Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

337 results about "Castability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Castability is the ease of forming a quality casting. A very castable part design is easily developed, incurs minimal tooling costs, requires minimal energy, and has few rejections. Castability can refer to a part design or a material property.

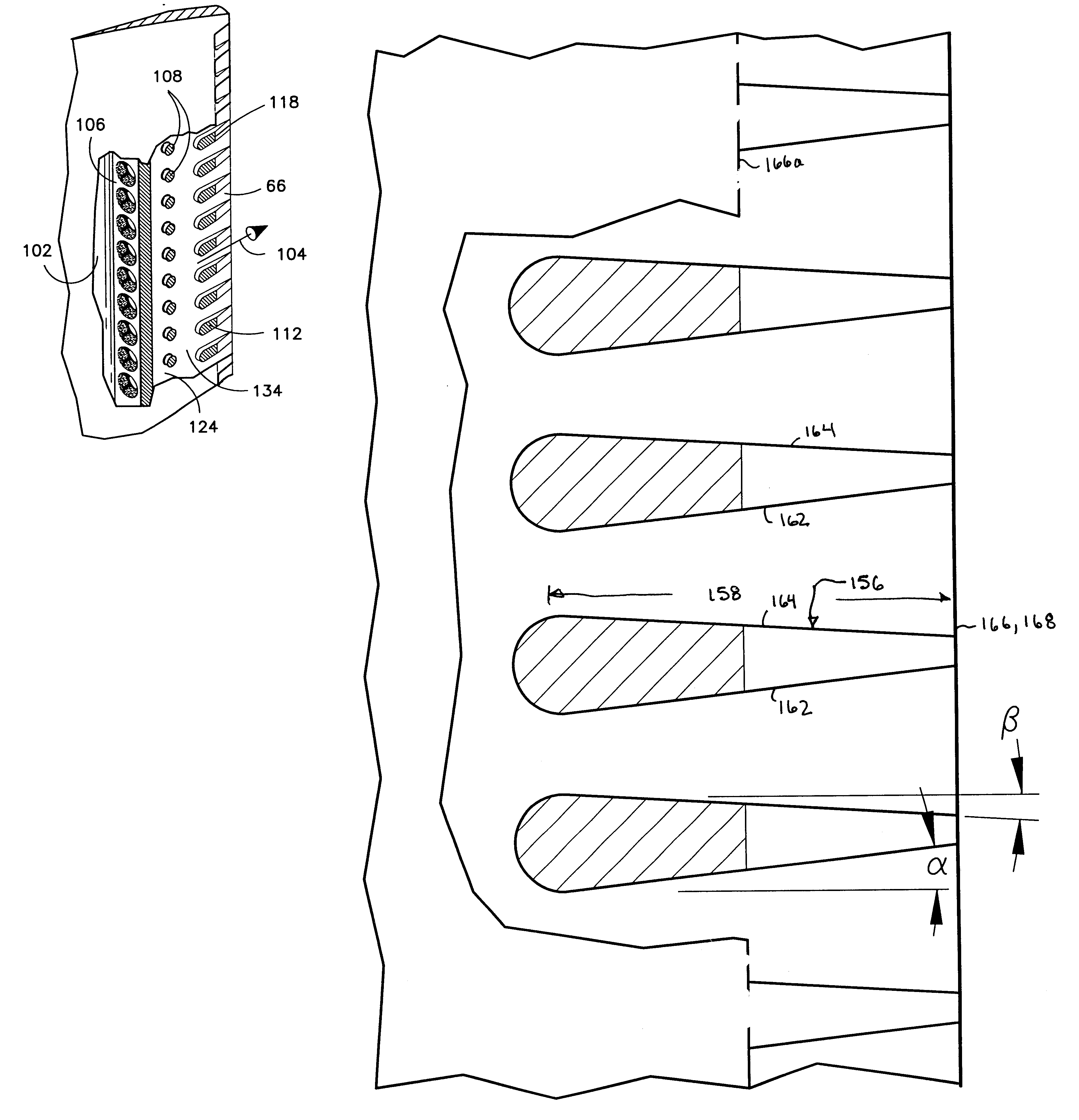

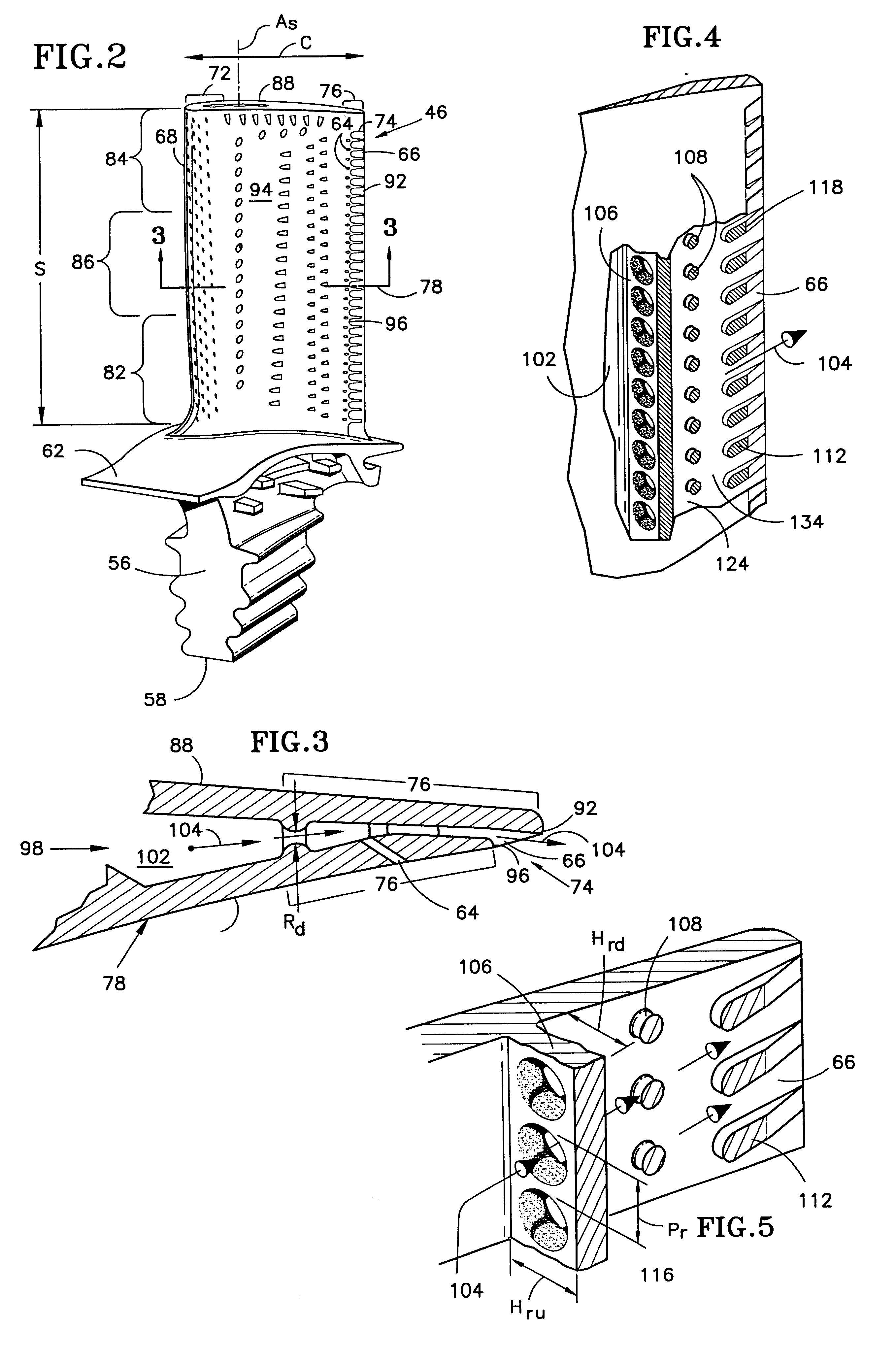

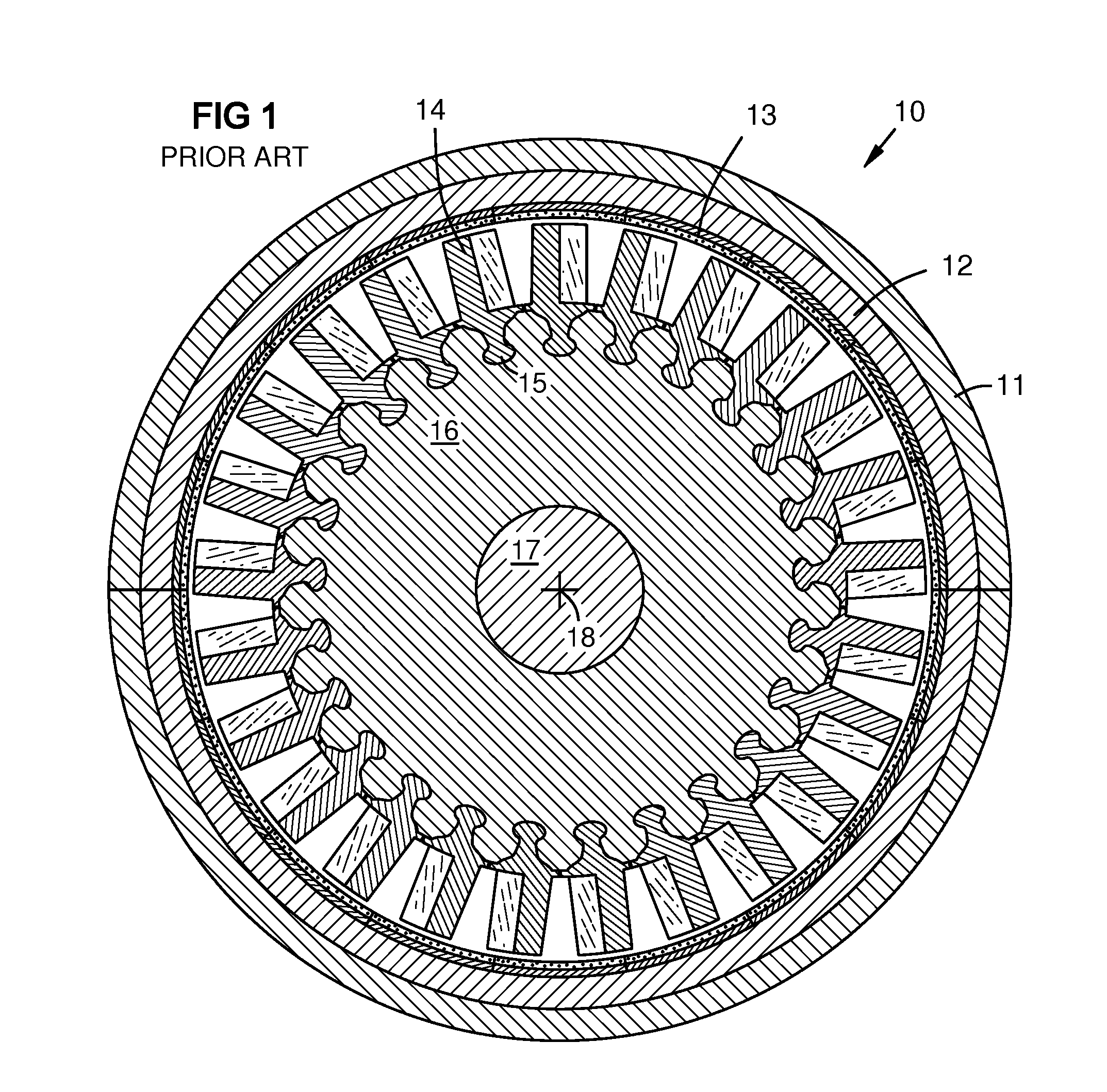

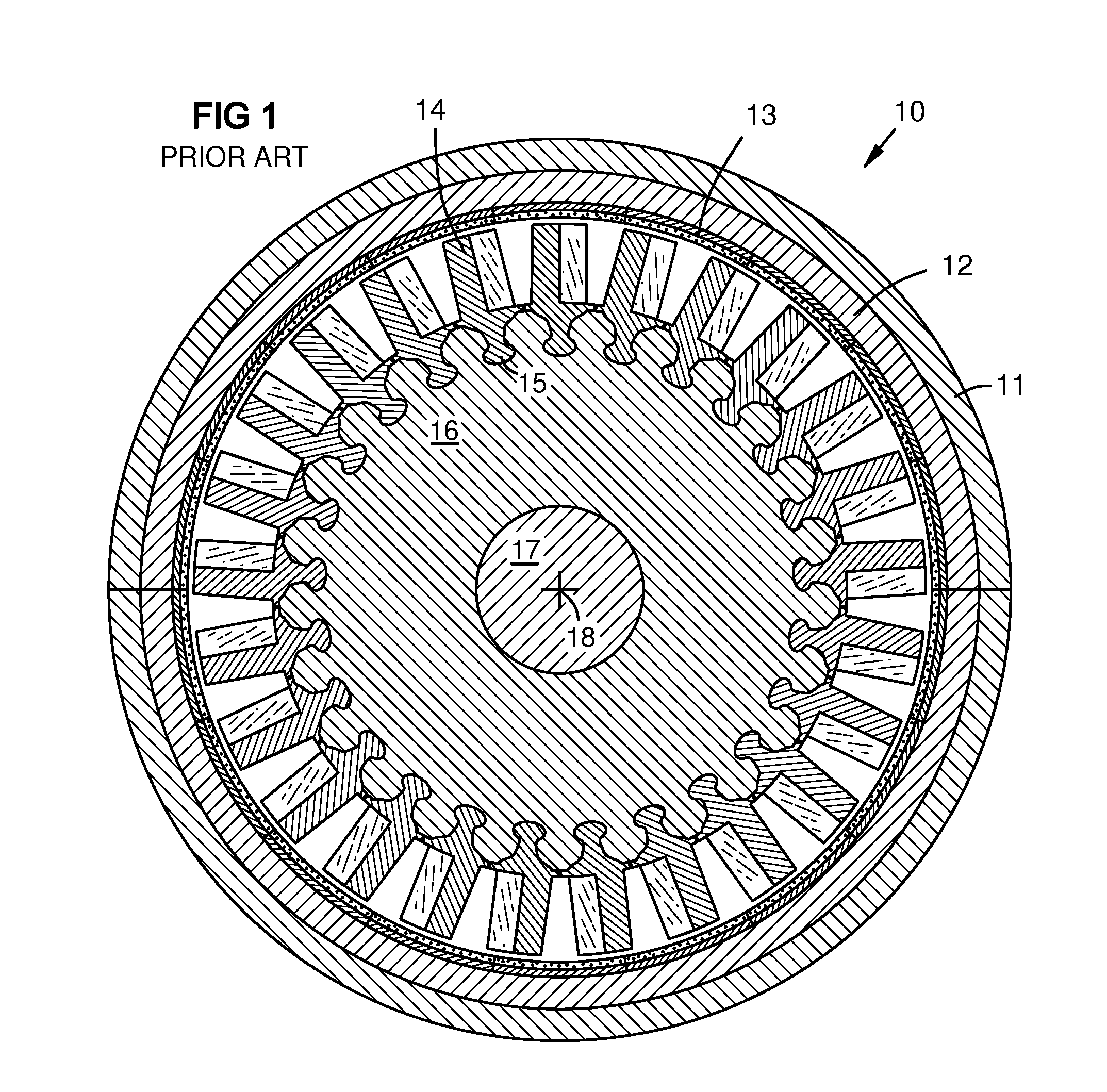

Coolable airfoil structure

InactiveUS6234754B1Durability and thermomechanical performanceIncreased durabilityPump componentsEngine fuctionsCastabilityInternal heat transfer

A coolable airfoil structure having internal heat transfer features through which cooling air is flowed under operative conditions is disclosed. Various construction details and features are developed which affect the castability and core strength during manufacture and strength and cooling effectiveness of the airfoil after manufacture. In one particular embodiment, the airfoil has a plurality of heat transfer members disposed in the rearmost section of the trailing edge region which comprises a single impingement rib, a single row of pedestals and a single row of chordwisely extending flow dividers.

Owner:UNITED TECH CORP

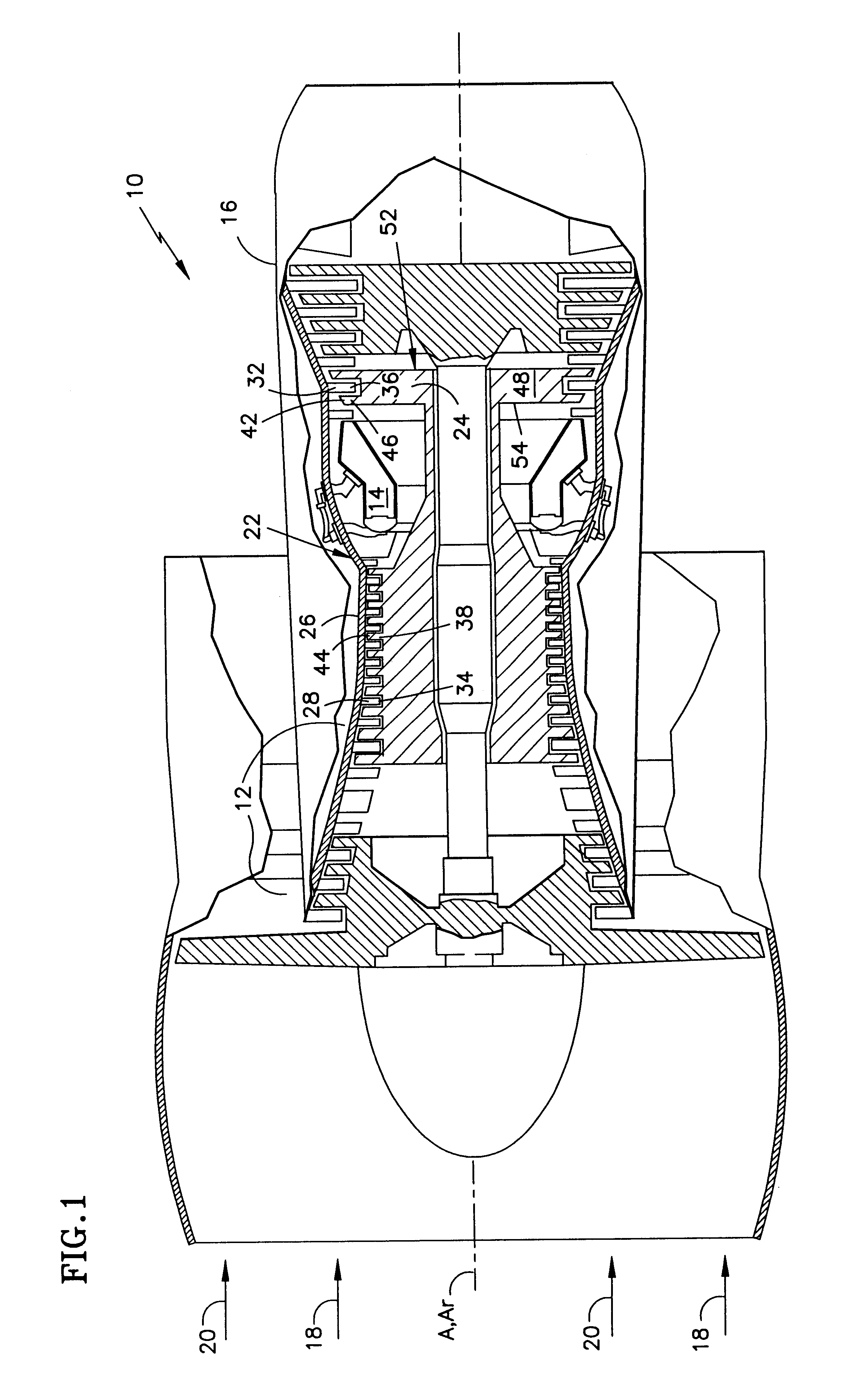

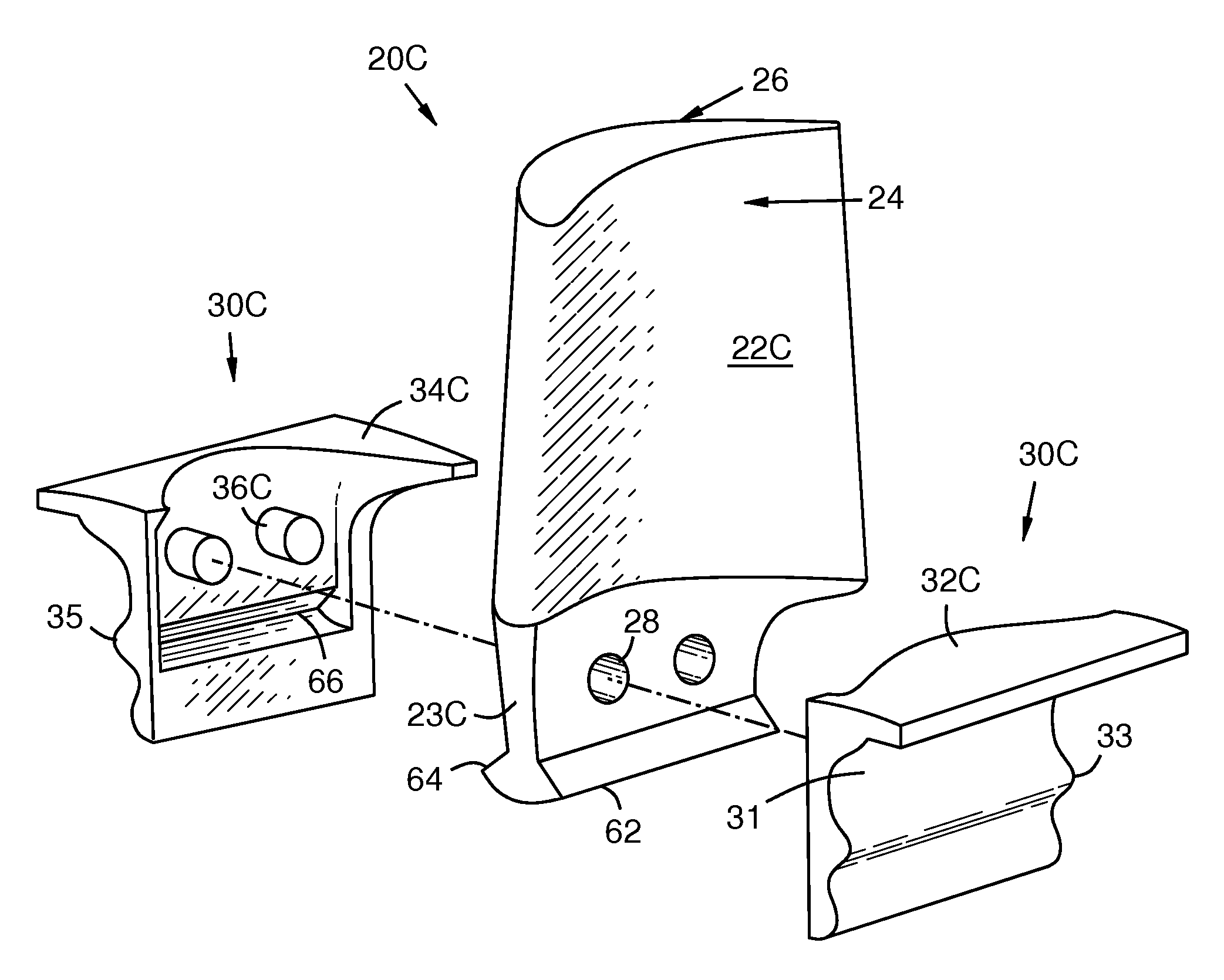

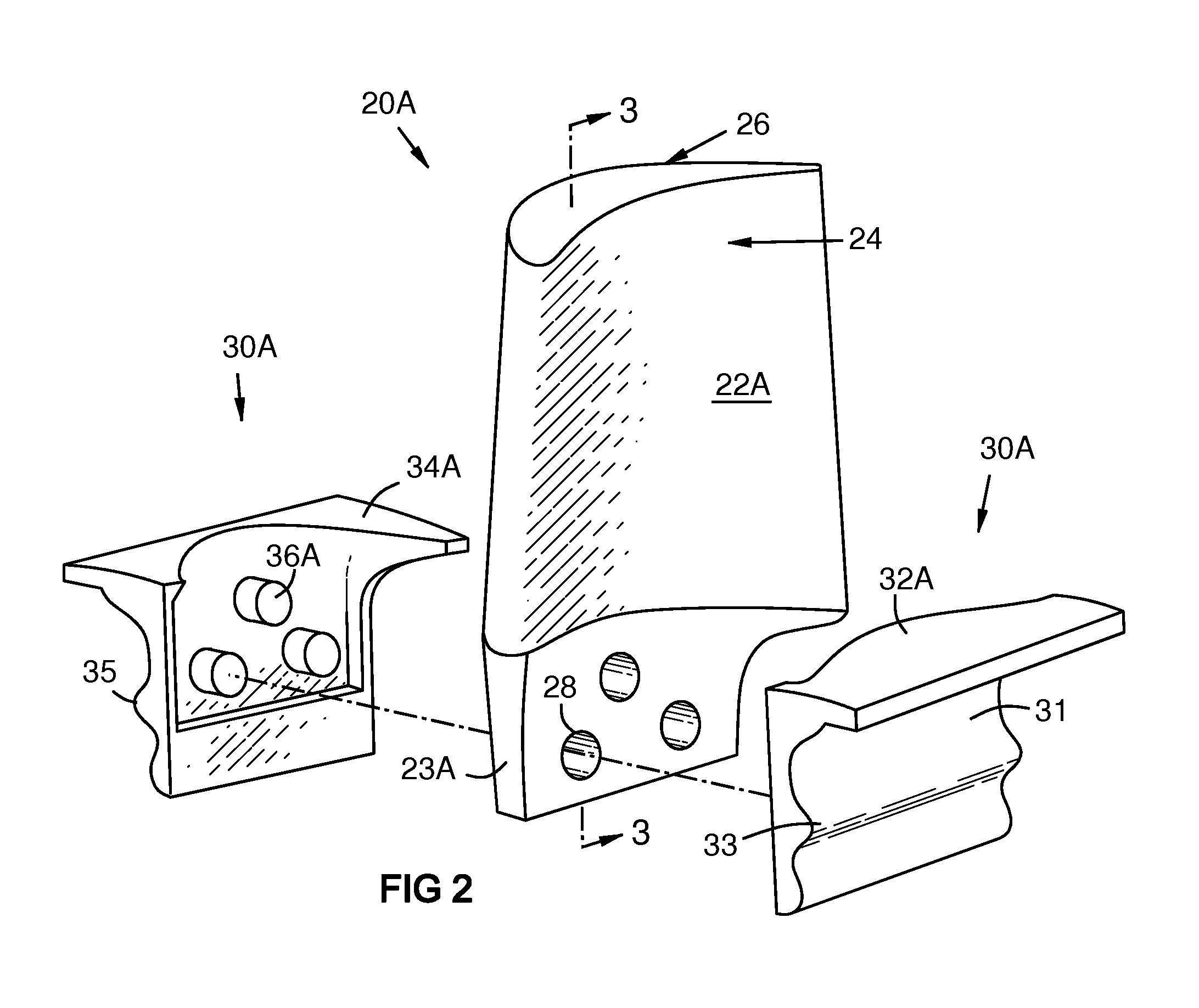

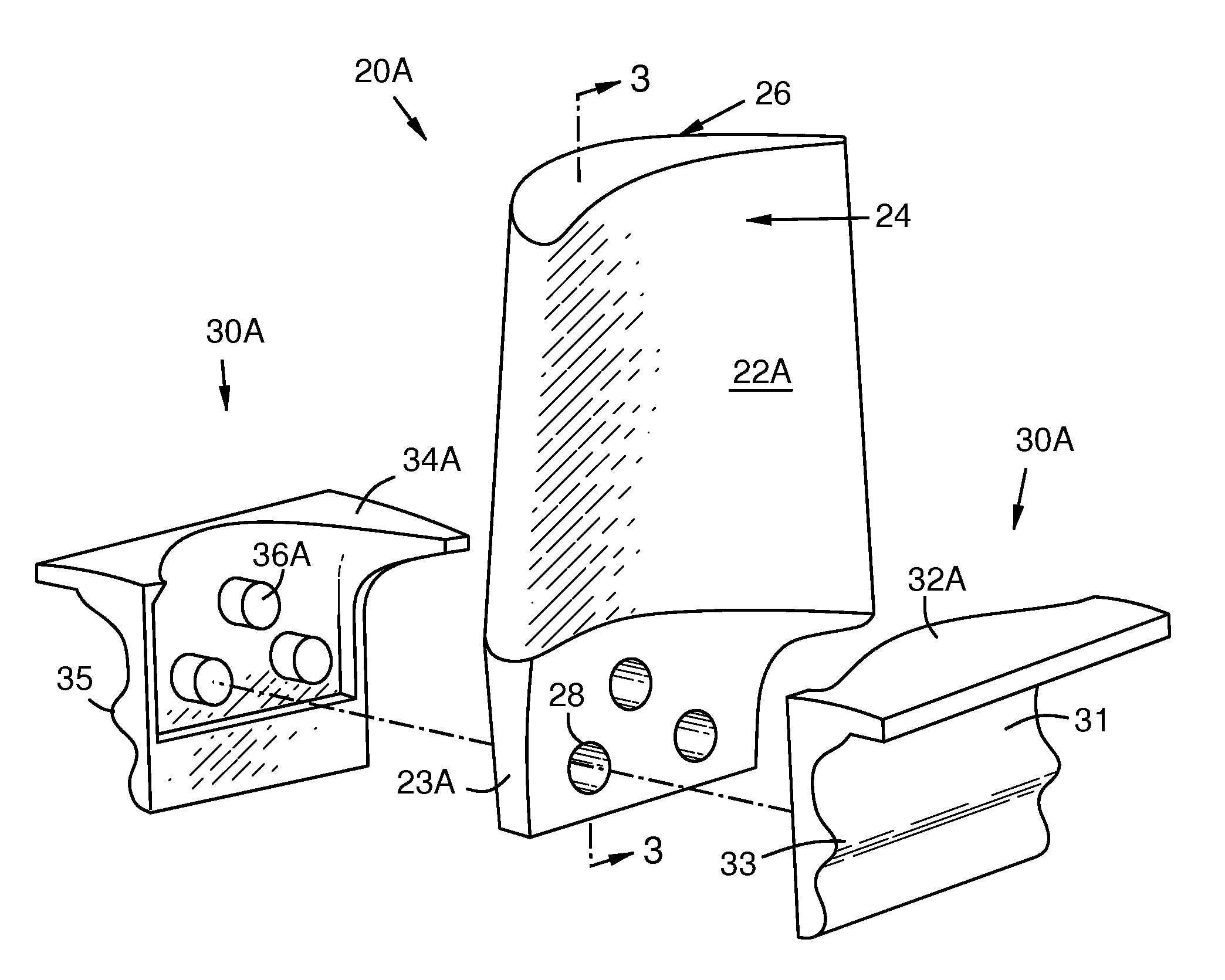

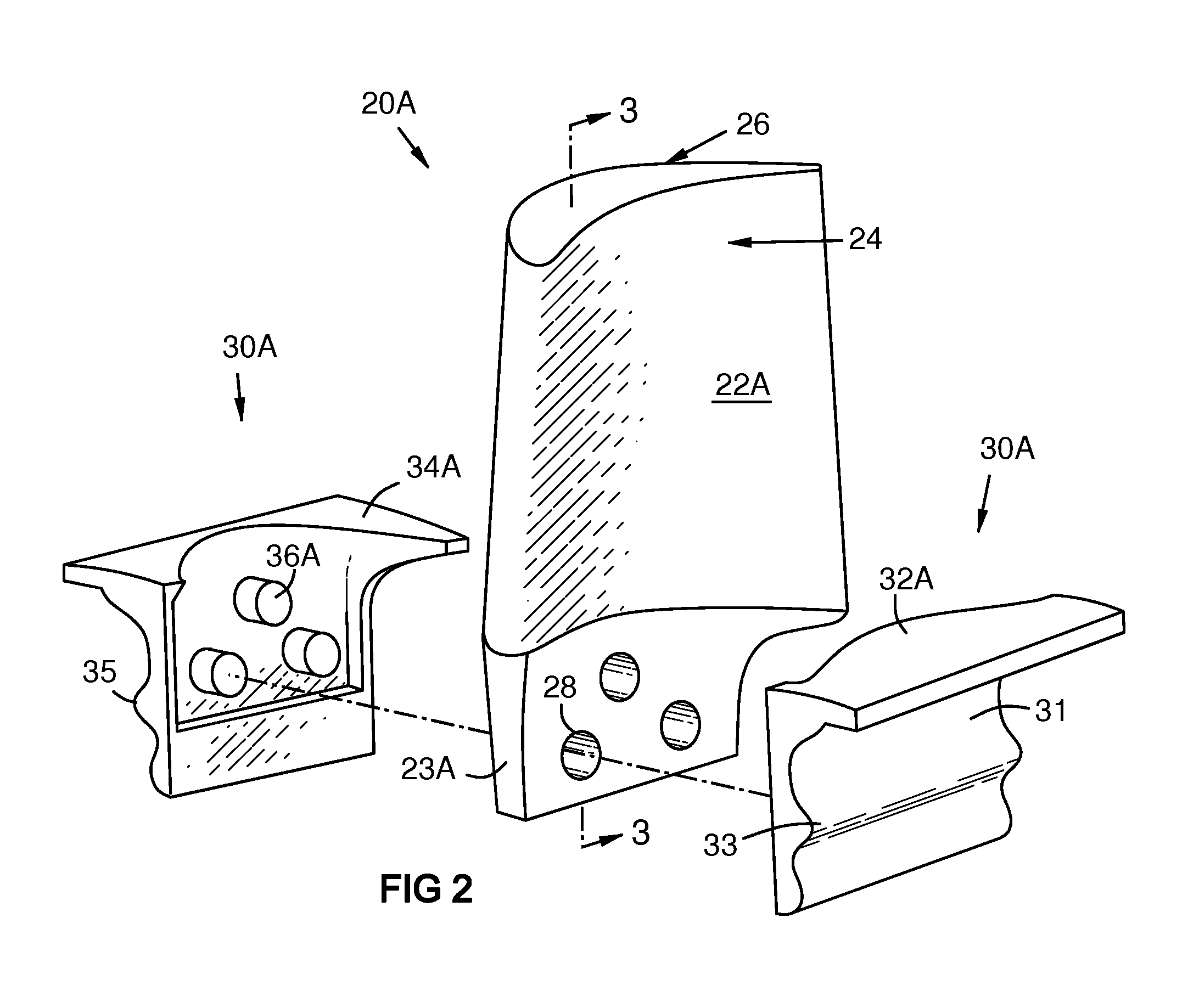

Turbine Engine Airfoil and Platform Assembly

A turbine airfoil (22A) is formed by a first process using a first material. A platform (30A) is formed by a second process using a second material that may be different from the first material. The platform (30A) is assembled around a shank (23A) of the airfoil. One or more pins (36A) extend from the platform into holes (28) in the shank (23A). The platform may be formed in two portions (32A, 34A) and placed around the shank, enclosing it. The two platform portions may be bonded to each other. Alternately, the platform (30B) may be cast around the shank (23B) using a metal alloy with better castability than that of the blade and shank, which may be specialized for thermal tolerance. The pins (36A-36D) or holes for them do not extend to an outer surface (31) of the platform, avoiding stress concentrations.

Owner:SIEMENS ENERGY INC

Method for producing ultra-low-carbon steel

A method for producing ultra-low-carbon steel belongs to steel-making technology field. The process route is: molten iron desulfuration preprocess -converter smelting -RH vacuum process -slab continuous casting. The iron desulfuration preprocess applies blowing magnesium granules for desulfuration; the converter smelting terminal carbon content and oxygen activity of molten steel; applying slag dam operation when tapping without deoxidation; the ladle furnace proceeds operation of top slag modification and temperature controlling; RH vacuum processing to control the maximum vacuum; applying Al for deoxidation when the decarburization is finished, and alloying if the deoxidation is finished and assuring the deep vacuum processing time after the deoxidation; calming the molten steel when the vacuum is finished; applying non-carbon covering agent and non-carbon protection slag in the slab casting process; the continuous casting process uses full protection casting, and the casting process controls a reasonable pulling speed according to slab section. The advantages are: the invention resolves problem of nozzle clogging and improves castability of the ultra-low-carbon steel and implements multi-furnace continuous casting, and the components of carbon, phosphorus, sulphur and nitrogen of the completed product conforms smelting request of the ultra-low-carbon steel.

Owner:SHOUGANG CORPORATION

Turbine engine airfoil and platform assembly

A turbine airfoil (22A) is formed by a first process using a first material. A platform (30A) is formed by a second process using a second material that may be different from the first material. The platform (30A) is assembled around a shank (23A) of the airfoil. One or more pins (36A) extend from the platform into holes (28) in the shank (23A). The platform may be formed in two portions (32A, 34A) and placed around the shank, enclosing it. The two platform portions may be bonded to each other. Alternately, the platform (30B) may be cast around the shank (23B) using a metal alloy with better castability than that of the blade and shank, which may be specialized for thermal tolerance. The pins (36A-36D) or holes for them do not extend to an outer surface (31) of the platform, avoiding stress concentrations.

Owner:SIEMENS ENERGY INC

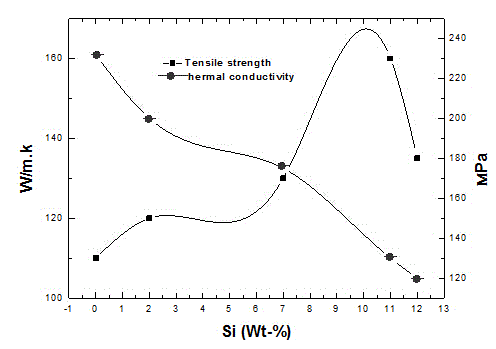

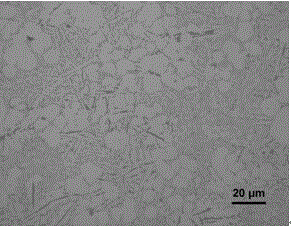

Hypoeutectic aluminum-silicon alloy with excellent thermal conductivity, preparation method and application thereof

ActiveCN104630576AReduce burning lossMeet the needs of casting long-term productionConductive materialMetal/alloy conductorsSilicon alloyCastability

The invention discloses a hypoeutectic aluminum-silicon alloy with excellent thermal conductivity. The alloy comprises the following chemical components: 5-9 wt% of Si, smaller than 0.5 wt% of Mg, smaller than 0.5 wt% of Cu, smaller than 0.7 wt% of Fe, smaller than 0.3 wt% of Mn, inevitable impurity elements and the balance of Al, a single inevitable impurity element is not less than 0.05 wt%, and the total amount of the inevitable impurity elements is lower than 0.25 wt%. The hypoeutectic aluminum-silicon alloy with thermal conductivity of 170-200 W / (m.K) can be obtained in a preparation process by such technical means as controlling the chemical components of the alloy and casting, and thermal treatment and the like. Good castability and mechanical properties of the aluminum-silicon alloy are guaranteed, and excellent thermal conductivity of the aluminum-silicon alloy is guaranteed at the same time.

Owner:JIANGSU ZHONGSE RABILY IND CO LTD

Method for smelting ultra-low-carbon steel

InactiveCN101215618ARealize continuous pouringRealize multi-furnace continuous pouringManufacturing convertersSlagSulfur

The invention relates to a process for smelting ultra-low-carbon steel, which comprises melted iron pretreatment desulfuration, converter smelt, LF furnace refining, RH vacuum process and continuous casting procedure in turn. Converter smelt tapping adopts non deoxidization tapping, steel which is tapped off is refined by LF ladle furnace before carried out melt iron vacuum decarburization processing, wherein refining is mainly used to proceed modifying property processing and further desulfuration and heating for top slag of melted iron, and the melted iron is reinforced with positive oxygen blowing decarburization after shifted into a RH vacuum container. The process can control carbon, nitrogen and sulfur in steel to preset objects which are required, and has excellent castability when a casting machine casted, thereby realizing casting by several furnaces.

Owner:BENGANG STEEL PLATES

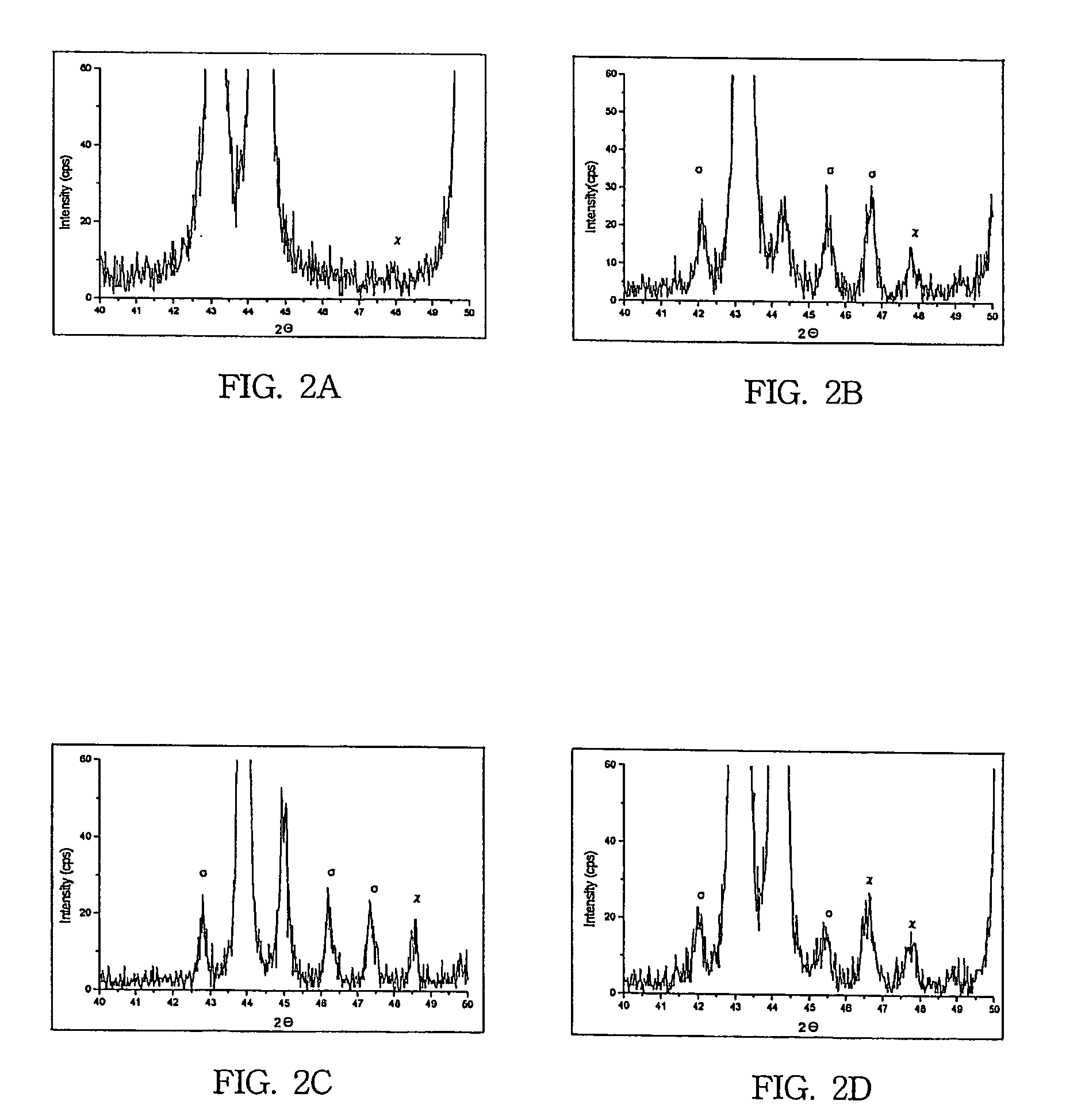

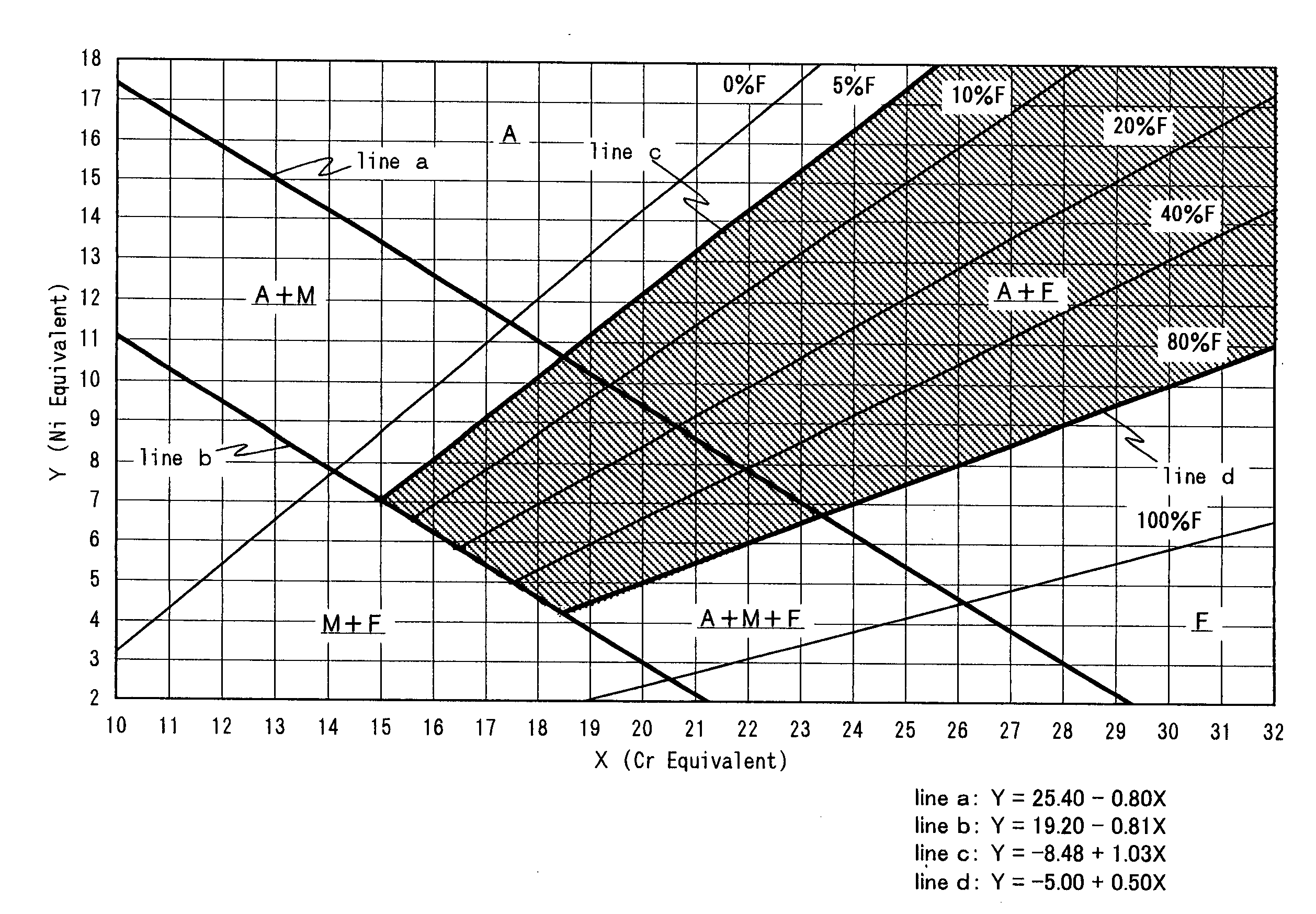

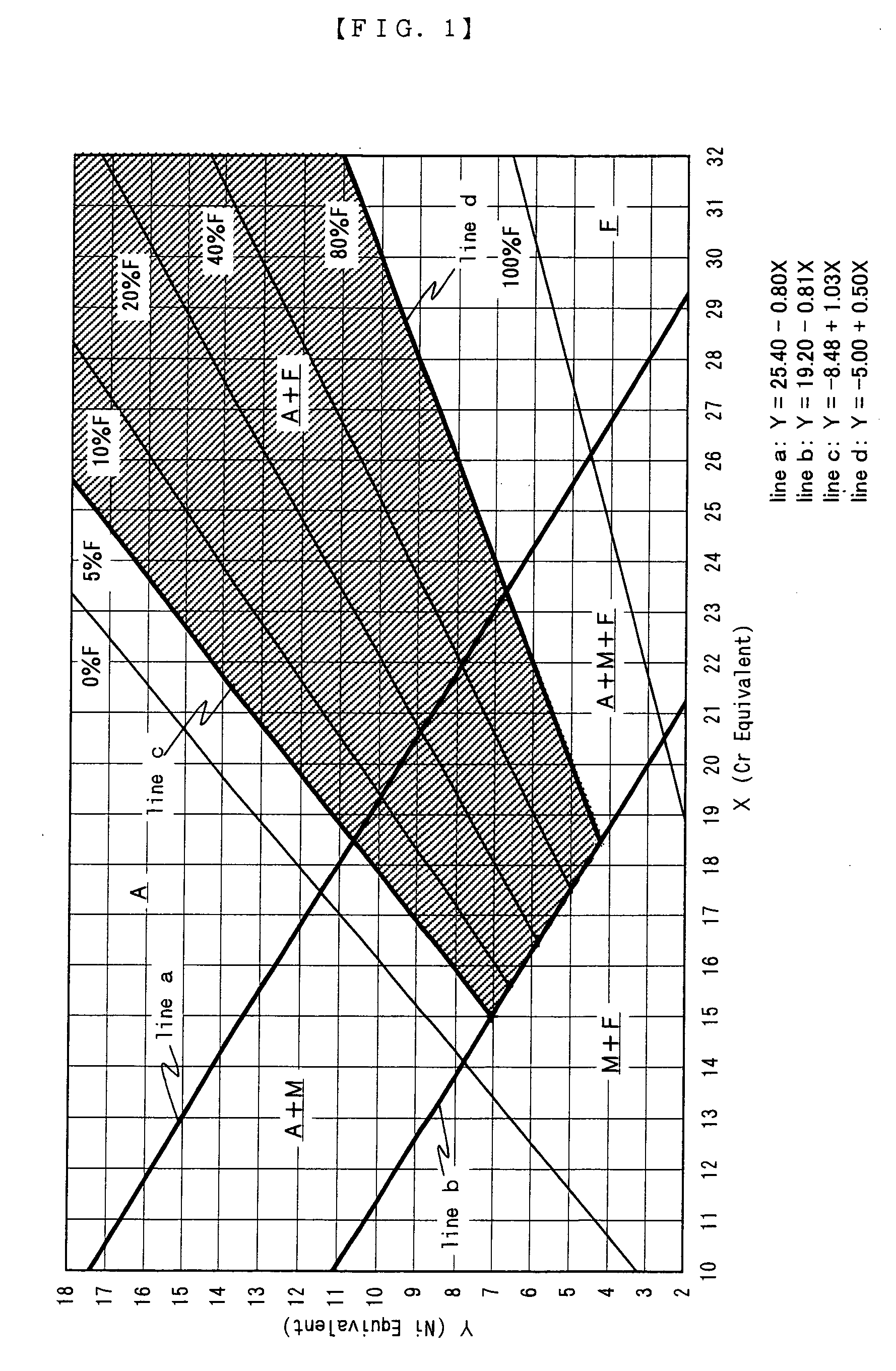

High-grade duplex stainless steel with much suppressed formation of intermetallic phases and having an excellent corrosion resistance, embrittlement resistance castability and hot workability

InactiveUS20050158201A1Eliminate brittlenessImprove corrosion resistanceChemical compositionCastability

Formation of intermetallic phases such as sigma (σ) and khi (χ) shows detrimental effects on the corrosion and mechanical properties of high-grade duplex stainless steel. The present invention provides high-grade duplex stainless steel with much suppressed formation of intermetallic phases, of which the chemical composition consists essentially, on a weight basis, of: Cr: 21.0%˜38.0%, Ni: 3.0%˜12.0%, Mo: 1.5%˜6.5%, W: 6.5% or less, Si: 3.0% or less, Mn: 8.0% or less, N: 0.2%˜0.7%, C: 0.1% or less, at least one element selected from the group consisting of Ba: 0.0001˜0.6% and one or more elements of Mischmetal (MM) and Y: 0.0001˜1.0% in total, and a balance of Fe and incidental impurities. The pitting resistance equivalent has a value of 40≦PREW≦67 defined by the following formula (1): PREW=wt. % Cr+3.3(wt. % Mo+0.5 wt. % W)+30 wt. % N ((1)The present high-grade duplex stainless steel exhibits an excellent corrosion resistance, embrittlement resistance, castability and hot workability.

Owner:YONG SO PARK

Control method for preventing nozzle clogging in casting process of ultra-low carbon-aluminium deoxidized molten steel

InactiveCN103451349AAvoid secondary oxidationImprove pourabilityMelt-holding vesselsManufacturing convertersSteelmakingCastability

The invention relates to a control method for preventing nozzle clogging in a casting process of ultra-low carbon-aluminium deoxidized molten steel, and belongs to the technical field of a steelmaking technology. The technical scheme is that a process path of molten iron desulfurization treatment, converter smelting, converter steel tapping, Rheinstahl Heraeus (RH) vacuum treatment, and continuous casting of a dual-flow slab is adopted to smelt ultra-low carbon steel, so that the castability of the ultra-low carbon-aluminium deoxidized molten steel is improved; the oxygen content of the molten steel of a converter blowing end-point, the carbon content and the temperature of the endpoint are reasonably controlled; a favorable condition is provided for RH vacuum decarburization; pouring is protected in a continuous casting manner; secondary oxidization of the molten steel is prevented by adopting blowing-argon sealing protection of a long-nozzle and a submersed nozzle; secondary oxidization of the molten steel is prevented by using an alkaline covering agent; an occluded foreign substance in the molten steel is well adsorbed; the castability of the ultra-low carbon-aluminium deoxidized molten steel is improved; the targets of no choking of the submersed nozzle and no change of the submersed nozzle in a complete multi-furnace continuous casting process are achieved. Thus, the effect on a casting blank caused by replacement of the submersed nozzle is avoided.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

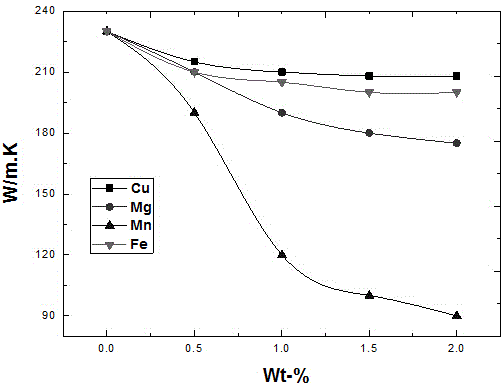

Pressure cast rare earth aluminum alloy with high thermal conductivity and high electrical conductivity and preparing method thereof

The invention discloses pressure cast rare earth aluminum alloy with high thermal conductivity and high electrical conductivity and a preparing method thereof. The aluminum alloy comprises 0.5-2.0 wt% of Si, 0.001-0.05 wt% of Cu, 0.2-0.6 wt% of Fe, 0.001-0.50 wt% of Mn, 0.8-3.0 wt% of Mg, 0.07-0.15 wt% of Zn, 0.001-0.05 wt% of B, 0.05-0.20 wt% of La, 0.05-0.2 wt% of Y, 0.05-0.2 wt% of Ce, and the balance Al and less than 0.1 wt% of impurities. The aluminum alloy has high castability, excellent thermal conductivity and electrical conductivity, excellent corrosion resistance and medium mechanical performance and can be applied to 3C mobile phones, notebook computer shells, communication, illumination, rail transit, civil hardware and other fields.

Owner:GAOAN JINLIANGXUAN SCI & TECH

Preparation method for sulfur-containing ultra-low titanium high-standard bearing steel

The invention relates to a production method for a round steel, and specifically to a preparation method for a sulfur-containing ultra-low titanium high-standard bearing steel. The preparation method comprises a converter smelting procedure, an LF secondary refining procedure, a VD furnace vacuum refining procedure, a bloom continuous casting procedure, and a rolling procedure. Converter smelting is carried out by means of a double-slag process with an endpoint [C] controlled within a range of 0.15% to 0.25%; a double-slag stopping operation with a slag stopping ball and a sliding plate is performed during tapping; a slag skimming treatment is carried out before feeding into the LF; an operation of forming white slag as soon as possible is performed; an appropriate slag layer thickness is ensured before VD; VD vacuum breaking is followed by feeding of a Fe-S wire; an operation of remaining steel and slag is performed at the final stage of steel ladle casting; cold charging is adopted for rolling of a casting blank; and heating time is prolonged appropriately. The sulfur-containing ultra-low titanium high-standard bearing steel produced by means of the preparation method is good in machinability, and extremely high in purity, and has a titanium content controlled within 10 ppm and an oxygen content controlled within 6 ppm; moreover, the steel is good in castability, and has more than 10 continuous casting heats without feeding of a si-ba wire; therefore, high production efficiency is achieved.

Owner:ZENITH STEEL GROUP CORP +1

High-grade duplex stainless steel with much suppressed formation of intermetallic phases and having an excellent corrosion resistance , embrittlement resistance, castability and hot workability

Formation of intermetallic phases such as sigma (sigma) and khi (chi) shows detrimental effects on the corrosion and mechanical properties of high-grade duplex stainless steel. The present invention provides high-grade duplex stainless steel with much suppressed formation of intermetallic phases, of which the chemical composition consists essentially, on a weight basis, of : Cr : 21.0% ~ 38.0%, Ni : 3.0% ~ 12.0%, Mo : 1.5% ~.6.5%, W : 6.5% or less, Si : 3.0% or less, Mn : 8.0% or less, N : 0.2% ~ 0.7%, C :0.1% or less, at least one element selected from the group consisting of Ba : 0.0001 ~ 0.6% and one or more elements of Mischmetal (MM) and Y : 0.0001 ~ 1.0% in total, and a balance of Fe and incidental impurities. The pitting resistance equivalent has a value of 40 <= PREW<= 67 defined by the following formula (1) : PREW = wt.%Cr + 3.3(wt.%Mo + 0.5wt.%W) + 30wt.%N(1) The present high-grade duplex stainless steel exhibits an excellent corrosion resistance, embrittlement resistance, castability and hot workability.

Owner:朴庸秀

High-strength alloy and preparation method thereof

The invention provides a high-strength alloy and a preparation method thereof. Taking the total amount of the alloy as a standard, the alloy contains the following elements in weight percent: 21-40% of Mn, 3.1-15% of Al, 45-75.9% of Cu, and 5-20% of Ni. The alloy disclosed by the invention is high in strength and low in cost, has excellent corrosion resistance and good castability, cannot easy generate crack during casting, and is high in mechanical strength, good in toughness and good in corrosion resistance.

Owner:BYD CO LTD

Die-casting aluminium alloy

InactiveCN1607261AMake up for the disadvantage of about 45% higher densitySave electricityMold fillingManganese

A aluminium alloy for press casting very thin parts (0.7-1.2 mm) is composed of (by weight) 10.0-14.0 % of silicon, 2.5-4.5 % of copper, 0-2.0 % of nickel, 0-1.5 % of manganese, the total content of nickel and manganese keeps in 0.5-2.0 %. The alloy castability (mold filling ability) increases by more than 20 %. Under high pressure press casting, 0.7-1.2 mm wall casting can be made and can be used as casing of 3C products, also the cost is reduced by more than 20-30 % compared with magnesium alloy.

Owner:ALLOY MATERIALS LAB

Method for producing medium and low carbon aluminum killed steel

The invention provides a method for producing medium and low carbon aluminum killed steel, which comprises the following steps of: controlling the content of sulfur in molten iron to be not more than 0.015 percent; primarily smelting the molten iron to form molten steel, and tapping; adding an aluminum deoxidizer into the molten steel when 20 to 30 weight percent of molten steel is tapped; adding4.0 to 6.0kg of active lime and fluorite in an amount which is 0.2 times that of the active lime into each ton of molten steel when 31 to 50 weight percent of molten steel is tapped; performing argonblowing refining for the first time; adding aluminum in two or three batches and 1.5 to 4kg of refining slag into each ton of steel in a steel ladle, heating, and refining; performing calcium treatment on the molten steel; performing argon blowing refining for the second time; and performing continuous casting. By the method, the castability of the molten steel can be improved, the phenomenon of water nozzle clogging is avoided, and the continuous casting heats of a single tundish in the continuous casting process of the medium and low carbon aluminum killed steel are not less than 8 heats.

Owner:PANZHIHUA IRON AND STEEL +2

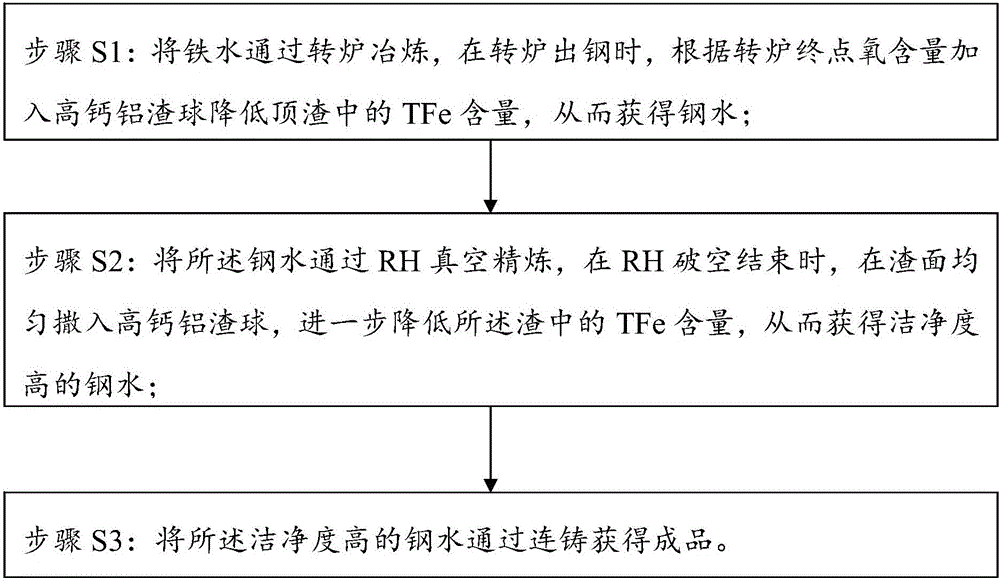

Smelting method for ultra-low carbon steel

ActiveCN105821178AReduce TFe contentReduce oxidationManufacturing convertersProcess efficiency improvementSlagCastability

The invention discloses a smelting method for ultra-low carbon steel. The smelting method for the ultra-low carbon steel comprises the steps that molten iron is smelted through a converter; when steel is discharged out of the converter, high-calcium aluminum slag balls are added according to the end-point oxygen content of the converter so as to reduce the TFe content in top slag, so that molten steel is obtained; the molten steel is subjected to RH vacuum refining, the high-calcium aluminum slag balls are scattered to the slag surface evenly when RH vacuum breaking is completed, and the TFe content in the slag is further reduced, so that molten steel with a high clean degree is obtained; and a finished product is obtained by continuously casting the molten steel with the high clean degree. By means of the smelting method for the ultra-low carbon steel, the oxidability of ladle slag of the ultra-low carbon steel can be reduced remarkably, the castability of the molten steel is improved, and the clean degree of the molten steel is increased.

Owner:SHOUGANG CORPORATION

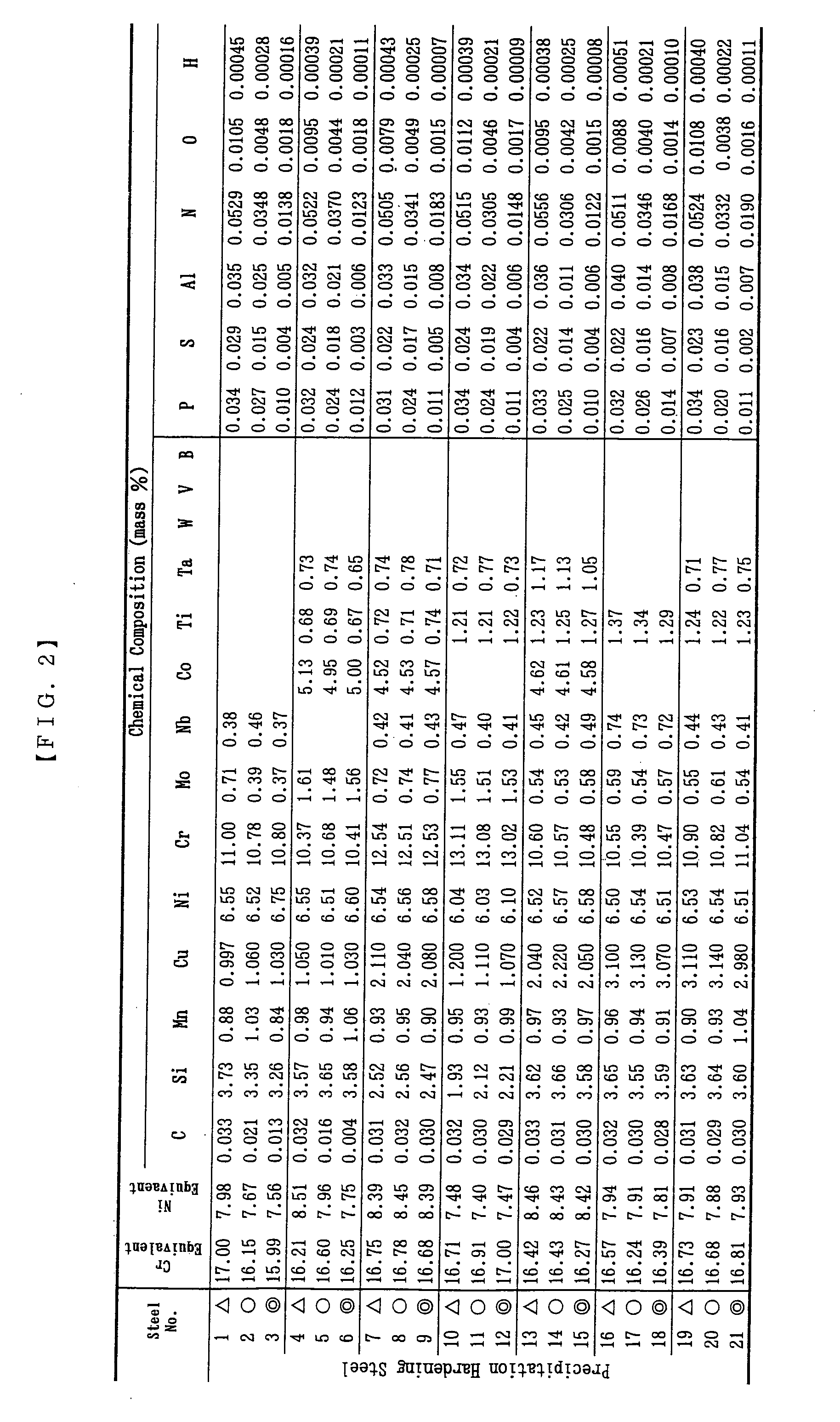

High-silicon stainless

A high-Si stainless steel excellent in various characteristics, inclusive of strength, corrosion resistance, workability and castability, consists of, on the mass % basis, Si: 2 to 5%, Cr: 8 to 25%, Ni: 4 to 16%, Mn: not more than 5%, Cu: not more than 4%, Co: not more than 8%, Mo: not more than 4%, Nb: not more than 3%, Ta: not more than 3%, Ti: not more than 3%, W: not more than 4%, V: not more than 4%, B: not more than 0.01%, Mg: not more than 0.01%, Ca: not more than 0.01%, rare earth elements: not more than 0.01%, the balance being Fe. Impurities in this steel are as follows: C: not more than 0.04%, P: not more than 0.03%, S: not more than 0.02%, Al: not more than 0.03%, N (nitrogen): not more than 0.05%, O (oxygen): not more than 0.005%, and H (hydrogen): not more than 0.0003%.

Owner:SHIMIZU YOSHIYUKI

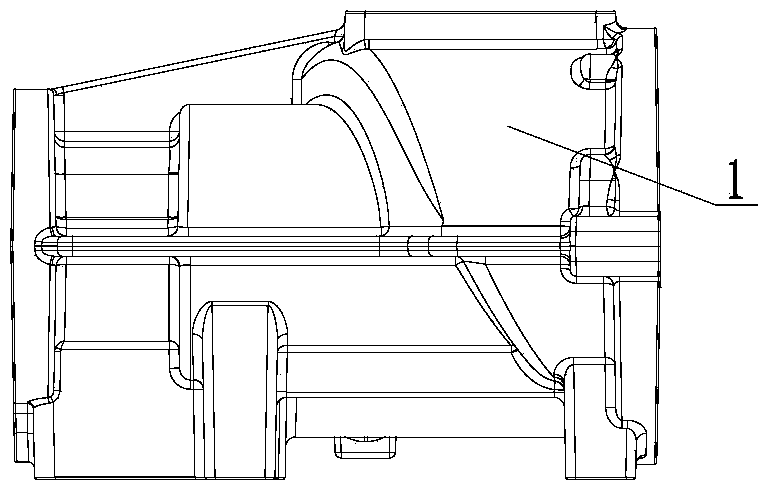

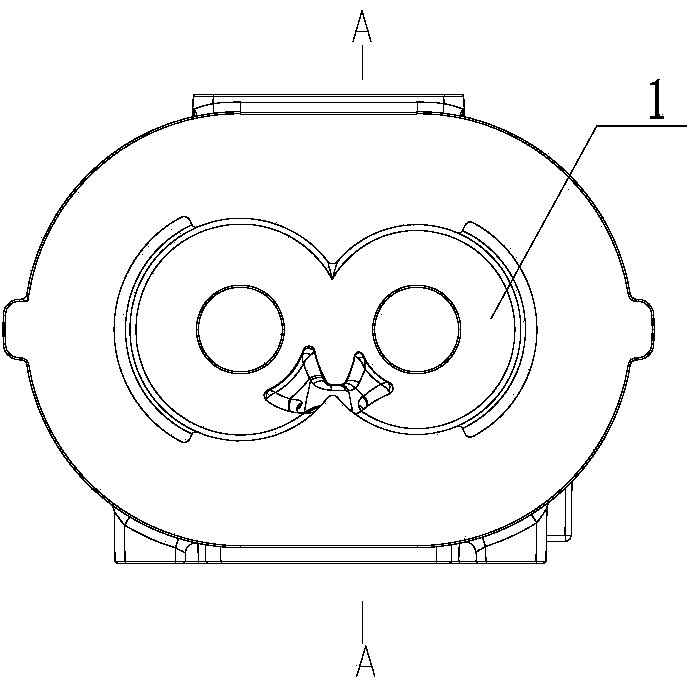

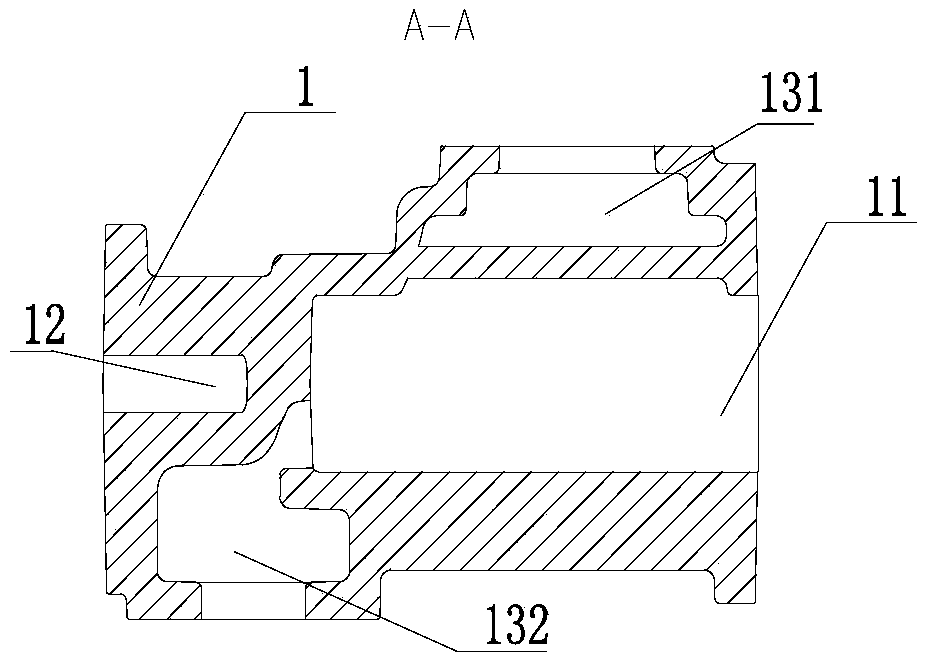

Sand mold structure for integrally molded screw compressor case and manufacture and use method of sand mold structure

ActiveCN103464680AShort structure lengthGuaranteed assembly accuracyFoundry mouldsFoundry coresCastabilityUltimate tensile strength

The invention relates to a sand mold structure for an integrally molded screw compressor case. The sand mold structure comprises a lower sand mold, an upper sand mold, a second sand core and a first sand core, wherein the upper sand mold is provided with a plurality of air outlet holes for communicating a mold cavity with the outer part of the sand mold structure and a sprue for injecting molten iron. The invention also provides a manufacture and use method of the sand mold structure. The manufacture and use method comprises the following steps: modeling, manufacturing a core, milling a pouring cup and air holes, combining boxes, casting and cleaning. The sand mold structure and the manufacture and use method of the sand mold structure have the advantages that a bearing seat and a cast main body are integrally molded, so that the structure length of the case is short, the quantity of needed high-strength bolts is less and the cost is reduced; by means of castability of casting pieces, the strength and the sealability are guaranteed, and safe and reliable effects are achieved; the rotor assembling accuracy is guaranteed only by adopting a positioning pin for the air suctioning end, and a bearing hole and a rotor hole in the air exhausting end are machined by one step, so that high accuracy is guaranteed.

Owner:SUZHOU TORIN MACHINERY CASTING

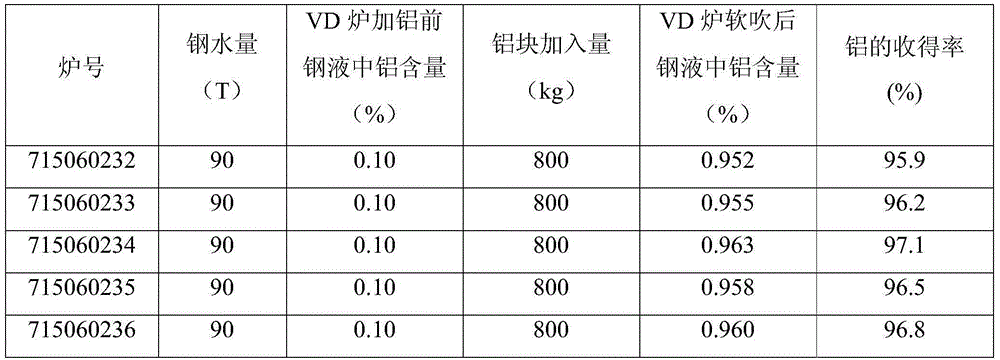

Efficient production process of high aluminum-alloy-content structure round steel

ActiveCN105177215AImprove absorption rateHigh yieldManufacturing convertersSmelting processCastability

The invention relates to a production method of round steel, in particular to an efficient production process of high aluminum-alloy-content structure round steel. Al accounts for 0.70-1.20% in the round steel by weight. The preparation method comprises the converter smelting process, the LF external refining process, the VD furnace vacuum refining process, the square bloom continuous casting process and the rolling process. The high aluminum-alloy-content structure round steel produced through the method is low in cost, high in purity and good in castability, the adsorption rate of aluminum can be higher than 95%, calcium treatment is not needed, sequence casting of 12-15 times can be achieved, the production efficiency is greatly improved, the surface quality of the round steel is high, and the technical problems of high aluminum-alloy-content structure round steel produced in the prior art that the continuous castability is poor, nodulation occurs easily, the adsorption rate of aluminum is low, the yield is unstable, the purity is low, the surface quality of the round steel is low and the quality is unstable are solved.

Owner:ZENITH STEEL GROUP CORP +1

Aluminum-containing and sulfur-containing series gear steel smelting process

ActiveCN104611502AControl Si contentInhibit peroxidationProcess efficiency improvementElectric furnaceGranularitySmelting process

The invention discloses an aluminum-containing and sulfur-containing series gear steel smelting process. Liquid iron is required to contain 0.20-0.50% of Si, less than or equal to 0.035% of S, and less than or equal to 0.110% of P, and at a temperature T greater than or equal to 1250 DEG C; lime for an electric furnace and refining is required to contain greater than or equal to 90% of CaO and less than or equal to 1.2% of SiO2, and has the activity degree of greater than or equal to 300 and the granularity of 10-40mm; a low-silicon refining agent is required to contain greater than or equal to 45% and less than or equal to 55% of CaO, less than or equal to 2.0% of SiO2, and greater than or equal to 35% and less than or equal to 40% of Al2O3. The liquid iron hot charge ratio of the electric furnace reaches up to 90%; for LF refining, a first strong and later weak deoxidization manner is adopted; at the middle-late stages, a weak deoxidizer is adopted for furnace slag maintenance to realize further deoxidization. Meanwhile, deoxidization and S removal are performed, and then an S wire is fed to obtain a certain S content; in addition, the S wire is allowed to be fed only in more than 5 minutes after the denaturalization treatment of feeding a calcium-iron wire into VD liquid steel, and therefore, the formation of CaS inclusion in a clogging material at other water gap is prevented; and at last, the castability of the liquid steel is guaranteed while excellent structural properties of the steel product are obtained, and the purity of the liquid steel is improved.

Owner:ZENITH STEEL GROUP CORP +1

Non-quenched and tempered steel used for welding and electroplating hydraulic rod and production method thereof

The invention discloses non-quenched and tempered steel used for welding and electroplating a hydraulic rod and a production method thereof. The non-quenched and tempered steel consists of the following elements according to mass percentages: 0.28-0.35% of C, 0.30-0.80% of Si, 1.00-1.60% of Mn, 0.10-0.30% of Cr, 0.06-0.20% of V, 0.015-0.10% of Ti, less than or equal to 0.020% of P, 0.010-0.035% of S, 0.020-0.060% of Alt, less than or equal to 0.20% of Cu, less than or equal to 0.20% of Ni, less than or equal to 0.10% of Mo, less than or equal to 15*10-4% of O and the balance of Fe and unavoidable impurities. The strength and plasticity index of the non-quenched and tempered steel reaches the level of 45 quenched and tempered steel, and the non-quenched and tempered steel is excellent in machinability and good in welding technological properties. The production method of the non-quenched and tempered steel solves the technical problems of low castability of molten steel caused by adding S and the like, and improves the purity of the steel. The non-quenched and tempered steel provided by the invention can be used for replacing the 45 quenched and tempered steel for manufacturing the hydraulic rod without thermal refining, thus belonging to energy-saving and environmentally-friendly steel.

Owner:LAIWU IRON & STEEL GRP

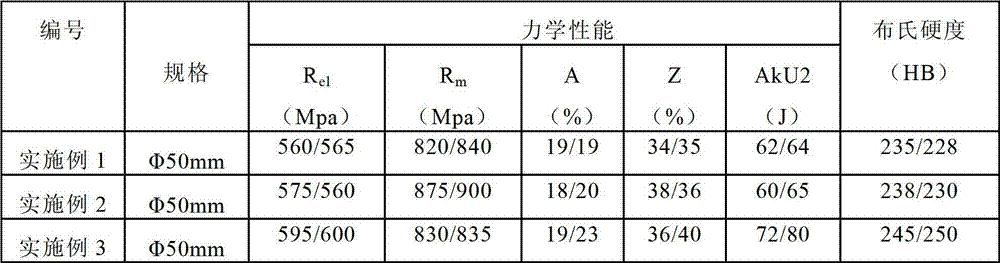

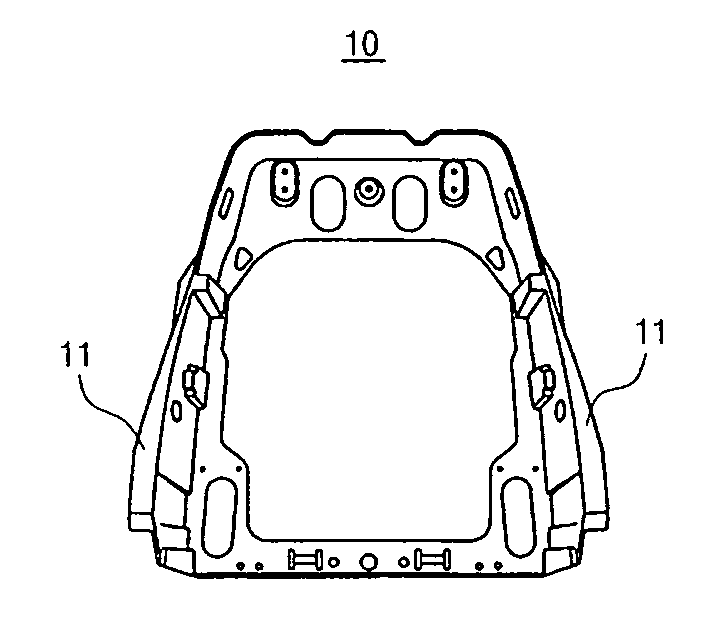

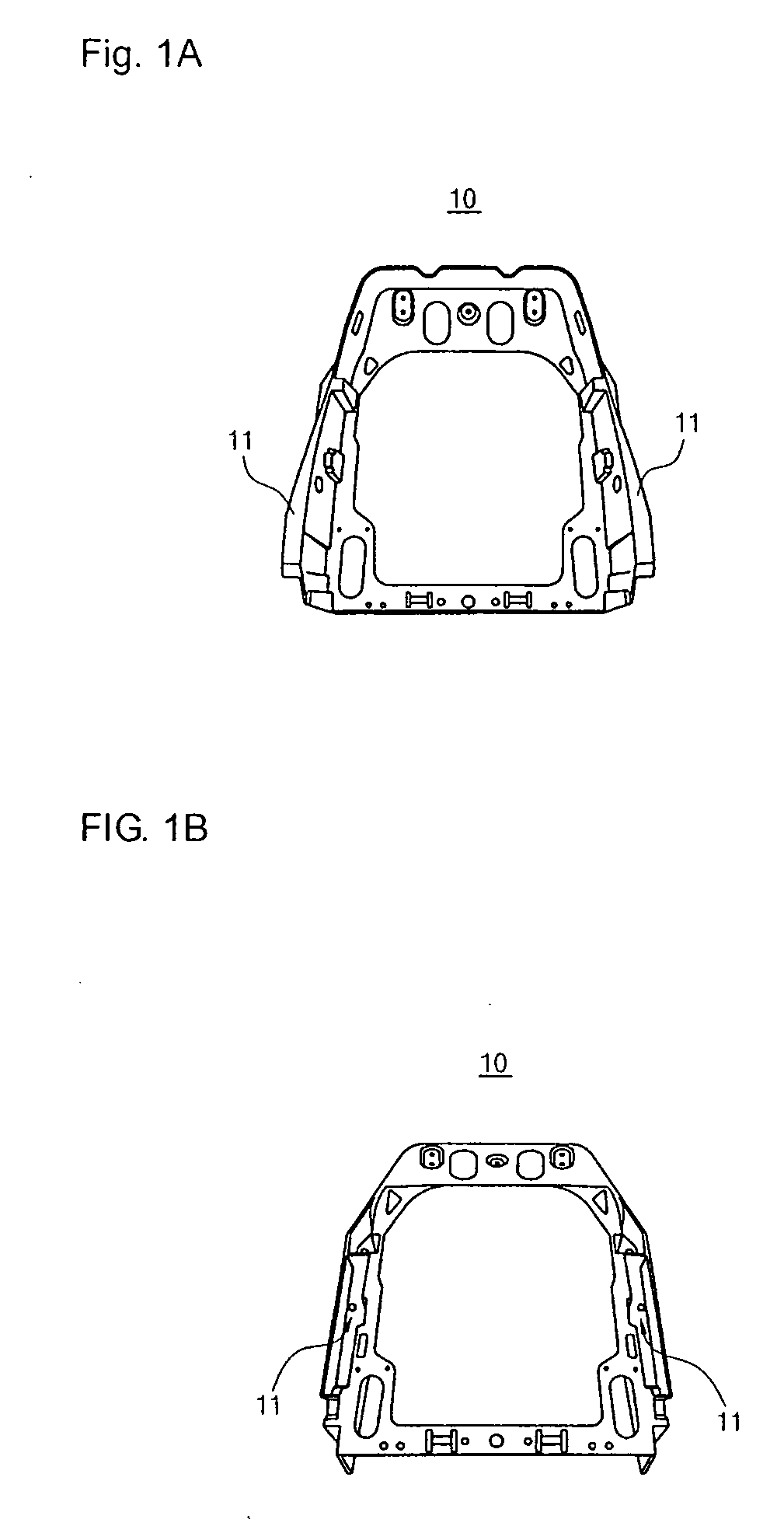

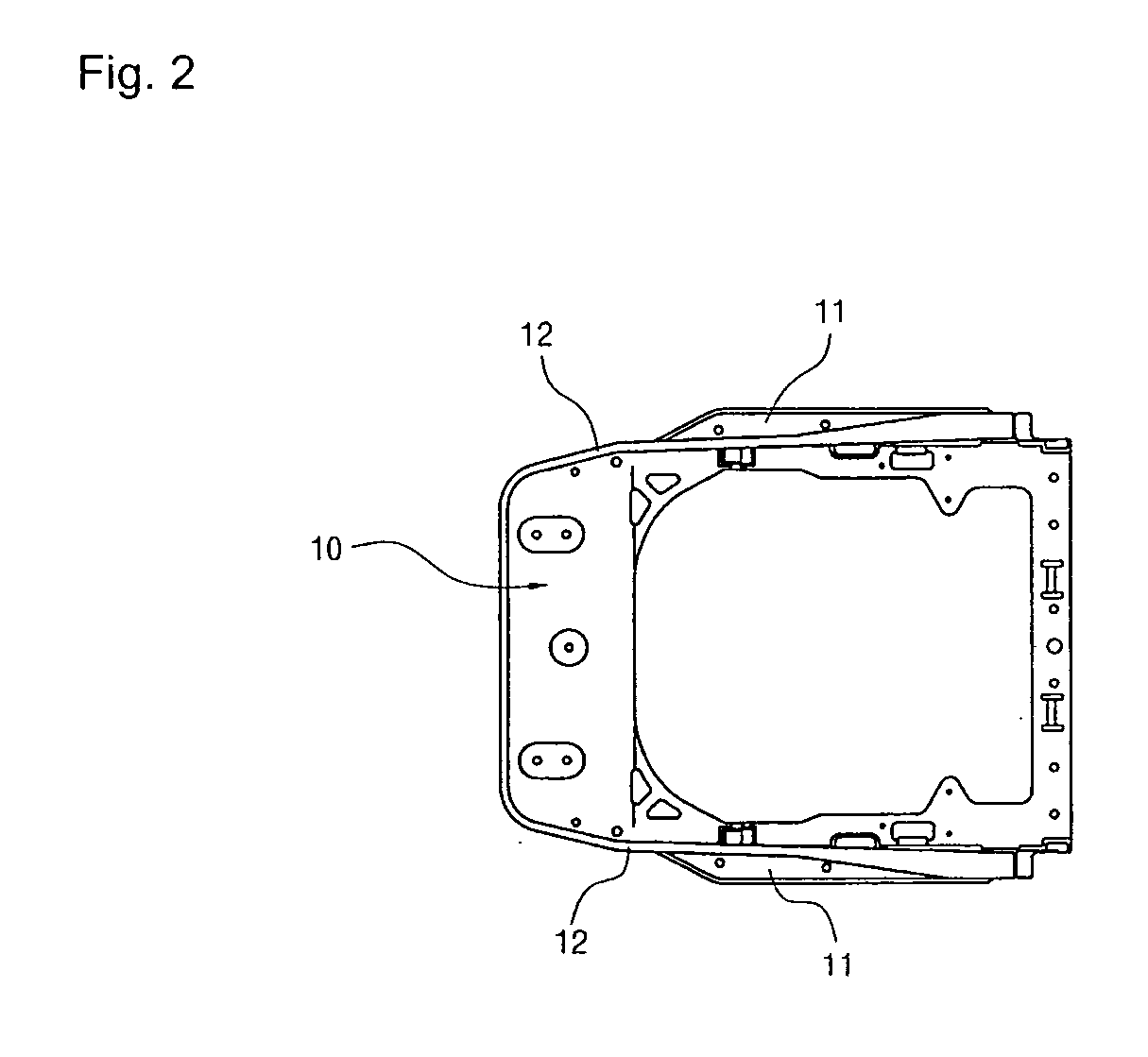

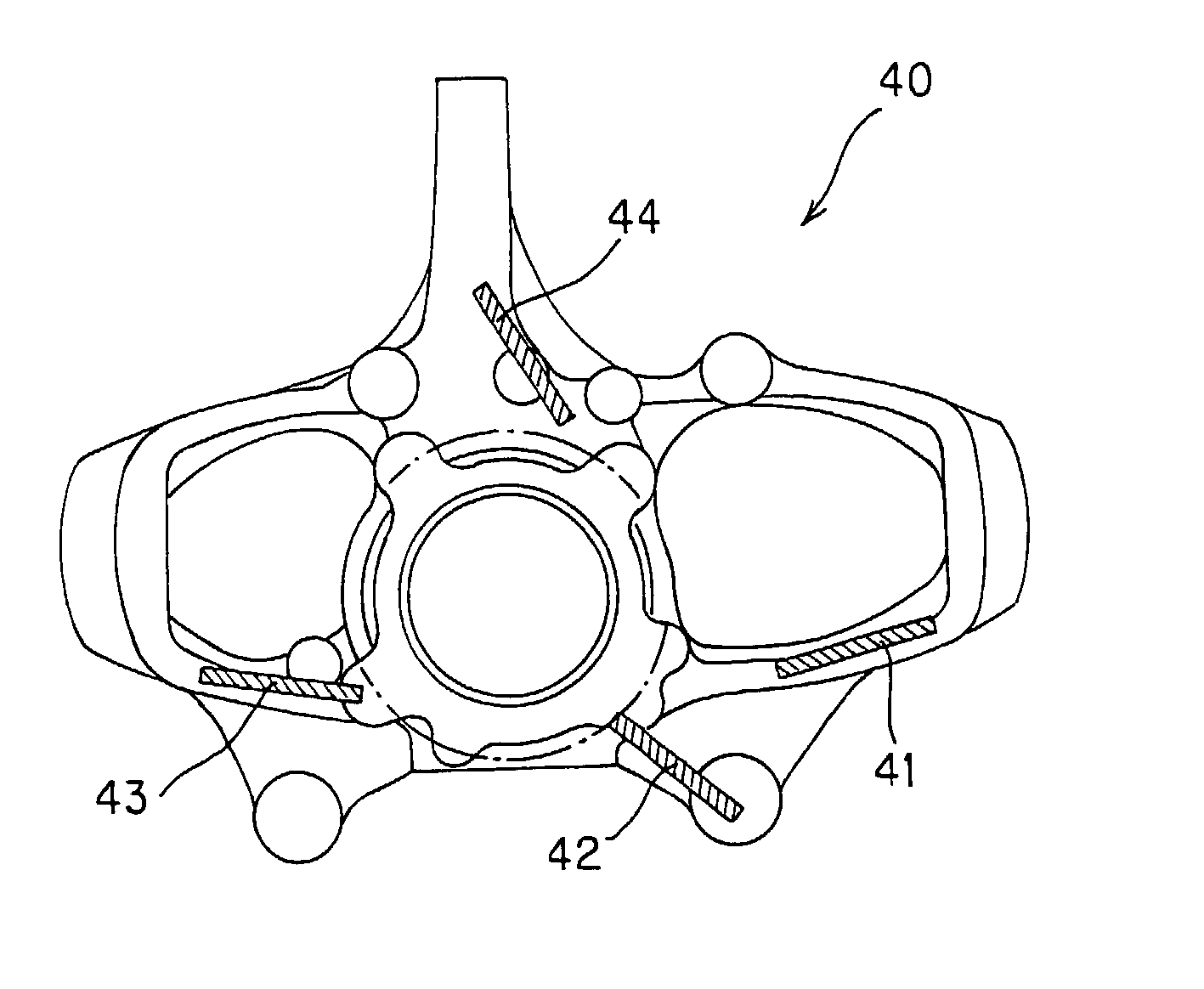

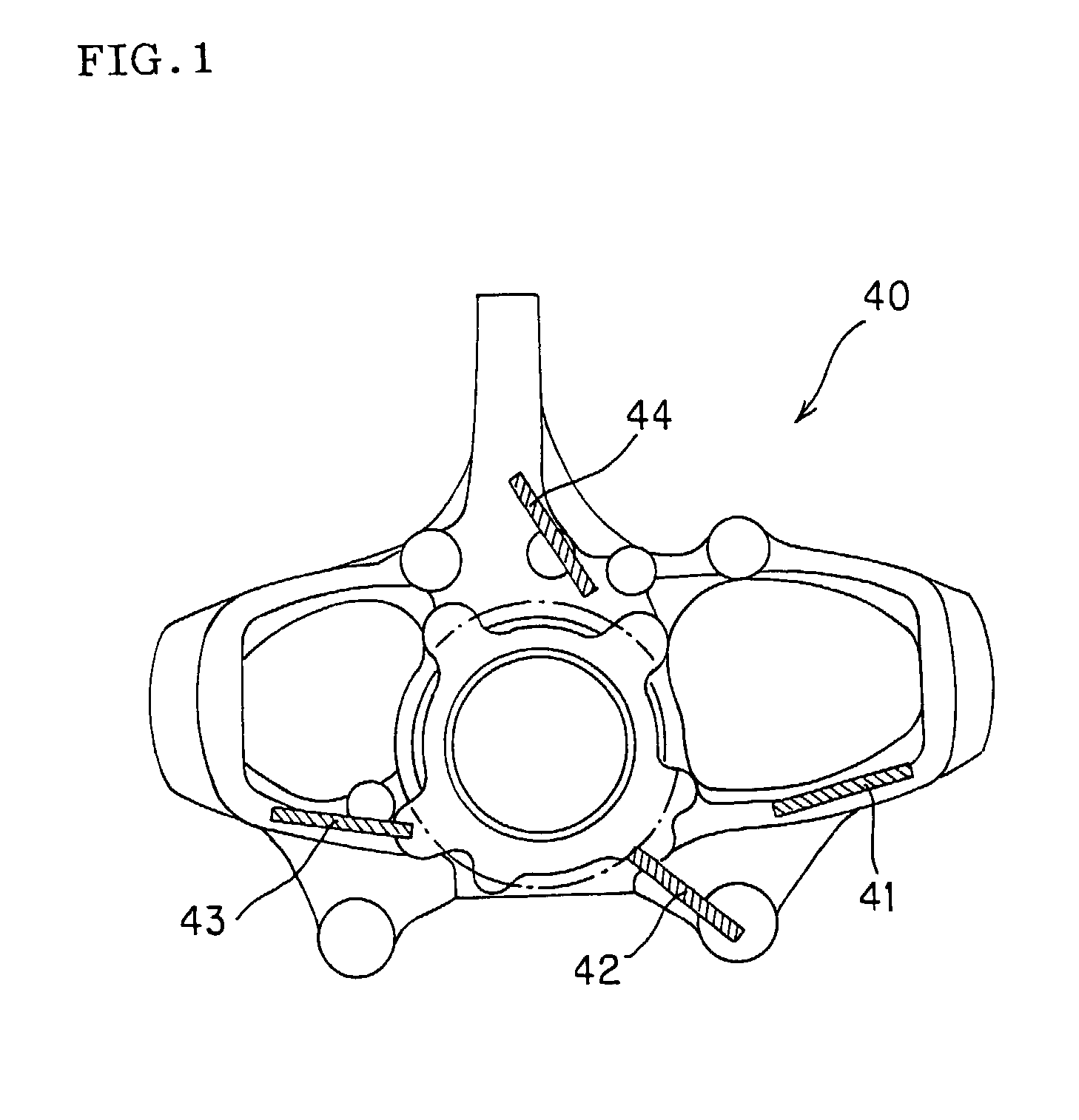

Seat back frame and method of manufacturing the same

InactiveUS20050269856A1High mechanical strengthEasy to installBack restsSeat framesCastabilityUltimate tensile strength

A seat back frame of a vehicle using a magnesium alloy results in a seat back frame having the properties of a conventional steel press seat back frame. The seat back frame is reinforced regarding its strength and tapers from wider at the lower portion to thinner toward a head rest. The advantageous properties of the alloy seat, such as weight and castability, are much improved over the conventional. The method of molding such a seat back frame include molding the alloy into a mold via even disbursement about a casting gate.

Owner:HYUNDAI MOTOR CO LTD

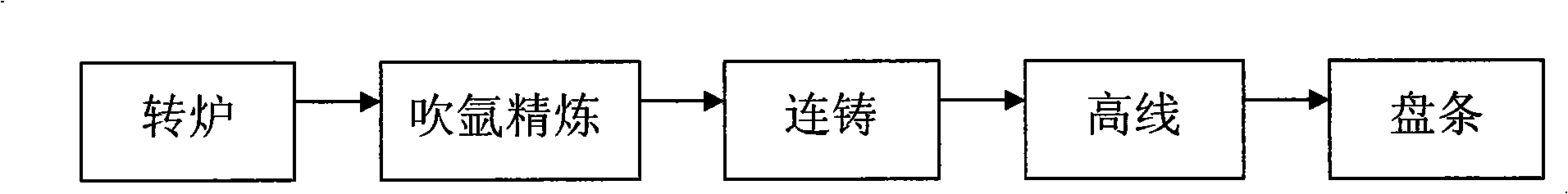

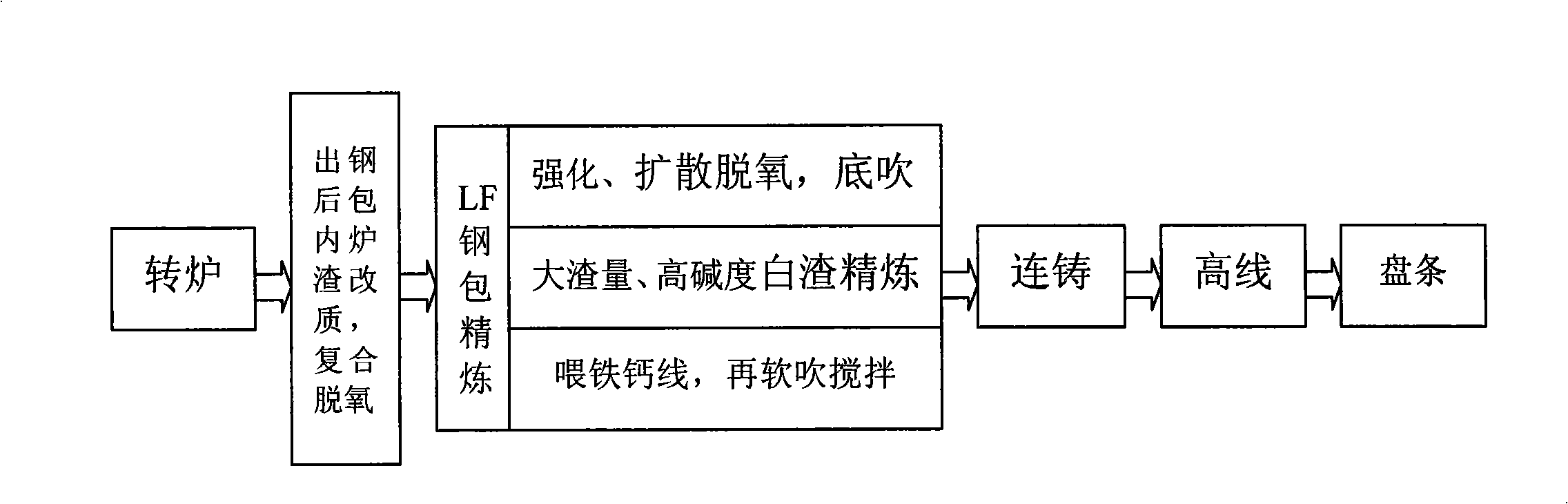

Technique for producing wire rod for low carbon drawn wire

The invention relates to a technique of a wire rod for producing a low-carbon wire drawing. A production technique of converter - Ar-blowing refining - continuous casting - highline mill is adopted currently, which has the advantages of low production cost and little carburization and silicon-adding to the molten steel, but has the disadvantages of poor refining effect, high oxygen content, being difficult to deeply desulfurize and to remove inclusions, which influence the drawability of the wire rods, therefore, the technique of converter - ladle furnace (LF) refining - continuous casting - highline mill is invented, wherein, the LF ladle refining adopts reduction operation, aluminum wires are fed to enhance the molten steel to oxidize, then deoxidizers such as calcium carbide, aluminum granules, etc. are added to carry out diffusive deoxidation, and the whole course stirring on the condition of bottom argon-blowing is done simultaneously; when in refining, a white-slag refining system is adopted; before finishing the refining, calcium iron wires are fed in the LF, and then stirring on the condition of soft argon-blowing is done. The technique of the invention substitutes the original Ar-blowing refining with the ladle furnace (LF) refining so as to realize deoxidation and desulfurization of the molten steel and removal of the non-metal inclusions by absorption, therefore, the (O) in the steel is less than 20 PPm and the (S) is less than 0.010 percent, and the amount of carburization and silicon-adding to the molten steel can be respectively controlled within 0.02 percent; that continuous casting heats of the molten steel are more than 10 heats is realized in the invention, thus improving the quality and castability of the steel.

Owner:TIANJIN IRON & STEEL GRP

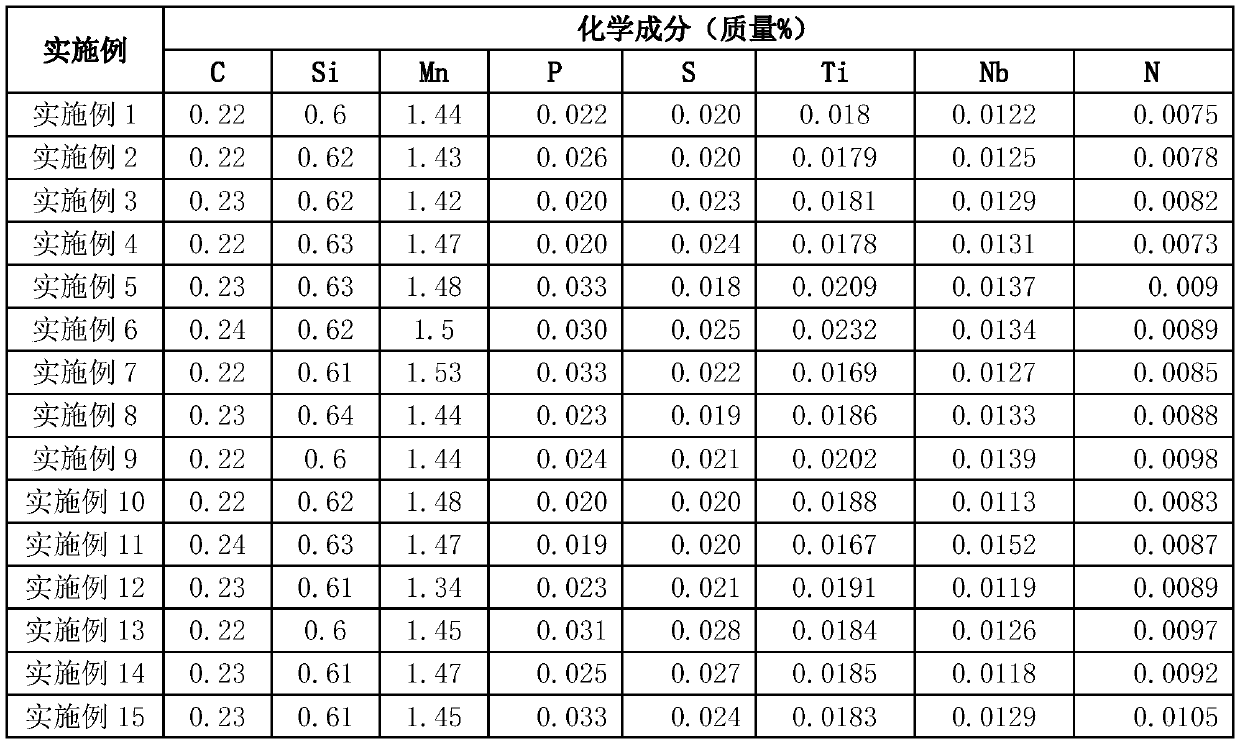

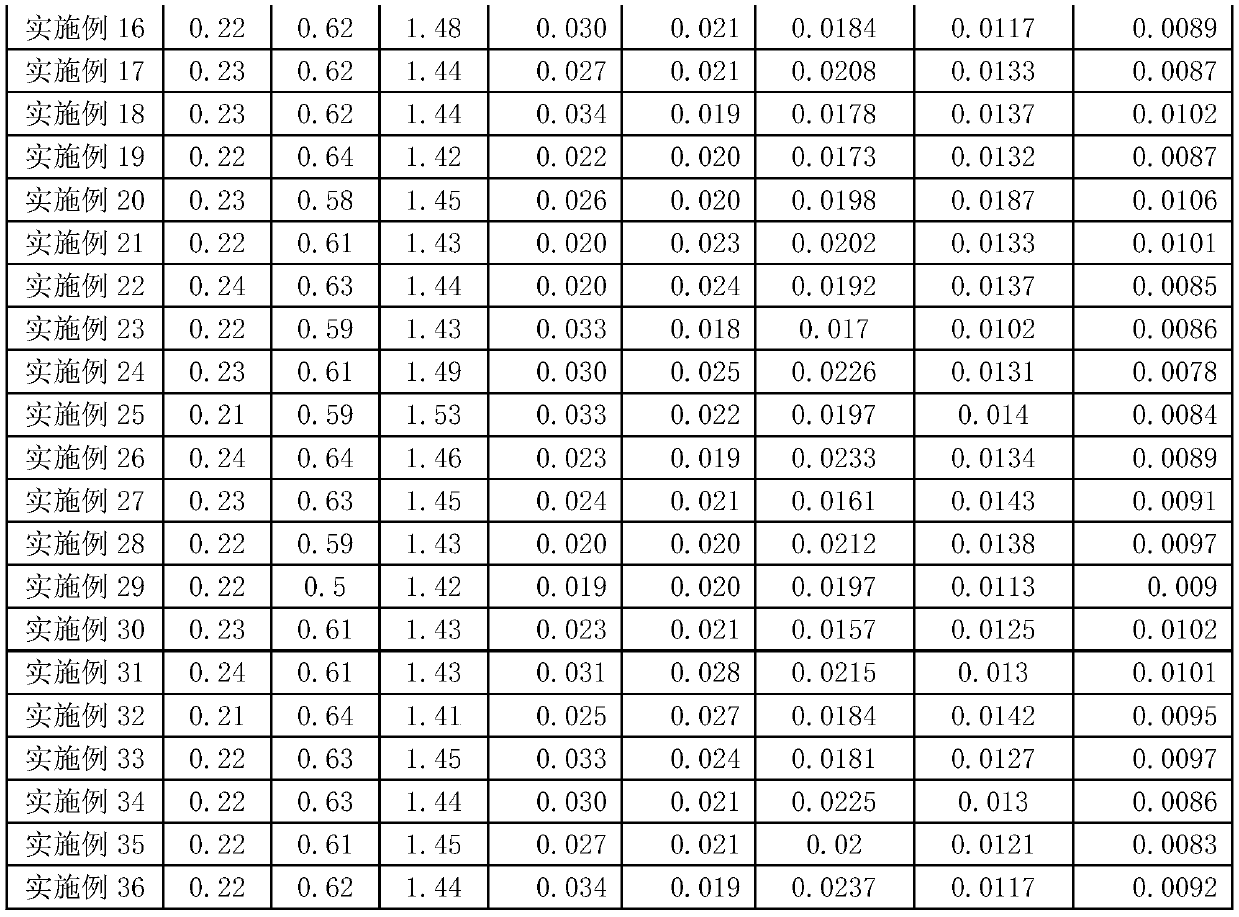

Niobium-titanium-nitrogen and titanium-nitrogen composite micro-alloyed HRB400E steel bar and production method thereof

The invention provides a niobium-titanium-nitrogen and titanium-nitrogen composite micro-alloyed HRB400E steel bar and a production method thereof, and belongs to the technical field of iron and steelsmelting. The niobium-titanium-nitrogen and titanium-nitrogen composite micro-alloyed HRB400E steel bar comprises, by mass, 0.21-0.25% of C, 0.50-0.65% of Si, 1.40-1.55% of Mn, not greater than 0.045% of P, not greater than 0.045% of S, 0.015-0.025% of Ti, 0.010-0.020% of Nb, 0.0070-0.0110% of N, and the balance Fe and other impurities. In the production method, ferrosilicon, silicomanganese anda carburant are added at the time of 1 / 4 tapping, and all alloys are added at the time of 3 / 4 tapping; the titanium-nitrogen alloy is added at an argon blowing station, and the argon blowing time is greater than or equal to 6 minutes; and high-casting-speed casting powder is adopted for continuous casting, a billet is heated, rolled and fed onto a cooling bed, and finally, the finished product isobtained. According to the niobium-titanium-nitrogen and titanium-nitrogen composite micro-alloyed HRB400E steel bar and the production method thereof, by adding the titanium-nitrogen alloy at the molten steel exposure positon of the argon blowing station, the titanium yield is increased; by reducing the influence of the niobium and titanium content on the quality of the high-casting-speed continuous casting billet, the titanium inclusion in steel is reduced, and the castability of molten steel meets requirements; and by adopting the high-casting-speed continuous casting powder, the cast billet quality is improved.

Owner:YANGCHUN NEW STEEL CO LTD

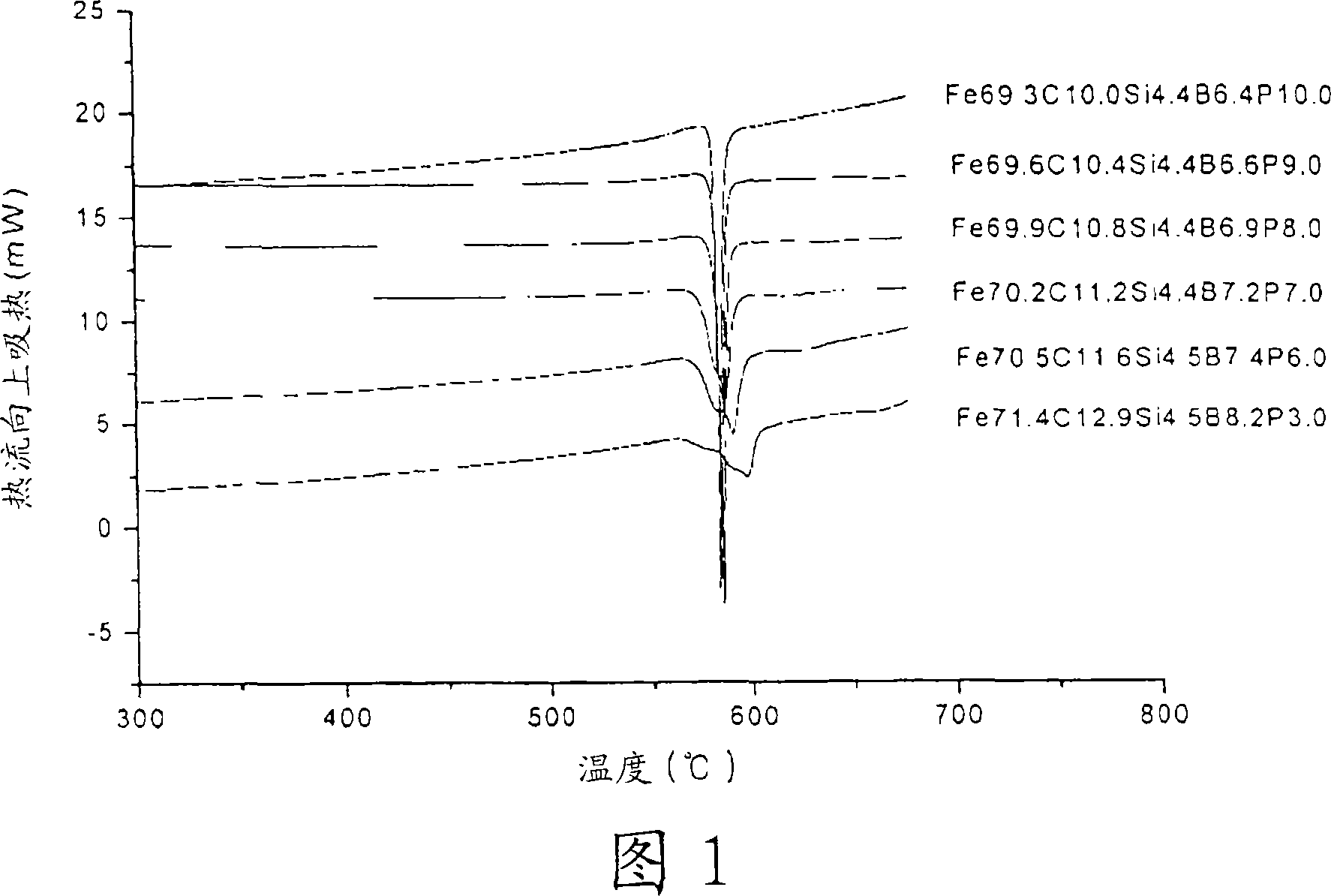

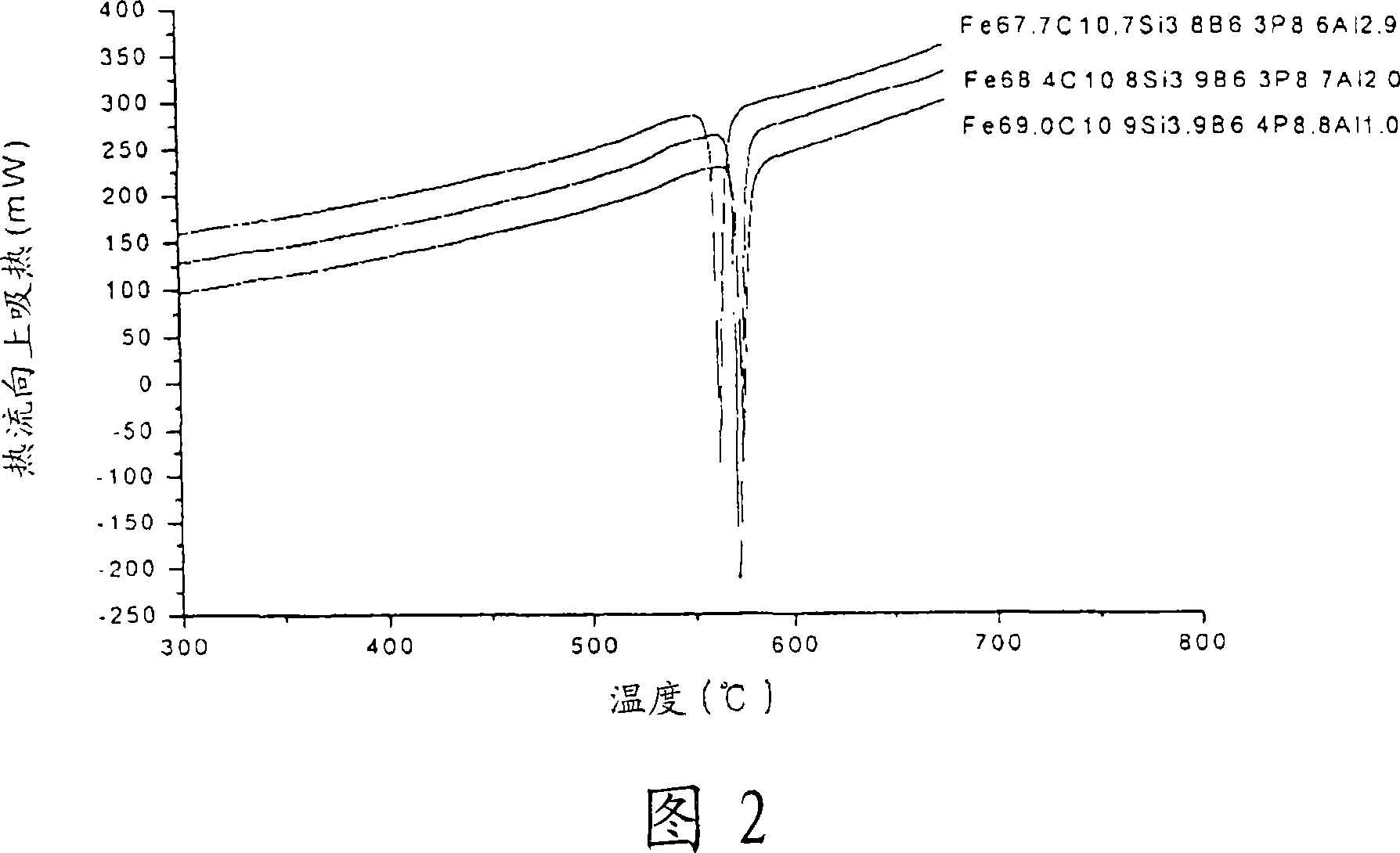

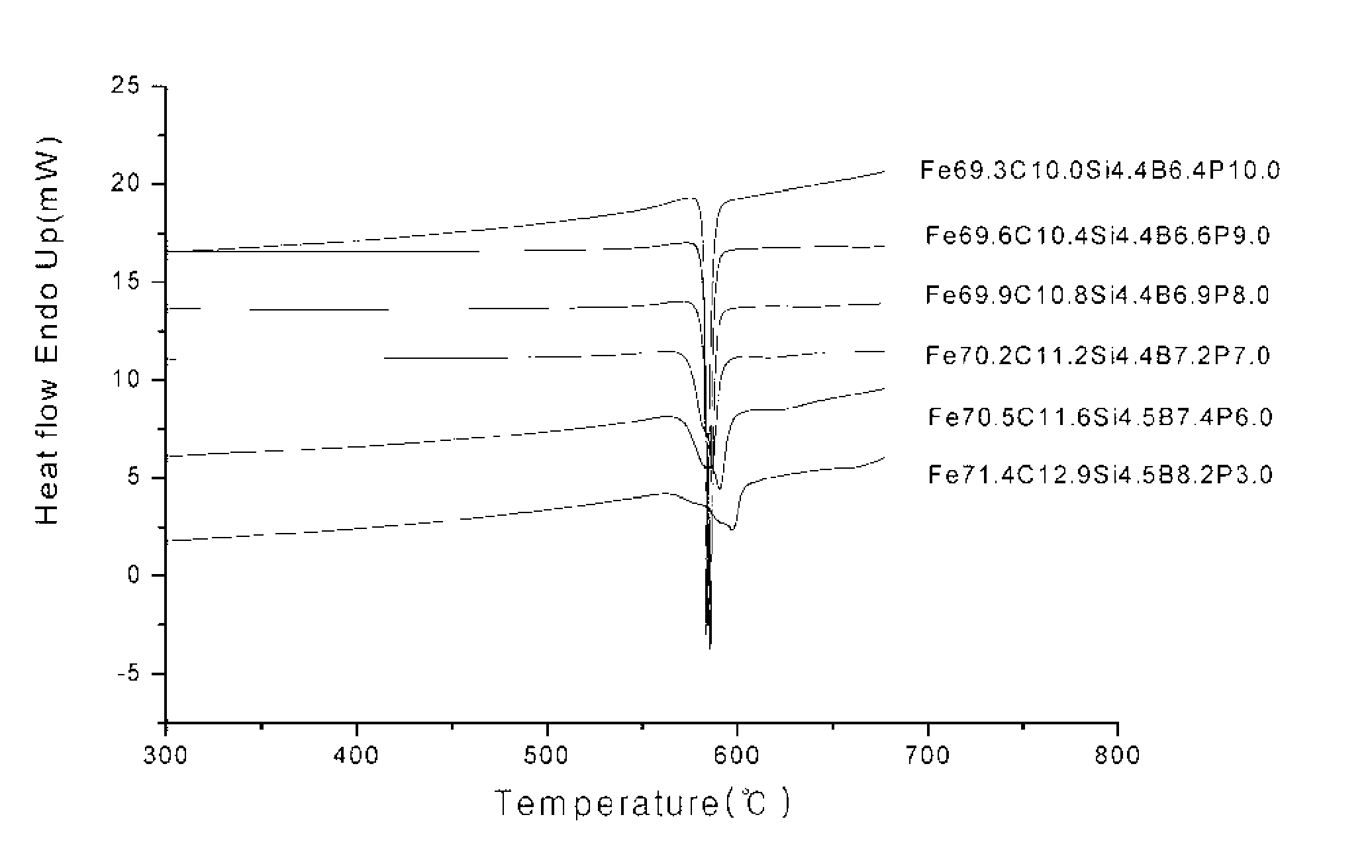

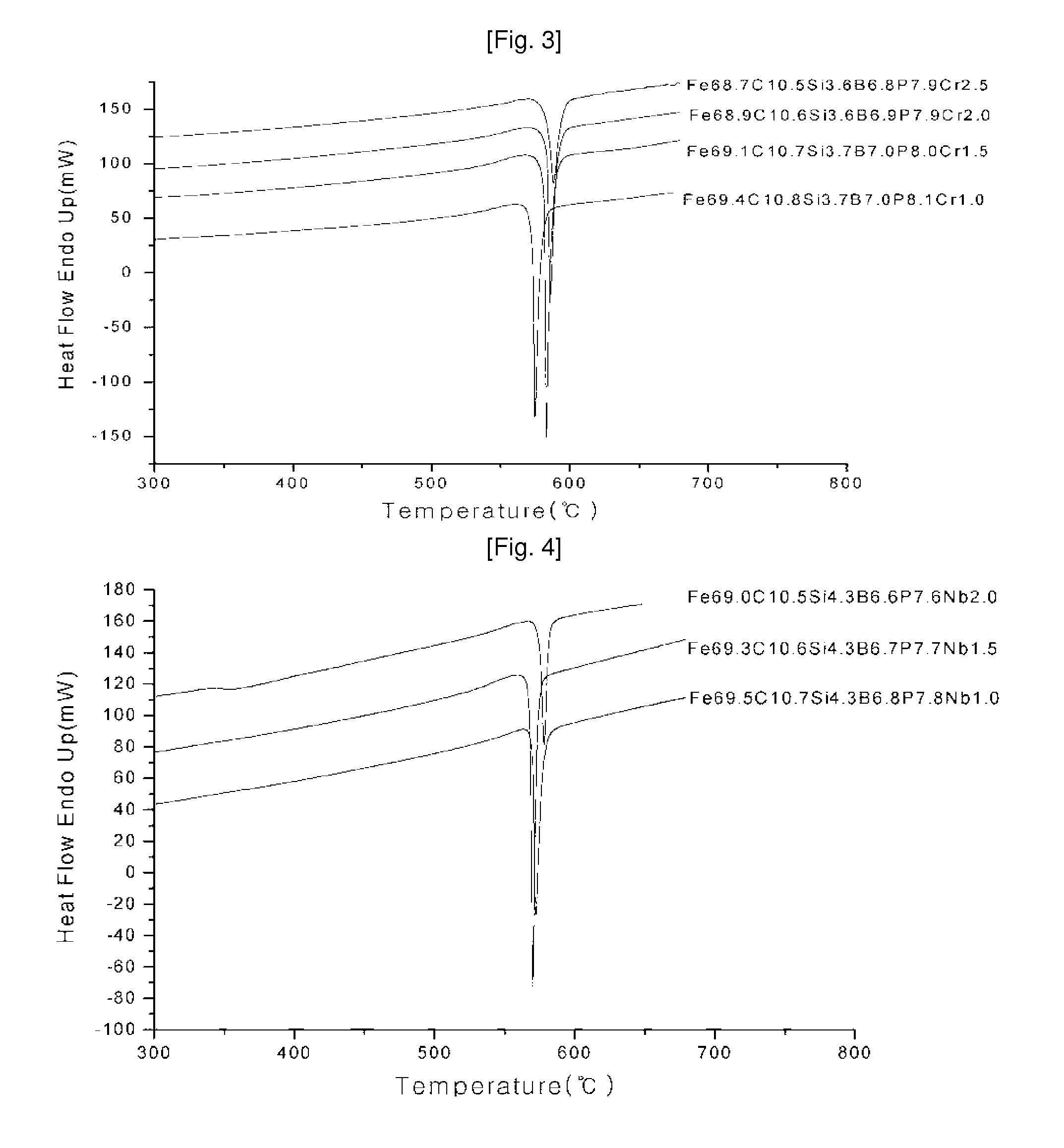

Fe-based bulk amorphous alloy compositions containing more than 5 elements and composites containing the amorphous phase

Disclosed is a Fe-based bulk amorphous alloy composition which forms a bulk amourphose substance due to its excellent amorphous formability when it is cooled to a temperature lower than its glass transition temperature from the liquid state at a relatively low cooling rate of 1000 K / s or less, has high warm processability in a low temperature range owing to its supercooled liquid region of 2OK or higher and has excellent fluidity in the liquid state and thereby good castability. The Fe-based multi-element bulk amorphous alloy composition is represented by a formula of Fe a C ss Si B x Py M a , in which M is an element selected from Ti(titanium), Cr(chromium), Mo(molybdenum), Nb(niobium), Zr (Zirconium), Ta( tantalum), W(tungsten) and V(vanadium), a, ss, , x, y, and a each represent atomic % of iron(Fe), Carbon(C), silicon(Si), boron(B), phosphorus (P) and the selected metal element, in which a is 100-(ss++x+y+a) atomic %, ss is 6 atomic % or more and 13 atomic % or less, is 1 atomic % or more and 5 atomic % or less, x is 4.5 atomic % or more and 9.5 atomic % or less, y is 3 atomic % or more and 10 atomic % or less and a is 0.1 atomic % or more and 6 atomic % or less.

Owner:POHANG IRON & STEEL CO LTD

Fe-Based Bulk Amorphous Alloy Compositions Containing More Than 5 Elements And Composites Containing The Amorphous Phase

Disclosed is a Fe-based bulk amorphous alloy composition which forms a bulk amorphous substance due to its excellent amorphous formability when it is cooled to a temperature lower than its glass transition temperature from the liquid state at a relatively low cooling rate of 1000 K / s or less, has high warm processability in a low temperature range owing to its supercooled liquid region of 20K or higher and has excellent fluidity in the liquid state and thereby good castability. The Fe-based multi-element bulk amorphous alloy composition is represented by a formula of Feα, CβSiγBxPyMa, in which M is at least one element selected from Ti (titanium), Cr (chromium), Mo (molybdenum), Nb (niobium), Zr (Zirconium), Ta (tantalum), W (tungsten) and V (vanadium), α, β, γ, x, y, and a each represent atomic % of iron (Fe), Carbon (C), silicon (Si), boron (B), phosphorus (P) and the selected metal element, in which α is 100-(β+γ+x+y+a) atomic %, β is 6 atomic % or more and 13 atomic % or less, γ is 1 atomic % or more and 5 atomic % or less, x is 4.5 atomic % or more and 9.5 atomic % or less, y is 3 atomic % or more and 10 atomic % or less and a is 0.1 atomic % or more and 6 atomic % or less.

Owner:POHANG IRON & STEEL CO LTD

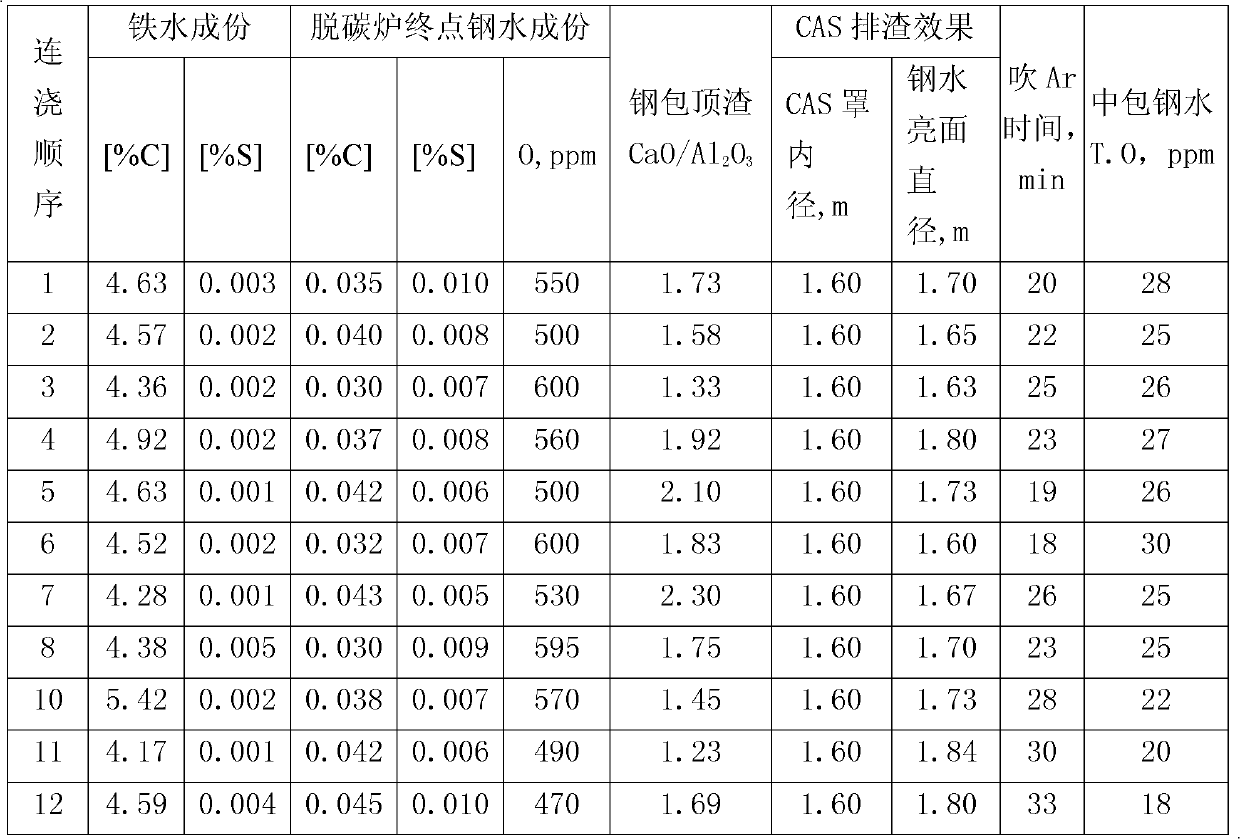

Method for improving cleanliness of low-carbon molten aluminum-killed steel

ActiveCN102140566AImprove adsorption capacityFloating fullyManufacturing convertersAlkalinitySmelting process

The invention provides a method for improving the cleanliness of low-carbon molten aluminum-killed steel, which belongs to the technical field of killed steel. By adopting two-step smelting process of converter molten iron dephosphorization and less-slag decarburization steel making, a converter has low endpoint oxygen content, deoxidized molten steel has less original impurities, and the control is executed at the very beginning of the impurities generation. Top slag of ladles is modified to slag with stronger capacity of adsorbing the impurities, the fully upward floatation of the impurities is ensured by emphasizing slag-free operation in a CAS refining cover and a longer pure argon blowing time, adopting a high-alkalinity covering agent and special protecting slag for a crystallizer for continuous casting is beneficial to impurity adsorption, and then the impurities are removed by adopting measures in each point where the impurities are generated. By adopting the method, the T.O content of molten steel in ladles is not more than 30ppm, and the molten steel has high cleanliness and good continuous castability. The method has the advantages of reasonable process and low production cost.

Owner:SHOUGANG CORPORATION

Aluminum alloy for casting-forge, and aluminum casting forged product and manufacturing method therefor

InactiveUS20030010412A1High strengthLow costSuspensionsSteering linkagesConventional castingManganese

An aluminum casting forged product is provided by using an aluminum alloy for casting forge including a useless raw material for forging such as flash as a raw material and by controlling a weight percentage of an alloy element such as silicon, magnesium, copper, and manganese; the product having an enhanced fluidity, and an improved castability, with retaining a sufficient strength, preventing useless intermetallic compounds from forming, restraining deterioration due to oxidation and corrosion, and further improved strength by a forging effect: and there is also provided a simple manufacturing method, with a high yield and high productivity. An aluminum casting forged product of high tensile strength, high proof, and elongation, higher mechanical properties than those of the conventional casting forged product, high corrosion resistance, and high quality without defects, and being low in cost is also obtainable as a thick-wall aluminum product.

Owner:ASAHI TEC CORP +1

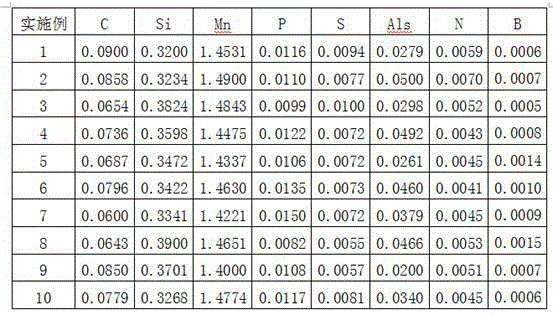

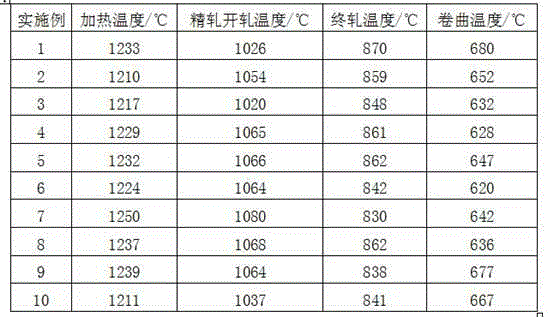

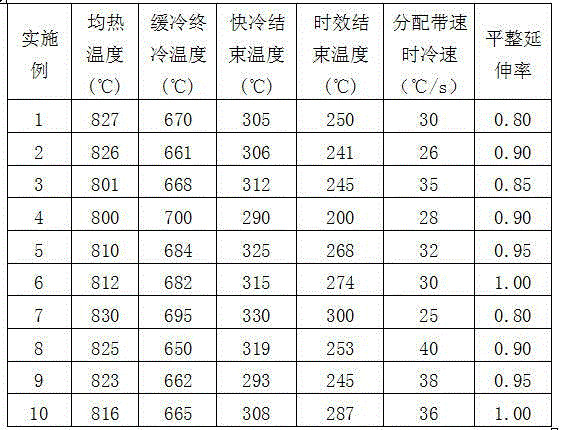

500MPa-grade cold rolling dual-phase steel and production method thereof

The invention discloses a 500MPa-grade cold rolling dual-phase steel and a production method thereof. The method comprises the working procedures of hot rolling and cold rolling continuous annealing; the dual-phase steel comprises the following chemical components by mass percent: 0.06-0.09% of C, 0.32-0.39% of Si, 1.40-1.49% of Mn, less than or equal to 0.015% of P, less than or equal to 0.01% of S, 0.020-0.050% of Als, less than or equal to 0.007% of N, 0.0005-0.0015% of B and the balance of Fe. According to the 500MPa-grade cold rolling dual-phase steel, on the basis of the components of C-Si-Mn dual-phase steel, the content of the Si is reduced, the content of Al is properly increased, and the stability of austenite is improved by the Si and the Al; furthermore, the B element is fed into the steel, and the content of the N is reasonably controlled, so that AlN particles are generated by part of acid-soluble aluminum (Als) in the steel, BN is produced by part of B in the steel, and elution is enhanced; and therefore, the production difficulty is reduced, the smelting castability is not influenced, the cost is low, the production continuity is better, and the product quality is stable. According to the method, the alloy element is not fed into the steel, so that the components of the C-Si-Mn serial dual-phase steel can be improved; the cold rolling dual-phase steel with low yield ratio and high elongation can be produced by steelmaking improvement, the hot rolling process and the cold rolling continuous annealing process.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

Calcium treatment process of rod wire alloy steel

The invention belongs to the technical field of metallurgy of iron and steel, and particularly relates to a calcium treatment process of rod wire alloy steel. The invention adopts a converter smelting-LF (ladle furnace) refining-RH refining-square billet continuous casting production technique. The calcium treatment process is implemented in a way that: after the LF refining finishes, feeding an iron calcium wire, silico-calcium wire or solid calcium wire into molten steel at the linear speed of 50-250m / min to control the mass percent of calcium aluminum in the molten steel at 0.08-0.16%; after the soft blow, carrying out RH treatment; after the RH treatment finishes, carrying out calcium carbonate treatment, and feeding the iron calcium wire, silico-calcium wire or solid calcium wire into molten steel at the linear speed of 50-250m / min to control the mass percent of calcium aluminum in the molten steel at 0.04-0.08%; and carrying out soft blow, and casting. When the treatment process is used for producing high-quality steel, the inclusion level can not deteriorate, the castability of the molten steel is good, the number of continuous casting furnaces is increased, the calcium content of the molten steel is low but does not influence the casting performance, and the treatment process plastifies the inclusions and improves the mechanical properties of steel.

Owner:NORTHEASTERN UNIV +1

800 MPa grade cold-rolled double-phase steel and production method thereof

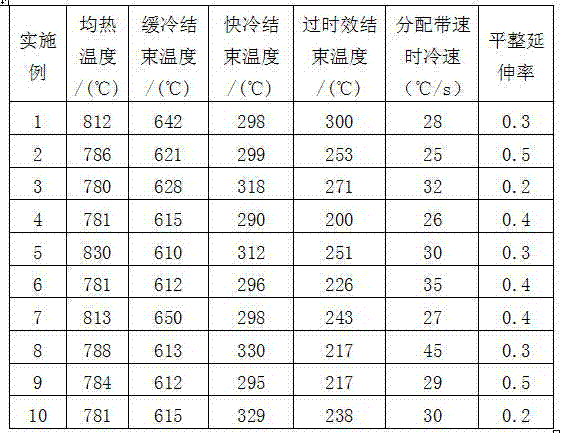

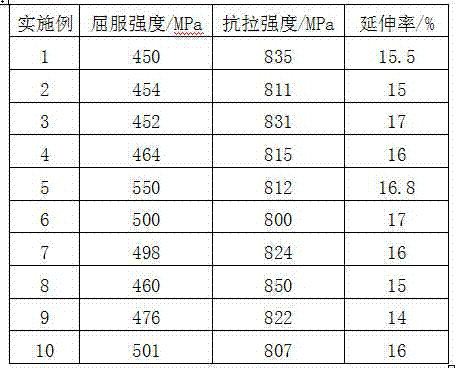

The invention discloses 800 MPa grade cold-rolled double-phase steel and a production method thereof. The production method comprises a hot rolling process and a cold rolling continuous annealing process. The chemical compositions of a casting entering the hot rolling process comprise, in percent by mass, 0.14-0.17% of C, 0.45-0.55 of Si, 1.6-1.8 of Mn, 0.55-0.65% of Cr, P<=0.016%, S<=0.008%, 0.02-0.05% of Als, N<=0.004%, and the balance Fe. In the double-phase steel, the Si content is increased and the Mn content is reduced on the basis of the compositions of C-Si-Mn-Cr, so that the strength is increased without adding Al, Nb, Mo, Ti and other high-cost elements, and the purposes of reducing production difficulty and production cost while not influencing smelting castability are realized. The method improves the Si content, reduces the Mn content, improves the composition system of the C-Si-Mn-Cr system and realizes the purpose of reducing production cost. By improving the smelting, hot rolling and cold-rolling continuous annealing technologies, the cold-rolled double-phase steel with the tensile strength of 800-850 MPa, the yield strength of 450-550 MPa and the elongation percentage of 15-17% is produced, and the production method has the characteristics of simple technology, low cost and stable product quality.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com