Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2351 results about "Phosphorus pentoxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phosphorus pentoxide is a chemical compound with molecular formula P₄O₁₀ (with its common name derived from its empirical formula, P₂O₅). This white crystalline solid is the anhydride of phosphoric acid. It is a powerful desiccant and dehydrating agent.

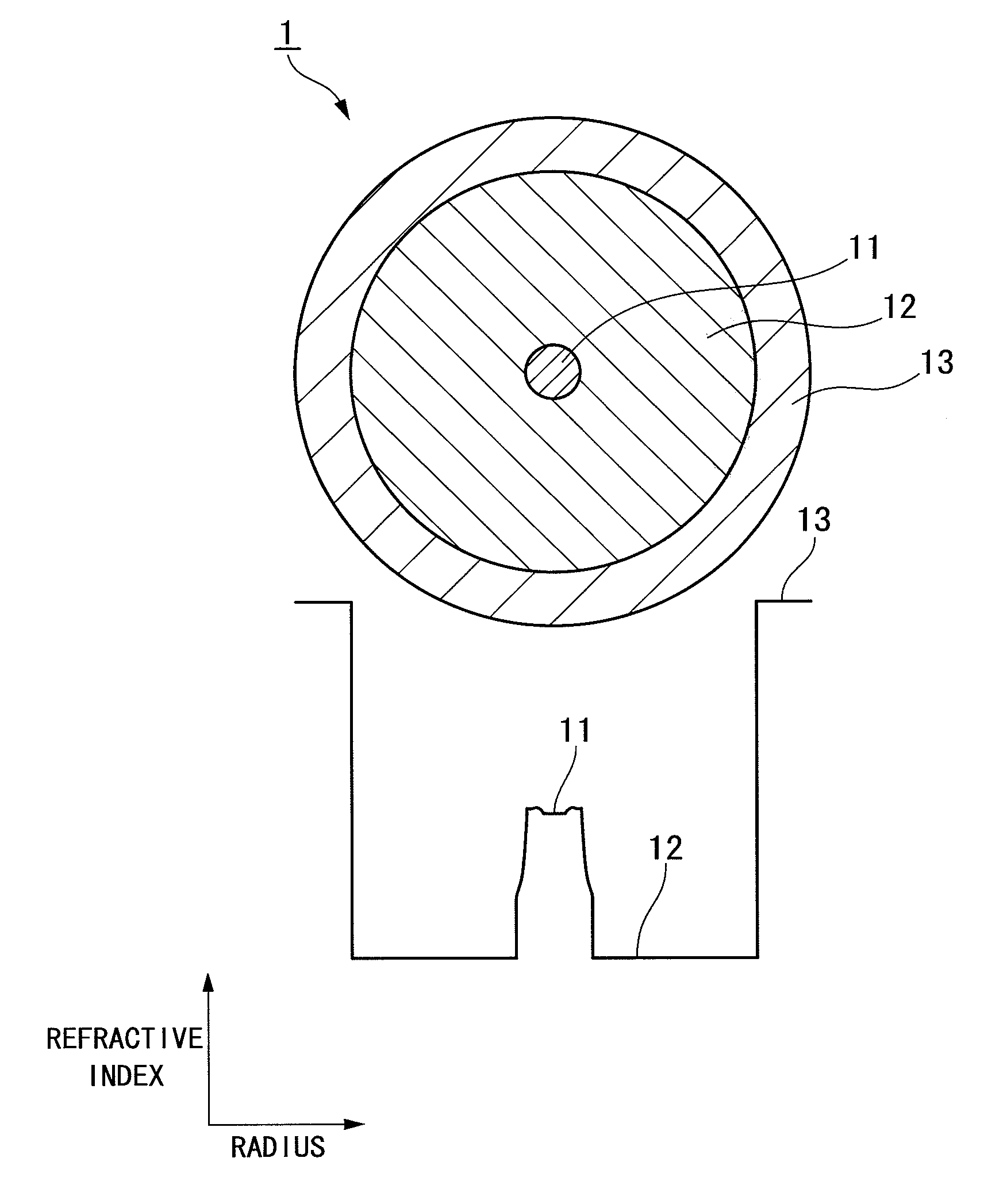

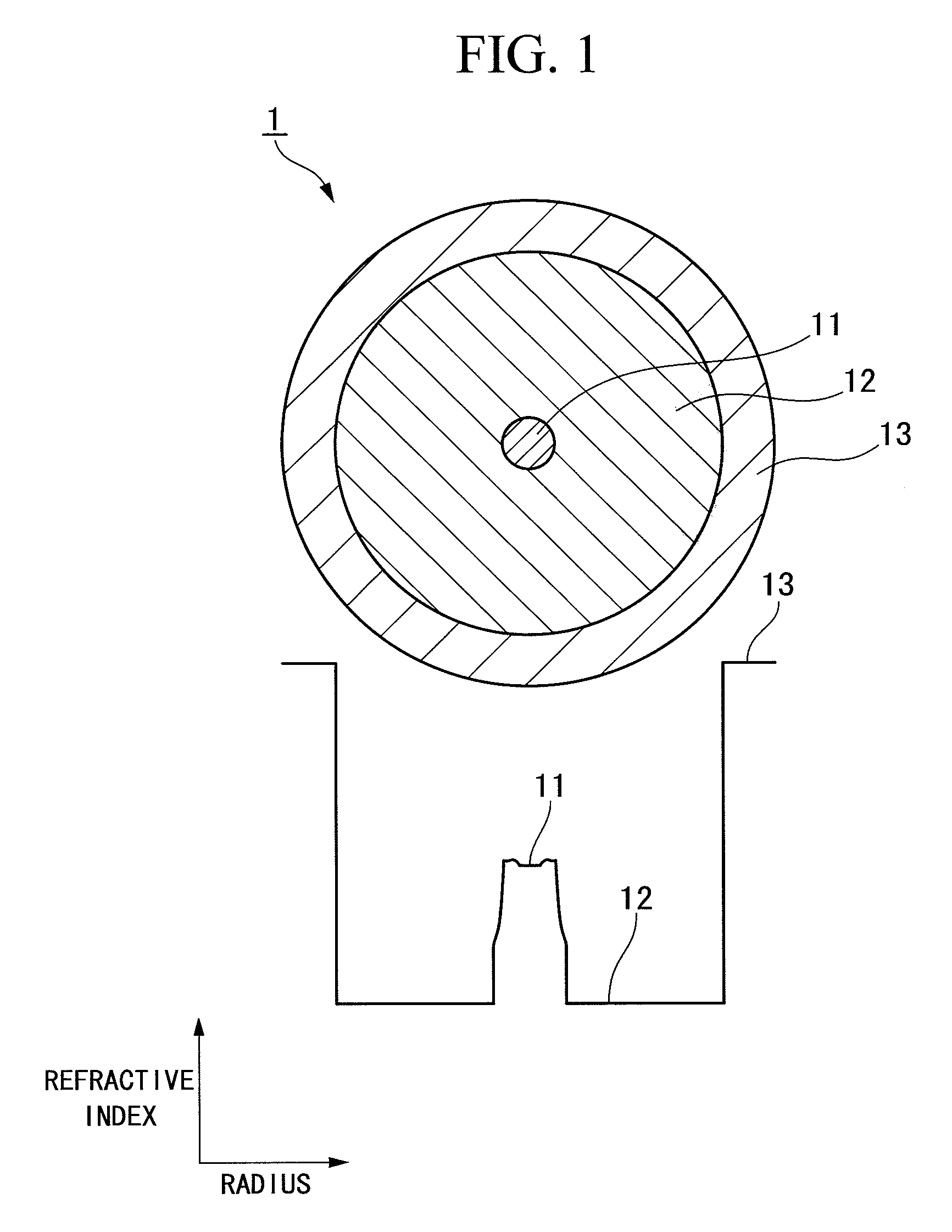

Ytterbium-doped optical fiber, fiber laser, and fiber amplifier

ActiveUS8363313B2Avoid small quantitiesSuperior optical amplificationLaser using scattering effectsOptical fibre with polarisationYTTERBIUM OXIDEDiphosphorus

An ytterbium-doped optical fiber of the present invention includes: a core which contains ytterbium, aluminum, and phosphorus and does not contain germanium; and a cladding which surrounds this core. The ytterbium concentration in the core in terms of ytterbium oxide is 0.09 to 0.68 mole percent. The molar ratio between the phosphorus concentration in the core in terms of diphosphorus pentoxide and the above ytterbium concentration in terms of ytterbium oxide is 3 to 30. The molar ratio between the aluminum concentration in the core in terms of aluminum oxide and the above ytterbium concentration in terms of ytterbium oxide is 3 to 32. The molar ratio between the above aluminum concentration in terms of aluminum oxide and the above phosphorus concentration in terms of diphosphorus pentoxide is 1 to 2.5.

Owner:FUJIKURA LTD

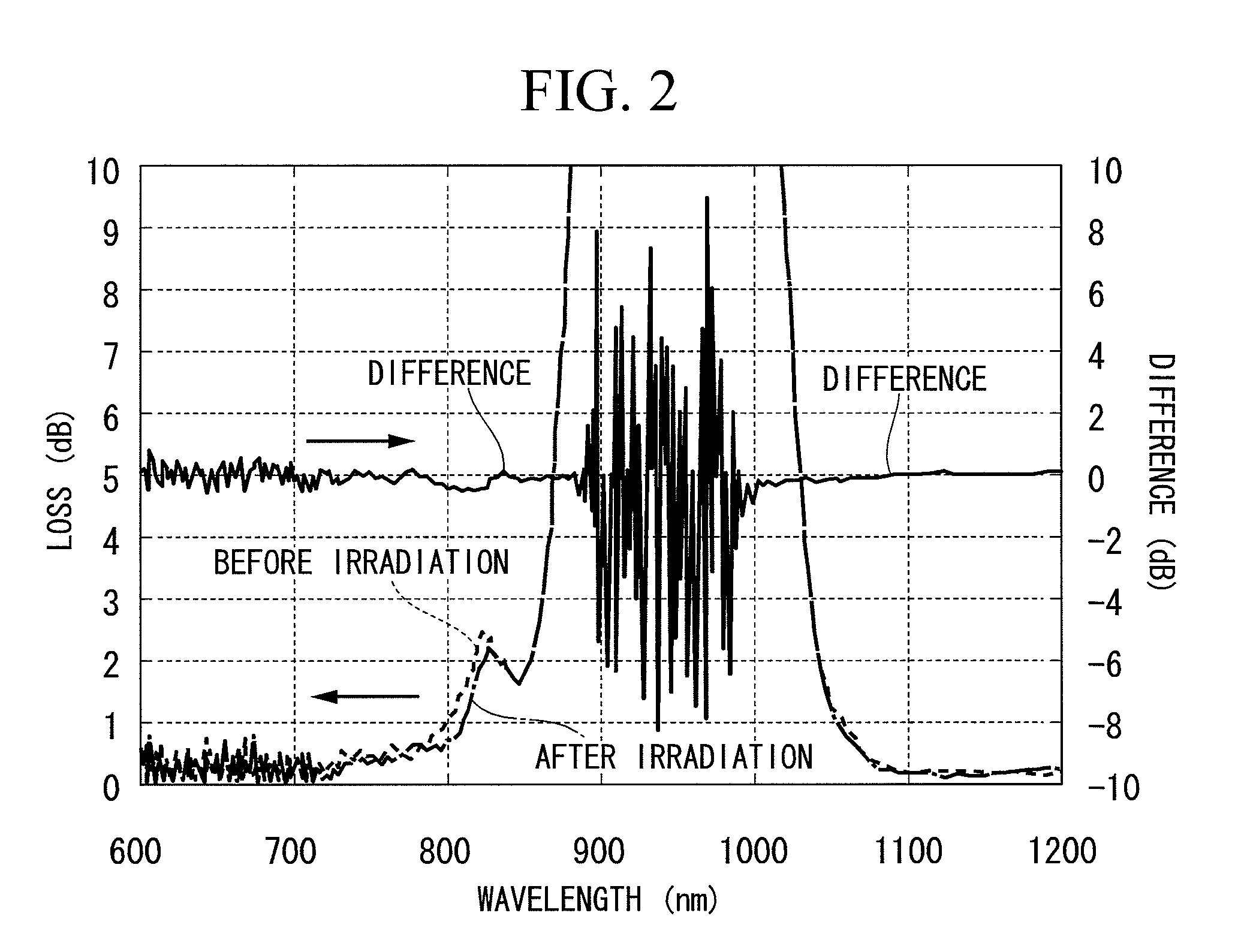

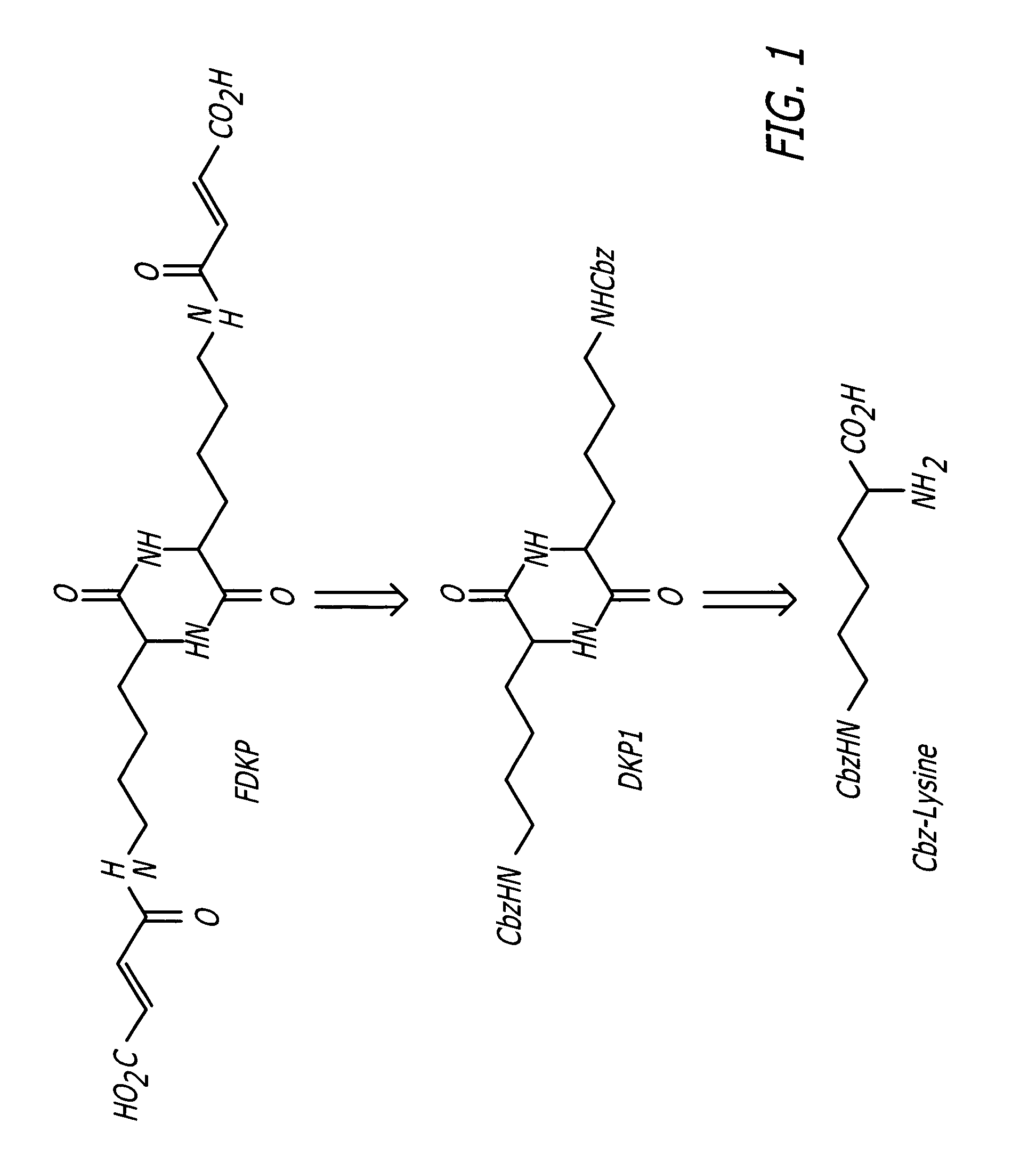

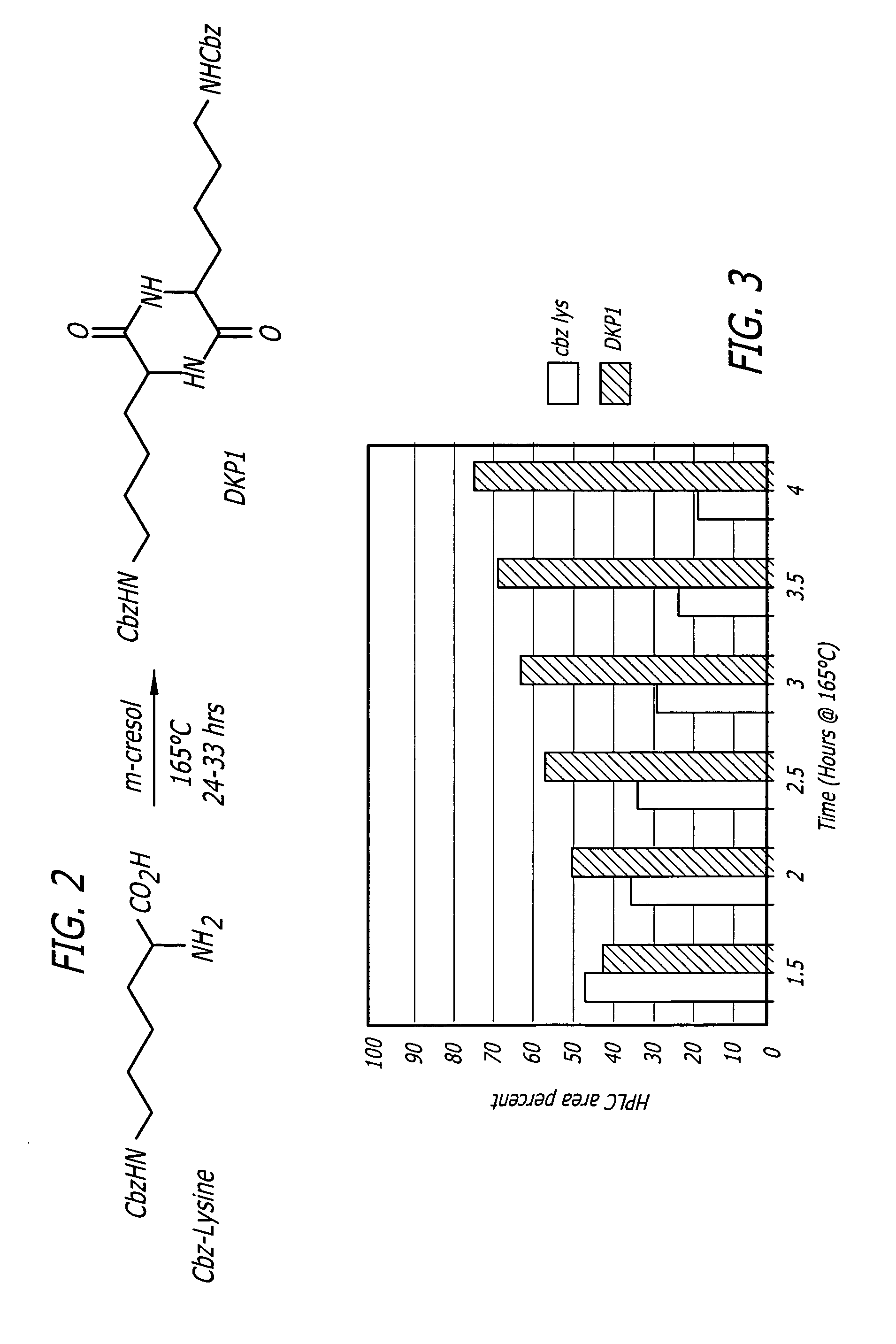

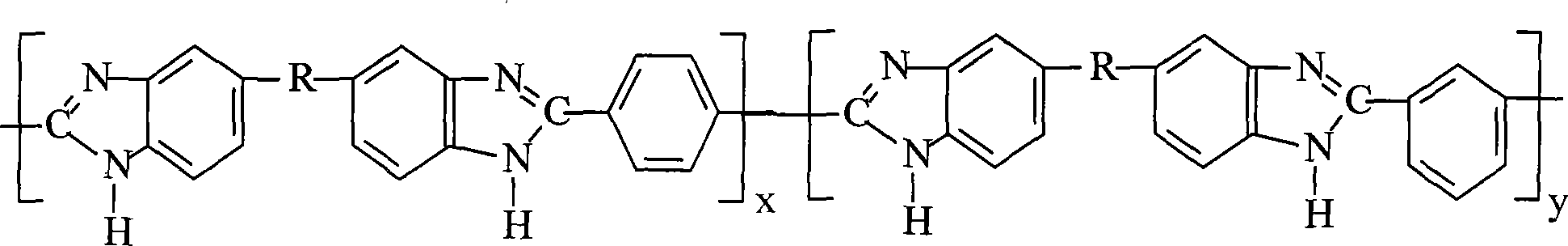

Catalysis of diketopiperazine synthesis

ActiveUS20060041133A1Fast reaction timeHigh yieldOrganic chemistryPhysical/chemical process catalystsPhosphoric acidDiketopiperazines

Provided is a method for the synthesis of N-protected bis-3,6-[4-aminobutyl]-2,5-diketopiperazine including the step of heating a solution of c-amino protected lysine in the presence of a catalyst selected from the group consisting of sulfuric acid, phosphoric acid, and phosphorus pentoxide.

Owner:MANNKIND CORP

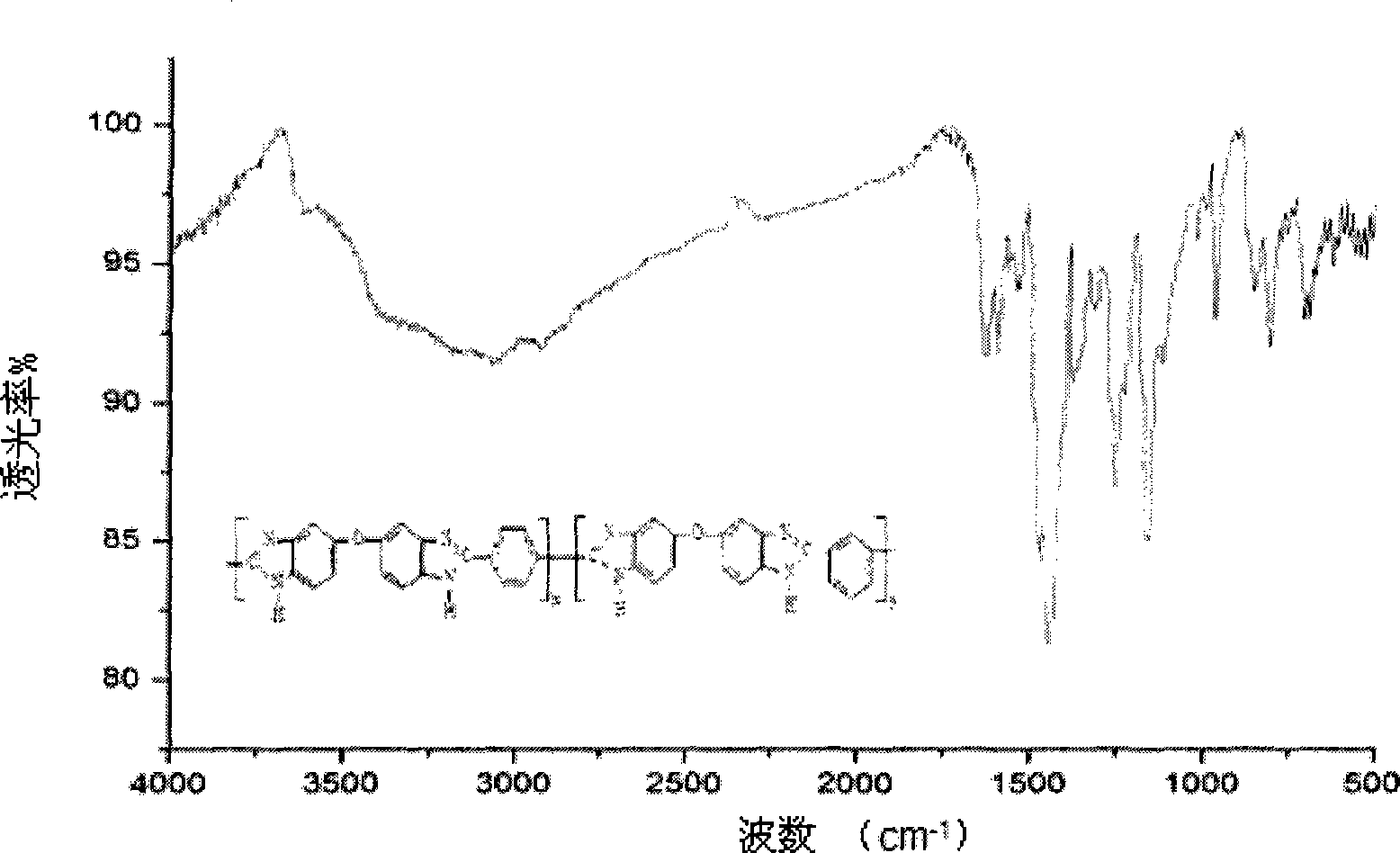

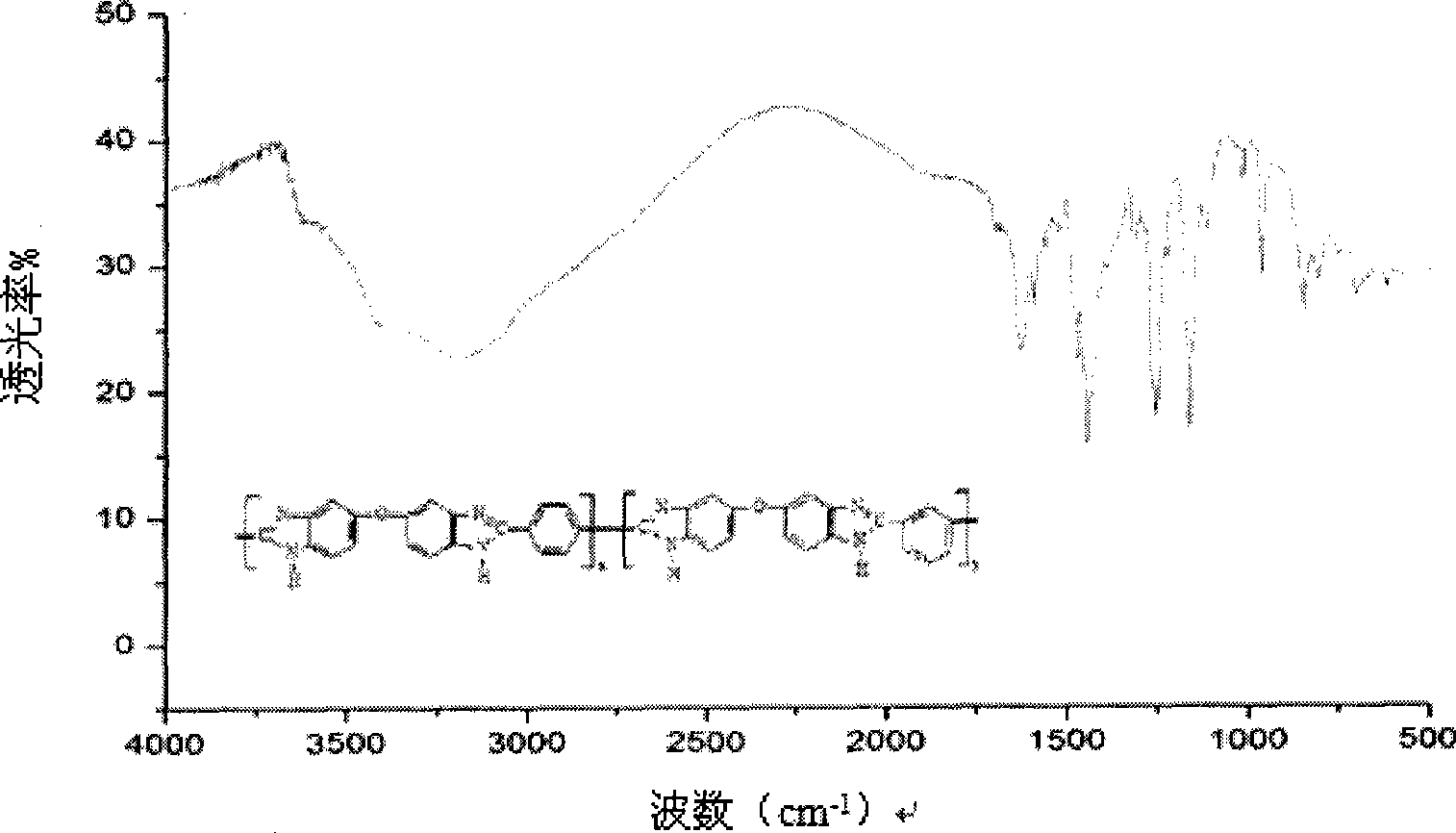

Method for preparing aromatic polybenzimidazole resin film

InactiveCN101456964AHigh molecular weightImprove thermal stabilitySemi-permeable membranesCell component detailsSolubilityNitrogen gas

The invention relates to a preparation method for aromatic series polybenzimidazole resin film, comprising: (1) under function of polyphosphoric acid / phosphorus pentoxide system, condensation polymerization reaction is carried out to aromatic series amine and aromatic series dicarboxylic acids mixed according to mol ratio of 1:1 in nitrogen atmosphere; (2) after cooling, polymer is poured into water and broken down into powder in a resin pulper and washed over and over again by distilled water and soaked for 48 hours in NaHCO3 solution and washed till pH value shows neutral and drawn and filtered for drying in vacuum; (3) the polymer dried is dissolved in even solution prepared by organic solvent with mass percent of 5 percent, and then is dried at temperature of 130 DEG C for 12 hours, and is soaked in hot water for boiling and striping, and is dried in vacuum at temperature of 100 DEG C for 5 hours and then is obtained. The polybenzimidazole prepared by the invention has the advantages of big molecule weight, stable thermal stability, fine solubility and film forming performance, etc. The preparation has simple technology, low cost, convenient operation and can be finished in common equipments through preparation procedure.

Owner:DONGHUA UNIV

Lithium ion battery composite cathode material and preparation method

InactiveCN101604743APromote circulationImprove cycle performanceElectrode manufacturing processesActive material electrodesFuranEpoxy

The invention relates to a lithium ion battery composite cathode material and a preparation method. The cathode material comprises a hard carbon precursor material containing hetero atoms, and natural spherical graphite, wherein the hard carbon precursor material selects one or more than two of phenolic resin, polyfurfural, furan resin, polyvinyl alcohol, epoxide resin or polyacrylonitrile as raw materials, and accounts for 5 to 45 percent of the natural spherical graphite by mass; modifier of the hetero atoms is boron-containing modifier including boric acid and diboron trioxide, phosphor-containing modifier including phosphoric acid and phosphorus pentoxide, and nitrogen-containing modifier HNO3; and one of the modifiers accounts for 5 to 35 percent of the hard carbon precursor by mass. An analog battery formed by the cathode material which is prepared by the method has the capacity over 350 mAH / g and first coulomb efficiency up to 95.8 percent, and has good circulation performance. The preparation method has the advantages of low cost and simple process.

Owner:珠海华丽新能源科技有限公司

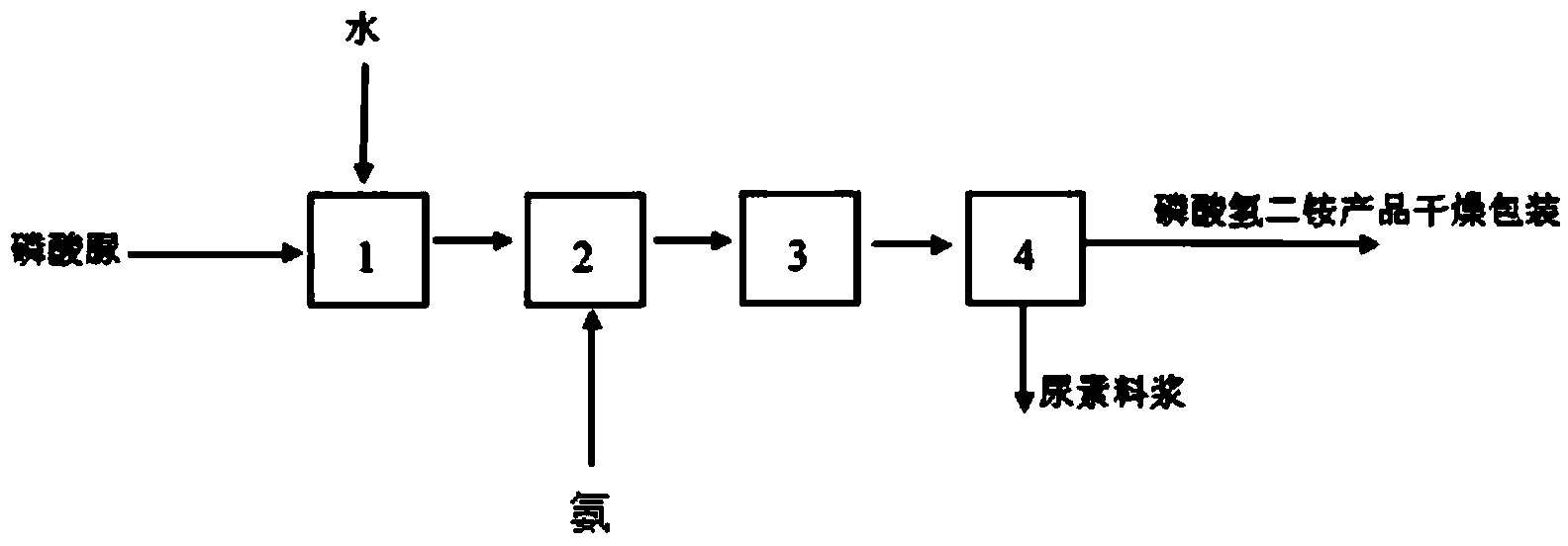

Production method for monoammonium phosphate

InactiveCN104016323AReduce energy consumptionReduce manufacturing costPhosphatesWater insolubleDecomposition

The invention relates to the technical field of chemical engineering, and particularly relates to a production method for monoammonium phosphate. A monoammonium phosphate product is prepared by directly subjecting high pure urea phosphate and ammonia to a double decomposition reaction and reacting for 20-60 min with stirring by controlling a reaction temperature at 40-80 DEG C and a pH value at a reaction endpoint being 4.2-4.6, and through the steps of cooling for crystallization; separating by centrifugation and drying. Measurements of physical and chemical indexes of the produced product show that the physical and chemical indexes of the produced monoammonium phosphate product meet an industrial first level standard. Specifically, the total nutrient content of monoammonium phosphate is higher than 73%; the content of total nitrogen is 12.01-12.23%; the content of phosphorus pentoxide is 61.05-61.25%; the content of moisture is 0.35-0.52%; a pH value is 4.2-4.6; the content of water insoluble materials is 0.090-0.096%; and the content of fluoride is 0.15-0.19%.

Owner:GUIYANG KAILIN FERTILIZER CO LTD

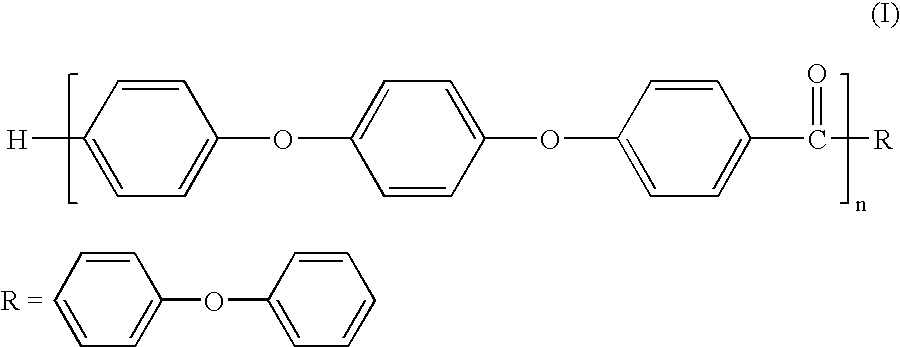

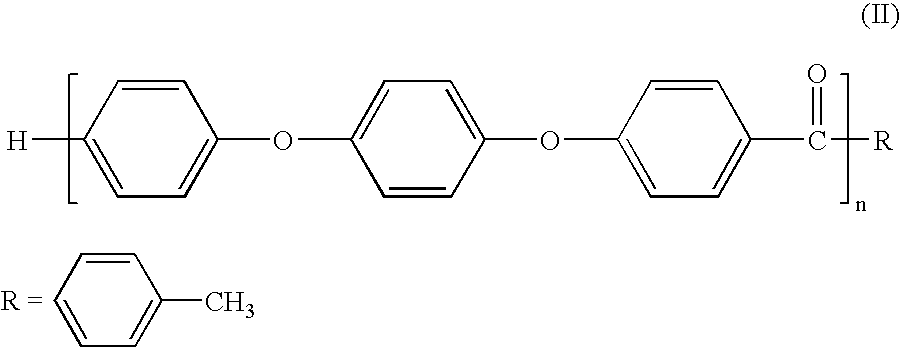

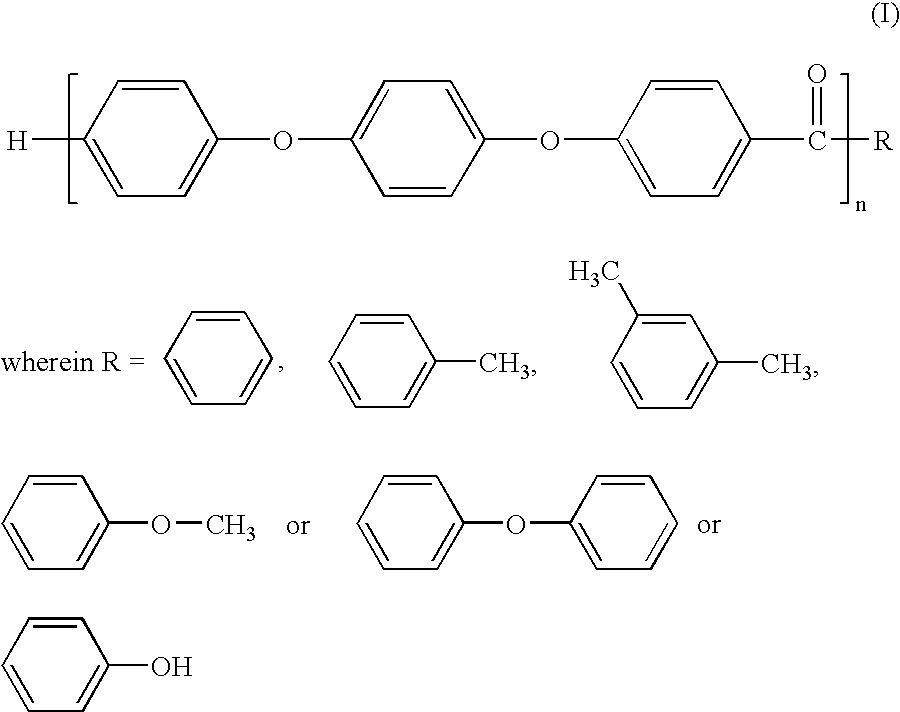

Melt processible polyether ether ketone polymer

InactiveUS6881816B2Easy to processReduce the temperatureChemical recyclingMethane sulfonic acidEnd-group

A melt processible Polyether Ether Ketone (PEEK) polymer with novel end-group structure is synthesized electrophilically using Methane Sulfonic Acid containing Methane Sulfonic Anhydride or Phosphorous Pentoxide. The product so obtained shows controlled structure with elimination of reactive end group like —COOH and is therefore melt processible by conventional techniques and exhibits high thermal and mechanical properties making it useful high temperature engineering and specialty plastics. It can be extruded into a rod, film and can also be molded into commercially useful products.

Owner:GHARDA CHEM LTD

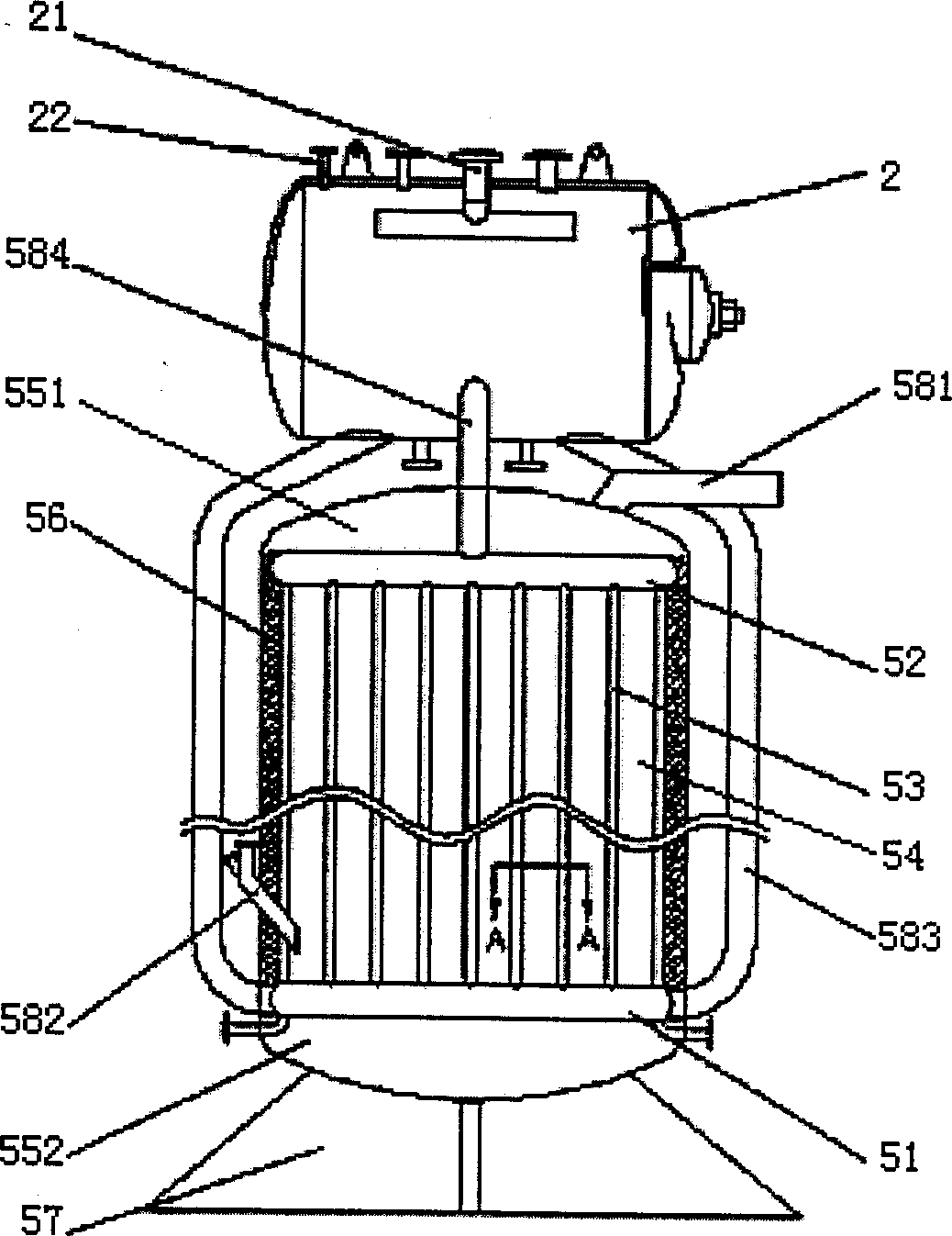

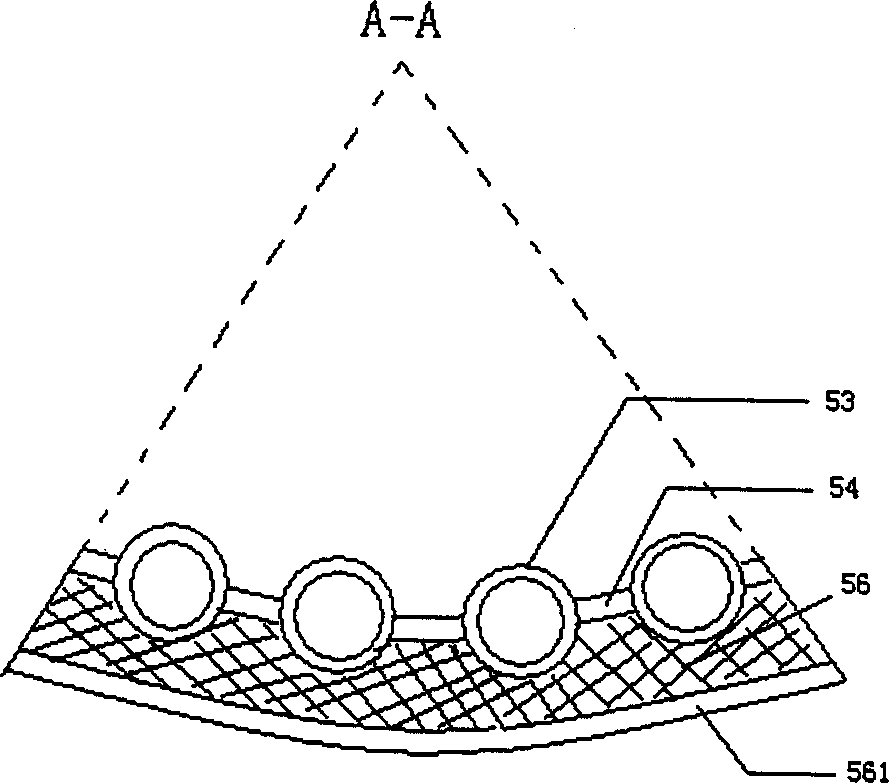

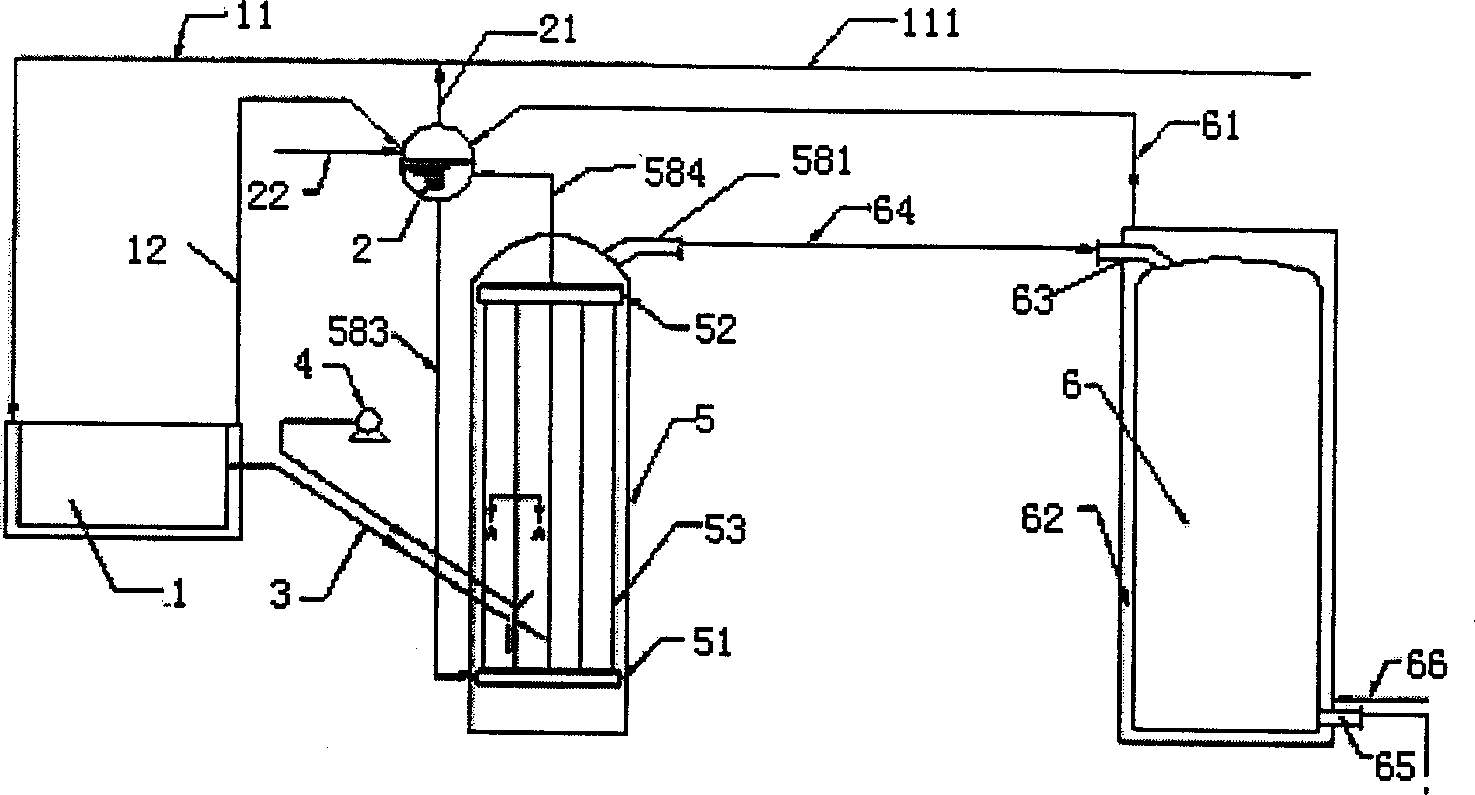

Equipment for recovering and utilizing heat energy generated by phosphor combustion and system for preparing phosphoric acid by hot method

An equipment for recovering and utilizing the heat energy generated by burning yellow phosphorus and a system for preparing phosphoric acid by the hot method are disclosed. It is composed of steam manifold and burning tower with heat energy recovering function. The burning tower consists of ring-shaped membrane heat exchanger with fins, heat-insulaitng enclosed casing, P2O5 gas outlet tube, connecting tube of phosphorus sprayer, etc.. Its advantages include low consumption of coal, water and energy, low cost and reduced environmental pollution.

Owner:TSINGHUA UNIV +1

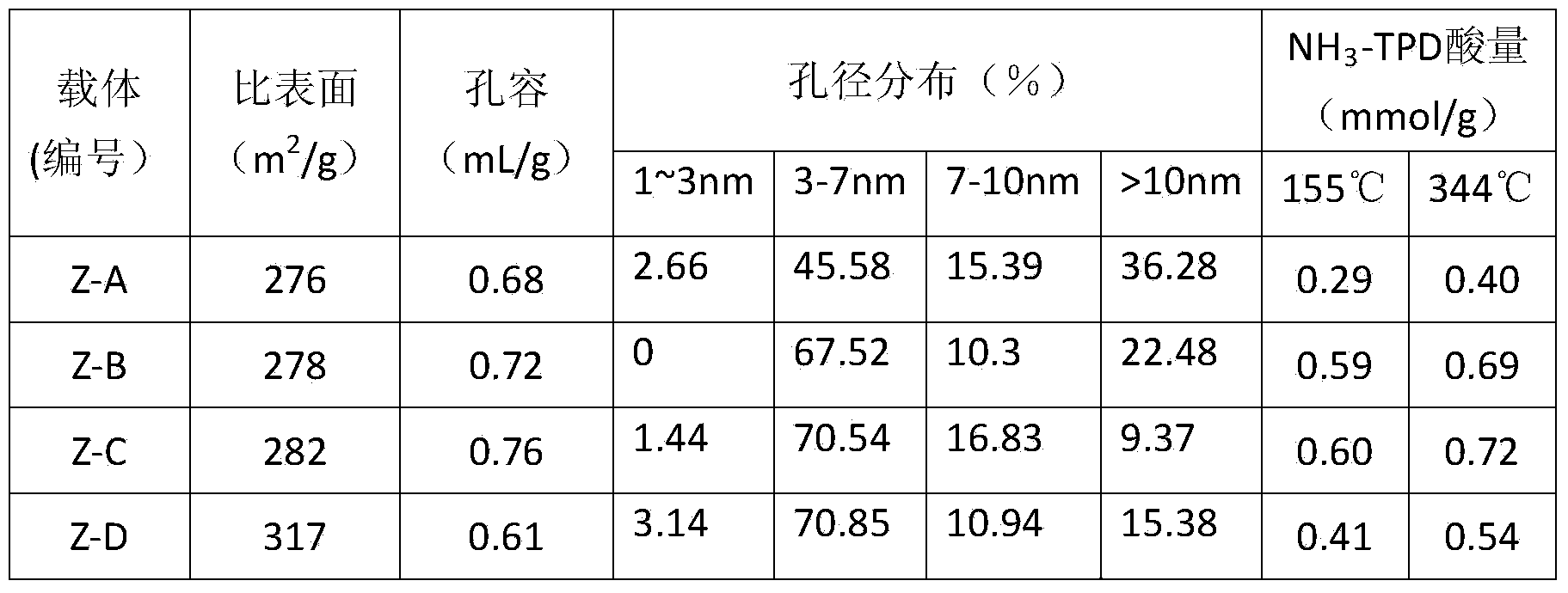

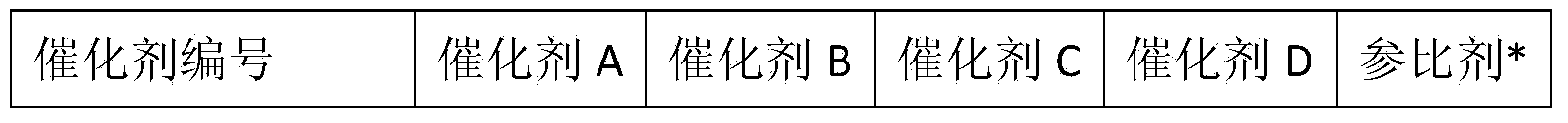

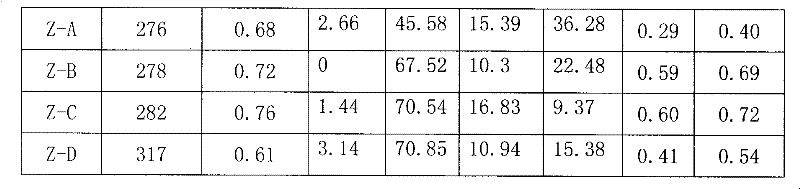

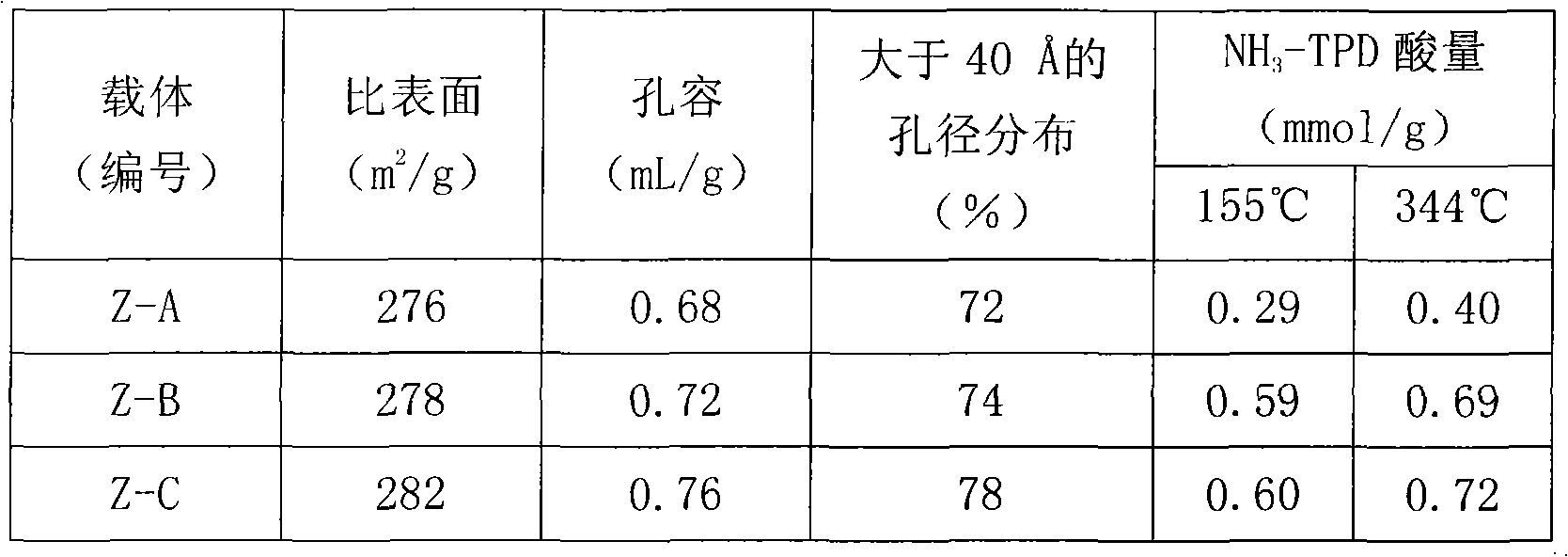

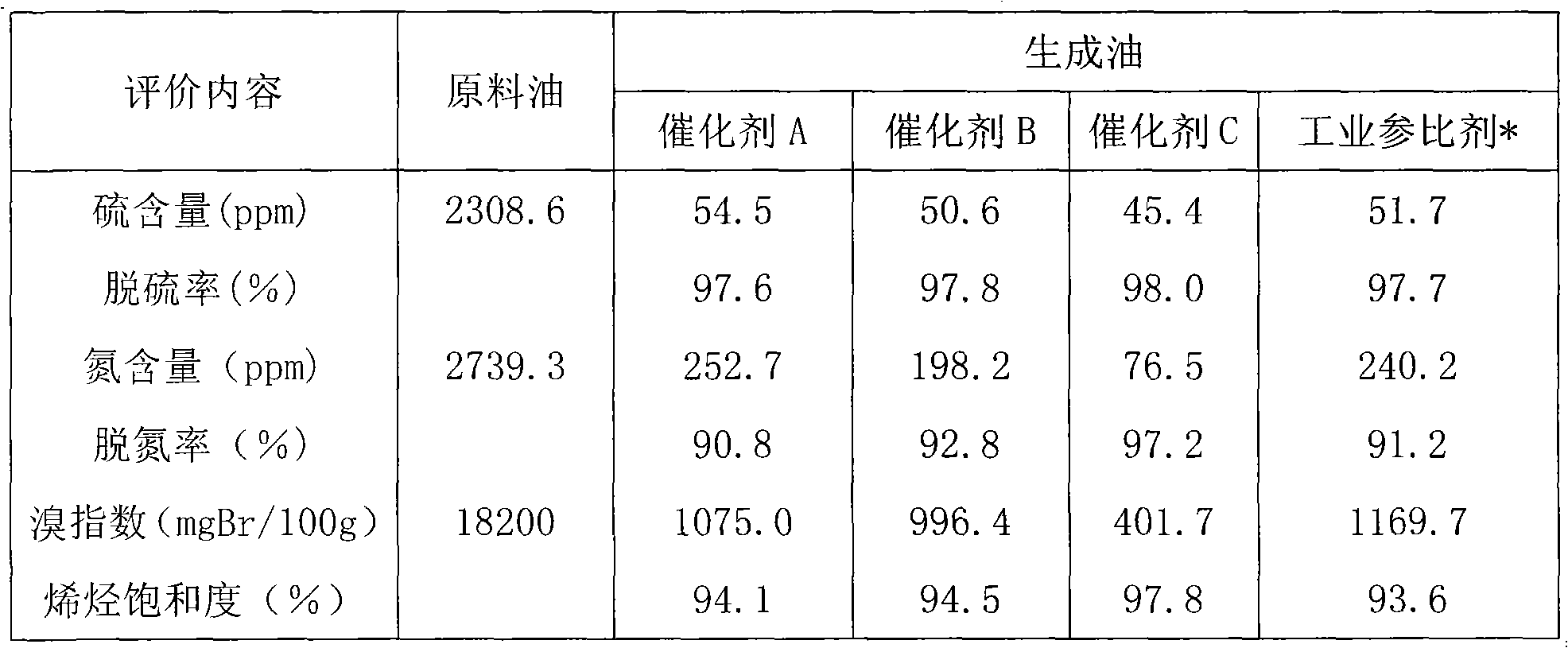

Diesel hydrodesulfurization and denitrification catalyst and preparation method thereof

InactiveCN103551162AGood dispersionIncrease profitMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsHydrodesulfurizationOxide composite

The invention discloses a diesel hydrodesulfurization and denitrification catalyst. The catalyst comprises the following compositions: a carrier, an additive, and an active metal, wherein the carrier is an Al2O3-ZrO2-TiO2-SiO2 multibasic oxide composite carrier; the additive is phosphorus; nickel, cobalt, molybdenum and tungsten are taken as active components; through taking the catalyst as a benchmark, in terms of oxides, the catalyst comprises the following components in percentage by weight, 1-6wt% of cobalt oxide, 1-15wt% of nickel oxide, 2-12wt% of molybdenum oxide, 12-35wt% of tungsten oxide and 1.5-5wt% of an additive phosphorus pentoxide; and the pore volume of the catalyst is not less than 0.2 mL / g, the specific surface area of the catalyst is not less than 140 m<2> / g, and the mechanical strength of the catalyst is not less than 15N / mm; and the composite carrier comprises the following components in percentage by weight: 2-15wt% of titanium oxide, 2-20wt% of silicon oxide, 5-15wt% of zirconium oxide, and the balance of aluminum oxide.

Owner:CHINA NAT OFFSHORE OIL CORP +2

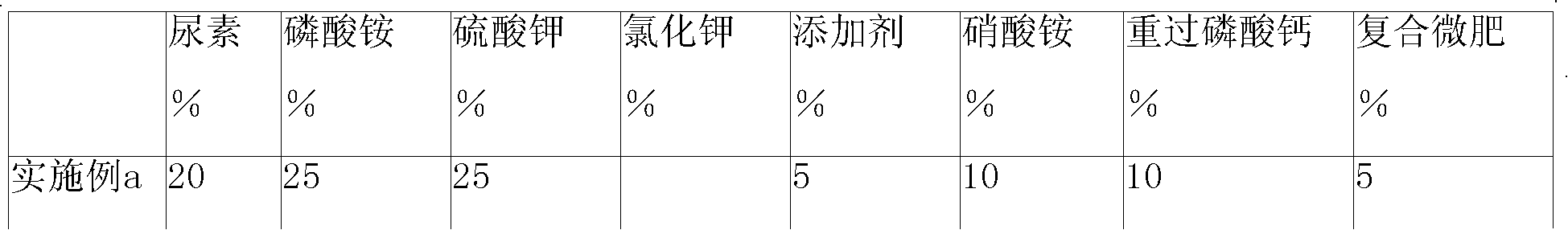

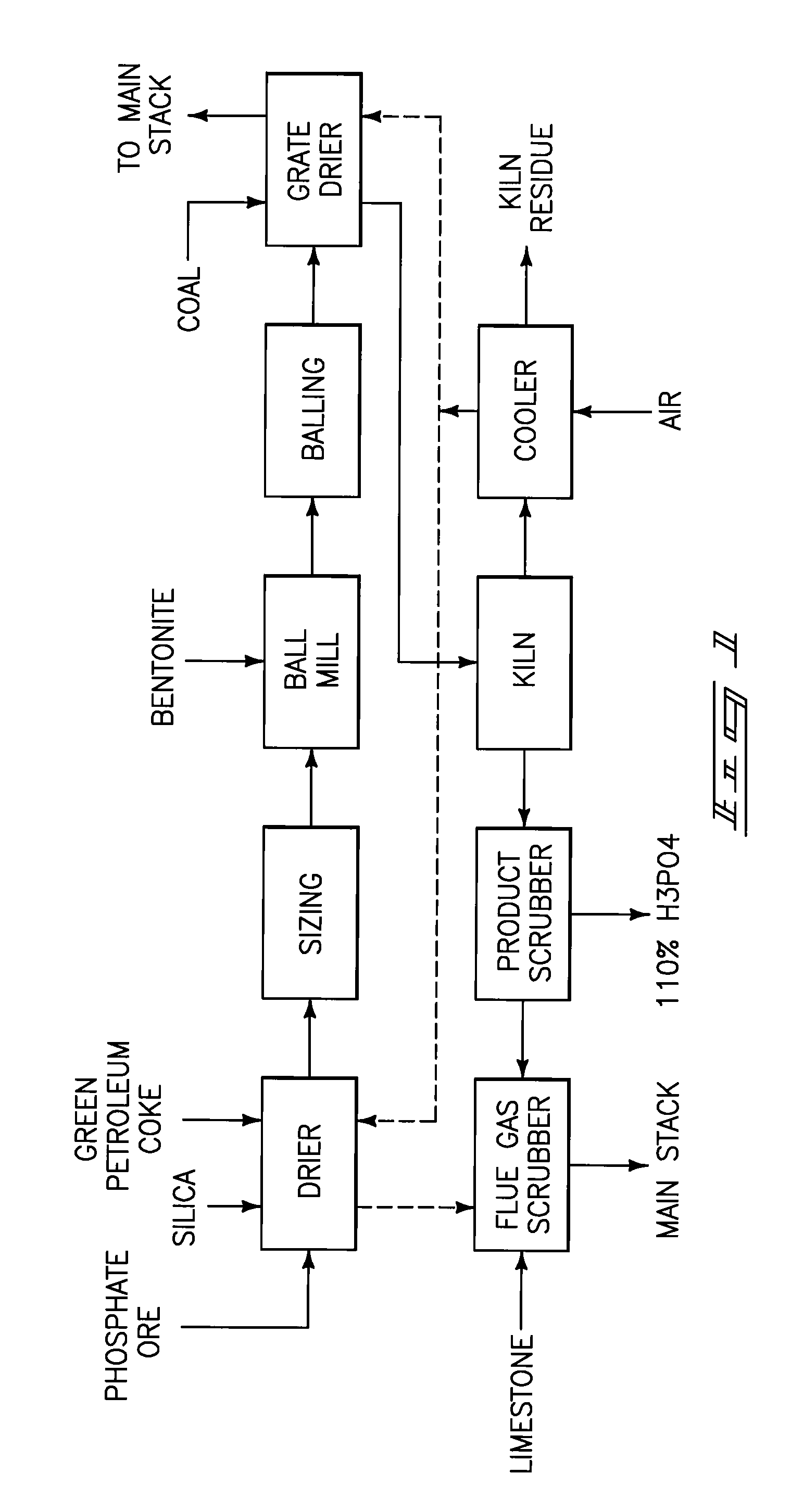

Long-acting special controlled release fertilizer for corn and preparation method thereof

InactiveCN101177365ALess hygroscopic expansion and contractionSimple preparation processFertilizer mixturesPotassiumNutrient

A special controlled-release fertilizer for long-acting corn and its preparation method. The fertilizer core accounts for 80-92% of the total weight of the fertilizer, wherein the weight sum of nitrogen fertilizer, phosphorus fertilizer and potassium fertilizer calculated by pure nitrogen, phosphorus pentoxide and potassium chloride is the fertilizer 25%-50% of the total weight, the weight ratio is: 2-4:1-2:1-3; the coating coating accounts for 8-20% of the total weight of the fertilizer, including: 69.5-93% sulfur, 530 % polyethylene wax, 0.5-2% leveling agent. Melt sulfur, add montmorillonite and stir evenly, then add leveling agent, stir evenly to form molten sulfur. The molten sulfur and polyethylene wax are simultaneously sprayed on the surface of the fertilizer core to form a slow-release coating layer. The process occupies less land, requires less investment in equipment, and consumes less energy. It has the characteristics that one fertilization can meet the nutrient needs of corn throughout the growth period. The fertilizer effect is long and safe, and fertilization is simple.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Biological multi-effect fertilizer

ActiveCN101492324AEffective controlReduce reproductive rateOrganic fertilisersFertilizer mixturesMedicinal herbsPins needles

The invention discloses a multi-effect biofertilizer, comprising sarcandra glabra, cortex fraxini, radix stemonae, lightyellow sophora root, pin needles, isatis root, phellodendron, aloe, humic acid and inorganic fertilizers of nitrogen, phosphorus and potassium; the weight percentages of the components are as follows: 1-2.5% of sarcandra glabra extract, 1-2.5% of radix stemonae extract, 1-2.5% of phellodendron extract, 5-10% of aloe extract, 10-15% of pin needles, 7-10% of isatis root, 7-10% of cortex fraxini, 10-15% of lightyellow sophora root, 15-20% of humic acid, 10-20% of available nitrogen, 5-10% of phosphorus pentoxide and 5-10% of potassium oxide. The Chinese medicinal herbs of the invention have the advantages of sterilization and disinfestation, safety without pollution, combined herbs and fertilizers, compound multielements, comprehensive nutrition, long-acting slow release and improved utilization rate. The multi-effect biofertilizer can be widely applied to such cash crops as corn, cotton, rapeseed plants, peanuts, legume, silkworm and mulberry, tea forests, fruit grove and various vegetables.

Owner:何同林

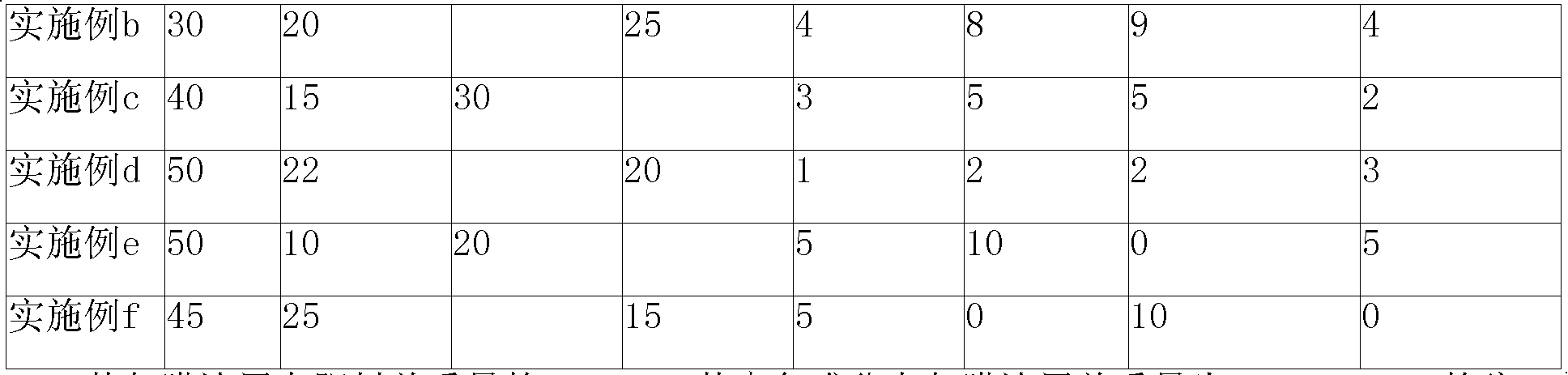

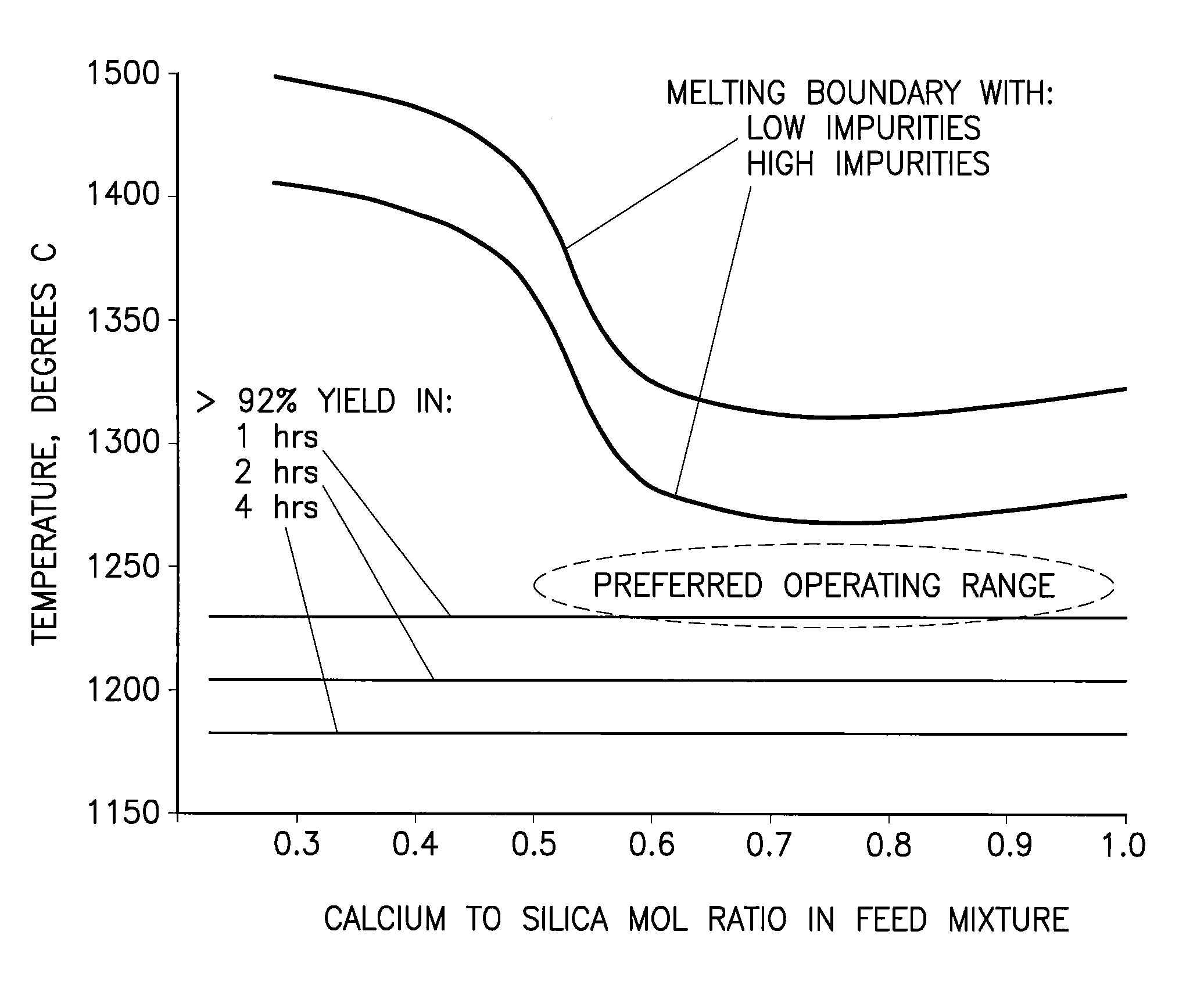

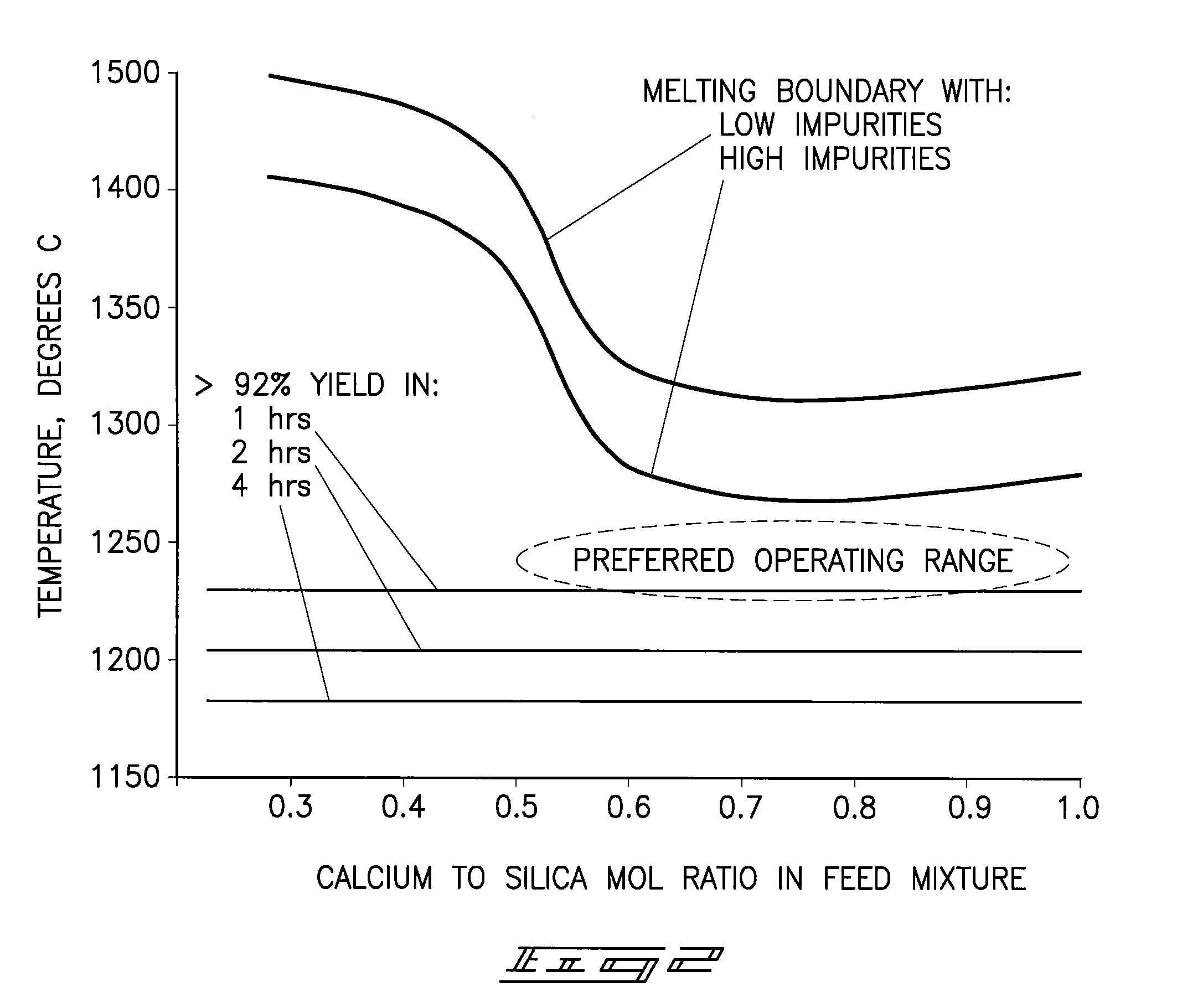

Phosphorous pentoxide producing methods

A phosphorous pentoxide producing method includes forming a kiln bed using feed agglomerates with a calcium-to-silica mole ratio of from 0.5 to 1.0 and maintaining a bed temperature at or above 1260° C. along a portion of the bed length without exceeding 1380° C. along the entire bed length. Less than 10% of the agglomerates' phosphate input to the kiln remains in the kiln residue as phosphate. Another method includes maintaining a bed temperature at or above 1180° C. along a portion of the bed length and establishing a bed surface-to-volume ratio multiplied by a time for bed heat up to 1180° C. of less than 50 minutes-ft2 / ft3.

Owner:NOVAPHOS INC

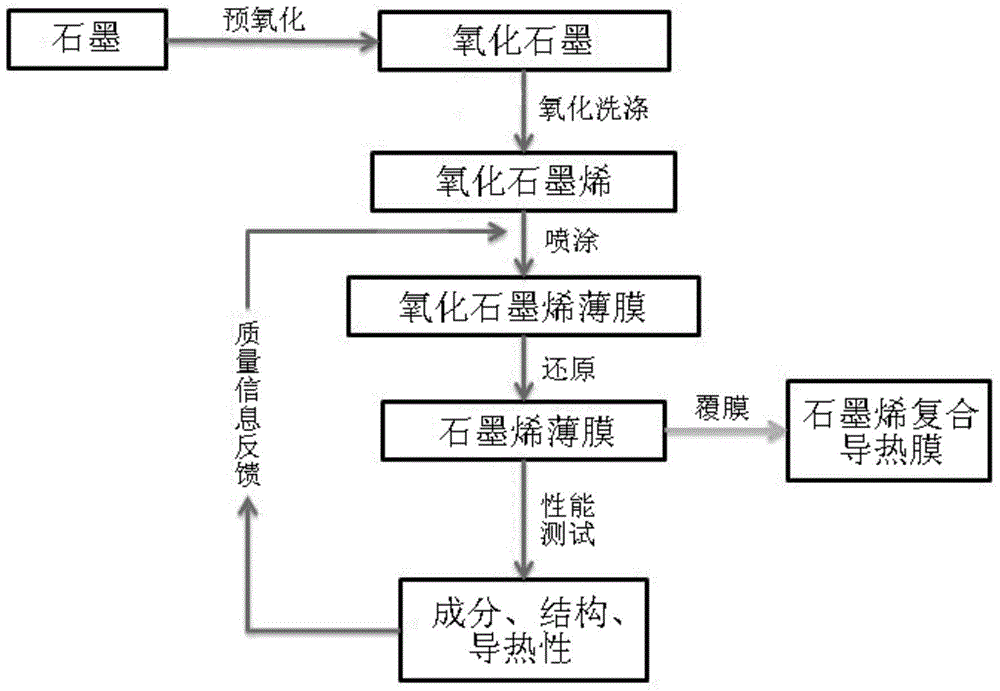

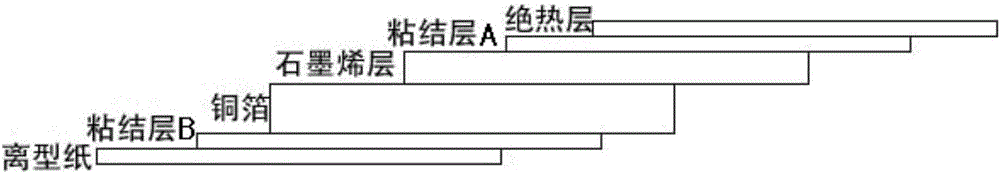

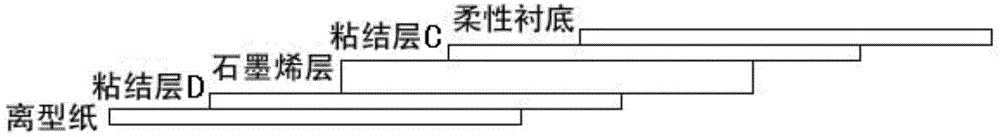

Preparation method of composite heat conduction graphene film and composite heat conduction graphene film

ActiveCN104085143AIncrease layer spacingThoroughly oxidizedMetal layered productsPotassium persulfateFiltration

The invention discloses a preparation method of a composite heat conduction graphene membrane and the composite heat conduction graphene film. The preparation method comprises the following steps: S1, putting crystalline flake graphite or graphite powder into a mixed solution of concentrated sulfuric acid, potassium persulfate and phosphorus pentoxide, soaking for a day and a night, then carrying out suction filtration, drying, and carrying out pre-oxidizing; S2, oxidizing pre-oxidized graphite further by adopting a Hummers method, that is, oxidizing fully in concentrated sulfuric acid and potassium permanganate, then adding deionized water for diluting, and carrying out repeated washing and suction filtration, so as to obtain an oxidized graphene aqueous solution; S3, spraying the oxidized graphene aqueous solution on a substrate by adopting a thermal spray method, and depositing, so as to obtain an oxidized graphene film; S4, reducing the oxidized graphene film, so as to obtain the graphene film; and S5, laminating the graphene film, so as to obtain the composite heat conduction graphene film. Compared with the prior art, the preparation method is simple, the cost is low, and the prepared composite heat conduction graphene film has a favorable heat conduction performance.

Owner:成都科愿慧希科技有限公司

Optical glass

InactiveCN1450010AHigh coefficient of thermal expansionPrecise without migrationOptical elementsLithium oxideSilicic acid

The present invention relates to an optical glass using silicic acid group as main body, said optic glass has high expansion coefficient, high Young modulus, excellent weatherability and high transmissivity in the infrared wave zone. Said glass composition contains (mole%) 36-66% of silicon dioxide, 0-12% of aluminium oxide, 0-6% of boric oxide, 0-10% of magnesium oxide, 0-16% of calcium oxide, 0-16% of strontium oxide, 0-16% of baria, 0-8% of zinc oxide, 0-32% of lithium oxide, 0-25% of sodium oxide, 0-25% of potassium oxide, 0-20% of cesium oxide, 0-6% of phosphorus pentoxide, 0-8% of scandium oxide and others.

Owner:PICVUE OPTOELECTRONICS INT

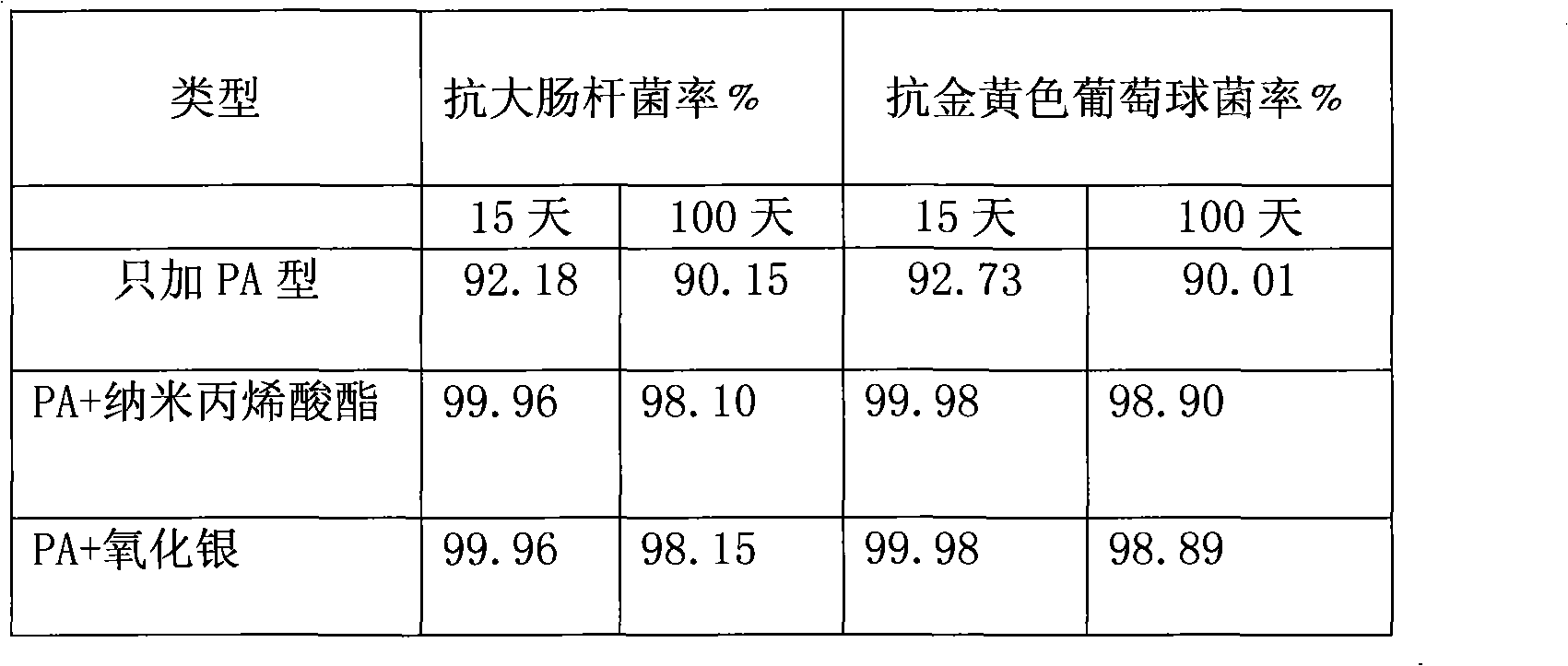

UV curing antibiotic coating and preparation thereof

InactiveCN101353545AImprove antibacterial propertiesSimple preparation processAntifouling/underwater paintsPaints with biocidesUV curingTMPTA

The invention discloses a UV-curable antimicrobial coating, the components of which are as follows: bisphenol A type epoxy acrylate EA; aliphatic PUA; special functional group acrylate PA; TPGDA; TMPTA; photoinitiators; nano acrylate; oxidized silver; and auxiliaries. The preparation method comprises the following steps of: step one, synthesizing special functional group heterocyclic compound PA and later adding phosphorus pentoxide to acrylic acid hydroxy esters so as to react with hydroxyl piperidine and then prepare special functional group heterocyclic compound PA; and step two, taking each component according to the formula, stirring and mixing each component so as to carry out dispersion at the speed of 900 to 1200r per min, then adding silver oxide and photoinitiators after being dispersed evenly, and finally obtaining UV-curable antimicrobial coating through dispersion. The UV-curable antimicrobial coating prepared by the invention has good anti-bacterial effect. As the self-prepared special functional group acrylate PA, the nano acrylate and the silver oxide are added, after UV-curable film-forming, the anti-coli rate can achieve over 99 percent and the anti-staphylococcal rate thereof achieves over 99 percent, and the effectiveness is long.

Owner:苏州市明大高分子科技材料有限公司

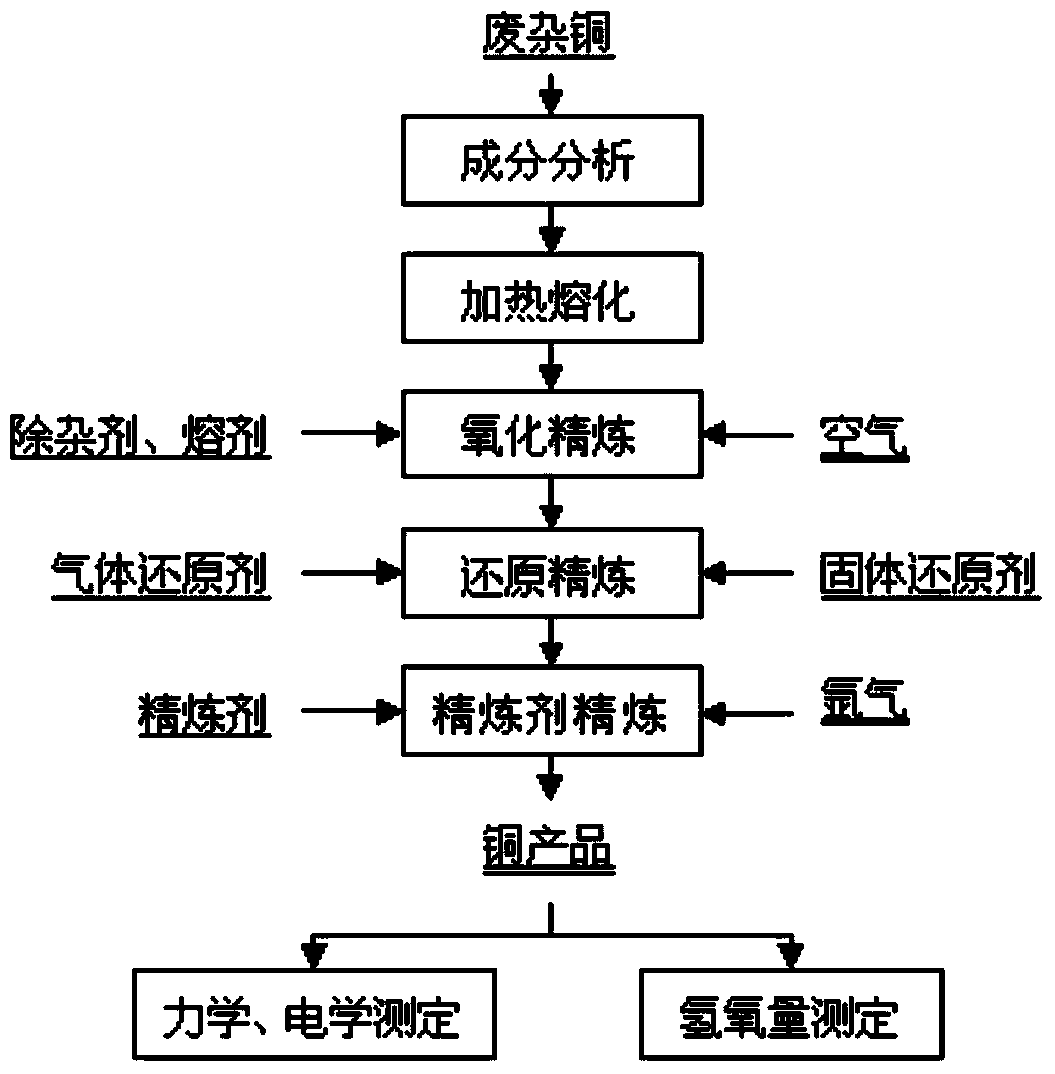

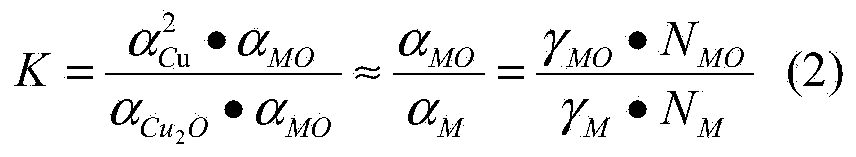

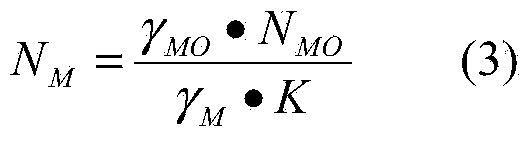

Method for directly producing high-purity oxygen-free copper by pyrogenic process continuous refining of scrap copper

ActiveCN103725897AOptimizing Process ParametersReduce manufacturing costProcess efficiency improvementElectrolysisCopper wire

The invention relates to a method for directly producing high-purity oxygen-free copper by pyrogenic process continuous refining of scrap copper, and belongs to the technical field of non-ferrous metallurgy. The method comprises the following steps: by taking scrap copper as a raw material; analyzing the component characteristics of each batch of raw material, and then preparing into a mixture, wherein the mass percent of a copper element in the mixture is greater than or equal to 93%; adding metaphosphate or phosphorus pentoxide and flux to the mixture; refining by oxidation; stewing and drossing after oxidation is finished, and then orderly carrying out reduction refining and refining agent refining under an agitation state, so as to obtain the high-purity oxygen-free copper of which the copper content is greater than or equal to 99.95% and the oxygen content is smaller than 0.003%, wherein the electrical resistivity of the obtained copper wire after drawing is below 0.017241omega / (mm), and the relative electrical conductivity is over 100% of International annealed copper standard (IACS). The method is strong in flexibility, significant in refining effect, and applicable to different components of scrap copper materials; the scrap copper can be used for directly making a rod after being refined. Compared with the traditional pyrogenic process smelting-electrolytic refining-copper cathode purification process, the method disclosed by the invention has the beneficial effects that the flow is shortened, the cost is reduced, the energy is saved, and continuous operation is achieved.

Owner:CENT SOUTH UNIV

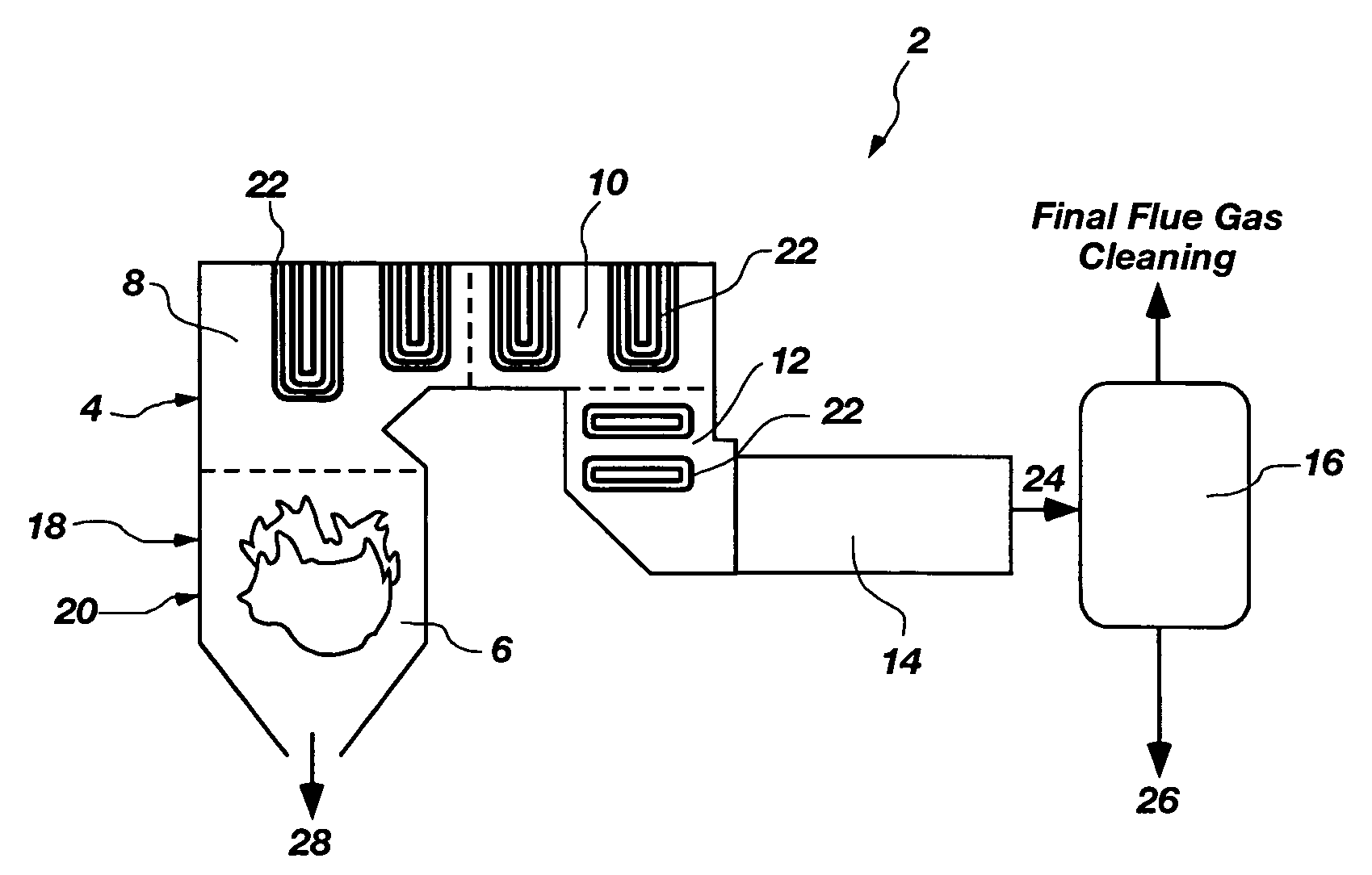

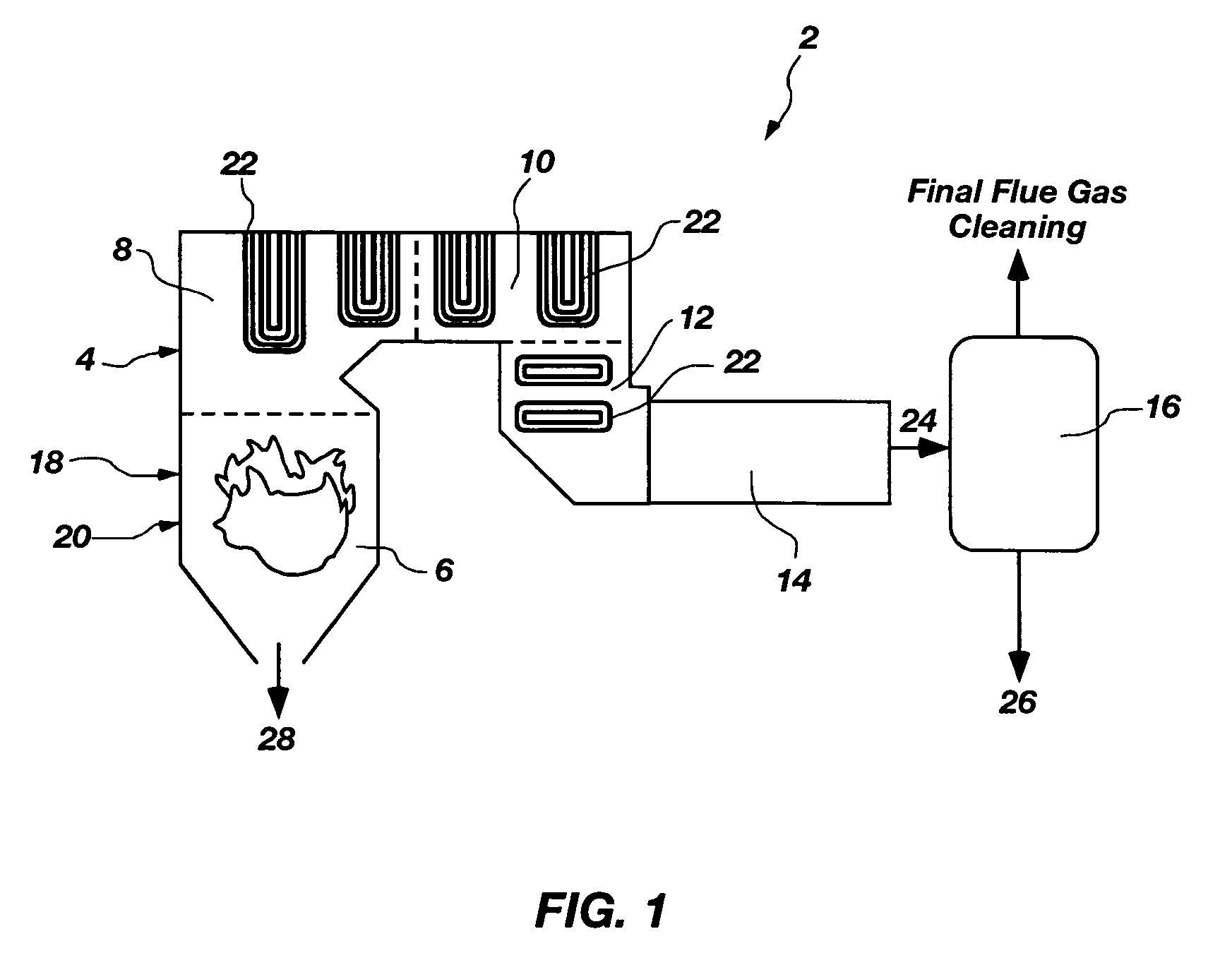

Method for oil shale pollutant sorption/NOx reburning multi-pollutant control

A method of decreasing pollutants produced in a combustion process. The method comprises combusting coal in a combustion chamber to produce at least one pollutant selected from the group consisting of a nitrogen-containing pollutant, sulfuric acid, sulfur trioxide, carbonyl sulfide, carbon disulfide, chlorine, hydroiodic acid, iodine, hydrofluoric acid, fluorine, hydrobromic acid, bromine, phosphoric acid, phosphorous pentaoxide, elemental mercury, and mercuric chloride. Oil shale particles are introduced into the combustion chamber and are combusted to produce sorbent particulates and a reductant. The at least one pollutant is contacted with at least one of the sorbent particulates and the reductant to decrease an amount of the at least one pollutant in the combustion chamber. The reductant may chemically reduce the at least one pollutant to a benign species. The sorbent particulates may adsorb or absorb the at least one pollutant. A combustion chamber that produces decreased pollutants in a combustion process is also disclosed.

Owner:BATTELLE ENERGY ALLIANCE LLC

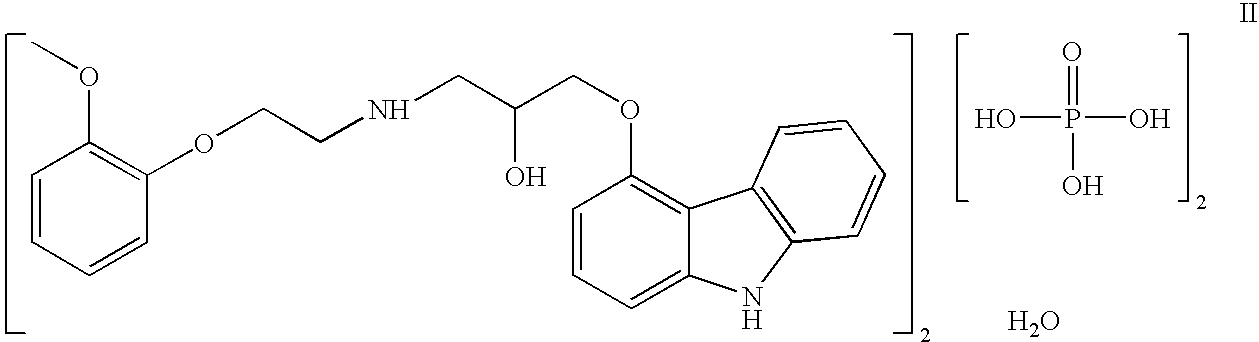

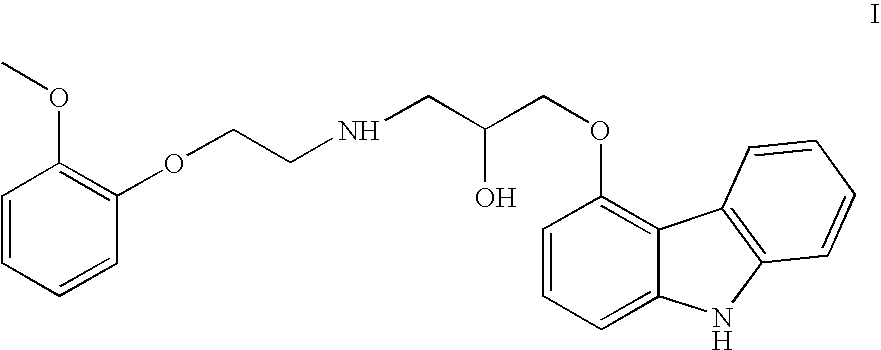

Efficient process for production of carvedilol phosphate

InactiveUS7777053B2High purityHigh yieldOrganic chemistryDipotassium hydrogen phosphateCarvedilol Phosphate

A novel cost effective process for the synthesis of phosphate salts of 1-(9H-carbazol-4yloxy)-3-[[2-(2-methoxyphenoxy)ethyl]amino]-propan-2-ol, (carvedilol phosphate) of formula (II) with high yields and purity is disclosed. More particularly, the invention discloses a process for preparation of crystalline phosphate salts of carvedilol using various phosphate forming reagents such as phosphorous pentoxide, polyphosphoric acid, dipotassium hydrogen phosphate, ammonium dihydrogen ortho phosphate, and sodium dihydrogen ortho phosphate in solvents selected from Acetonitrile, acetone and tetrahydrofuran. The solvents used to prepare solvates of carvedilol dihydrogen phosphate are methanol, ethanol and isopropyl alcohol.

Owner:WANBURY

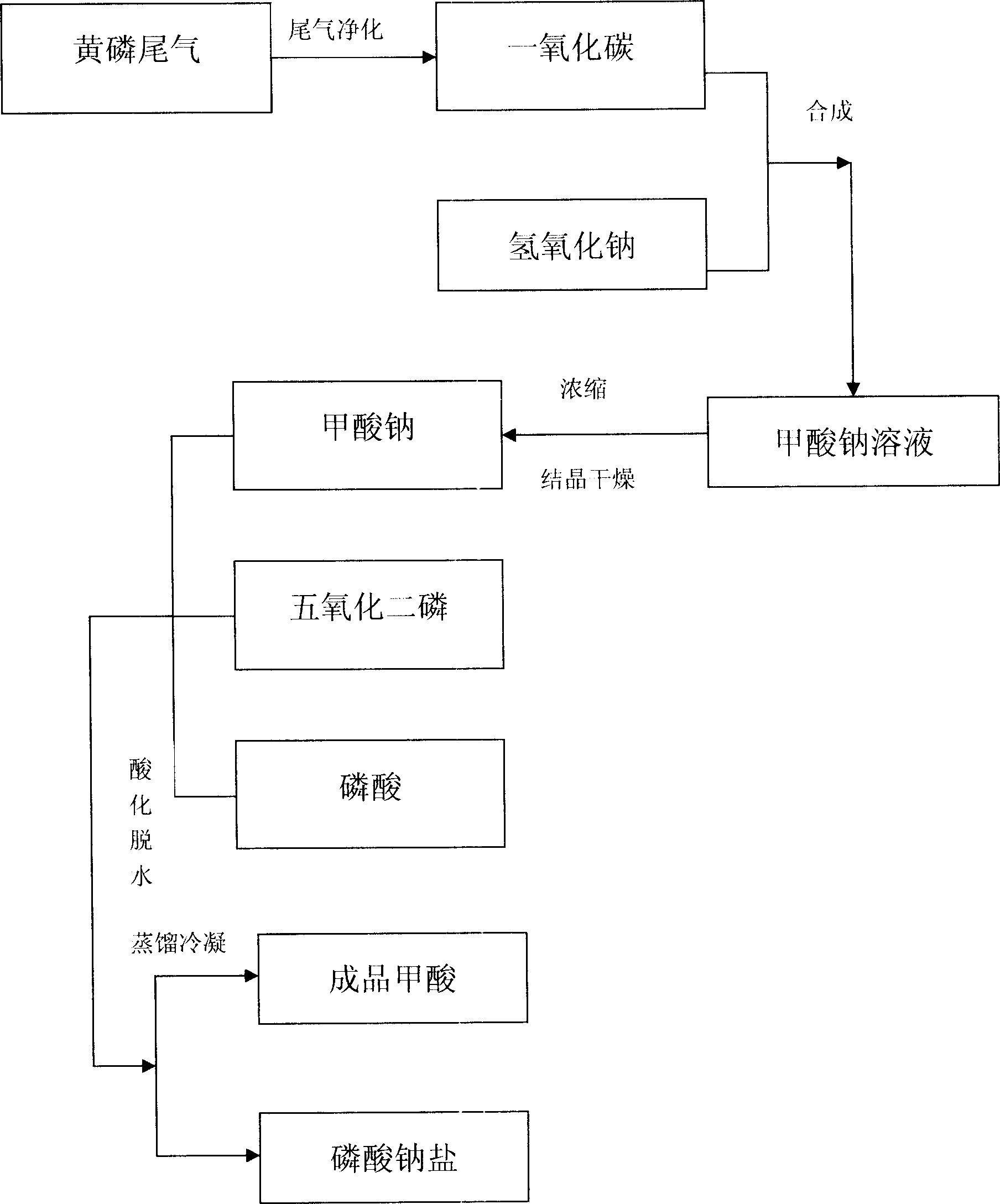

Method for producing formic acid through phosphoric acid and sodium formate

InactiveCN1915954AImprove utilizationEmission reductionPreparation from carboxylic acid saltsPhosphoric acidFormic acid

This invention discloses a method for preparing formic acid from phosphoric acid and sodium formate. The method comprises: reacting CO produced from yellow phosphorus manufacture with caustic soda to obtain sodium formate, then reacting with phosphoric acid, dehydrating with P2O5, and distilling to obtain formic acid. The method can reduce CO2 emission, thus is environmentally friendly. Besides, the method can lower the cost of yellow phosphorus and formic acid manufacture.

Owner:HUBEI XINGFA CHEM GRP CO LTD

Phosphorus doped graphene and preparation method thereof

The invention provides a preparation method for phosphorus doped graphene. The preparation method comprises the following steps: uniformly mixing graphite oxide and phosphorus pentoxide in a mass ratio of 1: 0.5-3 and placing an obtained mixture in a reactor; introducing protective gas into the reactor, wherein introduction flow velocity of the protective gas is 200 to 400 ml / min; heating the interior of the reactor to a temperature of 800 to 900 DEG C at a heating speed of 15 to 20 DEG C / min and maintaining the temperature for 30 min to 2 h; and cooling the reactor to room temperature in the protective gas with flow velocity of 200 to 400 ml / min so as to prepare the phosphorus doped graphene. According to the method, phosphorus pentoxide is used as a phosphorus source, the maximum doping amount of elemental phosphorus can approach 10%, so the adjustable range of phosphorus is wide; and the method has the advantages of simple process, convenient operation, no special requirements on equipment and easy realization of large scale industrial production. The invention further provides the phosphorus doped graphene prepared by using the preparation method.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

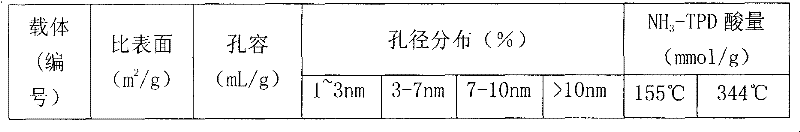

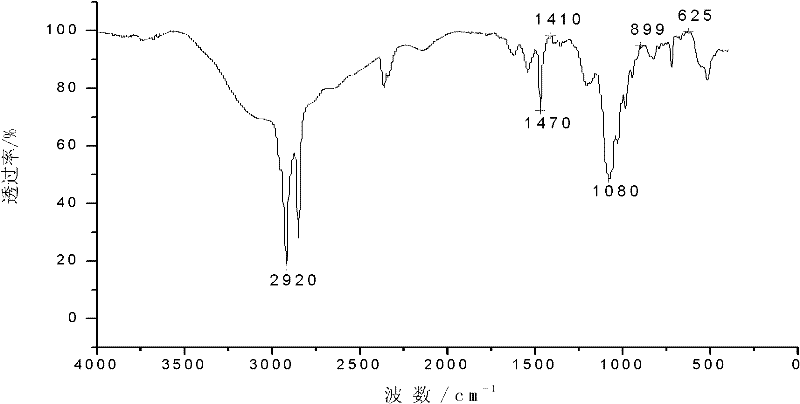

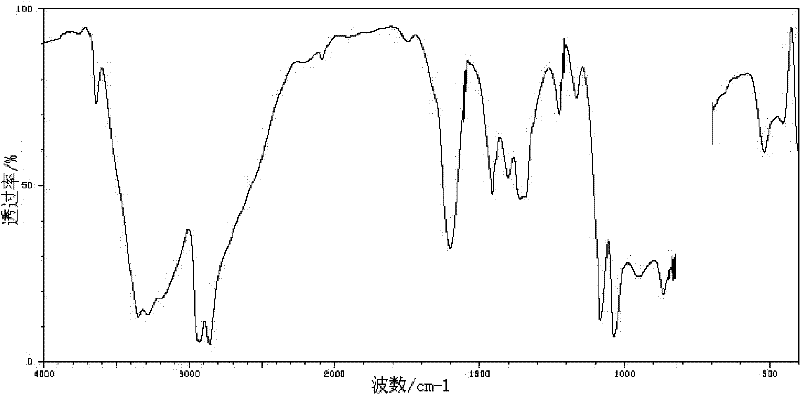

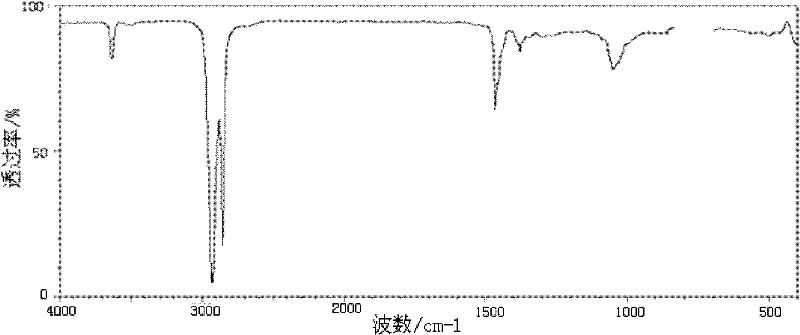

Preparation method of catalyst for hydrogenation desulfurization and denitrification of light-weight oil

InactiveCN102247864AGood dispersionIncrease profitCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsSilicon oxideTitanium oxide

The invention discloses a preparation method of a catalyst for hydrogenation desulfurization and denitrification of light-weight oil and is characterized in that the composition of the catalyst comprises a carrier, an auxiliary agent and active metals, wherein the carrier contains aluminum oxide, titanium oxide and silicon oxide; the auxiliary agent is phosphorus; the active metals are oxides of nickel, molybdenum and tungsten; and on the basis of the catalyst, the contents of all components in percentage by weight are as follows: 1 to 4 percent of cobalt oxide, 3 to 10 percent of nickel oxide, 2 to 12 percent of molybdenum oxide, 18 to 30 percent of tungsten oxide, 2 to 5 percent of phosphorus pentoxide, 2 to 15 percent of titanium oxide, 2 to 20 percent of silicon oxide, and the balance of aluminum oxide. The catalyst is obtained by the steps of carrier preparation, co-immersion, calcination and the like.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Natural gas pipeline drag-reducing agent and preparation method thereof

InactiveCN102443022ASource directlyEasy to operateGroup 5/15 element organic compoundsPipeline systemsEsterification reactionFatty alcohol

Owner:CHINA NAT OFFSHORE OIL CORP +2

Method for improving solar battery diffusion

InactiveCN101237010AImprove electrical performanceEasy to operateFinal product manufactureSemiconductor devicesHigh resistanceChemical reaction

The present invention discloses a method for improving the diffusion of a solar cell, comprising the following steps: A. adopting silicon material and P conductive type; B. diffusion: a silicon wafer chemically reacts with oxygen and phosphorus oxychloride at high temperature to produce phosphor, phosphorus pentachloride, phosphorus pentoxide and chlorine; C. feeding oxygen to reallocate: feeding oxygen to continue to react with unexhausted PCl5 to produce phosphorus; D. a phosphor atom Drive in process which is combined with the reallocation; E. the surface block resistance is 28-38 omega after the diffusion, the reallocation and Drive in processes. The method is capable of improving the conversion efficiency of high resistance rate single crystal silicon solar cells, the diffusion of the diffused silicon wafer surface is uniform; the method is easily implemented, the operation is convenient and the cost is low.

Owner:JIAWEI SOLAR WUHAN

Preparation method of hydrodesulfurization catalyst for high-nitrogen low-quality gasoline and diesel

ActiveCN102151582ALarge specific surface areaGood dispersionPhysical/chemical process catalystsRefining to eliminate hetero atomsHydrodesulfurizationGasoline

The invention relates to a preparation method of a hydrodesulfurization catalyst for high-nitrogen low-quality gasoline and diesel. The catalyst is characterized in that an A12O3-TiO2-SiO2 ternary oxide is taken as a composite carrier; the catalyst comprises the carrier, an auxiliary and active metals; the active metals comprise oxides of nickel, molybdenum and tungsten; the auxiliary is phosphorus; the carrier comprises aluminum oxide, titanium oxide and silicon oxide; based on the weight of the catalyst, nickel oxide accounts for 1-15 wt%, molybdenum oxide accounts for 2-12 wt%, tungsten oxide accounts for 12-35 wt%, phosphorus pentoxide accounts for 2-5% wt%, the titanium oxide accounts for 2-15 wt%, the silicon oxide accounts for 2-20 wt%, and the balance is aluminum oxide. In the method, a room-temperature complexation method is adopted for preparing W-Mo-Ni-P co-impregnation solution with stable dissolution performance, and then the step-by-step saturated impregnation technologyis adopted for loading the active metal components W-Mo-Ni and the auxiliary P on the carrier..

Owner:CHINA NAT OFFSHORE OIL CORP +1

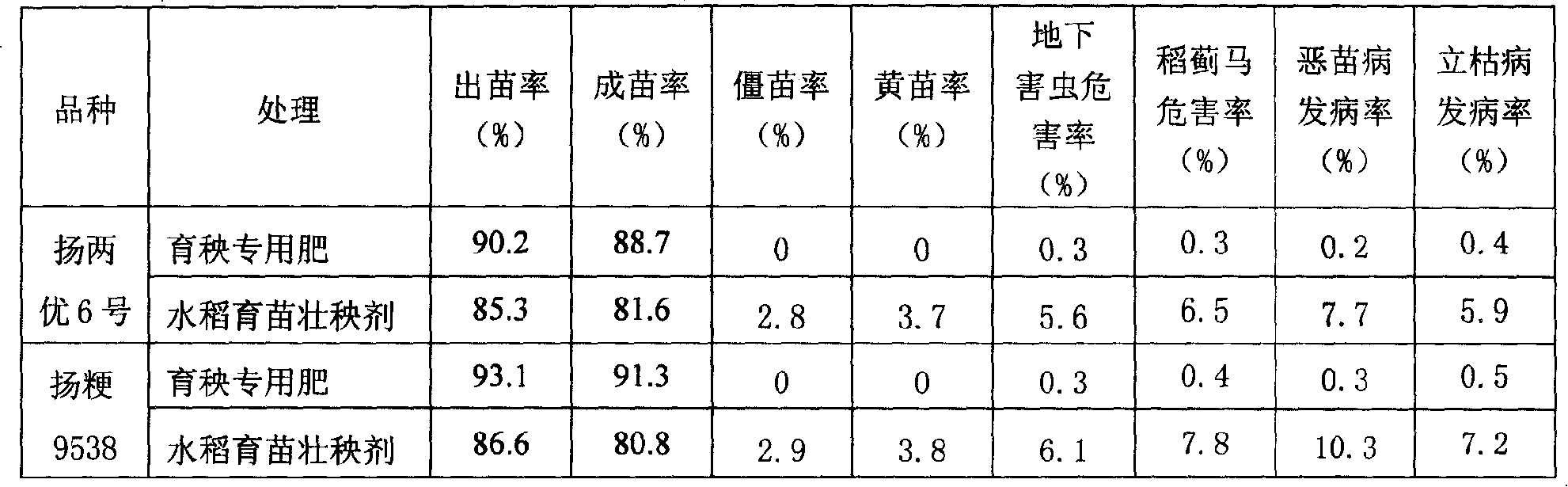

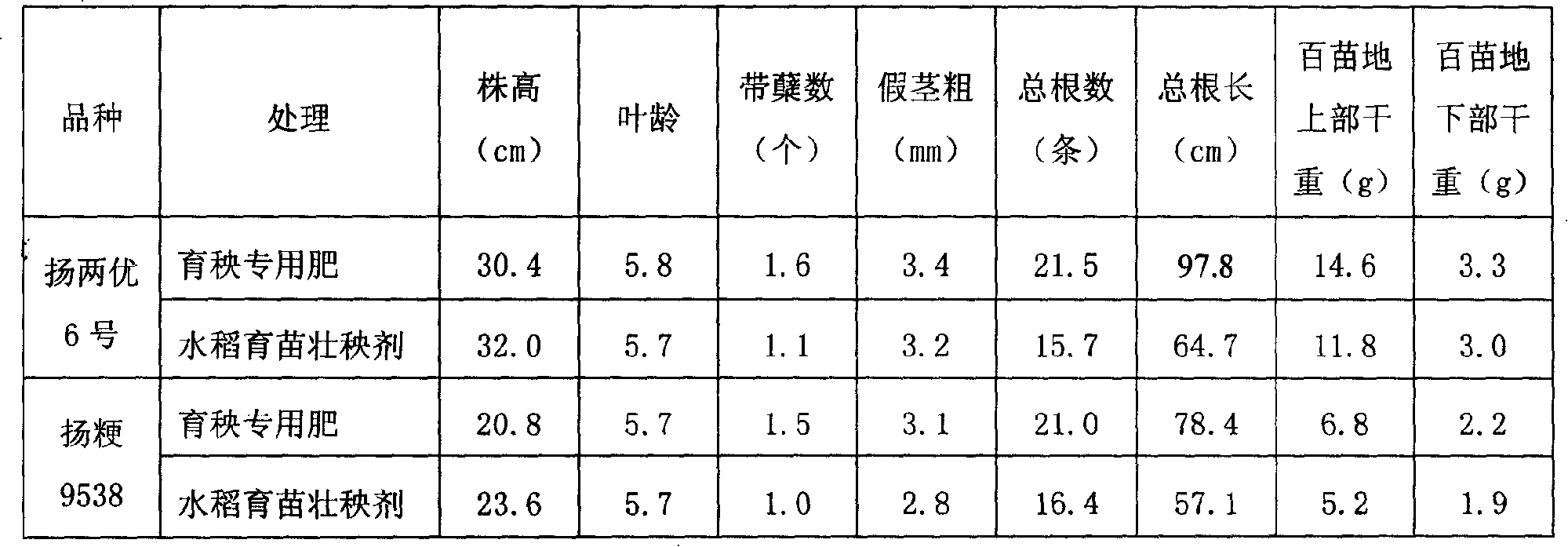

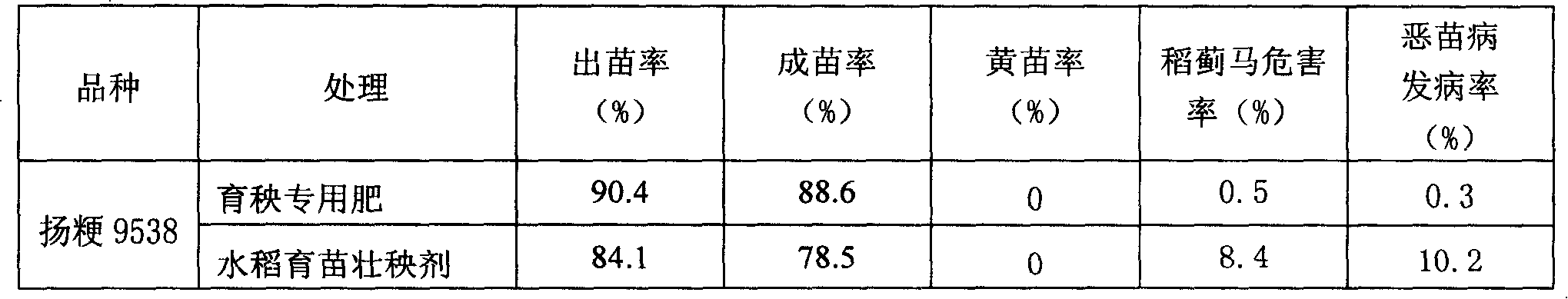

Special-purpose slow release fertilizer for water-retention sprout-cultivation

ActiveCN101209938AIncreased supply bufferReduce water consumptionFertilizer mixturesRoot growthAdditive ingredient

The invention discloses a special fertilizer with medical fertilizer slowly released and water conserved for seedlings growth which is characterized in that the fertilizer mainly consists of the following ingredients according to weight propotion: 5-10 percent of super-absorbent resin, 8-20 percent of nitrogen (N), 5-12 percent of phosphorus pentoxide (P2O5), 3-7 percent of potassium oxide (K2O), 1-3 percent of zinc (Zn), 1-3 percent of ferrite (Fe), 1-5 percent of ingredients of boron, magnesium, molybdenum, manganese and copper, 0.2-2 percent of pesticide, 0.1-2 percent of fungicide, 0.001-0.01 percent of root growth promoting agent and 0.001-0.01 percent of dwarfing agent and the rest is adsorbent. The special fertilizer with medical fertilizer slowly released and water conserved for seedlings growth of the invention has functions of good water holding and supplying, slow releasing of medical fertilizer, seedlings and roots strengthening, elements applying and growth promotion, diseases prevention, insect disinfesting and production increasing, and is characterized by less dosage, low cost and convenient application, etc., and can be applied to rice seedlings dry raising, seedling raising on plastic trays and upland crops raising.

Owner:JIANGSU LIXIAHE REGION AGRI RES INST

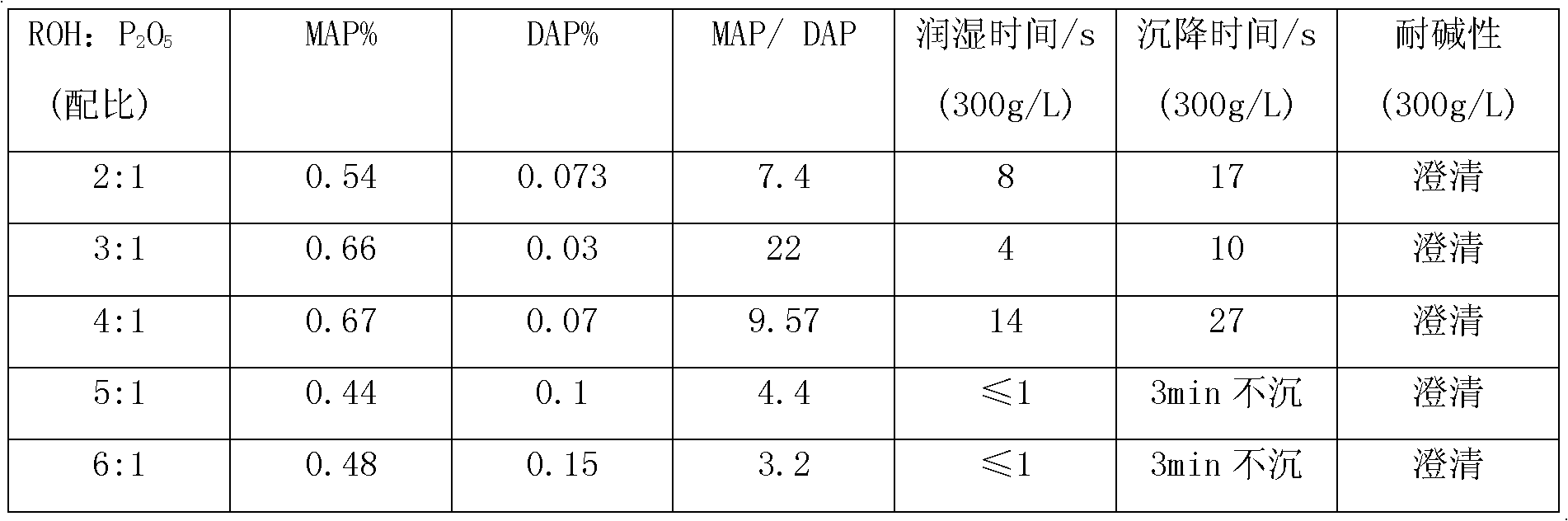

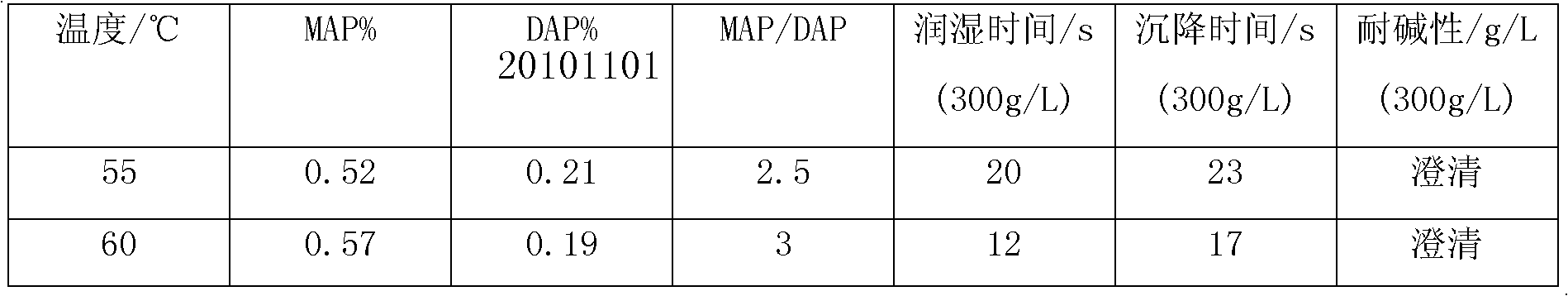

Hexatomic-ring alkylsiloxane-phosphate natural gas pipeline corrosion-inhibition drag reducer and preparation method thereof

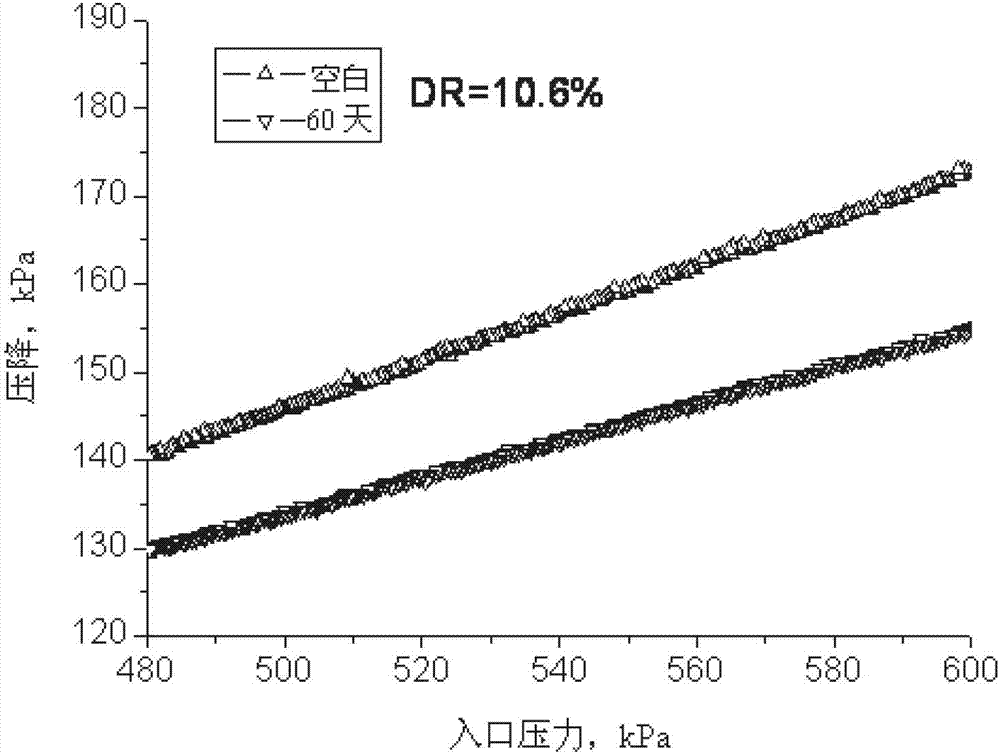

The invention relates to a hexatomic-ring alkylsiloxane-phosphate natural gas pipeline corrosion-inhibition drag reducer and a preparation method thereof. The preparation method comprises the following steps: reacting raw materials phosphorus pentoxide and long-chain alkyl alcohol in a mol ratio of 2:1-4:1 to generate the product mainly comprising long-chain monoalkyl phosphate (MAP); reacting long-chain alkylmethyl dimethoxysilane and the MAP product in a mol ratio of 2:1-2.5:1 to generate an alkylsiloxane-phosphate product mixture, wherein the content of the hexatomic-ring long alkylsiloxane-phosphate is 80-85 wt.%, and the content of the linear alkylsiloxane-phosphate is 15-20 wt.%; and dissolving the obtained alkylsiloxane-phosphate product mixture in n-heptane to form a 30-50 wt.% solution, thereby obtaining the hexatomic-ring alkylsiloxane-phosphate natural gas pipeline corrosion-inhibition drag reducer. The invention has the advantages of high corrosion inhibition efficiency, high drag reduction rate and long effective period.

Owner:PIPECHINA SOUTH CHINA CO

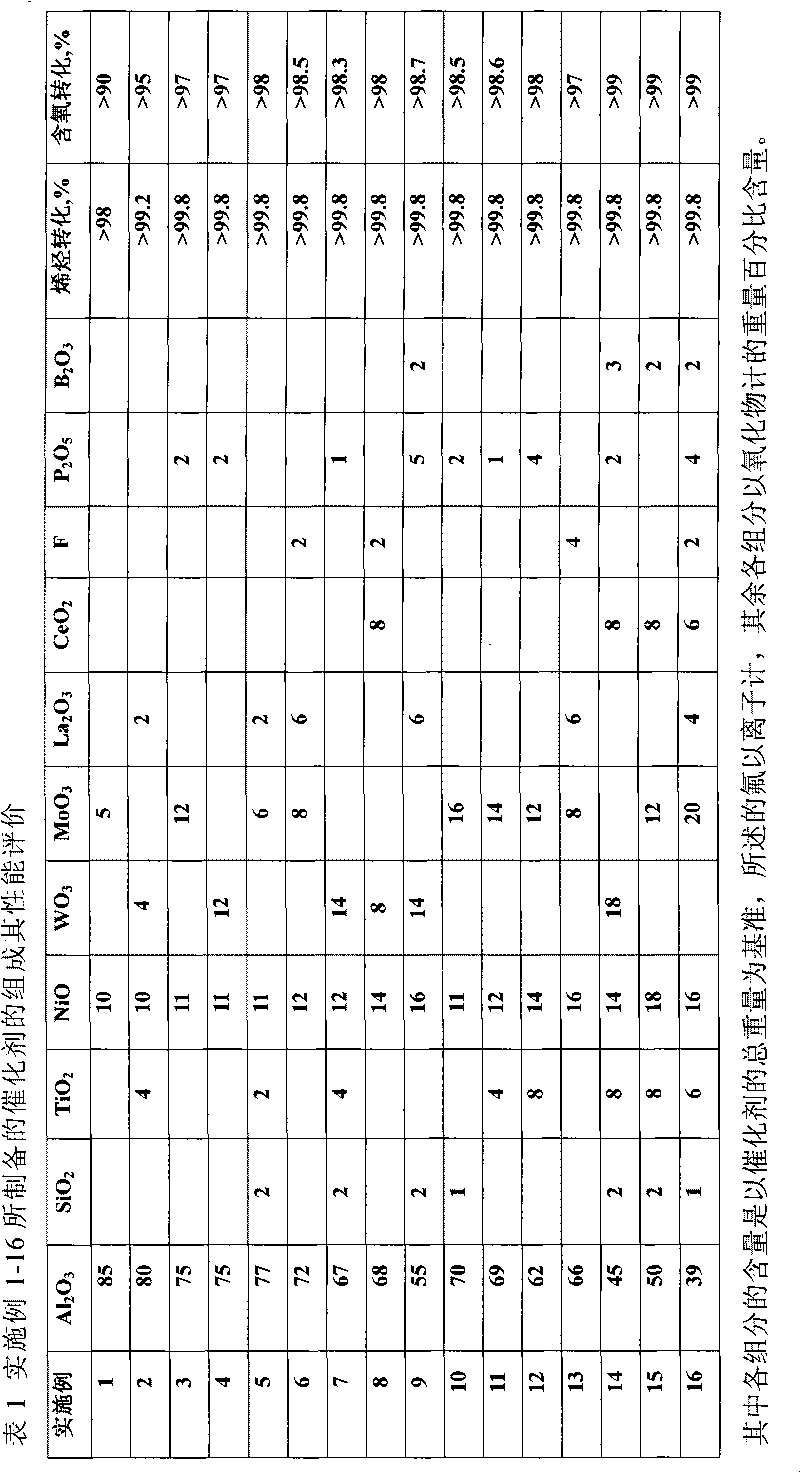

Catalyst for hydrogenation of Fischer-Tropsch synthesis oil, preparation method as well as application thereof

ActiveCN101733119AMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsCeriumLanthanide

The invention relates to a catalyst for hydrogenation of Fischer-Tropsch synthesis oil, which is characterized in that lanthanide metal lanthanum and / or cerium, and / or non-metallic element phosphorus and / or boron and / or fluorine which are used as cocatalysts are added into active component nickel and tungsten and / or molybdenum, and the catalyst comprises the following components in percentage by weight: 10-18% of nickel oxide, 1-20% of tungsten oxide or molybdenum oxide, 0-15% of silicon oxide and / or titanium oxide; 0-10% of lanthanum oxide and / or cerium oxide; 0-10% of phosphorus pentoxide and / or boron oxide and / or fluorine oxide and 35-89% of aluminum oxide. The preparation method of the catalyst comprises the steps of preparing carriers, soaking active components and adding cocatalyst components. The catalyst of the invention is suitable for the hydrogenation process of oil products having high olefin content and containing a certain amount of oxygen compounds, is especially suitable for hydrogenation of Fischer-Tropsch synthesis oil products, and has the advantages of high hydrogenation activity, good catalyst stability and the like.

Owner:SYNFUELS CHINA TECH CO LTD

High-alkali-resistance wet cloth silkete penetrating agent and preparation method thereof

InactiveCN102011317AImprove adsorption capacityImprove flexibilityFibre treatmentPhosphorus organic compoundsChemistryPhosphorus pentoxide

The invention discloses a high-alkali-resistance wet cloth silkete penetrating agent and a preparation method thereof. The penetrating agent is Lutensol TO phosphate. Compared with the prior art, the high-alkali-resistance wet cloth silkete penetrating agent has high alkali resistance, high biodegradability, excellent wettability and emulsification performance and no side or toxic effect, and can be widely mixed with other auxiliary agents. The high-alkali-resistance penetrating agent is synthesized by a phosphorus pentoxide direct phosphating method, so the preparation method is simple in operation and mild in reaction condition. The developed high-alkali-resistance wet cloth silkete penetrating agent can be applied to the wet cloth mercerizing process of cotton, linen fabric and blend fabric of the cotton and the line fabric.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

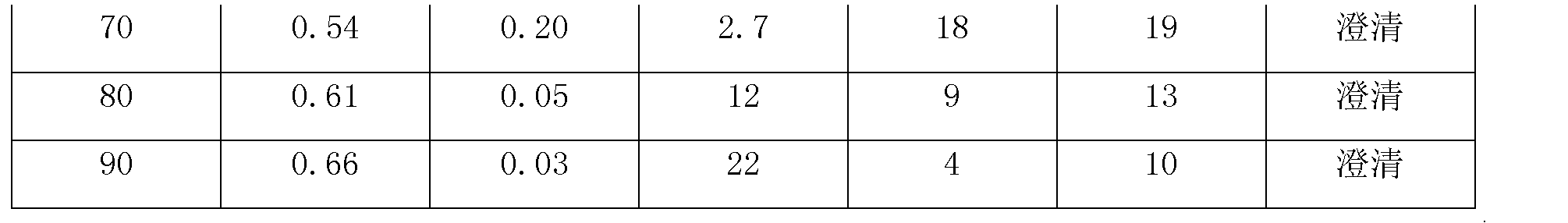

Coproduction method of potassium dihydrogen phosphate, sulfur base composite fertilizer and aluminium polychloride

InactiveCN100999312AReduce in quantityReduce the precipitation rateAluminium chloridesPhosphorus compoundsDecompositionPhosphate

Owner:宜昌市欣龙化工新材料有限公司

Special formulation fertilizer for rice

ActiveCN101054326APromote growthIn line with the law of absorptionSuperphosphatesUrea compound fertilisersFiberProcess quality

The invention belongs to fertilizer technical field, more particularly relates to a rice special formula fertilizer, which is characterized in that effective elements of the fertilizer are calculated by weight percent of pure nutrient are nitrogen 25-15, phosphorus pentoxide 15-9, potassium oxide 20-12, silicon dioxide 5-0, calcium 8-0, sulphur 5-1 and zinc 2-1. Compared with the present technique, the rice special formula fertilizer of the invention has reasonable match, accords with the nutrient absorption law of rice, can promote rice growth obviously and raise rough rice output, increase economic benefits and improve rice nutriment quality. In application test, the rice special formula fertilizer of the invention increases the rice yield by 660-820 kg per hectare, increases income 756-146 RMB, increases crude protein, raw fat, crude fiber, nitrogenfree extract and crude ash by 4.1-8.6, 0.14-0.80, 0.4-0.8, 0.1-3.0, 0.4-1.0 percentage points respectively, increases brown rice rate, integral white rice rate, white rice rate of rice processed quality by 1.4%, 1.7% and 1.8% respectively, reduces chalkiness granule rate, chalkiness by 3.2% and 1.9% respectively, reduces content of amylose by 1.0%. In the meanwhile, the fertilizer utilization efficiency is raised by 5.1%-13.8%.

Owner:HUBEI YISHIZHUANG AGRI TECH

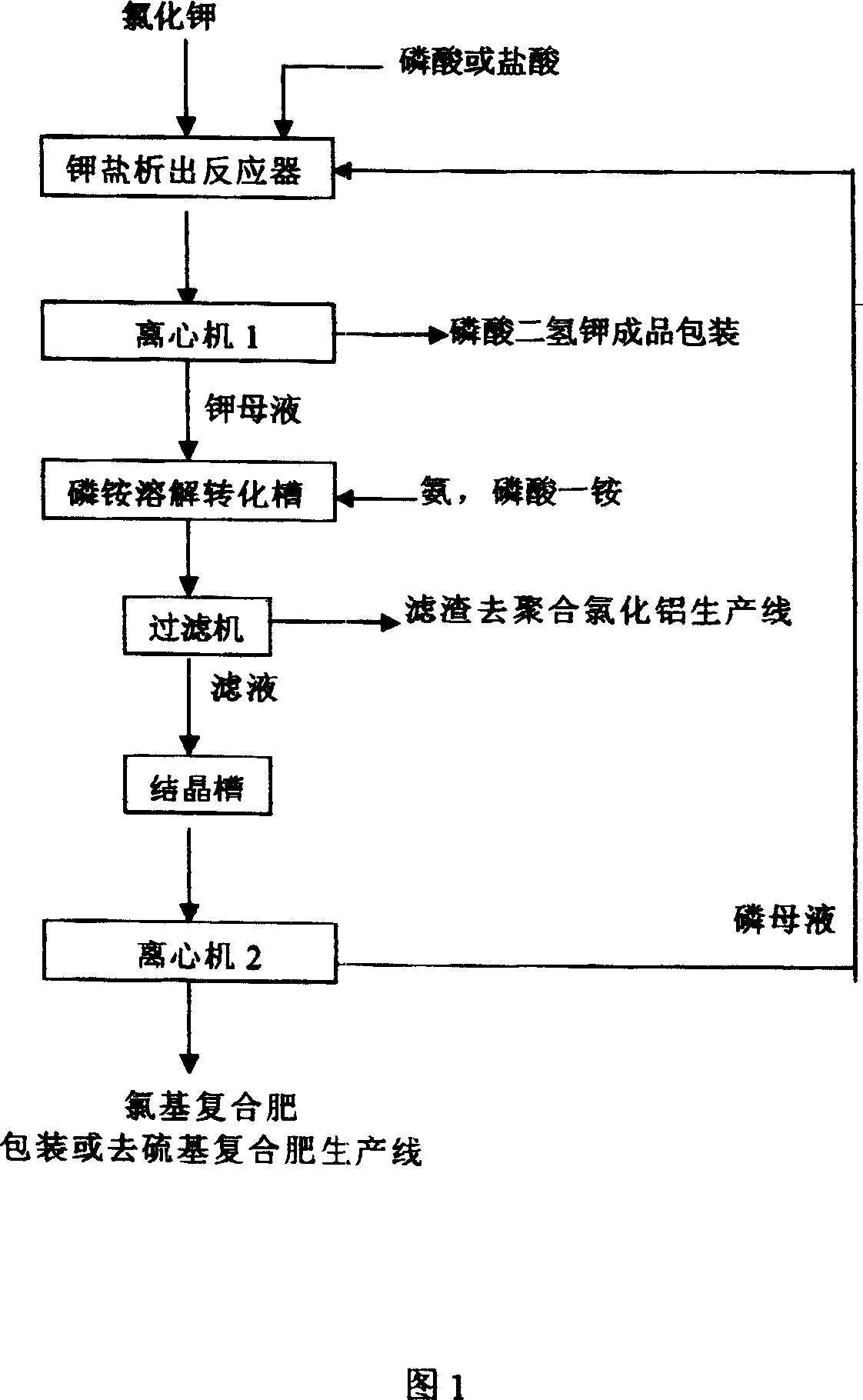

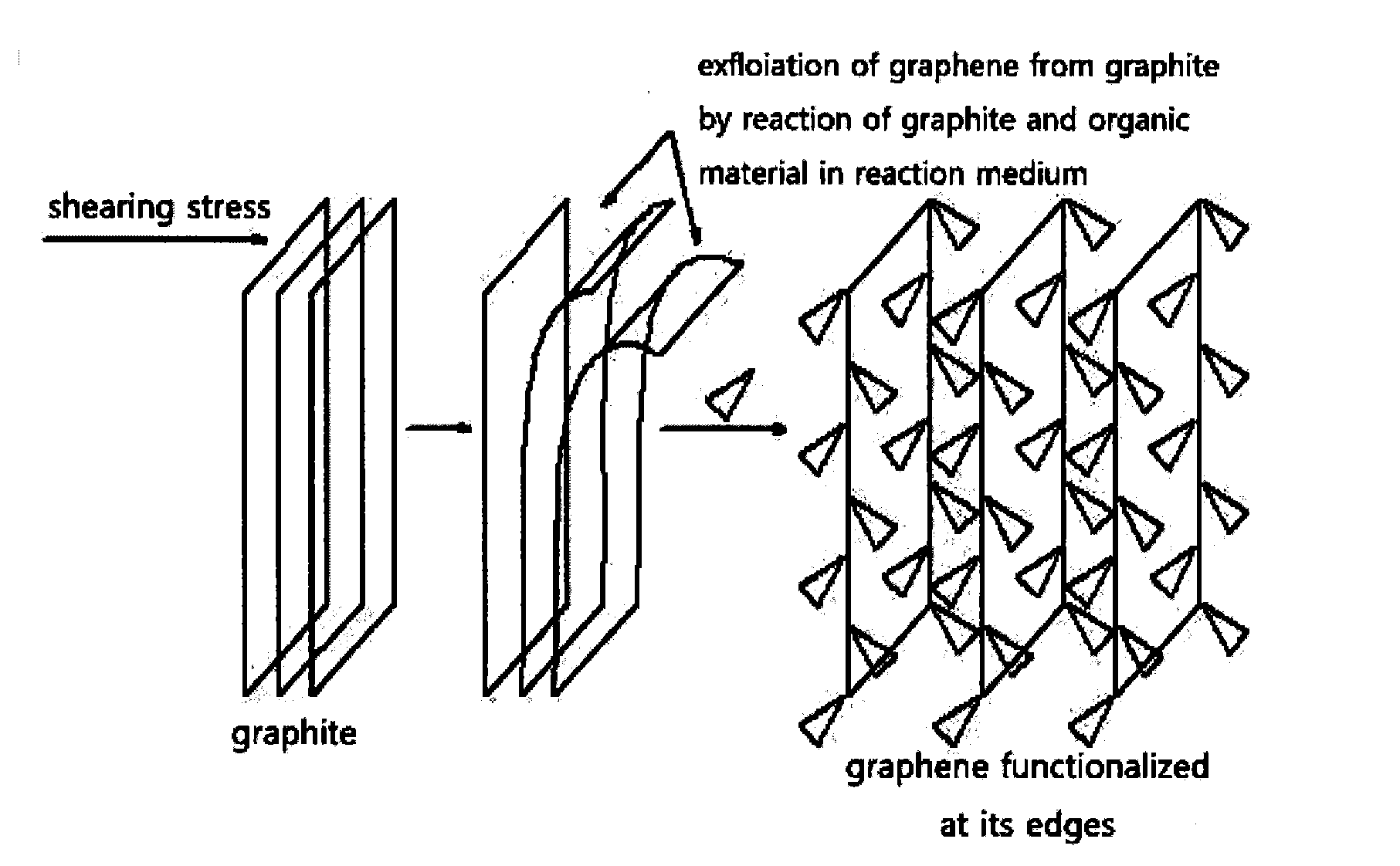

Graphene prepared by using edge functionalization of graphite

Disclosed is a method for producing graphene functionalized at its edge positions of graphite. Organic material having one or more functional groups is reacted with graphite in reaction medium comprising methanesulfonic acid and phosphorus pentoxide, or in reaction medium comprising trifluoromethanesulfonic acid, to produce graphene having organic material fuctionalized at edges. And then, high purity and large scaled graphene and film can be obtained by dispersing, centrifugal separating the functionalized graphene in a solvent and reducing, in particular heat treating the graphene. According to the present invention graphene can be produced inexpensively in a large amount with a minimum loss of graphite.

Owner:UNIST ULSAN NAT INST OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com