A production method for an electroformed stencil with mark points

A production method and positioning point technology, which are applied in the preparation of printing surface, photoengraving process of pattern surface, printing and other directions, can solve the problems that the precision and quality of the opening of the steel mold cannot meet the requirements well, and the quality of the board surface is not high enough.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

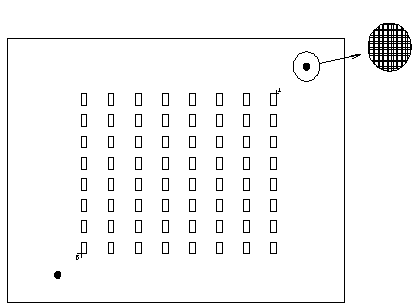

[0067] In order to better align with the PCB accurately and transfer an accurate amount of material to an accurate position, the electroforming process is used to make the electroforming stencil. The process steps include:

[0068] (1) Pre-treatment of the mandrel: degreasing, pickling and sandblasting the mandrel to remove oil stains and impurities on the surface, and smooth the surface;

[0069] (2) Film: apply film to the surface of the mandrel;

[0070] (3) Exposure: Expose the pattern opening area so that the unexposed area can be removed by development, leaving the exposed part as a protective film for the subsequent electroforming step;

[0071] (4) Single-sided development: develop the unexposed part in step (3), leaving the exposed part as a protective film for the subsequent electroforming step;

[0072] (5) Electroforming: The electroforming method is used to electroform the electroforming material to the exposure area;

[0073] (6) Fading film: remove the exposed...

Embodiment 2

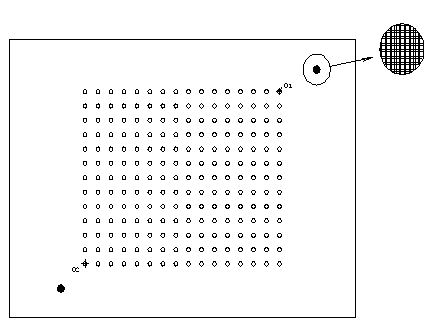

[0086] In order to better align with the PCB accurately and transfer an accurate amount of material to an accurate position, the electroforming process is used to make the electroforming stencil. The process steps include:

[0087] (1) Pre-treatment of the mandrel: degreasing, pickling and sandblasting the mandrel to remove oil stains and impurities on the surface, and smooth the surface;

[0088] (2) Film: apply film to the surface of the mandrel;

[0089] (3) Exposure: Expose the pattern opening area so that the unexposed area can be removed by development, leaving the exposed part as a protective film for the subsequent electroforming step;

[0090] (4) Single-sided development: develop the unexposed part in step (3), leaving the exposed part as a protective film for the subsequent electroforming step;

[0091] (5) Electroforming: The electroforming method is used to electroform the electroforming material to the exposure area;

[0092] (6) Fading film: remove the exposed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| evenness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com