Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

512 results about "Hydroforming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydroforming is a cost-effective way of shaping ductile metals such as aluminium, brass, low alloy steel, and stainless steel into lightweight, structurally stiff and strong pieces. One of the largest applications of hydroforming is the automotive industry, which makes use of the complex shapes made possible by hydroforming to produce stronger, lighter, and more rigid unibody structures for vehicles. This technique is particularly popular with the high-end sports car industry and is also frequently employed in the shaping of aluminium tubes for bicycle frames.

Absorbent article with a response surface

InactiveUS20020133132A1Improve the immunitySimple structureLayered productsSanitary towelsHydroformingBody fluid

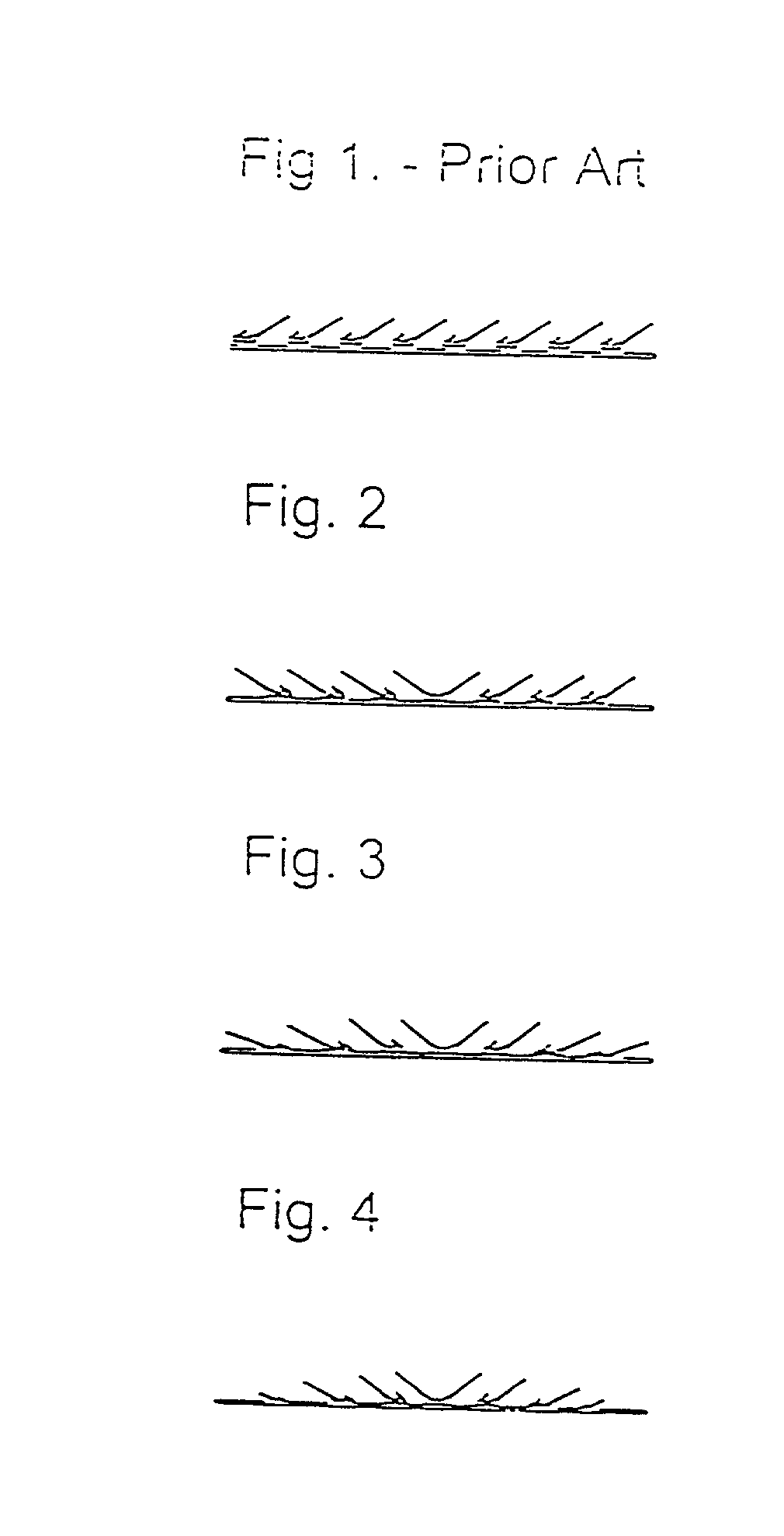

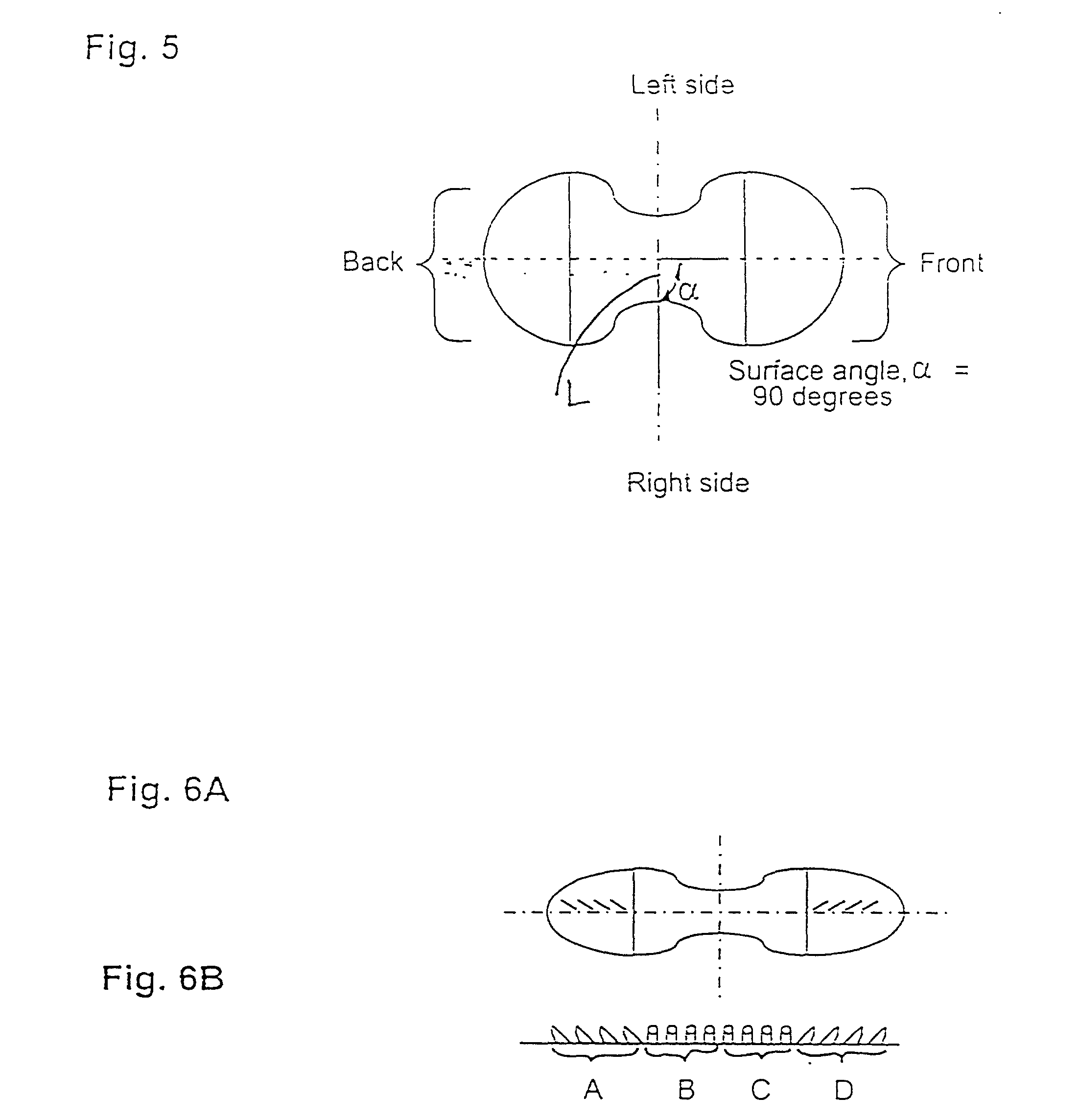

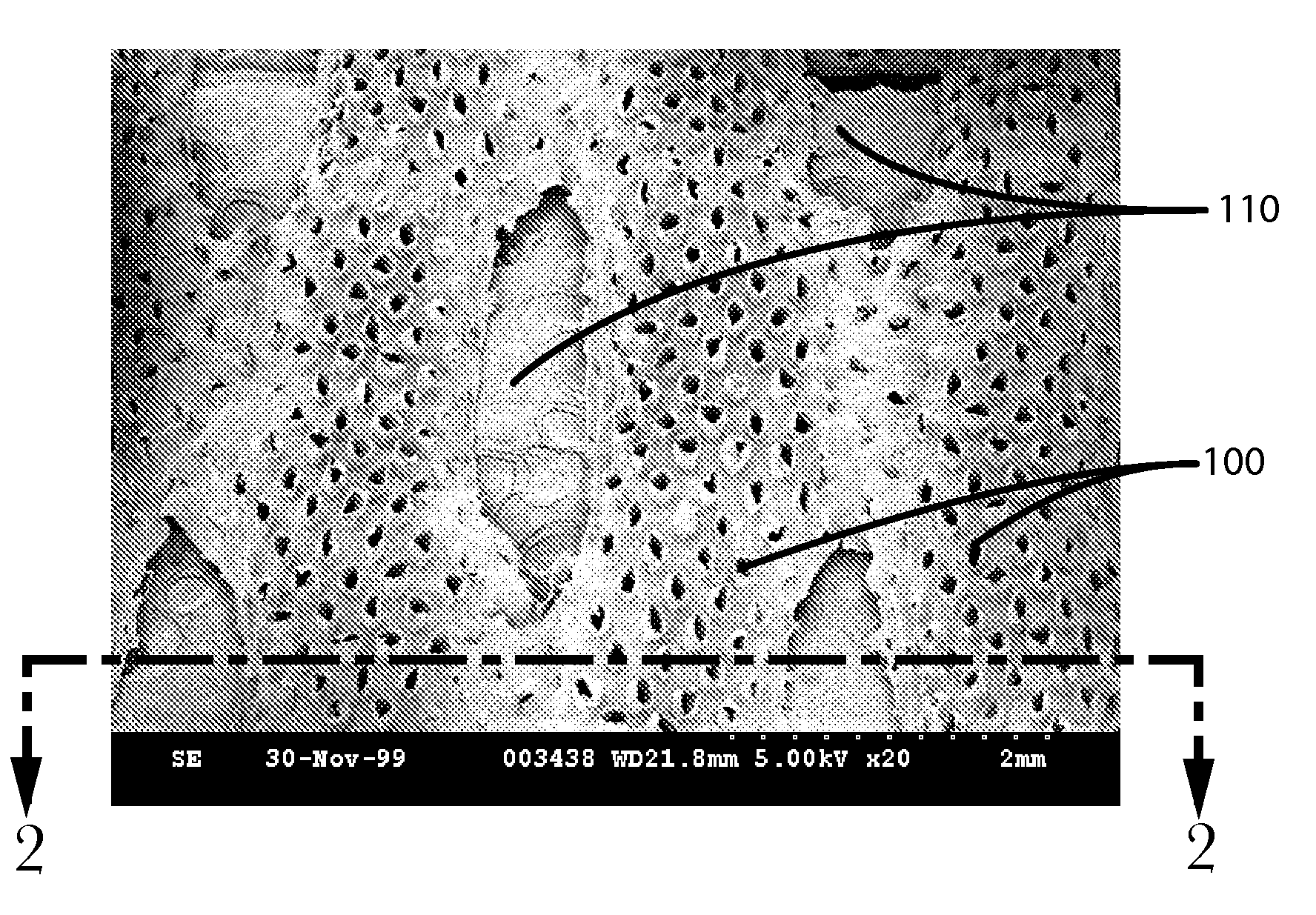

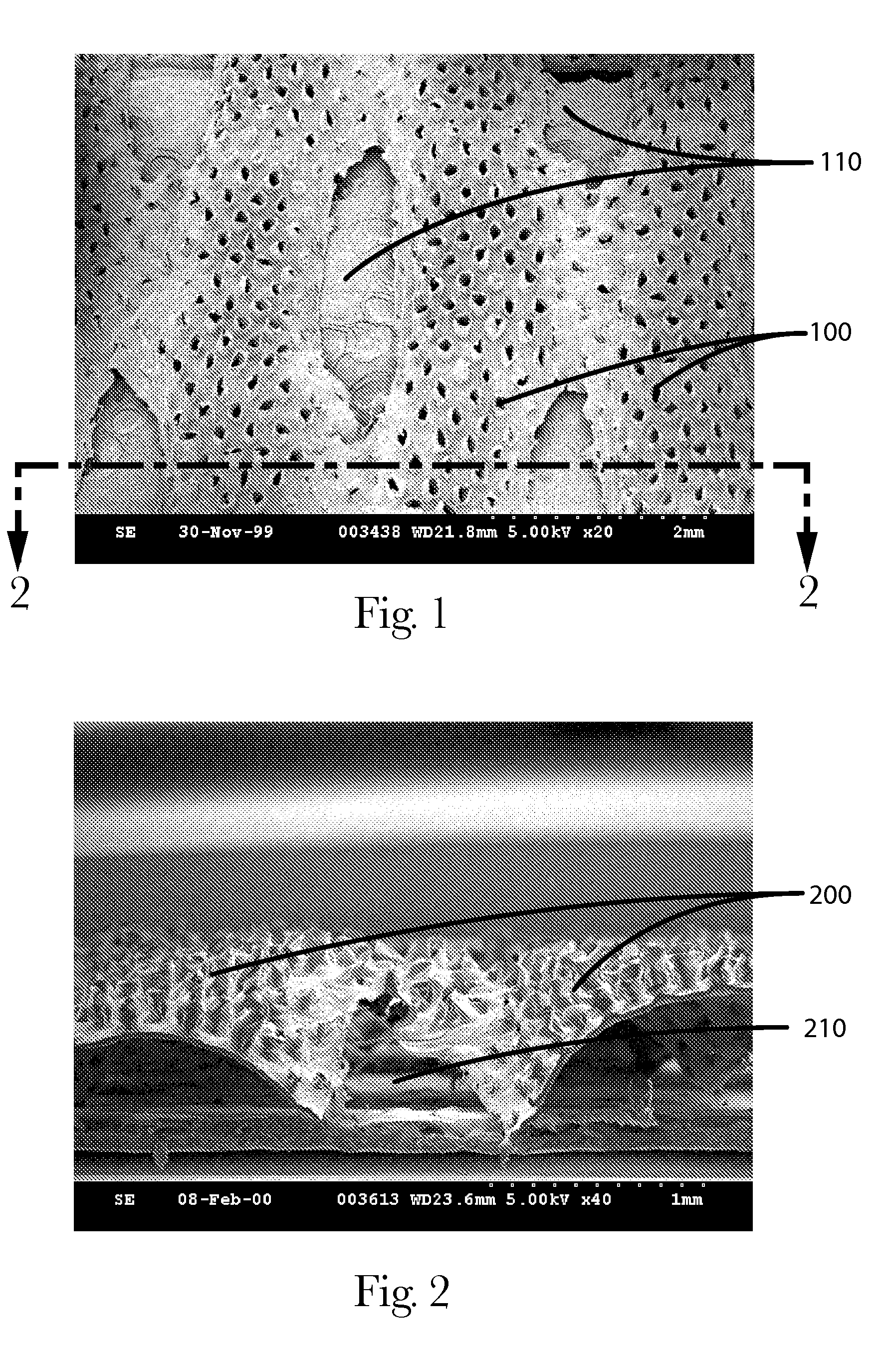

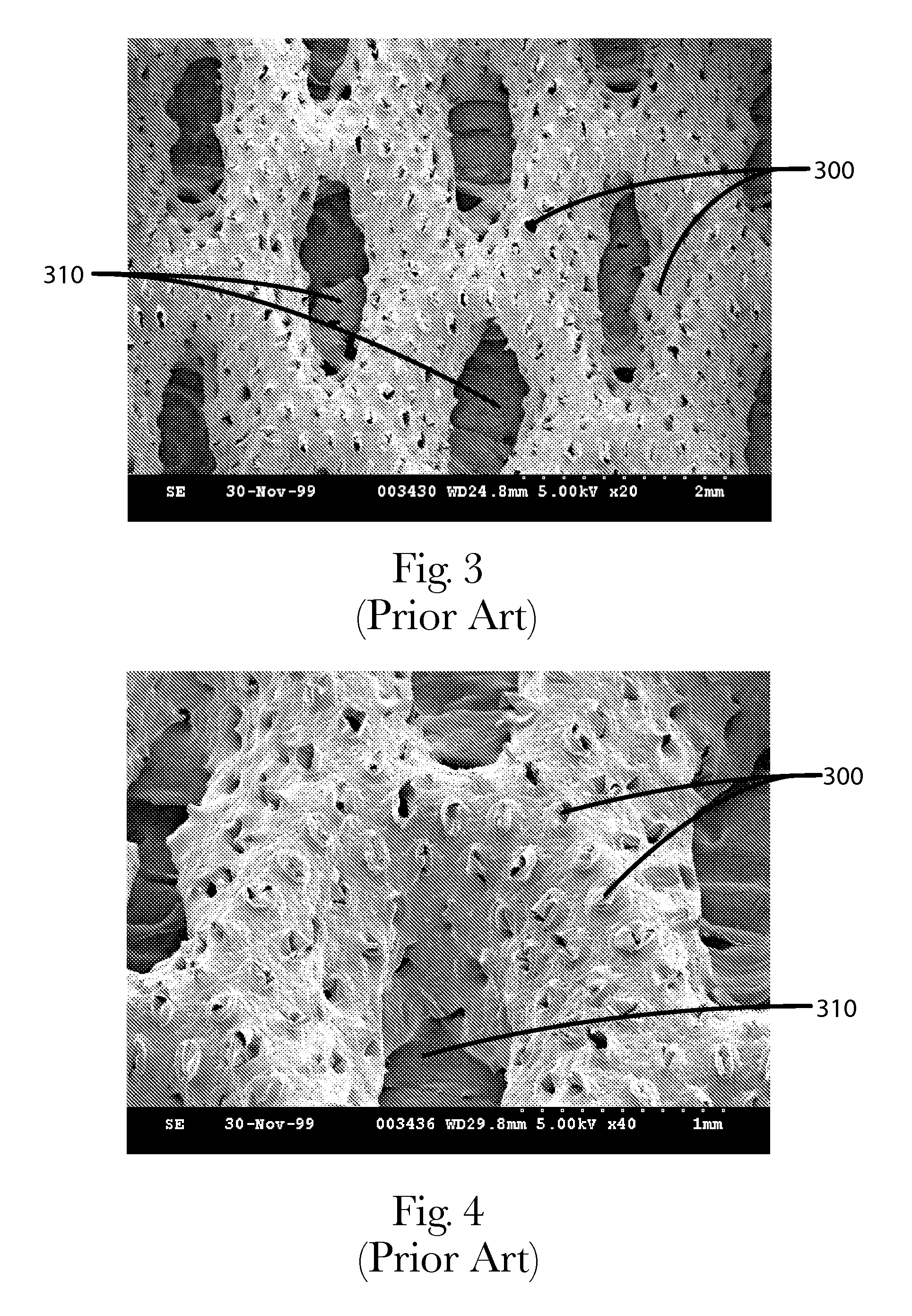

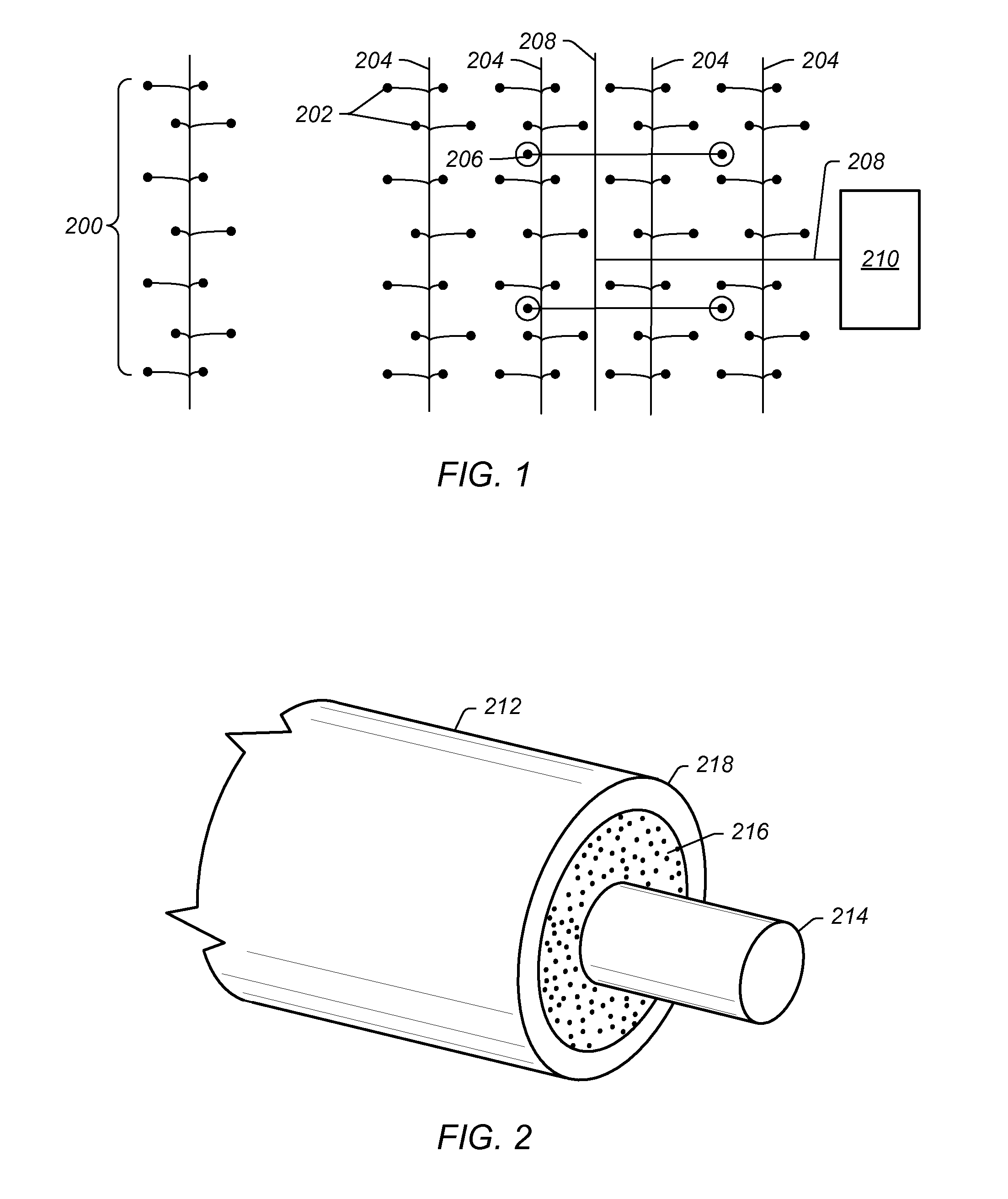

A breathable absorbent article has at least one of a topsheet, an absorbent core, an optional distribution layer or a backsheet that comprises at least one to layer of a resilient, three dimensional liquid impervious polymeric film having apertures. The apertures form capillaries which are disposed at multiple directions, and / or have different diameters and lengths to create a response surface that is proportional to the pressure applied by the user's body, volume distribution of bodily fluid discharged by the user, the location of the discharge with respect to the position of the article, or a combination thereof, while the article is in use. The polymeric film can be formed by various processes, for example, vacuum forming or hydroforming methods.

Owner:TREDEGAR FILM PROD CORP

Apertured polymeric film webs and absorbent articles using such webs

A method for making an apertured polymeric film web, the method comprising the steps of:a. providing a polymeric film web;b. providing a first process selected from the group consisting of, hydroforming, vacuum forming, needle punching, mechanical embossing, flocking, ultrasonics, printed hair, brushing, and combinations thereof;c. providing a second process, different from the first process, the second process selected from the group consisting of, hydroforming, vacuum forming, needle punching, mechanical embossing, ultrasonics, stretch rupturing, hydrocutting, hydrosonics, slitting, ring-rolling, and combinations thereof;d. forming three dimensional surface structures in the polymeric film web by the first process; ande. forming fluid transport apertures in the polymeric film web by the second process.

Owner:THE PROCTER & GAMBLE COMPANY

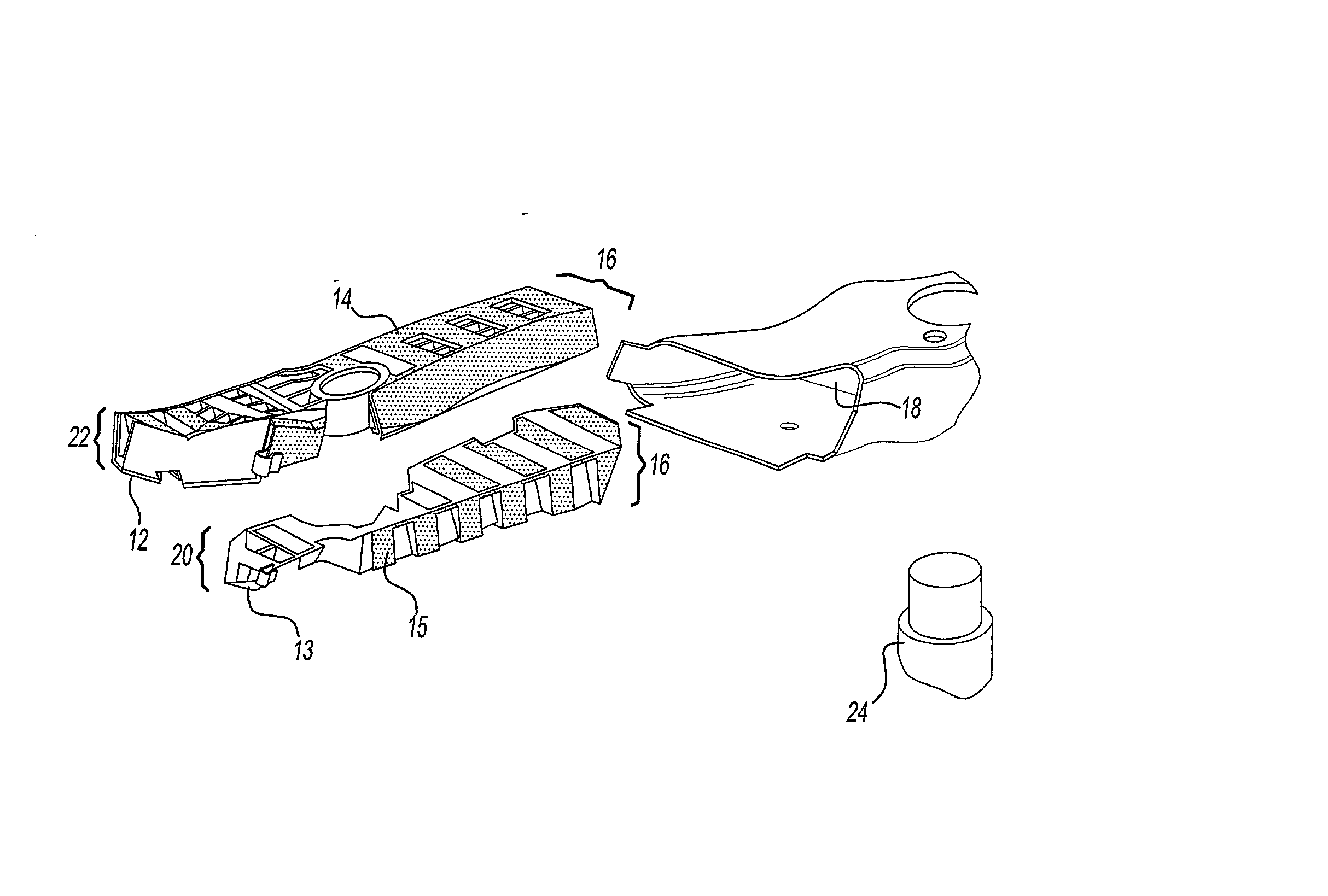

Hydroform structural reinforcement system

An structural reinforcement system for use with hydroforms and other closed forms having a plurality of members designed to be secured to a closed form, such as an hydroform tube used in automotive applications. A bonding material, such as an epoxy-based reinforcing foam, is disposed on at least a portion of the outer surface of each of the plurality of members. Once the system is attached to the closed form, the foam expands and cures during an automobile assembly operation, bonding the reinforcement system to the hydroform tube and the members. As a result, the reinforcement system provides enhanced load distribution over the vehicle frame without adding excessive weight and further serves to reduce noise and vibrational characteristics of the automotive vehicle.

Owner:ZEPHYROS INC

Hydroformed space frame and rearward ring assembly therefor

A space frame for a motor vehicle having a pair of laterally spaced, longitudinally extending side rail structures, a pair of forward-most upright structures each being connected to a respective side rail structure, thereby forming a pair of A pillars, a pair of roof rail structures, a forward end of each roof rail structure being connected to an upper end of an associated A pillar, and a rearward ring assembly connected at upper portions thereof with the roof rail structures and at bottom portions thereof with the side rail structures. The rearward ring assembly having (a) a tubular hydroformed inverted U-shaped upper member having a cross portion and a pair of leg portions extending downwardly from opposite ends of the cross portion, (b) a pair of tubular hydroformed side members, and (c) a cross structure rigidly connected in ring-forming relation between the second ends of the side members.

Owner:MAGNA INTERNATIONAL INC

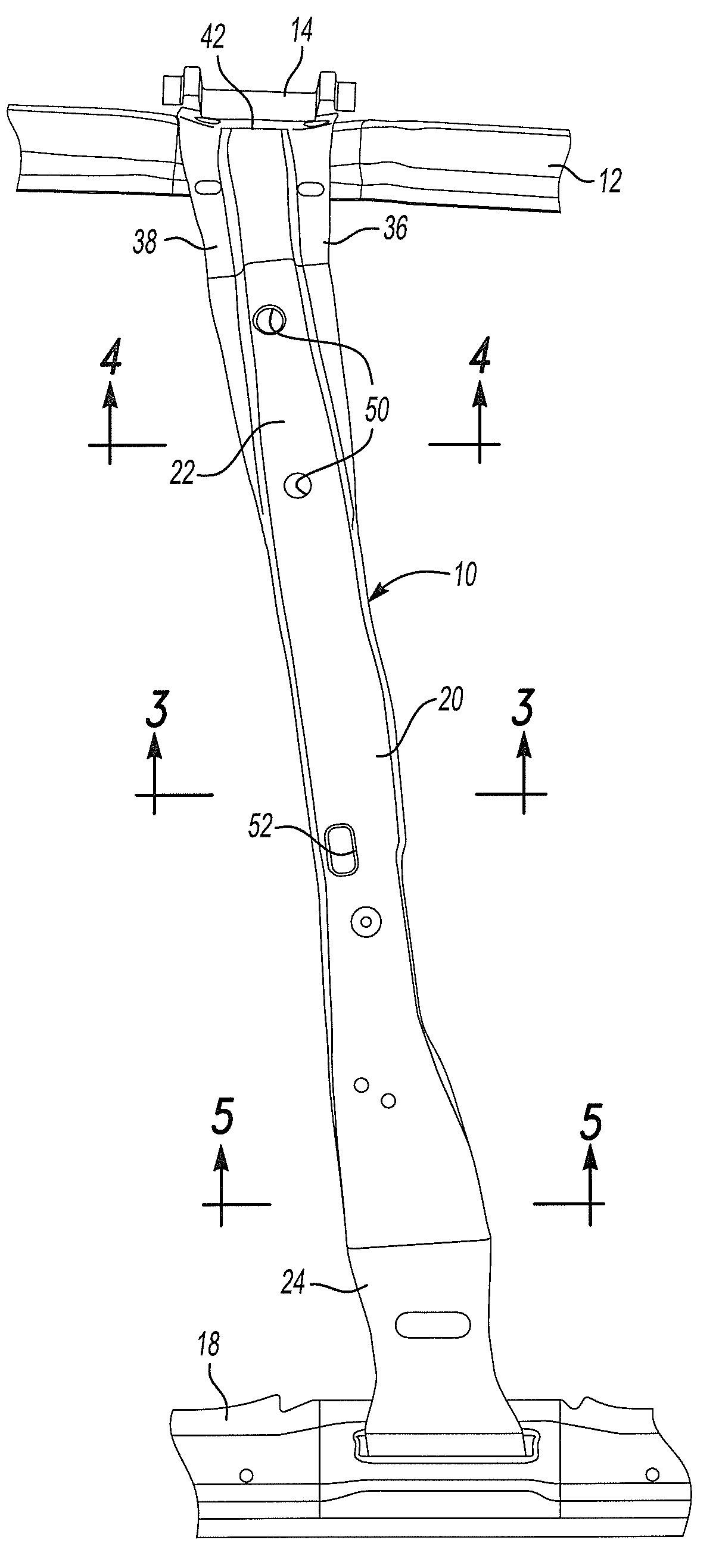

Unitary hydroformed roof support pillar

A one-piece B-pillar having a front flange and a rear flange formed on an upper portion of the B-pillar. The front and rear flanges extend forwardly and rearwardly from a trapezoidal section of the B-pillar. An inner concave portion is provided in a lower portion of the B-pillar. The one-piece B-pillar is secured to the outer and upper surfaces of a roof rail and to the outer surface of a rocker to provide side impact strength. The B-pillar is hydroformed in one-piece to provide superior strength for roof crush performance. The tubular portion of the B-pillar is partially collapsed to form a trapezoidal section in the upper portion of the B-pillar.

Owner:FORD GLOBAL TECH LLC +1

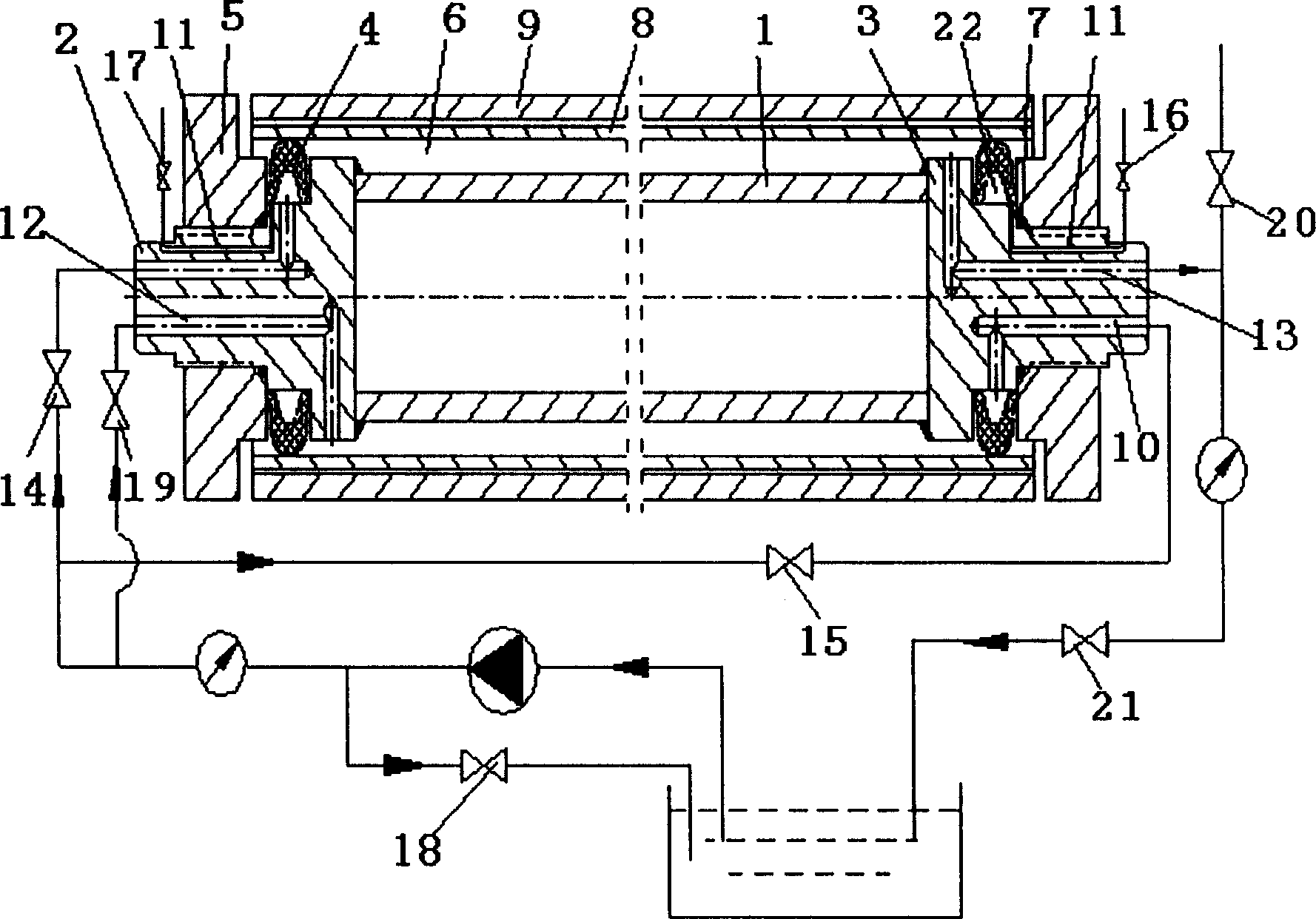

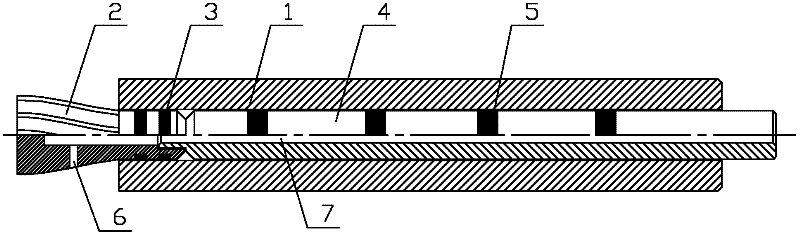

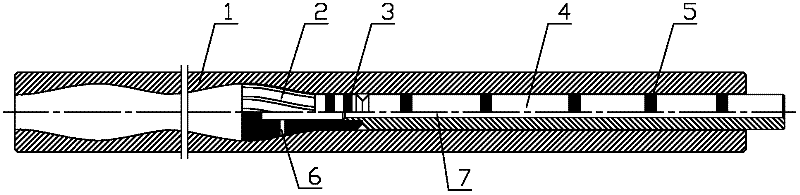

Hydraulic shaping device of stainless steel lined compound pipe and its shaping method

InactiveCN1651163AUniform expansion forceManufacturing quality is easy to guaranteeHydroformingCopper

A hydraulic apparatus for forming a composite pipe with stainless steel liner is composed of core rod, left and right expanding ehads fixed respectively to both ends of said core rod, two self-fastened sealing rings for left and right expanding heads, and the fixers at the ends of said expanding heads. Its forming technology is also disclosed.

Owner:EAST CHINA UNIV OF SCI & TECH

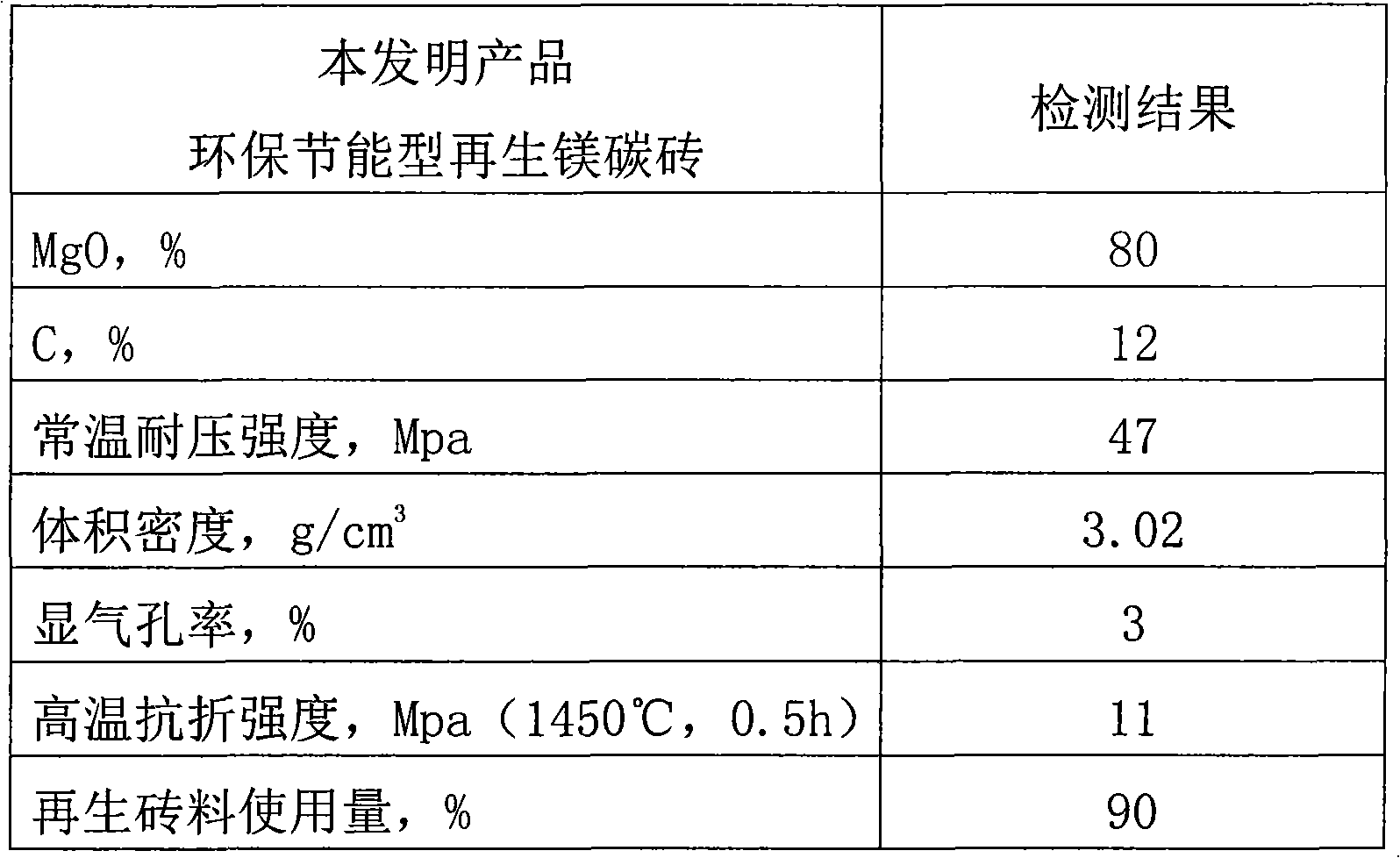

Production method of environment-friendly and energy-saving type regenerative magnesia-carbon brick

InactiveCN101851103AImprove recycling ratesSolve the problem of unstable performanceSolid waste managementBrickResonance

The invention discloses a production method of an environment-friendly and energy-saving type regenerative magnesia-carbon brick, comprising the following production steps: (1) sorting and crushing waste magnesia-carbon bricks; (2) powdering with weak acid aqueous solution; (3) carrying out high-temperature drying to dehydrate and electromagentic resonance to homogenize; (4) carrying out crushing, particle shaping, iron removing and screening; (5) mixing materials: mixing regenerative aggregates, fine powder and newly-added and electrically-fused magnesite aggregates, and fine powder; and (6)forming. The mixed material is added with a bonding agent, is treated by high-speed constant-temperature mixing, hydraulic forming and electric heating drying and obtains a regenerative magnesia-carbon brick product. The production method solves the problem that the product in the prior art has unstable performance, can retain usable components such as electrically-fused magnesite, crystalline flake graphite and the like in the raw material furthest, has high recovery and utilization rate and is energy-saving and environment-friendly.

Owner:吴钦合

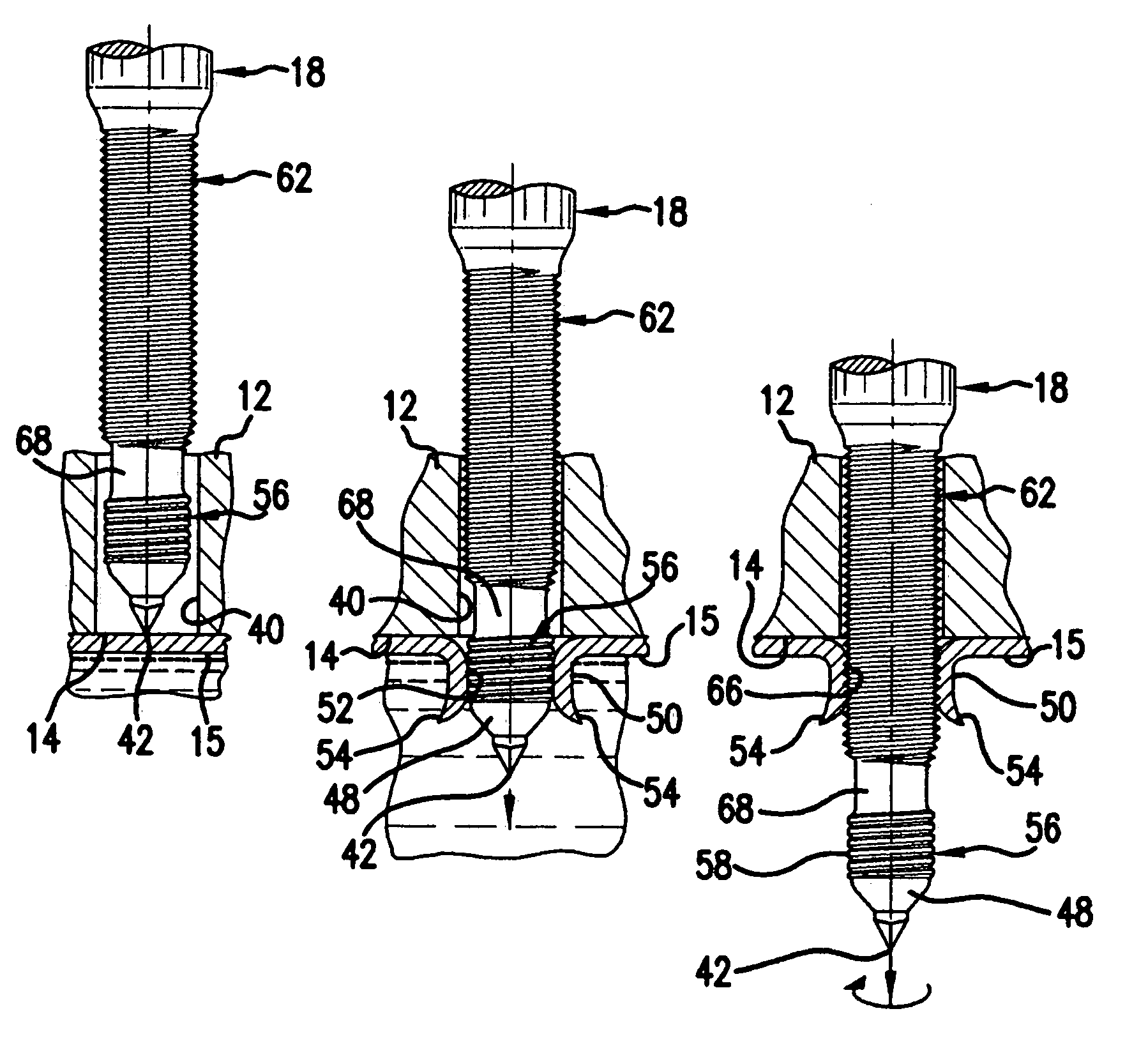

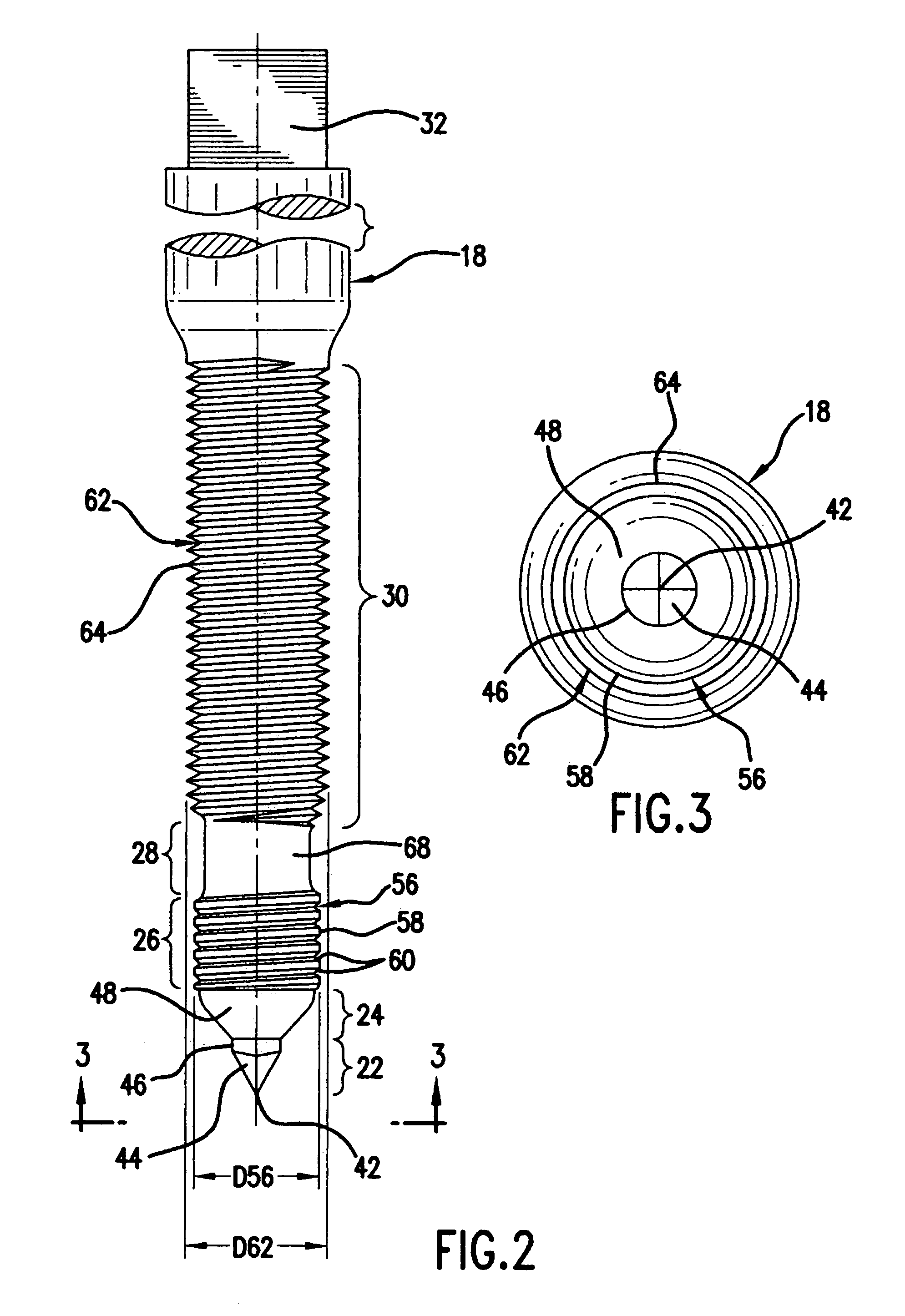

Method and apparatus for forming a threaded hole in a hydroformed part

InactiveUS6931901B2Reduce frictionRequires minimizationMetal working apparatusEngineeringHydroforming

Method and apparatus are disclosed wherein a required threaded hole is formed in a hydroformed part with a single tool while the part remains in a hydroforming die cavity. In forming the threaded hole, a hole is first pierced in the wall of the part and then an annular region of the part extending about the hole is extruded inwardly to form an integral tubular neck defining a hole of predetermined depth. The hole is then expanded in a sizing operation to a diameter determined by the required thread to be formed therein by material displacement and the required thread is then formed in the wall of the hole in a material displacing manner.

Owner:GM GLOBAL TECH OPERATIONS LLC

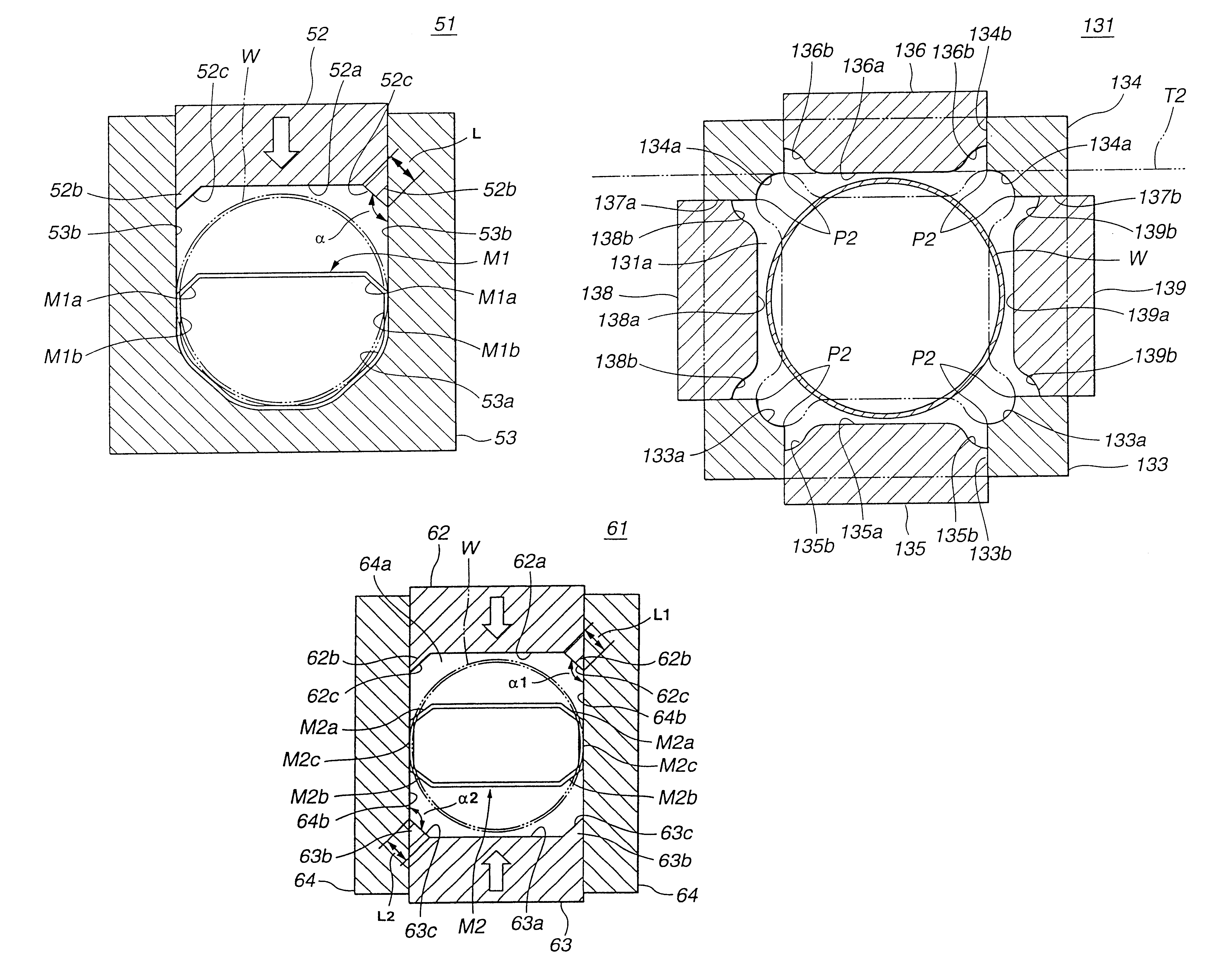

Method and device for forming tubular work into shaped hollow product by using tubular hydroforming

For forming a tubular work into a shaped hollow product by using hydroforming process, a method and a device are described. In the method, female and male dies are prepared. The female die has a longitudinally extending cavity which has a polygonal cross section when receiving the male die. The tubular work is placed into the cavity of the female die. The interior of the tubular work is then fed with a hydraulic fluid, and the pressure of the fluid is increased to a given level. The given level is smaller than a critical level that causes a bulging of the tubular work. The male die is then pressed against the tubular work to deform the same while keeping the hydraulic fluid at the given level, thereby forming a shaped hollow product that has a polygonal cross section that conforms to that of the cavity. The pressing work is continued until a circumferential length of the shaped hollow product becomes shorter than that of the tubular work.

Owner:NISSAN MOTOR CO LTD

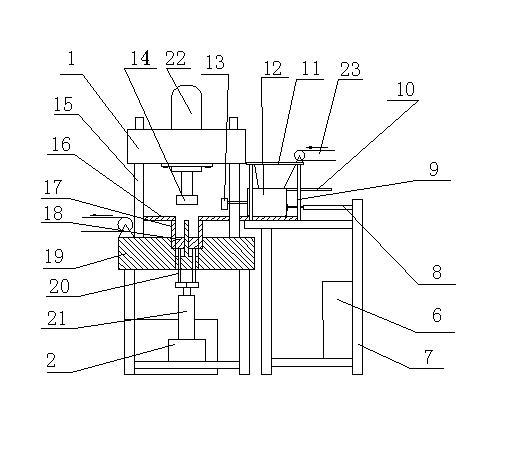

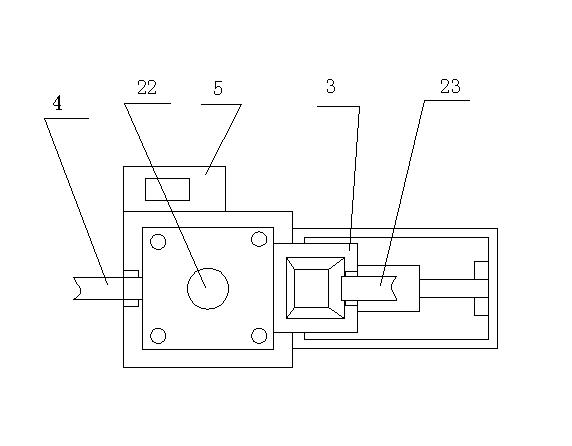

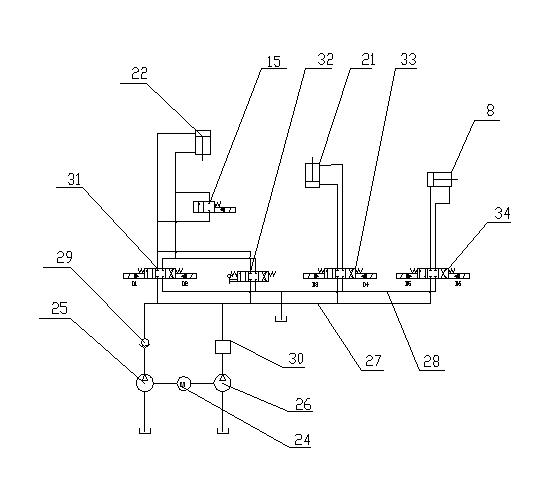

Automatic hydraulic molding machine for pulverized coal

InactiveCN102120367AHigh degree of automationImprove production continuityPress ramControl systemMolding machine

The invention provides an automatic hydraulic molding machine for pulverized coal. The machine mainly comprises a frame, a molding mechanism, a feeding mechanism, a pushing mechanism, a hydraulic control system and an electrical control system, wherein the pushing mechanism is arranged on one side of the frame; the molding mechanism is arranged on the upper part of the pushing mechanism through apillar; the feeding mechanism is arranged on the frame; and the feeding mechanism mainly comprises a feeding cylinder, a storage hopper, a feeding cart, a conveying plate and a feeding belt, the storage hopper is arranged on the frame through a mounting bracket, the feeding belt is arranged at the opening of the upper end of the storage hopper, the feeding cart is arranged on the lower side of the storage hopper, and the feeding cart is connected with the feeding cylinder. The device optimally integrates the feeding mechanism, the molding mechanism and the pushing mechanism, and is cooperatedwith constant material feeding and discharging molded blocks to ensure that the whole production process does not require staff on duty, thus the device has the advantages of high automation degree, good production continuity performance and high production efficiency improved by over 2 times, and can be widely applied to industrial production.

Owner:平顶山市通运矿山机械厂

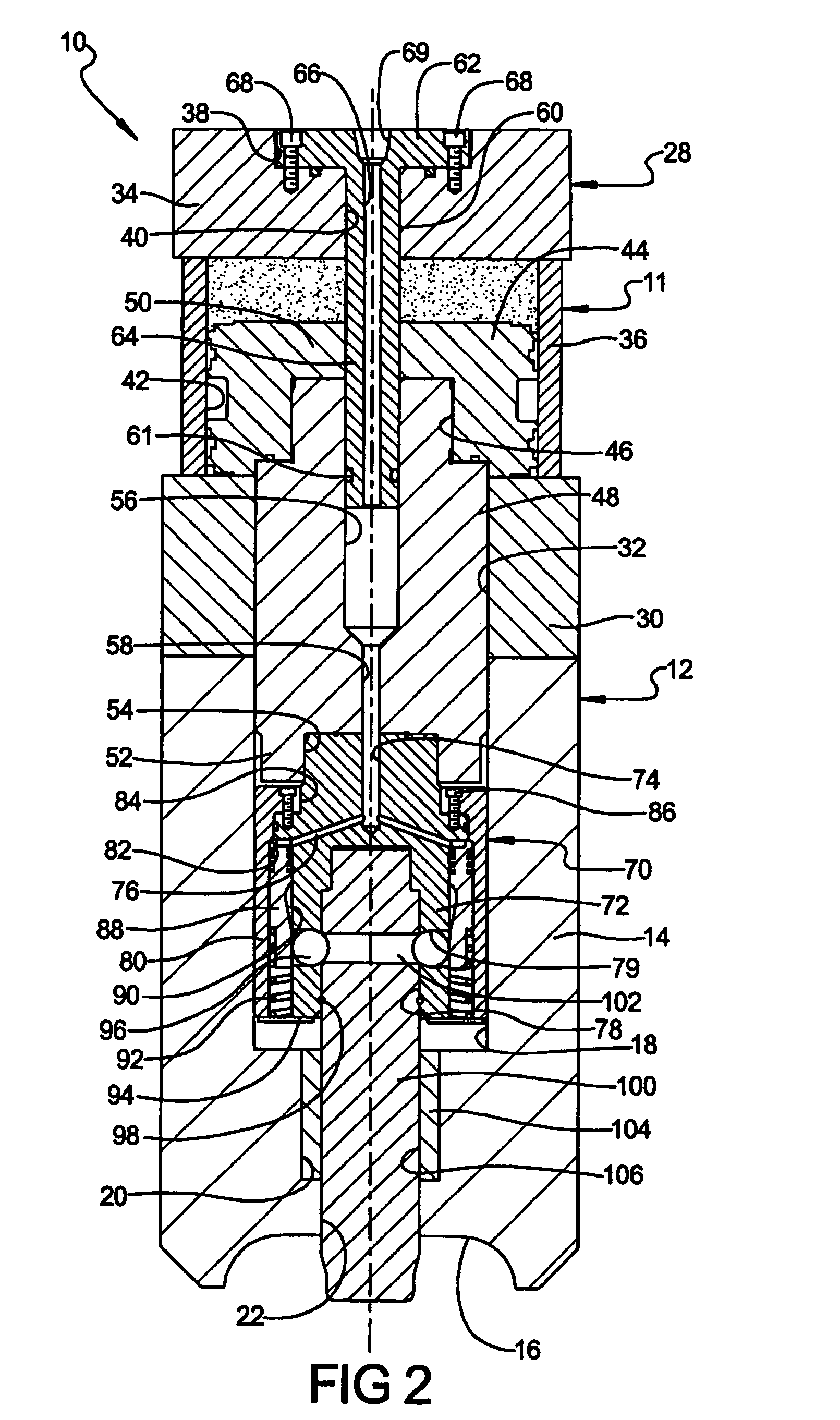

Quick change assembly for hydroforming punches

InactiveUS7159426B1Good opening qualityReduce downtimePerforating toolsVehicle componentsEngineeringHydroforming

A punch assembly used with a hydroforming die includes a punch cylinder for mounting to the hydroforming die and having a movable rod. The punch assembly also includes a punch for piercing an opening in a tubular member disposed in the hydroforming die. The punch assembly further includes a quick change assembly interconnecting the rod of the punch cylinder and the punch for allowing the punch to be removably attached to the punch cylinder.

Owner:GM GLOBAL TECH OPERATIONS LLC

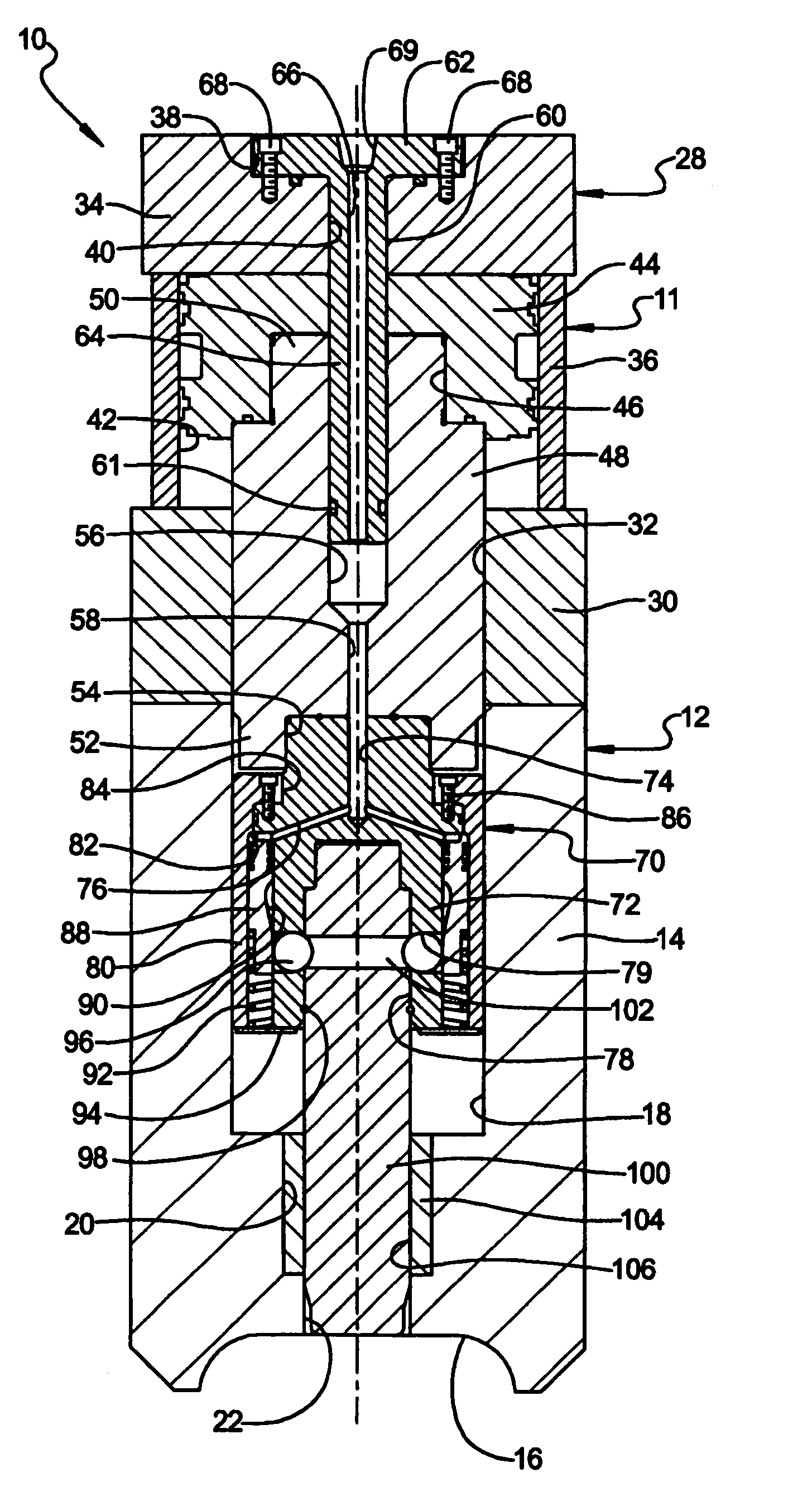

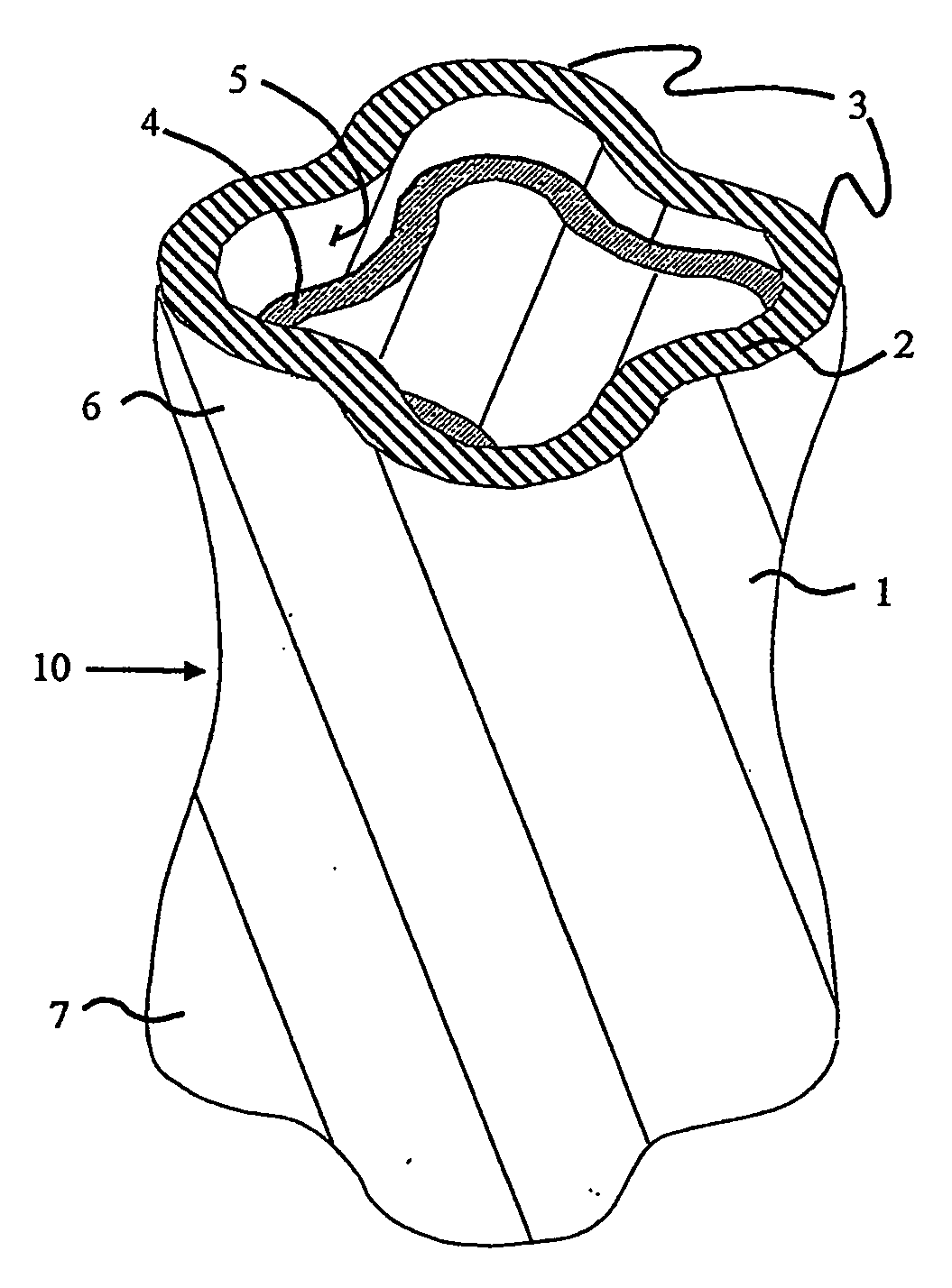

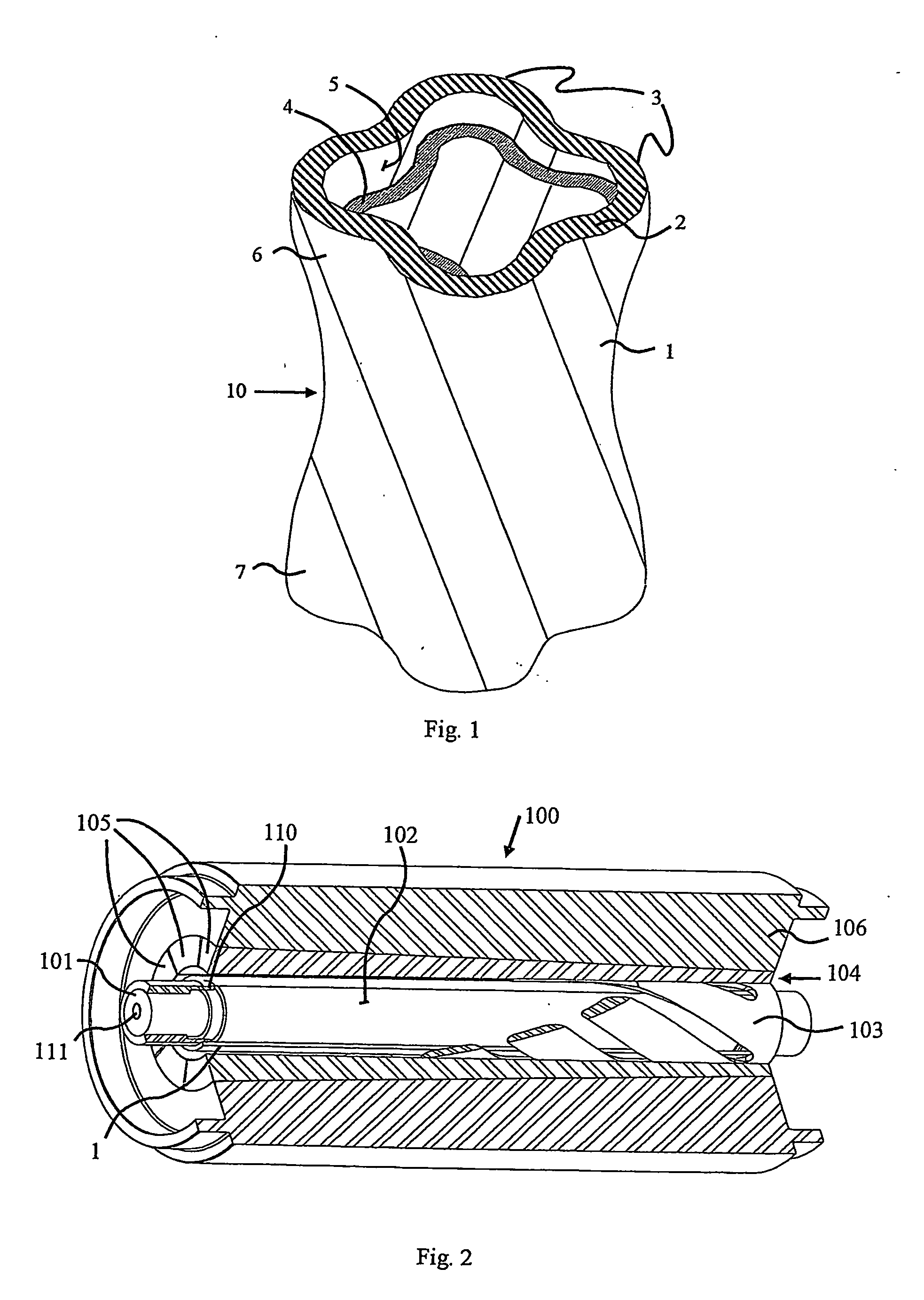

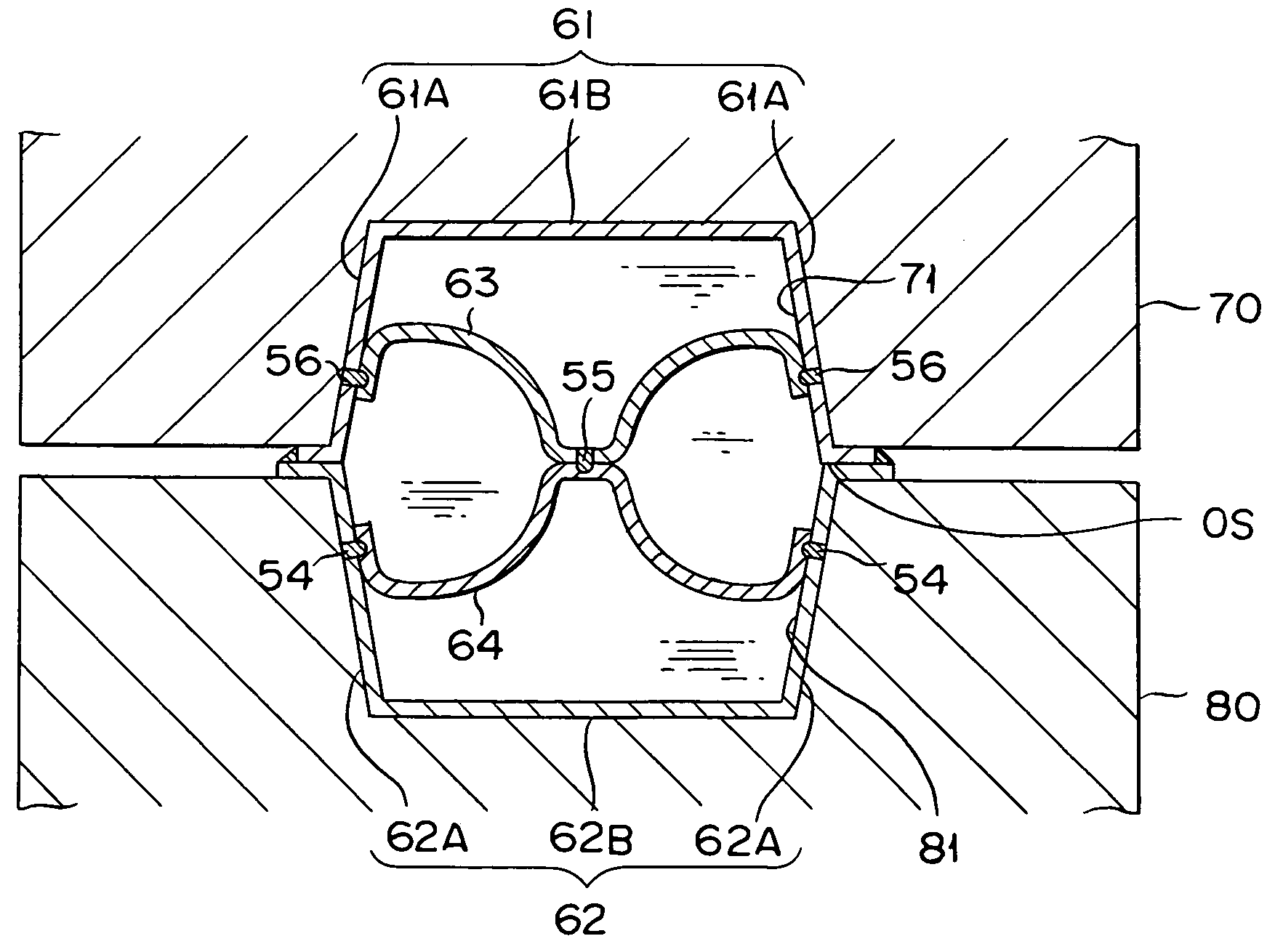

Stator of a moineau-pump

InactiveUS20060029507A1Improve rigidityHigh strengthOscillating piston enginesEngine of intermeshing engagement typeHydroformingStator

Owner:NOETIC TECH INC

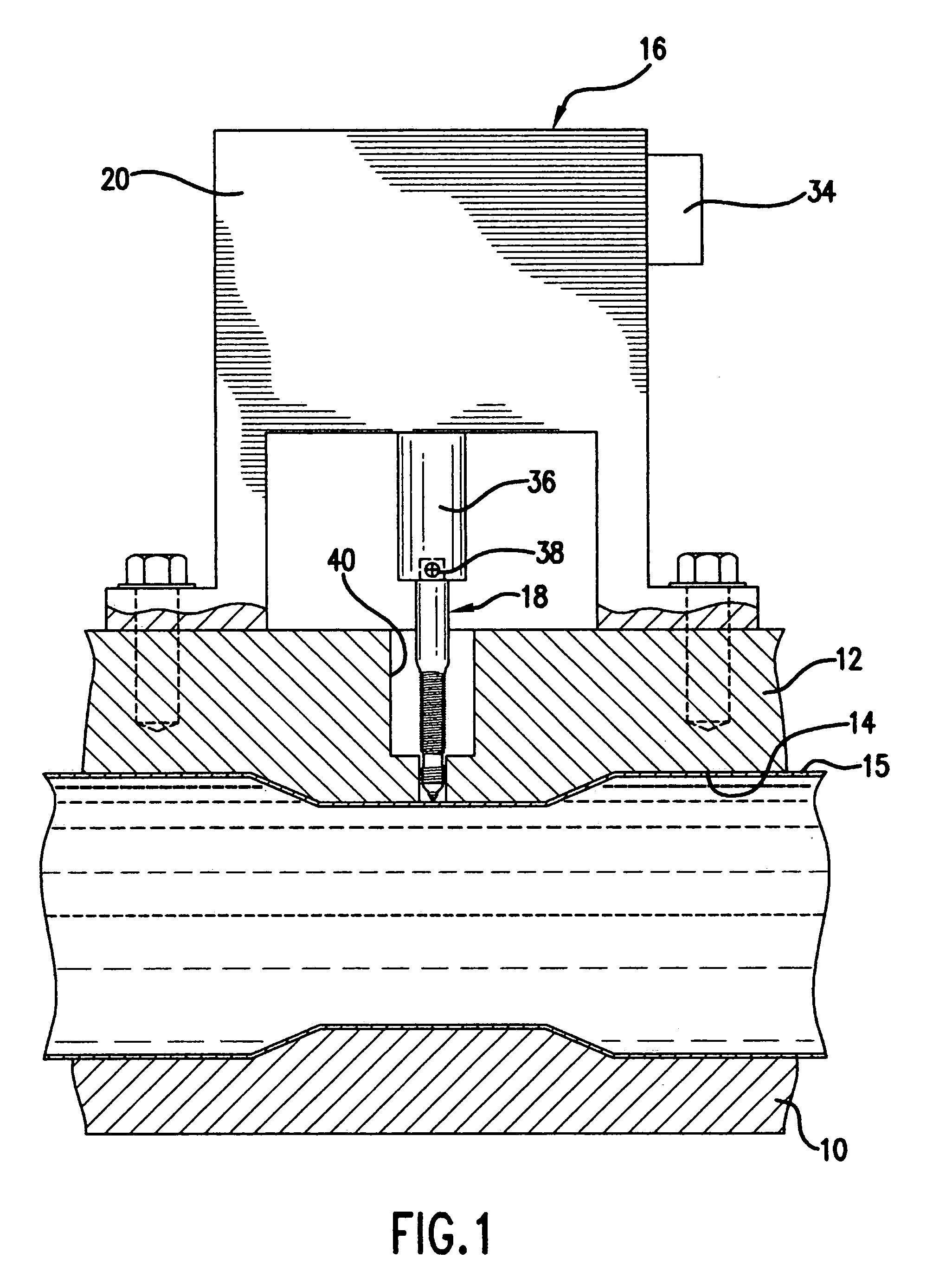

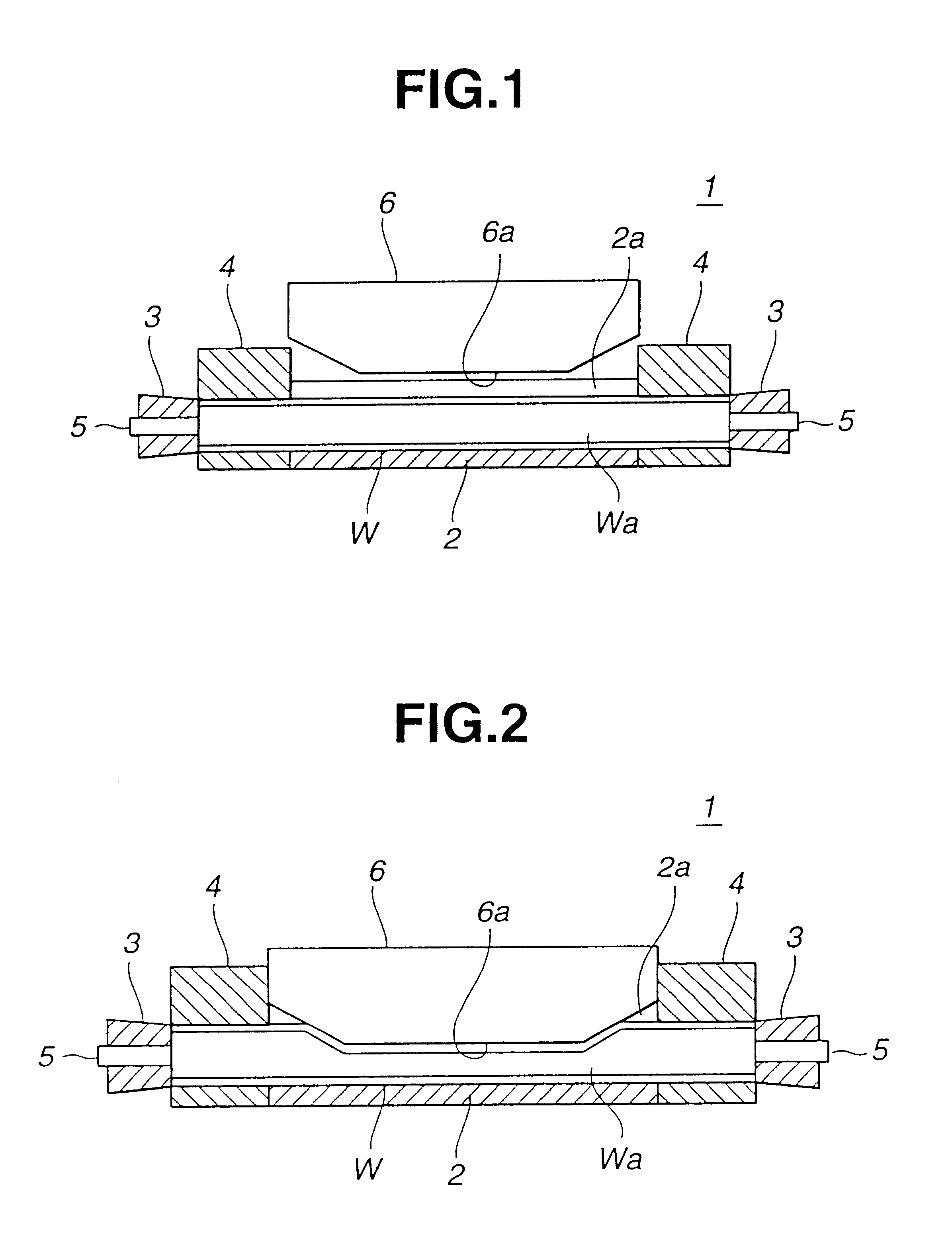

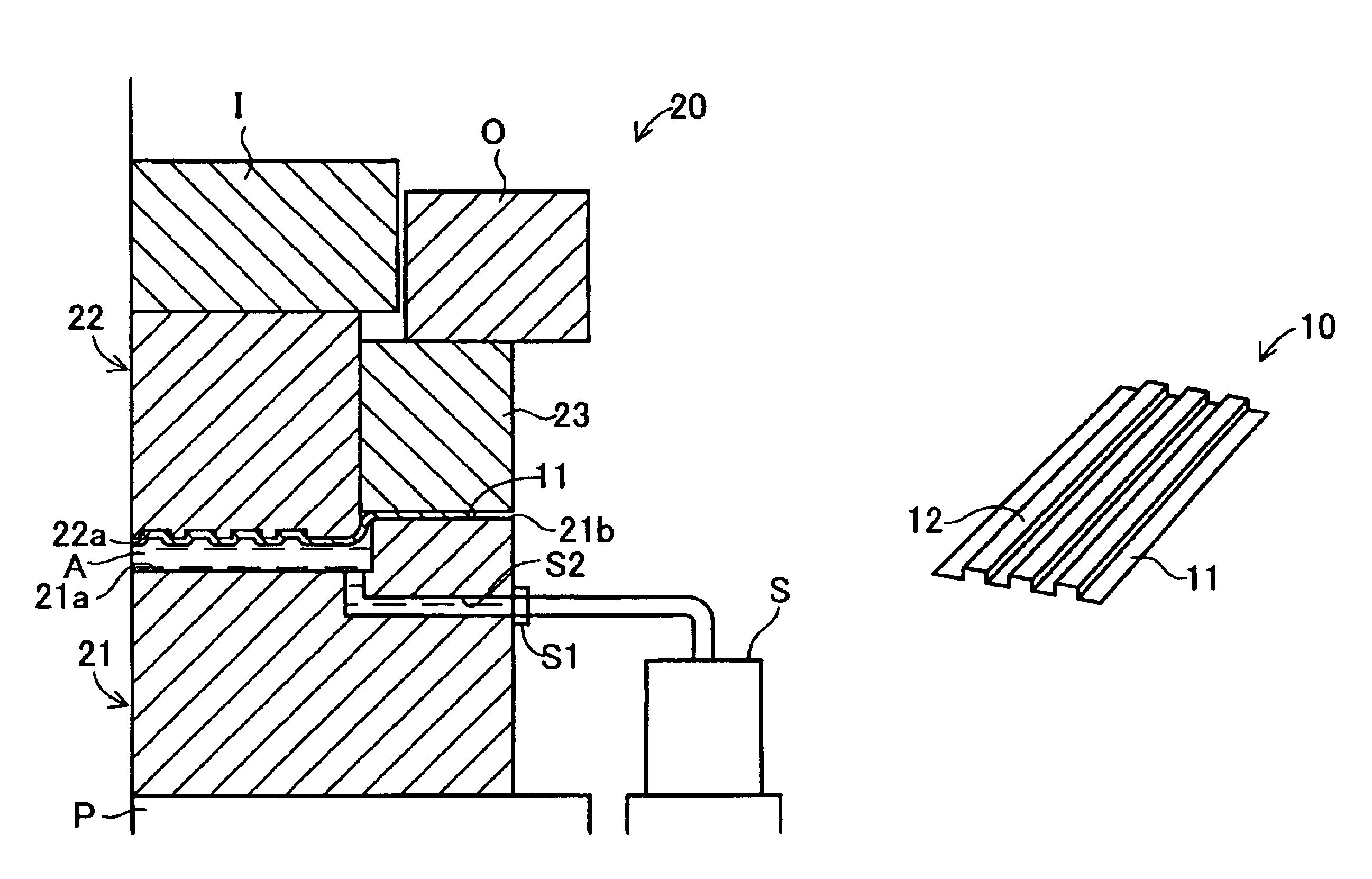

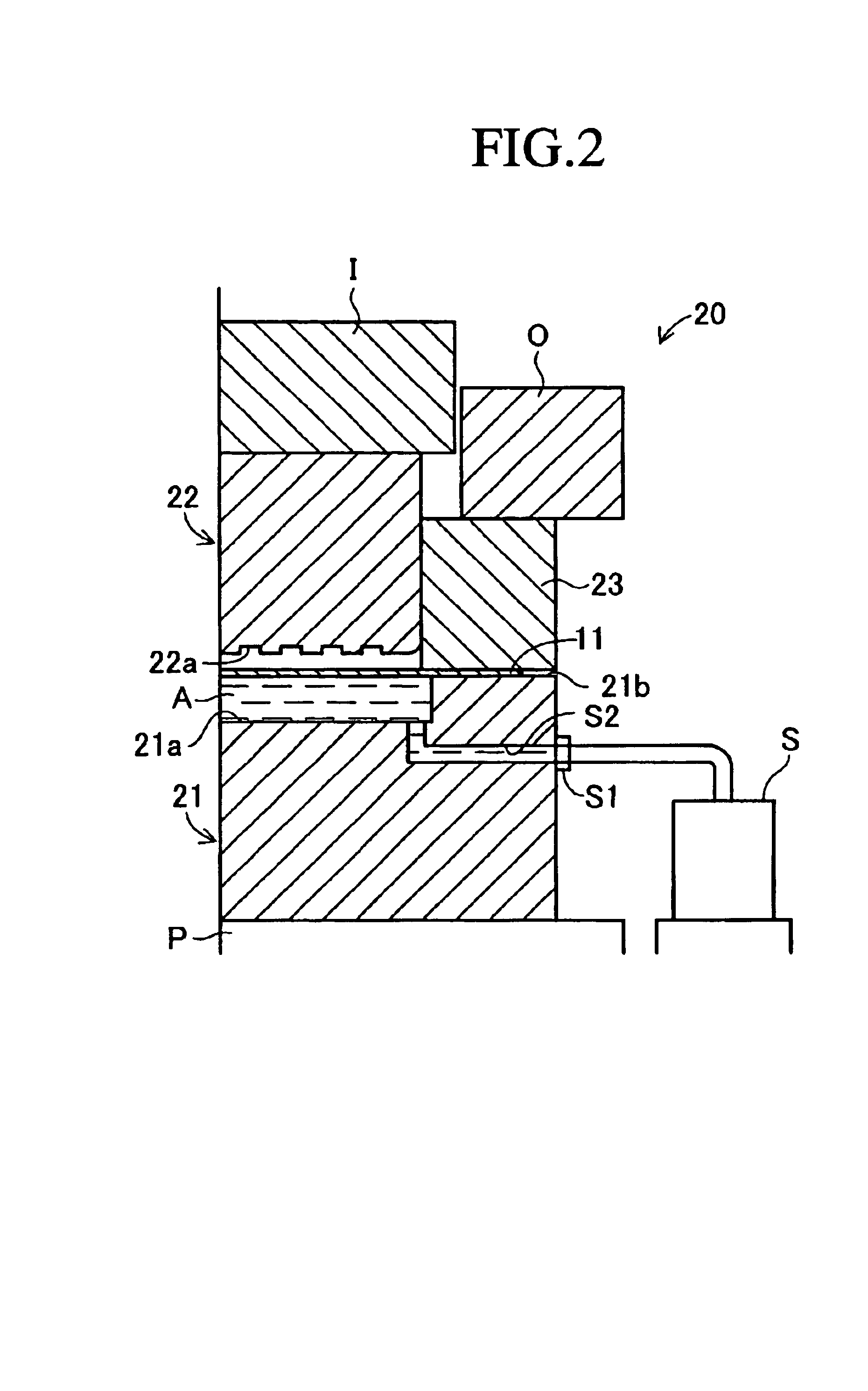

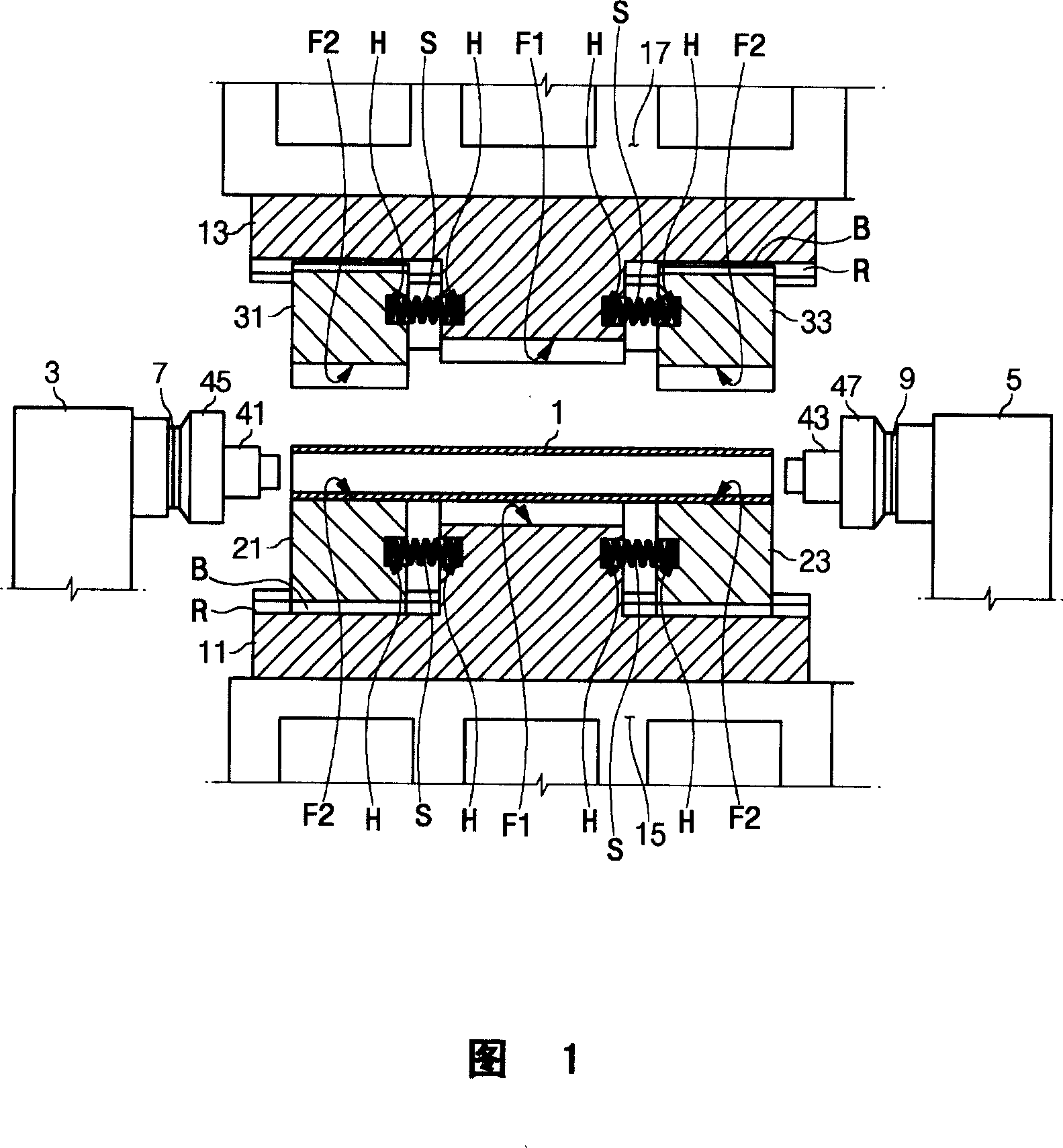

Hydraulic forming process, hydraulic forming device and metal separator for a fuel cell formed by hydraulic forming process

InactiveUS6938449B2Increase joint areaImprove conductivityFinal product manufactureCell electrodesFuel cellsHydroforming

By using a hydraulic forming device 20, a metal plate body 11 is placed on a support section 21b with a hollow section 21a formed on a lower die 21 filled with hydraulic fluid A. Subsequently, a blank holder 23 is lowered to clamp the peripheral edge section of the placed metal plate body 11 with the support section 21b. Then, the upper die 22 is lowered relative to the lower die 21 to pressedly deform the central section of the metal plate body 11 and to compress the hydraulic fluid A to increase the fluid pressure. A rib-like convex section 12 is transferred onto the metal plate body 11 by the increased fluid pressure of the hydraulic fluid A and a formed section 22a. Further, the fluid pressure of the hydraulic fluid A is kept for a predetermined time. Then, the increased fluid pressure of the hydraulic fluid A is released.

Owner:TOYOTA SHATAI KK

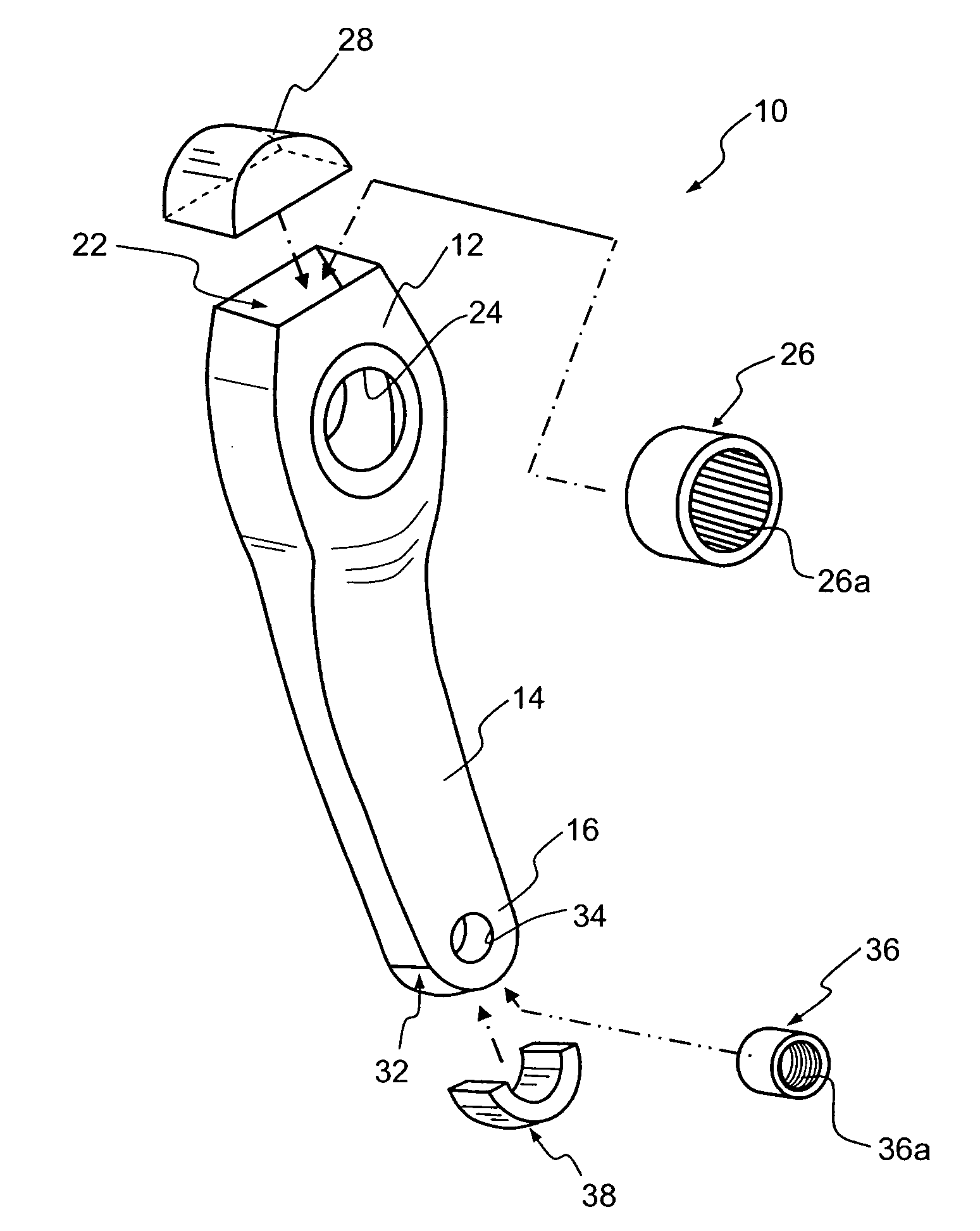

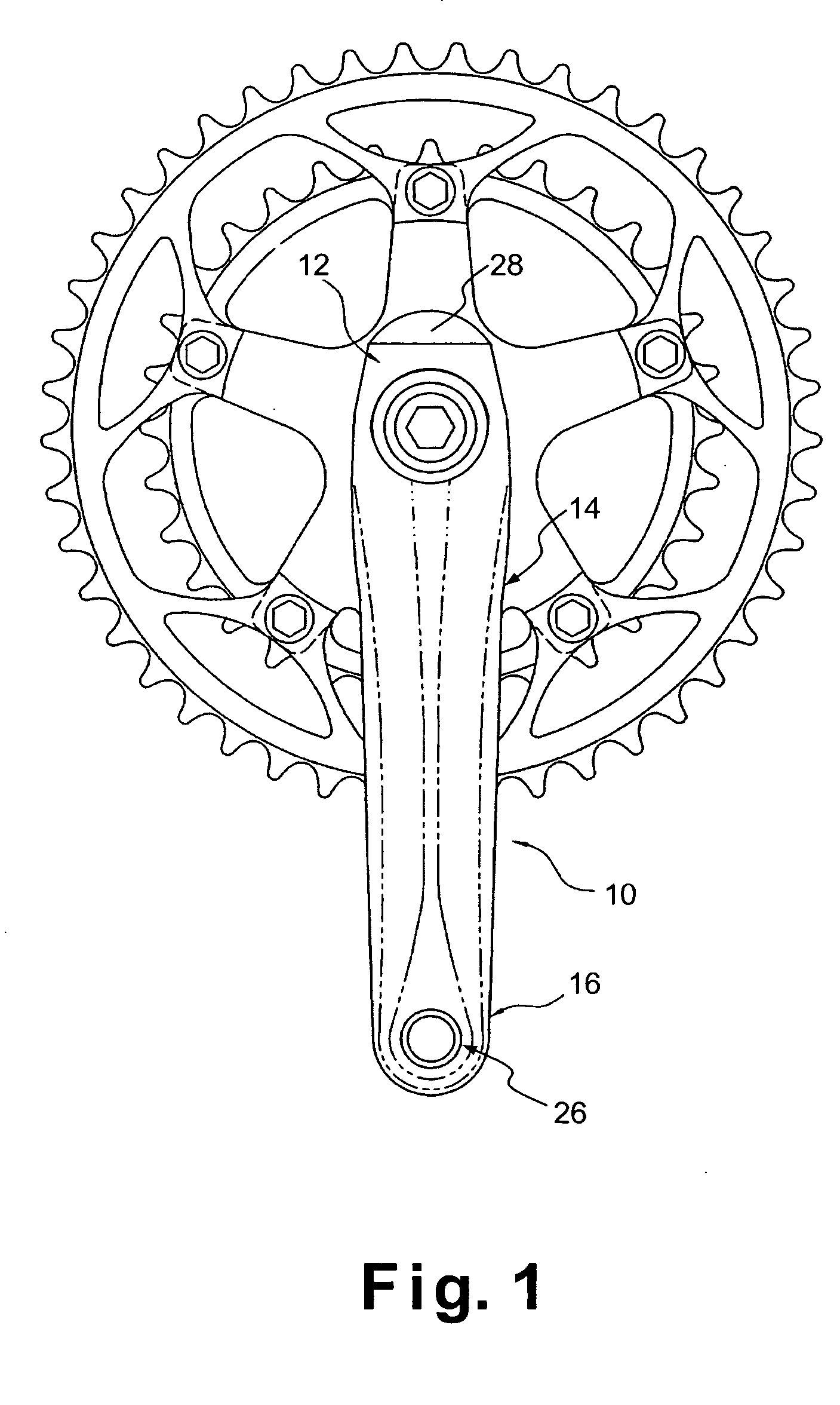

Bicycle crank arm

InactiveUS20050217417A1Improve rigidityHighly complex shapeControlling membersMechanical apparatusHydroformingBellcrank

A bicycle crank arm is provided that is a light, highly strong, highly rigid and highly designed in a complex shape. The bicycle crank arm has a crank axle mounting end portion, a central crank body portion and a pedal mounting end portion. The hollow bicycle crank arm is preferably a one-piece, unitary member that is produced by a tube hydroforming method. The hollow bicycle crank arm has a crank axle attachment part located within the crank axle mounting end portion and a pedal spindle attachment part located within the pedal mounting end portion. The mounting end portions have a crank axle hole and a pedal spindle hole, respectively, with outside diameters that are smaller than the attachment parts, respectively.

Owner:SHIMANO INC

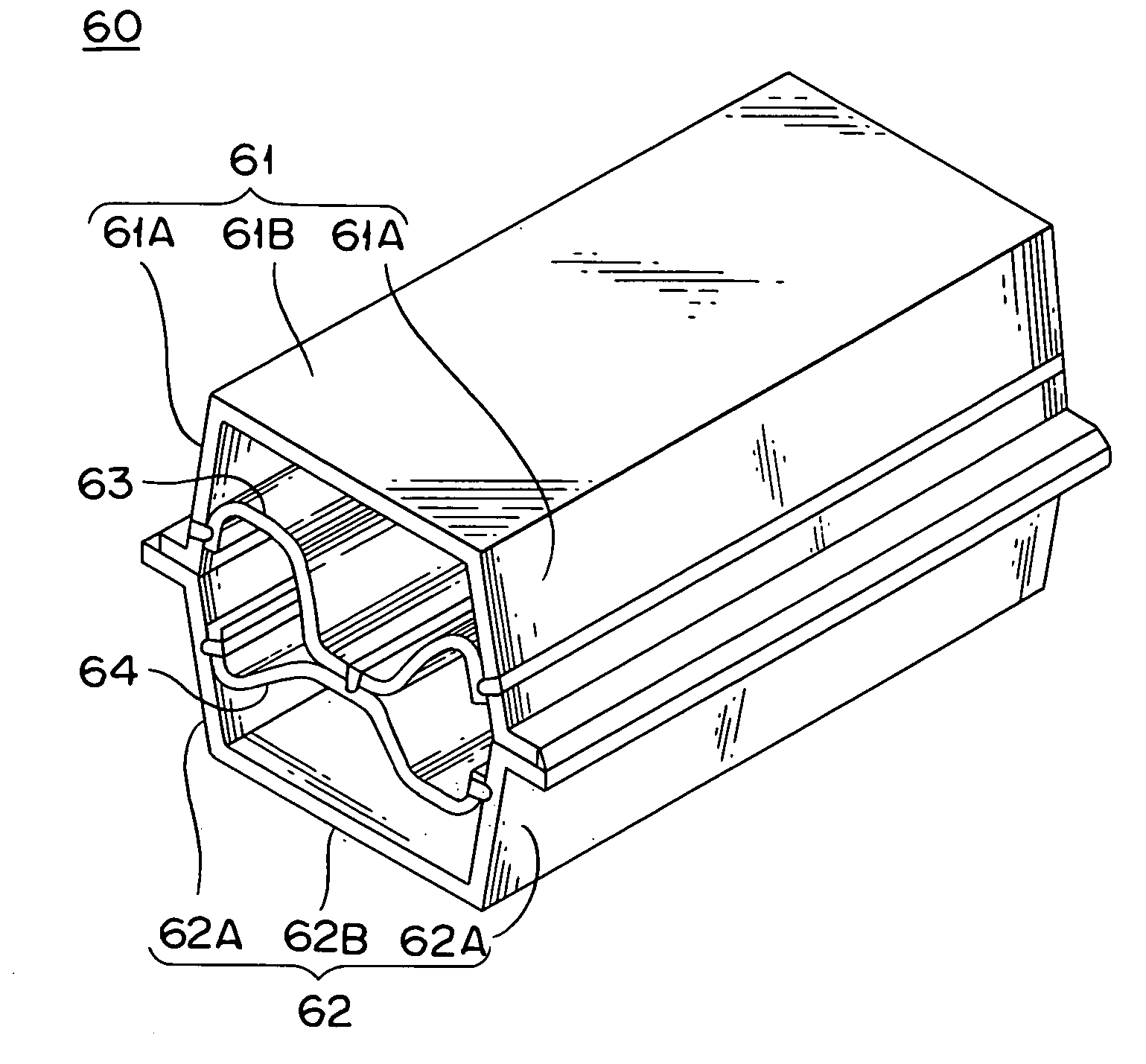

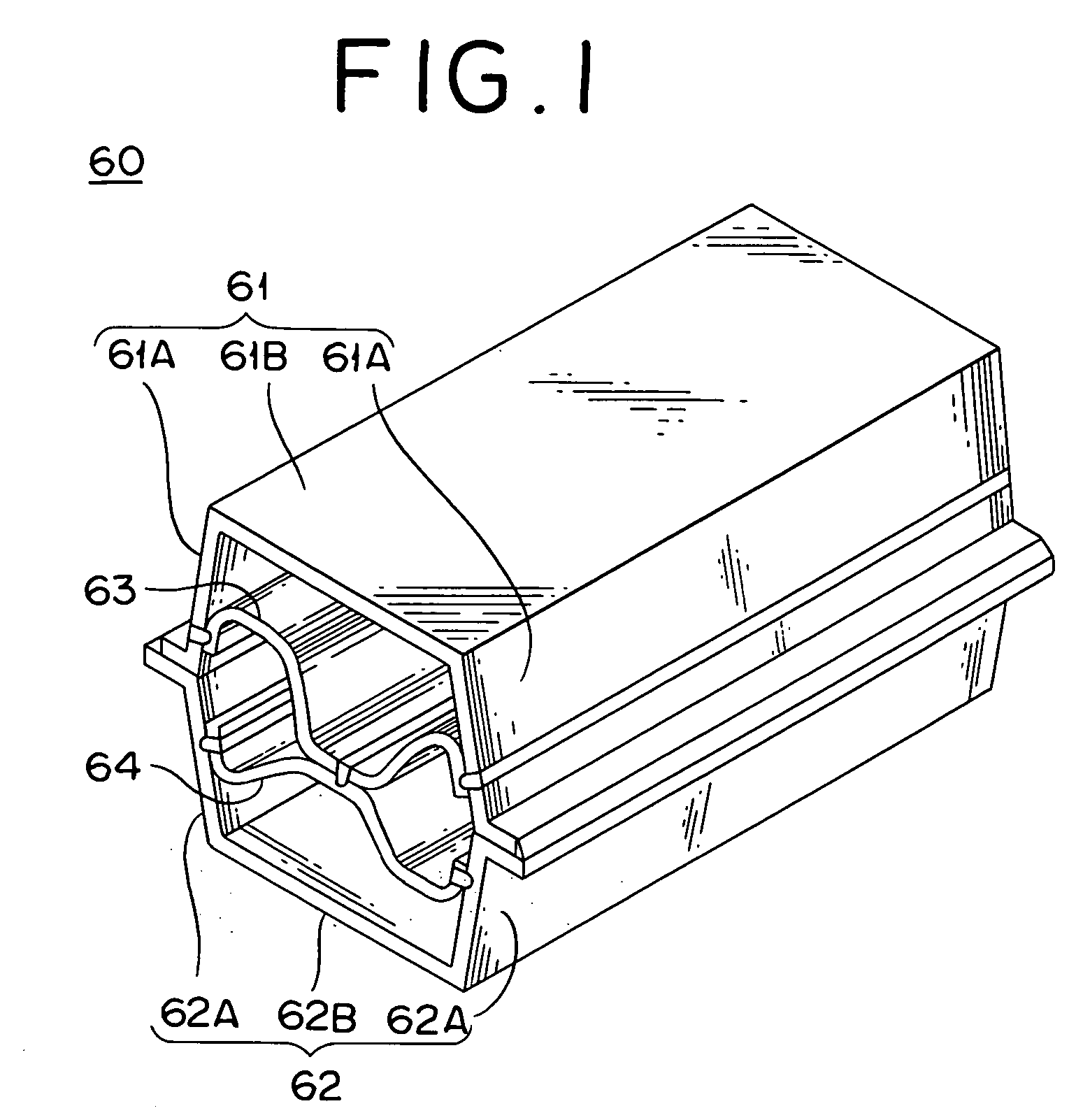

Preform, hydroforming method, and hydroformed product

InactiveUS7406849B2Avoid fracturesExcellent and stable qualityVehicle seatsLoad-supporting pillarsEngineeringHydroforming

A preform with edges overlapped and jointed each other and first and second outer members for forming outer surfaces of a hydroformed product, and reinforcement members that are jointed to the first and second outer members to form reinforcement ribs that divide a hollow cross section of the outer surfaces, the reinforcement members having dimensions capable of suppressing elongation in a tensile direction due to a tensile force that develops during hydroforming.

Owner:NISSAN MOTOR CO LTD

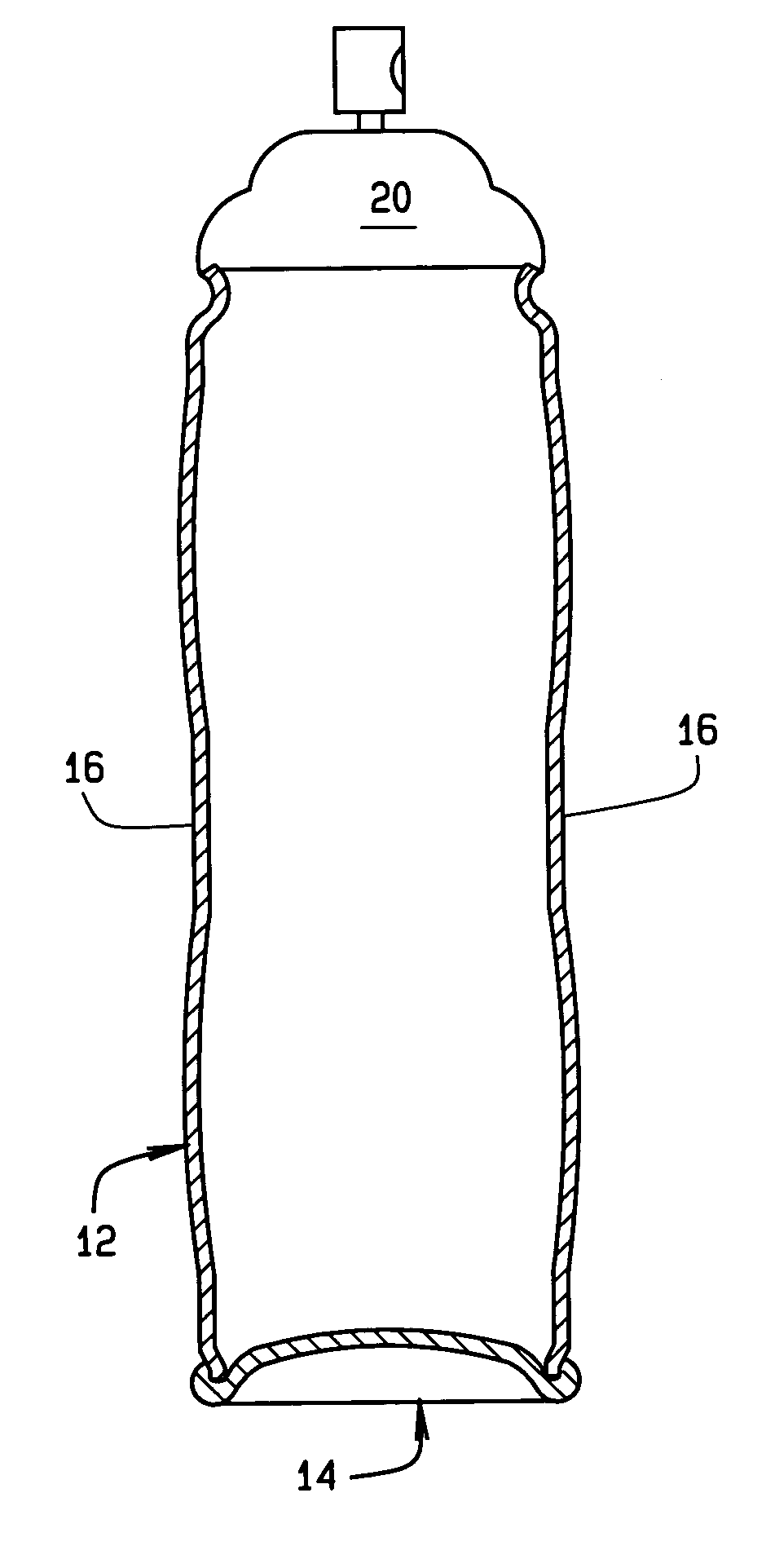

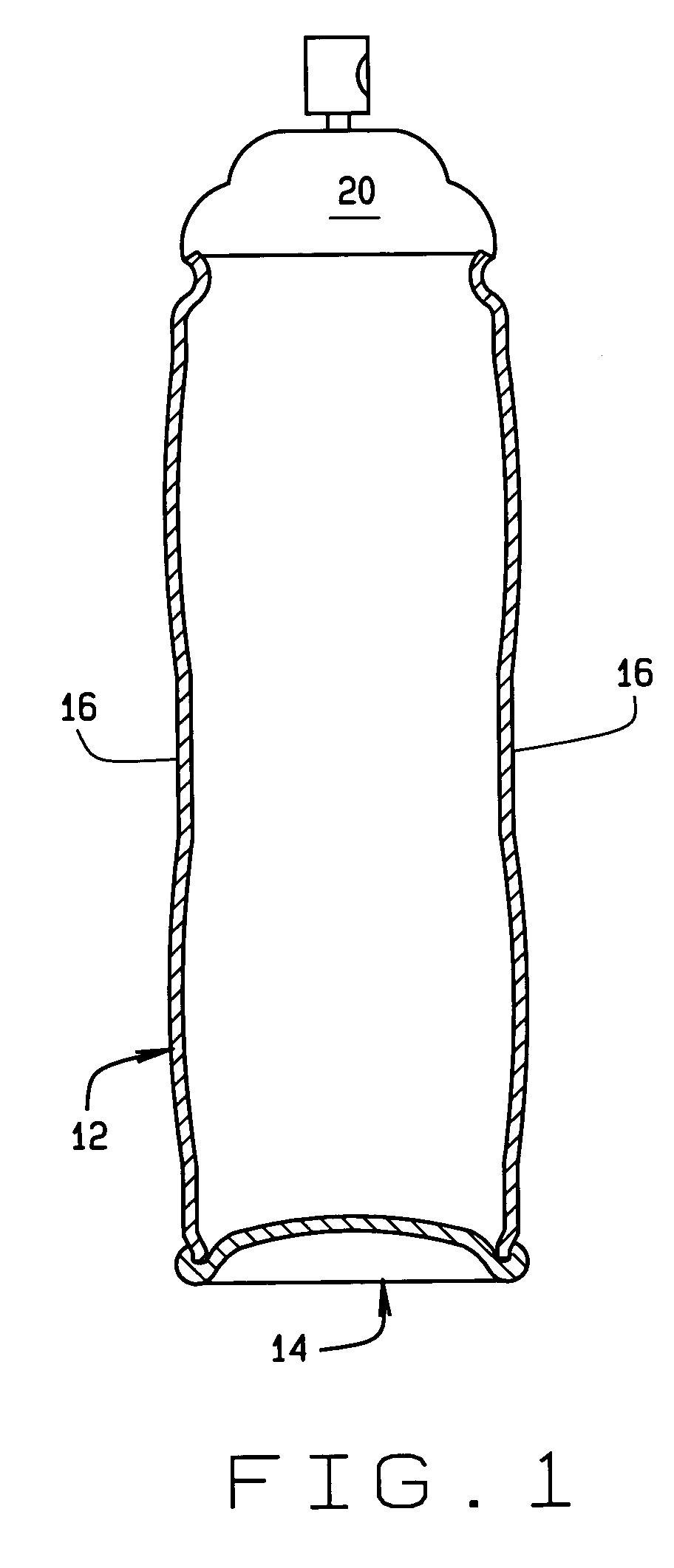

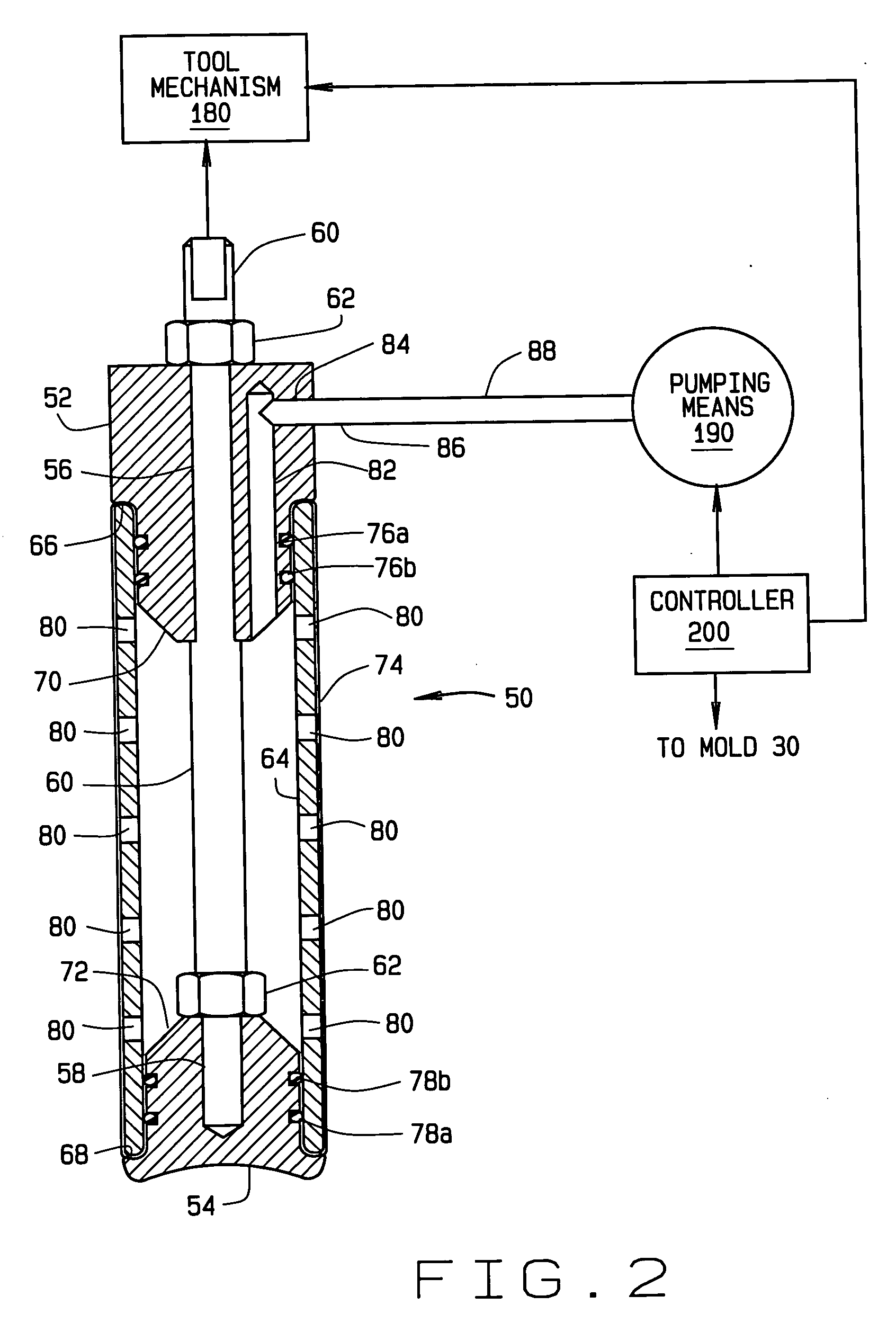

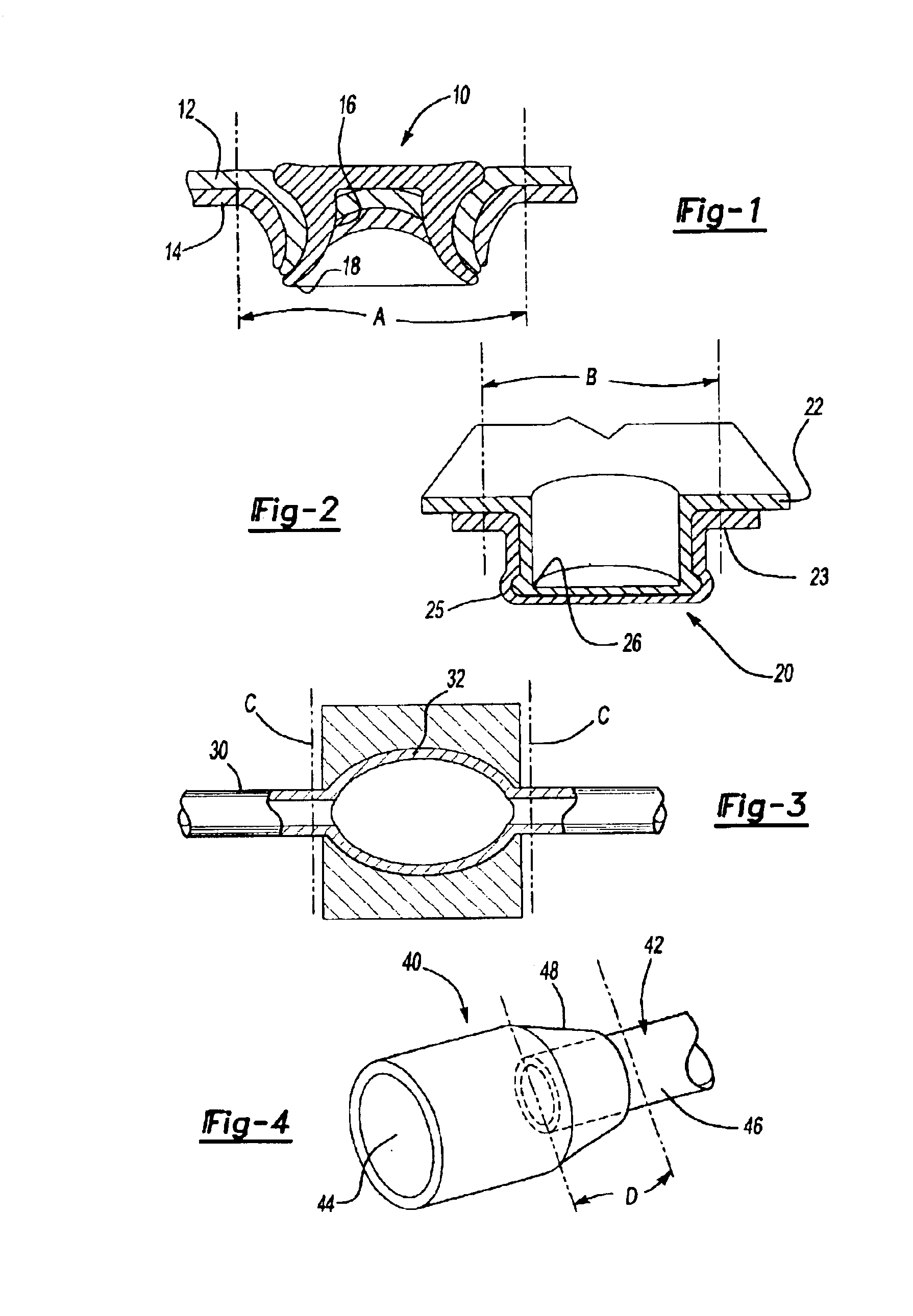

Dry hydraulic can shaping

ActiveUS20060060601A1Reduce manufacturing stepsShorten production timeOpening closed containersBottle/container closureEngineeringHydraulic fluid

A method for shaping an aerosol container (10) to a desired body contour. A container body (12) is formed into a cylindrical shape and installed into a mold (30) whose inner surface defines the desired body contour. A bladder (74) is fitted onto a tool (50) insertable into an open end (M) of the container body. Once the tool is inserted, the bladder is inflated with a hydraulic fluid. Pressurizing the bladder forces the bladder against a sidewall of the body forcing the body outwardly and deforming it against the inside of the mold. After the container body is shaped, the bladder is de-pressurized and the tool withdrawn leaving the container with a defined body contour. The hydraulic fluid with which the bladder is pressurized is, at all times, contained within the bladder and does not contact the container sidewall so no subsequent drying of the container is required after the shaping process is complete.

Owner:BALL METALPACK LLC

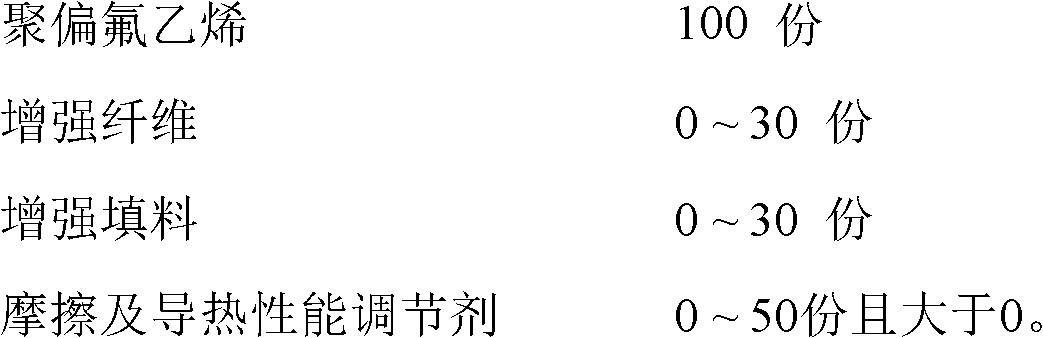

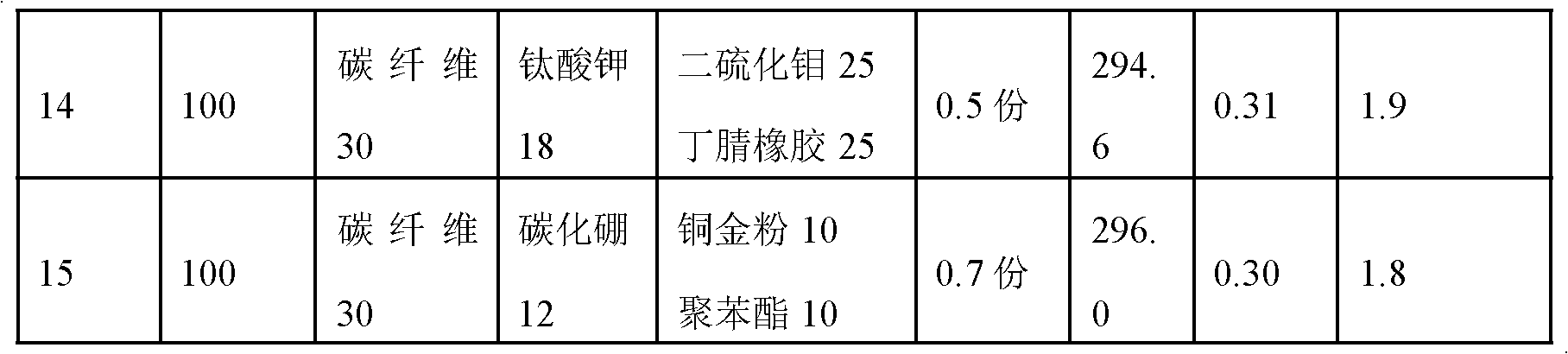

Polyvinylidene fluoride based composite frictional material for traveling wave type revolving ultrasonic motor and preparation method thereof

ActiveCN102634147AExcellent mechanical propertiesExtended service lifeOther chemical processesFiberHeat conducting

The invention relates to a polyvinylidene fluoride based composite frictional material for a traveling wave type revolving ultrasonic motor and a preparation method thereof. The frictional material comprises the following compositions in parts by weight: 100 parts of polyvinylidene fluoride, 0-30 parts of reinforced fibers, 0-30 parts of reinforced filler and 0-50 parts of friction and heat-conducting property conditioning agent. The the preparation method comprises the steps of: premixing the compositions weighed in a proportion for 20 minutes in a ball mill; mixing for 3-5 hours by adopting an ethanol wet method; drying at temperature of 80 DEG C; adding granules into a mold cavity, and conducting hydraulic forming under the conditions that pressure is 25-40MPa and is maintained for 5-15 munites; demoulding, sintering for 1.5-2.5 hours at the temperature of 220-250 DEG C, and cooling along with a furnace; and machining to a needed dimension. The obtained frictional material can increase the mechanical characteristic and the service life of the ultrasonic motor.

Owner:NUAA SUPER CONTROL TECHNOLOGY CO LTD

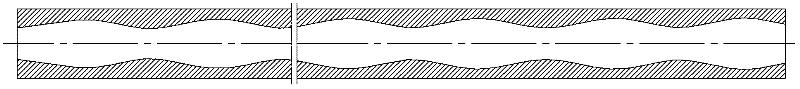

Method for machining all-metal screw pump stator

InactiveCN102501016ASolve processing difficultiesReduce processing difficultyElectrochemical machining apparatusHydroformingScrew pump

The invention discloses a method for machining an all-metal screw pump stator. The method comprises the following steps of: 1) machining a stator blank, so that a central hole for forming a stator inner cavity is formed in the stator blank; 2) forming the stator inner cavity by an electrolytic process; 3) polishing the stator inner cavity; and 4) performing surface-hardening treatment on the stator inner cavity. According to the method, the problem of difficulty in machining of the all-metal screw pump stator is solved by combining polishing treatment and surface-hardening treatment by adopting the electrolytic process. The method has obvious advantages on the machining of materials which are difficult to machine and parts with complex shapes or thin-wall parts, and has the characteristics of wide range of the machined materials, high production efficiency, high forming accuracy, capability of recycling electrode assemblies and the like. By the method, the technical blockade of hydraulically-formed all-metal screw pump stators which are used abroad is broken through, and a new method for manufacturing the all-metal screw pump stator is opened up, so that the machining difficulty of the all-metal screw pump stator is reduced effectively, and the machining efficiency is improved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

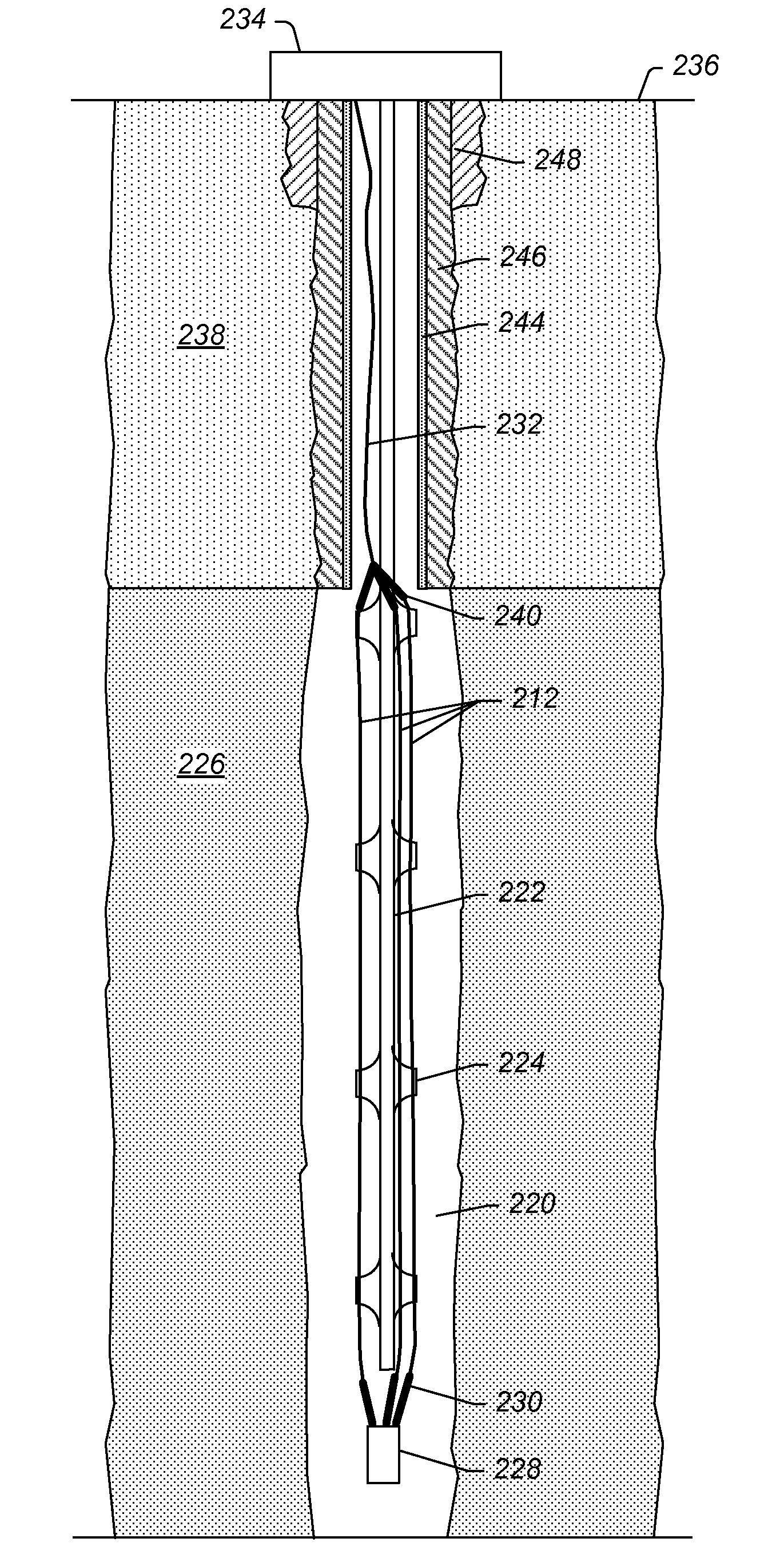

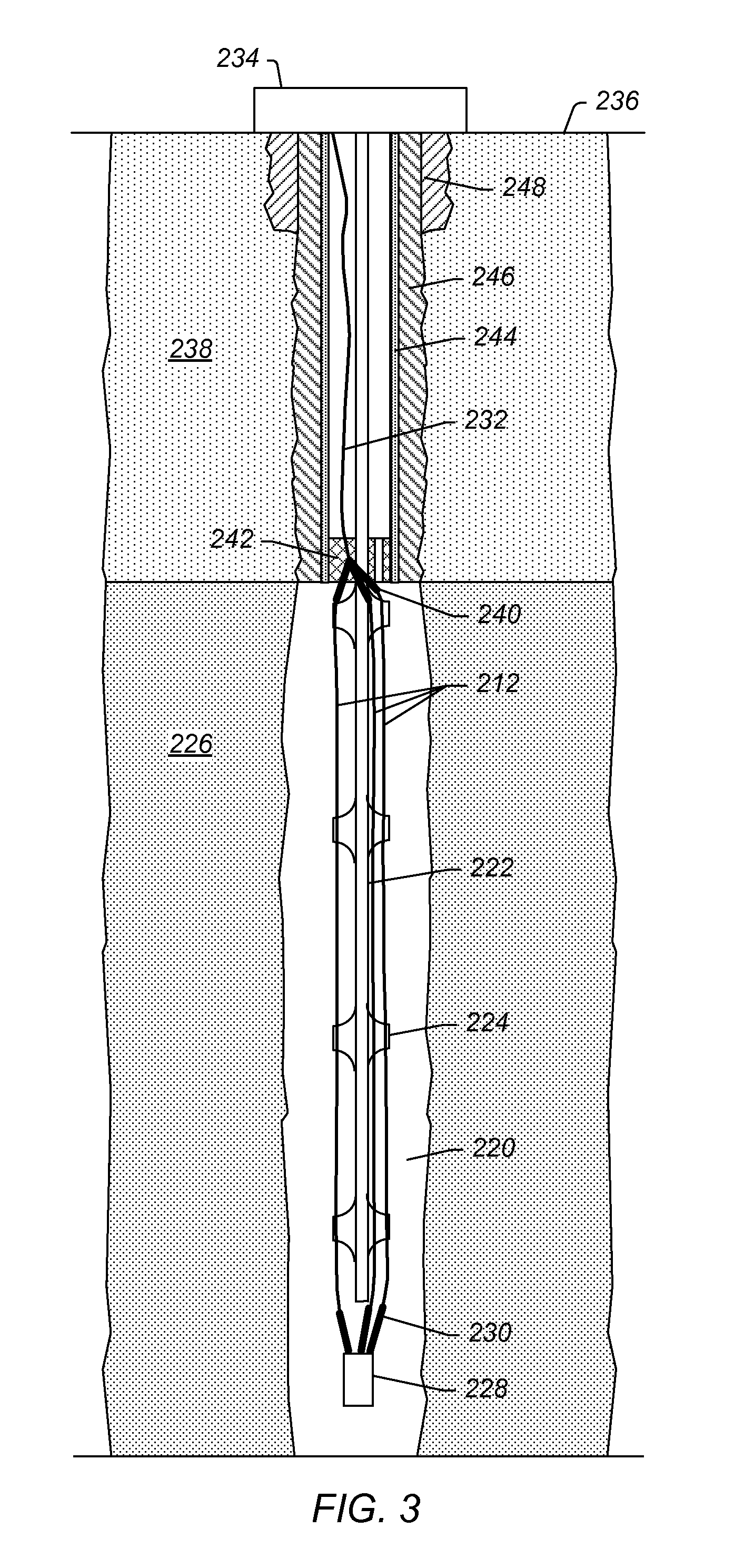

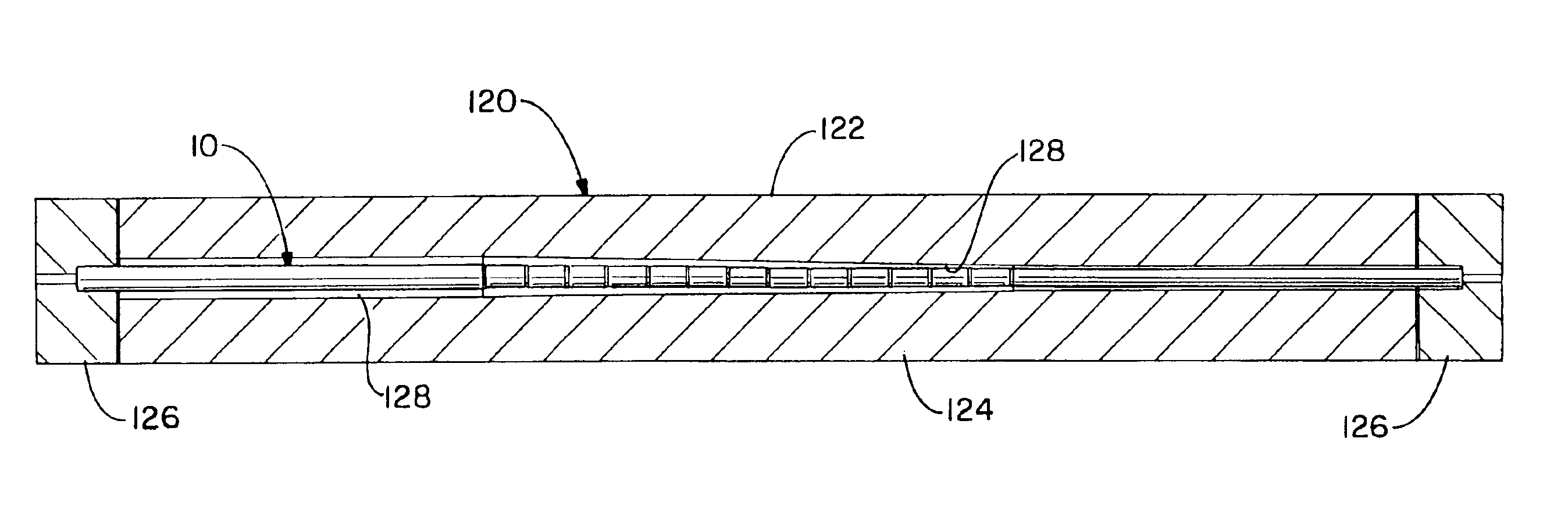

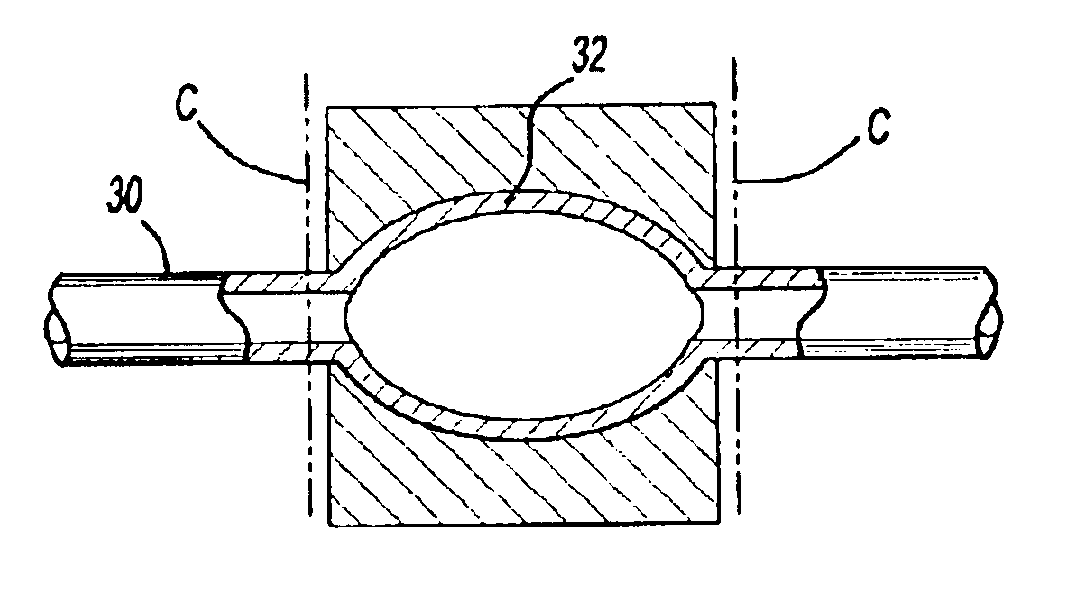

Hydroformed splice for insulated conductors

A method for coupling ends of two insulated conductors includes coupling an end portion of a core of a first insulated conductor to an end portion of a core of a second insulated conductor. At least a part of the end portions of the cores are at least partially exposed. Electrically insulating material is placed over the exposed portions of the cores. An inner sleeve is placed over end portions of the two insulated conductors to be coupled. An outer sleeve is placed over the inner sleeve. There is an open volume between the inner sleeve and the outer sleeve. The inner sleeve and the outer sleeve are coupled to jackets of the insulated conductors. A pressurized fluid is provided into the open volume between the inner sleeve and the outer sleeve to compress the inner sleeve into the electrically insulating material and compact the electrically insulating material.

Owner:SHELL OIL CO

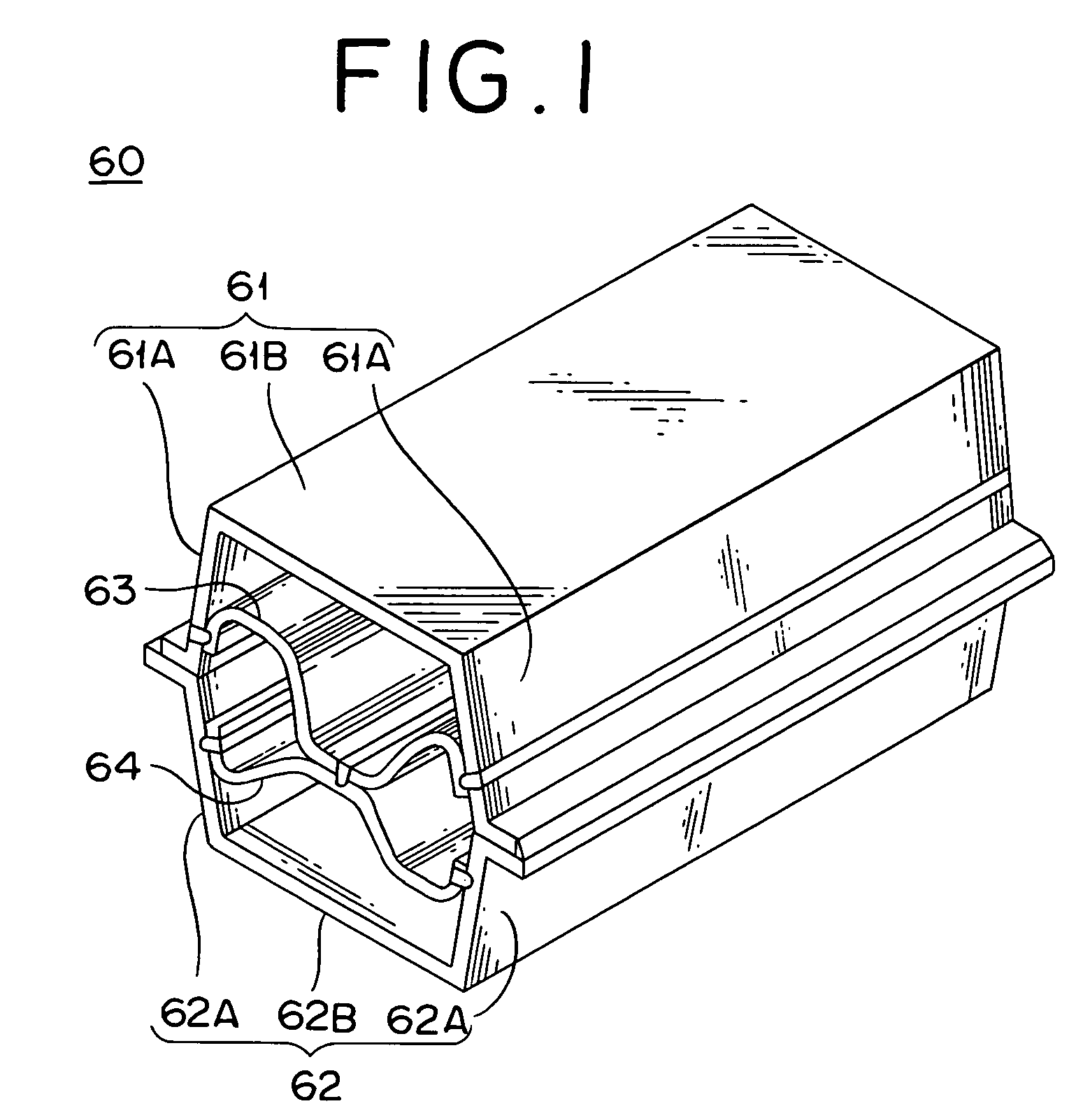

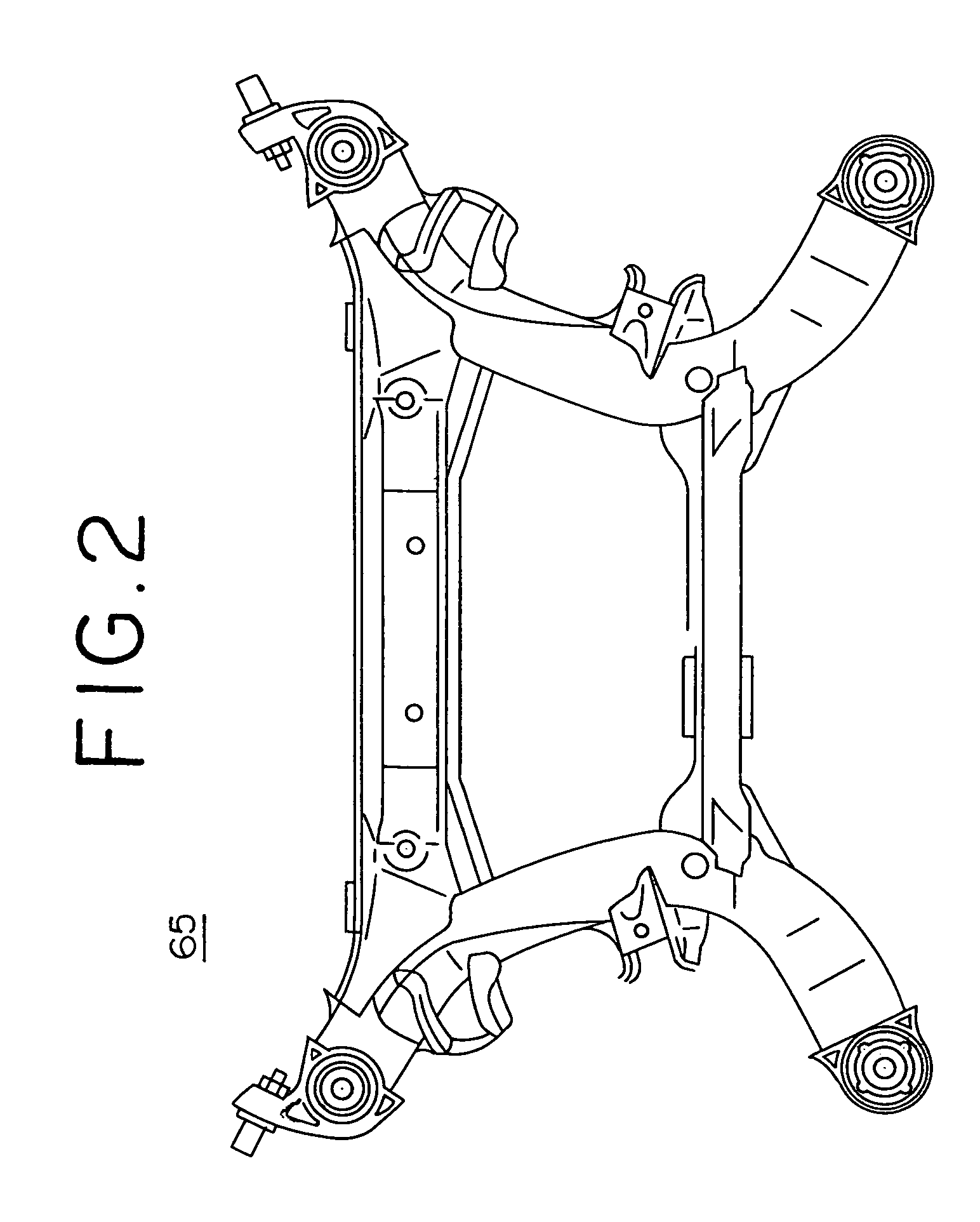

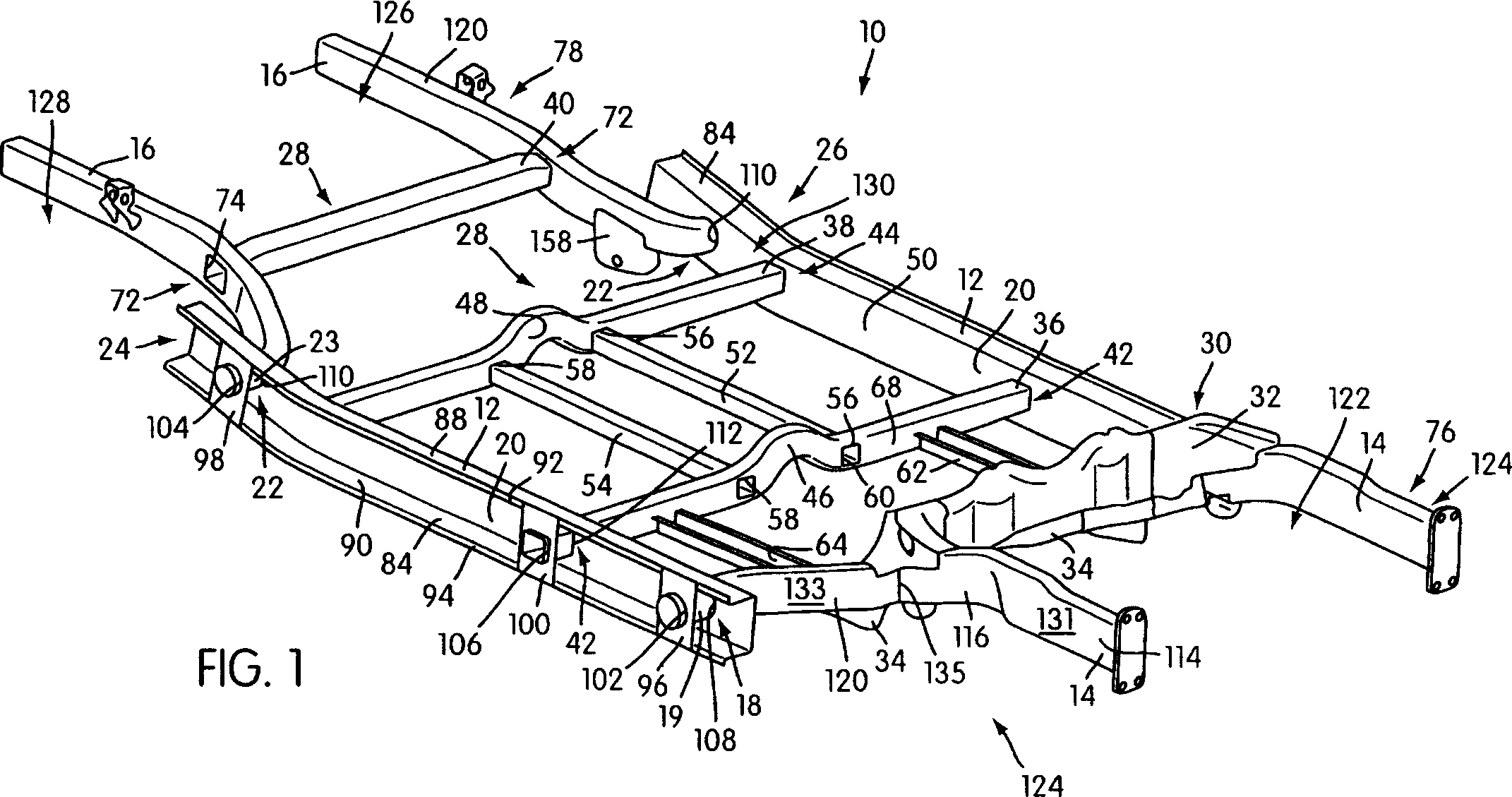

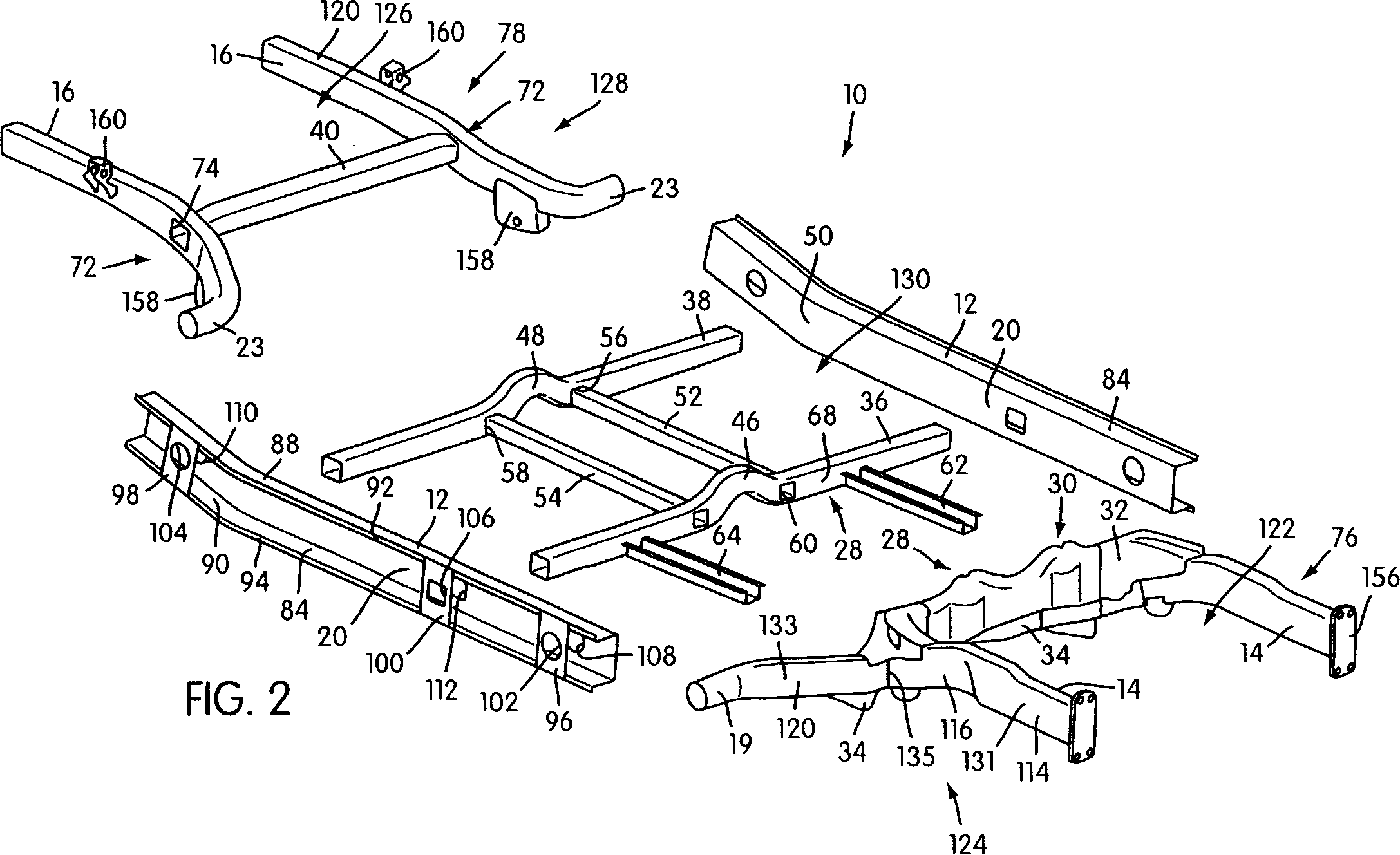

Modular underbody for a motor vehicle

Owner:MAGNA INTERNATIONAL INC

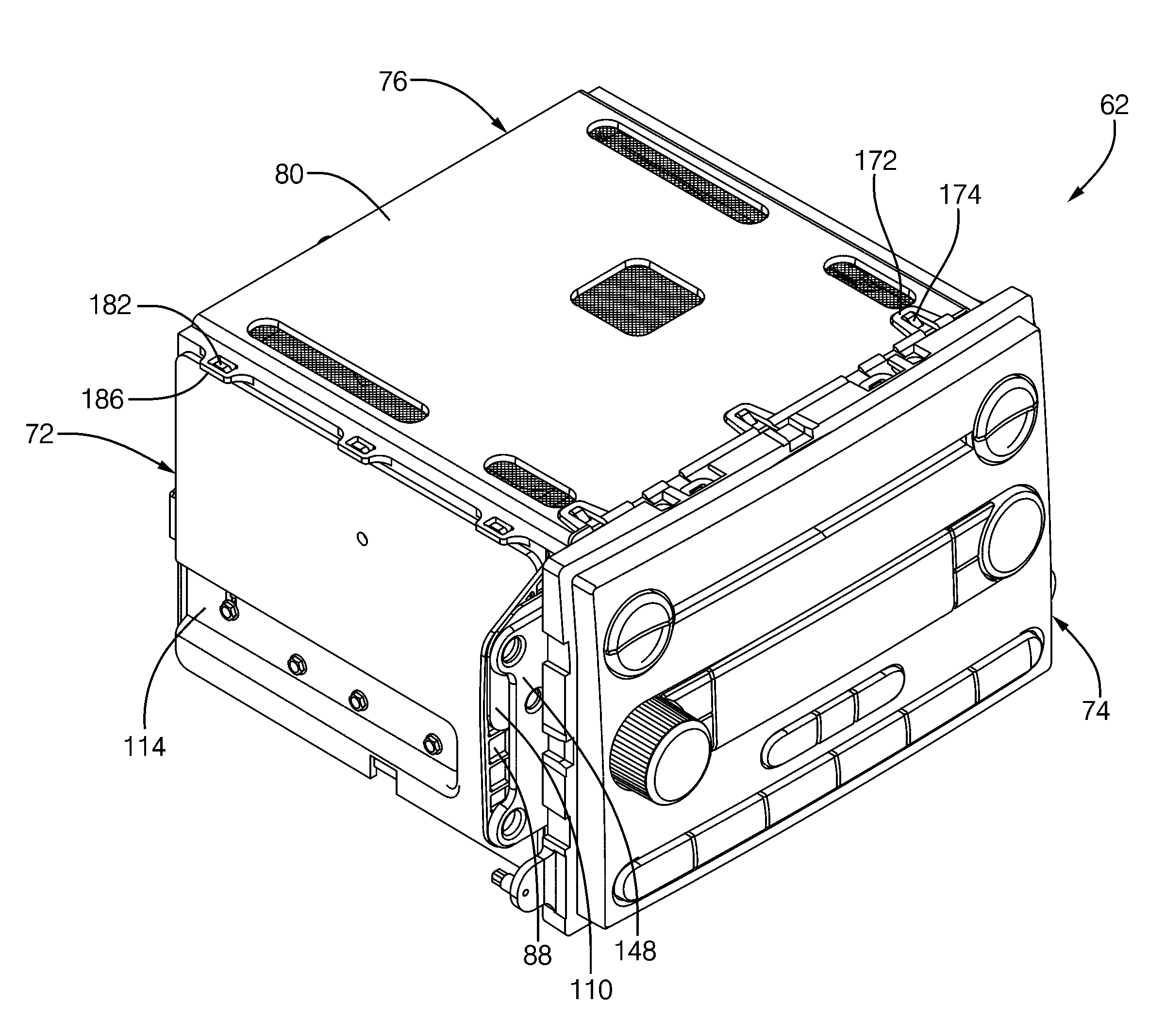

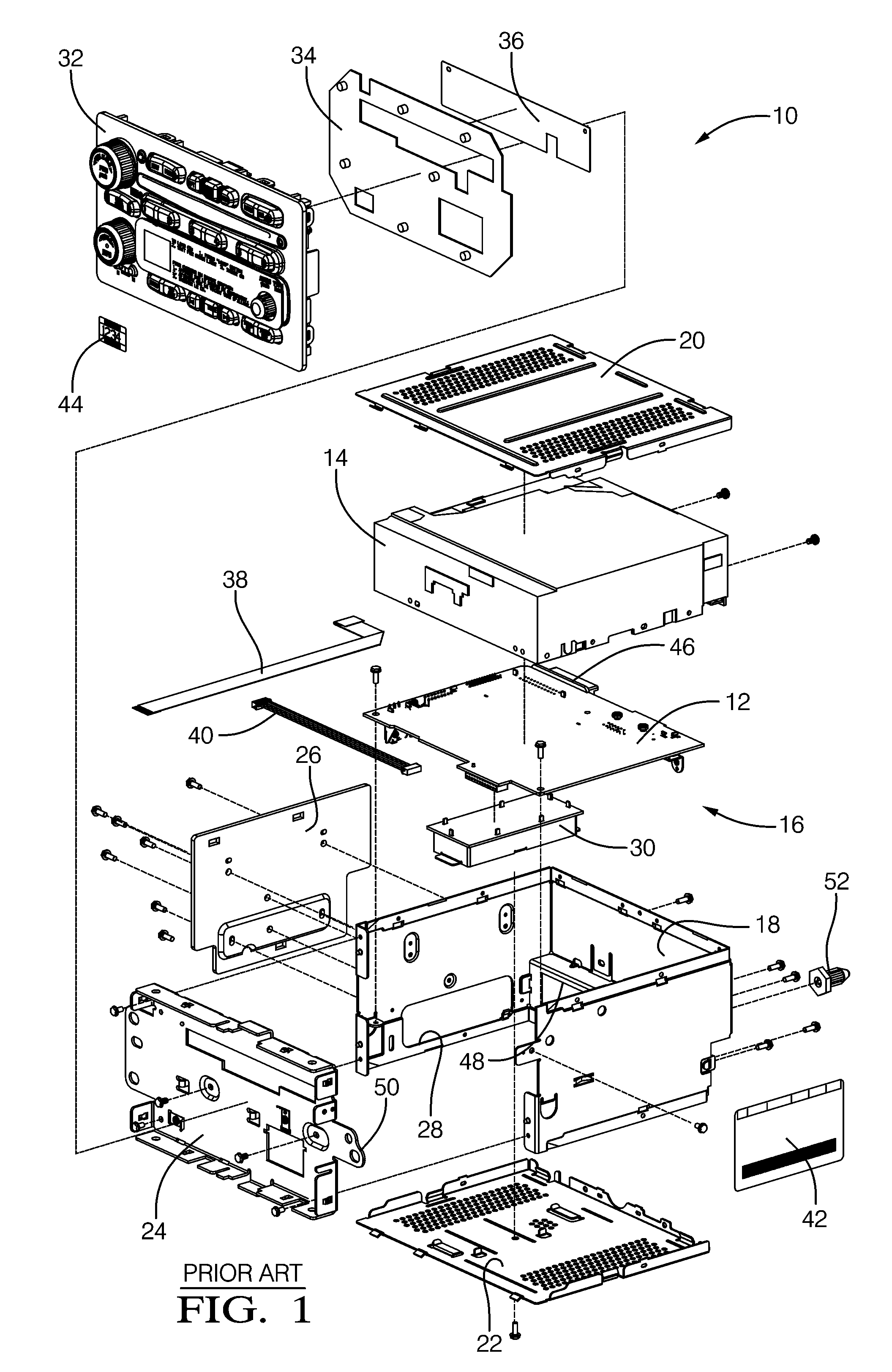

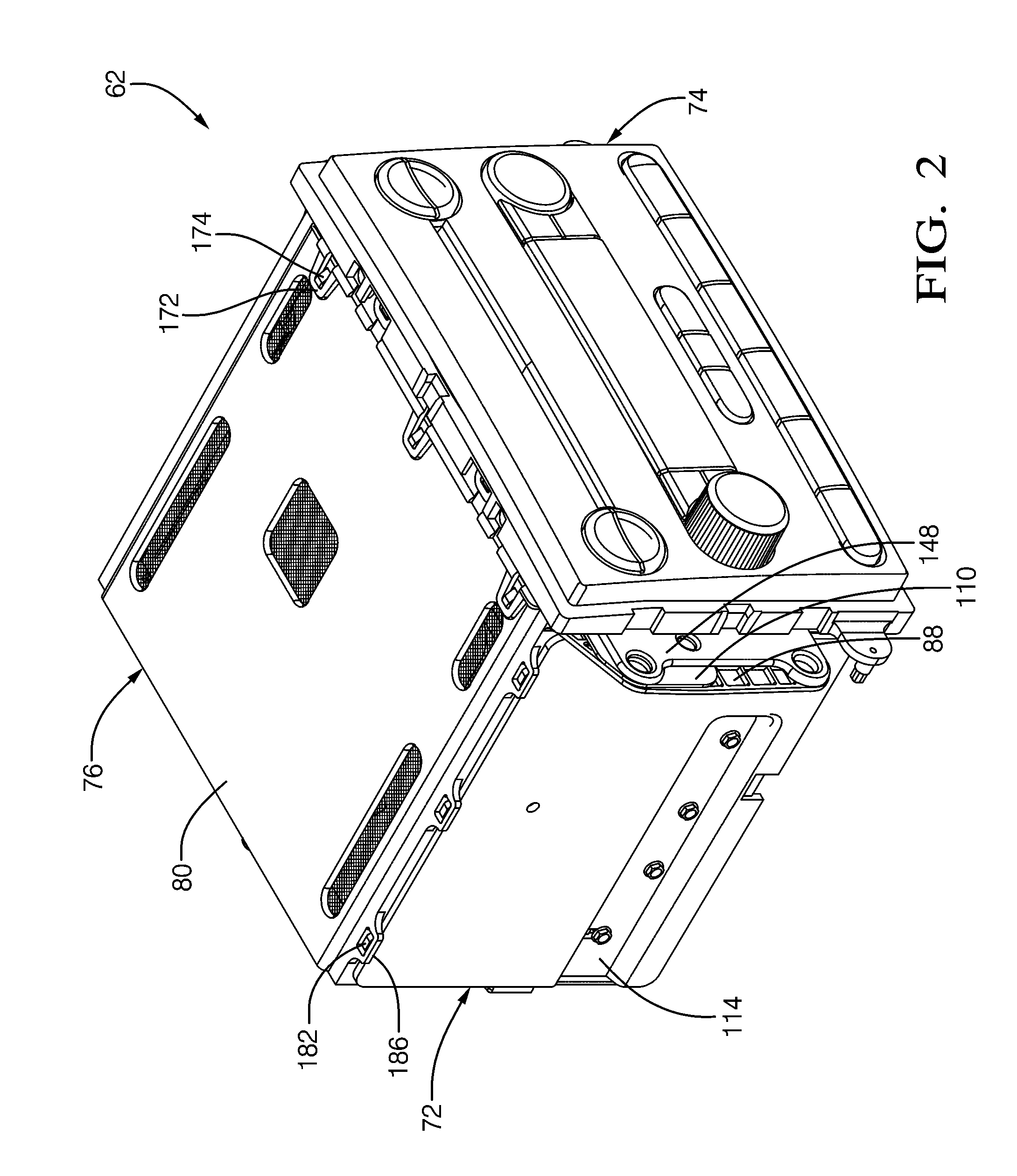

Lightweight audio system for automotive applications and method

InactiveUS20100246155A1Minimizes required handlingMinimize the numberAdhesivesElectrical apparatus interference reductionElectricityElectrical control

A housing assembly for a lightweight electronic device for vehicular application is virtually “fastenerless” and includes a one-piece case formed of a layered composite structure including polymer based, electrically insulating sheet material and electrically conductive sheet material that is compression molded or hydroformed to provide three-dimensional case details to accept one or more electronic devices such as circuit boards required for electrical control and display of vehicle based systems. The conductive sheet material is preferably a wire mesh which provides shielding from electrical anomalies and grounding of the circuit boards via exposed wire mesh pads and adjacent ground clips. Major components and subassemblies are self-fixturing during the final assembly process, eliminating the need for dedicated tools, fixtures and assembly equipment.

Owner:APTIV TECH LTD

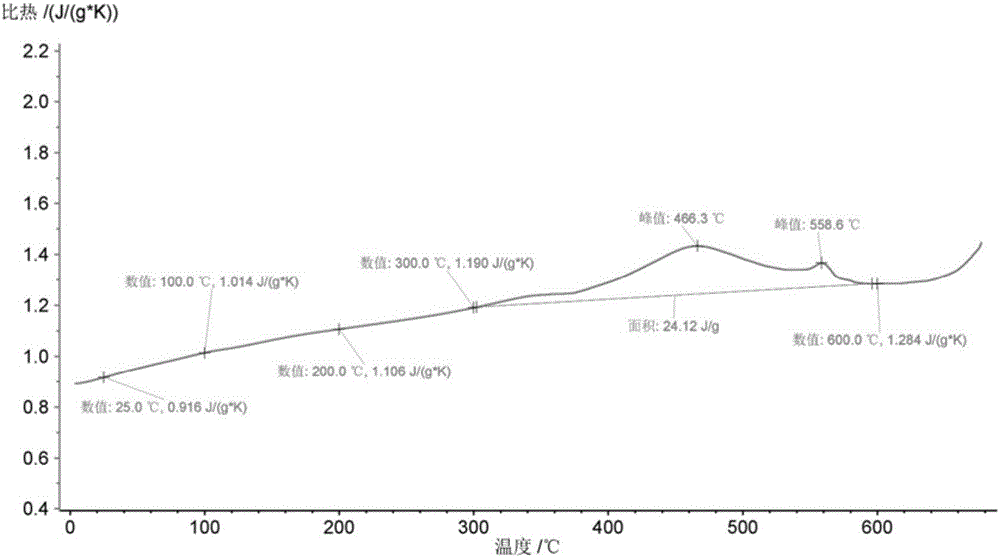

Solid composite phase-change thermal storage material and preparation method thereof

InactiveCN106701034ANo pollution in the processHigh heat storage densityHeat-exchange elementsVolumetric Mass DensityHydroforming

The invention discloses a solid composite phase-change thermal storage material, belonging to the technical field of energy storage materials. The solid composite phase-change thermal storage material comprises water, sodium carbonate, potassium carbonate, magnesium oxide, kieselguhr, quartz sand and kaolin. The thermal storage material is non-toxic, harmless and free of pollution. The invention further discloses a preparation method of the solid composite phase-change thermal storage material. The preparation method comprises the following steps: stirring, rubbing sand, filtering, performing hydraulic molding, and performing sintering molding. By adopting the preparation method, the thermal storage density is improved, the thermal storage density of the material is 2 times better than that of a common material, the thermal storage material can endure high temperature, can be heated to be greater than 650 DEG C, and is not liable to efflorescence when being used for a long time.

Owner:BEIJING SONDEX ENERGY TECH

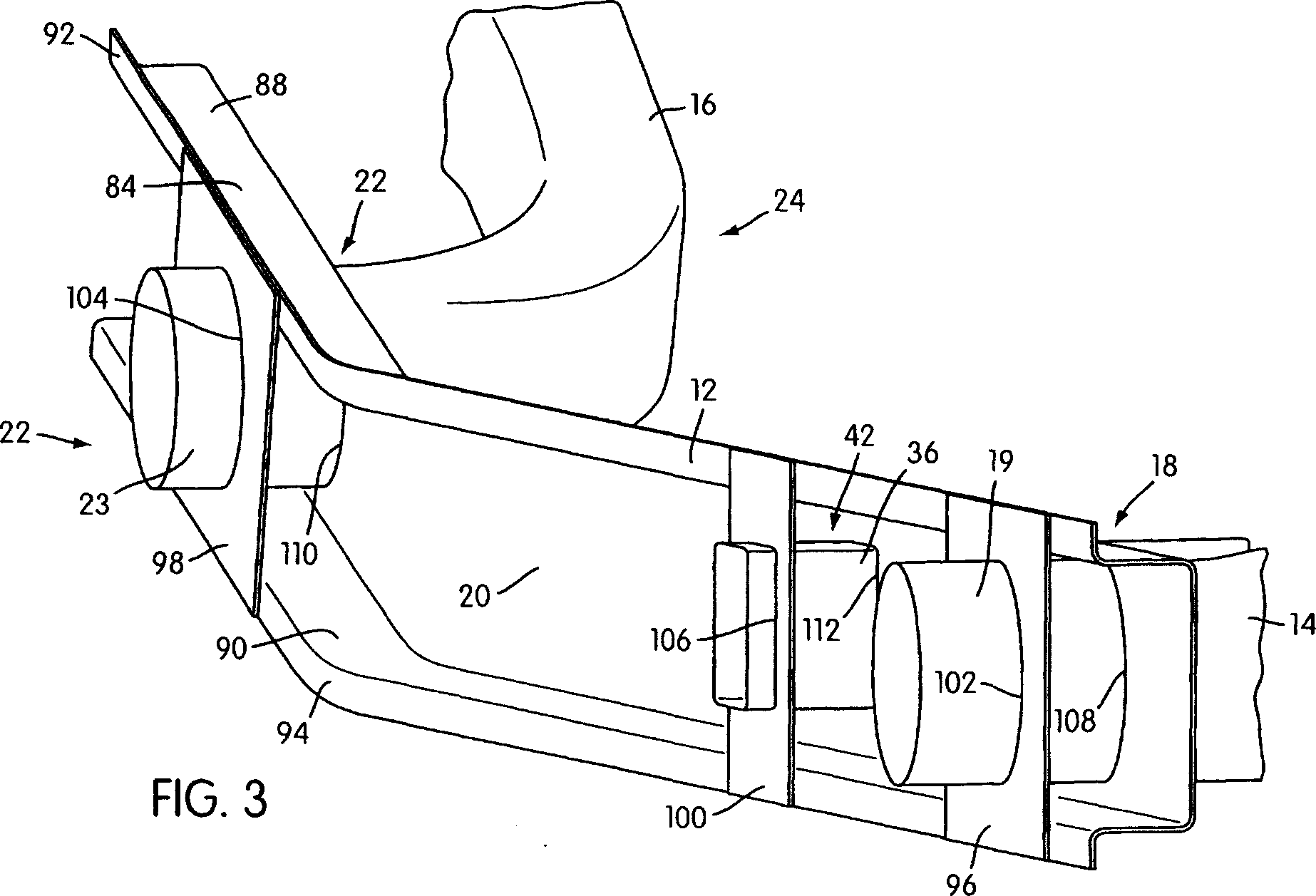

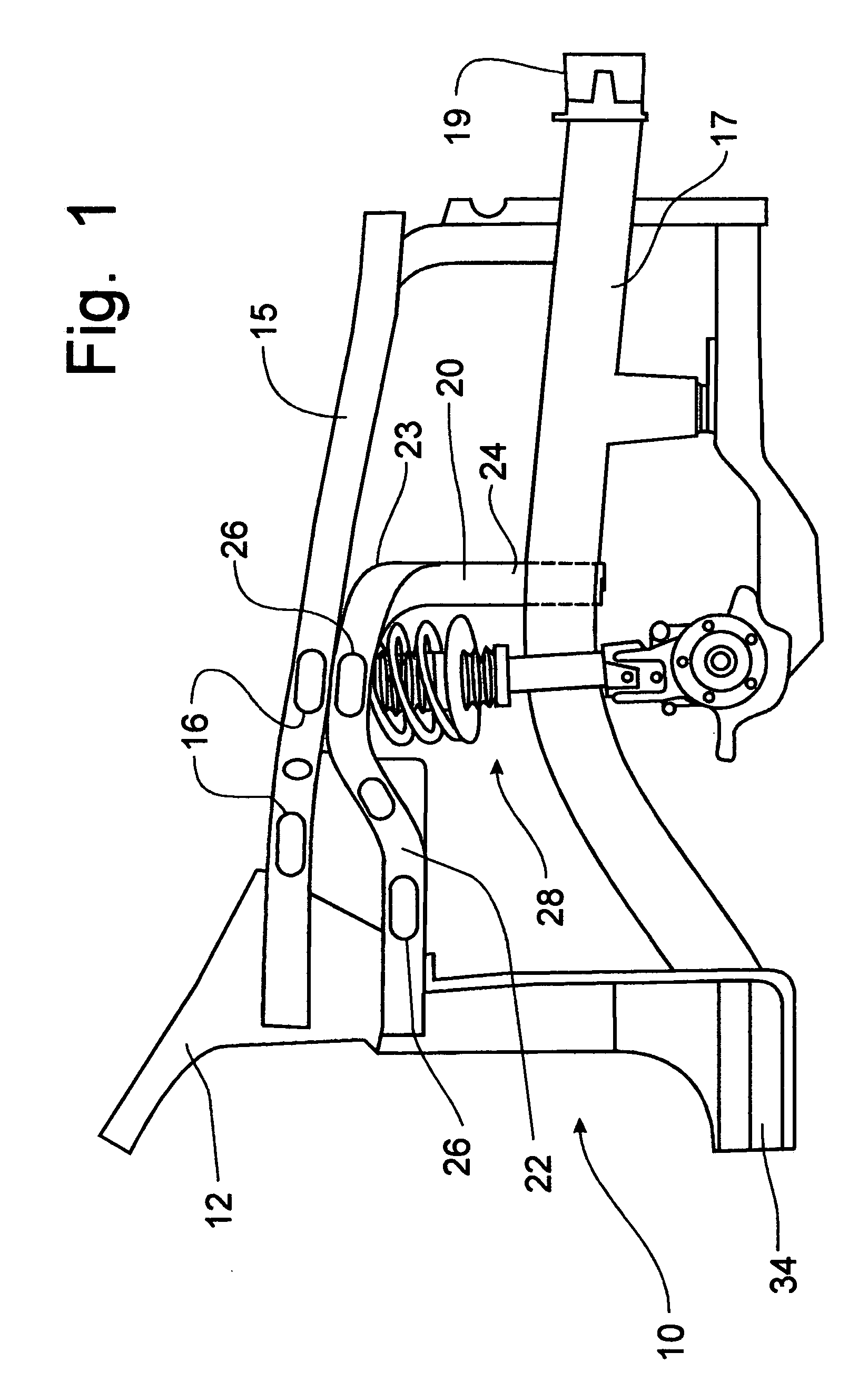

Rail to rocker joint using hydroformed members

InactiveUS20070187995A1Facilitate spot-weldingLow costVehicle seatsSuperstructure subunitsVehicle frameEngineering

A process for connecting a hydroformed front rail member of an automotive frame to the body side inner (rocker) beam does not require a substantive re-design of the frame to accommodate an overlapping parallel orientation of two tubular frame members. The hydroformed front rail member is laser cut at the rearward end thereof to remove a portion of a side wall of the tubular member to form a C-shaped section. The front rail member is formed with a vertical dimension that provides a nesting relationship between the C-shaped section of the front rail member and the body side inner member so that the rocker beam can be received into the C-shaped section. Welding between the two members can be accomplished using either MIG-welding or spot-welding processes. A body side reinforcement can be added to provide a stiff frame joint as the reinforcement is swept off the rail structure to provide a box section.

Owner:FORD GLOBAL TECH LLC

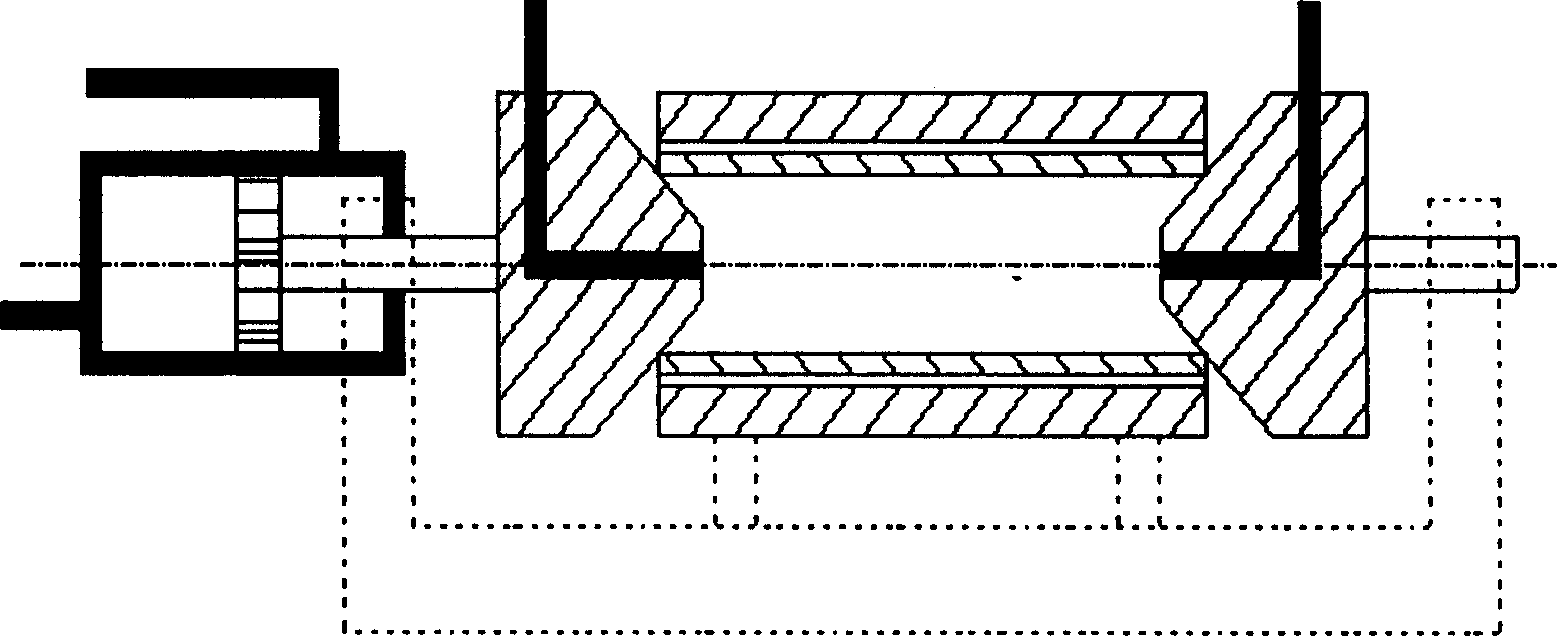

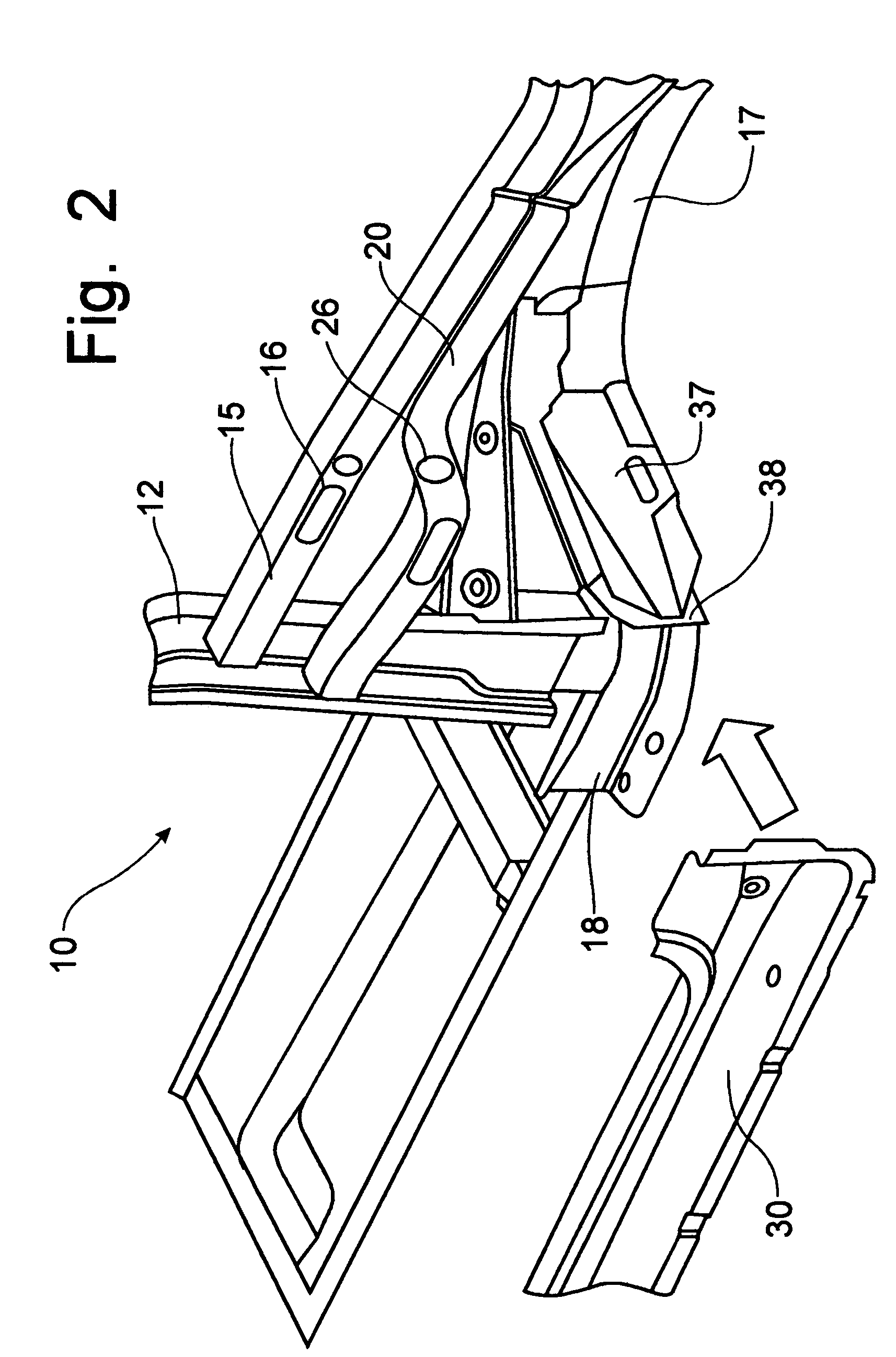

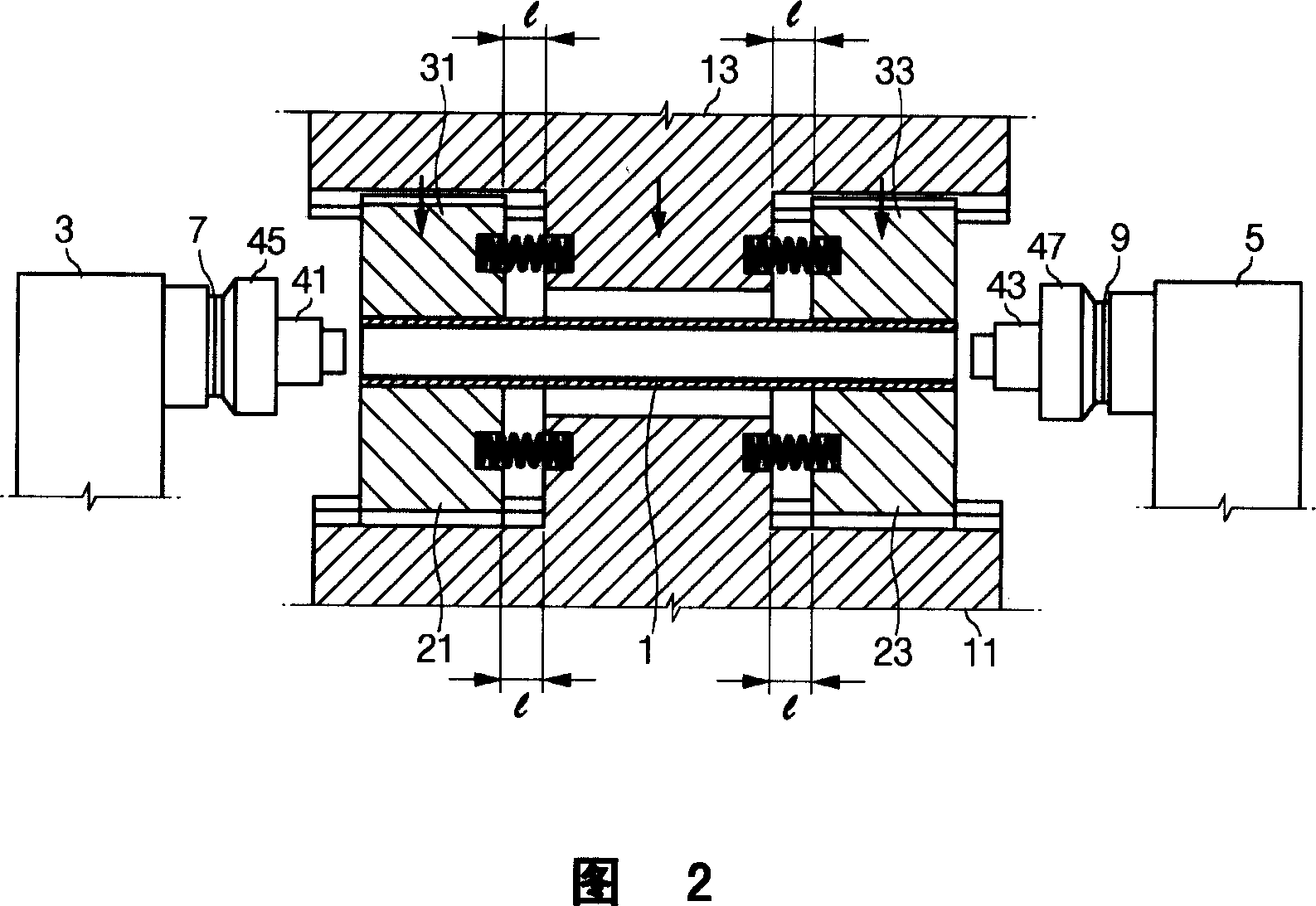

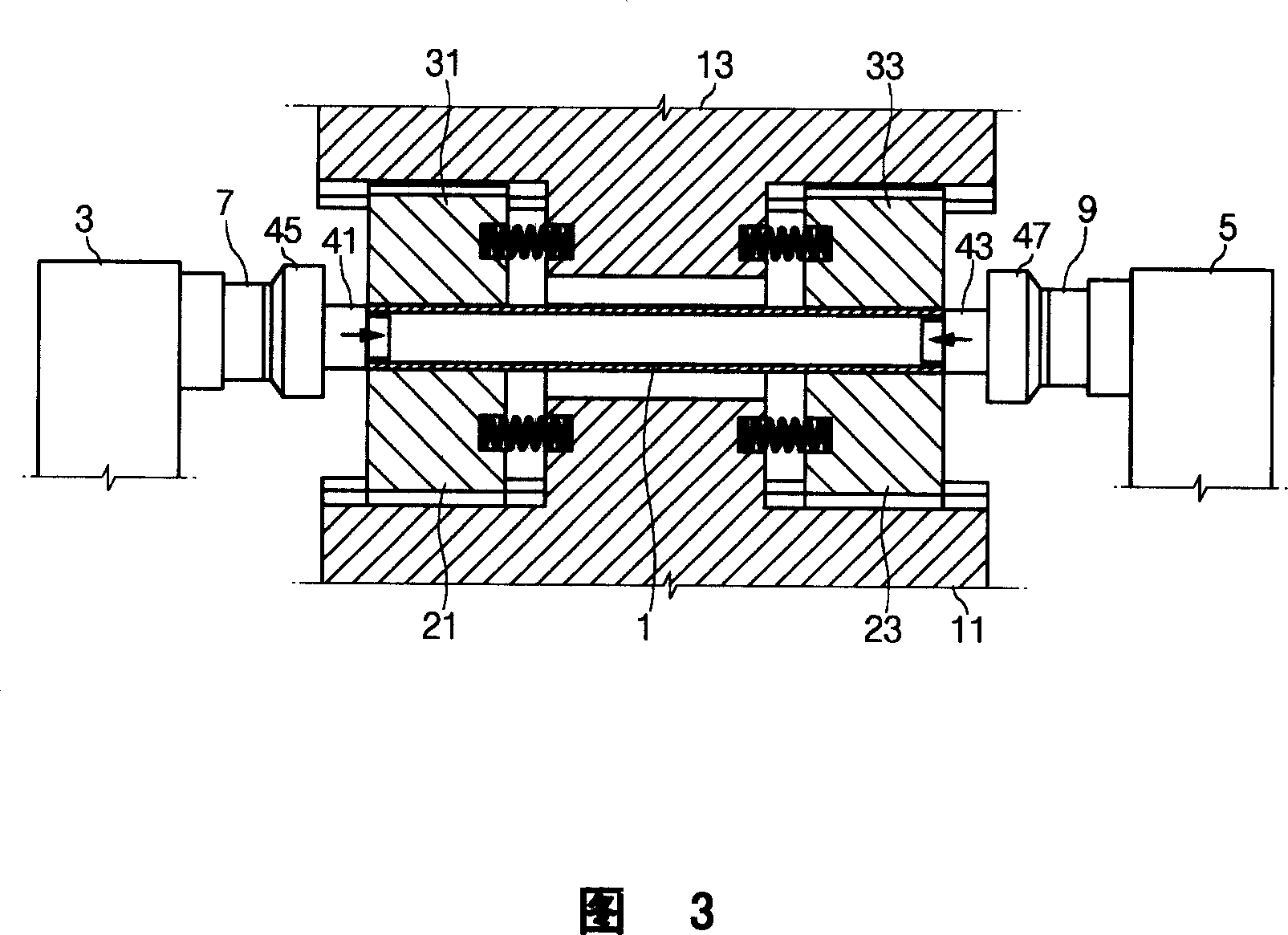

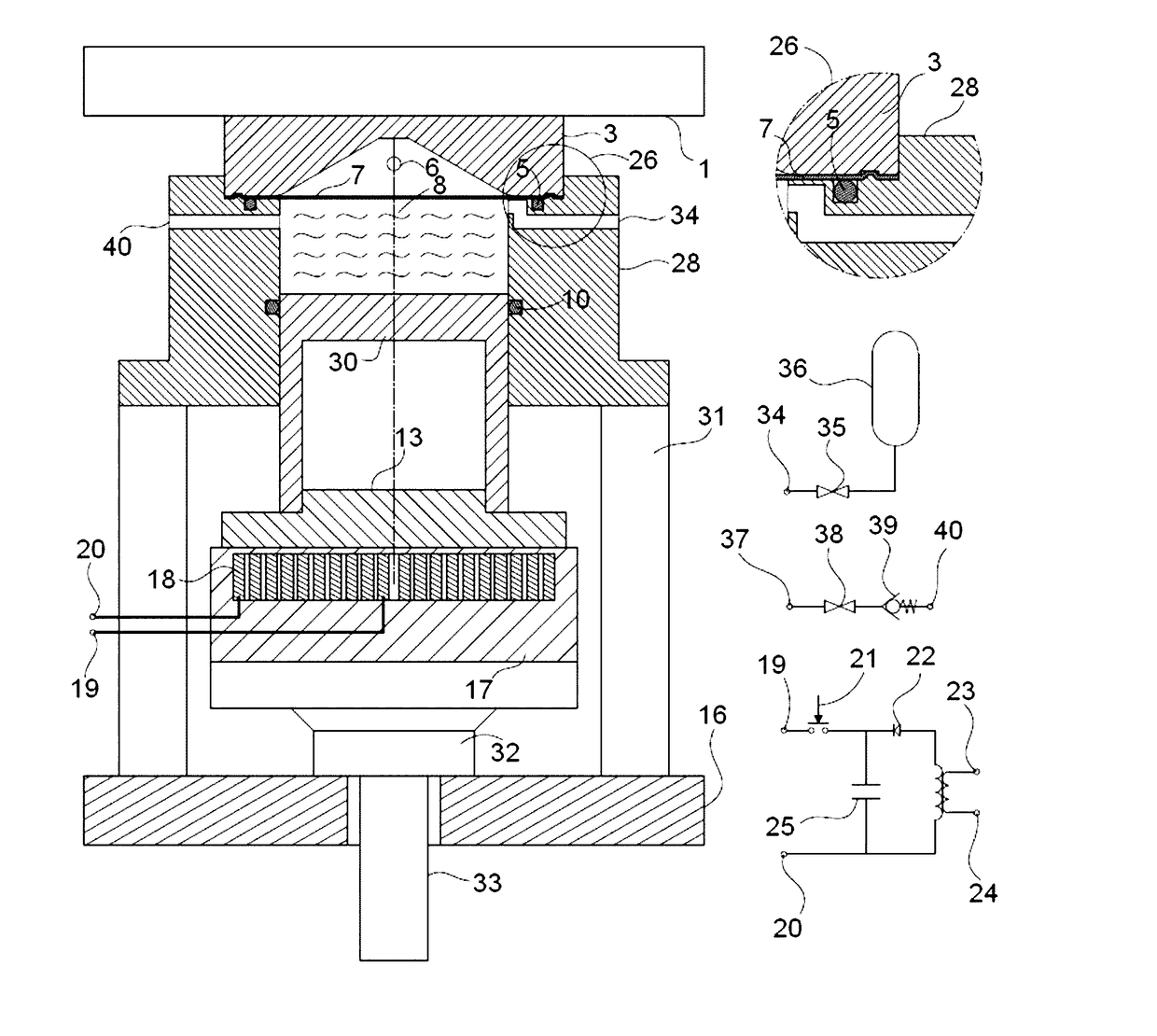

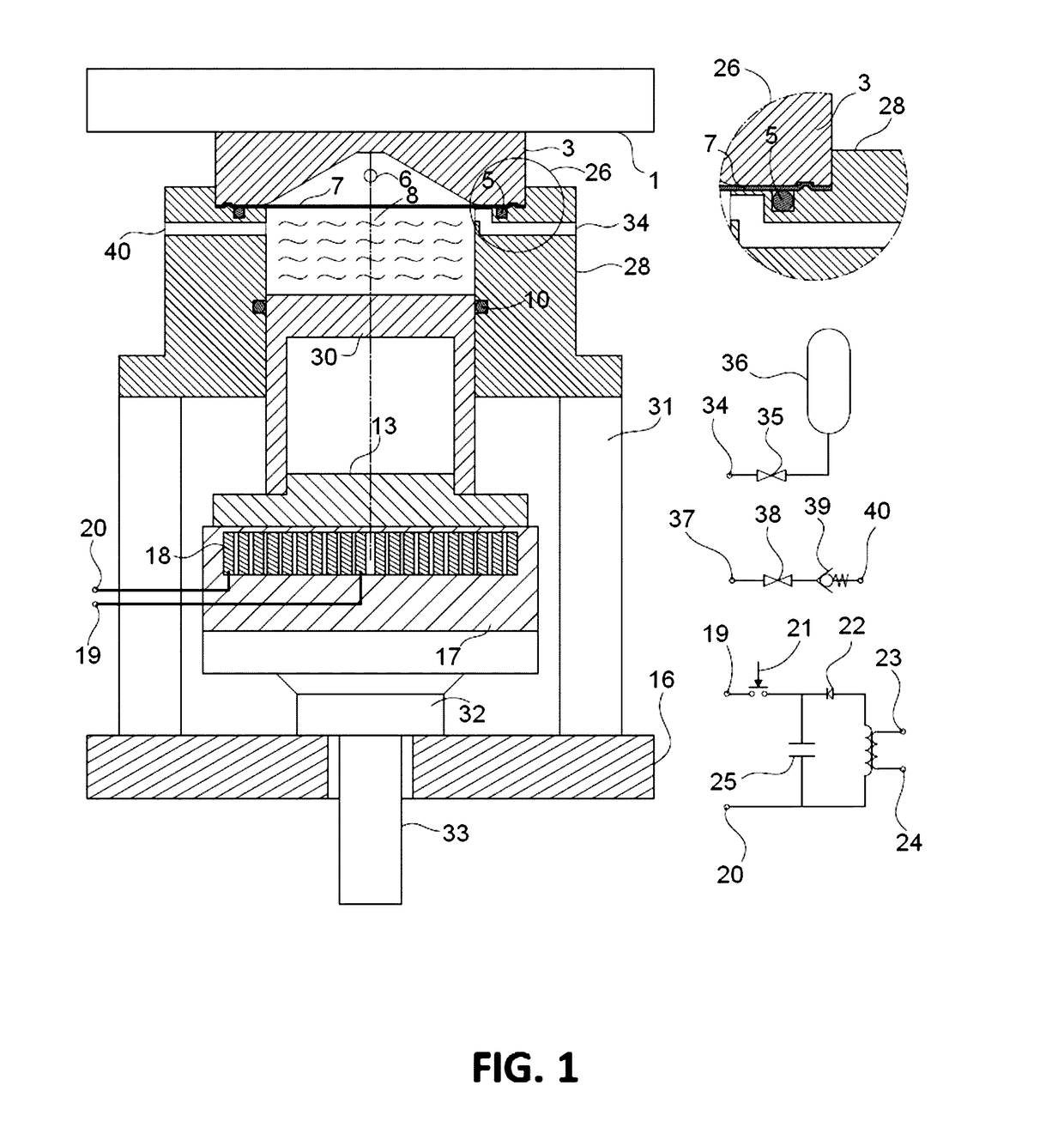

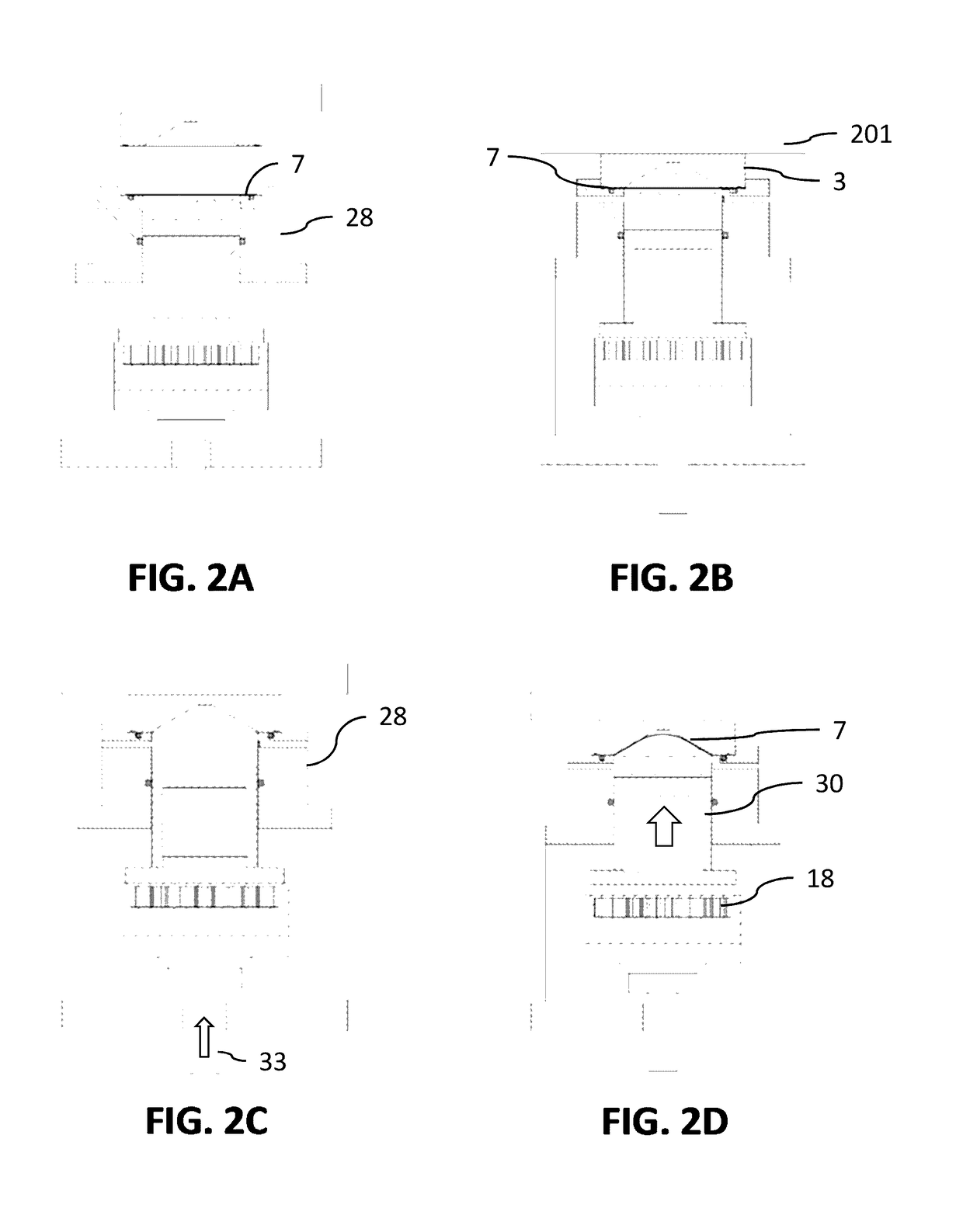

Hydraulic forming press system and press method thereof

A hydraulic pressing system for forming a workpiece and its pressing method are disclosed. The part A to be expanded maximally and a part B linked to said part A and to be bent are first expanded and said part B is then bent inward by upper and lower dies to obtain the beautiful contour with minimal curvature radius.

Owner:SUNG WOO HITECH

Preform, hydroforming method, and hydroformed product

InactiveUS20060066133A1Avoid fracturesStable and excellent strength qualityVehicle seatsLoad-supporting pillarsEngineeringHydroforming

A preform with edges overlapped and jointed each other and first and second outer members for forming outer surfaces of a hydroformed product, and reinforcement members that are jointed to the first and second outer members to form reinforcement ribs that divide a hollow cross section of the outer surfaces, the reinforcement members having dimensions capable of suppressing elongation in a tensile direction due to a tensile force that develops during hydroforming.

Owner:NISSAN MOTOR CO LTD

Method of improving properties of hydroforming fluids using overbased sulfonate

A method for improving lubricants employed in hydroforming processes is disclosed wherein said method comprises adding to said lubricants at least one overbased detergent and at least one friction modifier.

Owner:CHEMTURA CORP

Method of preparing hydroformed metallic golf club shafts

Method for preparing a golf club shaft, set of shafts, or golf clubs having shafts which have been produced by a process that includes a hydroforming step. By utilizing a hydroforming prosses step, a metal or metal matrix composite golf club shaft can be formed into a variety of configurations or shapes heretofore not possible and can include hydroformed ornamental design features.

Owner:TRUE TEMPER SPORTS

Method of locally heating a part to reduce strength and increase ductility for subsequent manufacturing operation

A method of performing manufacturing operations on a workpiece made of a high strength alloy is disclosed in which a local area of a workpiece is heated to micro-structurally soften the local area. The local area of the workpiece becomes softened and more ductile. A manufacturing operation involving deformation of the heat softened area is performed with the metal in the heat softened region being more ductile and having less strength than the surrounding portions thereof. Manufacturing operations may include riveting, clinching, hydro-forming, and magnetic pulse joining.

Owner:FORD GLOBAL TECH LLC

High-speed hydraulic forming of metal and non-metal sheets using electromagnetic fields

A system and method for hydraulic forming of sheets is provided. A coil is connected to a pulse generator storing electric energy and discharging the electric energy to the coil, creating a first electromagnetic field in the coil. A conductive plate placed on the coil such that the first electromagnetic field causes creating of a second electromagnetic field in the conductive plate, in a direction opposite to the first electromagnetic field, creating a force. A pressure chamber filled with a fluid and placed on the conductive plate. A piston placed inside the pressure chamber to transfer the force to the fluid. A sheet placed on the pressure chamber, the fluid being configured to receive the force from the piston and transfer the force to the sheet. A die placed on the sheet, wherein the force transferred to the sheet from the fluid causes the sheet to take a shape of the die.

Owner:NIARAKI RASOUL JELOKHANI +2

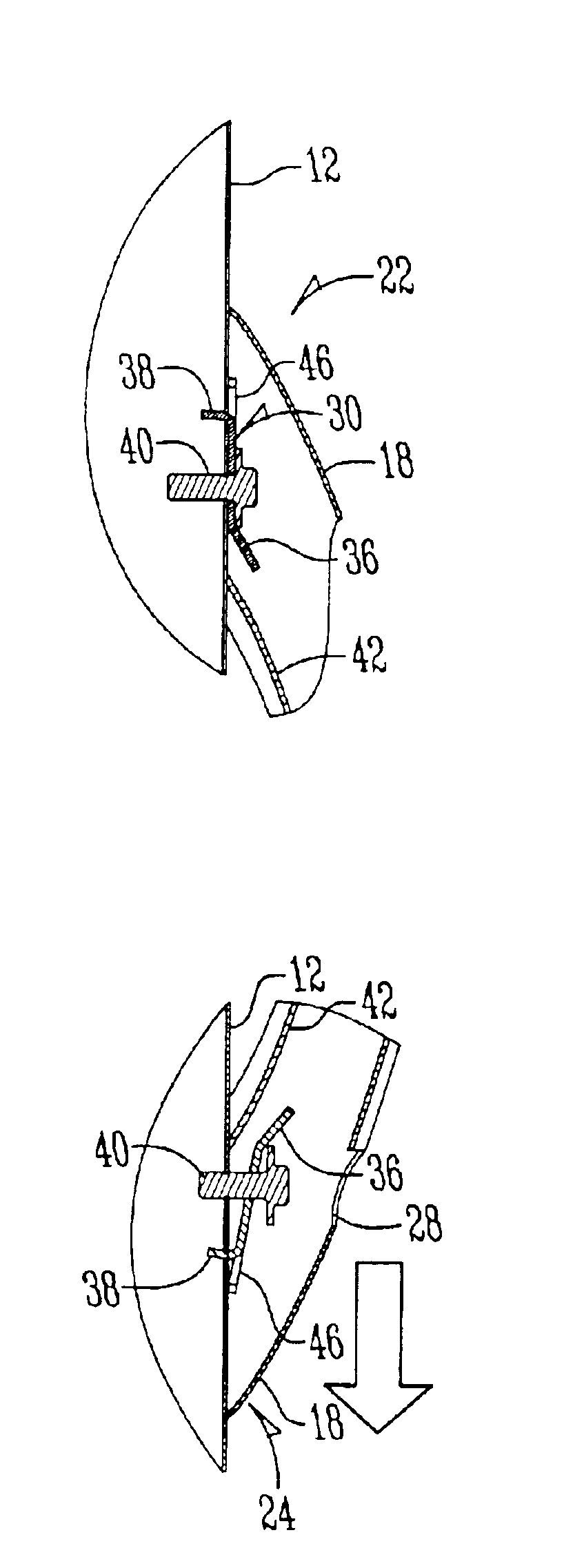

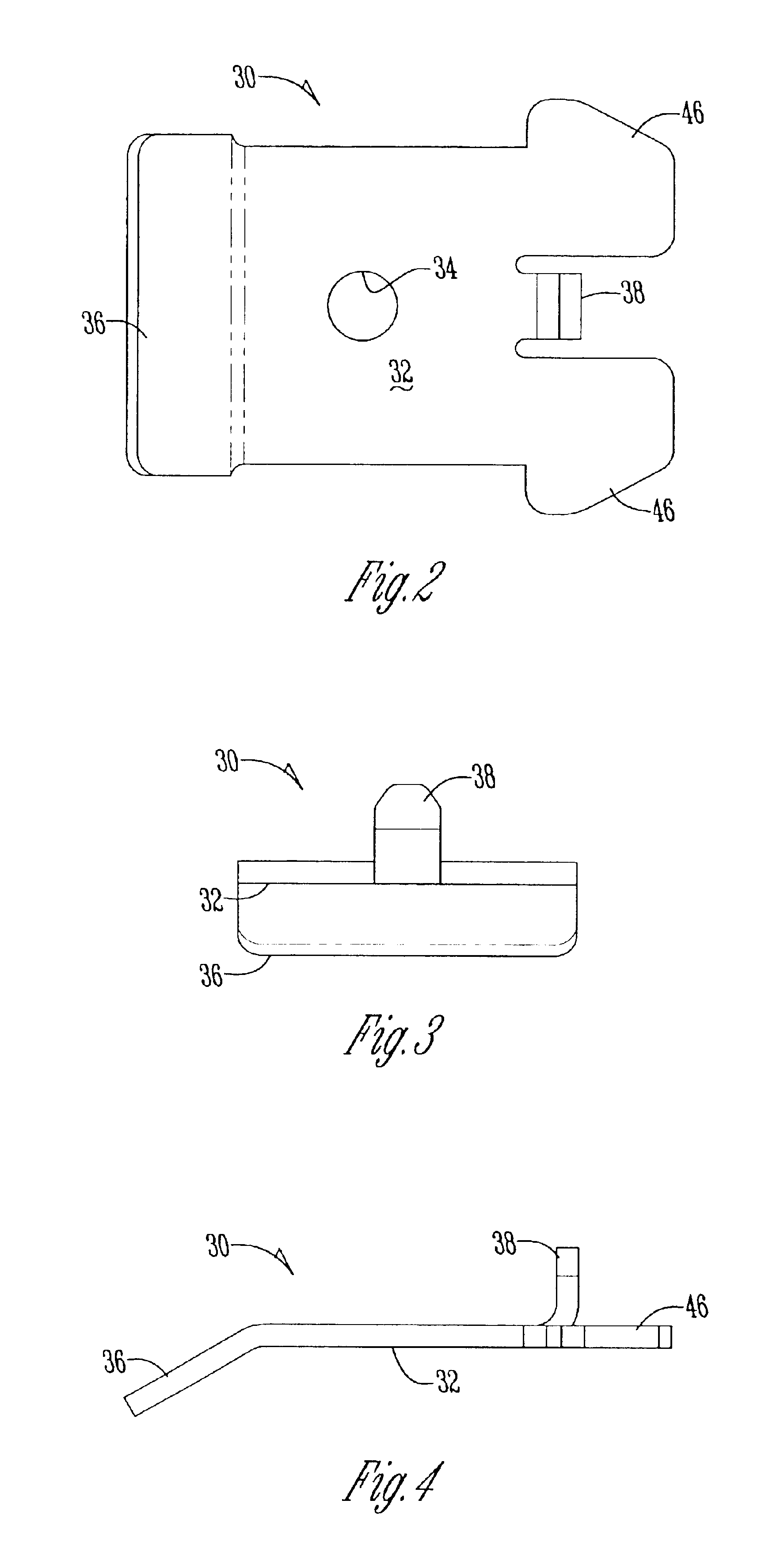

Apparatus, method and device for attaching hydroformed handle to an appliance

An apparatus and method for securing a handle to a door includes a first clip fastened to the door, a second clip fastened to the door and a handle clamped to the door by the first and second clips. The clip has a flat surface with an aperture therethrough and two wings at one end. A bent or beveled portion at the other end of the flat surface allows the clip to clamp the inner wall of the handle. A fastener, such as a screw, is placed through the aperture in the clip and into the exterior surface of the door to secure the clip and the handle to the door.

Owner:MAYTAG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com