Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1631 results about "(Hydroxyethyl)methacrylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydroxyethylmethacrylate or HEMA is the organic compound with the formula HOCH2CH2O2CC(Me)=CH2. It is a colorless viscous liquid that readily polymerizes. HEMA is a monomer that is used to make various polymers.

Modified Molecular Arrays

InactiveUS20110059865A1Less reactiveAccelerated programSequential/parallel process reactionsNucleotide librariesMolecular array(Hydroxyethyl)methacrylate

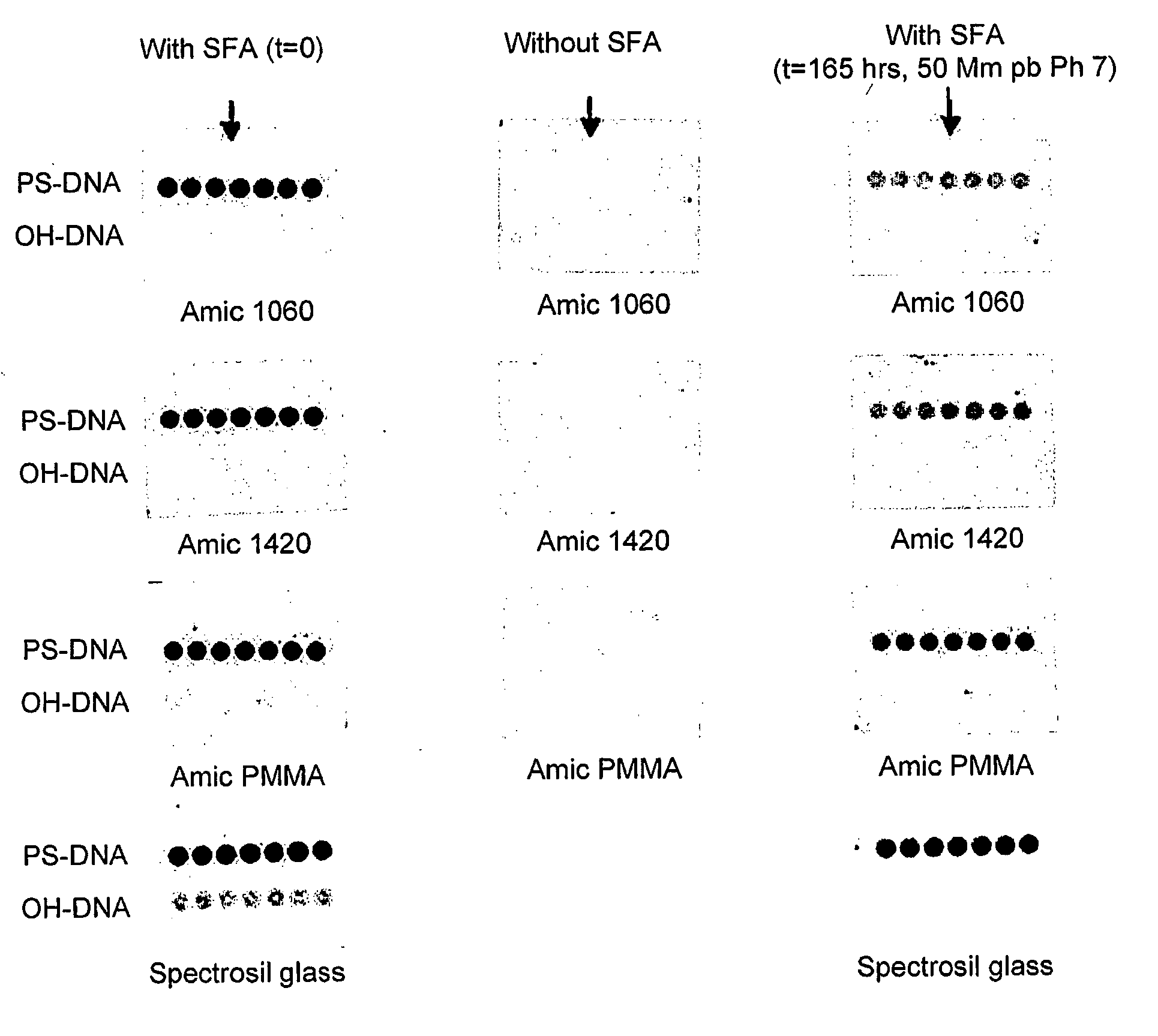

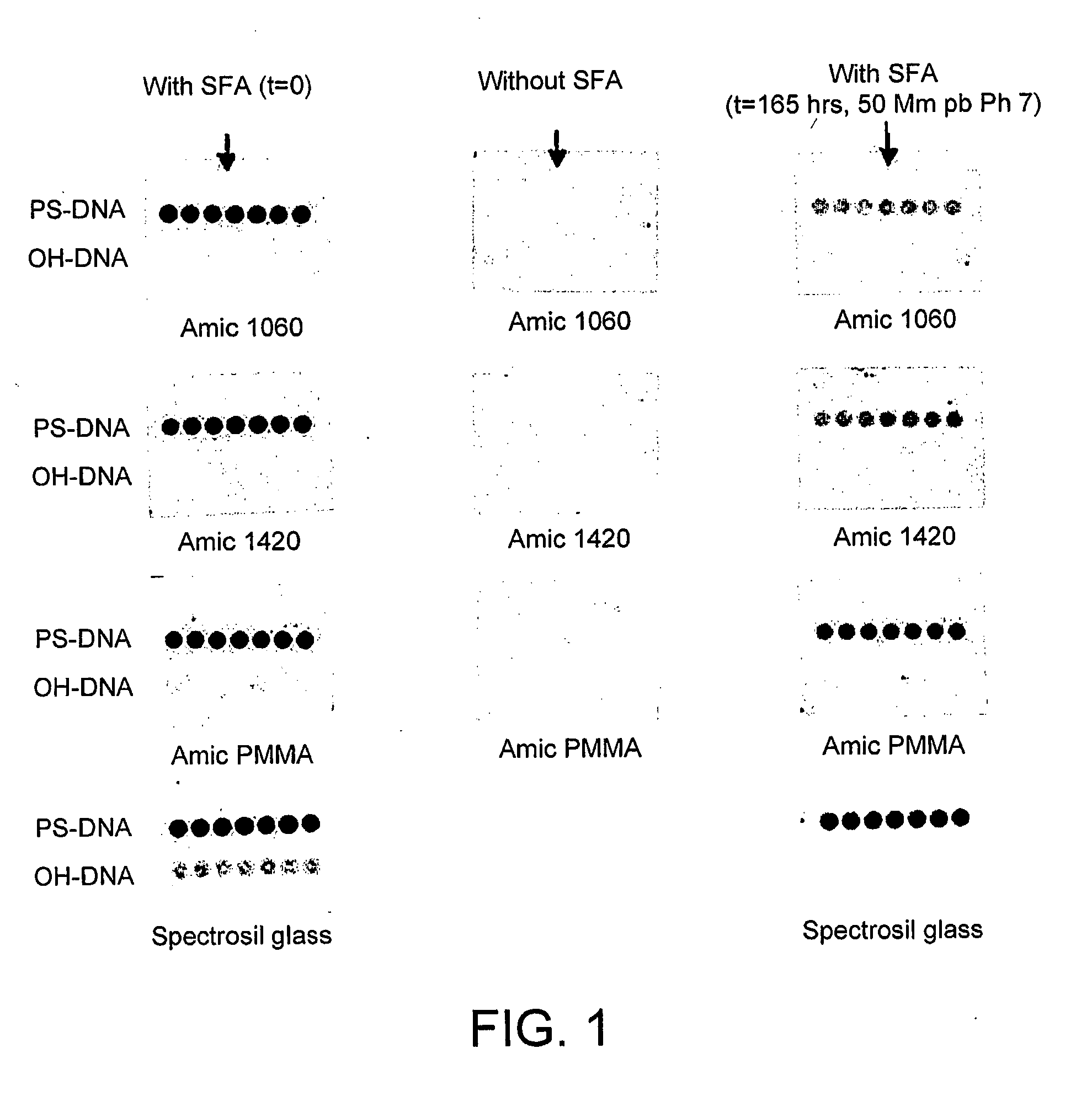

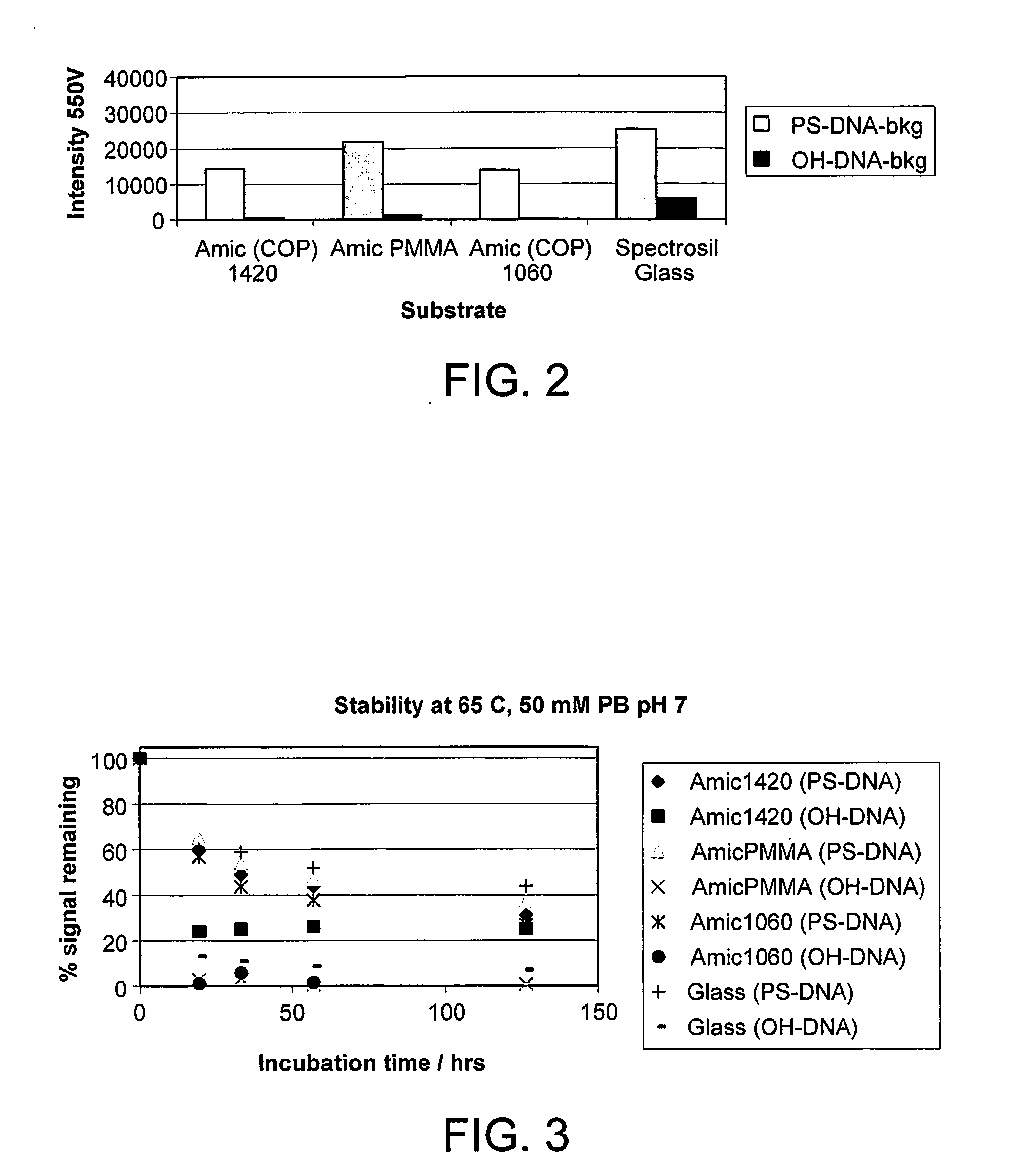

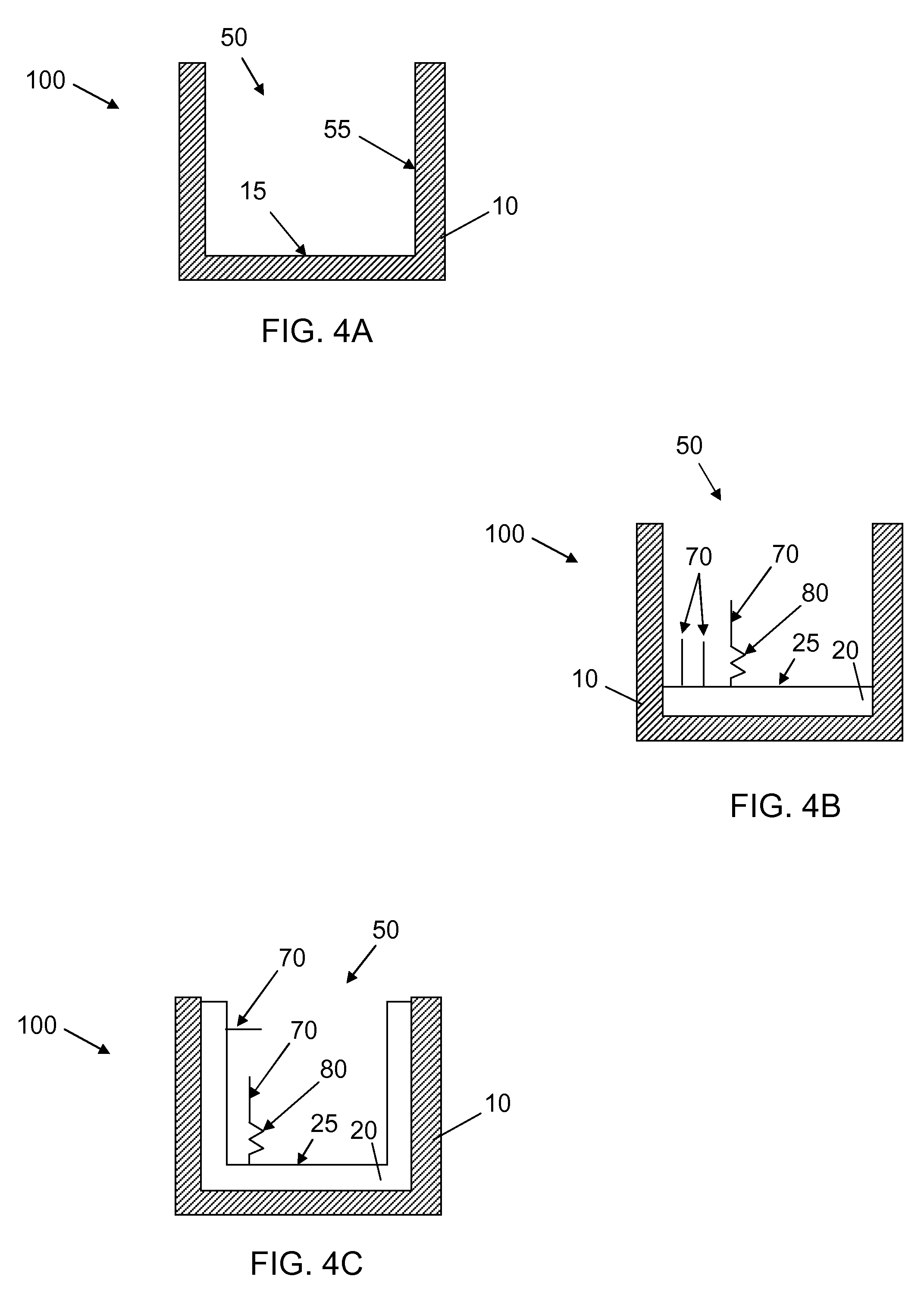

The invention relates to the preparation of a hydrogel surface useful in the formation and manipulation of arrays of molecules, particularly polynucleotides and to the chemical modification of these and other arrays. In particular, the invention relates to a method of preparing a hydrogel immobilised to a solid support comprising polymerising on the support a mixture of a first comonomer which is acrylamide, methacrylamide, hydroxyethyl methacrylate or N-vinyl pyrrolidinone and a second comonomer which is a functionalised acrylamide or acrylate.

Owner:ILLUMINA CAMBRIDGE LTD

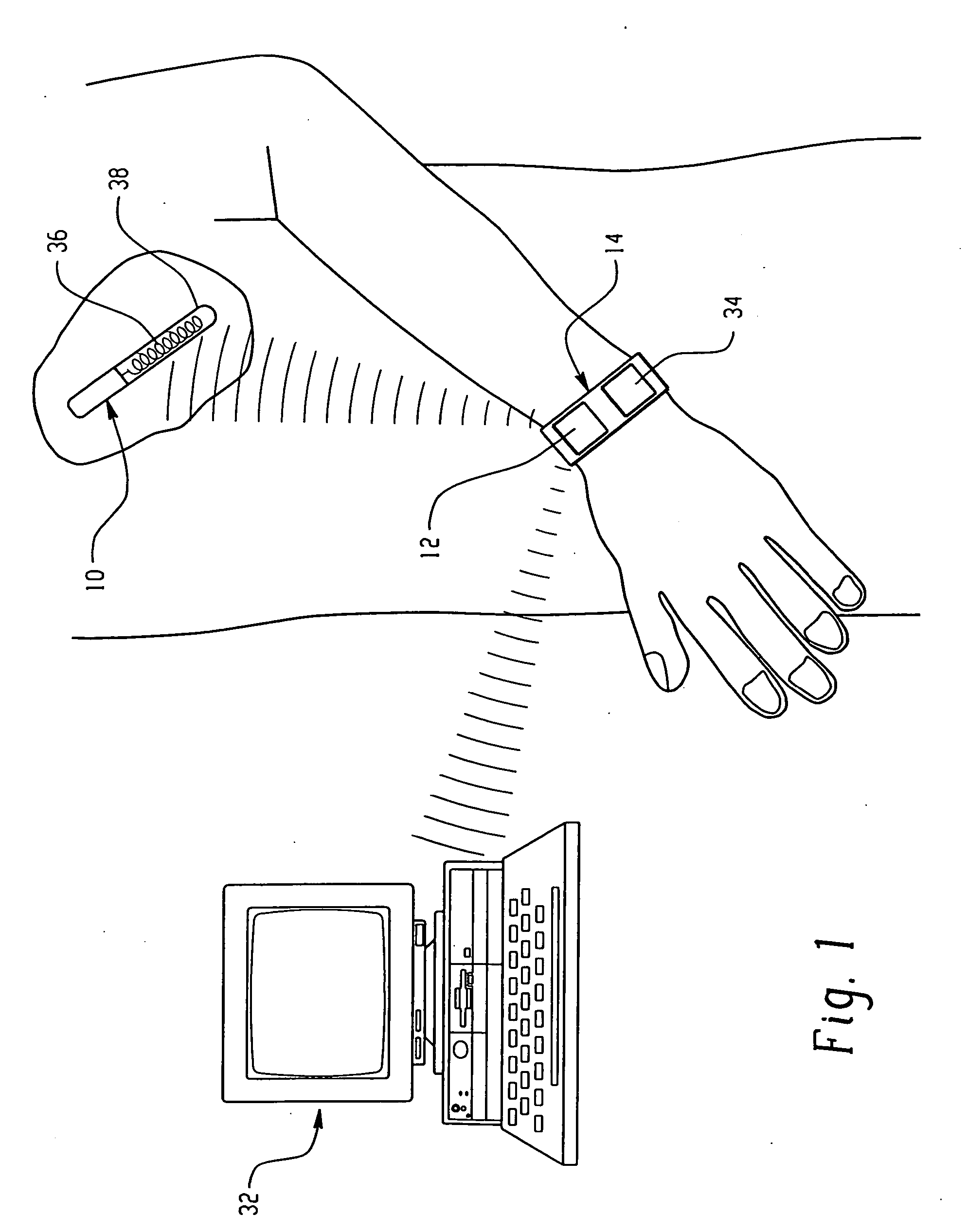

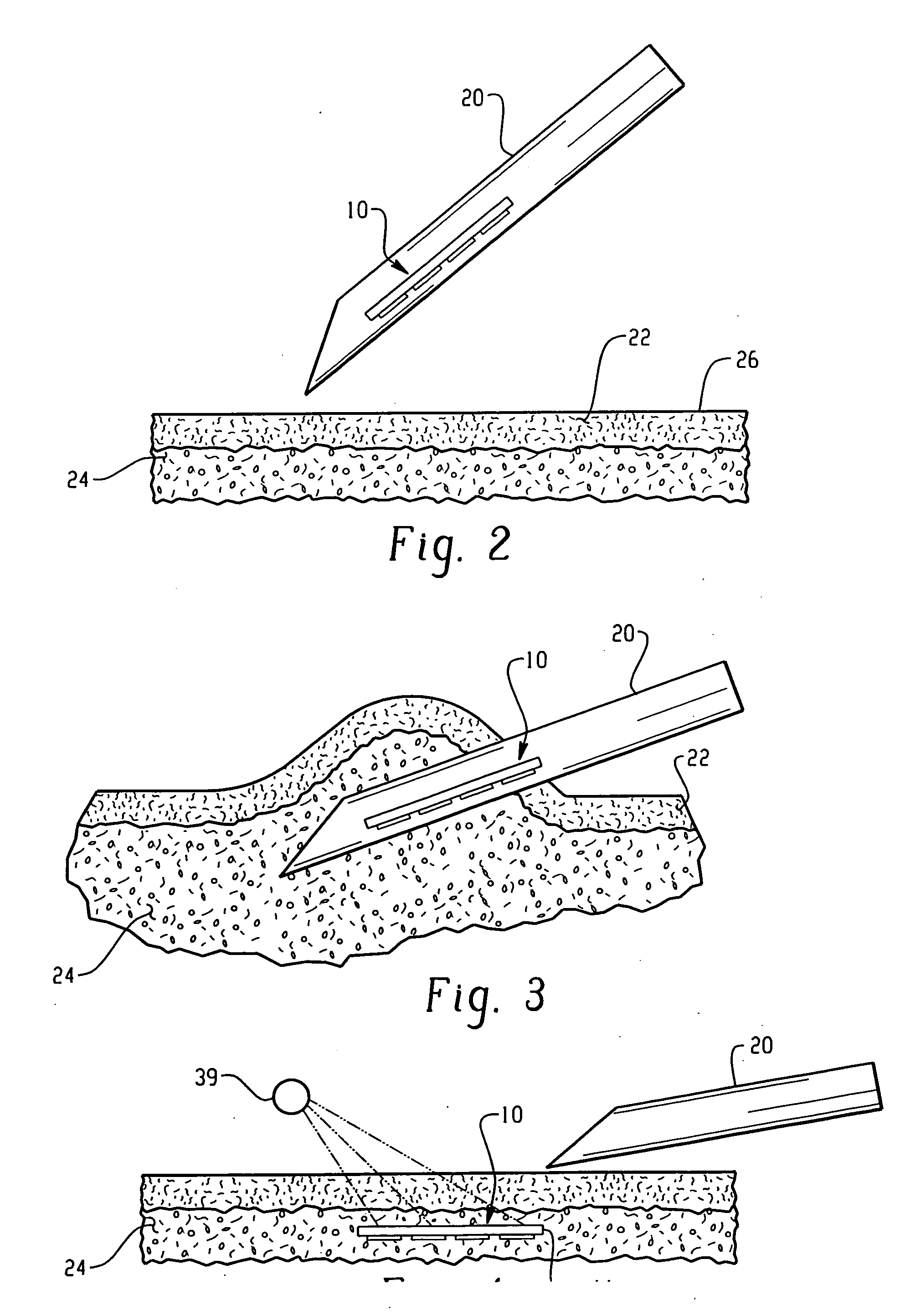

Sensor system

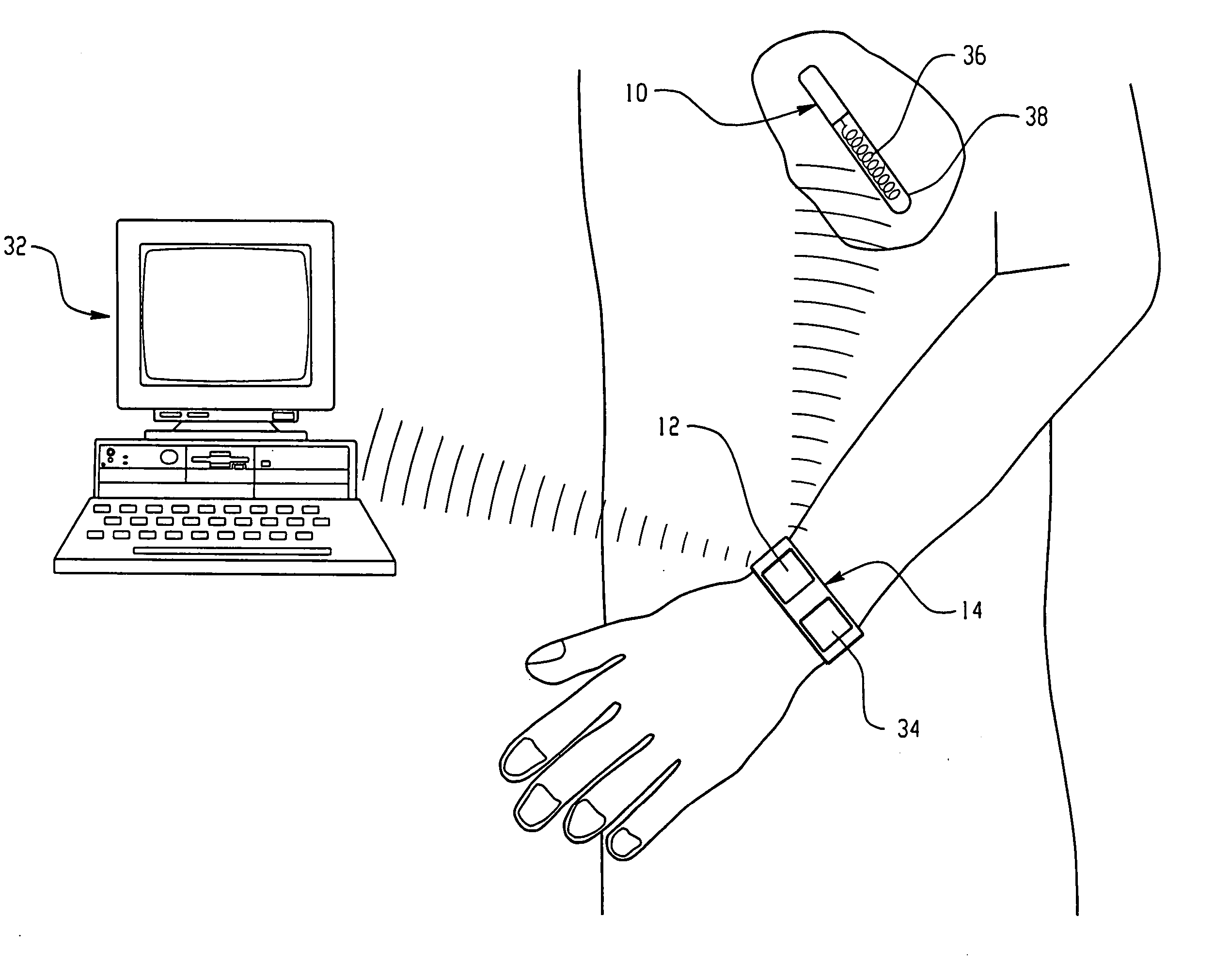

ActiveUS20050221276A1Readily apparentBioreactor/fermenter combinationsBiological substance pretreatmentsAnalyte(Hydroxyethyl)methacrylate

A sensor probe suited for implanting into the skin of a person includes a sensor body which may be formed from a polymer which includes 2-hydroxyethyl methacrylate (HEMA). A sensing system is supported by the body. The sensing system exhibits a detectable change when the probe is exposed to the analyte in the fluid. The sensing system may include an enzyme capable of catalyzing a reaction of the analyte to form a reaction product and a dye system which absorbs in the infrared region of the spectrum in response to the reaction product.

Owner:CASE WESTERN RESERVE UNIV

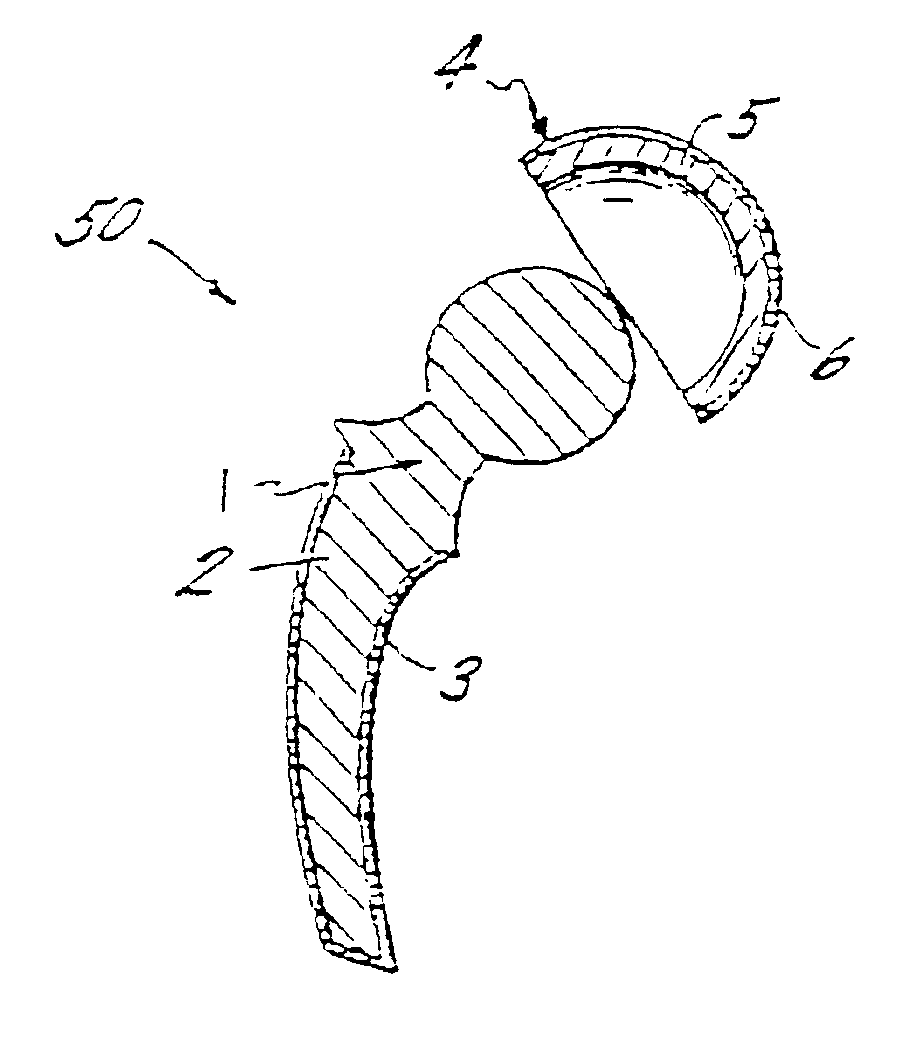

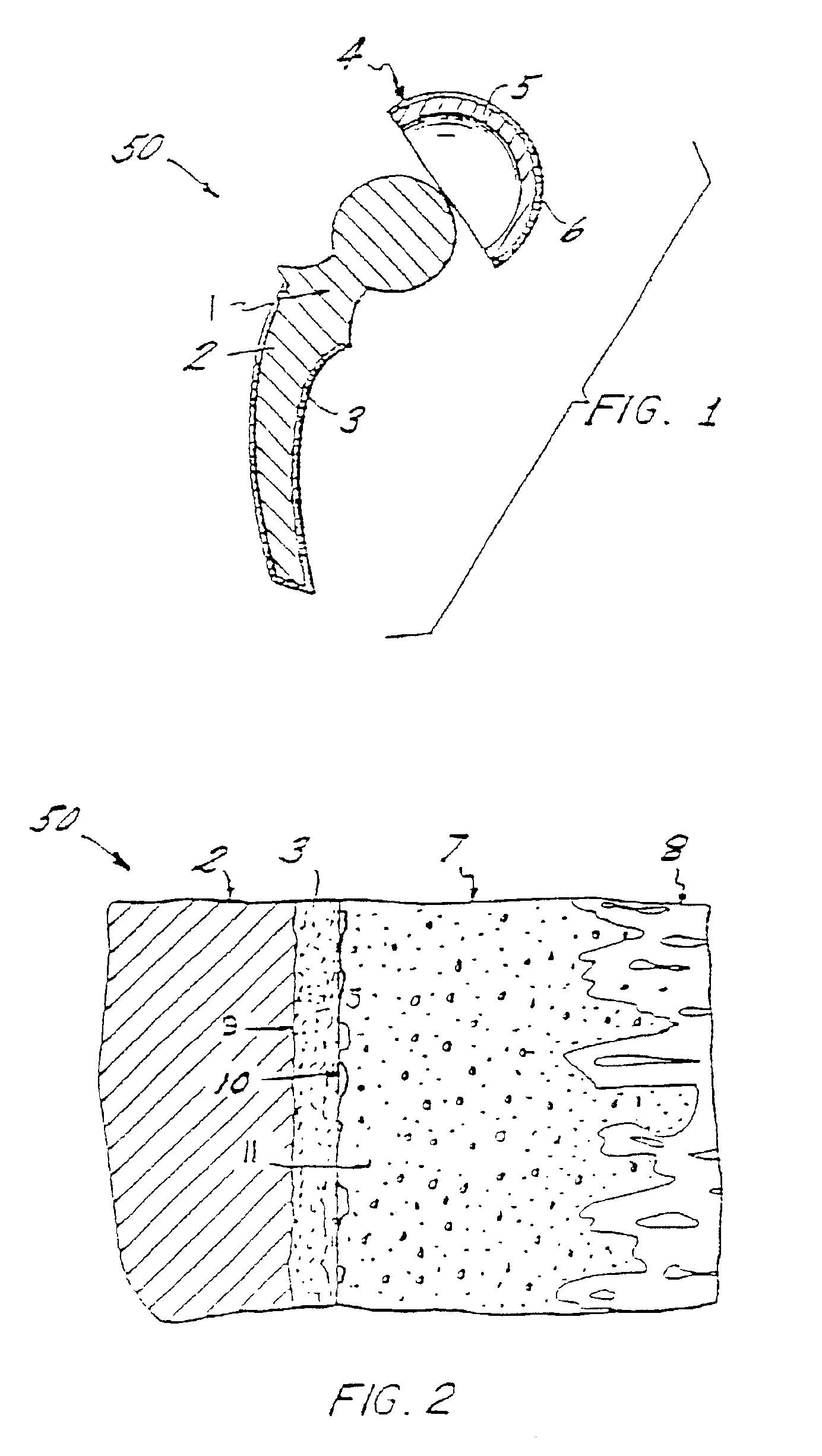

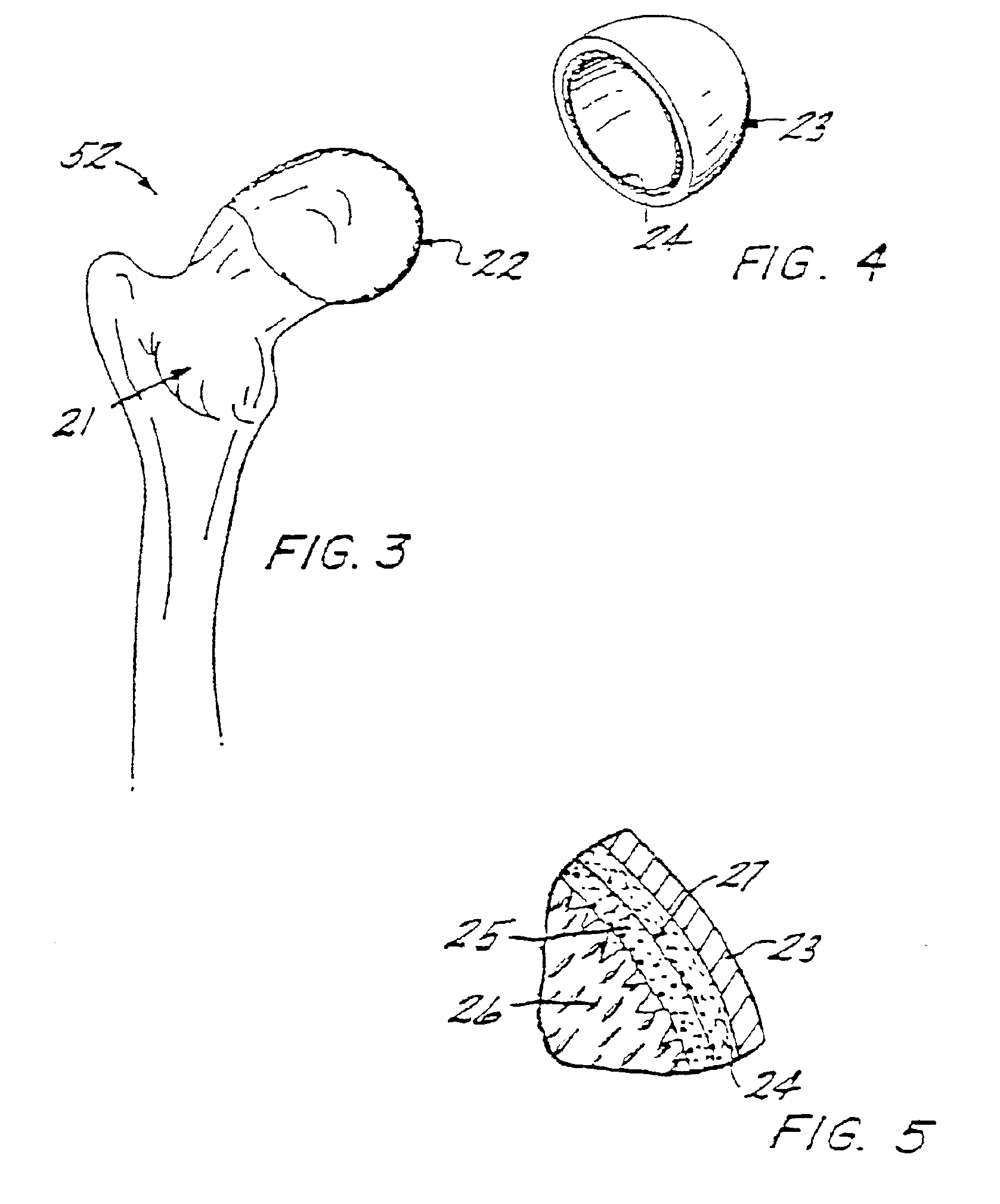

Bone connective prosthesis and method of forming same

InactiveUS6984236B2Improve cohesionImprove adhesionImpression capsBone implant2-methylpropene(Hydroxyethyl)methacrylate

The above-discussed and other problems and deficiencies of the prior art are overcome or alleviated by the improved bone connective prosthesis and method of forming the same of the present invention, comprising the addition of at least one biocompatible metal coupling agent to a prosthetic element, and then adding the biocompatible copolymerizer 2-hydroxyethyl methacrylate (“HEMA”) to the PMMA film and / or cement in an amount effective to enhance the cohesion between the prosthetic and the bone cement. In general, a PMMA / HEMA film is applied to the prosthetic element in the presence of a silane coupling agent by dipping, painting, spraying, etc.

Owner:FARO TECH INC

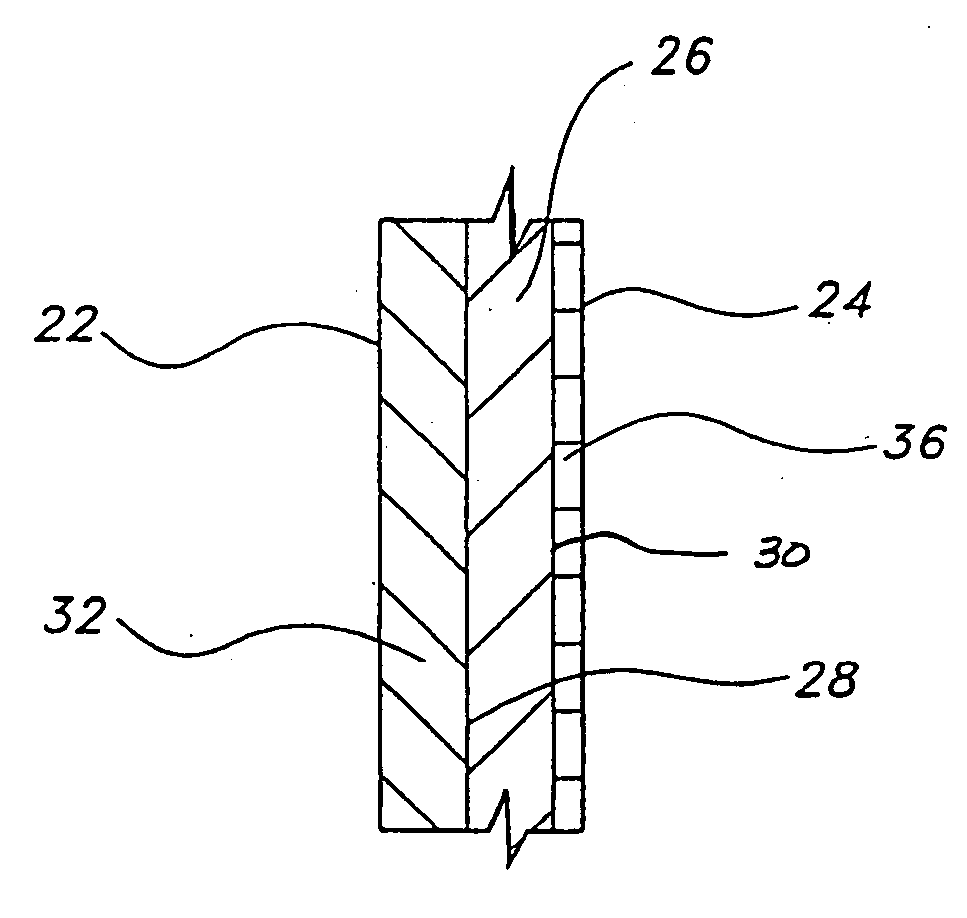

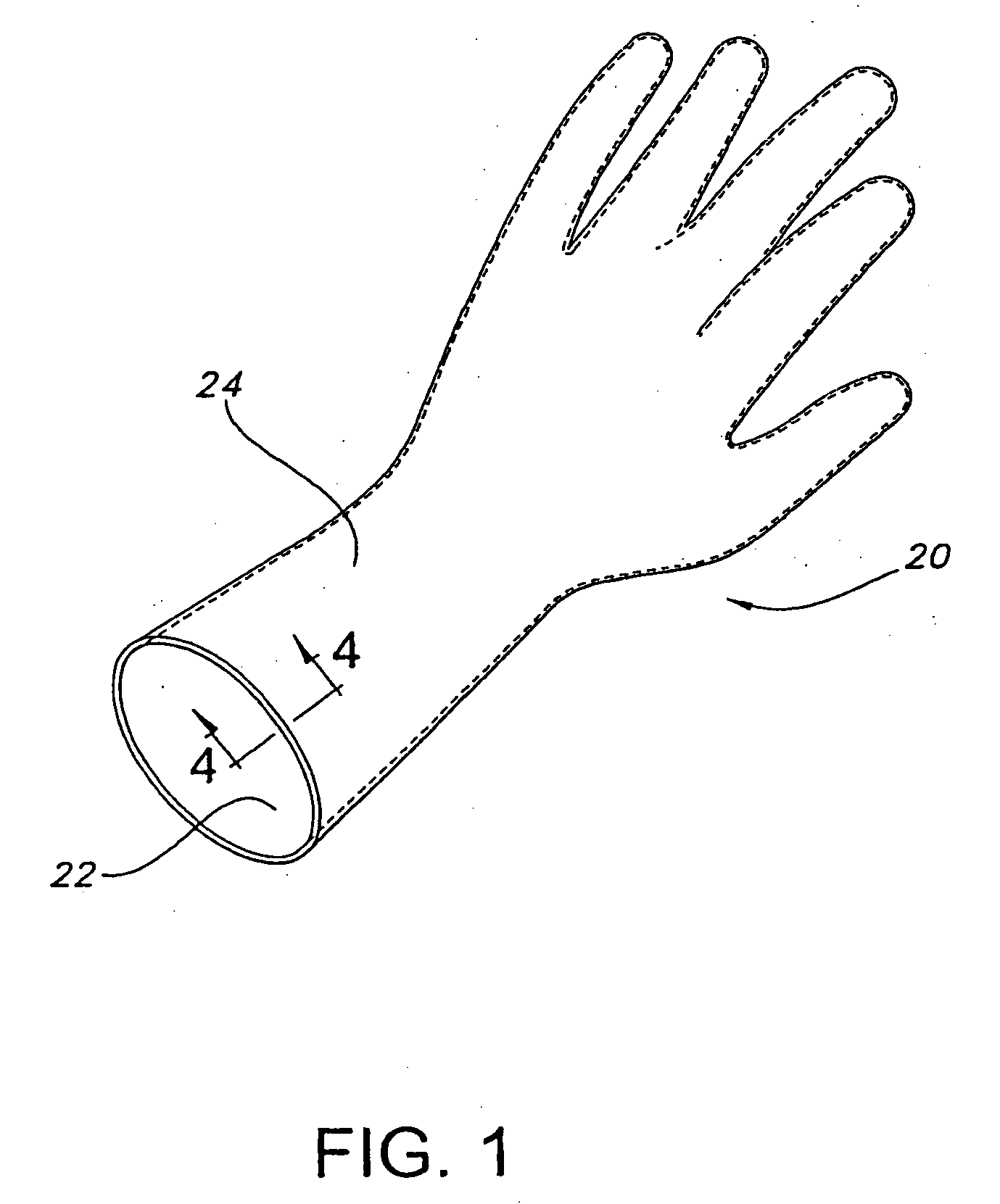

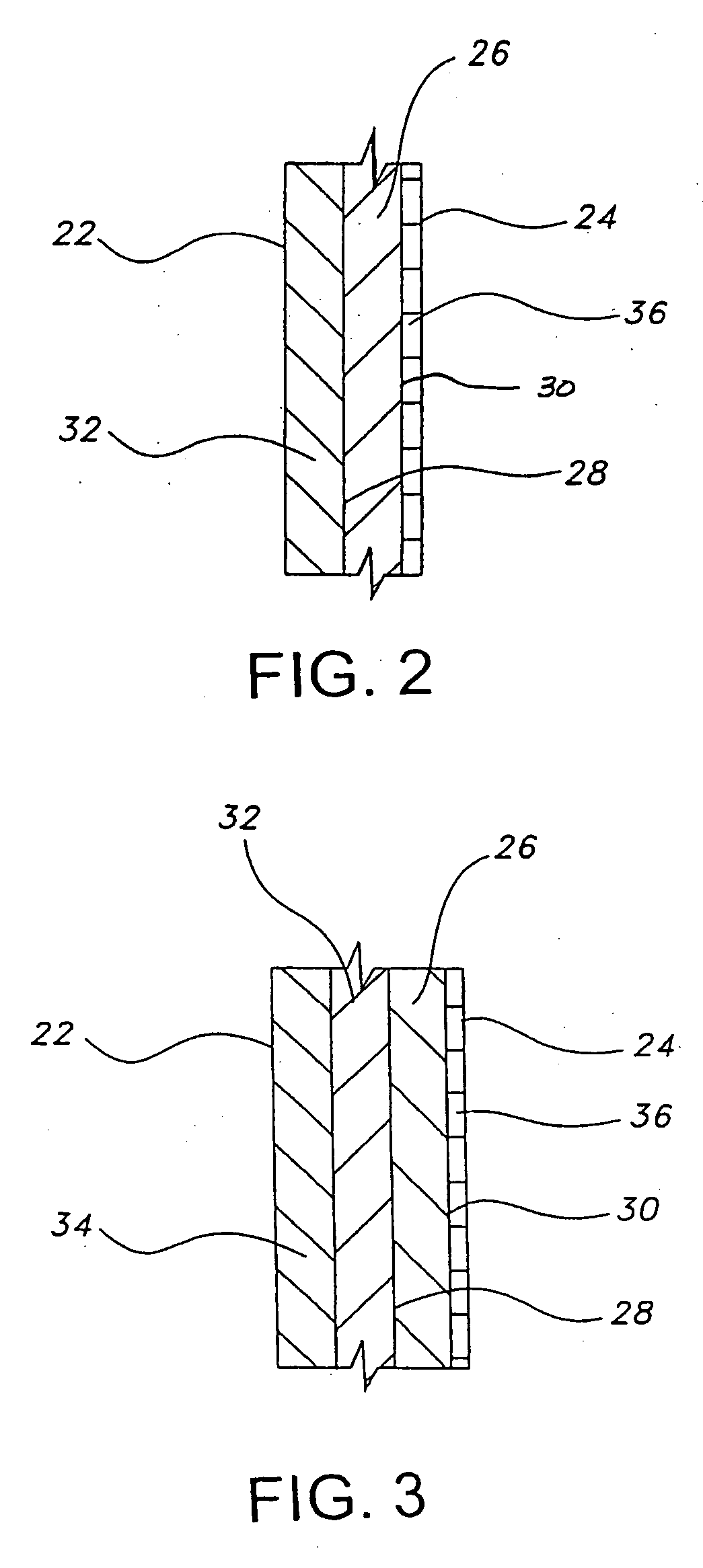

Gloves with hydrogel coating for damp hand donning and method of making same

InactiveUS20060141186A1Garment special featuresDiagnostics(Hydroxyethyl)methacrylateOrganic chemistry

Disclosed herein is an elastomeric article having a hydrogel donning coating. The hydrogel donning coating is made of a copolymer of hydroxy ethyl acrylate (HEA), hydroxy ethyl methacrylate (HEMA), and acrylic acid. The hydrogel donning coating is applied to the elastomeric article using an aqueous hydrogel dipping solution containing the hydrogel donning coating copolymer. The aqueous hydrogel dipping solution demonstrates thixotropic characteristics which allows for better manufacturing process control.

Owner:KIMBERLY-CLARK WORLDWIDE INC

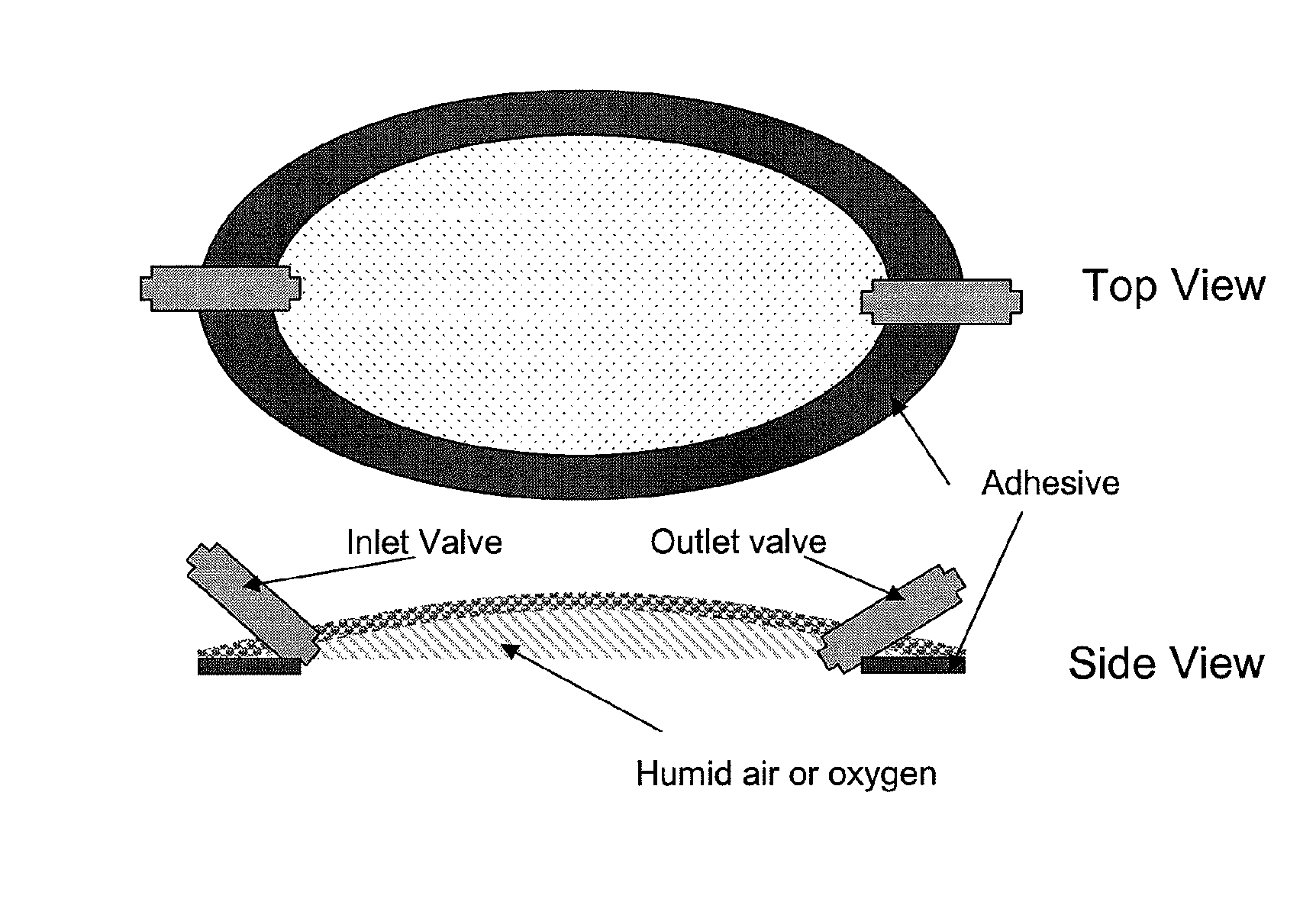

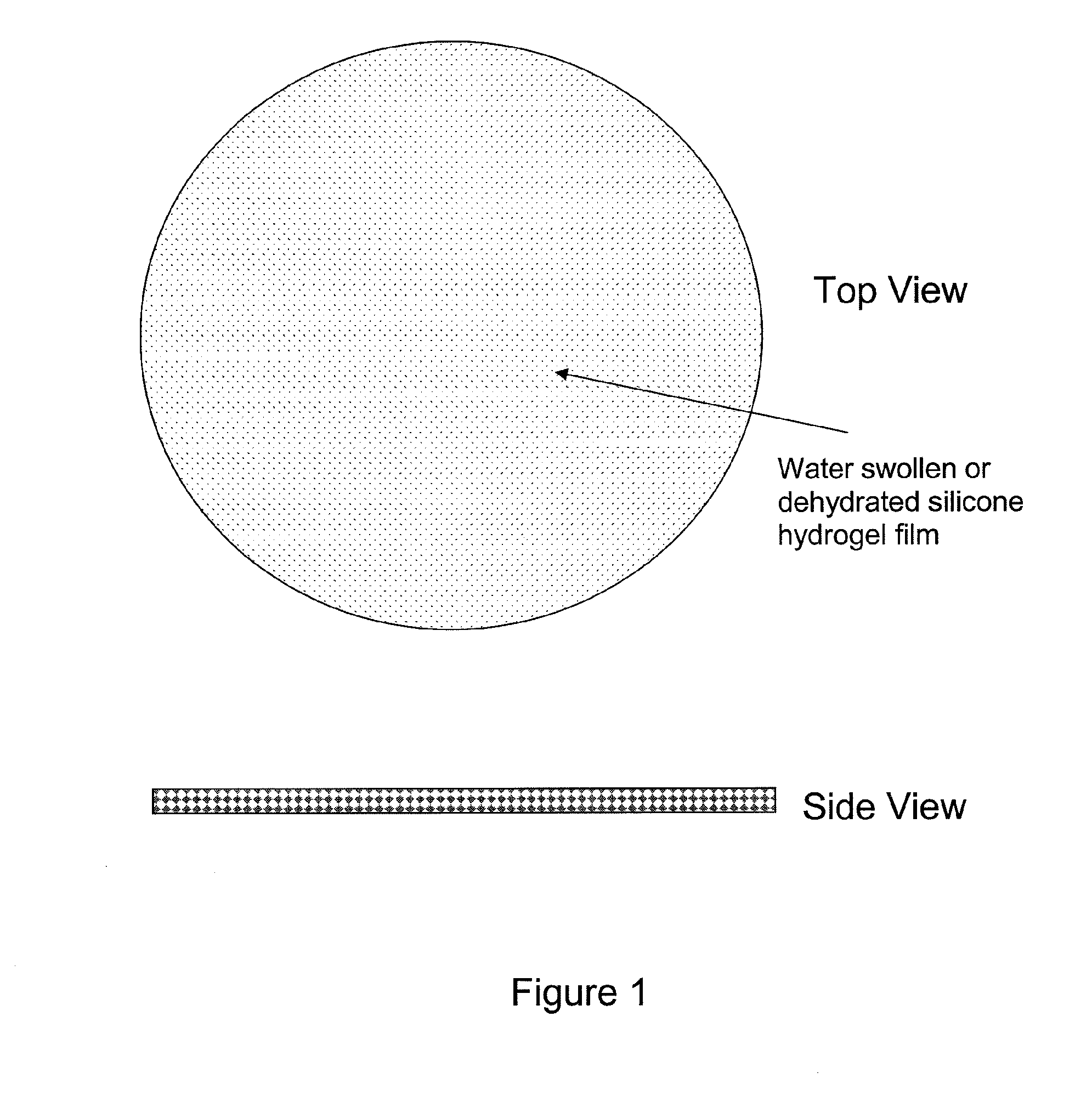

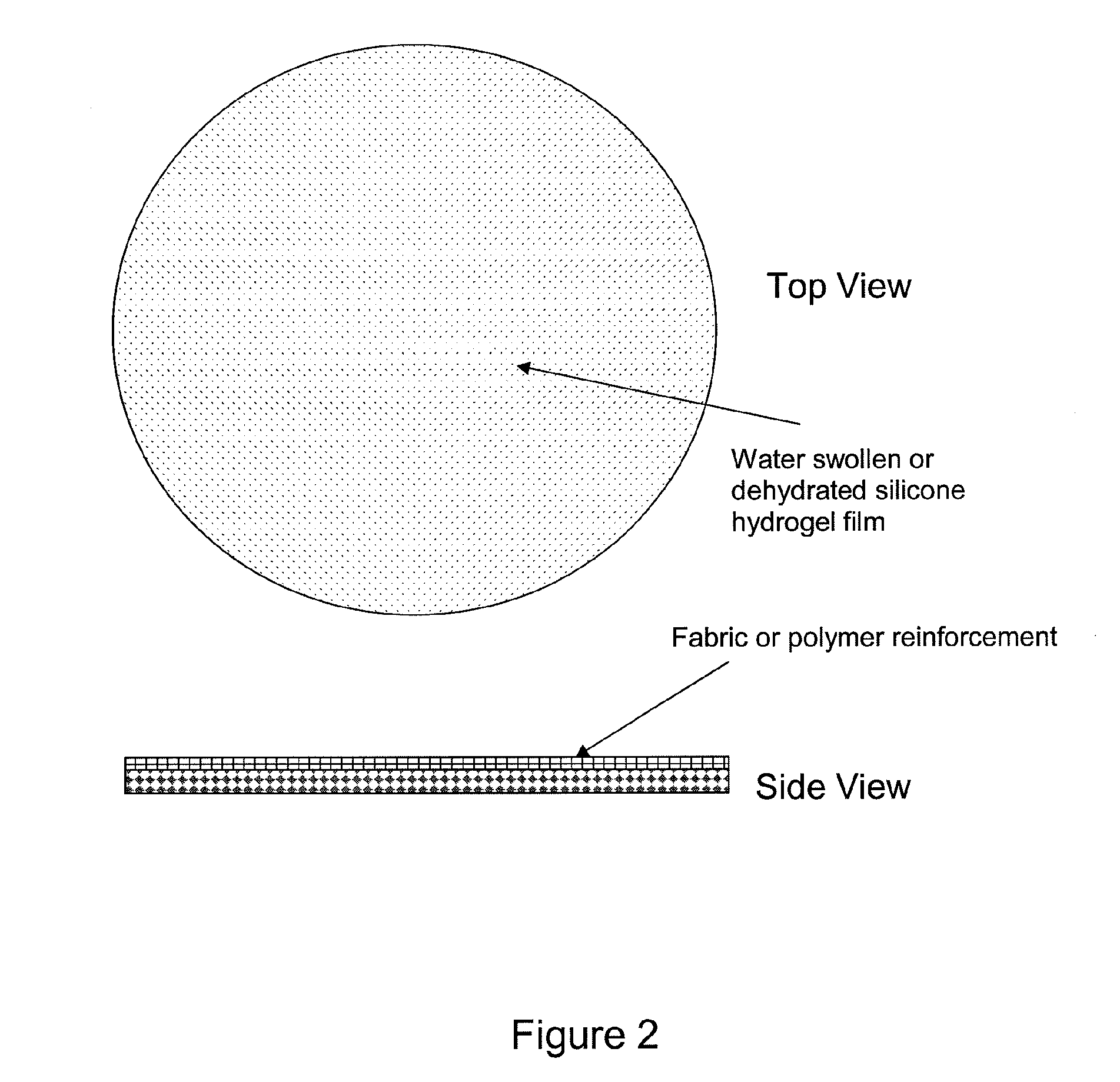

Silicone hydrogels for tissue adhesives and tissue dressing applications

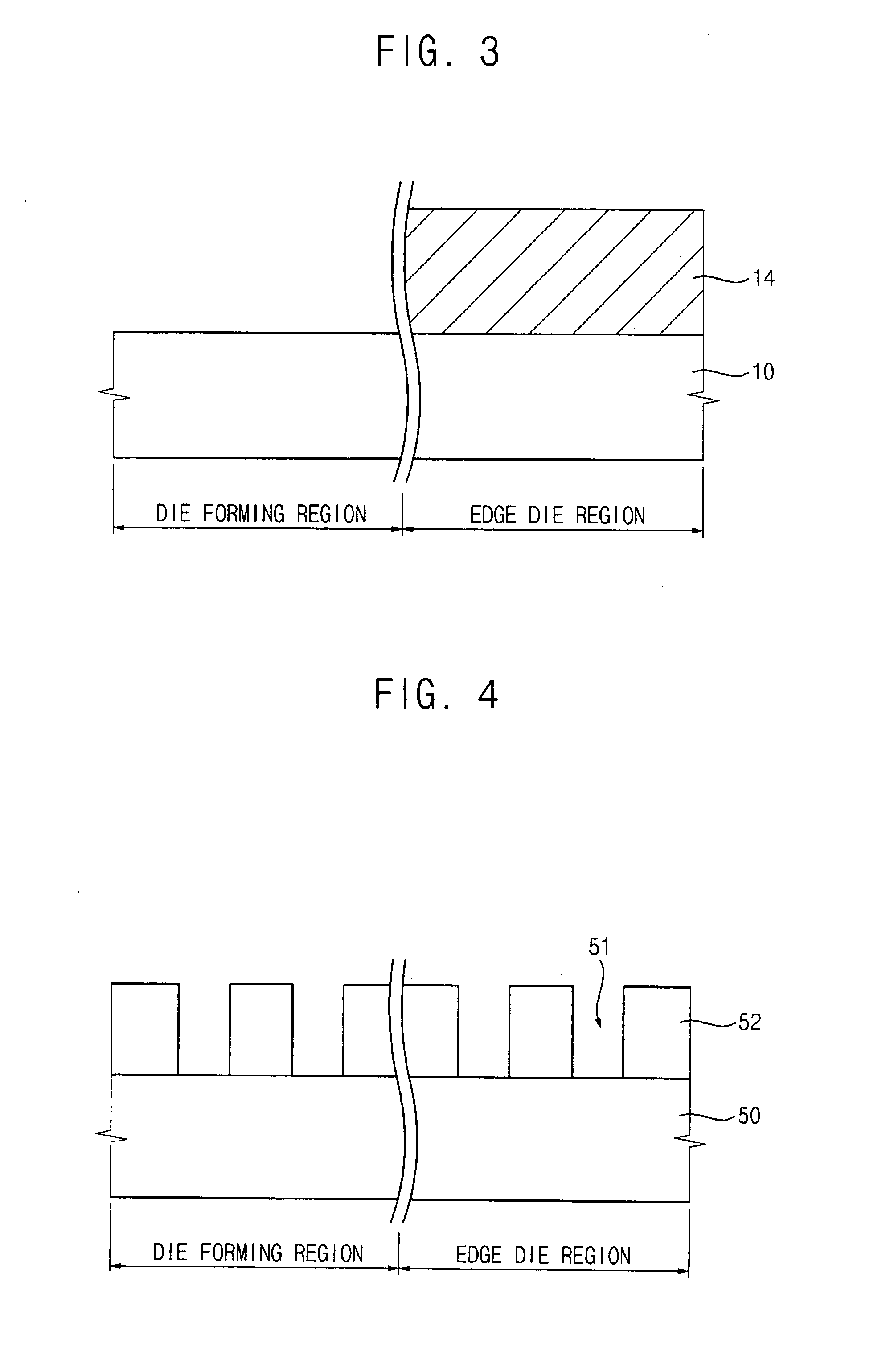

InactiveUS20110086077A1Provide strengthFacilitated releaseBiocidePeptide/protein ingredientsWound dressingSilanes

A silicone hydrogel formulation may contains random and / or block copolymers or oligomers or macromers. The silicone copolymer is copolymerized or blended with other polymers or monomers or macromers to obtain final formulation. The silicone hydrogel may contain crosslinking groups to provide a complete or partially crosslinked final structure. The silicone hydrogel formulation may be pre-formed as a film or other structure, or it may be polymerized during application as in the case of an adhesive formulation. A wound dressing comprising a silicone hydrogel formed as a film, either prior to application to a wound or in situ on a wound, which film has gas permeability, moisture permeability, and high water content, wherein said silicone hydrogel is formed from a polymerizable silicone such as a difunctional polydimethylsiloxane methacrylate and crosslinking agents such as N,N-dimethyllacrylamide (DMA), 2-hydroxyethyl methacrylate (HEMA), and trimethylsiloxy silane (TRIS).

Owner:DSM IP ASSETS BV

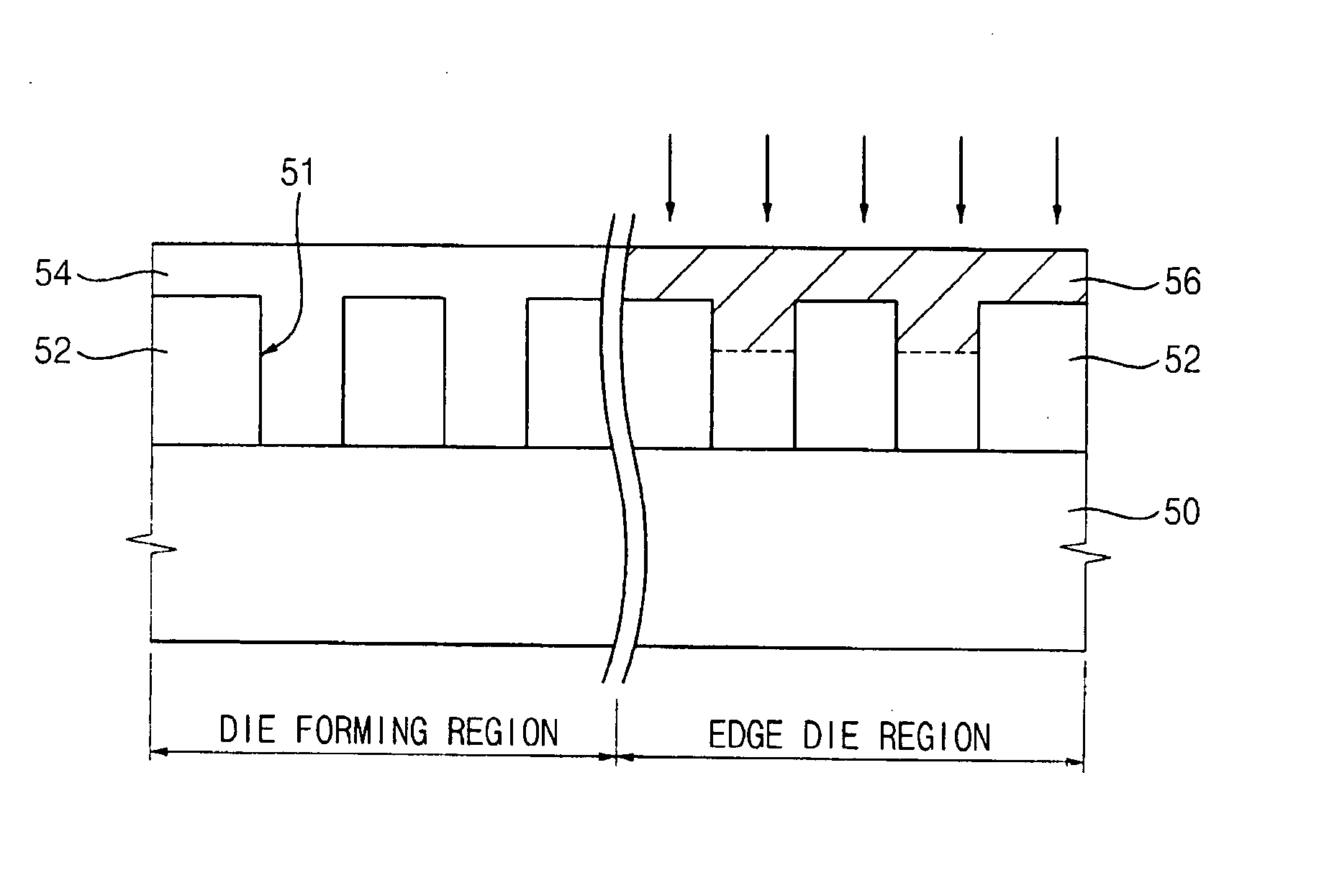

Polymer resin composition, related method for forming a pattern, and related method for fabricating a capacitor

InactiveUS20070249117A1Reduce in quantityReduce processing timeSolid-state devicesSemiconductor/solid-state device manufacturingCross-link(Hydroxyethyl)methacrylate

Owner:SAMSUNG ELECTRONICS CO LTD

Swellable (METH)acrylate surfaces for culturing cells in chemically defined media

InactiveUS20090191632A1Reduce Potential ContaminationExtended shelf lifeCell culture supports/coatingEmbryonic cellsSerum free mediaPolymer science

Synthetic surfaces capable of supporting culture of undifferentiated human embryonic stem cells in a chemically defined medium include a swellable (meth)acrylate layer and a peptide conjugated to the swellable (meth)acrylate layer. The swellable (meth)acrylate layer may be formed by polymerizing monomers in a composition that includes hydroxyethyl methacrylate, 2-carboxyehylacrylate, and tetra(ethylene glycol) dimethacrylate. The conjugated peptide may include an amino acid sequence of XaanProGlnValThrArgGlyAspValPheThrMetPro, where n is an integer from 0 to 3 and where Xaa is any amino acid. Further, disclosed herein is a swellable (meth)acrylate synthetic surface which can be sterilized by gamma irradiation.

Owner:GERON CORPORATION

Process for preparing ultraviolet curable aqueous polyurethane resin

This invention is the preparation method of ultraviolet light stabilized polyurethane resin with aquosity. The procedure is as followings: add diatomic alcohol with isoallyl group, solvent, polymerization inhibitor and catalysis into polyurethane. React at 50-80deg C for 2-4hours. Add hydroxyethyl methacrylate to react at 50-70deg C for 2-3hours. Use diatomic alcohol with isoallyl group to amplify the NCO group and polyurethane pre-polymer. Then cap with hydroxyethyl methacrylate to add acroleic acid double bond into polyurethane's branch chain and chain ends. With this method, polyurethane is NCOgroup-free. It helps increase the emulsion's storage stability. This invention increase the product's double bonds contents as well as hard block contents to lift crosslinking density, coating hardness and resistance of wiping with methyl-ethyl ketone.

Owner:UNIV OF SCI & TECH OF CHINA +1

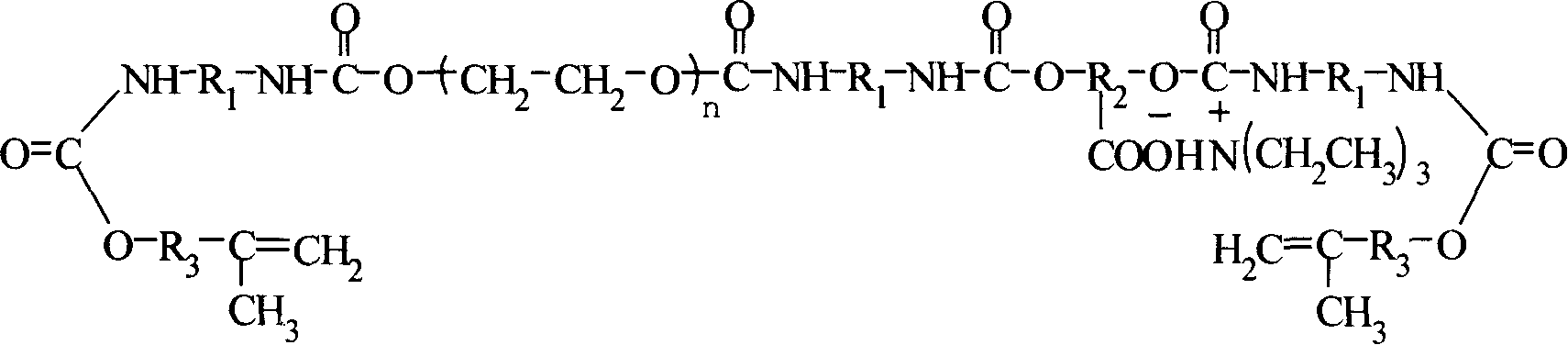

Ultraviolet curing organic silicon modified polyurethane aqueous dispersoid and preparation method thereof

InactiveCN101735599AGood mechanical propertiesImprove water resistanceInksPolyurea/polyurethane coatingsPolyesterPropanoic acid

The invention discloses ultraviolet curing organic silicon modified polyurethane aqueous dispersoid and a preparation method thereof. The method comprises the following steps: firstly, dripping polyester or polyether diol, end hydroxyalkyl silicon oil, trimethylolpropane and the like into aromatic or aliphatic diisocyanate, and reacting the mixture to obtain organic silicon modified polyurethane prepolymer; then, adding polyhydromethyl propionic acid into the organic silicon modified polyurethane prepolymer, and reacting the mixture to obtain chain-extended organic silicon modified polyurethane prepolymer; and performing end capping reaction on the chain-extended organic silicon modified polyurethane prepolymer by using hydroxyethyl methacrylate or hydroxy-propyl acrylate to obtain organic silicon modified polyurethane acrylate oligomer, finally adding a neutralizer such as triethylamine and the like into the oligomer to perform neutralization reaction on the system, adding water into the mixture for diluting, and stirring and emulsifying the mixture to obtain the ultraviolet curing organic silicon modified polyurethane aqueous dispersoid. The ultraviolet cured coating film has better water tolerance and adhesive force, and can be widely applied in the fields of environmental protection, building, household appliances, ink, coating and the like.

Owner:SOUTH CHINA UNIV OF TECH +1

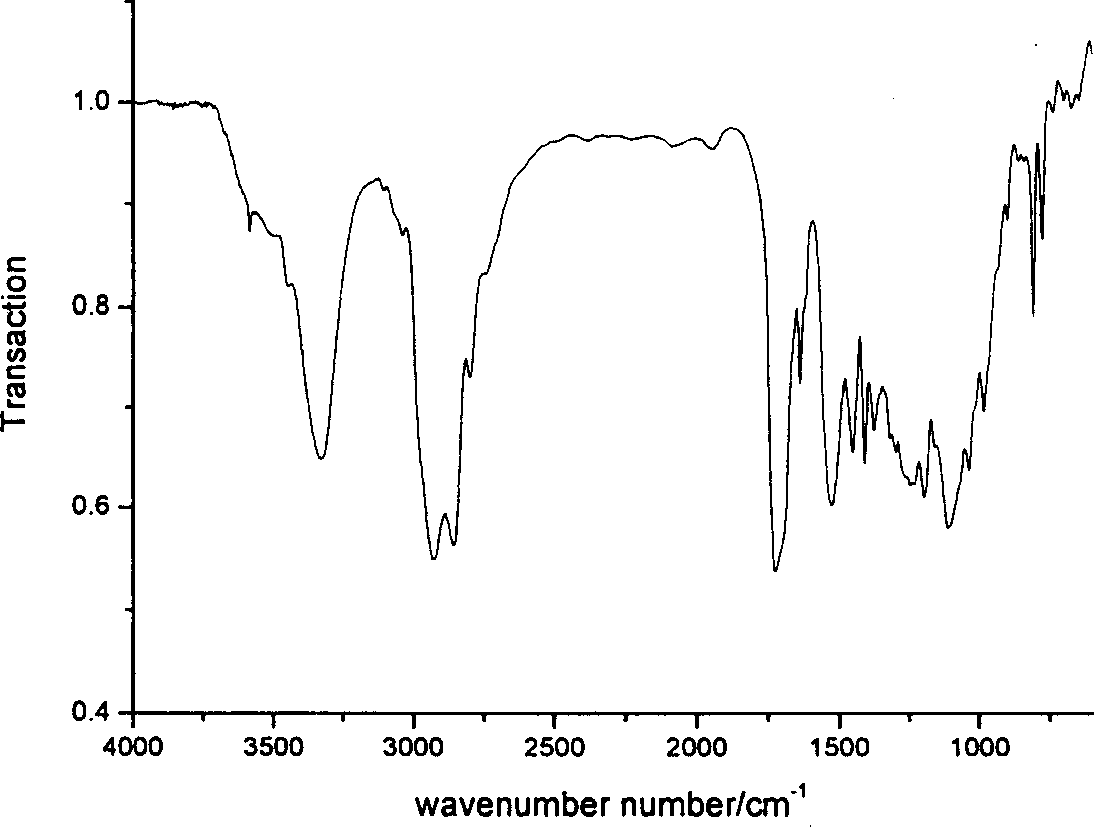

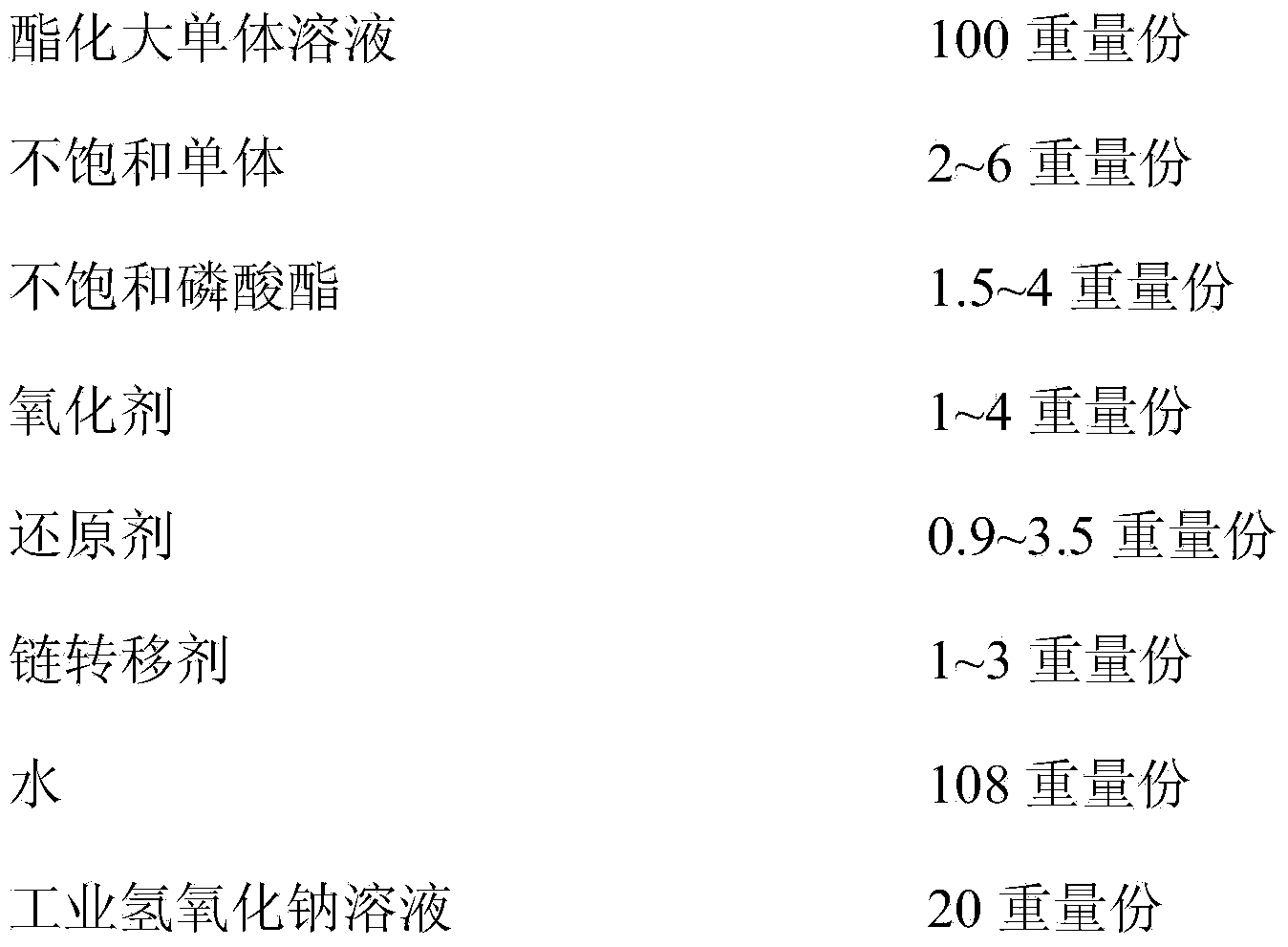

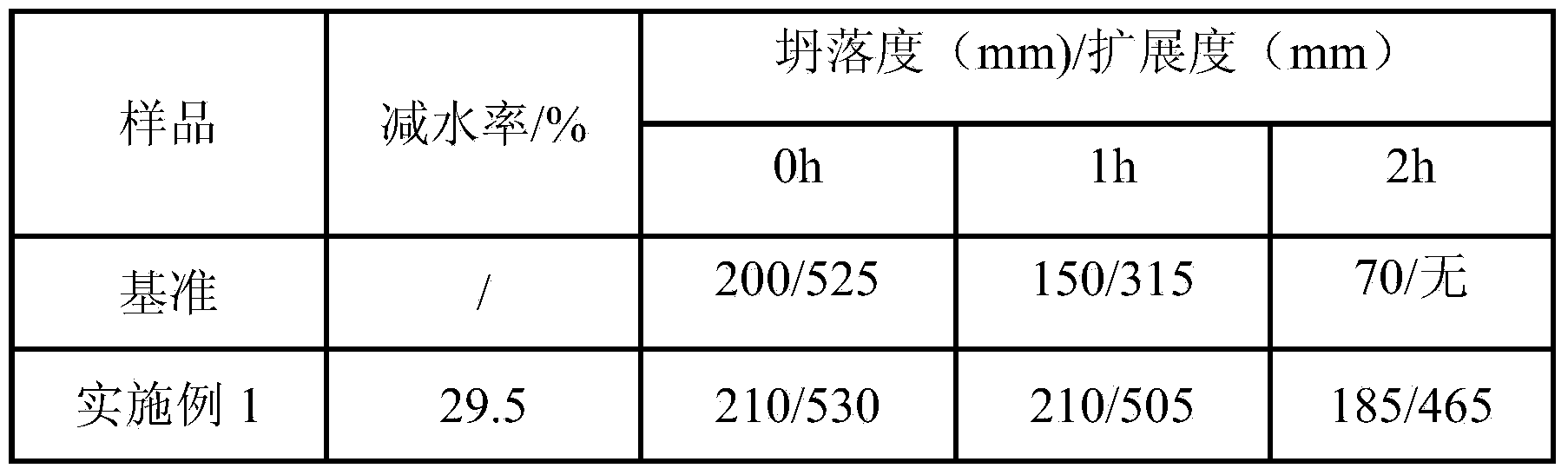

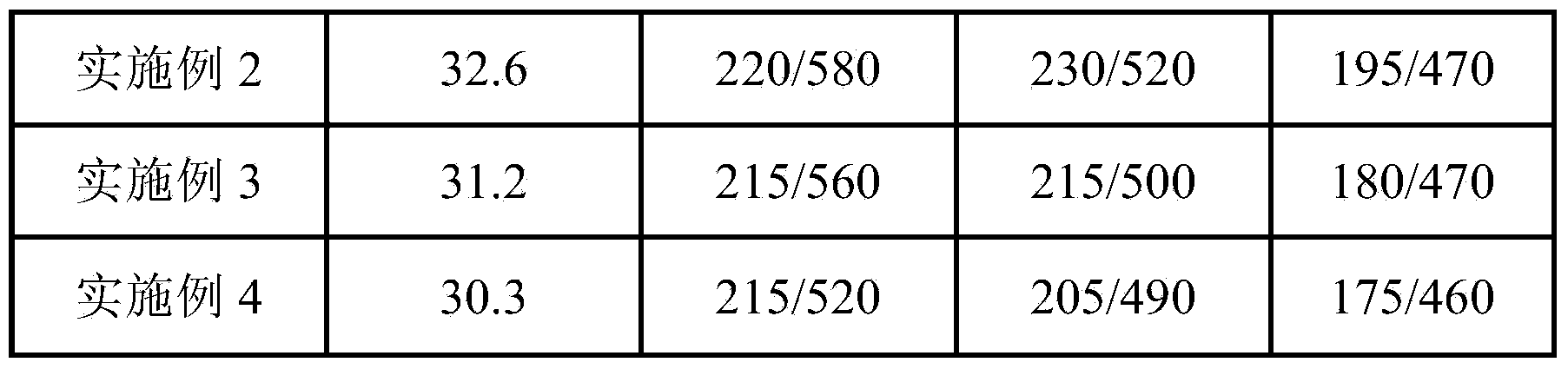

Ester slump retaining type polycarboxylate water reducer and preparation method thereof

The invention discloses an ester slump retaining type polycarboxylate water reducer and a preparation method thereof. The ester slump retaining type polycarboxylate water reducer is made from raw materials comprising the following components in parts by weight: 100 parts of esterified macromer solution by weight, 2-6 parts of unsaturated monomer by weight, 1.5-4 parts of unsaturated phosphate by weight, 1-4 parts of an oxidizing agent by weight, 0.9-3.5 parts of a reducing agent by weight, 1-3 parts of a chain transfer agent by weight, 108 parts of water by weight, and 20 parts of industrial sodium hydroxide solution by weight, wherein the concentration of the esterified macromer solution is 75-85%, and a solute thereof is the mixture of methoxy polyethylene glycol methacrylate, crosslinking monomers triethylene glycol dmethylacrglate and methyl methacrylate; the unsaturated monomer is methacrylic acid, acrylic acid, hydroxyethyl methylacrylate, hydroxyethyl acrylate, hydroxypropyl methacrylate or hydroxypropyl acrylate. The ester slump retaining type polycarboxylate water reducer provided by the invention has good slump retaining performance, good dispersibility, good adaptability and low cost.

Owner:KZJ NEW MATERIALS GROUP CO LTD +1

Oil absorbing fibre and perparing method thereof

InactiveCN1584148ABroaden the fieldLarger specific surface area for oil absorptionWet spinning methodsMonocomponent synthetic polymer artificial filamentFiberBenzoyl peroxide

The invention relates to a kind of oil-absorbed fiber and its producing method. Its prescription is: 100% polymer monomer, 10-40% of potential gemel agent, 0.1-0.5% solicitation, 0.5-1% dispersant. Moreover the water-like body is 3-4 times more in volume than polymer monomer. The polymer monomer is methacrylate monomer involving butyl methacrylate, the potential gemel agent is 2-hydroxyethyl methacrylate, the solicitation is benzoyl peroxide, and dispersant is poly-vinyl-alcohol. The process is (1) use water-suspending polymerization to produce butyl methacrylate under 70-80 deg.C for blending and polymerizing for 8-10 hours. (2) dissolve the polymer into proper solvent to deploy 20-25% liquid and then insert potential gemal agent and solicitation to polymerize for 3-5 hours under 75-80 deg.C to obtain the original liquid. (3) take off dunking. (4) spin using one of wet or dry method or both, (5) treat with fibre for 10-60 minutes under 120-165 deg.C to obtain the production. The solvent discussed above is one of DMF, DMAC or dimethoxysulfoxide.

Owner:TIANJIN POLYTECHNIC UNIV

Automobile metal sparkling paint and preparation method thereof

ActiveCN101077954ANo condensationImprove stabilityLiquid surface applicatorsCoatingsFiberWater dispersible

The water-thinned flash paint consists of water dispersible acrylic resin, deionized water, water-thinned curing cross-linking agent, water dispersible aluminum powder, dispersant, carboxymethyl butyl acetate resin fiber and water thinned assistant. The water dispersible acrylic resin is prepared with monomer mixture of methyl methacrylate, styrene, butyl acrylate, methacrylic acid, ethoxy methacrylate and acetyl acetoxy methacrylate, and through free radical polymerization. The water-thinned flash paint has regularly arranged water dispersible aluminum powder, and can form paint film with high flash number, great adhesion of metal grain, high water tolerance, etc.

Owner:GUANGDONG YATU CHEM +1

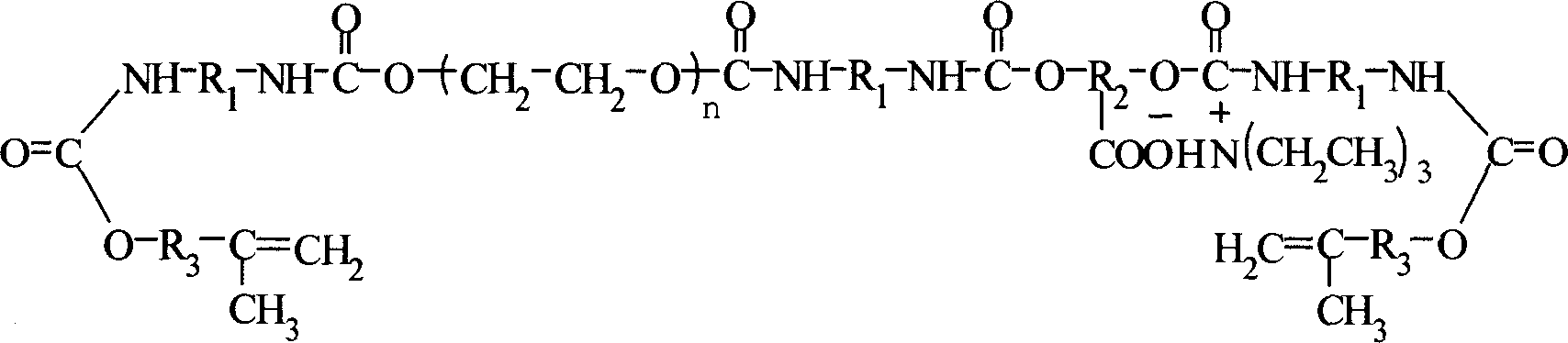

Ultraviolet light solidfication water polyurethane acrylate paint resin and its preparation method

InactiveCN1869139AThe molecular structure is well controlledImprove performancePolyurea/polyurethane coatingsSolubility(Hydroxyethyl)methacrylate

The invention relates to an ultraviolet light solidified water urethane acrylate coating resin. It is mainly made up of aromatic diisocyanate, polyethylene glycol, polyhydroxy-carboxylic acid, dihydric alcohol, hydroxyethyl methacrylate ethyl ester, and tri-ethylamine. It is prepared by adding the above materials orderly. It has the advantages of good water solubility, pliability, and stability.

Owner:SHANTOU UNIV +1

Aqueous fluorine-containing acrylate modified polyurethane coating, preparation method and application thereof

The present invention belongs to the field of polymer material synthesis, relates to aqueous polyurethane acrylate emulsion modification, and especially to an aqueous fluorine-containing acrylate modified polyurethane coating, a preparation method and an application thereof. The preparation method comprises: dissolving polyether polyol in an N-methyl pyrrolidone solution of dimethylol propionic acid; adding diisocyanate in a dropwise manner; adopting dibutyltin dilaurate as a catalyst, and adding hydroxyethyl methacrylate to carry out end capping; adding triethylamine to form a salt, then adding deionized water to prepare an aqueous polyurethane acrylate prepolymer emulsion; and finally adding hexafluorobutyl acrylate and azodiisobutyronitrile to prepare the aqueous fluorine-containing acrylate modified polyurethane coating. The synthesized emulsion of the present invention has the following advantages that: dispersion is uniform; stability is good; water resistance and mechanical property of the cured film are substantially improved; elasticity and mechanical property of polyurethane are provided; ultraviolet resistance, nuclear radiation resistance, flexibility, excellent surface properties, water resistance and corrosion resistance of the fluorine-containing material are provided; and the coating can be adopted as coatings for building and furniture.

Owner:BOMEX CHEM SHANGHAI

Textile water-based pigment printing binding agent and preparation method

ActiveCN102605648AMeet printing requirementsHigh fastnessEster polymer adhesivesDyeing processTextile printerPolymer science

The invention relates to a textile water-based pigment printing binding agent and a preparation method. The textile water-based pigment printing binding agent is prepared in a way that acrylonitrile, ethyl acrylate, butyl acrylate, crylic acid, hydroxyethyl methacrylate, acrylamide, sodium dodecyl sulfate, alcohol dodecyl polyoxyethylene (10) ether, deionized water, ammonium persulfate and sodiumhydrogen sulfite are subjected to emulsion polymerization and then are mixed with pyrolysis closed polyurethane crosslinking agent according to proportion. The product is cured in low temperature condition, has remarkable advantages in the aspects of dry rubbing fastness, wet rubbing fastness, soaping fastness and the like, is simple and easily-controllable in production operation, and is energy-saving and environment-friendly.

Owner:LIAONING FIXED STAR FINE CHEM

Terpolymer dispersants and preparation technique and use thereof

InactiveCN101391194AGood dispersionImprove thermal stabilityTransportation and packagingMixingSolubilityDispersion stability

The invention discloses a terpolymer dispersing agent with high dispersion and stability, low preparation cost and environmental protection as well as a preparation process and applications thereof. The terpolymer dispersing agent is prepared through free radical copolymerization of acrylic acid, sodium styrene sulfonate, hydroxypropyl acrylate or 2-hydroxyethyl methacrylate, the number average relative molecular weight of the terpolymer is between 2000 and 40000, and the dispersing agent has advantages of high thermal stability, good water solubility, excellent adaptability to acid and alkali and good dispersion stability, and also has good dispersion effects to calcium carbonate, zinc oxide, barium sulfate, titanium dioxide and pesticide Atrazine water dispersible granules and fipronil water dispersible granule, and can be widely used in the pesticide, pigment, dyestuff, coal water slurry and other industries. In addition, the preparation process has the advantages of simple operation, short cycle, environmental protection and low cost, and is suitable for the industrial scale production.

Owner:SHANGHAI NORMAL UNIVERSITY

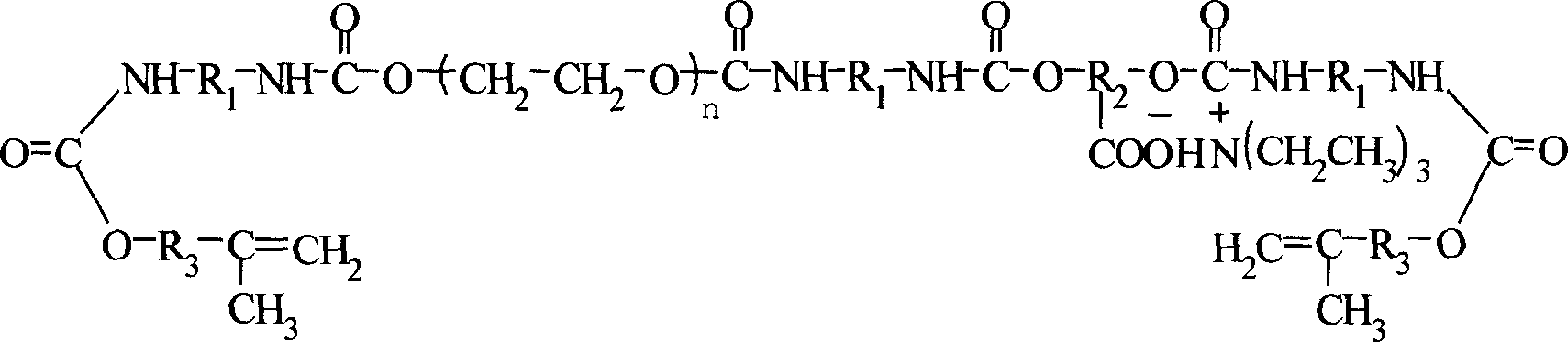

Method for preparing organosilicon/acrylate double modified aqueous polyurethane

The invention relates to a method for preparing organosilicon / acrylate double modified aqueous polyurethane, which comprises the following steps: carrying out a reaction on isocyanate, polyhydric alcohol and dimethylolpropionic acid to obtain polyurethane prepolymer I; dropwise adding dimethylolpropionic acid into the polyurethane prepolymer I, and dropwise adding hydroxyethyl methacrylate containing a polymerization inhibitor into the polyurethane prepolymer I, thereby obtaining polyurethane prepolymer II containing double bonds; dropwise adding organosilane into the polyurethane prepolymer II to obtain silane-modified polyurethane; adding triethylamine into the silane-modified polyurethane to carry out salification reaction, adding deionized water, and stirring to obtain organosilicon-modified aqueous polyurethane emulsion; and finally, adding methyl methacrylate and butyl acrylate into the organosilicon-modified aqueous polyurethane emulsion to carry out emulsion polymerization, thereby obtaining the organosilicon / acrylate double modified aqueous polyurethane. The method has the advantages of convenient operation and simple technique; and the prepared polyurethane chain segment contains silane and acrylate and has the advantages of favorable water resistance and mechanical properties.

Owner:QINGDAO UNIV OF SCI & TECH +1

Macromolecule material cold keeping agent making method

InactiveCN1570016ALow costUse low concentrationHeat-exchange elementsPolymer science(Hydroxyethyl)methacrylate

The invention discloses a macromolecule material cold keeping agent making method which consists of, preparing aqueous solution of polymers having strong hydrophilic radicals in the molecular structure, charging propenoic acid, hydroxyethyl methacrylate and maleic anhydride monomer, mixing homogeneously, charging bis-ethyl acrylate cross linking agent, agitating homogeneously, charging potassium peroxodisulfate initiating agent, mixing homogeneously, obtaining macromolecular material, dissolving into water of different mass.

Owner:TSINGHUA UNIV +2

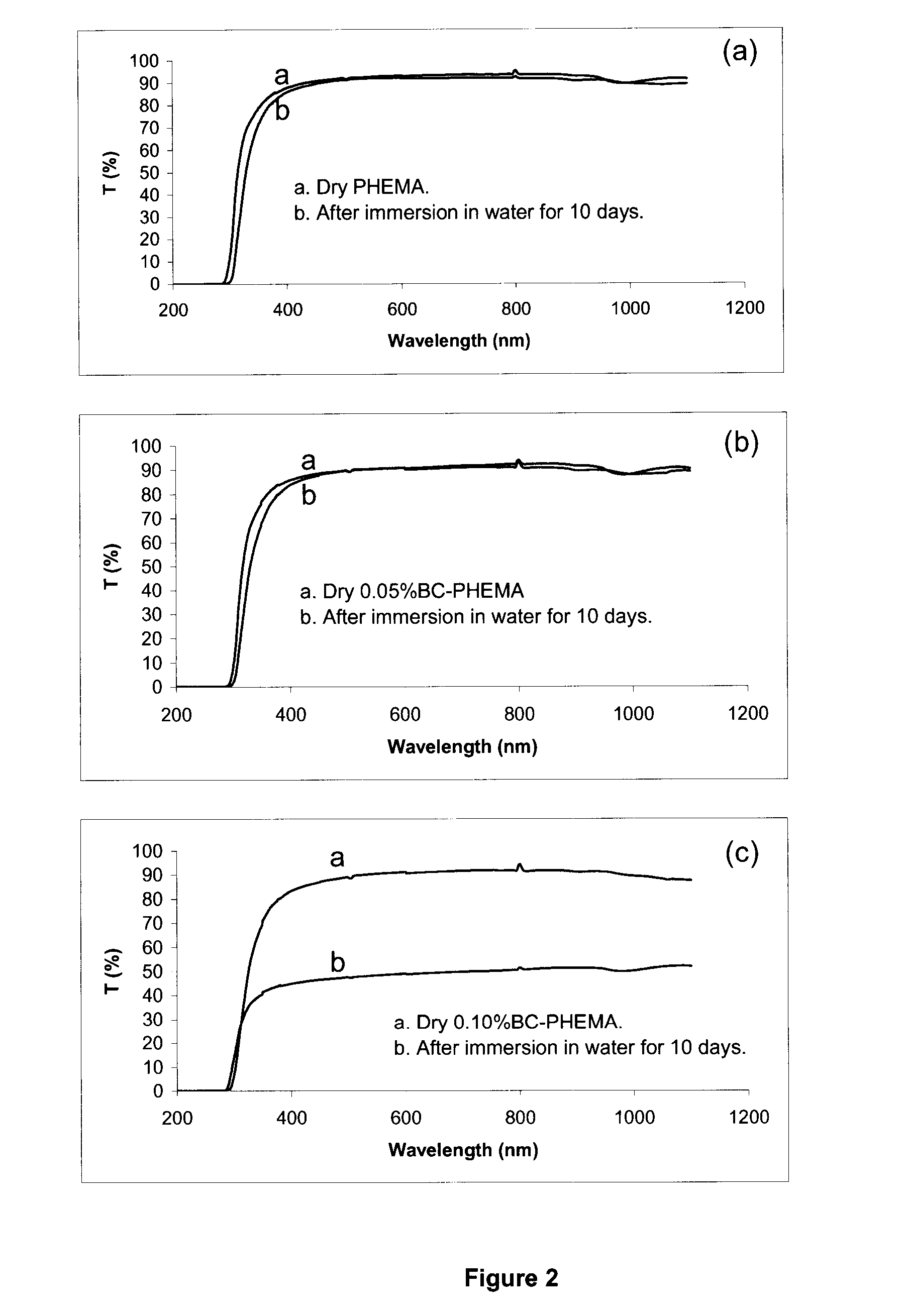

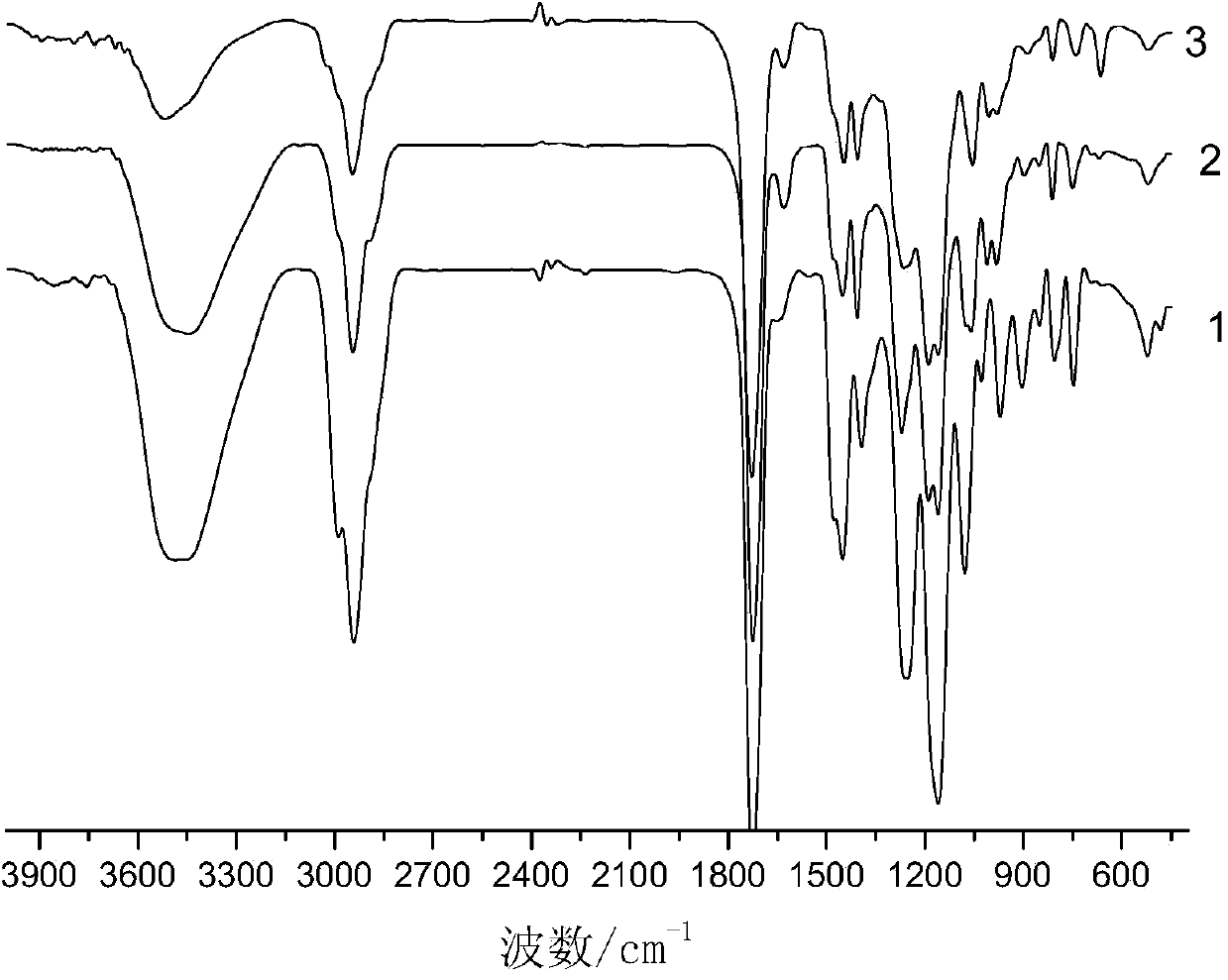

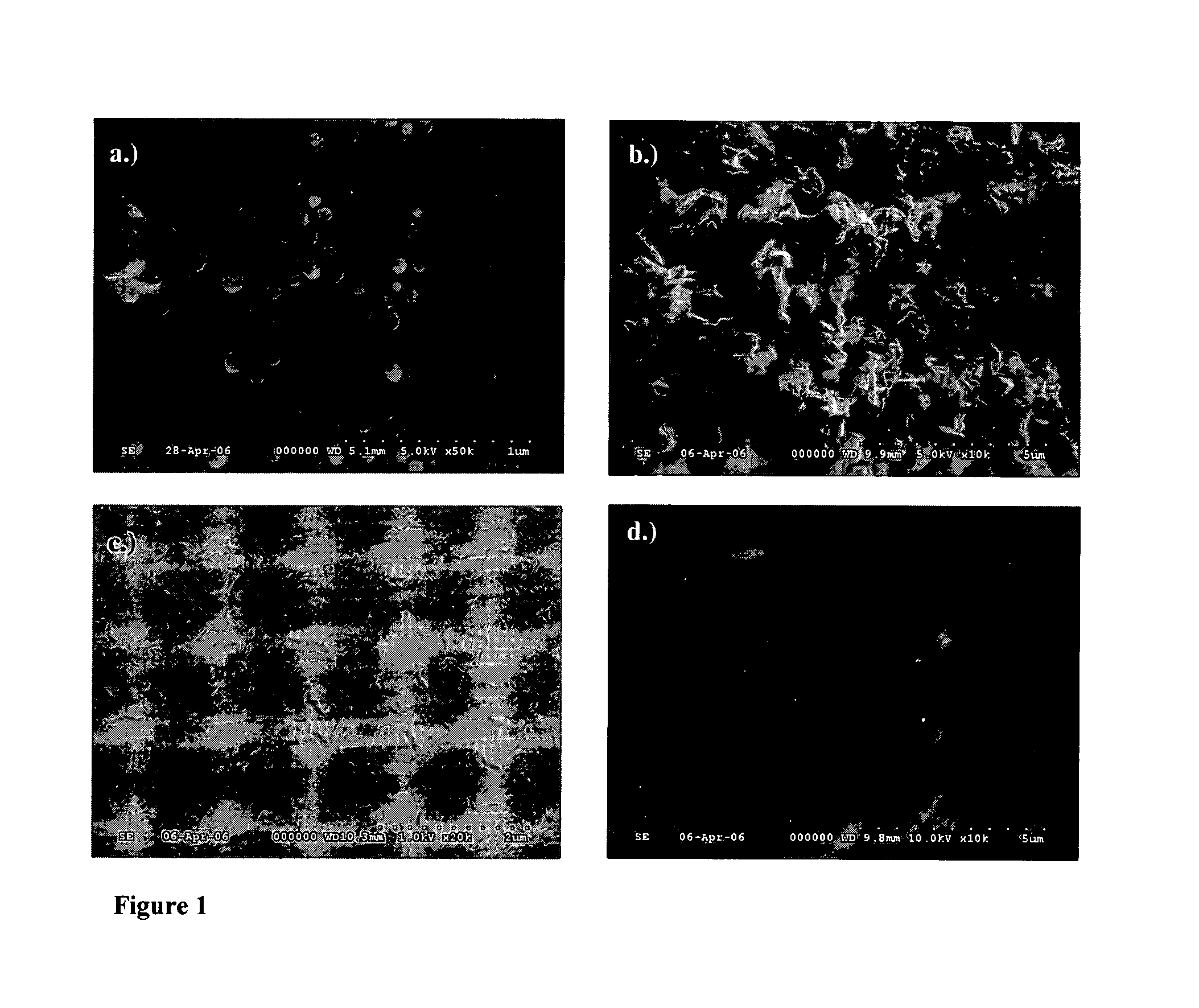

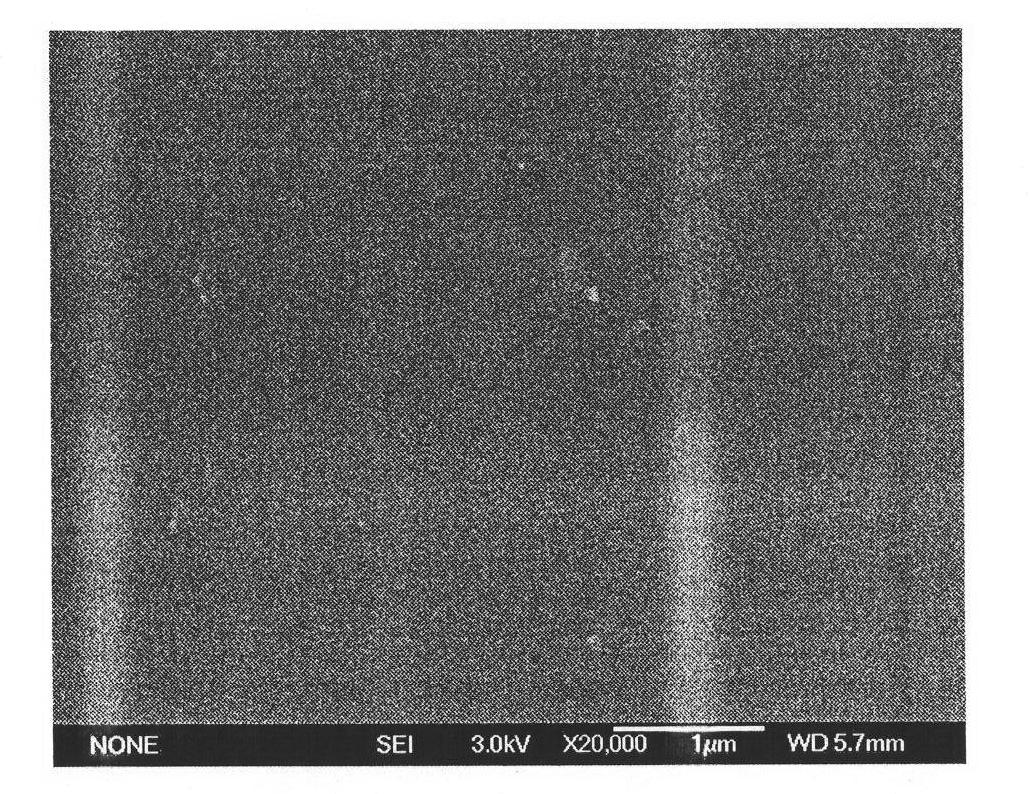

Transparent bacterial cellulose nanocomposite hydrogels

InactiveUS20130011385A1High mechanical strengthEnhanced interactionOrganic active ingredientsBiocidePolymer scienceWater insoluble

A transparent polymeric nanocomposite hydrogel is provided, wherein the polymeric nanocomposite hydrogel is made from a water insoluble polymer, i.e. poly(2-hydroxyethyl methacrylate) (PHEMA) or / and crosslinked PHEMA and a water insoluble nanofiber, i.e., bacterial cellulose (BC). Disclosed is a synthetic route for polymeric nanocomposites hydrogels. The preferred polymeric nanocompositions are produced through free radical polymerization of HEMA monomer in the presence of bacterial cellulose with an assistance of ultrasound to enhance the mixing of bacterial cellulose, initiator, and the monomers. The polymeric nanocomposite hydrogel is then formed by immersion of the dry polymeric nanocomposite in water. Disclosed is a high transmittance polymer nanocomposite hydrogel with a preferred BC loading less than 0.1%, water content of about 40% in weight, good mechanical integrity and strength. The disclosed polymer nanocomposite hydrogel and compositions pertain to hydrogel applications, particularly contact lenses and optic components for biosensor.

Owner:AXCELON BIOPOLYMERS COPRORATION

Preparation method of high temperature and yellowing resistant alkali-soluble epoxy acrylate UV resin

InactiveCN104086701AHigh glass transition temperatureImprove heat resistanceInksCoatingsGlycidyl methacrylate(Hydroxyethyl)methacrylate

The invention discloses a preparation method of a high temperature and yellowing resistant alkali-soluble epoxy acrylate UV resin. The preparation method comprises the following steps: carrying out free radical polymerization on an alicyclic epoxy acrylate monomer, glycidyl methacrylate, and hydroxyethyl methacrylate or hydroxypropyl methacrylate to prepare an alicyclic epoxy acrylate copolymer; reacting acrylic acid with an epoxy group in the above epoxy acrylate resin, and introducing a double bond to make the resin have photosensitive activity; and reacting acid anhydride with a hydroxy group, and introducing a carboxyl group to make the resin alkali-soluble in order to prepare the high temperature and yellowing resistant alkali-soluble epoxy acrylate UV resin with a carboxyl group. The glass transition temperature of the resin finally obtained in the invention is 65-100DEG C, and the finally obtained resin has the characteristics of good high temperature resistance, yellowing resistance, acid and alkali resistance of a curable film, solvent resistance, excellent mechanical performances and the like, and can be widely applied in yellowing resistant optical imaging solder resistant inks, photoresist, yellowing resistant UV inks and coatings, adhesion promoters, ink crosslinking agents and the like.

Owner:SOUTH CHINA UNIV OF TECH +1

Radiation-proof light-filtering contact lens and production method thereof

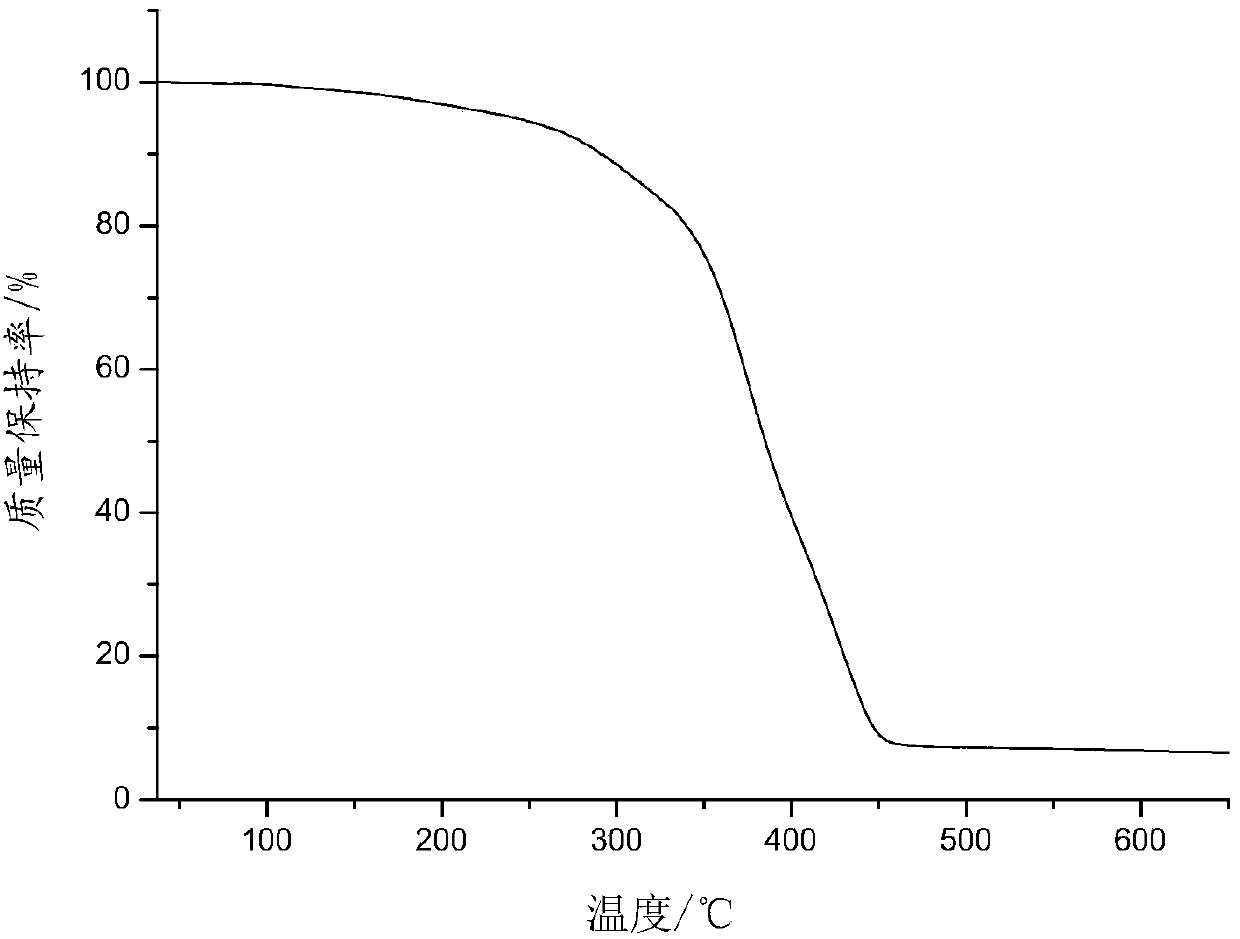

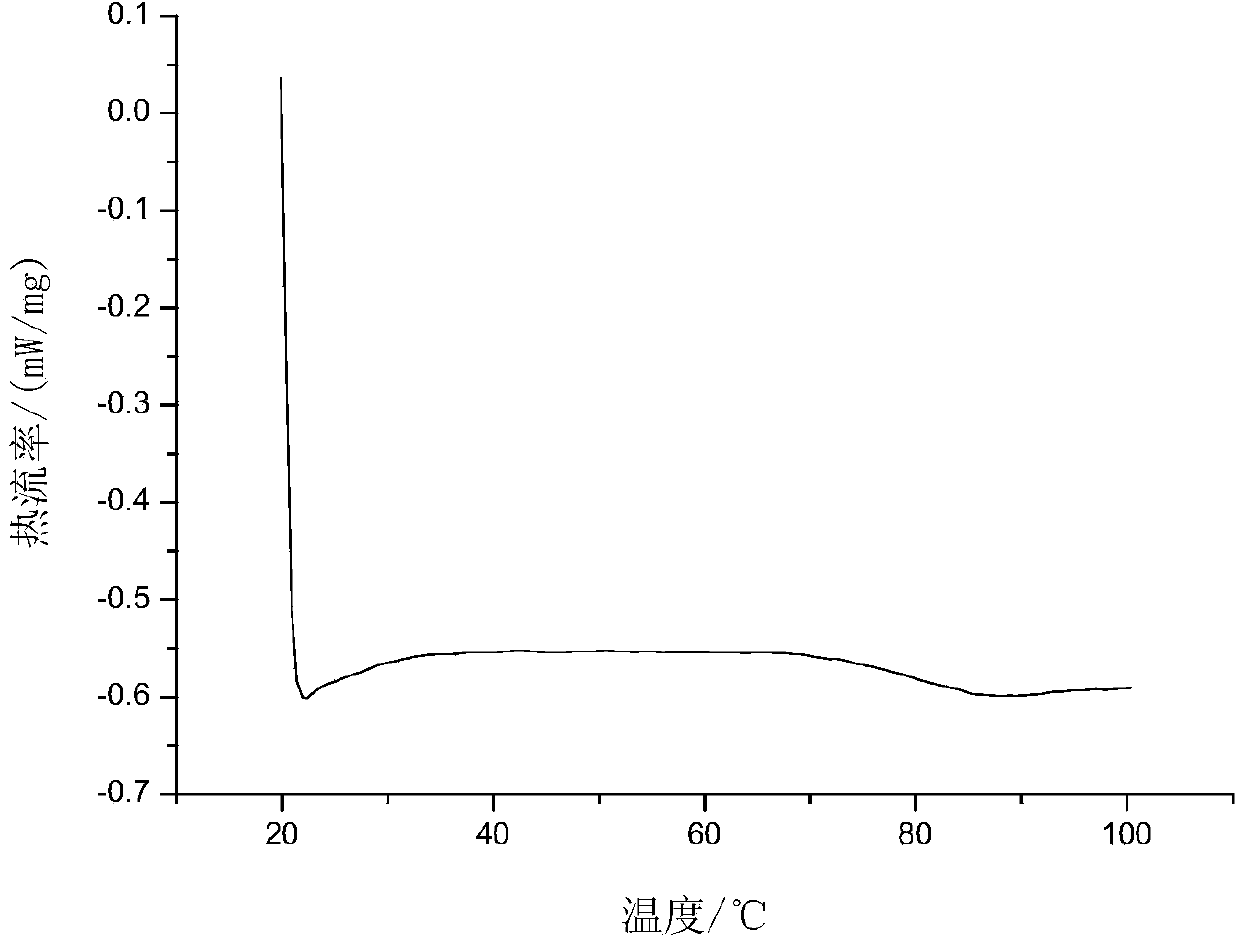

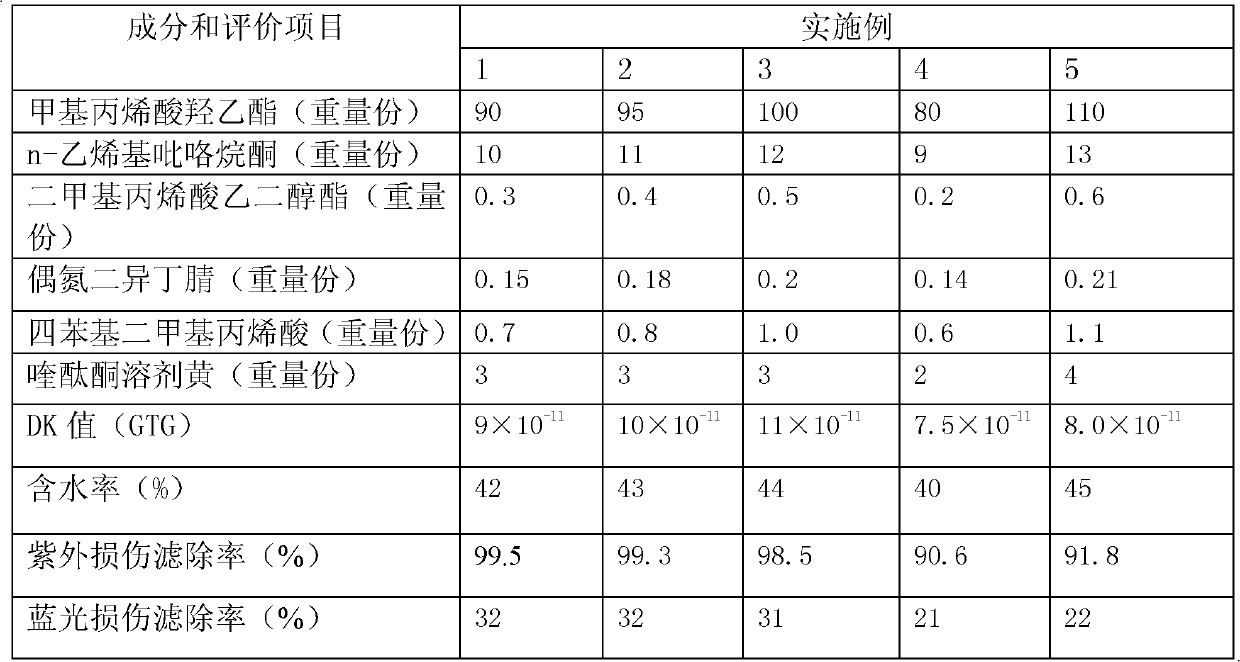

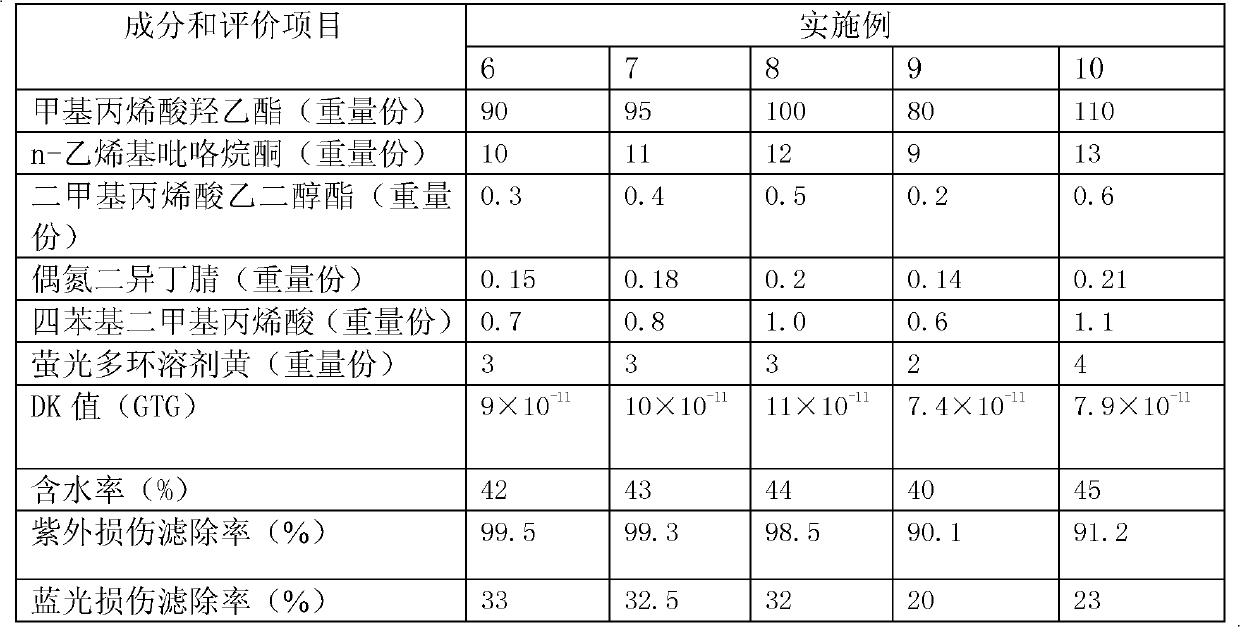

ActiveCN102382237AGood oxygen transmission coefficientIncrease moisture contentOptical articlesOptical parts(Hydroxyethyl)methacrylateUltraviolet

A radiation-proof light-filtering contact lens is characterized in that the weight ratio of each component of liquid material is as follows: 90 to 100 parts of hydroxyethyl methacrylate; 10 to 12 parts of ethenyl pyrrolidinone; 0.3 to 0.5 part of 2-propenoic acid, oxybis(2,1-ethanediyloxy-2,1-ethanediyl)ester; acrylic acid, diester with tetraethylene glycol; 0.15 to 0.2 part of 2,2'-dicyano-2,2'-azopropane azobisisbutyronitrile; 0.7 to 1 part of 4-[(E)-phenyldiazenyl]phenyl-2-methacrylate; and 3 parts of yellow pigment and dye for contact lenses. The contact lens has a good oxygen permeation coefficient, high moisture content, moderate hardness and fewer residues, and also has a good ultraviolet radiation protection effect and a good filtering effect on purple light and blue light.

Owner:北京自然美光学有限公司

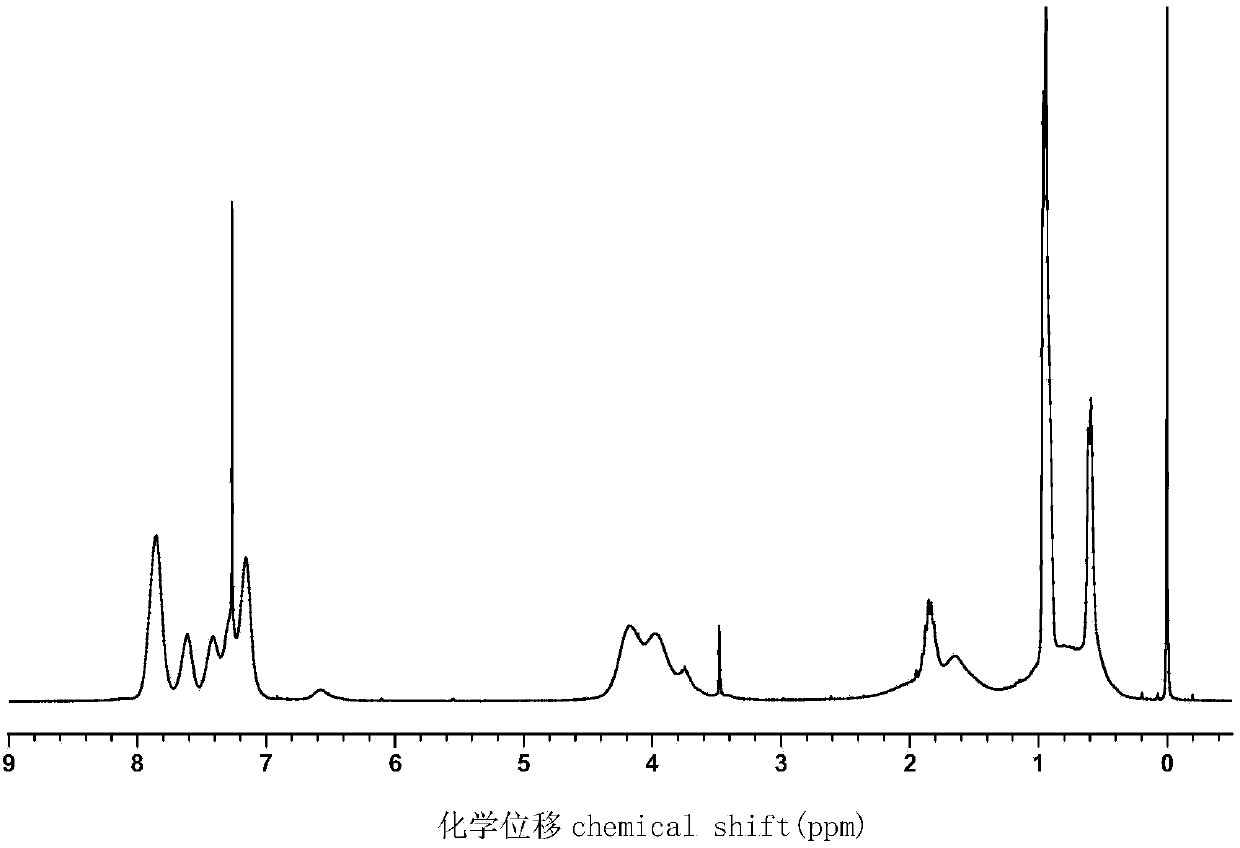

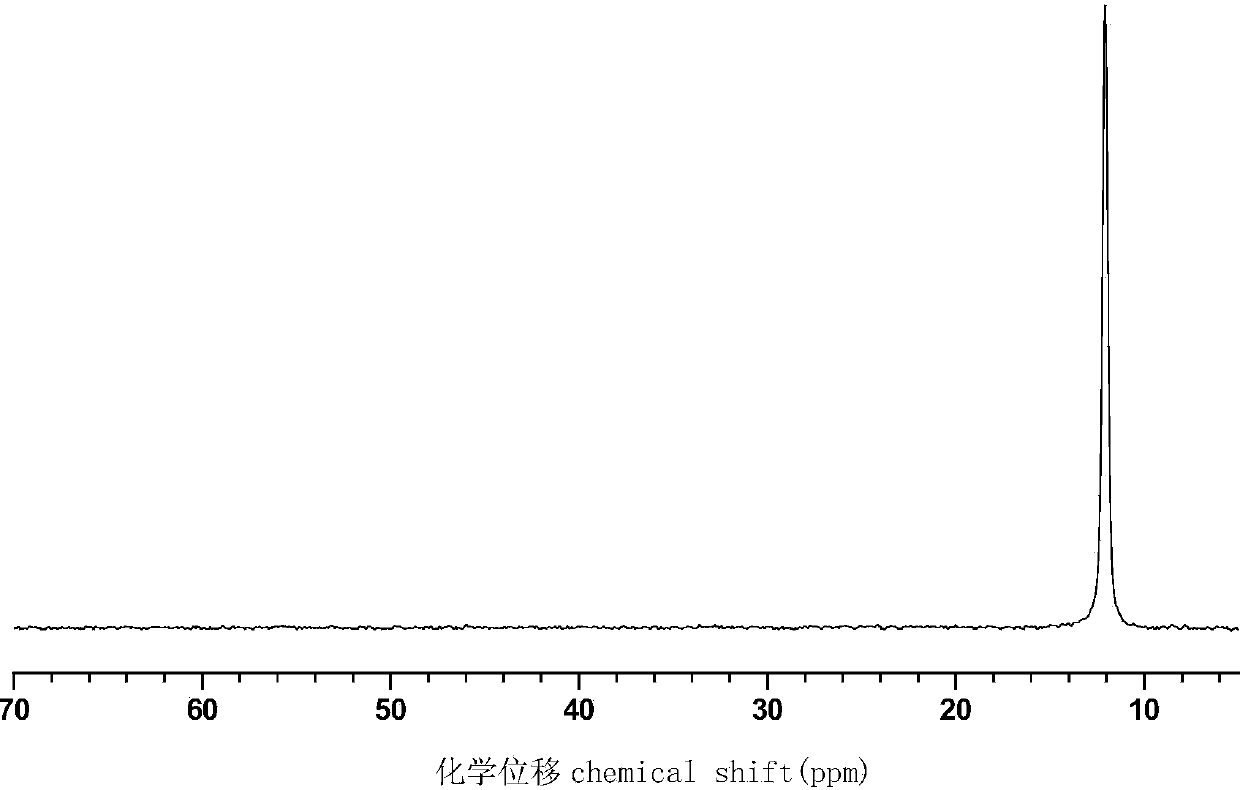

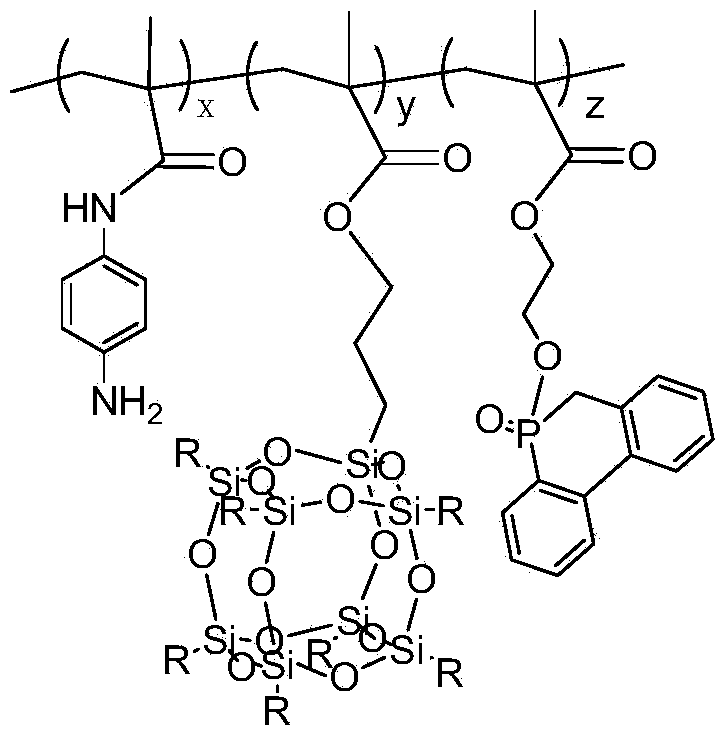

Phosphorus/silicon-containing reactive high-molecular flame retardant, and preparation method and application thereof

The invention provides a phosphorus / silicon-containing reactive high-molecular flame retardant, and a preparation method and application thereof, relating to flame retardants. The preparation method comprises the following steps: reacting methacryloyl chloride and p-phenylenediamine in the presence of a solvent and an acid-binding agent, carrying out vacuum filtration to remove the acid-binding agent salt generated by the reaction, and purifying the crude product by water washing, rotary evaporation and drying to obtain 4-methacrylamidoaniline; reacting hydroxyethyl methacrylate and 9,10-dihydro-9-oxa-10-phosphaphenanthryl-10-oxide in the presence of carbon tetrachloride, a solvent and an acid-binding agent, carrying out vacuum filtration to remove the acid-binding agent salt generated by the reaction, and purifying the crude product by water washing, rotary evaporation and drying to obtain a phosphorus-containing monomer; and carrying out free-radical polymerization on the 4-methacrylamidoaniline, phosphorus-containing monomer and methylacryloyloxypropyl heptaisobutyl POSS (polyhedral oligomeric silsesquioxane) under the initiation conditions of a solvent and an initiator to obtain the phosphorus / silicon-containing reactive high-molecular flame retardant. The phosphorus / silicon-containing reactive high-molecular flame retardant can be used for preparing a flame-retardant epoxy resin.

Owner:XIAMEN UNIV

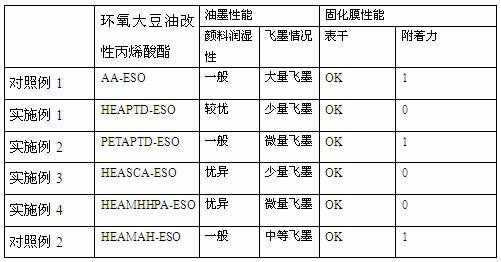

Acrylic acid ester modified epoxy soybean oil, its preparation method and application thereof

ActiveCN102660387ANovel structureImprove adhesionOrganic chemistryFatty acid chemical modificationPolymer scienceMeth-

The invention discloses an acrylic acid ester modified epoxy soybean oil, its preparation method and an application thereof. According to the preparation method of the acrylic acid ester modified epoxy soybean oil, acrylate monomer bearing a hydroxyl group reacts with acid anhydride to obtain a half-ester intermediate, and the half-ester intermediate reacts with epoxy soybean oil to obtain the acrylic acid ester modified epoxy soybean oil. The acrylate monomer bearing a hydroxyl group is hydroxyethyl acrylate, hydroxyethyl methacrylate, pentaerythritol triarylate, hydroxypropyl acrylate, hydroxypropyl methacrylate, trimethylol propane diacrylate or trimethylol propane dimethacrylate. Acid anhydride is o phthalic anhydride, succinic anhydride, methyl hexahydrophthalicanhydride, hexahydrophthalic anhydride or tetrahydrophthalic anhydride. The acrylic acid ester modified epoxy soybean oil has a novel structure. When applied in paper printing ink, the acrylic acid ester modified epoxy soybean oil can improve adhesive force of a cured film and also can improve wetability of pigments and remarkably minimize occurrence of misting. The preparation method helps widen the application range of the modified epoxy soybean oil.

Owner:GUANGDONG BOSSIN NOVEL MATERIALS TECH CO LTD

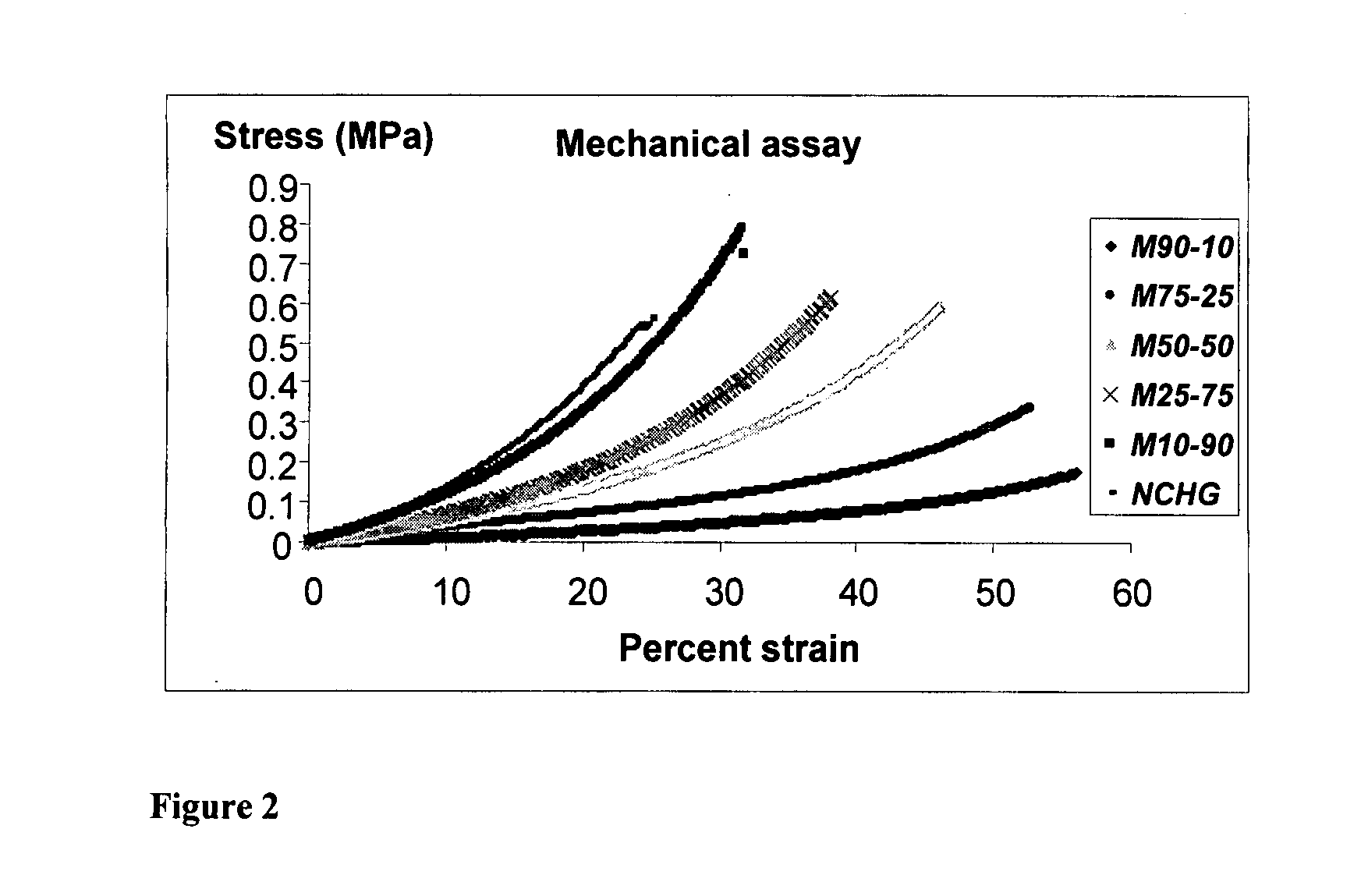

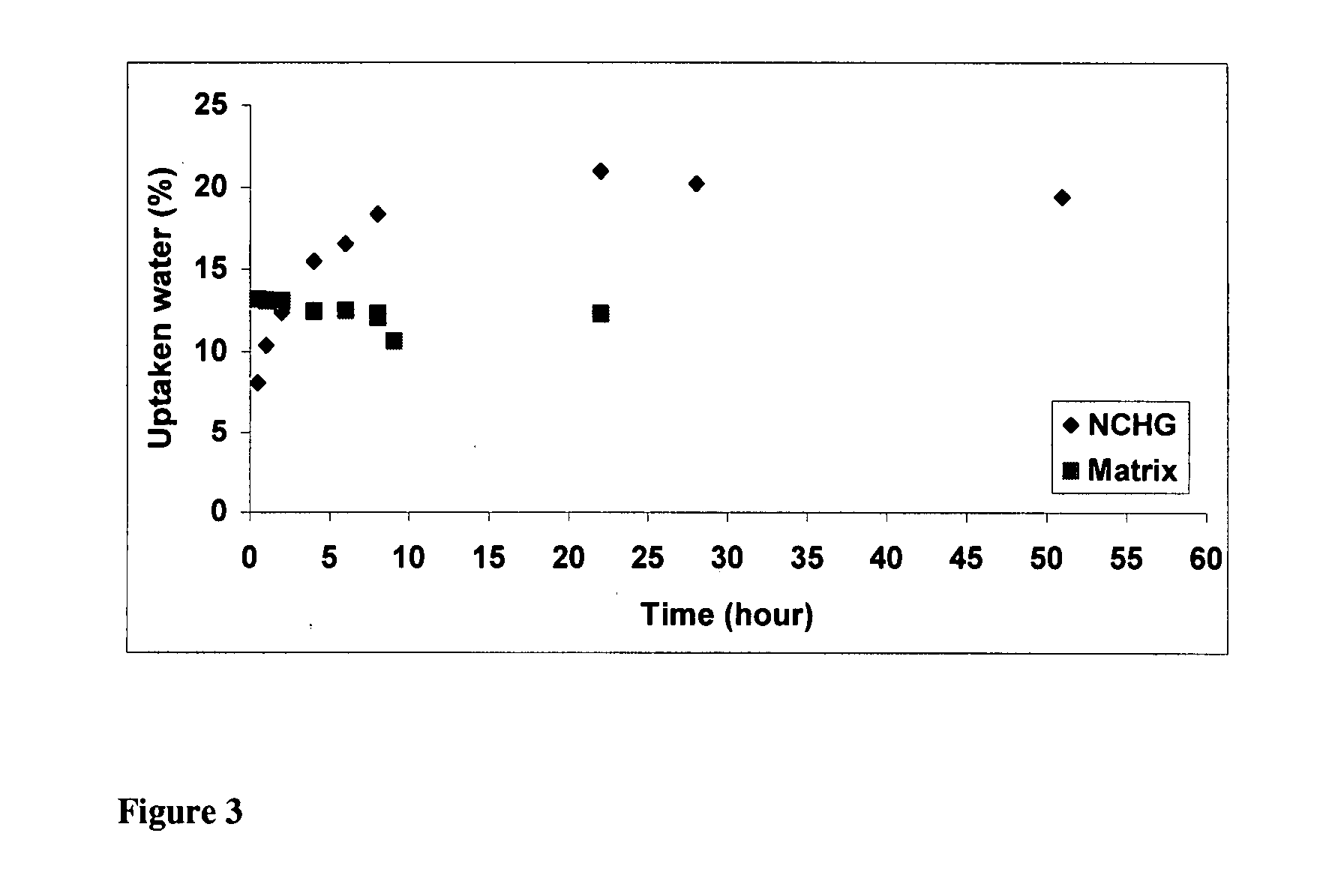

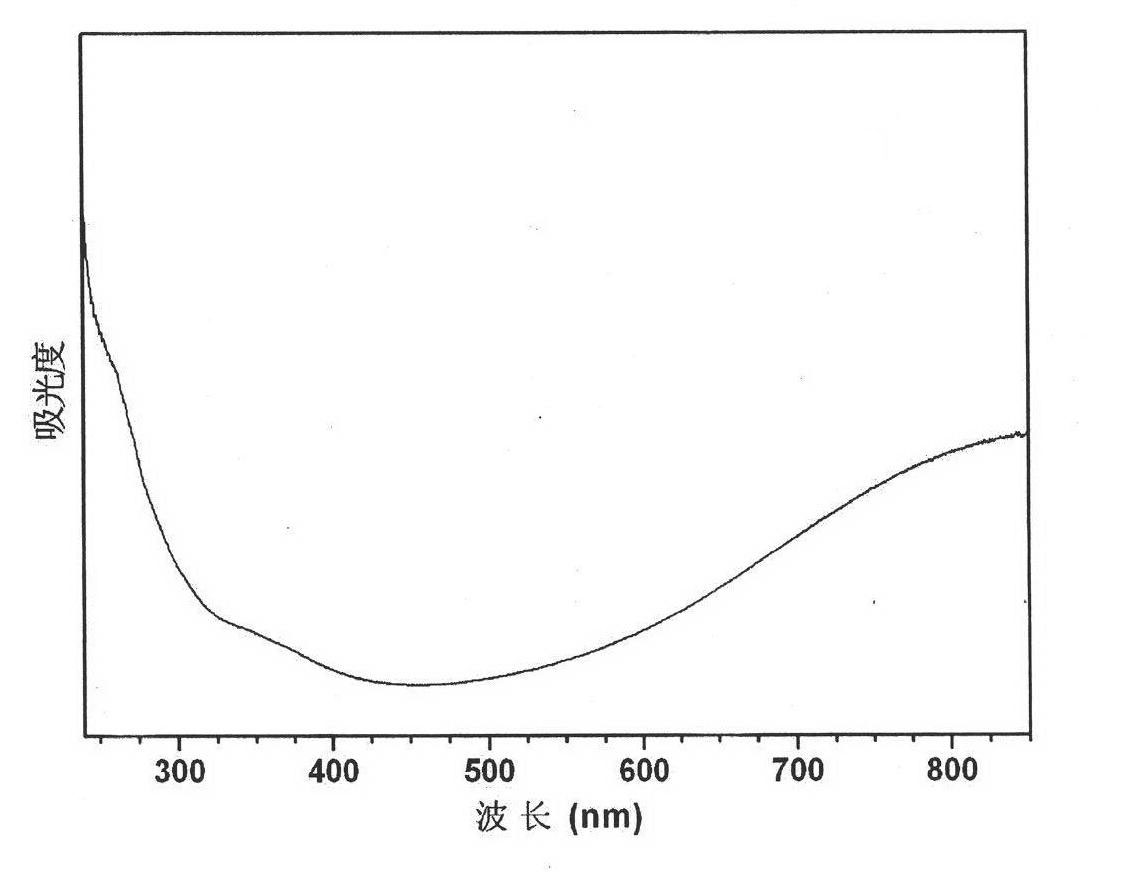

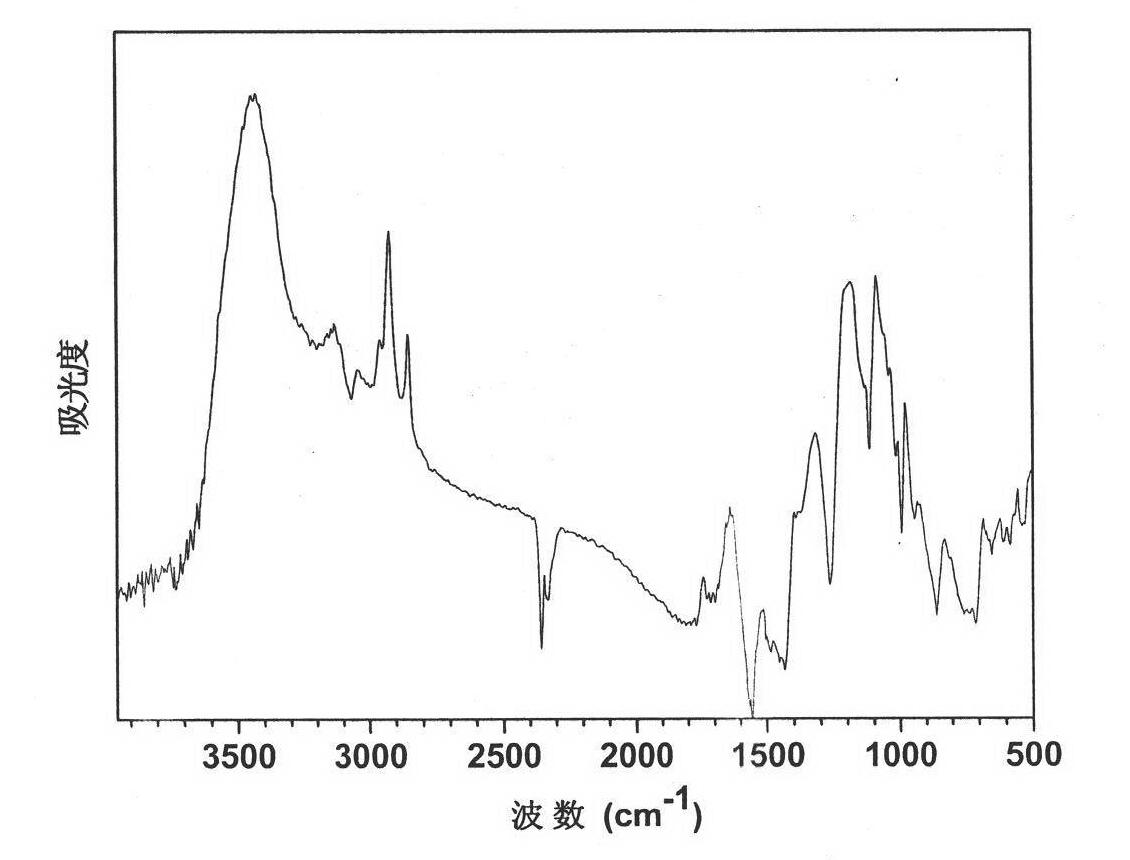

Synthesis of biocompatible nanocomposite hydrogels as a local drug delivery system

InactiveUS20070212419A1Slow drug releaseHigh compressive strengthOrganic active ingredientsBiocide(Hydroxyethyl)methacrylateModel system

Nanocomposite biocompatible hydrogels (NCHGs) may be synthesised as model systems for in situ cured local drug delivery devices for treatment of inter alia periodontal infections. The composite includes the following components: nanoparticles (NPs), a matrix gel, and chlorhexidine (CHX) or other antibacterial drug. The NPs were obtained by free radical initiated copolymerization of the monomers, 2-hydroxyethyl methacrylate (HEMA) and polyethyleneglycol dimethacrylate (PEGDMA), in aqueous solution. The same monomers were used to prepare crosslinked matrices by photopolymerization. NCHGs were obtained by mixing NPs, monomers, and drug in an aqueous solution then crosslinked by photopolymerization.

Owner:BAKO JOZSEF +6

UV-LED (ultraviolet-light emitting diode) photocureable coating and preparation method thereof

ActiveCN103980812AOxidizingImprove curing effectPolyurea/polyurethane coatings(Hydroxyethyl)methacrylateFunctional monomer

The invention discloses a UV-LED (ultraviolet-light emitting diode) photocureable coating and a preparation method thereof. The photocureable coating is characterized by consisting of the following components in percentage by mass: 20-30% of high-functionality fatty acid polyurethane acrylate oligomer 6197, 10-20% of two-functionality polyurethane acrylate 6071, 10-20% of TMPTA (trimethylolpropane triacrylate) serving as a three-functionality functional monomer and an active diluent, 0.1-0.3% of foam inhibitor TEGO920, 10-20% of NPGDA (neopentyl glycol diacrylate) serving as a two-functionality functional monomer and an active diluent, 10-20% of HEMA (hydroxyethyl methacrylate) serving as a single-functionality functional monomer and an active diluent, 0.2-0.5% of flatting agent BYK358N, and 5-10% of HABI-L (hexaarylbiimidazole-L) serving as a photo-initiator. The photocureable coating has the advantages of quick curing, energy conservation, environmental friendliness and the like, and the production efficiency of UV-LED photocuring is promoted.

Owner:SHANGHAI ZHENGOU IND

Polymer-type water glass curing agent and application in water glass chemical grouting materials

InactiveCN101885591AResolution timeSolve the strength problemOther chemical processesBuilding constructionsSolubility(Hydroxyethyl)methacrylate

The invention relates to a polymer-type water glass curing agent with easily-controlled curing time and high toughness. The curing agent is mainly formed by polymerizing and copolymerizing double bonds-containing acids such as crylic acid, methacrylic acid and the like and double bonds-containing esters such as butyl methacrylate, vinyl acetate, hydroxy-ethyl methacrylate and the like by latex. The polymer-type water glass curing agent of the invention is a novel water-soluble water glass curing agent, which can control the curing time of the water-soluble grouting materials by controlling the content of carboxyl and ester group in a polymer. By using the curing agent, a water glass consolidating body has vey high compressive strength and toughness, synthetically overcomes the shortages of too fast curing time, high corrosiveness, low consolidating body strength and the like of an acid curing agent which is commonly used in the water glass grouting materials and the shortages of poor water solubility, slow curing time and the like of an organic ester curing agent, and can be widely applied in the field of anti-seepage stoppage engineering.

Owner:GUANGZHOU CHEM GROUTING CO LTD CAS

Nanometer SiO2 modifying process of ultraviolet ray cured adhesive

InactiveCN1887972AGood compatibilityGood dispersionNon-macromolecular adhesive additivesPigment treatment with organosilicon compounds(Hydroxyethyl)methacrylateAdhesive

The present invention discloses nanometer SiO2 modifying process of UV ray cured adhesive. The long chain polyether silane coupler in the general expression of (R1O)3SiCH2CH2CH2O(CH2CH2O)a(CH2CH(CH3)O)bC=OC(R2)=CH2 is first used in surface modifying SiO2 of grain size of 5-50 nm inside isopropyl alcohol dispersing medium; the obtained composite pre-polymer is then mixed with epoxy acrylate, hydroxyethyl methacrylate or hydroxypropyl methacrylate, trimethylopropane-3ethoxyl -triacrylic ester, acrylic cid or acrylate with acid functional radical, photoiniitator, KH570, triethanolamine and maleic acid through stirring to obtain the UV adhesive product. The present invention has improved SiO2 dispersivity and stability, and the UV adhesive product has greatly raised adhesion performance.

Owner:ZHEJIANG UNIV +1

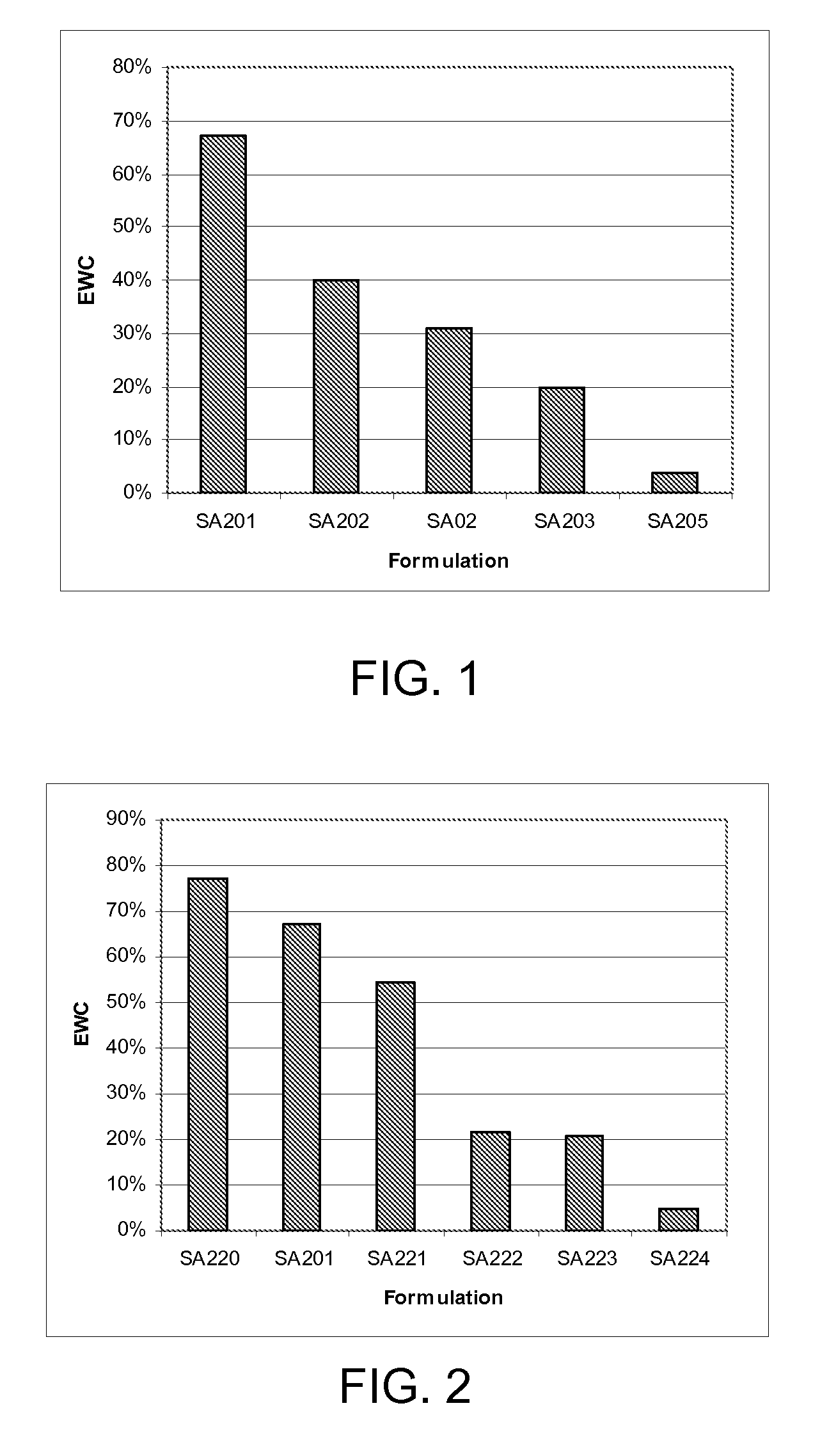

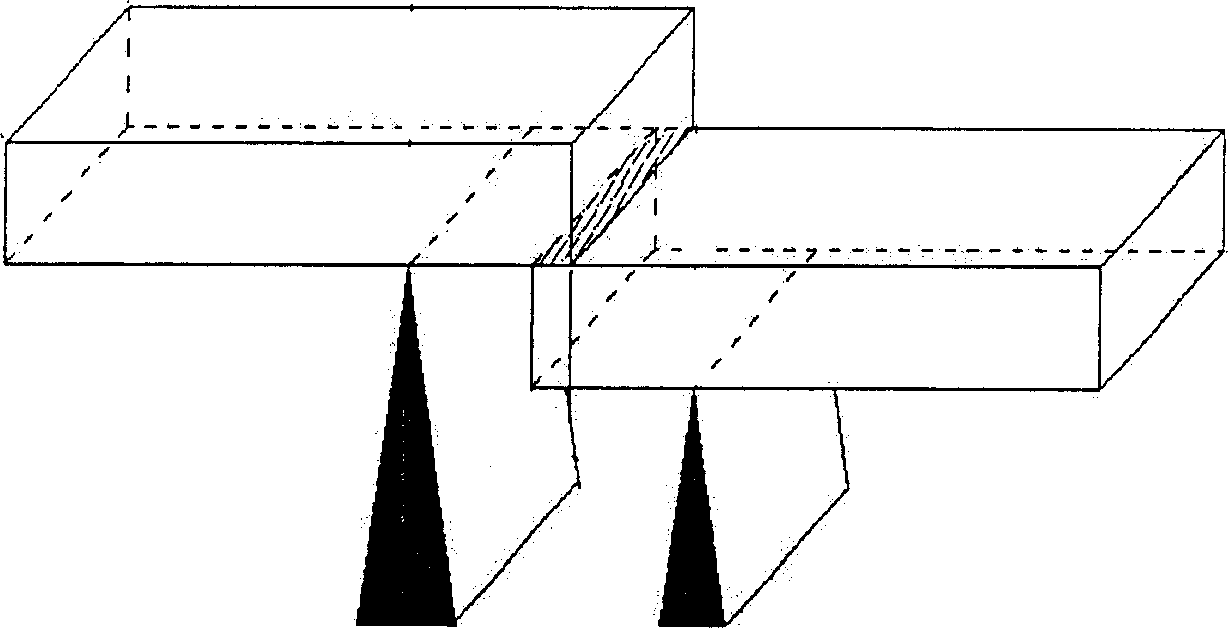

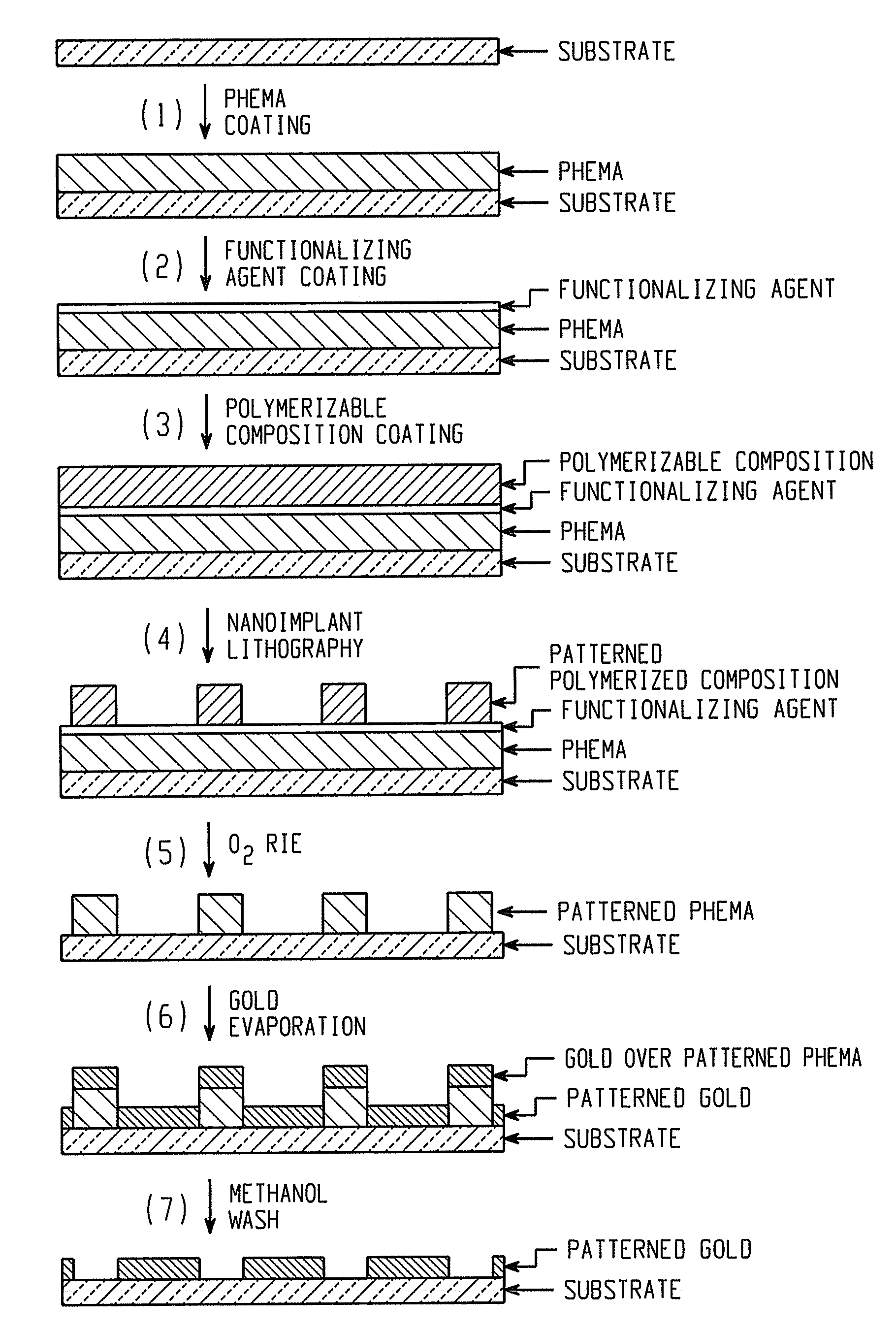

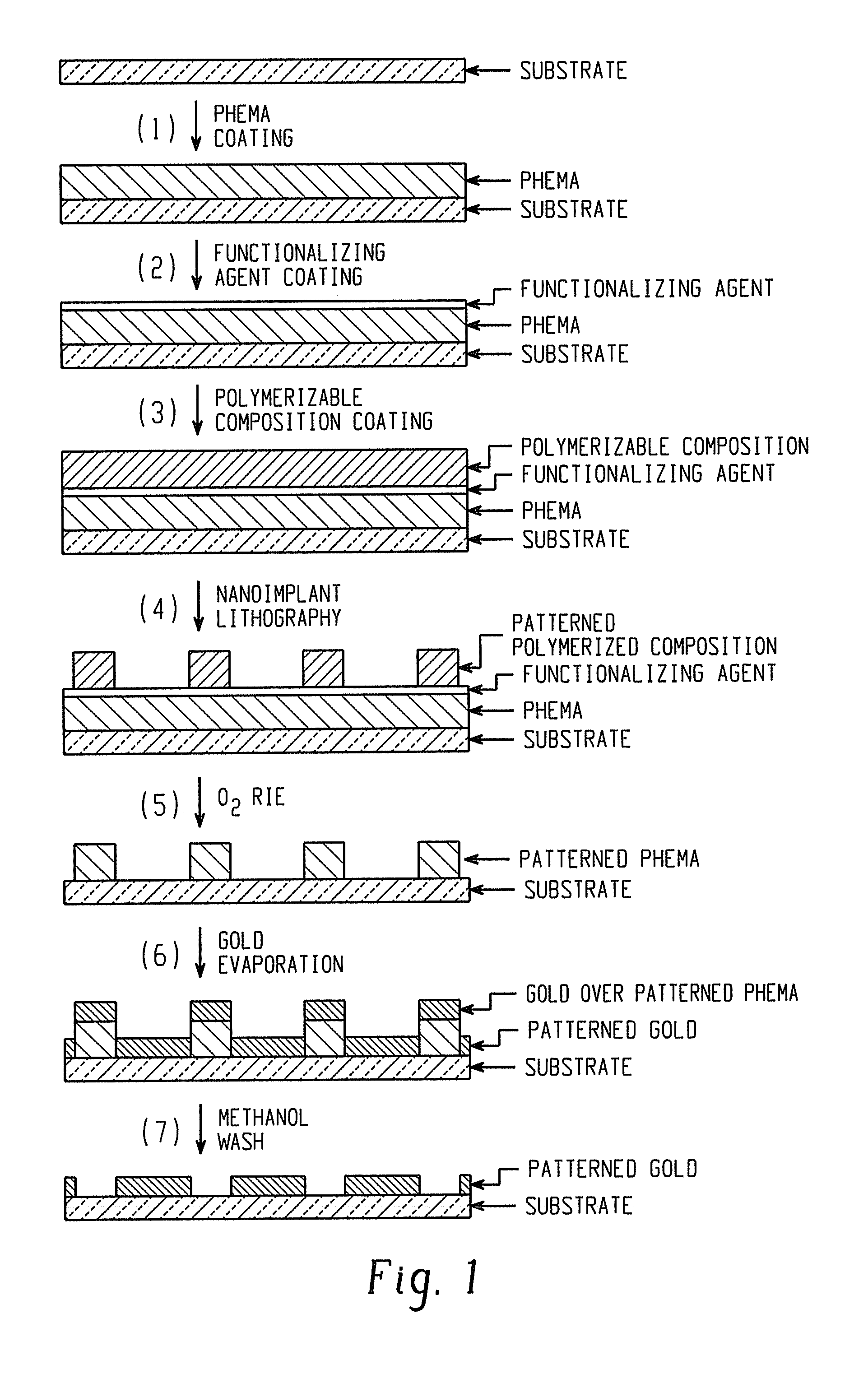

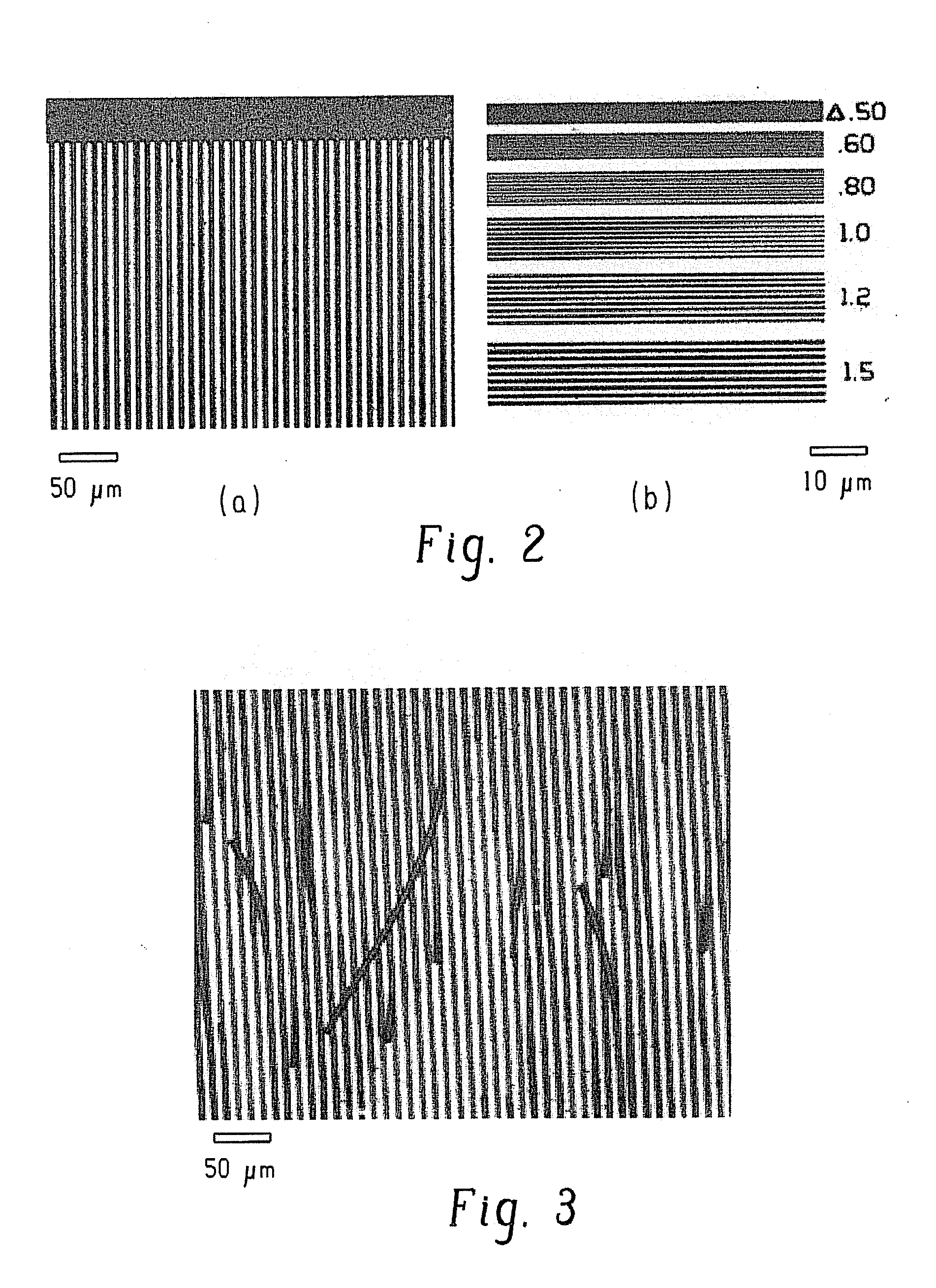

Article with phema lift-off layer and method therefor

A method of forming a patterned functional layer on a substrate using a poly(hydroxyethyl methacrylate) lift-off layer is described. The method can be used with substrates that would not tolerate the organic solvents required for processing of known poly(methyl methacrylate) lift-off layers. When used in combination with known nanoimprint lithography and step-and-flash imprint lithography techniques, the method can be used to generate patterned functional structures with dimensions as small as five nanometers.

Owner:UNIV OF MASSACHUSETTS

Water-soluble poly(3,4-ethylenedioxythiophene) and preparation method for conductive coating thereof

InactiveCN101845136AImprove conductivityElectrically-conductive paintsWater basedPotassium persulfate

The invention provides water-soluble poly(3,4-ethylenedioxythiophene) and a preparation method for a conductive coating thereof. The method comprises the following steps of: adding 3,4-ethylenedioxythiophene and an oxidant into the aqueous solution of the copolymer of sodium styrene sulfonate and an allyl monomer, regulating a pH value to be 1 to 5 by using a sulfuric acid, and polymerizing the mixture at the room temperature for 16 to 72h to obtain the water-soluble poly(3,4-ethylenedioxythiophene), wherein the oxidant may be ammonium persulfate, potassium persulfate or sodium persulfate; and the allyl monomer may be an acrylic monomer, a methacrylates monomer, hydroxyethyl acrylate , hydroxyethyl methacrylate, polyethylene glycol methacrylate or styrene. The electrical conductivity of the prepared water-soluble poly(3,4-ethylenedioxythiophene) is higher than that of the poly(3,4-ethylenedioxythiophene) generally using a polystyrene sulfonate acid as a dopant. The conductive coating is obtained by mixing the prepared water-soluble poly(3,4-ethylenedioxythiophene) and other water-based emulsion coatings or water-soluble polymers, and has the characteristics of high transparency and high electrical conductivity.

Owner:BEIJING UNIV OF CHEM TECH

Emulsion for bi-component wood bonding adhesive and synthesis method thereof

ActiveCN103709971AImprove water resistanceImprove conversion rateNon-macromolecular adhesive additivesGraft polymer adhesives(Hydroxyethyl)methacrylateFunctional monomer

The invention discloses an emulsion for a bi-component wood bonding adhesive and a synthesis method thereof. The emulsion for a bi-component wood bonding adhesive comprises: 11-15 parts by weight of polyvinyl alcohol, 1.5-2.0 parts by weight of an emulsifier, 0.3-0.5 part by weight of a buffering agent, 135-145 parts by weight of vinyl acetate, 8-14 parts by weight of vinyl ester of versatic acid, 5-8 parts by weight of hydroxyethyl methylacrylate, 2.0-3.5 parts by weight of a functional monomer, 1.5-2.5 parts by weight of methacrylic acid, 5-10 parts by weight of a plasticizer, 0.5-1 part by weight of a preservative, 0.4-0.6 part by weight of an initiator, and 185-205 parts by weight of water. The emulsion for the bi-component wood bonding adhesive takes water as a dispersion medium, is convenient to use, and has no pollution to the environment. After compounding, a polyisocyanate curing agent is added to form the bi-component wood bonding adhesive, which has no pollution to bonded materials, and has the characteristics of room temperature curing, high bonding strength, and good resistance to water, heat and aging.

Owner:顶立新材料科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com