Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4090results about "Rolls" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

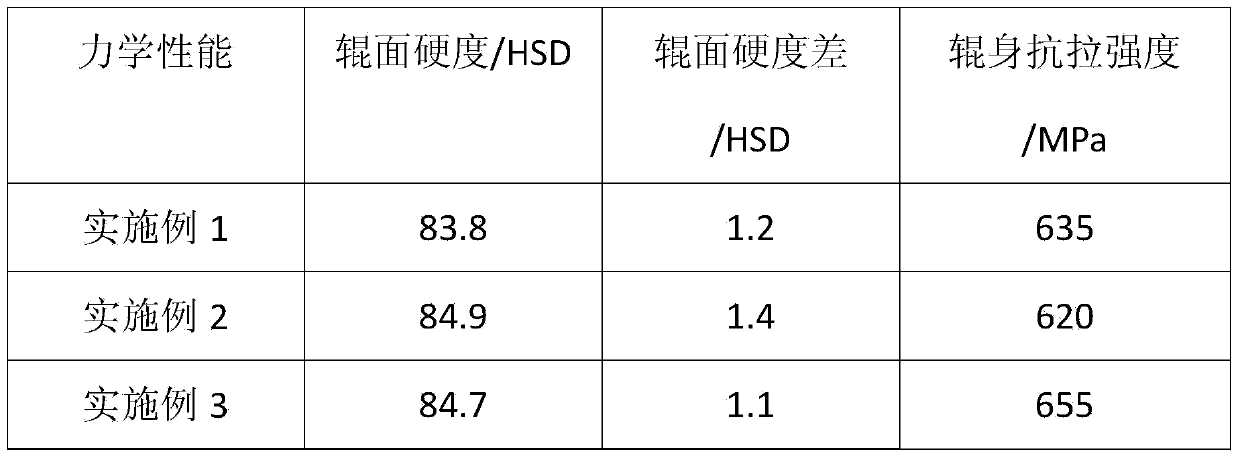

Centrifugal casting high-speed steel composite roll and manufacture method thereof

InactiveCN102615108AGood metallurgical bondHigh strengthRollsMetal rolling arrangementsNiobiumEconomic benefits

The invention relates to a centrifugal casting high-speed steel composite roll and a manufacture method thereof and belongs to the field of casting. The composite roll is composed of outer layer high-speed steel, middle layer graphitic steel and core high-strength nodular cast iron by centrifugal compounding. The centrifugal casting high-speed steel composite roll is based on the conventional high-carbon high-vanadium high-speed steel roll, the content of vanadium is appropriately reduced, niobium is added at the same time, and the Nb / V is controlled to be 0.3 to 0.5 so that Nb and V form complex carbide (V, Nb) C so as to avoid forming segregation under the action of centrifugal force. A roll core of the high-speed steel composite roll adopts high-strength nodular cast iron, and a multivariate graphite steel middle layer is poured between an outer layer and the roll core for preventing interfusing elements of Cr, B, and the like which cause embrittlement when the nodular cast iron is poured to be fused with the outer layer high-speed steel. Microalloying processing for refining the organization is carried out on a roll surface high-speed steel material and the middle layer graphitic steel so as to achieve the purpose of improving the thermal cracking capacity of the roll material. The centrifugal casting high-speed steel composite roll has high overall performance, long service life and good economic benefits.

Owner:BEIJING UNIV OF TECH

Fixing device for an image forming apparatus and fixing roller for the same

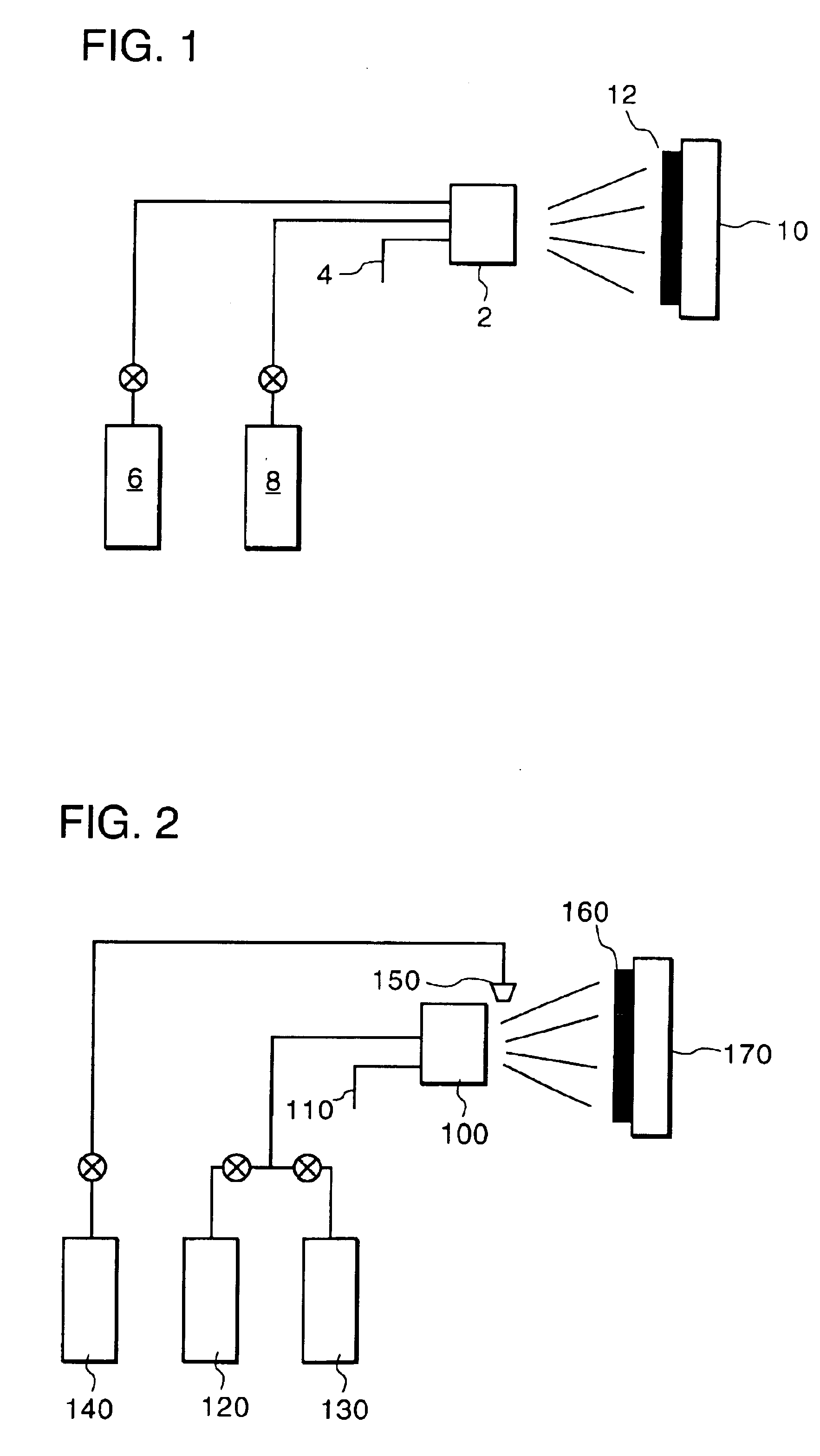

InactiveUS6122479AReduce power consumptionIncreased durabilityShaft and bearingsOhmic-resistance heating detailsElectricityImage formation

In a fixing device for an image forming apparatus, a heat roller includes a hollow cylindrical base, a heating layer formed of strip-like fibers implementing desired power consumption, and a parting layer provided on the outer periphery of the heating layer with the intermediary of an electrical insulating layer. The strip-like fibers of the heating layer are wound on the base and provided with a preselected resistance.

Owner:RICOH KK

Resistive heaters and uses thereof

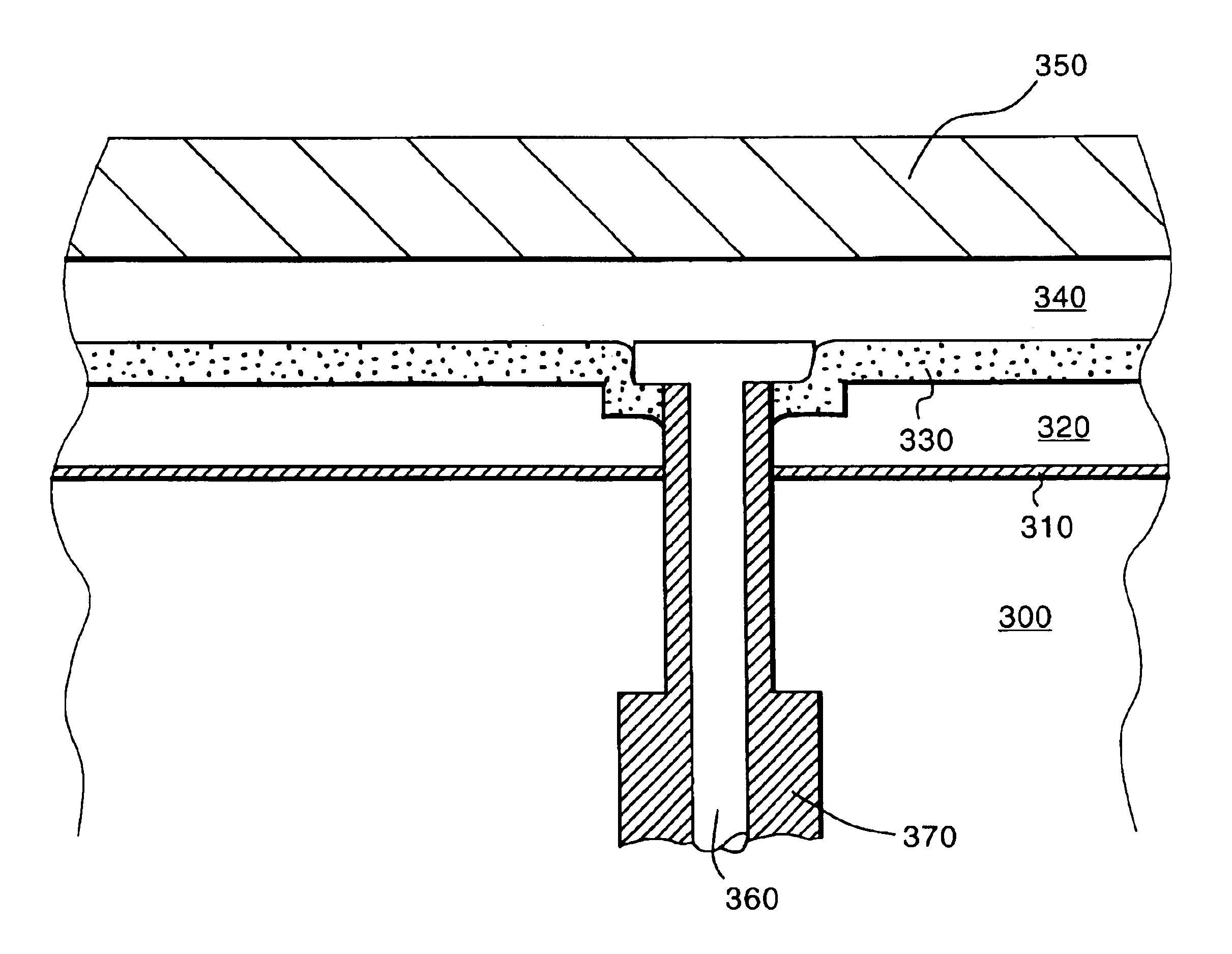

InactiveUS6919543B2Thermally matched wellAvoid bendingMolten spray coatingLinings repairBorideCarbide

A metallic resistive heater and a method of production are described. The resistive heater has a metallic component that is electrically conductive (i.e. has low resistivity) and an oxide, nitride, carbide, and or boride derivative of the metallic component that is electrically insulating (i.e., has high resistivity). The resistivity is controlled by controlling the amount of oxide, nitride, carbide, and boride formation during the deposition of the metallic component and the derivative.

Owner:REGAL WARE

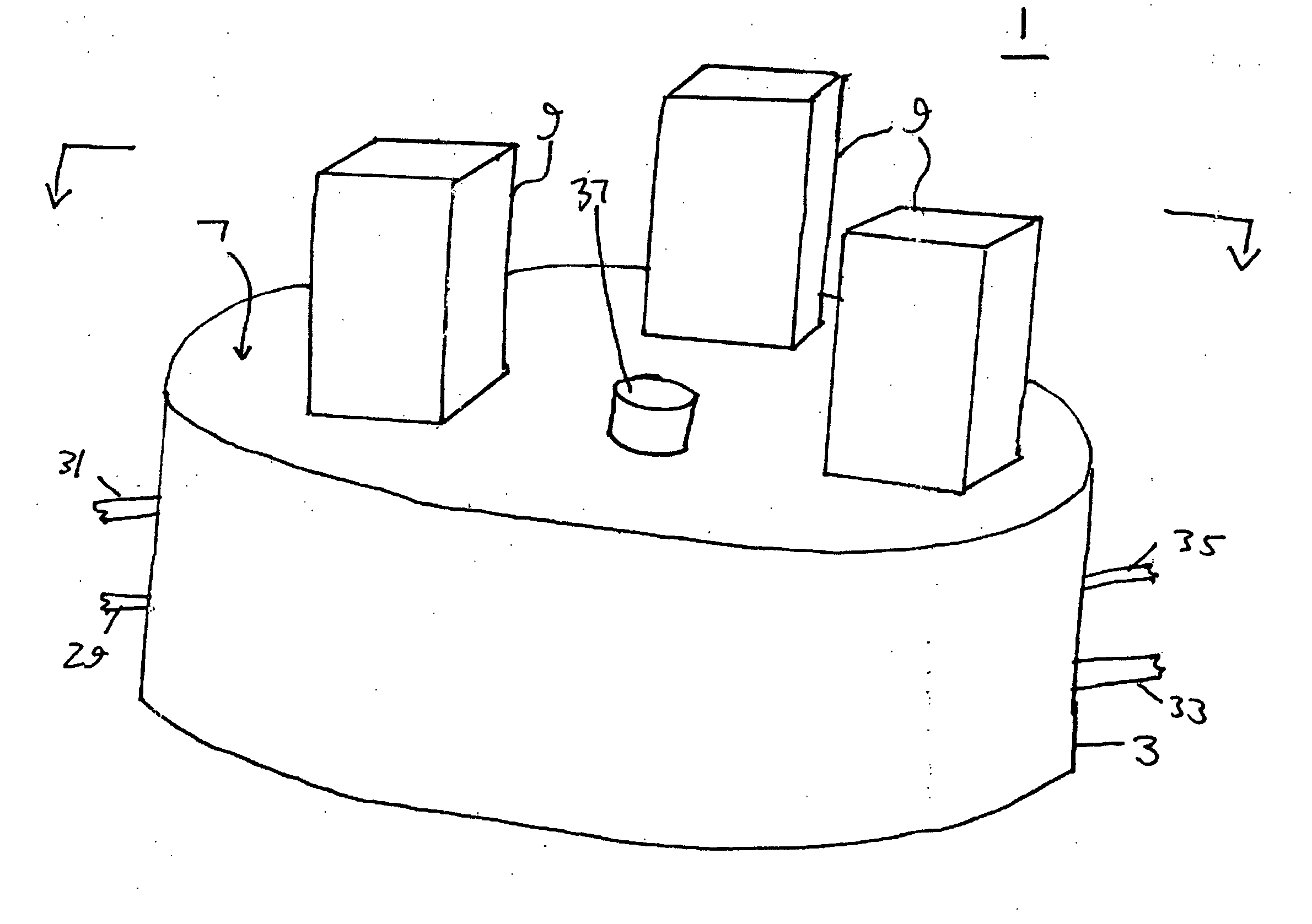

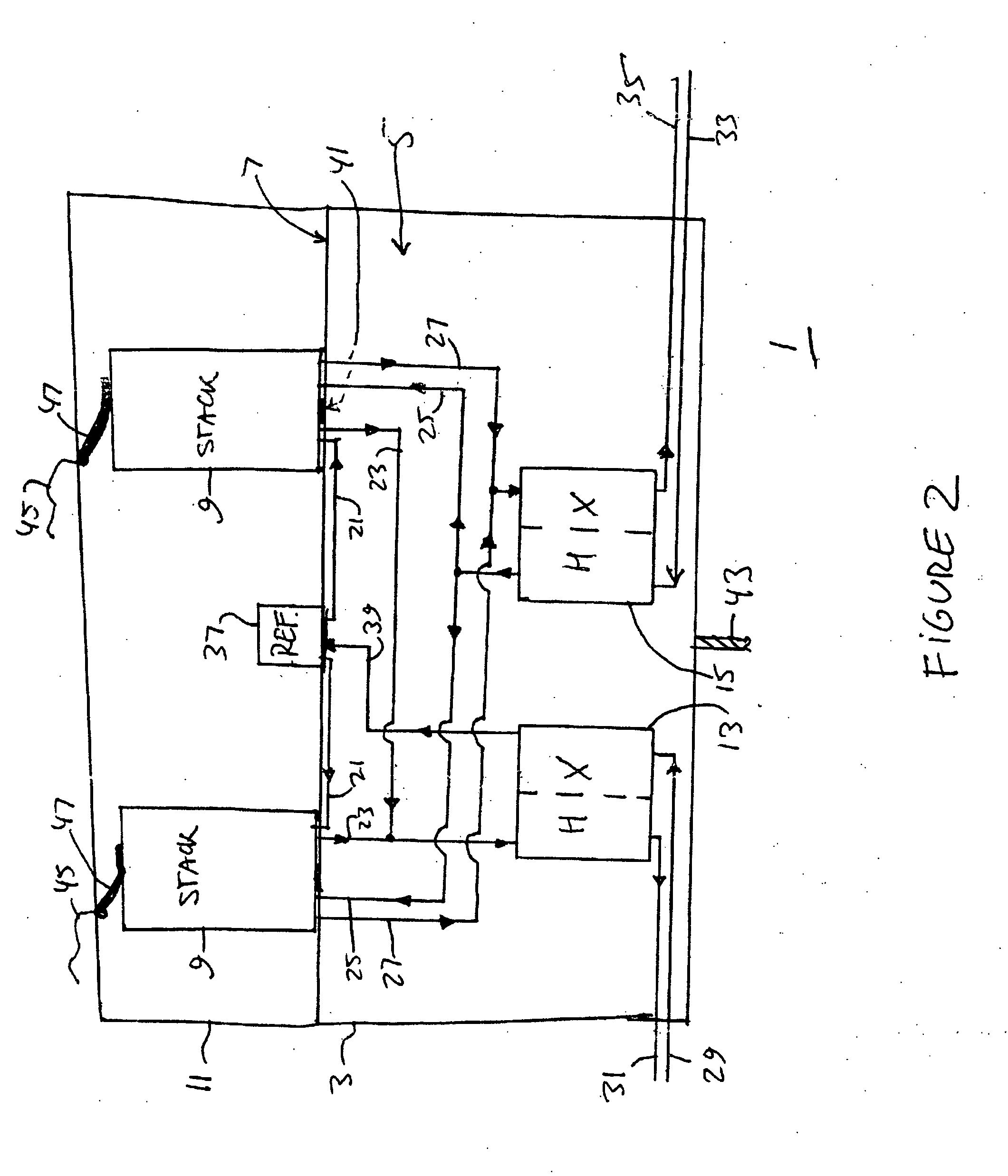

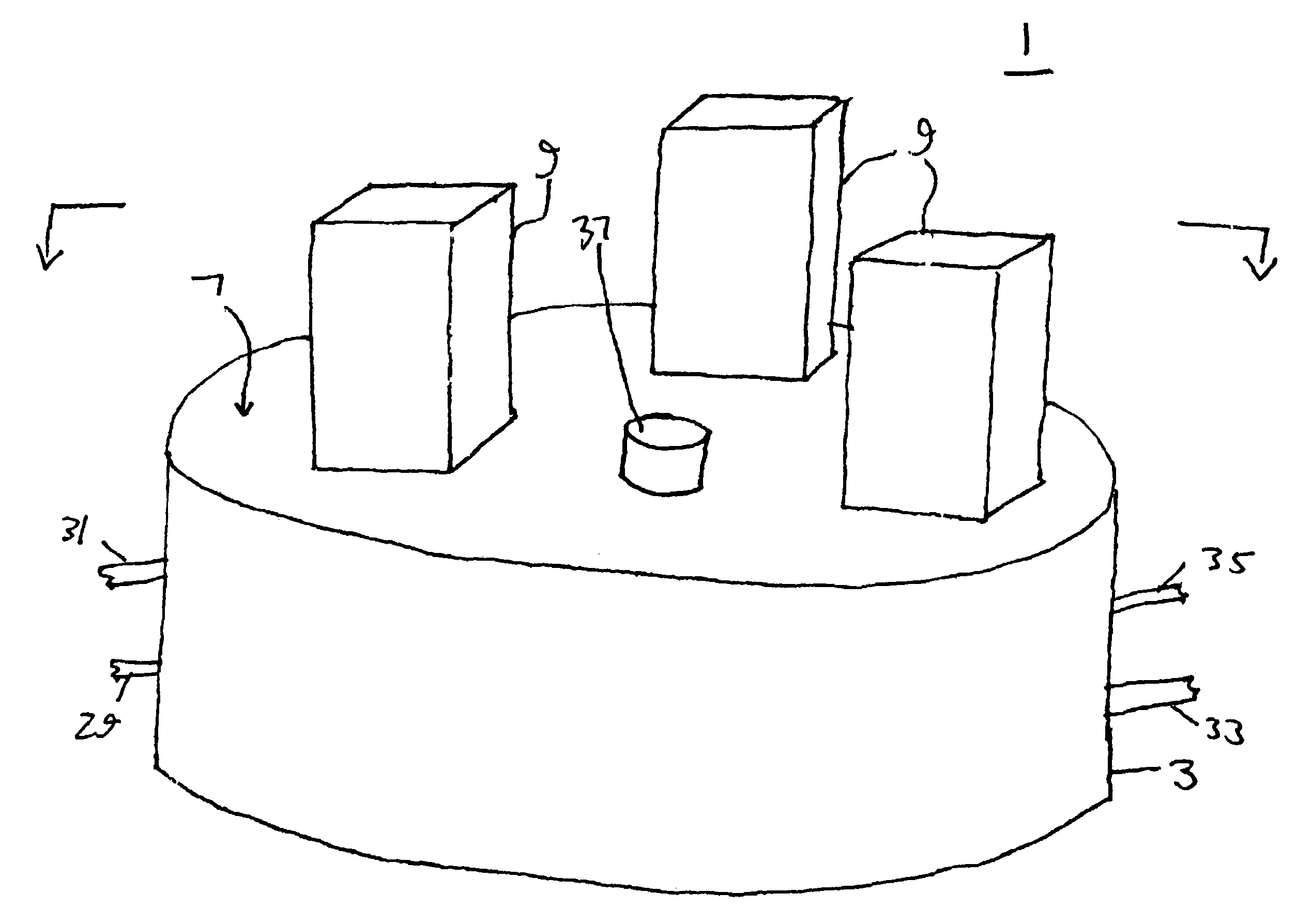

Modular fuel cell system

ActiveUS20110281185A1Improve efficiencyIncrease costFuel cell heat exchangeReactant parameters controlFuel cellsCell system

A fuel cell stack module includes a base, a cover dome removably positioned on the base, and a plurality of fuel cell stacks removably positioned on the base below the cover dome. A modular fuel cell system includes a plurality of the fuel cell stack modules, where each fuel cell stack module may be electrically disconnected, removed from the fuel cell system, repaired or serviced without stopping an operation of the other fuel cell stack modules in the fuel cell system.

Owner:BLOOM ENERGY CORP

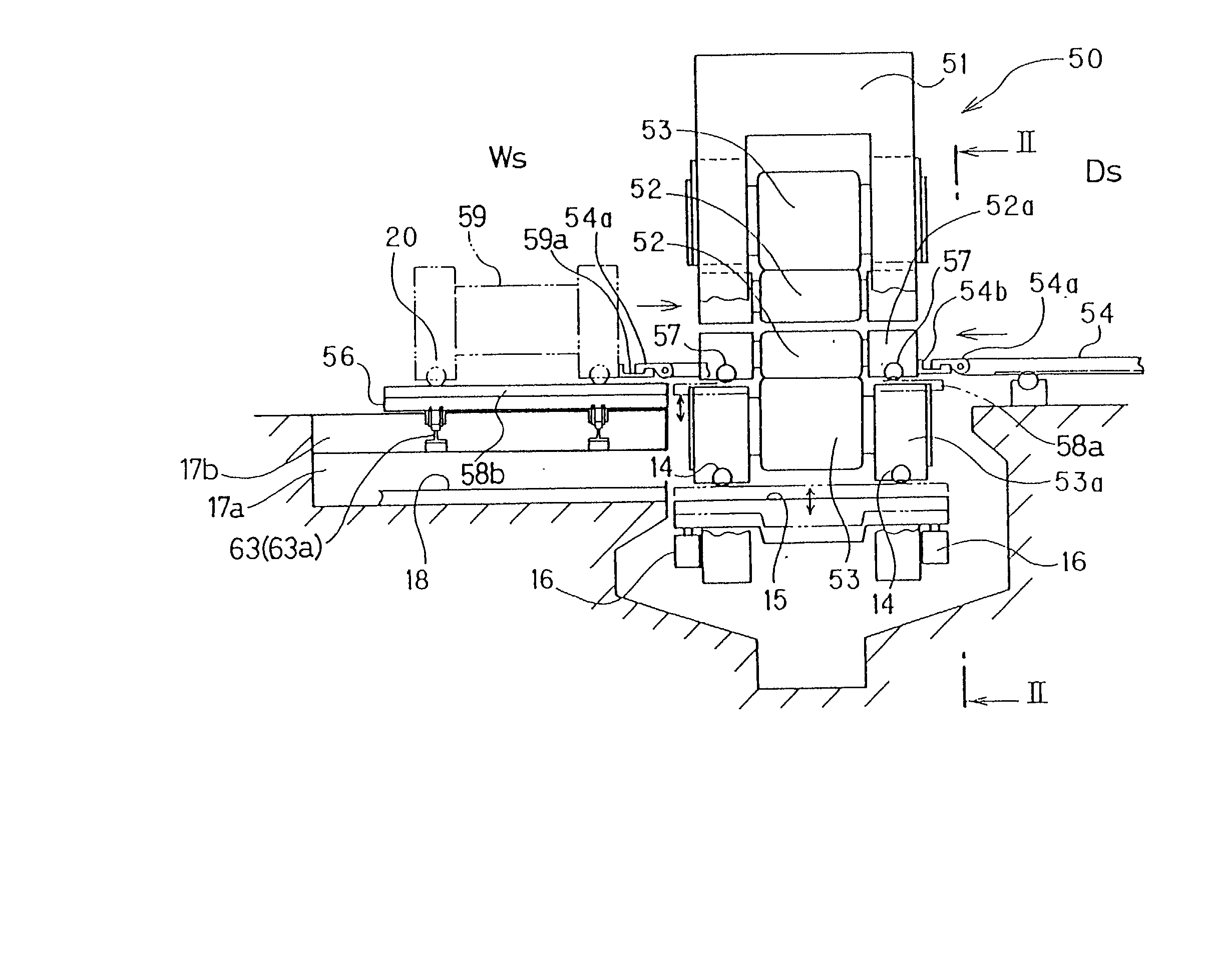

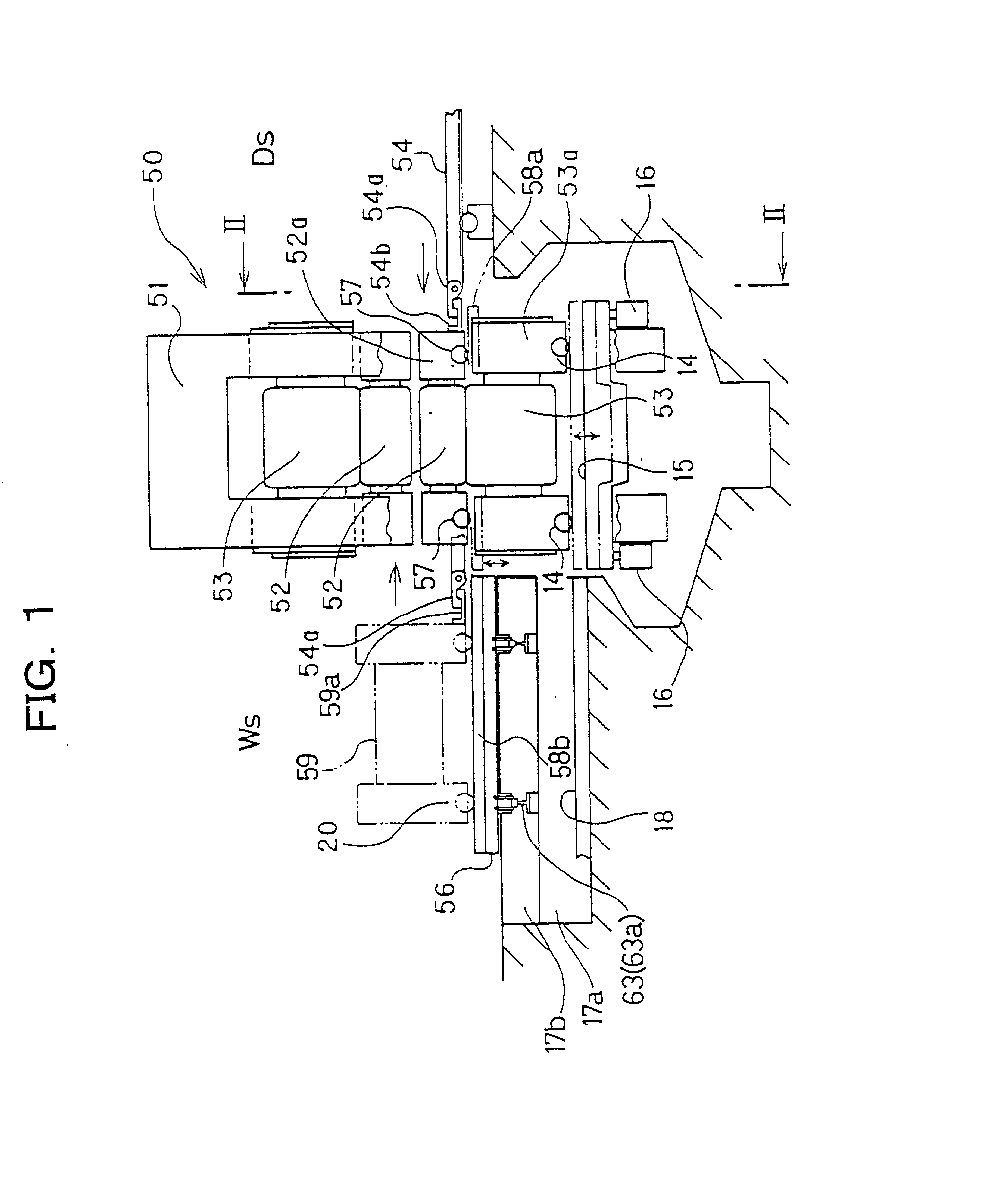

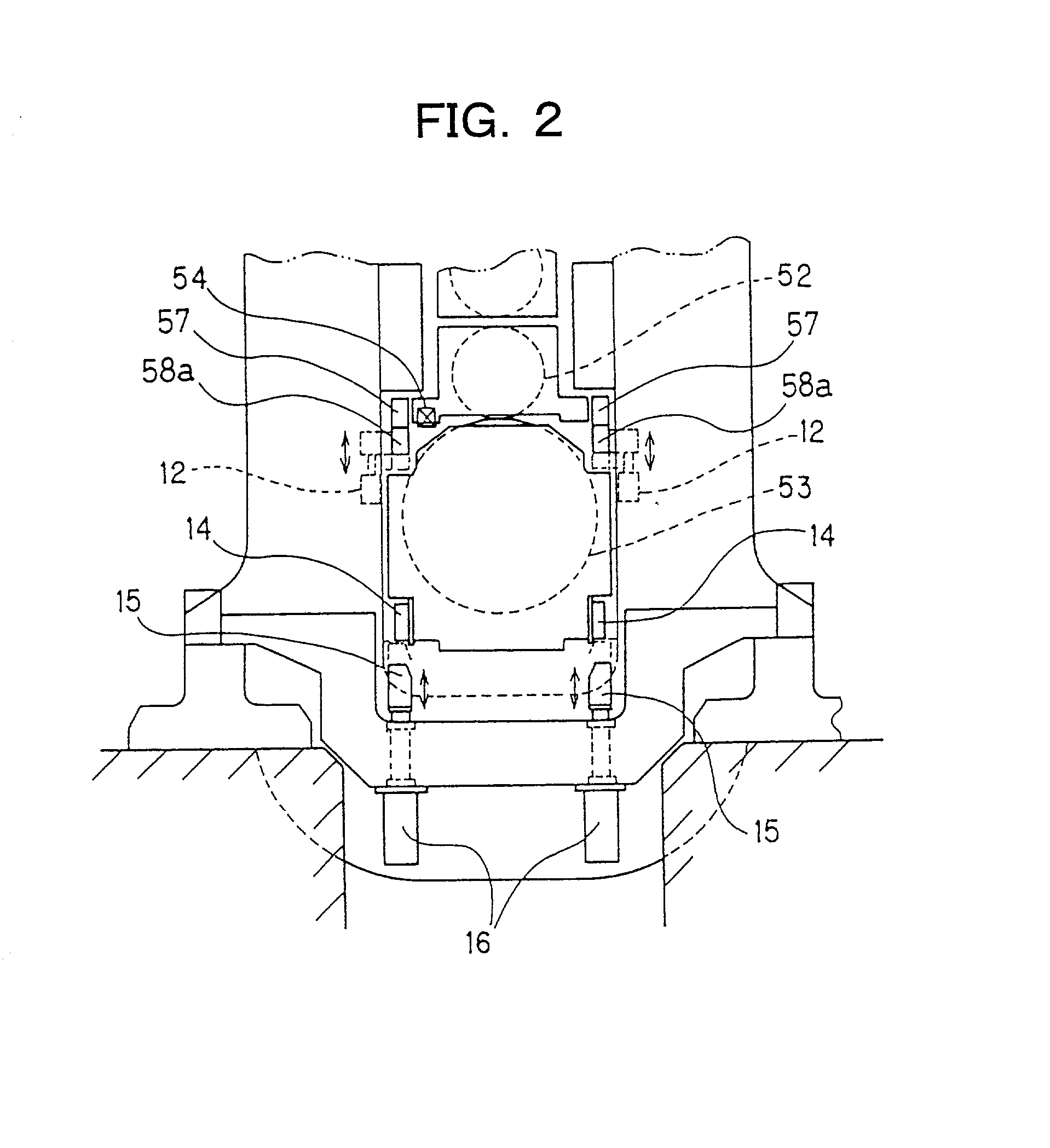

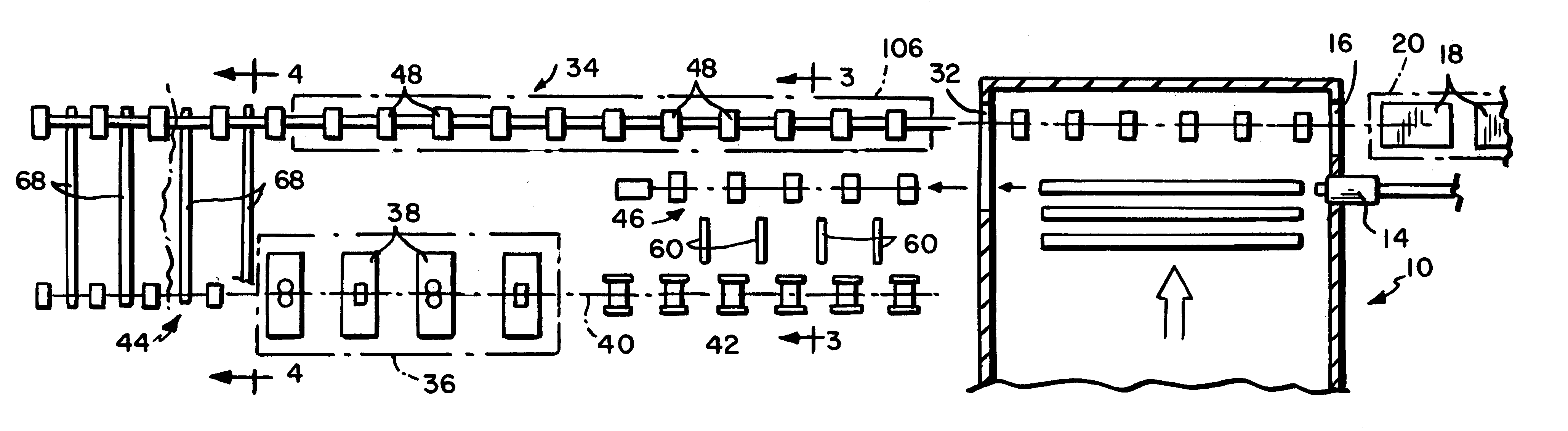

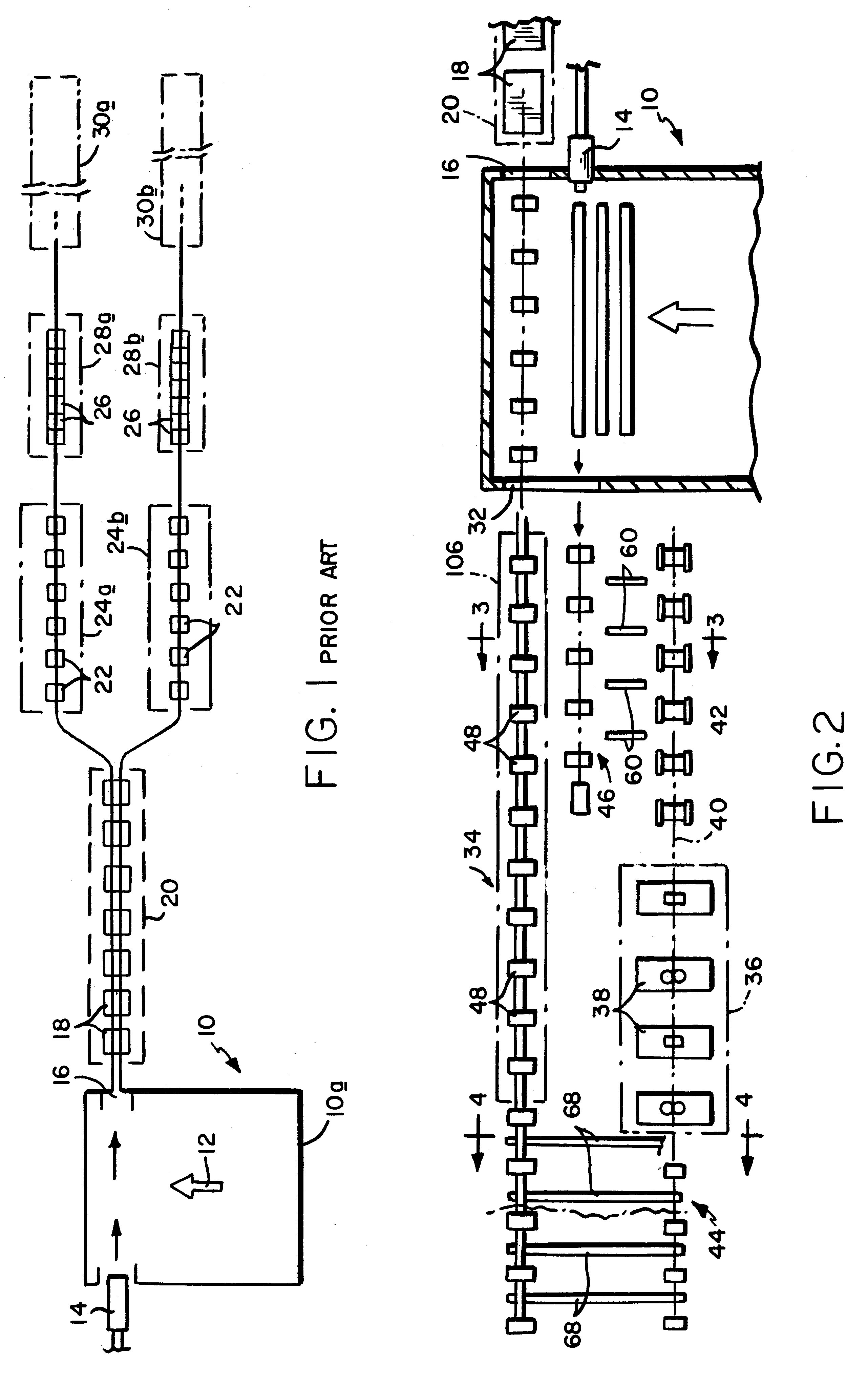

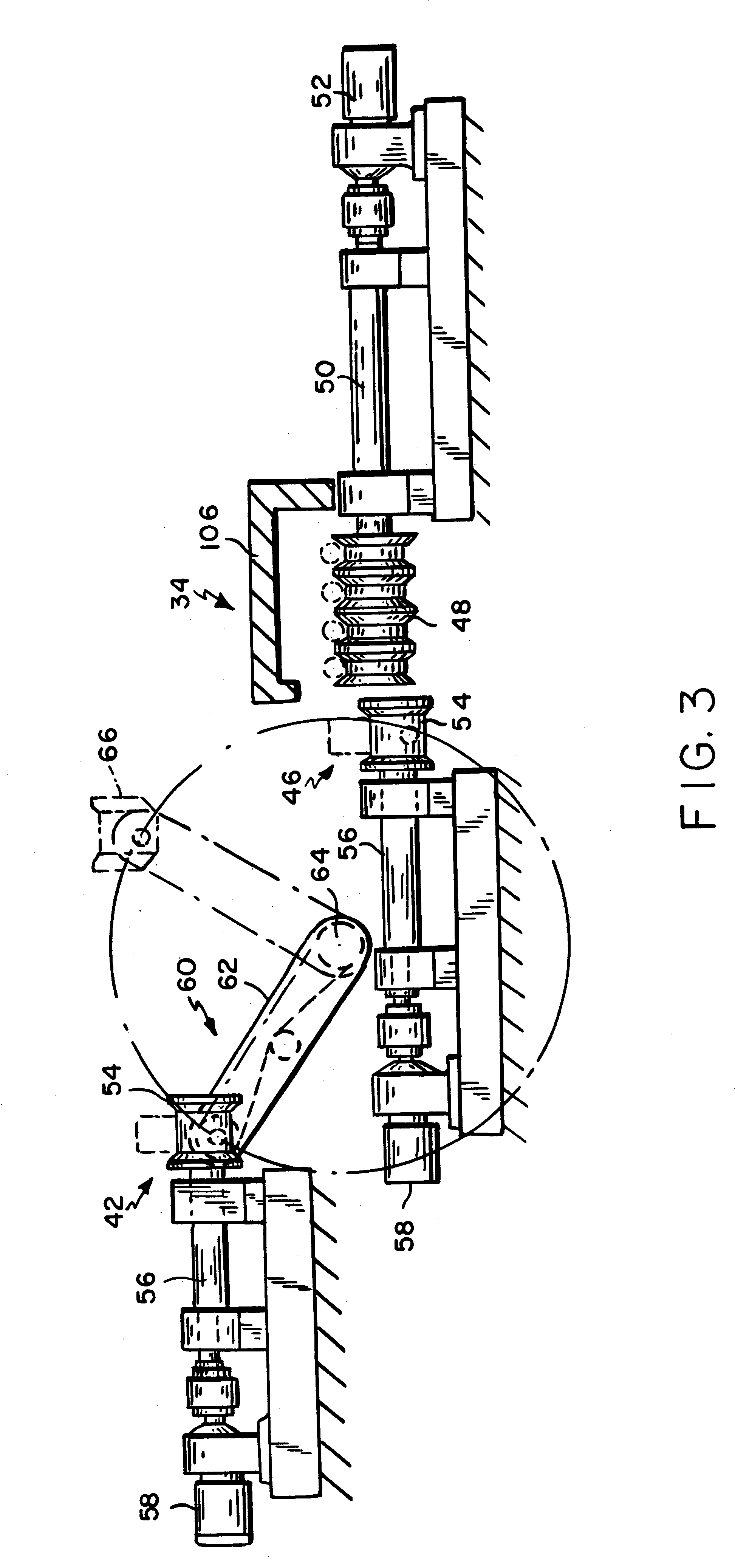

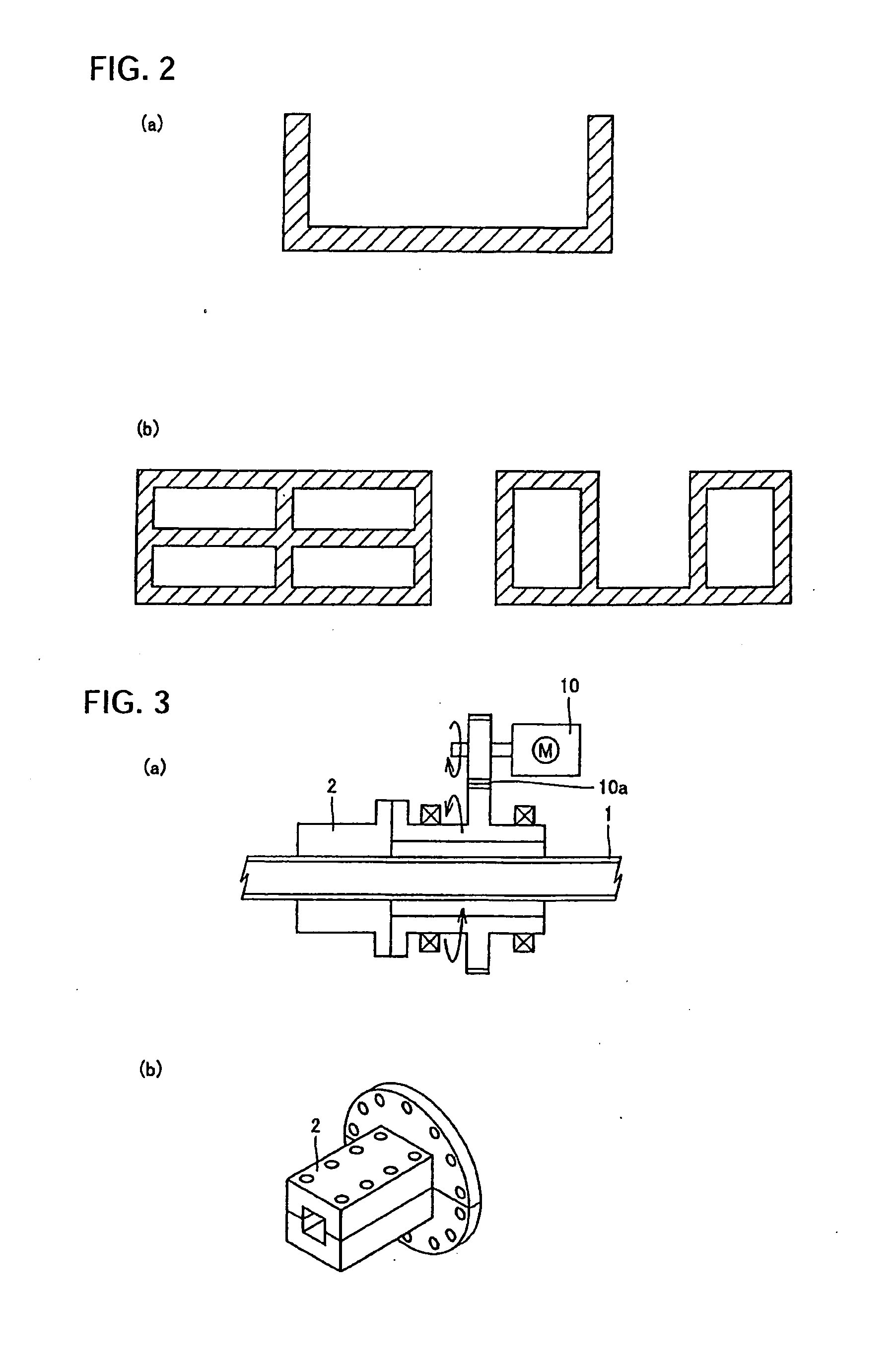

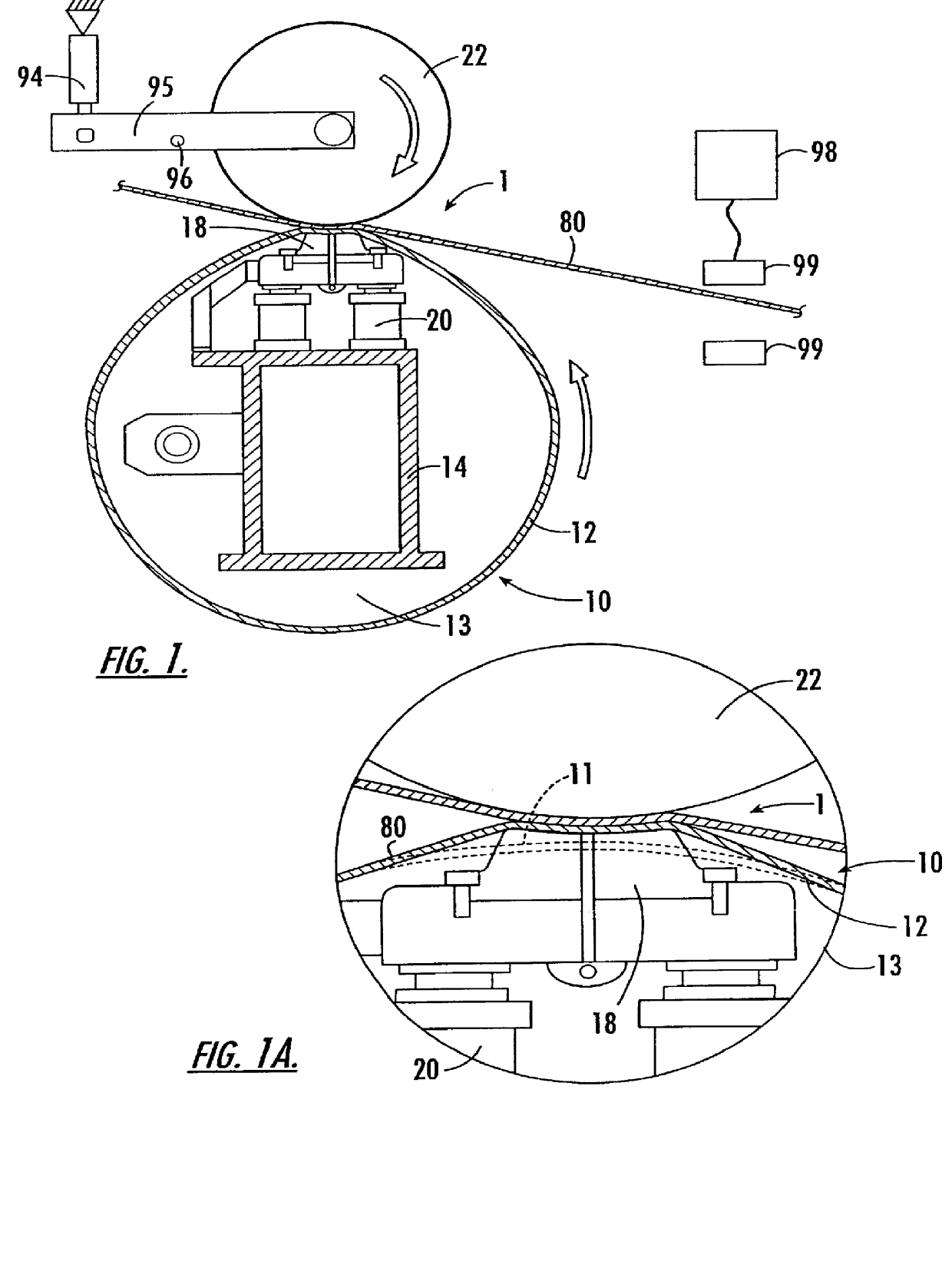

Roll changing apparatus and roll changing method for rolling mill

InactiveUS20020078728A1Low costReduce Fixture CostsMetal rolling stand detailsRollsWork rollEngineering

A roll changing apparatus for a four-high rolling mill comprises rails, provided in a rolling mill stand and on a work side of the rolling mill, for incoming and outgoing of a work roll assembly and a backup roll assembly, and a pusher, provided on a drive side or the work side of the rolling mill, for roll admission and withdrawal for both of work rolls and backup rolls. The roll changing apparatus can be modified into a side shift type roll changing apparatus with ease, at a low cost, and in a short time.

Owner:MITSUBISHI HEAVY IND LTD

Apparatus for and method of processing billets in a rolling mill

A rolling mill has roughing, intermediate and finishing roll stands on a first side of a billet reheating furnace, and a breakdown mill on an opposite second side of the furnace. Billets are heated to an elevated rolling temperature in the furnace and are then ejected to the second side of the furnace for rolling in the breakdown mill before being directed back through the furnace for continued rolling into finished products at the first side of the furnace in the roughing, intermediate and finishing roll stands.

Owner:MORGAN CONSTR CO

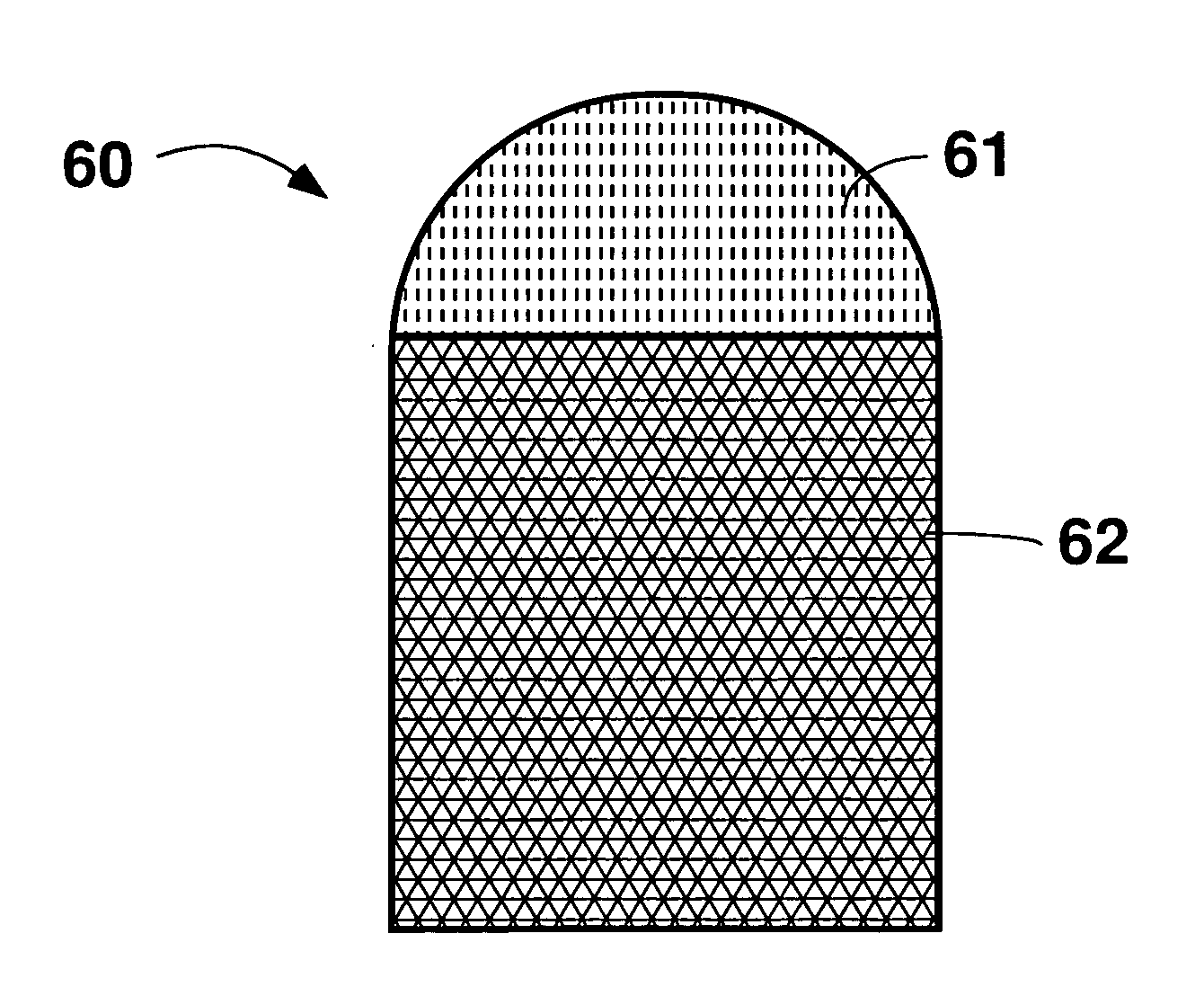

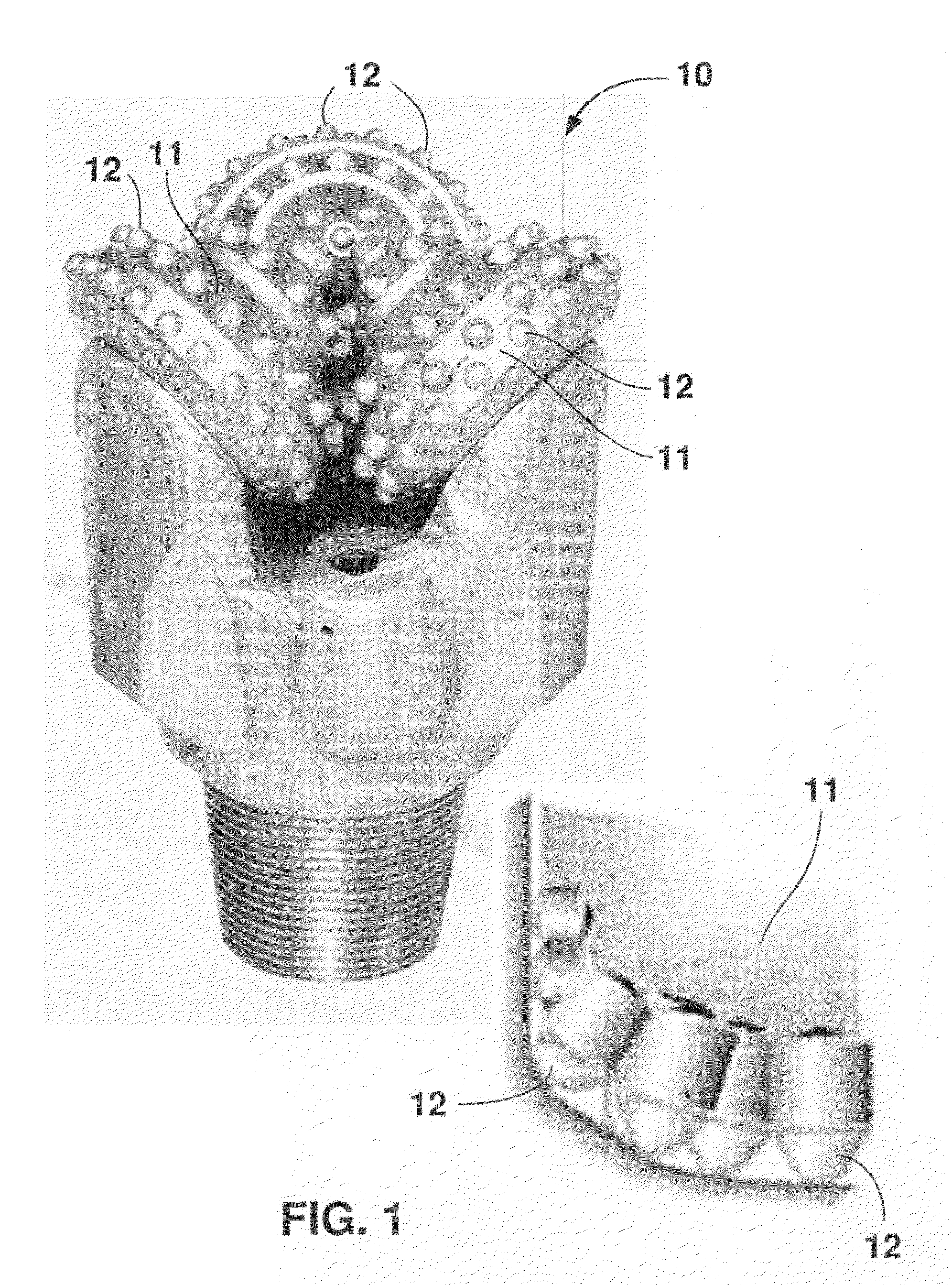

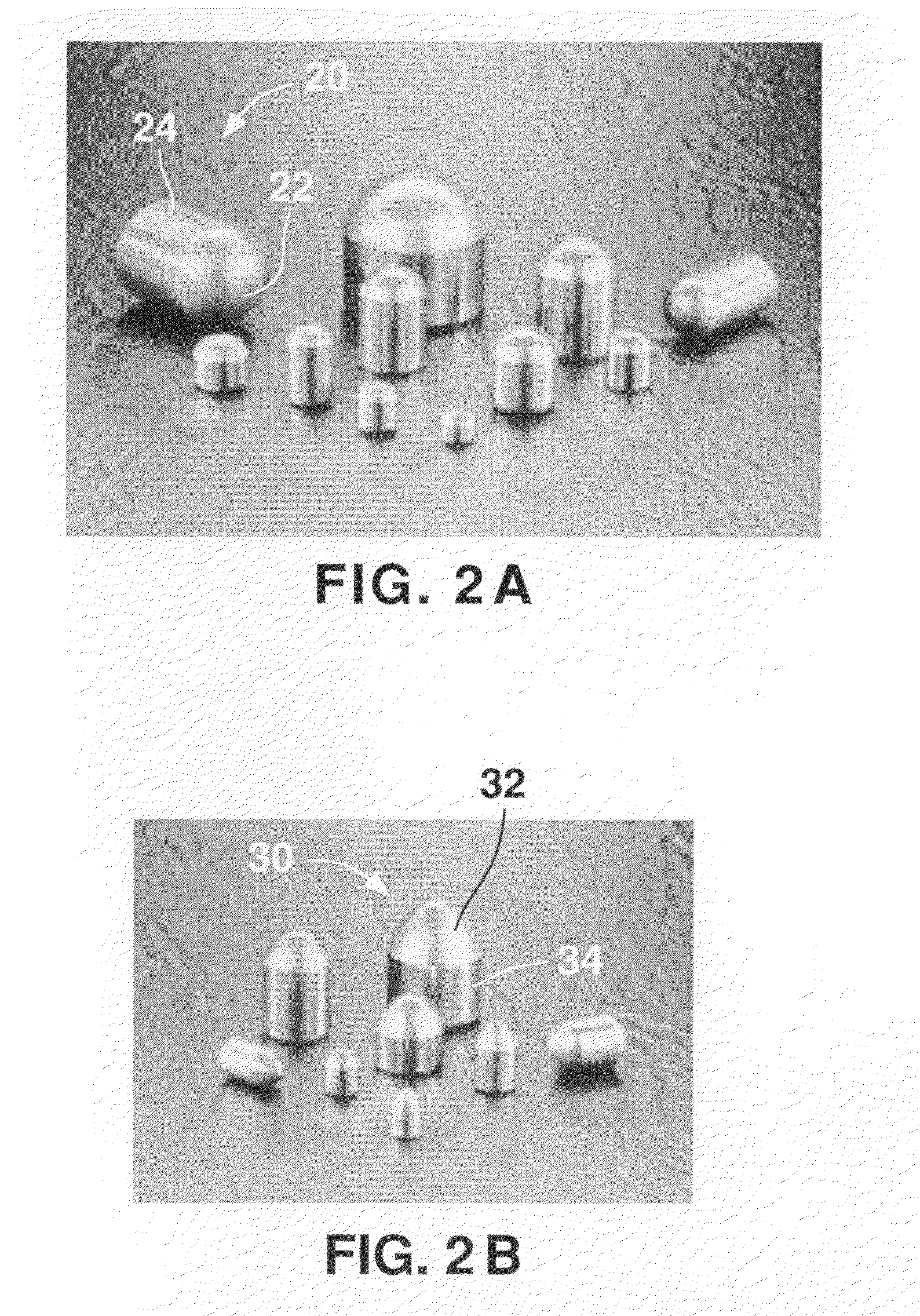

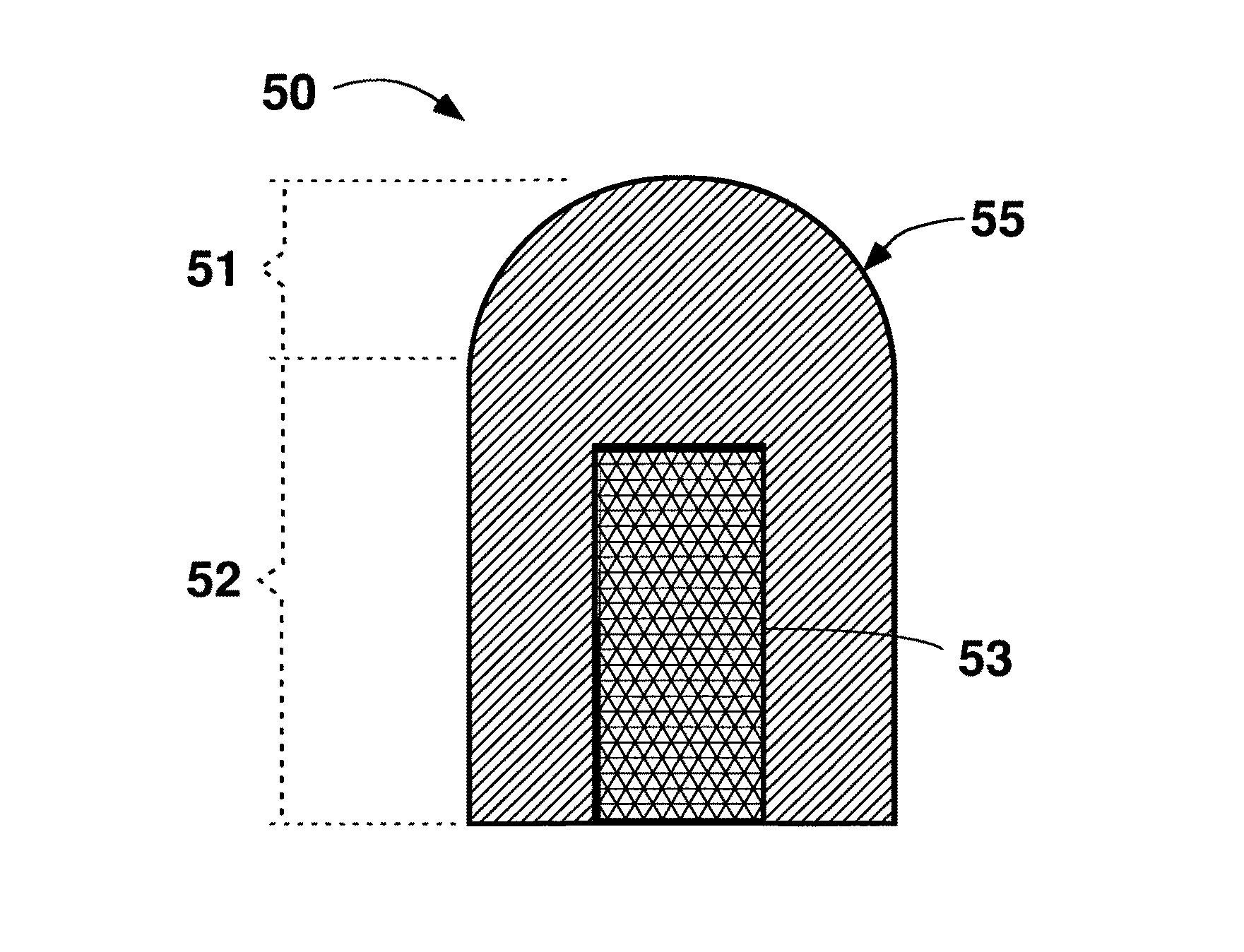

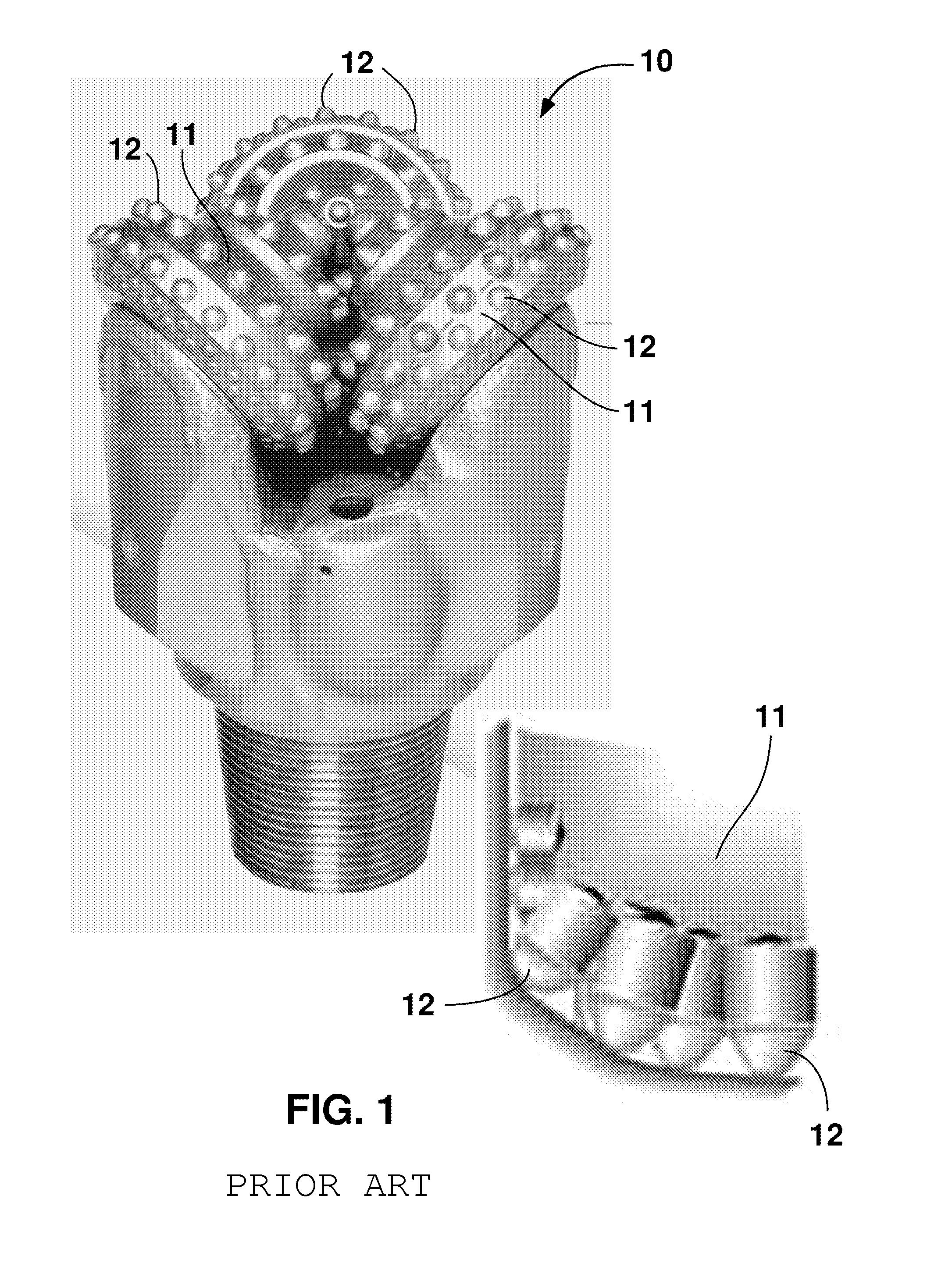

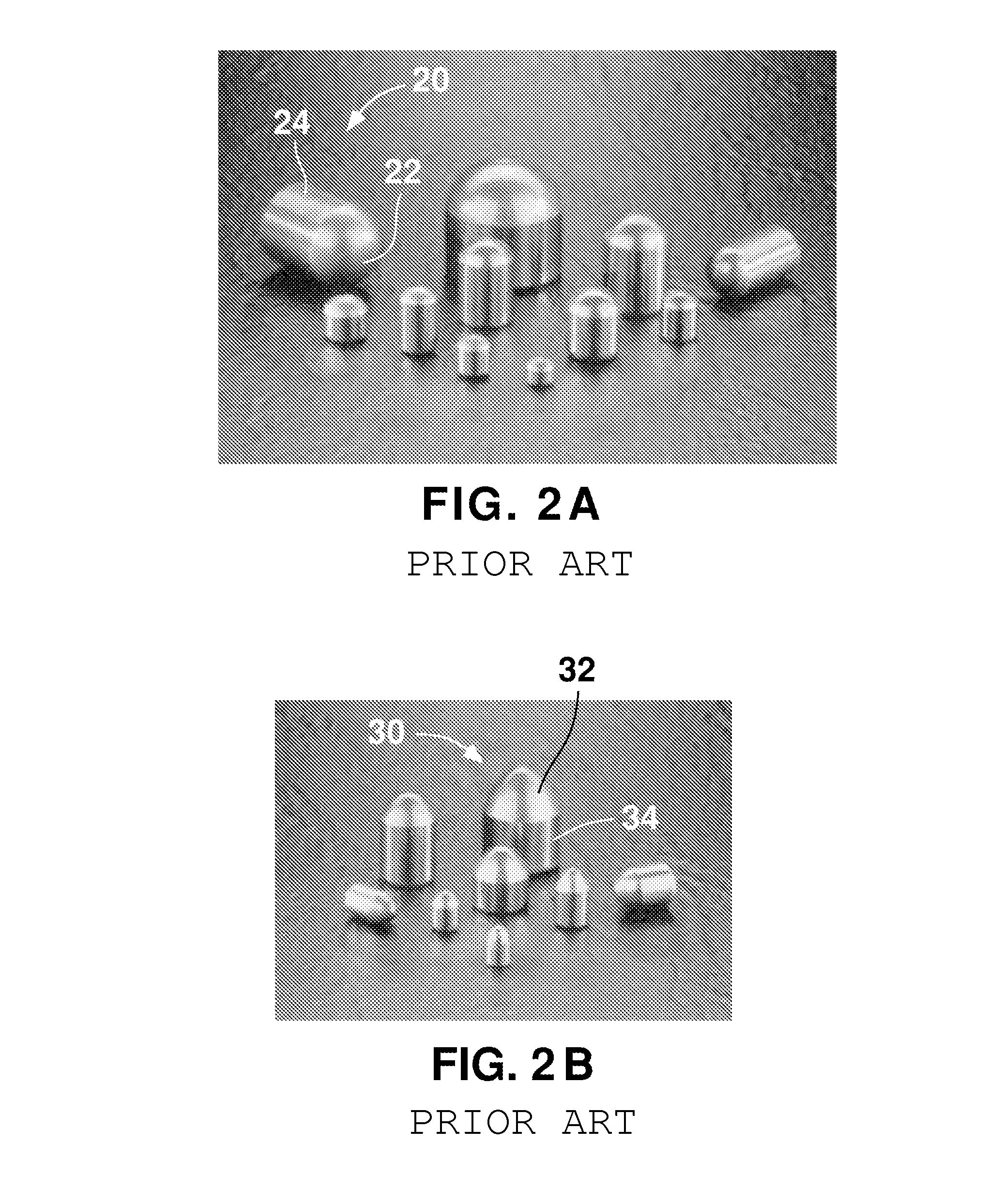

Articles Having Improved Resistance to Thermal Cracking

An article includes a working portion including cemented carbide, and a heat sink portion in thermal communication with the working portion. The heat sink portion includes a heat sink material having a thermal conductivity greater than a thermal conductivity of the cemented carbide. Also disclosed are methods of making an article including a working portion comprising cemented carbide, and a heat sink portion in thermal communication with the working portion and including a heat sink material having a thermal conductivity that is greater than a thermal conductivity of the cemented carbide. The heat sink portion conducts heat from the working portion.

Owner:KENNAMETAL INC

Resource-saving type high-boron high-speed steel composite roll and manufacturing method thereof

ActiveCN103624084AStrong metallurgical bondLow costRollsMetal rolling arrangementsSocial benefitsResource saving

The invention discloses a resource-saving type high-boron high-speed steel composite roll and a manufacturing method of the resource-saving type high-boron high-speed steel composite roll, and belongs to the technical field of rolls. The composite roll is composed of outer-layer high-boron high-speed steel, middle transition-layer graphitic steel and roll core hot rolling medium-carbon round steel, the outer-layer high-boron high-speed steel and the middle transition-layer graphitic steel are formed in a centrifugal combination mode, and the transition-layer graphitic steel and the roll core hot rolling medium-carbon round steel are formed in a hot charging combination mode. The composite roll is high in roll face rigidity and good in rigidity uniformity, and it is guaranteed that the composite roll is excellent in abrasive resistance. A roll core is formed by machining the hot rolling medium-carbon round steel and is good in obdurability, the roll breakage accident cannot happen in the roll using process, and good economic benefits and social benefits are achieved through popularization and application.

Owner:枣庄瑞兴机械制造有限公司

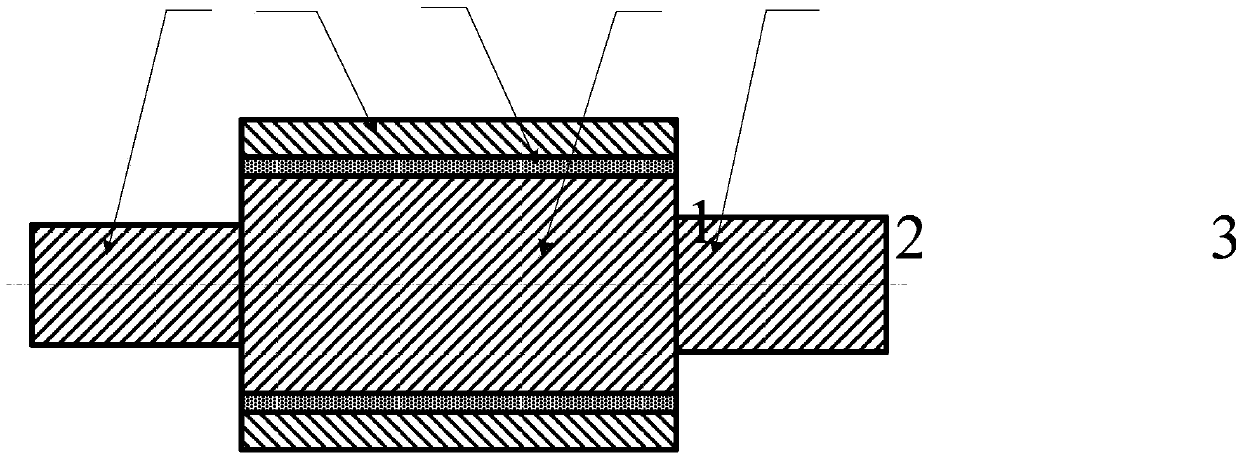

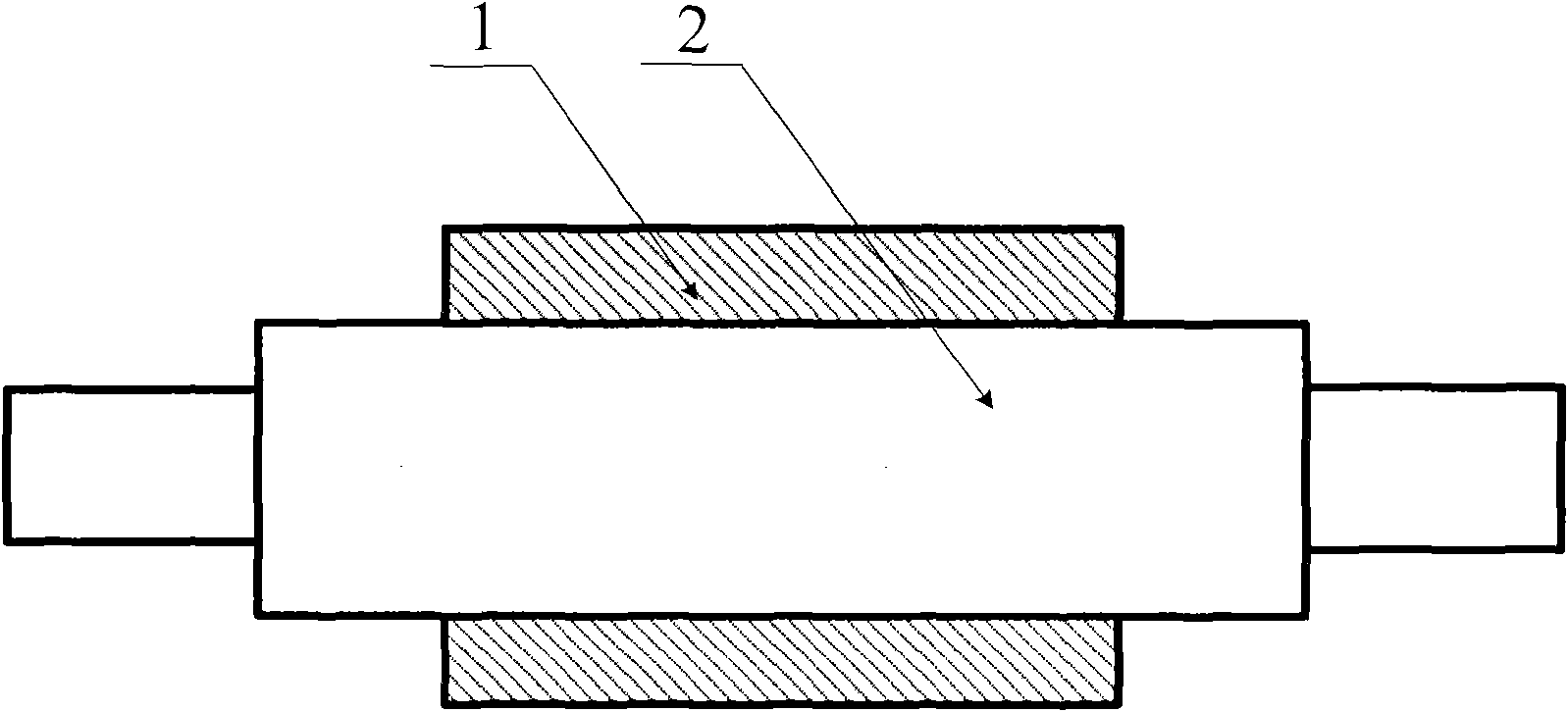

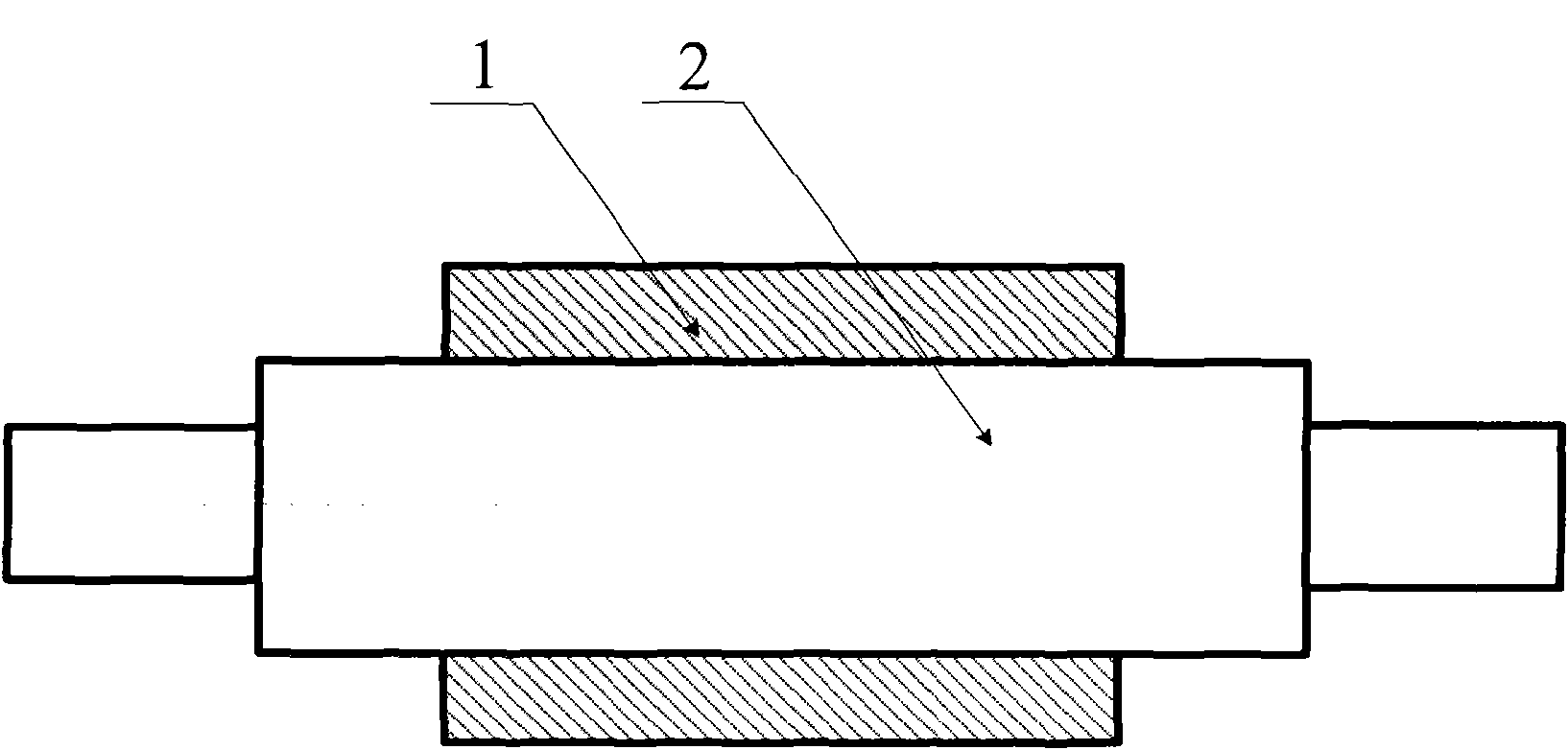

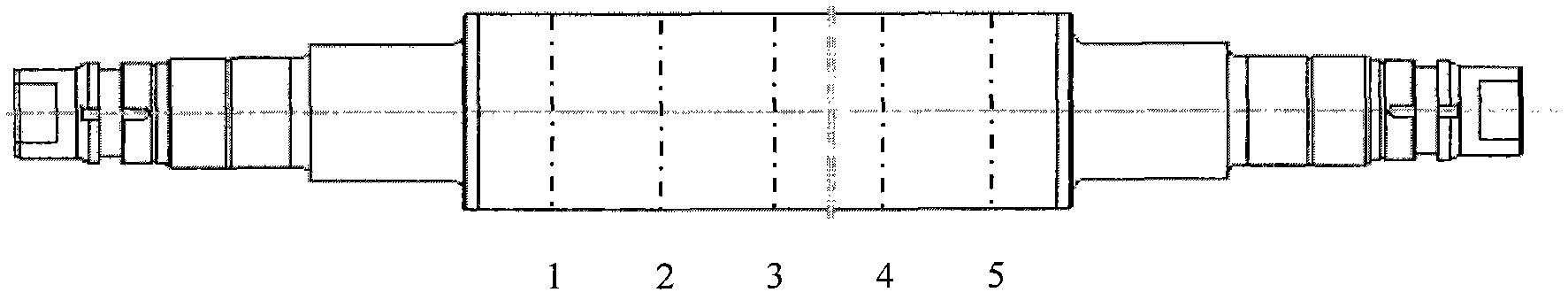

High-boron low-alloy high-speed steel roll and preparation method thereof

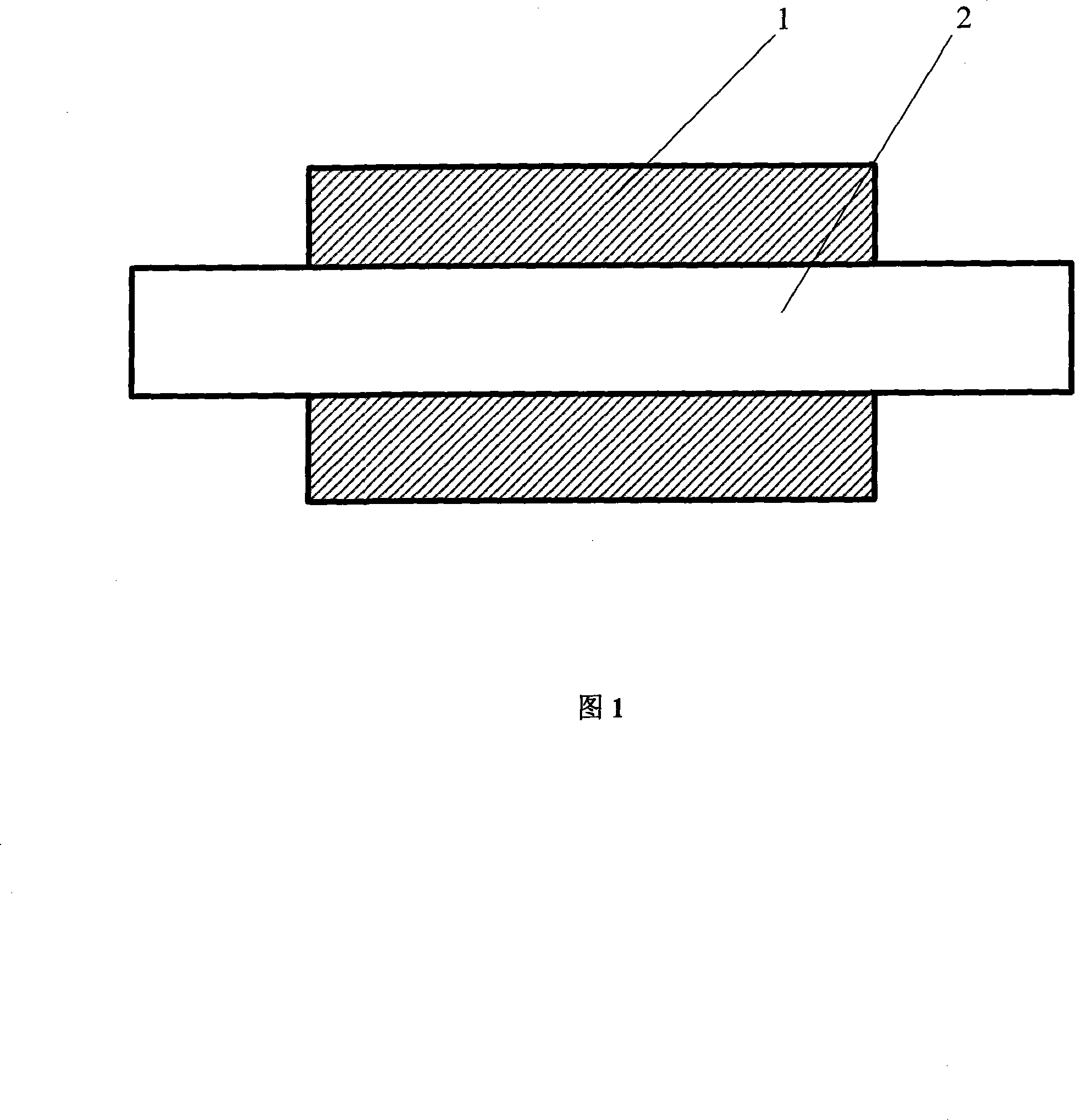

ActiveCN101831590AReduce the amount addedReduce manufacturing costRollsElectric furnaceHardnessHigh-speed steel

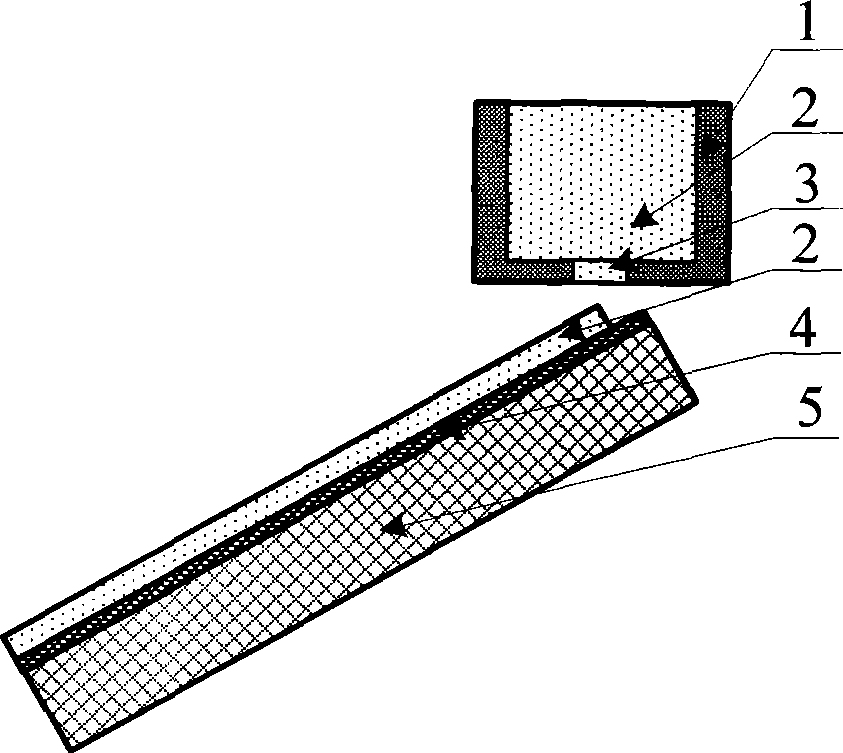

The invention relates to high-boron low-alloy high-speed steel roll and a preparation method thereof. The roll comprises two parts, namely a roll barrel (1) and a roll core (2), wherein the roll barrel comprises the following chemical components by weight percent: 0.32-0.55% of C, 1.42-2.13% of B, 5.2-6.5% of Cr, 2.5-4.5% of W, 1.6-1.8% of V, 0.5-1.0% of Nb, 0.3-1.0% of Si, 0.3-1.0% of Mn, 0.10-0.20% of Ti, 0.05-0.12% of N, 0.04-0.12% of Y, 0.08-0.15% of Mg, less than 0.04% of P, less than 0.04% of S and the balance Fe. The roll prepared by the method of the invention is characterized by high hardness, deep quenched depth and good wear resistance and thermal fatigue resistance, and has good use effect in the production of hot rolled steel.

Owner:JIANGSU DONGYE ROLL

Compound high speed steel roll and its making process

InactiveCN1846887AImprove efficiencySimple production processFurnace typesRollsChemical compositionHigh intensity

The present invention discloses compound high speed steel roll and its making process. The compound high speed steel roll consists of roll body and roll core compounded through central casting. The roll body is made of high speed steel comprising chemically C 1.8-2.8 (in wt%, same as below), Mo 4.0-8.0, V 3.0-7.0, Nb 1.5-4.0, Cr 6.0-12.0, RE 0.1-0.25, Ti 0.15-0.40, N 0.08-0.20, K 0.06-0.18, Si<2.0, Mn<2.0, S<0.05 and P<0.05, except Fe and inevitable impurity. The roll core is made of high strength nodular cast iron comprising chemically C 3.2-3.6 (in wt%, same as below), Si 1.8-2.4, Mn 0.4-0.8, Ni 0.3-1.2, Cr 0.3-0.8, Mo 0.2-0.5, Mg 0.03-0.08, RE 0.05-0.14, P<0.08 and S<0.03, except Fe and inevitable impurity. The compound high speed steel roll has high wear resistance, simple making process and high production efficiency.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

High-speed steel roll ring and its production

A high-speed steel roller ring for rolling wire or rod material contains C, W, Mo, V, Cr, Al, Ni, Co, Nb, Ti, Ce, Na, Mg, Si, Mn, S, P and Fe proportionally. It is prepared through smelting in electric furnace, centrifugal casting, and annealing, high-temp quenching and tempering twice. Its advantages are high hardness, tension strength and toughness for breaking, smooth surface and high size stability.

Owner:XI AN JIAOTONG UNIV

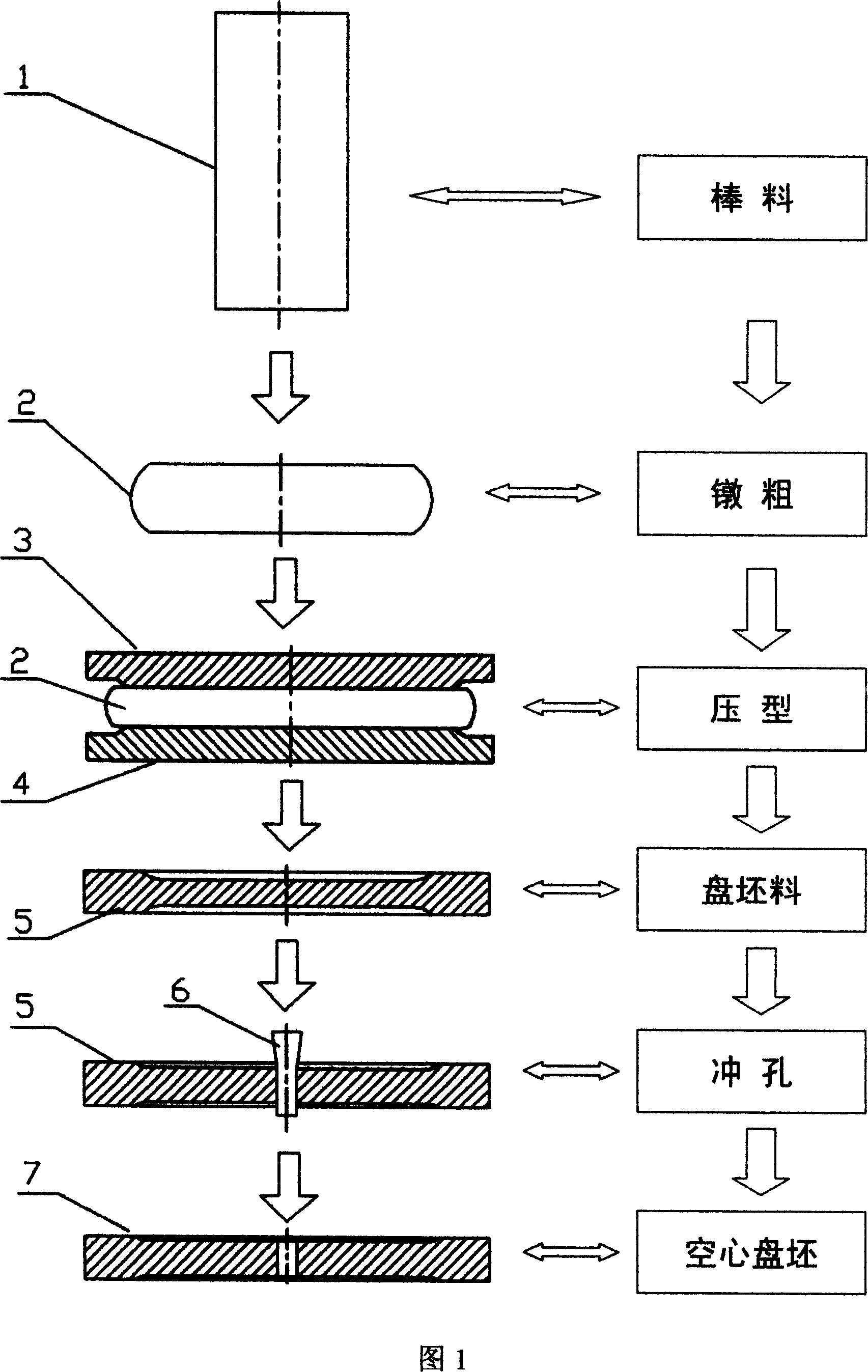

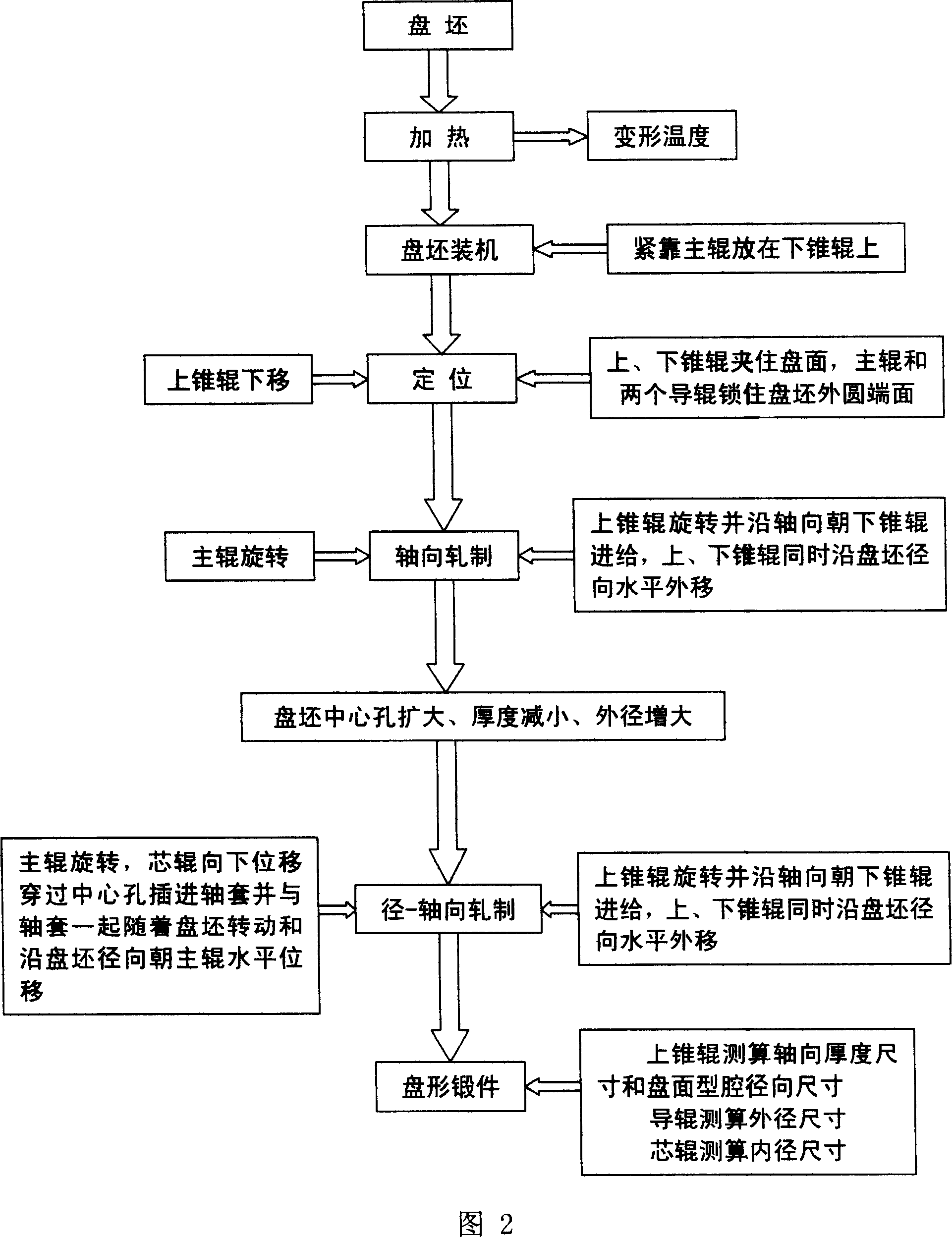

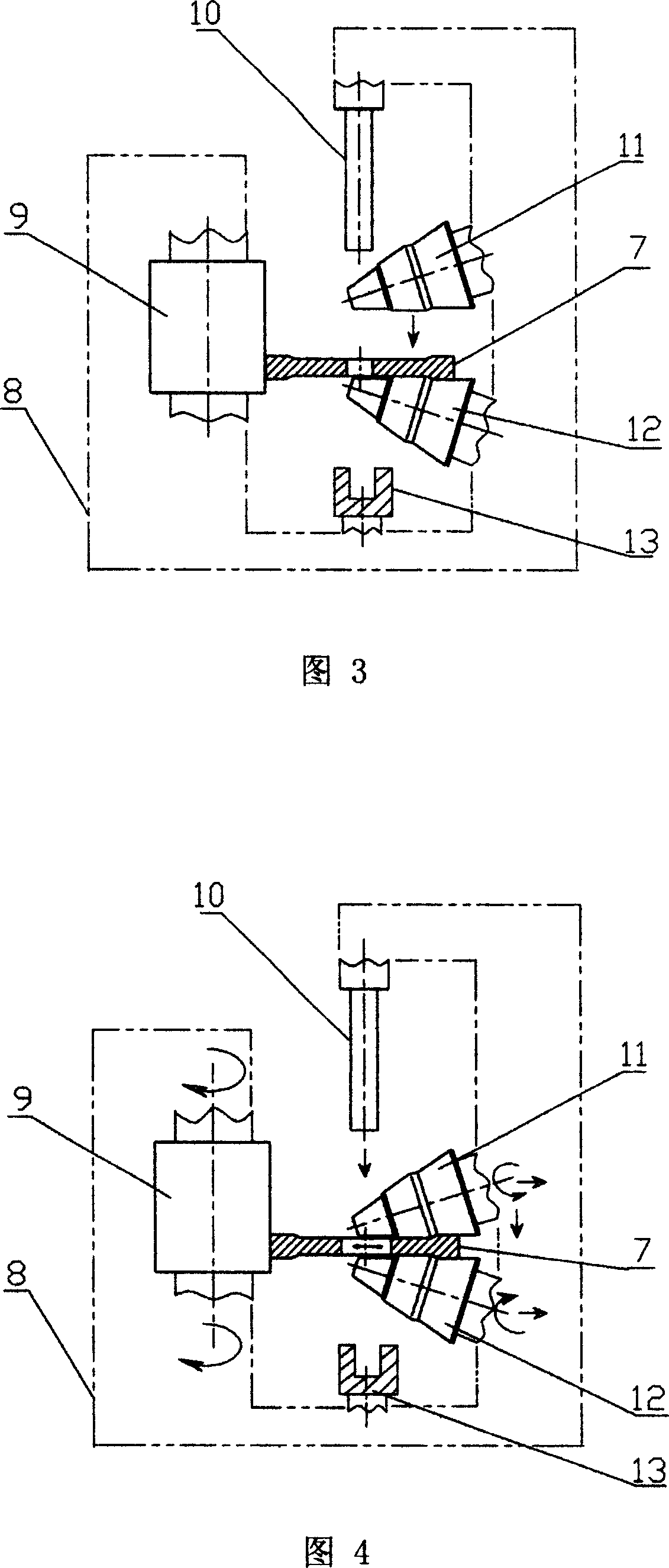

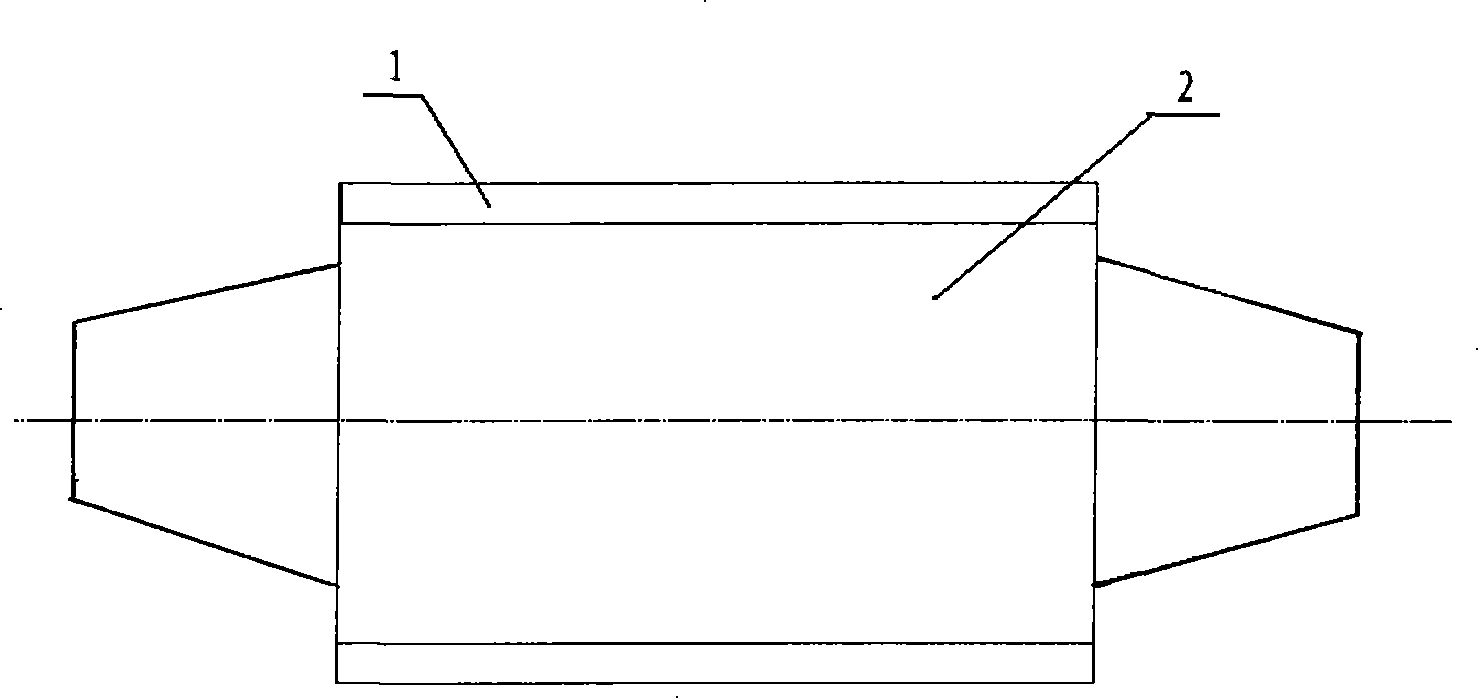

Rolling forming process for large hollow disc forging

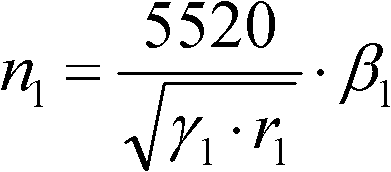

ActiveCN101020282ARadial wall thickness reductionReduce axial thicknessRoll force/gap control deviceMeasuring devicesMaterials scienceMetal

The technological process of rolling and forming large hollow disc forging includes the steps of: deforming metal rod material, heating, upsetting to form cake blank, profiling to obtain disc blank, punching hole to obtain hollow disc blank, heating, locating, axial rolling, radial and axial rolling, and measuring size to obtain hollow disc forging. The rolling process has axial rolling force of (2-5)x10<5> kg, radial rolling force of (5-20)x10<4> kg, and broadening speed of 5-15 mm / s. The rolled disc forging has outer diameter of 800-3000 mm, inner diameter of 300-2000 mm and thickness of 30-250 mm. By means of altering the conic size and sizes of the conic roll, disc forgings of different sizes may be rolled. The present invention can form disc forging continuously and form large forging in small apparatus.

Owner:GUIZHOU ANDA AVIATION FORGING

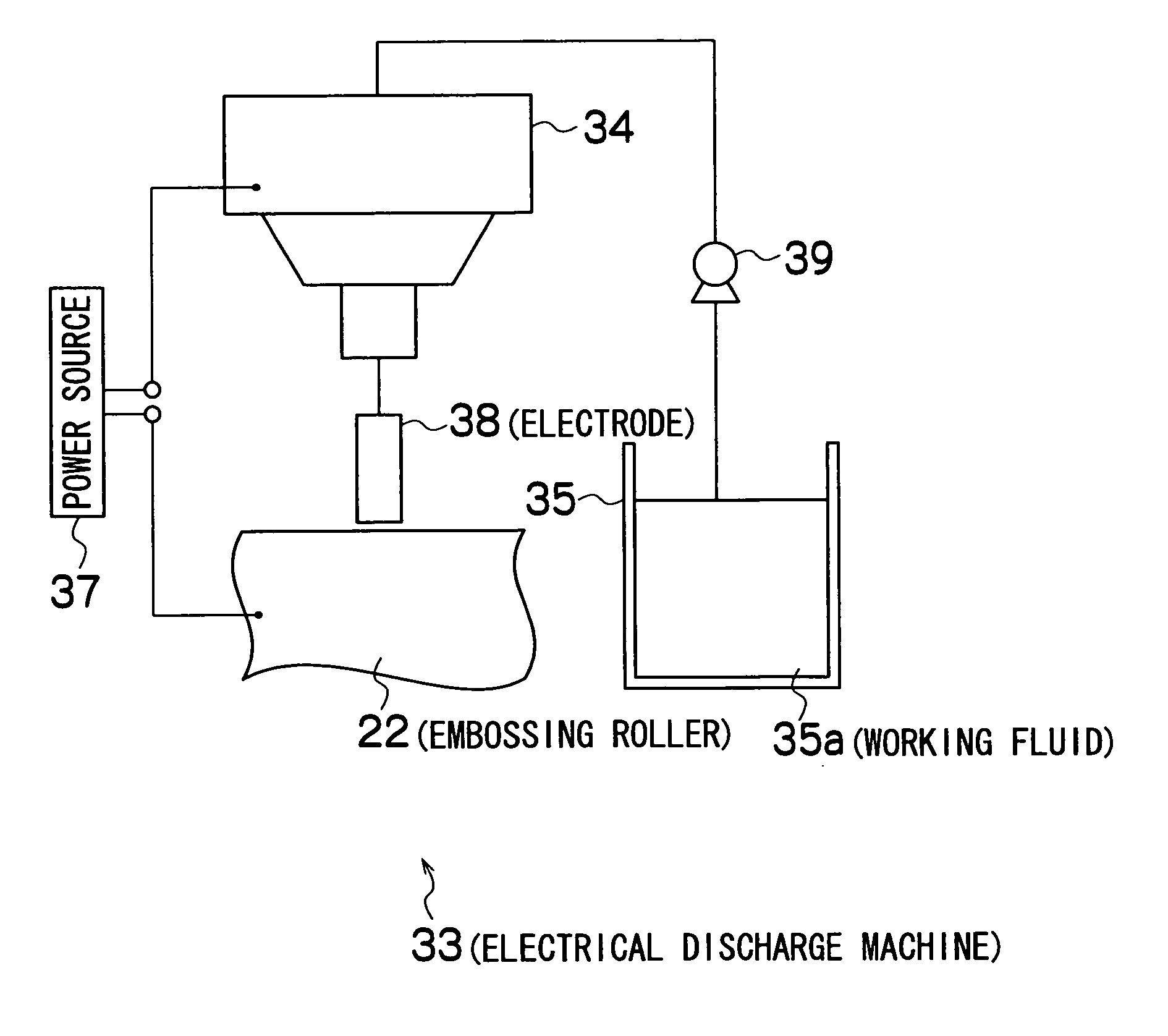

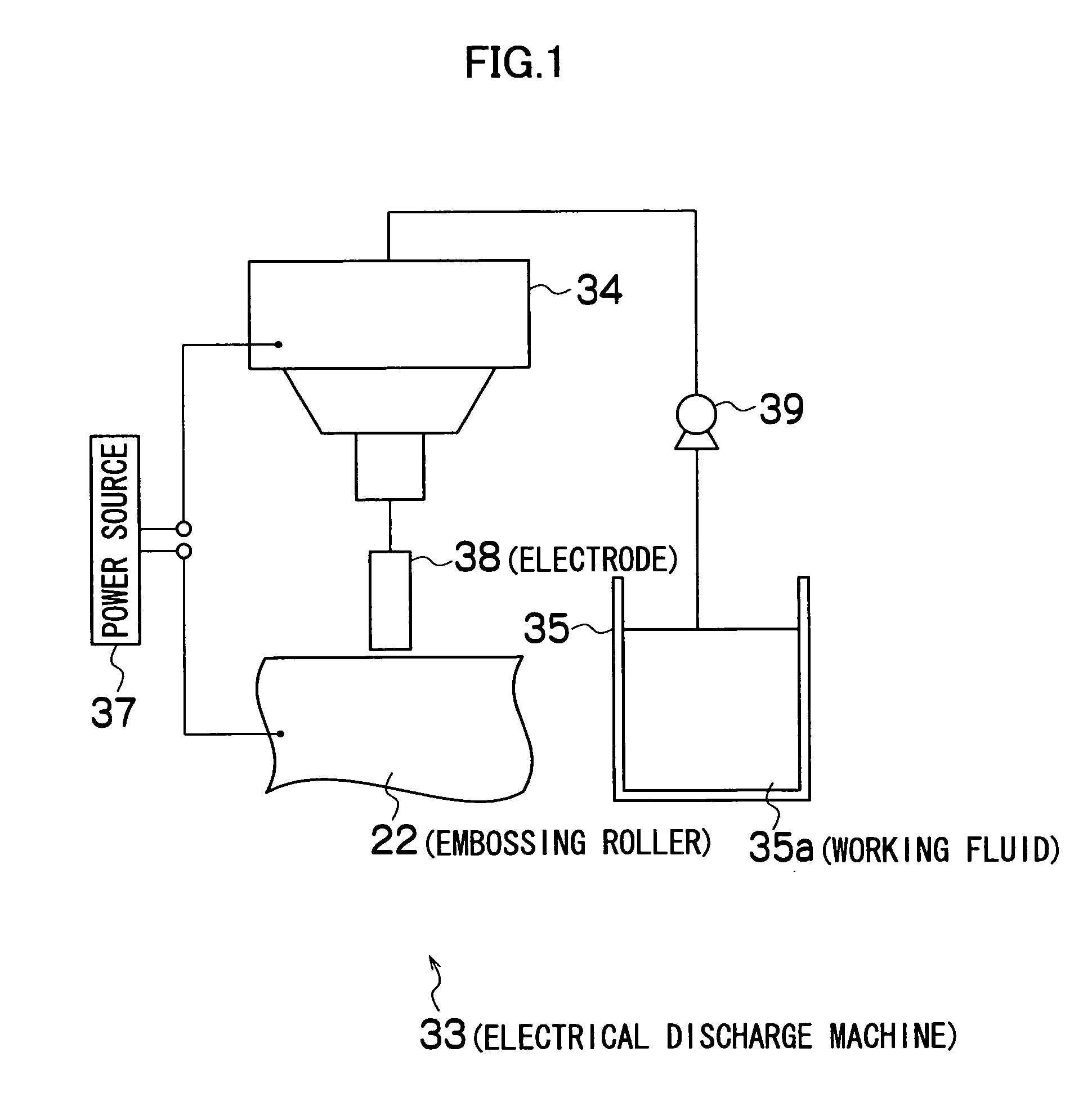

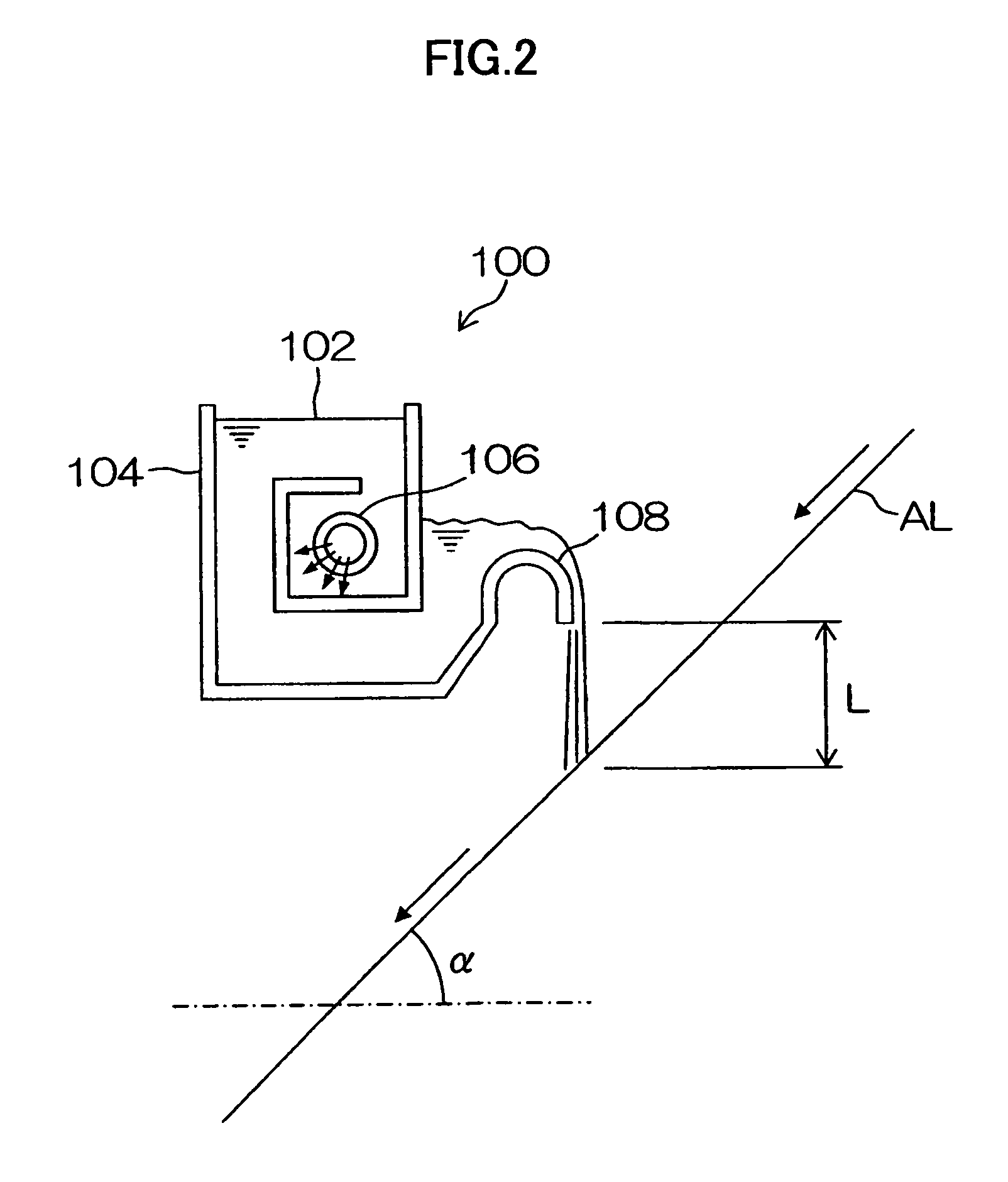

Method for providing surface texturing of aluminum sheet, substrate for lithographic plate and lithographic plate

InactiveUS20050258136A1Layered productsSurface reaction electrolytic coatingEngineeringAluminum substrate

According to the present invention, since the concavo-convex pattern of the embossing form is formed by electrical discharge machining, the peaks on the surface of the resultant embossing form are all of the same level or height, which enables the enhancement of the service life of the embossing form. Further, since the concavo-convex pattern of the embossing form is formed by electrical discharge machining, even a complicated and minute concavo-convex pattern can be formed. Accordingly, when applying the method of the present invention to, for example, the production of a substrate for a lithographic plate, an aluminum substrate for a lithographic plate which excels in plate wear, sensitivity and resistance to stains can be produced. And when applying the same to the production of an aluminum decorative laminate, an aluminum decorative laminate which excel in glossiness and paint adhesion can be produced.

Owner:FUJIFILM HLDG CORP +1

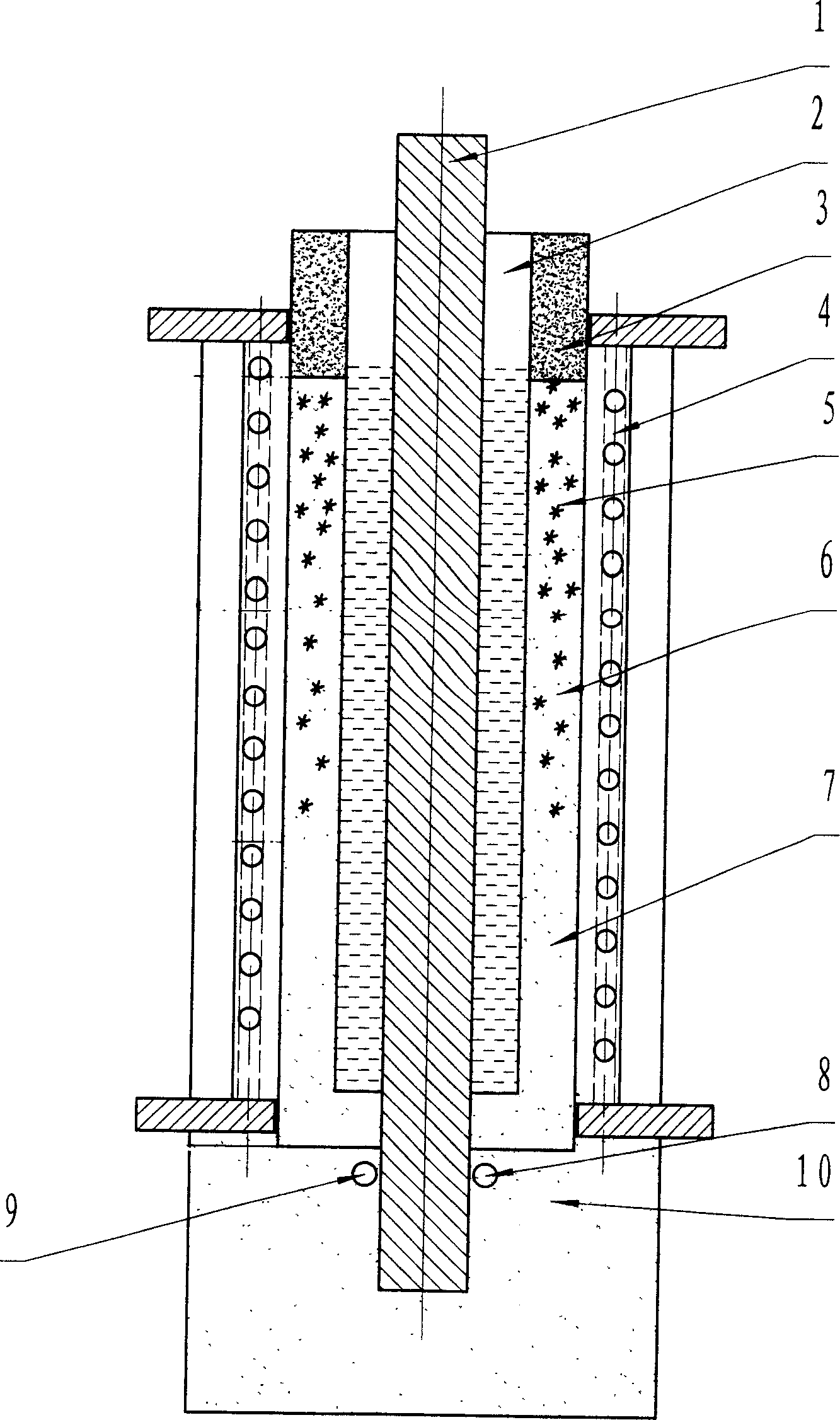

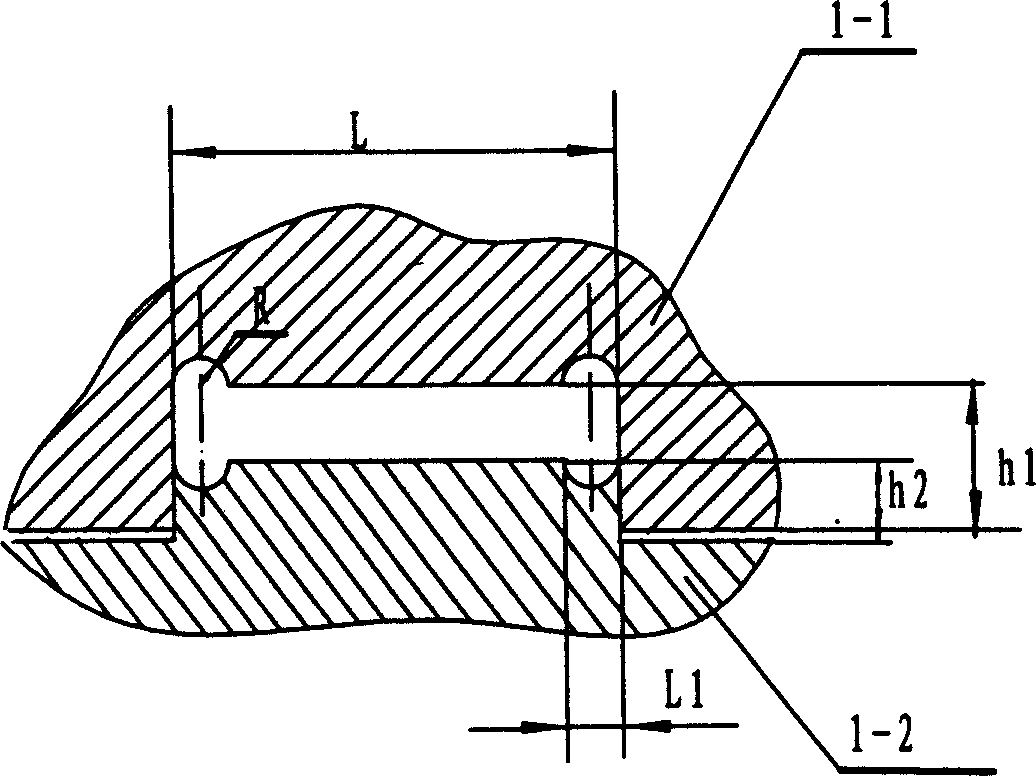

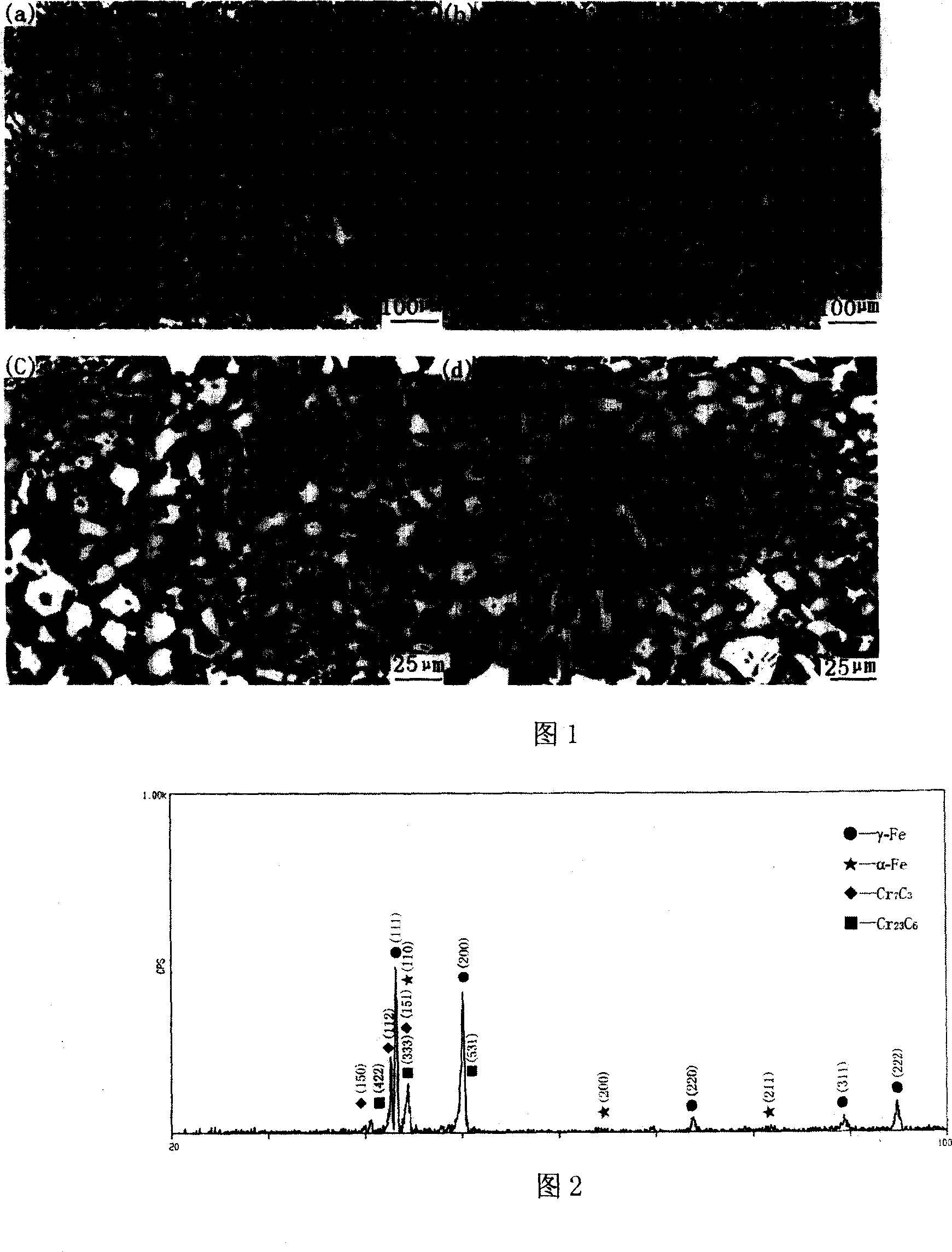

Centrifugal composite modified indefinite chilled cast iron roller and preparation method thereof

InactiveCN101177759AFine structure of roll bodyEvenly distributedRollsMetal rolling arrangementsCrazingImpurity

The invention relates to a centrifugal combined indefinite chill cast-iron roller and a preparation method thereof, pertaining to steel rolling technical field. The chemical composition of a roll barrel is (weight percent): 3.2-3.8 C, 3.8-4.5 Ni, 1.2-1.8 Cr, 0.2-0.4 Mo, 0.2-0.5Cu, 1.0-1.8 Si, <0.8Mn, 0.10-0.30 Nb, 0.05-0.20 V, 0.05-0.20 Ti, 0.04-0.07Mg, 0.02-0.05 Y, 0.01-0.03 Sb, and the rest are Fe and unavoidable microimpurity. The invention employs a electric stove to produce a roller, and the roller is moulded with centrifugal casting method; the roller is characterized by high strength and hardness, good toughness, hardness uniformity and hardenability, excellent wear resistance and oxidation resistance and the anti-cold shock and heat shock properties are also good; no phenomena like breaking, peeling, crazing and steel sticking are in the operation process; the service performance is apparently better than high nickel-chrome indefinite chill cast-iron roller; the processing technique is simple, high-heat treatment is not needed and the production cost is low. The invented roll has the advantages that: the rolling mill operating rate is significantly improved, the production cost of mill bar is reduced, the surface quality of the mill bar is improved and the economic and social benefits are good.

Owner:BEIJING UNIV OF TECH

Repaired roller and method for repairing roller

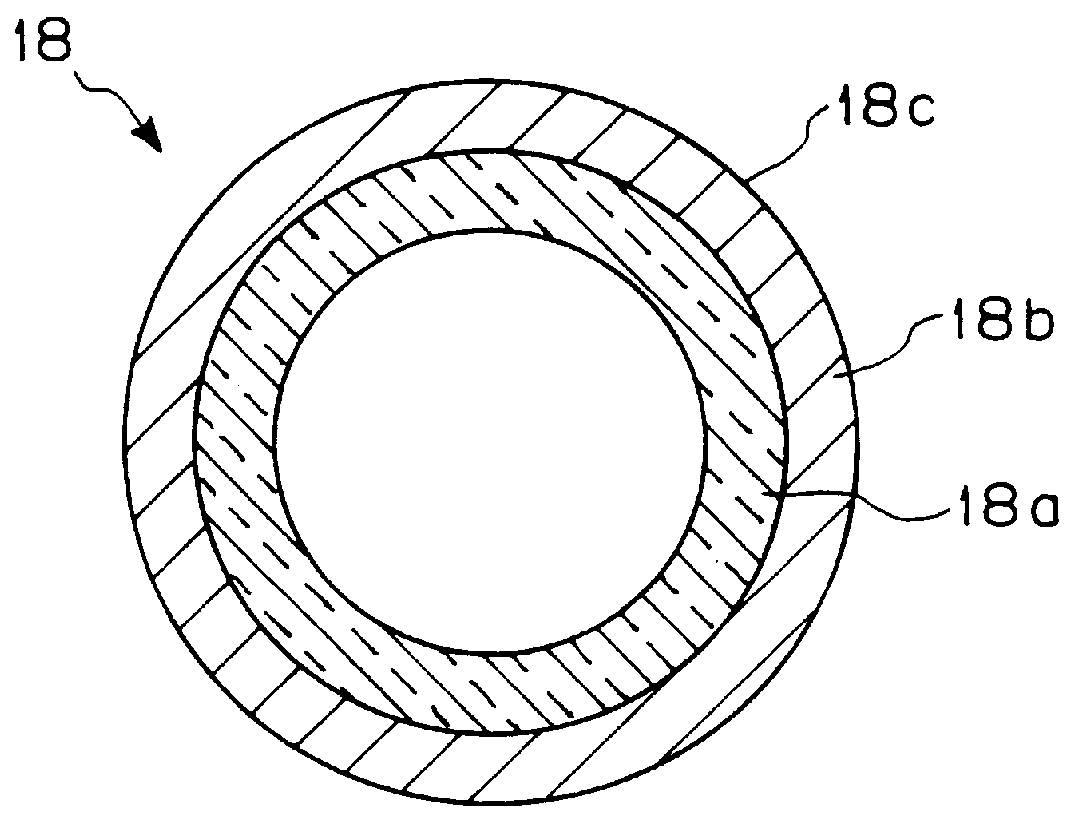

InactiveCN101249510AUniform hardnessImprove wear resistanceLayered productsRollsSurface layerOptoelectronics

The invention relates to a repaired roller and a method for repairing a roller. The method comprises the following steps of: mechanically cutting the waste roller to be repaired along the external surface to remove a worn layer to obtain a roller core, arranging selected cladding material on the surface of the roller core by different addition manners, and irradiating with laser to melt the cladding material together with the surface of the roller to form a cladding layer. The laser cladding layer consists of a cladding surface layer, a cladding intermediate layer and a laser cladding bottom layer and can form gradual functional materials with respective characteristics. The repaired roller has improved mechanical performance, prolonged service life and lowered production cost.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY +1

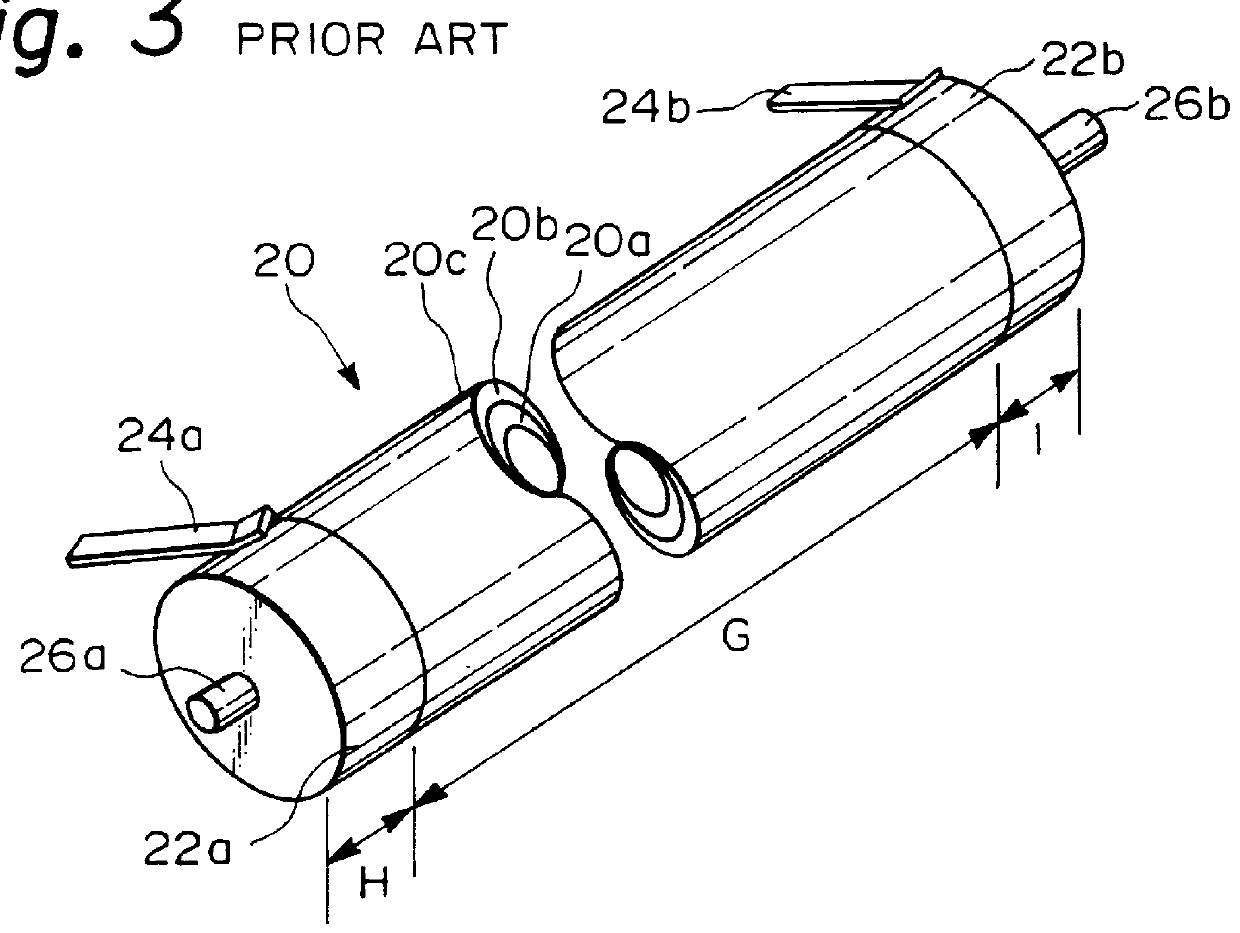

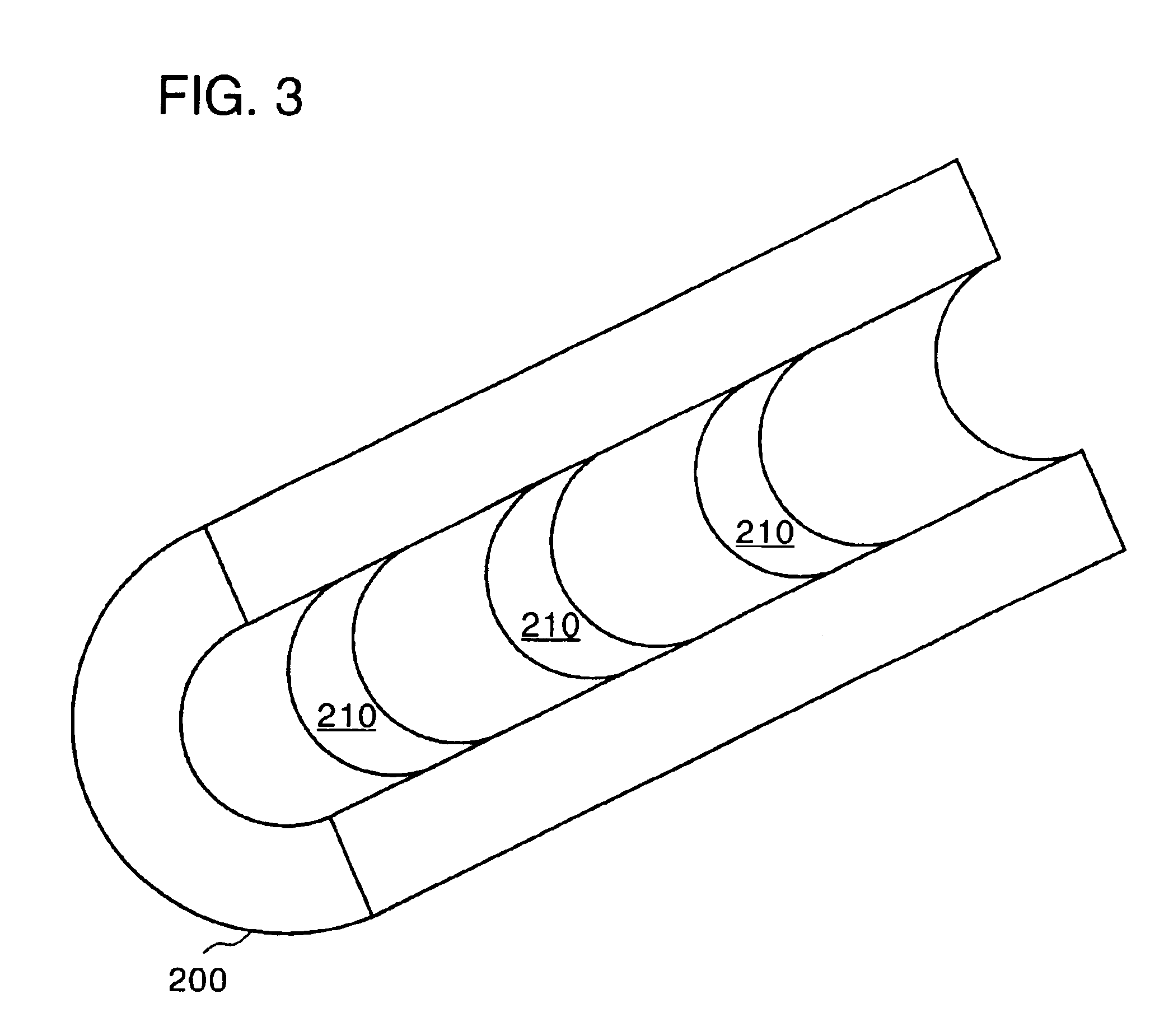

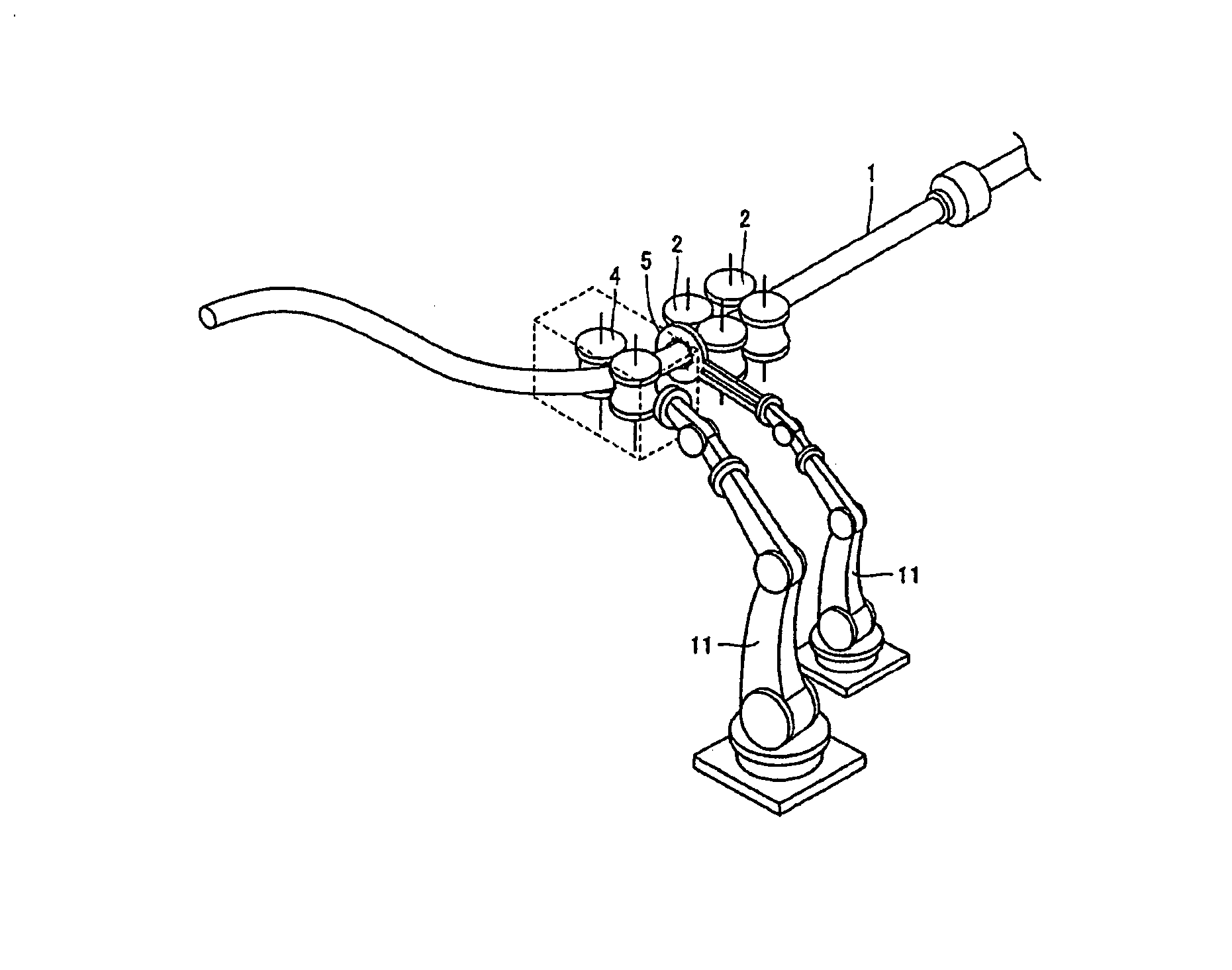

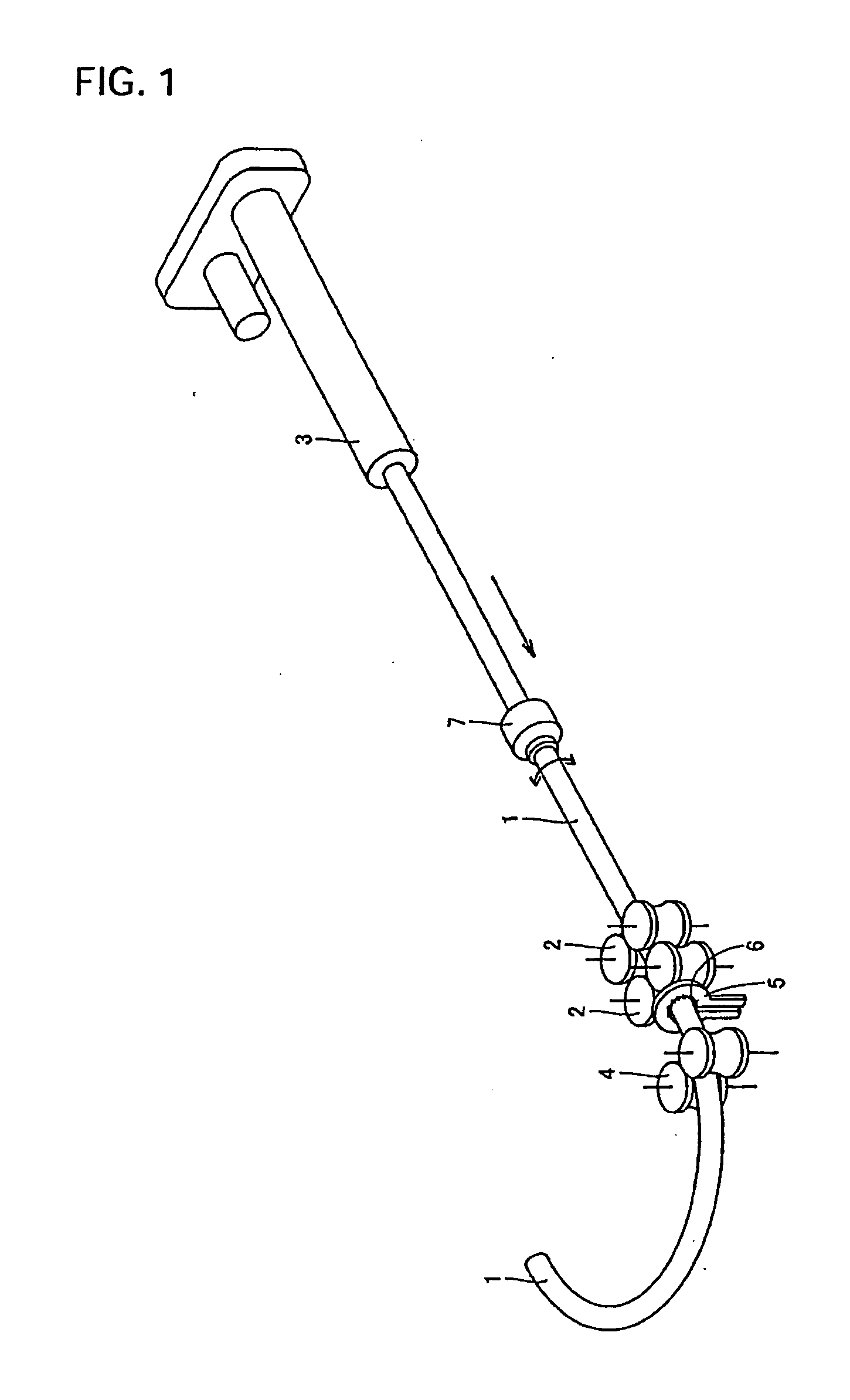

Method for bending metal material, bending machine, bending-equipment line, and bent product

InactiveUS20080066517A1Excellent shape fixabilityUniform hardness distributionBlade accessoriesMachines/enginesMetallic materialsEngineering

A method, bending machine, and bending equipment line for bending a workpiece involves successively or continuously feeding the workpiece held by a supporting unit from an upstream side of the supporting unit, and performing bending at a downstream side of the supporting unit. The bending method includes: supporting the metal material with a movable roller die; controlling the position of the movable roller die and / or the moving speed of the metal material; heating the metal material in a temperature range in which the heated portion can be plastically deformed and in a temperature range in which quenching can be performed, by using a heating unit that is provided around the outer circumference of the metal material, to apply a bending moment to the heated portion; and rapidly cooling the heated portion, by using a cooling unit that is provided around the outer circumference of the metal material.

Owner:SUMITOMO METAL IND LTD +1

Articles having improved resistance to thermal cracking

An article includes a working portion including cemented carbide, and a heat sink portion in thermal communication with the working portion. The heat sink portion includes a heat sink material having a thermal conductivity greater than a thermal conductivity of the cemented carbide. Also disclosed are methods of making an article including a working portion comprising cemented carbide, and a heat sink portion in thermal communication with the working portion and including a heat sink material having a thermal conductivity that is greater than a thermal conductivity of the cemented carbide. The heat sink portion conducts heat from the working portion.

Owner:KENNAMETAL INC

Roll sleeve of ultra-strong wear-resistant high alloy steel roll squeezer and manufacturing method roll sleeve

The invention relates to a roll sleeve of an ultra-strong wear-resistant high alloy steel roll squeezer and a manufacturing method of the roll sleeve, belonging to the technical field of casting in building material industry. The technical scheme is as follows: an outer layer adopts ultra-strong wear-resistant high alloy steel, an inner layer is formed by compounding low-carbon medium alloy steel, and the roll sleeve is manufactured through the process steps of melting the outer-layer ultra-strong wear-resistant high alloy steel, melting the inner-layer low-carbon medium alloy steel, centrifugally casting the compound roll sleeve and performing heat treatment on the compound roll sleeve. The roll sleeve and the manufacturing method thereof, disclosed by the invention, have the positive effects that: the preferential mixture ratio of the inner-layer material to the outer-layer material of the roll sleeve is adopted and a reasonable centrifugal compound casting process is adopted, thereby the inner layer and the outer layer are subjected to metallurgical bonding and a good bonding state is achieved. According to the characteristics of high alloy of the roll sleeve, the fracture toughness of the roll sleeve is enhanced by raising tempering temperature and performing multiple tempering processes. The outer layer of the roll sleeve disclosed by the invention has the hardness of 60-64HRC and the impact toughness of 12J / cm<2>, the inner layer has the hardness of 26-30HRC, the tensile strength of 800-900MPa and the yield strength of 730MPa, and the service life of the roll sleeve is prolonged by above 2 times in comparison with the traditional roll sleeve formed by forging and overlaying welding.

Owner:河北津西钢铁集团重工科技有限公司

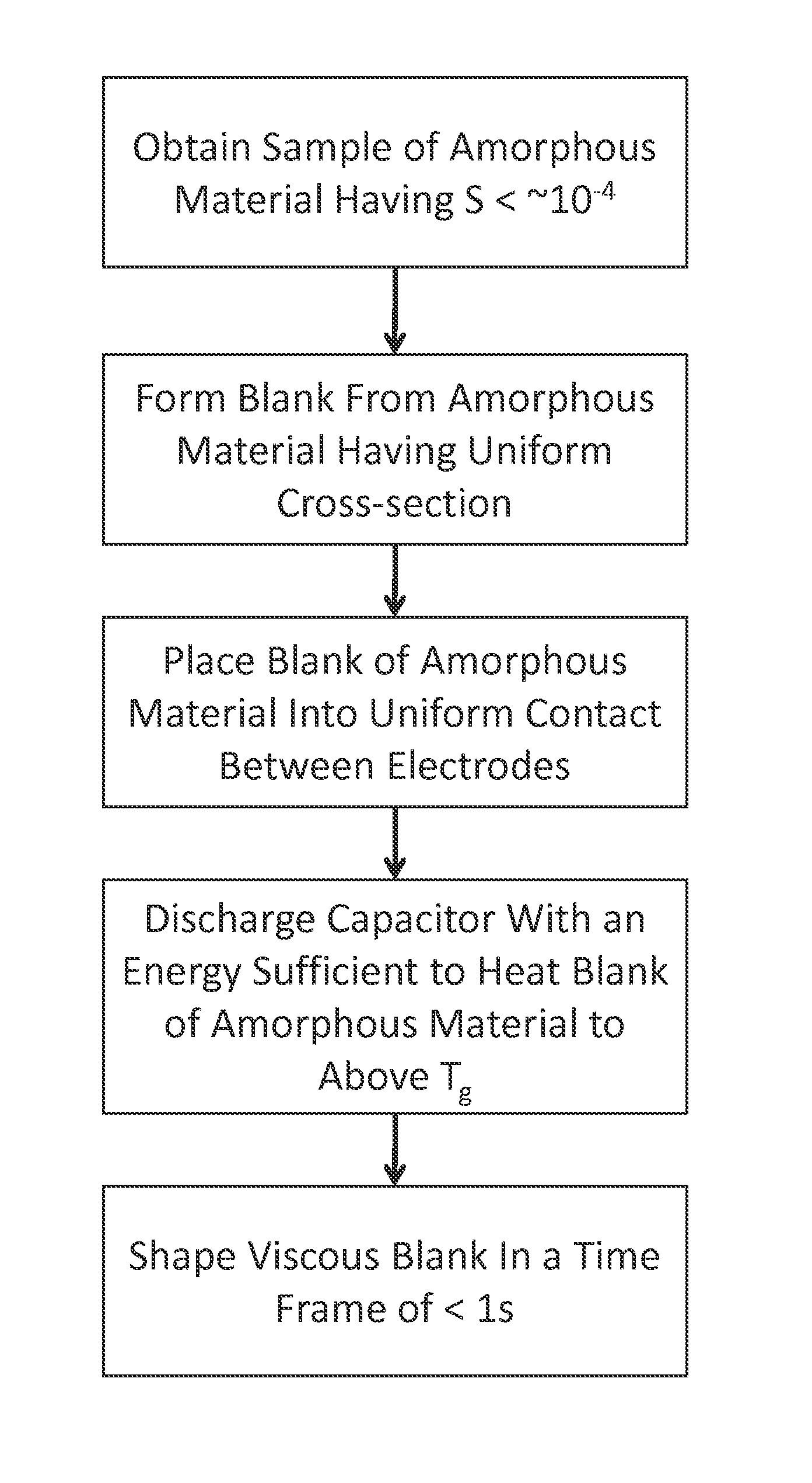

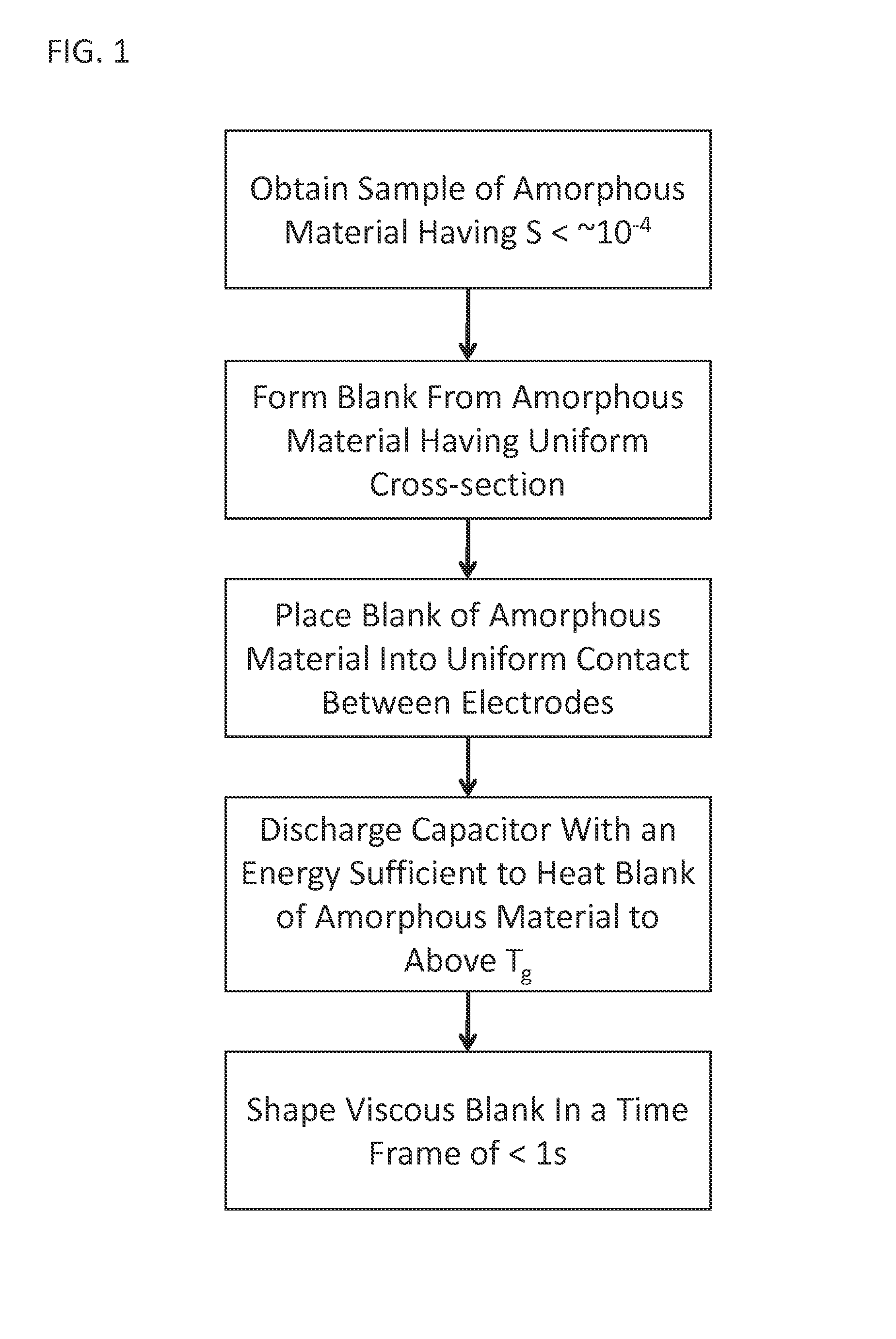

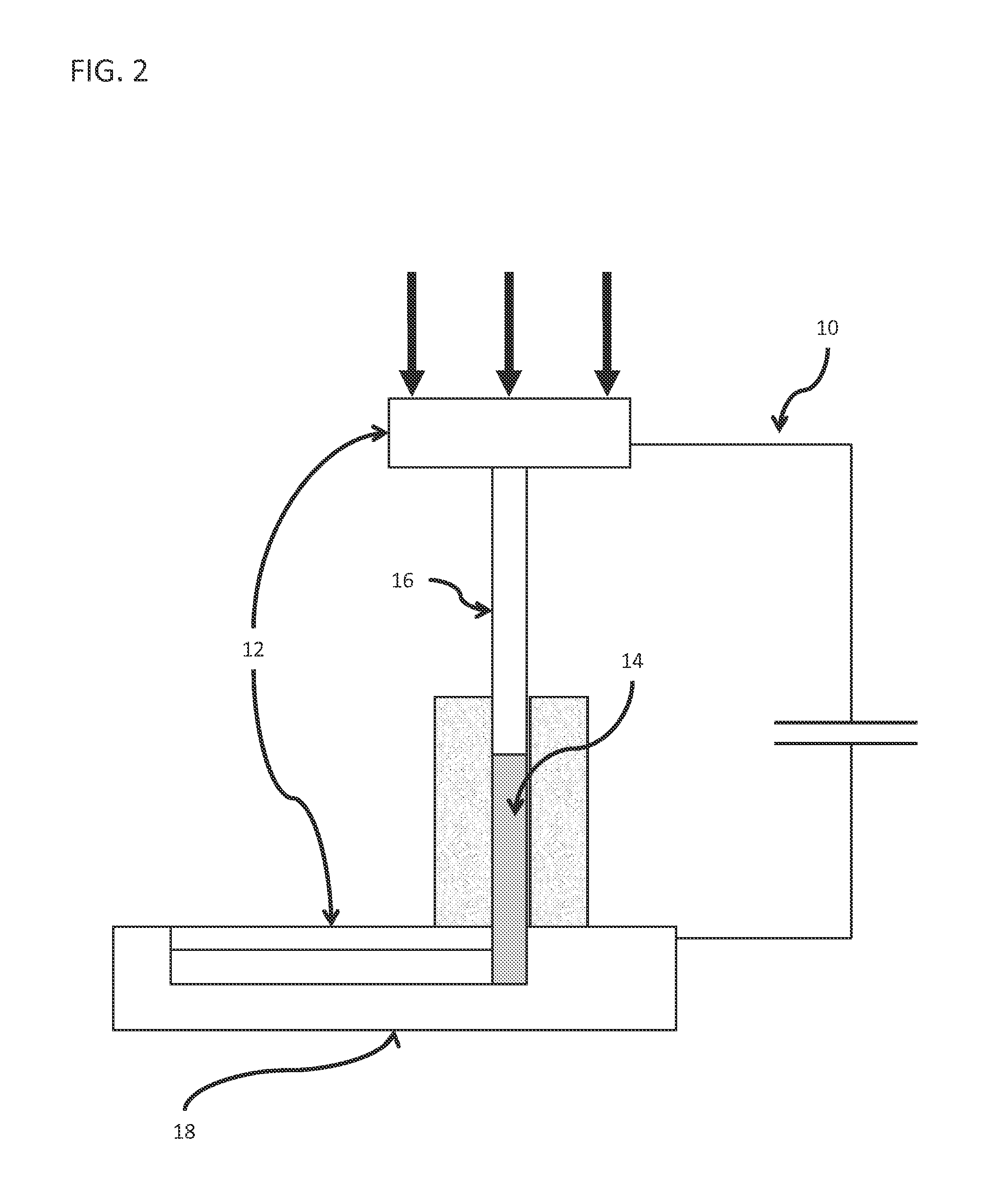

Sheet forming of metallic glass by rapid capacitor discharge

ActiveUS8613815B2Avoid thermal transport and development of thermalHeating evenlyDielectric heatingShaping toolsAlloyGlass transition

Owner:CALIFORNIA INST OF TECH

Low-alloy high speed steel roll material and preparation method thereof

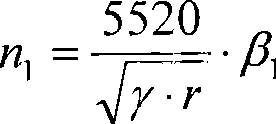

InactiveCN101078090AReduce manufacturing costImprove red hardnessFurnace typesRollsProduction rateChemical composition

A kind of low alloy high speed steel roller material and the method to produce it. The chemical components of it is( weight percent): C: 1.2-1.8%, Cr: 4.5-6.5%, W: 1.0-3.0%, Mo: 1.0- 3.0%, V: 3.0-5.0%, Al: 0.6-1.2%, Si: 0.8-1.2%, N: 0.05-0.15 %, B: 0.04-0.12%, Nb: 0.05-0.20%, Ti: 0.06-0.18%, Y: 0.04- 0.15%, Mn<0.5%, P<0.04%, S<0.04%, the other is Fe, and the actual content of carbon of it is: 0.033W+0.063Mo+0.060Cr+0.200V+(0.08-0.20). It is made by smelting with electric cooker, the roller is molded by centrifugal complex cast or continuous complex cast, the roller will be quenched and tempered after it has been processed rudely, and the regulated size and accuracy will fulfilled after a fine machining at last. Less Tungsten and Molybdenum element are contained in the low alloy high speed steel roller material, and it does not contain the expensive Cobalt, the production cost of it is lower, and it own high red-hardness, obdurability and abrasion resistance. This patent can improve the productivity of the rolling mill, and prolong the life of roller, and decrease the cost of rolled metal.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

Composite roller for high vanadium high speed steel and its production process

The invention offers the high V super-speed steel complex roller and its producing craft. The roller includes roller heart and roller shell, the roller heart uses low metal alloy steel or middle carbon steel to produce, the shell uses high V super-speed steel, whose main element is : C: 1.8--3.5A%, V: 7--12%, Cr: 4--5%, Mo: 2--4%, Ni: 0.5--1.5%, other is Fe. The producing craft is: melt and cast the heart and shell by responding heat way. The roller in the invention has good whet feature, high rate of feature and price, using safely. Fine roller, high strength of combination, no crush in use; it can reduce the stop times. It efficiently increase the roller tenacity and whet feature, solve the problems in the heart leaving foundry, and solve the problems of complicated craft and high cost.

Owner:HENAN UNIV OF SCI & TECH +1

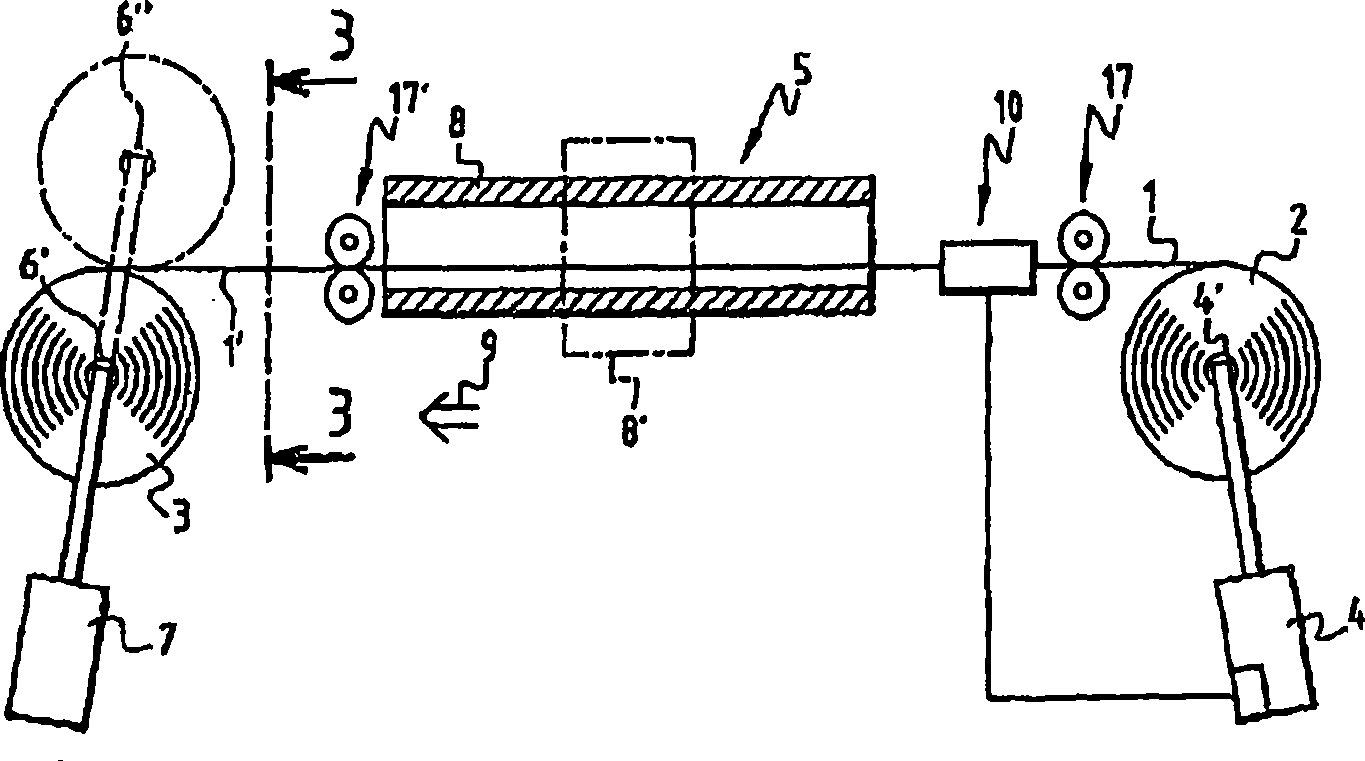

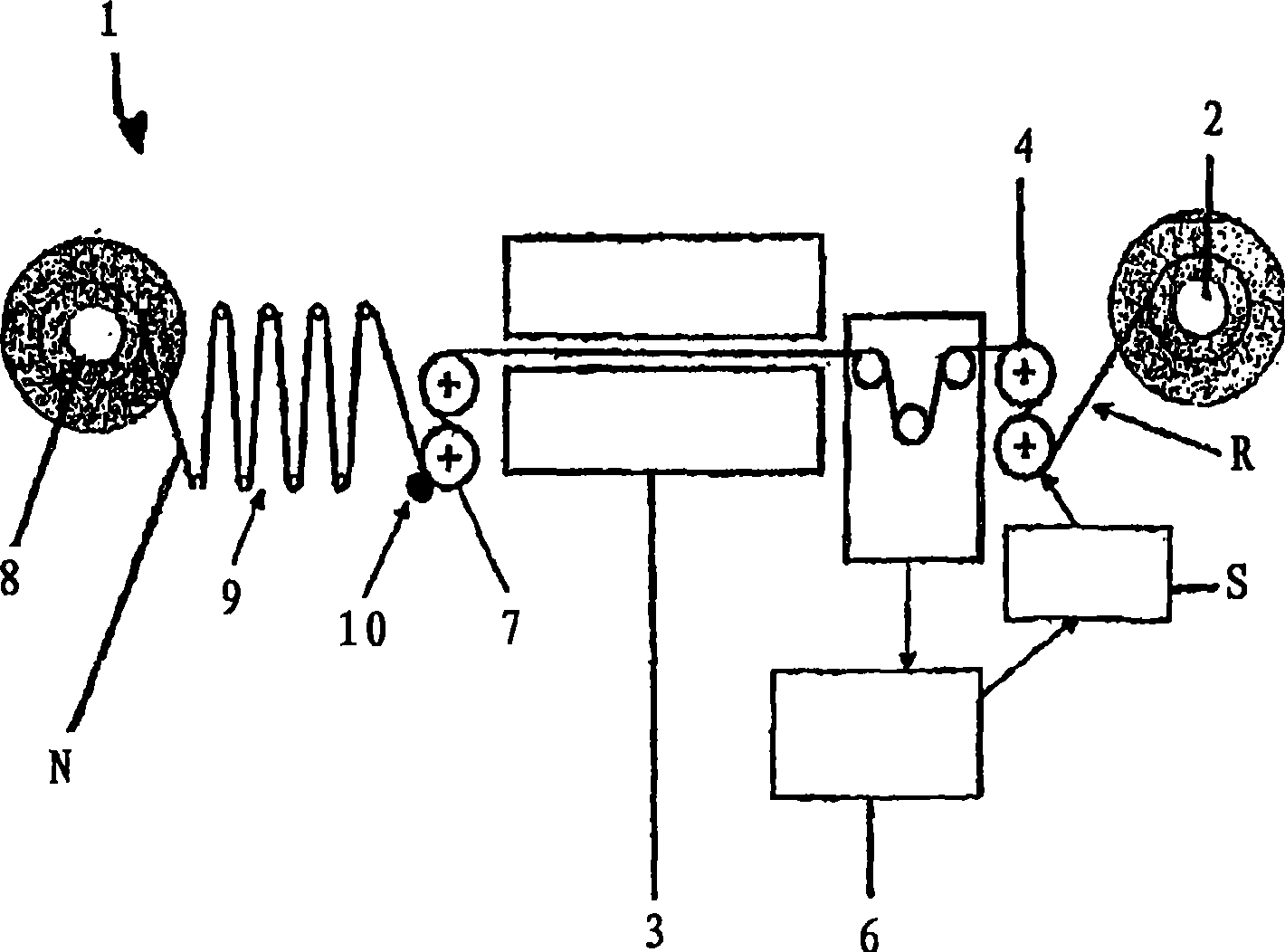

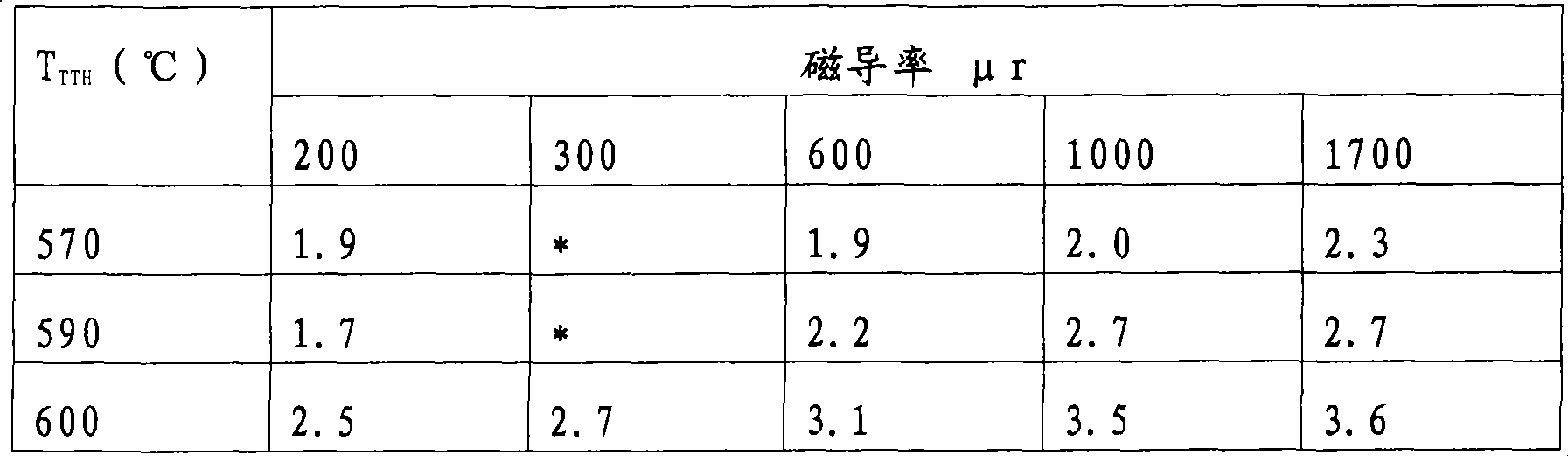

Method of producing a strip of nanocrystalline material and device for producing a wound core from said strip

The invention relates to a method of producing a strip of nanocrystalline material which is obtained from a wound ribbon that is cast in an amorphous state, having atomic composition [Fe1-a-bCoaNib]100-x-y-2-alpha-beta-gamma Cu<x>Si<y>BzNbalphaM'betaM''gamma, M' being at least one of elements V, Cr, Al and Zn, and M being at least one of elements C, Ge, P, Ga, Sb, In and Be, with: a <= 0.07 and b = 0.1, 0.5 <= x <=1.5 and 2 <= a <= 5, 10 <= y <= 16.9 and 5 <= z <= 8, beta <= 2 and gamma <= 2. According to the invention, the amorphous ribbon is subjected to crystallisation annealing, in which the ribbon undergoes annealing in the unwound state, passing through at least two S-shaped blocks under voltage along an essentially longitudinal axial direction of the ribbon, such that the ribbon is maintained at an annealing temperature of between 530 DEG C and 700 DEG C for between 5 and 120 seconds and under axial tensile stress of between 2 and 1000 Mpa. The tensile stress applied to the amorphous ribbon, the displacement speed of the ribbon during annealing and the annealing time and temperature are all selected such that the cross-section profile of the strip is not in the form of Omega and the maximum deflection of the cross-section of the strip is less than 3% of the width of the strip and preferably less than 1% of the width. The invention also relates to the strip and the core thus obtained and to the device used to implement the method.

Owner:IMPHY ALLOYS

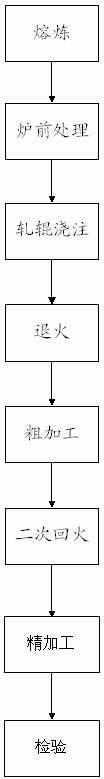

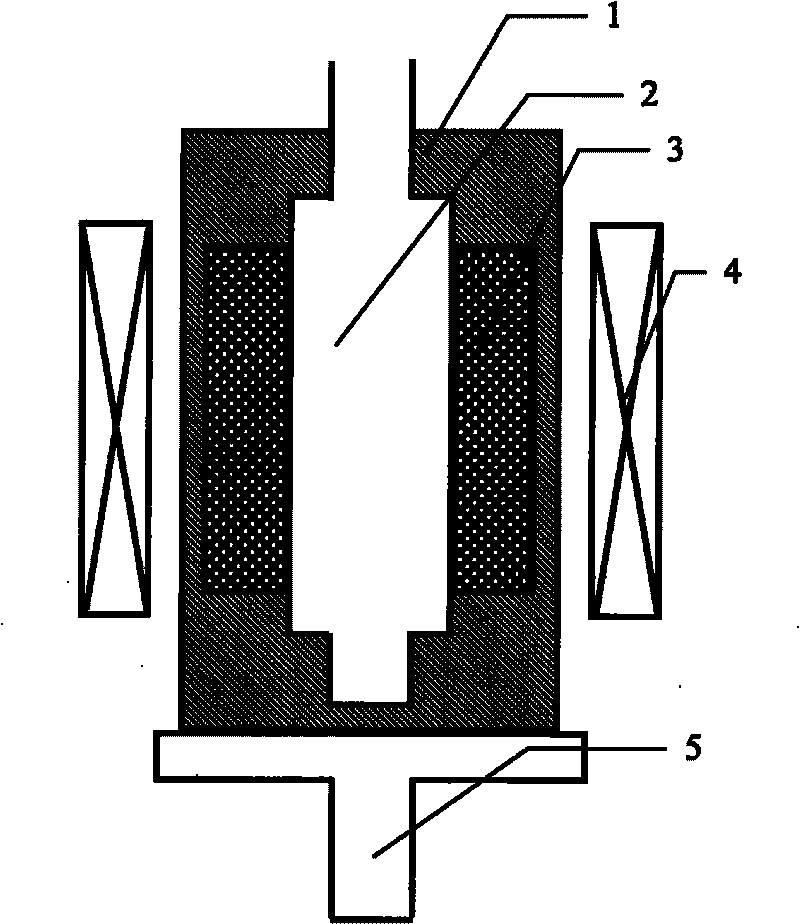

Boron-contained centrifugal composite high-speed steel roller and manufacturing method thereof

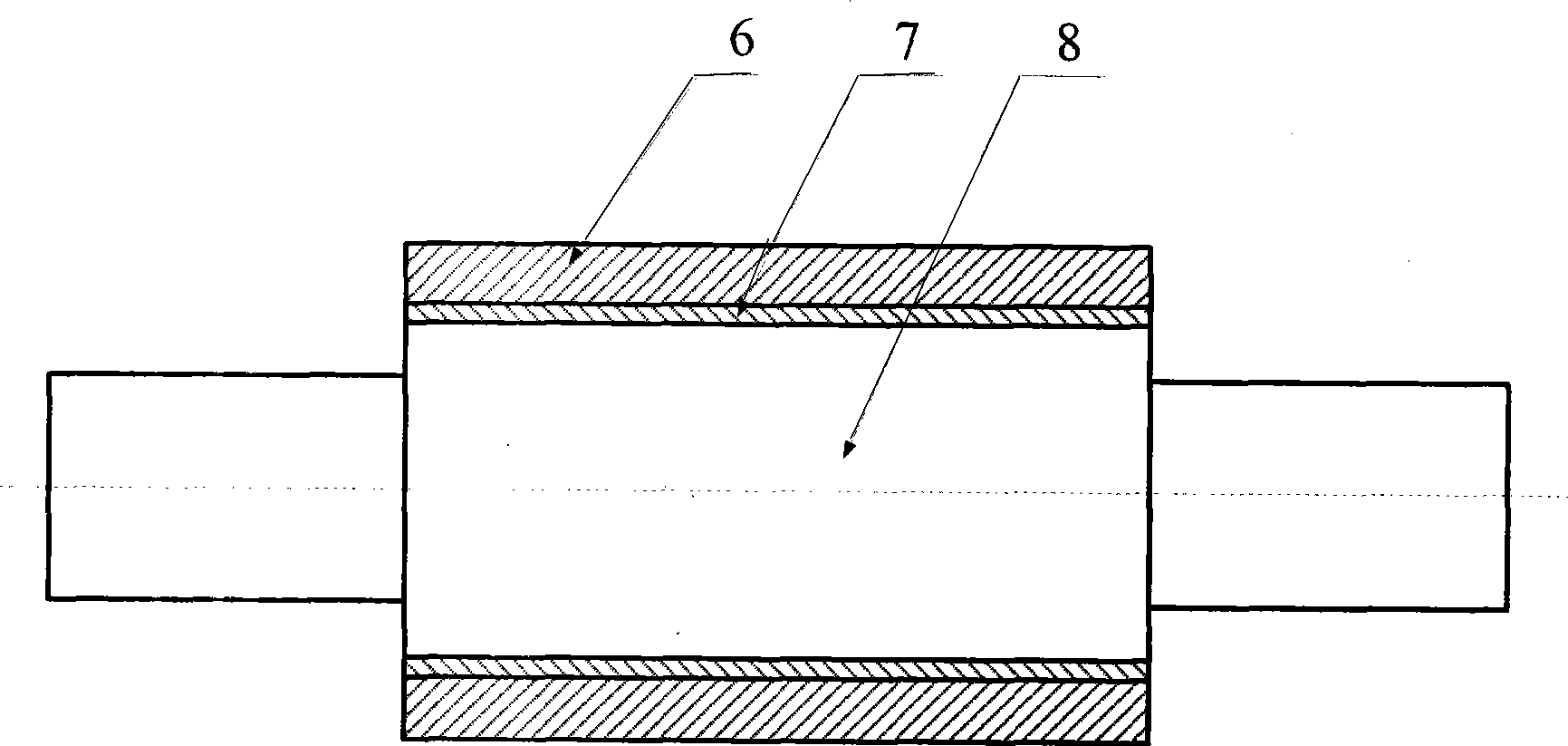

InactiveCN102615106AImprove composite effectNot easy to peel offRollsMetal rolling arrangementsUltimate tensile strengthWear resistance

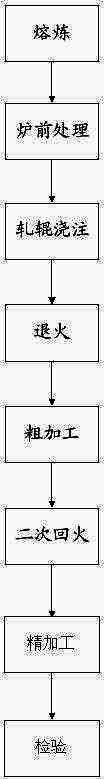

The invention discloses a boron-contained centrifugal composite high-speed steel roller, which comprises an outer layer of the high-speed steel roller, a middle layer of the high-speed steel roller and a core of the high-speed steel roller. The manufacturing method includes steps of smelting, interrupted front treatment, roller pouring, annealing, rough machining, double tempering, finish machining and testing. By the method, three-layer composite roller technology is adopted in the boron-contained centrifugal composite high-speed steel roller, composite ability of the outer layer of the high-speed steel roller and the core of the high-speed steel roller is increased, the roller is less prone to spalling, high in rigidity and accident resistant ability, fine in abrasion resistance, safe in use, low in energy consumption and short in cycle in heat treatment, oxidation and decarburization of the roller and roller breakage in use are avoided. The manufacturing method is simple and hot quenching process is omitted.

Owner:常熟市轧辊厂有限公司

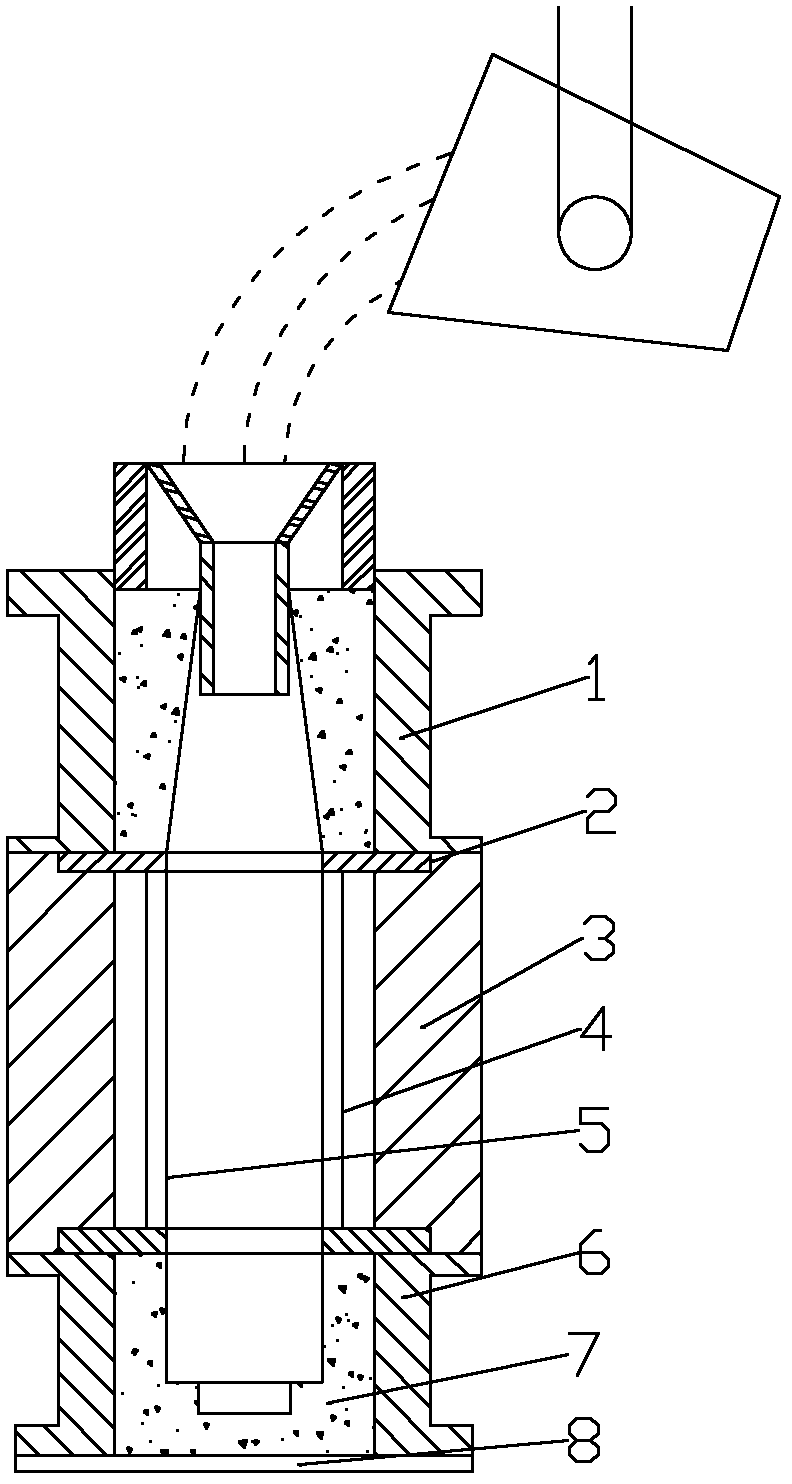

Centrifugal casting production method of high-boron high-speed steel composite roller

A manufacturing method for centrifugally casting high-boron high-speed steel composite roller belongs to the technical field of rolled steel. The invention aims to provide the manufacturing method for centrifugally casting the high boron high-speed steel composite roller without element segregation. The manufacturing method comprises the following steps: injecting high-seed steel liquid into a metal casting mould rotating at high speed on a centrifugal machine after the high-seed steel liquid is cooled by an inclined cooling plate; spaying, cooling and casting the high-seed steel liquid during a pouring process; and then centrifugally pouring an intermediate layer; finally pouring cast steel or alloyed ductile cast iron in a rolling core in a static state; and then obtaining the high-boron high-speed steel composite roller. The high-boron high-speed steel composite roller has the advantages of fine tissues on an external layer, compactness and no element segregation; and a boron element on the external layer cannot be mixed into a rolling core.

Owner:BEIJING UNIV OF TECH

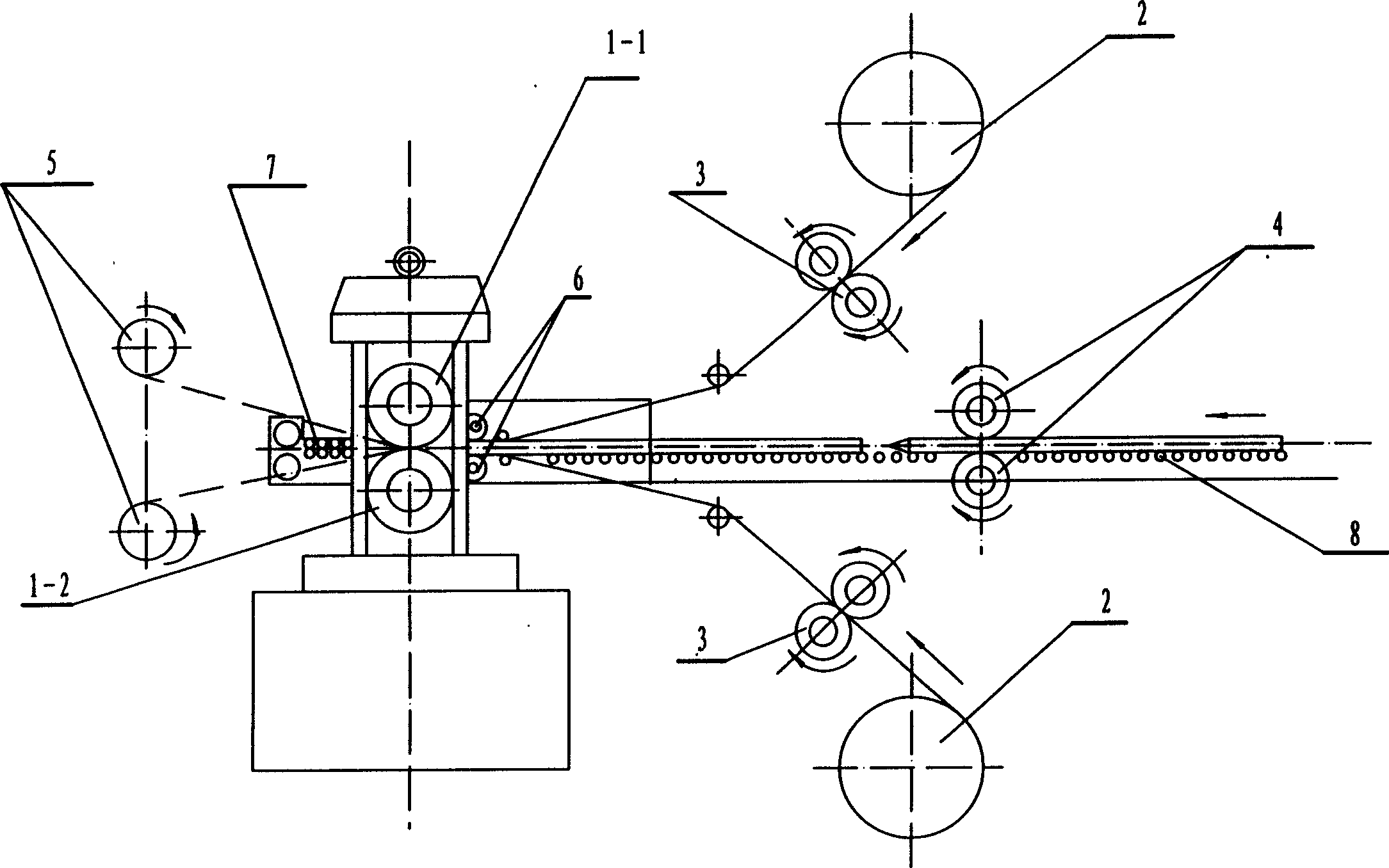

Rolling method and apparatus for copper-aluminium double-face composite board

A technology for rolling the composite Cu-Al plate includes such steps as preheating the copper band and aluminium plate respectively at different temp for different time, acid washing of copper band, alkali washing of aluminium plate, brushing surface by steel wire brush, rolling by a pair of upper concave roller and lower convex roller, annealing in inertial gas, and straightening.

Owner:SHENYANG POLYTECHNIC UNIV

Rare earth multicomponent micro-alloying high-chromium cast iron and uses thereof

ActiveCN101012526AInhibition of germinationInhibition of scalabilityExtrusion profiling toolsRollsRare earthManganese

The invention discloses a polyvalent microalloying high-chromium cast-iron and usage of rare earth, which comprises the following parts: 1.0-3.5% carbon, 8.0-26.0% chromium, 0.5-4.5% nickel, 0.15-2.0% molybdenum, 0.5-2.0% copper, 0.05-2.0% aluminium, 0.03-0.3% vanadium, 0.005-0.20% rare earth, not more than 0.5% silicon, not more than 0.7% manganese, not more than 0.05% phosphor and ferric.

Owner:JINAN JIN PIN MAGNETIC MATERIALS & DIVECES

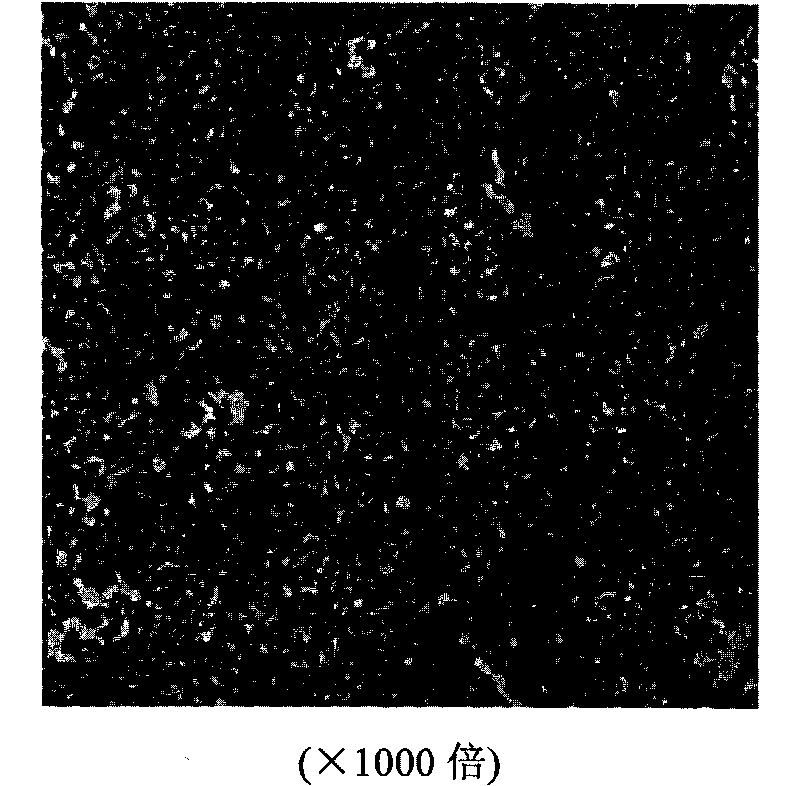

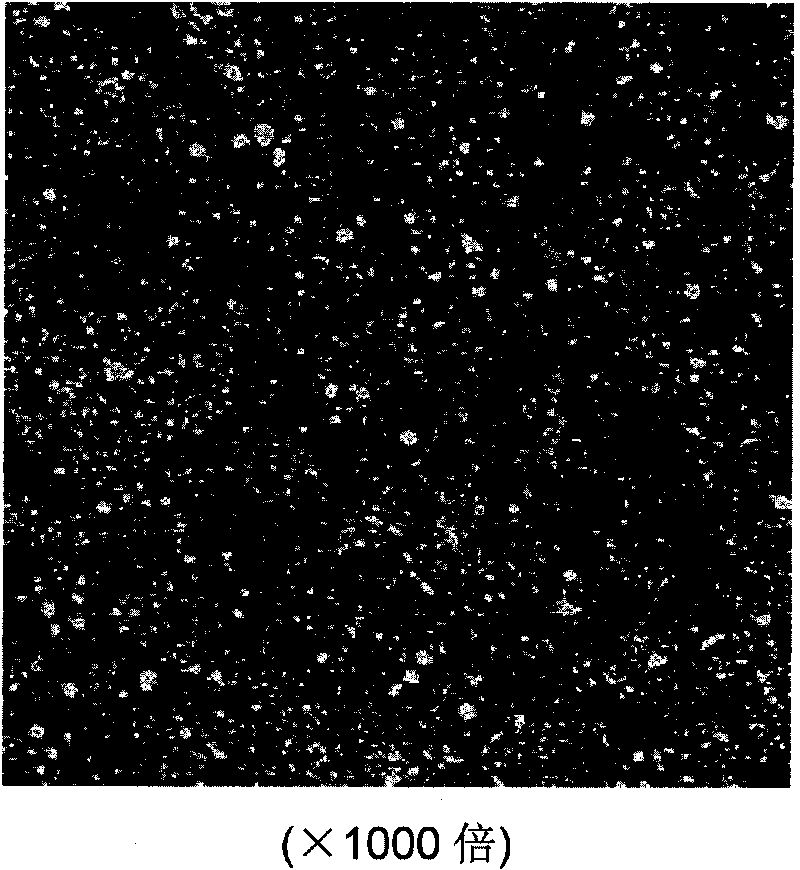

High-speed steel roll and preparation method thereof by centrifugal compounding in electromagnetic field

InactiveCN101705430AInhibition of segregationUniform coagulation tissueFurnace typesRollsCasting moldUltimate tensile strength

The invention relates to a high-speed steel roll and a preparation method thereof by centrifugal compounding in an electromagnetic field, belonging to the technical field of preparation of the high-speed steel roll. The components of a working layer material of the high-speed steel roll are as follows (in weight percent): 1.5 to 2.5 percent of C, 4.0 to 6.0 percent of V, 4.0 to 6.0 percent of W, 1.5 to 4.5 percent of Mo, 2.0 to 4.0 percent of Cr, 0.04 to 0.18 percent of Zr, 0.001 to 0.003 percent of B, less than or equal to 0.5 percent of Si, less than or equal to 0.5 percent of Mn, and the balance of Fe and impurity elements; and in the impurity elements, the required contents of S, P and O are respectively less than 0.01 percent, less than 0.01 percent and less than 0.0010 percent. The roll is cast by adopting a centrifugal compounding method in a pulse electromagnetic field, the frequency of the pulse magnetic field is 0.1 to 10Hz, and the peak strength of a central magnetic field of a cast mold is 1 to 10T. The roll has a plurality of precipitation strengthening phases, and the applied pulse magnetic field leads the strengthening phases and matrix crystal grains to be refined effectively and leads the strengthening phases to be distributed in a dispersed manner, thus overcoming the segregation of alloy elements and greatly improving the performance of the roll.

Owner:JIANGSU UNIV

Cold work roll steel for high-strength steel rolling, cold work roll and its manufacturing method

The invention discloses cold work roll steel for high-strength steel rolling, a cold work roll and its manufacturing method. The material of cold work roll is composed of the following chemical components of: by weight, 0.6-0.8% of C; 0.6-1.5% of Si; 0.6-1.5% of Mn; 4.0-6.0% of Cr; 0.5-2.0% of Mo; 0.5-1.0% of V; P being less than or equal to 0.020%; S being less than or equal to 0.015%; and the balance being Fe and unavoidable impurities. The manufacturing process comprises steps of: electric furnace smelting; secondary refining; vacuum degasification; electric bar casting; electroslag refining; ingot casting; forging; preheat treatment; rough machining; quenching and tempering treatment; semi-finish machining; final heat treatment; finish machining; and finished product. According to thenovel cold work roll provided by the invention, the ratio of the alloy elements is optimized based on 5% of Cr. By the adoption of a short-time high-temperature solid solution quenched-tempered heat treatment technology, the roll strength and wear resistance of the cold work roll are improved, thus satisfying production requirements of high-strength cold rolled strips.

Owner:BAOSHAN IRON & STEEL CO LTD

Apparatus for calendering paper

The invention relates to a method for operating a calender, comprising a cylindrical heated roll and a flexible belt surrounding a stationary support beam which supports at least one actuator which may urge a concave load shoe against the heated roll by means of said flexible belt to form an extended and heated nip through which a fiber web passes to be calendered and a separating mechanism for having at least one of the rolls movable into and away from the nip characterized in that said flexible belt is a flexible tubular jacket which forms a part of an enclosed shoe roll such that the ends of said jacket have end walls mounted thereto, which end walls are rotatably mounted in relation to said support beam, and in that at least one of said end walls is driven by means of a drive arrangement which drive arrangement may be activated to drive the end walls and thereby also the jacket independently of its position in relation to the fiber web or the heated roll.

Owner:VALMET TECH INC

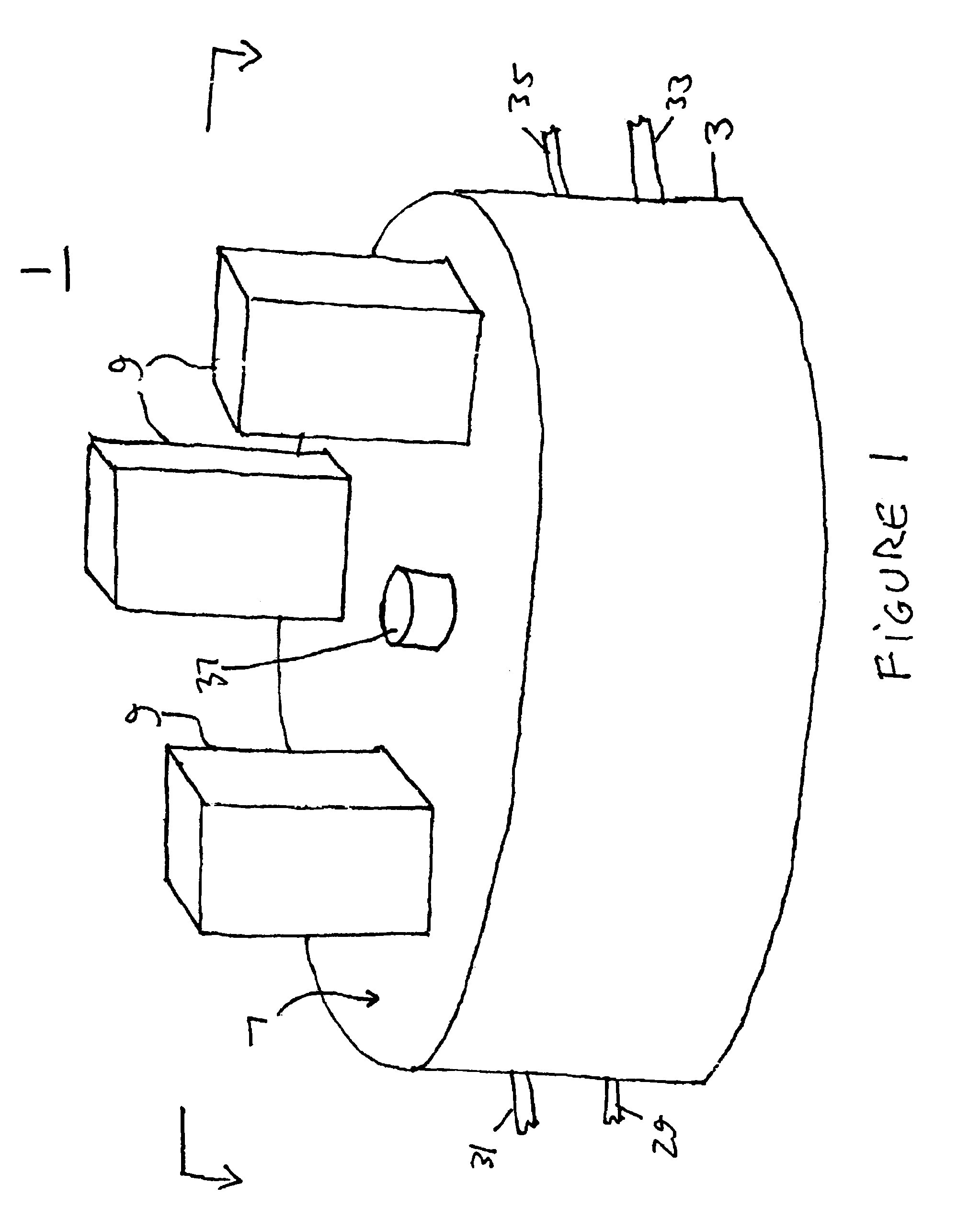

Modular fuel cell system

ActiveUS9190693B2Improve efficiencyIncreased complexityFuel cell heat exchangeReactant parameters controlFuel cellsAutomotive engineering

A fuel cell stack module includes a base, a cover dome removably positioned on the base, and a plurality of fuel cell stacks removably positioned on the base below the cover dome. A modular fuel cell system includes a plurality of the fuel cell stack modules, where each fuel cell stack module may be electrically disconnected, removed from the fuel cell system, repaired or serviced without stopping an operation of the other fuel cell stack modules in the fuel cell system.

Owner:BLOOM ENERGY CORP

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com