Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Good opening quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

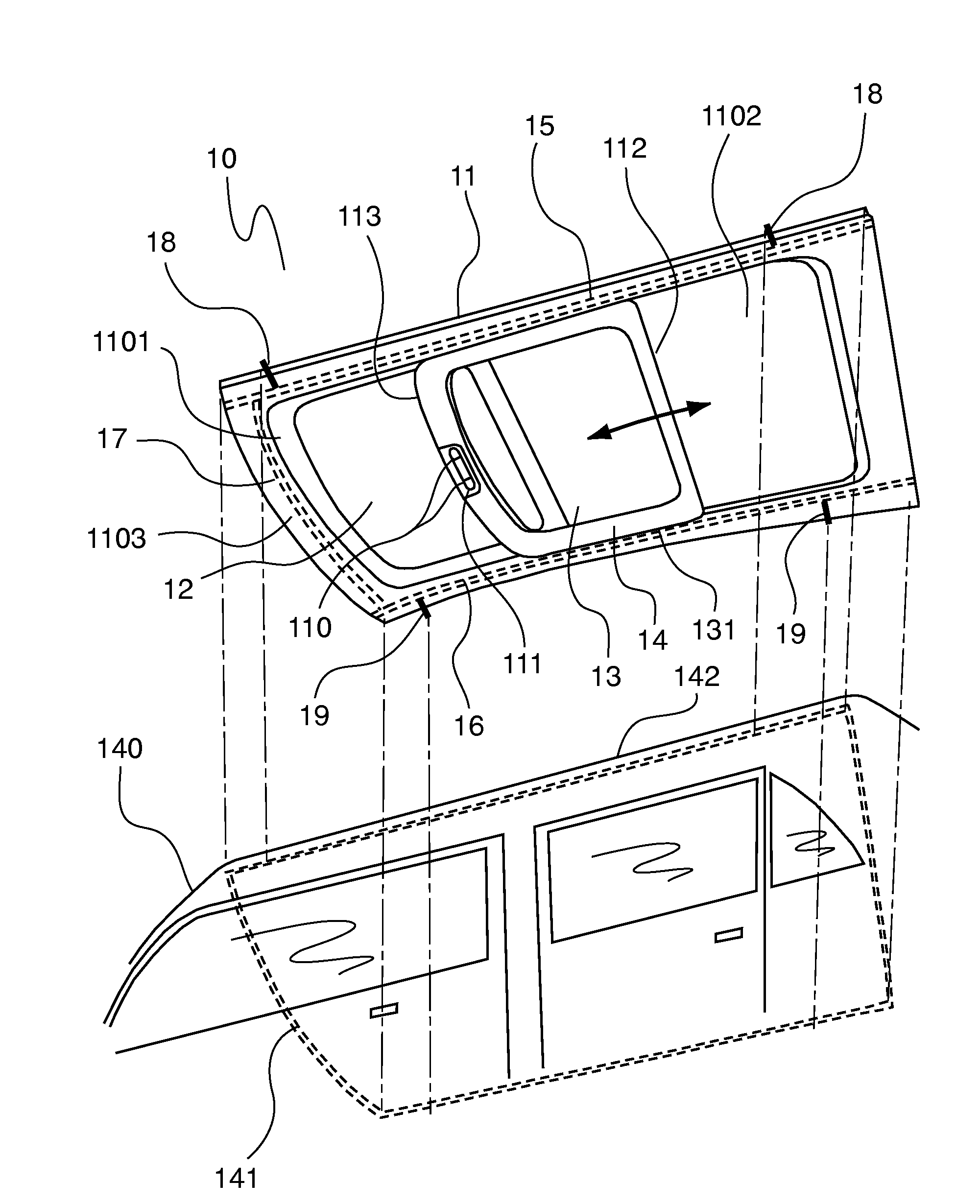

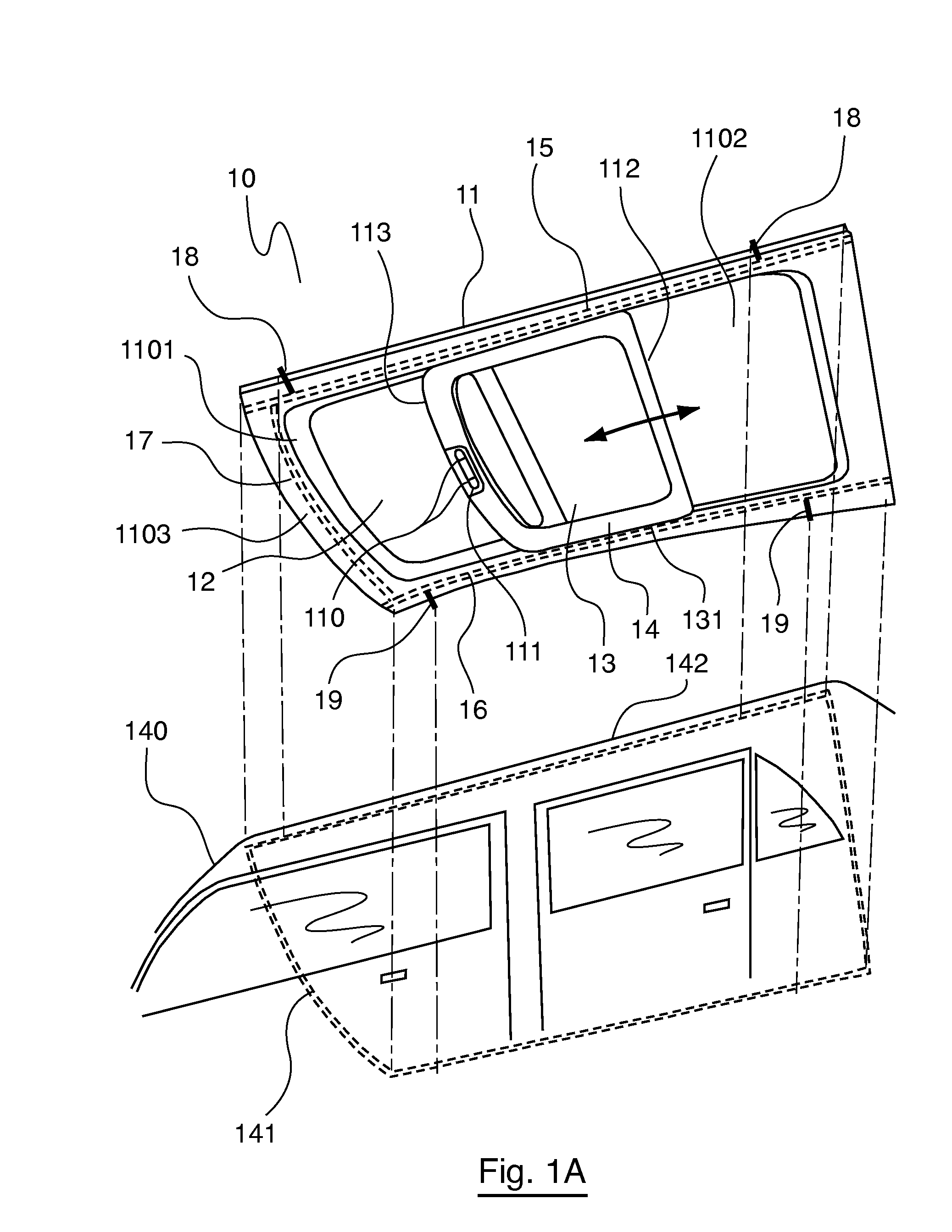

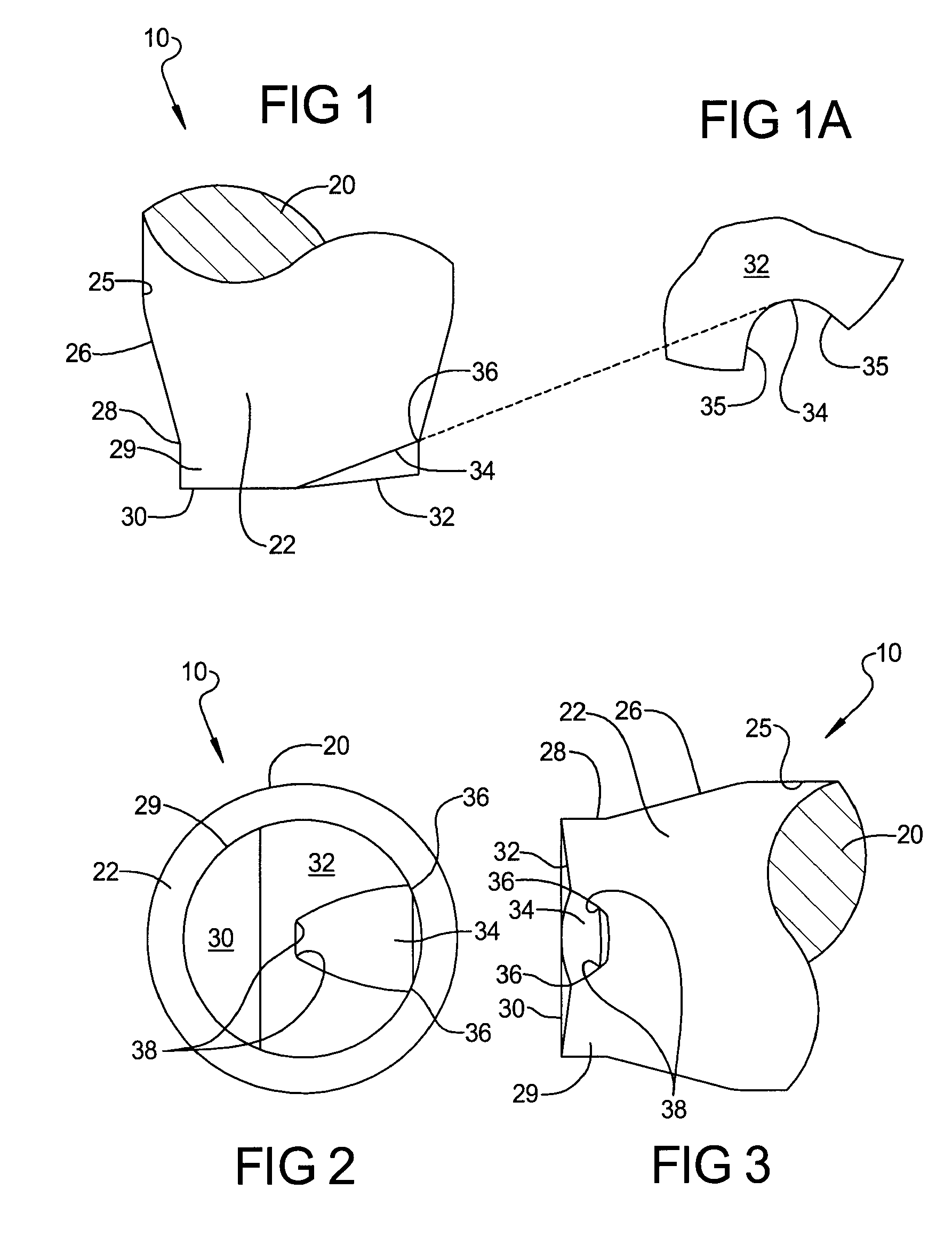

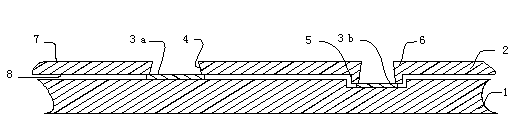

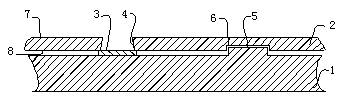

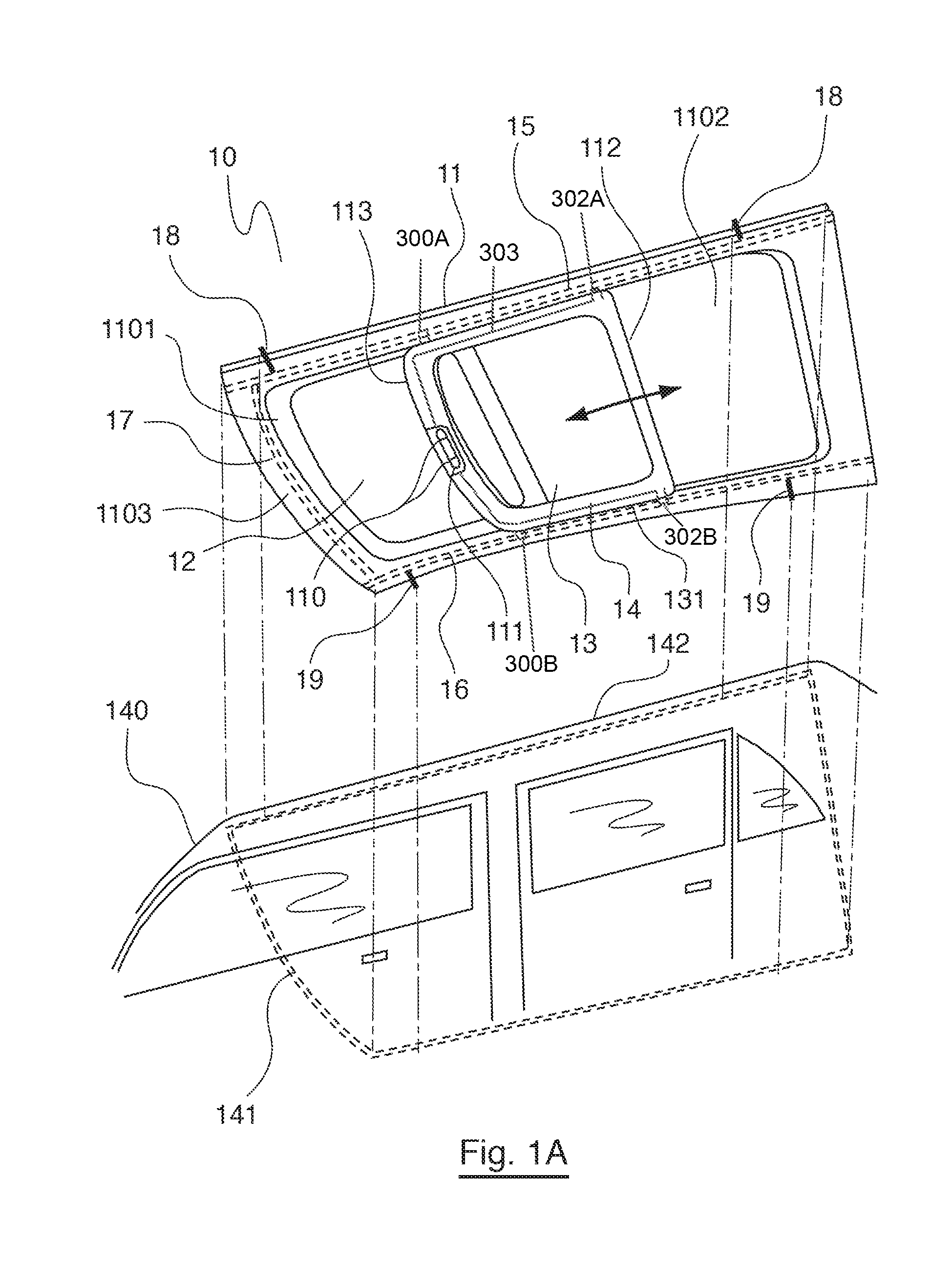

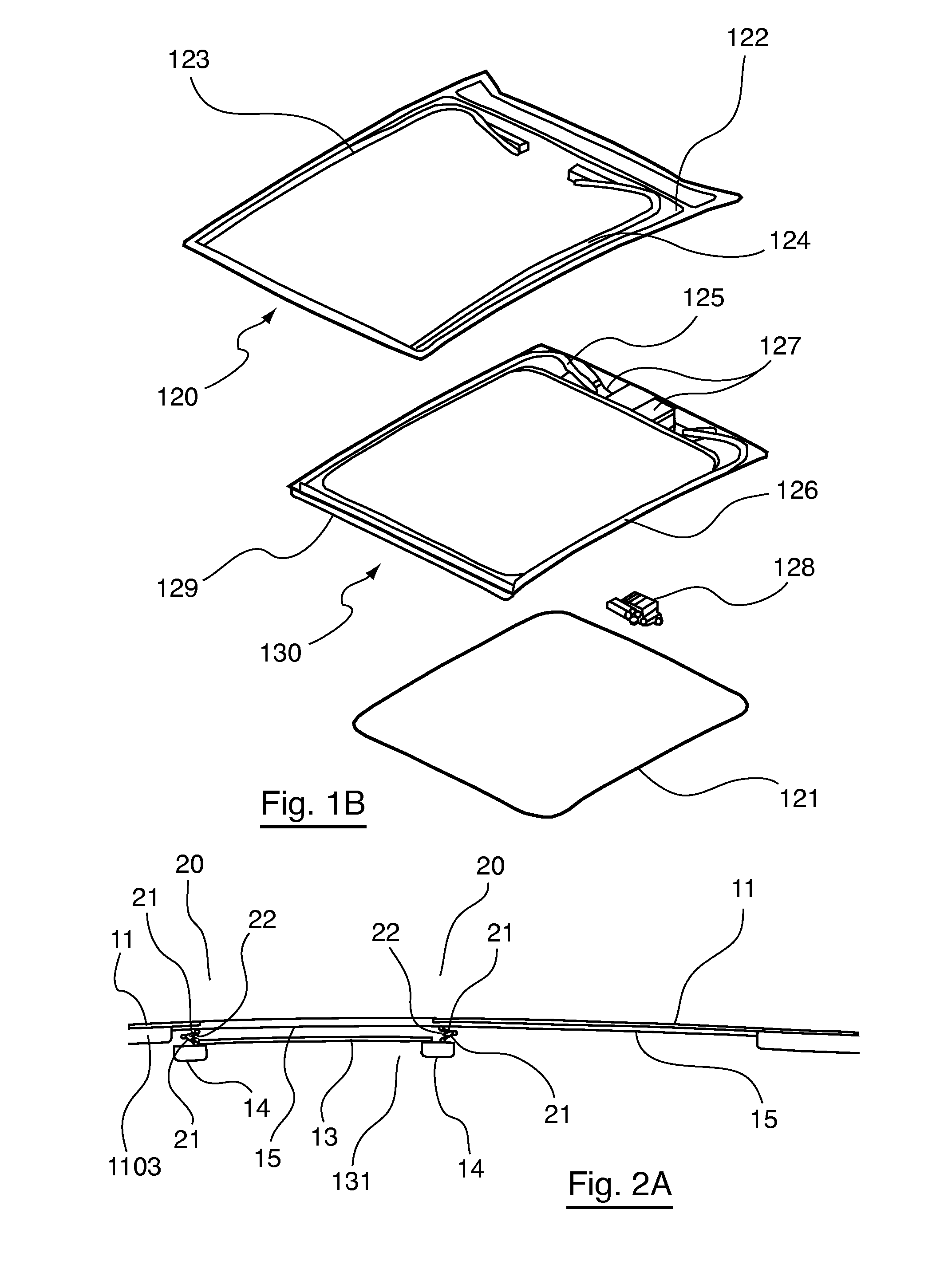

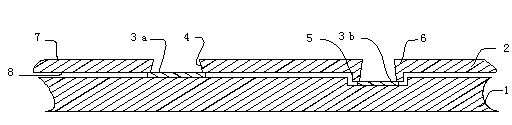

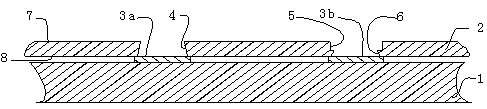

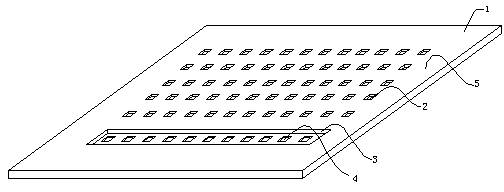

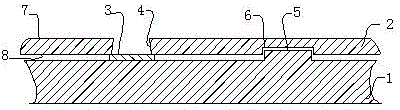

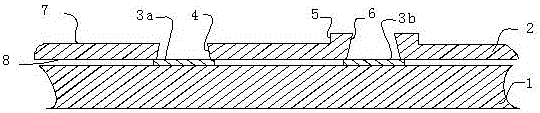

Glazed Roof of a Motor Vehicle, Corresponding Method of Assembly and Corresponding Vehicle

InactiveUS20100084894A1Simplify mountingSimple to produce and to mountWindowsEngine sealsEngineeringRolling chassis

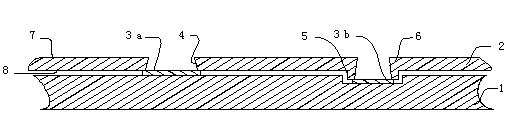

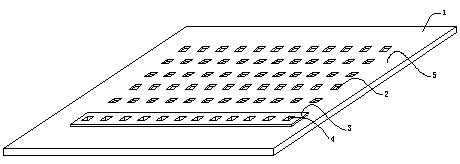

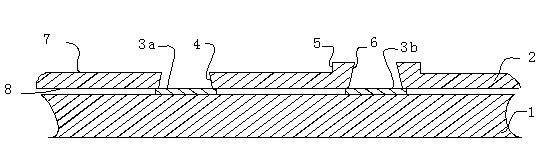

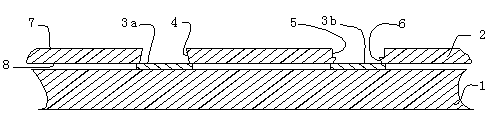

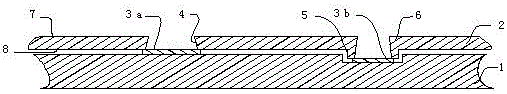

A glazed roof of a motor vehicle is provided, which includes at least one opening and a fixed glazed structure bearing at least one element sliding on the inside of the vehicle and intended to close the opening(s). The glazed structure has an external contour coinciding with an accommodating surround on the chassis of the vehicle so the contour can be secured to the accommodating surround, as a flush fit. Each of the sliding elements is guided along two rails secured to the surface of the fixed structure, in a region distant from the external contour so as not to interfere with the securing of the latter to the accommodating surround. The roof has at least one retaining element, having a first end secured to one of the rails and a second end secured to the chassis. Each of the retaining elements is positioned at right angles to the rail.

Owner:WAGON SAS

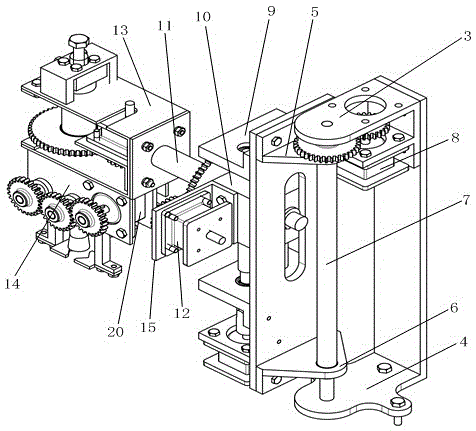

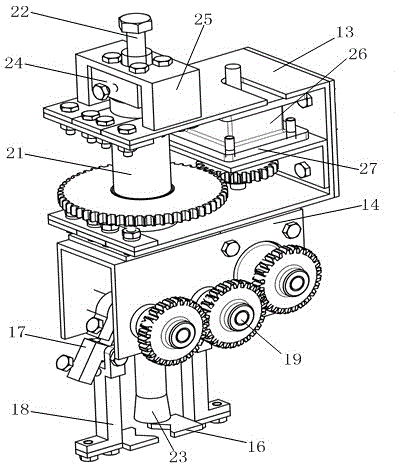

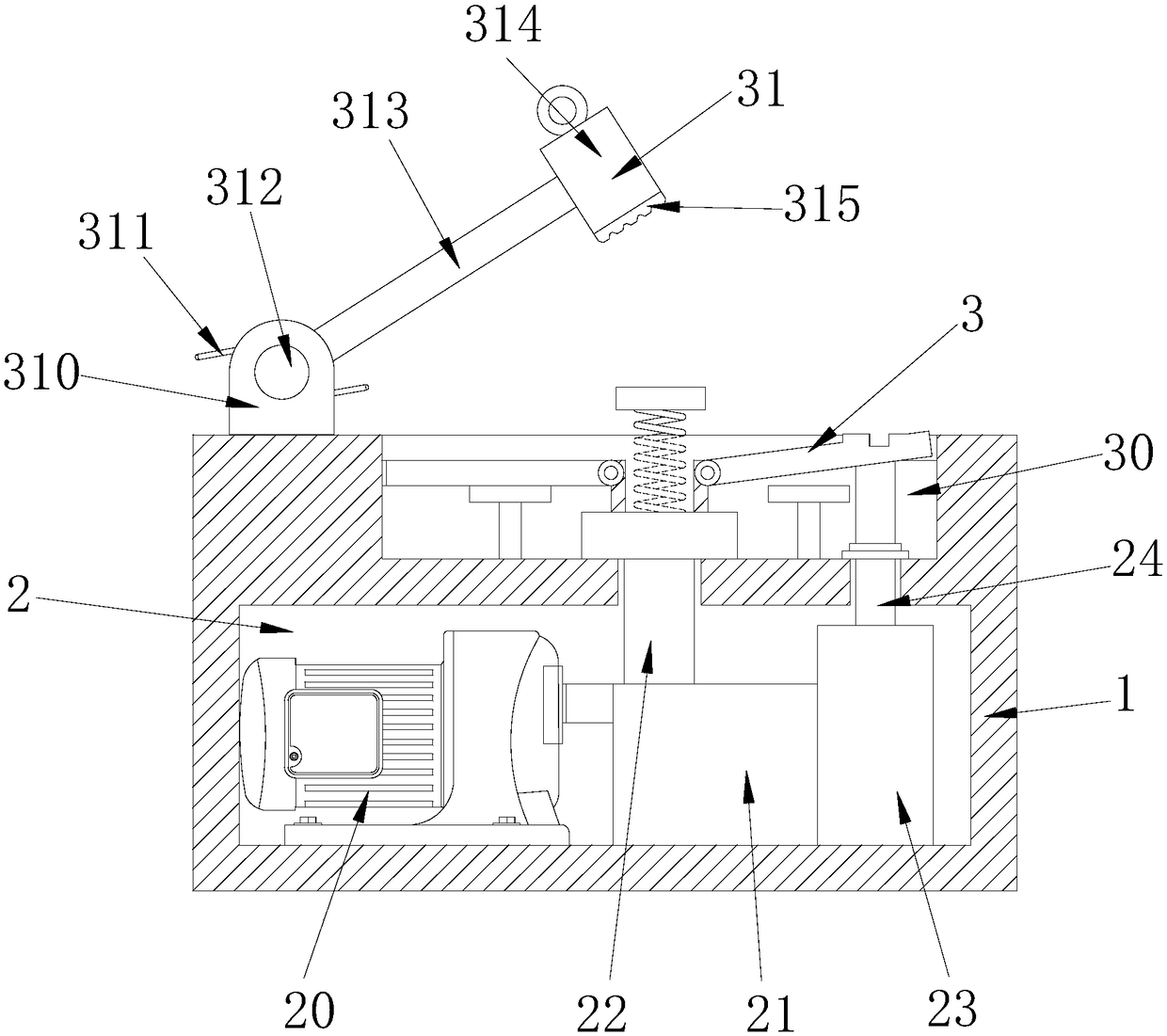

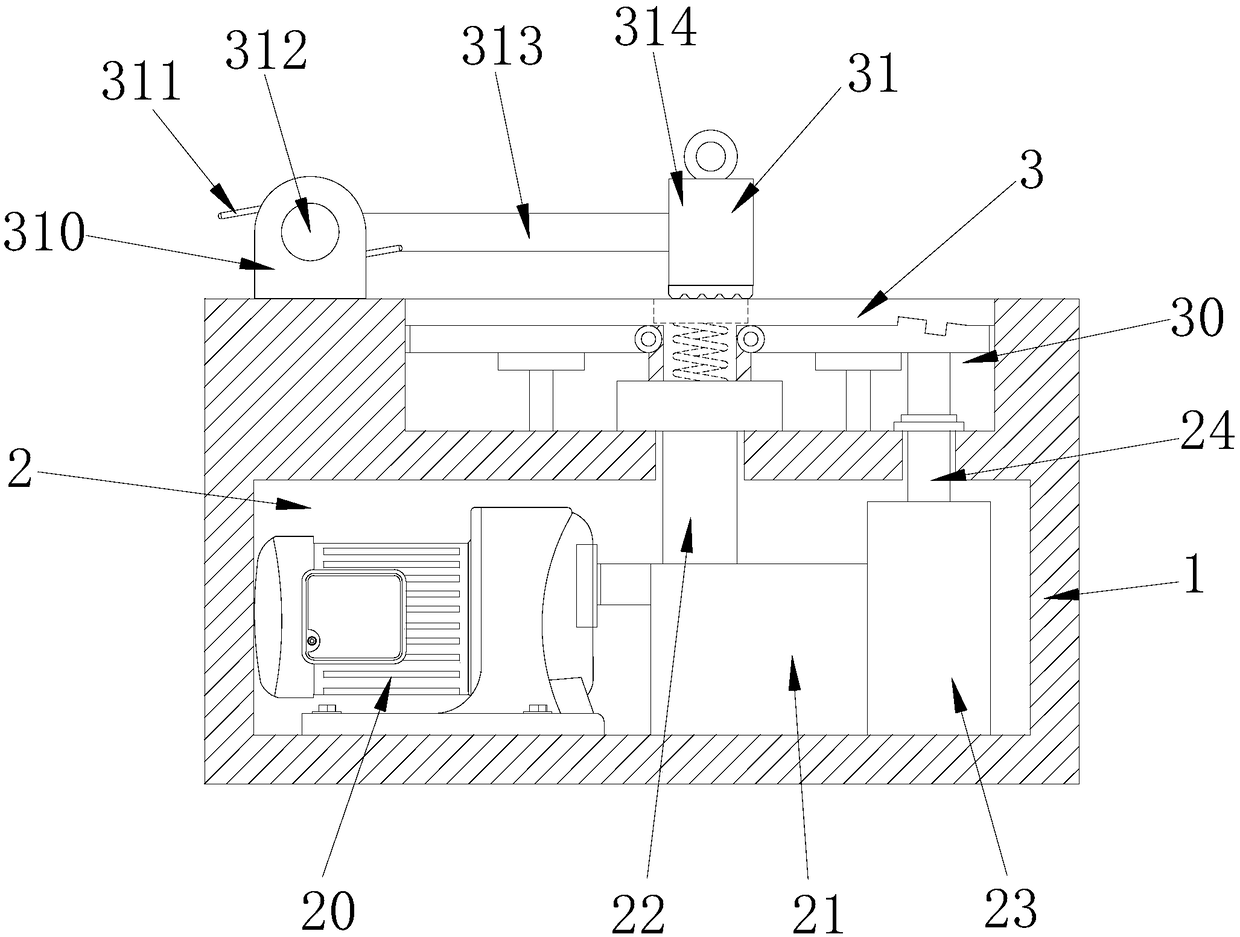

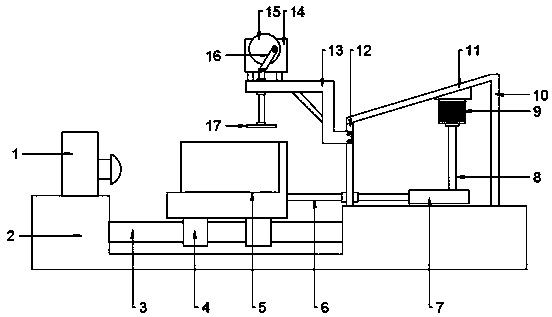

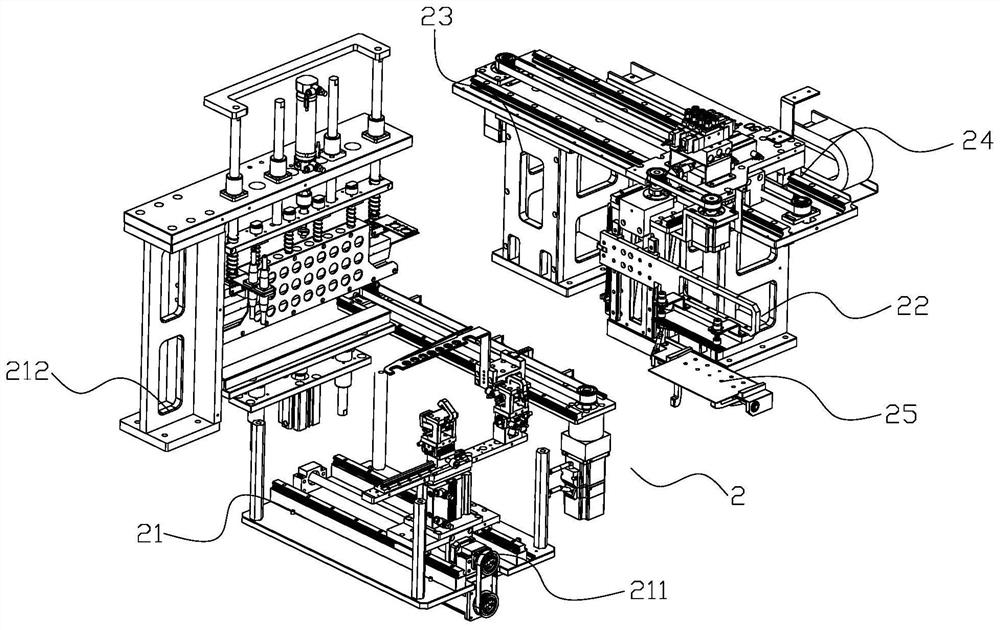

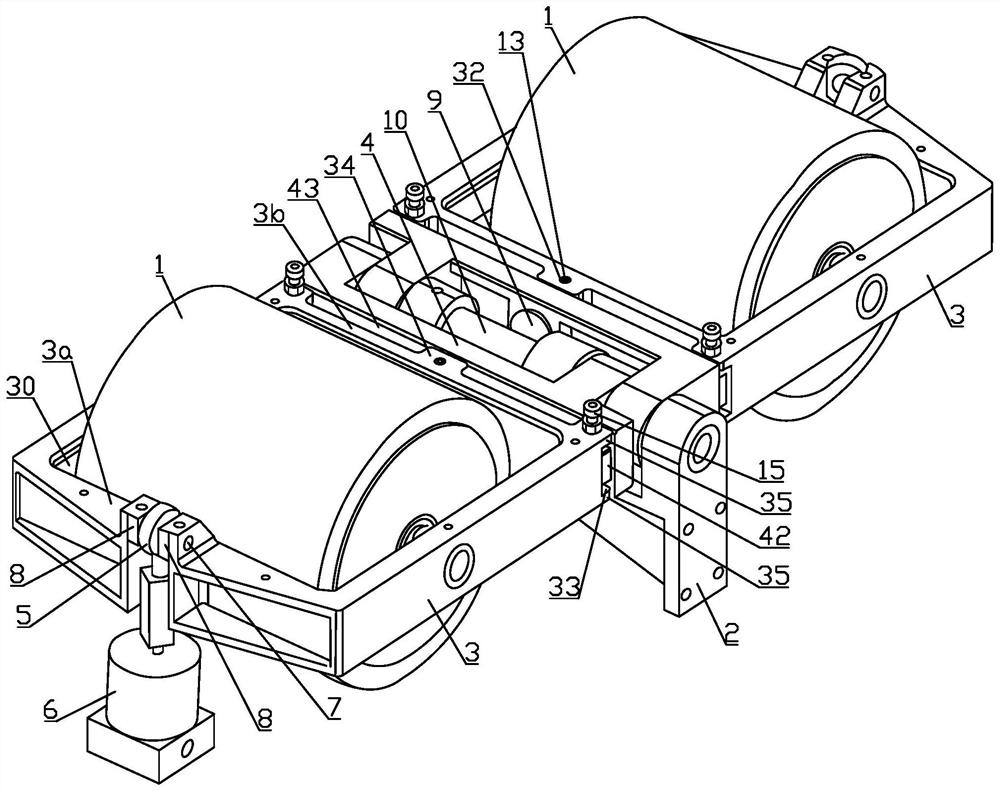

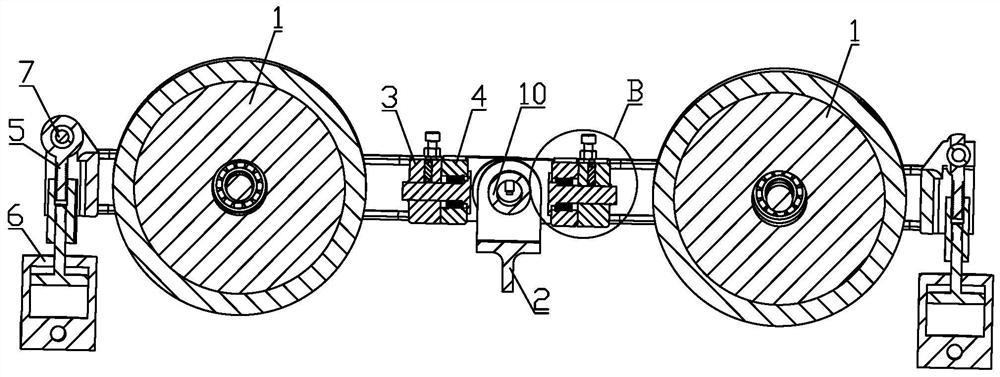

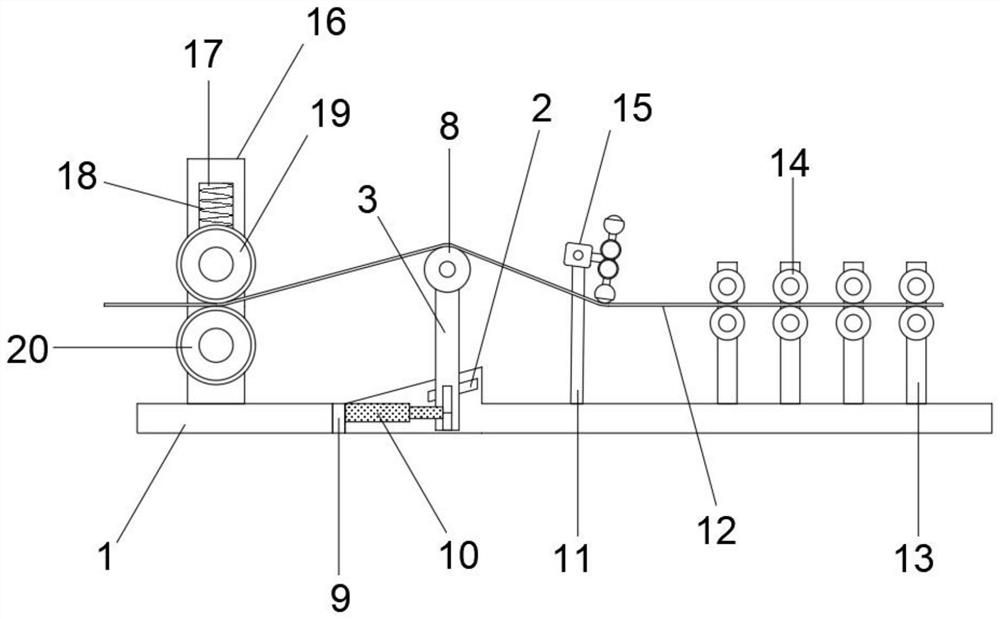

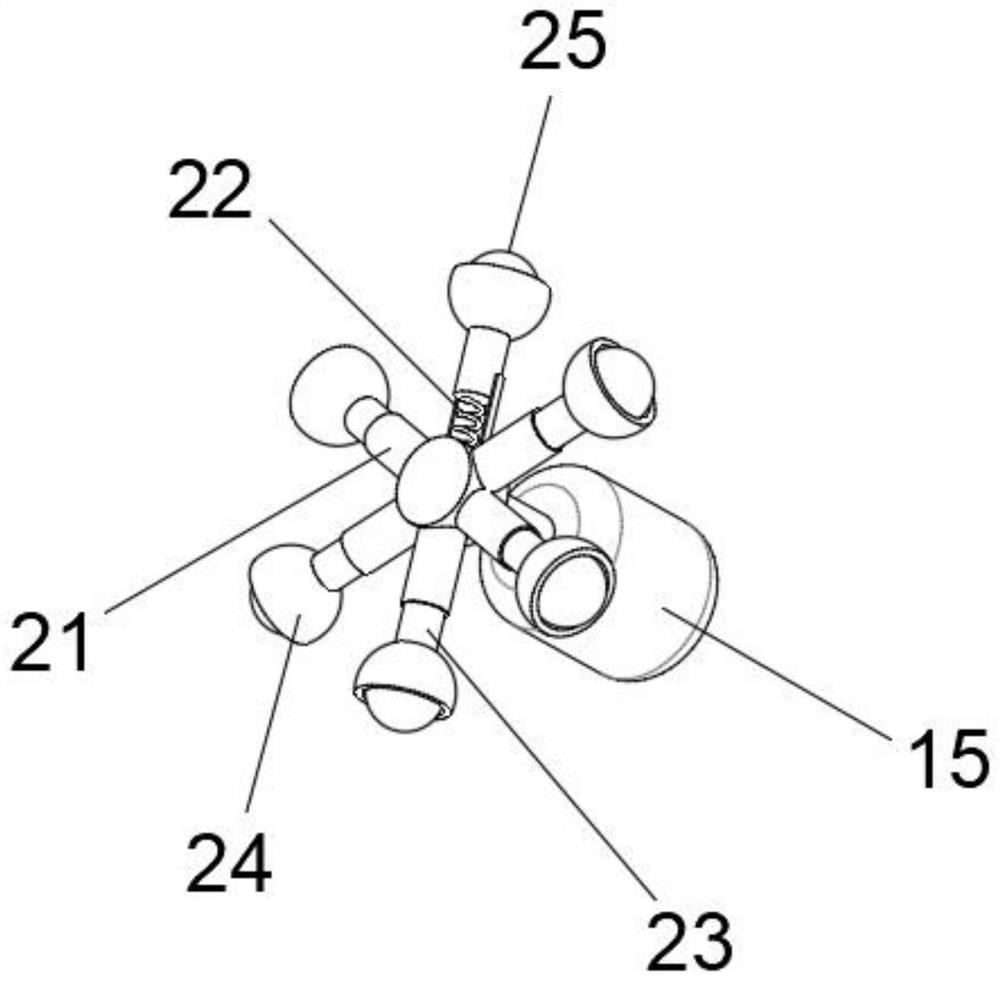

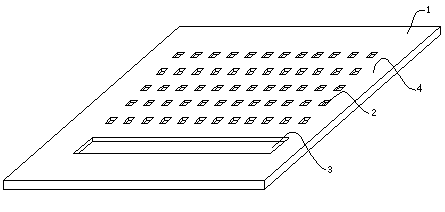

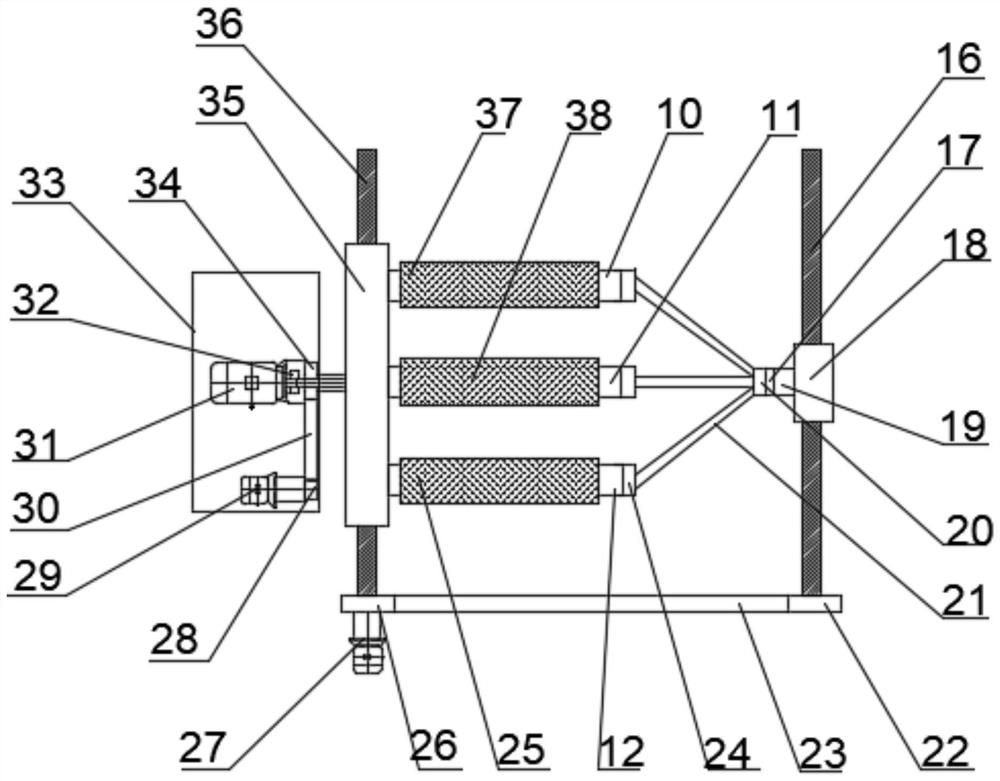

Ampoule bottle opening robot

InactiveCN105129691AReduce workloadAvoid scratchesBottle/container closurePower operated devicesFinger jointEngineering

The invention relates to an ampoule bottle opening robot. The ampoule bottle opening robot comprises an arm module, an opening module, a conveying module, a clamping module and a base plate. The arm module is mainly used for installation of the opening module and used for adjusting the position and the height of the opening module, can drive the opening module to accomplish the bottle opening working procedure and the recovery working procedure, and comprises a lead screw nut sliding platform, a bottle opening gear shaft, a recovery gear shaft and two U-shaped frames. The opening module is used for polishing the concave neck of each ampoule bottle and breaking the sharp mouth of the corresponding ampoule bottle off, and the polishing process and the breaking process are accomplished through a polishing gear shaft, a set of hinged finger joints and a pair of grinding wheels. The conveying module is used for conveying the ampoule bottles to be opened to the corresponding positions of the opening module, and conveying the opened ampoule bottles to the medicine taking positions, and comprises conveying chains, conveying chain wheels, conveying shafts and a conveying motor. The clamping module is used for tightly clamping the ampoule bottles, comprises clamp bodies, springs and V-shaped blocks, and enables the ampoule bottles to keep stable in the conveying and opening process. The base plate is a base where the whole device is constructed, and is used for placement and installation of the modules.

Owner:HARBIN UNIV OF SCI & TECH

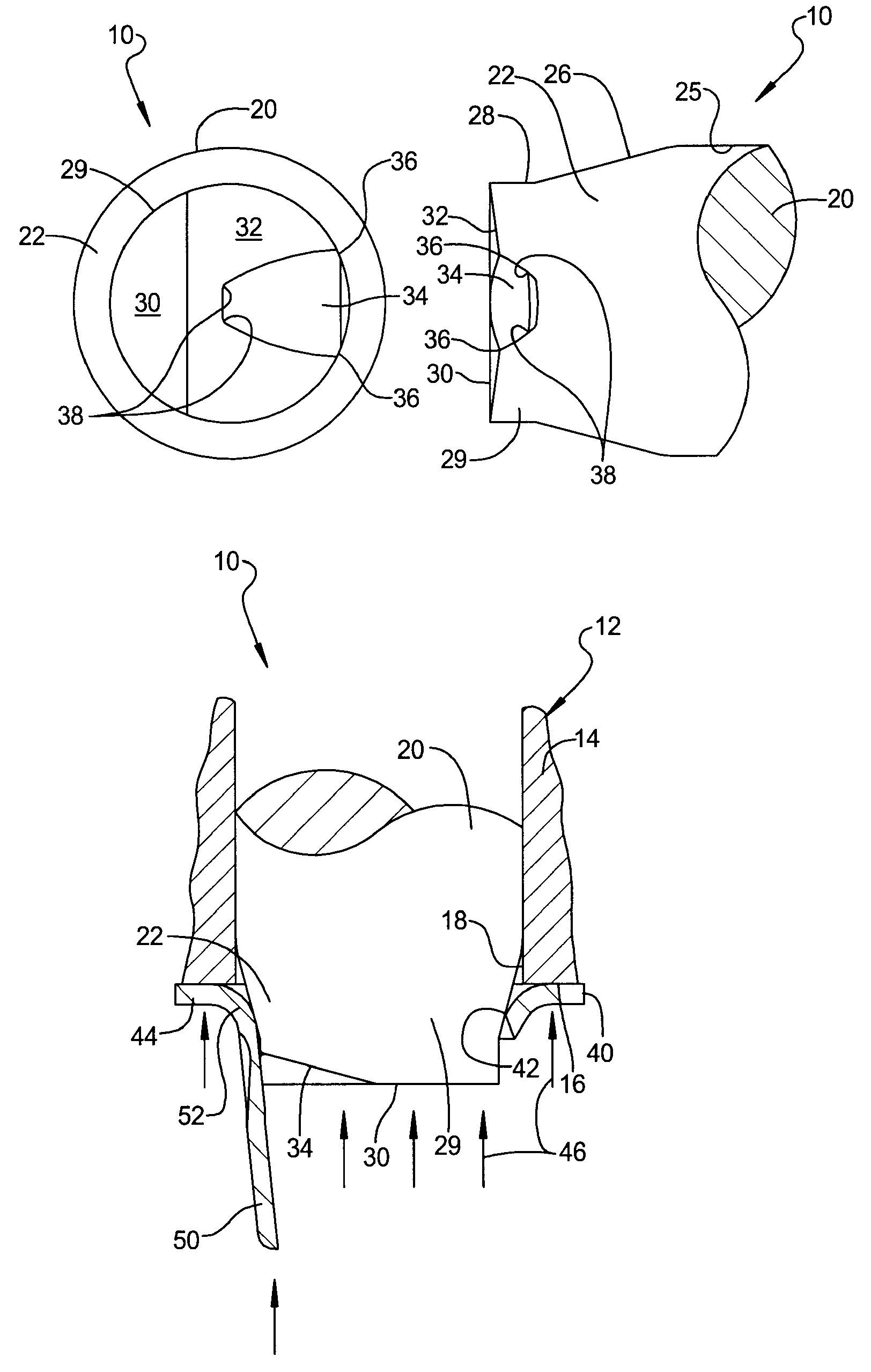

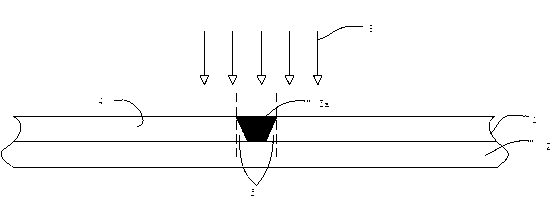

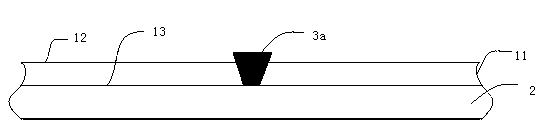

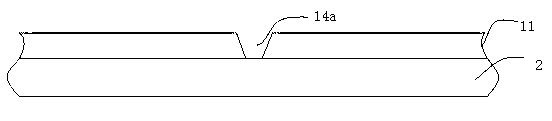

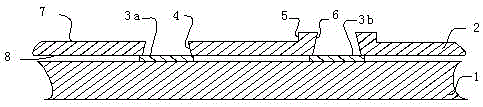

Punch for hydroforming die

InactiveUS7204113B1Improve sealingGood opening qualityMetal working apparatusHydroformingEngineering

A punch for a hydroforming die includes a body, a neck extending axially from the body, a head extending axially from the neck and having a diameter less than a diameter of the body and a thumbnail slot extending axially and radially into the head to allow fluid within a tubular member to force a wall portion of the tubular member outward into the slot of the punch and be sheared by the punch to produce an opening in the tubular member.

Owner:GM GLOBAL TECH OPERATIONS LLC

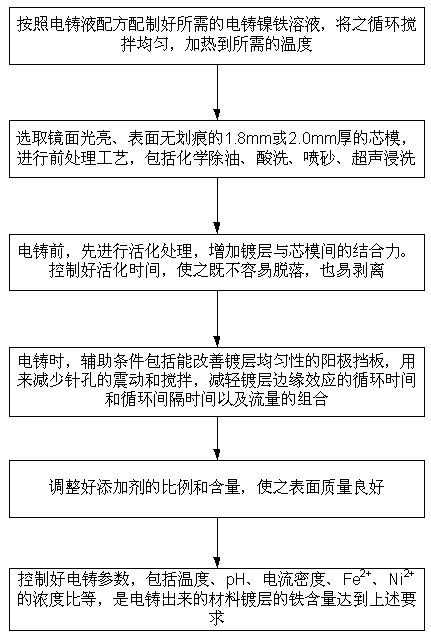

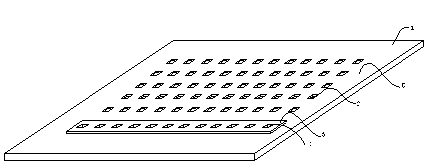

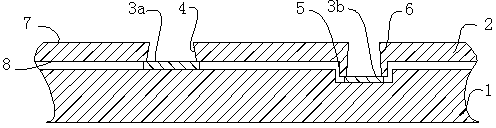

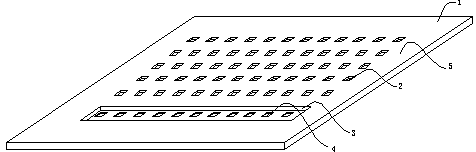

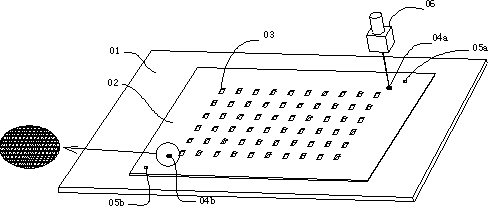

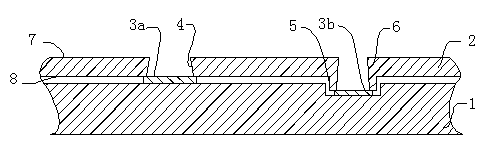

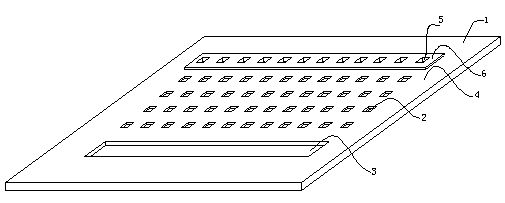

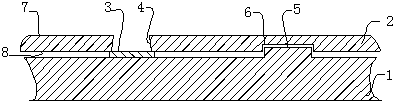

A preparation method for a vapor plating mask plate

InactiveCN103205784AReduce usageGood opening qualityVacuum evaporation coatingSputtering coatingAlloy coatingMetal anode

The invention discloses a preparation method for a vapor plating mask plate. The mask plate is produced from a nickel-iron alloy material by using an electroforming process. The nickel-iron alloy material comprises two elements of nickel and iron, with an iron content being 56%-62%. In a preparation method for the nickel-iron alloy material, an electroforming method is adopted, a sulfate system is used as an electroforming solution, a metal cathode and a metal anode are placed in the electroforming solution, and the nickel-iron alloy is deposited on the cathode; wherein the electroforming solution concretely comprises: 220-260g / L nickel sulfate, 30-50g / L nickel chloride, 40-50g / L boric acid, and 21-25g / L ferrous sulfate. According to the preparation method of the invention, the electroforming process is employed to replace an etching process, openings of obtained products are smooth, have good quality, no blurs, and high accuracy; by employing the process, the use amount of nickel is reduced, the cost is low, the three-waste management burden is alleviated, and an alloy coating with the iron content in the range of 56%-62% can be obtained, which means large flat surface metal mask coatings with different magnetisms can be obtained.

Owner:KUN SHAN POWER STENCIL

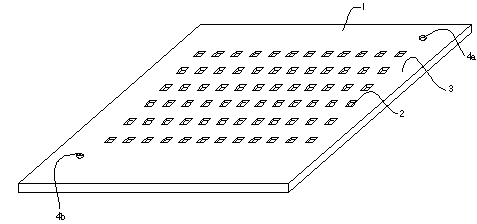

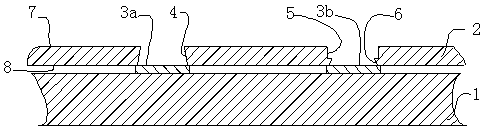

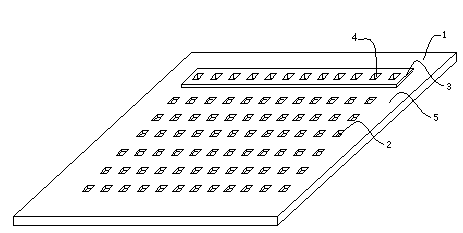

A production process for a step stencil

A step stencil and a hybrid production process thereof. The step stencil is a metal mask having up steps on a PCB surface, and the base material of the mask is one of stainless steel, pure nickel and a nickel-iron alloy. The hybrid production process flow is as follows: (1) the fabrication of the up step area on the stencil PCB surface; (2) the fabrication of a half-etched blind hole of the stencil; (3) the fabrication of stencil openings; and (4) subsequent processing of the stencil openings. The hybrid production process includes three processes of etching, laser cutting and electropolishing, by using which the metal stencil having the PCB surface with up step can be produced. Through the fabrication of the half-etched blind holes, alignment holes for precise alignment can be produced; the metal screen has an opening pattern both in the flat area and the up step area; and the opening has good quality, smooth hole walls, and no blurs; by using the etching process, the stencil surface can be made to be flat and no-tilting phenomenon; and the flat area of the metal stencil has good thickness uniformity.

Owner:KUN SHAN POWER STENCIL

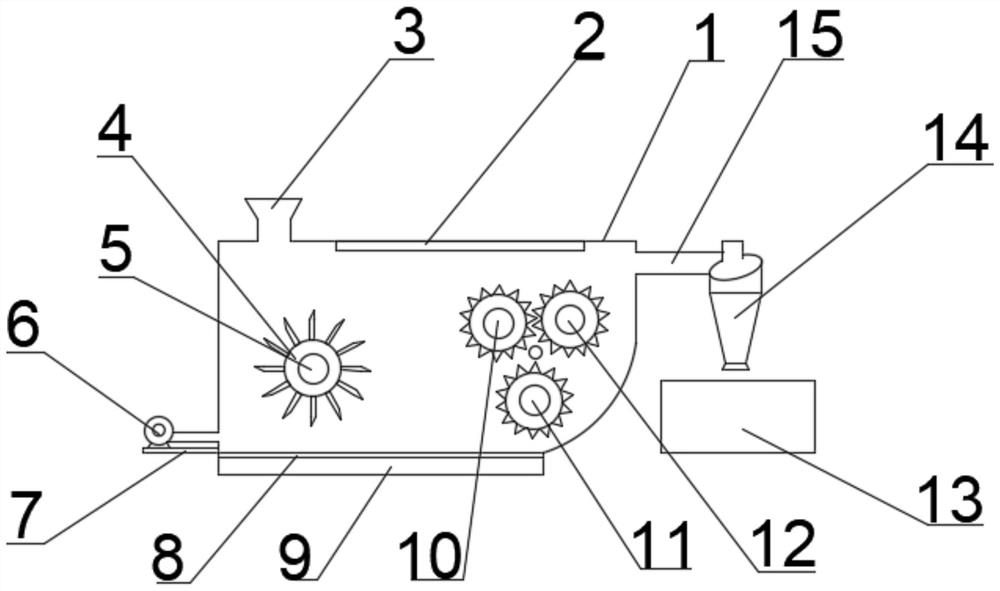

Fiber raw material opener

InactiveCN106012113AContact surface changeIncrease contact surfaceFibre cleaning/opening by toothed membersFibre cleaning/opening machinesCorrosionEngineering

The invention discloses a fiber raw material opener. The opener comprises an opener shell and a preprocessing machine shell. The opener shell forms an opening cavity, the preprocessing machine shell forms a preprocessing cavity, the inlet end of the opening cavity is connected with the outlet end of the preprocessing cavity, a driven roller is arranged between the two inner walls of the opening cavity and located at the inlet end, a driving roller is arranged between the two inner walls of the opening cavity and located at the outlet end, a transmission chain is disposed between the driving roller and the driven roller in a sleeving mode, a conveying mesh belt is arranged on the transmission chain, a plurality of brads are arranged on the conveying mesh belt, a conveying belt is disposed in the preprocessing cavity, a feed hopper communicated with the preprocessing cavity is arranged on the left side of the upper end of the preprocessing machine shell, and a plurality of sprayers are evenly distributed in the preprocessing cavity and on the top above the conveying belt. The opener is simple in structure, wet fiber raw materials can be wetted conveniently, dust spread is avoided, tiny impurities can be adsorbed, raw material opening quality is improved, overall strength is high, and the opener is resistant to corrosion and oxidation.

Owner:GUANGDE TIANYUN NEW TECH

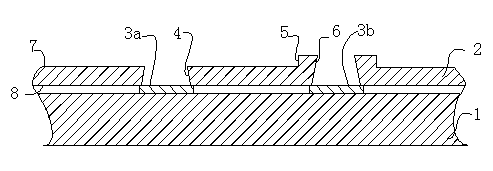

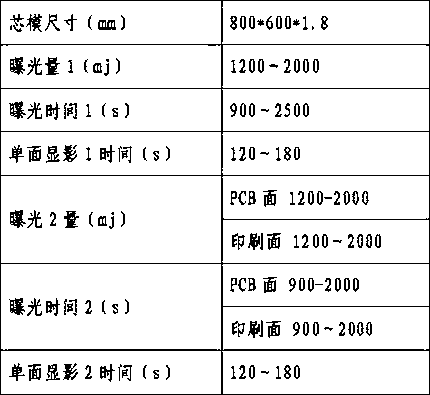

A hybrid production process for a printing stencil used in surface-mounting technology (SMT)

InactiveCN103203965AMix crafting improvementsGood opening qualityForme preparationEtchingSurface mounting

A hybrid production process for a printing stencil used in surface-mounting technology (SMT). The process flow is as follows: the fabrication of the up step area on a PCB surface and the down step area on a printing surface: substrate processing -> pretreatment (degreasing and pickling) -> double sided film mounting -> PCB surface exposure -> printing surface exposure -> double sided developing -> double sided etching; and the fabrication of the openings of the stencil: printing surface laser cutting. A metal stencil having the PCB surface with up steps, and the printing surface with down steps can be produced by using the process. According to the metal stencil produced by using the process, the openings of the substrate pattern area and the up step pattern area have good quality, smooth hole walls and no phenomena of blurs or slag; the surface of the metal stencil is good in quality and flat, the opening areas thereof without phenomena of protruding deformation; and the position precision of the pattern opening area of the up steps with the opening area of the substrate is high.

Owner:KUN SHAN POWER STENCIL

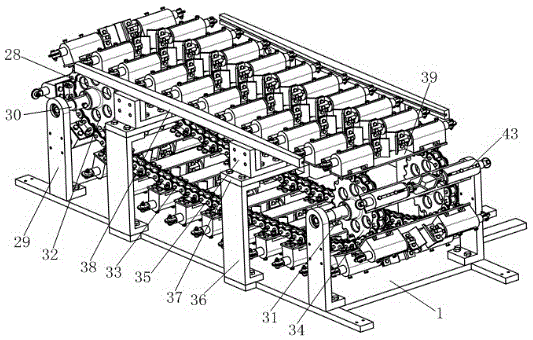

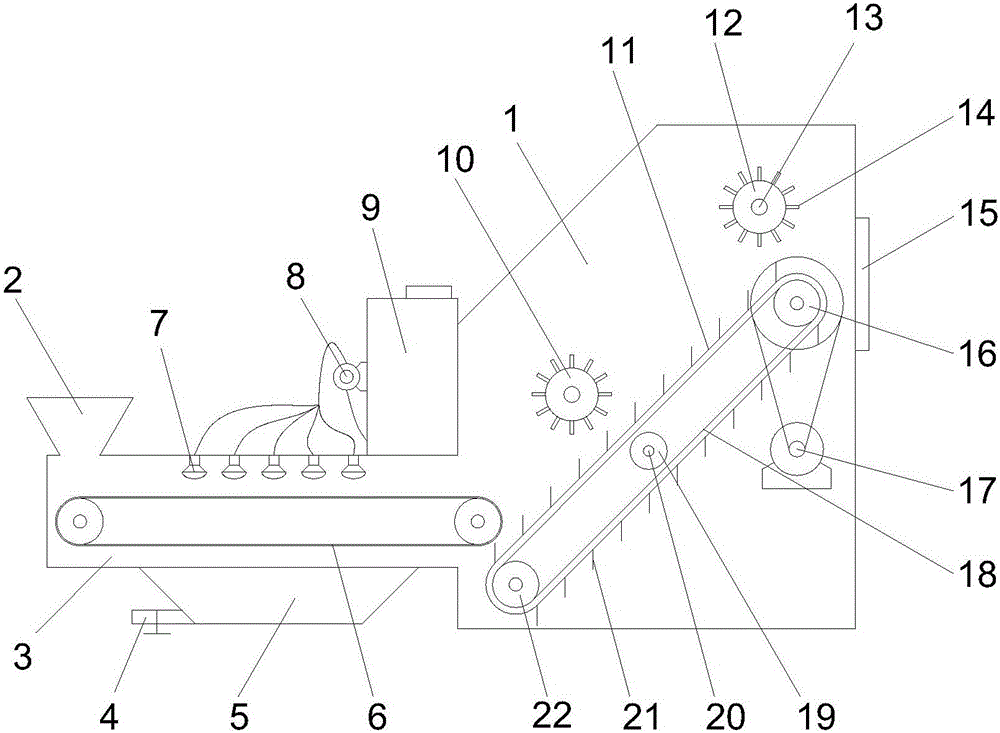

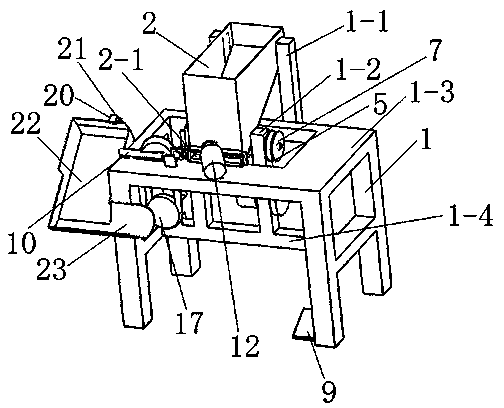

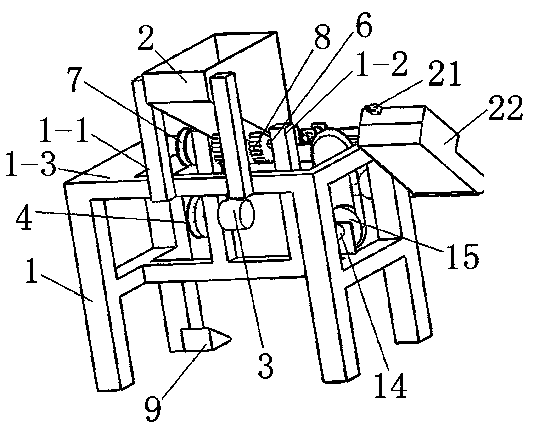

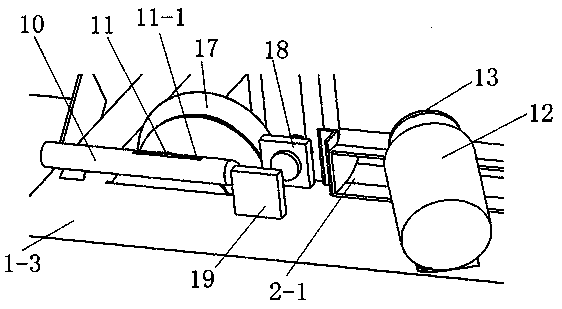

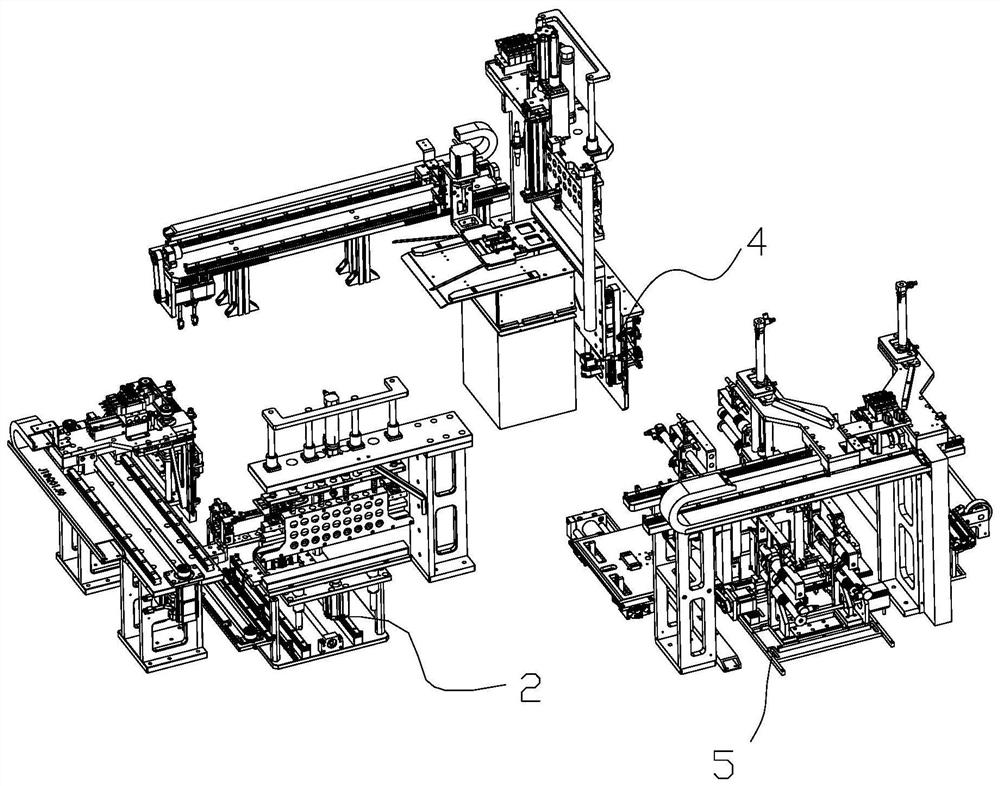

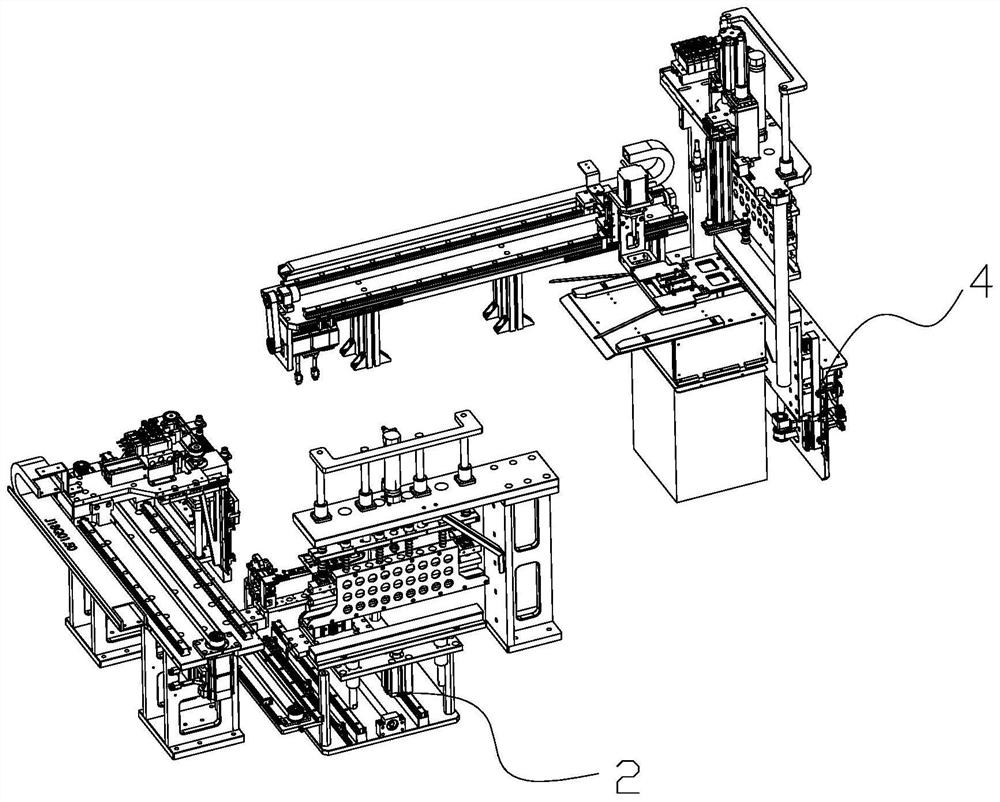

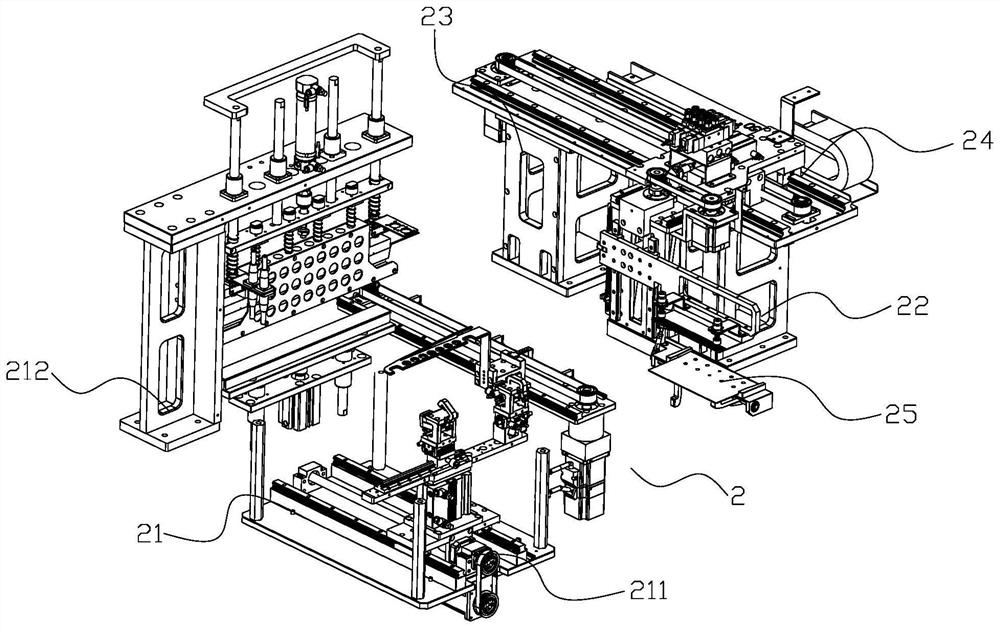

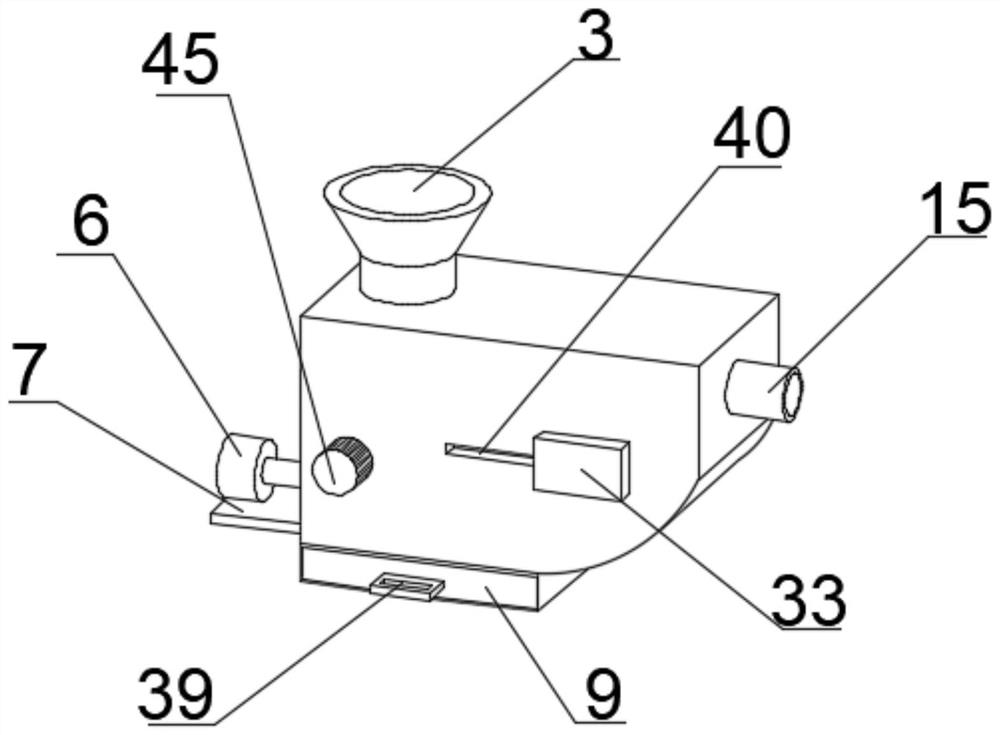

Wall honeycomb tube opening counting packaging machine

InactiveCN103770983AGood opening qualityReasonable structural designPackaging automatic controlMetal working apparatusHoneycombEngineering

The invention relates to a packaging machine, in particular to a technical packaging machine capable of opening a wall honeycomb tube, and belongs to the technical field of packaging machine structures. The wall honeycomb tube opening counting packaging machine is characterized by comprising a feeding device, wherein an opening device is arranged at the calandria opening (2-1) of the feeding device; a counting device is arranged between an opening cuter rest (10) and a tube conveyer of the opening device; a discharge device is arranged at the tail end of the opening device. Due to the arrangement of the opening device and the counting device, the wall honeycomb tube opening counting packaging machine is capable of both counting and opening, and is reasonable in structural design; one equipment is not required to be designed for opening, so that the cost is lowered; the equipment is stable in tube feeding and accurate in counting, the opening is tidy without burr, the opening of the tube is good in quality, no relevant equipment is available in the industry, the blank in the industry is filled up, and the packaging machine has a wide market prospect.

Owner:宋妍

A production method for a step stencil

InactiveCN103203960AGood opening qualitySmooth holePhotomechanical apparatusPlate printingLaser cuttingEngineering

A production method for a step stencil and the specific process flow of the method is as follows: substrate processing (cutting)->pre-treatment (degreasing, pickling, and sandblasting)->film mounting->double sided exposure->double sided developing->etching (up step areas on a PCB surface, and a printing surface)->film stripping->pre-treatment (degreasing and pickling)->laser cutting (flat openings and openings of the up step areas). By using the method, a metal stencil having up step areas on the PCB surface and the printing surface can be produced. The pattern area of the metal stencil has good opening quality, smooth hole walls, no undesirable phenomena such as blurs or jags; the position alignment precision of the opening pattern area is high; and the thickness uniformity is good, with uniformity COV less than 10%.

Owner:KUN SHAN POWER STENCIL

A hybrid production process and a step stencil produced by using the process

InactiveCN103203959AGood opening qualitySmooth holePhotomechanical apparatusPlate printingL&D processEngineering

A hybrid production process and a step stencil produced by using the process. The hybrid production process is as follows: electroforming a first electroformed layer; electroforming the up step area on a PCB surface; and etching a down step area on a printing surface. The hybrid production process is characterized by comprising two techniques of electroforming and etching. The stencil produced by the process has external characteristics of: the PCB surface having up steps, and the printing surface having down steps and having an opening pattern. According to the metal stencil, the produced electroformed layer of the up step area has a relatively high bonding strength with the plane electroformed layer; the produced entire electroformed stencil has smooth opening walls, good surface quality and has no pinholes or pittings; the thickness uniformity of the opening pattern area of the produced entire electroformed stencil is good; and a special spreader plate used in the second electroforming process can effectively reduce the current density, thereby reducing the edge effect of the up step area.

Owner:KUN SHAN POWER STENCIL

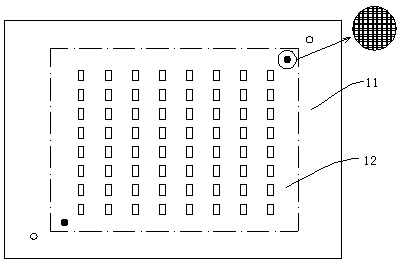

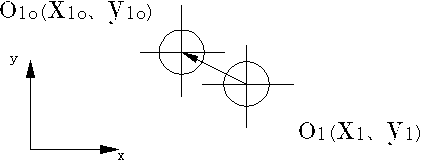

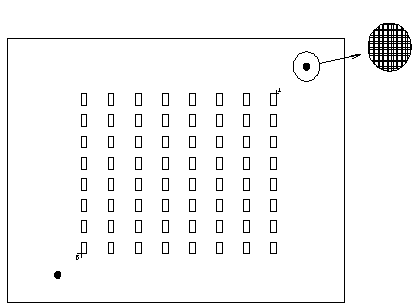

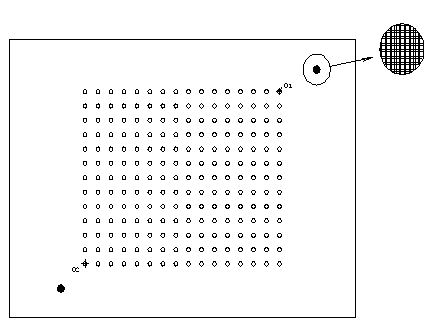

Production method for an electroformed stencil with mark points

InactiveCN103203977AImprove surface qualityImprove taperLaser beam welding apparatusForme preparationEngineeringLaser cutting

The present invention relates to a production method for an electroformed stencil with mark points, including the production of the electroformed stencil and the production of the mark points. The production method is characterized in that the stencil surface area outer the opening pattern area of the electroformed stencil is provided with two round holes diagonally positioned for determining the coordinates of the mark points. The production of the mark points comprises the steps of: placing the fixed electroformed stencil on a cutting base platform; then determining the coordinates of the mark points; adjusting cutting parameters and the vertical height of a laser cutting head to enable a laser focus to fall on the surface of the electroformed stencil; emitting laser light through the laser cutting head to perform cutting at the mark point area on the surface of the electroformed stencil. According to the production method for the electroformed stencil with mark points, the obtained electroformed stencil has good surface quality, no pinholes or pittings, thereby improving printing quality; and the mark points have high positioning accuracy, and relatively high degrees of recognition, improving alignment accuracy of a PCB with the electroformed stencil.

Owner:KUN SHAN POWER STENCIL

A production method for a step stencil

InactiveCN103203957AGood opening qualitySmooth holePhotomechanical apparatusPlate printingEngineeringPre treatment

A production method for a step stencil. Specifically, the production process flow is as follows: electroforming a first electroformed layer: core mold treatment->pre-treatment (degreasing, pickling and sandblasting)->film mounting 1->exposure 1->single sided development 1-> electroforming 1; electroforming up steps on a PCB surface: pretreatment (pickling and sandblasting)->double sided film mounting 2->double sided exposure 2->double sided development 2t->electroforming 2->film stripping->mold stripping; and etching down steps on the PCB surface: double sided film mounting on the electroformed layer->PCB surface exposure->PCB surface development->PCB surface etching ->film stripping->follow-up treatment (degreasing and pickling). By employing the method, the produced electroformed stencil has the PCB surface with up steps and down steps, and the step areas have opening patterns. The method of the invention solves the following technical problems: the pattern openings of the obtained up step area are in high position alignment precision with the openings of the first electroformed layer; the produced entire electroformed stencil has smooth opening hole walls, no undesirable phenomena such as blurs and diffusion coating, good surface quality, no undesirable defects such as pinholes and pittings; the stencil thickness uniformity COV is less than 10%; the stencil surface is in first grade brightness; and the bonding strength of the electroformed layer of the up step area and the first electroformed layer is strong, without the proneness of falling off.

Owner:KUN SHAN POWER STENCIL

Round leatherware intermittent punching and cutting positioning device

InactiveCN109280724AReduce cutting error rateImprove opening qualityLeather clicking/perforating/clickingSkins/hides/leather/fur manufacturing apparatusConstant speedFixed length

The invention discloses a round leatherware intermittent punching and cutting positioning device. The device structurally comprises a cutting device main body, a bottom control box and a positioning cutting table; the bottom control box is provided with a control motor, a transmission device, a control rotating shaft, a hydraulic cylinder and a hydraulic support rod; and the positioning cutting table is provided with a rotary disc positioning and cutting groove and a leatherware fixing device. The device has the beneficial effects that round leatherware is fixed through the leatherware fixingdevice, through constant-speed rotation of movable rotating discs, and under the assistance of the hydraulic support rod, movable support plates are pushed to raise upwards, so that a blade performs cutting in a cutting groove, and then arc-shaped cutting holes with fixed length are cut; and meanwhile, the distance between the cutting holes is controlled under the uniform motion of the movable rotating discs, the cutting error rate is reduced, and the punching quality of the round leatherware is improved.

Owner:魏晓华

A production process for an electroformed stencil

InactiveCN103203964AHigh positioning accuracyImprove bindingPhotomechanical apparatusPlate printingEngineeringPre treatment

A production process for an electroformed stencil. The process flow is as follows: electroforming a first electroformed layer: core mold treatment -> pre-treatment (degreasing, pickling and sandblasting 1) -> film mounting 1 -> exposure 1 -> single sided developing 1 -> electroforming 1-> film stripping -> mold stripping; and electroforming up steps on a printing surface: printing surface pre-treatment (pickling and sandblasting 2) -> film mounting 2 -> exposure 2 -> single sided developing sided 2 -> electroforming 2 -> film stripping. By using the process, the electroformed stencil having an up step area on the printing surface, wherein the up step area has an opening pattern, can be produced. The stencil has the following advantages: deposition thickness uniformity COV of the stencil is 10% or less; the stencil surface has good quality, grade-one surface brightness, no pinholes or pitting; the binding strength between the up step area and the first electroformed layer is large, without the proneness of falling off; and the position precision of the pattern opening area of the up steps with the opening area of the first electroformed layer is high.

Owner:KUN SHAN POWER STENCIL

Slitting machine device self-adaption calibration structure

InactiveCN108556092AAccurate limitCutting stabilityWood splittingCane mechanical workingSlide plateEngineering

The invention discloses a slitting machine device self-adaption calibration structure. The slitting machine device self-adaption calibration structure comprises a fixing platform, a calibration base and a supporting frame. The left side of the upper end of the fixing platform is provided with a slitting machine, and the right side of the upper end of the fixing platform is provided with a feedingsliding plate. The two sides and the rear end of the calibration base are all fixedly provided with protruding edges, the inner sides of the protruding edges on the two sides of the calibration base are each provided with a rotating plate, and the rotating plates are rotatably fixed to the side edge protruding edges of the calibration base through rotating shafts. The calibration base is fixed toa push rod, the push rod is fixed to a tooth frame, and the tooth frame is internally provided with incomplete teeth. The upper end of the supporting frame is fixedly provided with a second motor, anoutput shaft of the second motor is fixedly provided with a rotary table, the eccentric position of the rotary table is rotatably and fixedly provided with a lifting rotating rod, and the lower end ofthe lifting rotating rod is fixedly provided with a pressing plate. According to the slitting machine device self-adaption calibration structure, bamboo chip limiting is accurate and stable, and slitting quality is high.

Owner:安吉森虎机械有限公司

Packaging box film corner cutting device and method

InactiveCN112009815AAvoid cutting cornersImprove adaptabilityWrapping material feeding apparatusStructural engineeringManufacturing engineering

The invention relates to the field of packaging of packaging boxes, in particular to a packaging box film corner cutting device and method. The device comprises a corner cutting feeding mechanism, a corner cutting moving mechanism, a slitting mechanism and a corner cutting discharging mechanism; the input end and the output end of the corner cutting feeding mechanism are connected with the outputend of an edge sealing device and the input end of the corner cutting moving mechanism correspondingly, and the output end of the corner cutting moving mechanism is connected with the input end of theslitting mechanism and the input end of the corner cutting discharging mechanism correspondingly; the output end of the corner cutting discharging mechanism is connected with a discharging opening; the corner cutting feeding mechanism is used for feeding an edge-sealed packaging box; the corner cutting moving mechanism is used for moving the packaging box; the slitting mechanism is used for cutting off redundant films at the four corners of the edge-sealed packaging box; and the corner cutting discharging mechanism is used for discharging the processed packaging box. According to the device,by arranging the slitting mechanism, the adaptability of the packaging box film corner cutting device is improved, and the cost of the corner cutting device is lowered.

Owner:伍福庆

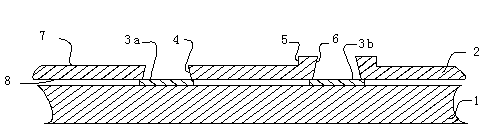

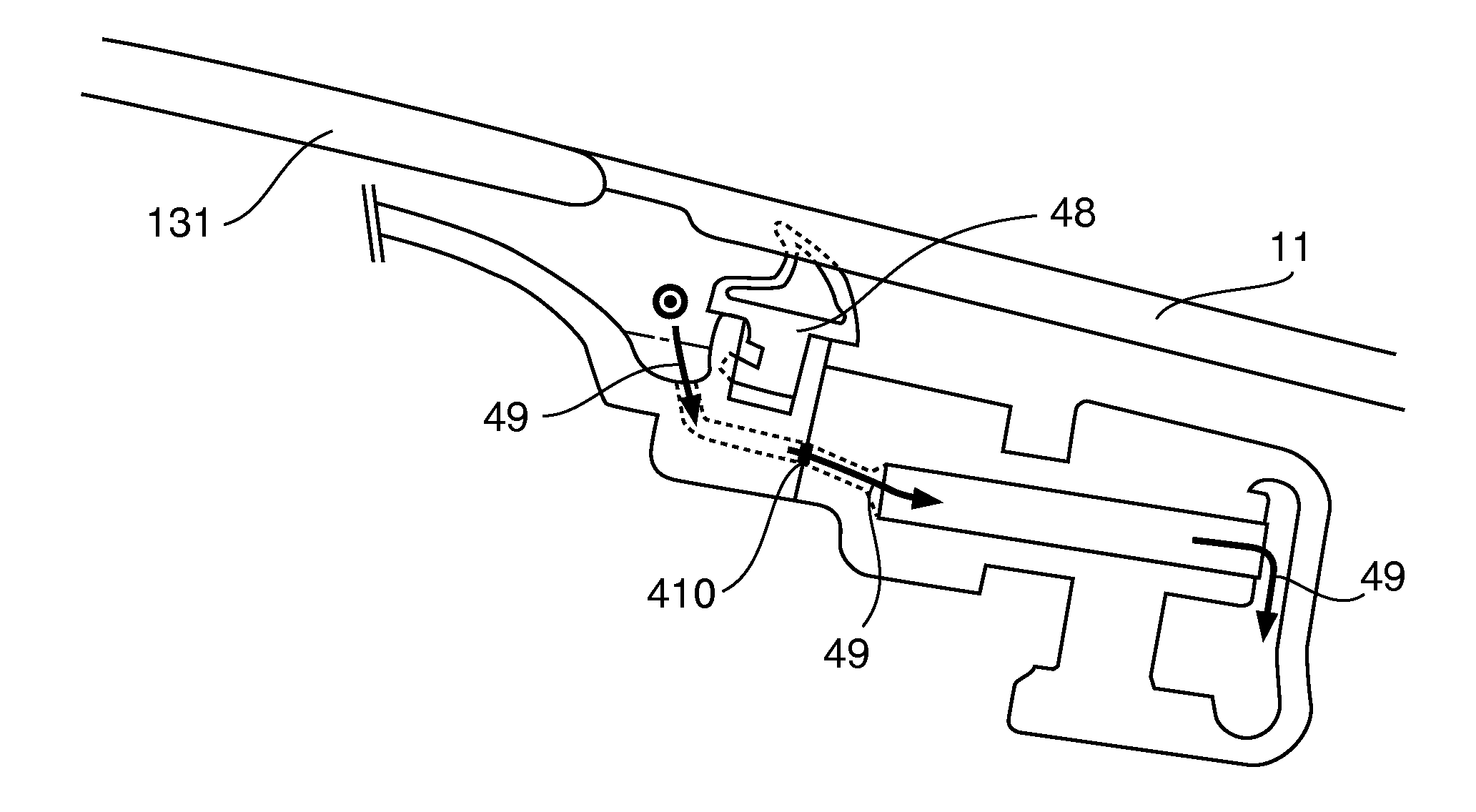

Glazed roof of a motor vehicle, corresponding method of assembly and corresponding vehicle

InactiveUS8678487B2Simple to produce and to mountGood opening qualityWindowsEngine sealsEngineeringChassis

A glazed roof of a motor vehicle is provided, which includes at least one opening and a fixed glazed structure bearing at least one element sliding on the inside of the vehicle and intended to close the opening(s). The glazed structure has an external contour coinciding with an accommodating surround on the chassis of the vehicle so the contour can be secured to the accommodating surround, as a flush fit. Each of the sliding elements is guided along two rails secured to the surface of the fixed structure, in a region distant from the external contour so as not to interfere with the securing of the latter to the accommodating surround. The roof has at least one retaining element, having a first end secured to one of the rails and a second end secured to the chassis. Each of the retaining elements is positioned at right angles to the rail.

Owner:WAGON SAS

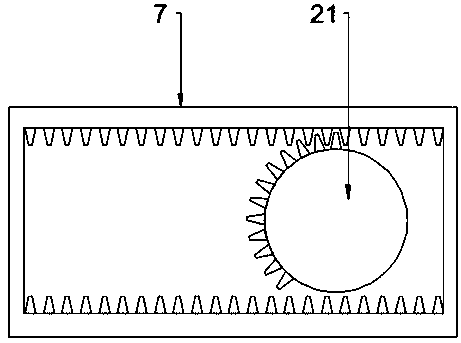

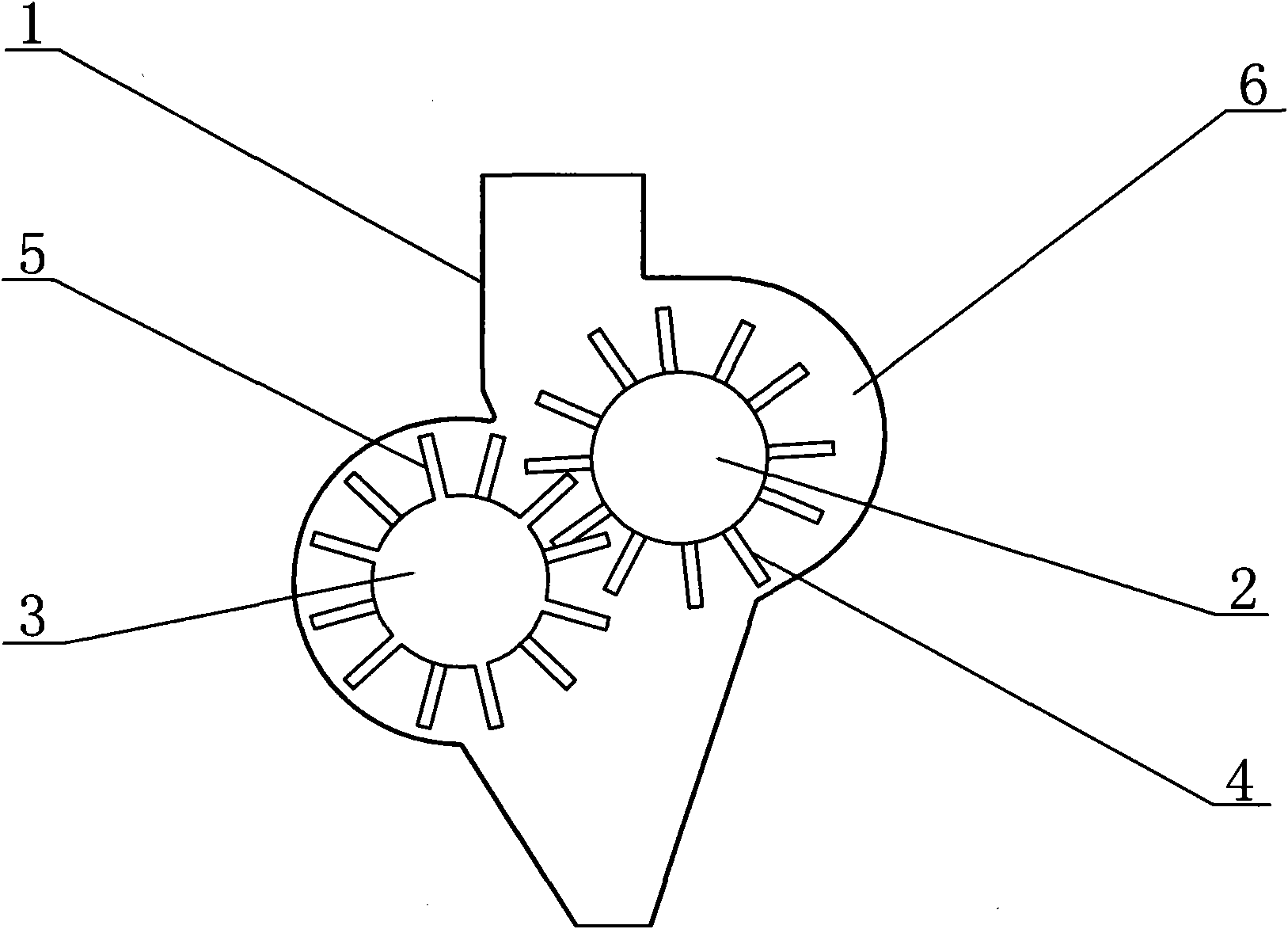

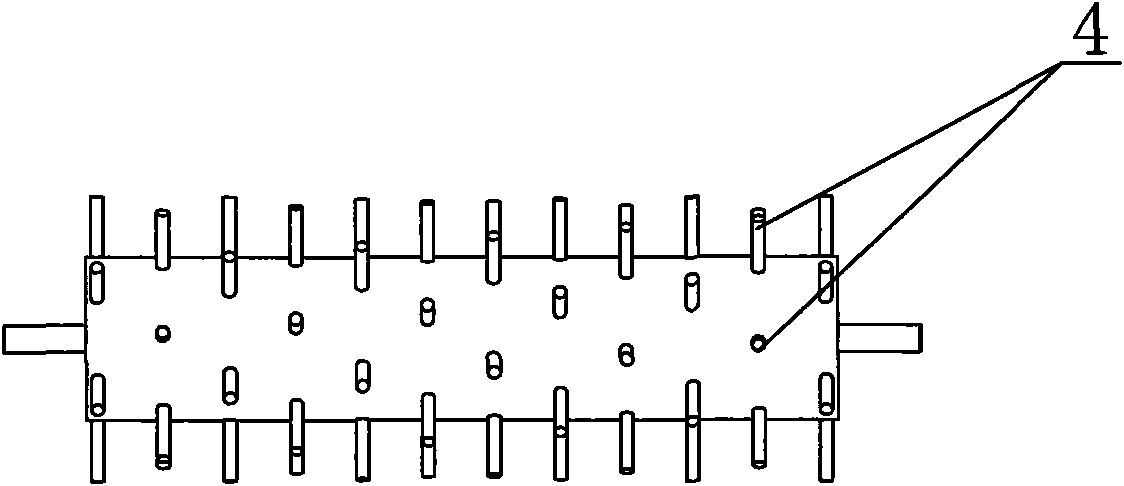

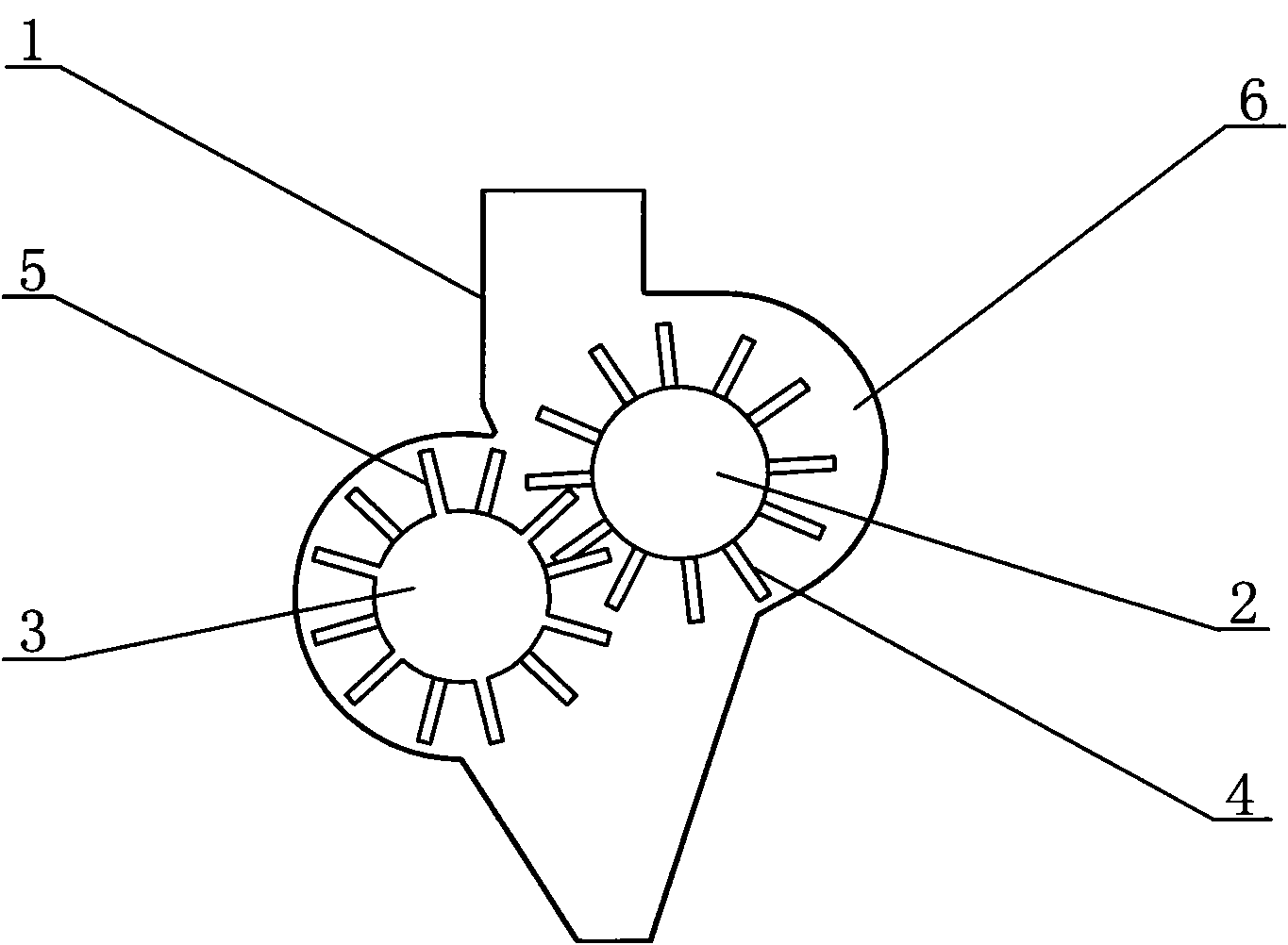

Seed cotton opening device of seed cotton foreign fiber stripping machine

InactiveCN101962826ASimple structureReasonable designFibre cleaning and opening machine combinationsFibre cleaning/opening machinesAirflowFiber

The invention relates to a seed cotton opening device of a seed cotton foreign fiber stripping machine. The device is provided with a casing, wherein the upper and lower ends of the casing are opened; a feeding roller and an opening roller are arranged in the casing; the feeding roller is correspondingly and obliquely arranged above the opening roller; feeding sticks are uniformly distributed on the feeding roller; opening sticks are uniformly distributed on the opening roller; the feeding sticks and the opening sticks are staggered with one another; the rotating directions of the feeding roller and the opening roller are opposite; the rotating speed of the feeding roller is between 15 and 45 r / min; the rotating speed of the opening roller is between 200 and 300 r / min; and the feeding roller and the opening roller are arranged in grooves on inner walls on both sides of the casing respectively. The device has a simple structure and a reasonable design. Seed cotton entering from the upper end opening of the casing and air current are prevented from directly flowing into a gap between the feeding roller and the opening roller and good opening effect is achieved. The seed cotton is rapidly dispersed between the feeding roller and the opening roller and opening efficiency is high.

Owner:LUOYANG FANGZHI MEASUREMENT & CONTROL

A production method for an electroformed stencil with mark points

InactiveCN103203974AImprove surface qualityImprove taperPhotomechanical apparatusPlate printingEngineeringLaser cutting

The present invention relates to a production method for an electroformed stencil with mark points, including the production of the electroformed stencil and the production of the mark points. The production method is characterized by comprising the steps of: placing the fixed electroformed stencil on a cutting base platform; selecting any two openings diagonally positioned on the electroformed stencil, reading coordinates of specific points of the openings, positioning the electroformed stencil through the coordinates of specific points, and determining coordinates of the mark points via comparing with an original file; adjusting cutting parameters and the vertical height of a laser cutting head to enable a laser focus to fall on the surface of the electroformed stencil; and emitting laser light through the laser cutting head to perform cutting at the mark point area on the surface of the electroformed stencil. According to the production method for the electroformed stencil with mark points, the obtained electroformed stencil has good surface quality, no pinholes or pittings, thereby improving printing quality; and the mark points have high positioning accuracy, and relatively high degrees of recognition, improving alignment accuracy of a PCB with the electroformed stencil.

Owner:KUN SHAN POWER STENCIL

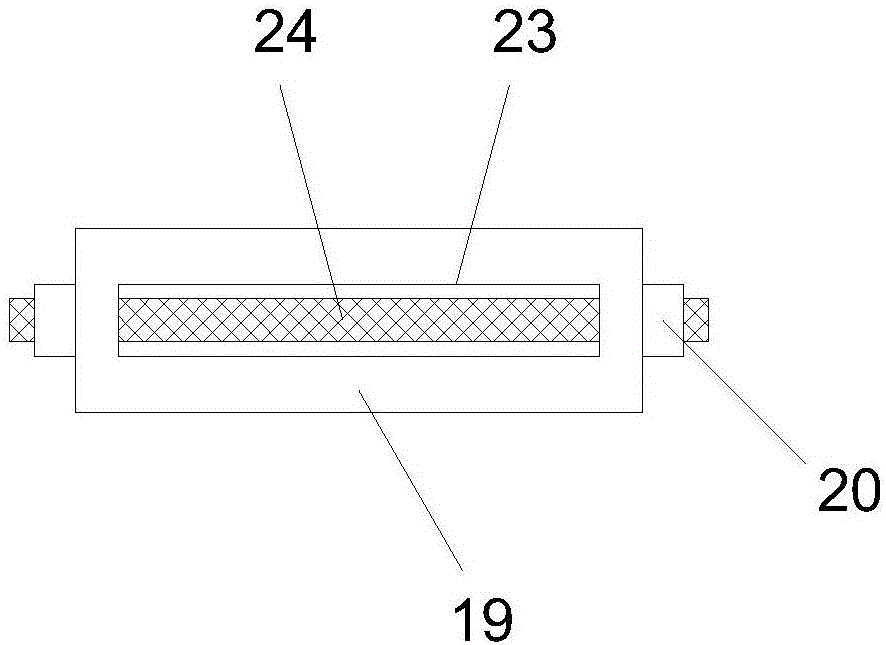

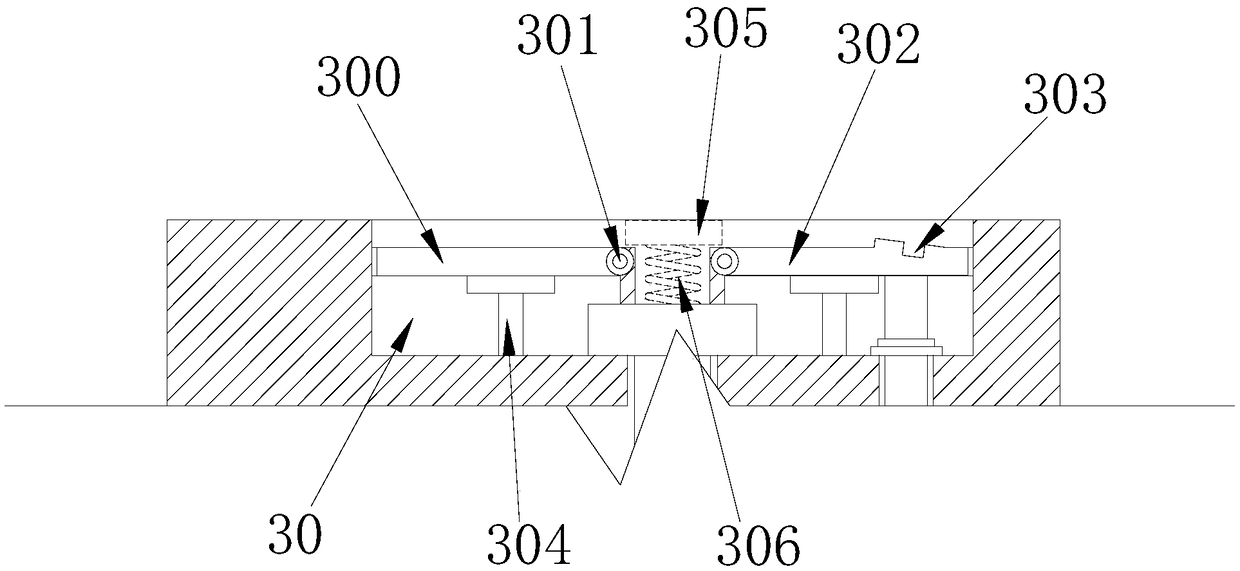

Mounting structure of opening rubber roller of filter stick forming machine

ActiveCN113430695AParallelism self-adjustingExtended service lifeTobacco smoke filtersTextiles and paperVertical planeMolding machine

The invention relates to the technical field of filter stick forming machines, in particular to a mounting structure of an opening rubber roller of a filter stick forming machine. The mounting structure comprises a large support for mounting the opening rubber roller and a small support for connecting a fixed support; the large support is provided with a first end and a second end which are positioned on two sides of the axis of the opening rubber roller respectively; the first end is movably connected with a driving piece through a hinge piece; the second end is hinged to the small support through a hinge shaft; and the axis of the hinge shaft is perpendicular to the axis of the opening rubber roller in the horizontal plane. Through the split structure that the large support is hinged to the small support, and the movable connection between the large support and the driving piece, the large support can drive the opening rubber roller to rotate in the direction perpendicular to the axis of the opening rubber roller in the vertical plane relative to the small support and the driving piece, so that the self-adjustment of the parallelism of the opening rubber roller and a threaded roller is achieved, the error of the parallelism of the opening rubber roller and the threaded roller cannot be generated, and the opening quality of a tow belt can be effectively improved.

Owner:SHANGHAI TOBACCO GRP CO LTD +1

A production process for a step stencil by using an electroforming method

InactiveCN103203967AGood opening qualitySmooth holeForme preparationPre treatmentElectrical and Electronics engineering

A production process for a step stencil by using an electroforming method. The specific process flow is as follows: electroforming a first electroformed layer: core mold processing -> pre-treatment (degreasing, pickling and sandblasting) -> film mounting 1 -> exposure 1 -> single sided developing 1 -> electroforming 1; electroforming an up step area on a PCB surface: pre-treatment (pickling and sandblasting) -> film mounting 2 -> exposure 2 -> single sided developing 2 -> electroforming 2 -> film stripping; electroforming a second electroformed layer (forming a down step area on a printing surface): printing surface film mounting -> exposure 3 -> single sided developing 3 -> electroforming 3 -> film stripping -> mold stripping -> subsequent treatment (degreasing and pickling). By using the process, the electroformed stencil having the PCB surface with up steps and the printing surface with up steps, wherein the up step areas has an opening pattern, can be produced. The openings of the pattern areas of the substrate and the step area have good quality, smooth hole walls and no blurs; the stencil surface has good quality, first class brightness, and no pinholes or pittings; the position precision of the opening area of the step area pattern and the opening area of the first electroformed layer is high; the binding strength between the up step area and the substrate is large, without the proneness of falling off; the thickness uniformity of the pattern areas of the electroformed stencil is good.

Owner:KUN SHAN POWER STENCIL

Cloth strip slitting device capable of performing respective rolling for curtain processing

PendingCN113173444AImprove stripping efficiencyPrevent breaks in stripsSevering textilesArticle deliveryEngineeringKnife blades

The invention discloses a cloth strip slitting device capable of performing respective rolling for curtain processing. The cloth strip slitting device comprises a bottom plate and cloth, wherein a driving rolling mechanism is arranged on the outer wall of the top of the bottom plate; a chute is formed in the outer wall of one side of the bottom plate; a slide block I is inserted into the inner wall of the chute; a slitting auxiliary assembly is arranged at the bottom of a knife rest; a paving mechanism is arranged on the outer wall of the top of the bottom plate; and a feeding assembly is arranged on the outer wall of the top of the bottom plate. According to the cloth strip slitting device capable of performing the respective rolling for the curtain processing, an air cylinder is started to make a piston rod of the air cylinder generate piston motion, the piston rod of the air cylinder moves up and down along a vertical groove and meanwhile drives the knife rest to slide back and forth along the inner wall of the chute, and then blades move up and down in the inclined direction; and at the moment, the blades move in the horizontal direction and the vertical direction, and then changeable and disordered pressure is generated on the cloth, so that the slitting of the cloth is efficiently and stably performed, the slitting efficiency is favorably improved, and the situation that the slitting is interrupted is prevented.

Owner:深圳汇信昌供应链有限公司

A method for improving opening quality of an electroformed plate

InactiveCN103207534AQuality improvementEasy to shapeSemiconductor/solid-state device manufacturingPhotosensitive material processingProcess engineeringPost exposure

The invention discloses a method for improving opening quality of an electroformed plate, and the method comprises the following steps: S10: after mounting film on a core mold, performing exposure to well expose the needed opening pattern area on dry film; S11: placing the well-exposed dry film in a toaster, setting a roasting temperature and a roasting time according to needs, and performing dry film roasting; and S12: after complete roasting, performing a process of developing to remove the unexposed dry film. According to the method for improving opening quality of the electroformed plate of the invention, thick dry film is subjected to roasting after the exposure, which enables the dry film fully cured, thereby preventing the problem of diffusion coating; at the same time opening shapes are good, thereby lowering the deviation of opening sizes of a PCB surface size and a printing surface, and improving the opening quality; and roasting after the exposure allows the range of development dots further widened, providing a wider controlling range for the production to make the production control simpler and easier.

Owner:KUN SHAN POWER STENCIL

Method for making a step formwork

InactiveCN103203960BGood opening qualitySmooth holePhotomechanical apparatusPlate printingLaser cuttingEngineering

A production method for a step stencil and the specific process flow of the method is as follows: substrate processing (cutting)->pre-treatment (degreasing, pickling, and sandblasting)->film mounting->double sided exposure->double sided developing->etching (up step areas on a PCB surface, and a printing surface)->film stripping->pre-treatment (degreasing and pickling)->laser cutting (flat openings and openings of the up step areas). By using the method, a metal stencil having up step areas on the PCB surface and the printing surface can be produced. The pattern area of the metal stencil has good opening quality, smooth hole walls, no undesirable phenomena such as blurs or jags; the position alignment precision of the opening pattern area is high; and the thickness uniformity is good, with uniformity COV less than 10%.

Owner:KUN SHAN POWER STENCIL

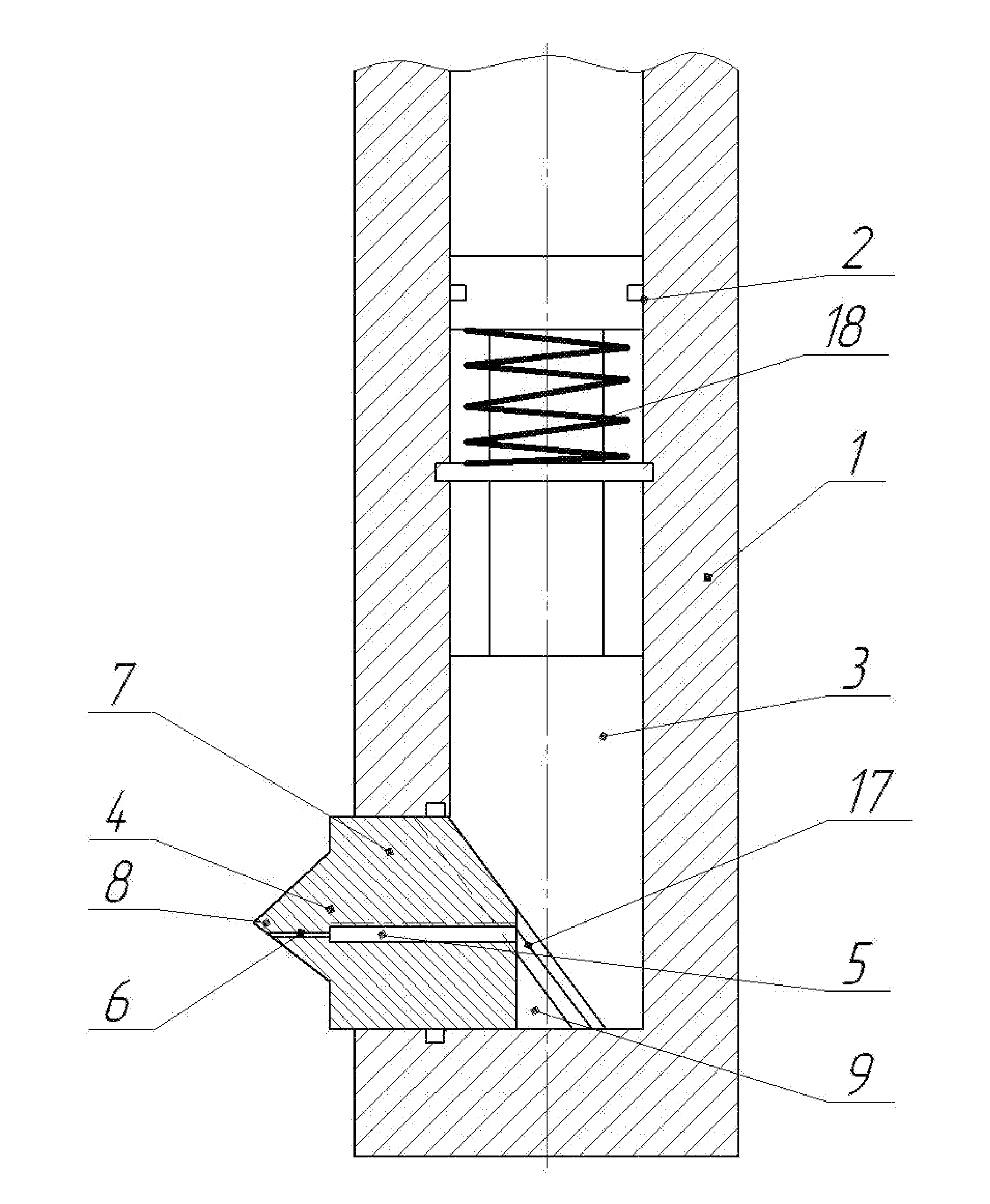

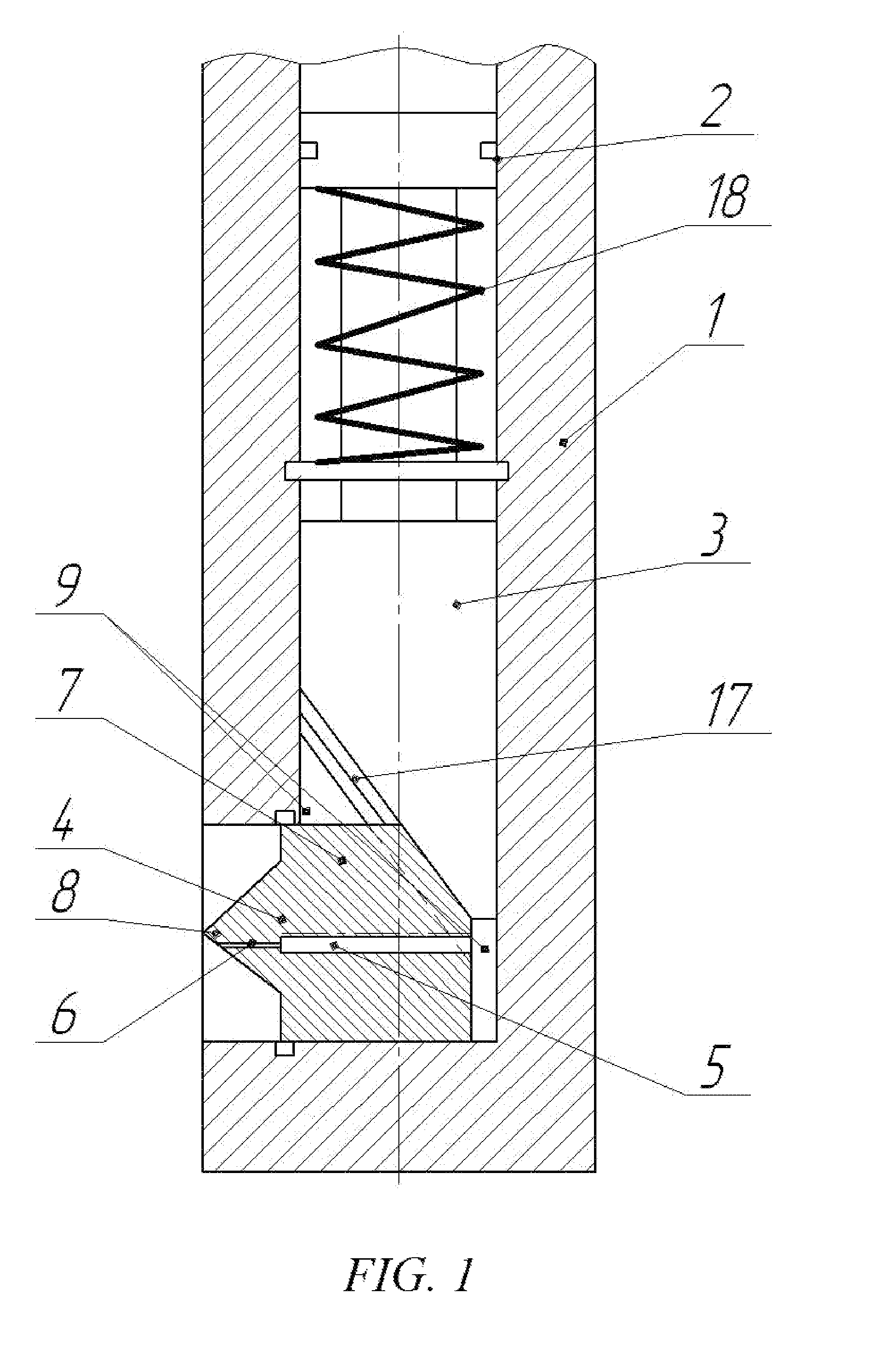

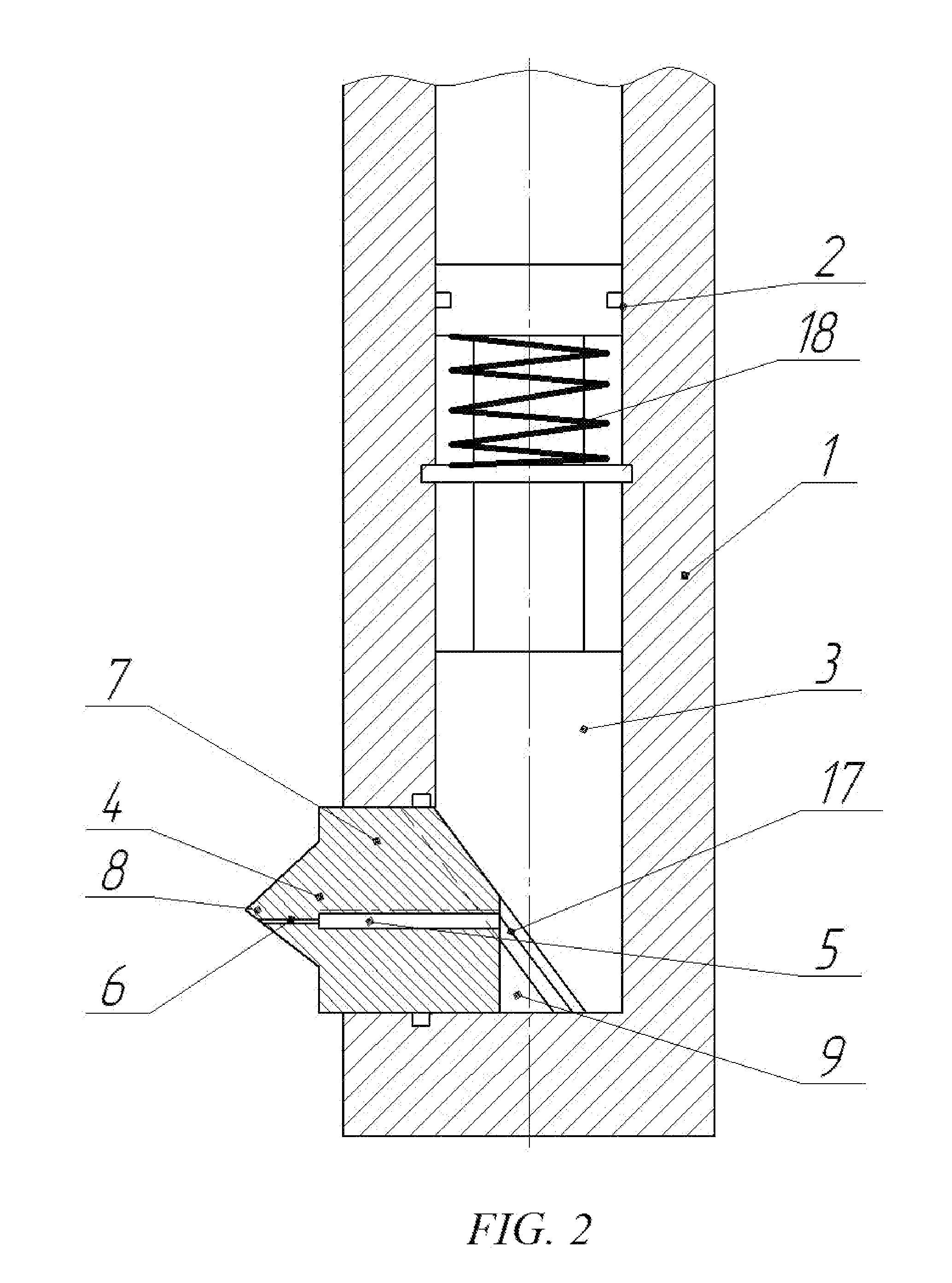

Hydromecanical piercing perforator and method of operation thereof

Proposed devices provide for a jetting process of formation critical areas after opening up a column, increasing a perforator's punch power and reliability, significantly preventing accidents. A hydro-mechanical piercing-type perforator includes a casing containing a hydraulic cylinder with a pusher, an operating tool radially movable and capable of interaction with the pusher. The tool is designed as a puncher, placed on a piston (plunger), mounted in a camera. The tool includes at least one through hydraulic channel and a jet. The camera is hydraulically connected with the cylinder. A proposed method for operating the perforator includes supplying a working fluid to the perforator through the column, creating pressure of the working fluid for an extension mechanism actuating the tool, extending the tool by applying the pressure through a piston rod system, to the piston with the puncher, and applying pressure to the piston through the hydraulic cylinder to the chamber.

Owner:KUZYAEV SALAVAT ANATOLYEVICH MR

A kind of manufacturing process of step formwork

InactiveCN103203956BGood opening qualitySmooth holePhotomechanical apparatusPlate printingEngineeringPre treatment

Owner:KUN SHAN POWER STENCIL

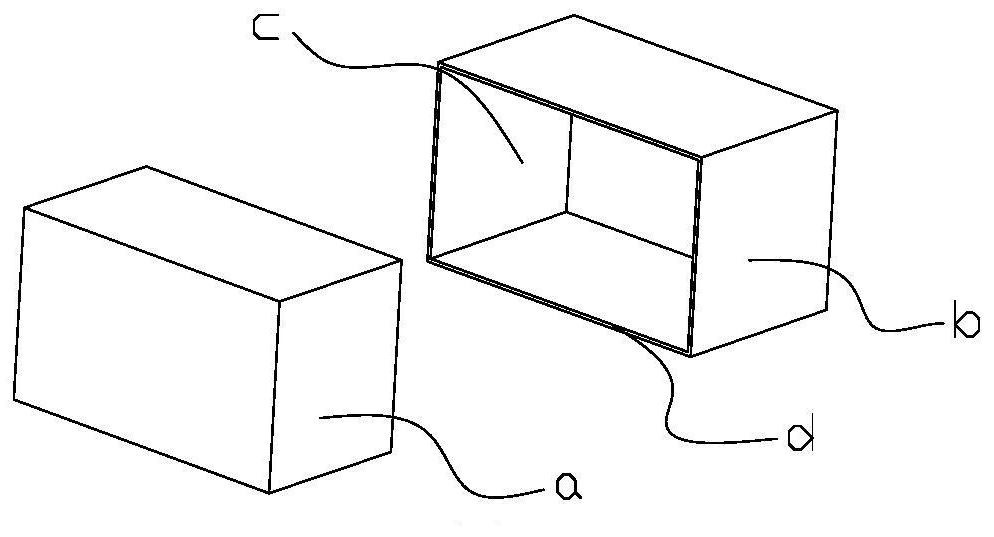

Thin film bag forming edge-sealing device and method

InactiveCN112009804AImprove adaptabilityAffects the phenomenon of poor suctionWrapping material feeding apparatusWrapper twisting/gatheringHeat sealerThin membrane

The invention relates to the field of thin film packaging, in particular to a thin film bag forming edge-sealing device and method. The device comprises an edge-sealing rack, an edge-sealing pushing mechanism, a heat sealing mechanism and a thin film suction mechanism; the heat sealing mechanism and the thin film suction mechanism are both fixed to the edge-sealing rack; the two ends of the edge-sealing pushing mechanism are connected with the output end of a bag making and opening device and the heat sealing mechanism correspondingly, and the edge-sealing pushing mechanism makes contact witha packaging box; the output end of the heat sealing mechanism makes contact with openings in the two ends of a film bag, and the output end of the thin film suction mechanism makes contact with a thinfilm sealed and cut off by the heat sealing mechanism; the edge-sealing pushing mechanism is used for pushing the opened film bag and the packaging box to the heat sealing mechanism; the heat sealingmechanism is used for sealing edges of the openings in two ends of the film bag; and the thin film suction mechanism is used for sucking and collecting the thin film cut off by the heat sealing mechanism. According to the thin film bag forming edge-sealing device, by arranging the thin film suction mechanism, the cut-off thin film is prevented from adhering to a heat sealing head, and the edge-sealing quality of the openings of the film bag is improved.

Owner:伍福庆

A kind of manufacturing process of step formwork

InactiveCN103203952BGood opening qualitySmooth holePhotomechanical apparatusPlate printingEngineeringLaser cutting

Owner:KUN SHAN POWER STENCIL

A production process for a step stencil

InactiveCN103203956AHigh positioning accuracyGood opening qualityPhotomechanical apparatusPlate printingEngineeringPre treatment

A production process for a step stencil. The production process flow is as follows: electroforming a first electroformed layer: core mold treatment->pre-treatment (degreasing, pickling and sandblasting)->film mounting 1->exposure 1->single sided development 1-> electroforming 1->film stripping->mold stripping; and etching down steps on a PCB surface: double sided film mounting on the electroformed layer->PCB surface exposure->PCB surface development->PCB surface etching ->film stripping->follow-up treatment (degreasing and pickling). According to the stencil obtained by using the process, the PCB surface has a down step area, a plane area has pattern openings, and the down step area has no openings. The pure electroforming process of the invention solves the following technical problems: the PCB surface of the produced electroformed stencil has down steps; the produced entire electroformed stencil has smooth opening hole walls, no undesirable phenomena such as blurs and diffusion coating, good surface quality, no undesirable defects such as pinholes and pittings; the stencil thickness uniformity COV is less than 10%; and the stencil surface is in first grade brightness, with uniform brightness in the down step area after etching.

Owner:KUN SHAN POWER STENCIL

A cashmere wool opening device

ActiveCN112195537BAchieve rotationConvenient nestingFibre cleaning/opening machinesRadiationAnimal scienceMedicine

The invention discloses a cashmere wool opening device, which comprises a first opening mechanism and a second opening mechanism. The second opening mechanism includes the first, second and third opening rollers. The three opening rollers are distributed in an equilateral triangle. The third motor drives the gear to rotate to realize the rotation, and the second motor drives the gearbox to rotate. , to realize the revolution of the second opening mechanism. A blower is installed at the bottom of the left side of the opening device body. By controlling the opening and closing of the blower to feed, the blower sends the cashmere wool that has been opened into the air outlet pipe, and the air outlet pipe is connected with the Saxon outlet. The material mechanism is connected, and the cashmere wool that has been opened falls into the collection box from the bottom of the Sacron discharge mechanism. The present invention improves the applicability of the opening device by providing a movable second opening mechanism, improves the opening quality through the rotation and revolution of the second opening mechanism, and completely removes impurities by feeding materials through the blower.

Owner:ZHEJIANG SCI-TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com