Adaptive adjustment method of spindle rotation speed for chatter-free high-efficiency milling

A technology of self-adaptive adjustment and spindle speed, applied in automatic control devices, measuring/indicating equipment, feeding devices, etc., can solve problems such as increasing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0083] A method for adaptively adjusting spindle speed for high-efficiency milling without chatter, comprising the following steps:

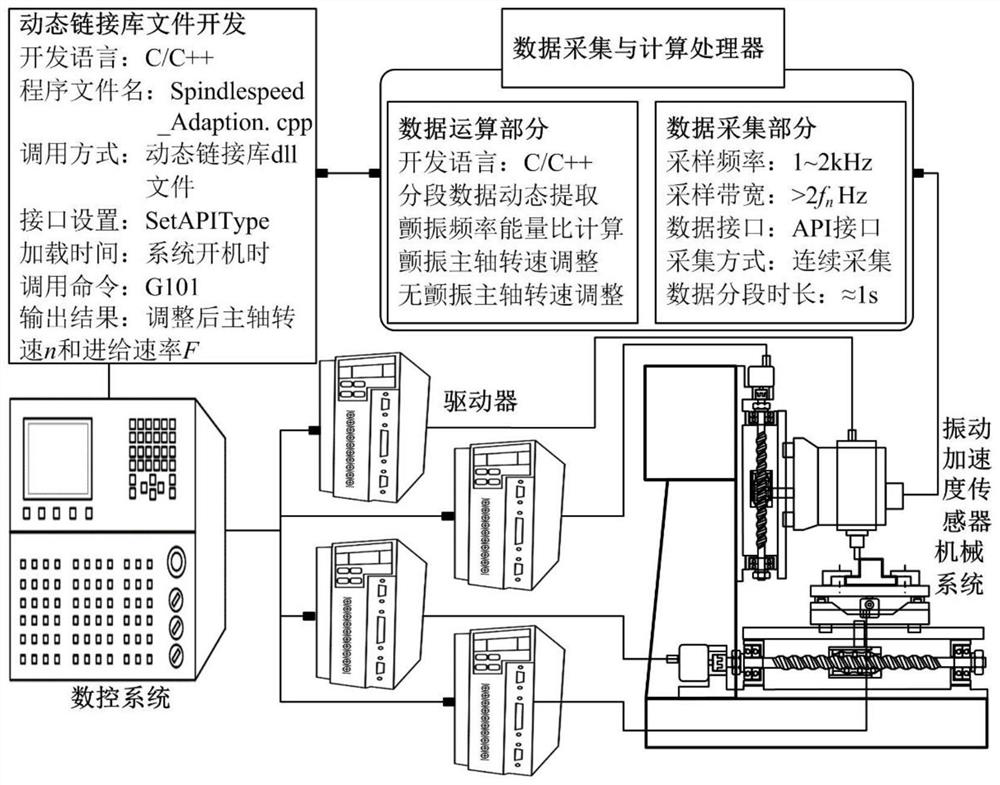

[0084] Step 1) Refer to figure 1 , Build a milling chatter spindle speed adaptive adjustment system, build and connect hardware, develop software programs, and prepare for processing;

[0085] 1.1) Build and connect hardware:

[0086] (1) CNC machine tool: Due to the need for real-time communication with external data, the CNC system of the CNC machine tool needs to have an open function, be able to provide an I / O interface for data exchange with external data acquisition equipment, and be able to realize the secondary of the dynamic link library Development to implement calls to external data;

[0087] (2) Vibration acceleration sensor: Paste the vibration acceleration sensor on the spindle head of the machine tool,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com