Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

223results about How to "Avoid processing quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

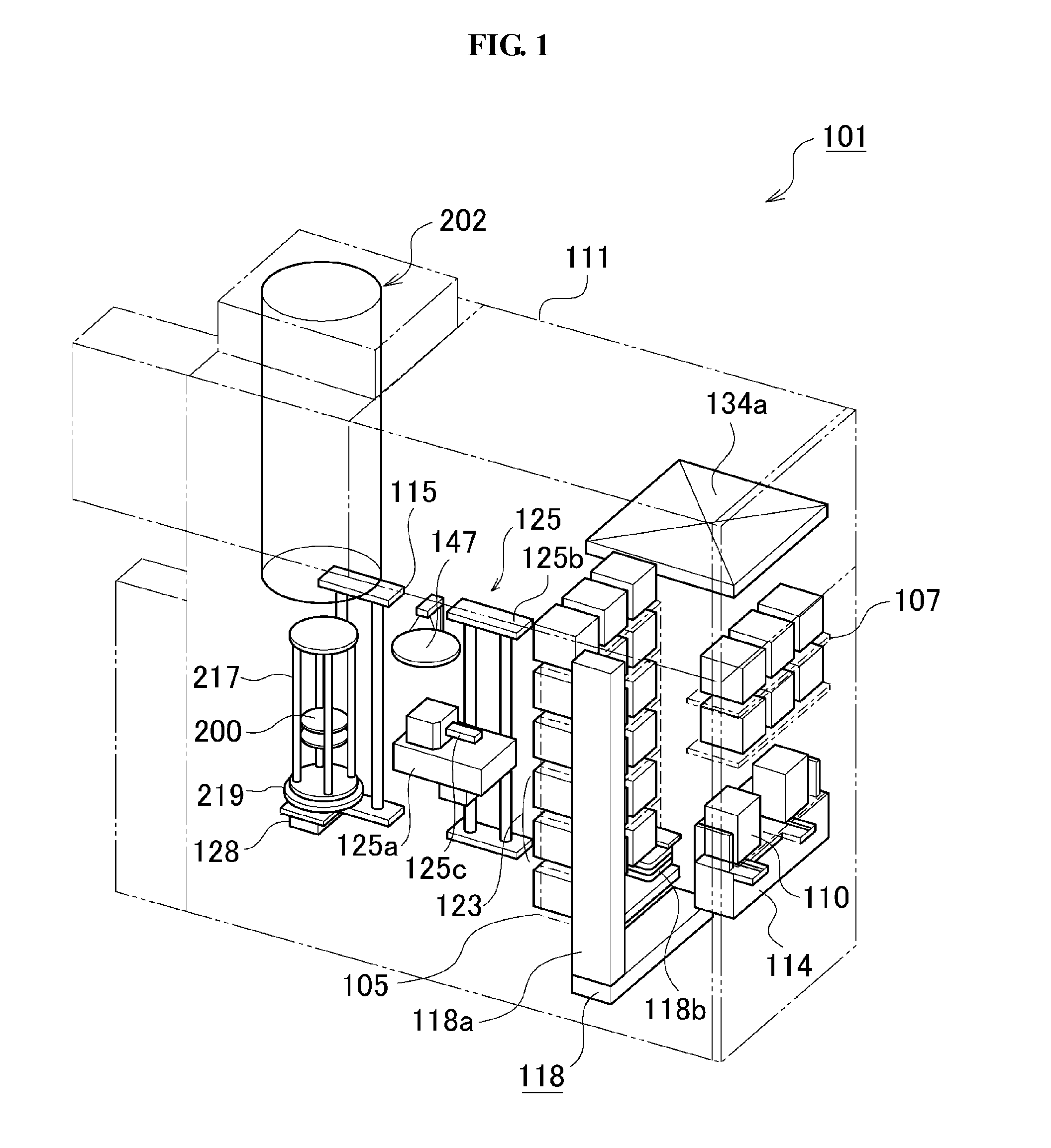

Substrate processing apparatus, method of manufacturing semiconductor device and semiconductor device

ActiveUS20120119337A1Avoid processing qualitySuppress scatterLiquid surface applicatorsSemiconductor/solid-state device detailsForeign matterThermodynamics

Provided is a substrate processing apparatus capable of suppressing accumulation of reaction products or decomposed matters on an inner wall of a nozzle and suppressing scattering of foreign substances in a process chamber. The substrate processing apparatus includes a process chamber, a heating unit, a source gas supply unit, a source gas nozzle, an exhaust unit, and a control unit configured to control at least the heating unit, the source gas supply unit and the exhaust unit. The source gas nozzle is disposed at a region in the process chamber, in which a first process gas is not decomposed even under a temperature in the process chamber higher than a pyrolysis temperature of the first process gas, and the control unit supplies the first process gas into the process chamber two or more times at different flow velocities to prevent the first process gas from being mixed.

Owner:KOKUSA ELECTRIC CO LTD

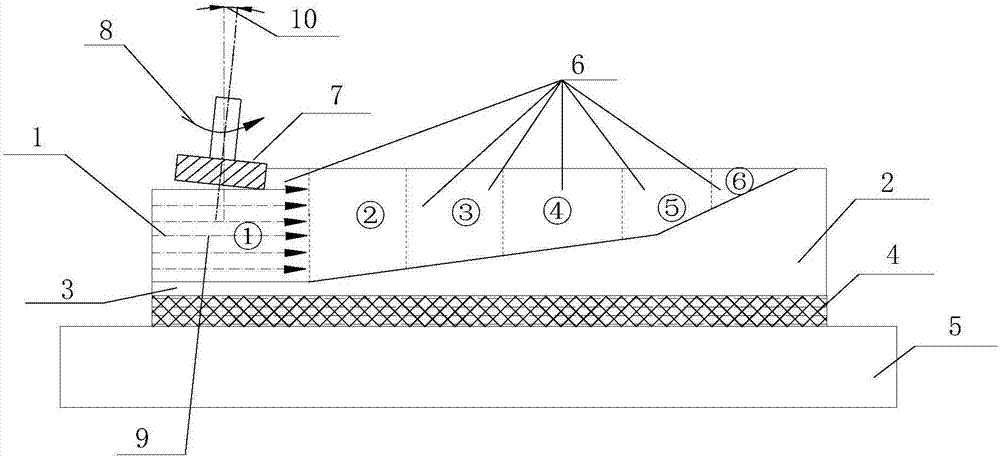

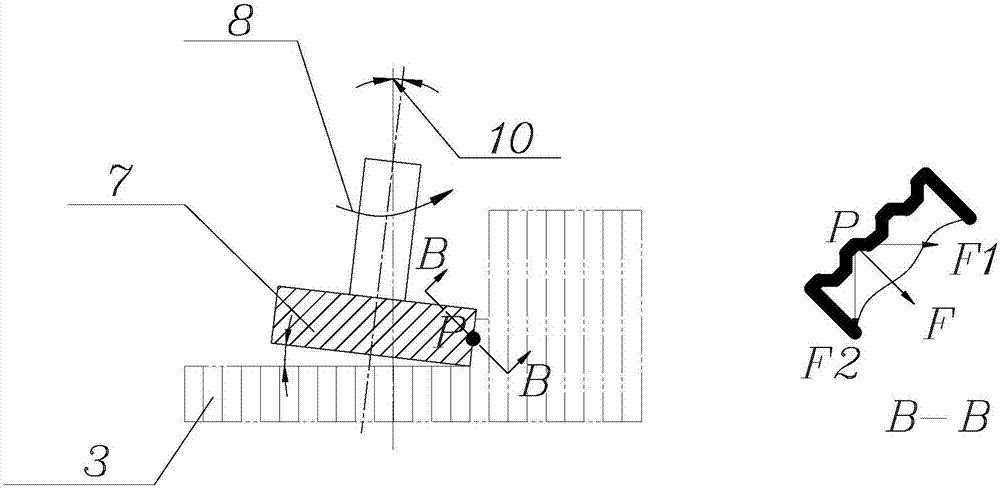

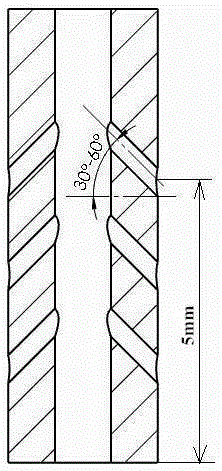

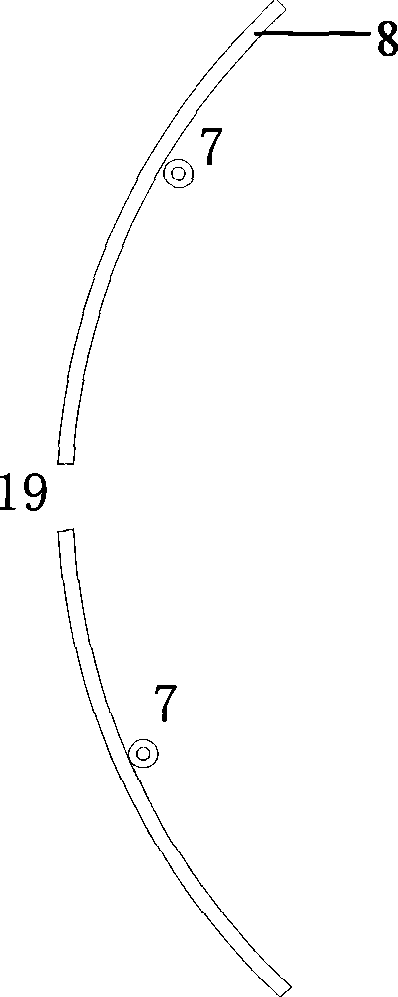

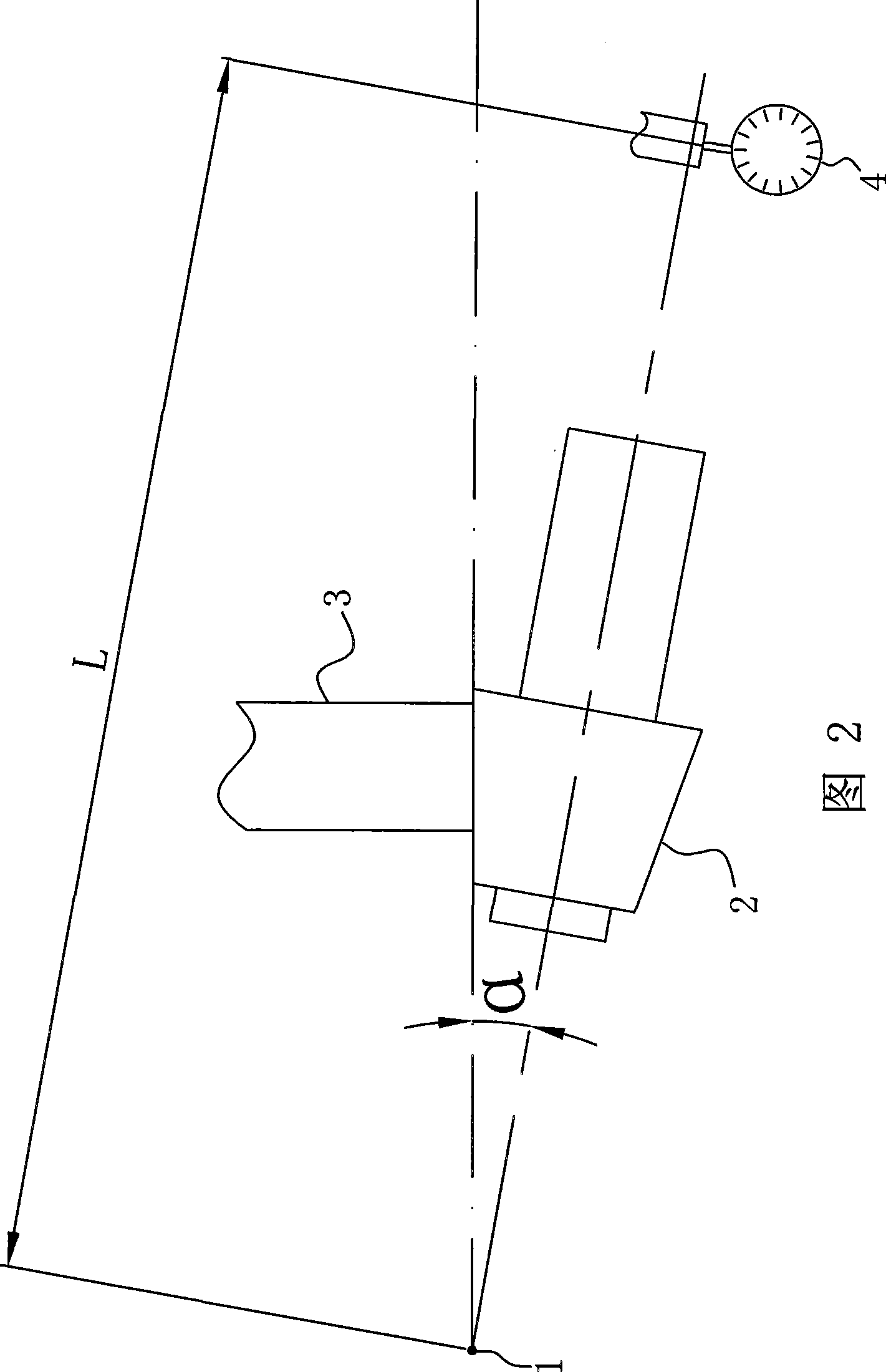

Machining method of thin-wall honeycomb core material curve machining molded surface

ActiveCN106903357AImprove milling efficiencyImprove machining accuracy and surface qualityWorkpiecesMilling equipment detailsThin walledHoneycomb

The invention discloses a machining method of a thin-wall honeycomb core material curve machining molded surface, and aims to provide a honeycomb machining method with high milling efficiency and capable of prolonging the life of a special honeycomb combined milling tool. The machining method is realized through the following technical scheme: when a double sided tape fixing state at the earlier stage of honeycomb machining is good, the special honeycomb combined milling tool with a conical disc return milling tool is changed for cutting; the rotating direction of the special honeycomb combined milling tool is changed; the conical disc return milling tool for feeding by a wedged angle of 30-45 degrees through high-speed rotation is used for cutting roughing; according to an anticlockwise tool rotating mode in the tool rotating direction, the downward pressure is applied to a honeycomb thin-edge area (1) through anticlockwise rotation; the part, easy to be pulled and damaged, of the thinnest honeycomb edge of the honeycomb bottom cutting profile is firstly machined; and after the honeycomb thin-edge area (1) of a NOMEX honeycomb part blank is machined, the sequential gradient machining is performed in (2-6) thickness direction of the thick-edge area cutting profile layer by layer, and the other parts are machined.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

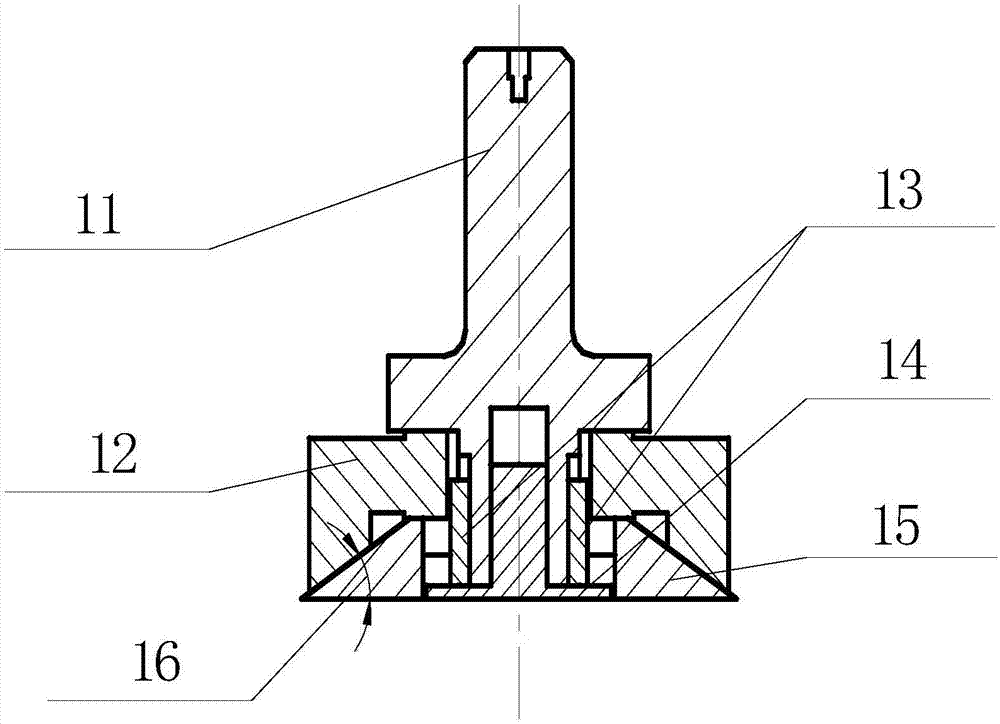

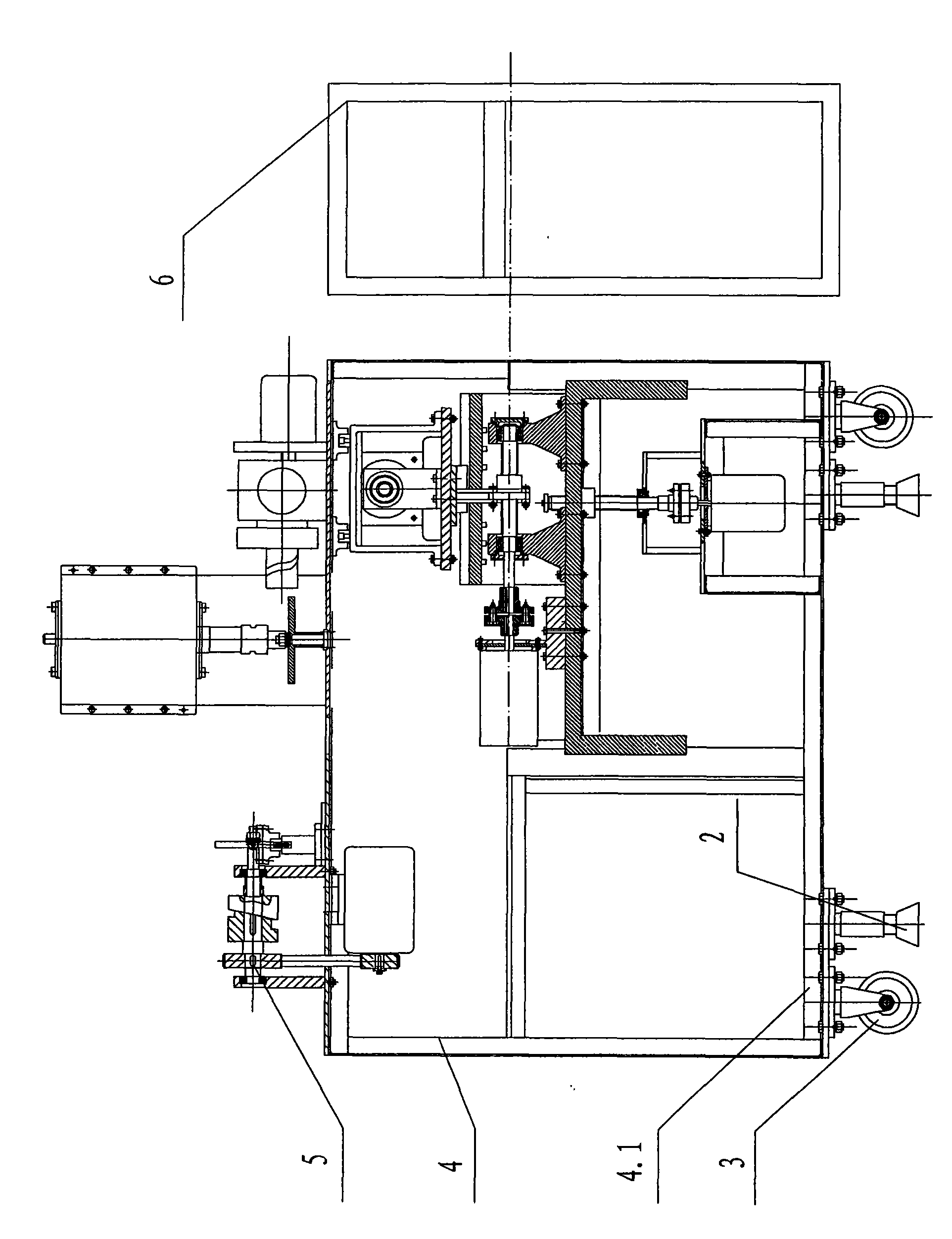

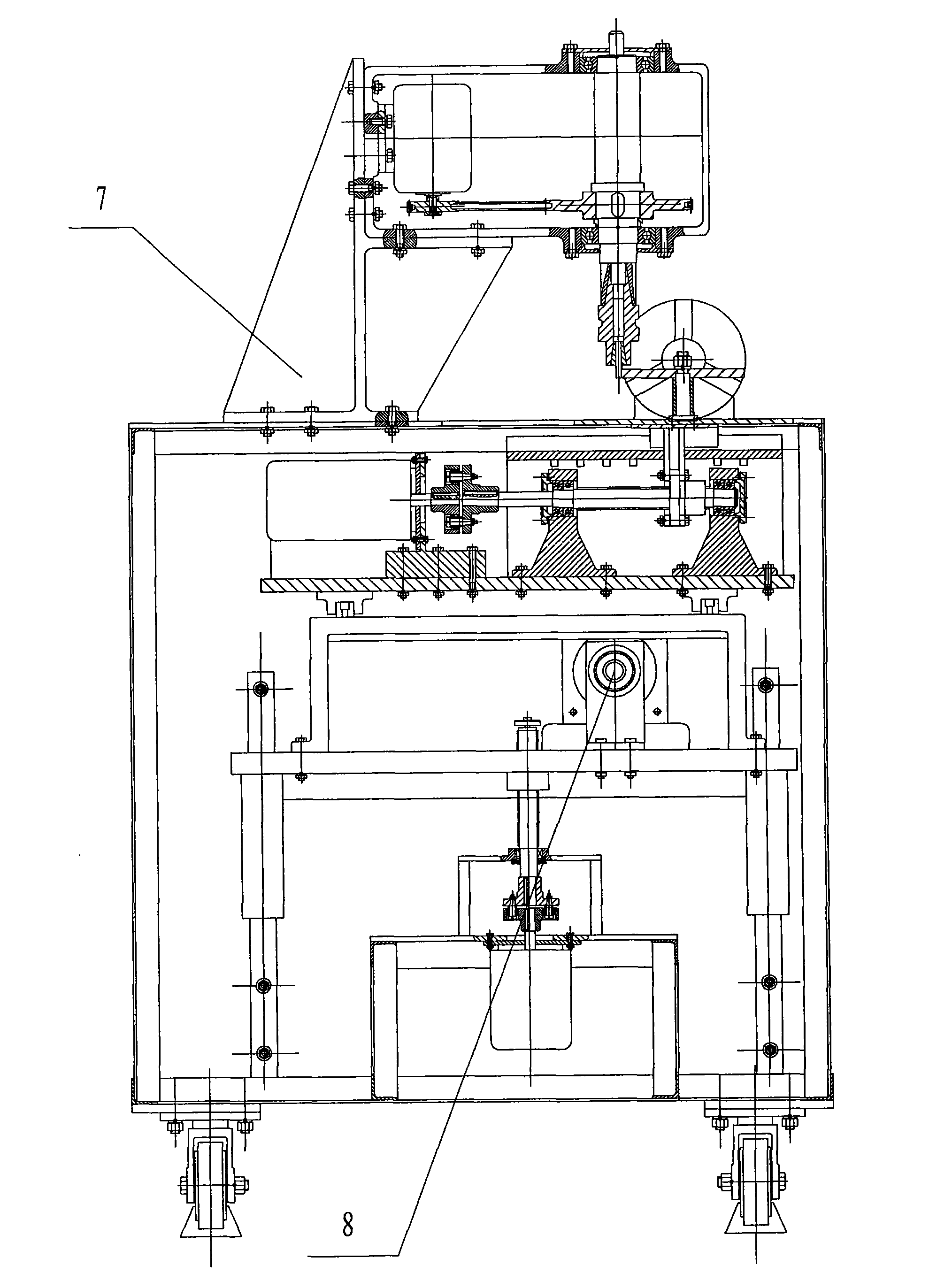

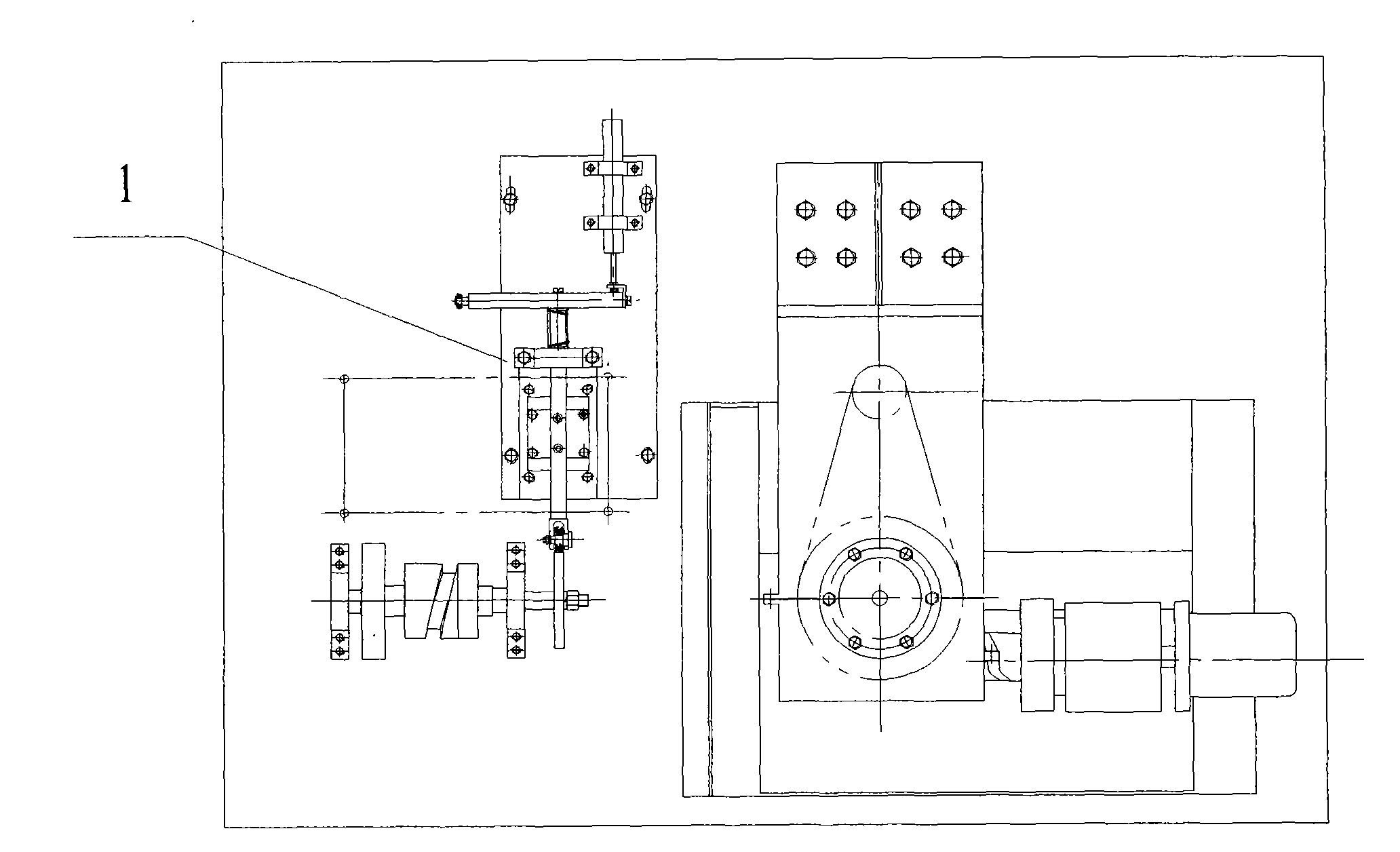

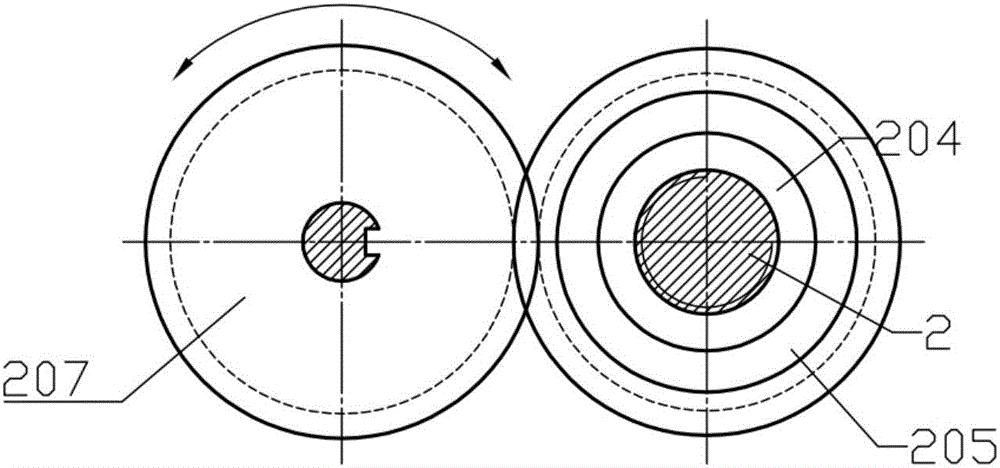

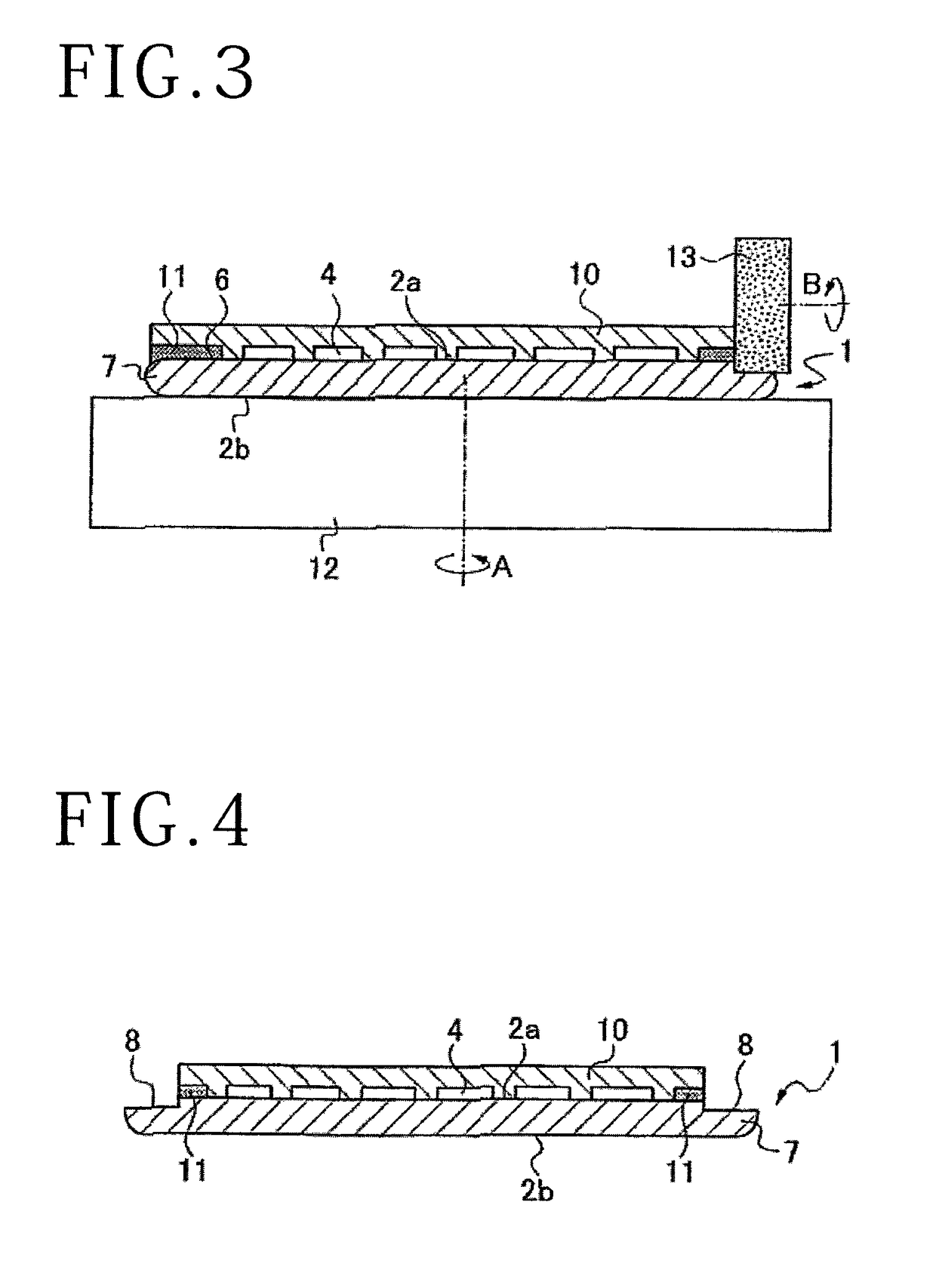

Cam profile detection and simulation processing experimental device

InactiveCN101673485AImprove machining accuracyVersatileMachine gearing/transmission testingEducational modelsMilling cutterEngineering

The invention belongs to experimental devices in the field of machines, in particular to a cam profile detection and simulation processing experimental device which can detect the motion profile of acam and simultaneously realize the simulation processing of the cam. The cam profile detection and simulation processing experimental device comprises a cabinet, a cam profile measuring mechanism, a mounting mechanism of the measured cam and a simulation processing experimental mechanism, wherein the cam profile measuring mechanism comprises a linear displacement sensor, a cylindrical cam profilemeasuring rod and a disc-shaped cam profile measuring rod, and the mounting mechanism of the measured cam comprises a cam shaft which is mounted on the cabinet, connected with the rotation power and used for mounting the measured cam; and the simulation processing mechanism comprises a milling cutter part with the vertical milling form and a workbench part, and the workbench part comprises a driving mechanism which can produce the three-axis movement and the one-axis movement, and a workbench mounted on the driving mechanism. The cam profile detection and simulation processing experimental device has the beneficial effects of integrating the cam profile simulation design processing and the detection into a whole, having complete functions, and compact structure, and realizing multiple purposes on an experimental platform.

Owner:ZHONGBEI UNIV

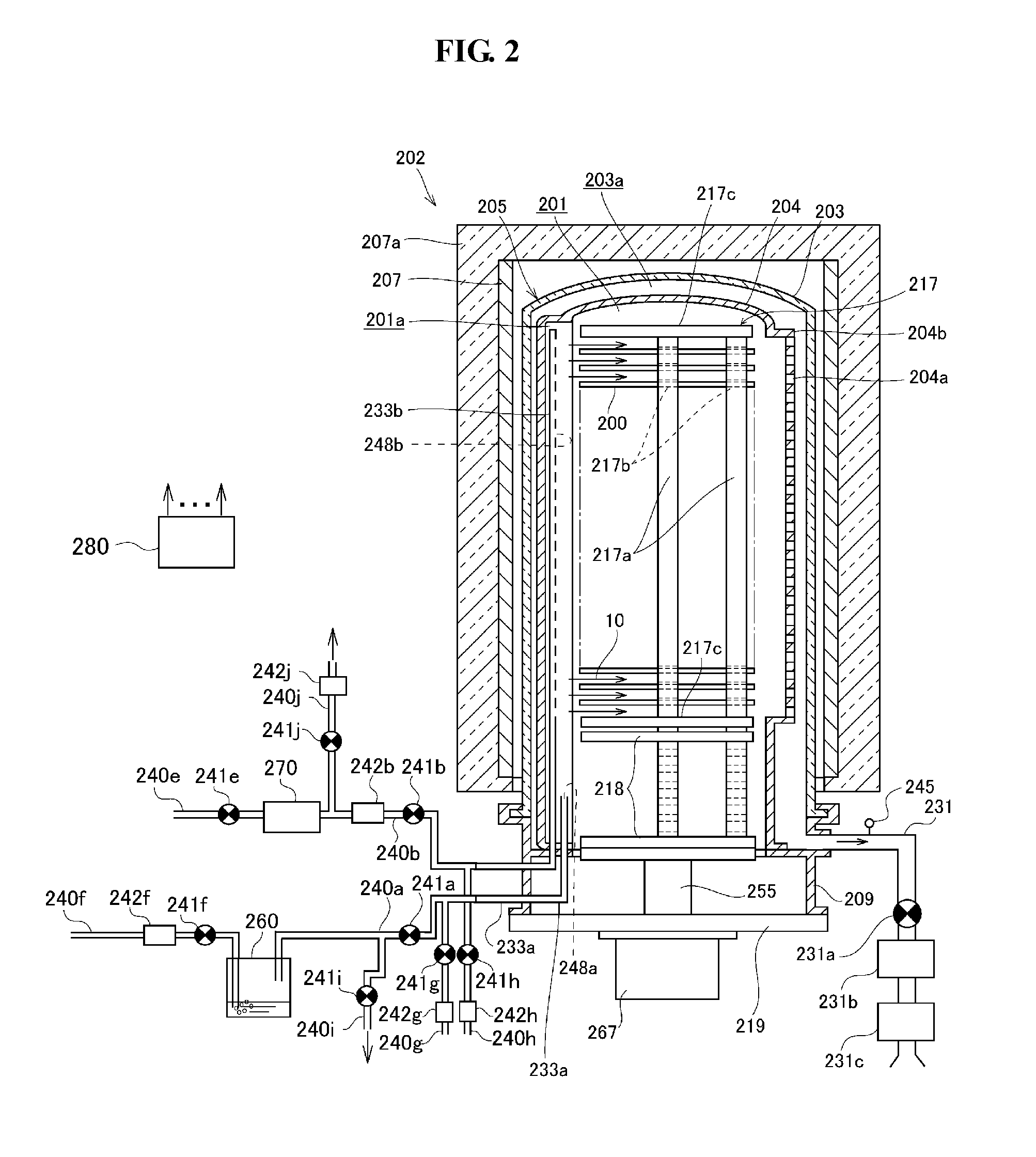

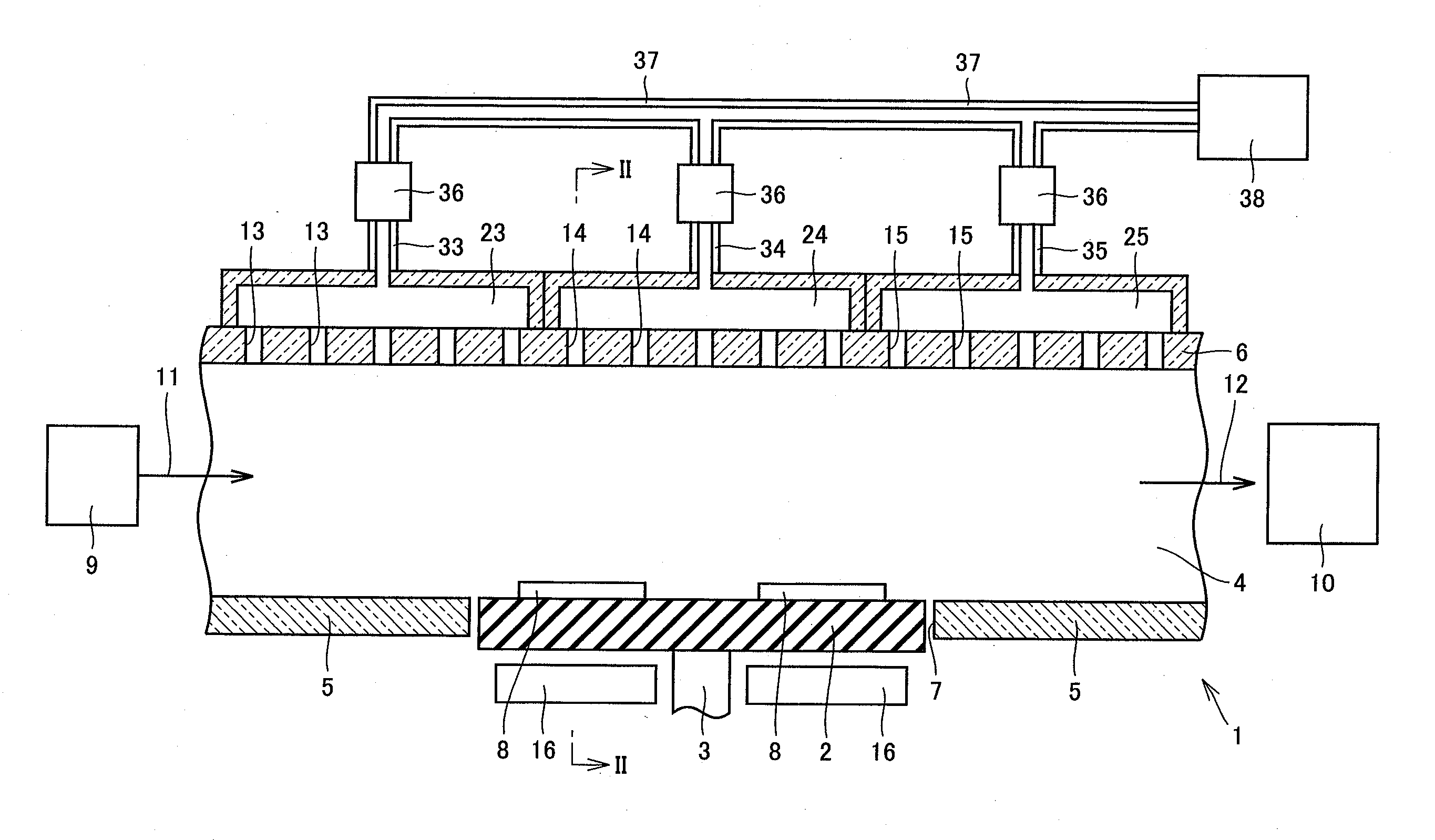

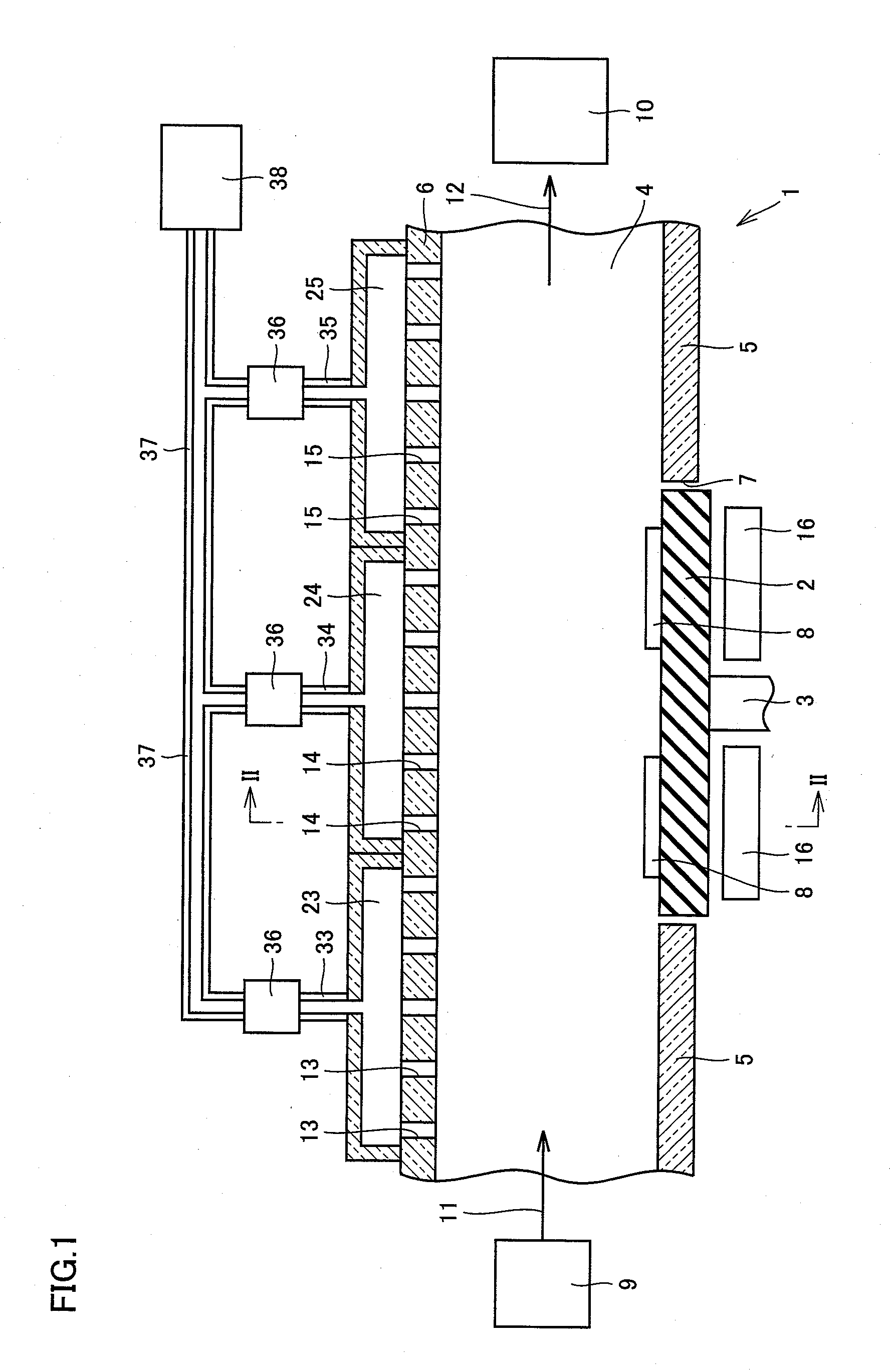

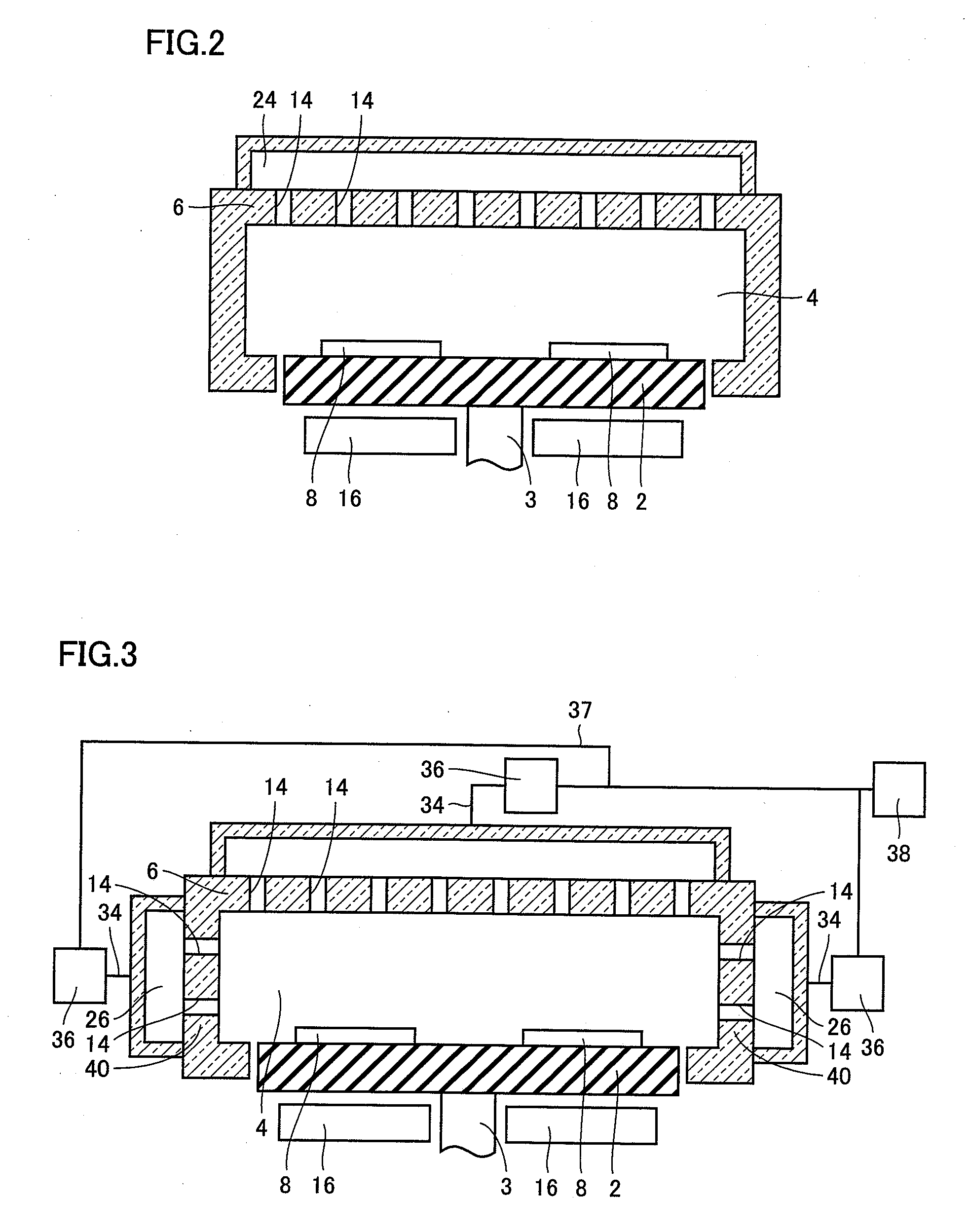

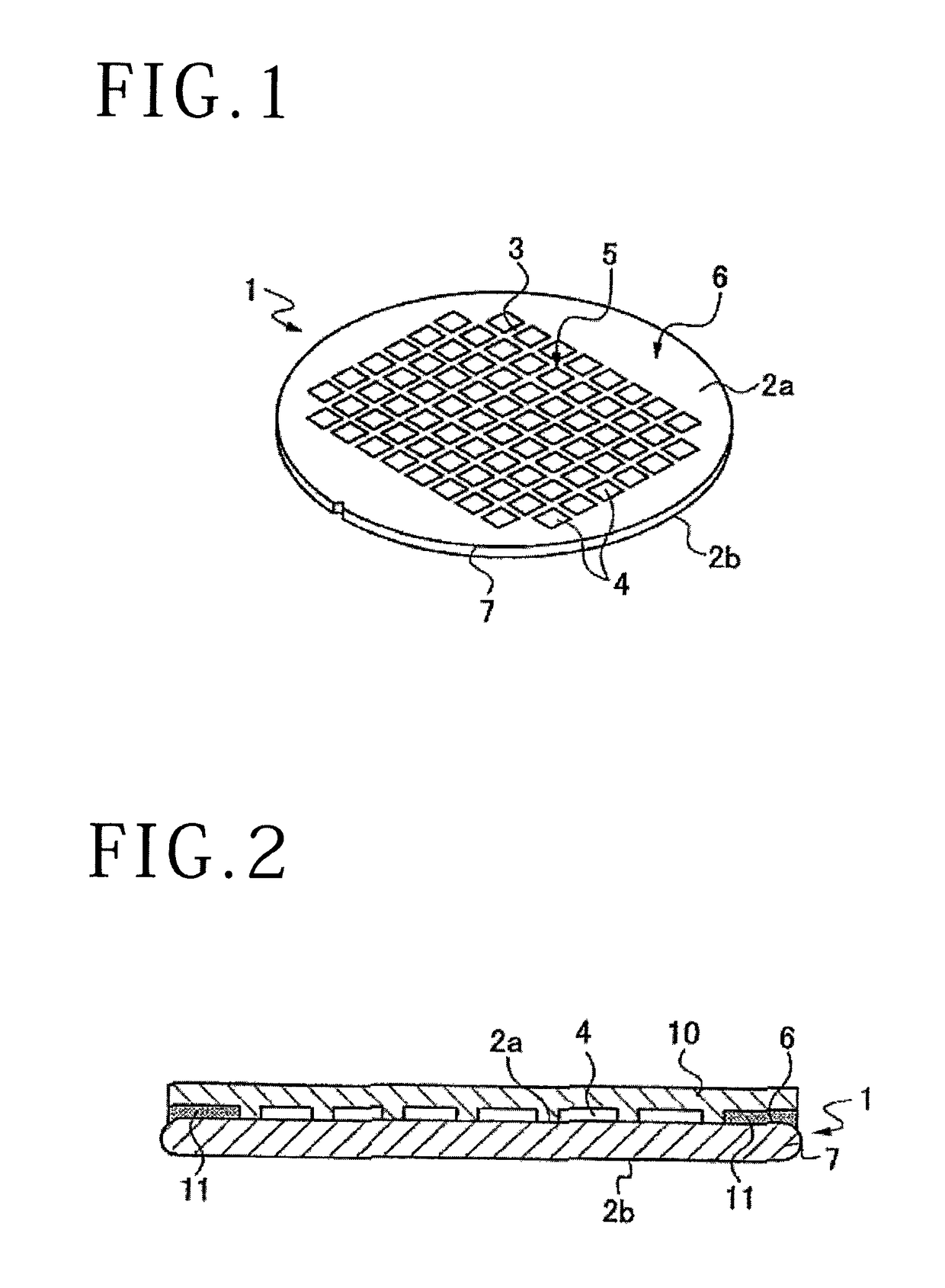

Vapor-phase process apparatus, vapor-phase process method, and substrate

InactiveUS20090148704A1Reduce amountReduce amount of depositPolycrystalline material growthElectric discharge tubesProcess engineeringProduct gas

A vapor-phase process apparatus and a vapor-phase process method capable of satisfactorily maintaining quality of processes even when different types of processes are performed are obtained. A vapor-phase process apparatus includes a process chamber, gas supply ports serving as a plurality of gas introduction portions, and a gas supply portion (a gas supply member, a pipe, a flow rate control device, a pipe, and a buffer chamber). The process chamber allows flow of a reaction gas therein. The plurality of gas supply ports are formed in a wall surface (upper wall) of the process chamber along a direction of flow of the reaction gas. The gas supply portion can supply a gas into the process chamber at a different flow rate from each of one gas supply port and another gas supply port different from that one gas supply port among the plurality of gas supply ports.

Owner:SUMITOMO ELECTRIC IND LTD

Method for eliminating flow field vortexes in tubular electrode electrolytic machining interval

InactiveCN105312691AReduce vibration amplitudeReduce the amplitudeMachining electrodesElectrical-based machining electrodesElectricityPunching

The invention provides a method for eliminating flow field vortexes in a tubular electrode electrolytic machining interval. The method comprises the following steps that the lateral face of a tubular electrode is punched through a laser punching process; the punched tubular electrode is subjected to corresponding insulating treatment; electrolyte flows downwards in the tubular electrode during electrolytic machining and is sprayed outwards from an outlet in the lower end of the tubular electrode; the electrolyte beam sprayed out of the outlet of the tubular electrode impacts an electrolytic machining area; part of electrolyte is sprayed out of a hole in the lateral face of the tubular electrode; under the impact and disturbance function of the electrolyte sprayed out of the hole in the lateral face, a vortex area of the electrolyte of the machining area is eliminated, and electrolysate is discharged out of the machining area in time in the circular flowing of the electrolyte; and meanwhile, under the function of reactive force when the electrolyte impacts, the amplitude of vibration of the tubular electrode caused by flowing of the electrolyte is reduced. The occurrence of short circuit in the machining process can be effectively reduced by eliminating the electrolysate discharged out of the vortex area and reducing the amplitude of vibration of the tubular electrode, and the process stability of the electrolytic machining of the tubular electrode is improved.

Owner:SHANDONG UNIV OF TECH

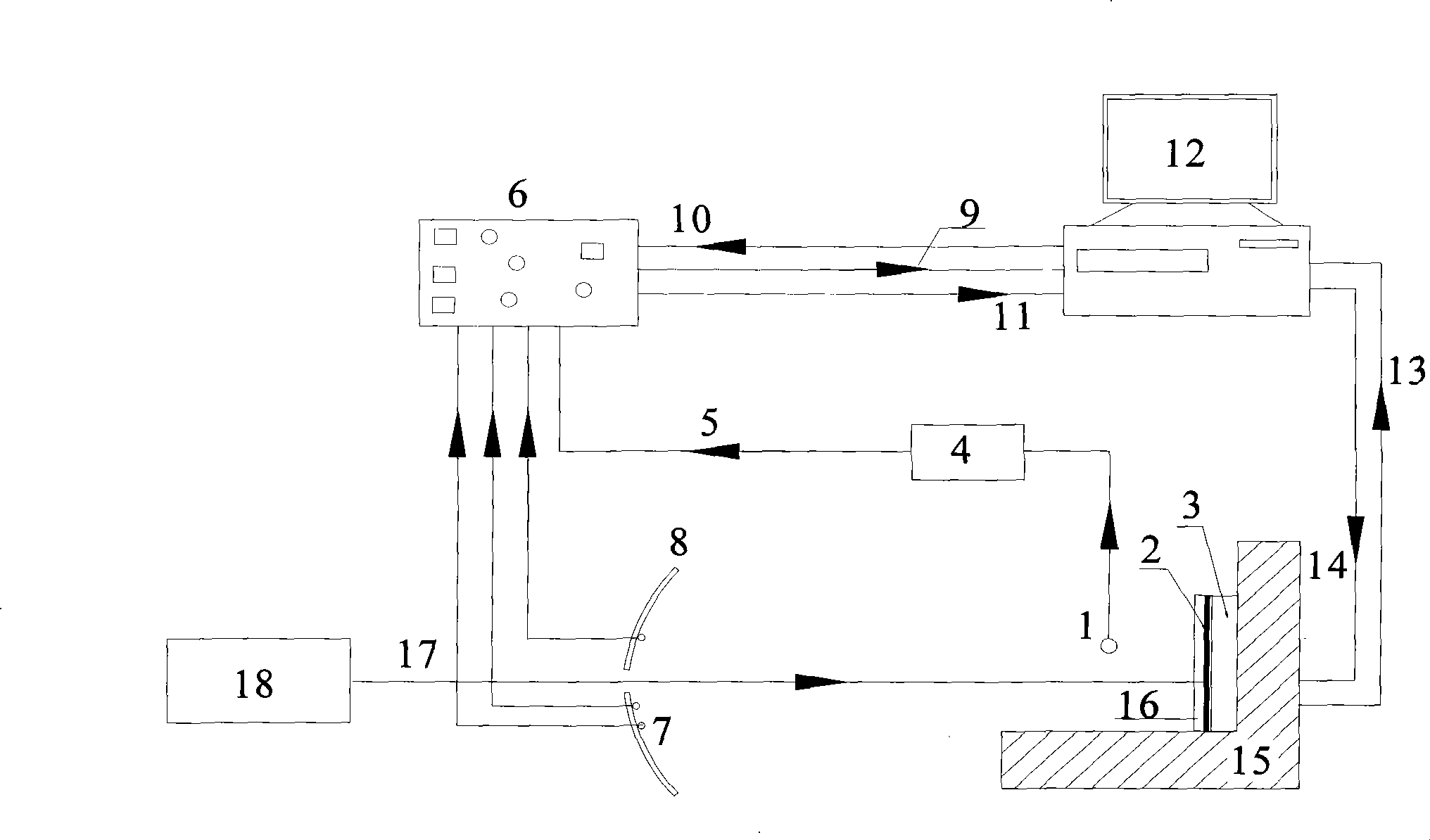

Laser impact intensified on-line detection method and apparatus based on waveform characteristics of shock wave

InactiveCN101482542APracticalReal-time online detection of impact strengthening effectUltrasonic/sonic/infrasonic wave generationMaterial analysis by electric/magnetic meansShock waveControl system

The invention relates to an on-line detection method and device of laser shock processing effect, belonging to the machine manufacturing and laser device field, mainly suitable for the laser shock processing technology capable of increasing the mechanical performance of the parts. The on-line detection of the laser shock processing effect is performed by detecting the amplitude and pulse width of the shock wave spreaded in the air. The detection device comprises a photoelectric trigger circuit; a sound sensing circuit composed of three sound sensors and acoustic wave absorption device; a shock wave sampling circuit and other subsidiary components. The laser shock processing effect can be judged in complicated environment and the effective on-line detection of the laser shock processing effect is realized and the processing automaticity is increased.

Owner:JIANGSU UNIV

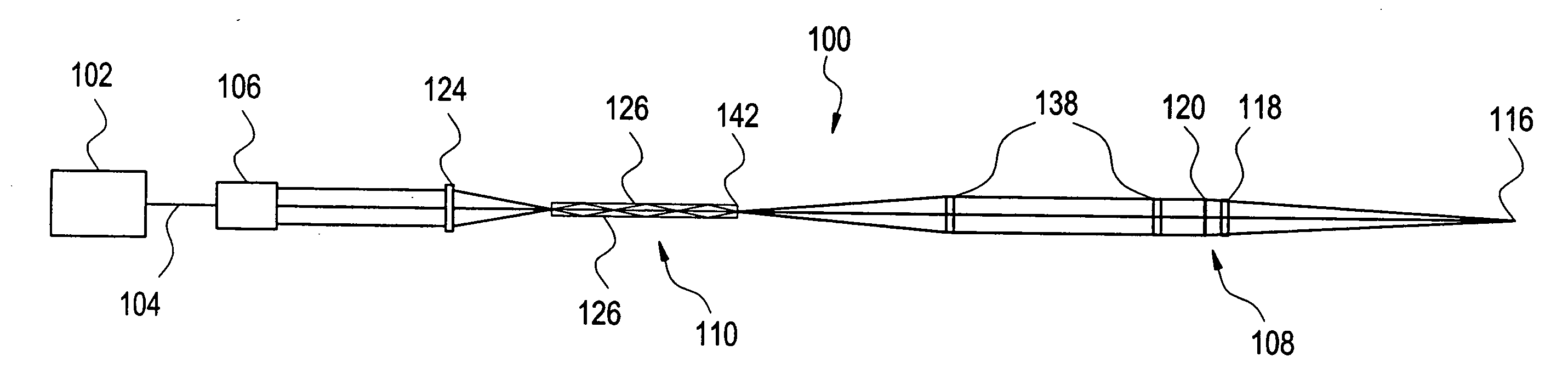

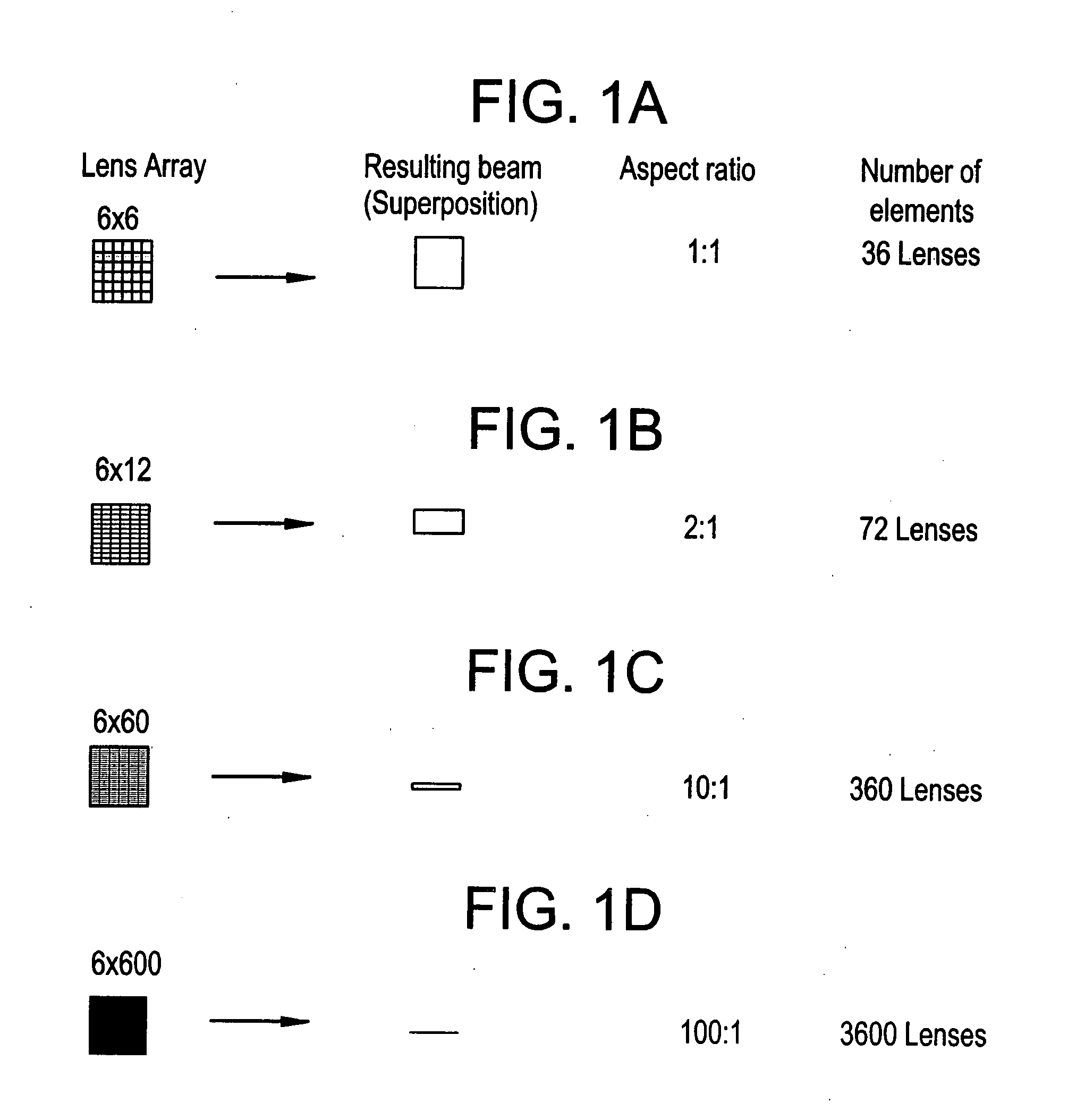

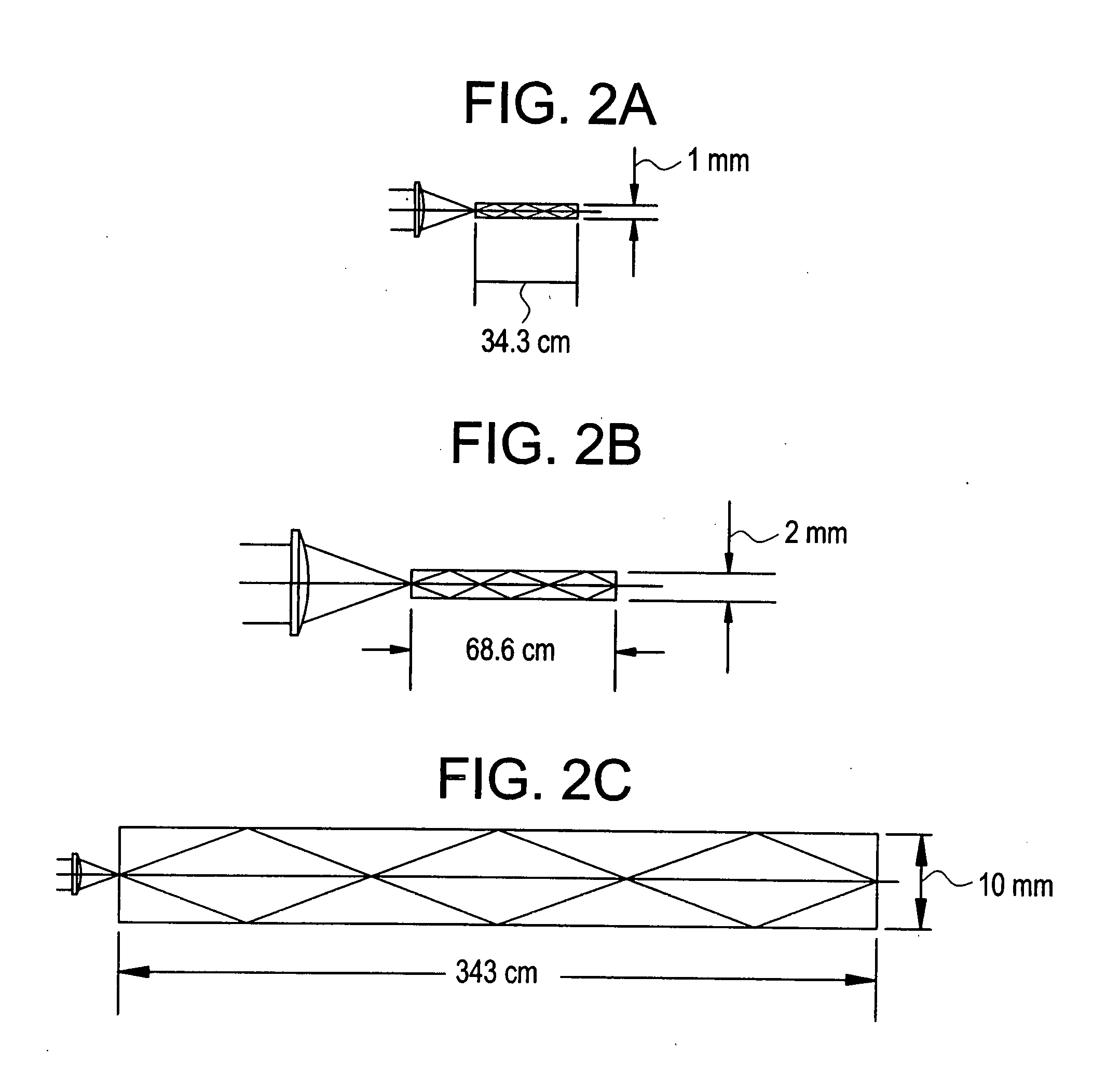

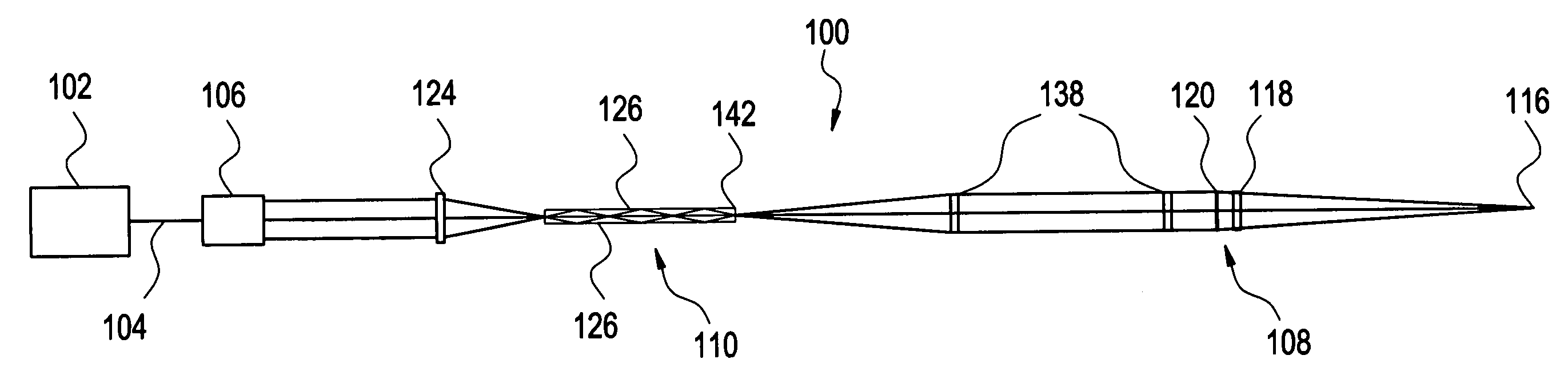

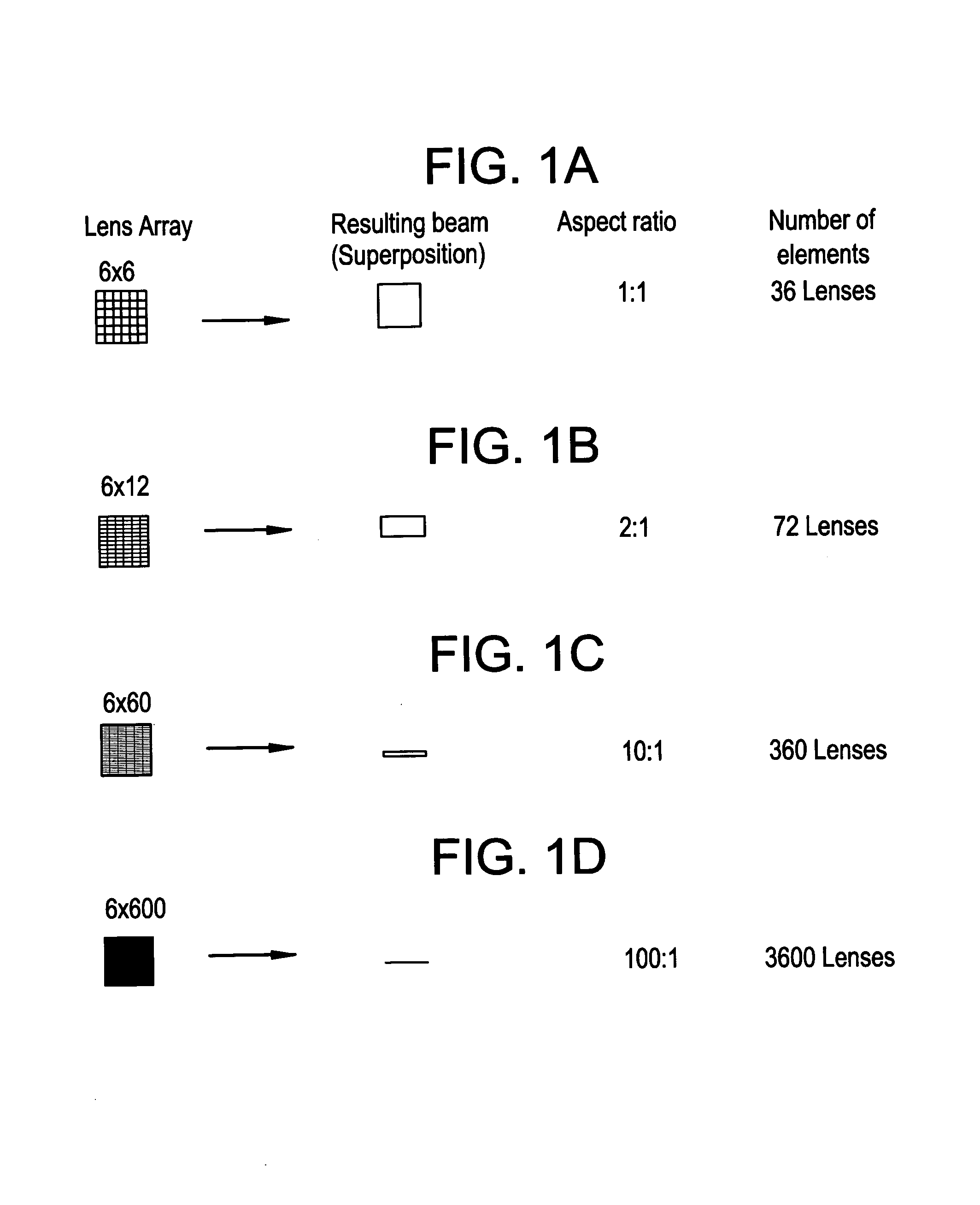

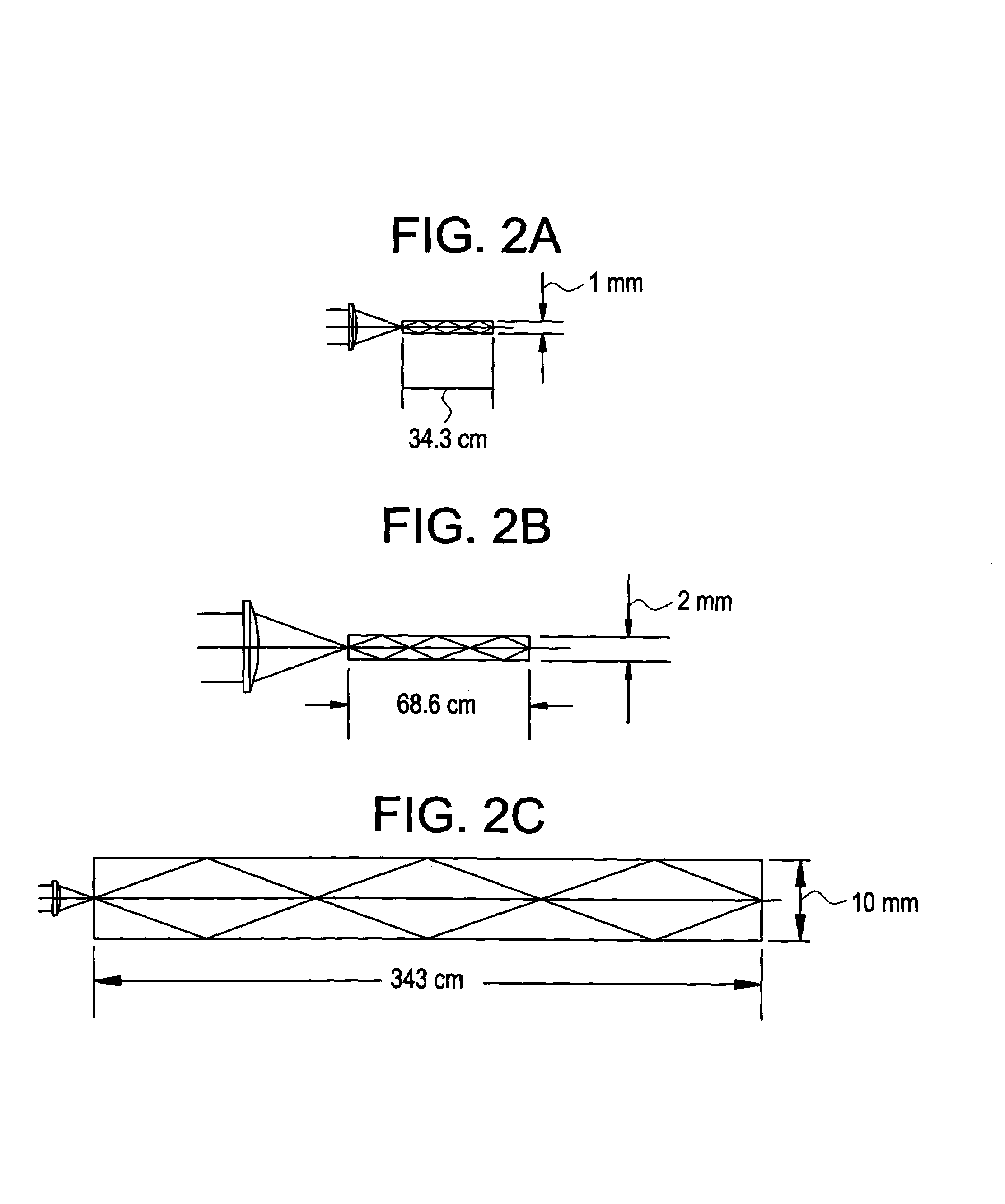

Methods and apparatuses for homogenizing light

InactiveUS20070206383A1Cost-effective and compactAvoid processing qualityPhotomechanical apparatusOptical elementsHomogenizerOptics

Embodiments of the present invention are directed to an illuminating optical device for forming a field of illumination. The optical device includes a first one-dimensional homogenizer positioned to homogenize a first dimension / axis of the field of illumination and a second one-dimensional homogenizer positioned to homogenize a second dimension / axis of the field of illumination.

Owner:RESONETICS

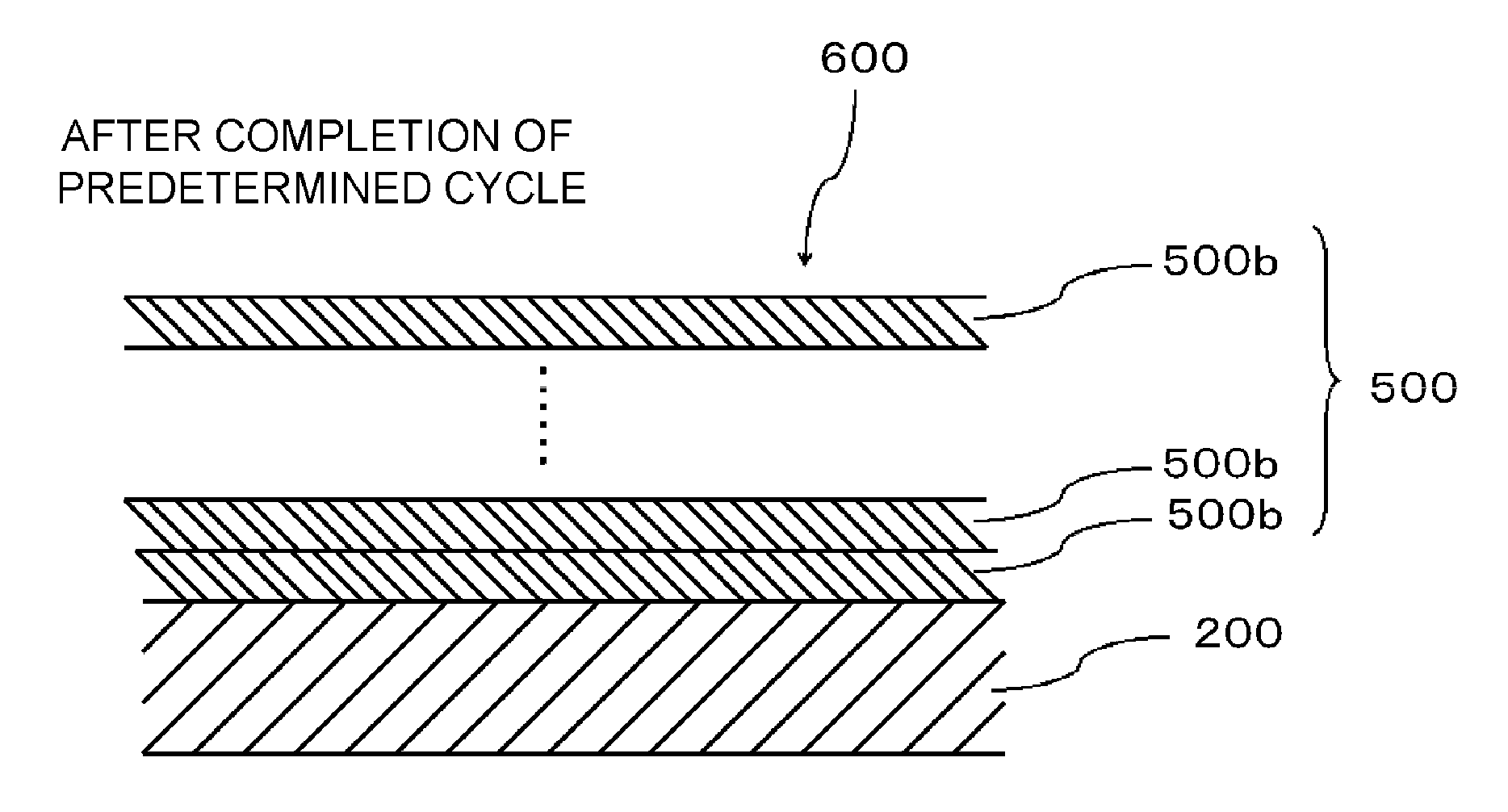

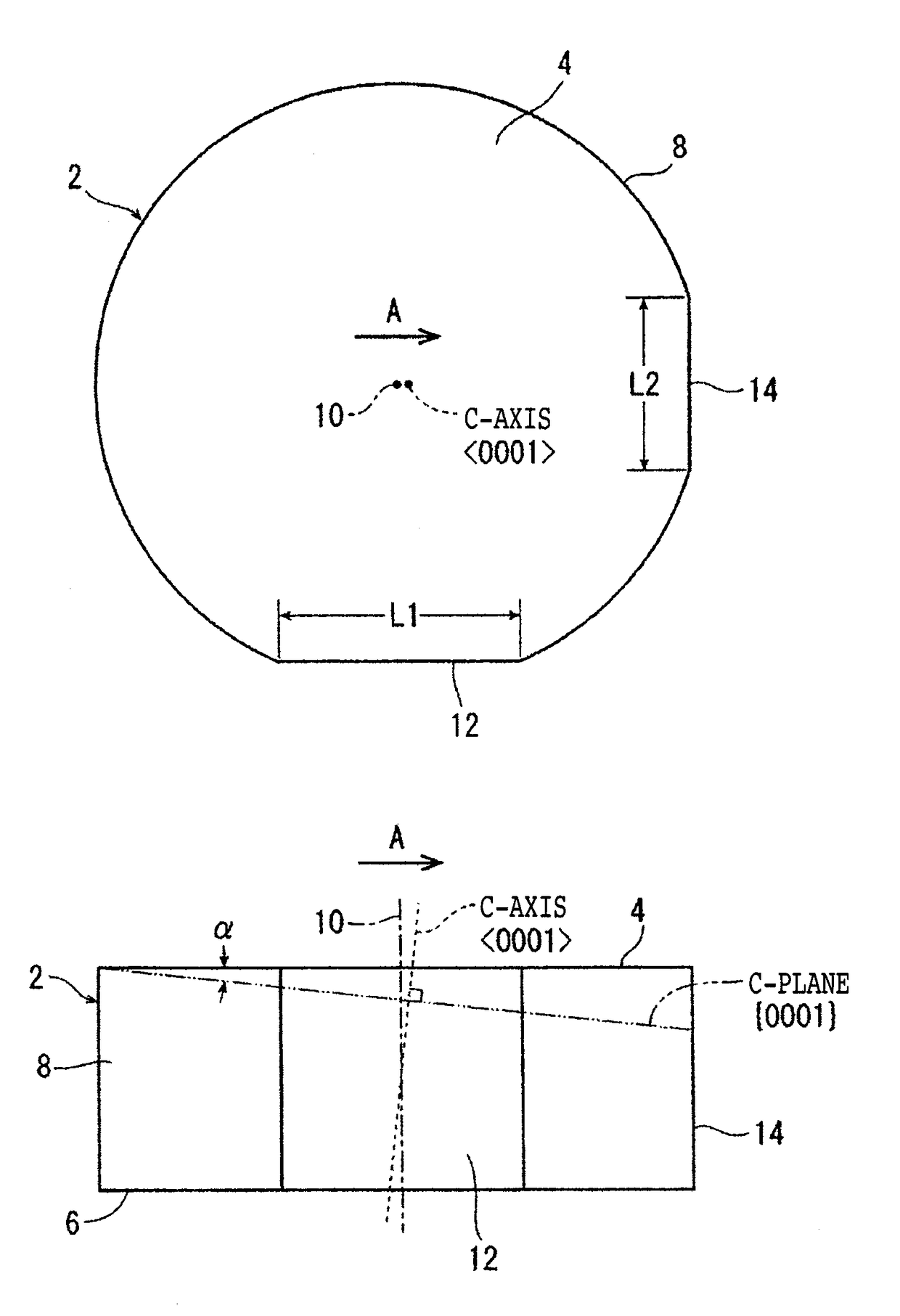

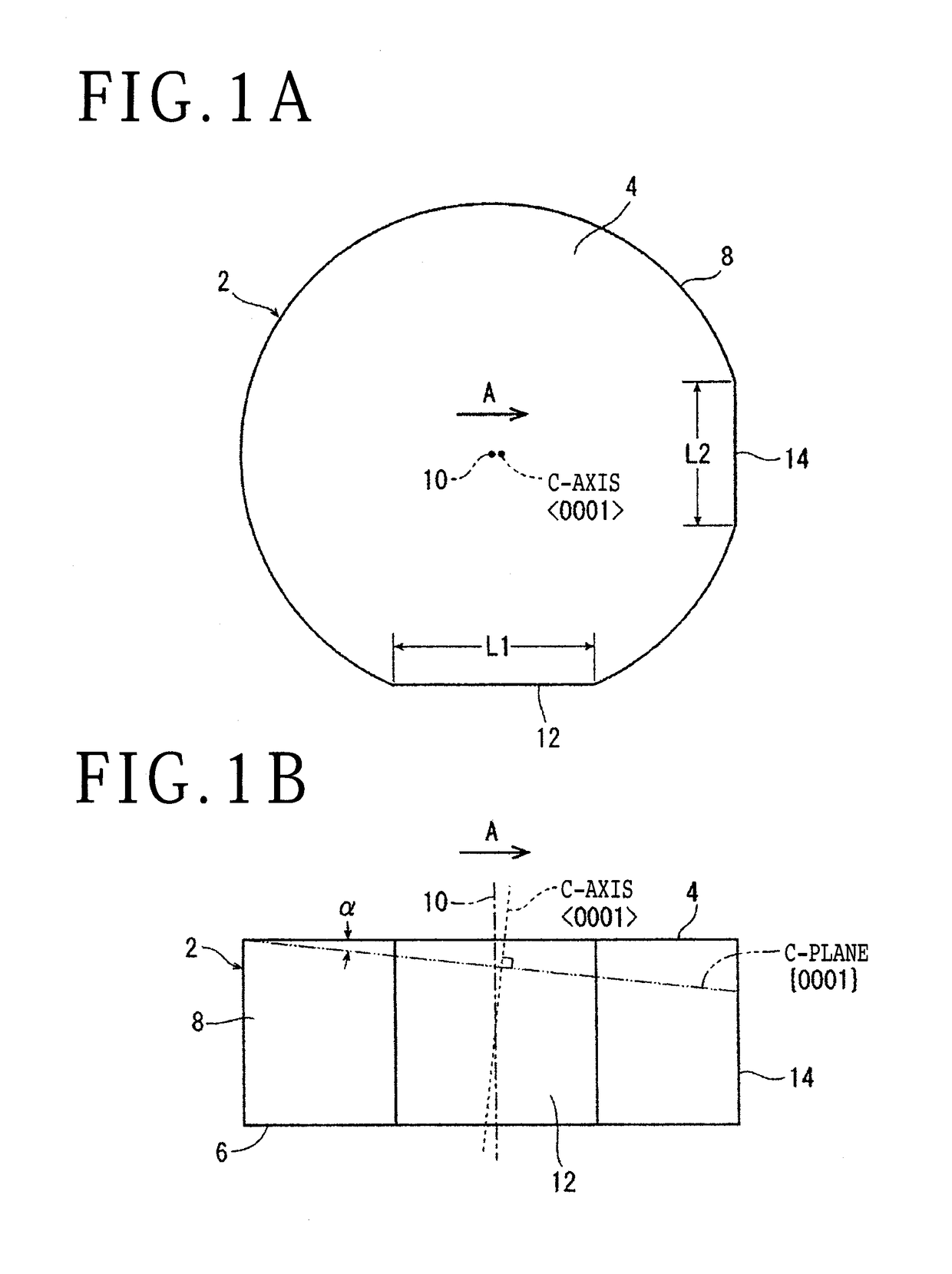

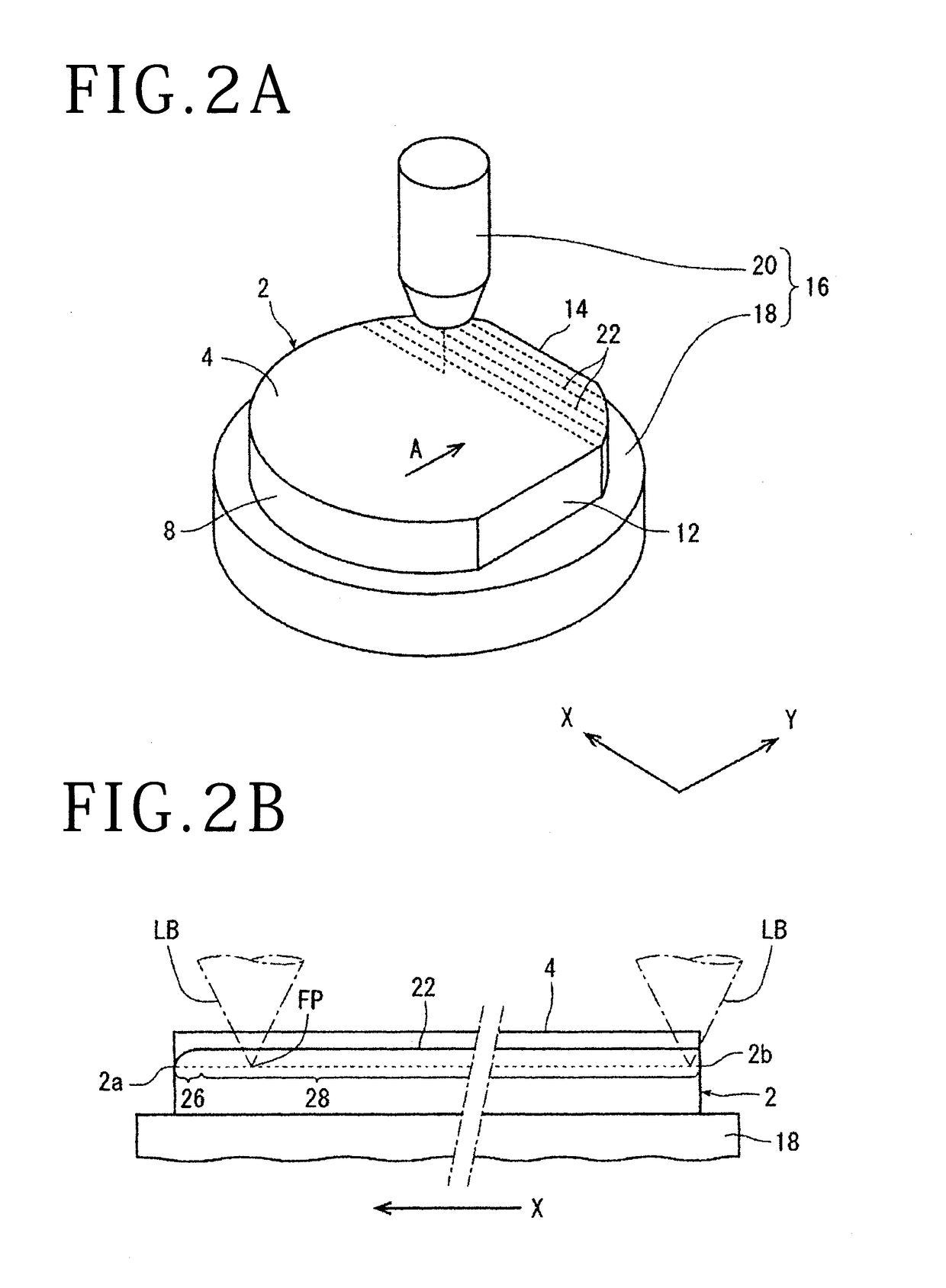

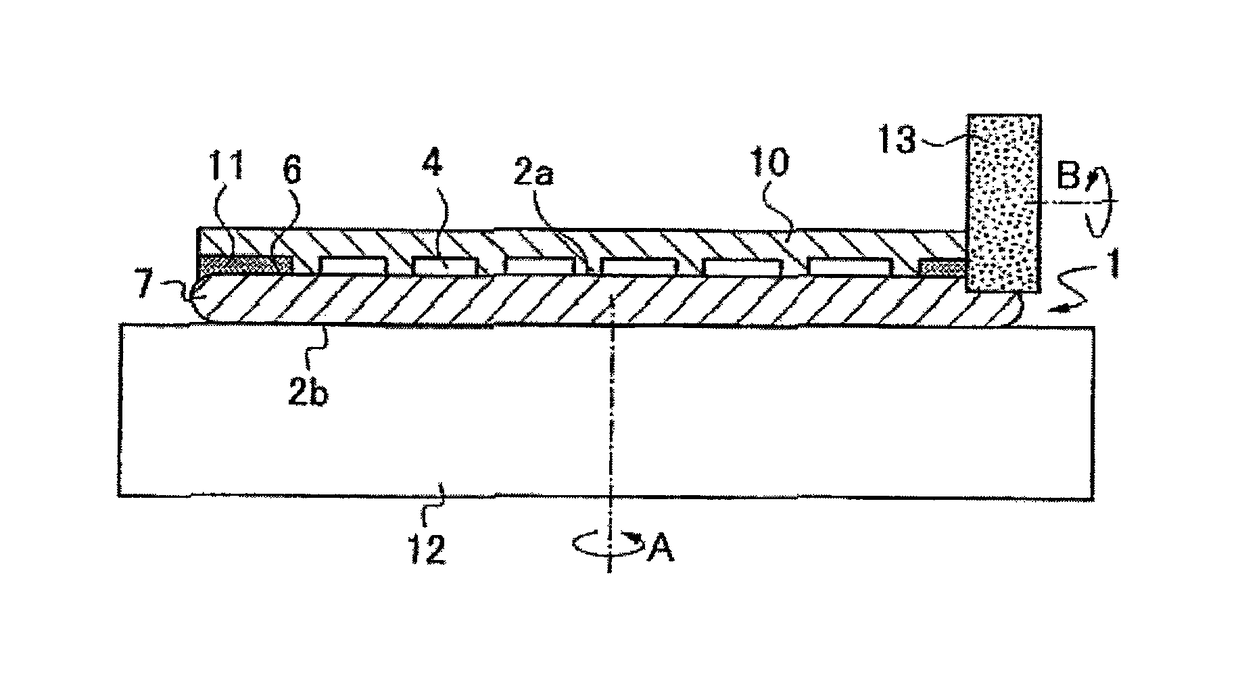

SiC WAFER PRODUCING METHOD

ActiveUS20180085851A1Reduction in quality of processSmoothly performSemiconductor/solid-state device manufacturingWelding/soldering/cutting articlesPhysicsOptoelectronics

A SiC wafer is produced from a single crystal SiC ingot. A modified layer is formed by setting a focal point of a pulsed laser beam inside the ingot at a predetermined depth from the upper surface of the ingot, the predetermined depth corresponding to the thickness of the wafer to be produced. The pulsed laser beam is applied to the ingot while moving the ingot in a first direction perpendicular to a second direction where an off angle is formed, thereby forming a modified layer in the first direction inside the ingot and cracks propagating from the modified layer along a c-plane. A separation surface is formed by indexing the ingot in the second direction and applying the laser beam plural times to thereby form a separation surface inside the ingot. Part of the ingot is separated along the separation surface to thereby produce the wafer.

Owner:DISCO CORP

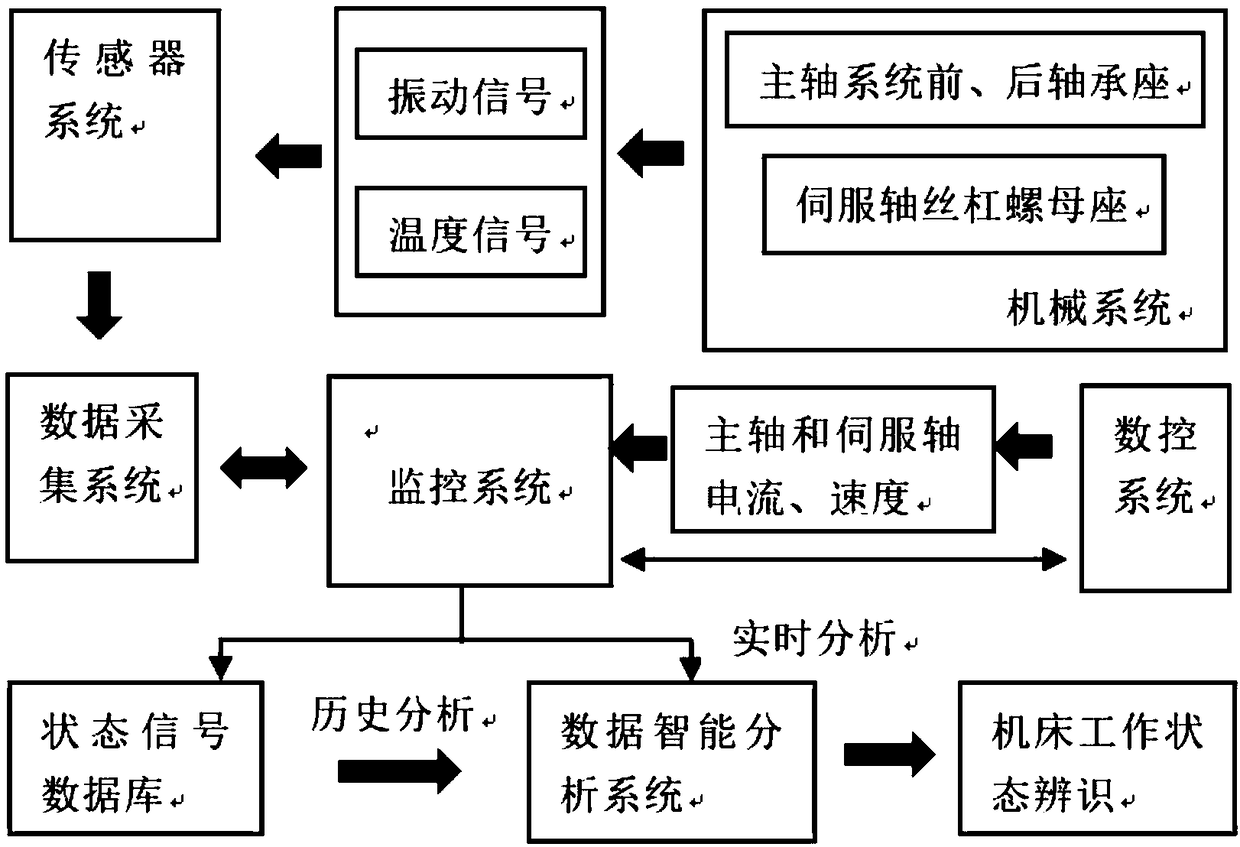

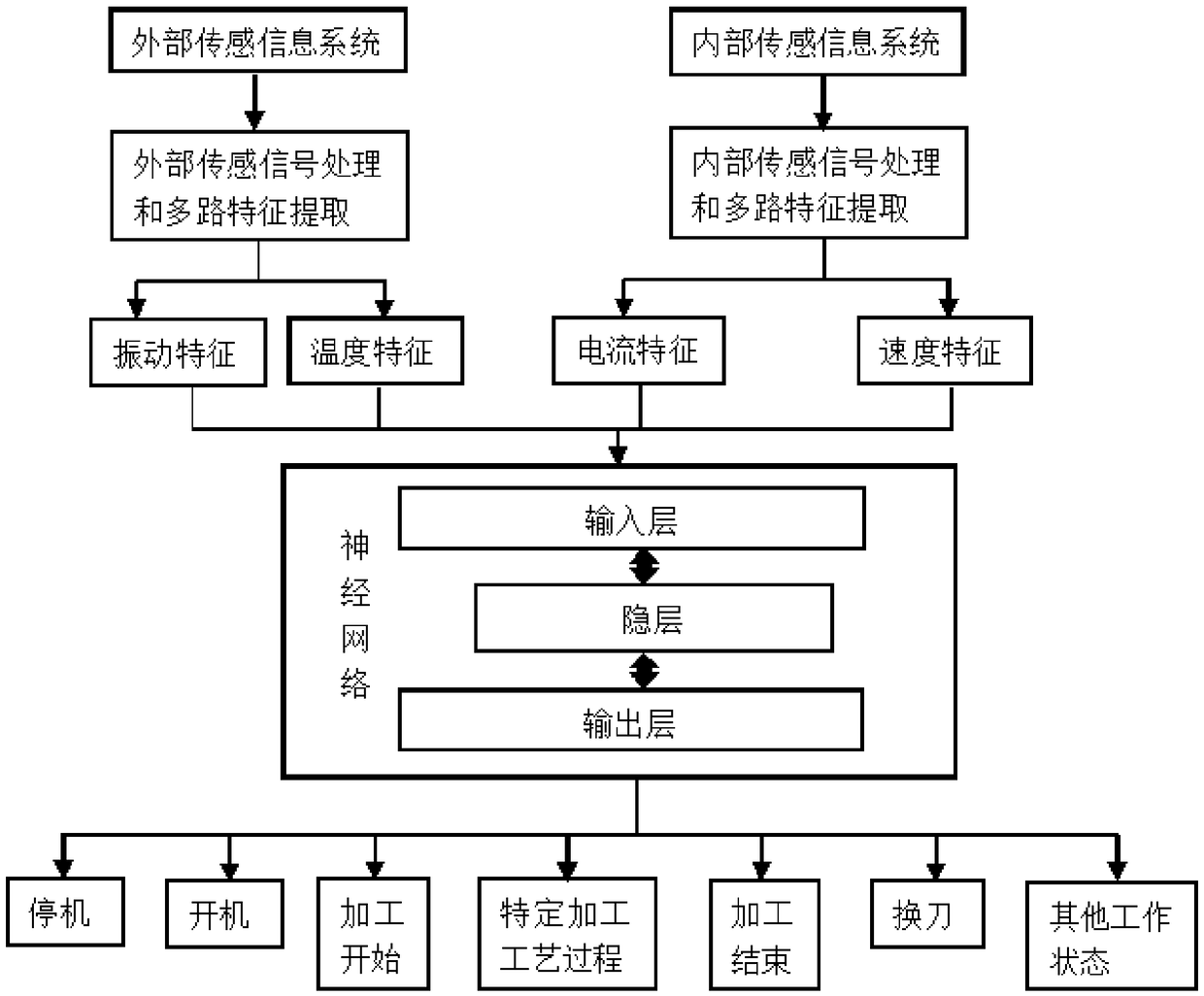

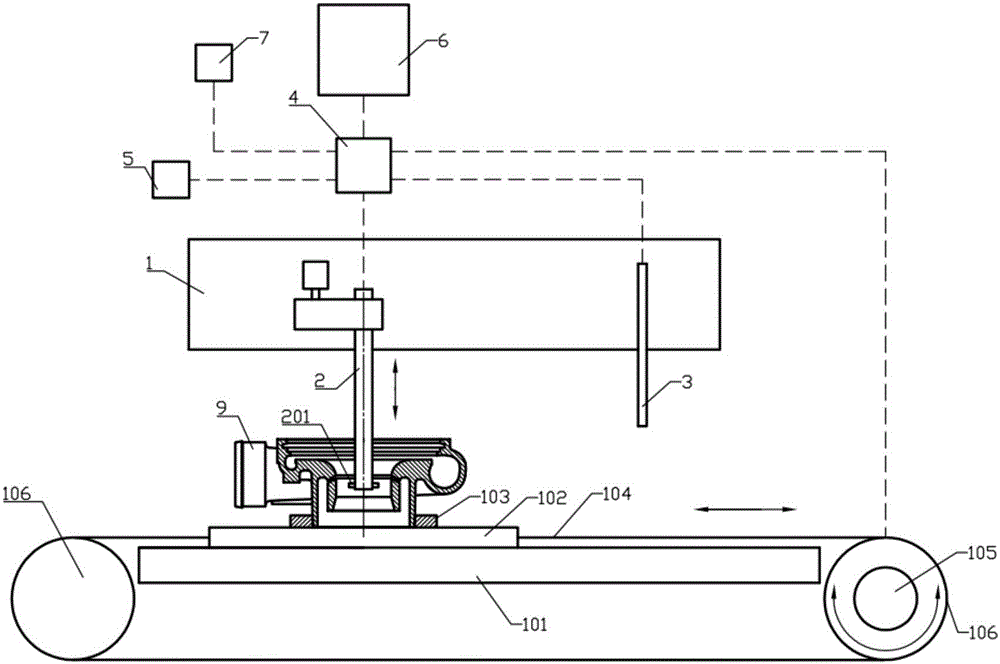

Intelligent machine tool working state identification system based on signal fusion

ActiveCN109396953AEliminate false positivesReduce judgment errorMeasurement/indication equipmentsPower sensorMultiple sensor

The invention provides an intelligent machine tool working state identification system based on signal fusion. A sensor system is installed on a mechanical system of a machine tool and used for collecting a vibration signal, a temperature signal, a current signal and a speed signal of the machine tool; the vibration signal and the temperature signal are converted into digital signals through a data collecting system and then sent to a monitoring system, and the current signal and the speed signal are sent to the monitoring system through a numerical control system; and the monitoring system isused for controlling the vibration signal, the temperature signal, the current signal and the speed signal to be sent to a state signal database system and / or controlling the vibration signal, the temperature signal, the current signal and the speed signal to be sent to an intelligent data analysis system to achieve real-time data analysis and output an intelligent machine tool working state identification result. According to the intelligent machine tool working state identification system based on signal fusion, erroneous judgment brought by machine tool state identification obtained through signals measured by a power sensor singly is effectively eliminated, information fusion of multiple sensors is combined, a BP neural network method is adopted, therefore, errors in judgment are reduced, the system robustness is improved, and meanwhile basic conditions are provided for dynamic monitoring of the machining technology process.

Owner:SHANGHAI JIAO TONG UNIV +1

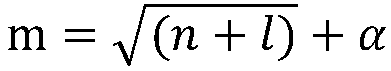

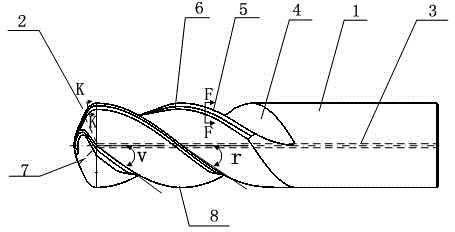

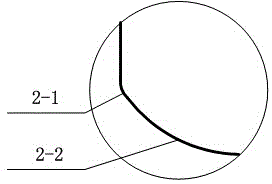

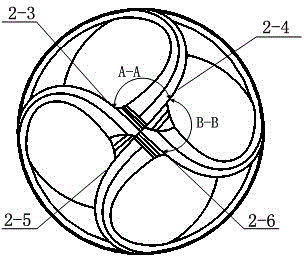

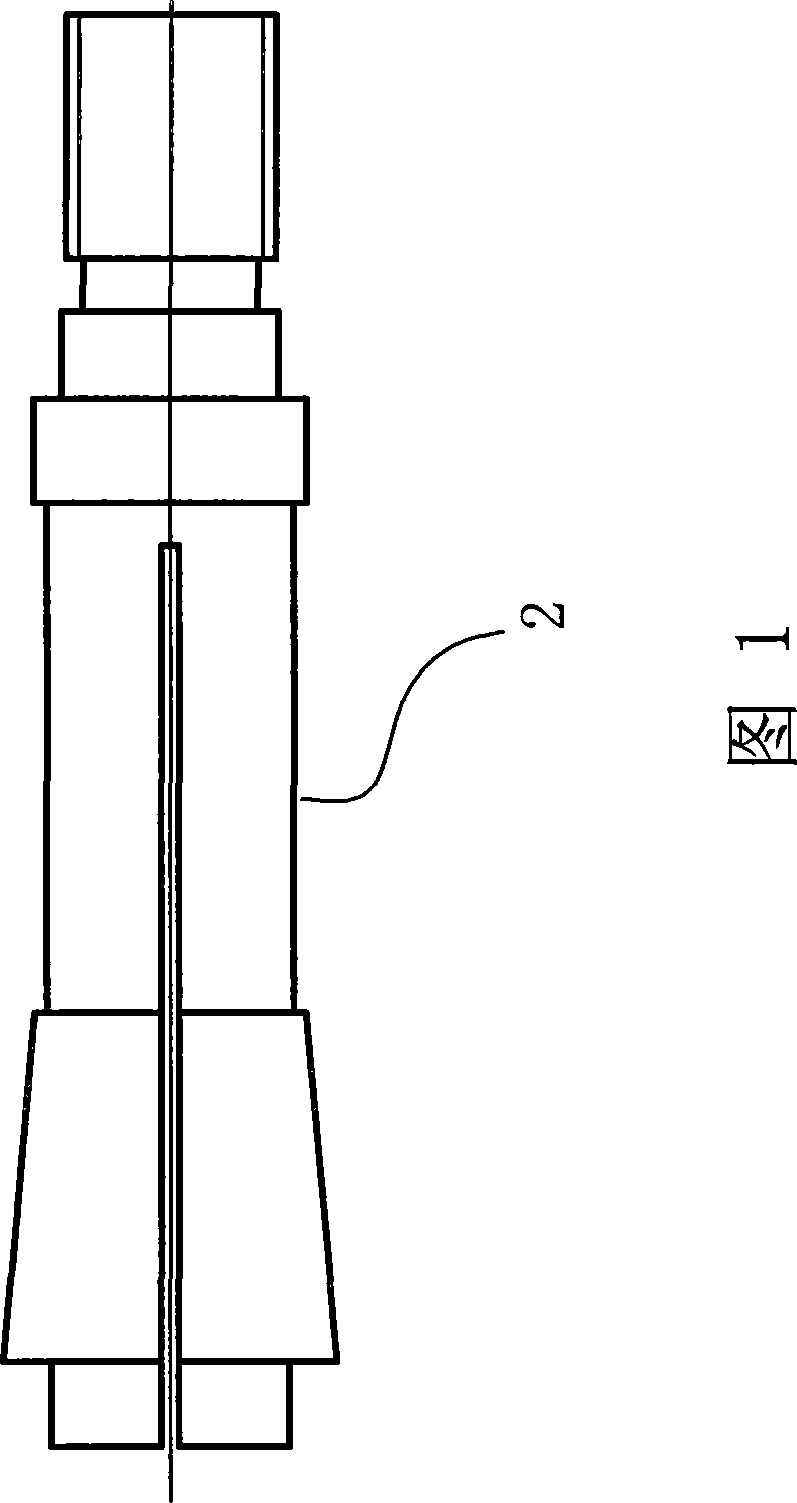

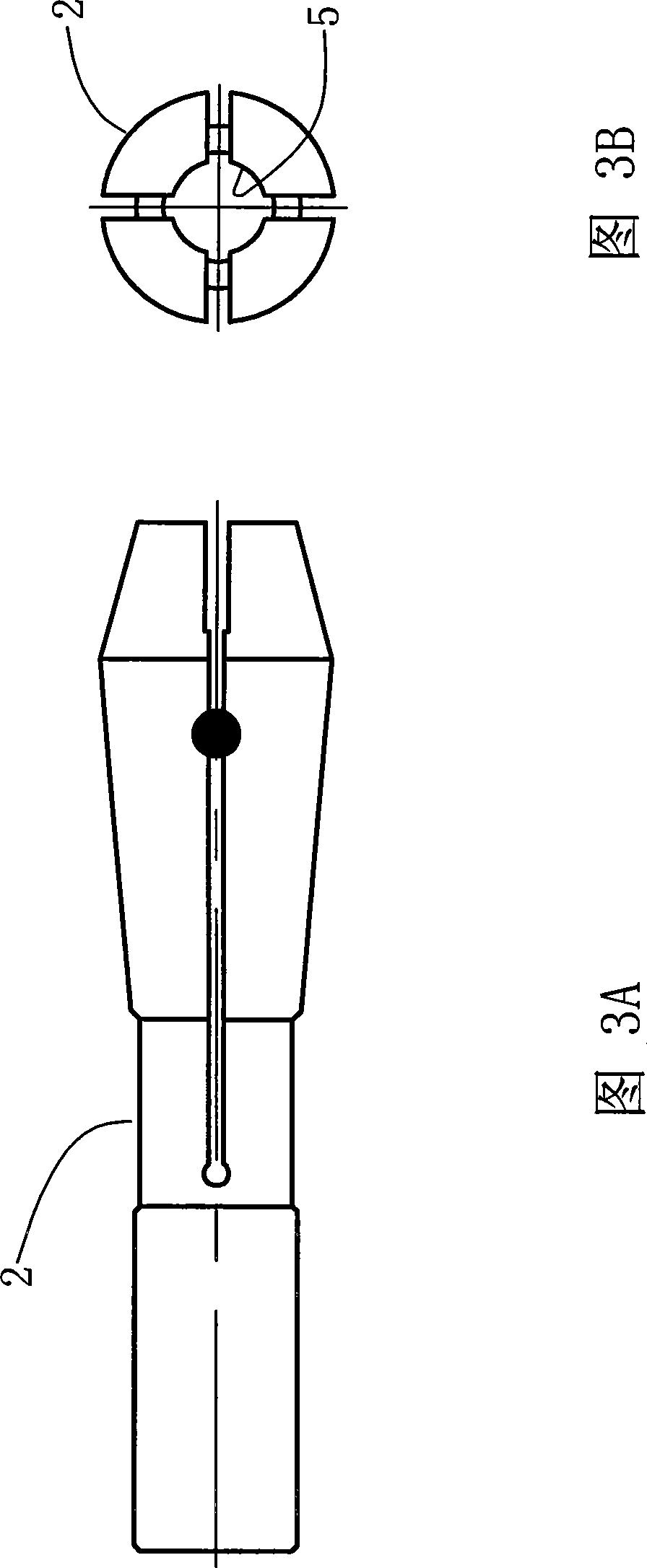

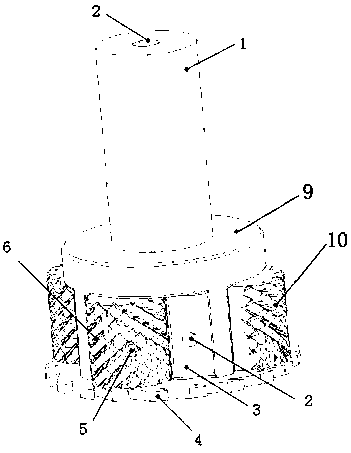

Milling cutter provided with equidistant arc head on eccentric shape flank surface and grinding method

InactiveCN104959667AAvoid vibrationExtend your lifeMilling cuttersWorkpiecesMilling cutterEngineering

The present invention relates to a milling cutter provided with an equidistant arc head on an eccentric shape flank surface and a grinding method, the cutter can reduce the vibration during the process of processing of different hardness of hardened steels for splicing of a mould, the cutter life and workpiece surface quality can be improved, the flank surface shape can be changed, and the cutter tip strength can be improved. The milling cutter is an overall hard alloy end milling cutter. The milling cutter includes a cutter shank (1) and the arc head (2), the arc head includes a large curvature arc (2-1) and a small curvature arc (2-2). Tooth-spacing angles are 87 degrees, 93 degrees, 87 degrees, and 93 degrees, tooth-spacing vertical angles are equal, helix angle (r) is 38 degrees, helix angle (v) is 40 degrees, and cutter end cutting edge flank surface (10) and circumferential cutting edge (6) are in eccentric shape. Front angle is in the range of 0-3 degrees, first clearance angle is in the range of 8-10 degrees, and second clearance angle is in the range of 15-22 degrees. The center position of the cutter is provided with cooling channels (3), the number of the cooling channels is four, and the four cooling channels respectively are located four cutting edge end tooth chip pockets. The present invention also provides a reference for the grinding of the cutter of the type.

Owner:HARBIN UNIV OF SCI & TECH

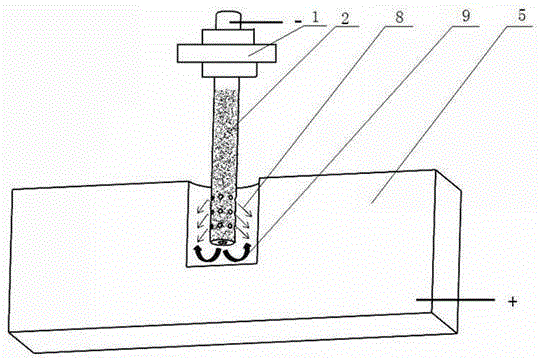

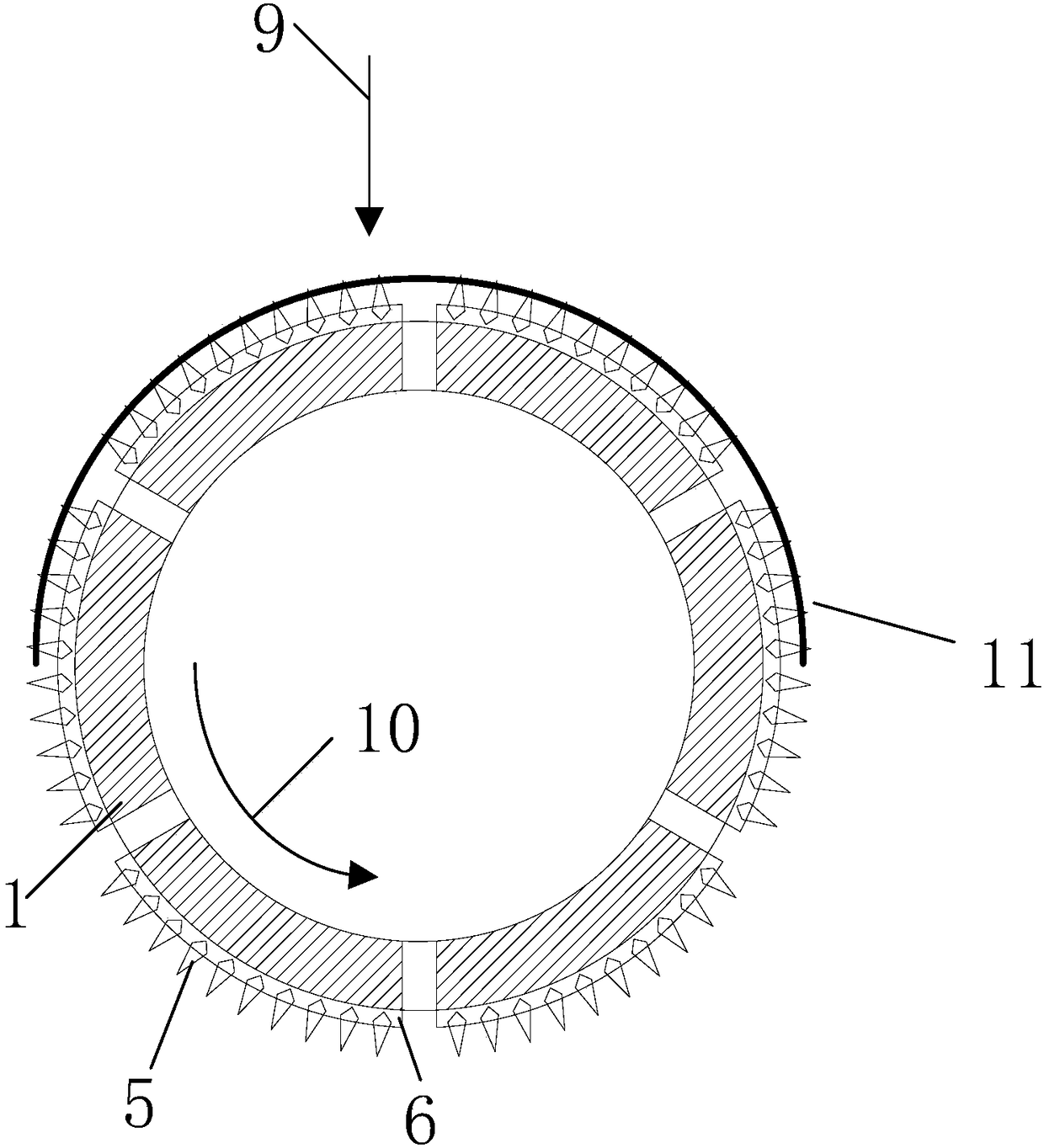

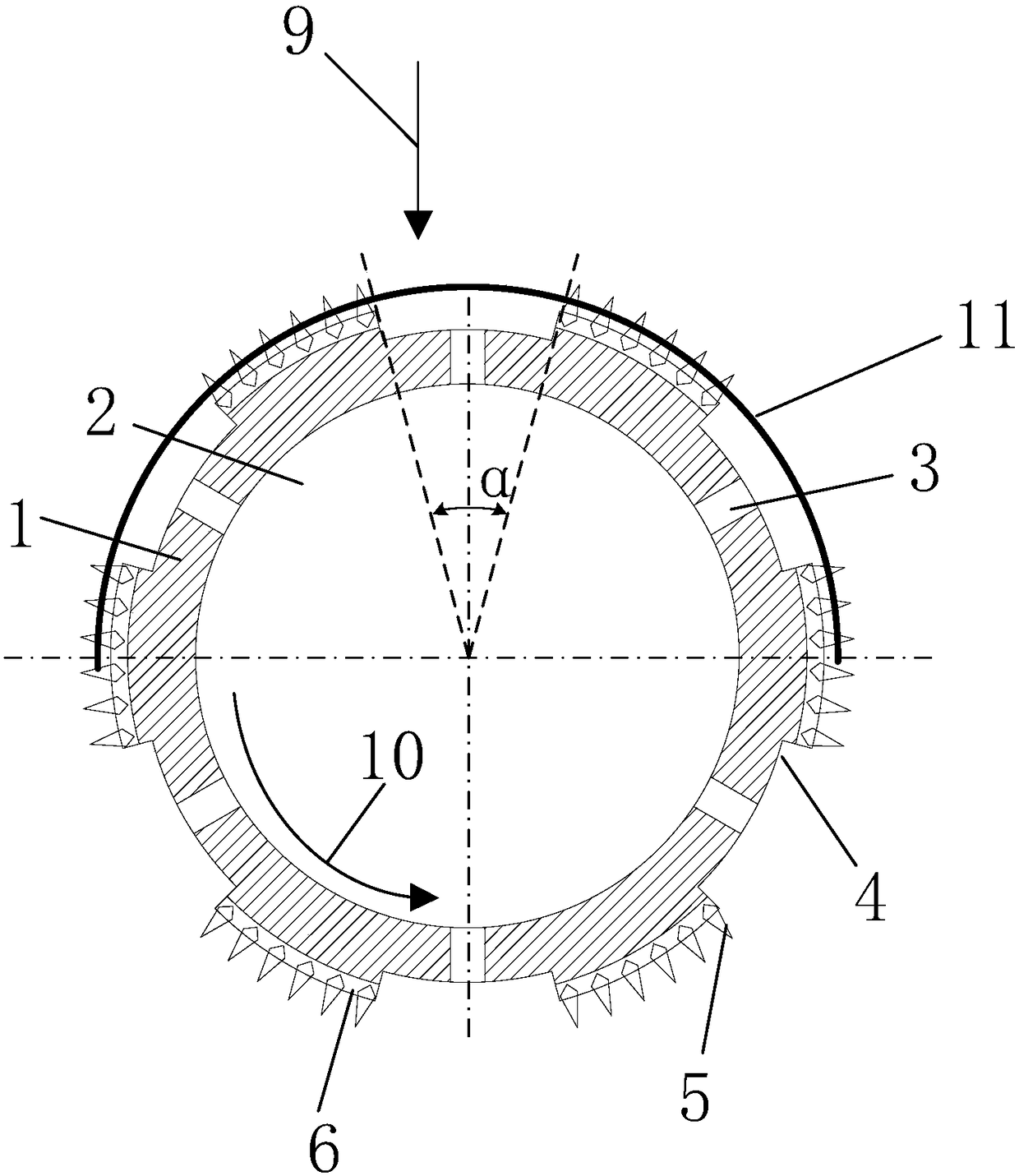

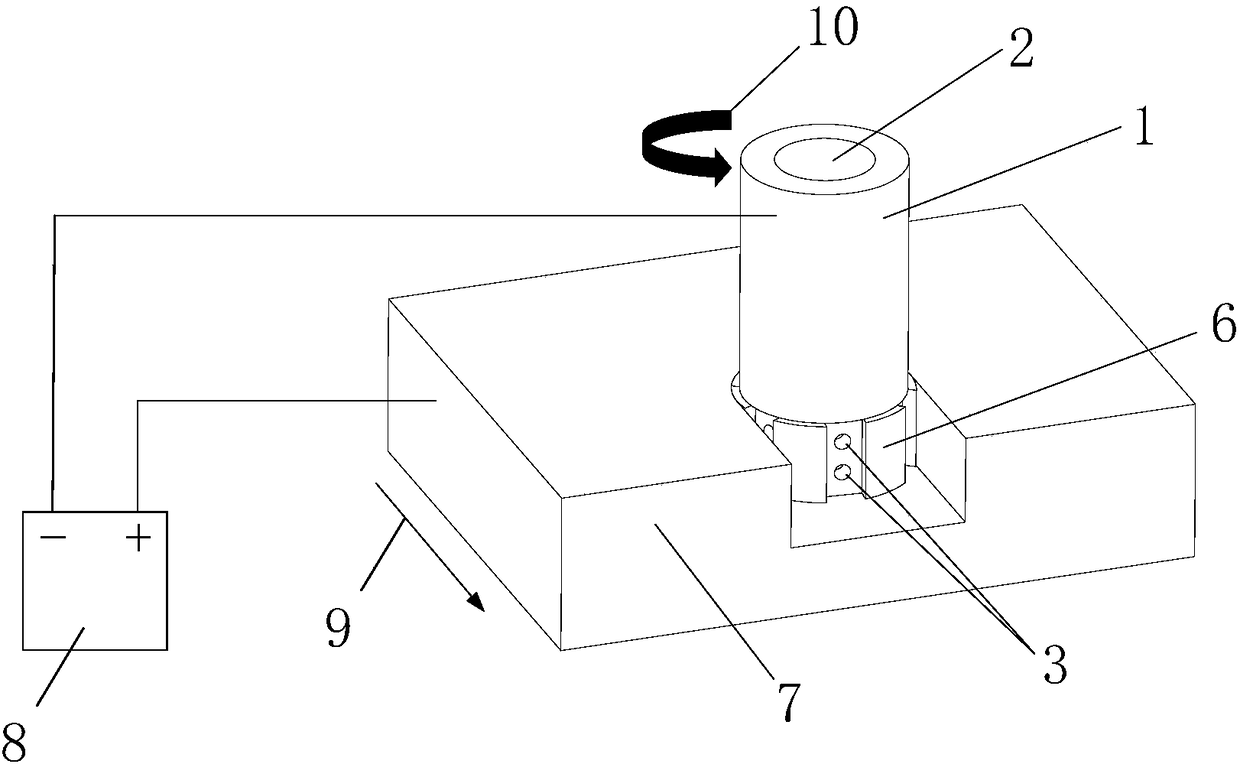

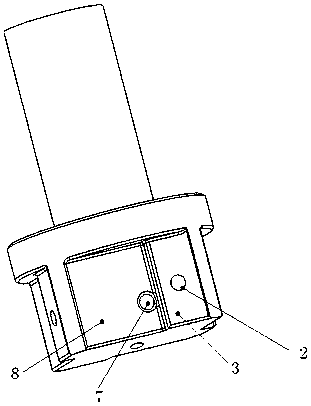

Electrolytic milling-grinding machining tool cathode with efficiency and precision and electrolytic milling-grinding method

The invention relates to an electrolytic milling-grinding machining tool cathode with efficiency and precision and an electrolytic milling-grinding method, and belongs to the field of electrolytic milling-grinding composite machining. According to the electrolytic milling-grinding machining tool cathode and the electrolytic milling-grinding method, a plurality of arc-shaped grooves at equal intervals are formed in the lower end of the side wall of the tool cathode, the side walls of the grooves are insulated, and diamond abrasive particles are inlaid in the wall surfaces of the portions, except for the grooves, of the side wall of a cathode base body through a resin binder, so that electrochemical anodic dissolution only exists in the surfaces of the portions, opposite to the grooves, of aworkpiece, at the moment, the depths of the grooves become a part of a machining gap, accordingly the contact depth between the diamond abrasive particles in the portions, except for the grooves, ofthe side wall of the cathode base body and the machining surface of the workpiece is increased, then the grinding effect of the diamond abrasive particles on the workpiece in the electrolytic milling-grinding process is enhanced, and the precision and the surface quality of the electrolytic milling-grinding machining can be improved; and moreover, compared with the electrolytic milling-grinding finish machining under the low current density in the past, the tool cathode can adopt higher current density, and the machining efficiency can be improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

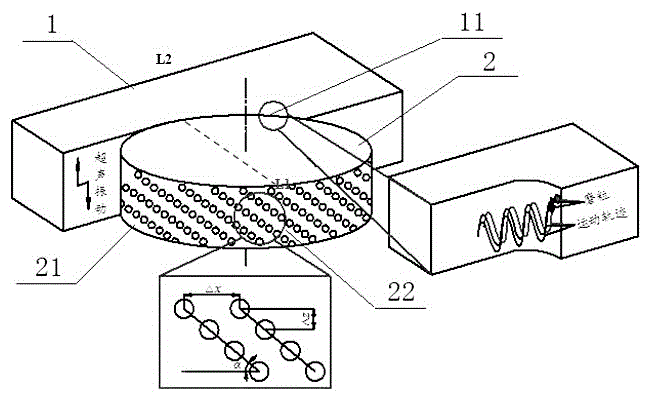

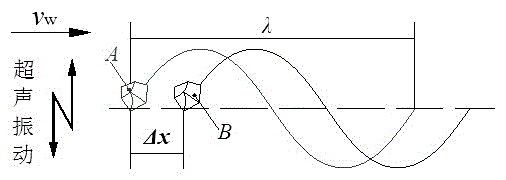

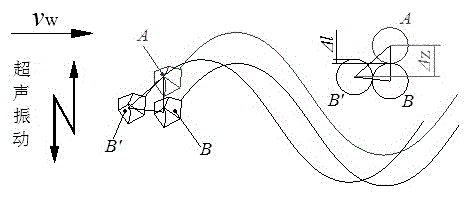

Ultrasonically-assisted grinding wheel grinding grain arrangement strategy and grinding grain thickness cutting model establishment method

ActiveCN106272118AOvercoming the defect that the quality of ultrasonic-assisted grinding is too dependent on engineering practice experienceEasy to implementGeometric CADBonded abrasive wheelsMetallurgyMachining process

The invention relates to an ultrasonically-assisted grinding wheel grinding grain arrangement strategy and a grinding grain thickness cutting model establishment method. The single grinding grain movement track during ultrasonically-assisted grinding is taken as the spacial sine curve characteristic, grinding grain circumferential spacing delta x, grinding grain axial spacing delta z and grinding grain arrangement angle beta which can reinforce the grinding wheel working layer grinding grain movement track overlapping action are determined, the control method for ultrasonically-assisted grinding wheel working layer grinding grain arrangement is put up, further the relation between single grain thickness cutting aU[gmax] during ultrasonically-assisted grinding and single grain thickness cutting a[gmax] during ordinary grinding is established according to the calculation method of the grinding layer average volume, and then the aU[gmax] is obtained according to the a[gmax]. Accurate control of the single grain grinding thickness cutting in the ultrasonically-assisted grinding process is realized so that accurate control of the processing surface quality is realized, and the defect that the existing ultrasonically-assisted grinding processing surface quality mainly depends on project practical experience is overcome.

Owner:JIANGSU UNIV OF TECH

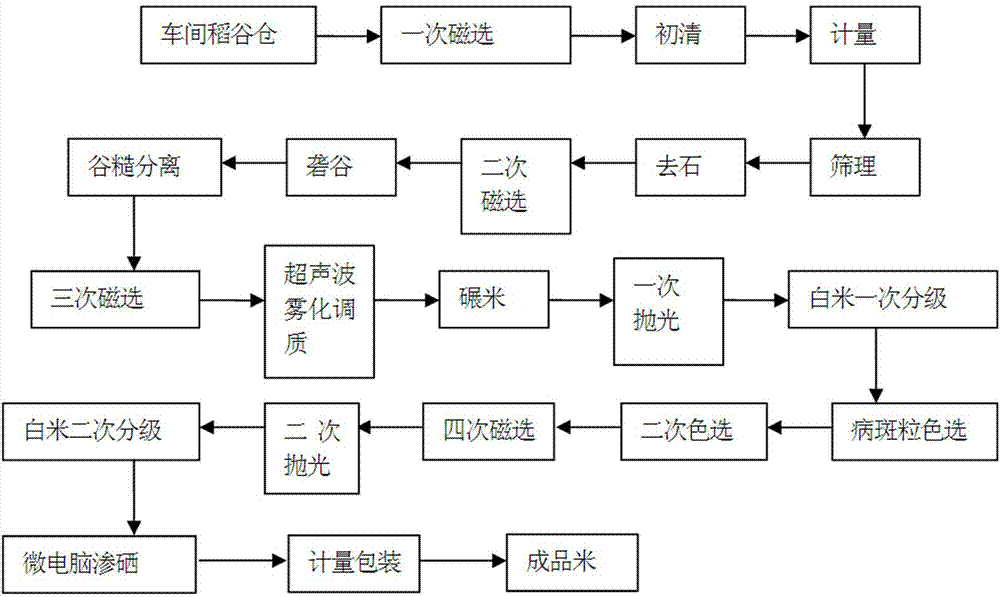

High-quality rice fine processing process

ActiveCN104772178AImprove Sorting Efficiency and PurityImprove the quality of finished riceSortingGrain millingSecondary colorChemistry

The invention provides a high-quality rice fine processing process, which comprises the processing flow processes of primary magnetic separation, primary cleaning, metering, sieving, stone removing, secondary magnetic separation, husking, husked rice separation, tertiary magnetic separation, ultrasonic atomization tempering, rice milling, primary polishing, polished rice primary grading, spotted rice color separation, secondary color separation, fourth magnetic separation, secondary polishing, polished rice secondary grading and metering and packaging. According to the ultrasonic atomization tempering, an ultrasonic atomization humidification mode is used for humidifying the rice, the tempering time is 10 to 20 minutes, the tempering temperature is controlled to be between 30 DEG C and 40 DEG C, the unit humidification quantity is 0.5 to 5 percent, the actual seeping quantity is 2 to 3 percent, and the moisture content of the polished rice finally obtained through processing is not greater than 14 percent; tempering agents adopt ultrasonic atomization water; during the spotted rice color section, a photoelectric color separation device is used for automatically picking out different-color rice, the full-process temperature reduction is carried out in the whole processing flow process, and the temperature rice in the processing process is controlled not to exceed 5 DEG C. The high-quality rice fine processing process has the advantages that the high-quality rice can be subjected to integrated utilization and deep processing, and the final product quality is improved.

Owner:YUNNAN HONGHE WOLONG RICE IND CO LTD

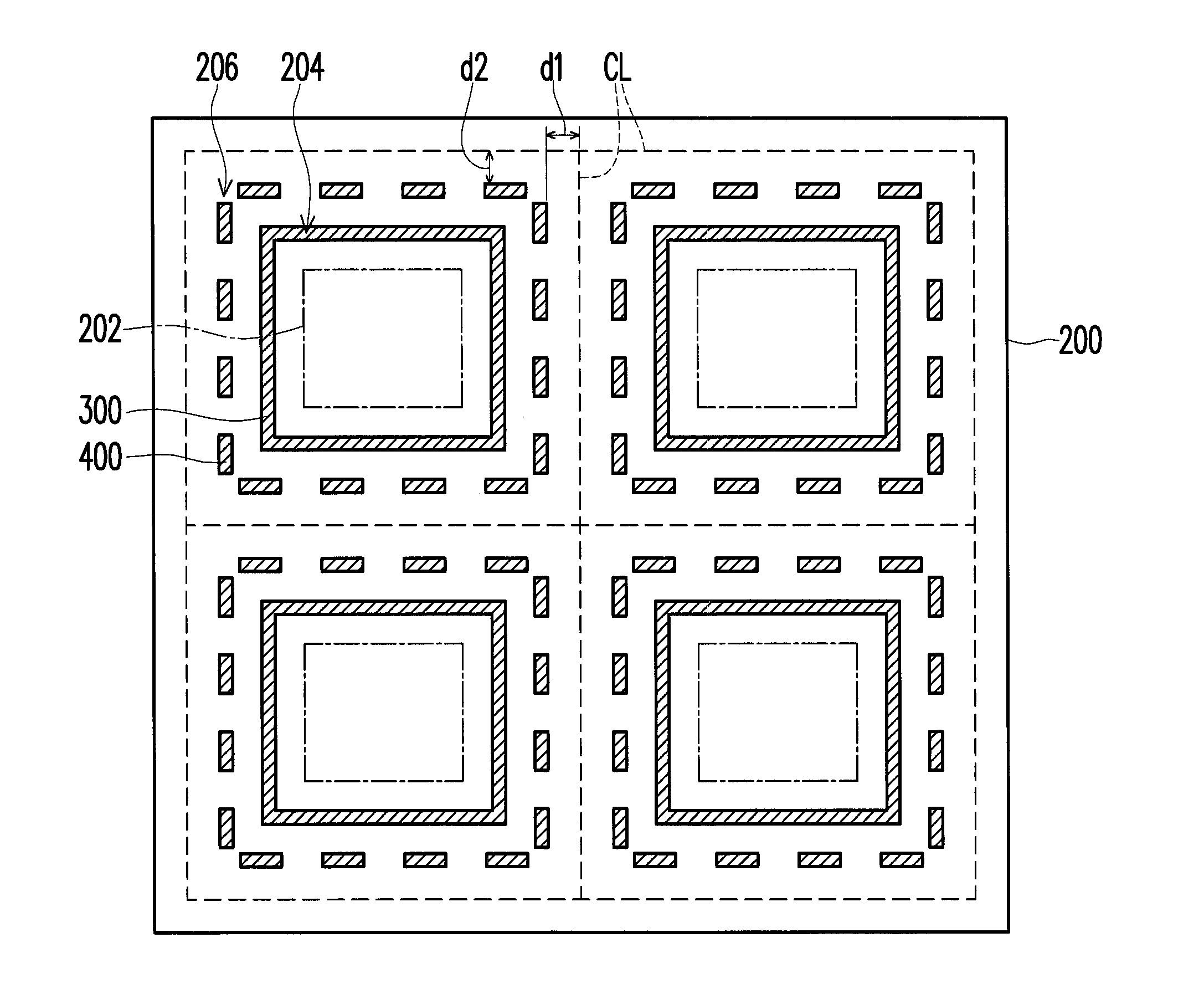

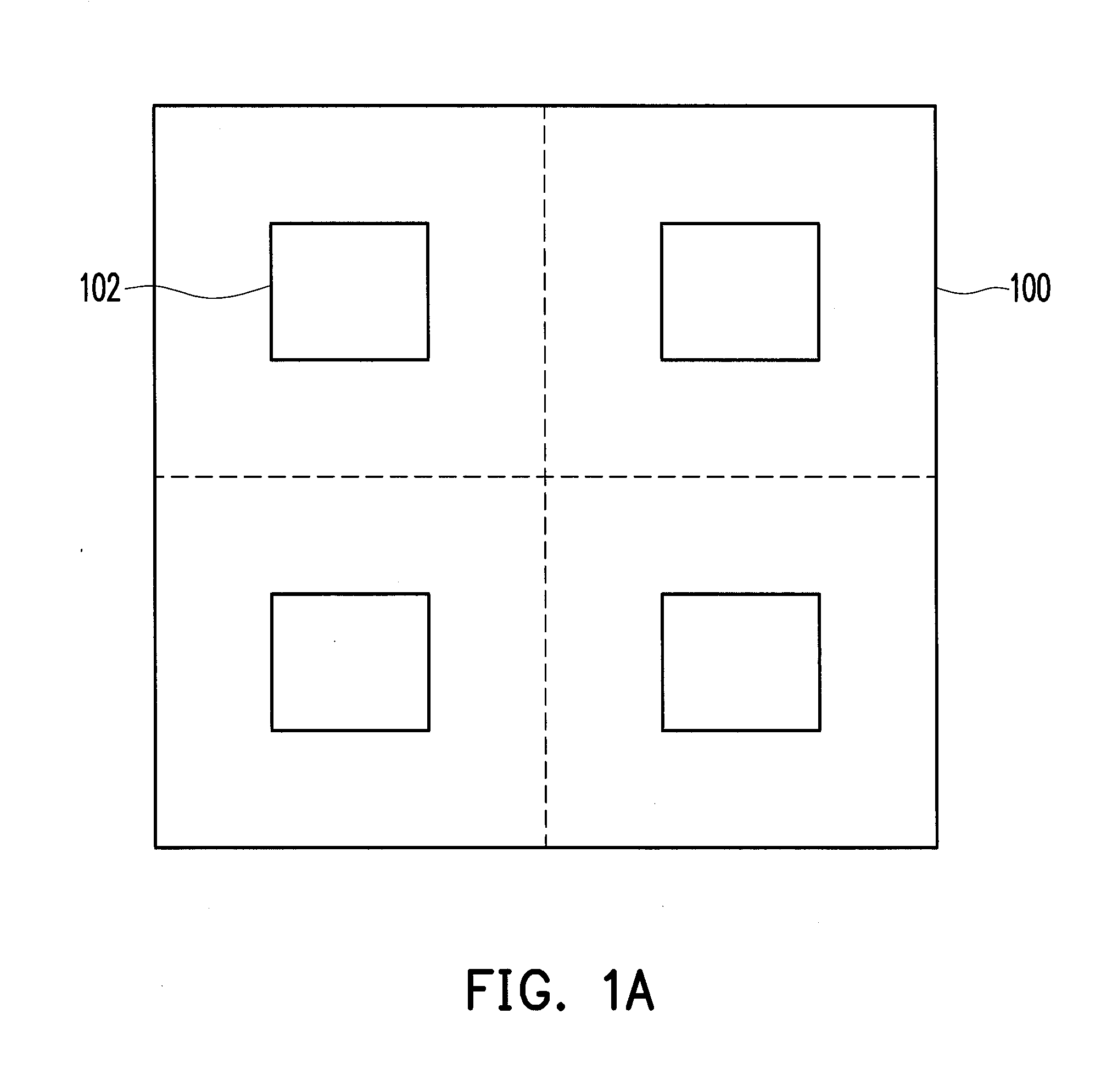

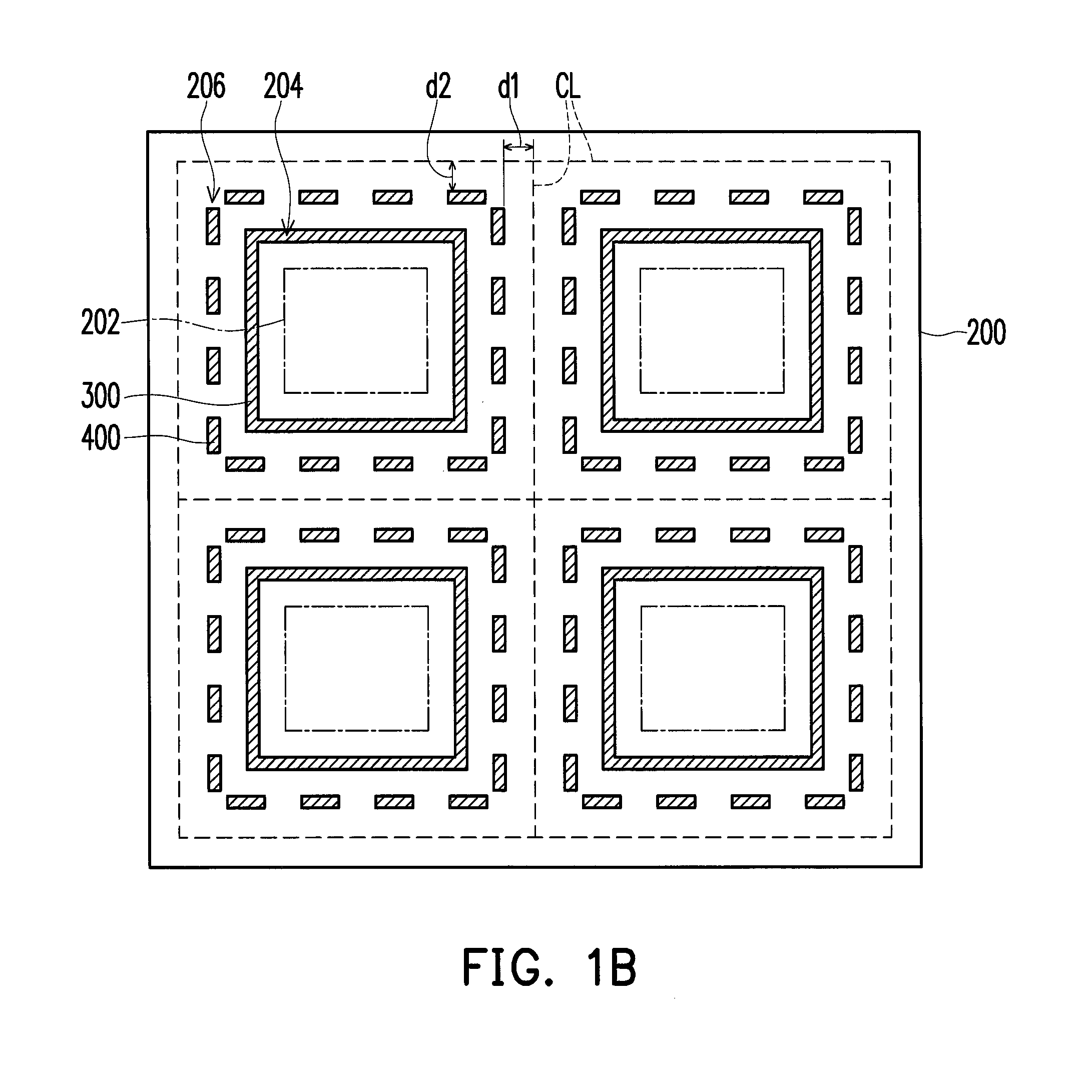

Mother substrate structure of light emitting devices, light emitting device and method of fabricating the same

ActiveUS20120294003A1Prevent processing damageAvoid processing qualityLamination ancillary operationsLighting support devicesLight emitting deviceMaterials science

A mother substrate structure includes a mother substrate, a cover plate, a sealant and a spacer structure. The mother substrate has light emitting units thereon. The cover plate is disposed above the mother substrate and has unit regions, each unit region corresponding to one of the light emitting unit. The cover plate has a cutting line around each unit region, sealant regions between the cutting line and each of the unit regions, and spacer disposing regions between the cutting line and each of the sealant regions, wherein a distance between the cutting line and each of the spacer disposing region is 0˜100 um. The sealant is disposed in the sealant regions to bond the mother substrate and the cover plate. The spacer structure is disposed in the spacer disposing regions and surrounds each of the light emitting units, and materials of the spacer structure and the sealant include a glass fit.

Owner:AU OPTRONICS CORP

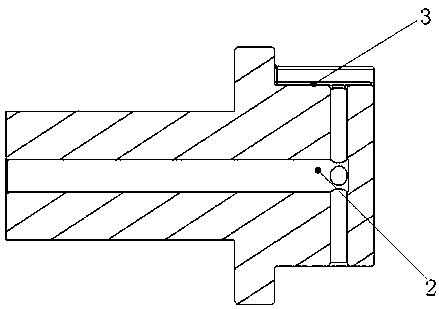

Process and testing method for PCB drilling machine drill chuck

ActiveCN101244525AAvoid processing qualityGuarantee processing qualityRevolution surface grinding machinesGrinding feed controlClosed loopCircular cone

The invention relates to a processing and detection method of drill bit chuck for PCB drilling machine, comprising: a. Using a closed-loop CNC cylindrical grinder to grind the external conical surface and external cylindrical surface of the chuck to make the straightness of the external conical bus of the chuck and the circularity of the cylindrical surface meet the design requirement; b. When processing the conic angle of the chuck through moving the grinder rail, using percent meter or dial indicator to ensure the design precision of the conic angle; c. Inserting a special mandrel in the guide hole of the chuck, the centre holes of both ends of the mandrel is the benchmark, fine grinding the conical surface and the external cylindrical surface to meet the requirement, using the center hole of the mandrel to locate and detect the straightness of the conical bus and cylindrical surface and the flop of the conical surface, cylindrical surface of the grinded finished product. The processing and detection method has the advantages that the operation and control are easy, the processed chuck is high-precision, the comprehensive performance of the chuck meets the design and production requirement.

Owner:SHENZHEN SUFENG TECH

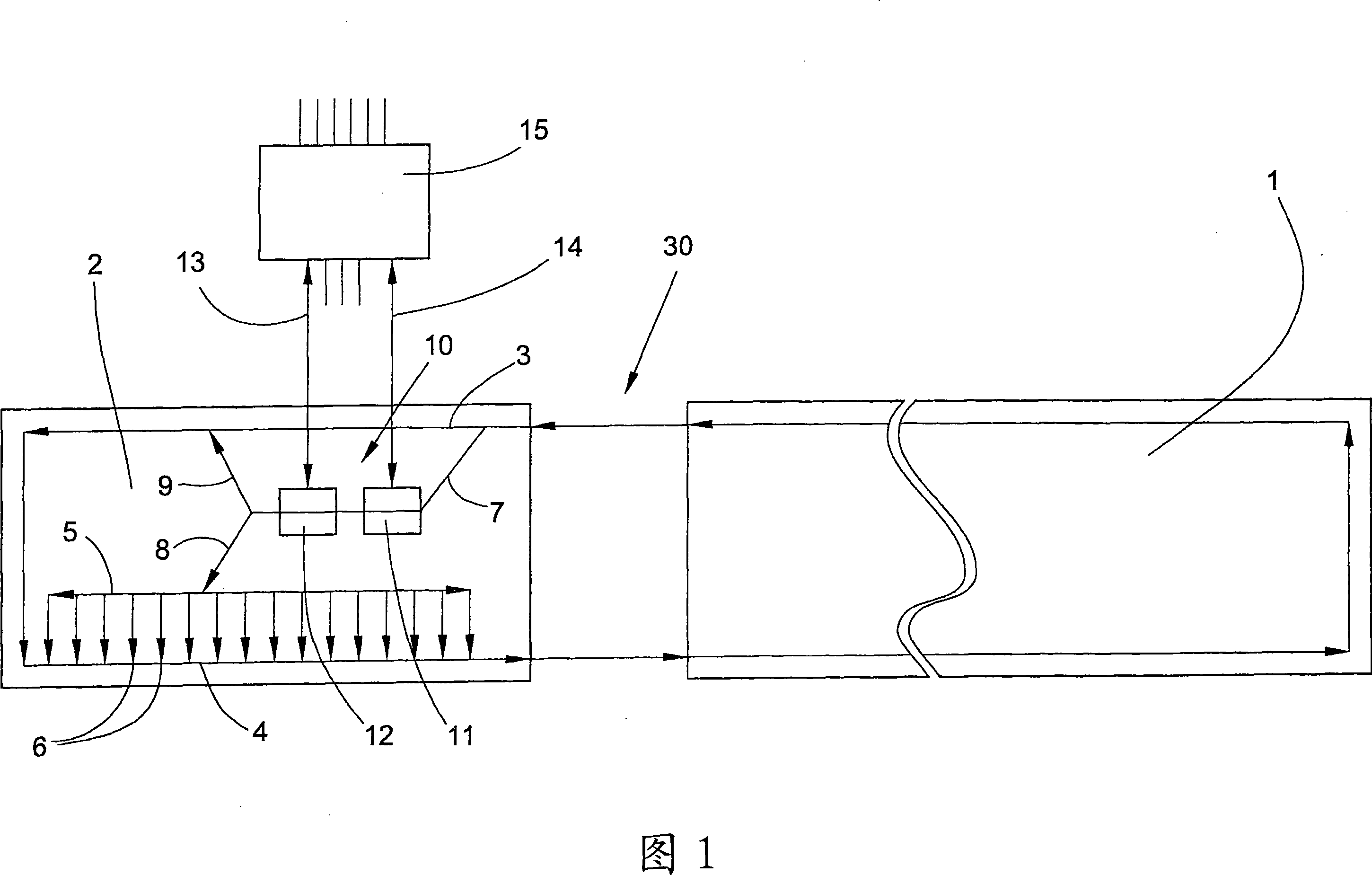

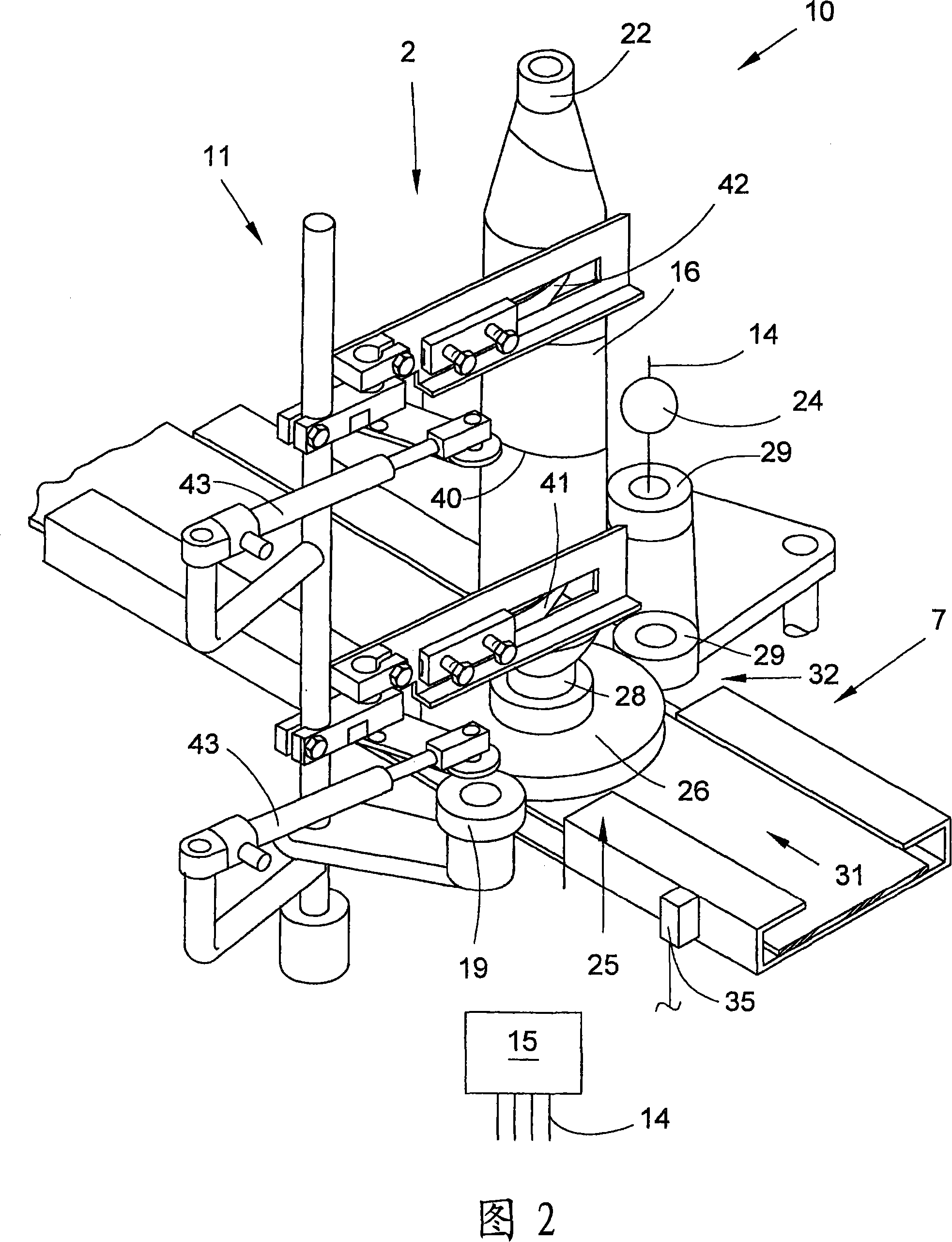

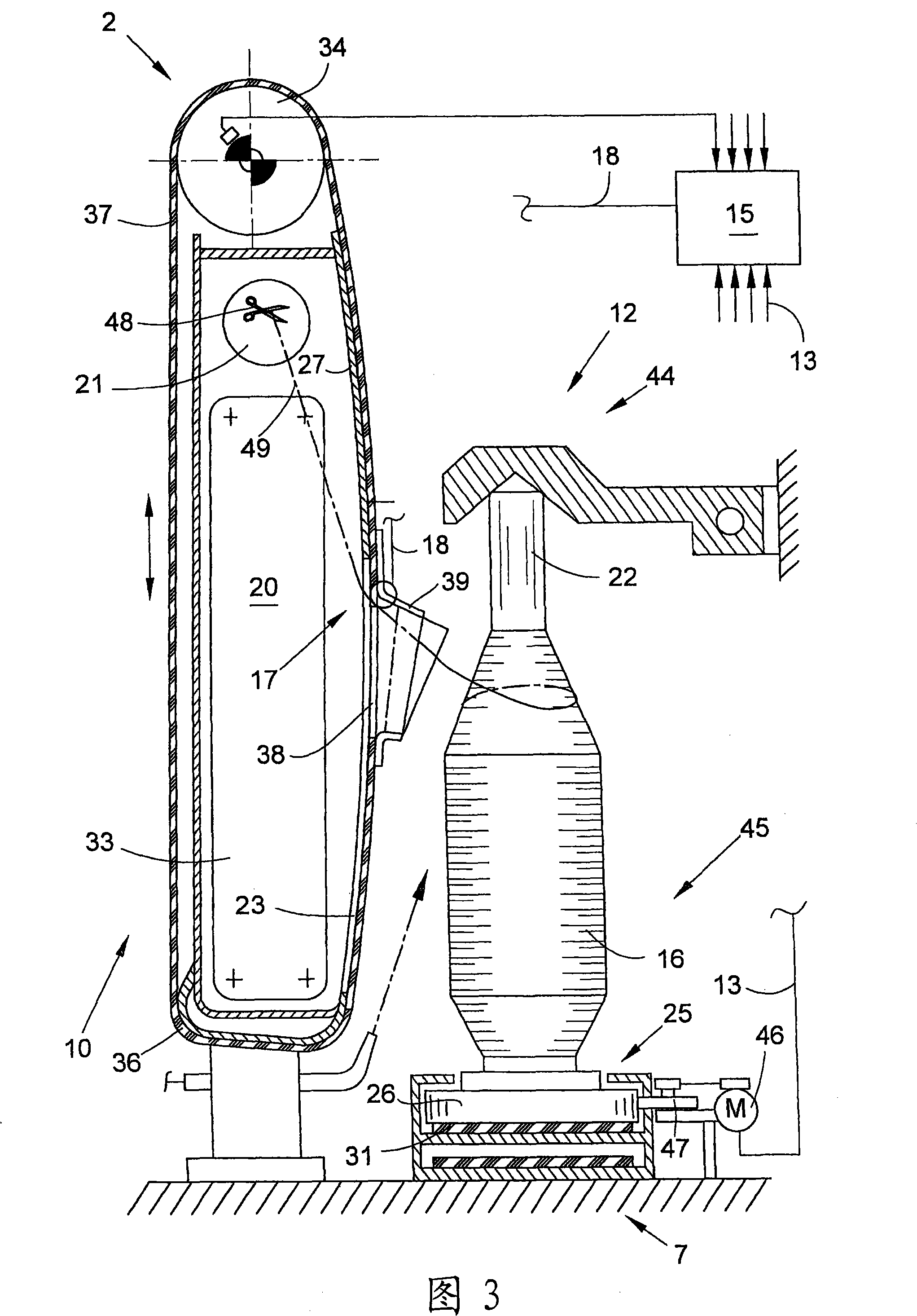

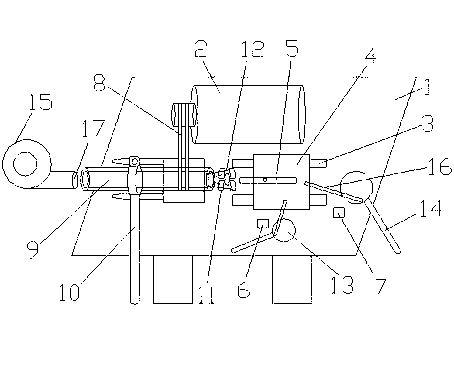

Method and device for preprocessing bobbin so as to compound-wound at an automatic cross-wound bobbin winder

The invention relates to a method of preprocessing bobbin made in a spinning machine to be rewound in an automatic cross-wound machine. Herein, the yarn preprocessing device comprises a yarn start station for starting a yarn and a yarn taking station for taking and setting the yarn at a preprocessing position. Activating mechanism for activating the bobbin to rotate around the longitudinal axle is provided at the yarn starting station and the yarn taking station respectively. The yarn taking station has a sensor for detecting taking the yarn successfully. According to the invention the number of revolution of each bobbin (16) is counted and reported to the controller (15) before the sensor (17) detects the yarn is taken successfully in the yarn taking station (12). An average value (MW) of bobbins (16) average revolutions in the yarn taking station (12) is calculated in the controller (15), and the top number of revolution is adjusted referring to MV. The subsequent bobbin (16)in the yarn taking station (12) will rotate with the top number of revolution when the yarn is not taken in successfully.

Owner:SAURER SPINNING SOLUTIONS GMBH & CO KG

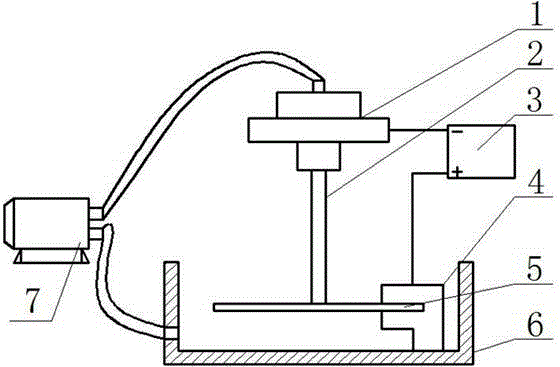

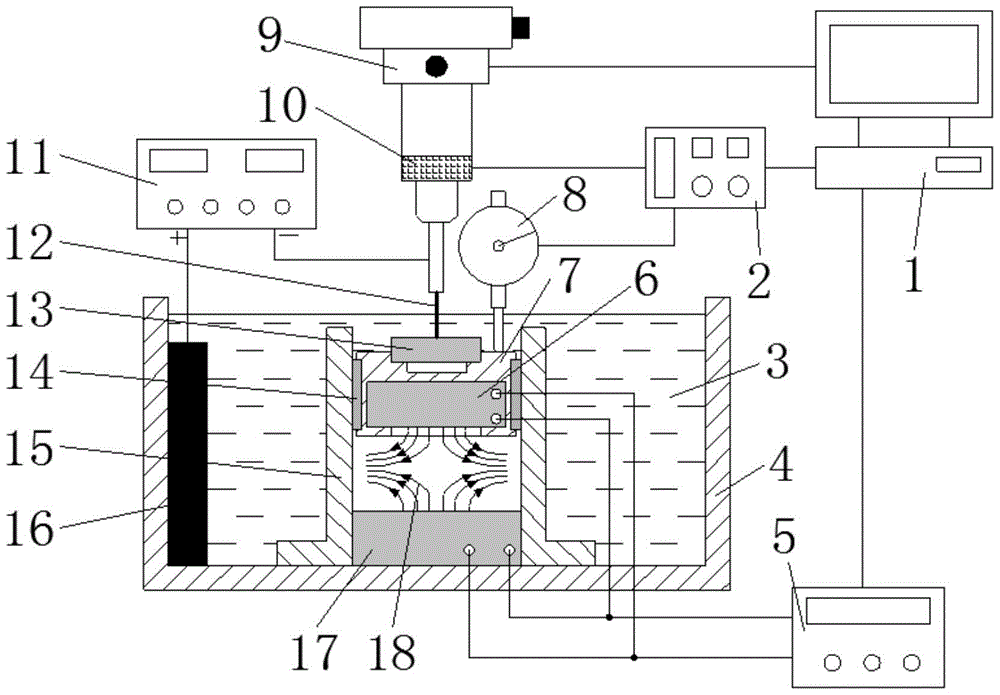

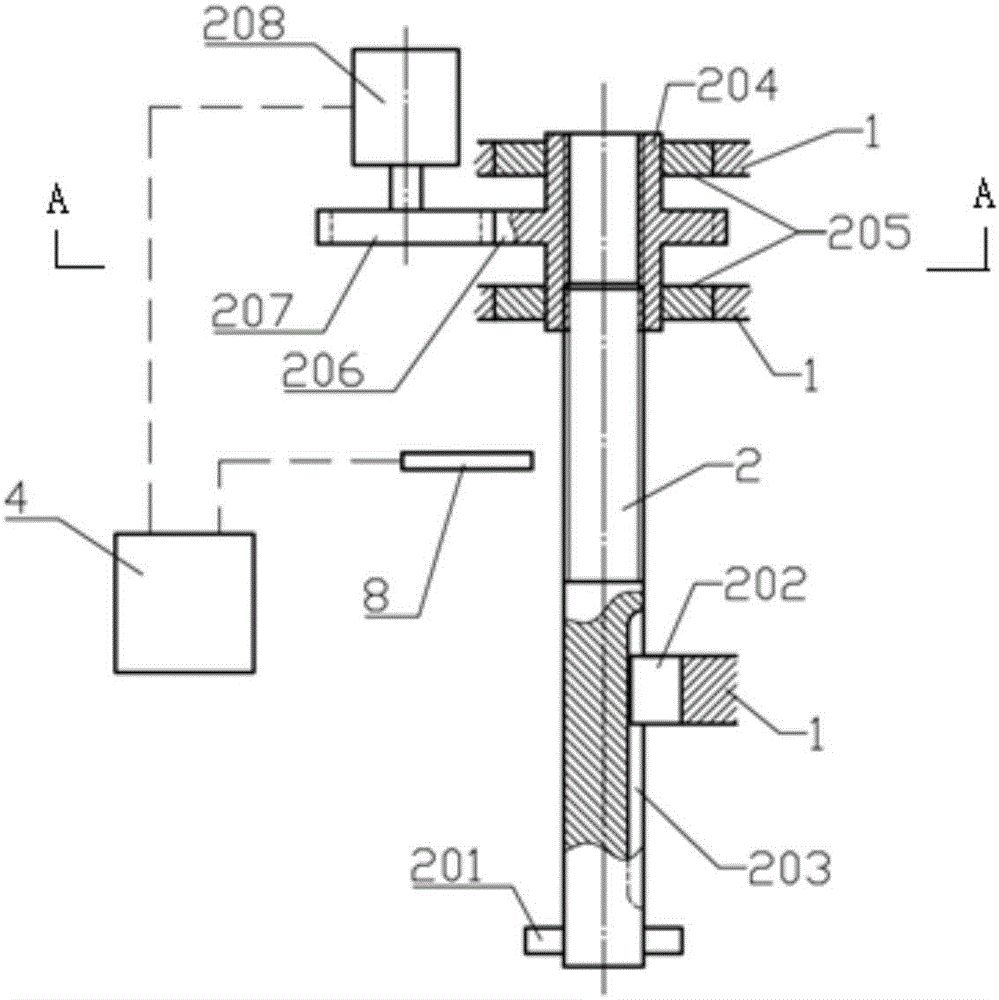

Magnetic feeding type electrolysis electric spark combined machining method and device

ActiveCN105033374APrecise control of contact forceAvoid processing qualityElectric circuitsManufacturing technologyElectrolysis

The invention provides a magnetic feeding type electrolysis electric spark combined machining method and device. A magnetic field is generated by an electromagnetic device, pushing force is generated under the effect that same magnetic poles of the magnetic field repel each other to push a sliding base, and the sliding base drives workpieces to conduct feeding; a force sensor and a distance sensor are arranged, and the contact force between an electrode of a tool and the workpieces and the machined depths of the workpieces are detected; data are collected through a data collecting card and uploaded to a computer, and analysis and comparison are carried out through the computer; and the contact force between the electrode of the tool and the workpieces is accurately adjusted through a control system, the magnitude of contact force generated when the workpieces are located at the positions with different depths is adjusted, and a force feedback adjusting system and a machining depth feedback adjusting system are constructed. The magnetic feeding type electrolysis electric spark combined machining method and device are suitable for efficient and accurate machining of insulation crisp and hard materials, and belongs to the field of special machining in the manufacturing technology.

Owner:JIANGSU UNIV

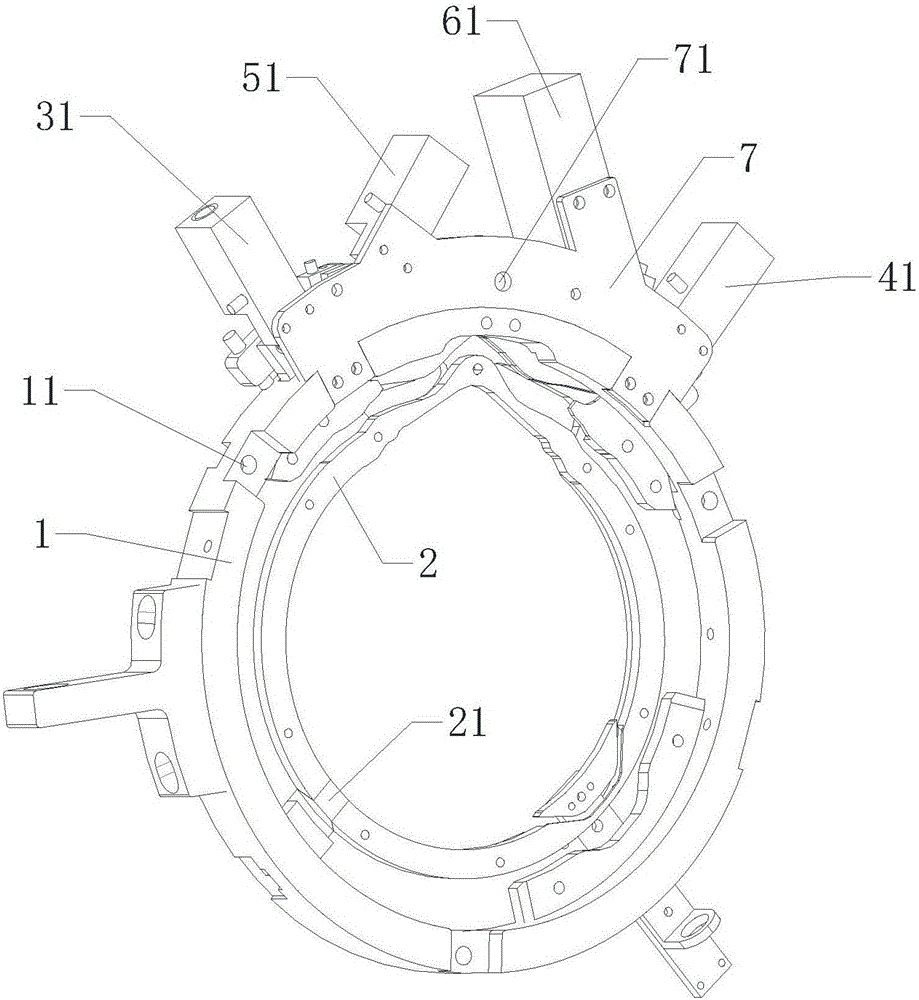

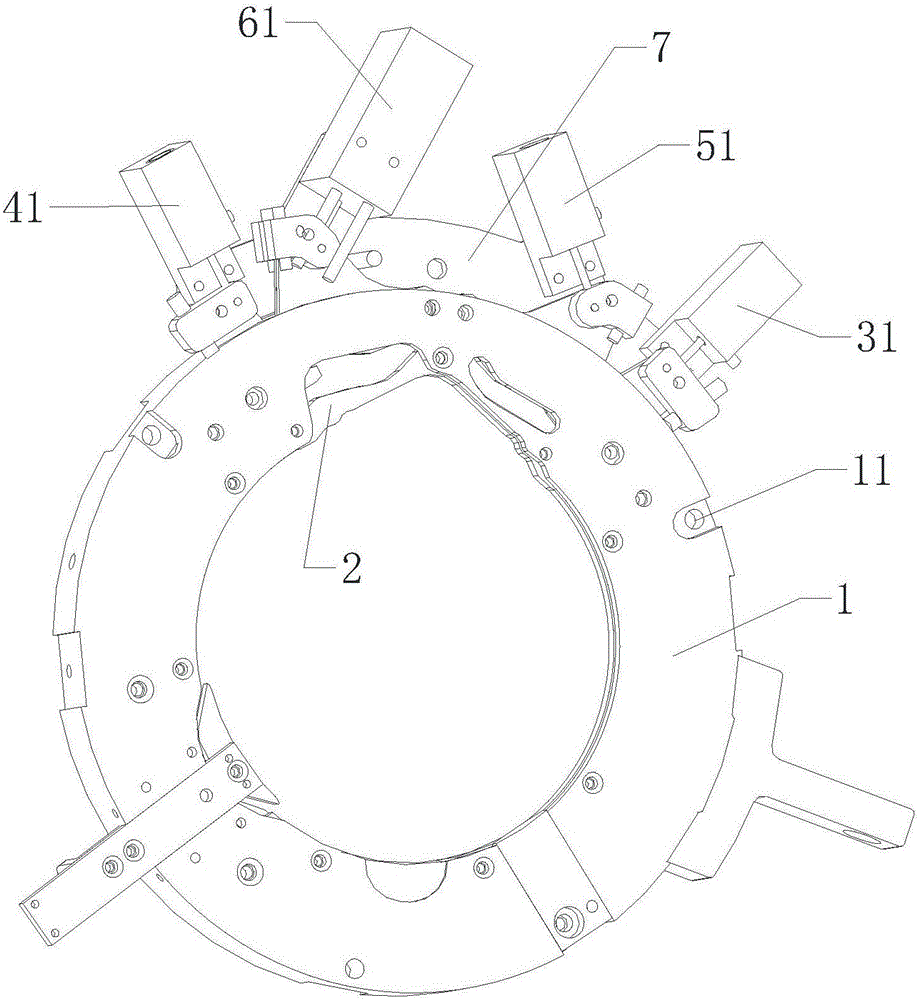

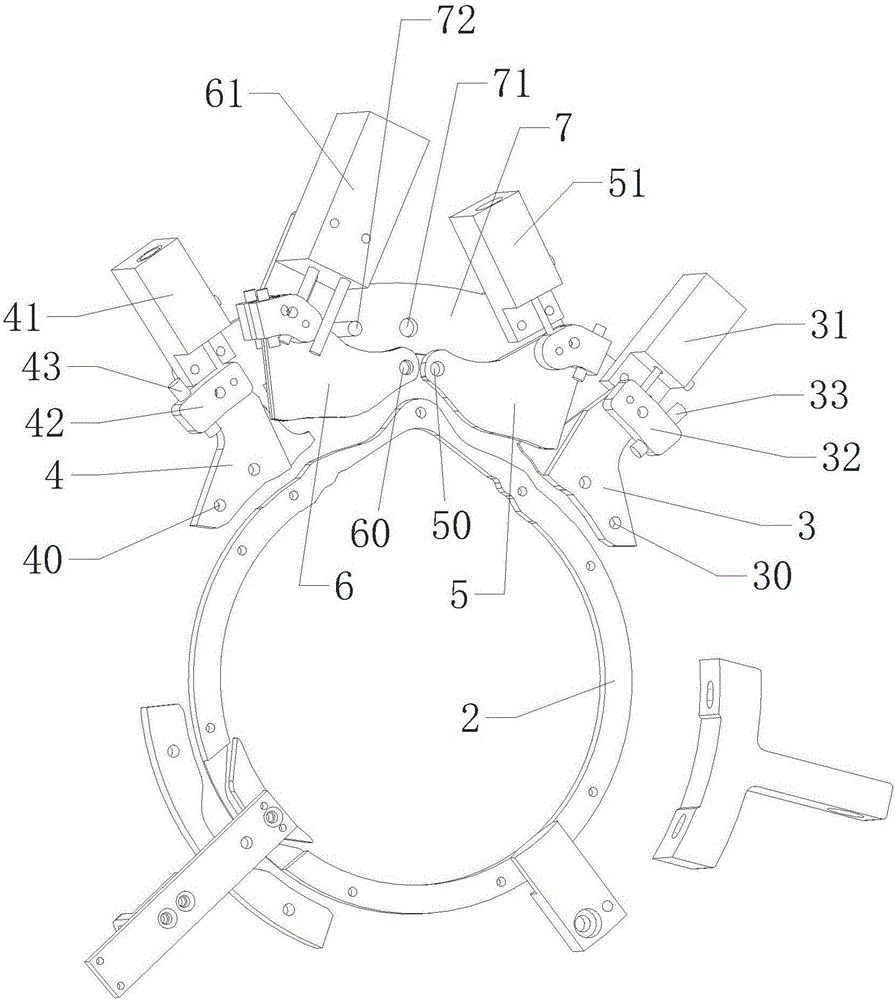

Sinker cap

The invention provides a sinker cap. The sinker cap comprises a sinker cap body, a middle brow, a left brow and a right brow, wherein the middle brow is in an integral annular structure, the middle brow is provided with a notch, the left brow and the right brow are provided with fulcrum holes, pin shafts are installed at the positions of the fulcrum holes, and the left brow and the right brow can respectively rotate by taking the pin shafts at the positions of respective fulcrum holes as centers. Since the middle brow of the sinker cap provided by the invention is in the integral annular structure and the middle is provided with the notch, the structure is more stable and is damage-resistant, and the service life is long; since the left brow and the right brow can respectively rotate by taking the pin shafts at the positions of respective fulcrum holes as centers, the rotation of the left brow and the right brow can be controlled according to the needs in the sock weaving process, the tightness of different parts of socks is controlled, the demand for weaving different loop patterns is satisfied and the processing quality of the socks is better controlled.

Owner:ZHEJIANG YEXIAO KNITTING MACHINERY

Combined type end mill for machining paper based honeycomb composite materials

The invention discloses a combined type end mill for machining paper based honeycomb composite materials. The combined type end mill comprises a cylindrical cutter body, a cutter handle arranged on the upper end face of the cutter body and a disc-swatooth-shaped cutting knife arranged on the lower end face of the cutter body. Not less than four sets of positioning faces, chipping containing grooves and internal cooling holes which are distributed in the peripheral direction at equal intervals are arranged on the cutter body, cutting blades matched with the positioning faces are fixedly installed on the positioning faces, and knife edges of the cutting blades extend out of the cylindrical face of the cutter body; and the internal cooling holes are through holes formed inside the cutter handle and the cutter body and are communicated with the chipping containing grooves to form air outlets. The cutting blades are detachable blades composed of a plurality of left and right double helix groove type thin tooth cutting edges. By means of the combined type end mill, the cutting force and the cutting temperature of the paper based honeycomb composite materials are better reduced, defects such as deformation and tearing are prevented, when dust-shaped cutting chippings are bonded to the cutting edges and are difficult to remove, replacement with a new blade can be achieved for use, andadverse effects caused by the fact that the dust cutting chippings are bonded to the cutting edges are avoided.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

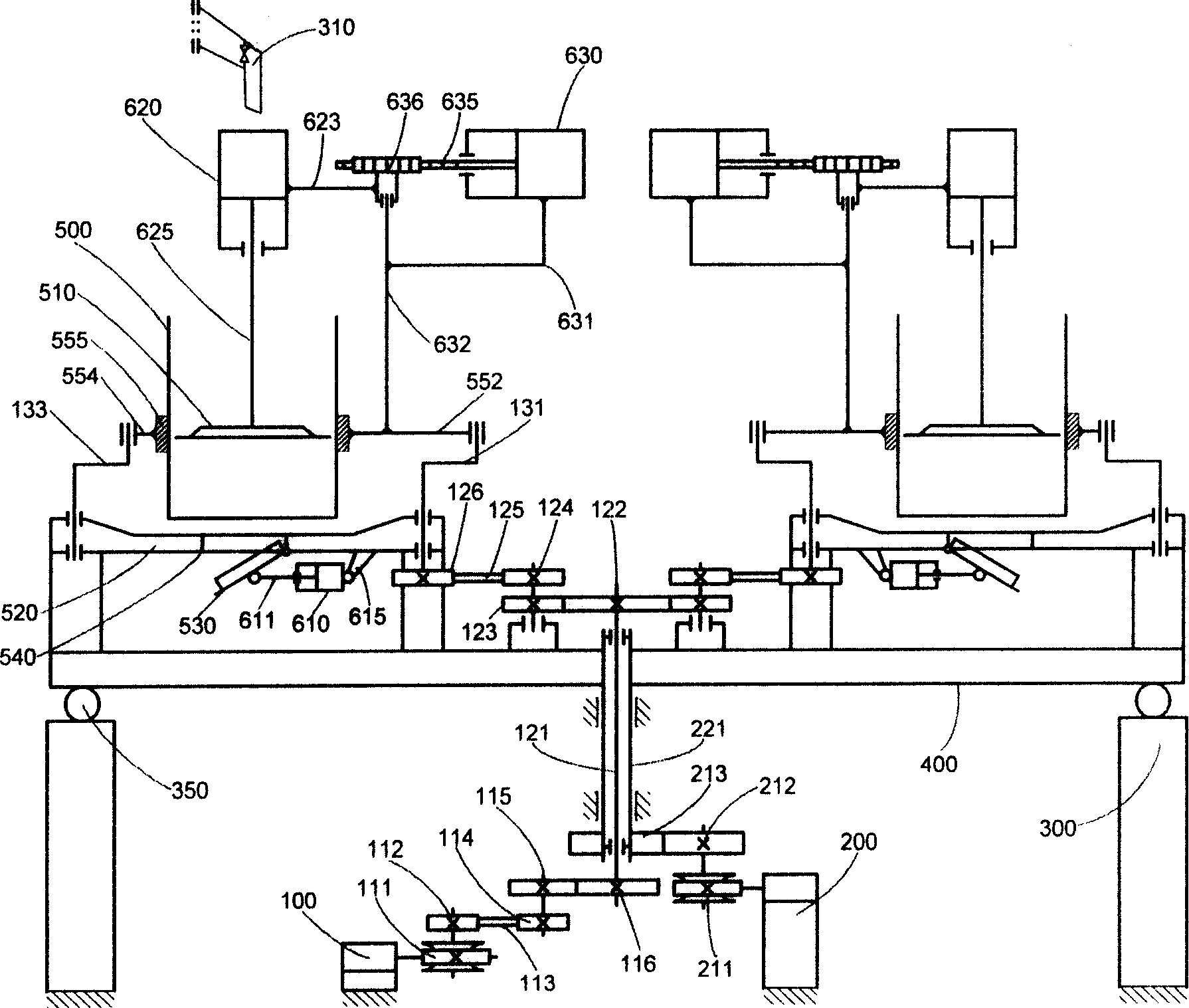

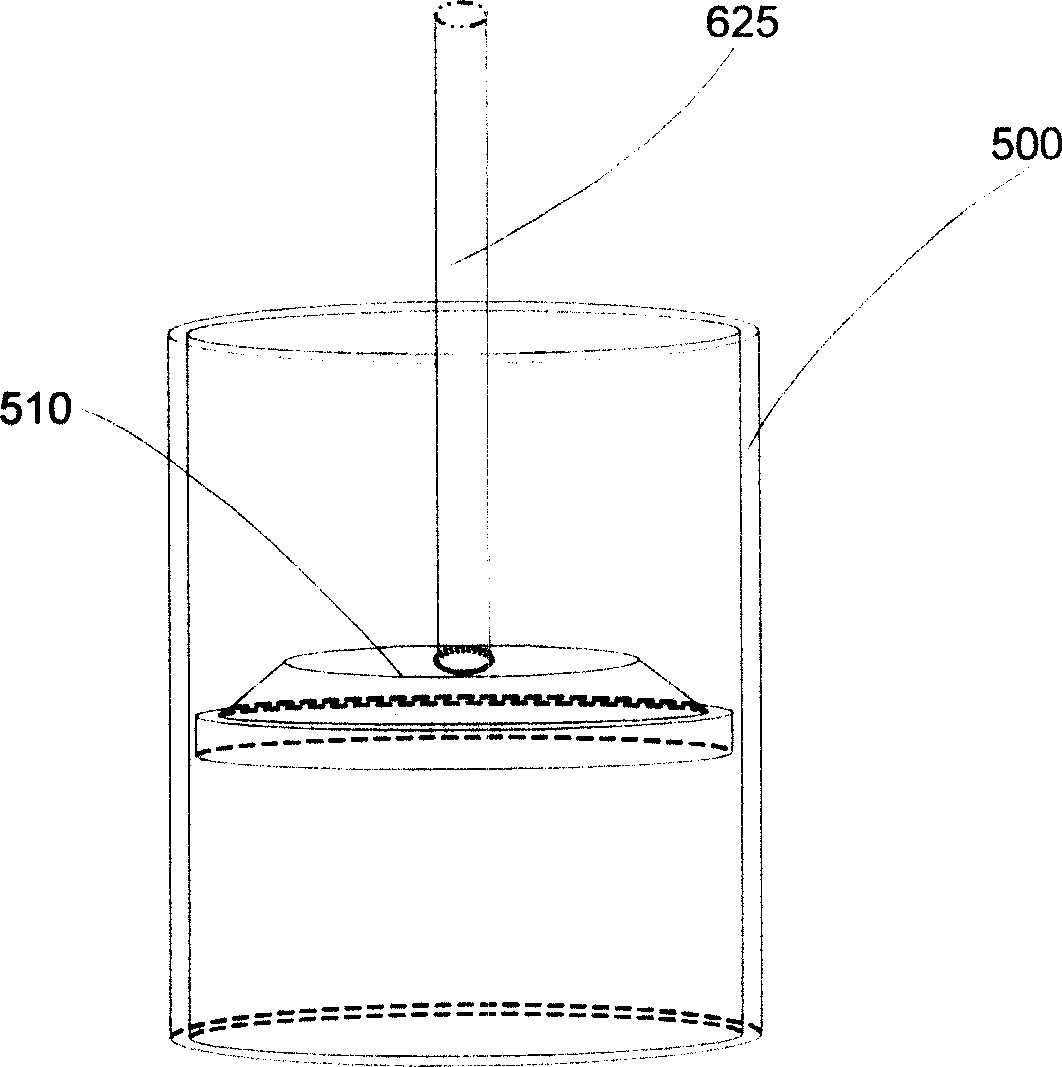

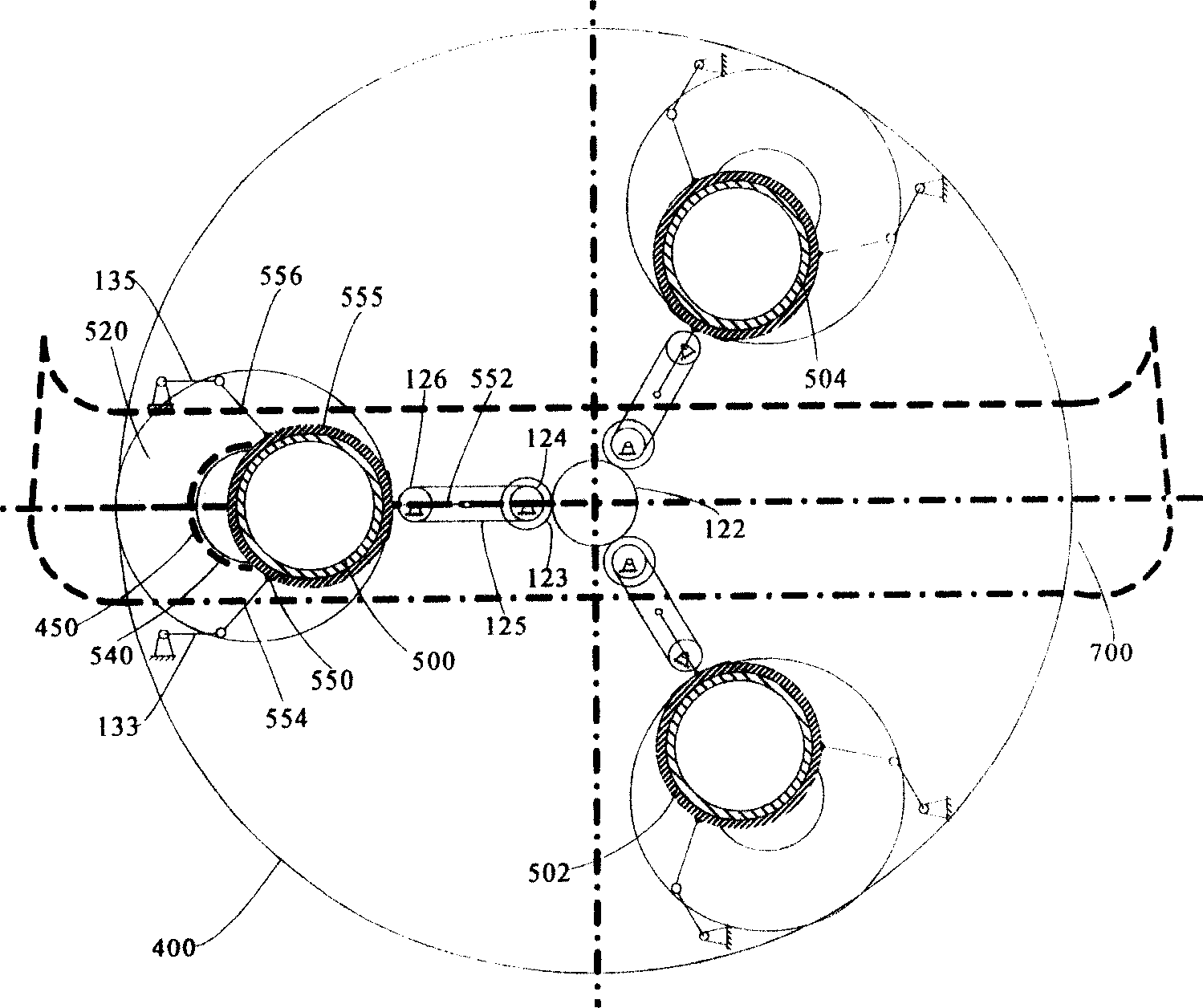

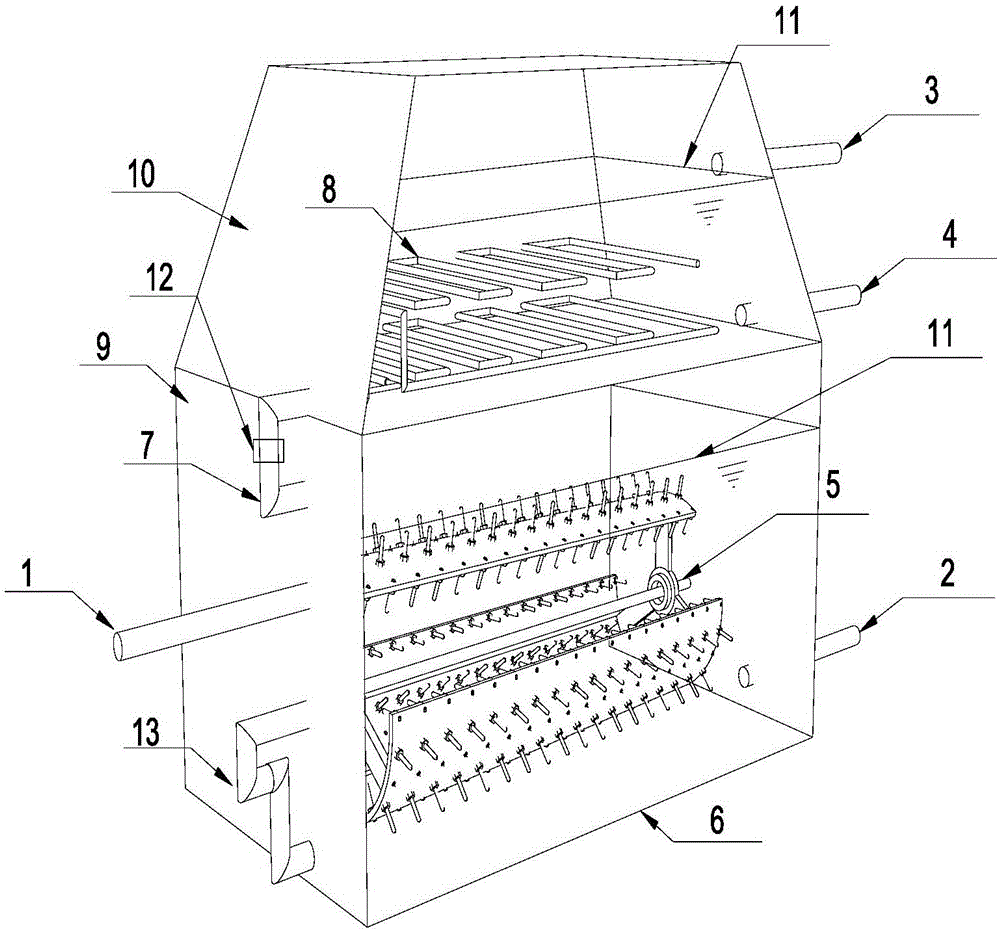

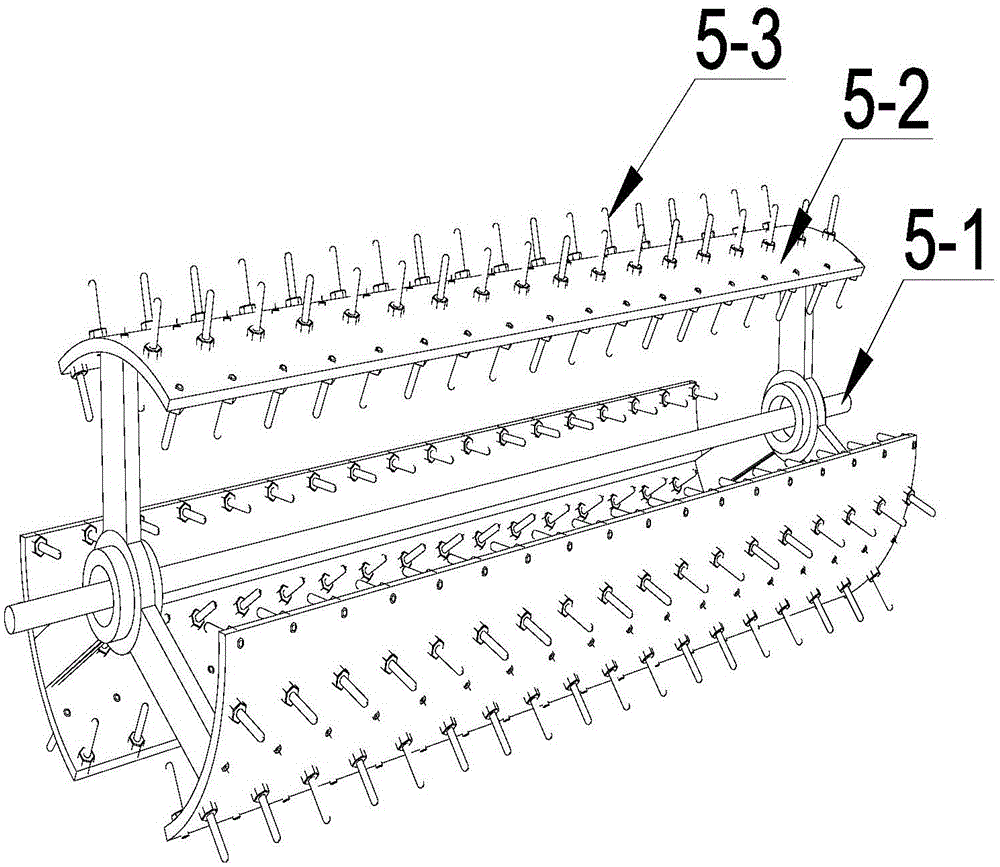

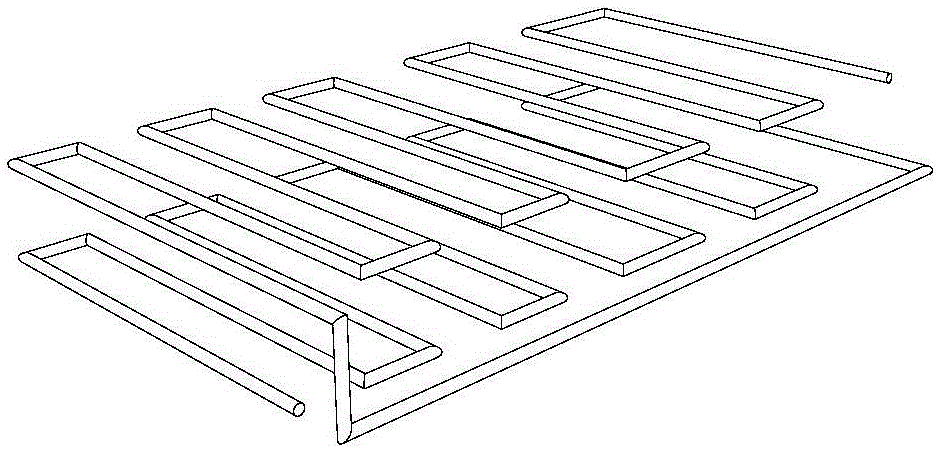

Multi-rubbing-bucket fully-automatic tea kneading machine

InactiveCN1709091AImprove efficiencyImprove processing efficiencyPre-extraction tea treatmentElectric machineryEngineering

Owner:HUAZHONG UNIV OF SCI & TECH

Supercharger shell detection system and method

ActiveCN106767622AAvoid processing qualityImprove inspection levelInternal combustion piston enginesUsing optical meansMeasurement deviceTurbocharger

The invention belongs to the field of manufacturing of turbo-superchargers, and in particular relates to a supercharger shell detection system and method. According to the technical scheme provided by the invention, the supercharger shell detection system comprises a rack, a displacement sensor, a horizontal reference detection platform, a measurement device, a code spraying device, a workpiece conveying device and a control device; the displacement sensor, the horizontal reference detection platform, the measurement device and the code spraying device are arranged on the rack; a working surface of the horizontal reference detection platform is horizontal; the measurement device is used for detecting a supercharger shell; the workpiece conveying device is used for conveying the supercharger shell; the control device is used for controlling the operation of the detection system. The supercharger shell detection system and method provided by the invention can be used for controlling the processing quality of the supercharger shell, so that the detection level and production efficiency of the supercharger shell can be improved.

Owner:凤城市时代龙增压器制造有限公司

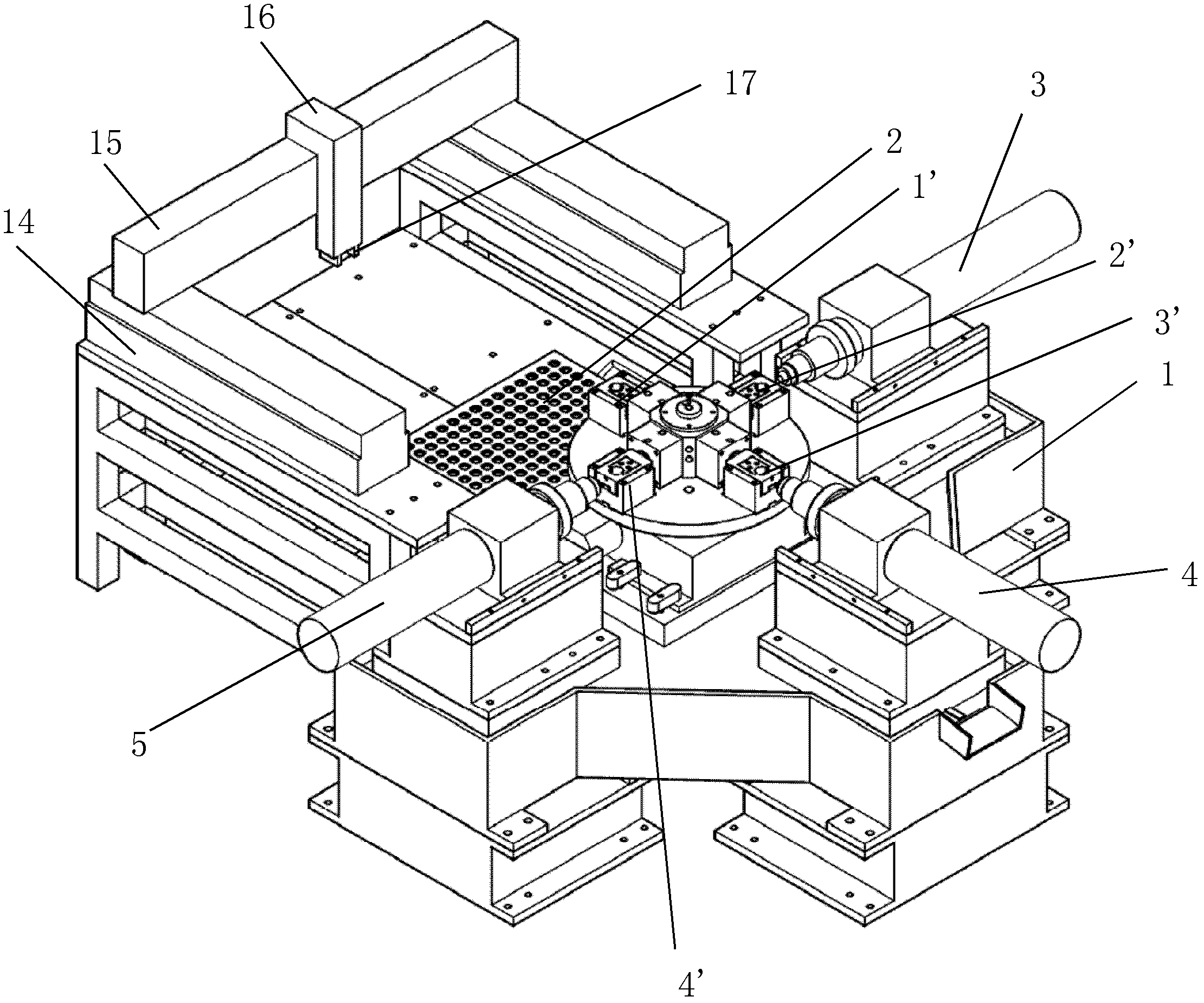

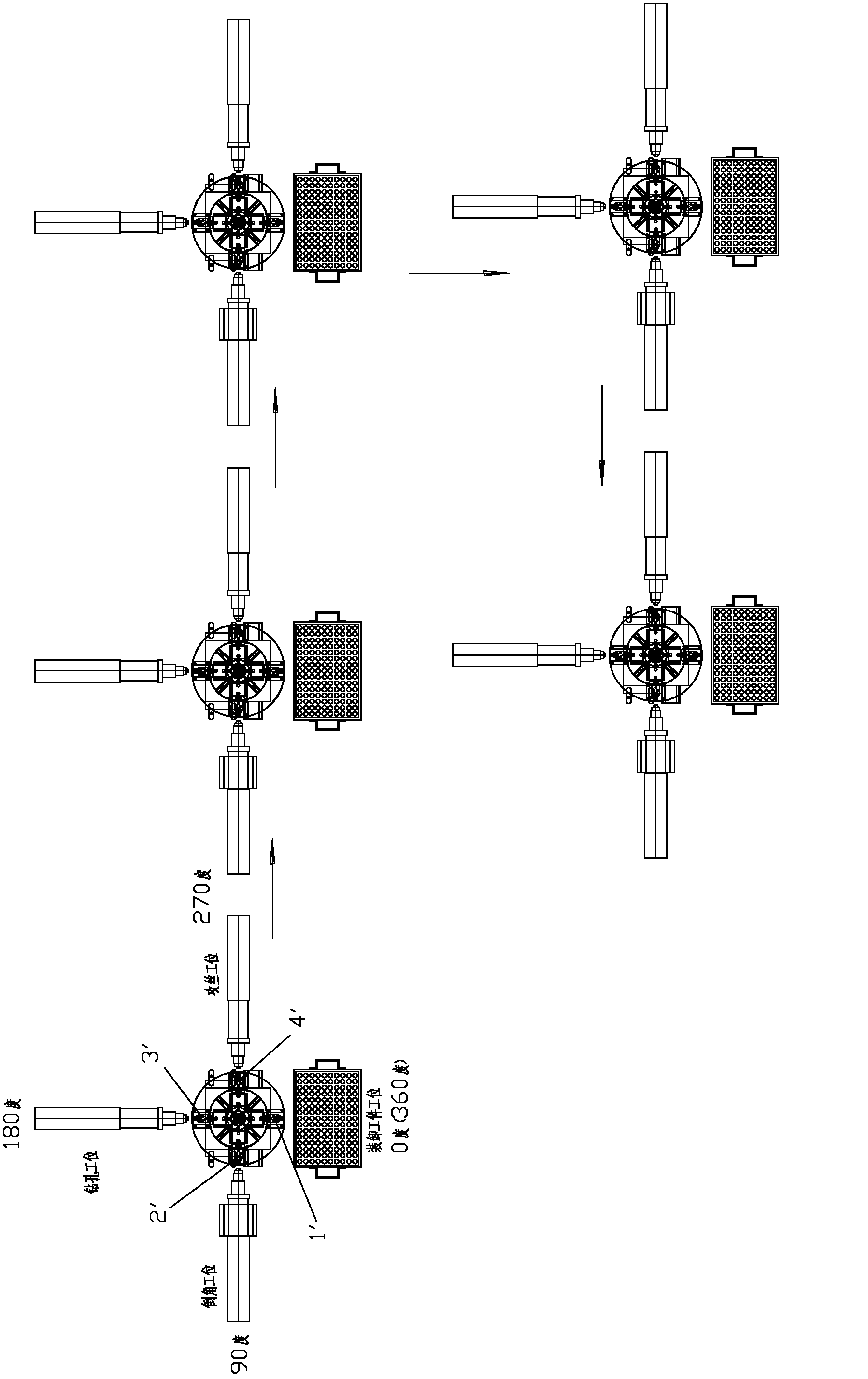

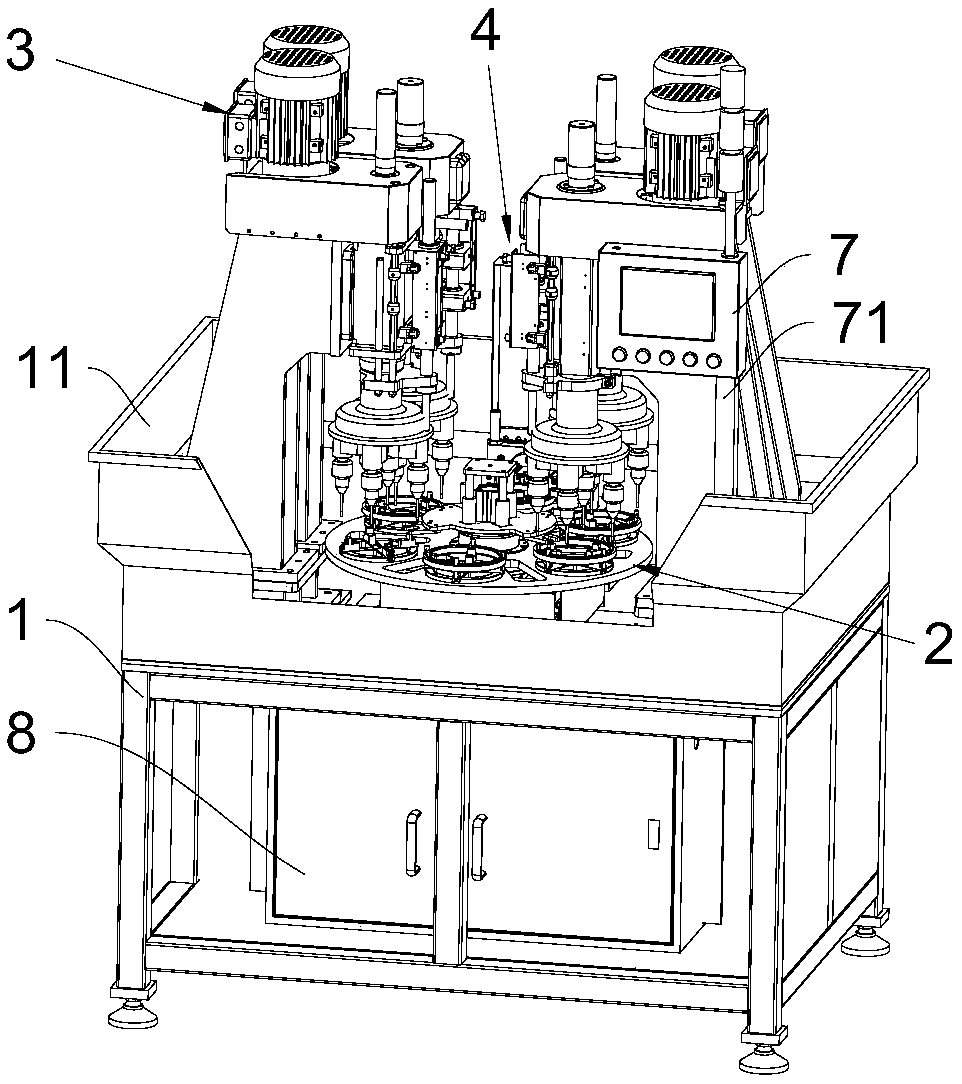

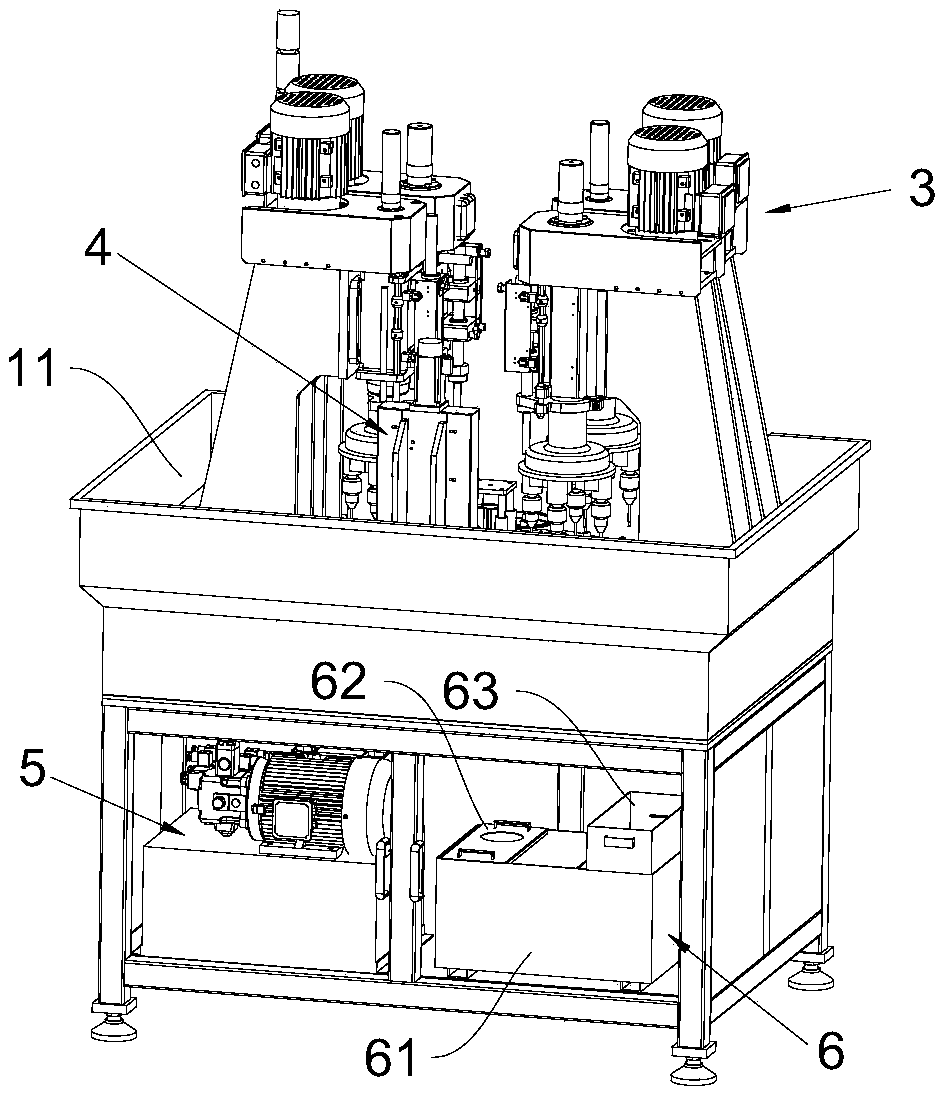

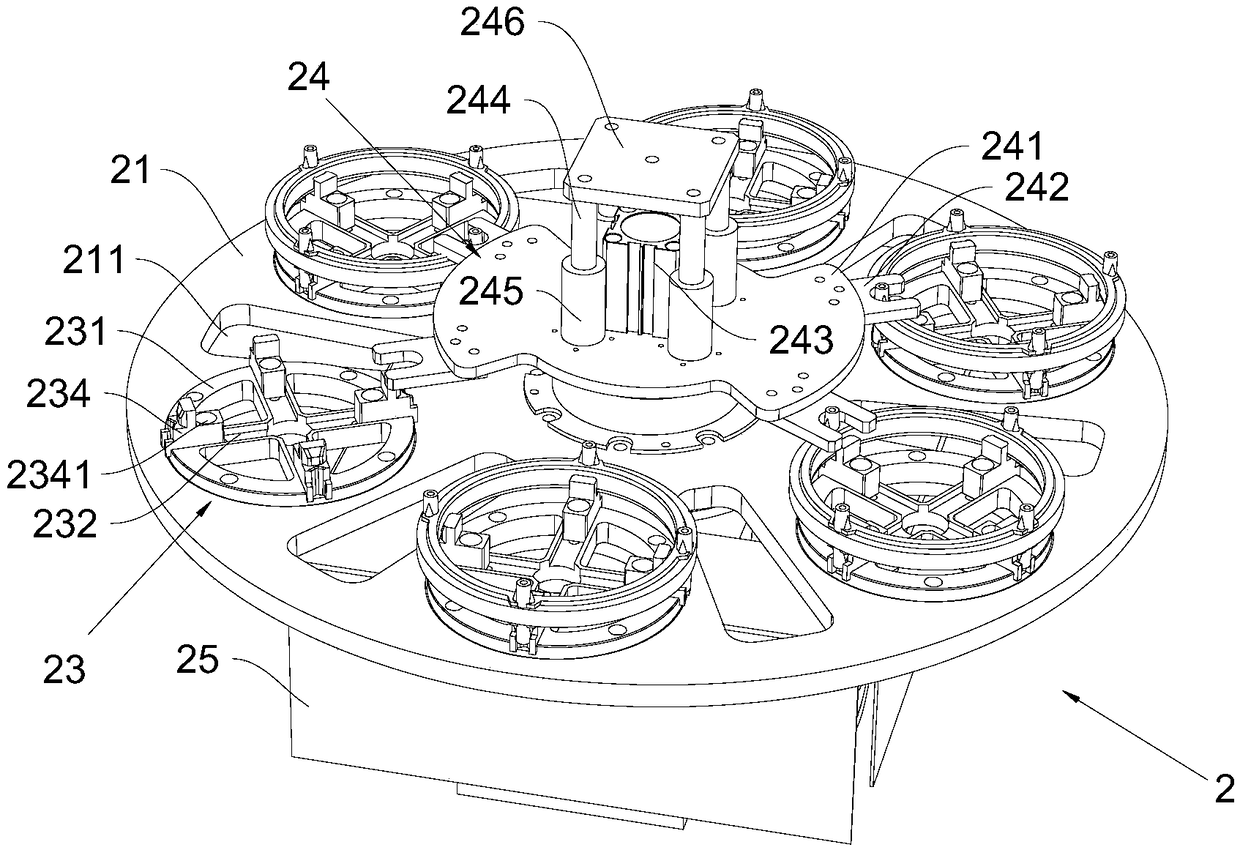

Special four-station machine tool for jackscrew holes of worms

InactiveCN102909554AReduce labor costsProcess concentrationOther manufacturing equipments/toolsMetal working apparatusTransverse axisDrill hole

The invention relates to a special four-station machine tool for jackscrew holes of worms. The special four-station machine tool is characterized by comprising a tool body, a tray, a chamfering power head, a drilling power head, a tapping power head, a hydraulic turntable and fixtures; the hydraulic turntable is fixedly connected to the center of a working table of the tool body, the chamfering power head and the tapping power head are symmetrically fixedly connected onto the working table of the tool body along the transverse axis of the hydraulic turntable, the drilling power head is fixedly connected to the central position between the chamfering power head and the tapping power head along the radial direction of the hydraulic turntable, and the fixtures for mounting a workpiece are arranged on rotary work stations of the hydraulic turntable. The special four-station machine tool has the advantages that the special four-station machine tool are fully automatic, and labor cost is greatly reduced; various working procedures are centralized and can be carried out simultaneously, and accordingly the efficiency is improved; and influence of skills of operators to the machining quality is avoided, and the special four-station machine tool is stable and reliable.

Owner:天津市中马骏腾精密机械制造有限公司

Non-destructive repair method of contaminated soil

InactiveCN105057336AImprove removal efficiencyLow site requirementsContaminated soil reclamationContaminated soilsSoil science

The invention relates to a non-destructive repair method of contaminated soil, and belongs to the field of environmental protection machines. The method is carried out through a contaminated soil repair system, wherein the system comprises a soil mixing device; a feeding opening and a discharging opening are formed in the soil mixing device; an absorbent feeding hopper is arranged above the feeding opening; a conveyor on which a magnetic separating device is arranged is arranged below the discharging opening; a soil liquefying device is arranged below the tail end of the conveyor and connected with a soil repair device through a pipeline. The non-destructive repair method of contaminated soil has the advantages that the automation degree is high, and the treatment effect is good.

Owner:WUXI LEHUA AUTOMATION TECH

Methods and apparatuses for homogenizing light

ActiveUS7210820B2Cost-effective and compactAvoid processing qualityCosmonautic condition simulationsLaser using scattering effectsOpticsHomogenizer

Embodiments of the present invention are directed to an illuminating optical device for forming a field of illumination. The optical device includes a first one-dimensional homogenizer positioned to homogenize a first dimension / axis of the field of illumination and a second one-dimensional homogenizer positioned to homogenize a second dimension / axis of the field of illumination.

Owner:RESONETICS

Wafer processing method

ActiveUS9595463B2Increase volumeShorten speedSolid-state devicesSemiconductor/solid-state device manufacturingElectrical and Electronics engineering

A wafer processing method which includes a protective tape attaching step of attaching a protective tape through an adhesive layer to a front side of a wafer in only a peripheral marginal area thereof, and a cutting step of cutting the front side of the wafer in its peripheral portion by using a rotating cutting blade to thereby form a peripheral cut portion having a predetermined width and a predetermined depth. Accordingly, edge trimming to the peripheral portion of the wafer can be easily performed without adhering of particles generated in cutting the wafer to a device area.

Owner:DISCO CORP

Machining device for shaft sleeve oil groove

The invention relates to a machining device for a shaft sleeve oil groove. The machining device for the shaft sleeve oil groove comprises a lathe body and a motor which is arranged on the front end of the lathe body, wherein a guide rail is fixed on the lathe body; a boss is arranged on the guide rail; a cutter is fixed on the boss; the left end of the lathe body is fixed with a first limiting plate and a second limiting plate; the right end of the lathe body is provided with a clamping component for clamping a shaft sleeve; and the motor is connected with the clamping part by a chain belt. The machining device for the shaft sleeve oil groove has the beneficial effect of being simple to operate and being precisely positioned to machine, thereby reducing repeated acknowledging time and solving inconvenience caused by an inaccurate oil groove machining position, greatly reducing machining cost and time, ensuring machining quality and improving production efficiency, and satisfying large-scale production requirements; and moreover, the machining device has the advantages of low cost, high quality and the like.

Owner:吴江同新自润滑轴承厂

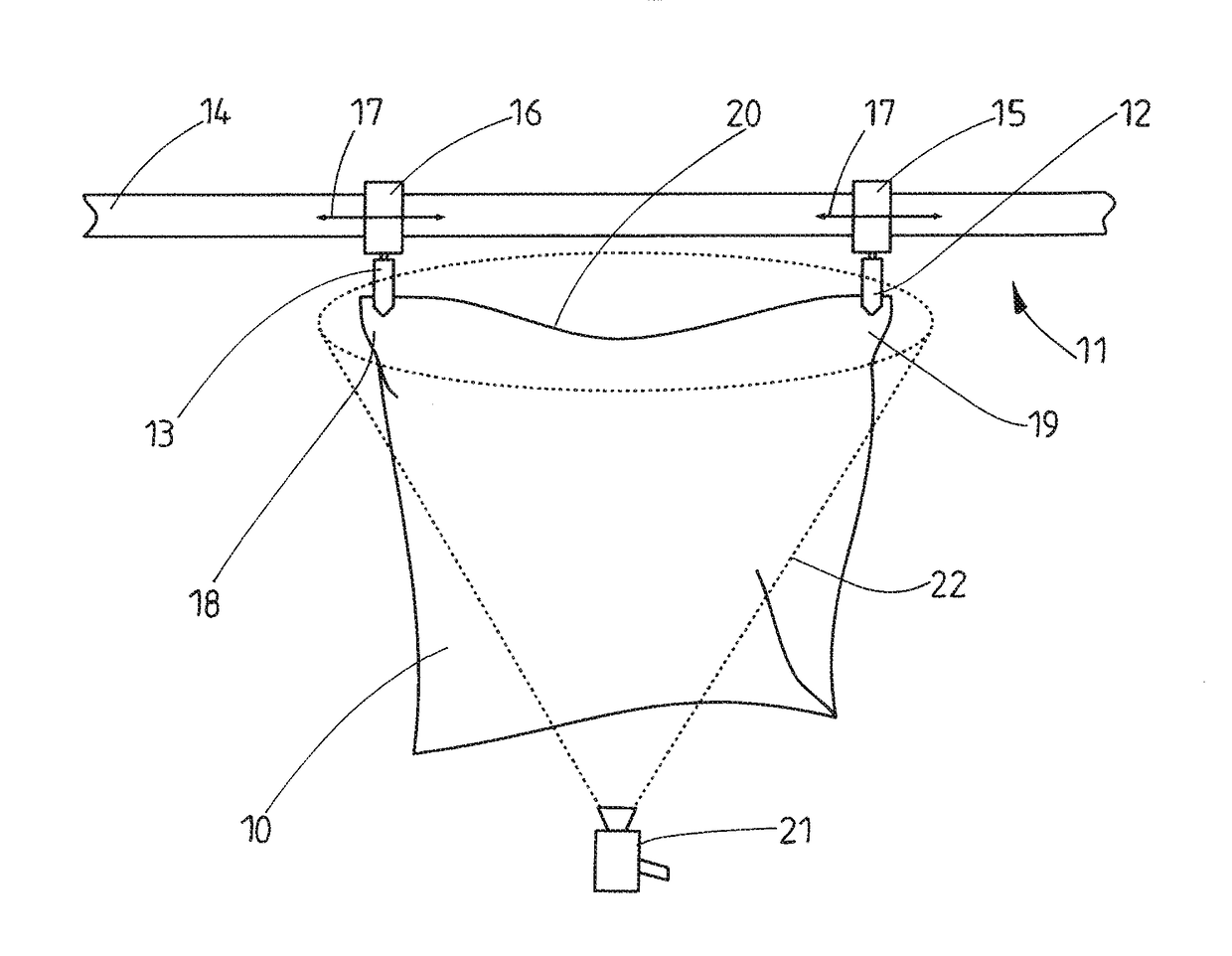

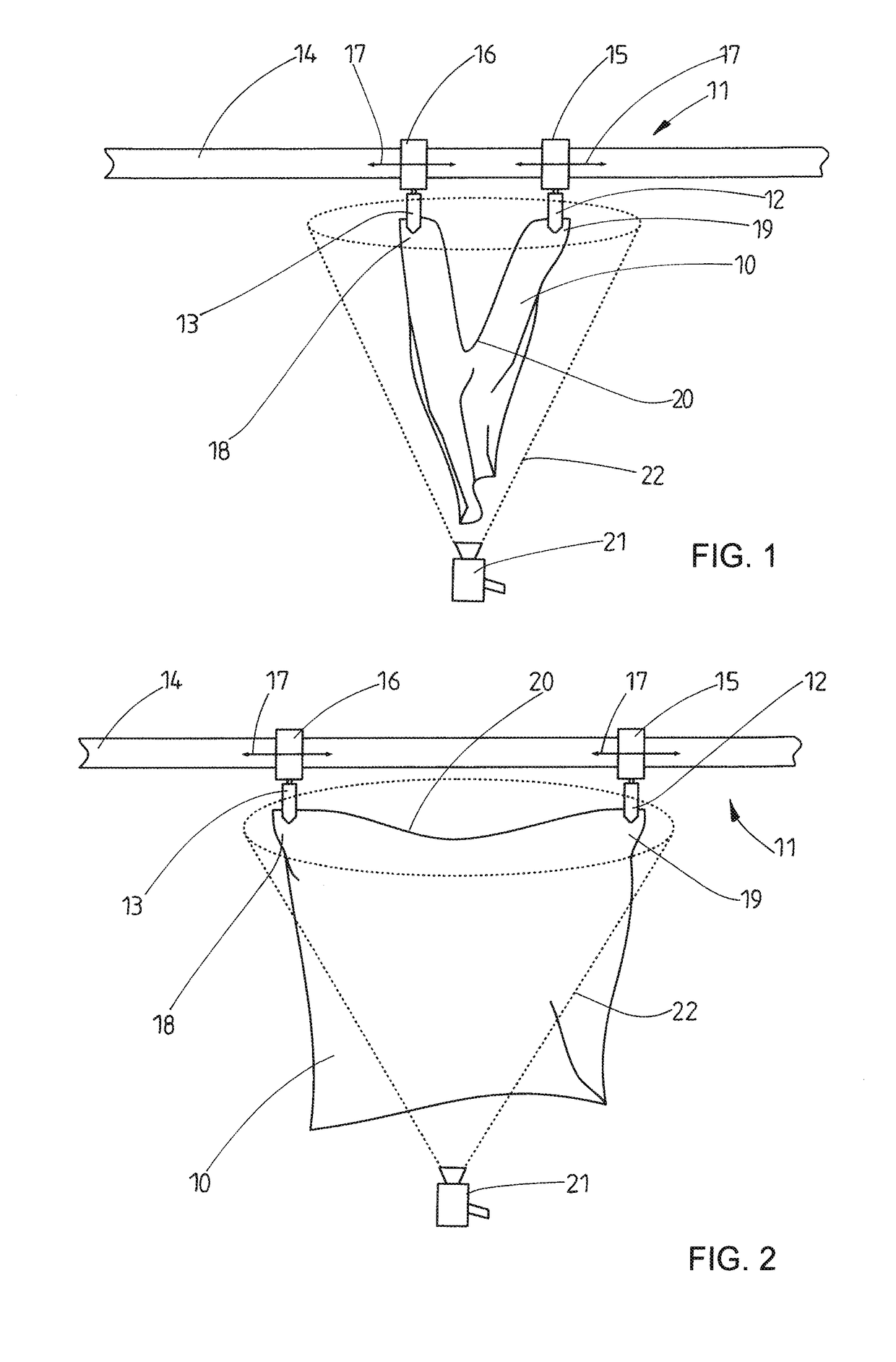

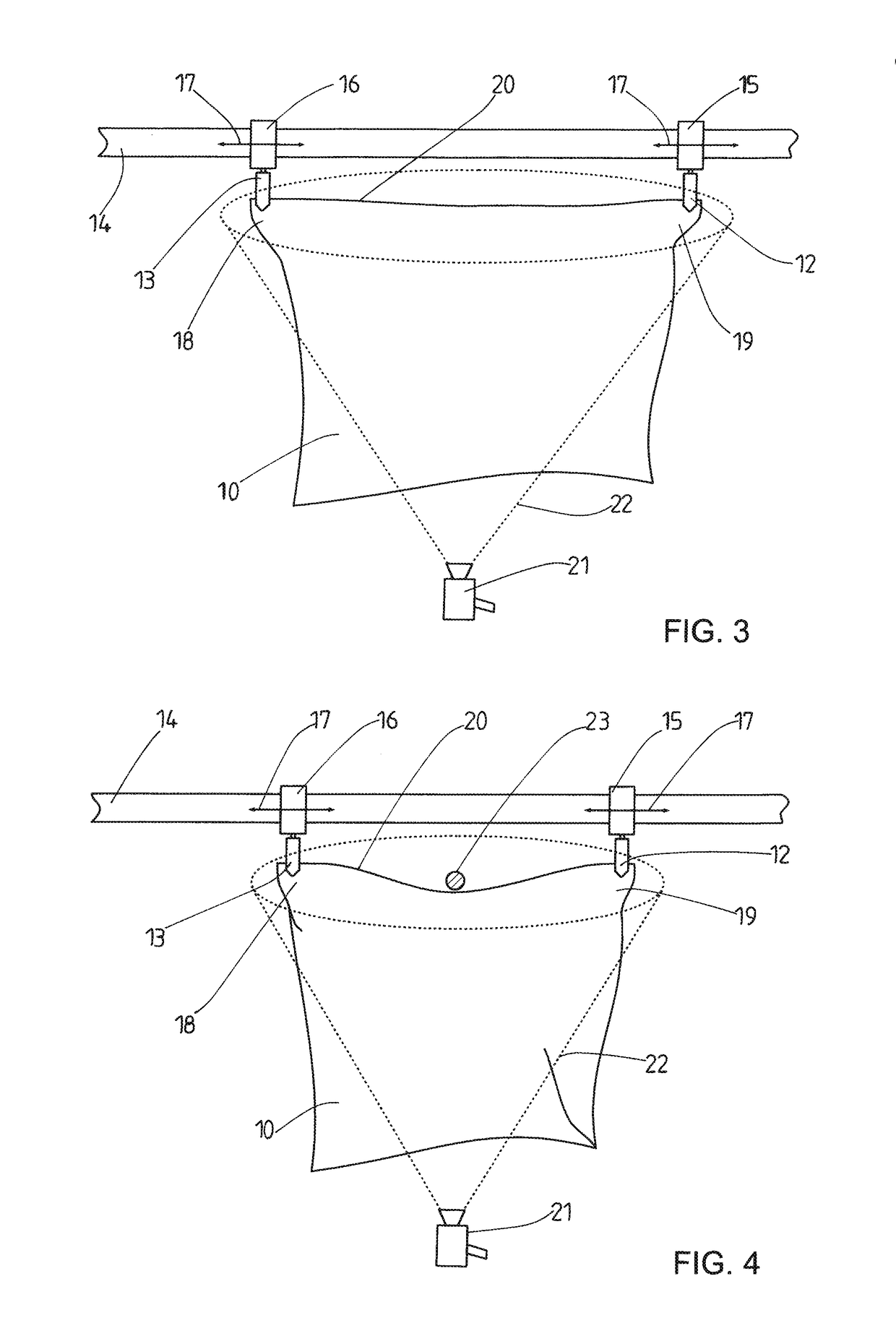

Method and device for spreading a laundry item

ActiveUS20170073881A1Efficient deliveryGentle processRegistering devicesIroning machinesLong term resultsEngineering

For the purpose of delivering a laundry item (10) to an ironer, the laundry item (10) is spread, by opposite corners of a lateral edge (20), by means of spreader clips (18, 19). In this case, deformations, or “ear formation” may occur at the corner regions (12, 13) of the laundry item (10) that are gripped by the spreader clips (18, 19). This “ear formation” is mostly irreversible, and in the long term results in damage to the laundry items (10). The invention creates a method and a device by which the laundry item (10) is delivered to an ironer in a gentle manner. For this purpose, at least one corner region (12, 13) of the laundry item (10) that is gripped by a spreader clip (18, 19) is captured by an imaging means as the laundry item (10) is being spread.

Owner:KANNEGIESSER GMBH CO HERBERT

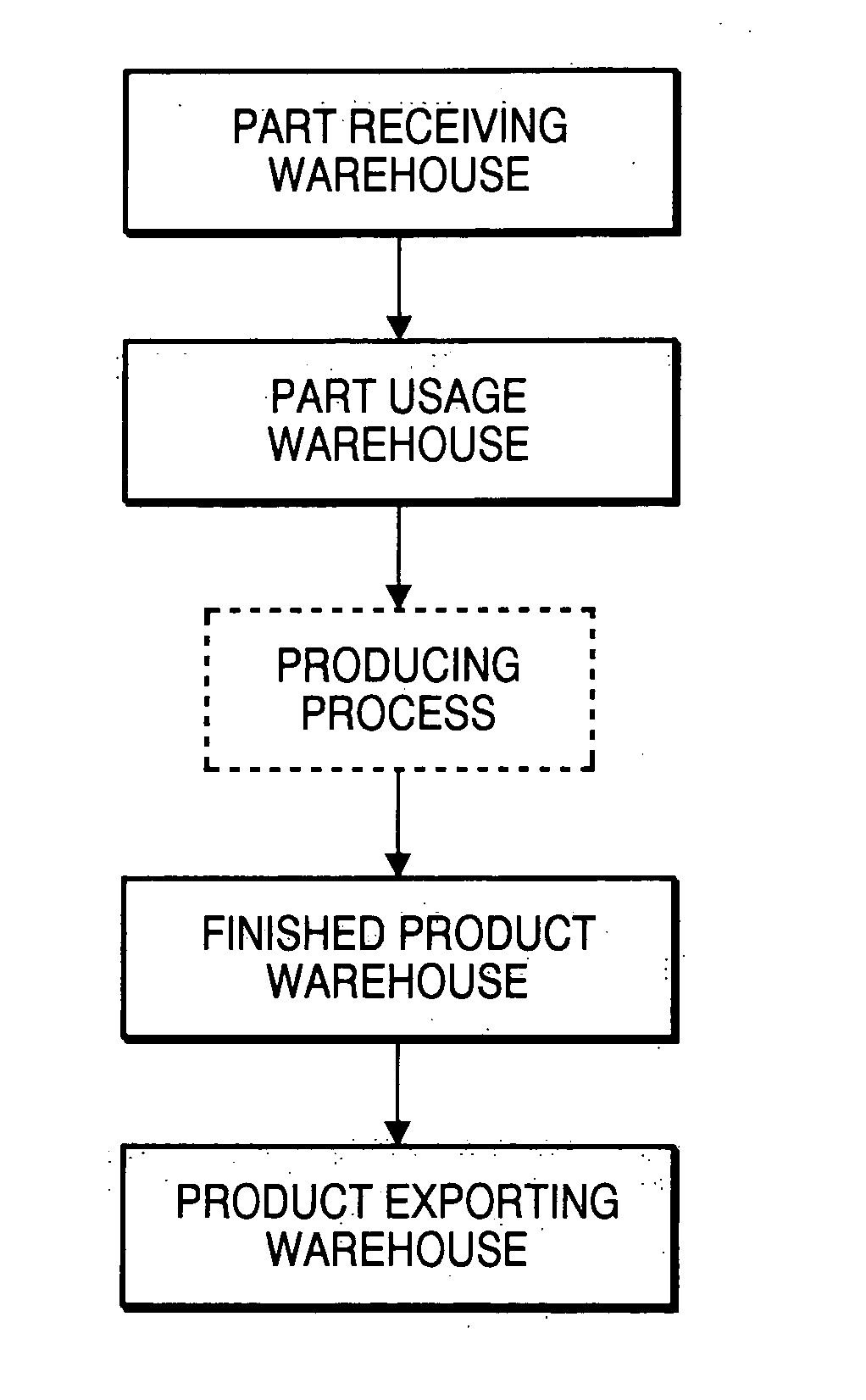

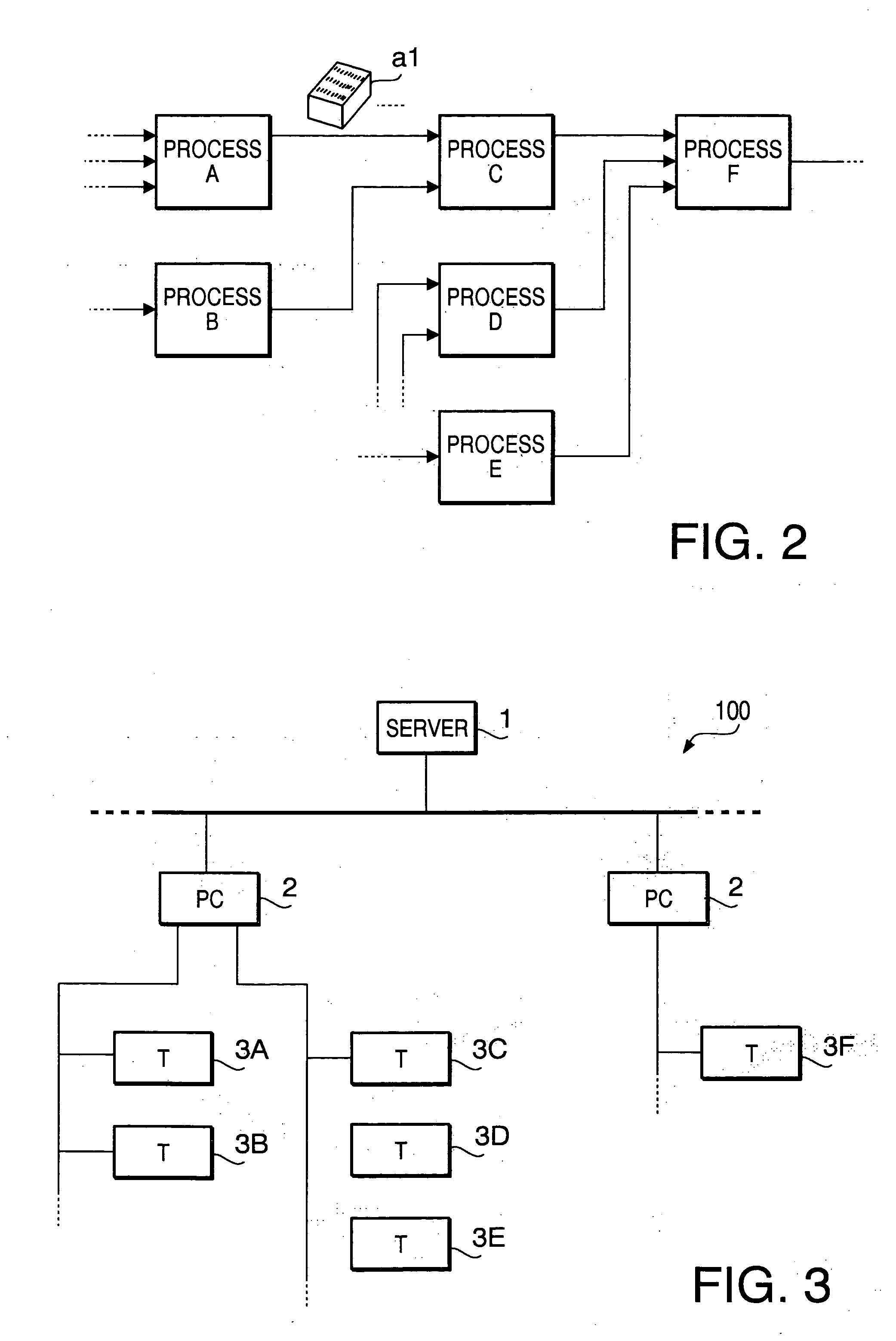

Process control system

InactiveUS20050119776A1Quality improvementAvoid processing qualityData processing applicationsTotal factory controlControl systemData storing

A process control system for controlling a production process includes a data generating system that generates at least first data regarding first products produced in a previous process and second data regarding parts used in a next process. The first data and the second data are related to link information indicating a link between the previous process and the second process. The process control system further includes a data storing system that stores data generated by the data generating system.

Owner:ASAHI KOGAKU KOGYO KK

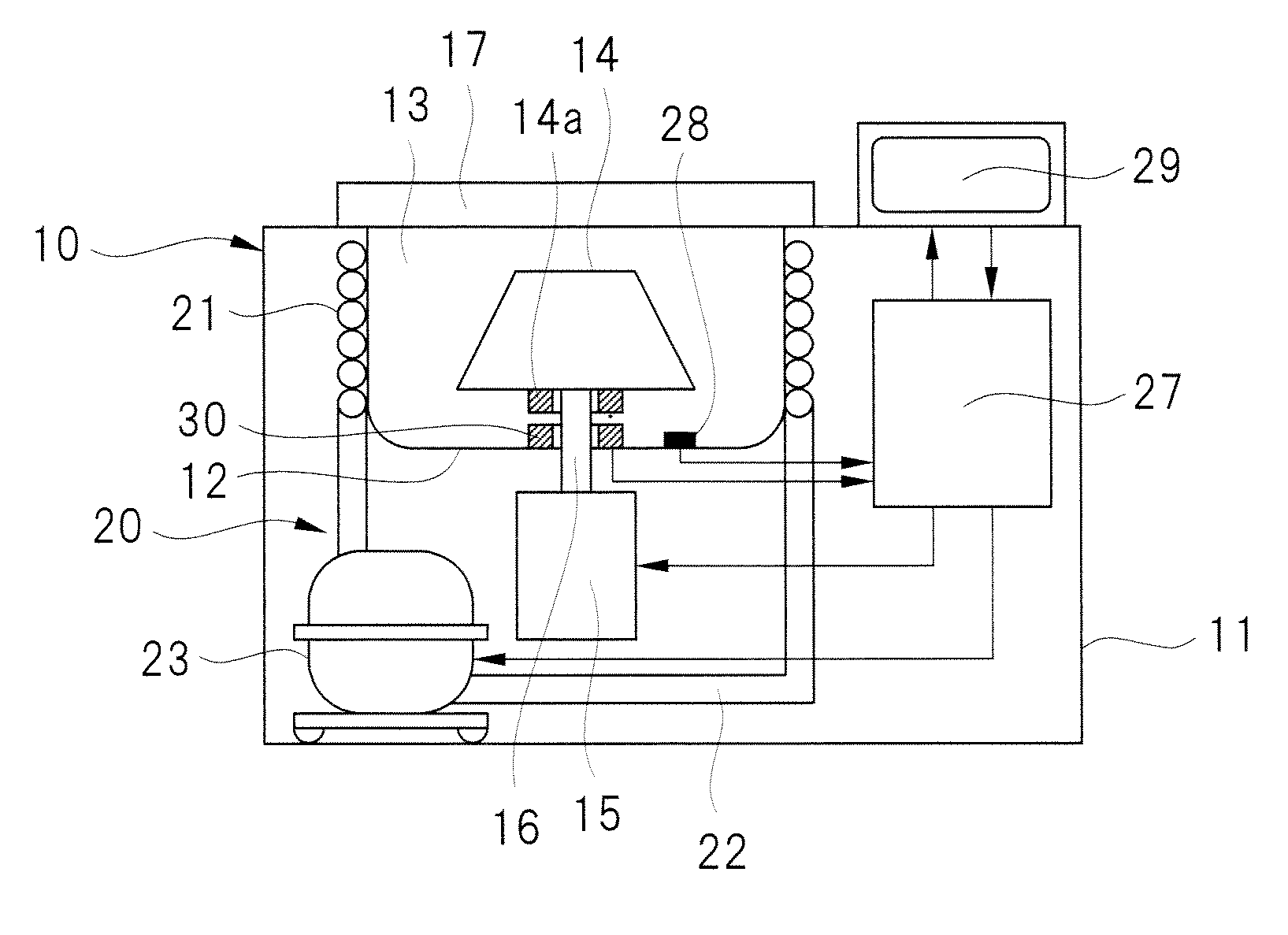

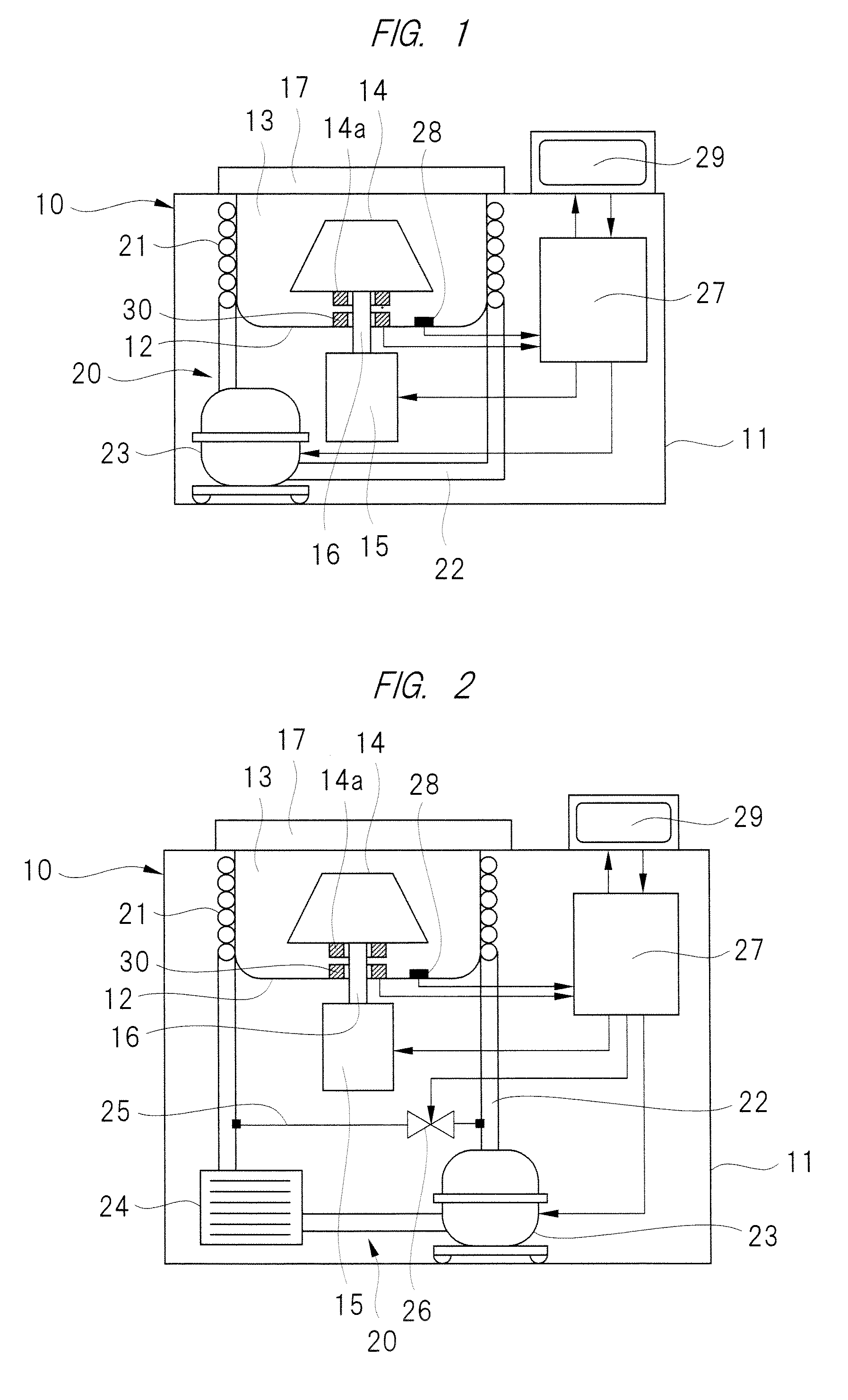

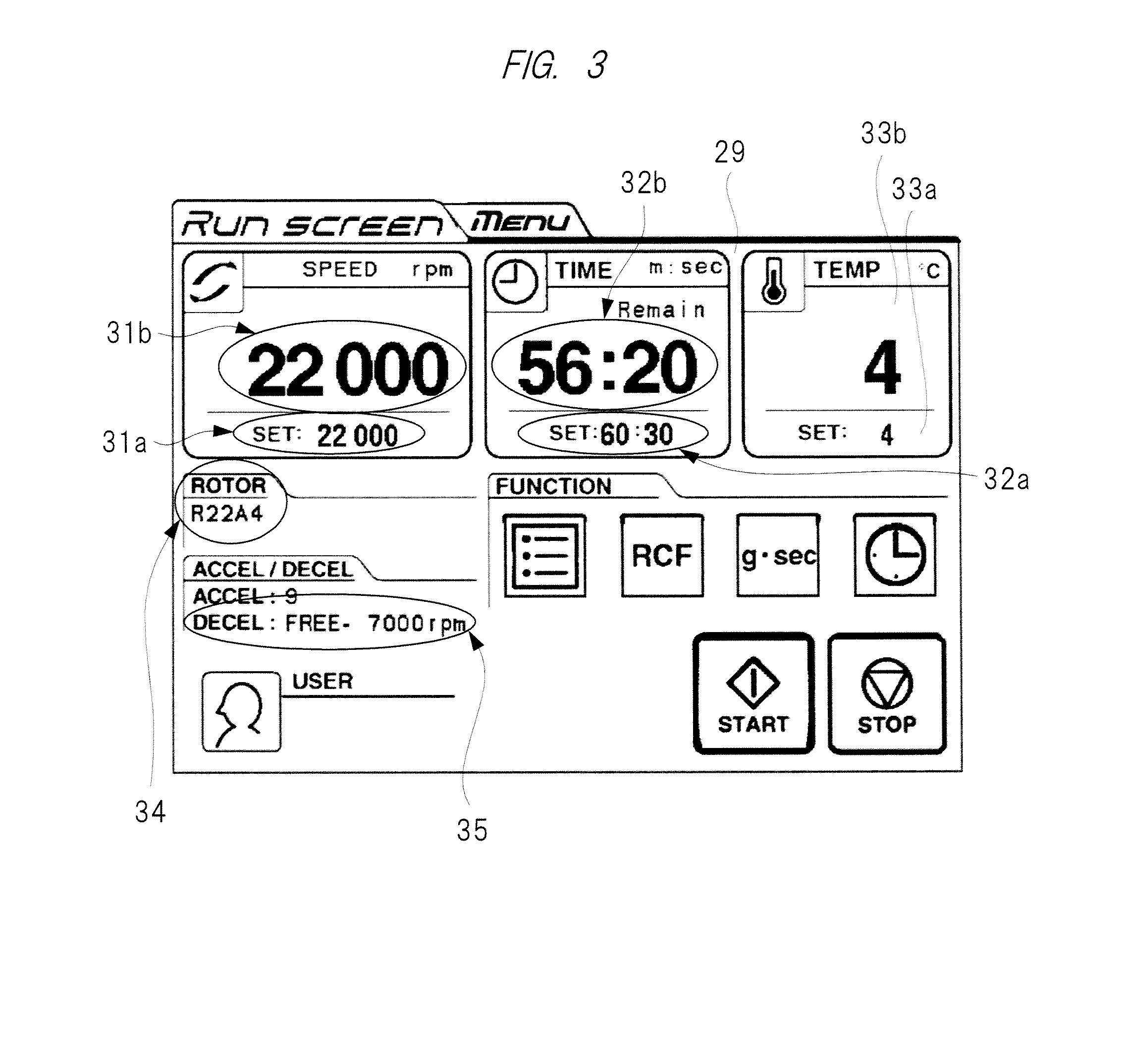

Centrifuge

Owner:EPPENDORF HIMAC TECH CO LTD

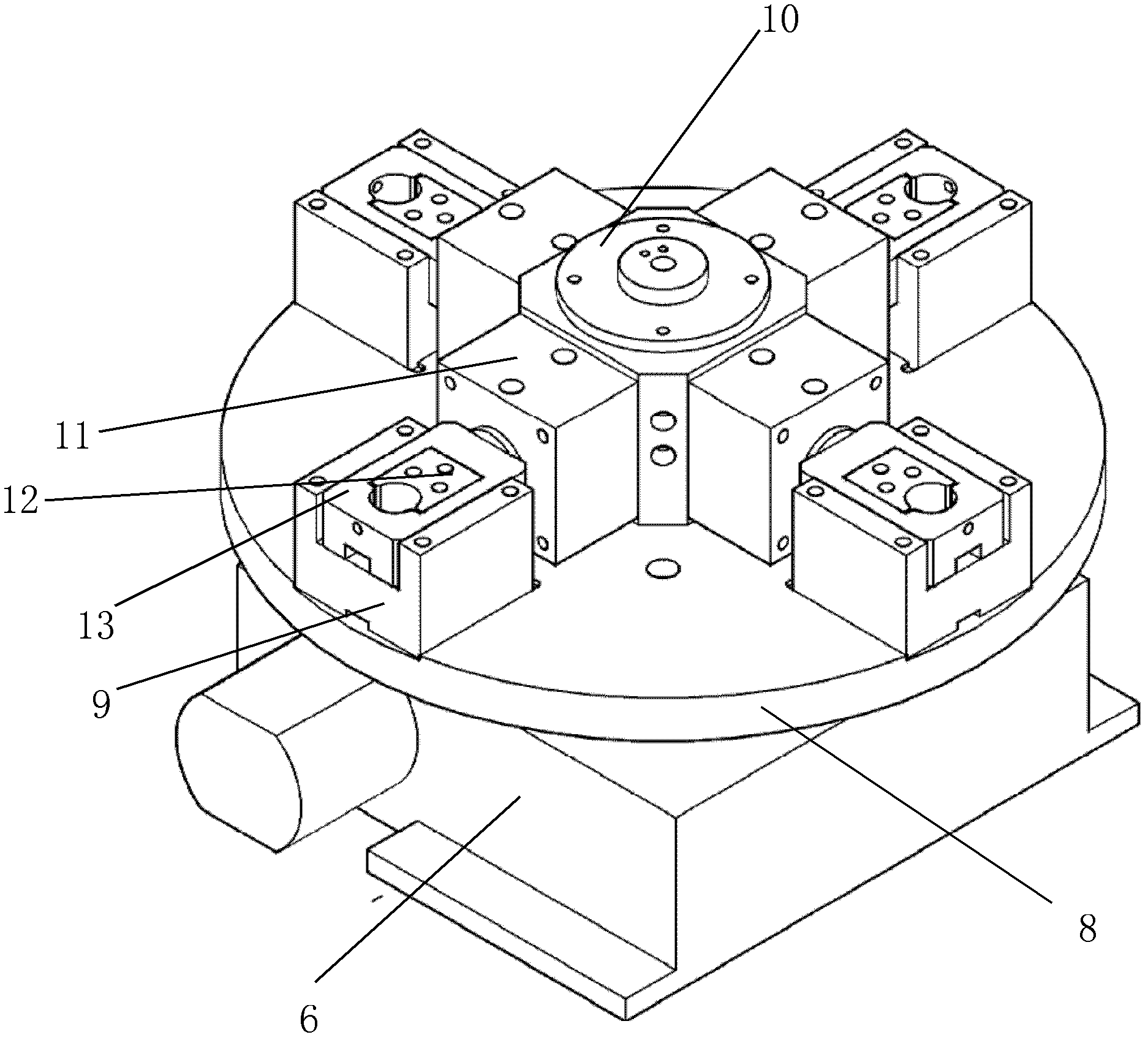

Drilling-tapping all-in-one machine

PendingCN109454457AReduce dependenceImprove processing efficiencyPrecision positioning equipmentOther manufacturing equipments/toolsTransport timeWorking environment

The invention provides a drilling-tapping all-in-one machine which solves the problem that an existing motor ring processing process is complex. According to the technical scheme, the key point is that the drilling-tapping all-in-one machine comprises a rack and an oil supply system, wherein an indexing positioning device which is rotatably connected with the rack is arranged on the rack; a turnover device for turning over workpieces is arranged on the rack; processing devices are arranged on the positions, at the two sides of the turnover device, of the rack; and each processing device comprises a drilling device and a tapping device. The indexing positioning device, the processing devices and the turnover device are arranged on the rack, so that the workpieces are transported to each station through the indexing positioning device, one workpieces is clamped once and processing of positive and negative surfaces is accomplished, multi-time calibration is not needed, processing time isshortened, and processing efficiency is improved; and moreover, the turnover device can automatically turn over the workpiece, equipment processing speed is increased, transportation time is saved, workpiece collision is avoided, working environment of a worker is improved, working strength is reduced, fatigue of the worker is reduced, and processing quality of the workpiece is guaranteed.

Owner:广东顶固集创家居股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com