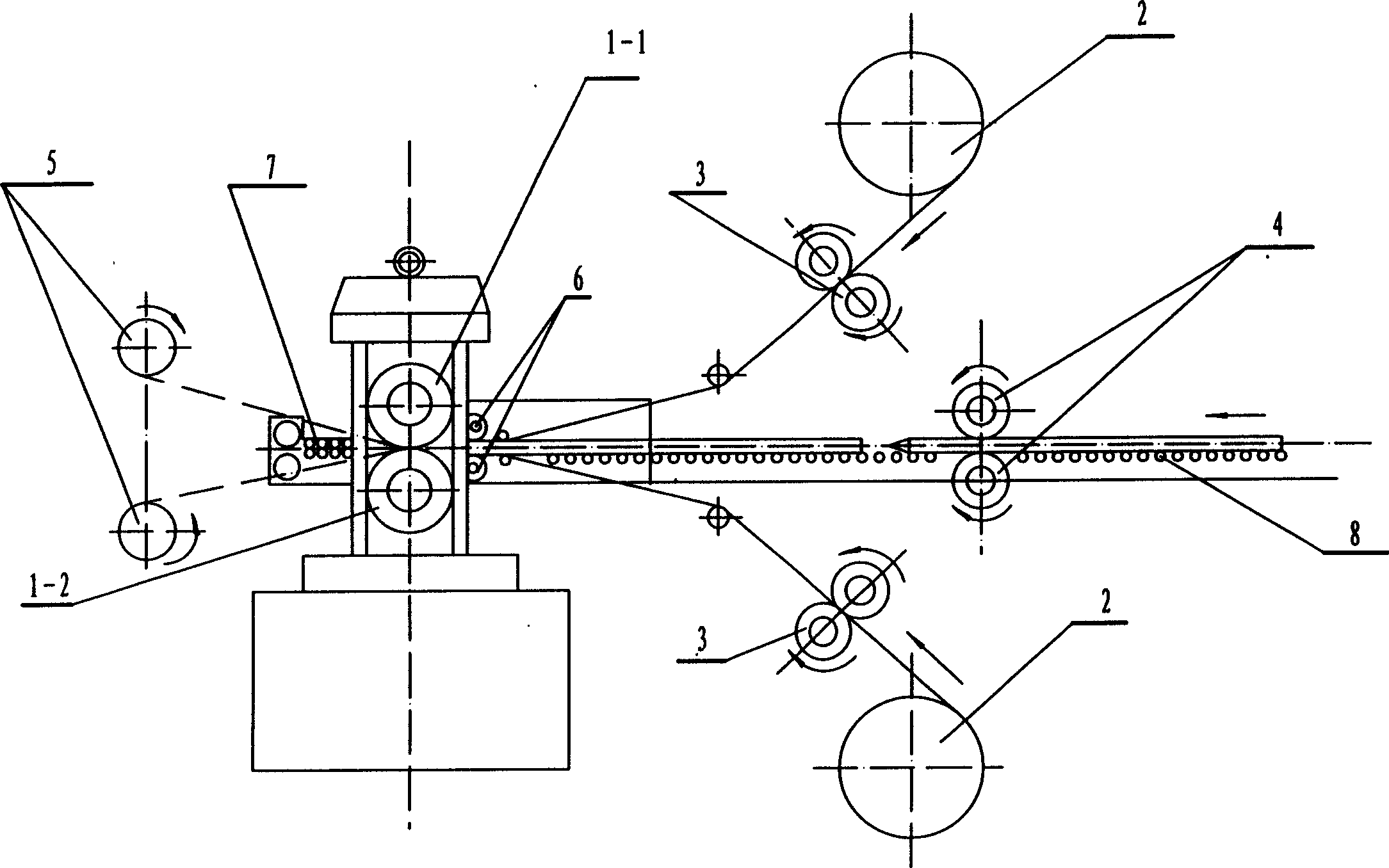

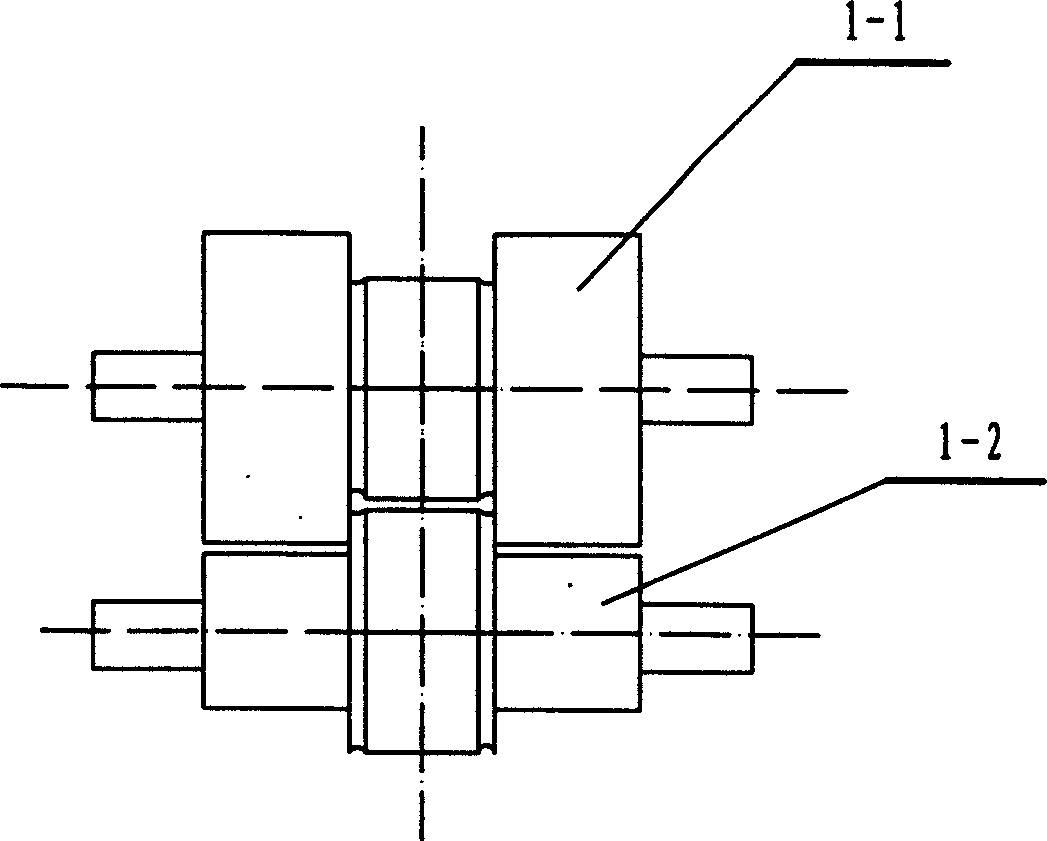

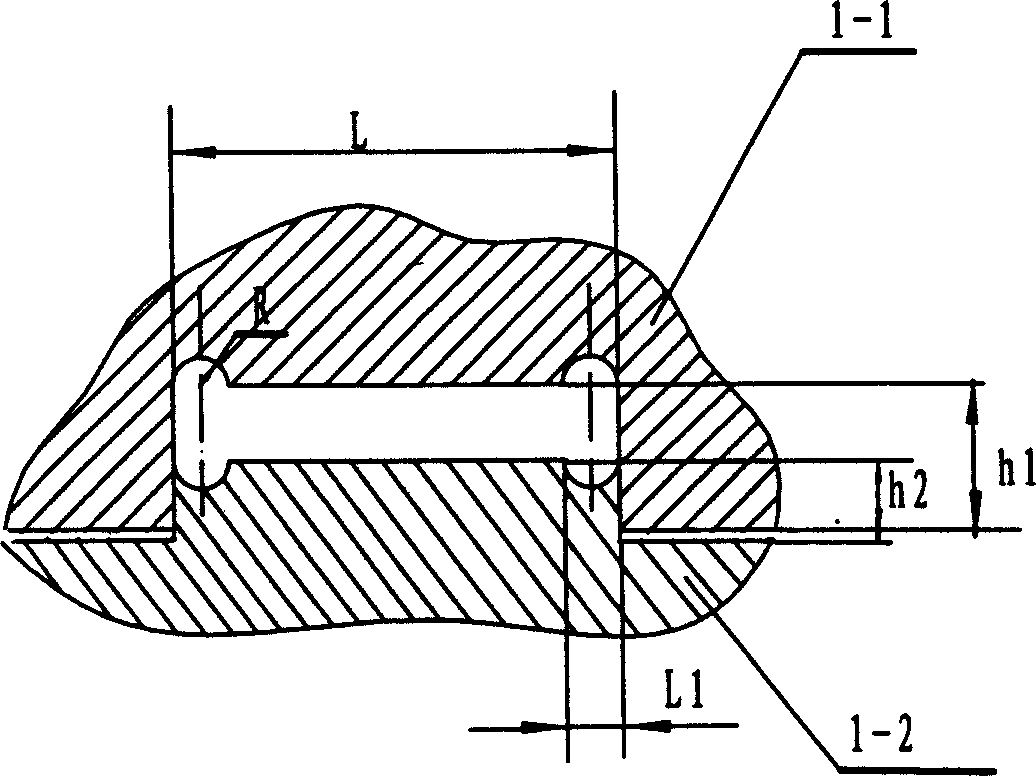

Rolling method and apparatus for copper-aluminium double-face composite board

A composite plate, double-sided technology, used in workpiece surface treatment equipment, metal rolling, metal rolling, etc., can solve problems such as fusing at joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] First, a Cu: 99.9% copper strip with a thickness of 0.8 mm and a length of 1000 mm and an Al: 99.8% aluminum plate with a thickness of 18 mm, a width of 80 mm and a length of 1000 mm were subjected to preliminary heat treatment. Copper was kept at 330°C for 1.5 hours and aluminum at 300°C for 1.5 hours. After the preparatory heat treatment, the copper strip is pickled. The formula of the acid solution is to add H to one liter of water. 2 SO 4 ≥93% concentrated sulfuric acid 115g, HCl≥30% concentrated hydrochloric acid 100g, HF≥24% hydrofluoric acid 15g, HNO 3 ≥90% concentrated nitric acid 110 grams, soak the copper strip at room temperature for 30 minutes and then wash it with water to remove the residual acid.

[0047] The aluminum plate is washed with alkali, and the formula of the alkali solution is to add 100 grams of solid sodium hydroxide, 105 grams of sodium carbonate, and 110 grams of sodium bicarbonate to one liter of water, soak the aluminum plate at room te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com