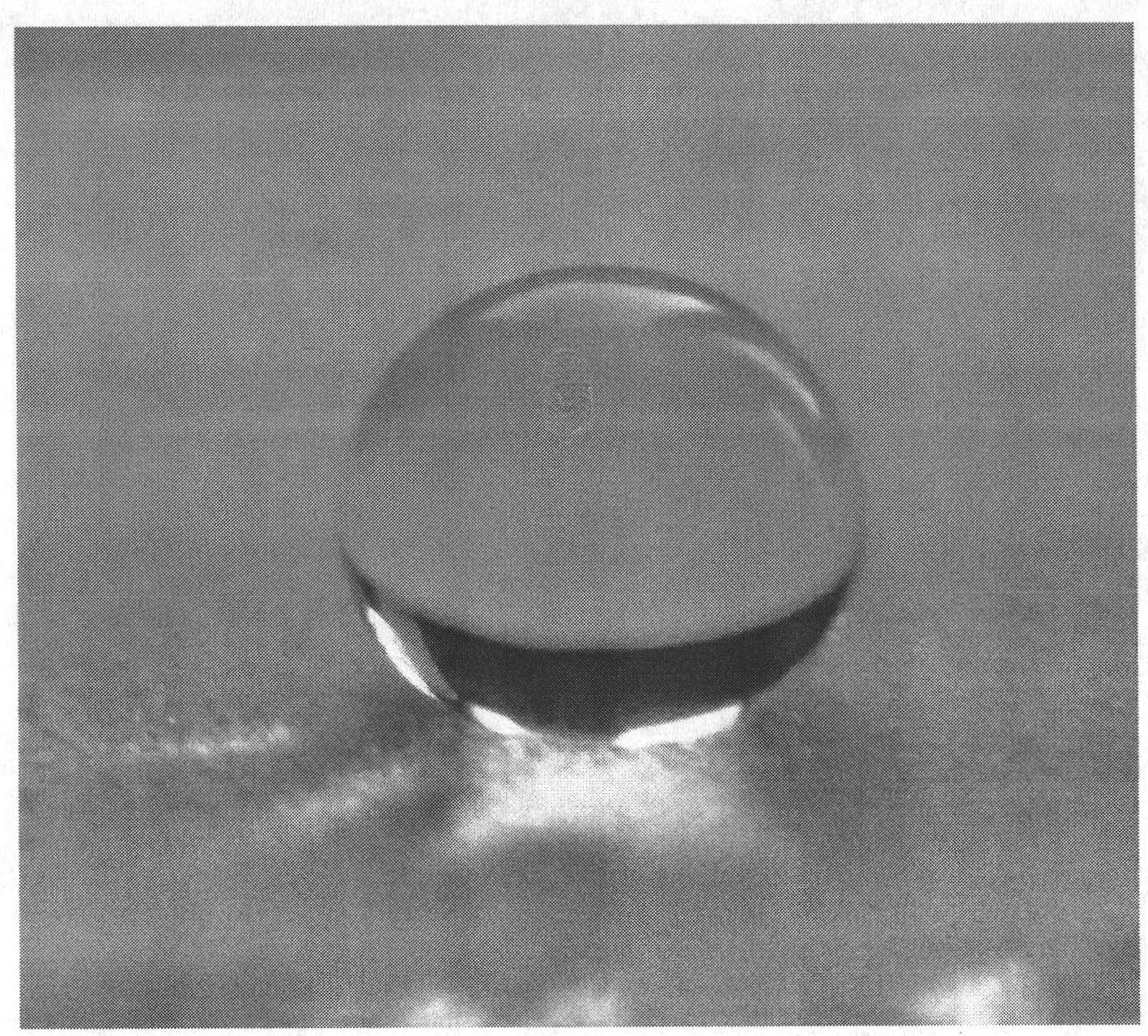

Superhydrophobic and superhydrophilic materials, surfaces and methods

A broadly applicable method requiring no more than a single step facilitates the preparation of large area super hydrophobic or super hydrophilic surfaces on a variety of substrates such as such as glass, metal, plastic, paper, wood, concrete and masonry. The technique involves the free radical polymerization of common acrylic or styrenic monomers in the presence of porogenic solvents in a mold or on a free surface. The material can be semi- or fully-transparent and either super hydrophobic or super hydrophilic depending on the choice of the monomers. Because porosity and dual scale roughness are intrinsic bulk properties of the monolithic materials and not only a surface characteristic, the polymers can be powdered to produce a super hydrophobic powder or otherwise fragmented and attached to the surface of any object to render it super hydrophobic or super hydrophilic. The surface properties of the porous material may also be altered locally by photografting with selected monomers.

Owner:RGT UNIV OF CALIFORNIA

Method of preparing polypropylene graft polymer

The invention relates to a polypropylene graft polymer preparing method which is characterized in that: (a) calculated by weight parts, the polypropylene graft polymer comprises 100 parts of polypropylene, 0.1-20 parts of graft monomer maleic anhydride, 0.1-20 parts of graft monomer styrene monomer or vinyl acetate monomer, 0.01-10 parts of peroxide initiator and 1-20 parts of other vinyl monomers; (b) the graft monomers, the initiator and the polypropylene are evenly mixed; (c) the reactants are heated to reach a temperature of 70-120 DEG C and then react for 1-10 hours; and (d) after the reaction, the polypropylene graft polymer can be obtained through cooling. During the implementation of the method, no solvent, suspending medium or interfacial agent needs to be used, the obtained product can be applied without needing further treatment, for example, a compatilizer for a polypropylene composite material; and the obtained product is particularly used for improving the interfacial compatibility and dispersivity of inorganic filler and polyolefine. The conversion rate of the graft monomers of the invention is greater than 95 percent, and at least 55 percent of the graft monomers form graft polypropylene.

Owner:BEIJING UNIV OF CHEM TECH

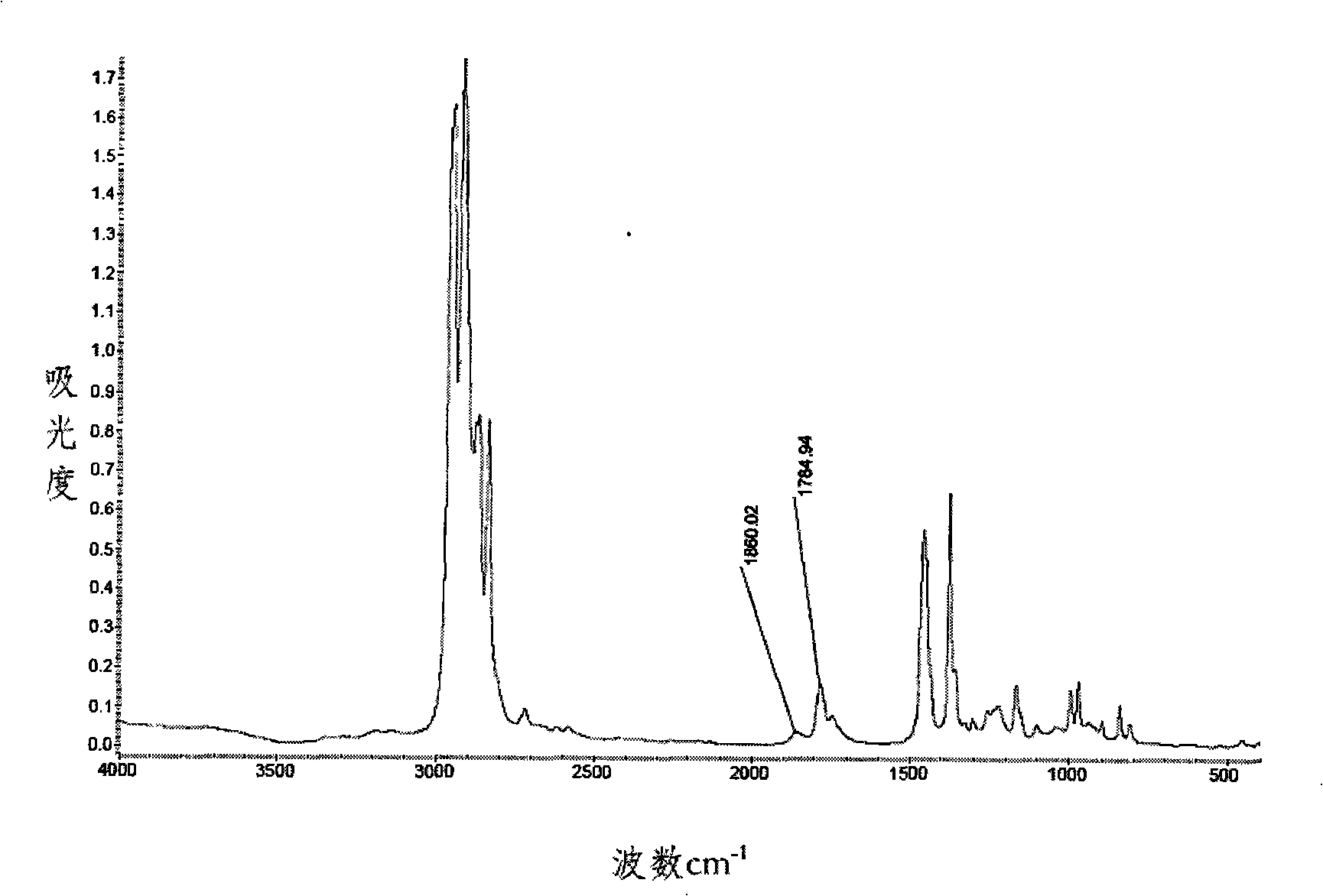

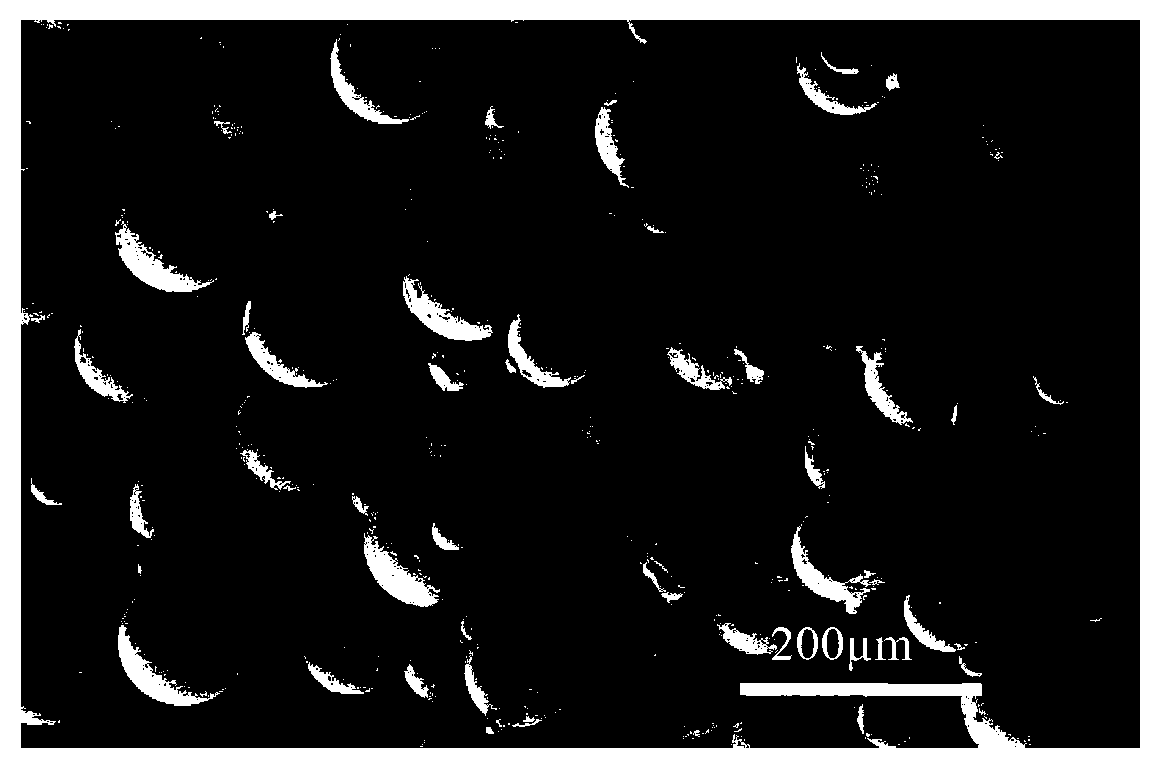

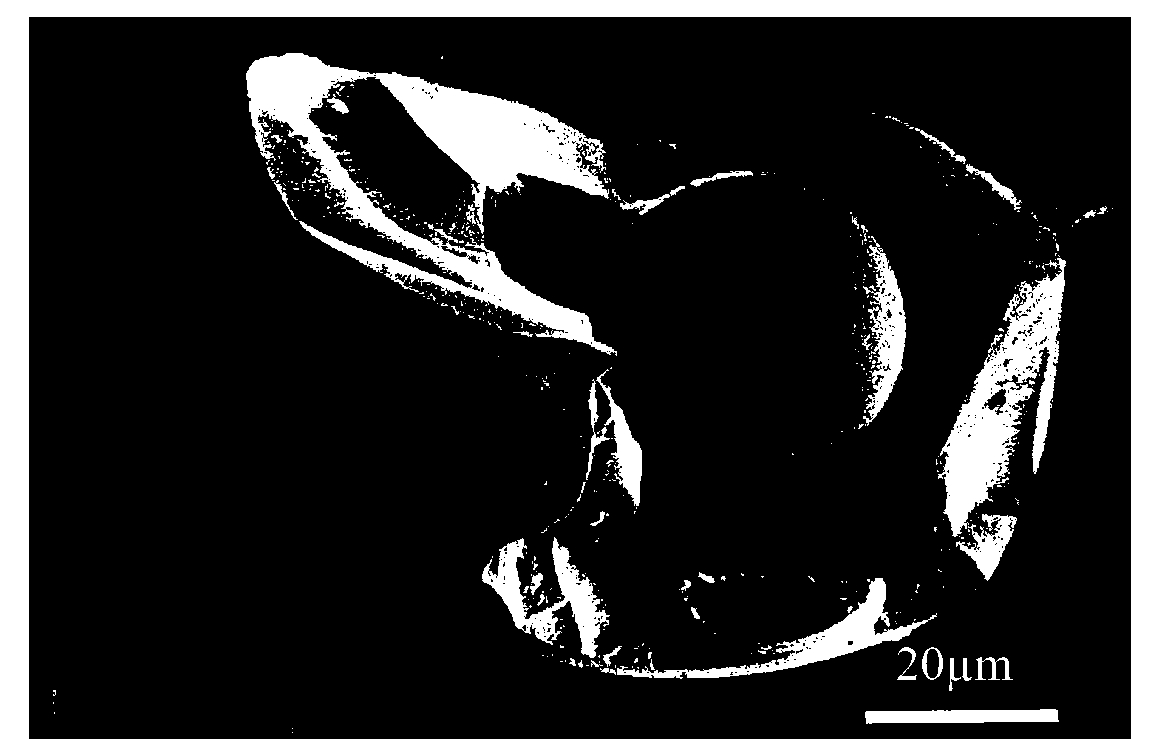

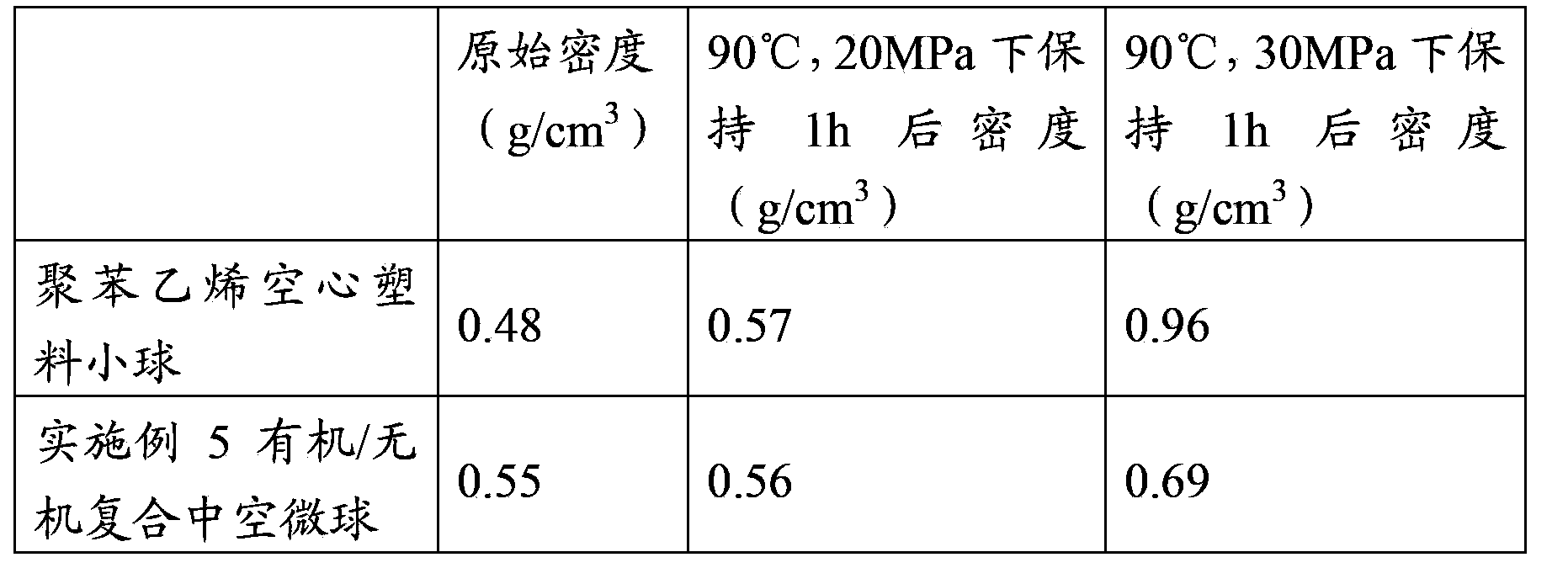

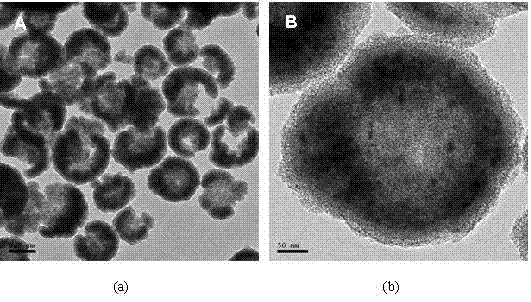

Organic/inorganic composite hollow microspheres, and preparation method and application thereof

ActiveCN103387717AUniform particle sizeSmall particle sizeDrilling compositionMicroballoon preparationPolymer scienceMicrosphere

The invention relates to organic / inorganic composite hollow microspheres, and a preparation method and an application thereof. According to the invention, a part of hydrophobically modified inorganic nano-grade material is added into styrene monomer or styrene monomer dissolved with polystyrene; the mixture is uniform, and is adopted as an oil phase; the viscosity of the oil phase is controlled through controlling the concentration of polystyrene and the addition amount of the nano-grade material; and temperature resistance and pressure resistance of the hollow microspheres are improved through adding an inorganic nano-grade material. In a W1 / O / W2 triple emulsion, initiation and polymerization of the styrene monomer, precipitation hardening of polystyrene and the inorganic nano-grade material, and the like are realized, such that the organic / inorganic composite hollow microspheres with the hollow structure are formed.

Owner:CHINA PETROLEUM & CHEM CORP +1

High oil absorption resin and synthetic method thereof

The invention discloses a high oil absorbing resin, and a process for preparation comprises utilizing short-chain ester of (metyl group) acrylic acid, long-chain ester of acrylic acid and styrene monomer to be monomers, adding dispersing agent and surface active agent, and getting through suspension polymerization and random copolymerization under the condition of the existence of cross linker and initiating agent. The process for synthesizing has lithe time consumption, which can be industrialized, and high oil absorbing resin which is got has high oil absorbing efficiency, fast oil absorbing speed, and which can be recycled to be repeatedly used.

Owner:SUZHOU TIMELYBLUE ENVIRONMENTAL TECH

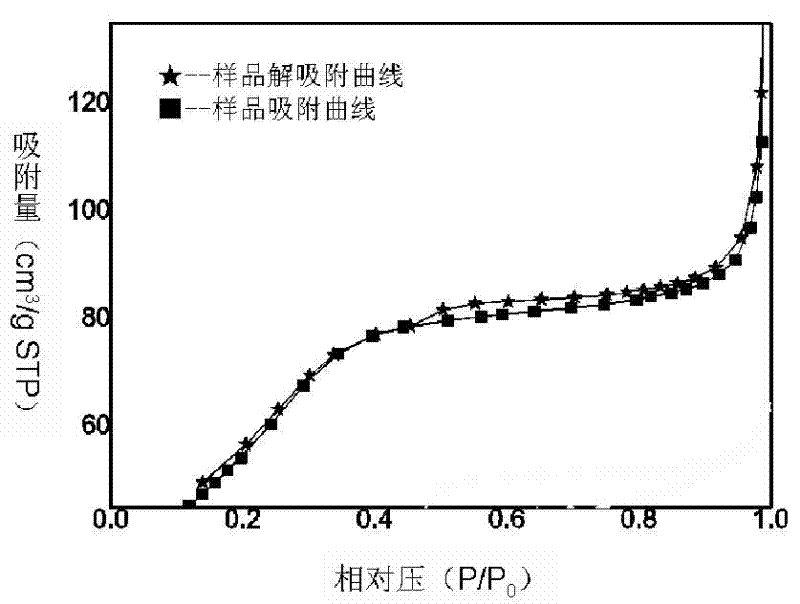

Preparation method for mesoporous silicon oxide hollow microspheres with magnetic nanoparticles embedded in shell layers

ActiveCN102500296AAdjustable sizeAdjust wall thicknessInorganic material magnetismSilicon oxidesPtru catalystSilicic acid

The invention relates to a preparation method for mesoporous silicon oxide hollow microspheres with magnetic nanoparticles embedded in shell layers. In the invention, the magnetic nanoparticles are prepared by using a coprecipitation method, are subjected to oleic acid surface modification and then are dispersed in normal octane; an oil phase constructed by styrene monomer, cetane, normal octane dispersion of the magnetic nanoparticles, alkoxysilane and a silane coupling agent is mixed with a water phase which dissolves a surfactant; a fine emulsion liquid droplet system is obtained through pre-emulsification and fine emulsification processes; controlling formation of silicon oxide and phase separation of organic and inorganic components in the system to obtain a template with a nested structure during free radial polymerization of the liquid droplets by adding a base catalyst; based on the template, generating a raw material by taking long-chain alkyl silane coupling agent and alkoxysilane as mesoporous silicon oxide; performing one-step ablation to remove an inner core of a polymer and a pore forming agent; or by taking a cationic surfactant as the pore forming agent, removing the pore forming agent and the inner core of the polymer through a solvent dissolving method and obtaining the magnetic / mesoporous silicon oxide hollow composite microspheres. The composite microspheres have large specific surface area and good magnetic operability and can be used for application fields of biomedicine, environment, water treatment and the like.

Owner:SUZHOU WIN BIO TECH CO LTD

Method for preparing acrylonitrile-butadiene-styrene latex having high total solid content

The present invention relates to a method of acrylonitrile-butadiene-styrene (ABS) rubber latex, and the acrylonitrile-butadiene-styrene (ABS) rubber latex is prepared by graft-polymerizing butadiene rubber with the monomers of acrlylonitrile and styrene through emulsion-polymerization, so that the ABS rubber latex of the present invention has high solid content. The method of ABS rubber latex of the present invention comprises the step of emulsion-polymerizing i) polybutadiene rubber latex; ii) aromatic vinyl compound; and iii) vinyl cyanide with the addition of a reactive emulsifier. According to the method of the present invention, the ABS rubber latex has high solid content due to a decrease in the amount of coagulated materials and film which is formed on the rubber latex during polymerization, and an increase in the production volume.

Owner:LG CHEM LTD

Butylbenzene emulsion and its preparing method and application

ActiveCN101077902AImprove water resistanceImprove adhesionPaper coatingCoatingsPolymer scienceEmulsion

The present invention discloses one kind of styrene-butadiene emulsion and its preparation process and application. The preparation process includes the following steps: the free radical emulsion polymerization of water solution of mixture of carboxylic acid monomer, butadiene monomer, styrene monomer, molecular weight regulator, emulsifier and initiator for 3-10 hr; regulating the pH value of the resultant to pH 7-10 and filtering. The styrene-butadiene emulsion has high performance and may be used in building paint and papermaking paint to form coating with high water resistance and high adhesion to the base material.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Preparation method of amphiphilic segmented copolymer

The invention which relates to a preparation method of an amphiphilic segmented copolymer belongs to the field of chemical engineering materials. According to the method, polyethylene glycol monomethyl ether with the molecular weight of 200-5000 and alpha-halogenated acyl halide undergo an esterification reaction to obtain a hydrophilic macromolecular initiator; and the segmented copolymer with controllable molecular weight and narrow molecular weight distribution (PDI is equal to or less than 1.5) is obtained by catalyzing ARGET ATRP of a (methyl) acrylic acid ester monomer, a fluorine-containing (methyl)acrylic acid ester monomer or a styrene monomer with the hydrophilic macromolecular initiator as an initiator and a low concentration oxidation state transition metal salt as a catalyst in the presence of an organic reductant. Compared with common atom free radical polymerization methods, the novel atom free radical polymerization method allows the catalyst consumption amount to be less, the sensitivity to a small amount of water and air to be reduced, the obtained polymer to be almost colorless, post-treatment steps to be reduced, even omitted, the production cost to be reduced, and industrialization production requirements to be better satisfied.

Owner:CHANGZHOU UNIV

Preparation of polystyrene/expanded graphite composite foaming material

InactiveCN101891852APhysical and mechanical properties do not deteriorateImprove physical and mechanical propertiesCompression moldingFoaming agent

Owner:SHANGHAI BOTAO ENVIRONMENT PROTECTION SCI & TECH +1

Method for preparing styrene grafted silicon dioxide superhydrophobic thin film

The invention discloses a method for preparing a styrene grafted silicon dioxide superhydrophobic thin film, which comprises: firstly, adding tetraethoxysilane into mixed solution of a catalyst and an alcohol solvent to obtain nano silicon dioxide spheres by reaction; secondly, adding the nano silicon oxide spheres into the alcohol solvent, and adding a silane coupling agent and the catalyst to obtain vinyl modified nano silicon oxide spheres; and finally, adding the vinyl modified nano silicon oxide spheres into a benzene or ketone organic solvent, adding an initiator and a styrene monomer in turn to obtain the styrene grafted silicon dioxide spheres, dispersing the styrene grafted silicon dioxide under ultrasonic waves, and preparing the styrene grafted silicon dioxide by using an organic or inorganic material as a substrate and by a coating method. The preparation process is simple and high in repeatability, the cost is low, and the promotion is more convenient.

Owner:QILU UNIV OF TECH

Production of soft-segment total saturated block copolymer

Production of soft-segment saturated block multi-polymer is carried out by taking styrene monomer or isoalkene as the first monomer under cation polymerization, taking water as initiating agent, taking Lewis acid as coinitiator in polymer system containing solvent and additive, controlling cation polymerization, adding into isoalkene containing additive or styrene the second kind monomer to two-block copolymer or adding into the first monomer containing additive and the third segment polymerizing to obtain the three-block copolymer. It's simple and cheap.

Owner:BEIJING UNIV OF CHEM TECH

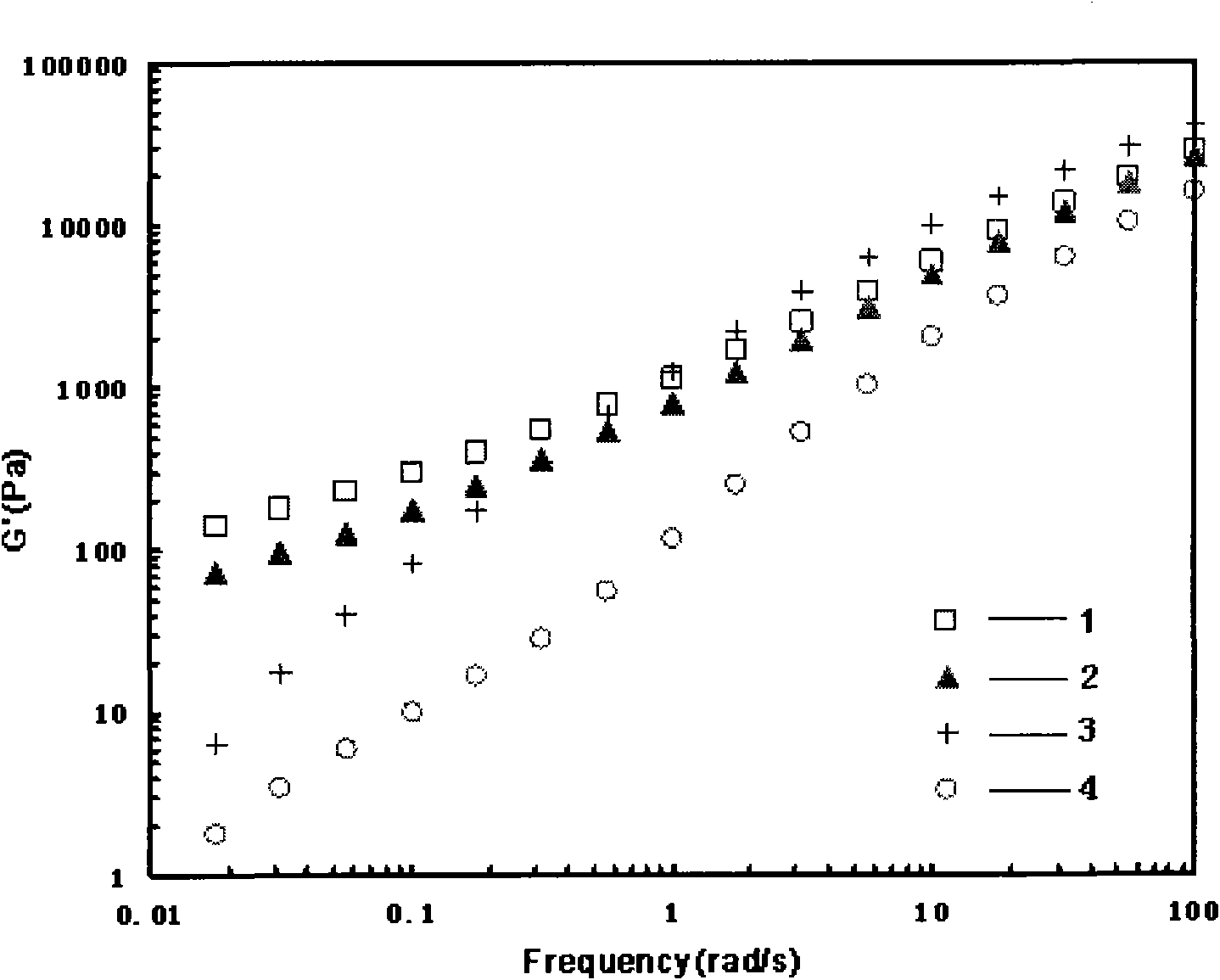

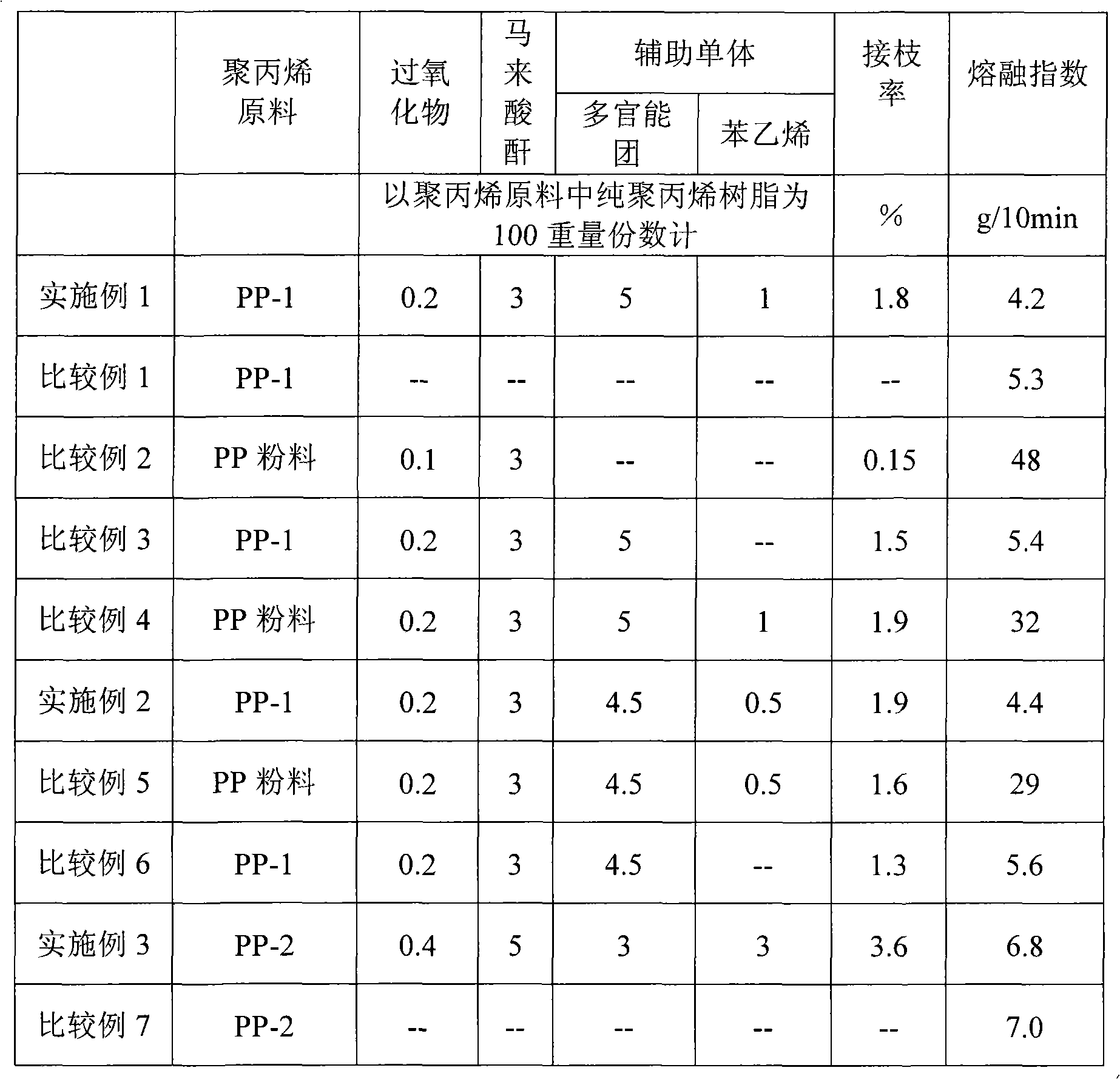

Preparation method for polypropylene resin graft

ActiveCN101885806AMitigation of thermo-oxidative degradationImprove graft conversion efficiencyAntioxidantGraft reaction

The invention provides a preparation method for a polypropylene resin graft, and relates to a maleic anhydride grafted polypropylene resin. The polypropylene resin is polypropylene powder which does not contain an antioxidant. Based on 100 weight parts of the polypropylene powder, 0.05 to 1 part of the antioxidant and the polypropylene powder are melted and blended; a molten free radical grafting reaction is performed on the polypropylene resin; the grafting reaction is initialized by using an oxide initiator; auxiliary monomers are introduced besides adding polar monomer maleic anhydride; the auxiliary monomers comprise a first auxiliary monomer and a second auxiliary monomer; the first auxiliary monomer is a styrene monomer; the dosage of the first auxiliary monomer is 0.5 to 3 parts based on 100 weight parts of the polypropylene resin; the second auxiliary monomer is an organic monomer of which the molecules comprise two or more carbon-carbon double bonds; and the dosage of the second auxiliary monomer is 2 to 8 parts based on 100 weight parts of the polypropylene resin. The grafted polypropylene resin which has high grafting rate, high molecular weight and high viscosity can be prepared by the preparation method of the polypropylene resin graft of the invention.

Owner:CHINA PETROLEUM & CHEM CORP +1

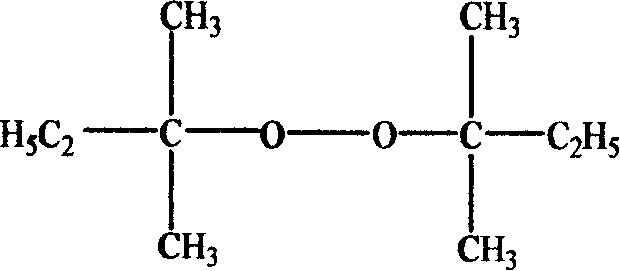

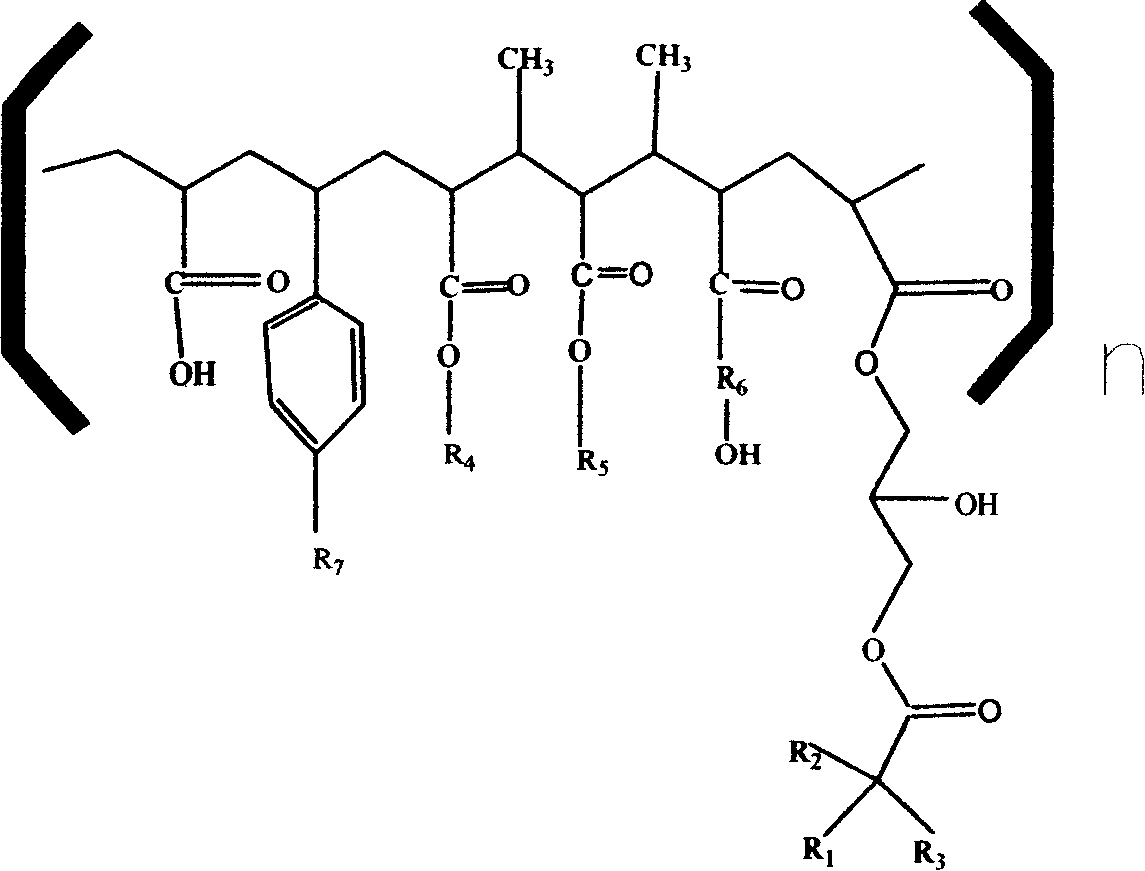

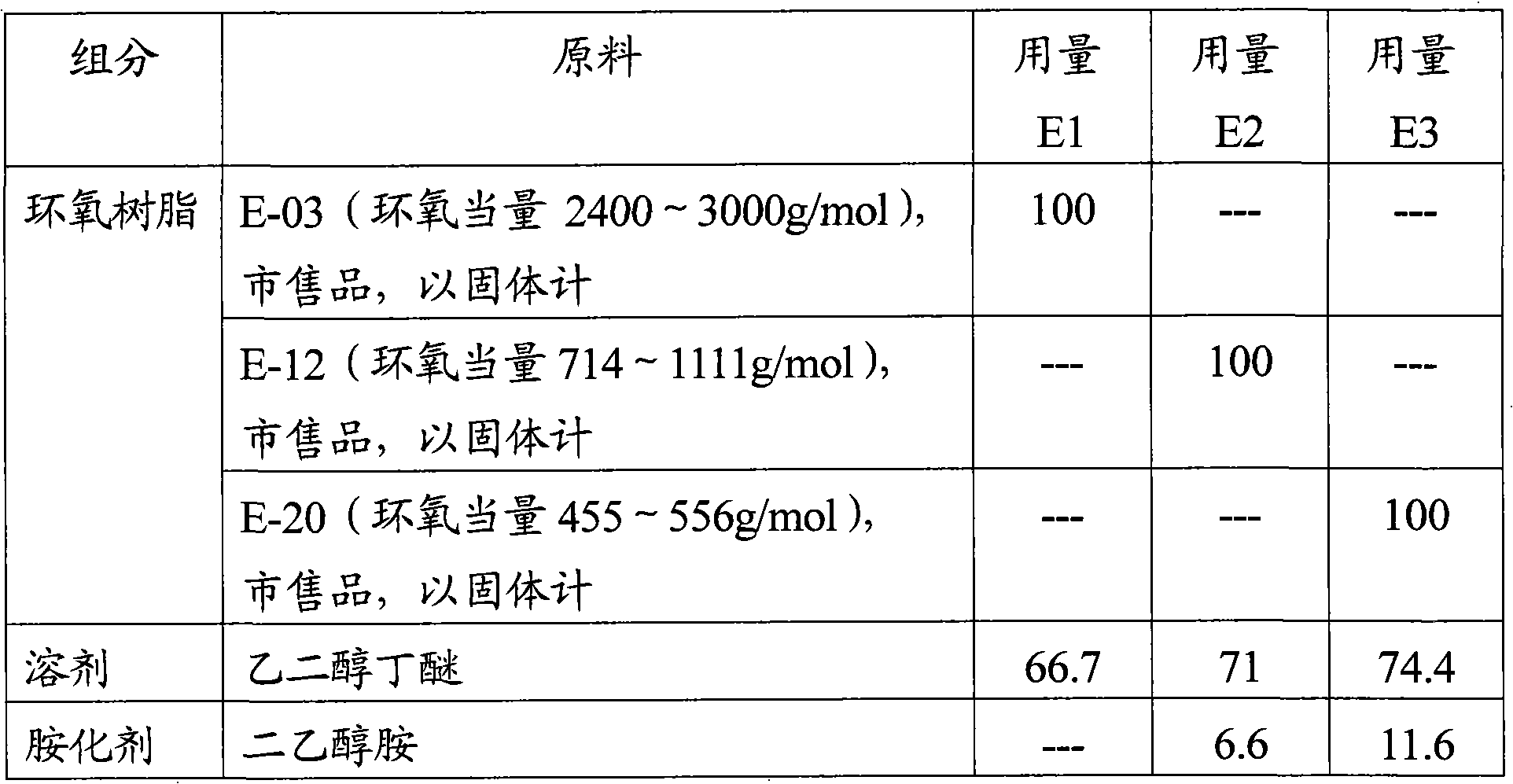

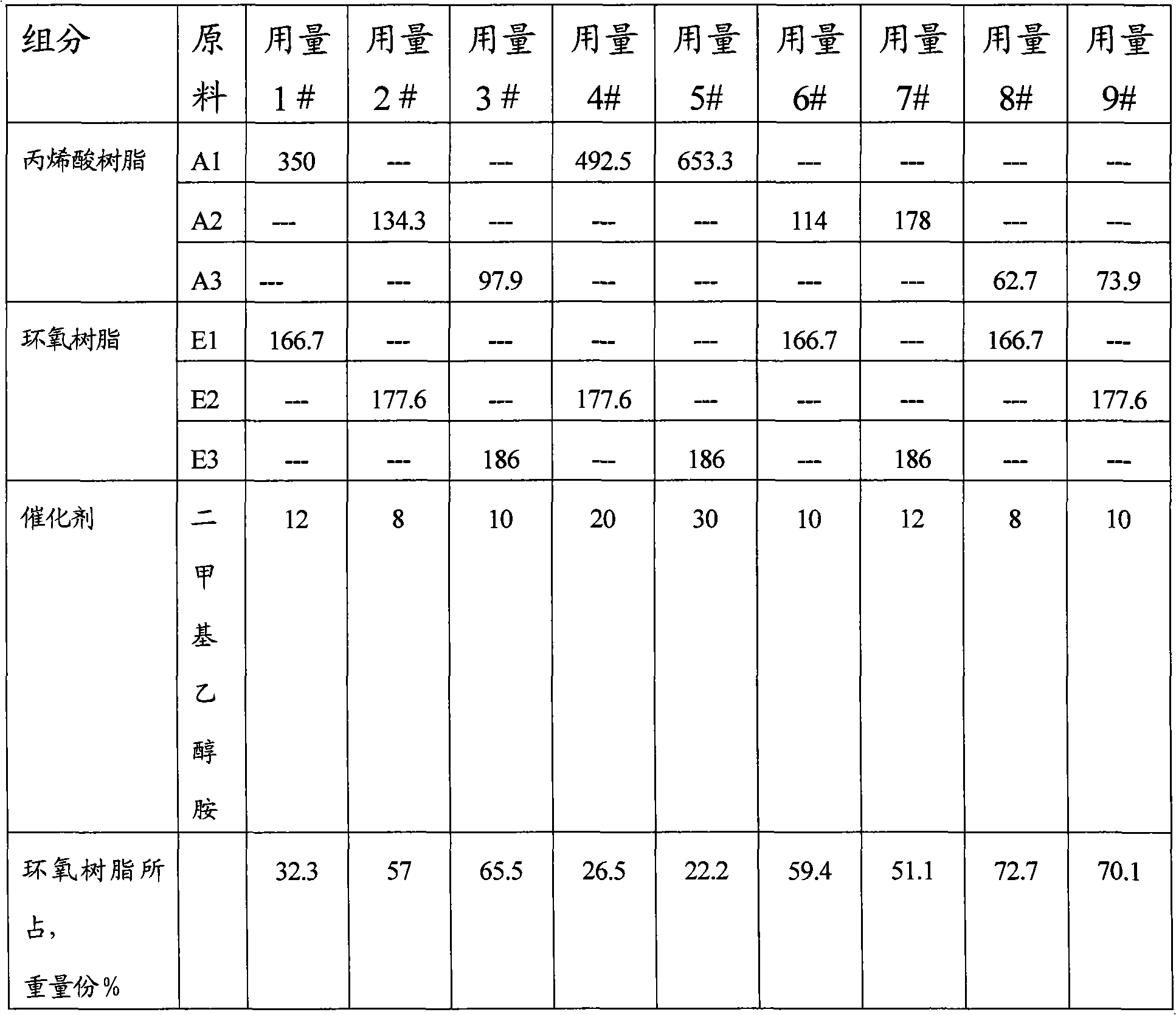

Water soluble acrylic acid epoxy resin and preparation method thereof

The invention relates to water soluble acrylic acid epoxy resin and a preparation method thereof. The epoxy resin is emulsion formed by neutralizing and self-emulsifying a product of a catalytic esterification reaction of acrylic acid resin and epoxy resin, and the variation of tu-4 cup viscosity of the emulsion stored for 6 months is less than 5 percent; epoxy equivalent of the epoxy resin is between 180 and 5,000g / mol, and the epoxy resin accounts for 10 to 80 percent of gross weight of the epoxy resin and the acrylic acid resin; the acrylic acid resin is polymerized from hydroxyl-containing acrylic acid, carboxyl-containing acrylic acid, other acrylic acids and styrene monomers which are initiated by peroxide, and has the acid value of between 50 and 500mgKOH / g and the number average molecular weight of between 5,000 and 60,000g / mol; and the epoxy resin with the epoxy equivalent less than 1,300g / mol does not need bisphenol A chain extension, has simple operation, and is convenient for regulating the proportion of the epoxy resin. The method can be used for preparing the water soluble acrylic acid epoxy resin with wider proportion of the epoxy resin and stable storage.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +1

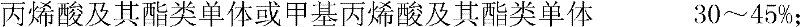

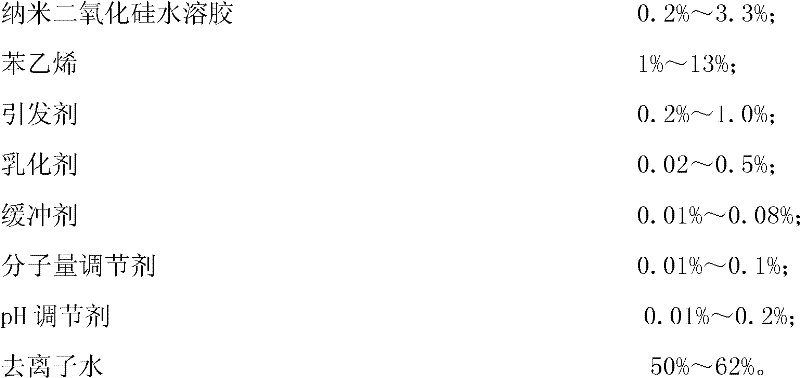

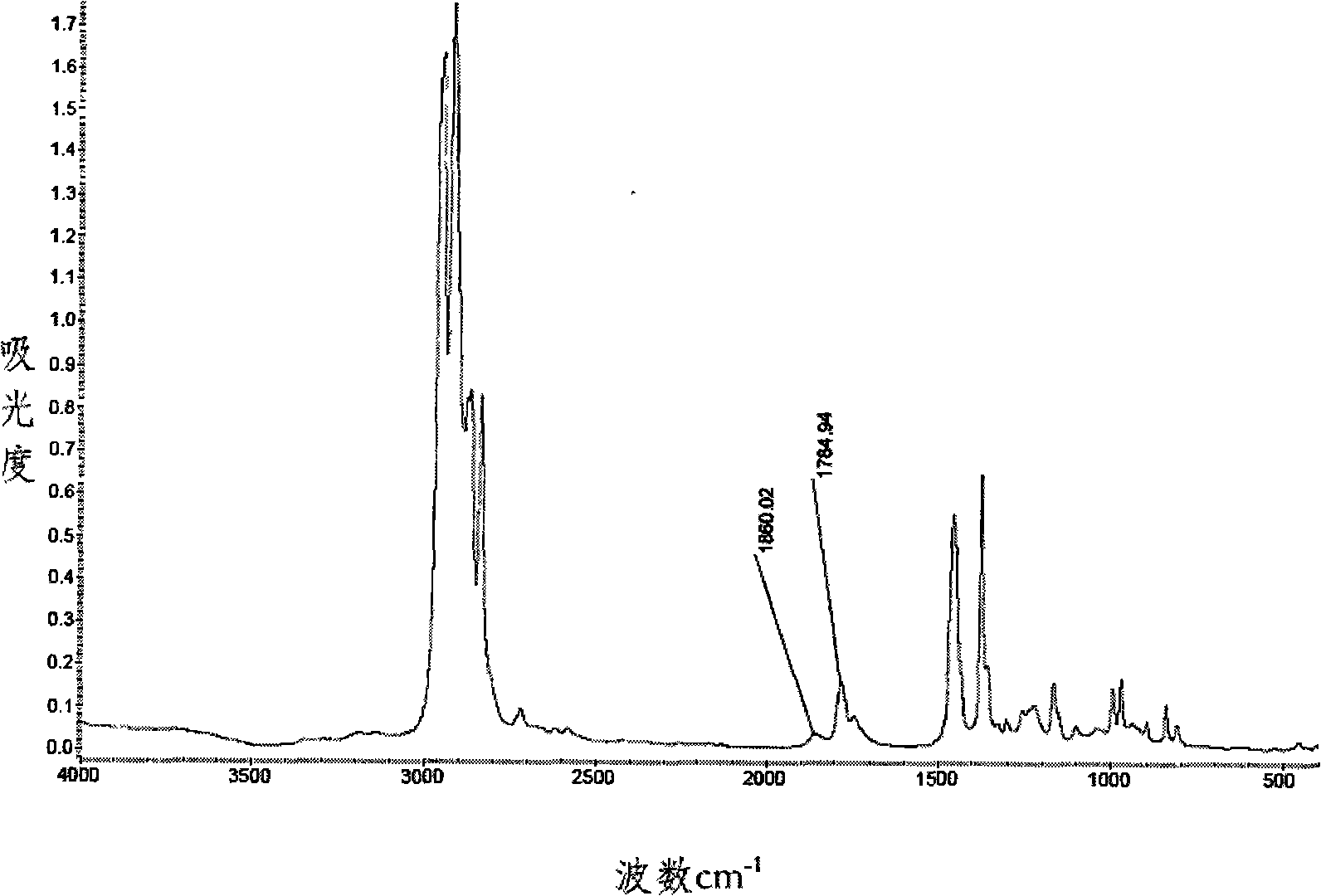

Adhesive for alkali resistant acrylate glass fiber mesh cloth shaping, and preparation method thereof

InactiveCN102533186AImprove sticking powerExcellent dry resistanceGraft polymer adhesivesPolymer adhesivePolymer science

The invention discloses an adhesive for alkali resistant acrylate glass fiber mesh cloth shaping, and a preparation method thereof, and belongs to the field of polymer adhesive preparation. The adhesive is prepared through the reaction of the following components, wherein the components comprise: a material selected from acrylic acid and an ester monomer thereof, or methacrylic acid and an ester monomer thereof; nano-silicon dioxide; a styrene monomer; an initiator; an emulsifier; a buffering agent; a molecular weight regulator; a pH value modulator; and deionized water. According to the adhesive, the nano-silicon dioxide is adopted as the core, a copolymer of the styrene monomer and the acrylic acid monomer is adopted as the shell layer, and the shell layer hard monomer is the acrylate copolymer emulsion with the significant core-shell structure, wherein the concentration of the shell layer hard monomer shows the gradient change. The glass fiber mesh cloth treated by the adhesive of the present invention has advantages of excellent positioning effect, strong adhesive force, bright mesh cloth, good elasticity, high alkali resistance, good water resistance, strong weathering resistance, no yellowing, and no after tack. The adhesive of the present invention is the single mass component glue, is easy to use, does not contain any organic solvents, and has advantages of aquosity and environmental protection.

Owner:BEIJING COMENS NEW MATERIALS

Composite flame-retardant expandable polystyrene particles and preparation technology thereof

Disclosed are composite flame-retardant expandable polystyrene particles and a preparation technology thereof. The particles are prepared from the following components of: by weight, 100 parts of styrene monomer, 100-150 parts of water, 1-10 parts of expandable graphite, 1-12 parts of a phosphorus compound, 0.1-0.5 part of white oil, 0.1-0.5 part of polyethylene wax, 0.05-0.2 part of dicumyl peroxide, 0.2-0.8 part of benzoyl peroxide, 0.1-0.4 part of polyvinyl alcohol, 1.1-2.1 parts of tricalcium phosphate and 8-12 parts of pentane. By the addition of a composite fire retardant of expandable graphite and the phosphorus compound before polymerization of styrene, adverse influence of the fire retardant on performance of the product is reduced; expandable graphite and the phosphorus compound are halogen-free fire retardants, the particles have good environmental protection performance; by the addition of white oil, the particles have plasticising and internal lubricant functions as well as good stability and low volatility, and fluidity during the forming of polystyrene particles can be greatly improved; polyvinyl alcohol and tricalcium phosphate are dispersion stabilizers and by timely adding a proper amount of the dispersion stabilizers, the product appearance can be improved, the production efficiency can be raised, and cost can be reduced; and the addition of all the components guarantees the performance of the product.

Owner:BEIJING HUACHEN DECHUANG CHEM TECH

Method of preparing polypropylene graft polymer

The invention relates to a polypropylene graft polymer preparing method which is characterized in that: (a) calculated by weight parts, the polypropylene graft polymer comprises 100 parts of polypropylene, 0.1-20 parts of graft monomer maleic anhydride, 0.1-20 parts of graft monomer styrene monomer or vinyl acetate monomer, 0.01-10 parts of peroxide initiator and 1-20 parts of other vinyl monomers; (b) the graft monomers, the initiator and the polypropylene are evenly mixed; (c) the reactants are heated to reach a temperature of 70-120 DEG C and then react for 1-10 hours; and (d) after the reaction, the polypropylene graft polymer can be obtained through cooling. During the implementation of the method, no solvent, suspending medium or interfacial agent needs to be used, the obtained product can be applied without needing further treatment, for example, a compatilizer for a polypropylene composite material; and the obtained product is particularly used for improving the interfacial compatibility and dispersivity of inorganic filler and polyolefine. The conversion rate of the graft monomers of the invention is greater than 95 percent, and at least 55 percent of the graft monomers form graft polypropylene.

Owner:BEIJING UNIV OF CHEM TECH

Sizing agent for treating paper surface and its preparing method and use

ActiveCN1944792AIncreased ring compressive strengthImprove Cobb valueWater-repelling agents additionEmulsion polymerizationStyrene Monomer

The present invention discloses one kind of paper surface sizing agent and its preparation process and application. The preparation process includes the free radical emulsion polymerization of dispersant, emulsifier, initiator, cationic monomer, (methyl) acrylate monomer and (methyl) styrene monomer at 30-95 deg.c for 2-6 hr. The dispersant is gelatin, and the initiator is persulfate. The paper surface sizing agent has high performance and environment friendship, and when it is used together with starch in sizing paper surface, it can raise the ring pressure strength greatly, improve Cobb value obviously and speed the curing obviously.

Owner:SHANGHAI DONGSHENG NEW MATERIALS +1

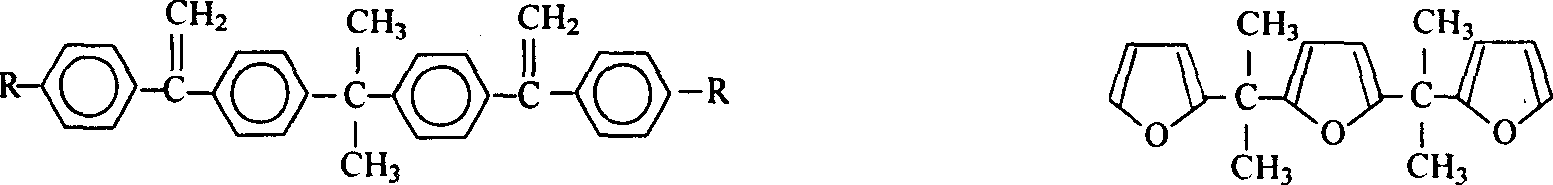

Functionalized block copolymers, method for making same, and various uses for such block copolymers

The present invention is a, solid block copolymer comprising at least two polymer end blocks A and at least one polymer interior block B wherein each A block is a polymer block resistant to lithiation and each B block is a polymer block susceptible to lithiation, and wherein said A and B blocks do not contain any significant levels of olefinic unsaturation. Preferably, each A block comprising one or more segments selected from polymerized (i) para-substituted styrene monomers not having hydrogen on a para benzylic carbon center, (ii) ethylene, (iii) alpha olefins of 3 to 18 carbon atoms; (iv) hydrogenated 1,3-cyclodiene monomers, (v) hydrogenated monomers of conjugated dienes having a vinyl content less than 35 mol percent prior to hydrogenation, (vi) acrylic esters, (vii) methacrylic esters, and (viii) mixtures thereof; and each B block comprising segments of one or more polymerized vinyl aromatic monomers selected from (i) unsubstituted styrene monomers, (ii) ortho-substituted styrene monomers, (iii) meta-substituted styrene monomers, (iv) alpha-methylstyrene, (v) para-substituted styrene having hydrogen on a para benzylic carbon center (vi) 1,1-diphenylethylene, (vii) 1,2-diphenylethylene and (viii) mixtures thereof. After lithiation, the lithiated polymer is reacted with at least one graftable functional molecule selected from the group consisting of an electrophilic graftable molecule containing a functional group and an electrophile. Preferred are carbon monoxide and ethylene oxide. Also claimed are processes for making such block copolymers, and the various end uses and applications for such block copolymers.

Owner:KRATON POLYMERS US LLC

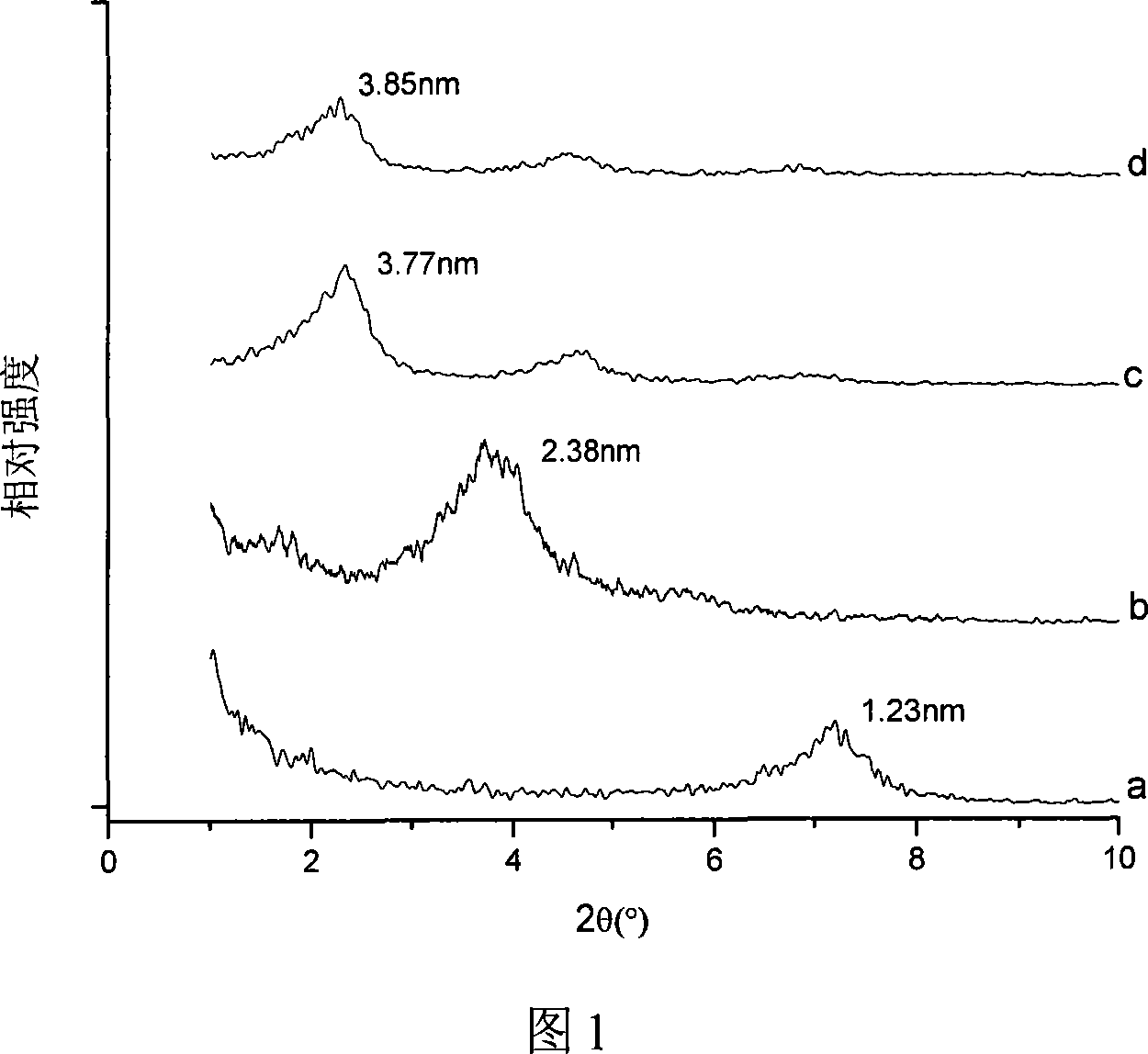

Polymer/organic montmorillonite nano composite flame-proof masterbatch, its preparing method and application

This invention relates to a polymer / organic montmorillonite nano-composite fire retardant material, its preparation and application, which takes water as the media, and under the condition of emulsifier, acrylic monomers or styrene monomers that enter organic montmorillonite layers through initiator conduct polymerization, obtaining the polymer / organic montmorillonite nano-composite fire retardant material. It can prepare flame-retardant plastic with good retardant and mechanical properties if this material is melt with acrylonitrile-butadiene-(ABS), HIPS or PP together.

Owner:SOUTH CHINA UNIV OF TECH

Method for synthesizing low molecular weight phenylethylene / maleic anhydride alternate copolymer

A synthetic method of a styrene / maleic anhydride alternating copolymer with low molecular weight belongs to the field of macromolecular precipitation polymerization. Media and chain transfer agents used in the existing methods for preparing styrene / maleic anhydride copolymers by precipitation polymerization have disadvantages. In the synthetic method, the styrene / maleic anhydride alternating copolymer is prepared by taking a mixed solvent of organic acid alkyl ester and alkane as a reaction medium for the precipitation polymerization, alpha-methylstyrene or vinyl acetate as a molecular weight regulator and organic peroxide or an azo compound as an initiator for initiating a copolymerization reaction between styrene monomers and styrene. The synthetic method has simple process, the synthesized copolymer has good properties, and the method has the advantages of being economical, environment-friendly and the like.

Owner:BEIJING UNIV OF CHEM TECH

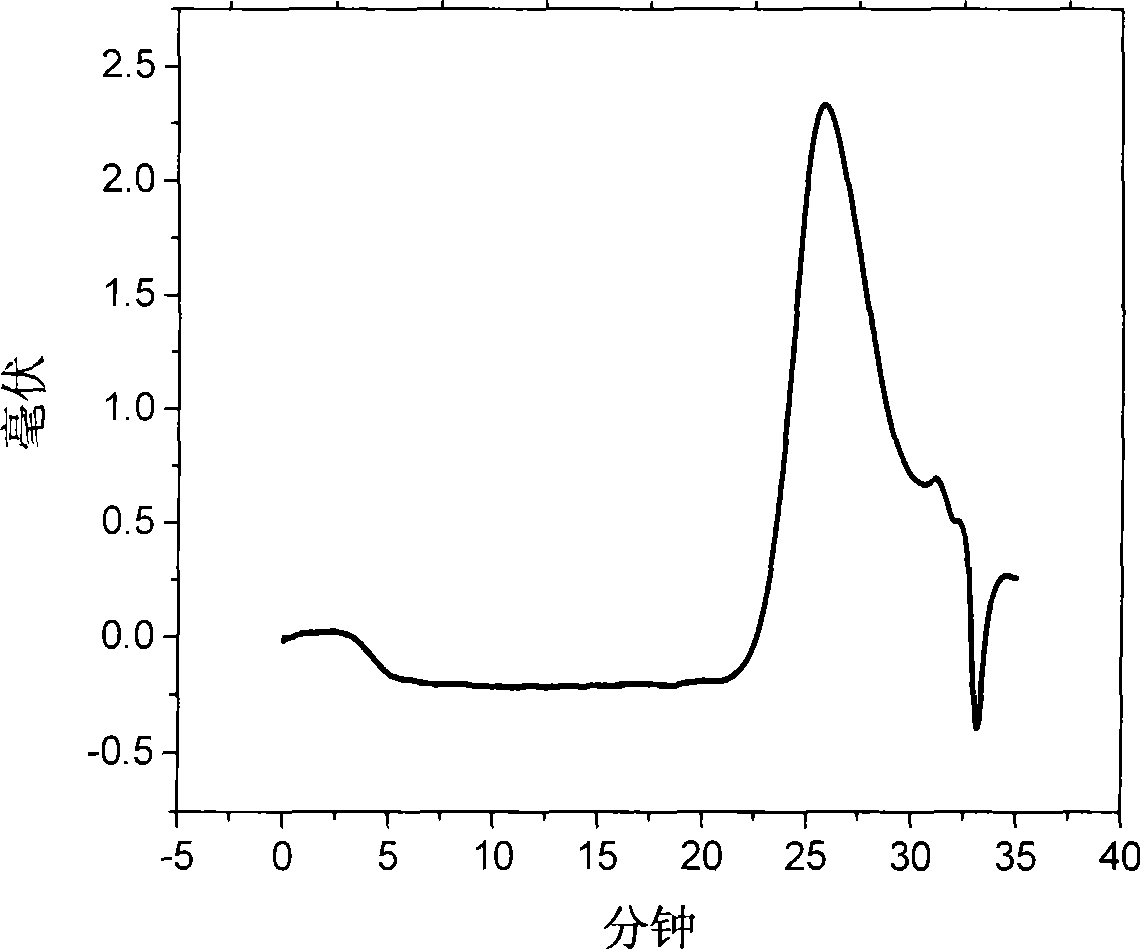

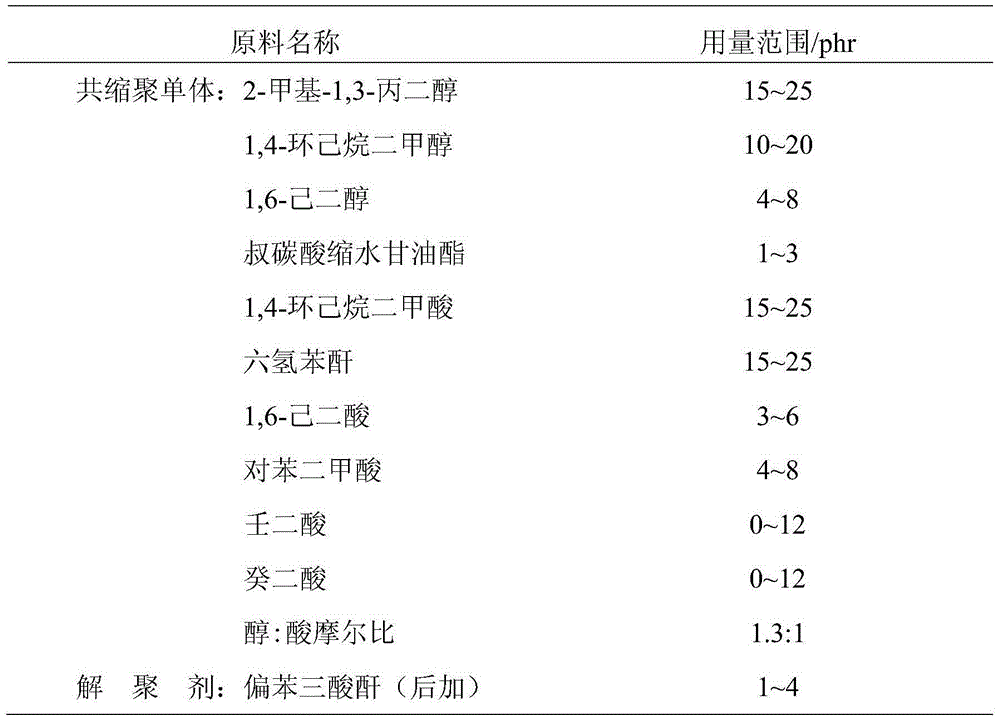

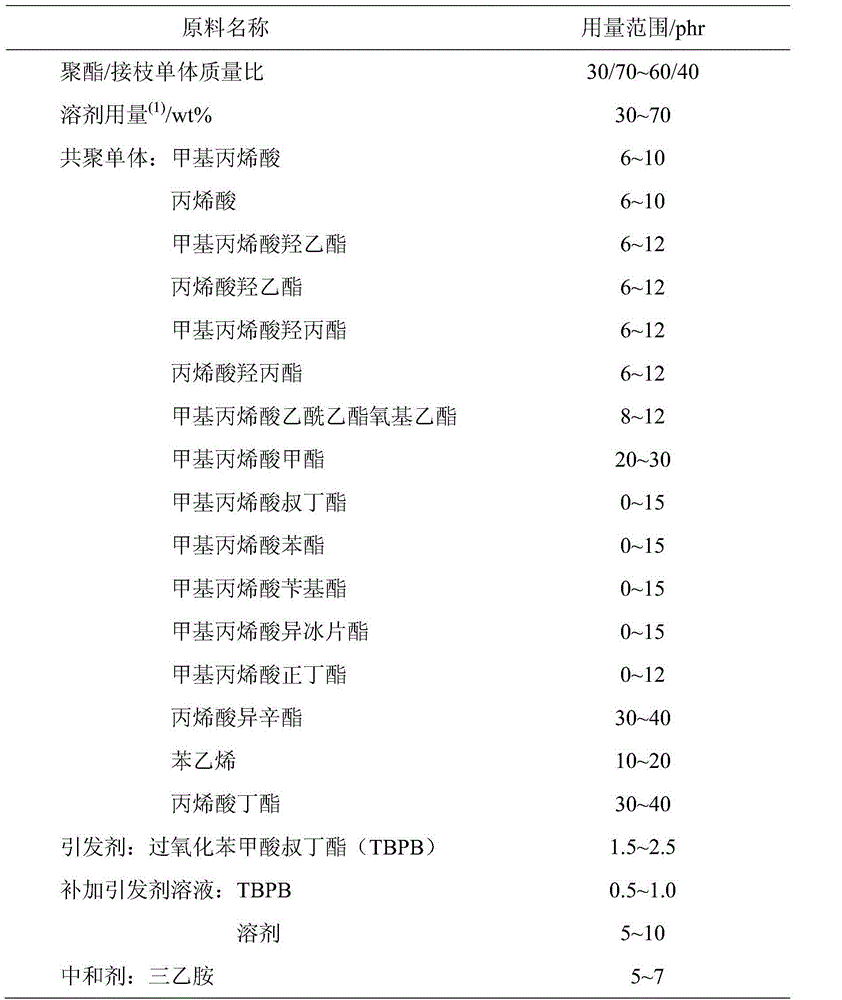

Polyacrylate grafted modified polyester water-based coating and preparation method thereof

The invention discloses a preparation method of a polyacrylate grafted modified polyester water-based coating. The preparation method is as follows: first, selecting a dihydric alcohol and a dibasic acid for a copolycondensation reaction at 240 DEG C for synthesis of a polyester with grafting activity, then adding the dibasic acid or a polybasic acid for polyester depolymerization and end capping for synthesis of water-dispersible polyester resin, then dissolving the water-dispersible polyester resin with a water soluble cosolvent, at 105 DEG C dropping a mixed liquid of a functional monomer, an acrylate monomer, a styrene monomer and an organic peroxide initiator for a free radical grafting copolymerization reaction for synthesis of a solution of water-dispersible-type polyacrylate grafted modified polyester resin with a water-dispersible main chain and a water-soluble graft chain, adding an amine neutralizer for neutralizing the solution of the water-dispersible-type polyacrylate grafted modified polyester resin, mixing the neutralized solution of the polyacrylate grafted modified polyester resin with an amino resin curing agent or an aziridine curing agent, a coating additive and deionized water for preparation of the polyacrylate grafted modified polyester water-based coating. The polyacrylate grafted modified polyester water-based coating has the advantages of a polyester coating and a polyacrylate coating, and is high in cured paint film glossiness and strong in water resistance.

Owner:GUANGDONG YATU CHEM

Nano-ferroferric oxide/polystyrene magnetic composite material and its preparation method

A nano-class magnetic composite Fe3O4 / polystyrene material is prepared through mixing the aqueous solution of two-valence Fe salt with that of three-valence one, adding alkali solution containing surfactant, reacting to obtain Fe3O4 nanoparticles, and ball grinding for dispersing them in styrene monomer while polymerizing reaction.

Owner:EAST CHINA UNIV OF SCI & TECH +1

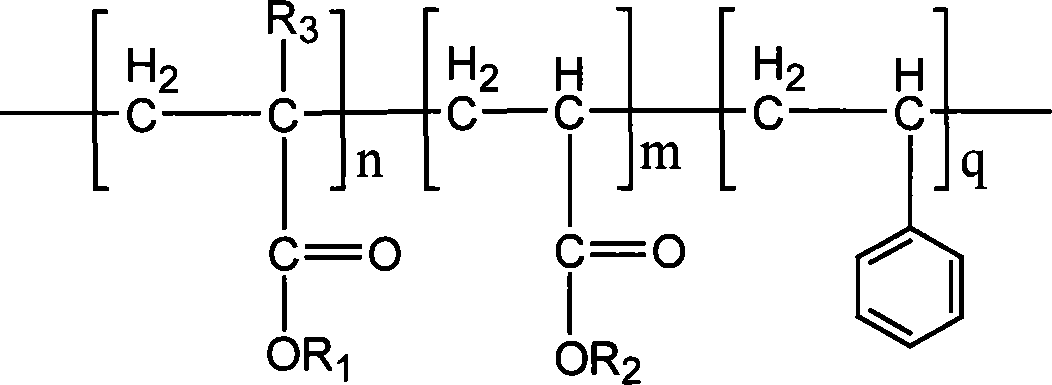

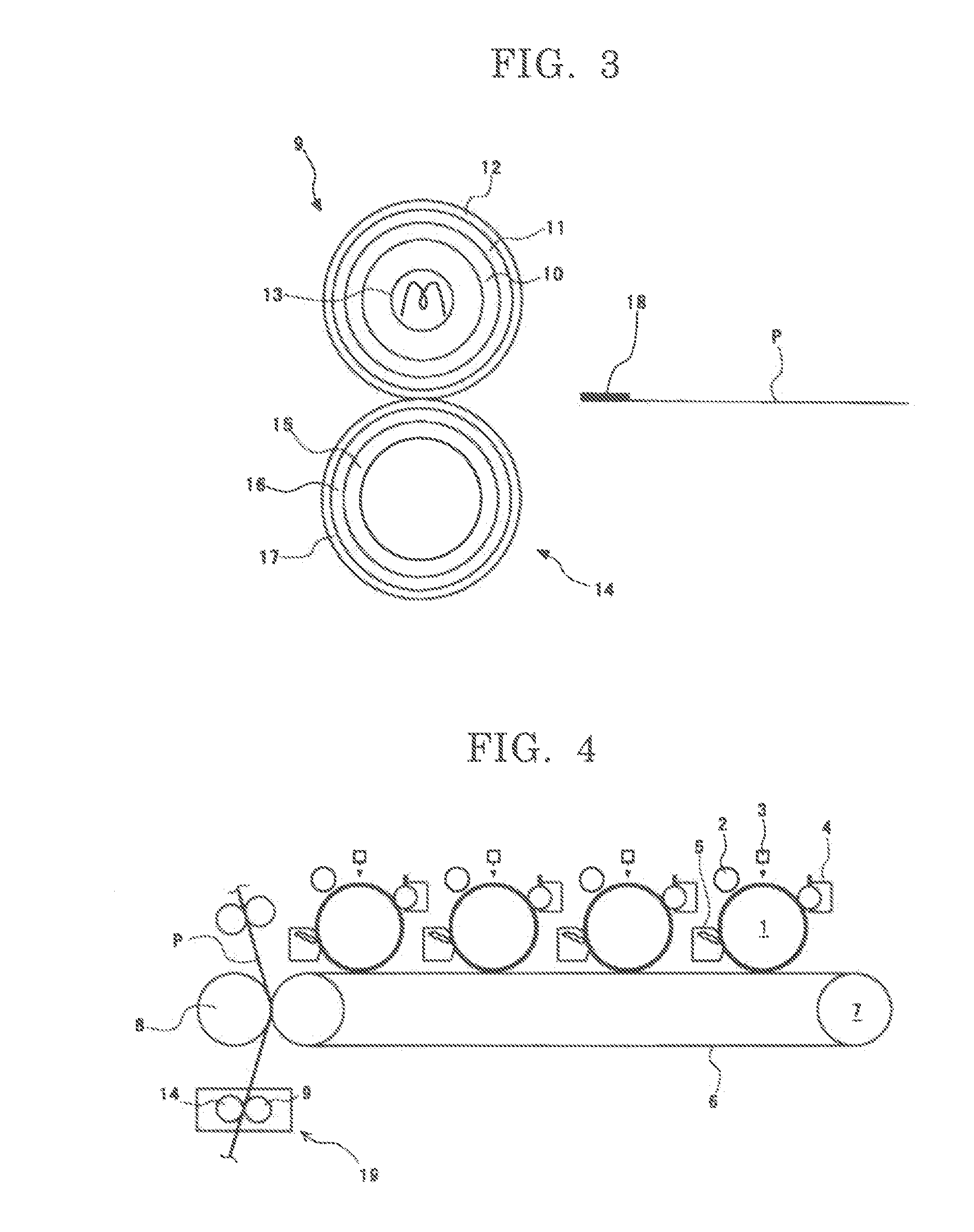

Toner, image forming apparatus, and process cartridge

ActiveUS20110053071A1Excellent releasing ability and charging ability and durabilityFacilitated releaseElectrographic process apparatusDevelopersHydrogen atomPolyester resin

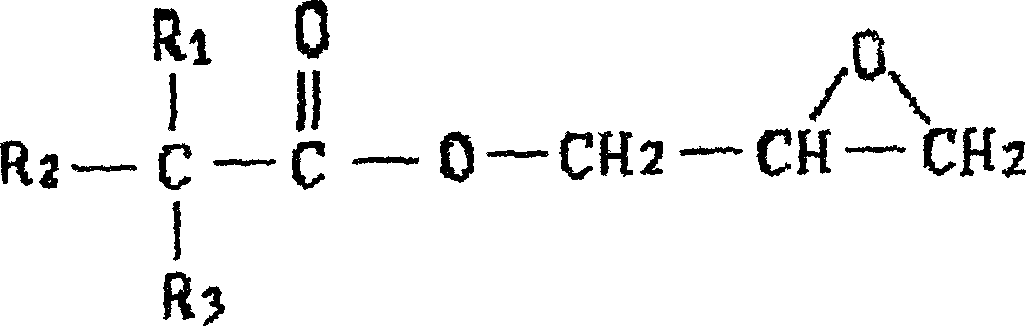

To provide a toner comprising: a binder resin, a colorant, and a releasing agent, wherein the toner has a core shell structure, and wherein the core contains at least one resin selected from the group consisting of a hybrid resin and a polyester resin, where the hybrid resin is a resin in which a polyester resin and a vinyl resin are chemically bonded to each other, and the shell contains a resin prepared by polymerizing at least a styrene monomer and an ester monomer represented by the following General Formula (1):where, ‘n’ is 2 or 3, ‘X’ is any of 0 to 9, R1 is a hydrogen atom, or an alkyl group, and R2 is a hydrogen atom, an alkyl group, or a phenyl group.

Owner:RICOH KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com