Method for preparing aromatic polybenzimidazole resin film

A polybenzimidazole, resin film technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation and other directions, can solve problems that have not been reported in literature or patent reports, and achieve good solubility and film-forming performance, operation Convenient, high molecular weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

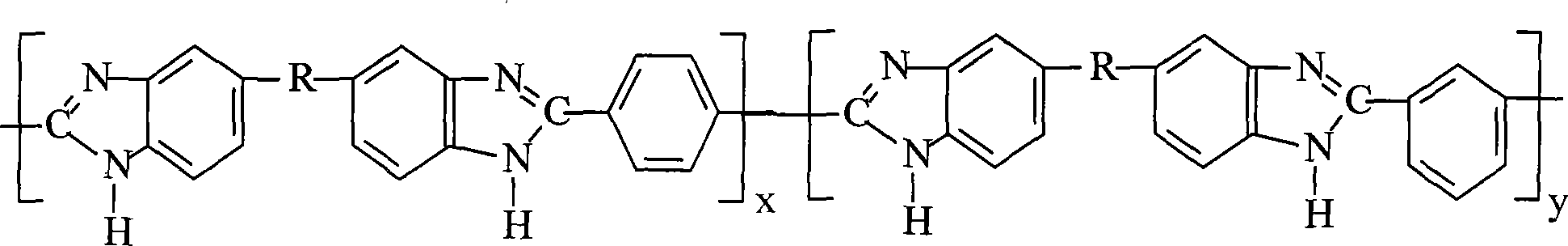

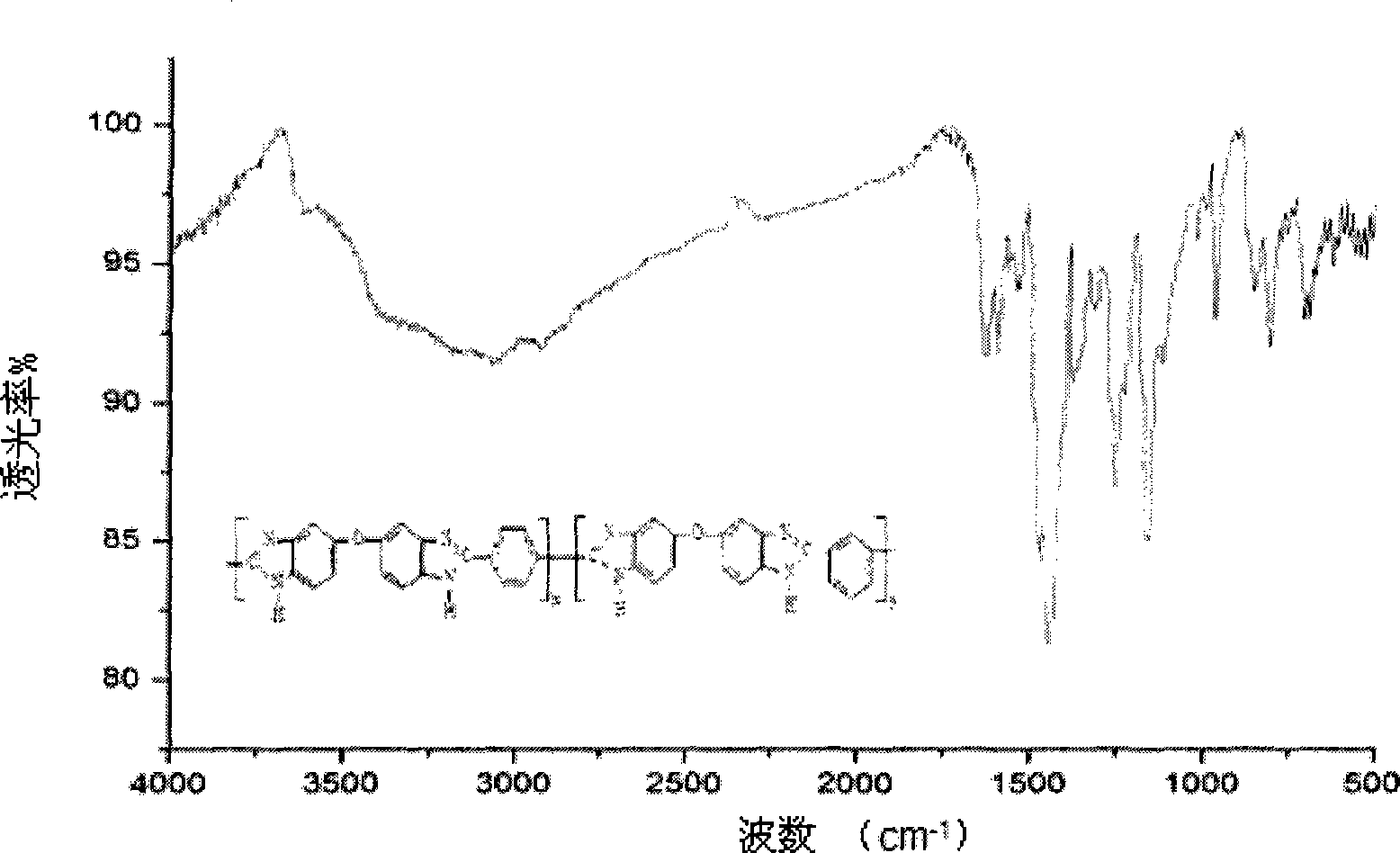

[0041] figure 1 In the structural formula, when y=0, the binary polycondensate of 3,3',4,4'-tetraaminodiphenyl ether and terephthalic acid will be obtained, and the operation is as follows: 40.0g polyphosphoric acid (80%) Add 10.0g of phosphorus pentoxide into a 250mL three-necked round-bottom flask equipped with a stirrer and an airway tube, and deoxidize with stirring at 90°C under the protection of nitrogen until the white powder of phosphorus pentoxide is completely dissolved into a transparent and clear solution , cooled to room temperature under nitrogen protection. Add 3,3',4,4'-tetraaminodiphenyl ether (1.0000g, 4.3mmol) and terephthalic acid (0.7222g, 4.3mmol), pass nitrogen gas at room temperature for about 15min, then stir at 90°C for reaction 3 hours, 130°C for 3 hours, and 200°C for 5 hours. After the reaction, a dark red rubber elastomer-like polymer was obtained. Pour it into water after cooling, crush it into powder in a resin grinder, soak and rinse the resu...

Embodiment 2

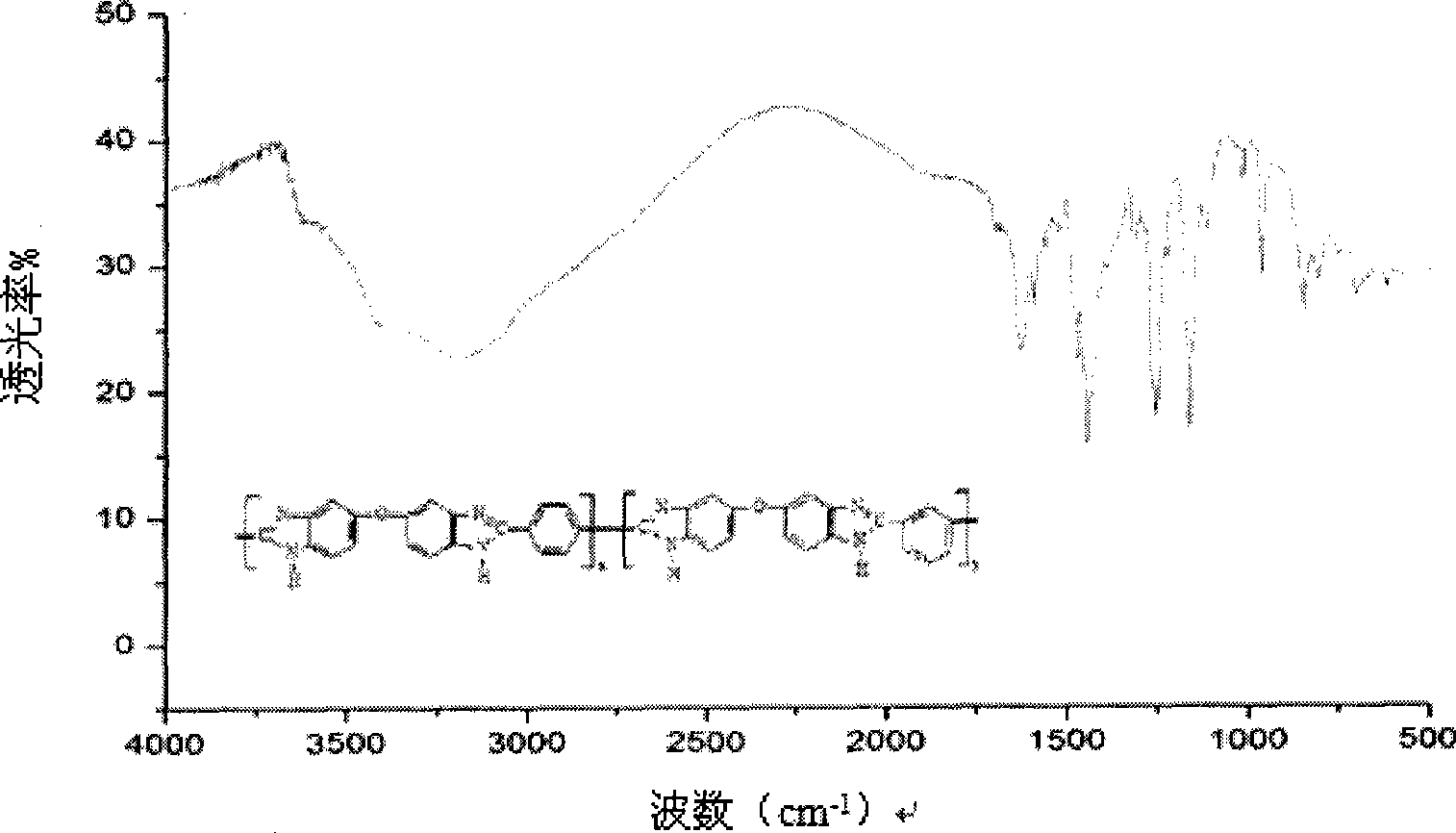

[0044] figure 1In the structural formula, when x=0, the binary polycondensate of 3,3',4,4'-tetraaminodiphenyl ether and isophthalic acid is operated as follows: 40.0g PPA (80%) and 10.0g P 2 o 5 Add it into a 100mL three-necked round-bottomed flask equipped with a stirrer and an airway tube, and stir it at 140°C for deoxidation under the protection of nitrogen until the white powder of phosphorus pentoxide is completely dissolved into a transparent and clear solution (P 2 o 5 , 84%), cooled to room temperature under nitrogen protection. Add 3,3',4,4'-tetraaminodiphenyl ether (1.0000g, 4.3mmol), isophthalic acid (0.7222g, 4.3mmol), and pass N at room temperature 2 After about 15 minutes, stir and react at 90°C for 3 hours, 130°C for 3 hours, and 200°C for 10 hours. After the reaction, a dark red rubber elastomer-like polymer is obtained. Pour it into water after cooling, crush it into powder in a resin grinder, soak and rinse the resulting product in distilled water repeat...

Embodiment 3

[0047] figure 1 In the structural formula, when x=y, the terpolymer of 3,3',4,4'-tetraaminodiphenyl ether, isophthalic acid (1PA) and terephthalic acid (TPA) is polymerized, and the operation is as follows: 40.0g PPA (80%) and 10.0g P 2 o 5 Add it into a 100mL three-necked round-bottomed flask equipped with a stirrer and an air tube, and deoxidize with stirring at 140°C under the protection of nitrogen until P 2 o 5 The white powder completely dissolves into a transparent and clear solution (P 2 o 5 , 84%), cooled to room temperature under nitrogen protection. Add 3,3',4,4'-tetraaminodiphenyl ether (1.0000g, 4.30mmol), TPA (0.3611g, 2.15mmol), IPA (0.3611g, 2.15mmol) in equal amounts, and pass through N at room temperature 2 After about 15 minutes, stir and react at 90°C for 3 hours, 130°C for 3 hours, 160°C for 3 hours, and 200°C for 10 hours. After the reaction, a dark red rubber elastomer-like polymer is obtained. Pour it into water after cooling, crush it into powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com