Seat for heavy equipment having buffer means in forward and backward directions

一种重型设备、缓冲装置的技术,应用在座椅架、活动座椅、车辆座椅等方向,能够解决昂贵设备可靠性和工作效率降低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

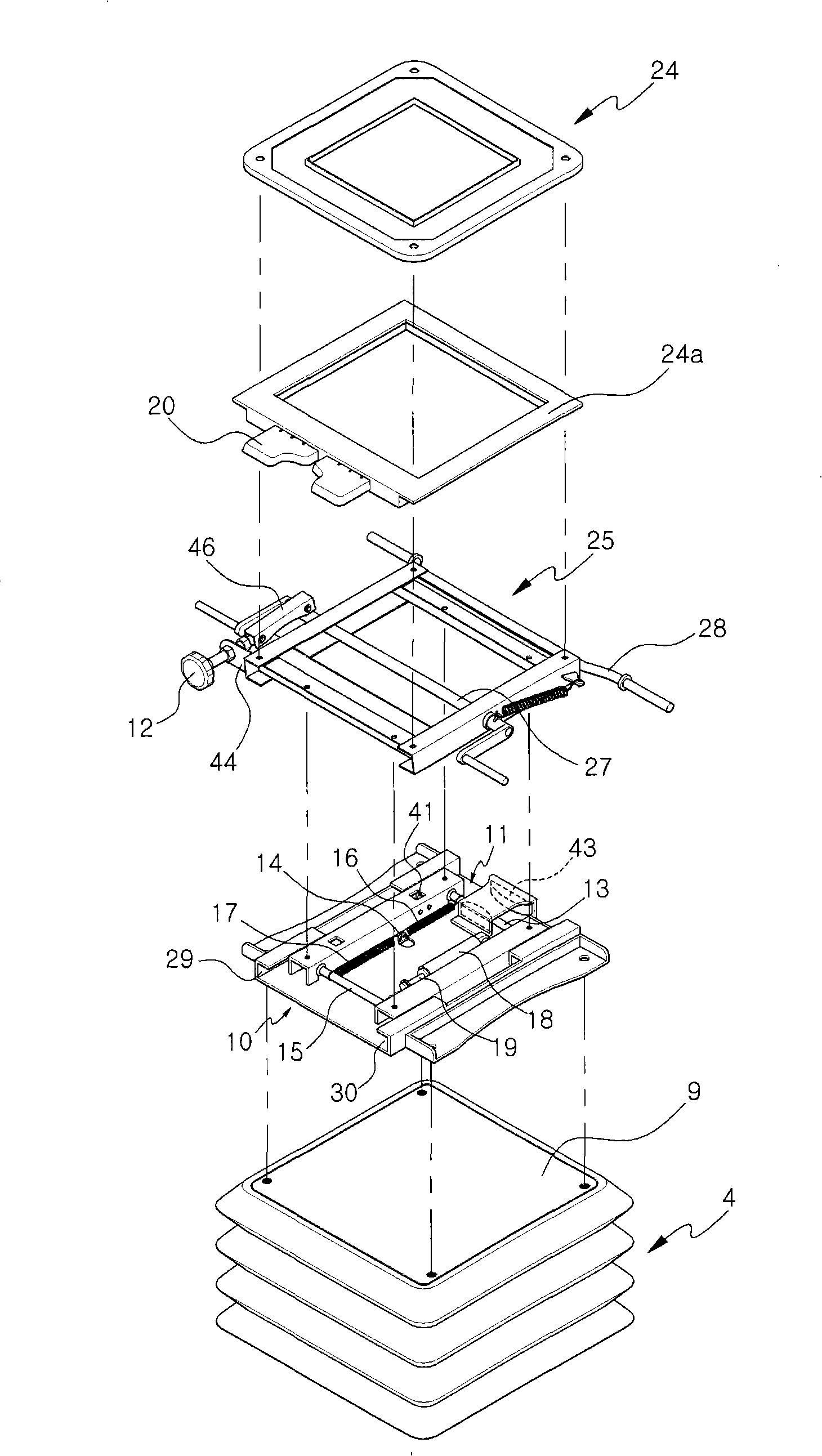

[0035] Hereinafter, preferred embodiments of the present invention will be described with reference to the accompanying drawings. The contents defined in the description, such as detailed structures and parts, are just specific details provided to help those of ordinary skill in the art fully understand the present invention, and thus the present invention is not limited thereto.

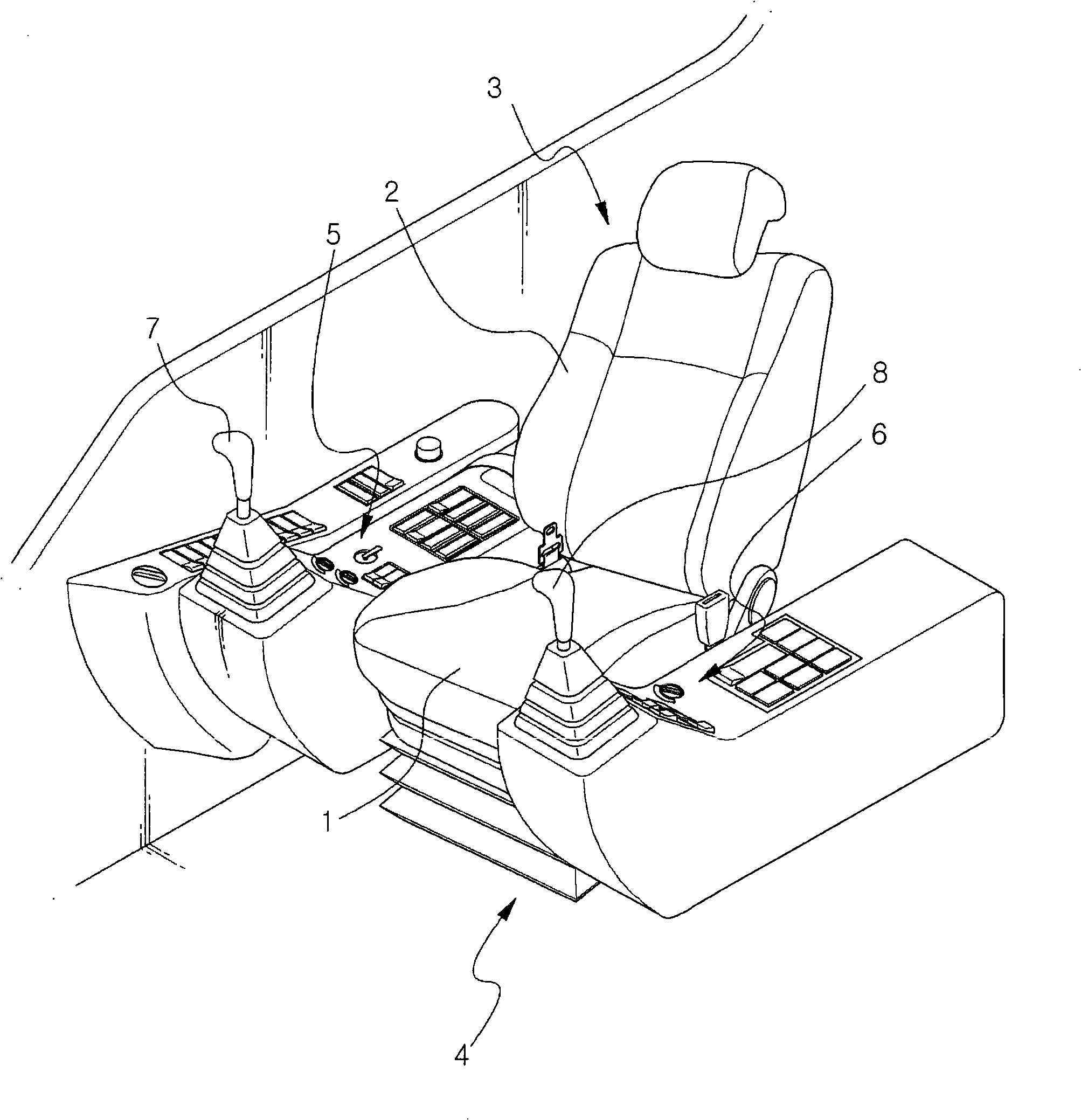

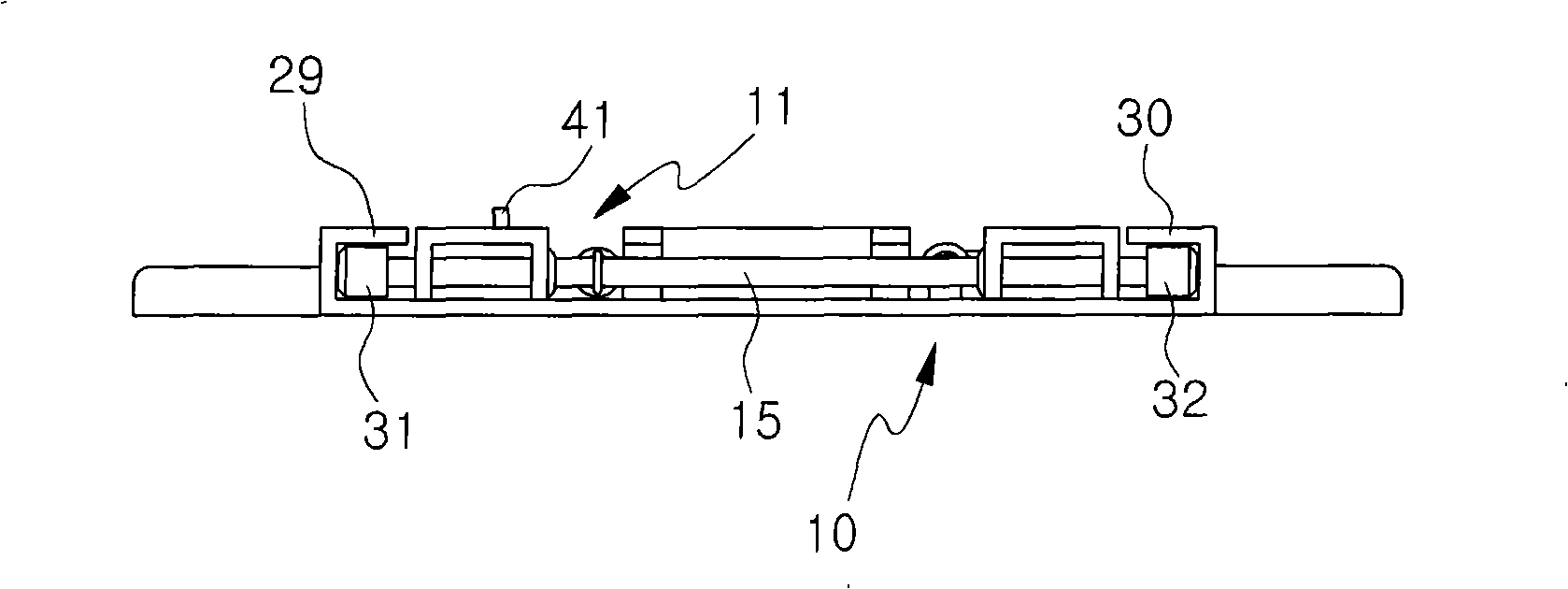

[0036] Such as Figures 2 to 9As shown, the seat for heavy equipment with the cushioning device in the front-rear direction installed on the suspension plate is composed of a seat part and a seat back part, and is located between the left control box and the right control box, according to this An embodiment of the invention comprising: a lower element 10 mounted on the suspension plate 9 and having guide rails 29 and 30 formed on its left and right sides; Rollers 31 and 32 are slidably mounted on the lower element 10 along the front-back direction of the equipment (that is, the X-axis direction in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com