Colored dual-curing UV coating for automobile interior trim parts

A dual-curing technology for automotive interior parts, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as difficult production of colored primers, and achieve pinhole-free bubbles, plump paint films, and coatings. even layer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

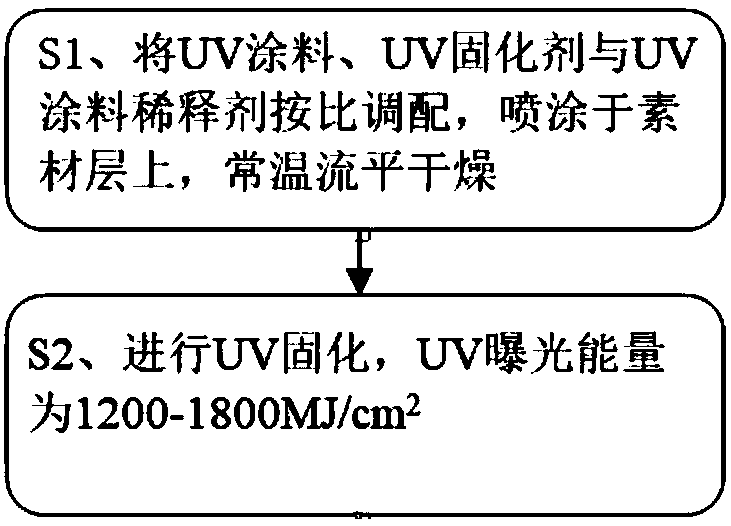

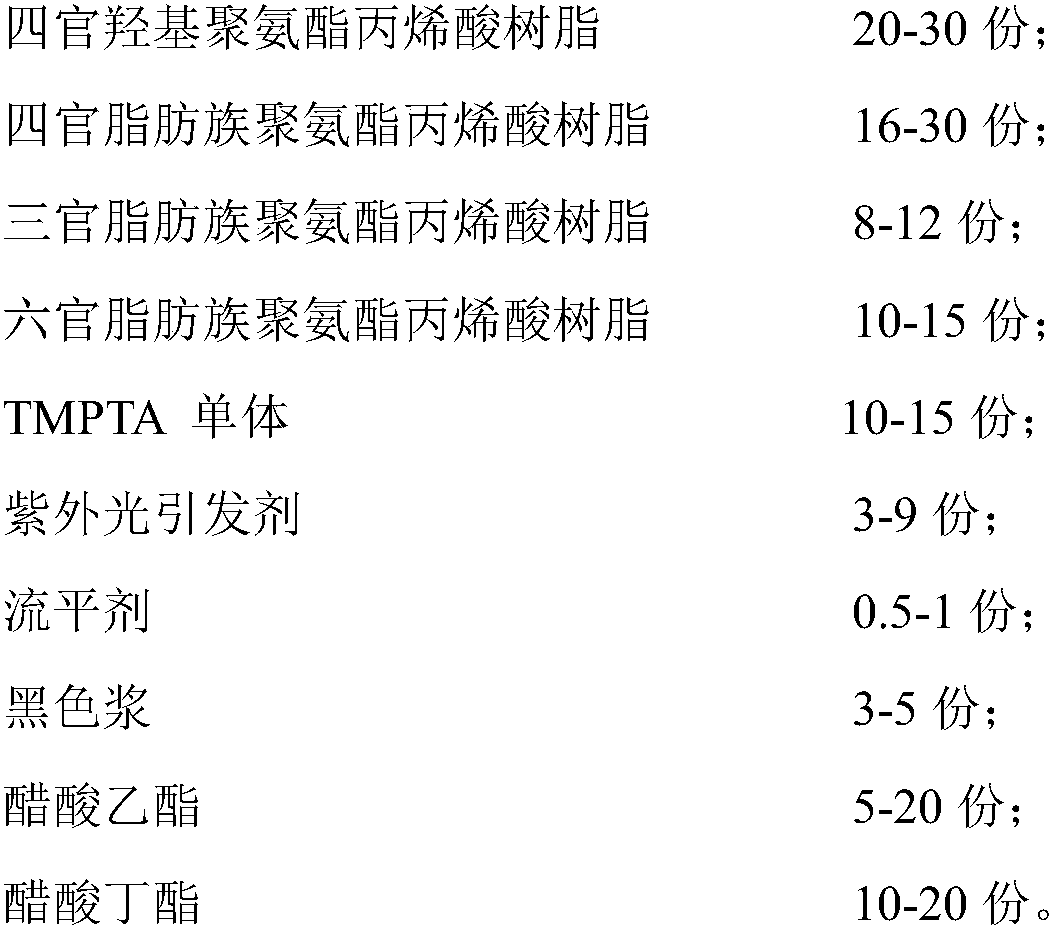

[0040] Such as figure 1 with figure 2 As shown, a colored dual-curing UV coating for automotive interior parts in this embodiment includes the following raw materials in parts by weight:

[0041] 20 parts of tetragonal hydroxyl urethane acrylic resin;

[0042] 18 parts of tetragonal aliphatic polyurethane acrylic resin;

[0043] Wherein the tetrahedral aliphatic urethane acrylic resin includes: 9 parts by weight of tetrahedral aliphatic urethane acrylic resin A and 9 parts by weight of tetrahedral aliphatic polyurethane acrylic resin B;

[0044]

[0045] The ultraviolet light initiator includes 2 parts by weight of ultraviolet light initiator A, 1.5 parts by weight of ultraviolet light initiator B, and 2 parts by weight of ultraviolet light initiator C;

[0046]

[0047] In this embodiment, the six-member aliphatic polyurethane acrylic resin is a polyurethane acrylic oligomer; the three-member aliphatic polyurethane acrylic resin and the four-member aliphatic polyurethane acrylic resi...

Embodiment 2

[0070] A colored dual-curing UV coating for automotive interior parts in this embodiment is basically the same as Embodiment 1, except that the coating in this embodiment includes the following raw materials by weight:

[0071] 20 parts of tetragonal hydroxyl urethane acrylic resin;

[0072] 25.9 parts of tetragonal aliphatic polyurethane acrylic resin;

[0073] Wherein, the tetrahedral aliphatic urethane acrylic resin comprises: 10.9 parts by weight of tetrahedral aliphatic urethane acrylic resin A and 15 parts by weight of tetrahedral aliphatic polyurethane acrylic resin B;

[0074]

[0075] Wherein the ultraviolet light initiator includes 1 part by weight of ultraviolet light initiator A, 2 parts by weight of ultraviolet light initiator B, and 2 parts by weight of ultraviolet light initiator C;

[0076]

[0077] The coating preparation method of this embodiment is basically the same as that of embodiment 1, except that the stirring condition in step 1 of this embodiment is 800 rpm an...

Embodiment 3

[0084] A colored dual-curing UV coating for automotive interior parts in this embodiment is basically the same as Embodiment 1, except that the coating in this embodiment includes the following raw materials by weight:

[0085] 25 parts of tetragonal hydroxyl polyurethane acrylic resin;

[0086] 20 parts of aliphatic urethane acrylic resin;

[0087] Wherein the tetrahedral aliphatic urethane acrylic resin includes: 12 parts by weight of tetrahedral aliphatic urethane acrylic resin A and 8 parts by weight of tetrahedral aliphatic polyurethane acrylic resin B;

[0088]

[0089] Wherein, the ultraviolet light initiator includes 2 parts by weight of ultraviolet light initiator A, 1.3 parts by weight of ultraviolet light initiator B, and 1 part by weight of ultraviolet light initiator C;

[0090]

[0091] The coating preparation method of this embodiment is basically the same as that of embodiment 1, except that the stirring condition in step 1 of this embodiment is 700 rpm and the stirring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com