Conductive heat-conductive graphene slurry and coating

A technology of electrical and thermal conductivity and graphene, applied in the field of materials, can solve the problems of low resistance, poor chemical stability, and low aspect ratio, and achieve the effects of increased overall adhesion, high resin content, and reduced pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of conductive and heat-conducting graphene slurry and coating thereof, concrete preparation is as follows:

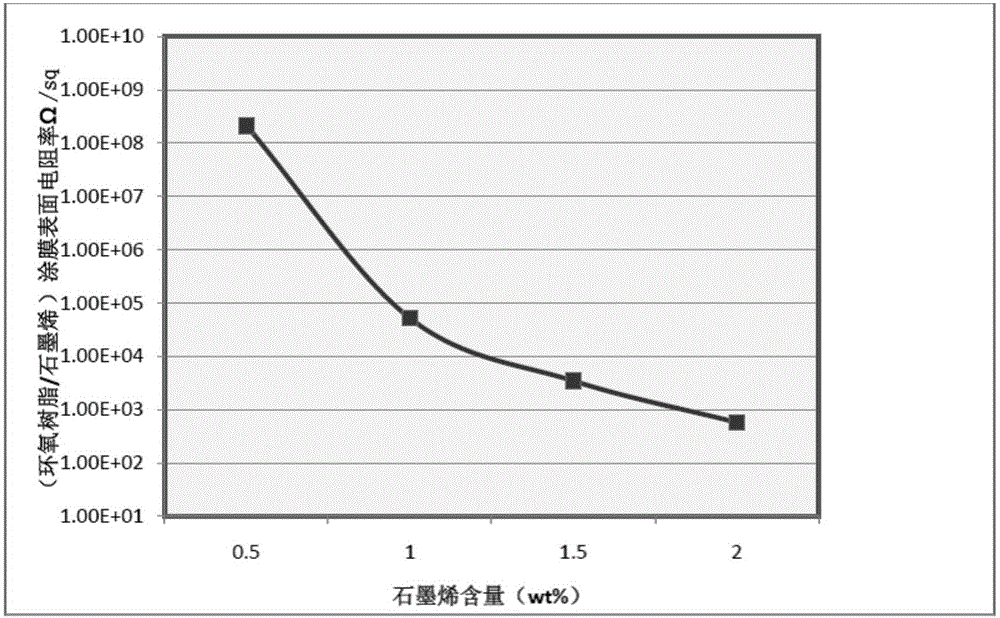

[0032] Take few-layer graphene: 5.3g, epoxy resin E51: 50.0g, organic solvent: 50.0g, after high-speed mixing, stirring, and cleavage, a conductive and heat-conducting graphene slurry is prepared and set aside.

[0033] Take the above-mentioned graphene slurry: 12.8g, 25.0g, 37.5g, 50g; E51 epoxy resin: 50.0g, 45g, 42g, 38g; curing agent EN125: 50g, 45g, 42g, 38g; talcum powder: 20g; Leveling agent: 0.1g; coupling agent: 0.1g; appropriate amount of organic solvent; high-speed mixing uniformly to prepare conductive and thermally conductive coatings.

[0034] Apply the paint, wait for the film to dry, and test the resistivity (see figure 1 ).

Embodiment 2

[0036] A kind of conductive and heat-conducting graphene slurry and coating thereof, concrete preparation is as follows:

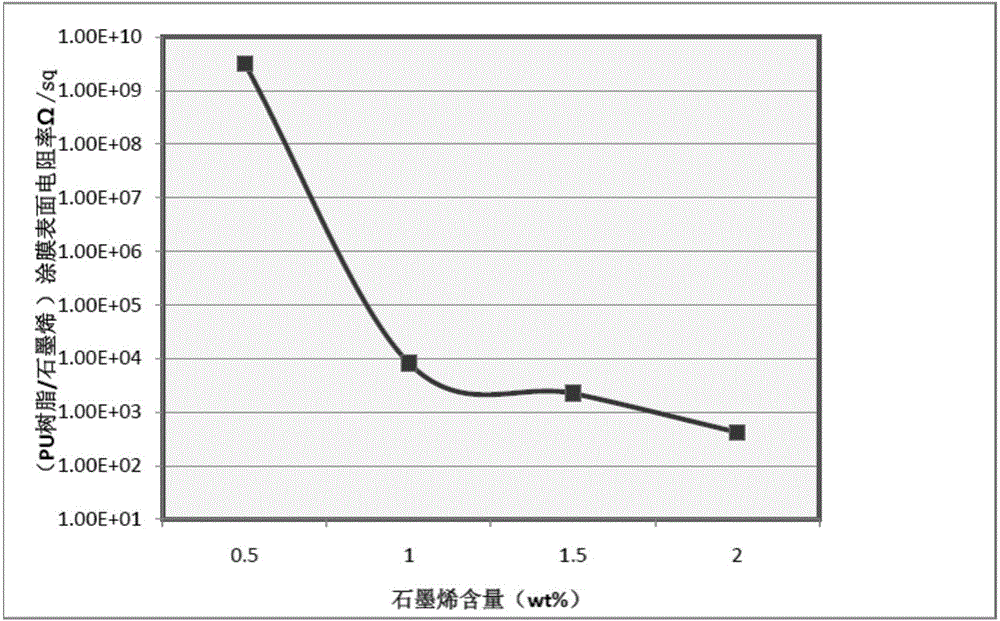

[0037] Take few-layer graphene: 5.3g; polyester polyol 1200: 50.0g; organic solvent: 50.0g; after high-speed mixing, stirring, and cleavage, a conductive and thermally conductive graphene slurry is prepared for future use.

[0038] Take the above-mentioned few-layer graphene slurry: 2.8g, 25.0g, 37.5g, 50g; polyester polyol 1200: 50.0g, 45g, 42g, 38g; curing agent N3390: 50g, 45g, 42g, 38g; talcum powder : 20g; leveling agent: 0.1g; coupling agent: 0.1g; appropriate amount of organic solvent mixed evenly at high speed to prepare conductive and thermally conductive coating.

[0039] Apply the paint, wait for the film to dry, and test the resistivity (see figure 2 ).

Embodiment 3

[0041] A kind of conductive and heat-conducting graphene slurry and coating thereof, concrete preparation is as follows:

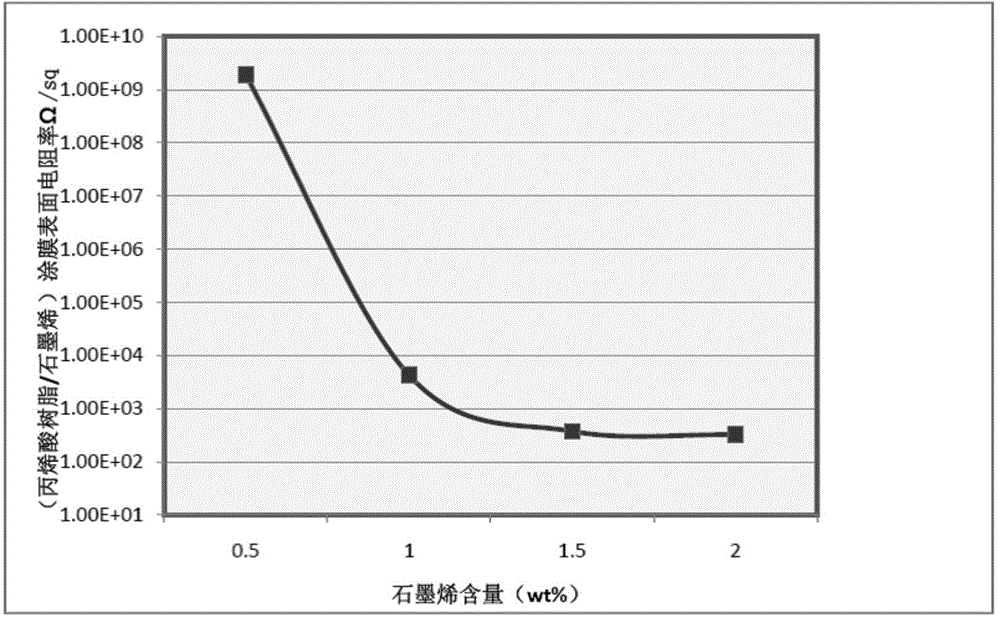

[0042] Take few-layer graphene: 5.3g; hydroxyacrylic acid A160: 50.0g; organic solvent: 50.0g, mix and stir at a high speed, and cleavage to prepare a conductive and thermally conductive graphene slurry for future use.

[0043] Take the above slurry: 12.8g, 25.0g, 37.5g, 50g; hydroxyacrylate A160: 83.3g, 75g, 70g, 63.3g; curing agent N3390: 50g, 45g, 42g, 38g; talcum powder: 20g; Leveling agent: 0.1g; coupling agent: 0.1g; organic solvent: appropriate amount; high-speed mixing evenly; high-speed mixing evenly to prepare a conductive and thermally conductive coating.

[0044] Apply the paint, wait for the film to dry, and test the resistivity (see image 3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com