Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6380results about "Electrically-conductive paints" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coatings comprising carbon nanotubes and methods for forming same

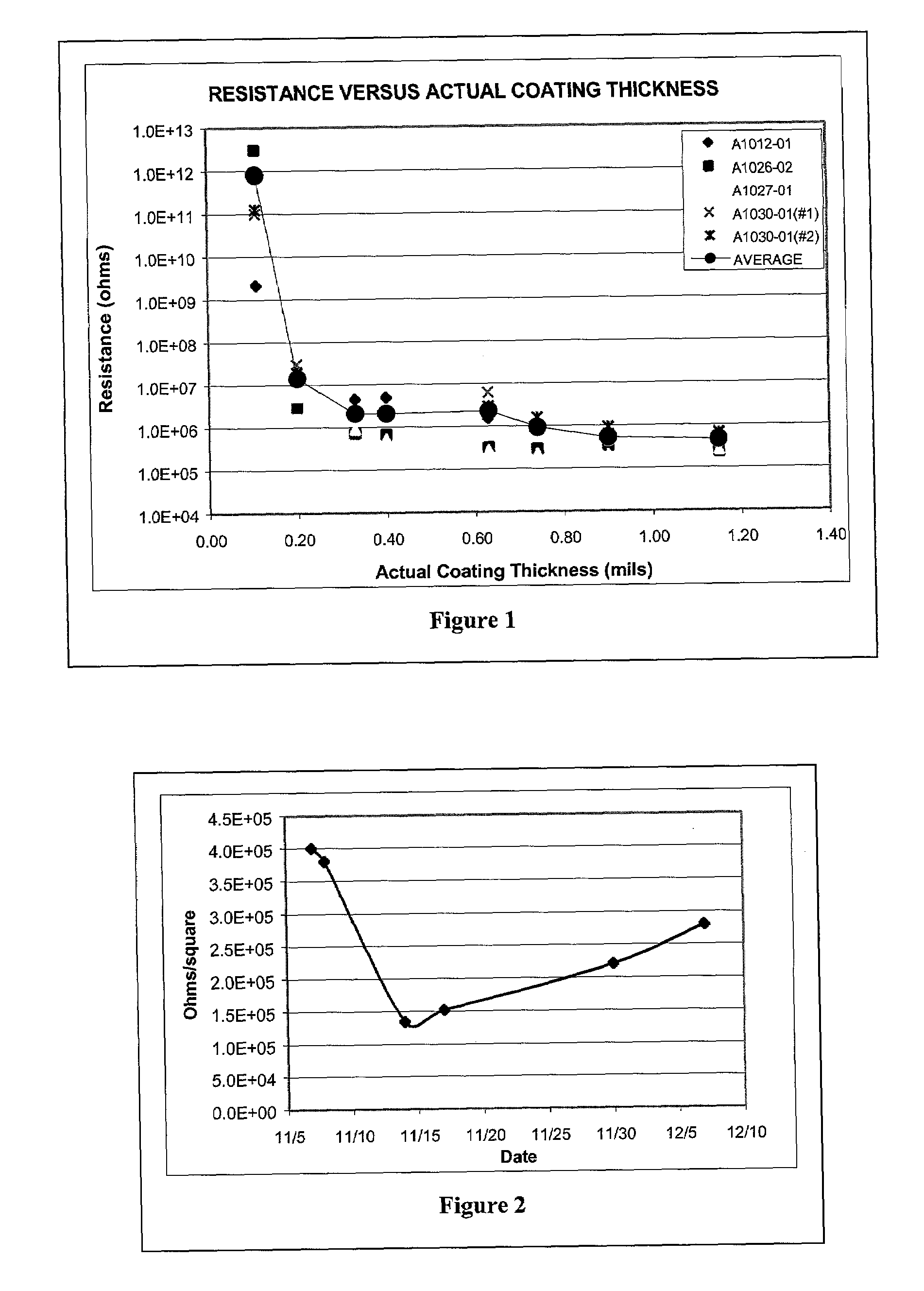

InactiveUS7060241B2Reduce manufacturing costImprove efficiencyMaterial nanotechnologyConductive layers on insulating-supportsSingle-Walled NanotubeCoating

Owner:NANO C INC

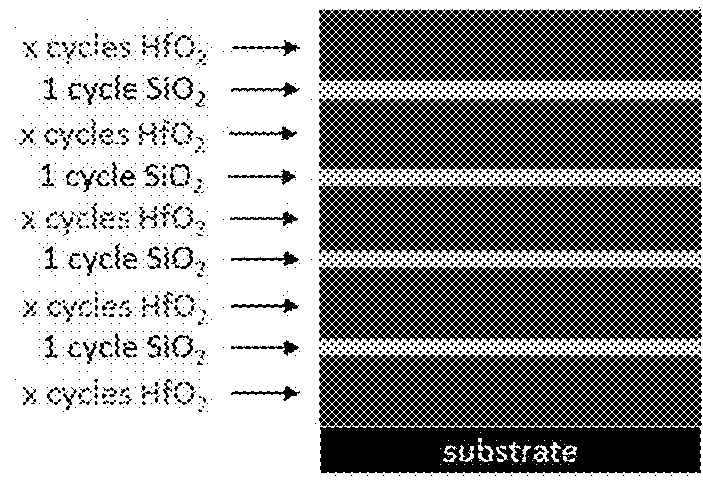

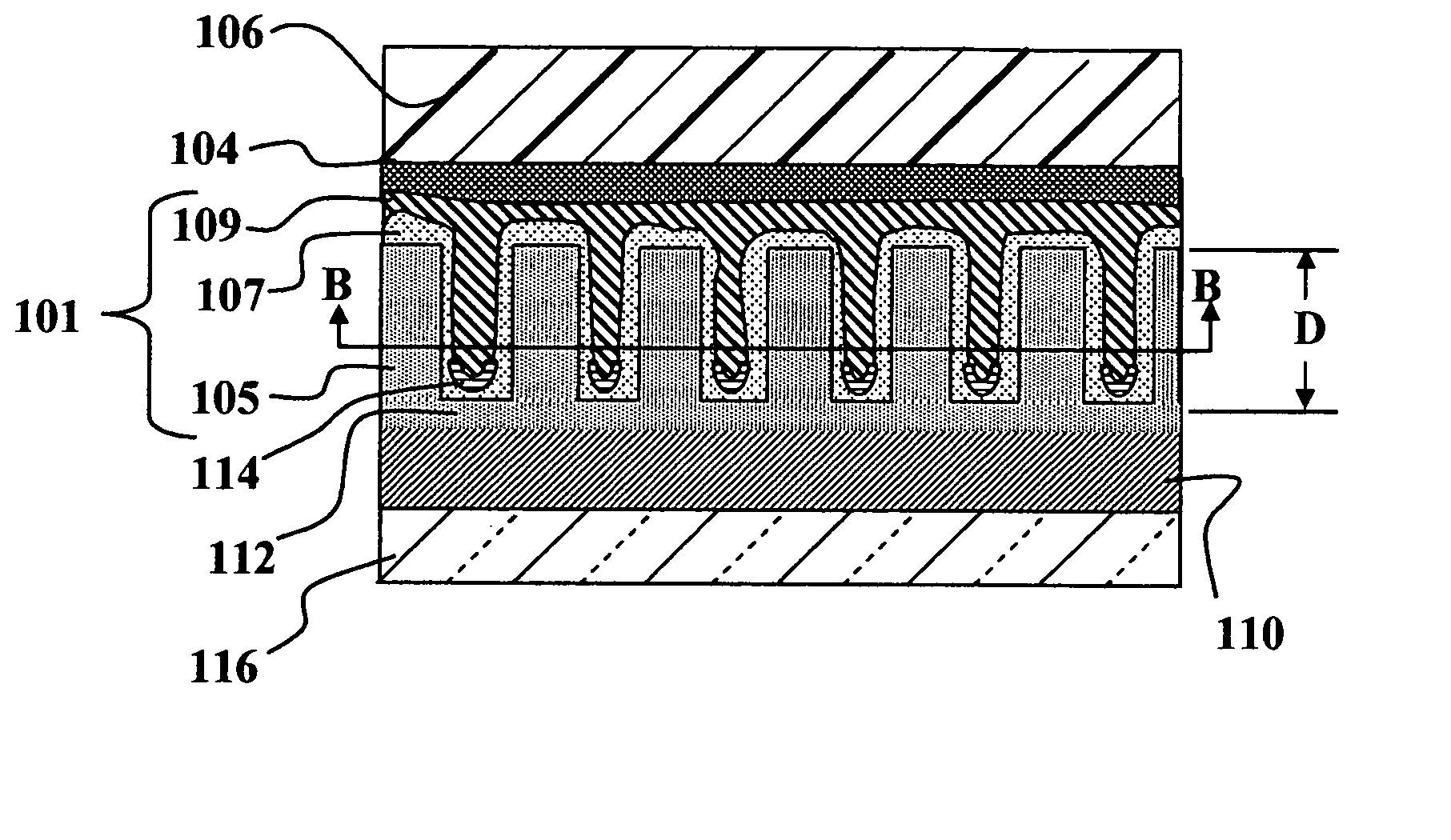

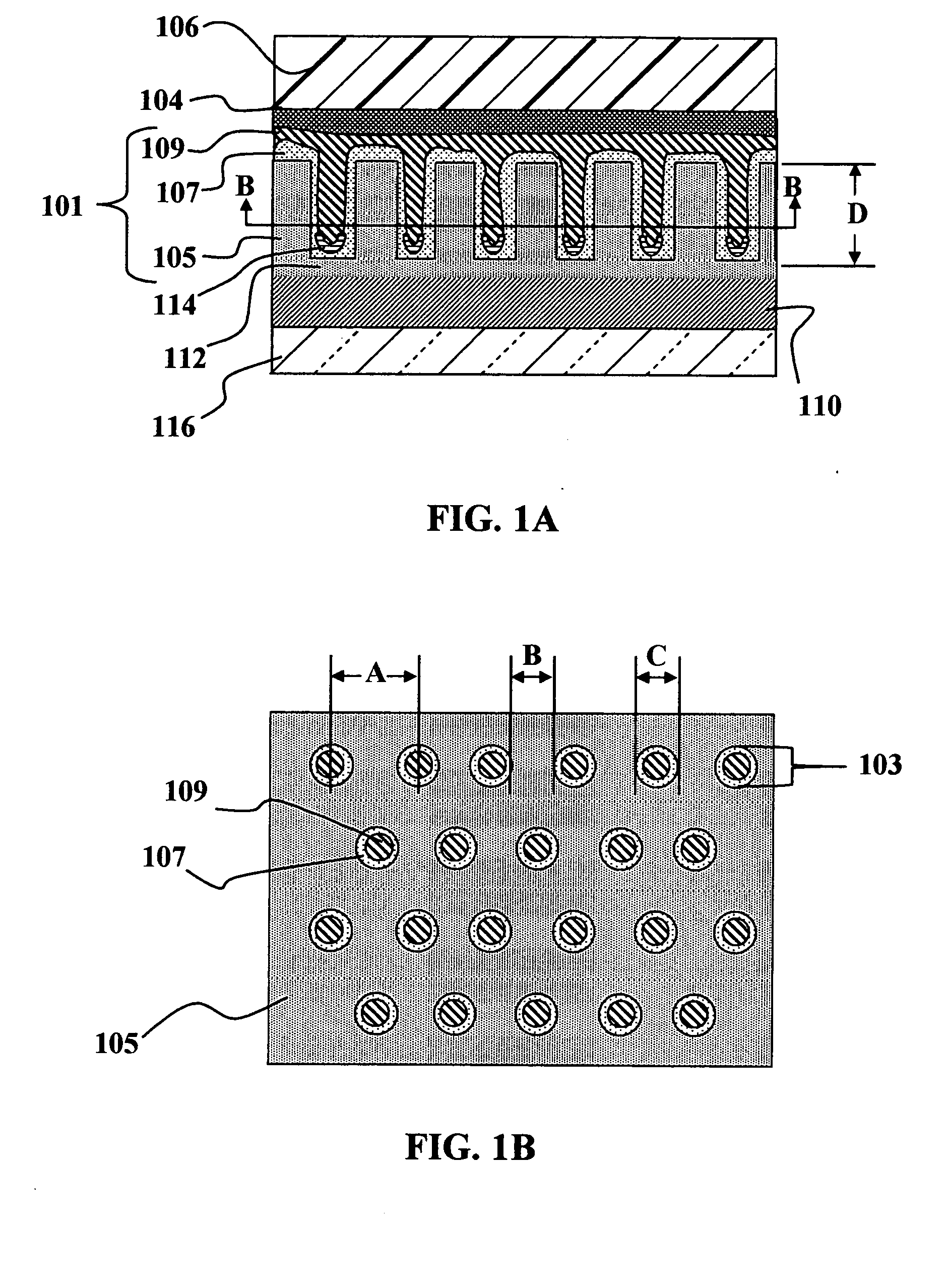

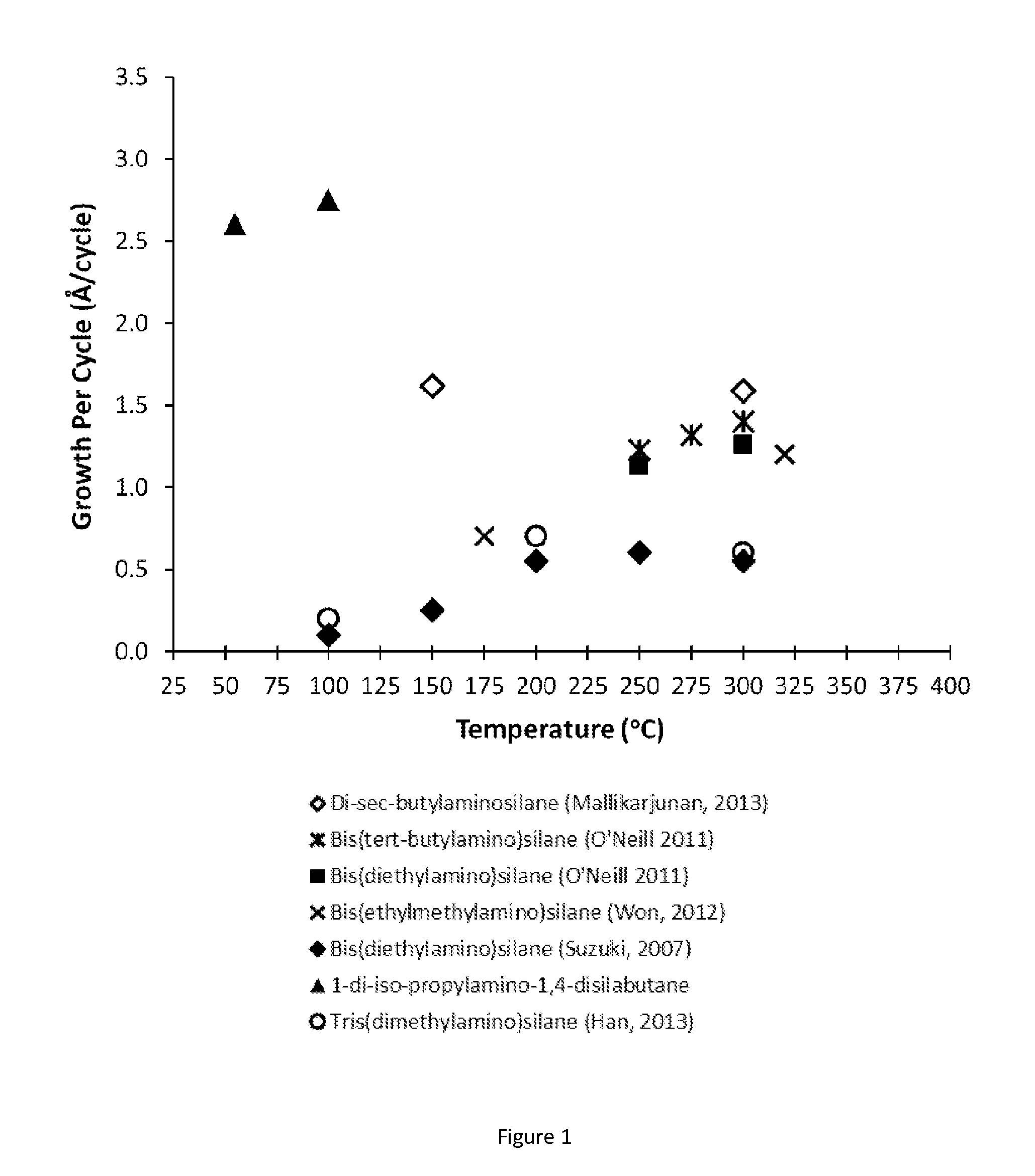

Formulation for Deposition of Silicon Doped Hafnium Oxide as Ferroelectric Materials

ActiveUS20180269057A1Reduce and increase reactivityEasy to controlSolid-state devicesSemiconductor/solid-state device manufacturingHafniumSilicon

In one aspect, the invention is formulations comprising both organoaminohafnium and organoaminosilane precursors that allows anchoring both silicon-containing fragments and hafnium-containing fragments onto a given surface having hydroxyl groups to deposit silicon doped hafnium oxide having a silicon doping level ranging from 0.5 to 8 mol %, preferably 2 to 6 mol %, most preferably 3 to 5 mol %, suitable as ferroelectric material. In another aspect, the invention is methods and systems for depositing the silicon doped hafnium oxide films using the formulations.

Owner:VERSUM MATERIALS US LLC

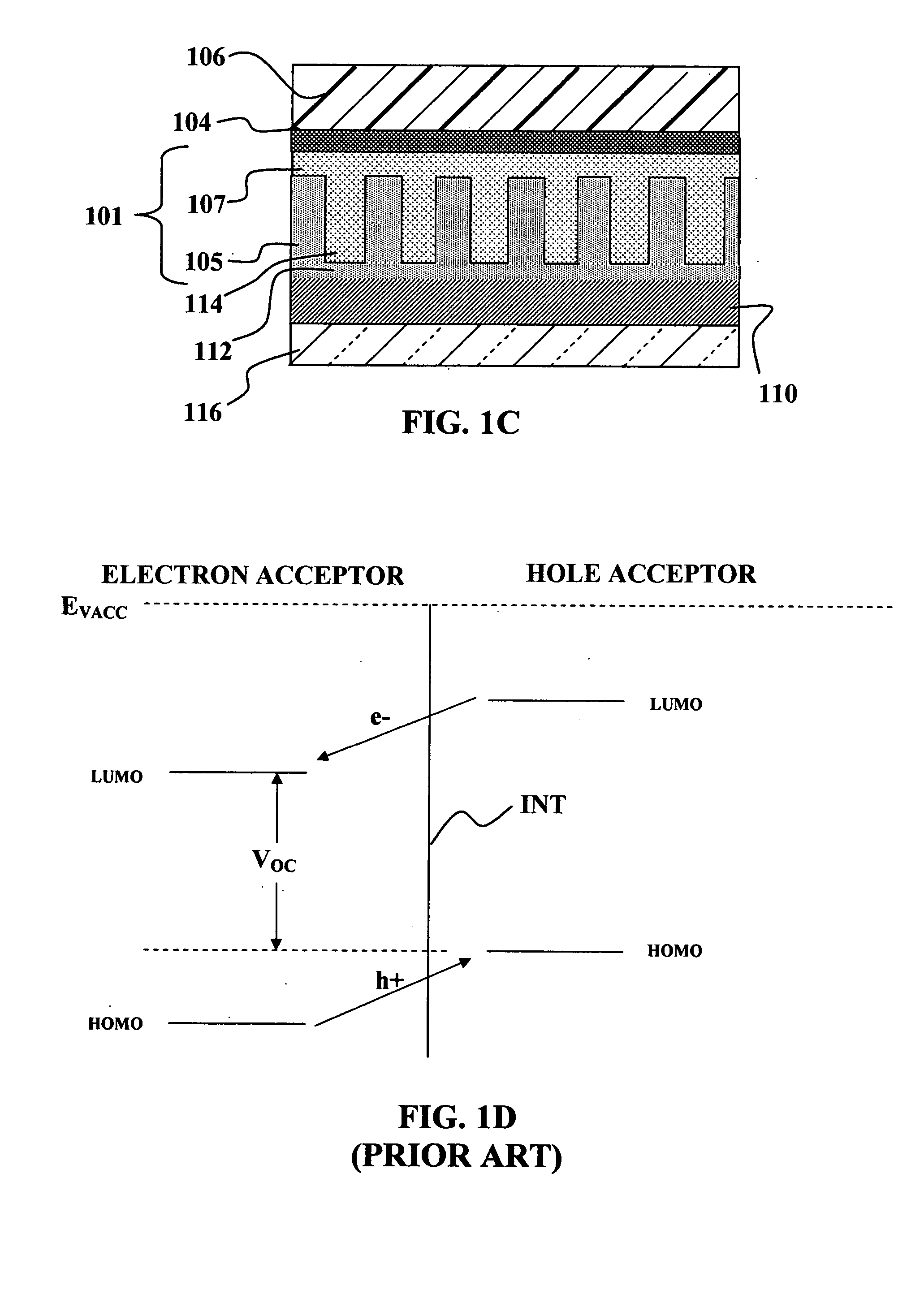

Photovoltaic devices fabricated from nanostructured template

Photovoltaic devices, such as solar cells, and methods for their manufacture are disclosed. A device may be characterized by an architecture having a nanostructured template made from an n-type first charge transfer material with template elements between about 1 nm and about 500 nm in diameter with about 1012 to 1016 elements / m2. A p-type second charge-transfer material optionally coats the walls of the template elements leaving behind additional space. A p-type third charge-transfer material fills the additional space volumetrically interdigitating with the second charge transfer material.

Owner:AERIS CAPITAL SUSTAINABLE IP

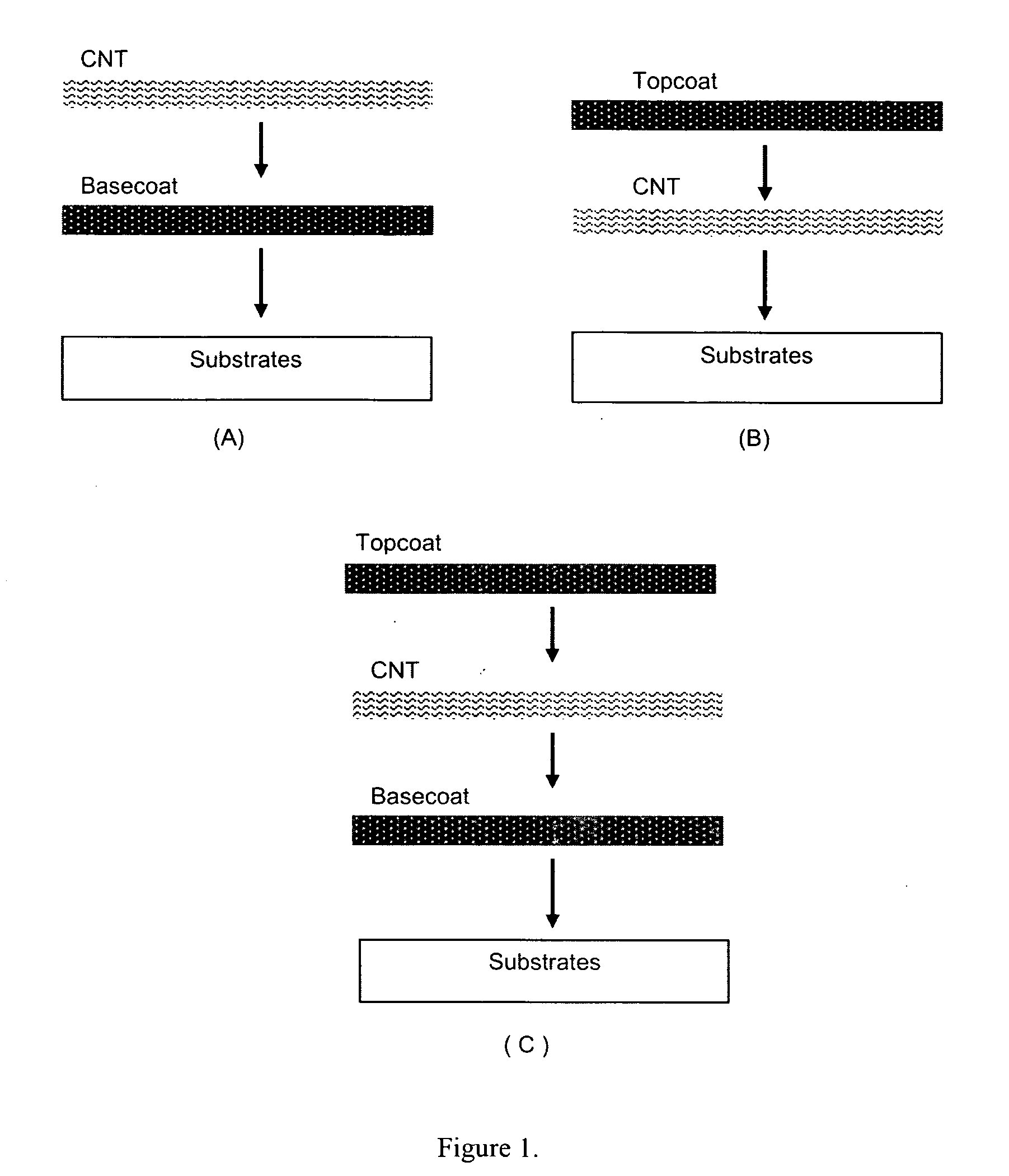

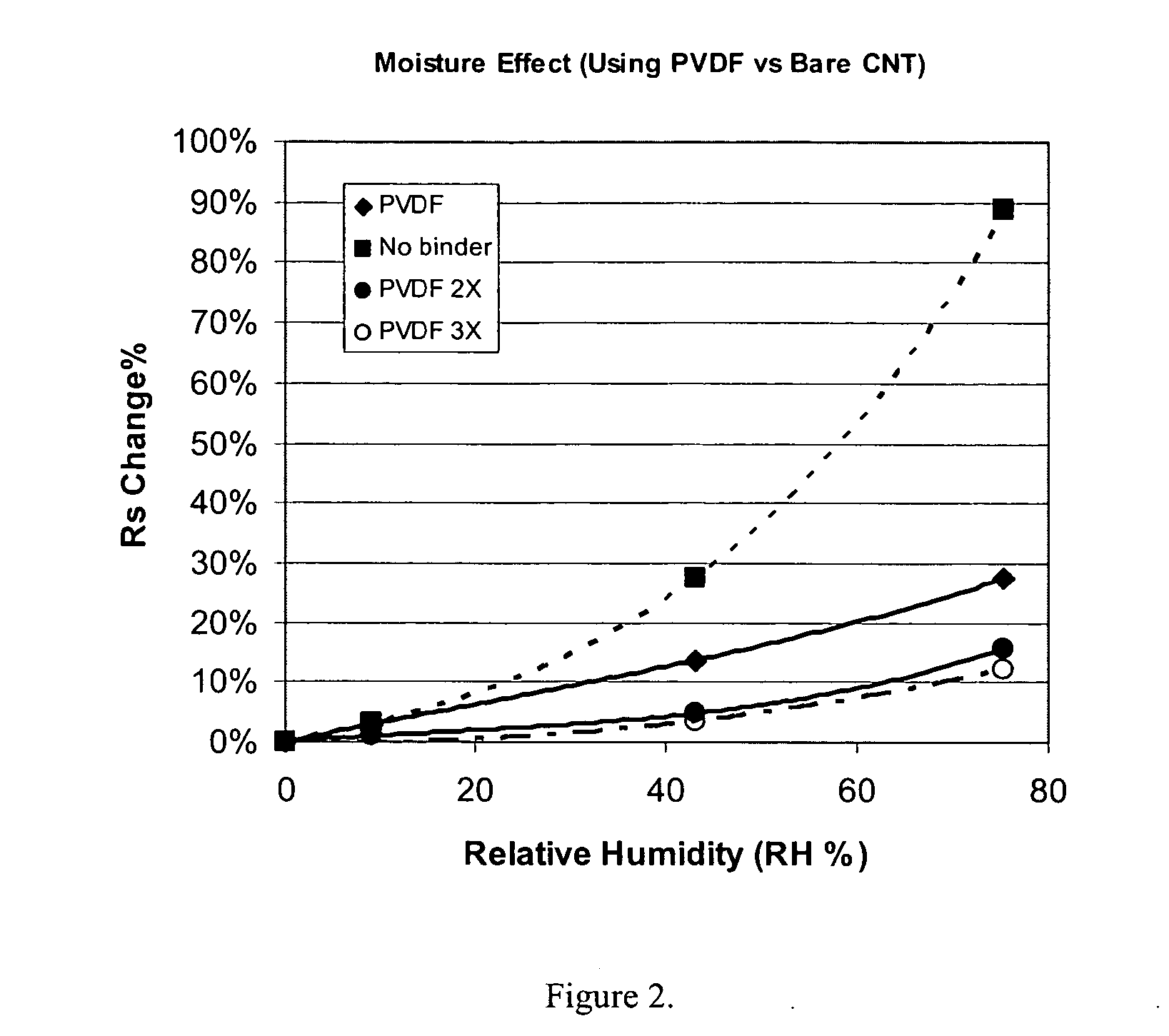

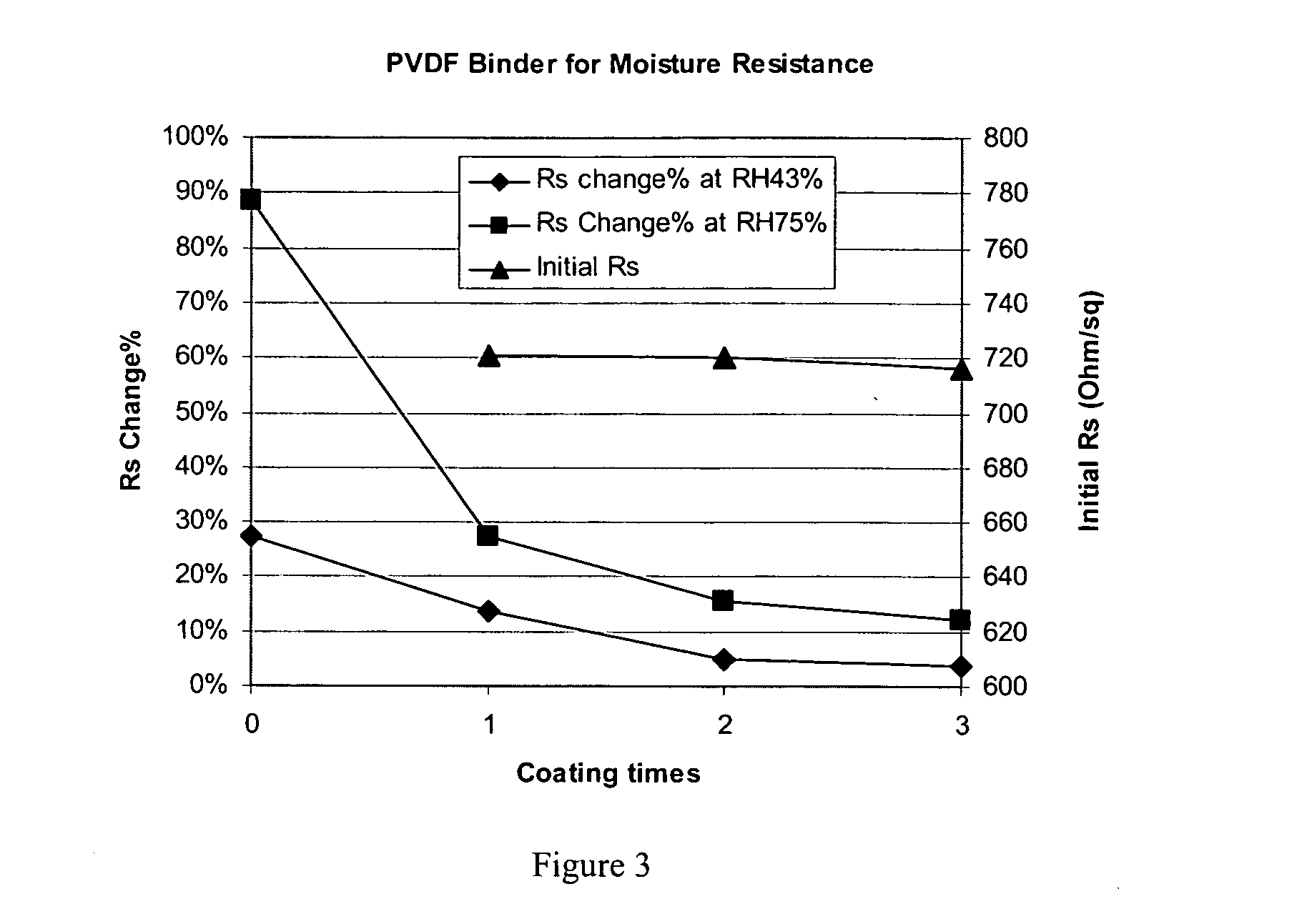

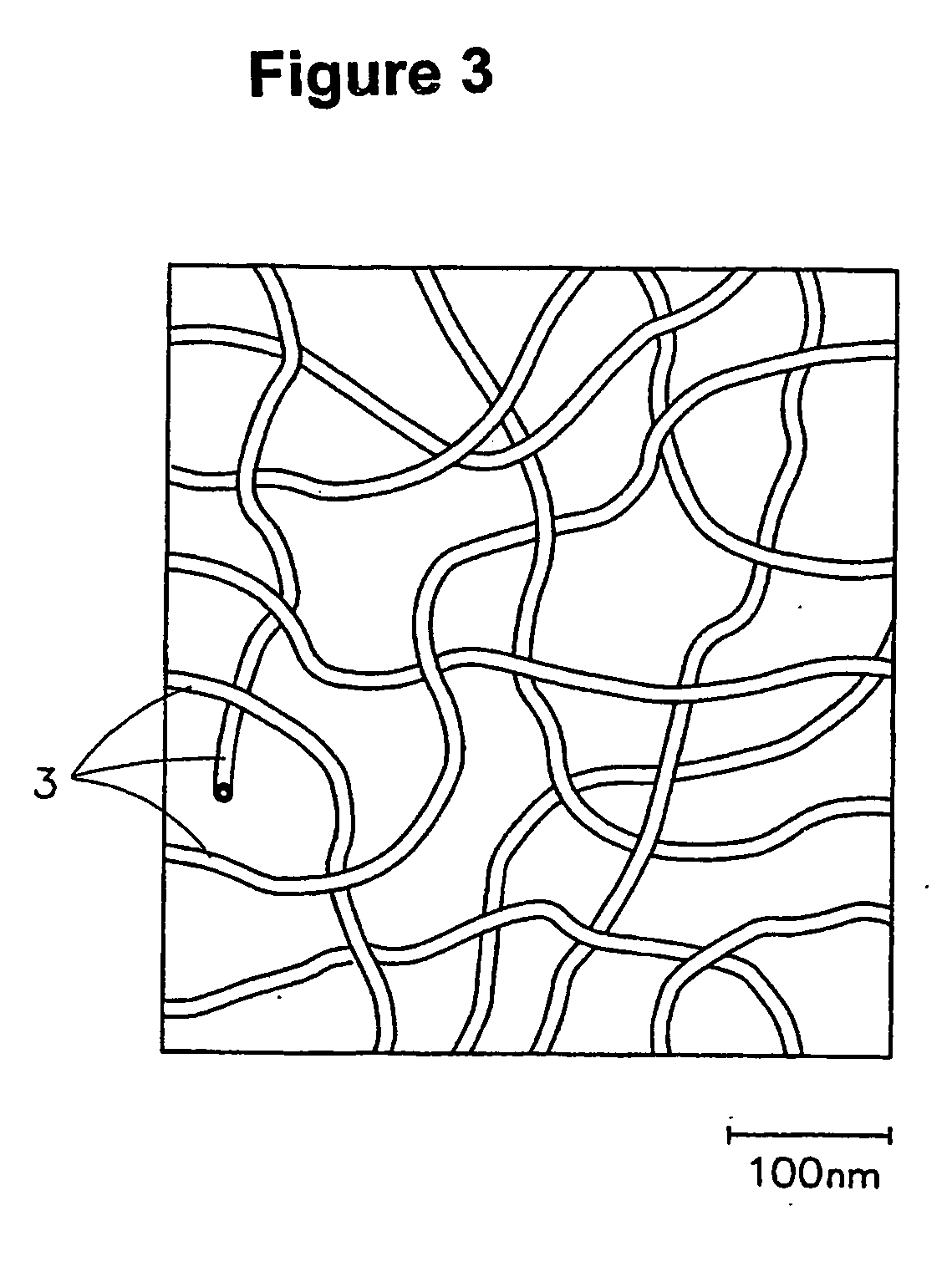

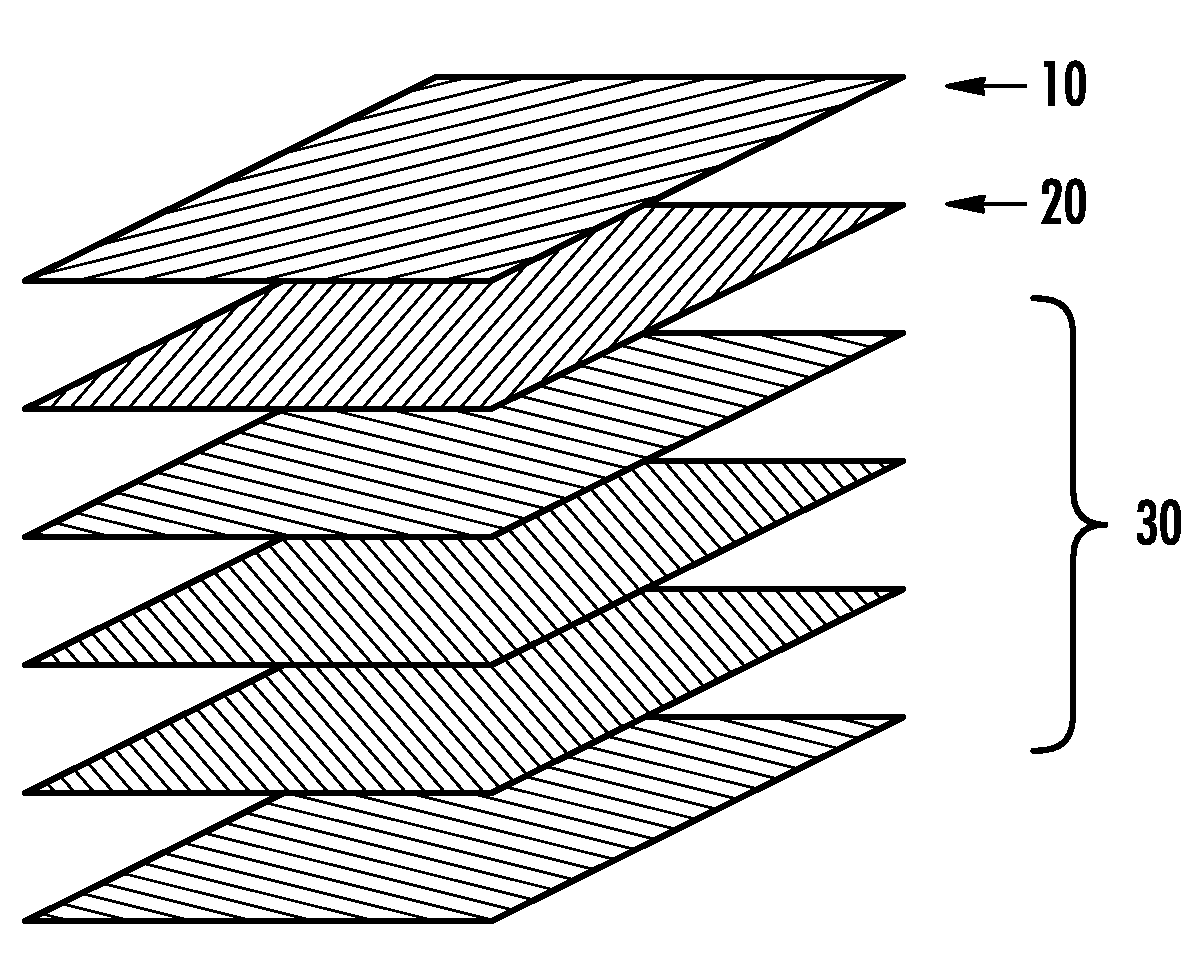

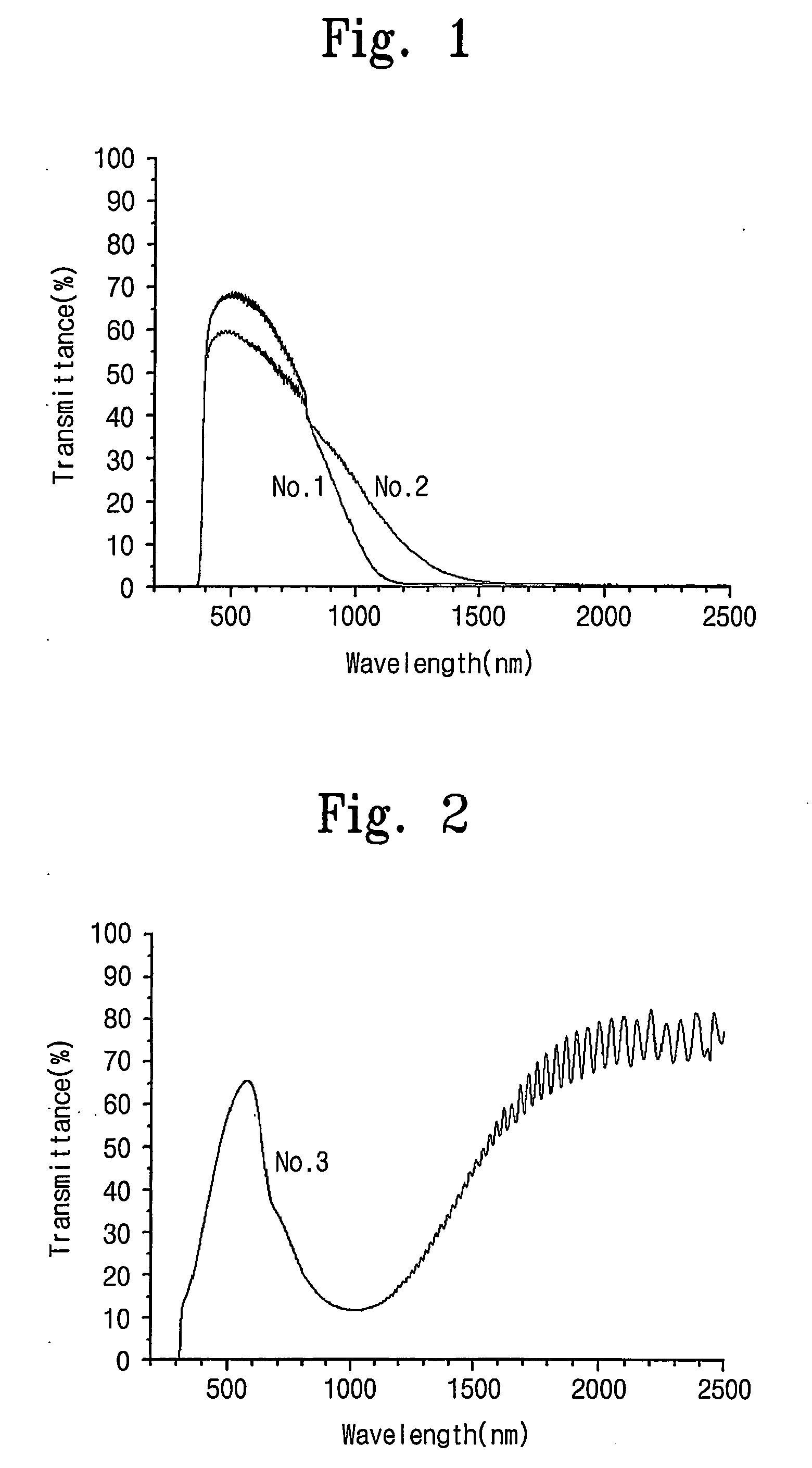

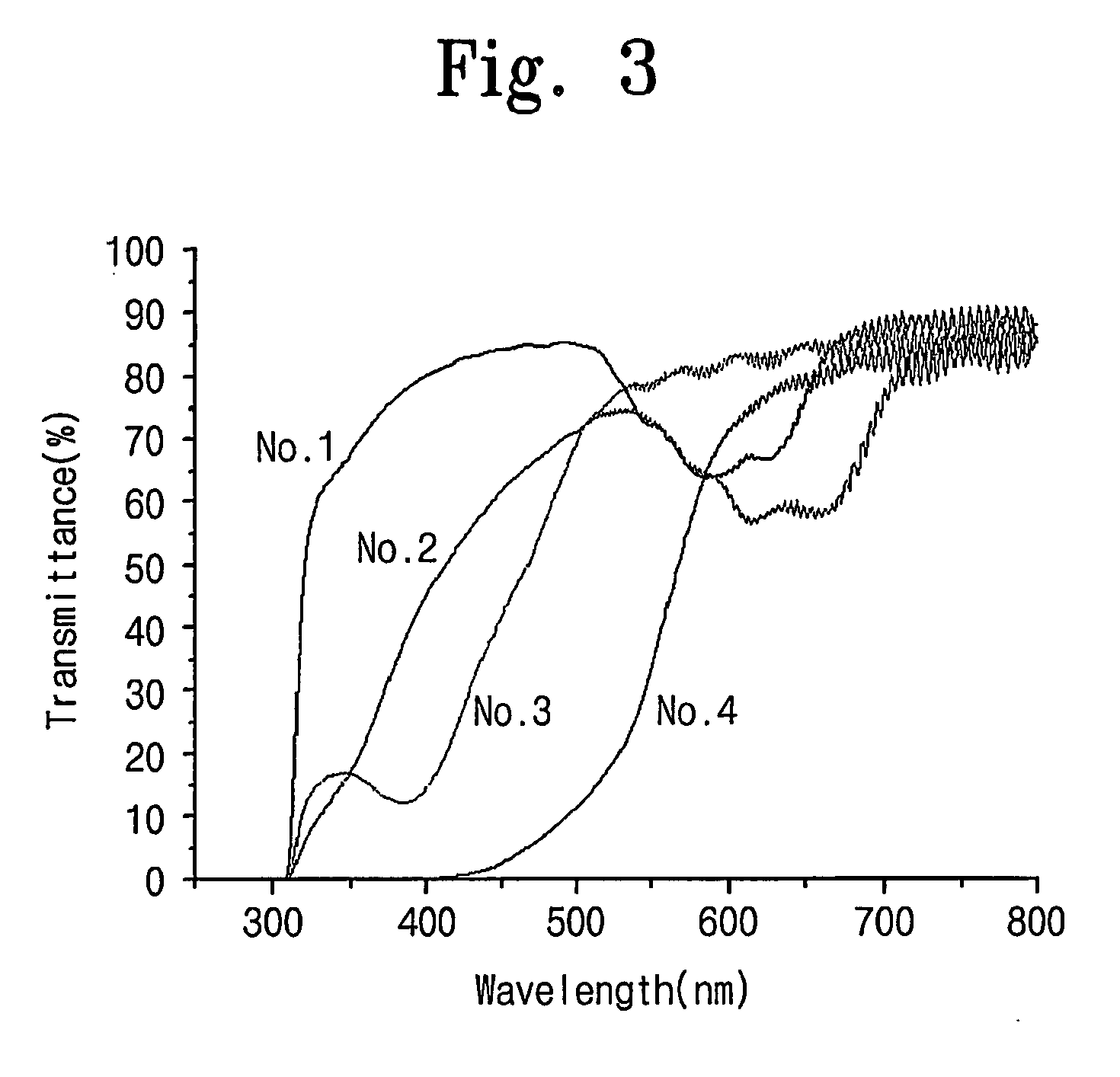

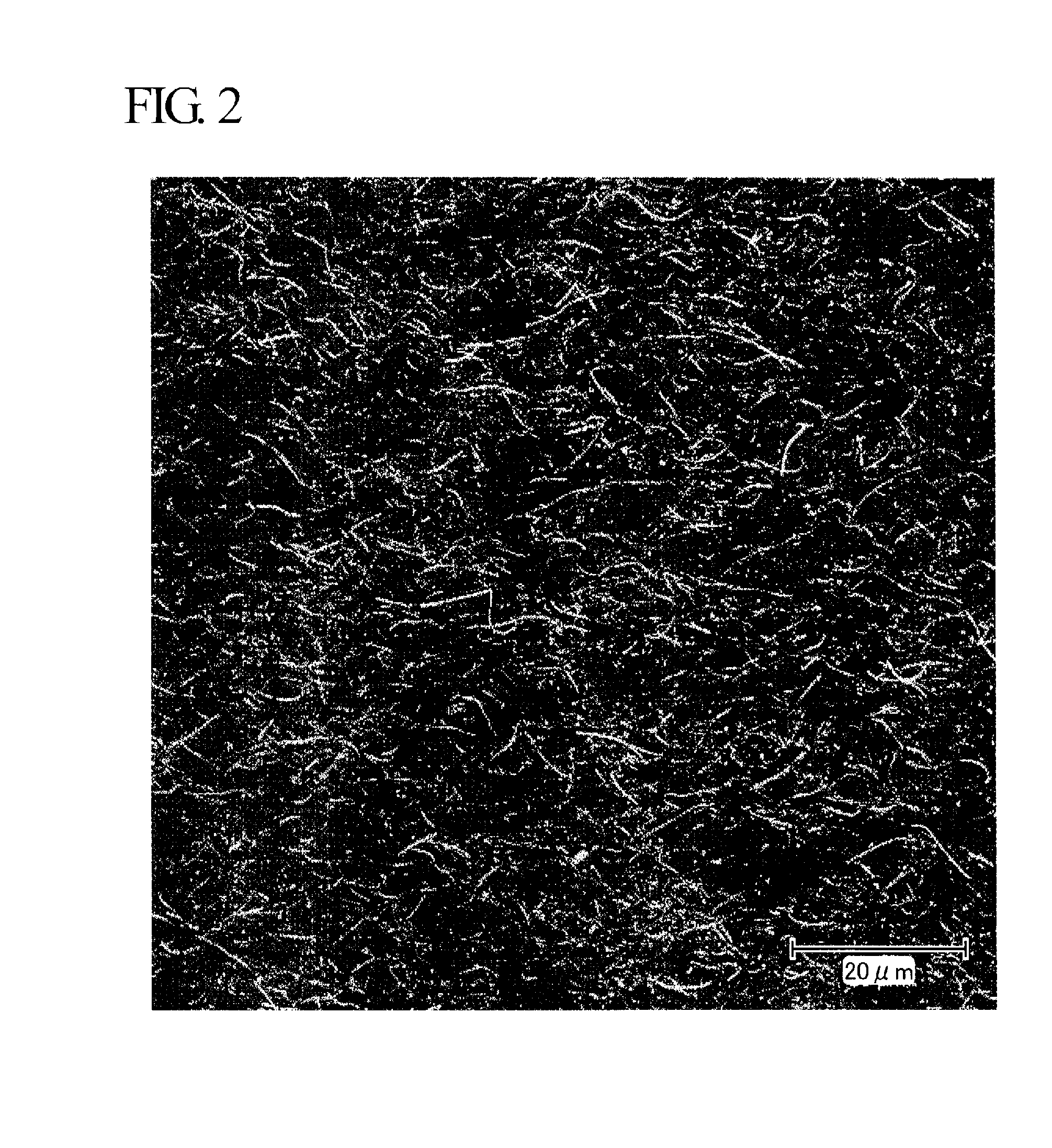

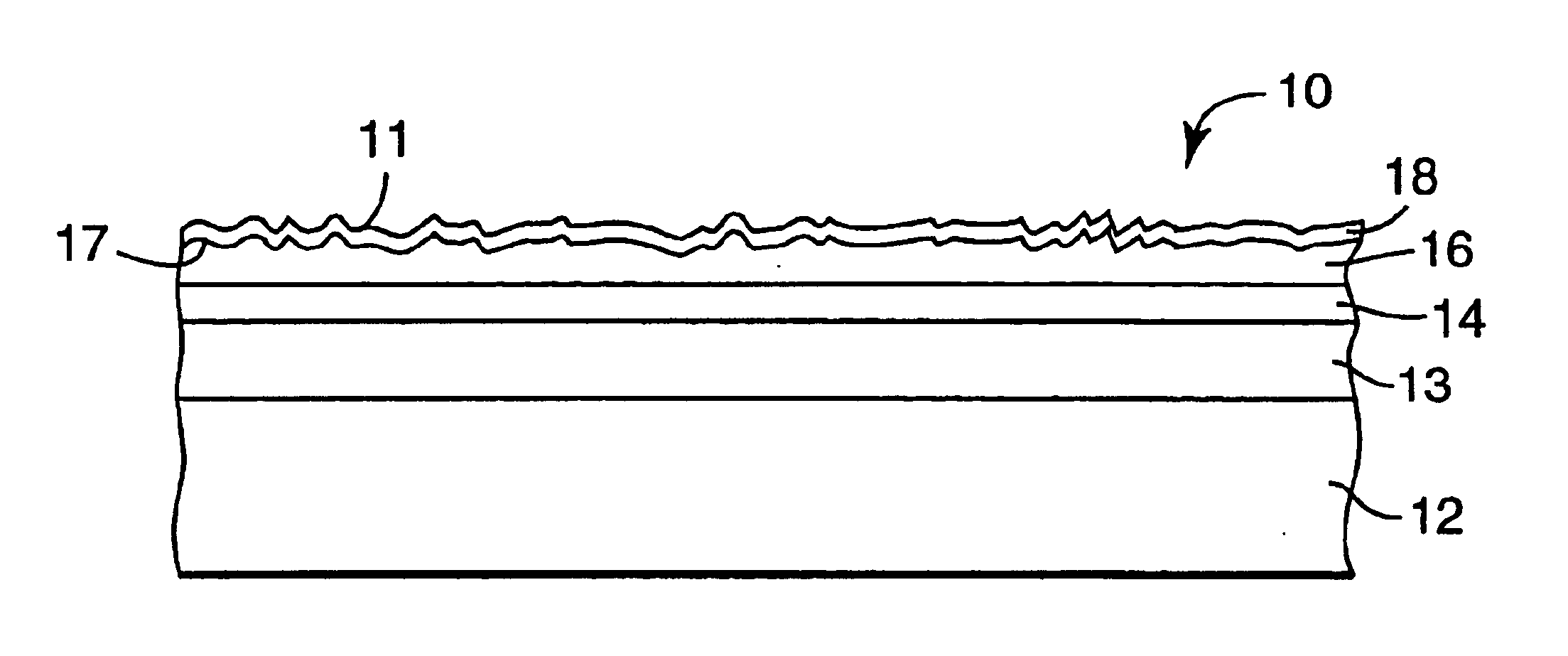

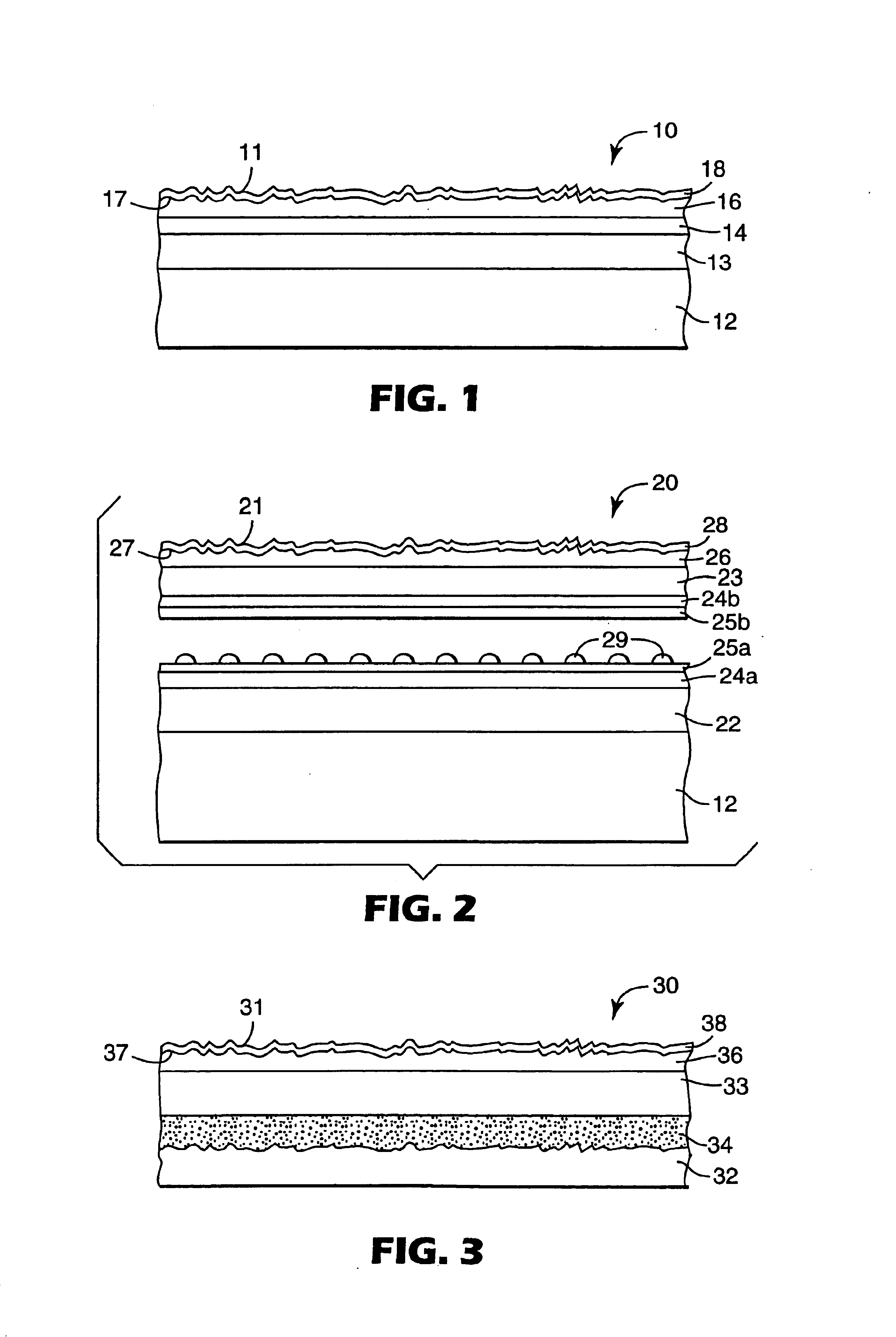

Polymer binders for flexible and transparent conductive coatings containing carbon nanotubes

InactiveUS20050209392A1Decrease in optical transparencyDecrease in surface conductivityMaterial nanotechnologySpecial tyresThermoplasticCarbon nanotube

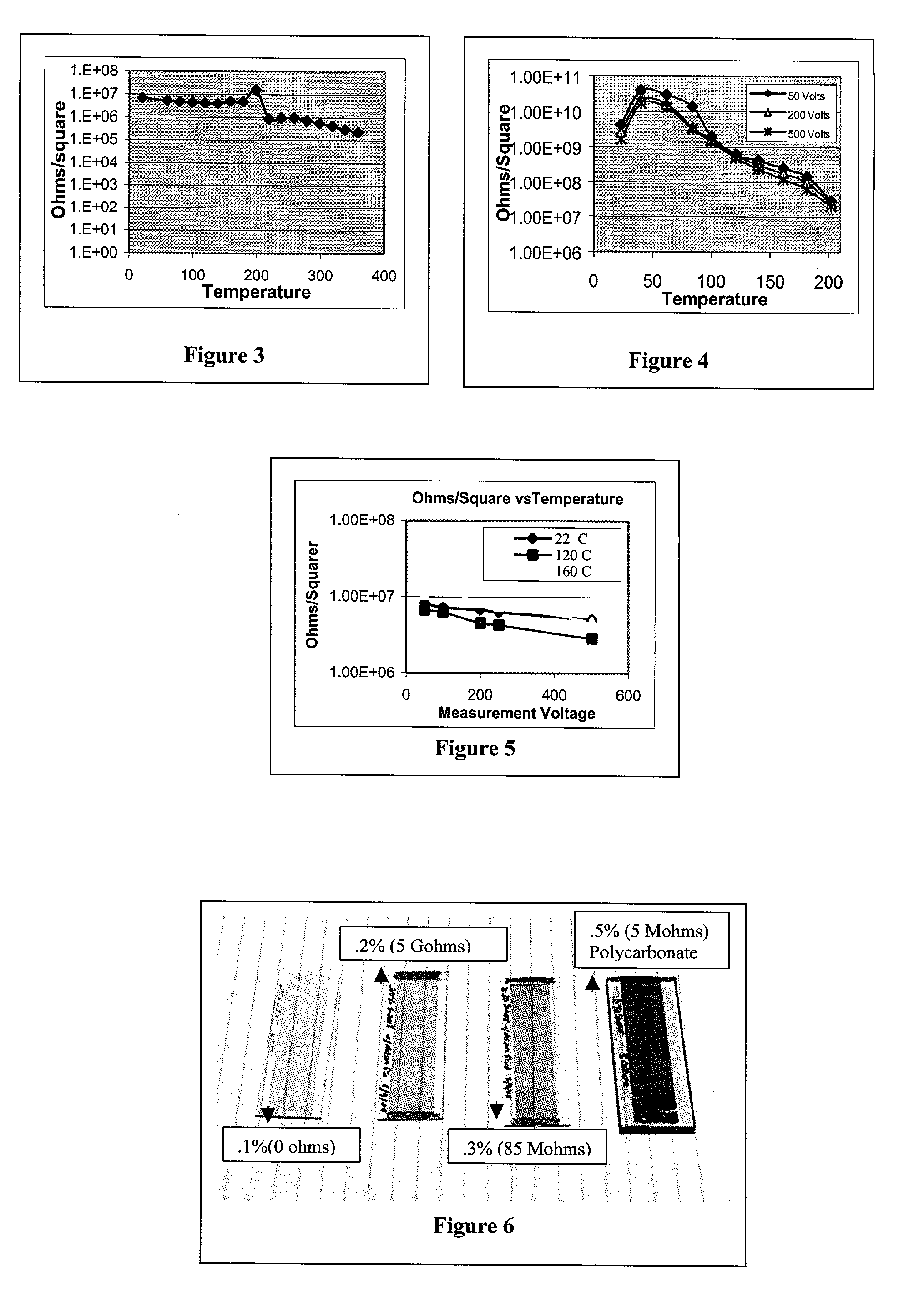

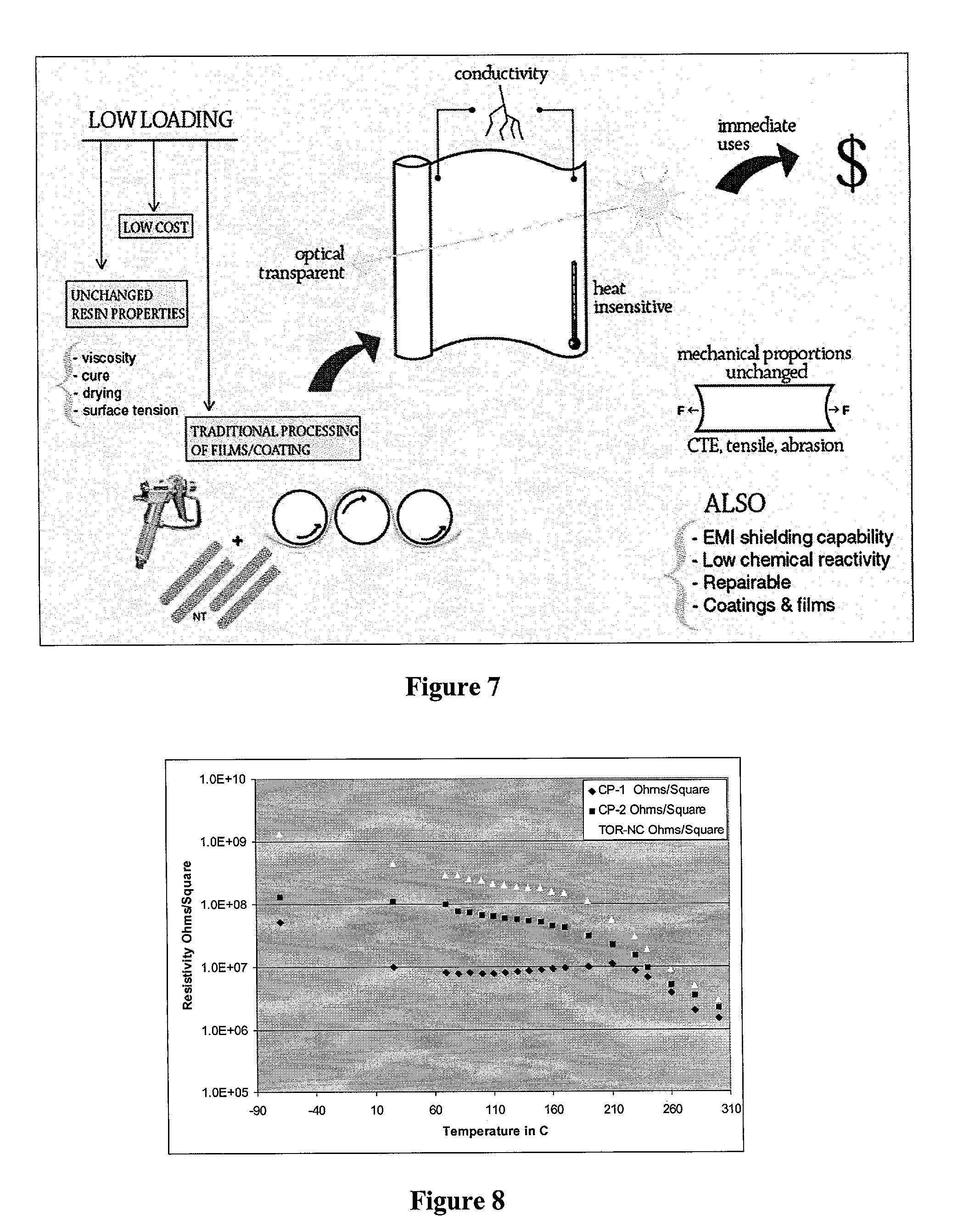

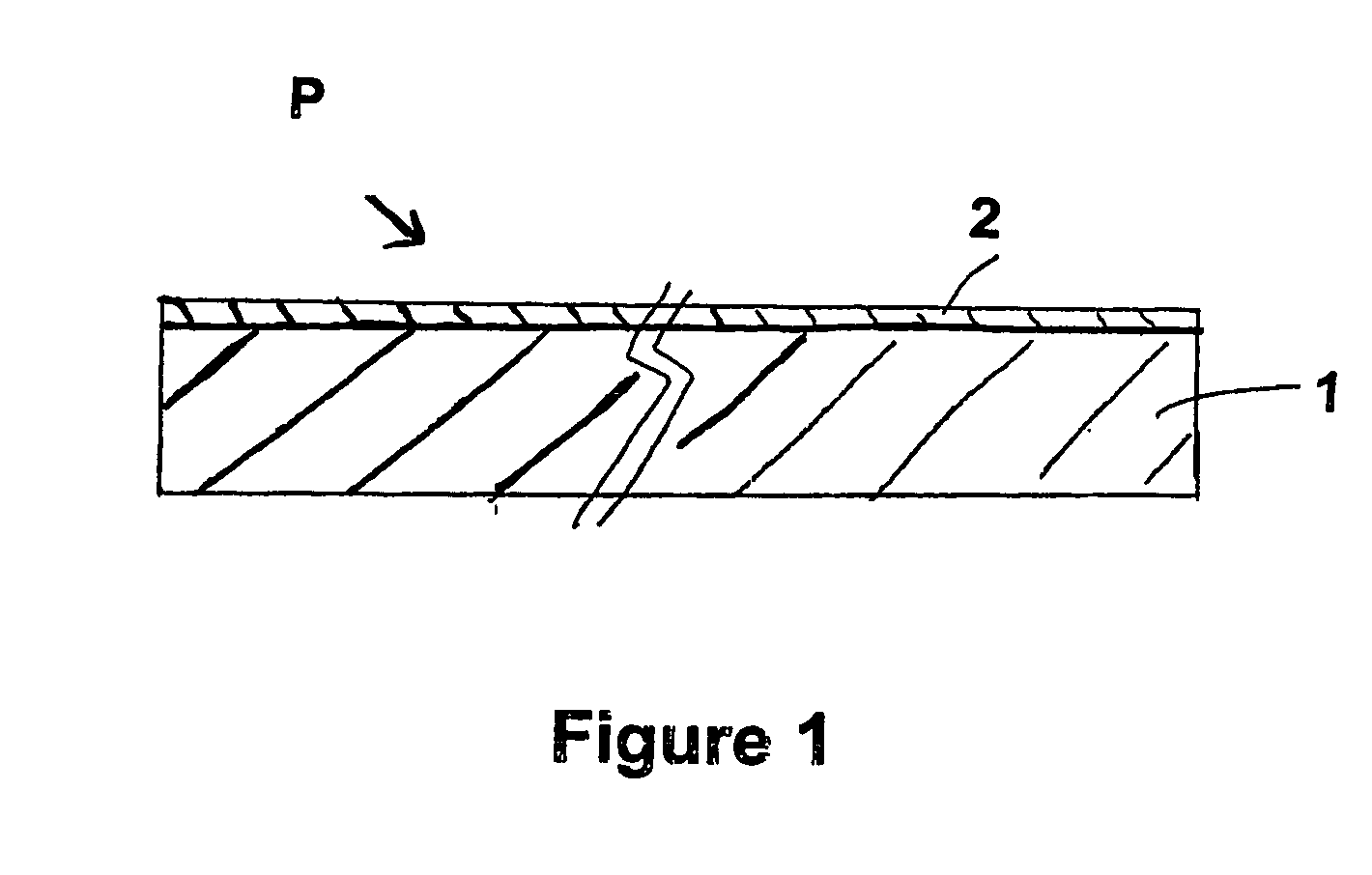

This invention relates to flexible, transparent and conductive coatings and films formed using single wall carbon nanotubes and polymer binders. Preferably, coatings and films are formed from carbon nanotubes (CNT) applied to transparent substrates forming one or multiple conductive layers at nanometer level of thickness. Polymer binders are applied to the CNT network coating having an open structure to provide protection through infiltration. This provides for the enhancement of properties such as moisture resistance, thermal resistance, abrasion resistance and interfacial adhesion. Polymers may be thermoplastics or thermosets, or any combination of both. Polymers may also be insulative or inherently electrical conductive, or any combination of both. Polymers may comprise single or multiple layers as a basecoat underneath a CNT coating, or a topcoat above a CNT coating, or combination of the basecoat and the topcoat forming a sandwich structure. Binder coating thickness can be adjusted by changing binder concentration, coating speed and / or other process conditions. Resulting films and articles can be used as transparent conductors for flat panel display, touch screen and other electronic devices.

Owner:EIKOS

Composition containing carbon nanotubes having coating thereof and process for producing them

ActiveUS20060052509A1Not impair characteristicImprove conductivityMaterial nanotechnologySynthetic resin layered productsColloidal silicaConductive polymer

The object of the present invention is to provide a carbon nanotube composition that does not impair the characteristics of the carbon nanotubes itself, allows the carbon nanotubes to be dispersed or solubilized in a solvent, does not cause separation or aggregation of the carbon nanotubes even during long-term storage, has superior electrical conductivity, film formability and moldability, can be easily coated or covered onto a base material, and the resulting coated film has superior moisture resistance, weather resistance and hardness; a composite having a coated film composed thereof; and, their production methods. In order to achieve this object, the present invention provides a carbon nanotube composition that contains a conducting polymer (a) or heterocyclic compound trimer (i), a solvent (b) and carbon nanotubes (c), and may additionally contain a high molecular weight compound (d), a basic compound (e), a surfactant (f), a silane coupling agent (g) and colloidal silica (h) as necessary; a composite having a coated film composed of the composition; and, their production methods.

Owner:MITSUBISHI CHEM CORP

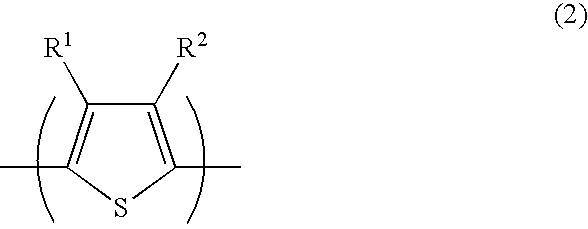

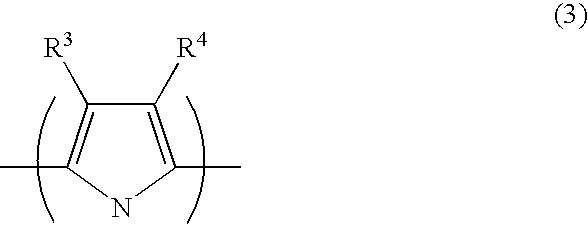

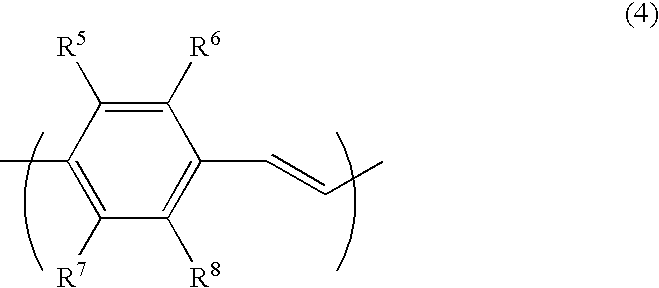

Organoaminosilane precursors and methods for depositing films comprising same

ActiveUS20150087139A1Low temperature efficientlySilicon organic compoundsOrganic compound preparationSilanesPhysical chemistry

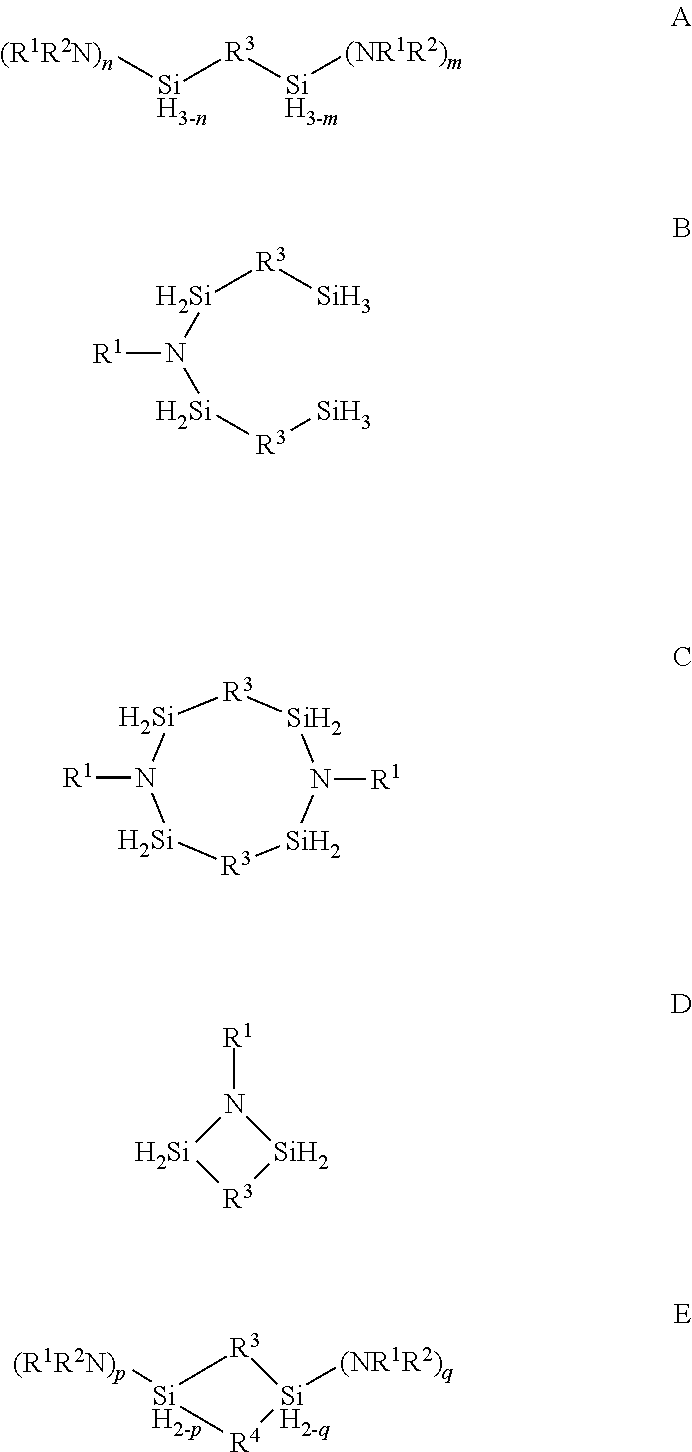

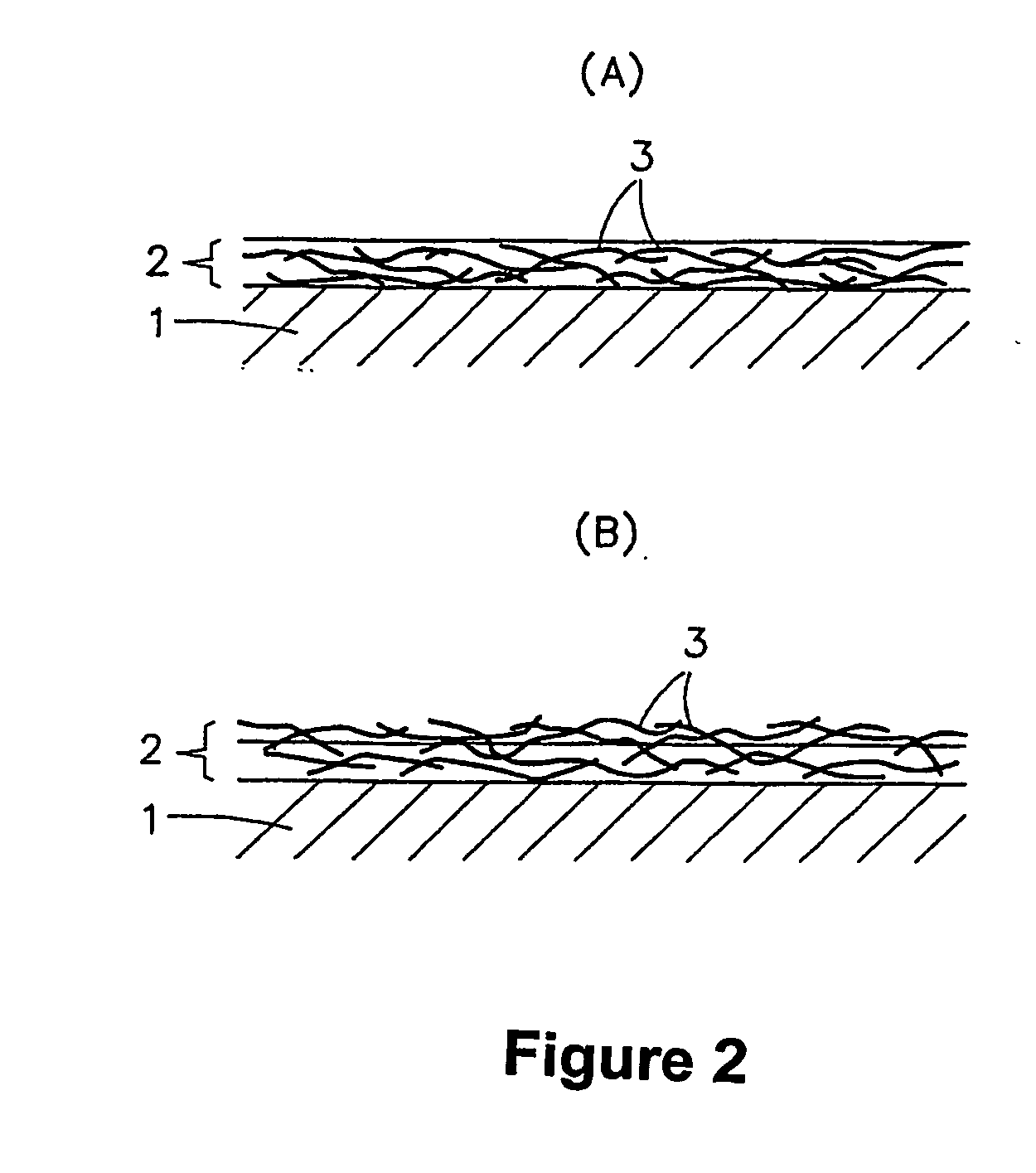

Described herein are precursors and methods for forming silicon-containing films. In one aspect, the precursor comprises a compound represented by one of following Formulae A through E below:In one particular embodiment, the organoaminosilane precursors are effective for a low temperature (e.g., 350° C. or less), atomic layer deposition (ALD) or plasma enhanced atomic layer deposition (PEALD) of a silicon-containing film. In addition, described herein is a composition comprising an organoaminosilane described herein wherein the organoaminosilane is substantially free of at least one selected from the amines, halides (e.g., Cl, F, I, Br), higher molecular weight species, and trace metals.

Owner:VERSUM MATERIALS US LLC

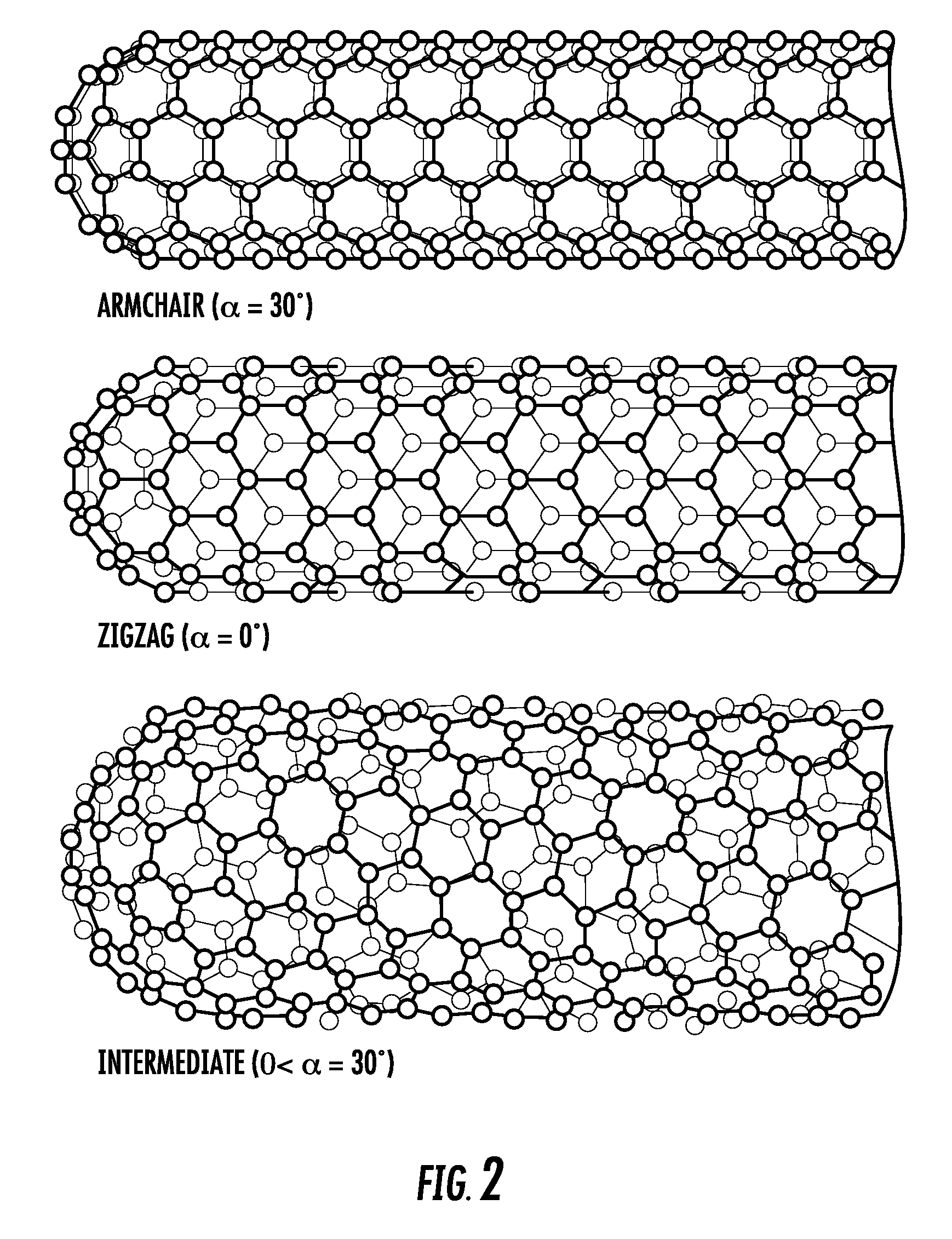

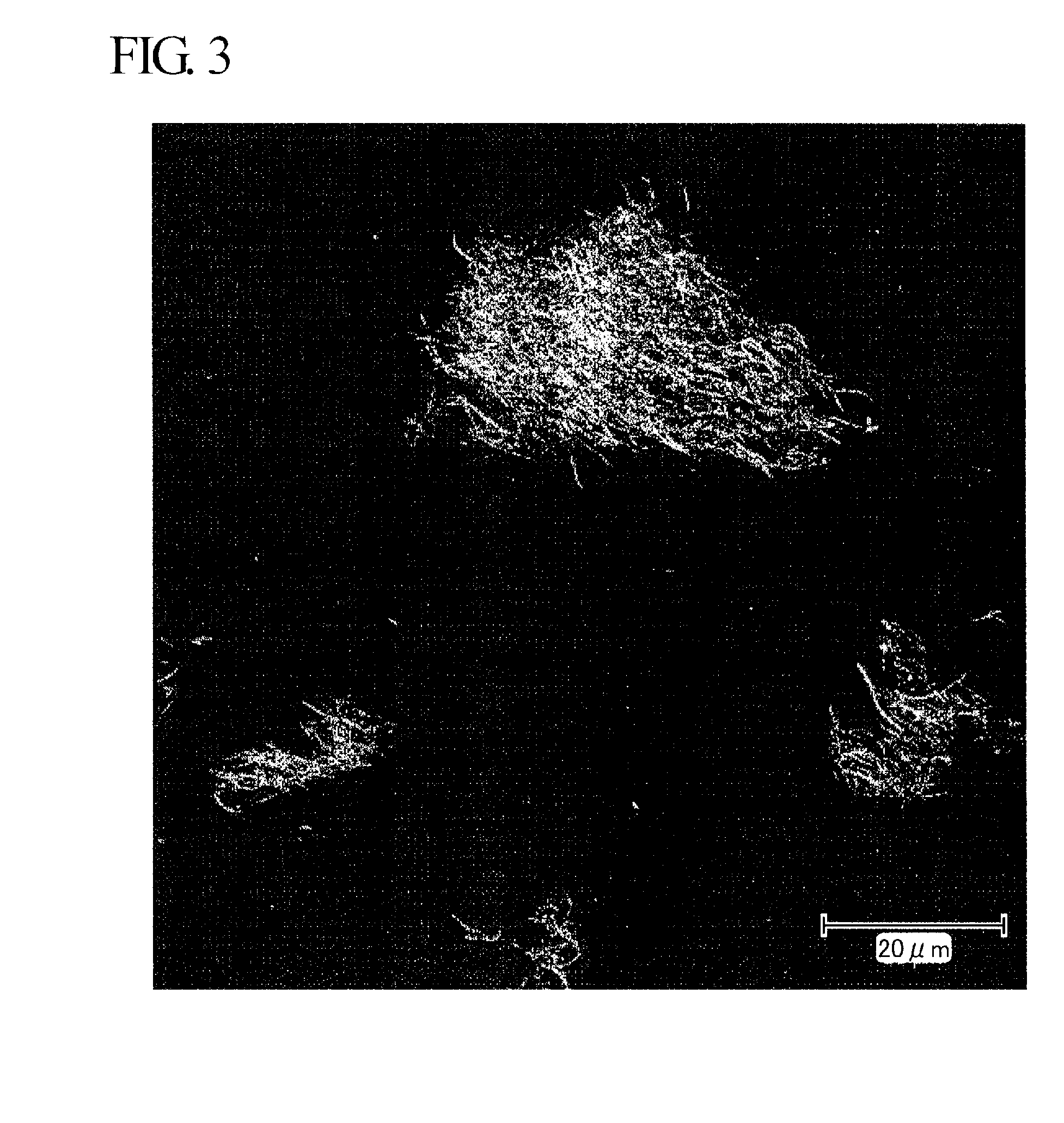

Conformal coatings comprising carbon nanotubes

InactiveUS7118693B2Material nanotechnologyMagnetic/electric field screeningModified carbonElectromagnetic interference

Owner:EIKOS

Articles with dispersed conductive coatings

InactiveUS20060257638A1Improve conductivityHigh transparencyNon-conductive material with dispersed conductive materialNon-woven fabricsConductive coatingCarbon nanotube

A conductive article includes a substrate made of a thermoplastic resin, and a transparent and conductive layer comprising carbon nanotubes and formed on at least one face of the substrate. The carbon nanotubes are electrical in contact with each other and dispersed so that each of the carbon nanotubes is separated form other carbon nanotubes, or that each of bundles of the carbon nanotubes is separated from other bundles.

Owner:EIKOS

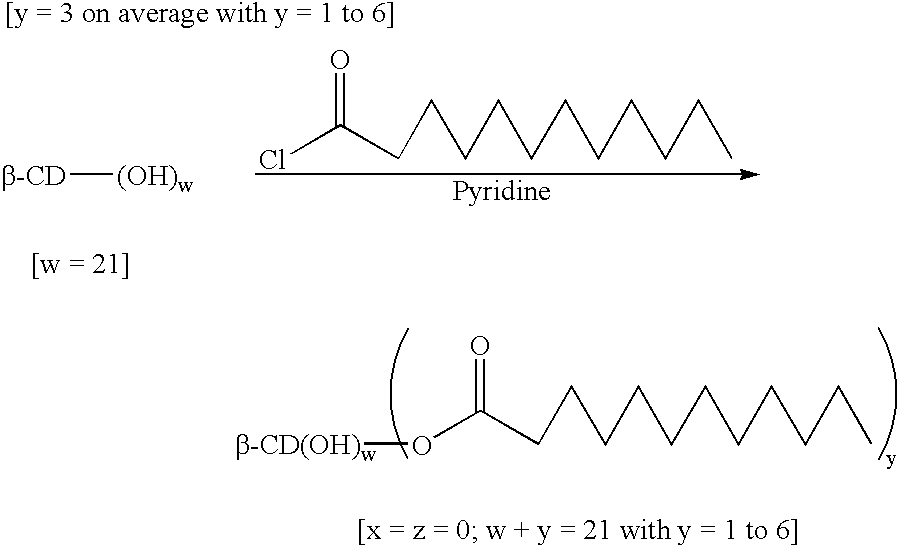

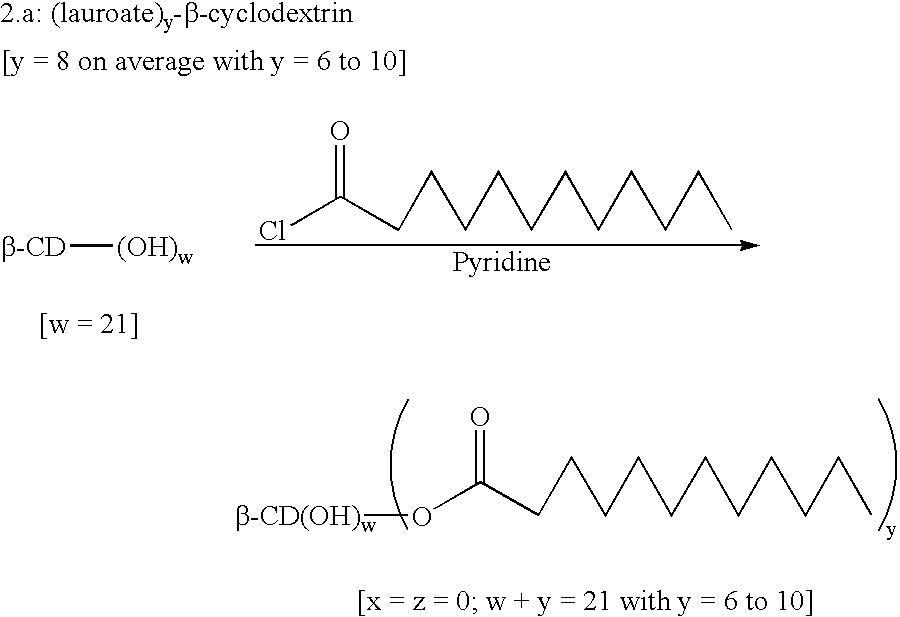

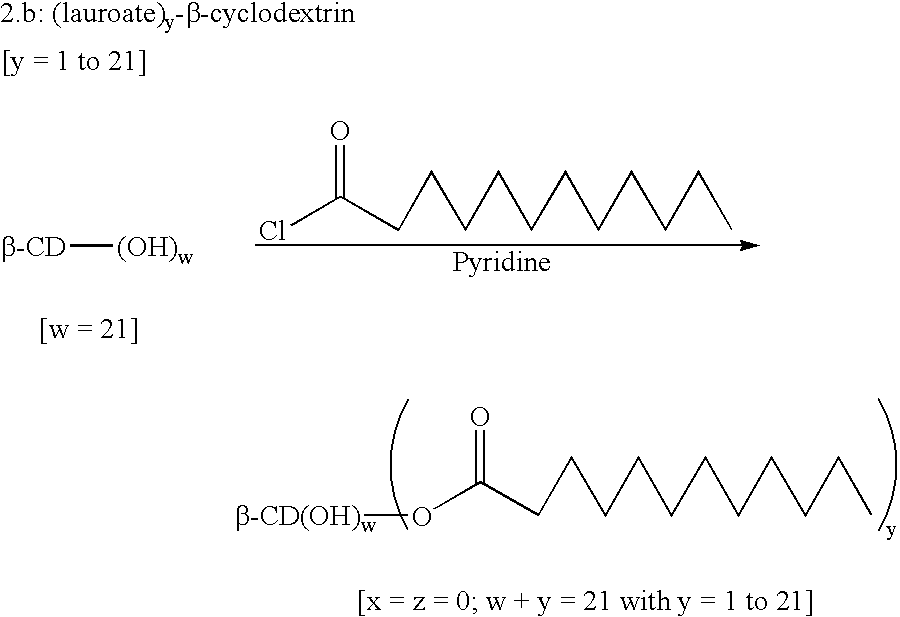

Cyclodextrins preferentially substituted on their primary face by acid or amine functions

InactiveUS6524595B1Improve bioavailabilityEasy to synthesizeBiocideOrganic active ingredientsCyclodextrinBULK ACTIVE INGREDIENT

Non-hydroxyalkylated cyclodextrins are disclosed wherein at least one primary alcohol function (CH2OH) is substituted, the -OH portion being replaced by a substituent with formula -O-CO-R or -NR1R2, where:R, R1 and R2 independently represent a linear or cyclic, saturated or unsaturated, hydroxylated or non-hydroxylated alkyl group containing 1 to 30 carbon atoms, preferably 1 to 22 carbon atoms, more preferably a fatty chain containing 2 to 22 carbon atoms. These cyclodextrins are used as vectors for at least one active ingredient, in particular to encourage tissue penetration, in a cosmetic application, or for the production of pharmaceutical compositions, in particular dermopharmaceuticals.

Owner:BASF BEAUTY CARE SOLUTIONS FRANCE SAS

Low density lightning strike protection for use in airplanes

ActiveUS20090227162A1Minimize micro-crackingWeight optimizationConductive materialWarp knittingFiberEpoxy

Surface films, paints, or primers can be used in preparing aircraft structural composites that may be exposed to lightning strikes. Methods for making and using these films, paints or primers are also disclosed. The surface film can include a thermoset resin or polymer, e.g., an epoxy resin and / or a thermoplastic polymer, which can be cured, bonded, or painted on the composite structure. Low-density electrically conductive materials are disclosed, such as carbon nanofiber, copper powder, metal coated microspheres, metal-coated carbon nanotubes, single wall carbon nanotubes, graphite nanoplatelets and the like, that can be uniformly dispersed throughout or on the film. Low density conductive materials can include metal screens, optionally in combination with carbon nanofibers.

Owner:ROHR INC +1

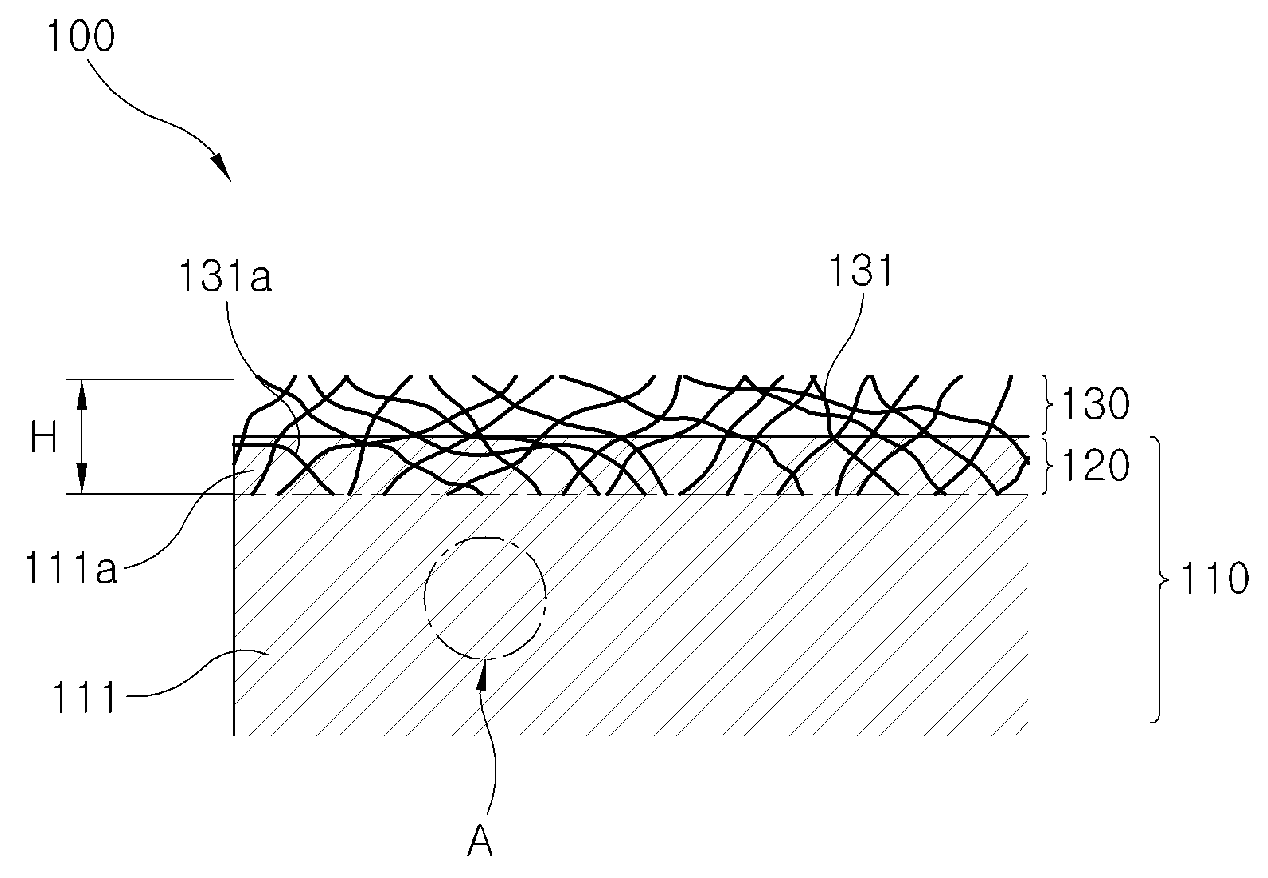

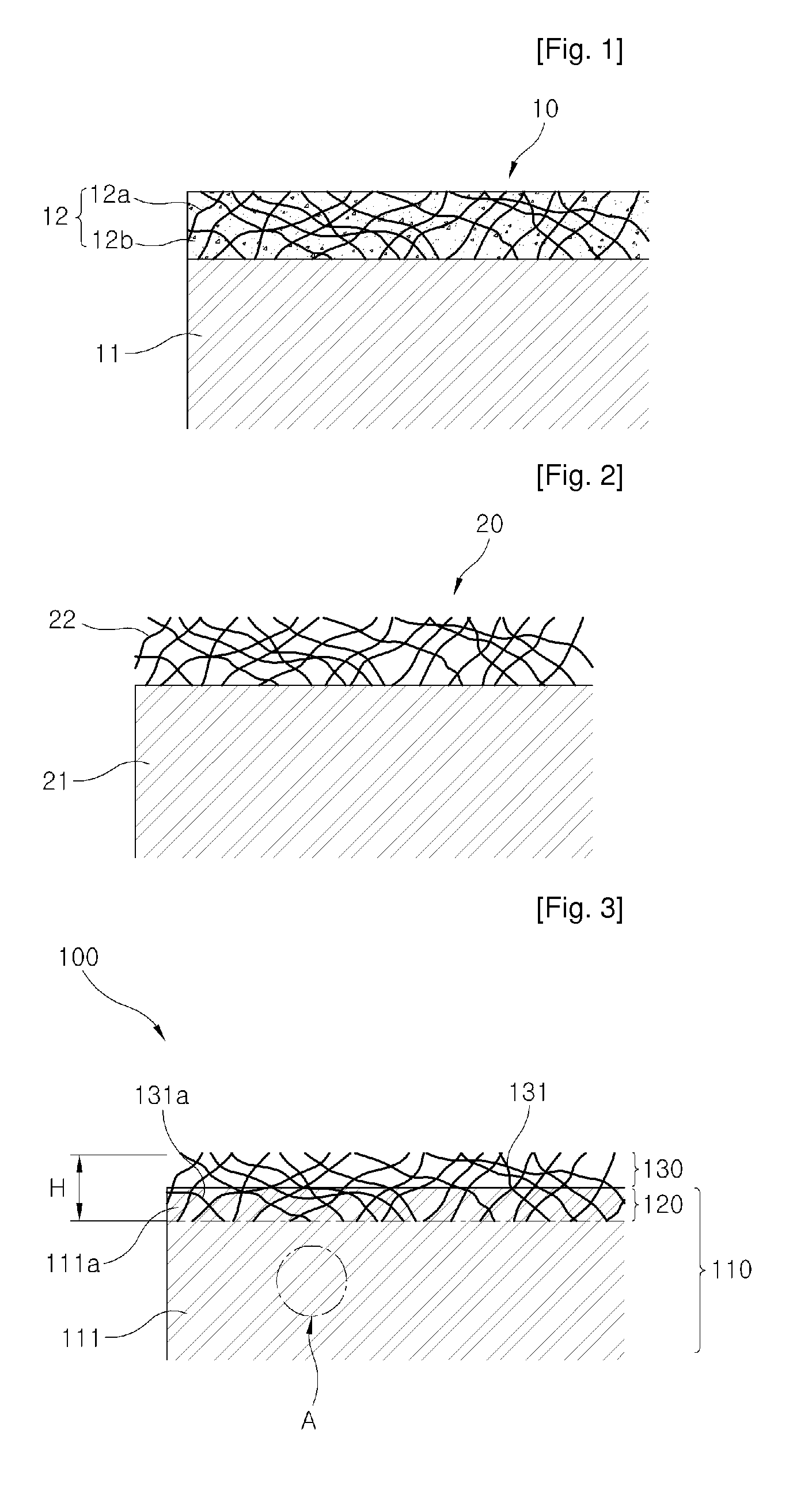

Method for manufacturing conductive composite material

InactiveUS20090056854A1Reduce thicknessHigh transparencyCathodes manufactureElectric discharge tubesFiberOptoelectronics

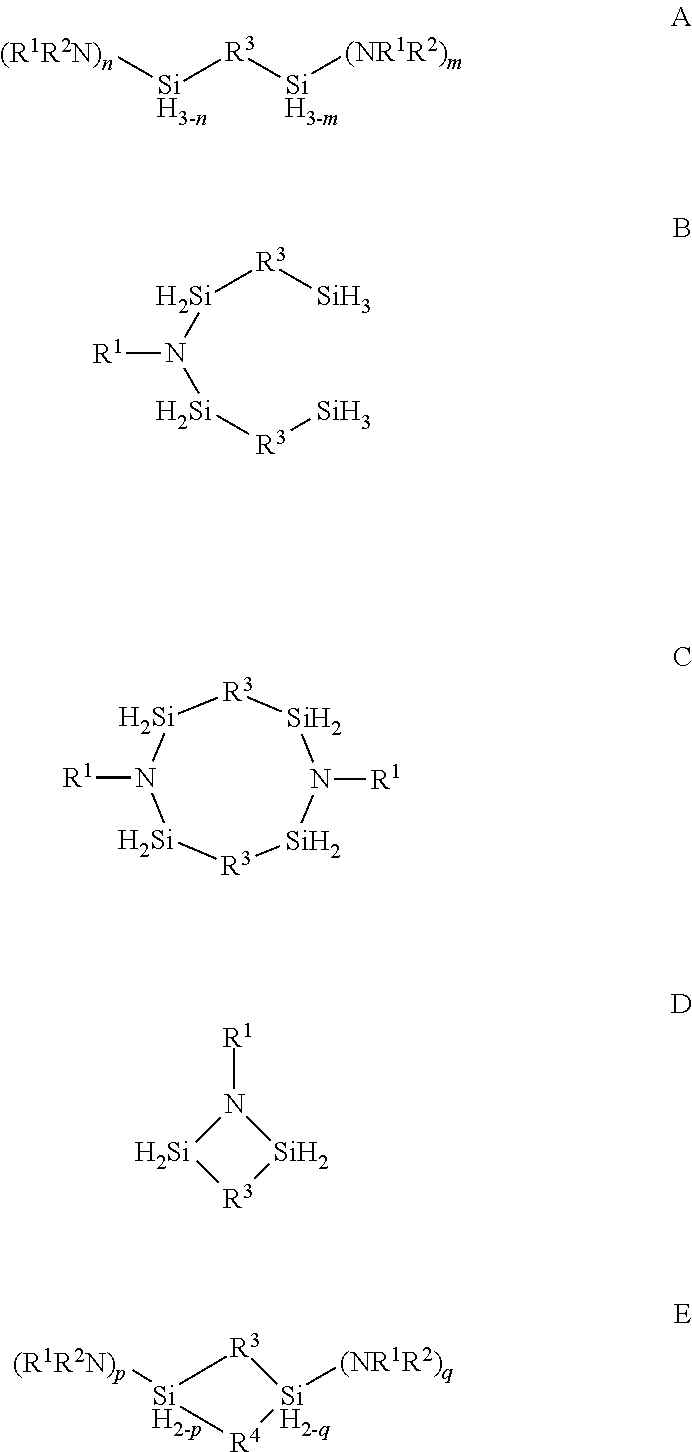

A conductive composite material is provided, including: a base layer; a conductive fiber thin-film made of conductive fiber and formed on the base layer; and a mixture layer in which part of the conductive fiber is inserted into part of the base layer.

Owner:TOPNANOSIS

Functionalised graphene oxide

ActiveUS20110052813A1Good dispersionReadily deoxidised to grapheneMaterial nanotechnologyOrganic chemistryHigh concentrationRoom temperature

A functionalised graphene oxide and a method of making a functionalised graphene oxide comprising: (i) oxidizing graphite to form graphite oxide wherein the graphene sheets which make up the graphite independently of each other have a basal plane fraction of carbon atoms in the sp2-hybridised state between 0.1 and 0.9, wherein the remainder fraction comprises sp3-hybridised carbon atoms which are bonded to oxygen groups selected from hydroxyl and / or epoxy and / or carboxylic acid; and (ii) exfoliating and in-situ functionalizing the graphite oxide surface with one or more functional groups such that functionalisation of the surface is effected at a concentration greater than one functional group per 100 carbon atoms and less than one functional group per six carbon atoms. The functionalised graphene oxide is dispersible at high concentrations in appropriate solvents without aggregating or precipitating over extended periods at room temperature.

Owner:NAT UNIV OF SINGAPORE

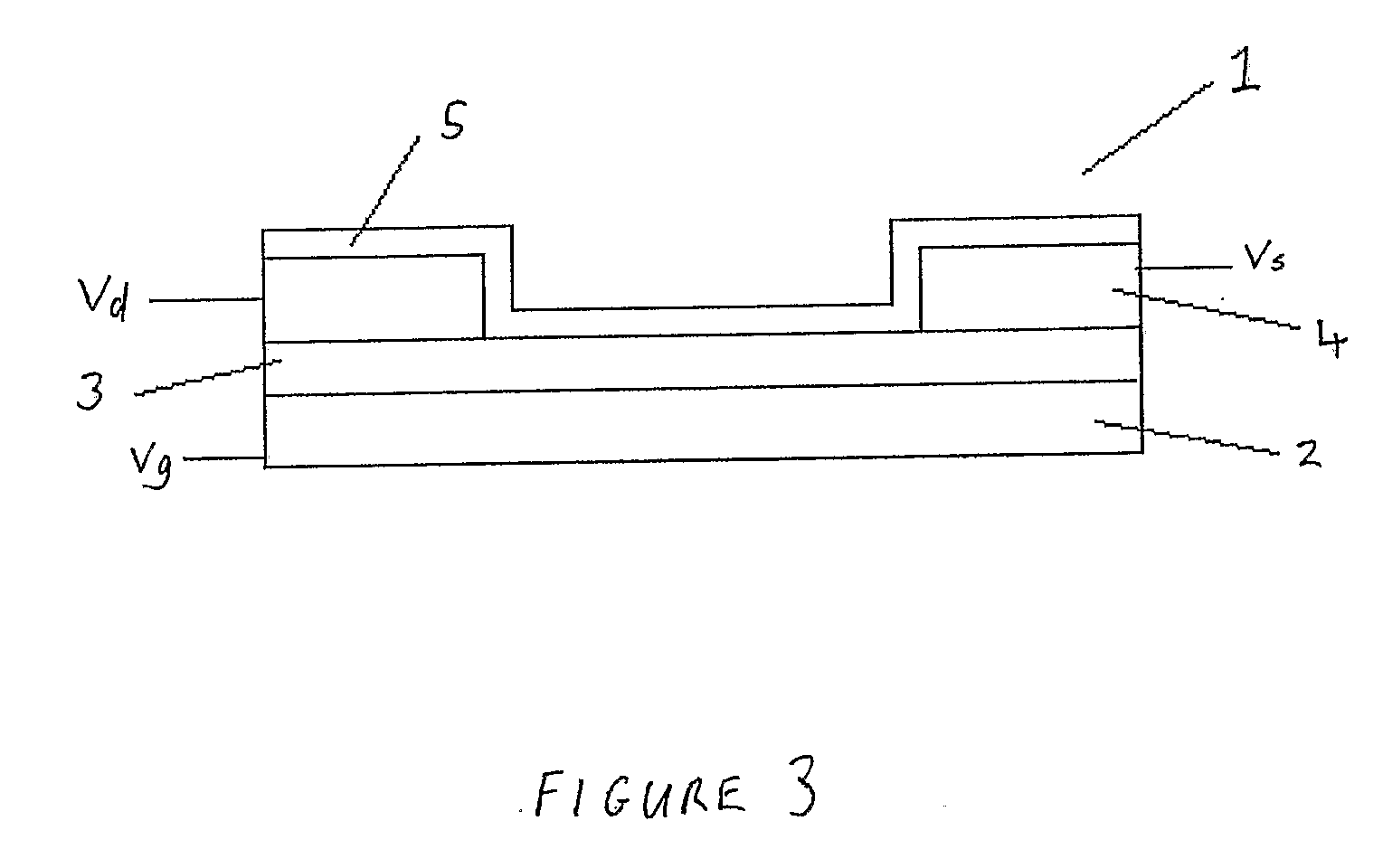

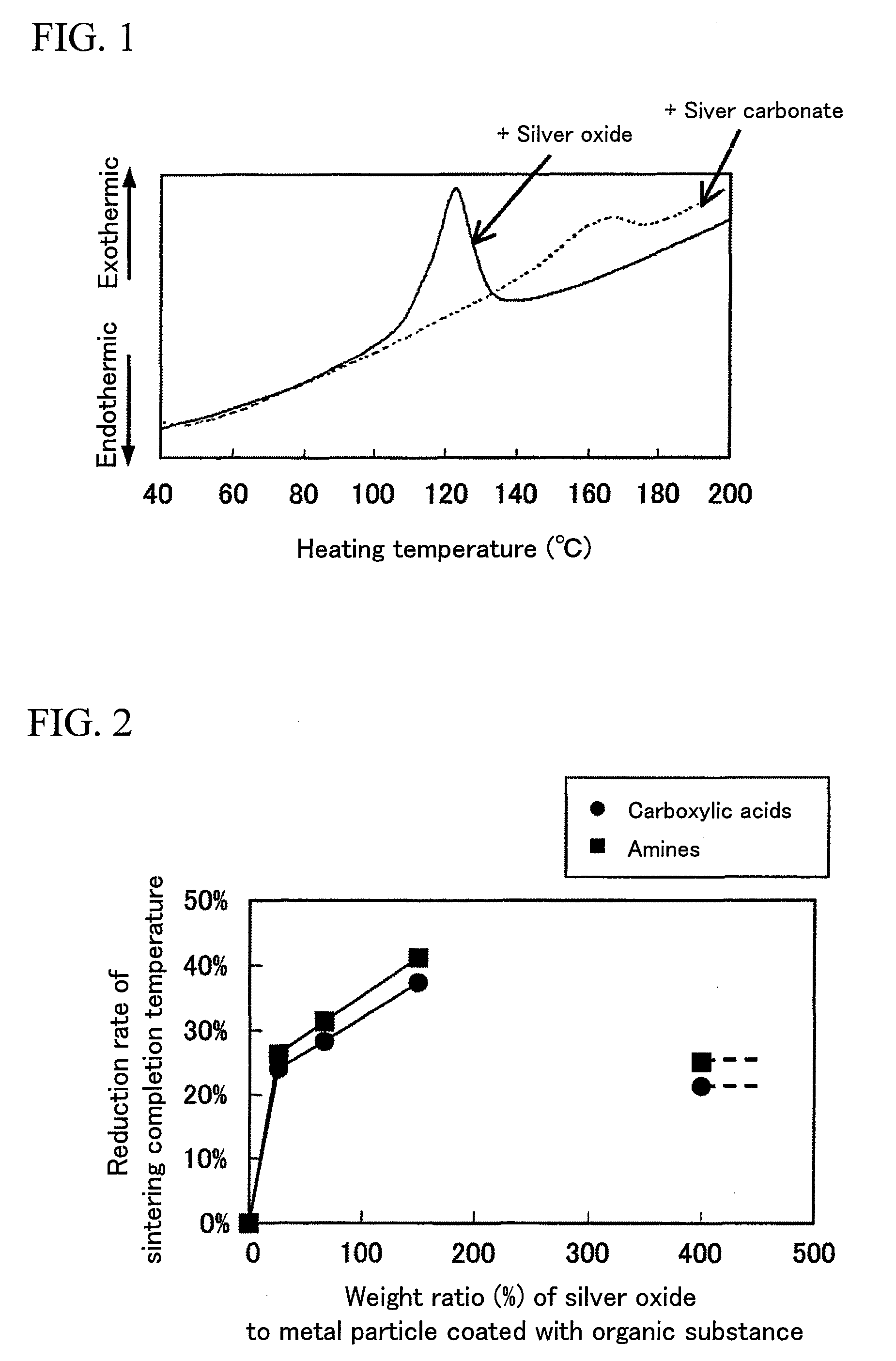

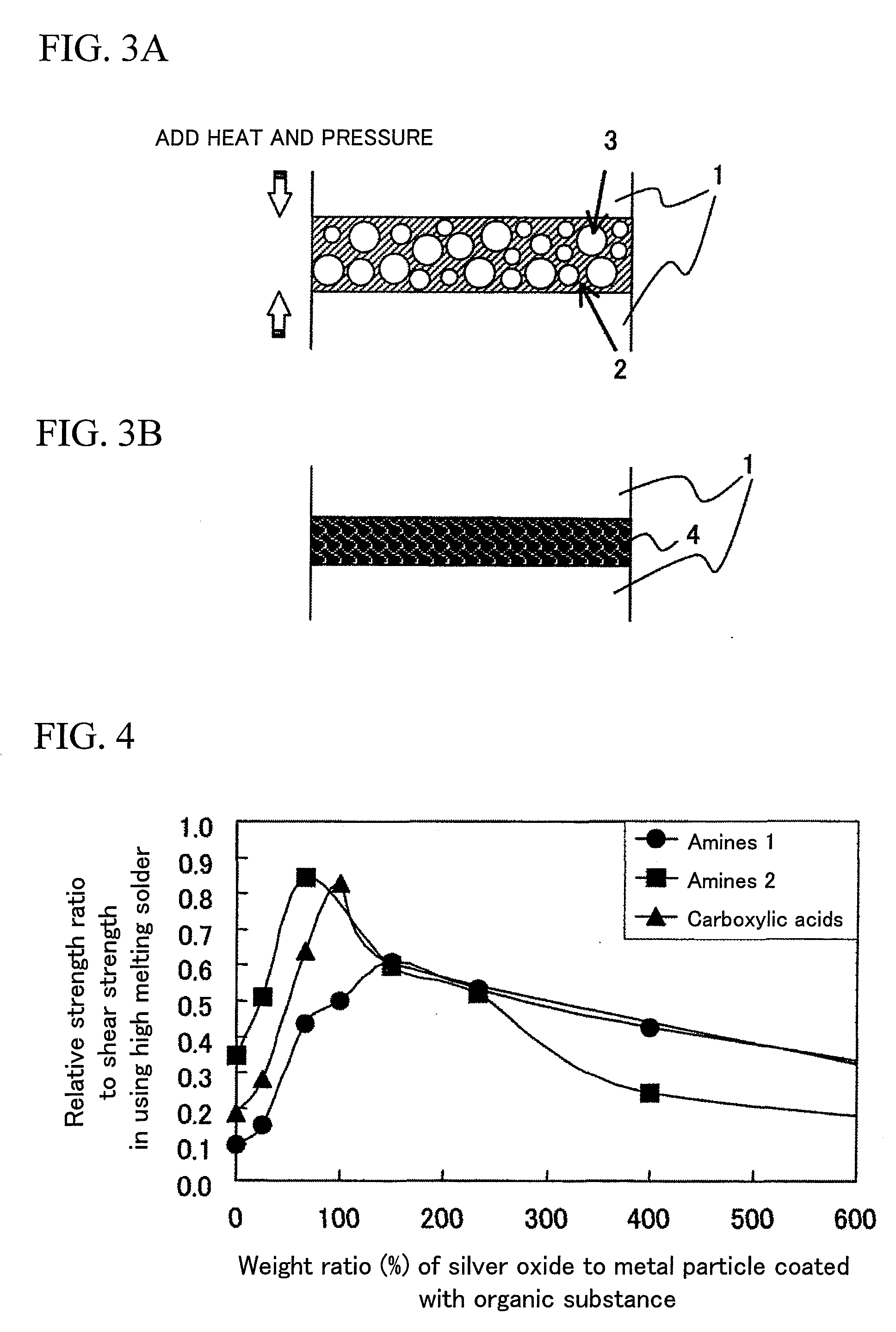

Conductive sintered layer forming composition and conductive coating film forming method and bonding method using the same

InactiveUS20080160183A1Low heating temperatureShorten heating timeSemiconductor/solid-state device detailsConductive materialHeating timeConductive coating

There is provided a conductive sintered layer forming composition and a conductive sintered layer forming method that can lower heating temperature and shorten heating time for a process of accelerating sintering or bonding by sintering of metal nano-particles coated with an organic substance. The conductive sintered layer forming composition may be obtained by utilizing a phenomenon that particles may be sintered at low temperature by mixing silver oxide with metal particles coated with the organic substance and having a grain size of 1 nm to 5 μm as compared to sintering each simple substance. The conductive sintered layer forming composition of the invention is characterized in that it contains the metal particles whose surface is coated with the organic substance and whose grain size is 1 nm to 5 μm and the silver oxide particles.

Owner:HITACHI LTD

Composition for Functional Coatings, Film Formed Therefrom and Method for Forming the Composition and the Film

InactiveUS20080311308A1Preservation deteriorateLow viscosityConductive materialPhotomechanical apparatusElectrochromismChrominance

The present invention relates to compositions for functional films, and more particularly to compositions for functional films such as a heat ray screening film compatible with hydrolic or alcoholic and anti-hydrolic resin binder, a near infrared screening film, a chrominance correcting film, a conductive film, a magnetic film, a ferromagnetic film, a dielectric film, a ferroelectric film, an electrochromic film, an electroluminescence film, an insulating film, a reflecting film, a reflection preventing film, a catalyst film, a photocatalyst film, a light selectively absorbing film, a hard film, and a heat resisting film, films formed therefrom, and a method of forming the compositions and the films.

Owner:LEE HAE WOOK

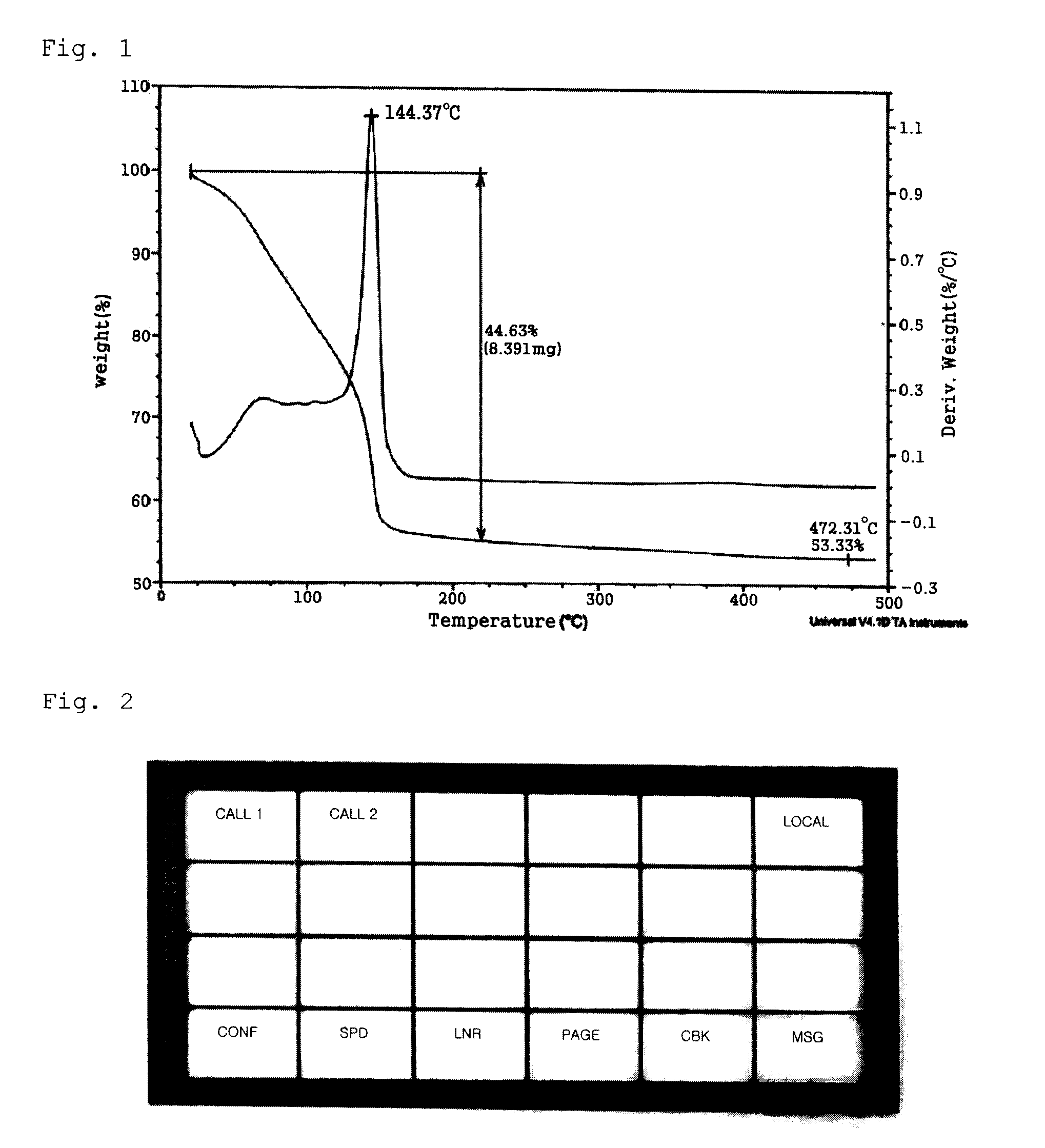

Conductive Inks and Manufacturing Method Thereof

ActiveUS20080206488A1Improve stabilityImprove solubilityElectric discharge heatingConductive materialAmmonium carbonateAmmonium carbamate

The present invention relates to a variety of conductive ink compositions comprising a metal complex compound having a special structure and an additive and a method for preparing the same, more particularly to conductive ink compositions comprising a metal complex compound obtained by reacting a metal or metal compound with an ammonium carbamate- or ammonium carbonate-based compound and an additive and a method for preparing the same.

Owner:INKTEC CO LTD

Coatings containing functionalized graphene sheets and articles coated therewith

Coatings comprising functionalized graphene sheets and at least one binder. In one embodiment, the coatings are electrically conductive.

Owner:THE TRUSTEES FOR PRINCETON UNIV +1

Conductive slurry for solar battery front side electrode and production method thereof

ActiveCN101295739AImprove photoelectric conversion efficiencyImprove adhesionFinal product manufactureNon-conductive material with dispersed conductive materialConductive pasteElectrical battery

The invention relates to a conductive paste for the surface electrode of a solar cell, which comprises conductive metal powders, organic carriers, adhesives, solvents and addition agent, wherein, the conductive paste also comprises additives which are selected from phosphorus pentachloride and one or more VIII group metal halide. The additive in the conductive paste of the invention can help improve the adhesive force between the conductive paste and silicon substrate, and lead adhesion between compounds obtained after electrode sintering and silicon substrate to be more firm; the formed compound does not have cracks and bubbles and the electrode surface is flat and smooth, thus providing the solar cell finally prepared with higher photoelectric conversion efficiency.

Owner:BYD CO LTD

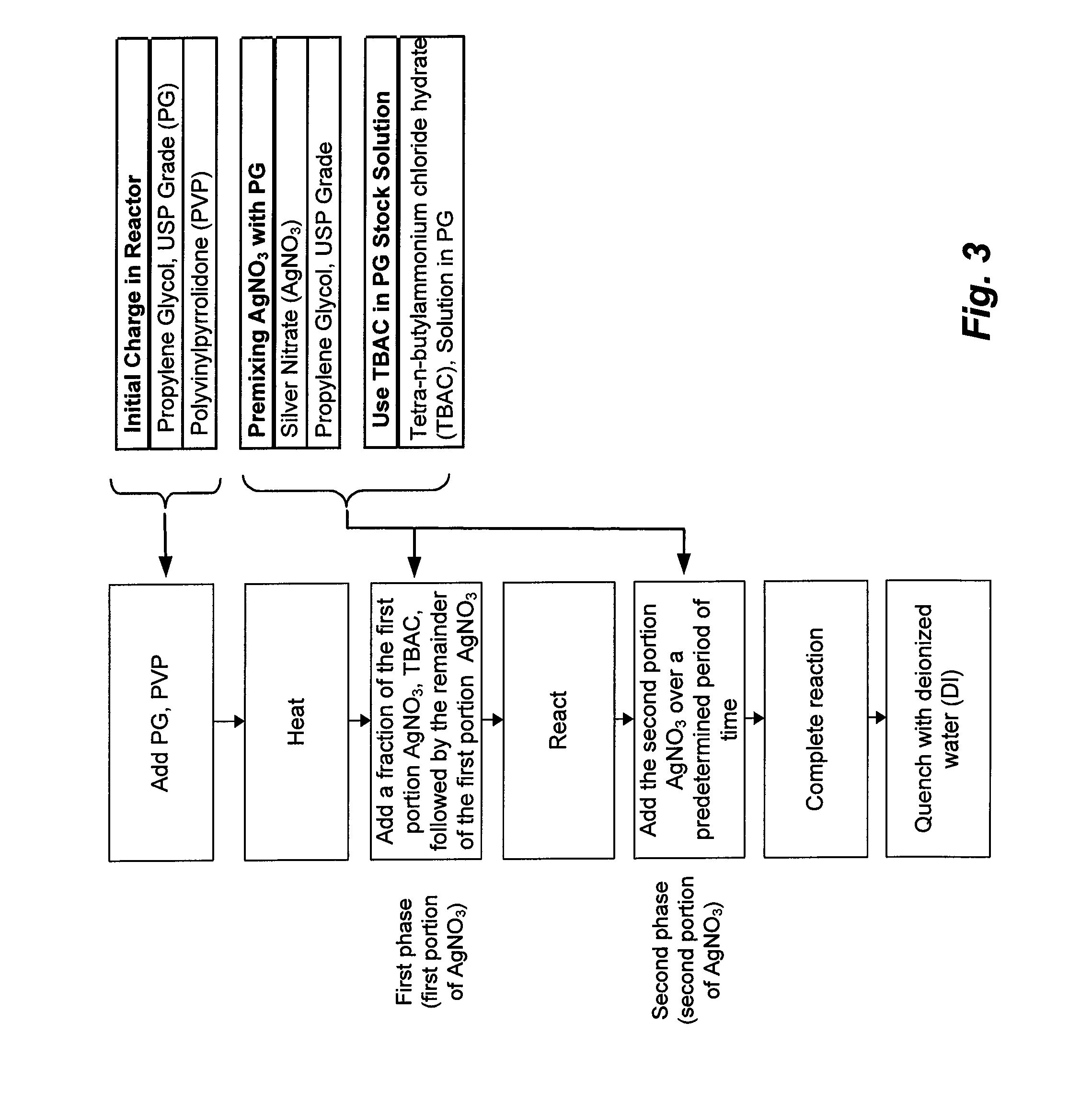

Low-haze transparent conductors

ActiveUS20110174190A1Material nanotechnologyConductive layers on insulating-supportsElectrical conductorHaze

This disclosure is related to low-haze transparent conductors, ink compositions and method for making the same.

Owner:CHAMP GREAT INTL

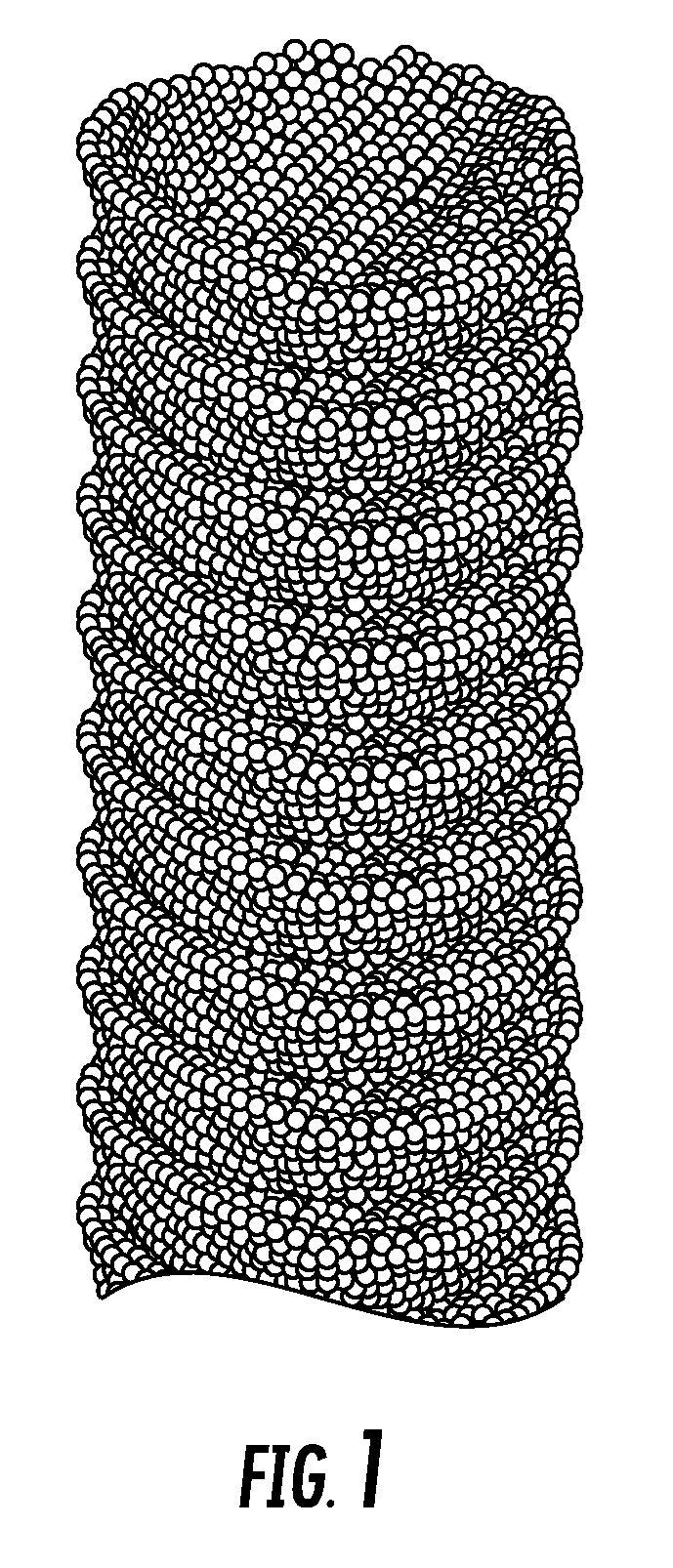

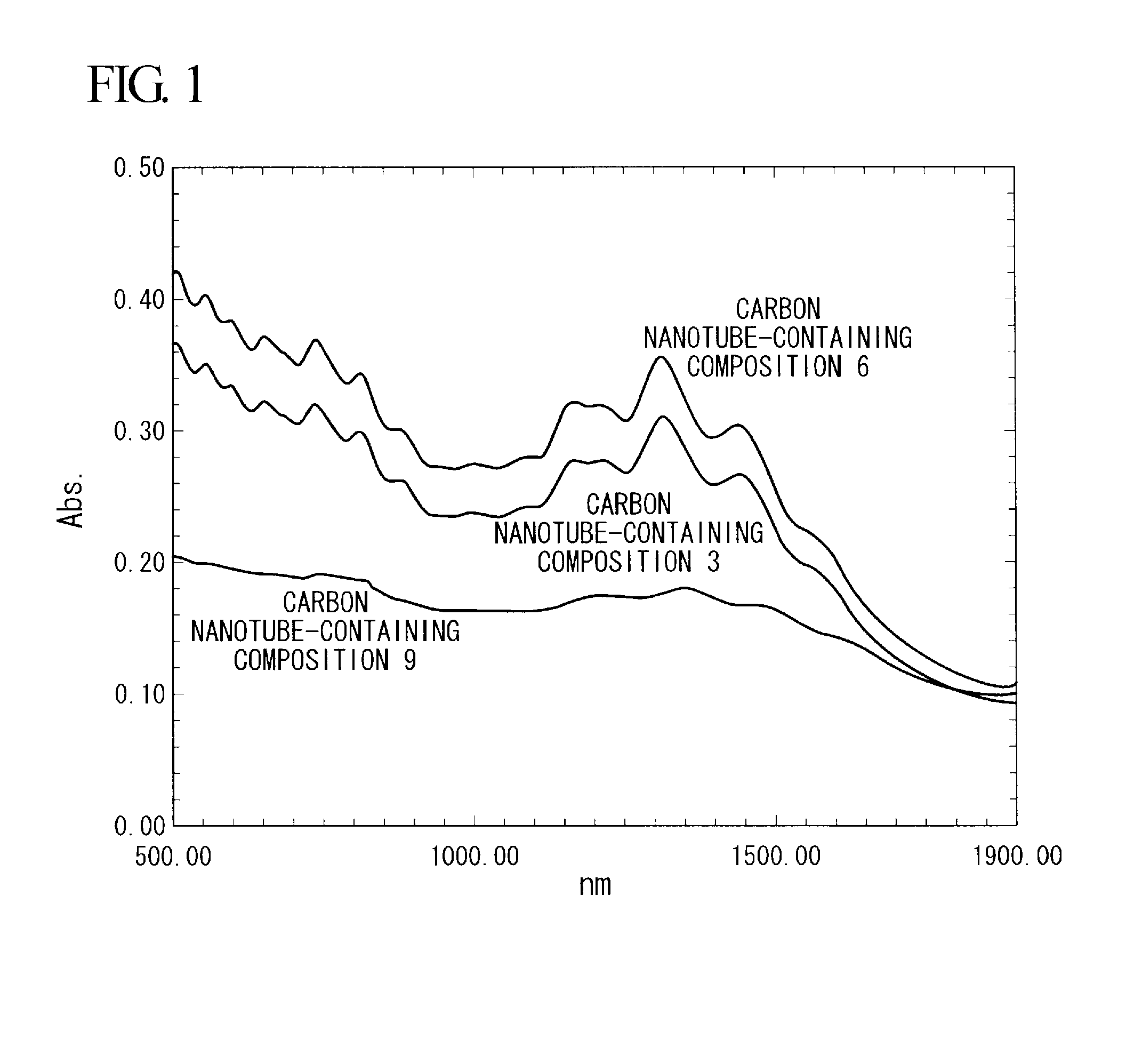

Carbon nanotube-containing composition, composite, and methods for producing them

ActiveUS20100065788A1Improve conductivityInhibit coloringMaterial nanotechnologyConductive materialMeth-Carbon nanotube

Disclosed is a carbon nanotube-containing composition which contains a carbon nanotube and a urethane compound obtained by a reaction between a hydroxyl group-containing (meth)acrylate and a isocyanate compound. Also disclosed is a composite having a coating film or a cured film composed of the carbon nanotube-containing composition on at least one surface of a base material. The carbon nanotube-containing composition and the composite are excellent in electrical conductivity, film-formability, moldability, and transparency without deteriorating the characteristic properties of the carbon nanotube itself.

Owner:MITSUBISHI CHEM CORP

Coatings Comprising Carbon Nanotubes

InactiveUS20080044651A1Overcome problemsImprove conductivityPigmenting treatmentSemiconductor/solid-state device detailsNanometreNanotube

An electrically conductive coating is disclosed. According to one embodiment of the present invention, the coating includes a plurality of single-wall or multi-walled Carbon nanotubes having a diameter less than 20 nanometers. The disclosed coating demonstrates excellent conductivity and smooth surface morphology. Methods of preparing the coating as well as methods of its use are also disclosed herein.

Owner:DOUGLAS JOEL S

Conductive heat-conductive graphene slurry and coating

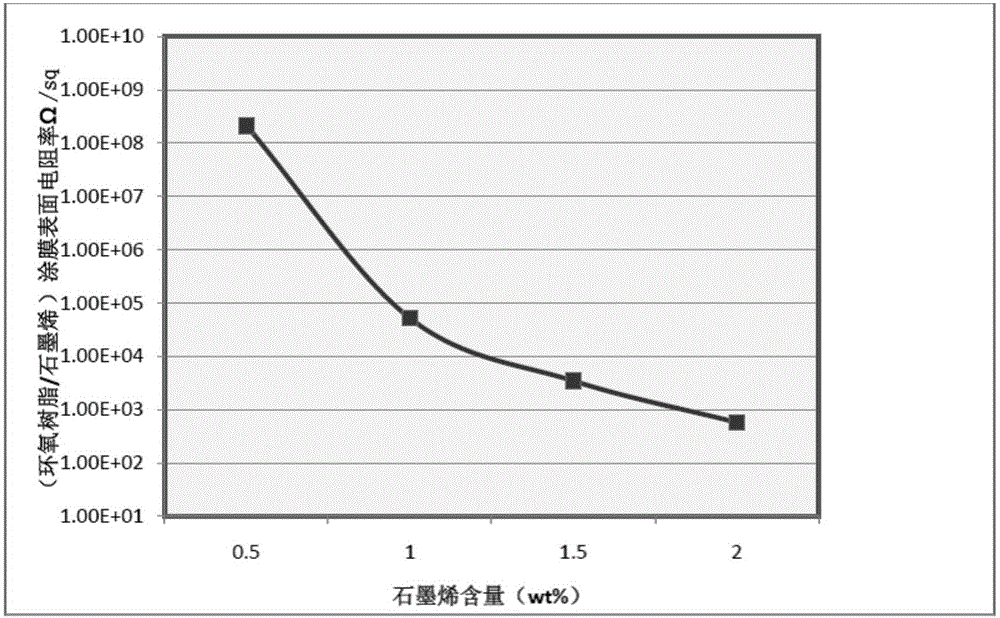

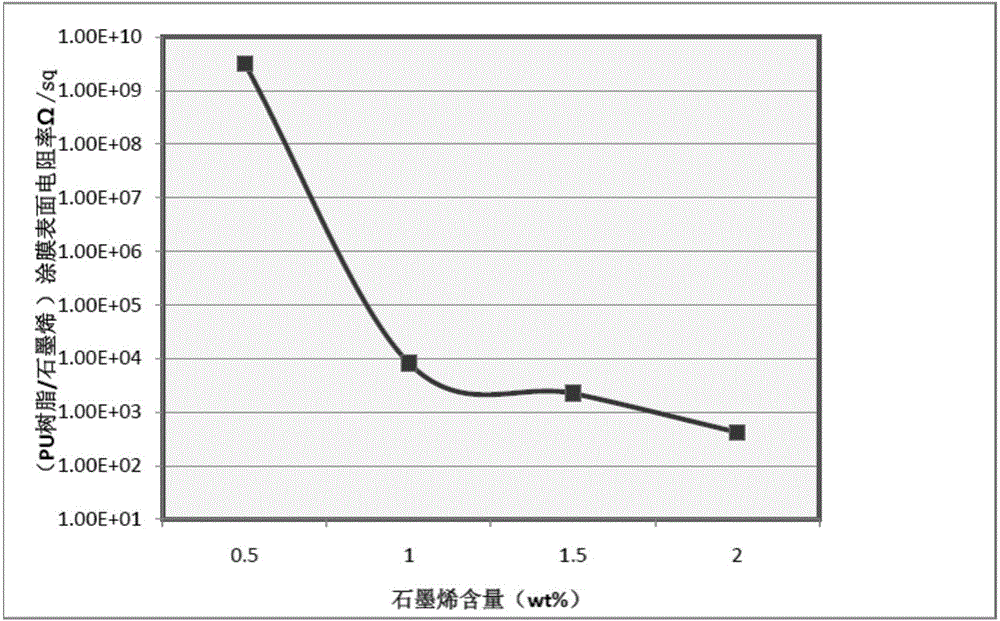

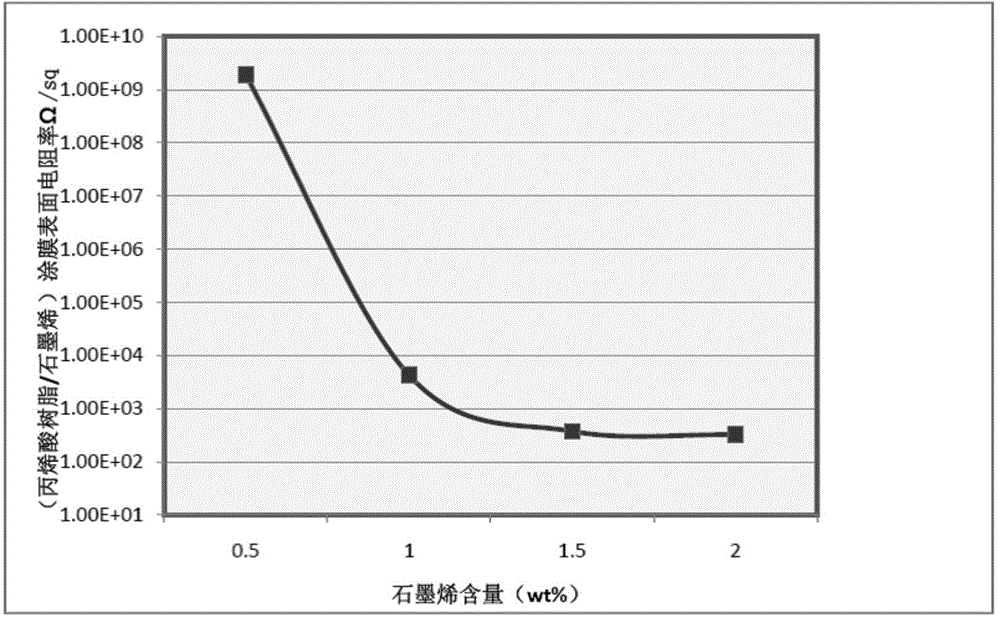

InactiveCN104163928AAdd lessReduce pollutionPolyurea/polyurethane coatingsEpoxy resin coatingsHeat conductingConductive materials

The invention relates to a conductive heat-conductive graphene slurry and a coating. The conductive heat-conductive graphene slurry comprises the following raw materials: 0.1-90wt% of conductive heat-conductive graphene slurry ( consisting of 3-20wt% of less graphene, 0-80wt% of base solvent, 0-80wt% of base resin), 0-60wt% of filler, 0-10% of dispersing agent, 10-60wt% of resin, 10-60wt% of curing agent, and 30-70wt% of solvent, wherein not only can the graphene slurry be antistatic, conductive and heat-conducting despite of less addition amount, but also the surface of a coated article is smoother and finer, firmer and more durable; compared with the addition amount of the existing conductive material, the conductive heat-conductive graphene slurry is lower in addition amount and can also reach lower resistivity.

Owner:SUPERCDONGGUAN TECH

Antisoiling hardcoat

InactiveUS6841190B2Easy to storeImprove the immunityTelevision system detailsCathode-ray/electron-beam tube vessels/containersSheet filmPerfluoropolyether

Owner:3M INNOVATIVE PROPERTIES CO

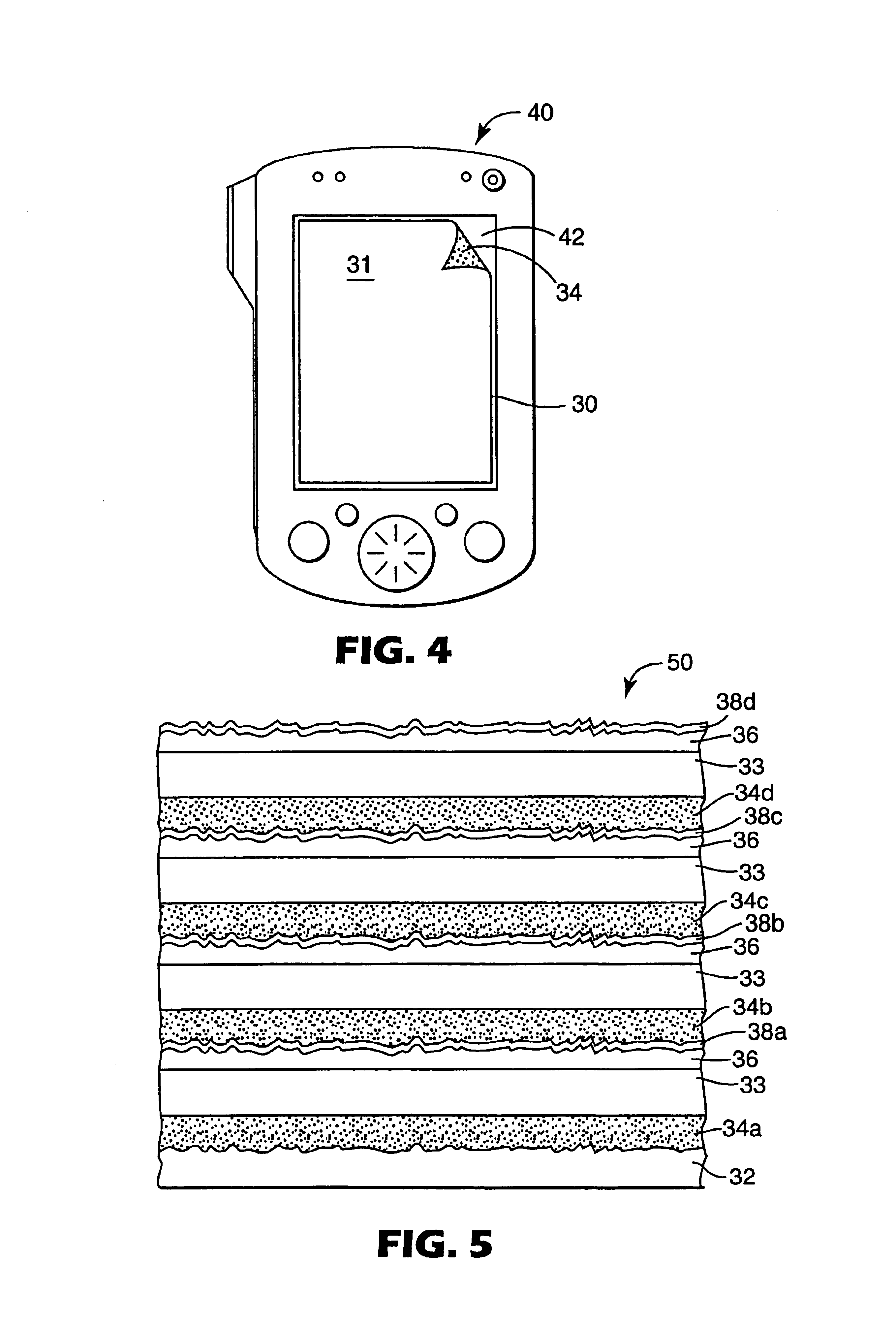

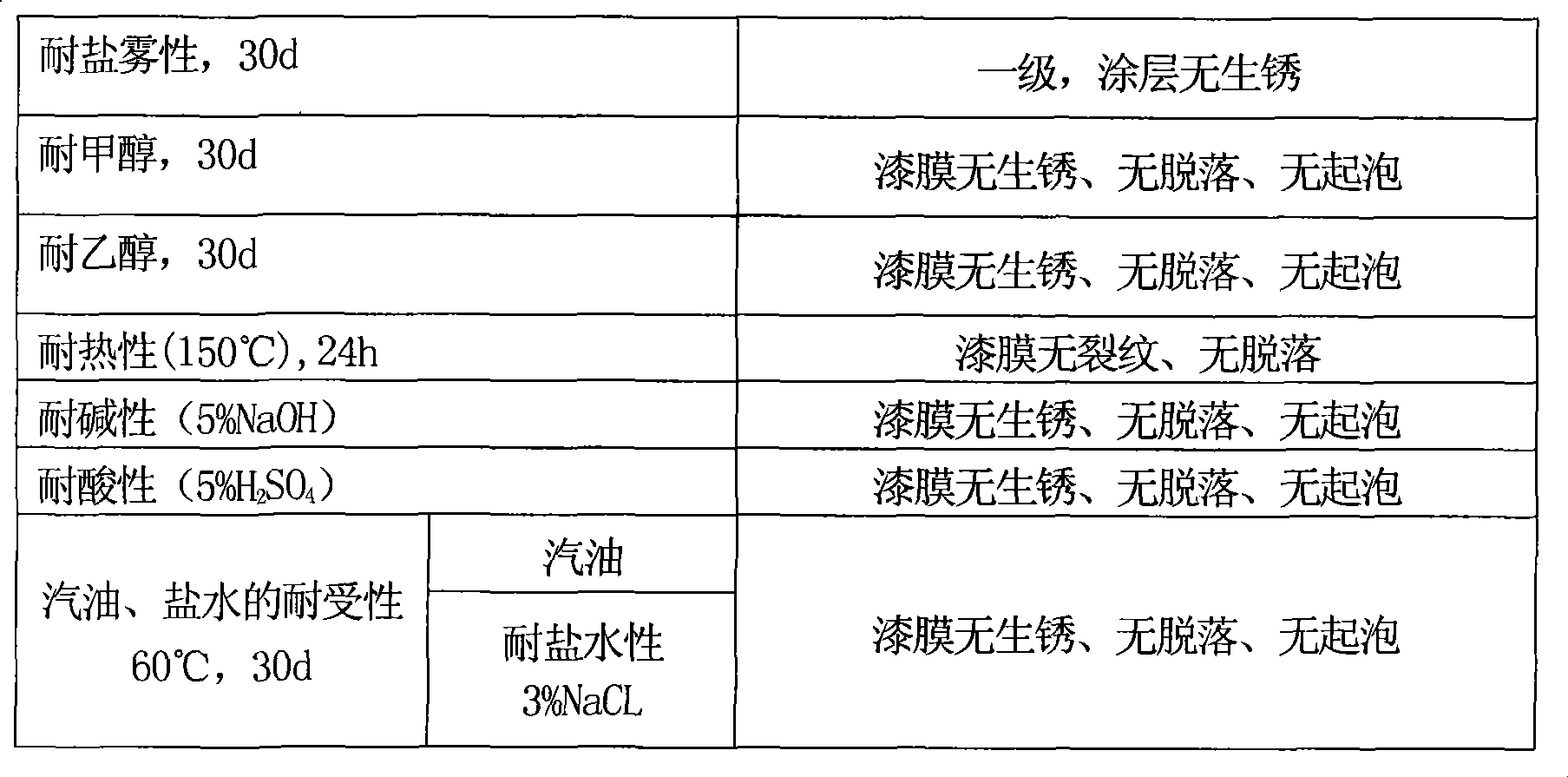

Oil resistant (solvent), heatproof static conducting anti-corrosive paint and preparation thereof

InactiveCN101372601AHigh solid contentReduce the number of coatsAnti-corrosive paintsPolyurea/polyurethane coatingsPlasticizerSolvent

The invention belongs to the corrosion protective coating technique field and provides an oil resistance (solvent) and temperature resistance electrostatic conducting corrosion protective coating and a preparation method thereof. The coating is mainly made by raw components by weight percentage of 20-35 percent of resinI which is used as basic material, 0-15 percent of modified resin II, 15-30 percent of conductive fillers, 1-3 percent of coupling agent, 8-20 percent of fillers, 10-15 percent of solvent, 2-10 percent of plasticizer, 0.5-1 percent of defoamer, 0.5-1 percent of flatting agent and 6-15 percent of curing agent. The coating is prepared according to the following steps: the resin I, the modified resin II, the coupling agent, the plasticizer, the flatting agent and the defoamer are put in a distributing tank. And part of mixed solvent is added to be stirred and distributed uniformly. The fillers are added proportionally and are put in a sand mill for sand milling after being dispersed and stirred uniformly at high speed, so as to obtain upper grinding pigment paste. The conductive fillers and the rest mixed solvent are added at low stirring speed. The conductive fillers are totally blended into the upper grinding pigment paste and stirring is carried out at middle speed, the viscosity is adjusted to be qualified and the fillers are filtered to obtain a qualified component A product. The curing agent is carried out subpackage according to proportion.

Owner:洛阳双瑞防腐工程技术有限公司

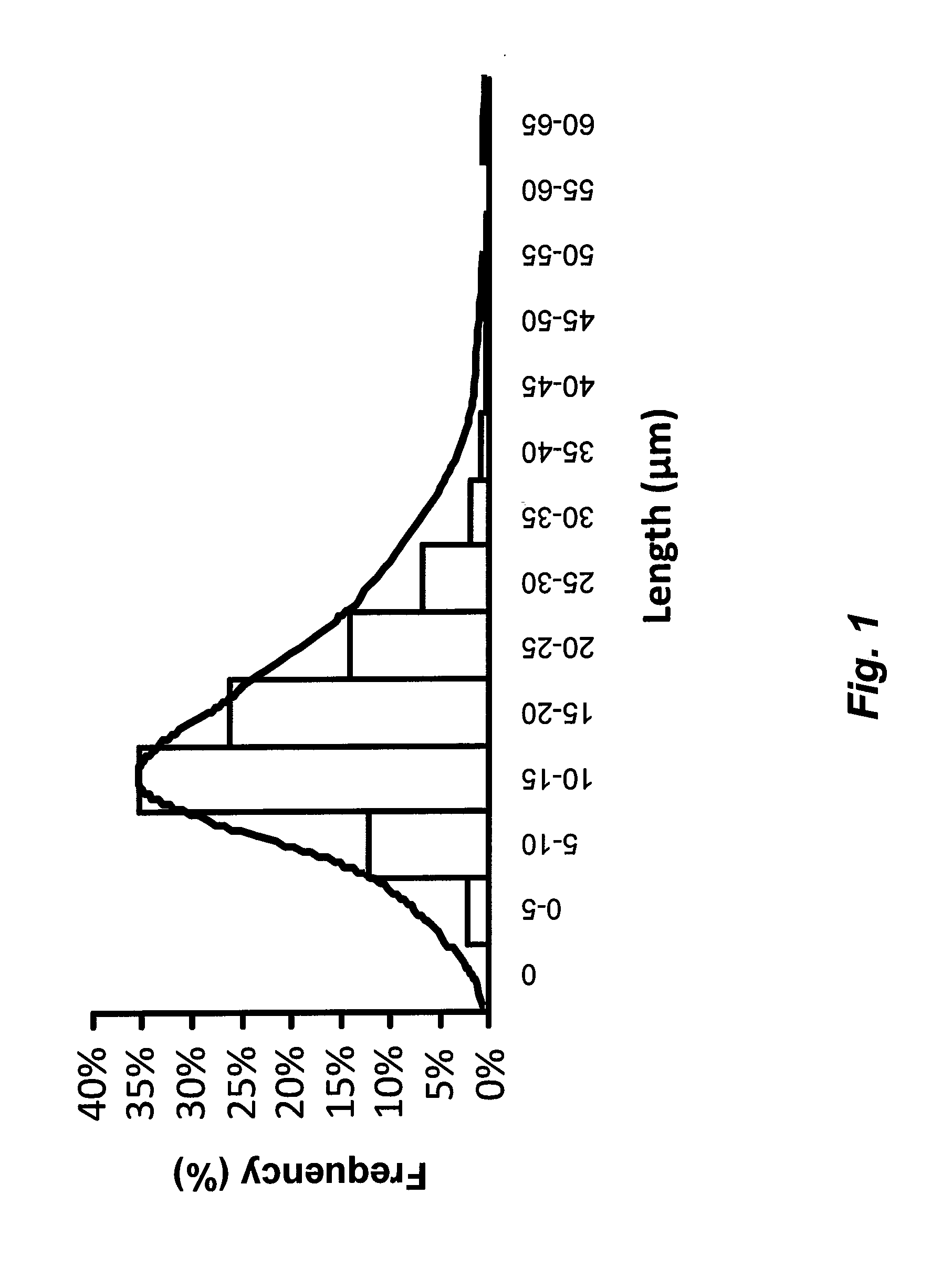

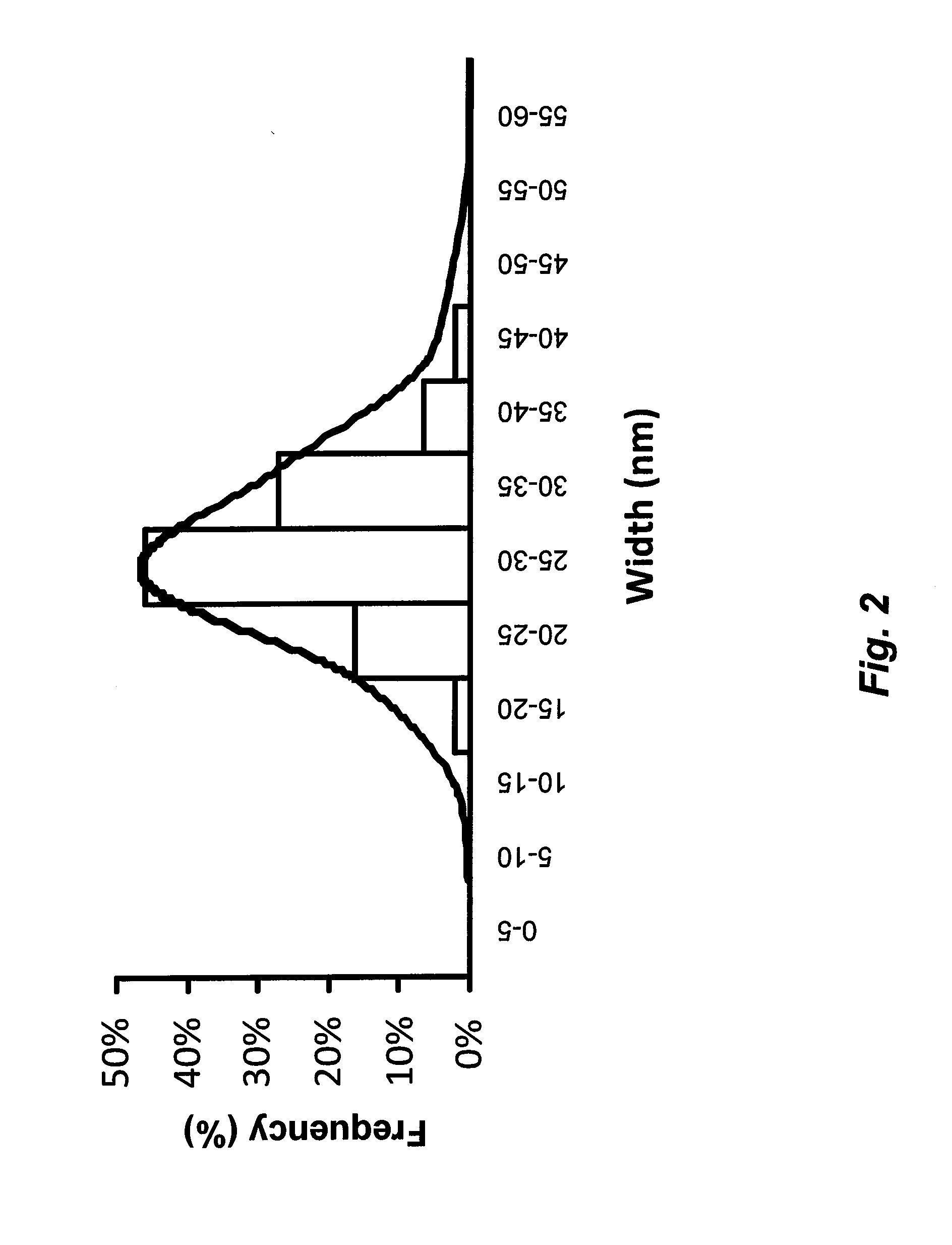

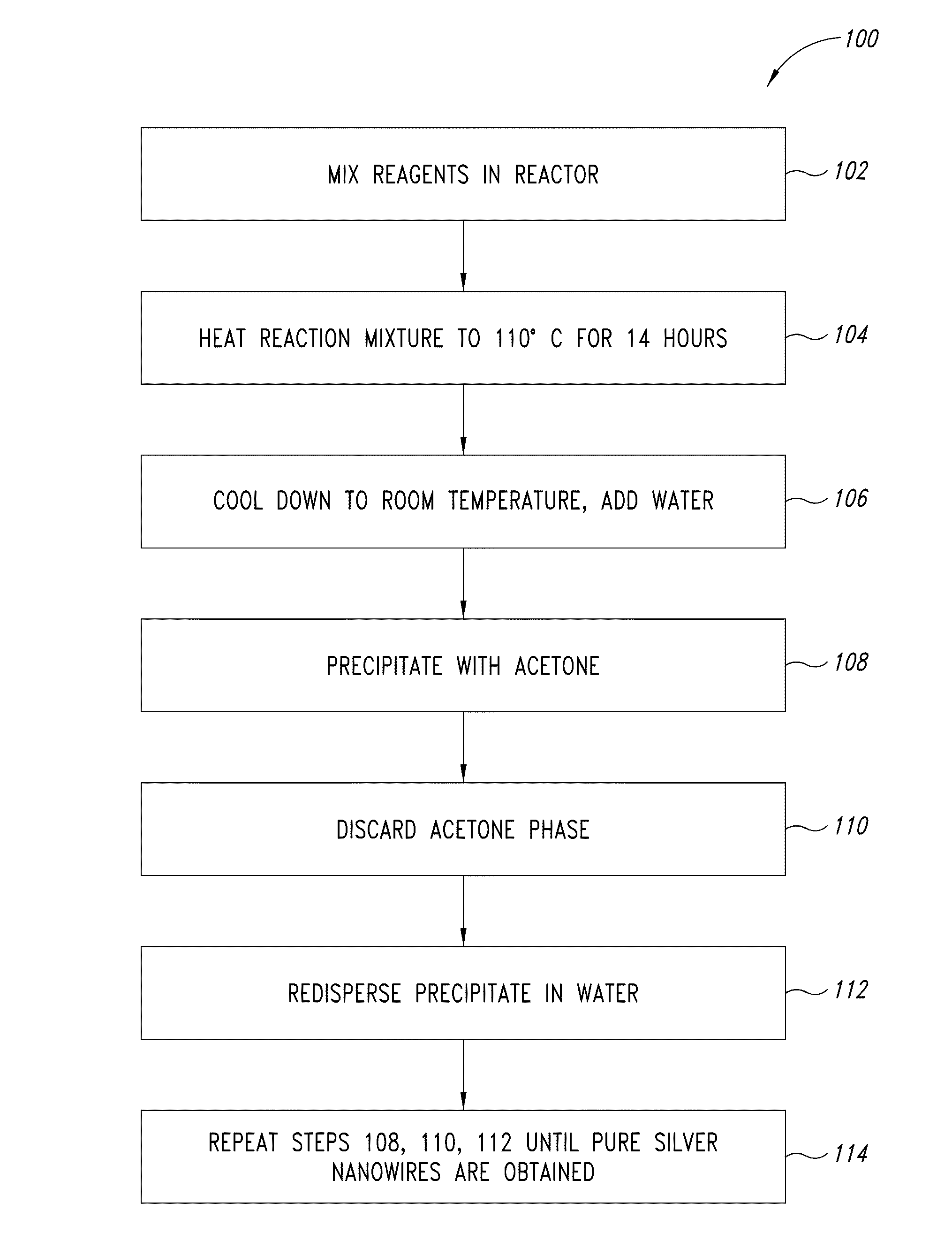

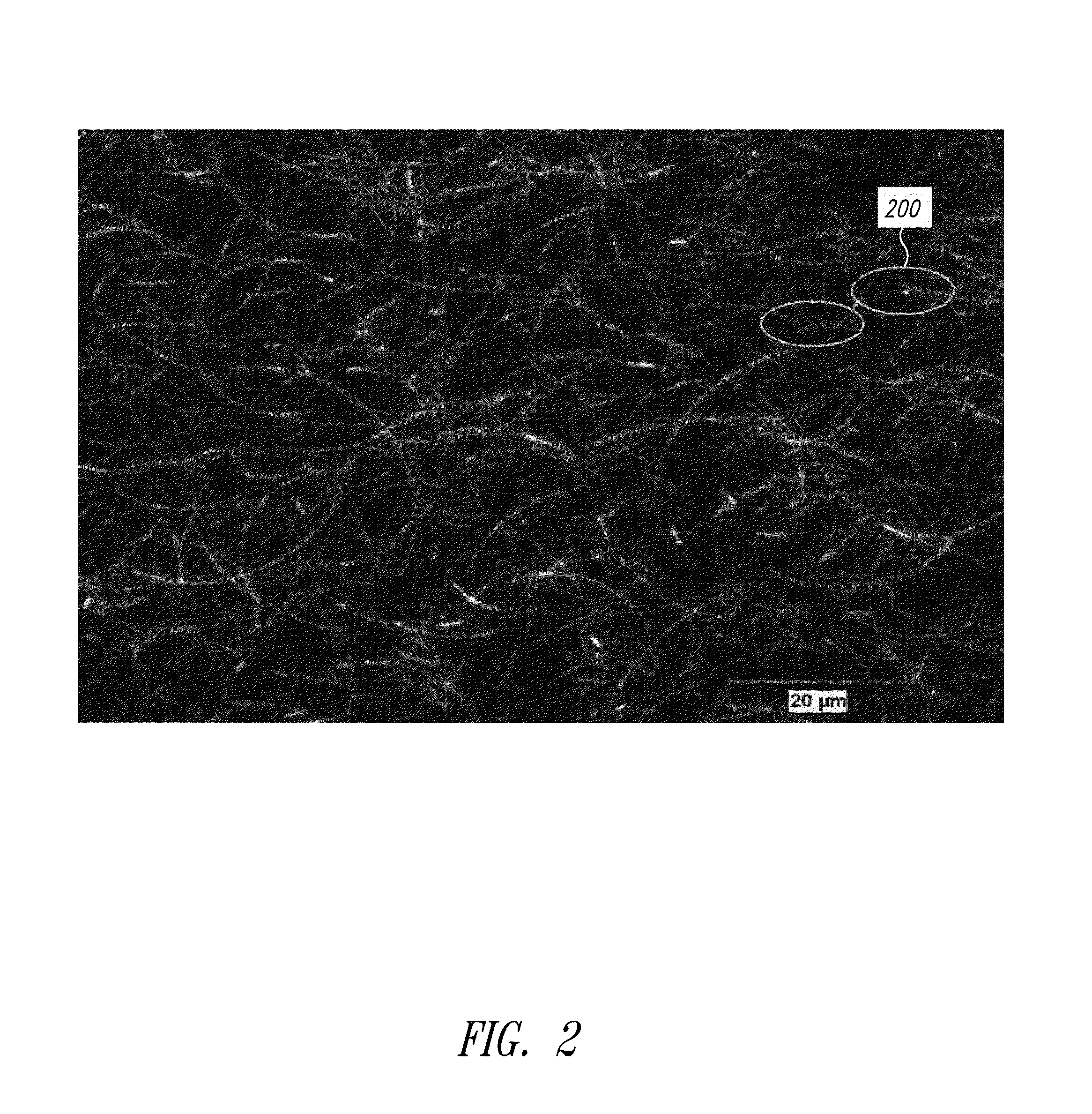

Purification of metal nanostructures for improved haze in transparent conductors made from the same

InactiveUS20110045272A1Material nanotechnologyConductive layers on insulating-supportsMetal nanowiresNanometre

Provided are a method of isolating and purifying metal nanowires from a crude and complex reaction mixture that includes relatively high aspect ratio nanostructures as well as nanostructures of low aspect ratio shapes, and conductive films made of the purified nanostructures.

Owner:CHAMP GREAT INTL

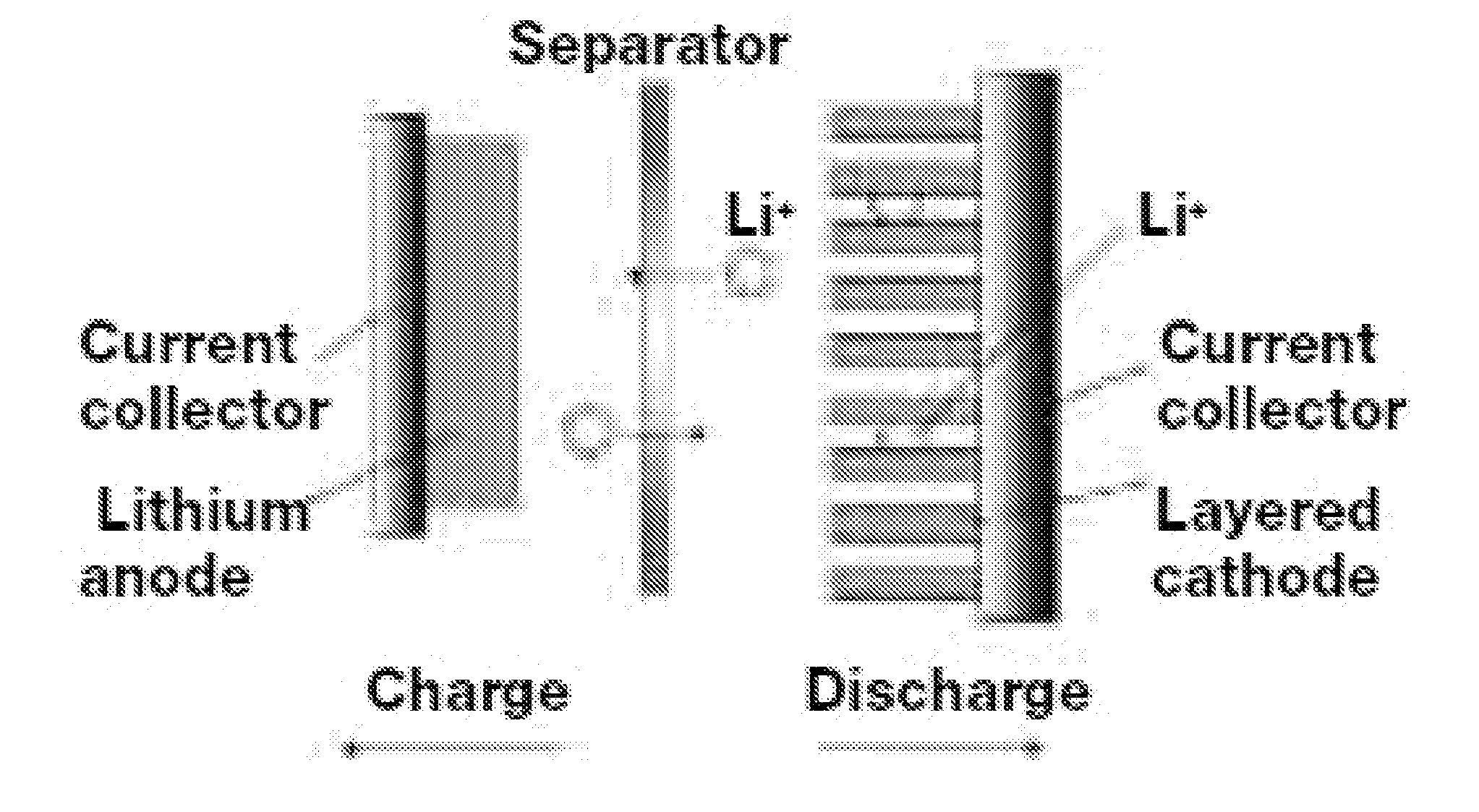

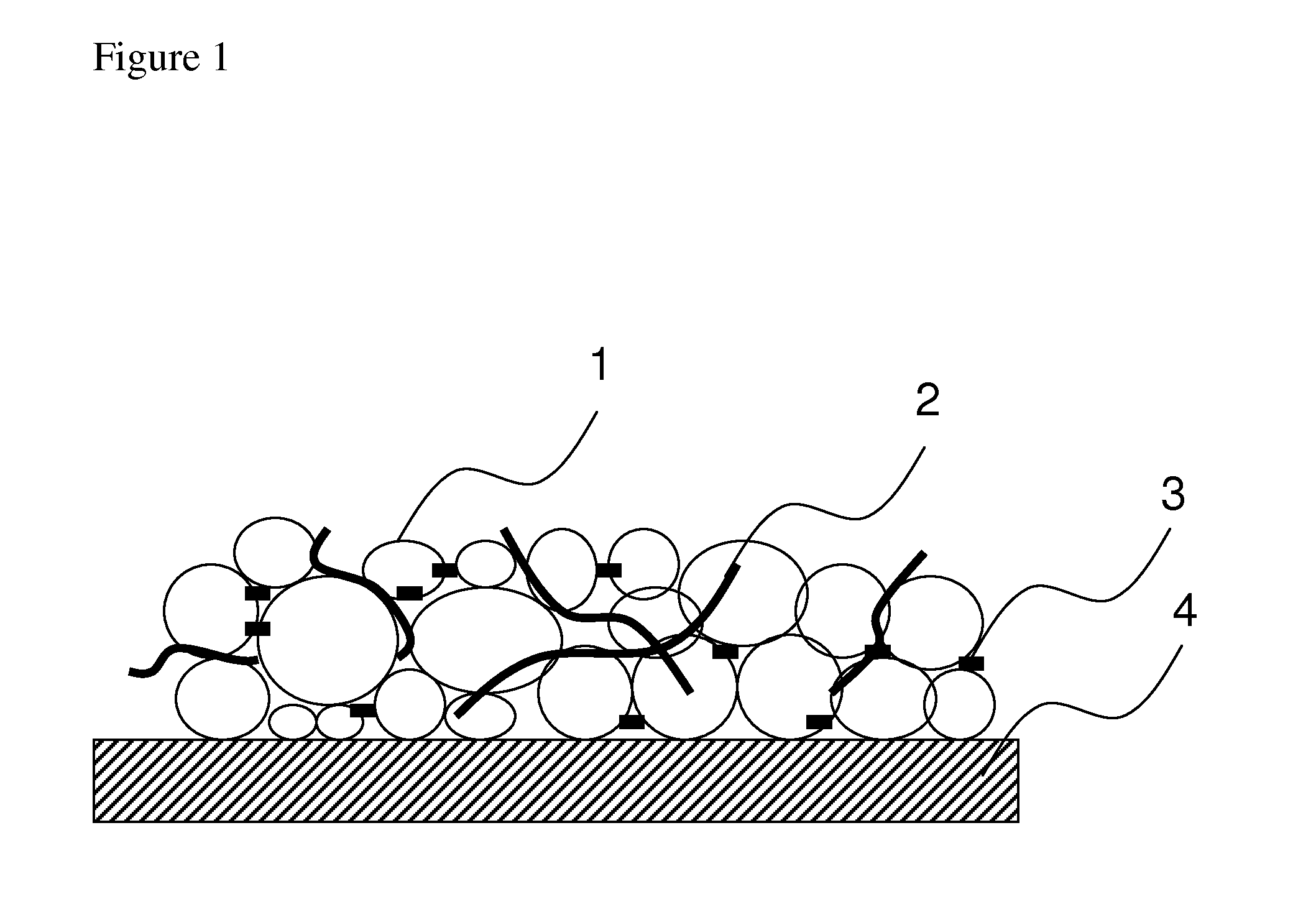

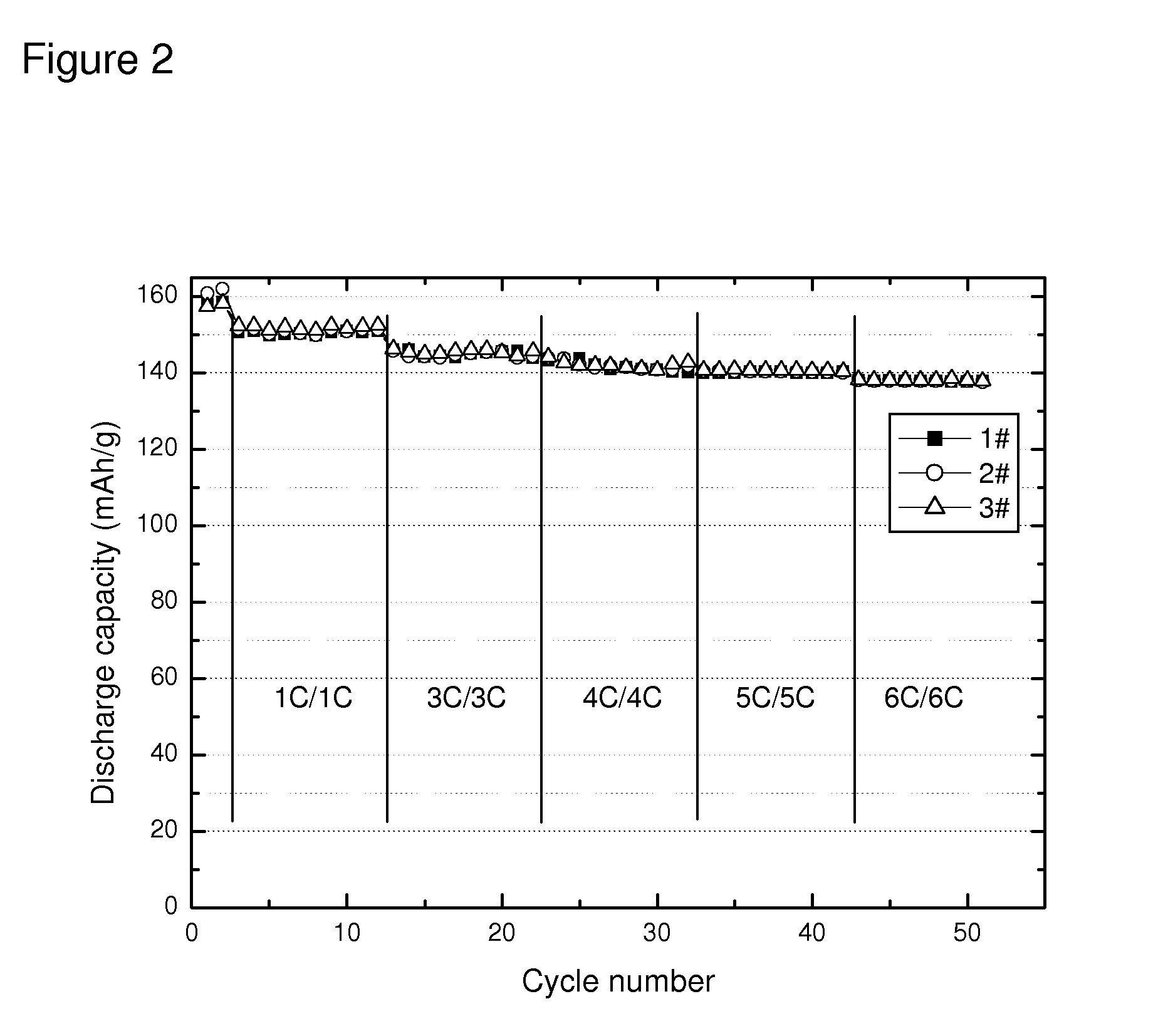

Enhanced Electrode Composition for Li ion Battery

InactiveUS20110171371A1Less filler loadingLess loadNon-metal conductorsMaterial nanotechnologyCarbon nanotubeLithium-ion battery

Carbon nanotube-based compositions and methods of making an electrode for a Li ion battery are disclosed. It is an objective of the instant invention to disclose a composition for preparing an electrode of a lithium ion battery with incorporation of carbon nanotubes with more active material by having less conductive filler loading and less binder loading such that battery performance is enhanced.

Owner:JIANGSU CNANO TECHNOLOGY CO LTD

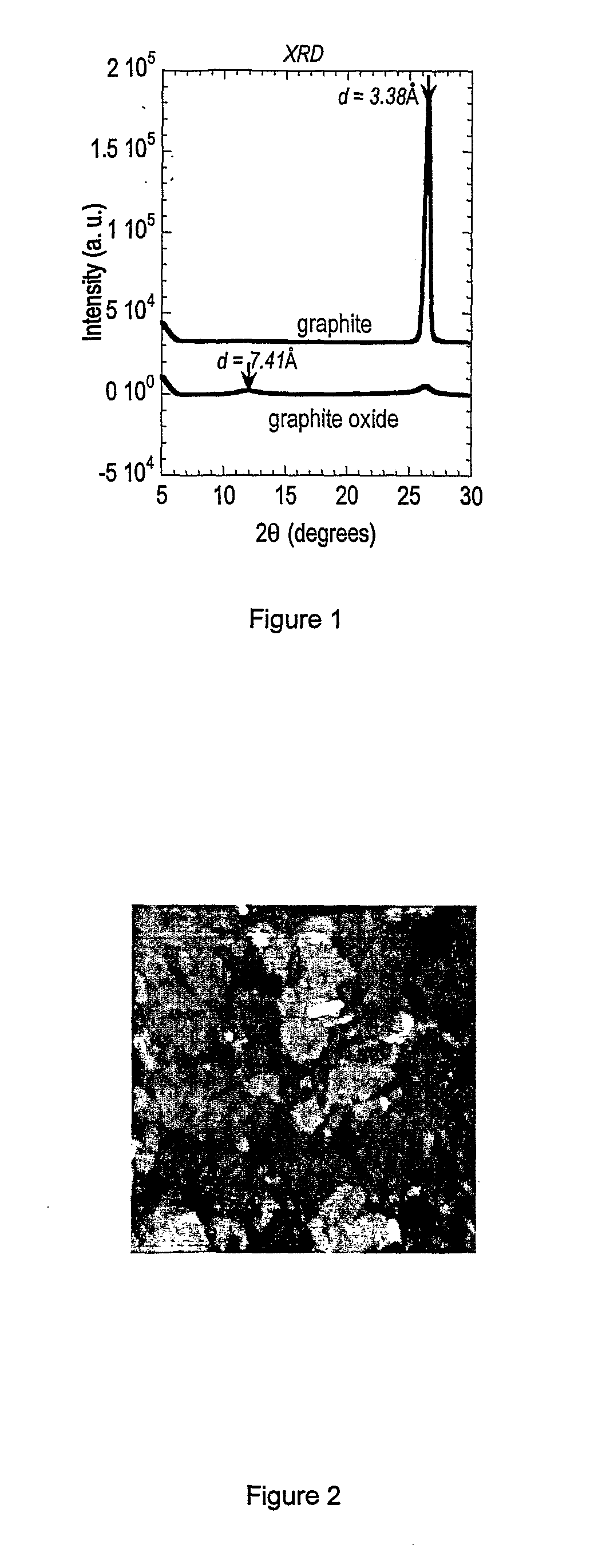

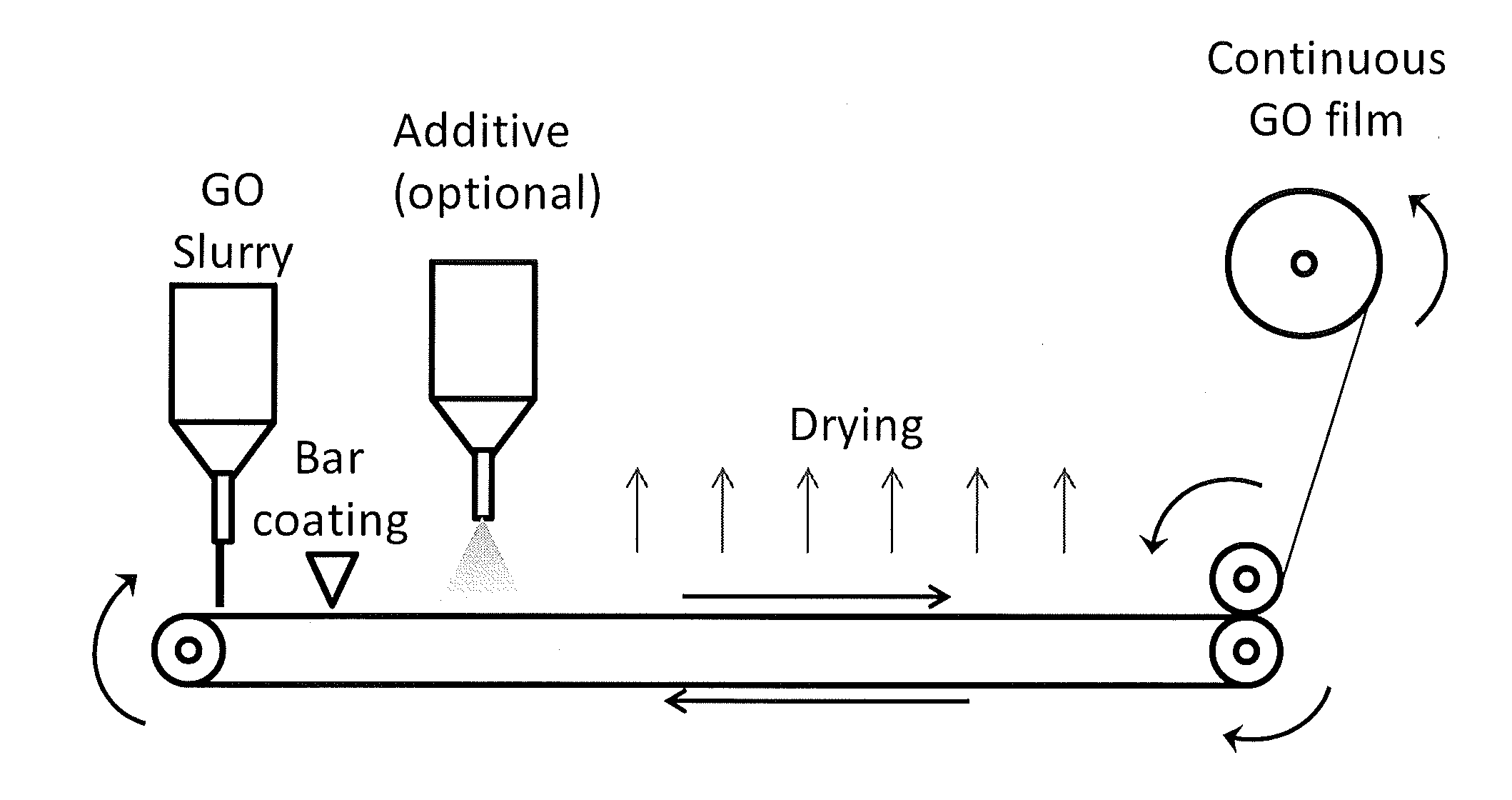

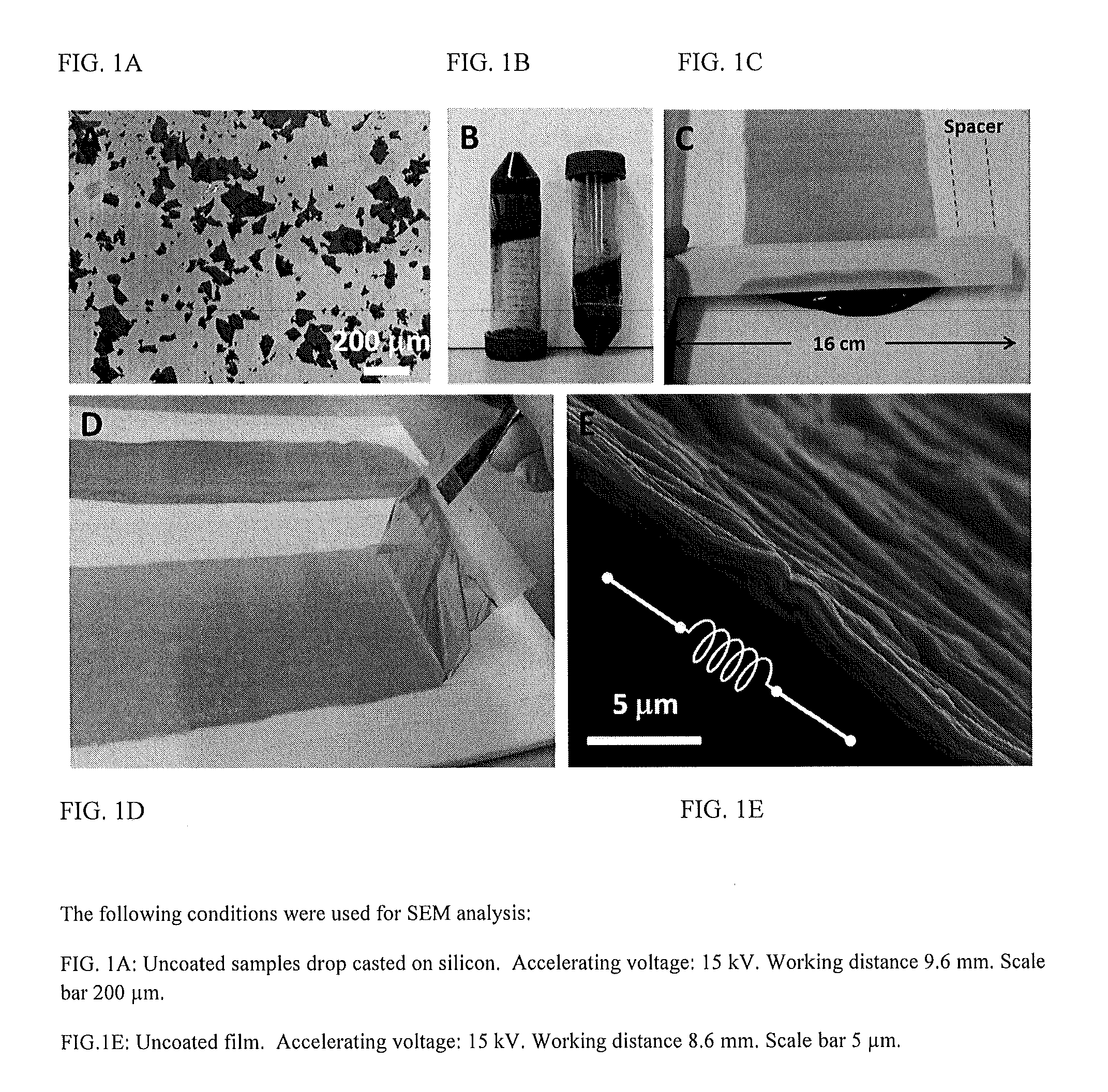

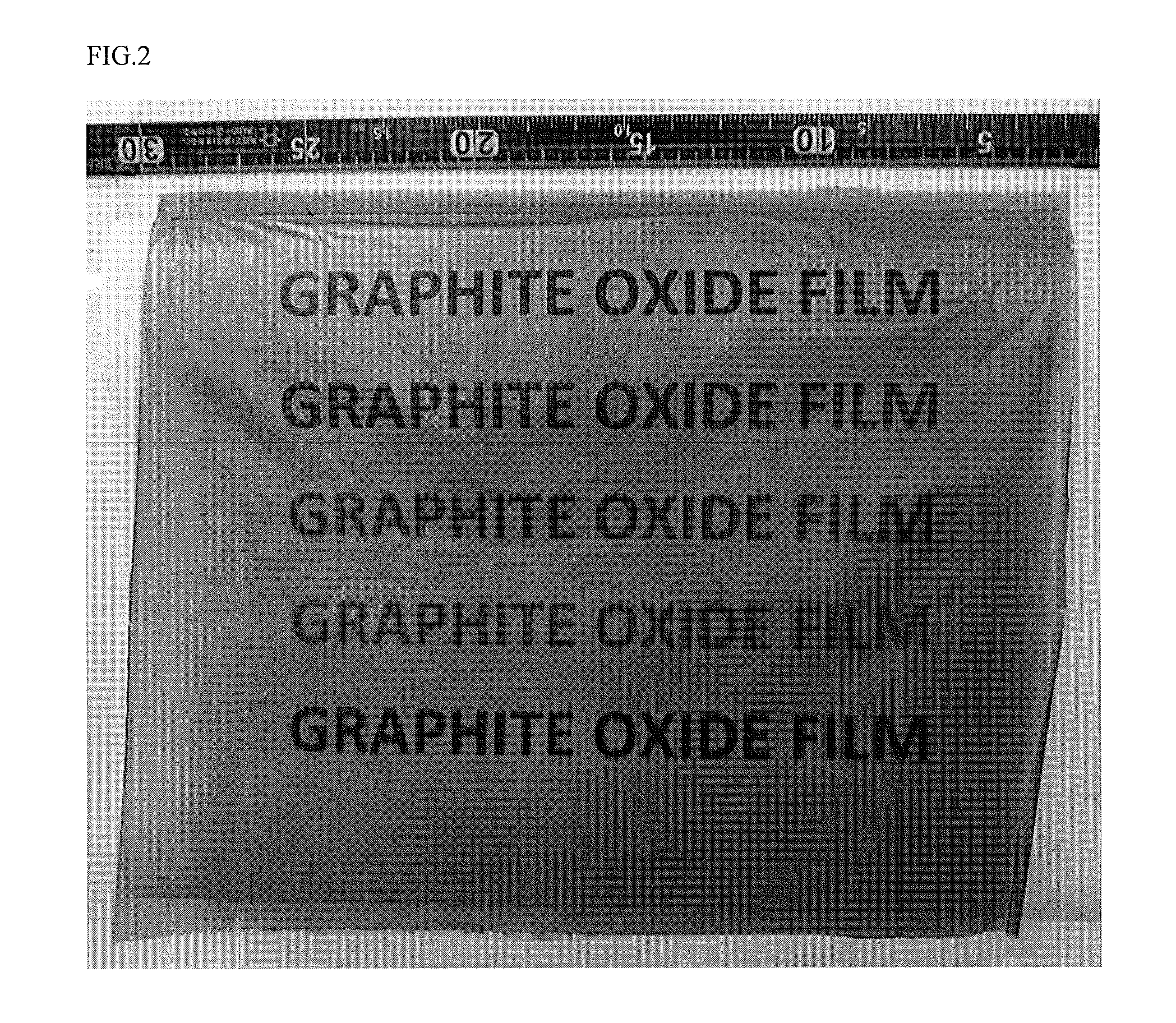

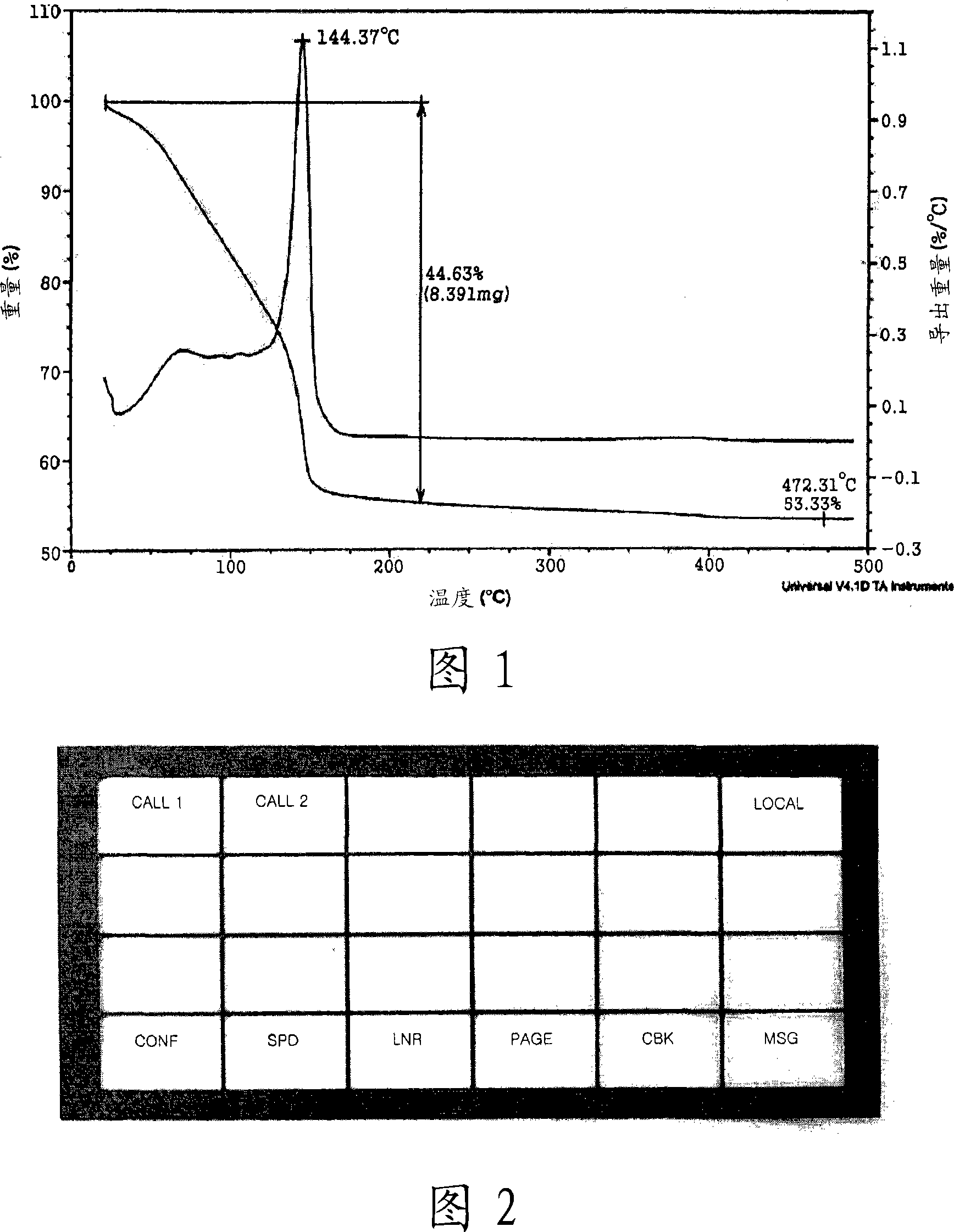

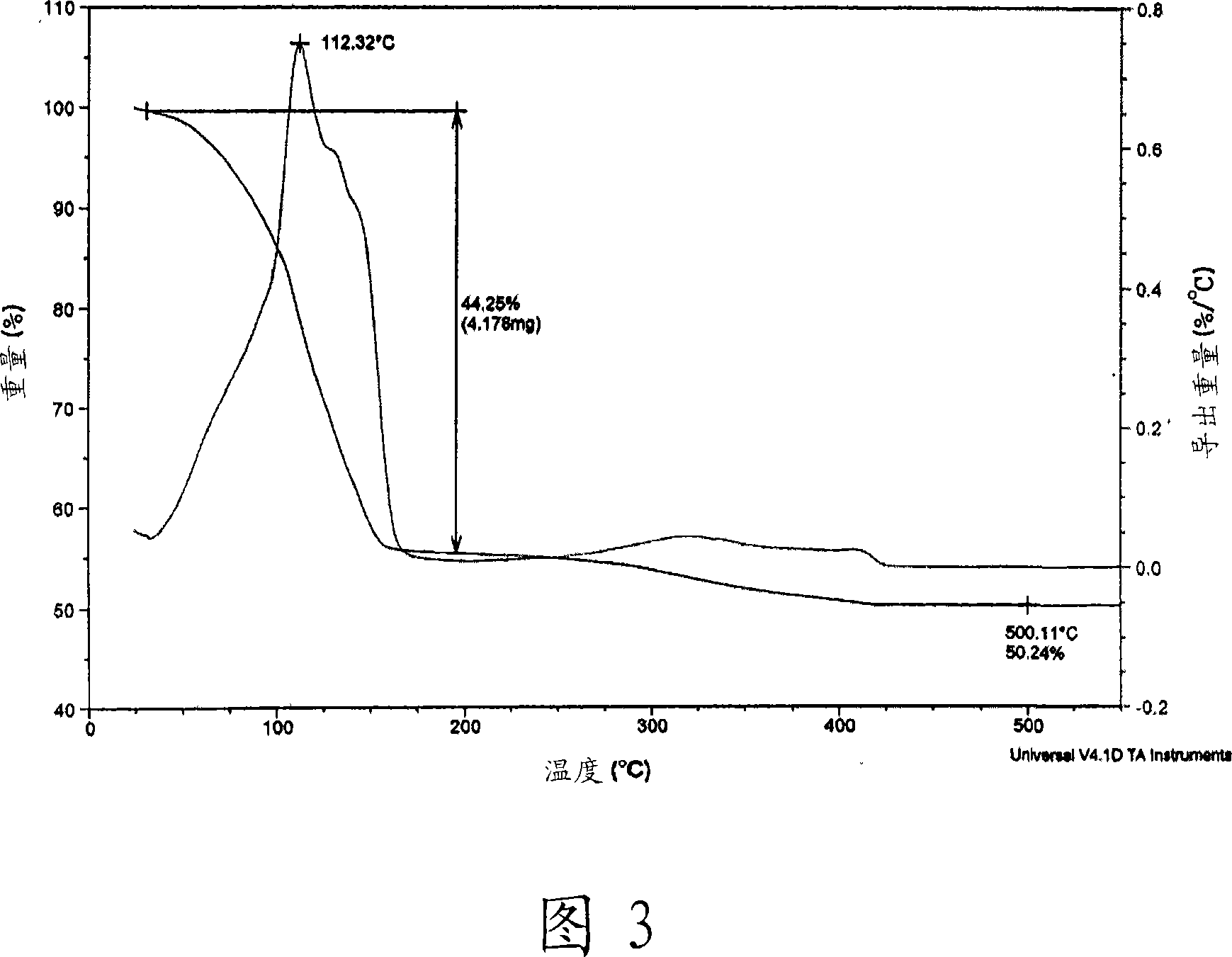

Method for preparing graphene oxide films and fibers

ActiveUS20150111449A1Improve conductivityHigh densityCarbon compoundsFilament/thread formingFiberSolid content

We report a method of preparation of highly elastic graphene oxide films, and their transformation into graphene oxide fibers and electrically conductive graphene fibers by spinning. Methods typically include: 1) oxidation of graphite to graphene oxide, 2) preparation of graphene oxide slurry with high solid contents and residues of sulfuric acid impurities. 3) preparation of large area films by bar-coating or dropcasting the graphene oxide dispersion and drying at low temperature. 4) spinning the graphene oxide film into a fiber, and 5) thermal or chemical reduction of the graphene oxide fiber into an electrically conductive graphene fiber. The resulting films and fiber have excellent mechanical properties, improved morphology as compared with current graphene oxide fibers, high electrical conductivity upon thermal reduction, and improved field emission properties.

Owner:PENN STATE RES FOUND +1

Conductive inks and manufacturing method thereof

The present invention relates to a variety of conductive ink compositions comprising a metal complex compound having a special structure and an additive and a method for preparing the same, more particularly to conductive ink compositions comprising a metal complex compound obtained by reacting a metal or metal compound with an ammonium carbamate- or ammonium carbonate-based compound and an additive and a method for preparing the same.

Owner:INKTEC CO LTD

Conductive carbon film based on graphene as well as preparation method and application

InactiveCN101474898AForm evenlySimple processMaterial nanotechnologyCarbon compoundsCarbon filmFilm base

The invention relates to a general conductive carbon film based on Graphene and a preparation method. The method for preparing the carbon film mainly comprises the following steps: (1) preparing water-soluble single-layer or multi-layer grapheme; (2) preparing organic soluble single-layer or multi-layer Graphene; (3) shaping the solution (or dispersion liquid) containing the Graphene in 1 or 2 by methods of spin coating, spraying, soaking or casting and the like to prepare a film based on the single-layer or multi-layer Graphene; and (4) chemically reducing or roasting the film obtained in 3 to prepare the carbon film based on the single-layer or multi-layer Graphene. The method can be used for preparing the carbon film on various matrixes such as steel, glass, ceramics, quartz, carbon materials, organic substances and the like.

Owner:NANKAI UNIV

Coating material for protecting metals, especially steel, from corrosion and/or scaling, method for coating metals and metal element

InactiveCN101360796AVarious usabilityImprove conductivityPretreated surfacesAnti-corrosive paintsAfter treatmentSpot welding

The invention surprisingly finds that when a suitable binder including a suitable filler is used during the high temperature treatment of a curing process, the coating materials of the invention change in such a manner that electrically conducting reactive layers are formed that allow welding and especially spot welding together with the metal substrate even after treatment at temperatures of more than 800 DEG C.

Owner:NANOX

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com