Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2576 results about "Potassium persulfate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Potassium persulfate is the inorganic compound with the formula K₂S₂O₈. Also known as potassium peroxydisulfate or KPS, it is a white solid that is sparingly soluble in cold water, but dissolves better in warm water. This salt is a powerful oxidant, commonly used to initiate polymerizations.

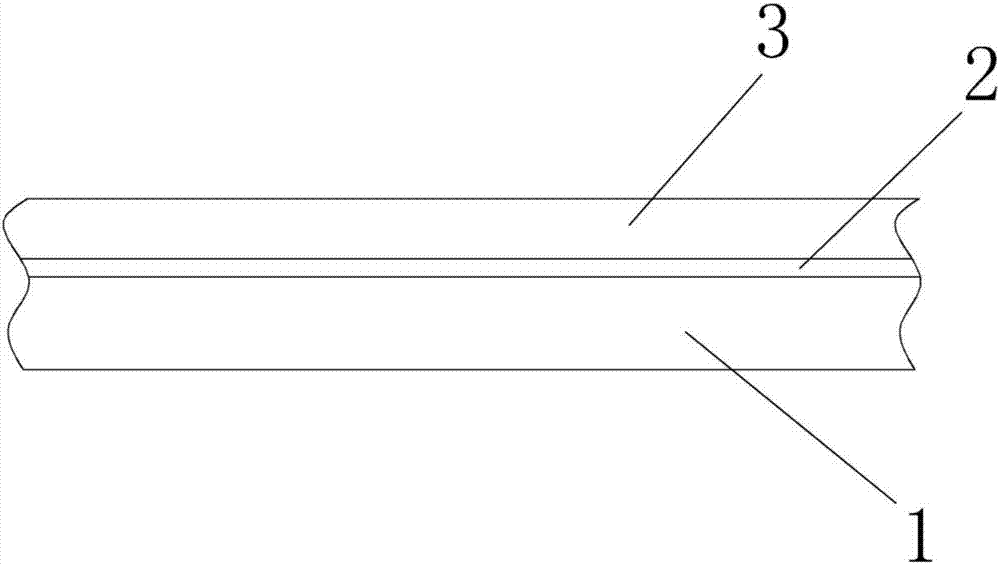

Dual layer tablet, method of making and use thereof

InactiveUS6863830B1Easy to optimizeComprehensive treatmentOrganic chemistryOther chemical processesPotassium persulfateLithium hypochlorite

A method for treating a recirculating water system which comprises introducing into said water system a multifunctional, multilayer tablet, wherein the multilayer tablet comprises a fast dissolving layer and a slow dissolving layer, wherein said fast dissolving layer releases a combination of active ingredients including a member selected from the group consisting of lithium hypochlorite, calcium hypochlorite, trichloroisocyanuric acid (TCCA), anhydrous sodium dichloroisocyanurate, sodium persulfate, potassium persulfate, potassium monopersulfate, sodium monopersulfate, and mixtures thereof, and at least one of a clarifier, chelating agent, sequesterant, algaestat, water softener, algaecide, corrosion inhibitor, scale inhibitor, flocculent, disintegrant, dispersant, colorant, dissolution control agent, fragrance, or surfactant and, wherein said slow dissolving layer includes a member selected from the group consisting of trichloroisocyanuric acid (TCCA), calcium hypochlorite, 1,3-dichloro-5,5-dimethylhydantoin (DCDMH), 1,3-dibromo-5,5-dimethylhydantoin (DBDMH), 1-bromo-3-chloro-5,5-dimethylhydantoin (BCDMH), 1,3-dichloro-5-ethyl-5-methylhydantoin (DCEMH), 1,3-dibromo-5-ethyl-5-methylhydantoin (DBEMH), 1-bromo-3-chloro-5-methyl-5-ethylhydantoin (BCEMH), and mixtures thereof, and at least one of a clarifier, chelating agent, sequesterant, algaestat, water softener, algaecide, corrosion inhibitor, scale inhibitor, flocculent, disintegrant, dispersant, colorant, dissolution control agent or surfactant.

Owner:BIO LAB

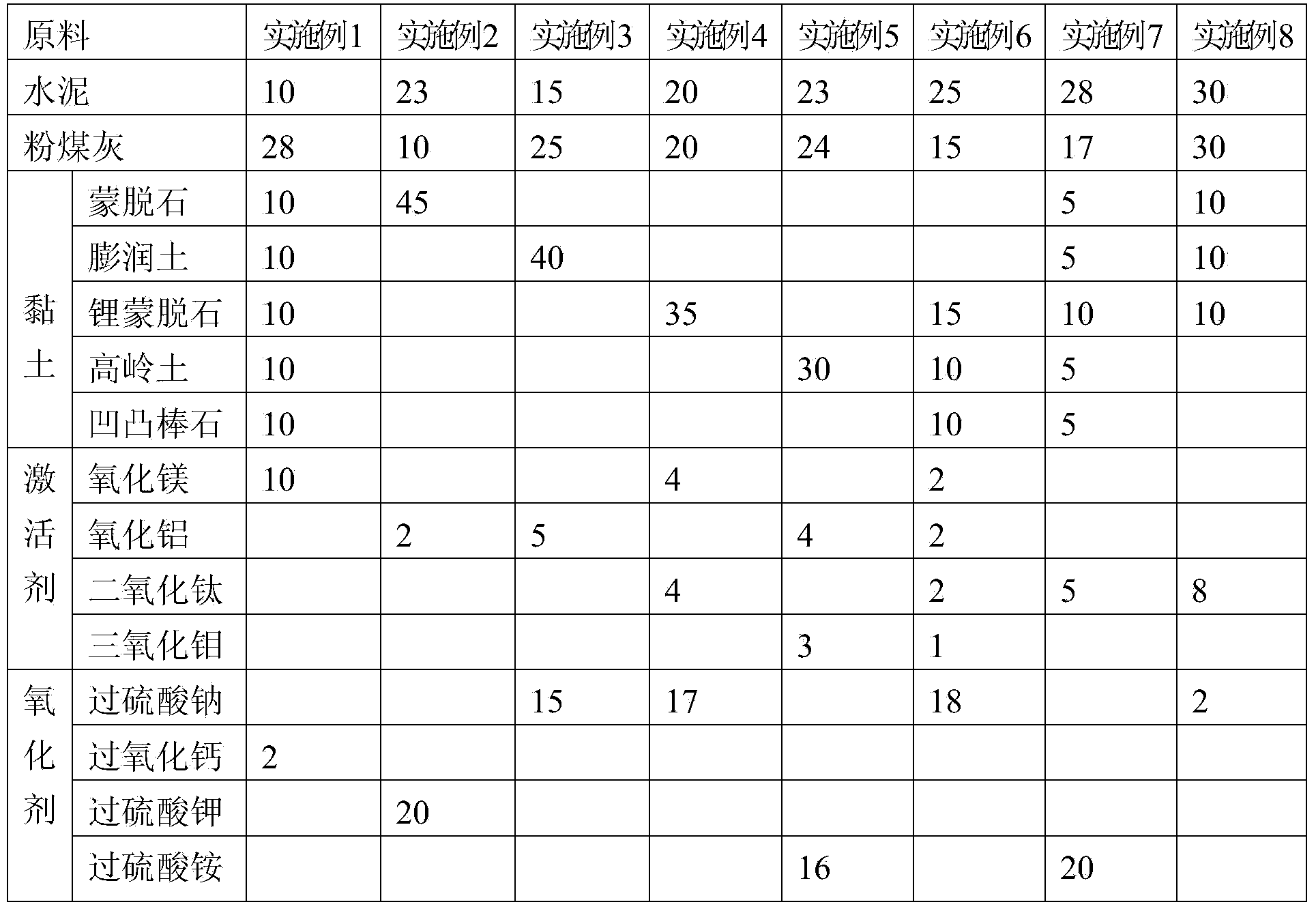

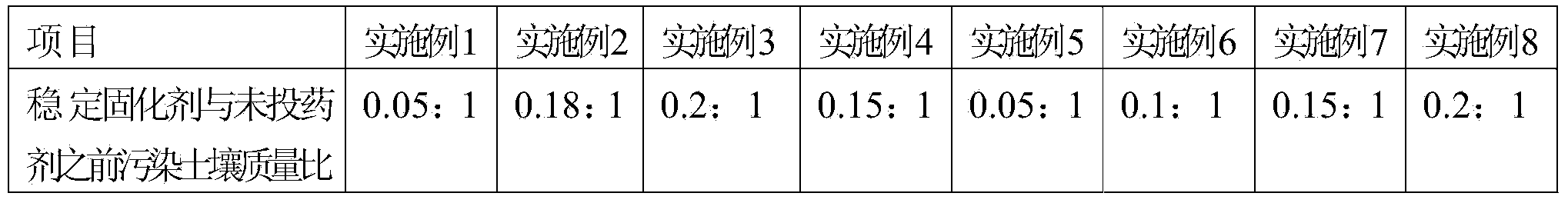

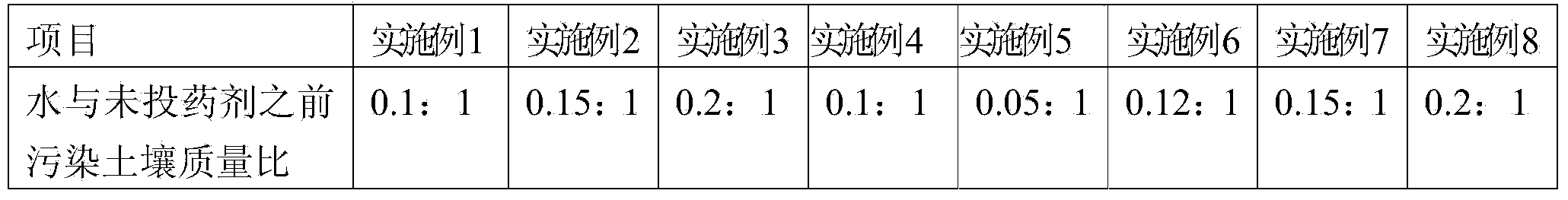

Stable curing agent of repairing heavy metal and toxic organic matter combined polluted soil and using method of curing agent

ActiveCN103881727AImprove repair effectBioeffectiveAgriculture tools and machinesContaminated soil reclamationPotassium persulfateCoal

The invention relates to a stable curing agent of repairing heavy metal and toxic organic matter combined polluted soil. The stable curing agent comprises the following raw materials in percentage by weight: 10-30% of cement, 10-30% of coal ash, 20-50% of clays, 2-10% of an activating agent and 2-20% of an oxidizing agent, wherein the activating agent is a composition of one or more than two of magnesium oxide, aluminum oxide, titanium dioxide or molybdenum trioxide, and the oxidizing agent is a composition of one or more than two of sodium persulfate, calcium peroxide, potassium persulfate and ammonium persulfate. The raw materials are put into a grinder to be uniformly grinded and mixed to prepare the stable curing agent with the specific surface area of 400-800 / kg. The stable curing agent provided by the invention has the characteristics of low cost, good soil repairing effect and simplicity in construction.

Owner:WELLE ENVIRONMENTAL GRP CO LTD

Dual layer tablet, method of making and use thereof

InactiveUS20050040116A1Easy to optimizeComprehensive treatmentOrganic chemistryOther chemical processesPotassium persulfateLithium hypochlorite

A method for treating a recirculating water system which comprises introducing into said water system a multifunctional, multilayer tablet, wherein the multilayer tablet comprises a fast dissolving layer and a slow dissolving layer, wherein said fast dissolving layer releases a combination of active ingredients including a member selected from the group consisting of lithium hypochlorite, calcium hypochlorite, trichloroisocyanuric acid (TCCA), anhydrous sodium dichloroisocyanurate, sodium persulfate, potassium persulfate, potassium monopersulfate, sodium monopersulfate, and mixtures thereof, and at least one of a clarifier, chelating agent, sequesterant, algaestat, water softener, algaecide, corrosion inhibitor, scale inhibitor, flocculent, disintegrant, dispersant, colorant, dissolution control agent, fragrance, or surfactant and, wherein said slow dissolving layer includes a member selected from the group consisting of trichloroisocyanuric acid (TCCA), calcium hypochlorite, 1,3-dichloro-5,5-dimethylhydantoin (DCDMH), 1,3-dibromo-5,5-dimethylhydantoin (DBDMH), 1-bromo-3-chloro-5,5-dimethylhydantoin (BCDMH), 1,3-dichloro-5-ethyl-5-methylhydantoin (DCEMH), 1,3-dibromo-5-ethyl-5-methylhydantoin (DBEMH), 1-bromo-3-chloro-5-methyl-5-ethylhydantoin (BCEMH), and mixtures thereof, and at least one of a clarifier, chelating agent, sequesterant, algaestat, water softener, algaecide, corrosion inhibitor, scale inhibitor, flocculent, disintegrant, dispersant, colorant, dissolution control agent or surfactant.

Owner:BIO LAB

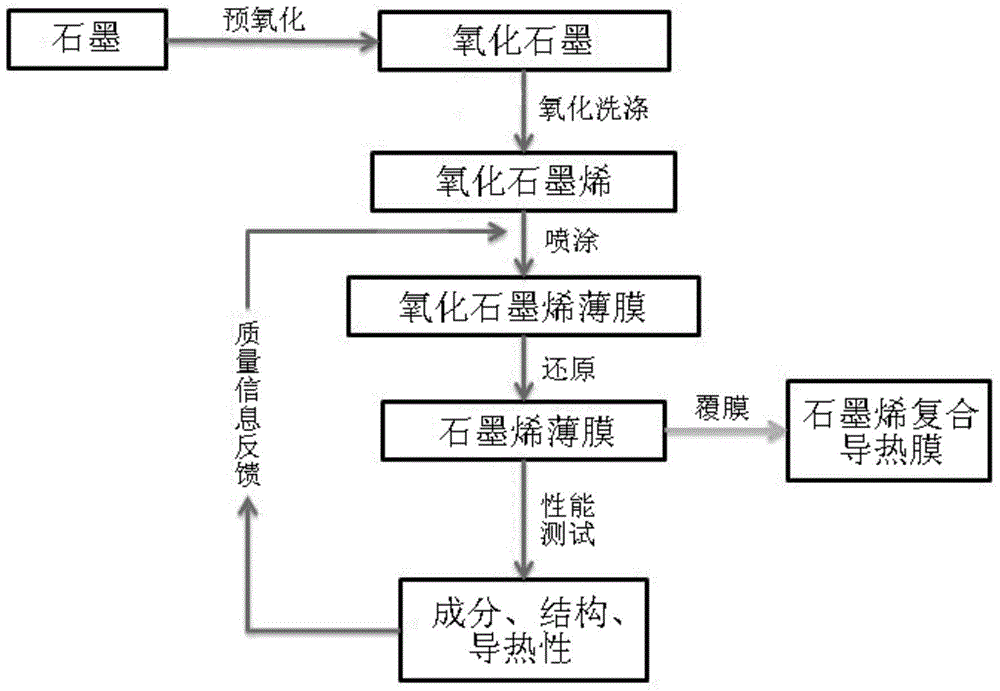

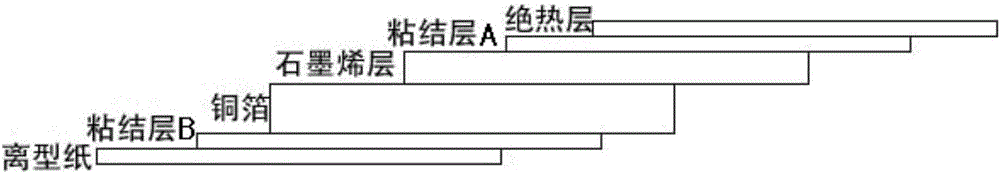

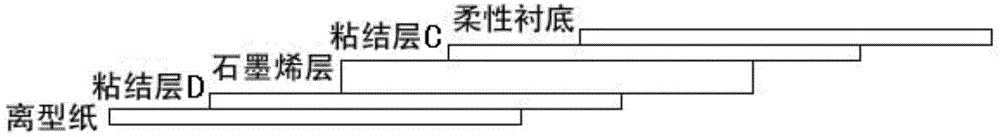

Preparation method of composite heat conduction graphene film and composite heat conduction graphene film

ActiveCN104085143AIncrease layer spacingThoroughly oxidizedMetal layered productsPotassium persulfateFiltration

The invention discloses a preparation method of a composite heat conduction graphene membrane and the composite heat conduction graphene film. The preparation method comprises the following steps: S1, putting crystalline flake graphite or graphite powder into a mixed solution of concentrated sulfuric acid, potassium persulfate and phosphorus pentoxide, soaking for a day and a night, then carrying out suction filtration, drying, and carrying out pre-oxidizing; S2, oxidizing pre-oxidized graphite further by adopting a Hummers method, that is, oxidizing fully in concentrated sulfuric acid and potassium permanganate, then adding deionized water for diluting, and carrying out repeated washing and suction filtration, so as to obtain an oxidized graphene aqueous solution; S3, spraying the oxidized graphene aqueous solution on a substrate by adopting a thermal spray method, and depositing, so as to obtain an oxidized graphene film; S4, reducing the oxidized graphene film, so as to obtain the graphene film; and S5, laminating the graphene film, so as to obtain the composite heat conduction graphene film. Compared with the prior art, the preparation method is simple, the cost is low, and the prepared composite heat conduction graphene film has a favorable heat conduction performance.

Owner:成都科愿慧希科技有限公司

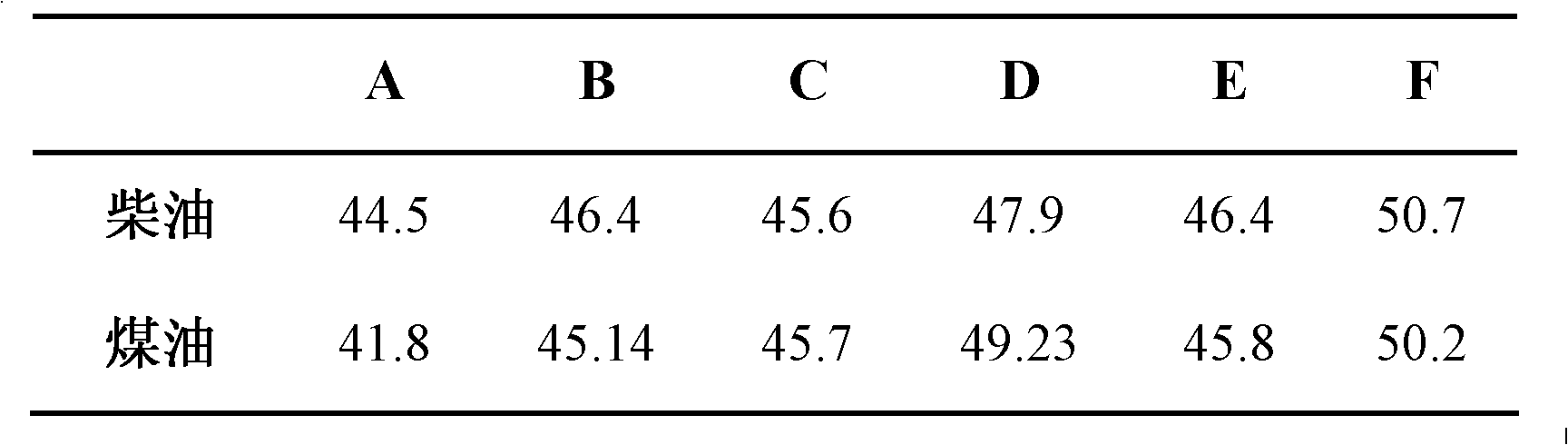

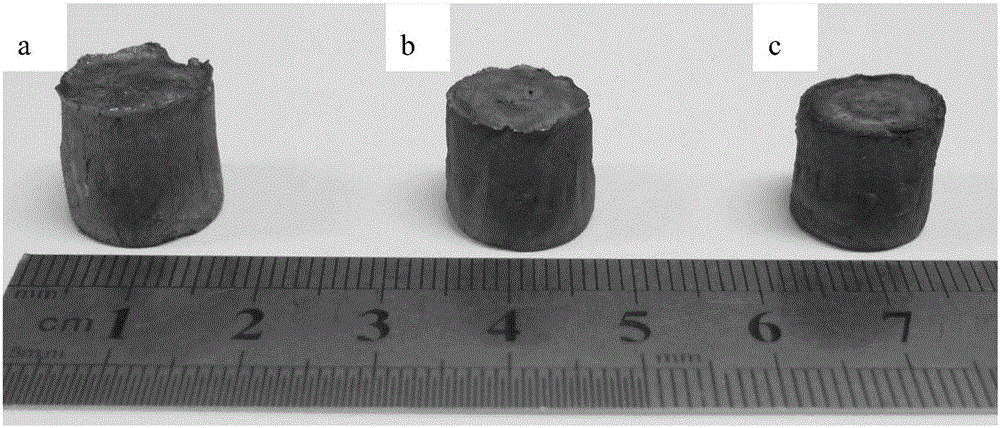

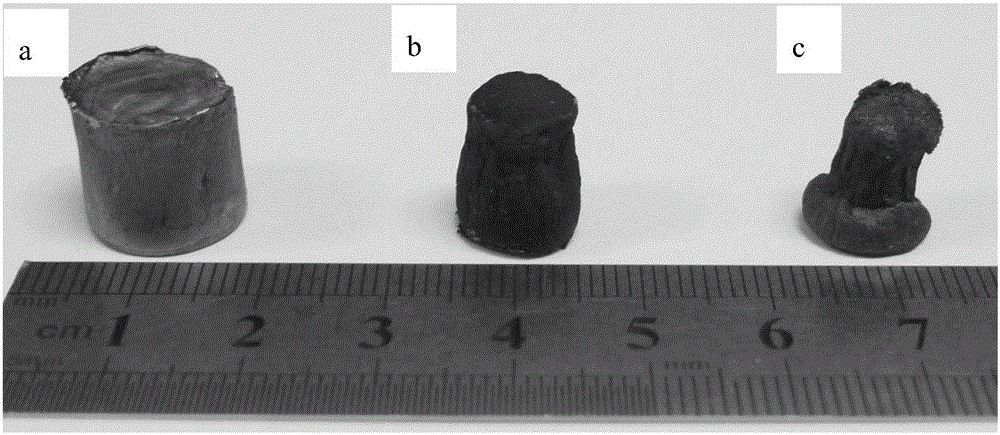

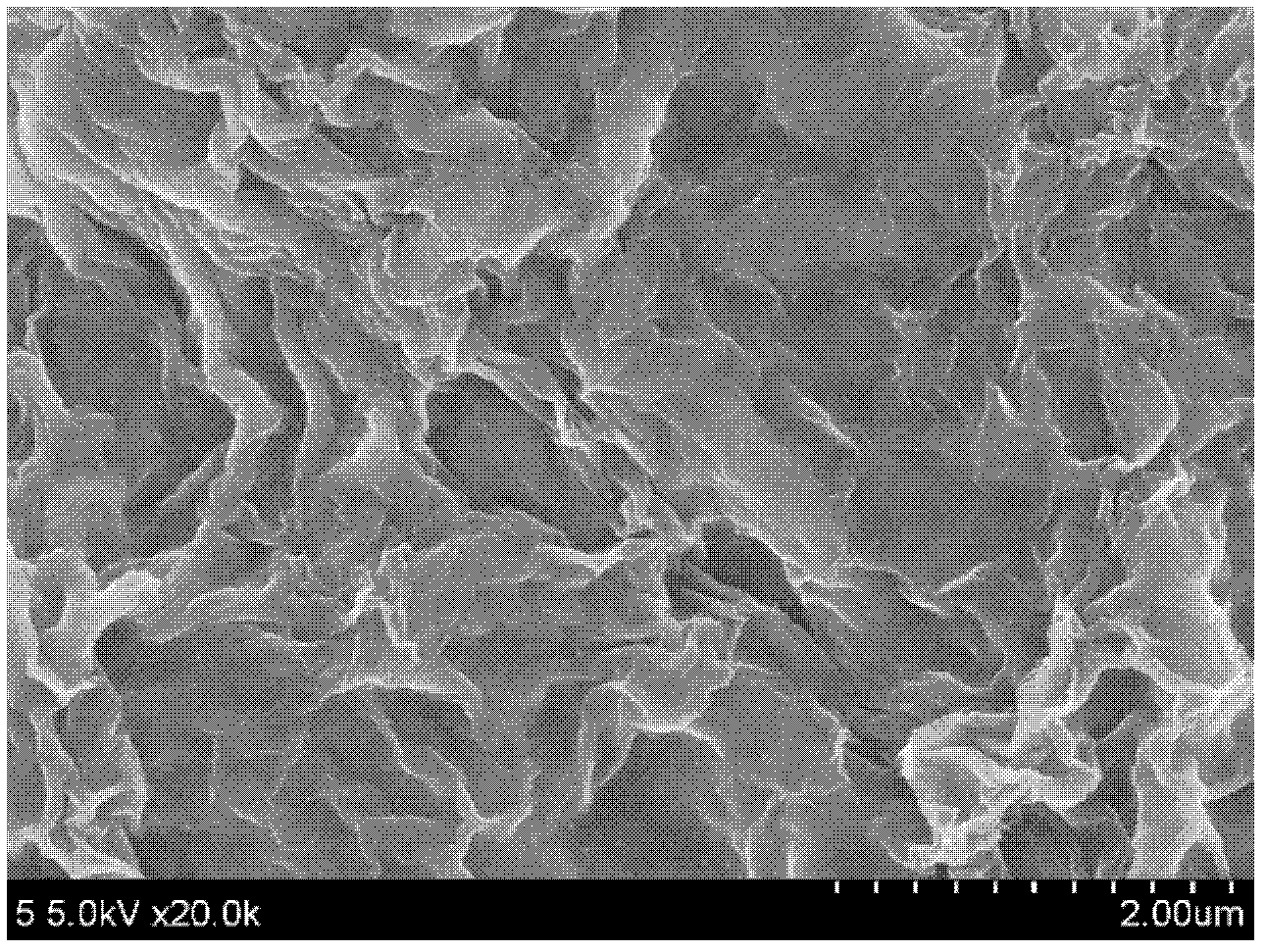

Preparation method of foamed porous graphene/polypyrrole composite oil absorption material

InactiveCN102617853AEasy to operateMild reaction conditionsOther chemical processesPotassium persulfatePorous graphene

The invention relates to a preparation method of a foamed porous graphene / polypyrrole composite oil absorption material, belonging to the technical fields of environmental protection and composite materials. The method is characterized by comprising the following steps: carrying out KH570 functionalization on graphite oxide prepared from graphite; carrying out ultrasonic treatment on the functionalized graphite oxide product to obtain a graphene oxide aqueous solution with a certain concentration, adding certain amounts of pyrrole, styrene or butyl methacrylate or lauryl methacrylate and an initiator (ammonium persulfate or potassium persulfate); carrying out thermostatic reaction in a hydrothermal reaction kettle for 10 hours, thereby obtaining a black solid; and carrying out freeze-drying on the black solid to obtain the foamed porous graphene / polypyrrole composite oil absorption material in a three-dimensional structure. The graphene / polypyrrole composite oil absorption material ina three-dimensional structure is prepared by a chemical process, so the material has hydrophobicity and large specific area of the graphene, can contain abundant oil molecules, and has high oil adsorbability. The preparation method is simple to operate, and has the advantage of mild reaction conditions.

Owner:DALIAN UNIV OF TECH

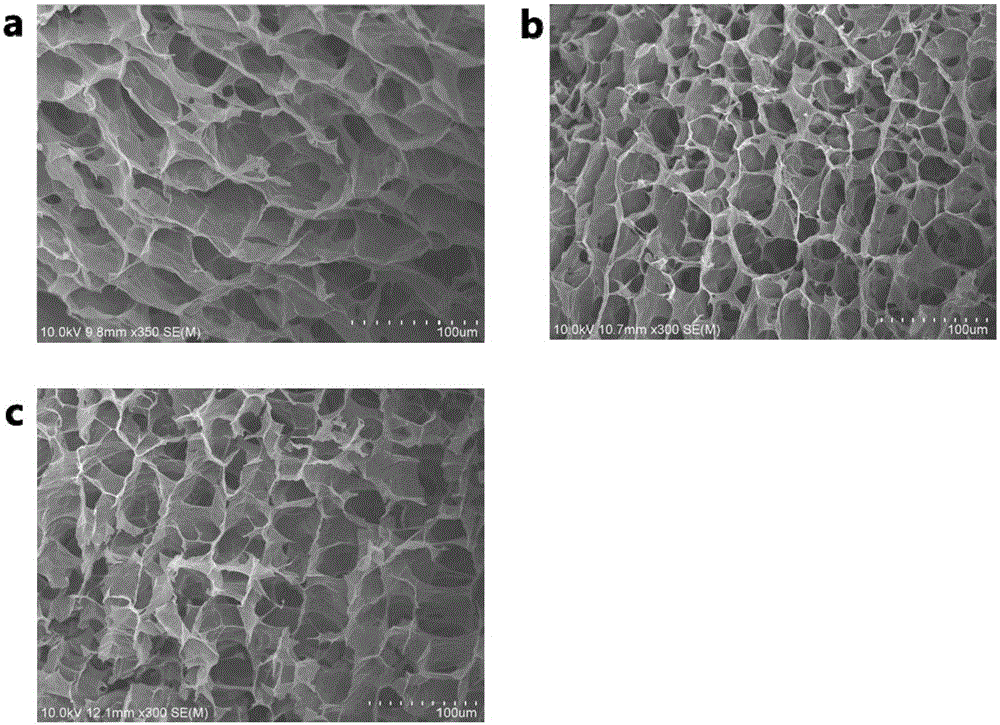

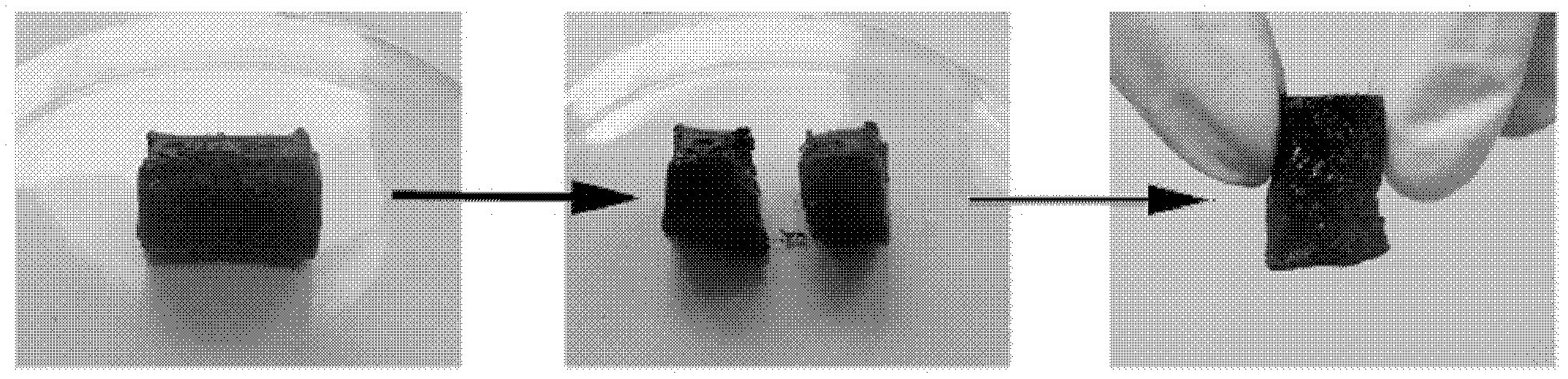

Graphene aerogel and hybrid composite material thereof as well as preparation method and application of graphene aerogel

ActiveCN106422995AUniform cell structureIncrease elasticityColloidal chemistry detailsPotassium persulfateNanoparticle

The invention discloses graphene aerogel and a hybrid composite material thereof as well as a preparation method and application of the of graphene aerogel. The preparation method comprises the following steps: 1) mixing graphene oxide, a reducing agent, acrylamide, N,N-methylene-bisacrylamide and potassium persulfate and reacting to obtain partially-reduced graphene / polyacrylamide hydrogel; 2) carrying out pre-freezing and reduction on the partially-reduced graphene / polyacrylamide hydrogel in sequence to obtain graphene / polyacrylamide hydrogel; 3) dialyzing and drying the graphene / polyacrylamide hydrogel in sequence to obtain the graphene aerogel. The graphene aerogel has the characteristics of uniform cellular structure and light weight, excellent resilience, relatively high mechanical strength and good solvent resistance; a preparation process is simple, rapid and low in cost; the graphene aerogel can also be used for preparing polymer / graphene composite aerogel, nanoparticle / graphene composite aerogel and polymer / graphene composite materials and the like, so that application of the graphene aerogel is expanded.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Etching liquid composition and etching method

The invention relates to an etchant composition and an etching method, wherein, the etchant composition comprises any two components of oxidants, acid and salt, and the pH value of the etchant composition is between 1 and 7. The oxidant components are selected from hydrogen peroxide, ammonium persulfate, potassium persulfate and ceric ammonium nitrate; the acid components are selected from chloric acid, perchlorate, acetic acid, nitric acid, hydrofluoric acid, sulfuric acid and oxalic acid, and the salt components are selected from ammonium fluoride, ammonium bifluoride, diammonium phosphate, ammonium phosphate, ammonium chloride and perfluorinated octyl sulfanilic acid (C8F17SO3NH4).

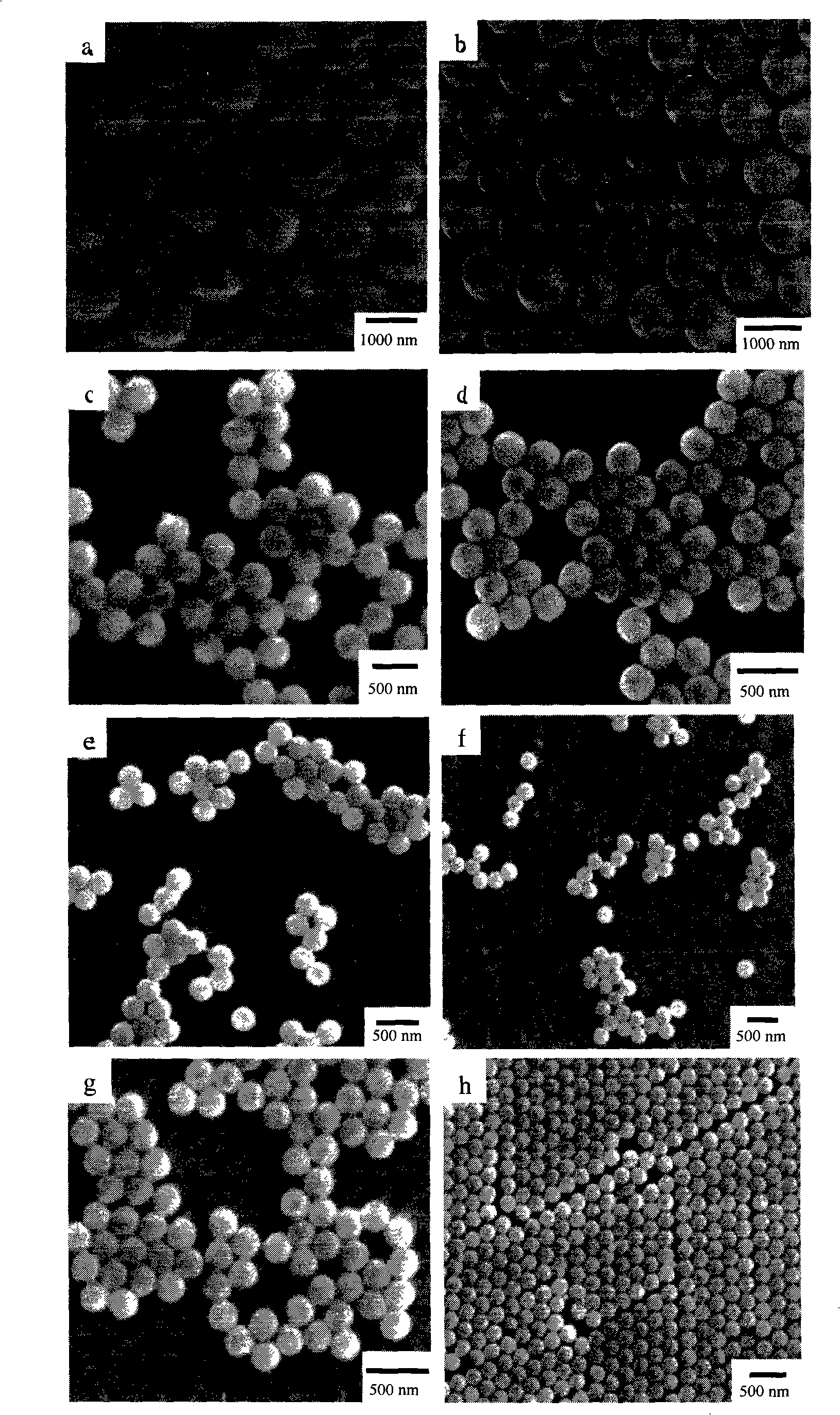

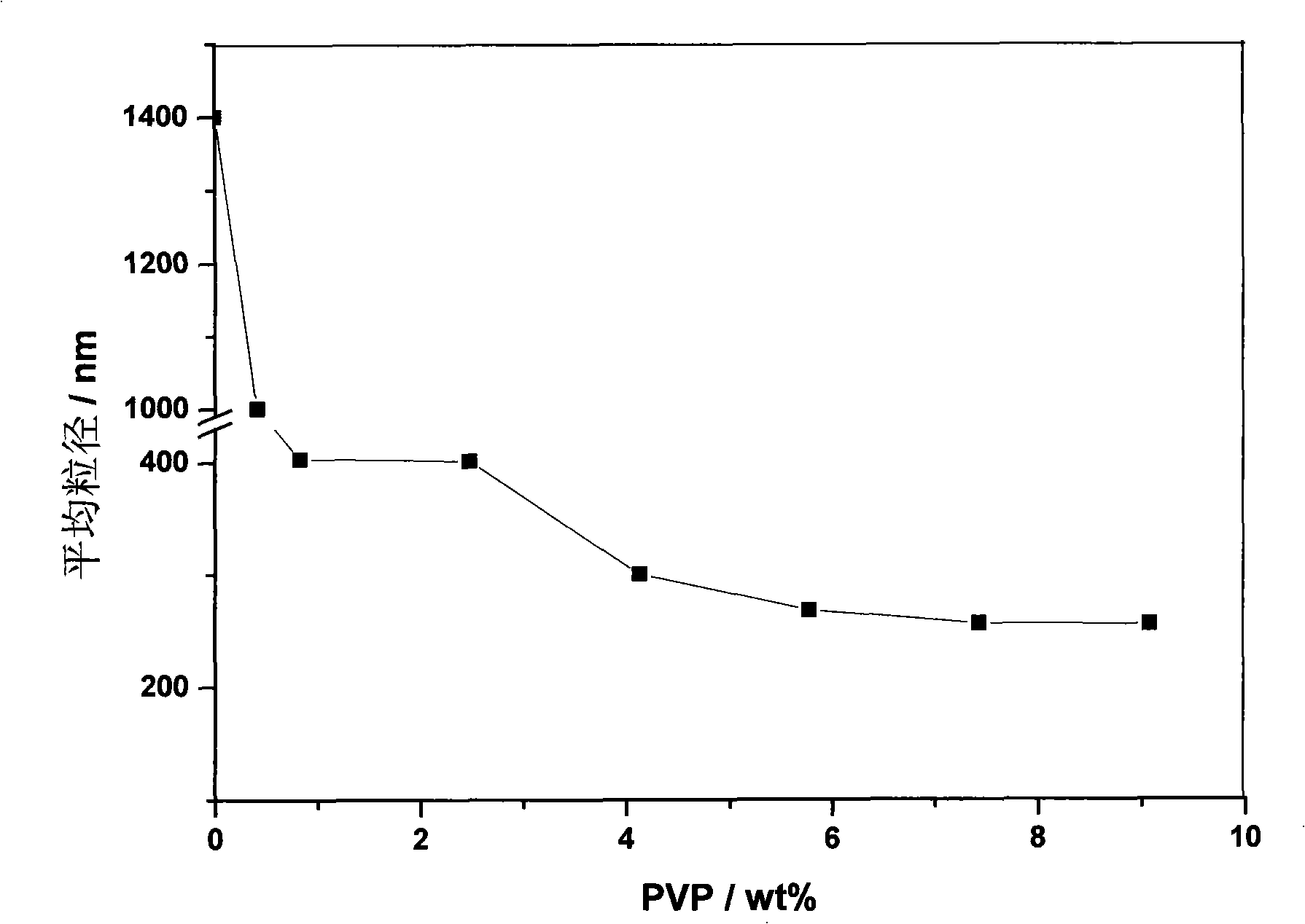

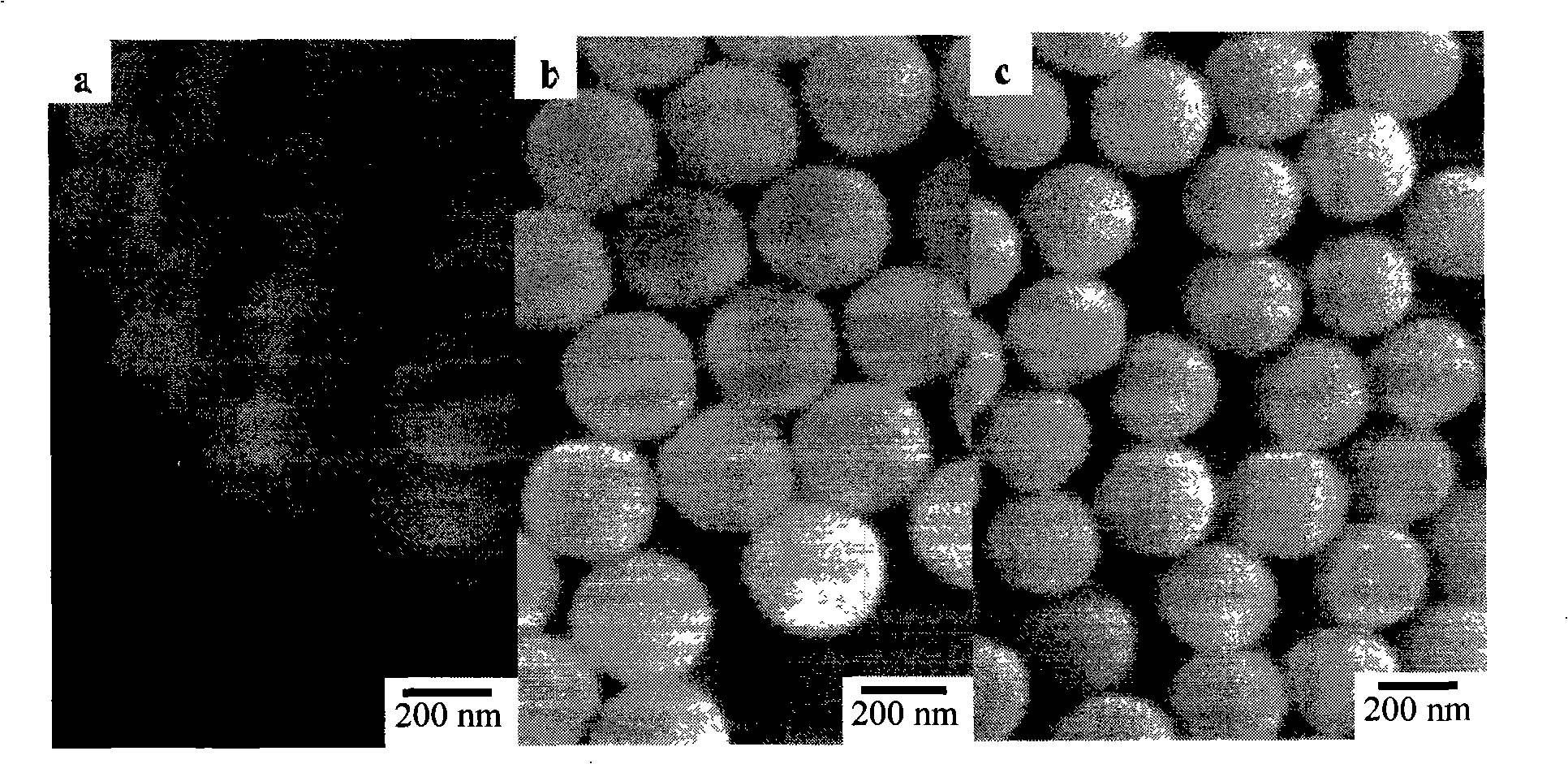

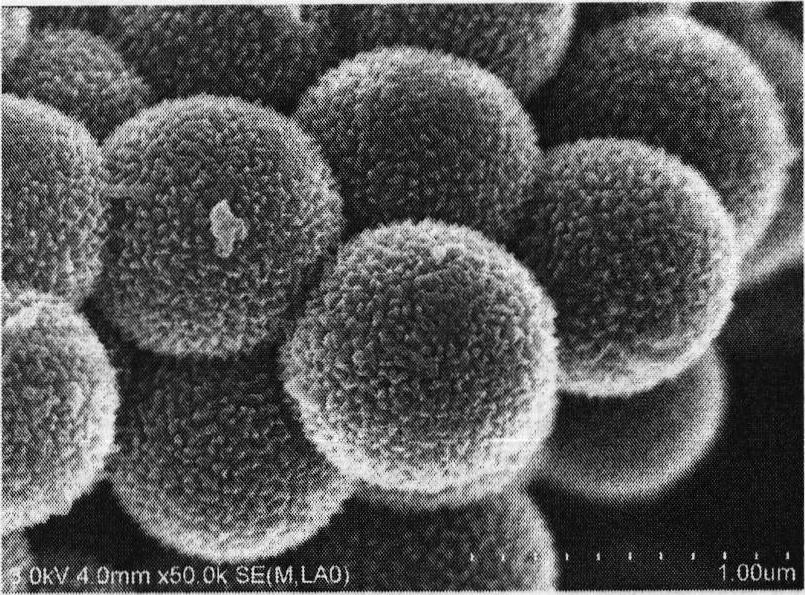

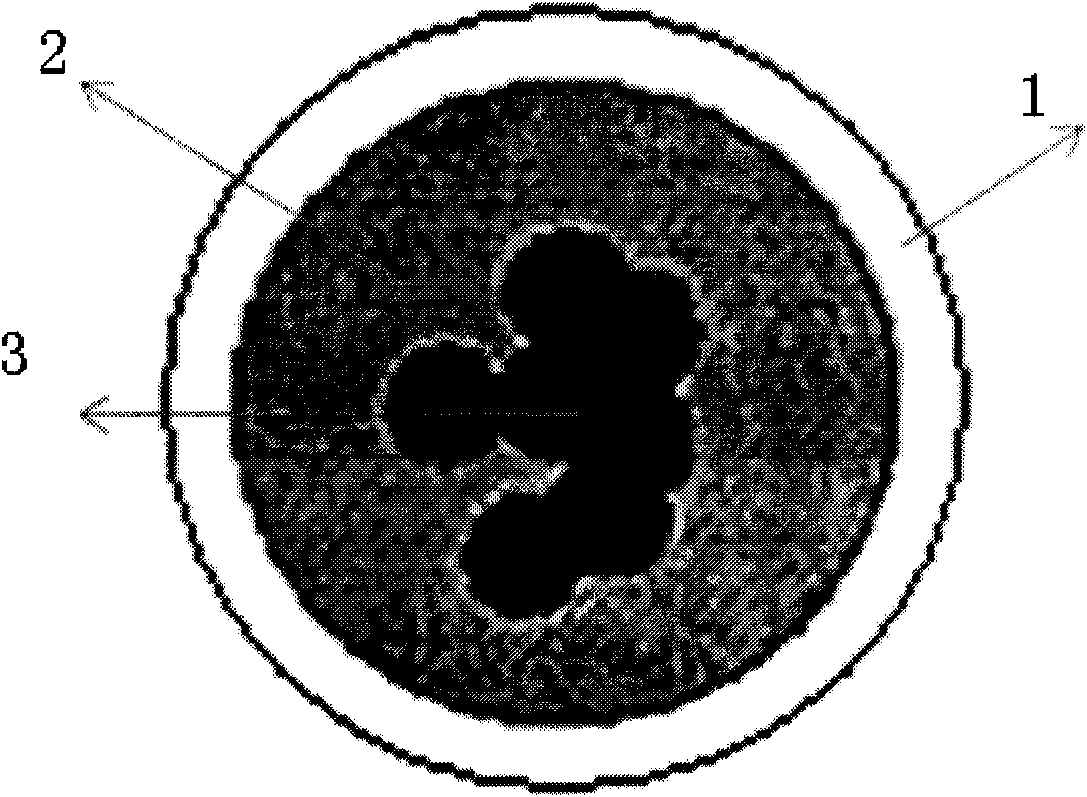

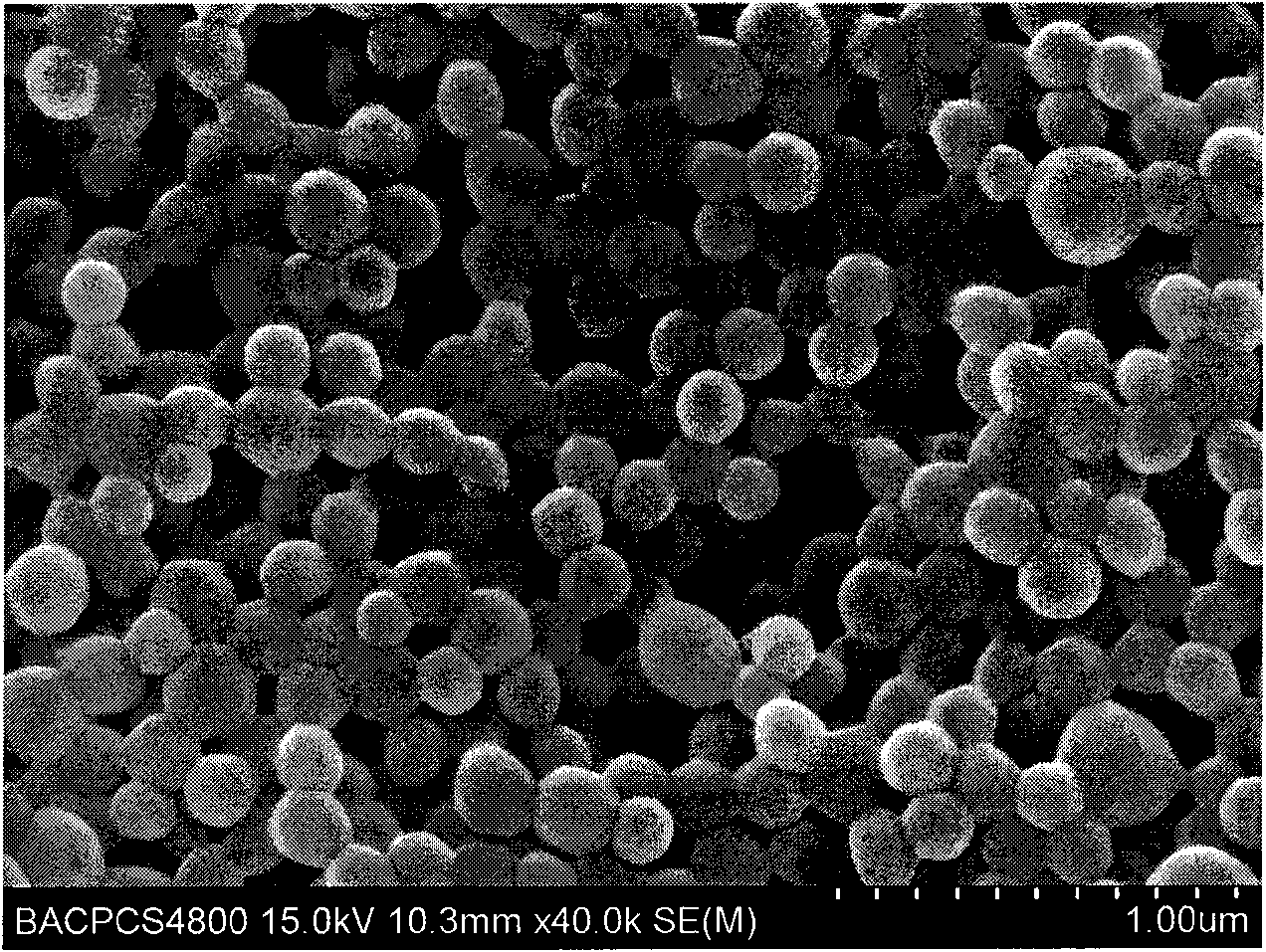

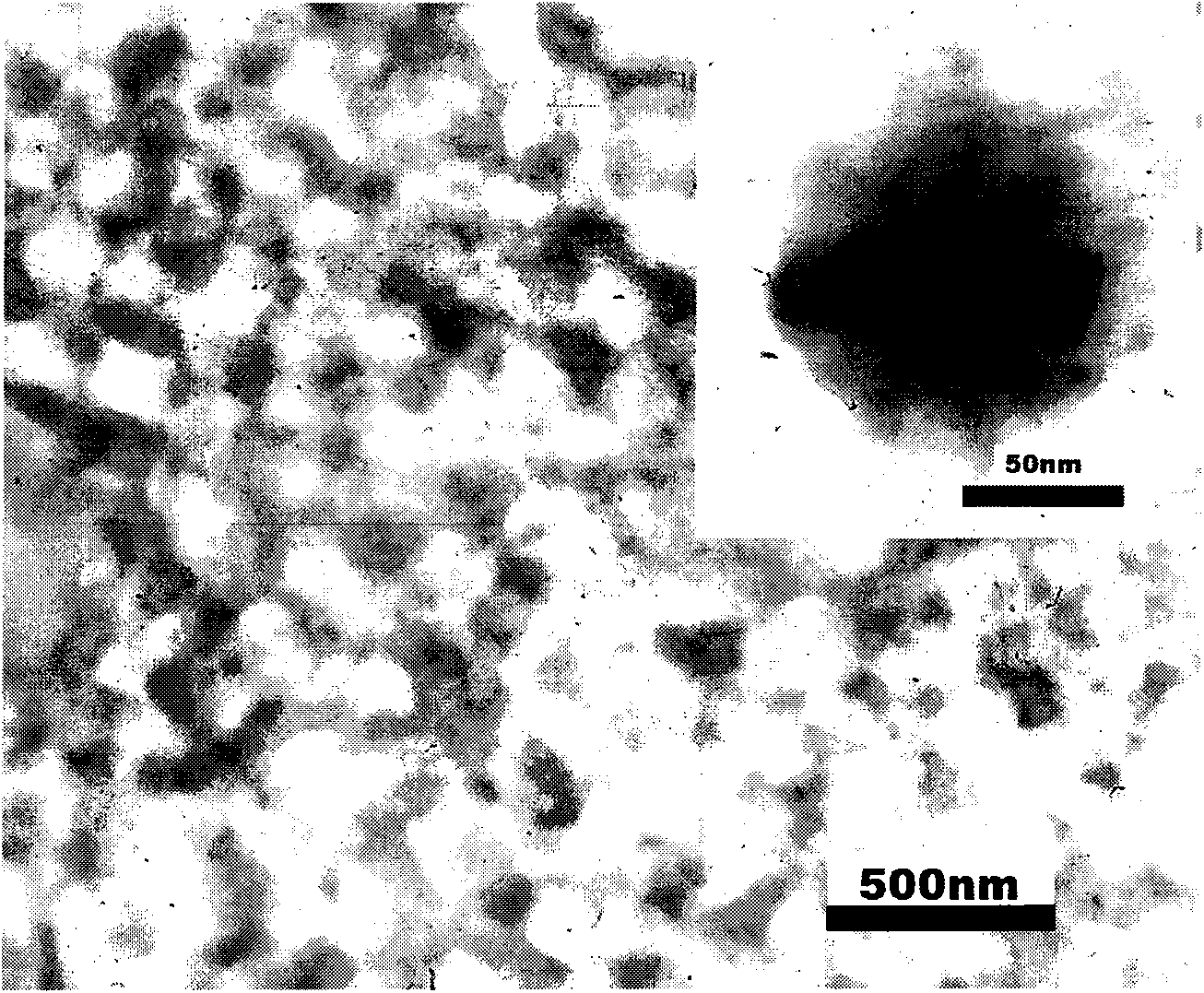

Method for preparing monodisperse polystyrene microsphere with controllable grain diameter

InactiveCN101293936ALow purity requirementGood monodispersityHydrocarbon purification/separationHydrocarbonsPotassium persulfateMicrosphere

The invention belongs to the technology field of nanometer materials preparation, particularly relates to a preparation method of monodisperse polystyrene microspheres capable of controlling the particle size of the polystyrene microspheres within a certain range by changing the use amount of a stabilizer. The invention prepares polystyrene microspheres with simply purified styrene as a monomer, potassium persulfate as an initiator, water as a reaction medium and polyvinylpyrrolidone as a stabilizer by using soap-free emulsion polymerization. The preparation method uses electromagnetic stirring instead of electric stirring; and has the advantages of relatively low requirements for the uniformity of stirring speed, no need of surfactant, simple process, and low cost. The obtained polystyrene microspheres have good monodispersity, and the particle size thereof can be controlled within the range of 250-1,400nm by changing the use amount of the stabilizer. The monodispersed polystyrene microspheres have important application value as a module or template in construction of photonic crystals, inorganic / organic nanometer composite materials and hollow micrometer / nanometer spheres.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

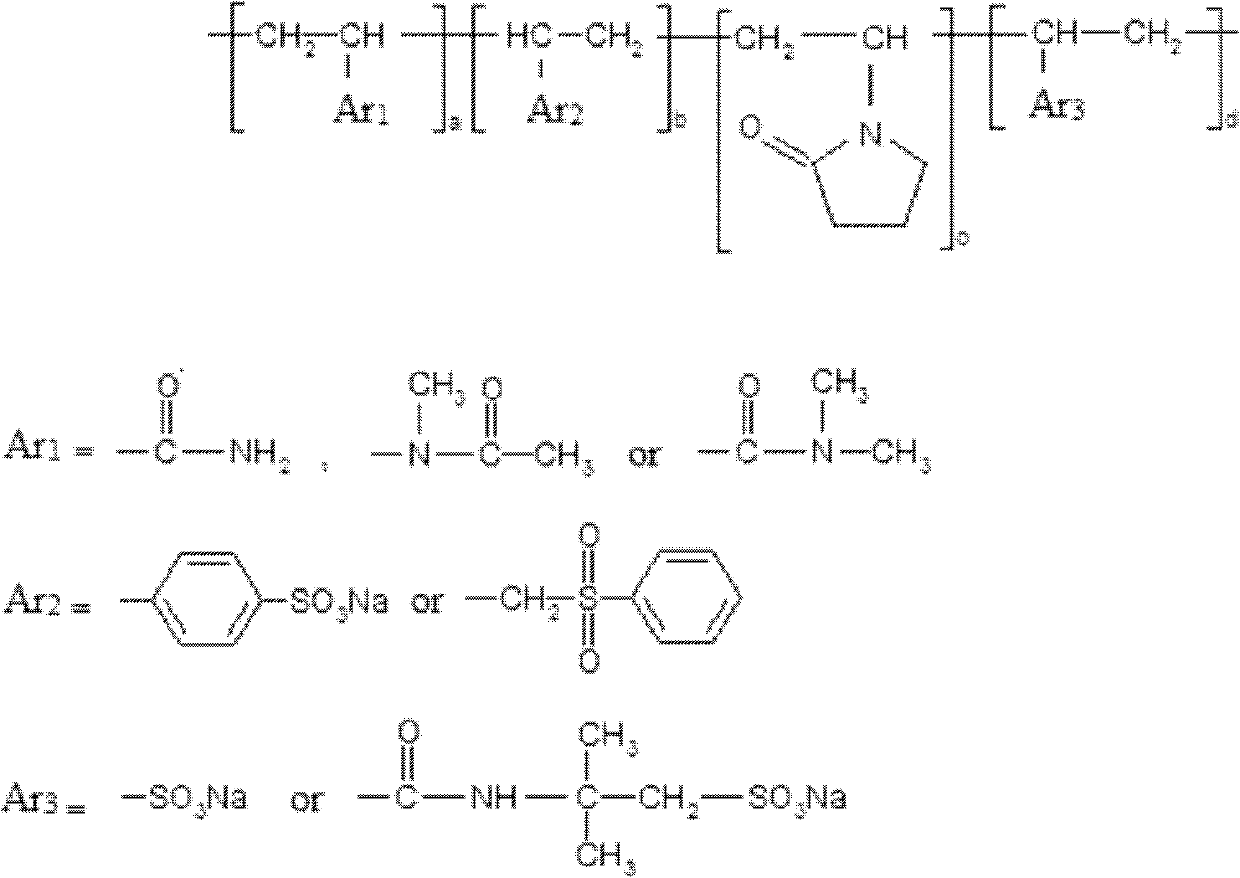

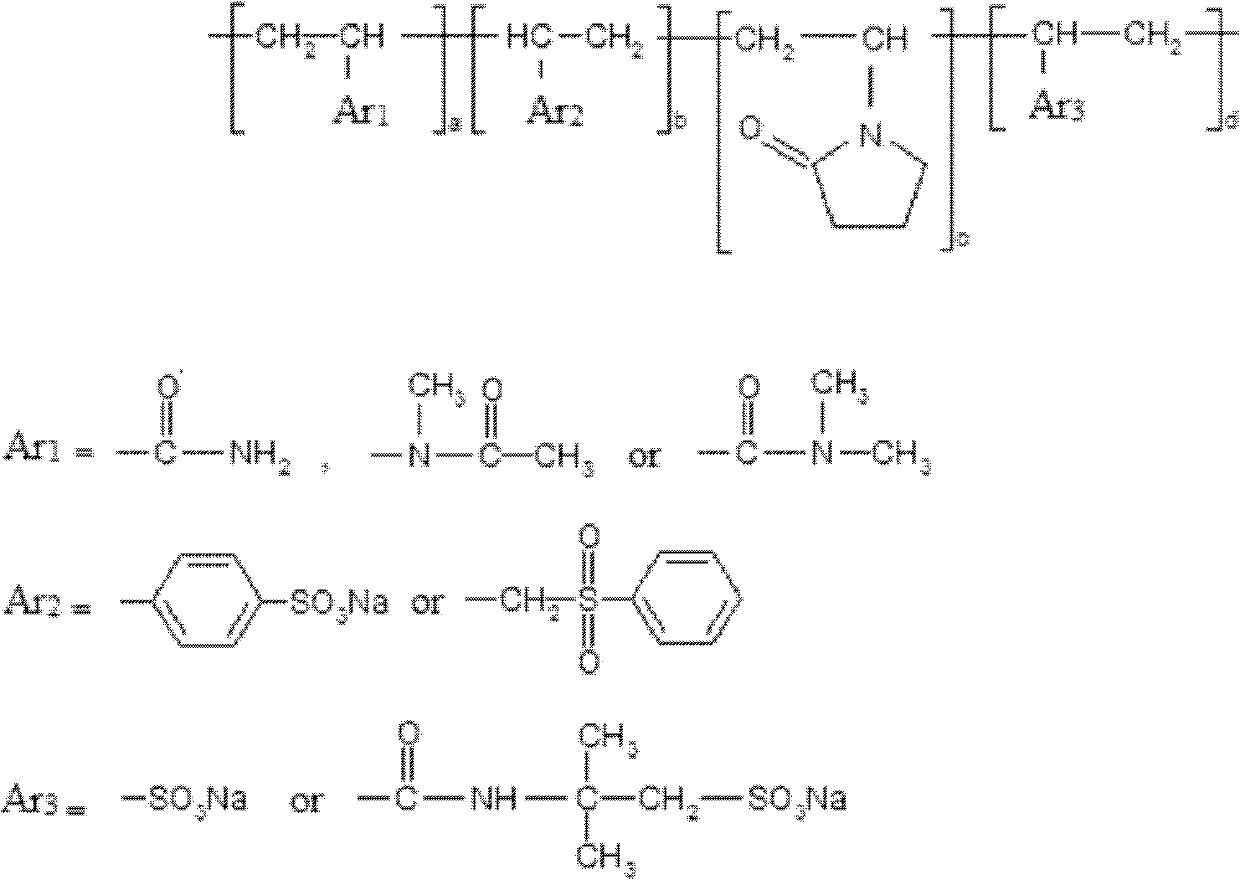

Multi-element co-polymerization oil well cement fluid loss additive and preparation method thereof

ActiveCN101397491ASimple preparation processDrilling compositionPotassium persulfateSodium hydroxide

The invention relates to a multicomponent copolymerization oil well cement fluid loss additive and a preparation method thereof. The method comprises: 10-120 portions of 2-acrylamide-2-methyl-1-AMPSA, 1-5 portions of acrylic acid and 15-50 portions of deionized water are added, stirred and then added with sodium hydroxide aqueous solution with the mass fraction of 5-10 percent for neutralizing to pH equal to 3-11; then 10 portions of acrylamide, 0.1-1 portion of complexing agent EDTA and 0.01-1 portion of chain transfer agent are added, the chain transfer agent is isopropyl alcohol or sodium benzoate, the temperature is controlled between 30 DEG C and 60 DEG C and N2 is introduced for 30 minutes; 2-10 portions of N-vinyl pyrrolidone and 0.01-0.5 portion of initiator are added, the initiator is potassium persulfate or ammonium persulfate, and the reaction is carried out for 4-12 hours. The solution keeps still for 5 hours at the temperature of 180 DEG C, and is cooled through flowing water after being taken out, without sedimentation or water separating; and the water loss is zero at the temperature of 180 DEG C according to the standards of drilling fluid, and the water loss is 48ml according to the standards of cement.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

High temperature-resistance salt-resistance oil well cement filtrate reducer

The invention discloses a high temperature-resistance salt-resistance oil well cement filtrate reducer. The raw materials used in the production of the reducer comprise AMPS(2-acrylamido-2-methyl propane sulfonic acid), acrylic acid, acrylamide, sodium hydroxide, potassium persulfate and water in a mass part ratio of 32-36:2.5-3:12-15:4-6:0.3-0.5:120. The high temperature-resistance oil well cement filtrate reducer prepared according to the formula is applicable to all-grade cement in accordance with API standards; the additive amount of the reducer in a slurry system at a high temperature of 210 DEG C is 5 to 8 percent of the total volume of slurry; and the water loss rate in well cementation can be effectively controlled within 50ml.

Owner:山东胜油固井工程技术有限公司

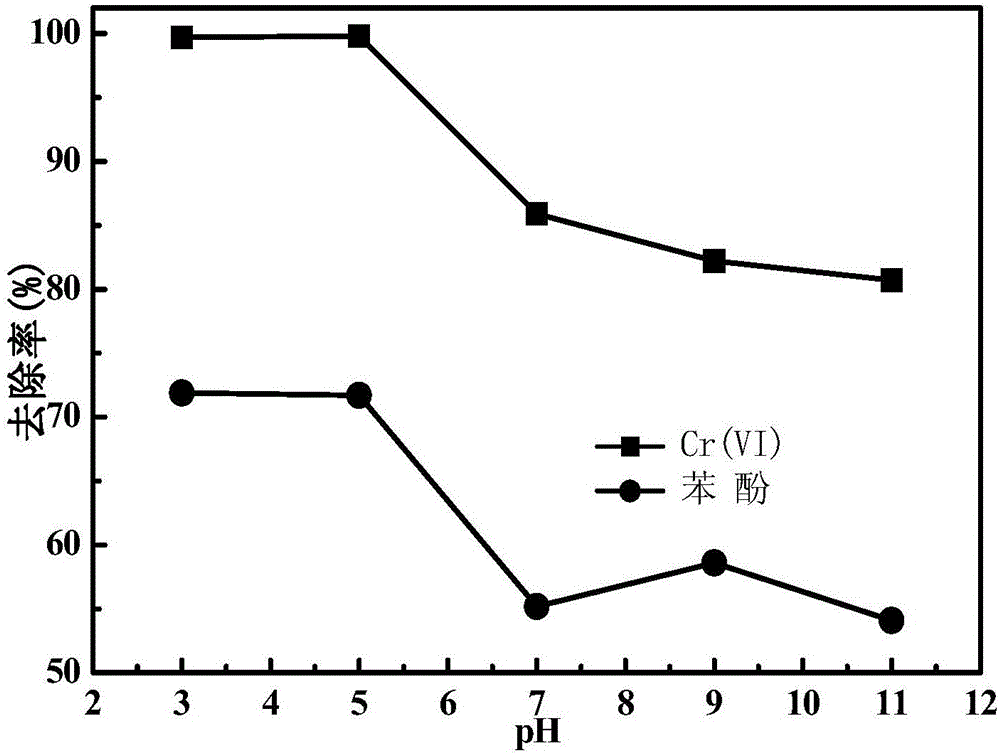

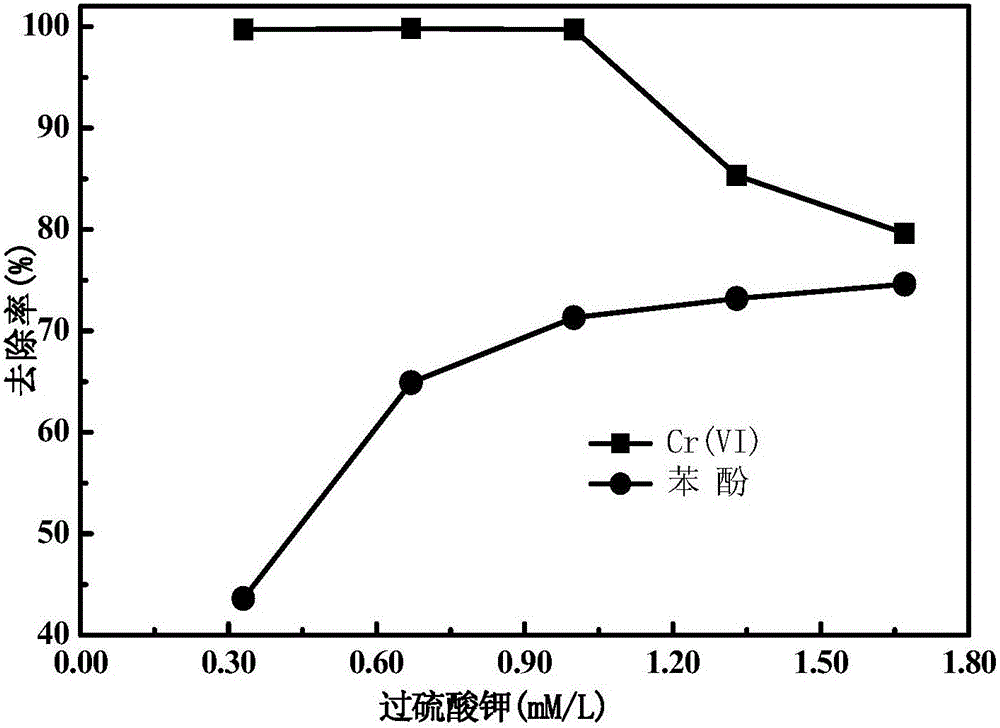

Method for removing heavy metal and organic matter composite pollutants in water body by means of zero-valent iron and persulfate

ActiveCN105110448ALarge specific surface areaSimple preparation processWater contaminantsWater/sewage treatment by reductionPotassium persulfateSodium Bentonite

The invention discloses a method for removing heavy metal and organic matter composite pollutants in a water body by means of zero-valent iron and persulfate. According to the method, bentonite-supported nanoscale zero-valent iron and persulfate are added to the water body containing heavy metal and organic matters, a multi-phase coexistent system is formed, and the heavy metal and the organic matters are removed. Cr(VI) and phenol contained in the water body can be removed simultaneously with the bentonite-supported nanoscale zero-valent iron and potassium persulfate combined method, the heavy metal Cr(VI) is removed through the strong reduction performance of the nanosacle zero-valent iron, Fe2+ generated by the nanoscale zero-valent iron in the reaction process is fully used to activate potassium persulfate, so that SO4<->* is continuously generated to oxidize and degrade phenol, and the heavy metal and organic matter composite pollutants in the water body are removed synergistically.

Owner:SOUTH CHINA SEA INST OF OCEANOLOGY - CHINESE ACAD OF SCI

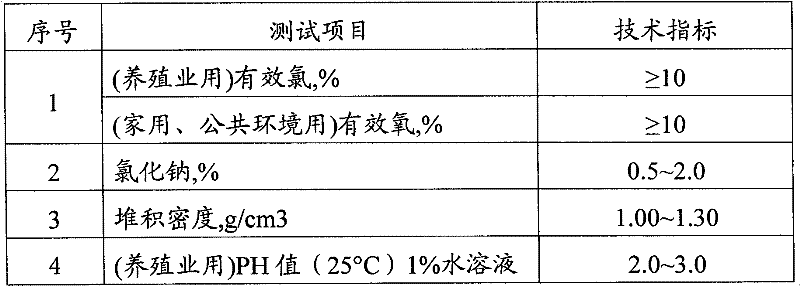

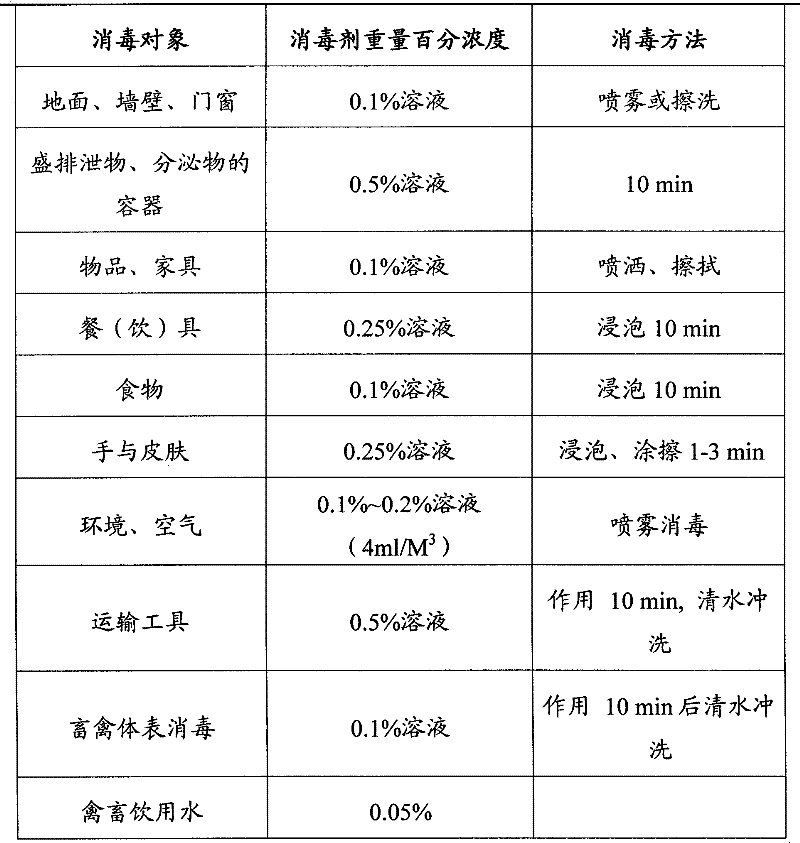

Composite potassium hydrogen persulfate disinfectant and its manufacturing process

ActiveCN102265904AMeet needsWith low toxicity and ultra-low toxicityBiocideFungicidesPotassium persulfateDisinfectant

The invention relates to a compound potassium hydrogen persulfate disinfectant and a manufacturing process thereof. The compound potassium hydrogen persulfate disinfectant comprises the following components in percentage by weight: 60-65% of potassium hydrogen persulfate complex, 0-1.8% of sodium chloride, 2-10% of aminosulfonic acid, 0-2% of sodium dodecyl benzene sulfonate, 0-10% of sodium hexametaphosphate, 0-25% of sodium citrate, 0-25% of sodium tartrate, 0-0.2% of flavoring agent and 0-0.12% of pigment. In the compound potassium hydrogen persulfate disinfectant provided by the invention, the different disinfection requirements of medical, family and livestock and poultry breeding industries are sufficiently considered and the contents of the components in the formula are adjusted according to different users, so that the compound potassium hydrogen persulfate disinfectant can meet the needs of different users; the compound potassium hydrogen persulfate disinfectant has good killing effects on almost all zoonotic bacteria, fungi and viruses, and simultaneously has the characteristics of low toxicity and ultra-low toxicity; and the wide application ranges and good stability and security are perfectly combined.

Owner:上海泰缘生物科技股份有限公司

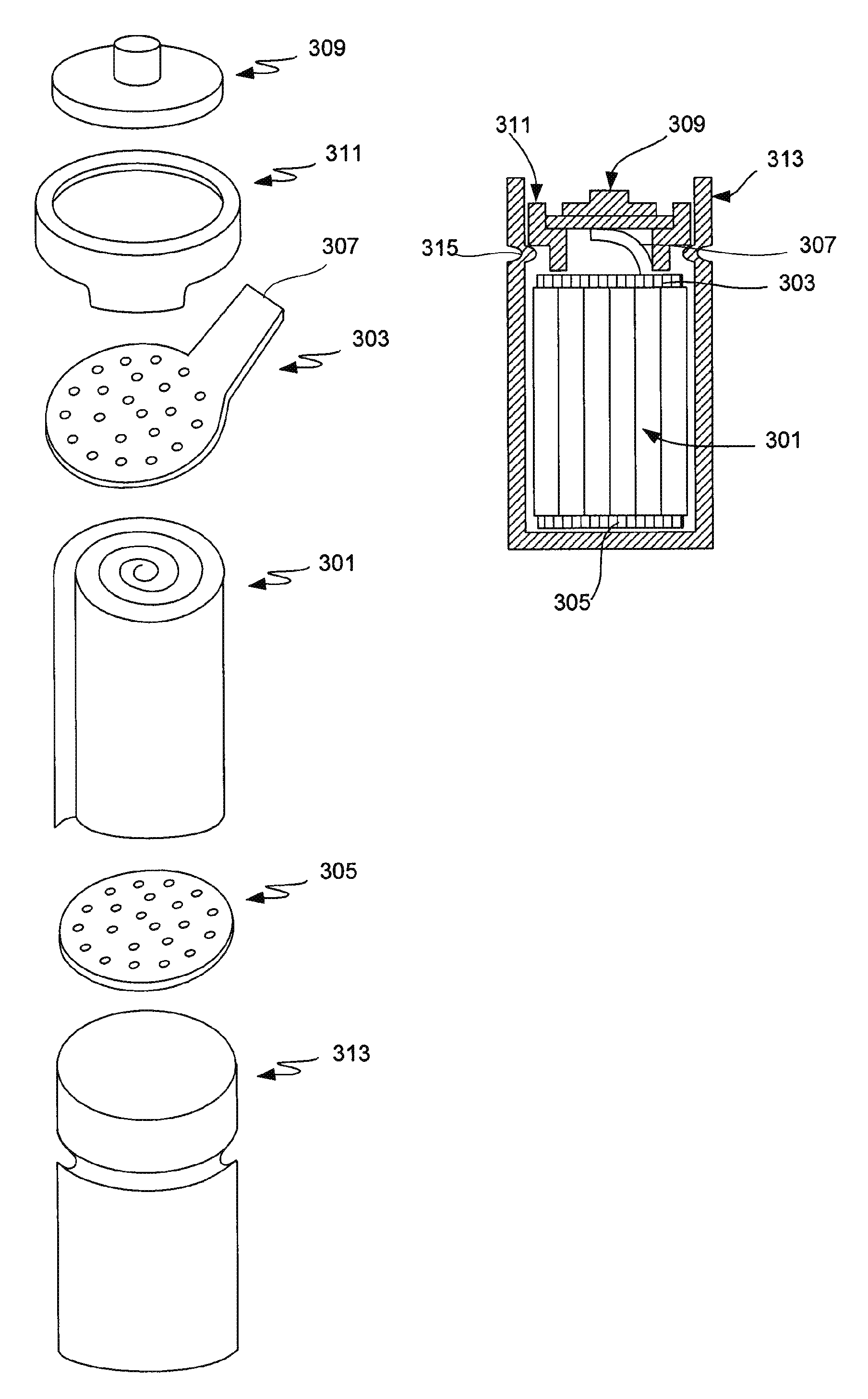

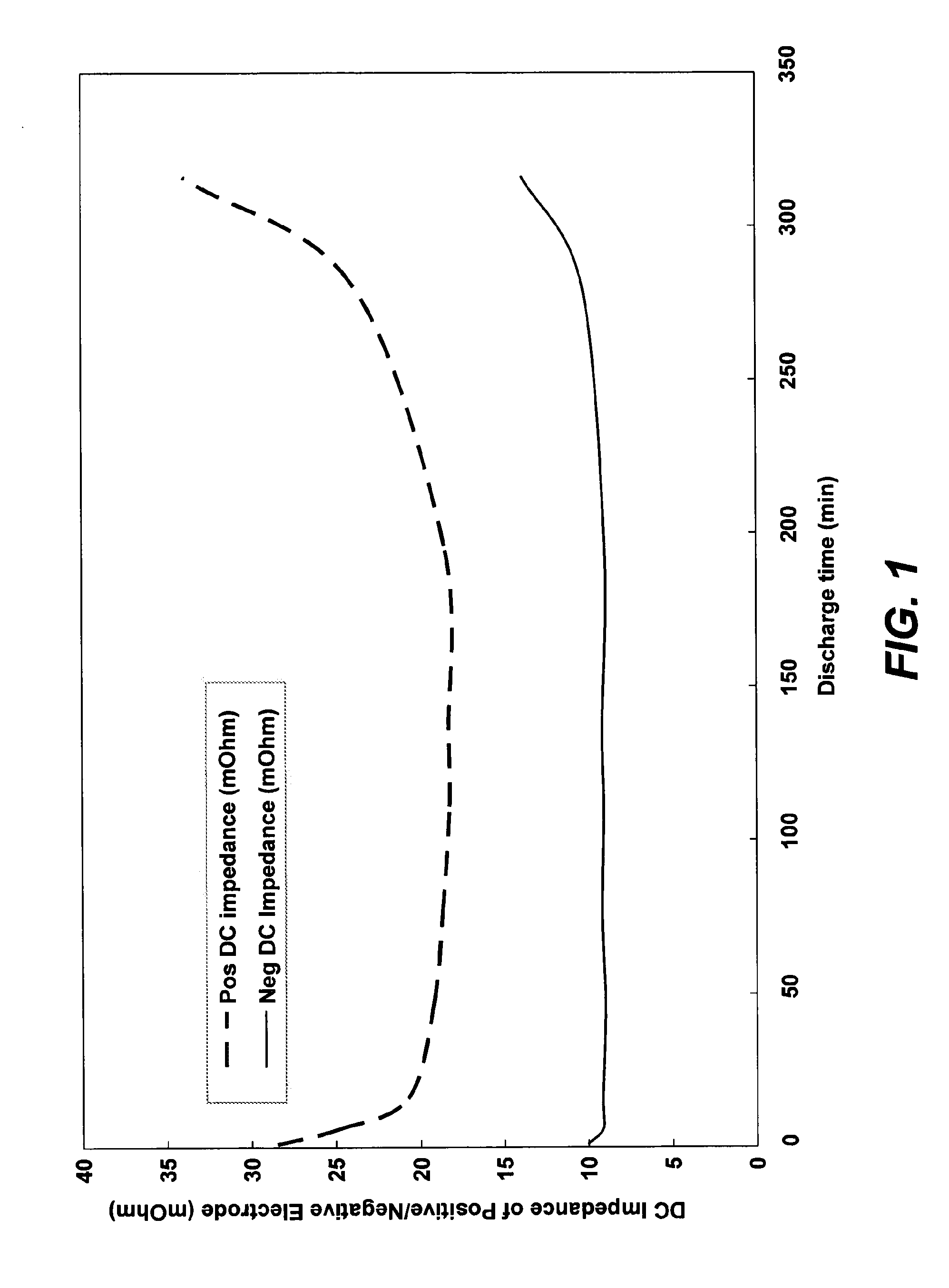

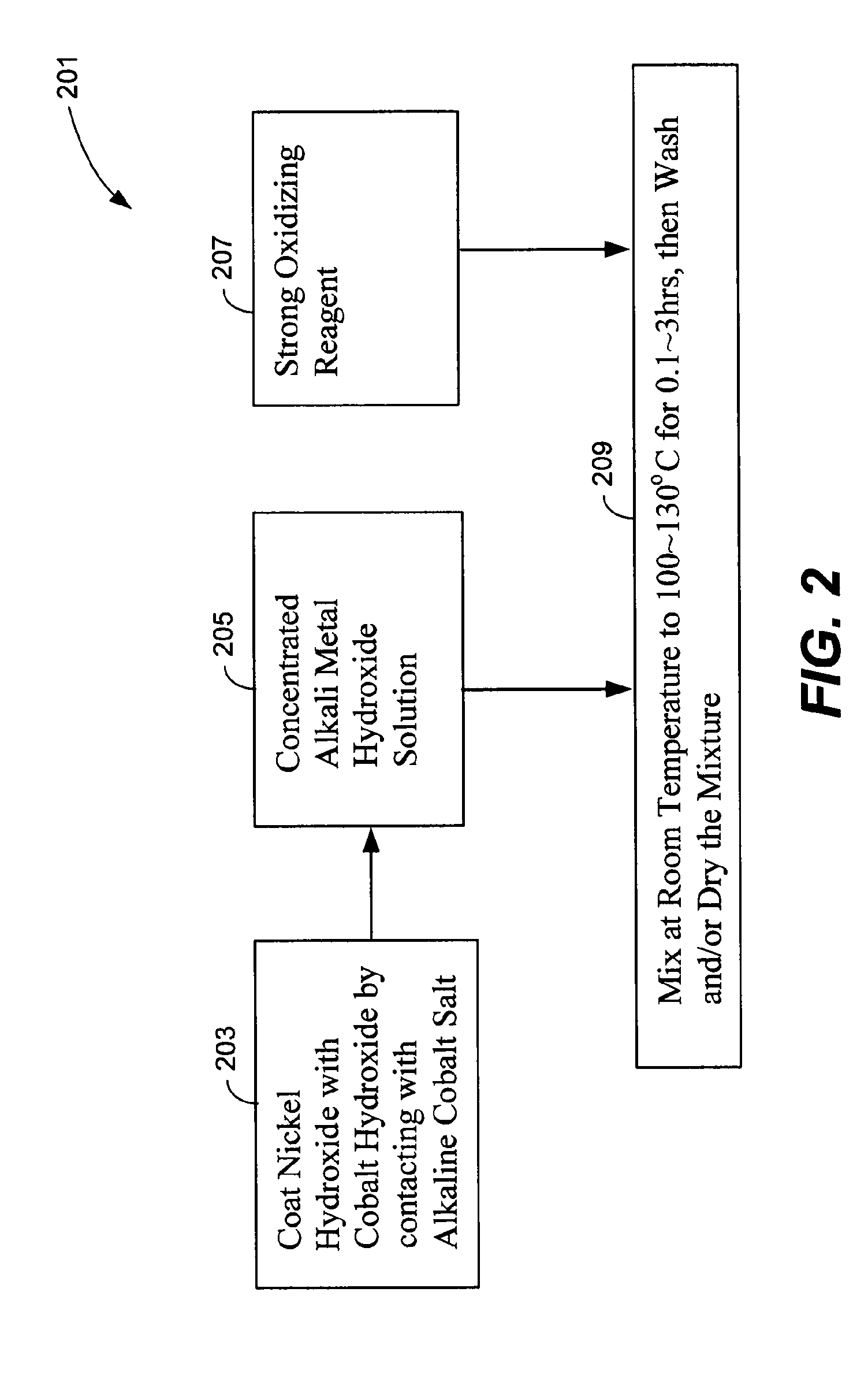

Nickel hydroxide electrode for rechargeable batteries

ActiveUS20090208839A1Facilitate interface reactionImprove reliabilityMaterial nanotechnologyHybrid capacitor electrodesPotassium persulfateNickel oxide hydroxide

The nickel hydroxide particles for a nickel hydroxide electrode may be treated using an alkaline solution of a strong oxidizing agent such as sodium or potassium persulfate to modify the surface nickel hydroxide structure. The resulting modified surface structure has been found to impart various benefits to electrodes formed from the nickel hydroxide. It is believed that the oxidation of cobalt compounds at the surface of the nickel hydroxide particles results in a highly conductive cobalt compound that plays an important role in the high reliability, high stability and high capacity utilization of nickel electrodes as described herein.

Owner:ZINCFIVE POWER INC

Flotation method of brass ore-containing complex lead-zinc sulphide ore

The invention discloses a flotation method of a brass ore-containing complex lead-zinc sulphide ore, which comprises the steps of: adjusting the pH value to be 10-11 in the process of ore grinding; adding ore pulp electric potential regulating agent-sodium pyrosulfite to adjust the electric potential of the ore pulp to be at 220-260mV (relative to hydrogen standard potential); adding zinc sulfate, ethoxy-dithioformicacid ethyl formate and ethyl thio carbamate grinding ore; performing one roughing, one scavenging and two selecting to enrich copper-lead mineral by means of mixing and floating and to form into copper-lead mixed concentrate; performing reagent desorption to the copper-lead mixed concentrate by adding active carbon; adding potassium peroxydisulfate and carboxymethyl starch to restrain lead-containing mineral in the copper-lead mixed concentrate such as galena and the like; performing one roughing, one scavenging and three selecting to obtain copper concentrate; adjusting the pH value of tailings after recovering copper mineral by floating the copper-lead mixed concentrate to be 9.0; adding sodium pyrosulfite, ethyl thio carbamate and butyl ether alcohol; and performing one roughing, one scavenging and two selecting to obtain lead concentrate. The method guarantees the grade of the copper and the lead concentrate, and reduces the environmental pollution.

Owner:CENT SOUTH UNIV +1

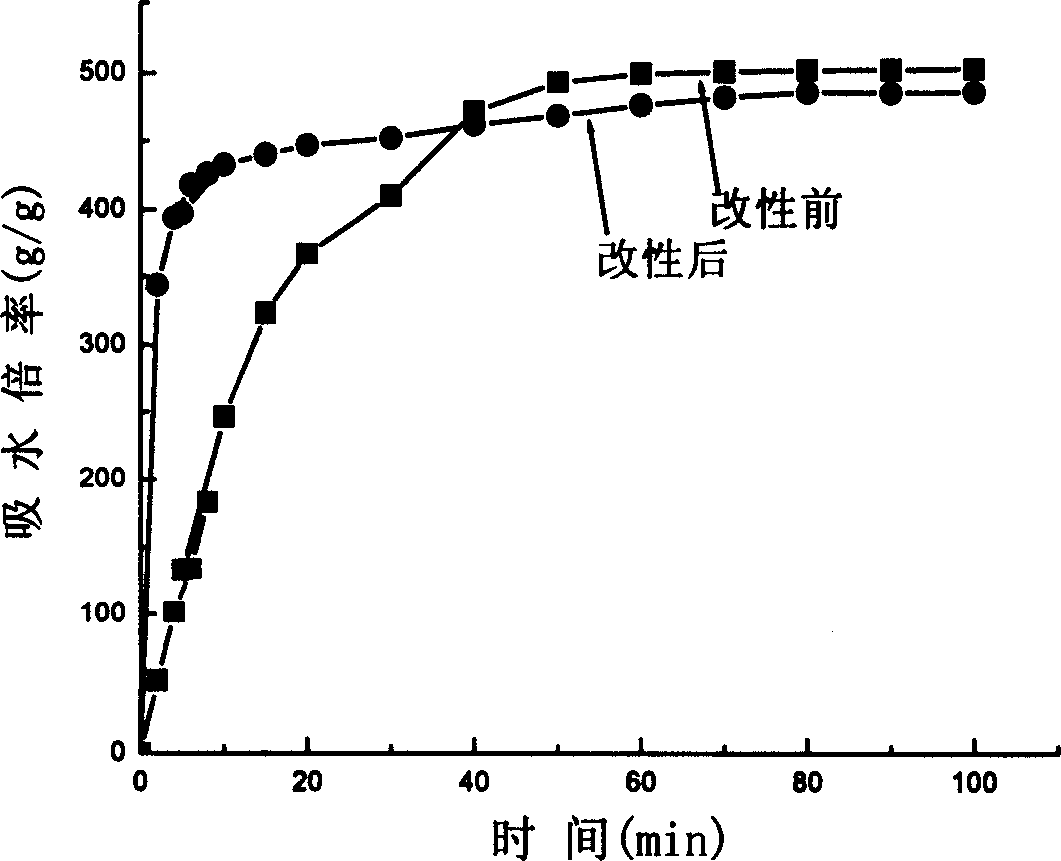

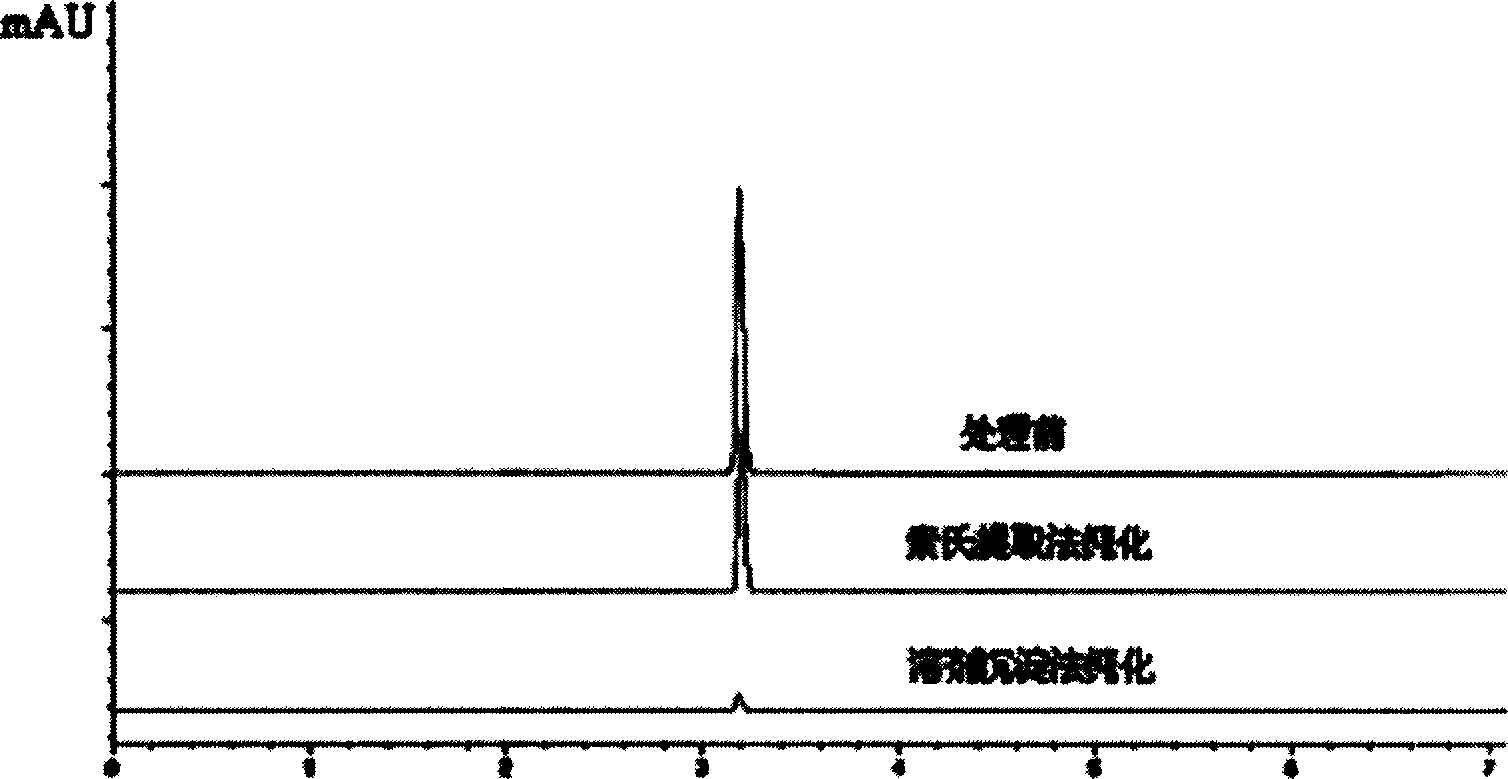

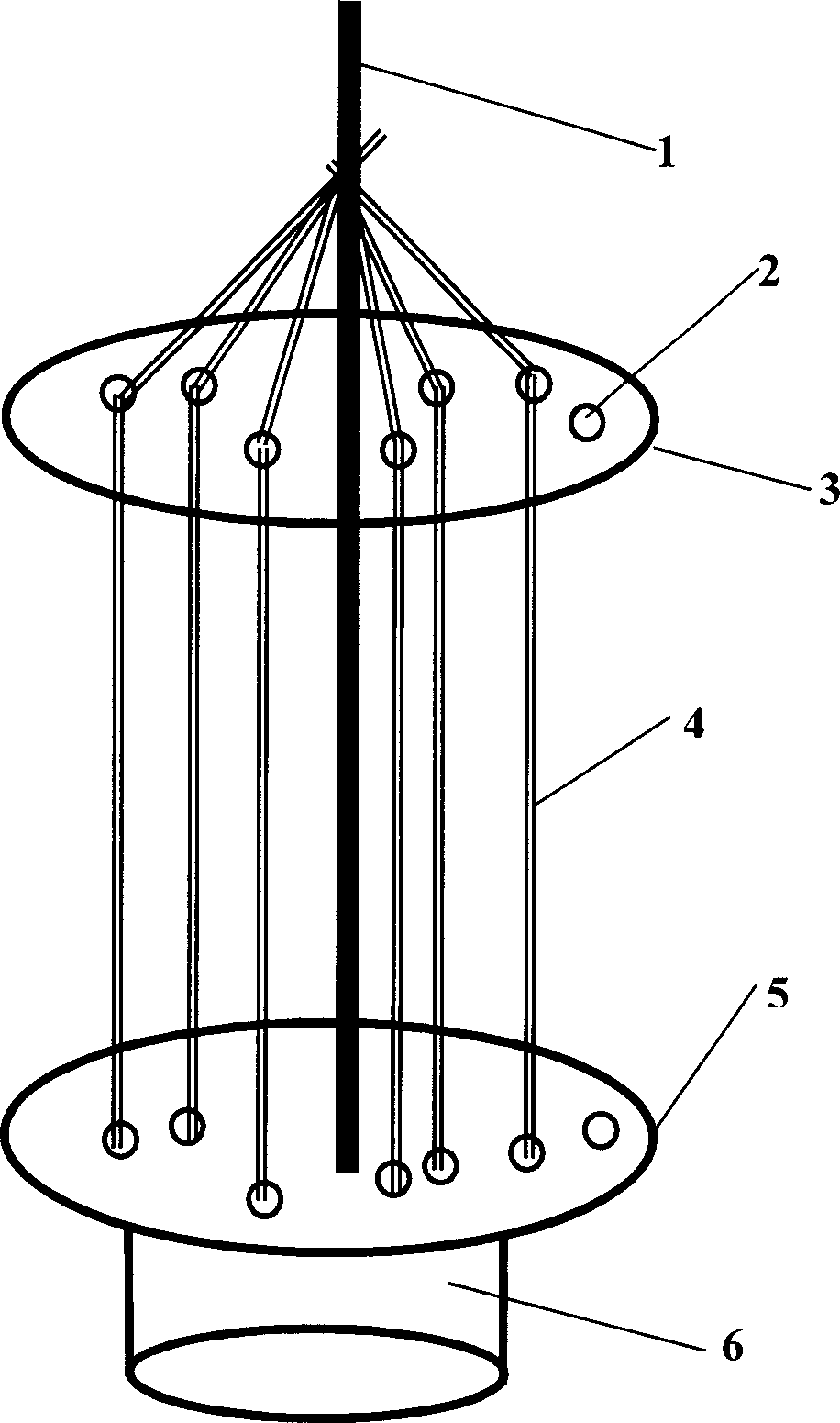

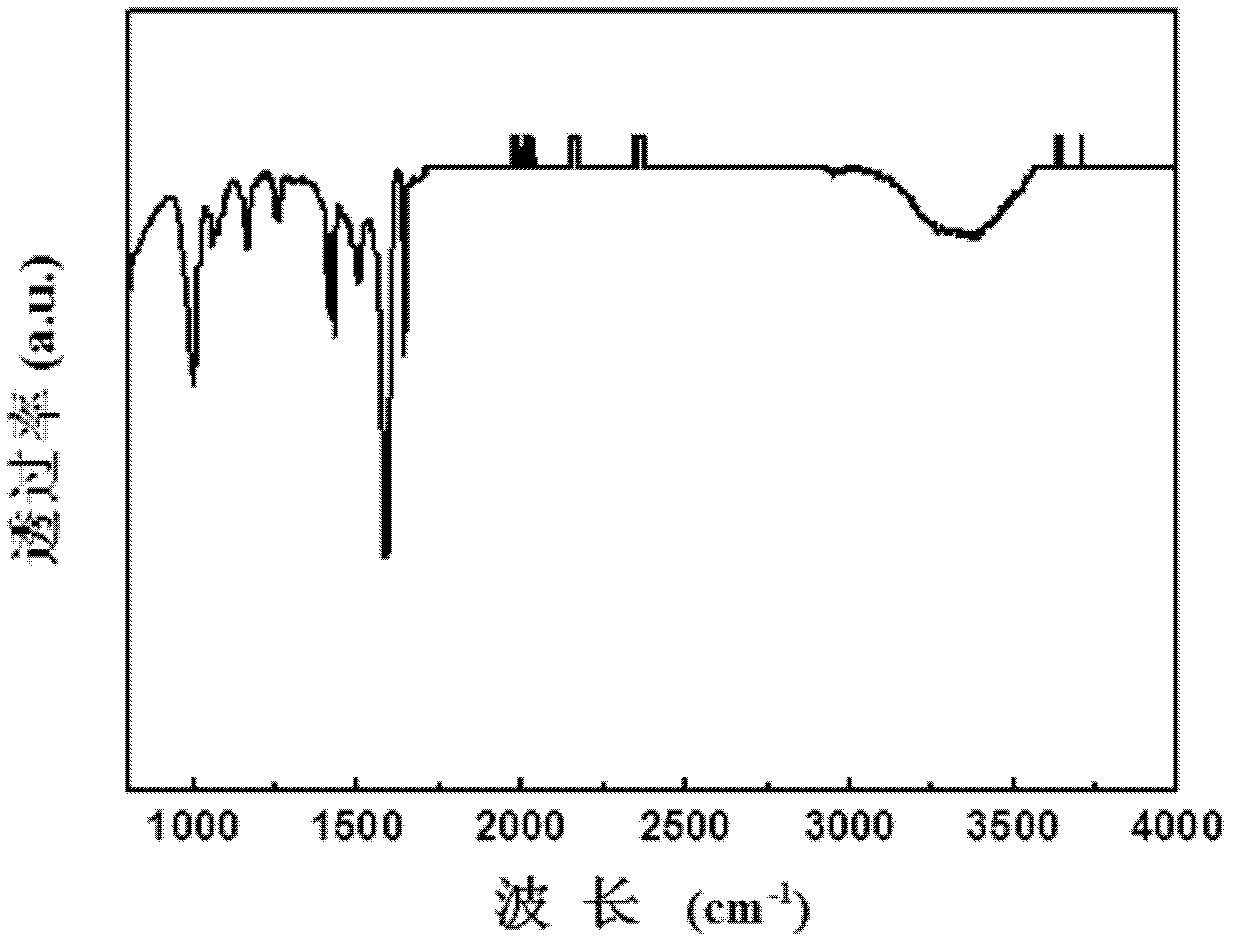

Process for preparing chitosan base macroporous high water absorptive resin

InactiveCN1616505AThe synthesis steps are simpleProcess conditions are easy to controlCross-linkPotassium persulfate

The present invention relates to the preparation process of chitosan base macroporous high water absorption resin. After chitosan is dissolved in dilute acetic acid solution, acrylic acid is made to graft on the molecular chain of chitosan under the initiation of ammonium or potassium persulfate and the product is cross-linked with cross-linking agent, so as to produce high water absorption chitosan grafted acrylic resin with distilled water absorption of 560-1210 g / g and physiological saline absorption of 76-125 g / g. The prepared resin is further modified via solvent deposition process to form macroporous structure to raise the water absorbing rate greatly. High efficiency liquid phase chromatographic test shows that the resin has greatly reduced acrylic acid monomer residue.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

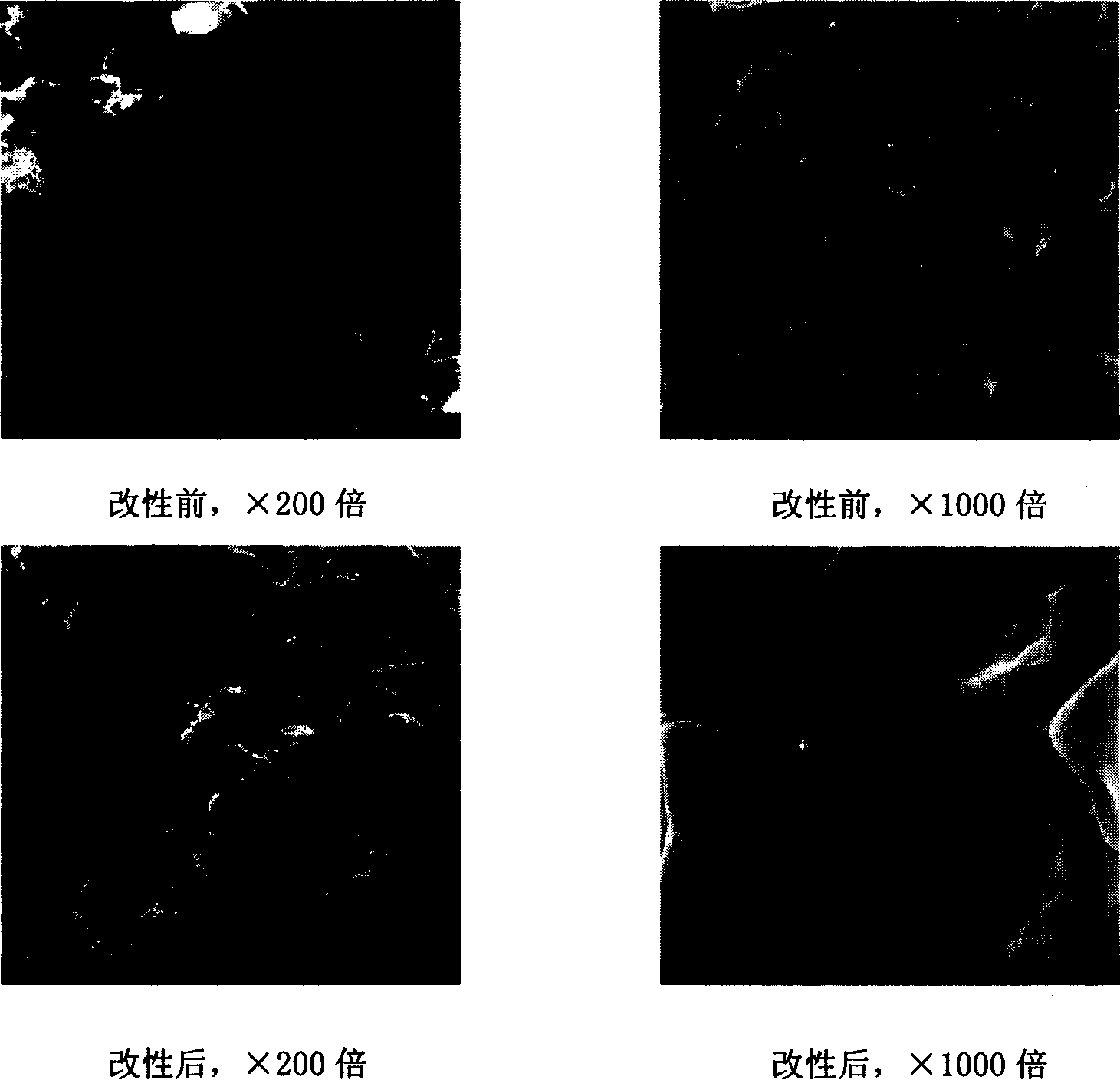

Chemical modification technique for microfiltering separation film of polyvinylidene fluoride

InactiveCN1772359AChemical modification applicableImprove hydrophilicitySemi-permeable membranesPotassium persulfateFiber

The present invention is chemical modification technique for grafting radical with hydrophilic and ion exchange performance onto the surface of hollow fiber microfiltering film and plate microfiltering film of polyvinylidene fluoride. By using acrylic acid, PVA, acrylamide, methylene bis-acrylamide, potassium persulfate and other reagents as material and through chemical cross-linking polymerization reaction, carboxyl radical and hydroxyl radical are grafted onto the surface of the microfiltering film. The technique has the advantages of simple operation and high grafting efficiency, and can improve the hydrophilic performance of the microfiltering film and raise the treating capacity of the microfiltering film. The modified microfiltering film can eliminate the suspended matter, colloid matter and water soluble heavy metal ion in water simultaneously, and has raised drinking water purifying effect and expanded application field of microfiltering film of polyvinylidene fluoride.

Owner:YANSHAN UNIV

Preparation method of biocompatible photo-thermal response self-healing conductive hydrogel

The invention relates to a preparation method of biocompatible photo-thermal response self-healing conductive hydrogel, which includes: preparing solution from N,N-dimethyl acrylamide monomer, potassium persulfate serving as initiator and N,N,N',N'-tetramethylethylenediamine serving as accelerator; then soaking graphene hydrogel into the monomer solution for solution displacement and standing; and finally, initiating polymerization reaction at the room temperature, so that the biocompatible photo-thermal response self-healing conductive hydrogel is prepared. The preparation method is simple in process, mild in reaction condition, short in reaction time and suitable for industrial production. The hydrogel uses the graphene as a three-dimensional network framework, the graphene is high in reduction degree, chemical stability, electric conductivity and mechanical strength and good in photothermal conversion effect, and the hydrogel shows good self-healing performance within the body temperature range and under near-infrared irradiation.

Owner:DONGHUA UNIV

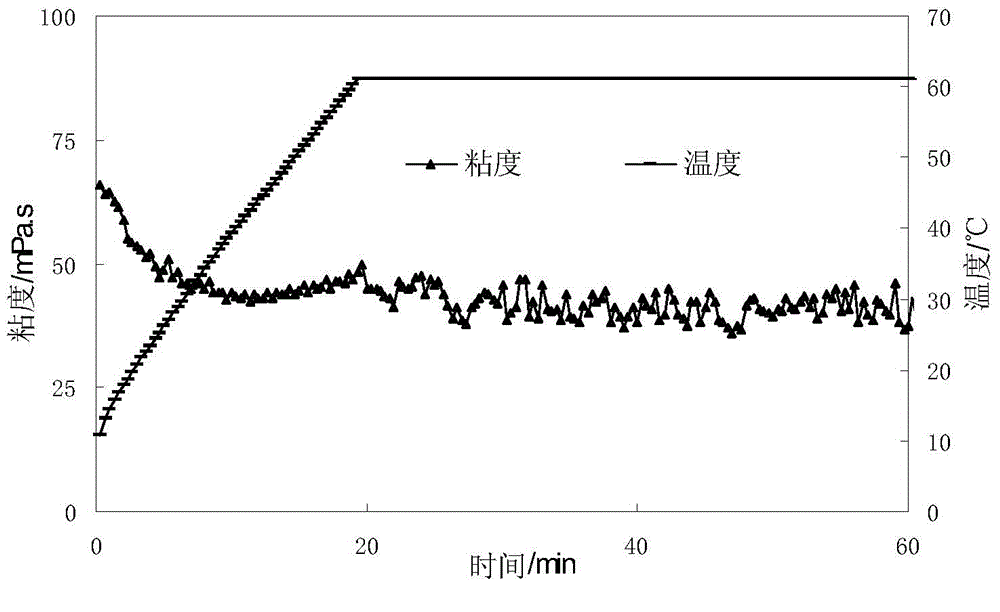

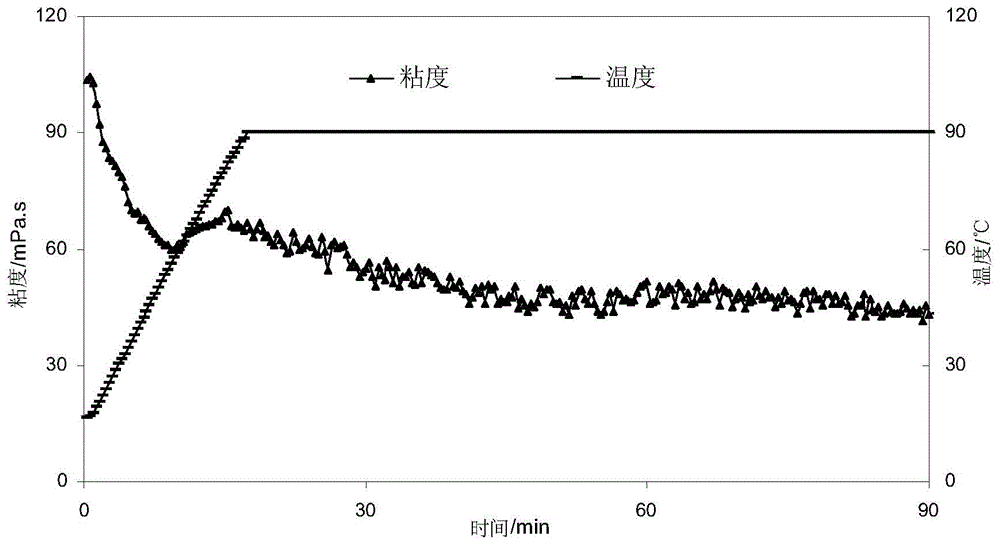

Clean carbon dioxide foam fracturing fluid and preparation method thereof

ActiveCN104531129AFine foamImprove foam stabilityDrilling compositionPotassium persulfatePolymer science

The invention discloses clean carbon dioxide foam fracturing fluid and a preparation method thereof, and relates to the technical field of oilfield chemistry and fracturing production increase. The carbon dioxide foam fracturing fluid is mainly composed of a base solution, a foaming agent, a gel breaker and liquid carbon dioxide with the mass ratio being 100 to 0.15-0.45 to 0.02-0.08 to 100-900. The base solution is formed by 0.2%-0.55% of a thickening agent and water. The thickening agent is mainly formed by bisacrylamide, vinyl pyrrolidone, kation unsaturated monomer, anion unsaturated monomer, an initiator, sodium carbonate, an emulsifying agent and a hydrotropy agent. The foaming agent is mainly formed by hexadecyl dimethyl tertiary amine, dimethyl sulfate, caustic soda flakes, potassium persulfate and solvent. The clean carbon dioxide foam fracturing fluid has the advantages of being high in foam stability, high in temperature resistance and shear resistance, high in sand-carrying performance, wide in applicable temperature range, extremely low in residue content, high in backflow performance, and small in secondary damage to a reservoir after fracturing, thereby improving the fracturing effect and increasing the reservoir productivity.

Owner:CHENGDU BAICHUN PETROLEUM TECH

Stain-resistant and oil-resistant wallpaper and preparation method thereof

The invention discloses stain-resistant and oil-resistant wallpaper. The stain-resistant and oil-resistant wallpaper comprises a substrate layer, a stain-resistant layer and an oil-resistant layer, wherein the outer periphery of the substrate layer is coated with the stain-resistant layer, and the outer periphery, far away from the substrate layer, of the stain-resistant layer is coated with the oil-resistant layer; the oil-resistant layer is prepared from the raw materials: acrylic perfluoroalkyl ester, alkyd resin, polyester resin, perfluoroalkyl acrylate, butyl acrylate, hydroxyethyl acrylate, aluminum tripolyphosphate, nano zinc borate, potassium persulfate, hydroxymethyl cellulose, nano zinc oxide, nano titanium dioxide, diatomite, magnesium hydroxide, aluminum oxide, organobentonite, sericite powder, perfluorocarbon, ferric phosphate, sodium molybdate, sodium persulfate, chlorinated paraffin, silane coupling agent KH-560, dibutyltin dilaurate, octadecyl trimethyl ammonium chloride, polyethylene glycol, fluorosilicon oil, a thickener, an antifoamer, a curing agent and modifying auxiliaries. The invention further provides a preparation method of the stain-resistant and oil-resistant wallpaper. The prepared wallpaper has excellent stain resistance and oil resistance.

Owner:安徽易有墙纸有限公司

Method for prepaing granular profile control agent in copolymerization crosslinking type

This invention describes a process for preparing a new copolymerized and cross-linked granular profile control agent. The process uses two organic monomers, acrylamide and acrylic acid, as the major raw materials, bentonite or montmorillonite as the reinforcing agent, ammonium persulfate or potassium persulfate as the initiator, potassium metabisulfite as the reductant, and N,Ní»-methylene diacrylamide as the cross-linker to synthesize the granular profile control agent. Since the process uses bentonite or montmorillonite as the reinforcing agent, and ammonium persulfate or potassium persulfate / potassium metabisulfite as the oxidation-reduction system, ití»s easy to operate and the PH value is adjustable.

Owner:李松棠

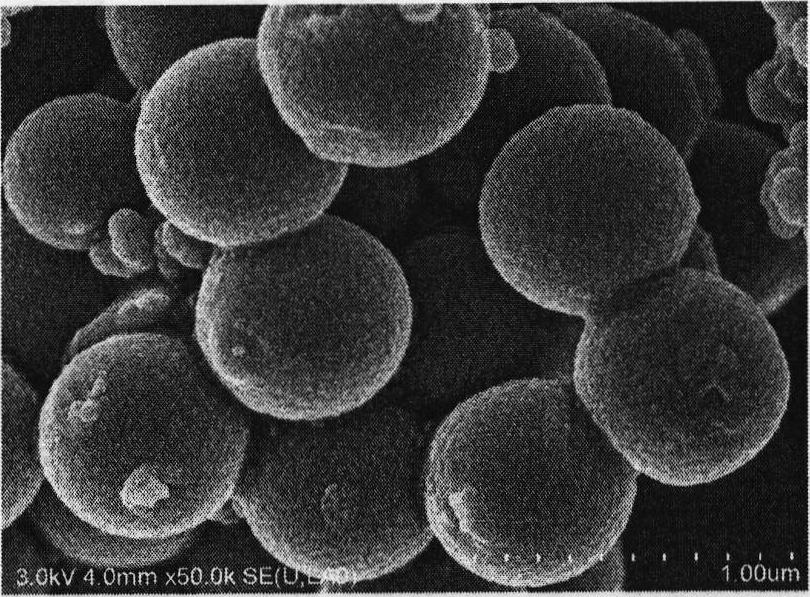

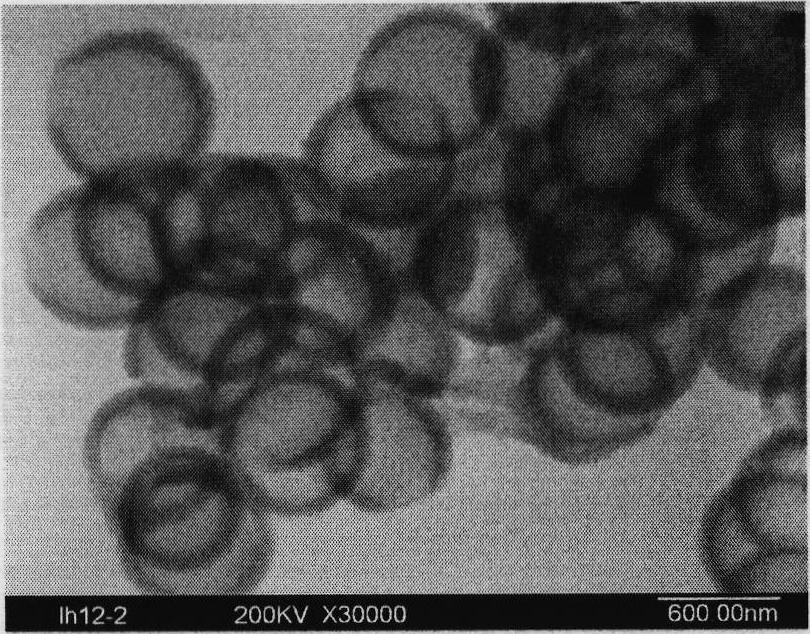

Method for preparing polystyrene/conductive polymer composite hollow microspheres

The invention discloses a method for preparing polystyrene / conductive polymer composite hollow microspheres, which comprises the following steps of: adding aniline or pyrrole and acid or mixture thereof into polystyrene emulsion under the protection of inert gas, stirring the obtained mixture for at least 10 minutes, and then adding an initiator into the mixture to perform polymerization, whereinthe molar ratio of the aniline or the pyrrole to the acid is 0.2 to 0.8, the weight ratio of the aniline or the pyrrole to the polystyrene is 0.1 to 1.0, and the initiator is ammonium persulfate, potassium persulfate, iron trichloride or ferrous sulfate heptahydrate / hydrogen peroxide. Different from the traditional method for preparing the hollow polymer microspheres, the method does not need high-temperature calcination or solvent denucleation treatment and can prepare the polymer composite hollow microspheres by one step, and the microspheres have good appearance and monodispersity. The method is simple, has a few operation steps, and is easy for subsequent treatment; and because the used solvent is a green solvent, the method is safe and reliable, and has low cost.

Owner:BEIJING NORMAL UNIVERSITY

A method to prepare the phase-change material wrapped by microcapsule

InactiveCN101550328AMeet the needs of full-band camouflageInorganic material magnetismHeat-exchange elementsPotassium persulfateParaffin wax

A method to prepare the phase-change material wrapped by microcapsule, wherein, 1. Weigh paraffin and methyl methacrylate (MMA) at a mass ratio of 1:3; 2. Weigh 0.5% glycol dimethacrylate (GDMA), 1% methacrylic acid (MAA) and 1% sodium dodecyl sulfate (SDS), 1.5% potassium persulfate, 1%-15% ferrite and 400% deionized water (to the total mass of Item 1); 4. Add ferrite and molten paraffin into the solution of Item 3; 5. Emulsify the solution under ultrasonic sound and add MMA, GDMA and MAA; 6. Re-emulsify and transfer the obtained solution into a device with mechanical agitation, condenser tube, gas inlet and feed inlet; 7. Aerate and remove oxygen 0.5h, heat it in water bath to 70 DEG C, add potassium persulfate and cool the solution to room temperature to obtain the phase-change material wrapped by microcapsule. The material is used in such fields as building, heat-storing temperature-adaptable textile, and electronic equipment.

Owner:BEIJING JIAOTONG UNIV

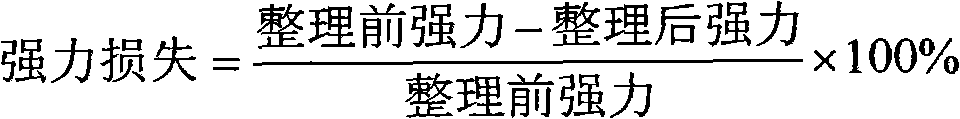

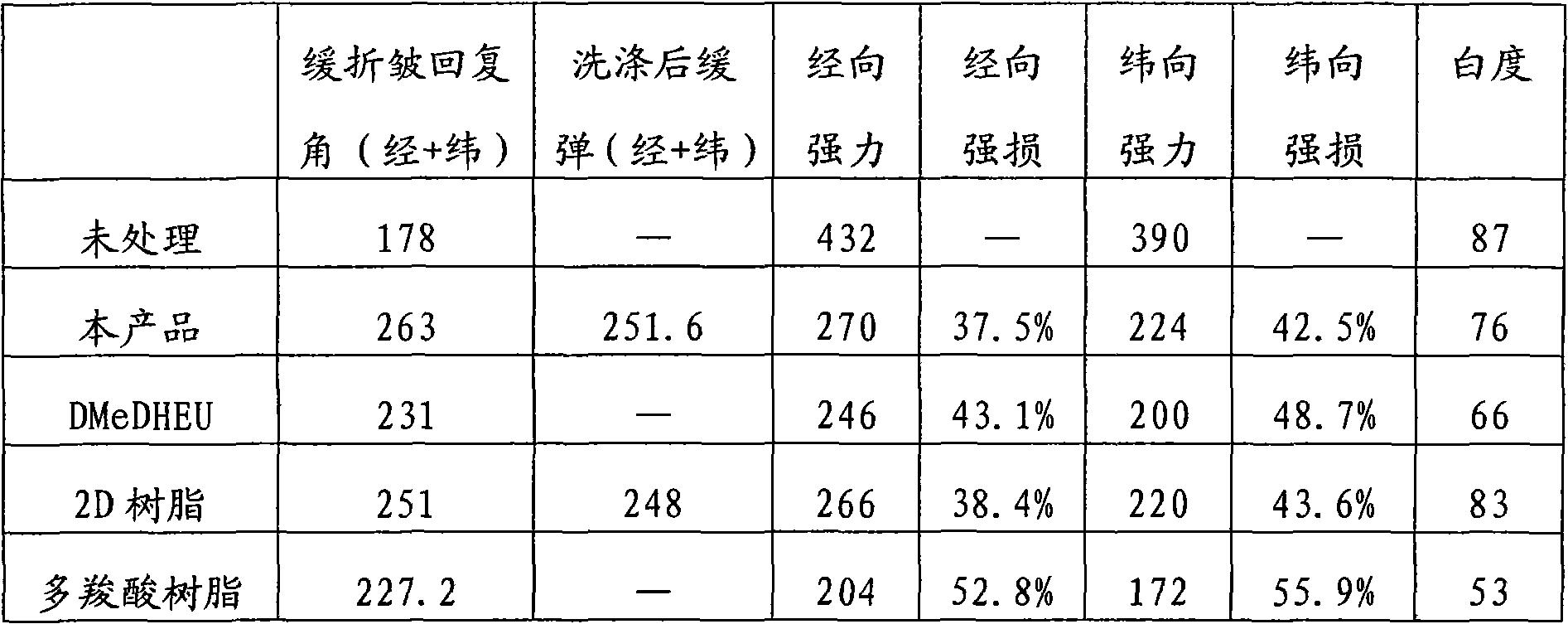

Formaldehydeless permanent press finishing agent for fabric and preparation method and application thereof

ActiveCN101956322AOvercome lossImprove wrinkle resistanceVegetal fibresPotassium persulfatePolymer science

The invention discloses a novel formaldehydeless permanent press finishing agent for a fabric and a preparation method and application thereof. The formaldehydeless permanent press finishing agent for the fabric is prepared by performing a polymerization reaction on acrylamide, glyoxal, phthalic anhydride, sulfuric acid, potassium persulfate and the like. The product of the invention is mainly used for performing noniron finish on the fabric and improving the firmness of a dyed fabric and a printed fabric. Compared with the conventional N-methylol acrylamide resin, the permanent press finishing agent has prominent advantages of excluding of formaldehyde and crease resilience equivalent to or surpassing those of etherfied 2D (etherfied dimethylol dihydroxy ethylene urea) after being used for finishing a cotton fabric; and compared with the conventional formaldehydeless resin, the agent has the advantages of high crease resilience, strength loss less than that of a polycarboxylic formaldehydeless resin, cost lower than those of dimethylol dihydroxy ethylene urea (DMeDHEU) and butanetetracarboxylic acid (BTCA) and cost performance far higher than that of a polycarboxylic resin.

Owner:SICHUAN YIXIN TECH

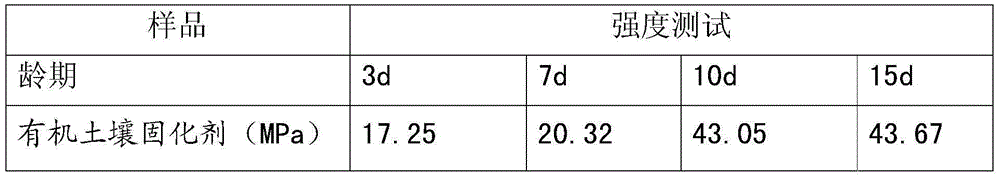

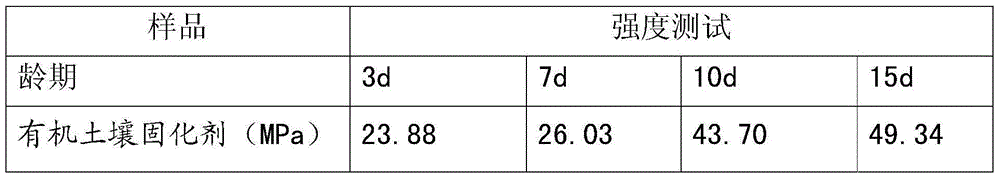

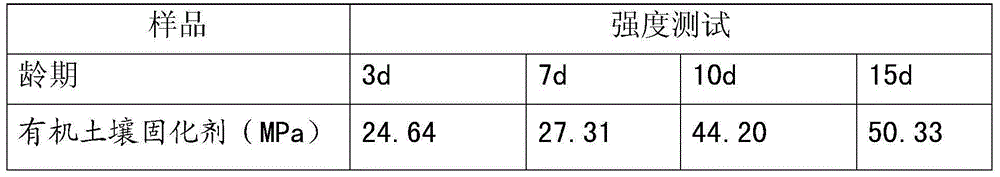

High-molecular organic soil solidifying agent and synthetic method of same

ActiveCN105038806AImprove curing effectEasy to operateBuilding constructionsOrganic fertilisersCellulosePotassium persulfate

The invention discloses a high-molecular organic soil solidifying agent and a synthetic method of same. The solidifying agent includes 2-6 parts of magnesium chloride, 4-8 parts of calcium chloride, 0.3-0.8 parts of calcium oxide, 0.3-0.8 parts of magnesium oxide, 3-8 parts of acrylamide, 0.1-0.4 parts of ammonium persulfate, 0.2-0.6 parts of potassium persulfate, 10-20 parts of soluble cellulose, 5-15 parts of sodium carboxymethylcellulose, 0.5-1 part of sodium hydroxide and 50-70 parts of water. The high-molecular organic soil solidifying agent is simple in operation, is low in cost, is quick in effect and is green and environment-friendly, is excellent in solidifying effect on soil, is strong in anti-pressure ability, achieves standard requirement, and is suitable for construction of various roads, fields and the like.

Owner:CHENGDU KEHENG ENVIRONMENTAL PROTECTION TECH

Surfactant/polymer water repellent identification composite oil displacement agent and preparation method thereof

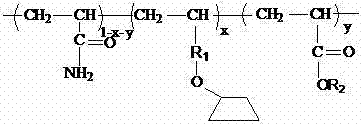

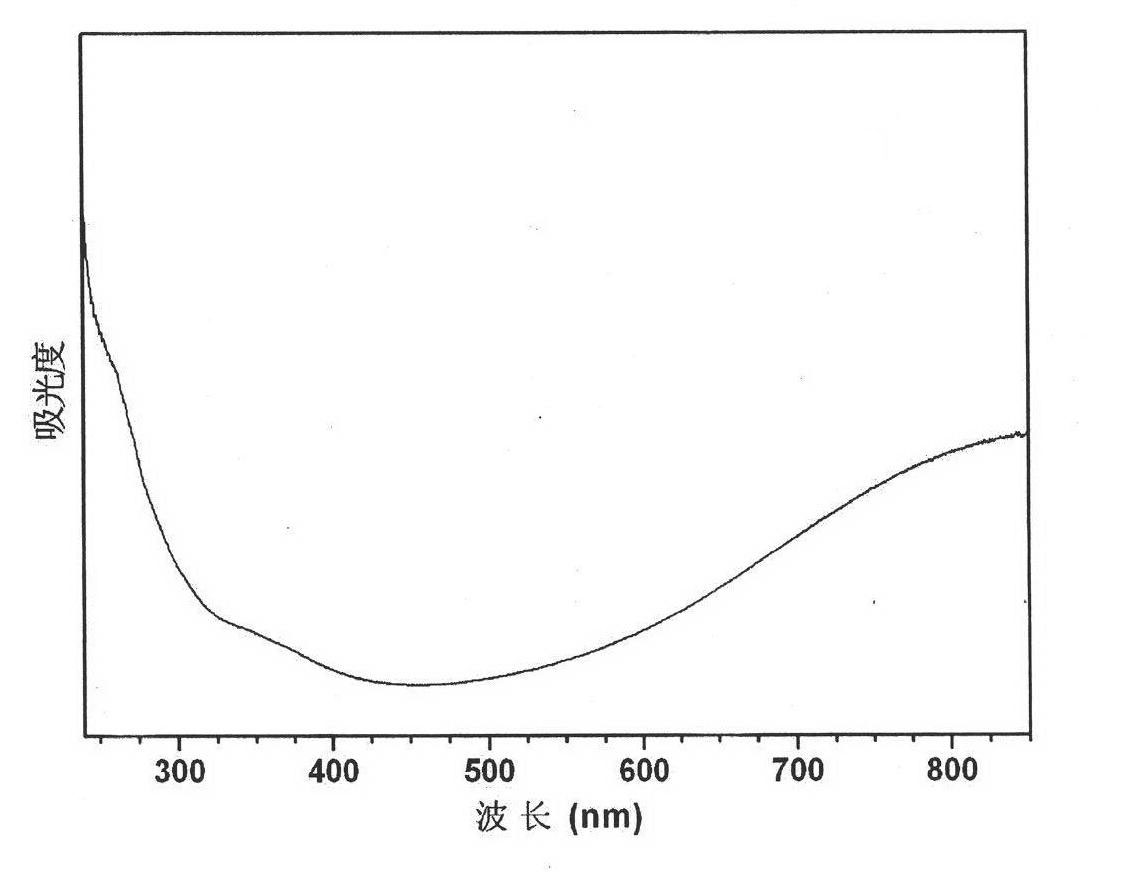

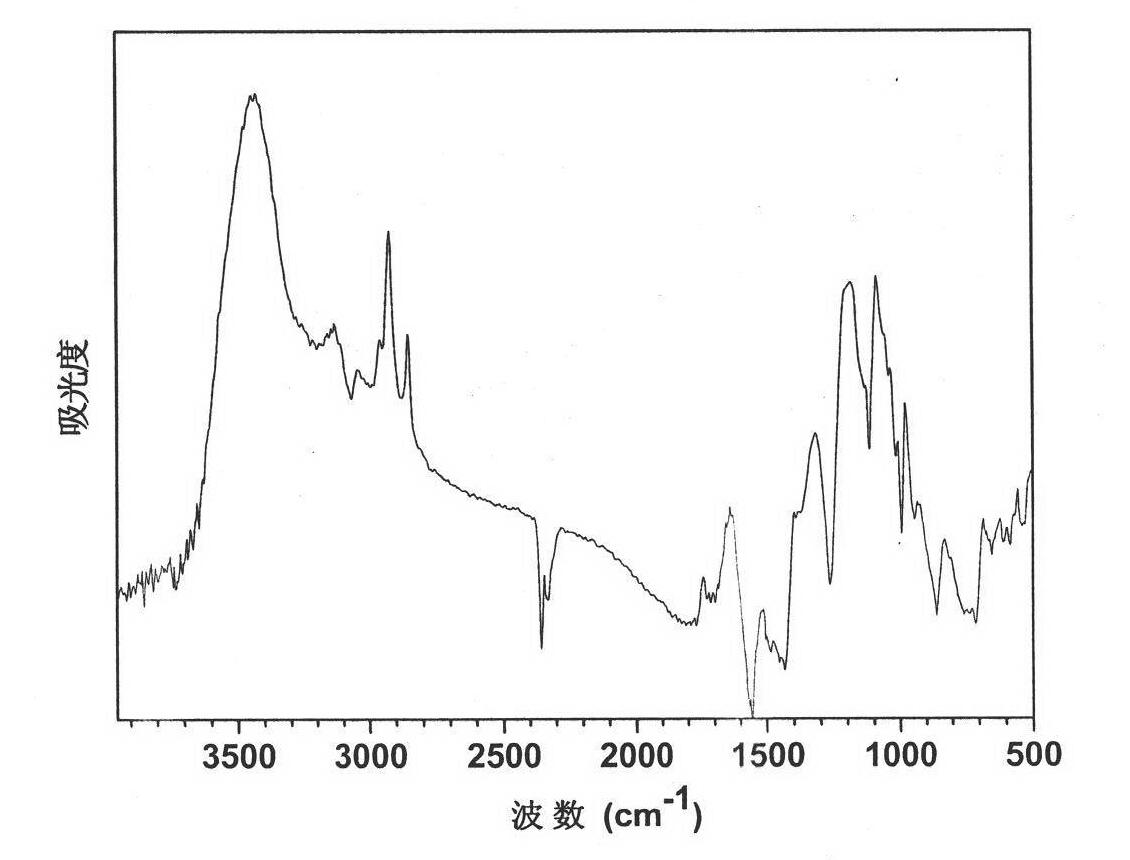

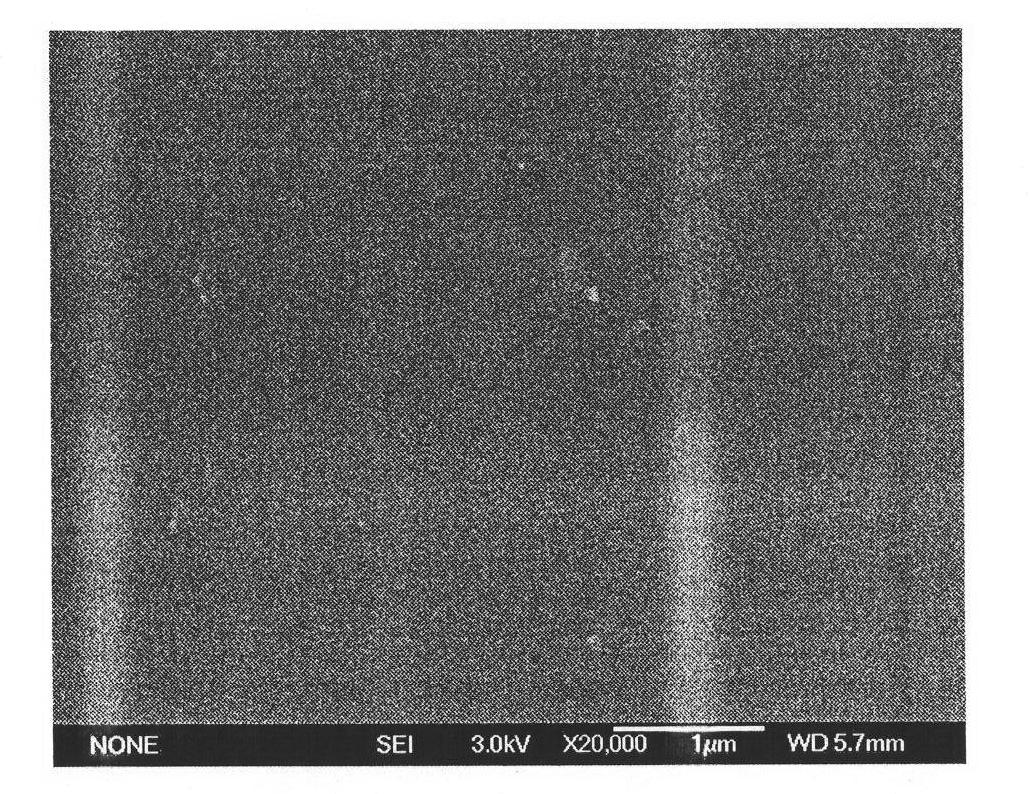

InactiveCN102206483AImprove lipophilicityIncrease frictionDrilling compositionPotassium persulfateCyclodextrin

The invention relates to a surfactant / polymer water repellent identification composite oil displacement agent for improving the mining rate of crude oil in an oil field and a preparation method of the oil displacement agent. The oil displacement agent can be used for oil displacement in a cooperation way, has water repellent and identification functions and cannot be adsorbed by stratum. In the technical scheme, the composite oil displacement agent comprises the following raw materials and components in percentage by mass: 2.7*10<-4> percent of surfactant which is one of sodium dodecyl benzene sulfonate, cetyltrimethylammonium chloride or nonyl phenol poly ethoxylate polyoxyethylene ether, and 1.2*10<-3> percent of polymer which is prepared by mixing allyl cyclodextrin or maleic anhydridemodified cyclodextrin with acrylamide and acrylic acid according to a certain proportion by using grafted cyclodextrin acrylamide, adding chelates, potassium persulfate and sodium hydrosulfite into the mixture, introducing nitrogen for oxygen removal and reacting for 6 to 8 hours. The preparation method comprises the following steps of: preparing solution by using the surfactant and the polymer respectively; mixing according to the volume ratio of 1 to 300; and stirring at the temperature of between 30 and 40 DEG C for 12 to 48 hours to obtain the composite oil displacement agent. The composite oil displacement agent has a good oil displacement effect, can improve the mining rate of the crude oil and can be used as an oil displacement agent in the oil field.

Owner:SOUTHWEST PETROLEUM UNIV

Water-soluble poly(3,4-ethylenedioxythiophene) and preparation method for conductive coating thereof

InactiveCN101845136AImprove conductivityElectrically-conductive paintsWater basedPotassium persulfate

The invention provides water-soluble poly(3,4-ethylenedioxythiophene) and a preparation method for a conductive coating thereof. The method comprises the following steps of: adding 3,4-ethylenedioxythiophene and an oxidant into the aqueous solution of the copolymer of sodium styrene sulfonate and an allyl monomer, regulating a pH value to be 1 to 5 by using a sulfuric acid, and polymerizing the mixture at the room temperature for 16 to 72h to obtain the water-soluble poly(3,4-ethylenedioxythiophene), wherein the oxidant may be ammonium persulfate, potassium persulfate or sodium persulfate; and the allyl monomer may be an acrylic monomer, a methacrylates monomer, hydroxyethyl acrylate , hydroxyethyl methacrylate, polyethylene glycol methacrylate or styrene. The electrical conductivity of the prepared water-soluble poly(3,4-ethylenedioxythiophene) is higher than that of the poly(3,4-ethylenedioxythiophene) generally using a polystyrene sulfonate acid as a dopant. The conductive coating is obtained by mixing the prepared water-soluble poly(3,4-ethylenedioxythiophene) and other water-based emulsion coatings or water-soluble polymers, and has the characteristics of high transparency and high electrical conductivity.

Owner:BEIJING UNIV OF CHEM TECH

High temperature and salt resistant polymer fluid loss additive for drilling fluid and preparation method of high temperature and salt resistant polymer fluid loss additive

InactiveCN102585783AIdeal resistance to high temperature and saltGood fluid loss controlDrilling compositionPotassium persulfateSide chain

The invention relates to a high temperature and salt resistant polymer fluid loss additive for a drilling fluid and a preparing method of the high temperature and salt resistant polymer fluid loss additive. The fluid loss additive is a copolymer generated during the reaction of alkenyl amide, alkenyl benzene sulfuric acid, alkenyl flavanone and alkenyl sulfuric acid. The preparing method comprises the following steps: (1), weighing the four materials; (2) mixing the alkenyl sulfuric acid liquor with the alkenyl amide, the alkenyl flavanone and the alkenyl benzene sulfuric acid in a reactor, mixing, stirring, and adding nitrogen while discharging oxygen; (3) reacting at the temperature of 30 to 90 DEG C, adding initiating agents (namely, potassium persulfate and sodium hydrosulfite) with the contents of 15 to 30 percent by weight respectively, and reacting for 2 to 12 h so as to obtain a viscous-elastic jelly; and (4) pelletizing the jelly, and drying and crashing at high temperature to obtain the fluid loss additive. At high temperature, the oxydrolysis degree is low, and the action effect between functional groups on a lateral chain and clay particles is remarkable, the quality of a mud cake formed according to the method is better, and the fluid loss effect is favorable in both fresh water and a composite salt water drilling fluid.

Owner:SOUTHWEST PETROLEUM UNIV

Preparation method of hollow titanium dioxide microspheres

The invention discloses a preparation method of hollow titanium dioxide microspheres. The invention is realized through the following technical scheme: first preparing polymer microspheres through using a method of soap-free emulsion polymerization and using styrene as a monomer, methyl acrylic acid as a comonomer, deionized water as a reaction medium, and potassium persulfate as an initiator; forming an emulsion through ultrasonic dispersion of the prepared polymer microspheres, cationic surfactant cetyl trimethyl ammonium bromide, absolute ethyl alcohol, and the deionized water; adding a mixed solution of ethanol, butyl titanate and triethylamine, obtaining core shell particles through reflux reaction for 4 hours at 50 DEG C with mechanical stirring, and finally obtaining the hollow titanium dioxide microspheres through calcining. According to the preparation method, the triethylamine is used as an inhibitor, titanium dioxide smoothly and uniformly coats surfaces of the polymer microspheres through control of hydrolysis rate of the butyl titanate, and the hollow titanium dioxide microspheres with a higher yield are obtained.

Owner:NANJING UNIV OF SCI & TECH

Etchant composition and method

InactiveUS20100252530A1High strengthDecorative surface effectsSemiconductor/solid-state device manufacturingOrganic acidPotassium persulfate

The present invention provides an etchant composition comprisingA) high strength potassium monopersulfate providing from about 0.025% to about 0.8% by weight of active oxygen;B) from about 0.01% to about 30% by weight of the composition of B1) an organic acid, alkali metal salt of an organic acid, ammonium salt of an organic acid, or a homopolymer of an organic acid, or B2) a halogen or nitrate salt of phosphonium, tetrazolium, or benzolium, or B3) a mixture of component B1) and B2); andC) from about 0% to about 97.49% by weight of the composition of water; and a method of etching a substrate using said composition.

Owner:EI DU PONT DE NEMOURS & CO +1

Method for preparing amphiprotic starch solution for papermaking

ActiveCN101759880ASolve aging problemsAging does not occurNon-fibrous pulp additionPaper/cardboardPotassium persulfateHigh concentration

The invention provides a method for preparing amphiprotic starch solution for papermaking, which belongs to the field of fine chemicals for papermaking. The amphiprotic starch solution is added at a papermaking wet end, and has a dry strengthening effect on paper. Starch is used as the basic material, water, sodium hydroxide, sodium hypochlorite or potassium persulfate and cationic etherifying agent are added. The amphiprotic starch solution is obtained after the aqueous solution is heated. The preparation method is fulfilled by the heating reaction of aqueous solution. The amphiprotic starchsolution has high concentration, can be diluted by cold water to any concentration and cannot be aged, so the technical problem of starch aging is solved. When in use, the amphiprotic starch solutioncan be added at the wet end without being heated to gelatinize, the amphiprotic starch solution as dry-strengthening agent for papermaking can notably increase the dry strength indexes of paper, suchas burst index and ring crush index, and under the circumstance of the same added amount, the amphiprotic starch solution has a better effect than the like product. The innovation of the invention isthat a simple technique for producing the amphiprotic starch solution is provided, the production time is not longer than 2 hours, the aging and retrograding problems of the amphiprotic starch are solved, and the invented amphiprotic starch solution can be directly added at the papermaking wet end without going through the step of gelatinization by heating.

Owner:GUANGDONG PAPER IND RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com