Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6082 results about "Steelmaking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steelmaking is the process of producing steel from iron ore and/or scrap. In steelmaking, impurities such as nitrogen, silicon, phosphorus, sulfur and excess carbon (most important impurity) are removed from the sourced iron, and alloying elements such as manganese, nickel, chromium, carbon and vanadium are added to produce different grades of steel. Limiting dissolved gases such as nitrogen and oxygen and entrained impurities (termed "inclusions") in the steel is also important to ensure the quality of the products cast from the liquid steel.

Multi-purpose, multi-oxy-fuel, power burner/injector/oxygen lance device

InactiveUS20030075843A1Reduce the numberSmall sizeTuyeresCharge manipulationSteelmakingLiquid medium

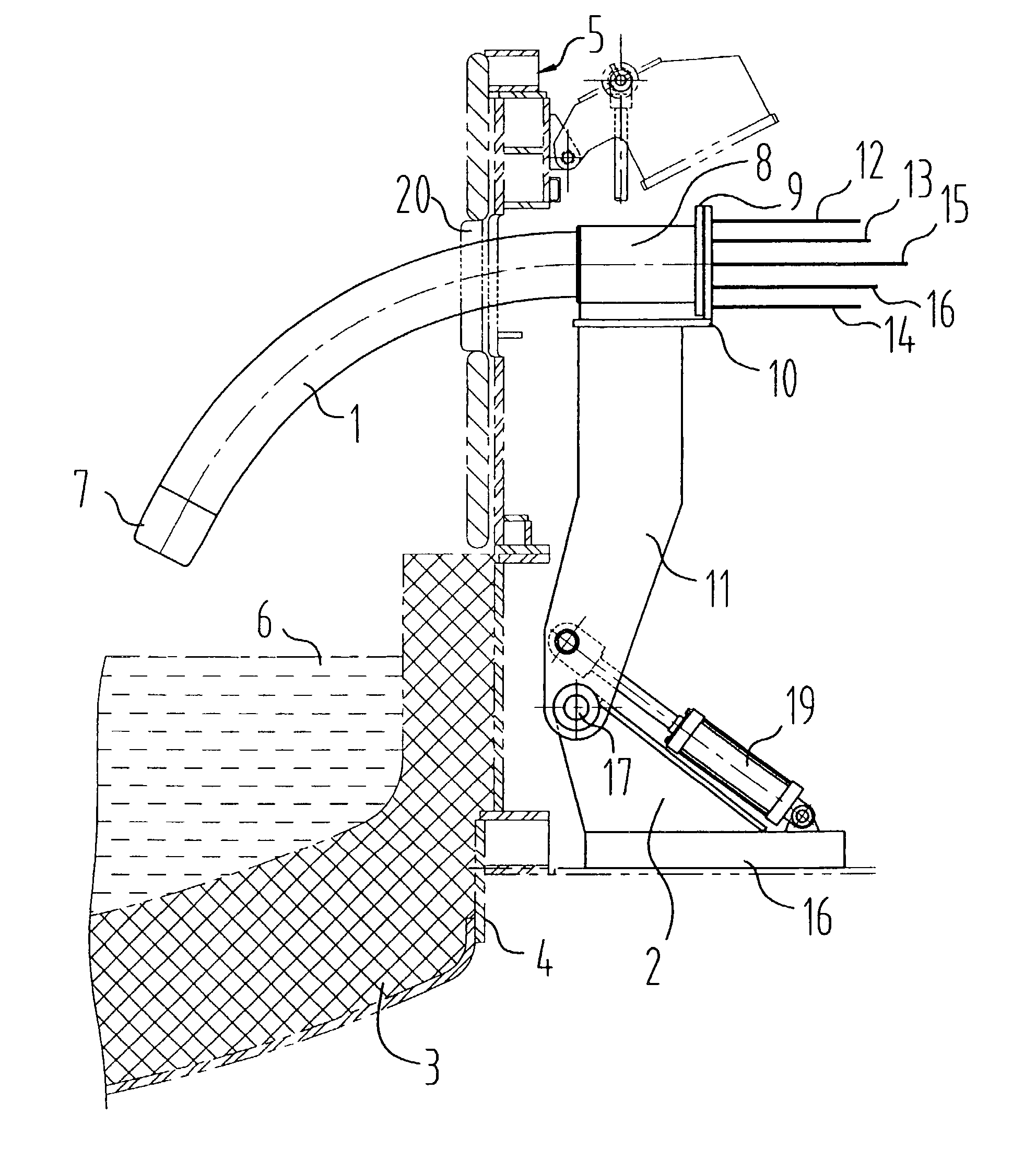

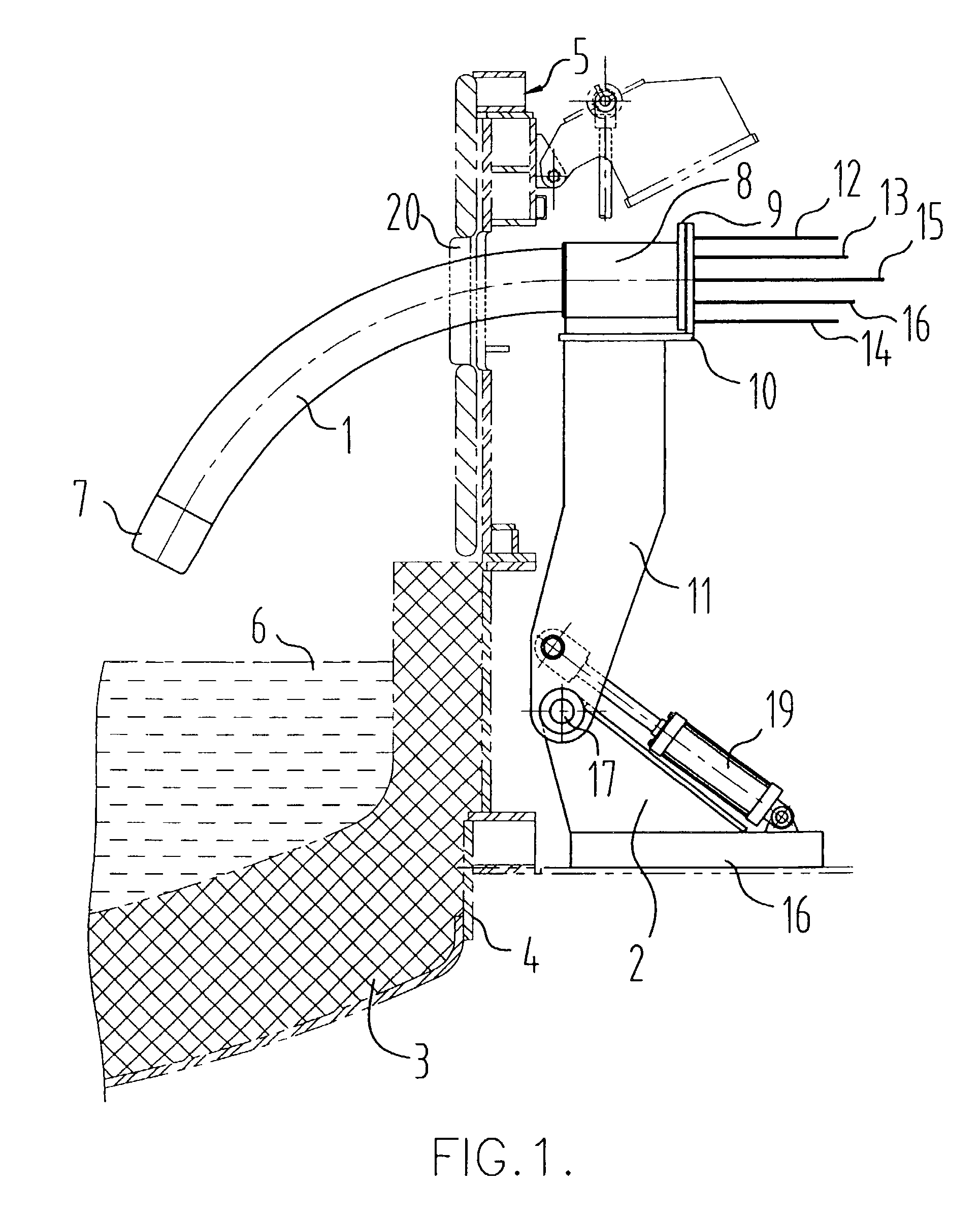

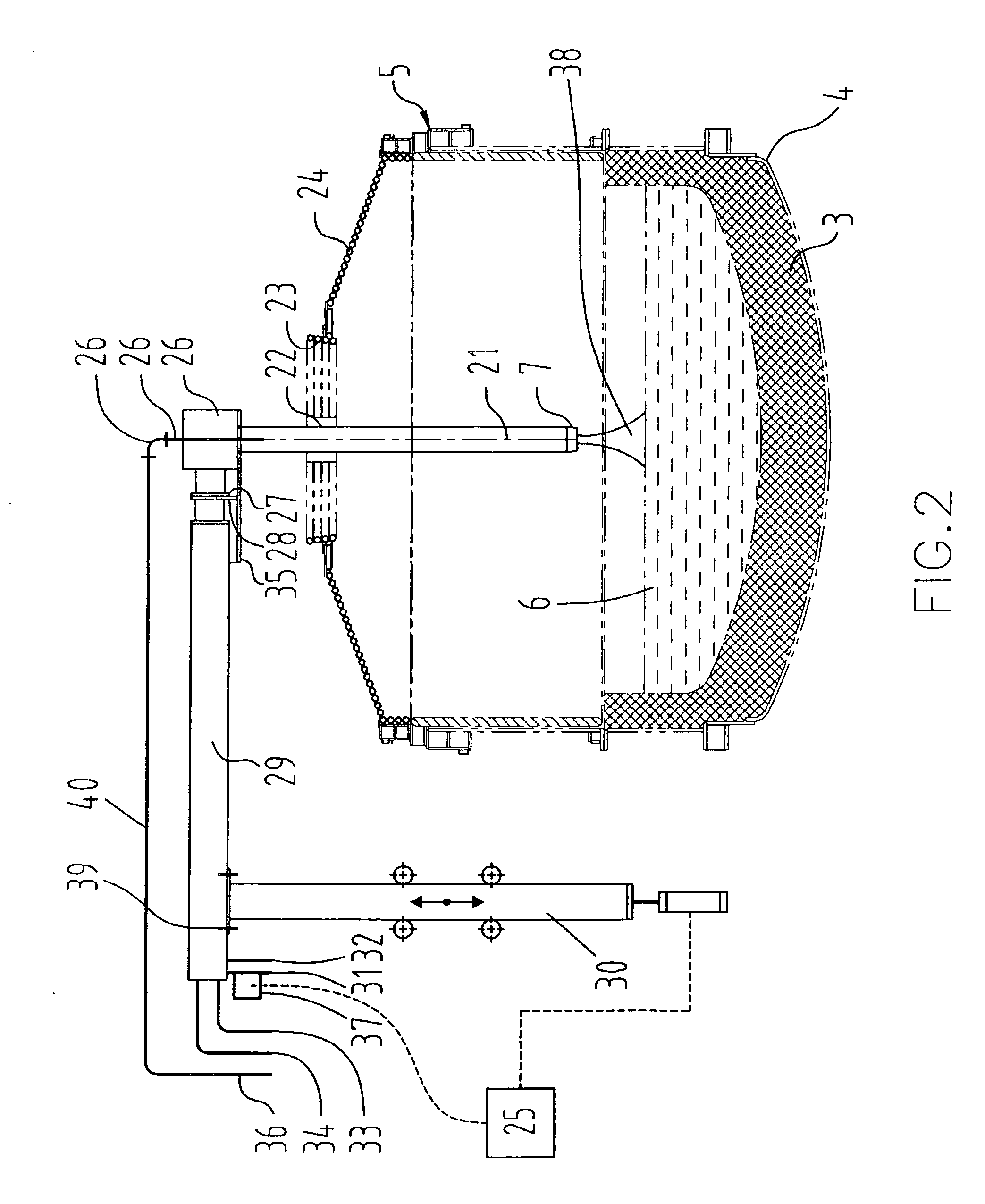

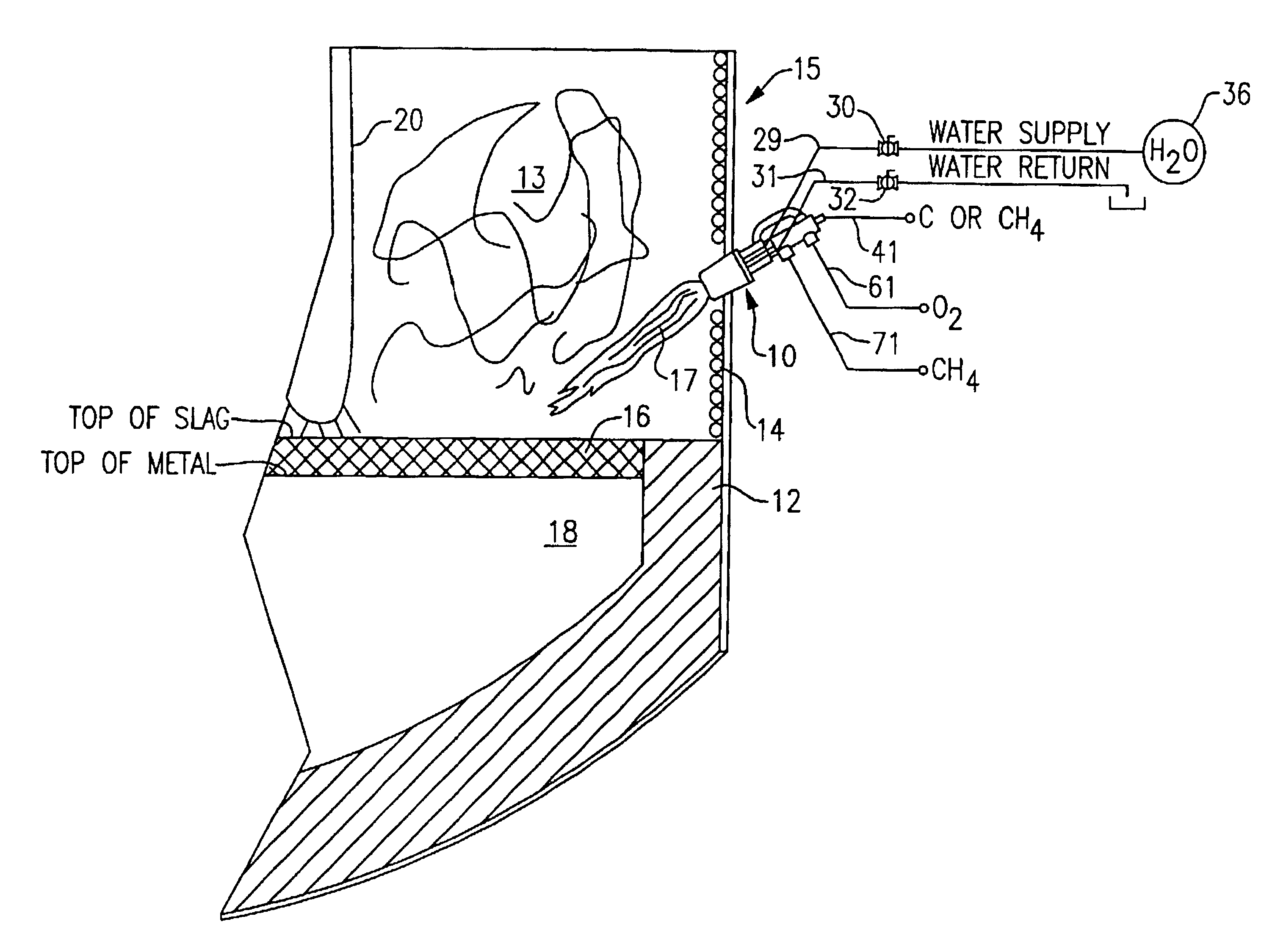

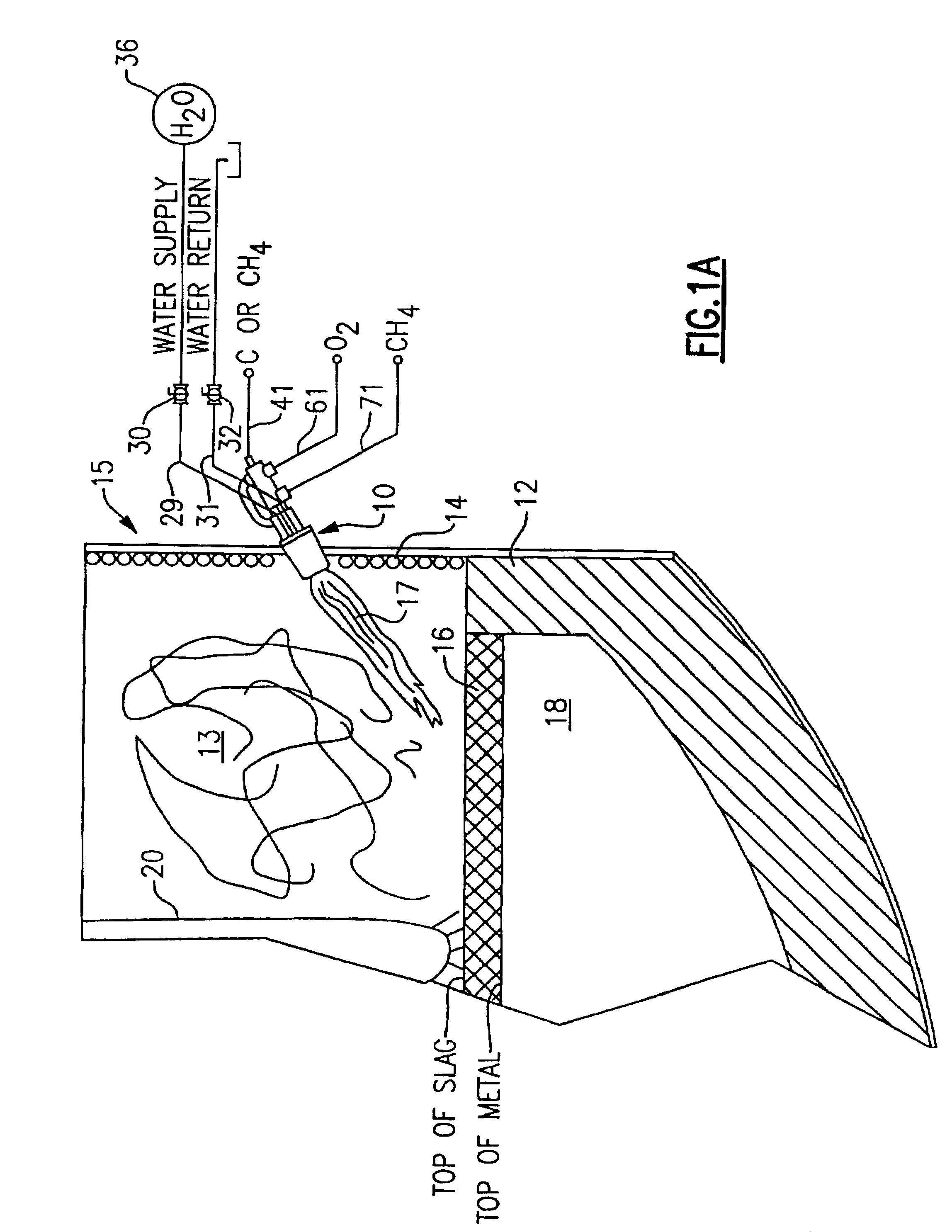

A multi-purpose, multi-oxy-fuel High Temperature Power Burner / Injector / Oxygen Lance, Mechanical System Apparatus Device, for steelmaking from recycled scrap and / or virgin ferrous charge, which can be employed in multi-oxy-fuel (natural gas; pulverized carbonaceous matter; heavy oil), especially by Oxygen Combusted mixture of Natural Gas / Pulverized Carbonaceous Matter in High Temperature Power Burner Mode, for efficient and rapid melting of solid ferrous charge (cold or preheated) in a special steelmaking Metallurgical Furnace or Open Hearth Furnace, Tandem Furnace, BOF, EAF, as its augmenting or only source of thermal energy; more than one Device in Oxygen-Natural Gas / Pulverized Carbonaceous Matter Power Burner Mode, can be employed as the only source of thermal energy in a modified, originally Electric Arc Furnace, as total replacement of Graphite Electrodes and Electric Arc System, the replacement being noticeably more primary energy efficient than the thermal energy provided by Graphite Electrode / Arc System; it also can be employed in an Solid Particles Injector Mode, for injecting of adequately granulated carbonaceous materials or lime into the molten steel for its carburizing or for foamy slag control; further it can be employed in a natural gas shrouded, pulsating oxygen stream, for vertically to the charge oriented soft blow supersonic Oxygen Injection Lance Mode, for decarburization of the molten metal contained in the hearth of the metallurgical furnace and foamy slag control; in one of the embodiments-generally arcuate-pivotally mounted, liquid media cooled composite body, is pivoted into and out of a furnace vessel through a small opening in the shell wall for auto-regulated constant optimal positioning of the Composite Body Tip against solid or molten charge, in each and all multi-purpose modes; furthermore, when inserted into the furnace vessel, the arcuate composite body can be rotated about its longitudinal axis for directing the oxy-fuel high temperature flame towards unmolten charge in the furnace; in an other-generally linear-embodiment, the liquid cooled composite body is attached to the mast type carrier allowing vertical movement of the composite body which enters the furnace vessel through a small opening in the furnace roof; the bimetallic, liquid cooled special tip assembly of both-arcuate and linear embodiments-of the composite body includes easy replaceable, independent, multi-opening nozzles, mounted in a protective, retracted position inside of the liquid cooled special tip assembly.

Owner:EMPCO (CANADA) LTD

Investment precision casting technology for producing automobile I-shaped front axle

InactiveCN101147954ALess investmentReduce manufacturing costFoundry mouldsFoundry coresSteelmakingWax

The present invention relates to a fusible pattern precision casting process for producing automobile H-shaped front axle. Said casting process includes the following steps; (1), preparing wax pattern; (2), applying coating material onto the wax pattern surface for several times, spreading sand and making the coating material hardened pattern shell be primarily formed, removing wax and forming pattern shell; (3), firing pattern shell; (4), pouring the molten steel into the pattern shell, before steel-smelting having to make analysis of charge mixture ratio, in the course of smelting steel having to make on-the-spot sample analysis and furnace rear analysis, adding required additive and deoxidant so as to make the molten steel be reached to the defined chemical components requirement; (5), removing pattern shell from obtained automobile H-shaped front axle casting, cleaning sand and cutting spure; (6), grinding, finishing and checking casting; (7), making quenching and tempering, heat treatment; (8), making correction and shot blasting treatment; and (9), making metalworking treatment.

Owner:NANPING AUTO FORGING & STAMPING FACTORY

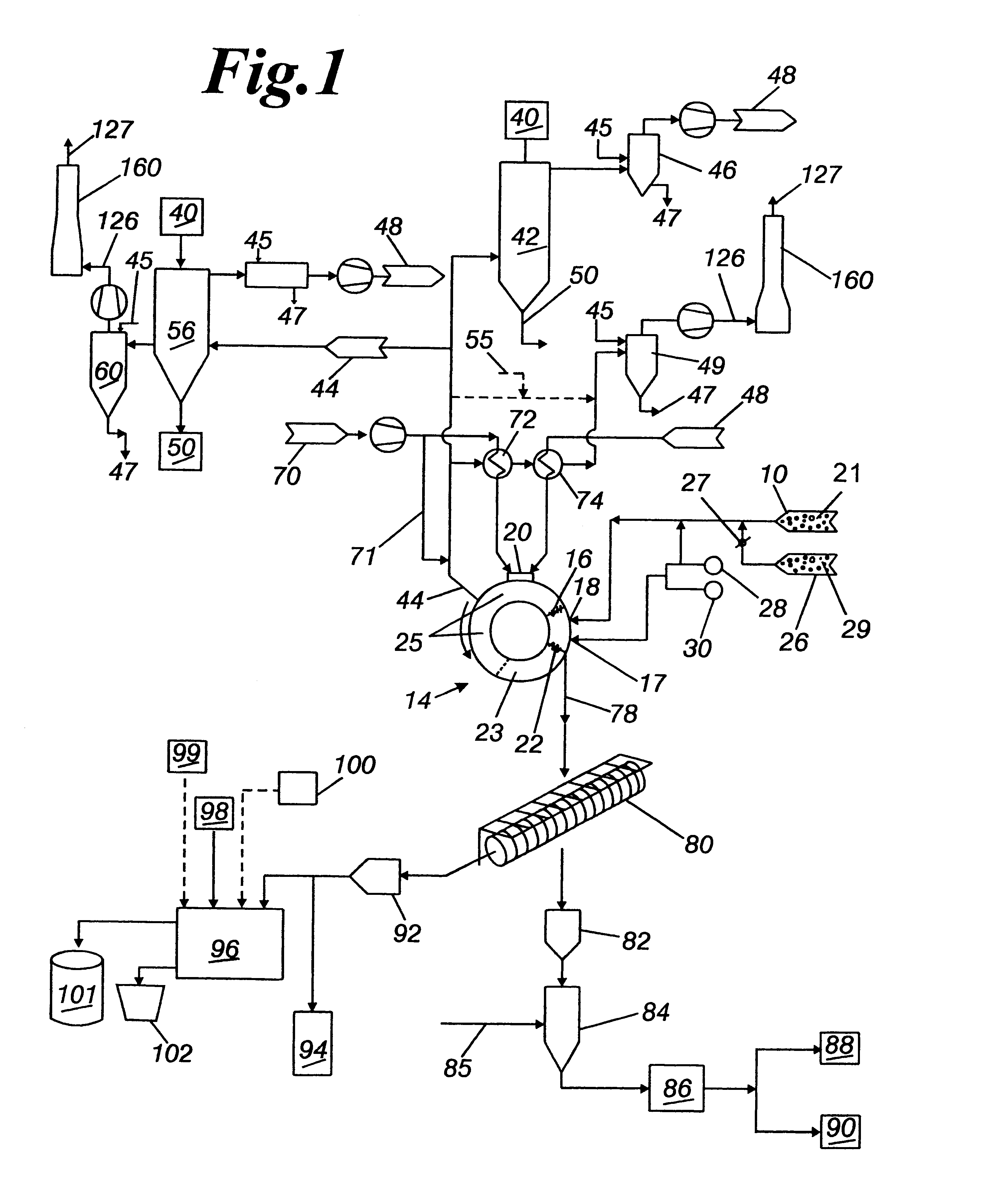

Method of direct iron-making / steel-making via gas or coal-based direct reduction and apparatus

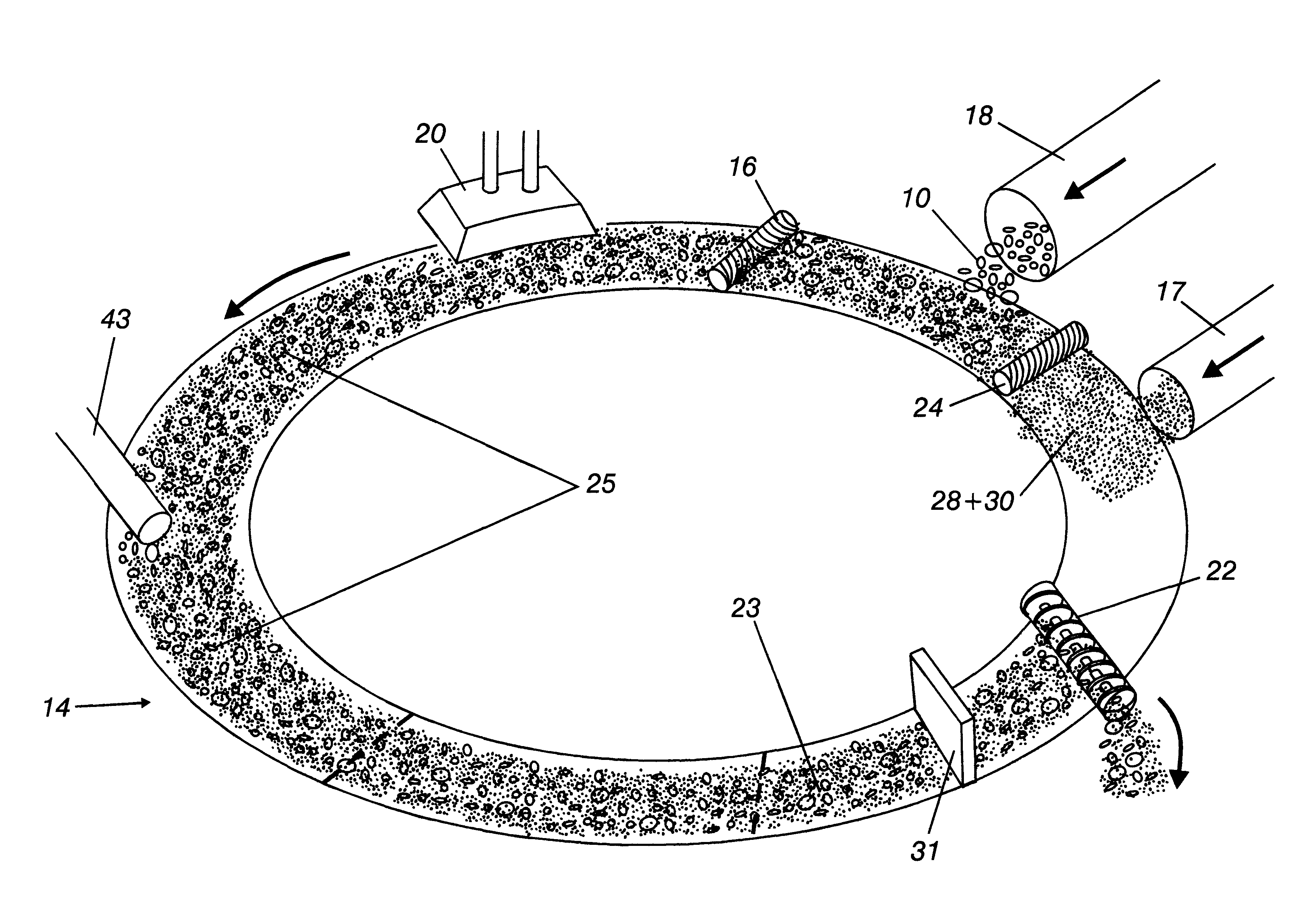

The invention is a method and apparatus for iron-making / steel-making using a modified rotary hearth furnace, that is a finisher-hearth-melter (FHM) furnace. In the method the refractory surface of the hearth is coated with carbonaceous hearth conditioners and refractory compounds, where onto said hearth is charged with pre-reduced metallized iron. The pre-reduced metallized iron is leveled, then heated until molten, and then reacted with the carbon and reducing gas burner gases until any residual iron oxide is converted to iron having a low sulfur content. Nascent slag separates from the molted iron forming carburized iron nuggets. The nuggets are cooled, and then the iron nuggets and the hearth conditioners, including the refractory compounds, are discharged onto a screen, which separate the iron nuggets from the hearth conditioner. The hearth conditioner is recycled, and the iron nuggets are either prepared for sale or for additional treatment, such as alloying, in a final melter, where the final melter is preferably an electric furnace. Exhaust gases from the FHM furnace are recovered for calcining coal into fuel gases and coke.

Owner:KOBE STEEL LTD

Cold bonded pellet and method of producing the same

The invention provides a cold-bonded pellet used on the raw material of steelmaking or ironmaking and a preparation method thereof. The component and the mass ratio of the cold-bonded pellet are as follows: 8 to 60 percent of precipitator dust and dust sludge, 20 to 85 percent of iron sheet, concentrate powder and iron-bearing auxiliary material, 0.4 to 15 percent of binder. In the preparation method, the moisture in raw material is utilized to directly mix the raw material with other components in a mixer, then the mixture is pressed and formed via a briquetting press after uniform mixing, and the pellet after forming is maintained at room temperature and dried naturally. The cold-bonded pellet of the invention has the advantages of the simple forming process, the low fabrication cost, the rapid hardening of pellet and taking the short time, the high compressive strength, achieving not only the waste recycling and reducing the environmental pollution, but also the high granulation rate, the low damage rate, the wide applicability and the stable quality. The invention is especially suitable for wide application in sintering plant, ironmaking plant and steelmaking plant.

Owner:尚国洪

600-MPa grade vanadium-containing high-strength hot-rolled steel bar and production method thereof

The invention relates to a 600-MPa grade vanadium-containing high-strength hot-rolled steel bar and a production method thereof, and belongs to the technical field of metallurgical steel-making and processing; the technical scheme is that the steel bar is prepared by the following components by mass: 0.21-0.25% of C, 0.35-0.60% of Si, 1.35-1.55% of Mn, 0.08-0.12% of V, 0.005-0.04% of N, not more than 0.040% of S, not more than 0.040% of P, and the balance of Fe and inevitable impurities; by adopting vanadium-increasing, nitrogen-increasing, and nitrogen-fixing processes during the smelting process, and by decreasing the initial rolling temperature and the finish rolling temperature during the rolling process, fine-grain, solid-solution and precipitation strengthening are realized at a lowtemperature and a high pressure, so the strength is increased; the hot-rolled steel bar contains a dual-phase structure of ferrite and pearlite, wherein the pearlite accounts for 25-50%; good cooperation of strength and toughness can be reached by controlling ratios, forms and sizes of the phases.

Owner:HEBEI IRON AND STEEL

Method for producing low phosphorus steel by smelting semisteel

InactiveCN101696462APrevent rephosphorizationEasy to operateManufacturing convertersSteelmakingHigh magnesium

The invention belongs to the field of metallurgy, and relates to a method for producing low phosphorus steel by smelting semisteel, which solves the technical problem of controlling the steelmaking end point of a converter within 0.006 percent. The method is mainly realized by adjusting slag-making parameters of the converter smelting by adopting a single slag method, which comprises that: the slag-making materials added in the converter slag-making process consist of 40-50kg of active lime, 20-30kg of high-magnesium lime and 15-25kg of composite slag former based on per ton of tapping molten steel; and the slag-making materials are added in twice. In addition, by controlling an oxygen supply system and an end point control system, the dephosphorization rate of the converter can reach over 92 percent; molten steel containing less than 0.006 percent of phosphorus is obtained; steel ladle slag de-P and alloy re-P are controlled within 0.002 percent. The method can stably produce finished low phosphorus steel containing less than 0.010 percent of phosphorus, and is characterized by simple operation method, small investment on equipment and low production cost.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +3

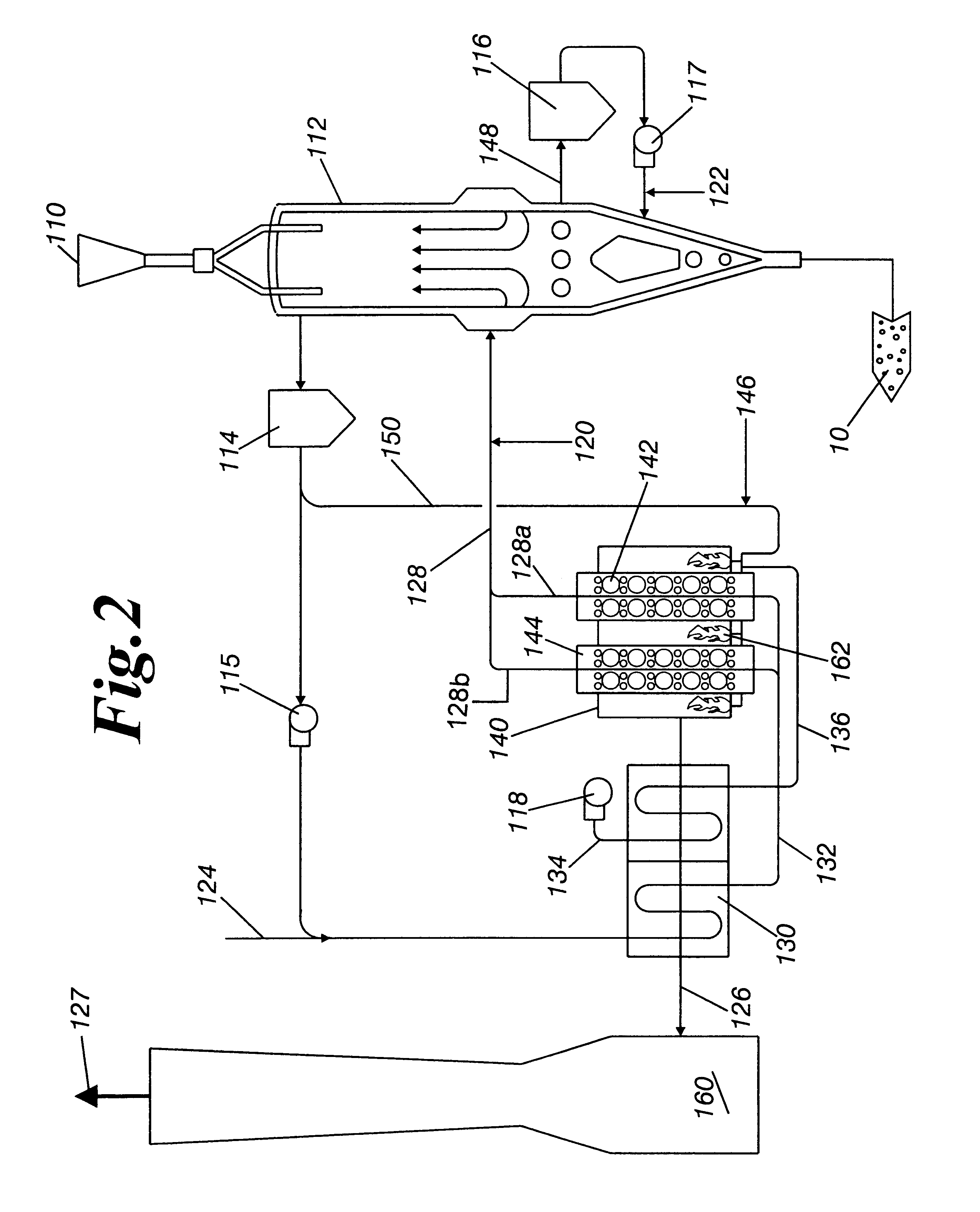

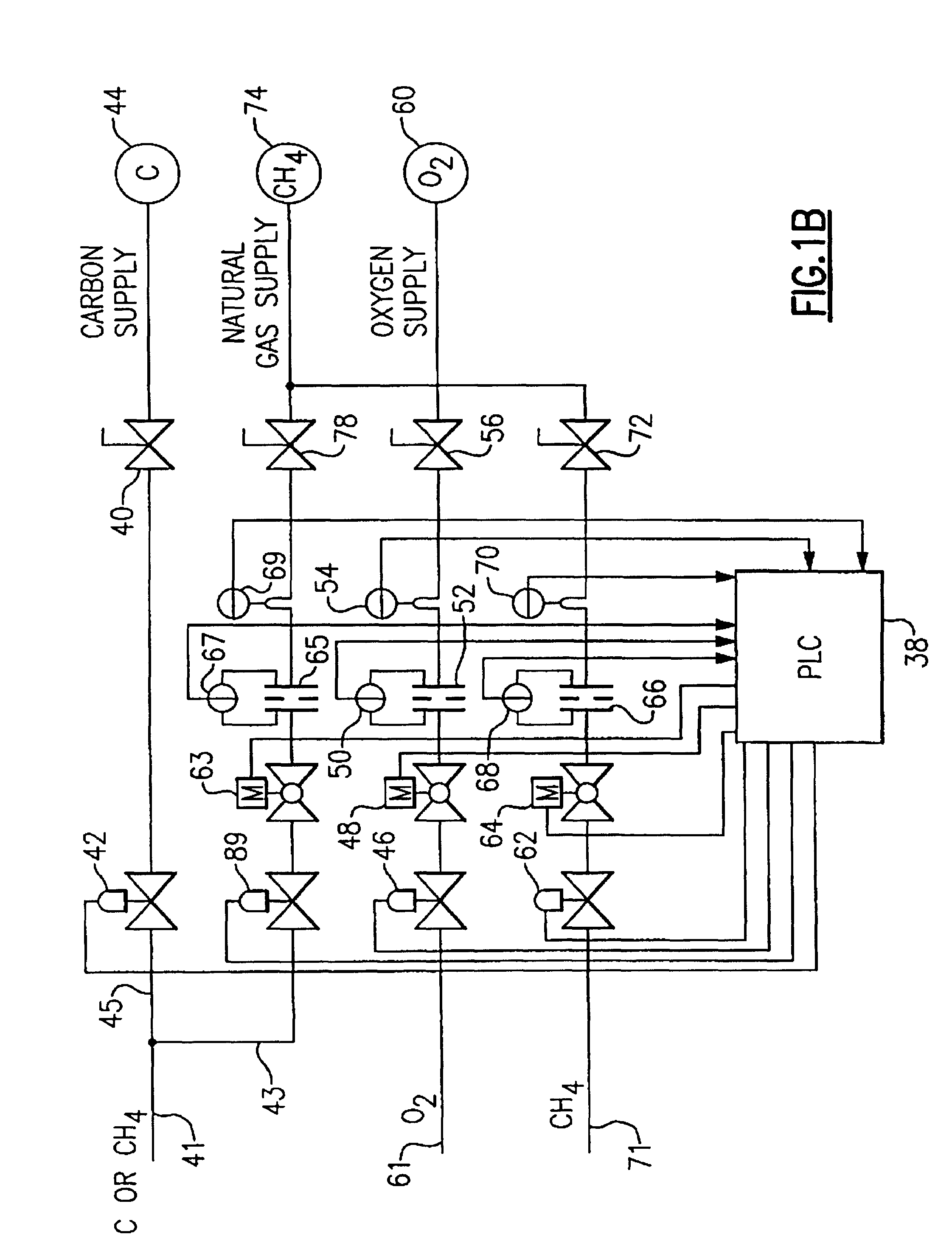

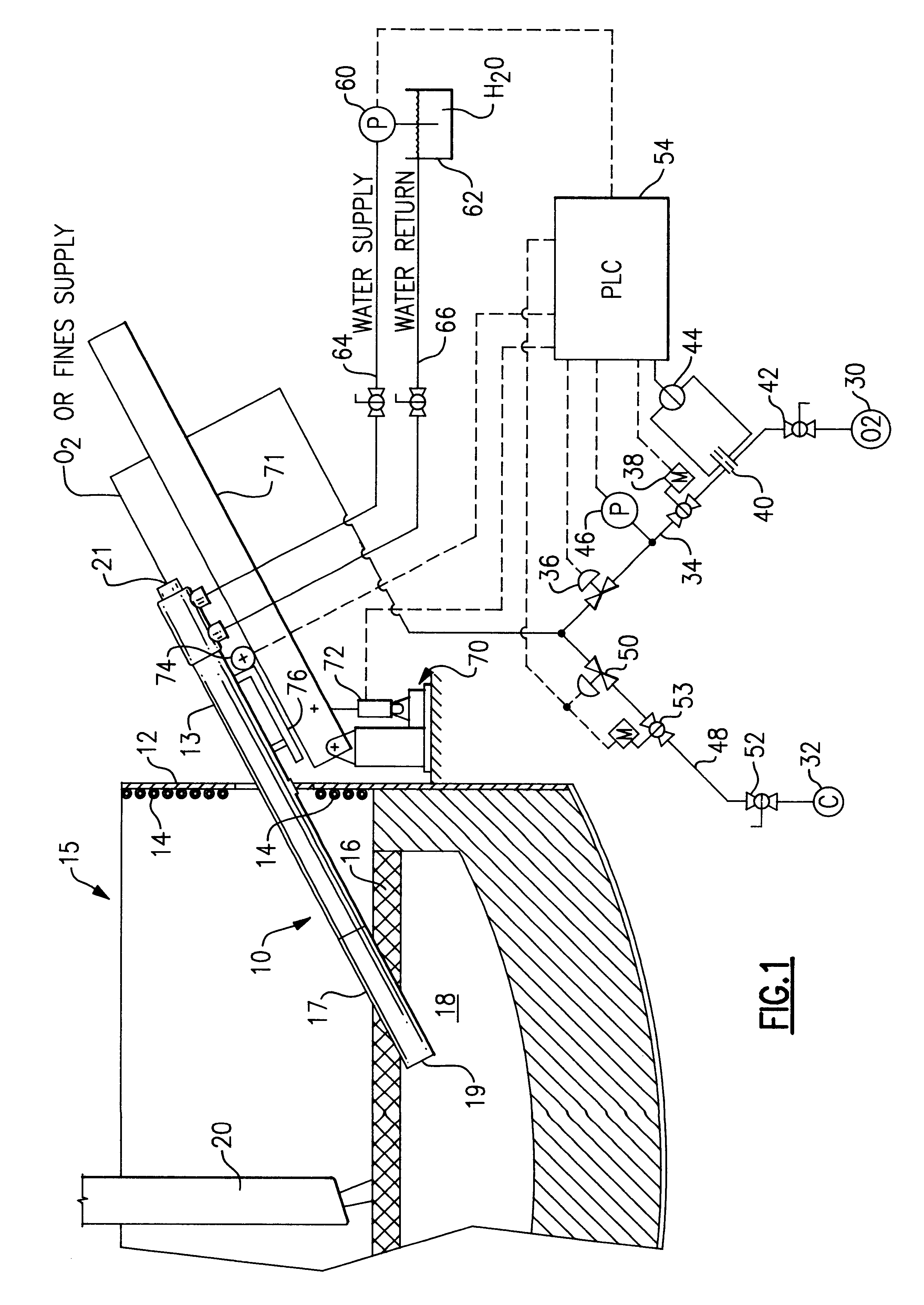

Method and apparatus for improved EAF steelmaking

An improved method and apparatus for EAF steelmaking wherein the method provides additional thermal energy to the steel making process, carbon injection for the formation of foamy slag, and oxygen injection for the decarburization of the melt, the formation of foamy slag and post combustion burning of carbon monoxide. The apparatus comprises a unique burner configuration which has a central conduit for alternatively supplying fluid hydrocarbon fuel or particulate carbon with a carrier gas which are discharged through a exit opening. The fuel or carbon is mixed with a high speed, preferably supersonic, stream of oxidizing gas. The high speed stream of oxidizing gas is provided by an annular supersonic nozzle which causes the oxidizing gas to surround the fuel or the particulates with an annular flow. The annular nozzle design can be adjusted to direct the flows of particulates and oxidizing gases in the areas and shapes desired for efficient management of the steelmaking process. Optionally, the burner can have another conduit for the secondary supply of a pressurized flow of hydrocarbon fluid fuel to a series of apertures which surround the annular flow. Further, optionally, the burner can have another conduit for the supply of a pressurized flow of a secondary oxidizing gas to a series of apertures which surround the annular flow.

Owner:PROCESS TECH INT

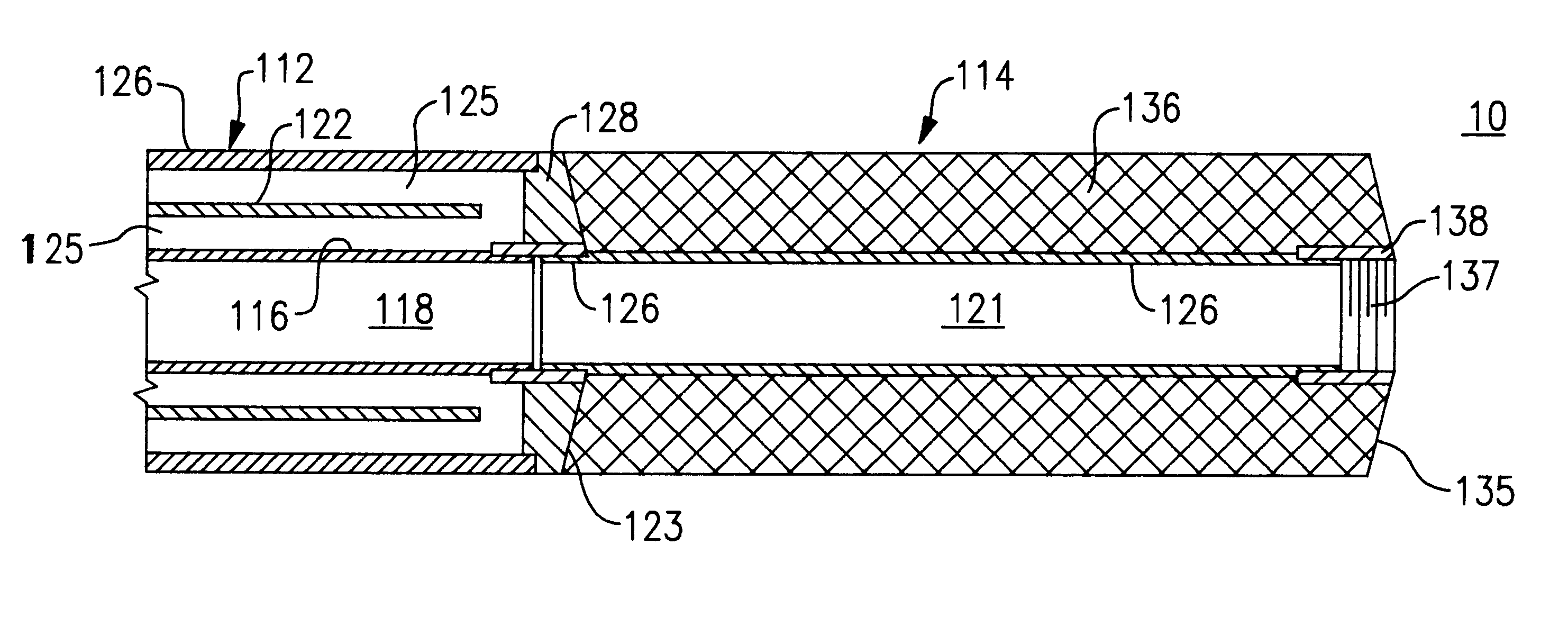

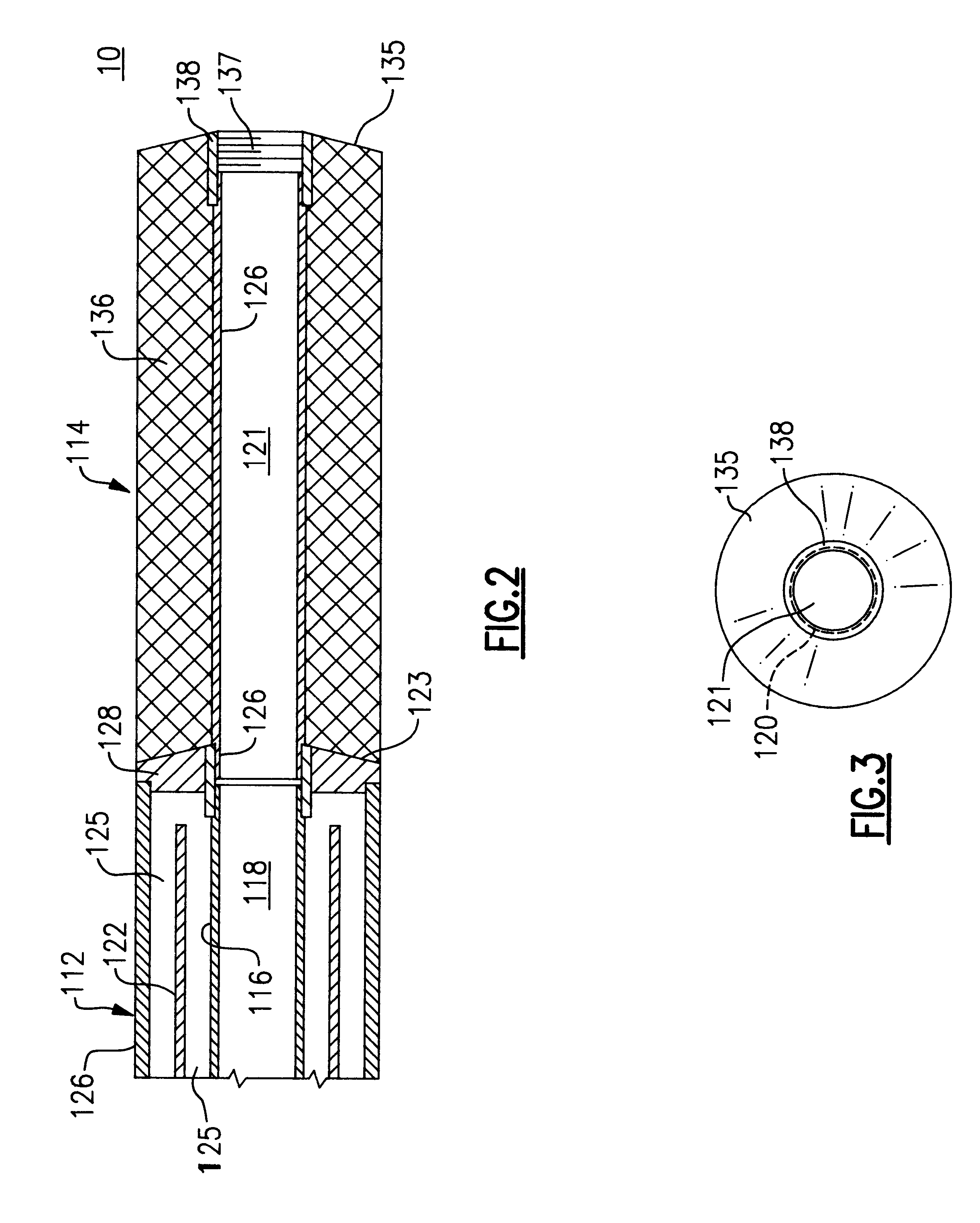

Reusable lance with consumable refractory tip

An improved apparatus for EAF steelmaking providing a lance for the injection of oxidizing gas, preferably oxygen, or other metallurgical gases and particulate materials into a steelmaking process. In one embodiment, the apparatus comprises a lance body configuration which has a central conduit for the supply of a pressurized flow of oxygen. A consumable lance tip made of refractory material is connected to the lance body such that it is in fluid communication with the central conduit.

Owner:PROCESS TECH INT

Method for producing ultra-low-carbon steel

A method for producing ultra-low-carbon steel belongs to steel-making technology field. The process route is: molten iron desulfuration preprocess -converter smelting -RH vacuum process -slab continuous casting. The iron desulfuration preprocess applies blowing magnesium granules for desulfuration; the converter smelting terminal carbon content and oxygen activity of molten steel; applying slag dam operation when tapping without deoxidation; the ladle furnace proceeds operation of top slag modification and temperature controlling; RH vacuum processing to control the maximum vacuum; applying Al for deoxidation when the decarburization is finished, and alloying if the deoxidation is finished and assuring the deep vacuum processing time after the deoxidation; calming the molten steel when the vacuum is finished; applying non-carbon covering agent and non-carbon protection slag in the slab casting process; the continuous casting process uses full protection casting, and the casting process controls a reasonable pulling speed according to slab section. The advantages are: the invention resolves problem of nozzle clogging and improves castability of the ultra-low-carbon steel and implements multi-furnace continuous casting, and the components of carbon, phosphorus, sulphur and nitrogen of the completed product conforms smelting request of the ultra-low-carbon steel.

Owner:SHOUGANG CORPORATION

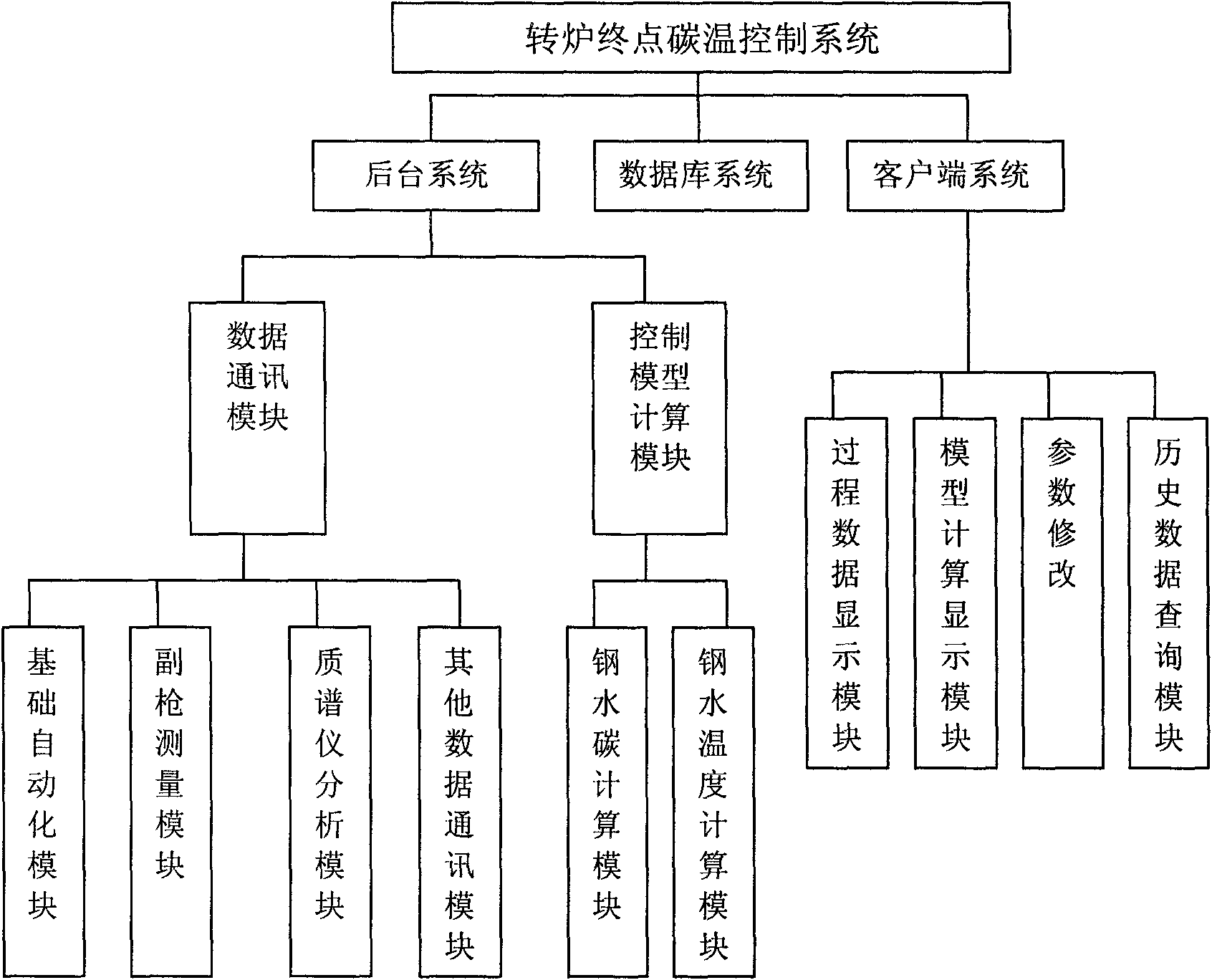

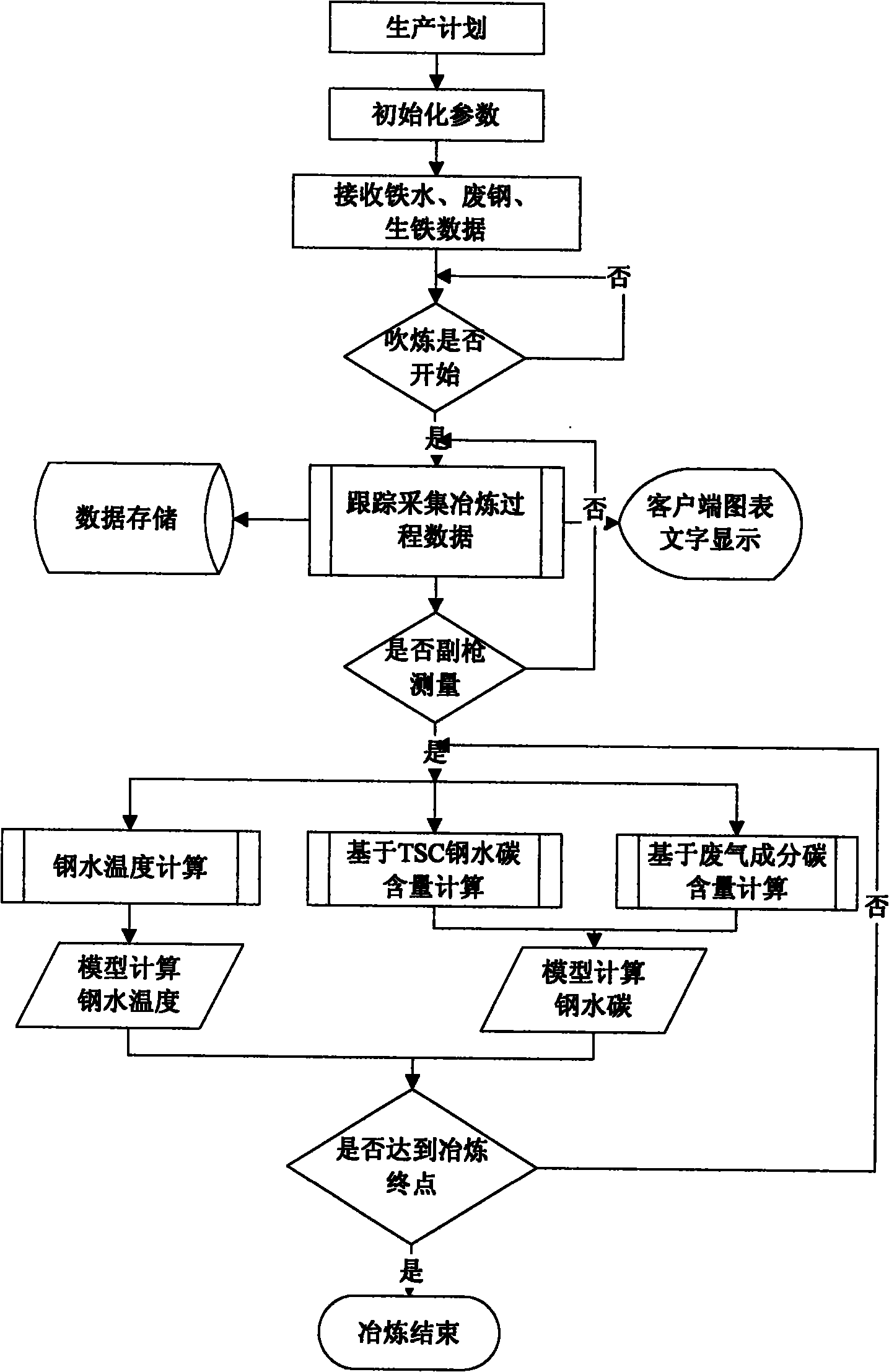

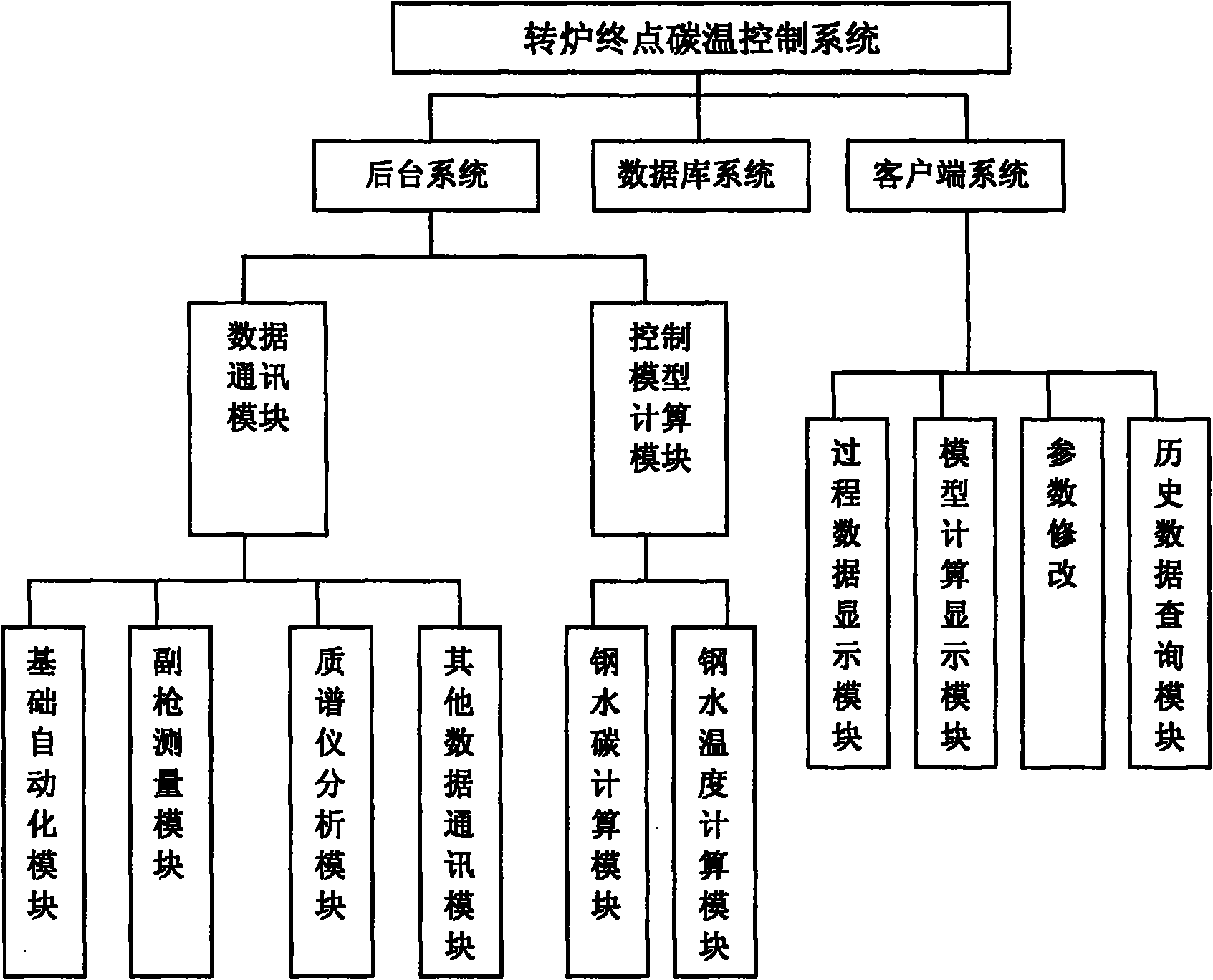

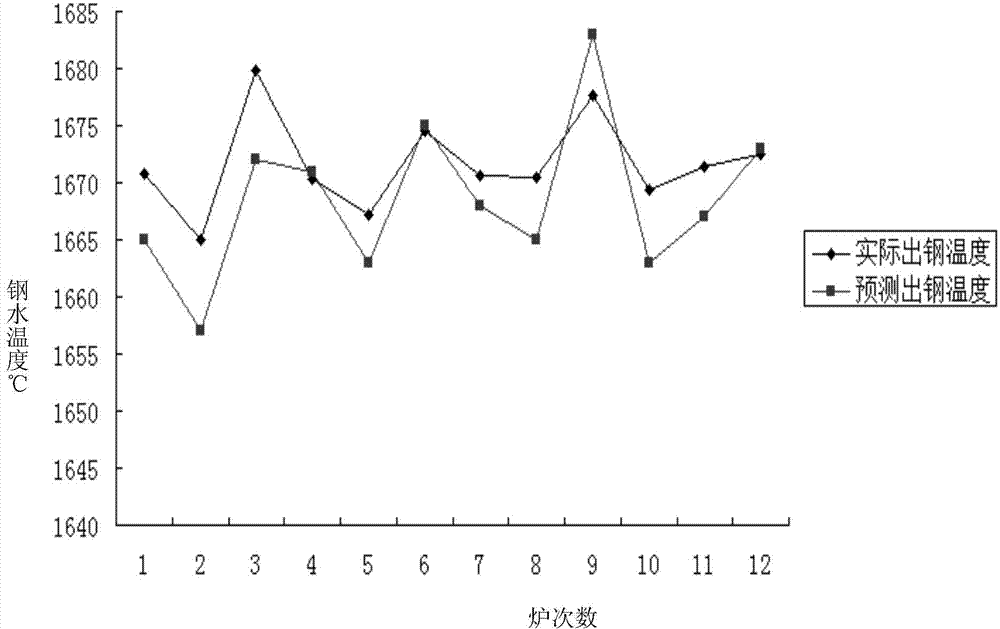

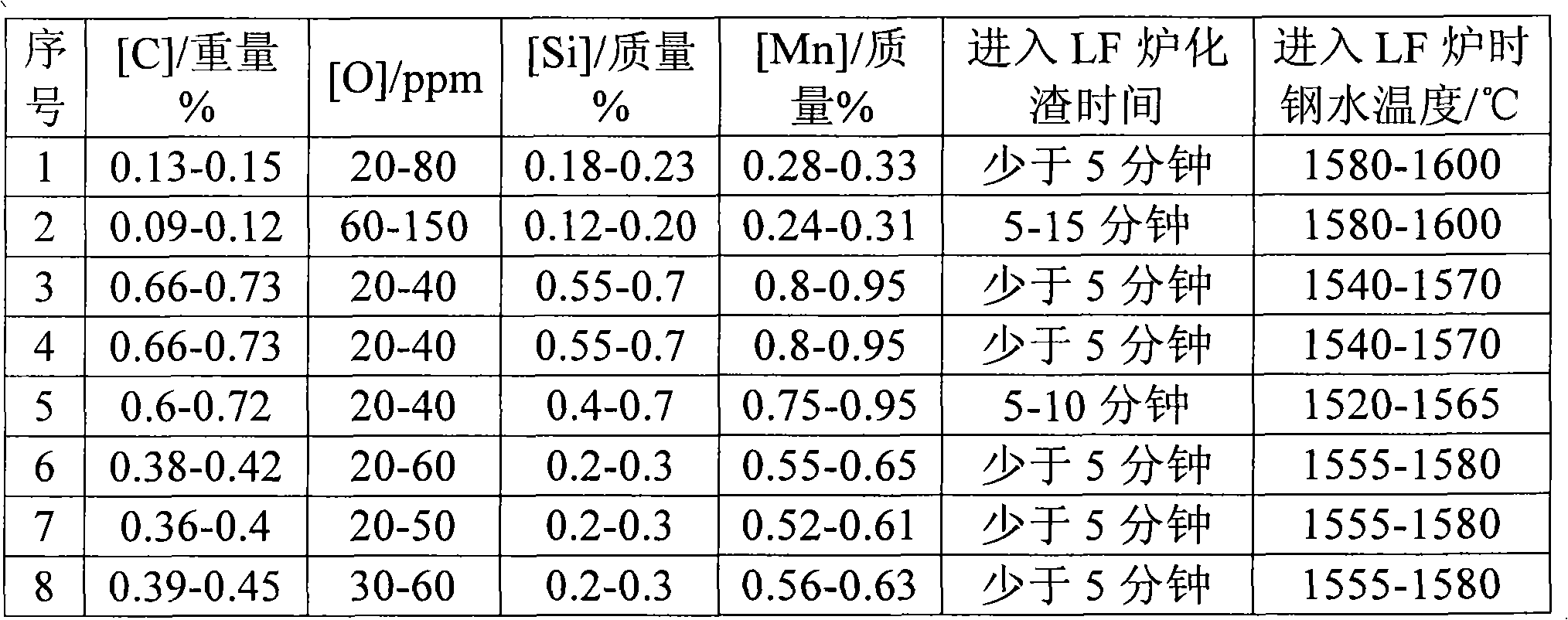

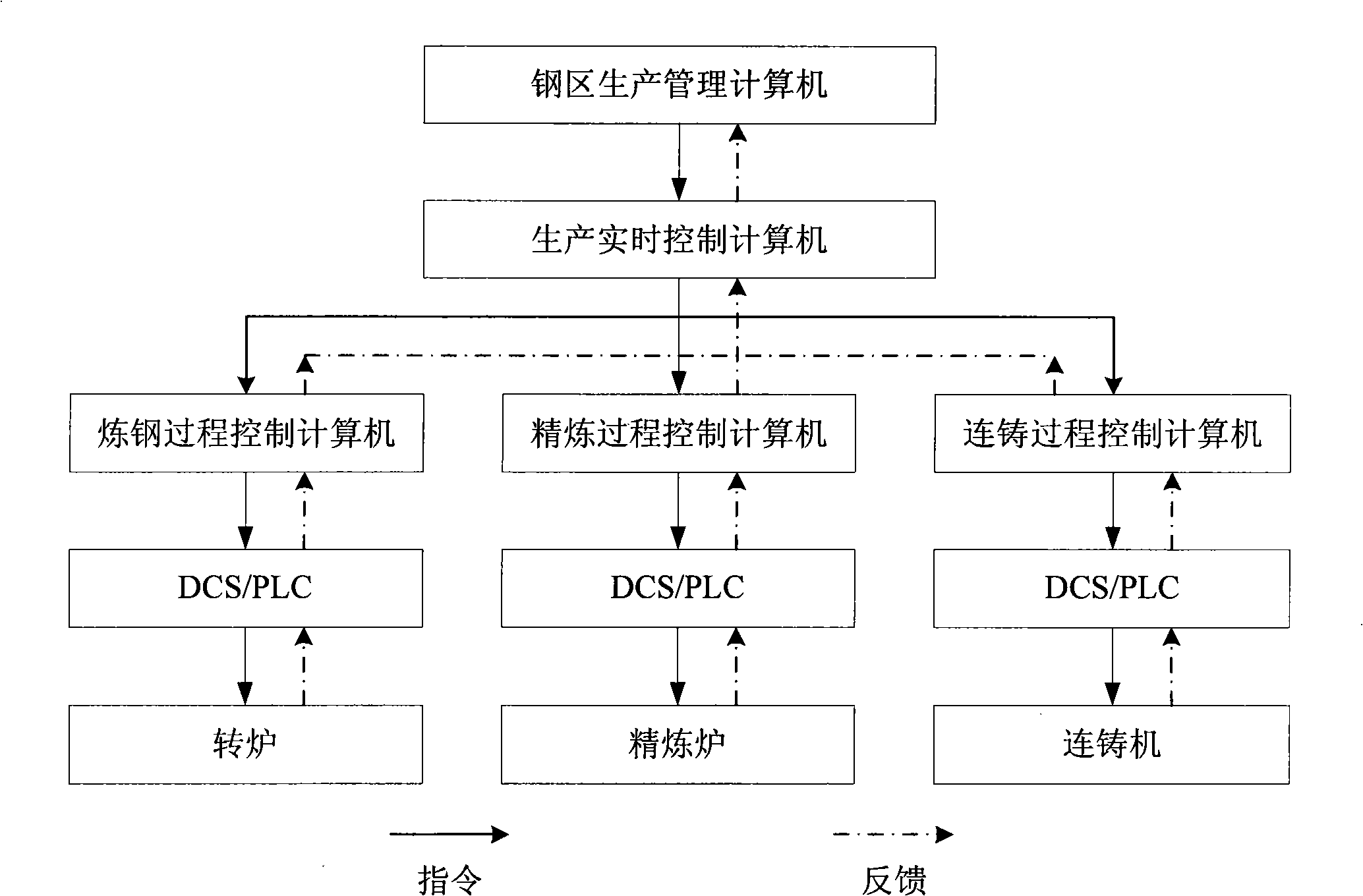

Converter smelting endpoint molten steel carbon and temperature control system and method thereof

ActiveCN101845531AEffective controlUnderstand clearlyManufacturing convertersSteelmakingTemperature control

The invention discloses a converter smelting endpoint molten steel carbon and temperature control system and a method thereof, and belongs to the technical field of converter steelmaking automation control. The converter smelting endpoint molten steel carbon and temperature control system comprises hardware equipment and a software processing module, and is characterized in that: the hardware equipment comprises converter sublance measuring equipment and converter exhaust gas analysis equipment; the software processing module comprises a converter production process data acquisition module, a converter smelting endpoint carbon calculation module, a converter smelting endpoint temperature calculation module, and an information display module; the software processing module is operated on a computer; and the hardware equipment and the software module are connected with a converter production process database through an Ethernet to realize data interaction. The control system and the method thereof have the advantages of accurately controlling the converter smelting endpoint molten steel carbon content and the molten steel temperature, along with stable operation, cost conservation, and wide application range.

Owner:HEBEI SHOUGANG QIAN AN IRON & STEEL CO LTD +2

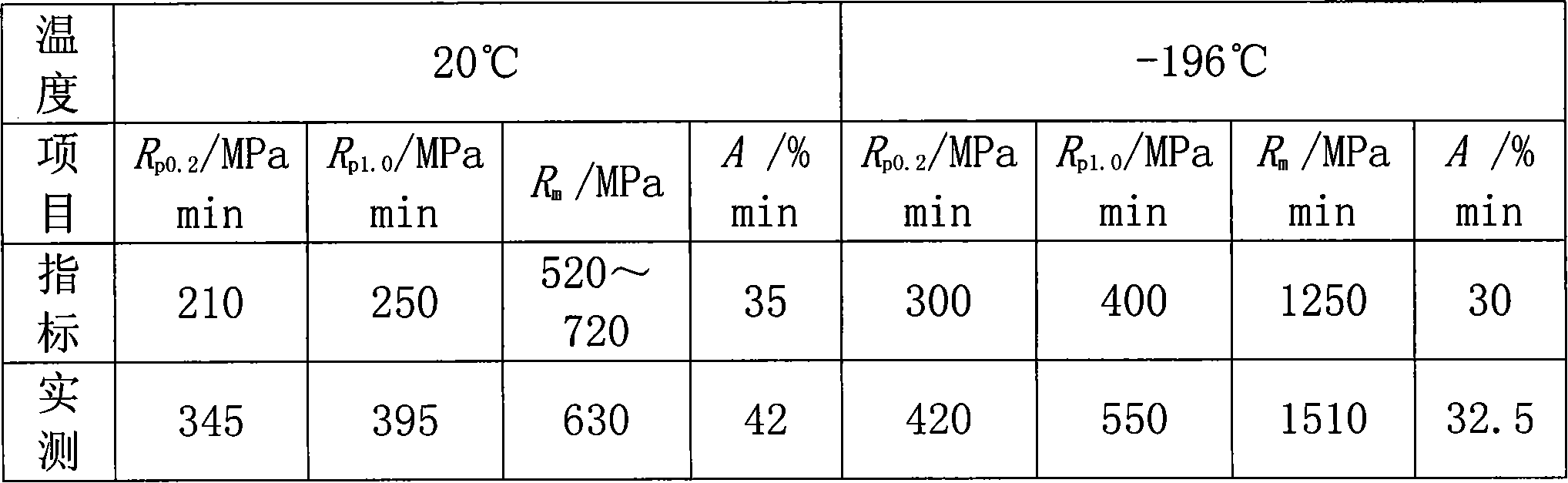

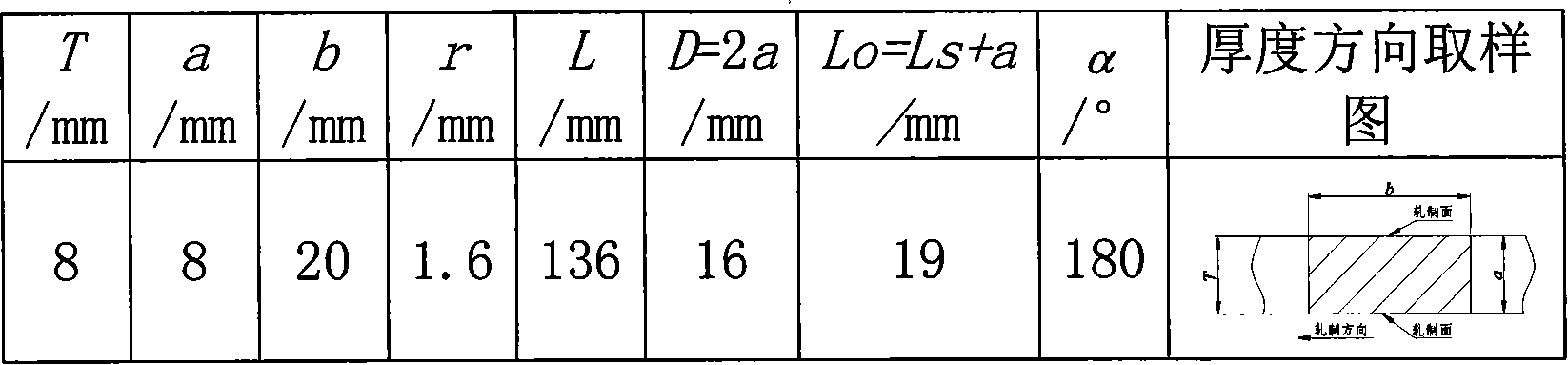

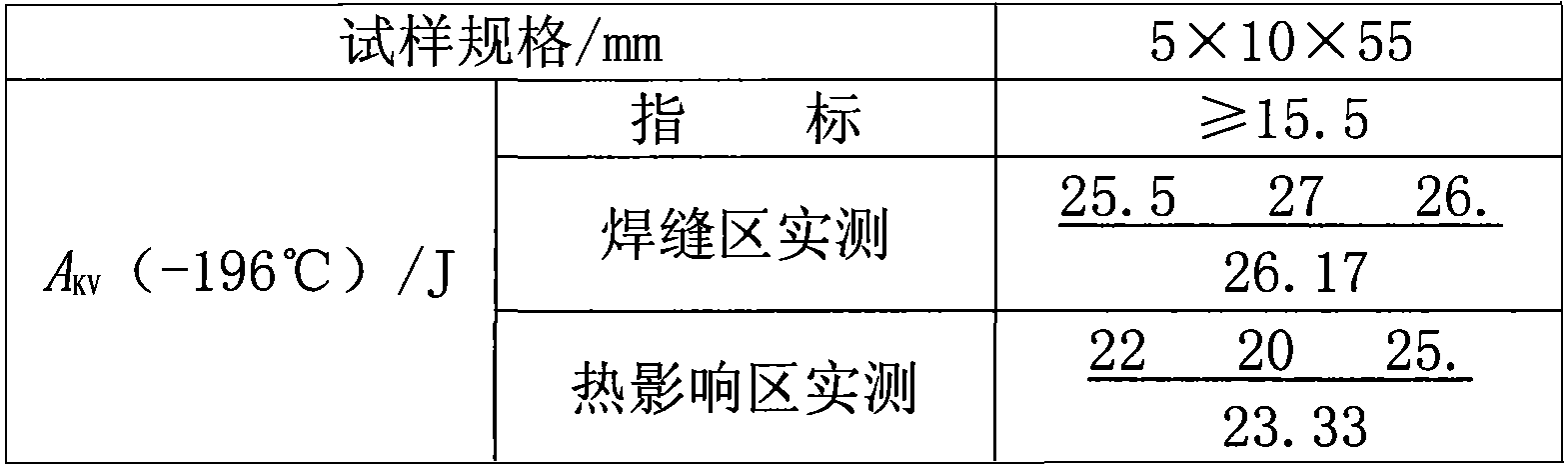

Austenitic stainless steel buried arc welding wire for low-temperature equipment

ActiveCN101244494AEasy to rollImprove low temperature resistanceWelding/cutting media/materialsSoldering mediaSteelmakingChemical composition

The invention relates to a welding wire, in particular to a welding wire applying to austenitic submerged arc welding for low-temperature equipments, in terms of chemical composition and weight percent, comprising Cr: 19.0 to 23.0%, Ni: 9.0 to 12.0%, C: <=0.03%, Mn: 1.60 to 2.50%, Si: 0.30 to 0.60%, Mo: <=0.30%, Cu: <=0.30%, Co: <=0.20%, Ti: <=0.015%, Nb: <=0.05%, V: <=0.10%, B: <=0.005% and Fe as allowance. The welding wire has the advantages that: the welding wire steelmaking craft is stable; the drawing performance is good; the invention meets the welding technical requirements of the high-intensity, high-toughness and anti-corrosion steel with low temperature and low temperature equipments; the invention can apply to the steel of 500 to 750MPa strength level; the invention is suitable for large range of welding current and no blowhole; the moulding is beautiful; the weld joint can be well matched with the base material.

Owner:哈焊所华通(常州)焊业股份有限公司

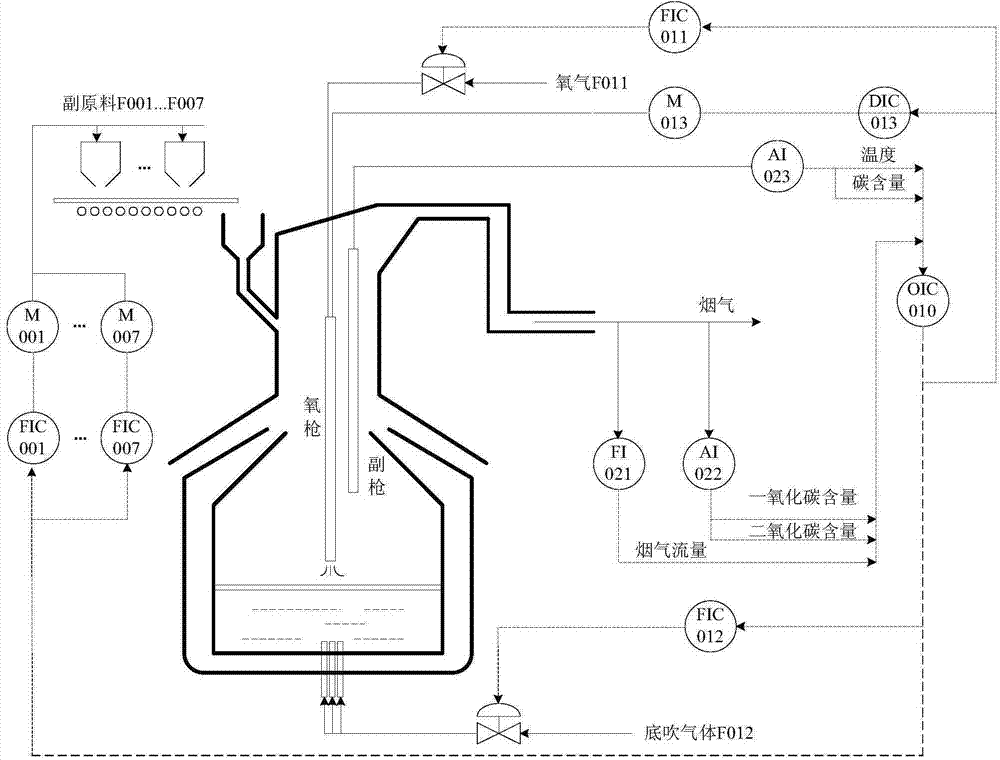

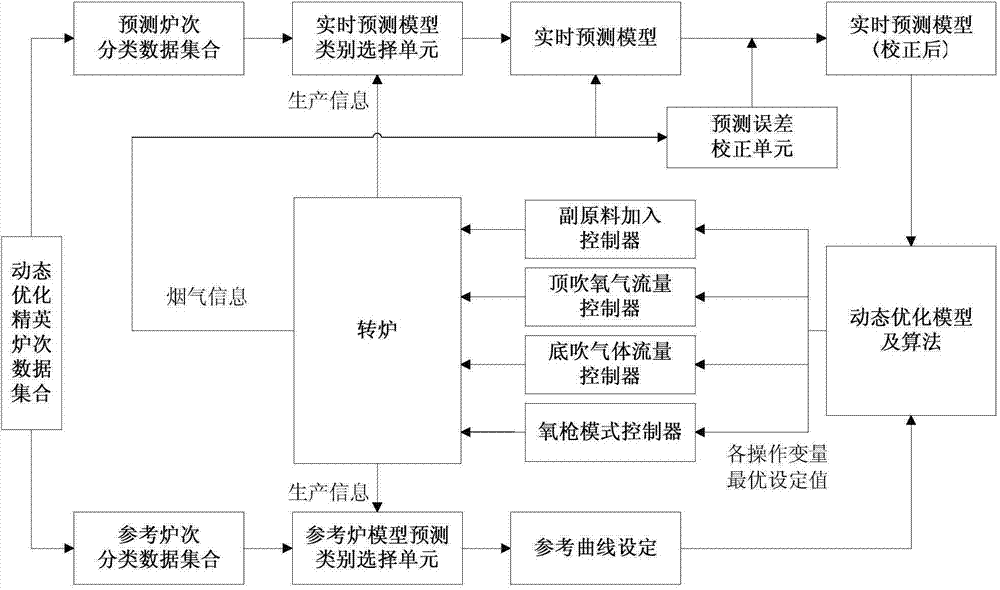

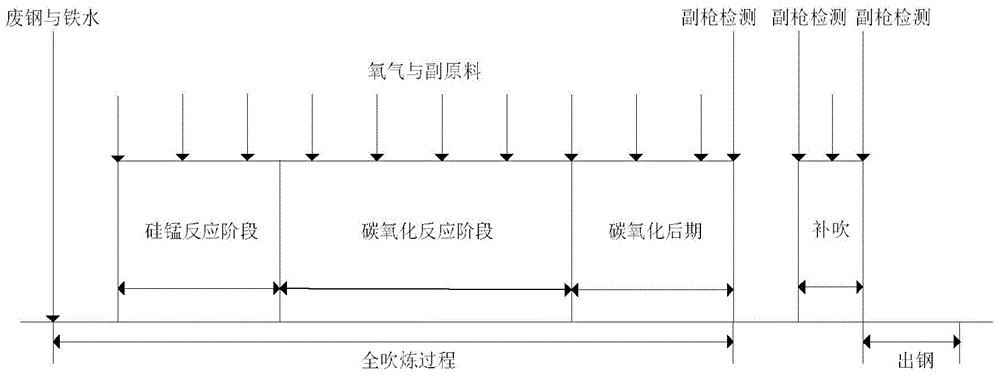

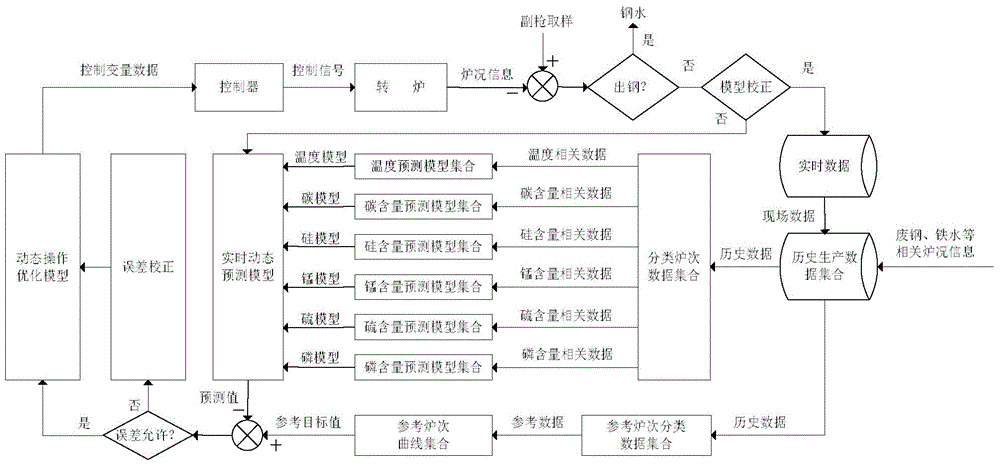

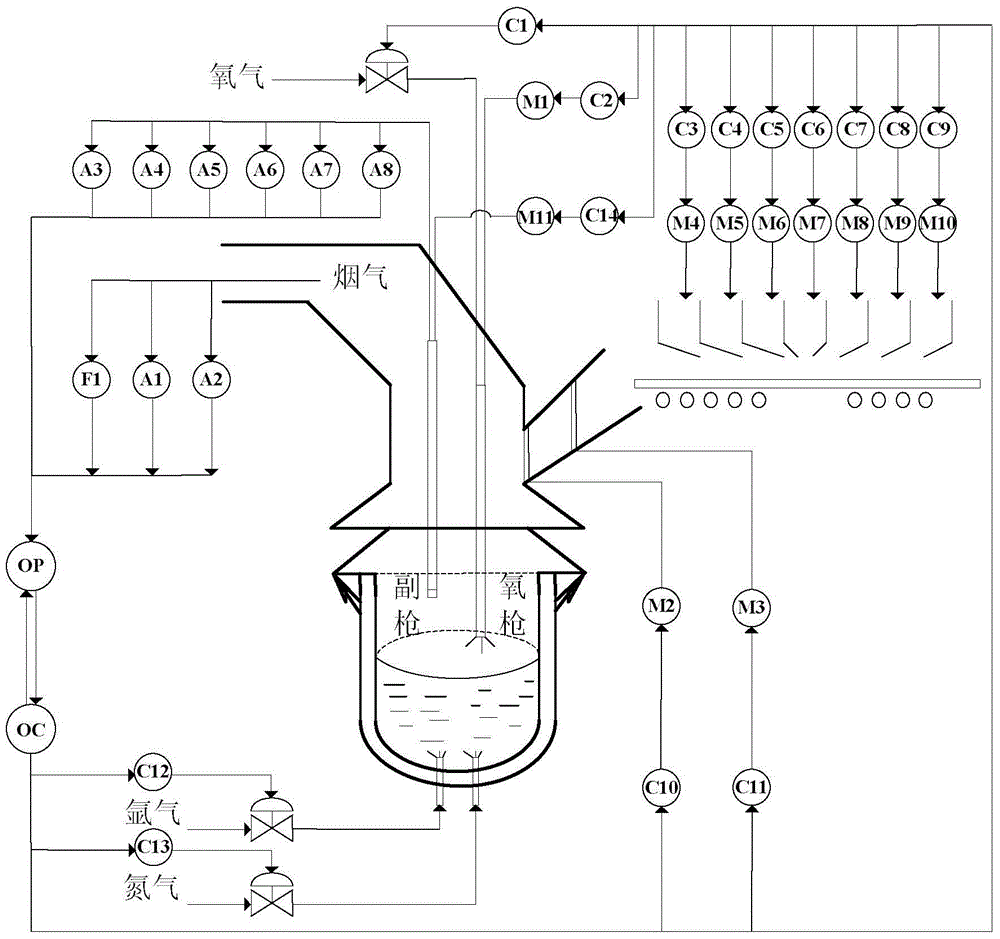

On-line dynamic optimization control method for converter steelmaking process based on data driving

ActiveCN103882176AImprove hit rateIncrease productivityManufacturing convertersSteelmakingDynamical optimization

The invention discloses an on-line dynamic optimization control method for a converter steelmaking process based on data driving. The method comprises the following steps: building an off-line prediction model database; building a liquid steel temperature prediction model and a carbon content prediction model by use of a data driving method to obtain a corresponding relationship between operating variables and the temperature and carbon content of liquid steel in the converter steelmaking process; selecting a melt data unit matched with the information of the current converter steelmaking production process and determining a control reference curve of the liquid steel temperature and carbon element content; building a real-time dynamic optimization model of the converter steelmaking process and determining an optimized set value unit of each operating variable; and selecting the set value of each operating variable from the optimized set value unit so as to carry out control operation. The method disclosed by the invention can be used for realizing real-time on-line control over the converter steelmaking process and providing convenience for an operator to set selection conditions according to actual working conditions, thus the production efficiency of a steelmaking plant is improved.

Owner:NORTHEASTERN UNIV

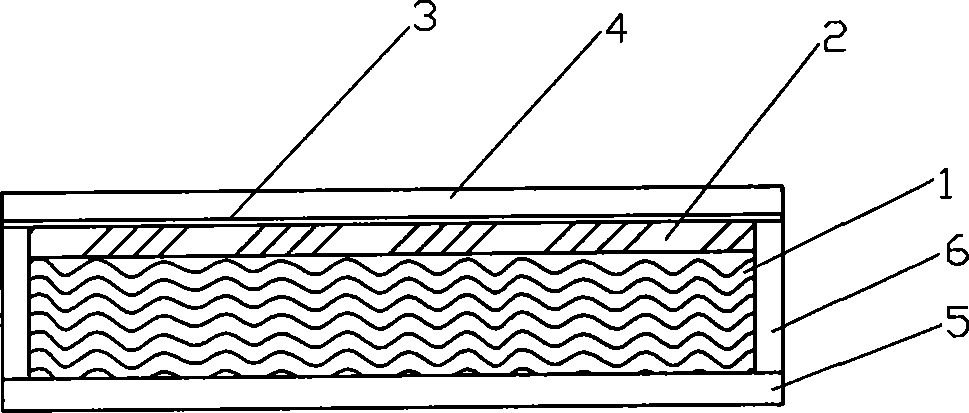

Tearing-proof high temperature resisting conveyer belt

InactiveCN101214880AImprove tear resistanceImprove high temperature resistanceConveyorsSteelmakingPolyester

The invention discloses an anti-tear and high temperature resistant conveyor belt, including a skeleton layer, a working face glue-covering layer, a non-working face glue-covering layer, a transverse reinforcement layer and a buffer glue layer. The transverse reinforcement layer is arranged between the skeleton layer and the buffer glue layer and is adjacent to the skeleton layer. The buffer glue layer is arranged between the transverse reinforcement layer and the working face glue-covering layer and is adjacent to the working face glue-covering layer. The skeleton layer adopts low hear shrinkage polyester canvas and the transverse reinforcement adopts polyester curtain net or metal wire. The material of the working face glue-covering layer is made by mixing ethylene propylene diene monomer with other filers with proper proportion. The material of the buffer glue layer is made by mixing the blend glue of ethylene-propylene-diene rubber and natural glue with other fillers of proper proportion. The invention improves the anti-tear and high temperature resistant performances and is widely applied to convey high temperature materials in such industrial enterprises as steelmaking plants, thermal power plants, cement plants, etc.

Owner:ZHEJIANG SOUTHEAST RUBBER CORP

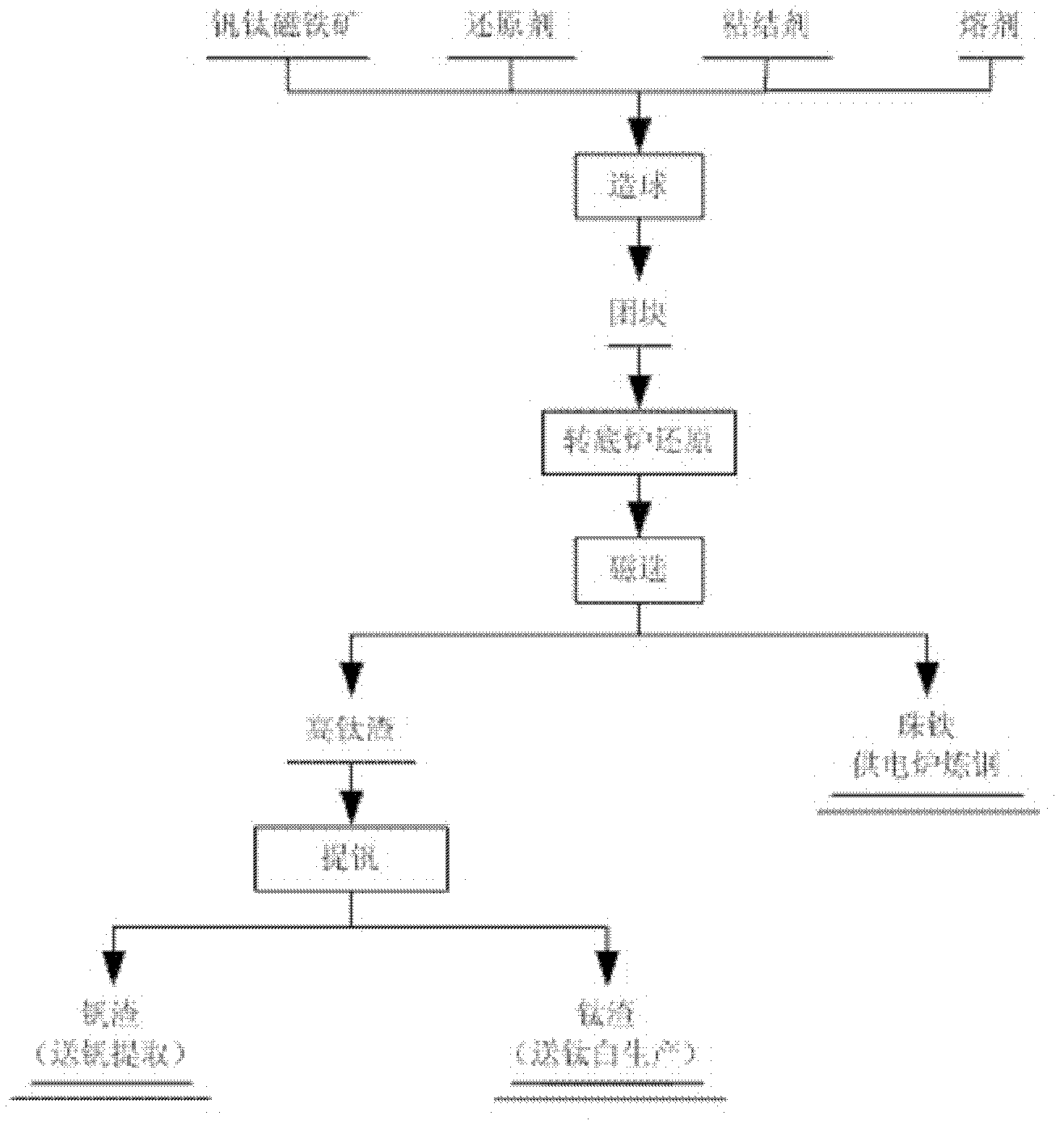

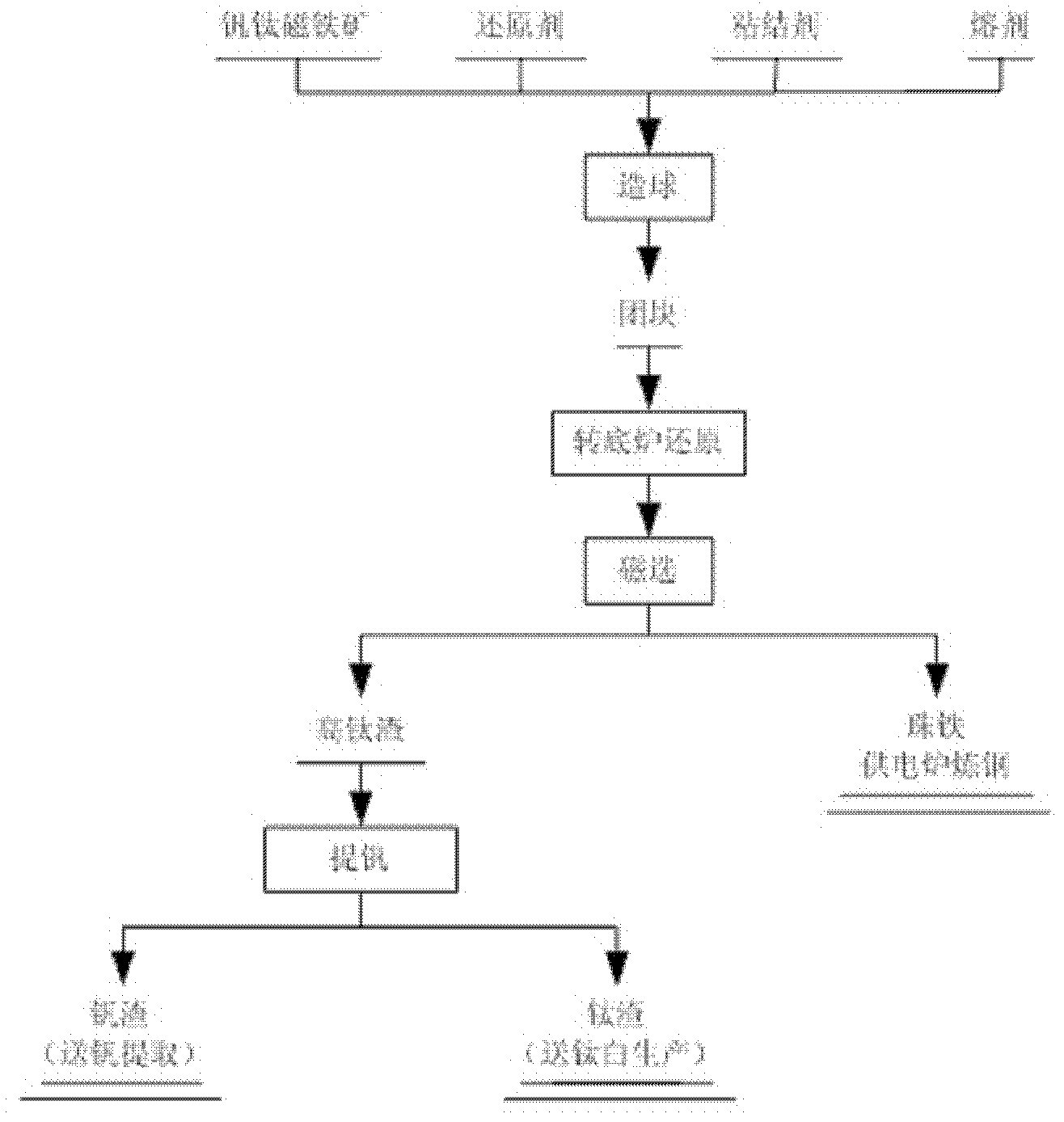

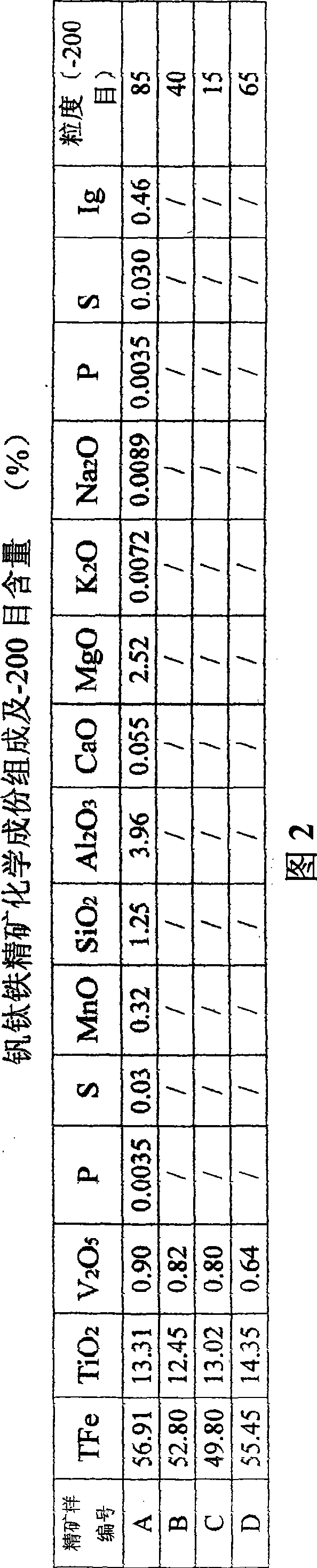

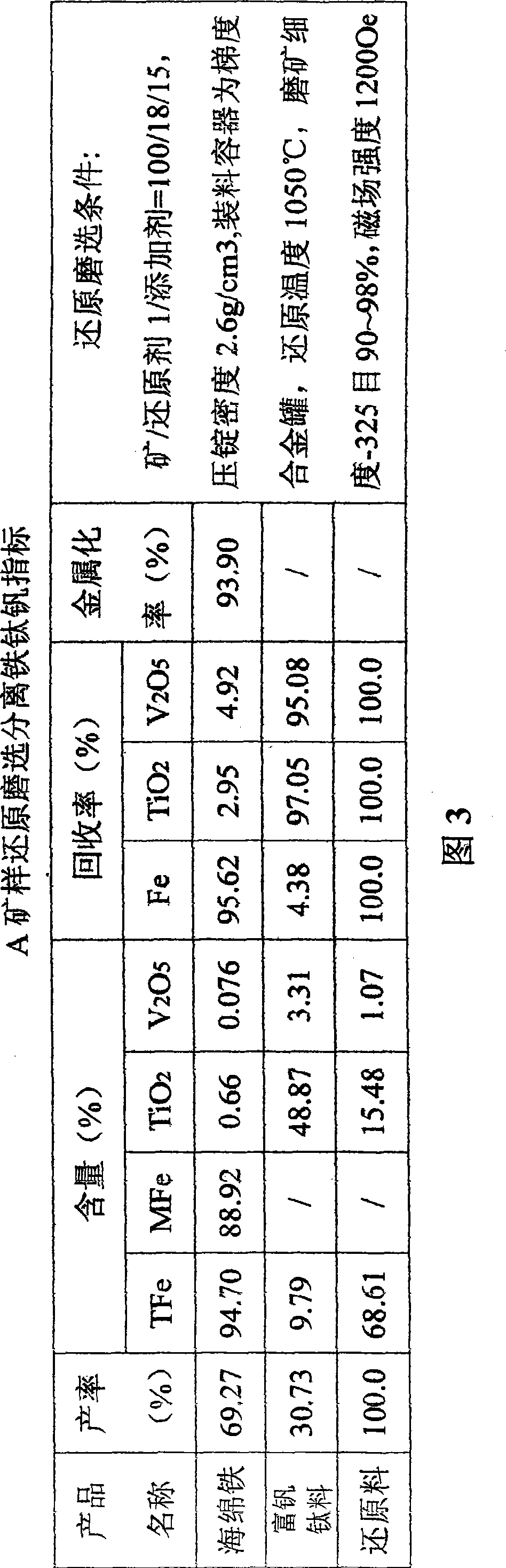

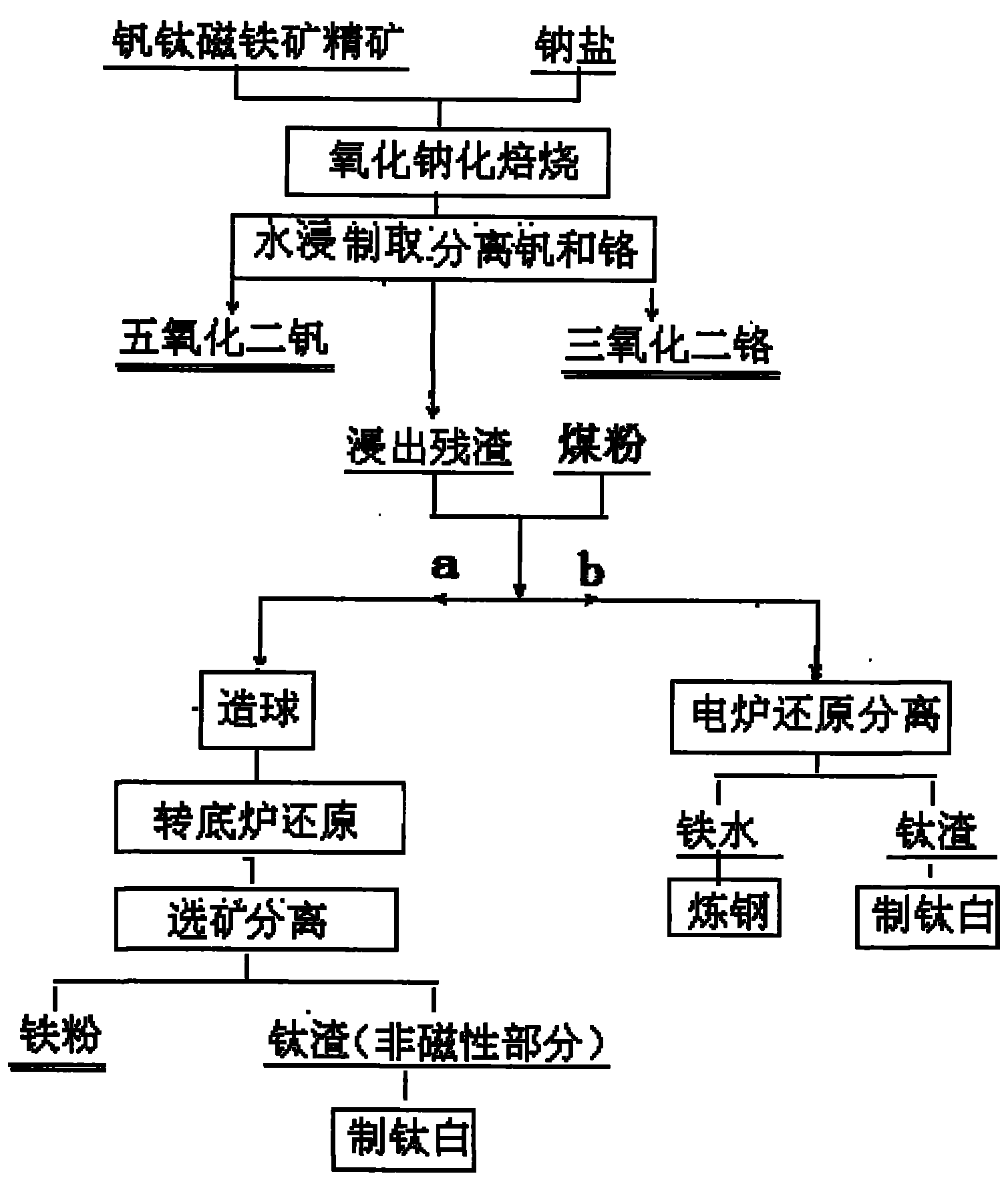

A method for comprehensive utilization of vanadium-titanium magnetite

InactiveCN102277462AReasonable useLess investmentMagnetic separationProcess efficiency improvementSteelmakingFurnace temperature

The invention relates to a method for comprehensive utilization of vanadium-titanium magnetite, which belongs to the field of new technology of direct reduction ironmaking in the metallurgical industry. In order to solve the problems of low utilization of iron, vanadium and titanium in vanadium-titanium magnetite, at the same time, due to the sintering process of traditional technology, the comprehensive energy consumption of the overall smelting process is relatively high, and the environmental pollution is serious. The invention provides a method of agglomerating vanadium-titanium magnetite and producing high-titanium slag and pearl iron by high-temperature reduction and melting in a rotary hearth furnace. The technical solution includes pelletizing of vanadium-titanium magnetite, high-temperature reduction in rotary hearth furnace, magnetic separation, and high-temperature reduction in rotary hearth furnace to directly produce high-titanium slag and pearl iron. Applying this method to process vanadium-titanium magnetite can not only effectively solve the problem of recovery of titanium and vanadium resources, but also obtain qualified iron pearls for steelmaking in electric furnaces, making full use of the iron, vanadium, and Valuable elements such as titanium.

Owner:UNIV OF SCI & TECH BEIJING

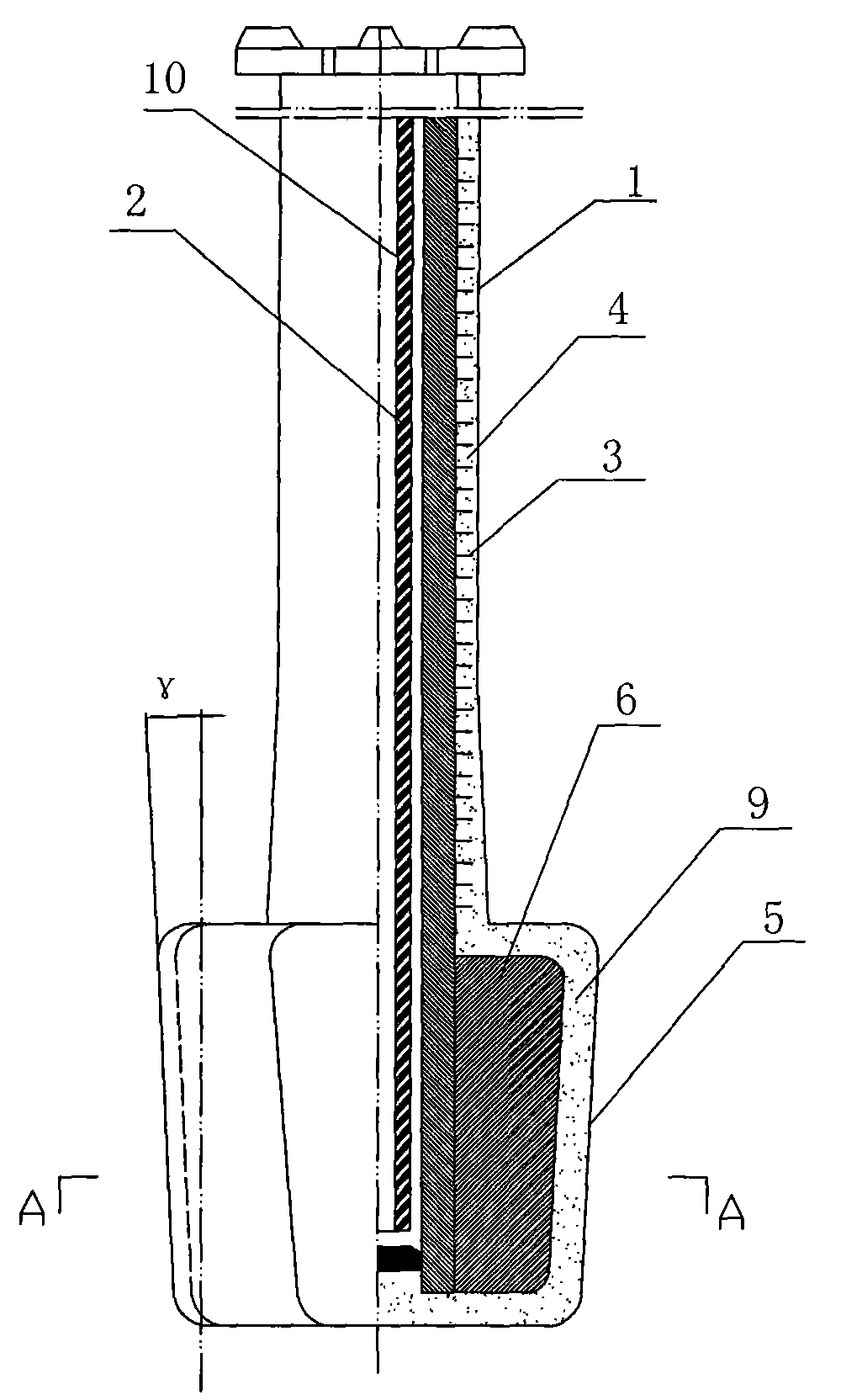

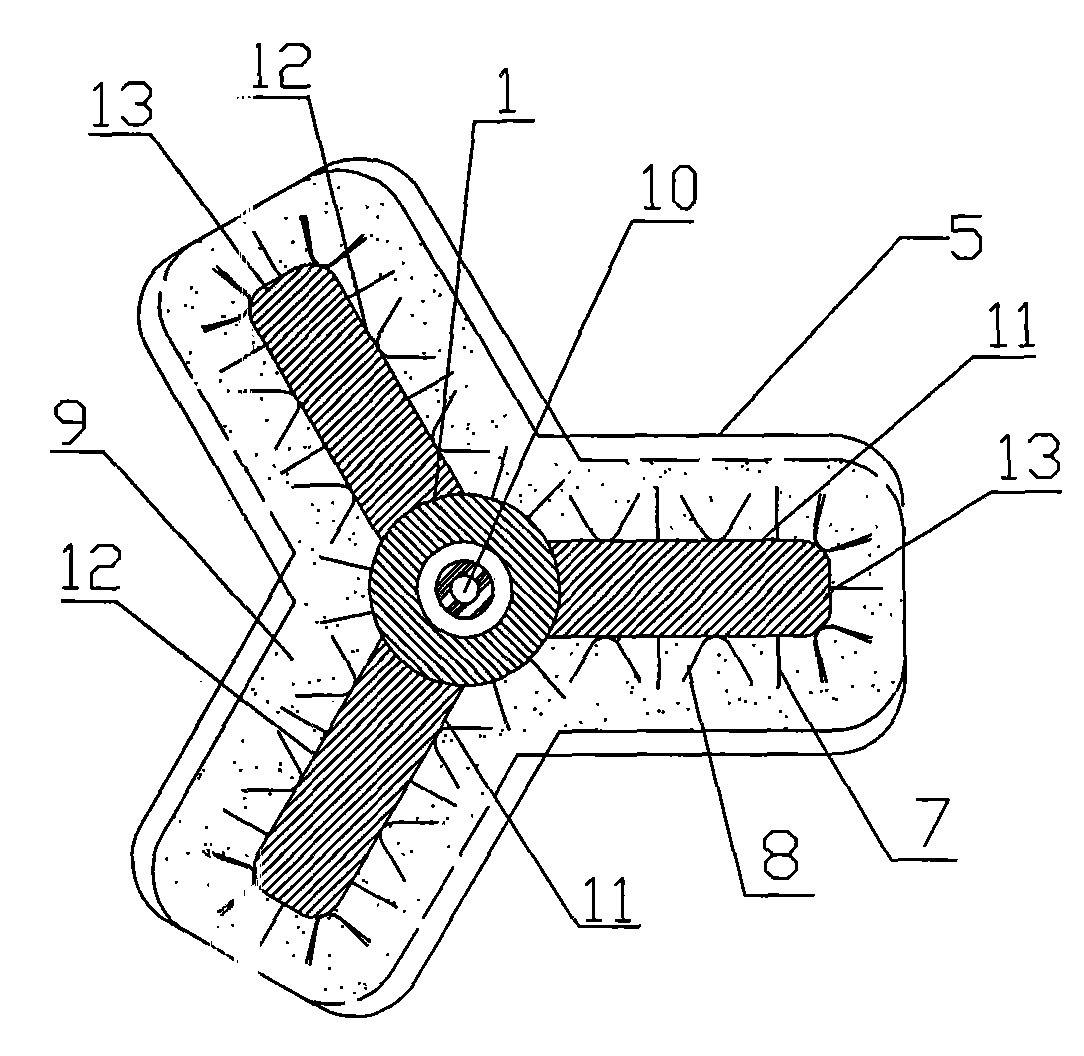

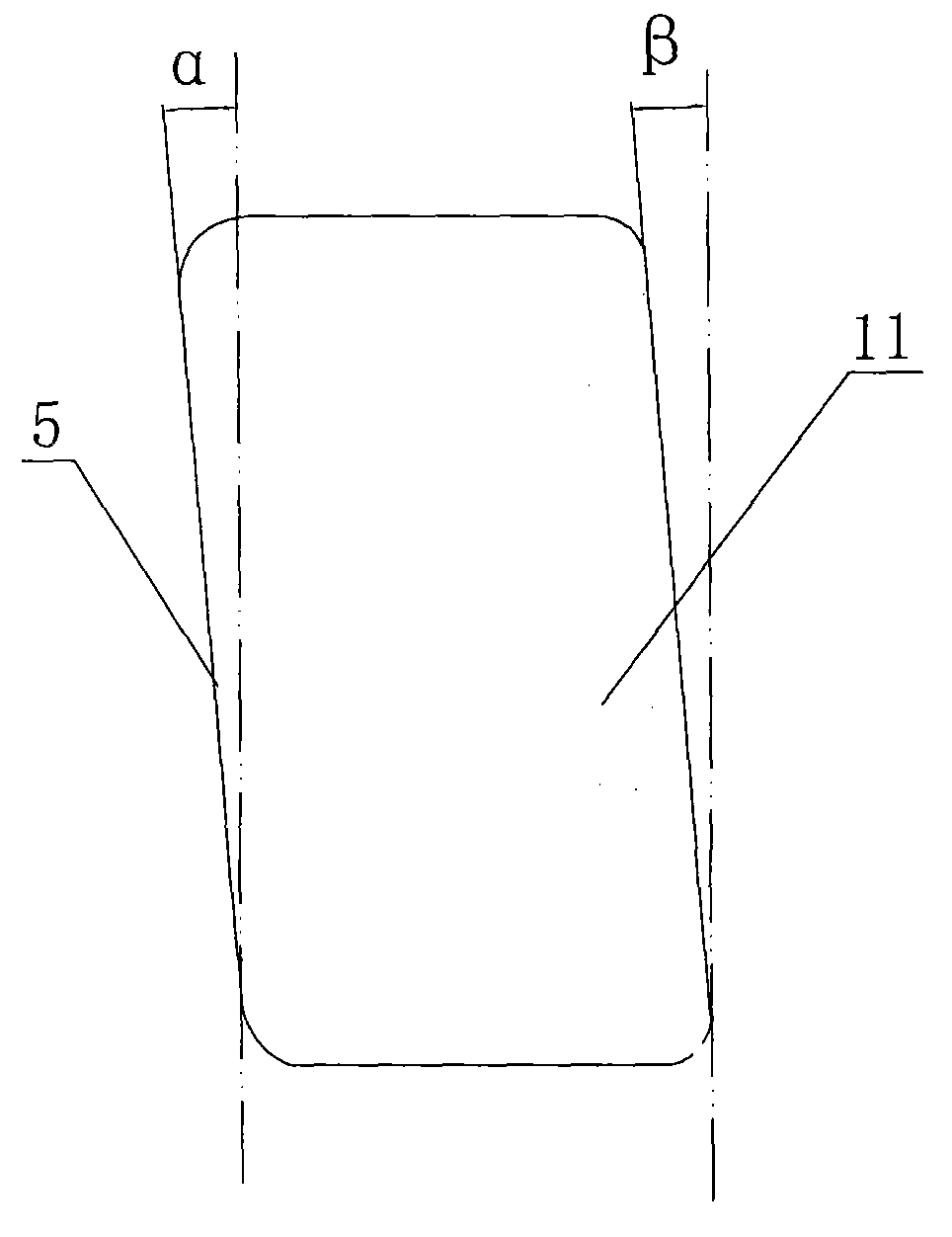

Stirrer for desulphurization of molten iron

The invention relates to a stirrer for external stirring desulphurization of molten iron before converter steelmaking, aiming at solving the existing deficiencies at present that slags among mixing blades are numerous, large intensity of vortex at the bottom of the metal opposing side of the mixing blades is disadvantageous to the discharging of the involved desulphurization slags. The invention comprises the following measures: the stirrer for desulphurization of molten iron is composed of a metal core 2, a V-shaped rivet firmware 3, a refractory liner 4, a metal chip 6, a V-shaped rivet firmware 7, a double V-shaped rivet firmware 8, a refractory liner 9 and an air cooling tube 10; the metal core 2, the V-shaped rivet firmware 3 and the refractory liner 4 constitute a rotation axis 1; the metal chip 6, the V-shaped rivet firmware 7, the double V-shaped rivet firmware 8, the refractory liner 9 and the air cooling tube 10 constitute mixing blades 5; three mixing blades 5 above the rotation axis 1 are evenly distributed; the front rake angle alpha of the inclined plane from bottom to top of the metal facing water surfaces 11 of the mixing blades 5 is 4.1-30 degrees, the front rake angle beta of the inclined plane from bottom to top of the metal opposing surfaces 12 is 0.1-30 degrees, the camber angle gamma of the inclined plane from bottom to top of the outside surface 13 is 4.1-15 degrees. In the invention, slags among the mixing blades are small, the dynamic condition for stirring desulphurization is excellent, the service life is long and the structure is simple.

Owner:武汉钢铁有限公司 +1

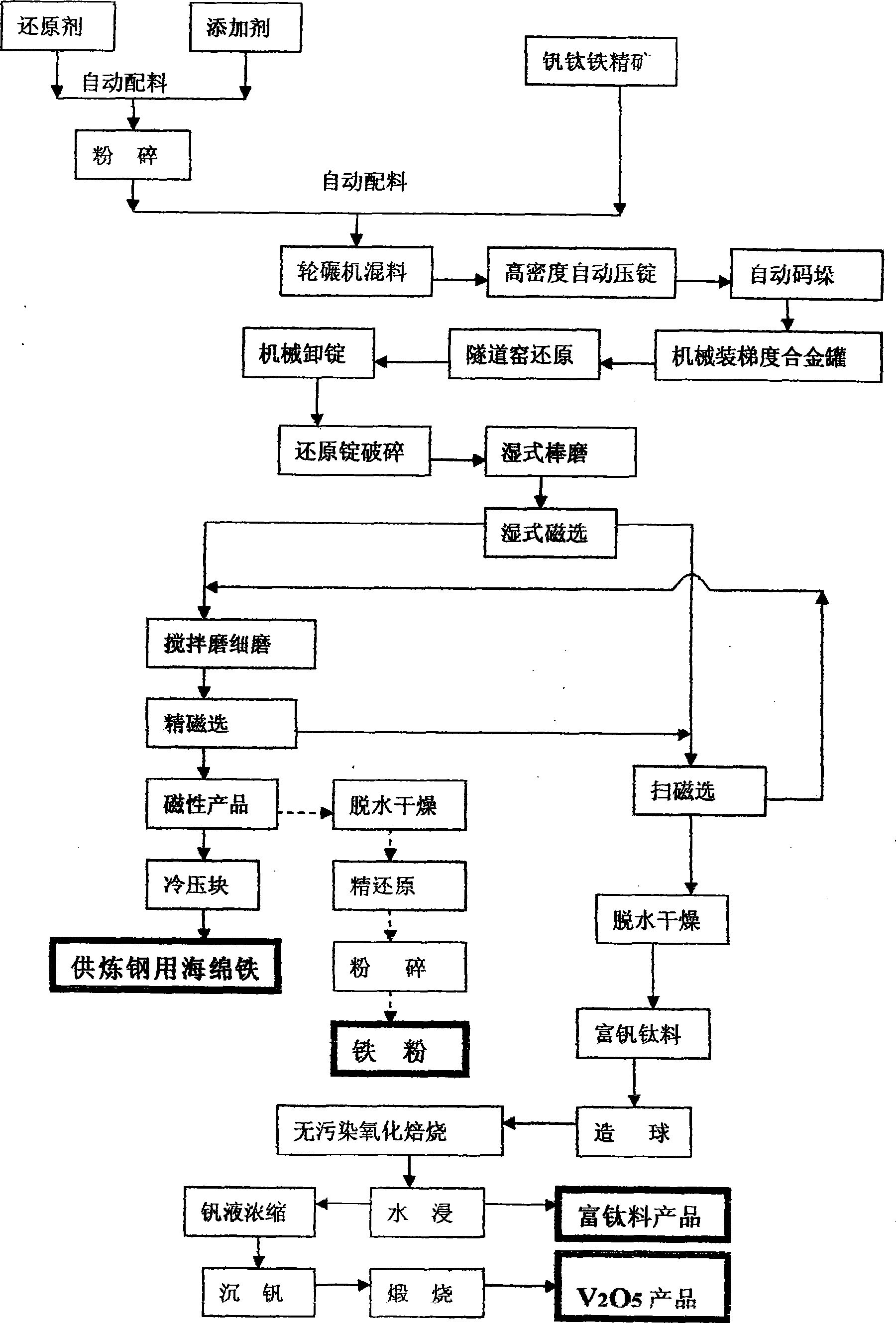

Novel industrialization method for comprehensive utilization of vanadium ferrotitanium ore concentrate

InactiveCN101418370AHigh Sponge Iron YieldHigh yieldVanadium oxidesMagnetic separationSteelmakingTunnel kiln

The invention relates to a novel industrialized method for comprehensively utilizing vanadium titanium iron ore concentrate. Raw material, an additive and a solid reducing agent are made into a higher-density round ingot through a full automatic press after being mixed evenly by an edge mill; the mixed material is charged into a gradient alloy can and is directly reduced in a tunnel kiln; and after being crushed, the reduced ingot is ground and is magnetically separated to obtain high-quality sponge iron with 92 to 96 percent of TFe and material containing abundant vanadium and titanium with 2.8 to 3.4 percent of V2O5 and 48 to 49 percent of TiO2. After being cold formed, the sponge iron is used for electric steelmaking or is sold as iron powder through deep processing. The material containing abundant vanadium and titanium can be used for producing V2O5 with the purity more than or equal to 98.5 percent through a simplified wet method vanadium extraction process; and vanadium slag with the TiO2 content more than or equal to 48 percent can be used as sulfuric acid method titanium white or other industrial raw materials. The method can greatly improve the capacity of the tunnel kiln and the service life of a charging vessel, has high comprehensive utilization degree, reliable technology, investment conservation and low production cost, energy conservation and emission reduction, and little pollution, and creates conditions for industrialization.

Owner:CHANGSHA DONGXIN MINING & METALLURGICAL TECH DEV

Molten steel deoxidizing and carbureting method and steelmaking method

The invention relates to a molten steel deoxidizing and carbureting method which comprises the step of adding a carburant and a deoxidizer to a steel ladle in sequence in the process of leading molten steel obtained by smelting to enter the steel ladle through steel tapping. The invention further provides a steelmaking method which comprises the following steps: tapping the molten steel obtained by smelting to the steel ladle, deoxidizing and carbureting the molten steel during the steel tapping process and then externally refining the molten steel after being deoxidized and carbureted, wherein the method for deoxidizing and carbureting the molten steel is the molten steel deoxidizing and carbureting method. In the deoxidizing and carbureting method, the carburant is firstly added and then reacted with oxygen in the molten steel to generate spontaneous mixing gas while the content of carbon is adjusted. Later, the added deoxidizer can be completely and uniformly mixed with the molten steel under the agitation action of spontaneous mixing gas, so that the molten steel that has uniform temperature and ingredients and satisfies the refining requirements can be obtained, so as to create good conditions for the next procedure.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

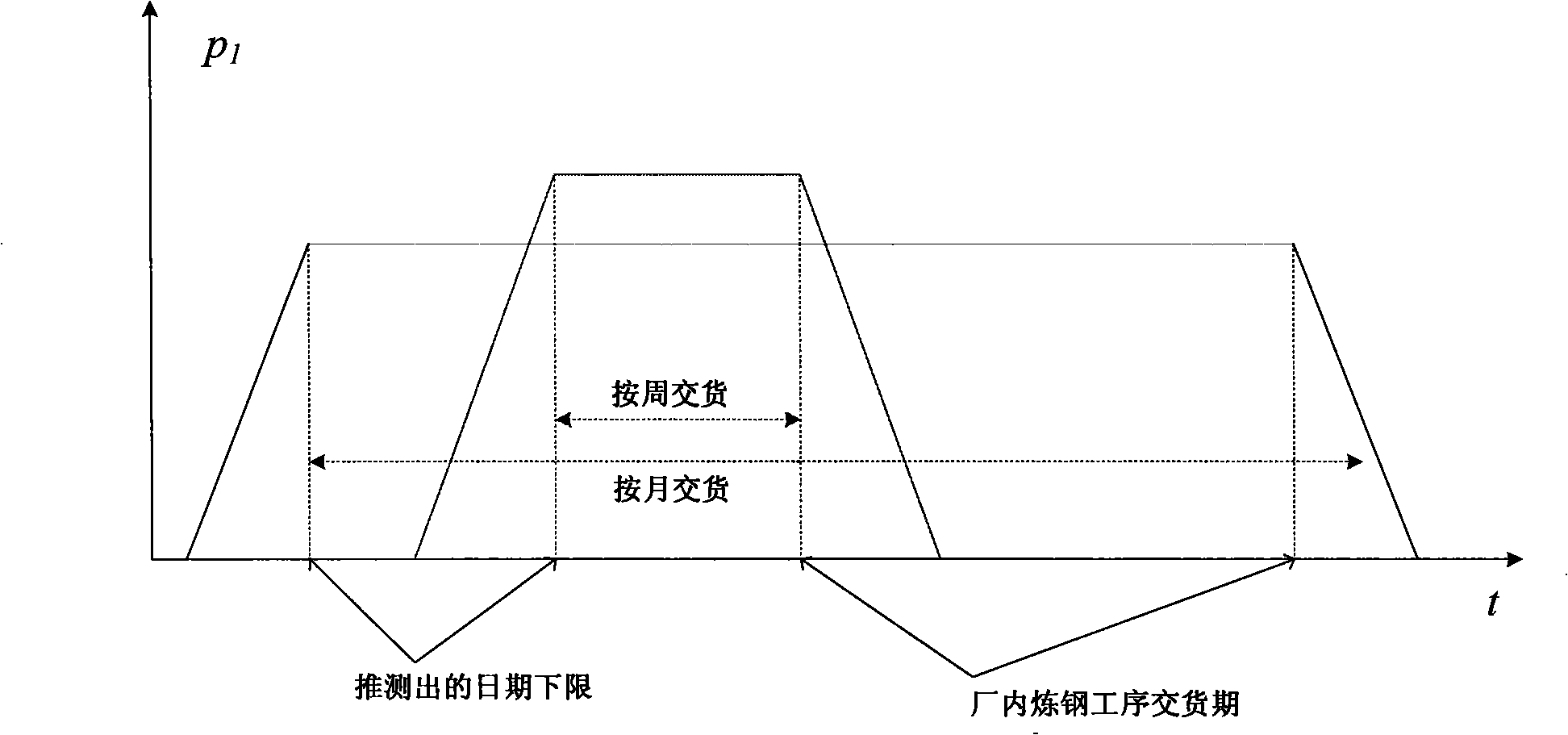

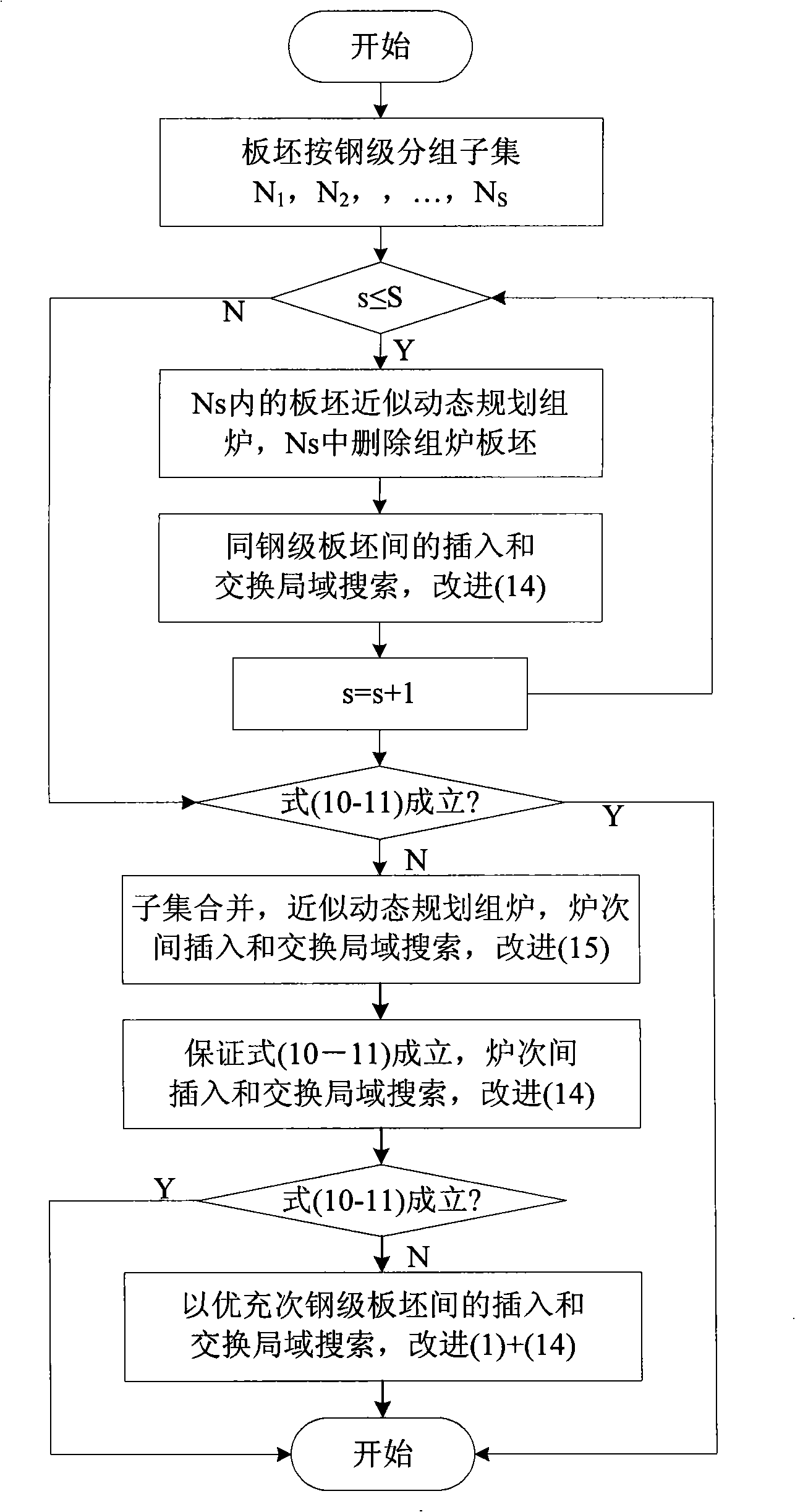

Method and system for automatically making steel-smelting continuous casting furnace sub batch plan

ActiveCN101303588AImprove scienceSolving inefficienciesTotal factory controlProgramme total factory controlSteelmakingOutcome assessment

The invention relates to an automatic planning method of a steelmaking and continuous casting heat batch plan and a system thereof, belonging to the IT field and including the following steps: 1, data collection; 2, construction of model; 3, optimization solution; 4, outcome assessment; 5, human-computer interaction; 6, sending down for executing. All indexes of the heat batch plan result obtained by adopting mathematical model and optimization algorithm of the invention are superior to that of the heat batch plan result obtained by the existing on-site manual planning pattern, in addition, the planning time (about 5 minutes) of the automatic planning method of the invention is far shorter than the planning time (about 2-3 hours) of the manual planning pattern. Therefore, the automatic planning method of the invention improves the scientificity of the traditional manual planning pattern, enhances planning level and quality, solves the problem of low efficiency in the manual planning pattern, and provides a scientific method for planning the on-line heat batch plan on a computer integrated manufacturing system in a steel enterprise.

Owner:NORTHEASTERN UNIV

Antisticking coating mixture for steel-smelting and preparation method threreof

The invention relates to an anti-sticking daubing material applied in steelmaking as well as the preparation method thereof, and is characterized in that the daubing material is composed of the following components by weight percentages as follows: 65 to 80 percent of 0 to 3 mm waste magnesia-carbon brick powder, 10 to 30 percent of waste magnesia-carbon brick powder, 5 to 30 percent of fused magnesia powder, 1 to 4 percent of fine silica powder, 1 to 4 percent of fine Alpha-Al2O3 powder, 0.1 to 1 percent of sodium hexameta phosphate, 0.1 to 0.8 percent of calcium lignosulfonat and 1 to 5 percent of soft clay. The daubing material can prevent the penetration of molten slag by utilizing the lubricating property of graphite in the waste magnesia-carbon bricks, and the slag is not easy to be hung on the surface, thereby not only effectively utilizing the waste magnesia-carbon bricks, but also prolonging the service life and reducing the cost.

Owner:PANZHIHUA SHUNTENG GRP METALLURGY MATERIAL

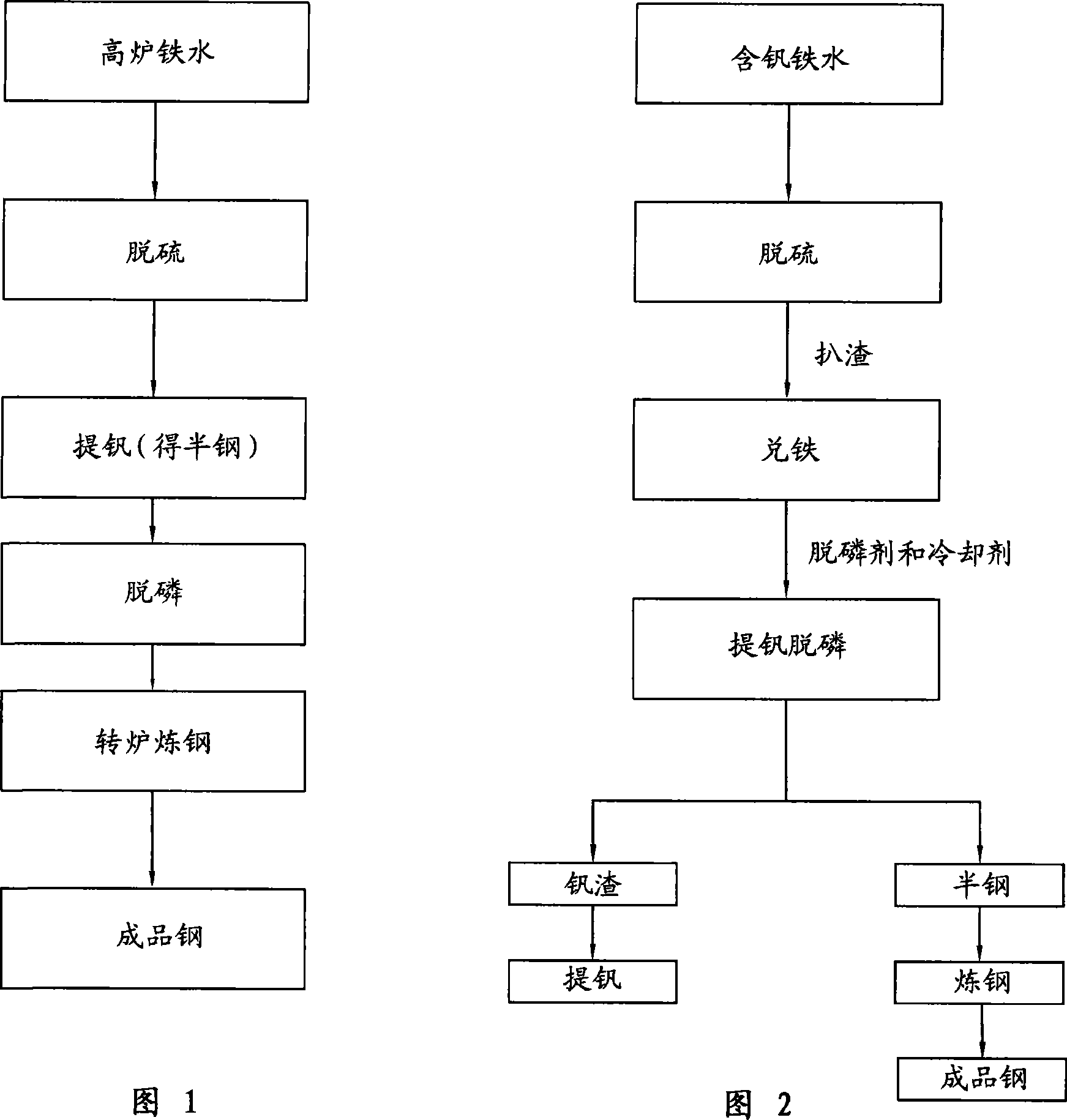

Method for extracting vanadium and removing phosphorus from vanadium-containing molten iron and steel-smelting technique using the same method

The invention provides a vanadium extraction dephosphorization process from vanadium melted iron and a steel-smelting technology which uses the process. The vanadium extraction dephosphorization process from vanadium melted iron comprises adding vanadium extraction dephosphorization agent and cooling agent in melted iron in the process of oxygen supply blowing for vanadium melted iron, and obtaining vanadium slag and low phosphorus semi-steel. The process can extract vanadium at the same time of dephosphorization, thereby not only guaranteeing the effective extraction of vanadium, but also effectively removing phosphorus in melted iron.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

Real-time dynamic converter steelmaking quality prediction method based on data analysis

ActiveCN104630410ADynamic operation optimization guaranteeIncrease productivityManufacturing convertersSteelmakingData set

The invention provides a real-time dynamic converter steelmaking quality prediction method based on data analysis. The method comprises the following steps: building a converter steelmaking quality off-line prediction model data base; respectively dividing liquid steel temperature and carbon element content into a plurality of stage ranges; building a real-time dynamic converter steelmaking quality prediction model; performing real-time dynamic converter steelmaking quality prediction according to the real-time dynamic converter steelmaking quality prediction model; testing the content of discharged steel components of the liquid steel; periodically updating the history data sets. The method provided by the invention is used for performing real-time dynamic prediction on liquid steel temperature and liquid steel quality during converter steelmaking on the premise of satisfying the technological requirements of converter steelmaking, can be used for tracking the condition inside a furnace in real time, and has the advantages of overcoming the defect of on-site delaying, improving the detection precision of each component content, lowering the production cost, also lowering the demand cost of equipment and providing valuable reference information for control of operators.

Owner:NORTHEASTERN UNIV

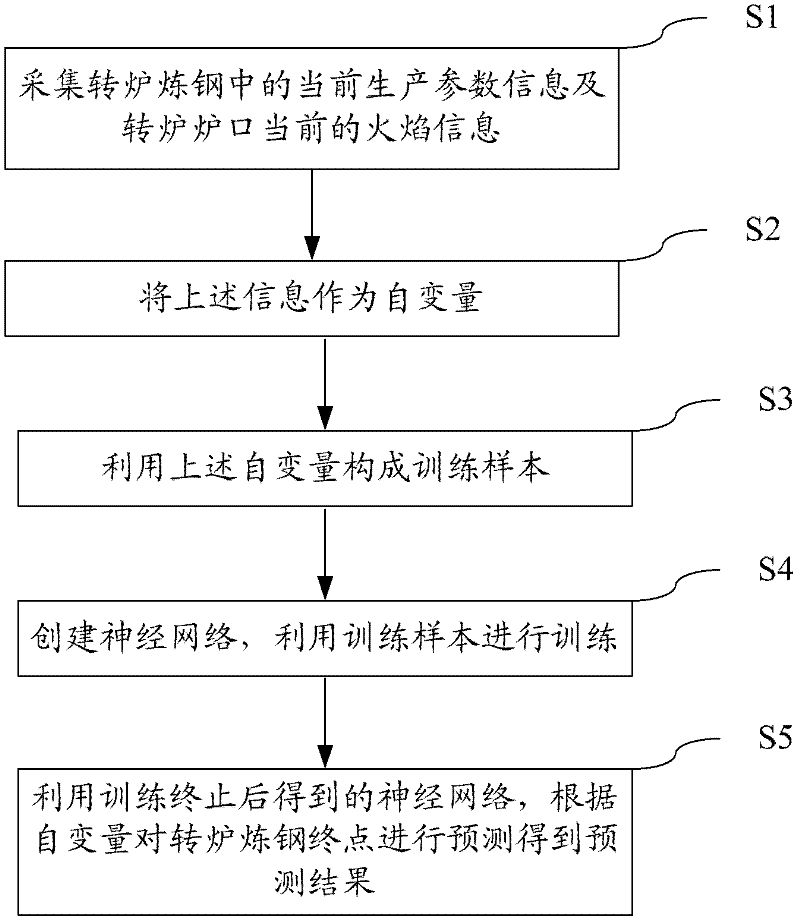

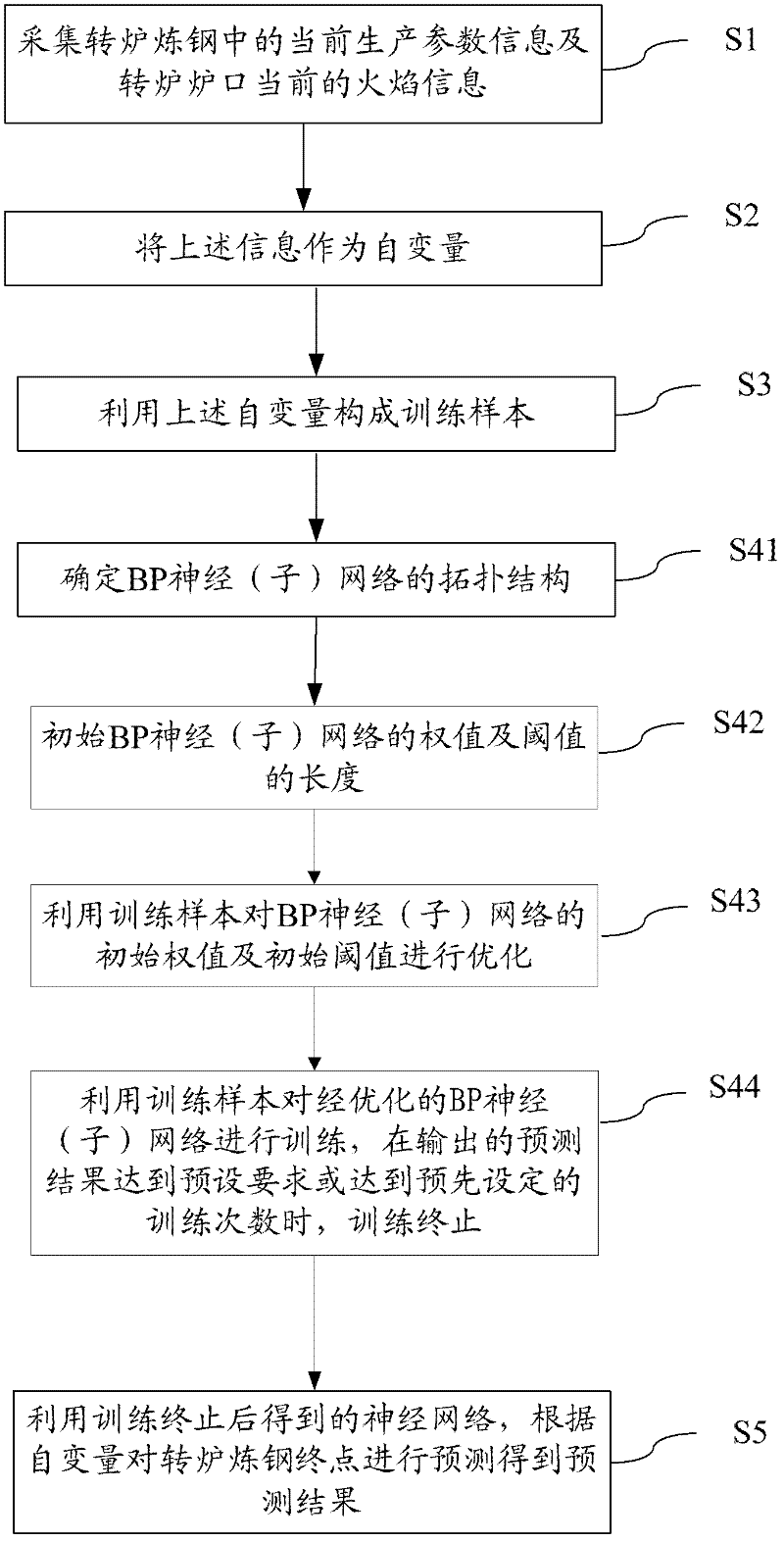

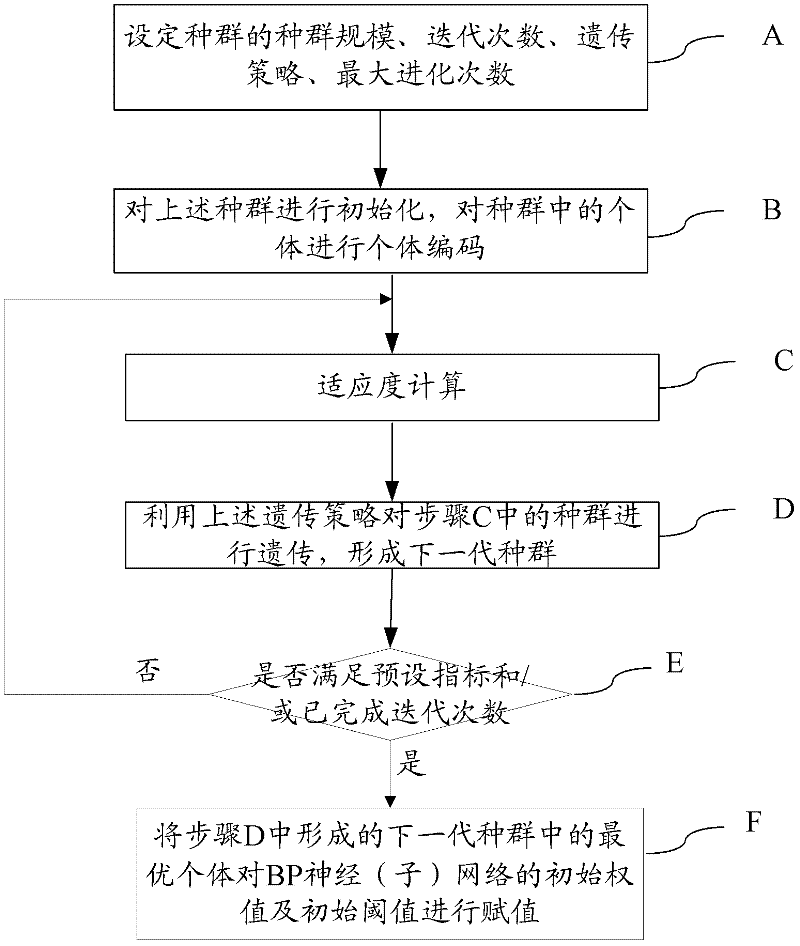

Termination point prediction method and system for converter steelmaking

ActiveCN102392095AIncrease the level of automationIncrease productivityManufacturing convertersIncreasing energy efficiencySteelmakingMolten steel

The embodiment of the present invention discloses a termination point prediction method and a system for converter steelmaking. The method includes the following steps: collecting current production parameter information in converter steelmaking and current flame information at the mouth of a converter as independent variables; creating a neural network, and training the created neural network with a training sample made up of the independent variables; and predicting the termination point of converter steelmaking by the neural network obtained after the training according to the independent variables, so as to obtain a termination point time prediction result, a carbon content prediction result and a molten steel temperature prediction result. Therefore, with the technical scheme provided by the embodiment of the present invention, by obtaining the production information of the converter and the flame information at the mouth of the converter in real time, the steelmaking terminationpoint time, the molten steel temperature and the carbon content can be analyzed precisely online in real time, so as to precisely control the process to improve the automation and the production efficiency of converter steelmaking and lower the cost.

Owner:HUNAN RAMON SCI & TECH

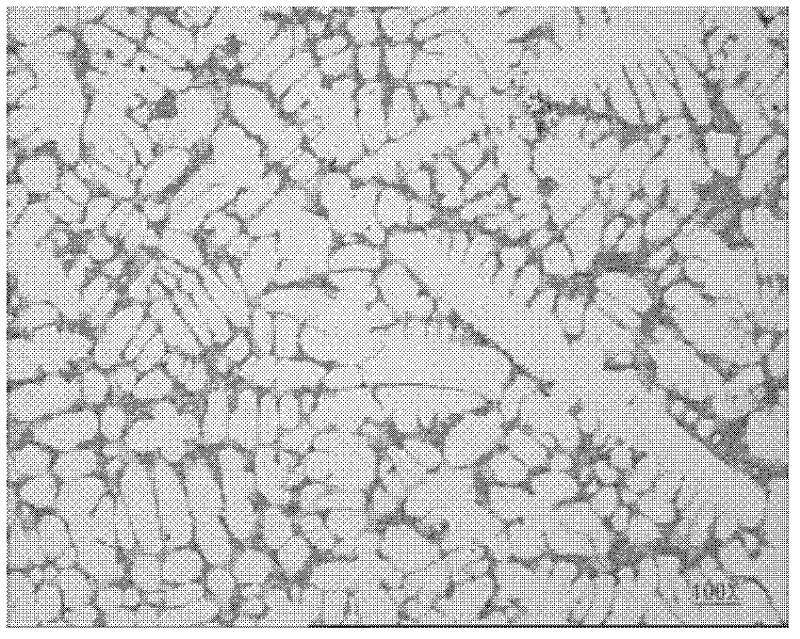

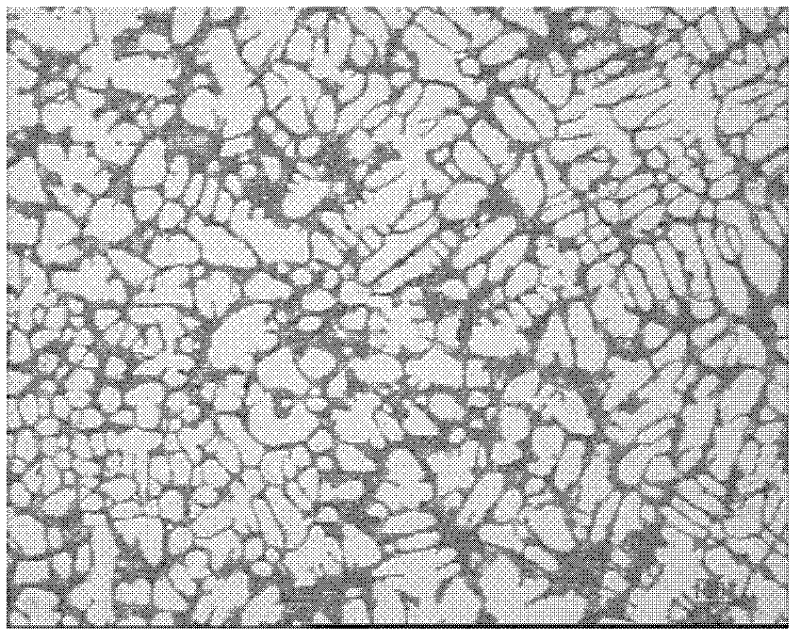

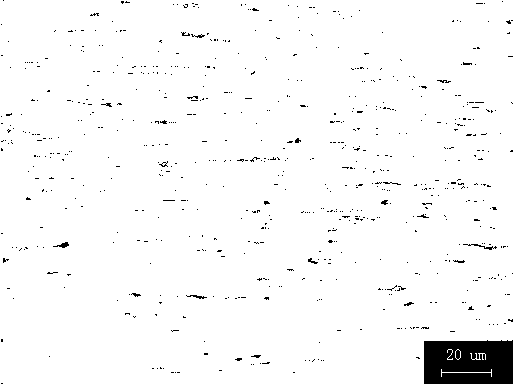

Novel manufacturing process of phi 300 mm-phi 700 mm high-carbon high-chromium cold-working die steel forged round steel

ActiveCN102418042AImprove cleanlinessImprove segregationMetal-working apparatusProcess efficiency improvementCarbideHot working

The invention discloses a manufacturing process of phi 300 mm-phi 700 mm high-carbon high-chromium cold-working die steel forged round steel, and the purpose is to solve the problems of quite severe ununiformity of large-section forging material eutectic carbides and the increase of defects of internal cracks and surface cracks during the forging process caused by segregation deterioration of cast structure carbides of large steel ingots. By using steel-making technical measures such as LF refining, VD degassing, aluminium wire feeding, and the like, the invention improves the molten steel cleanliness, the control of electroslag remelting output power, and the homogenization treatment before forging, and improves the segregation of eutectic carbides and the hot-working plasticity of steel; by controlling the forging heating numbers and various deformation amounts of large high-carbon high-chromium steel ingots, large granular carbides are crushed; the ununiformity of eutectic carbides is improved; crack defects during the forging process are prevented; and the produced high-carbon high-chromium steel large-section forging materials has ununiformity of eutectic carbides of up to grade 4-grade 6; the results of ultrasonic inspection are at good levels of E / e grade, D / d grade.

Owner:FUSHUN SPECIAL STEEL SHARES

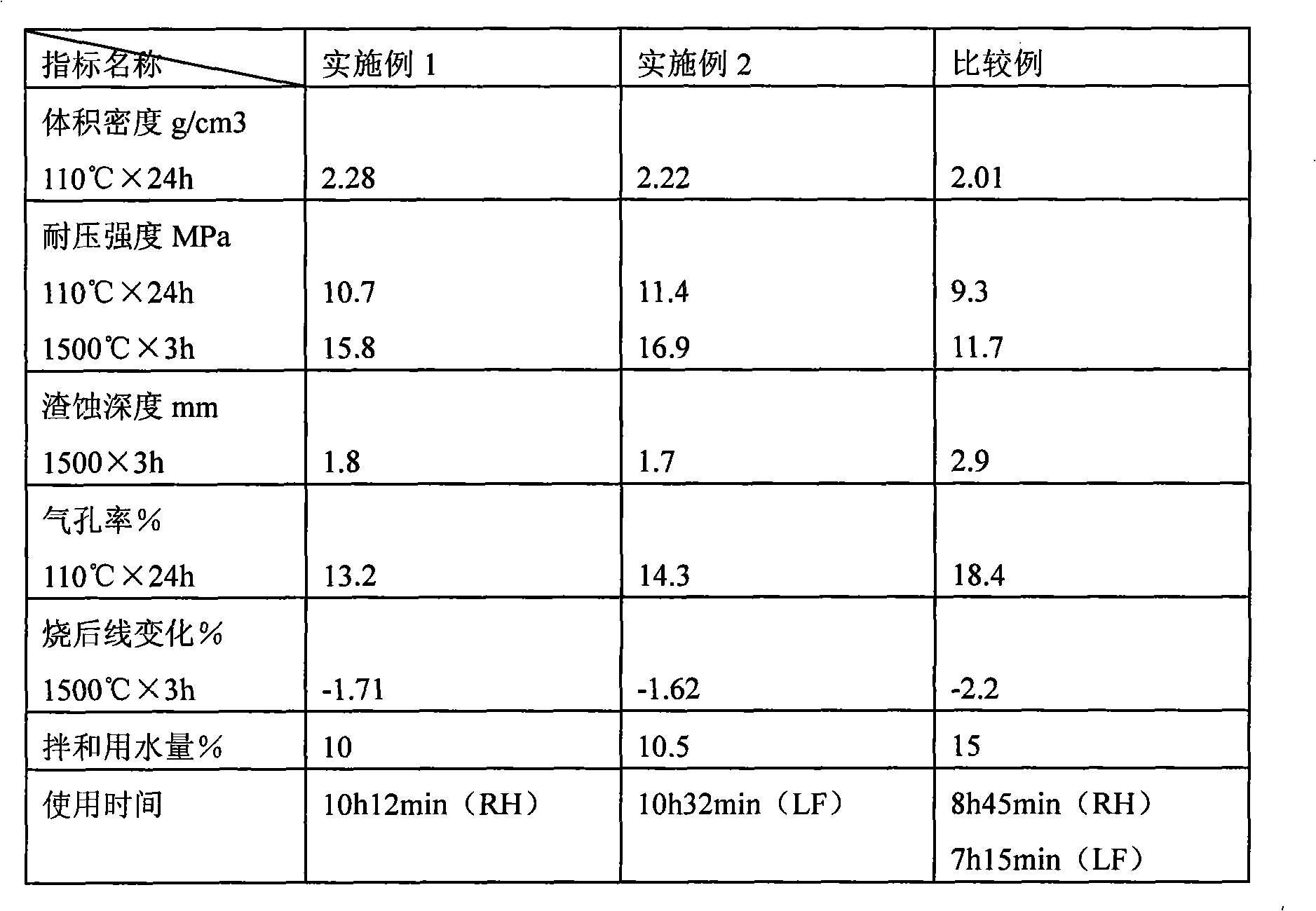

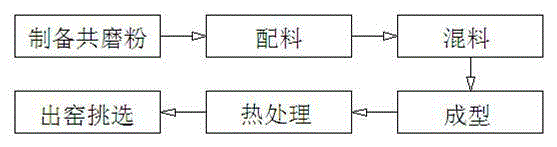

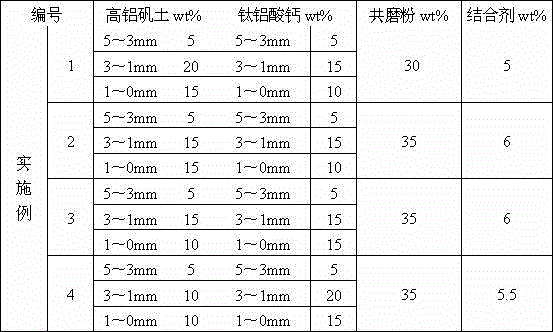

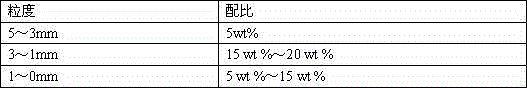

Titanium-containing calcium aluminate-high alumina bauxite modified refractory material, as well as preparation method and application thereof

ActiveCN104609872AHigh melting pointSmall coefficient of thermal expansionMelt-holding vesselsSteelmakingAluminate

The invention discloses a titanium-containing calcium aluminate-high alumina bauxite modified refractory material, as well as a preparation method and application thereof, belongs to the field of refractory materials, and adopts the technical scheme that the modified refractory material comprises 25 to 40 wt% of high alumina bauxite, 25 to 40 wt% of titanium-containing calcium aluminate, and 30 to 35 wt% of co-ground powder, and a phenolic resin binding agent which accounts for 3 to 6 wt% of the total mass of the raw materials is additionally added, wherein the co-ground powder is formed by uniformly mixing titanium-containing calcium aluminate fine powder, alpha-Al2O3 micro-powder, graphite powder, silicon carbide fine powder, graphite powder, silicon carbide fine powder, metal aluminum powder and high-temperature asphalt powder; titanium-containing calcium aluminate comprises the following ingredients by ratio: 76.21% of Al2O3, 10.6% of TiO2, 10.16% of CaO, 0.6% of Fe2O3, 1.82% of MgO, and 0.62% of SiO2. According to the invention, titanium-containing calcium aluminate being industrial slag of steelmaking is effectively recycled, so as to greatly reduce the production and manufacture cost; as titanium-containing calcium aluminate is a solid solution of calcium hexaluminate, calcium dialuminate, aluminum titanate, calcium titanate and rutile, the modified refractory material is favorable in thermal shock resistance and heat-insulating property.

Owner:MAANSHAN LIER KAIYUAN NEW MATERIAL

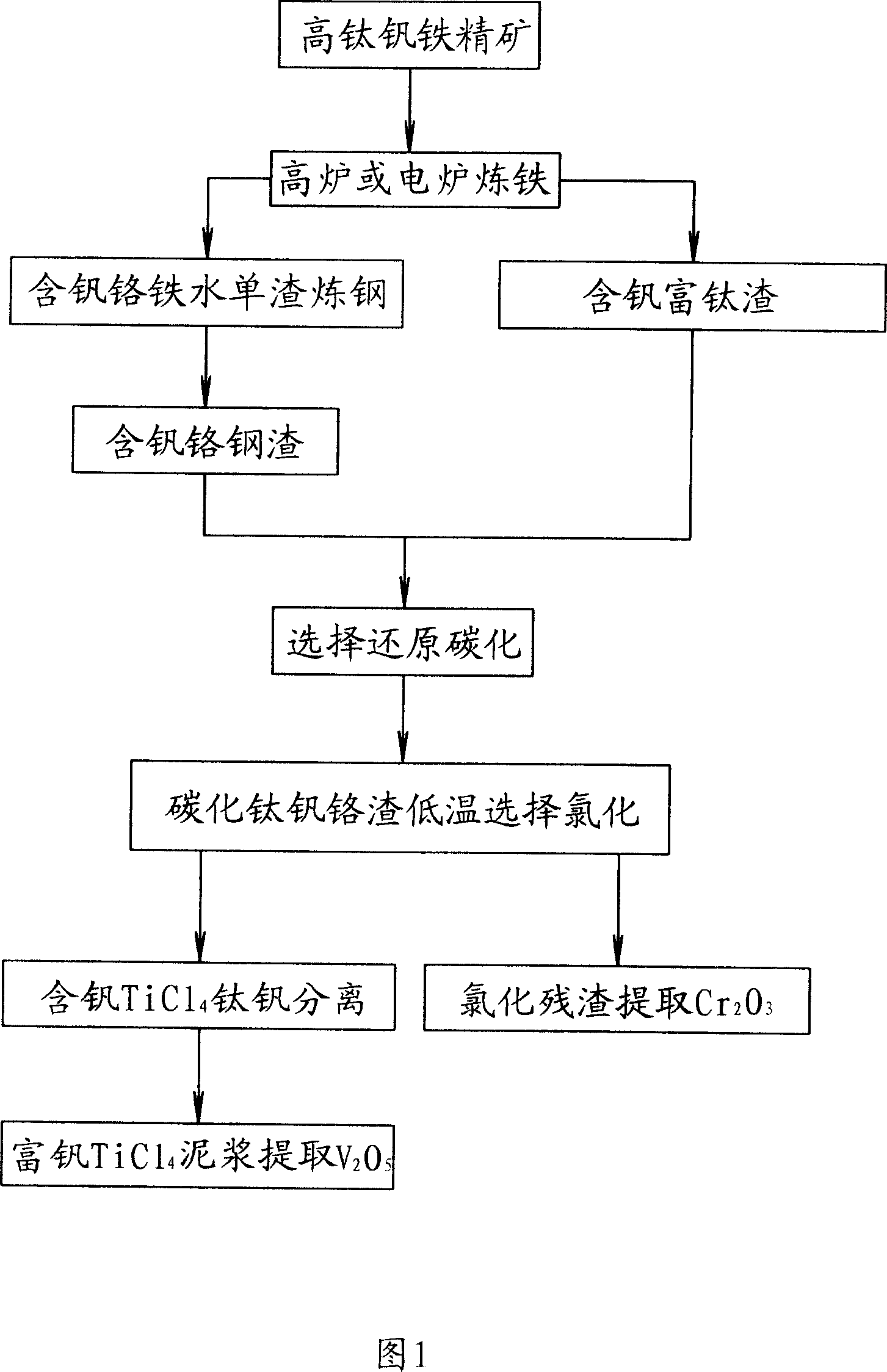

Method for extracting iron titanium vanadium from high-titanium iron concentrate

InactiveCN101113495AHigh yieldFew kindsBlast furnace detailsManufacturing convertersSteelmakingCarbonization

The invention discloses an iron-titanium-vanadium extracting method from high-titanium ferrovanadium concentrate ore. By adopting the method to make steel, fine TiCI4 and V2O5 have the advantages that: technological processes are simple and reasonable; energy consumption is low; yield rate of iron-titanium-vanadium is high and three wastes (waste gas, waste water and waste slag) are fewer. The method comprises the steps: iron smelting: a high furnace or an electric furnace is adopted to smelt iron to make melten iron containing vanadium and chromium and make titanium-enriched slag as byproduct and the rate of vanadium reduced and added into iron is 60-78 percent; single-slag steel-making: melten iron containing vanadium and chromium is put into a converter furnace directly to make steel by the function of oxygen blowing, and steel slag containing vanadium and chromium is obtained as byproduct; carbonized titanium-vanadium-chromium slag with 80-95 percent of carbonization rate is made by smelting reduction carbonization by the electric furnace smelting selection; TiCl4 containing vanadium is made by selective chlorination of carbonized titanium-vanadium-chromium slag in a fluidized bed at low temperature, and residual slag of chlorination containing CrCl3 is byproduct; vanadium titanium separation: VOCI3 is directly reduced by cycloolefine or naphthenic acid to make VOCl2 which can not dissolve in TiCI4, while the VOCI3 can be dissolved in TiCI4. Then the fine TiCI4 is made and the slurry TiCI4 containing rich vanadium is also made as byproduct; V2O5 is extracted from the rich vanadium containing slurry TiCI4.

Owner:张荣禄

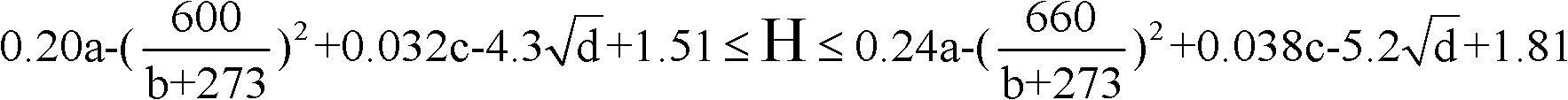

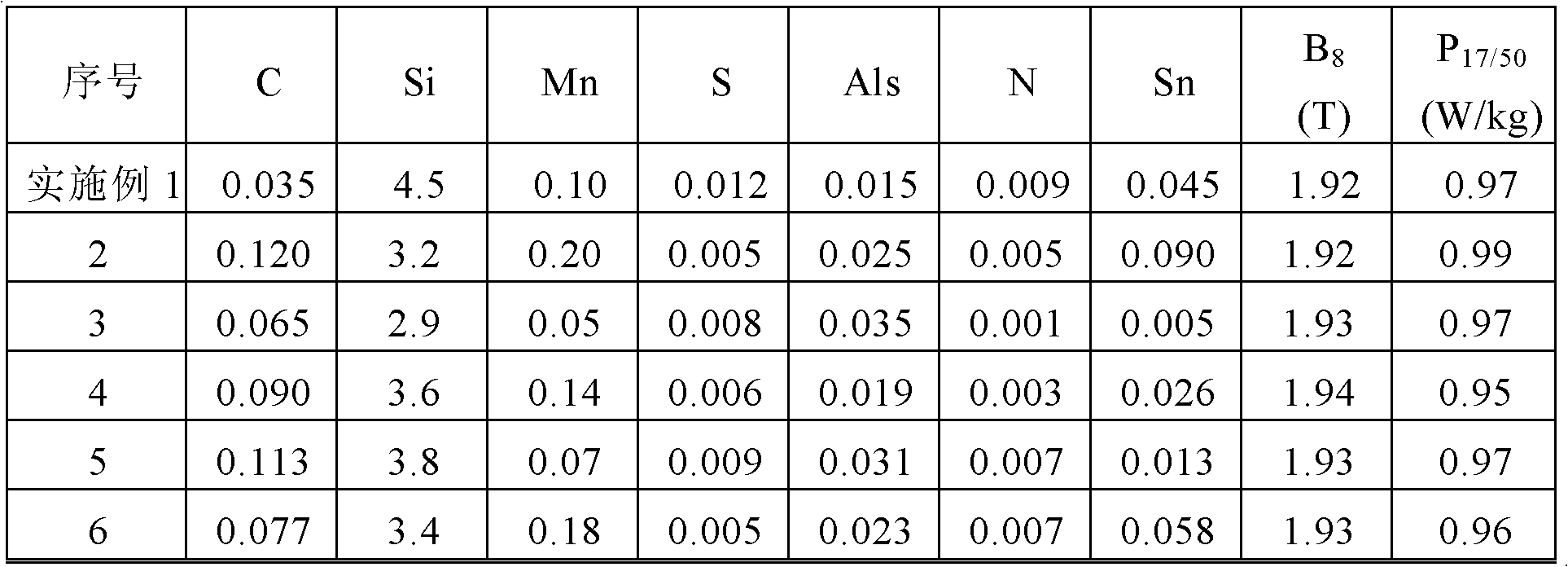

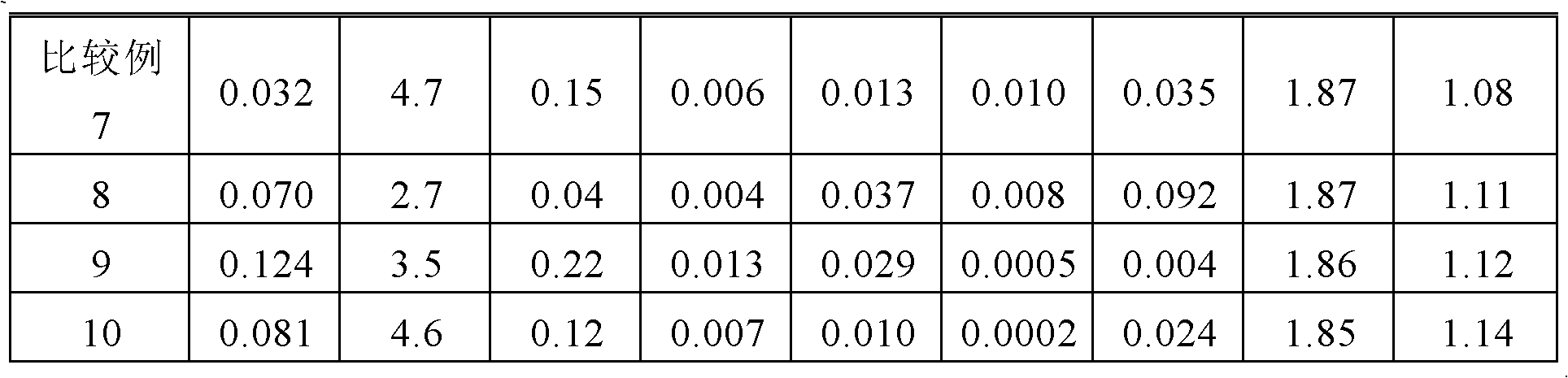

Method for producing high magnetic induction orientation silicon steel with excellent magnetic performance and good bottom layer

The invention relates to a method for producing high magnetic induction orientation silicon steel with excellent magnetic performance and a good bottom layer. The method comprises the following steps: (1) smelting, casting, making steel by using a converter or an electric furnace, and performing secondary refining and continuous casting on molten steel to obtain a plate blank; (2) performing hot rolling; (3) normalizing: performing two-section normalization, and then cooling; (4) performing cold rolling: rolling the normalized plate into the plate with the thickness of the finished product plate by a primary cold rolling method; (5) performing decarburizing annealing and nitriding annealing; (6) coating MgO coating and annealing at high temperature; and (7) coating insulating coating on the surface of a high-temperature annealing plate and performing heat drawing and flat annealing to obtain the high magnetic induction orientation silicon steel with excellent magnetic performance. According to the method, the problem of nitrogen stability in the plate after nitriding is solved, so that secondary recrystallization in the high-temperature annealing process is perfected and the high magnetic induction orientation silicon steel with excellent magnetic performance (B8 is more than or equal to 1.90 T and P17 / 50 is less than or equal to 1.00 w / kg), with the good bottom layer and without the defects of crystal exposure and frost descend is obtained finally.

Owner:BAOSHAN IRON & STEEL CO LTD

Hard tinned sheet steel and its production method

The invention relates to a hard tinned sheet steel produced from low carbon aluminium killed steel so as to solve the technical problems of easy appearance of local edge waves during current pickling rolling production of tinned sheet steel, high incidence of surface iron oxide scale during continuous annealing production, high yield ratio of tin plates, undesirable stamping processing and the like. The hard tinned sheet steel and its raw sheet comprise the following chemical components (by weight): 0.05-0.07% of C, less than or equal to 0.1% of Si, 0.20-0.30% of Mn, less than or equal to 0.020% of P, less than or equal to 0.020% of S, 0.010-0.060% of Alt, less than or equal to 0.0060% of N, and the balance Fe and some inevitable impurity elements. The production method of the hard tinned sheet steel includes: steelmaking, continuous casting, hot rolling, combined pickling rolling, continuous annealing, double-stand tempering, and electrotinning. The hard tinned sheet steel produced in the invention has the advantages of small production control difficulty, excellent appearance quality, thin specification, stable hardness, and good stamping processing performance, etc., can meet the use requirements of high-speed canning, and can be widely used as a food cans, beverage cans, aerosol cans and other packaging materials.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Cast steel for bearing parts in mechanical lifting system and its making process

The present invention relates to one kind of cast steel for bearing parts in mechanical lifting system and its making process. The cast steel of Cr-Ni-Mo line consists of C 0.15-0.30 wt%, Mn 0.60-1.10 wt%, Si 0.3-0.8 wt%, Ni 0.4-1.1 wt%, Cr 0.4-1.1 wt%, Mo 0.15-0.40 wt%, S less than 0.025 wt%, P less than 0.025 wt%, and residual elements including Cu, W and V less than 0.60 wt%. The making process of the cast steel includes the following technological steps: making steel in MF furnace or electric arc furnace; casting in sand mold with equivalent circular kiel test rod; normalizing, quenching and tempering of both cast part and test rod in the same furnace; and non-destructive detection of the cast part.

Owner:河南石油勘探局南阳石油机械厂

Method for producing cold-rolling low-carbon aluminum killed steel with uniform through plate mechanical property

ActiveCN102174683AImprove the uniformity of the mechanical properties of the plateThe mechanical properties of the plate are uniformMetal rolling arrangementsSteelmakingAcid washing

The invention discloses a method for producing cold-rolling low-carbon aluminum killed steel with a uniform through plate mechanical property, which belongs to the technical field of steel rolling. The method comprises the following process flows of: performing krypton (KR) desulfuration treatment, performing steelmaking by using the conventional converter, performing composition adjustment system (CAS) / relative humidity (RH) refining treatment, continuously casting, and performing hot loading and hot feeding; performing rough rolling, performing precision rolling, performing laminar cooling, and reeling; unreeling, performing acid washing, performing continuous cold rolling, and reeling; and unreeling, washing, continuously annealing, smoothing, and reeling. The method is characterized in that: the cold-rolling low-carbon aluminum killed steel which has the width of 750 to 1,580 mm, the thickness of 0.25 to 2.5 mm and the uniform through plate property is produced by a 2,250 mm or 1,580 mm continuous hot rolling machine set, a 1,700 mm acid rolling machine set and a 1,700 mm continuous annealing machine set. A trace amount of B is added into the low-carbon aluminum killed steel to appropriately improve finish rolling temperatures and appropriately reduce rolling process parameters such as reeling temperatures, annealing temperatures and the like, so that thick boron nitride (BN) is fully separated out; and thin dispersed aluminum nitride (AlN) is effectively prevented from being separated out, so that the uniformity of the through plate mechanical property of the cold-rolling low-carbon aluminum killed steel is improved.

Owner:SHOUGANG CORPORATION

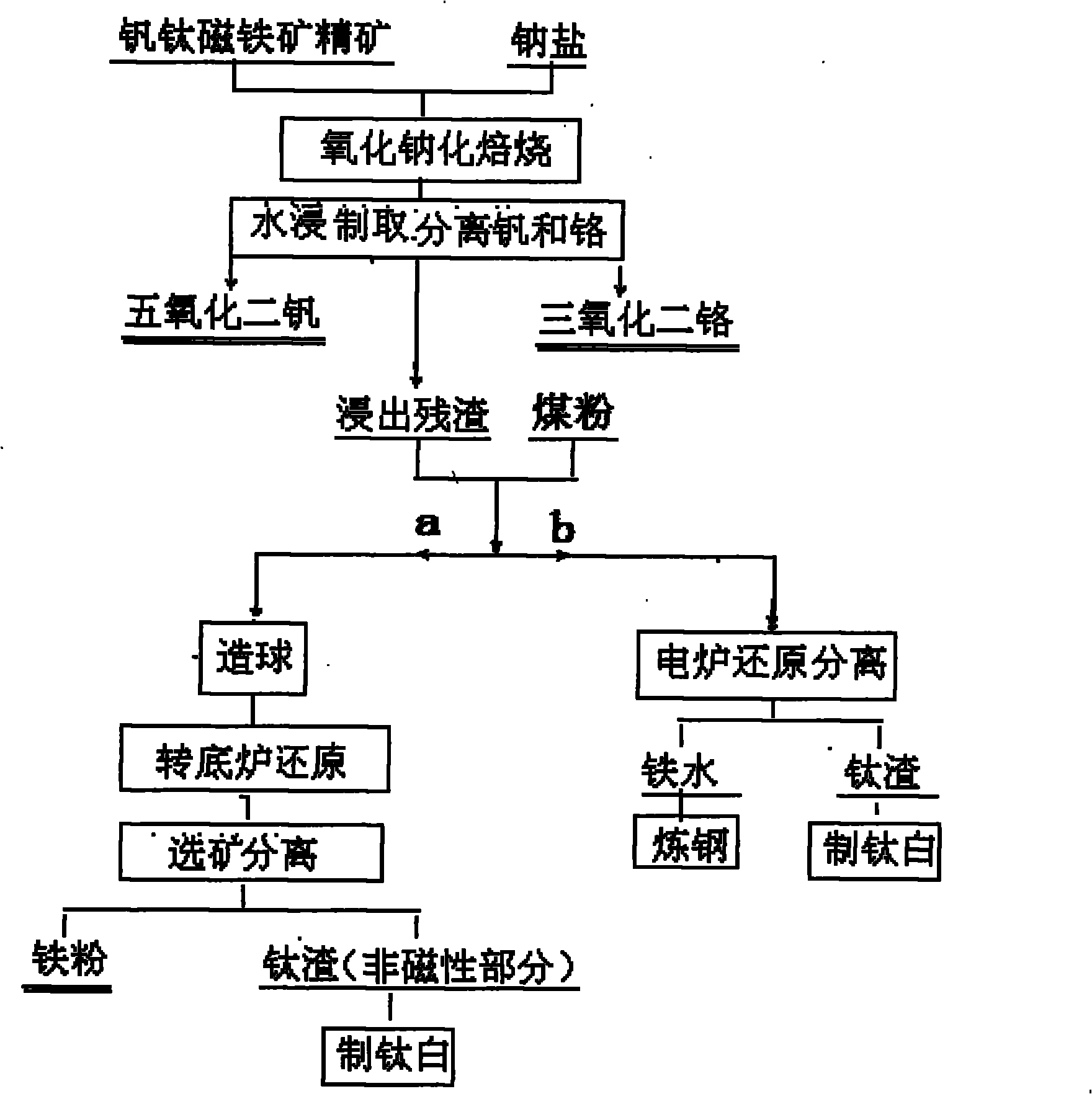

Method for recycling vanadium, chromium, titanium and iron from vanadium-titanium magnetite ore

ActiveCN102061397AHigh recovery rateSimple processProcess efficiency improvementSteelmakingMagnetite

The invention discloses a method for recycling valuable elements from vanadium-titanium magnetite ore, which comprises the following steps of: crushing the ore or concentrate, adding sodium salt, performing oxidizing roasting, converting vanadium and chromium into water-soluble sodium vanadate and sodium chromate, performing water leaching in solution, and separating the vanadium and chromium from the solution to obtain vanadium pentoxide and chromium sesquioxide products; and adding coal dust into the leached residue for pelletizing, reducing in a rotary hearth furnace, magnetically separating iron and titanium, using the obtained magnetic iron powder as a raw material for powder metallurgy or steelmaking, and using a nonmagnetic product containing more than 50 percent of TiO2 as a raw material for extracting the titanium; or reducing iron from the leached residue in an electric furnace, using the obtained molten iron as a raw material for steelmaking and using electric furnace slag containing more than 50 percent of TiO2 as a raw material for extracting the titanium. The method is short in process flow and economical; and the recovery rate of the vanadium, chromium, titanium and iron is high.

Owner:SICHUAN LOMON MINING & METALLURGY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com