Machining method of thin-wall honeycomb core material curve machining molded surface

A technology of honeycomb core material and processing method, which is applied in the field of machinery, can solve the problems of difficult bonding between aluminum alloy honeycomb and composite material panels, high processing precision requirements, and low equivalent strength, so as to improve efficacy, processing pass rate, and cutting effect The effect of enhancing and reducing processing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

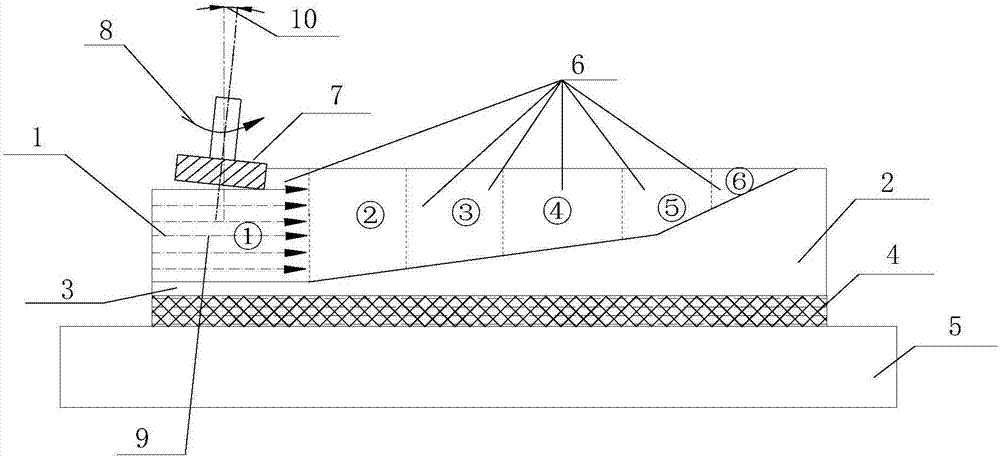

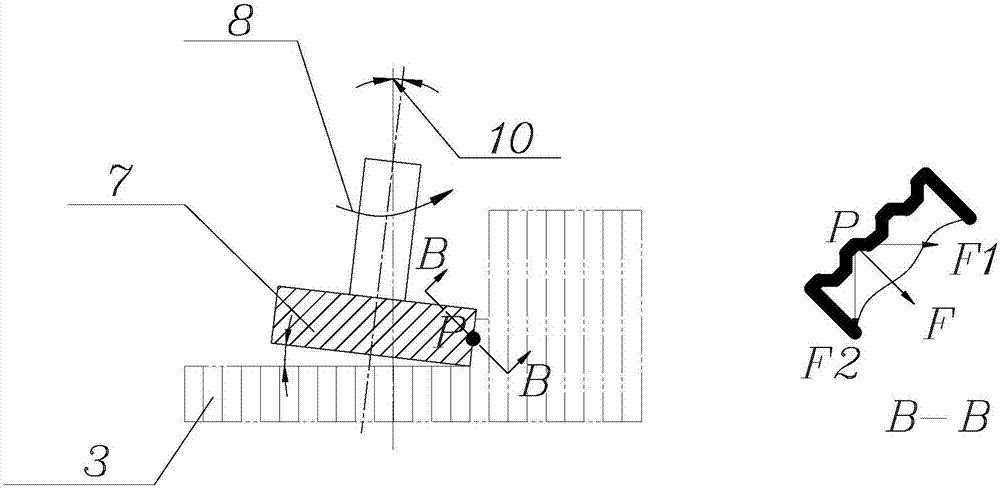

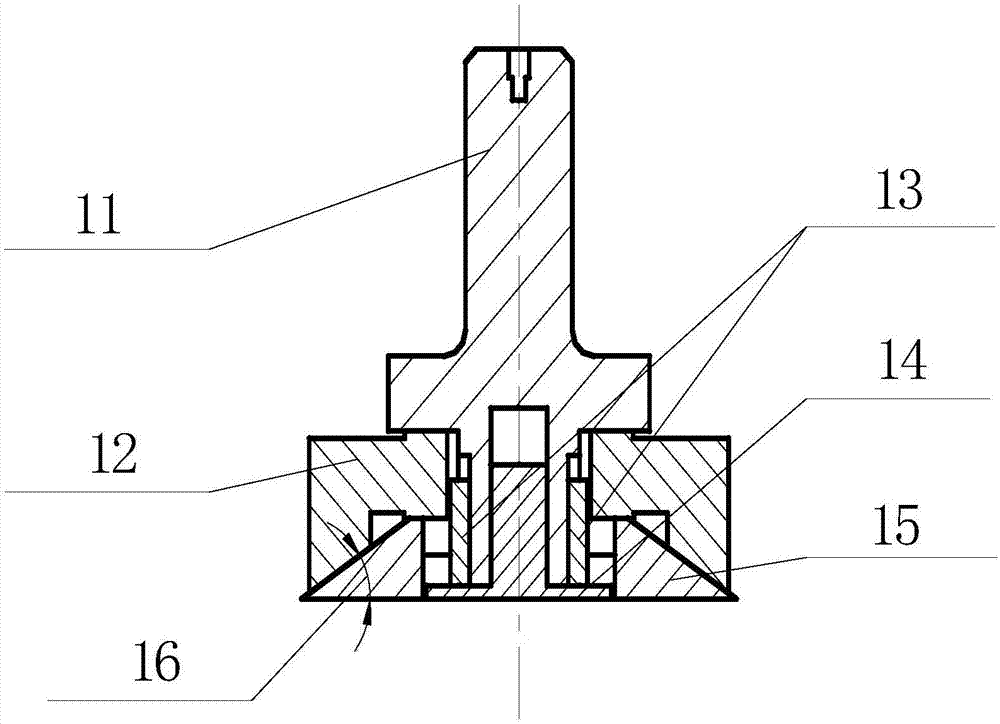

[0026] refer to Figure 1-Figure 3 . In the embodiment described below, according to the present invention, the processing machine tool selects a five-coordinate high-speed milling machine, based on the large-scale nonlinear finite element software ABAQUS, utilizes the PYTHON language to carry out secondary development, and writes ABAQUS for various honeycomb geometric modeling and grid division The plug-in calls the ABAQUS kernel to realize the automation of geometric modeling and meshing. The processing module composed of CATIA software, the VERICUT module and the NC program verification module, machine tool motion simulation module, optimized path module, multi-axis module, advanced machine tool feature module, entity comparison module and CAD / CAM interface developed by VERICUT software are used for programming. and other modules to form a NC machining simulation system for NC program optimization. For the combined honeycomb processing special milling cutter that is widel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com