Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

16637 results about "Foreign matter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

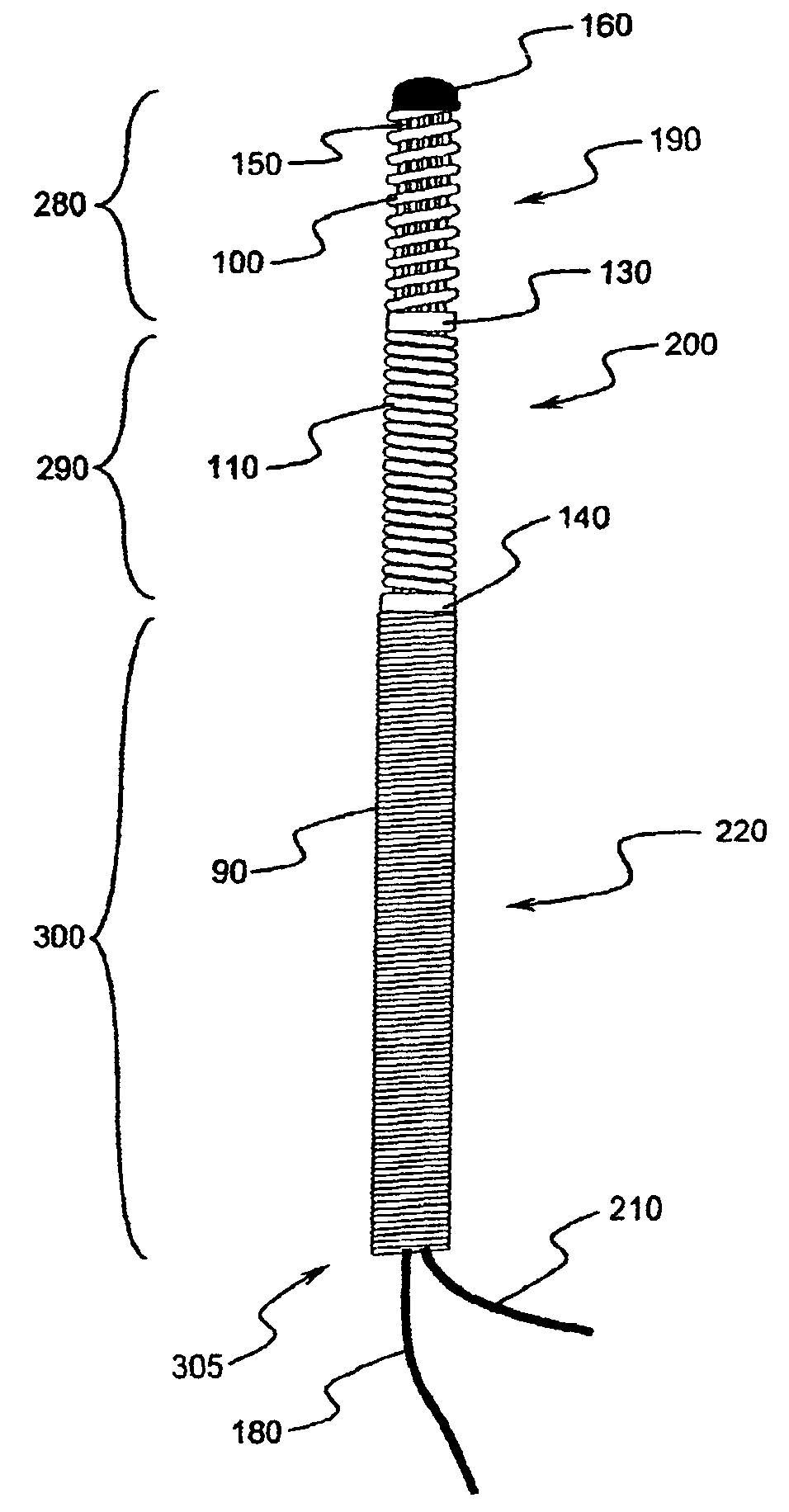

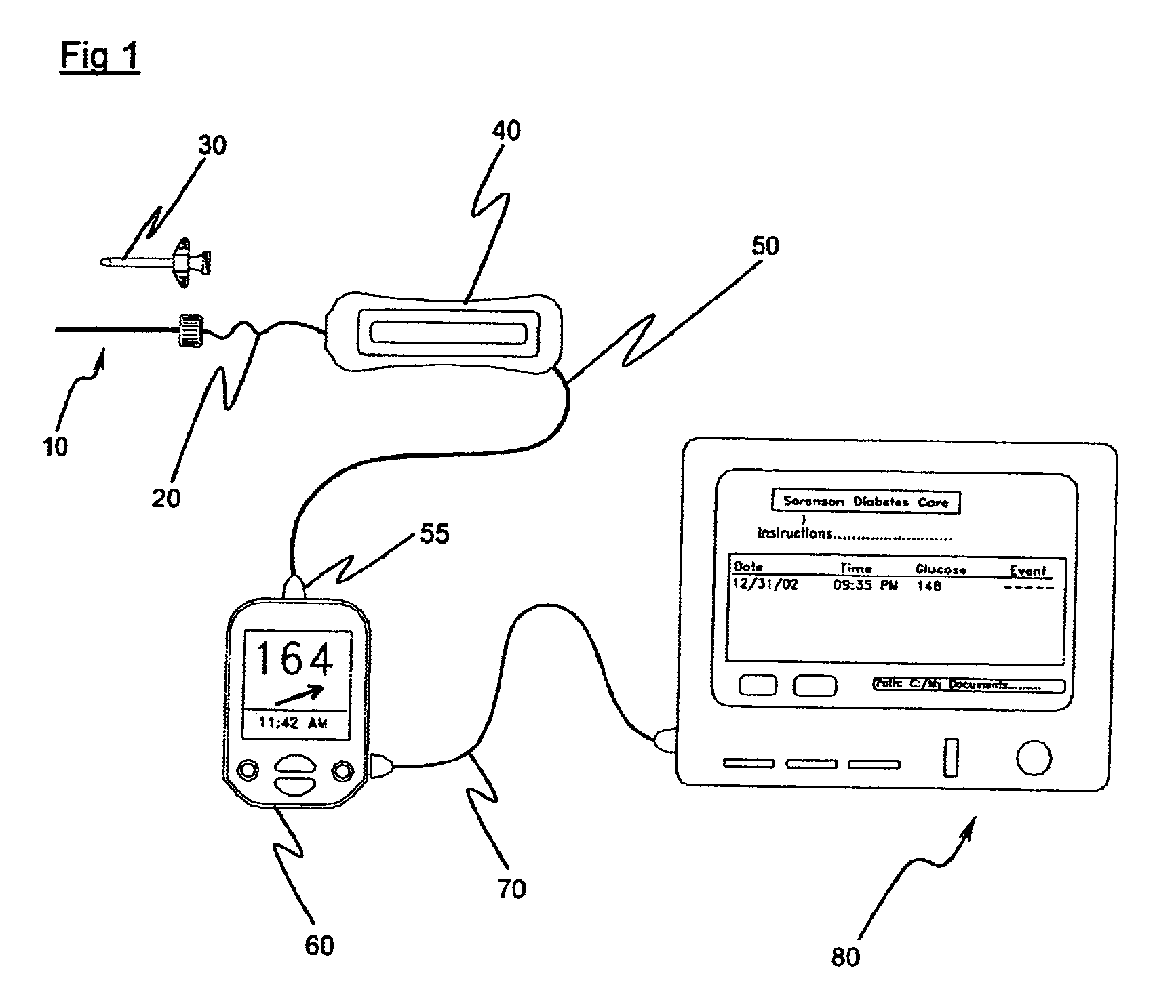

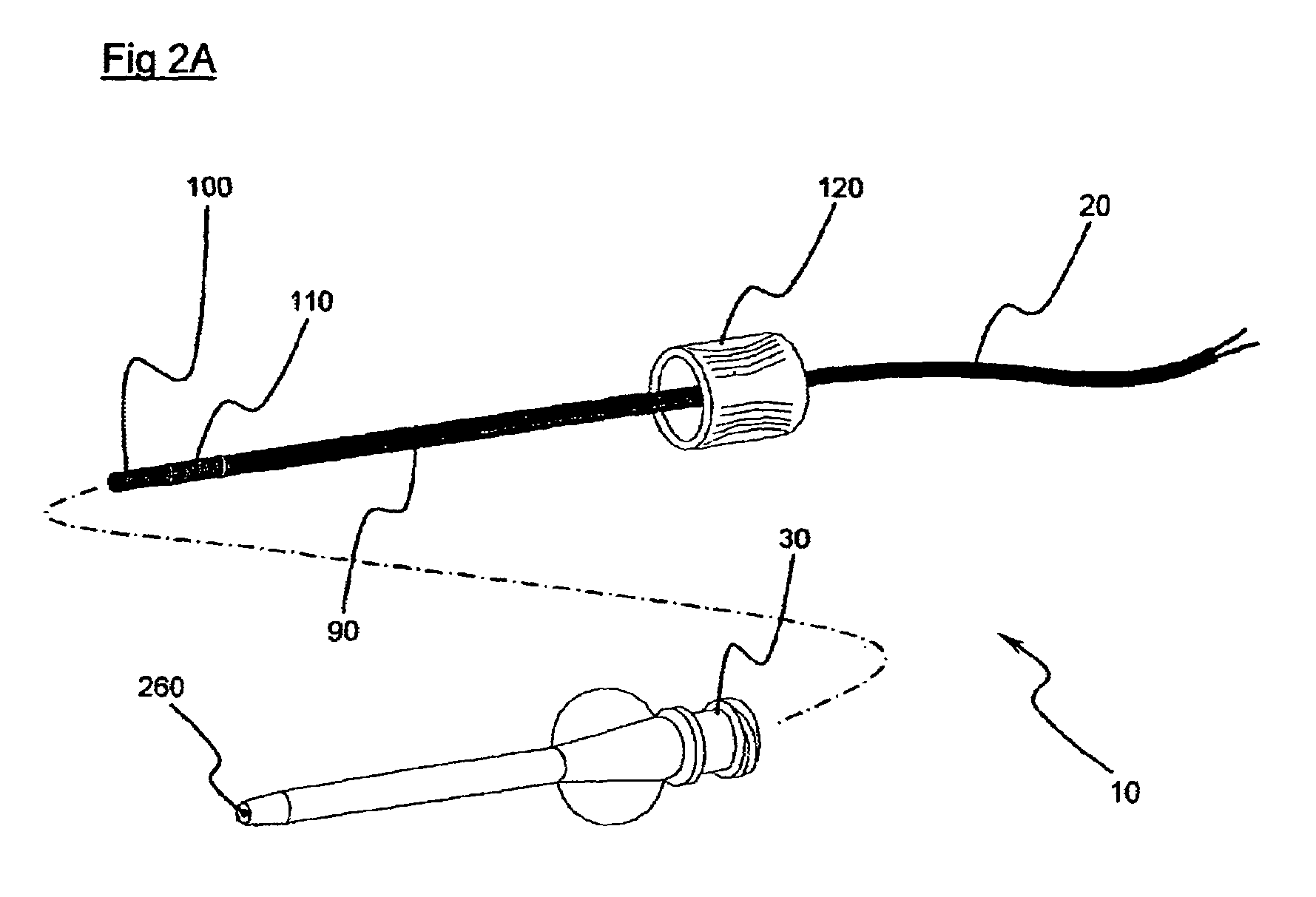

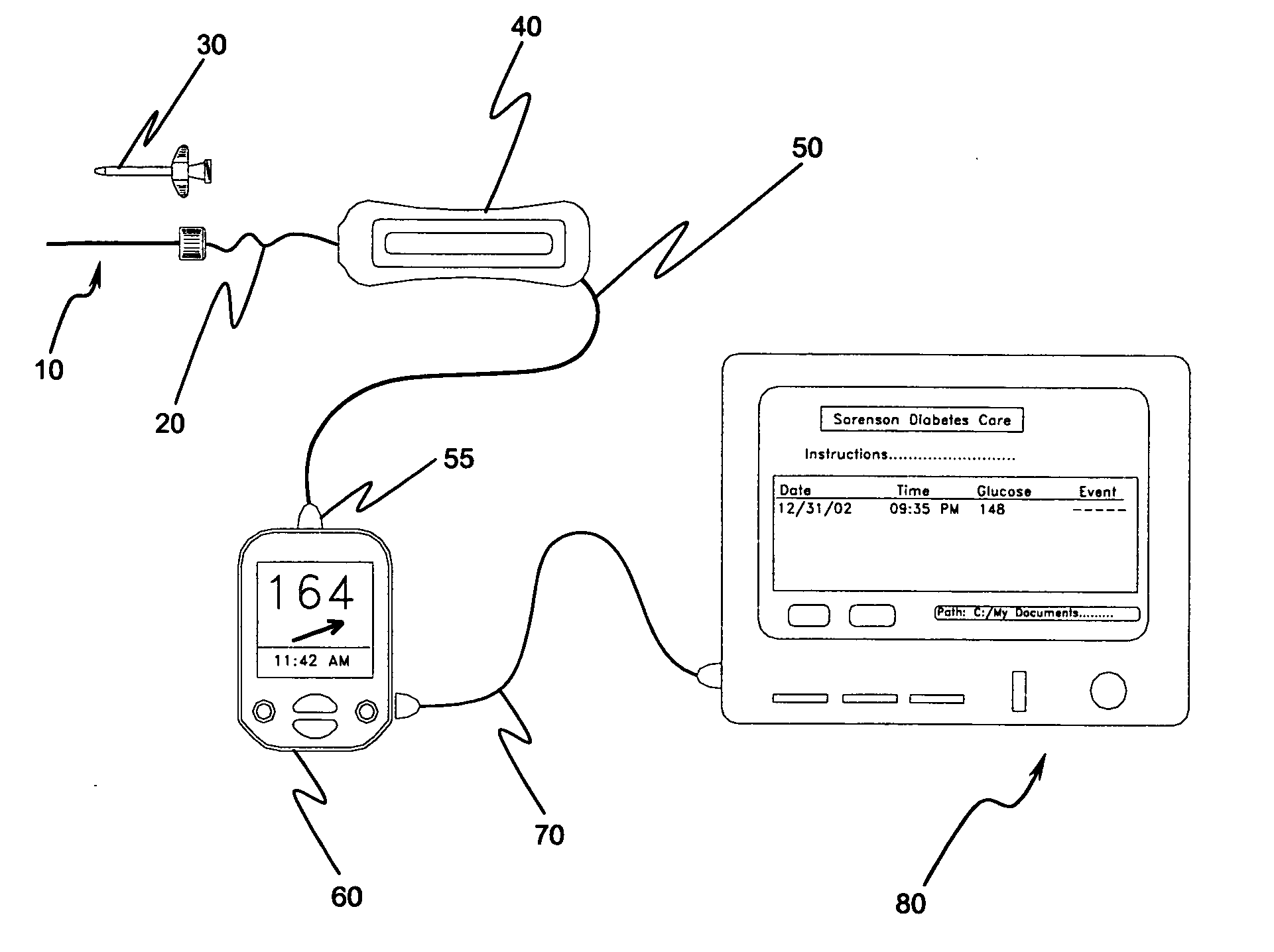

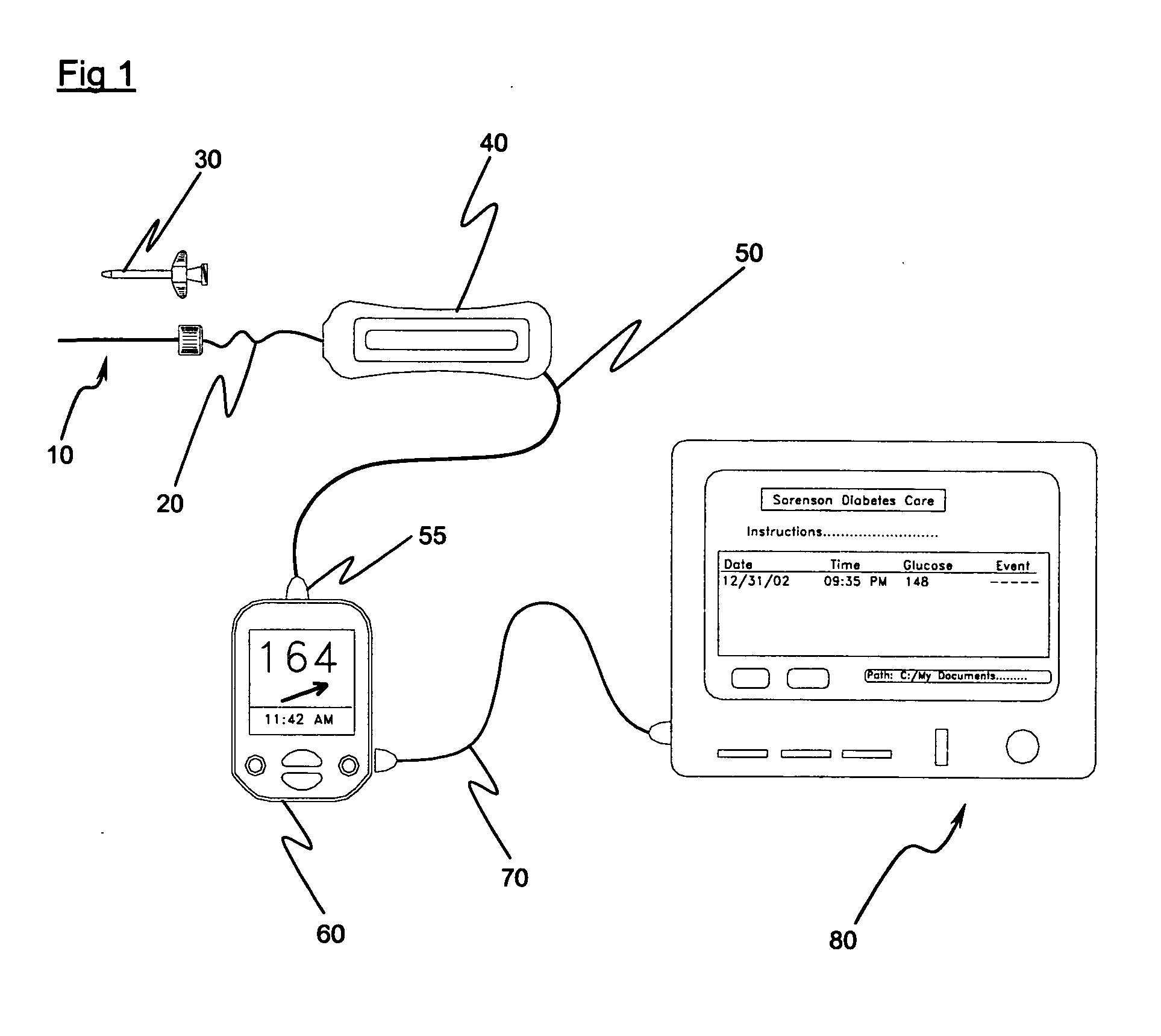

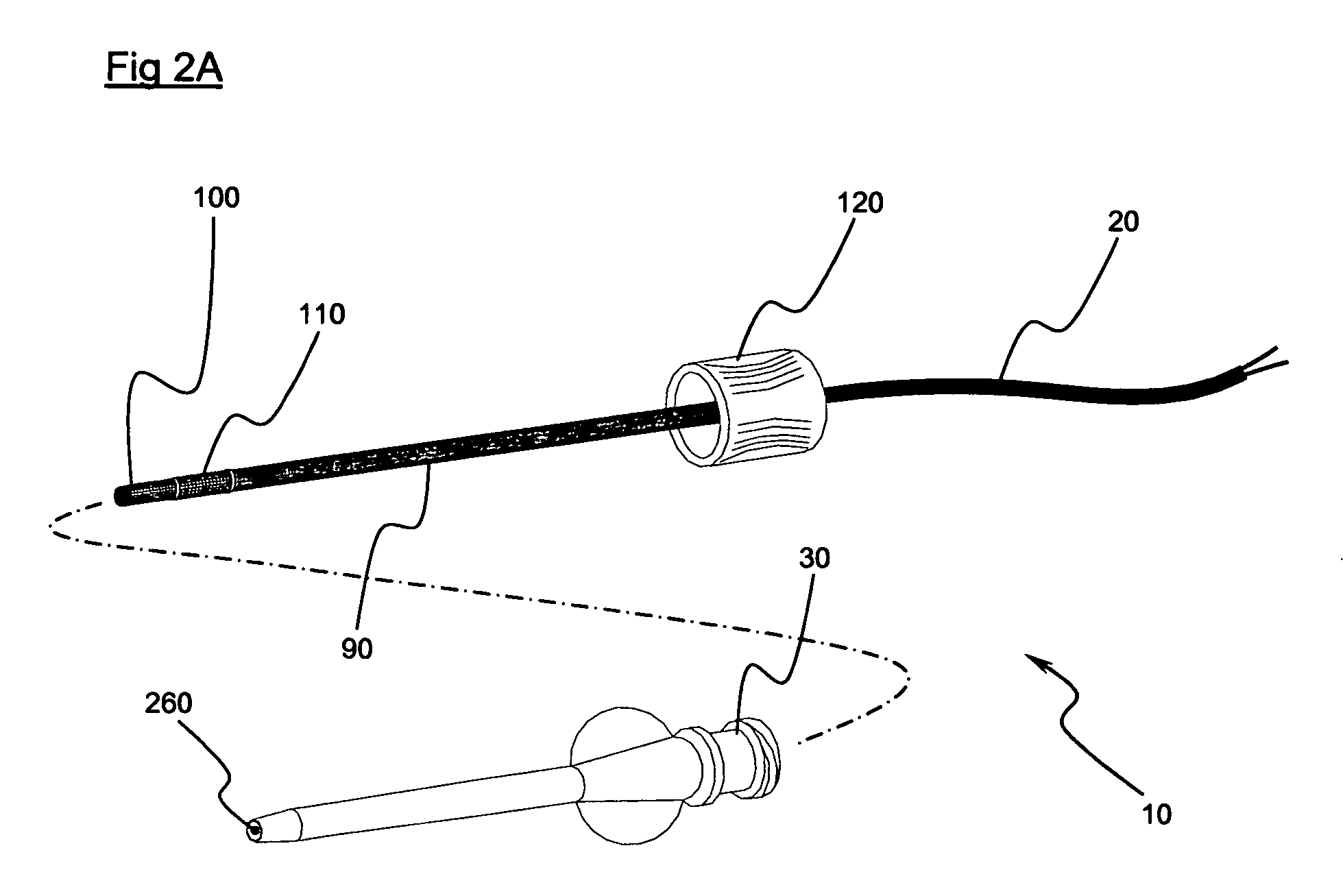

Implantable biosensor system, apparatus and method

InactiveUS6965791B1Good biocompatibilityIncrease volumeImmobilised enzymesBioreactor/fermenter combinationsForeign matterInterstitial glucose

An implantable biosensor assembly and system includes an enzymatic sensor probe from which subcutaneous and interstitial glucose levels may be inferred. The assembly may be associated by direct percutaneous connection with electronics, such as for signal amplification, sensor polarization, and data download, manipulation, display, and storage. The biosensor comprises a miniature probe characterized by lateral flexibility and tensile strength and has large electrode surface area for increased sensitivity. Irritation of tissues surrounding the probe is minimized due to ease of flexibility and small cross section of the sensor. Foreign body reaction is diminished due to a microscopically rough porous probe surface.

Owner:SORENSON DEVMENT

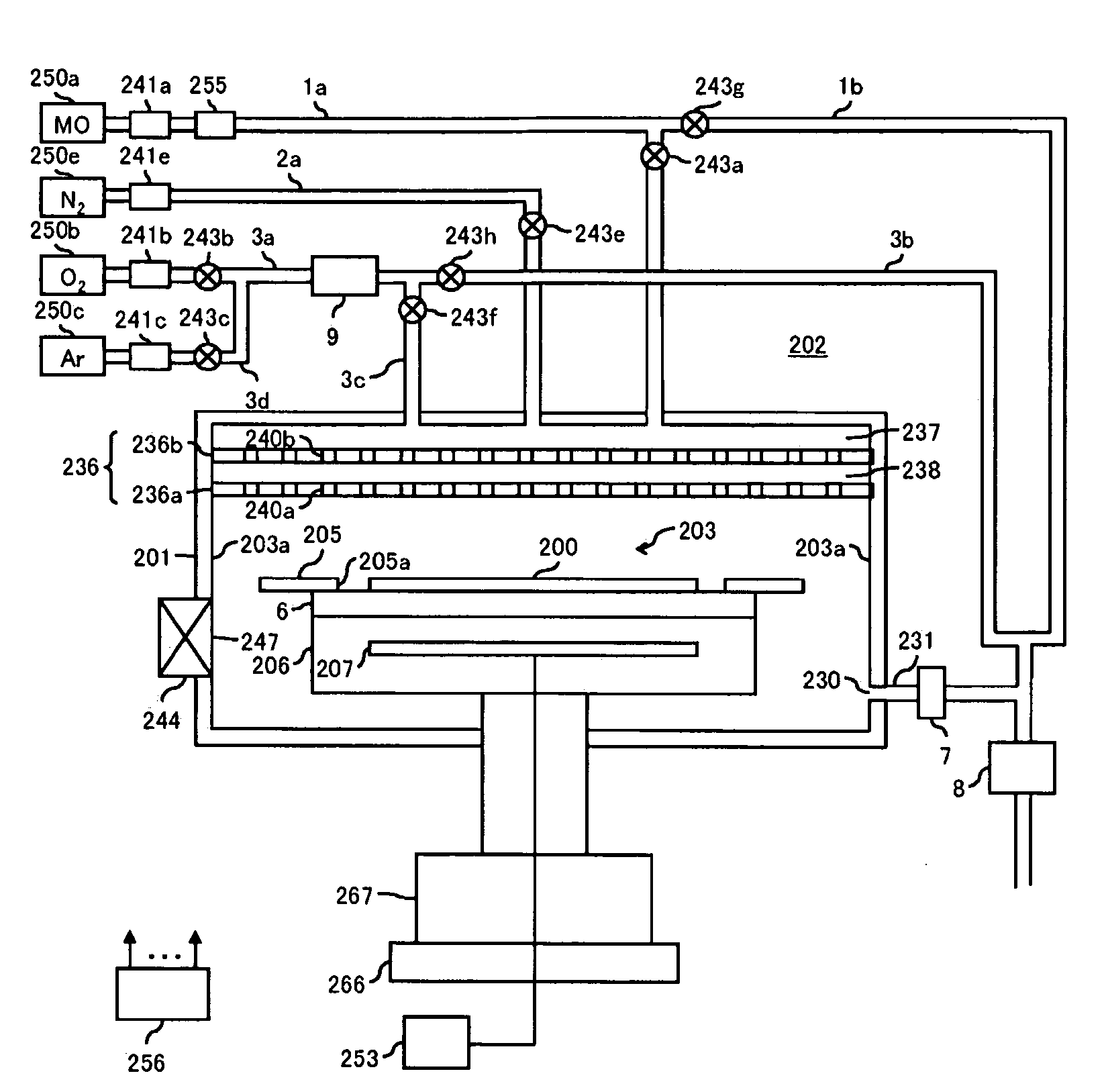

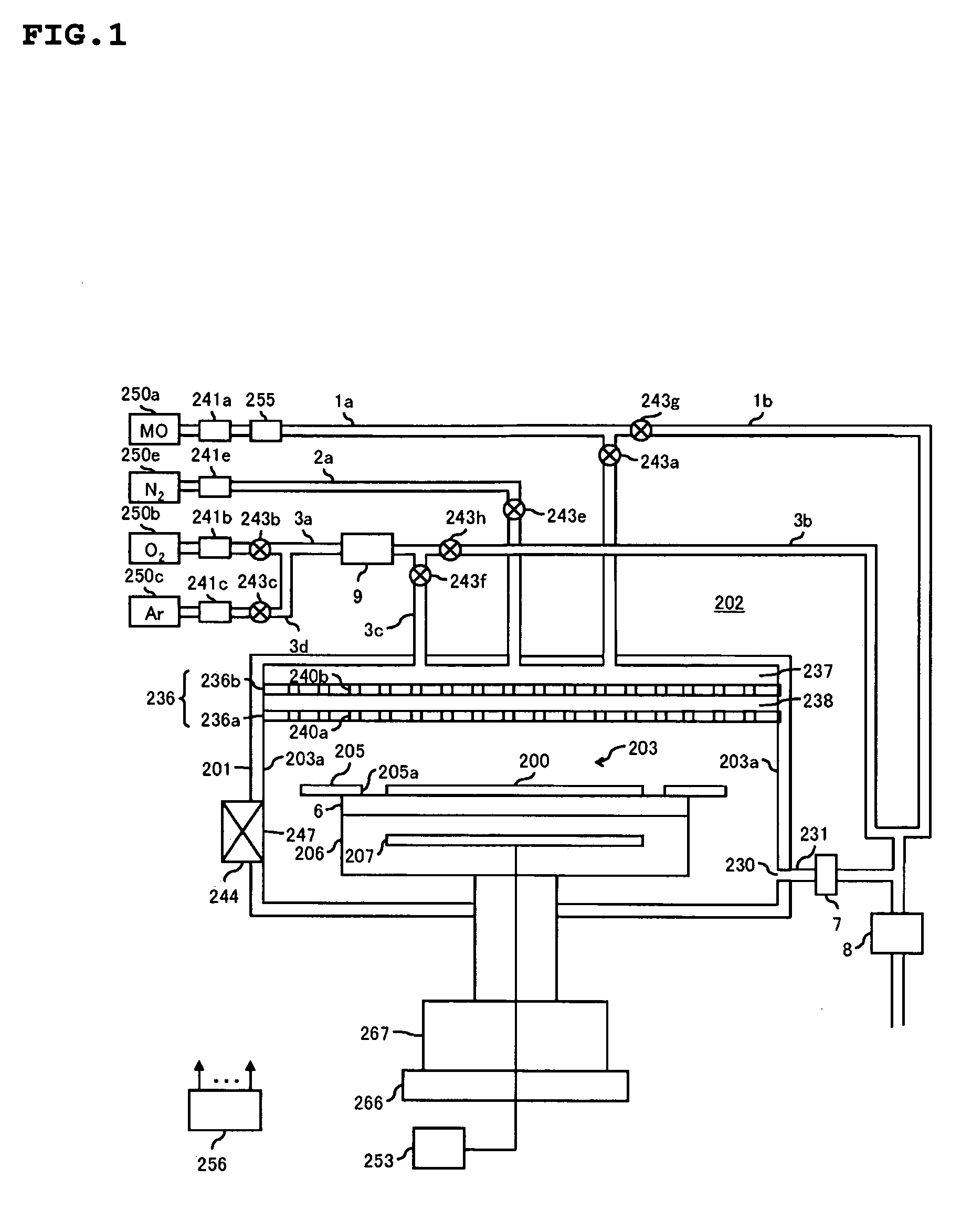

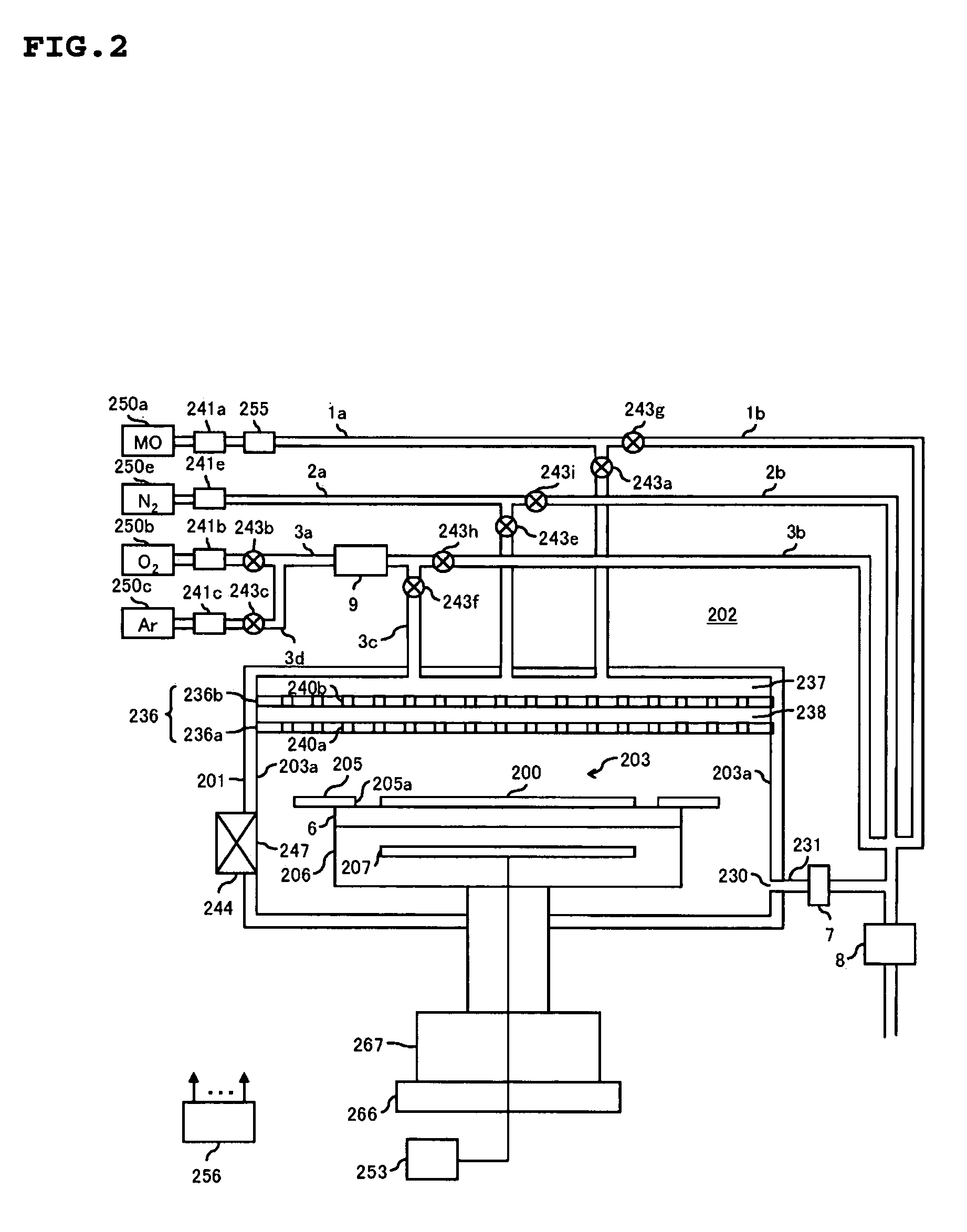

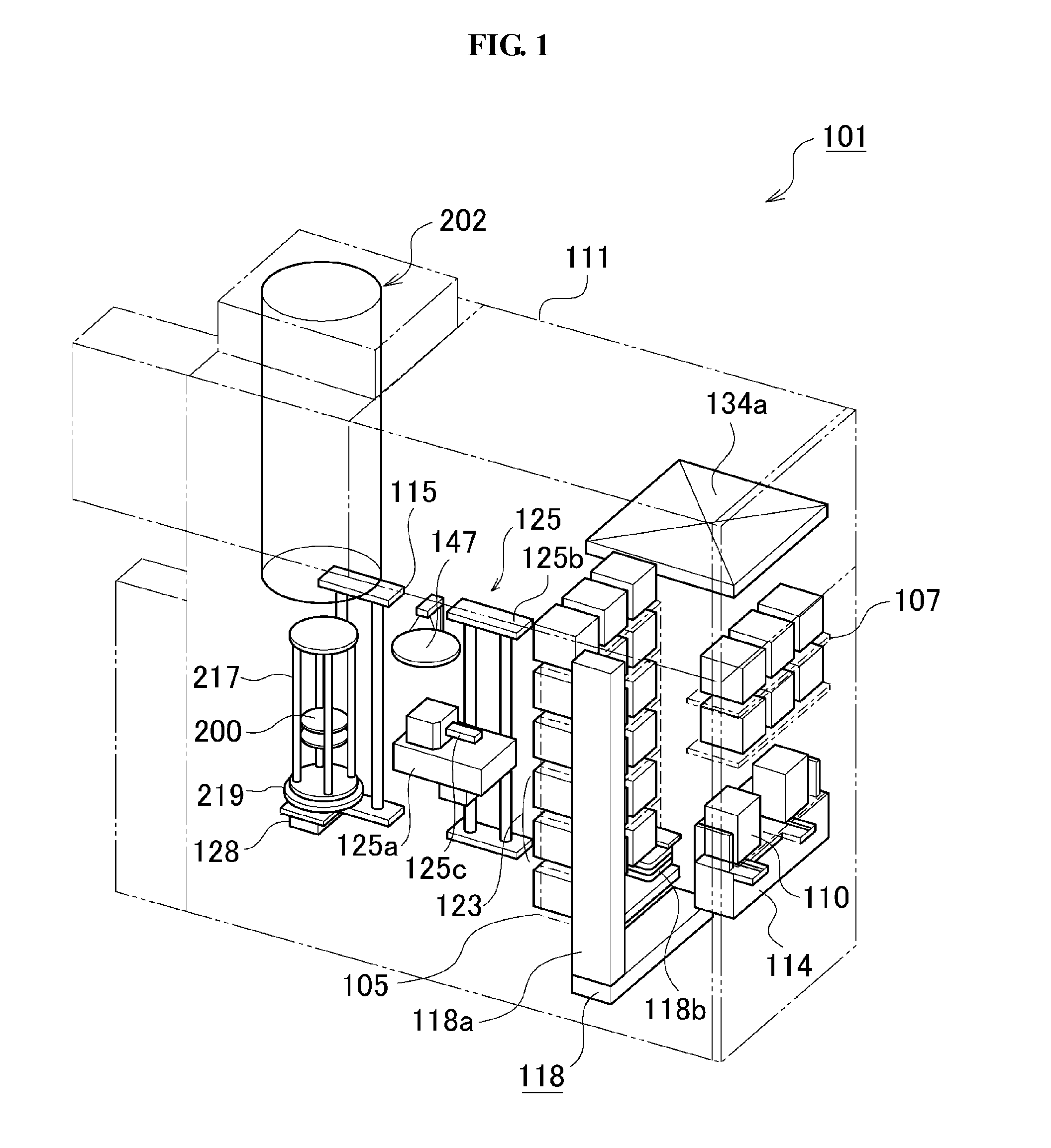

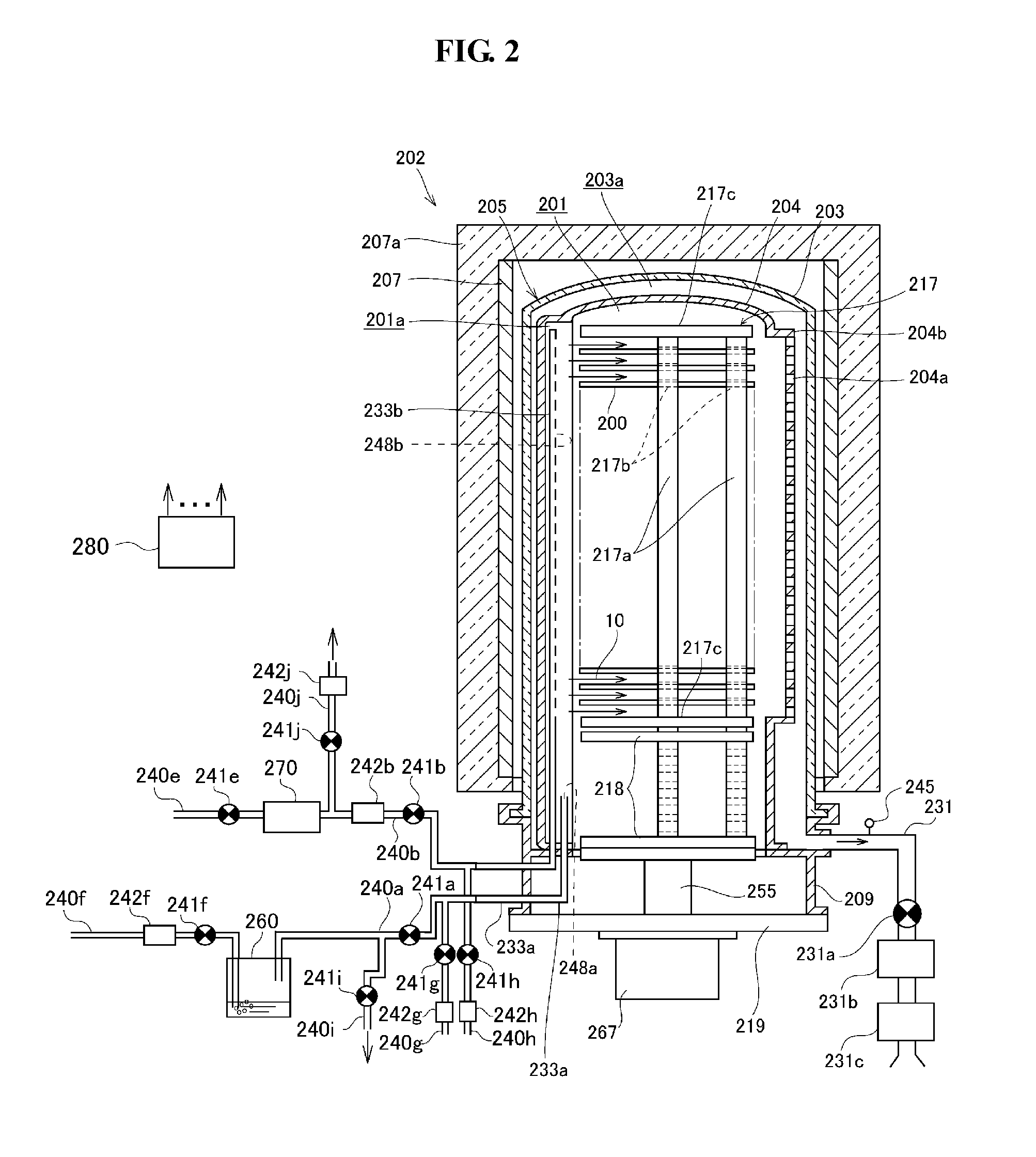

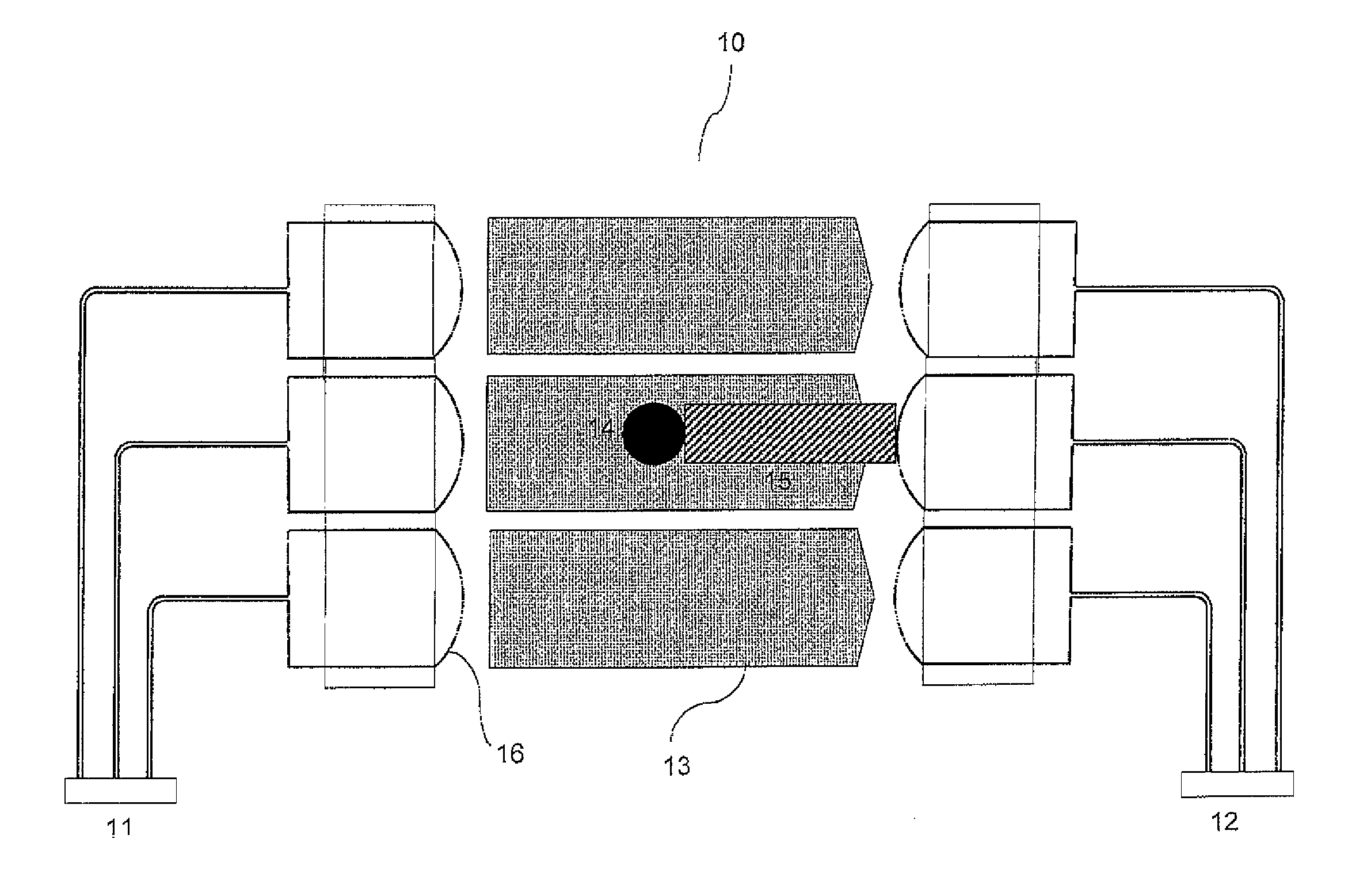

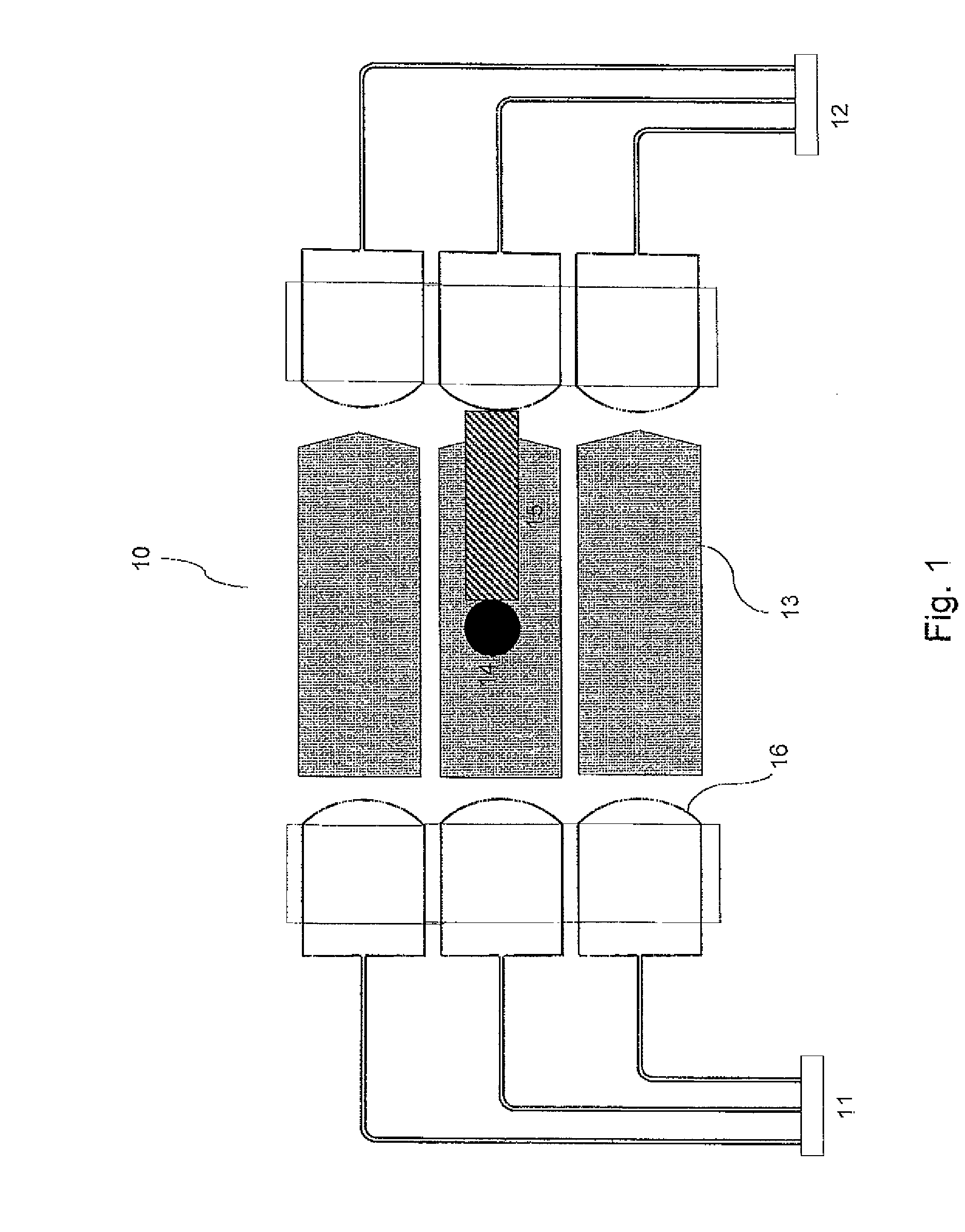

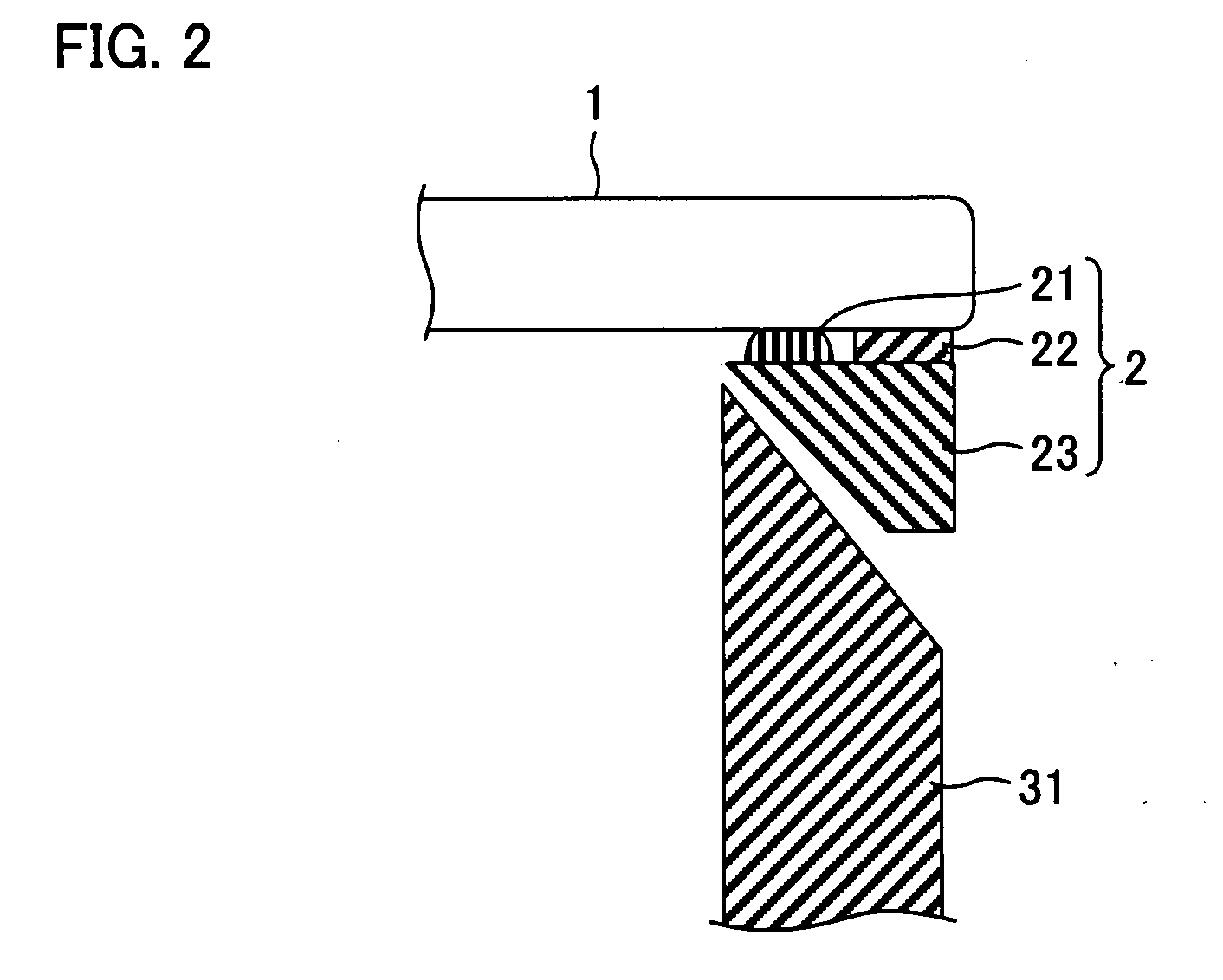

Substrate processing apparatus and method for manufacturing semiconductor device

ActiveUS20080264337A1Suppress agitationForeign matterLiquid surface applicatorsVacuum evaporation coatingForeign matterProduct gas

A substrate processing apparatus and a method for manufacturing a semiconductor device whereby foreign matter can be prevented from being adsorbed on the substrate, by suppressing agitation of foreign matter present in the processing chamber. The substrate processing apparatus comprises a processing chamber for processing a substrate; a processing gas feeding line for feeding a processing gas into the processing chamber; an inert gas feeding line for feeding an inert gas into the processing chamber; an inert gas vent line provided in the inert gas feeding line, for exhausting the inert gas fed into the inert gas feeding line without feeding the inert gas into the processing chamber; a first valve provided in the inert gas feeding line, on a downstream side of a part where the inert gas vent line is provided in the inert gas feeding line; a second valve provided in the inert gas vent line; and an exhaust line that exhausts an inside of the processing chamber.

Owner:KOKUSA ELECTRIC CO LTD

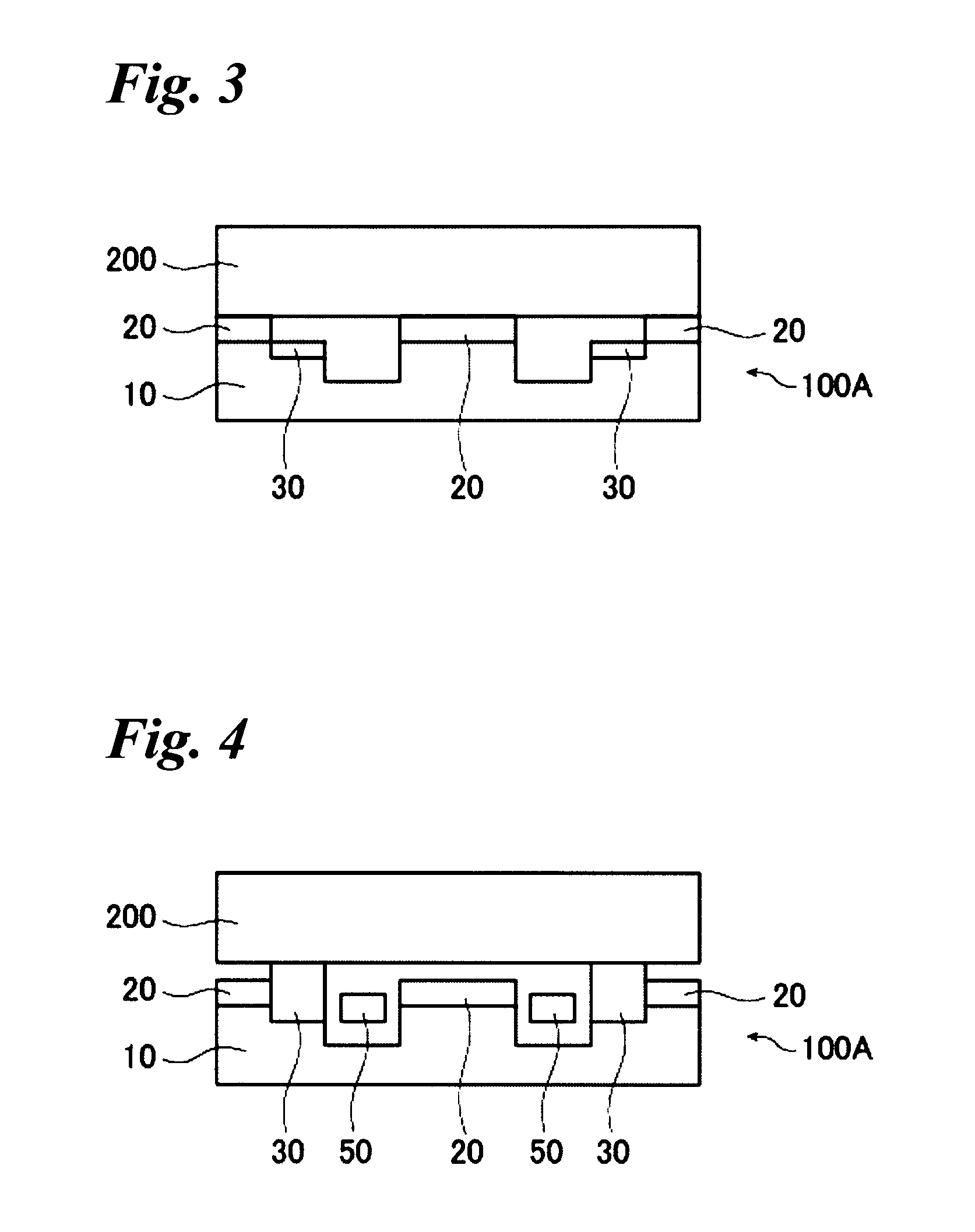

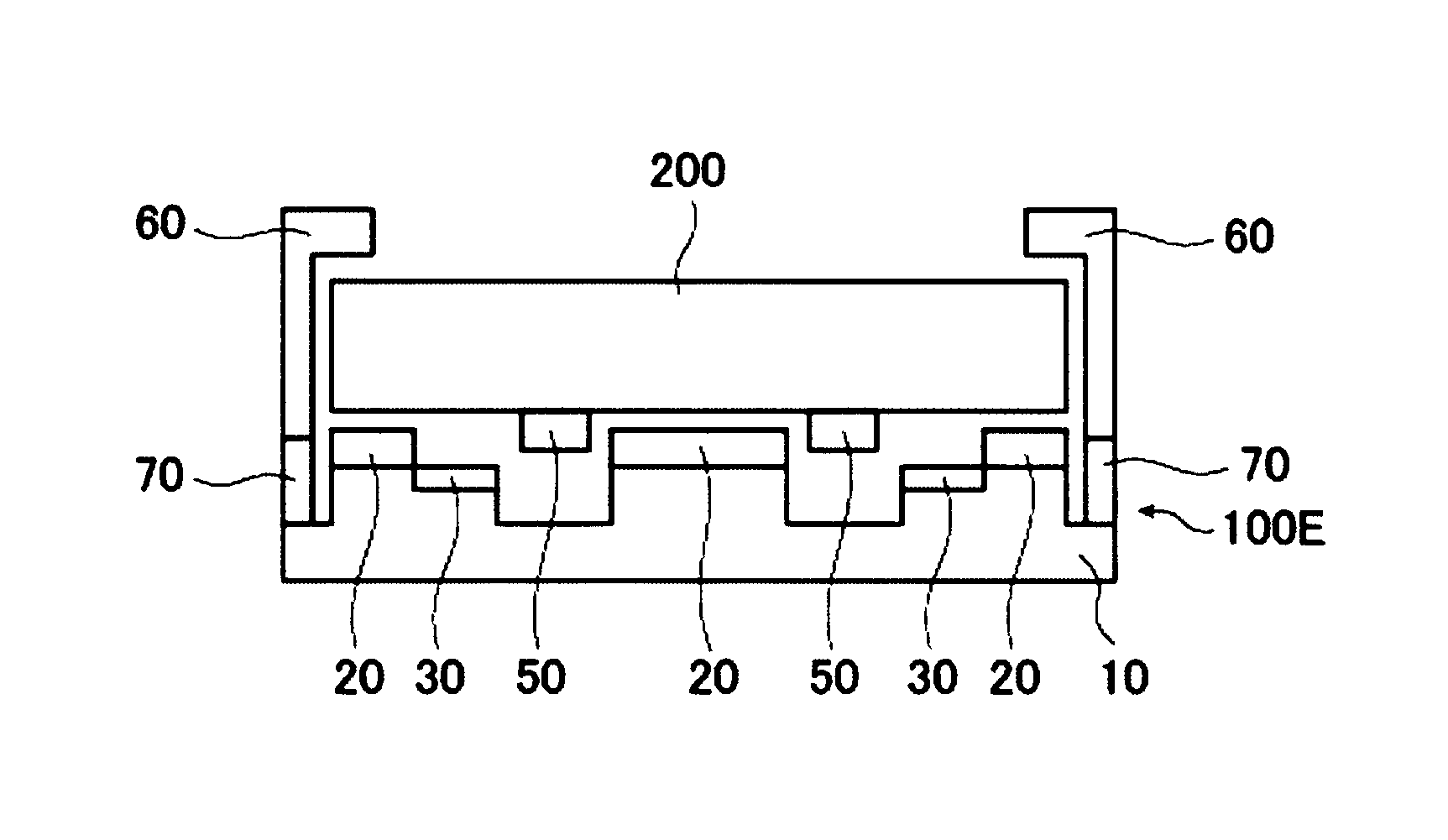

Glass substrate-holding tool

InactiveUS20120100464A1Avoid dustAvoid depositionSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEngineeringScratching

To provide a glass substrate-holding tool which is capable of avoiding scratching to the deposition surface of a glass substrate and dusting thereby caused as well as scratching and deposition of foreign substances at a center portion of the rear surface of the substrate and which is capable of suppressing dusting from the holding tool itself at the time of forming a multi-layered reflection film and an absorptive layer.A glass substrate-holding tool having, formed on a surface of a flat base, a catching portion for catching and holding by van der Waals forces, wherein the catching portion is in contact with only the periphery of the glass substrate.

Owner:ASAHI GLASS CO LTD

Glass substrate-holding tool

InactiveUS8192901B2Avoid dustAvoid depositionPhotomechanical apparatusSemiconductor/solid-state device manufacturingForeign matterEngineering

Owner:ASAHI GLASS CO LTD

Substrate processing apparatus, method of manufacturing semiconductor device and semiconductor device

ActiveUS20120119337A1Avoid processing qualitySuppress scatterLiquid surface applicatorsSemiconductor/solid-state device detailsForeign matterThermodynamics

Provided is a substrate processing apparatus capable of suppressing accumulation of reaction products or decomposed matters on an inner wall of a nozzle and suppressing scattering of foreign substances in a process chamber. The substrate processing apparatus includes a process chamber, a heating unit, a source gas supply unit, a source gas nozzle, an exhaust unit, and a control unit configured to control at least the heating unit, the source gas supply unit and the exhaust unit. The source gas nozzle is disposed at a region in the process chamber, in which a first process gas is not decomposed even under a temperature in the process chamber higher than a pyrolysis temperature of the first process gas, and the control unit supplies the first process gas into the process chamber two or more times at different flow velocities to prevent the first process gas from being mixed.

Owner:KOKUSA ELECTRIC CO LTD

Implantable biosensor system, apparatus and method

InactiveUS20050183954A1Good biocompatibilityIncrease volumeImmobilised enzymesBioreactor/fermenter combinationsForeign matterInterstitial glucose

An implantable biosensor assembly and system includes an enzymatic sensor probe from which subcutaneous and interstitial glucose levels may be inferred. The assembly may be associated by direct percutaneous connection with electronics, such as for signal amplification, sensor polarization, and data download, manipulation, display, and storage. The biosensor comprises a miniature probe characterized by lateral flexibility and tensile strength and has a large electrode surface area for increased sensitivity. Irritation of tissues surrounding the probe is minimized due to ease of flexibility and small cross section of the sensor. Foreign body reaction is diminished due to a microscopically rough porous probe surface.

Owner:SORENSON DEVMENT

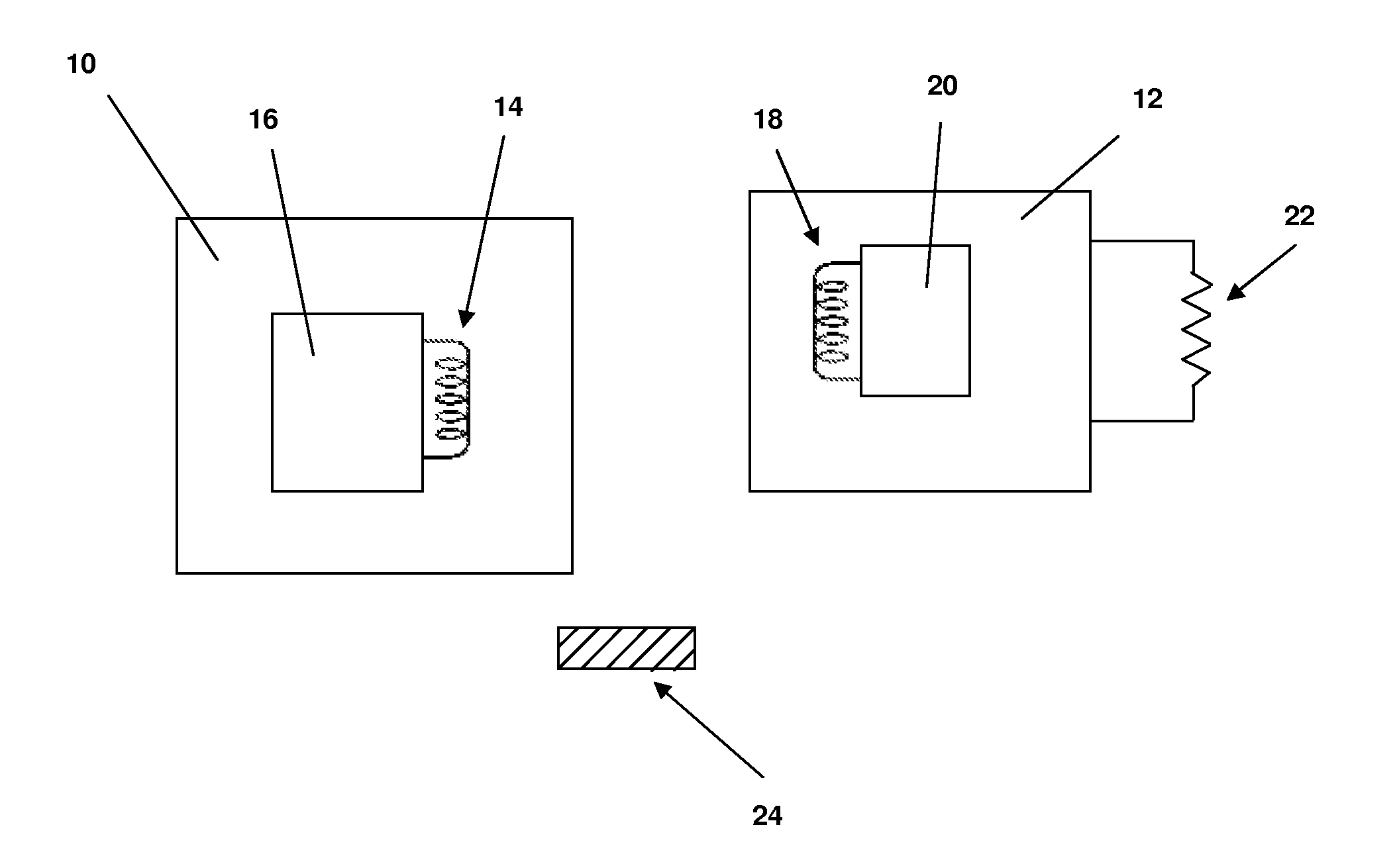

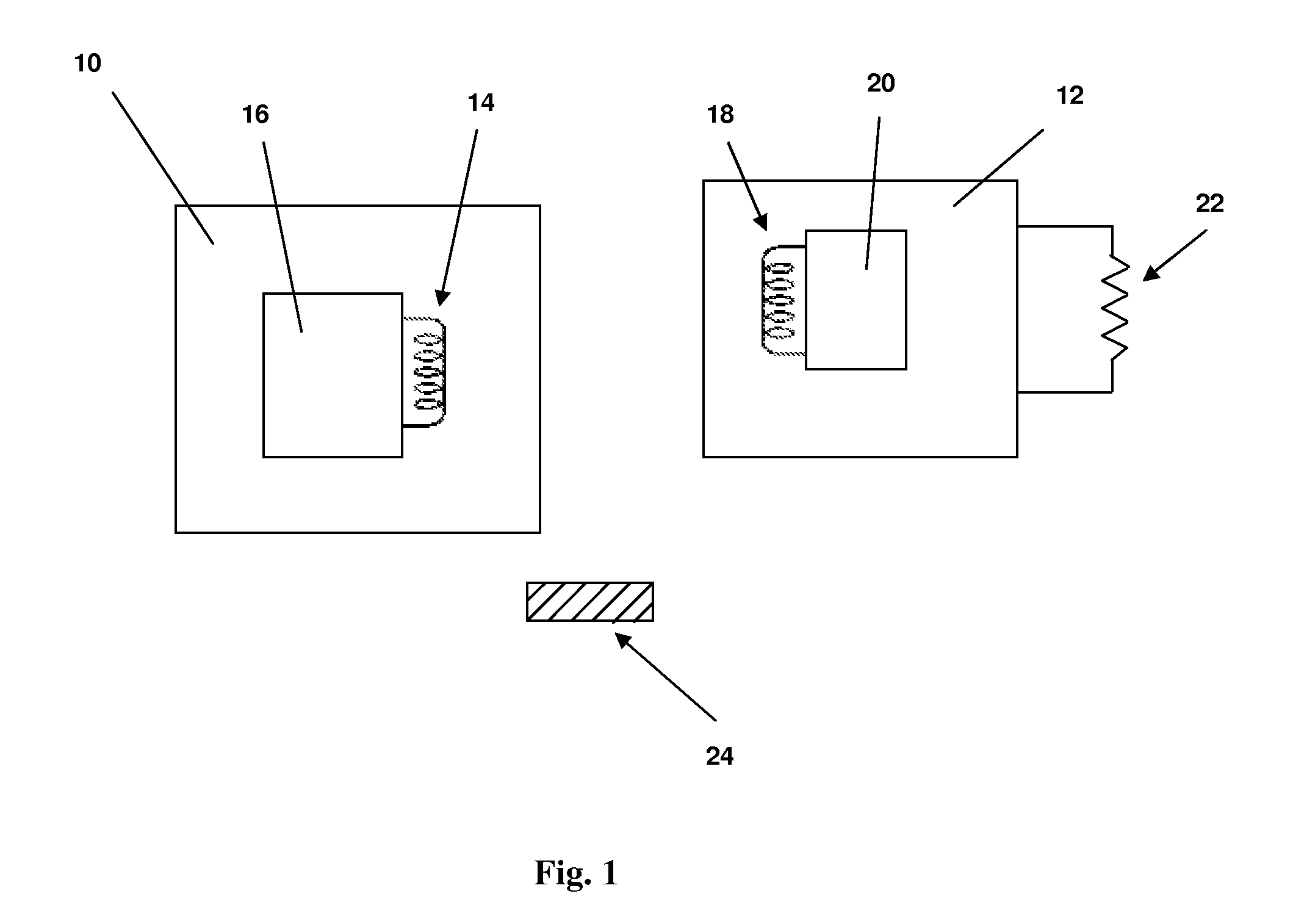

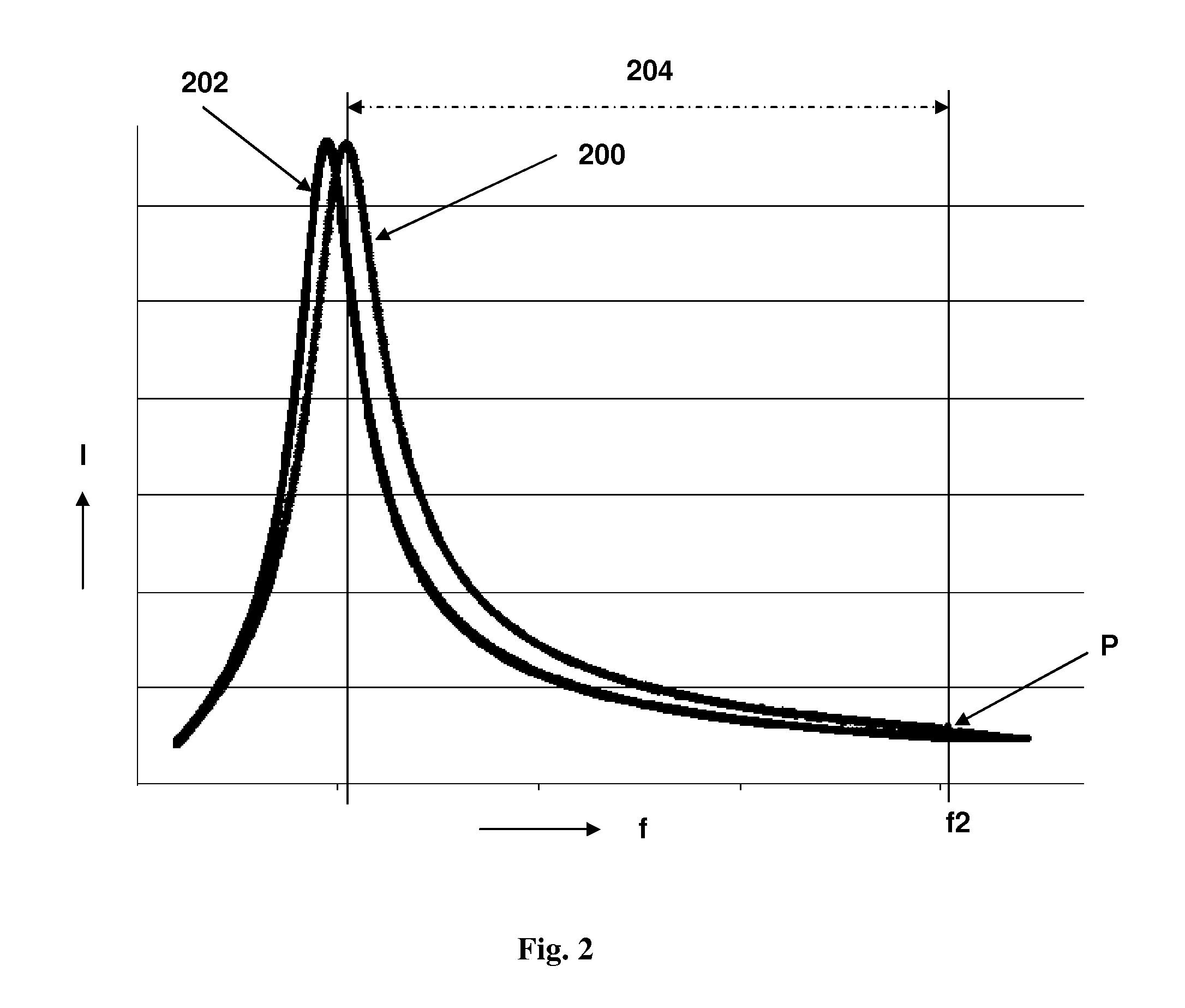

Foreign Object Detection in Inductive Coupled Devices

ActiveUS20110128015A1Batteries circuit arrangementsElectromagnetic wave systemForeign matterControl theory

A primary device for inductive power transfer to a secondary device is disclosed. The primary device includes a primary coil, the primary device being configured to (i) operate in a first mode during which the primary coil transfers power through inductive coupling to the secondary device, and (ii) operate in a second mode during which a foreign object is detected. The primary device further includes a primary controller configured to operate the primary coil (i) using a first frequency during the first mode, and (ii) using a second frequency during the second mode. A method to detect a foreign object which is in proximity of an inductively coupled environment of a primary device is also disclosed.

Owner:ROBERT BOSCH GMBH

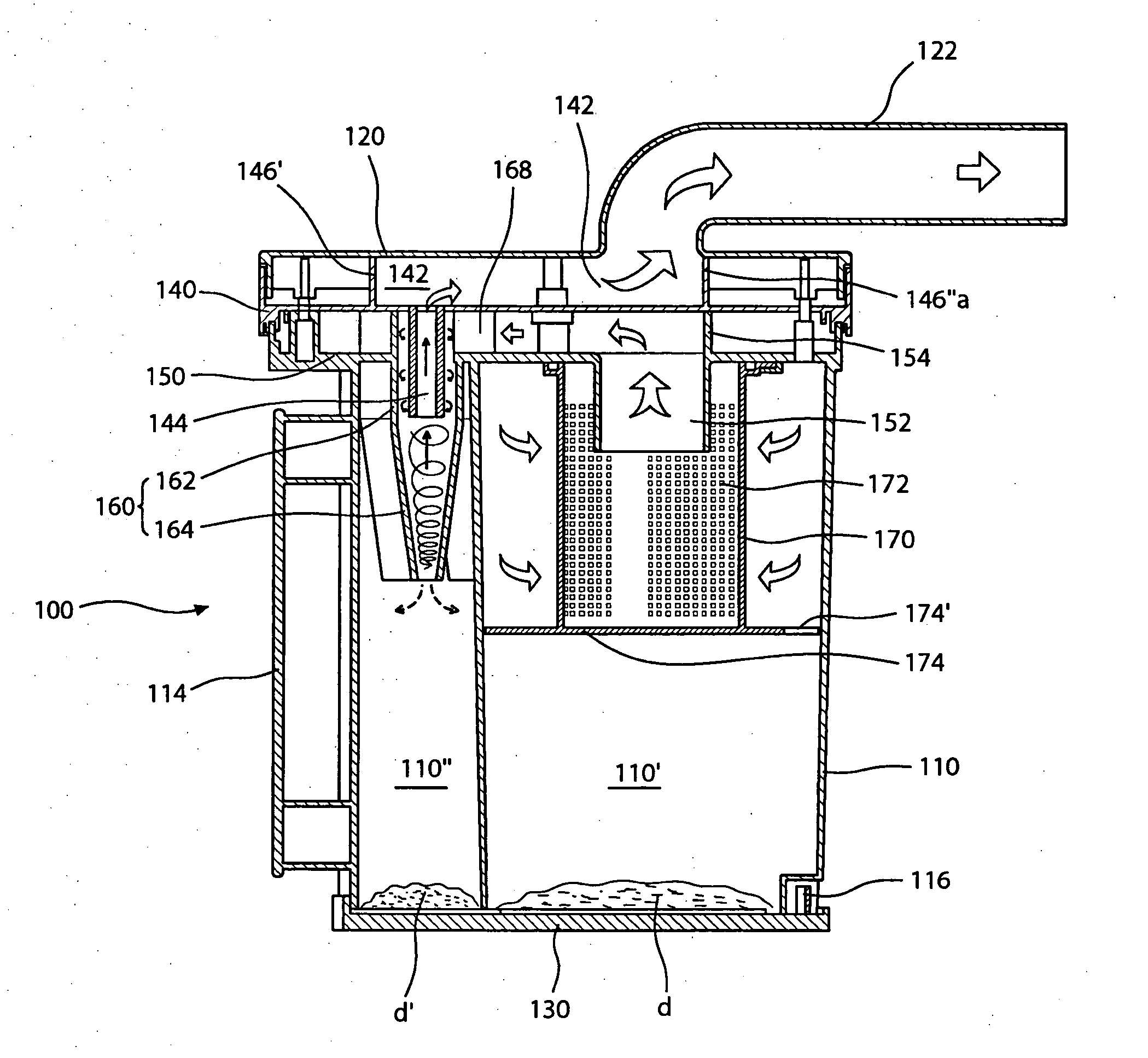

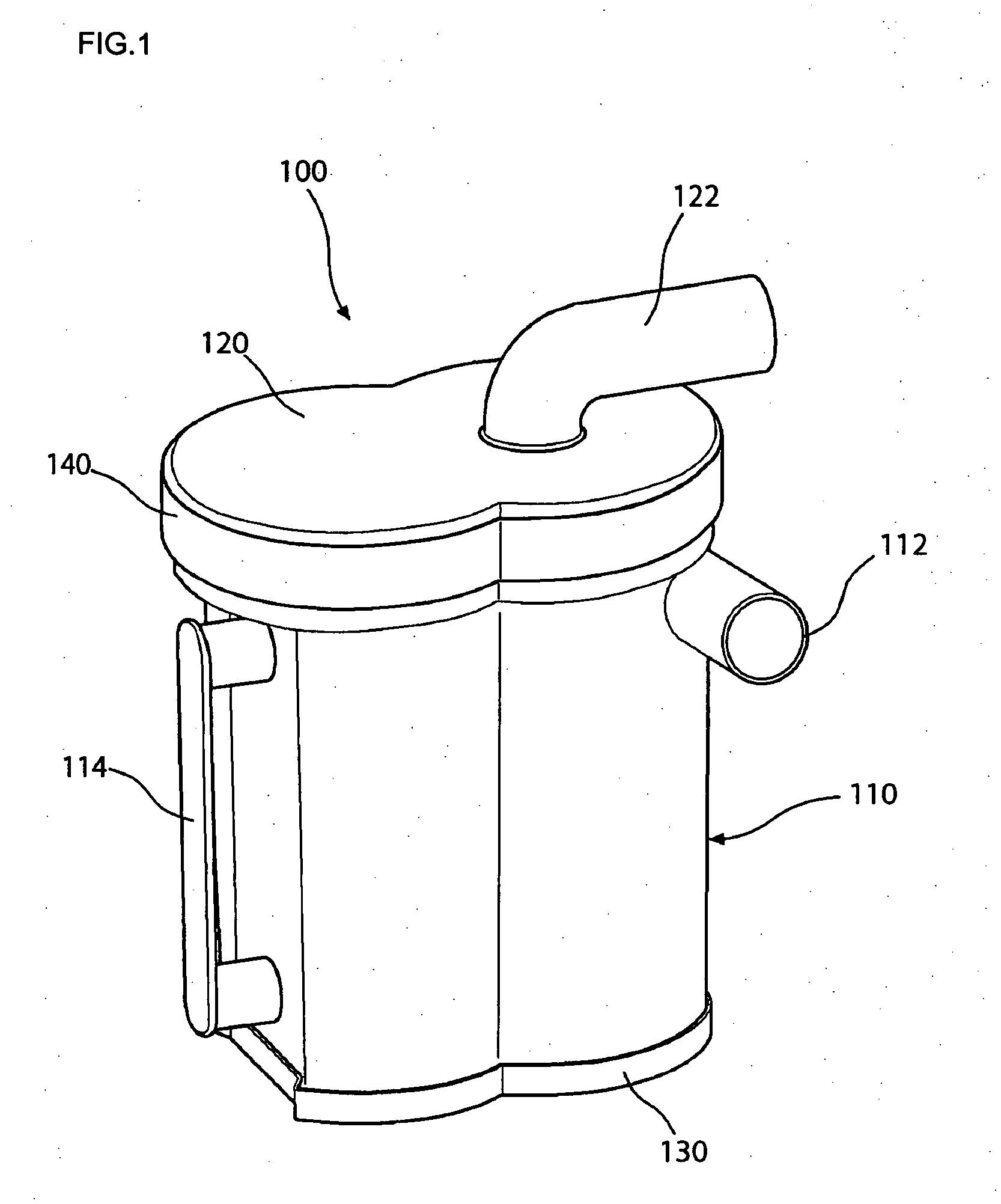

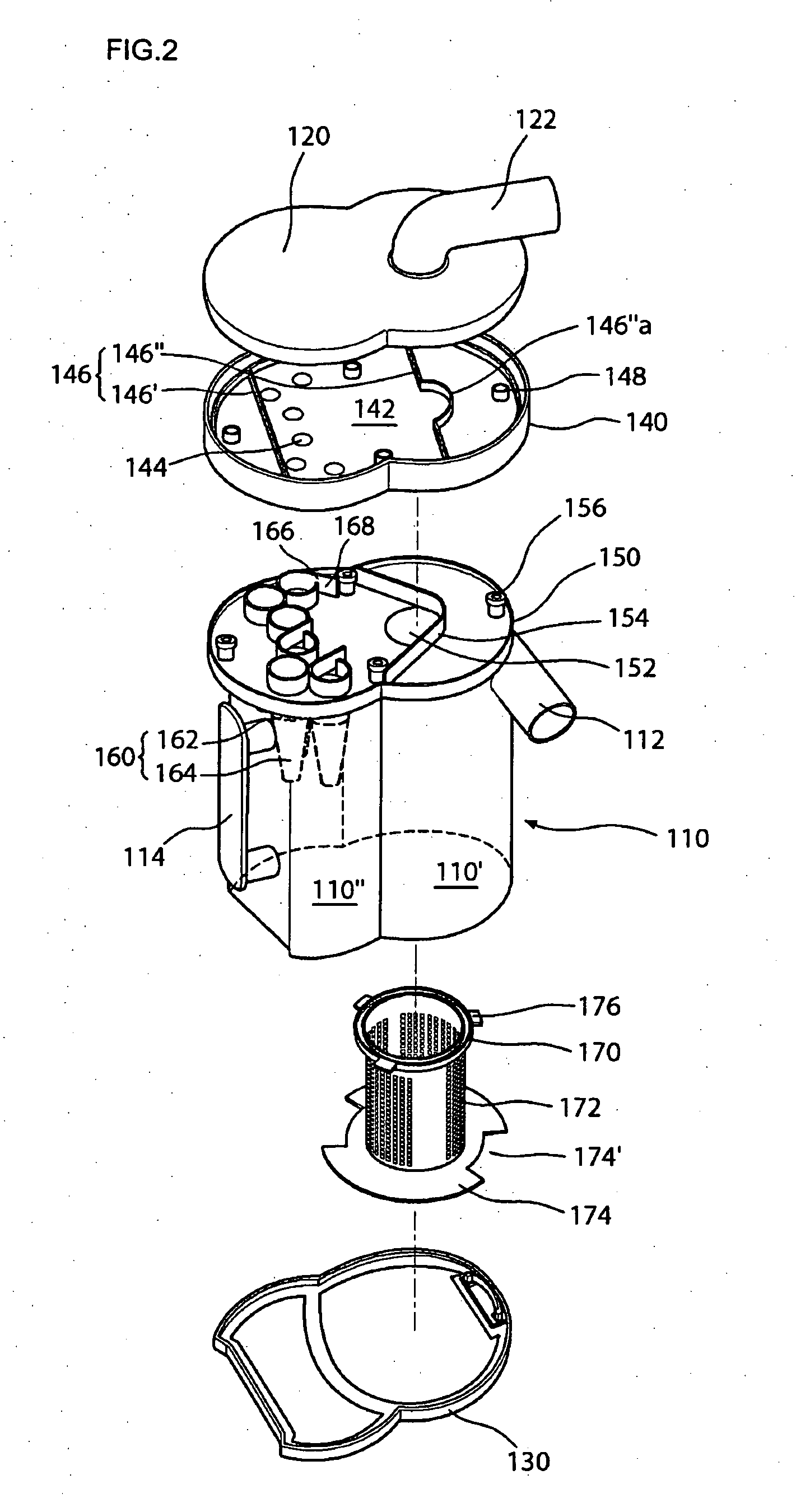

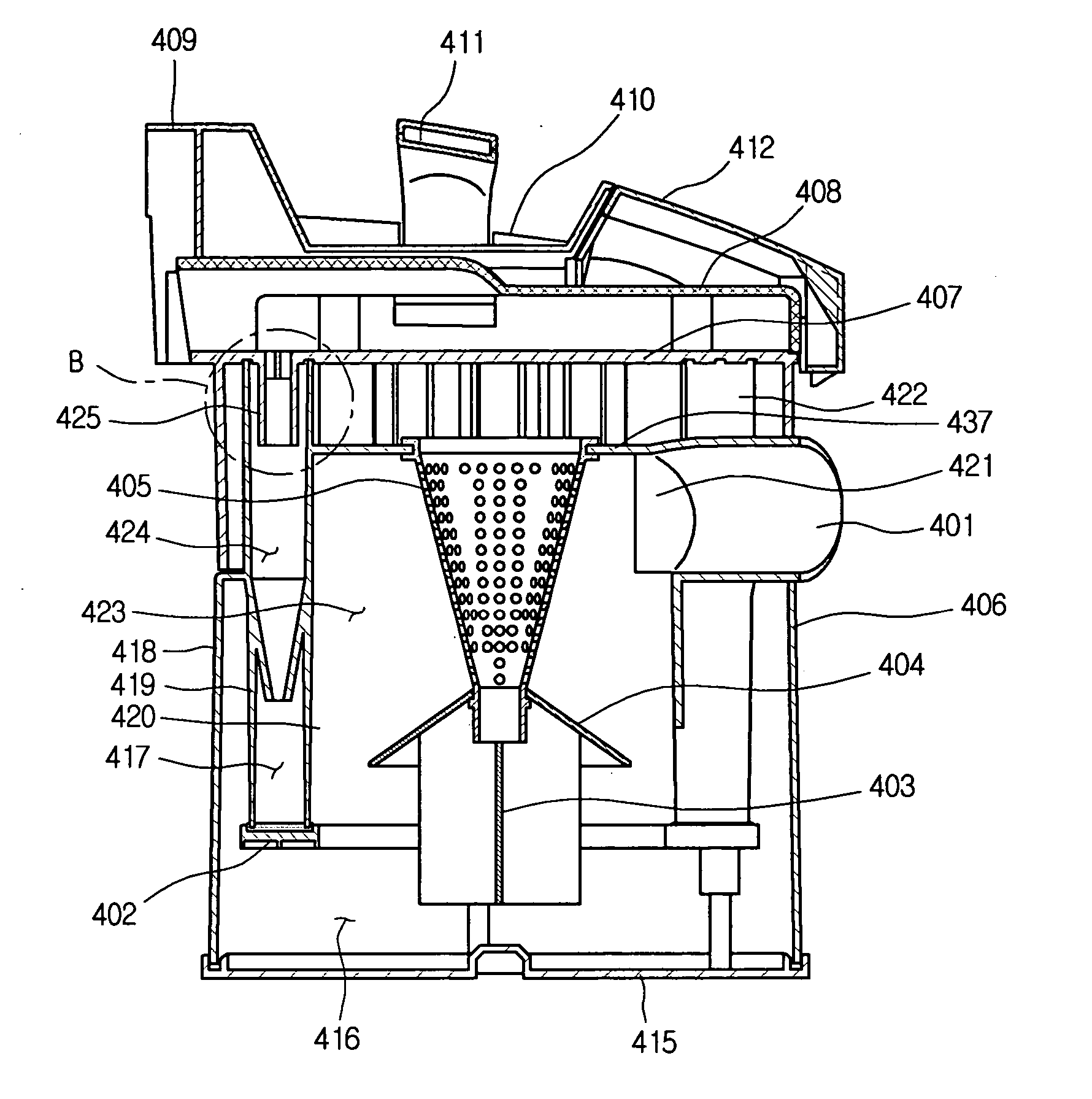

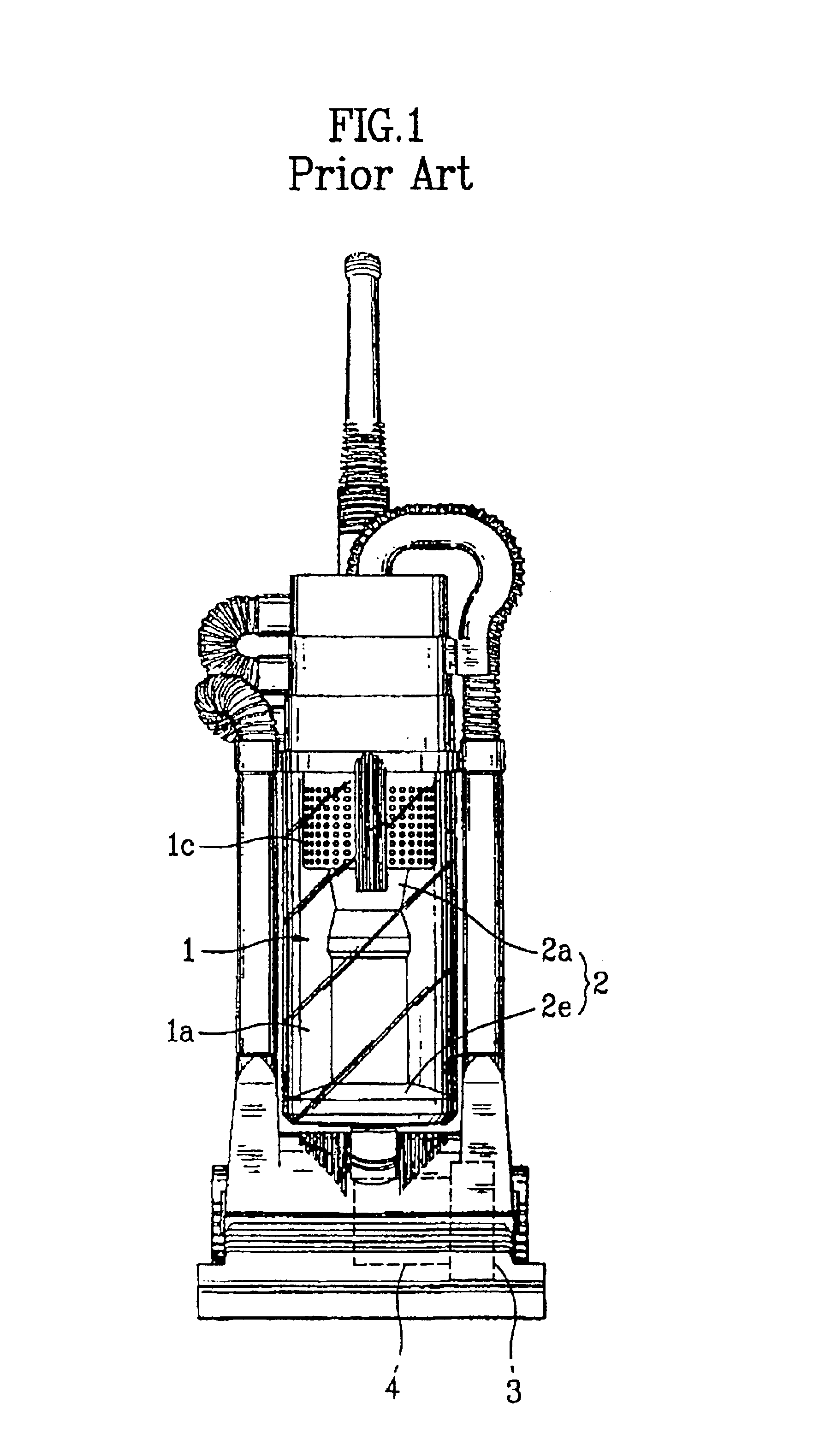

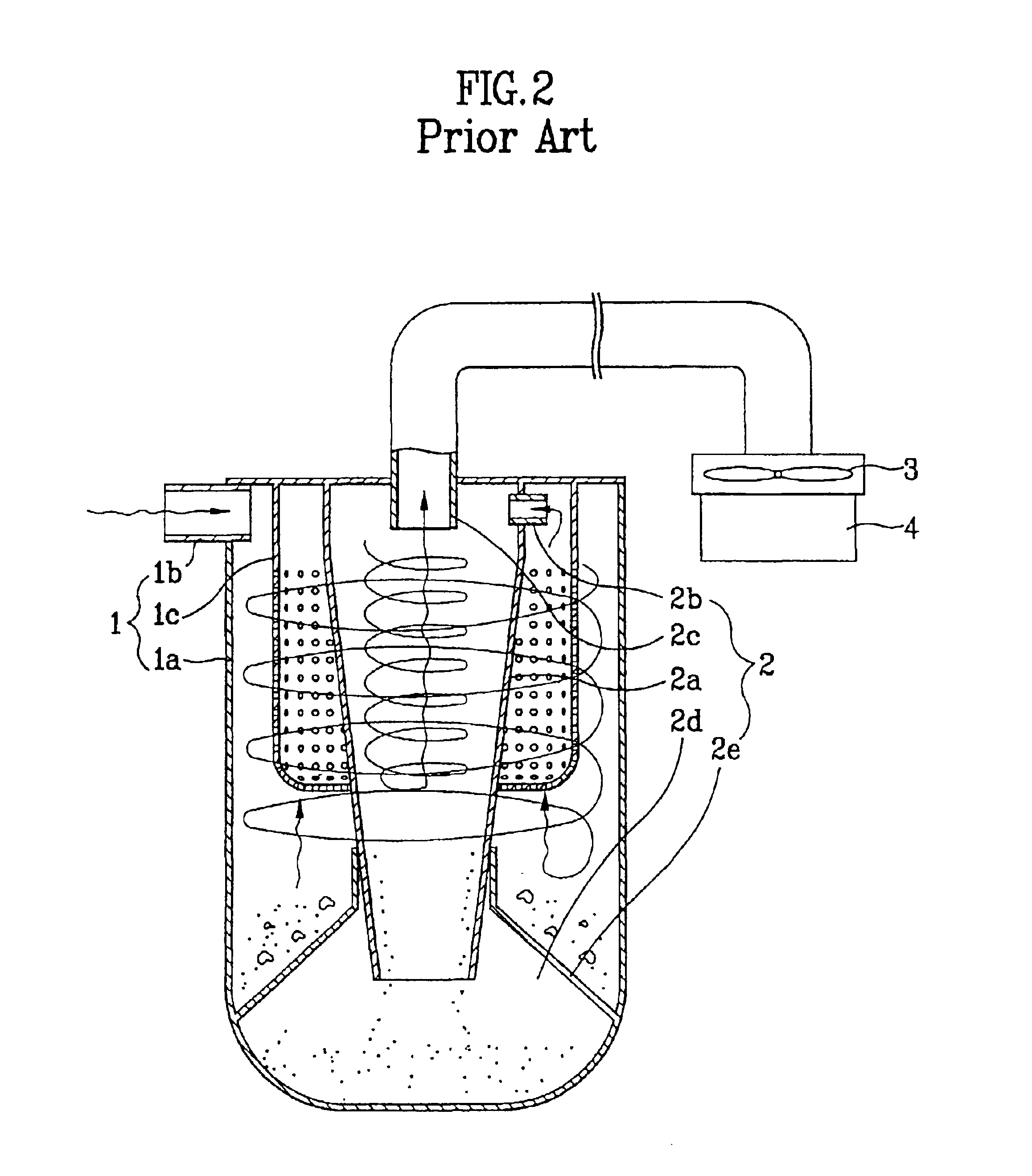

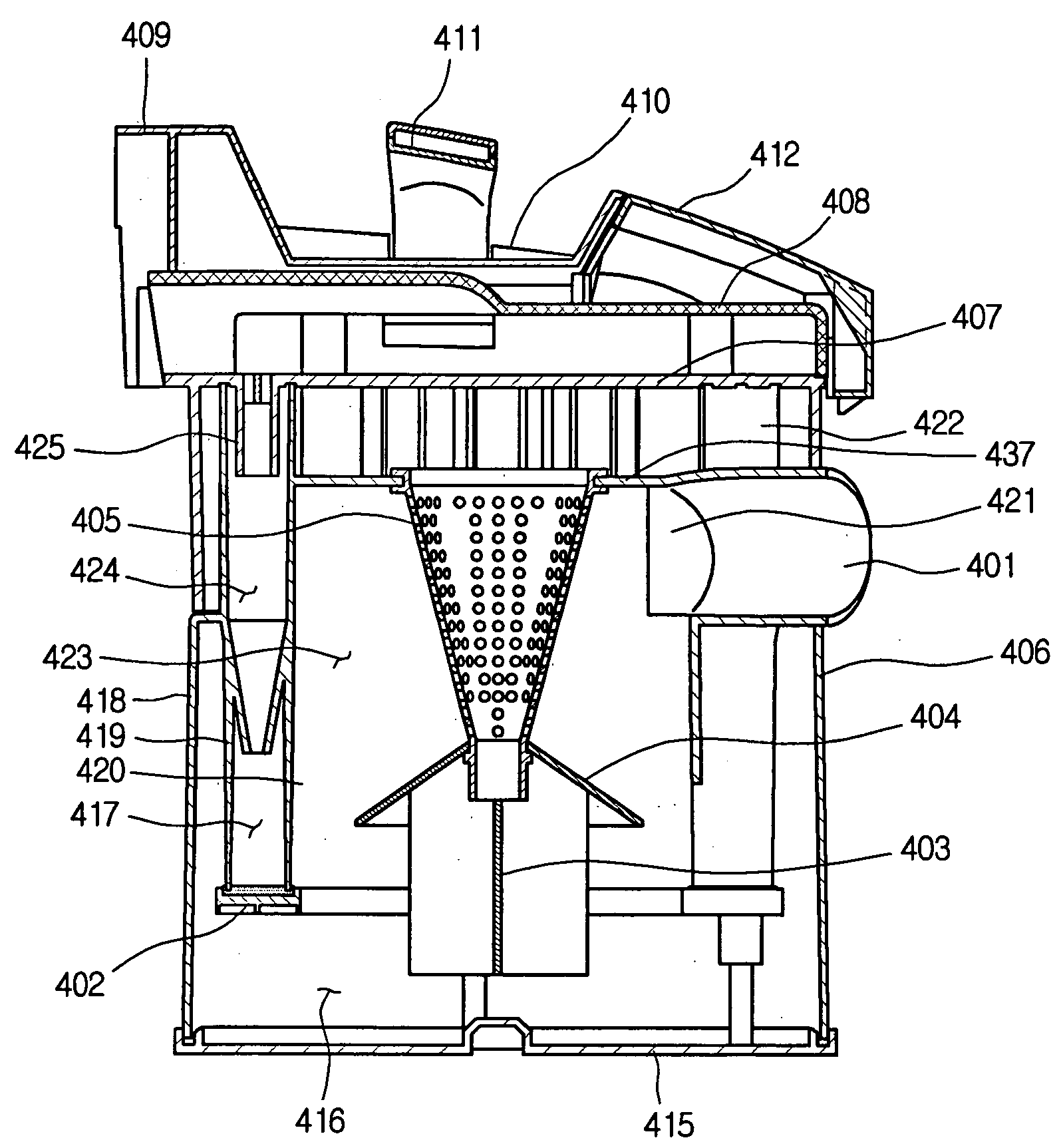

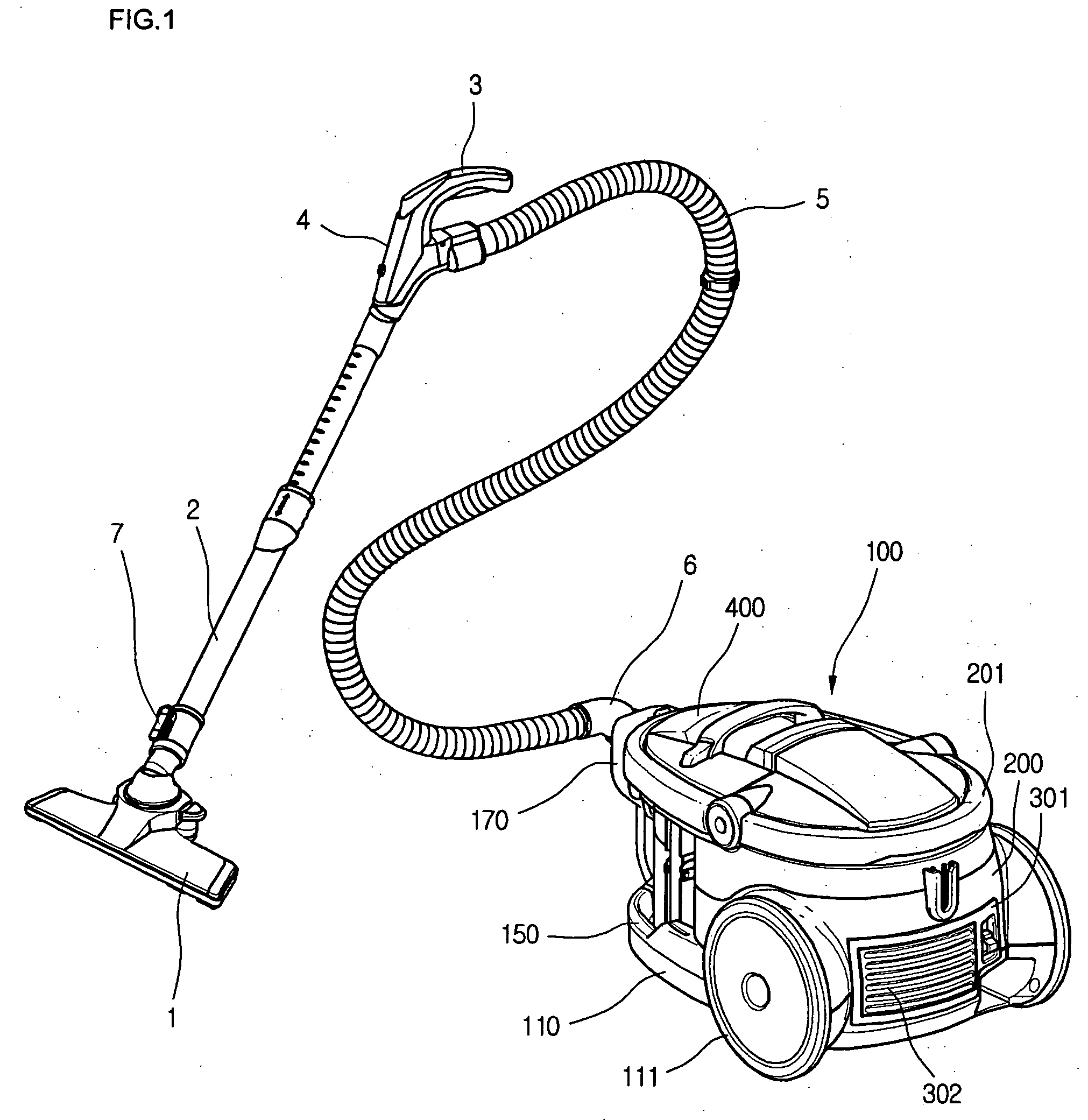

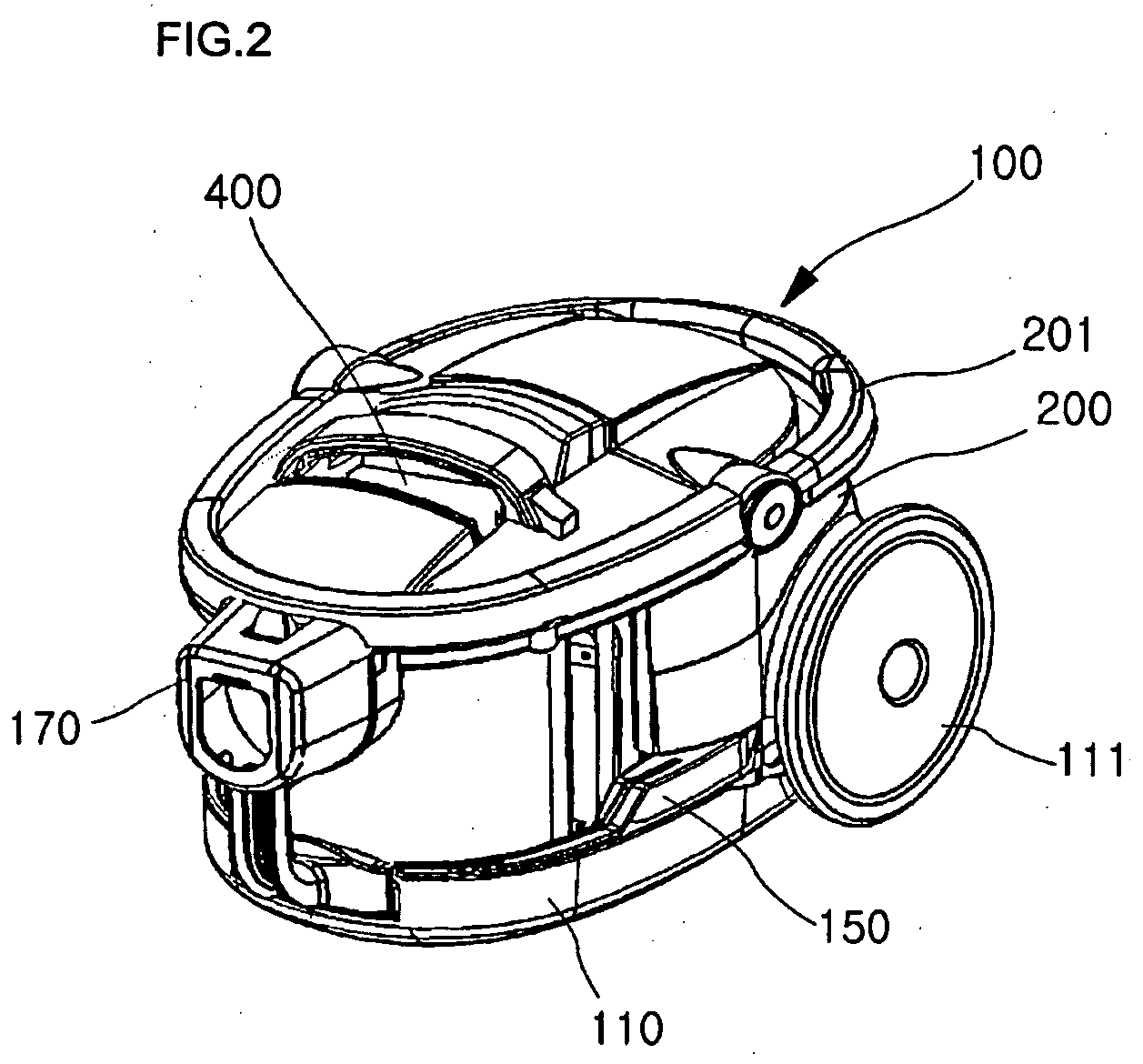

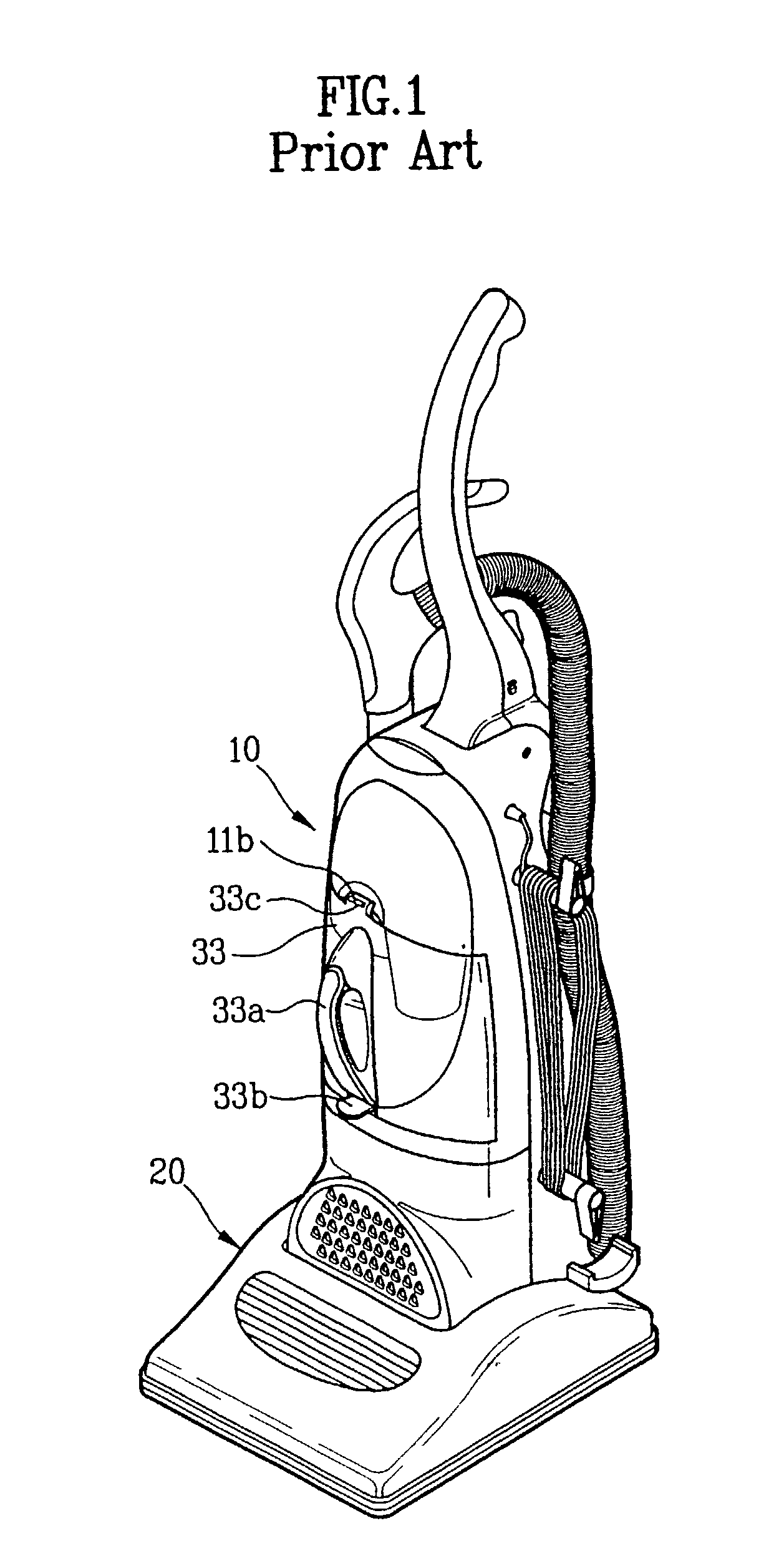

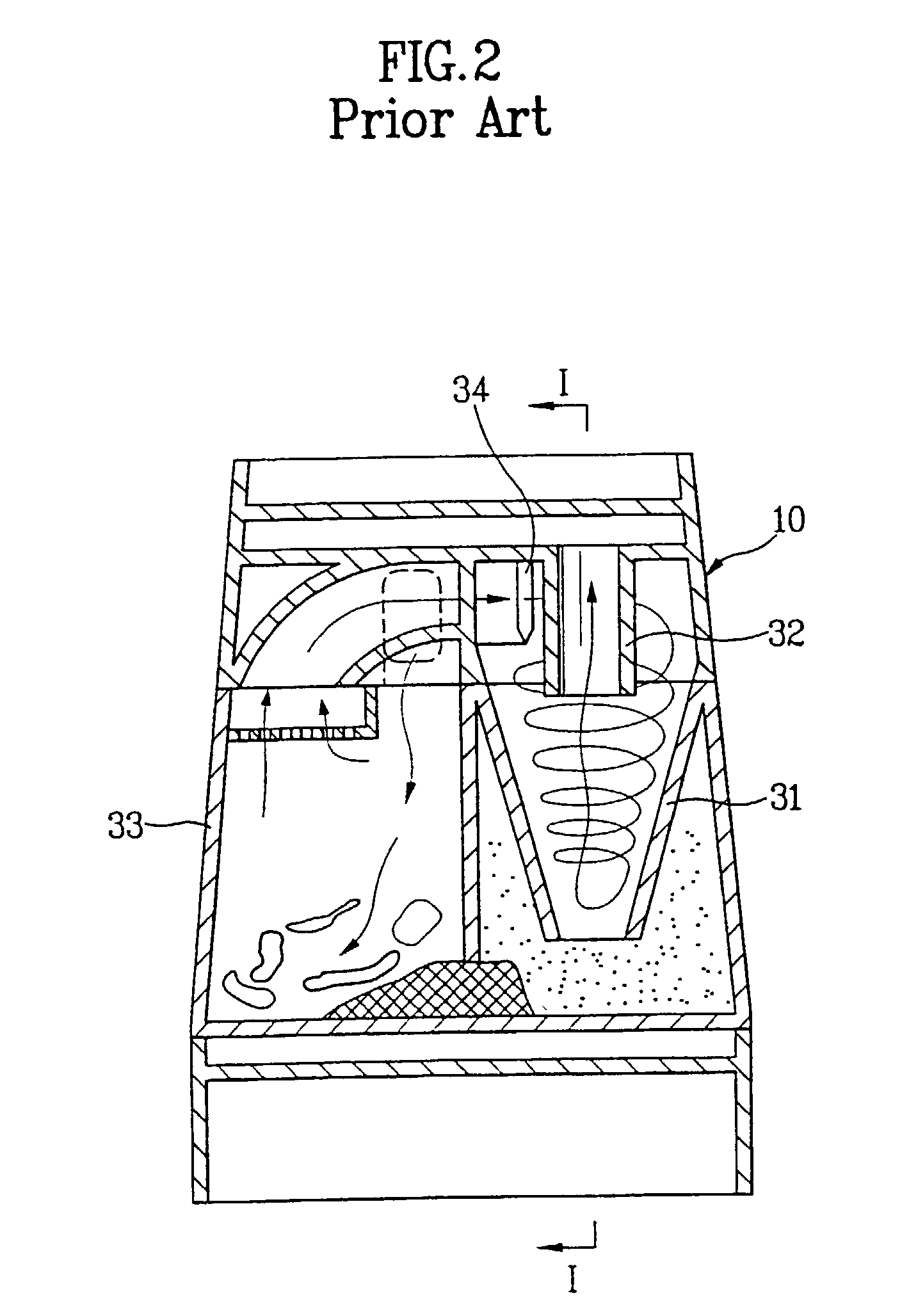

Dust and dirt collecting unit for vacuum cleaner

InactiveUS7160346B2Preventing mesh clogging of filterCleaning filter meansCombination devicesForeign matterEngineering

The present invention relates to a dust and dirt collecting unit for a vacuum cleaner capable of simultaneously performing a primary cyclonic dust collection and a secondary filter dust collection. According to the present invention, there is provided a dust and dirt collecting unit for a vacuum cleaner, which is mounted to one side of a main body of the vacuum cleaner to filter sucked air containing foreign substances. The dust and dirt collecting unit of the present invention comprises a dust casing which has an inlet formed in a direction tangential thereto for introducing the air containing the foreign substances thereinto and of which a top portion is open; a cover which is used to open and close the top portion of the dust casing and is provided at the center thereof with an outlet for discharging air from which the foreign substances have been filtered out; a filter assembly which is installed at a bottom surface of the cover corresponding to the outlet and includes a cylindrical filter of which the interior communicates with the outlet; a protective cylindrical body which is formed to wrap around an outer periphery of the filter assembly and installed below the cover so that the interior thereof can communicate with the exterior thereof through a plurality of vent holes formed at a lower portion thereof; and a separating plate which is coupled with the bottom of the filter assembly and extends radially to be spaced apart from an inner circumferential surface of the dust casing by a predetermined gap.

Owner:LG ELECTRONICS INC

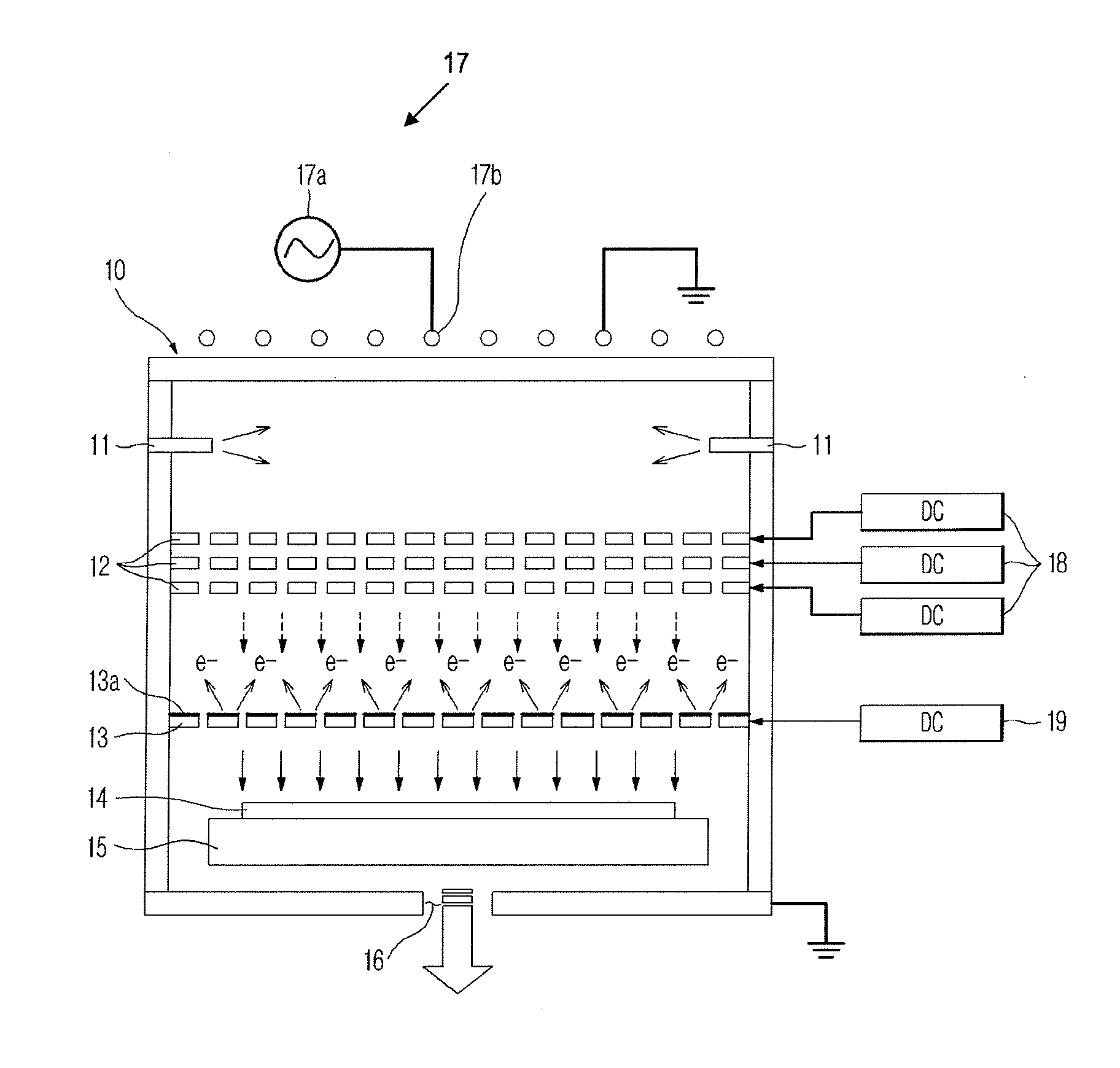

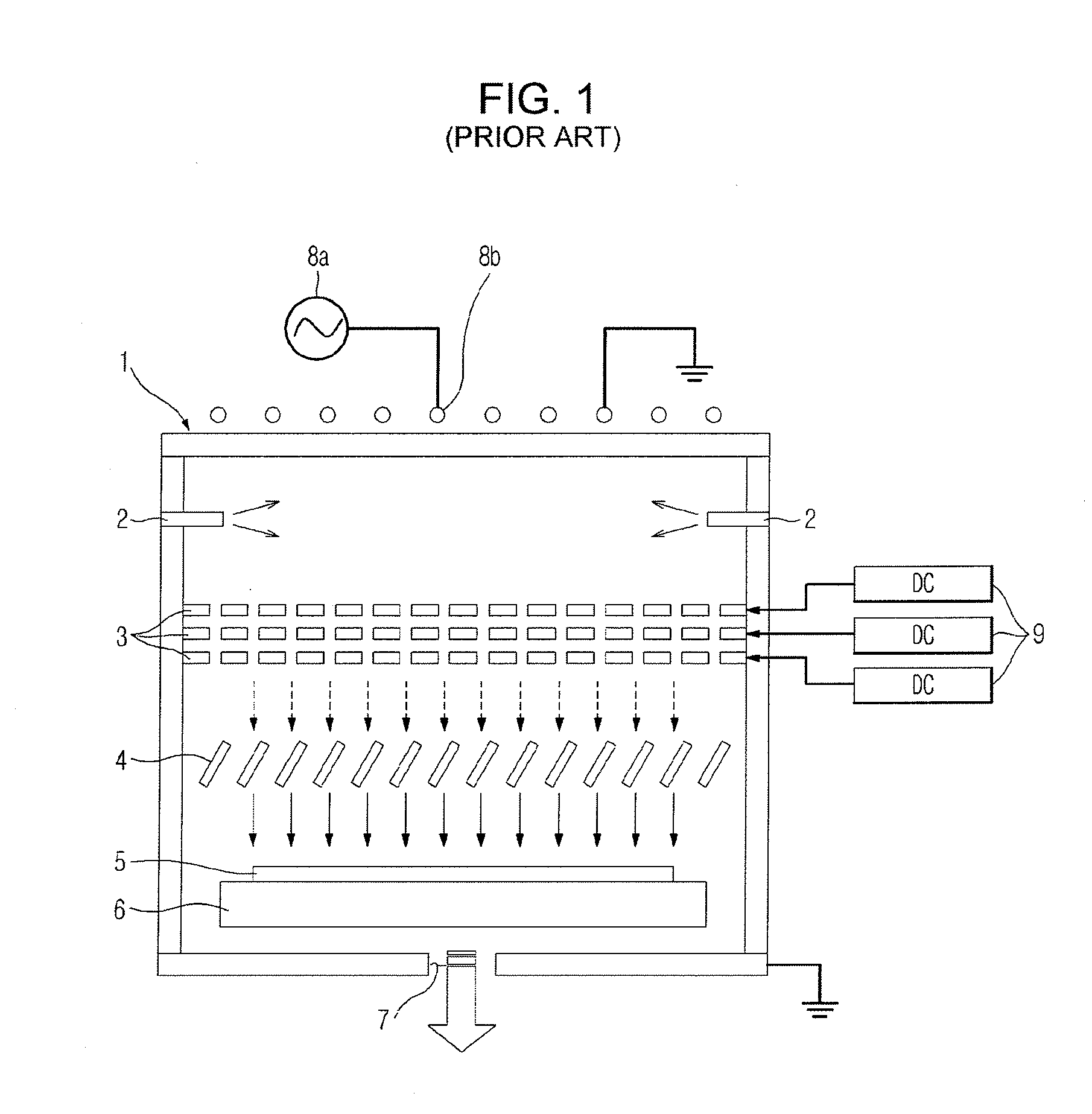

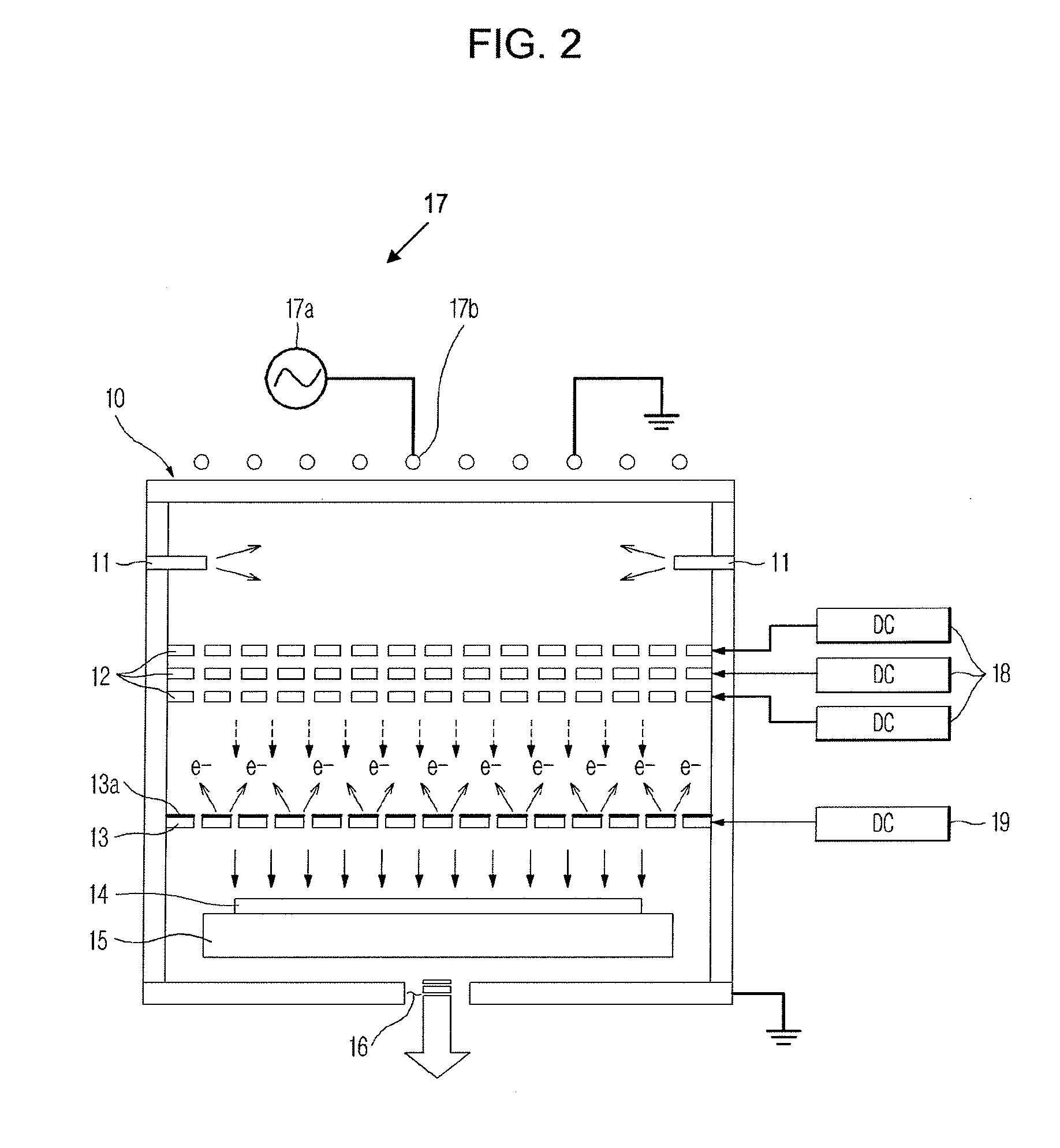

Etching apparatus using neutral beam and method thereof

InactiveUS20080156771A1Improve neutralization efficiencyCausing directionalityElectric discharge tubesDecorative surface effectsForeign matterIon beam

An etching apparatus using a neutral beam includes an electron emission unit to convert an ion beam, extracted from plasma by a plurality of grids, into a neutral beam by colliding the ion beam with electrons to prevent the ion beam from physically colliding with the electron emission unit, thus preventing the damage to a neutralization unit and generation of foreign substances with a simple structure. Further, the etching apparatus converts the ion beam into the neutral beam at a high neutralizing efficiency without causing directionality and energy losses, and generates a neutral beam having a large area, thus uniformly etching a semiconductor wafer.

Owner:SAMSUNG ELECTRONICS CO LTD

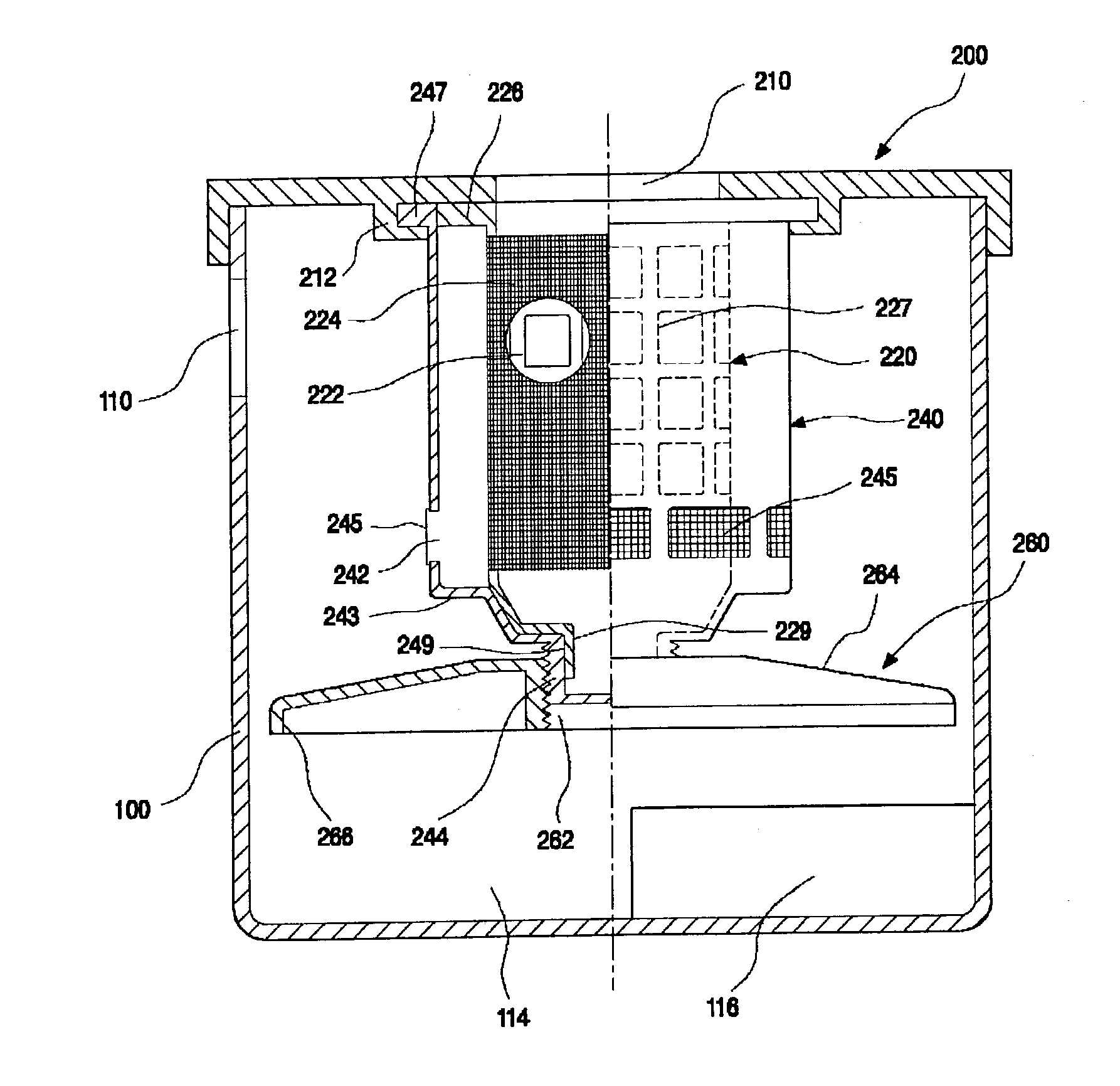

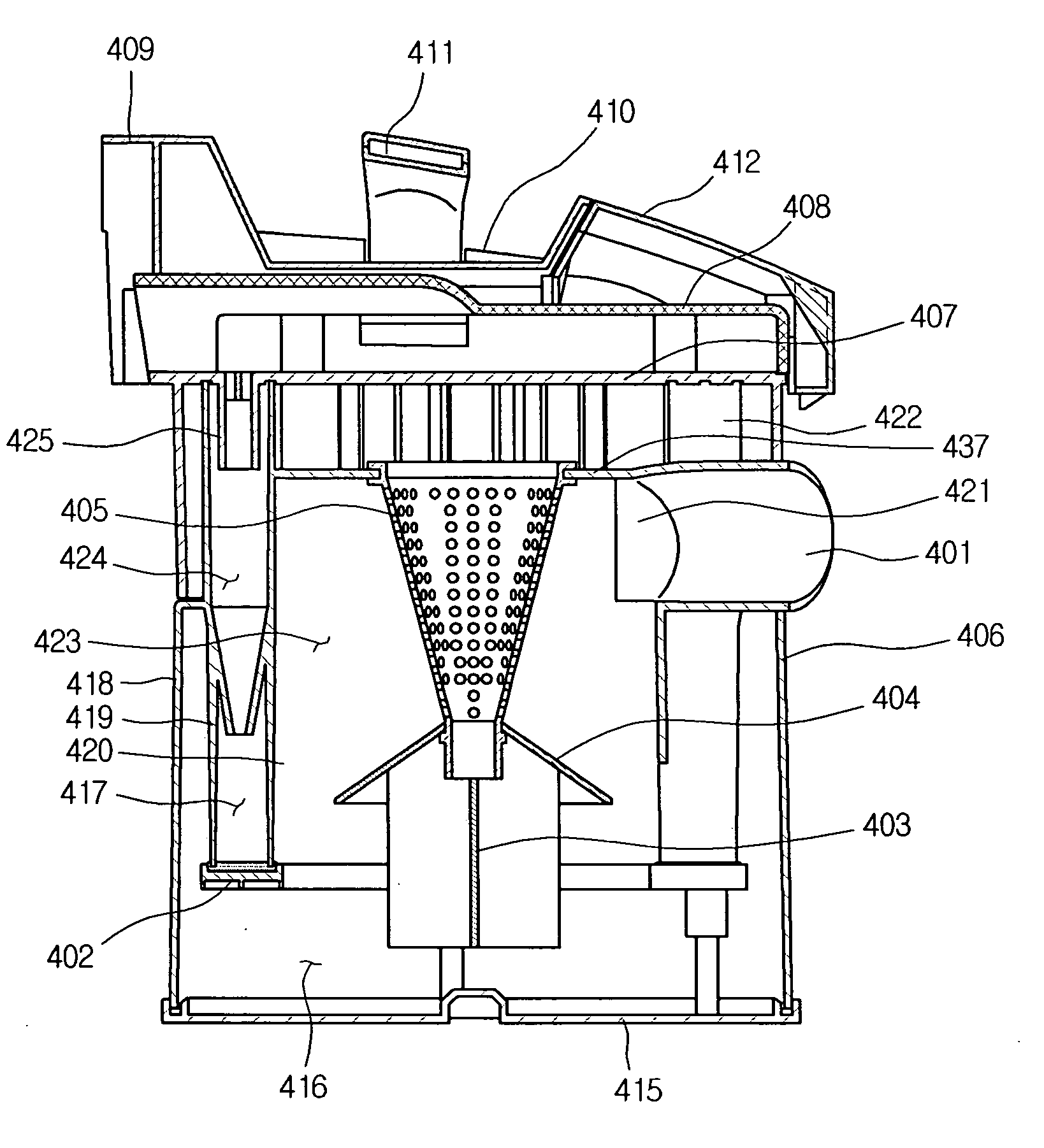

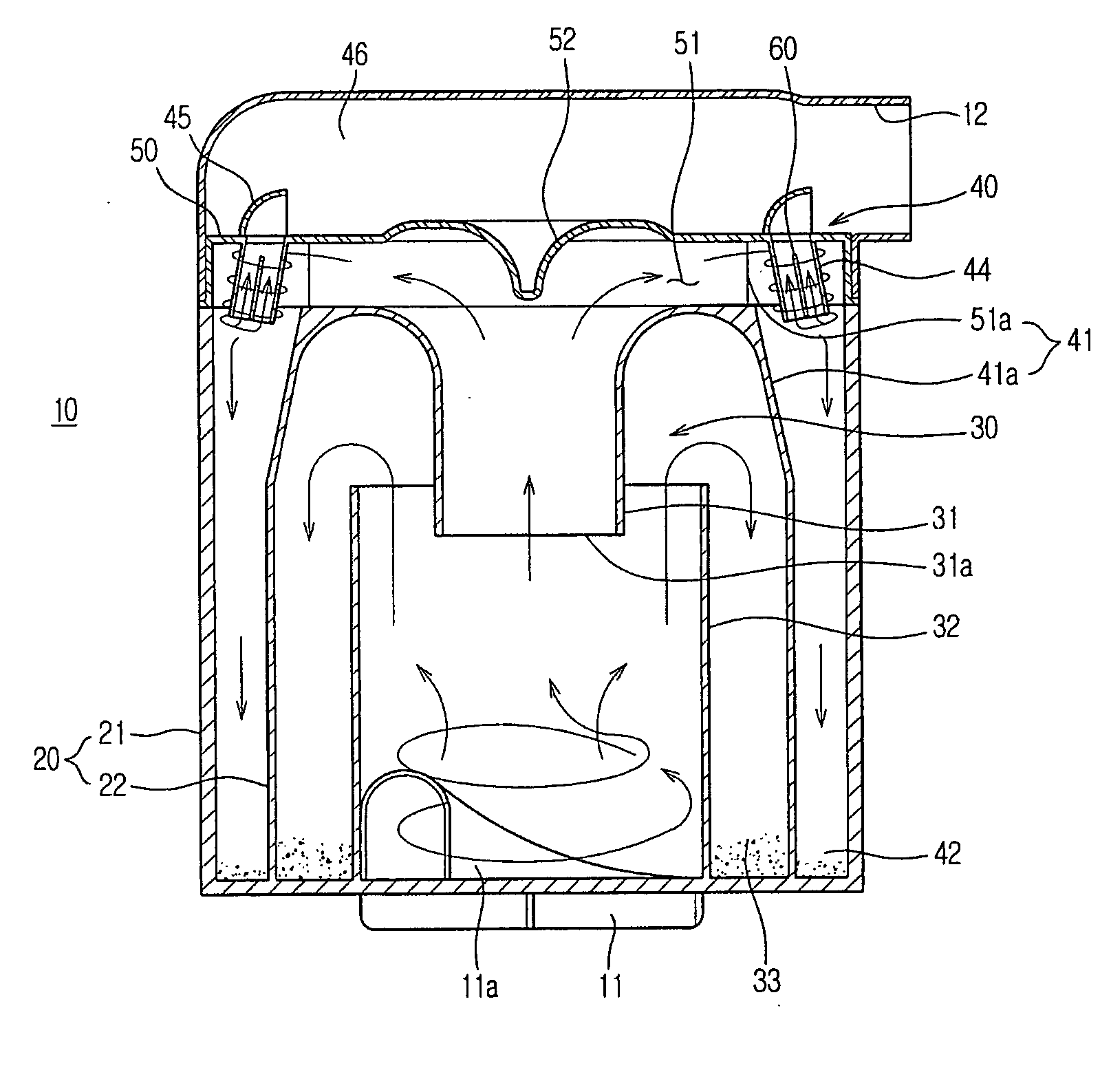

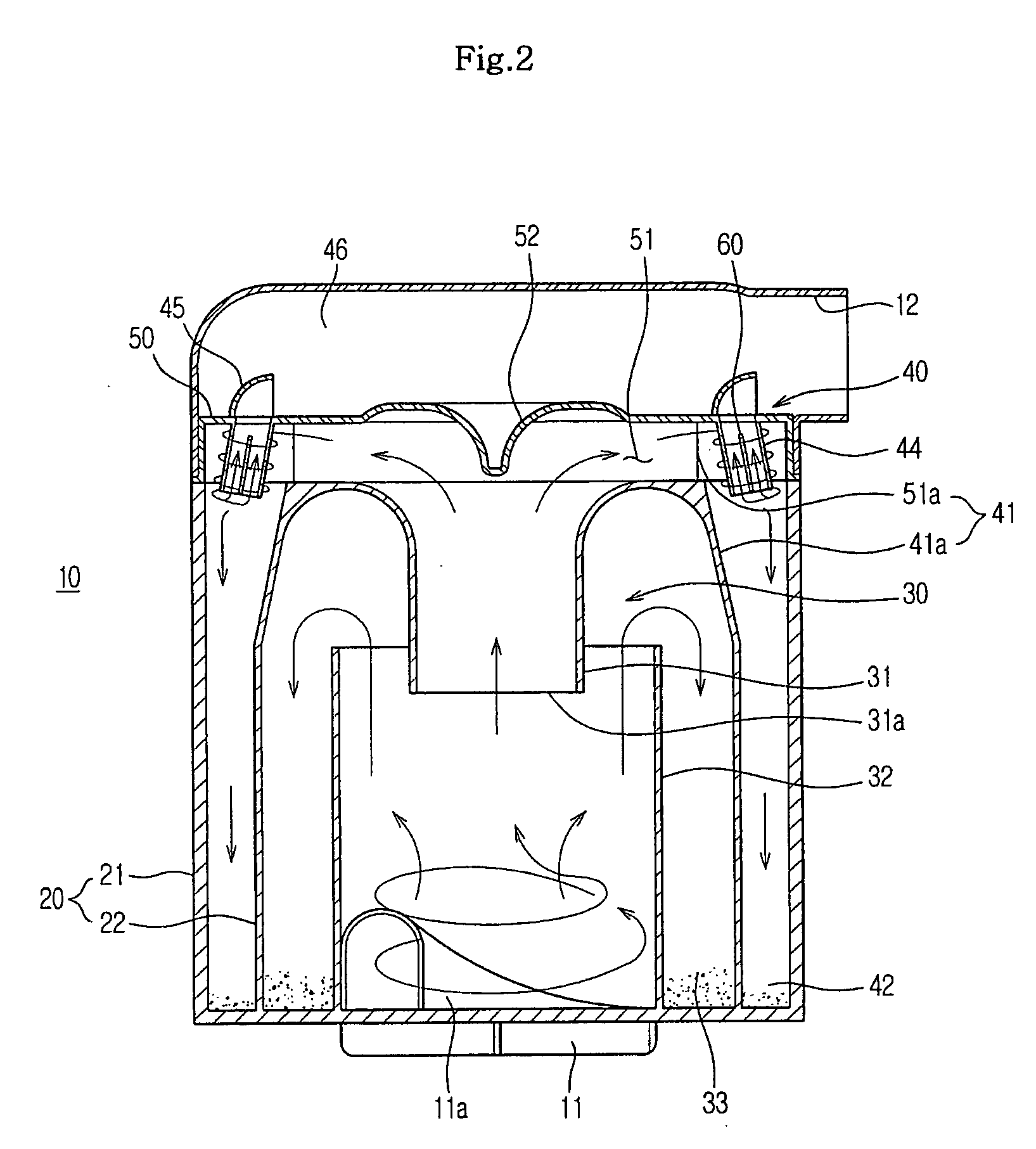

Dust collection assembly of vacuum cleaner

InactiveUS20060137304A1Improve dust removal efficiencyEasy constructionCombination devicesSuction filtersCycloneForeign matter

A dust collection assembly of a vacuum cleaner is provided. The dust collection assembly includes a dust collecting box, a filter, a flow guide unit, an exhaust guider, and an upper cover. The dust collecting box and the flow guide unit are integrally formed in a single body. The dust collecting box includes a first and second dust collecting spaces for collecting foreign objects. The filter is disposed in the inside of the dust collecting space to primarily filter foreign objects during operation of a cyclone. The flow guide unit guides airflow and has small cyclones integrally formed therein, for secondarily filtering the foreign objects in air. The exhaust guider guides airflow and has a plurality of discharge holes through which air filtered by the small cyclone flows. The upper cover is disposed on the upper side of the exhaust guider.

Owner:LG ELECTRONICS INC

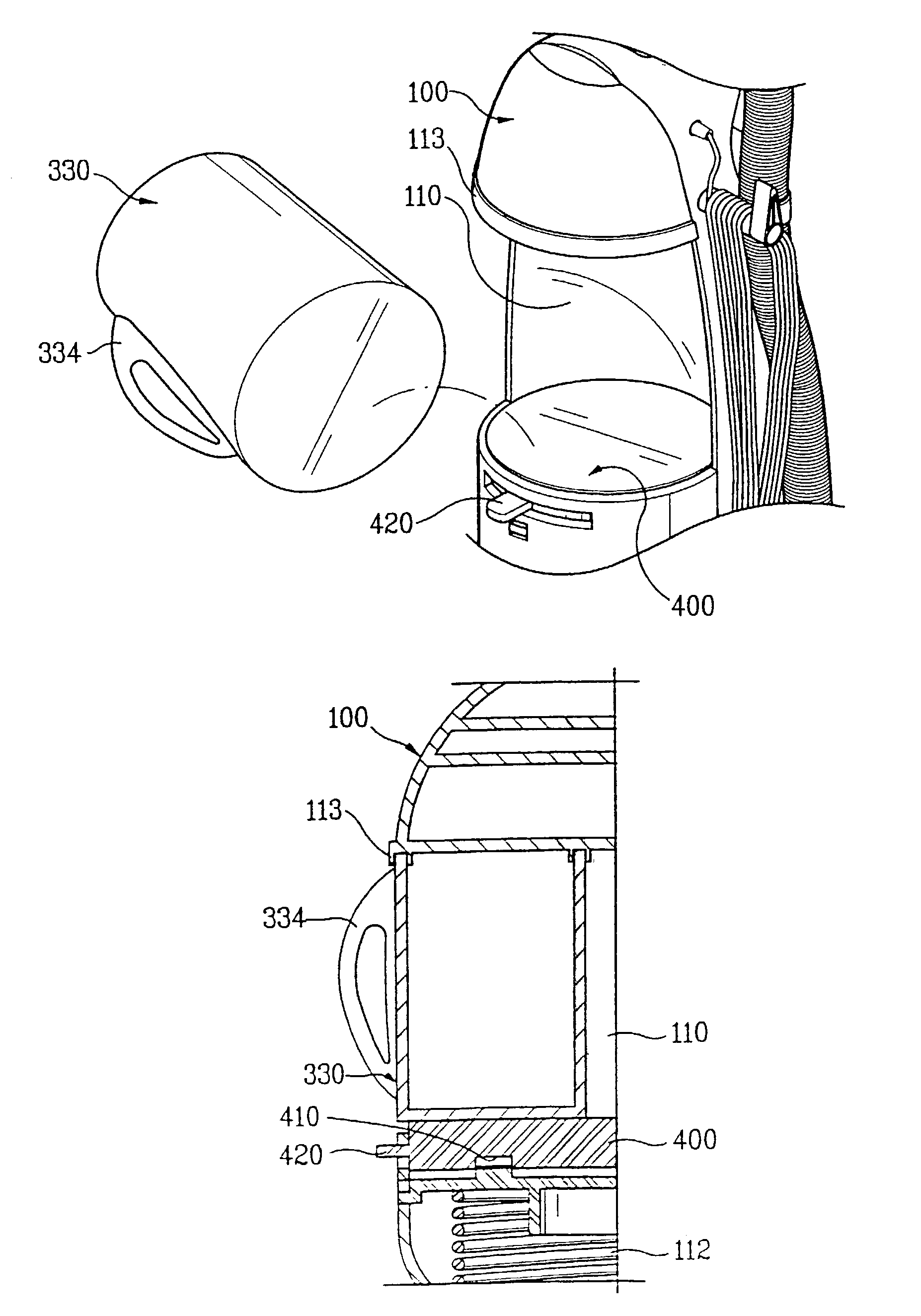

Dust collection unit and vacuum cleaner with the same

ActiveUS20060137309A1Improve foreign object removal efficiencyEasy to disassembleCombination devicesAuxillary pretreatmentForeign matterForeign object

A dust collection unit for a vacuum cleaner includes a first filtering chamber filtering foreign objects using a cyclone airflow, a separation plate defining a top surface of the first filtering chamber, a filter having a diameter that is reduced as it goes downward in response to airflow rate variation in the first filtering chamber, and a blocking member provided under the filter to prevent the foreign objects filtered in the first filtering chamber from flying.

Owner:LG ELECTRONICS INC

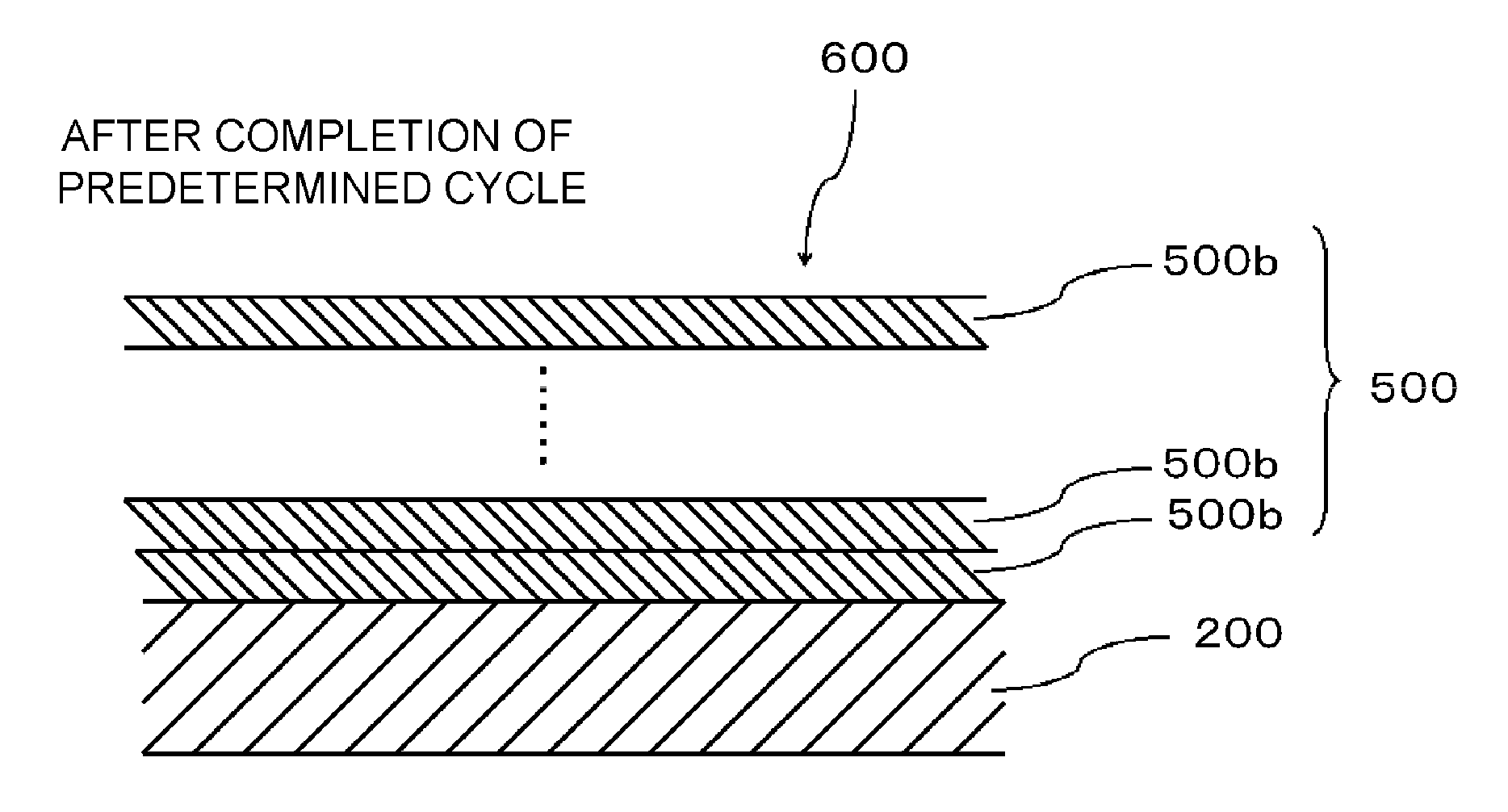

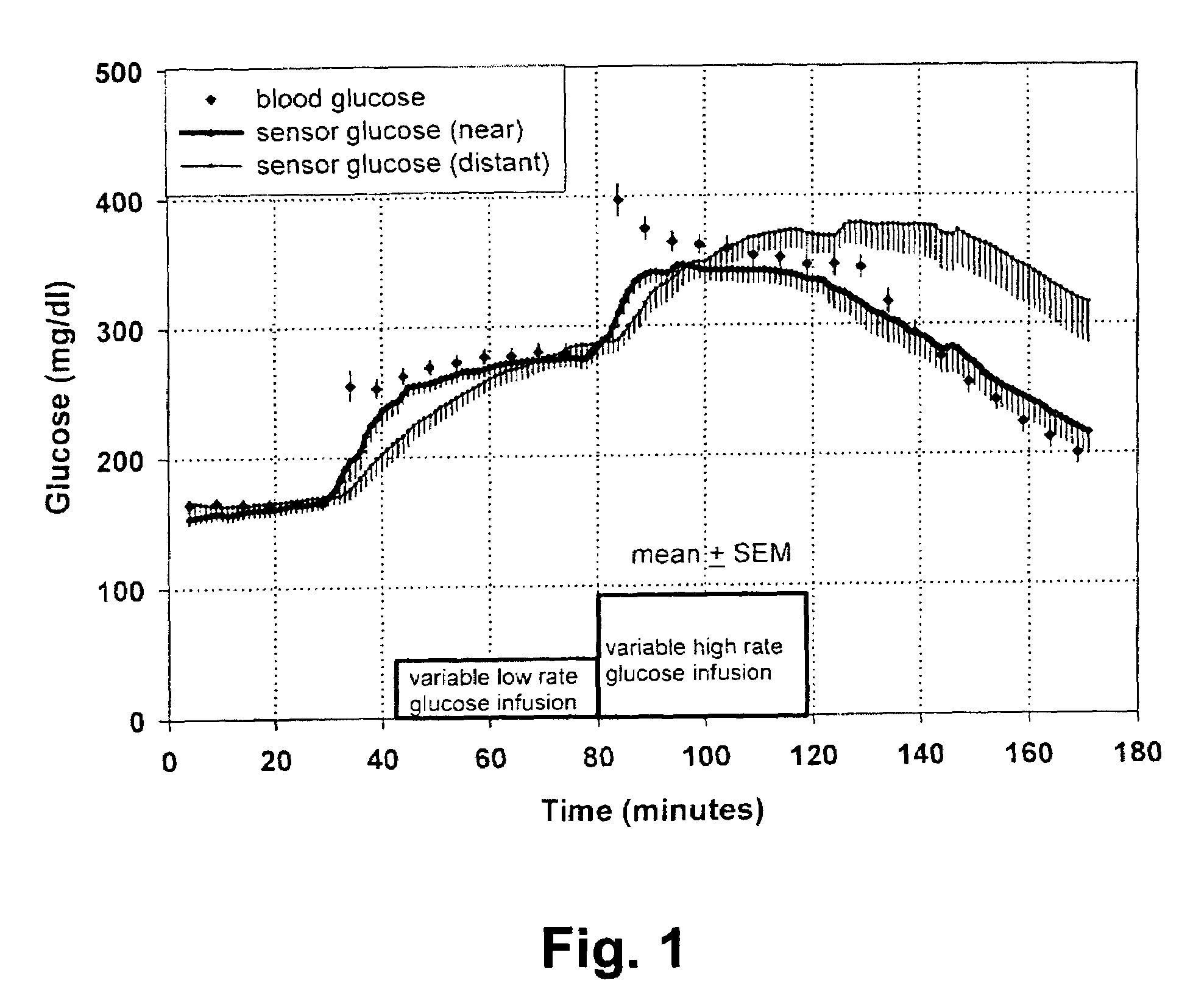

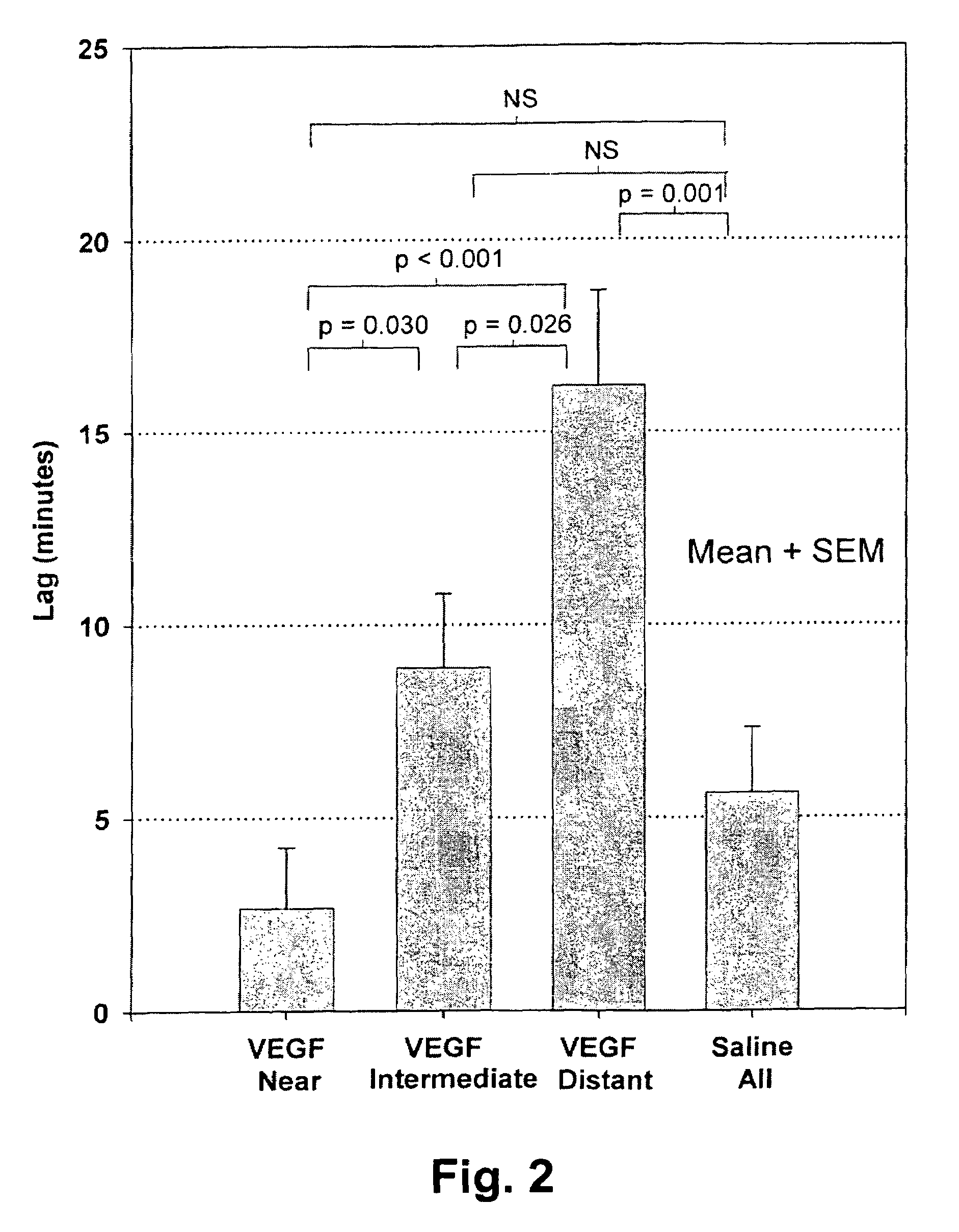

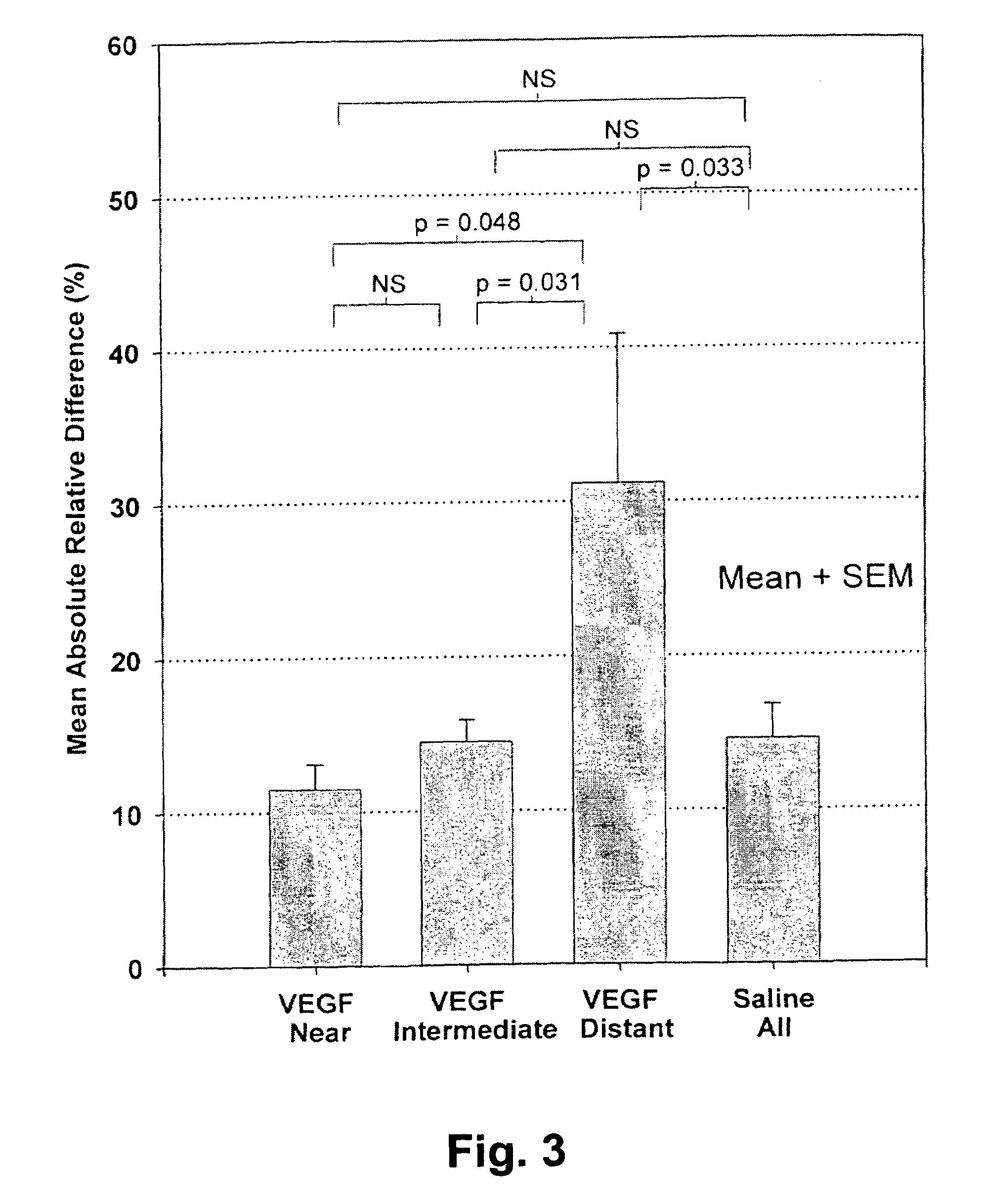

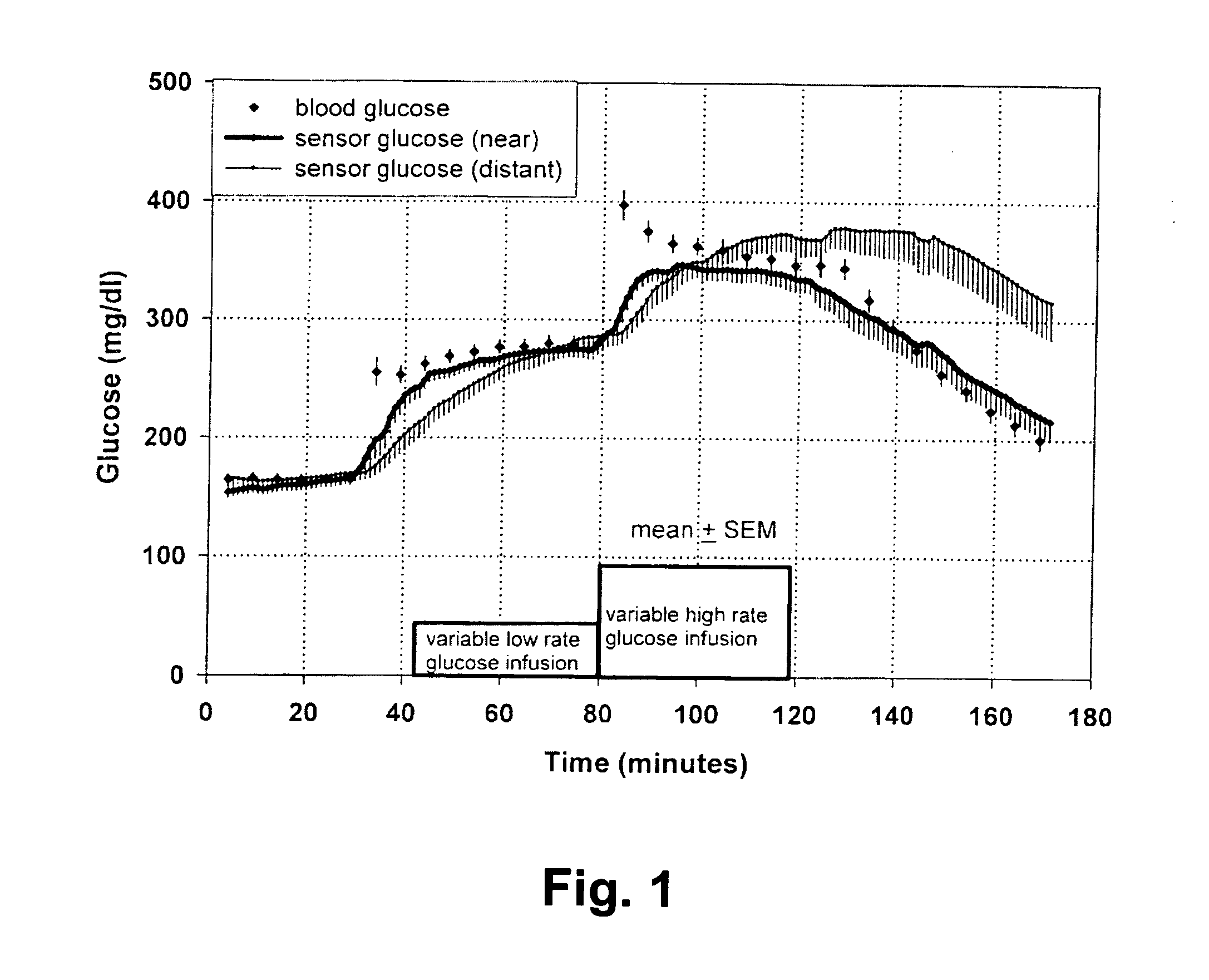

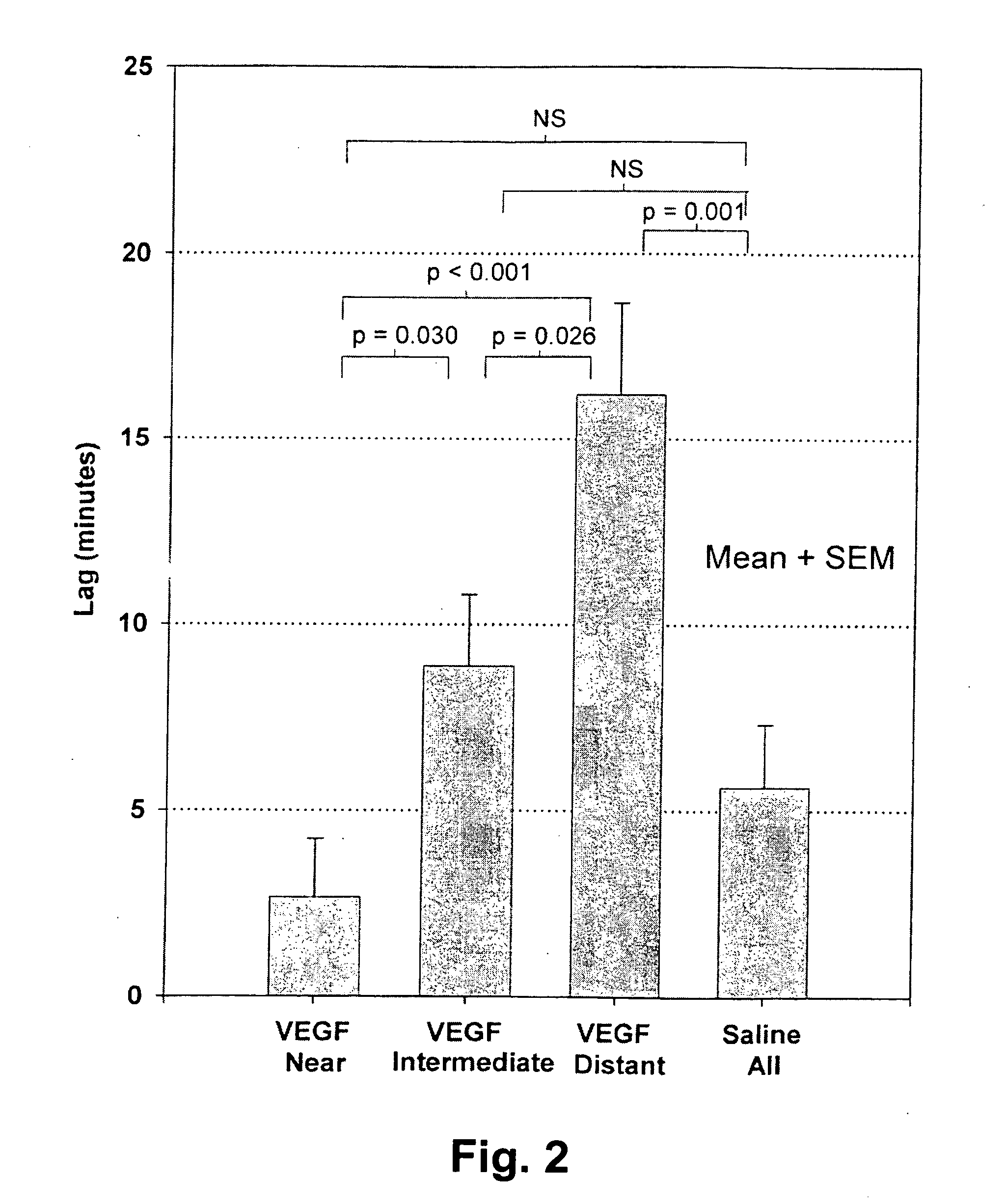

Implantable biosensor

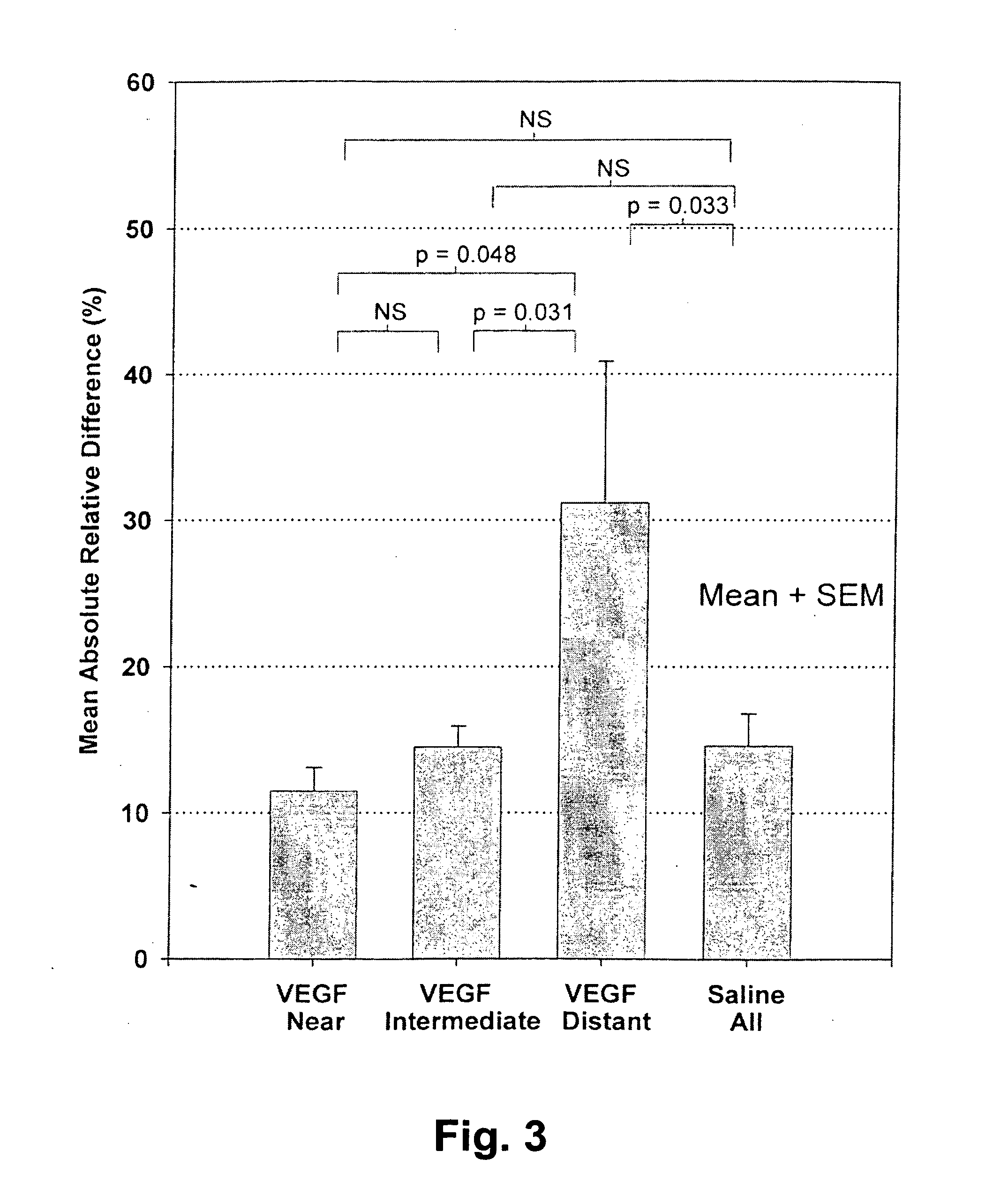

The invention consists of a sensor with multiple indicating (sensing) electrodes covered with a selectively permeable membrane for monitoring fluid concentrations in a biological environment. The indicating electrodes respond to changes in certain analytes, such as glucose, through an enzyme-mediated reaction. The currents generated from the enzyme-mediated reactions are transmitted through radio signals to an external receiver where the information is processed and recorded. Through the use of various biomaterials and biochemicals associated with the sensor, the monitoring accuracy is improved and the overall viability is prolonged. The process of foreign body fibrosis (formation of a scar capsule around the implanted sensor) eventually limits the functional life of the device. We teach methods of delivery of certain biochemicals that can increase the functional life of the sensor by inhibiting the formation of the foreign body capsule or by stimulating the growth of capillaries into the capsule.

Owner:LEGACY GOOD SAMARITAN HOSPITAL & MEDICAL CENT

Planar waveguide lens design

InactiveUS8064744B2Easy to mergeLess susceptible to stray lightCoupling light guidesOptical waveguide light guideForeign matterWaveguide

Owner:ZETTA RES & DEV LLC RPO SERIES

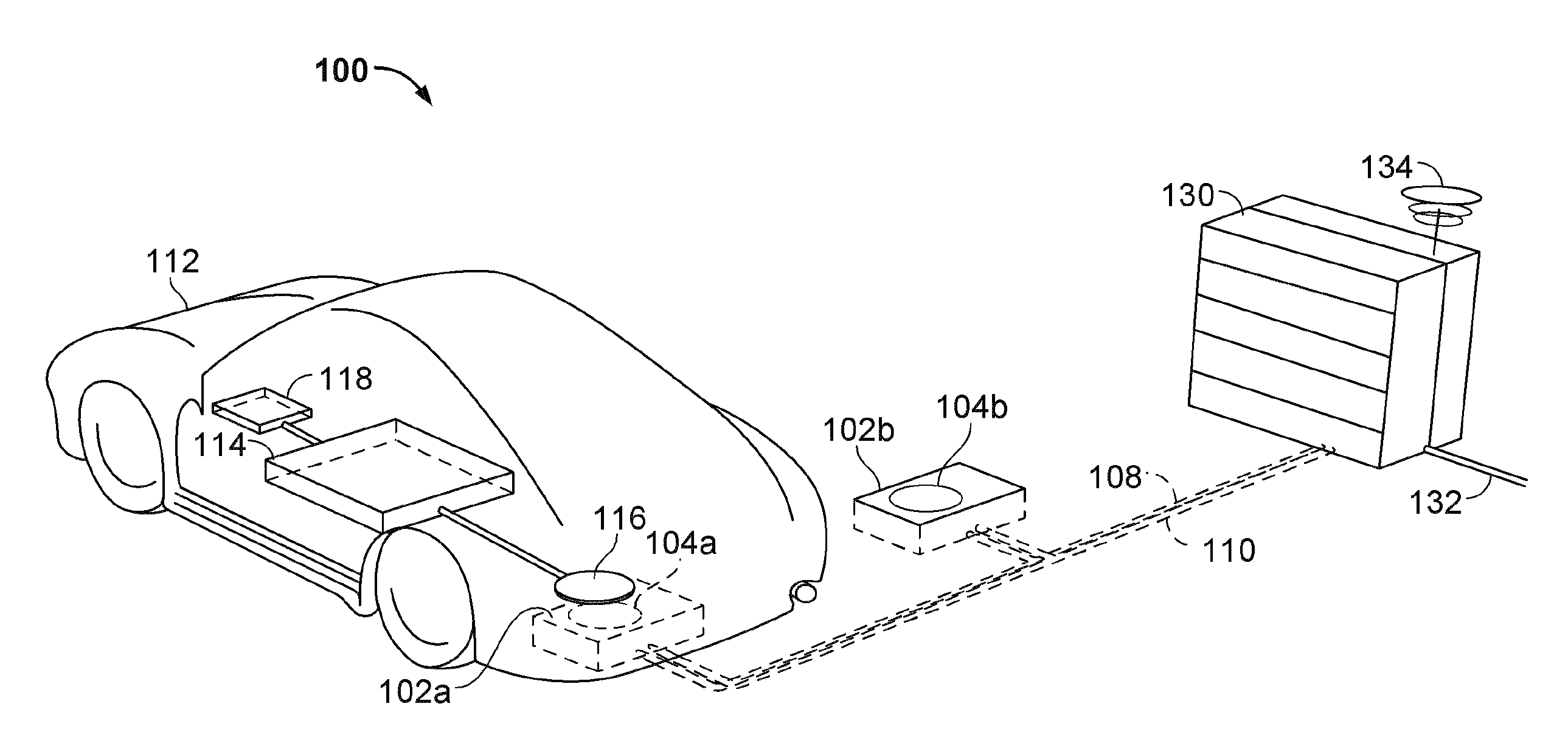

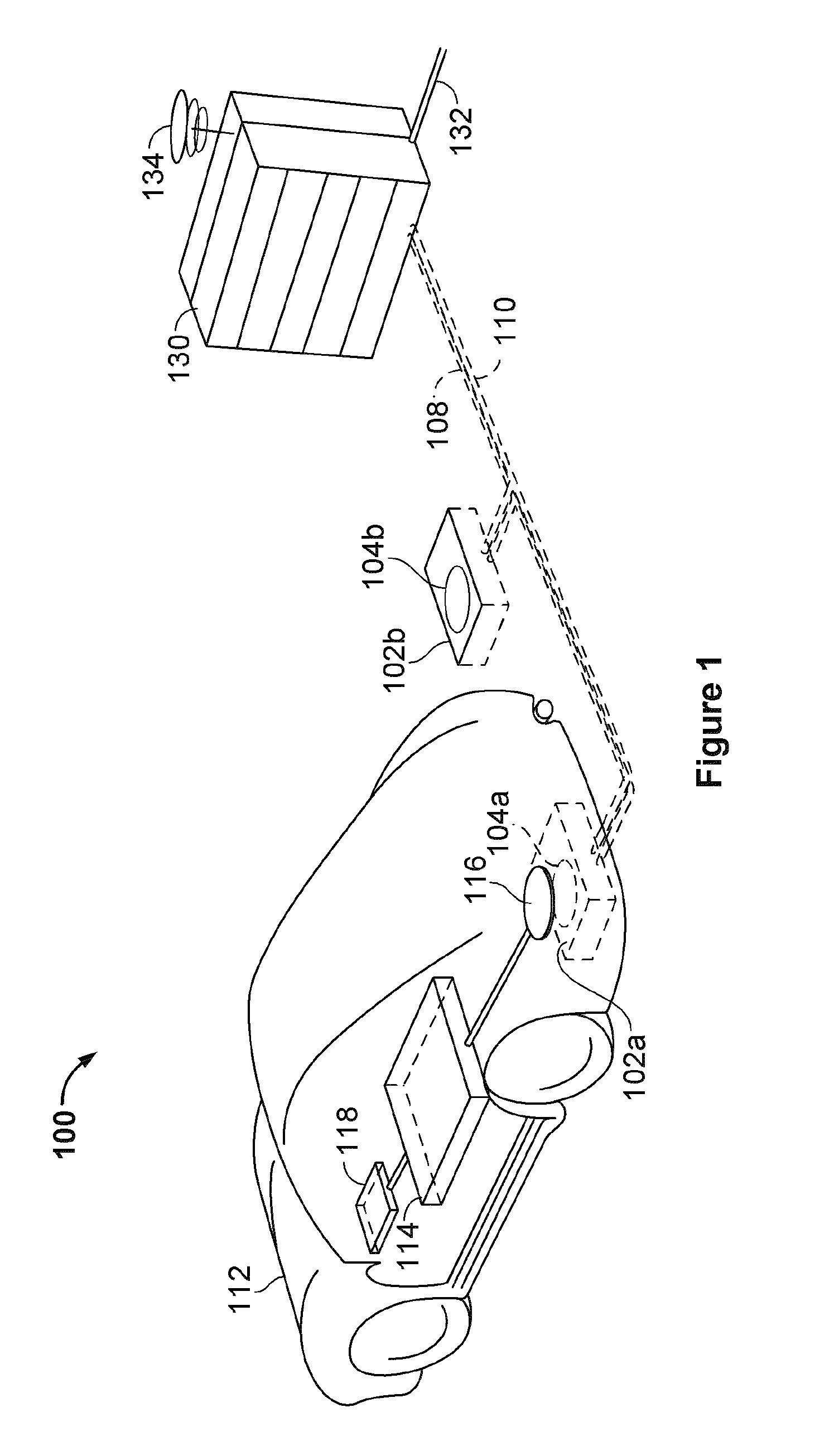

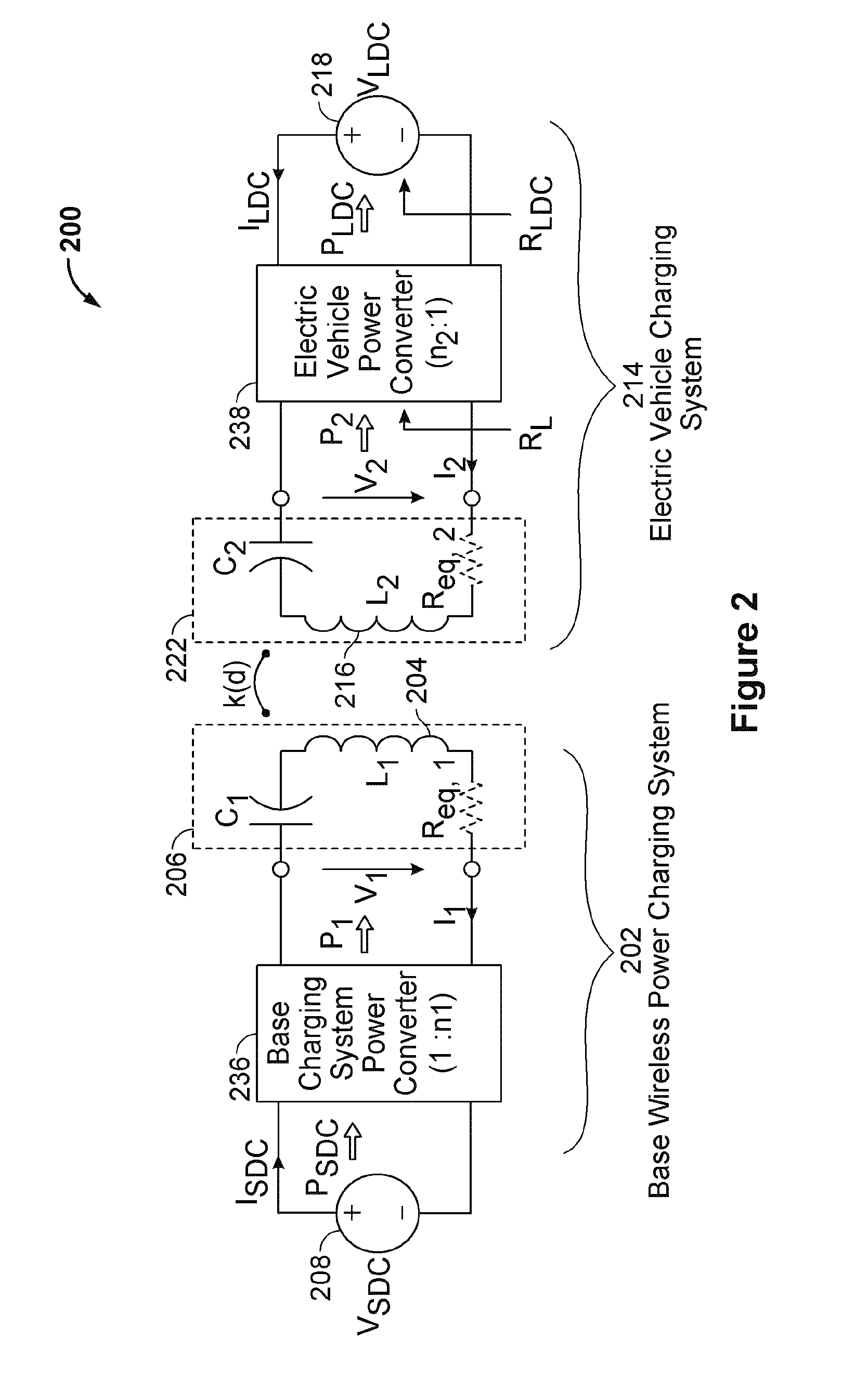

Systems, methods, and apparatus for radar-based detection of objects in a predetermined space

This disclosure provides apparatuses and methods for detecting foreign objects. An apparatus for detecting a presence of an object comprises at least one radar antenna attached to a wirelessly chargeable vehicle. The at least one radar antenna is configured to transmit a radar signal into a space between a wireless power receiver of the vehicle and a wireless charger as the vehicle moves in a primary direction of movement of the vehicle and receive the radar signal. The apparatus further comprises a radar processing circuit configured to determine a presence of the object in the space based on at least one characteristic of the received radar signal. The radar processing circuit is further configured to provide an indication to receive power from the wireless charger based at least in part on the determining the presence of the object.

Owner:WITRICITY CORP

Implantable biosensor

ActiveUS20050107677A1Readily availableMicrobiological testing/measurementCatheterForeign matterSurvivability

The invention consists of a sensor with multiple indicating (sensing) electrodes covered with a selectively permeable membrane for monitoring fluid concentrations in a biological environment. The indicating electrodes respond to changes in certain analytes, such as glucose, through an enzyme-mediated reaction. The currents generated from the enzyme-mediated reactions are transmitted through radio signals to an external receiver where the information is processed and recorded. Through the use of various biomaterials and biochemicals associated with the sensor, the monitoring accuracy is improved and the overall viability is prolonged. The process of foreign body fibrosis (formation of a scar capsule around the implanted sensor) eventually limits the functional life of the device. We teach methods of delivery of certain biochemicals that can increase the functional life of the sensor by inhibiting the formation of the foreign body capsule or by stimulating the growth of capillaries into the capsule.

Owner:LEGACY GOOD SAMARITAN HOSPITAL & MEDICAL CENT

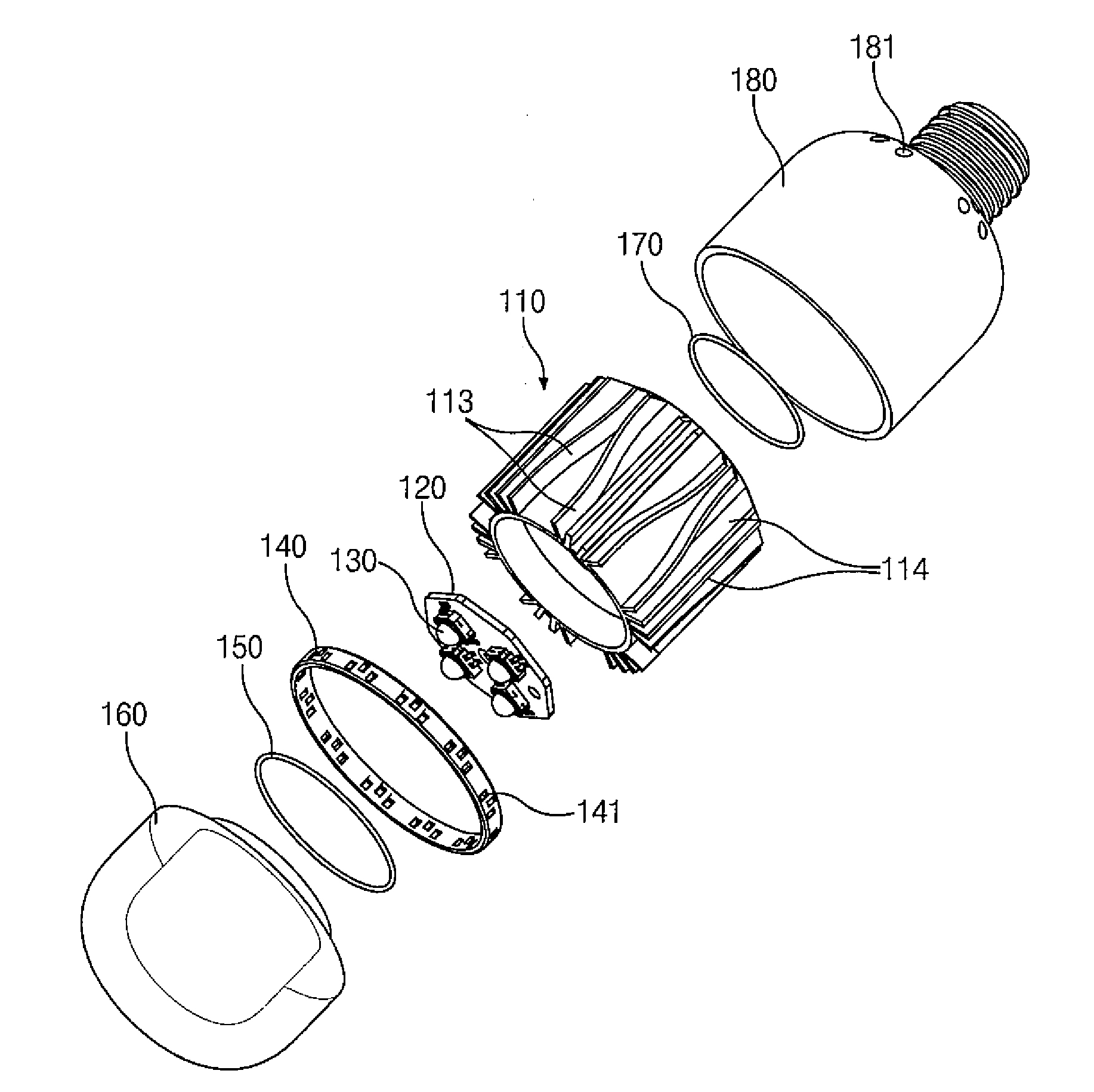

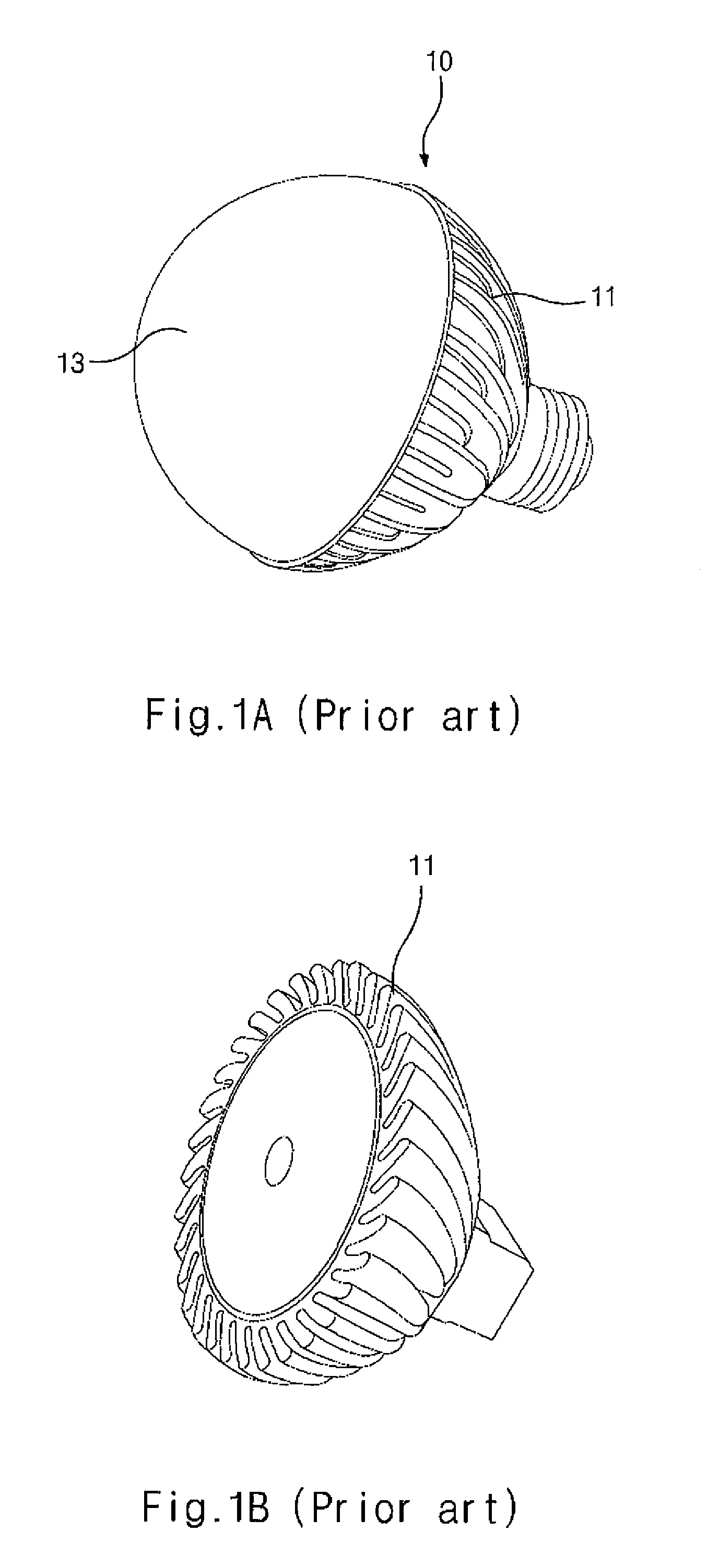

Heat dissipation member having variable heat dissipation paths and LED lighting flood lamp using the same

InactiveUS20100091487A1Avoid problemsImprove cooling effectPoint-like light sourceLighting support devicesForeign matterEffect light

Owner:HYUNDAI TELECOMM

Dust collection unit and vacuum cleaner with same

ActiveUS20060137306A1Reduce noiseAttenuating unpleasant sensationCombination devicesSuction filtersForeign matterVacuum cleaner

A dust collection unit for a vacuum cleaner includes a first filtering chamber filtering relatively large foreign objects, a second filtering chamber filtering relatively small foreign objects when air exhausted from the first filtering chamber is introduced into the second filtering chamber, an exhaust member disposed above the filtering chambers to guide airflow, a storing chamber disposed under the filtering chambers to store the foreign objects filtered in the filtering chambers, a sealing member sealing bottoms of the filtering chambers, and a rectifying unit formed on an exhaust side of the second filtering chamber to rectify airflow, thereby reducing noise generated by the airflow.

Owner:LG ELECTRONICS INC

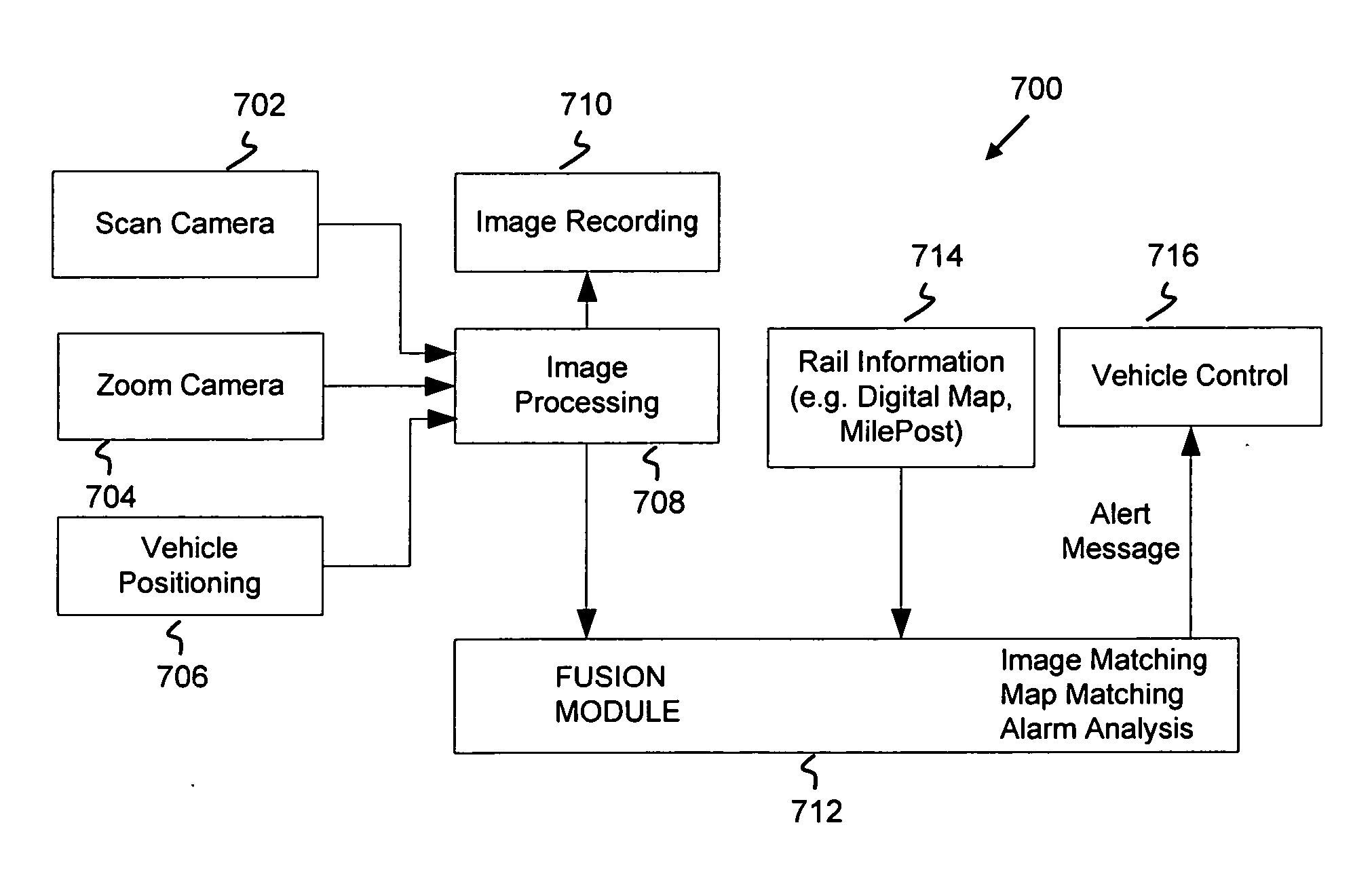

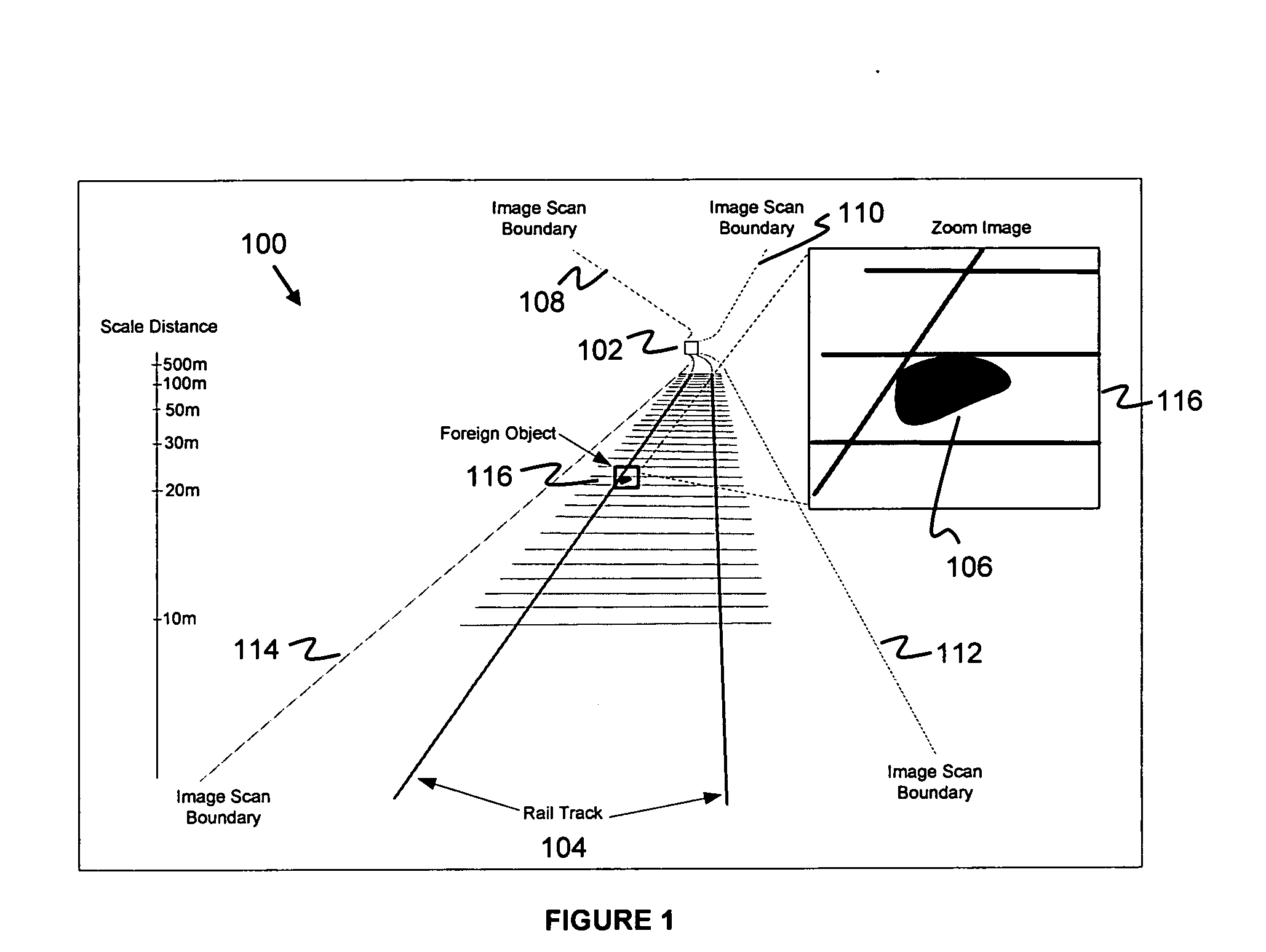

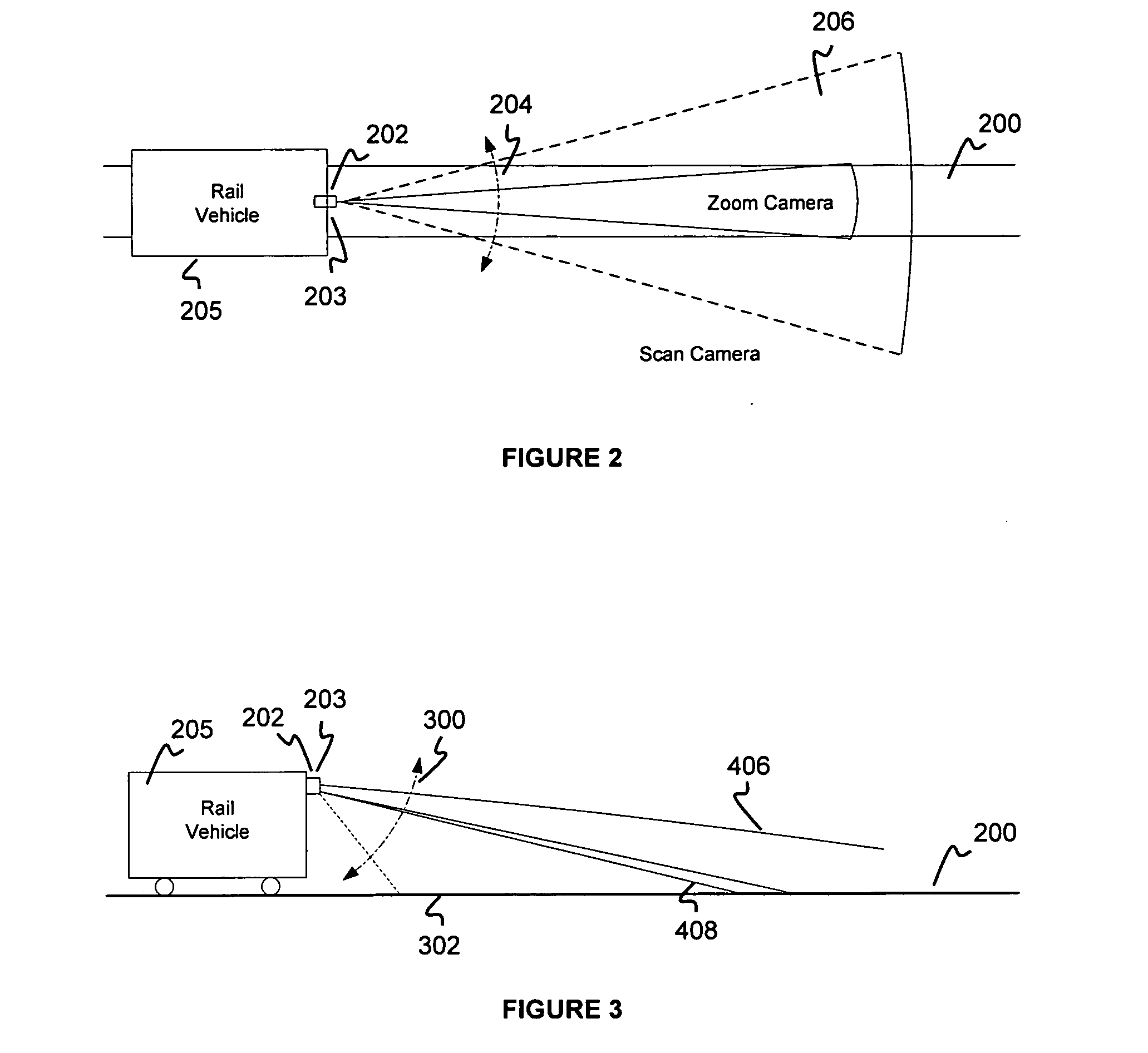

Method and system for rail track scanning and foreign object detection

InactiveUS20060098843A1Avoid destructionCharacter and pattern recognitionColor television detailsForeign matterEngineering

A method and system for detecting an object or abnormality on or near a rail track. The system comprises scanning means for scanning on and near a portion of the rail track; and detection means for determining the presence and location of the object or abnormality on or near the portion of the rail track based on information from the scanning means.

Owner:STRATECH SYST

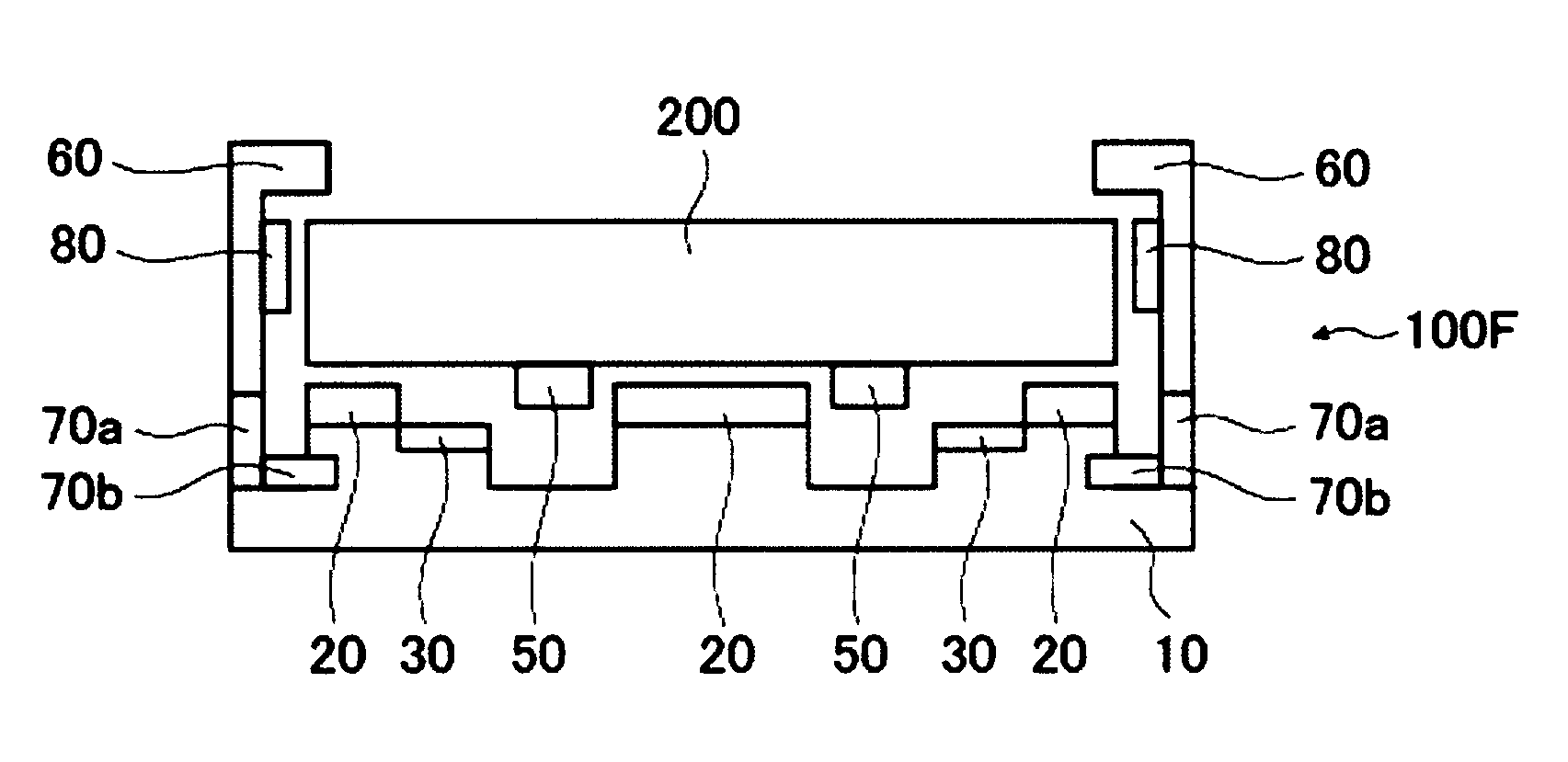

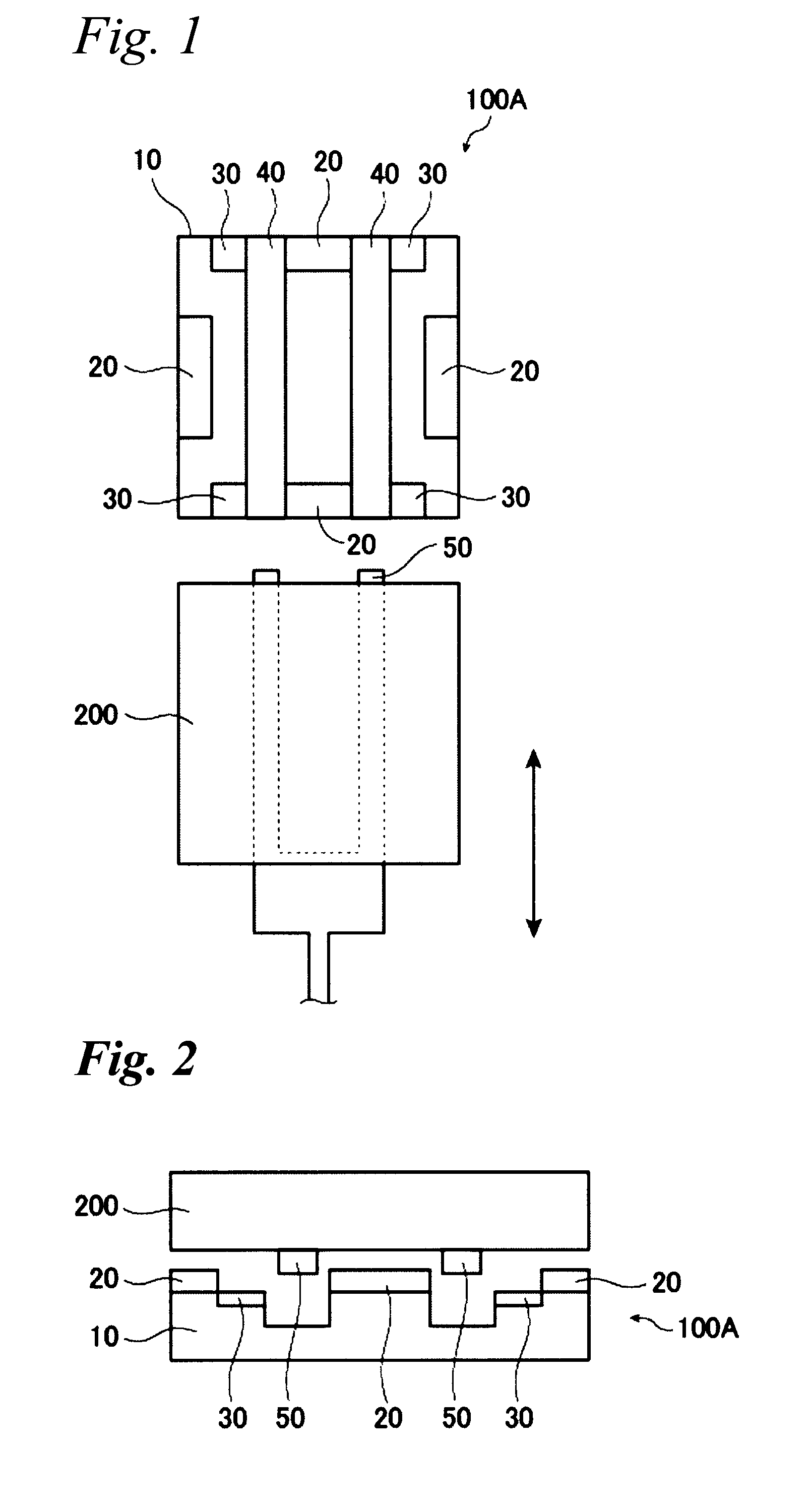

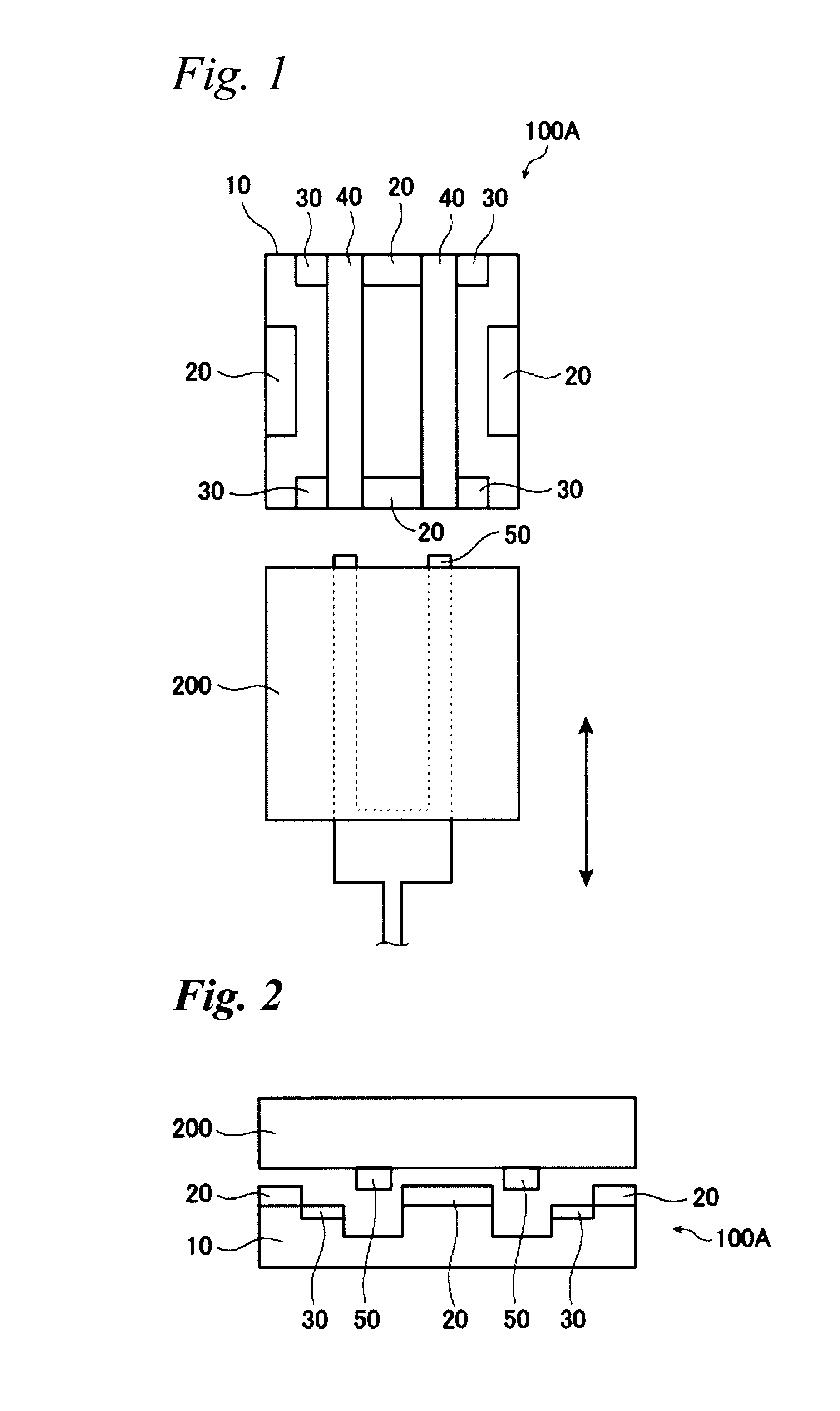

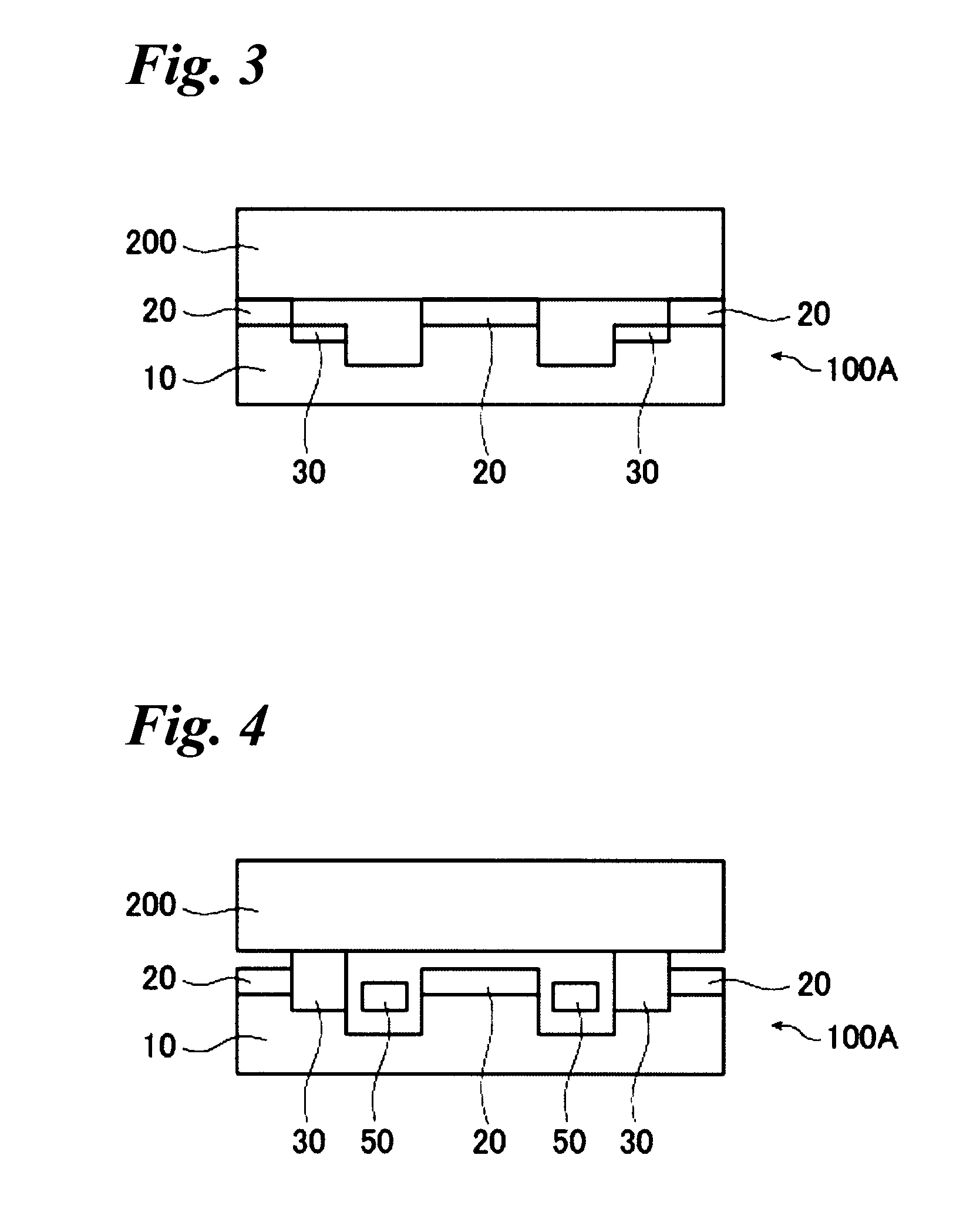

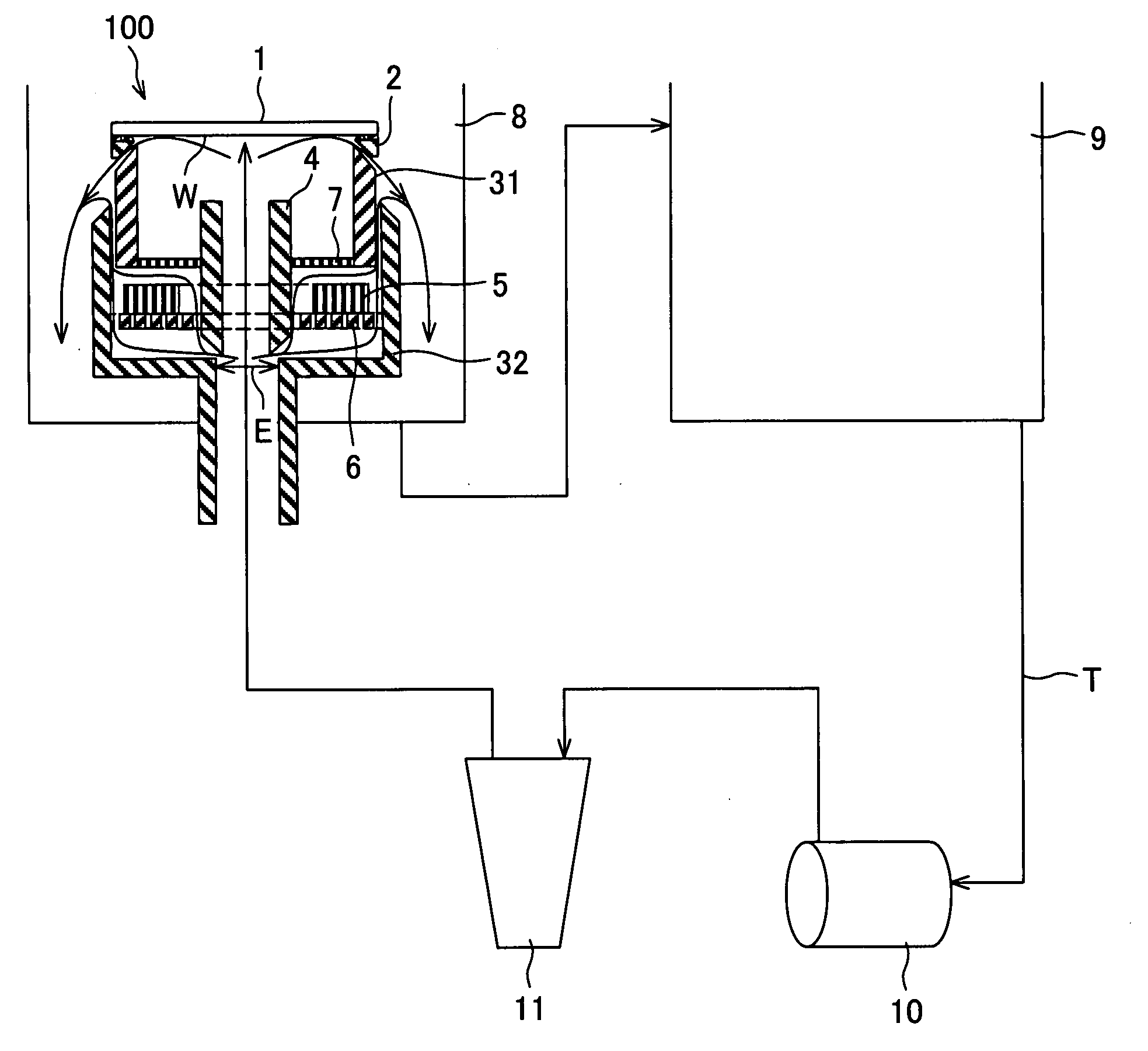

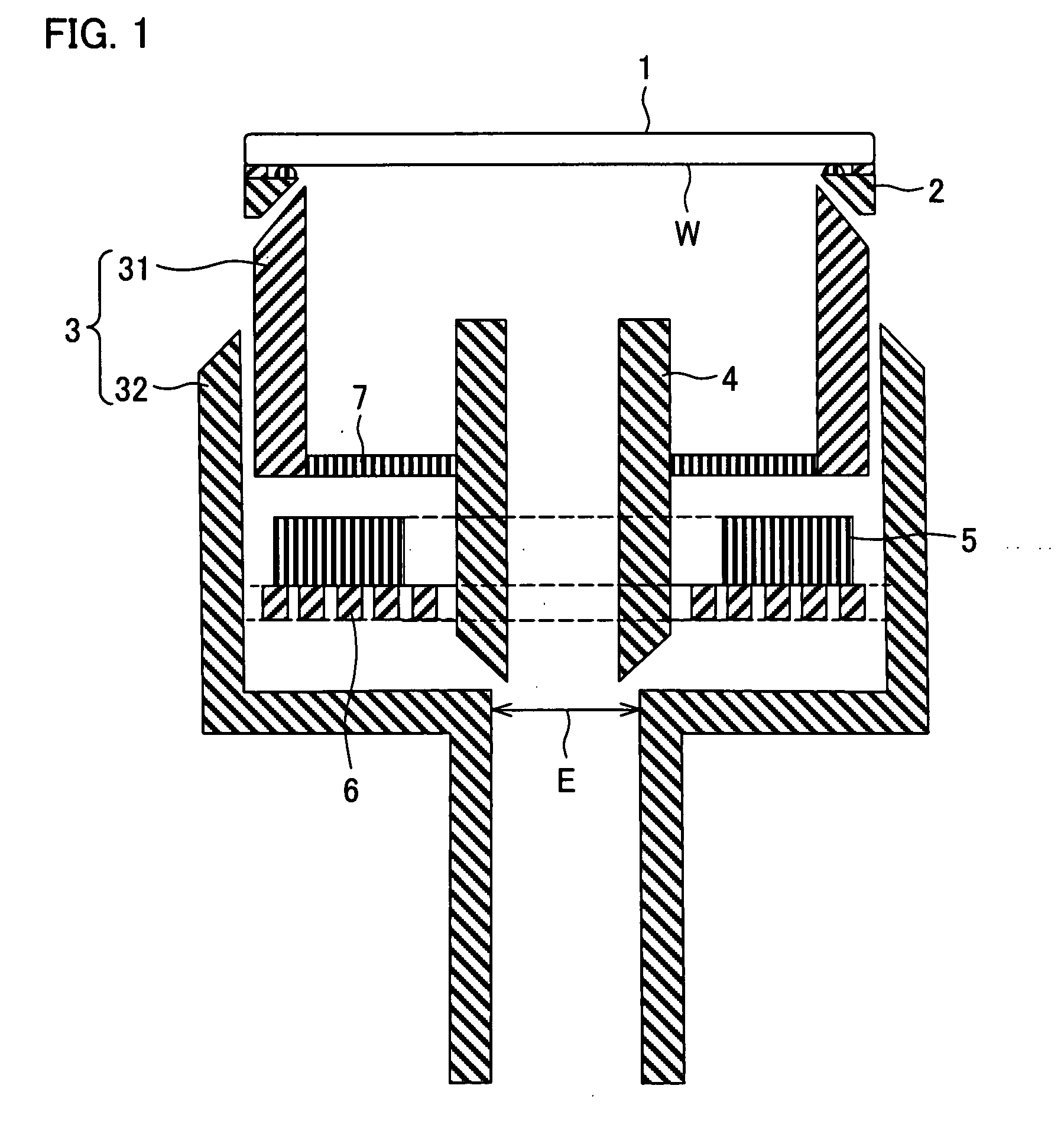

Plating Device, Plating Method, Semiconductor Device, And Method For Manufacturing Semiconductor Device

An object of the present invention is to provide a face-down type jet plating device in which deterioration in plating quality due to minute solid foreign matters derived from a black film etc. is prevented without impairing operativity. The plating device is designed such that a partition (7) is provided between a semiconductor wafer (1) and an anode (5) so that the anode (5) and the semiconductor wafer (7) are separated from each other and a plating tank (100) is divided into a substrate-to-be-plated chamber and an anode chamber.

Owner:SHARP KK

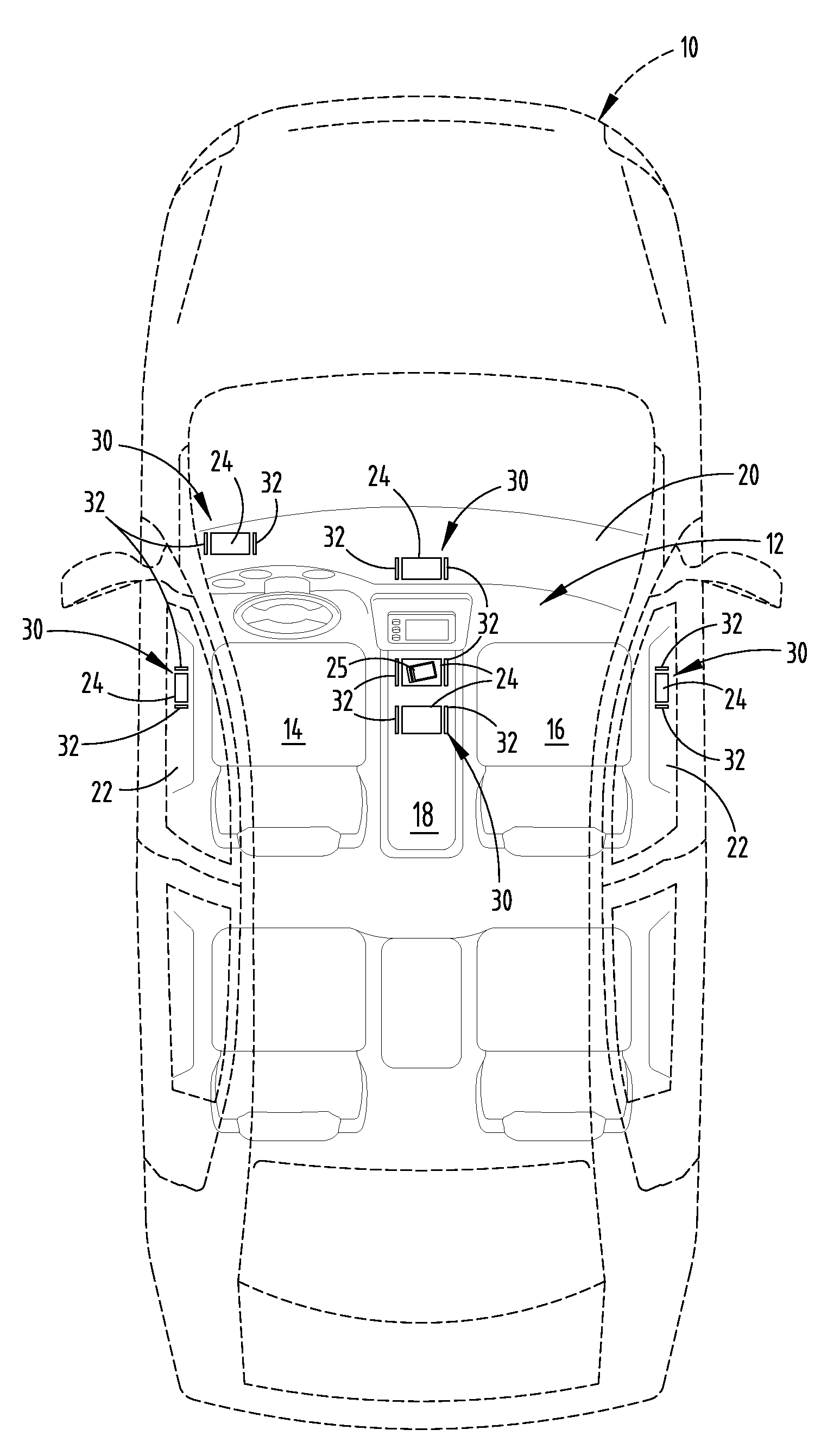

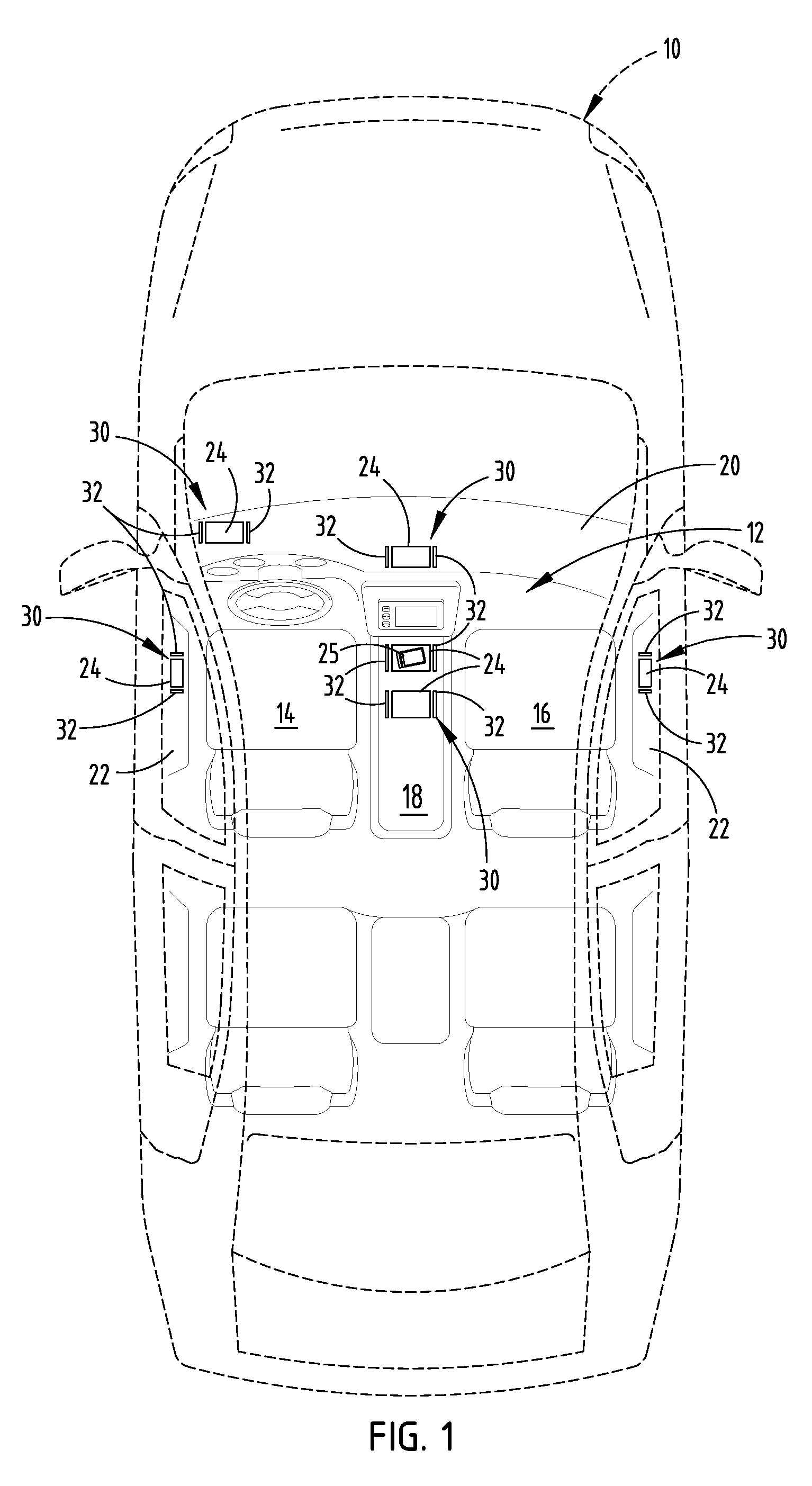

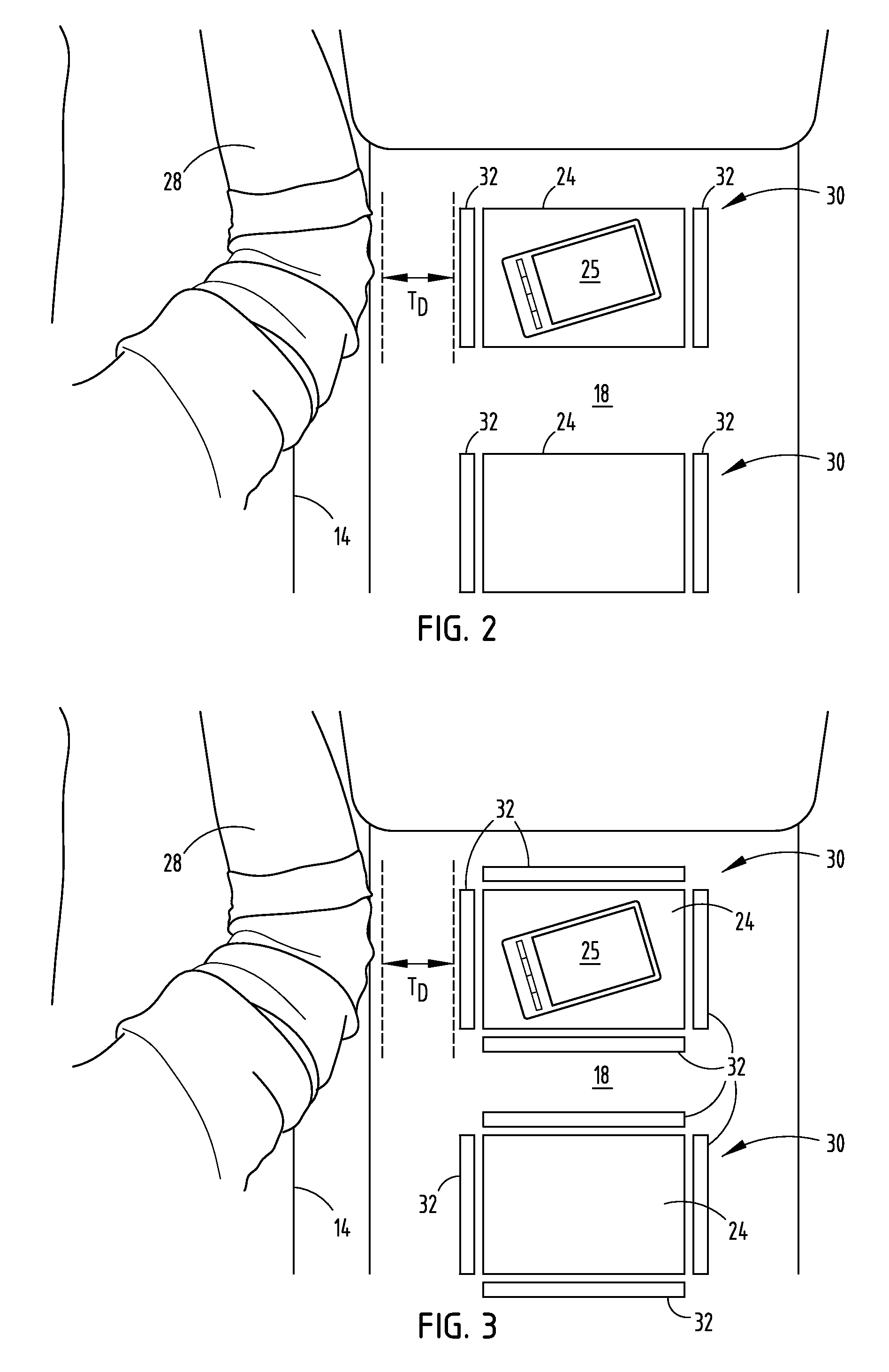

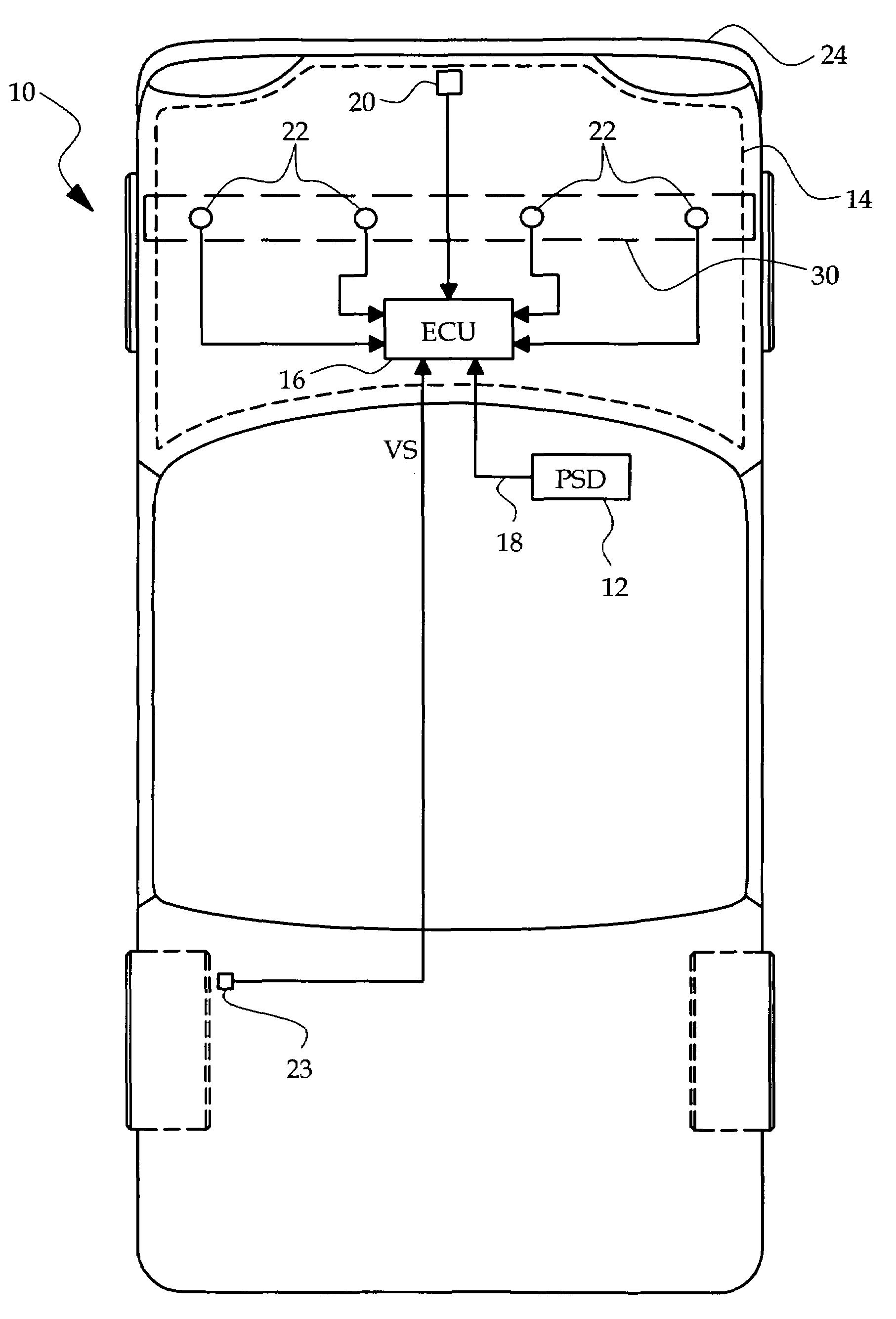

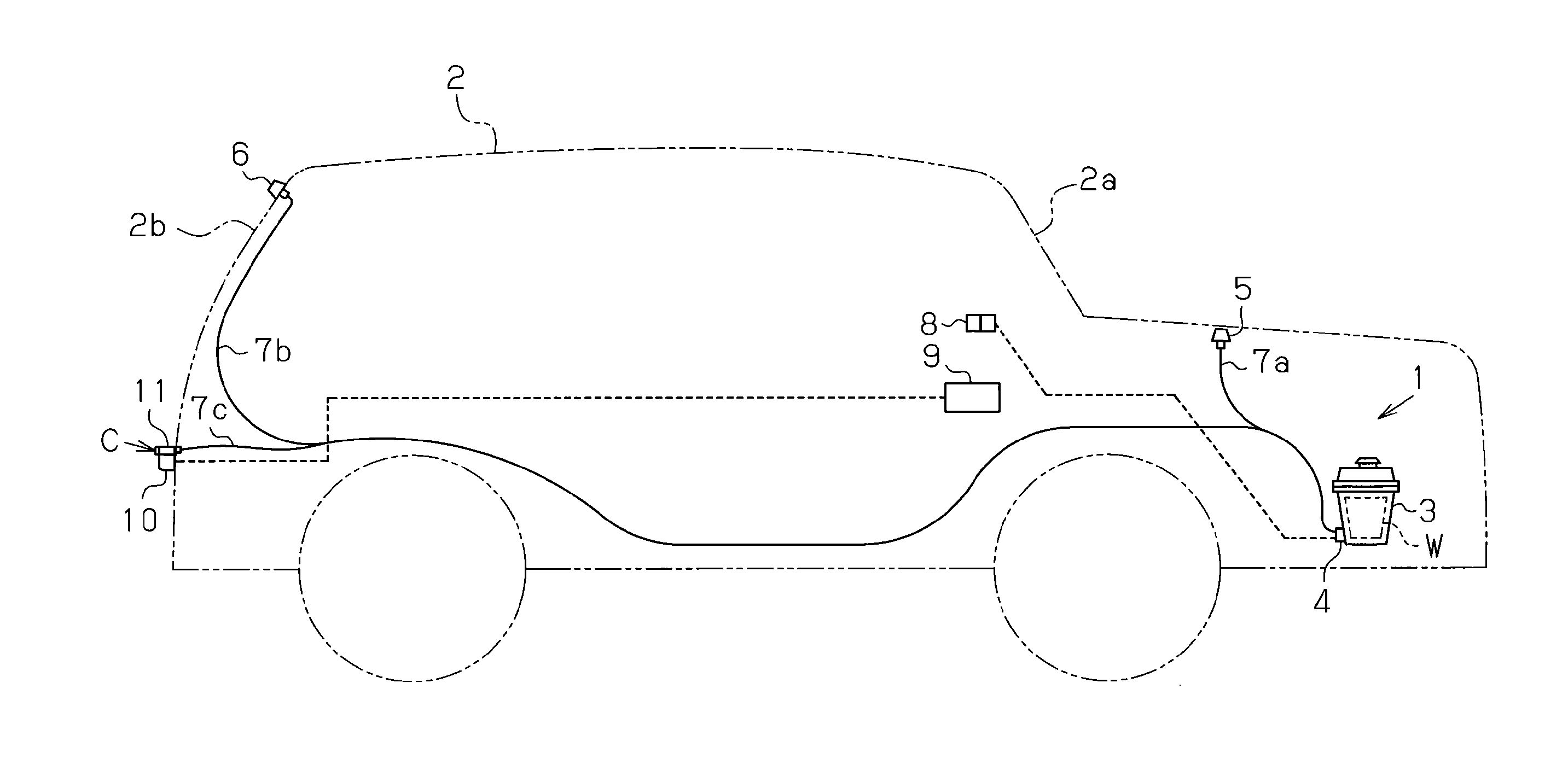

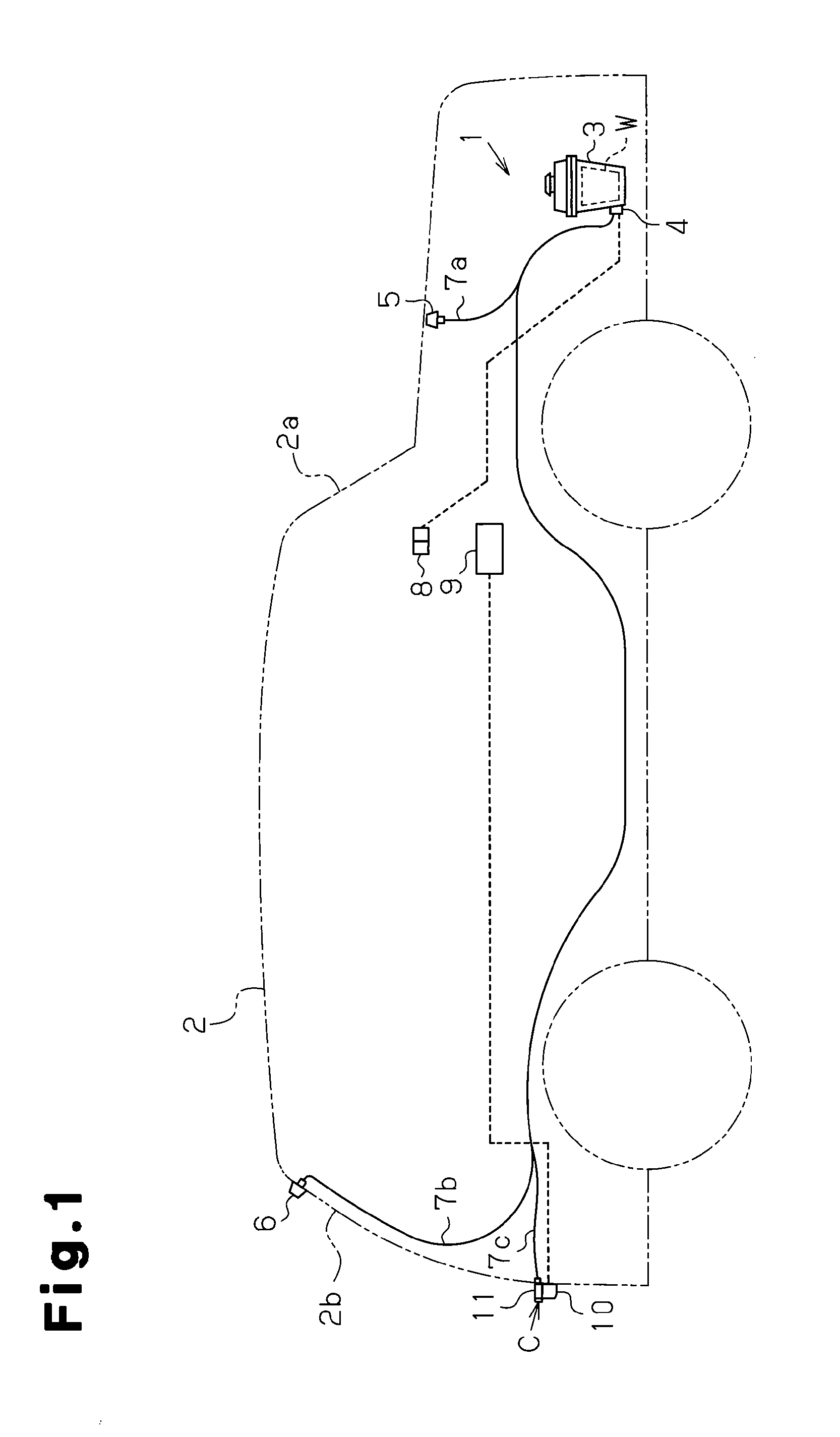

Vehicle wireless charger safety system

ActiveUS20130249682A1Reduce the electromagnetic fieldAnti-theft devicesPropulsion by batteries/cellsForeign matterBattery charge

A vehicular charging system is provided that includes a battery and a charger region. The system also includes a wireless charger for generating an electric charging signal in the charger region to charge the battery, and a plurality of sensors located to sense foreign objects and living beings in proximity to the charger region. The system further includes a controller for controlling the charger to at least reduce the charging signal when a foreign object or a living being is in proximity to the charger region. The controller may be configured to terminate the charging signal and / or activate an alarm element when a foreign object or a living being is in proximity to the charger region.

Owner:FORD GLOBAL TECH LLC

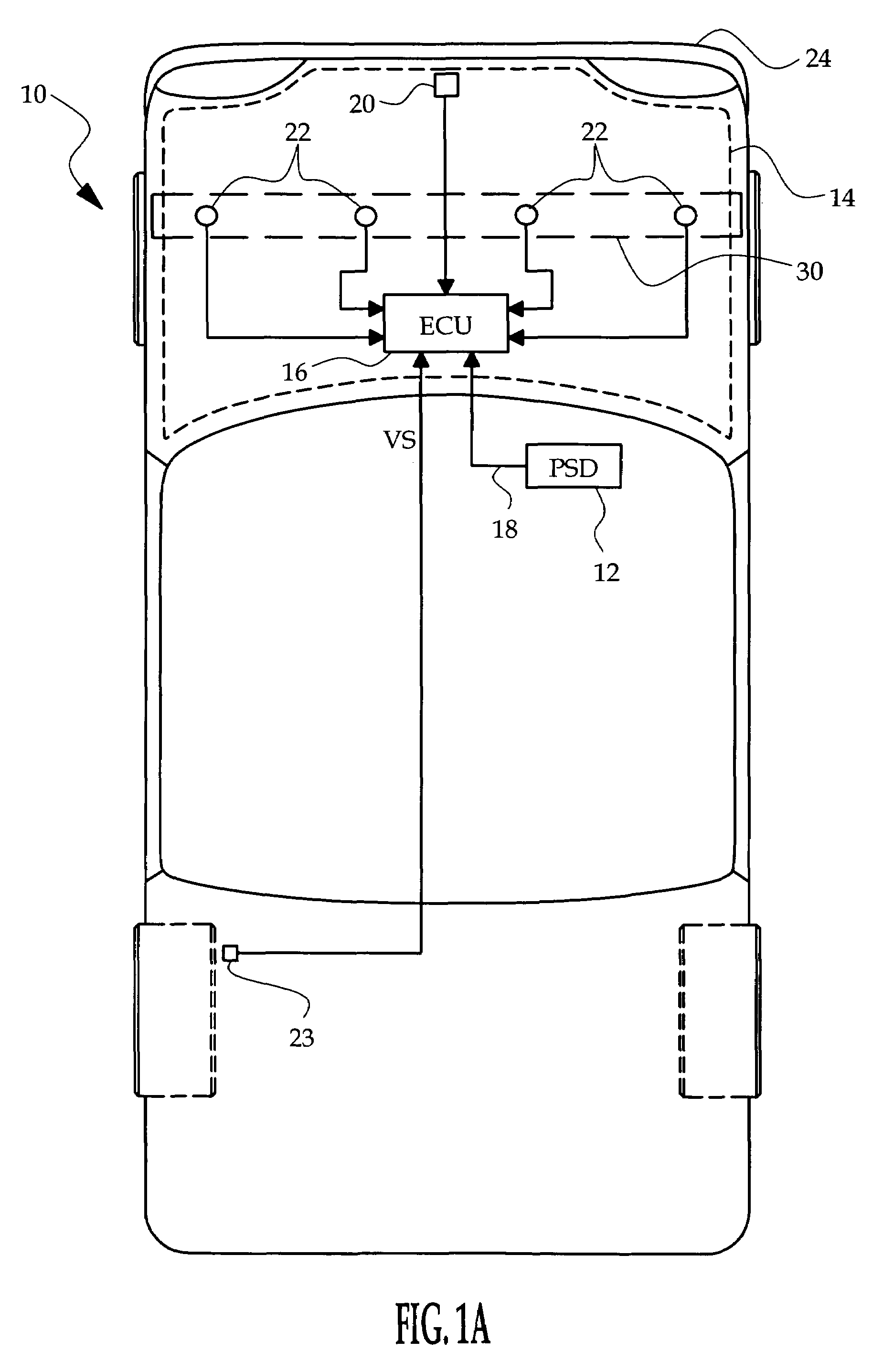

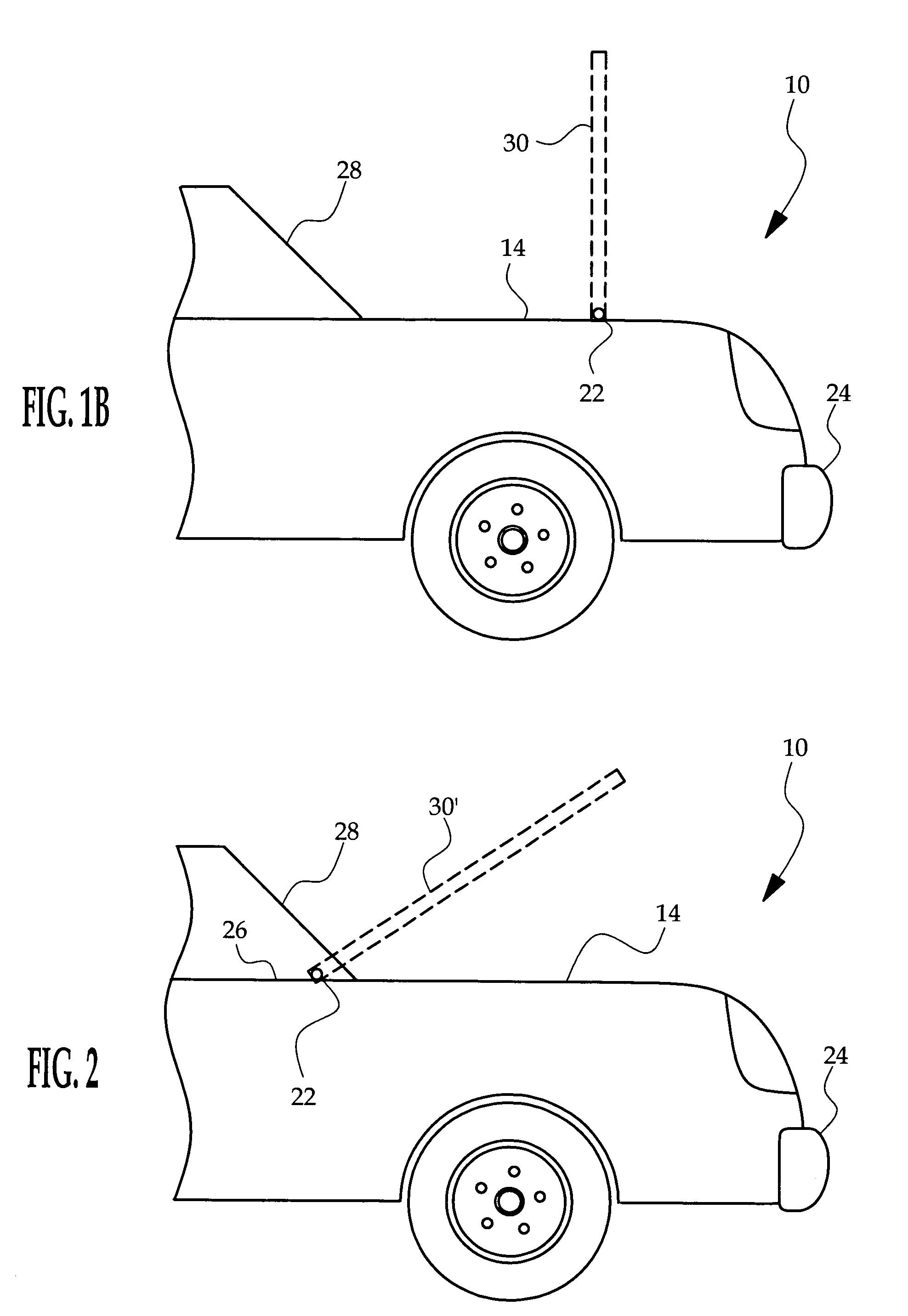

Vehicle sensing method for detecting a pedestrian impact

ActiveUS7380633B2Digital data processing detailsPedestrian/occupant safety arrangementForeign matterEngineering

The collision of a vehicle with a pedestrian is detected by the presence of a foreign object in a sensing zone above the hood of the vehicle within a prescribed time of an initial impact with the bumper of the vehicle. The initial impact is detected with an acceleration sensor disposed in or near the front bumper and the sensing zone is defined by object detection sensors disposed on the hood or behind the windshield of the vehicle. Vehicle speed is used to discriminate against events that occur while the vehicle is stationary or moving very slowly.

Owner:CARRUM TECH LLC

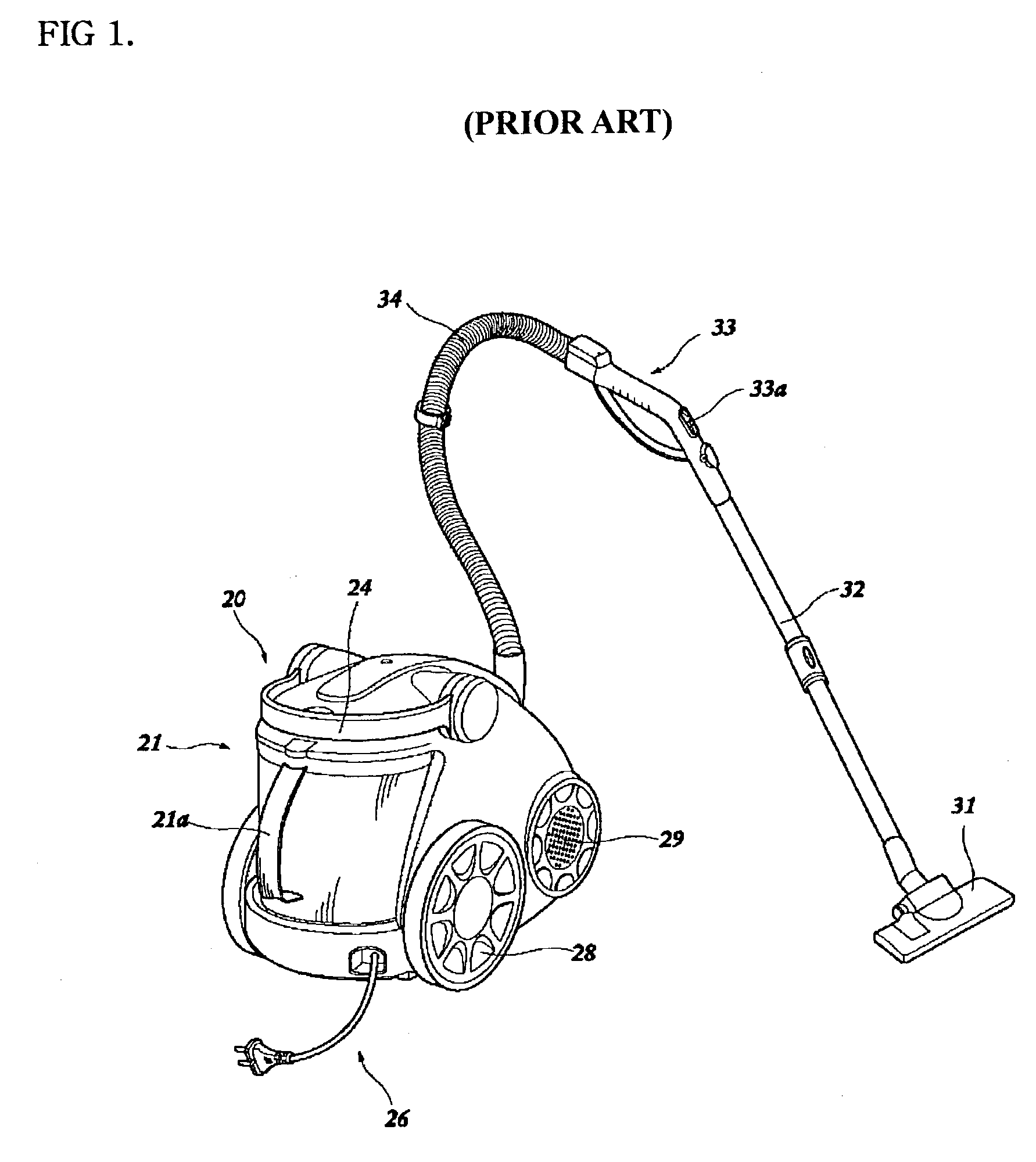

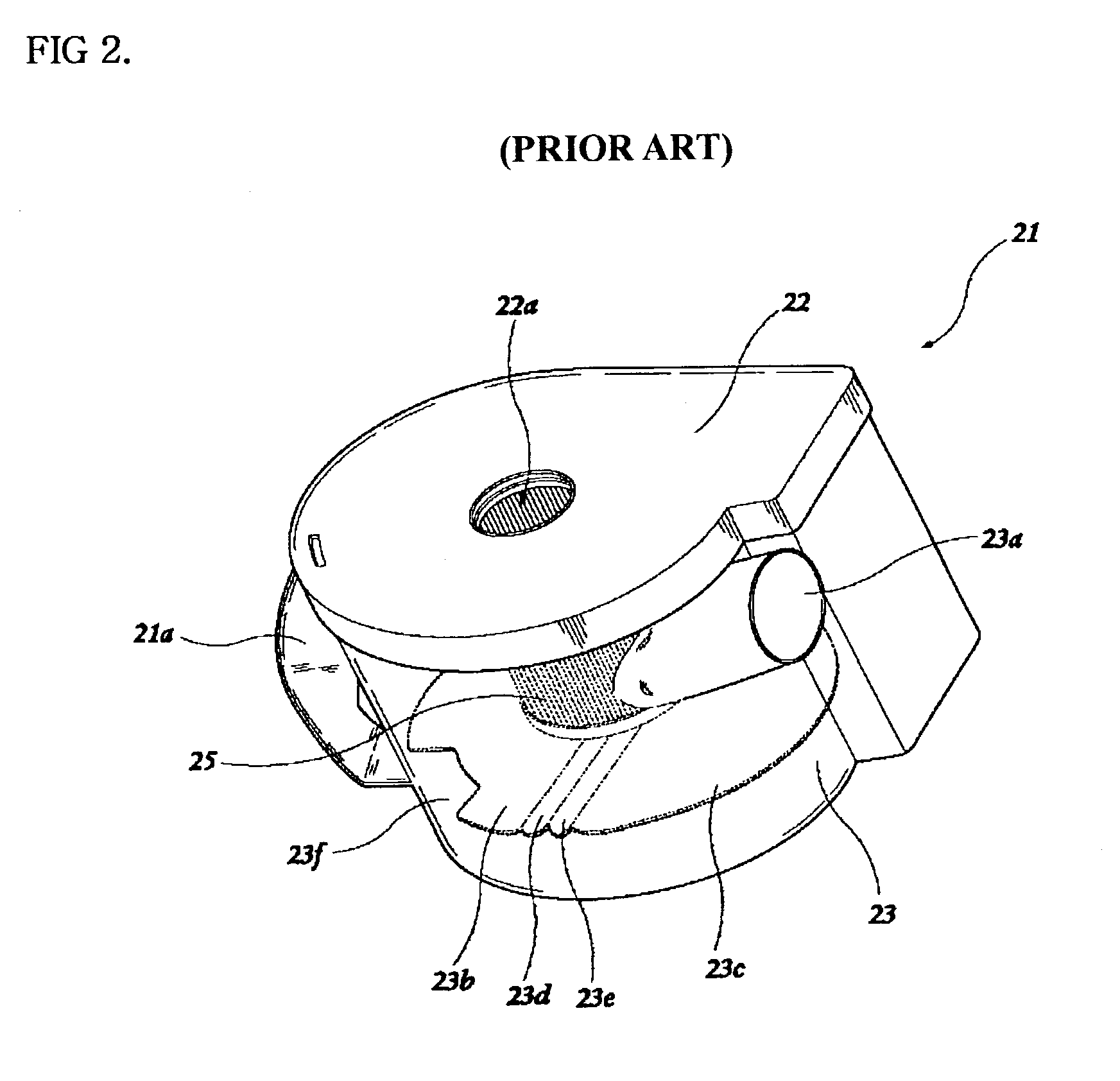

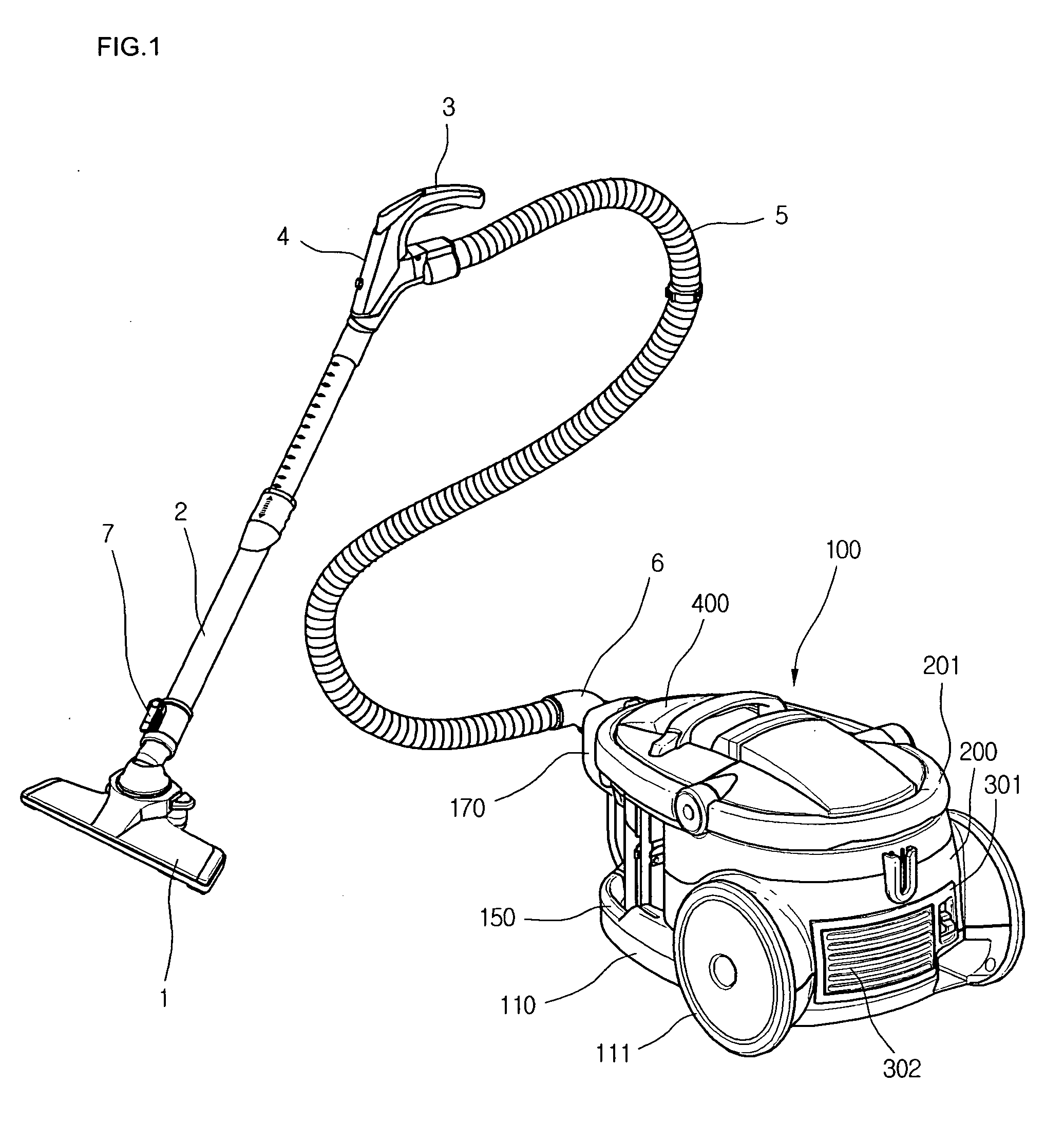

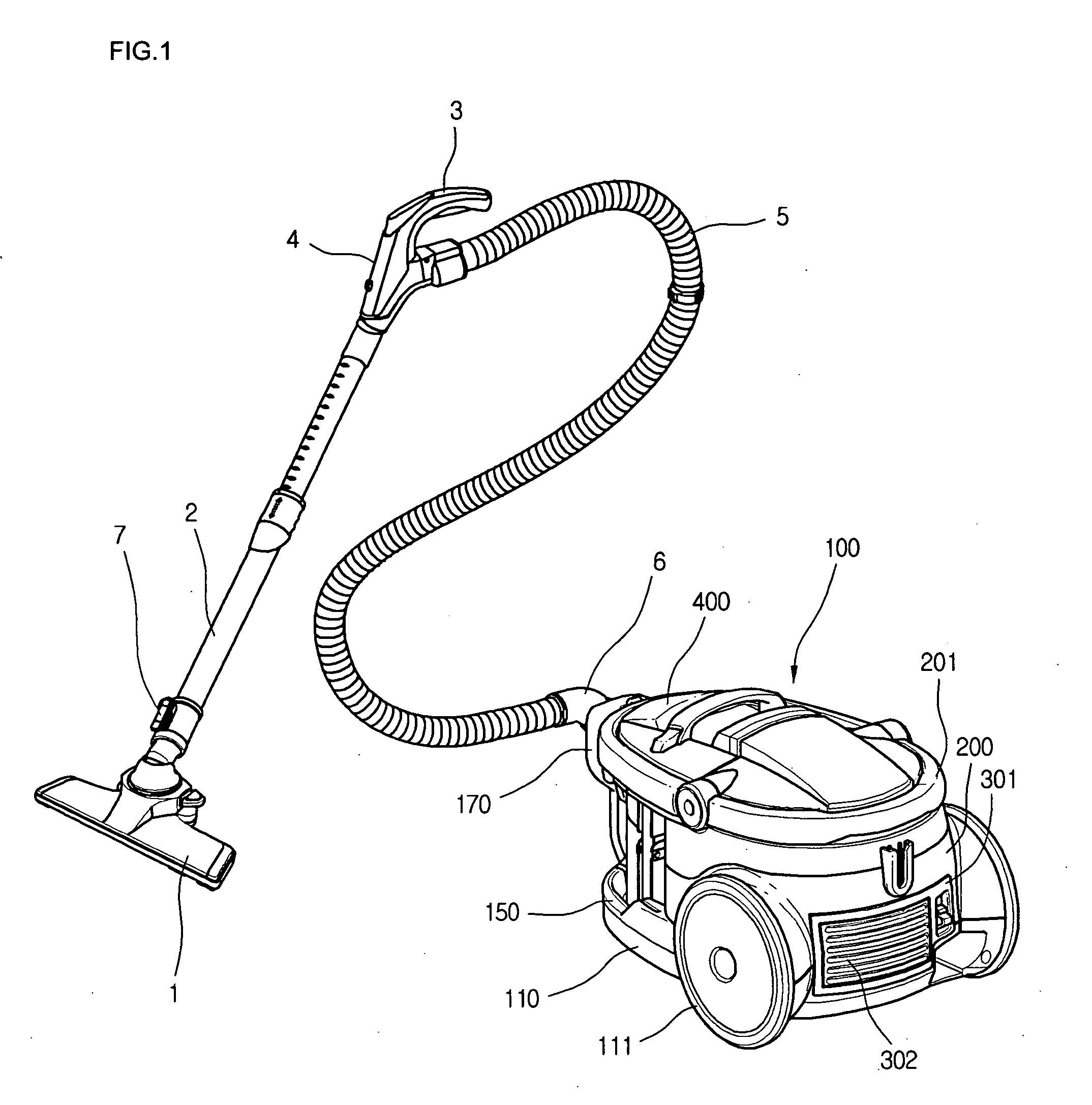

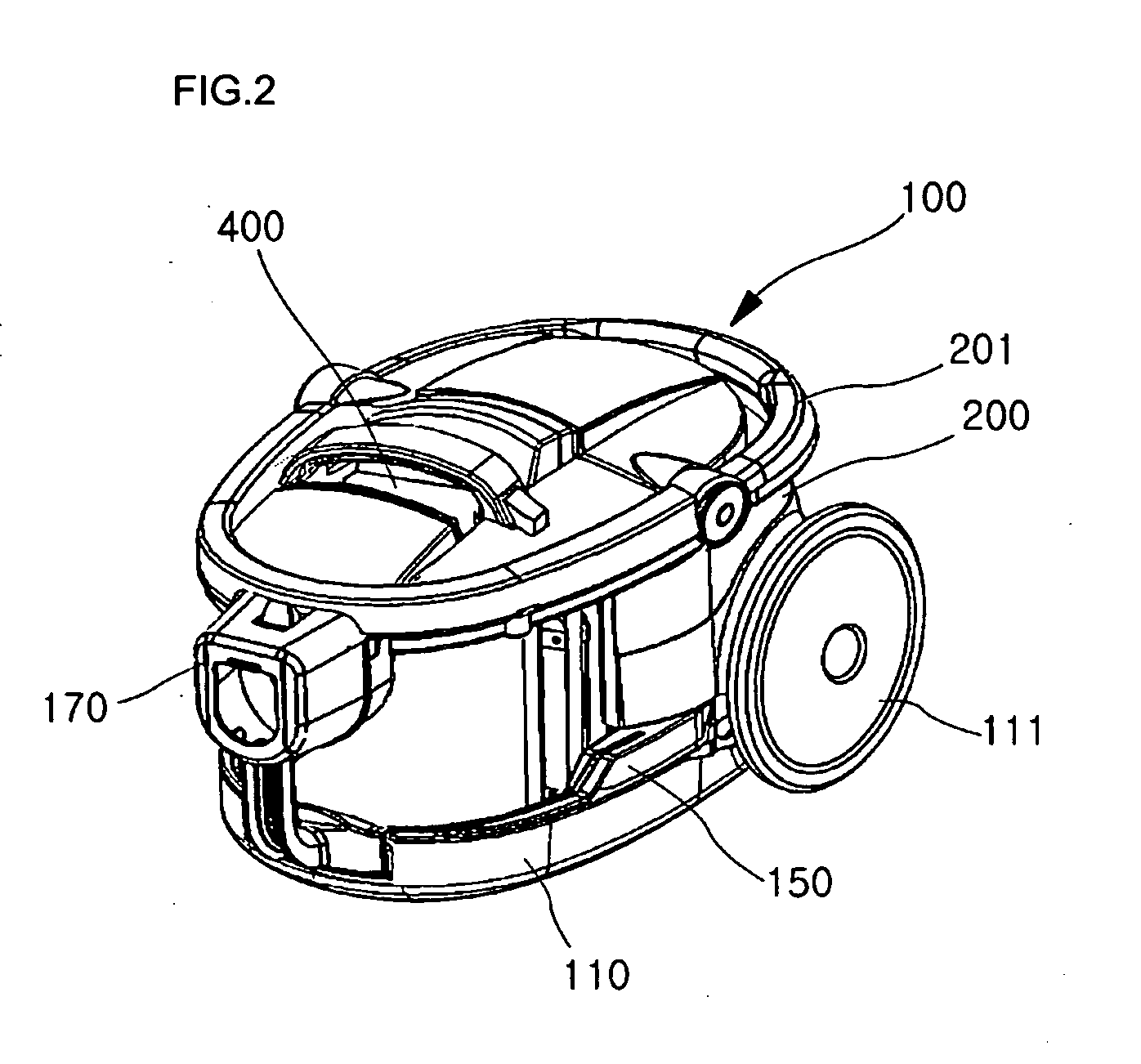

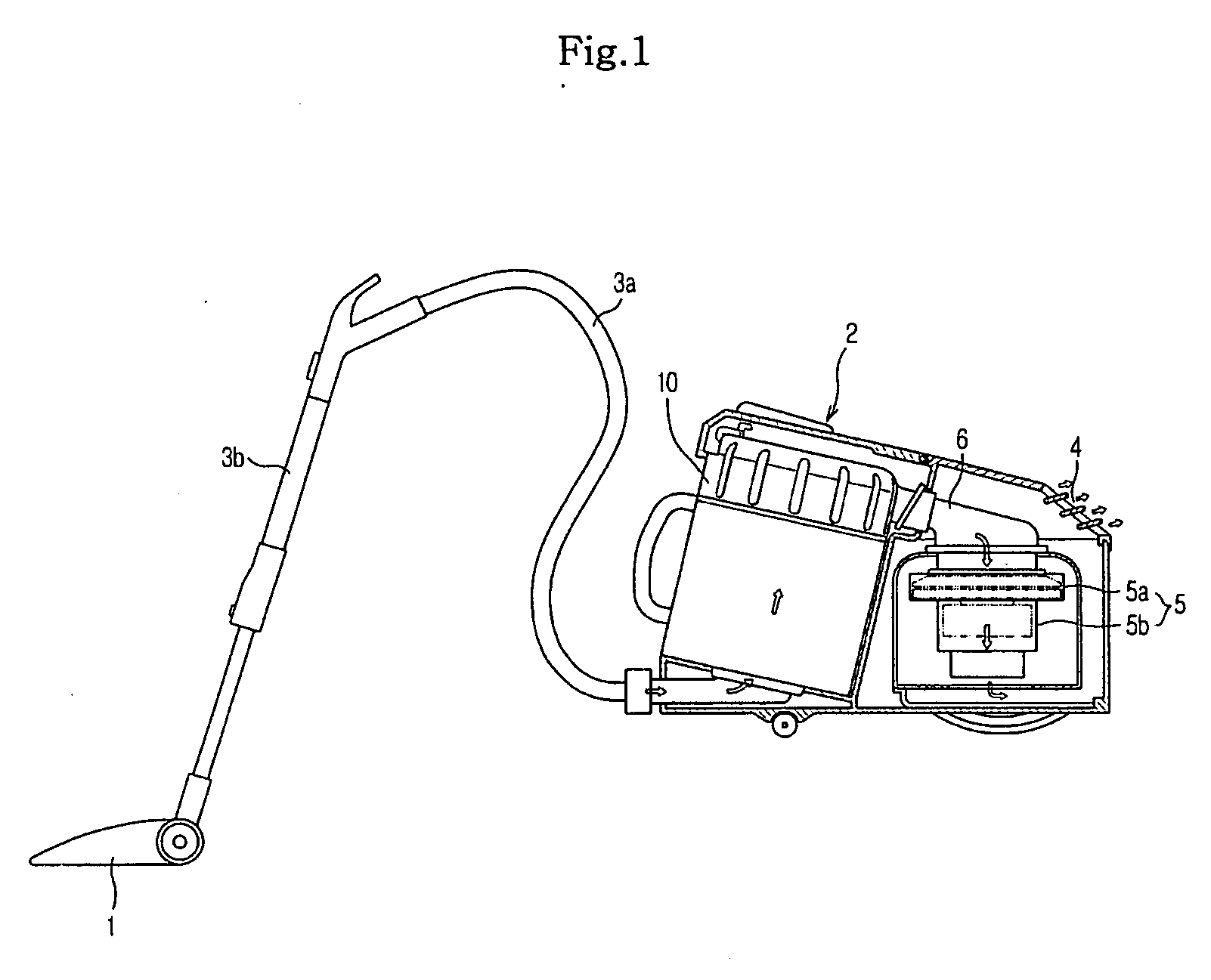

Multi cyclone vacuum cleaner

InactiveUS6840972B1Maximize capacityEasy to discardCombination devicesAuxillary pretreatmentCycloneForeign matter

The disclosure is directed to a cyclone dust collector for separating air from dusts by way of a centrifugal force and, more particularly, to a novel canister type vacuum cleaner capable of using a dual cyclone dust collector with maximized allowable dust capacity. The entire structure of the vacuum cleaner as suggested herein is configured for the user's simple manipulation in discarding various foreign matters collected in the vacuum cleaner, thereby improving reliability to the user.

Owner:LG ELECTRONICS INC

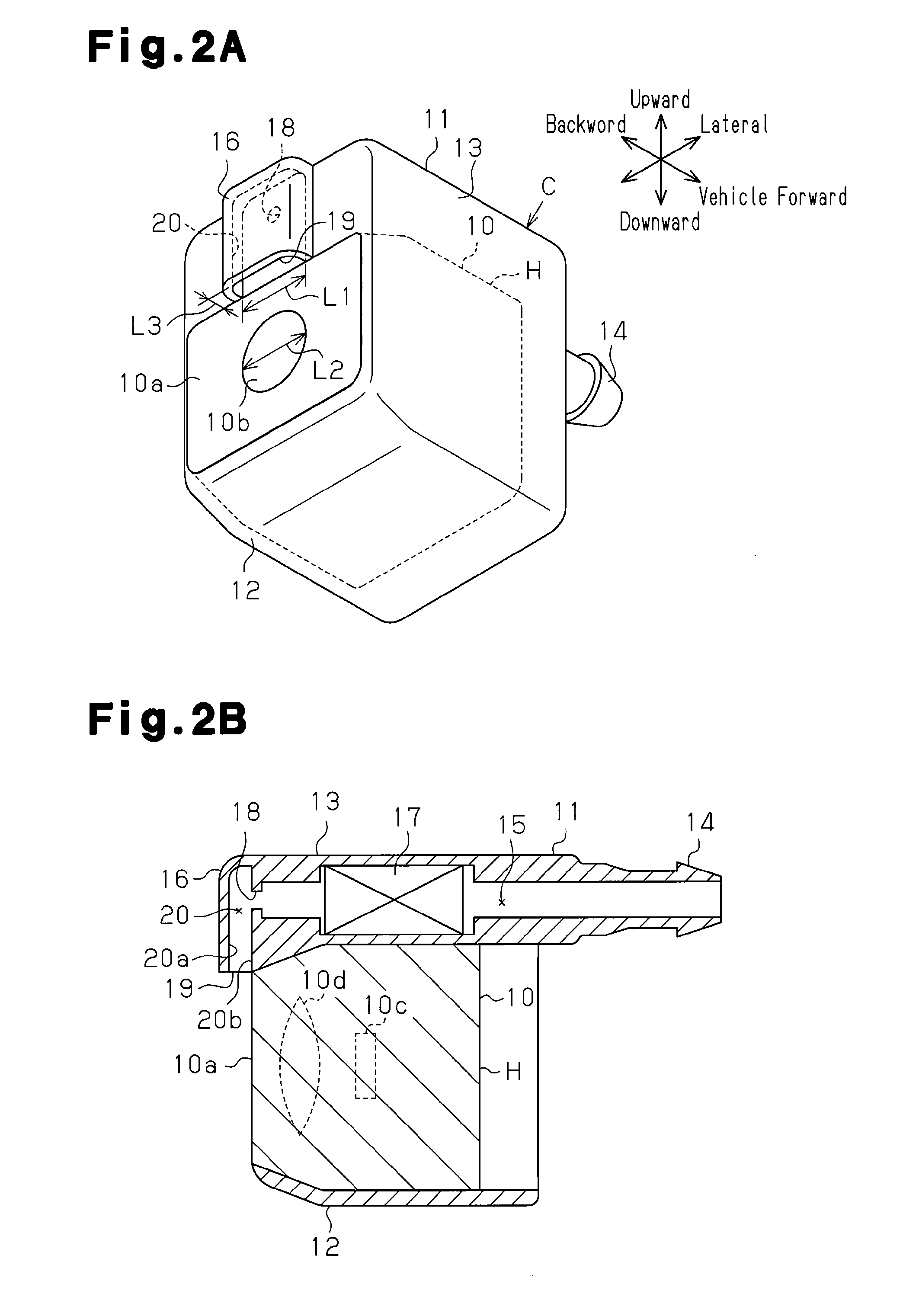

Washer nozzle for vehicle mounted camera, vehicle mounted camera, and washer device for vehicle

InactiveUS20110292212A1Reliable washingAvoid flowSpray nozzlesColor television detailsForeign matterOnboard camera

A washer nozzle removes foreign matter on an image capturing surface of a camera mounted to the outside of a vehicle by supplying washer fluid to the image capturing surface. The washer nozzle includes an inside spray hole and a discharge portion. The inside spray hole sprays the washer fluid introduced into the washer nozzle. The discharge portion receives washer fluid sprayed from the inside spray hole. The discharge portion has a passage extending in a direction intersecting the spray direction of the washer fluid and a discharge port connected to the passage. The discharge portion discharges, from the discharge port, washer fluid sprayed from the inside spray hole along the image capturing surface, while filling the passage with the washer fluid, thereby washing the image capturing surface.

Owner:ASMO CO LTD

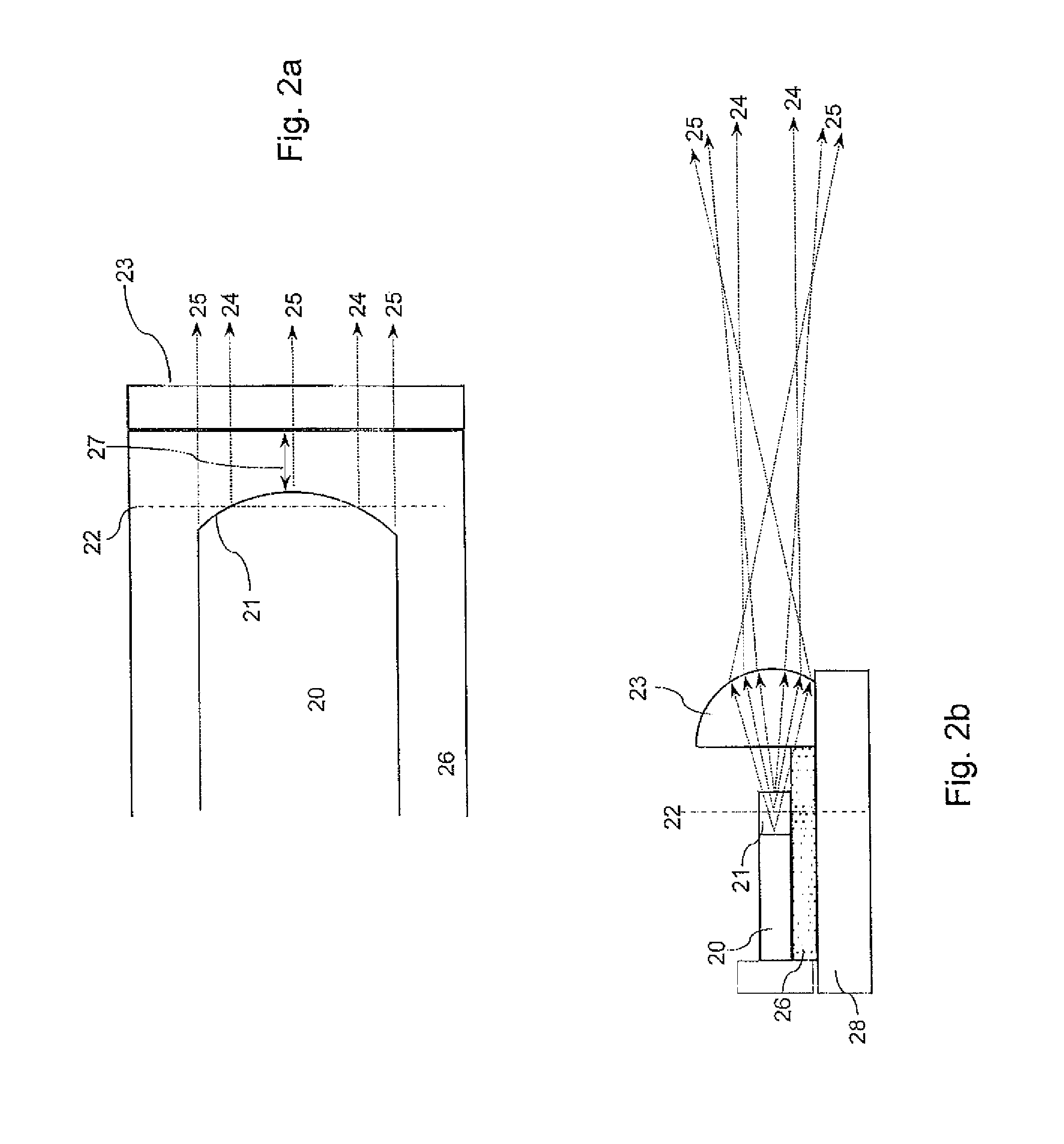

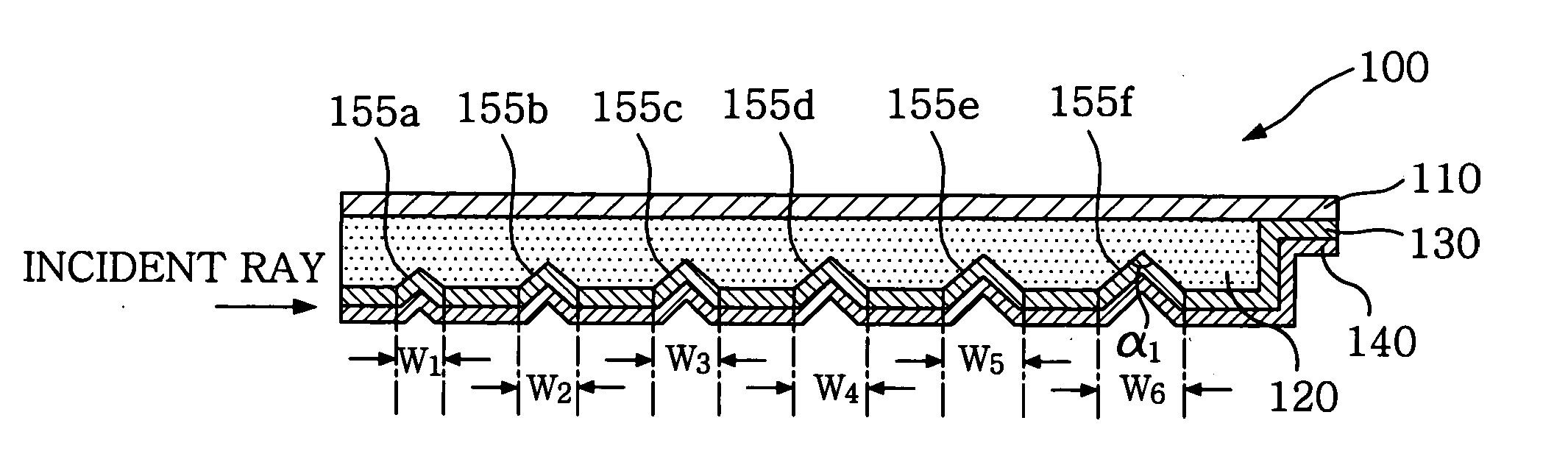

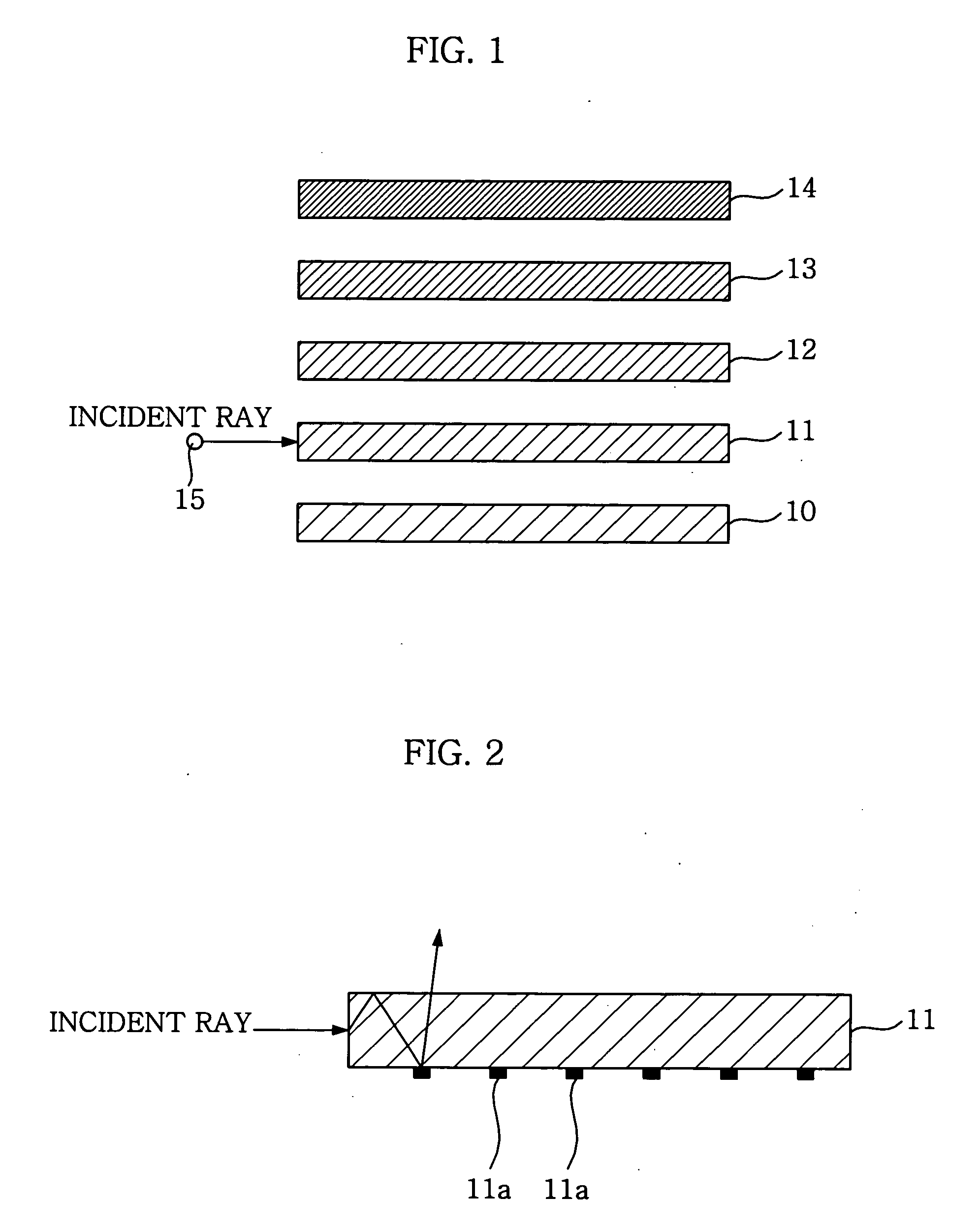

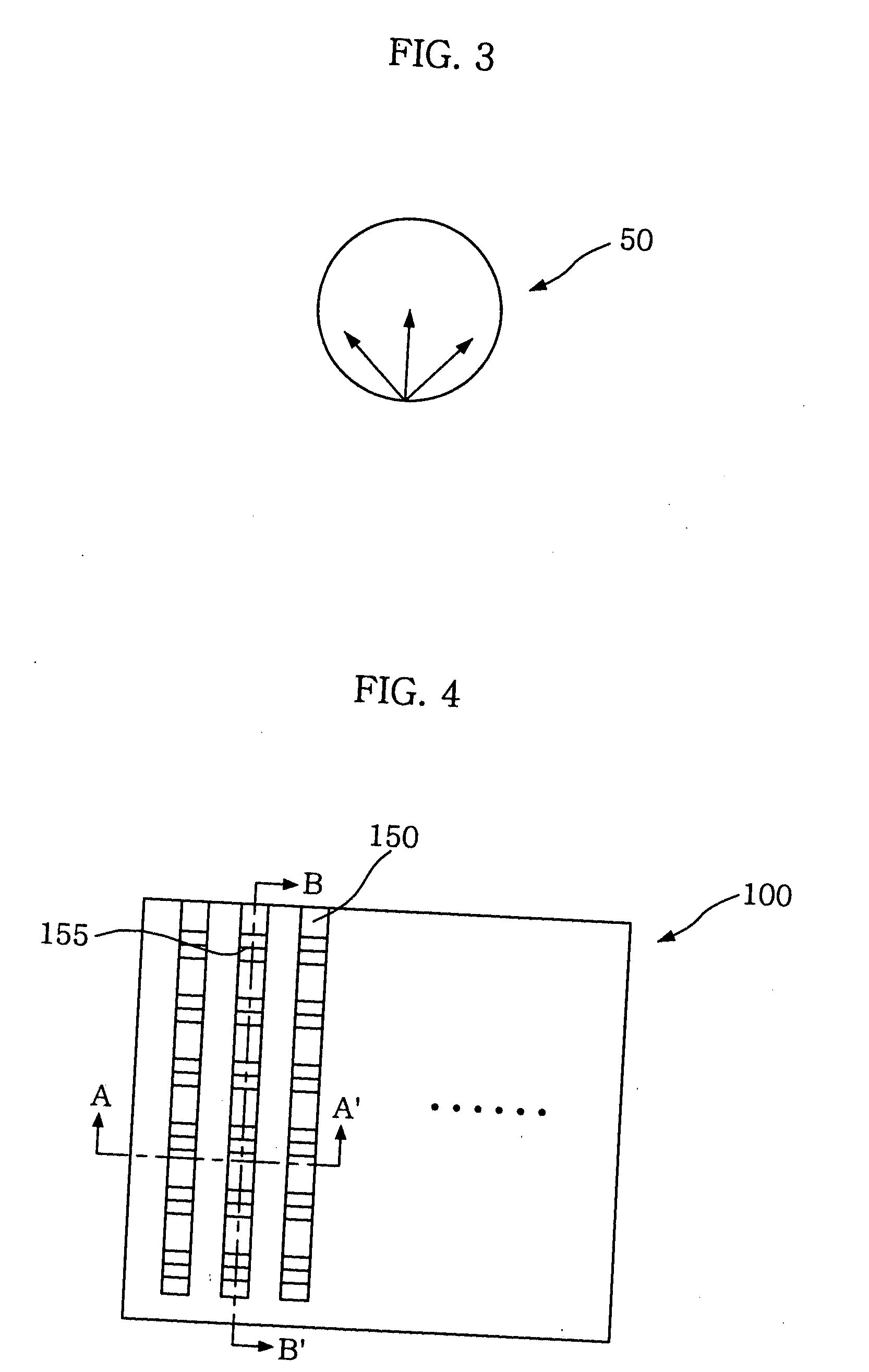

Light guide plate for surface light-emitting device and method of manufacturing the same

InactiveUS20060002675A1Reduce manufacturing costPlanar/plate-like light guidesOptical waveguide light guideForeign matterLight guide

A light guide plate for a surface light-emitting device and a method of manufacturing the same are disclosed wherein the light guide plate is constructed in the form of an optical waveguide including an upper cladding film, core films formed with V-cut grooves, and a lower cladding film, so that since the upper and lower cladding films with a relatively low refractive index are respectively located on upper and lower surfaces of the core films, external foreign substances cannot penetrate into the core films, and the core films are not brought into contact with other components, whereby optical transmission properties are not changed and brightness can be also enhanced, and since the V-cut grooves are formed or both the V-cut grooves and optical waveguides are formed at the same time by means of a simple hot embossing process, the manufacturing costs can be saved.

Owner:LG ELECTRONICS INC

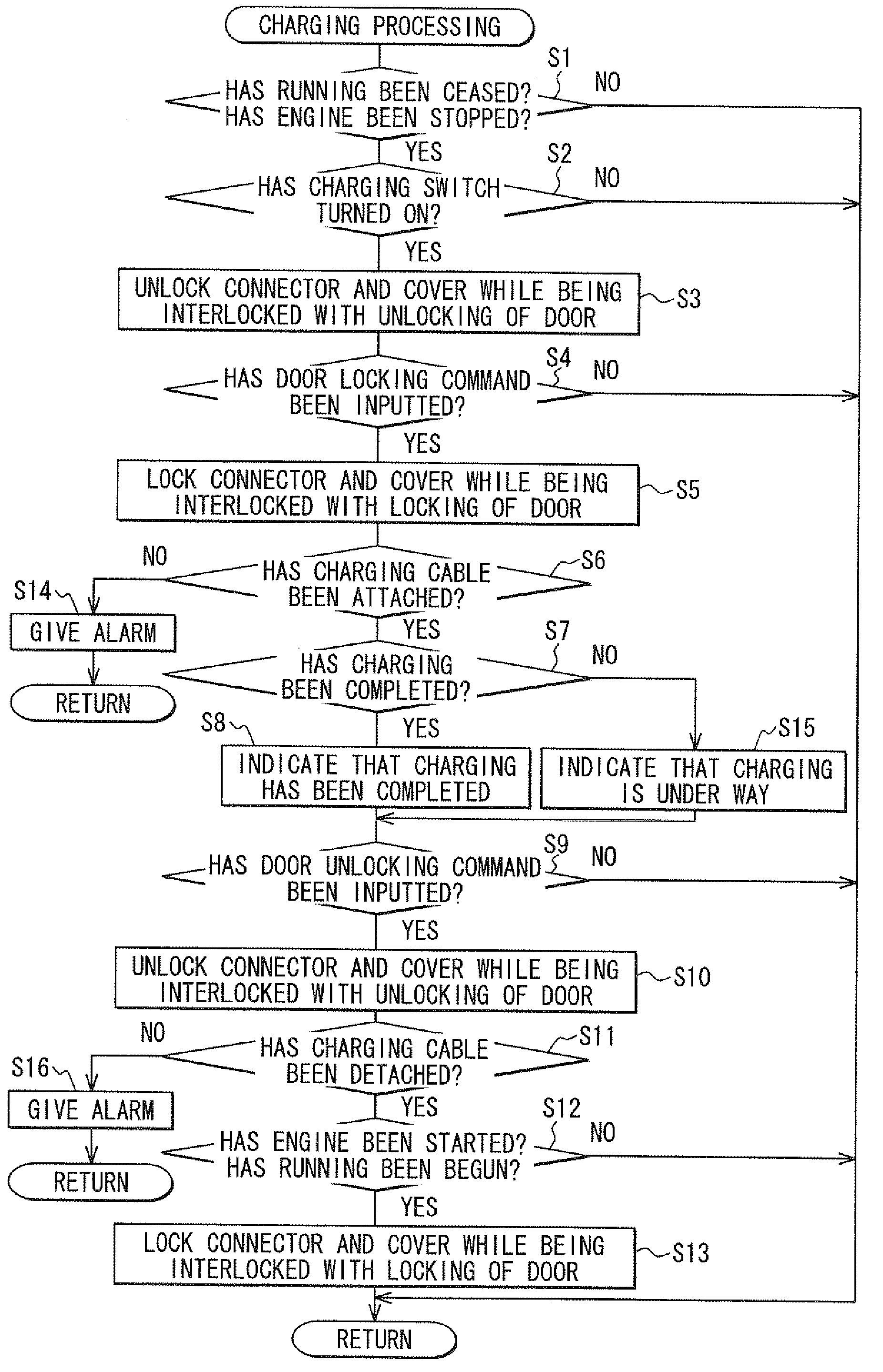

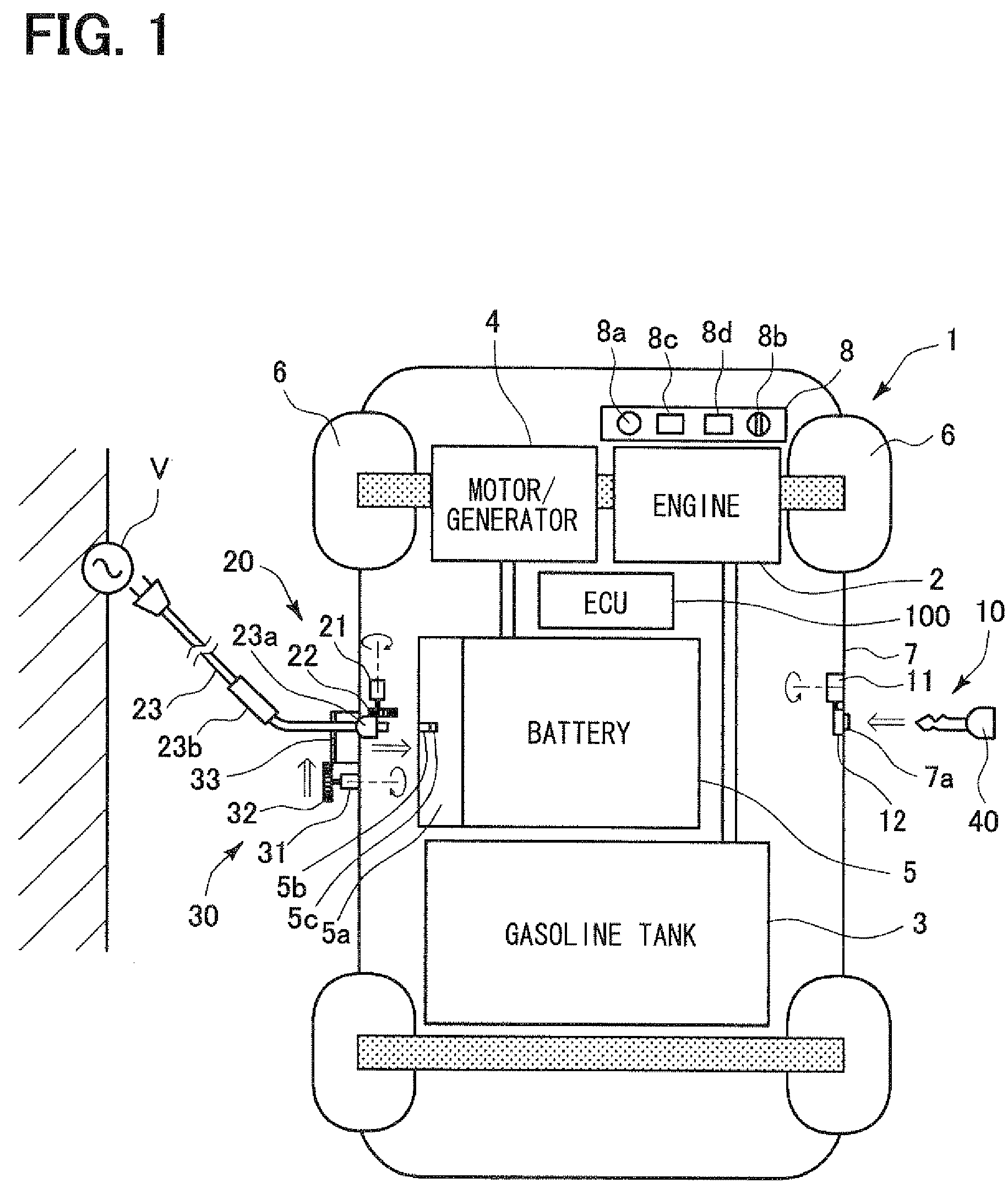

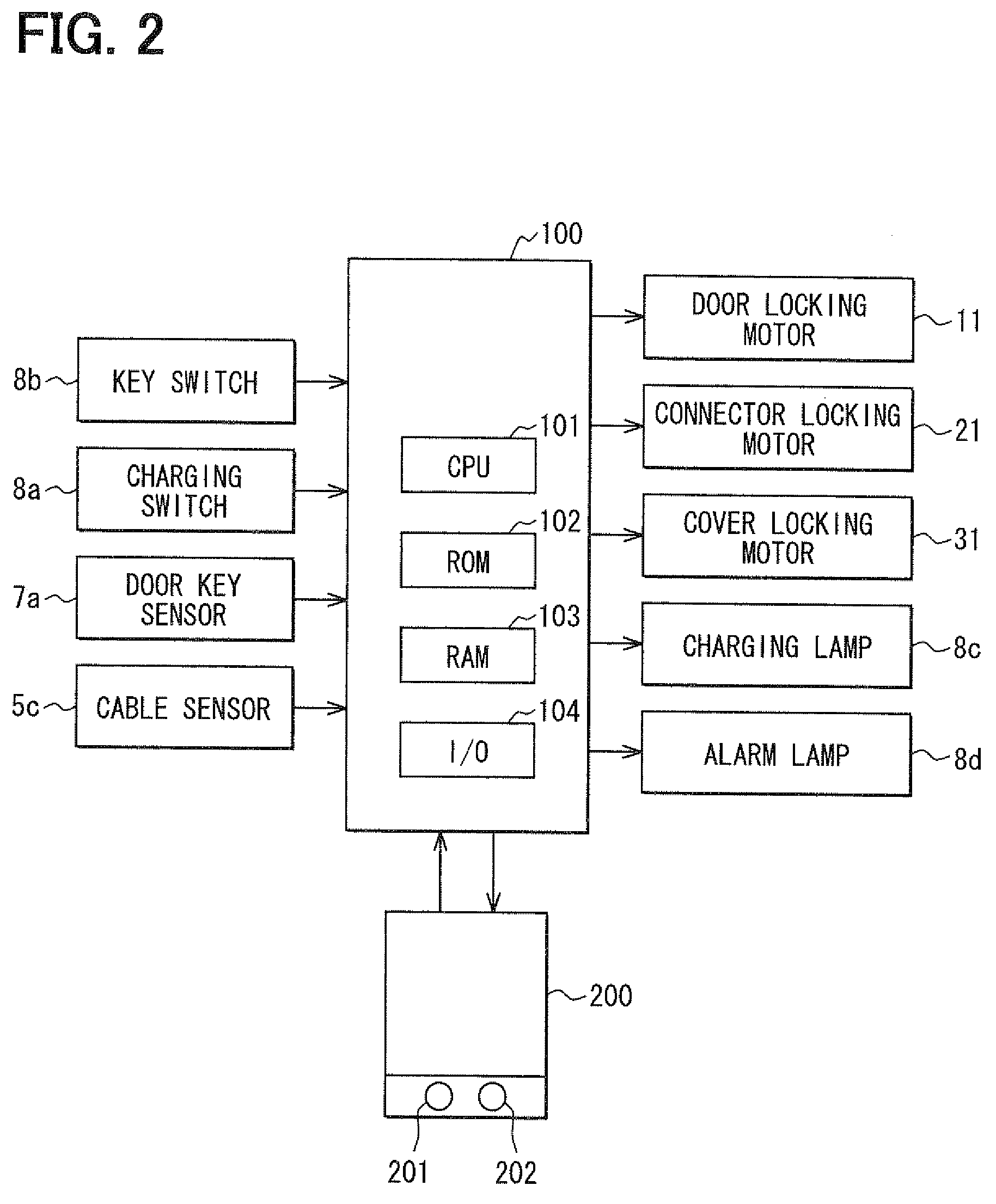

Charging system for vehicles

InactiveUS20090082916A1Avoid it happening againEasy to provideDigital data processing detailsBuilding locksForeign matterLocking mechanism

A charging system provided for vehicles prevents theft of a charging cable, insertion of foreign matter into a vehicle-side receptacle, or tampering when an onboard battery usable for running power is charged from a household power supply. A cable connector of the charging cable is opposed to the vehicle-side receptacle in a connecting part to prepare for charging. When a PHV is exited, a switching command switching from an unlocked state of a door locking mechanism to a locked state is inputted to a PHV ECU responsive to an inputting manipulation performed on a key or door key sensor. The PHV ECU allows the door locking mechanism to switch from the unlocked state to the locked state. The PHV ECU allows locking mechanisms to switch from the unlocked states to the locked states in the manner interlocked with the switching action of the door locking mechanism.

Owner:DENSO CORP

Dust collection unit for vacuum cleaner

InactiveUS20060137305A1Avoid problemsAvoid dirtyCombination devicesAuxillary pretreatmentForeign matterForeign object

Provided is a dust collection unit for a vacuum cleaner that can provide an improved collection efficiency, a reduced reduce, and a good outer appearance. The dust collection unit includes: a first filtering chamber for filtering first foreign objects; a plurality of second filtering chambers formed along an outer circumference of the first filtering chamber to receive air passed through the first filtering chamber and filter second foreign objects by using cyclone airflow, the second foreign objects being smaller than the first foreign objects; an air intake hole through which air is introduced into the second filtering chambers; at least one air introduction guide extended outward from the air intake hole to guide a flow of air introduced into the second filtering chamber; and a storing chamber formed under the filtering chamber.

Owner:LG ELECTRONICS INC

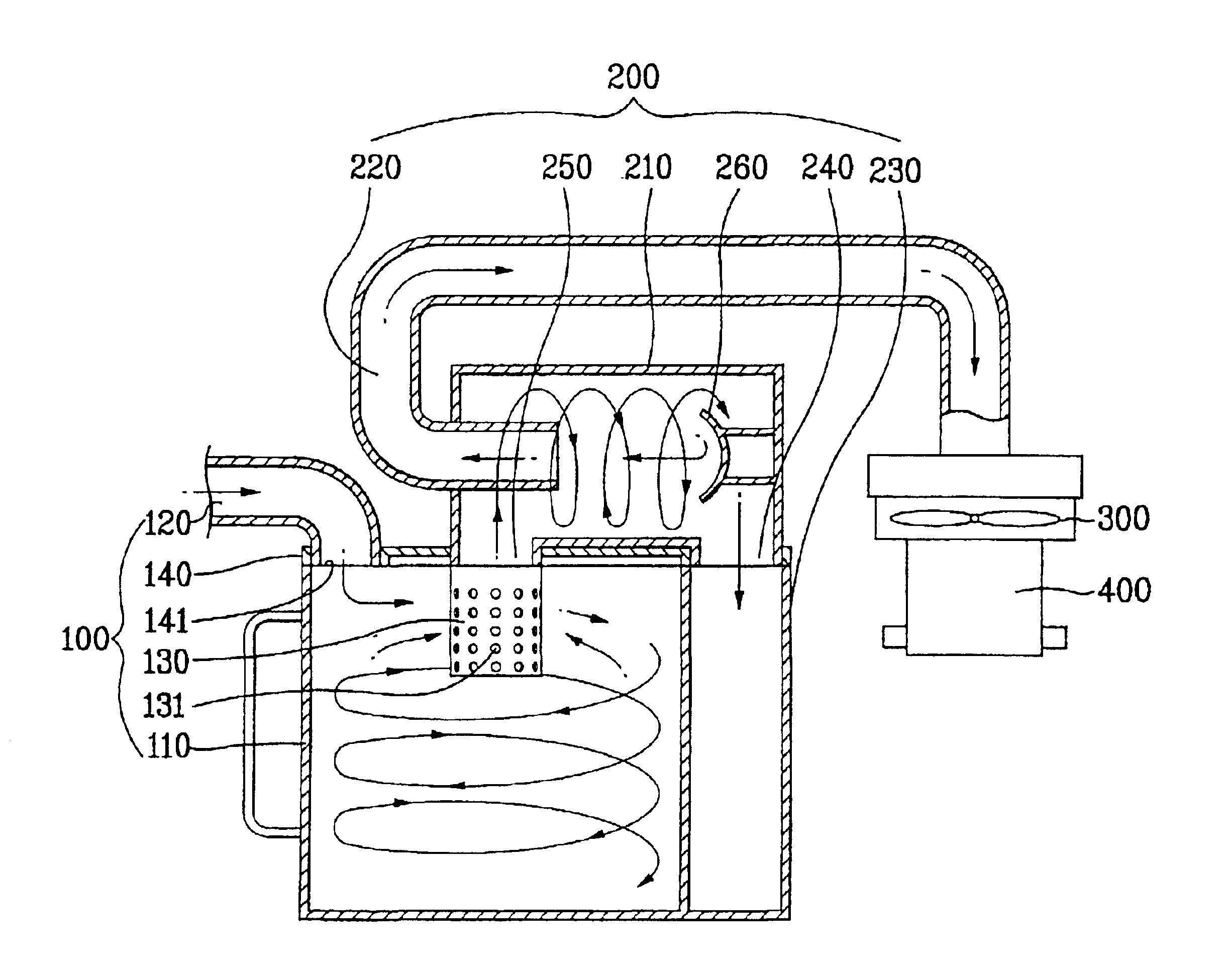

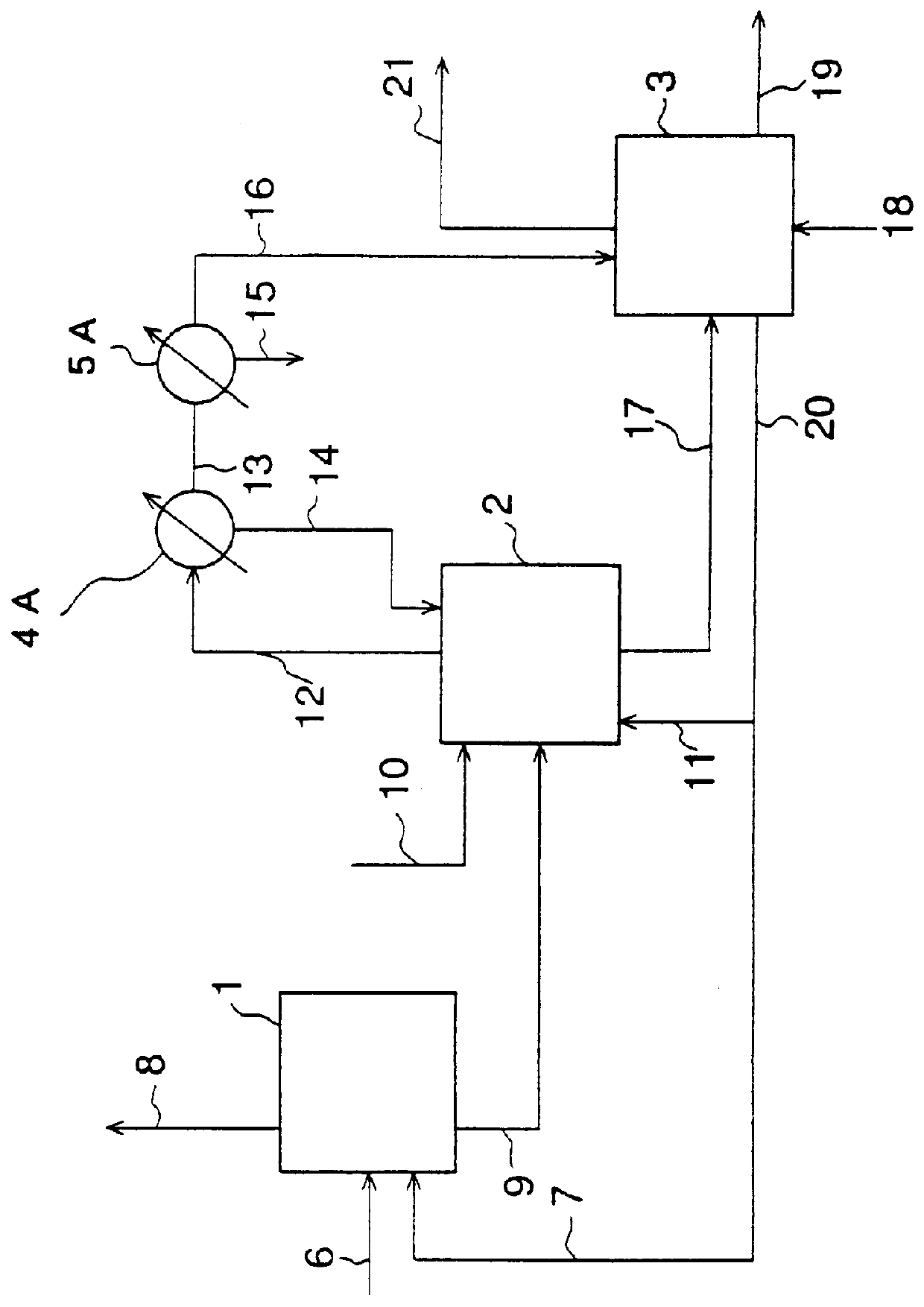

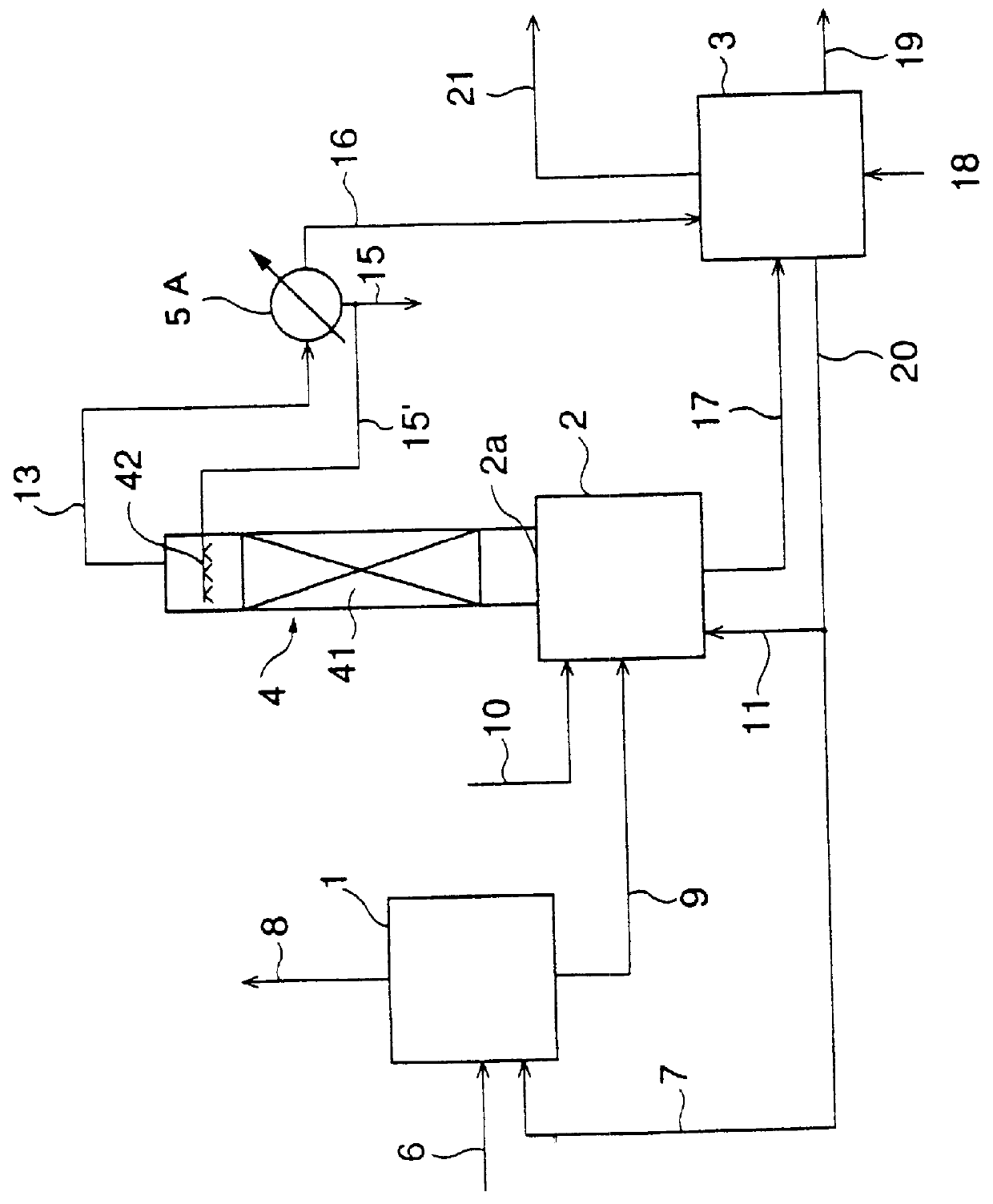

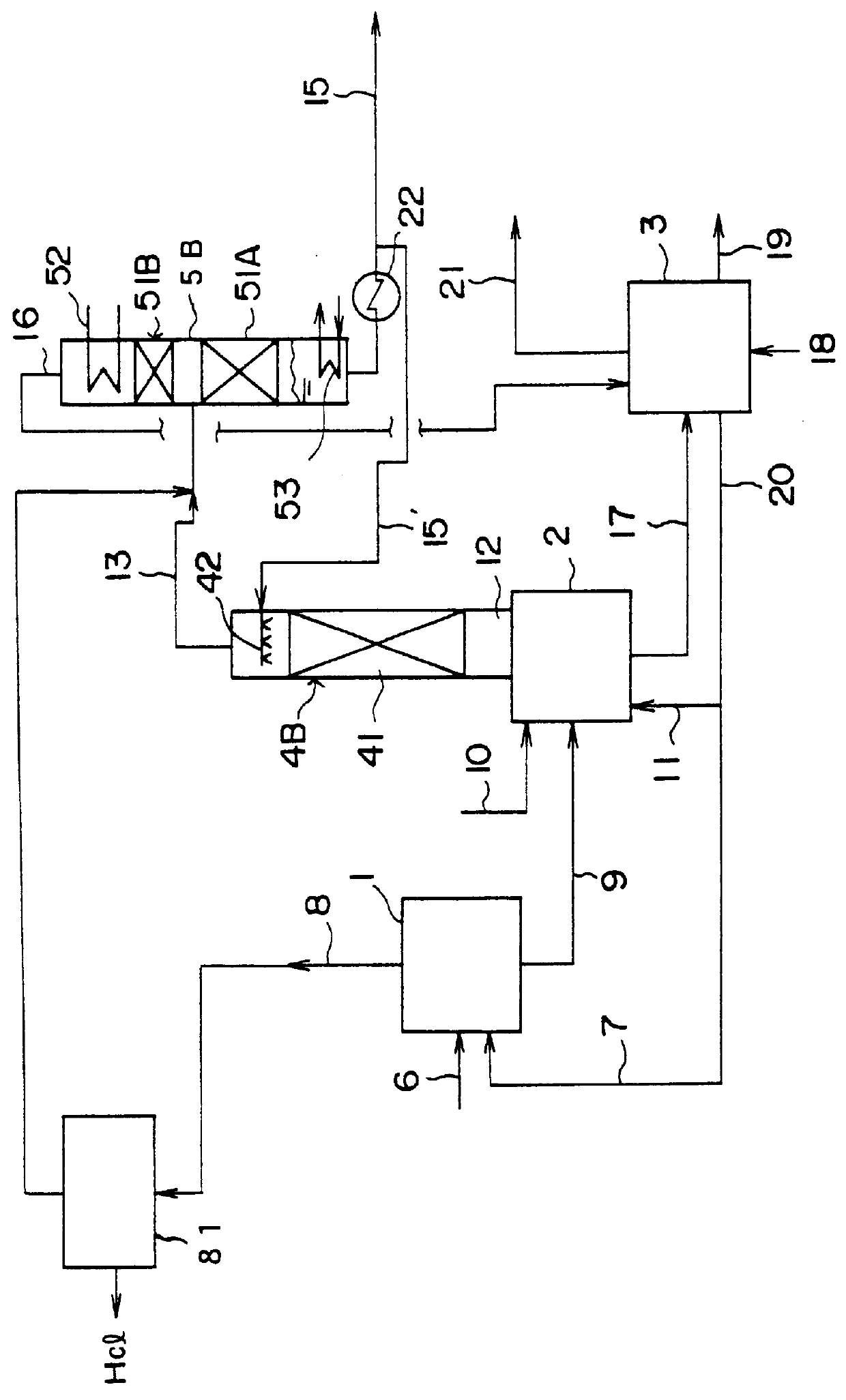

Method and apparatus for reclaiming oil from waste plastic

InactiveUS6011187AIncrease productionContinuous operationPlastic recyclingIndirect and direct heating destructive distillationForeign matterBoiling point

PCT No. PCT / JP97 / 00572 Sec. 371 Date Jan. 8, 1998 Sec. 102(e) Date Jan. 8, 1998 PCT Filed Feb. 27, 1997 PCT Pub. No. WO97 / 31990 PCT Pub. Date Sep. 4, 1997This invention provides a method for reclaiming oil from waste plastic in such a way that thermosetting resins and solid foreign matter in the plastic will not pose a problem. This method greatly reduces the burden of presorting the garbage or industrial waste. To achieve this objective when oil is to be reclaimed from a waste plastic containing chlorine compounds, such as vinyl chloride, the plastic must first be stripped of chlorine. Prior to pyrolysis, while being conveyed forward in a continuous stream, the plastic is mixed with heated sand and / or an additive agent to raise its temperature to 250-350 DEG C. This creates a product which is comprised of a mixture of sand and substantially dechlorinated plastic. The product is mixed with heated sand to heat it directly to a temperature of 350-500 DEG C. It is maintained at this temperature until pyrolysis occurs. In order to obtain high-quality oil with a low boiling point, a first gas / liquid separation process separates the product obtained from the aforesaid pyrolysis into liquid high-boiling point oil, gaseous low-boiling point oil and low molecular-weight gases, and recirculates the liquid high-boiling point oil to the pyrolysis process, and a second gas / liquid separation process separates the gaseous low-boiling point oil and low molecular-weight gases into liquid low-boiling point oil and low molecular-weight gases. The first and second gas / liquid separation process are connected in sequence.

Owner:MITSUBISHI HEAVY IND LTD

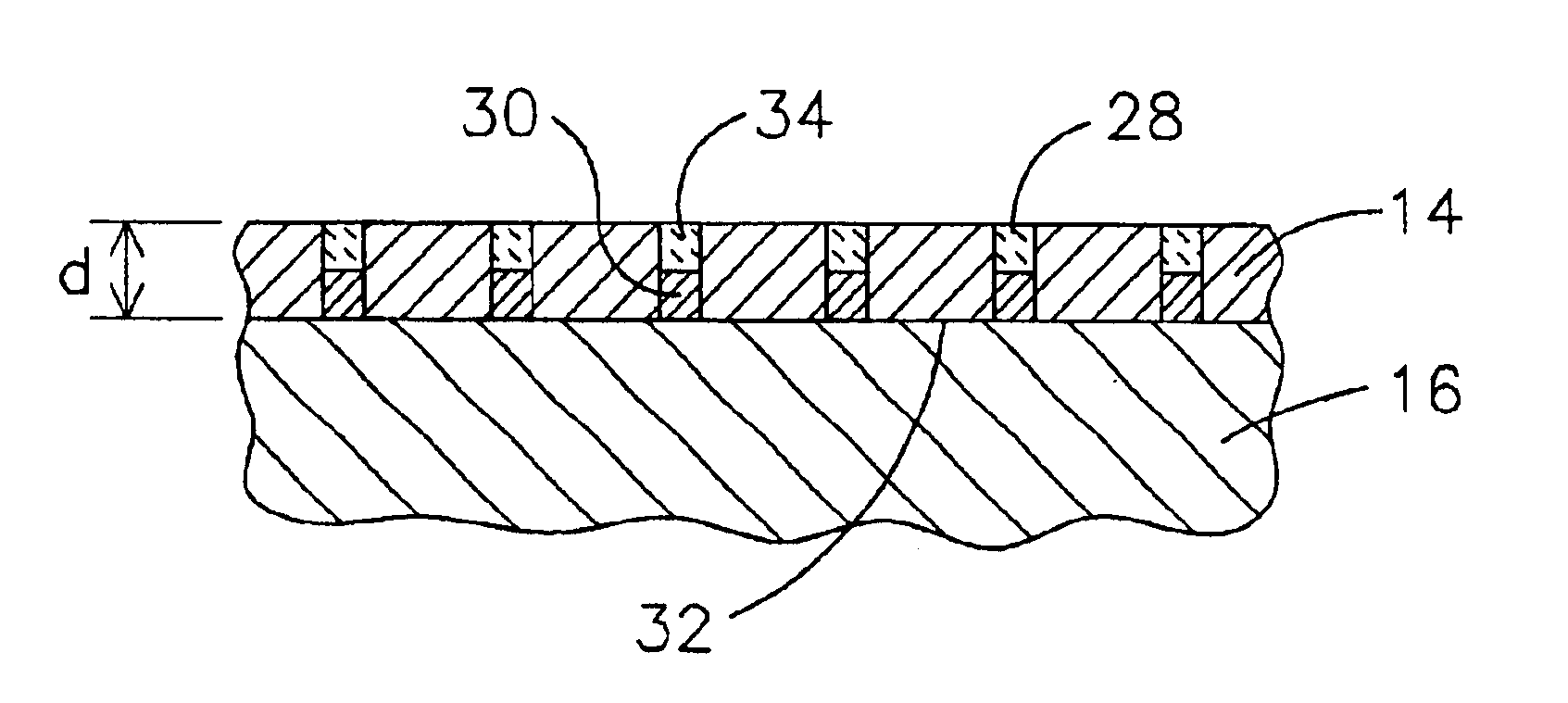

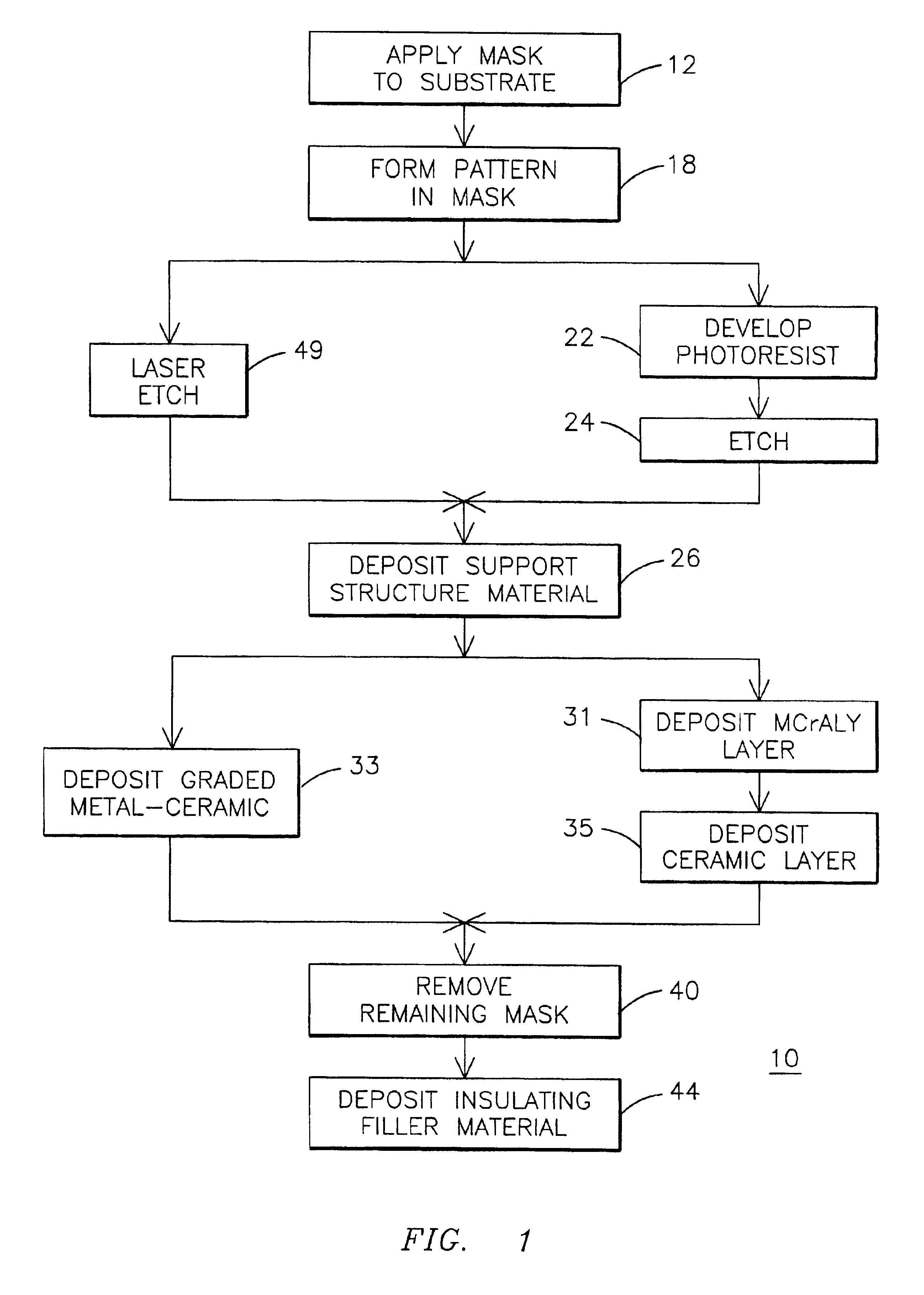

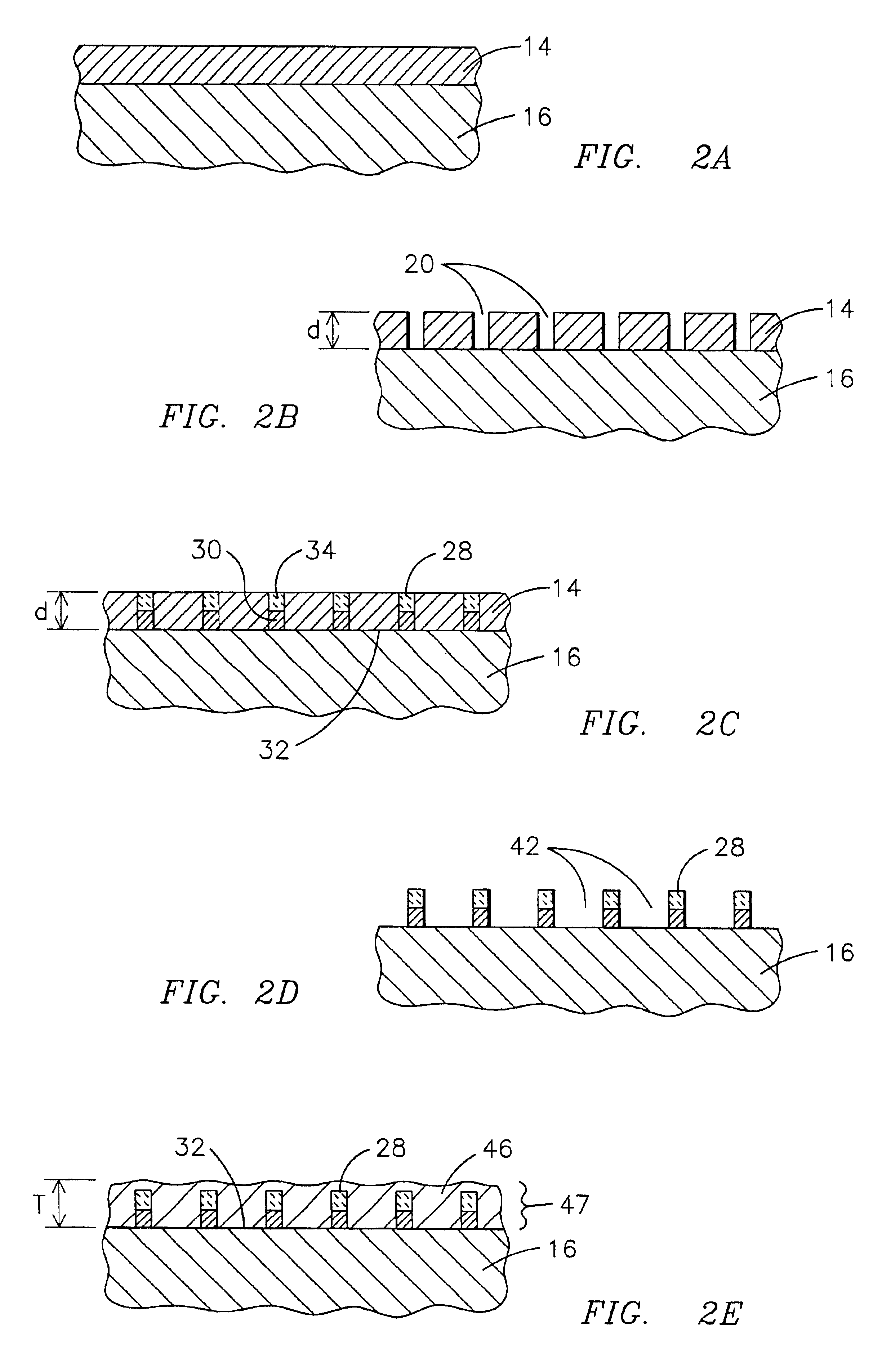

Honeycomb structure thermal barrier coating

InactiveUS6846574B2Minimize heat transfer rateConvenient coatingMolten spray coatingRecord information storageForeign matterLaser etching

A device having an improved thermal barrier coating (46) and a process for manufacturing the same. A support structure (28) for retaining a ceramic insulating material (46) on a substrate (16) is formed by the deposition of a support structure material through a patterned masking material (14). The support structure can define cells into which the ceramic insulating material is deposited following removal of the masking material. The masking material may be patterned by known photolithographic techniques (22,24) or by laser etching (48). The support structure (28) may be a composite metal-ceramic material having either discreet layers (30,34) or a graded composition and may be deposited by an electro-desposition process followed by a heat treatment to form a solid state diffusion bond with the substrate. The ceramic filler material may be deposited (44) by the electrophoretic deposition of ceramic particles coated with a bonding material that is subsequently heated to oxidize and to bond the particles together. The support structure may be provided with included walls in order to improve its resistance to foreign object impact damage.

Owner:SIEMENS ENERGY INC

Cyclonic cleaner

InactiveUS20070144116A1Reduce noiseLow efficiencyDispersed particle separationExhaust-air diffusionForeign matterCyclone

A cyclonic cleaner which includes a cyclone unit enabling a reduction of noise generated from the cyclone unit, and reduction in pressure loss by forming a smooth air flow. The cyclone unit includes a body having an air inlet and an air outlet, a primary cyclone to primarily separate foreign matter from air drawn through the air inlet, a plurality of secondary cyclones to secondarily separate foreign matter from air discharged from the primary cyclone and to discharge the air having the foreign matter removed therefrom through discharge holes of the secondary cyclones, and a noise reduction member positioned in the discharge hole of each secondary cyclone to reduce noise. The cyclone unit also includes a guide plate to allow the air discharged through the discharge holes of the secondary cyclones to be smoothly discharged through the air outlet.

Owner:SAMSUNG ELECTRONICS CO LTD

Union device for dust-box in cyclone type vacuum cleaner

InactiveUS6922868B1Maximize allowable dust collecting capacityCleaning filter meansSuction filtersCycloneForeign matter

Device for fastening a dust box to a cyclone vacuum cleaner, including an accommodating part having a space in a body of the cyclone vacuum cleaner, a dust box mounted in the accommodating part selectively, for collecting various foreign matters separated from air, and fastening means for moving the dust box in the accommodating part in up and down directions selectively for putting, or taking the dust box into / out of the accommodating part, whereby permitting smooth putting in and taking out the dust box with simple operation, and preventing escape of various foreign matters from the dust box during putting or taking the dust box in / out of the cleaner.

Owner:LG ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com