Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

14067 results about "Acrylate ester" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acrylates and methacrylates (the salts and esters of methacrylic acid) are common monomers in polymer plastics, forming the acrylate polymers. Acrylates easily form polymers because the double bonds are very reactive.

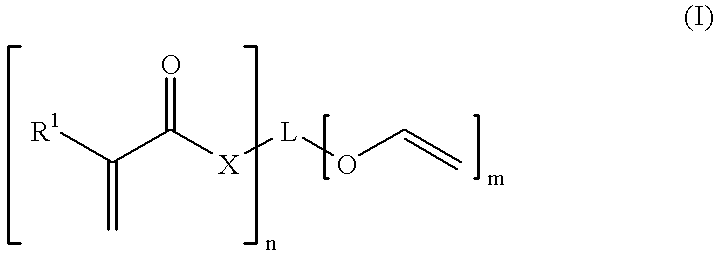

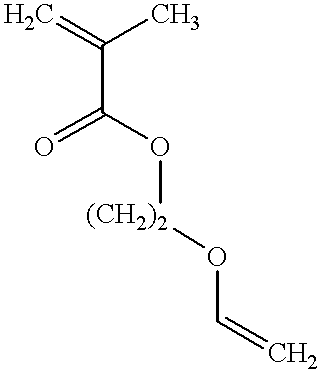

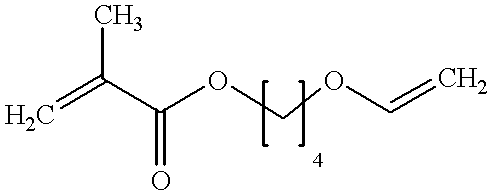

Ink compositions for ink jet printing

InactiveUS6310115B1Reduce viscosityLow viscosityLiquid surface applicatorsOrganic chemistryPolymer chemistryAcrylate

Owner:AGFA NV

Method of forming a hybrid polymer film

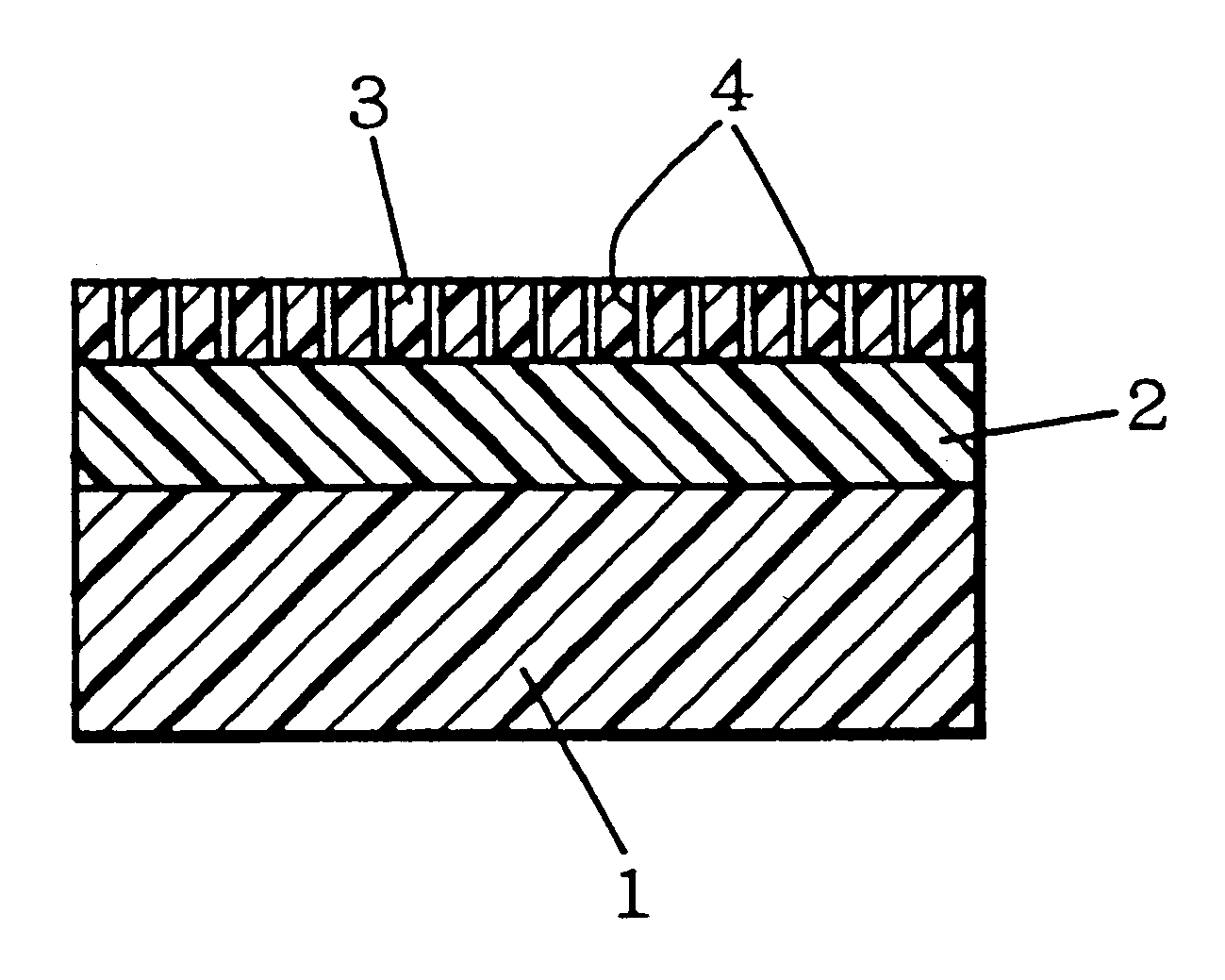

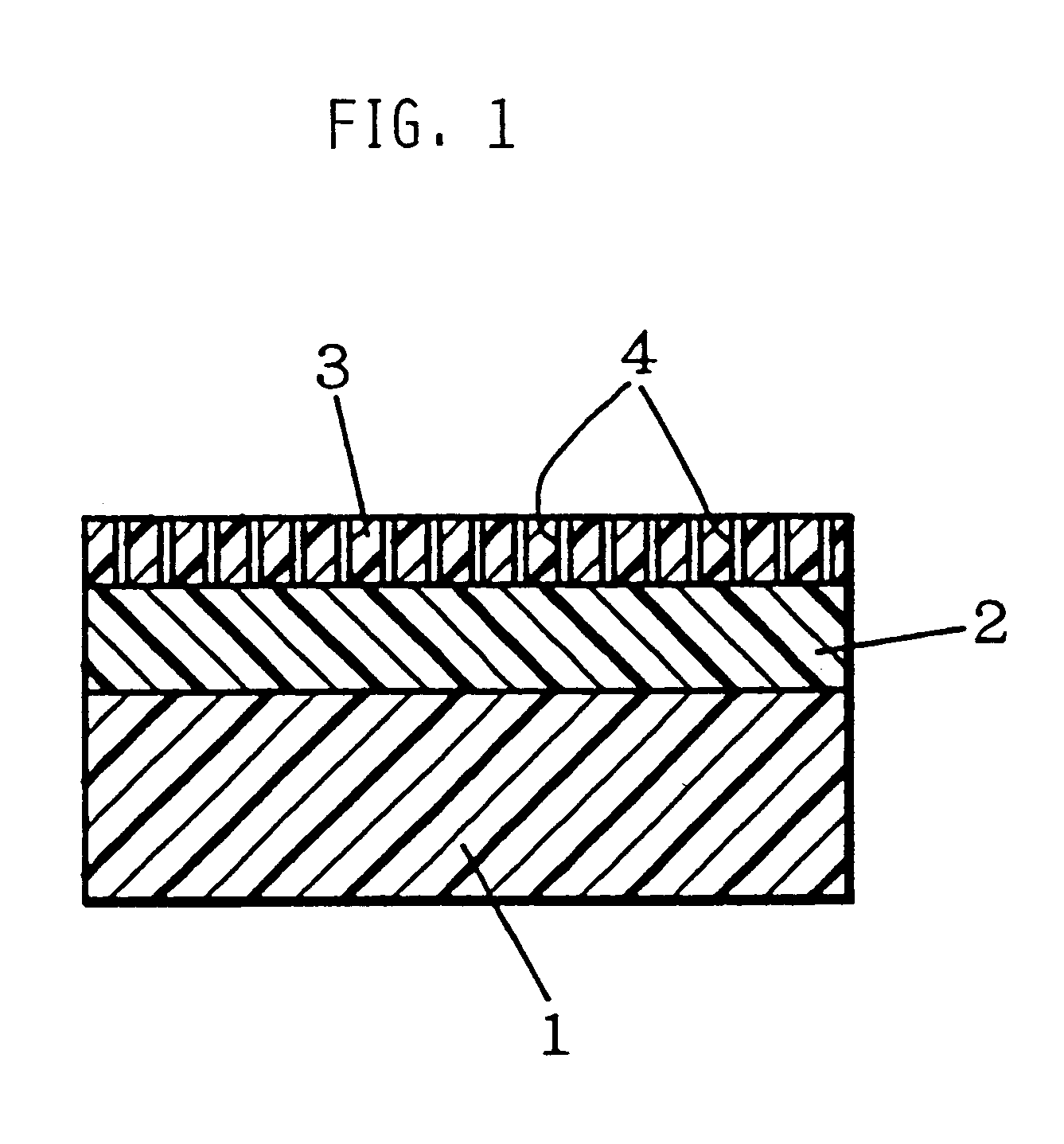

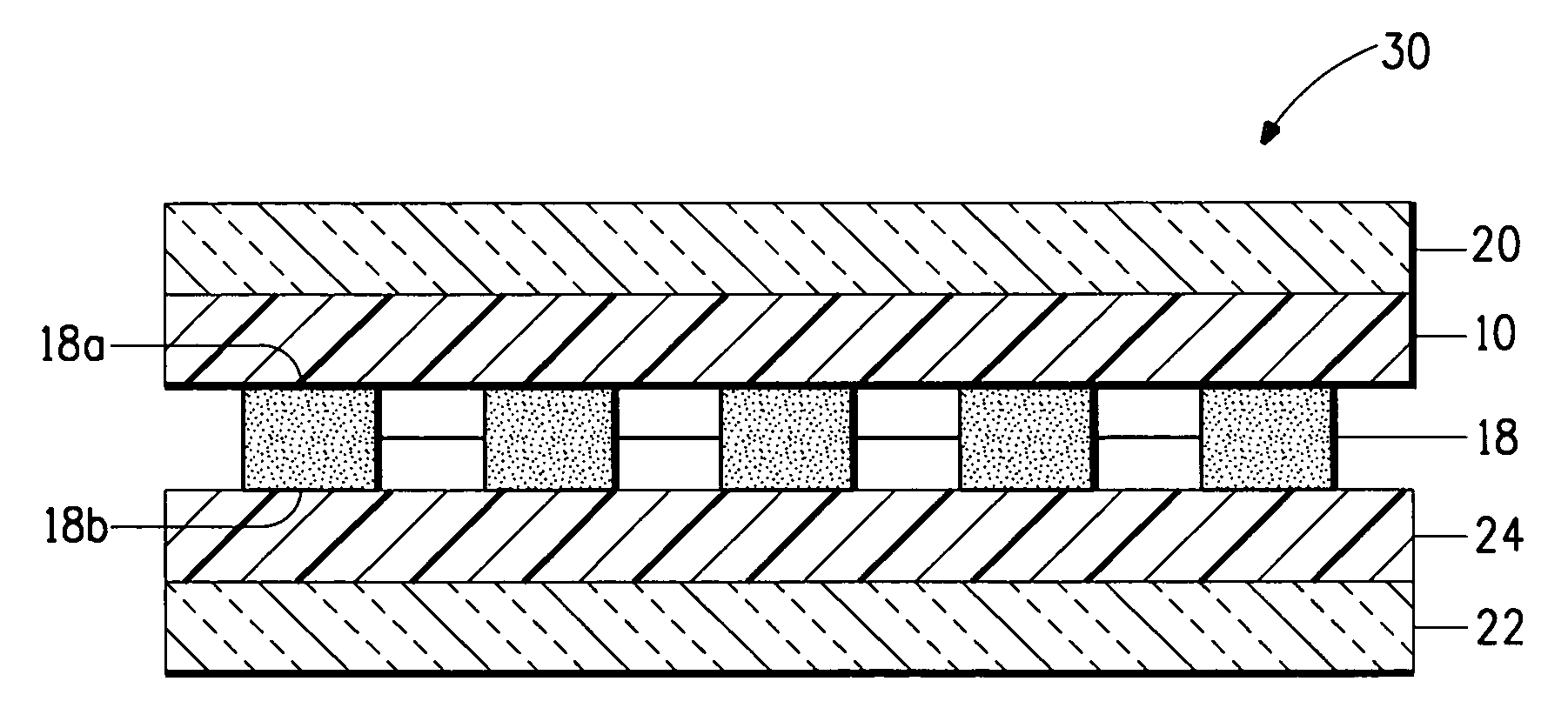

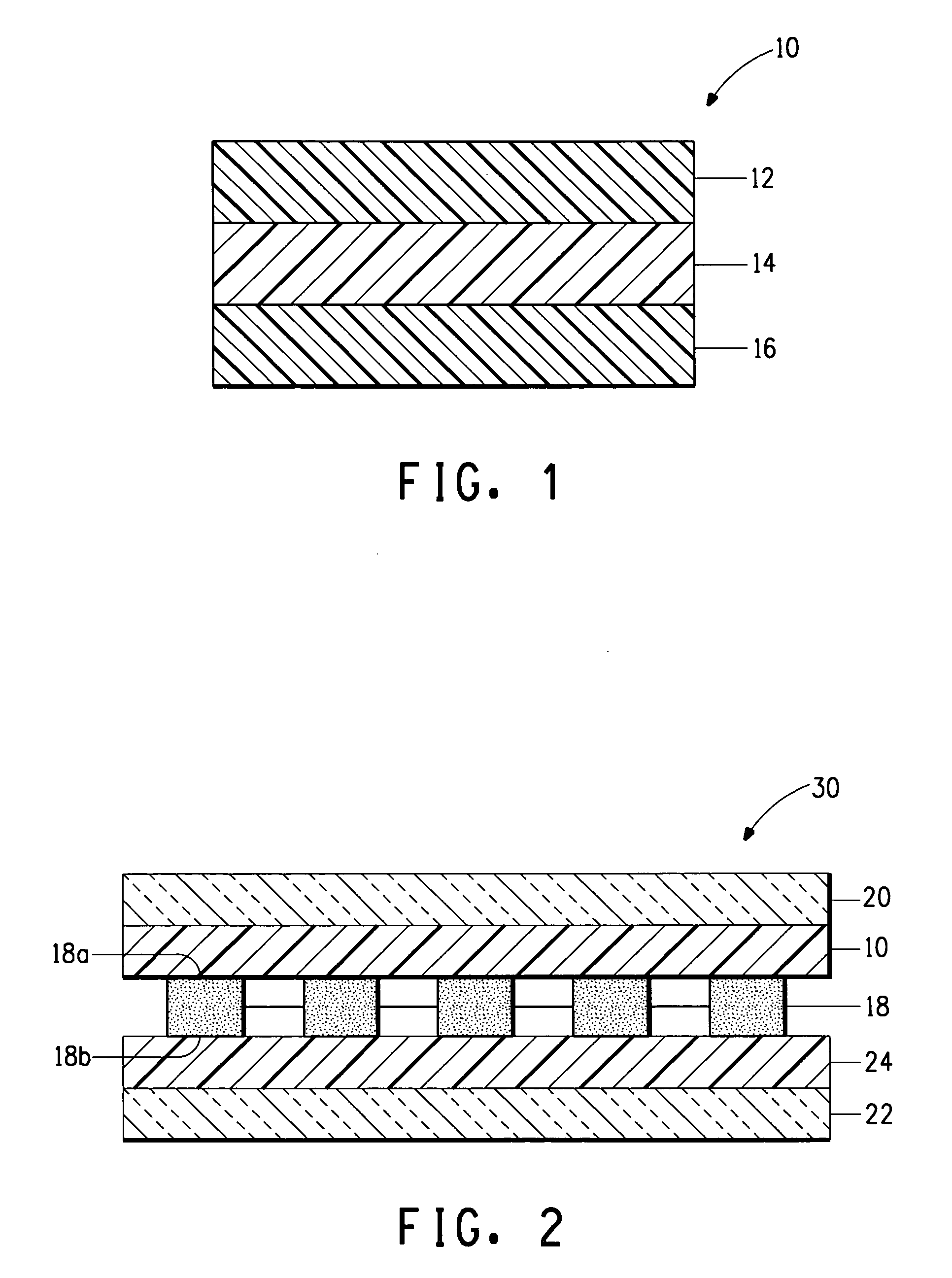

InactiveUS6214422B1Fine surfaceLow costFixed capacitor dielectricSynthetic resin layered productsThermoplasticCross-link

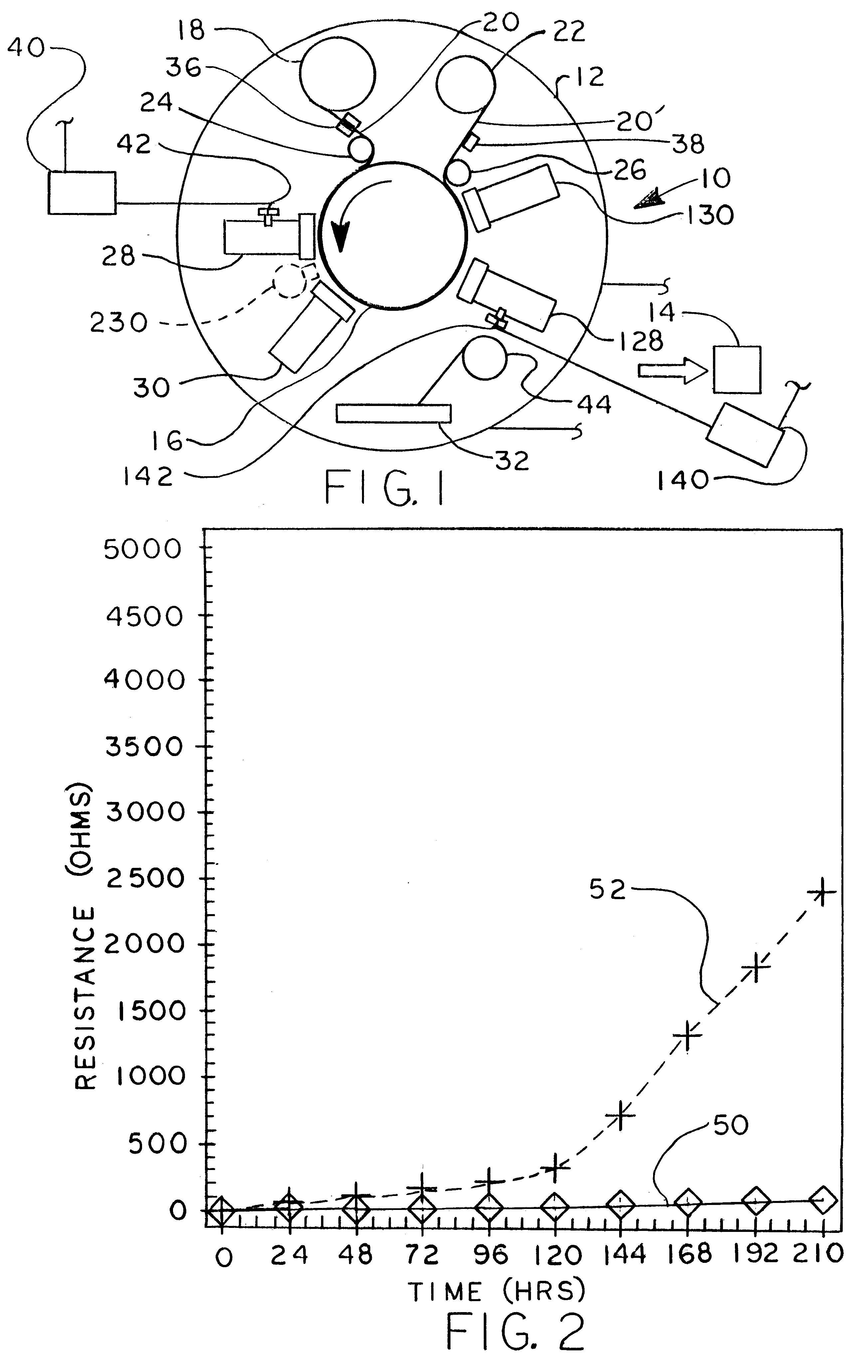

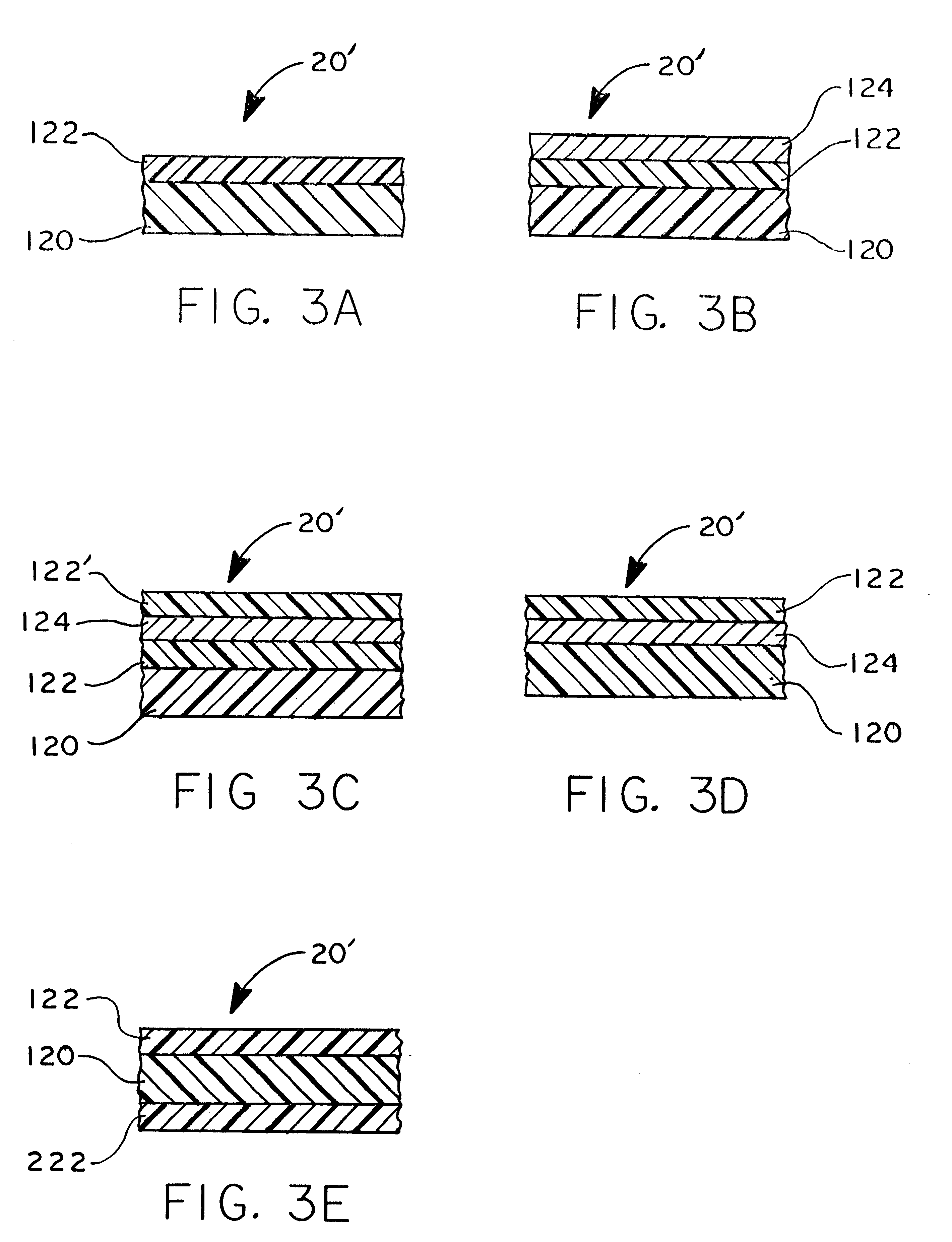

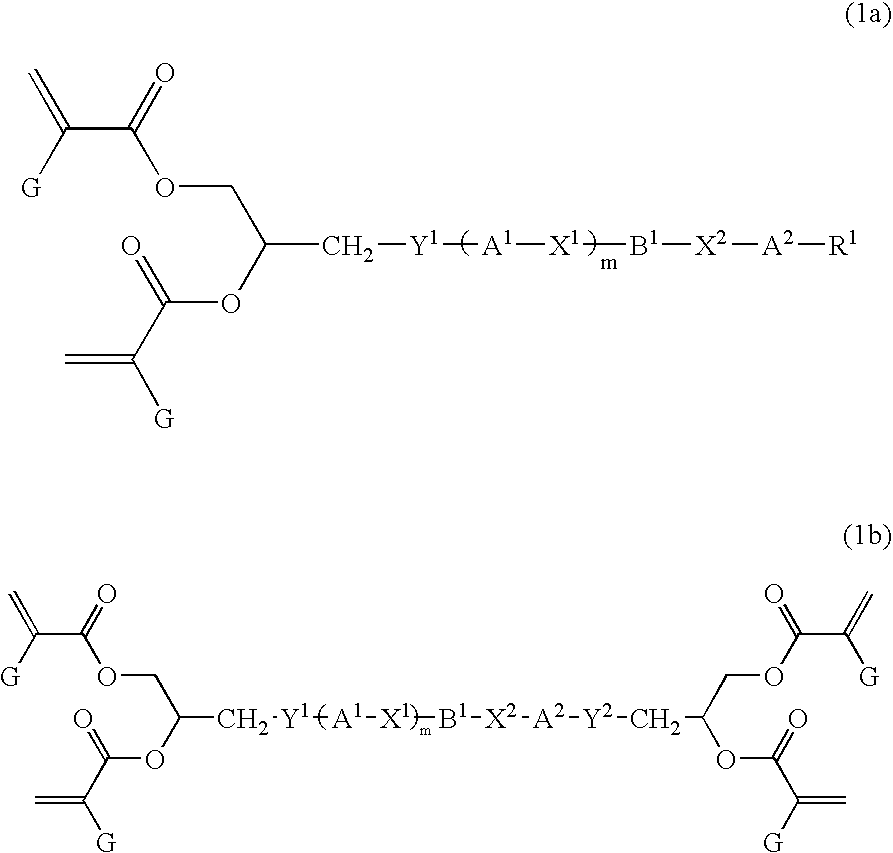

A hybrid film, comprising a first polymer film having a plasma-treated surface and a second polymer film having first and second surfaces, with the first surface of the second polymer film being disposed along the first plasma-treated surface of the first polymer film, has superior thermal and mechanical properties that improve performance in a number of applications, including food packaging, thin film metallized and foil capacitors, metal evaporated magnetic tapes, flexible electrical cables, and decorative and optically variable films. One or more metal layers may be deposited on either the plasma-treated surface of the substrate and / or the radiation-cured acrylate polymer A ceramic layer may be deposited on the radiation-cured acrylate polymer to provide an oxygen and moisture barrier film. The hybrid film is produced using a high speed, vacuum polymer deposition process that is capable of forming thin, uniform, high temperature, cross-liked acrylate polymers on specific thermoplastic or thermoset films. Radiation curing is employed to cross-link the acrylate monomer. The hybrid film can be produced in-line with the metallization or ceramic coating process, in the same vacuum chamber and with minimal additional cost.

Owner:SIGMA LAB OF ARIZONA

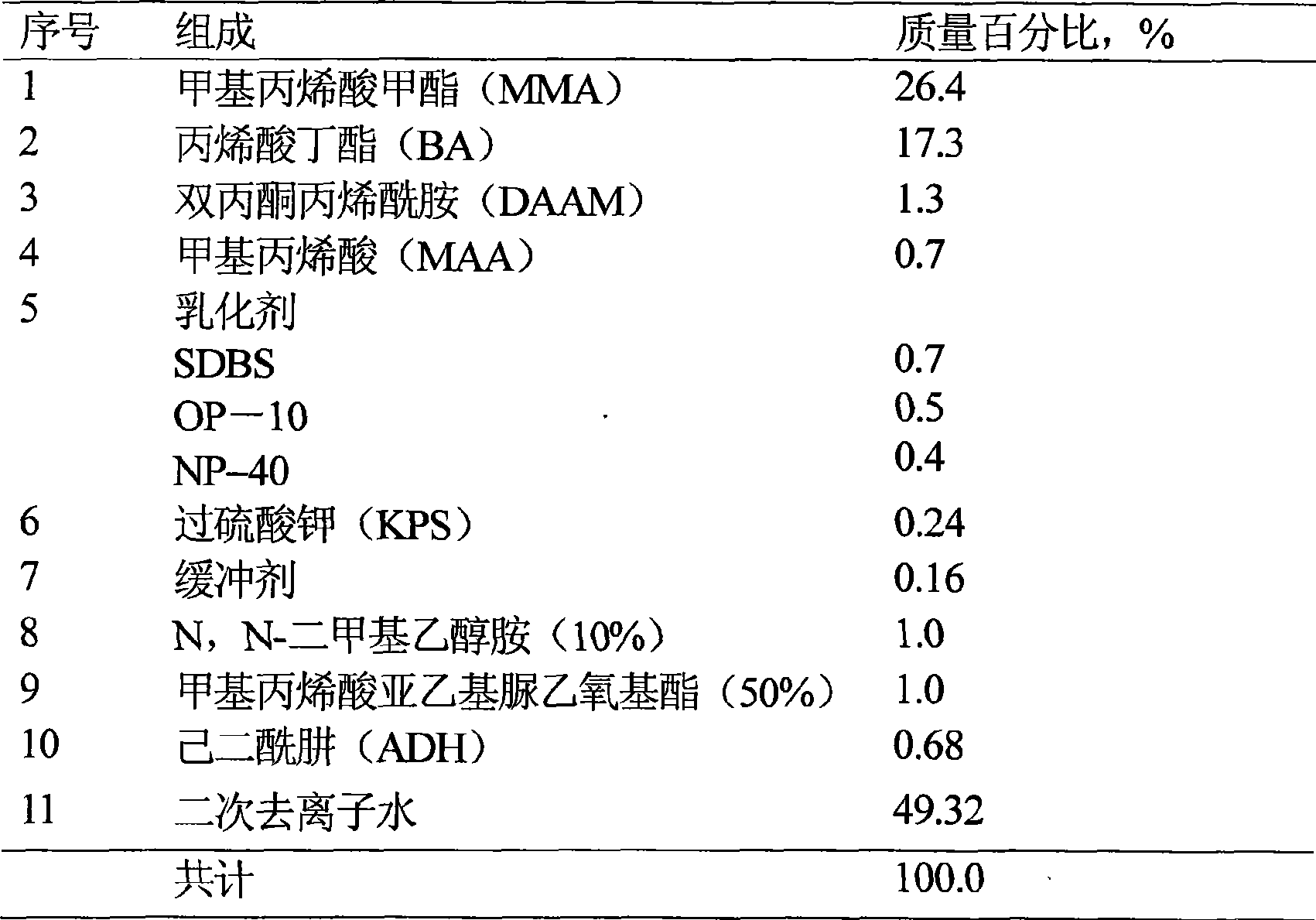

Liquid crystal polyfunctional acrylate derivative and polymer thereof

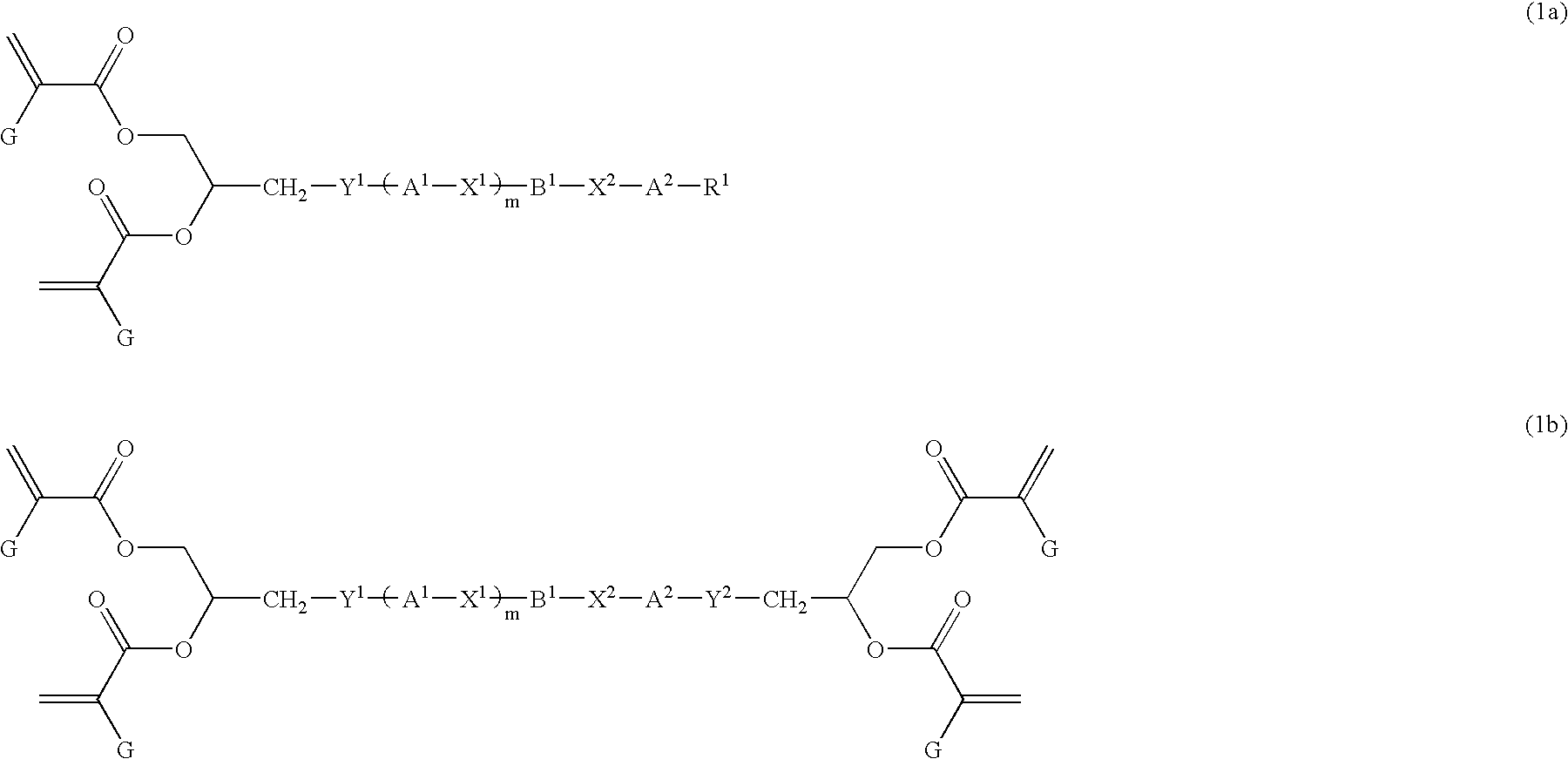

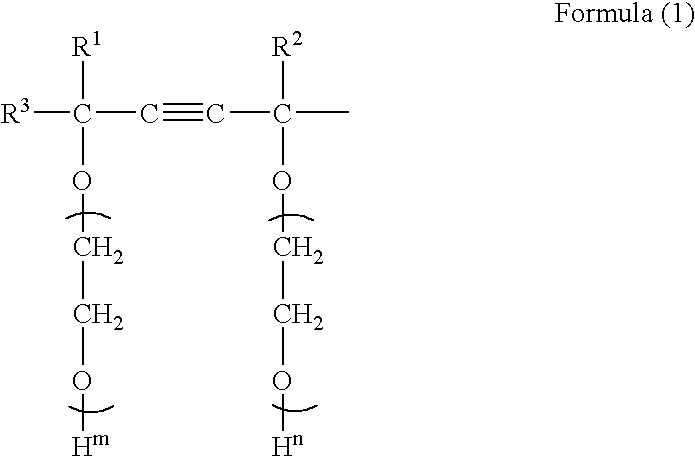

A compound represented by the following general formula (1a) or (1b), a liquid crystal composition containing the compound, and a polymer obtained by polymerizing the compound or the composition: wherein R1 represents a fluorine atom, an alkyl group or the like; Y1 and Y2 each independently represents alkylene or the like; A1, A2, B1 and B2 each independently represents 1,4-cyclohexylene, 1,4-phenylene or the like; X1 and X2 each independently represents a single bond, —COO—, —OCO— or the like; m represents 0, 1 or 2; and G represents hydrogen, methyl or the like.

Owner:JNC CORP +1

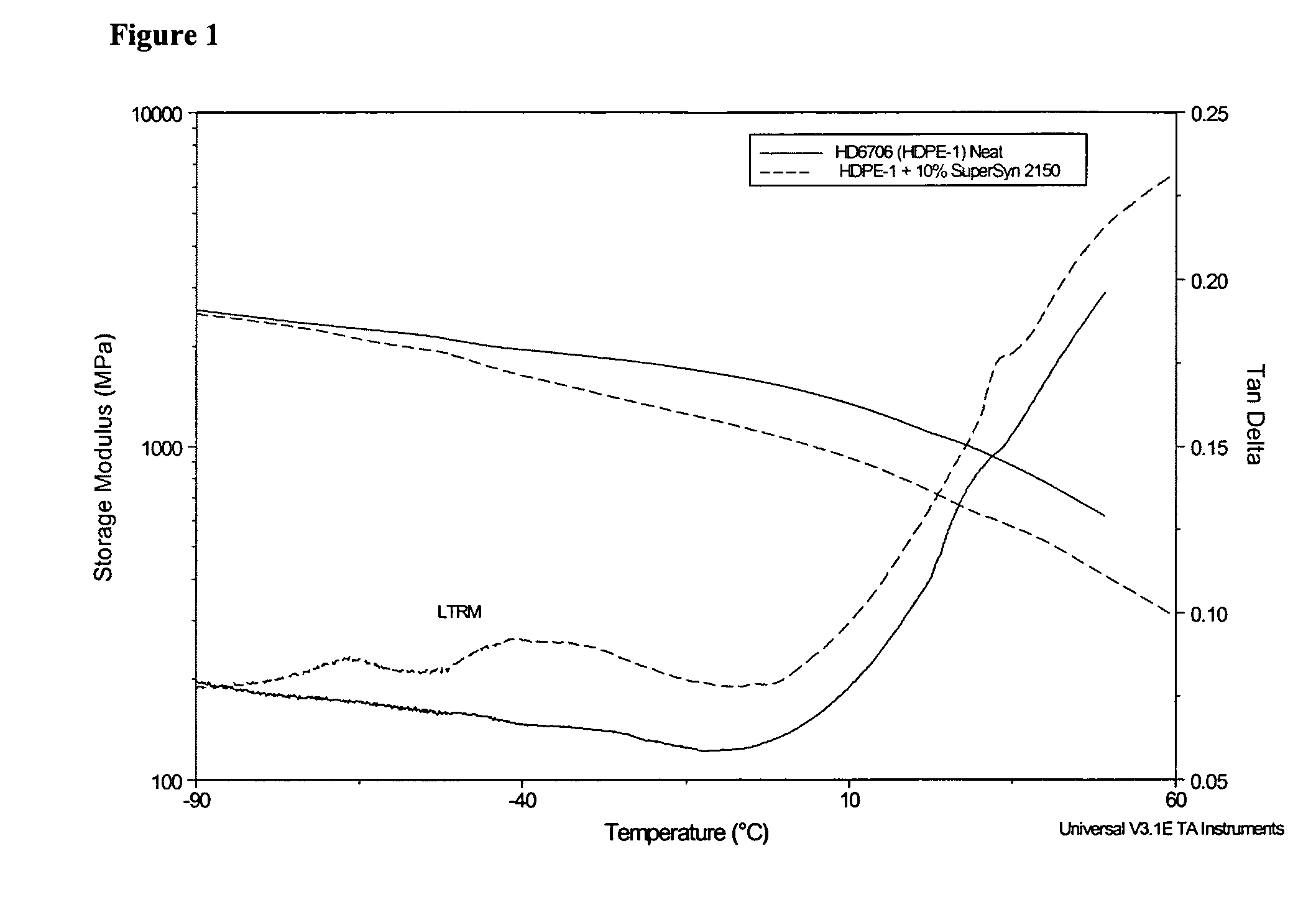

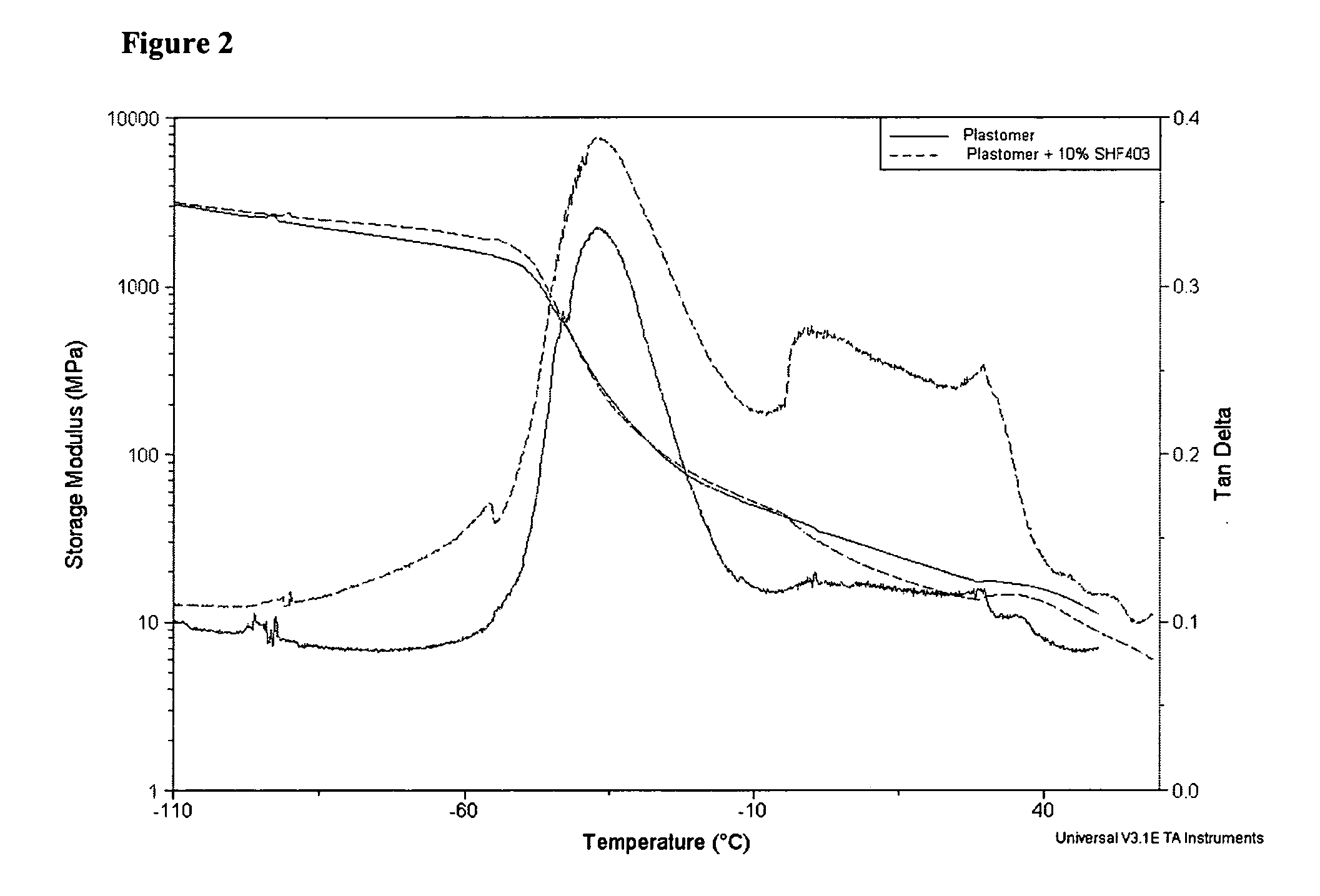

Modified polyethylene compositions

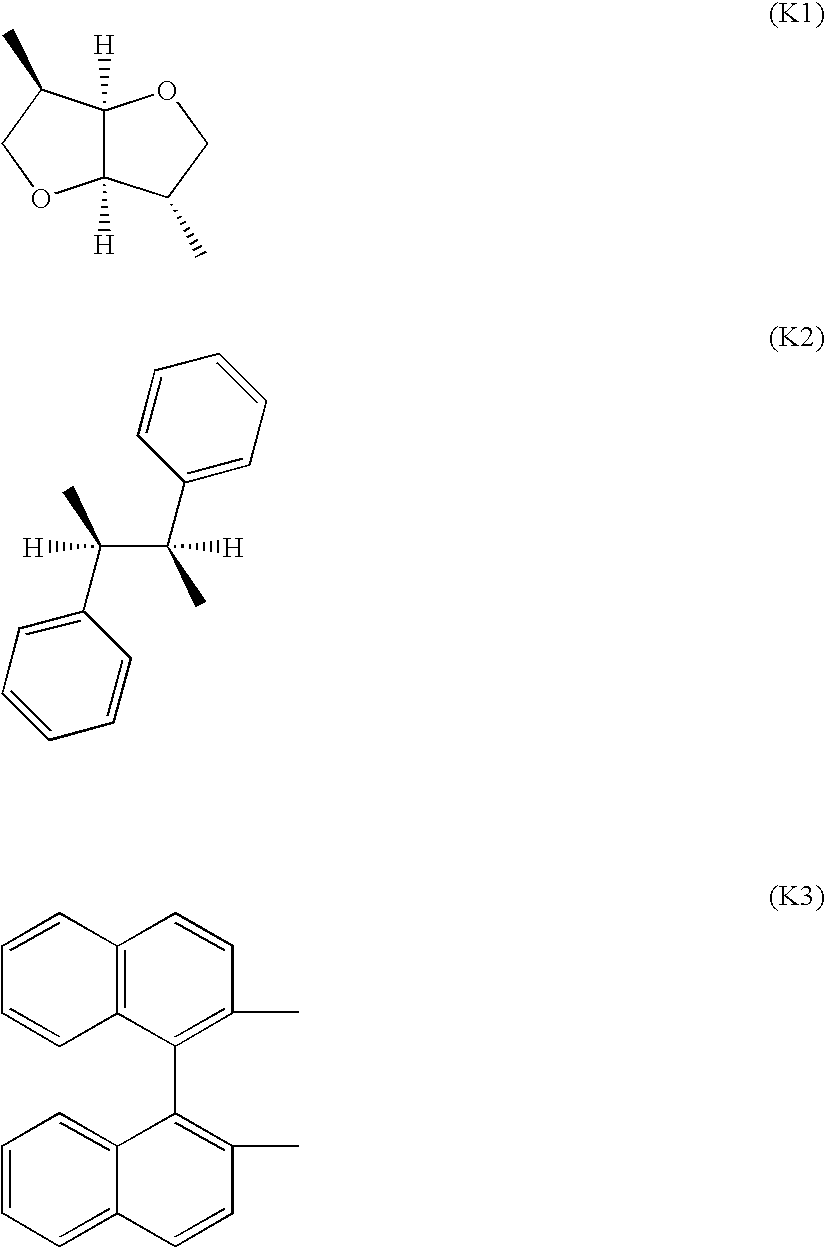

The present invention relates to a composition comprising more than 25 weight % (based on the weight of the composition) of one or more ethylene polymers having an Mw of 20,000 g / mole or more and at least 0.1 weight % of a liquid hydrocarbon modifier where the modifier has: 1) a viscosity index of 120 or more, and 2) an kinematic viscosity of 3 to 3000 cSt at 100° C., and 3) a pour point of −10° C. or less, and 4) a flash point of 200° C. or more; and wherein the modifier contains less than 5 weight % of functional groups selected from hydroxide, aryls, substituted aryls, halogens, alkoxys, carboxylates, esters, acrylates, oxygen, nitrogen, and carboxyl, based upon the weight of the modifier.

Owner:EXXONMOBIL CHEM PAT INC

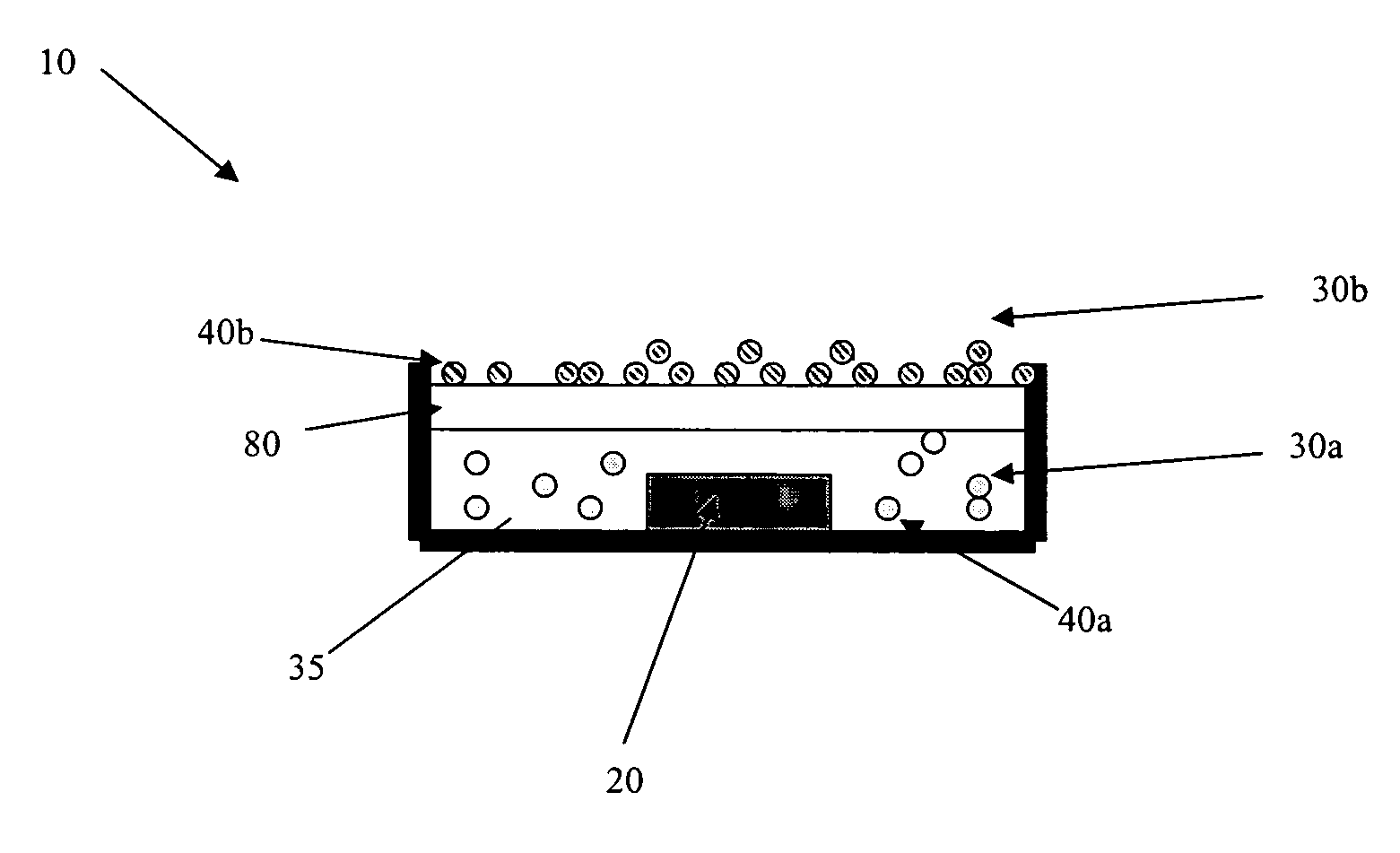

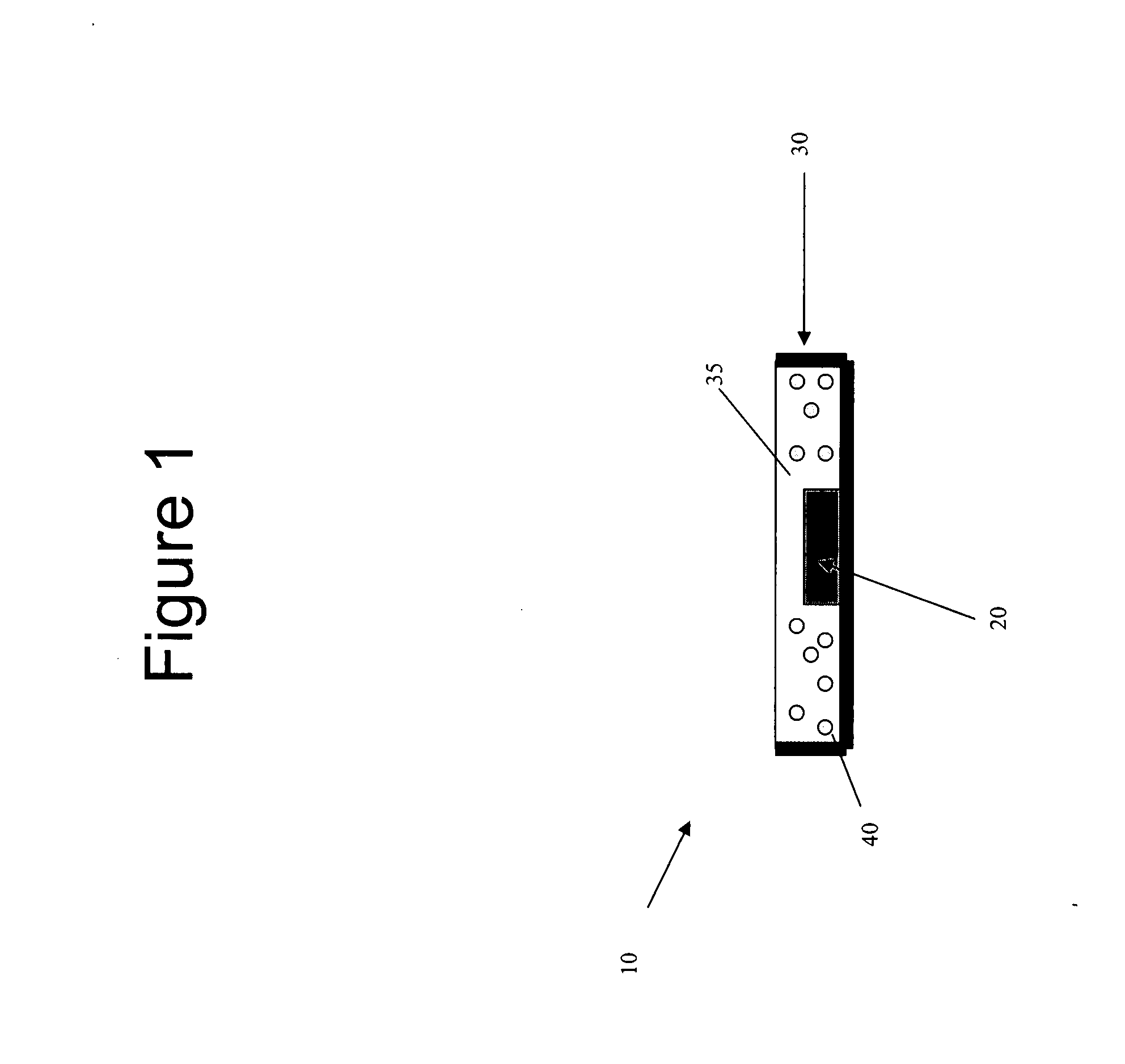

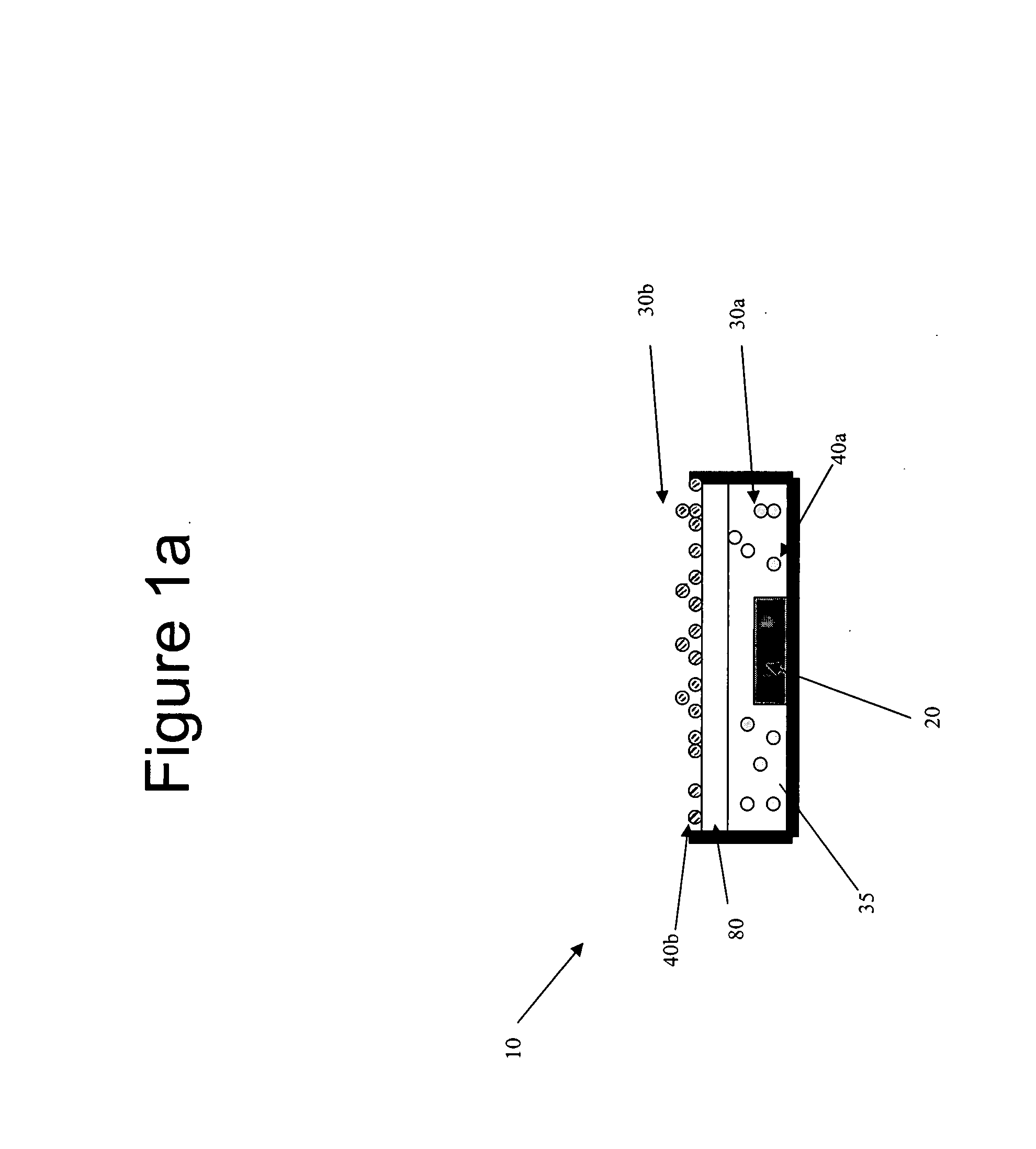

Solid state lighting devices comprising quantum dots

Solid state lighting devices containing quantum dots dispersed in polymeric or silicone acrylates and deposited over a light source. Solid state lighting devices with different populations of quantum dots either dispersed in matrix materials or not are also provided. Also provided are solid state lighting devices with non-absorbing light scattering dielectric particles dispersed in a matrix material containing quantum dots and deposited over a light source. Methods of manufacturing solid state lighting devices containing quantum dots are also provided.

Owner:SAMSUNG ELECTRONICS CO LTD

Structural modified epoxy adhesive compositions

InactiveUS6572971B2Raise the ratioReduce opening timeSynthetic resin layered productsEpoxy resin adhesivesFirming agentAliphatic amine

The present invention is directed to an adhesive composition, which comprises an epoxy resin, a coupling agent, filler, and an effective amount of an amine-curing agent or curative for said epoxy resin. Advantageously, tri-functional and / or tetrafunctional epoxy resins and / or acrylate monomers will be incorporated into the adhesive composition in order to reduce open time and enhance substrate adhesion. Advantageously, a mixture of amines will be used in the curative including aliphatic amines, which have low viscosities and efficiently wet the substrate for enhancing adhesion; polyamines, which can be used to manipulate open time and allow for improved ratio tolerance of the adhesive system; and amine-terminated rubbers (ATBN), which can improve impact resistance and the toughness of the cured adhesive. Preferred coupling agents are silanes.

Owner:ASHLAND LICENSING & INTPROP LLC

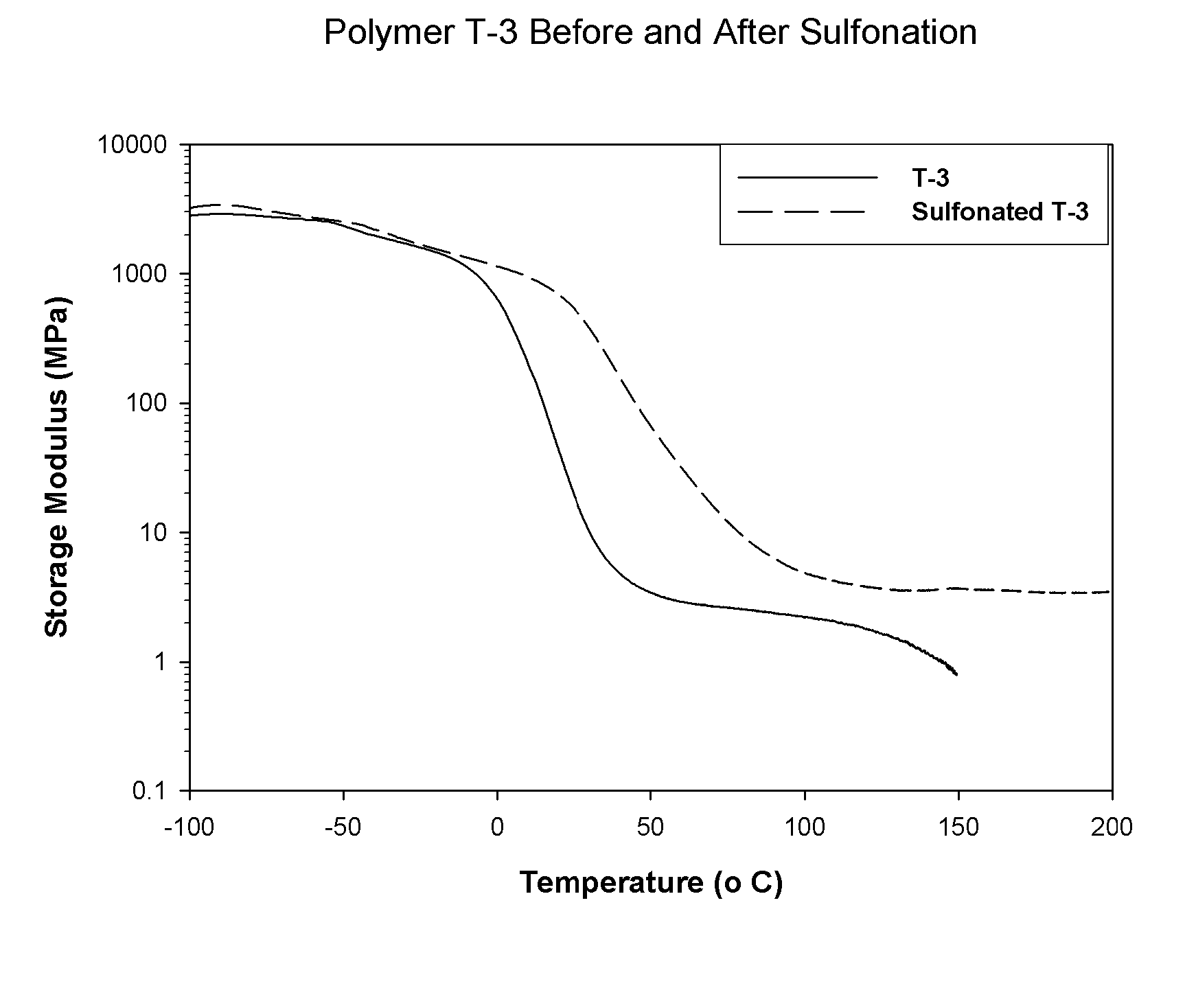

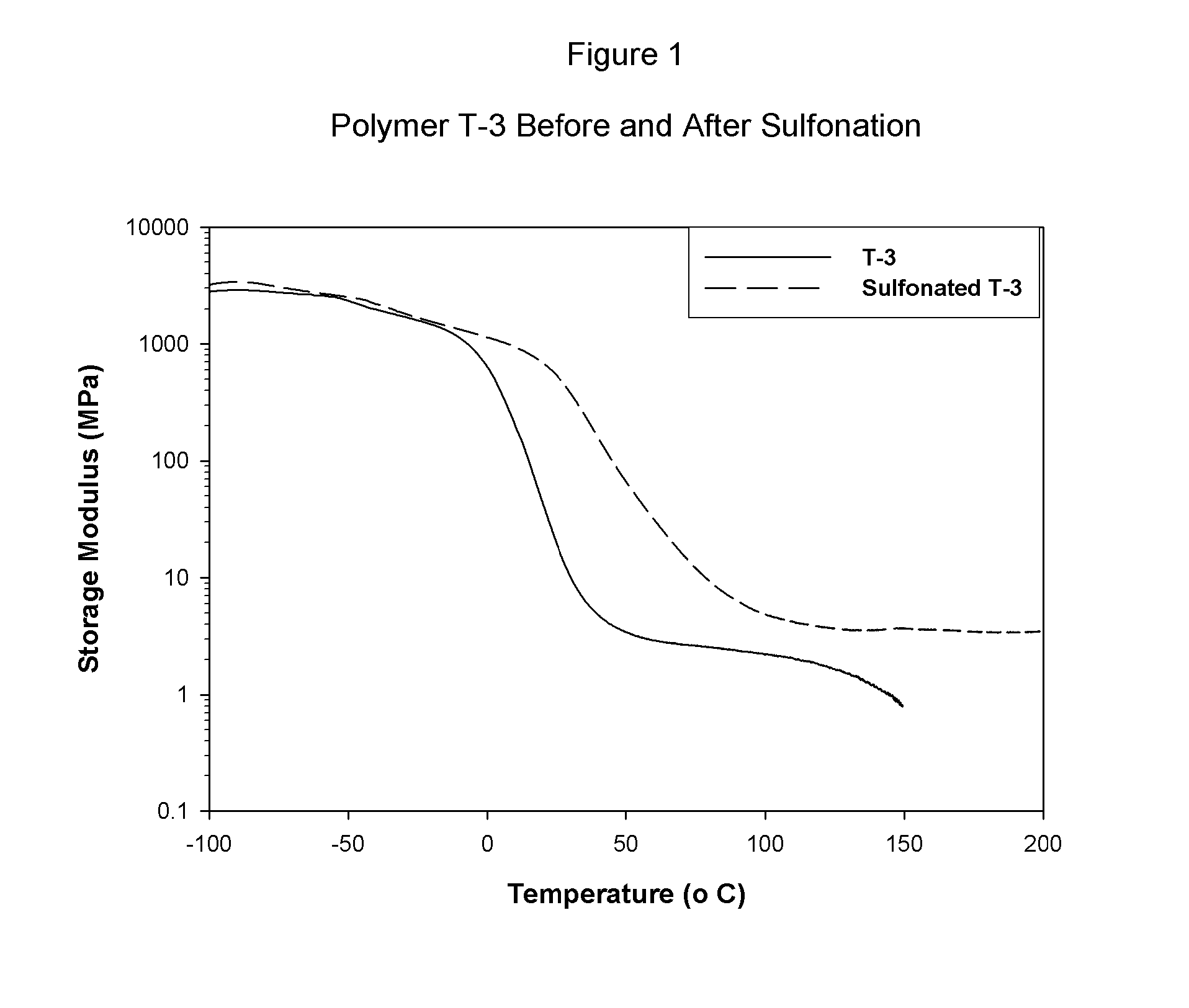

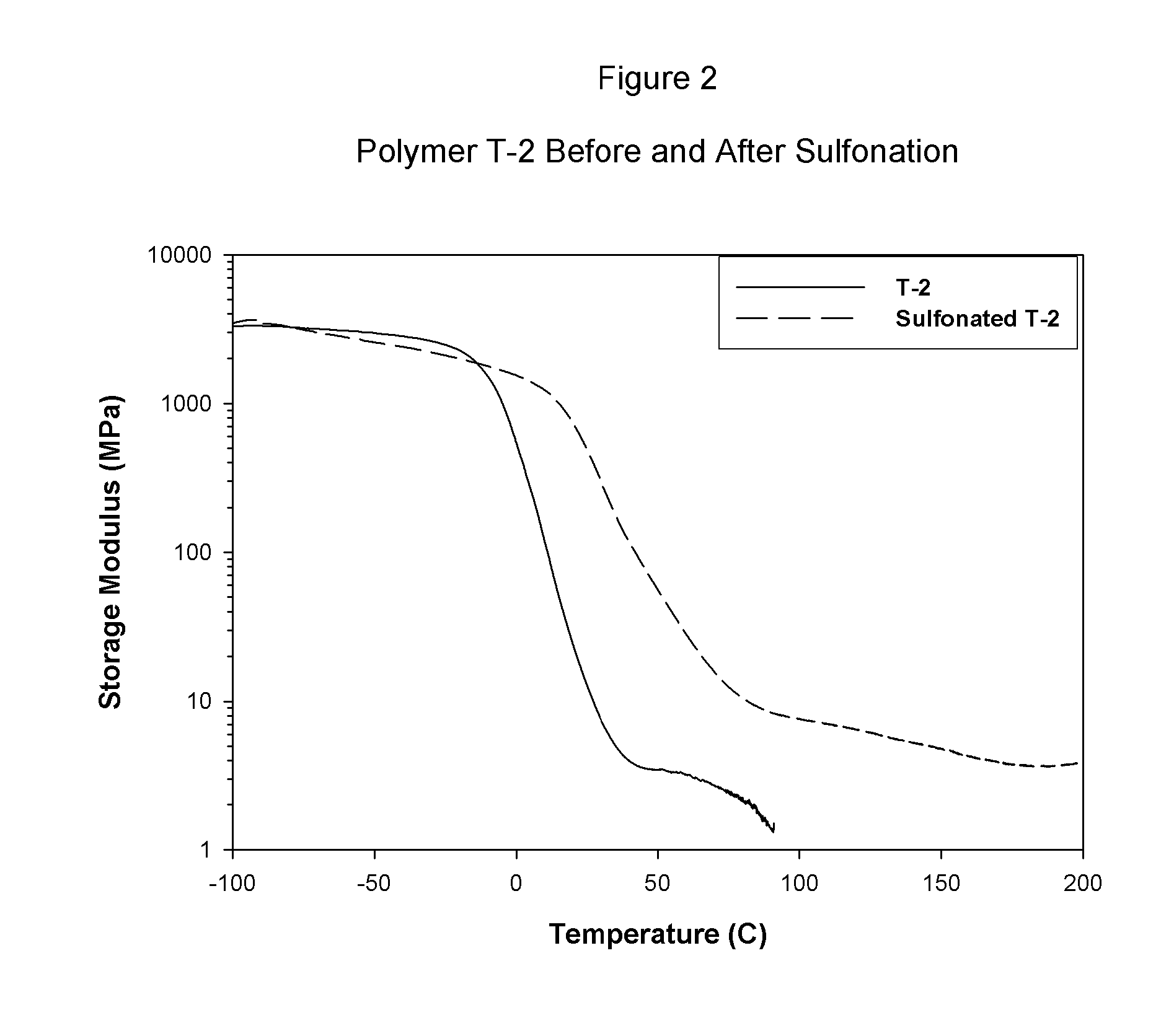

Sulfonated block copolymers, method for making same, and various uses for such block copolymers

ActiveUS20070021569A1High water transport propertyImprove wet strengthSemi-permeable membranesNegative electrodesMethacrylatePolymer science

The present invention is a, solid block copolymer comprising at least two polymer end blocks A and at least one polymer interior block B wherein each A block is a polymer block resistant to sulfonation and each B block is a polymer block susceptible to sulfonation, and wherein said A and B blocks do not contain any significant levels of olefinic unsaturation. Preferably, each A block comprising one or more segments selected from polymerized (i) para-substituted styrene monomers, (ii) ethylene, (iii) alpha olefins of 3 to 18 carbon atoms; (iv) hydrogenated 1,3-cyclodiene monomers, (v) hydrogenated monomers of conjugated dienes having a vinyl content less than 35 mol percent prior to hydrogenation, (vi) acrylic esters, (vii) methacrylic esters, and (viii) mixtures thereof; and each B block comprising segments of one or more polymerized vinyl aromatic monomers selected from (i) unsubstituted styrene monomers, (ii) ortho-substituted styrene monomers, (iii) meta-substituted styrene monomers, (iv) alpha-methylstyrene, (v) 1,1-diphenylethylene, (vi) 1,2-diphenylethylene and (vii) mixtures thereof. Also claimed are processes for making such block copolymers, and the various end uses and applications for such block copolymers.

Owner:KRATON POLYMERS US LLC

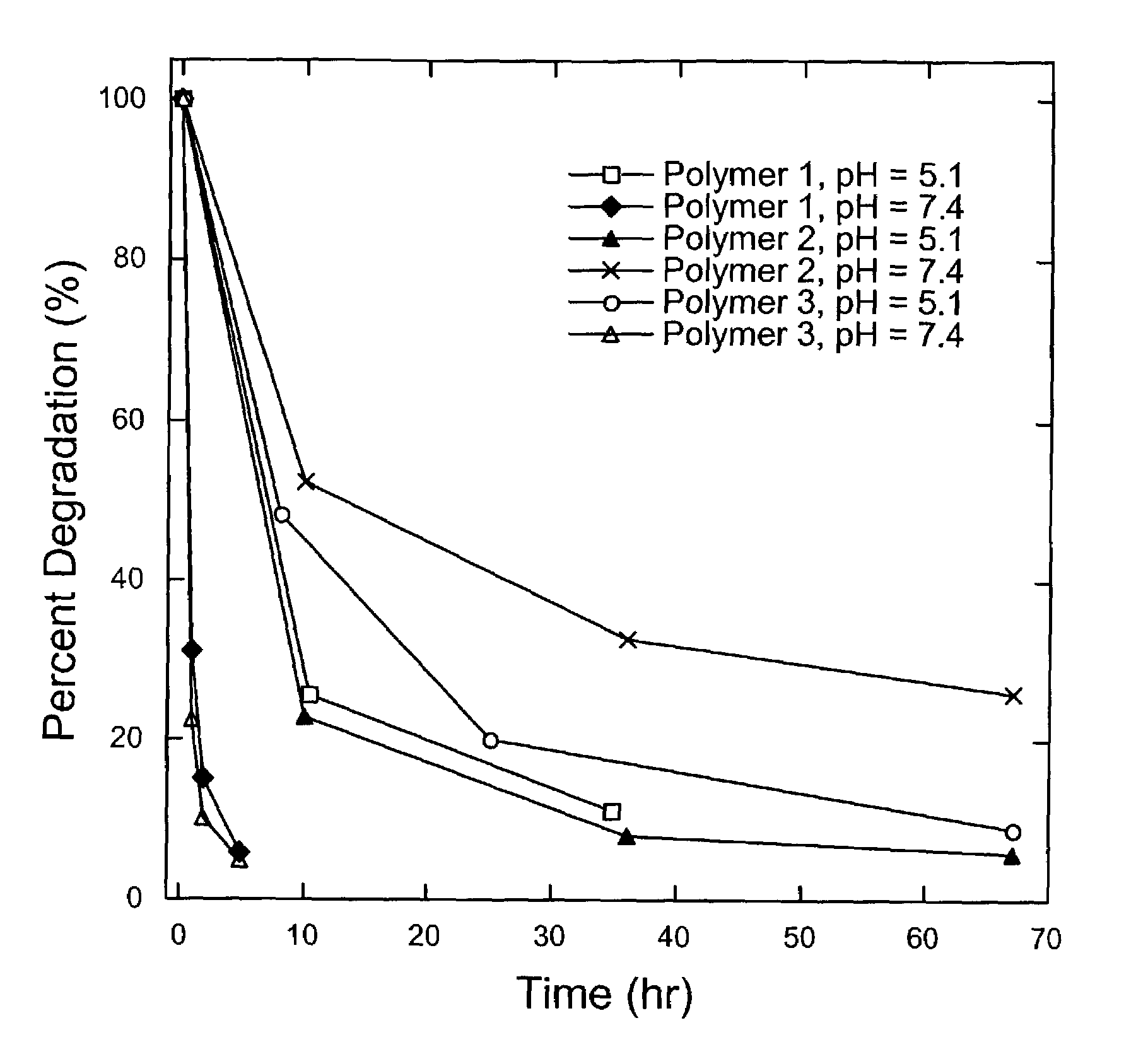

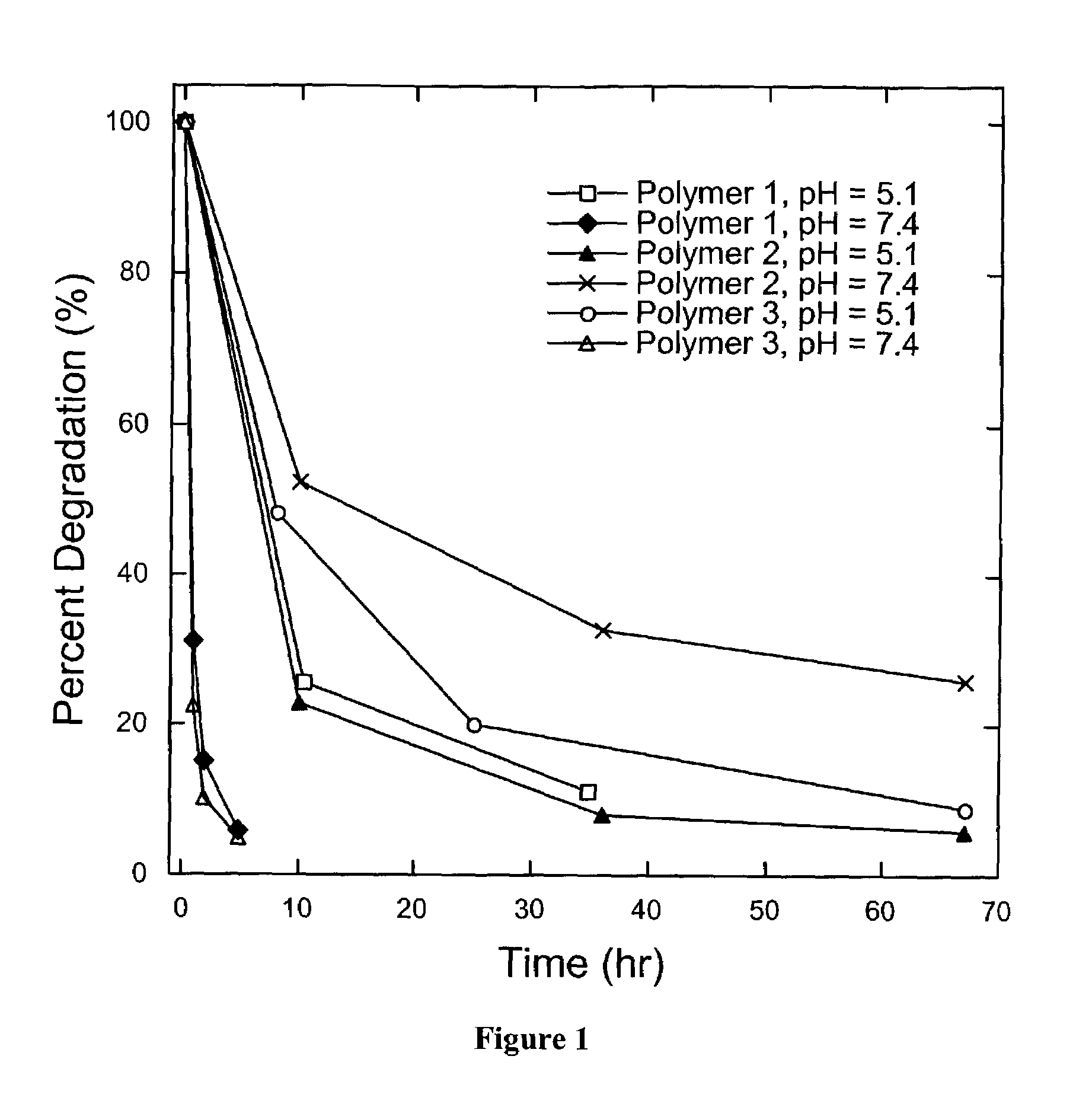

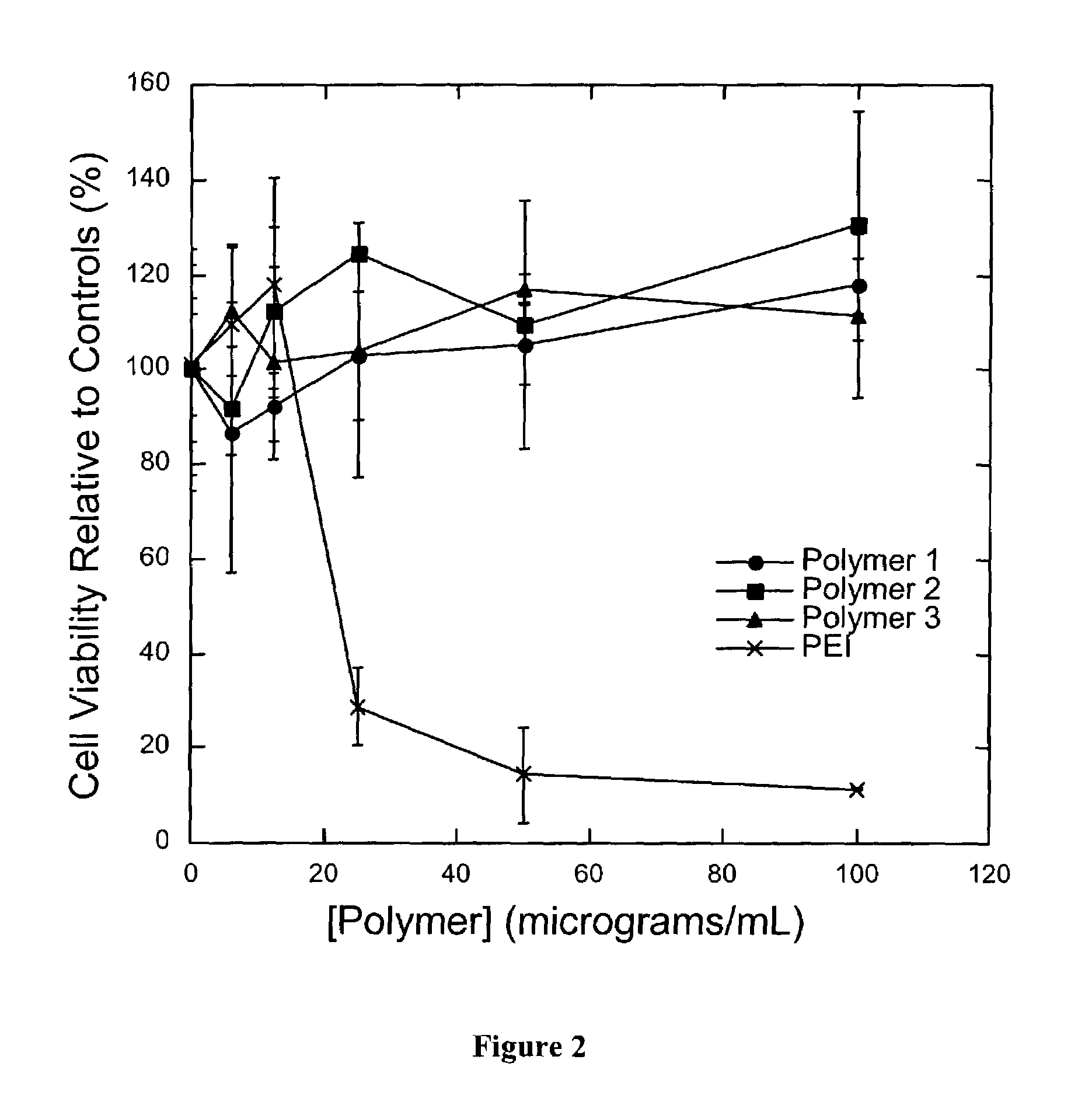

Biodegradable poly(beta-amino esters) and uses thereof

InactiveUS7427394B2High molecular weightHigh transfection efficiencyAntibacterial agentsOrganic active ingredientsAmino estersNucleotide

Poly(β-amino esters) prepared from the conjugate addition of bis(secondary amines) or primary amines to a bis(acrylate ester) are described. Methods of preparing these polymers from commercially available starting materials are also provided. These tertiary amine-containing polymers are preferably biodegradable and biocompatible and may be used in a variety of drug delivery systems. Given the poly(amine) nature of these polymers, they are particularly suited for the delivery of polynucleotides. Nanoparticles containing polymer / polynucleotide complexes have been prepared. The inventive polymers may also be used to encapsulate other agents to be delivered. They are particularly useful in delivering labile agents given their ability to buffer the pH of their surroundings. A system for preparing and screening polymers in parallel using semi-automated robotic fluid delivery systems is also provided.

Owner:MASSACHUSETTS INST OF TECH

High flow engineering thermoplastic compositions and products made therefrom

InactiveUS20040108623A1Improve moldability and flowabilityGood balance of impact and heat resistanceOrganic dyesThermoplasticAcrylate

High flow engineering thermoplastic compositions made from a thermoplastic host polymer and a low molecular weight flow modifier polymer, and products made therefrom. The flow modifier polymer is made by polymerizing at least one vinyl aromatic monomer and at least one (meth)acrylate monomer. The high flow engineering thermoplastics provide improved flowability and processability without sacrificing impact strength or heat resistance

Owner:JOHNSON POLYMER INC

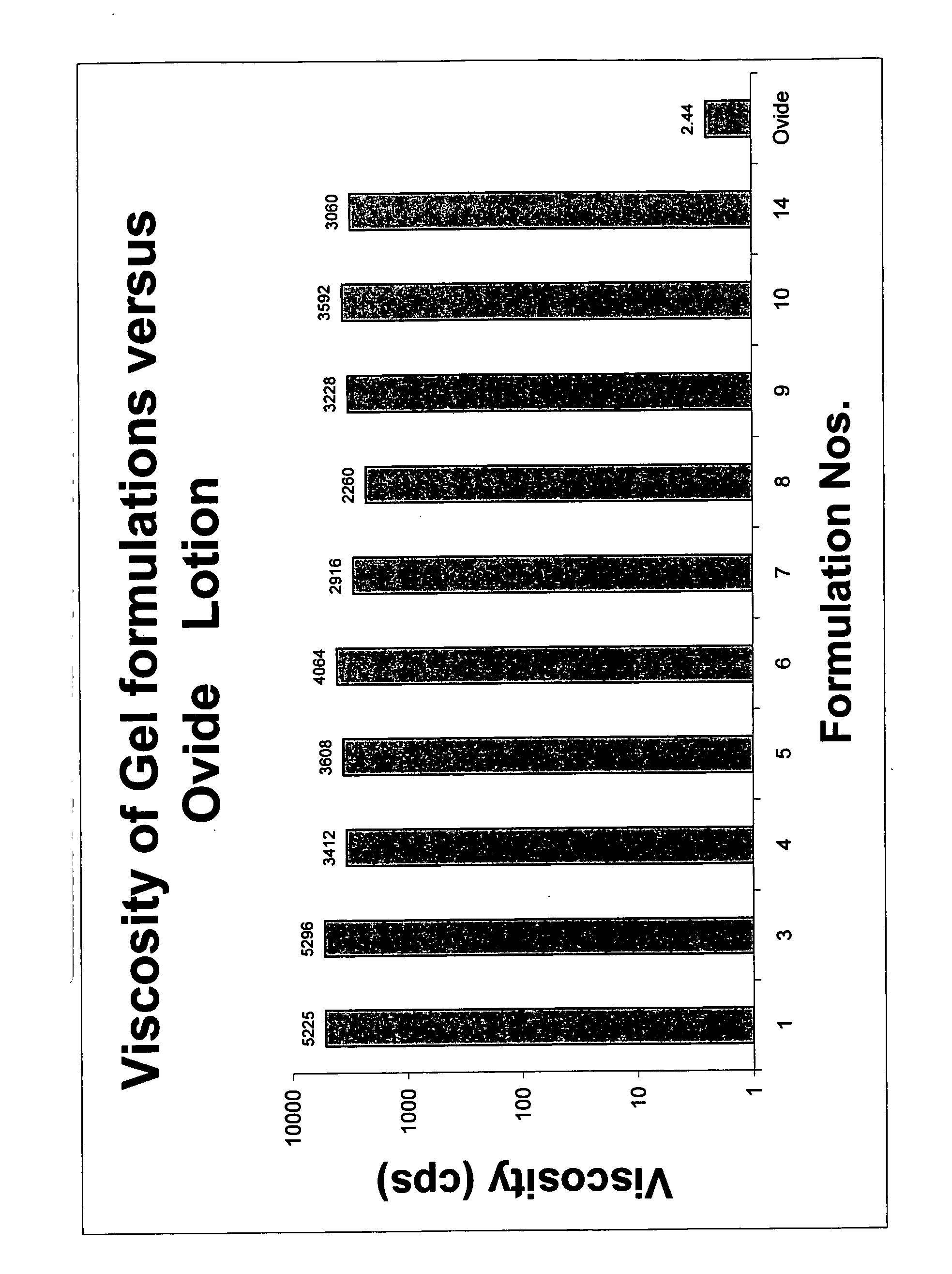

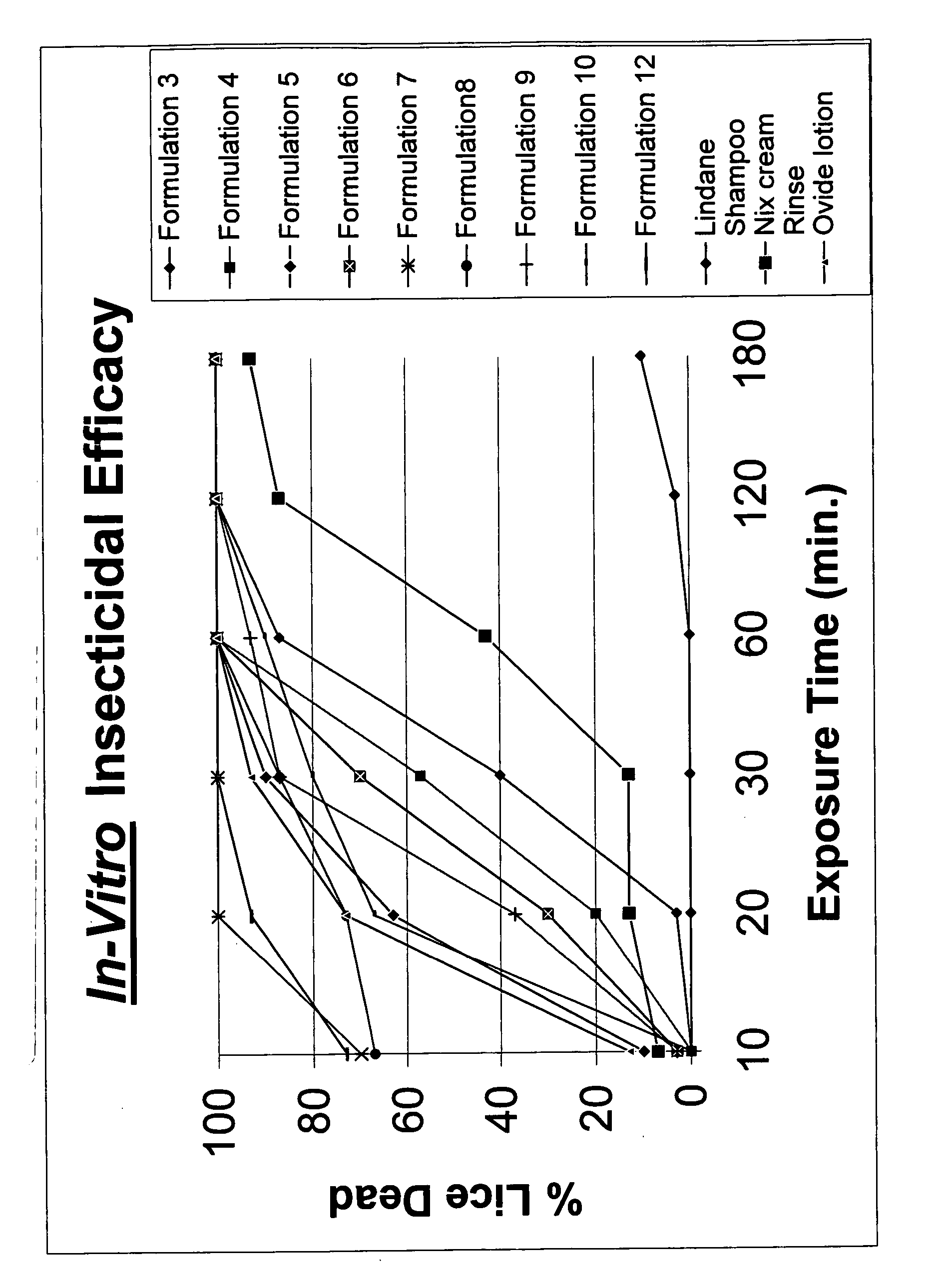

Topical gel formulation comprising insecticide and its preparation thereof

The present invention provides a topical gel pharmaceutical formulation of insecticide suitable for treating an ectoparasite in a mammal, comprising: a) about 0.1-10% by weight of an insecticide; b) at least about 75% by weight of an organic solvent selected from the group consisting of a lower alkyl alcohol, a ketone, a glycol and a mixture thereof, wherein the organic solvent contains at least about 40% by weight of the lower alkyl alcohol; and c) at least one polymer selected from the group consisting of a cellulosic polymer, acrylates, methacrylates, and polyvinyl pyrrolidone. The present invention further provides a process of preparing as well as a method of treating ectoparasites in a mammal using the same.

Owner:GOYAL SANDHYA +4

Coatings for implantable medical device containing polycationic peptides

Owner:ABBOTT CARDIOVASCULAR

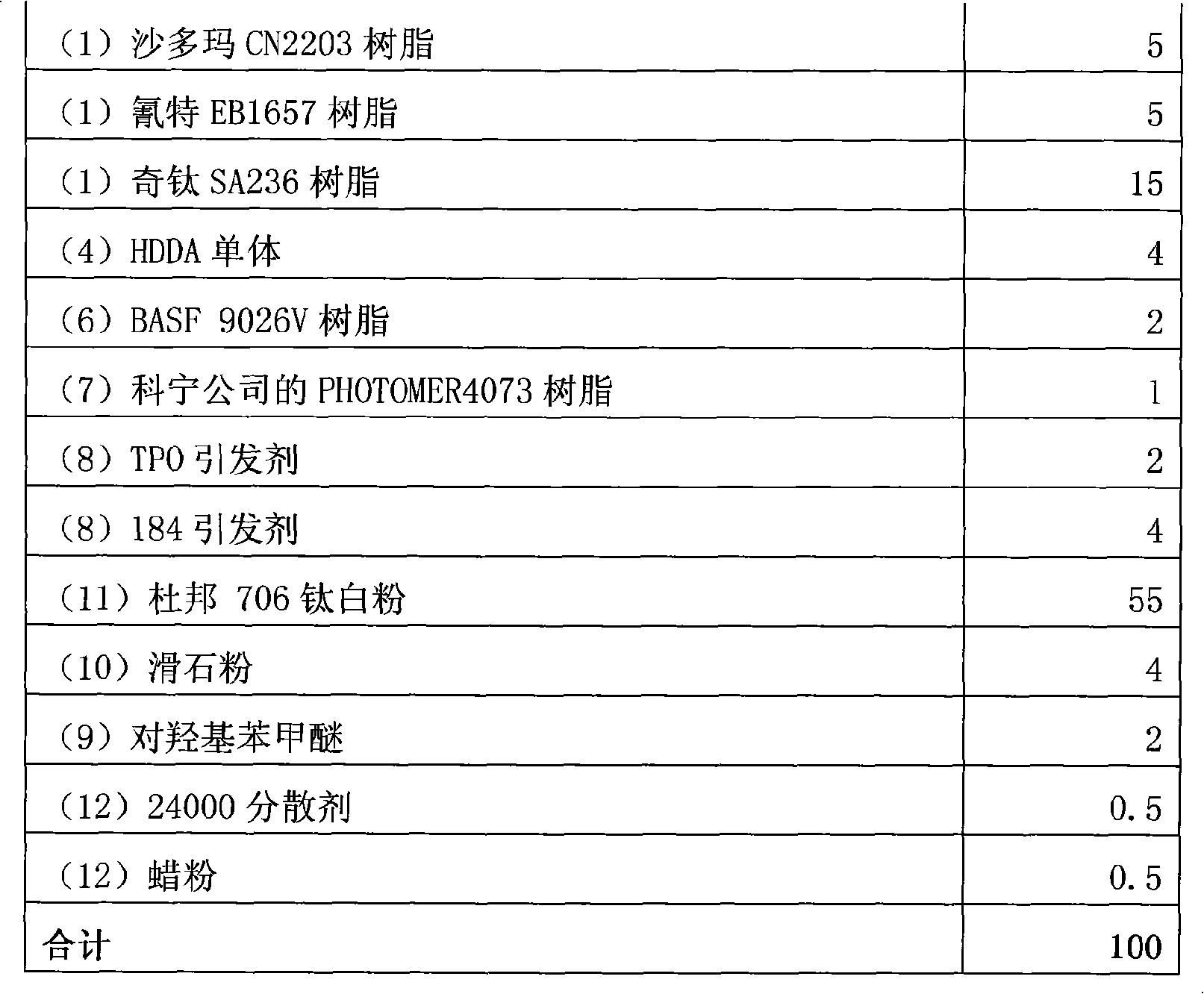

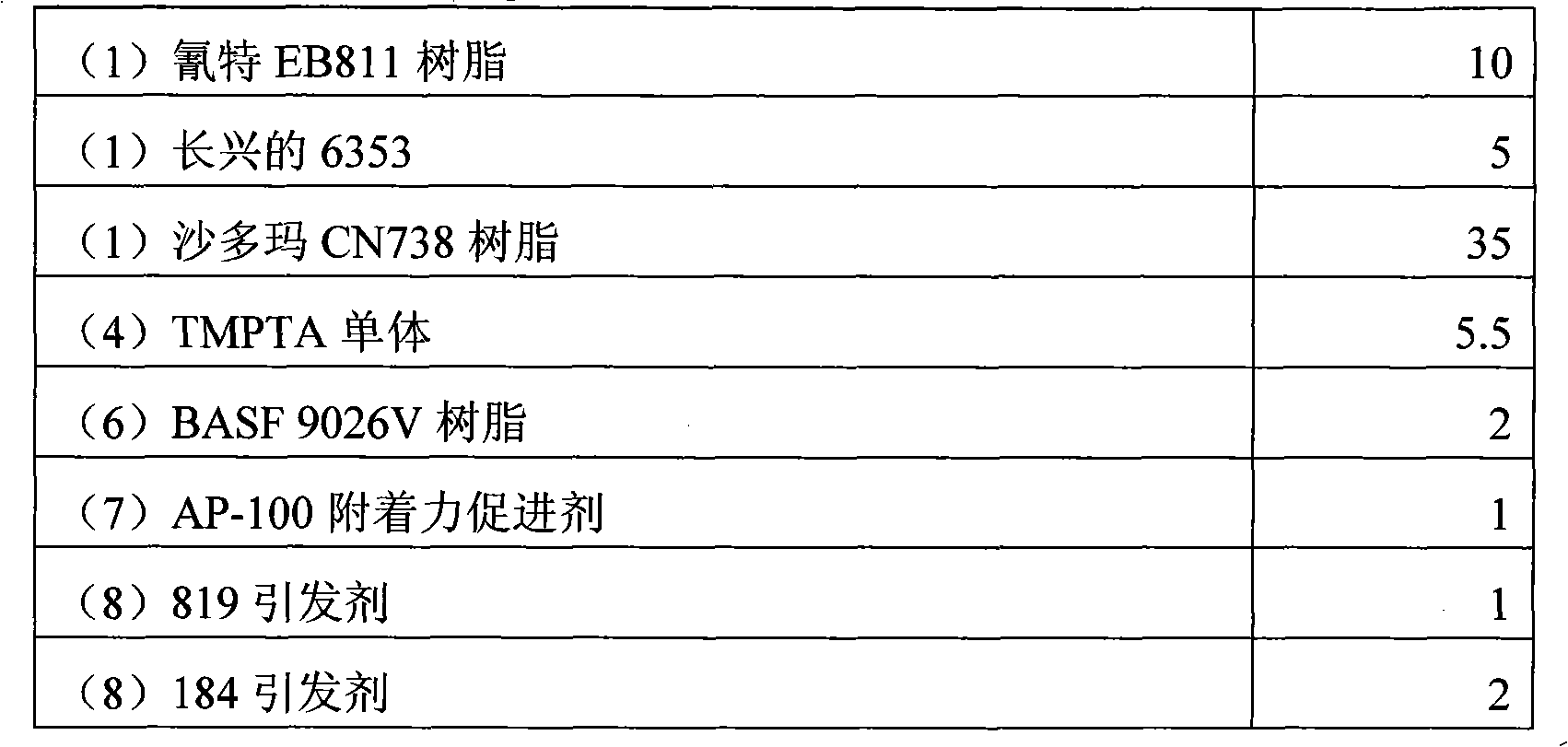

Ultraviolet light curing offset printing ink and preparation method thereof

The invention relates to an ultraviolet light curing offset printing ink and a preparation method thereof. The ultraviolet light curing offset printing ink is made of 25.0-50.0% of polyfunctional polyester acrylic resin or polyfunctional chlorinated polyester acrylate, 0.0-15.0% of epoxy acrylate oligopolymer, 0.0-20.0% of polyfunctional urethane acrylate, 0.0-15.0% of difunctional or polyfunctional acrylic monomer, 0.0-20.0% of grinding-type resin, 2.0-10.0% of polyether acrylate modified by nano silicon dioxide, 0.0-5.0% of adhesion promoter, 3.0-5.0% of photoinitiator, 0.1-2.0% of polymerization inhibitor, 0.0-10.0% of filler, 16.0-55.0% of paint or dye and 0.2-5.0% of accessory ingredient. The prepared offset printing ink has high transparency as well as good adhesive attraction and flexility, and can be widely applied to packages printing industry and the printing of various transfer paper.

Owner:CHUZHOU JINQIAO TEXAS NEW MATERIALS CO LTD

Porous films, process for producing the same, and laminate films and recording sheets made with the use of the porous films

InactiveUS6177181B1High in transparency and ink absorptionImprove waterproof performanceMembranesSemi-permeable membranesBoiling pointOptical transmittance

Porous membranes having a micro phase separation structure and showing a light transmittance at the wavelength of 400 nm of not less than 30% are obtained by the dry phase conversion method comprising drying a coating layer of a dope containing a polymer, a good solvent for the polymer and a poor solvent for the polymer which solvent has a higher boiling point than the good solvent. The polymer includes cellulose derivatives, vinyl-series polymers such as acrylonitrile-series polymers and (meth)acrylic acid ester-series polymers, polysulfone-series polymers, and the like. The porous polymer membranes have a porosity of 10 to 60%, a mean pore size of about 0.002 to 0.35 mum and a maximum pore size of not greater than 0.4 mum. These porous membranes shows not only excellent transparency but also high productivity.

Owner:DAICEL CHEM IND LTD

Low modulus solar cell encapsulant sheets with enhanced stability and adhesion

The present invention provides a thermoplastic film or sheet comprising two surface layers made of acid copolymers, or ionomers, or combinations thereof and at least one inner layer made of ethylene acrylate ester copolymers, a solar cell module comprising at least one encapsulant layer derived therefrom, and a process of manufacturing the solar cell module.

Owner:DOW GLOBAL TECH LLC

Method of making electron beam polymerized emulsion-based acrylate pressure sensitive adhesives

InactiveUS6103316AImprove adhesionHigh polymerizable contentFilm/foil adhesivesVacuum evaporation coatingEmulsionElectron

A one-step process using electron beam radiation to polymerize pressure sensitive adhesives on web from acrylate emulsions is disclosed. The radiation may be supplied in a single or multiple dose. Products using such pressure sensitive adhesives are also disclosed.

Owner:3M INNOVATIVE PROPERTIES CO

Toughened poly(lactic acid) compositions

Toughened poly(lactic acid) resin compositions comprising poly(lactic acid) and an impact modifier comprising an ethylene copolymer made from monomers (a) ethylene; (b) one or more olefins of the formula CH2═C(R1)CO2R2, where R1 is hydrogen or an alkyl group with 2-8 carbon atoms and R2 is an alkyl group with 1-8 carbon atoms, such as methyl, ethyl, or butyl; and (c) one or more olefins of the formula CH2═C(R3)CO2R4, where R3 is hydrogen or an alkyl group with 1-6 carbon atoms, such as methyl, and R4 is glycidyl. The ethylene copolymer may further be made from carbon monoxide monomers. The compositions may further comprise one or more ethylene / acrylate and / or ethylene / vinyl ester polymers, ionomers, and cationic grafting agents.

Owner:PERFORMANCE MATERIALS NA INC

Resist composition

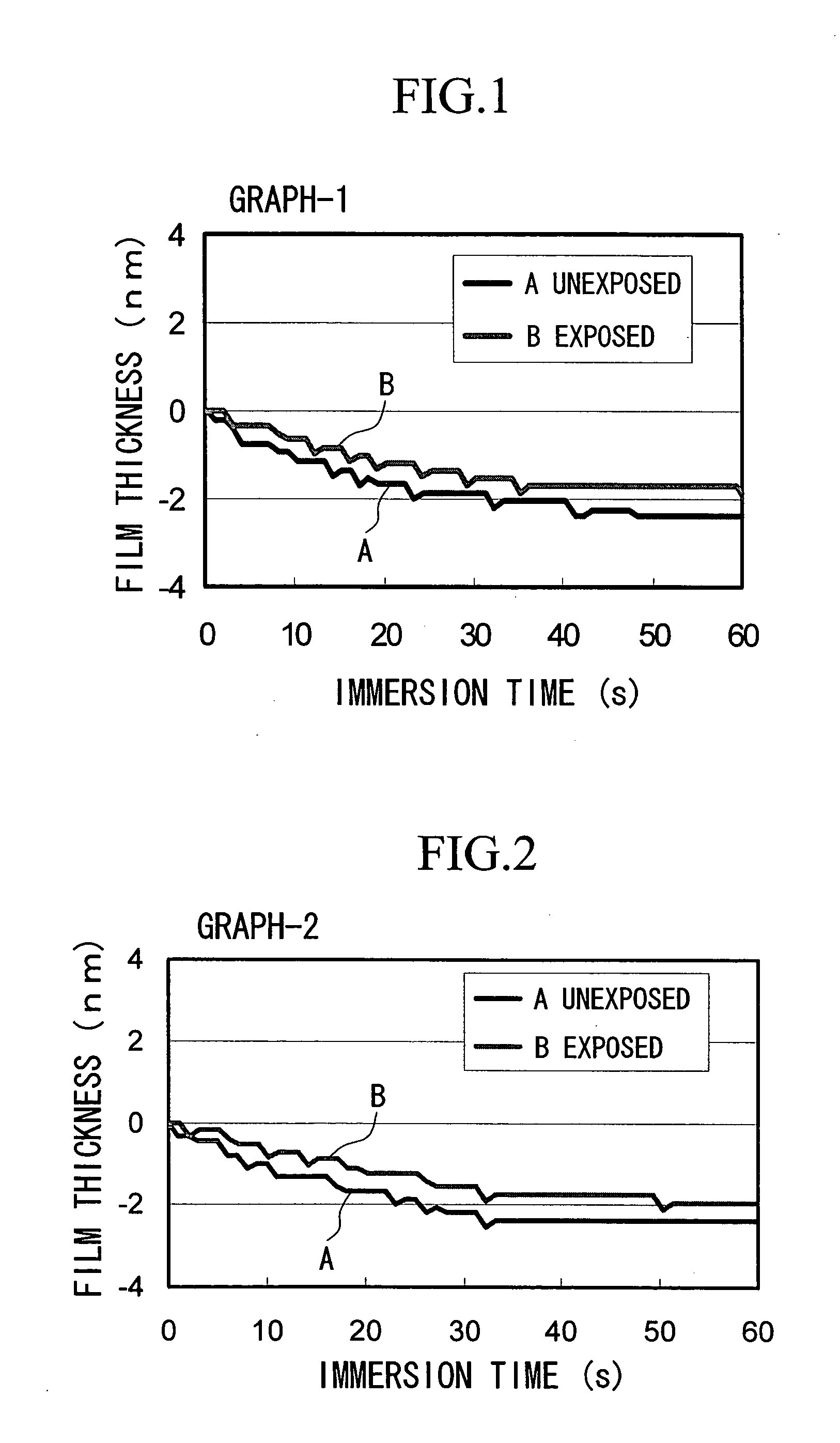

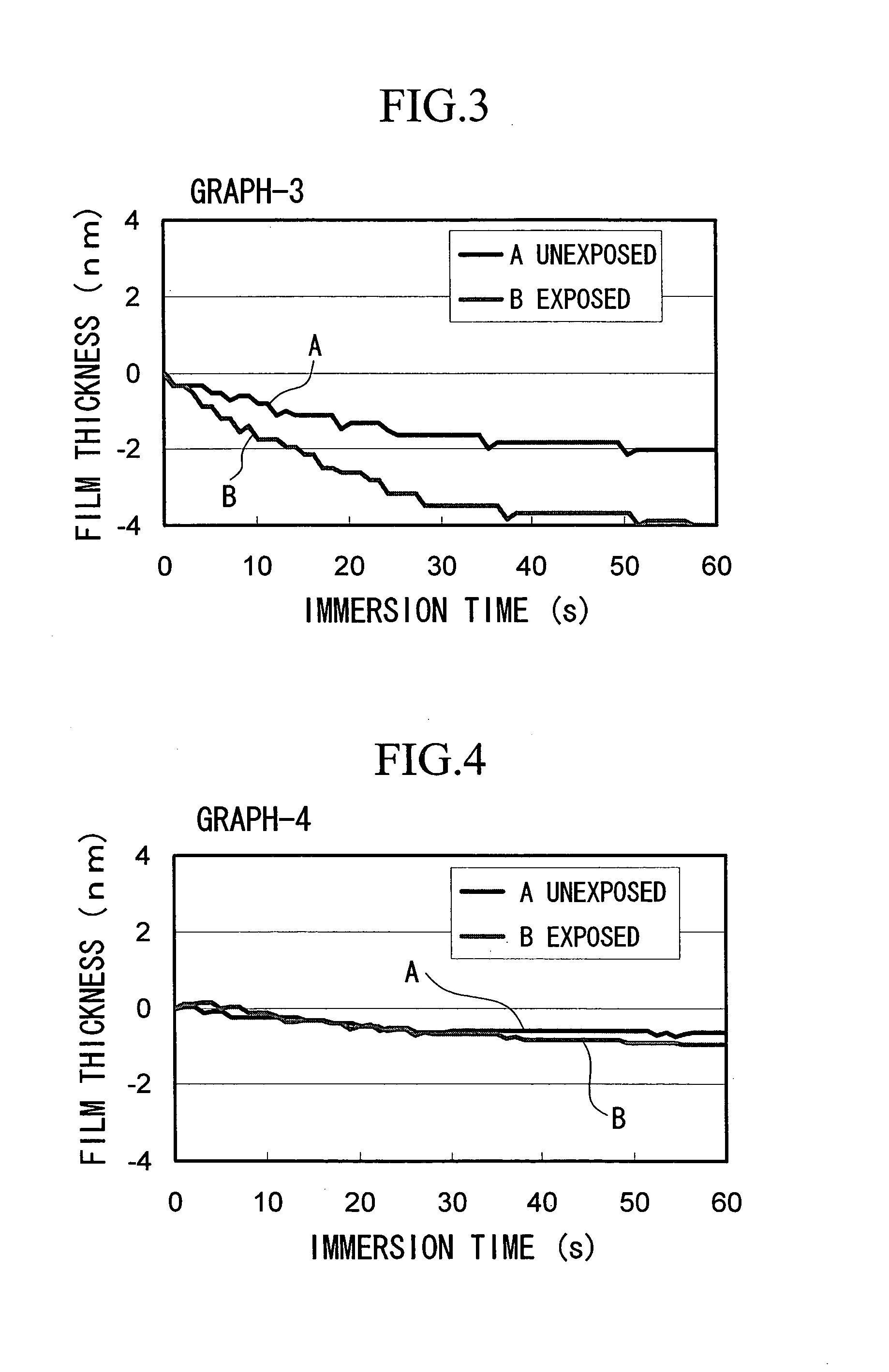

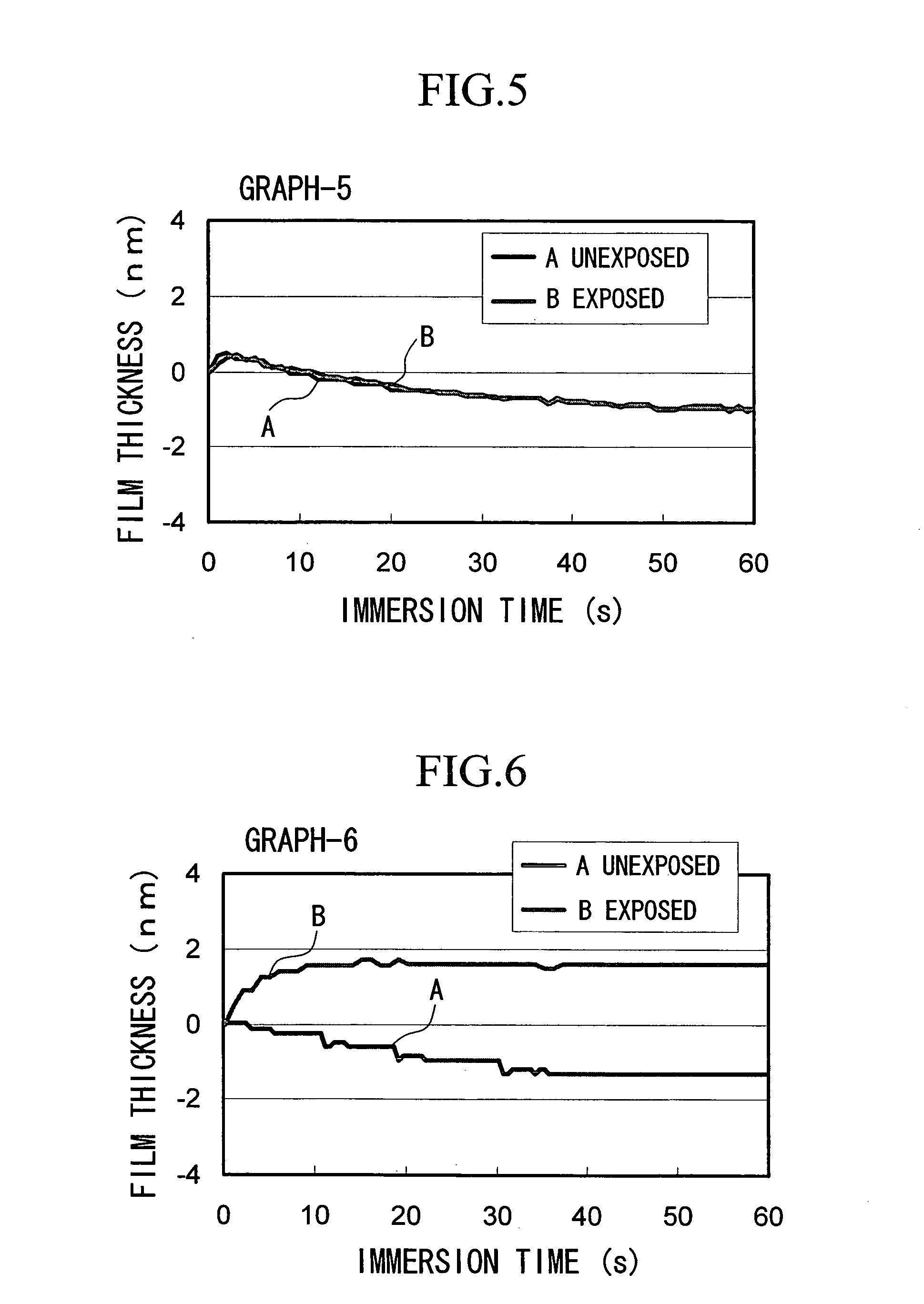

ActiveUS20050014090A1Minimal deterioration in sensitivitySmall swellingRadiation applicationsSemiconductor/solid-state device manufacturingMethacrylateSolubility

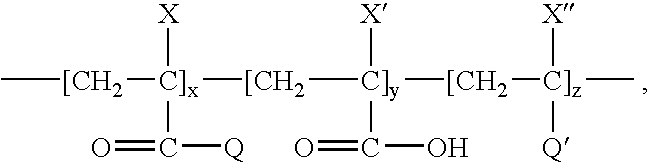

A resist composition which is stable relative to solvents used in immersion lithography processes and displays excellent sensitivity and resist pattern profile, and a method of forming a resist pattern that uses such a resist composition are provided. The resist composition is in accordance with predetermined parameters, or is a positive resist composition comprising a resin component (A) which contains an acid dissociable, dissolution inhibiting group and displays increased alkali solubility under the action of acid, an acid generator component (B), and an organic solvent (C), wherein the component (A) contains a structural unit (a1) derived from a (meth)acrylate ester containing an acid dissociable, dissolution inhibiting group, but contains no structural units (a0), including structural units (a0-1) containing an anhydride of a dicarboxylic acid and structural units (a0-2) containing a phenolic hydroxyl group.

Owner:TOKYO OHKA KOGYO CO LTD

Injection molding method for neutral and acidic-group containing (meth)acrylate copolymers

InactiveUS20020160042A1Reduce contentOrganic dyesPharmaceutical non-active ingredientsMeth-Additive ingredient

The invention relates to a process for producing mouldings by injection moulding, the steps in the process being A) Melting a mixture made from a) a (meth)acrylate copolymer composed of from 40 to 100% by weight of free-radical-polymerized C1-C4-alkyl esters of acrylic or methacrylic acid and from 0 to 60% by weight of (meth)acrylate monomers having an anionic group in the alkyl radical, where the copolymer comprises b) from 0.1 to 3% by weight of a release agent, and, where appropriate, the mixture may comprise c) from 0 to 50% by weight of a drier, d) from 0 to 30% by weight of a plasticizer, e) from 0 to 100% by weight of additives or auxiliaries, f) from 0 to 100% by weight of an active pharmaceutical ingredient, g) from 0 to 20% by weight of another polymer or copolymer, where the amounts given for components b) to g) are based on the (meth)acrylate copolymer a) and the mixture prior to melting has a content of more than 0.5% by weight of low-boiling constituents with vapour pressure of at least 1.9 bar at 120° C., B) Devolatilizing the mixture in the thermoplastic state at temperatures of at least 120° C., thereby lowering to not more than 0.5% by weight the content of the low-boiling constituents with vapour pressure of at least 1.9 bar at 120° C., C) Injecting the molten and devolatilized mixture into the mould cavity of an injection mould, the temperature of the mould cavity being below the glass transition temperature of the (meth)acrylate copolymer by at least 10° C., cooling the molten mixture, and removing the resultant moulding from the mould.

Owner:PFIZER INC +1

(Meth)acrylate esters of organosiloxane polyols, process for their preparation, and their use as radiation-curable materials

Owner:EVONIK DEGUSSA GMBH

Silyl (METH) acrylate copolymers, processes for preparing the same, antifouling paint compositions containing the silyl (METH) acrylate copolymers, antifouling coating films formed from the antifouling paint compositions, antifouling methods using the antifouling paint compositions, and hulls or underwater structures coated with the antifouling coating films

InactiveUS6458878B1Improve antifouling performanceSuppressed hydrolysis rateAntifouling/underwater paintsPaints with biocidesMeth-Unsaturated monomer

Disclosed is a silyl (meth)acrylate copolymer which comprises 20 to 80% by weight of (a) silyl (meth)acrylate constituent units (I), 0.01 to 40% by weight of (b) acrylic unsaturated monomer constituent units (II) and 5 to 79.9% by weight of Ĉ unsaturated monomer constituent units other than the constituent units (a) and (b). Also disclosed is a process for preparing the silyl (meth)acrylate copolymer, an antifouling paint composition comprising the copolymer, a coating film formed from the paint composition, a hull with the coating film and an antifouling method using the paint composition.

Owner:CHUGOKU MARINE PAINTS

Method for injection moulding moulded bodies consisting of (meth) acrylate copolymers

InactiveUS20040104501A1Reduce contentLittle reabsorptionPharmaceutical non-active ingredientsEndocrine system disorderPolymer scienceMeth-

The invention relates to a process for producing mouldings by injection moulding the steps in the process being a) melting and mixing of a (meth)acrylate copolymer composed of from 85 to 98% by weight of C1-C4-alkyl (meth)acrylates capable of free-radical polymerization and from 15 to 2% by weight of (meth)acrylate monomers having a quaternary ammonium group in the alkyl radical, with from 10 to 25% by weight of a plasticizer, and also from 10 to 50% by weight of a dryers [sic] and / or from 0.1 to 3% by weight of a release agent, and, where appropriate, with other conventional pharmaceutical additives or auxiliaries and / or with an active pharmaceutical ingredient, b) devolatilizing the mixture at temperatures of at least 120° C., thus reducing the content of the low-boiling constituents with a vapour pressure of at least 1.9 bar at 120° C. to not more than 0.5% by weight, and c) injecting the devolatilized mixture at a temperature of from 80 to 160° C. into the mould of an injection moulding system and removing the resultant moulding from the mould.

Owner:ROEHM GMBH & CO KG +1

Aqueous ink composition and method of manufacturing the same

InactiveUS20050004261A1Improve printing qualityReduce blurDuplicating/marking methodsInksMethacrylatePolymer science

An aqueous ink composition comprising: a pigment, having a particle diameter as determined by the light scattering method of no less than 20 nm and no more than 200 nm; and a water dispersible polymer, having a styrene-equivalent number average molecular weight of as determined by gel permeation chromatography no less than 5000 and no more than 200000, having a surface tension of no less than 20 mN / m and no more than 40 mN / m, and wherein the abovementioned pigment is a polymer-coated pigment that is coated with the abovementioned water dispersible polymer, is provided. The water-dispersible polymer may be a copolymer of monomers, mainly comprising acrylic acid and / or methacrylic acid and an acrylate and / or methacrylate. With this ink composition, the printing quality can be improved.

Owner:SEIKO EPSON CORP

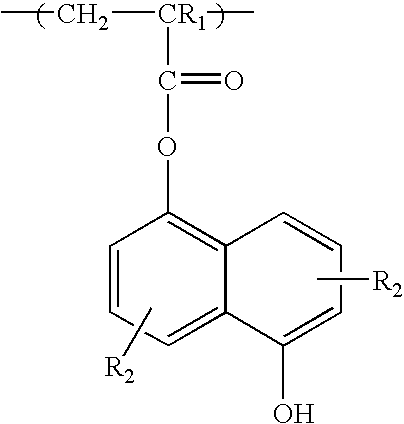

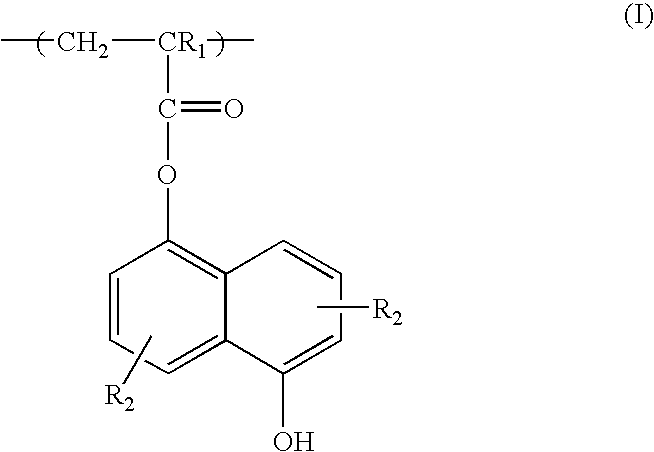

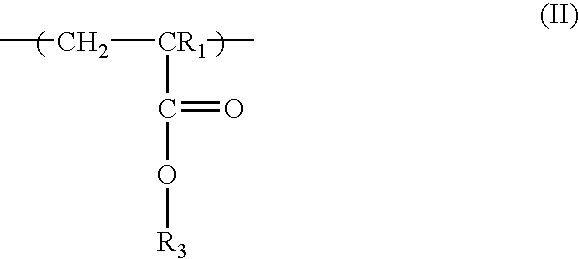

Positive resist containing naphthol functionality

ActiveUS20060105267A1Improve photolithographic effectExcellent etch resistancePhotosensitive material auxillary/base layersPhotosensitive material processingResistMethacrylate

Acid-catalyzed positive resist compositions which are imageable with 193 nm radiation are obtained using a polymer having acrylate / methacrylate monomeric units comprising a naphthol ester group. The resist may optionally contain polymer having acrylate / methacrylate monomeric units with fluorine-containing functional groups. The resists containing the polymer having acrylate / methacrylate monomeric units comprising a naphthol ester group have an improved process window, including improved etch resistance and reduced swelling compared to conventional fluorine-containing 193 nm resist.

Owner:IBM CORP

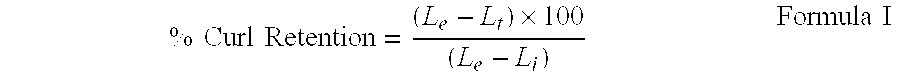

Stiff-feel hair styling compositions

InactiveUS6214328B1Increase stiffnessOptimum hydrophiliclhydrophobic balanceCosmetic preparationsHair cosmeticsMeth-Dicarboxylic acid

A method for enhancing the performance of hair fixative resins in hair styling compositions by using selected polymers having certain compositions is disclosed. In particular, the present invention involves a method of improving the stiffness performance of hair fixative resins by using polymers containing 5-95% (C1-C10)alkyl (meth)acrylate, 0-70% hydroxyalkyl (meth)acrylate, 0-50% monocarboxylic acid monomer and 1-25% dicarboxylic acid monomer. The selected polymers are particularly useful in aqueous hair styling compositions containing low (80% or less) volatile organic compound (VOC) concentrations.

Owner:ROHM & HAAS CO

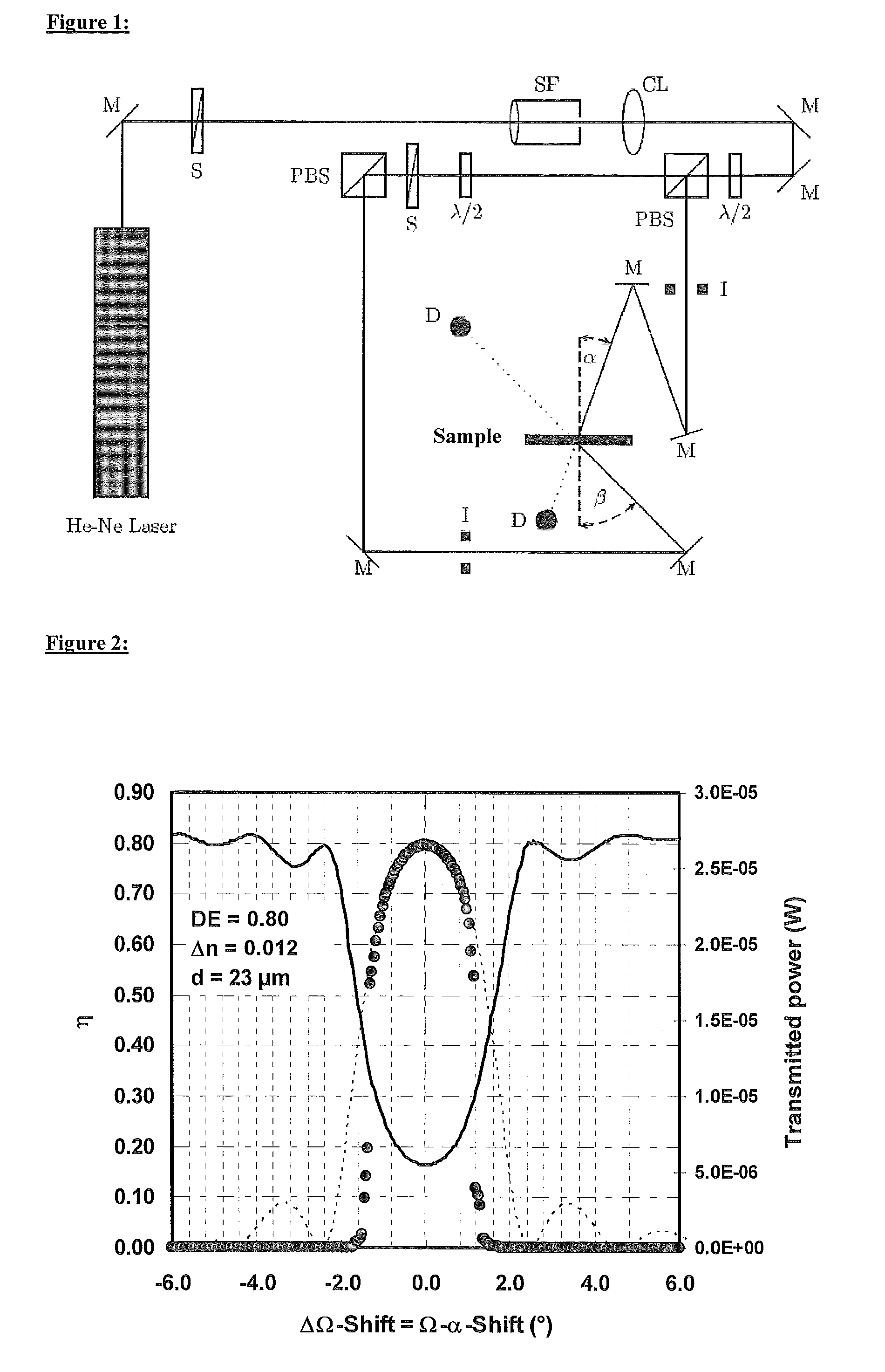

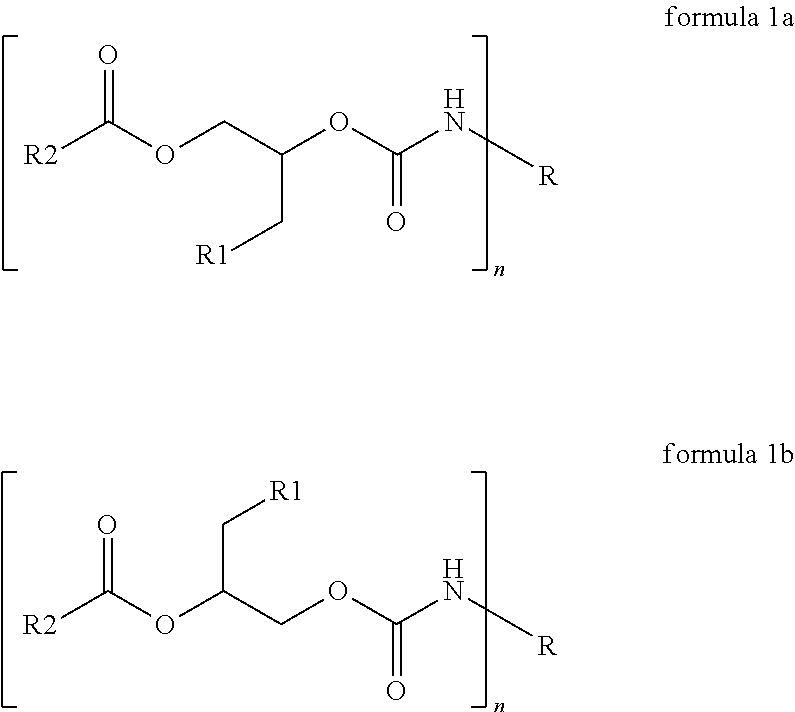

Holographic media and photopolymers

The invention relates to holographic media containing specific photopolymers, a process for the production thereof, and unsaturated glycidyl ether acrylate urethanes as writing monomers which are suitable for the preparation of photopolymers.

Owner:COVESTRO DEUTSCHLAND AG

Pressure-sensitive adhesive for optical films

ActiveUS20090305068A1High viscosityEasy to operateFilm/foil adhesivesSynthetic resin layered productsPolymer scienceHeat resistance

Pressure-sensitive adhesives for optical films exhibit high cohesion, excellent re-workability, adhesion properties, heat resistance and durability without chemical crosslinking.A pressure-sensitive adhesive contains an acrylic triblock copolymer (I) at not less than 60% by mass based on the total mass of all solids contained in the pressure-sensitive adhesive, the acrylic triblock copolymer being represented by the formula A1-B-A2 wherein: A1 and A2 are each independently an alkyl methacrylate polymer block having Tg of not less than 100° C. and B is an acryl acrylate polymer block having Tg of not more than −20° C.; the content of the polymer block B is 50 to 95% by mass; Mw is in the range of 50,000 to 300,000; and the molecular weight distribution is in the range of 1.0 to 1.5. In a preferred embodiment, the acrylic triblock copolymer (I) is a combination of an acrylic triblock copolymer (Ia) having Mw of 50,000 to less than 100,000 and an acrylic triblock copolymer (Ib) having Mw of 100,000 to 300,000, in a mass ratio (Ia):(Ib) of 45:55 to 75:25.

Owner:KURARAY CO LTD

Wood plastic composite material and its preparation method and application

A wood-plastics composition is prepared from used or waste plastics, wooden fibres for modifying plastics, and resin compatibilizer through fusing and proportionally mixing. Said resin compatibilizer is prepared from EVA, acrylic acid or acrylate and polyvinyl chloride through mixing. Its advantages are high strength toughness, and improved machinability.

Owner:CHINA PETROLEUM & CHEM CORP +1

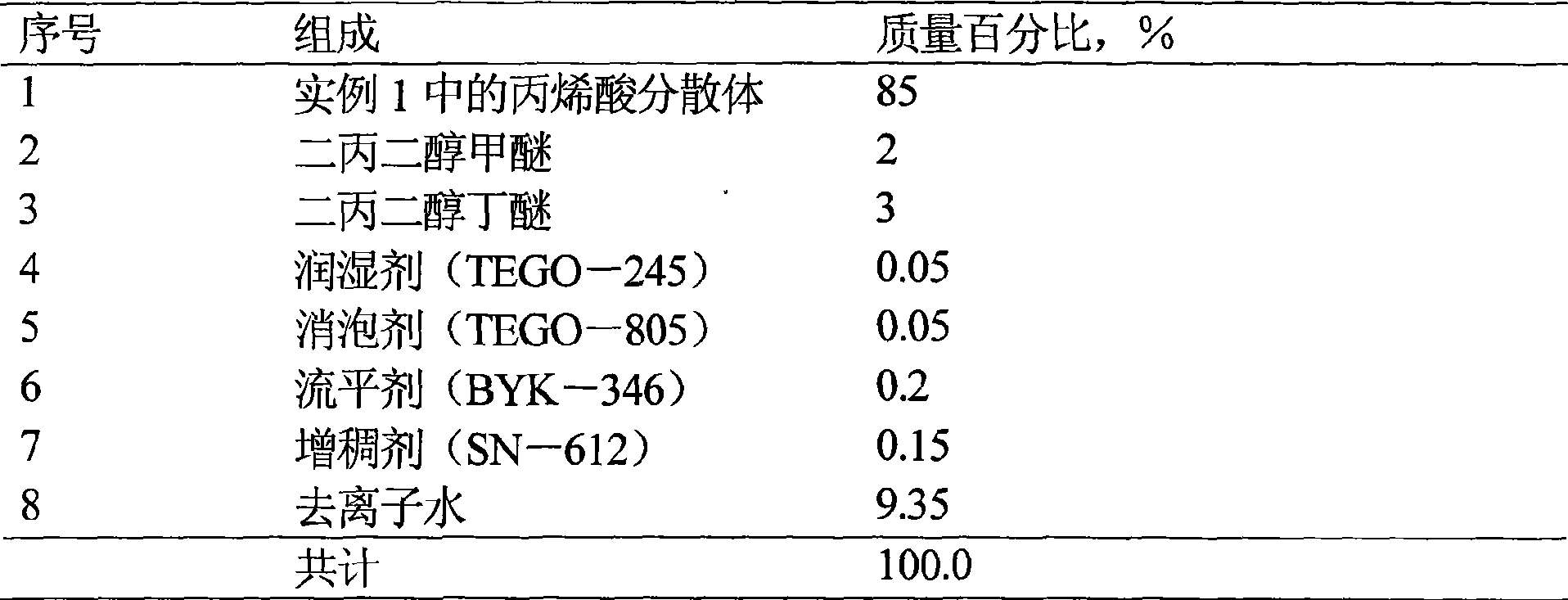

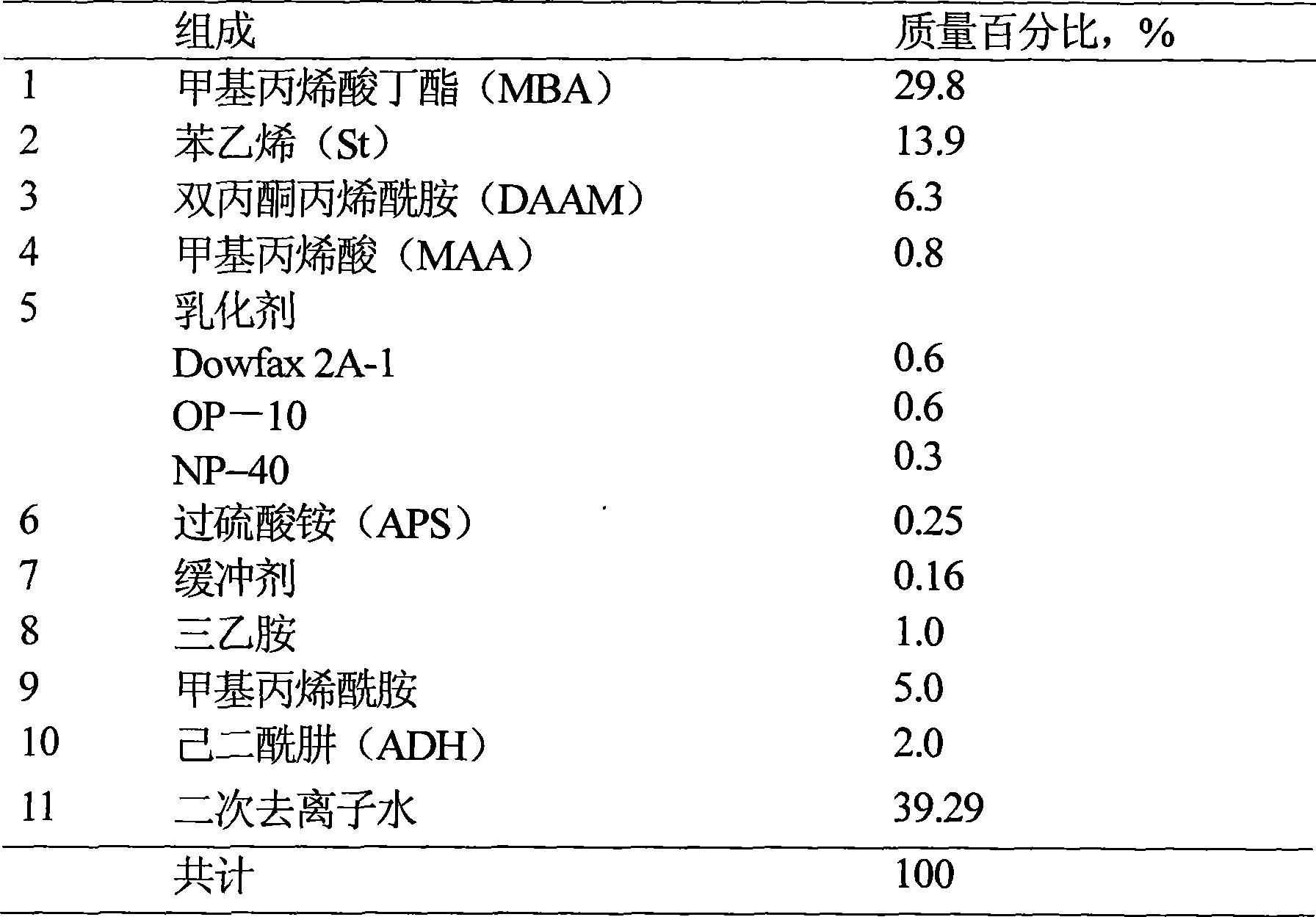

Preparation of high closeness polyacrylacid ester dispersion

The invention relates to a high-sealing polyacrylic ester dispersoid and a preparation method thereof; a multi-element emulsifier system which consists of an anionic emulsifier and a compound non-ionic emulsifier is adopted for controlling the charging process and components of the emulsifier in different polymerization periods, and the room-temperature self-crosslinking high-sealing polyacrylic ester dispersoid is prepared by a semi-continuous seeding emulsion polymerization process. The dispersoid has small particle size, good electrolyte-resistance (calcium ion) stability and high tolerance to various film forming accessory ingredients (various organic solvents with high boiling point). The dispersoid is used as seal coat of water-based wood coating and has good sealing performance to various woods; harmful volatile organic compounds (VOC) such as formaldehyde, and the like sealed against escaping from plates to pollute indoor environment, and the colored compounds such as turpentine, pine oil and tannin and the like are sealed against dissolving out of the plates to pollute pure top coating and white top coating of a water-based wooden ware; and in addition, the dispersoid can be used in water-based leather finishing agents.

Owner:SOUTH CHINA UNIV OF TECH

Method for producing an immediately decomposing oral form of administration which releases active ingredients

The invention relates to a method for producing an oral form of administration which decomposes immediately and releases active ingredients in the mouth. According to said method, (a) an anionic pharmaceutical active ingredient is intensively mixed with (b) a copolymer consisting of radically polymerized C1-C4 esters of the acrylic acid or methacrylic acid and other (meth)acrylate monomers containing functional tertiary amino groups, and (c) between 5 and 50 wt. %, in relation to (b), of a C12-C22 carboxylic acid in the melted mass; the mixture is solidified and ground to form a powder containing active ingredients having an average particle size of 200 μm or less; and the powder is encapsulated in a water-soluble matrix consisting of pharmaceutically standard adjuvants, on the condition that no more than 3 wt. %, in relation to the copolymer, of emulsifiers with an HLB value of at least 14 must be contained therein. The invention also relates to the powder containing active ingredients and the uses of the same.

Owner:EVONIK OPERATIONS GMBH

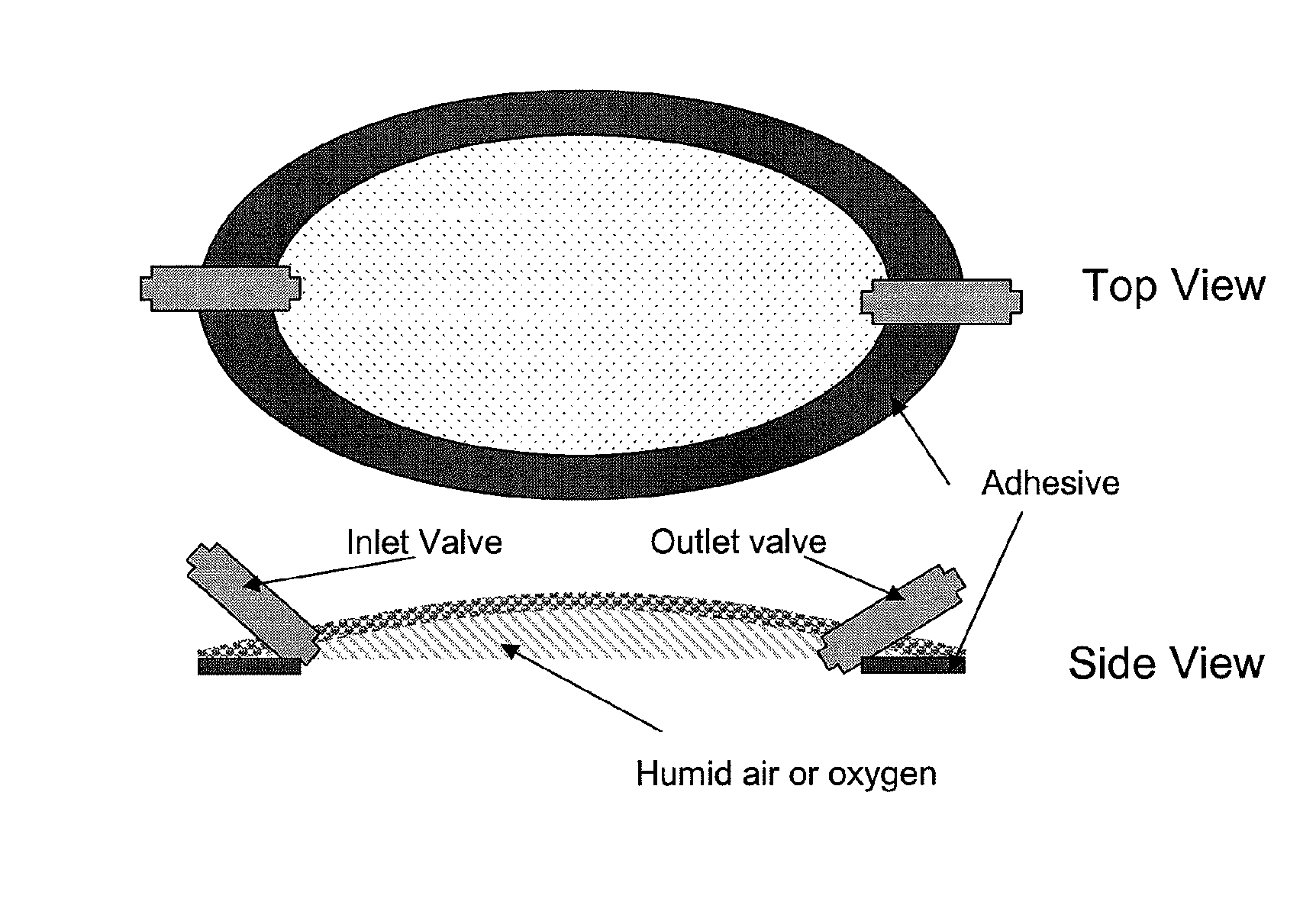

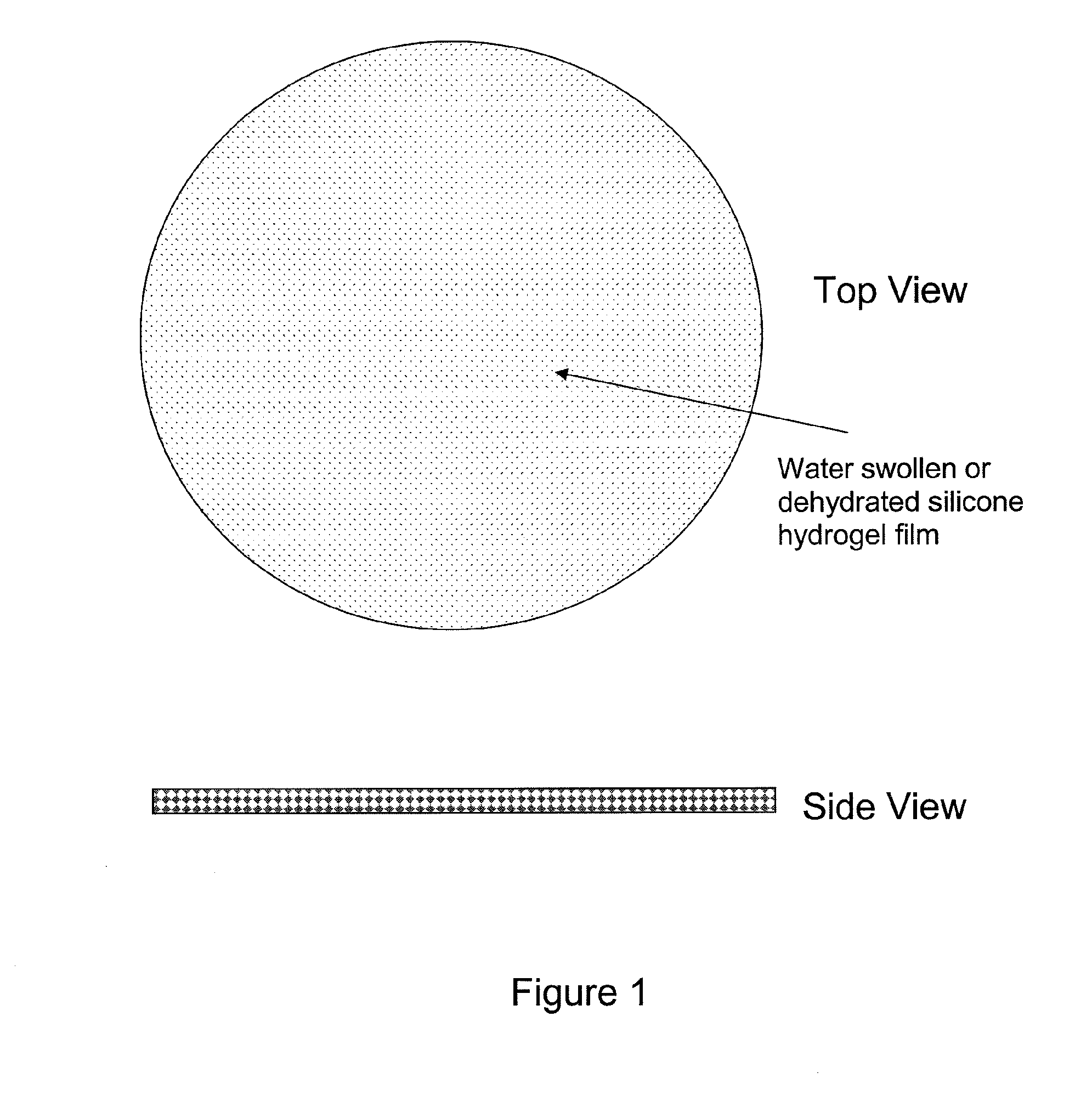

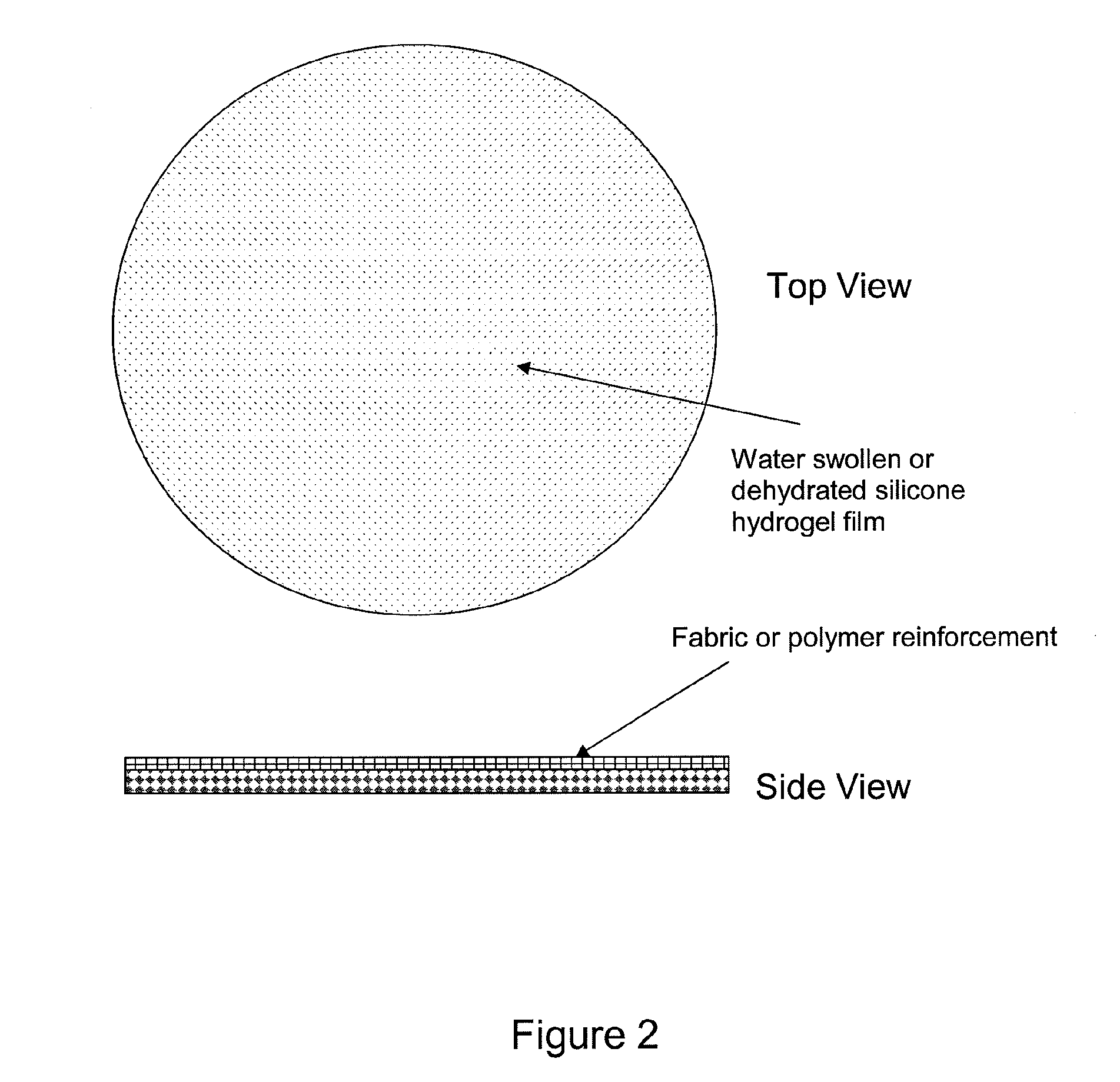

Silicone hydrogels for tissue adhesives and tissue dressing applications

InactiveUS20110086077A1Provide strengthFacilitated releaseBiocidePeptide/protein ingredientsWound dressingSilanes

A silicone hydrogel formulation may contains random and / or block copolymers or oligomers or macromers. The silicone copolymer is copolymerized or blended with other polymers or monomers or macromers to obtain final formulation. The silicone hydrogel may contain crosslinking groups to provide a complete or partially crosslinked final structure. The silicone hydrogel formulation may be pre-formed as a film or other structure, or it may be polymerized during application as in the case of an adhesive formulation. A wound dressing comprising a silicone hydrogel formed as a film, either prior to application to a wound or in situ on a wound, which film has gas permeability, moisture permeability, and high water content, wherein said silicone hydrogel is formed from a polymerizable silicone such as a difunctional polydimethylsiloxane methacrylate and crosslinking agents such as N,N-dimethyllacrylamide (DMA), 2-hydroxyethyl methacrylate (HEMA), and trimethylsiloxy silane (TRIS).

Owner:DSM IP ASSETS BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com