Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2032results about "Back rests" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

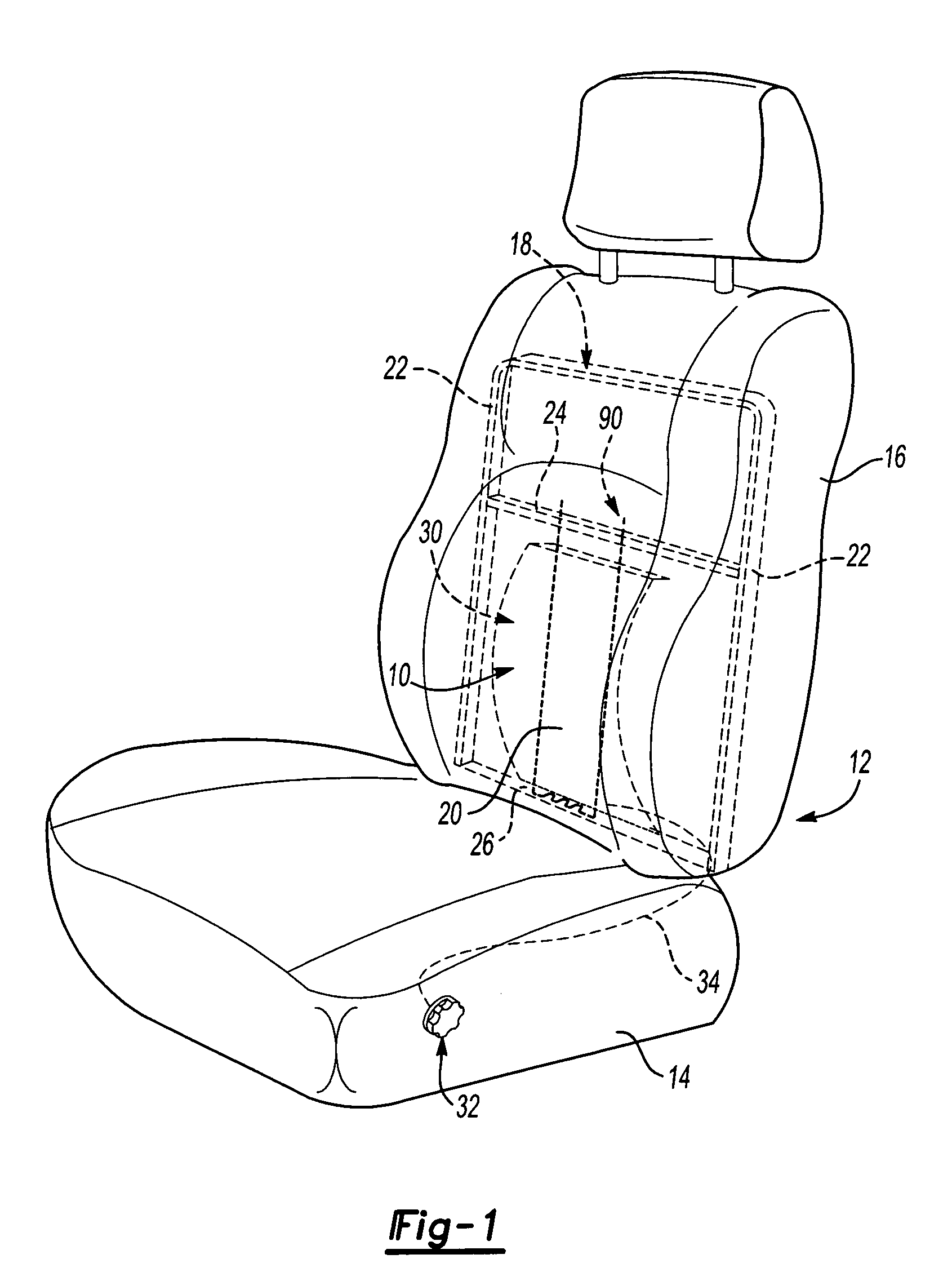

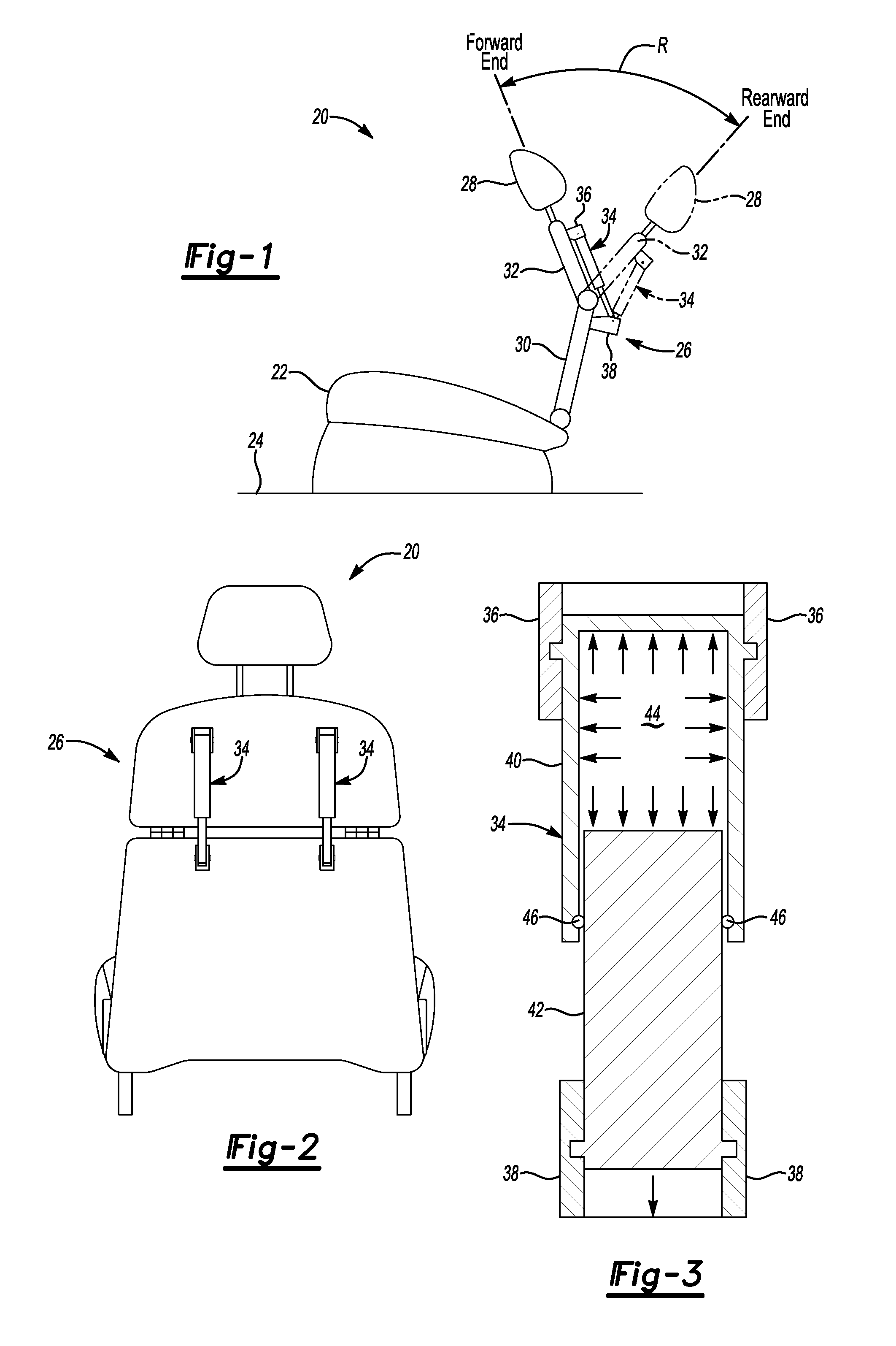

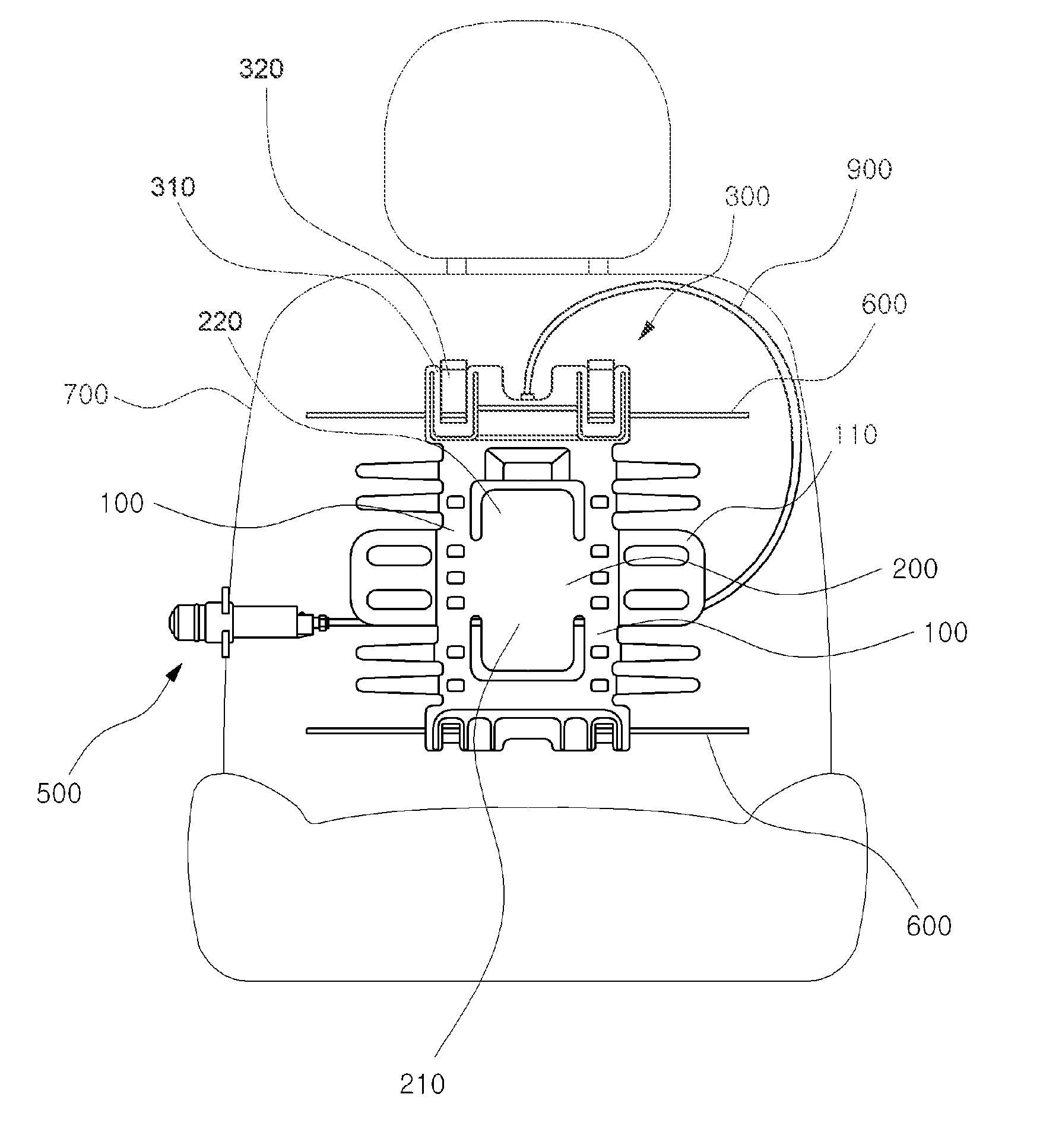

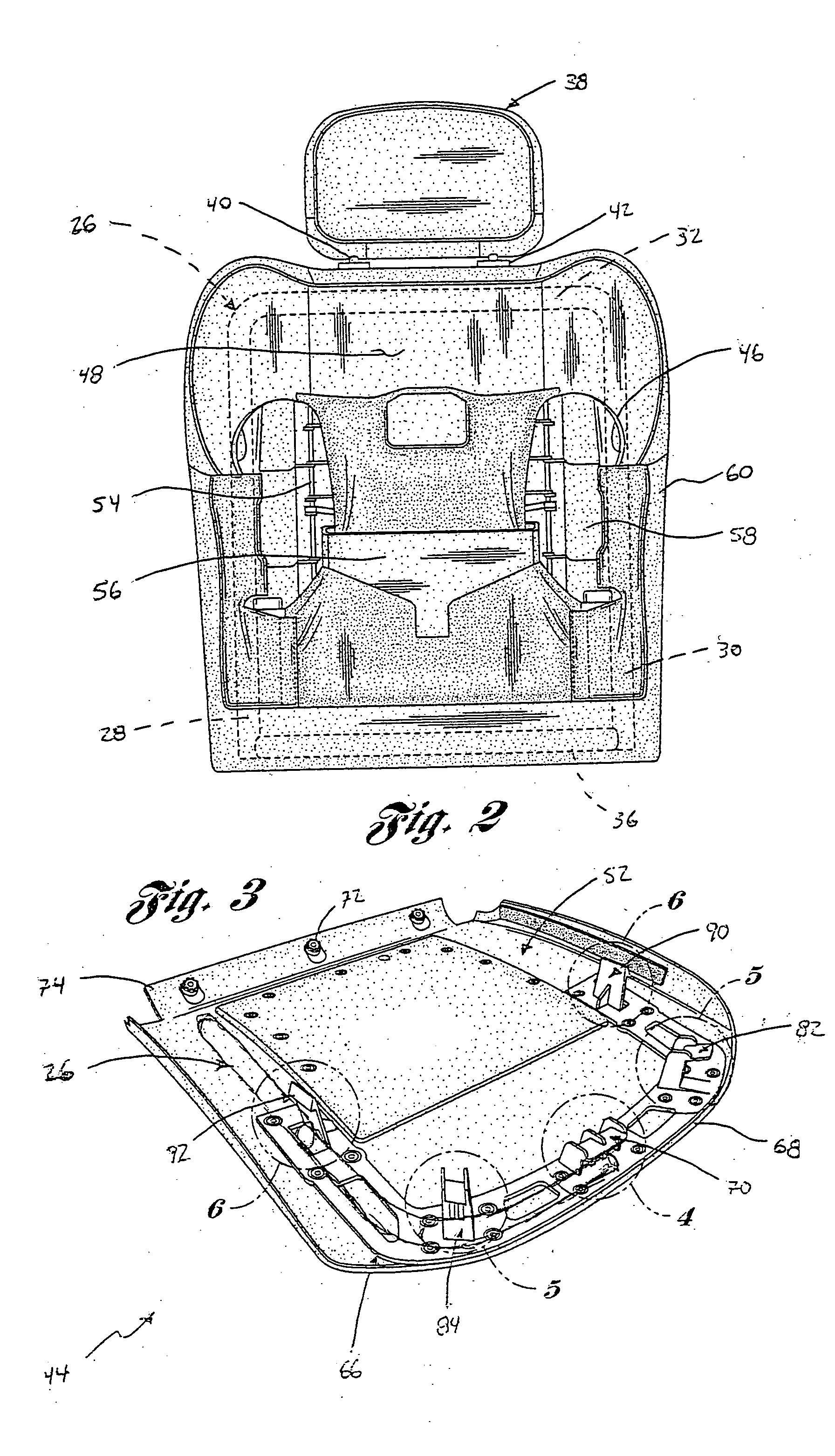

Apparatus for providing fluid through a vehicle seat

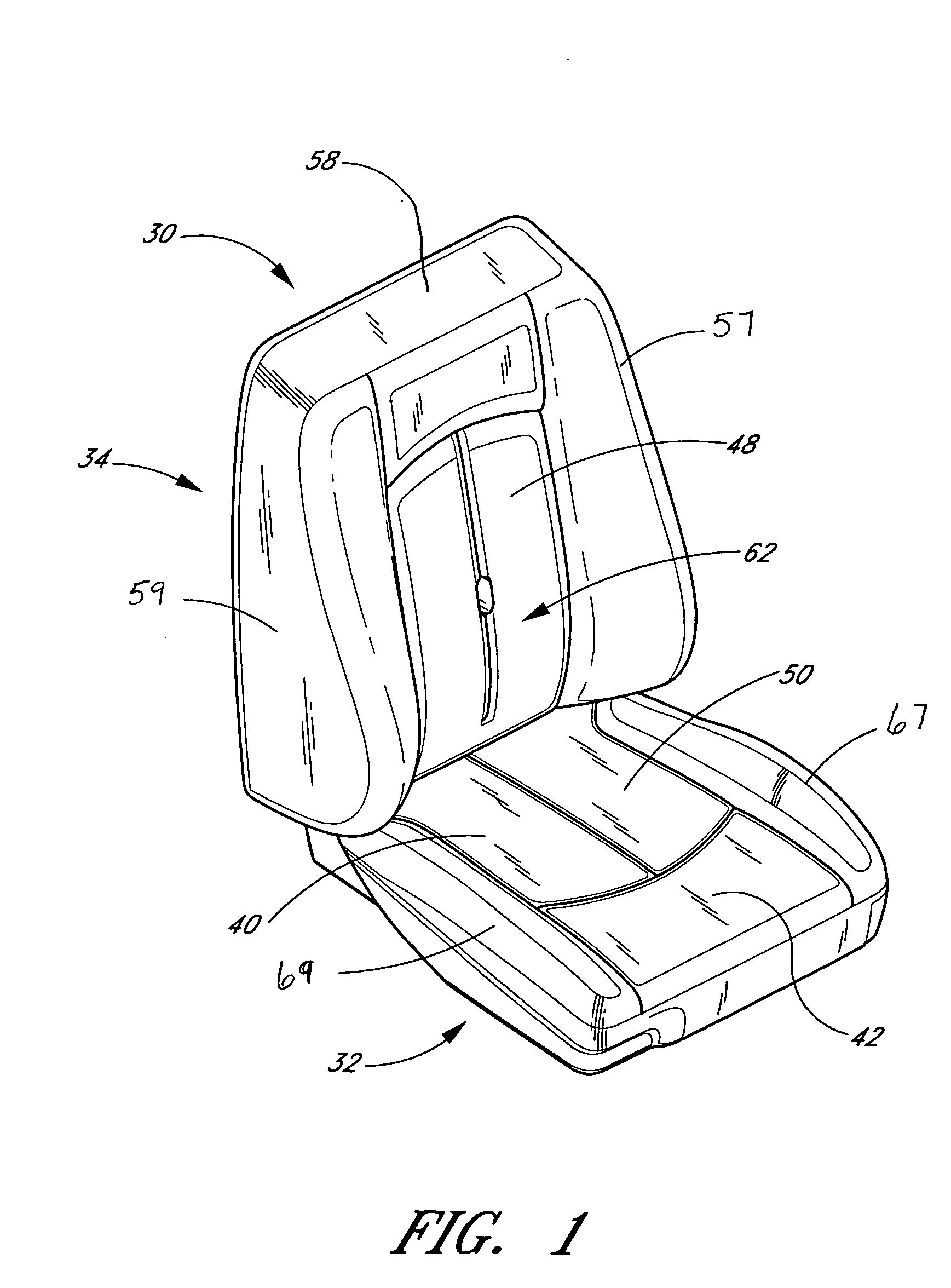

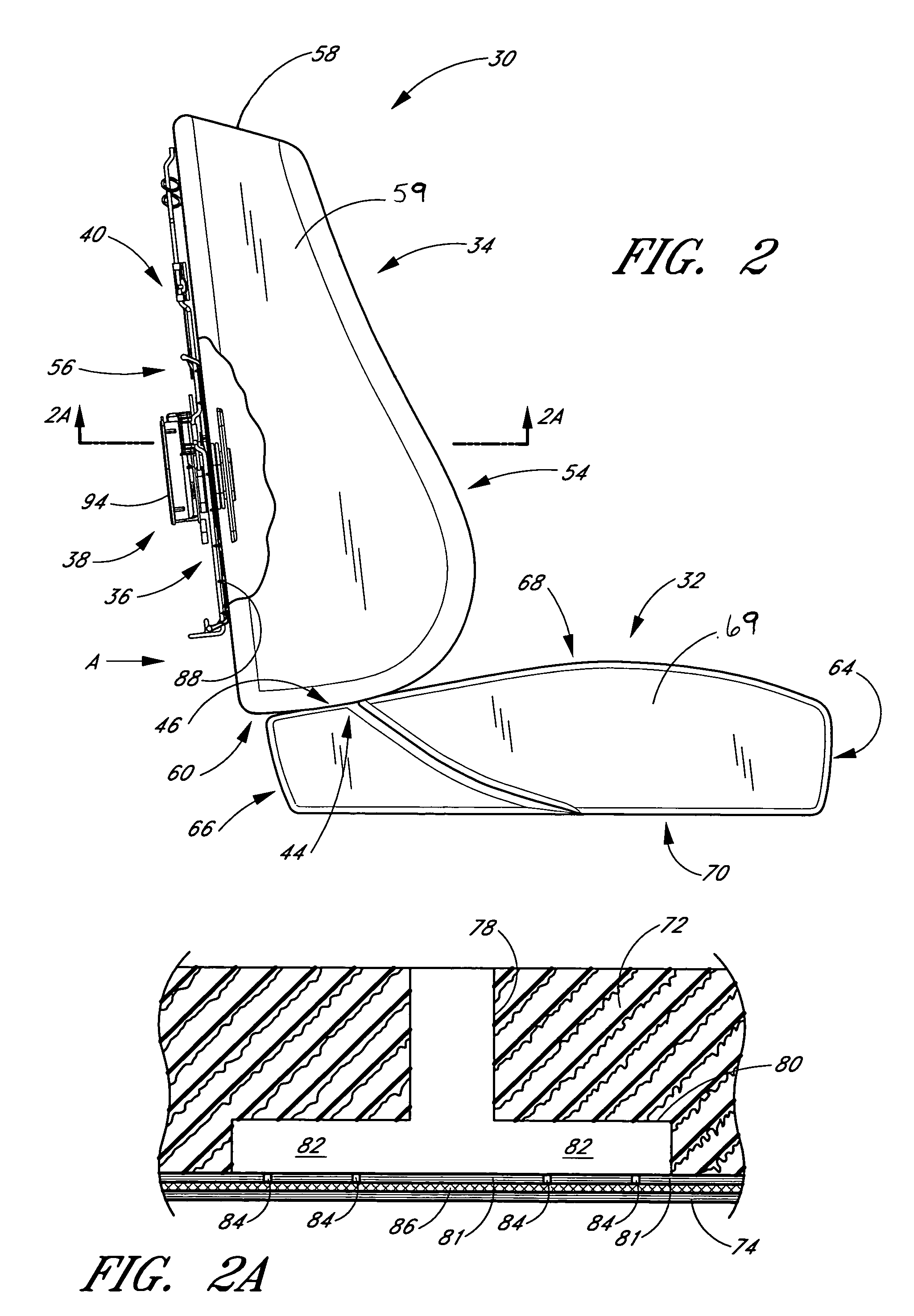

A seat assembly comprises a seat cushion having an outer surface comprising a front side for supporting an occupant in a sitting position and a rear side. A base member is positioned on the rear side of the seat cushion. An adjustable lumbar support device is provided on the rear side of the seat cushion. A first passage extends through the seat cushion. A ventilation system is provided for distributing air from the first passage along the support surface of the seat cushion. A climate control apparatus is provided for providing climate conditioned air to the ventilation system. A flexible conduit connects the climate control apparatus to the ventilation system.

Owner:AMERIGON INC

Adjustable lumbar support for vehicle seat

Owner:BUFFA JOHN A

Slouch rear seat system

Owner:LEAR CORP

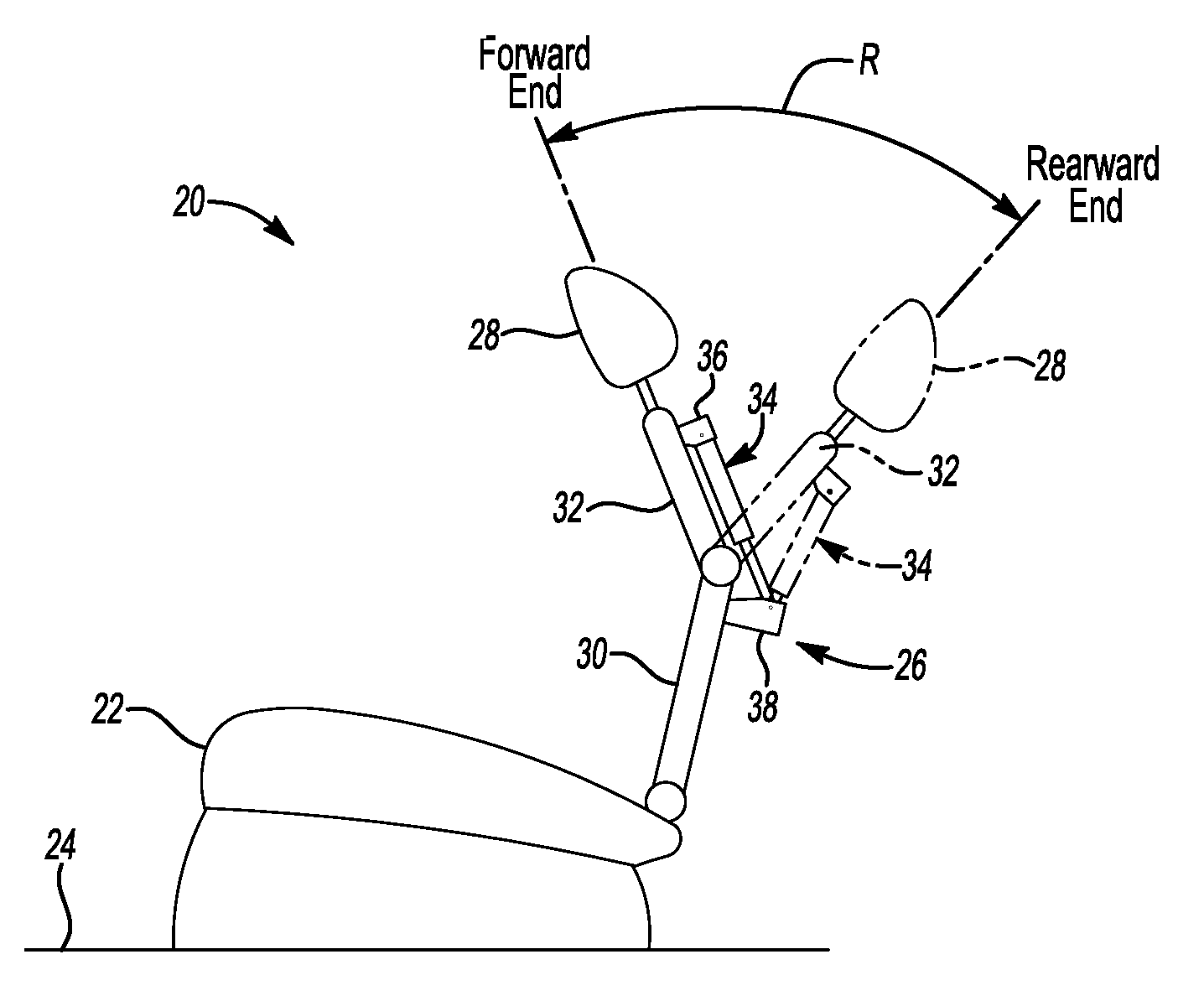

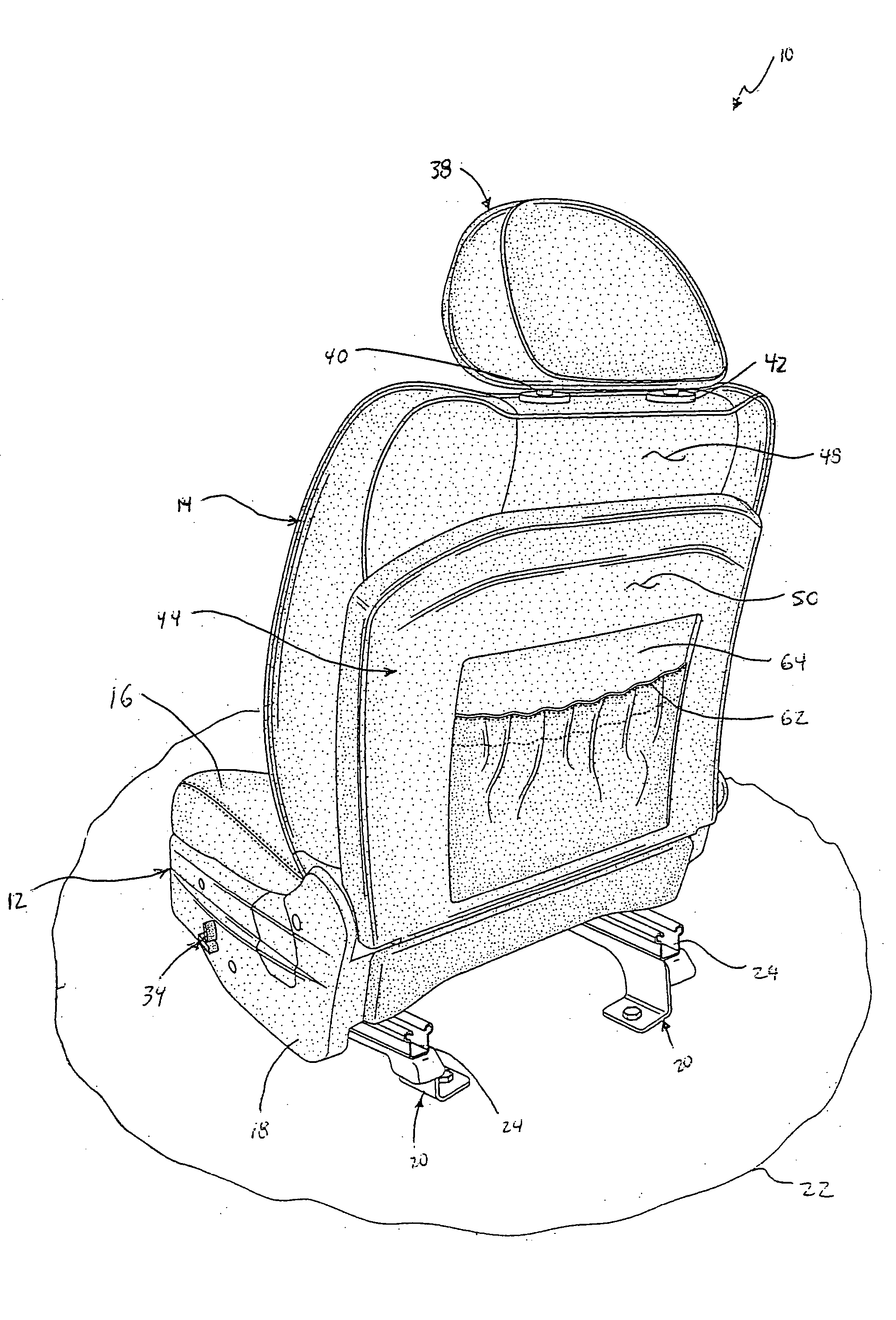

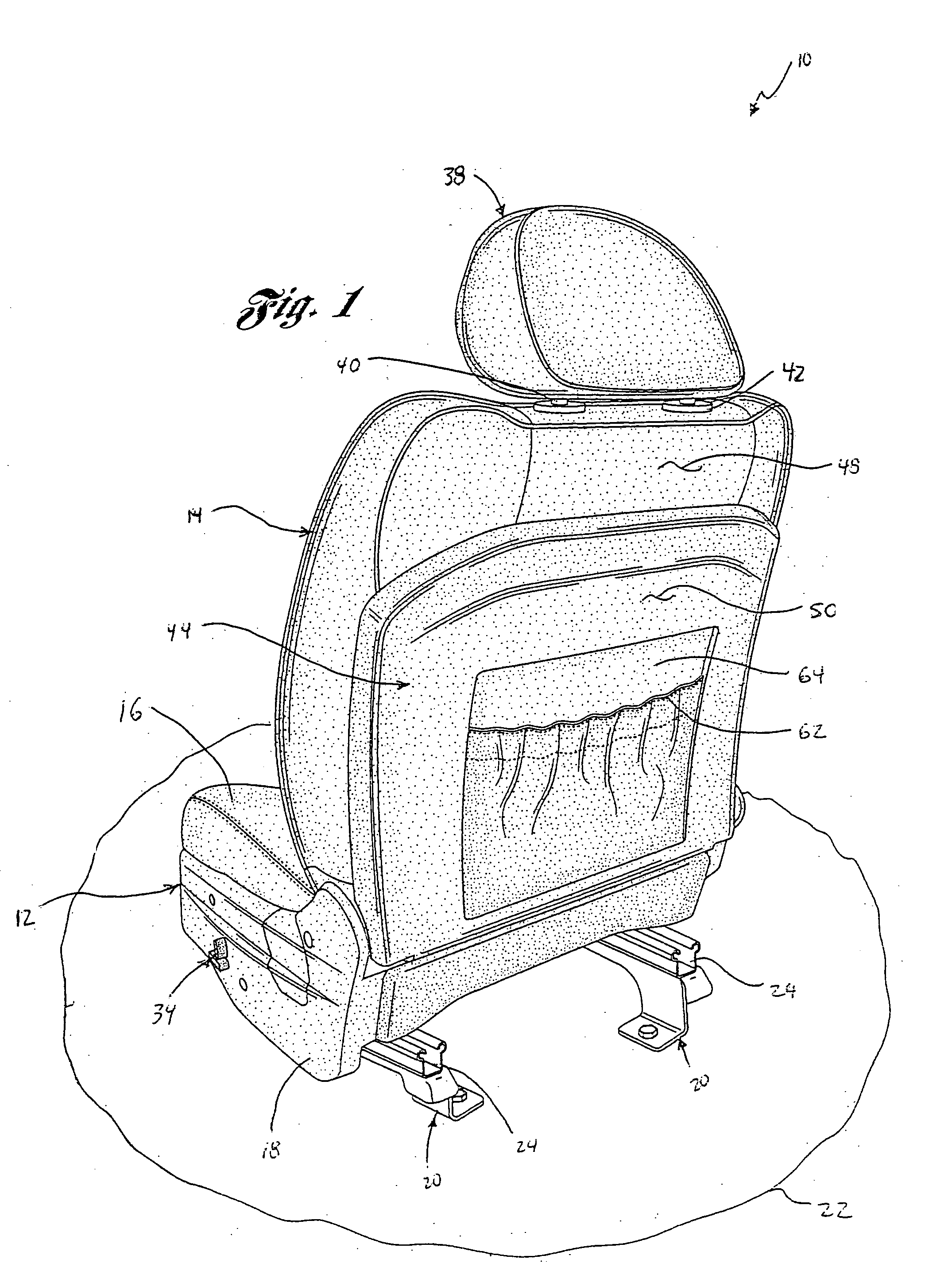

Vehicle seat assembly having a comfortable seat back portion

InactiveUS20100201167A1Hinder pivotal movementBack restsPedestrian/occupant safety arrangementEngineeringBack support

A vehicle seat assembly having a first back support member connectable to a seat bottom, a second back support member pivotally connected above the first back support member, the second back support member being configured to receive a headrest, and a biasing member connected to the second back support member. The second back support member pivots with respect to the first back support member though a defined range. The first biasing member is configured to urge the second back support member towards a forward end of the defined pivot range.

Owner:LEAR CORP

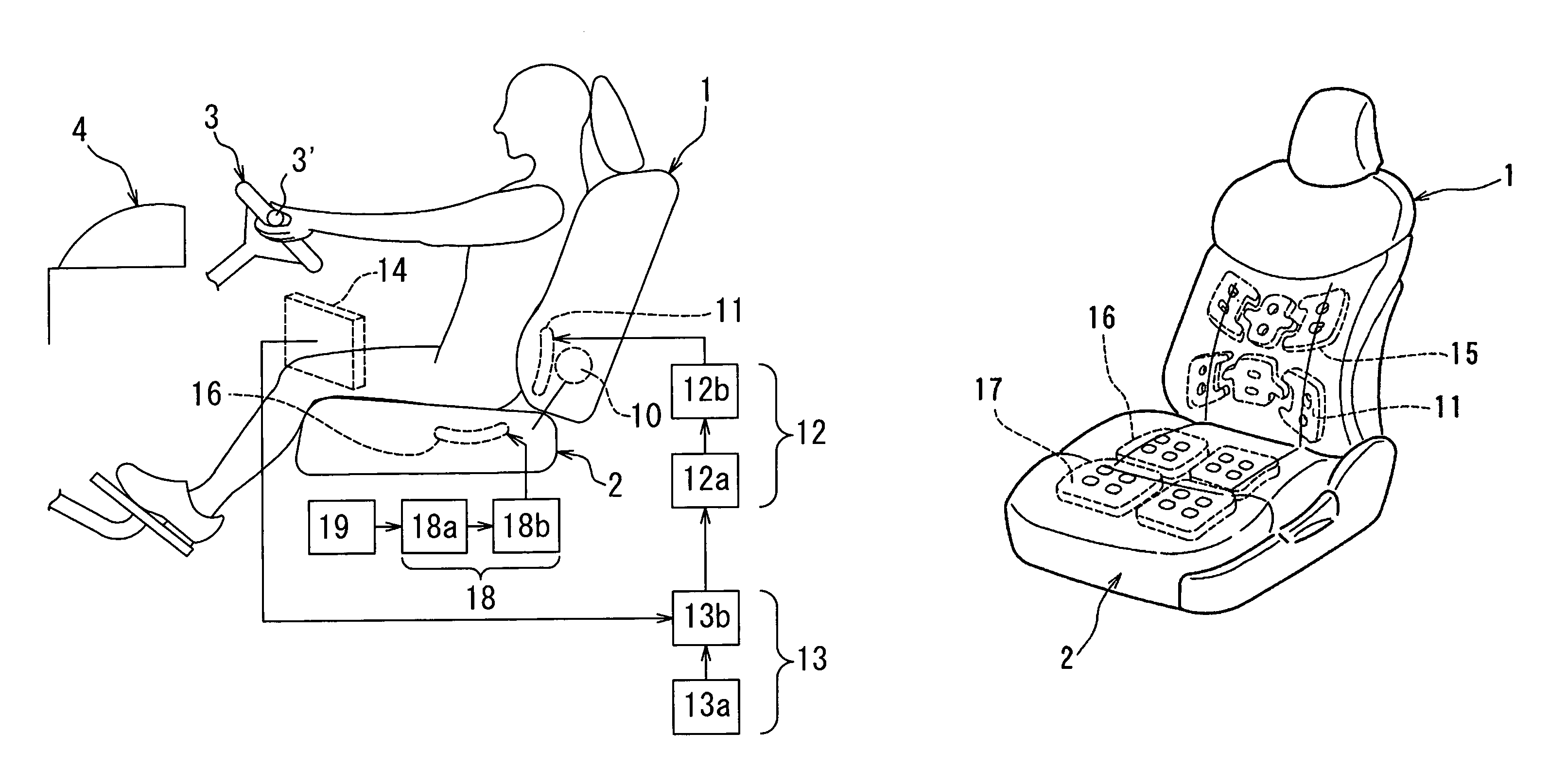

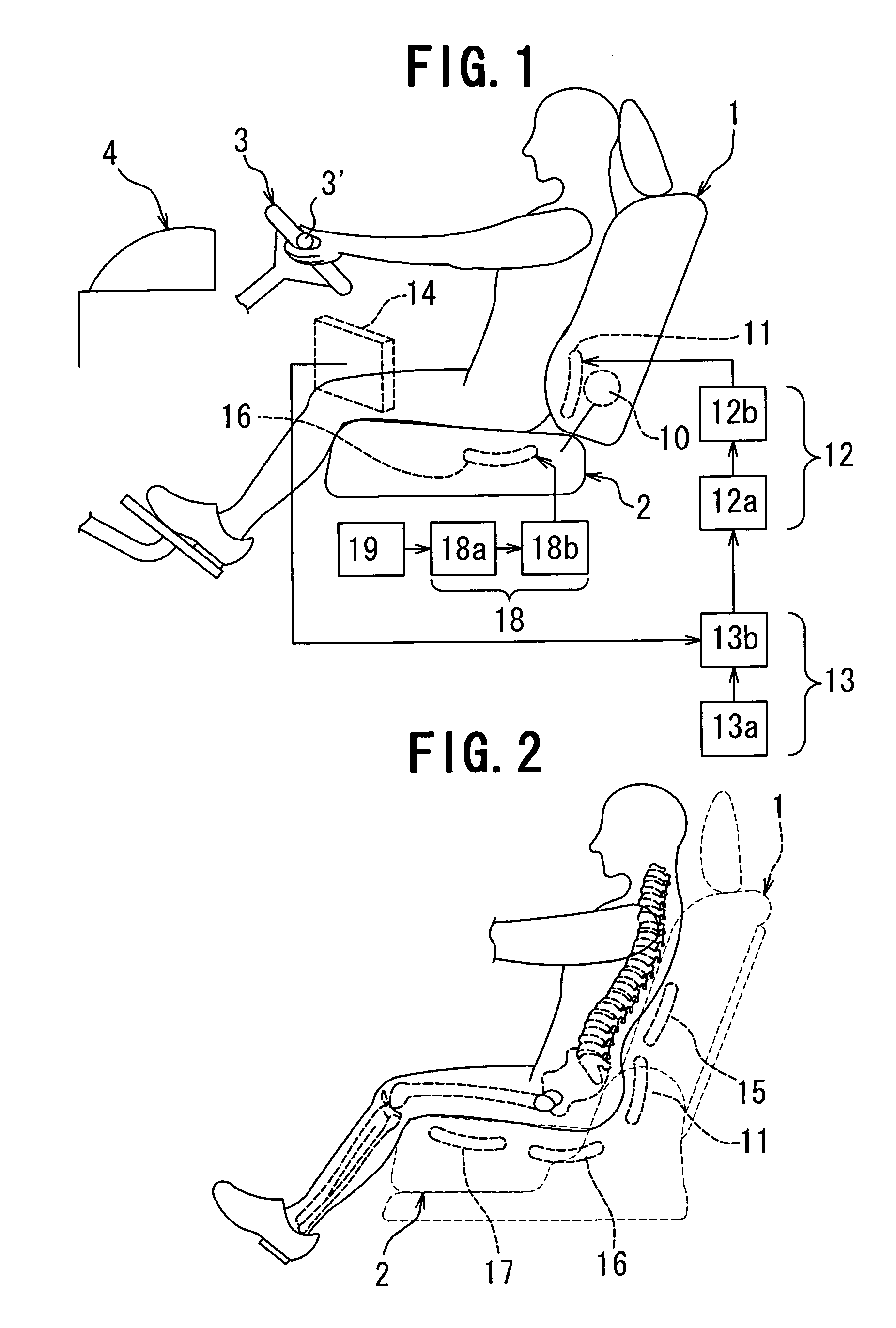

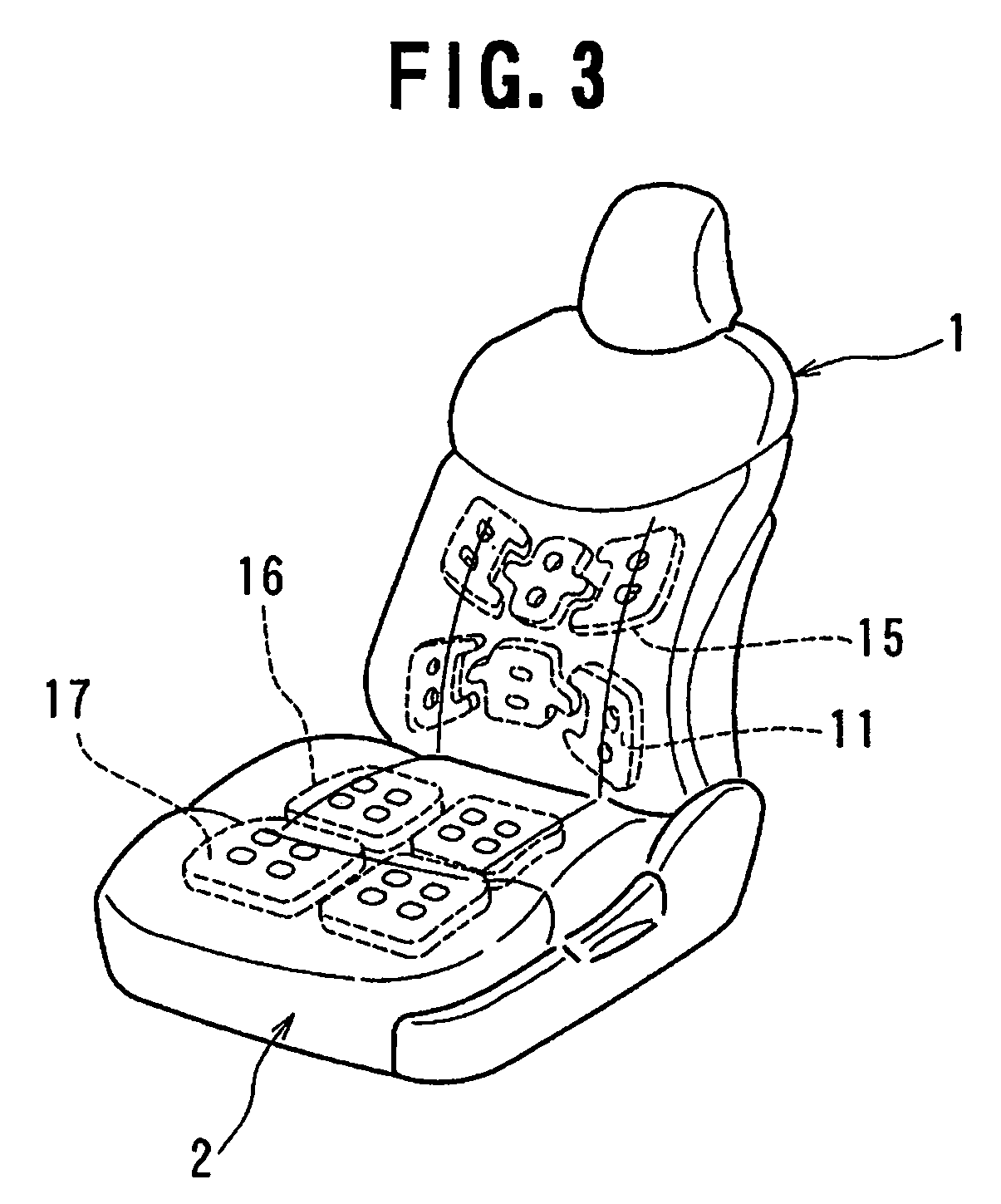

Vehicle seat with system for facilitating relieving of fatigue of person sitting on the seat

InactiveUS7152920B2Relieve fatigueImprove fatigueBack restsDismountable chairsPelvic regionElectricity

A vehicle seat includes a seat back, a seat cushion, and a system for facilitating relieving of fatigue of a person sitting on the vehicle seat for many hours. The system includes an angle sensor installed within the seat back for sensing variations in an angle of a pelvic region of the person sitting on the vehicle seat, an active device installed within the seat back for pressure-supporting the pelvic region of the person, an actuating device connected to the active device for actuating the active device and a sequential control unit electrically connected to the angle sensor and the actuating device for controlling the operation of the actuating device, the angle sensor being constructed so as to send the sequential control unit signals representing values of variations in the angle of the pelvic region of the person, the sequential control unit being constructed such that, when a value represented by a signal sent to the sequential control unit from the angle sensor is more than a predetermined value, the sequential control unit sends the actuating device a command to actuate the actuating device, whereby the active device is actuated, to thereby control supporting pressure that is applied to the pelvic region of the person.

Owner:TS TECH CO LTD

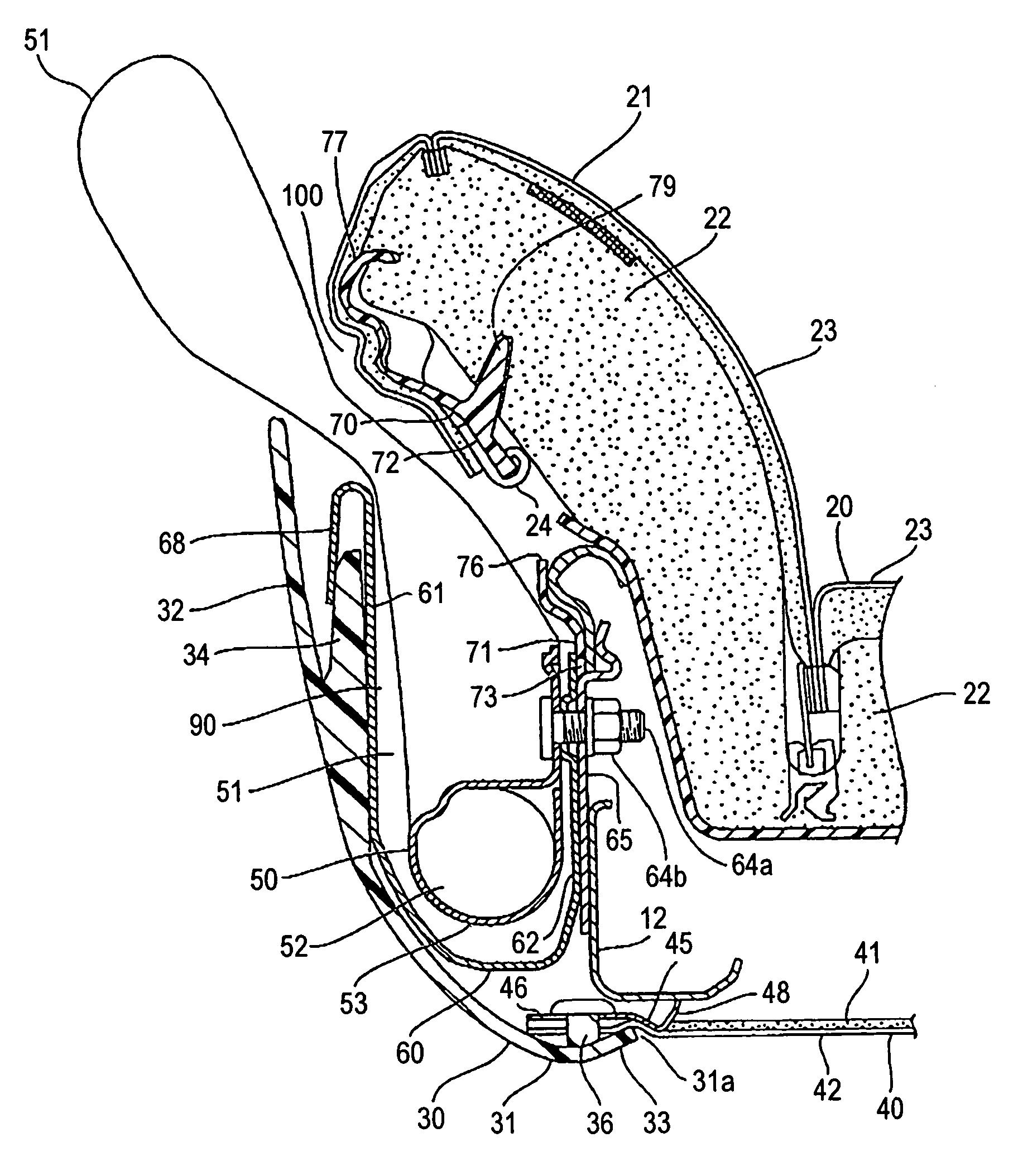

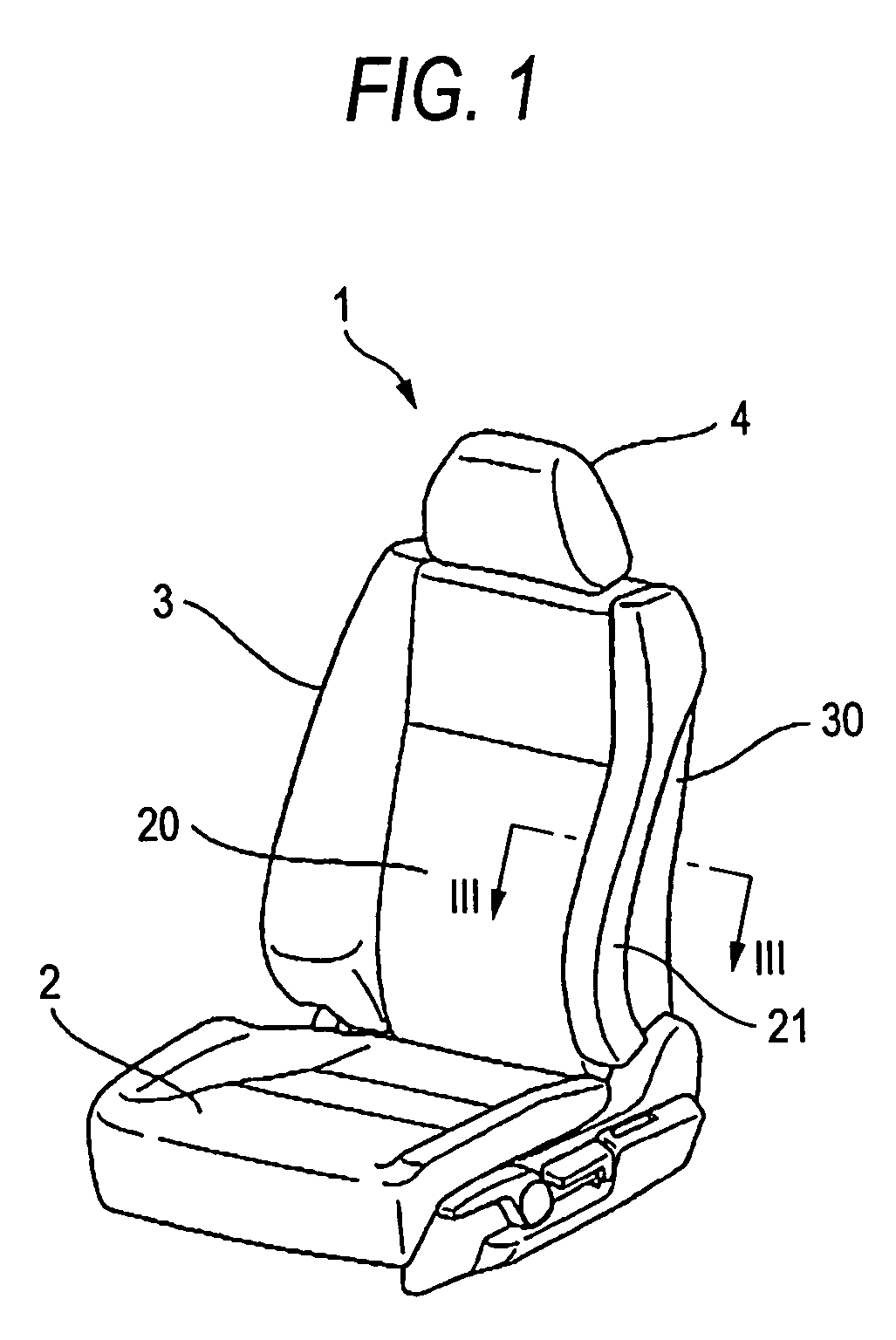

Seat for vehicle use

InactiveUS7393005B2Simple structureReduce manufacturing costSeat coveringsBack restsEngineeringMechanical engineering

In a back portion of a seat back provided with a lumbar support portion 20 and a side support portion 21, a seat back cover 30 for covering a back face of the seat back is provided. The seat back cover 30 is provided with a side portion 32 for covering an air bag module 50 by making a forward end portion, which is extended to the front side of a vehicle, come into contact with the side support portion 21. The side support portion 21 is provided being capable of oscillating to the front side of the vehicle with respect to the lumbar support 20. An air bag module 50 is arranged in an accommodation space 90 provided on the rear side of the side support portion 21.

Owner:HONDA MOTOR CO LTD

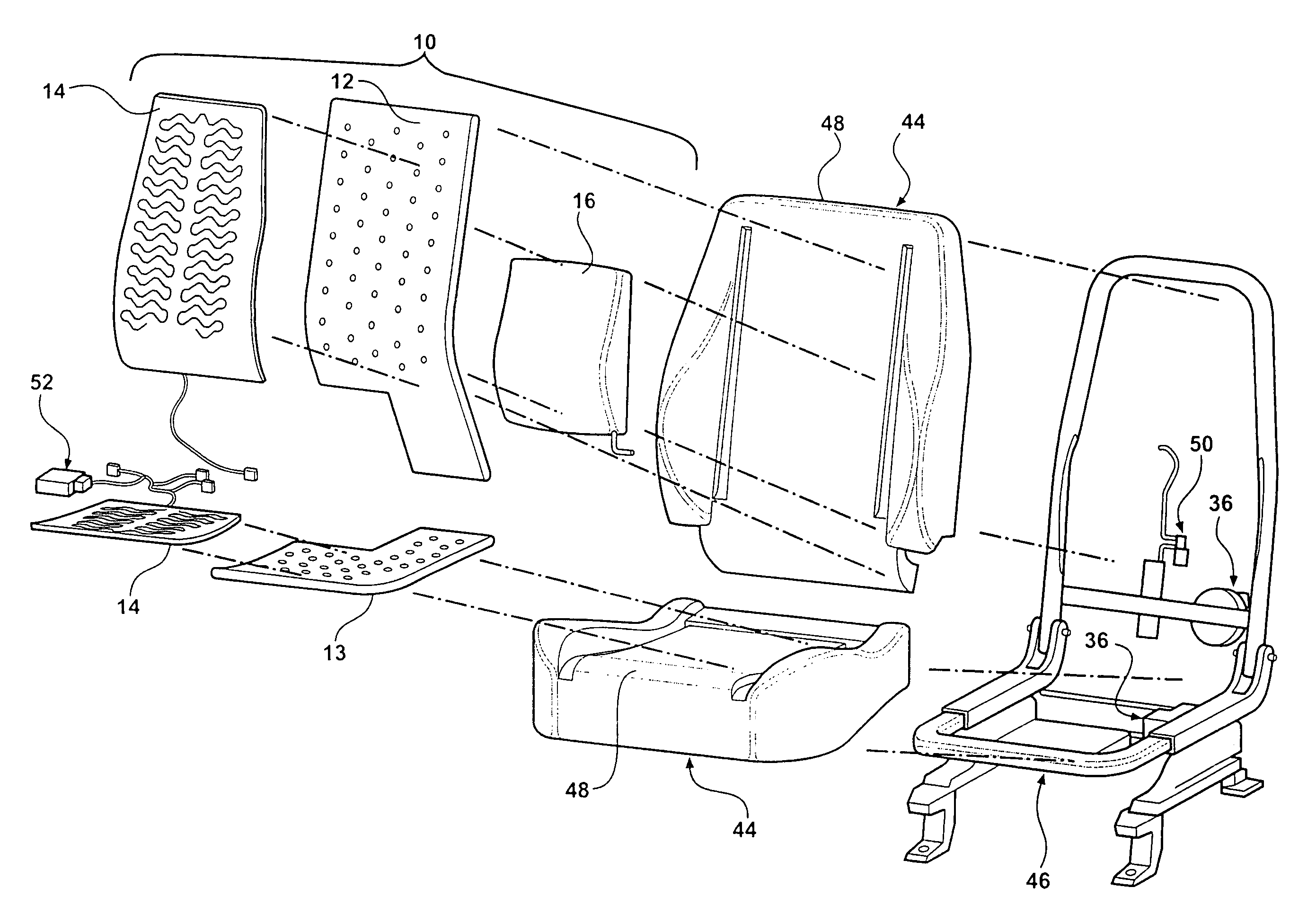

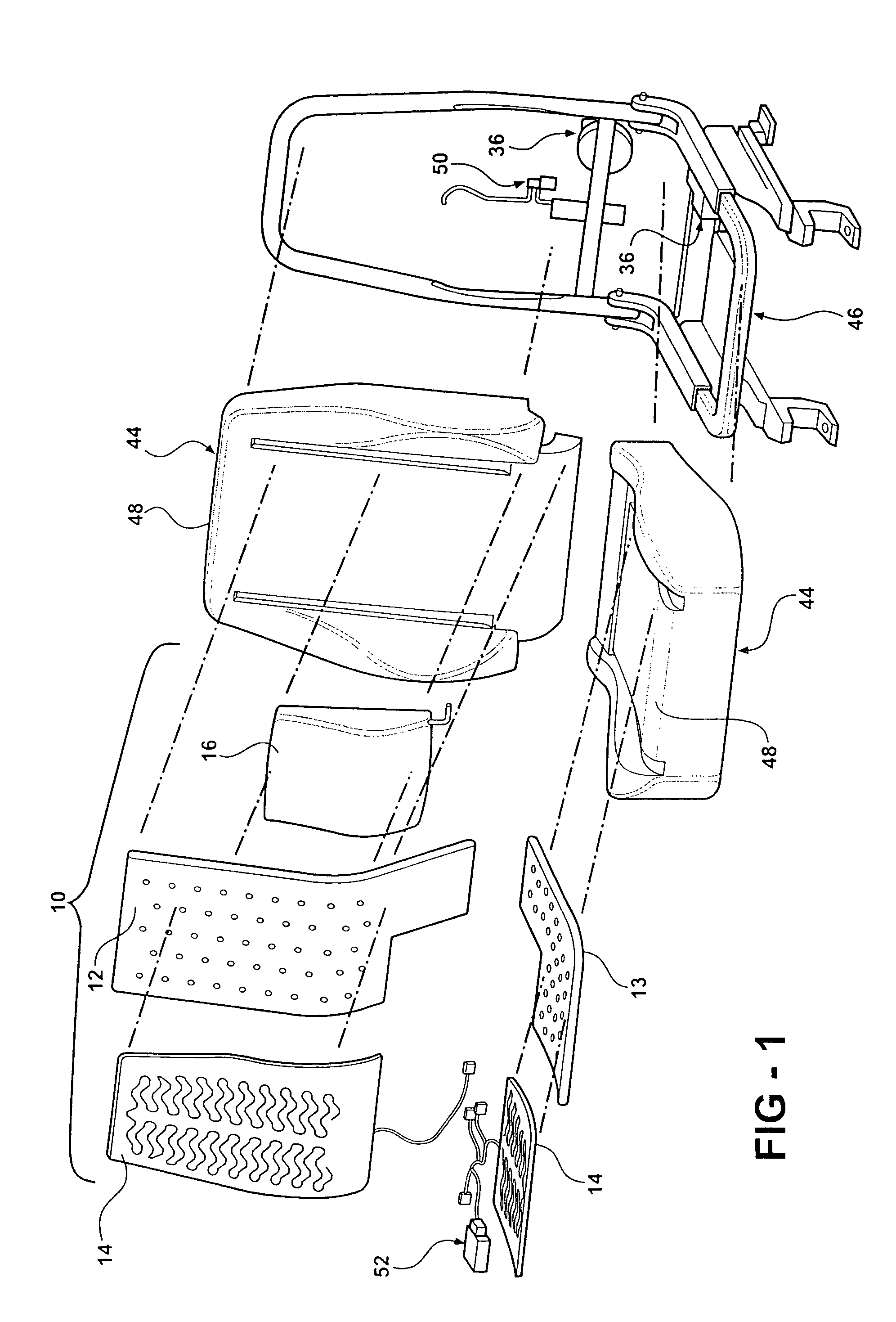

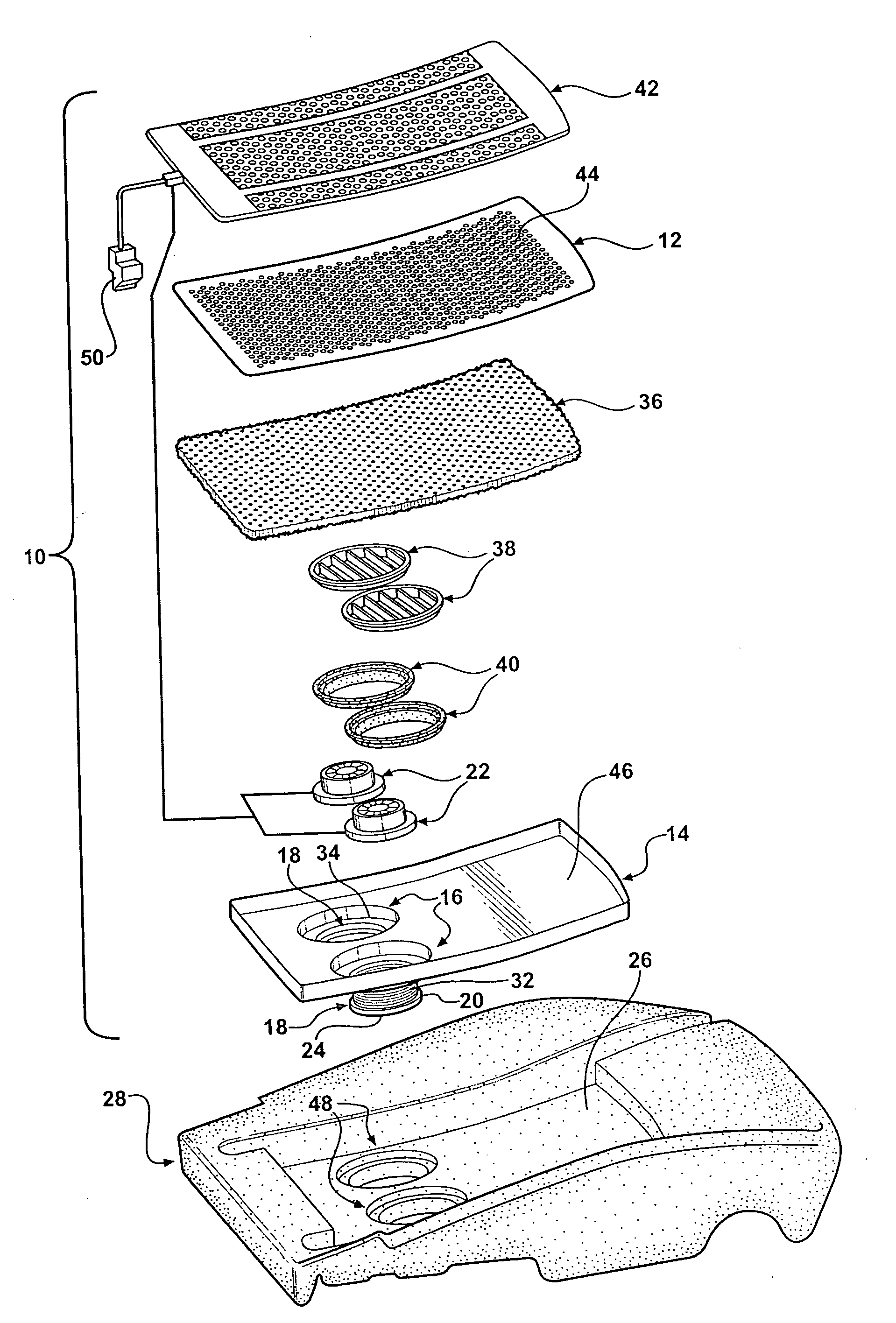

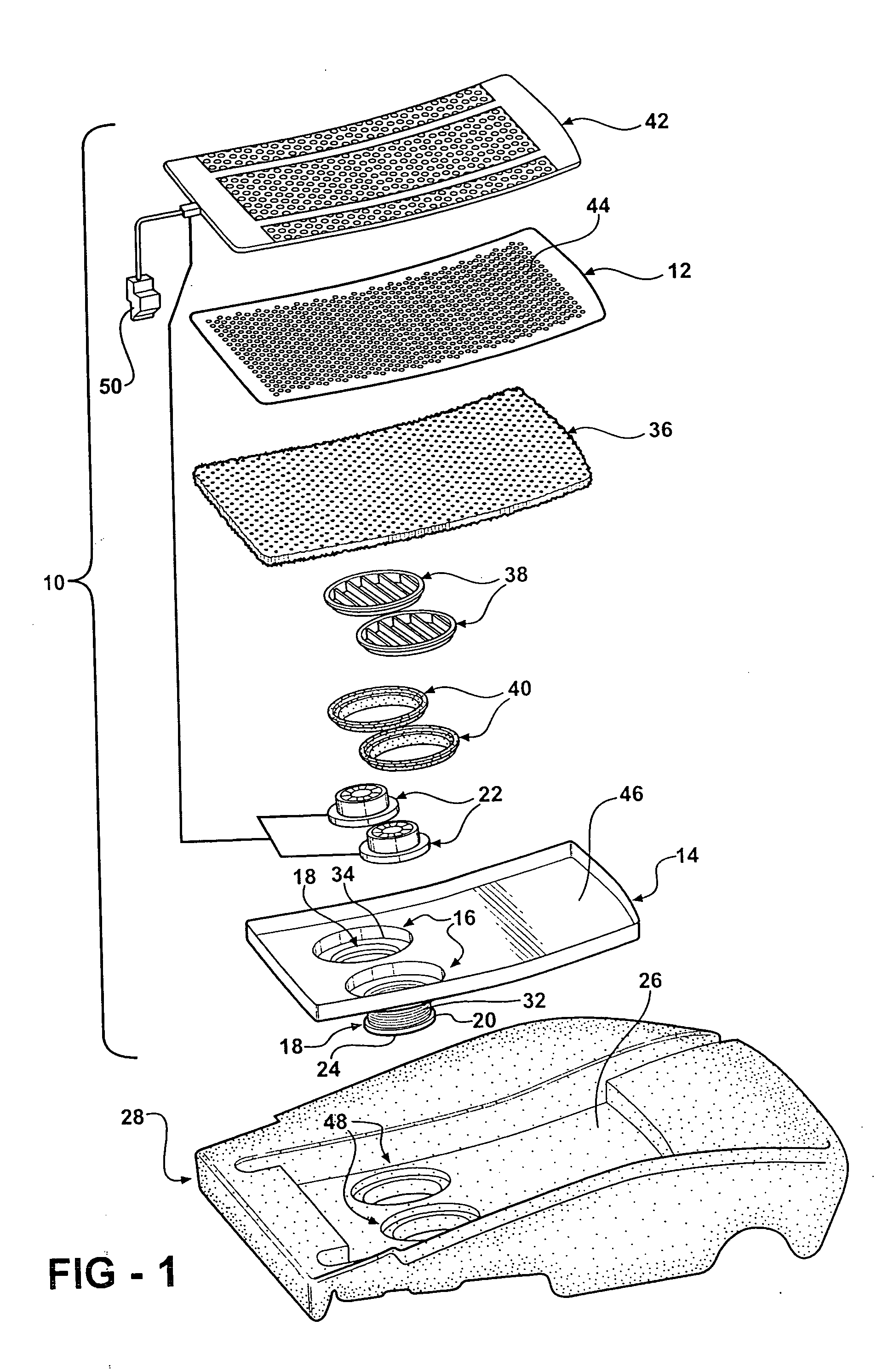

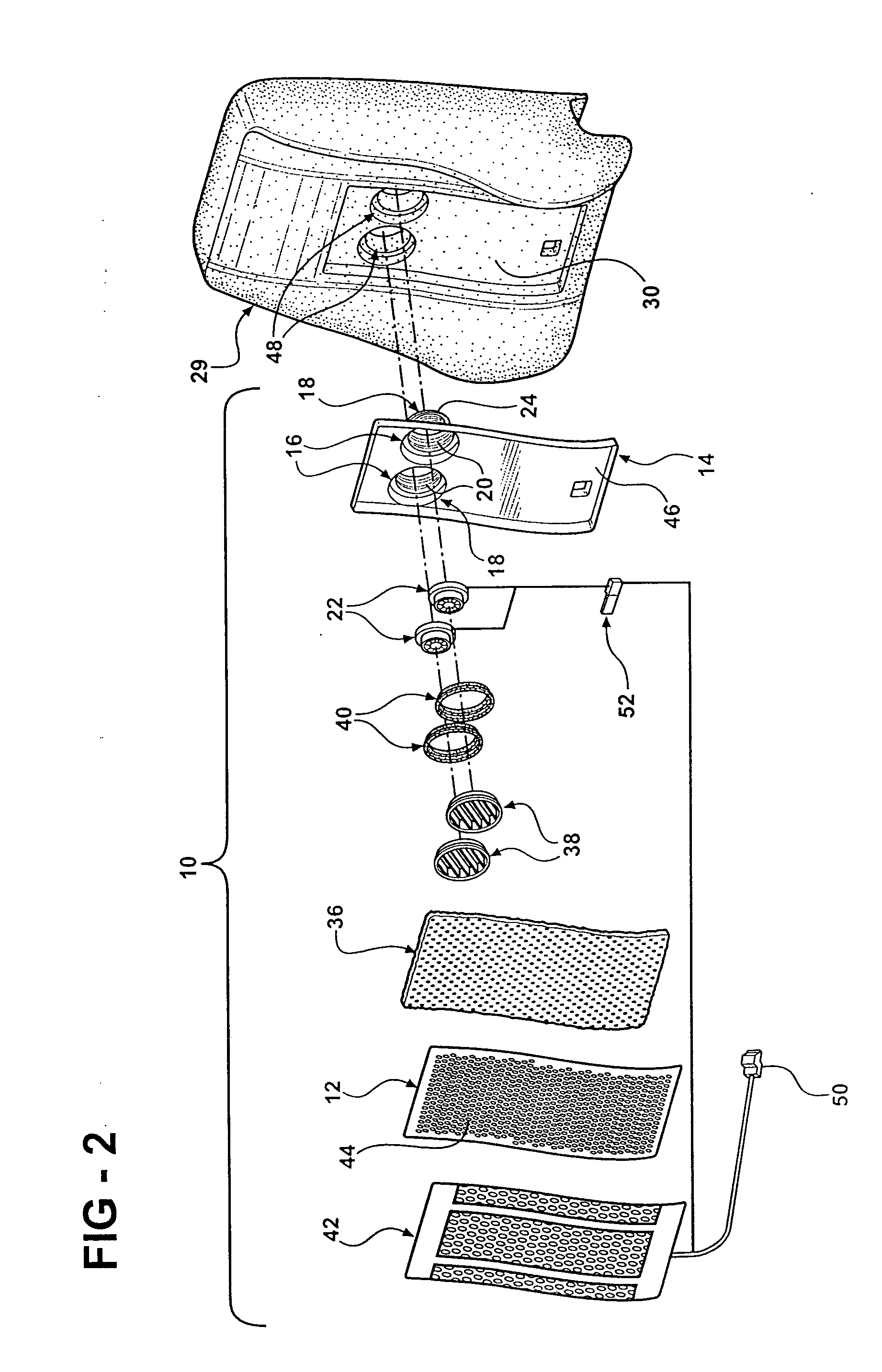

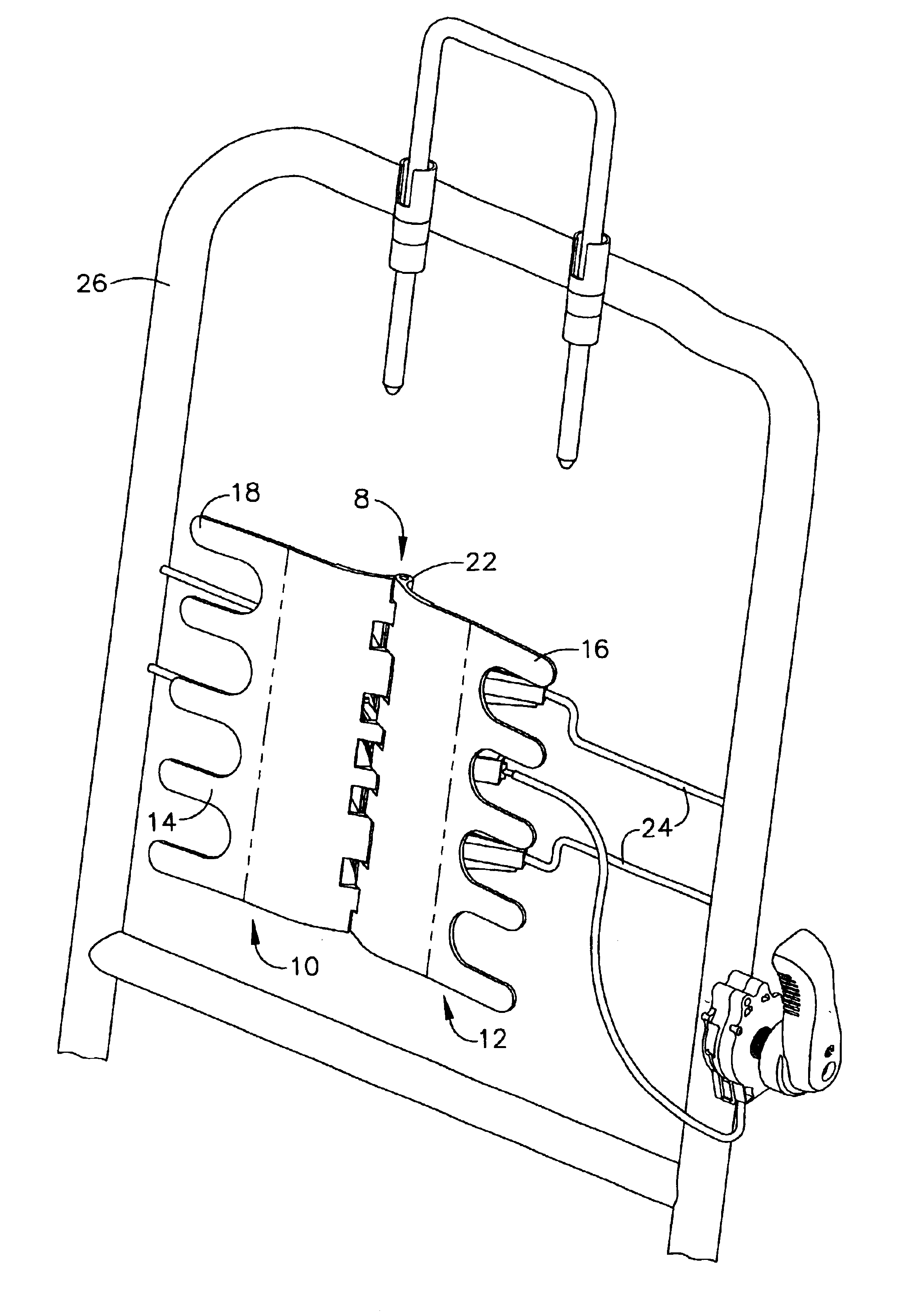

Modular comfort assembly for occupant support

A method of installing a modular comfort assembly within an occupant support includes the step of providing a modular comfort assembly including a heating element and at least one of a ventilation diffuser bag and a lumbar support system, the heating element, the diffuser bag, and the lumbar support system being modularly attachable to each other on sides thereof. The occupant support includes an outer cover, an internal foam bun, and a frame. The method further includes the step of mounting the modular comfort assembly onto a surface of the foam bun beneath the outer cover.

Owner:IGB AUTOMOTIVE

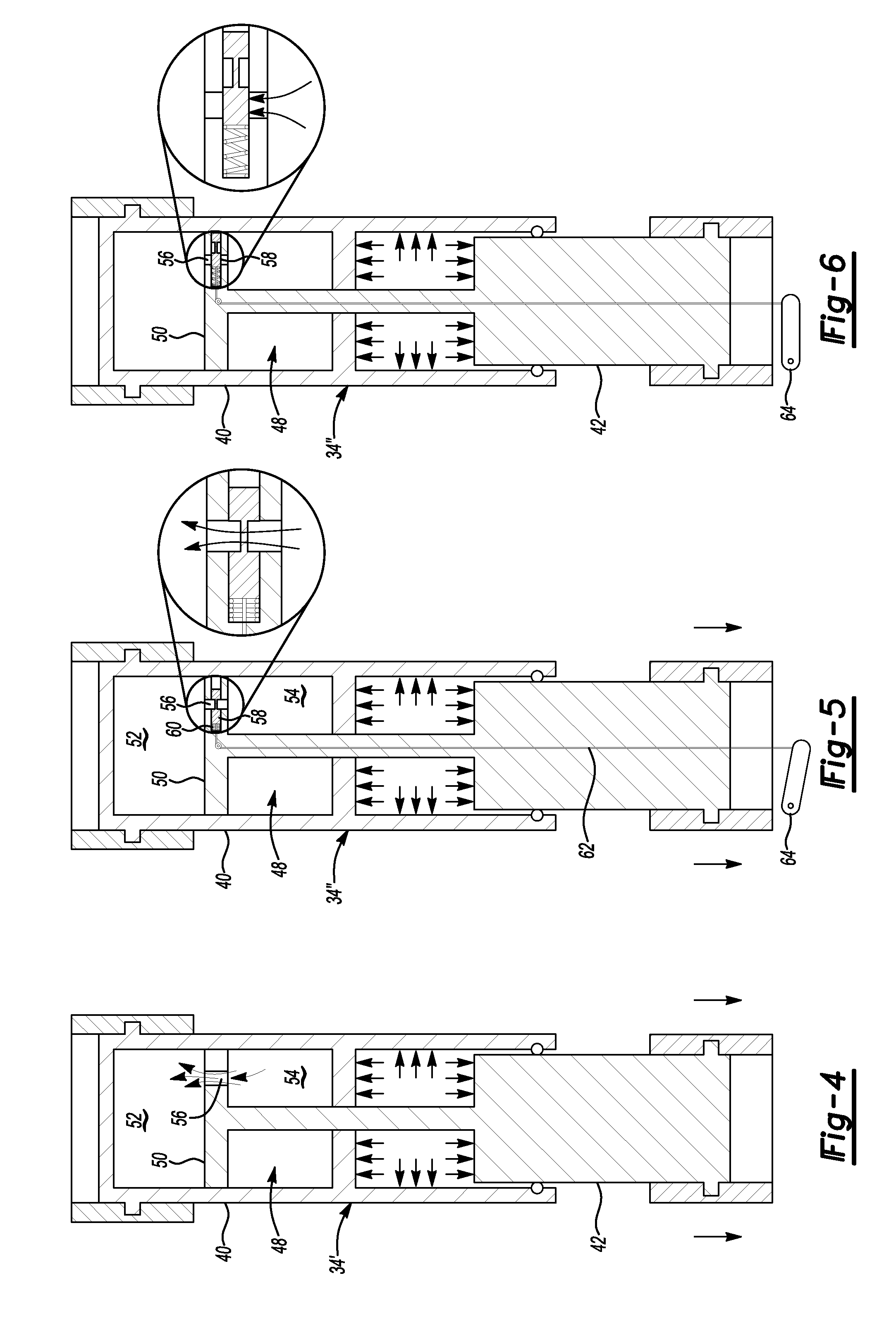

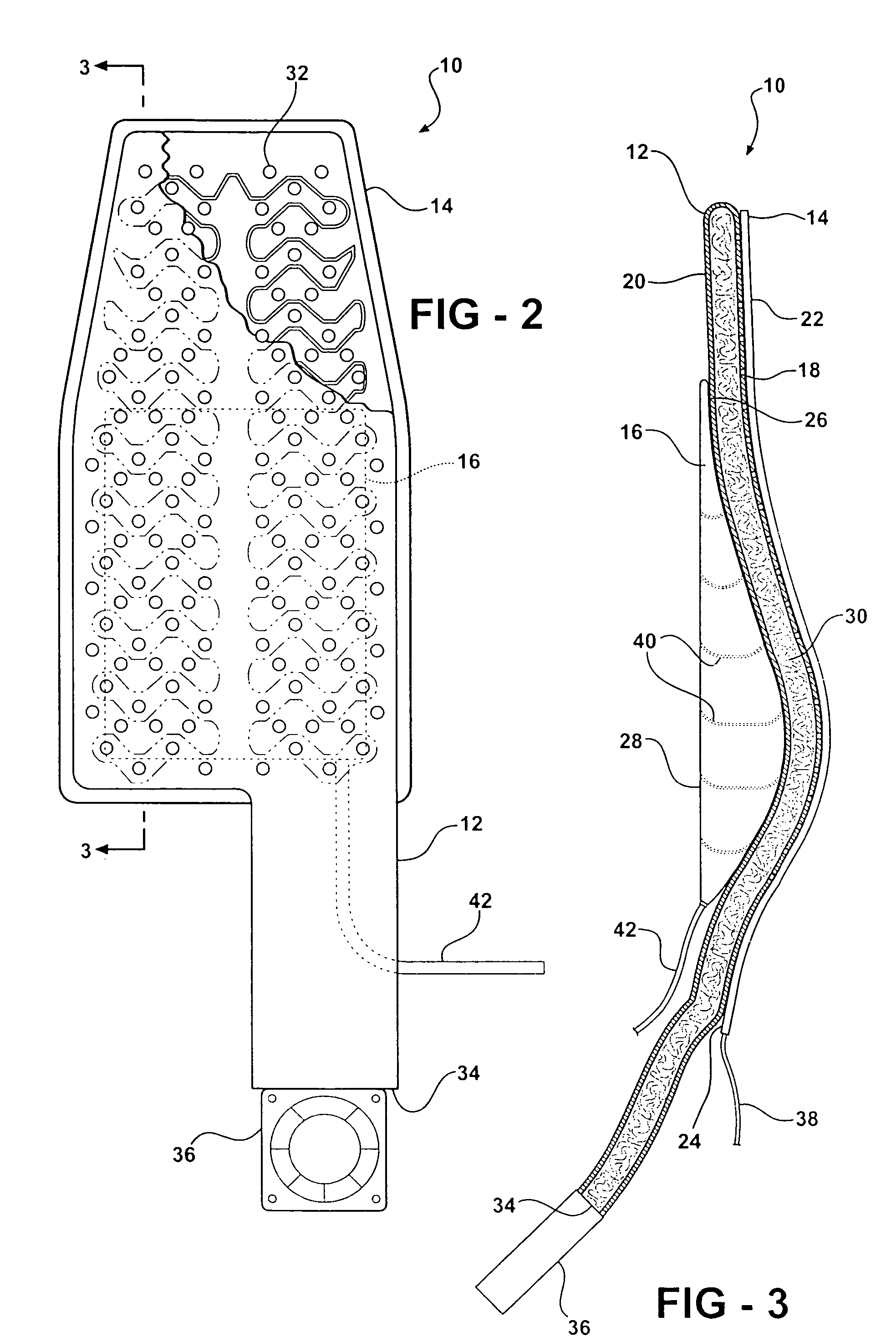

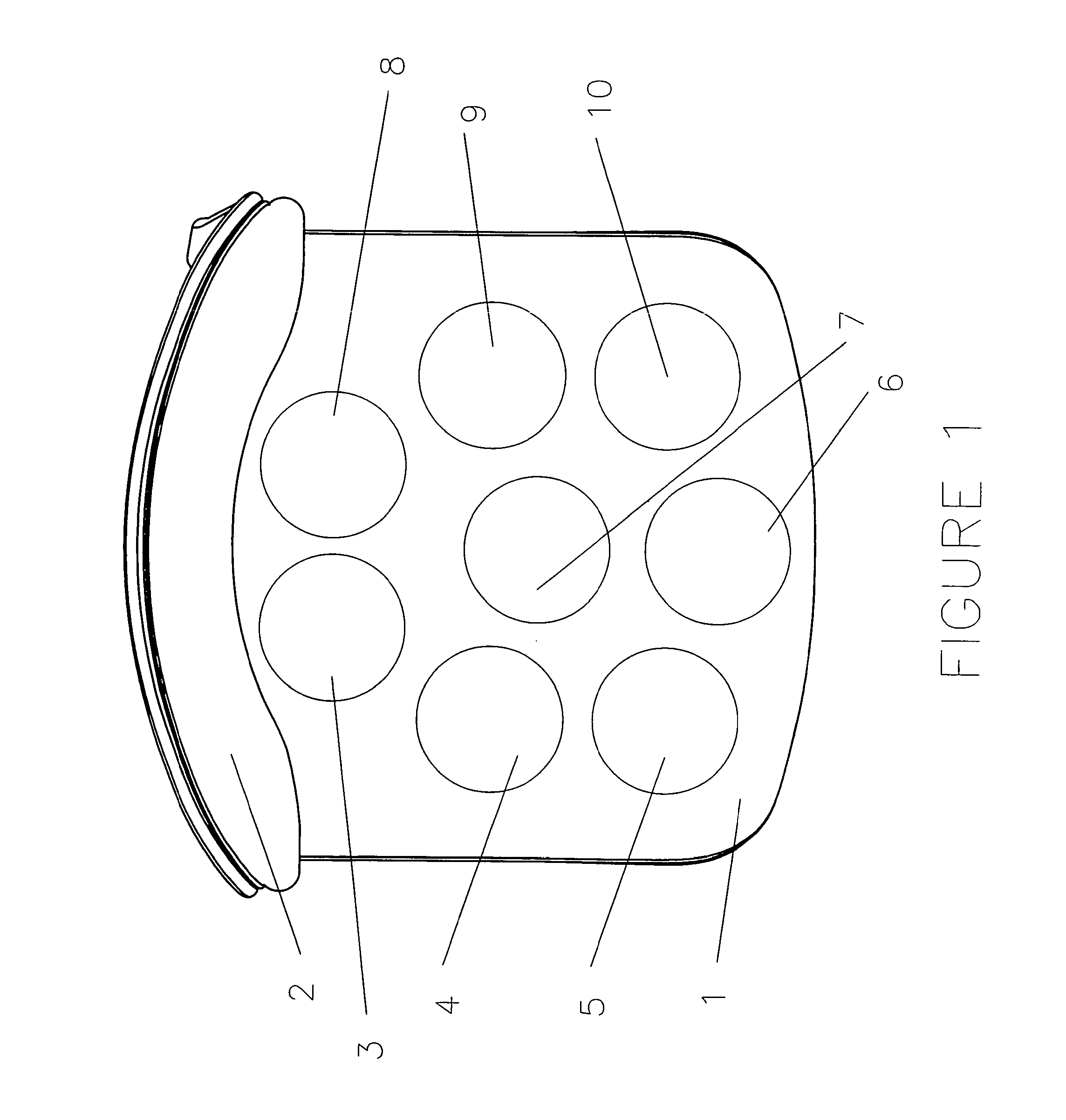

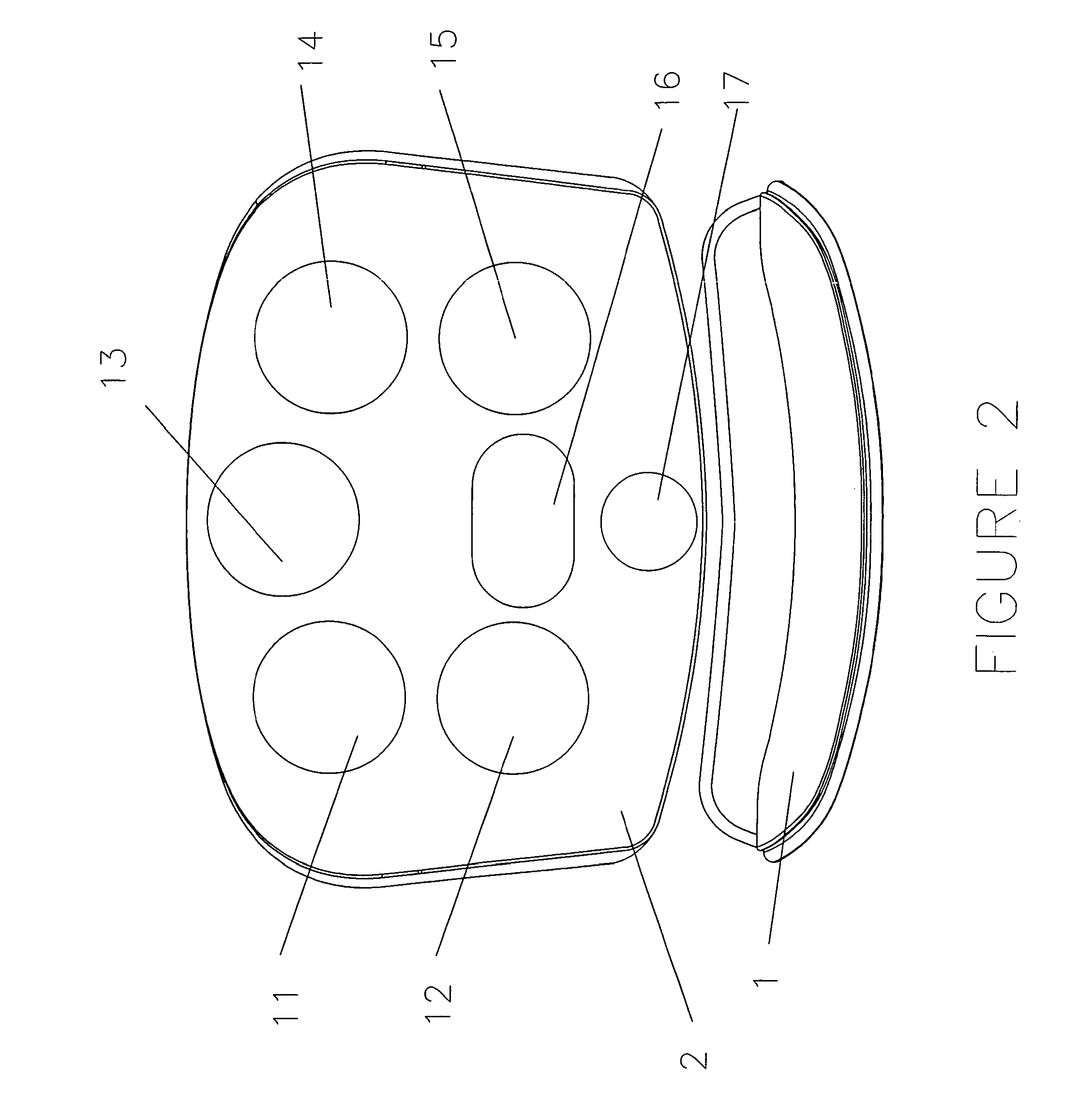

Modular comfort assembly diffuser bag having integral air mover support

A ventilation diffuser bag for disposition on a vehicle occupant support includes a perforated, occupant facing side and an opposite non-perforated, support surface facing side. The non-perforated side includes an opening to allow air flow into the diffuser bag. An air mover support integral with the non-perforated side includes an endless sidewall extending from the opening for providing support for an air mover. The endless sidewall includes a retaining edge spaced from the non-perforated side for suspendably retaining the air mover within the air mover support. The non-perforated side of the diffuser bag is supportable on an occupant facing surface of a vehicle occupant support, and the air mover support extends into the occupant support.

Owner:IGB AUTOMOTIVE

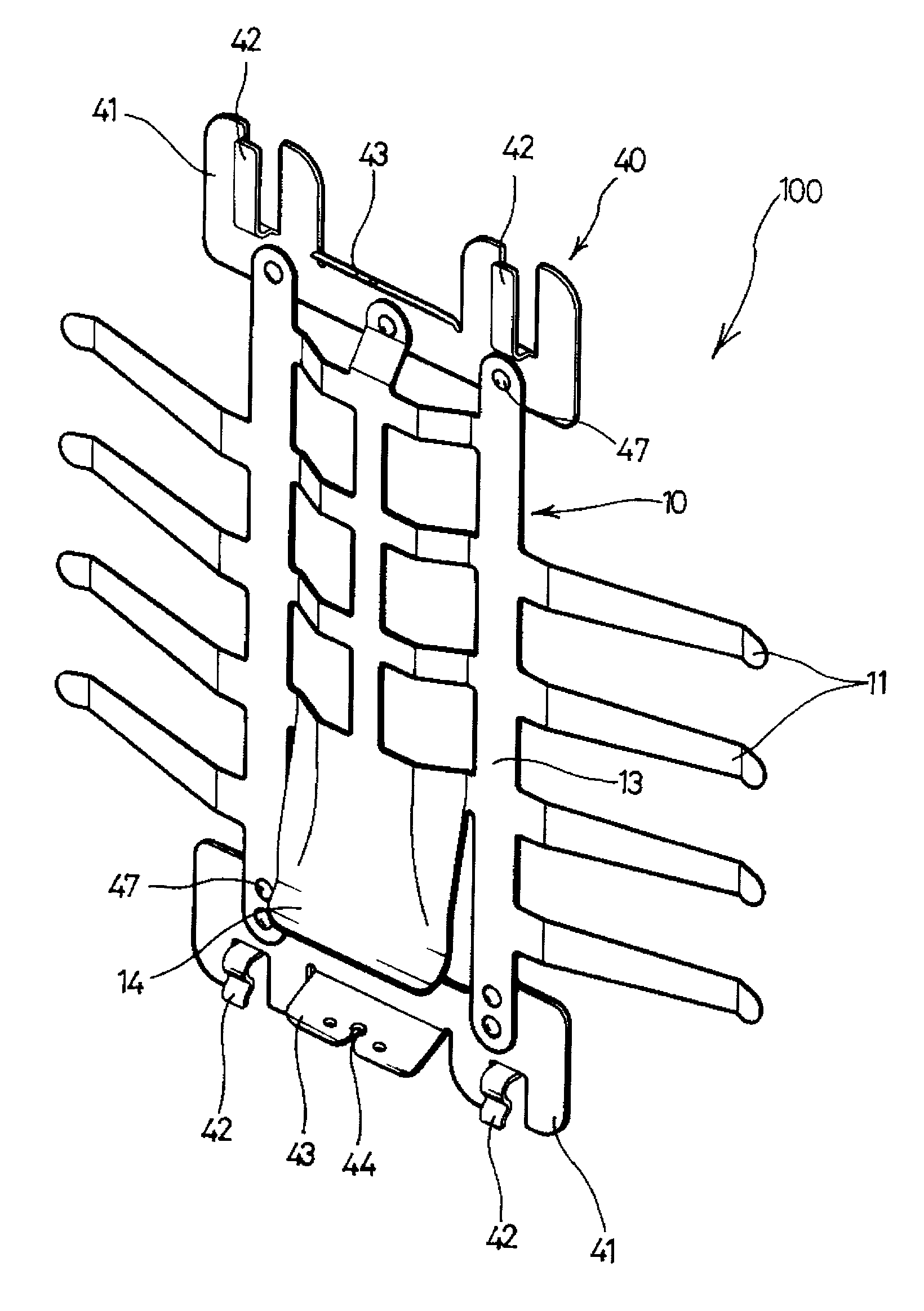

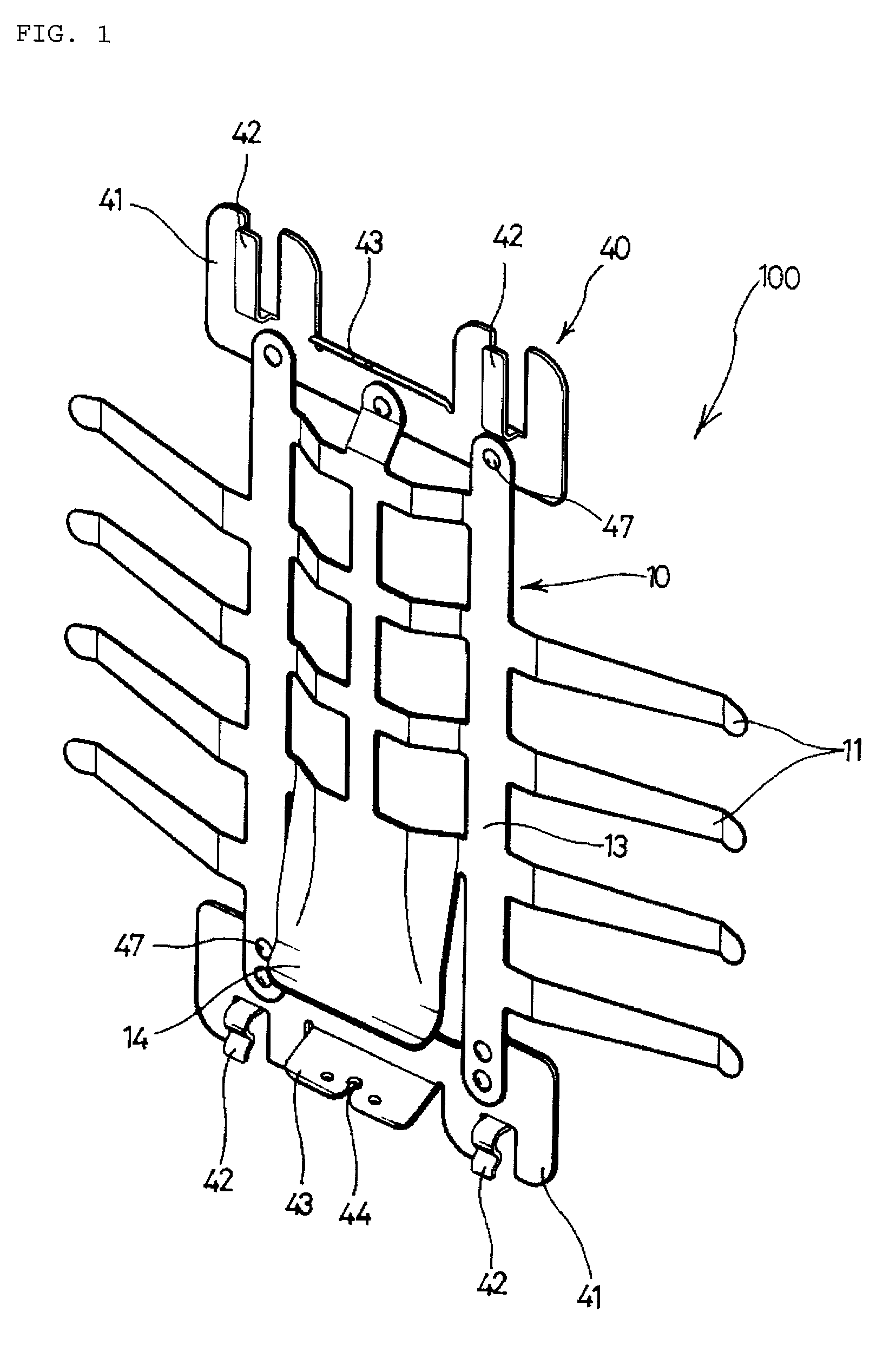

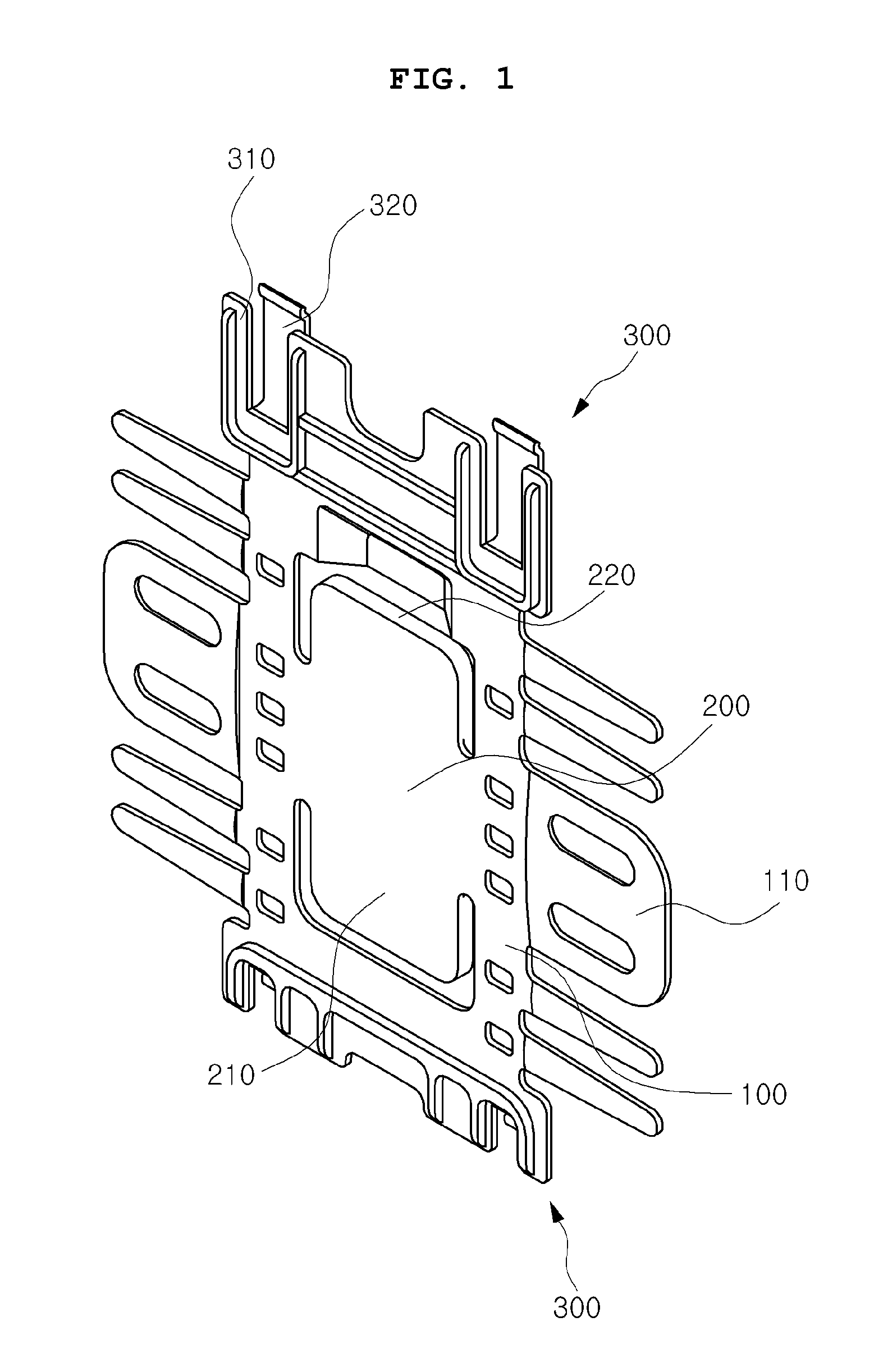

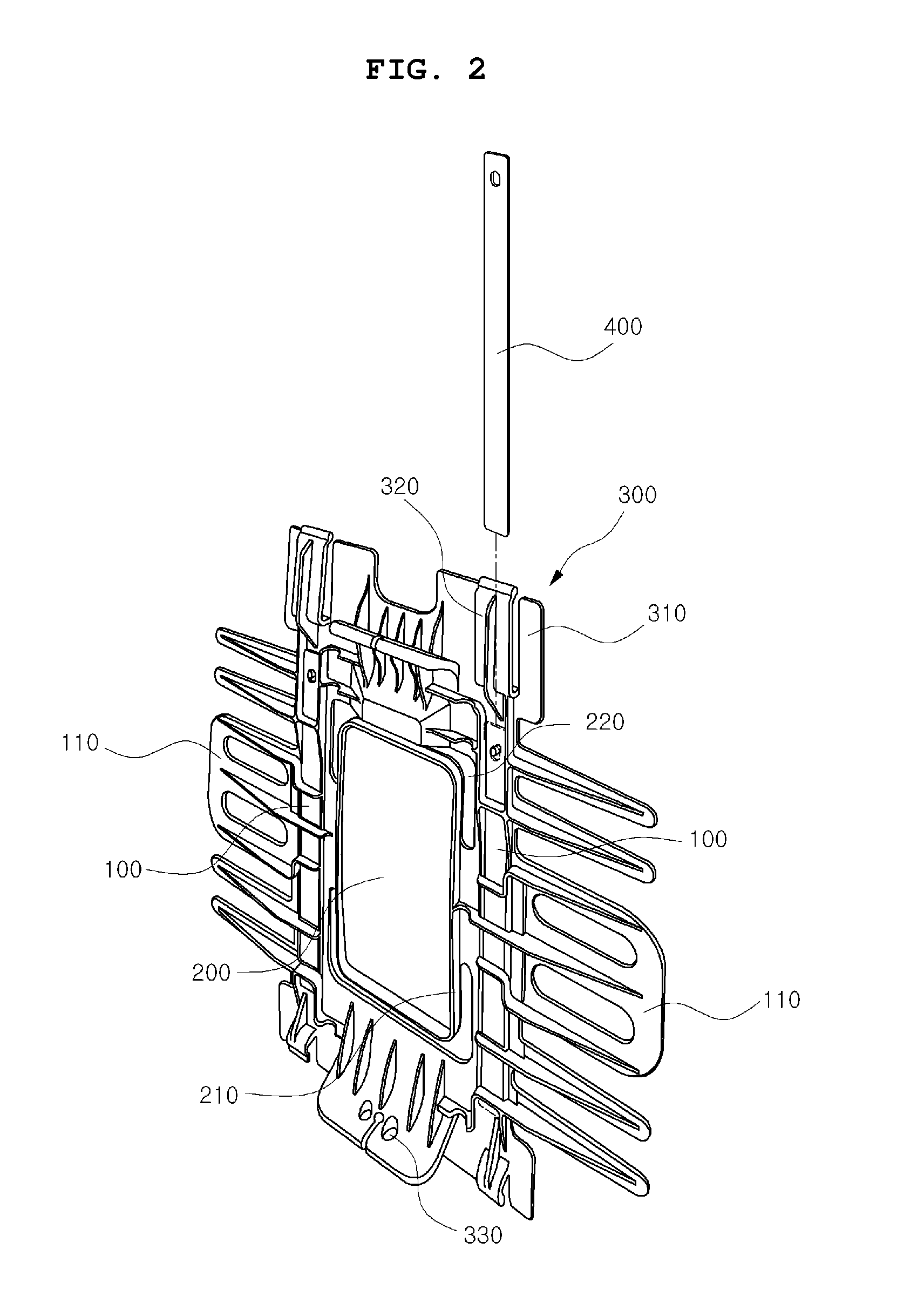

Lumbar support for car seat

A lumbar support for a car seat includes a support element formed of a plate spring having a high elasticity to be positioned between traverse fixing bars which are mounted at upper and lower parts in a seat back for supporting a lumbar portion of a driver, and having a plurality of support wings formed at both sides and folded outwardly for surrounding the lumbar portion of the driver and a curved protrusion optionally formed in the center for supporting the lumbar portion of the driver, coupling units for coupling the support plate with the traverse fixing bars, a supporting height control element for steplessly controlling a protruded height of the support plate which is selectively and curvedly protruded at a side of the support plate, and a pelvic supporting element formed at a lower part of the support plate and connected to the support plate to contact and support hips of the driver, wherein the contact between the seat and the driver may be improved by forming the pelvic supporting element at the lower part of the support plate for stably supporting the lumber region and the pelvic region of the driver seating in the seat, so that it is possible to promote the safety driving by preventing the driver from being tired easily even in case of the long time driving, and to prevent the bad pose of the driver by the stable supporting of the lumbar region and the pelvic region of the driver, thereby maintaining the safety and the health of the driver.

Owner:HONG CHEONG MYUNG

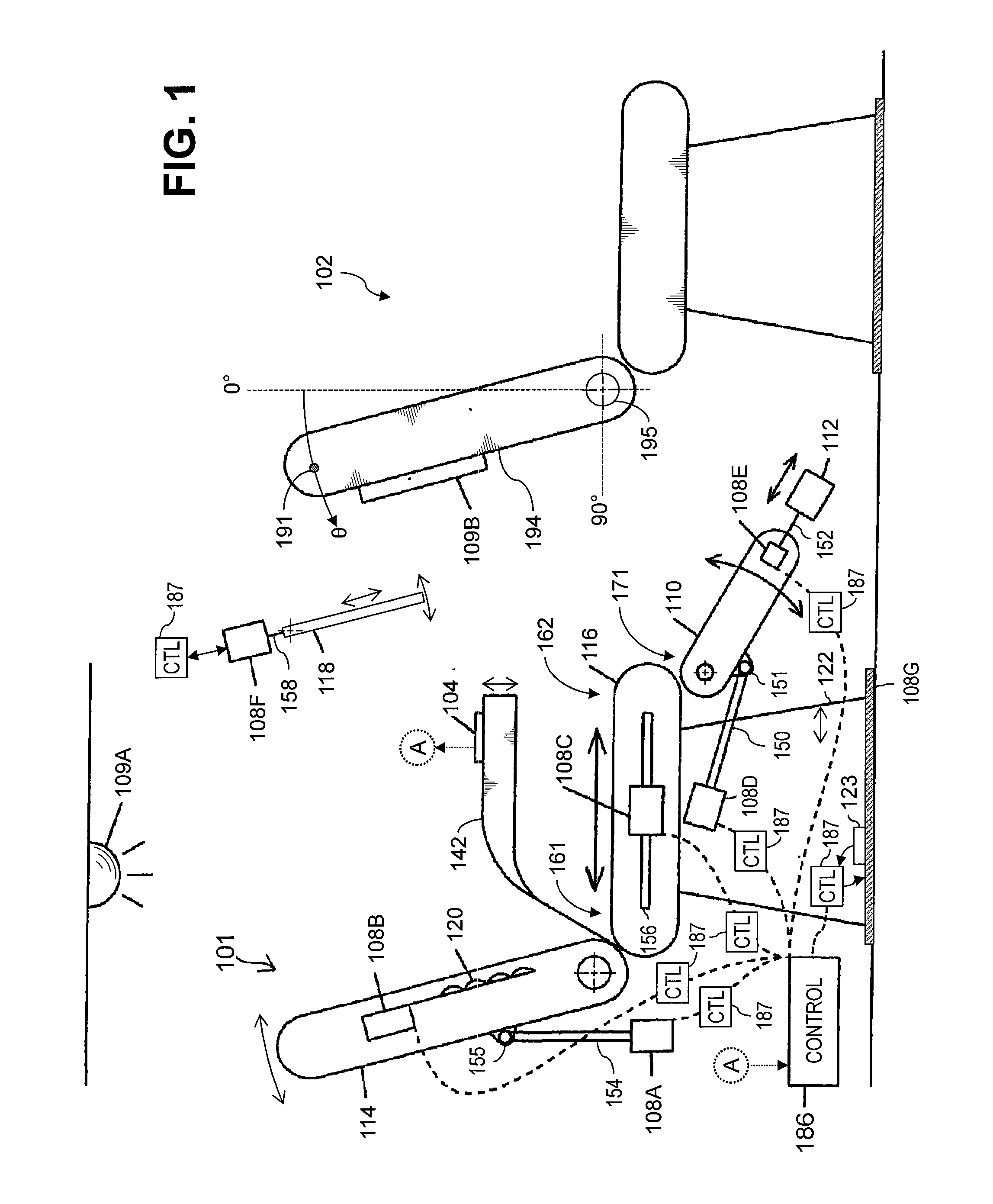

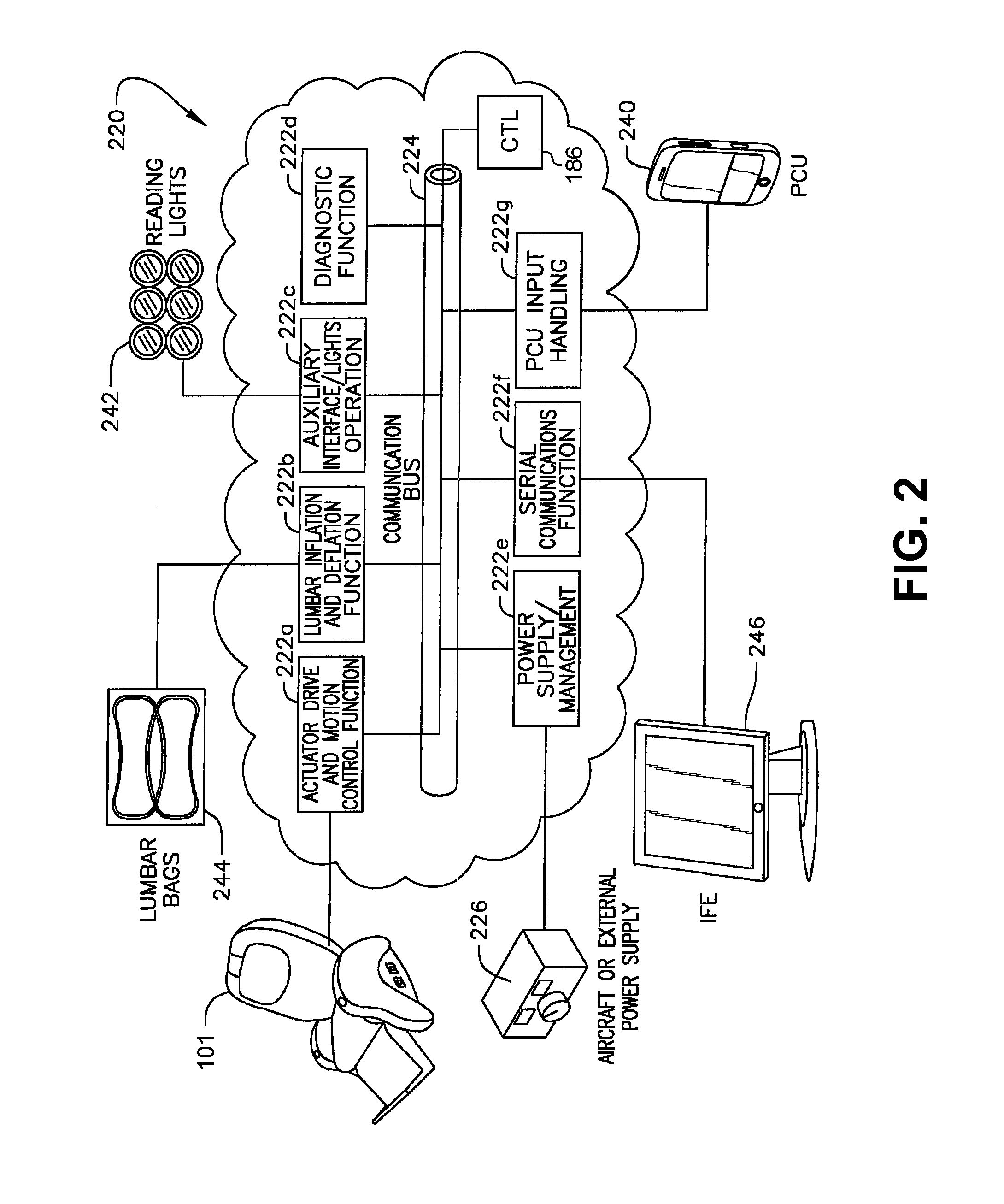

Powered seat and control thereof

A method of controlling motion of movable components of a powered seat includes, using the controller, monitoring a feedback signal of an actuator during motion of a component. During an acceleration phase of the motion of the component, a reference state of the time-varying motion command is detected and a reference value of the monitored feedback signal is determined as a reference value. A feedback-signal acceptance range is determined using the reference value of the monitored feedback signal. During a steady-state phase of the motion, the motion of the component is terminated if the monitored feedback signal departs the determined feedback-signal acceptance range. A control system for a powered seat of a vehicle is described. A powered seat assembly is described.

Owner:ITT MFG ENTERPRISES LLC

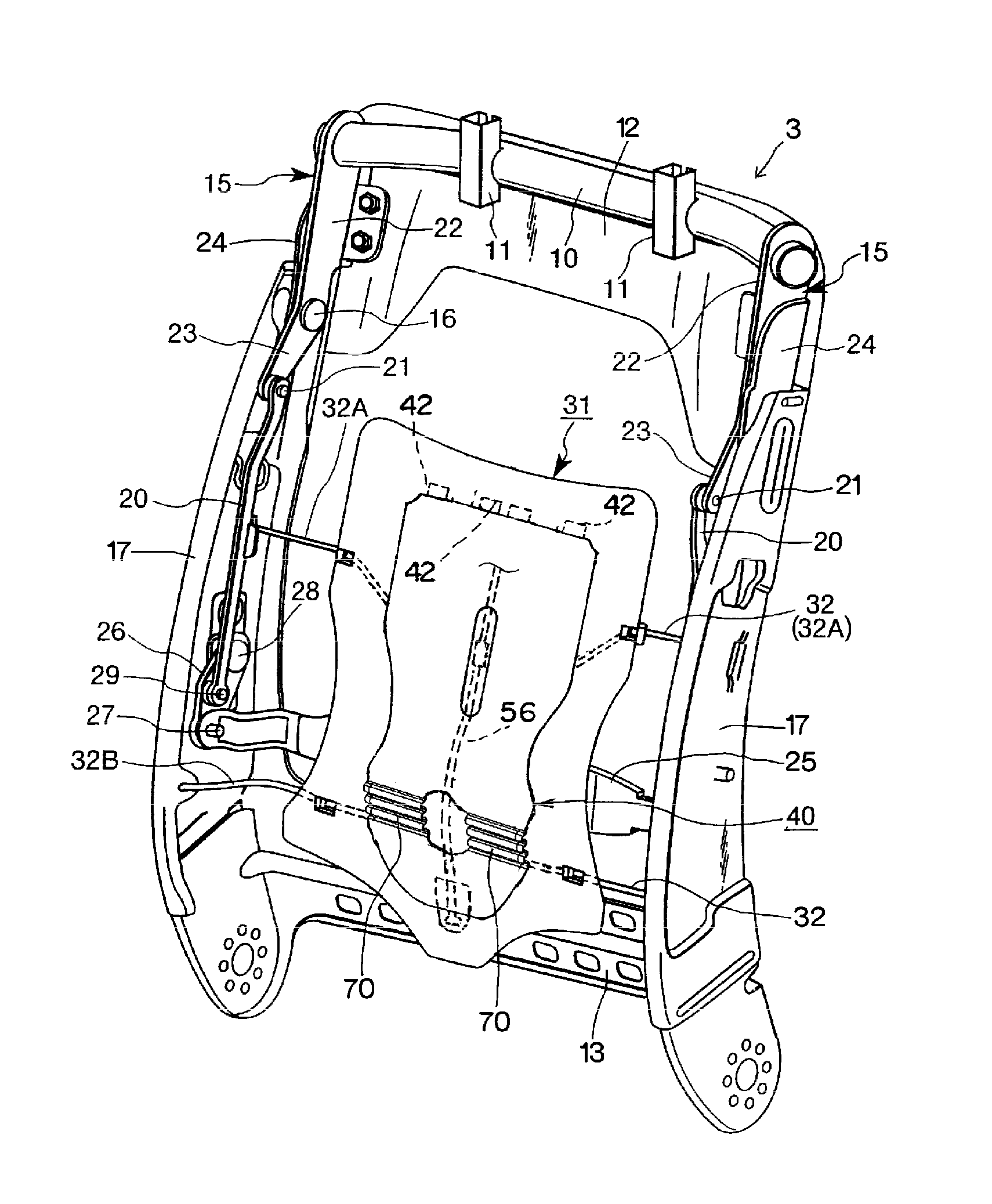

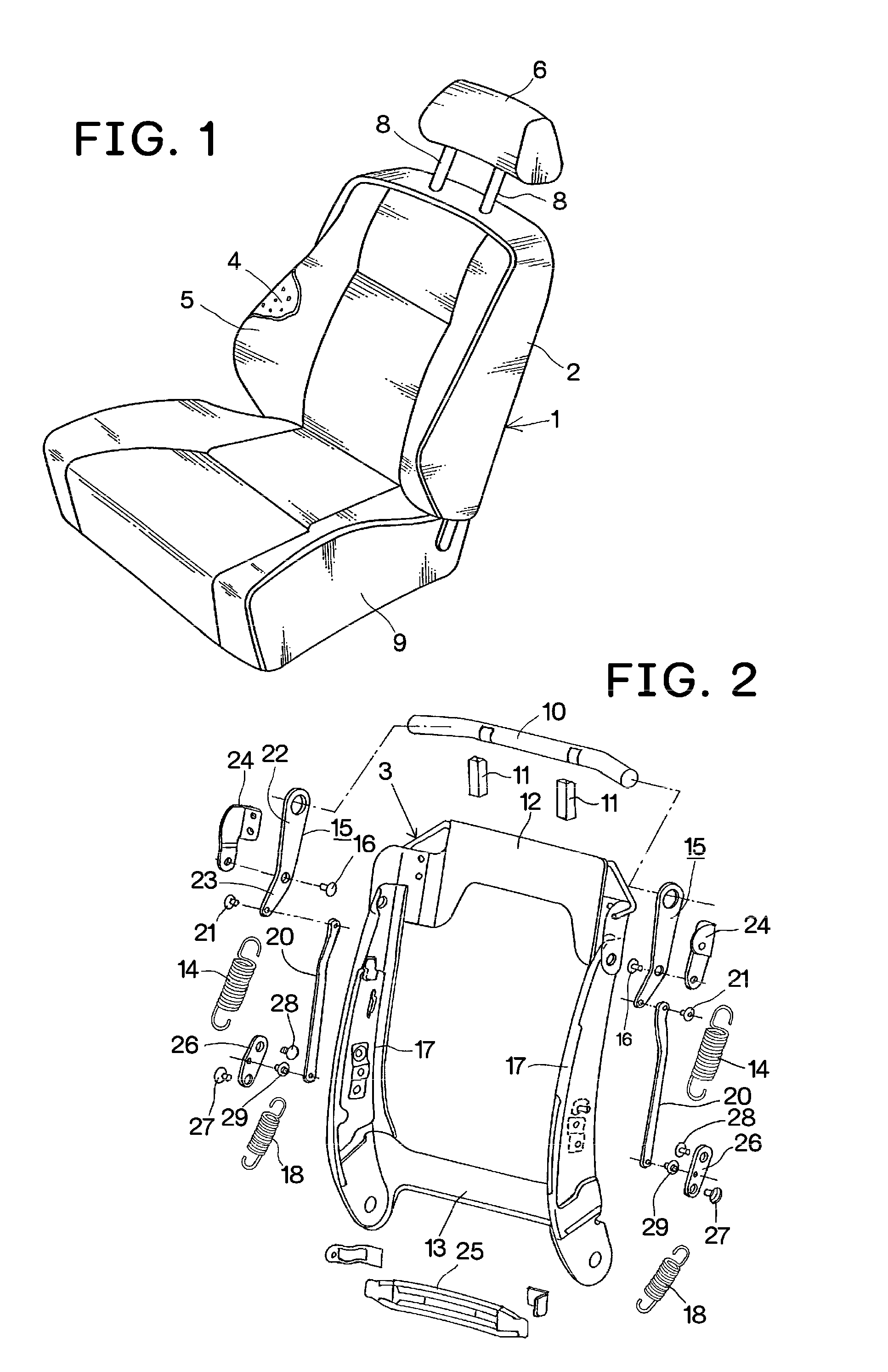

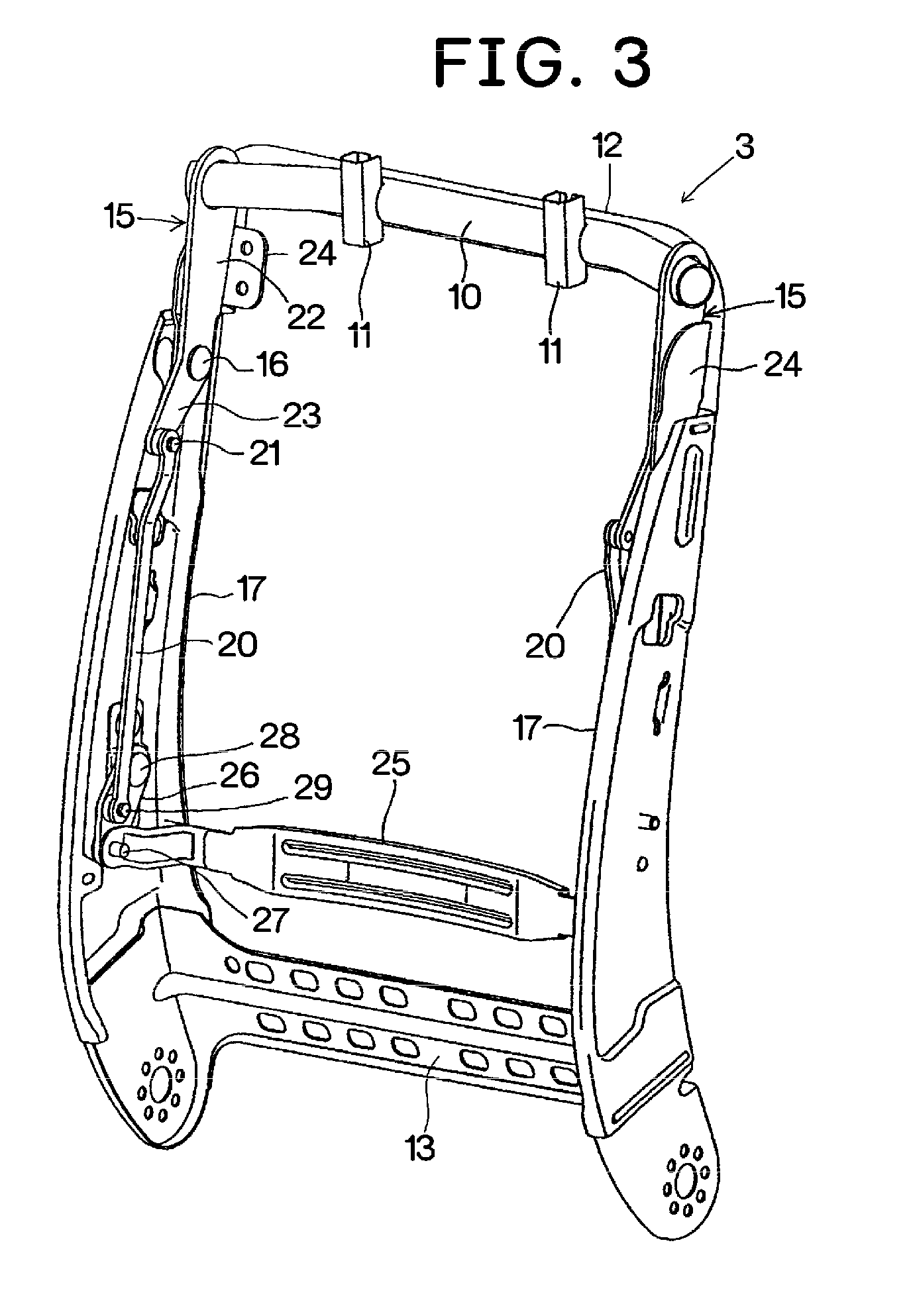

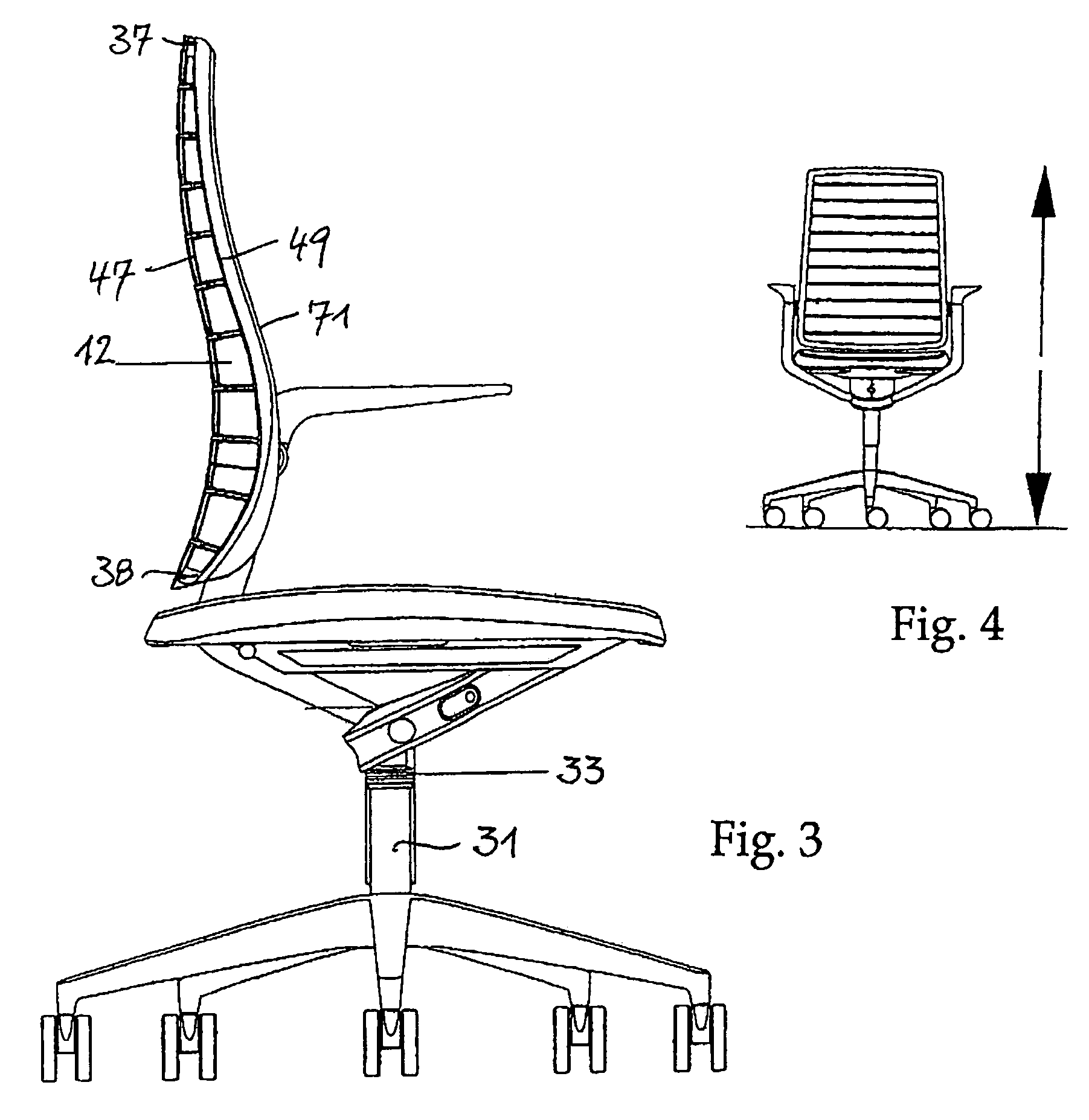

Vehicle seat

InactiveUS8226165B2Satisfactory supportReduce the cushioning forceBack restsStoolsEngineeringSynthetic resin

A vehicle seat comprises a synthetic resin cushion plate (31) attached to a back frame (3) by way of seat springs (32) so as to be movable forward or backward, a single elastic auxiliary plate (40) attached to the cushion plate (31) so as to be movable forward or backward relative to the cushion plate (31), a specific section of the auxiliary plate (40) formed as a push-out section (70) protruding forward when a distance between an upper edge and a lower edge of the auxiliary plate (40) is shortened by moving the lower edge upward. Elasticity of the auxiliary plate (40) supporting the body of the seated passenger is adjusted by moving the auxiliary plate (40) near the push-out section (70) forward or backward. The push-out section (70) has a corrugated part (71) formed from a sideways projection that projects forward or / and backward as viewed from a side.

Owner:TS TECH CO LTD

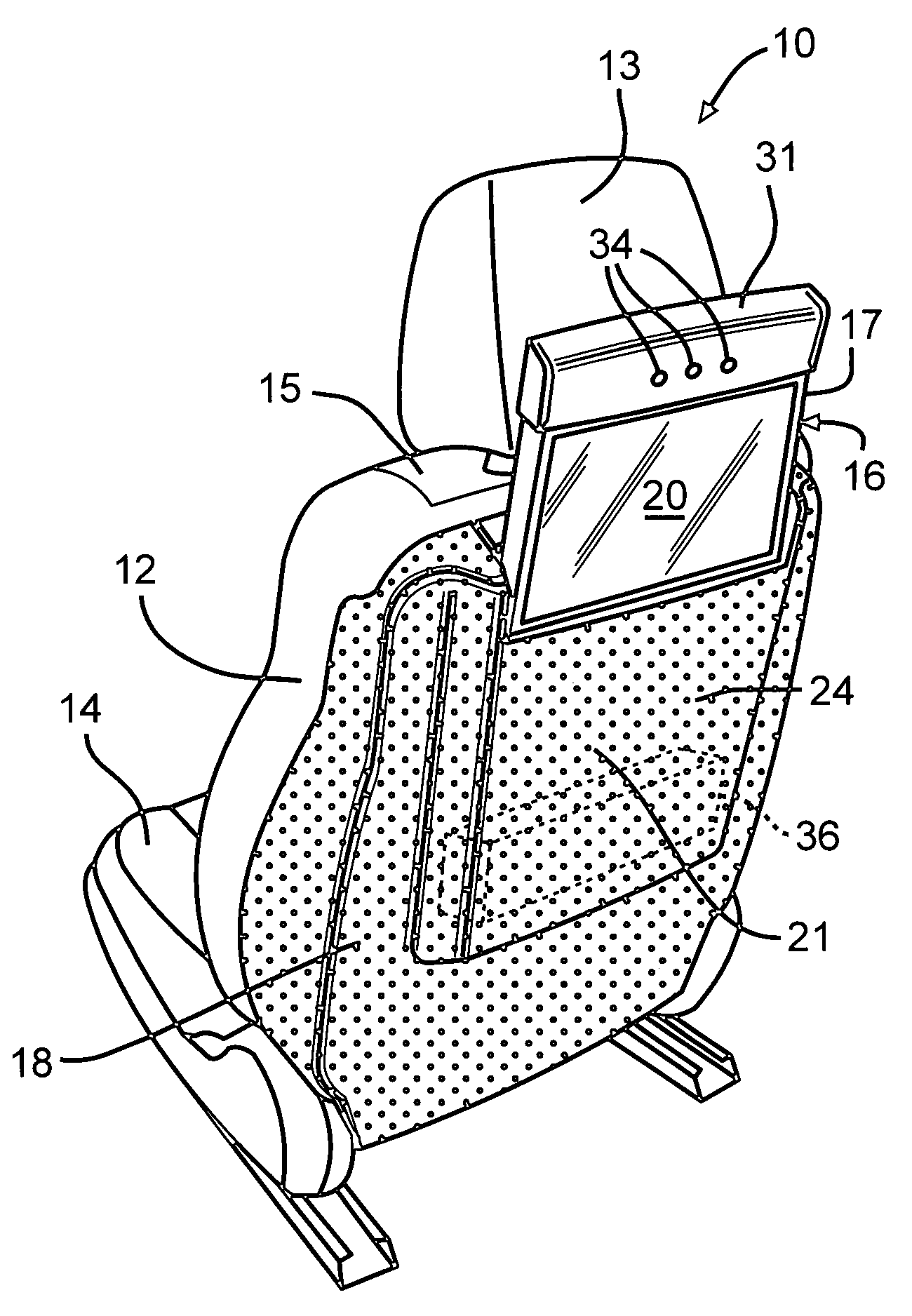

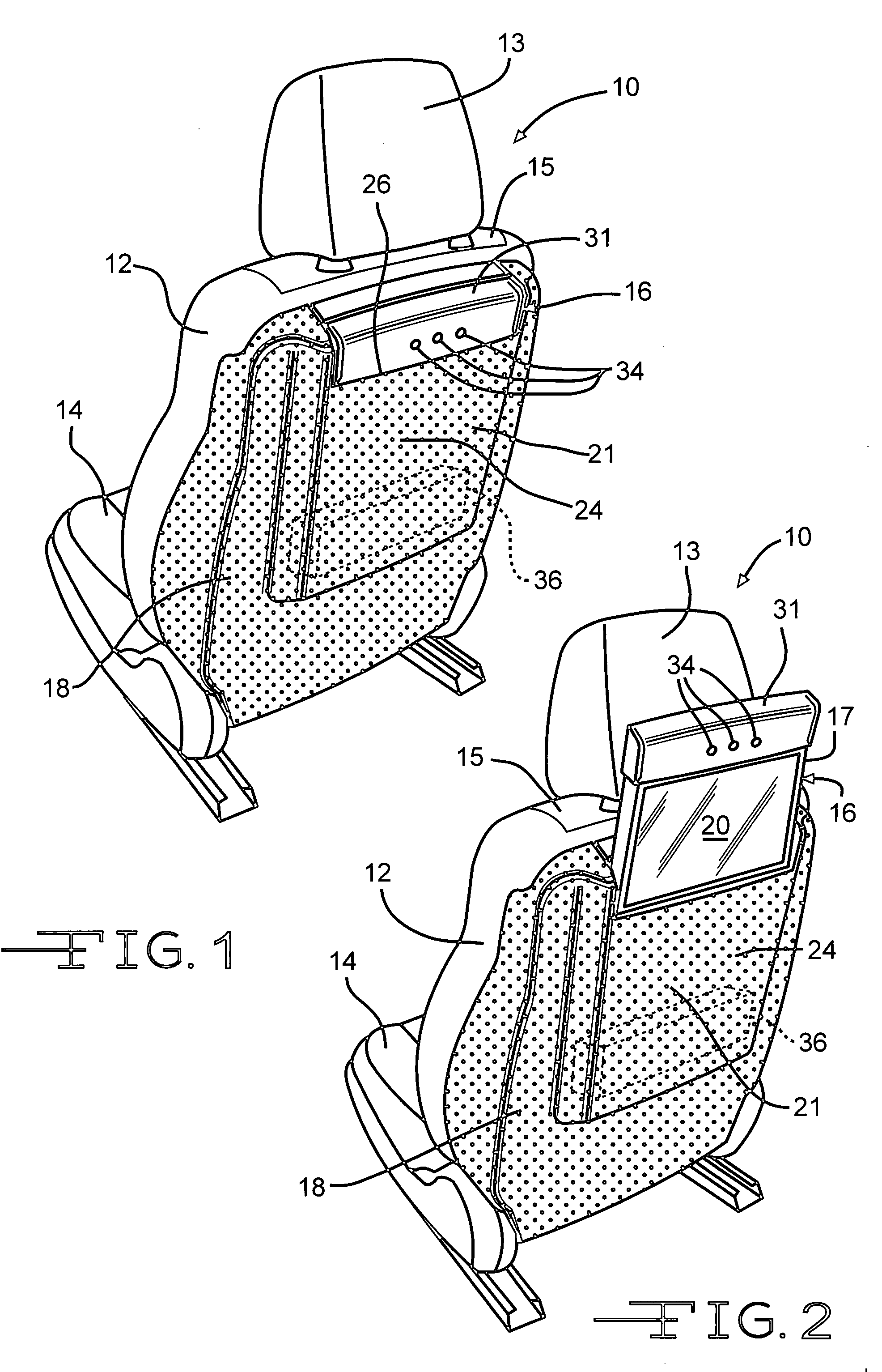

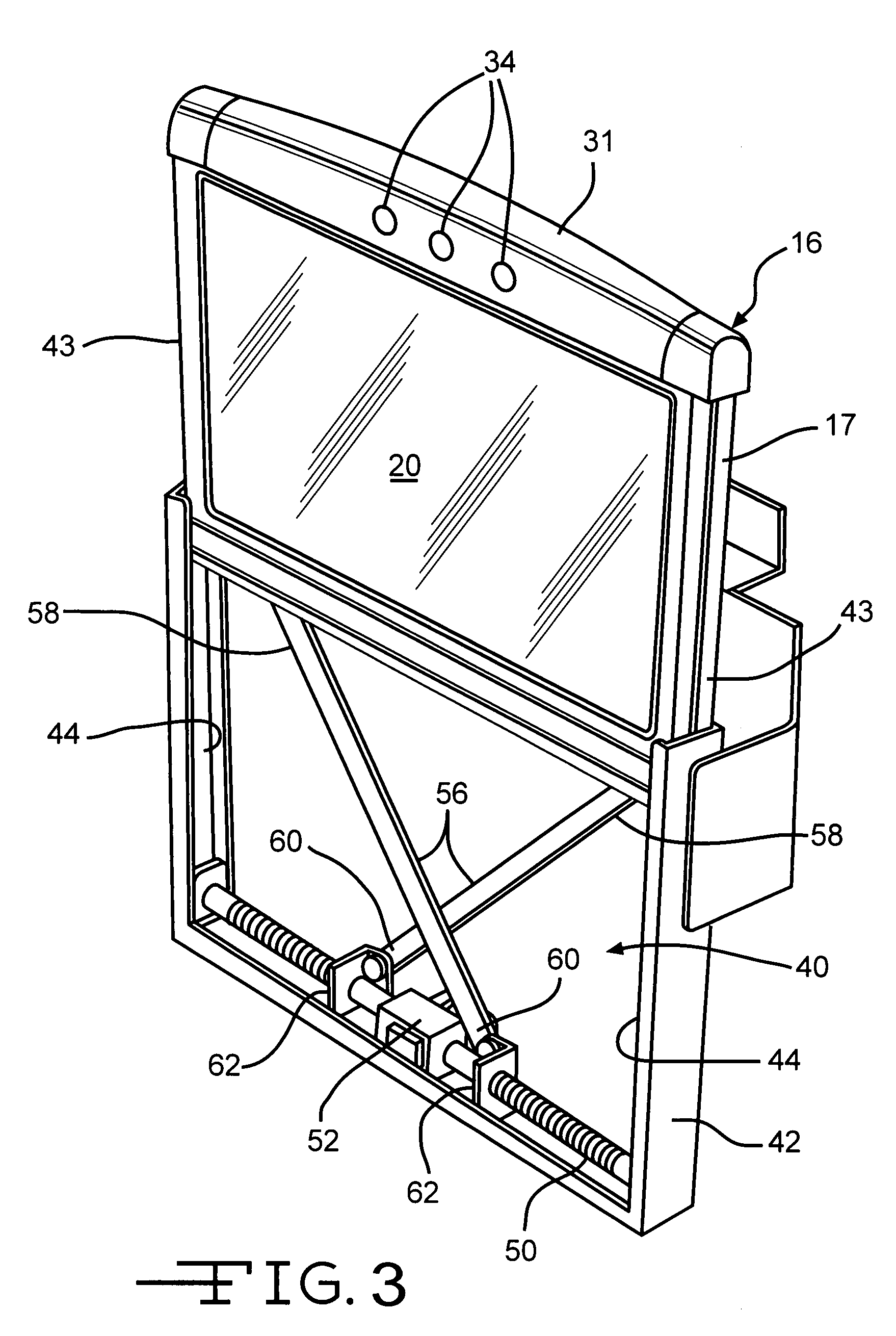

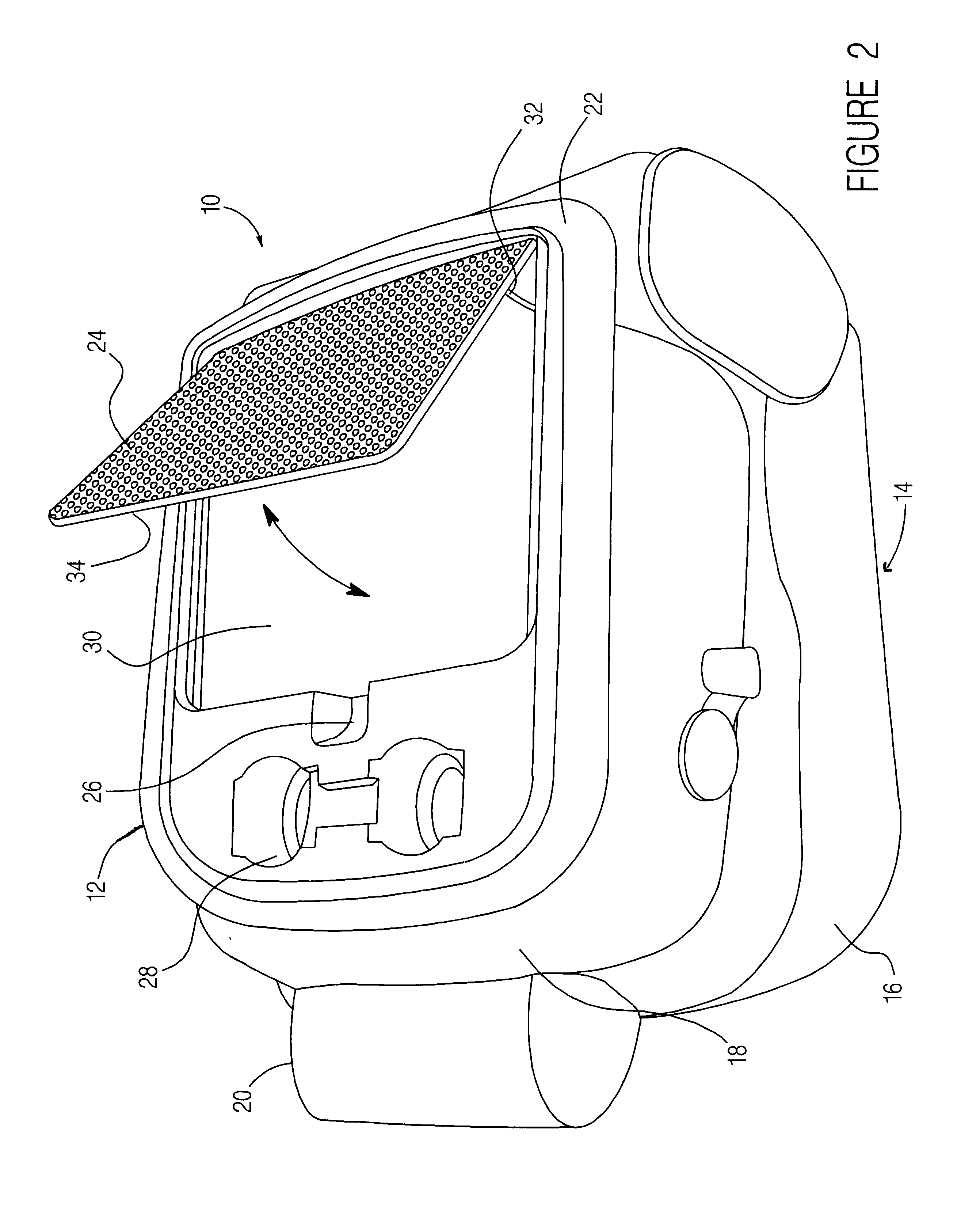

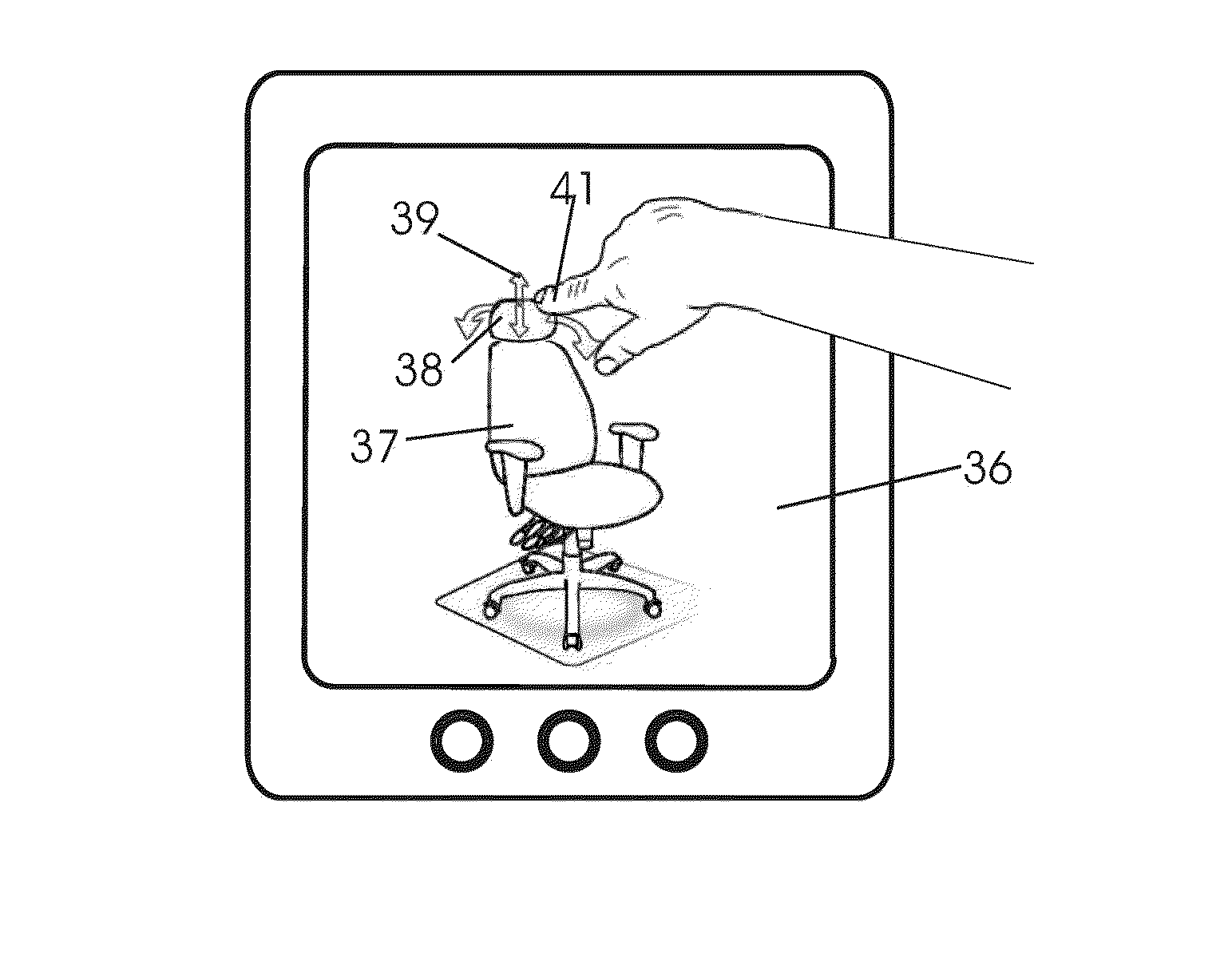

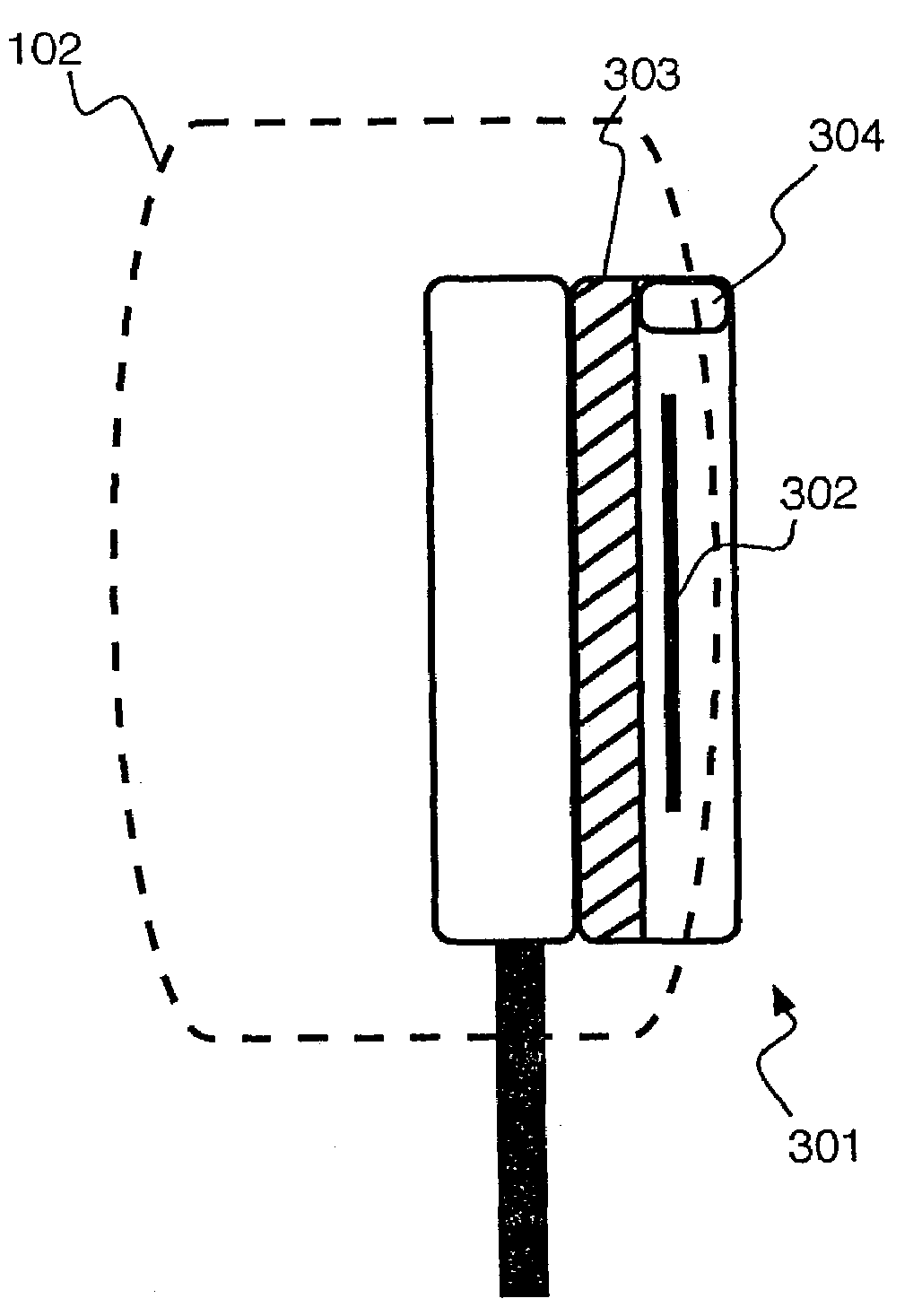

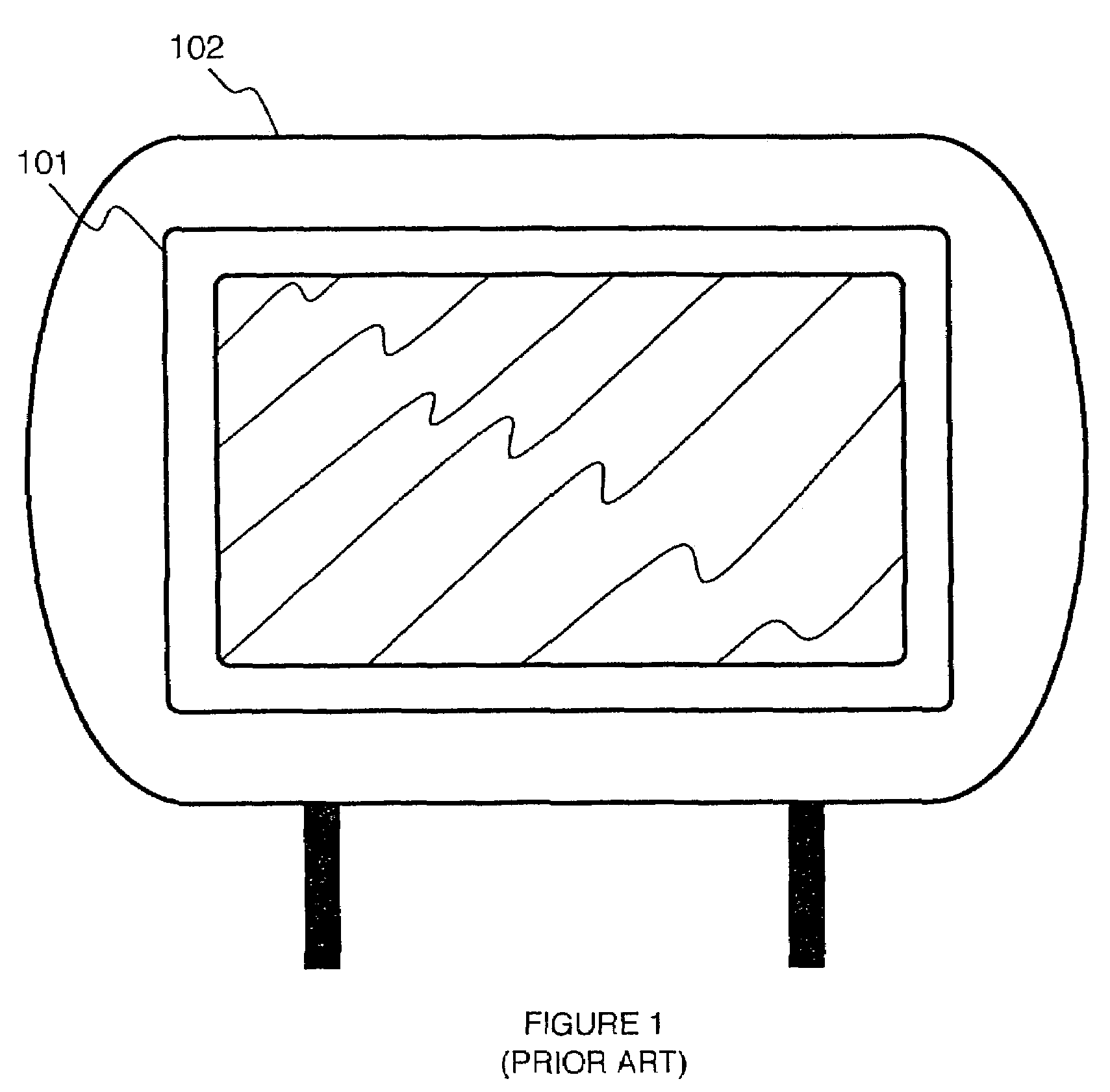

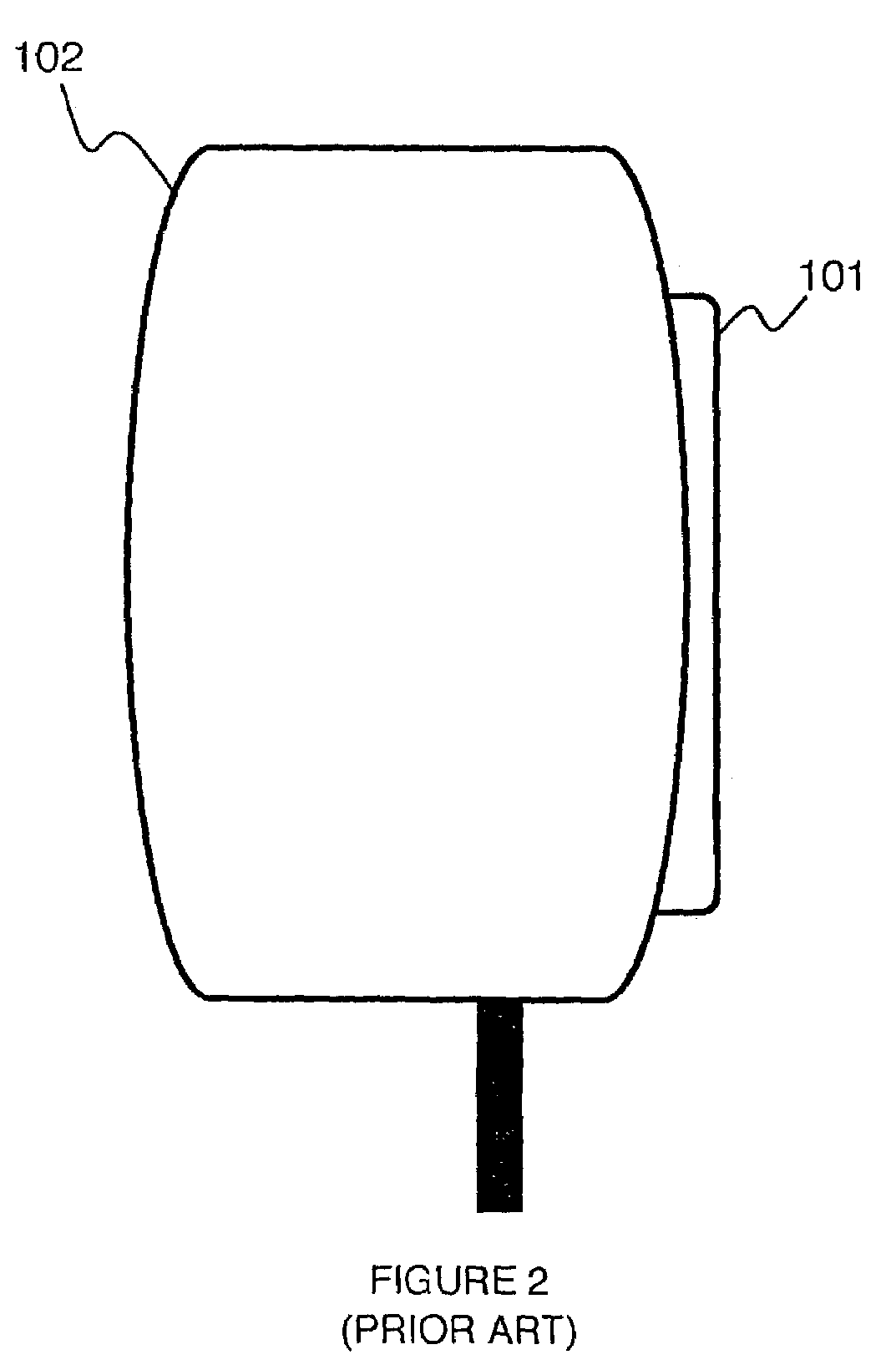

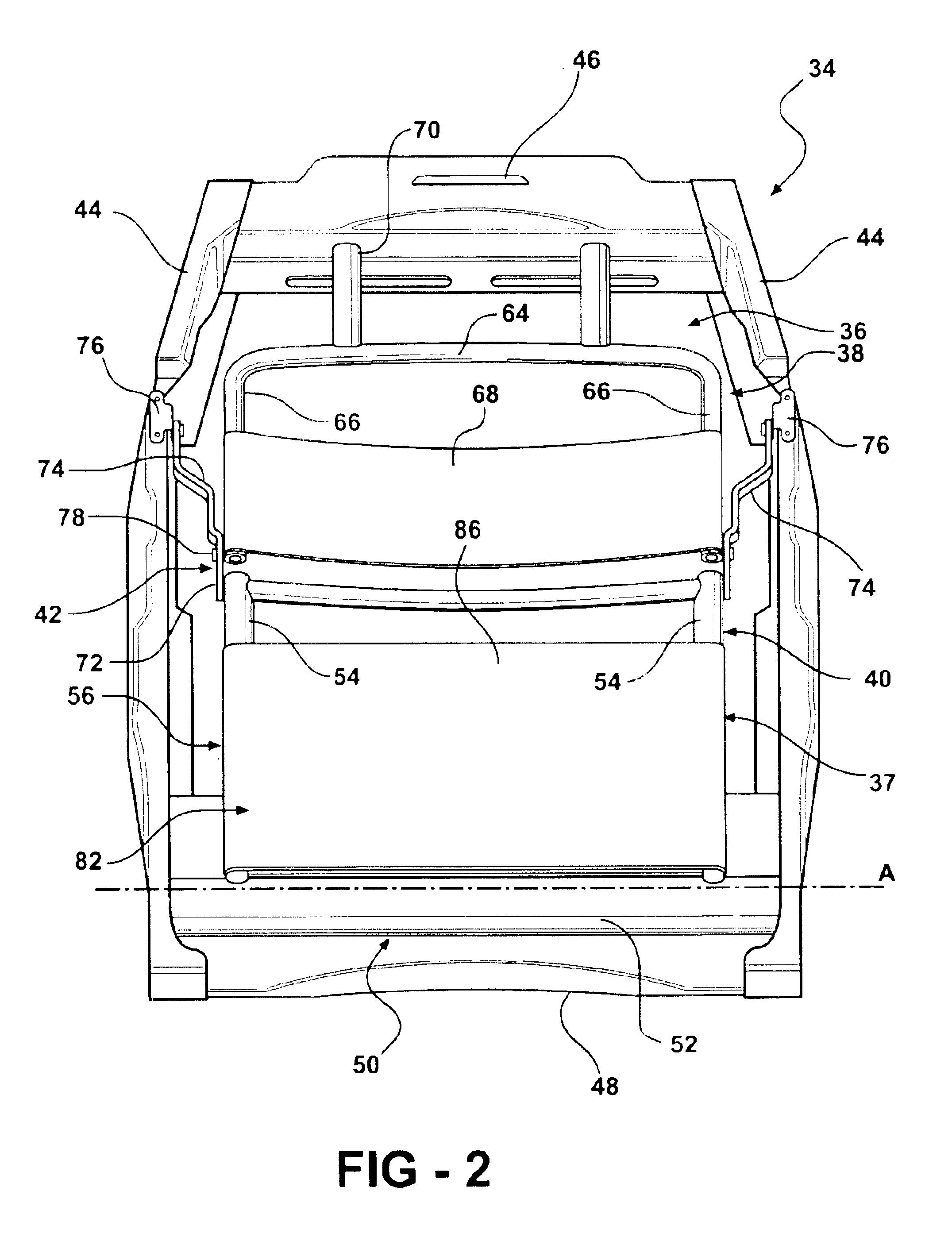

Vehicle seat having an electronic display mounted thereon

A vehicle seat assembly includes a seat back defining a rear side and a display assembly mounted on the seat back. The display assembly includes a display and a housing mounted on the rear side of the seat back. The housing defines a pocket. The seat assembly further includes a lifting mechanism connected between the housing and the display, wherein the lifting mechanism moves the display between a storage position within the pocket, and an extended position such that display is disposed out from the pocket.

Owner:LEAR CORP

Lumbar support for a car seat

A lumbar support for a car seat according to the present invention comprises a pair of coupling elements, respectively coupled with traverse fixing bars provided in internal upper and lower parts of a seat back; a pair of support plates provided on right and left sides between a pair of the coupling elements and respectively having a plurality of support wings; a support element including a sacrospinal muscle base at a lower part thereof; and a supporting height control element provided on one side of the support plate to alternatively control a protrusion height of the support plates; wherein the support element further includes a lumbar vertebra base integrally formed in an upper part of the sacrospinal muscle base.

Owner:HONG CHEONG MYUNG

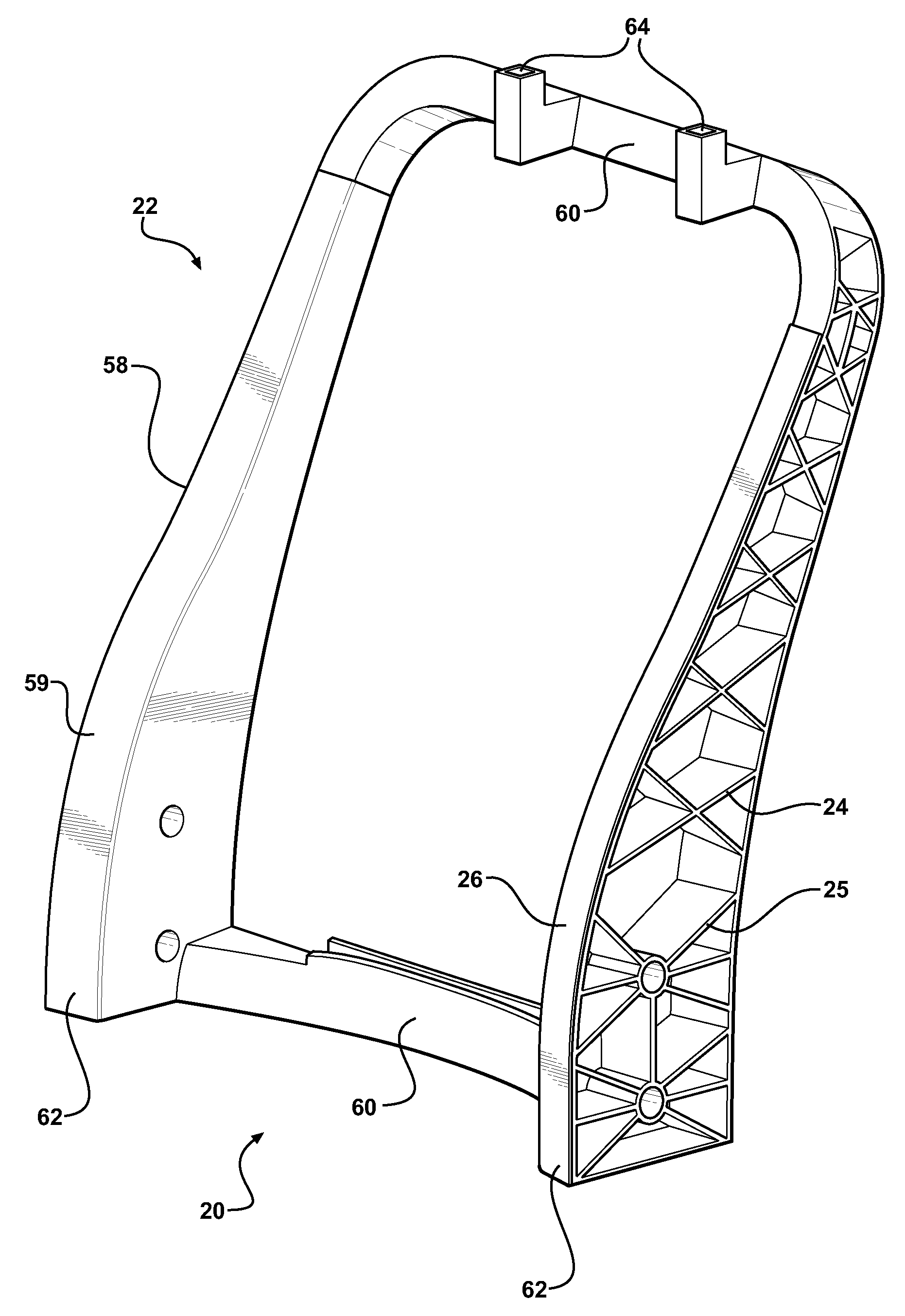

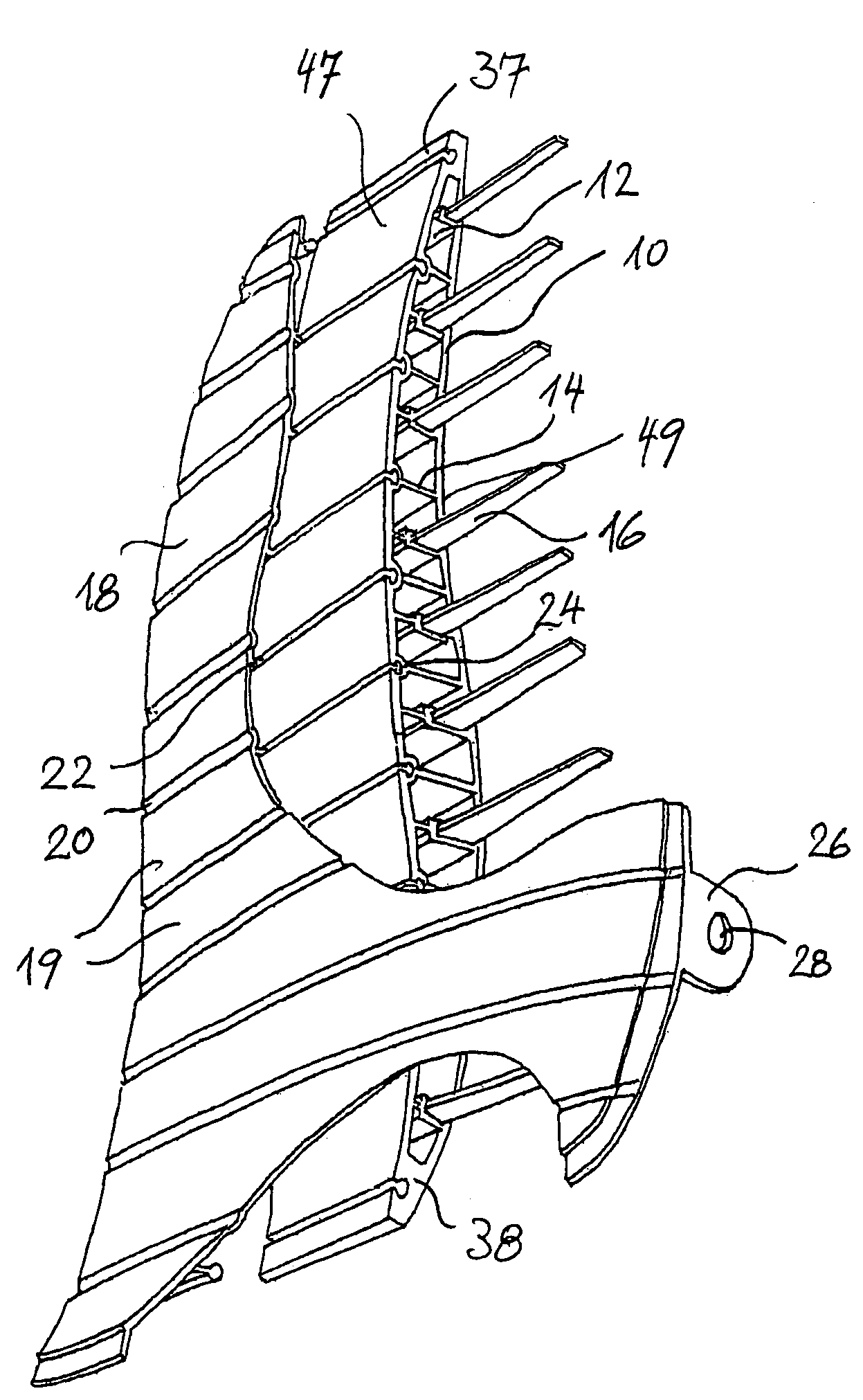

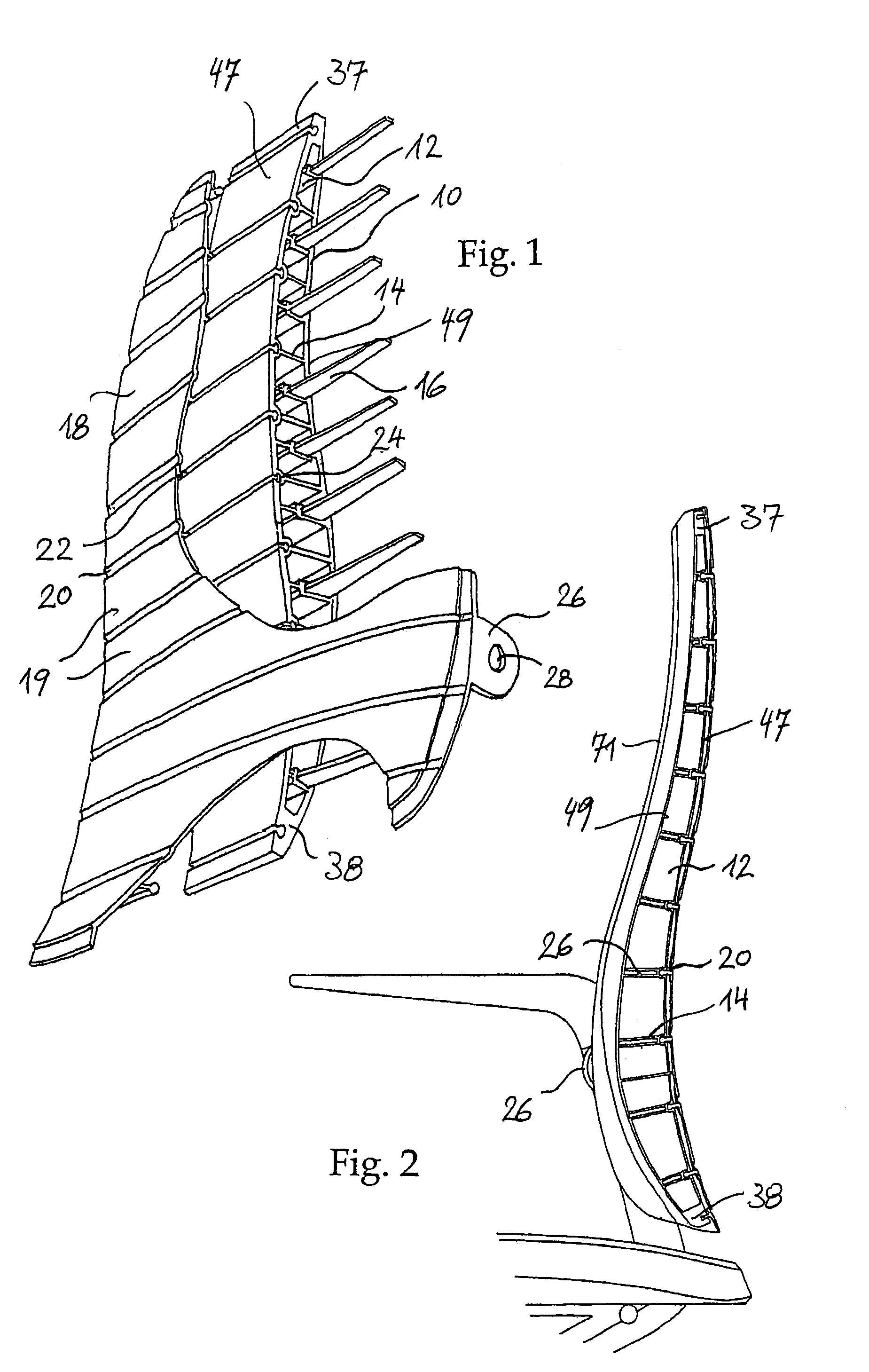

Composite component

ActiveUS20080038569A1Reduce weightEasy to recycleBack restsSynthetic resin layered productsFiberMolten state

A composite component such as a seat back for a vehicle comprises a support portion and at least one reinforcing composite layer. The support portion comprises a thermoplastic material and the reinforcing composite layer comprises a polymeric material impregnating a plurality of fibers. The polymeric material of the reinforcing composite layer is integrated with the thermoplastic of the support portion. A method of forming the composite component includes placing the composite layer into a mold, heating the thermoplastic material to a molten state, and disposing the thermoplastic material in the molten state into contact with the composite layer. The method further includes promoting interaction between the thermoplastic material and the polymeric material to integrate the support portion and the reinforcing composite layer. The thermoplastic material supports the reinforcing composite layer and the reinforcing composite layer reinforces the thermoplastic material to prevent failure when subjected to a load.

Owner:BASF AG

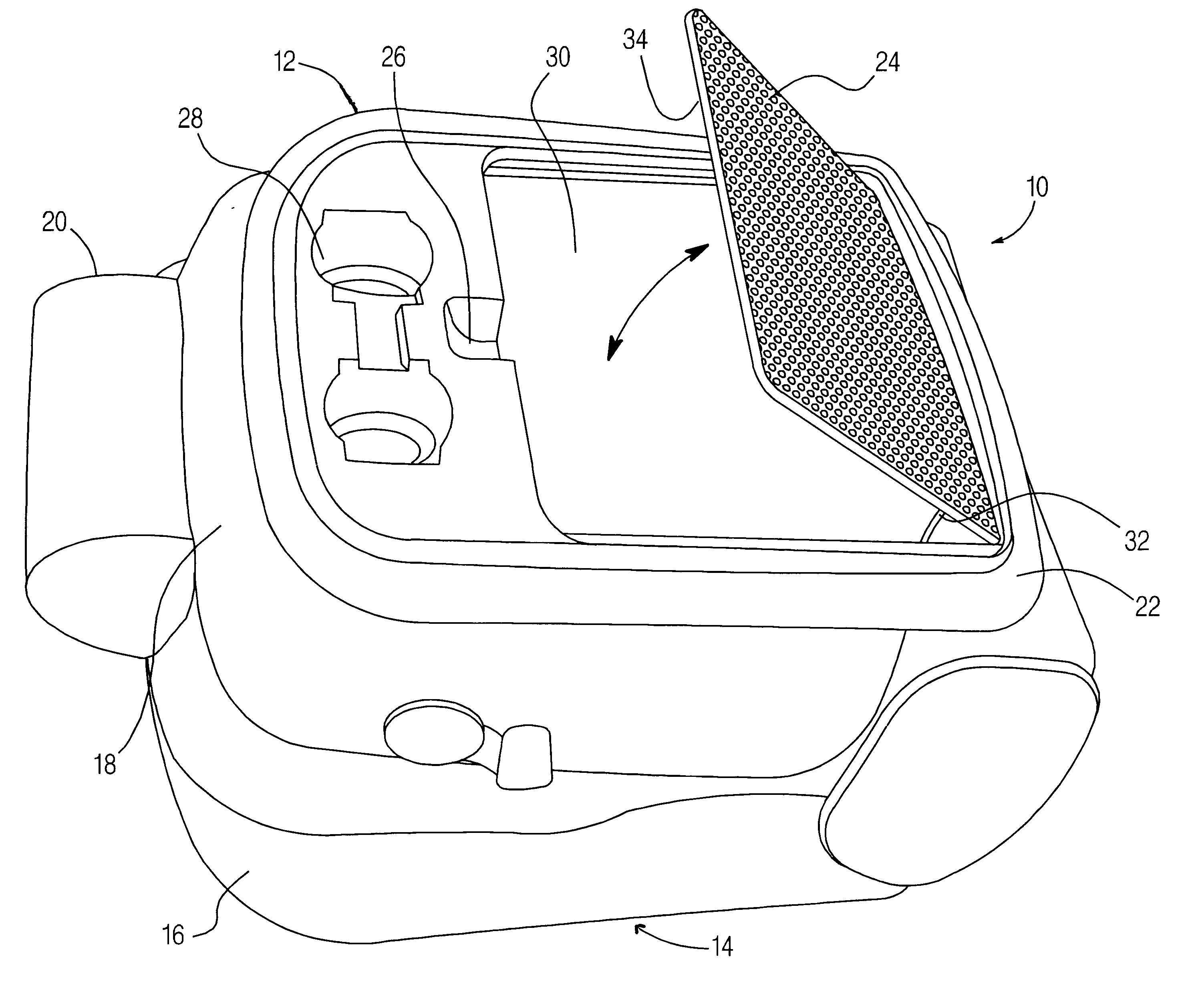

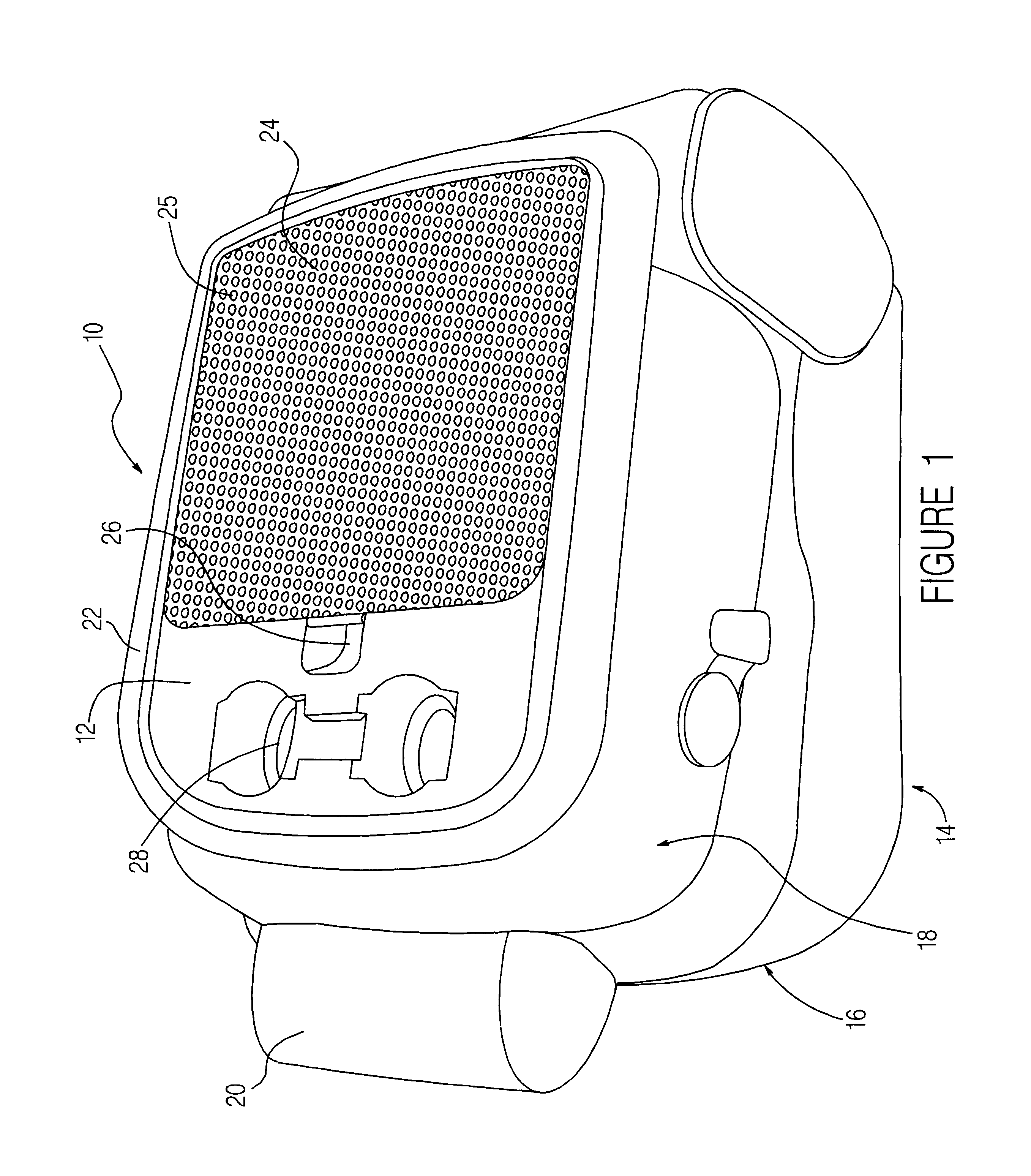

Activity center for a vehicle

An activity center for a vehicle includes a base defining a storage area and a panel having first and second surfaces. The base is connected to the rear surface of a vehicle seat back. The panel, in turn, is connected to the base for movement between a closed position, which prevents access to the storage area and an open position which allows access to the storage area. The panel is also preferably coupled to the base so that either the first or second surface thereof may face away from the base. The two surfaces of the panel may be configured for a wide variety of educational, entertainment or work-related uses.

Owner:JOHNSON CONTROLS TECH CO

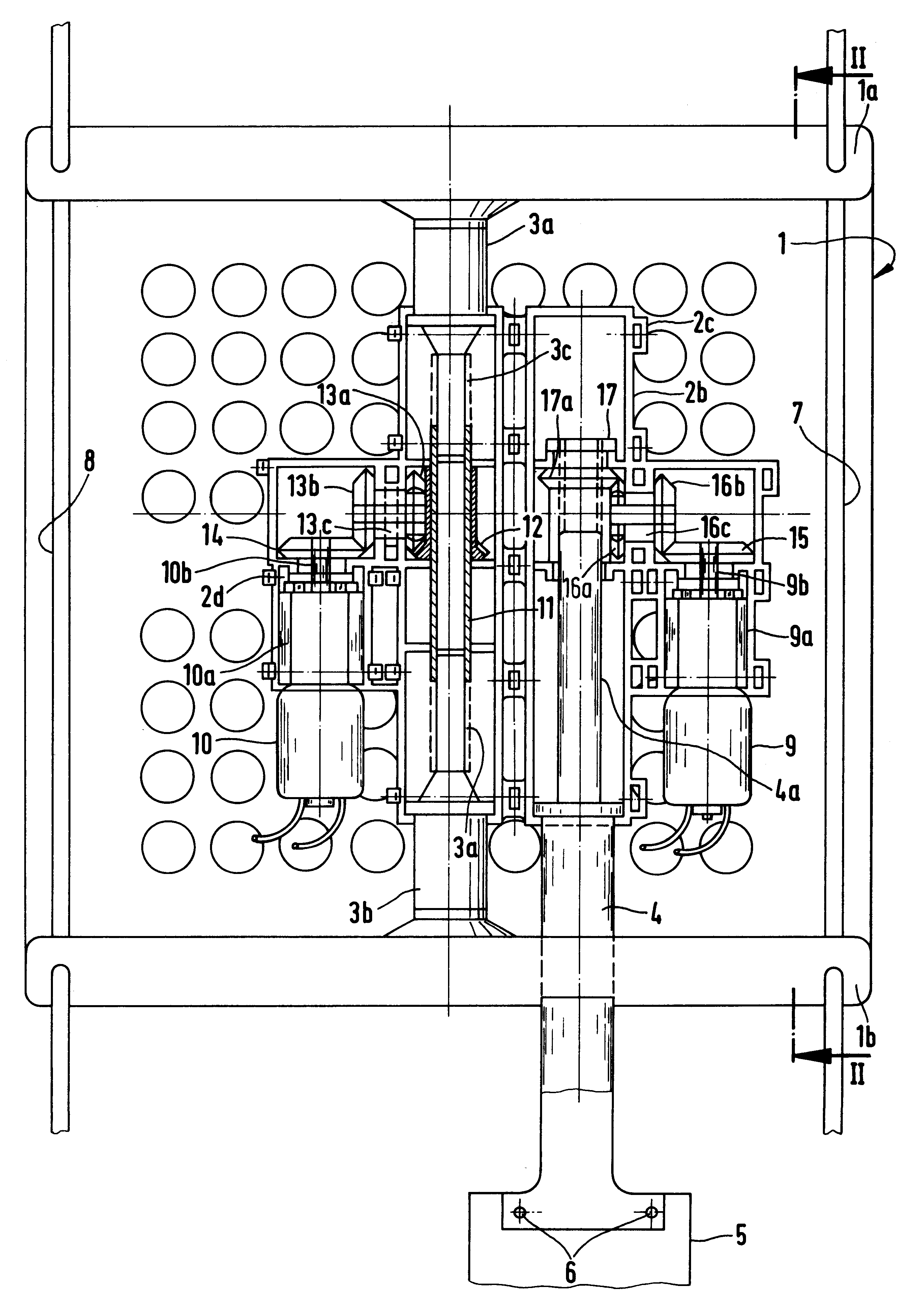

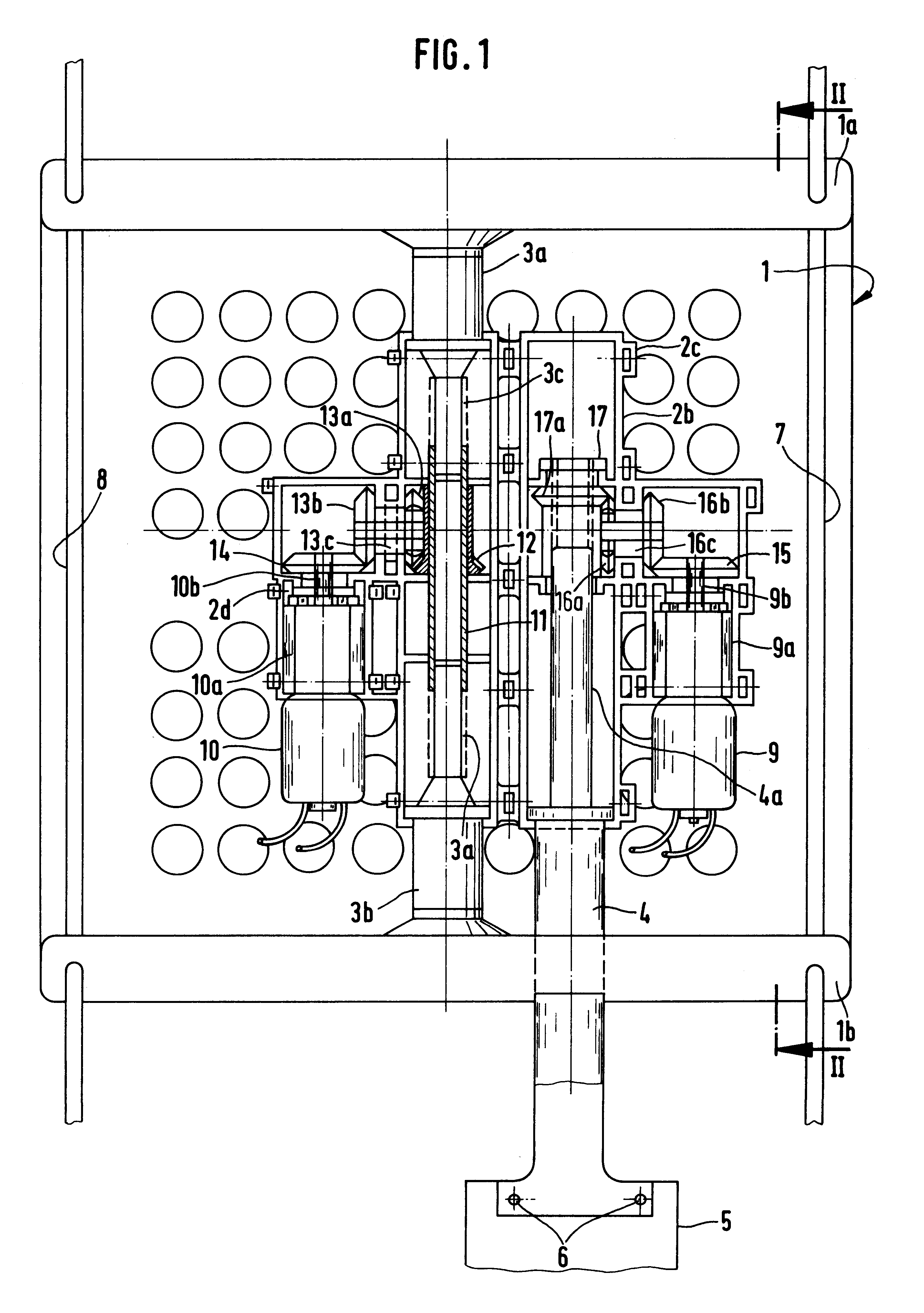

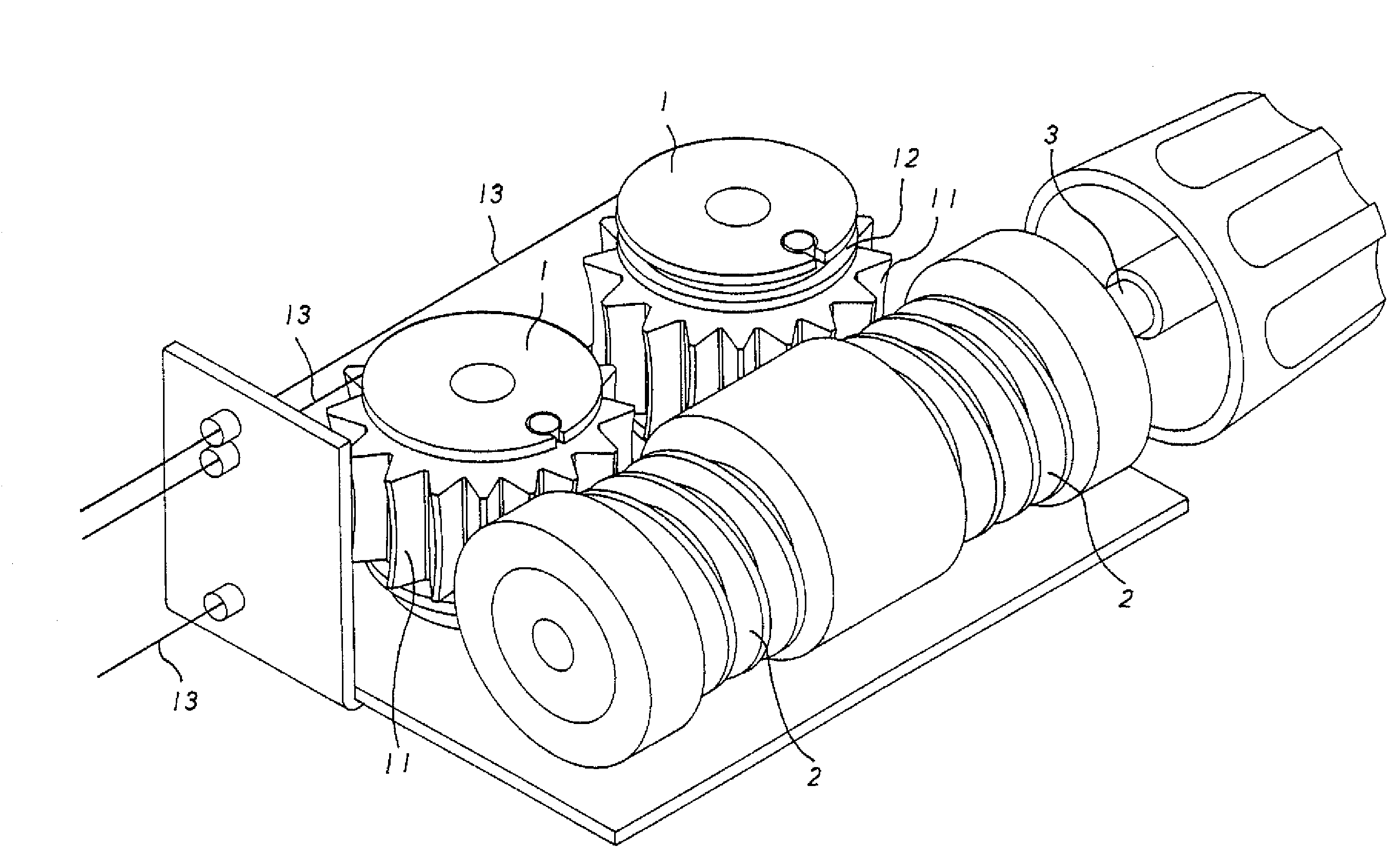

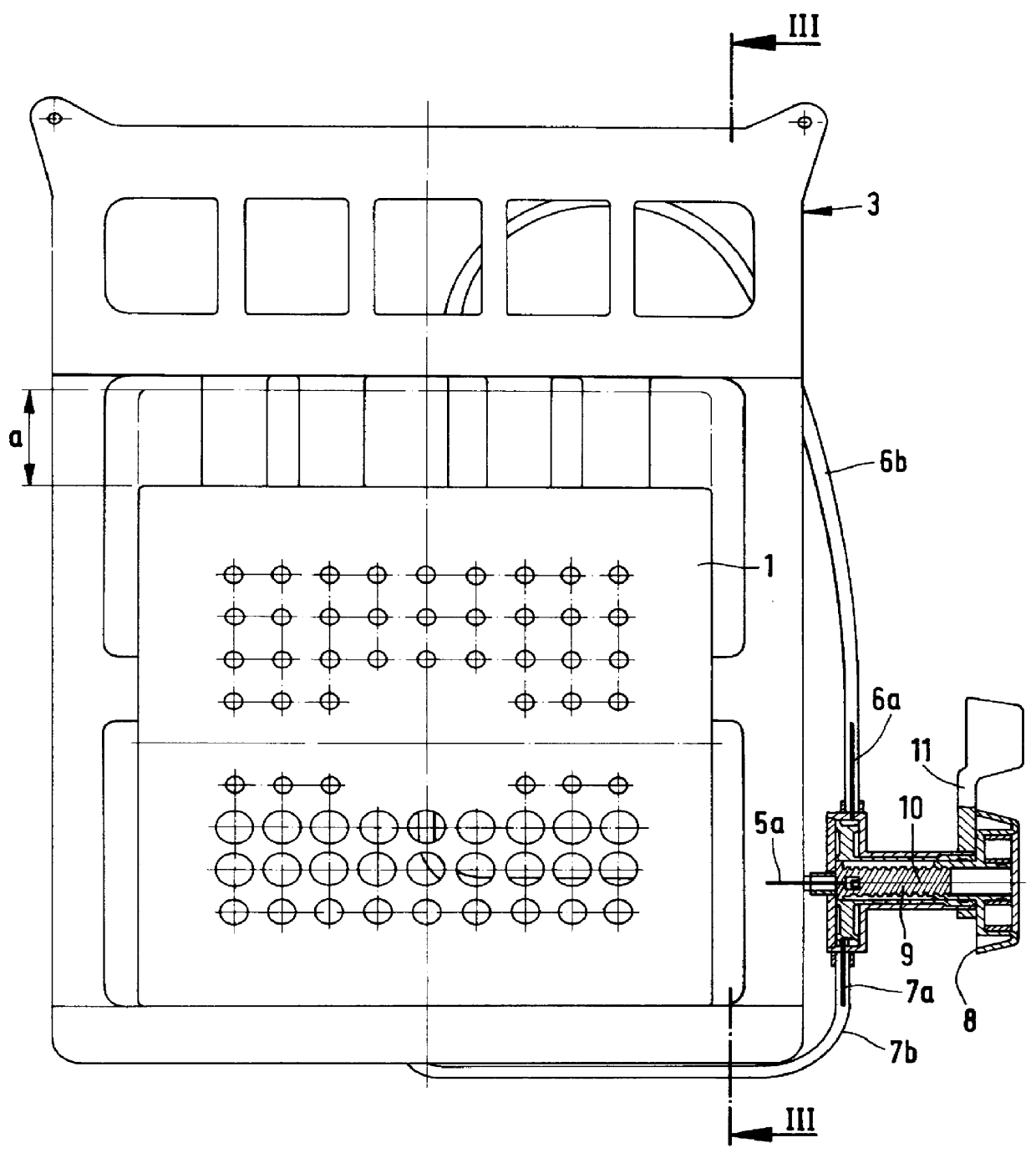

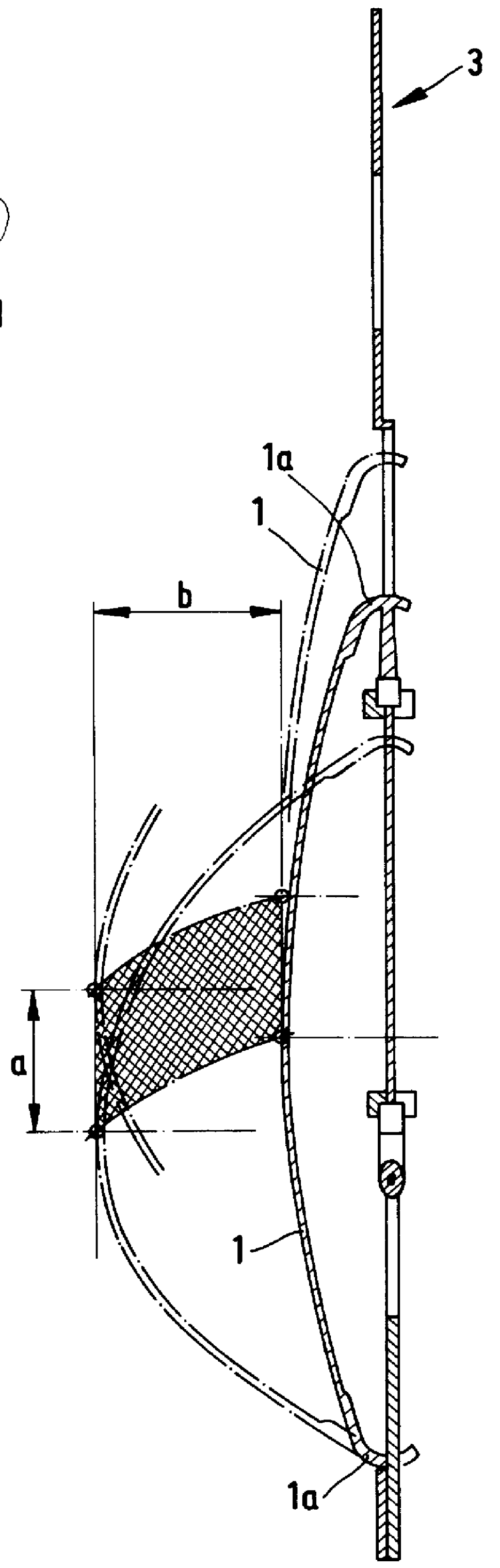

Back support for seat-backs, in particular for motor vehicle seats

A lumbar support for seat backs, in particular of motor vehicle seats, has a forward-bowed support plate (1). The support plate (1) is height-adjustable, moving upward and downward on guide organs that are fixed with respect to the seat back, and is also variable in its curvature through the use of a motor-driven tension bracket that can be lengthened or shortened. The tension bracket consists of bracket regions (3a and 3b) that act on upper end region (1a) and lower end region (1b) of the support plate (1). The bracket regions have thread regions of opposite handedness pointing toward one another which are externally engaged by a common rotatable sleeve (11) with appropriately designed meshing areas. The drive motor (10) is fixed to a gear case (2) arranged behind the support plate (1). The motor (10) drives gear wheels of a gearbox whose final gear wheel (13a) stands in engagement with the sleeve (11). The sleeve has inside thread regions of opposite handedness.

Owner:MEGAPLAST SA

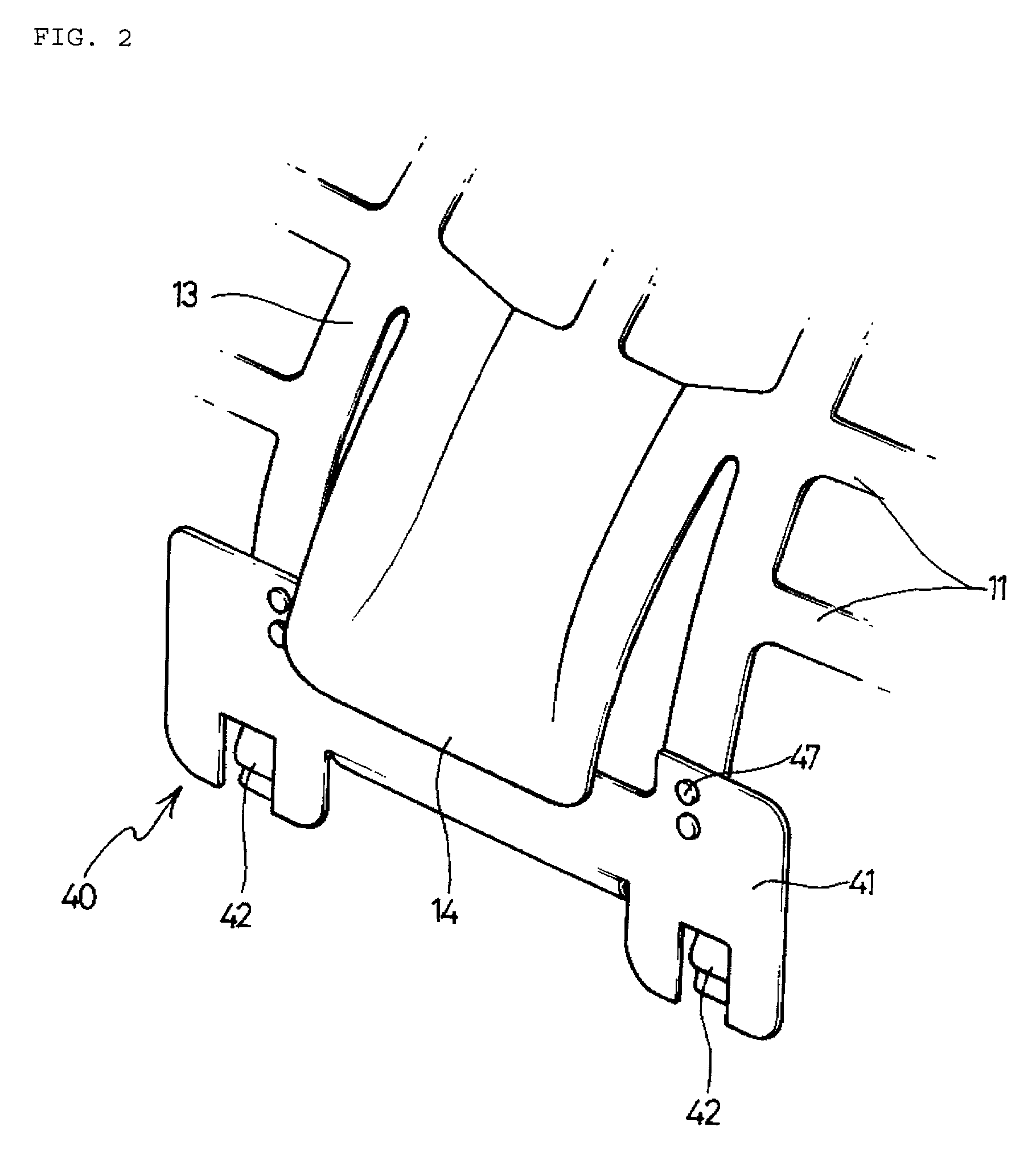

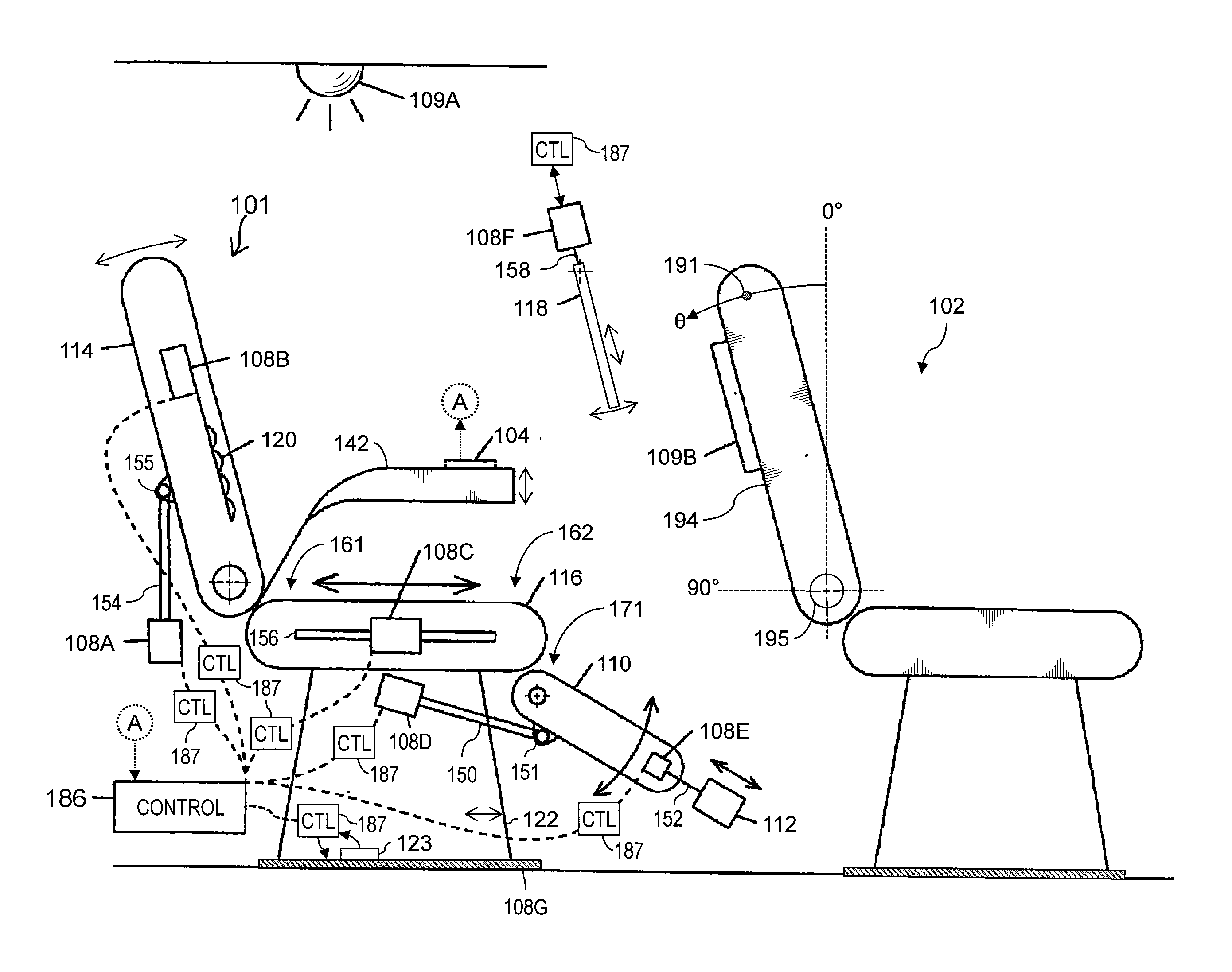

Custom controlled seating surface technologies

A system of controlling various actuators associated with human support surfaces is disclosed. Such a system is made up of a support surface, a controller, and an actuator. The system may optionally include batteries, a means of charging the batteries, and a graphical user interface as well as a communication link between the graphical user interface and the support surfaces. The actuators are capable of altering contour and / or firmness, of a support surface, they may be vibrational or heating / cooling in nature, and they may also alter the overall relative position of a support surface to another support surface, and / or to the ground plane.

Owner:CARUSO STEVEN JEROME

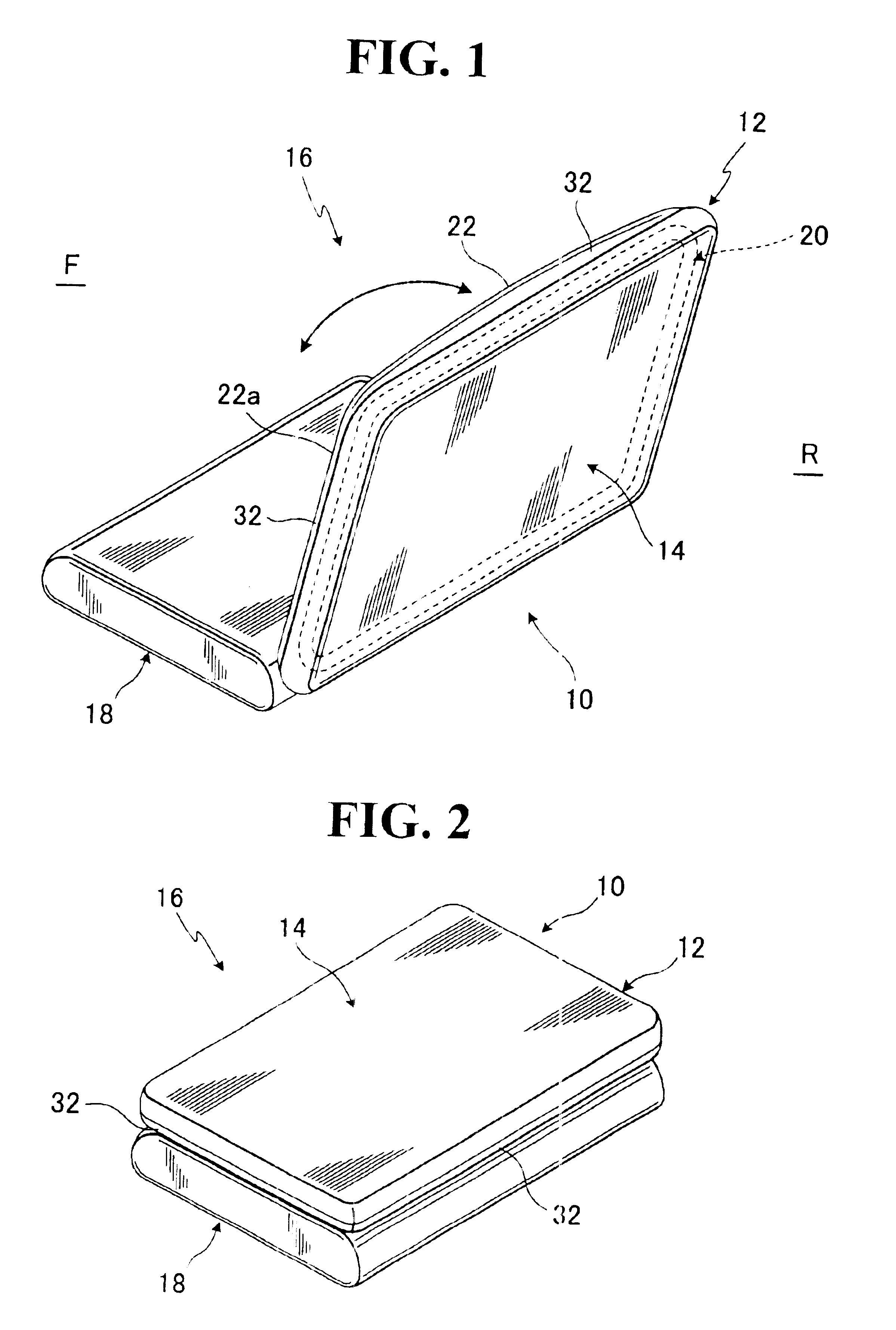

Seat back structure of vehicle seat

A seat back structure of vehicle seat which is reduced in thickness and yet deformable to provide a deep cushiony touch to a back of passenger. According thereto, an elastic back support element and a back board element are respectively provided in one and another sides of seat back, and a movable connection element is provided so as to allow displacement of the back board element from a home position, while allowing the elastic back support element to be resiliently warped. The back board element is normally biased by a biasing element of the home position. A stopper element is defined in the seat back for preventing movement of the back board element from the home position to the elastic back support element. The back board element per se may be formed by a plurality of plate elements connected movably with one another.

Owner:TACHI S CO LTD

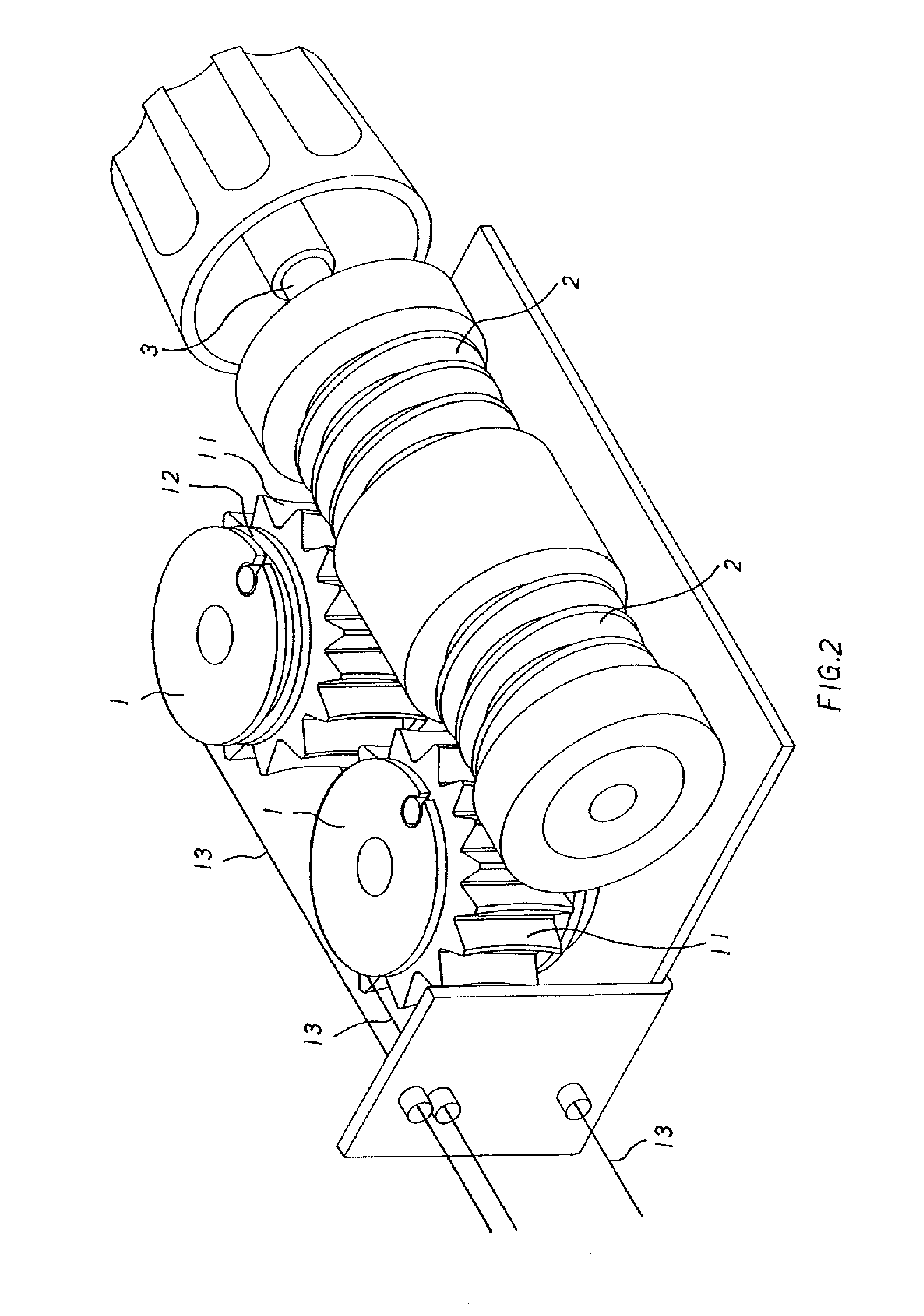

Adjustment device with a dual-guiding structure

ActiveUS7584682B2Convenient in assembly for worker and in operationBack restsToothed gearingsDrive shaftReciprocating motion

Owner:CHERN SHING TOP

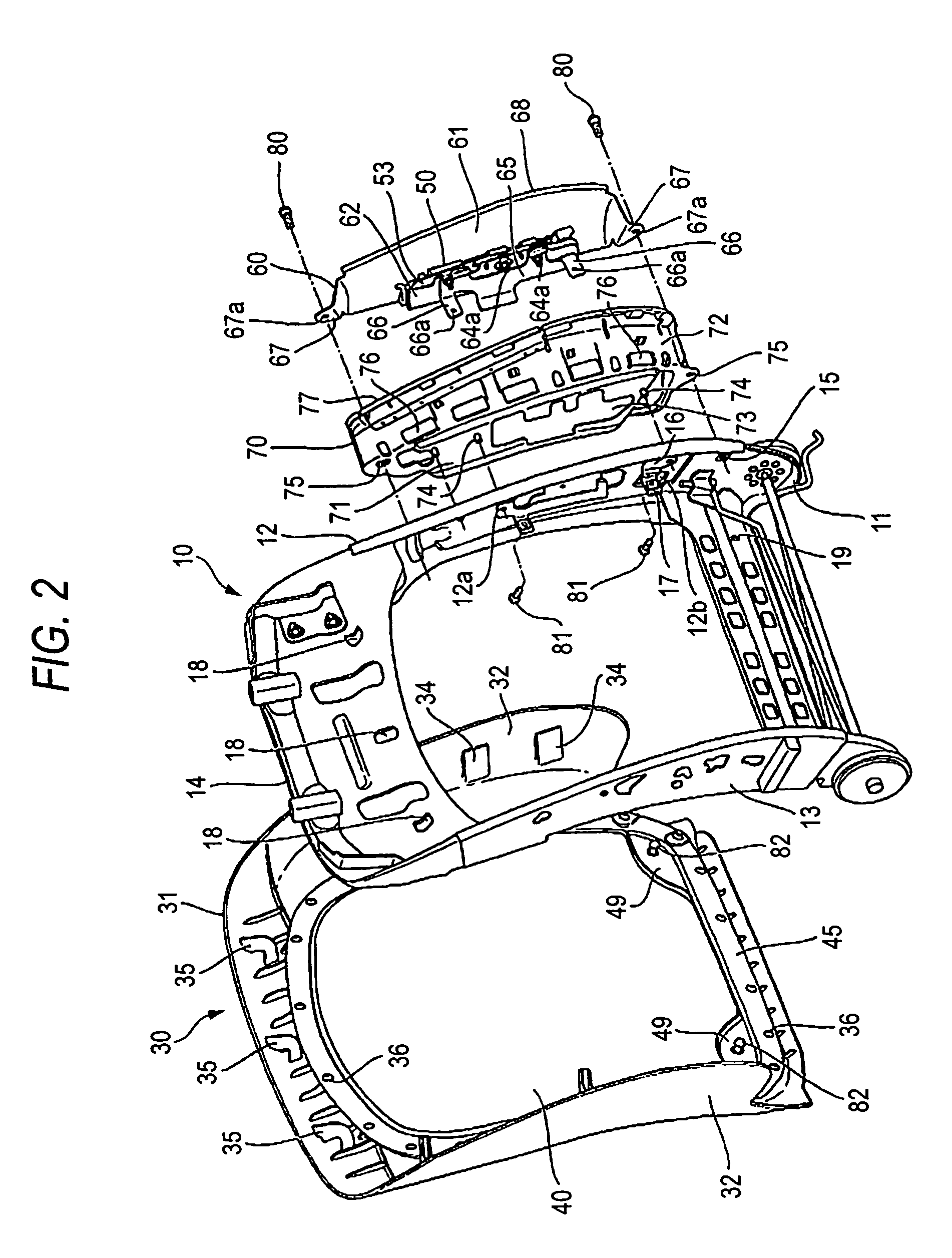

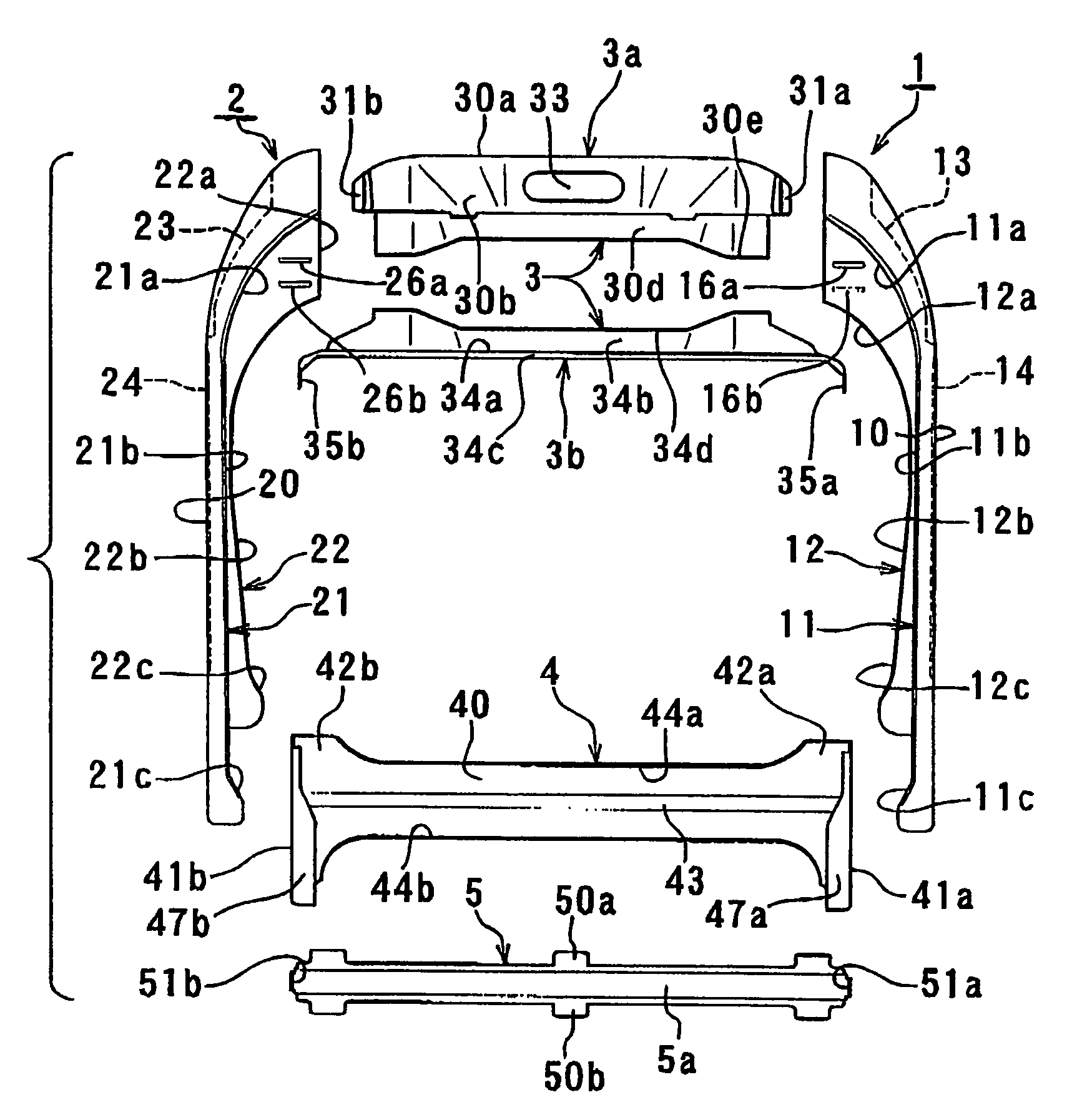

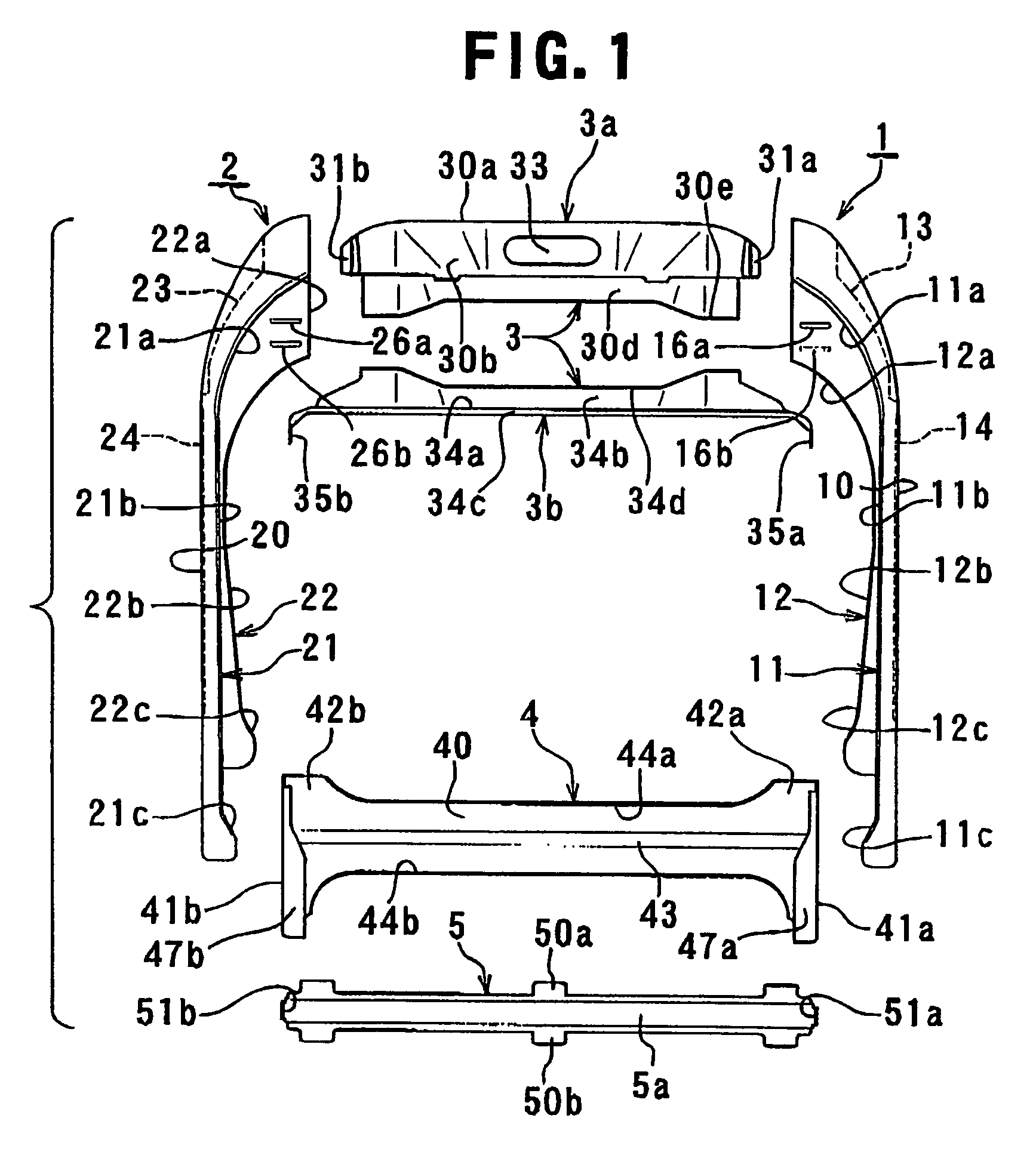

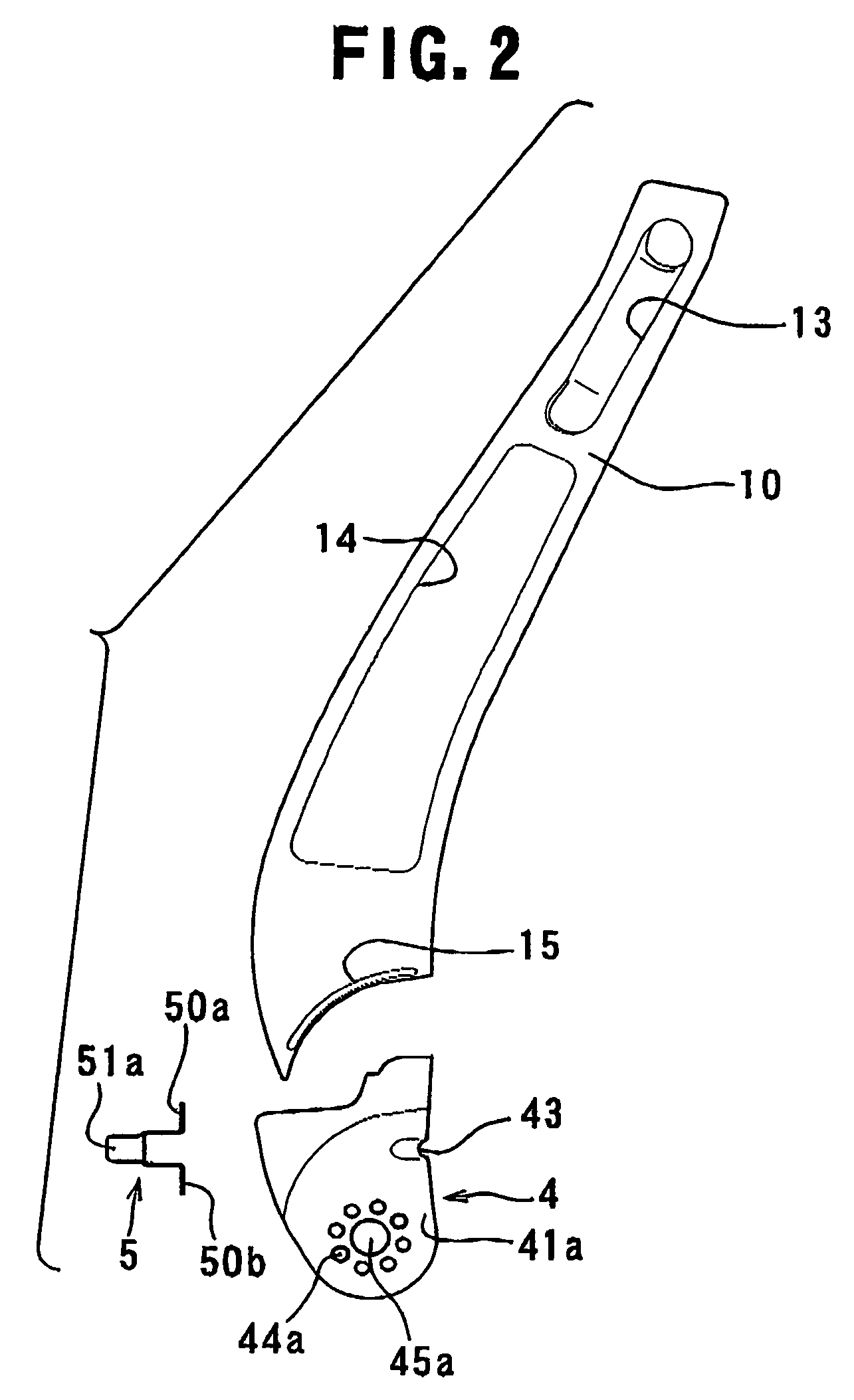

Seat back frame for vehicle seat

A seat back frame for a vehicle seat includes first and second side members spaced apart from each other, each of the first and second side members being made of ultra-high tensile strength steel, the first side member having a first longitudinal body of a substantially U-shape in cross-section, the first longitudinal body comprising a pair of first spaced apart flange sections and a first main plate section interconnecting the first spaced apart flange sections, the first side member having a first upper region and a first lower region, the second side member having a second longitudinal body of a substantially U-shape in cross-section, the second longitudinal body comprising a pair of second spaced apart flange sections and a second main plate section interconnecting the second spaced apart flange sections, the second side member having a second upper region and a second lower region, an upper member arranged between the first and second upper regions of the first and second side members, the upper member being made of ultra-high tensile strength steel, the upper member having first and second end portions, the upper member being mounted, by spot-welding, to the first and second upper regions of the first and second side members with the first and second end portions thereof being fitted in the first and second side members, and a lower member arranged between the first and second lower regions of the first and second side members, the lower member being made of ultra-high tensile strength steel, the lower member having third and fourth end portions, and the lower member being mounted, by spot-welding, to the first and second lower regions of the first and second side members with the third and fourth end portions thereof being fitted in the first and second side members.

Owner:TS TECH CO LTD

Head rest device

InactiveUS20060006709A1Reduce rigidityReliable holdBack restsPedestrian/occupant safety arrangementRear-end collisionBowden cable

When a pressure receiving plate provided at a seat back moves to a rear side of a vehicle body when a vehicle is collided from behind, a Bowden cable transmits movement of the pressure receiving plate to a headrest ascending mechanism as a tensile load, thereby quickly ascending a headrest to reliably hold a head of an occupant. The Bowden cable transmits only the tensile load, and hence the Bowden cable is not buckled. Reduction in weight is made possible as compared with the case using a rod for transmitting a compression load. Since the Bowden cable is light, it is not required to unreasonably place the pressure receiving plate at a position near the headrest ascending mechanism for reduction in weight, and hence the pressure receiving plate can be placed at the optimal position where a sufficient driving force is obtained at the time of collision. Thus, a headrest is ascended with favorable responsiveness upon a rear-end collision of a vehicle while using a thin transmission member with low rigidity.

Owner:HONDA MOTOR CO LTD

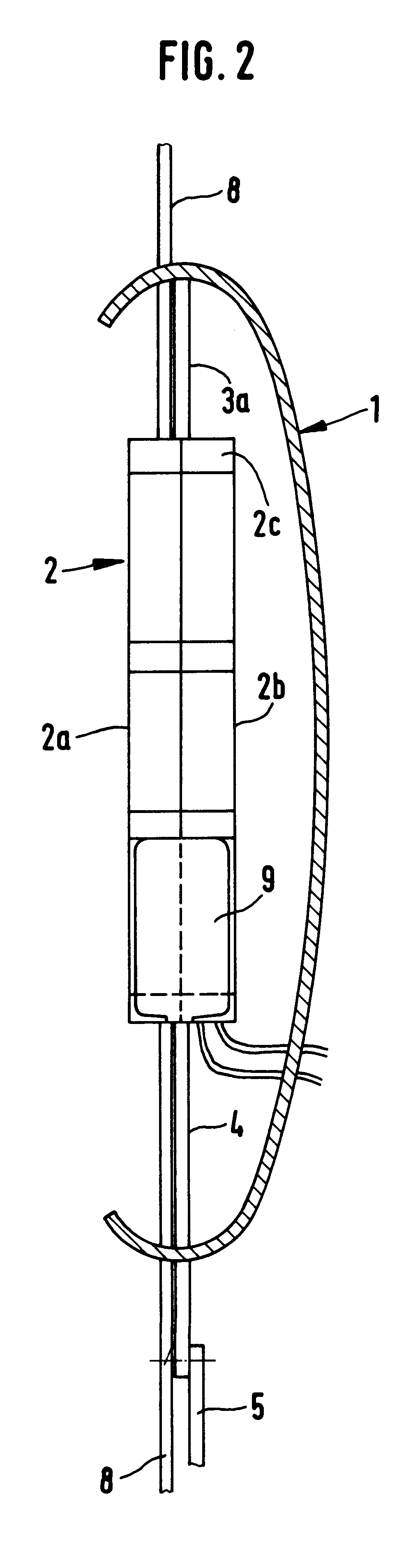

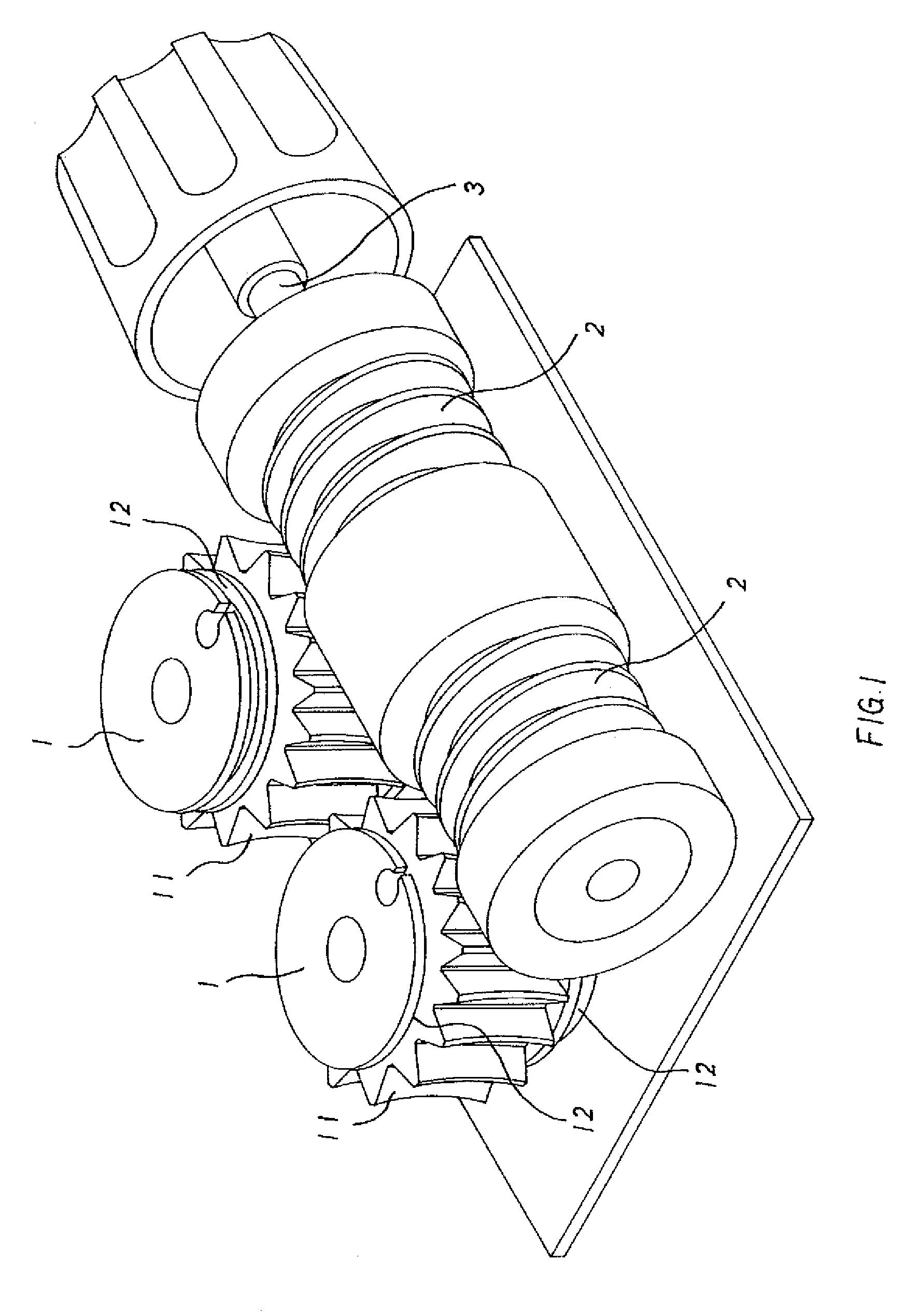

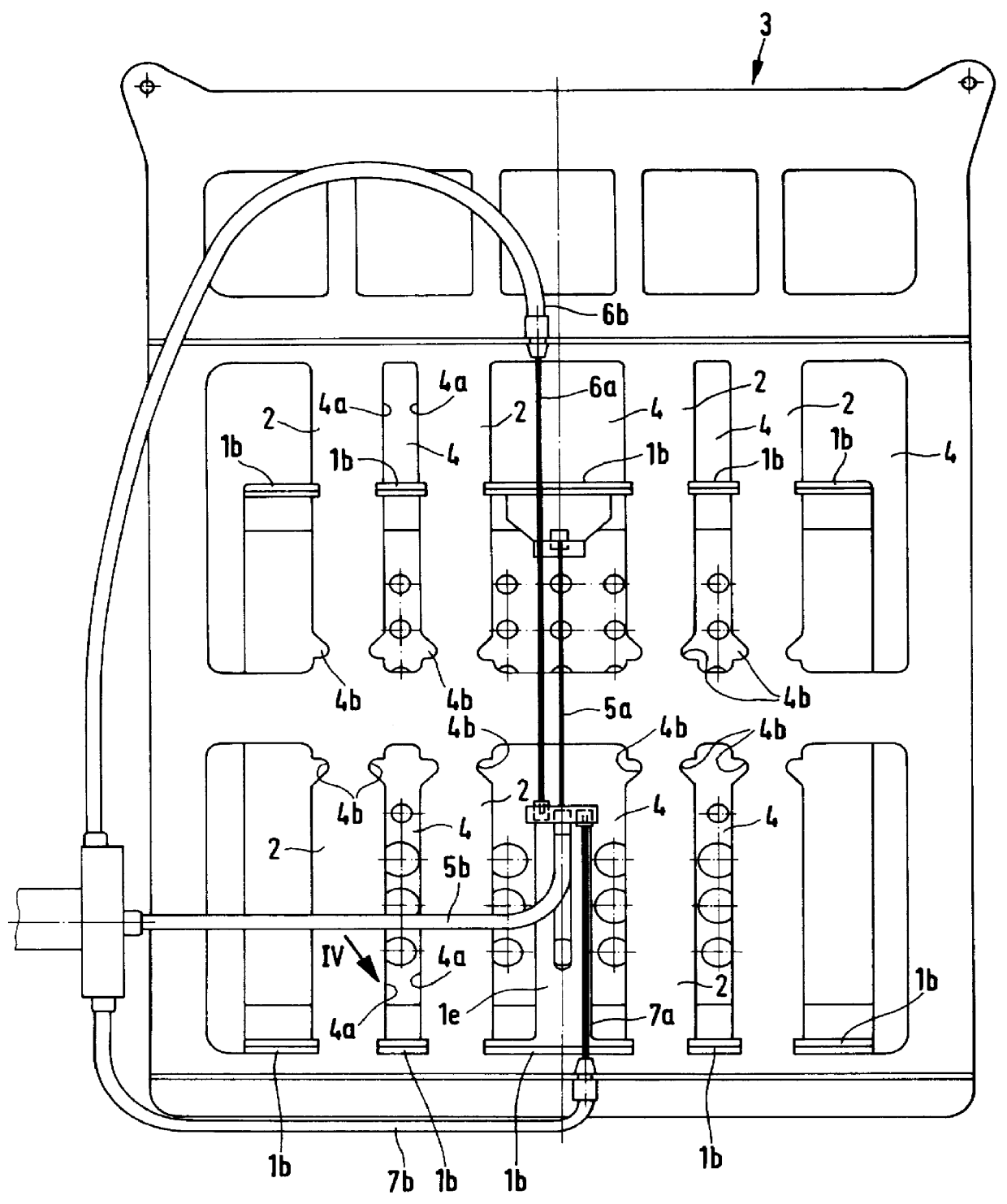

Back support for seat-backs, in particular for motor vehicle seats

PCT No. PCT / EP98 / 01655 Sec. 371 Date May 13, 1999 Sec. 102(e) Date May 13, 1999 PCT Filed Mar. 21, 1998 PCT Pub. No. WO98 / 45138 PCT Pub. Date Oct. 15, 1998A lumbar support for seat backs, in particular of motor vehicle seats, has a forward-bowed support plate (1) that is adjustable in its curvature. The support plate (1is mounted at one horizontal end region (1a) on laterally spaced guide elements that are parallel to one another and fixed with respect to the seat back so that it is vertically movable. The vertical guide elements consist of ribs (2) of a guide plate (3) that is fixed with respect to the seat back. The guide plate (3) has openings (4), which possess vertical guide edges (4a) that are parallel to one another. Through the guide edges (4a) pass, from the front, end-mounted brackets (1b) of the support plate (1). The brackets (1b) have necks (1c) corresponding to the spacing of the guide edges (4a), and widen again on the back of the guide plate (3).

Owner:MEGAPLAST SA

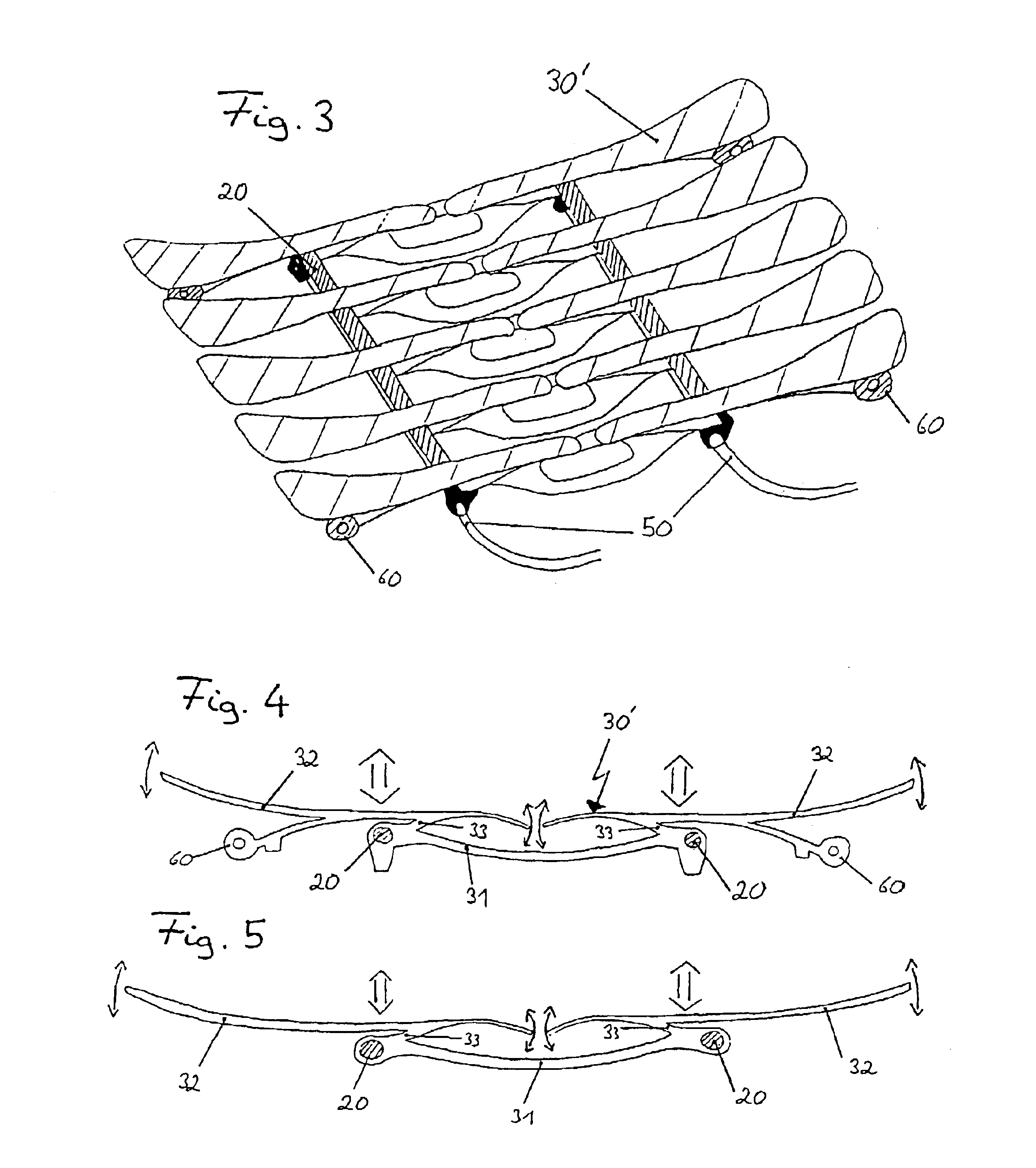

Backrest for seats and chairs having pressure and tensile elements

InactiveUS7320503B2Avoid displacementStiffness of connection can be influencedBack restsStoolsEngineeringMechanical engineering

Owner:EYSING VOLKER WILHELM +1

Vehicle seat

A vehicle seat includes a seat part, a backrest, and at least one shell structure comprising a plastic material and having foam padding on a side on which an occupant sits. The at least one shell structure is arranged on frame parts provided on at least one of the seat part and the backrest, the frame parts comprising a metal material.

Owner:DZHONSON KONTROLZ GMBKH

Headrest mountable video system

Owner:VOXX INT CORP

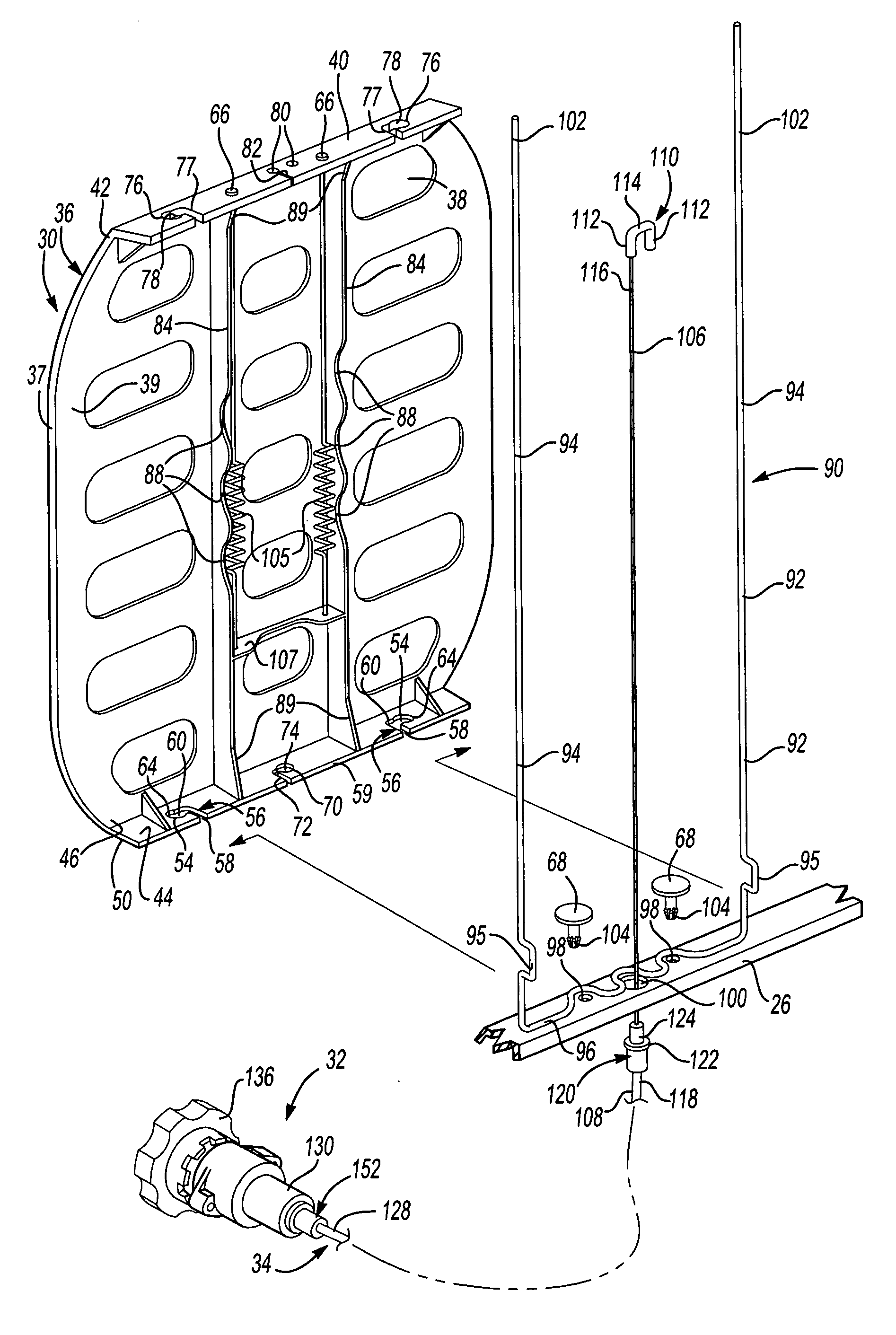

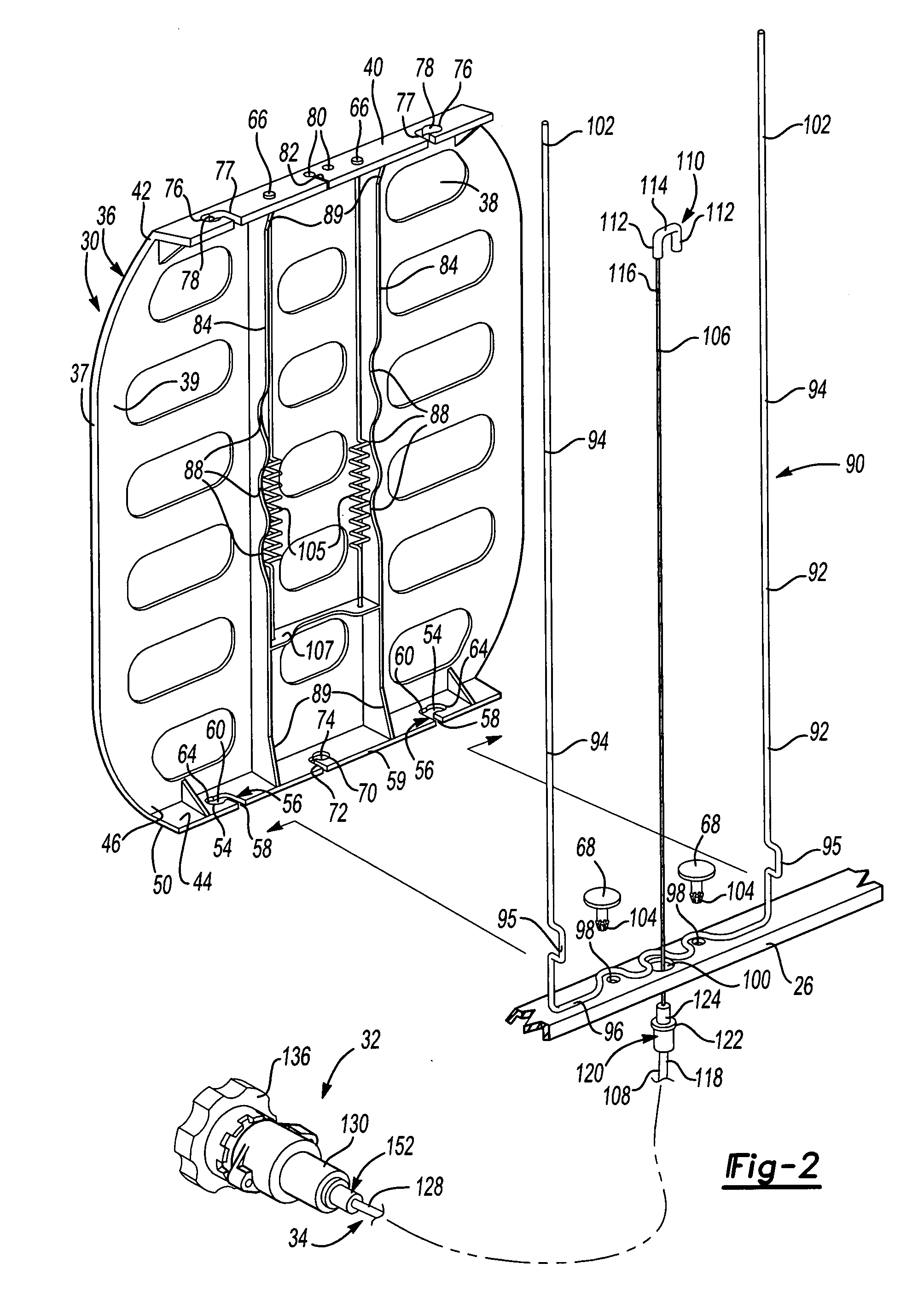

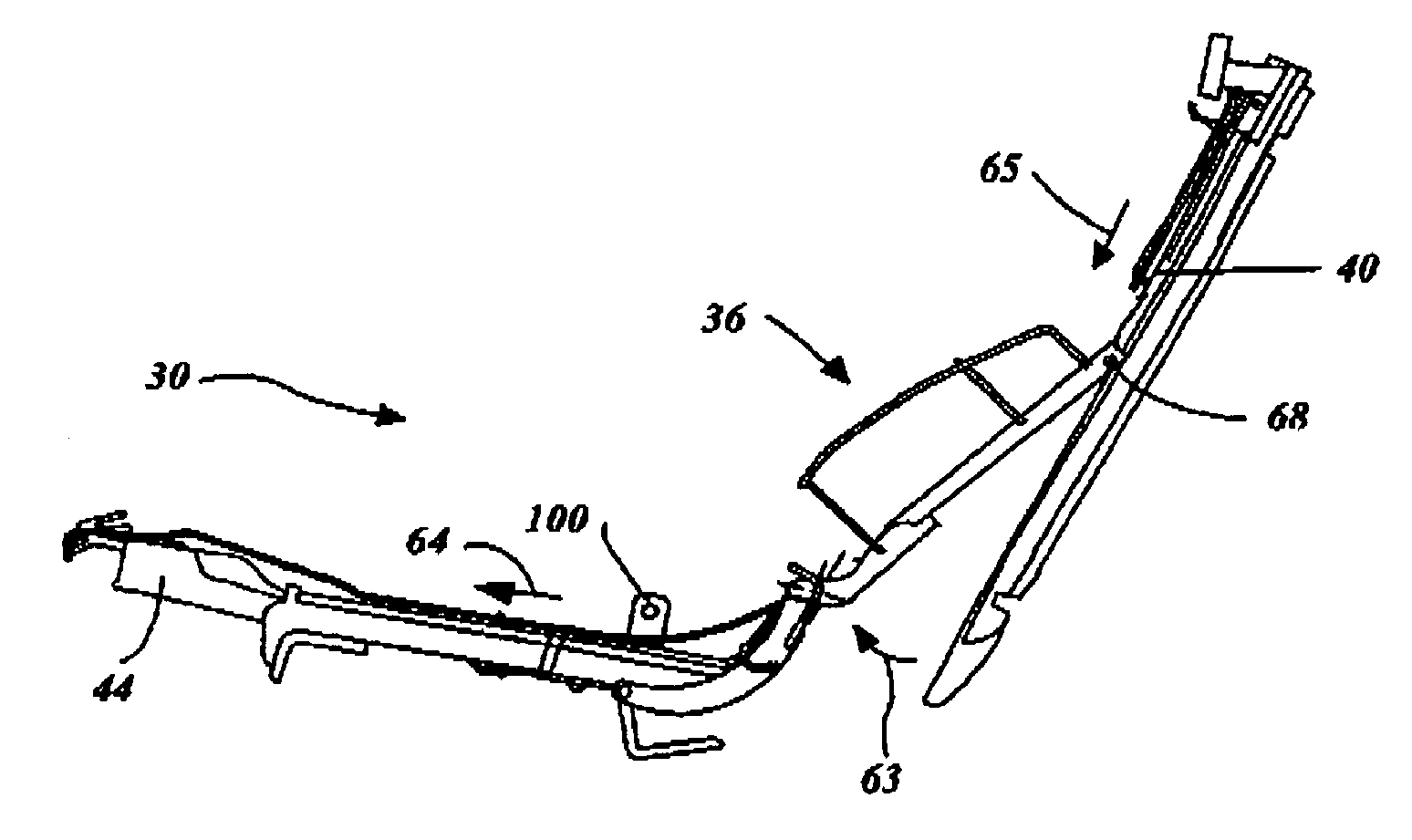

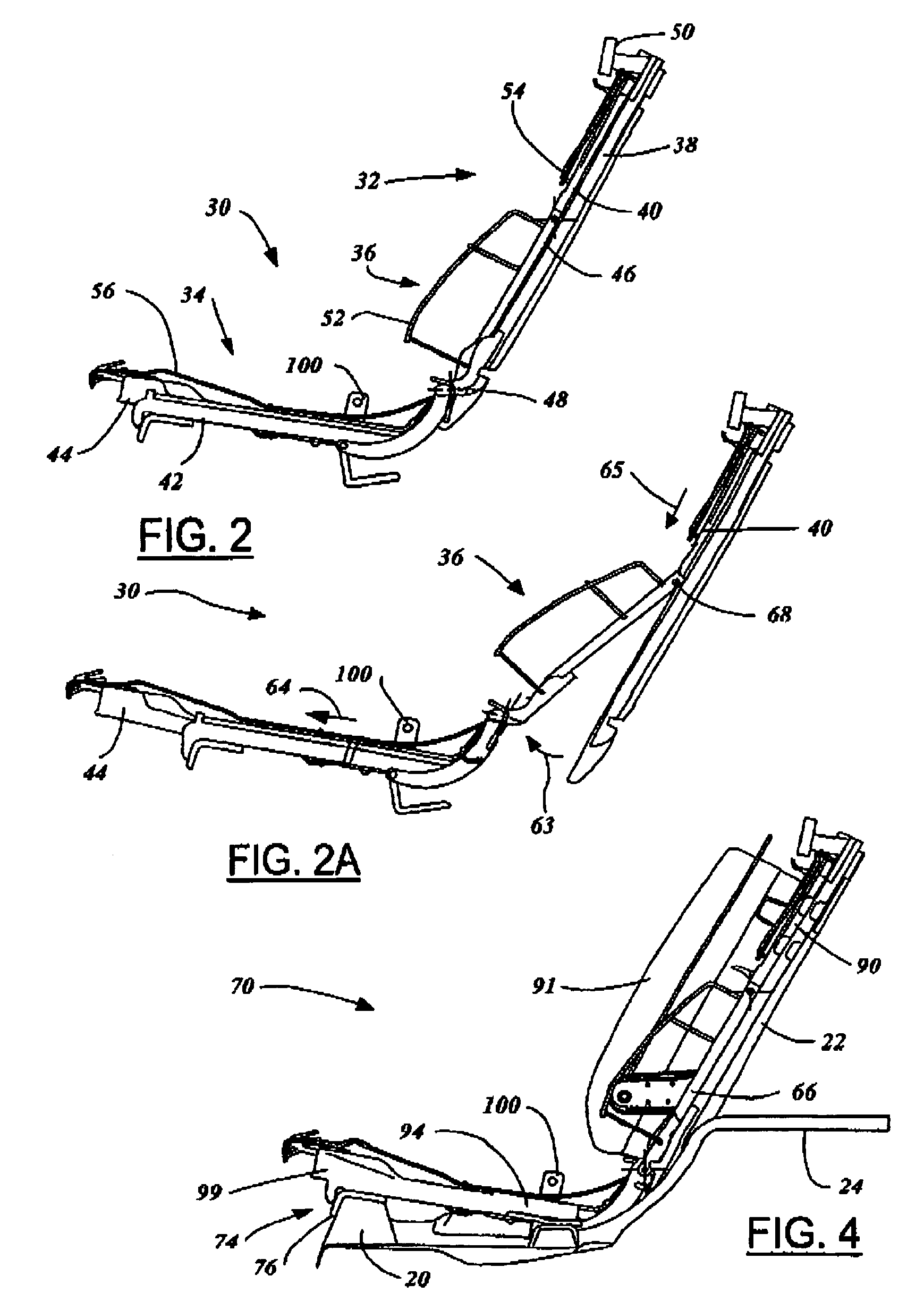

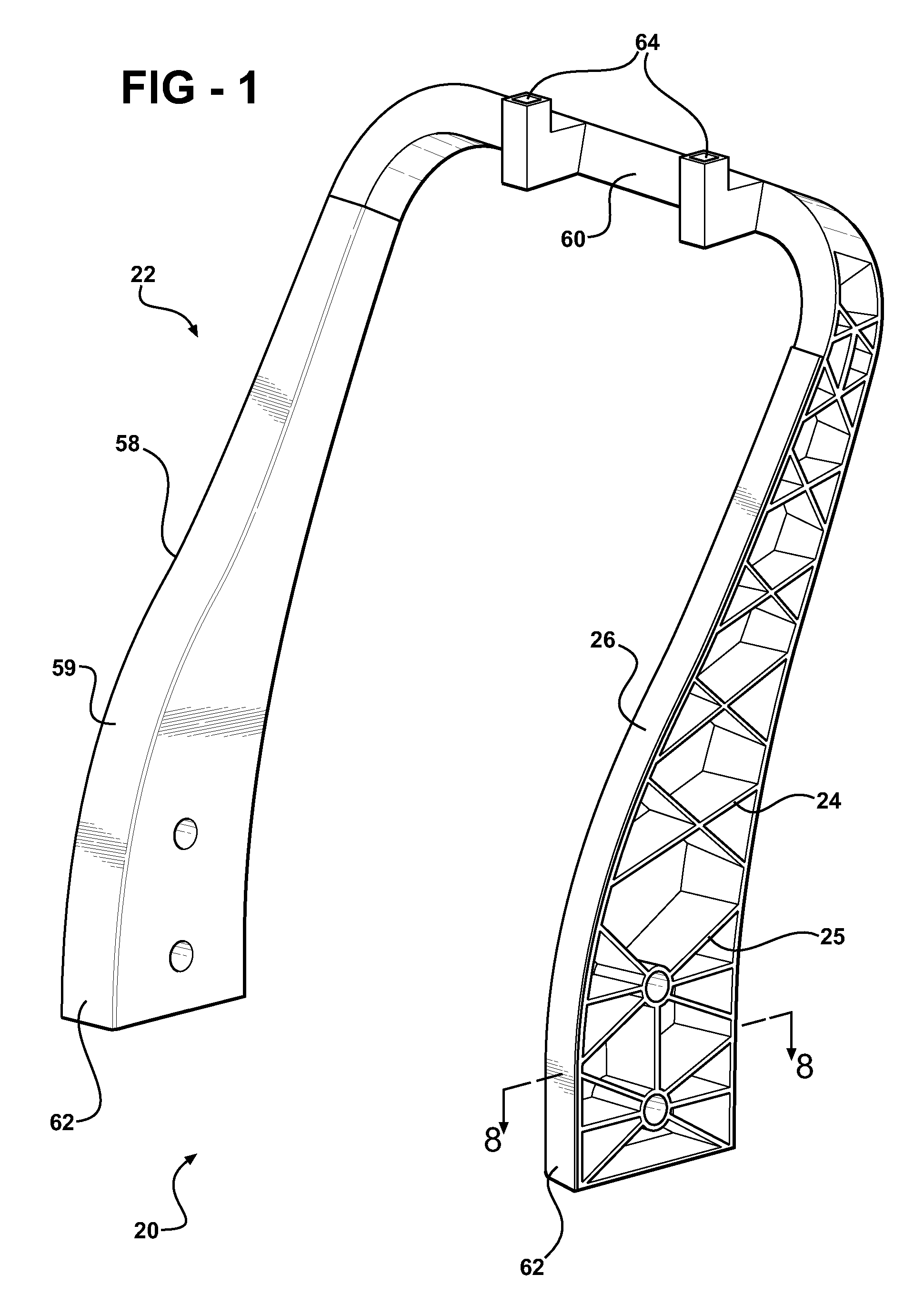

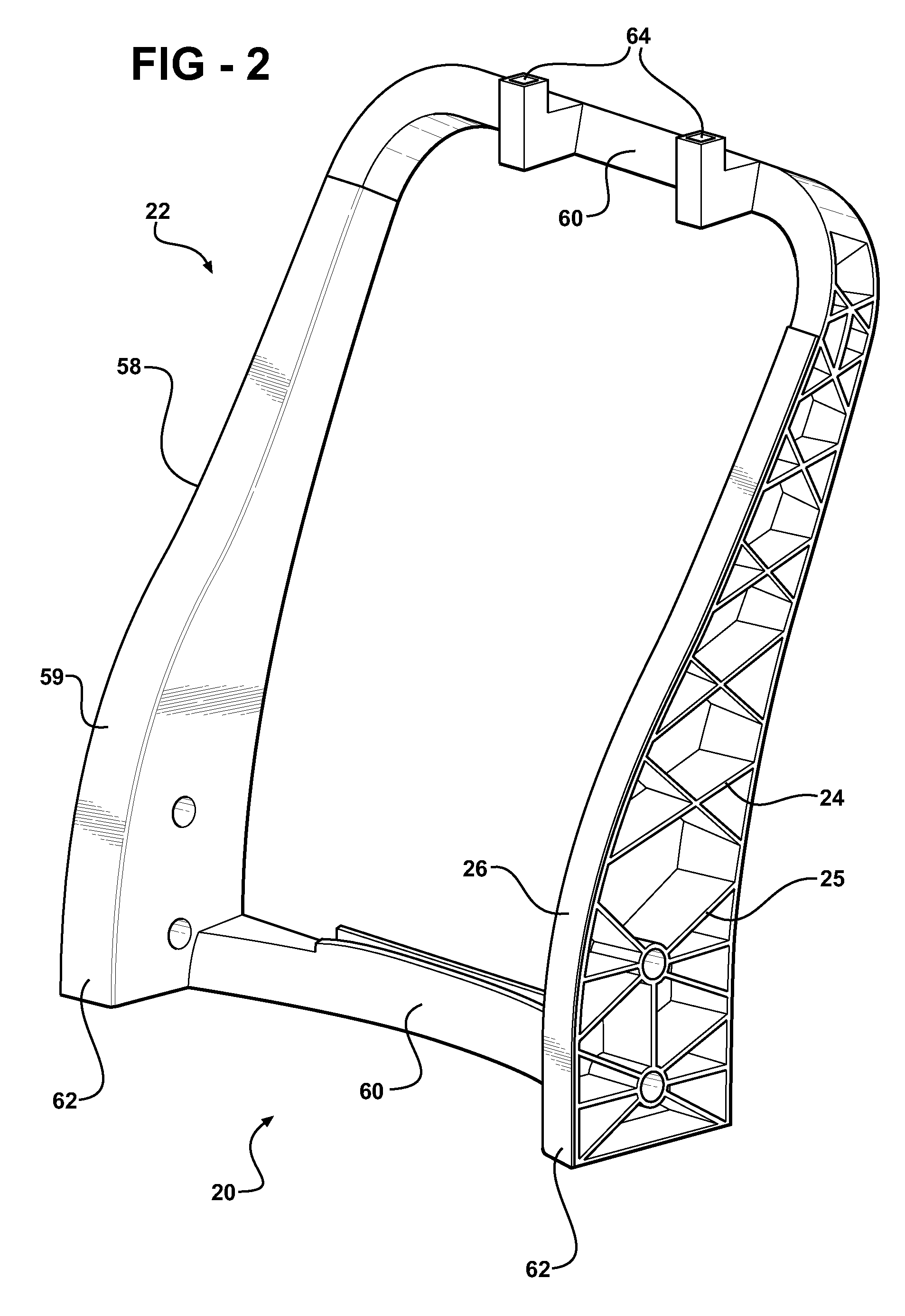

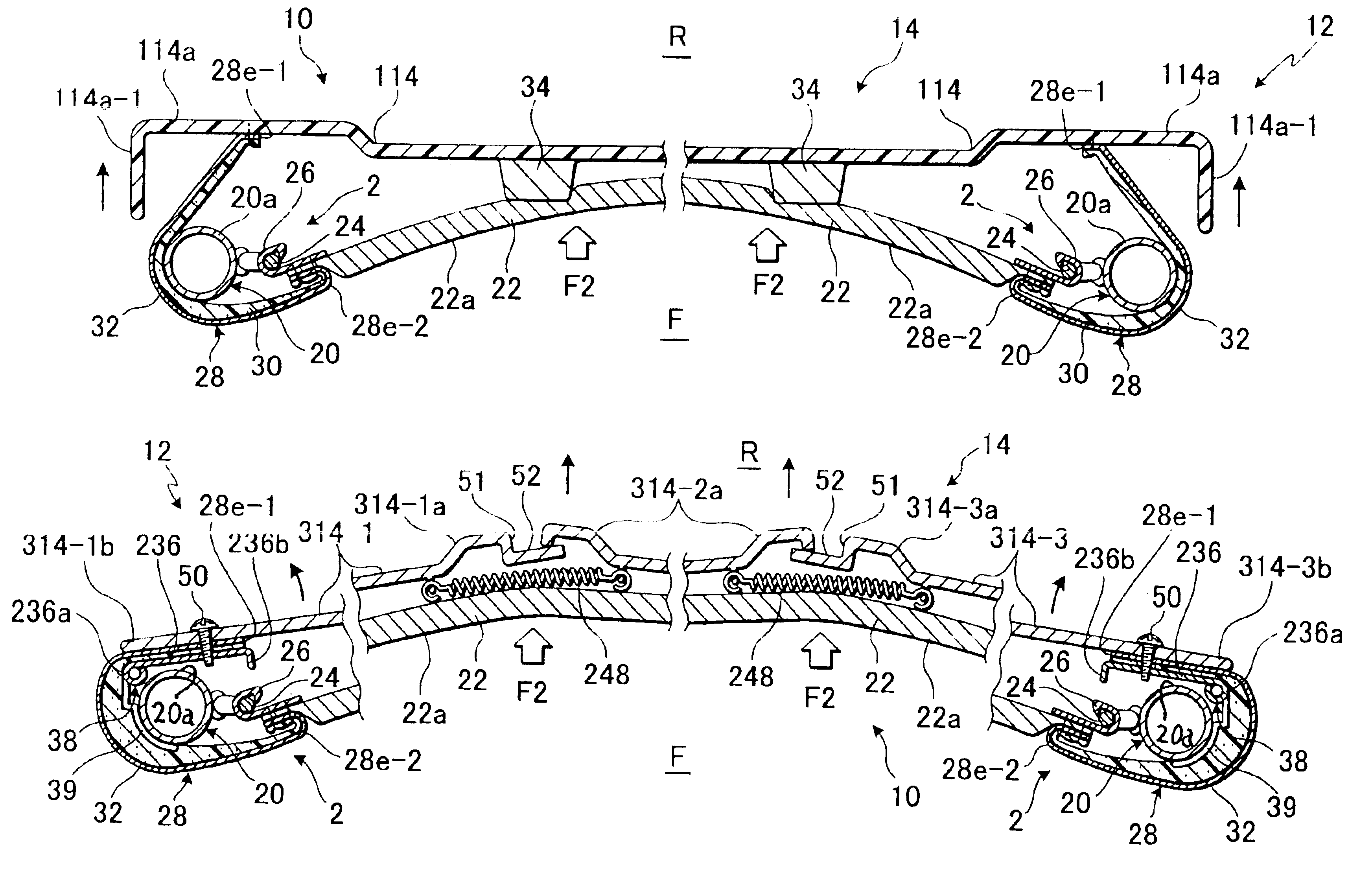

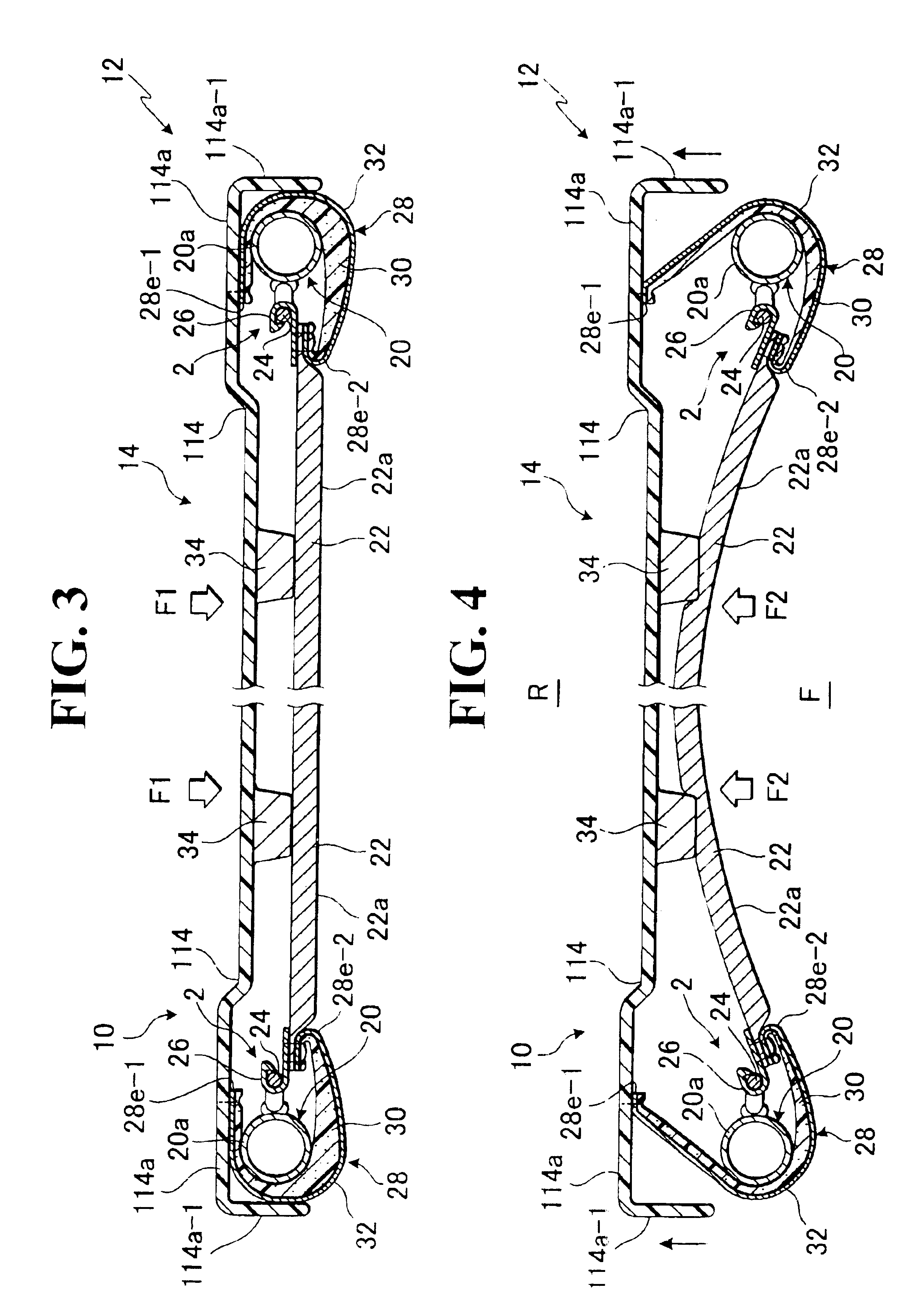

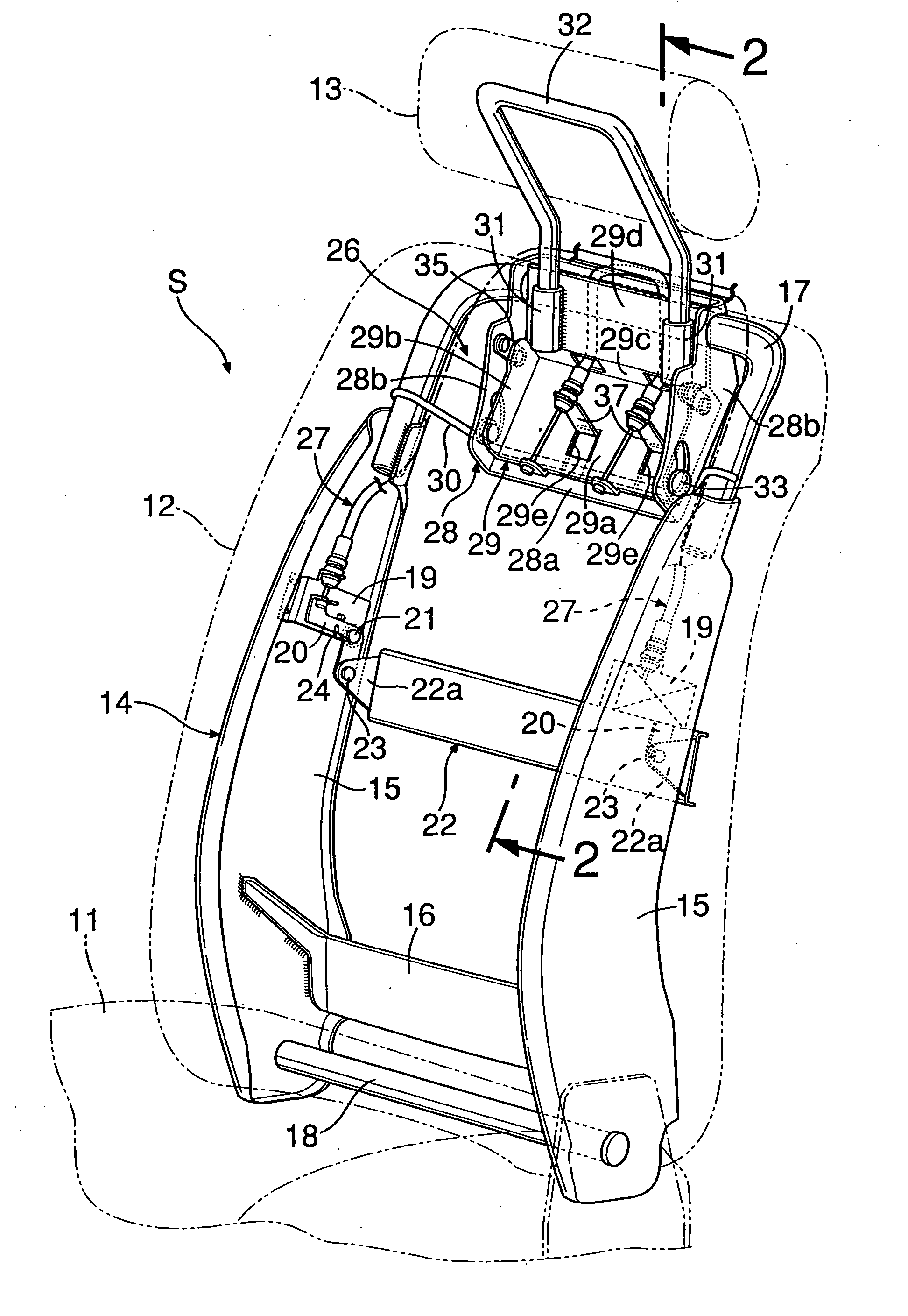

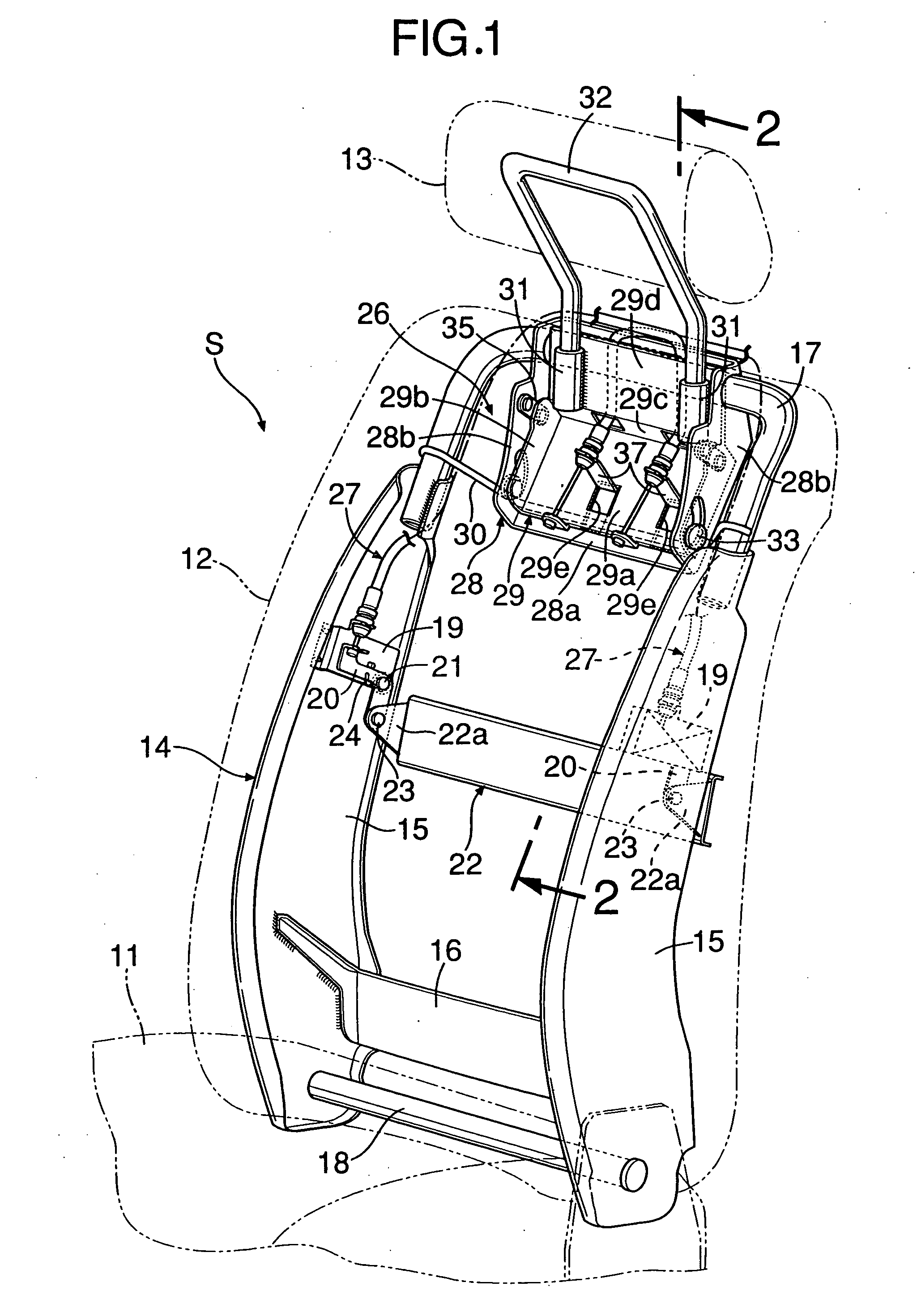

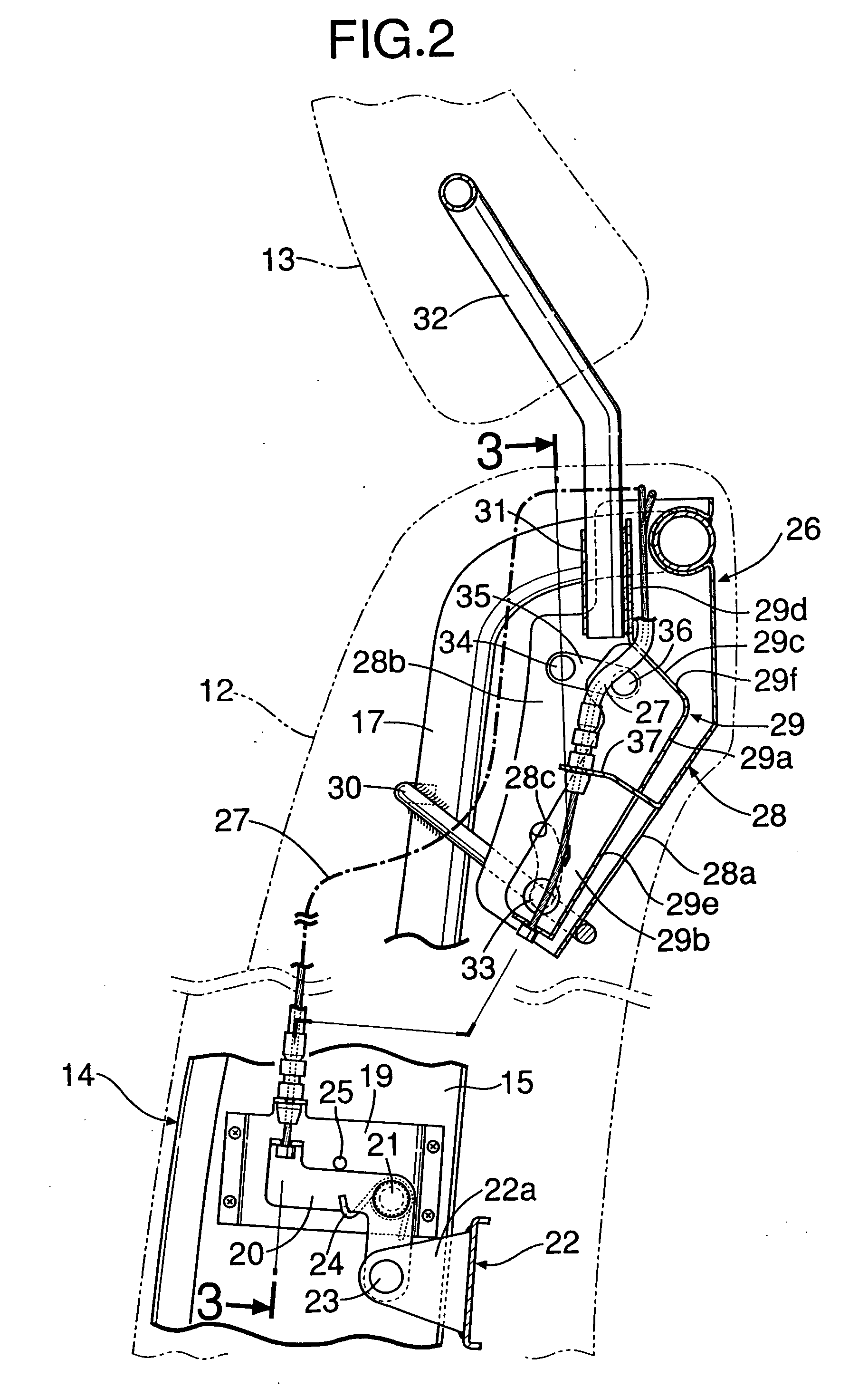

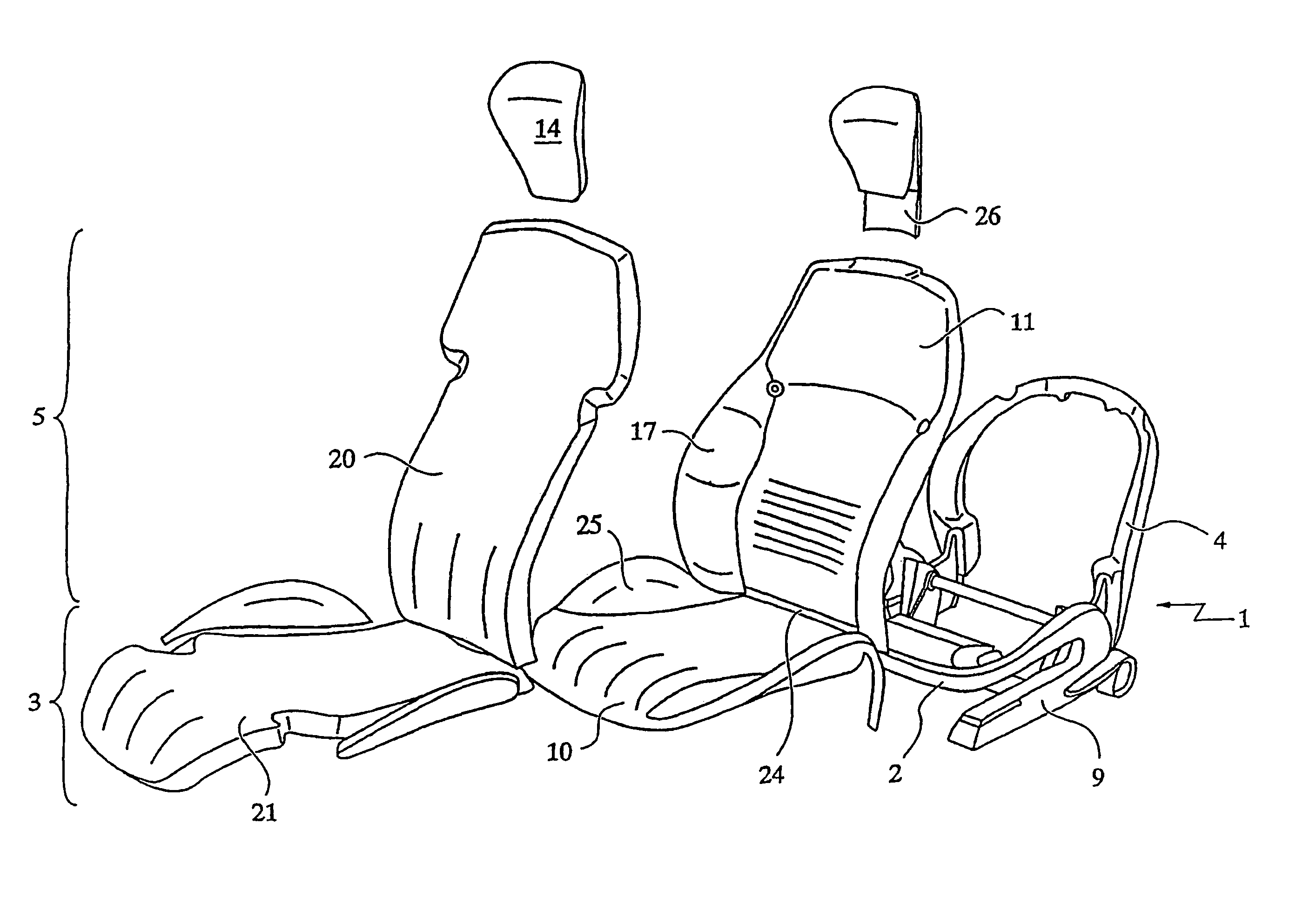

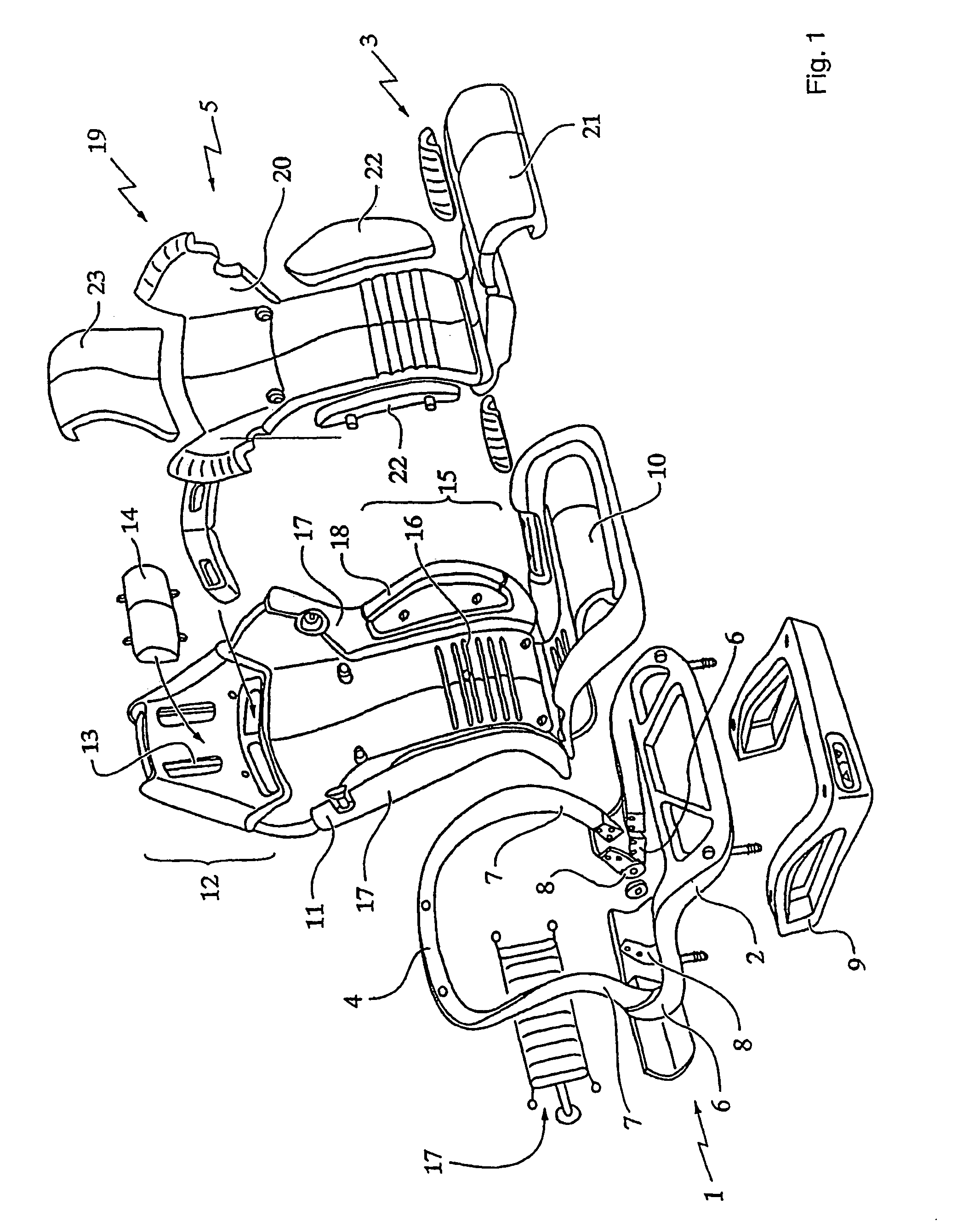

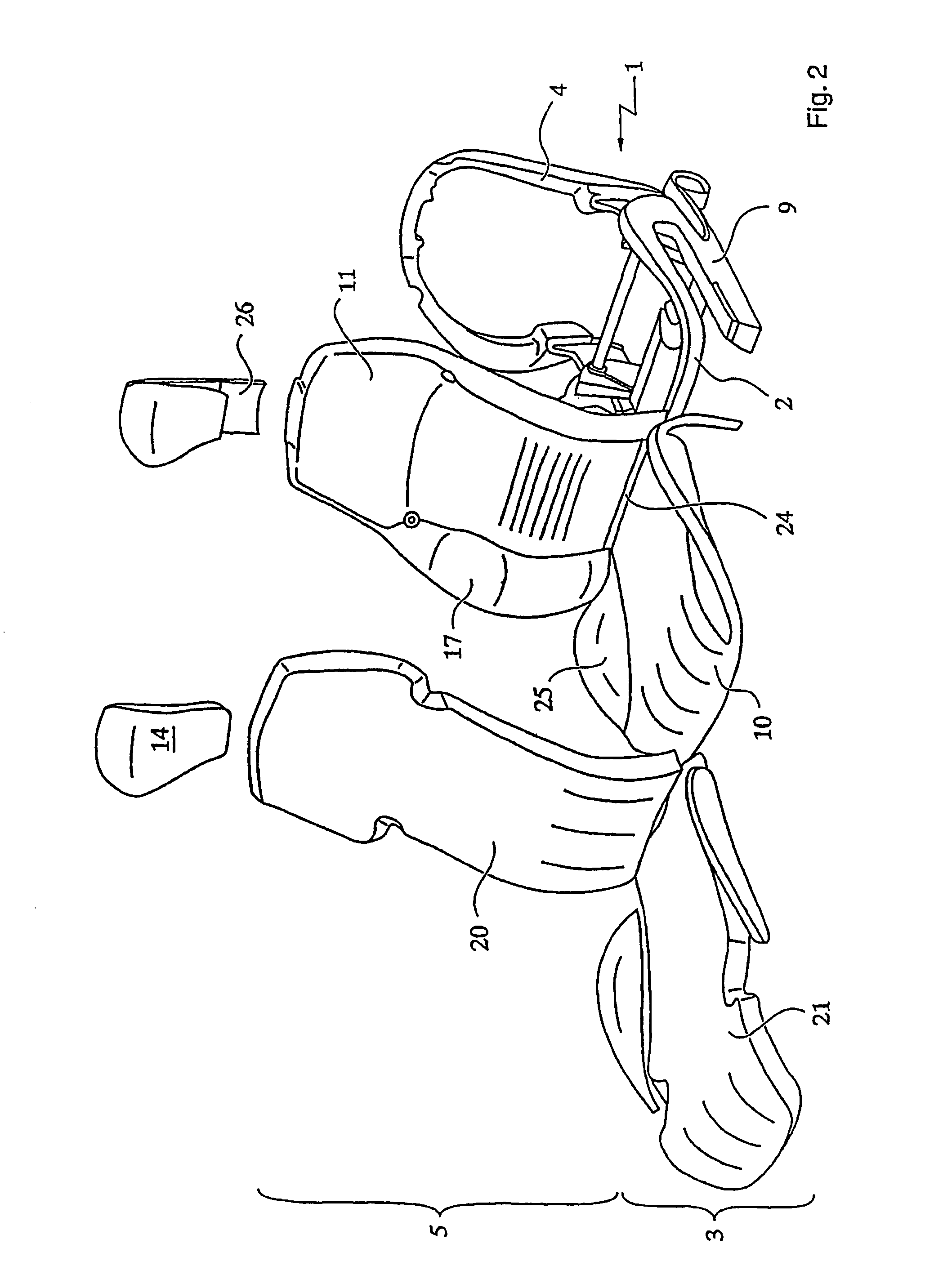

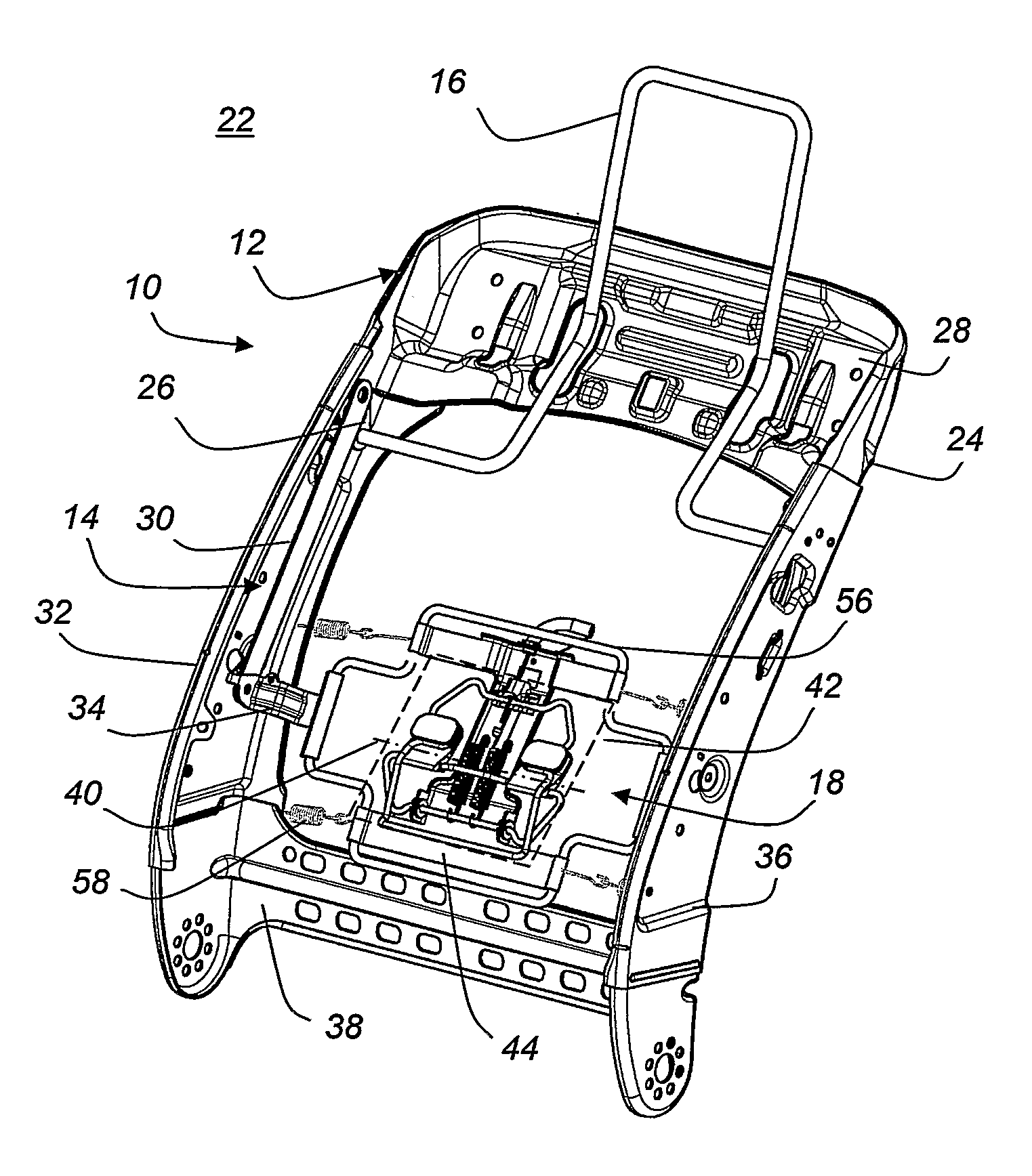

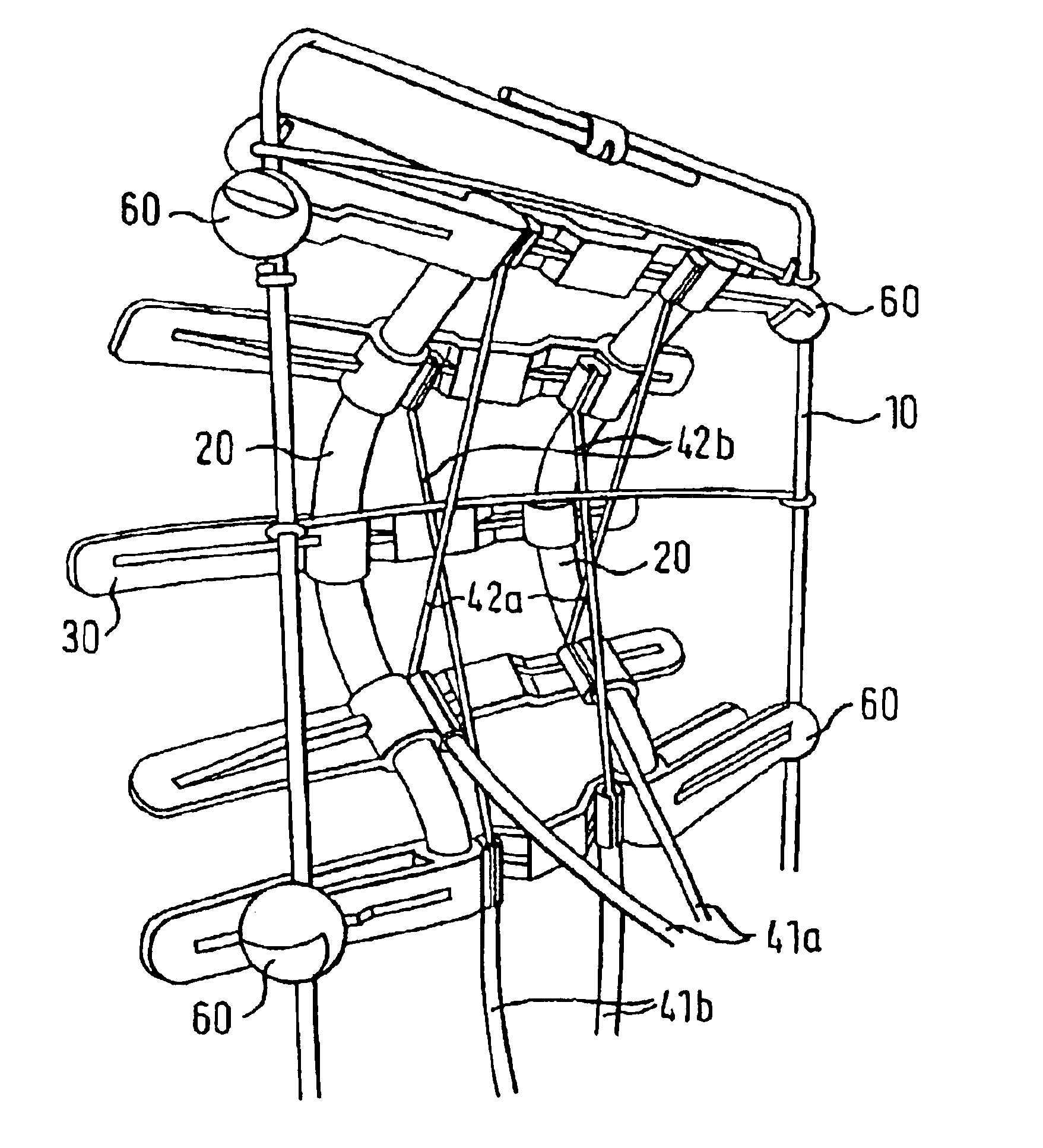

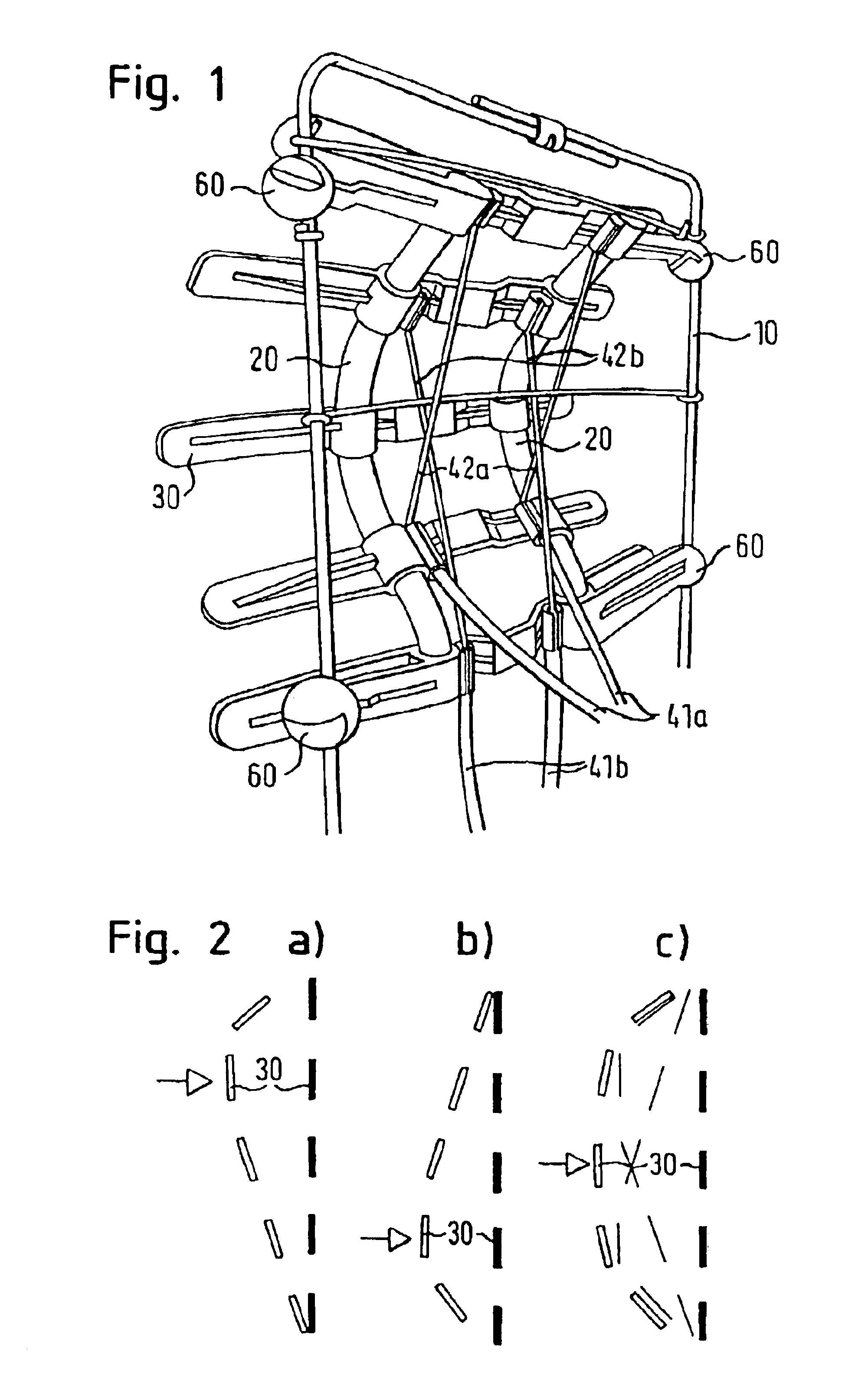

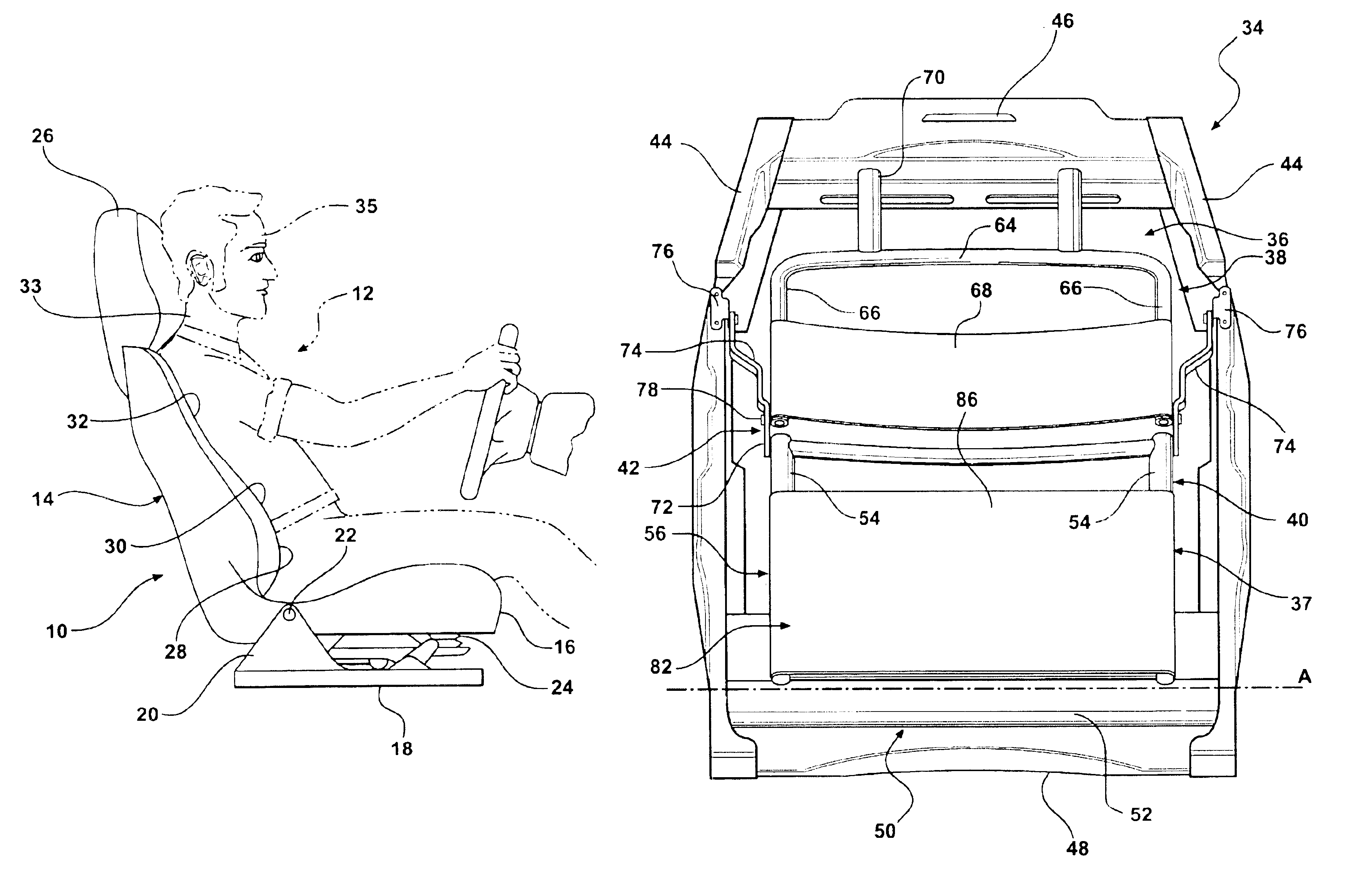

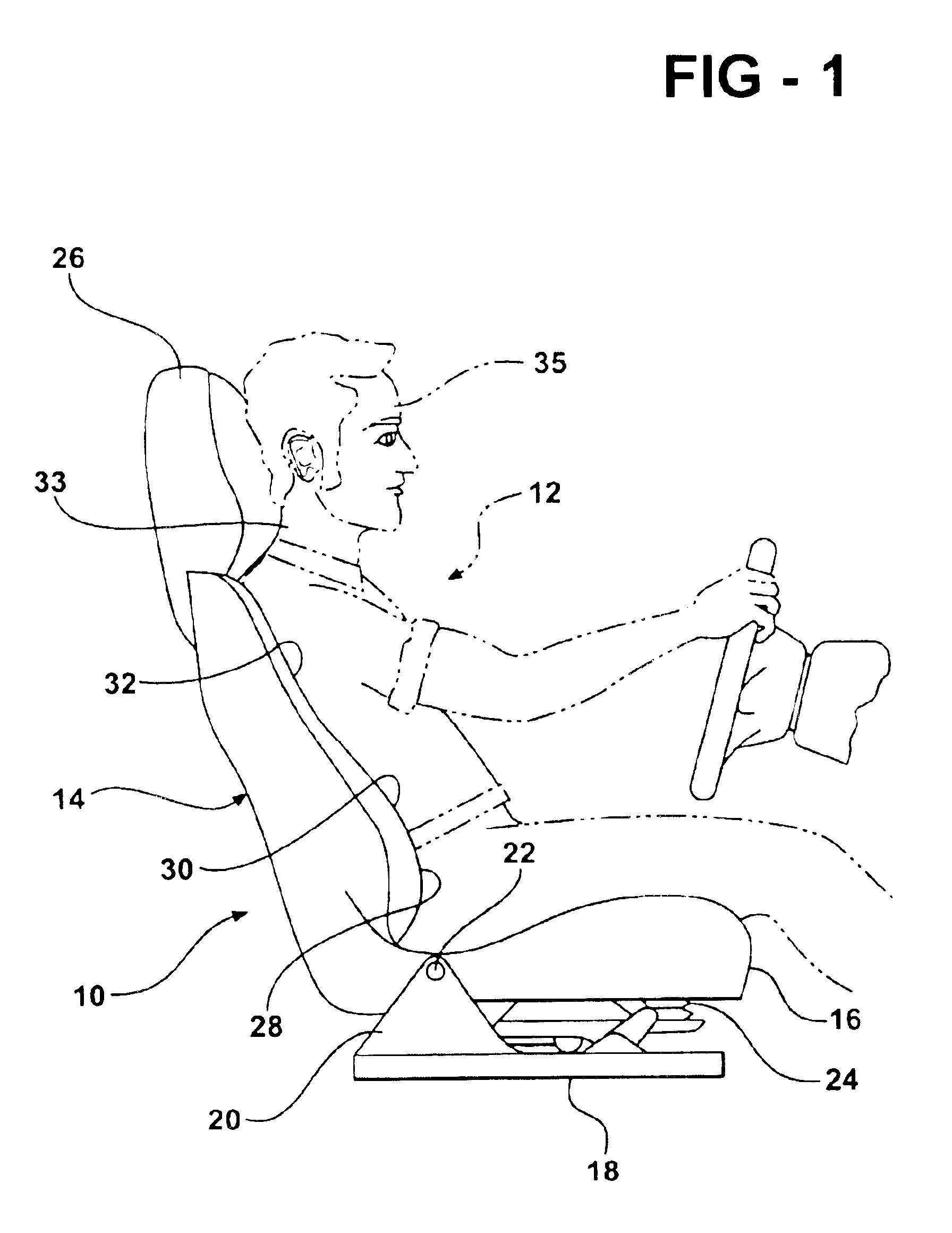

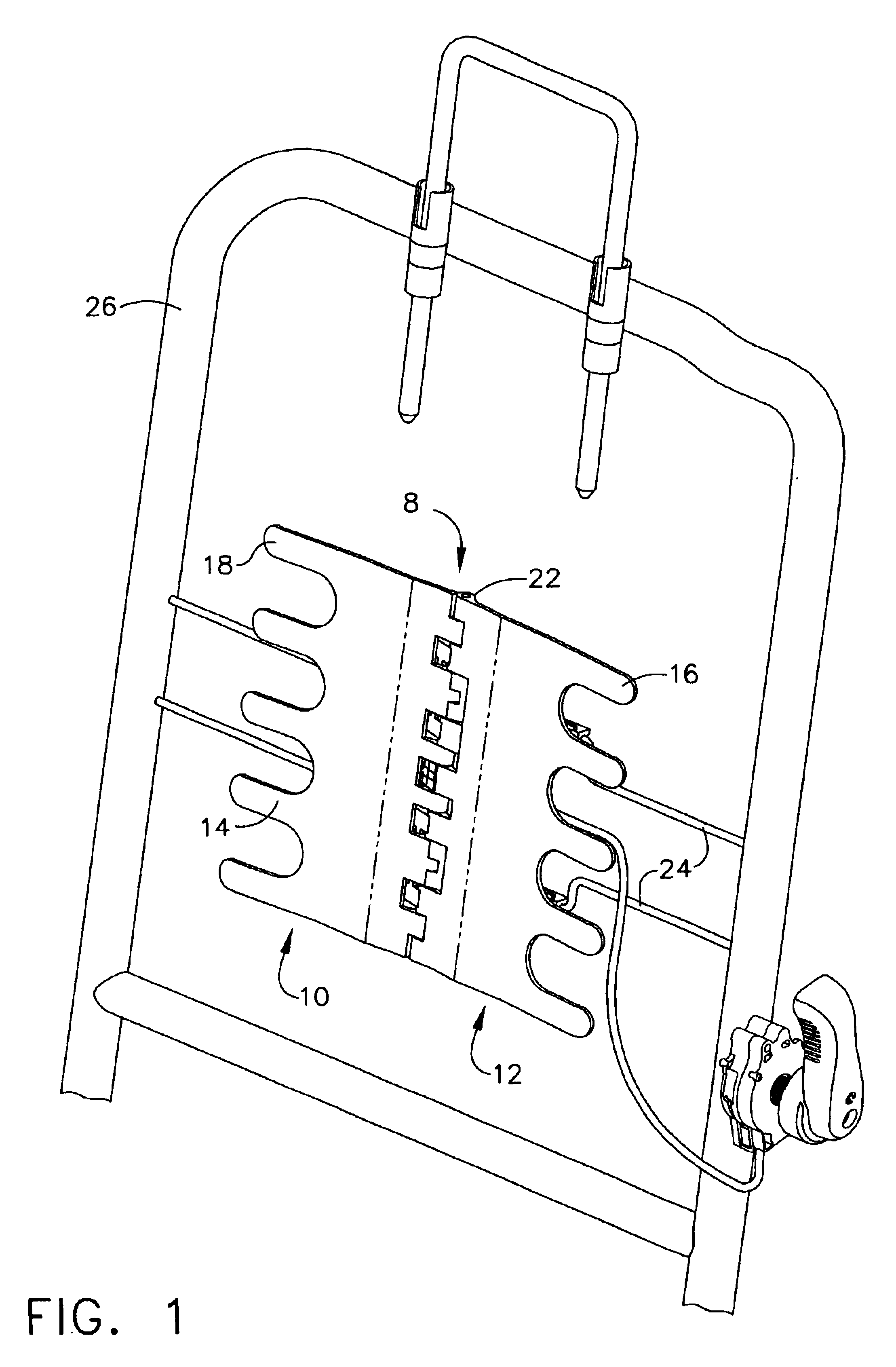

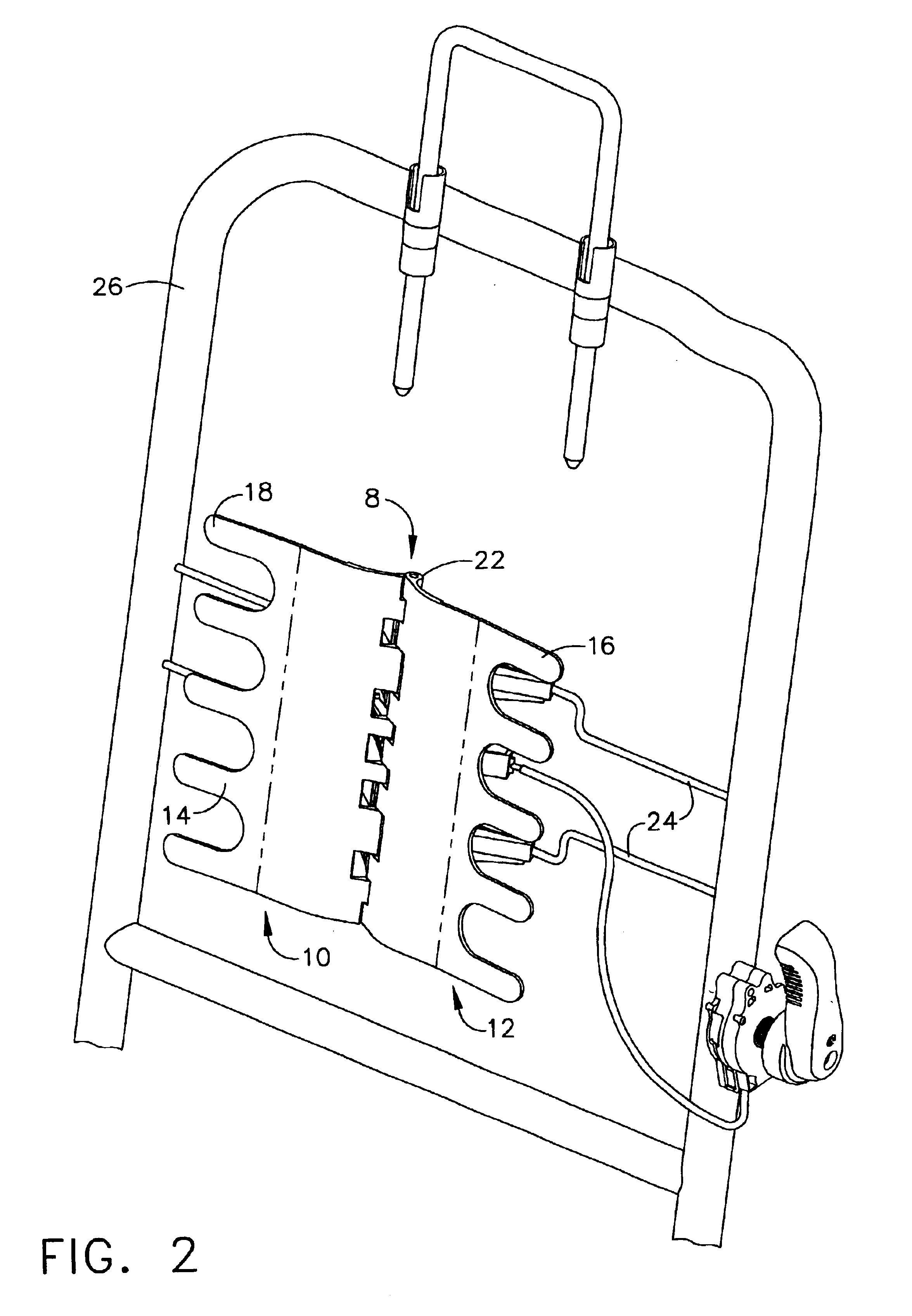

Integrated Lumbar and Active Head Rest System

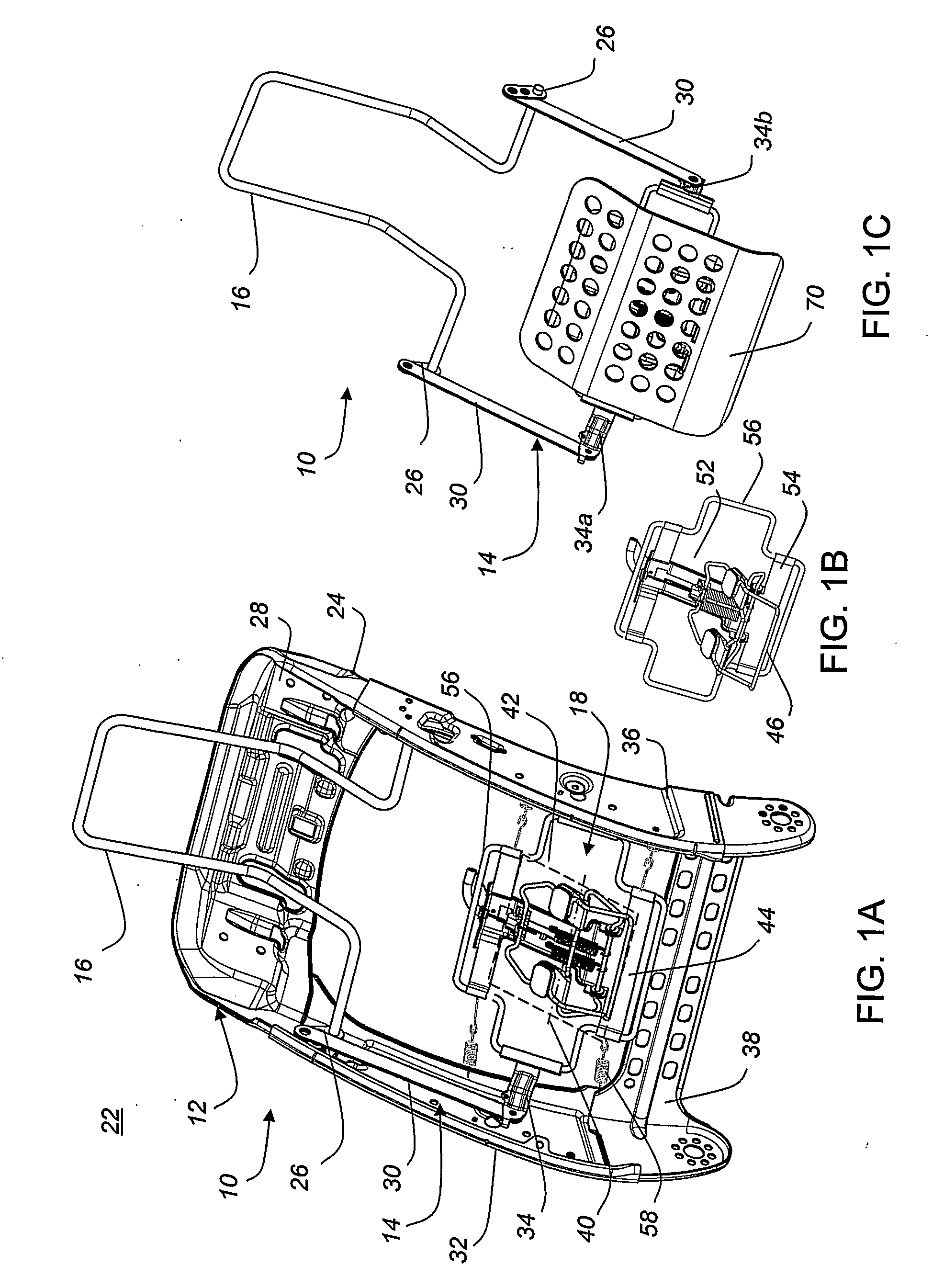

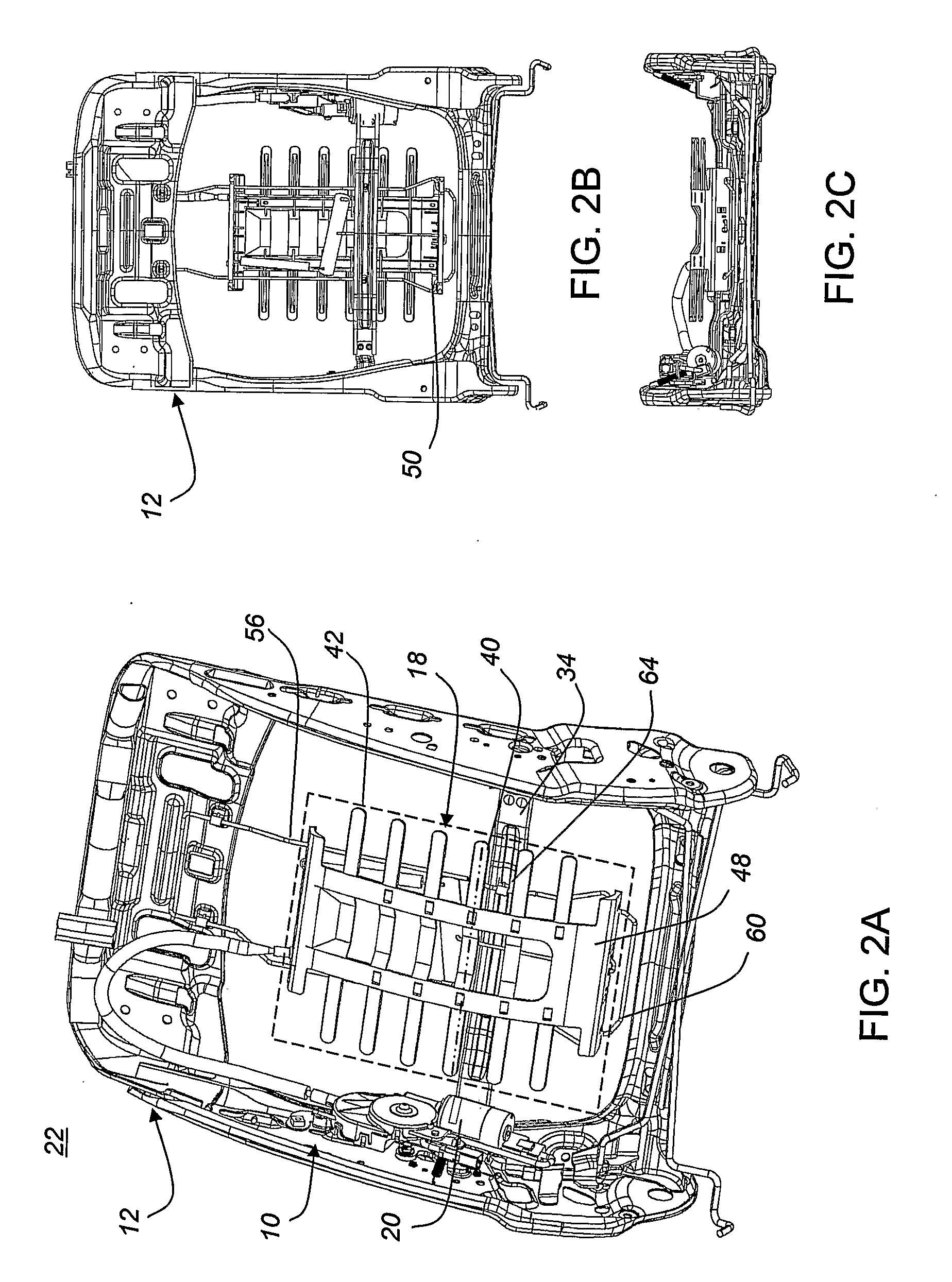

InactiveUS20090001785A1Increase the itineraryIncrease flexibilityBack restsPedestrian/occupant safety arrangementEnergy transferEngineering

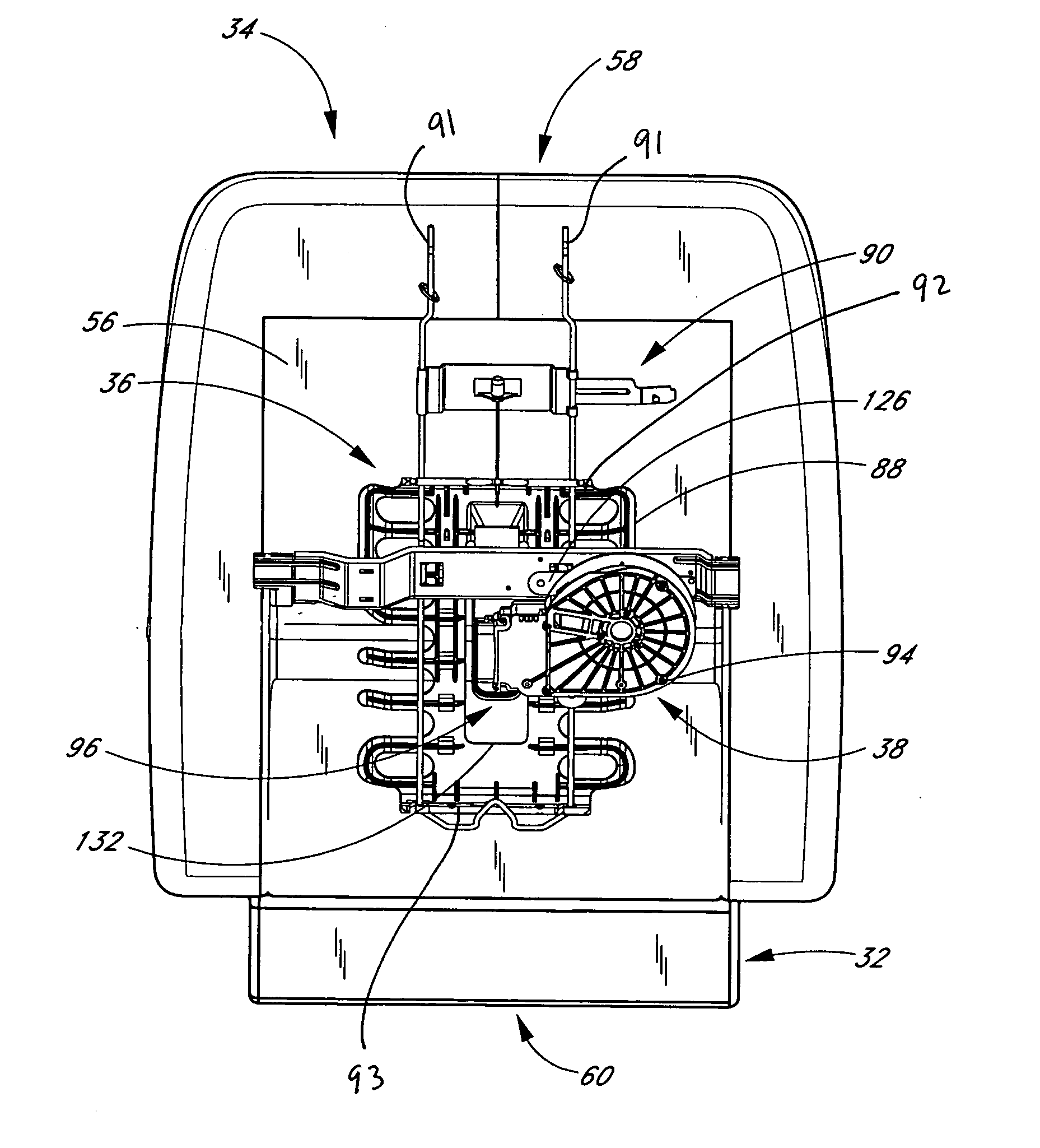

An integrated active headrest / lumbar seating system 22 includes an active headrest system 10 supported within a seat frame 12 of a vehicle. The active headrest system 10 includes an energy transfer mechanism 14 that connects the headrest 16 to the lumbar support 18. The lumbar support 18 is operated by an actuator 20. The energy transfer mechanism 14 includes a pair of linkages 26, a pair of side bars 30 and a cross bar 34. The linkages 25 connect to the headrest 16 and the pair of side bars 30 extend from the pair of linkages 26 along the side rails 32 of the seat frame 12 to the crossbar 34. The crossbar 34 connects the pair of side bars 30 and is situated at the middle section 40 of the lumbar support 18. The lumbar support 18 can fit between the side bars 30.

Owner:SCHUKRA OF NORTH AMERICA

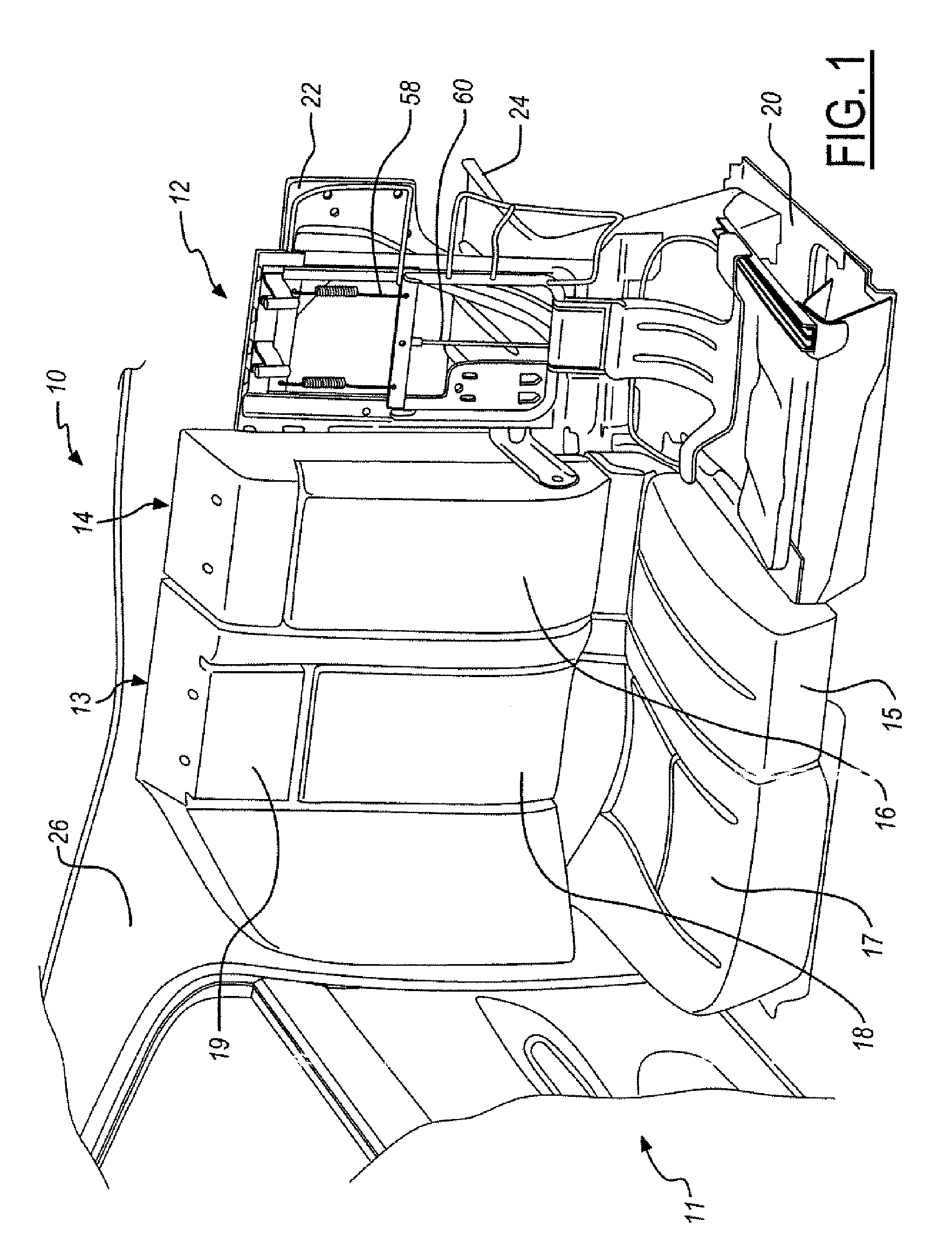

Vehicle seat incorporating a seat back panel

A vehicle seat includes a seat bottom and a seat back including a frame connected to the seat bottom. The seat back includes a front surface configured to support an occupant and a rear surface. A seat back panel securable to the seat back frame includes an outer appearance surface and a retainer structure disposed on an inner surface. The retainer structure is releasably secured to the seat back frame such that the seat back panel at least partially covers an opening in the rear surface of the seat back.

Owner:LEAR CORP

Spine support for vehicle seats

Owner:FICO CABLES LDA (PT)

Vehicle seat having a lumbar support system

InactiveUS6837541B2Absorbing and dissipating energyBack restsPedestrian/occupant safety arrangementSupporting systemEngineering

A vehicle seat assembly including a seatback frame and a lumbar support system operatively mounted to the seatback frame. The lumbar support system includes a lower suspension mechanism that is generally aligned with the pelvic and lumbar regions of the occupant of the seat assembly. The lower suspension mechanism includes a band of flexible material that is stretched about a pair of upstanding support members so as to have a predetermined tension for providing support for the occupant of the seat assembly at the pelvic and lumbar regions.

Owner:LEAR CORP

Method and apparatus for a scissors ergonomic support

A scissors lumbar support includes a hinge axle and two arms each having a forward portion and a rearward portion. The forward portions are lumbar support pads. At least one of the rearward portions of the arms are adapted to operatively engage a force applicator. Each of the arms hinge around a hinge axle upon application of force by a force applicator. At least one of the rearward portions of the arms are mountable on a seat frame.

Owner:L & P PROPERTY MANAGEMENT CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com