Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2098results about "Seat frames" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

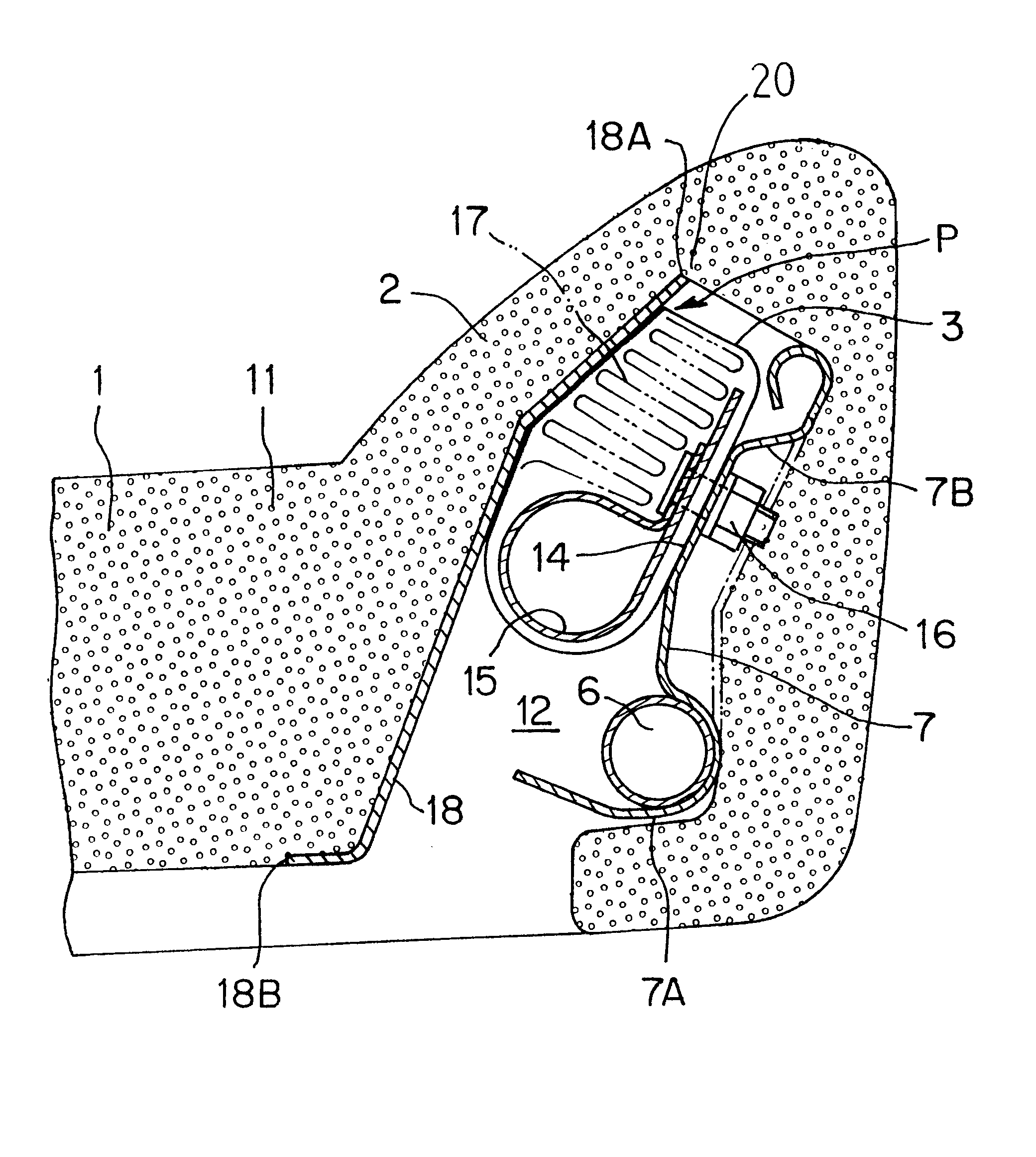

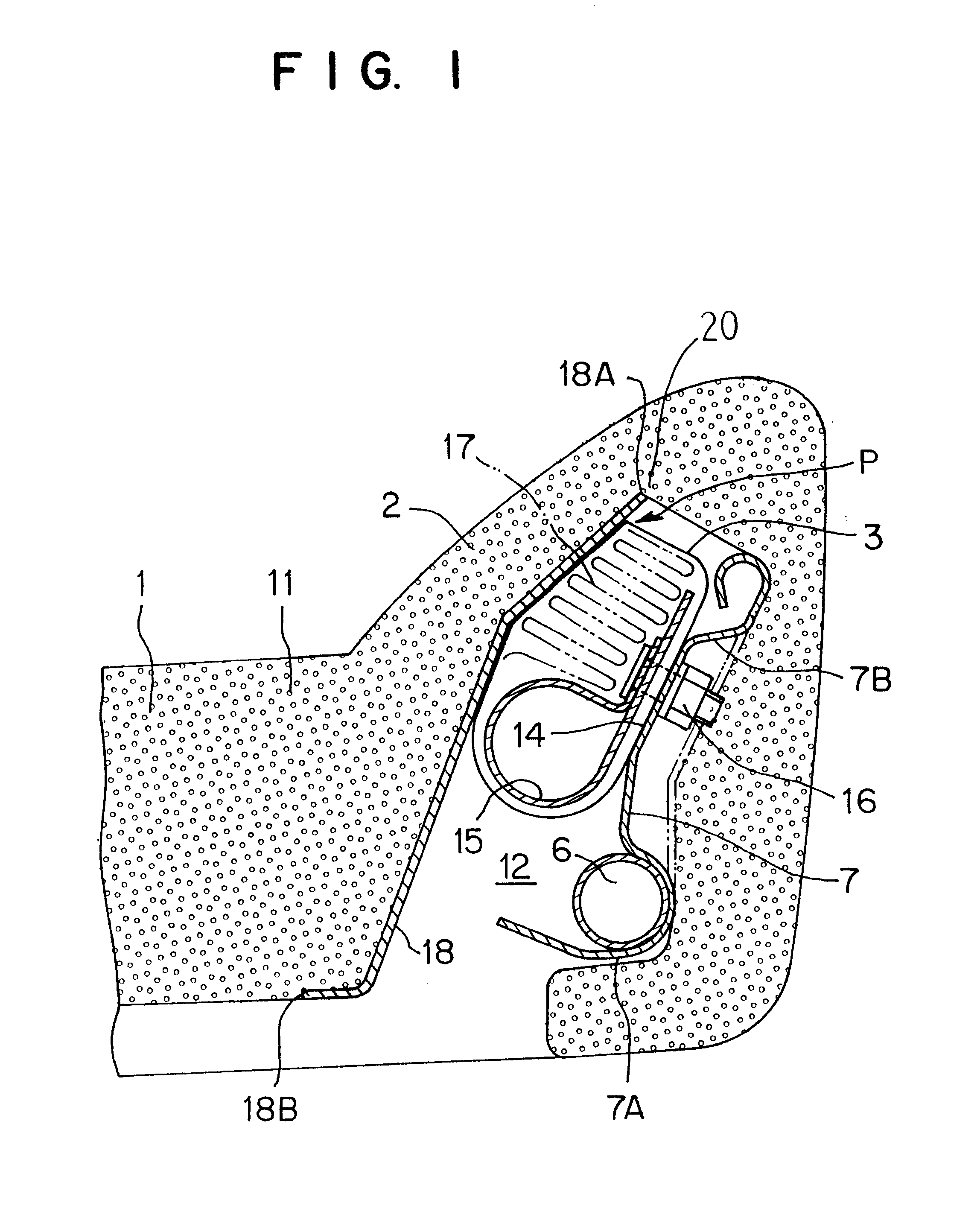

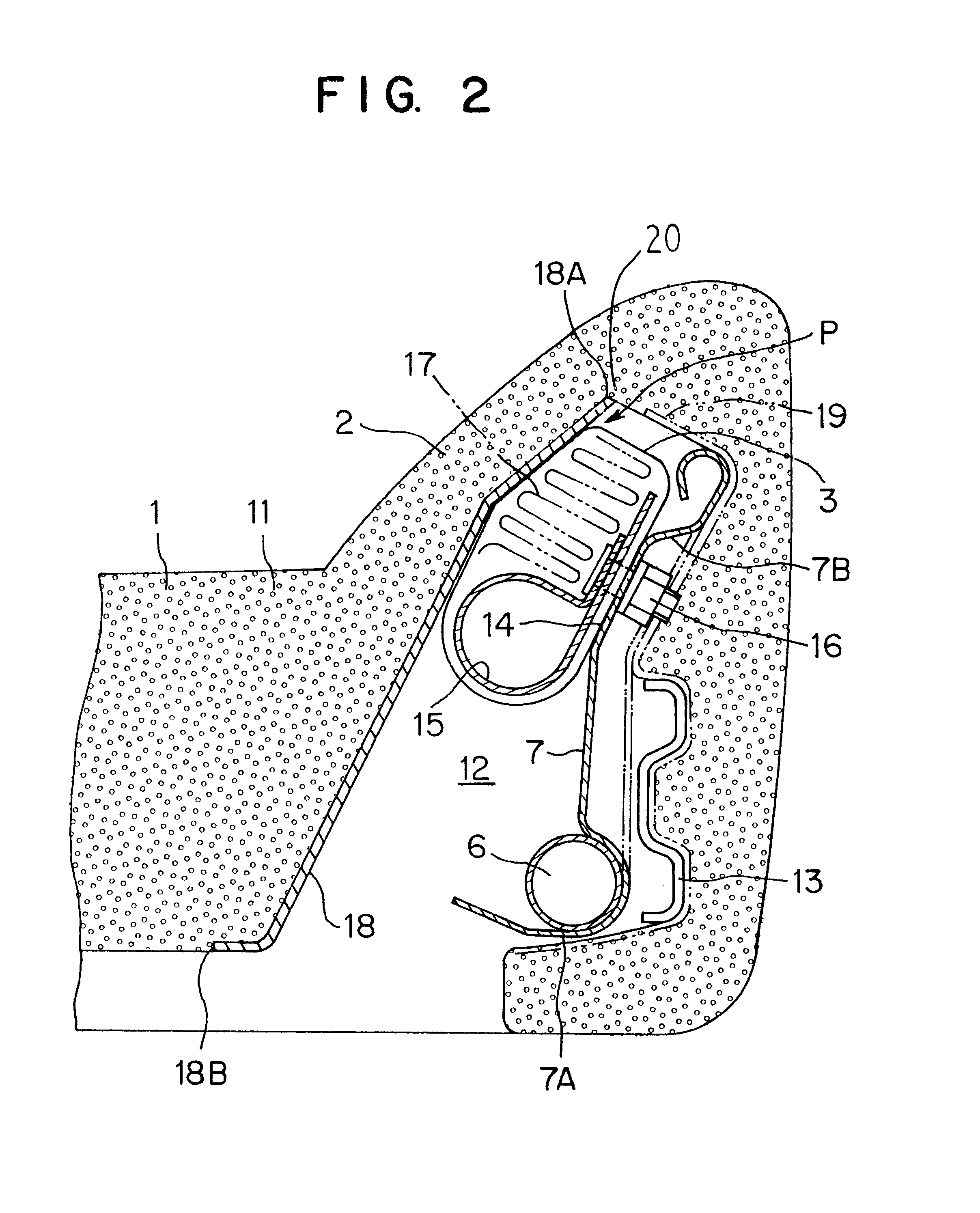

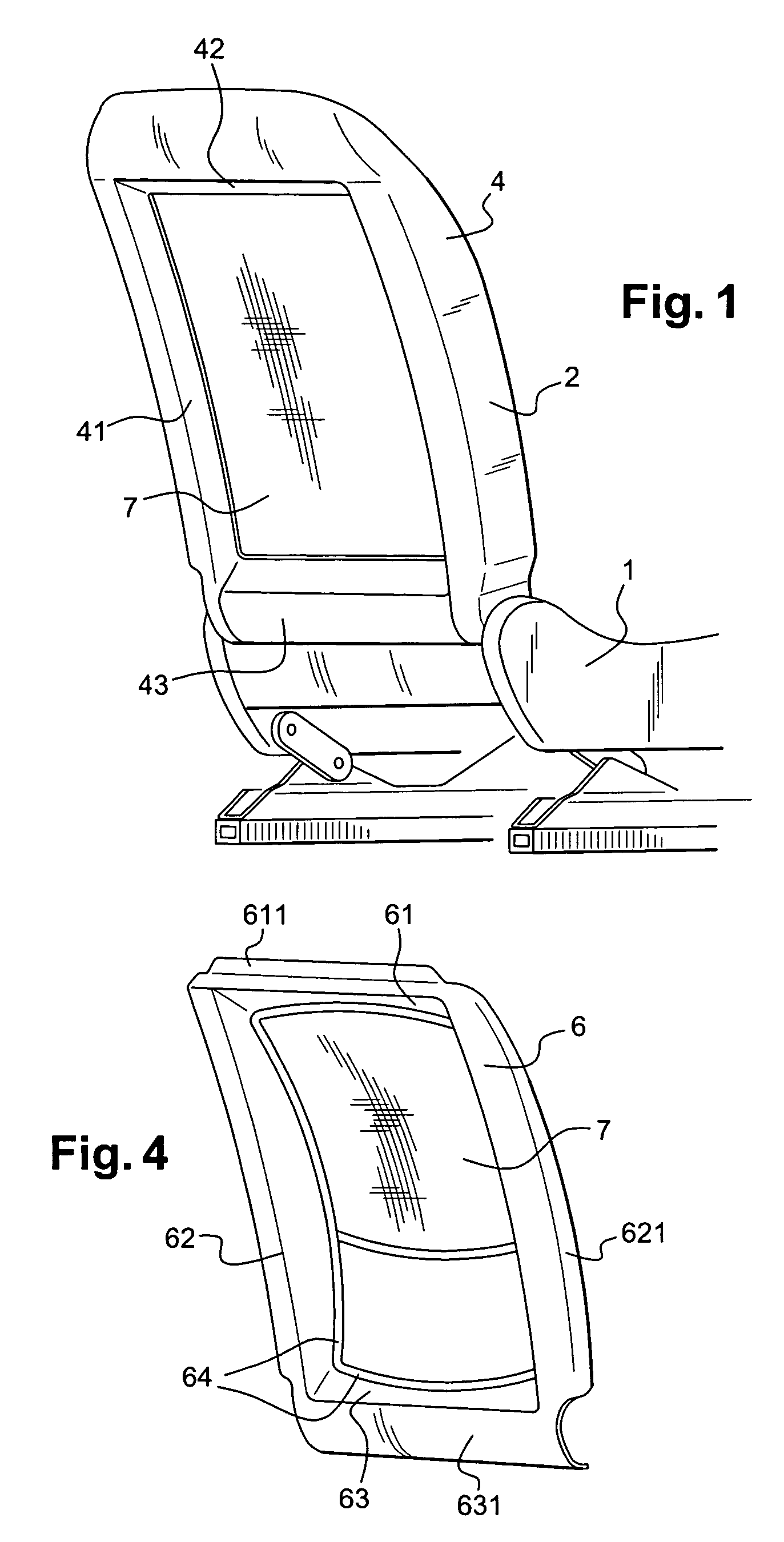

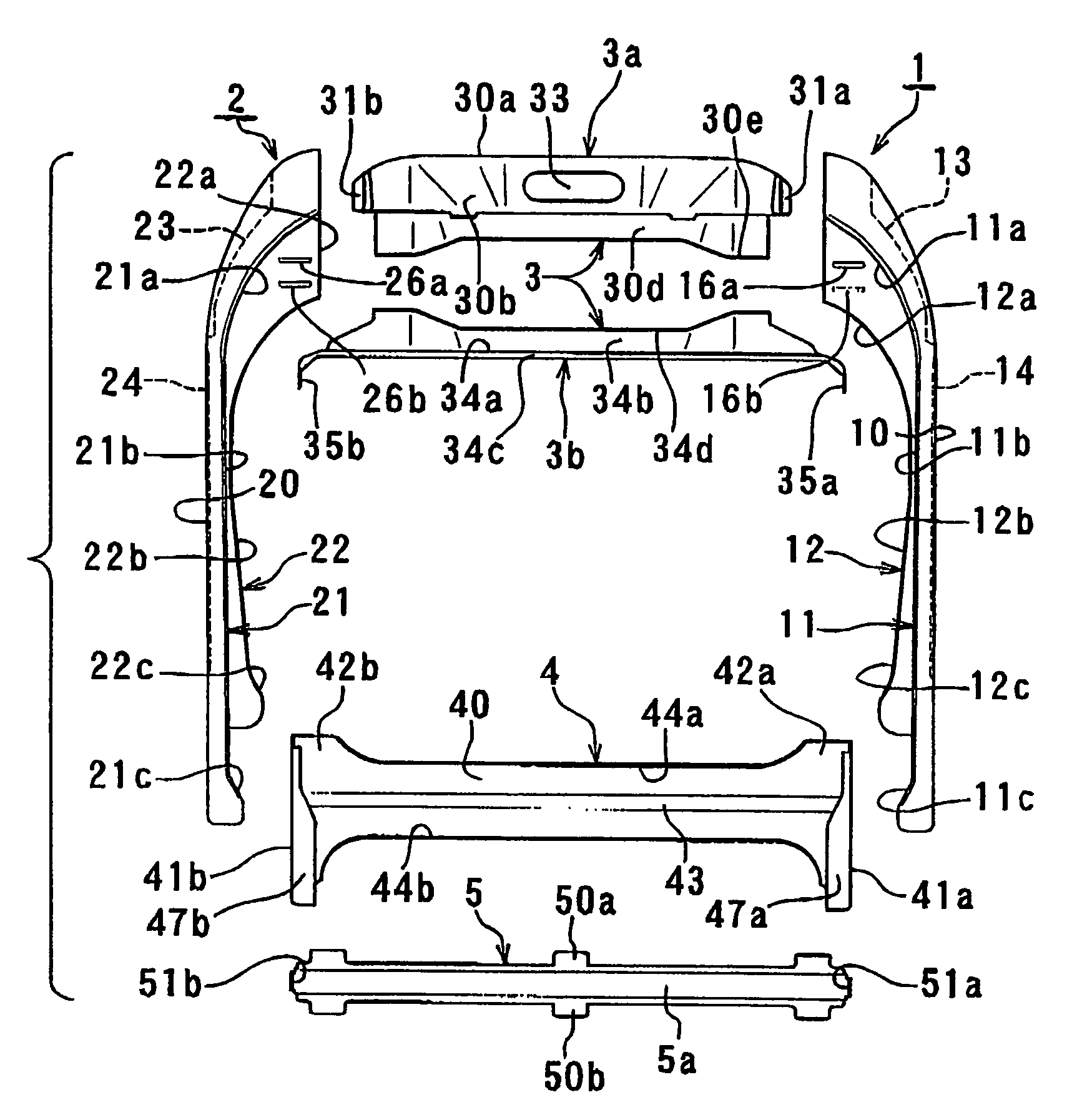

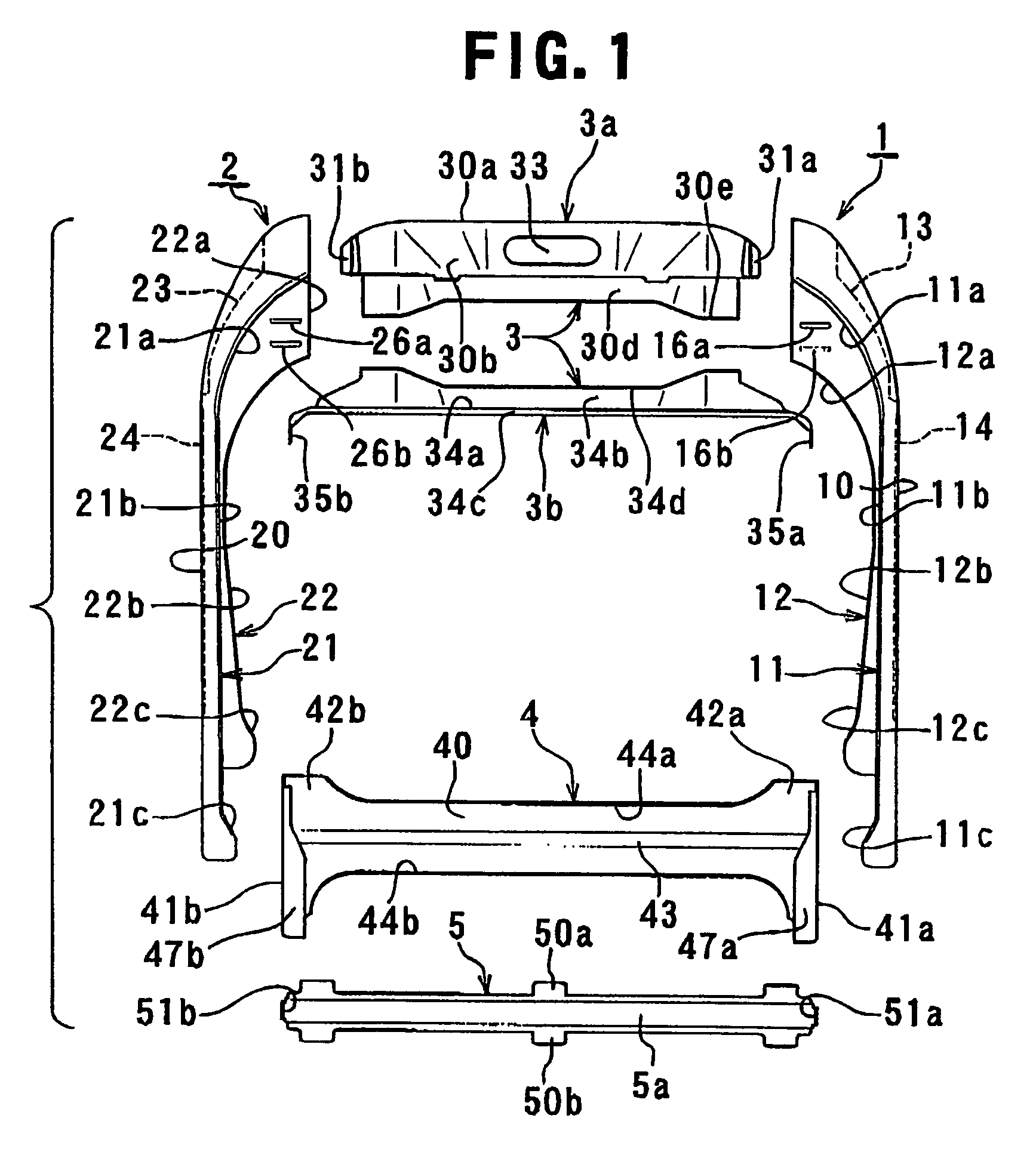

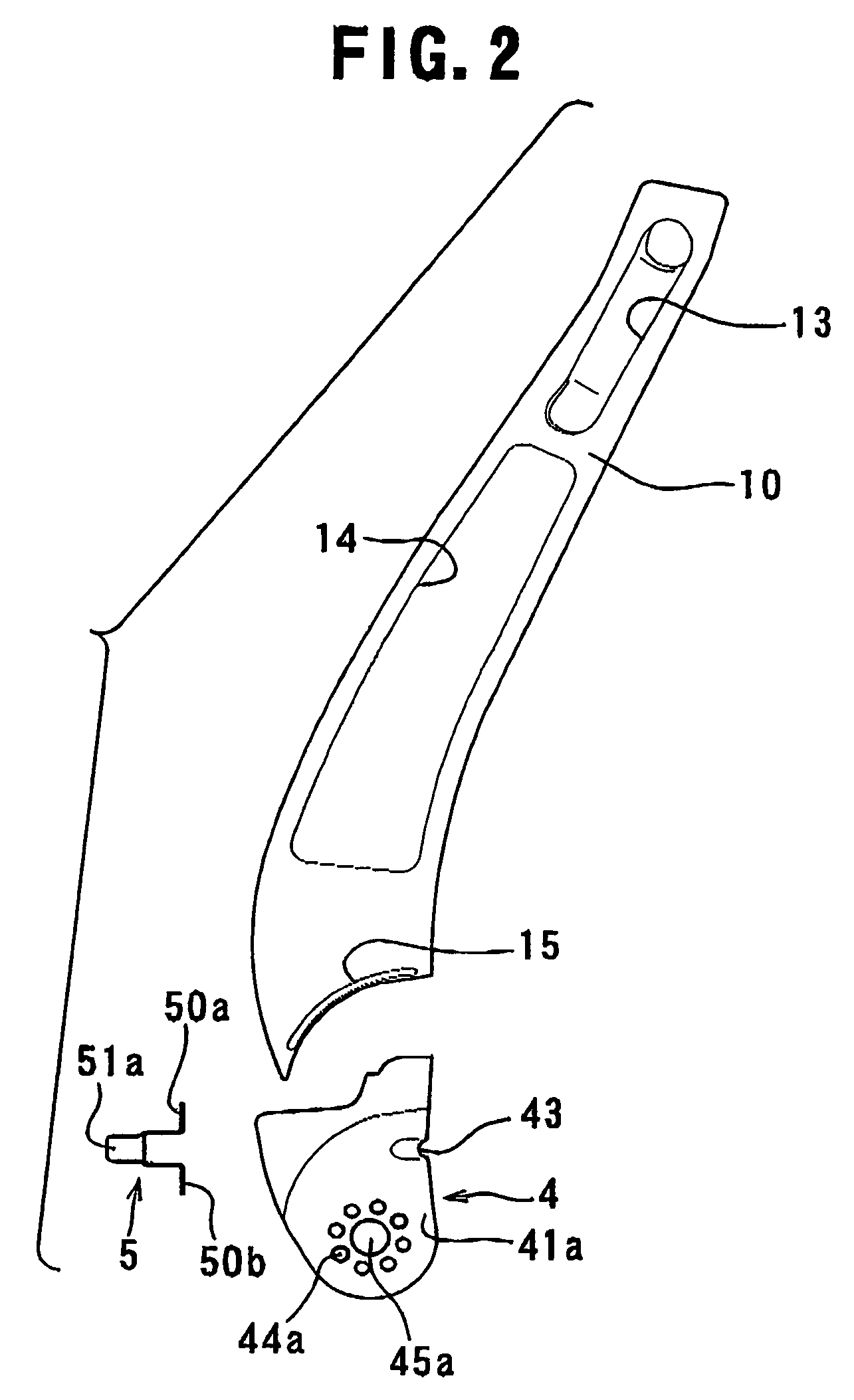

Automobile seat

InactiveUS6206466B1Stay attractiveGood effectPedestrian/occupant safety arrangementSeat framesBreaking strengthCar seat

An automobile seat is provided with a side impact air bag accommodated within a seat back. To permit prompt burst-out of the side impact air bag precisely at a predetermined position in a predetermined direction without the need for the arrangement of a member different in nature from a surface of the seat back on the surface of the seat back, an air bag module is arranged within a cushion pad of the seat back. Further, the cushion pad is provided, on a surface of a surrounding portion thereof with which the air bag is brought into contact upon spreading, with a guide member which increases breaking strength of the cushion pad and specifies the cushion pad to be broken at a break portion under inflating force of the air bag.

Owner:MITSUBISHI MOTORS CORP

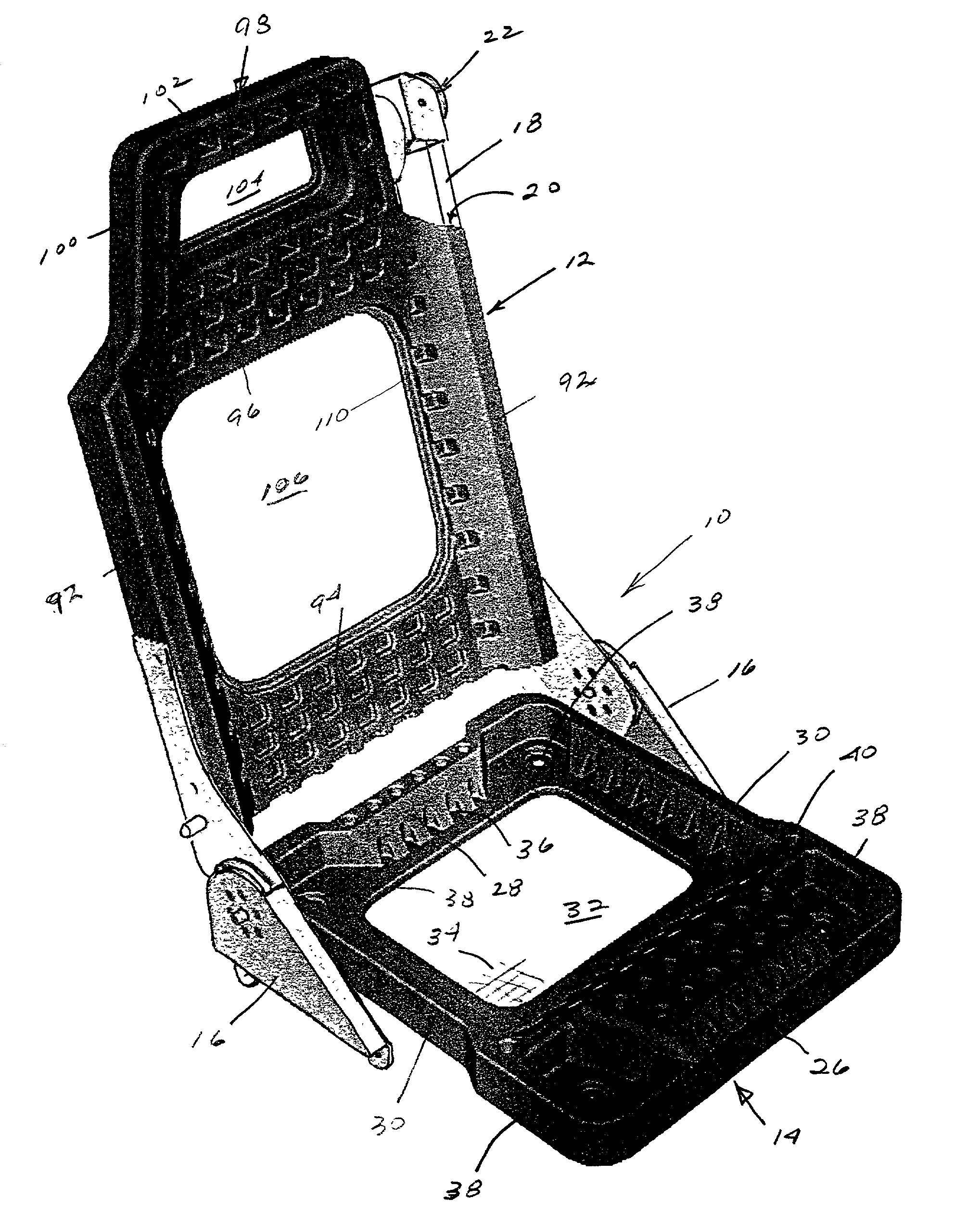

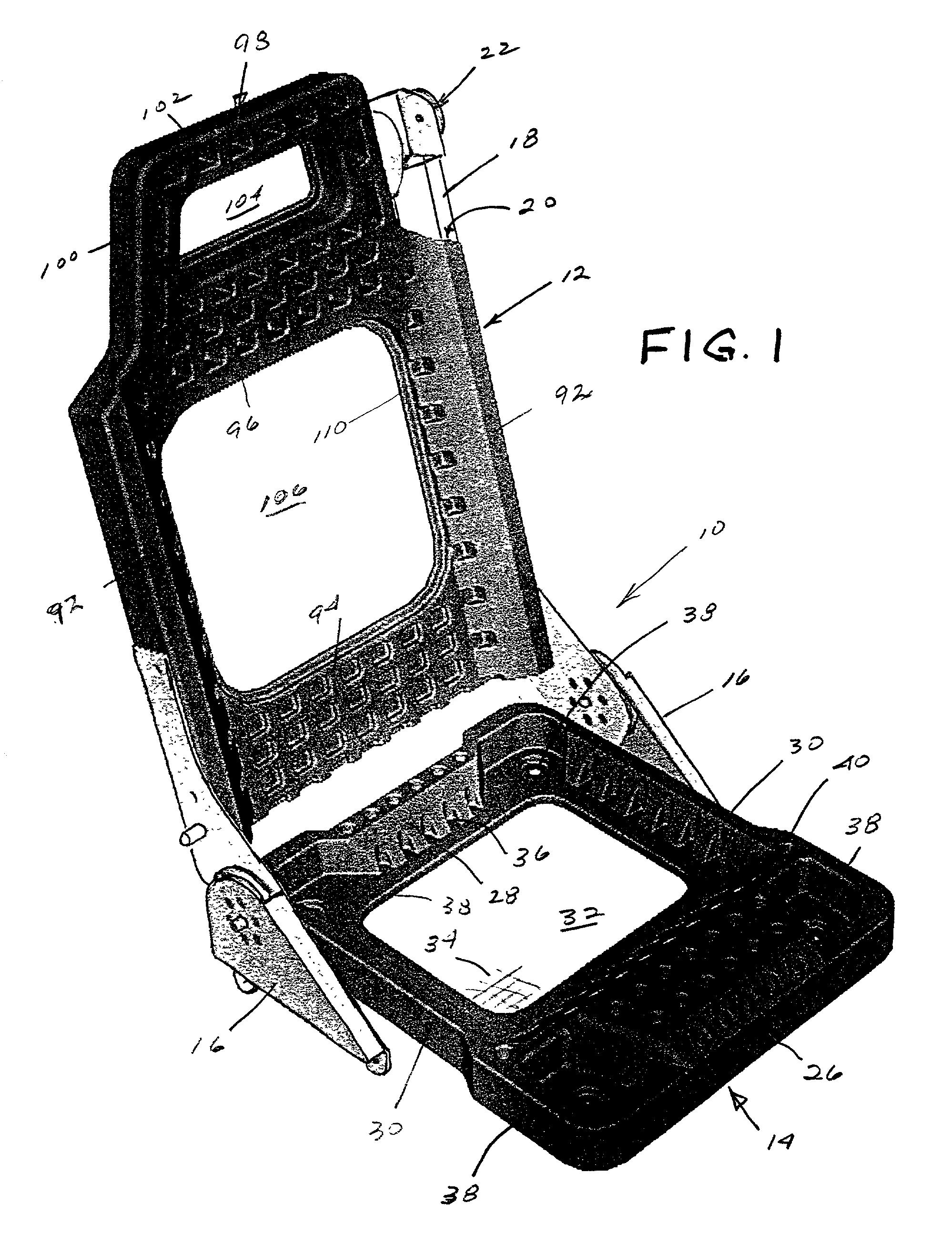

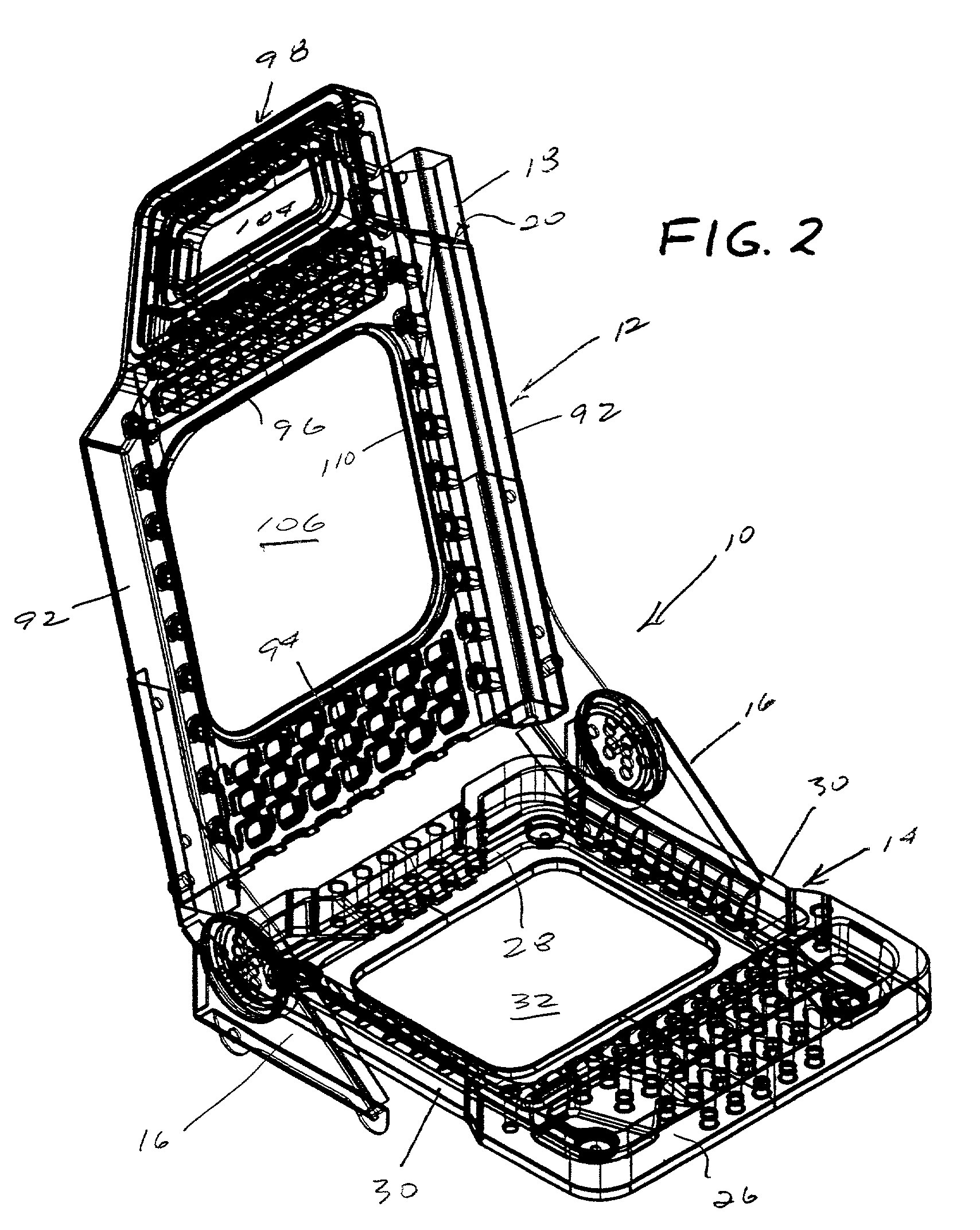

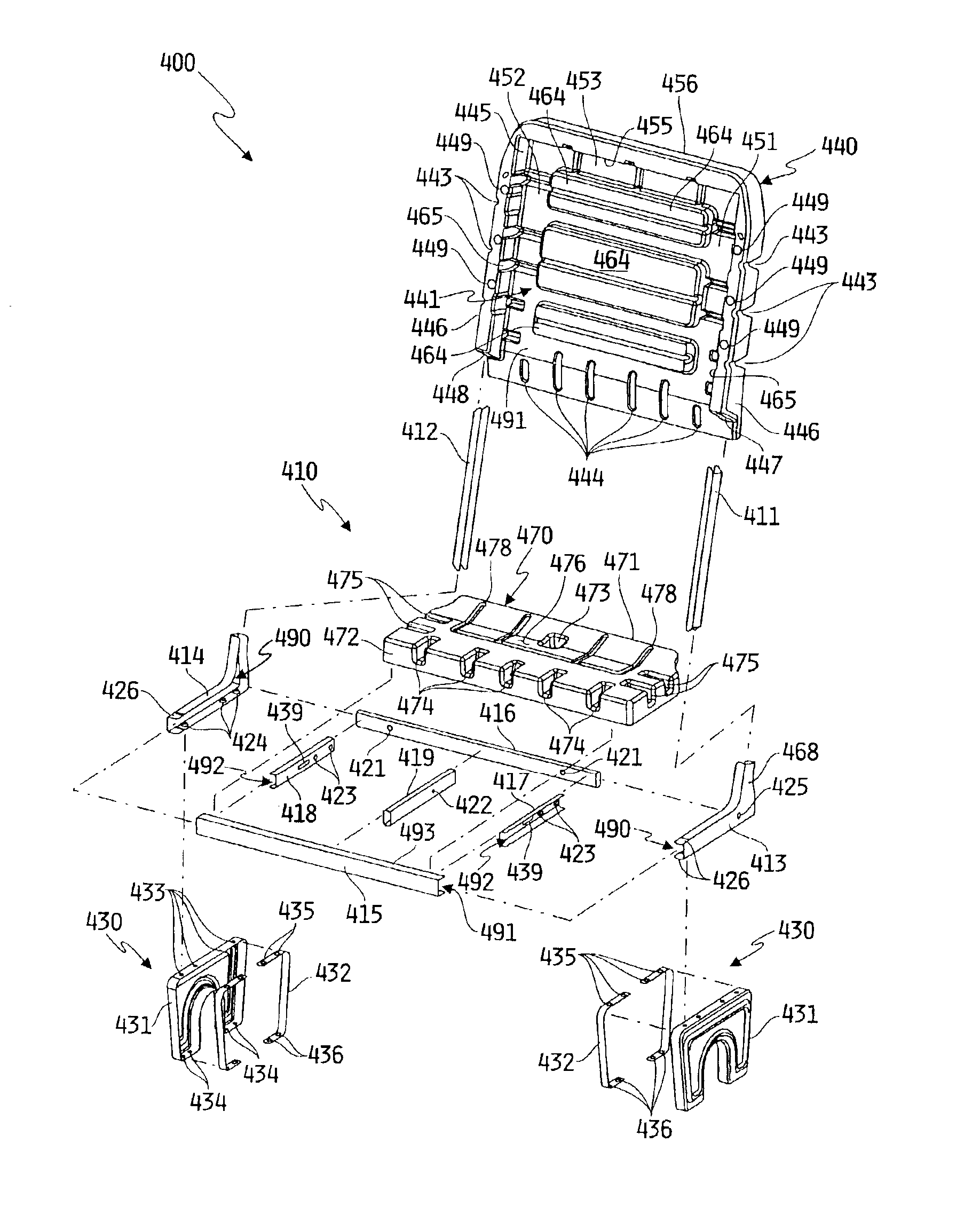

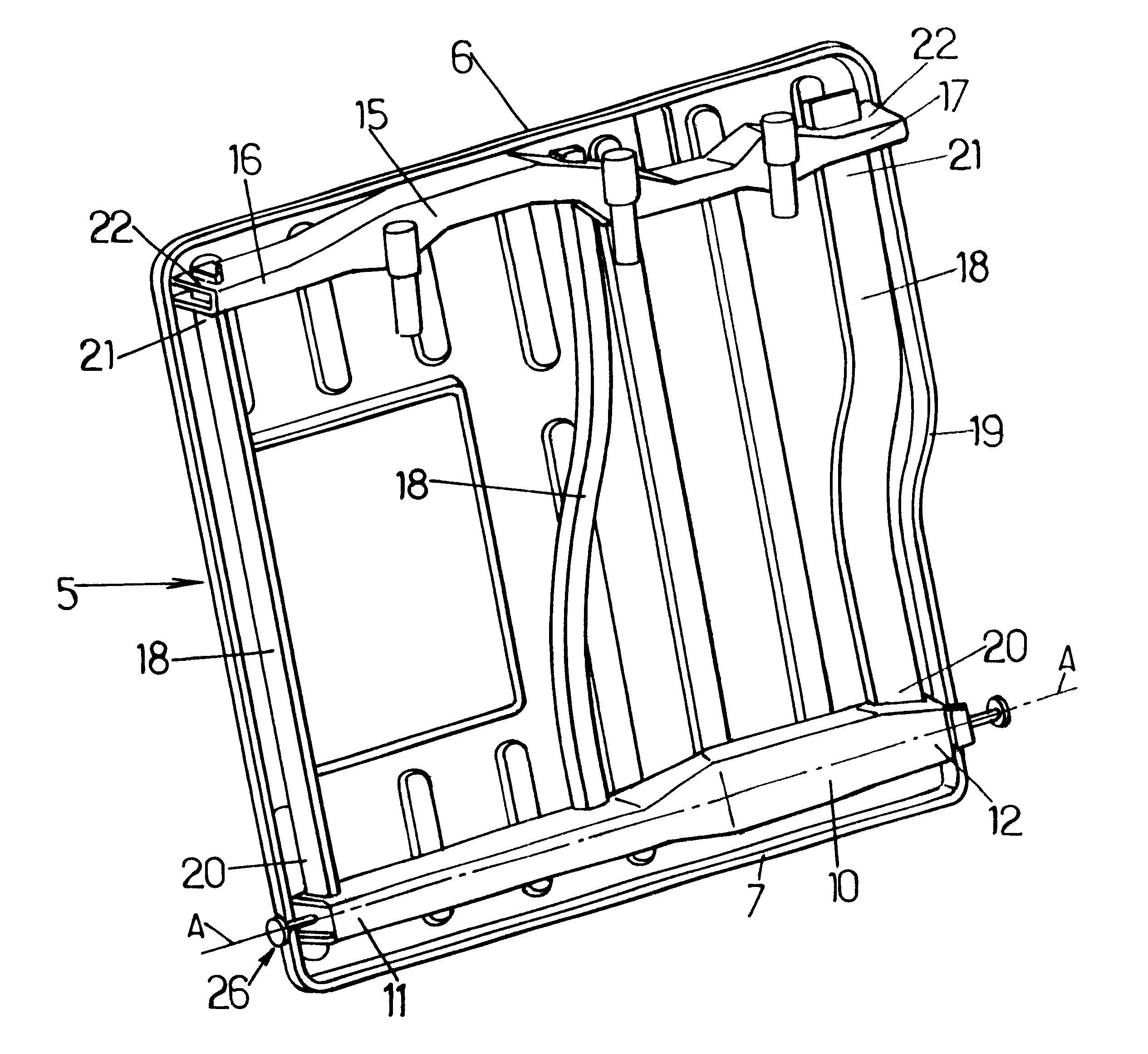

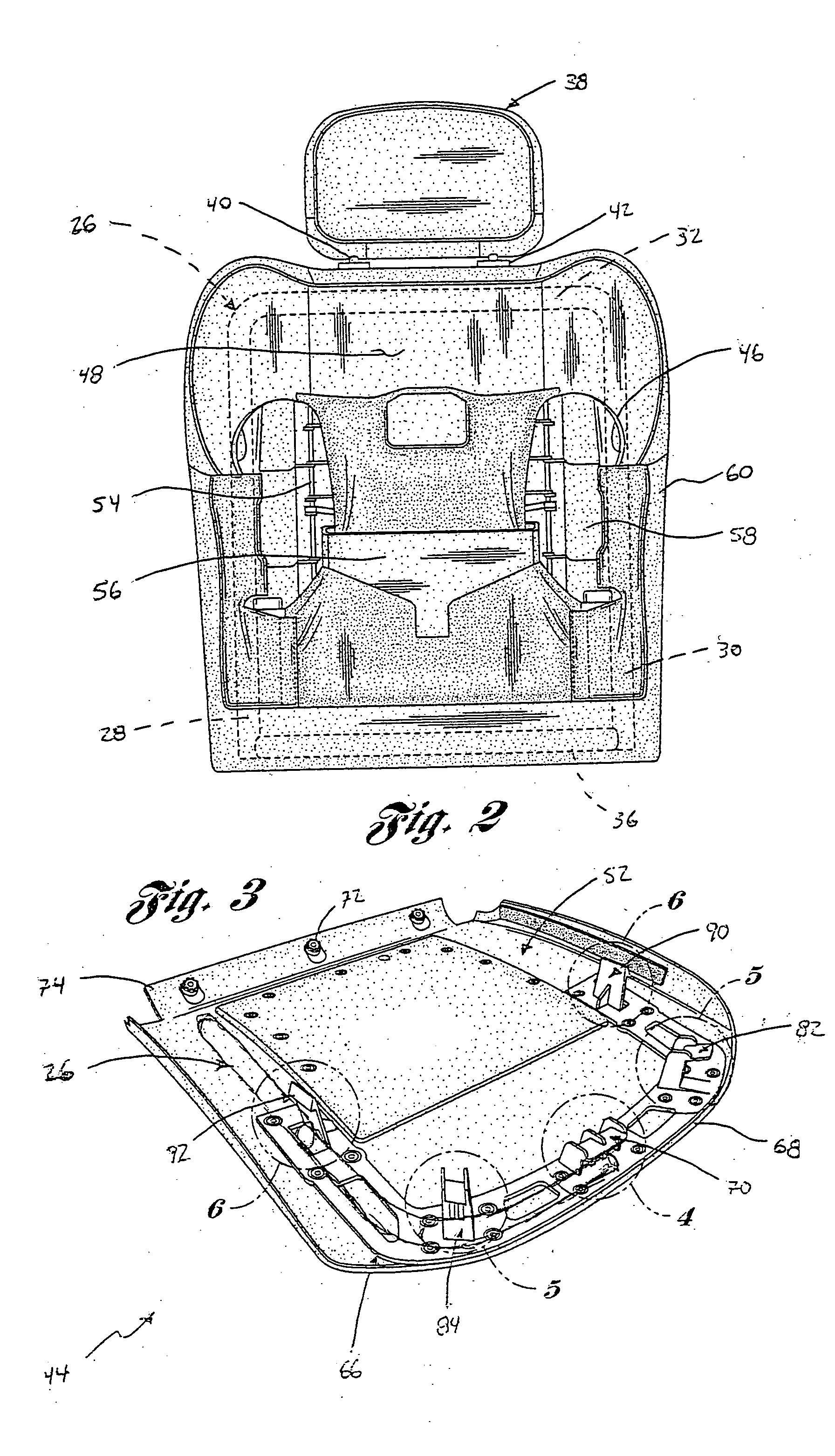

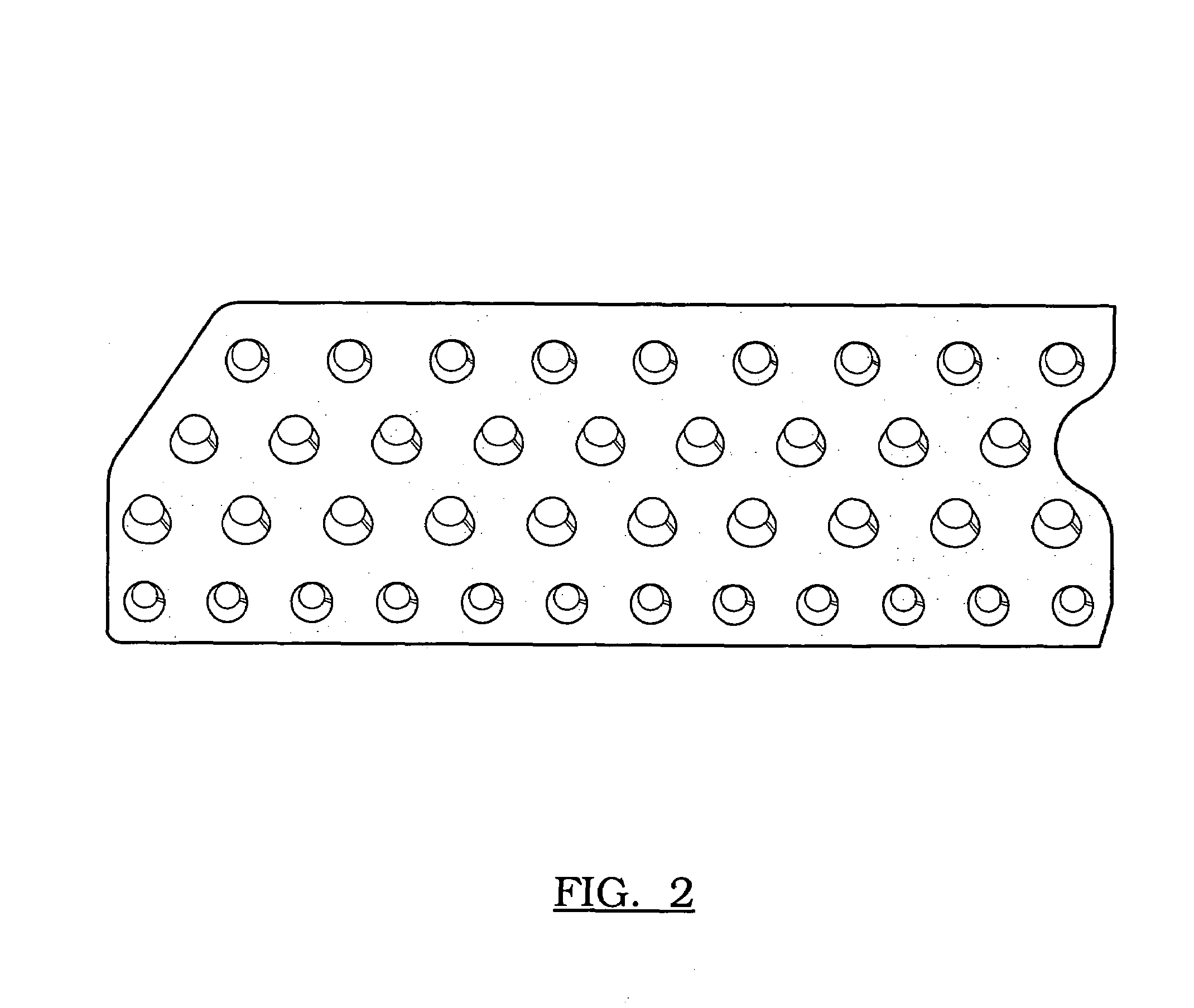

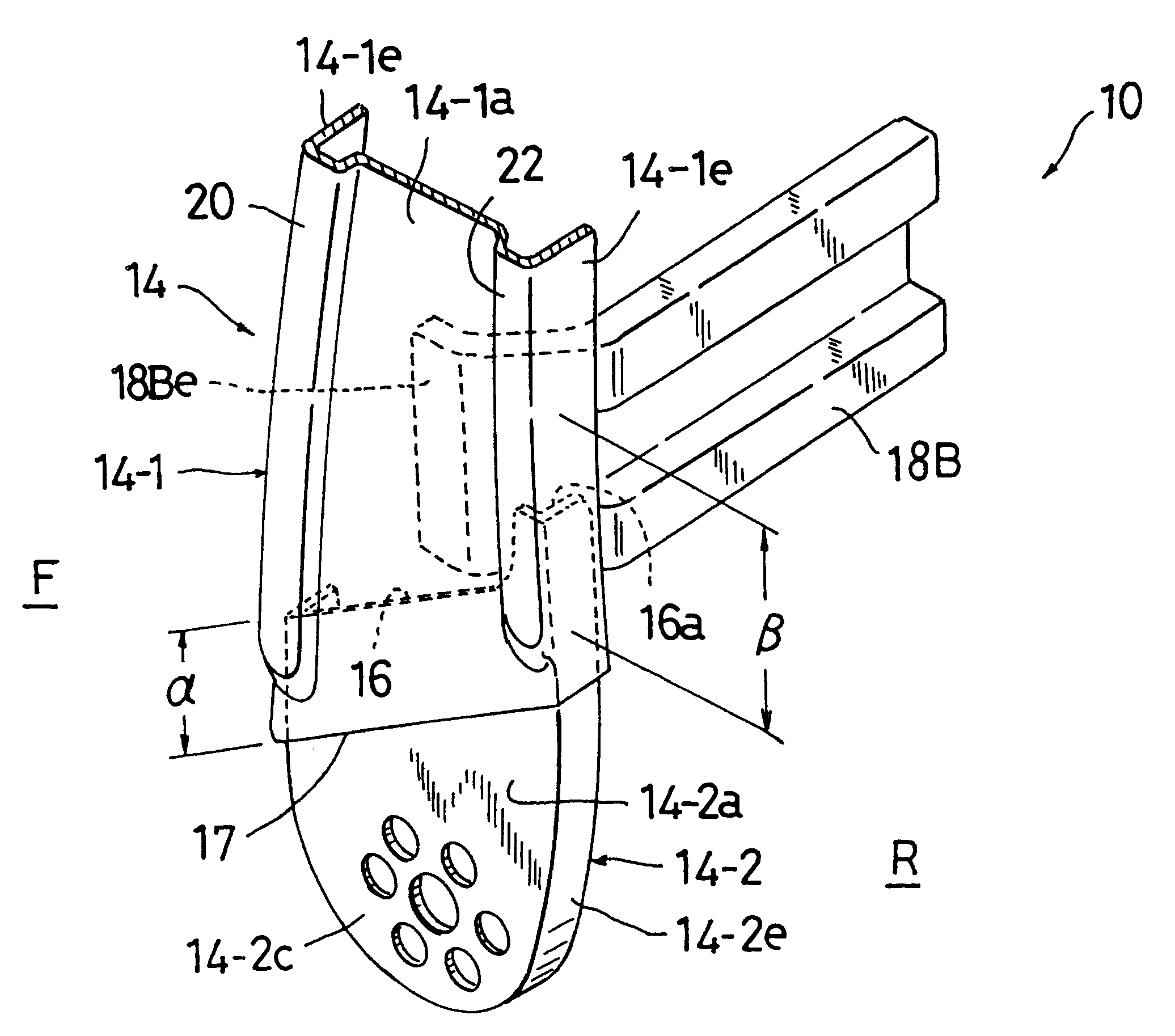

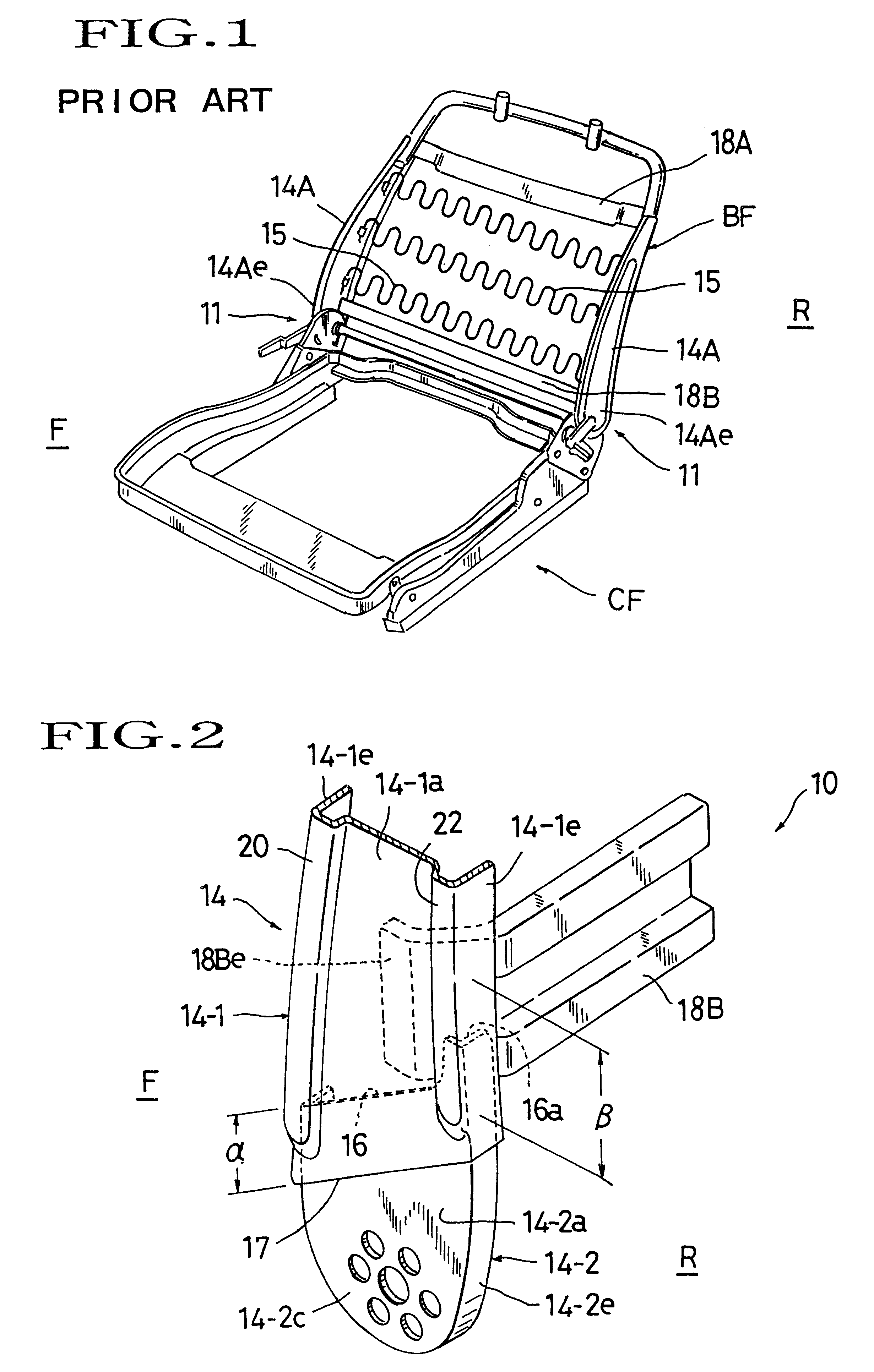

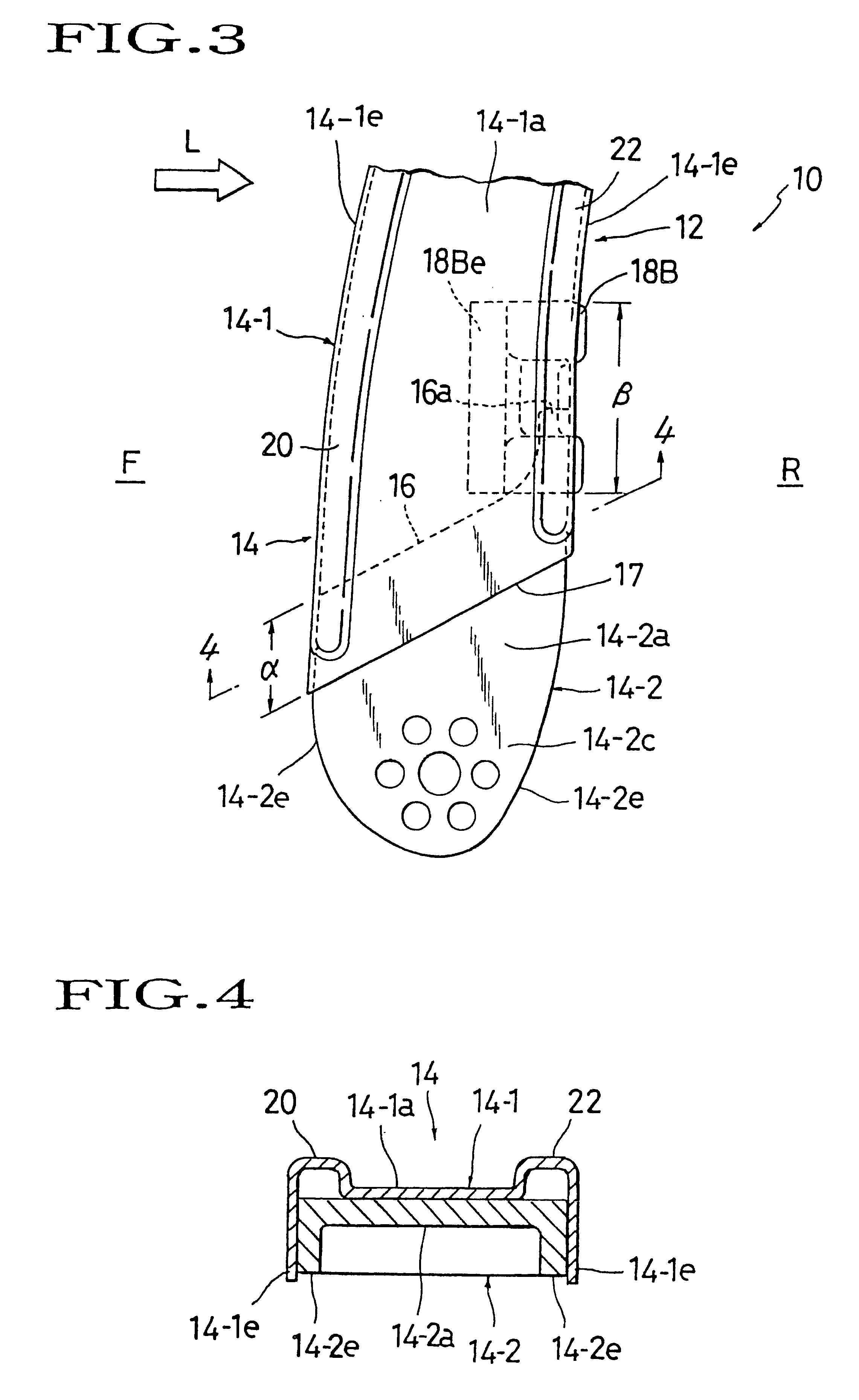

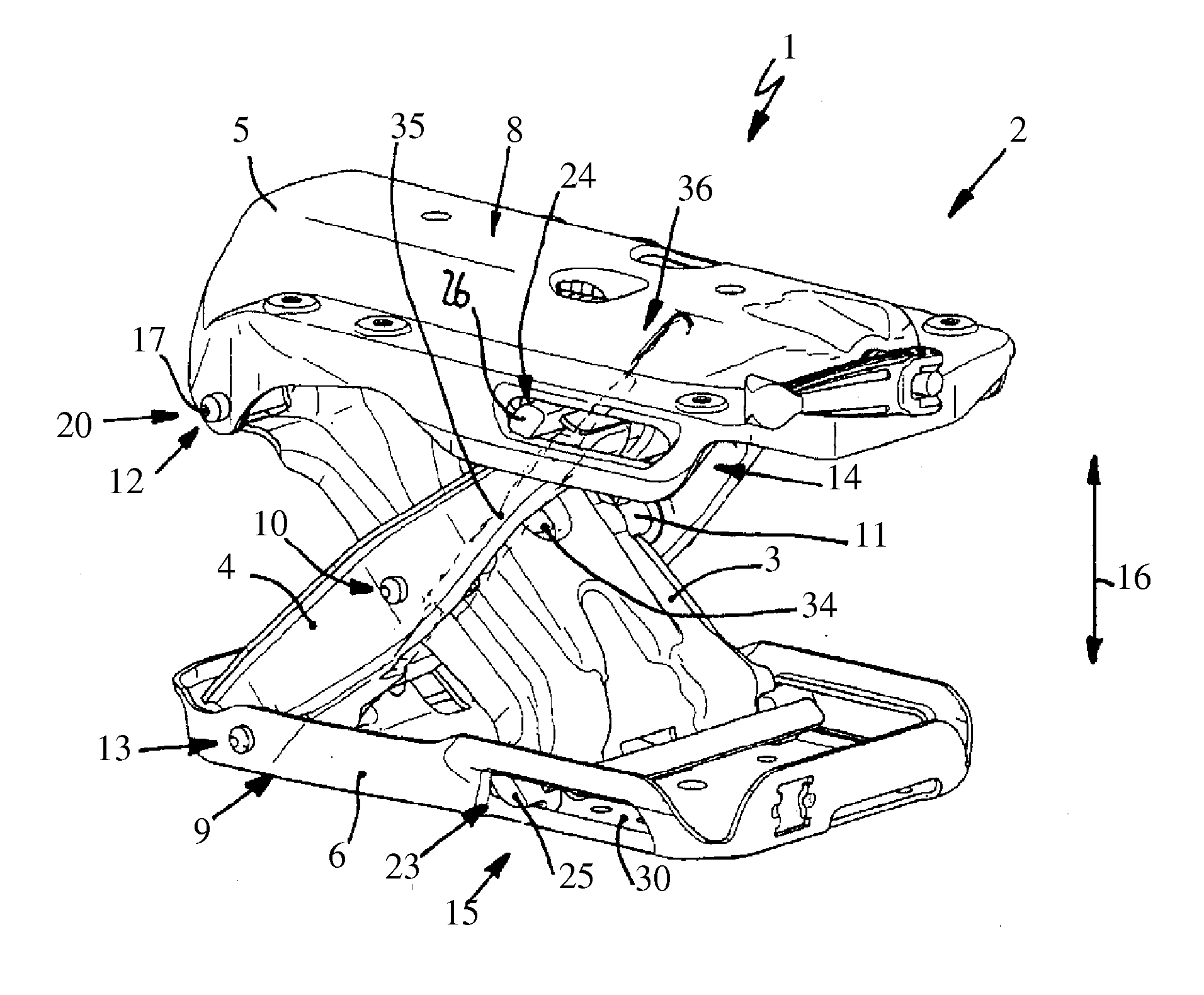

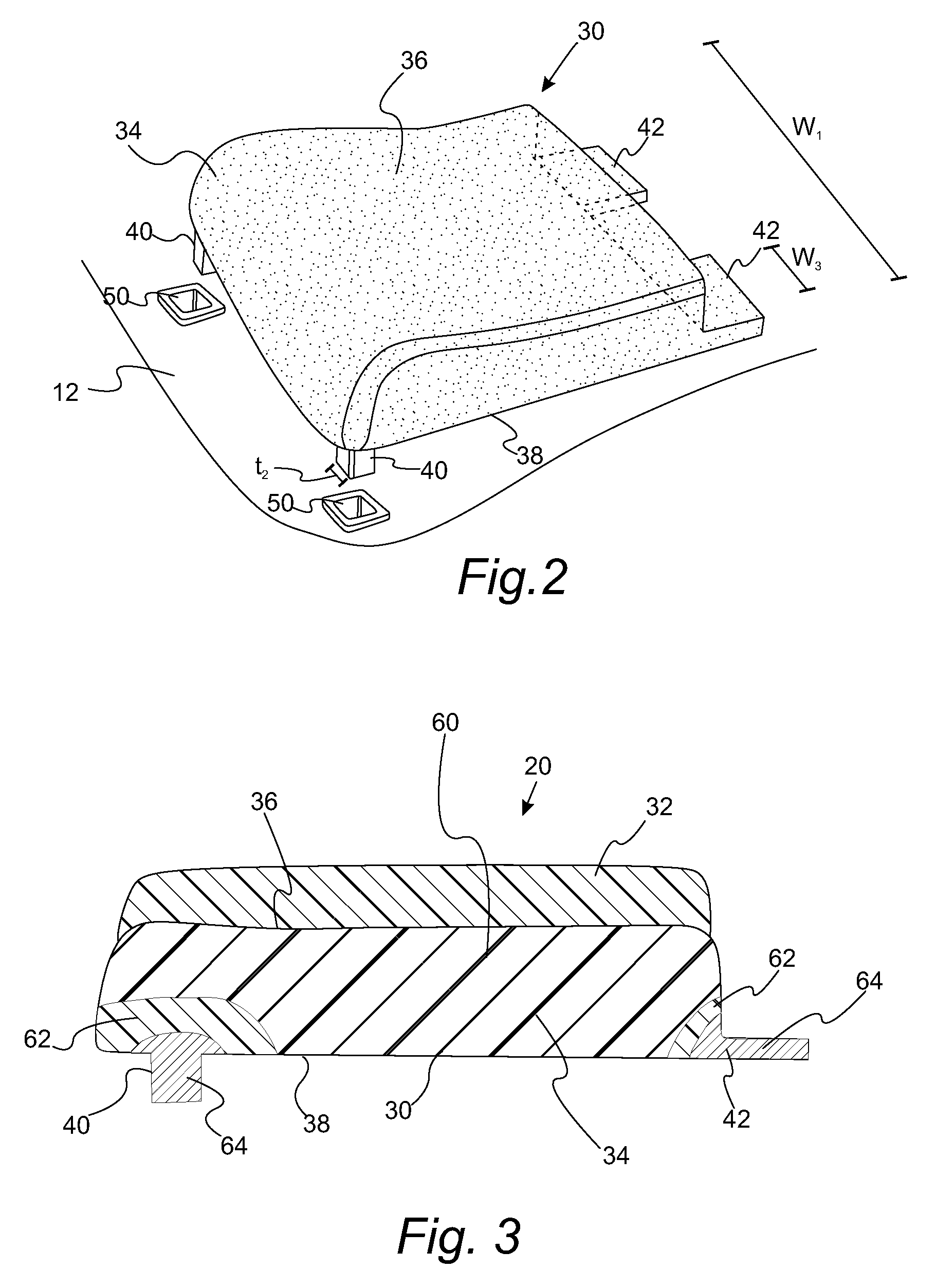

Thin, double-wall molded seat frame system

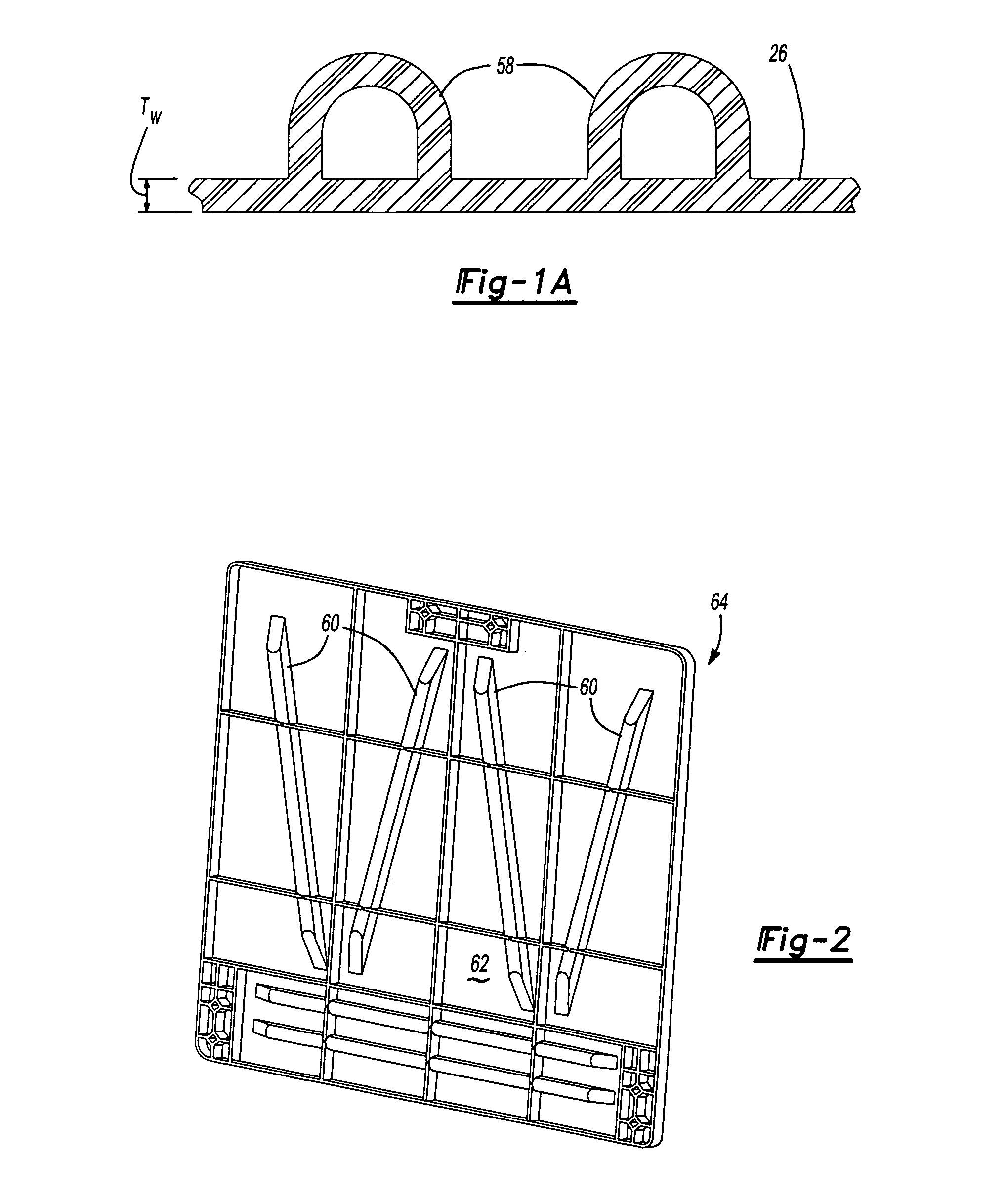

InactiveUS20050168041A1Improve structural performanceConvenience to mergeSeat framesStoolsDouble wallEngineering

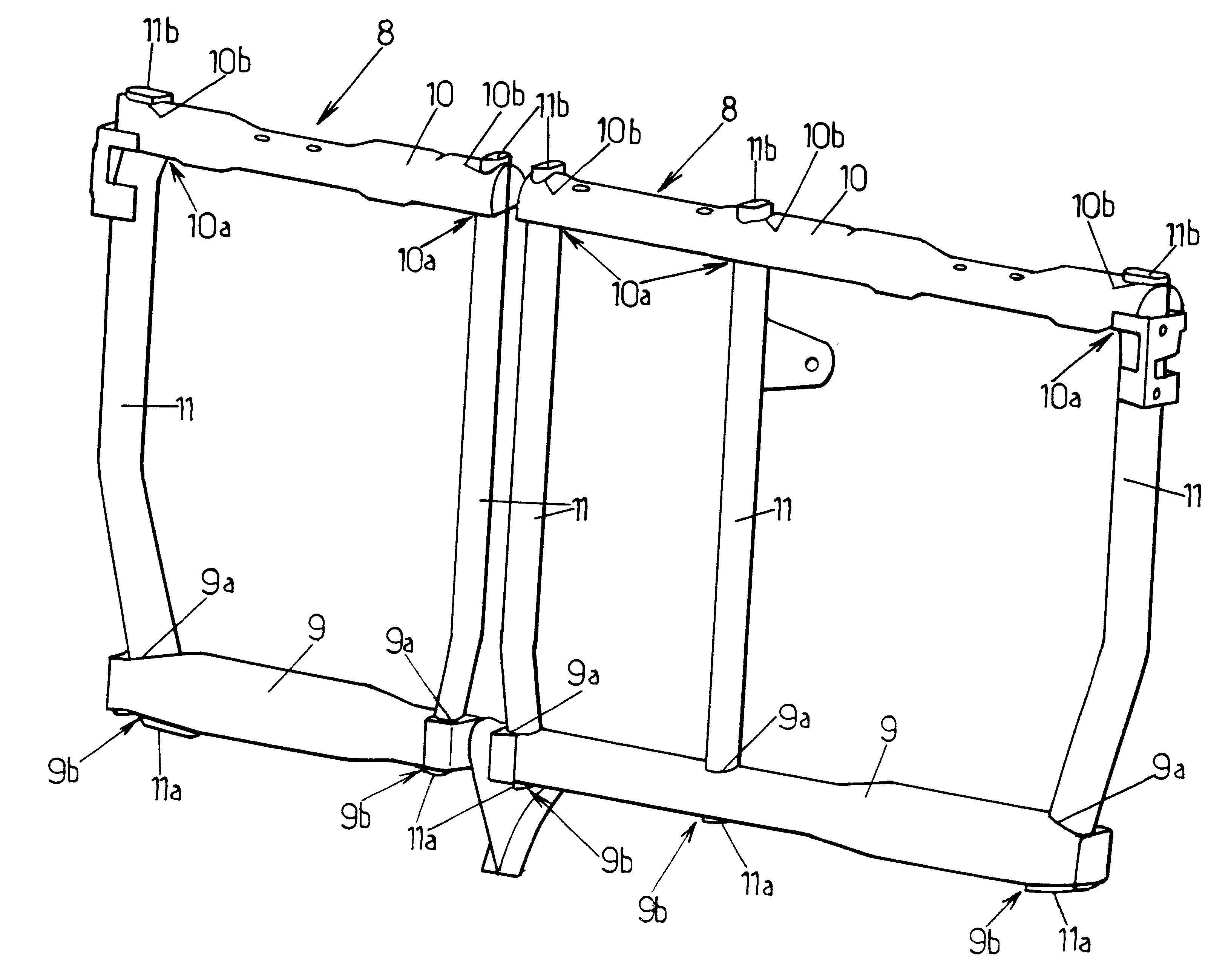

A seat frame for a vehicle or other seating comprises a seat back and a seat pan formed of molded double wall members having thin, substantially closed exterior walls and a substantially open interior. The exterior walls include front and back sections having a cavity therebetween, secured together to form a hollow, box beam type of structure. Integrally formed, spaced cup-shaped standoffs extend between the front and back sections between side walls thereof and provide internal reinforcement of the seat member between the side walls. The seat back includes a cavity for a seat back reinforcement member for either a restraint or non-restraint seat.

Owner:GLANCE PATRICK M +1

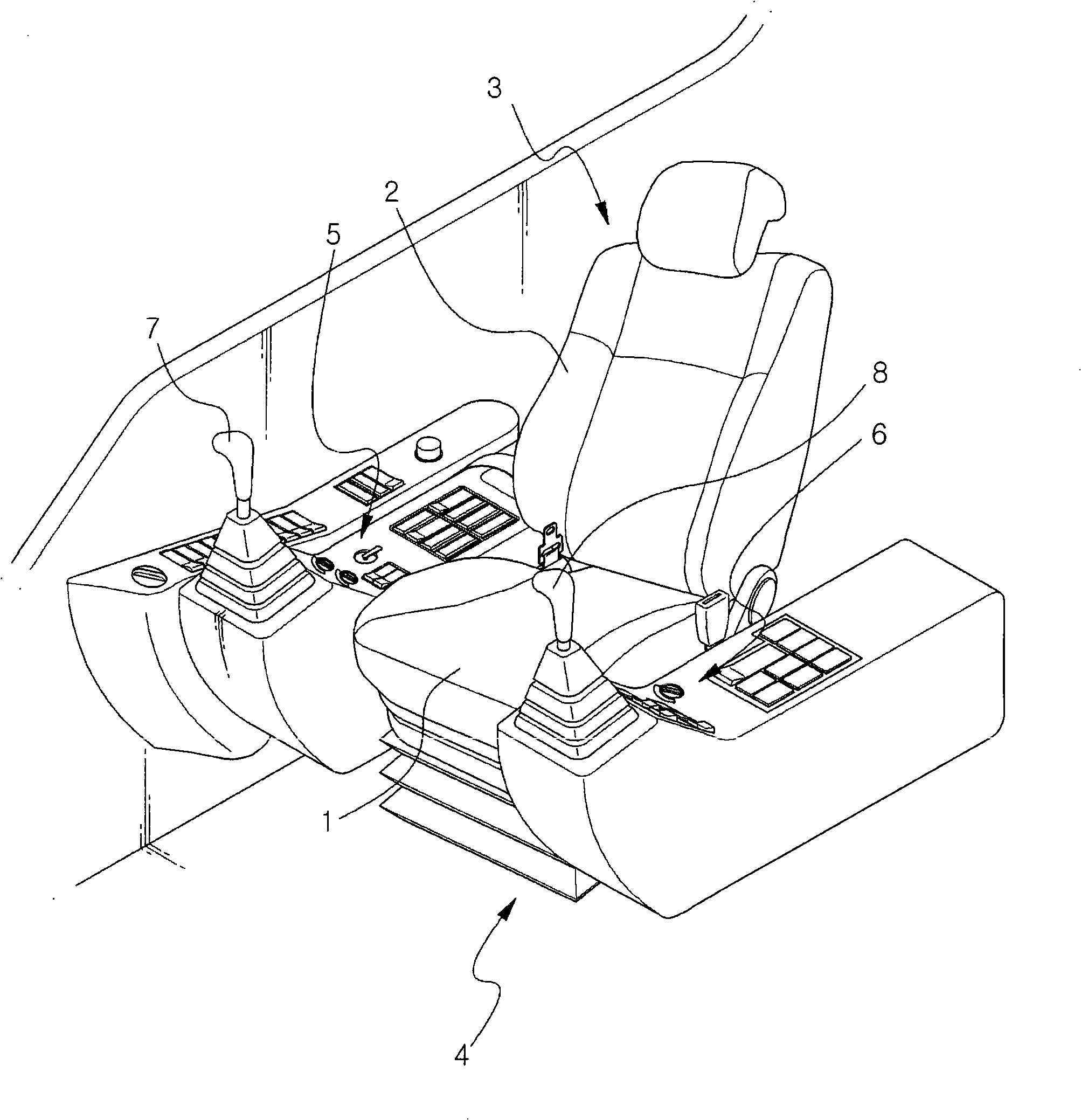

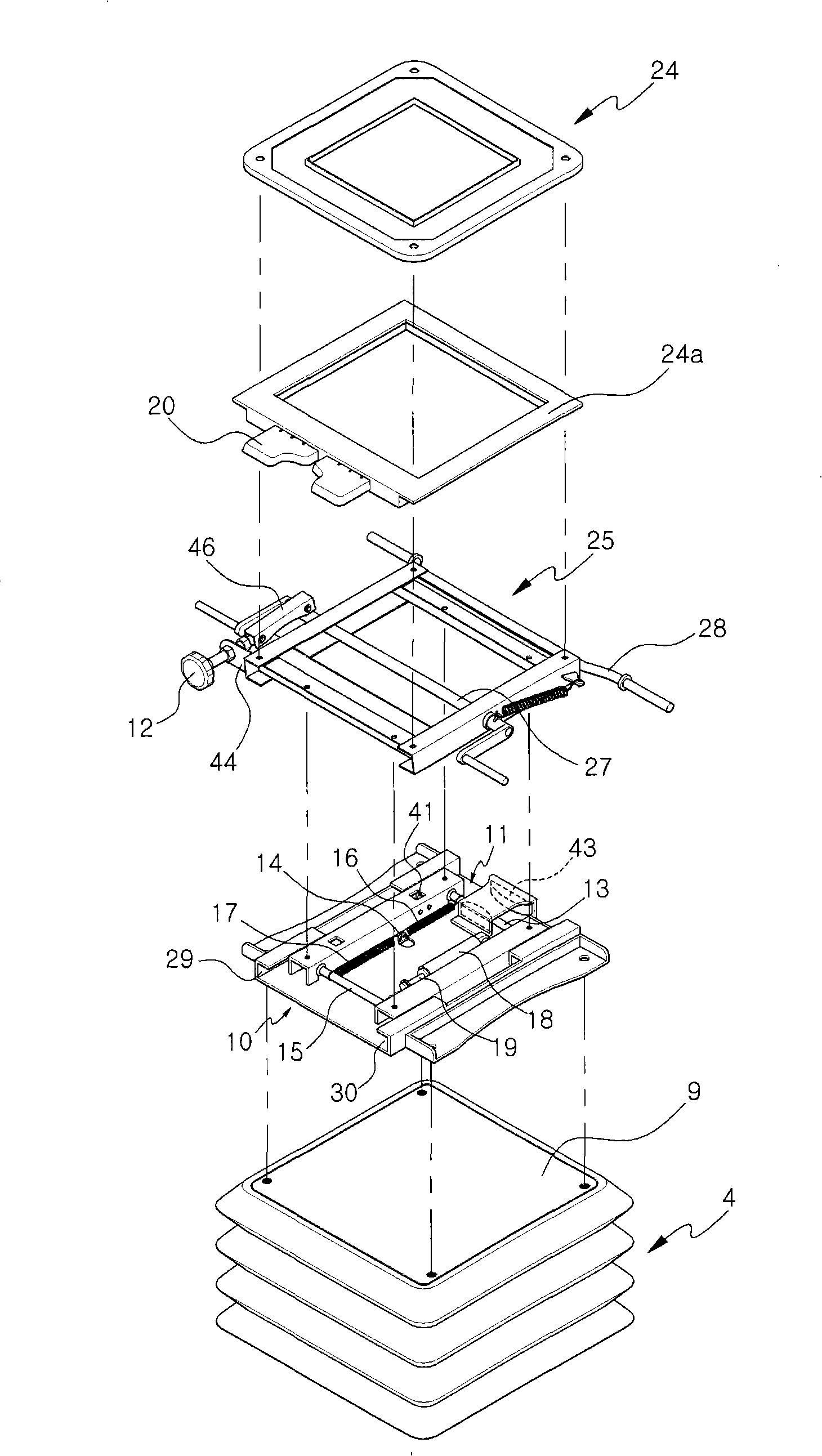

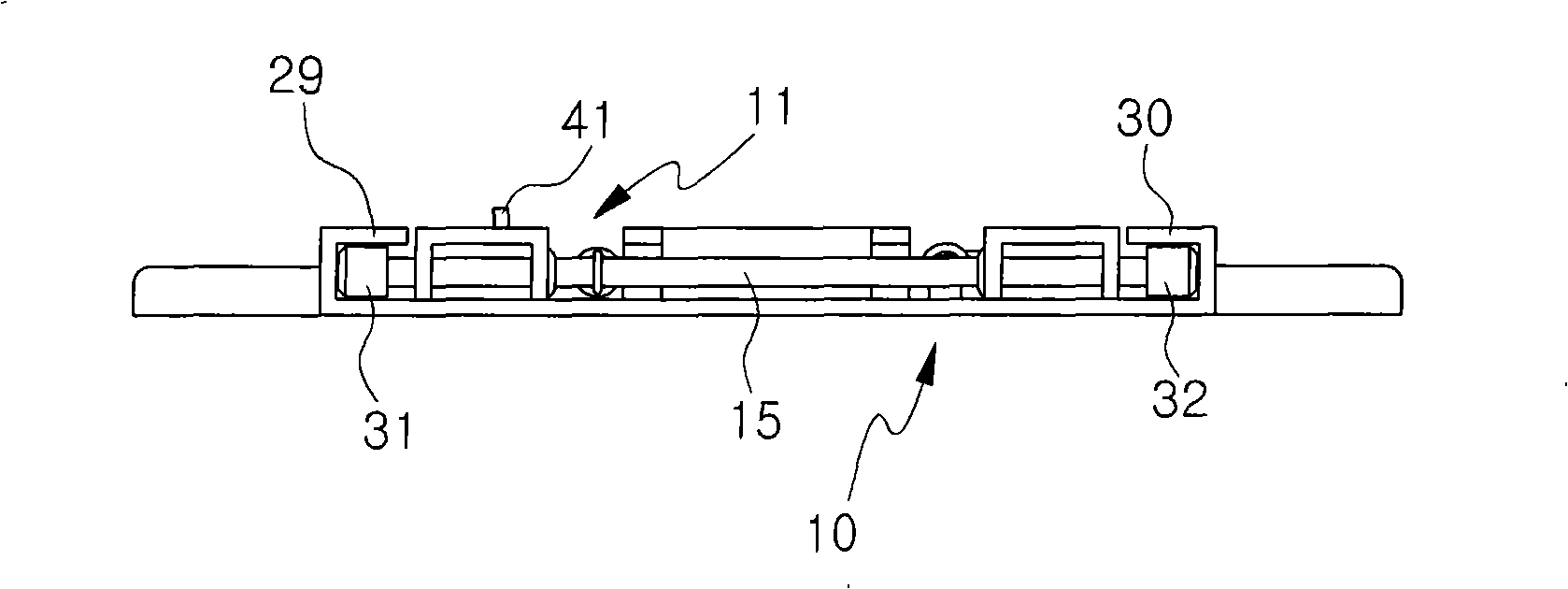

Seat for heavy equipment having buffer means in forward and backward directions

A seat for heavy equipment having a buffer means in forward and backward directions is provided, which can protect an operator by attenuating impact and vibration generated in a cab in forward and backward directions of an excavator in accordance with the driving of the buffer means in a main working mode of the excavator. The seat for heavy equipment is mounted on a suspension plate and is located between left and right console boxes.; The seat for heavy equipment includes a lower member mounted on the suspension plate; an upper member slidably mounted on the lower member in forward and backward directions of the equipment; a buffer means for attenuating impact and vibration generated in the forward and backward directions of the equipment; a tilting means including a frame, a hinge shaft, a driving shaft, and a control handle; and a locking means for locking and unlocking forward and backward movement of the upper member against the lower member when a pusher installed on one side of the frame is manipulated. In a main working mode of the equipment, a buffer function is performed through forward and backward movement of the upper member against the lower member, and when the main working mode is released, the buffer function is released.

Owner:VOLVO CONSTR EQUIP HLDG (SWEDEN) AB

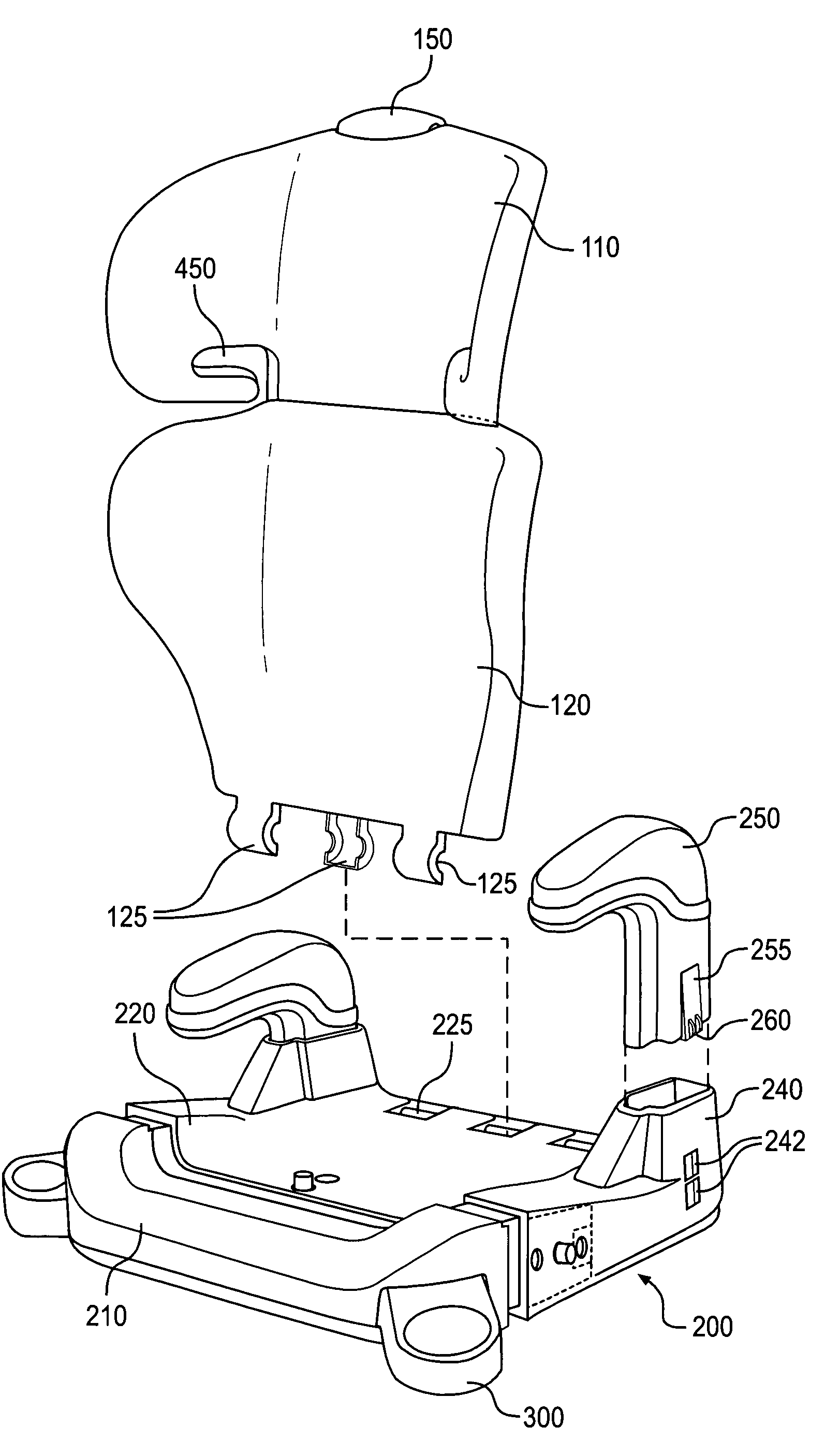

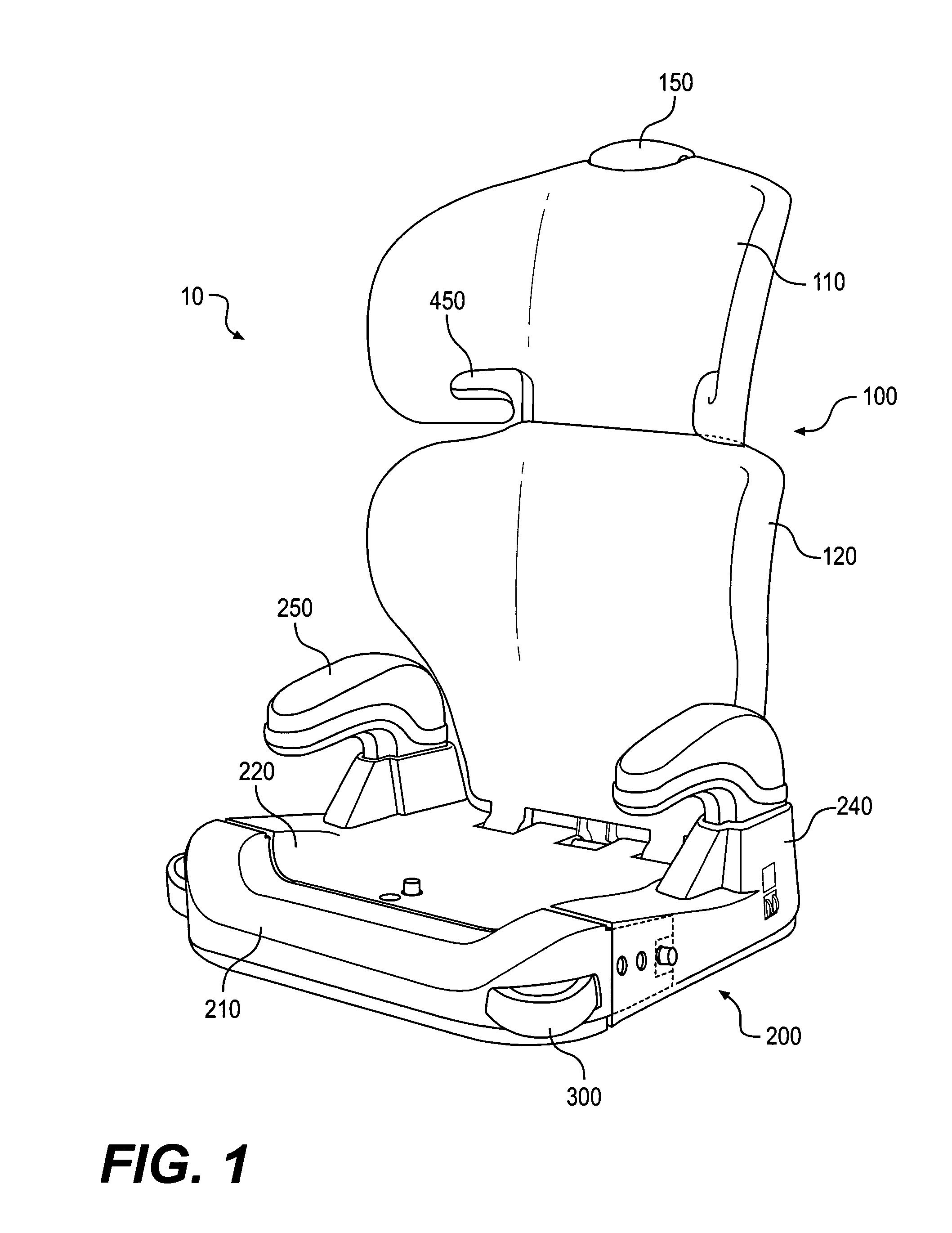

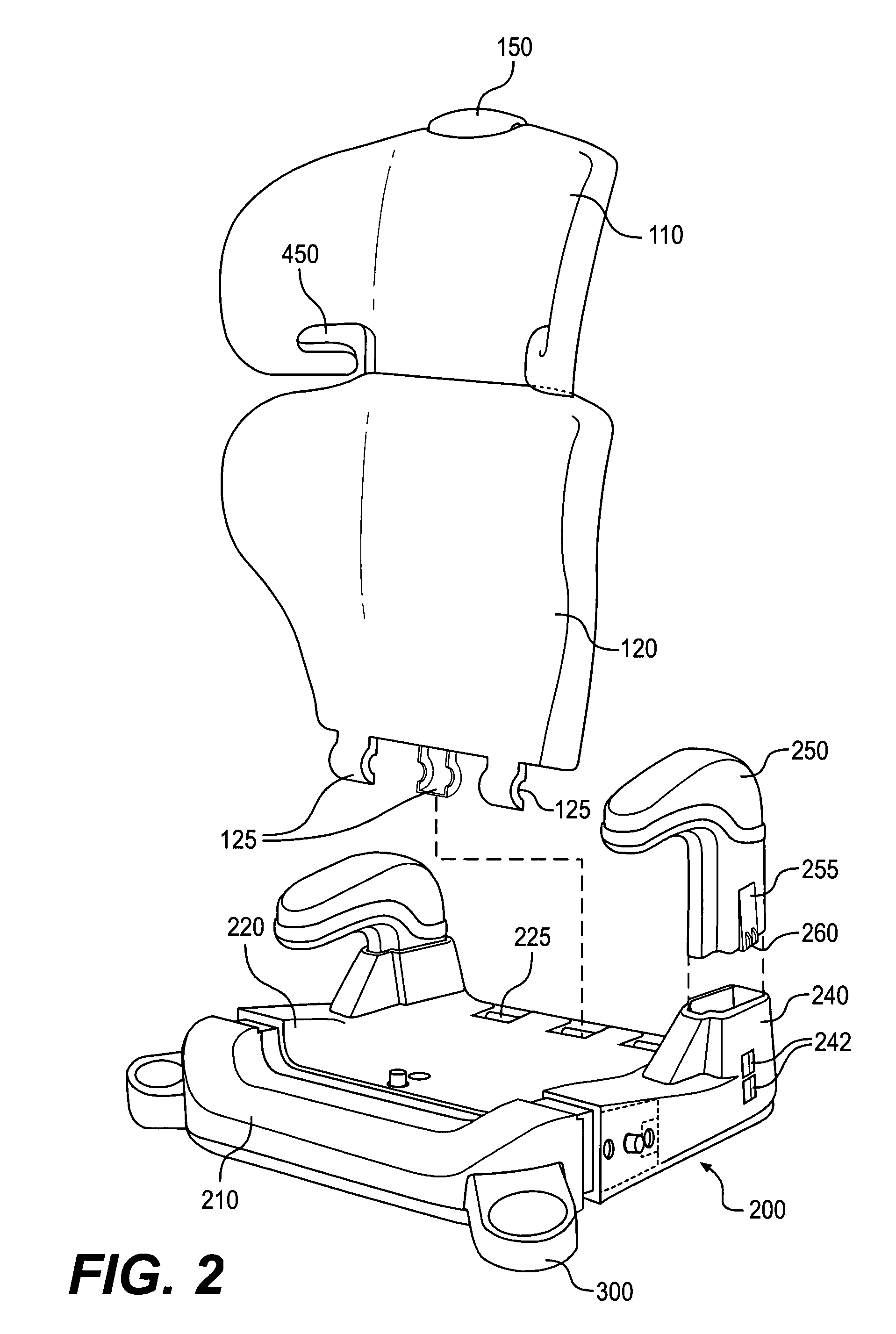

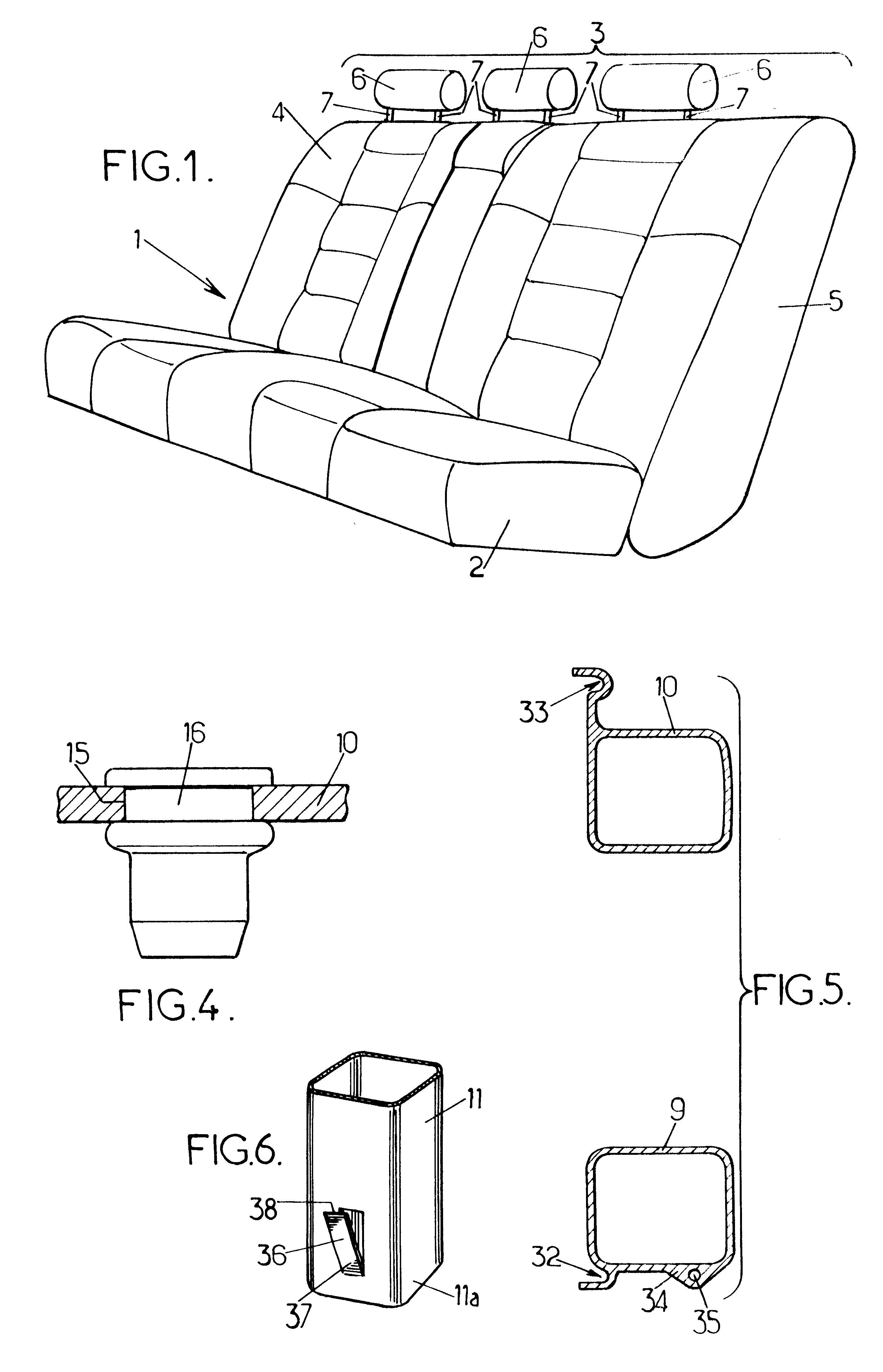

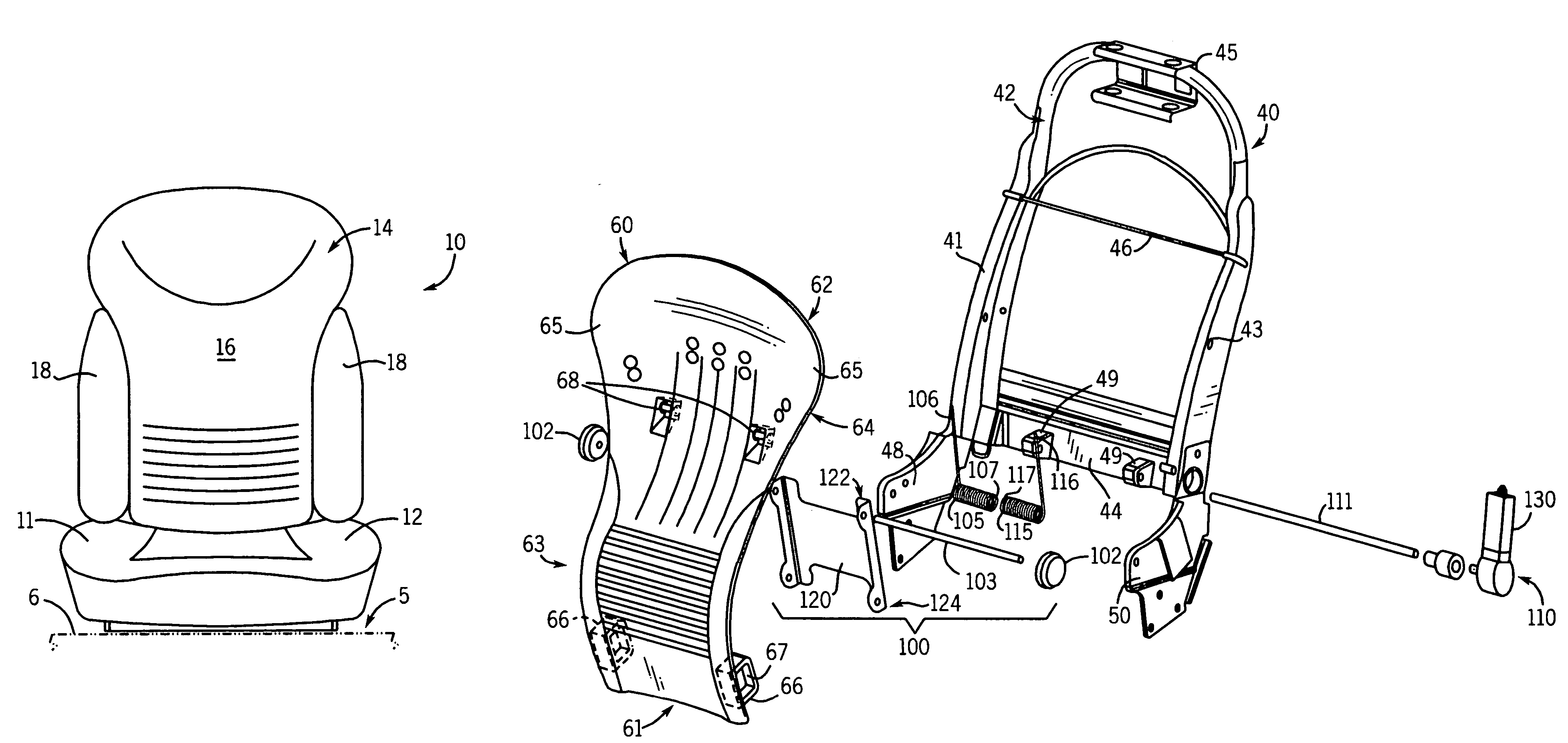

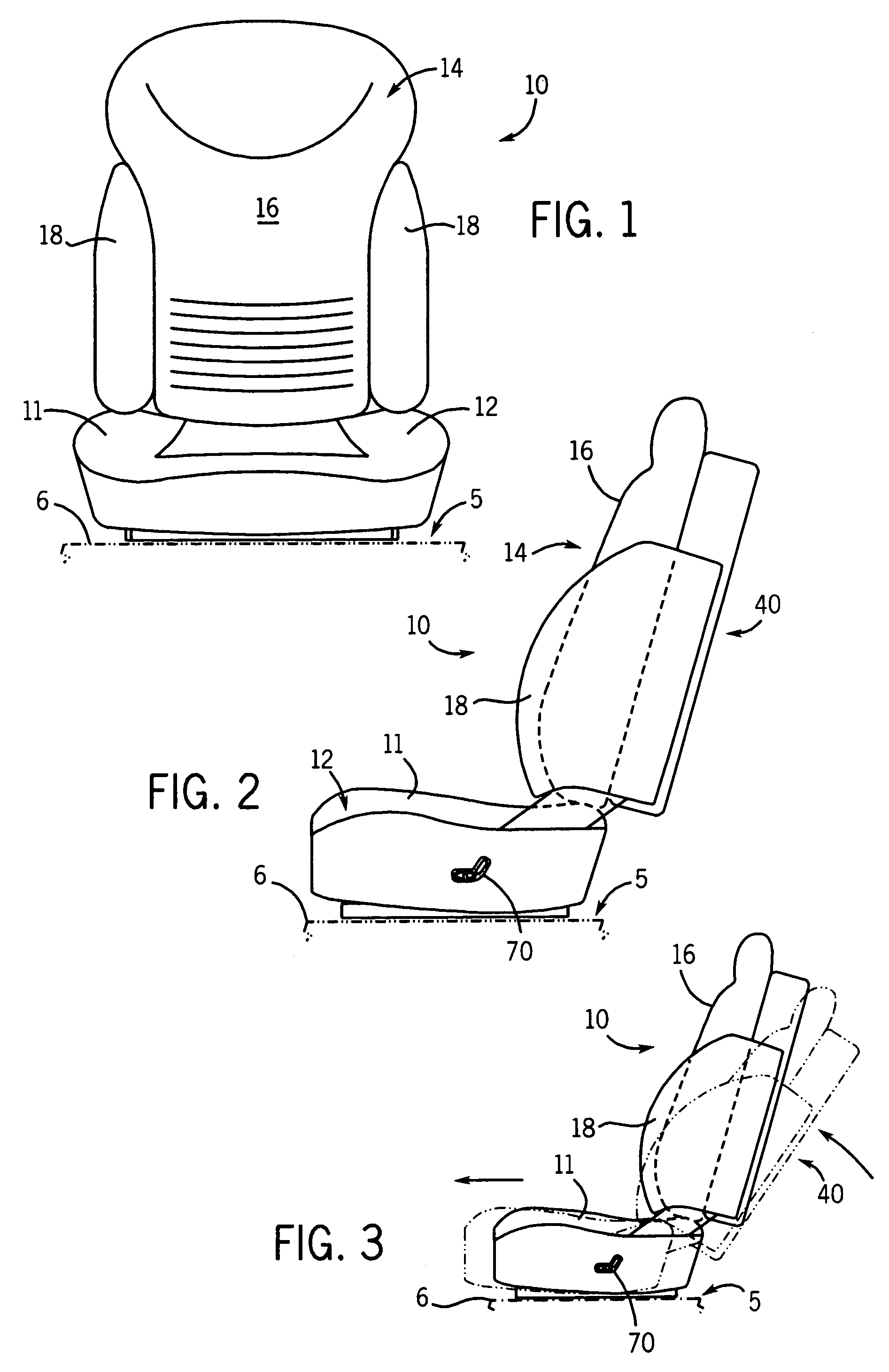

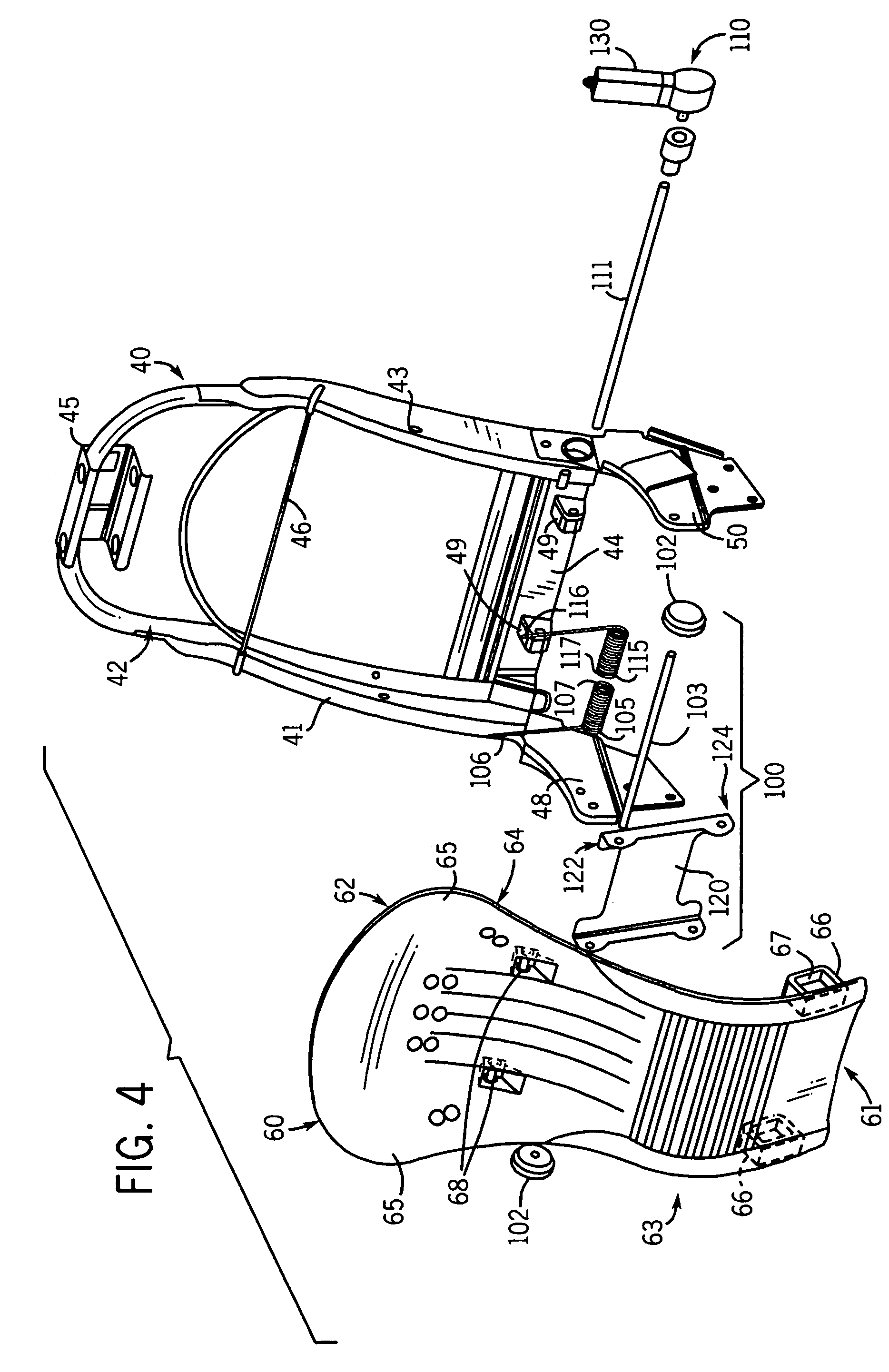

Child seat

An adjustable child seat includes a backrest and a seat base and may be used with or without the backrest. The child seat includes adjustable arm rests. The height of the backrest and the depth of the seat base are also adjustable. The connection between the backrest and the seat base is configured to prevent unintentional separation but allows simple and intuitive separation when desired. A belt guide operating in either a seat belt locking mode or a seat belt free mode is also provided.

Owner:GRACO CHILDRENS PROD INC

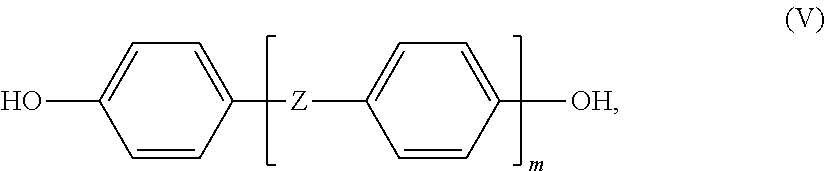

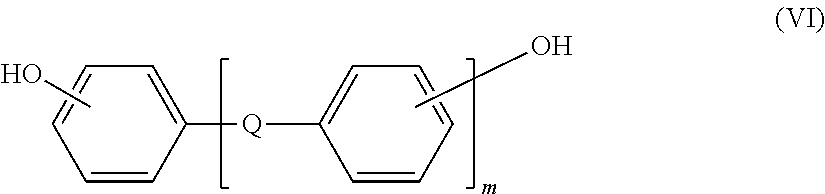

Composite component

ActiveUS20080038569A1Reduce weightEasy to recycleBack restsSynthetic resin layered productsFiberMolten state

A composite component such as a seat back for a vehicle comprises a support portion and at least one reinforcing composite layer. The support portion comprises a thermoplastic material and the reinforcing composite layer comprises a polymeric material impregnating a plurality of fibers. The polymeric material of the reinforcing composite layer is integrated with the thermoplastic of the support portion. A method of forming the composite component includes placing the composite layer into a mold, heating the thermoplastic material to a molten state, and disposing the thermoplastic material in the molten state into contact with the composite layer. The method further includes promoting interaction between the thermoplastic material and the polymeric material to integrate the support portion and the reinforcing composite layer. The thermoplastic material supports the reinforcing composite layer and the reinforcing composite layer reinforces the thermoplastic material to prevent failure when subjected to a load.

Owner:BASF AG

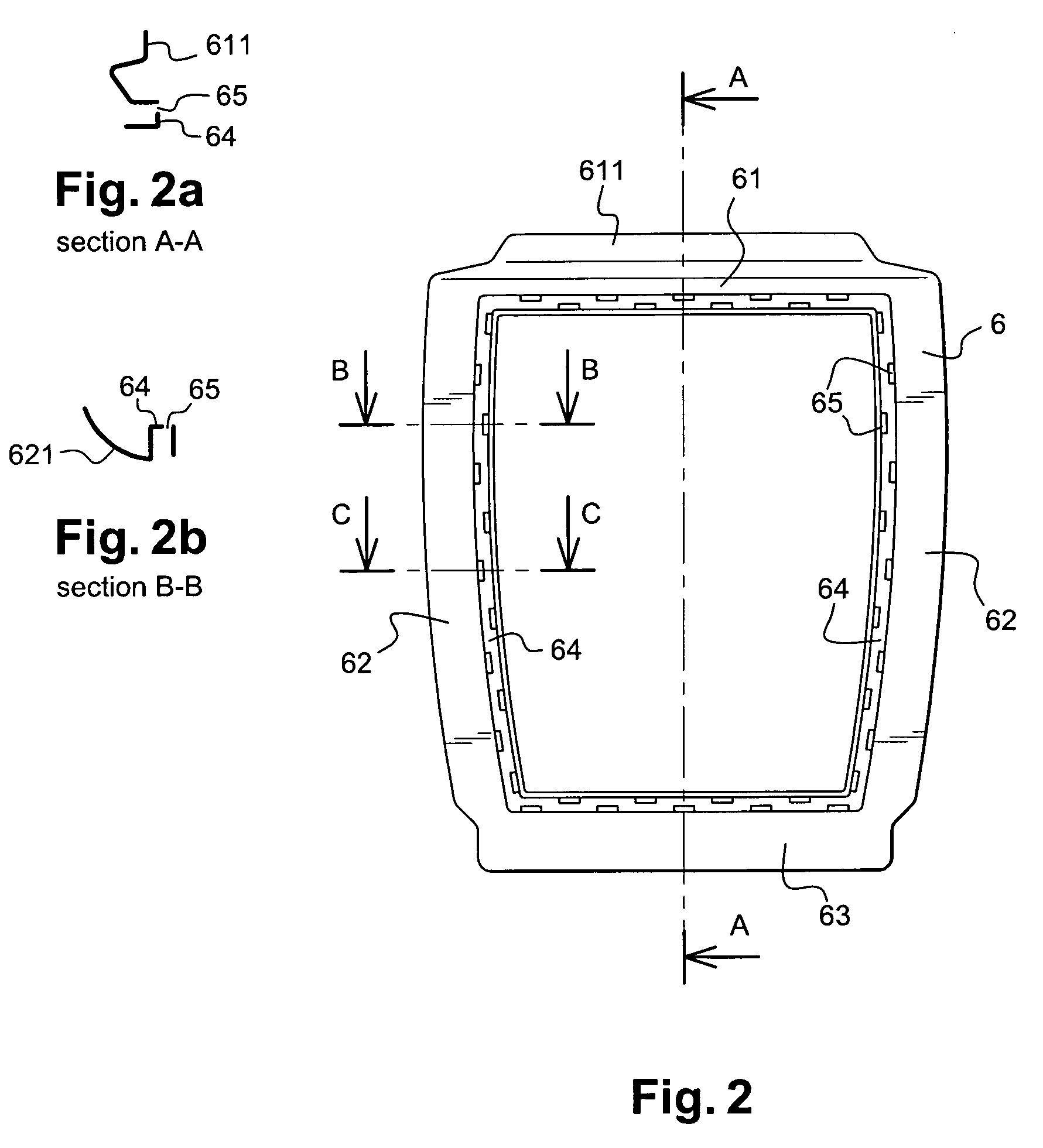

Backrest of an automobile vehicle seat

ActiveUS7222915B2Reduce in quantityEasy to installSeat coveringsPedestrian/occupant safety arrangementEngineering

Owner:FAURECIA

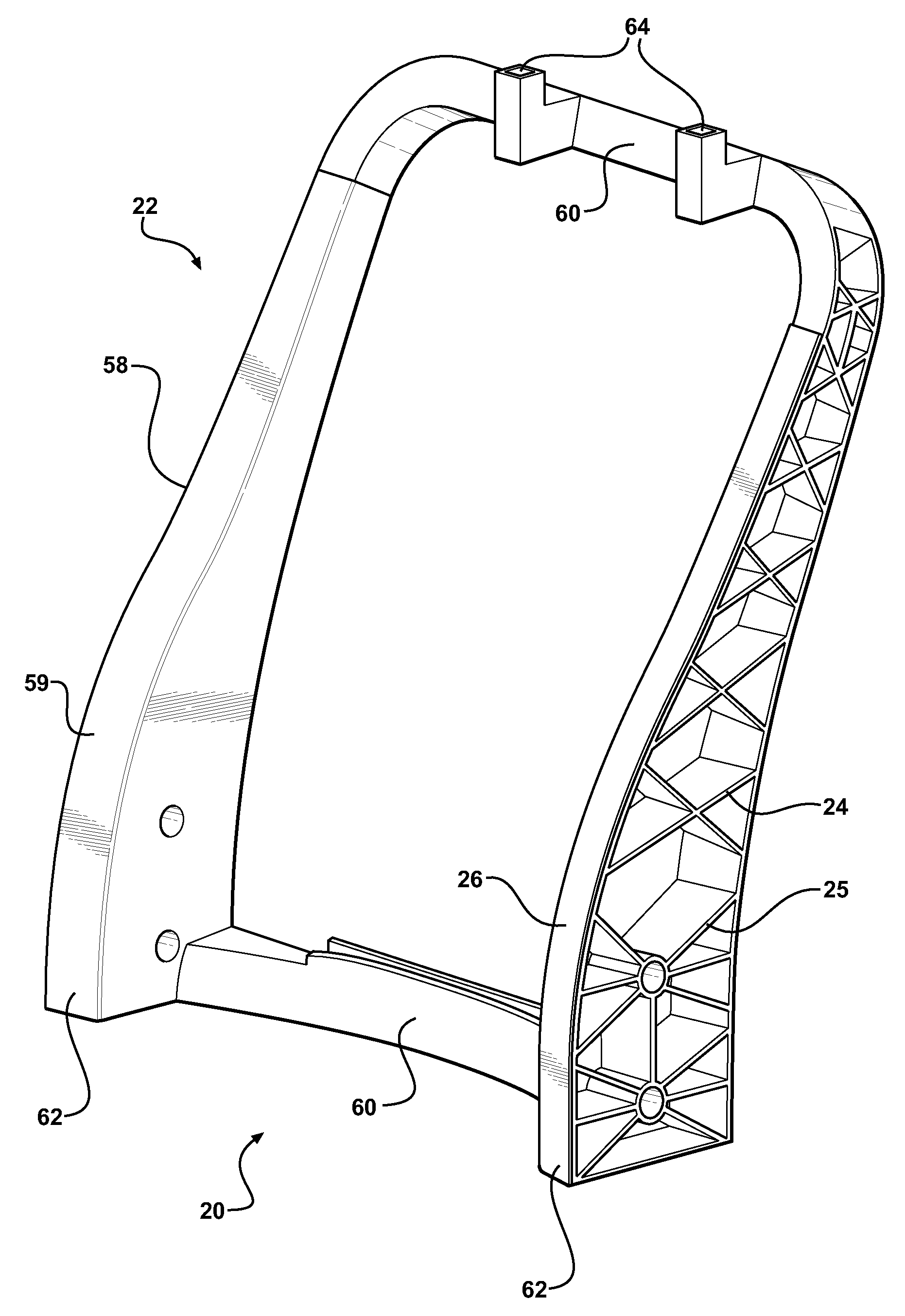

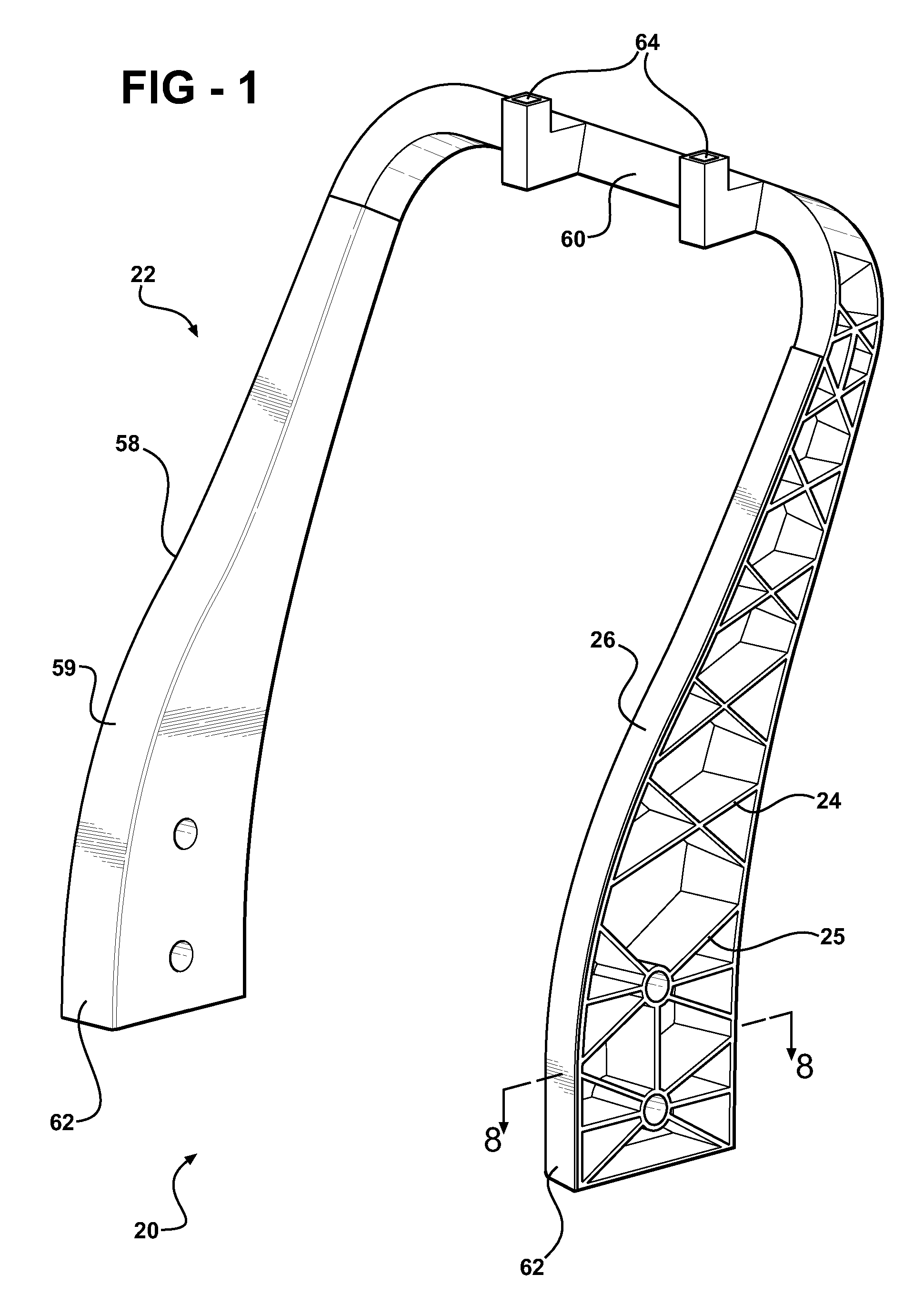

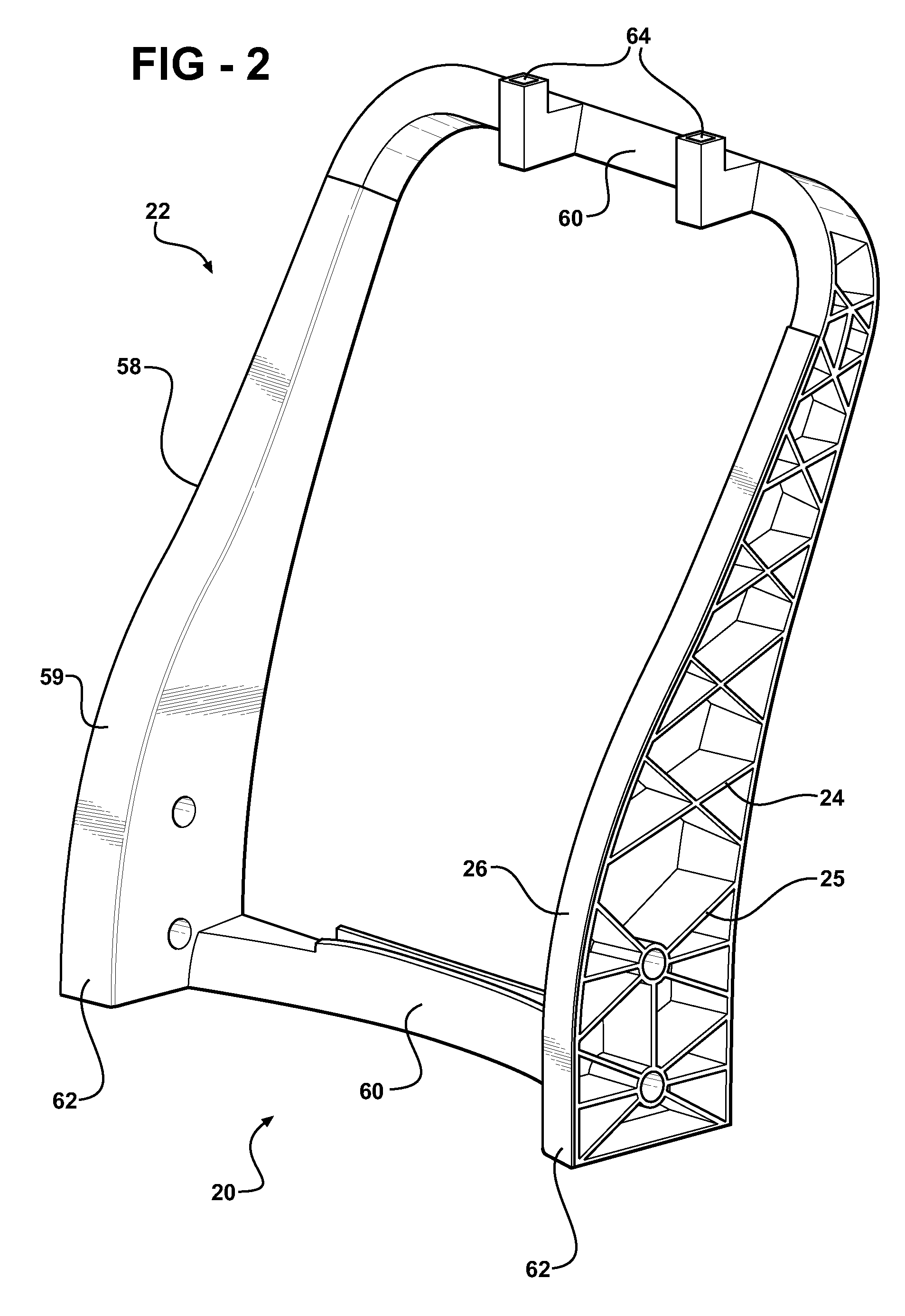

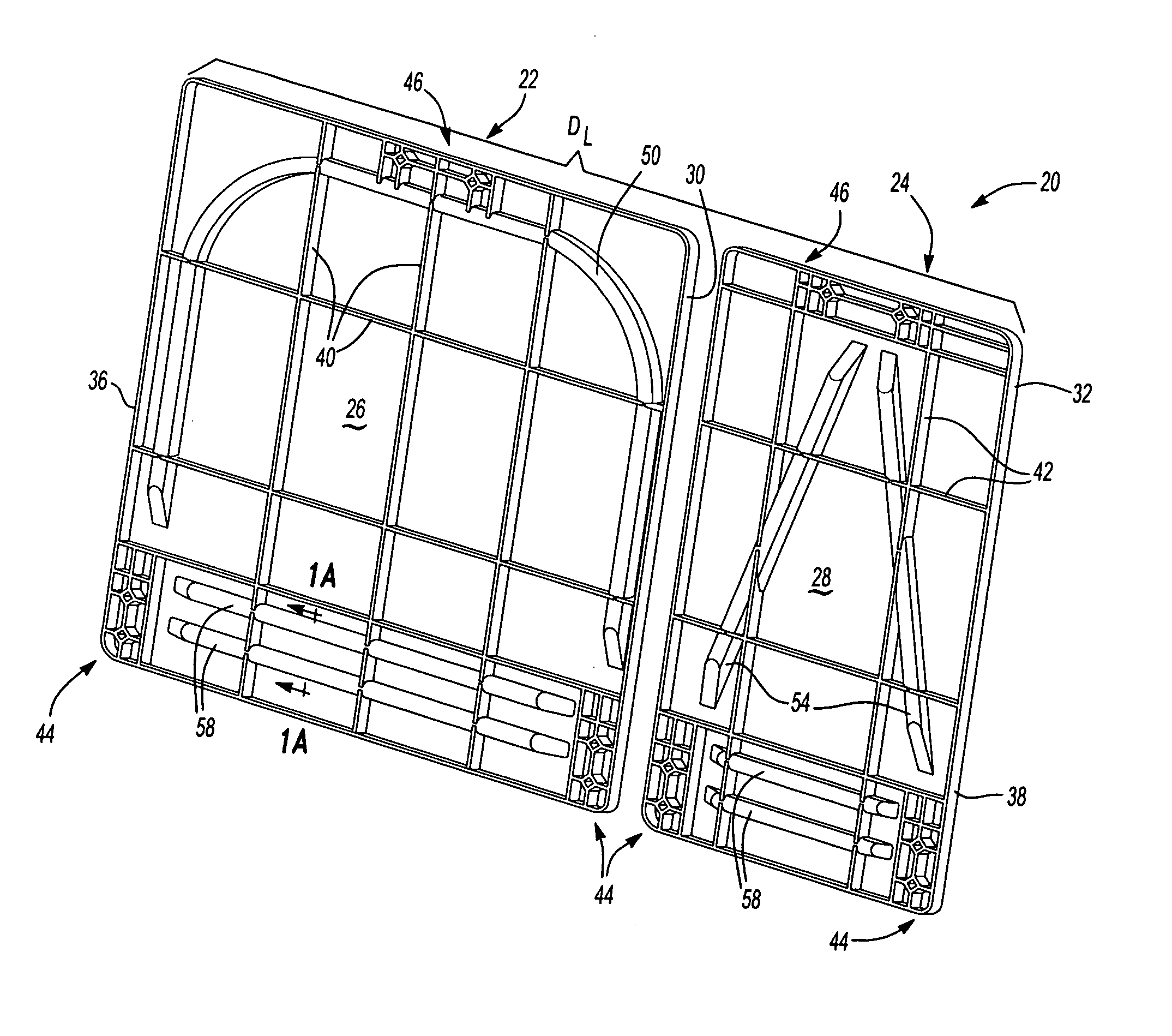

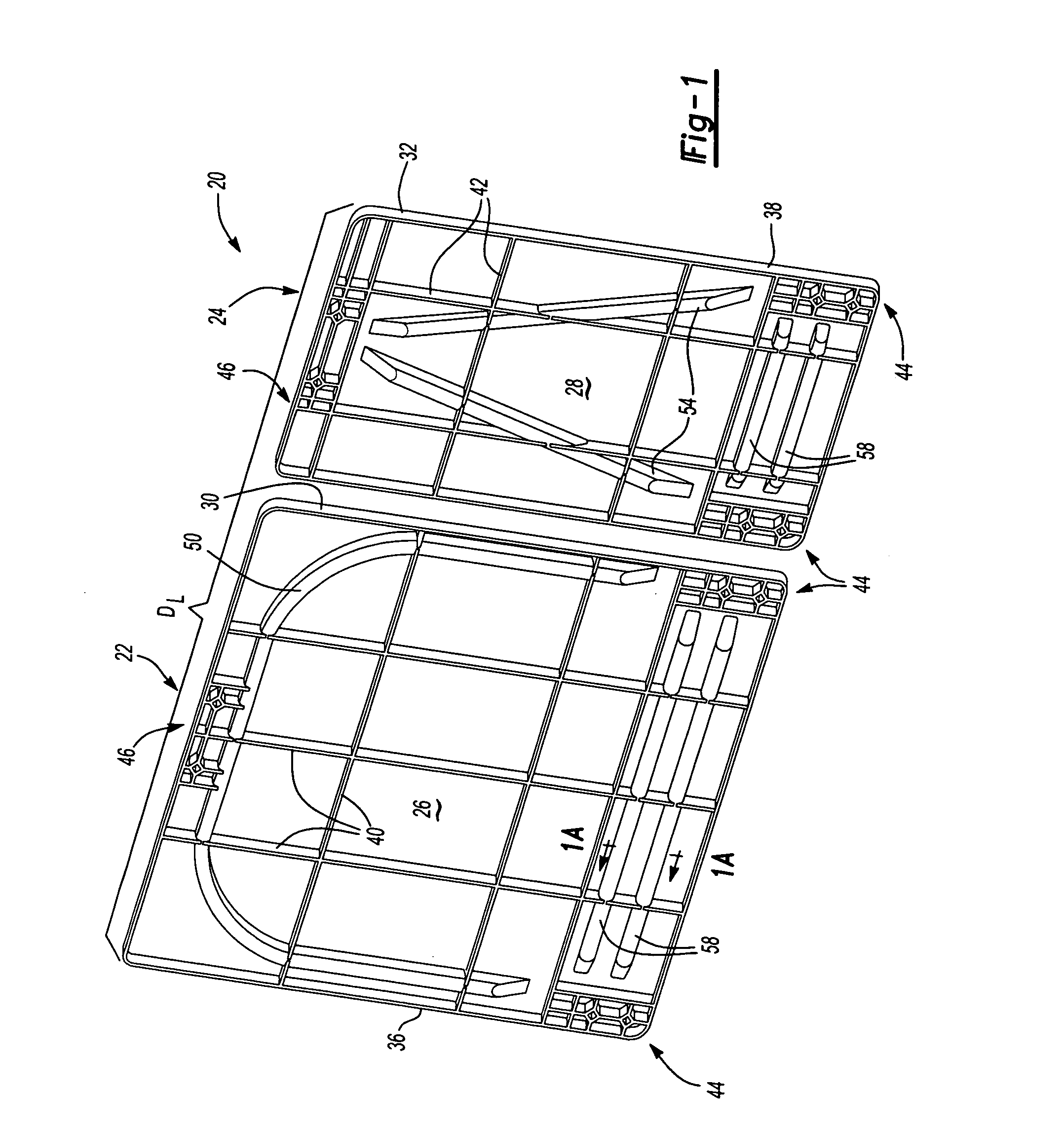

Seating system and method of forming same

InactiveUS7128373B2Provide strengthEasy to manufactureSeat framesStoolsMechanical engineeringEngineering

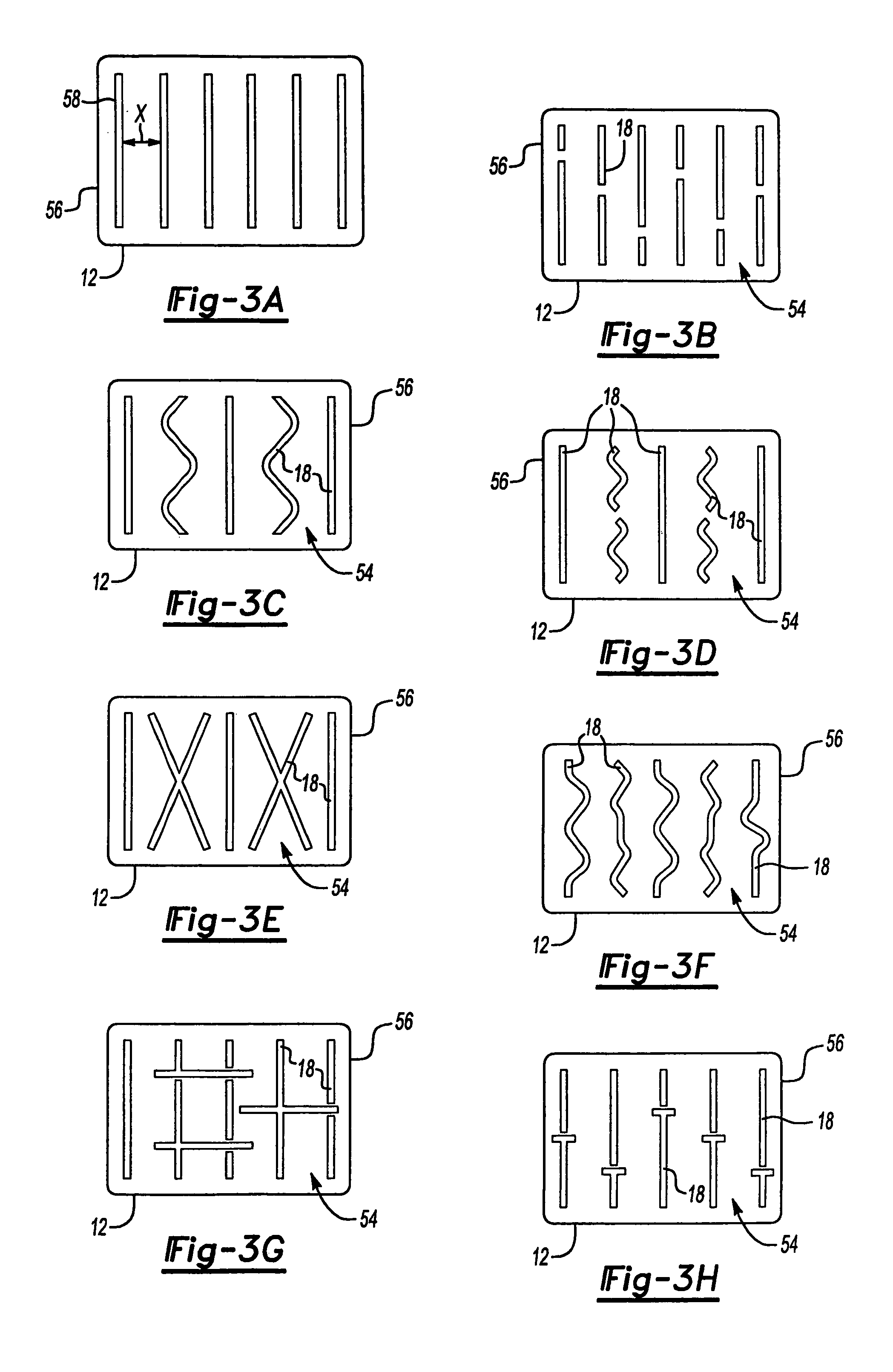

The present invention discloses a seating system that includes a seat back (20) with one or more plastic panels (22, 24) that extend across a lateral distance (D2) of the seat back (20). The seat back (20) preferably includes one or more channel forming ribs (50, 54, 58). Optionally the seat back (20) will be anchored to a body of an automotive vehicle with an improved attachment system (100).

Owner:DOW GLOBAL TECH LLC

Vehicle seat

ActiveUS20100140986A1Reduce intensityPedestrian/occupant safety arrangementSeat framesEngineeringCushion

A vehicle seat includes a seat cushion frame which comprises a pair of side frames and a front cross member located on a front side of the vehicle seat, the front cross member extending between the side frames and at least one leg support member is connected to the front cross member, and is arranged vehicle forward of the front cross member, wherein the at least one leg support member comprises at least a portion having a strength lower than a strength of the front cross member.

Owner:NISSAN MOTOR CO LTD

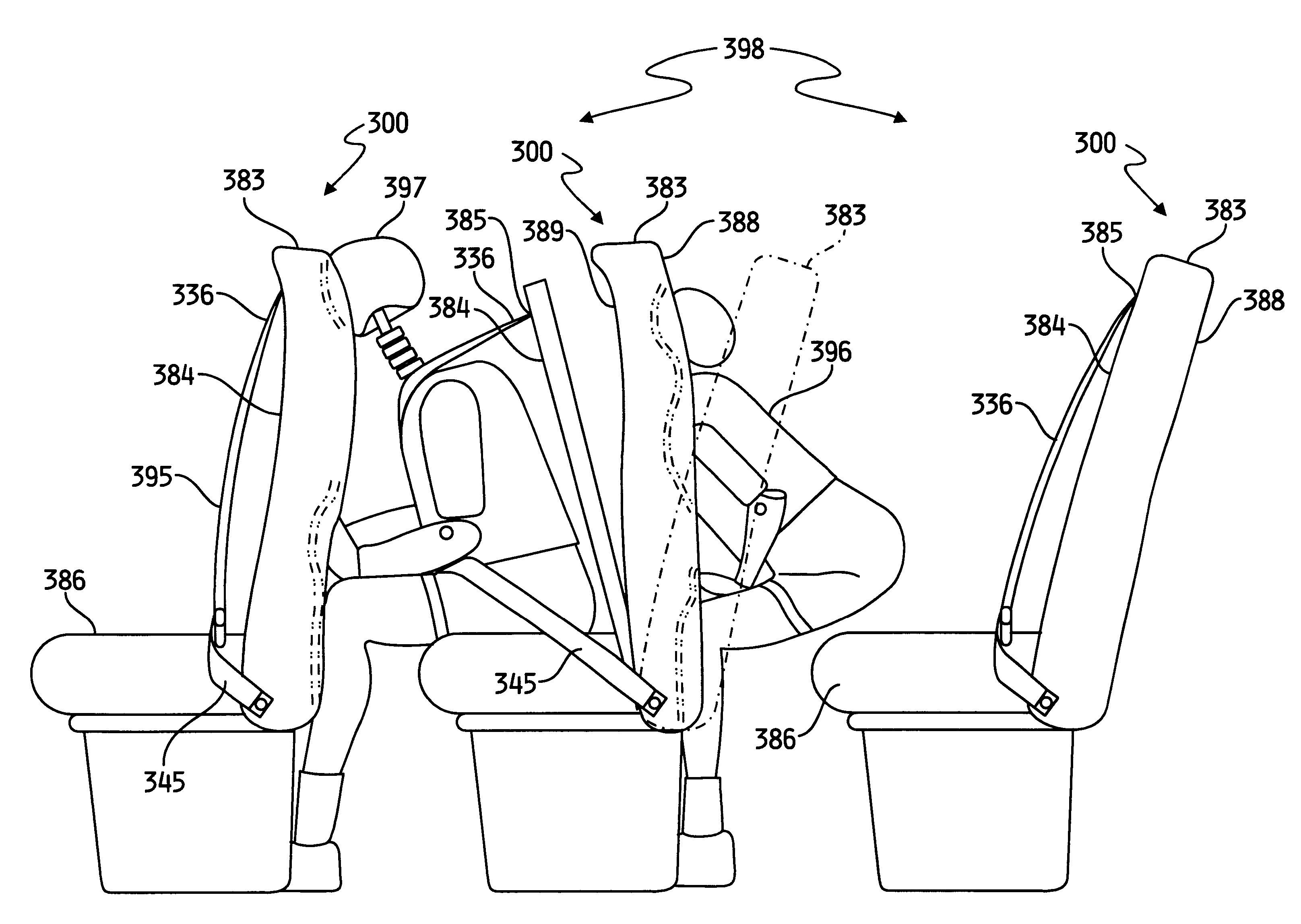

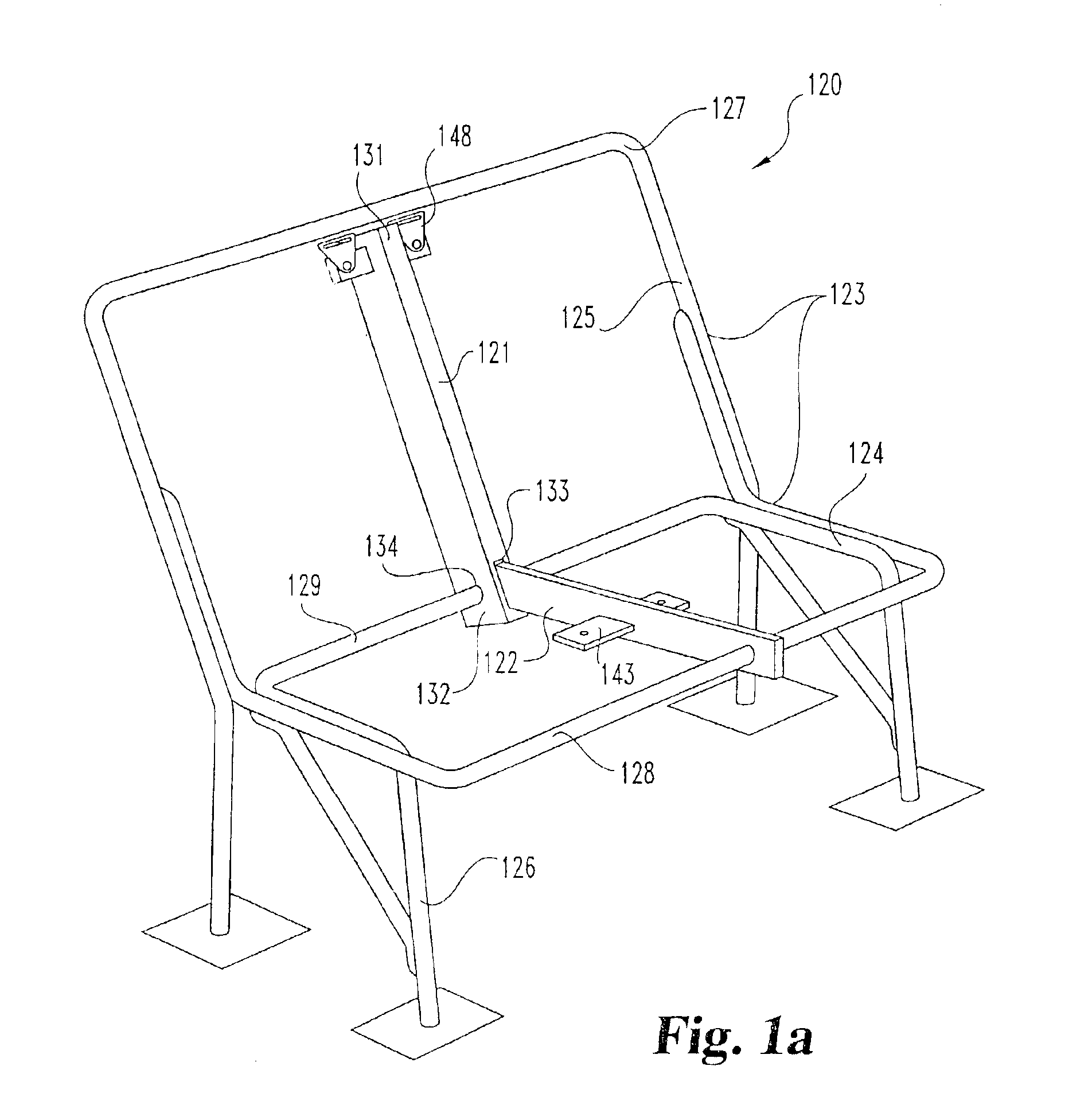

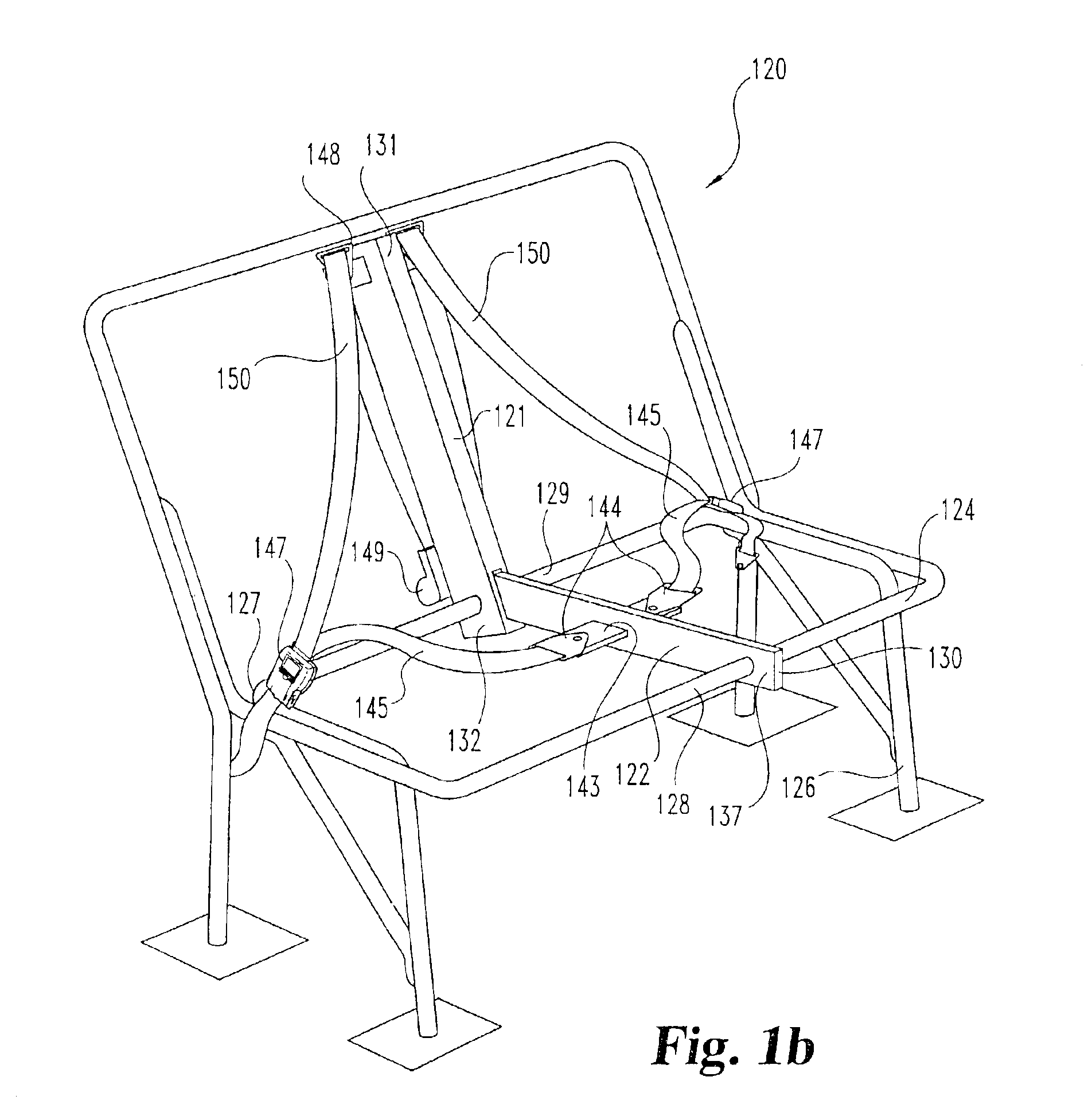

Restraint system for a school bus seat

A passenger restraining harness and support assembly for use with a bench seat mounted in a vehicle. The bench seat includes a frame having a seat support portion with a front portion and a rear portion, a seatback portion coupled to the seat support portion, and legs or supports anchoring the seat to the vehicle. A harness support assembly includes a tower member with a slotted bottom end pivotally coupled to the rear of the seat support, a connecting member having one end adapted to fit into the slot in the tower member and a second end connected to the front of the seat support portion, a belt guide connected to the top of the tower member, and an anchor wing connected to the connecting member. A belt or harness attaches to the support assembly.

Owner:INDIANA MILLS MFG

Seat back frame for vehicle seat

A seat back frame for a vehicle seat includes first and second side members spaced apart from each other, each of the first and second side members being made of ultra-high tensile strength steel, the first side member having a first longitudinal body of a substantially U-shape in cross-section, the first longitudinal body comprising a pair of first spaced apart flange sections and a first main plate section interconnecting the first spaced apart flange sections, the first side member having a first upper region and a first lower region, the second side member having a second longitudinal body of a substantially U-shape in cross-section, the second longitudinal body comprising a pair of second spaced apart flange sections and a second main plate section interconnecting the second spaced apart flange sections, the second side member having a second upper region and a second lower region, an upper member arranged between the first and second upper regions of the first and second side members, the upper member being made of ultra-high tensile strength steel, the upper member having first and second end portions, the upper member being mounted, by spot-welding, to the first and second upper regions of the first and second side members with the first and second end portions thereof being fitted in the first and second side members, and a lower member arranged between the first and second lower regions of the first and second side members, the lower member being made of ultra-high tensile strength steel, the lower member having third and fourth end portions, and the lower member being mounted, by spot-welding, to the first and second lower regions of the first and second side members with the third and fourth end portions thereof being fitted in the first and second side members.

Owner:TS TECH CO LTD

Restraint system for a vehicle

A passenger vehicle seat and restraint system comprising a frame mountable to a vehicle and a restraint member and a seat member coupled to the frame to form a seat for supporting an occupant. The vehicle seat may further comprise a seat back frame movably attached to the frame and a restraint harness affixed to the frame and the seat back frame for securing the occupant thereto.

Owner:INDIANA MILLS MFG

Vehicle seat

Owner:TS TECH CO LTD +1

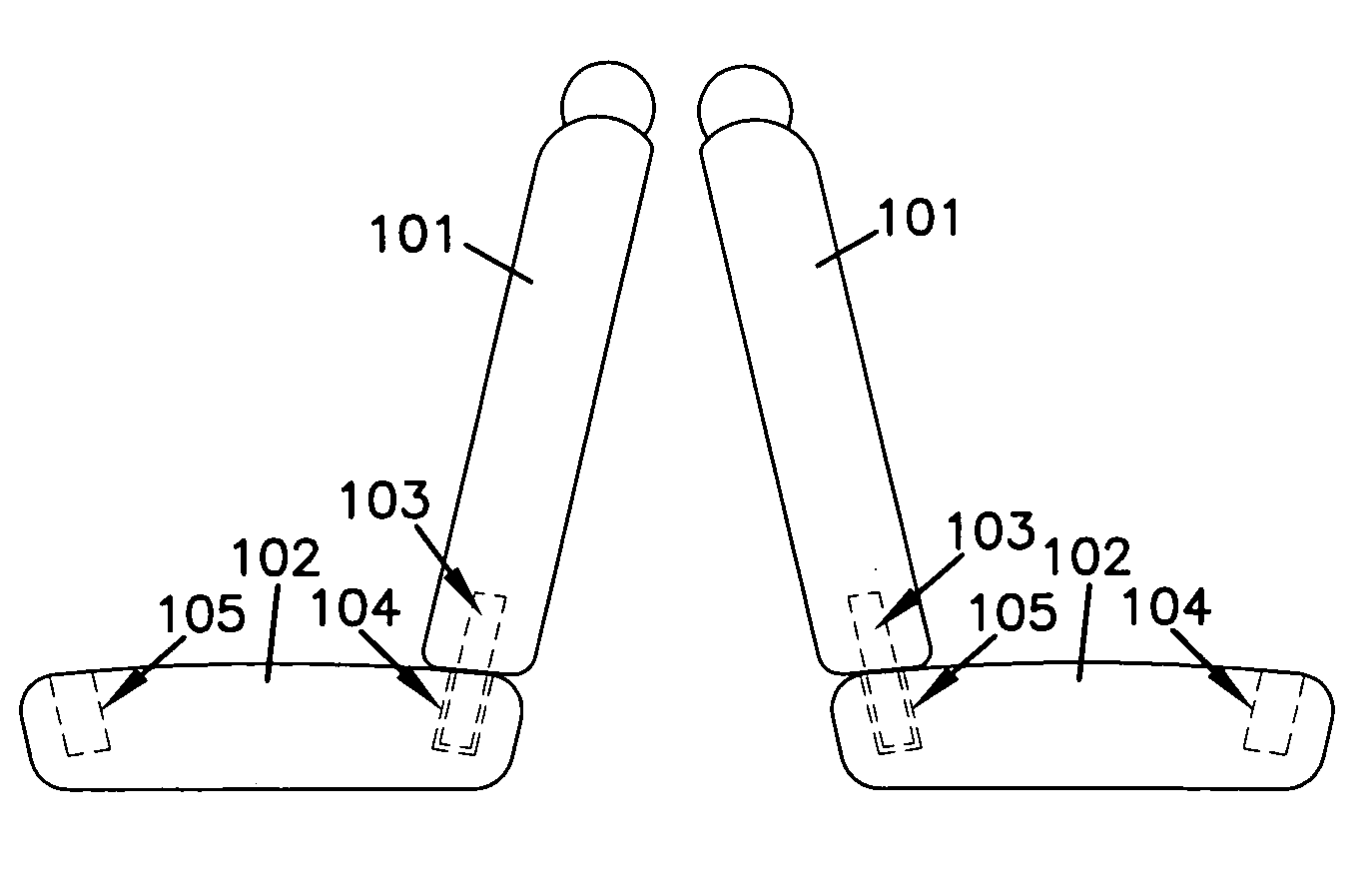

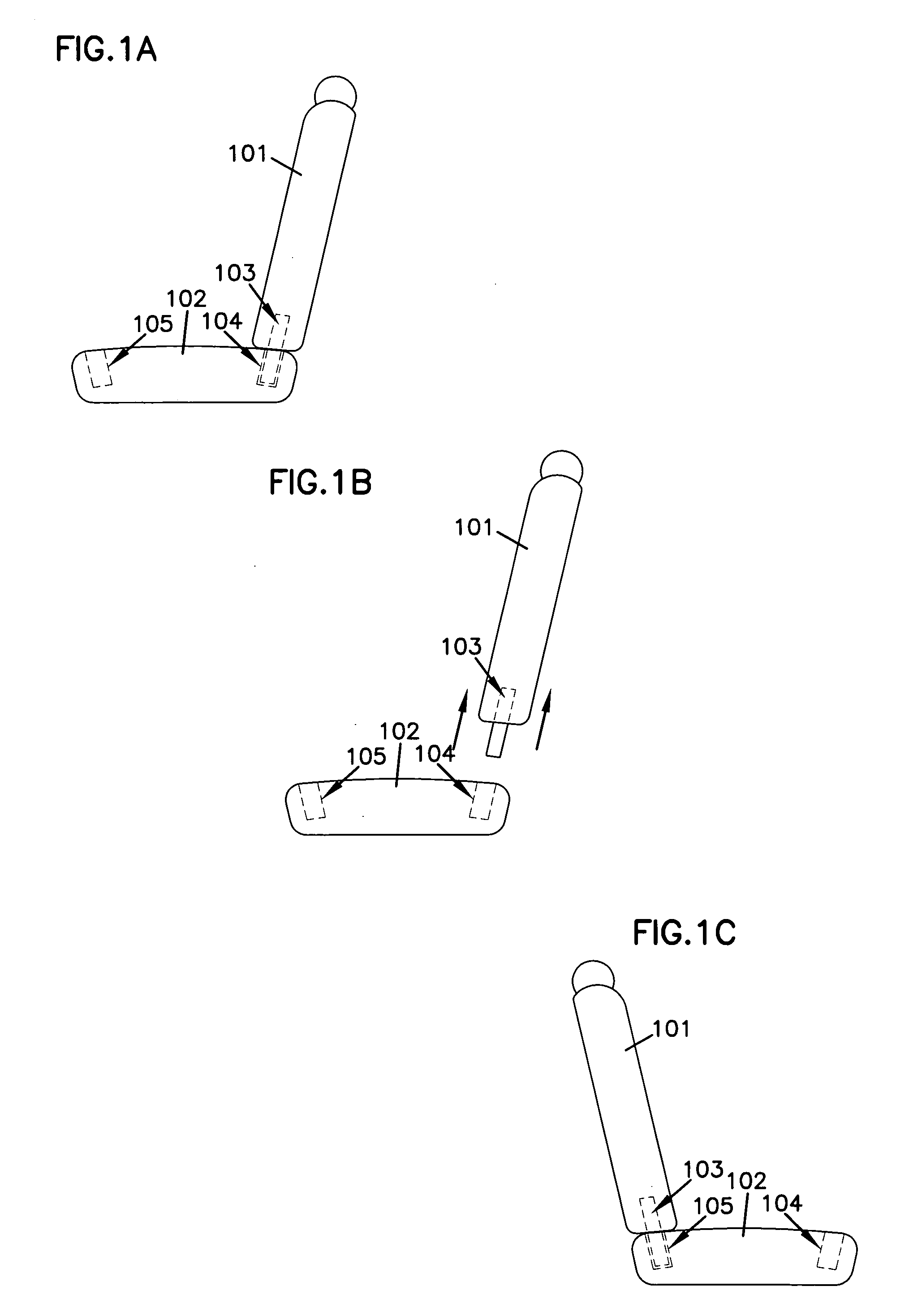

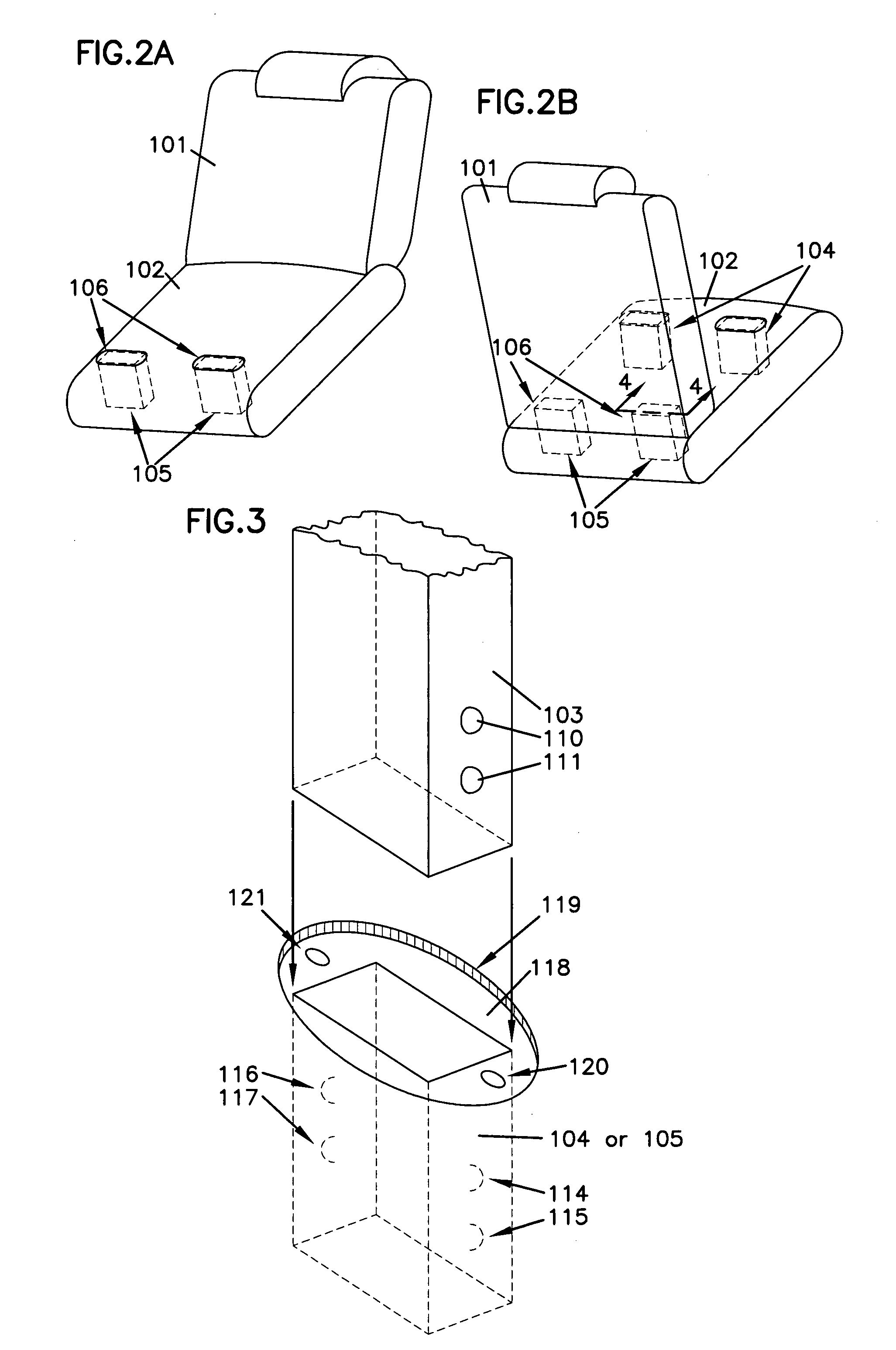

Reversible seatback for a vehicle

A reversible seat system for a vehicle is provided. A seatback includes at least one post-like element extending below a lower side of the seatback. At least one receiving slot is located on each of the anterior and posterior sides of the seat cushion. The receiving slots are configured to receive the post-like element. The seatback is removable and replaceable between a first position and a second position, where the first position is forward-facing and the second position is rearward-facing.

Owner:HEMENWAY MICHAEL S

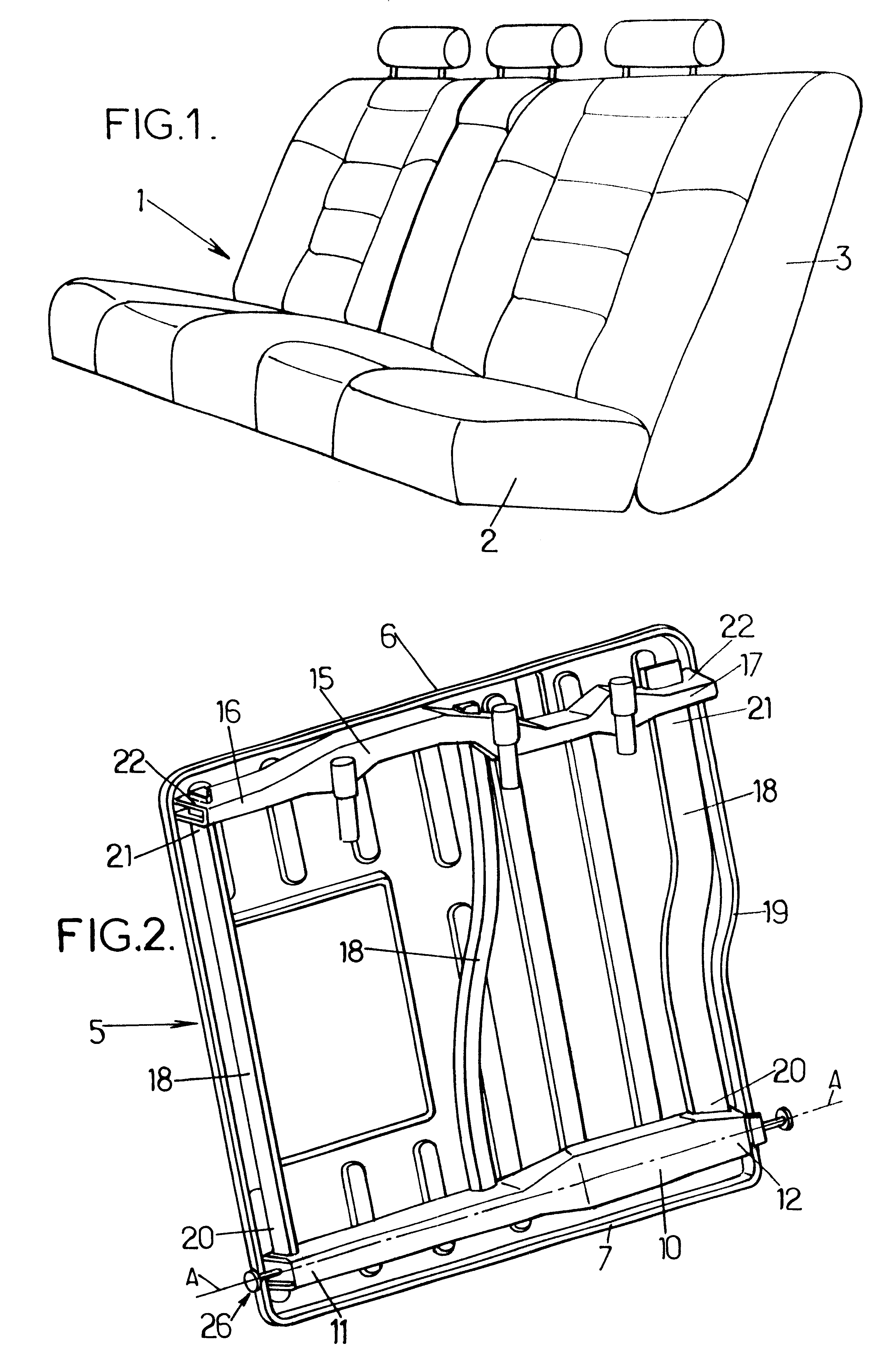

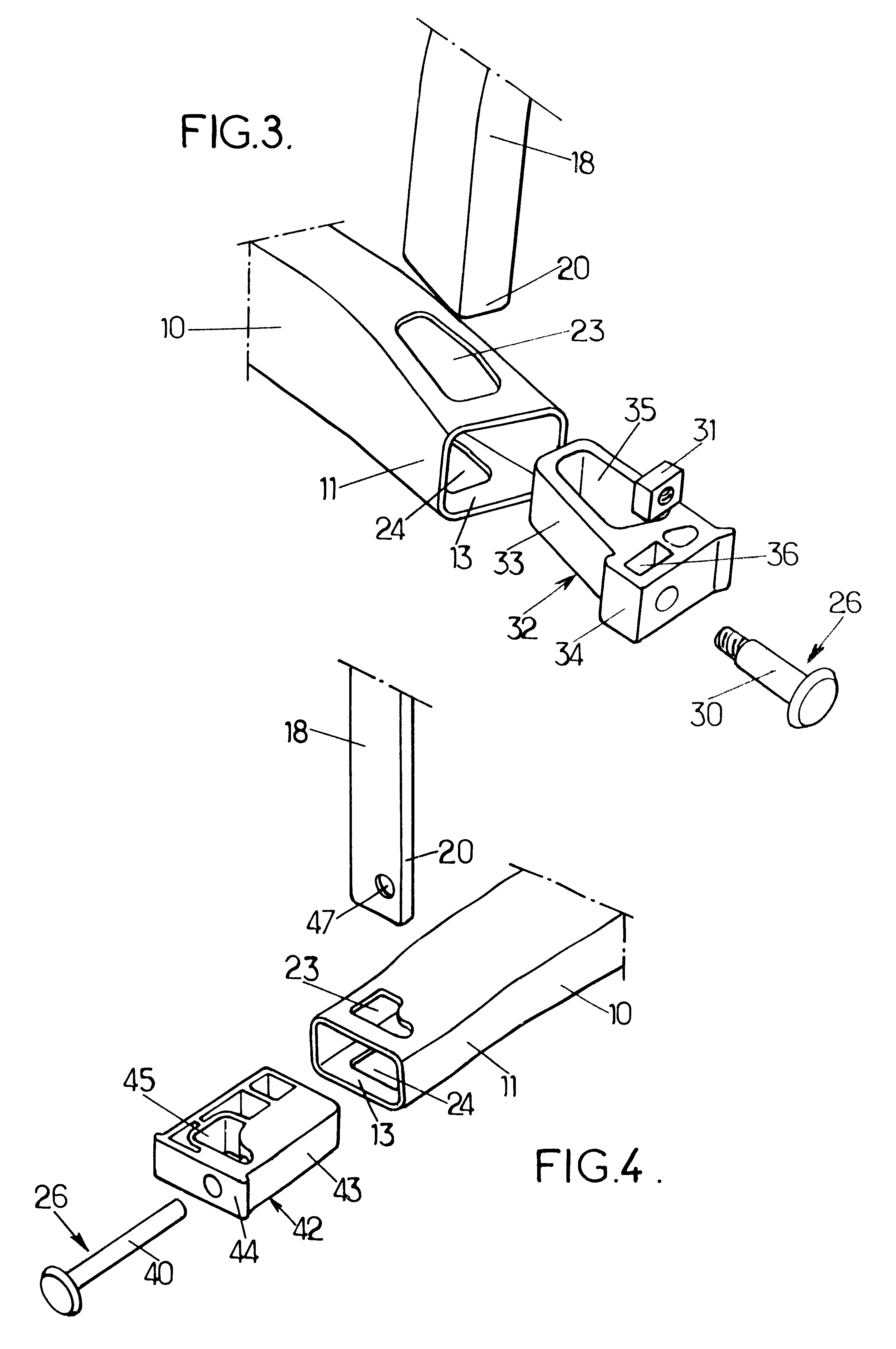

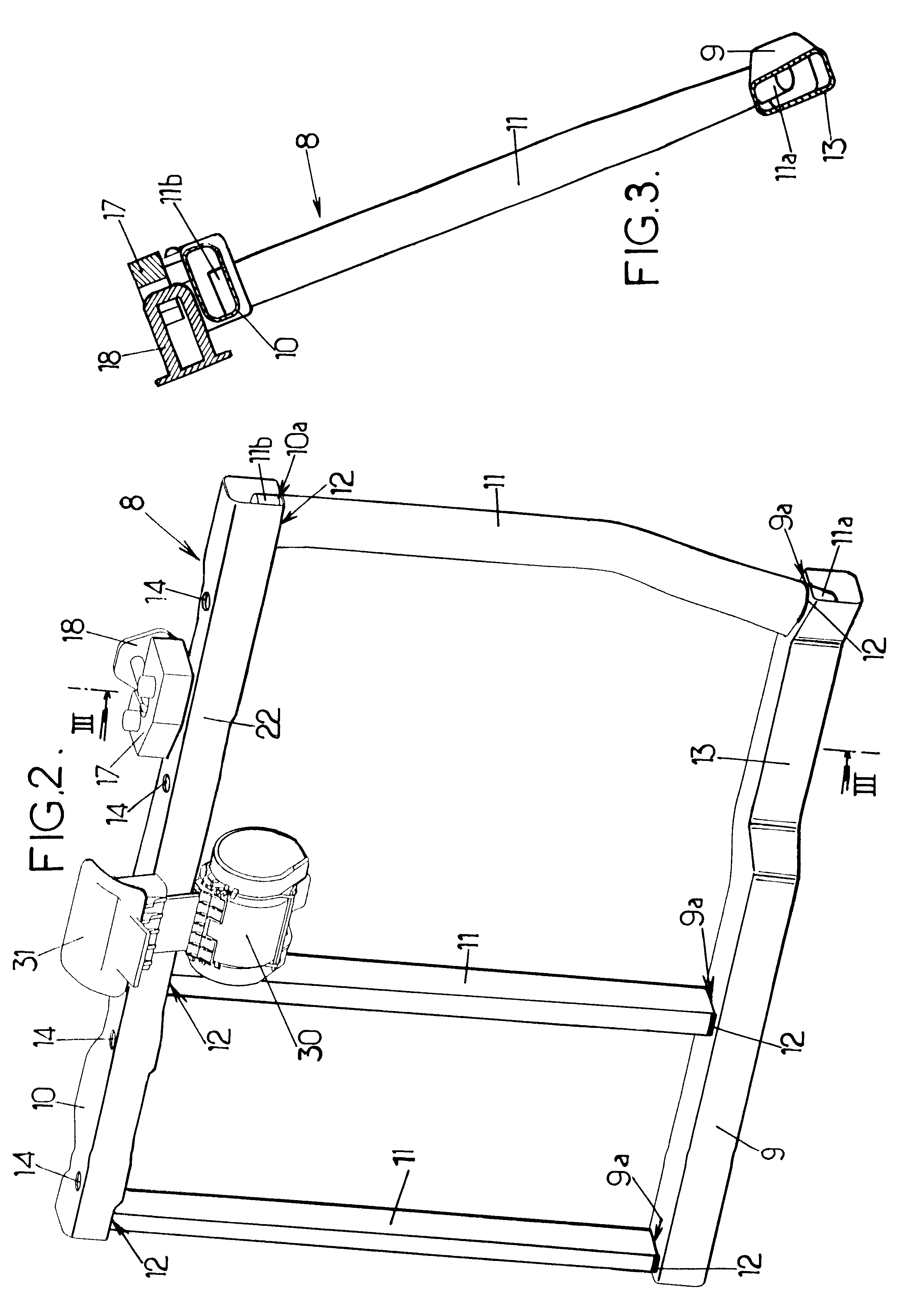

Automobile seat back structure articulated around fitted pivots

InactiveUS6347836B1Simple and efficient and inexpensive meanSeat framesStoolsBack structureEngineering

A seat back structure comprises a lower edge around which it is articulated and next to which is fixed a lower crosspiece the ends of which have pivoting means. These pivoting means are carried by a base which is itself added by fitting in the ends of the lower crosspiece.

Owner:BERTRAND FAURE EQUIP SA (FR)

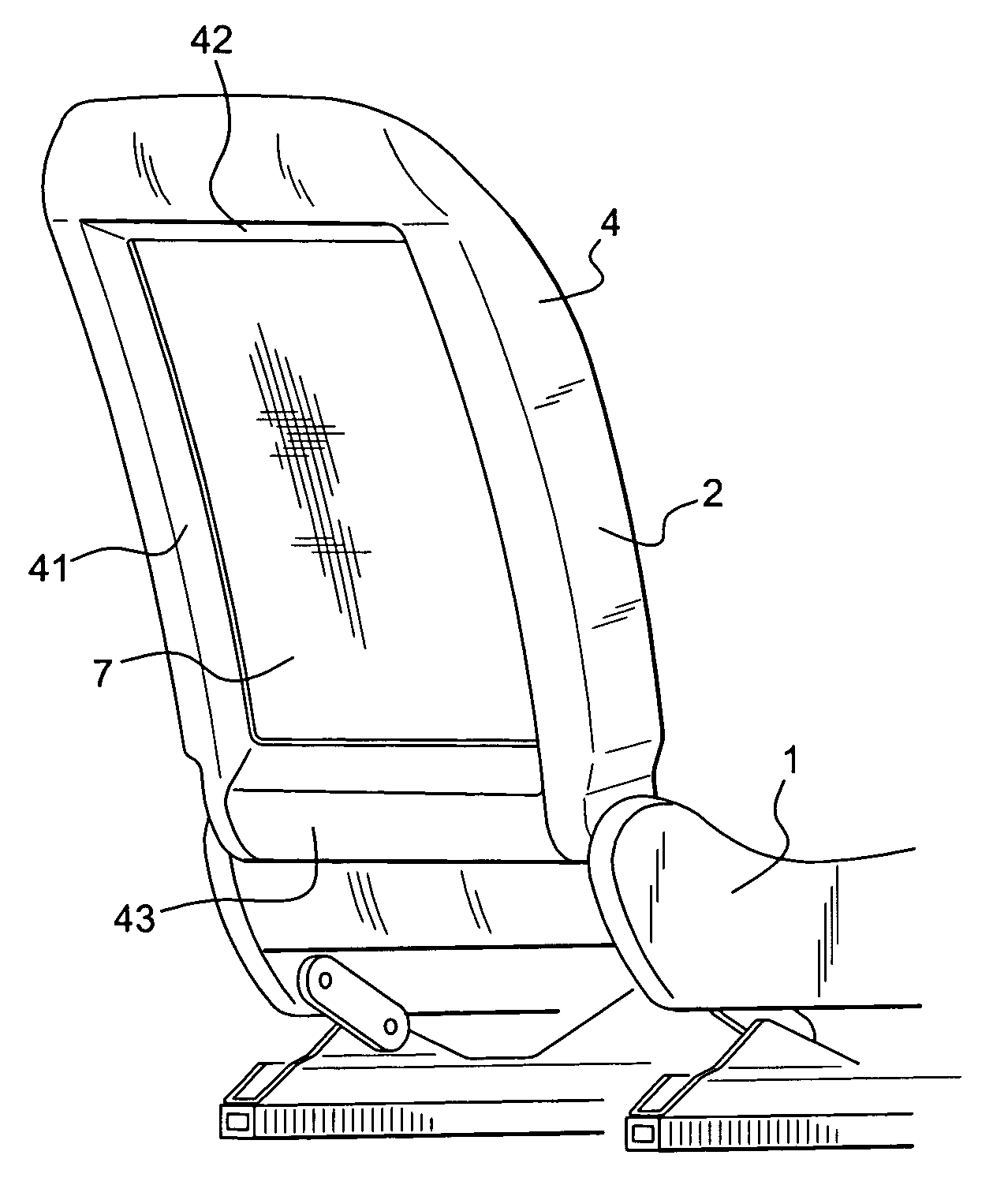

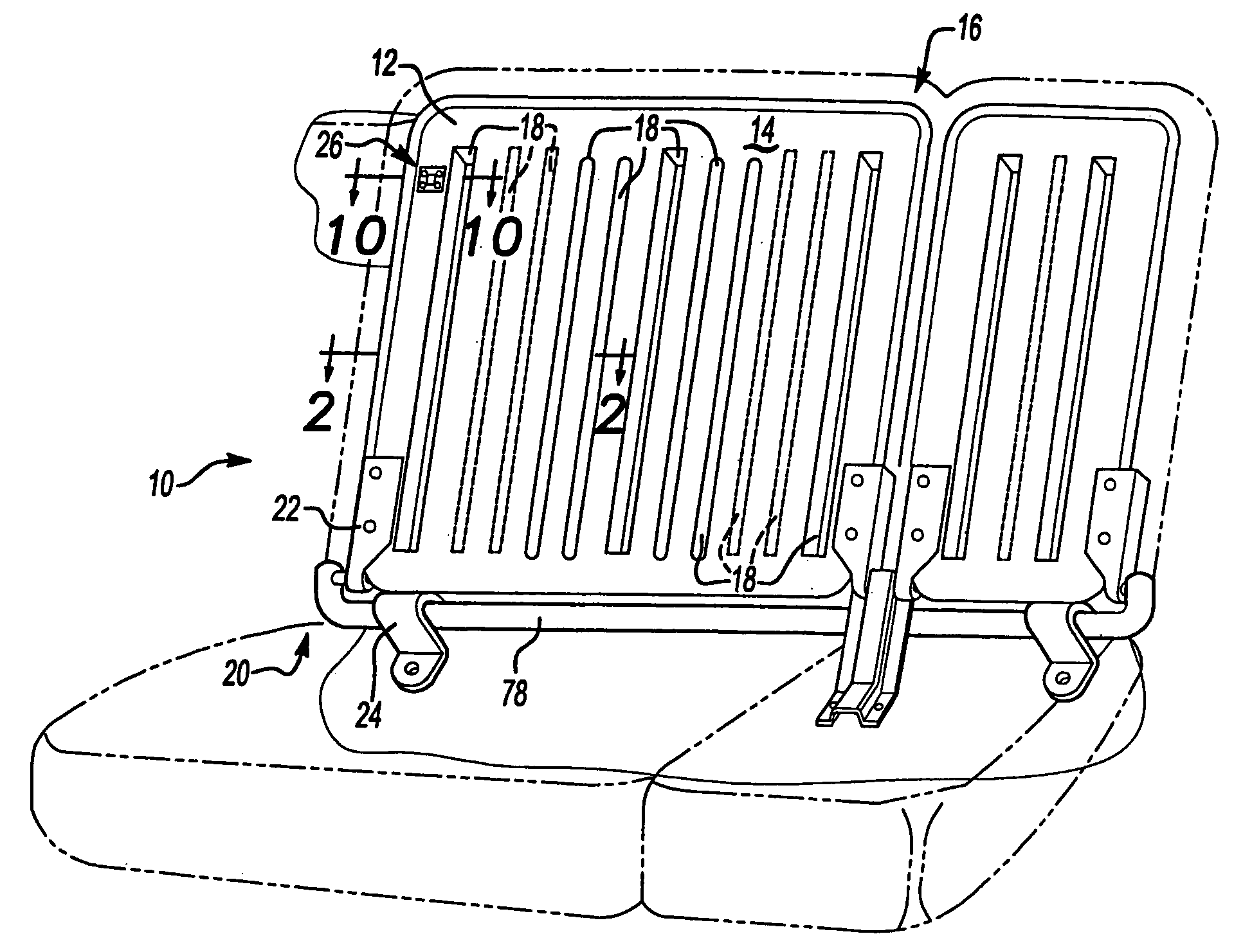

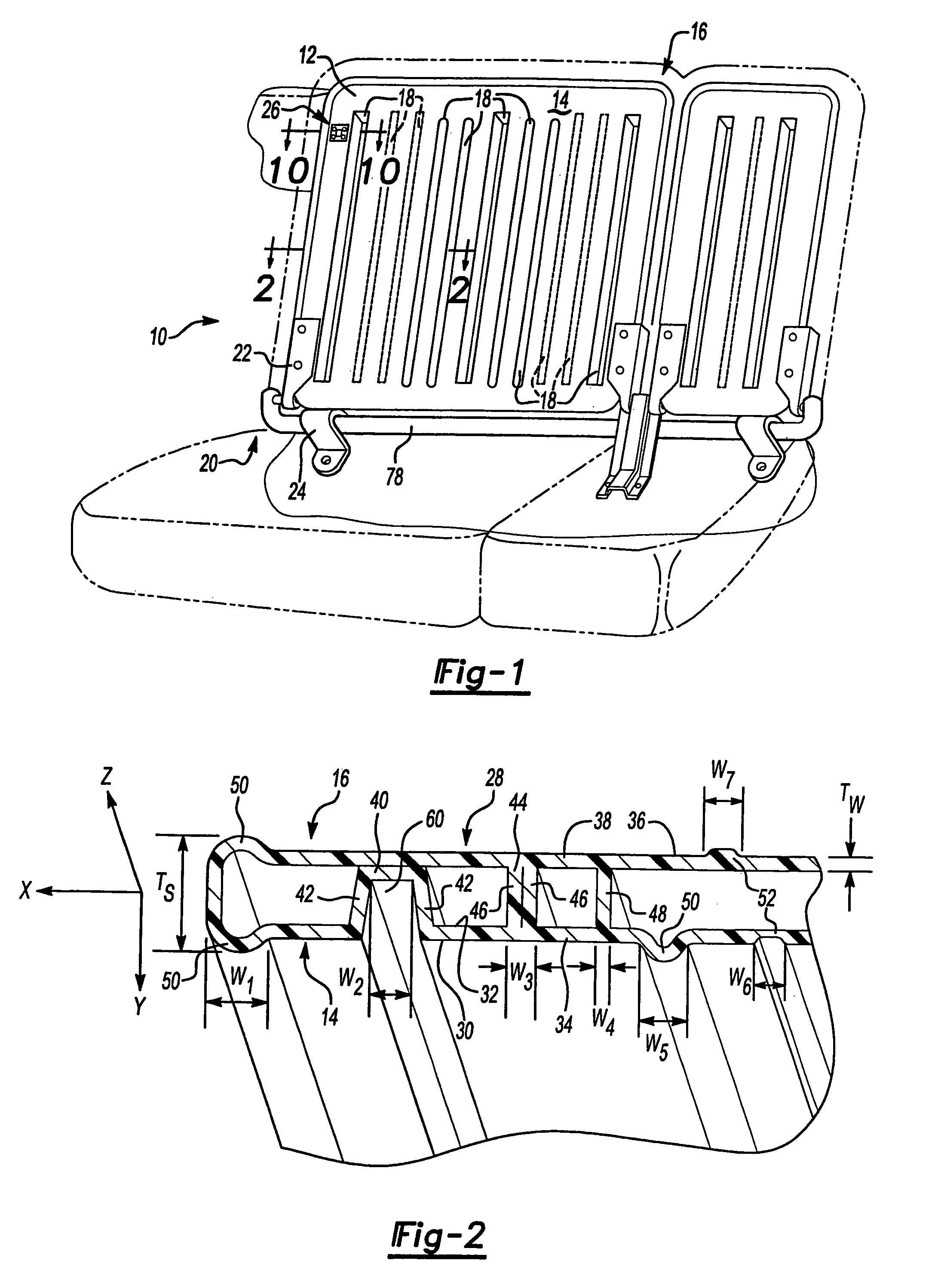

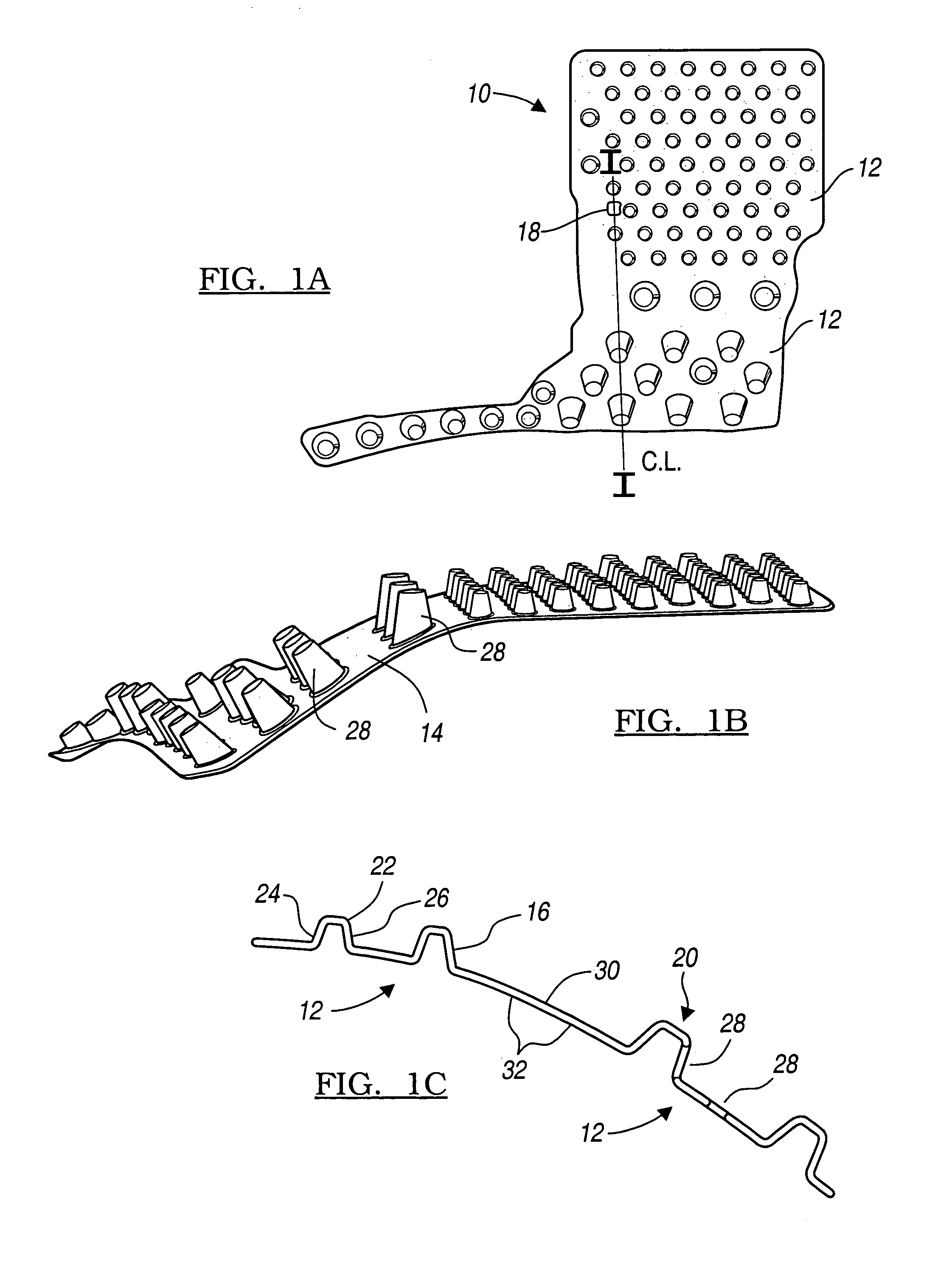

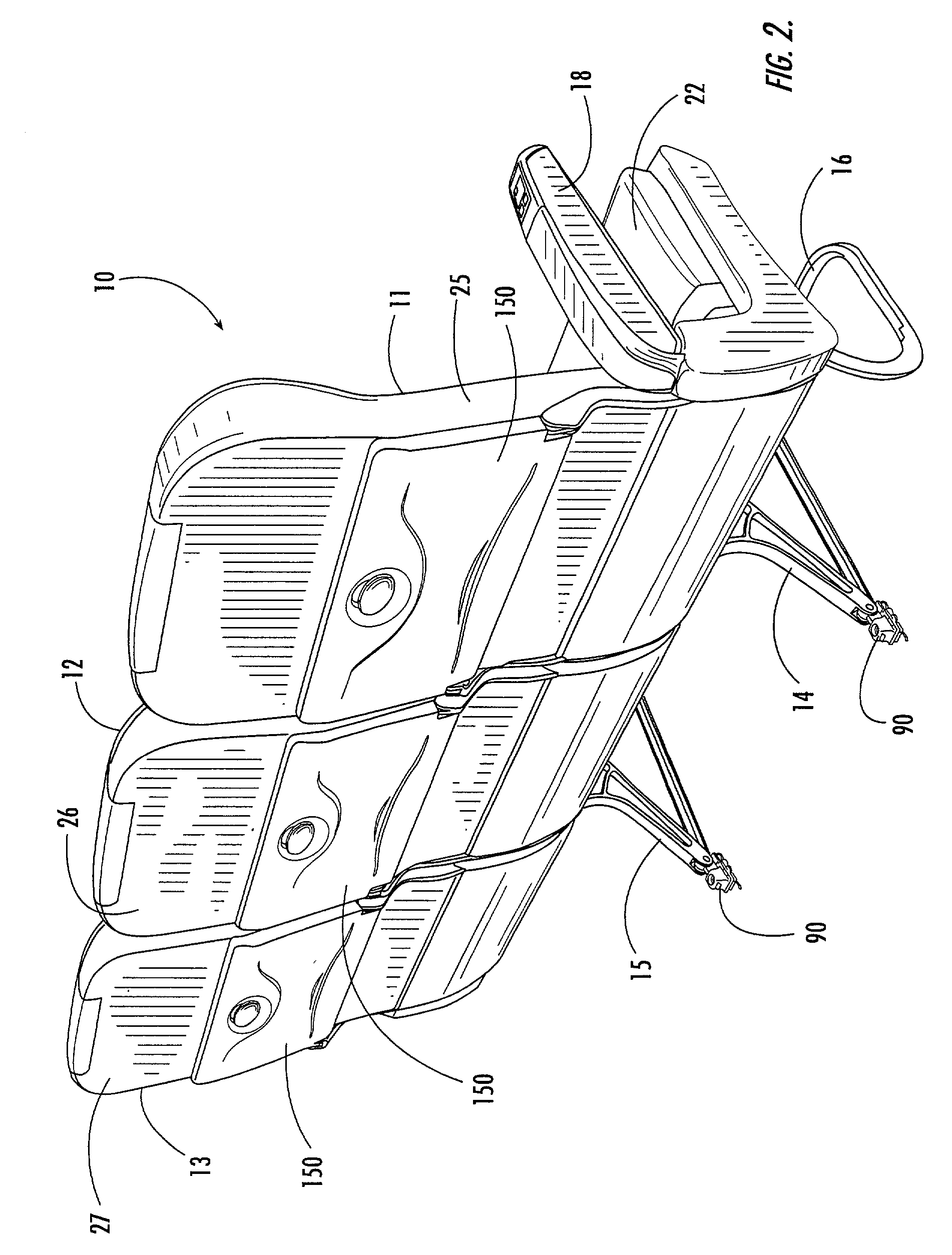

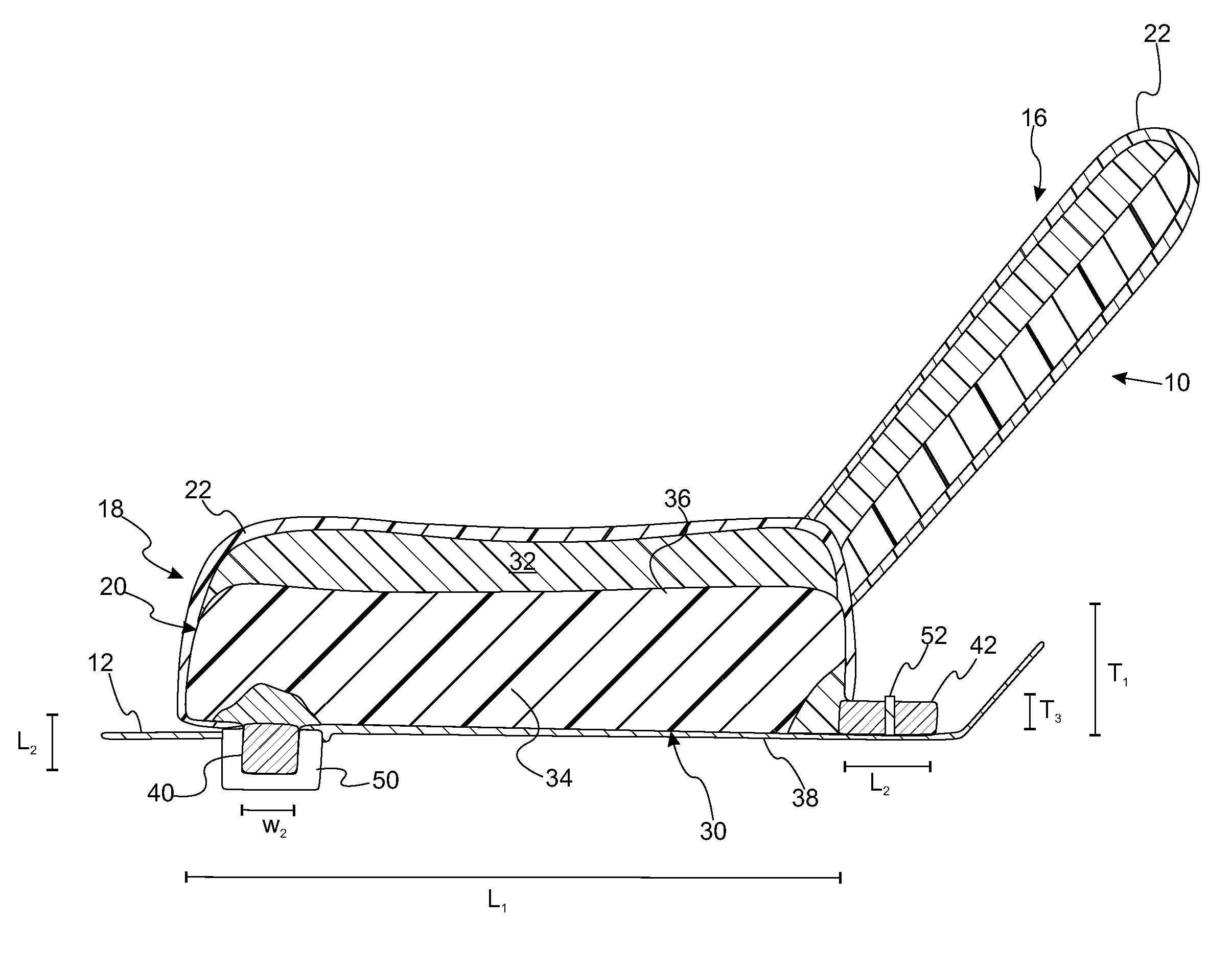

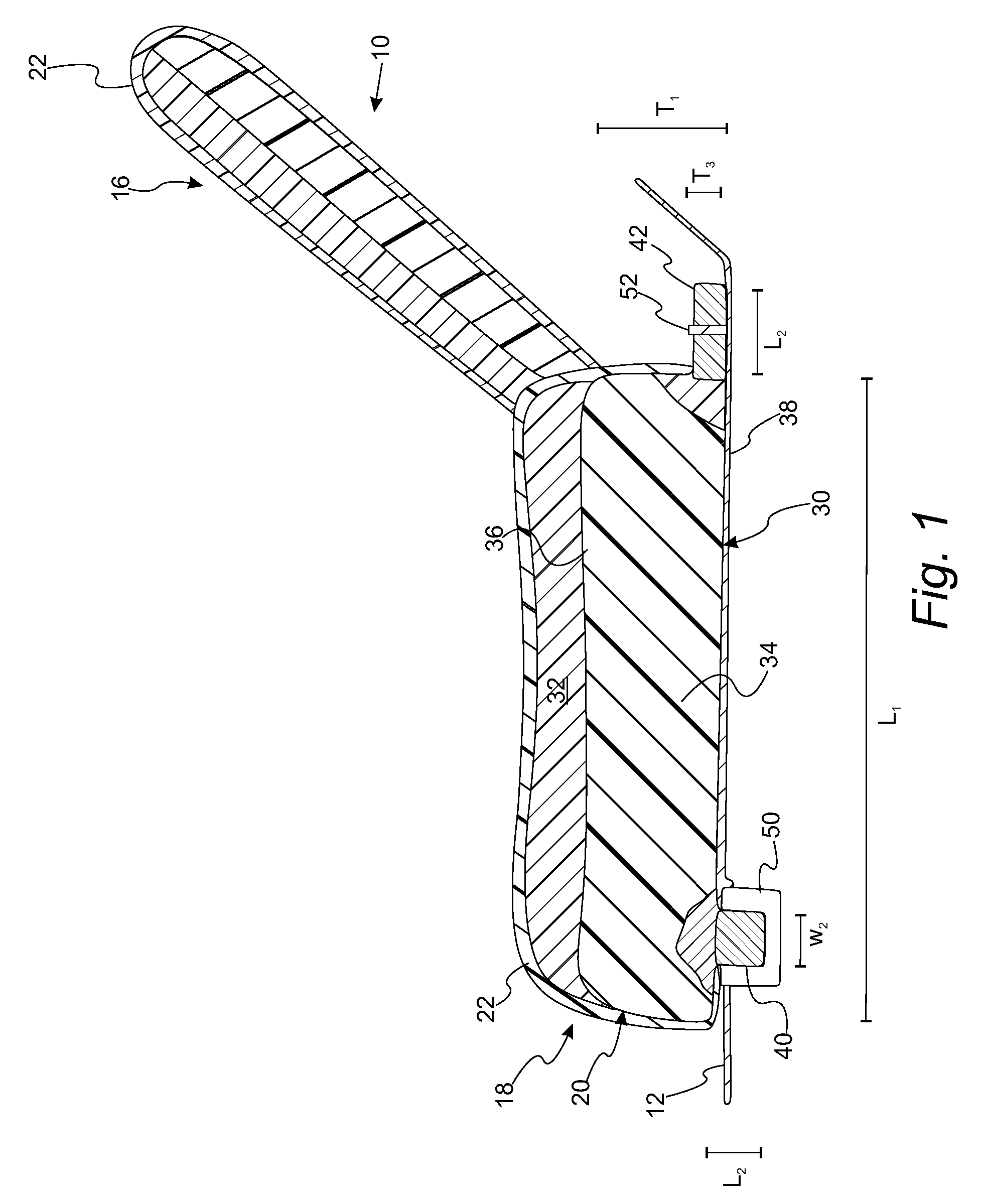

Seating system and method for making same

InactiveUS6997515B2Easy to manufactureWeight increaseSafety beltsPedestrian/occupant safety arrangementEngineeringBack rests

An improved seating system that includes a seat back assembly (10) that is fabricated to include a seat back (12) with first and second wall portions (14,16), and which may include an integrated reinforcement structure (18). The seating system is capable of either or both of withstanding without rupture at least about 11000 Newtons in the direction in which the seat back (12) faces in a plane, parallel to the longitudinal centerline of the vehicle or, upon rapid acceleration up to at least about 20 g, substantially no fragmentation of the seat back with at least a 30 kg mass placed behind the seat back.

Owner:TRINSEO EURO GMBH

Method of manufacturing a backrest structure for a vehicle seat and backrest structure obtained by this method

InactiveUS6352311B1Promote absorptionLow costMetal-working apparatusSeat framesEngineeringMechanical engineering

A backrest structure for a vehicle seat comprises two hydroformed, tubular, horizontal crosspieces and vertical uprights engaged without any clearance in orifices punched into these crosspieces during hydroforming.

Owner:BERTRAND FAURE EQUIP SA (FR)

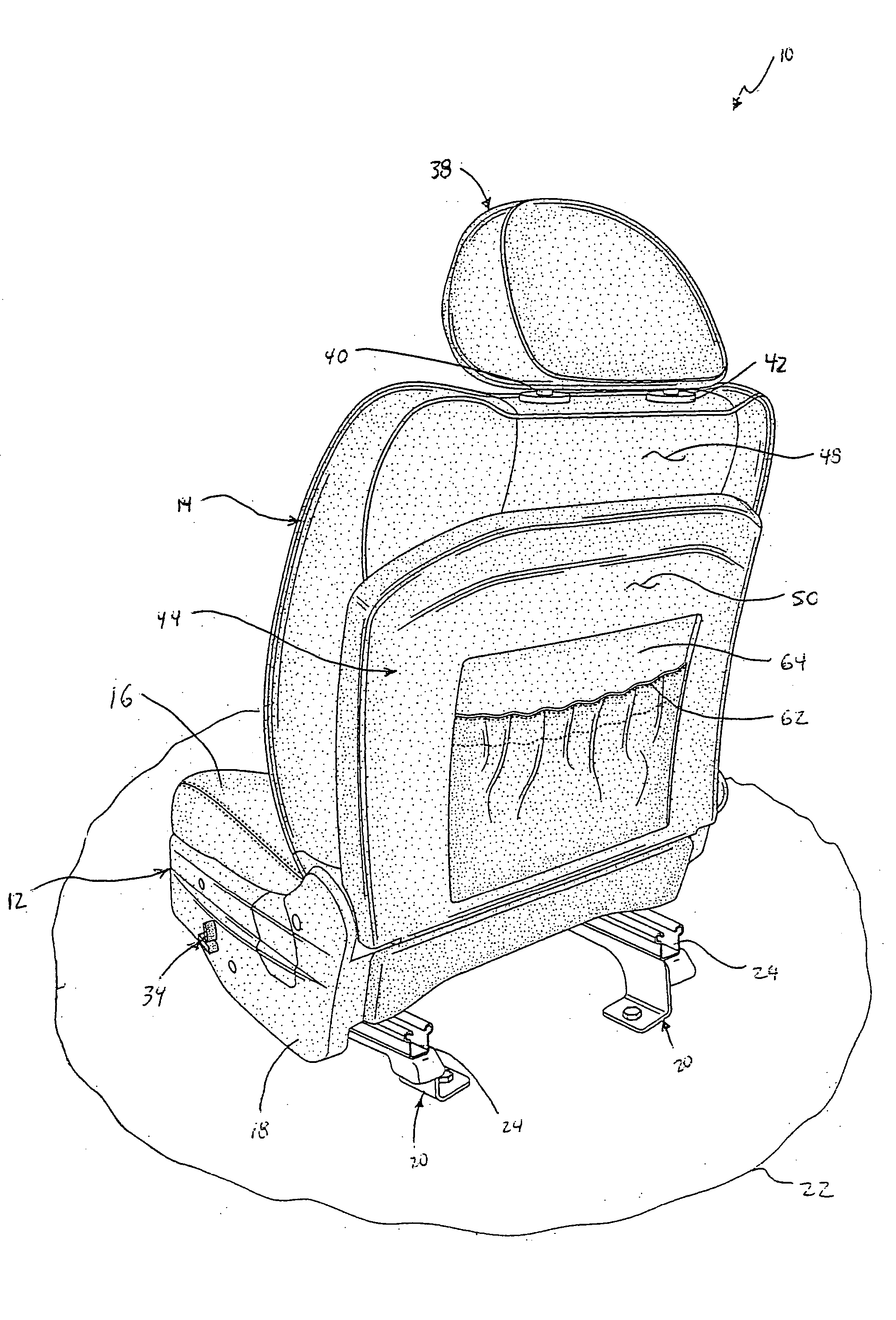

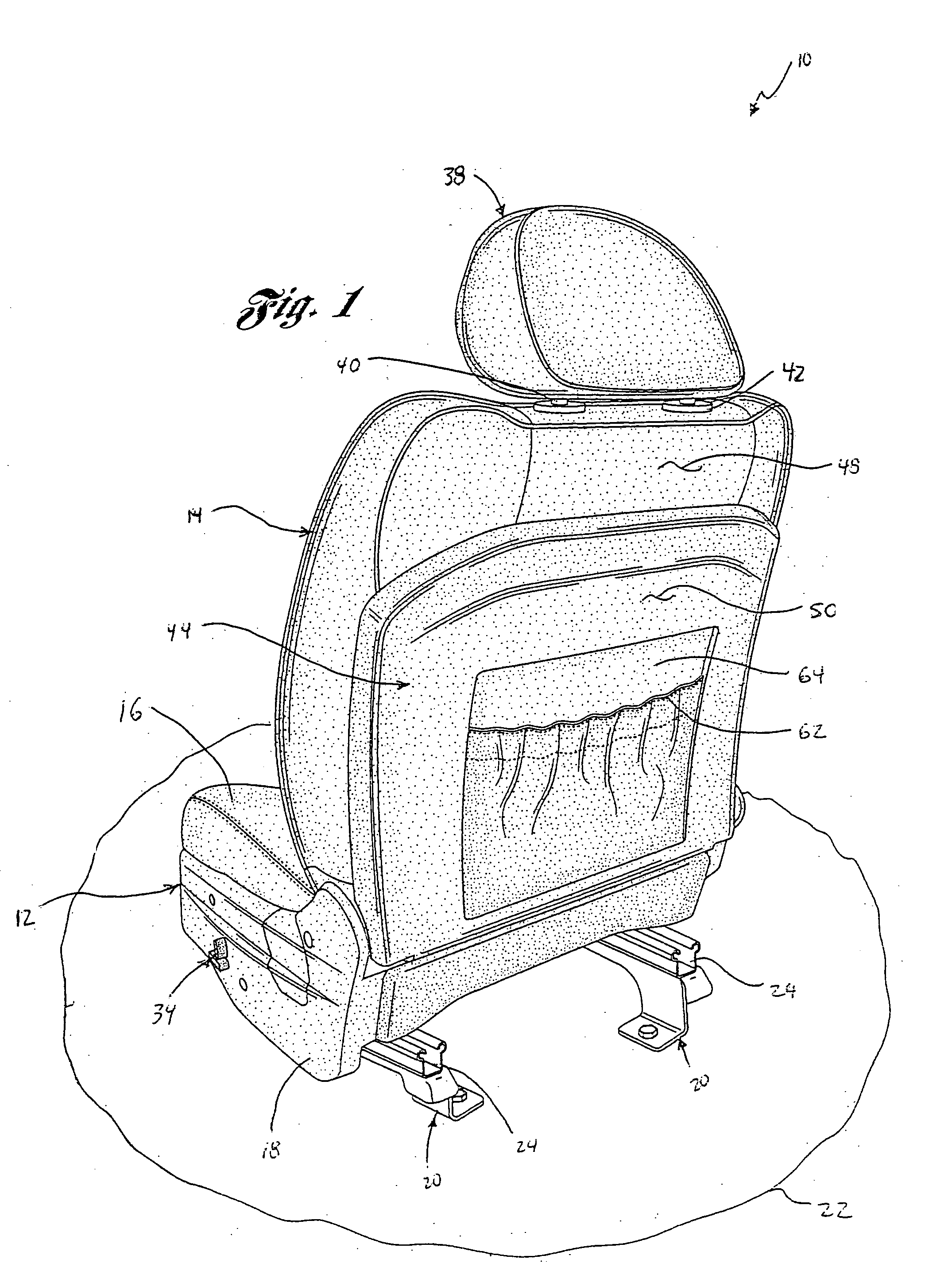

Vehicle seat incorporating a seat back panel

A vehicle seat includes a seat bottom and a seat back including a frame connected to the seat bottom. The seat back includes a front surface configured to support an occupant and a rear surface. A seat back panel securable to the seat back frame includes an outer appearance surface and a retainer structure disposed on an inner surface. The retainer structure is releasably secured to the seat back frame such that the seat back panel at least partially covers an opening in the rear surface of the seat back.

Owner:LEAR CORP

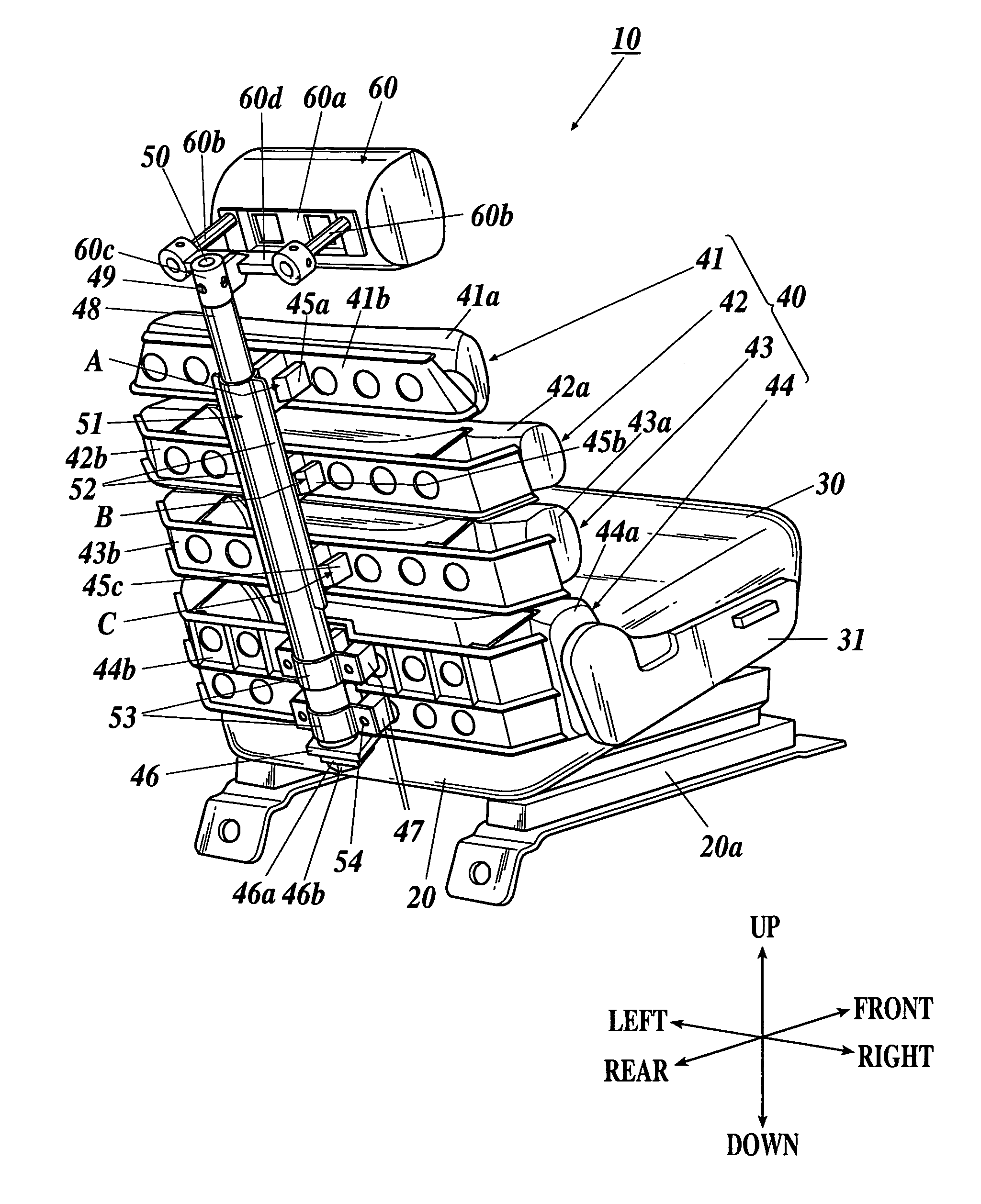

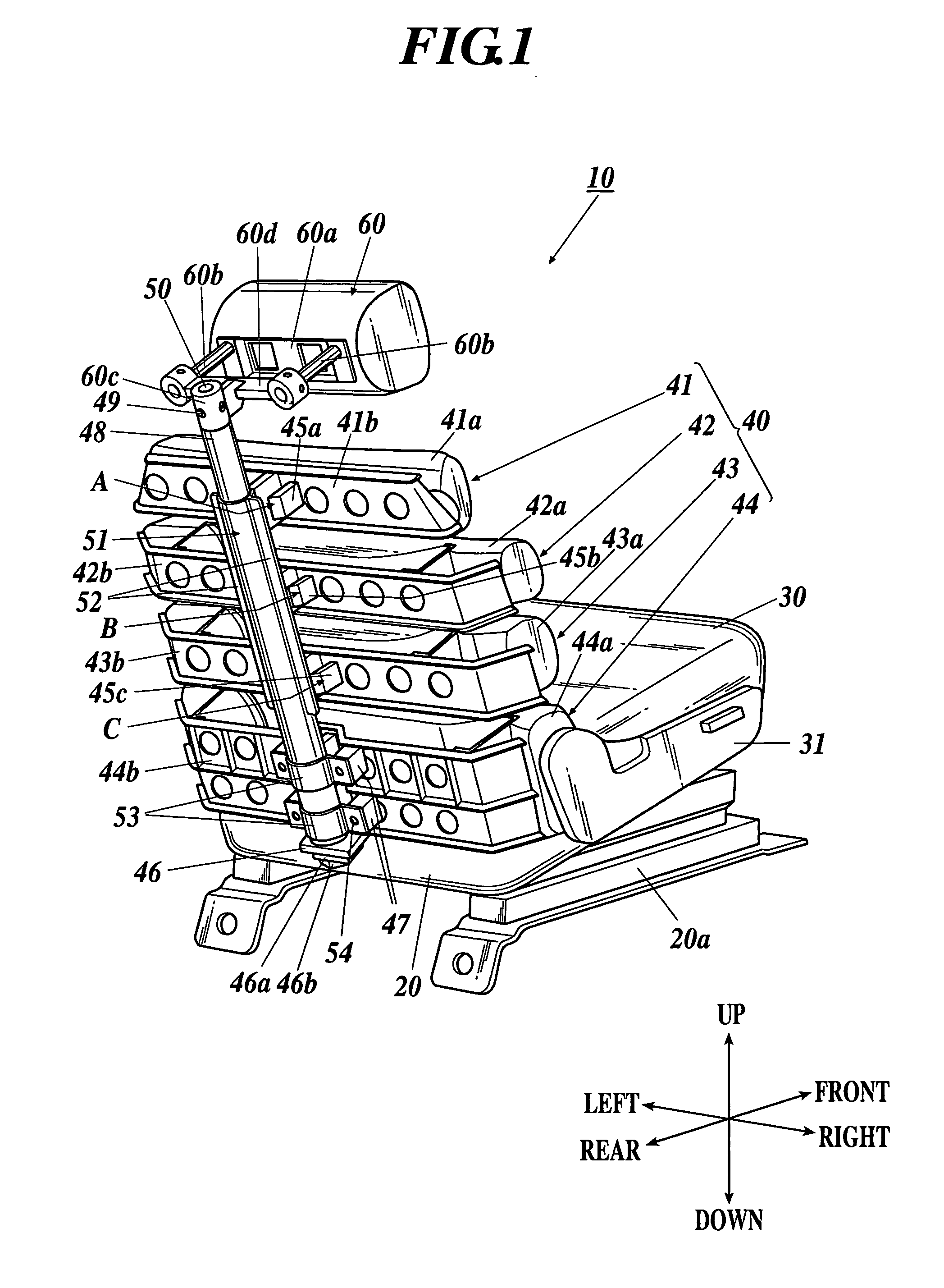

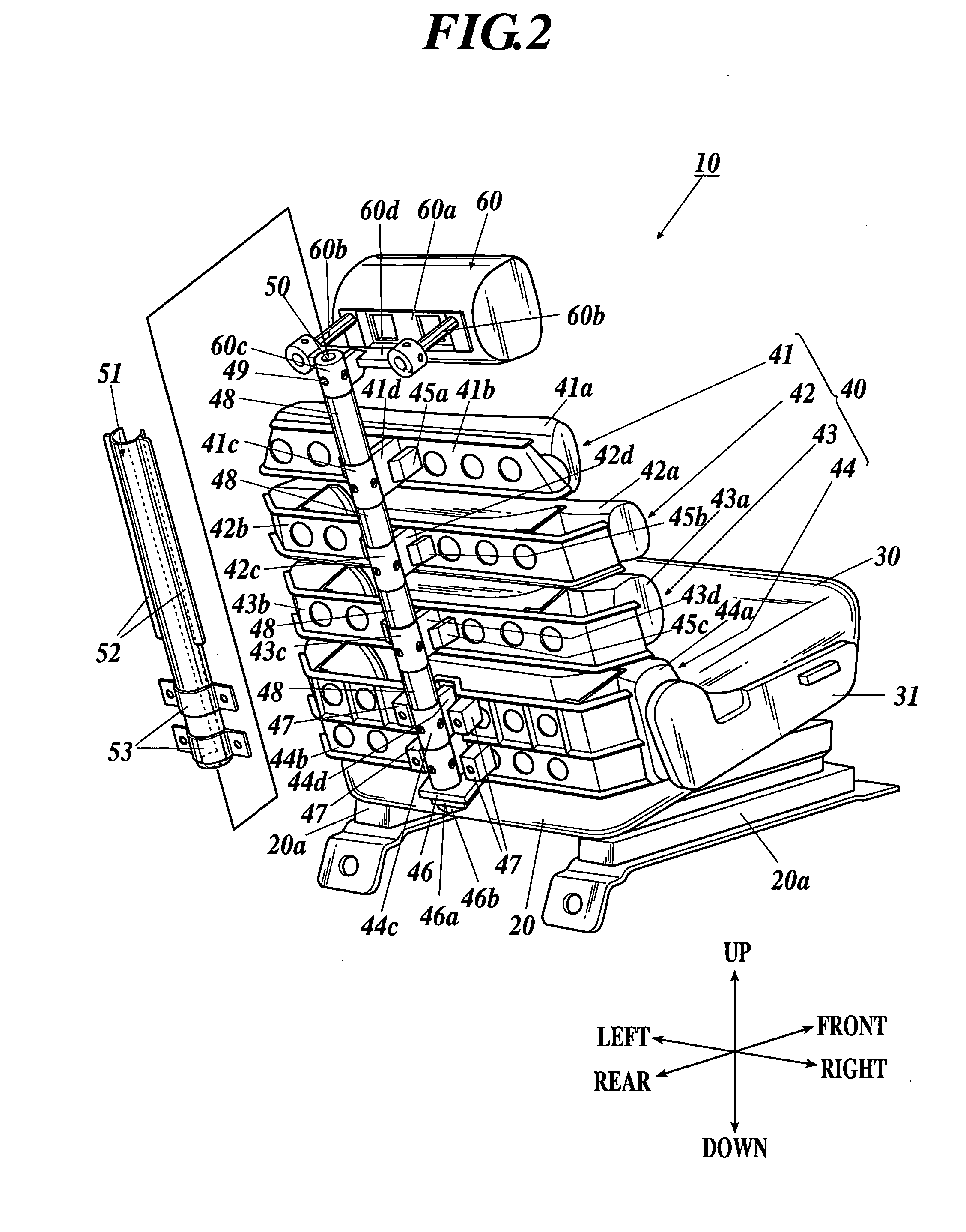

Modular energy absorber and method for configuring same

A modular energy absorber 10 that is tunable. It comprises one or more energy absorbing modules 12. The energy absorbing modules have means for coordinating energy absorbing units 16 of the one or more modules. The means 14 for coordinating position and support the units in relation to each other before, during and after relative motion between an incident object and the energy absorber. A crushable member is provided that has an upper perimeter, a lower perimeter and an intermediate section extending therebetween. It also includes a number (m) of breaches defined therein before impact.A method for configuring the modular energy absorber is also disclosed.

Owner:OAKWOOD ENERGY MANAGEMENT

Seat back adjustment mechanism

Owner:ADIENT LUXEMBOURG HLDG SARL

Seat back frame structure of a vehicle seat

A structure of seat back frame for use in a seat back of a vehicle seat, which includes a lateral frame section connected with upper and lower frame sections to comprise the seat back frame. The lower end portion of such seat-back lateral frame section has been cut to provide a reduced lower end area therein. On the other hand, a connecting bracket member is provided, which has an upper end portion with a slant edge and also has a large thickness relative to that of the lateral frame section. In the present structure, the connecting bracket member is fixedly connected, at that upper end portion thereof, to the reduced lower end area of lateral frame section, in such a manner that the slant edge thereof extends in a downwardly inclined way as it proceeds toward a forward side of the seat back, i.e. a running direction of a vehicle.

Owner:TACHI S CO LTD

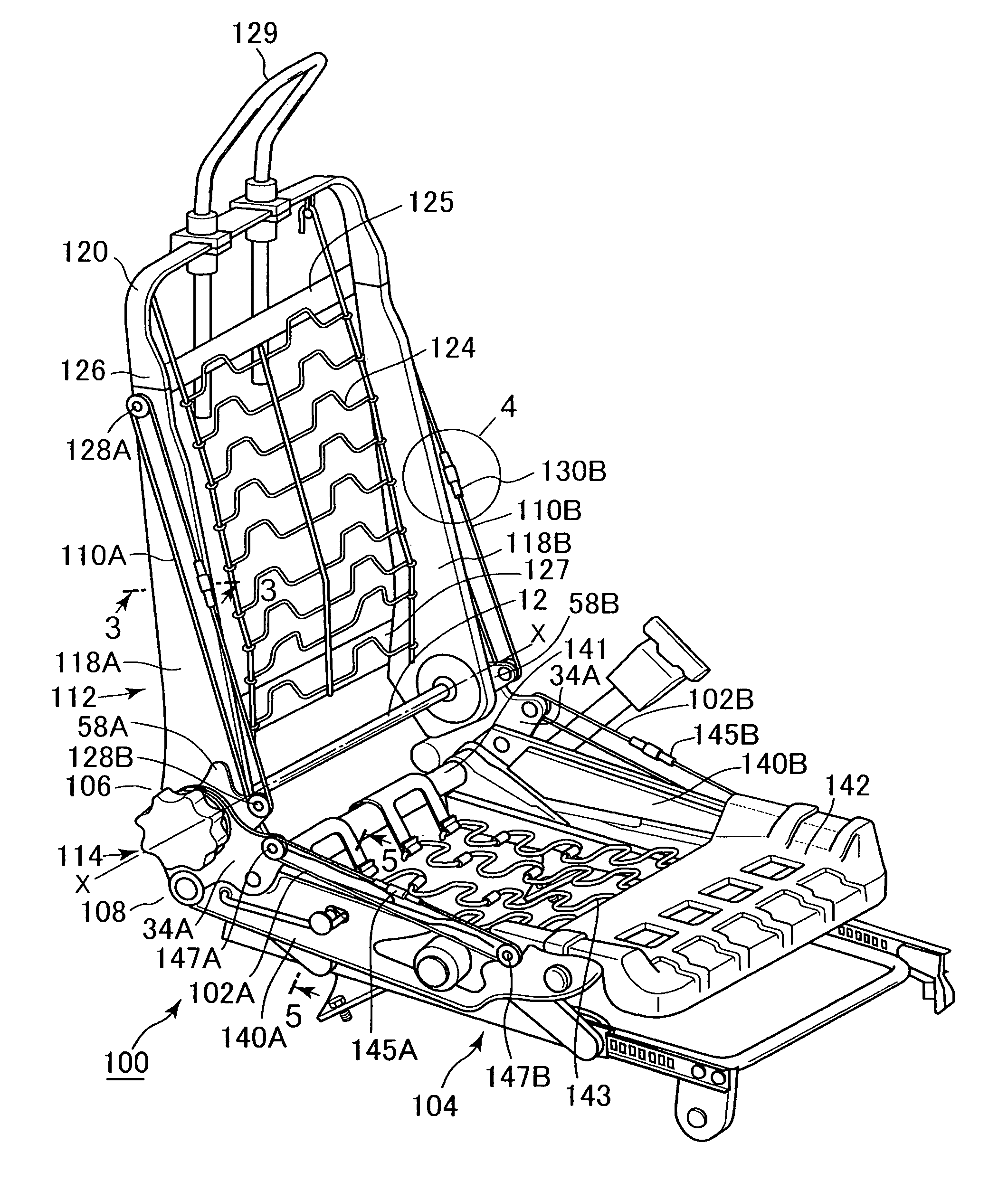

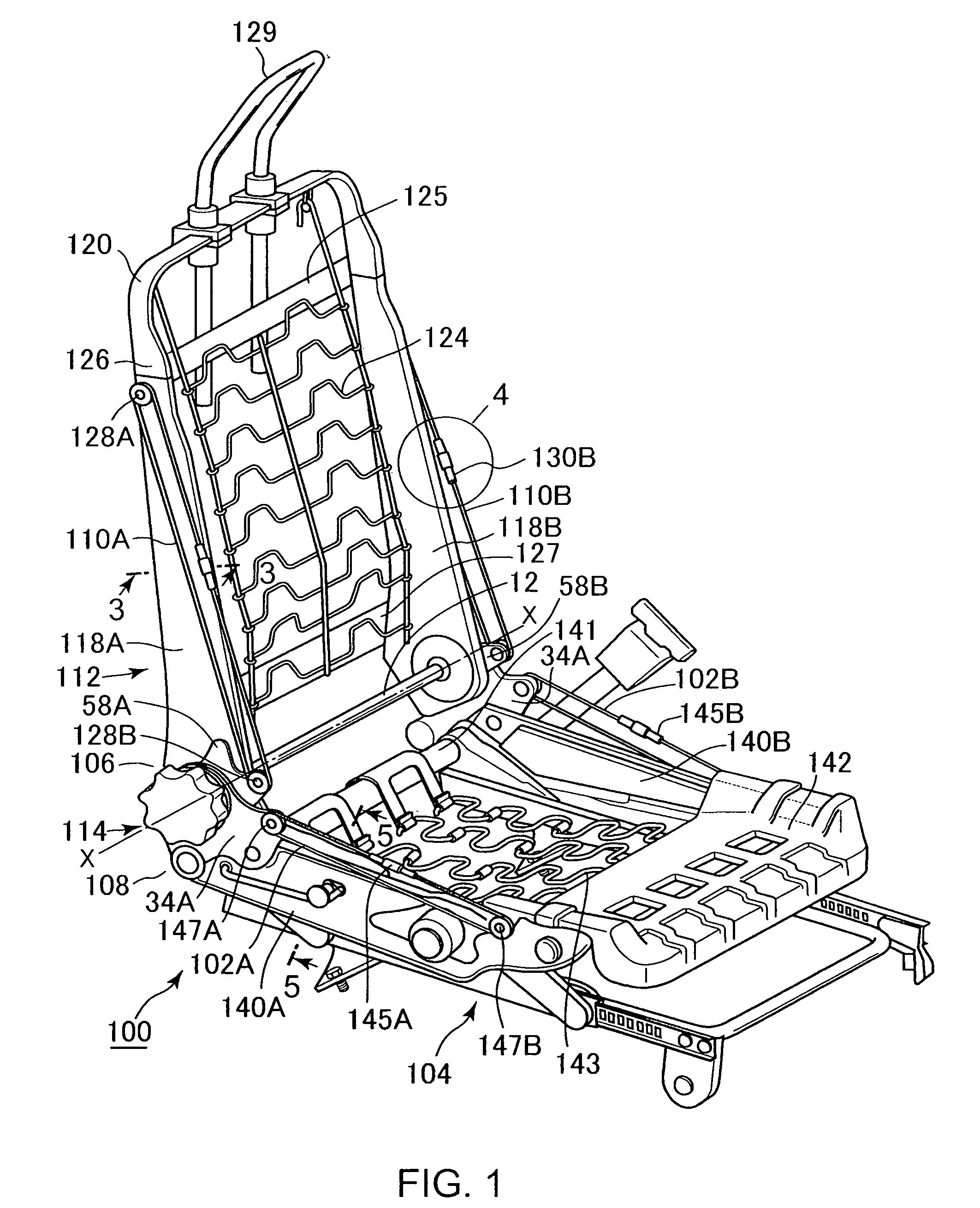

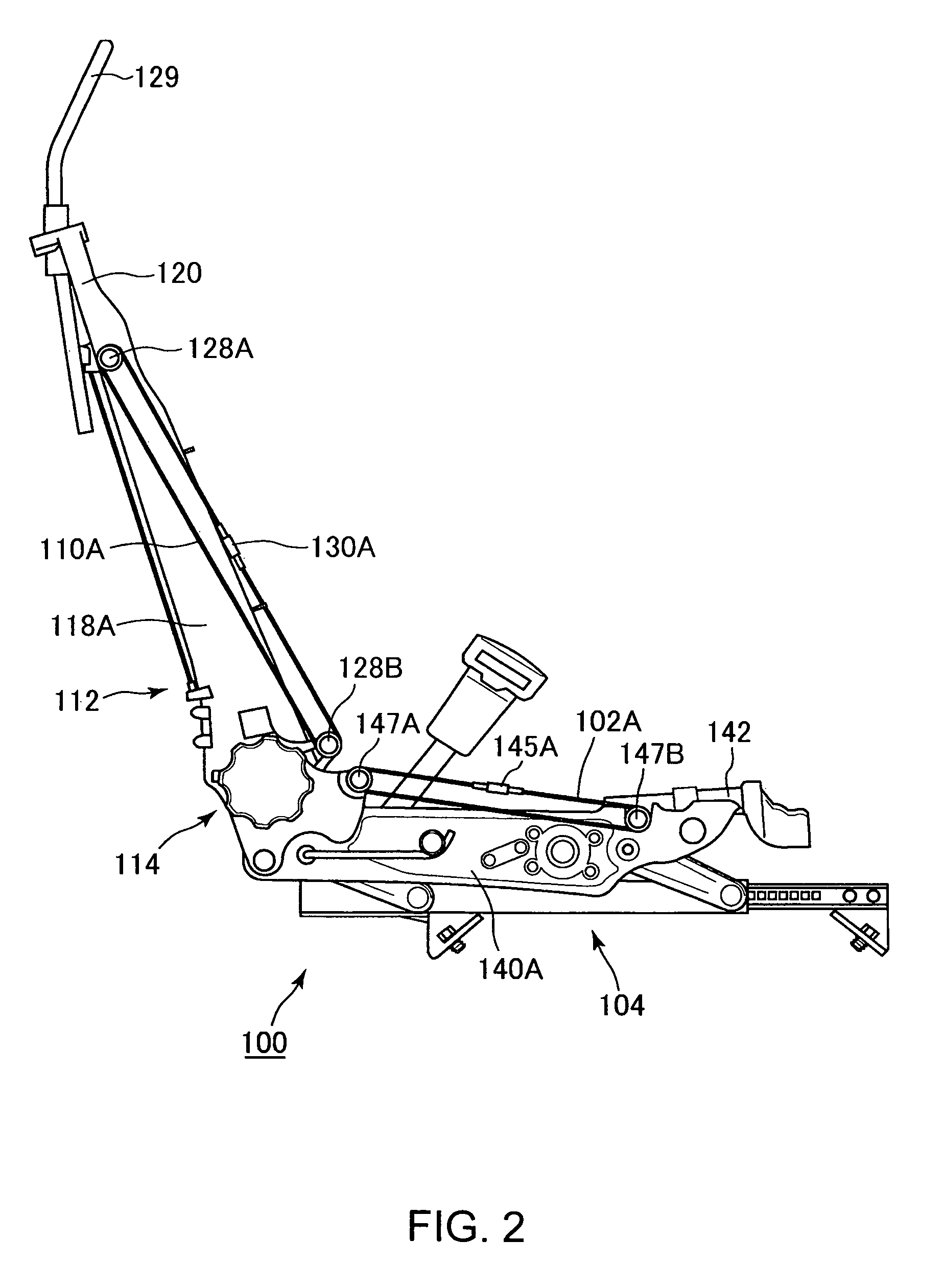

Seat adjustment device, and vehicle seat device with the seat adjustment device

InactiveUS8899683B2Increasing the thicknessHigh strengthOperating chairsSeat framesLine of actionEngineering

A seat adjustment device adjusts the pivoting angle formed by a first seat member and a second seat member. A hinge shaft connects at a first connection point, the first seat member, and the second seat member. An arm section and a connection mechanism are connected at a second connection point. The positions of the axes of the first connection point, the second connection point, and a pivoting section are set in such a manner that, when a load is applied to the front end of either the first seat member or the second seat member, the distance from the second connection point to the axis of the pivoting section is less than the distance from the first connection point to the second connection point with respect to the direction perpendicular to the line of action of a load applied to the second connection point.

Owner:AISIN SEIKI KK

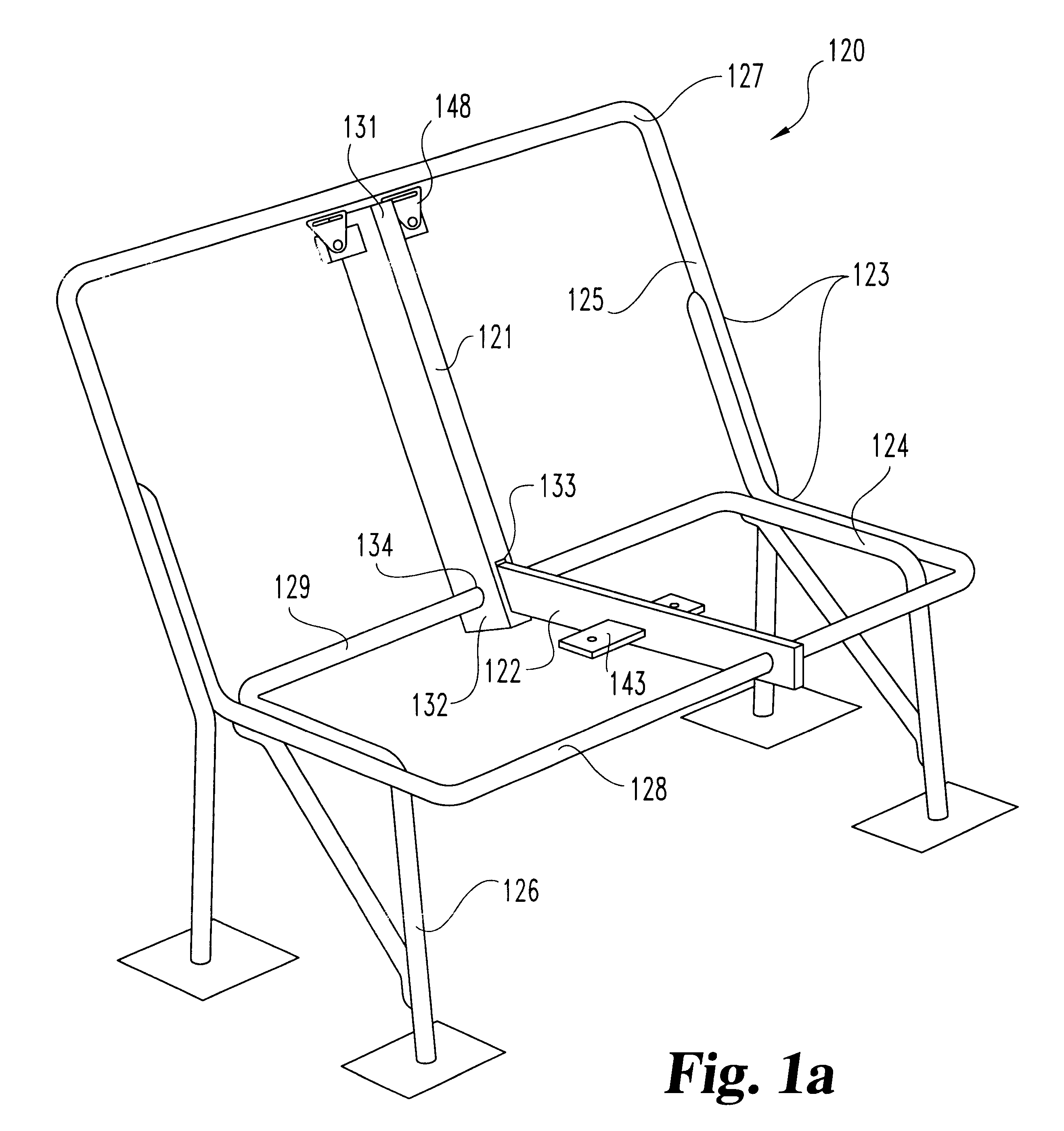

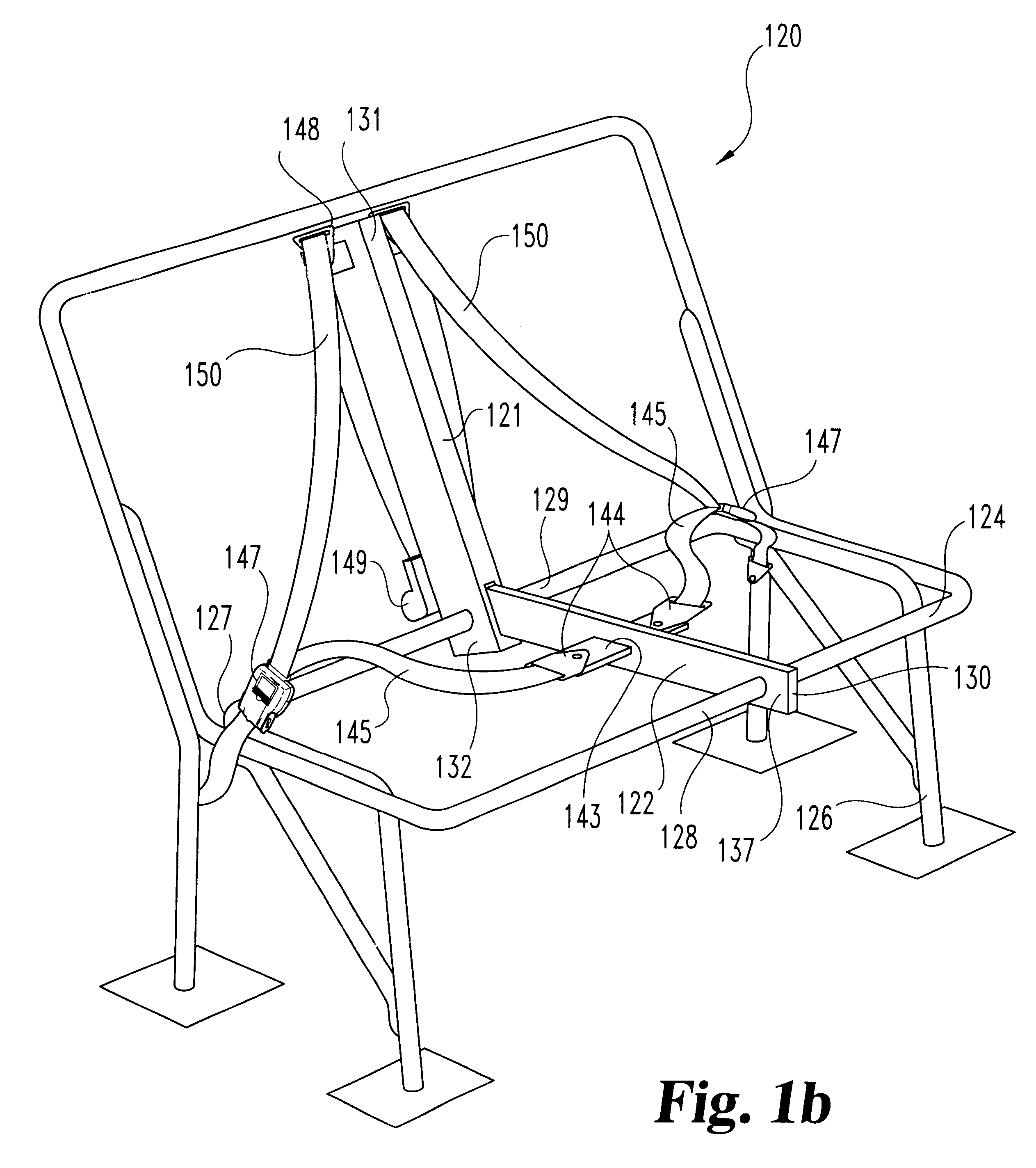

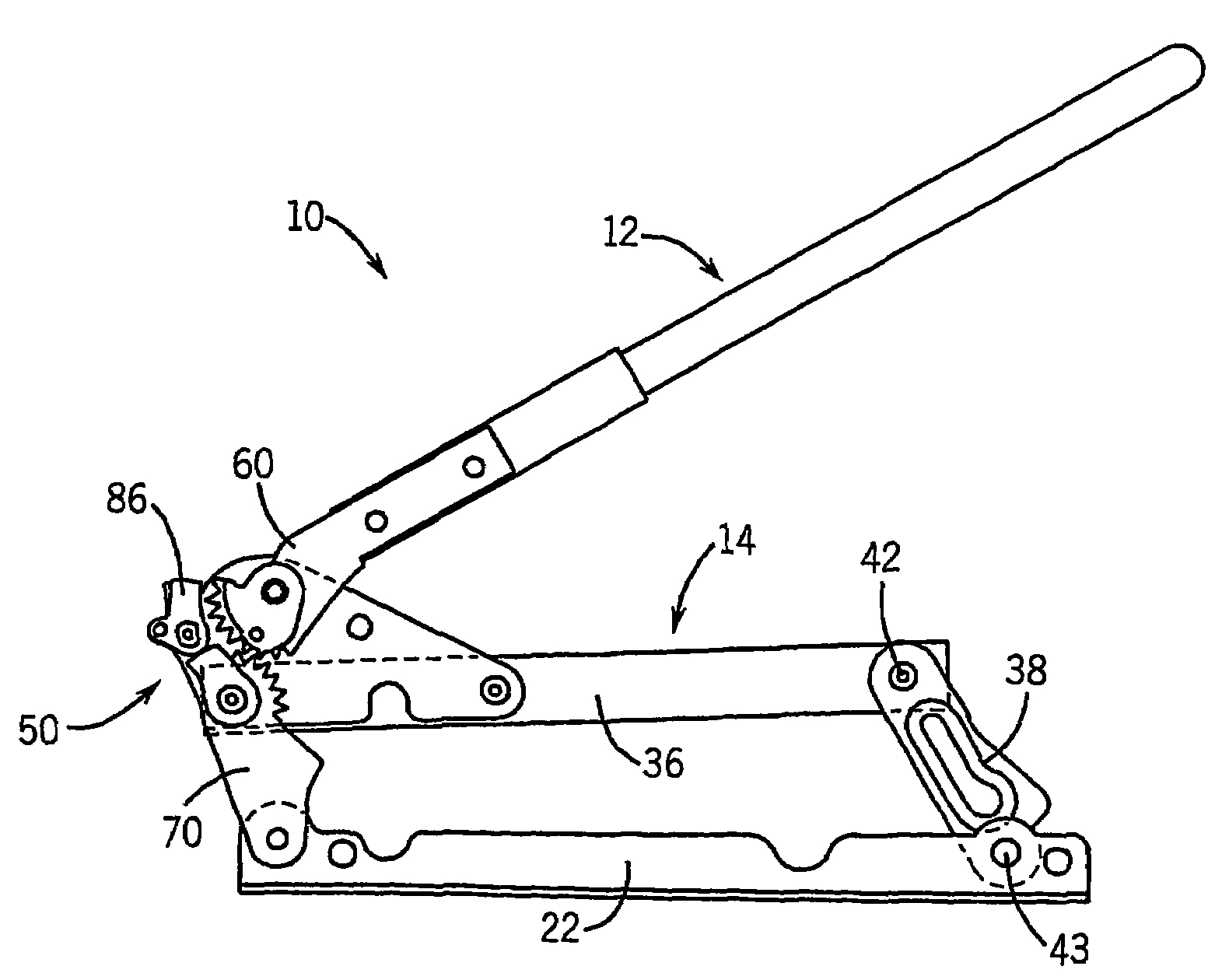

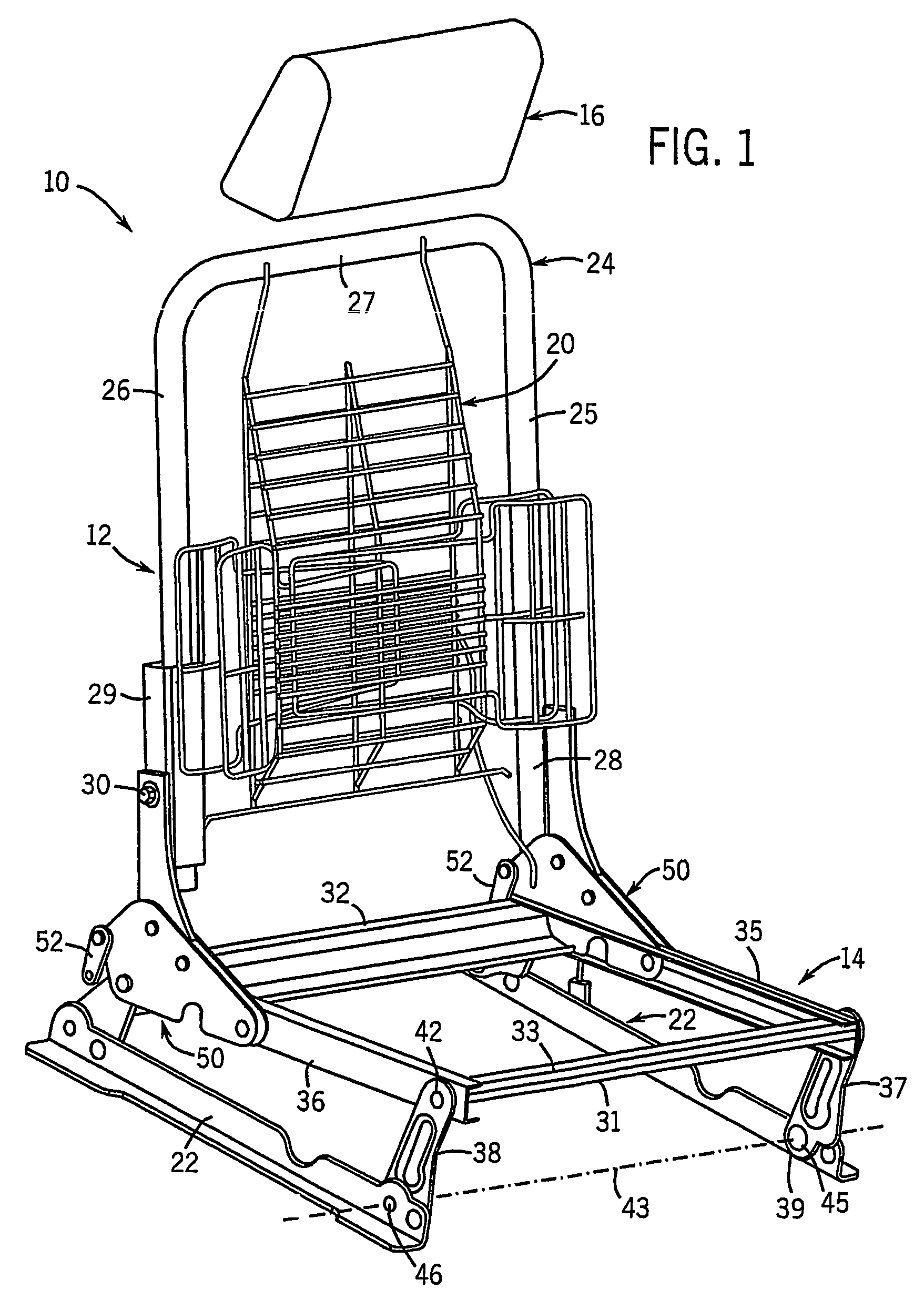

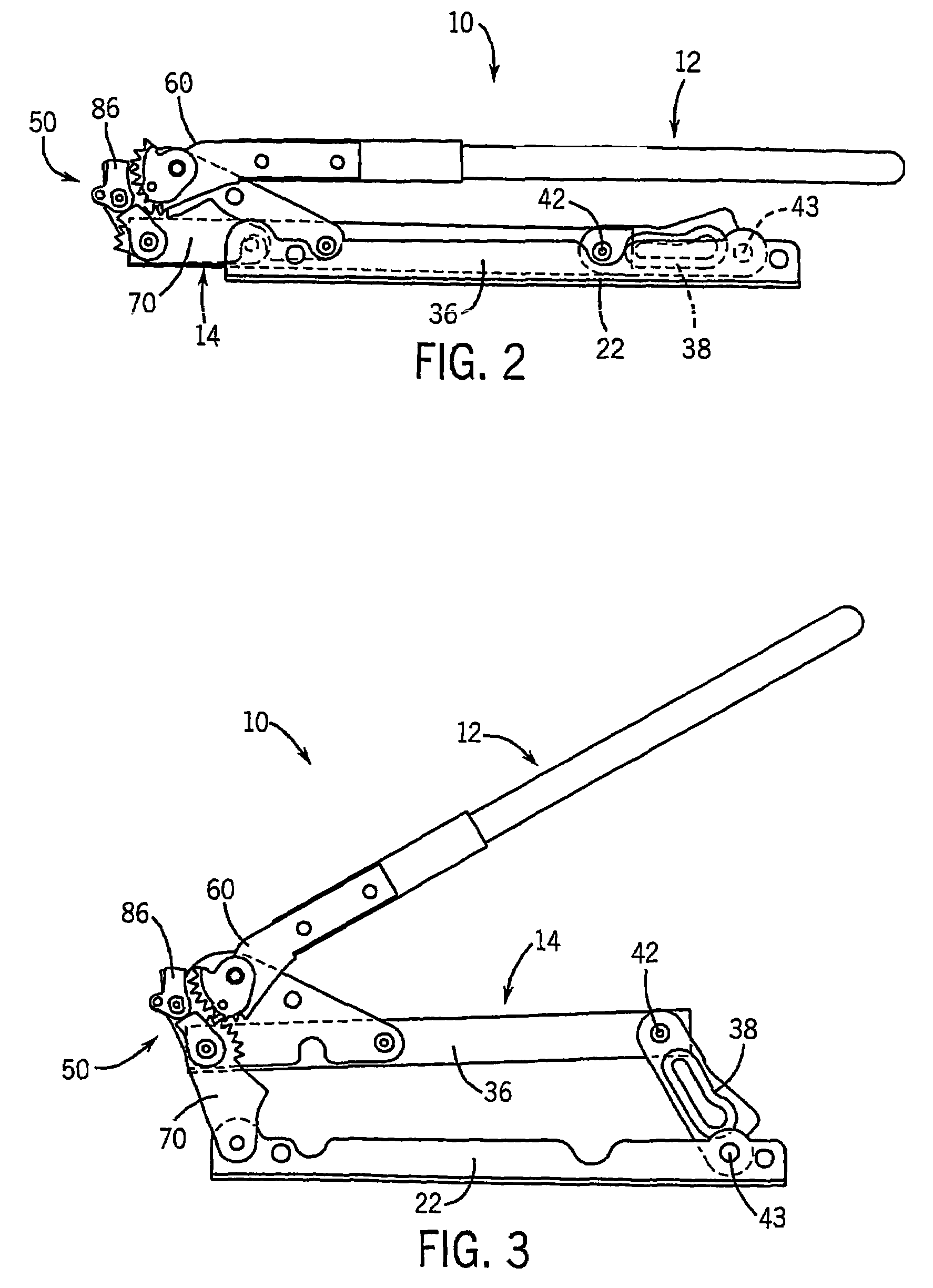

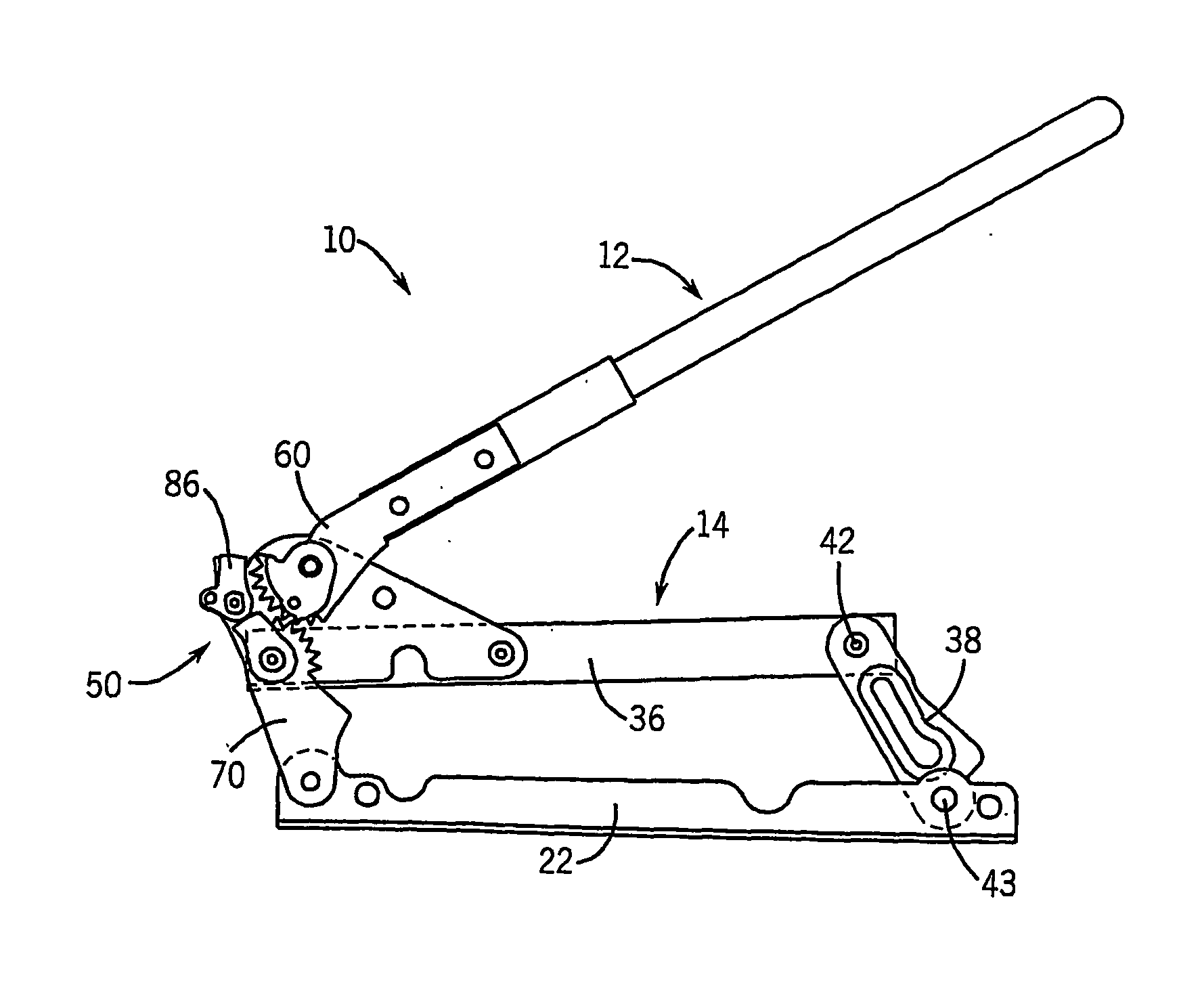

Thin profile folding vehicle seat

An ultra compact, easy to operate folding vehicle seat includes a seat back, seat base and support leg members and is movable between a stow position and a design position. The folding vehicle seat includes a folding mechanism having an upper member for connection to the seat back and a lower member for supporting the seat base; the upper and lower members of the folding mechanism include integrated teeth aligned in meshing relationship such that movement of the seat back causes the lower member to rotate and lift the seat base to move the folding vehicle seat to a design position. A pair of upper cams are provided for selective engagement with the upper member and a third cam tab of the lower member of the folding mechanism.

Owner:INTIER AUTOMOTIVE INC +1

Structural organosheet-component

The present invention relates to structural organosheet-components of hybrid design composed of an organosheet which is reinforced by means of thermoplastics and which is suitable for the transmission of high mechanical loads, where particular flow aids are added to the thermoplastic in order to improve its physical properties.

Owner:LANXESS DEUTDCHLAND GMBH

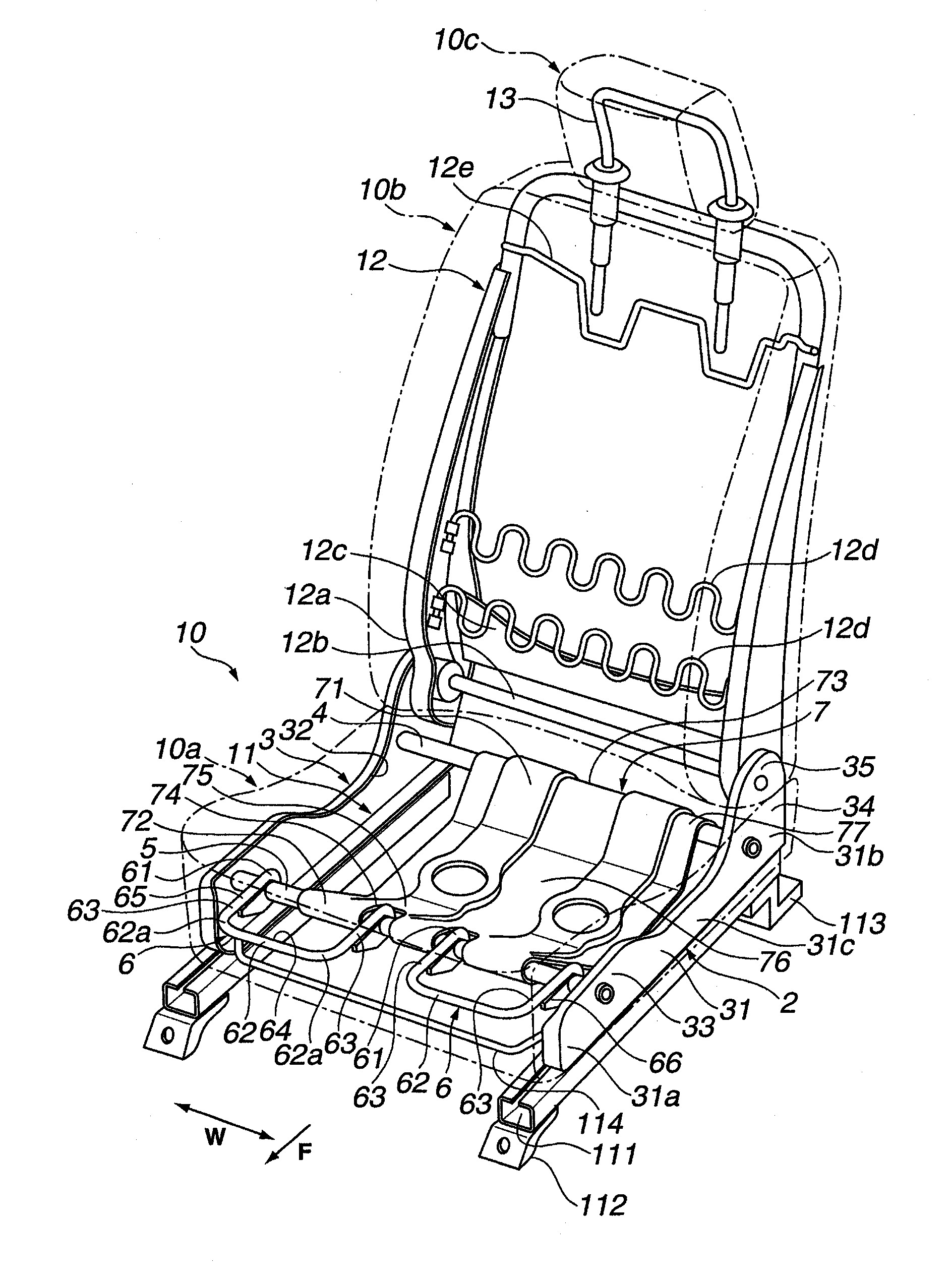

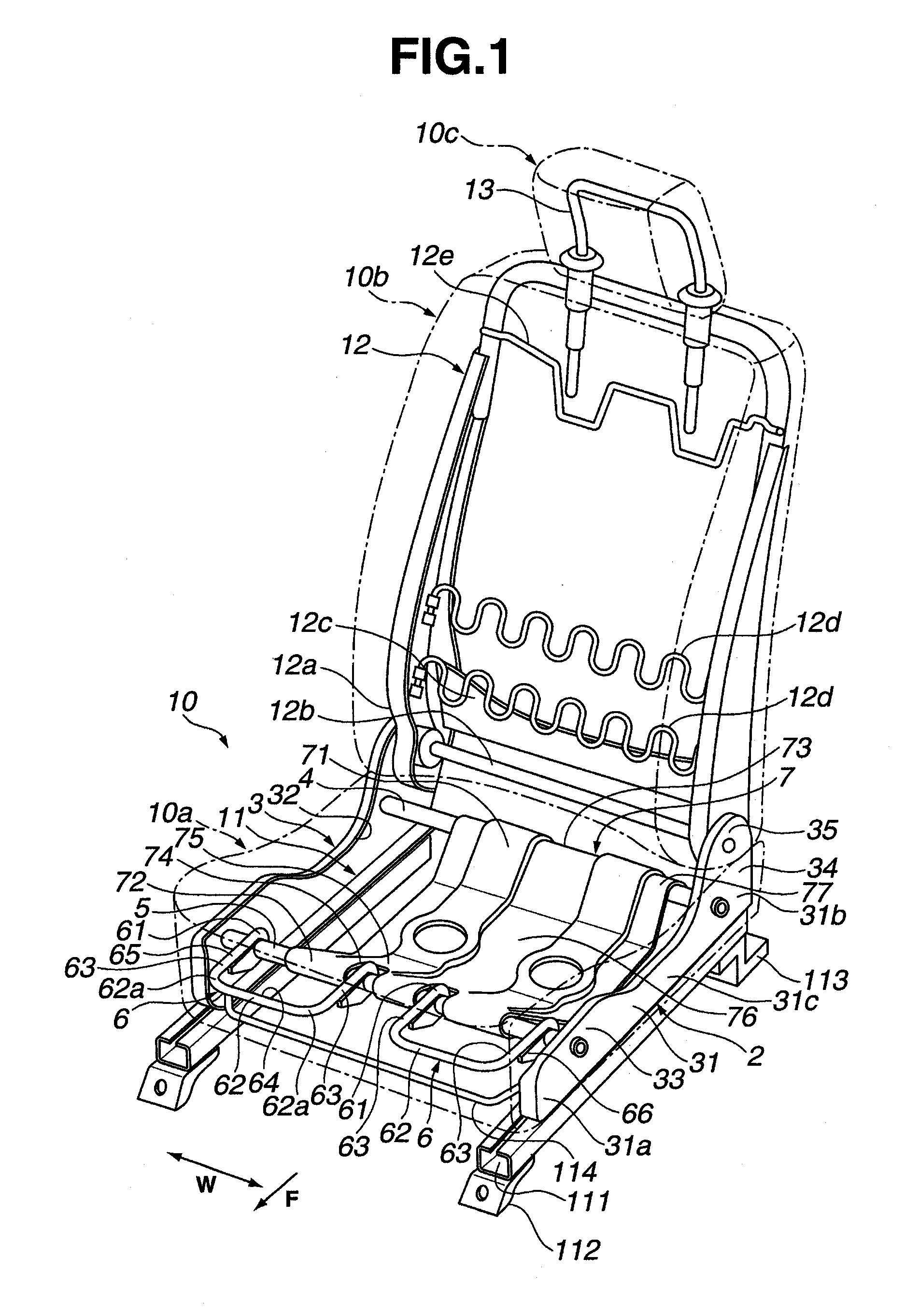

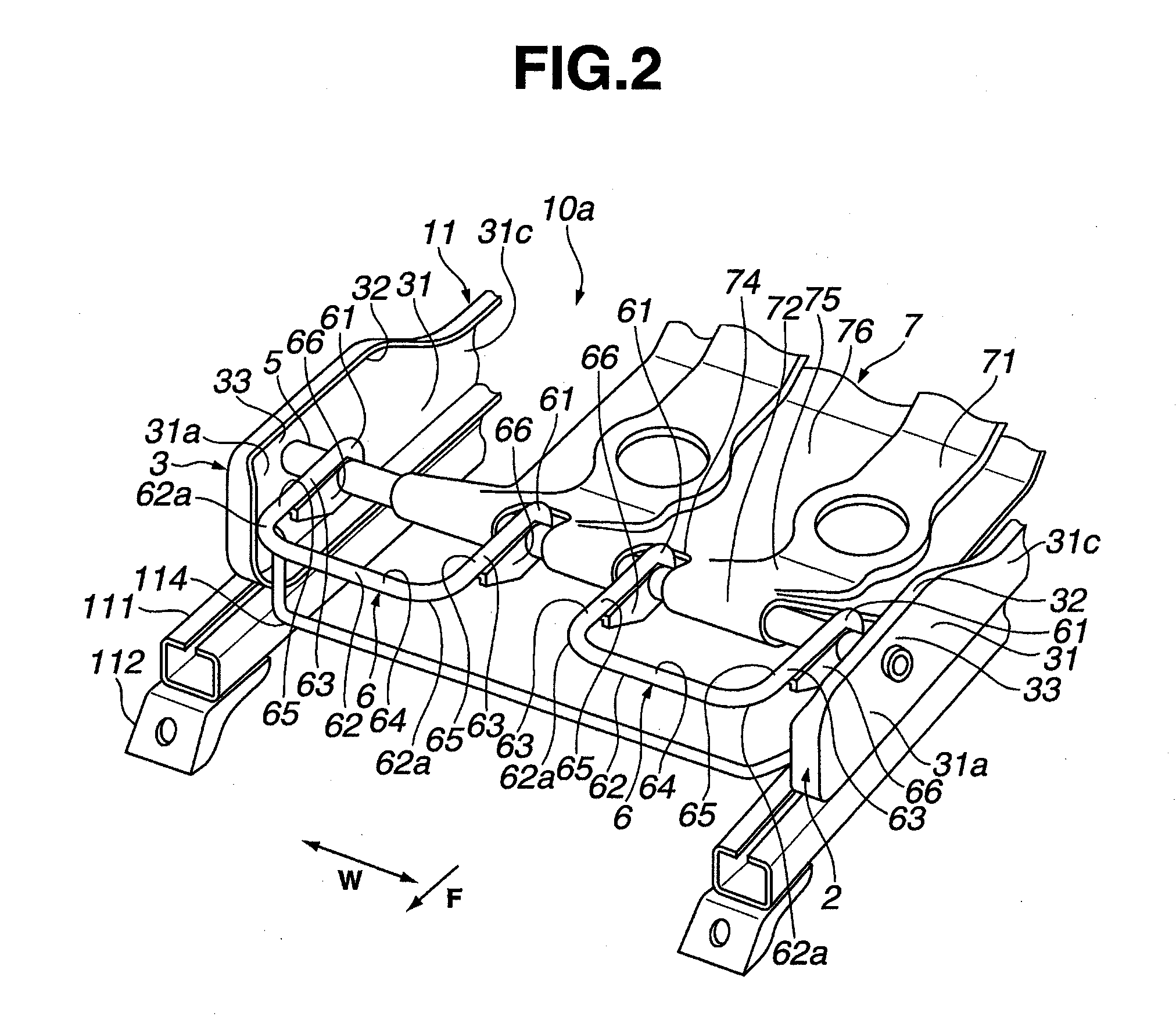

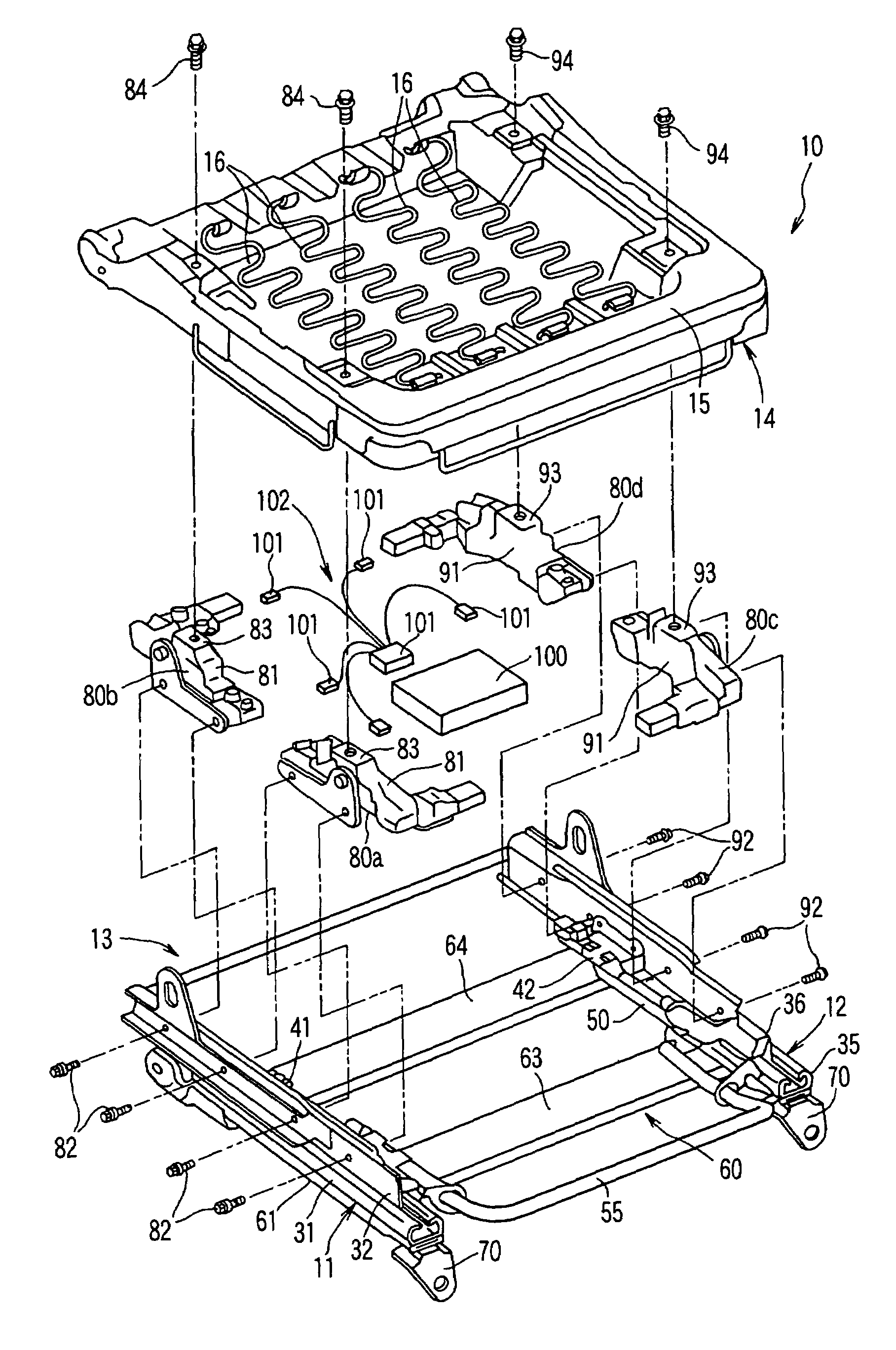

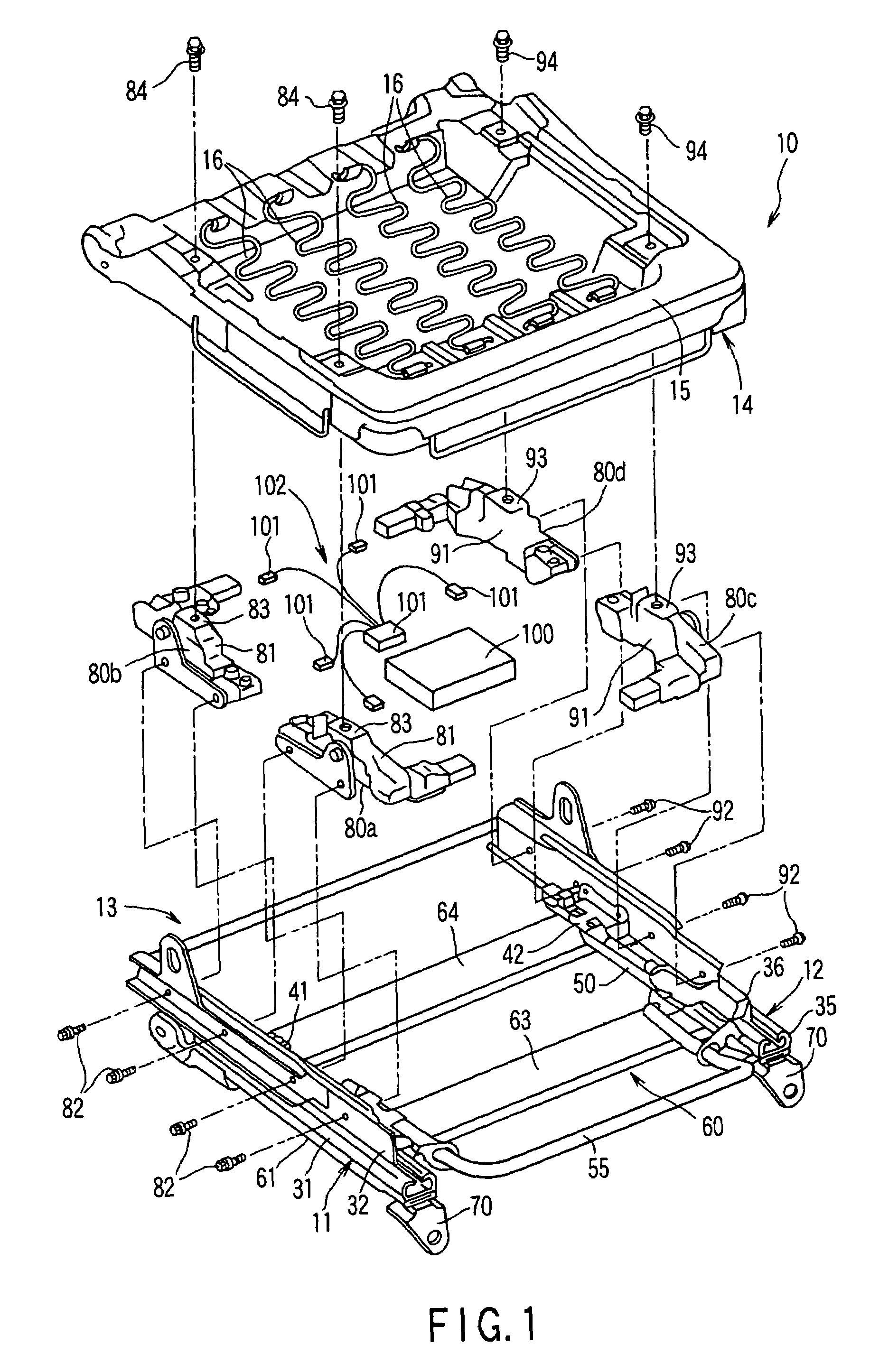

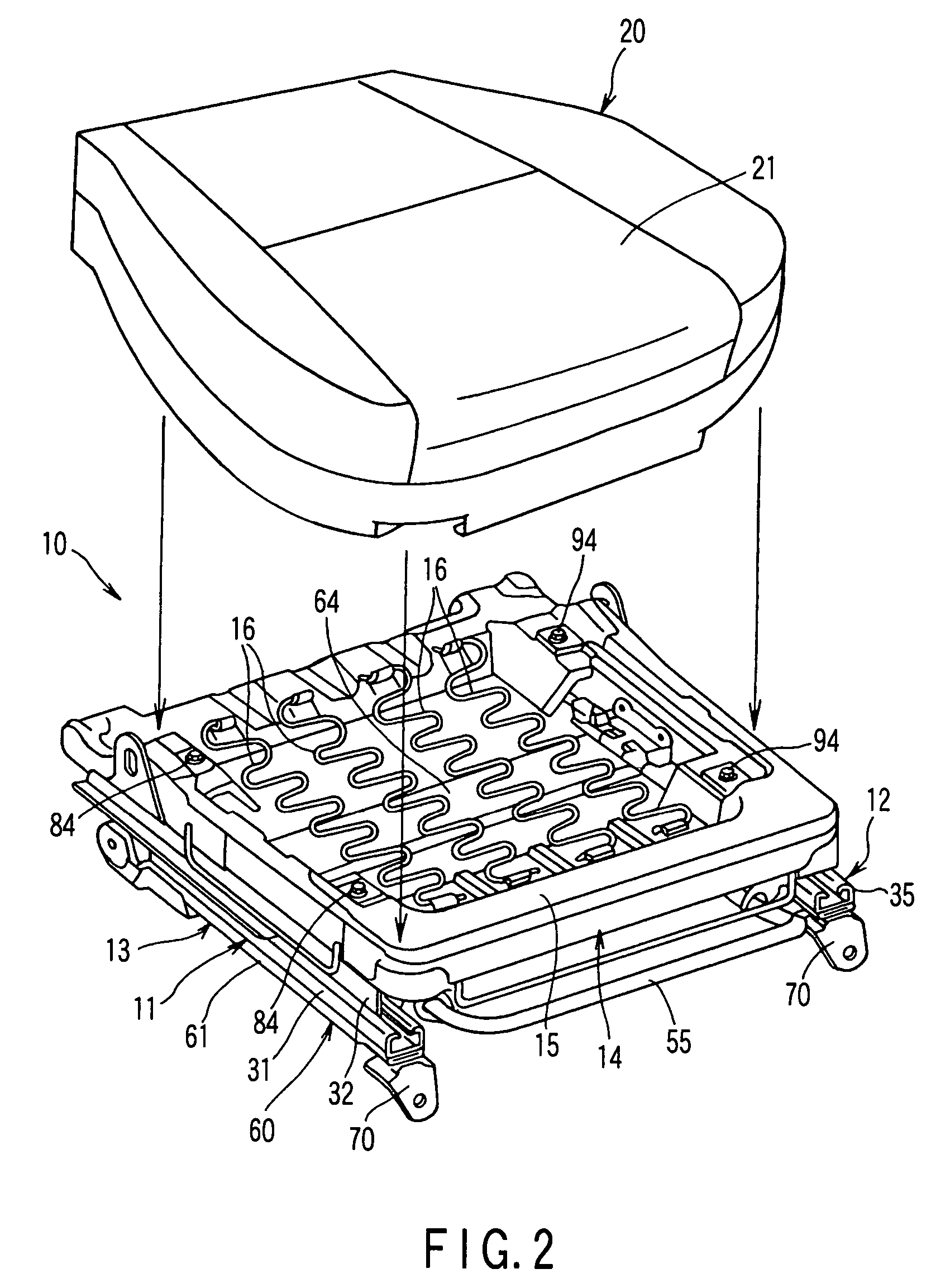

Seat cushion frame structure of seat for vehicle and seat for vehicle with seat cushion frame structure

InactiveUS8371655B2Reduce weightLow costPedestrian/occupant safety arrangementSeat framesEngineeringCushion

A seat cushion frame structure of a seat for a vehicle has a seat cushion frame structure, a rear end of which is connected to a lower end of a seat back frame structure in such a way that the seat back frame structure can be inclined relative to the seat cushion frame structure, the seat cushion frame structure includes a pair of side frames, each of which extends in a longitudinal direction of the vehicle, and an oblique wire on at least one of the pair of side frames, an upper end of which is fixed to a side portion of the at least one of pair of side frames and a lower end of which is fixed to the seat cushion frame structure at a position forward of the upper end.

Owner:NHK SPRING CO LTD

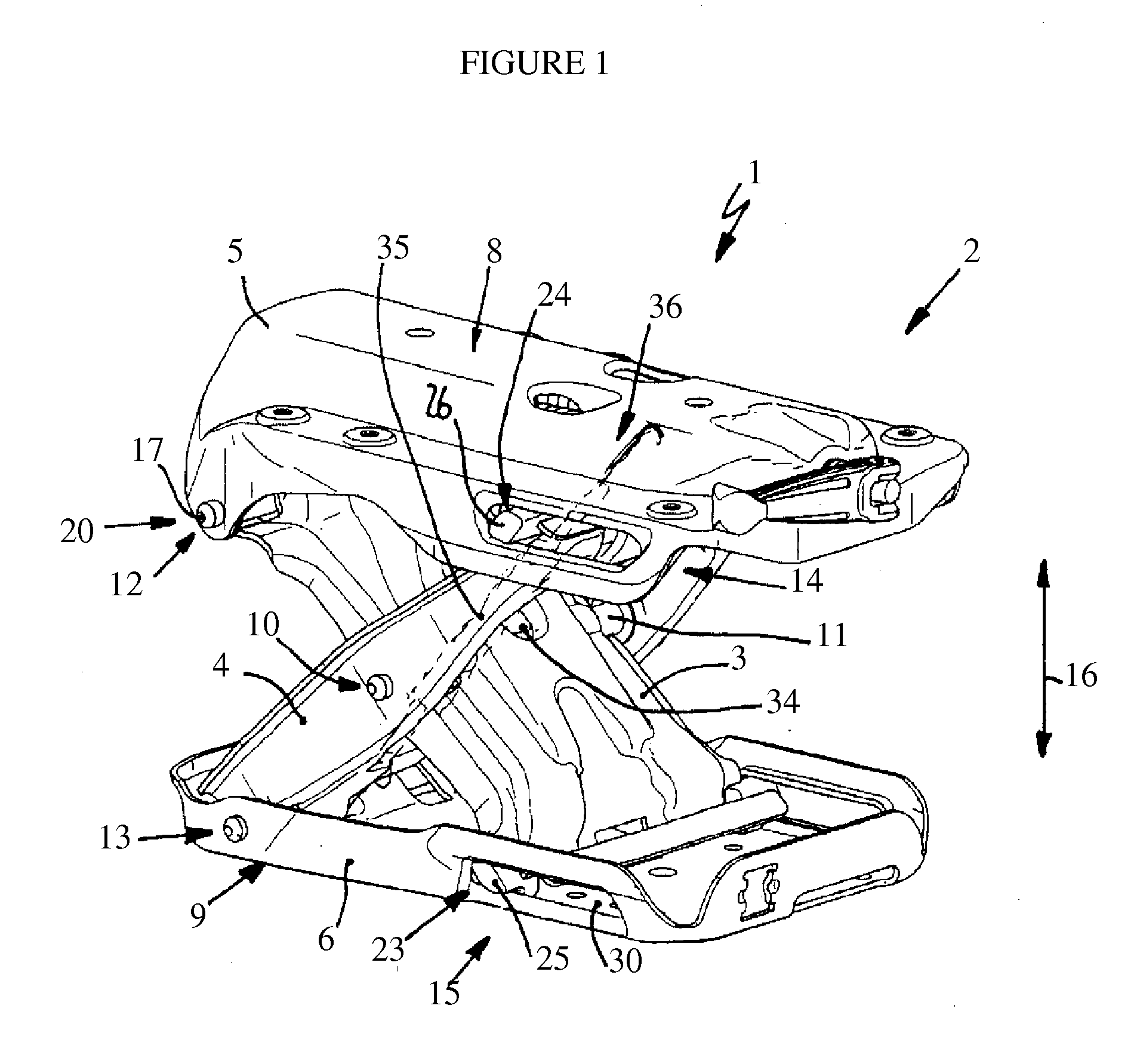

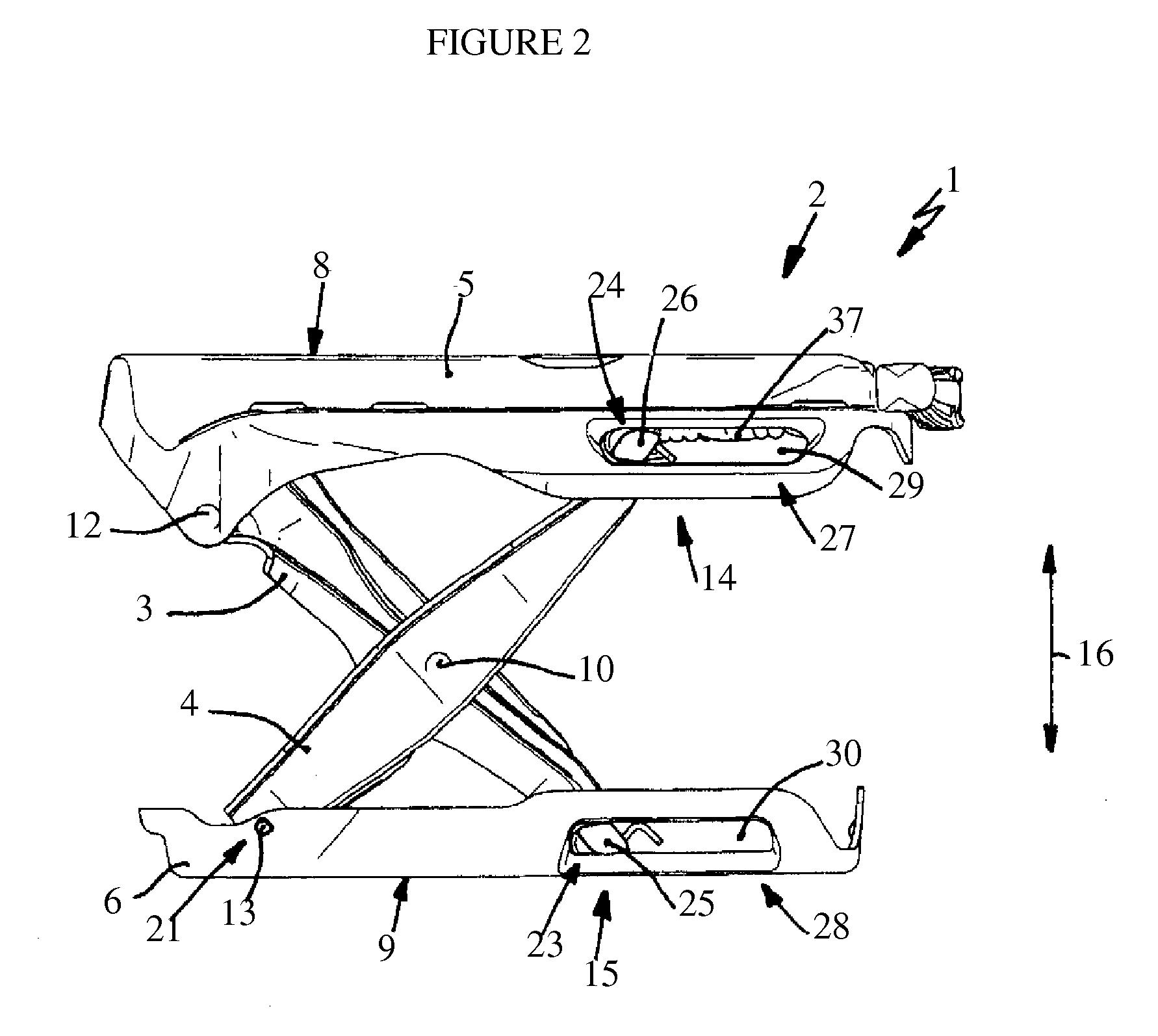

Scissors-type frame for a vehicle seat and method for producing a substructure of a vehicle seat

ActiveUS20100117428A1Speed up preparationEasily and quickly producedSeat framesStands/trestlesMobile vehicleEngineering

Owner:GRAMMER AG

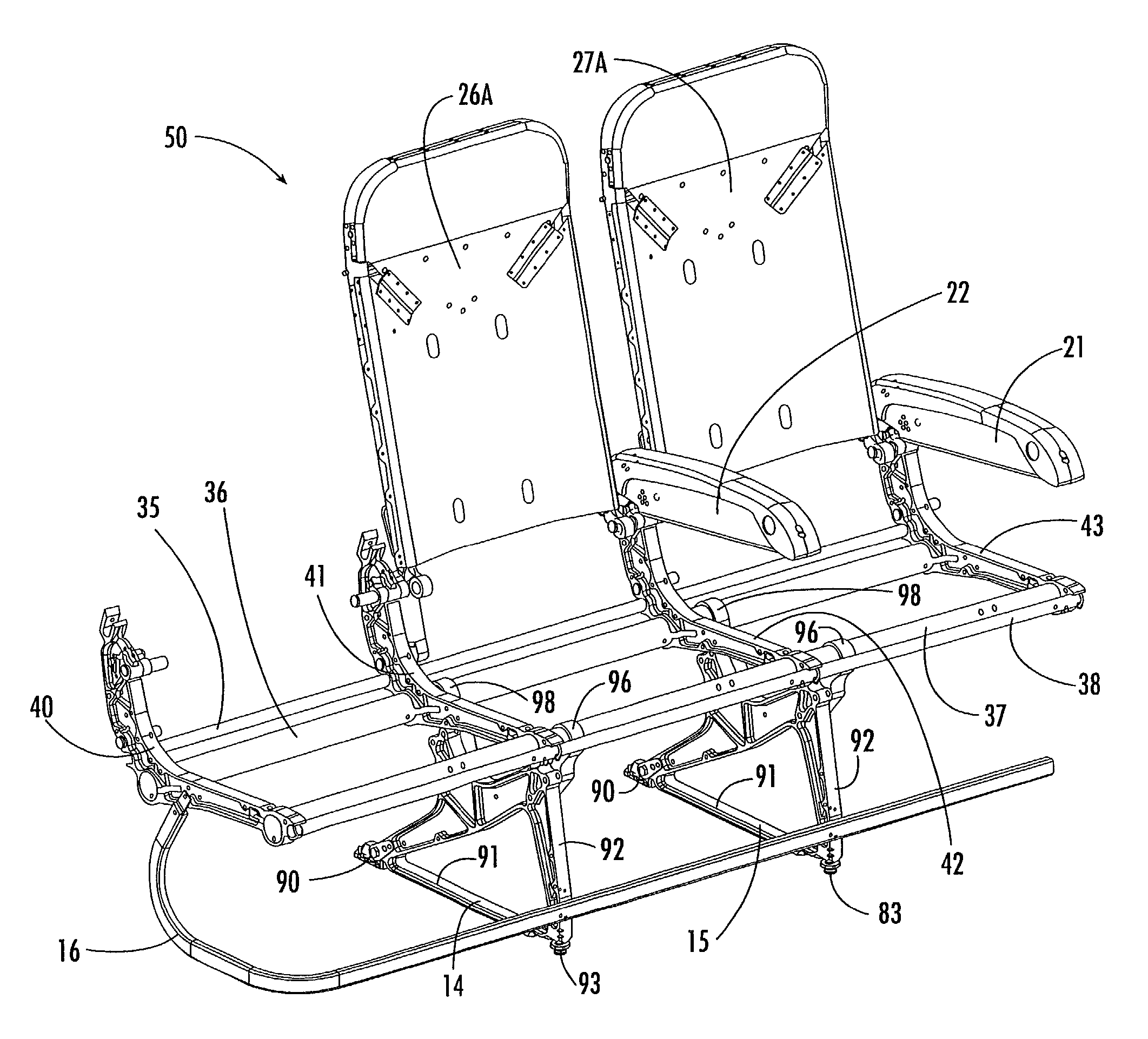

Aircraft passenger seat frame construction

InactiveUS20030094838A1Eliminates and reducesSeating arrangementsPedestrian/occupant safety arrangementEngineeringFuselage

A passenger seat frame assembly, including a seat bottom chassis including a plurality of leg modules and section assembly modules. The leg modules are attached to fixed, spaced-apart attachment points on a supporting surface, such as the deck of an aircraft fuselage. A plurality of beam elements are carried by the leg modules and section assembly modules. A plurality of clamp joints are provided for being positioned on the plurality of leg modules and for receiving the plurality of beam elements in spaced-apart relation to each other for defining a ladder frame assembly having a specified width and seat spacing.

Owner:BE AEROSPACE INCORPORATED

Vehicular seat apparatus

InactiveUS7137665B2Maintain positionInhibit outputStands/trestlesKitchen equipmentRigid frameCushion

A vehicular seat apparatus has a first slide rail unit including a first stationary rail and a first moving rail and a second slide rail unit including a second stationary rail and a second moving rail. Load sensors are provided between the seat cushion assembly and the moving rails. The first stationary rail and the second stationary rail are connected to each other by a rigid frame. The rigid frame can maintain the relative positions of the first and second slide rail units. Body mounting leg portions provided on the rigid frame are fixed to a seat mounting portion of a vehicle body.

Owner:NHK SPRING CO LTD +1

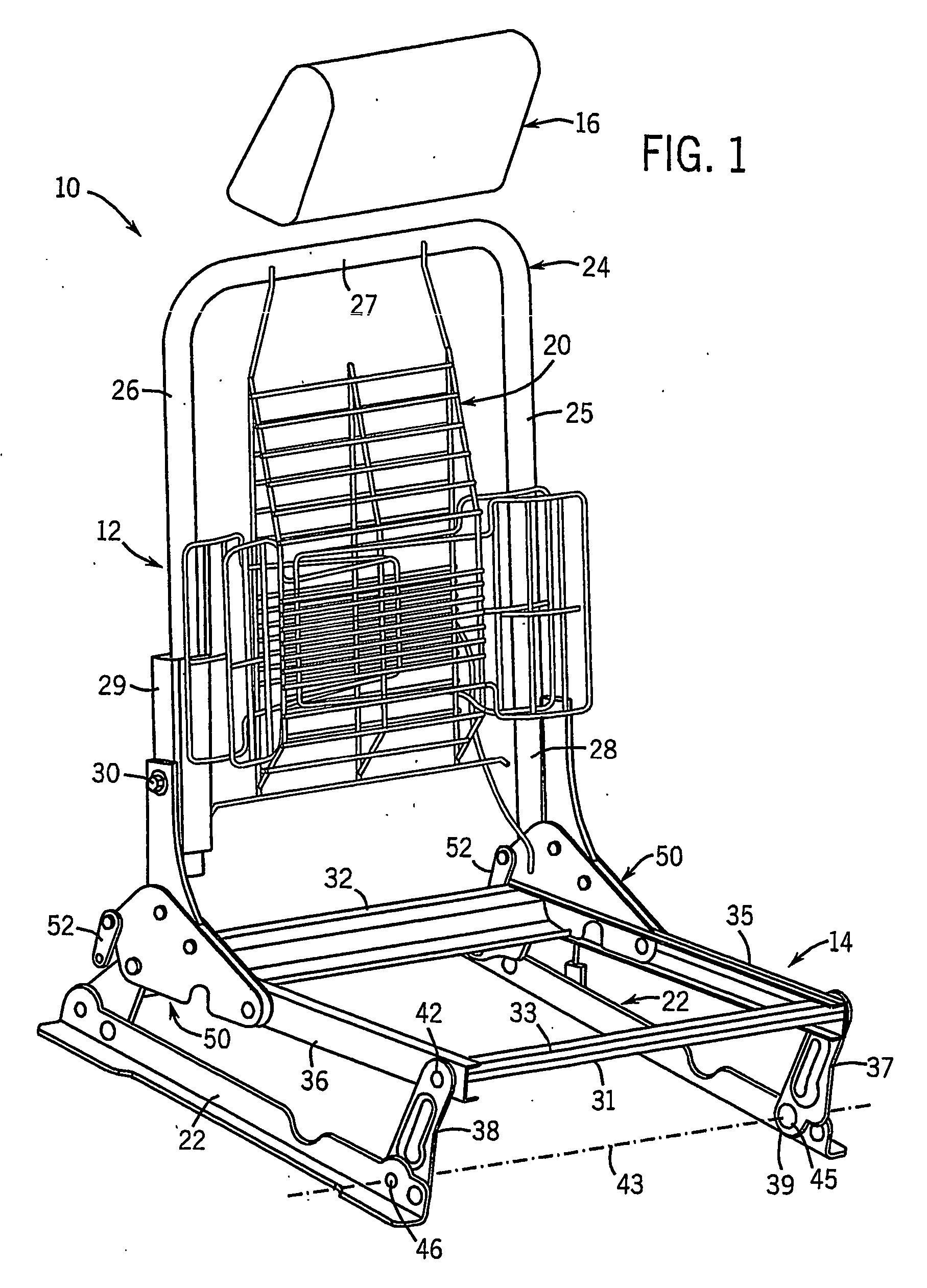

Thin profile folding vehicle seat

An ultra compact, easy to operate folding vehicle seat includes a seat back, seat base and support leg members and is movable between a stow position and a design position. The folding vehicle seat includes a folding mechanism having an upper member for connection to the seat back and a lower member for supporting the seat base; the upper and lower members of the folding mechanism include integrated teeth aligned in meshing relationship such that movement of the seat back causes the lower member to rotate and lift the seat base to move the folding vehicle seat to a design position. A pair of upper cams are provided for selective engagement with the upper member and a third cam tab of the lower member of the folding mechanism.

Owner:INTIER AUTOMOTIVE INC +1

Vehicle seating frame, assembly, and method of making

Owner:LEAR CORP

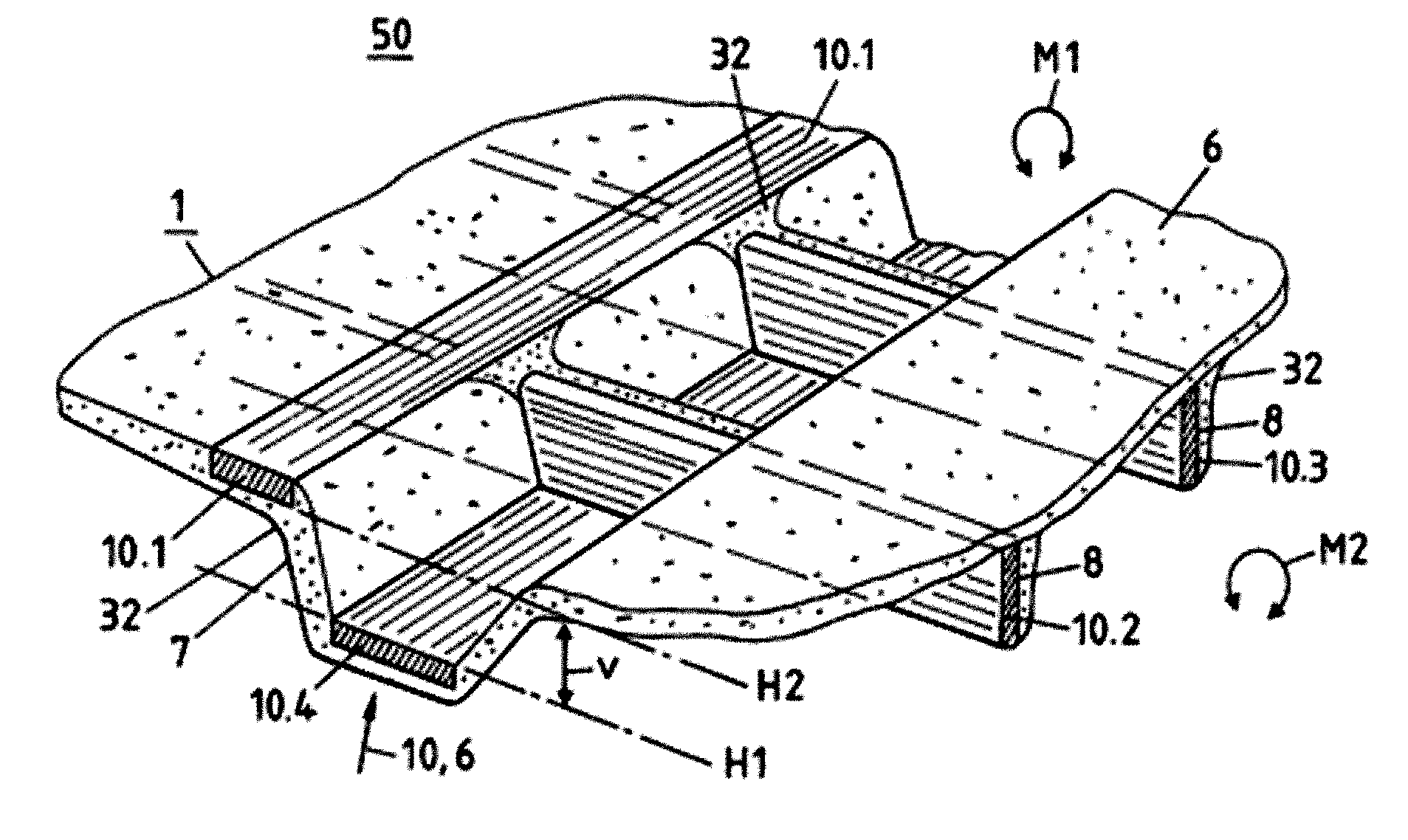

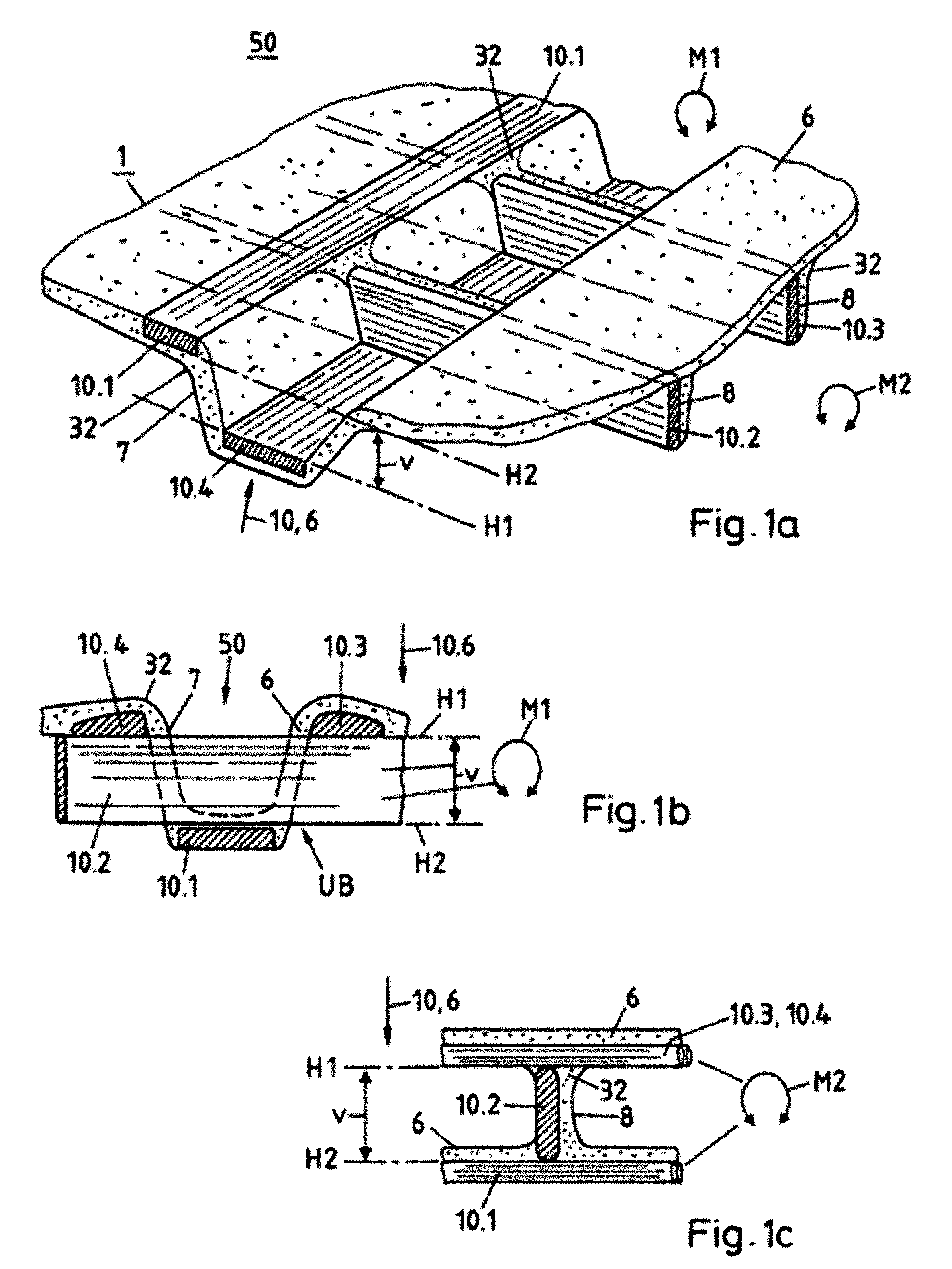

Structural Component Consisting of Fibre-Reinforced Thermoplastic

Abstract of the DisclosureA structural component (1) is made out of long- fiber reinforced thermoplastic material (LFT) with integrated continuous fiber (CF) – reinforcement. It includes at least three individually integrated, shaped CF - profiles (10), which form a three-dimensional intersection point (50). In this, at least one CF - profile (10) lies in an upper plane (H1), at least one CF-profile lies in a lower plane (H2) of the intersection point and at least one CF - profile extends continuously in a vertical direction (v) between these CF - profiles of the upper and of the lower main plane. The CF - profiles (10) are connected to one another by shapings (32) of the LFT - mass (6) at the intersection point in a force-transmitting manner. At several points loads (L) are exerted on the CF - profiles. Such three-dimensionally applied loads (L) are capable of being optimally supported.

Owner:RCC REGIONAL COMPACT CAR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com