Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

96 results about "TMPTA" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

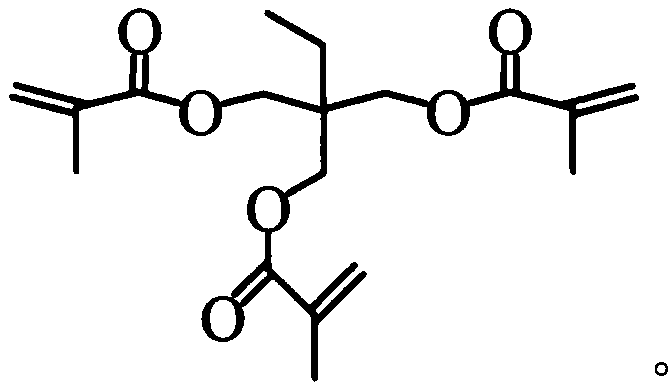

Trimethylolpropane triacrylate (TMPTA) is a trifunctional monomer used in the manufacture of plastics, adhesives, acrylic glue, anaerobic sealants, and ink. It is useful for its low volatility and fast cure response. It has the property of resistance against weather, chemical, water and abrasion. End products include alkyd coatings, compact discs, hardwood floors, concrete polymers, dental polymers, lithography, letterpress, screen printing, elastomers, automobile headlamps, acrylics and plastic components for the medical industry.

UV curing antibiotic coating and preparation thereof

InactiveCN101353545AImprove antibacterial propertiesSimple preparation processAntifouling/underwater paintsPaints with biocidesUV curingTMPTA

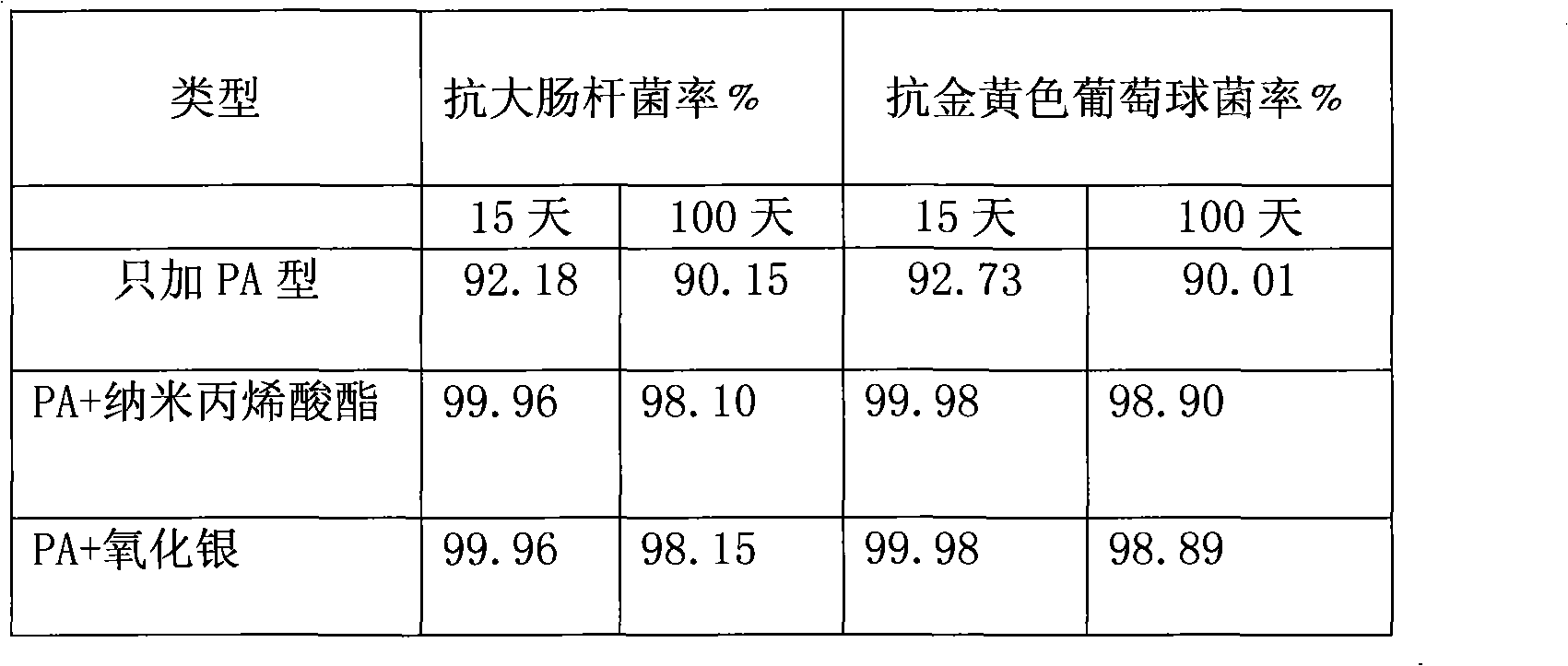

The invention discloses a UV-curable antimicrobial coating, the components of which are as follows: bisphenol A type epoxy acrylate EA; aliphatic PUA; special functional group acrylate PA; TPGDA; TMPTA; photoinitiators; nano acrylate; oxidized silver; and auxiliaries. The preparation method comprises the following steps of: step one, synthesizing special functional group heterocyclic compound PA and later adding phosphorus pentoxide to acrylic acid hydroxy esters so as to react with hydroxyl piperidine and then prepare special functional group heterocyclic compound PA; and step two, taking each component according to the formula, stirring and mixing each component so as to carry out dispersion at the speed of 900 to 1200r per min, then adding silver oxide and photoinitiators after being dispersed evenly, and finally obtaining UV-curable antimicrobial coating through dispersion. The UV-curable antimicrobial coating prepared by the invention has good anti-bacterial effect. As the self-prepared special functional group acrylate PA, the nano acrylate and the silver oxide are added, after UV-curable film-forming, the anti-coli rate can achieve over 99 percent and the anti-staphylococcal rate thereof achieves over 99 percent, and the effectiveness is long.

Owner:苏州市明大高分子科技材料有限公司

UV-LED (ultraviolet-light emitting diode) photocureable coating and preparation method thereof

ActiveCN103980812AOxidizingImprove curing effectPolyurea/polyurethane coatings(Hydroxyethyl)methacrylateFunctional monomer

The invention discloses a UV-LED (ultraviolet-light emitting diode) photocureable coating and a preparation method thereof. The photocureable coating is characterized by consisting of the following components in percentage by mass: 20-30% of high-functionality fatty acid polyurethane acrylate oligomer 6197, 10-20% of two-functionality polyurethane acrylate 6071, 10-20% of TMPTA (trimethylolpropane triacrylate) serving as a three-functionality functional monomer and an active diluent, 0.1-0.3% of foam inhibitor TEGO920, 10-20% of NPGDA (neopentyl glycol diacrylate) serving as a two-functionality functional monomer and an active diluent, 10-20% of HEMA (hydroxyethyl methacrylate) serving as a single-functionality functional monomer and an active diluent, 0.2-0.5% of flatting agent BYK358N, and 5-10% of HABI-L (hexaarylbiimidazole-L) serving as a photo-initiator. The photocureable coating has the advantages of quick curing, energy conservation, environmental friendliness and the like, and the production efficiency of UV-LED photocuring is promoted.

Owner:SHANGHAI ZHENGOU IND

Ultraviolet (UV) offset tin printing ink and method for preparing same

The invention relates to the technical field of ink, and in particular relates to an ultraviolet (UV) offset tin printing ink and a method for preparing the same. The UV offset tin printing ink consists of the following raw materials in parts by weight: 28-38 parts of urethane acrylate, 20-30 parts of polyester acrylate, 2-10 parts of 2-propenoic acid, 1, 1'-[(1-methyl-1, 2-ethanediyl) bis [oxy(methyl-2, 1-ethanediyl)]] ester (TPGDA), 5-12 parts of trimethyl propane triacrylate (TMPTA), 1-9 parts of hexanediol diacrylate (HDDA), 14-22 parts of pigment powder, 1-3 parts of dispersing agent, 0.2-1.2 parts of organic silicon defoamer, 1-4 parts of organic silicon flatting agent, 1-3 parts of photoinitiator and 0.2-1.5 parts of adhesion promoter. The UV offset tin printing ink has low adhesiveness, improved fluidity, good ink flexibility, good transfer printing performance and good adaptability to metal product printing.

Owner:东莞市佳烨化工科技有限公司

UV curing luminous plate and its preparing process

ActiveCN101397495ANo emissionsNo pollutionSynthetic resin layered productsLuminescent compositionsNon toxicityAcrylic resin

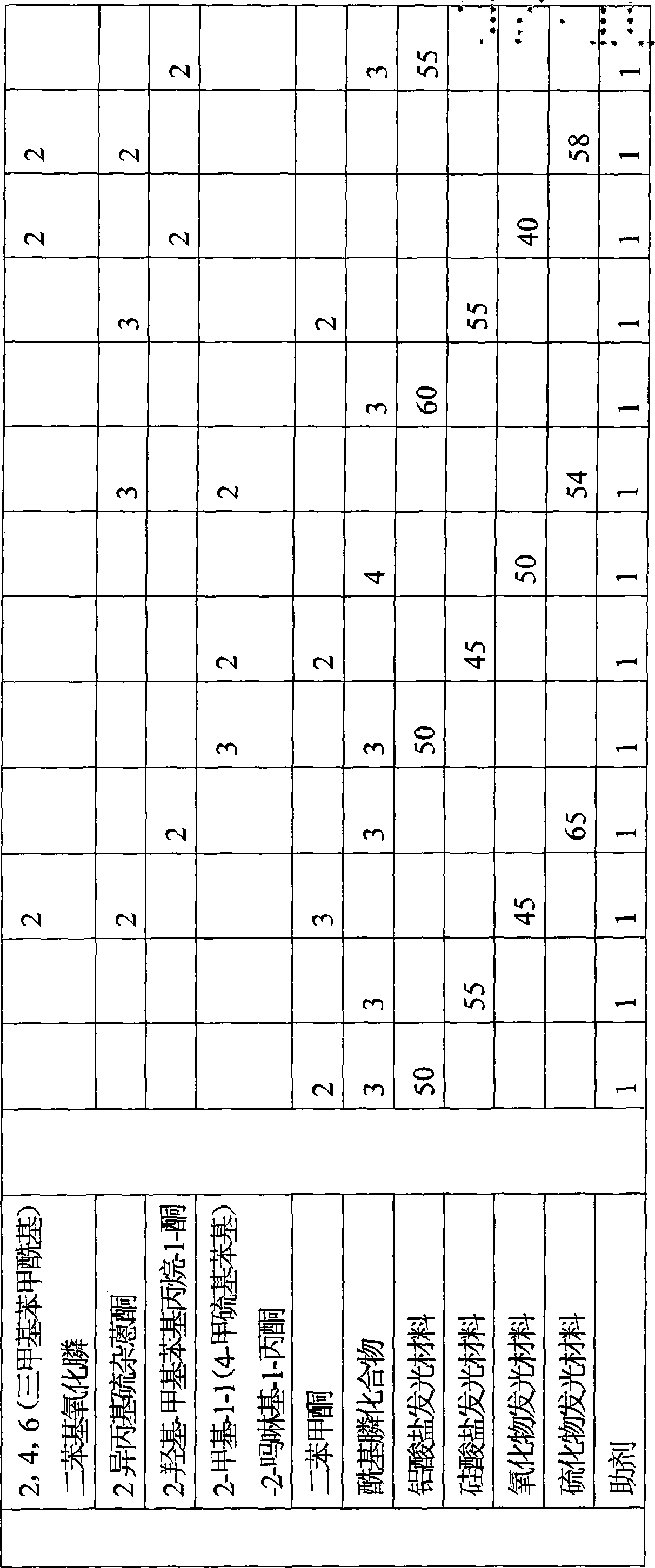

An UV curing luminescent panel consists of a luminescent layer and a reflective layer. The luminescent layer with the thickness of 0.02-5.0mm consists of light-cured resin (10-40 percent of resins such as epoxy acrylic resin, polyurethane acrylic resin, polyester acrylic resin and the like), photosensitive diluent (photosensitive diluent is 10-20 percent of resins of ethoxylated acrylic ester, propoxylated neopentyl glycol diacrylate, TMPTA and the like), photoinitiator (2-10 percent of beans development kit BDK and the like), luminescent materials (10-65 percent) and additive (0-5 percent). The UV curing luminescent panel has the advantages of no solvent emission, saving energy due to instant drying of UV curing, high production efficiency due to on-line processing, and being applicable to base materials sensitive to heat; furthermore, the prepared luminescent panel is characterized by high brightness, long luminescent time, excellent acid and alkali resistance and weatherability, good printing performance, non-toxicity, no radiation and stable physicochemical performance.

Owner:DALIAN LUMINGLIGHT SCIENCE & TECHNOLOGY CO LTD

Ink composition for ink-jet printing

ActiveCN101921511ASimplify the UV-curable printing processReduce inkjet production costsInksPolyesterUltraviolet

The invention relates to an ink composition for ink-jet printing, which contains 10-35% by weight of at least one selected from polyurethane (methyl) acrylate oligomer and polyester acrylate oligomer, 5-20% by weight of adhesion promoting oligomer, 40-70% by weight of at least one selected form EOEOEA, THFA, IBOA, PHEA, HDDA, DPGDA, TPGDA, HEMA, TMPTA, EO3TMPTA, PO3TMPTA, EO4PETA and DPHA, 0.1-3% by weight of at least one selected from N-(beta-aminoethyl)-alpha-aminopropyltrimethoxysilane, methacrylate propyltrimethoxysilane, styrene chloro diamino silane and 3-glycidyl propyltrimethoxysilane and 2-6% by weight of paint. The ink composition is applicable to applying direct printing on an inorganic matter without being precoated, thereby simplifying the ultraviolet curing and spray printing process carried out on the surface of the inorganic matter, reducing the production cost and improving the production efficiency of inkjet printing.

Owner:ZHUHAI FREE TRADE ZONE NEOJET APOLLOJET IMAGING MATERIALS

High wear-resistant epoxy coating, preparation method thereof and coating layer

The invention relates to high wear-resistant epoxy coating, a preparation method of high wear-resistant epoxy coating and a high wear-resistant epoxy coating layer. The high wear-resistant epoxy coating provided by the invention is characterized by being prepared from an A component and a B component, wherein (1) the A component is prepared from the following raw materials in percentage by mass: 45 to 55 percent of epoxy resin, 3 to 5 percent of toughening agent, 3 to 5 percent of diluting agent, 5 to 10 percent of accelerator, 2 to 5 percent of silane coupling agent, 20 to 25 percent of abrasive aggregates, 5 to 10 percent of filler and appropriate percent of pigment; (2) the B component is prepared from the following raw materials in percentage by mass: 15 to 20 percent of MXDA (M-Xylylenediamine), 15 to 20 percent of IPDA (Isophorone Diamine), 3 to 5 percent of 1,3-BAC (1,3-bis(aminomethyl)-cyclohexan), 25 to 35 percent of polyether amine D230, 25 to 30 percent of styrenated phenol and 5 to 10 percent of TMPTA (Trimethylolpropane triacrylate); the A component and the B component are mixed according to a proportion of 1:5. The high wear-resistant epoxy coating disclosed by the invention has excellent wear resistance, high hardness, good heat resistance and water resistance, good chemical reagent corrosion resistance, high fullness, high construction efficiency, convenience in construction and a wide application range.

Owner:SHANGHAI ZHENGOU IND

UV gloss oil, preparation method and application thereof

The invention discloses a UV gloss oil and a preparation method thereof and the use thereof; a monomer diluent TPGDA with the weight percentage of 8 to 12 percent and a monomer diluent TMPTA with the weight percentage of 8 to 12 percent are mixed to be stirred evenly, then a light-cured resin epoxy acrylic acid composite resin with the weight percentage of 50 to 55 percent is added in, after the mixture is dissolved fully, a photosensitizer 1173 with the weight percentage of 2 to 4 percent, the photosensitizer 184 with the weight percentage of 2 to 4 percent, a film-forming additive with the weight percentage of 10 to 20 percent and color powder with the percentage of 0 to 10 percent are added in, and after being stirred evenly, the UV gloss oil can be obtained by filtering. The prepared UV bright oil is used for being printed on films or films with lithography patterns to prepare UV preprinting decoration films which are used for product packing materials.

Owner:BEIJING SHUANGYAN TRADEMARK COLOR PRINTING

Ultraviolet (UV) screen plastic film printing ink and method for preparing same

The invention relates to the technical field of ink, and in particular relates to an ultraviolet (UV) screen plastic film printing ink and a method for preparing the same. The UV screen plastic film printing ink consists of the following raw materials in parts by weight: 18-28 parts of urethane acrylate, 16-25 parts of polyester acrylate, 6-15 parts of solid acrylic resin, 2-8 parts of 2-propenoic acid, 1, 1'-[(1-methyl-1, 2-ethanediyl) bis [oxy(methyl-2, 1-ethanediyl)]] ester (TPGDA), 7-15 parts of trimethyl propane triacrylate (TMPTA), 4-12 parts of hexanediol diacrylate (HDDA), 14-22 parts of pigment powder, 1-3 parts of dispersing agent, 0.2-1.2 parts of organic silicon defoamer, 1-4 parts of organic silicon flatting agent, 1-3 parts of photoinitiator and 0.2-1.5 parts of adhesion promoter. The UV screen plastic film printing ink adopts the solid acrylic resin as one basic material and has good flexibility and adhesiveness, the printing adaptability of the plastic film printing ink is greatly improved, moreover, the basic materials of the urethane acrylate and the polyester acrylate all have excellent adhesiveness, the adhesion firmness of the UV screen plastic film printing ink is further increased, and the UV screen plastic film printing ink has a good printing adaptability and a good printing effect.

Owner:东莞市佳烨化工科技有限公司

LED UV curing glass ink

The invention provides LED UV curing glass ink and mainly solves the technical problems that thermo-curing ink is universally in the existing glass ink industry, the energy consumption is high, the efficiency is low and the like. The main point of the technical scheme is that the glass ink is prepared from the raw materials, by weight, of 30%-60% of resin, 3%-20% of UV monomer, 1%-10% of photoinitiator, 0.1%-5% of auxiliary, 0.1%-10% of pigment and 5%-30% of filler, and the resin comprises organic silicone modified epoxy acrylic resin, polyester acrylic resin, acrylic modified alkyd resin and acrylic modified silicone resin; the UV monomer comprises IBXA, acryloyl morpholine, spiro orthocarbonate, DPHA, (EO)n-TMPTA, tetrahydrofuran acrylate, lauryl acrylate and 9,9'-bis[4-(2'-hydroxy-3'-methacryloyloxypropoxy)phenyl]fluorene. The glass ink is manufactured with an LED UV curing method, has the advantages that energy is saved and the environmental protection efficiency is high and is mainly applied to the glass ink industry.

Owner:湖南永红环保科技有限公司

Polyether polyurethane-acrylate and preparation method thereof

InactiveCN101608010AGood chemical resistanceImprove high temperature resistancePolyurea/polyurethane coatingsHydroxybenzoate EthersPolymer science

The invention provides polyether polyurethane-acrylate and a preparation method thereof. The polyether polyurethane-acrylate comprises the following compositions in portion by weight: 40 to 60 portions of polyether glycol, 10 to 30 portions of polyisocyanates, 10 to 30 portions of hydroxypropyl acrylate or hydroxy-ethyl acrylate, 0.1 to 0.5 portion of triethylamine or dibutyltin dilaurate, 5 to 10 portions of absolute ethanol, 0.1 to 0.8 portion of p-hydroxyanisole or 2.6- di-tert-butyl-4-methylphenol, 5 to 20 portions of tripropylene glycol diacrylate, 5 to 20 portions of TMPTA, and 0.01 to 0.02 portion of nitrobenzene. The invention has excellent mechanical abrasion resistance and toughness, high elongation at break, excellent chemical resistance and high temperature resistance when coating a film, has low temperature performance and good adhesive force. The polyether polyurethane-acrylate has better using effect when assembling epoxy acrylate, and is the polyurethane acrylate with lowest cost.

Owner:上海展辰涂料有限公司 +2

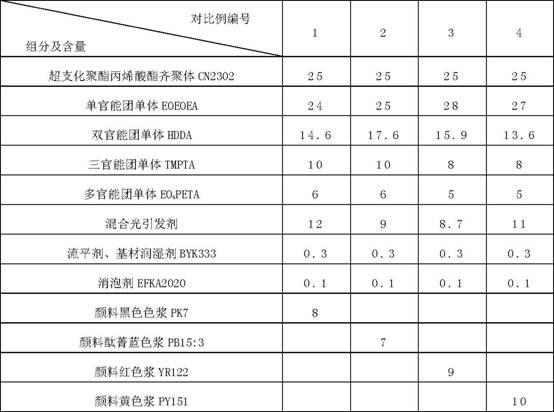

Colored dual-curing UV coating for automobile interior trim parts

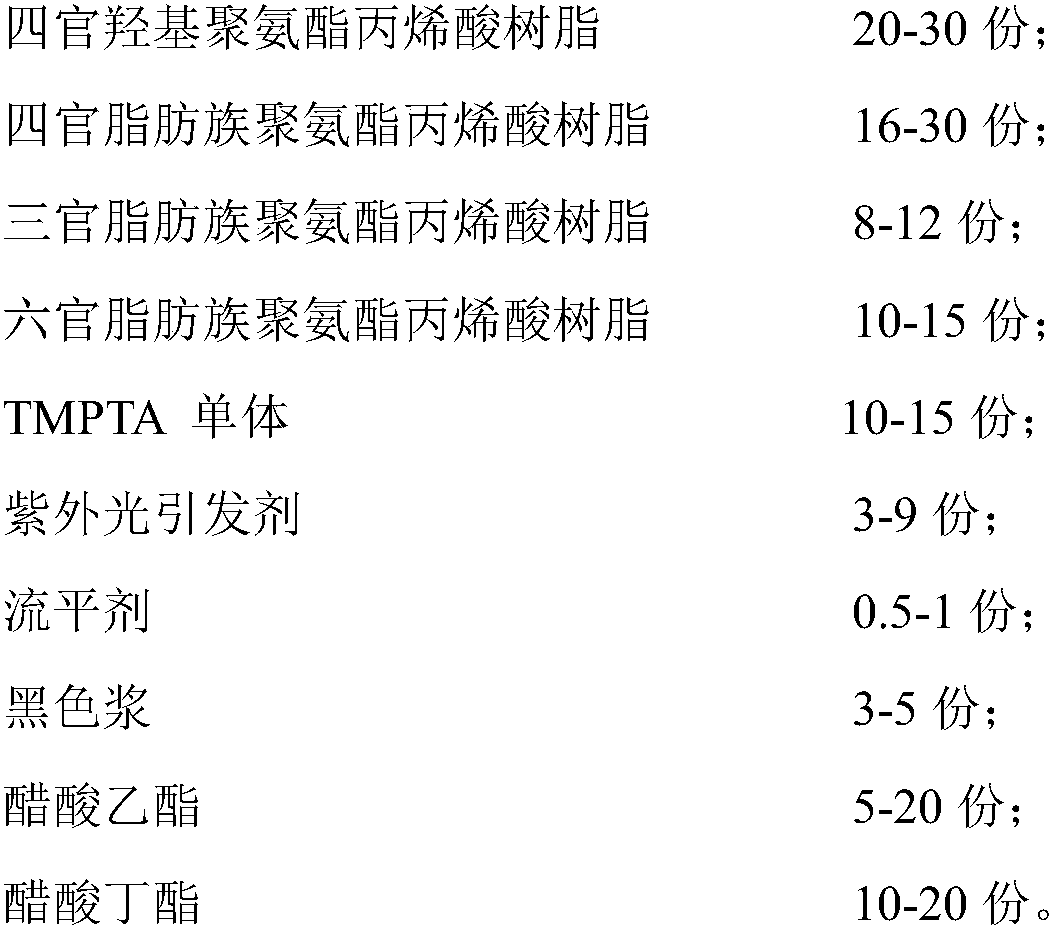

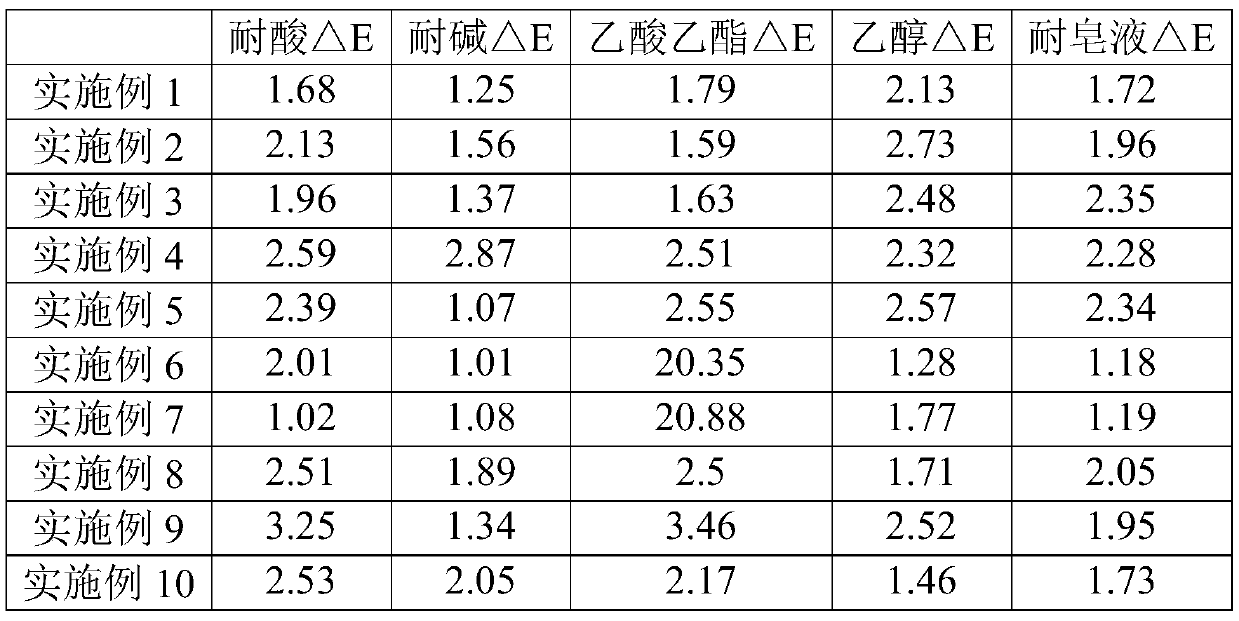

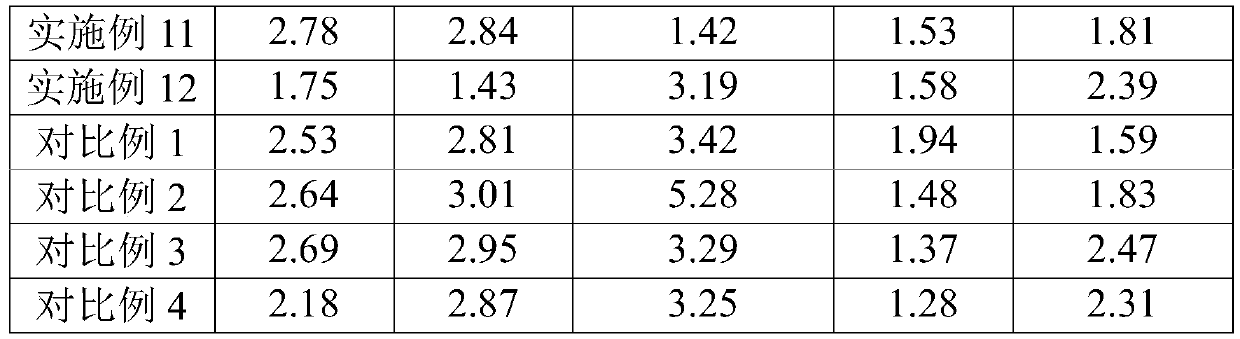

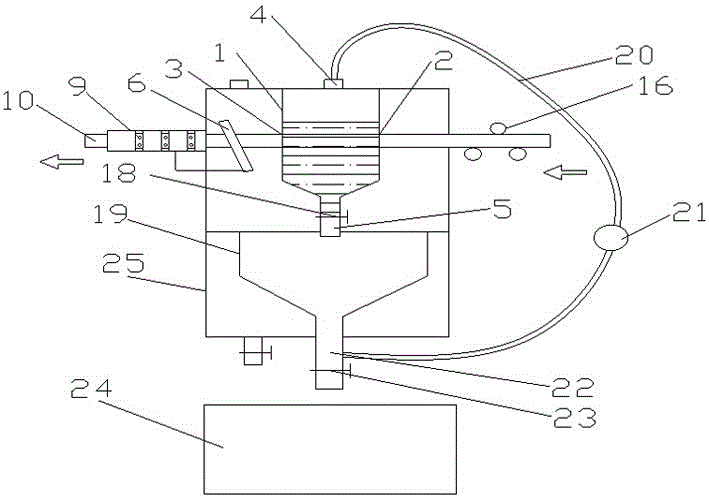

ActiveCN108997925AImproved two-spray methodHigh glossAnti-corrosive paintsPolyurea/polyurethane coatingsAcrylic resinEthyl acetate

The invention discloses a colored dual-curing UV coating for automobile interior trim parts, and belongs to the field of coating preparation. The invention relates to the colored dual-curing UV coating for the automobile interior trim parts, wherein the colored dual-curing UV coating comprises the following raw materials in parts by weight: 20-30 parts of tetra-functional hydroxyl polyurethane acrylic resin, 16-30 parts of tetra-functional aliphatic polyurethane acrylic resin, 8-12 parts of tri-functional aliphatic polyurethane acrylic resin, 10-15 parts of hexa-functional aliphatic polyurethane acrylic resin, 10-15 parts of a TMPTA monomer, 3-9 parts of an ultraviolet initiator, 0.5-1 part of a leveling agent, 3-5 parts of black pulp, 5-20 parts of ethyl acetate, and 10-20 parts of butylacetate. The shortcomings of two times of spraying and low production efficiency of automobile interior trim parts in the prior art are overcome, the colored dual-curing UV coating has good adhesion force to ABS, PC, ABS+PC and painted plastic substrates. A formed paint film has solvent resistance, water resistance and other properties, can improve a current secondary spraying effect, saves energyand improves the production efficiency.

Owner:WUHU CHUNFENG NEW MATERIAL

Nano conducting particle doped PDLC (polymer dispersed liquid crystal) membrane and preparation method thereof

The invention provides a nano conducting particle doped PDLC (polymer dispersed liquid crystal) membrane. The nano conducting particle doped PDLC is prepared by stirring polyurethane modified by acrylic acid, a TMPTA (trimethylolpropane triacrylate) monomer thinner, grapheme nano conductive particles, an antifoaming agents and liquid crystal for 60-120 minutes under the constant temperature ranging from 100r / min to 300r / min and subjecting the same to radiation curing with an electron beam 150-300keV in energy for 0.1-0.3 seconds. The grapheme nano conduction particles are combined with a traditional PDLC membrane, driving voltage of the PDLC membrane is lowered from dielectric constant and liquid crystal orientation, main materials for preparing the PDLC membrane are not needed to be changed, original optical-electrical characteristics of the PDLC are guaranteed, the driving voltage of the PDLC membrane is low, good thermal stability and mechanical stability are achieved, and simpleness in preparation process is realized.

Owner:BEIJING SAN WU JIU INVESTMENT

Ultraviolet-cured high-temperature-resistant epoxy acrylate and preparation method thereof

The invention discloses an ultraviolet-cured high-temperature-resistant epoxy acrylate and a preparation method thereof. The ultraviolet-cured high-temperature-resistant epoxy acrylate comprises the following raw materials in parts by mass: 42.5-43.5 parts of novolac epoxy resin, 15.5-15.8 parts of acrylic acid, 0.25-0.50 part of catalyst, 0.020-0.060 part of polymerization inhibitor and 40 parts of TMPTA (trihydroxymethyl propane triacrylate). The novolac epoxy resin is bisphenol-F type novolac epoxy resin. The ultraviolet-cured high-temperature-resistant epoxy acrylate has the characteristics that epoxy acrylate can be subjected to ultraviolet curing, and cured film can resist the temperatures being greater than 200 DEG C. The ultraviolet-cured high-temperature-resistant epoxy acrylate disclosed by the invention is simple and feasible in process, conveniently highlights high-temperature resistance advantages of an ultraviolet oligomer in vehicle lamps and heated coating, and is a safe and green macromolecular curing material.

Owner:苏州市明大高分子科技材料有限公司

Vacuum plating method for PP (polypropylene) plastic and UV (ultraviolet) oil used therein

InactiveCN102321263AImprove aging resistanceIncreased durabilityPolyester coatingsPolyesterPolyolefin

The invention relates to a vacuum plating method for PP (polypropylene) plastic, which comprises the following steps that: after the surface of a PP plastic workpiece is cleaned, the PP plastic workpiece enters an automatic spraying machine to be prayed with a PP treatment agent; vacuum plating UV (ultraviolet) base oil is sprayed by the automatic spraying machine; the PP plastic workpiece enters a UV machine; vacuum plating and inspection are carried out; the PP plastic workpiece enters the UV machine; and inspection and finished product packaging are carried out. The PP treatment agent comprises the following components: toluene and polyolefin with functional groups; and the UV base oil comprises the following components: toluene, ethyl acetate, xylene, polyester acrylate resin, pure acrylic resin, reactive monomer TMPTA (trimethylol propyl triacrylate), an acrylic advection agent, a phosphate adhesion additive and a photoinitiator. In the method, the production process of flame treatment can be eliminated actually, without open flame, thereby complying with fire safety requirements; compared with the prior art, the aging resistance and durability of PP plastic are improved; and the process of the vacuum plating process of PP plastic is saved, and efficiency and qualified product rate are improved.

Owner:DONGGUAN RONGCHANG CHEM

Water spray-resistant stamped UV-LED-curing oil polish for cigarette paper package printed matters

ActiveCN108373786AHigh reactivityImproves anti-fog performancePolyurea/polyurethane coatingsEpoxy resin coatingsDyneZahn cup

The invention discloses water spray-resistant stamped UV-LED-curing oil polish. The oil polish comprises, by weight, 10-40 parts of bisphenol A epoxy acrylate, 10-30 parts of nine functional polyesteracrylate, 5-15 parts of aliphatic polyurethane acrylate, 5-15 parts of TMPTA, 10-50 parts of HDDA, 3-10 parts of reactive amine, 0.1-0.5 parts of a leveling agent, 0.5-2 parts of mixed wax powder, 1-6 parts of a photoinitiator TPO, 0.5-5 parts of camphorquinone, 0.5-4 parts of N-[2-(dimethylamino)ethyl ester]-1, 8-naphthalimide, 0-5 parts of 819, and 0-5 parts of 4(2)-ITX. The viscosity is testedby a Zahn cup 4, and the surface tension is 20 to 30 Dynes / cm in 60 to 120 seconds. After coating, the oil polish can be rapidly cured under LED illumination conditions of center wavelength of 365-405 nm, illuminance of 0.5-1.5 W / cm<2> and a distance of 5 mm. The cured film has a surface water contact angle of 80-120 degrees, a dynamic friction coefficient of 0.05-0.2, a static friction coefficient of 0.1-0.3 and good water spray-resistant performances and stamping performances.

Owner:广西真龙彩印包装有限公司

UV gloss oil and application thereof

ActiveCN110982398AFast curingLow costPretreated surfacesPolyurea/polyurethane coatingsPolymer scienceChemical solution

The invention provides UV gloss oil and application thereof, and relates to the technical field of gloss oil. The UV gloss oil comprises the following components in parts by mass: 3-8 parts of prepolymer, 80-90 parts of acrylic monomers, 4-10 parts of free radical photoinitiator and optional auxiliaries, wherein the prepolymer comprises an unsaturated oligomer containing polymerizable carbon-carbon double bonds, and the functionality of the prepolymer is 2-18; and the acrylic monomers comprise at least two of EOEA, HDDA, TPGDA, NGPDA, ACMO, DPGDA, TMPTA, IBOA, DEGDA, TEGDA, BDDA, PDDA, DTMPTA,DPPA and DPHA. The UV gloss oil has good resistance to chemical solutions or solvents.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION +1

UV curing coating and application method thereof

The invention discloses a UV curing coating and an application method thereof. The UV curing coating is prepared from, by weight, 79.2% of polyester acrylate, 5.9% of HDDA, 2.9% of UV curing resin TMPTA, 10% of titanium dioxide, 1% of TPO and 1% of ITX. The UV curing coating can be matched with an infiltration type coating curing device to conduct curing under the wave length of 395 nm, the curing speed is high, energy consumption can be reduced, the energy source can be saved, and the use cost can be reduced.

Owner:武夷学院 +1

UV light curable camouflage paint used for fabric, and preparation method and application thereof

The invention belongs to the field of coatings, and relates to a UV light curable camouflage paint used for a fabric, and a preparation method and an application thereof. The UV light curable camouflage paint used for the fabric comprises a light curable resin, a reactive diluent, a camouflage pigment composition and a light initiator, wherein the light curable resin is tri-functional polyurethane acrylate; the reactive diluent is trimethylolpropane triacrylate (TMPTA); and the light initiator is 2,4,6-trimethylbenzoyldiphenyl phosphine oxide (TPO). The prepared UV light curable camouflage paint has good adhesive force, good flexibility, low cost and low pollution, and can be used for preparing camouflage fabrics.

Owner:JIANGSU LITIAN TECH

UV curable plastic paint

The invention discloses a UV curable plastic paint which is characterized by comprising 50-60% of modified epoxy UV resin, 10-20% of polyurethane UV resin, 10-20% of TPGDA activated monomer, 10-20% of TMPTA activated monomer, 3-5% of initiator and 5-10% of ethyl acetate solvent. The UV curable plastic paint has the advantages of low price, levelling property for large area construction of air conditioner, high glossiness and fullness of paint film, and excellent decorative effect.

Owner:JIANGMEN PAINT FACTORY

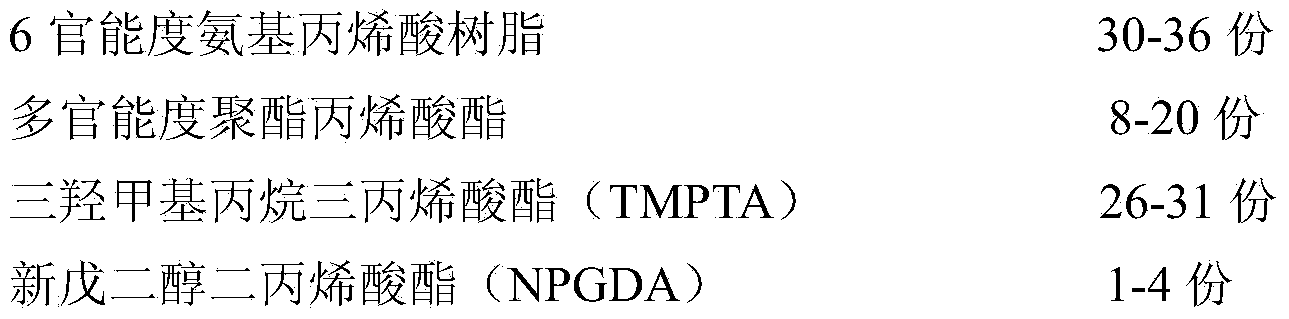

High-adhesion anti-yellowing gloss oil and preparation method thereof

InactiveCN103709892ALow viscosityInitiation efficiency is highPolyester coatingsEpoxyNeopentylglycol diacrylate

The invention discloses a kind of high-adhesion anti-yellowing gloss oil. Adopted matrix resin is 6-functionality amino acrylate resin, so that the curing speed is high, and the cost is lower than those of modified epoxy or polyurethane acrylate resins. Trimethylolpropane triacrylate (TMPTA) and neopentyl glycol diacrylate (NPGDA) are taken as active diluents, so that the system viscosity is lowered, the glossiness is increased, the shrinkage rate is controlled, and the adhesion is improved; an adhesion promoter enhances the mutual acting force with a substrate, so that the adhesion is better. An initiator is high in initiation efficiency, and has an excellent yellowing resistance.

Owner:ZHEJIANG RONGTAI TECH ENTERPRISE

UV varnish

InactiveCN101096558AImprove performanceHigh hardnessPretreated surfacesPolyurea/polyurethane coatingsPolymer scienceAdjuvant

The invention discloses a UV varnish, which comprises the following parts: 25-45% monomer, 50-70% photographic resin, 4-7% photo-initiation agent, 0.7-1.7% adjuvant and 40-60% solvent, wherein the monomer consists of TMPTA and DPHA; the photographic resin is aliphatic PUA, which contains UV7605B and 621A-8; the photographic resin includes Irgacure184 and the adjuvant contains EFKA3777, EFKA3034 and OB (optical brightener); the solvent contains toluene and acetic ester. The invention matches high hardness resin and high hardness active diluent with OB to realize the uniformity of high hardness and low yellow changing rate, which reduces cost with good economic benefit.

Owner:MITAC PRECISION TECH CO LTD SHUNDE DISTRICT FOSHAN CITY

UV wiping paint

ActiveCN101845244ALow shape requirementDoes not impede penetrationEpoxy resin coatingsPolyester coatingsAcrylic resinLacquer

The invention relates to the technical field of paint, in particular to a UV wiping paint comprising following components in percentage by weight: 5-30 percent of TPGDA, 1-10 percent of TMPTA, 1-15 percent of HEMA, 1-10 percent of 2-EHA, 4-15 percent of photoinitiators, 40-60 percent of acrylic resin, 10-25 percent of toner, 0.1-0.5 percent of defoamer and 0.1-0.5 percent of anti-settling agent. The invention breaks through the characteristics of the traditional UV paint, modifies the UV paint, dyes in a wiping mode, and squeezes color into a wood pipe to enable the pipe to have deep color but the surface to only have light color so as to form three-dimensional grain effect.

Owner:东莞大宝化工制品有限公司

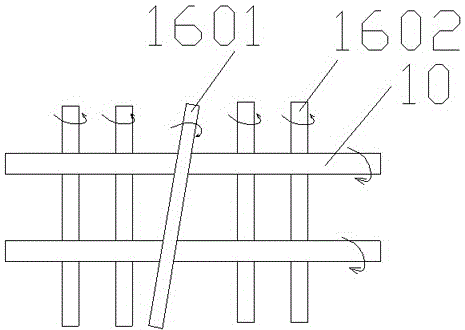

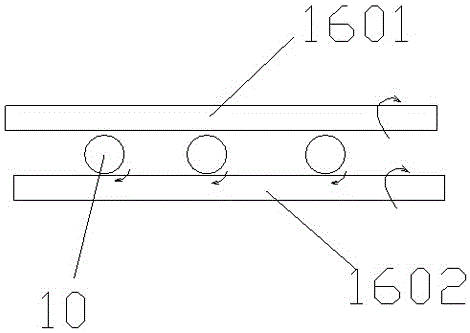

High rigidity light composite board for automobile roof and preparation method thereof

ActiveCN101735545AImprove mechanical propertiesEasy to processSuperstructure subunitsPolyolefinPolymer science

The invention discloses a high rigidity light composite board for an automobile roof and a preparation method thereof, and the composite board has the characteristics of light weight and heat preservation, high rigidity and high toughness, endurance and humidity resistance, rot resistance and no objectional odor and the like. The composite board is formed by compounding slightly foamed polyolefin boards and non-woven fabrics, wherein the slightly foamed polyolefin board is composed of the following raw materials by weight percent: 50-60% of polypropylene resin, 0-10% of high-density polyethylene, 2-8% of polyfunctional monomer, 15-30% of GFPP resin, 8-12% of TDPE resin, 0-5% of EAA resin, 0.5-3% of nano powder catalyst, 0.01-0.2% of accelerator, 0.05-0.5% of initiator, 0.2-2% of antioxygen, 0.1-0.3% of wetting and dispersing agent, and 0.5-2% of foaming agent; and the polyfunctional monomer is trimethylolpropane triacrylate (TMPTA) or trimethylolpropane trimethacrylate (TMPTMA).

Owner:JIANGSU QIYI TECH

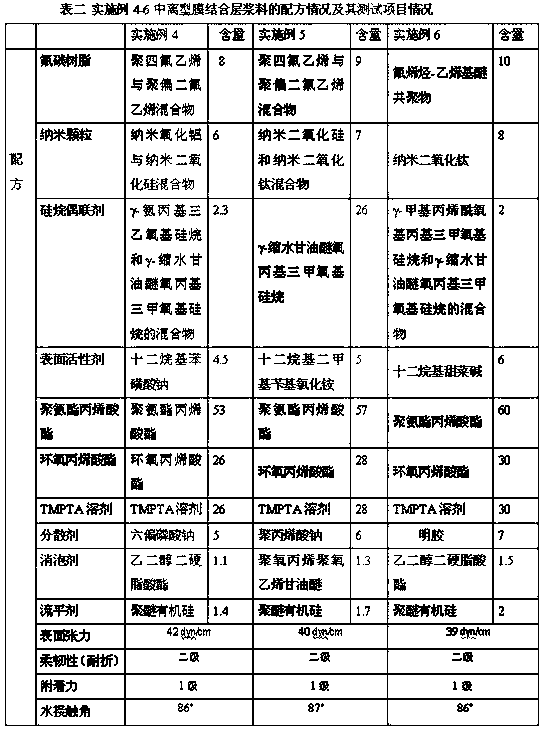

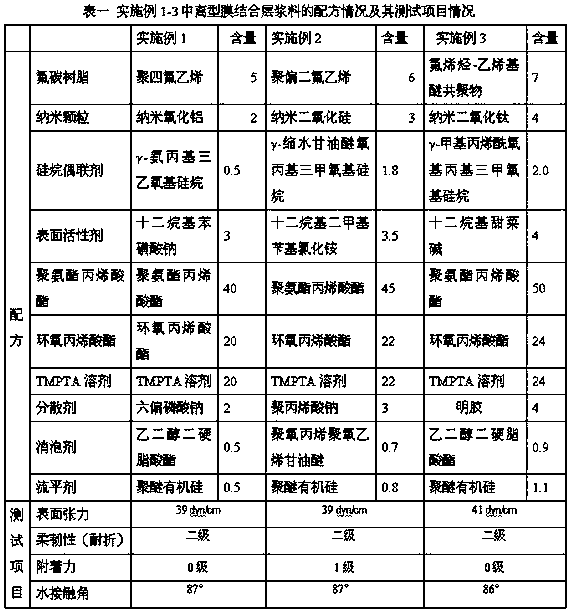

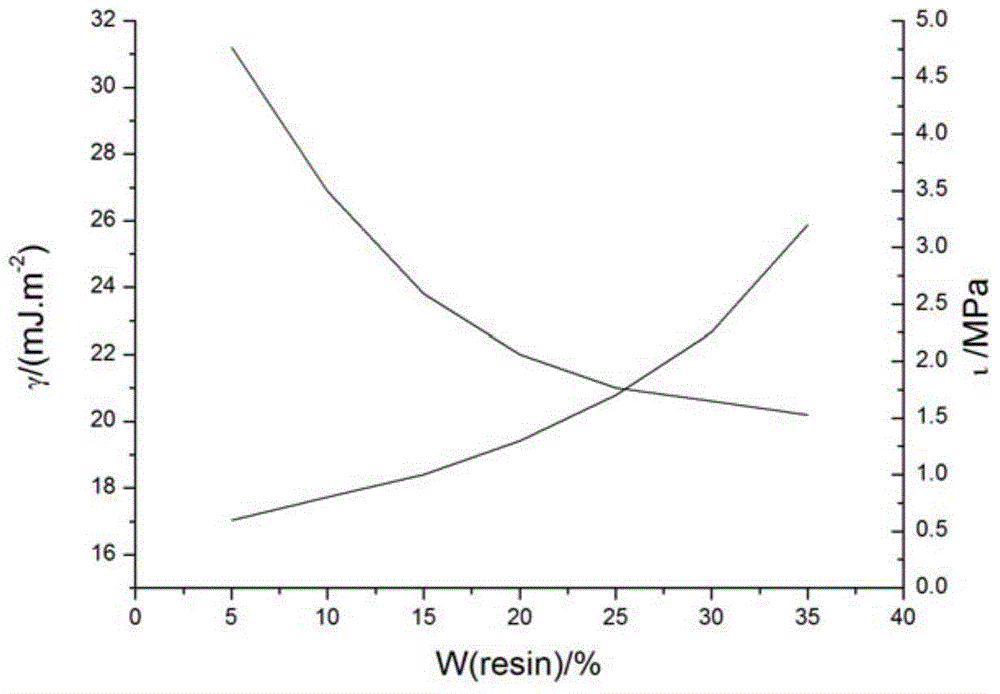

Formula of binding layer slurry used for release film of synthetic leather and preparation method of the binding layer slurry

ActiveCN107603458AImprove adhesionGood flexibilityPolyurea/polyurethane coatingsTextiles and paperSlurrySolvent

The invention discloses a formula of binding layer slurry used for a release film of synthetic leather and a preparation method of the binding layer slurry. The binding layer slurry includes, by weight, 5-10 parts of fluorocarbon resin, 2-8 parts of nano-particles, 0.5-2 parts of a silane coupling agent, 3-6 parts of a surfactant, 40-60 parts of polyurethane acrylate, 20-30 parts of epoxy acrylate, 20-30 parts of a TMPTA solvent, 2-7 parts of a dispersant, 0.5-1.5 parts of a defoamer, and 0.5-2 parts of a flatting agent. By means of the raw materials, which are cooperated with each other, in the formula, a binding layer has excellent adhesion force and flexibility, and can solve problems of an uneven and non-uniform coating surface when the surface of a base material is coated with a release agent directly. In addition, the binding layer is mainly used for improving combination between the base material and a release layer by being applied between the base material and the release layer and improving the performance of the release layer during production of the release film.

Owner:南京盛凯新材料有限公司

Nano titanium dioxide anti-bacterial UV (ultraviolet) varnish and preparation method thereof

InactiveCN103865368AShort preparation cycleHigh solid contentAntifouling/underwater paintsPaints with biocidesPolyesterPolyvinyl chloride

The invention relates to nano titanium dioxide anti-bacterial UV (ultraviolet) varnish and a preparation method thereof. The UV varnish comprises the following components of nano titanium dioxide paste, polyester acrylate, TMPTA (trihydroxymethyl propane triacrylate), NPGDA (dimethyltrimethylene glycol diacrylate), DMF (dimethyl formamide), benzophenone, active amine, 1-hydroxy cyclohexyl phenyl ketone, an organic silicon defoamer and an organic silicon leveler. The UV varnish is suitable for coating the surface of a PVC (polyvinyl chloride) gusset plate, is short in preparation cycle, simple in preparation process, low in production cost, relatively high in solid content, relatively good in glossiness, yellowing-resistant and high in adhesive force, and has the advantages of bacterial resistance, self cleaning capability, low odor, high drying speed and the like.

Owner:HENAN UNIV OF SCI & TECH

UV varnish adapted for black plastic bottom material

InactiveCN101096559ASolve curing problemsImprove performancePretreated surfacesPolyurea/polyurethane coatingsAdjuvantSolvent

The invention discloses a UV varnish of black plastic base, which comprises the following parts: 35-60% monomer, 35-65% photographic resin, 7-12% photo-initiation agent, 0.6-1.2% adjuvant and 50-60% solvent, wherein the monomer consists of TMPTA and DPHA; the photographic resin is aliphatic PUA, which contains UV7605B and GF5200; the photographic resin includes Irgacure184 and Irgacure819; the adjuvant contains EFKA3777 and EFKA3034; the solvent contains butyl acetate and petrohol.

Owner:MITAC PRECISION TECH CO LTD SHUNDE DISTRICT FOSHAN CITY

UV curing antibiotic coating and preparation thereof

InactiveCN101353545BImprove antibacterial propertiesLong-lastingAntifouling/underwater paintsPaints with biocidesTMPTASilver oxide

The invention discloses a UV-curable antimicrobial coating, the components of which are as follows: bisphenol A type epoxy acrylate EA; aliphatic PUA; special functional group acrylate PA; TPGDA; TMPTA; photoinitiators; nano acrylate; oxidized silver; and auxiliaries. The preparation method comprises the following steps of: step one, synthesizing special functional group heterocyclic compound PA and later adding phosphorus pentoxide to acrylic acid hydroxy esters so as to react with hydroxyl piperidine and then prepare special functional group heterocyclic compound PA; and step two, taking each component according to the formula, stirring and mixing each component so as to carry out dispersion at the speed of 900 to 1200r per min, then adding silver oxide and photoinitiators after being dispersed evenly, and finally obtaining UV-curable antimicrobial coating through dispersion. The UV-curable antimicrobial coating prepared by the invention has good anti-bacterial effect. As the self-prepared special functional group acrylate PA, the nano acrylate and the silver oxide are added, after UV-curable film-forming, the anti-coli rate can achieve over 99 percent and the anti-staphylococcal rate thereof achieves over 99 percent, and the effectiveness is long.

Owner:苏州市明大高分子科技材料有限公司

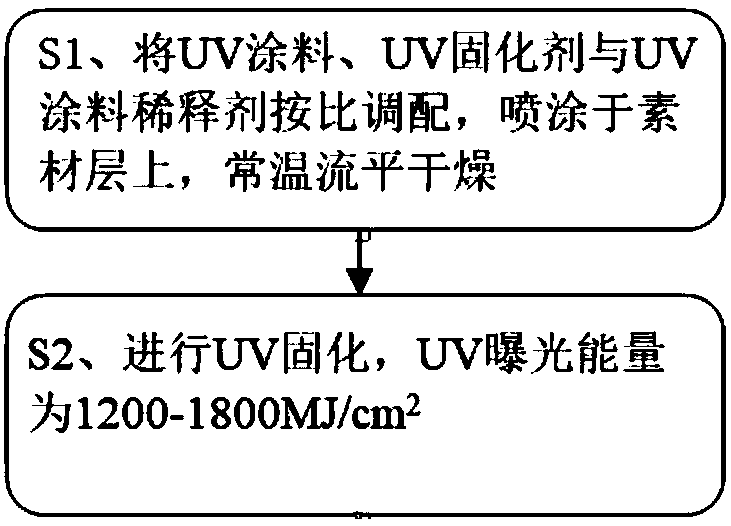

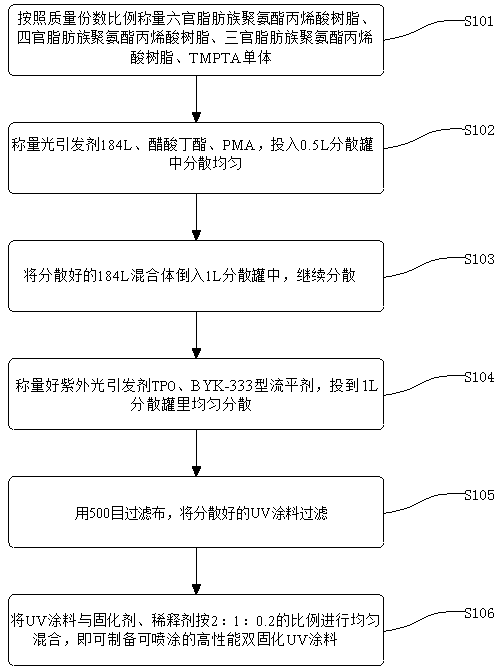

Special high-performance dual-curable UV coating for automotive interior decorative parts and preparation method thereof

InactiveCN110982419AHigh hardnessGood acid and alkali resistancePolyurea/polyurethane coatingsPolymer scienceWeather resistance

The invention discloses a special high-performance dual-curable UV coating for automotive interior decorative parts and a preparation method thereof. The special high-performance dual-curable UV coating for automotive interior decorative parts comprises the following raw materials in parts by mass, 2 to 8 parts of a six-functional aliphatic polyurethane acrylic resin; 30 to 50 parts of a four-functional aliphatic polyurethane acrylic resin; 20 to 30 parts of a trifunctional aliphatic polyurethane acrylic resin, 10 to 20 parts of TMPTA monomer, 1 to 5 parts of ultraviolet light initiator 184L,0.5 to 1.5 parts of ultraviolet light initiator TPO, 0.5 to 1.5 parts of BYK-333 type leveling agent, 2 to 8 parts of butyl acetate and 2 to 8 parts of PMA. An existing UV coating formula is optimized, and a coating film prepared from the optimized formula in cooperation with a special curing agent and a diluent has the excellent properties of high hardness, high acid and alkali resistance and high weather resistance.

Owner:QINGYUAN YAKOO CHEM CO LTD

Preparation method of ultraviolet cured silicon-containing acrylate conductive printed adhesive

InactiveCN104312453AReduce manufacturing costImprove conductivityOrganic non-macromolecular adhesiveElectrically-conducting adhesivesTrimethylsilyl chlorideAdhesive

The invention discloses a preparation method of an ultraviolet cured silicon-containing acrylate conductive printed adhesive. The adhesive is mainly prepared by synthesizing a silicon-containing acrylate resin substrate through a one-step process based on trimethyl chlorosilane and KH-550 as main raw materials and mixing the silicon-containing acrylate resin substrate with copper powder which is used as a conductive filler after wet milling, an active diluting agent vinyl pyrrolidone (NVP), a curing agent trihydroxymethyl propane triacrylate (TMPTA), a photoinitiator and the like. The preparation method of the conductive printed adhesive disclosed by the invention is simple and easy to control in process; and the prepared conductive printed adhesive has a good demoulding performance and dry etching resistance, and can replace a conventional Pb-Sn solder as a novel environment-friendly microelectronic packaging interconnection material.

Owner:SHANDONG UNIV OF SCI & TECH

Fireproof anti-corrosion coating material and preparation method thereof

ActiveCN109575734AImprove fire and corrosion resistanceStrong heat resistanceFireproof paintsAnti-corrosive paintsPolymer scienceTMPTA

The invention relates to a fireproof anti-corrosion coating material and a preparation method thereof. The fireproof anti-corrosion coating material can effectively solve the problems of poor water resistance, pollution resistance, heat resistance and corrosion resistance of an acrylate polymer emulsion in the prior art by introducing polysilsesquioxane, polysilane, TMPTA and graphene / nano-TiO2 / spiral carbon fiber composite particles to modify the acrylate polymer skeleton, so that the prepared aqueous acrylate polymer emulsion has better water resistance, pollution resistance, heat resistanceand corrosion resistance and strong fireproof and anti-corrosion performance.

Owner:深圳市天翔科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com