A Ni-Co-Cr-Al-W-Ta-Mo based high-entropy high-temperature alloy and a preparation method thereof

A high-temperature alloy and high-entropy technology, applied in the field of high-entropy alloys, can solve the problem of low heat resistance of structural steel, and achieve the effects of excellent high-temperature oxidation resistance, excellent creep resistance and fatigue resistance, and excellent room temperature and high temperature strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be specifically introduced from three aspects of composition design, alloy preparation and performance testing.

[0035] 1. Composition design

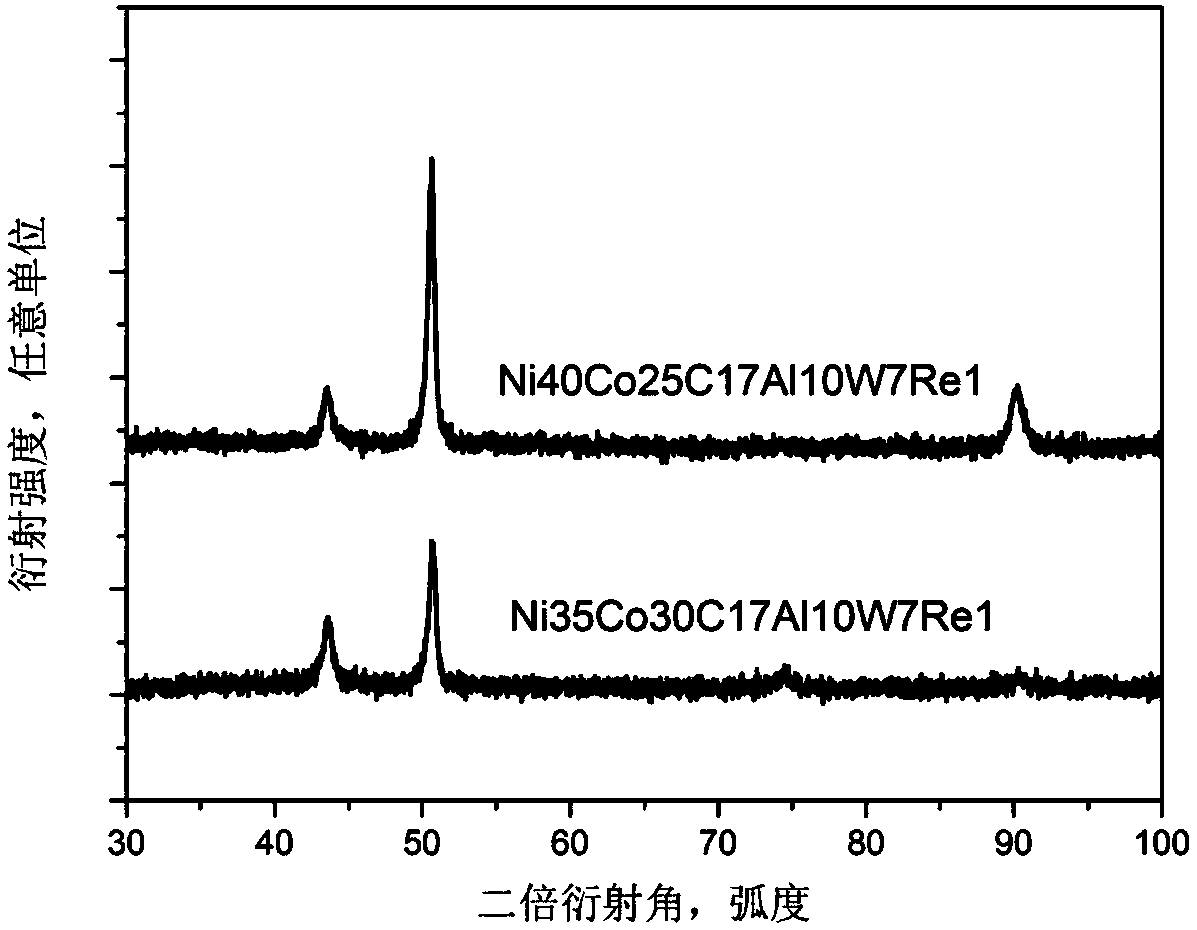

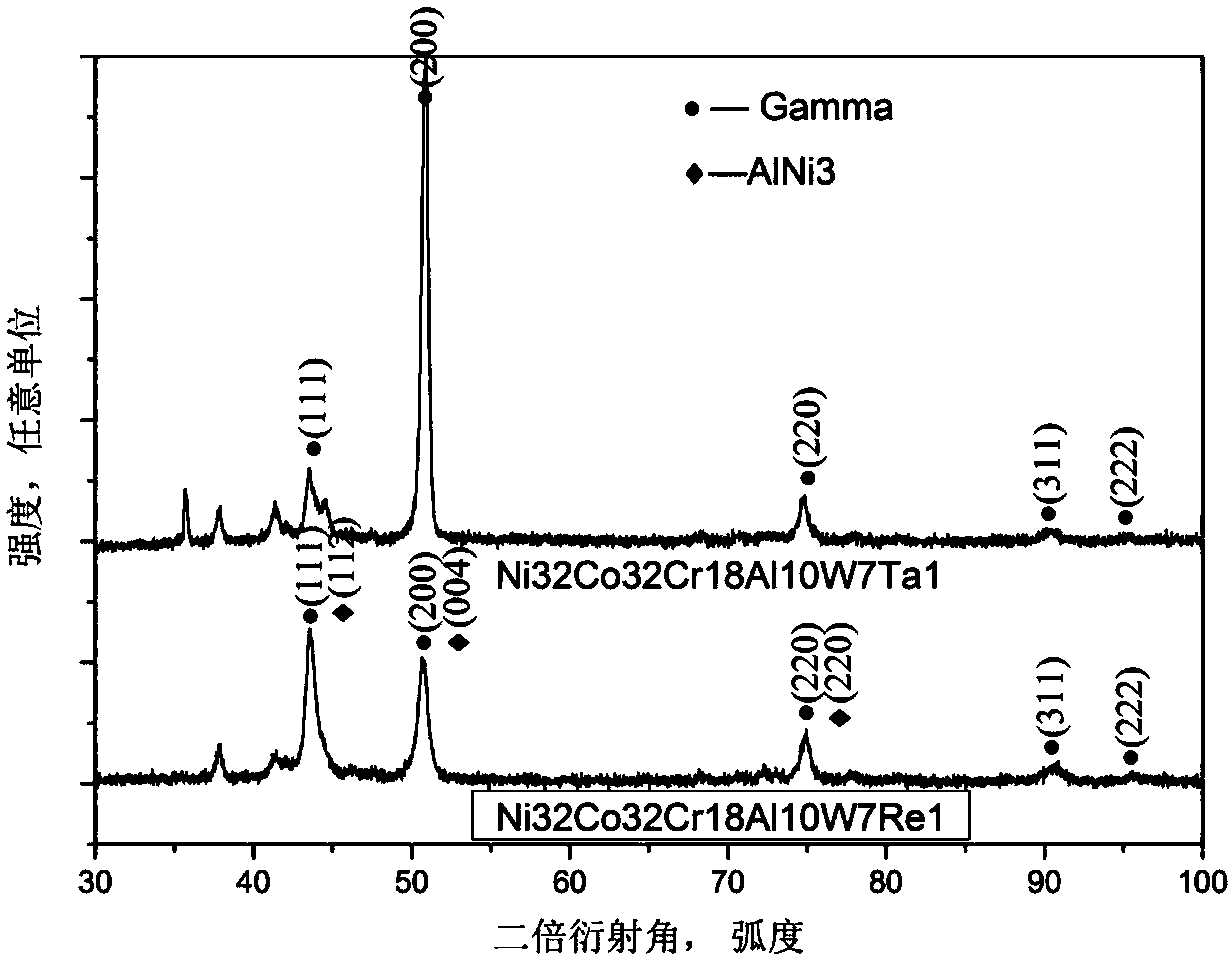

[0036] Design 10 kinds of Ni with different compositions a co b Cr c Al d W e Ta f Mo g Re x, where the composition range of each element is 31≤a≤40, 31≤b≤35, 10≤c≤18, d=10, 5≤e≤10, 0≤f≤1, 0≤g≤1, 0≤ x≤1, a+b+c+d+e+f+g+x=100. The specific compositions of the 10 alloys are shown in Table 1. The purpose of these 10 kinds of alloy composition design is mainly to study the influence of each element on the mechanical properties of the alloy. In addition to Ni, Co, Cr, Al, W, Ta, Mo, Re and Ru are selected as additional elements to further improve the high temperature strength. .

[0037] Table 1 Composition ratios (atomic percent) of 10 high-entropy superalloys

[0038] serial number

Ni

co

Cr

Al

W

Mo

Ta

Re

Ru

NC1

31.5

31.5

18

10

7

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com