Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1521 results about "Surface oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oxide Surface. Surface oxides are formed in three stages: (1) oxygen chemisorption, (2) formation of the oxide layer, and (3) thickening of the oxide (9).

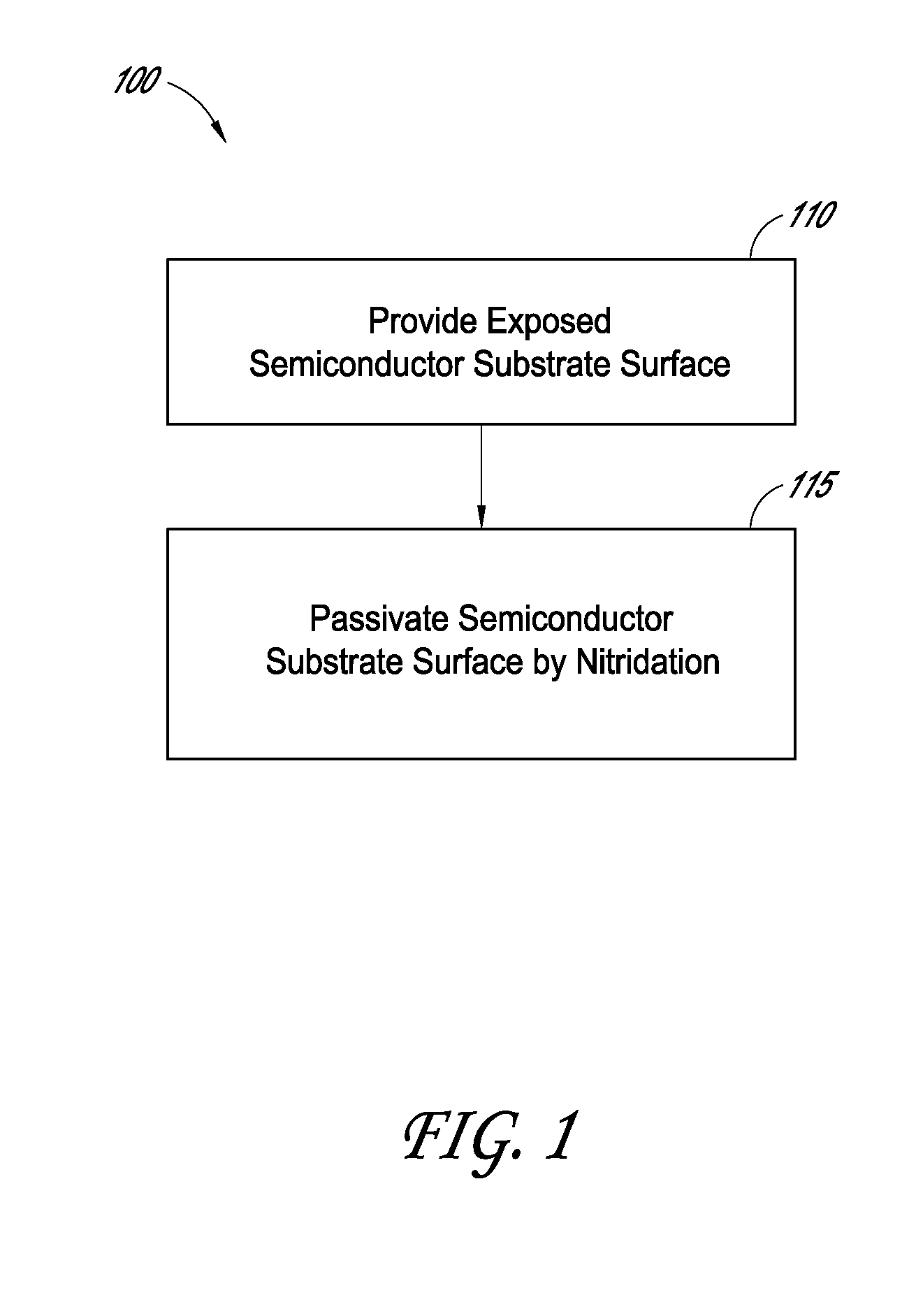

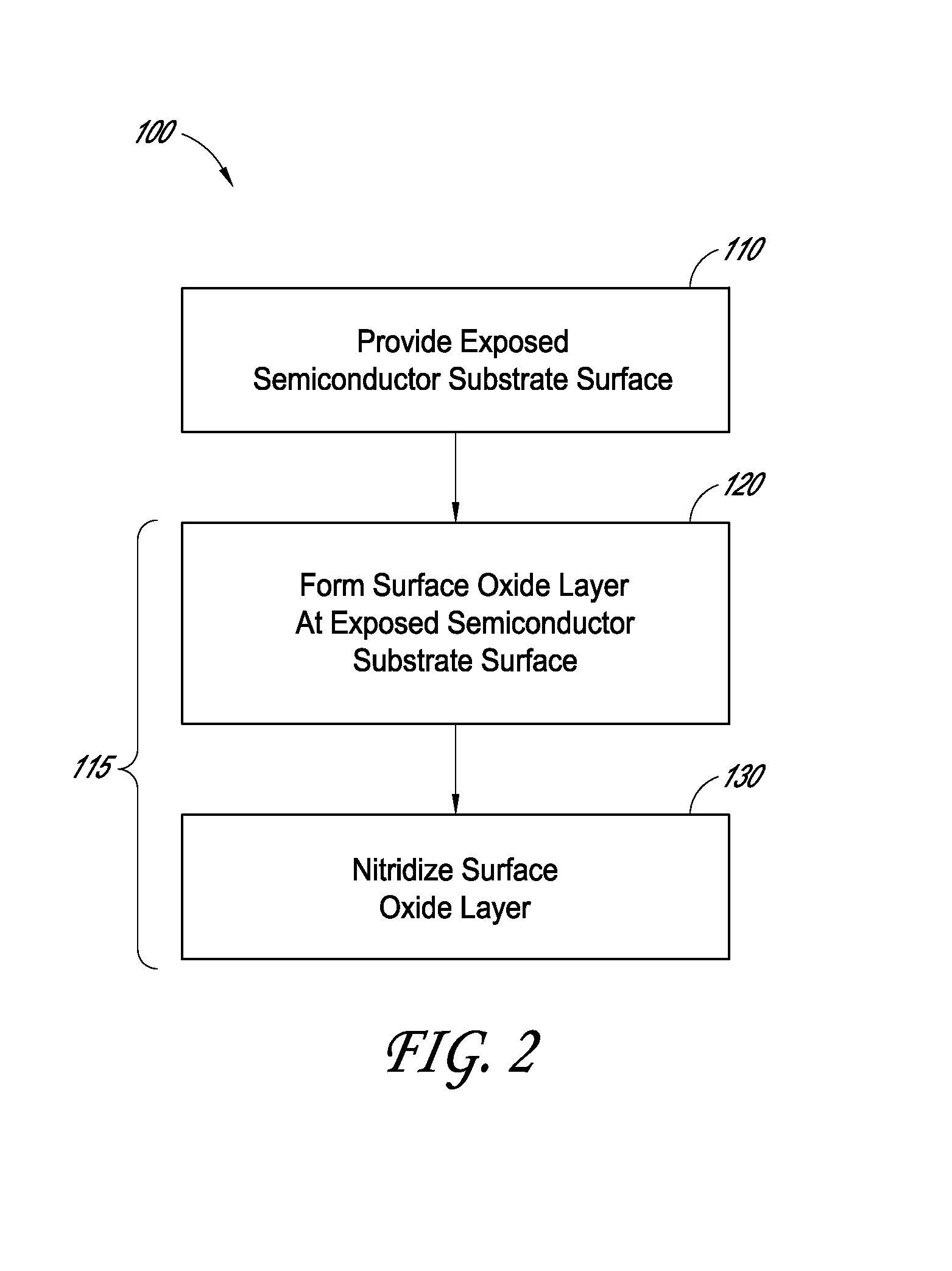

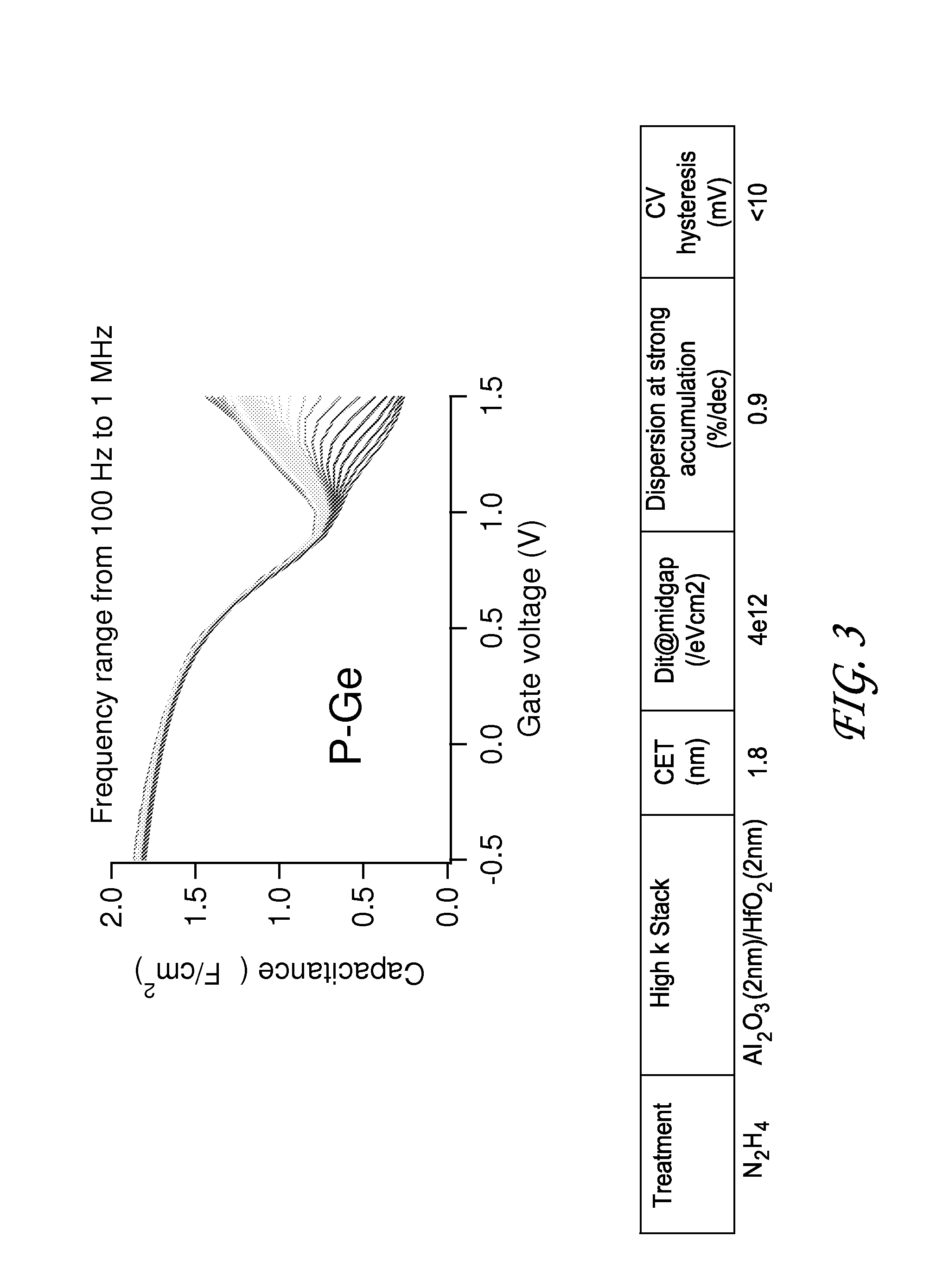

Methods for semiconductor passivation by nitridation

ActiveUS20160358772A1Improve mobilitySemiconductor/solid-state device detailsSolid-state devicesNitrogenAtomic layer deposition

In some embodiments, a semiconductor surface having a high mobility semiconductor may be effectively passivated by nitridation, preferably using hydrazine, a hydrazine derivative, or a combination thereof. The surface may be the semiconductor surface of a transistor channel region. In some embodiments, a semiconductor surface oxide layer is formed at the semiconductor surface and the passivation is accomplished by forming a semiconductor oxynitride layer at the surface, with the nitridation contributing nitrogen to the surface oxide to form the oxynitride layer. The semiconductor oxide layer may be deposited by atomic layer deposition (ALD) and the nitridation may also be conducted as part of the ALD.

Owner:ASM IP HLDG BV

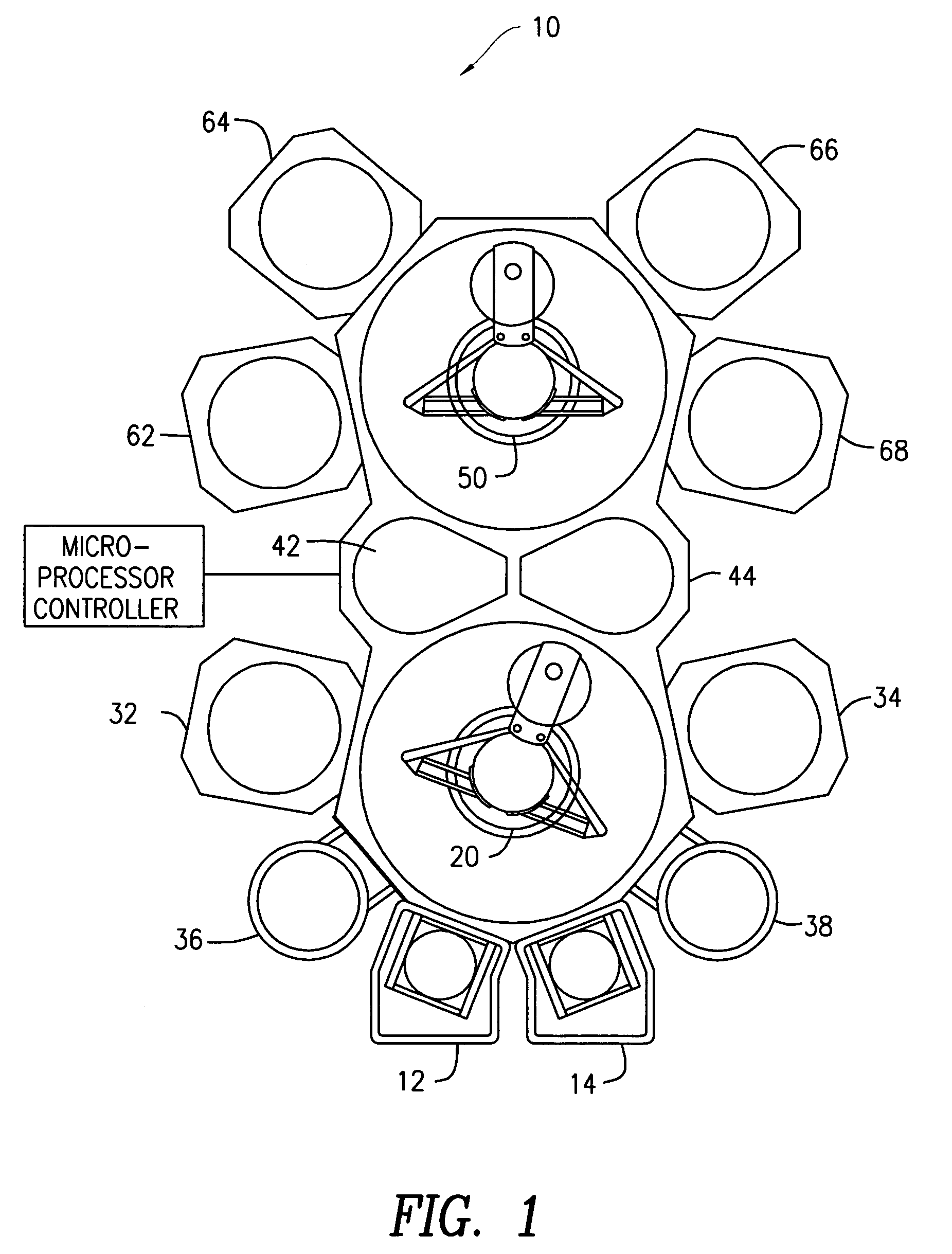

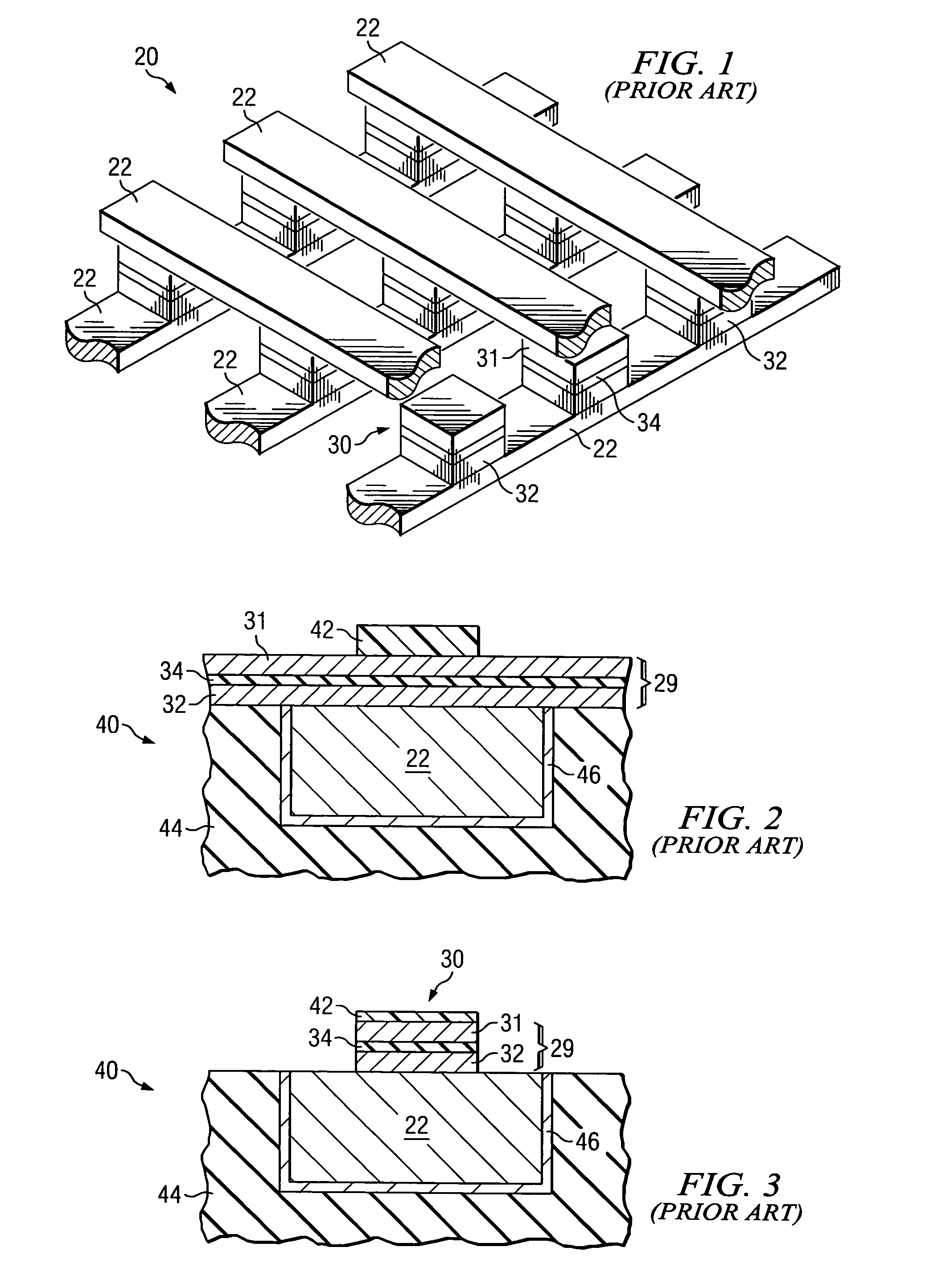

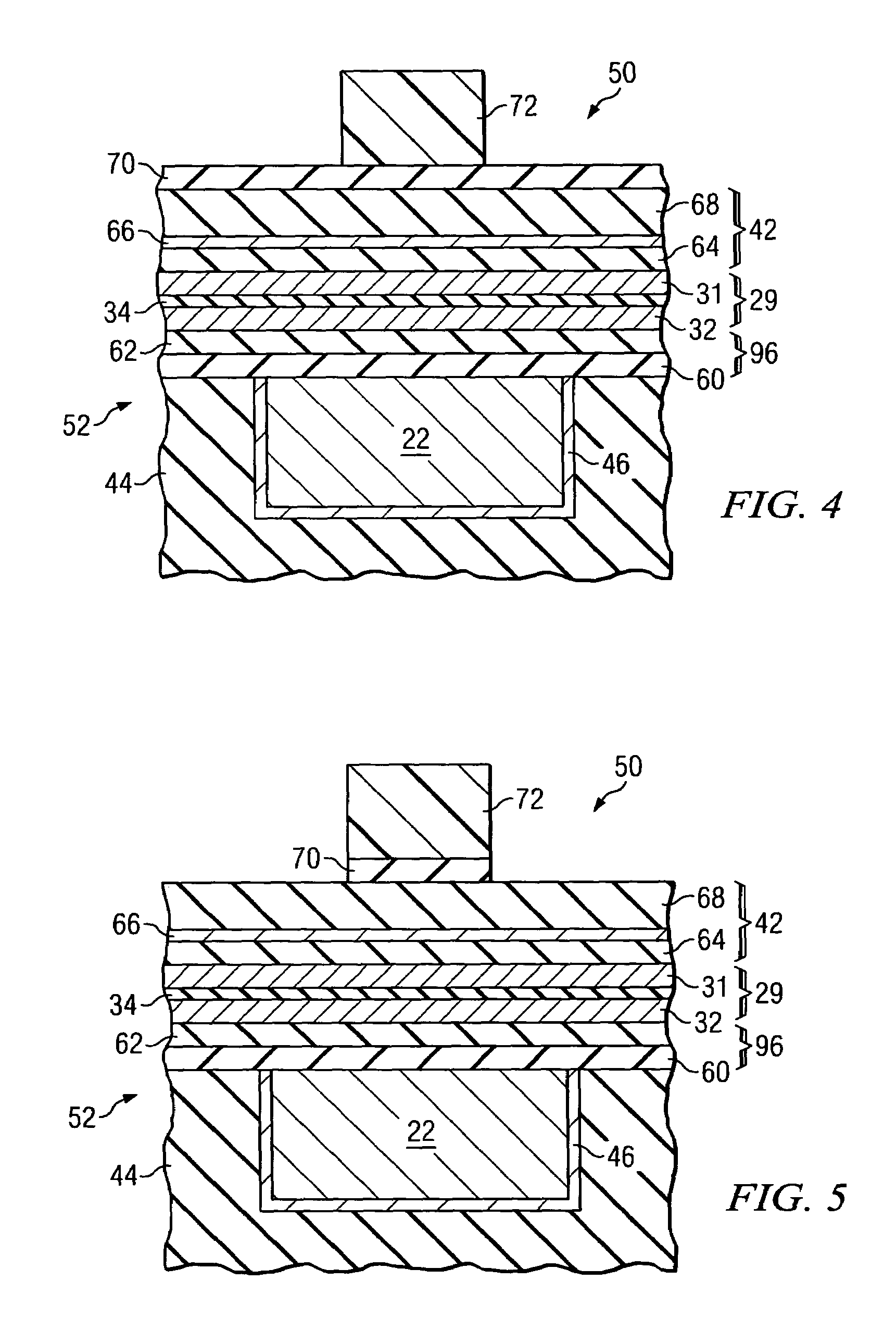

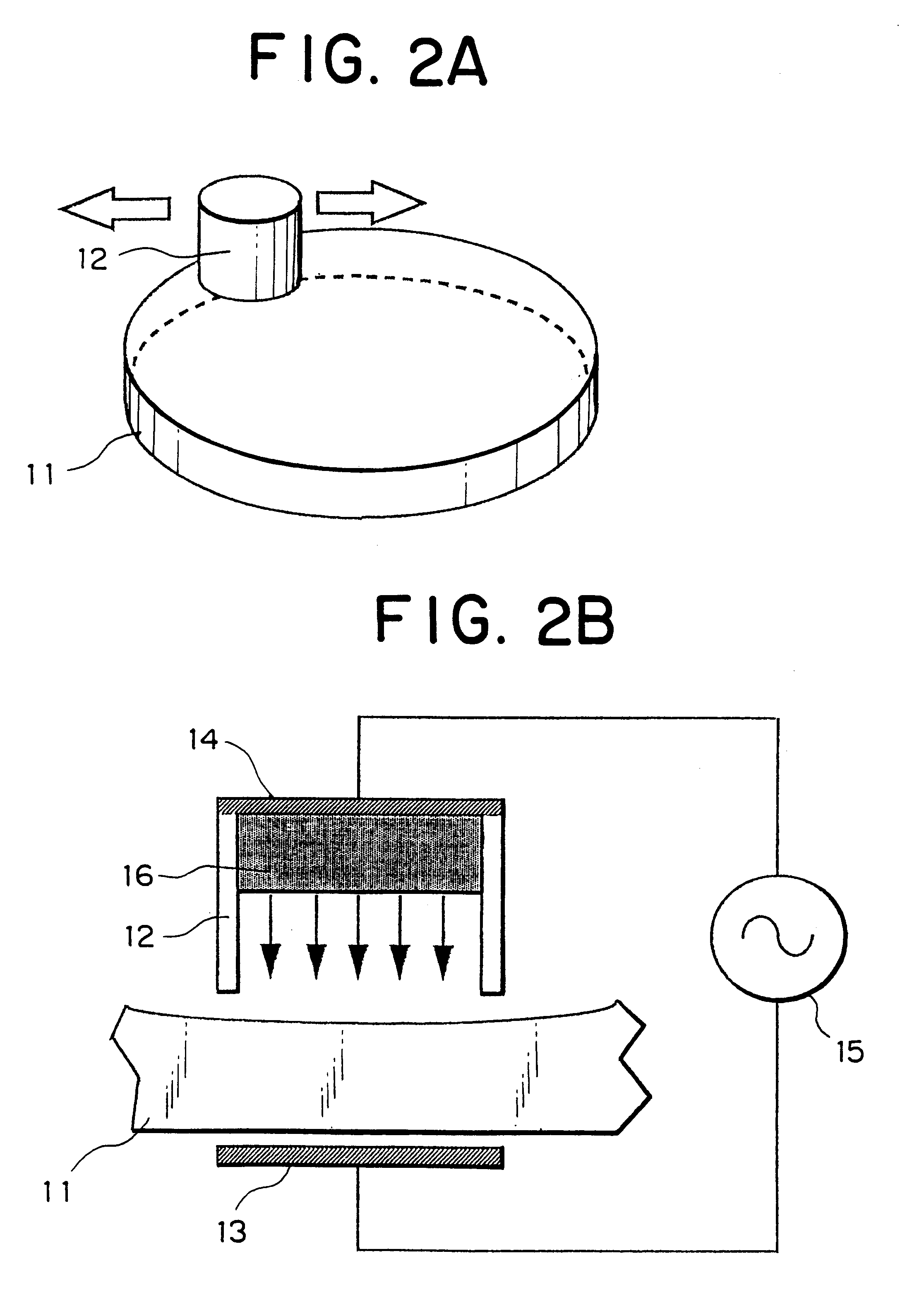

Epitaxial deposition process and apparatus

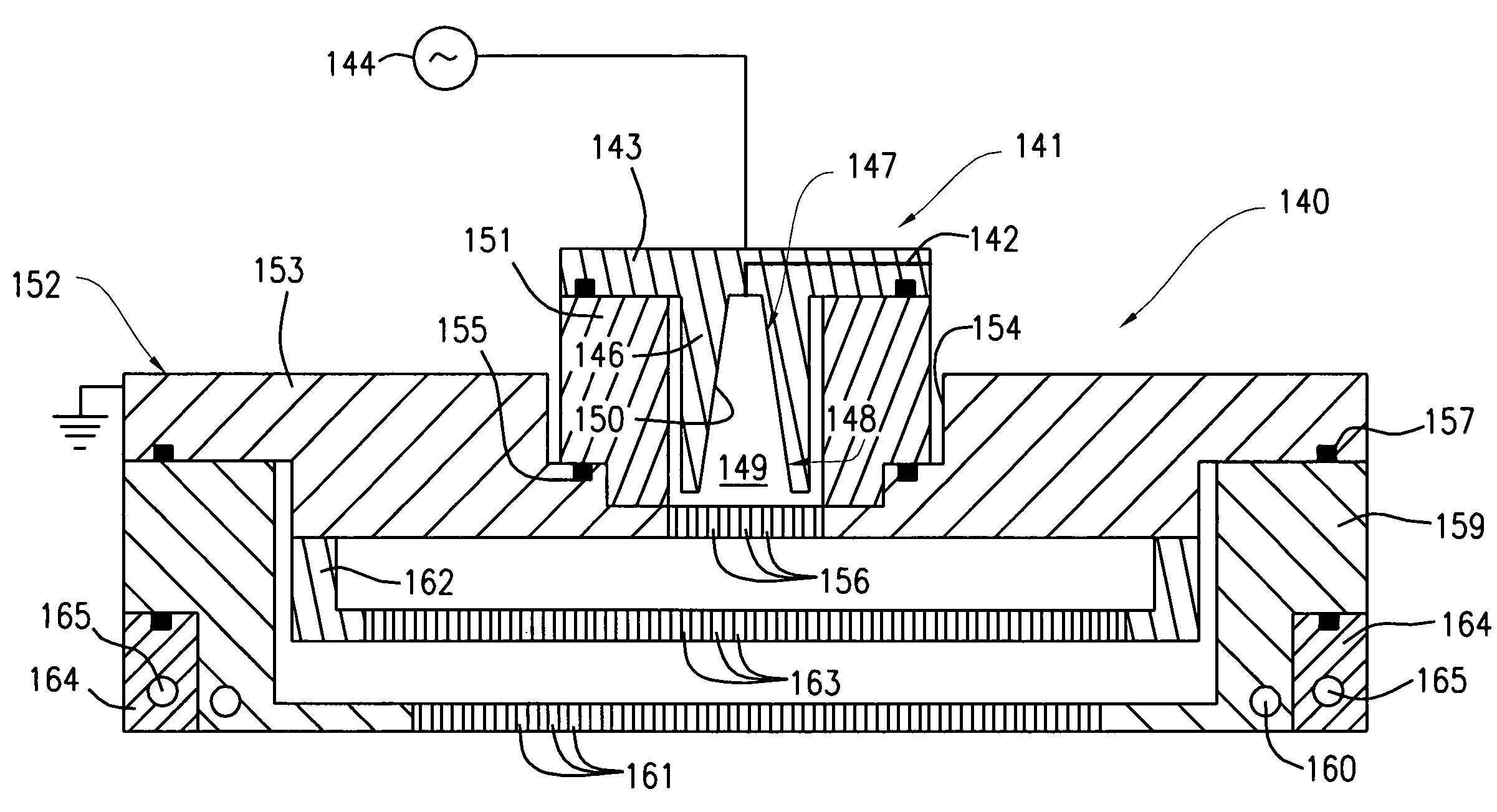

InactiveUS7494545B2Polycrystalline material growthSemiconductor/solid-state device manufacturingReactive gasDeposition process

An epitaxial deposition process including a dry etch process, followed by an epitaxial deposition process is disclosed. The dry etch process involves placing a substrate to be cleaned into a processing chamber to remove surface oxides. A gas mixture is introduced into a plasma cavity, and the gas mixture is energized to form a plasma of reactive gas in the plasma cavity. The reactive gas enters into the processing chamber and reacts with the substrate, forming a thin film. The substrate is heated to vaporize the thin film and expose an epitaxy surface. The epitaxy surface is substantially free of oxides. Epitaxial deposition is then used to form an epitaxial layer on the epitaxy surface.

Owner:APPLIED MATERIALS INC

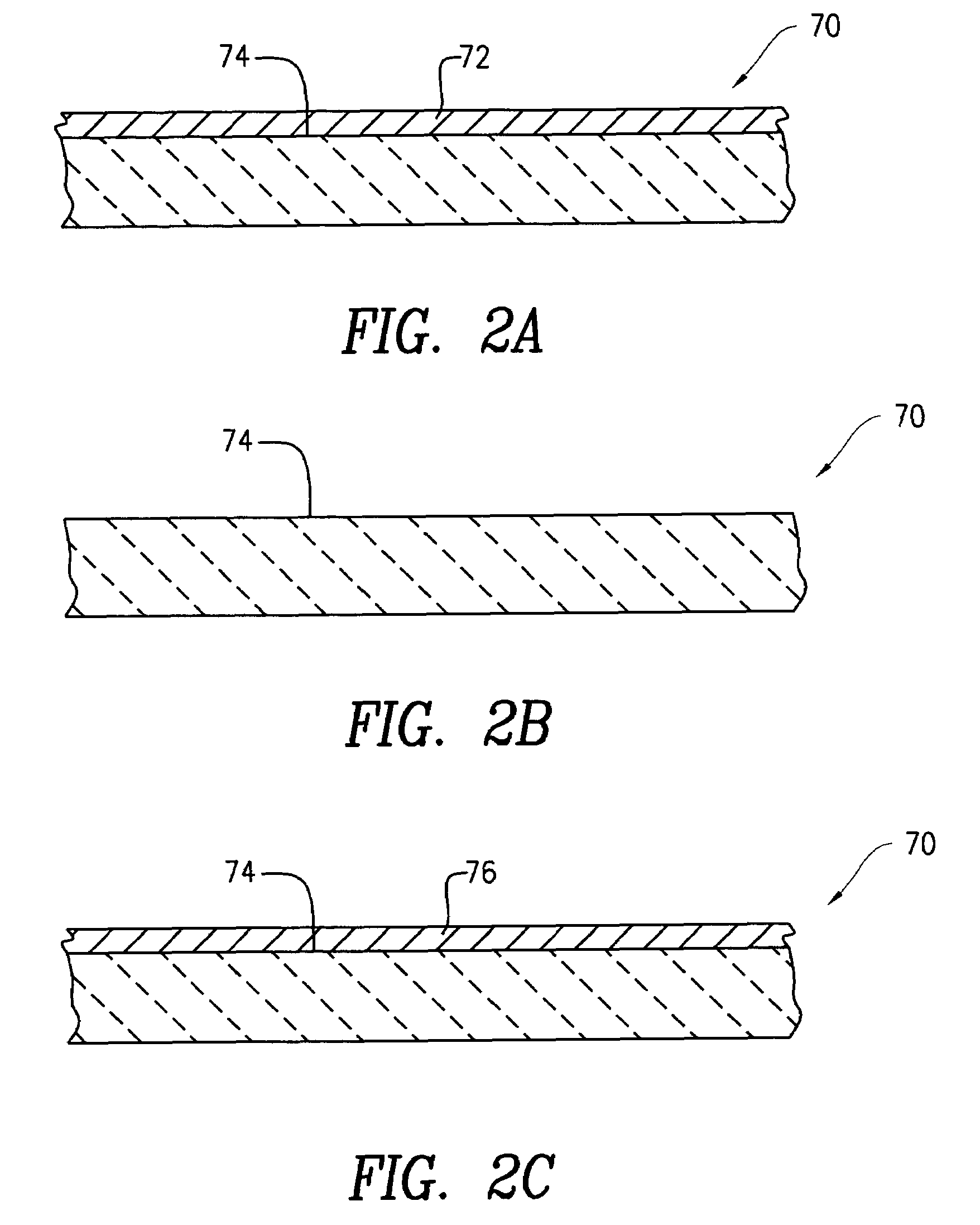

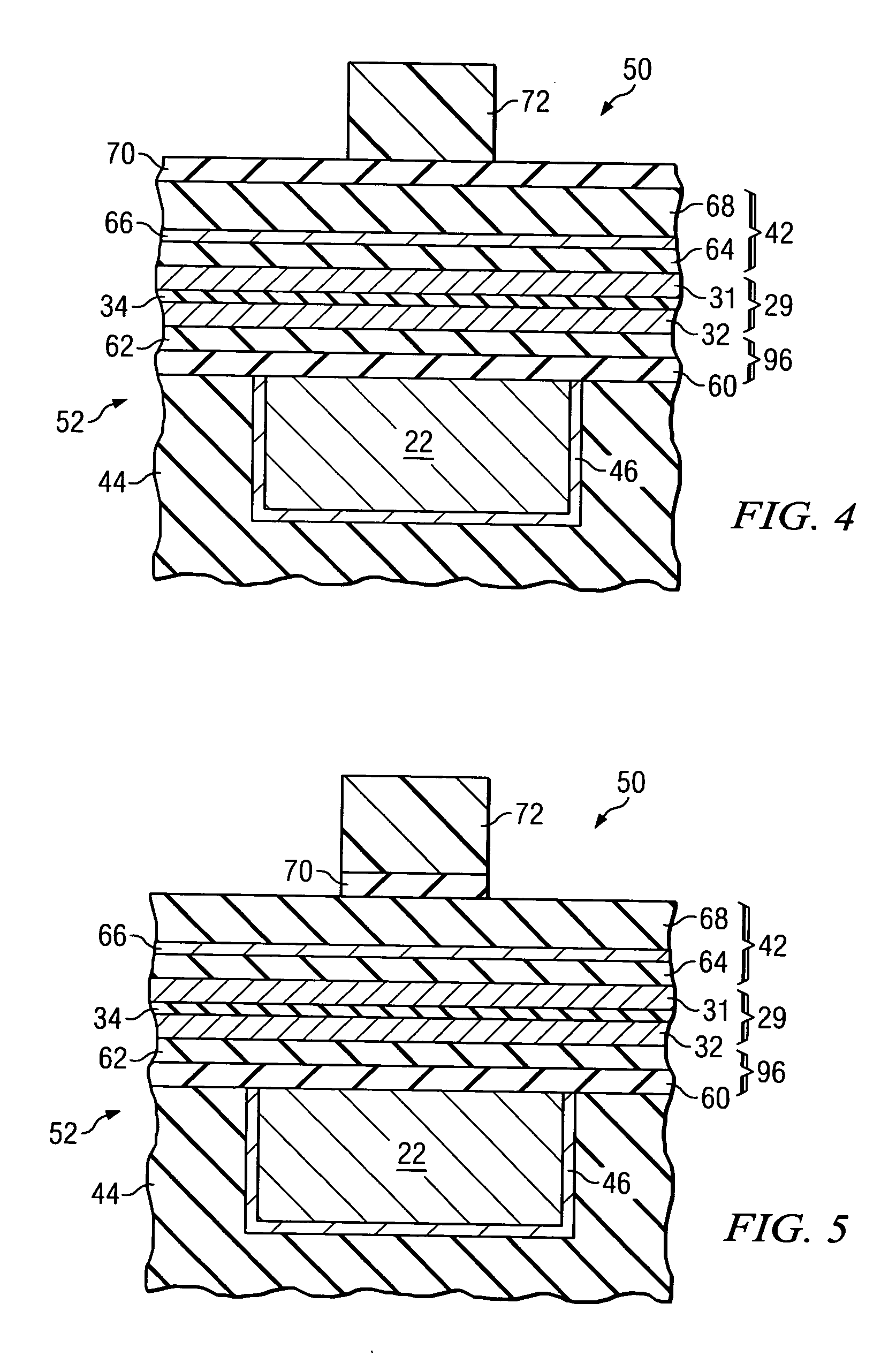

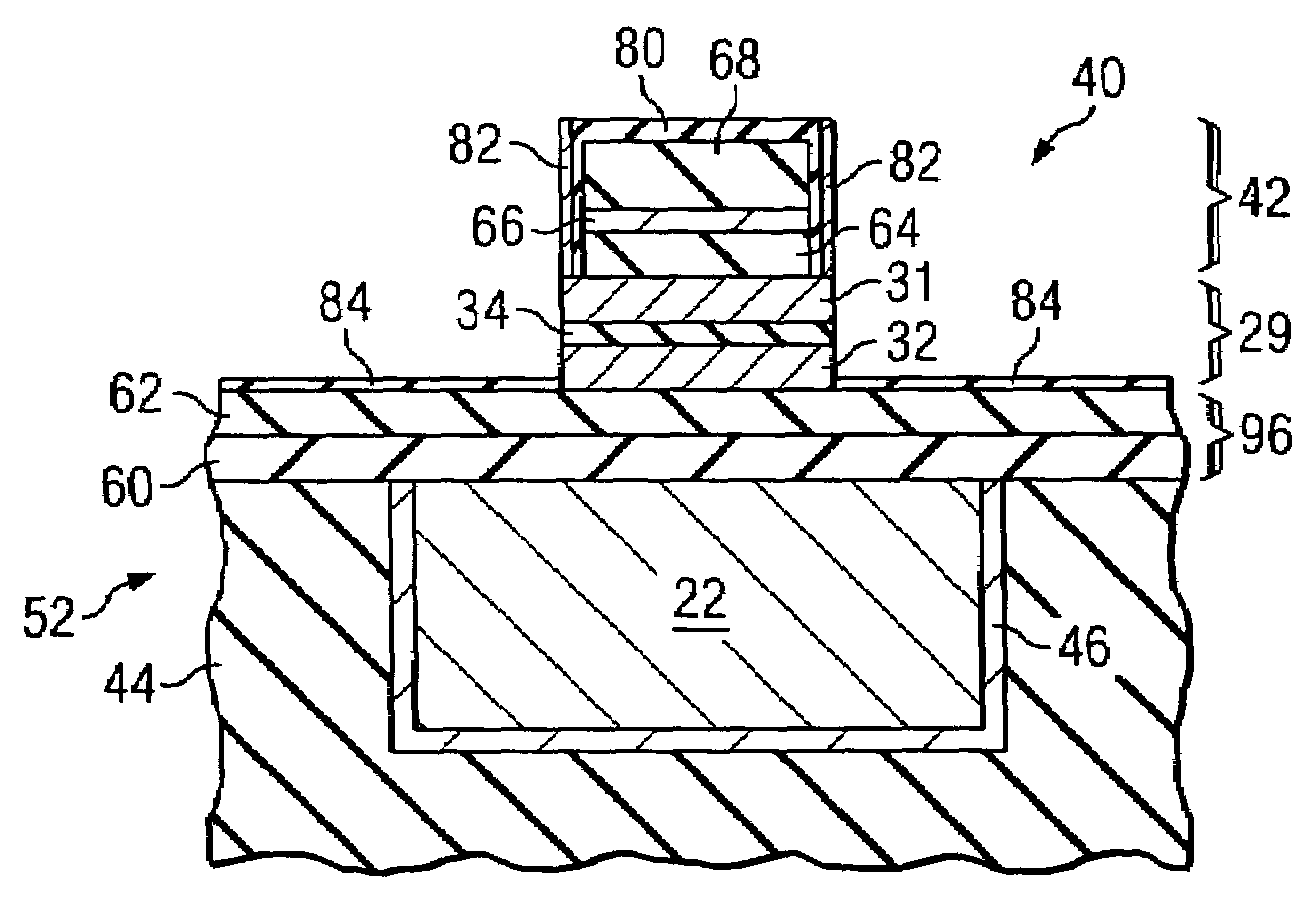

Fabrication process for a magnetic tunnel junction device

InactiveUS20050051820A1Avoid shortingMagnetic-field-controlled resistorsSolid-state devicesEngineeringOxygen

A method of fabricating a magnetic tunnel junction (MTJ) device is provided. A patterned hard mask is oxidized to form a surface oxide thereon. An MTJ stack is etched in alignment with the patterned hard mask after the oxidizing of the patterned hard mask. Preferably, the MTJ stack etch recipe includes chlorine and oxygen. Etch selectivity between the hard mask and the MTJ stack is improved.

Owner:INFINEON TECH AG +1

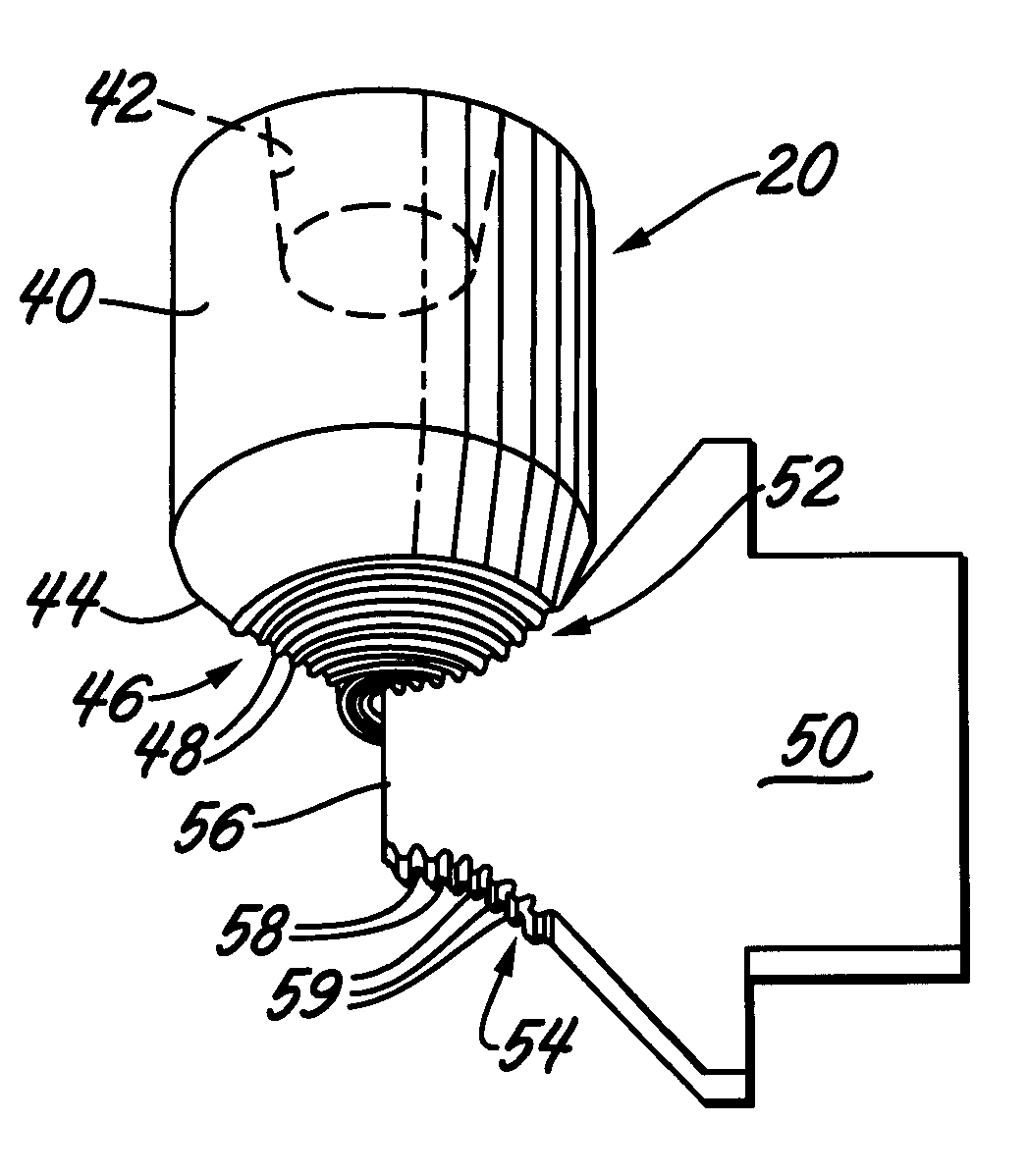

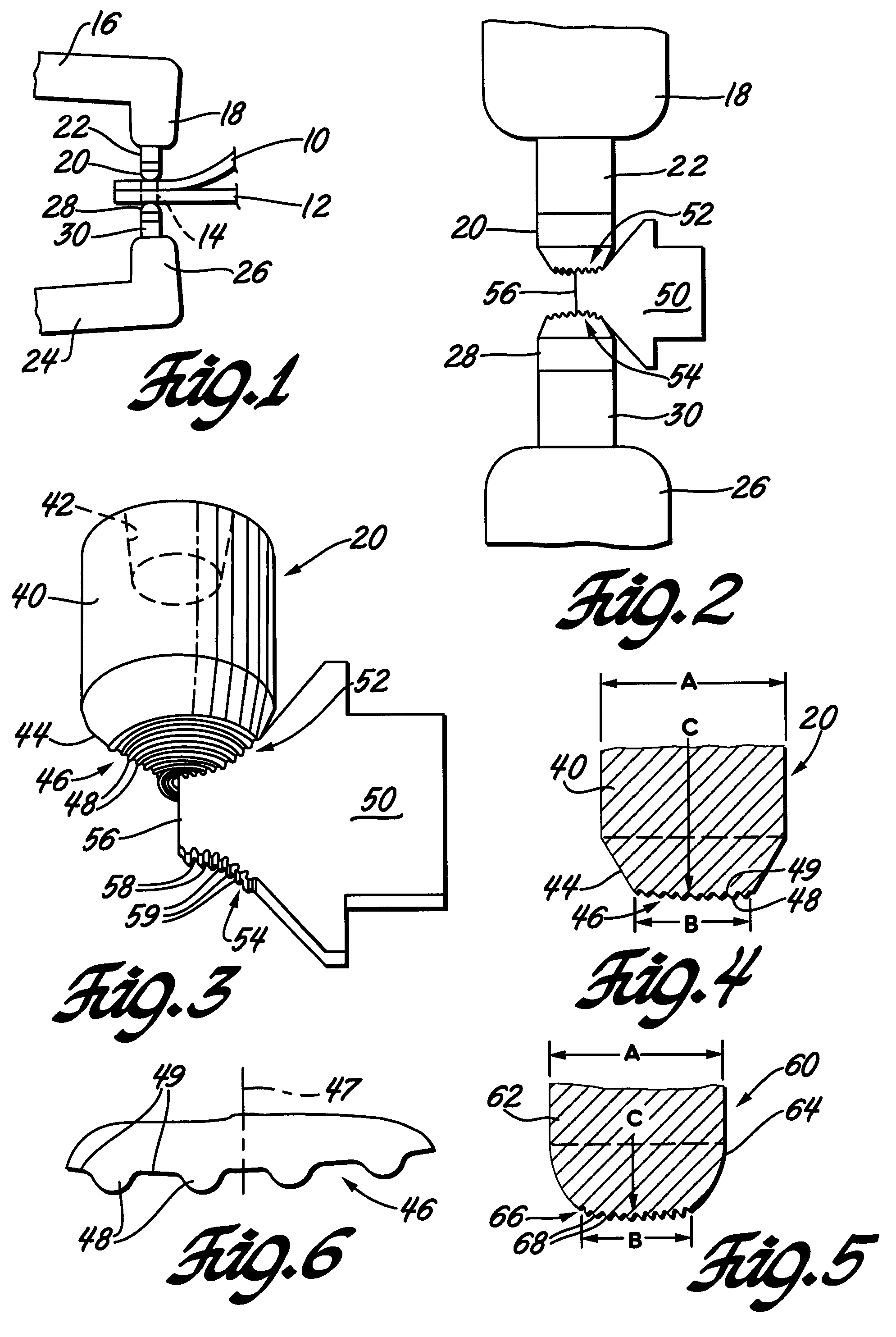

Welding electrode with contoured face

ActiveUS20080078749A1Well formedEasy alignmentTurning machine accessoriesOhmic-resistance electrodesElectrical resistance and conductanceEngineering

Welding electrodes with a welding face for contact with a metal surface for electrical resistance welding are provided with concentric contoured rings formed into the face. The rings may, for example, be ridges upstanding in the face or grooves depressed into the face. The contoured rings may be radially spaced with relatively flat (depending on the curvature of the face) intervening rings. When the electrode is pressed into contact with the surface of the workpiece for delivery of a welding current, the features of the concentric rings penetrate surface oxides or other conductivity barriers. When ongoing welding operations have eroded the contoured rings they may be rapidly reformed in the weld face in a surface re-dressing operation.

Owner:GM GLOBAL TECH OPERATIONS LLC

Fabrication process for a magnetic tunnel junction device

A method of fabricating a magnetic tunnel junction (MTJ) device is provided. A patterned hard mask is oxidized to form a surface oxide thereon. An MTJ stack is etched in alignment with the patterned hard mask after the oxidizing of the patterned hard mask. Preferably, the MTJ stack etch recipe includes chlorine and oxygen. Etch selectivity between the hard mask and the MTJ stack is improved.

Owner:INFINEON TECH AG +1

Quantum wires formed on a substrate, manufacturing method thereof, and device having quantum wires on a substrate

InactiveUS6130143ASmall diameterSufficient quantum effectPolycrystalline material growthSemiconductor/solid-state device manufacturingSilanesSurface oxidation

While a silicon substrate is heated, gold is evaporated thereon at a thickness of 0.6 nm, whereby melted alloy droplets are formed on the substrate surface. Then, the silicon substrate is heated to 450.degree.-650.degree. C. in a silane gas atmosphere of less than 0.5 Torr. As a result, a silane gas decomposition reaction occurs with the melted alloy droplets serving as catalysts, whereby silicon wires grow on the substrate surface. Subsequently, the metal alloy droplets at the tips of the silicon wires are removed and surface portions of the silicon wires are oxidized. Resulting surface oxide films are thereafter removed. As a result, silicon quantum wires that are thinner by the thickness of the surface oxide films are obtained.

Owner:SONY CORP

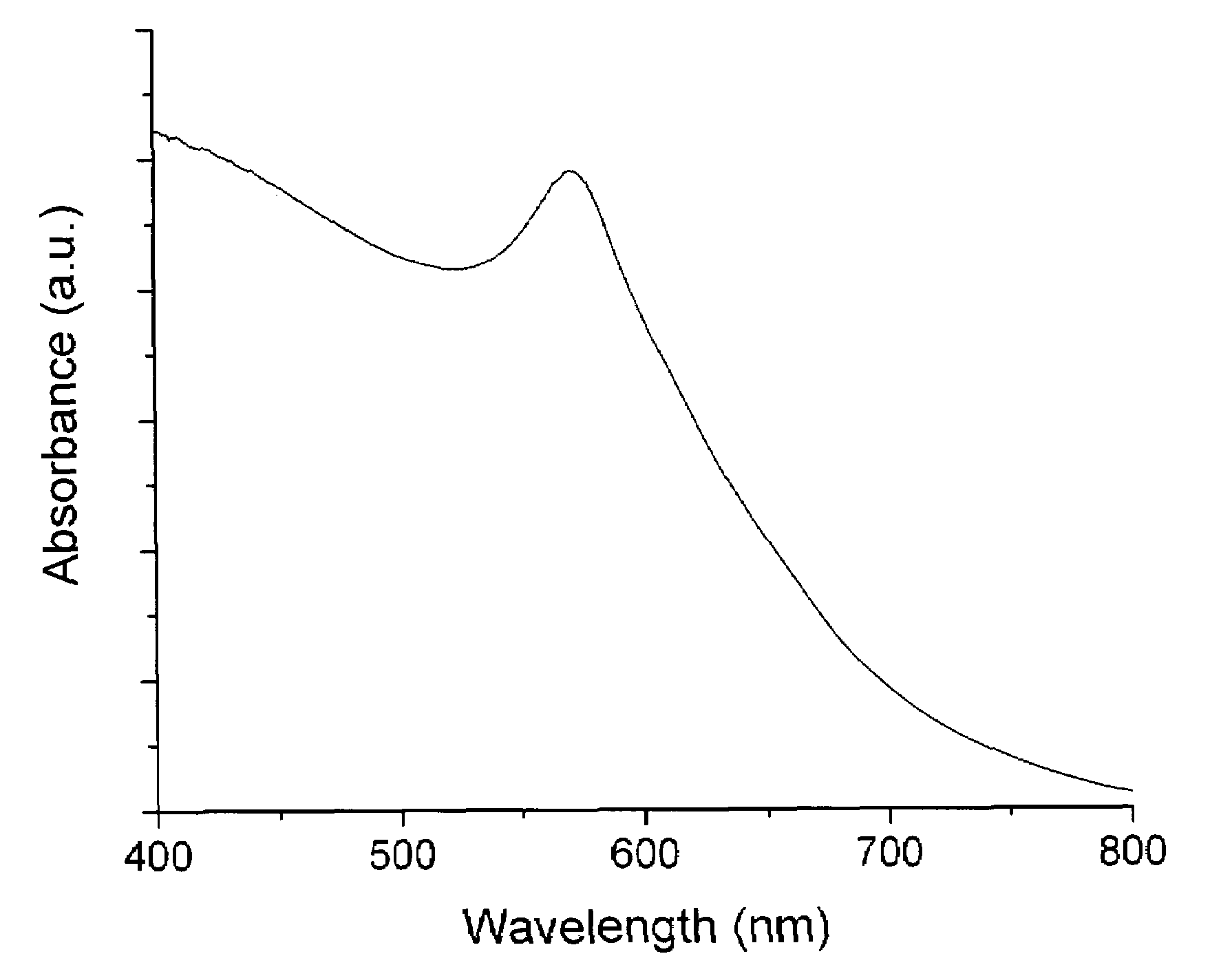

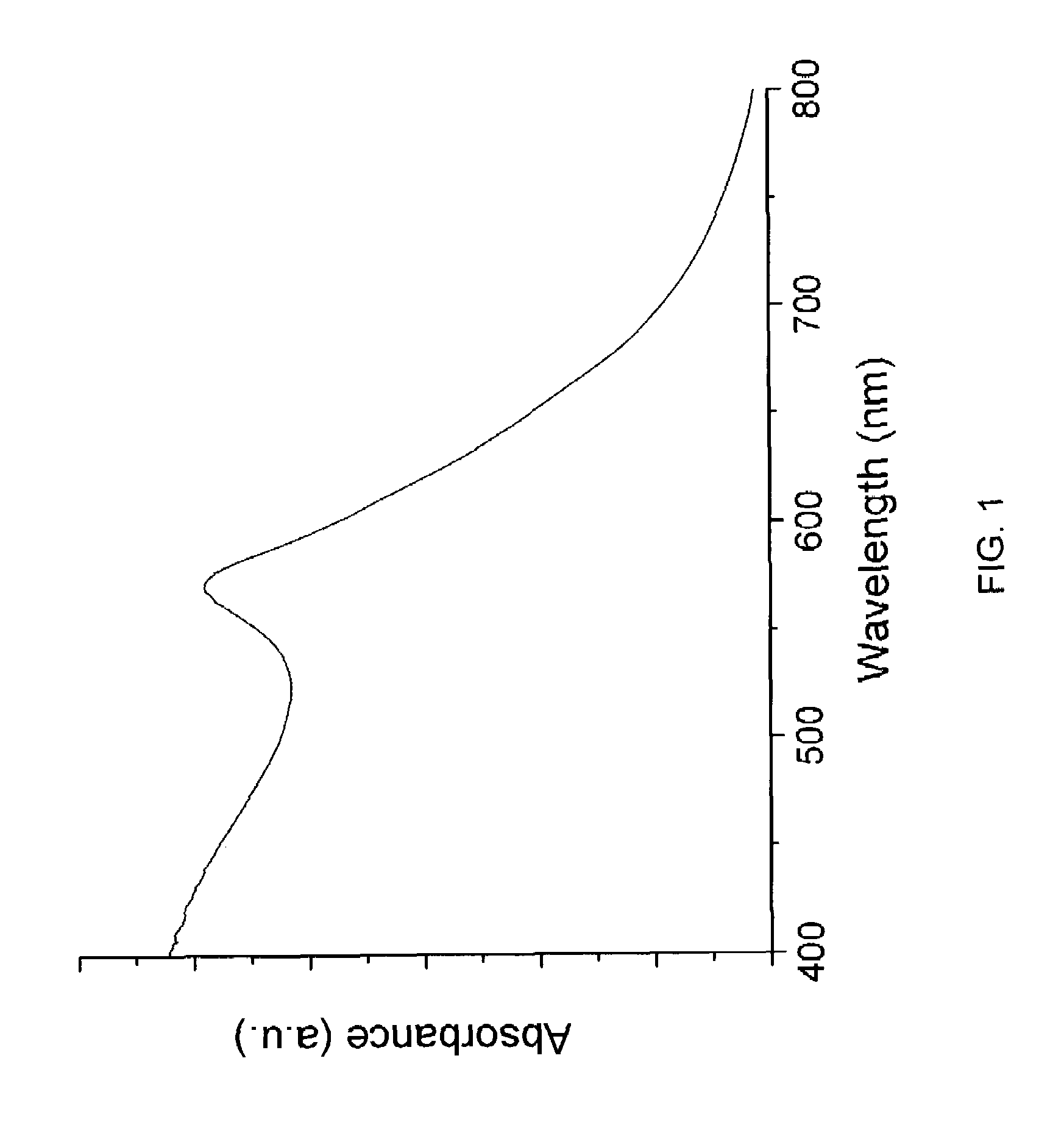

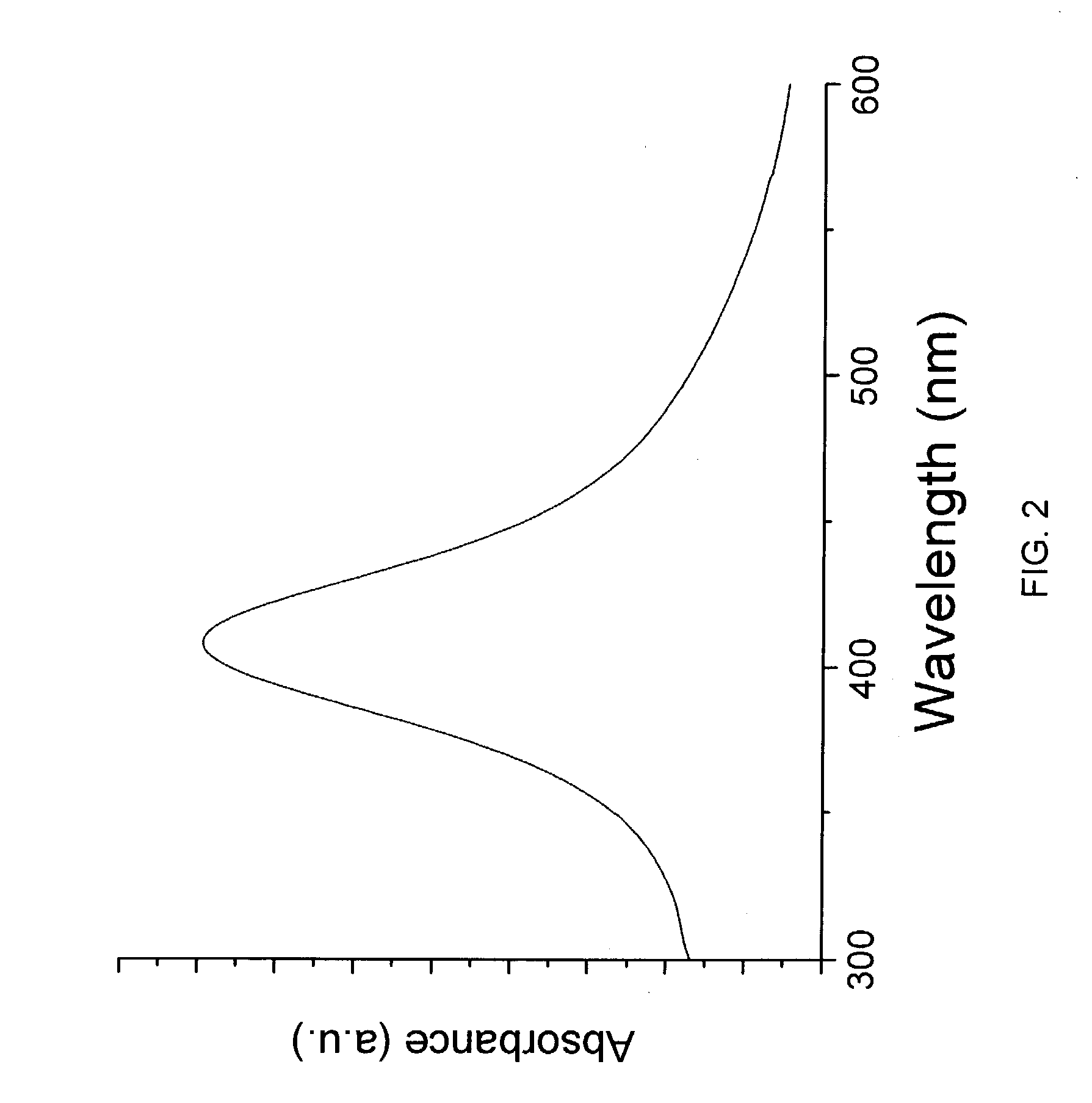

Synthesis metal nanoparticle

A method for providing an anhydrous route for the synthesis of amine capped coinage-metal (copper, silver, and gold) nanoparticles (NPs) using the coinage-metal mesityl (mesityl=C6H2(CH3)3-2,4,6) derivatives. In this method, a solution of (Cu(C6H2(CH3)3)5, (Ag(C6H2(CH3)3)4, or (Au(C6H2(CH3)3)5 is dissolved in a coordinating solvent, such as a primary, secondary, or tertiary amine; primary, secondary, or tertiary phosphine, or alkyl thiol, to produce a mesityl precursor solution. This solution is subsequently injected into an organic solvent that is heated to a temperature greater than approximately 100° C. After washing with an organic solvent, such as an alcohol (including methanol, ethanol, propanol, and higher molecular-weight alcohols), oxide free coinage NP are prepared that could be extracted with a solvent, such as an aromatic solvent (including, for example, toluene, benzene, and pyridine) or an alkane (including, for example, pentane, hexane, and heptane). Characterization by UV-Vis spectroscopy and transmission electron microscopy showed that the NPs were approximately 9.2±2.3 nm in size for Cu°, (no surface oxide present), approximately 8.5±1.1 nm Ag° spheres, and approximately 8–80 nm for Au°.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Technological process for producing super-thick plate

InactiveCN101439348AQuality improvementLow costTemperature control deviceElectron beam welding apparatusElectro-slag remeltingVacuum chamber

The invention relates to a process for producing an ultra-thick plate and belongs to the field of rolling and producing an ultra-thick steel plate in the metallurgical industry. The invention mainly overcome the defect of producing the ultra-thick steel plate by a traditional model casting manufacturing blank and an electro-slag remelting manufacturing blank. The method comprises the following steps: cutting and fixing lengths of the blanks, mechanically conditioning the blanks (eliminating, leveling and cleaning a single-surface oxide layer of a casting blank with a milling machine, a planer or a shot blast); clamping an assembly (relatively superposing the cleaning surfaces of the two blanks after processing, placing the two blanks oppositely and clamping the blanks); mounting the blanks in a vacuum chamber of an electronic beam welding machine for purpose of vacuuming; sewing the assembly on the electronic beam welding seal edge, heating the assembly in a furnace and rolling the assembly through temperature control; and then producing the ultra-thick steel plate. Compared with the traditional electro-slag remelting production process, the process has the advantages of high production efficiency, reduced electric power consumption, less investment of production devices and low production cost. Compared with the traditional die casting production process, the process solves the problem of segregation and looseness of a large-scale die casting ingot center part; the finished product ratio is high; and the finished product ratio of blank assembly is over 90 %.

Owner:SHANDONG IRON & STEEL CO LTD

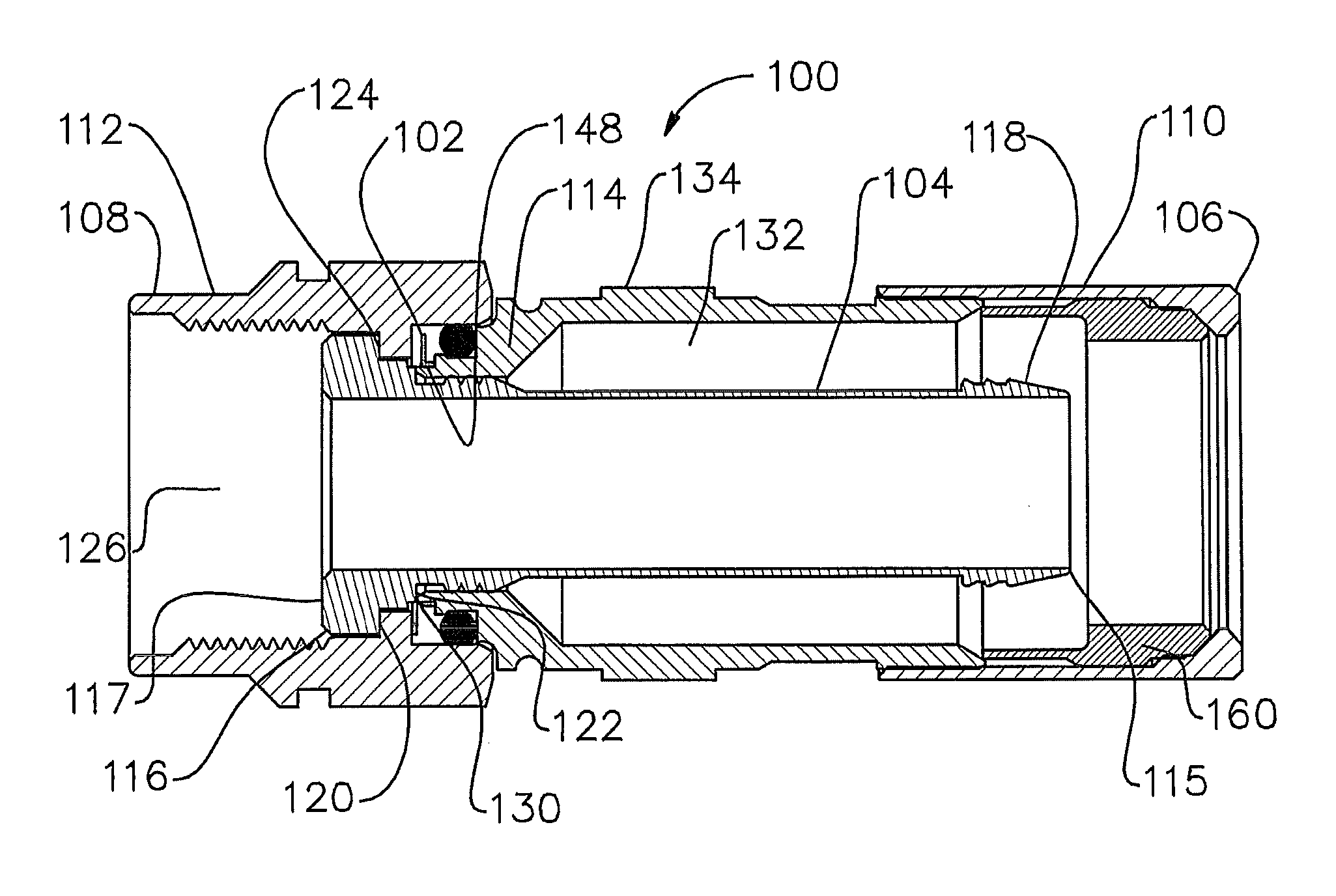

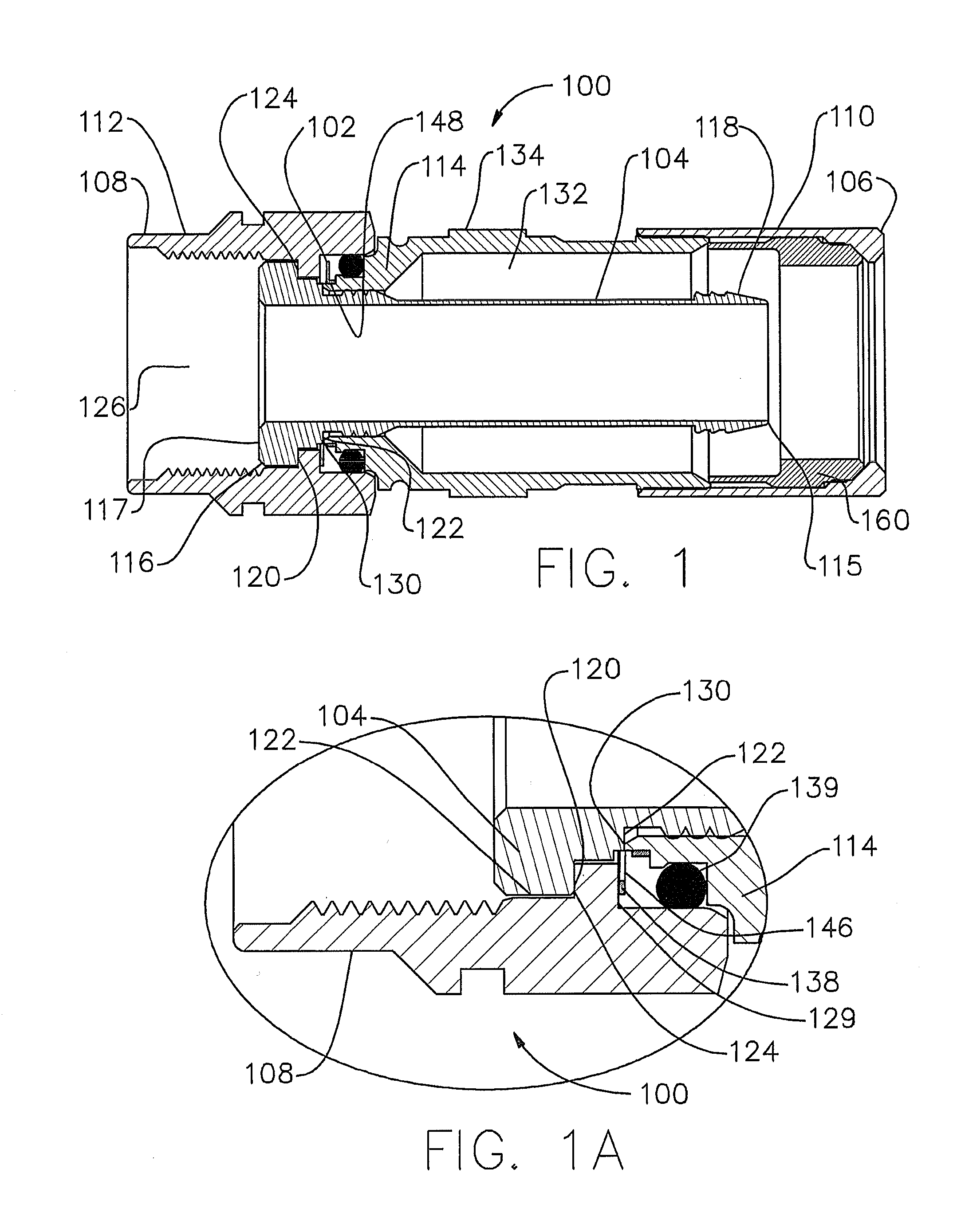

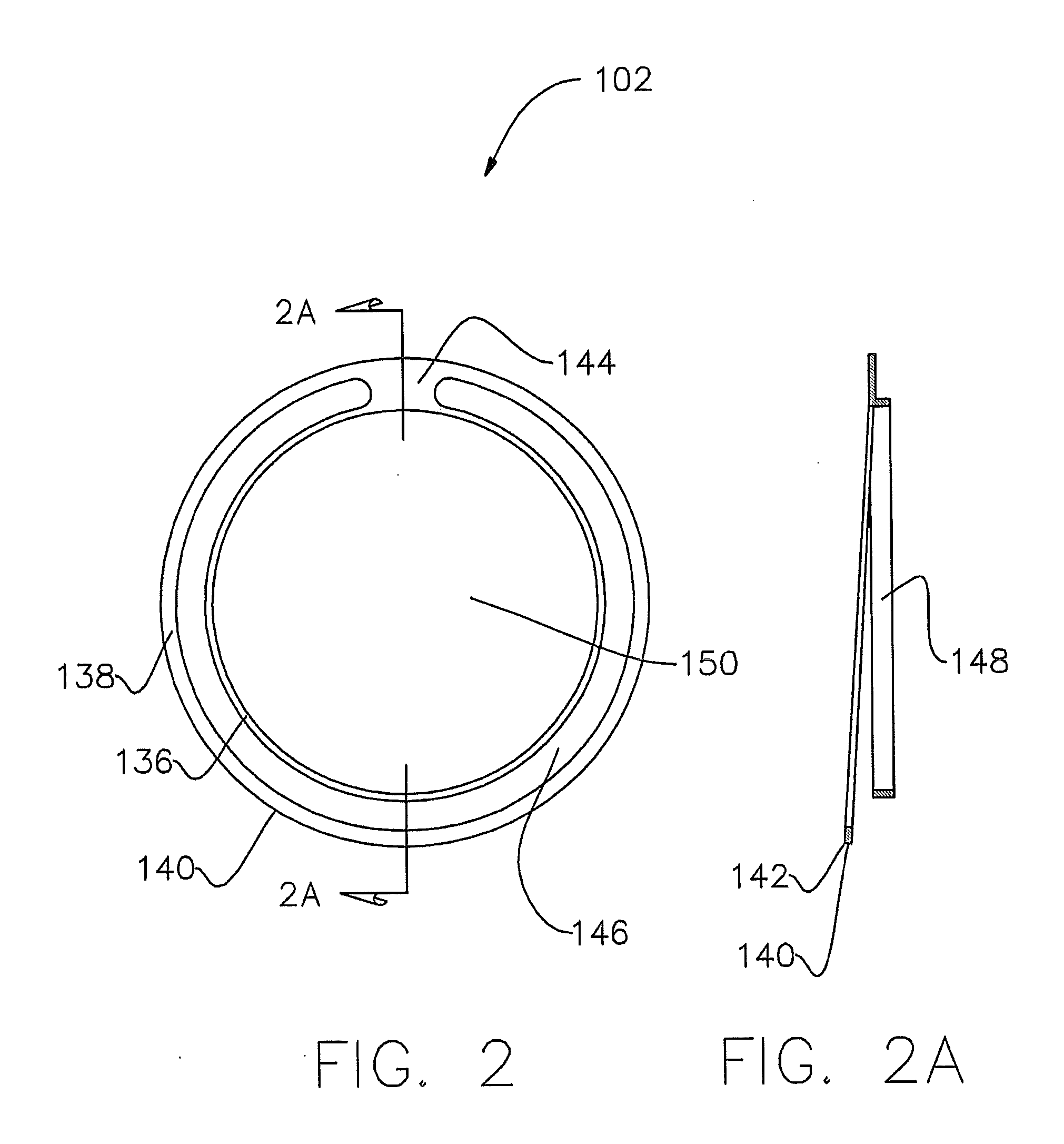

Coaxial cable connector with radio frequency interference and grounding shield

ActiveUS20130065433A1Smooth rotationCoupling device detailsClamped/spring connectionsCoaxial cableSpring force

A radio frequency interference (RFI) and grounding shield for a coaxial cable connector is disclosed. The shield comprises a circular inner segment and at least one arcuately shaped pre-formed cantilevered annular beam attached to the circular inner segment by a joining segment. The at least one pre-formed cantilevered annular beam extends angularly from a plane of the circular inner segment. The at least one pre-formed cantilevered annular beam applies a spring-force to a surface of the surface of a component of the coaxial cable connector establishing an electrically conductive path between the components. The at least one pre-formed cantilevered annular beam comprises an outer surface with a knife-like edge that provides a wiping action of surface oxides on component surfaces of the coaxial cable connector and allows for unrestricted movement when the coaxial cable connector is attached to an equipment connection port of an appliance.

Owner:PPC BROADBAND INC

Cleaning method

InactiveUS6348157B1Strong resistanceSuppress formationSemiconductor/solid-state device manufacturingElectrostatic cleaningCleaning methodsChemical cleaning

A cleaning method capable of processing at room temperatures without conducting heating, uses little chemicals and water, and does not require special devices or materials. The chemical cleaning processes and rinse processes employ pure water or ultrapure water in a semiconductor wet cleaning process, rinse water or chemicals which suppresses formation of surface oxide films, removes particles and prevent their redeposition, and aids in the hydrogen termination of the silicon atoms. The cleaning method of the resent invention includes cleaning which is conducted using pure water containing ozone, cleaning conducted using a cleaning liquid containing HF, H2O, and surfactant, while applying vibration having a frequency of 500 kHz or more, cleaning conducted using pure water containing ozone, cleaning conducted using a cleaning liquid containing HF and H2O in order to remove oxide films, and cleaning which is conducted using pure water. After cleaning a material to be cleaned using chemicals, rinsing is conducted using pure water or ultrapure water containing hydrogen gas in an amount of 0.5 ppm or more and containing oxygen gas in an amount of 100 ppb or less.

Owner:OHMI TADAHIRO +1

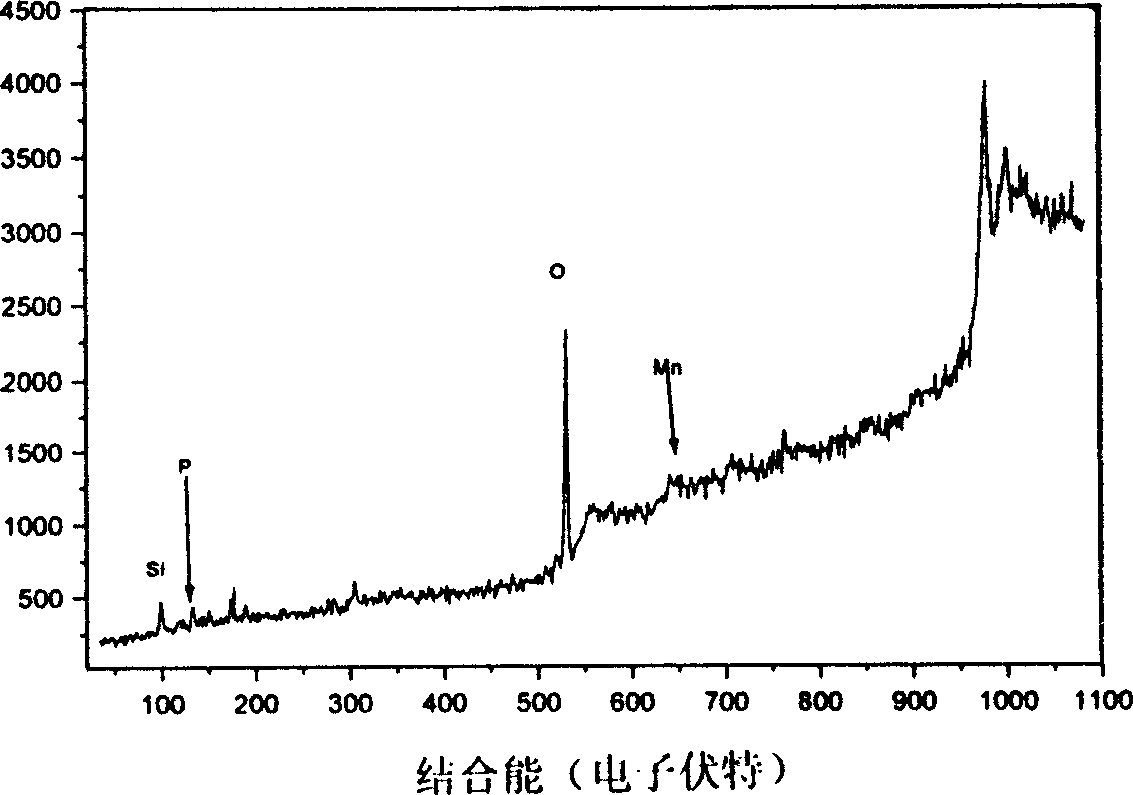

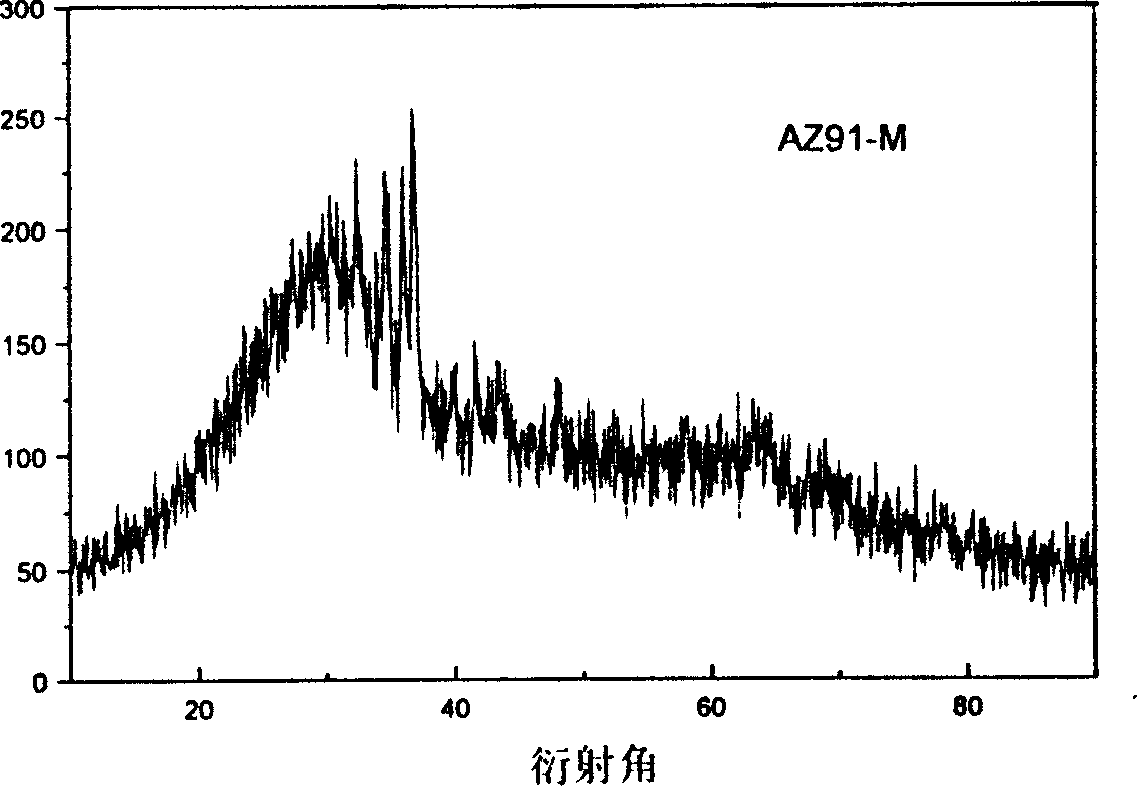

Preparation method of magnesium alloy chromeless chemical conversion film and its used film forming solution

InactiveCN1475602AReduce pollutionUniform thicknessMetallic material coating processesPhosphatePre treatment

A chemically transferred non-chromium Mg-alloy film is prepared through grinding said Mg-alloy, removing impurities, washing with alkali solution for defatting, washing with acidic solution for removing surfacial oxide, removing very thin oxidized film and pickling ash from its surface by fluoric acidic solution, immersing the Mg-alloy in filming solution to obtain phosphate film, and immersing in alkaline aqueous solution at 15-100 deg.C for 3-60 min for closing the pores in the film. Said filming solution is prepared from Mn salt, phosphate, fluoride and water.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

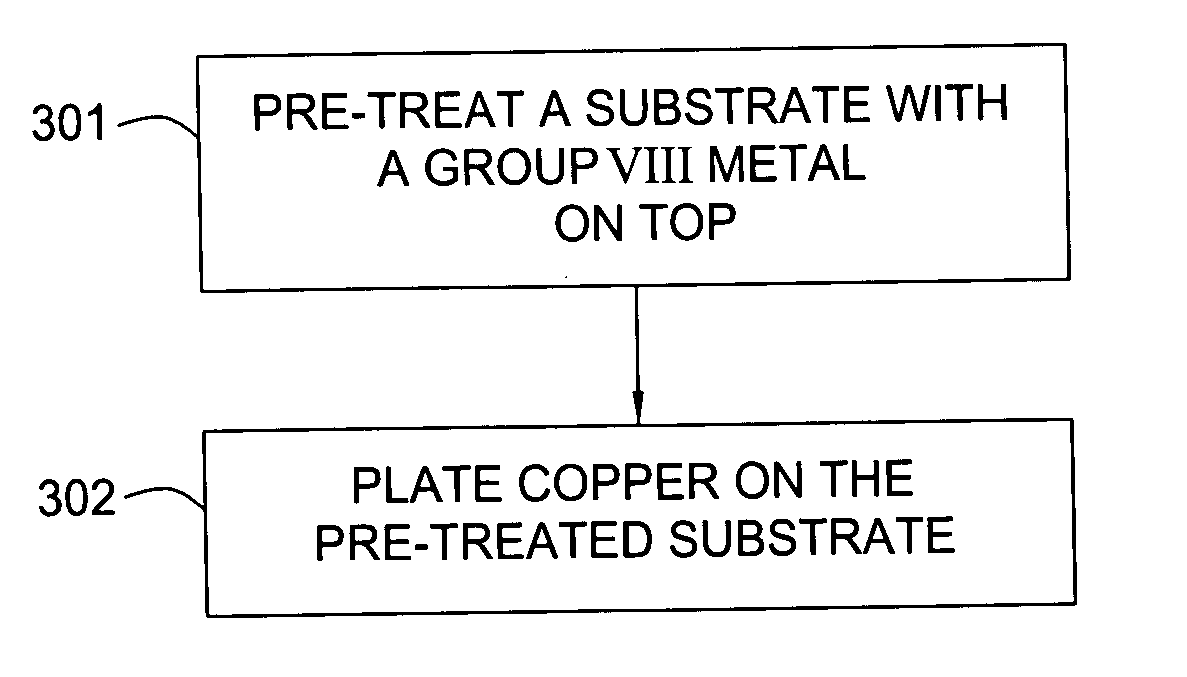

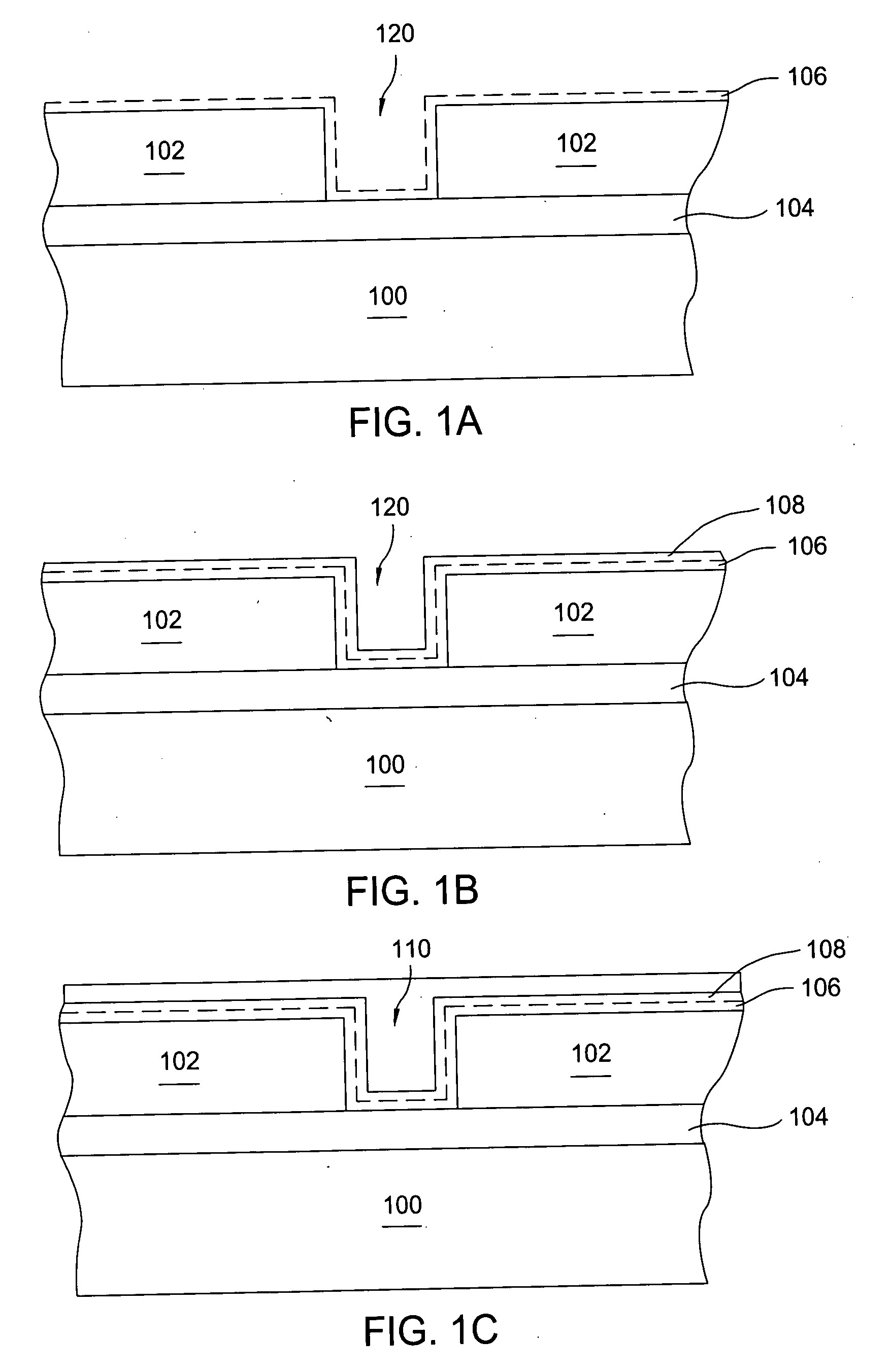

Plating chemistry and method of single-step electroplating of copper on a barrier metal

InactiveUS20050274622A1Semiconductor/solid-state device manufacturingSemiconductor devicesCopper platingHydrogen

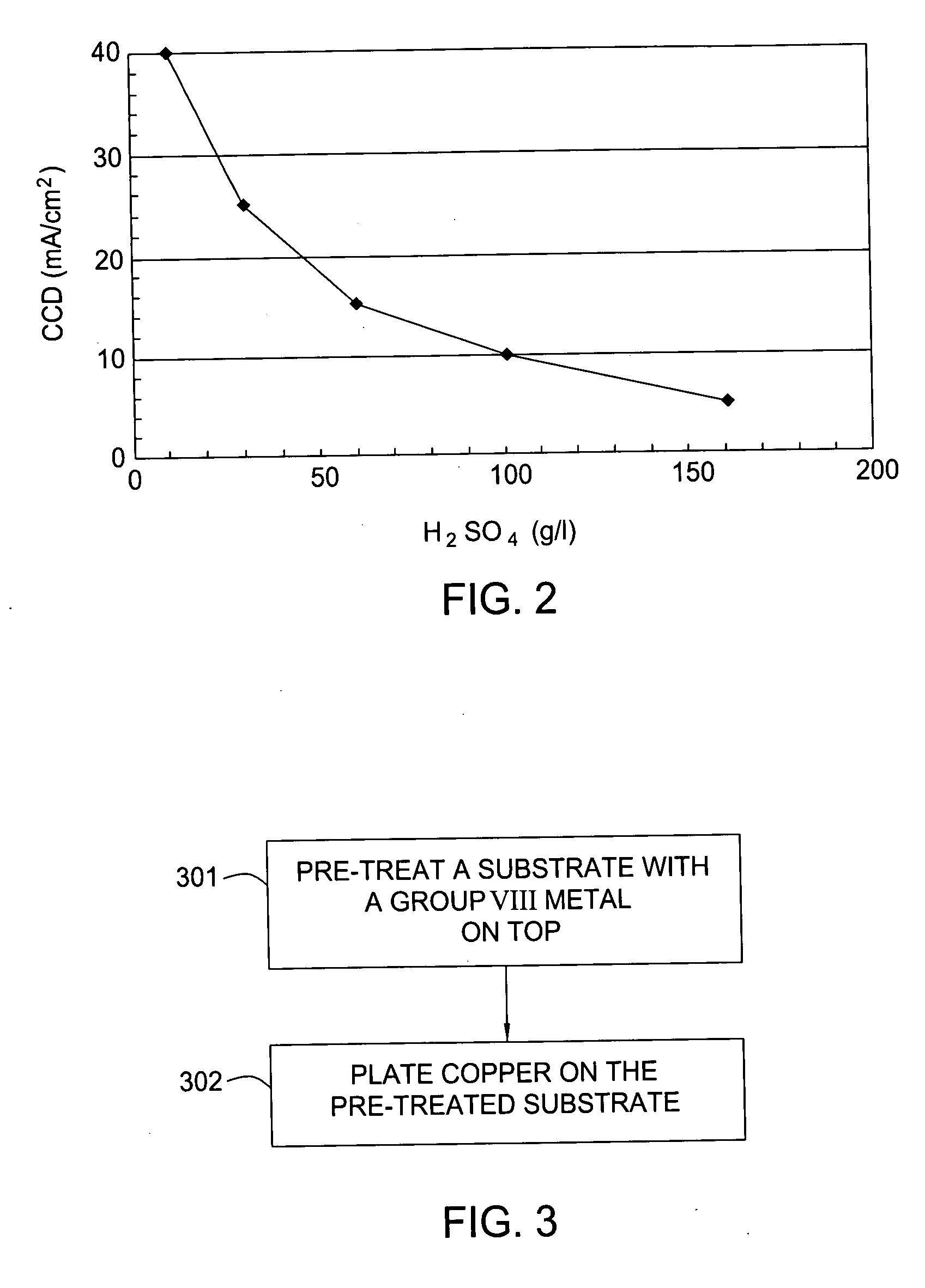

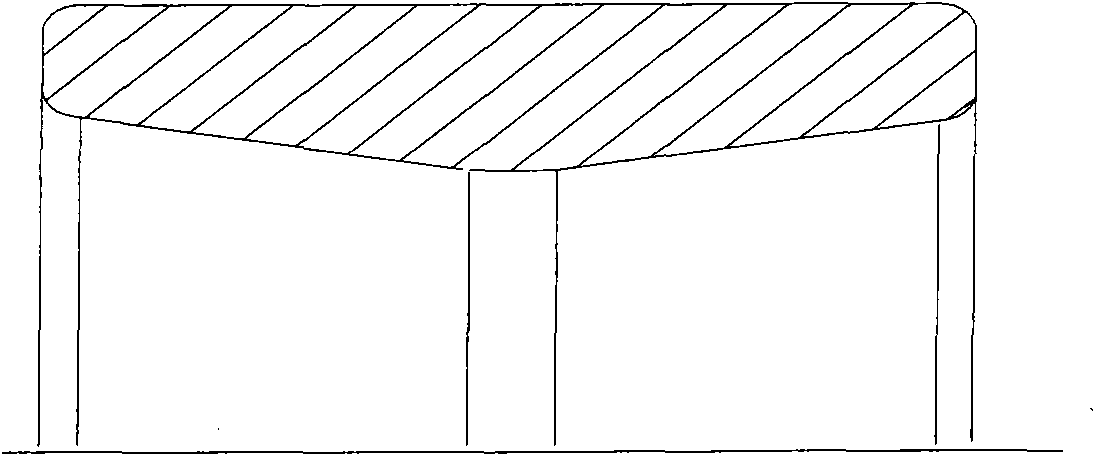

Embodiments of a method of copper plating a substrate surface with a group VIII metal layer have been described. In one embodiment, a method of plating copper on a substrate surface with a group VIII metal layer comprises pre-treating the substrate surface by removing a group VIII metal surface oxide layer and / or surface contaminants and plating the substrate in a copper plating solution comprising about 50 g / l to about 300 g / l of sulfuric acid at an initial plating current higher than the critical current density to deposit a continuous copper layer on the substrate surface. The Pre-treating the substrate can be accomplished by annealing the substrate in an environment with a hydrogen-containing gas environment and / or a non-reactive gas(es) to Ru, by a cathodic treatment in an acid-containing bath, or by immersing the substrate in an acid-containing bath.

Owner:APPLIED MATERIALS INC

Composite machining process for inner and outer rings of narrow-series thin-walled high-precision conical thin-walled bearings

The invention discloses a composite machining process for inner and outer rings of narrow-series thin-walled high-precision conical thin-walled bearings, belongs to the technical field of forging, turning, heating and grinding machining of the inner and outer rings of bearing components, and mainly solves the problems of low production efficiency and high rejection rate in a conventional machining method. The composite machining process is mainly characterized by comprising the following steps of: (1) cutting bar stock into straight material sections; (2) after heating, forming a single-forged inner ring and double combined-forged outer rings by using a pressing machine; (3) spheroidizing and annealing; (4) performing shot blasting to remove surface oxide scales; (5) after cutting the double outer rings, performing rough turning and soft grinding; (6) performing additional tempering; (7) performing the soft grinding on the outside diameter of the outer rings, and performing finish turning and rolling; (8) performing heat treatment in quenching and tempering furnaces, and performing shot blasting again; and (9) performing rough grinding machining, the additional tempering, finish grinding machining, super-finishing, cleaning and assembling. The composite machining process has the characteristics of great improvement on product qualification rate and production efficiency, and suitability for batch production on the premise of no increase of equipment investment, and is mainly used for machining the inner and outer rings of the narrow-series thin-walled high-precision conical thin-walled bearings.

Owner:XIANGYANG AUTOMOBILE BEARING CO LTD

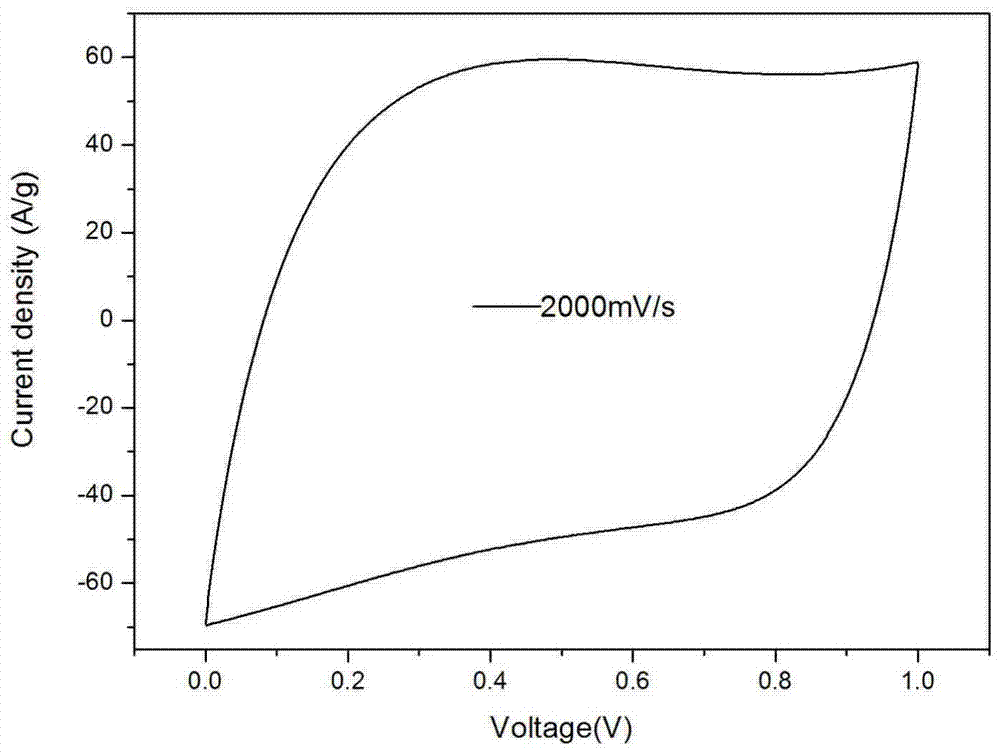

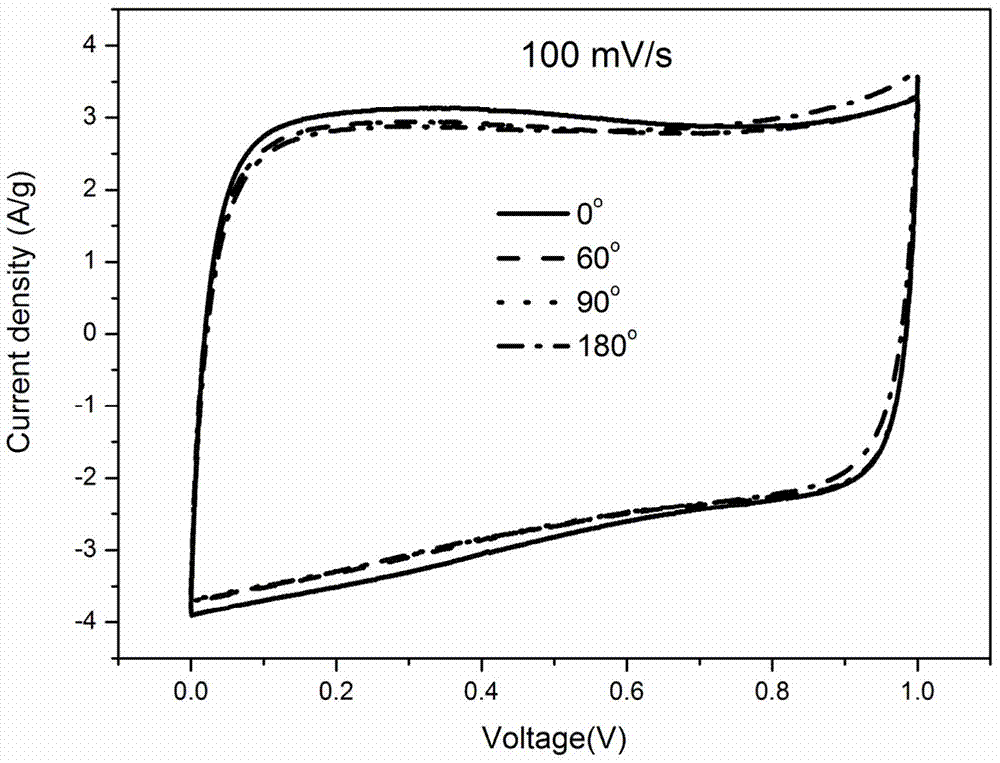

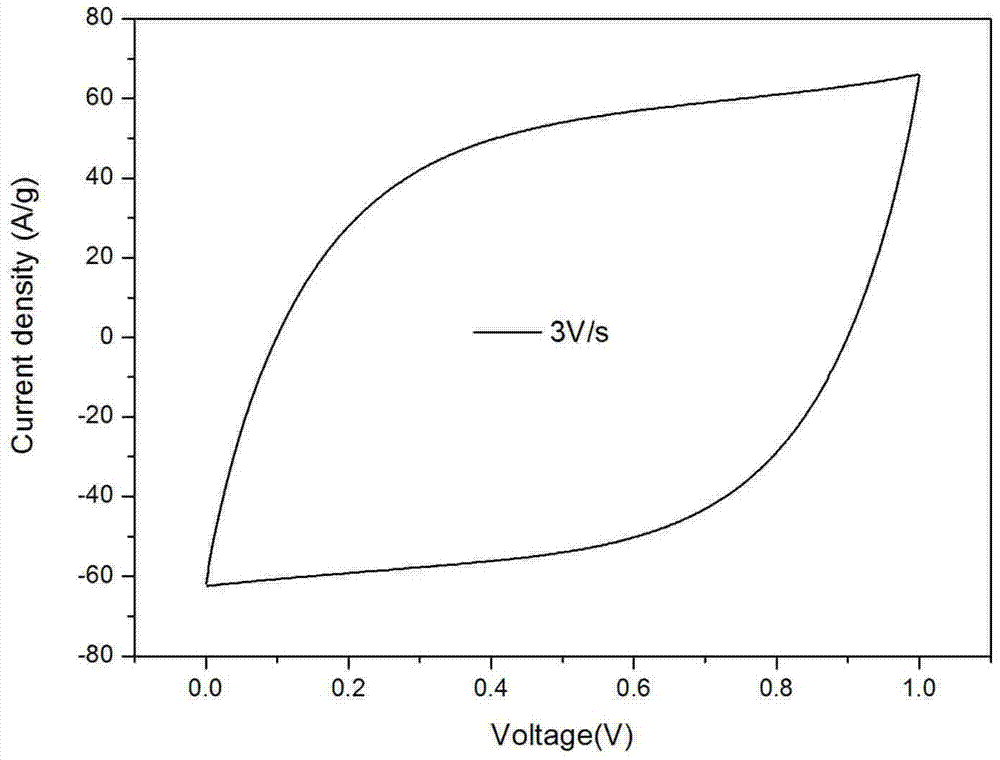

Supercapacitor electrode material preparation method based on three-dimensional graphene

InactiveCN103545121AImprove performanceReduce manufacturing costHybrid/EDL manufactureMoistureHydroiodic acid

A supercapacitor electrode material preparation method based on three-dimensional graphene comprises the steps that foamed nickel with surface oxide removed is steeped in oxidized graphene dispersion liquid, the oxidized graphene is made to be deposited on the foamed nickel, and then the foamed nickel is aired to remove moisture at room temperature after being taken out. The steeping method comprises the steps that the foamed nickel is steeped in the oxidized graphene dispersion liquid with the concentration of 0.5mg / ml-10mg / ml, and is aired after ultrasonic processing is carried out for 1-30 minutes; the quality of the oxidized graphene deposited on the foamed nickel is controlled through the concentration of the oxidized graphene and steeping times, and the steeping times is 1 to 30 times. The prepared oxidized graphene / foamed nickel composite electrodes are reduced through ascorbic acid, then a part of metal nickel is etched and removed by using a chemical etching method or a part of the metal nickel is simultaneously reduced, etched and removed through hydroiodic acid to obtain graphene / foamed nickel composite electrodes. The supercapacitor electrode material preparation method based on the three-dimensional graphene is simple, easy to operate, capable of improving the performance of supercapacitors and reducing manufacturing cost, and suitable for mass production.

Owner:NANJING UNIV

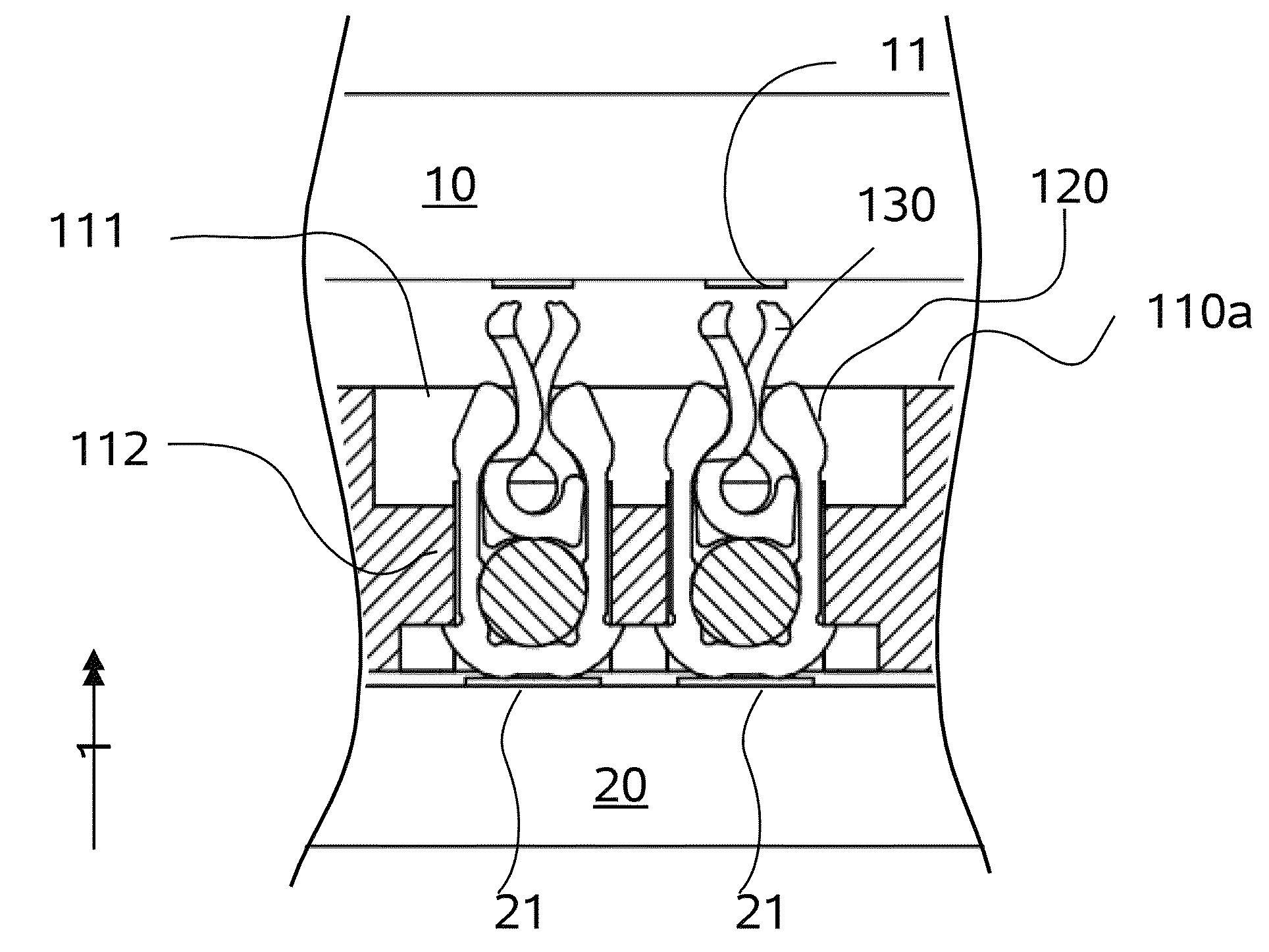

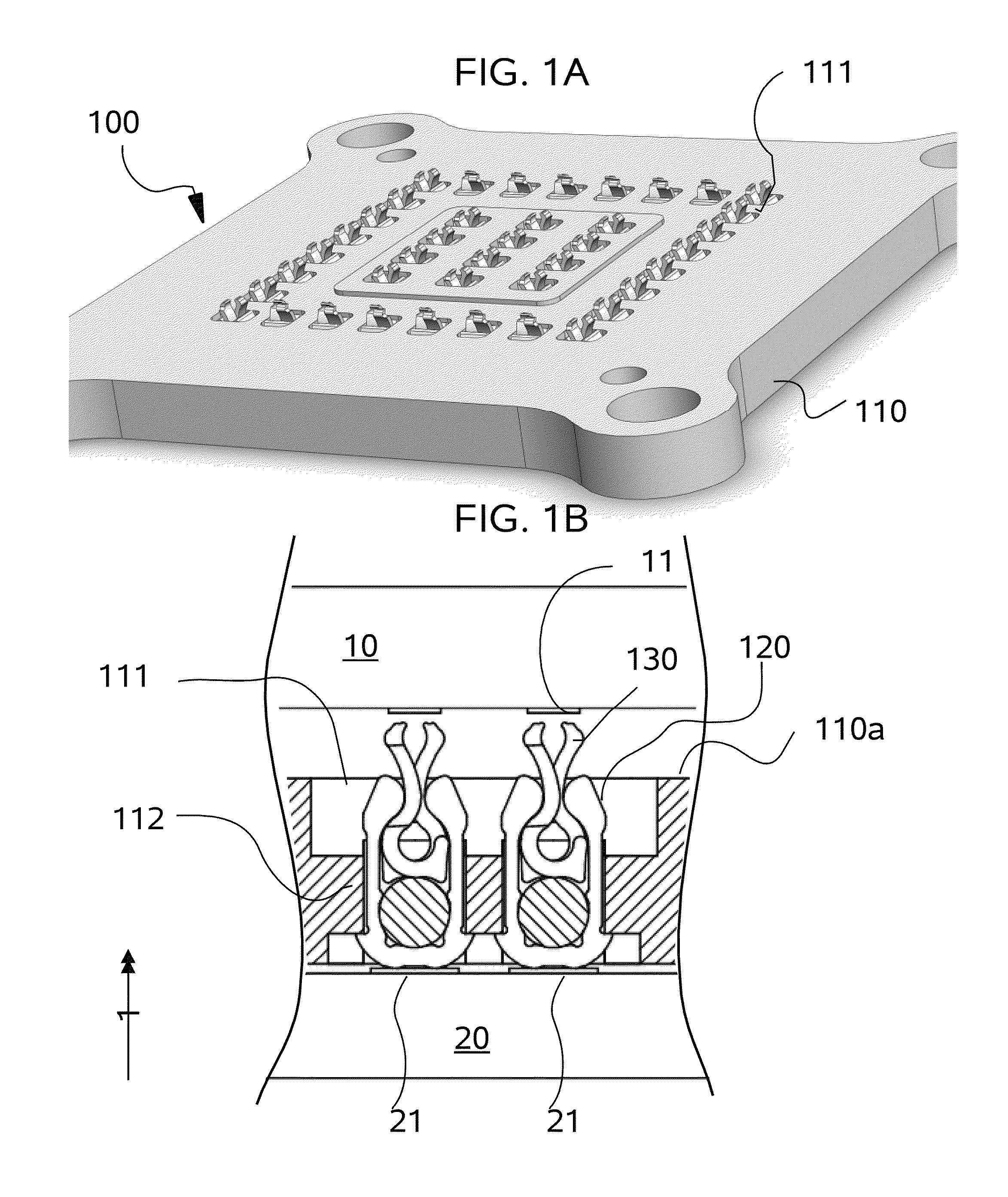

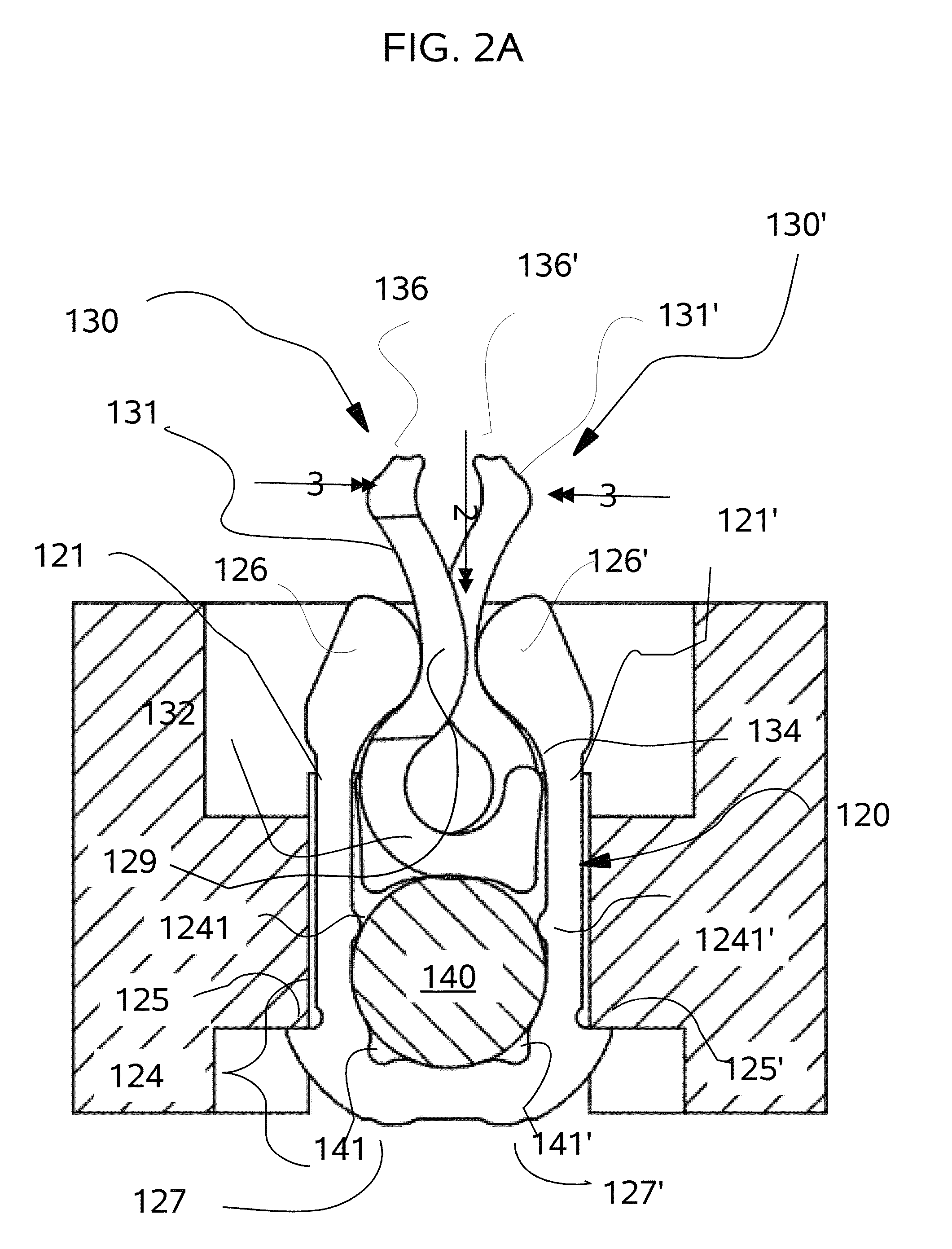

Electronic device test fixture

InactiveUS8441275B1Minimization requirementsImprove accuracyElectrical measurement instrument detailsPrinted circuitsElectrical junctionEngineering

An electronic device test fixture deploys a plurality of contact elements in a dielectric housing. The plumb arrangement of contact elements each include an armature or transversal configured to first depress and then slide laterally when urged downward by the external contacts of a device under test. The rotary movement of the transversal is optimized via the configuration of a surrounding forked regulator such that surface oxide deposition on the external device under test terminal is disrupted to reliably minimize contact resistance without damaging or unduly stressing the electrical junction of the device under test.

Owner:TAPT INTERCONNECT

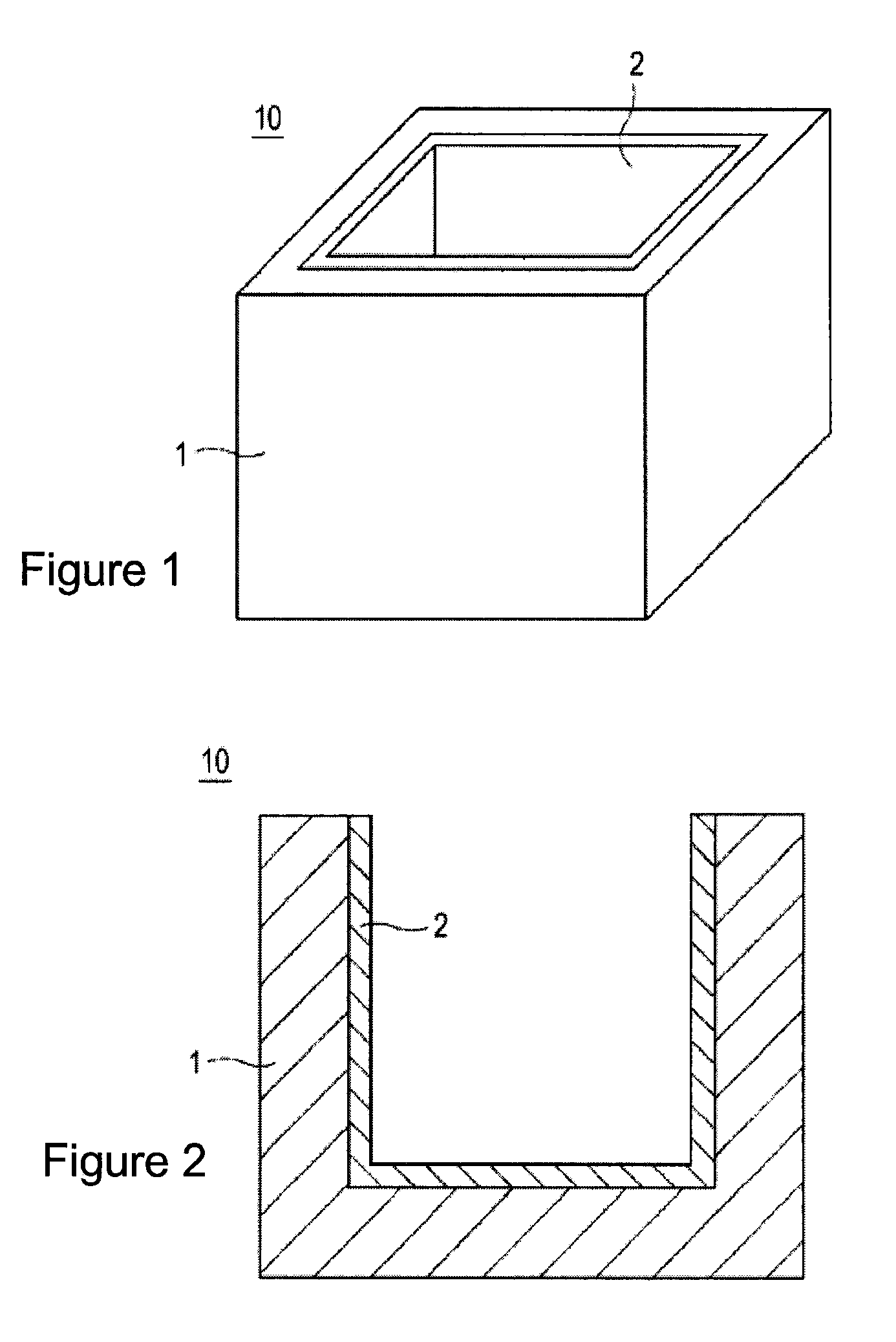

Mold Forming and Molding Method

A mold forming and molding technology operable to produce a silicon ingot suitable for obtaining a solar cell substrate is disclosed. A slurry is prepared comprising particles with surface oxide layers operable to bond the particles to each other. An external force is applied to the slurry to eliminate cohesion of the particles to form a de-cohesive slurry, and an inner surface of a mold base is coated with the de-cohesive slurry to form a releasing layer that reduces defects in the silicon ingot.

Owner:KYOCERA CORP

Self passivating transition metal nitride printhead heaters

InactiveUS7431431B2Improve antioxidant capacityLower energy requirementsInking apparatusOther printing apparatusOxygenNitride

A thermal inkjet printhead with heater elements formed from a self passivating transition metal nitride, but it oxidizes readily. By introducing an additive that allows the metal nitride to self passivate, the heater element forms a surface oxide layer, where the oxide has a low diffusion coefficient for oxygen so as to provide a barrier to further oxidation. With enhanced oxidation resistance, coatings to protect the heater from oxidative failure become unnecessary and the energy needed to form a bubble is reduced.

Owner:MEMJET TECH LTD +1

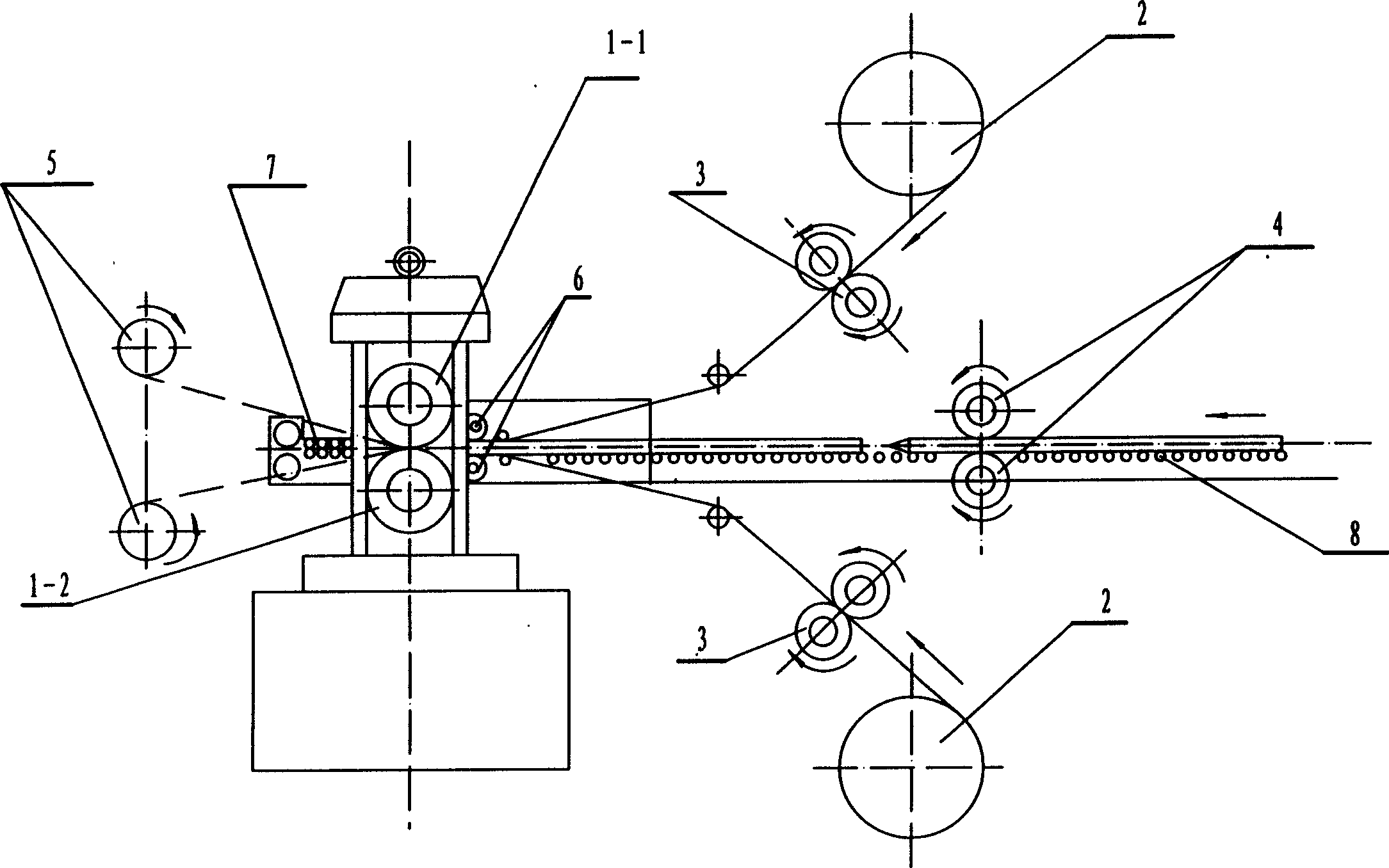

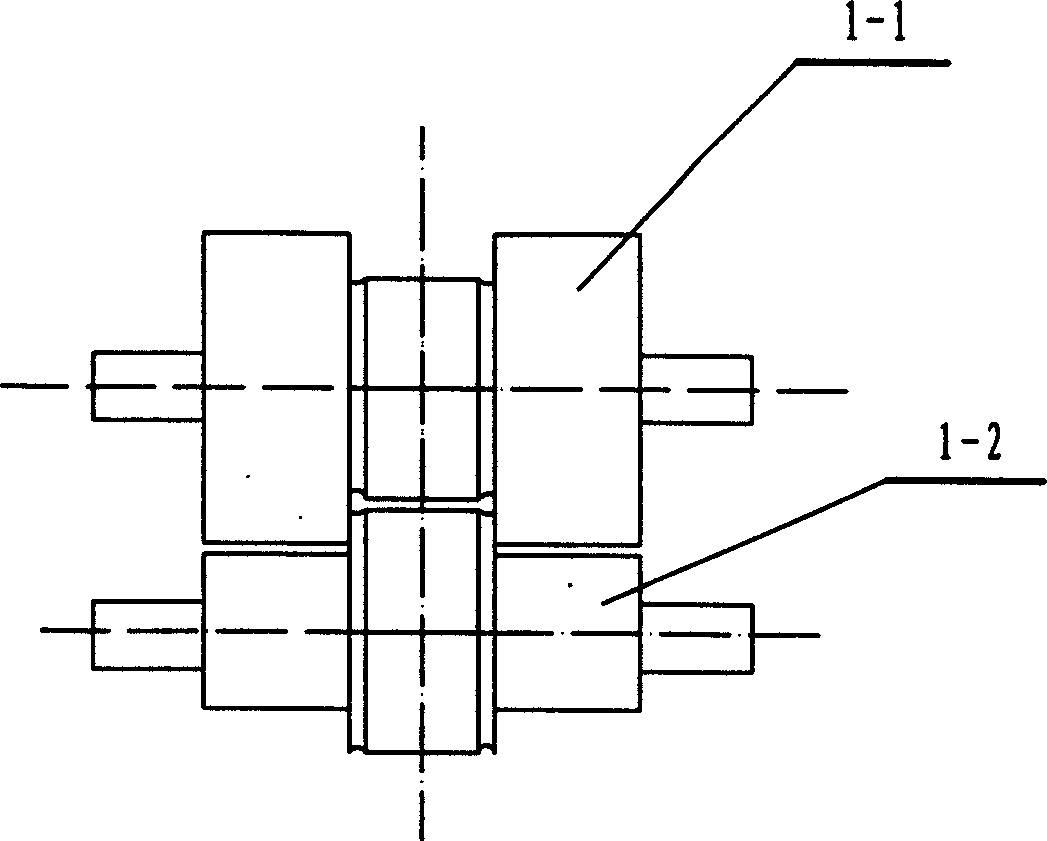

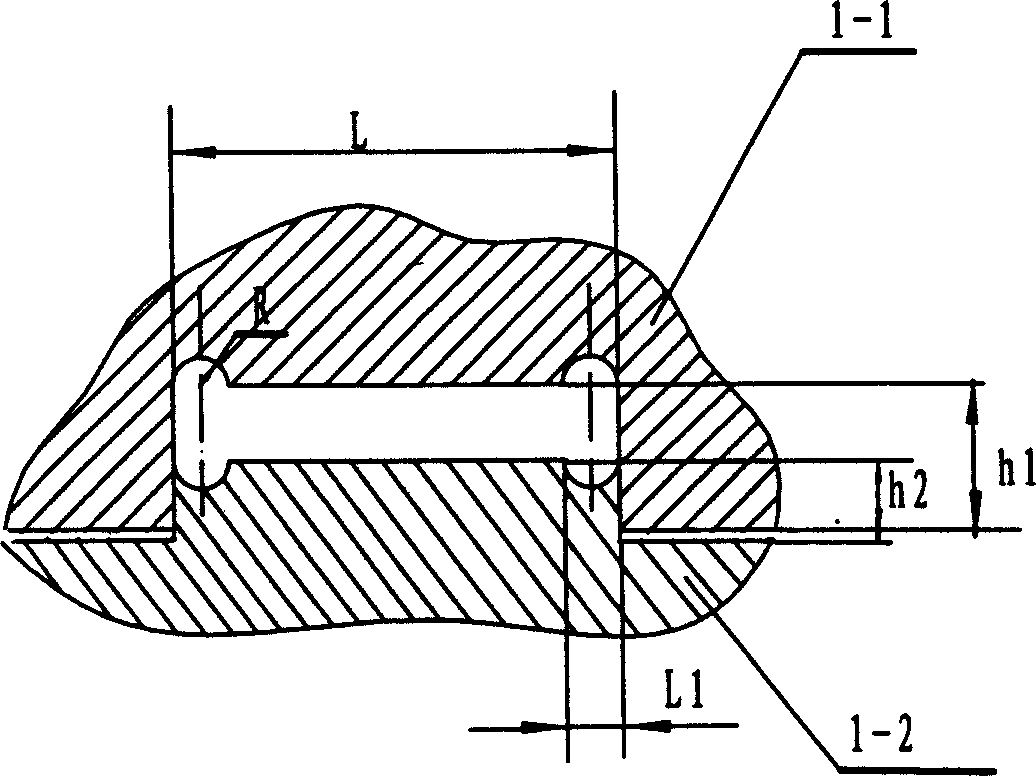

Rolling method and apparatus for copper-aluminium double-face composite board

A technology for rolling the composite Cu-Al plate includes such steps as preheating the copper band and aluminium plate respectively at different temp for different time, acid washing of copper band, alkali washing of aluminium plate, brushing surface by steel wire brush, rolling by a pair of upper concave roller and lower convex roller, annealing in inertial gas, and straightening.

Owner:SHENYANG POLYTECHNIC UNIV

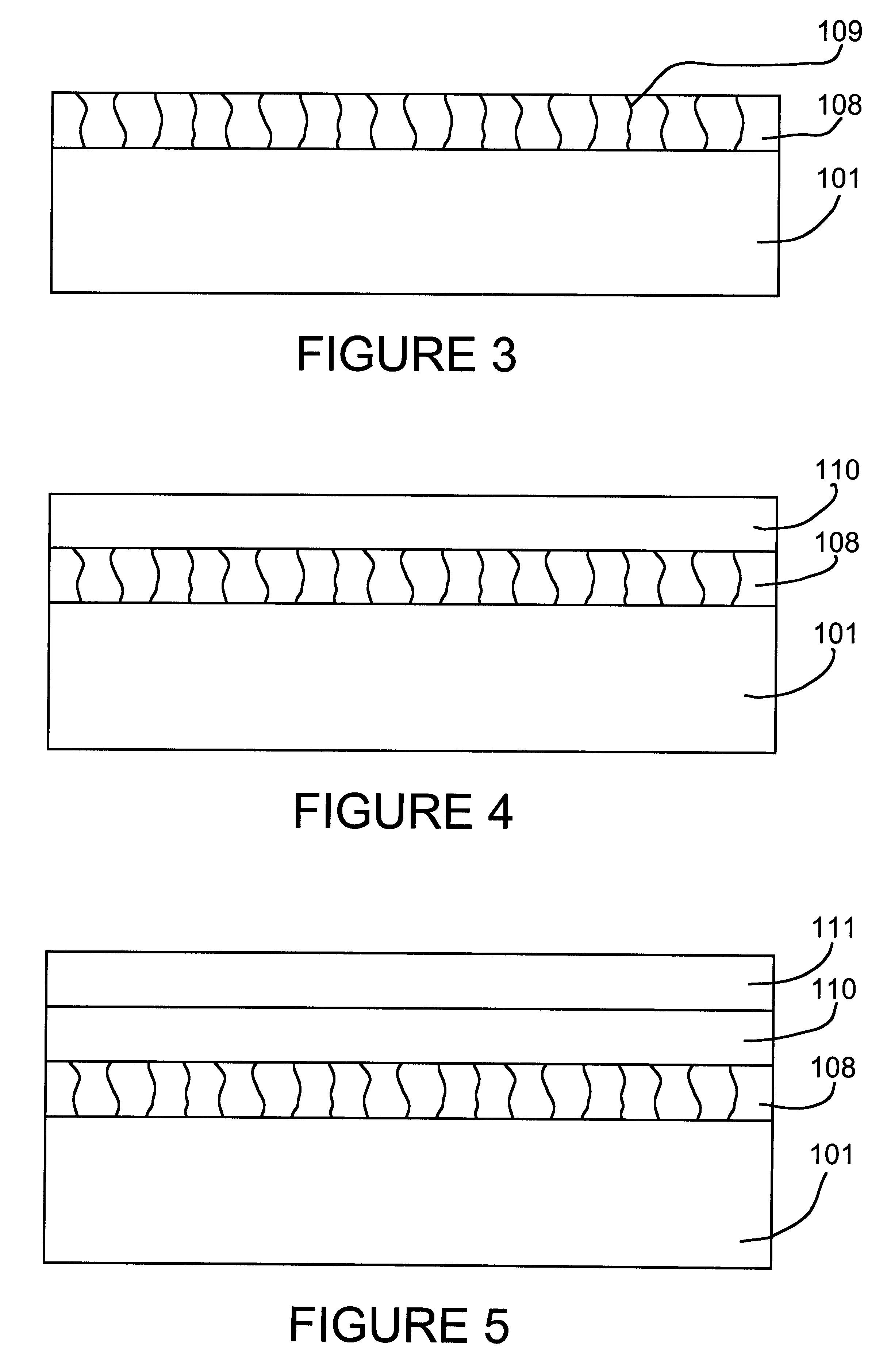

Ion beam process for deposition of highly abrasion-resistant coatings

InactiveUSRE37294E1High hardnessReduce coefficient of frictionLayered productsVacuum evaporation coatingEye lensVacuum chamber

An ion beam deposition method is provided for manufacturing a coated substrate with improved abrasion resistance, and improved lifetime. According to the method, the substrate is first chemically cleaned to remove contaminants. In the second step, the substrate is inserted into a vacuum chamber, and the air in said chamber is evacuated. In the third step, the substrate surface is bombarded with energetic ions to assist in the removal of residual hydrocarbons and surface oxides, and to activate the surface. <DEL-S DATE="20010724" ID="DEL-S-00001">Alter<DEL-E ID="DEL-S-00001"> <INS-S DATE="20010724" ID="INS-S-00001">After <INS-E ID="INS-S-00001">the substrate surface has been sputter-etched, a protective, abrasion-resistant coating is deposited by ion beam deposition. The ion beam-deposited coating may contain one or more layers. Once the chosen thickness of the coating has been achieved, the deposition process on the substrates is terminated, the vacuum chamber pressure is increased to atmospheric pressure, and the coated substrate products having improved abrasion-resistance are removed from the vacuum chamber. The coated products of this invention have utility as plastic sunglass lenses, ophthalmic lenses, bar codes scanner windows, and industrial wear parts that must be protected from scratches and abrasion.

Owner:MORGAN ADVANCED CERAMICS

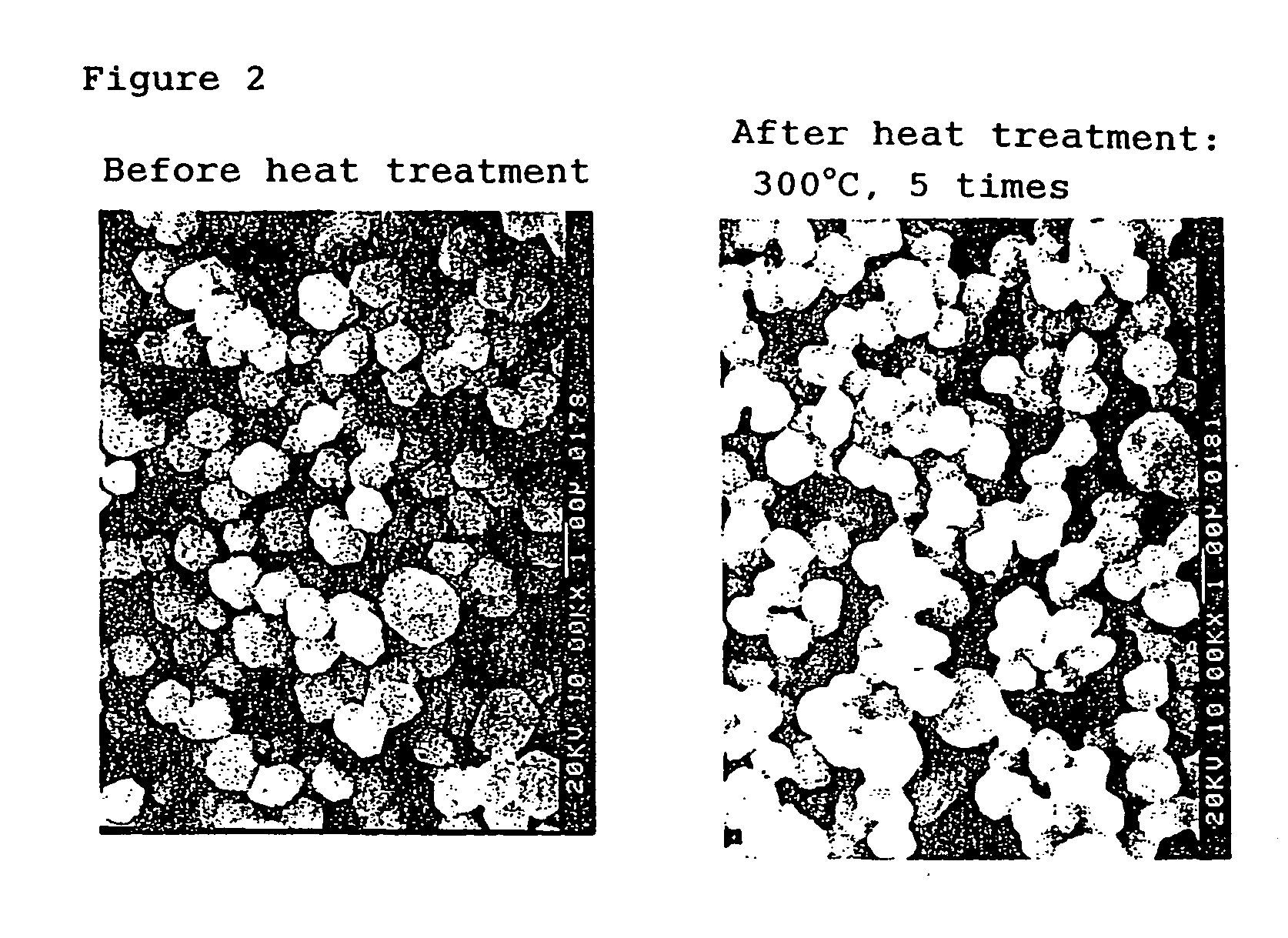

Method for forming fine copper particle sintered product type of electric conductor having fine shape, method for forming fine copper wiring and thin copper film using said method

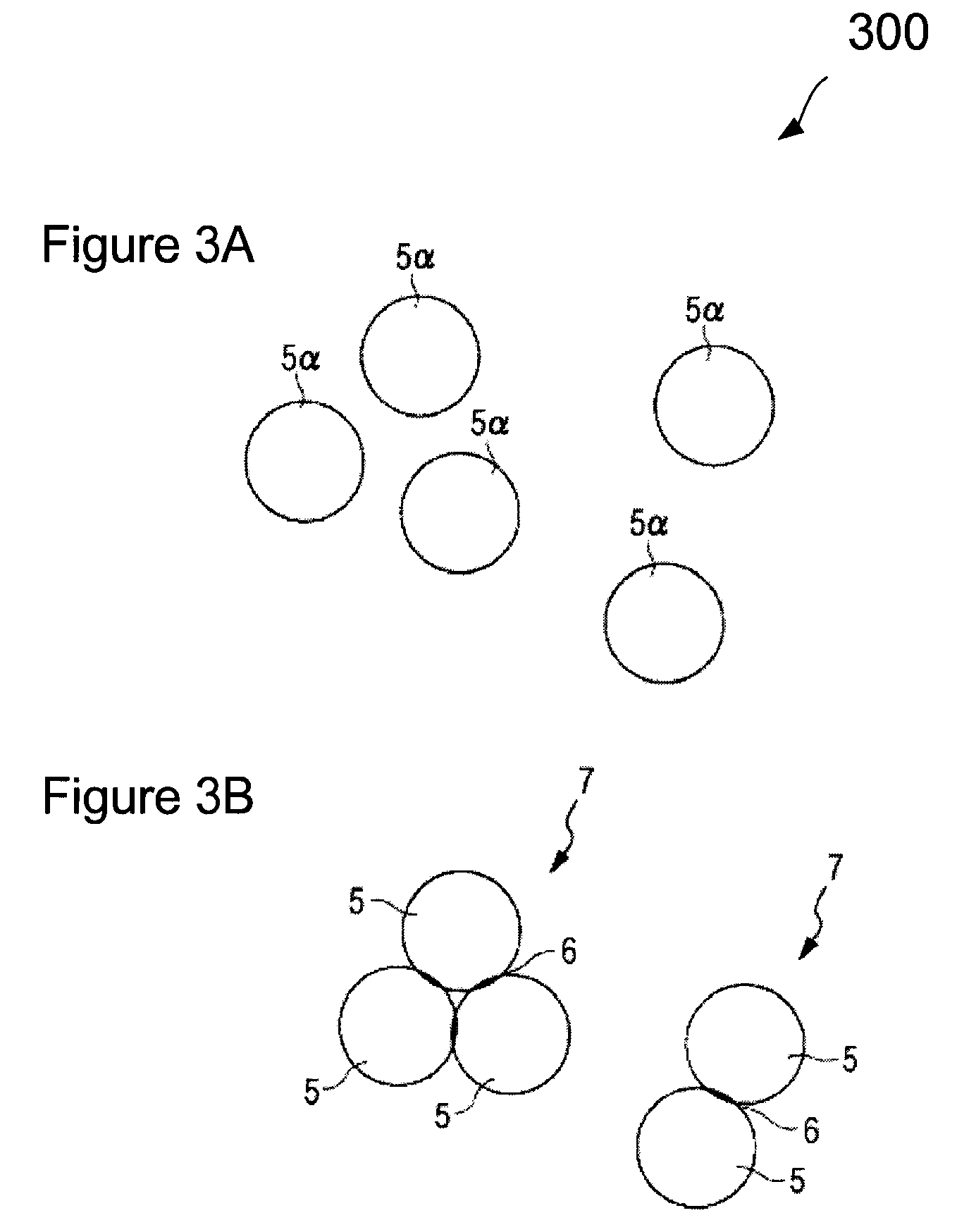

ActiveUS20060210705A1Good reproducibilityBroaden spectrumPrinted circuit aspectsPretreated surfacesSurface oxideProduct gas

The present invention provides a process for forming a copper fine particle sintered product type of a fine-shaped electric conductor showing superior electroconductivity, which comprises steps of drawing a fine pattern with the use of a dispersion containing the copper fine particles having a surface oxide film layer, conducting a treatment for reducing the copper fine particles with the surface oxide film layer or copper oxide fine particles included in the pattern at a comparatively low temperature, and baking the resultant copper fine particles. Specifically, the process carries out the processes of; applying a dispersion containing the copper fine particles having the surface oxide film layer thereon or the copper oxide fine particles with an average particle diameter of 10 μm or smaller onto a substrate; and then performing a series of the heat treatment steps of heating the particles in the coated layer at temperature of 350° C. or lower under an atmosphere containing a vapor and a gas of a compound having reducibility to reduce the oxide film by a reduction reaction which used the compound having reducibility as a reducing agent, subsequently repeating a heat treatment combining an oxidizing treatment of a short time with a re-reducing treatment, and sintering the resultant copper fine particles with each other to form a layer of the sintered product.

Owner:HARIMA CHEM INC

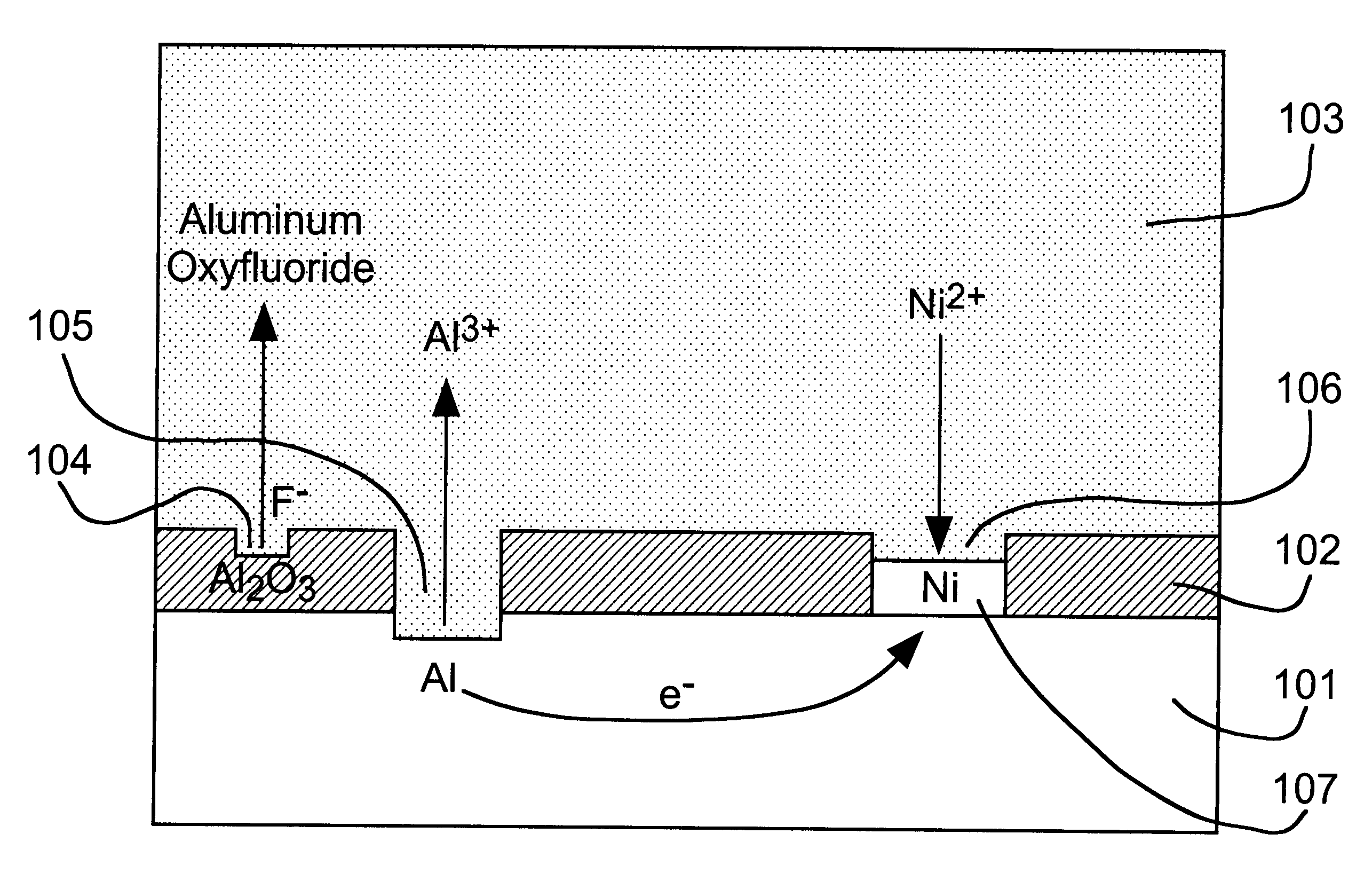

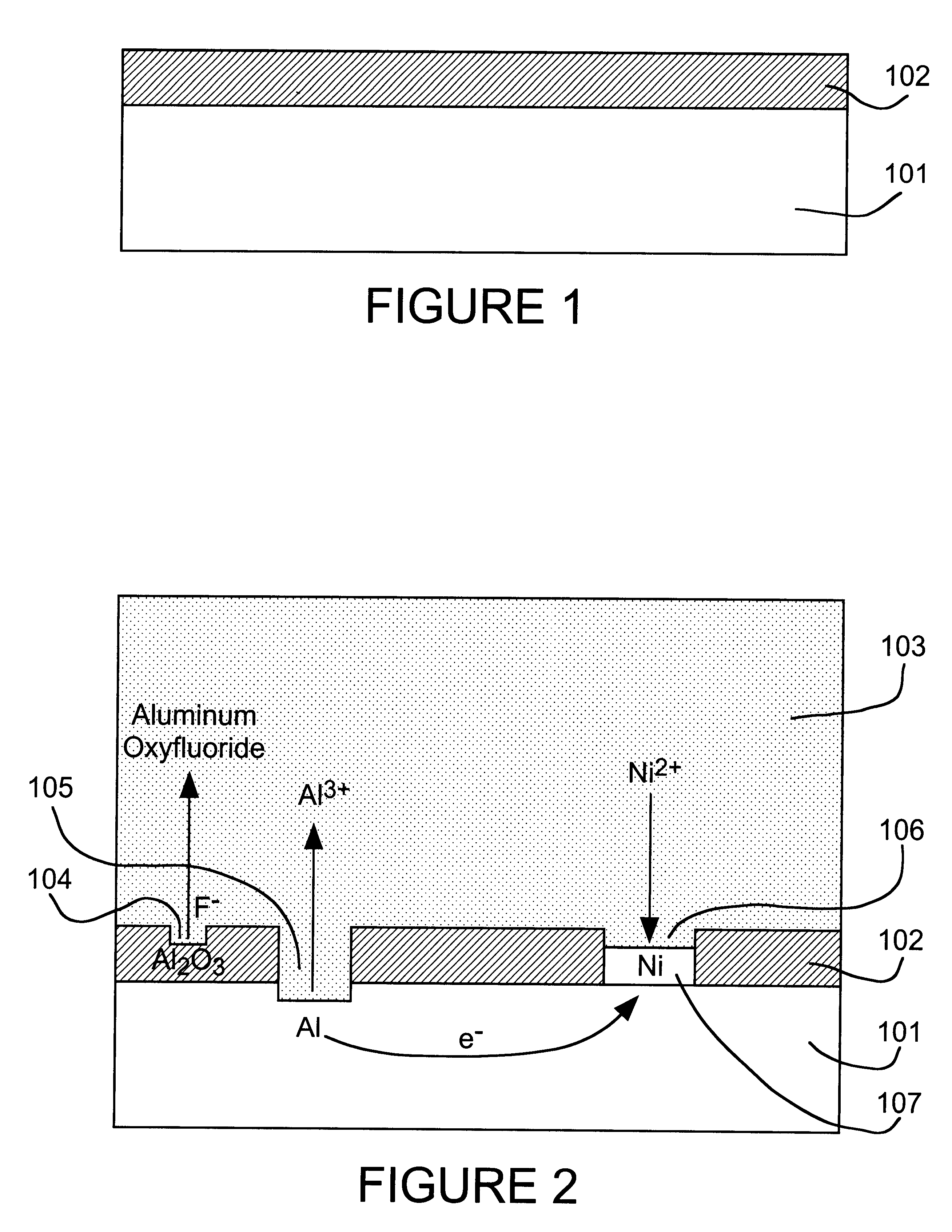

Controlled plating on reactive metals

InactiveUS6503343B1Avoid consumptionInhibited porositySolid-state devicesSemiconductor/solid-state device manufacturingElectroless nickelSolubility

A direct displacement plating process provides a uniform, adherent coating of a relatively stable metal (e.g., nickel) on a highly reactive metal (e.g., aluminum) that is normally covered with a recalcitrant oxide layer. The displacement reaction proceeds, preferably in a nonaqueous solvent, as the oxide layer is dissolved by a fluoride activator. Halide anions are used to provide high solubility, to serve as an anhydrous source of stable metal ions, and to control the rate of the displacement reaction. A low concentration of activator species and little or no solution agitation are used to cause depletion of the activator species within pores in the surface oxide so that attack of the reactive metal substrate is minimized. Used in conjunction with electroless nickel deposition to thicken the displacement coating, this process can be used to render aluminum pads on IC chips solderable without the need for expensive masks and vacuum deposition operations. Such coatings can also be used to preserve or restore wire bondability, or for corrosion protection of aluminum and other reactive structural metals and alloys. A thin layer of immersion gold can be used to protect the thickened coating from oxidation. The solderable aluminum IC chip pads provide the basis for a maskless bumping process for flip chip attachment.

Owner:CALLAHAN CELLULAR L L C

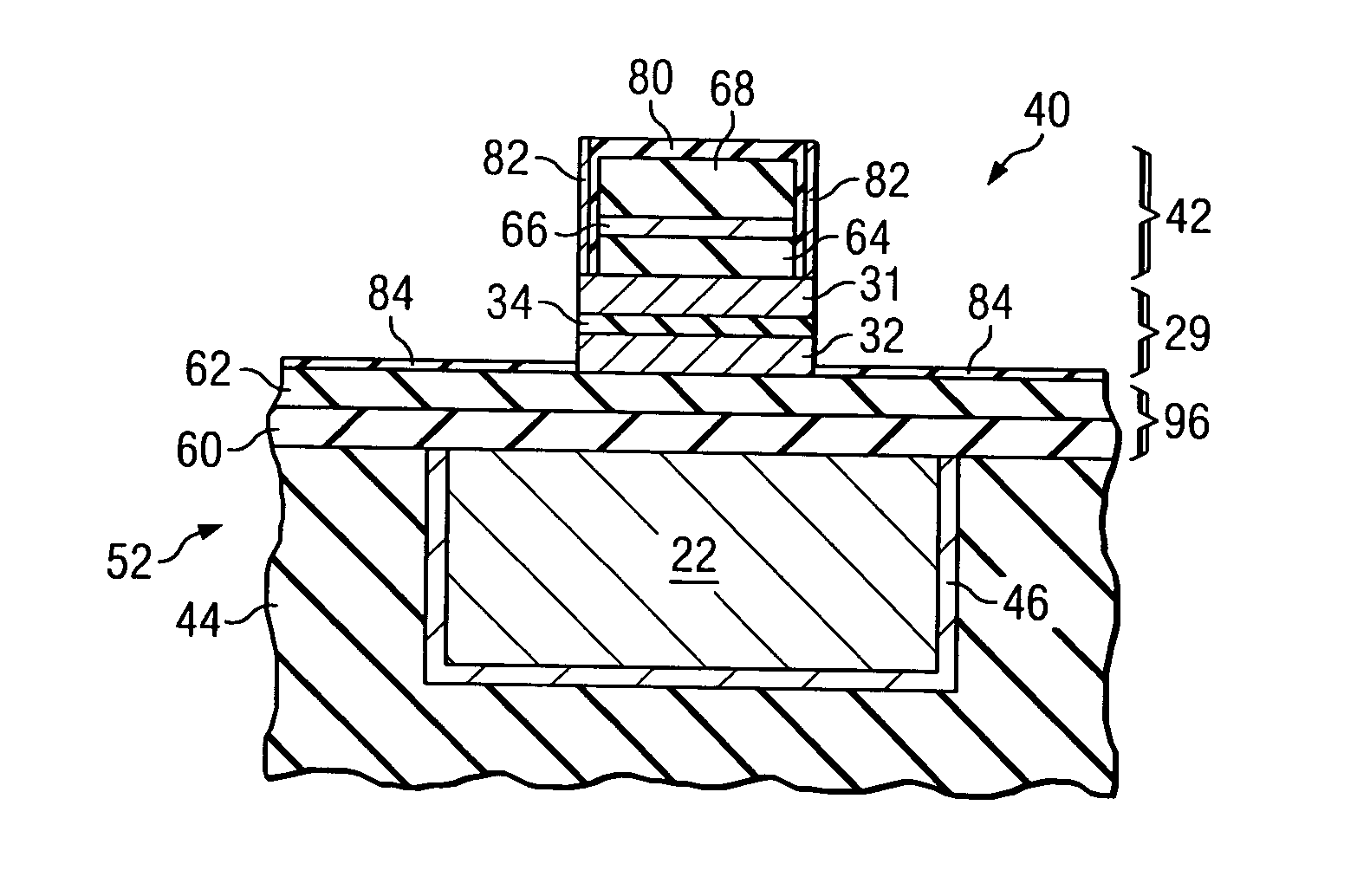

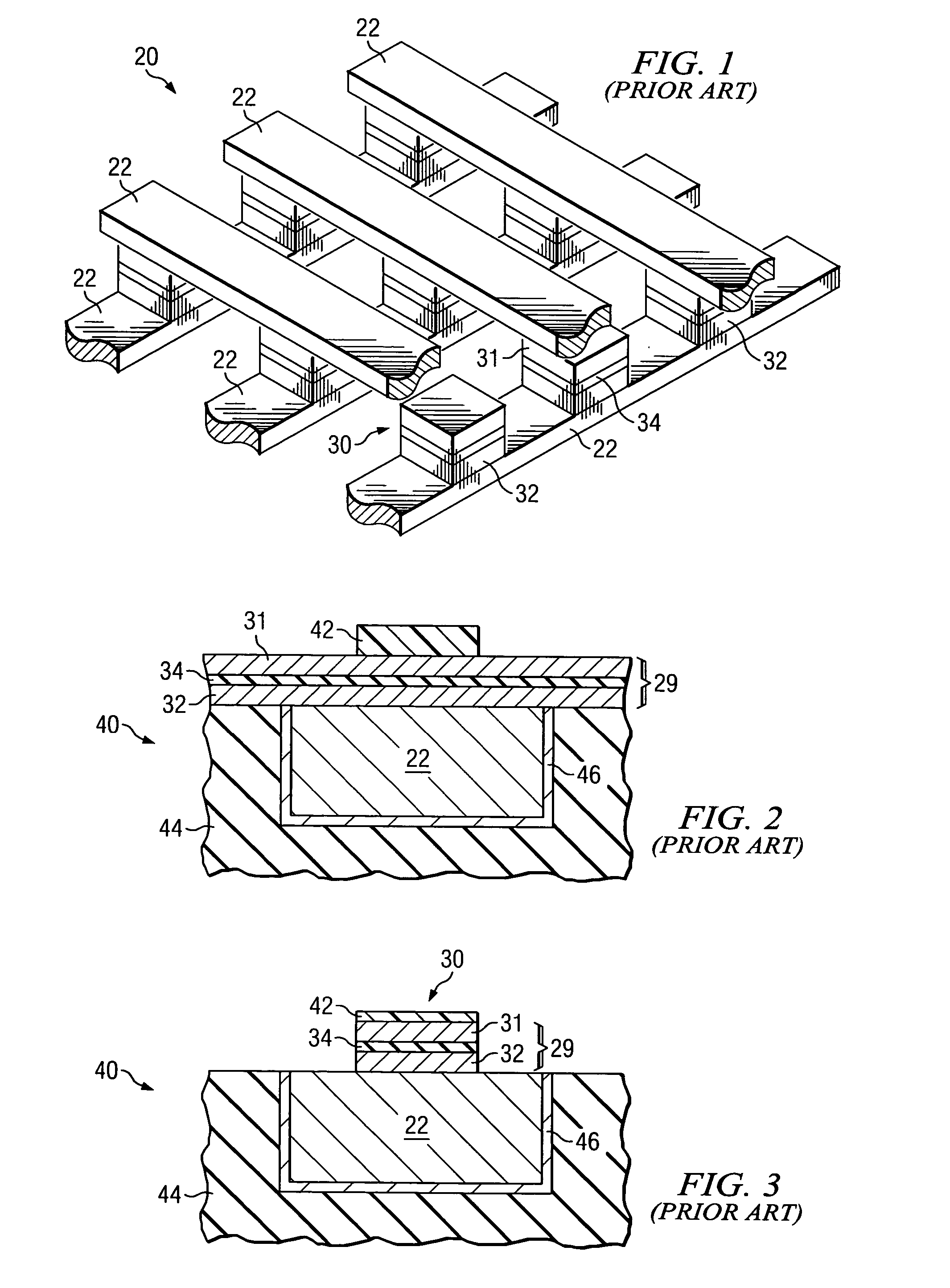

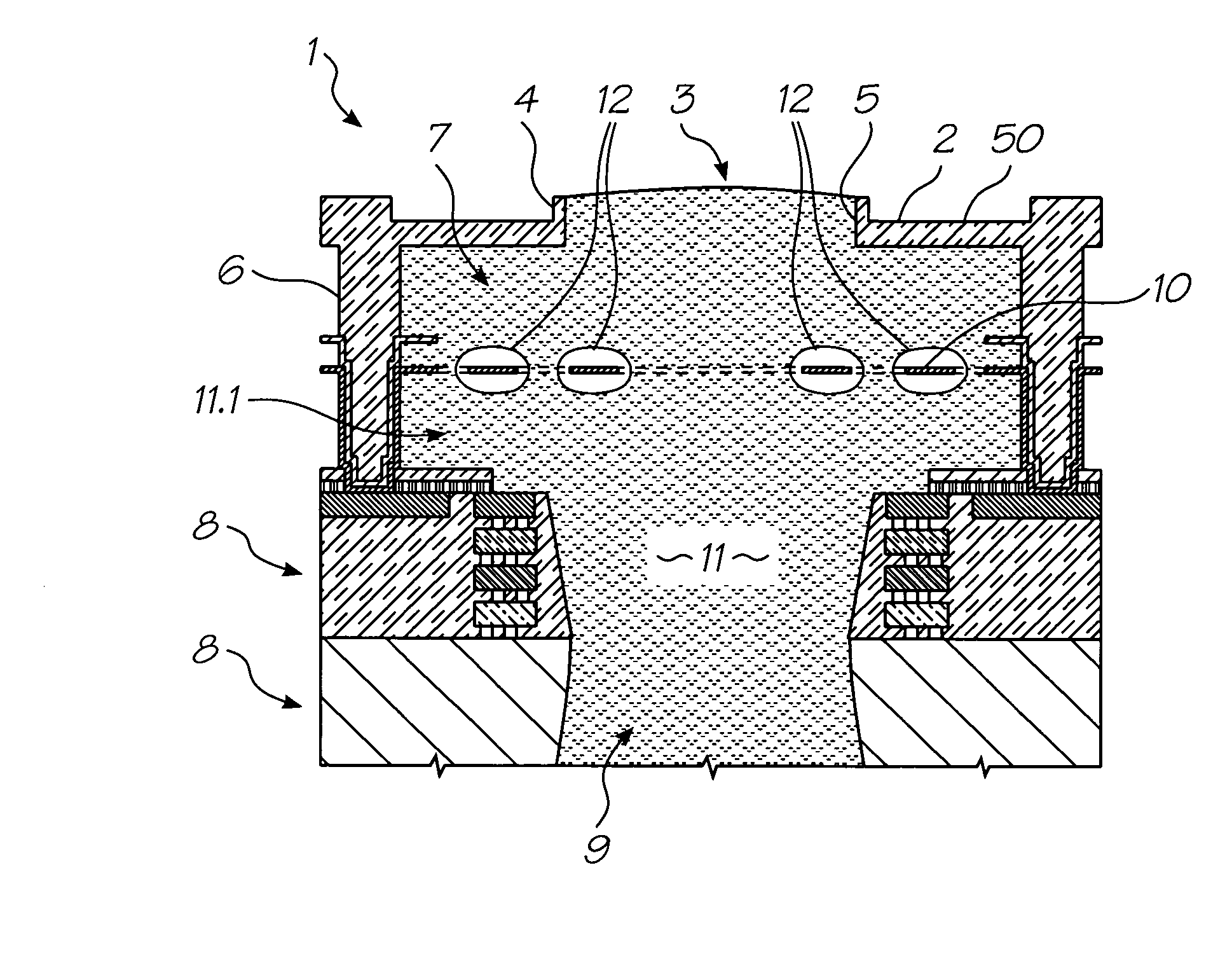

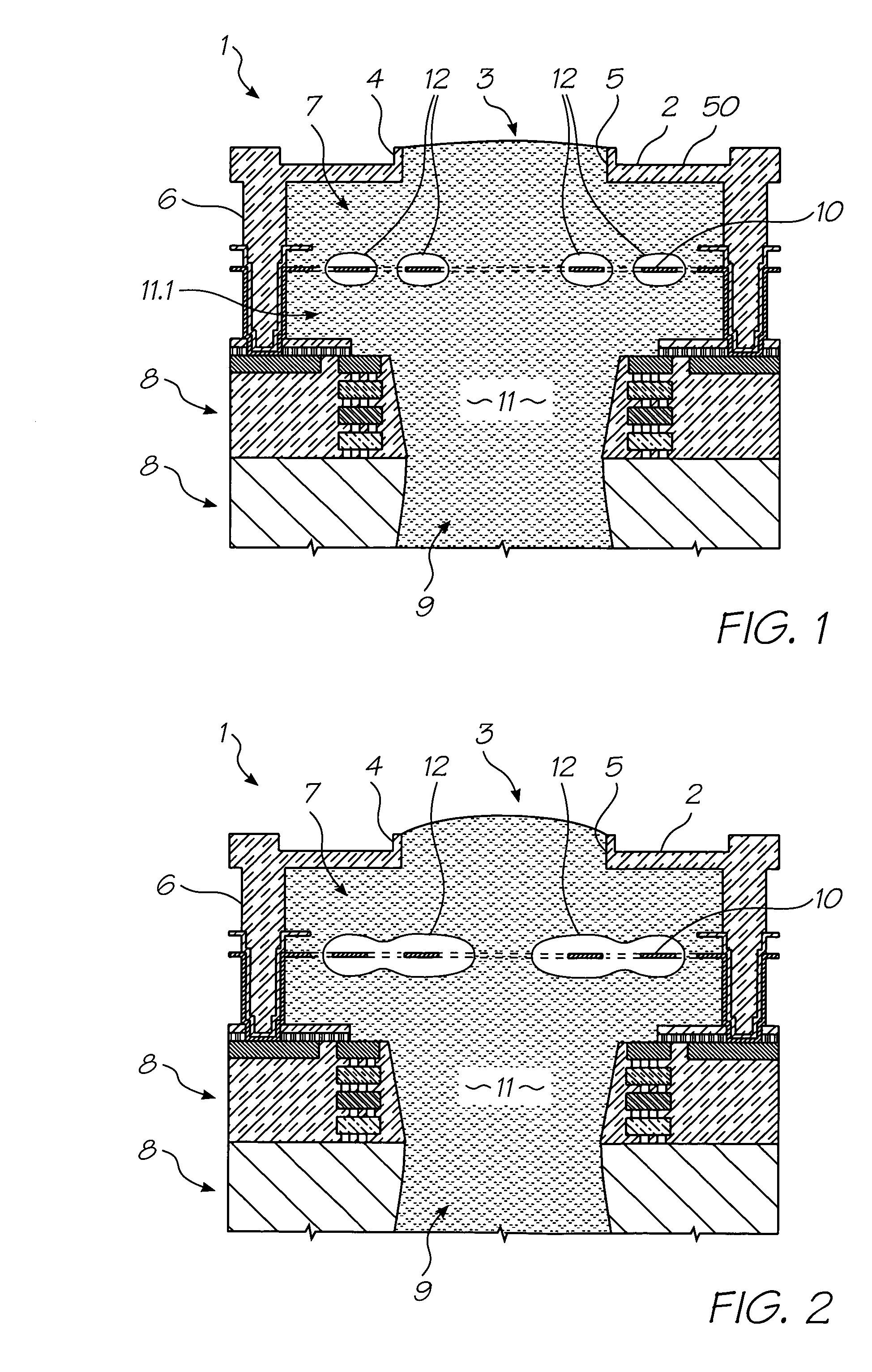

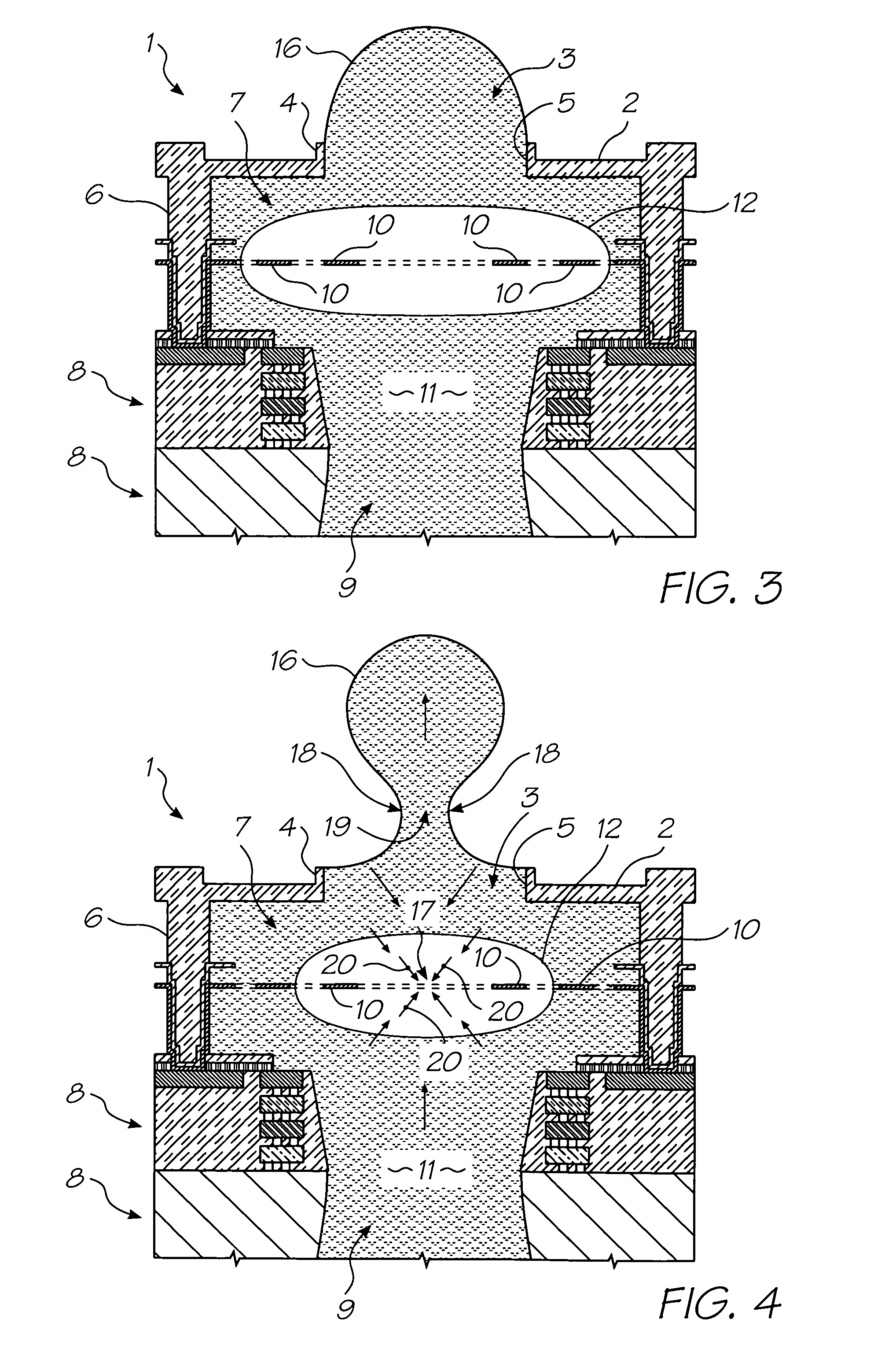

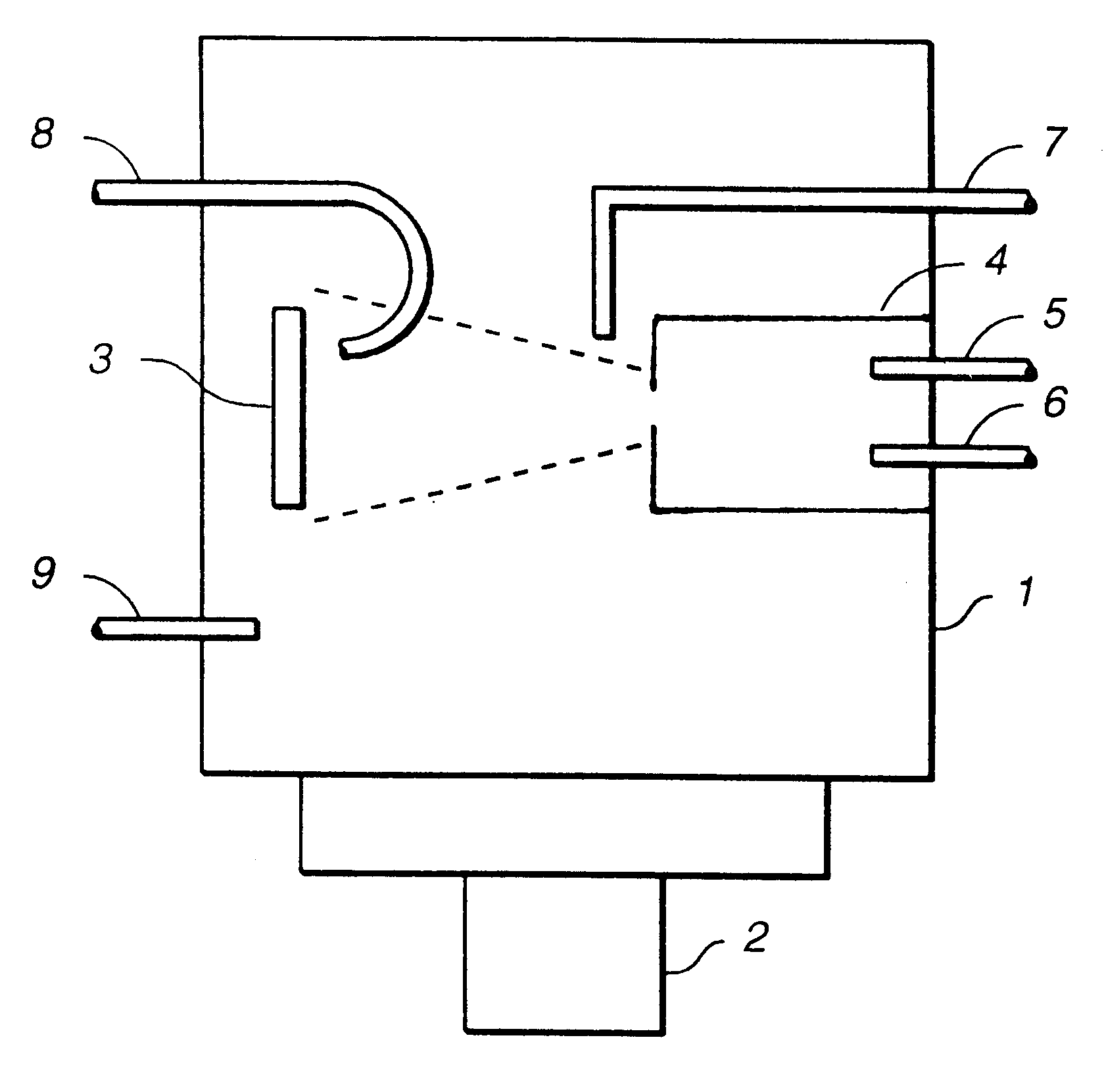

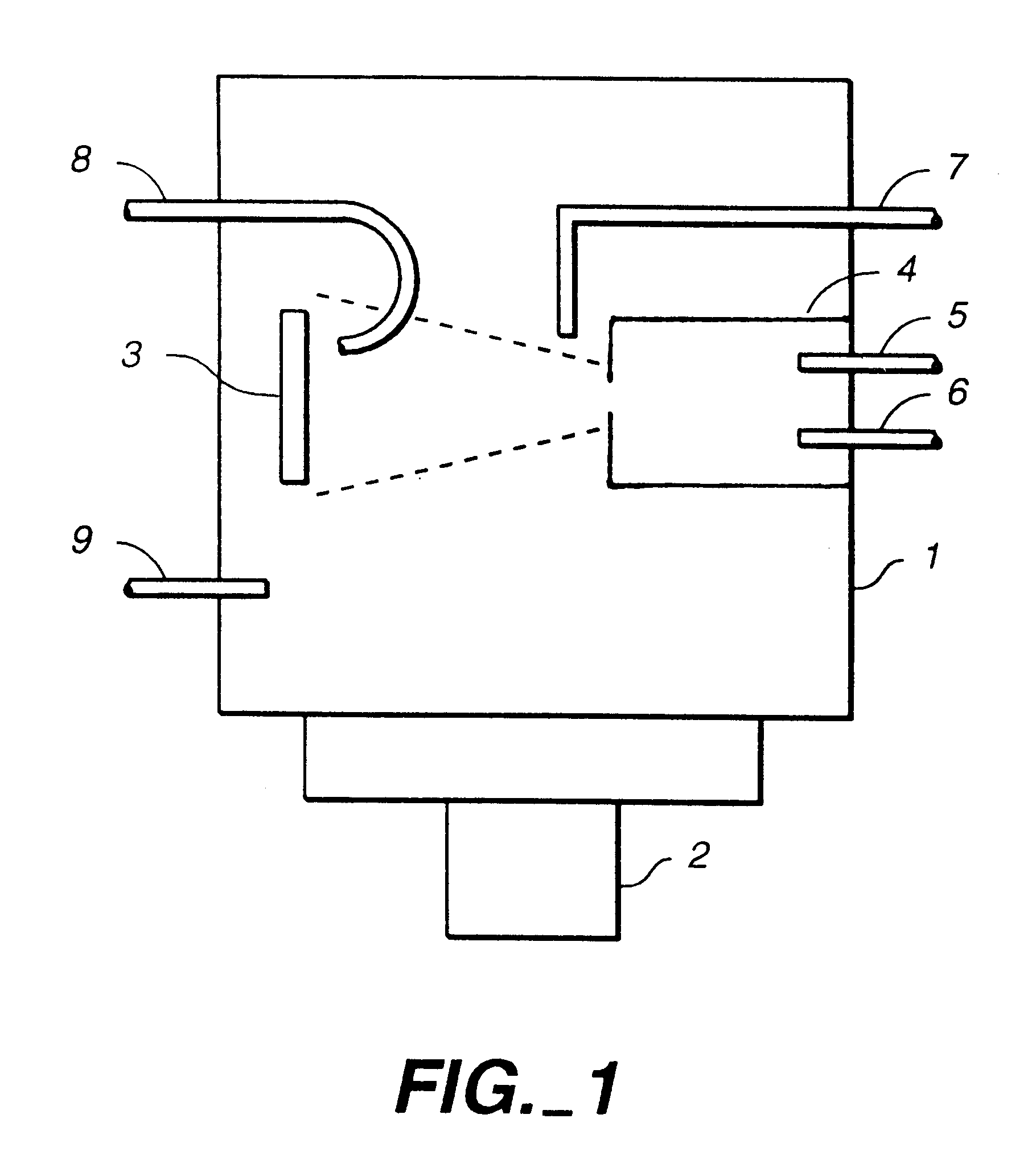

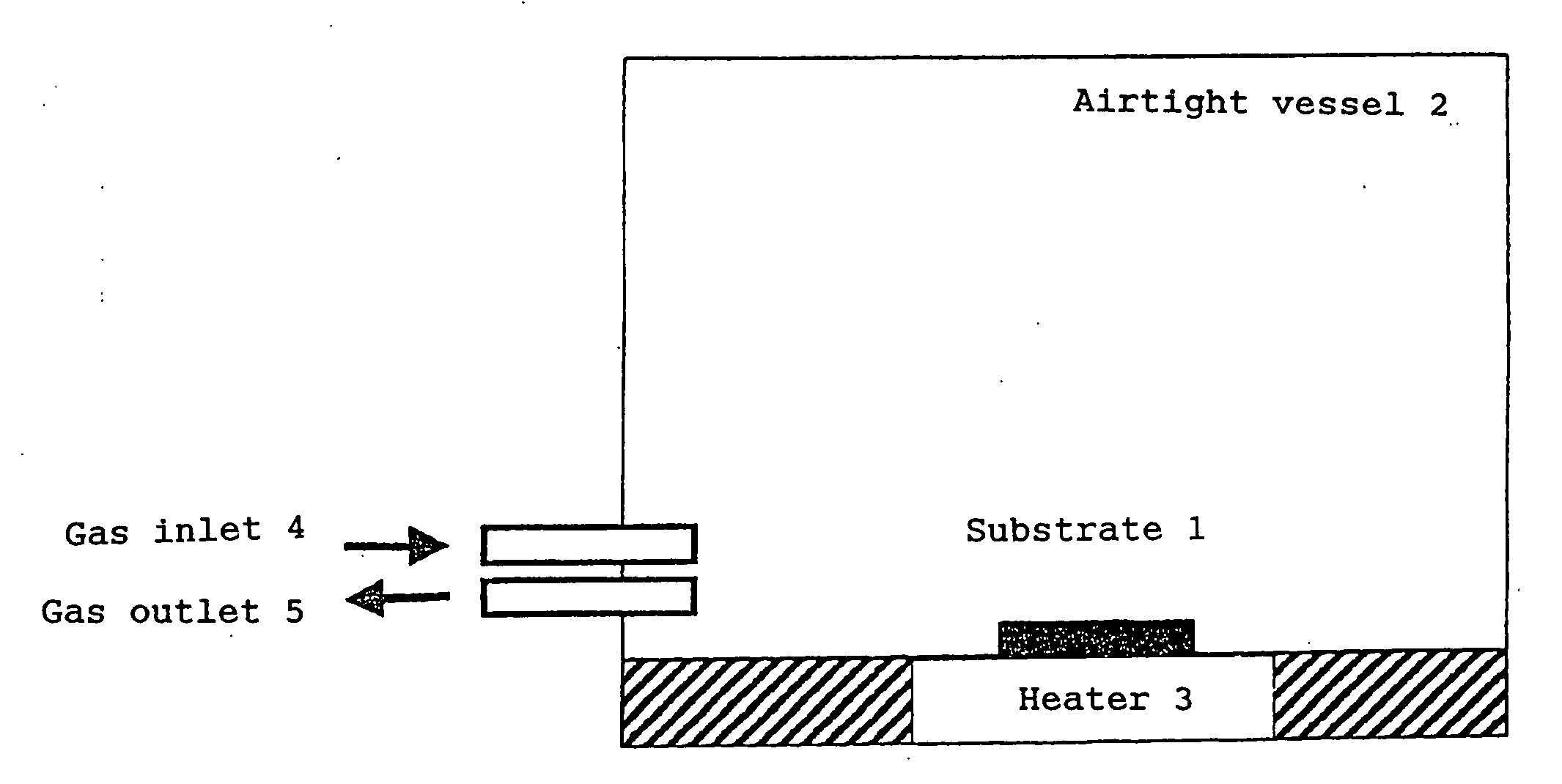

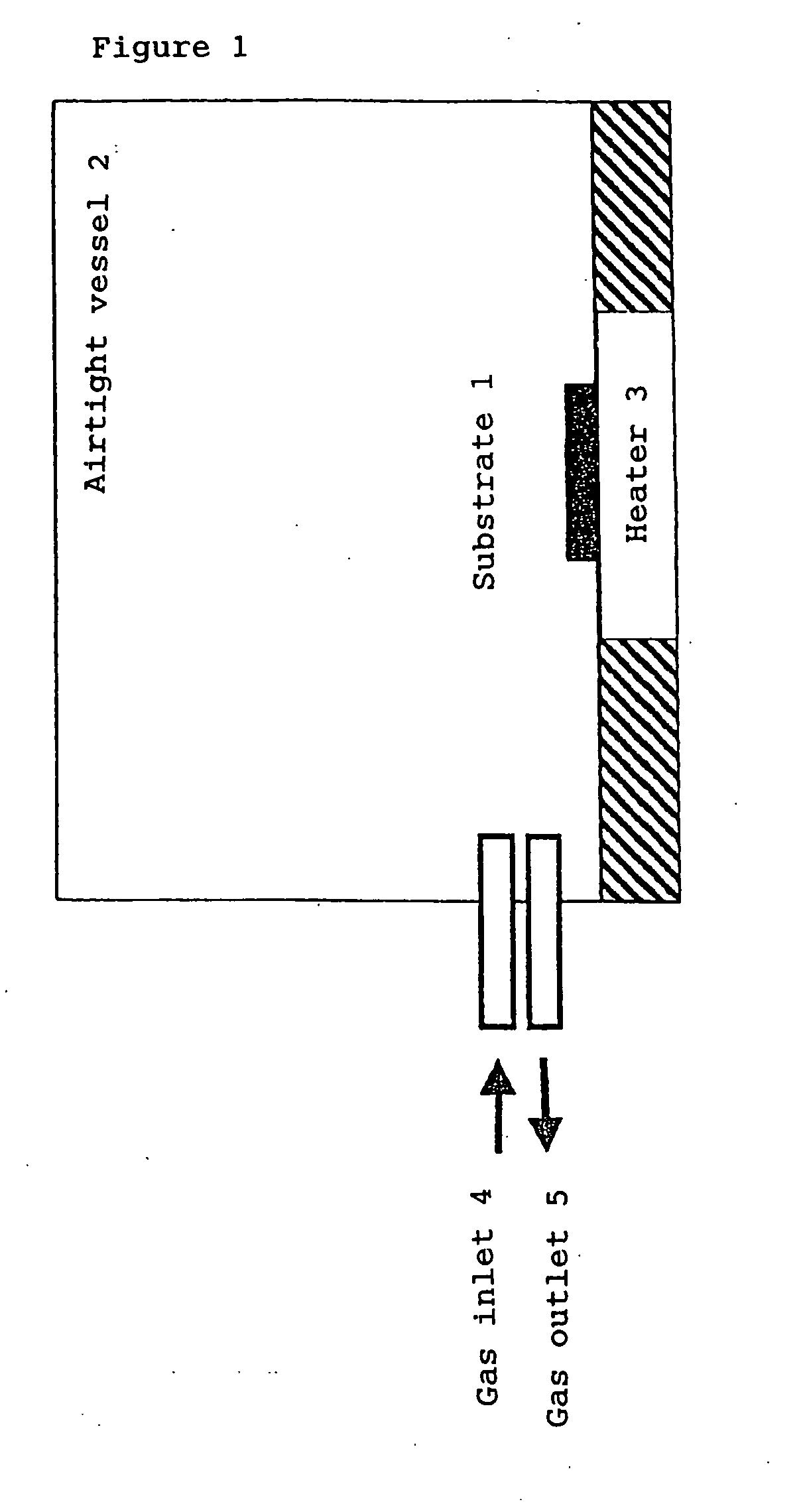

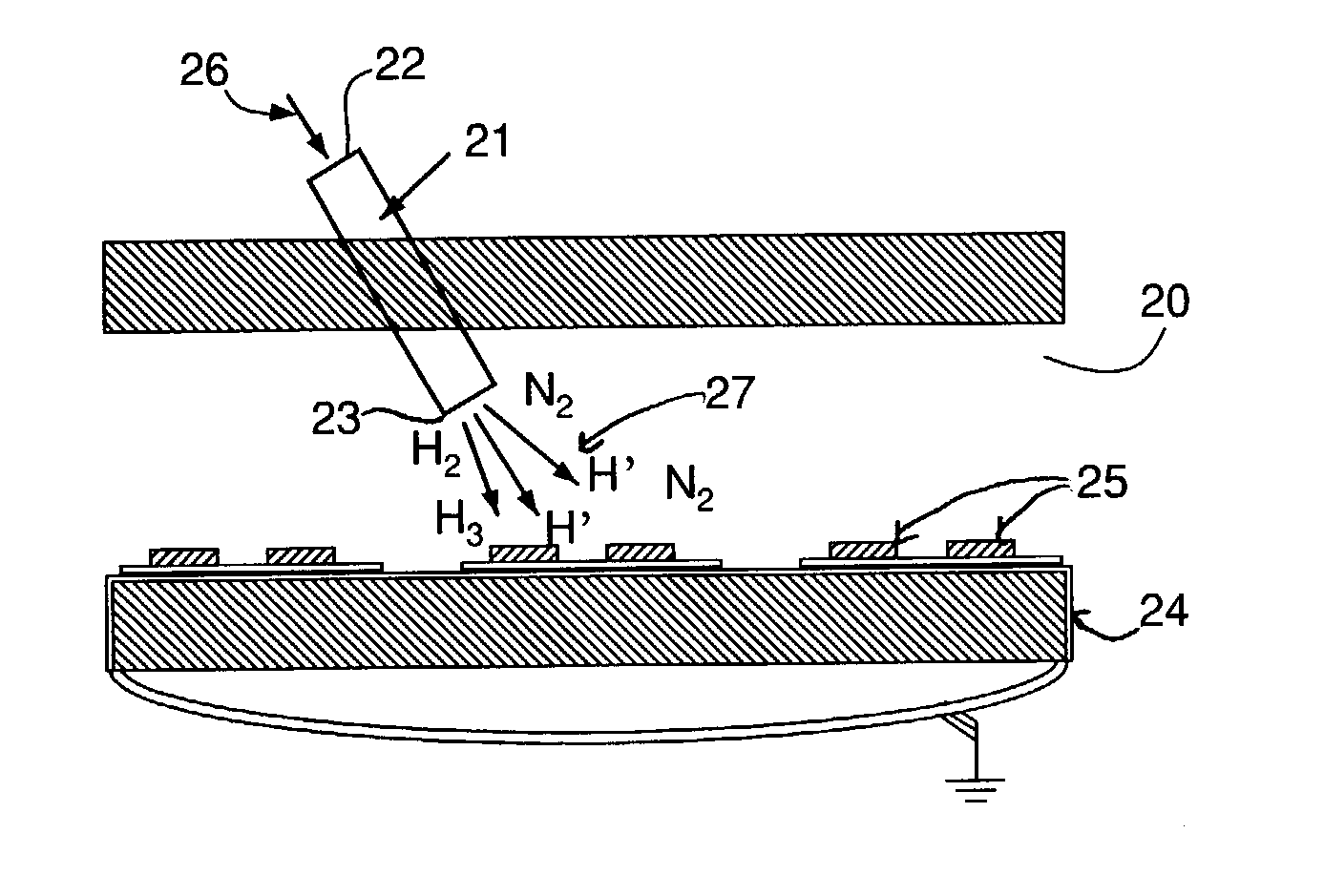

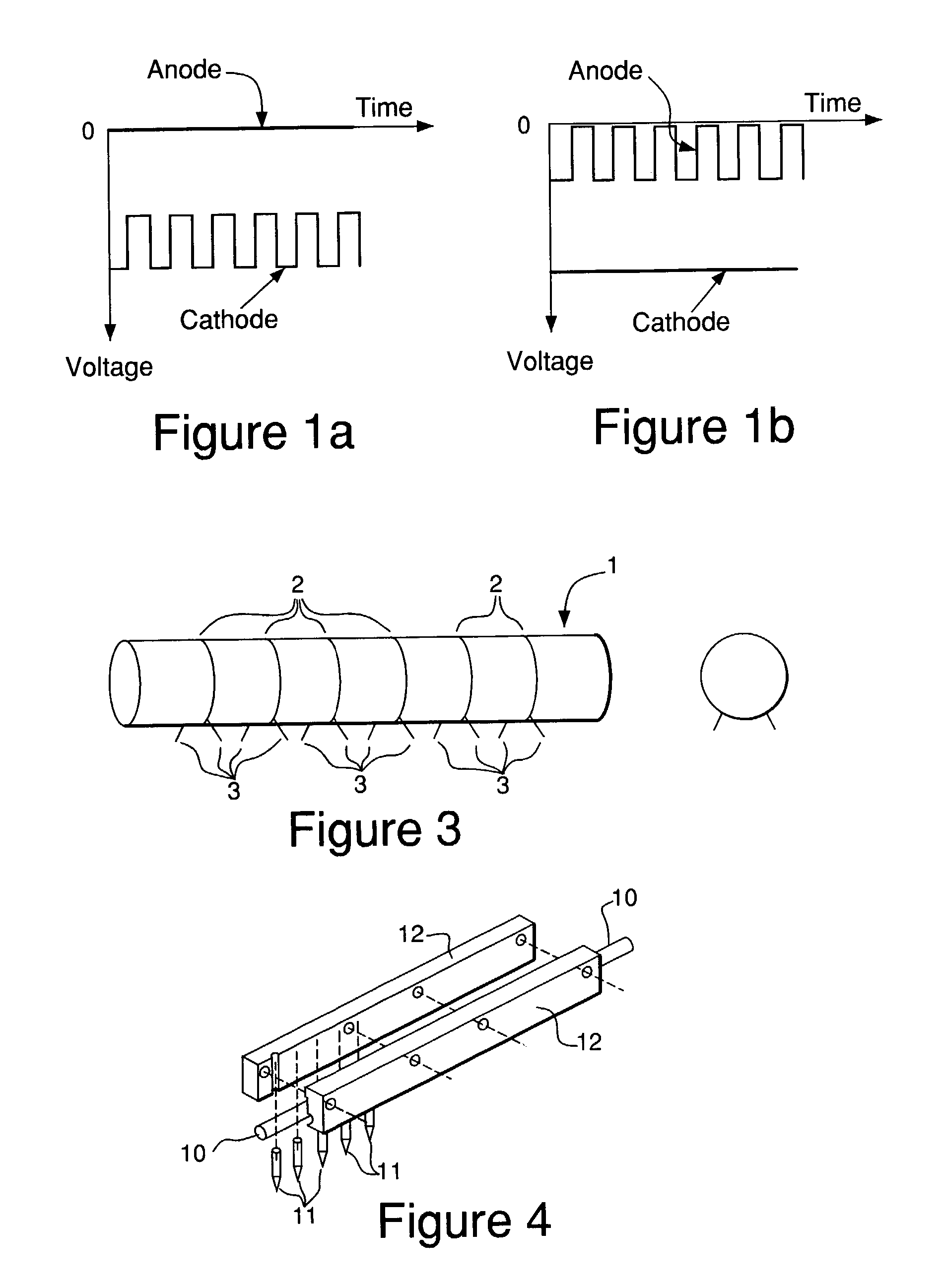

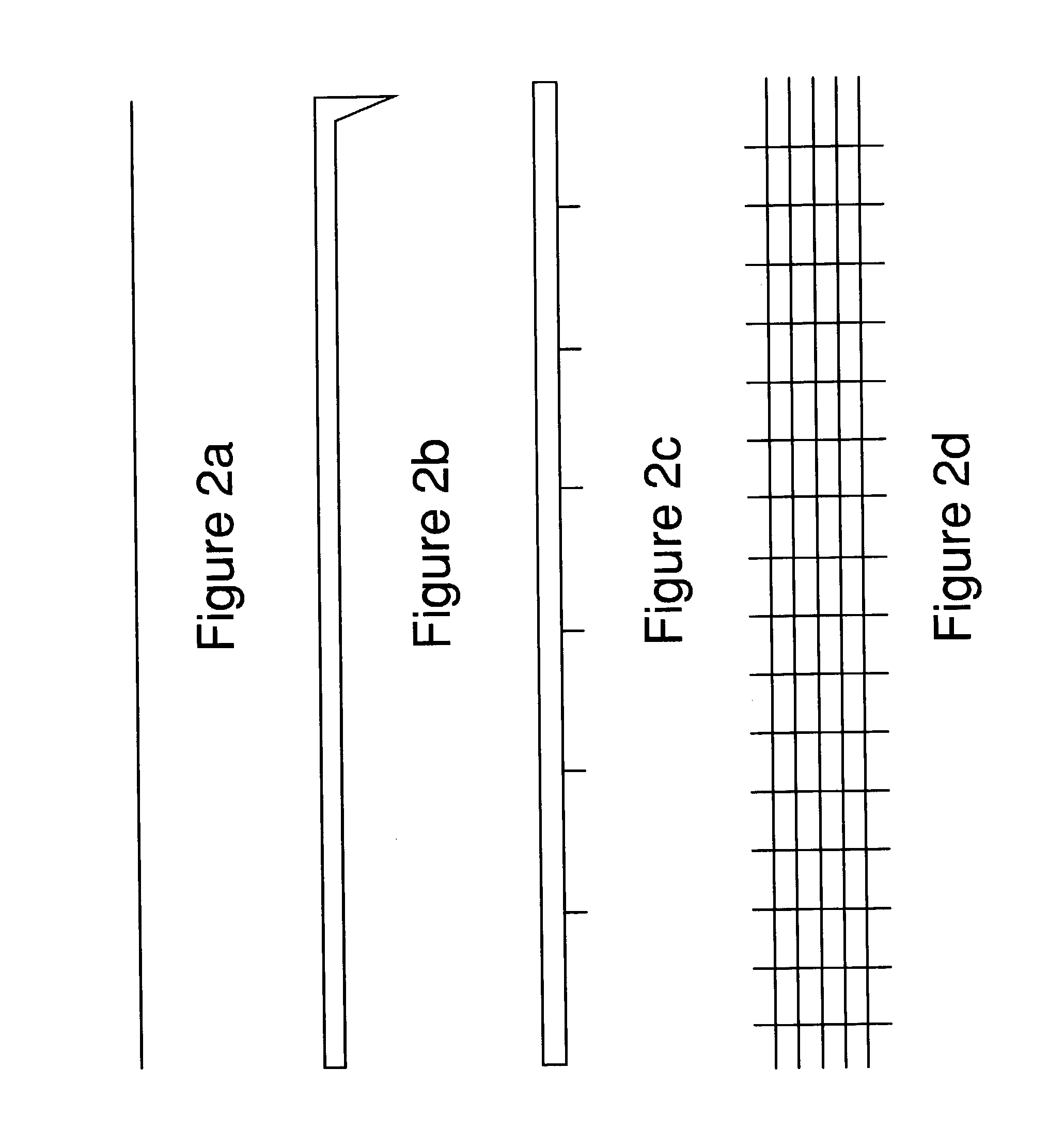

Apparatus and method for removal of surface oxides via fluxless technique electron attachment and remote ion generation

ActiveUS7079370B2Printed circuit assemblingDecorative surface effectsElectron attachmentMolecular physics

The present invention provides a method and apparatus for the dry fluxing of at least one component and / or solder surface via electron attachment. In one embodiment, there is provided a method for removing oxides from the surface of a component comprising: providing a component on a substrate wherein the substrate is grounded or has a positive electrical potential to form a target assembly; passing a gas mixture comprising a reducing gas through an ion generator comprising a first and a second electrode; supplying an amount of voltage to at least one of the first and second electrodes sufficient to generate electrons wherein the electrons attach to at least a portion of the reducing gas and form a negatively charged reducing gas; and contacting the target assembly with the negatively charged reducing gas to reduce the oxides on the component.

Owner:AIR PROD & CHEM INC

Method of improving adhesion of capping layers to copper interconnects

InactiveUS6383925B1Efficient and cost-effectiveSemiconductor/solid-state device detailsSolid-state devicesCopper interconnectHigh density

The adhesion of a barrier or capping layer to a Cu or Cu alloy interconnect member is significantly enhanced by treating the exposed surface of the Cu or Cu alloy interconnect member, after CMP, in a reaction chamber with a plasma containing ammonia and nitrogen for a brief period of time to reduce the surface oxide and then introducing silane into the reaction chamber to deposit the barrier layer, e.g., silicon nitride, under high density plasma conditions in the presence of nitrogen. The presence of nitrogen during plasma oxide layer reduction and plasma barrier layer deposition significantly improves adhesion of the barrier layer to the Cu or Cu alloy surface.

Owner:ADVANCED MICRO DEVICES INC

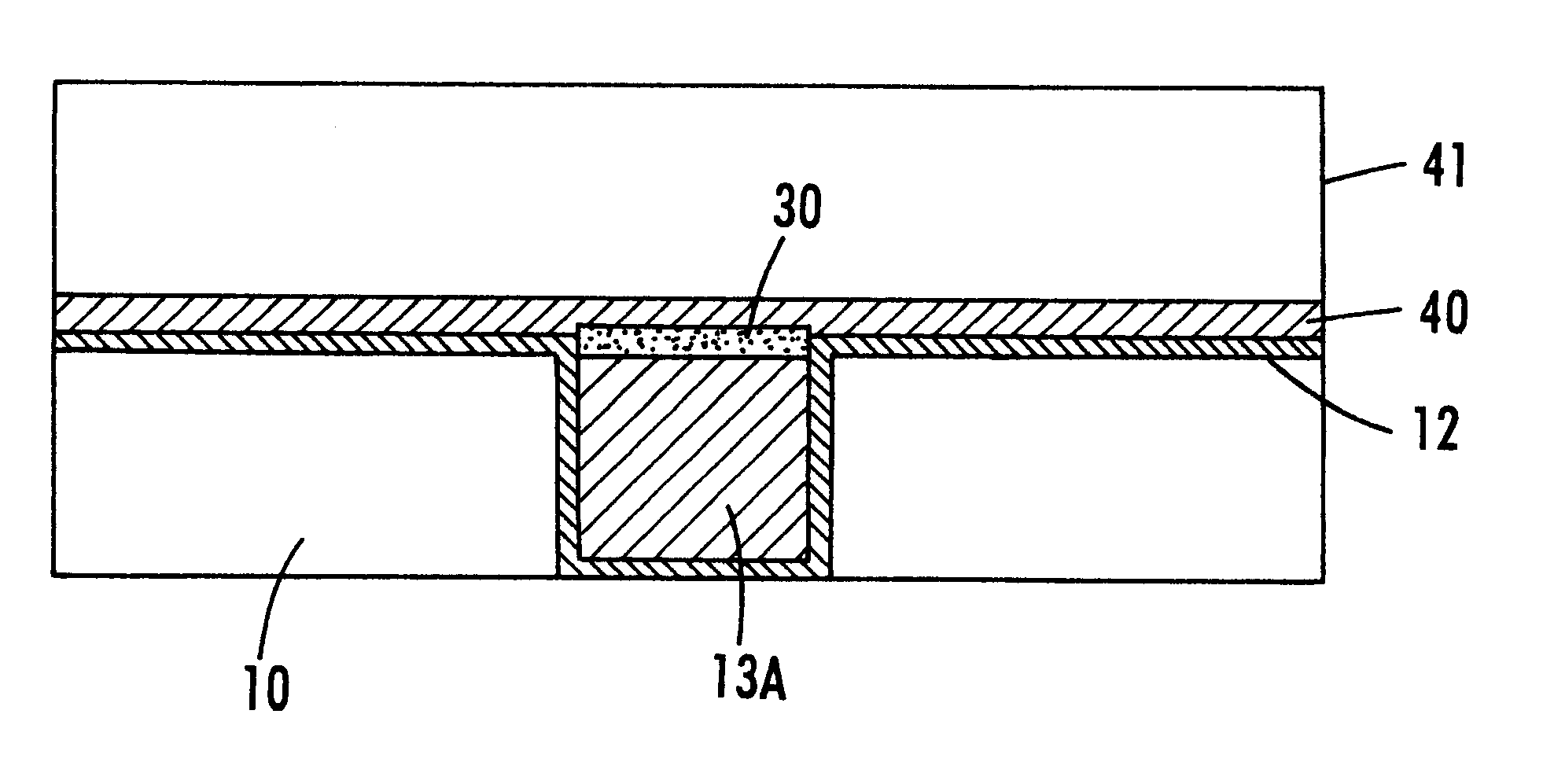

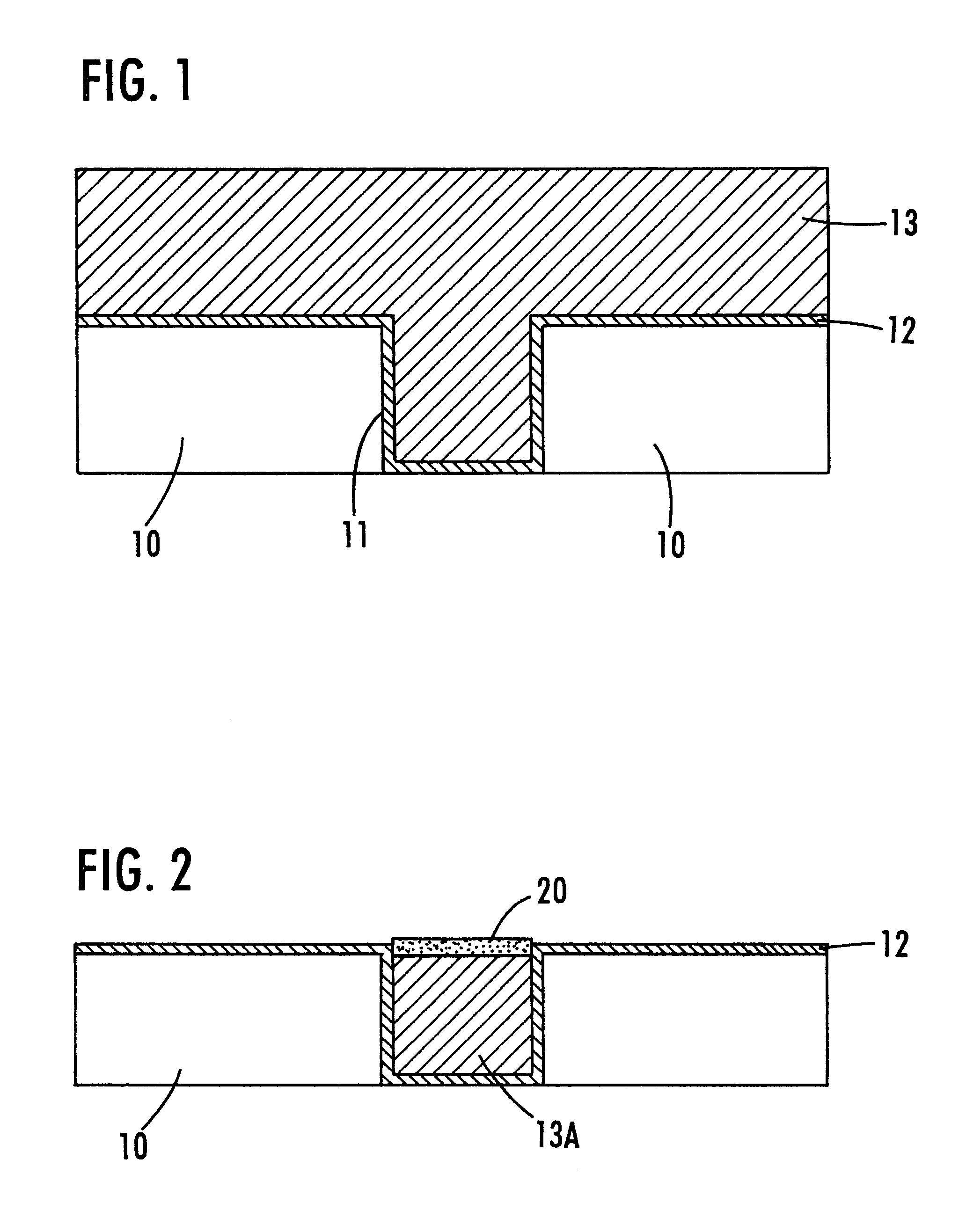

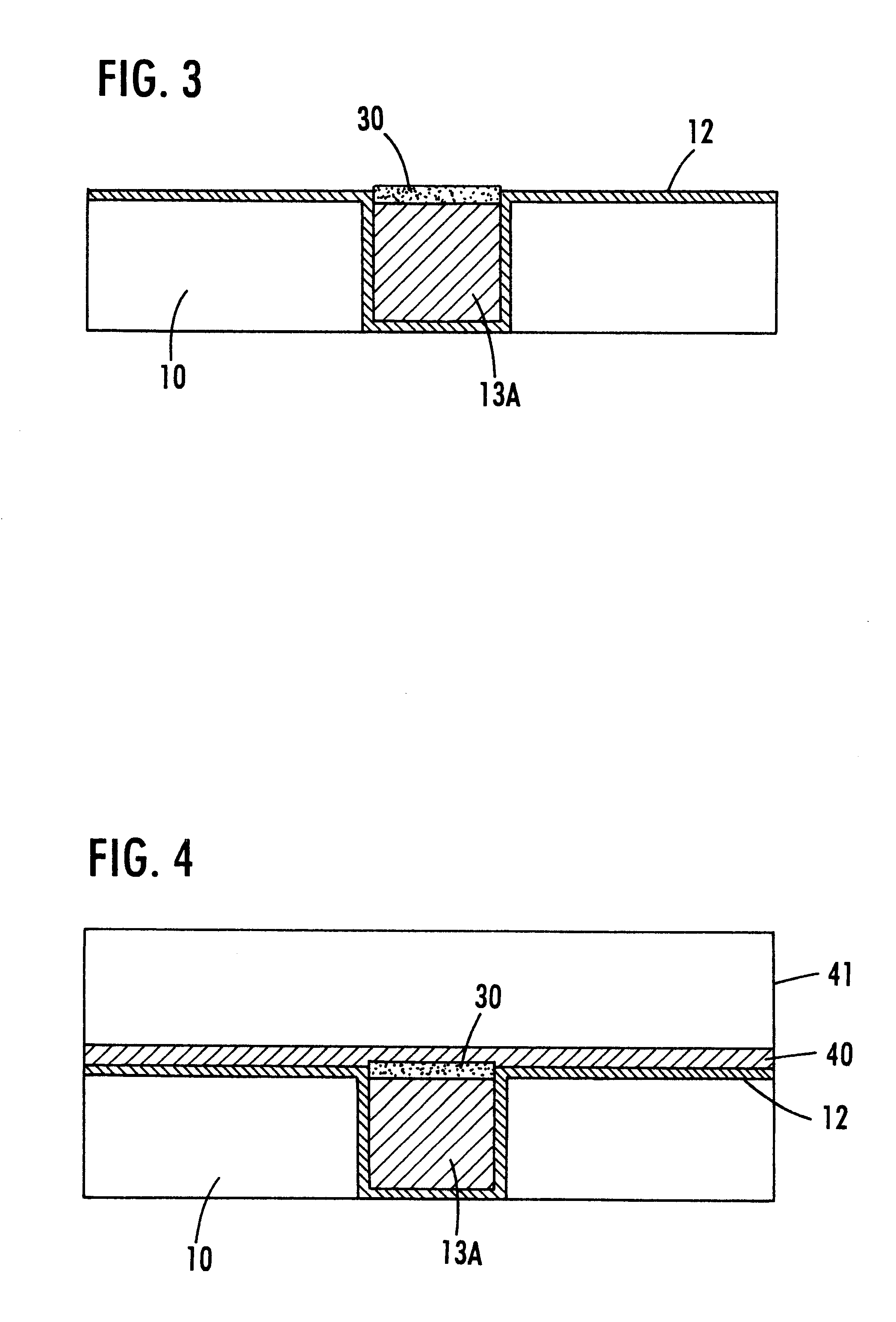

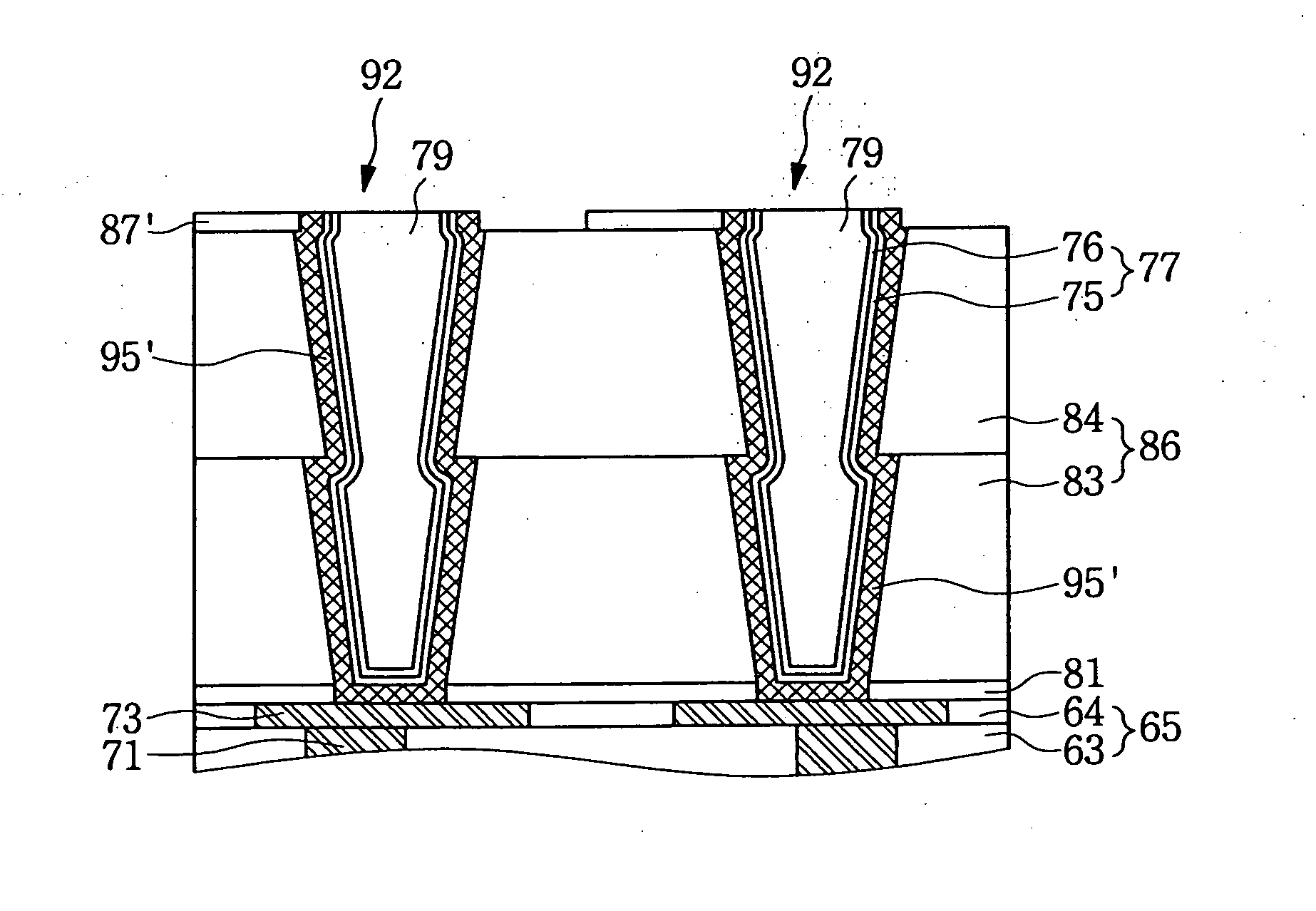

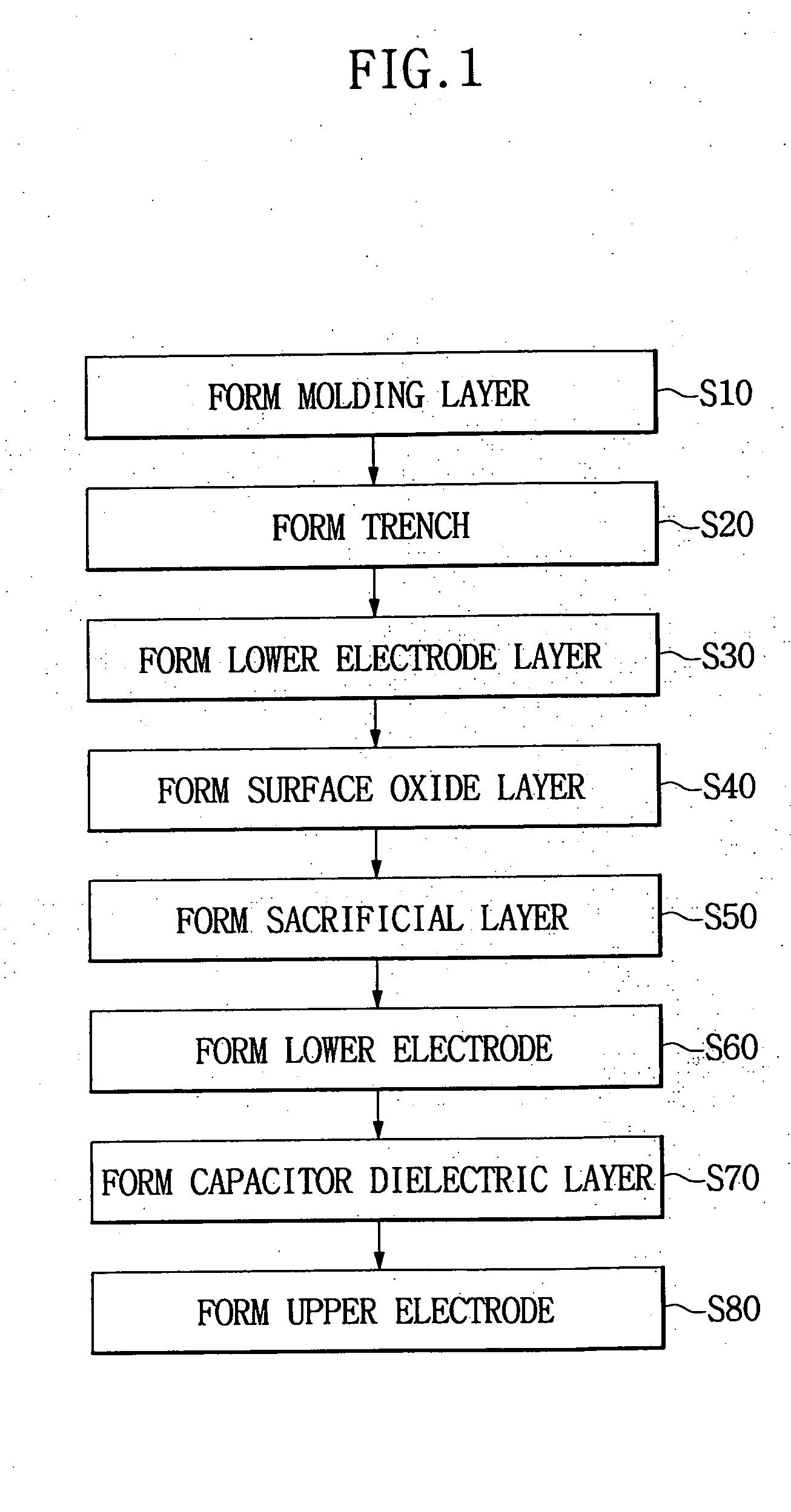

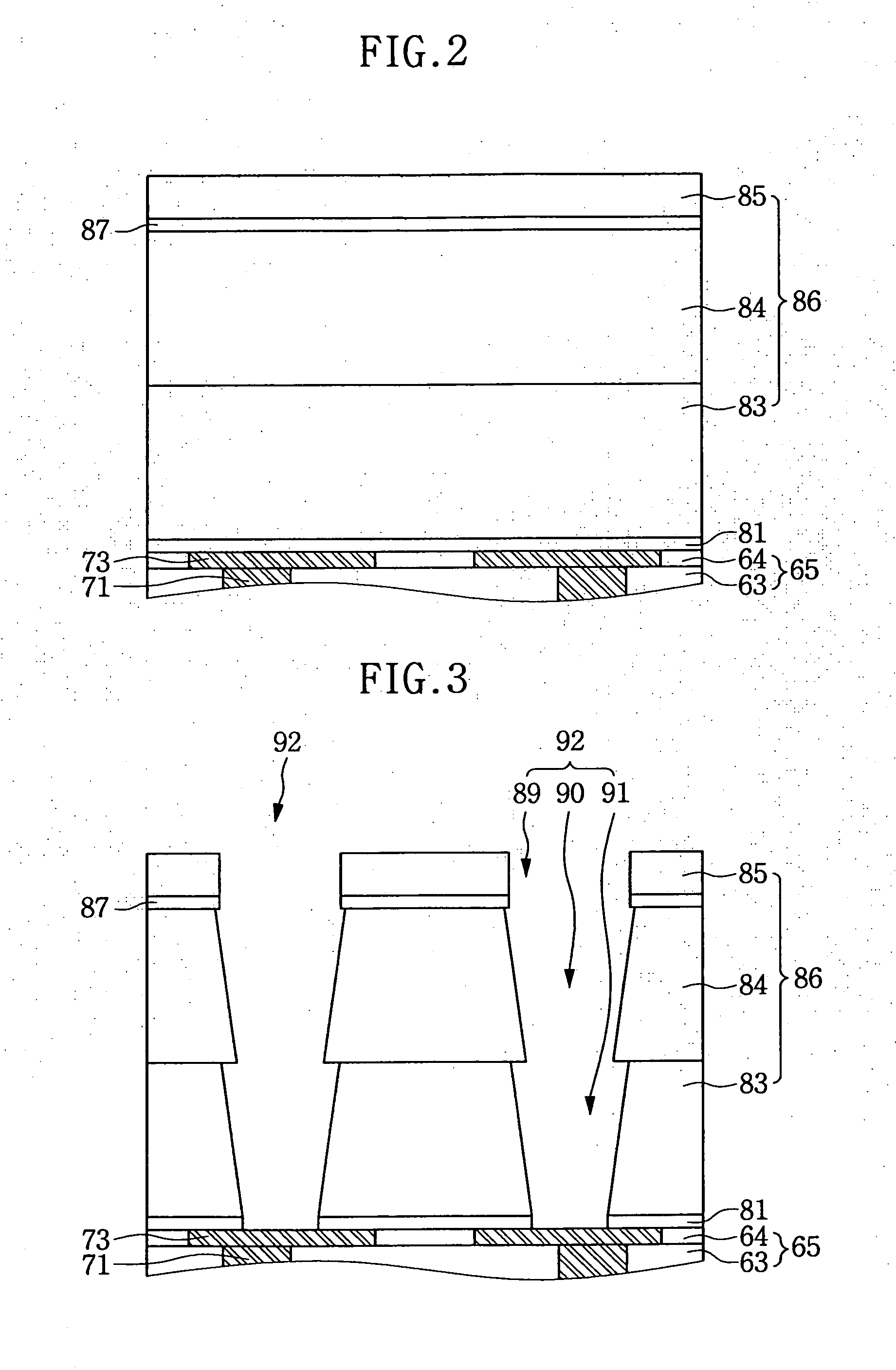

Method of forming semiconductor device having a capacitor

ActiveUS20100240191A1Avoid surface contaminationSolid-state devicesSemiconductor/solid-state device manufacturingSurface oxidationDielectric layer

A method of forming a semiconductor device includes forming a lower electrode layer on a substrate, forming a surface oxide layer on the lower electrode layer, partially removing the lower electrode layer to form a lower electrode, removing the surface oxide layer to expose the lower electrode, forming a capacitor dielectric layer on the lower electrode, and forming an upper electrode on the capacitor dielectric layer.

Owner:SAMSUNG ELECTRONICS CO LTD

Method for producing oriented silicon steel with good bottom by low-temperature heating

ActiveCN1978707AGuarantee normal implementationEfficient formationSolid state diffusion coatingFurnace typesHot TemperatureSilicon

The invention supplies a method used to produce orientation silicon steel by low temperature heating. It includes the following steps: heating the plate blank under 1280 degree centigrade; hot rolling; once or double cold rolling to gain finished product sheet thickness; nitriding treatment; decarburizing annealing; coating insulator; high temperature annealing. In the nitriding technology, heating area dew point is controlled at -15-40 degree centigrade. The invention has the advantages of high nitriding efficiency, no influence from the surface oxide film, excellent MgO coat formula which makes the magnesium silicate substrate have good magnetic property, ensure the implementation for the next hot leveling annealing and insulating coating.

Owner:BAOSHAN IRON & STEEL CO LTD

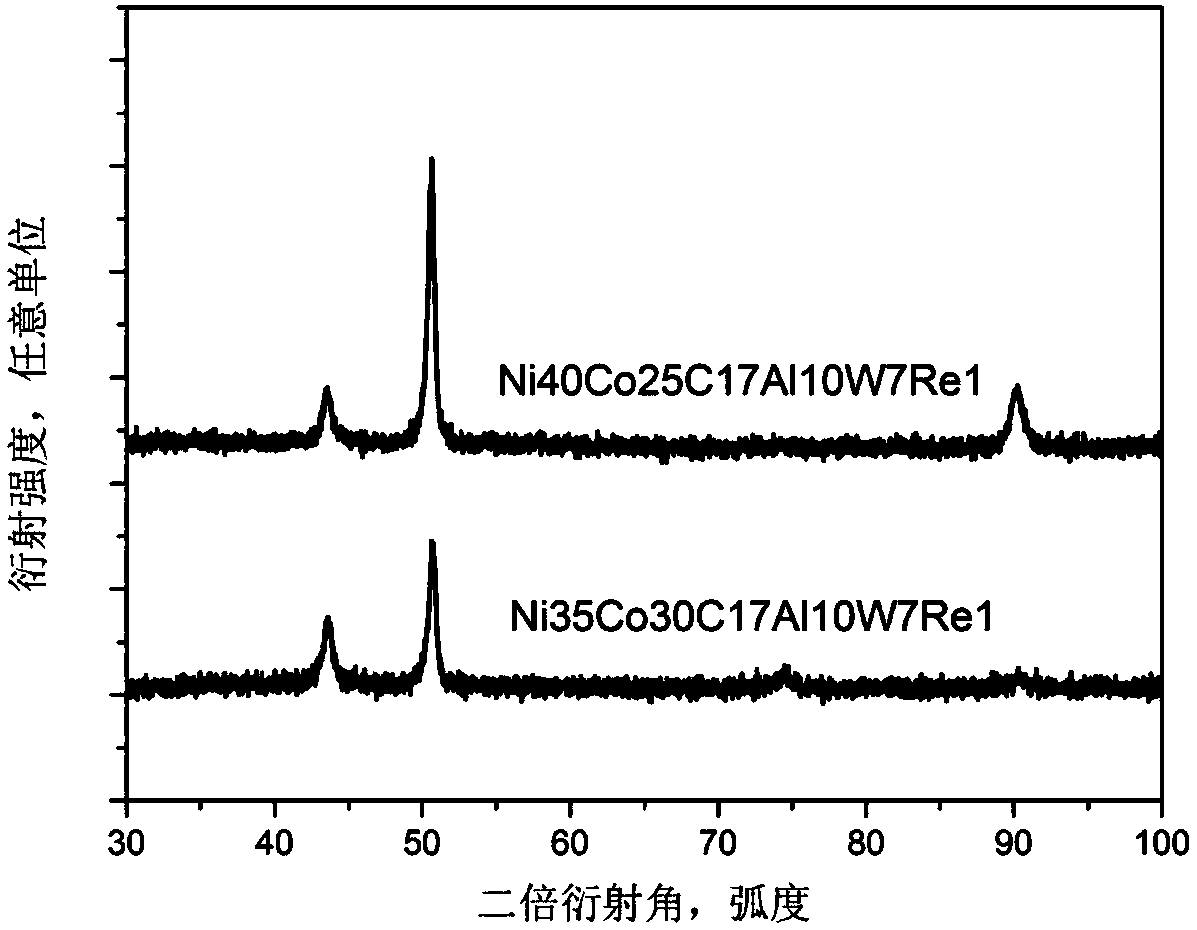

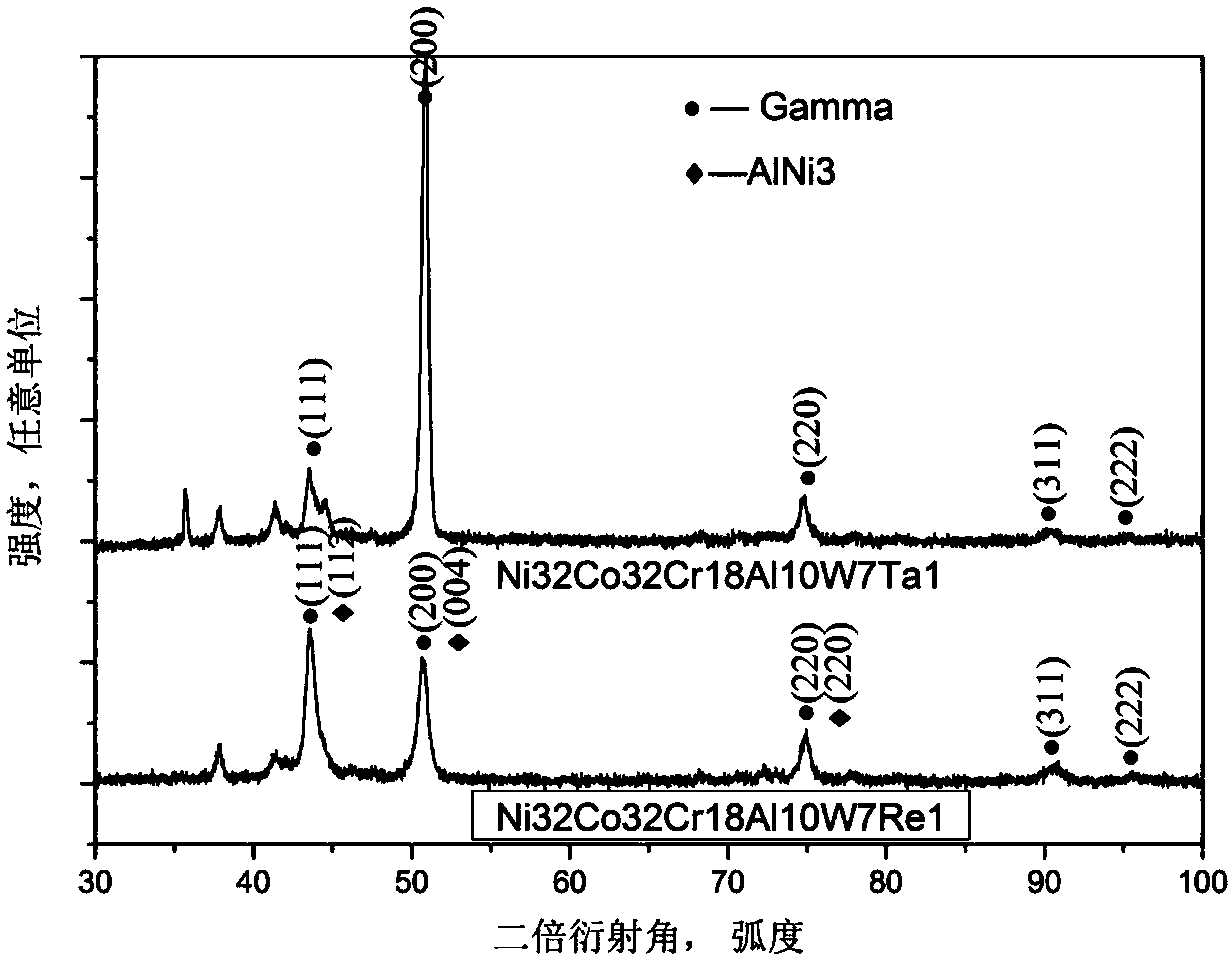

A Ni-Co-Cr-Al-W-Ta-Mo based high-entropy high-temperature alloy and a preparation method thereof

ActiveCN107747019AImprove high temperature strengthGood resistance to high temperature oxidationHigh entropy alloysRaw material

A Ni-Co-Cr-Al-W-Ta-Mo based high-entropy high-temperature alloy and a preparation method thereof are disclosed and belong to the field of high-entropy alloys. The chemical composition of the alloy isNiCoCr<c>Al<d>W<e>Ta<f>Mo<g>Rx, wherein R is one or two of Re and Ru. The method includes removing surface oxide skin of raw material metals by utilizing a mechanical-chemical combined process;cleaning the raw material metals by utilizing industrial ethanol and utilizing ultrasonic shaking; smelting the alloy by using a vacuum arc furnace; charging industrial argon when the vacuum degree is5*10<-2> Pa; after a master alloy is uniformly melted, injecting the alloy into a water cooling copper mould by utilizing a vacuum casting or suction casting device to obtain a high-entropy alloy rod; performing solution treatment at 1250 DEG C for 2-6 h; and then performing ageing heat treatment at 900 DEG C and 950 DEG C for 4-50 h. The disclosed alloy has excellent room-temperature and high-temperature strength, excellent resistance to high-temperature oxidation, and excellent creeping resistance, fatigue resistance and long-term tissue stability, is suitable for manufacturing hot end elements, such as blades and turbine discs, of aero-engines and gas turbines, and is used for engineering machines, special vehicles, coal, ore, railroads, and the like.

Owner:UNIV OF SCI & TECH BEIJING

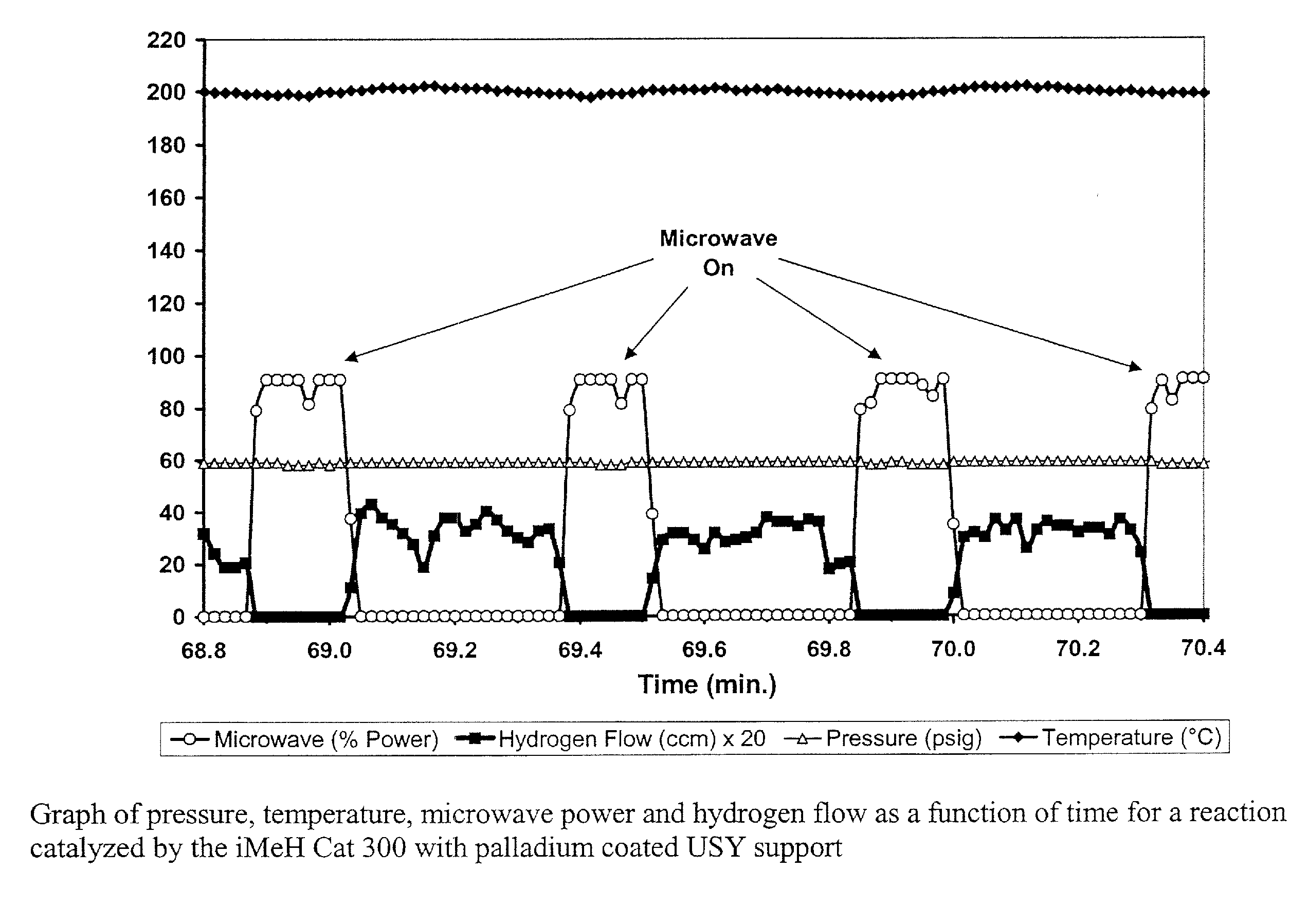

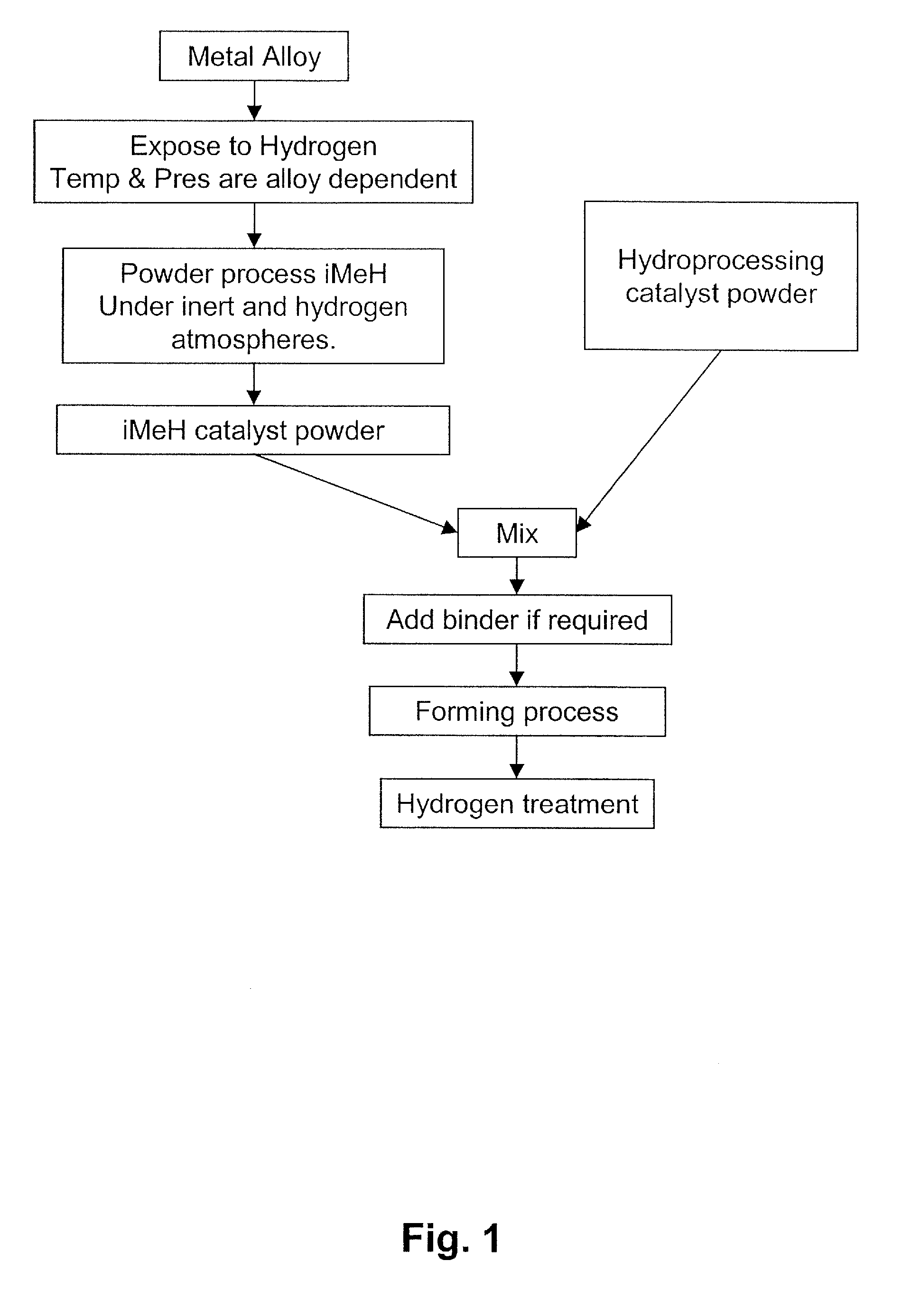

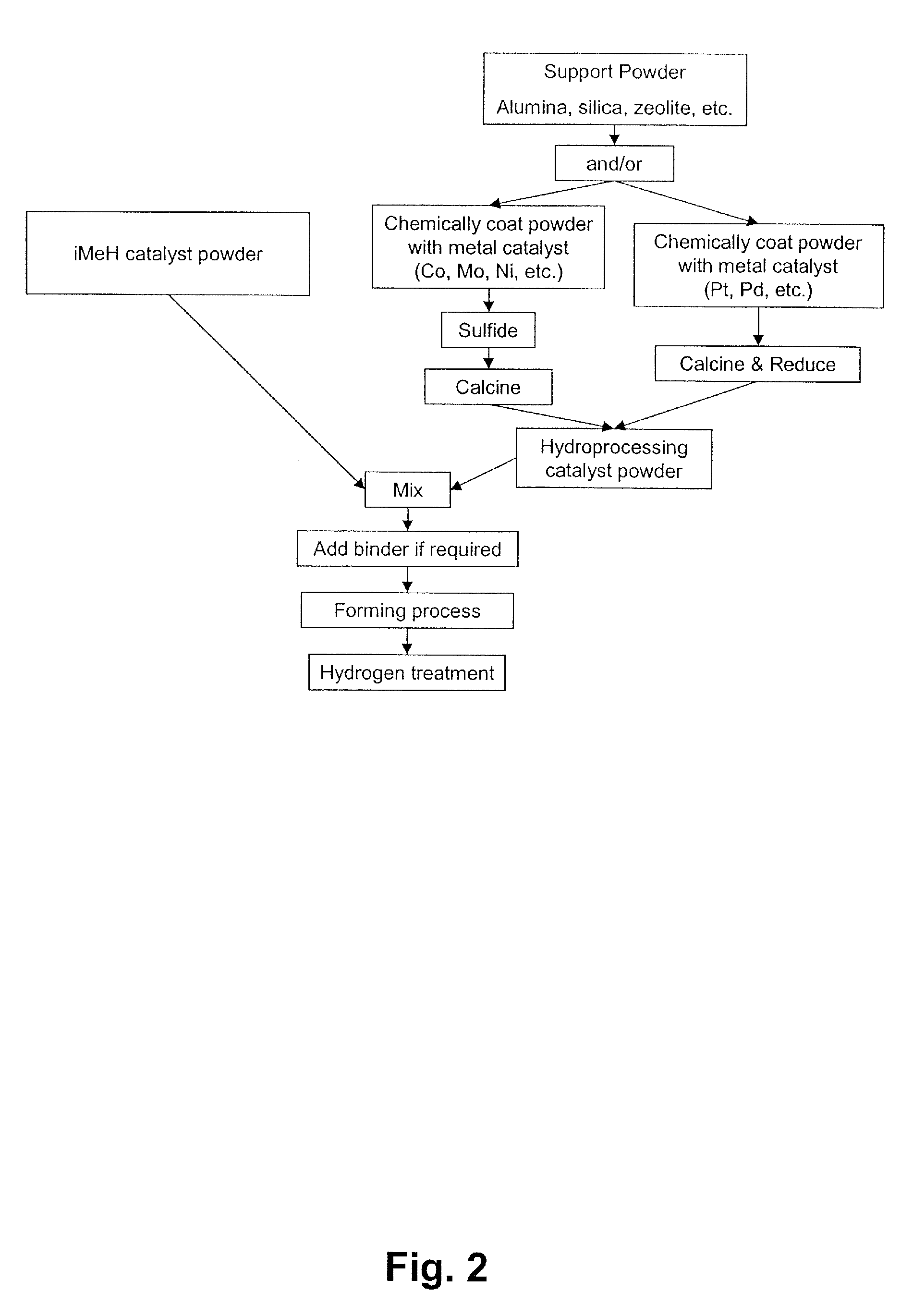

Catalyst for the Treatment of Organic Compounds

Owner:CARNEGIE MELLON UNIV

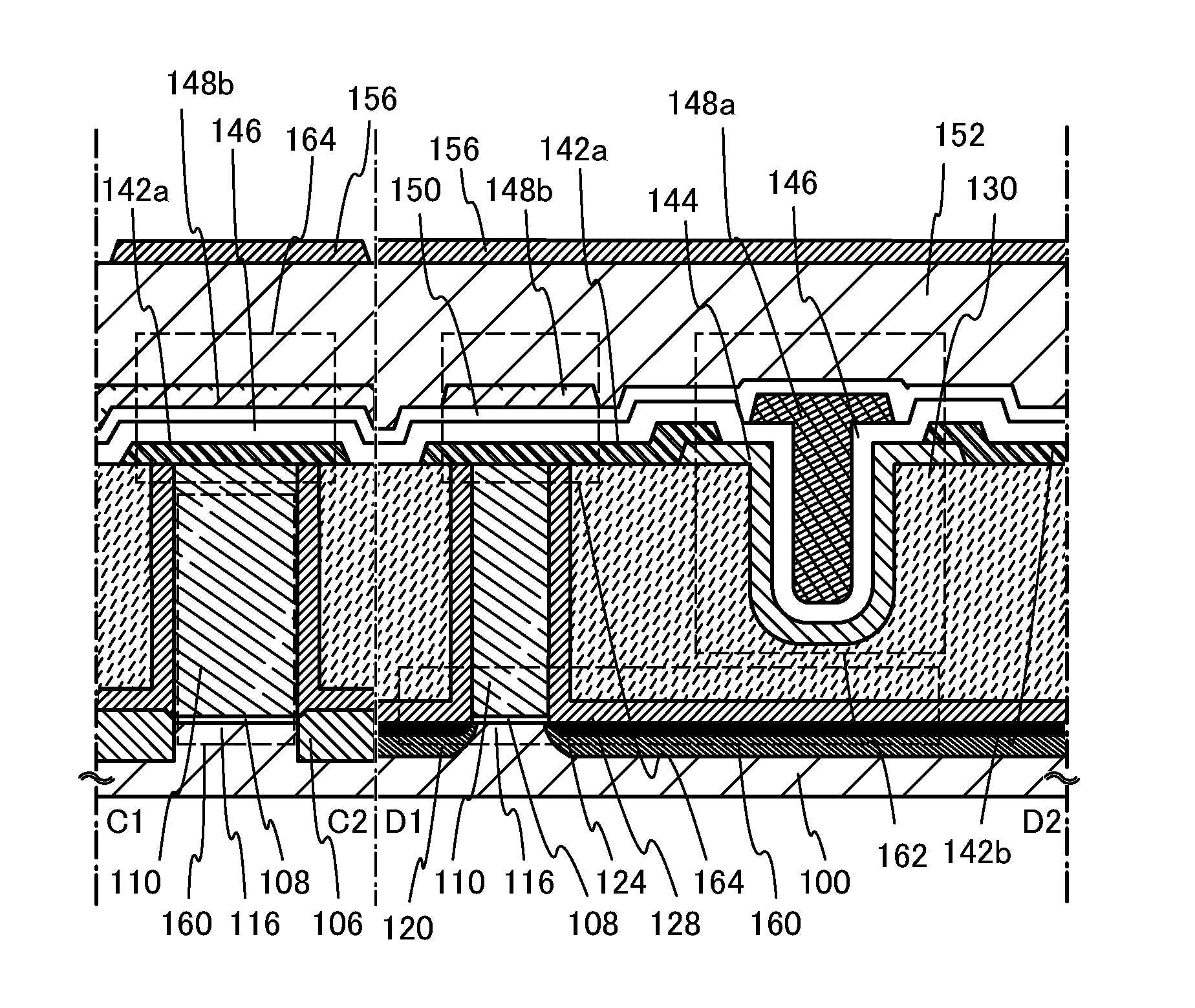

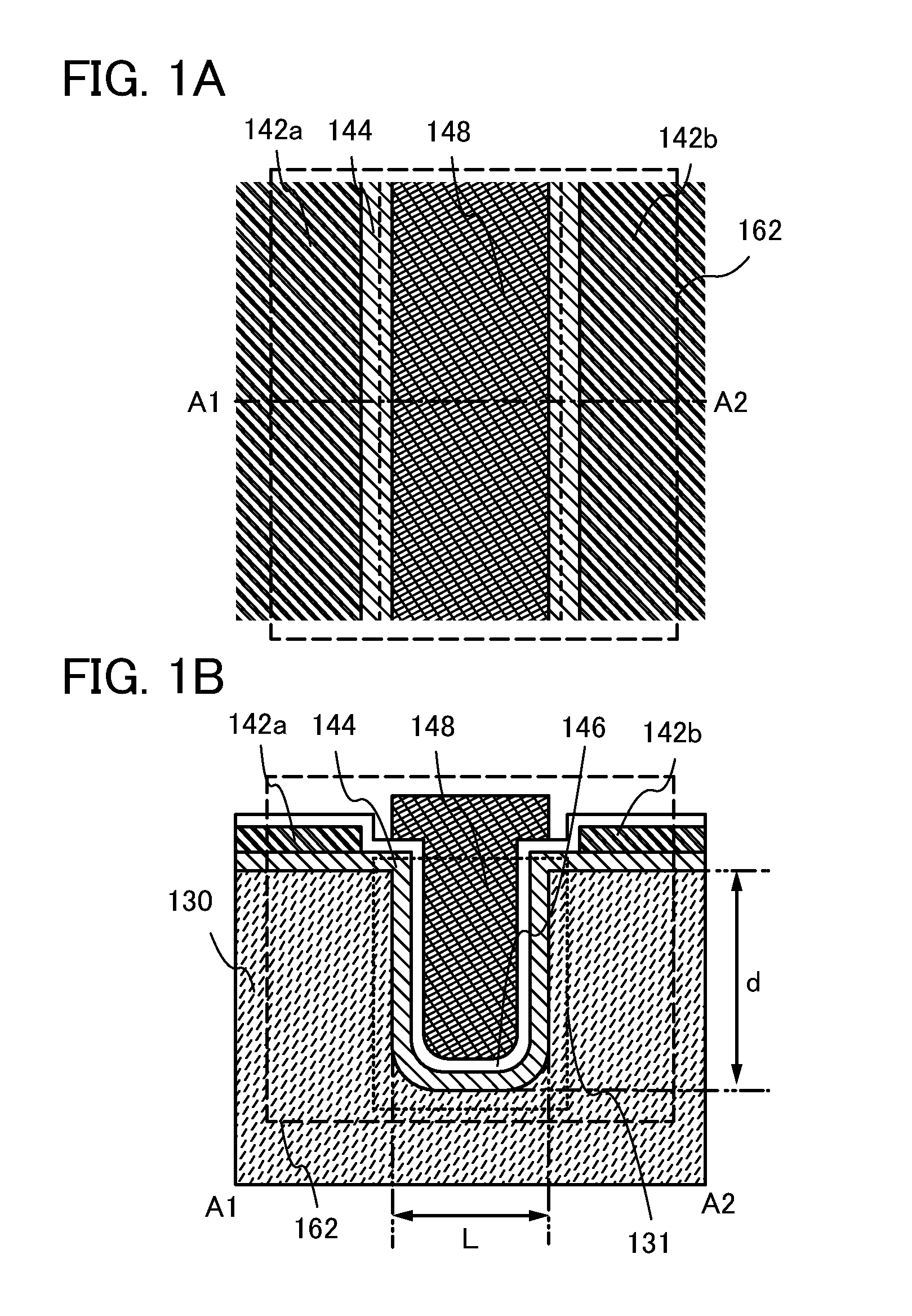

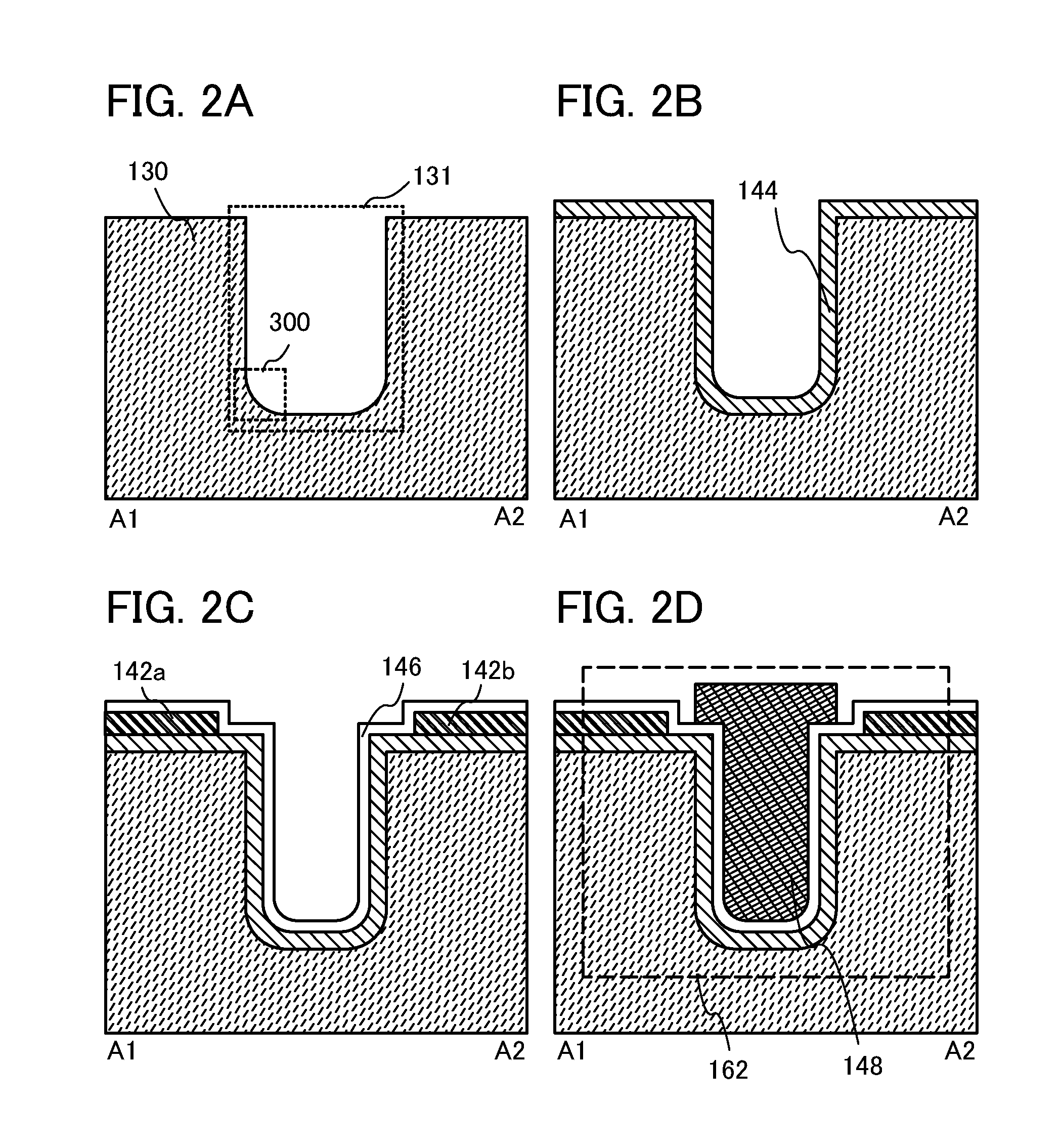

Semiconductor device

InactiveUS8809854B2Guaranteed high speed operationReduce power consumptionSemiconductor/solid-state device detailsSolid-state devicesDevice materialCurve shape

Stable electric characteristics and high reliability are provided to a miniaturized and integrated semiconductor device including an oxide semiconductor. In a transistor (a semiconductor device) including an oxide semiconductor film, the oxide semiconductor film is provided along a trench (groove) formed in an insulating layer. The trench includes a lower end corner portion having a curved shape with a curvature radius of longer than or equal to 20 nm and shorter than or equal to 60 nm, and the oxide semiconductor film is provided in contact with a bottom surface, the lower end corner portion, and an inner wall surface of the trench. The oxide semiconductor film includes a crystal having a c-axis substantially perpendicular to a surface at least over the lower end corner portion.

Owner:SEMICON ENERGY LAB CO LTD

AlN ceramic bonded copper substrate and preparation method thereof

The invention provides an AlN ceramic bonded copper substrate which comprises an AlN ceramic substrate and copper foil bonded and connected onto the AlN ceramic substrate and is characterized in that a spinel structure compound modification layer is formed between the AlN ceramic substrate and the copper foil and comprises one or two of CuAlO2, CuAl2O4, Cu2O and CuO. The invention further provides a preparation method of the AlN ceramic bonded copper substrate. The method comprises the steps of spraying nano Cu2O on the surface of the AlN substrate, sintering in inert gas with a micro oxygen content and air sequentially, and then removing a surface oxide by a pickling manner. The prepared modification layer is tightly combined with matrix ceramic, and also has good affinity characteristic with the Cu foil. A uniform oxidation layer can be formed on the surface of the Cu foil by putting the Cu foil in a prepared solution at a certain temperature for specified time and more facilitates an AlN-DBC (direct bonded copper) technology.

Owner:NANJING ZHONGJIANG NEW MATERIAL TECH

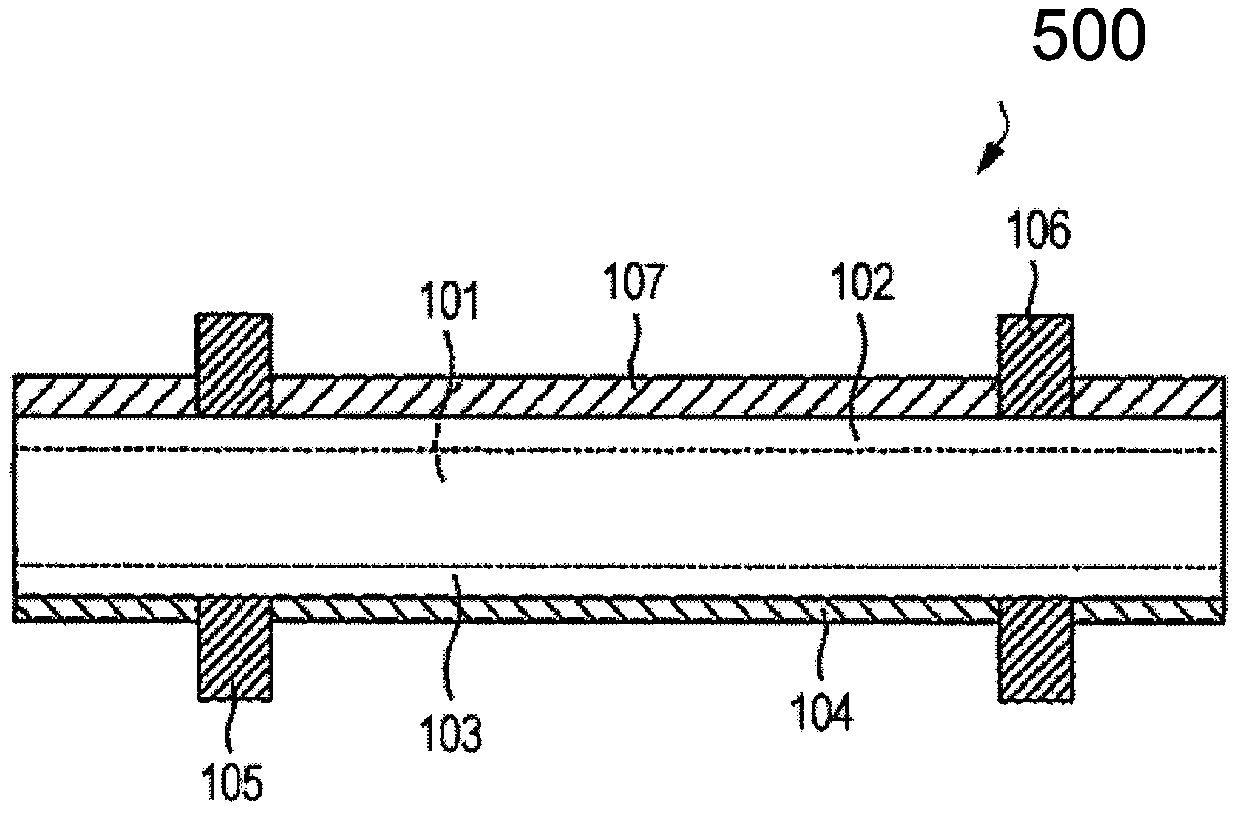

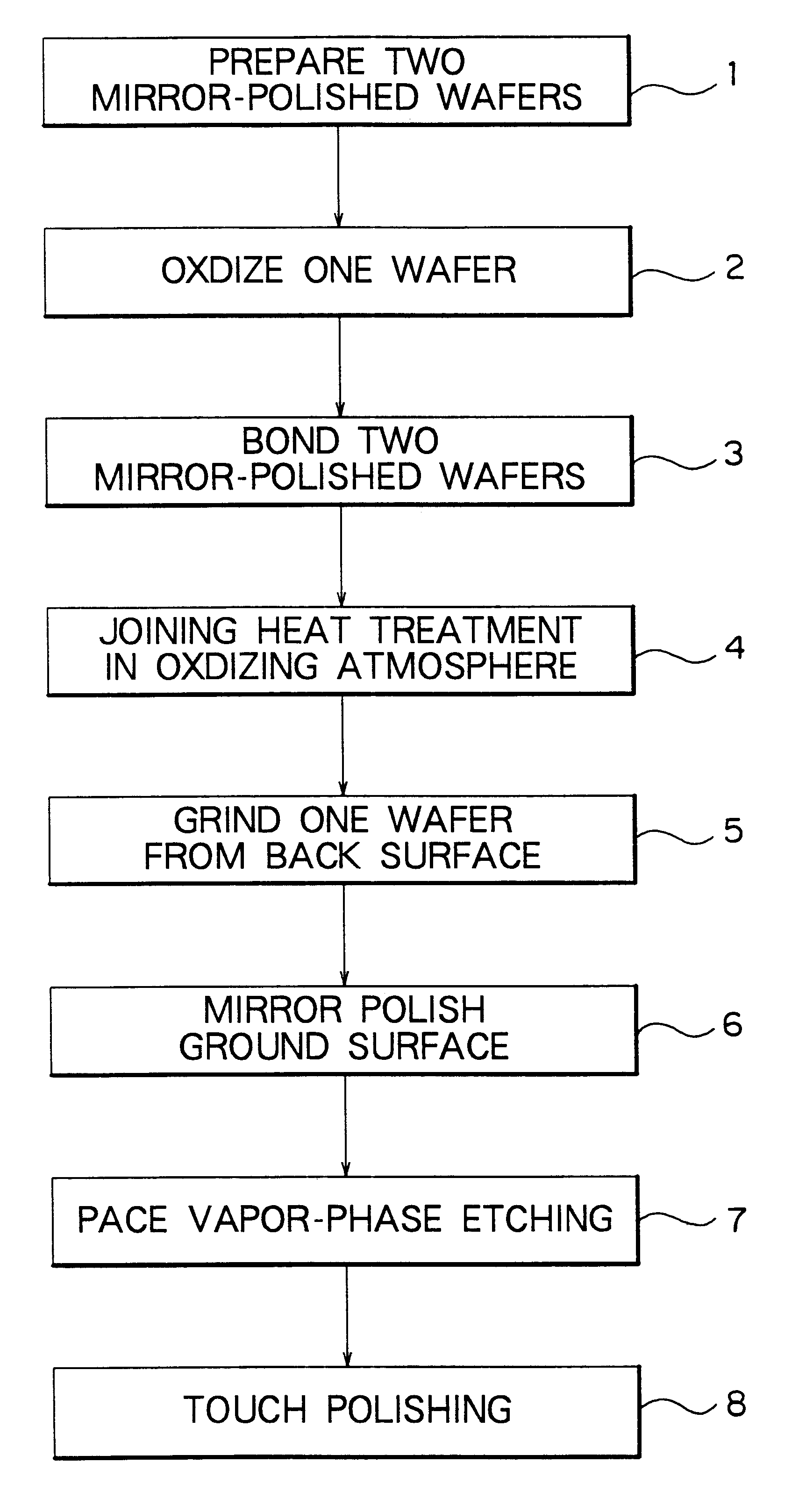

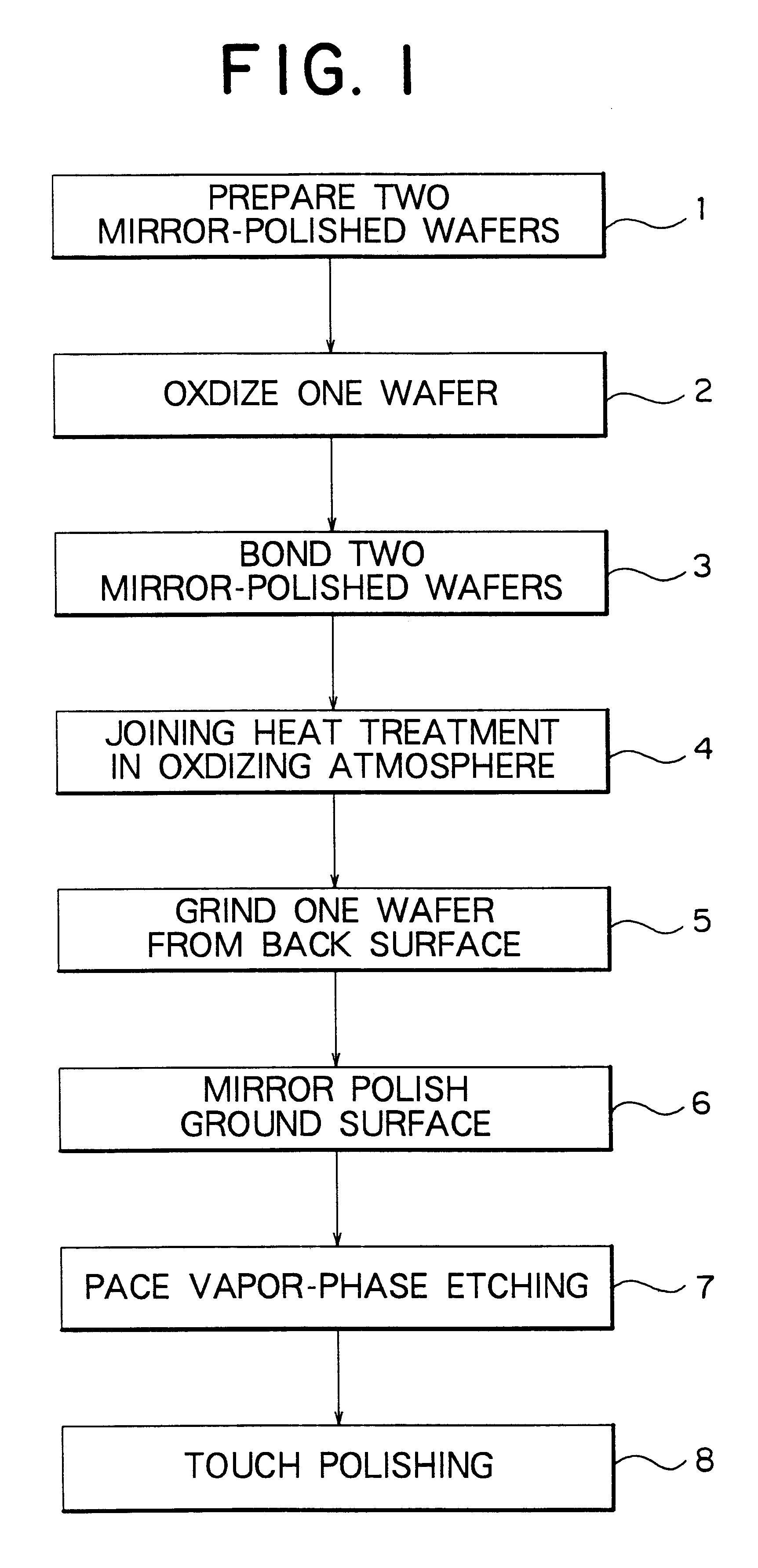

Method of forming oxide film on an SOI layer and method of fabricating a bonded wafer

InactiveUS6239004B1Avoid it happening againPromote generationSolid-state devicesSemiconductor/solid-state device manufacturingWaferingSurface oxidation

In a method of fabricating a bonded wafer, an oxide film is first formed on the surface of at least one of two mirror-polished silicon wafers. The two silicon wafers are superposed such that the mirror-polished surfaces come into close contact with each other, and heat treatment is performed in order to join the wafers together firmly. Subsequently, the thickness of one of the wafers is reduced so as to yield a thin film, the surface of which is then polished and subjected to vapor-phase etching in order to make the thickness of the thin film uniform. Optionally, the vapor-phase-etched surface is then mirror-polished. The surface of the bonded wafer is oxidized, and the generated surface oxide film is then removed. In the method, the thickness of the oxide film formed on the surface of the bonded wafer is made not greater than 50 nm. The method reliably eliminates damage and crystal defects generated during etching in accordance with PACE method or subsequent mirror polishing, and thereby enables relatively simple and low cost manufacture of bonded wafers having a very thin SOI layer that has good thickness uniformity and excellent crystallinity.

Owner:SHIN-ETSU HANDOTAI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com