Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

13351results about "Measurement/indication equipments" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

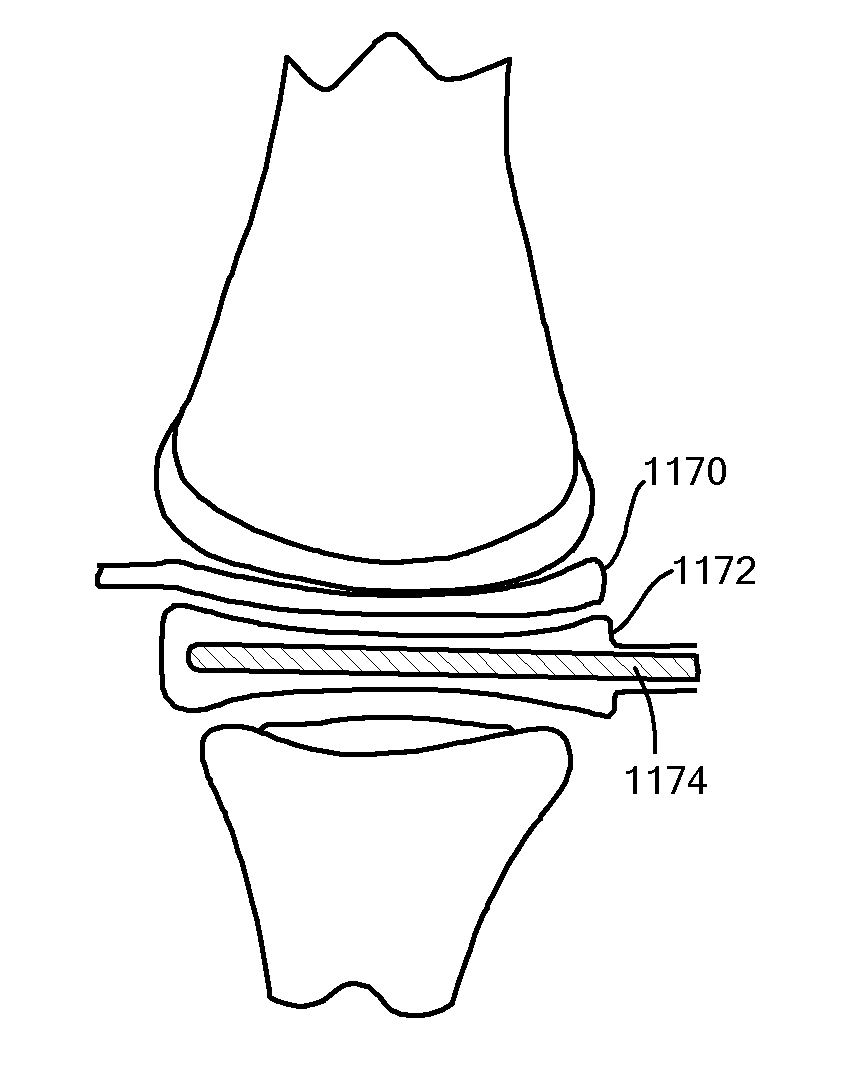

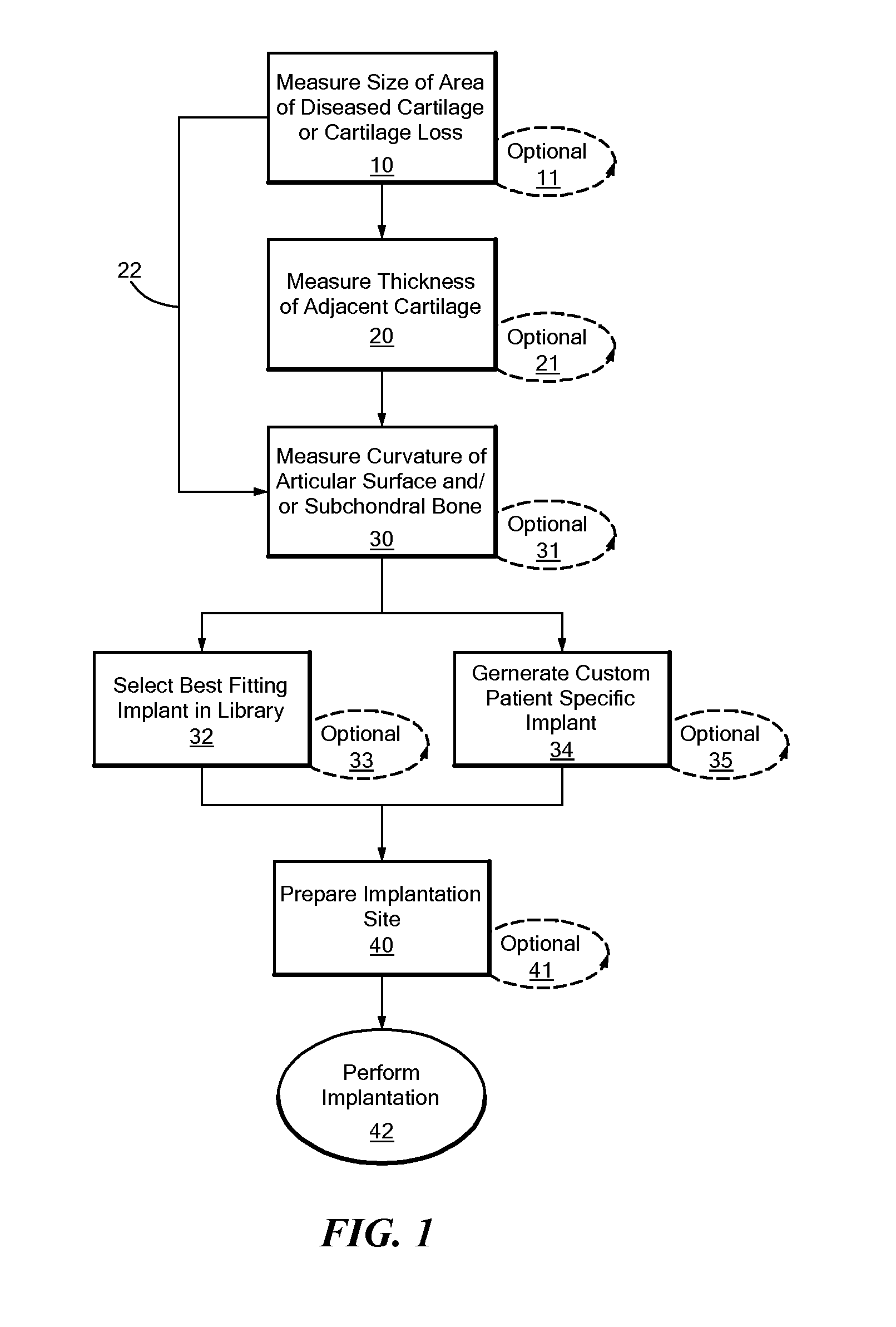

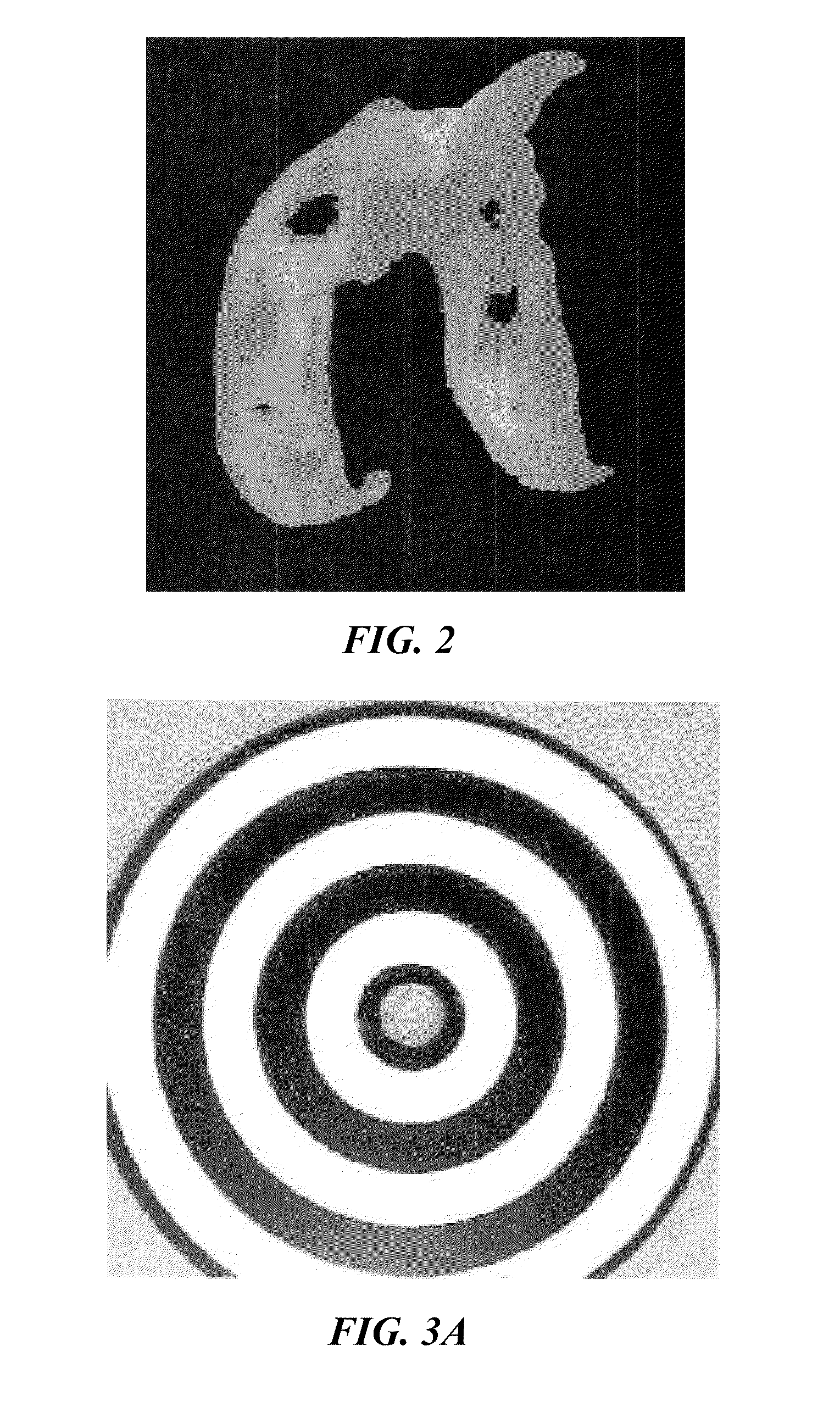

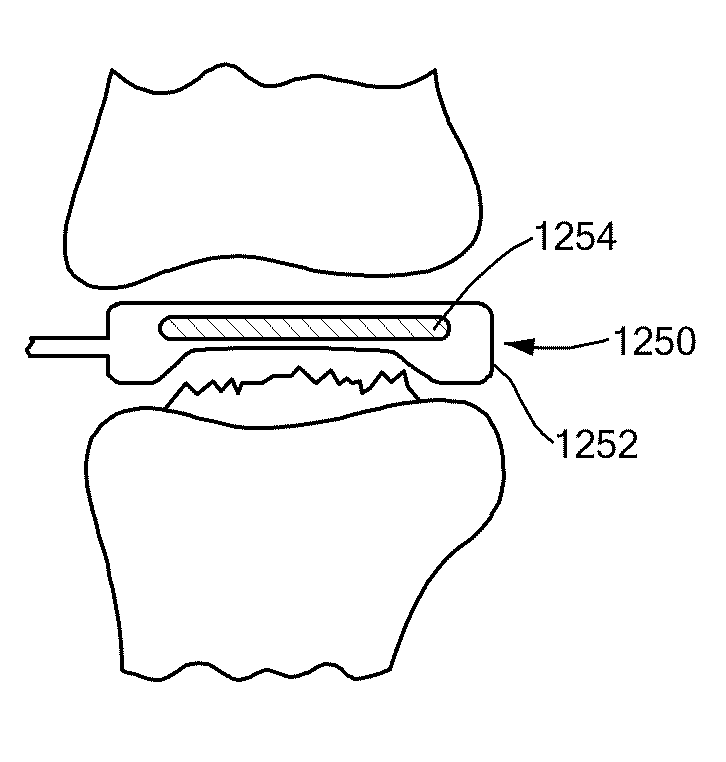

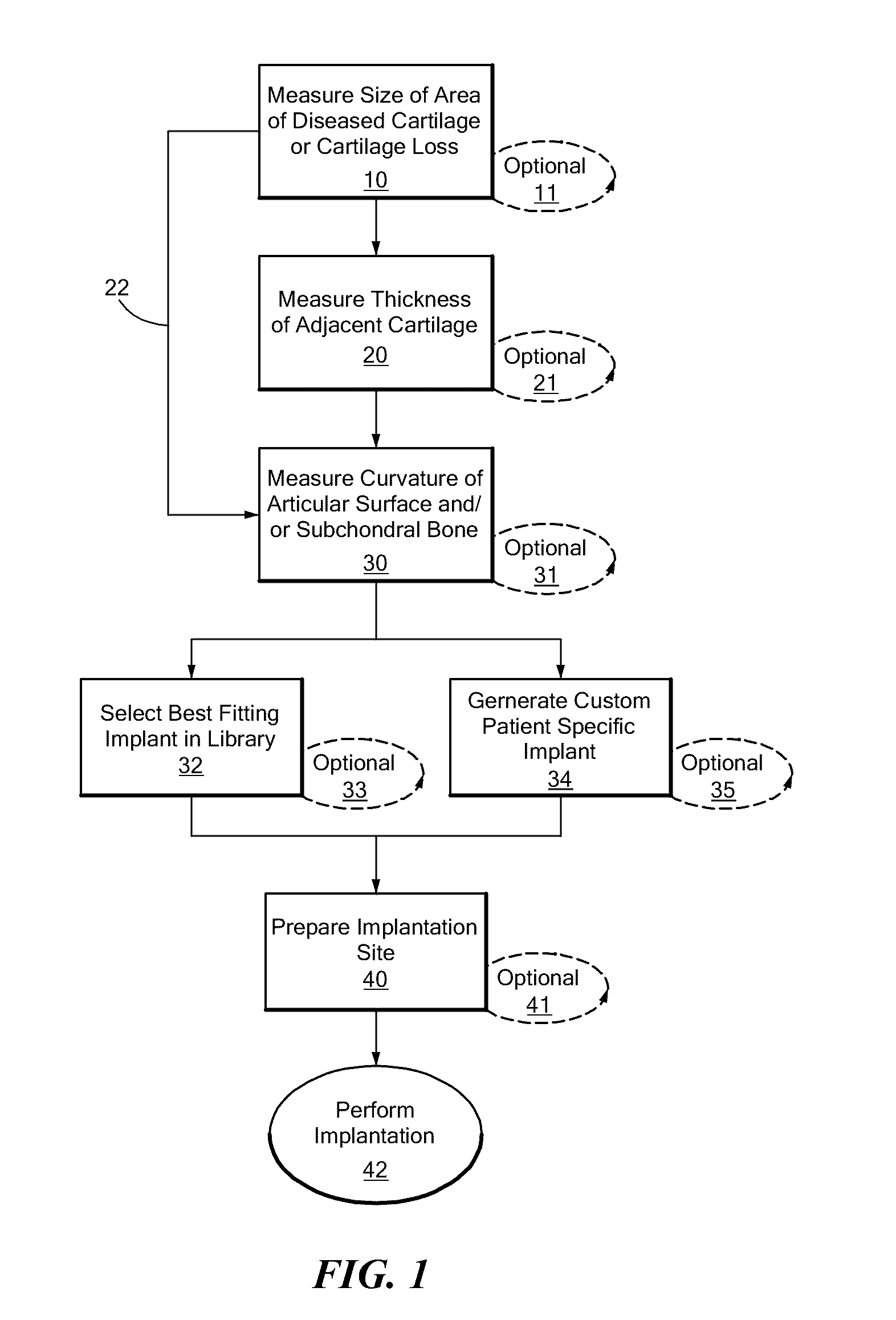

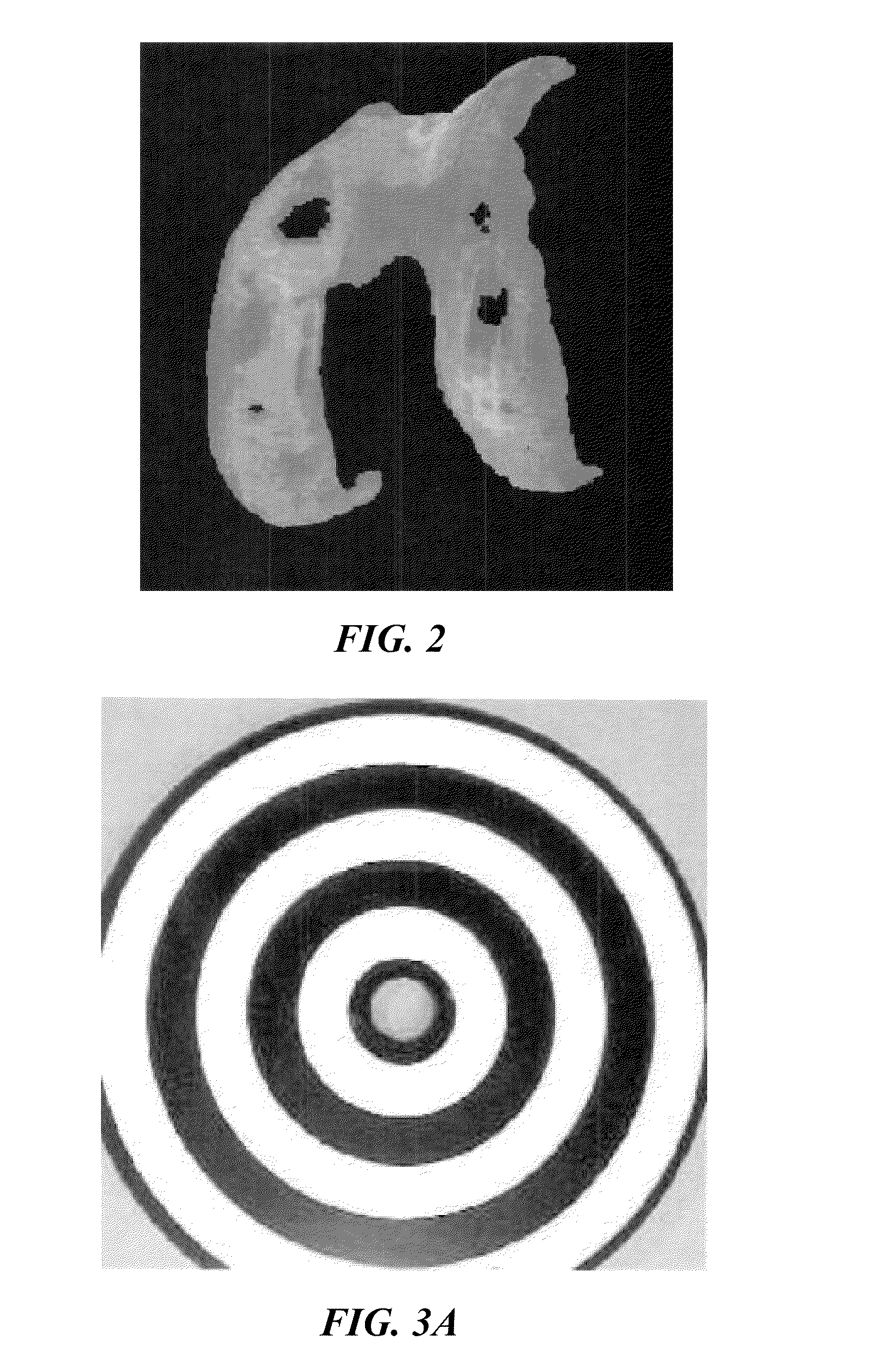

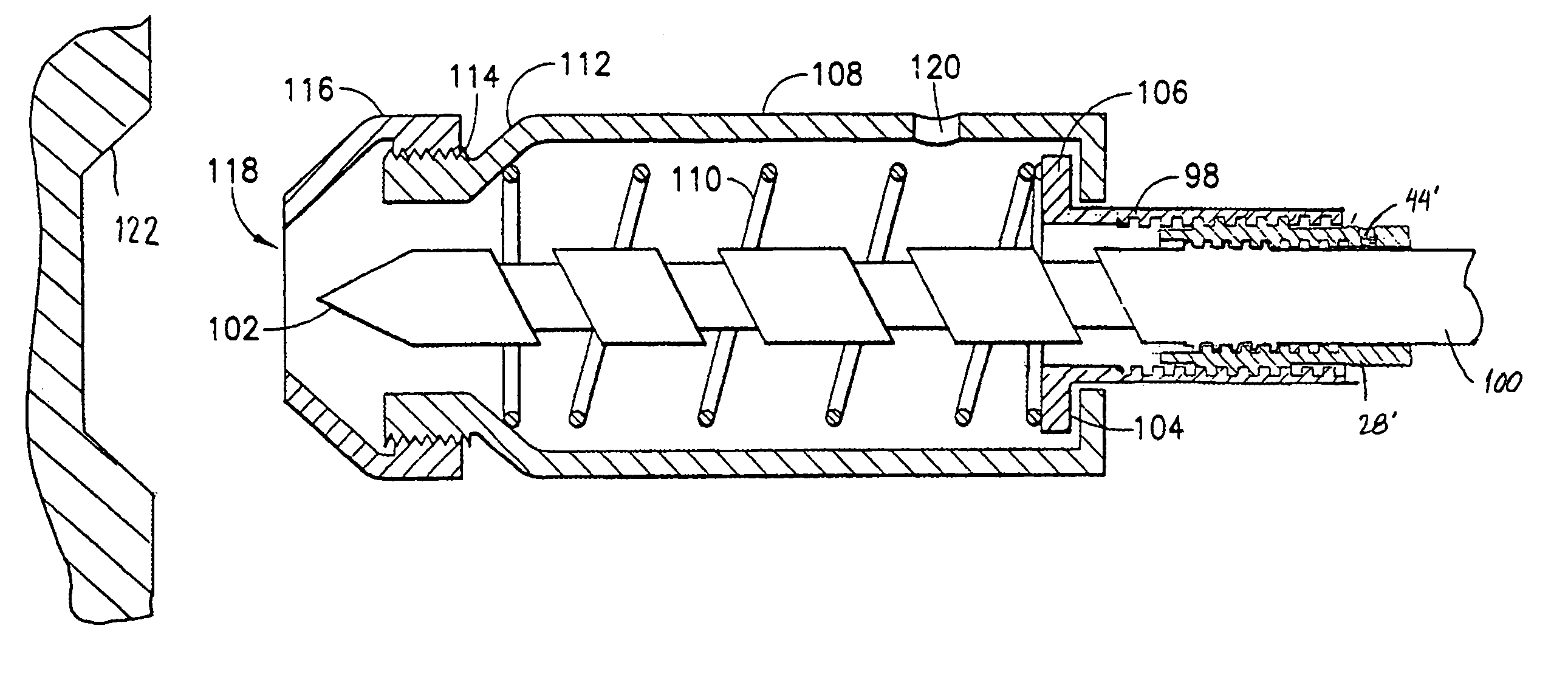

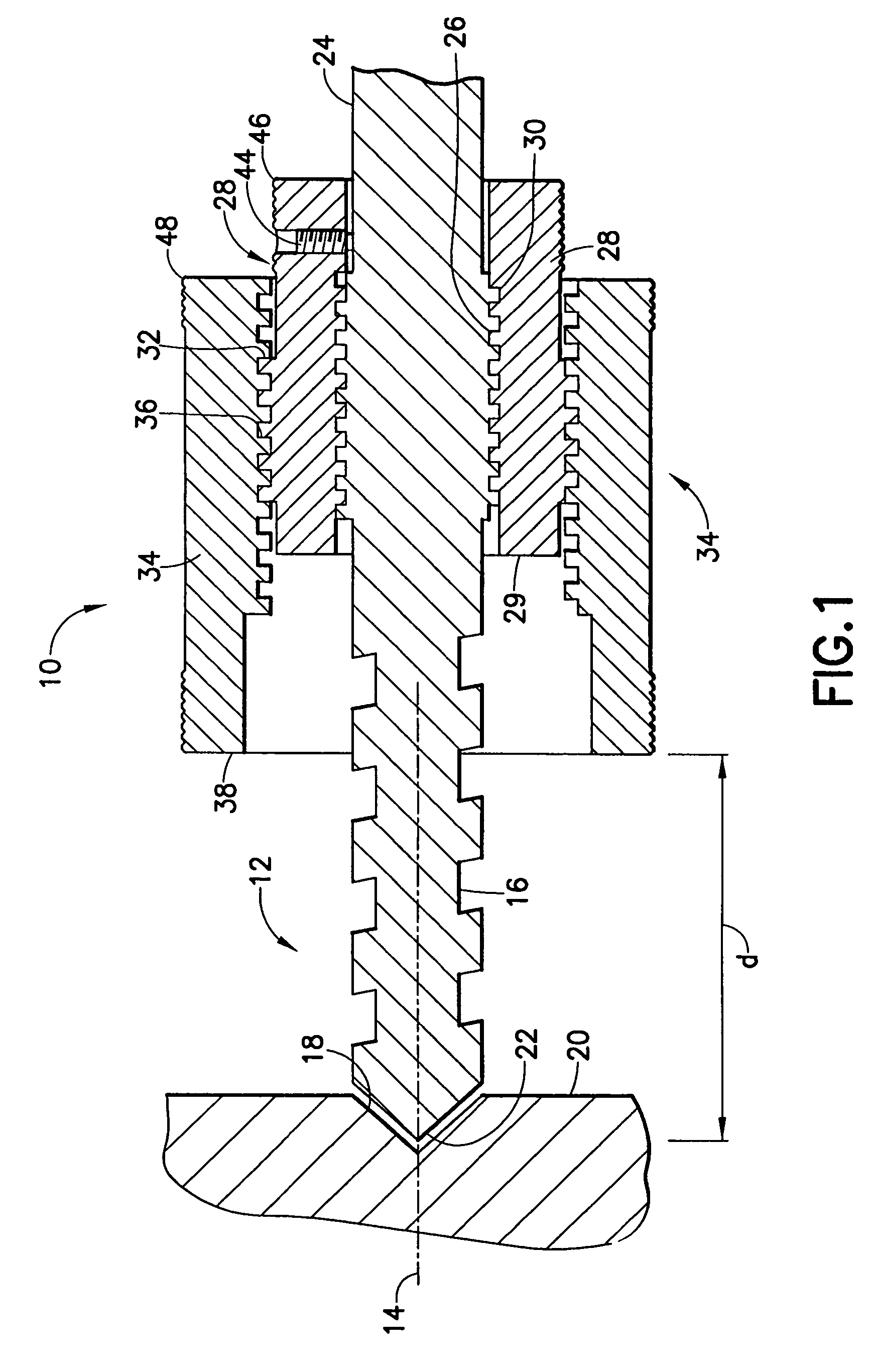

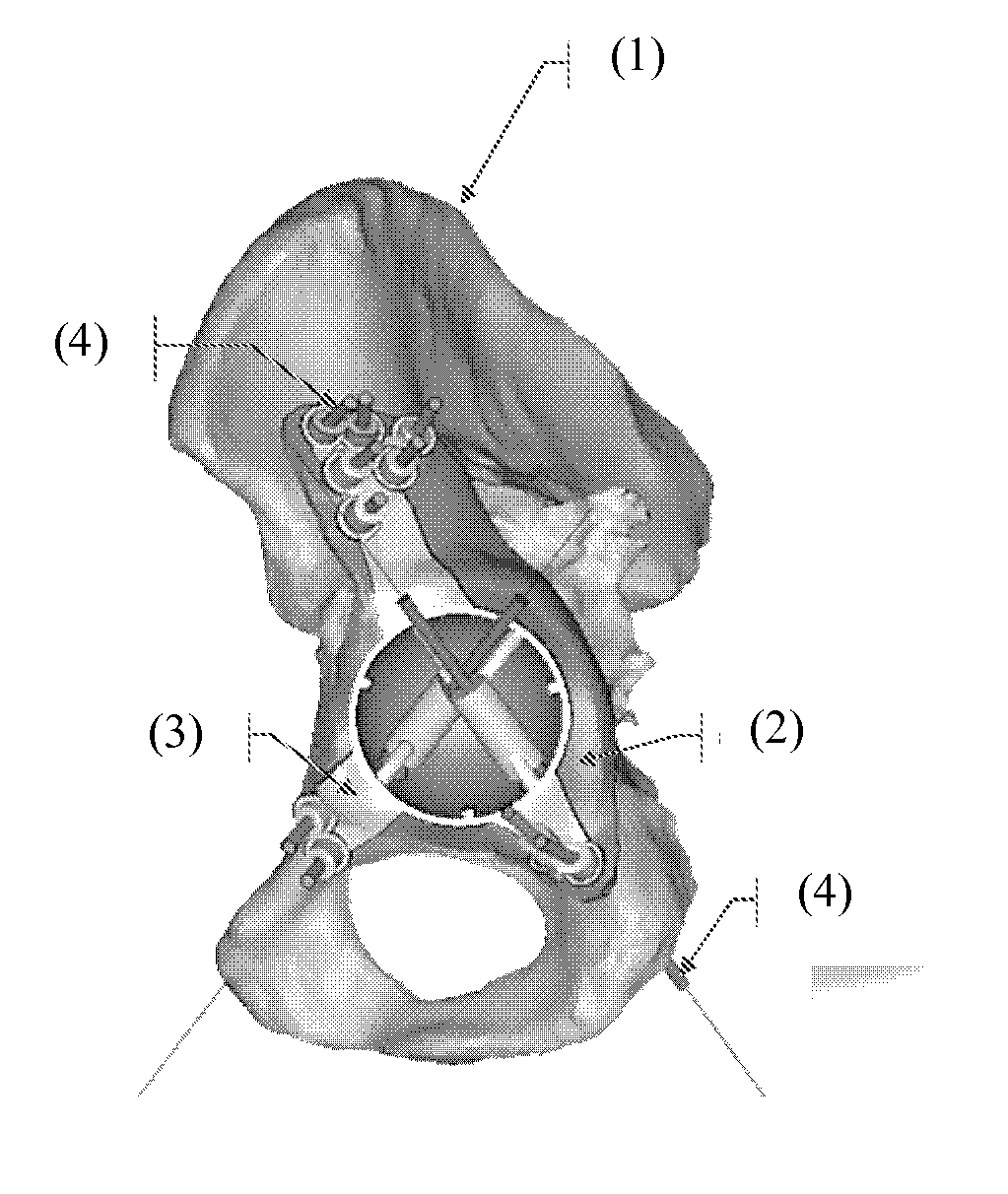

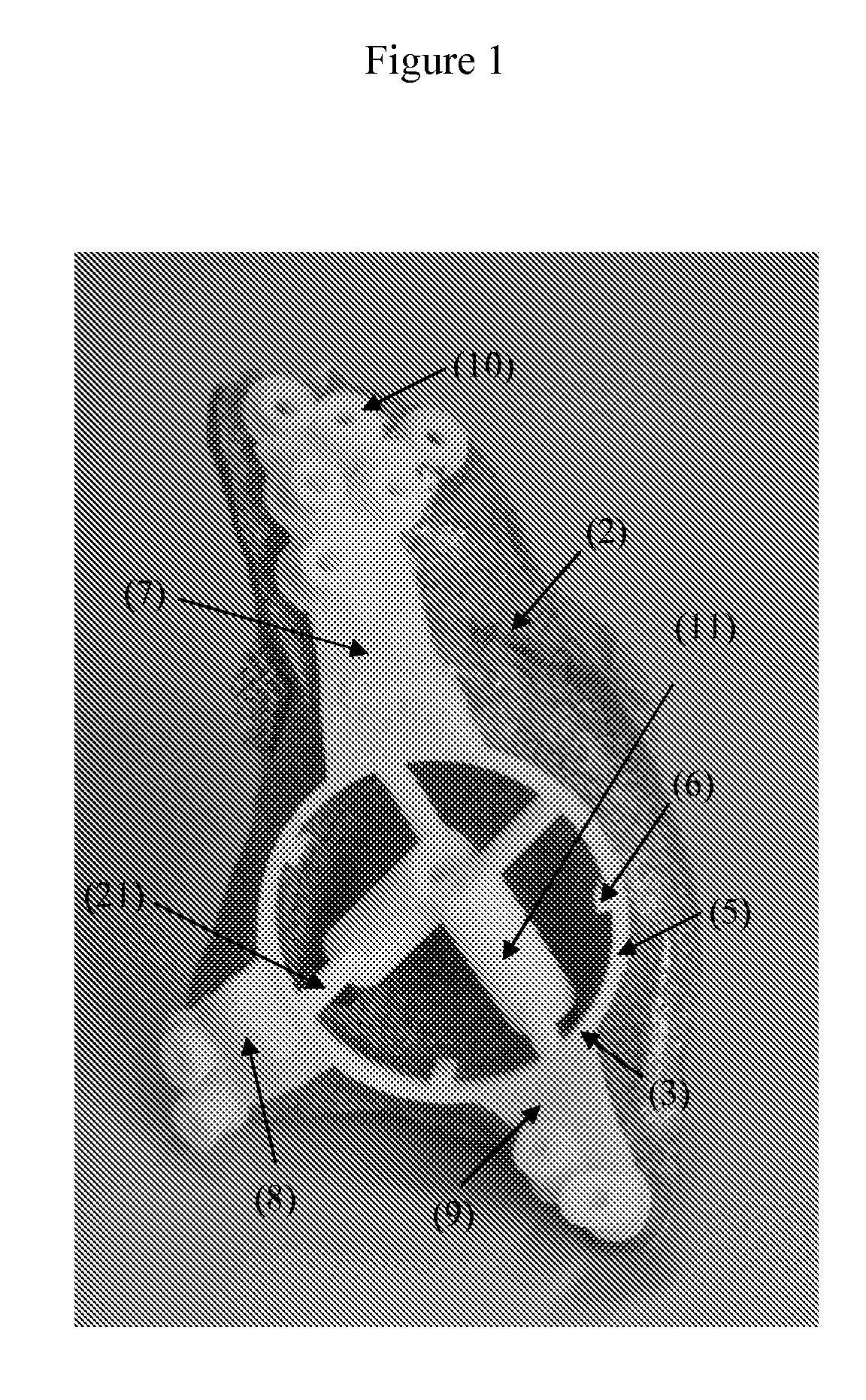

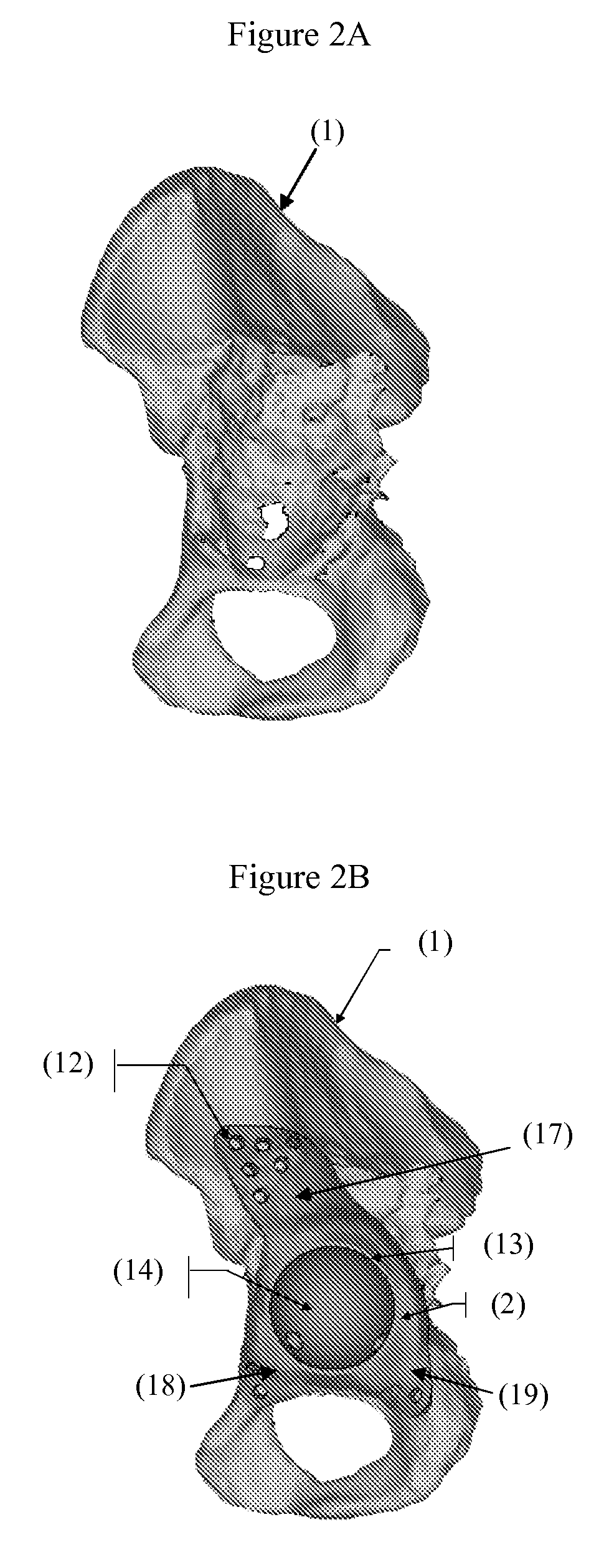

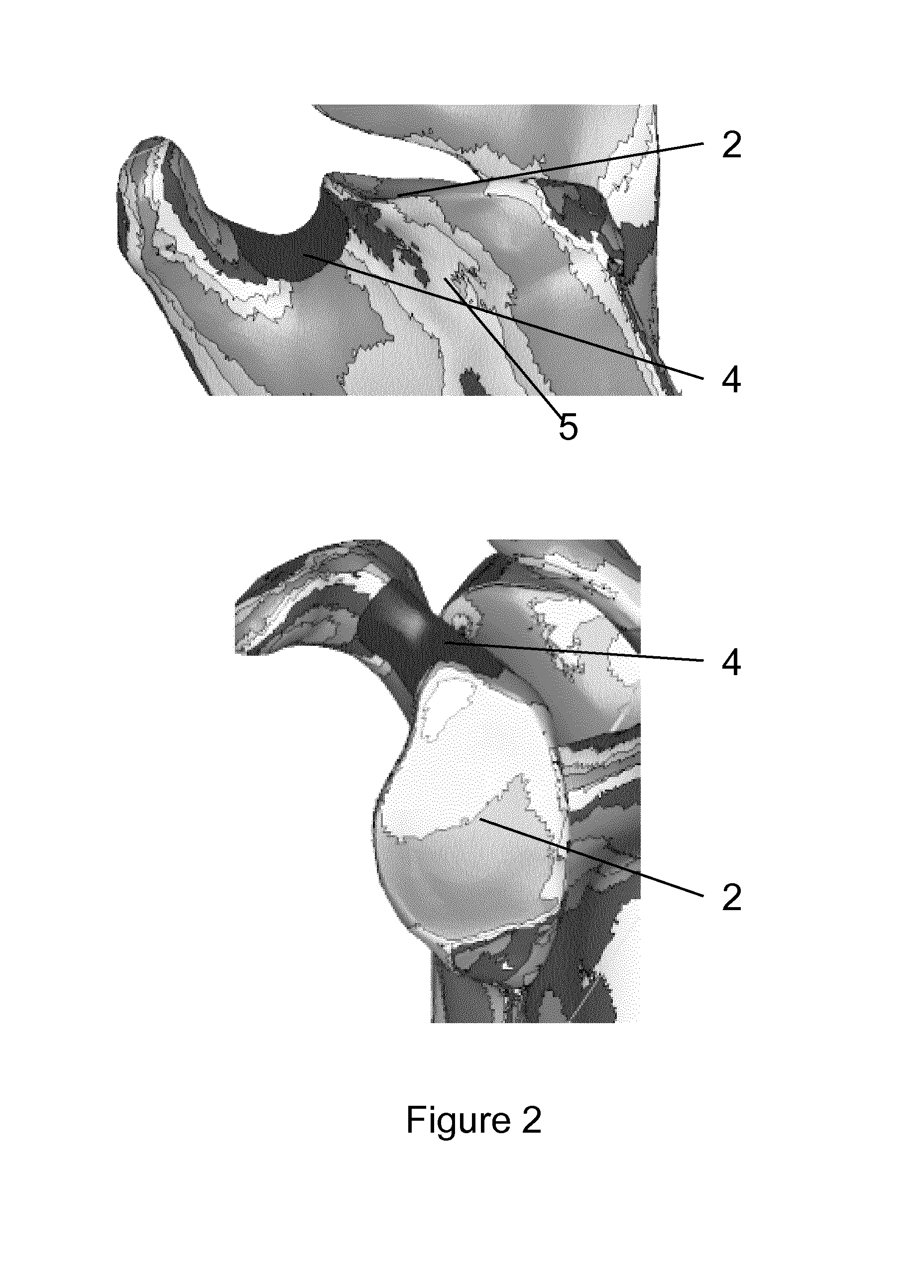

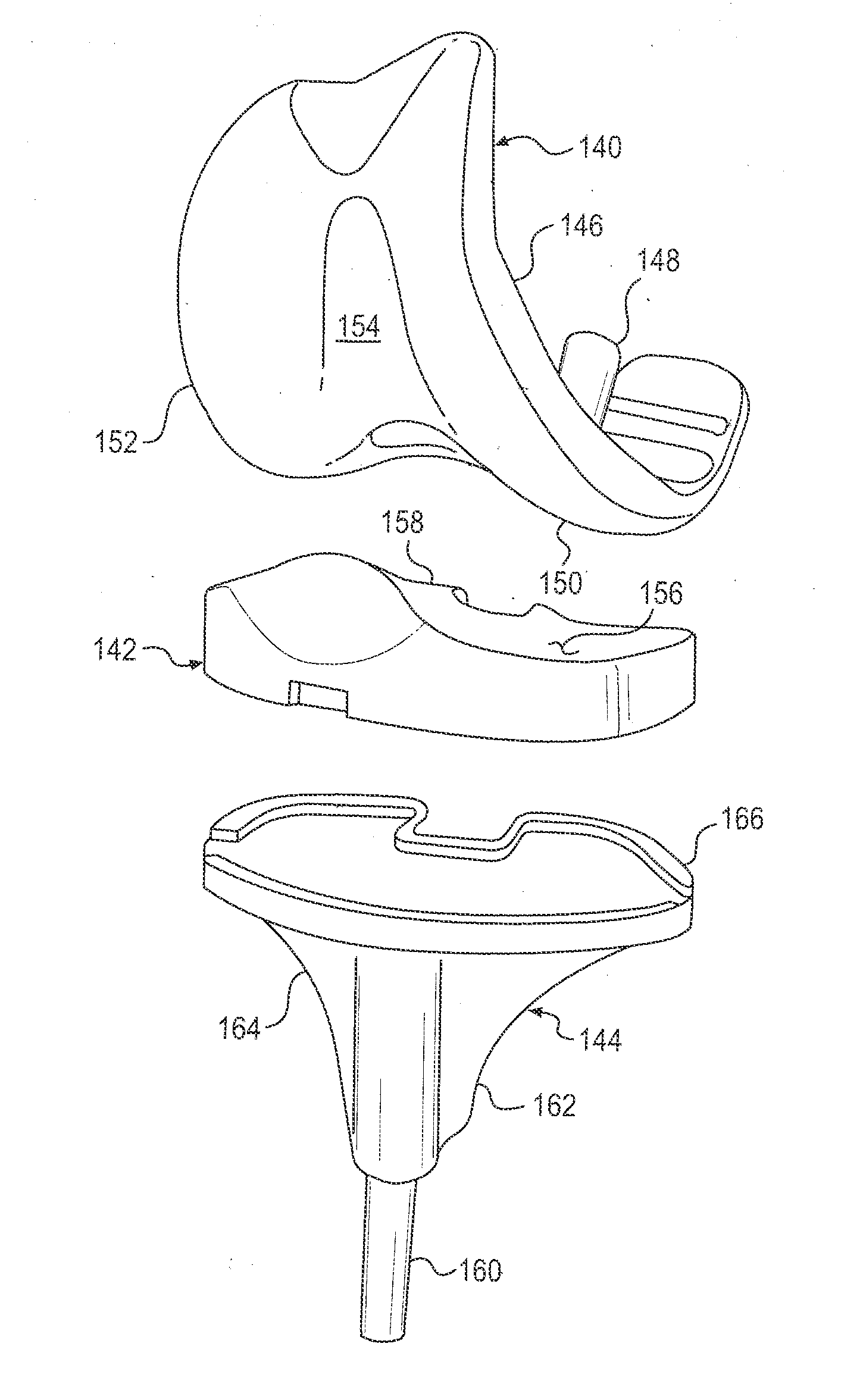

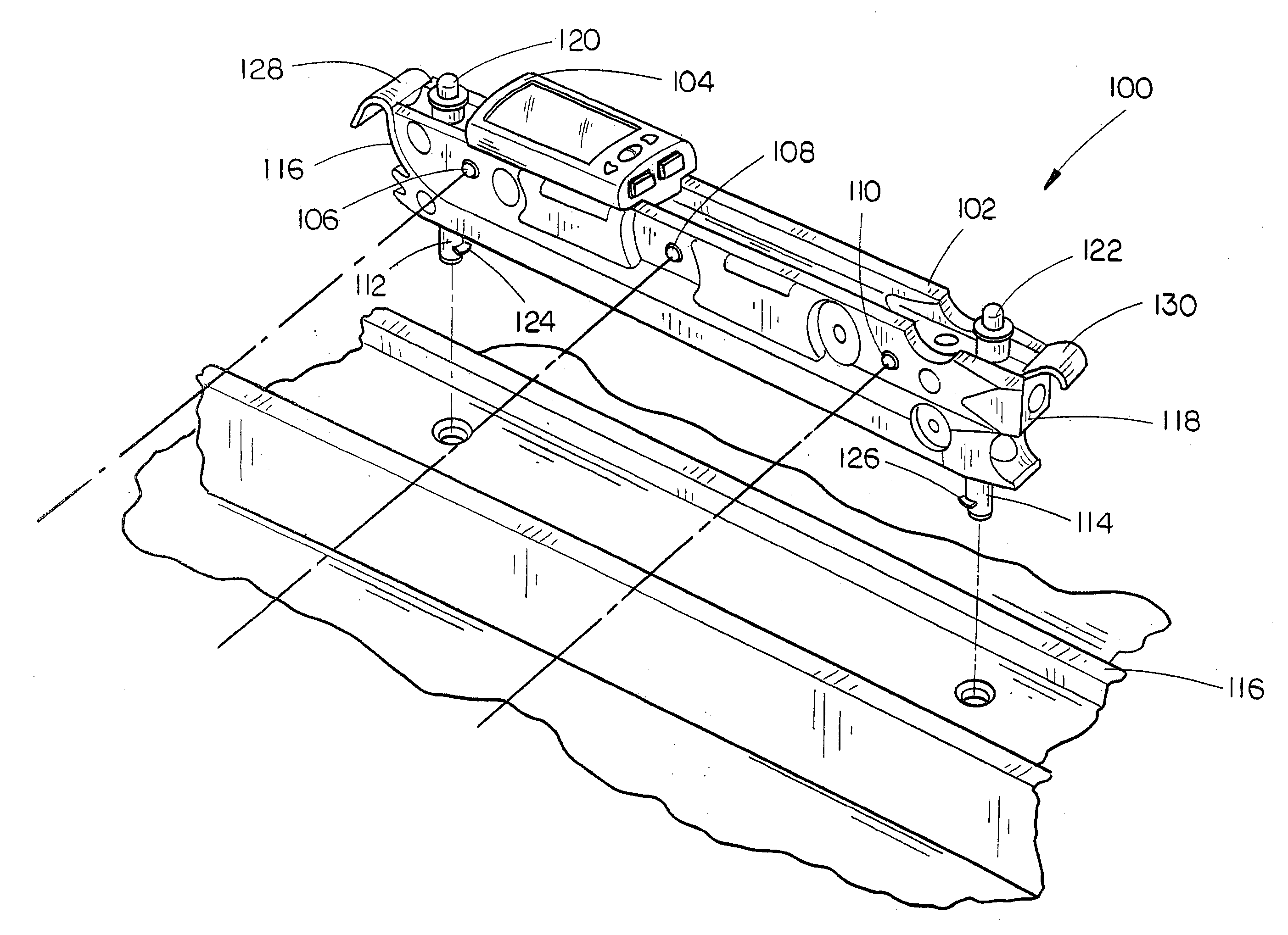

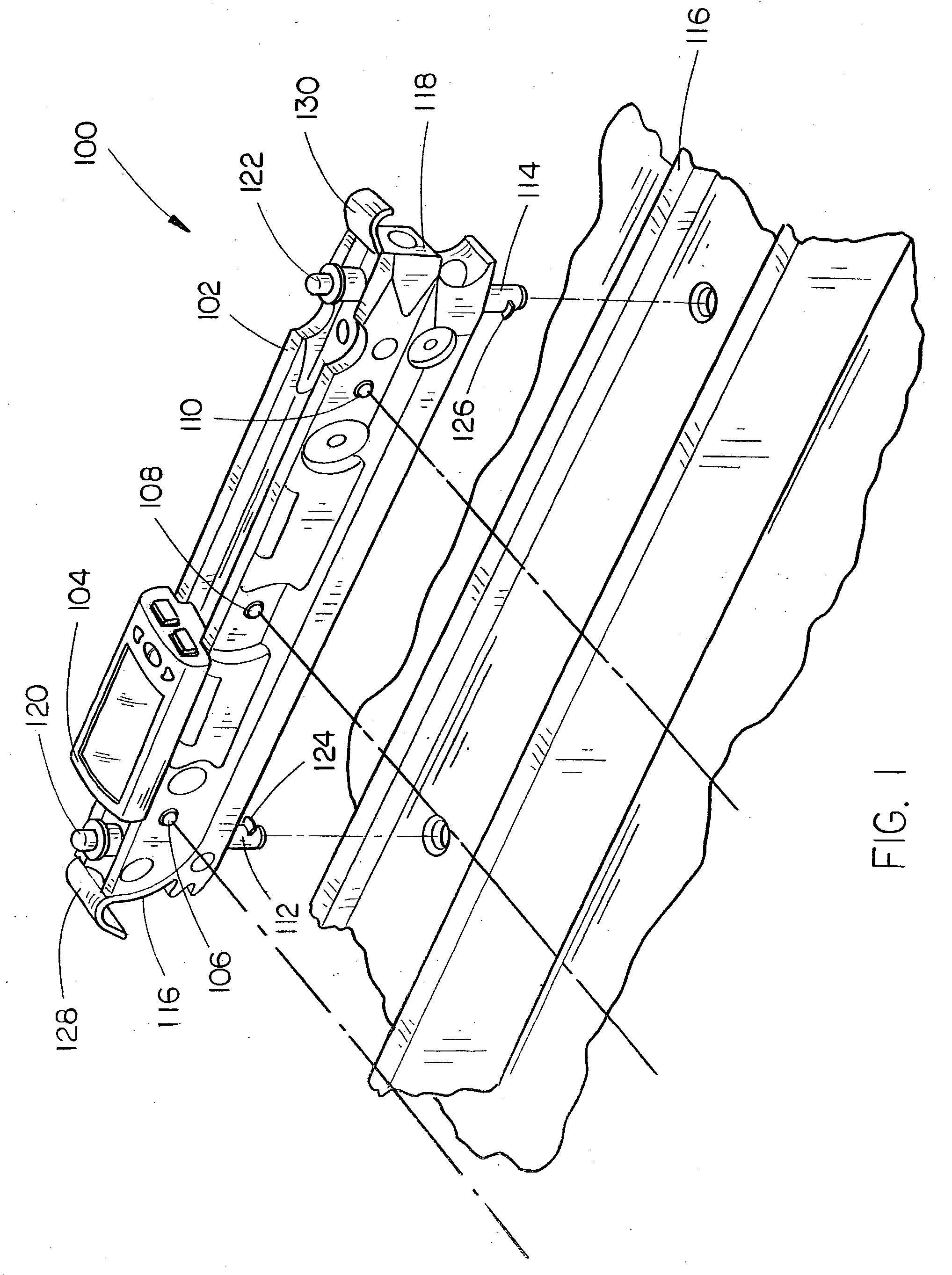

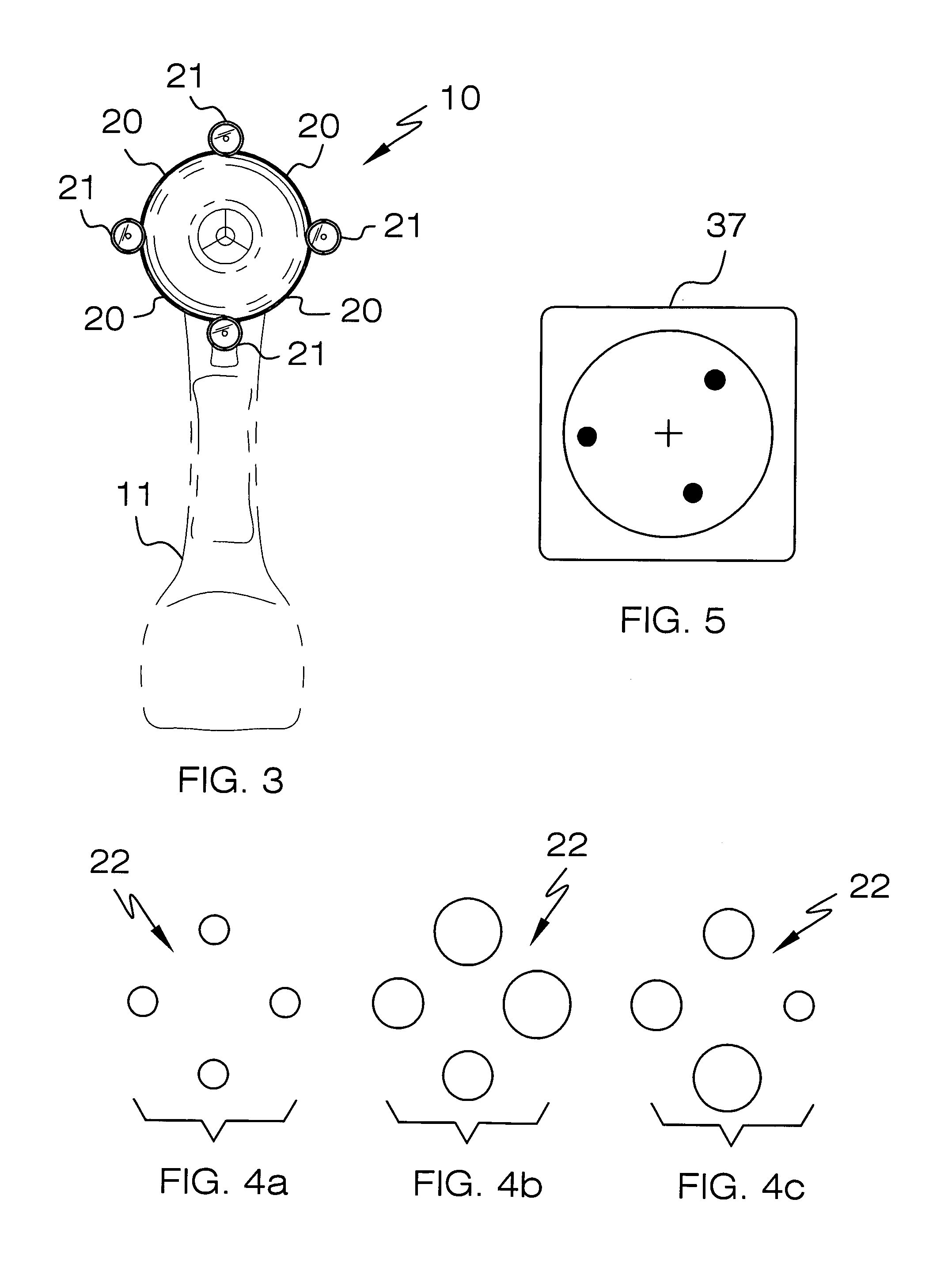

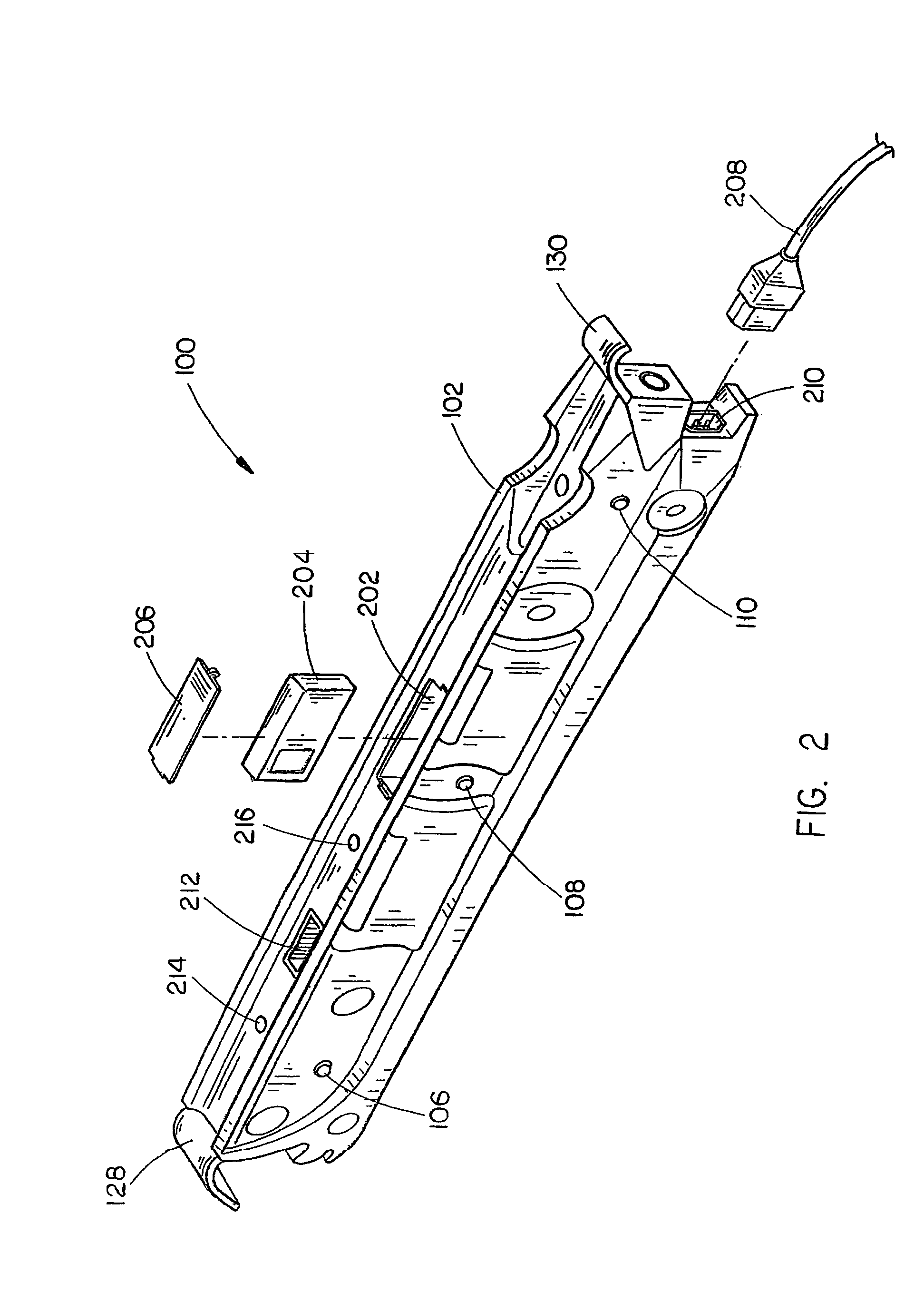

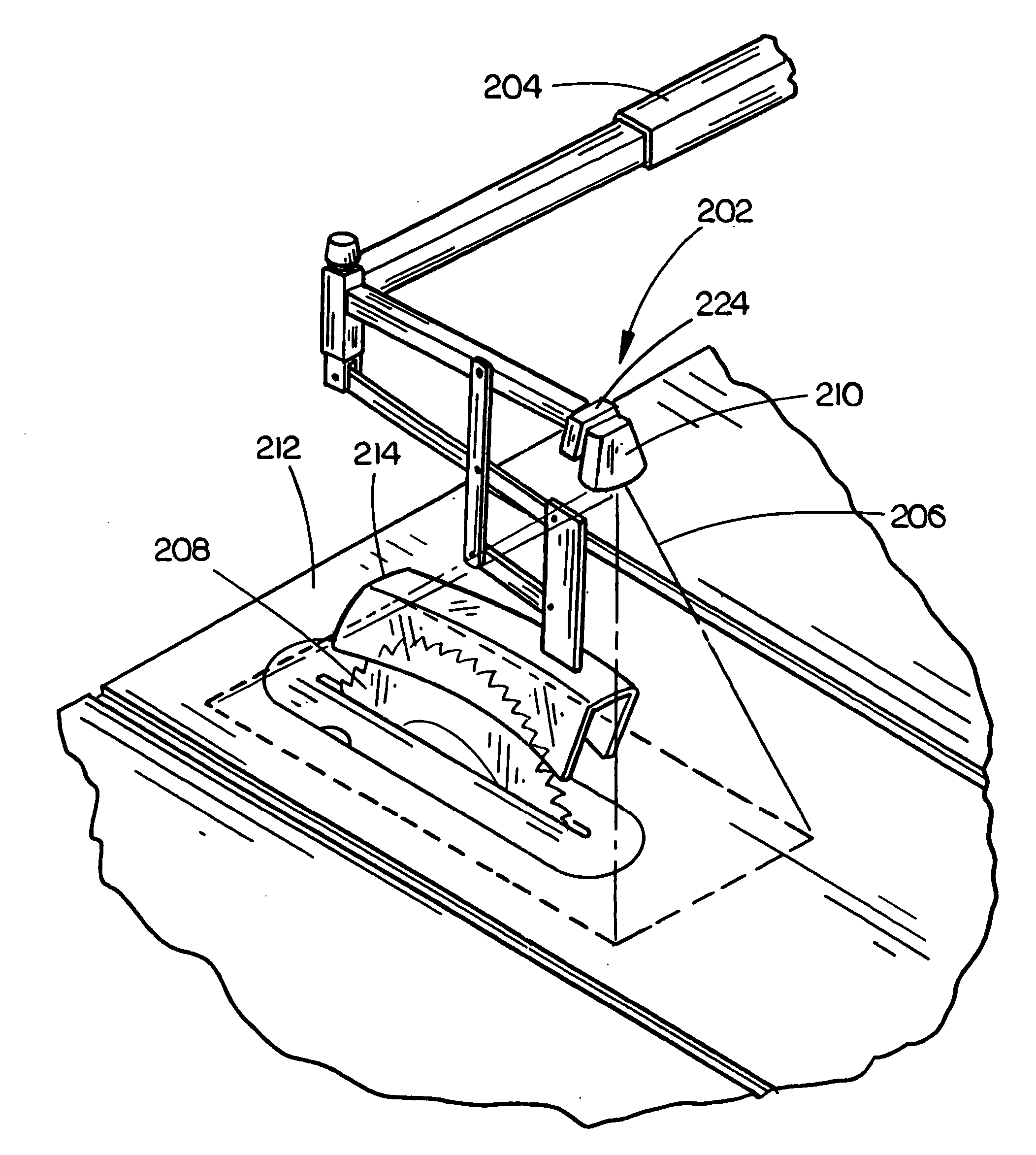

Joint Arthroplasty Devices and Surgical Tools

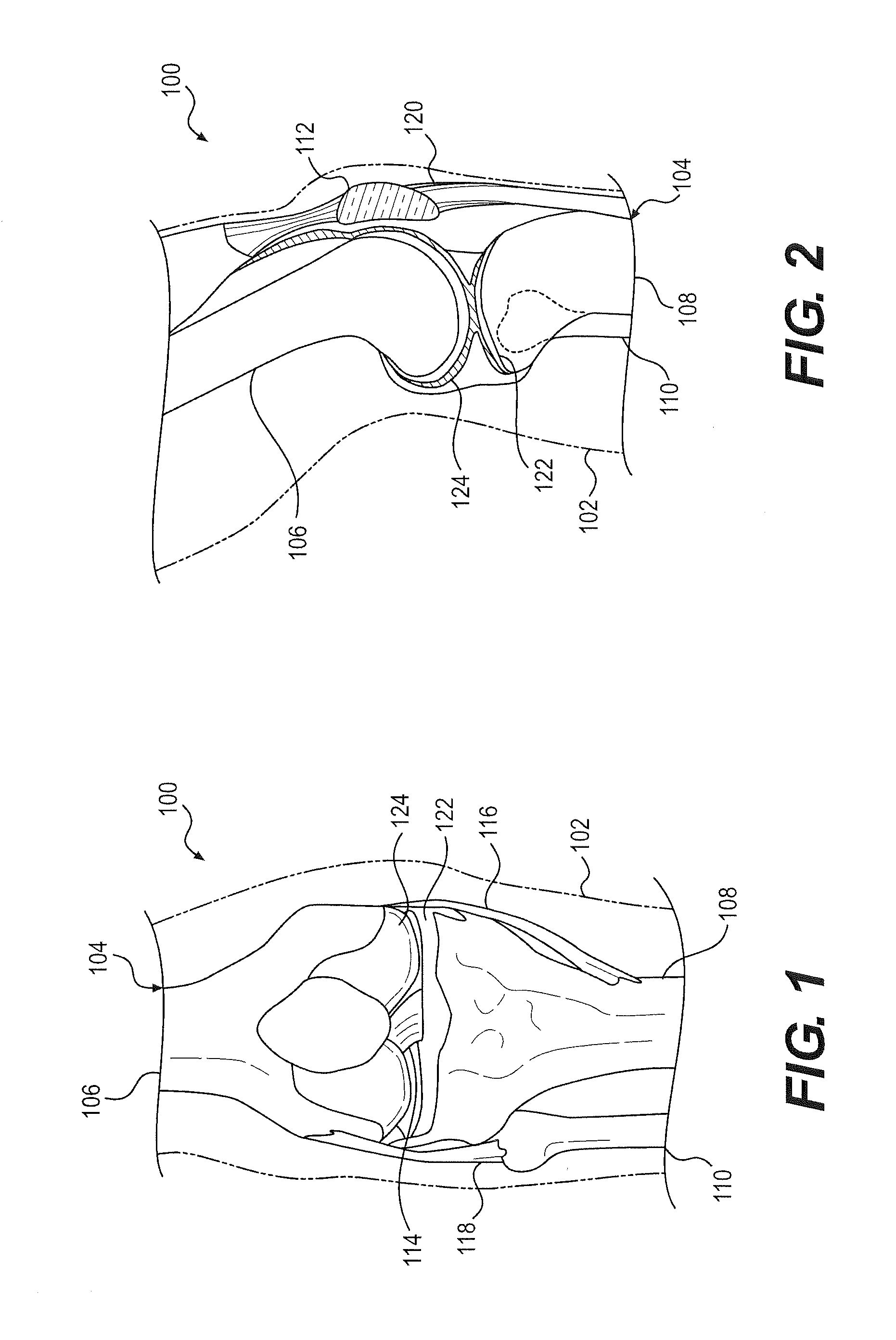

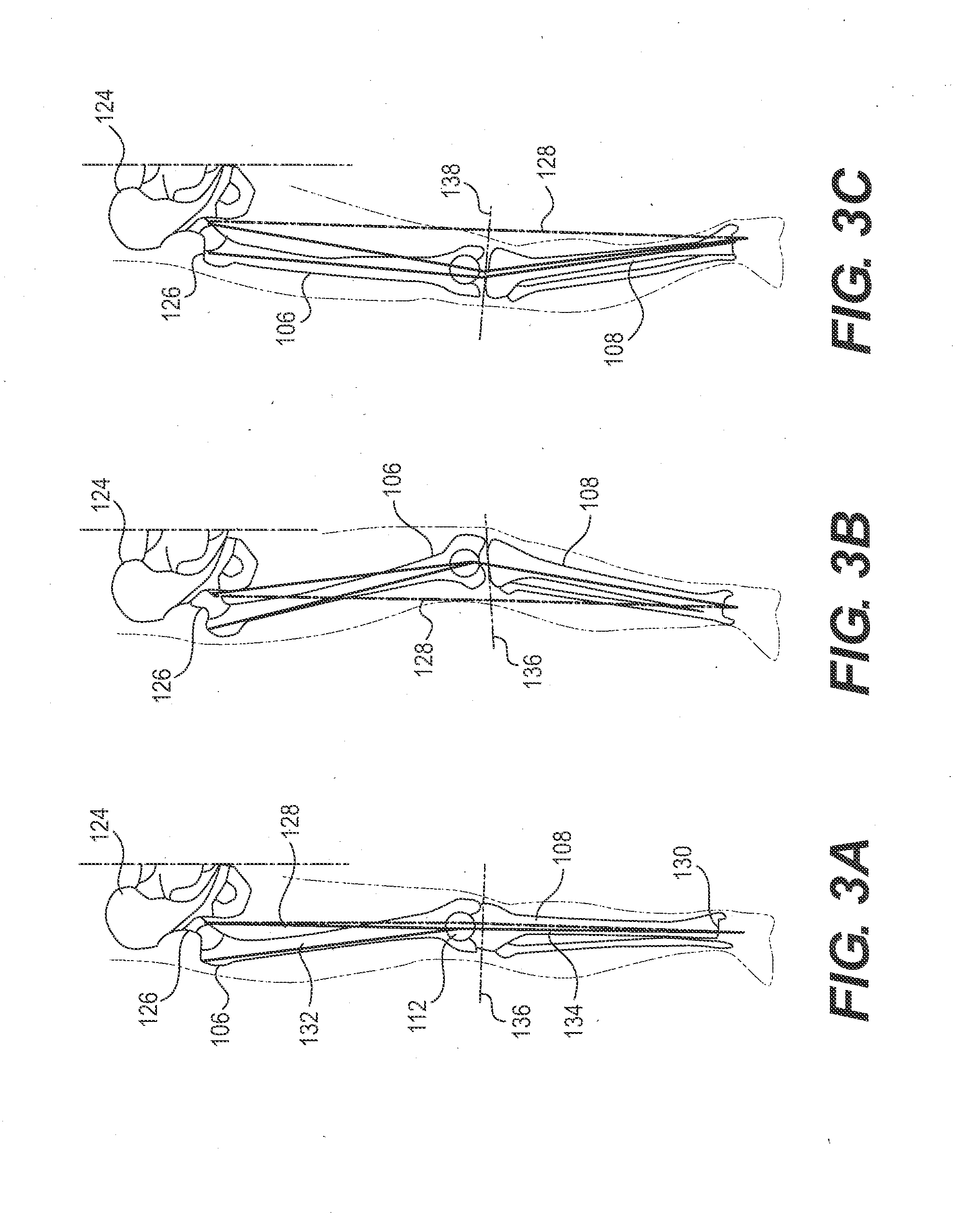

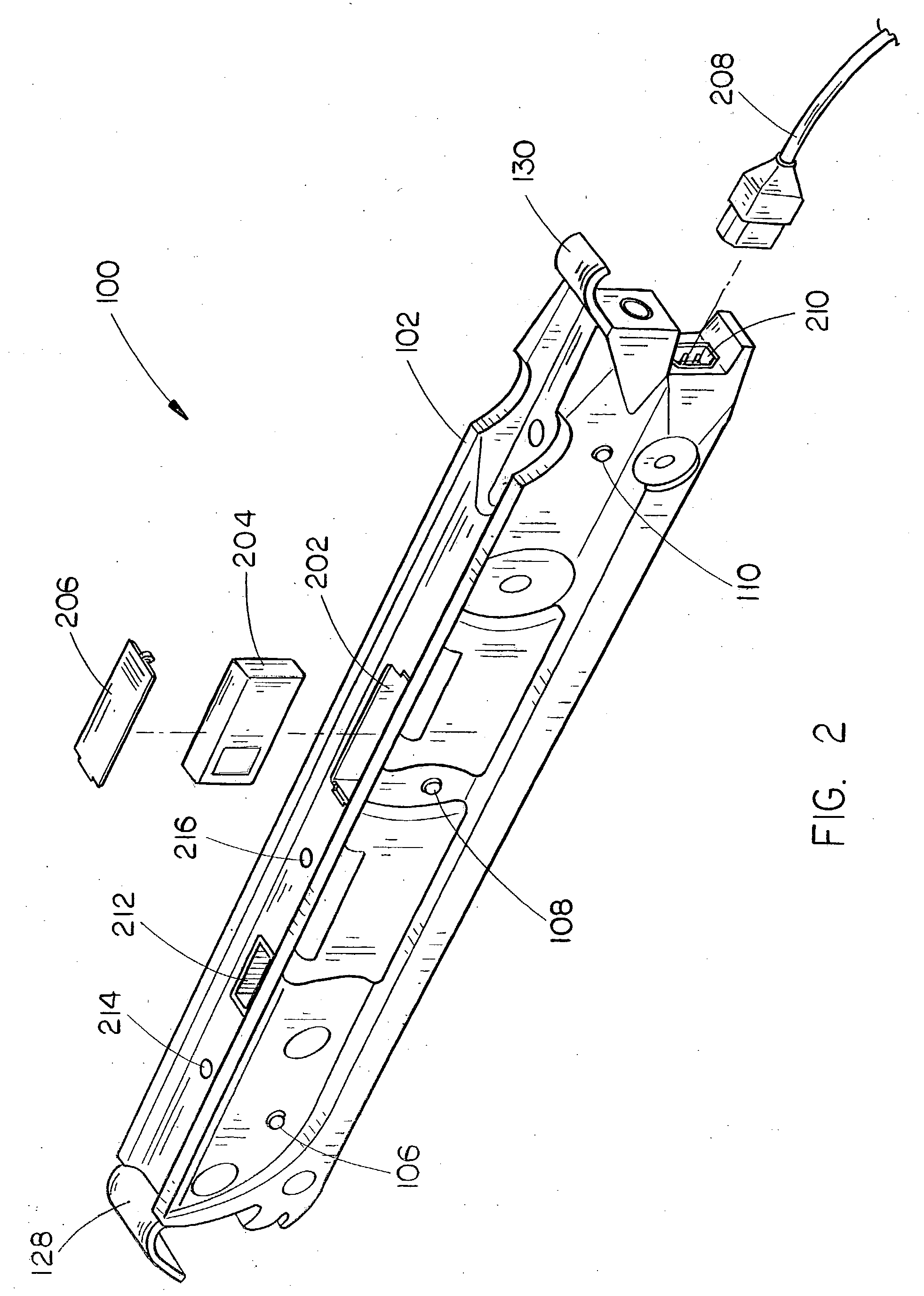

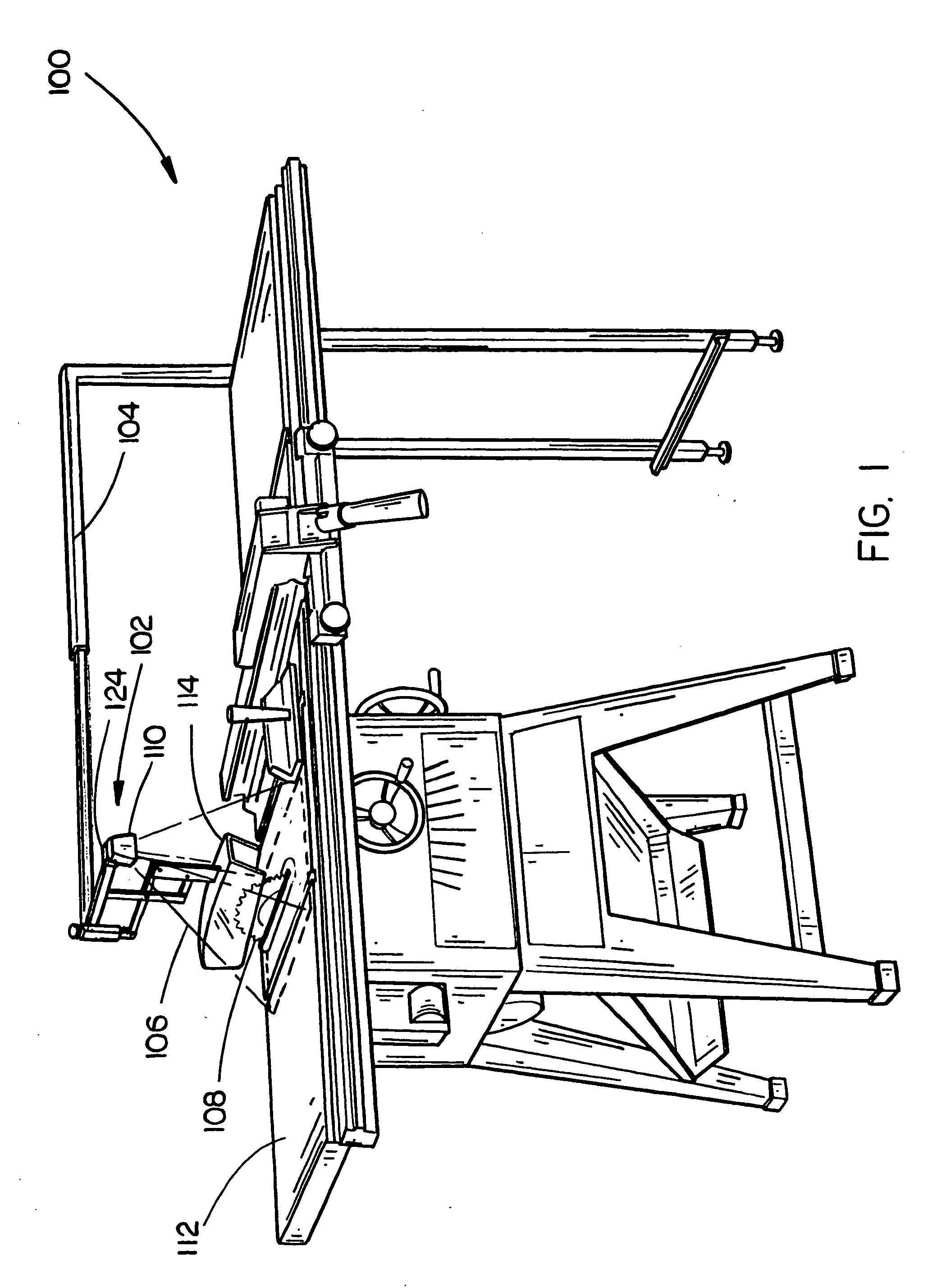

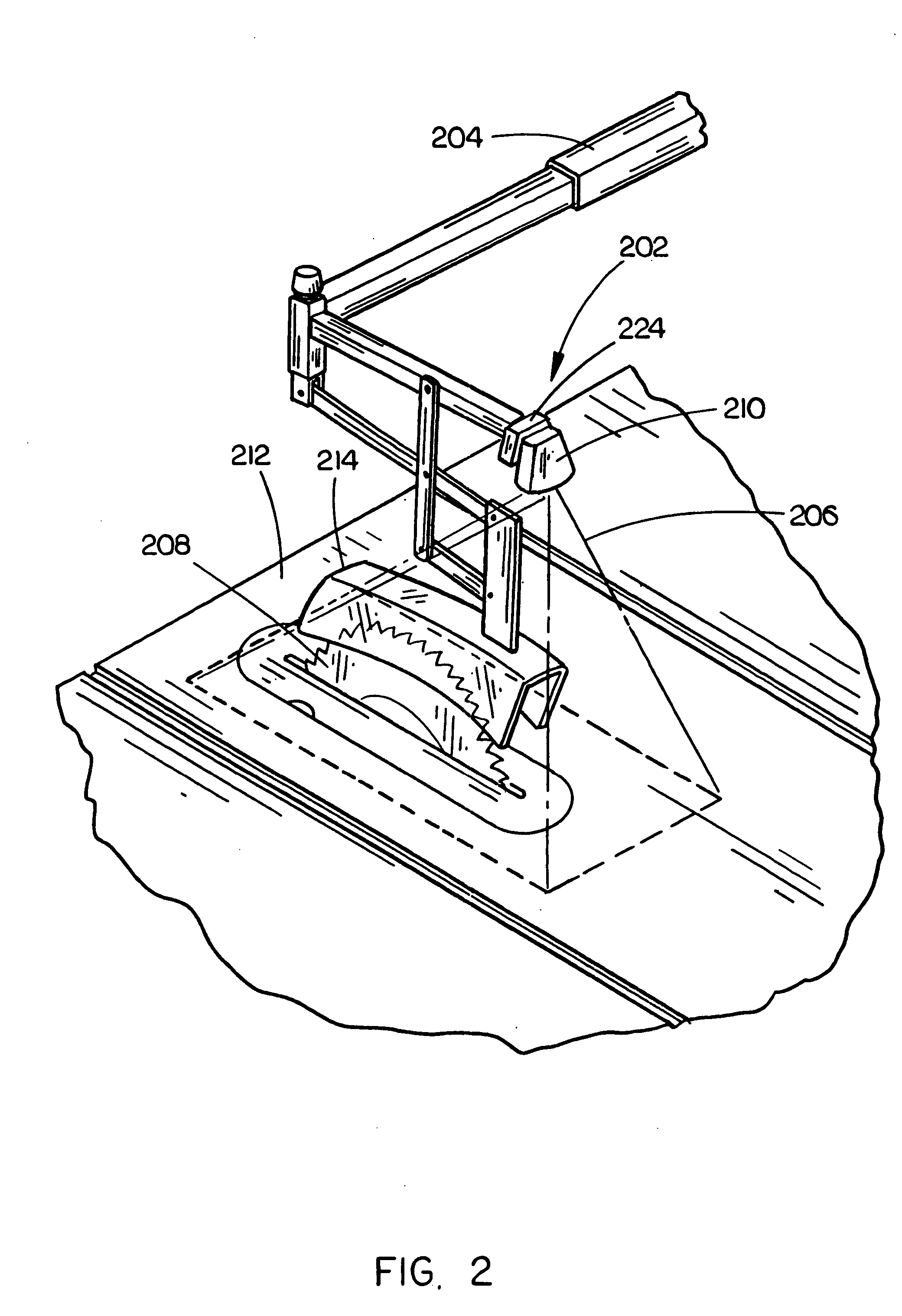

InactiveUS20100160917A1Accurate placementImage analysisInternal osteosythesisArticular surfacesArticular surface

Disclosed herein are methods, compositions and tools for repairing articular surfaces repair materials and for repairing an articular surface. The articular surface repairs are customizable or highly selectable by patient and geared toward providing optimal fit and function. The surgical tools are designed to be customizable or highly selectable by patient to increase the speed, accuracy and simplicity of performing total or partial arthroplasty.

Owner:CONFORMIS

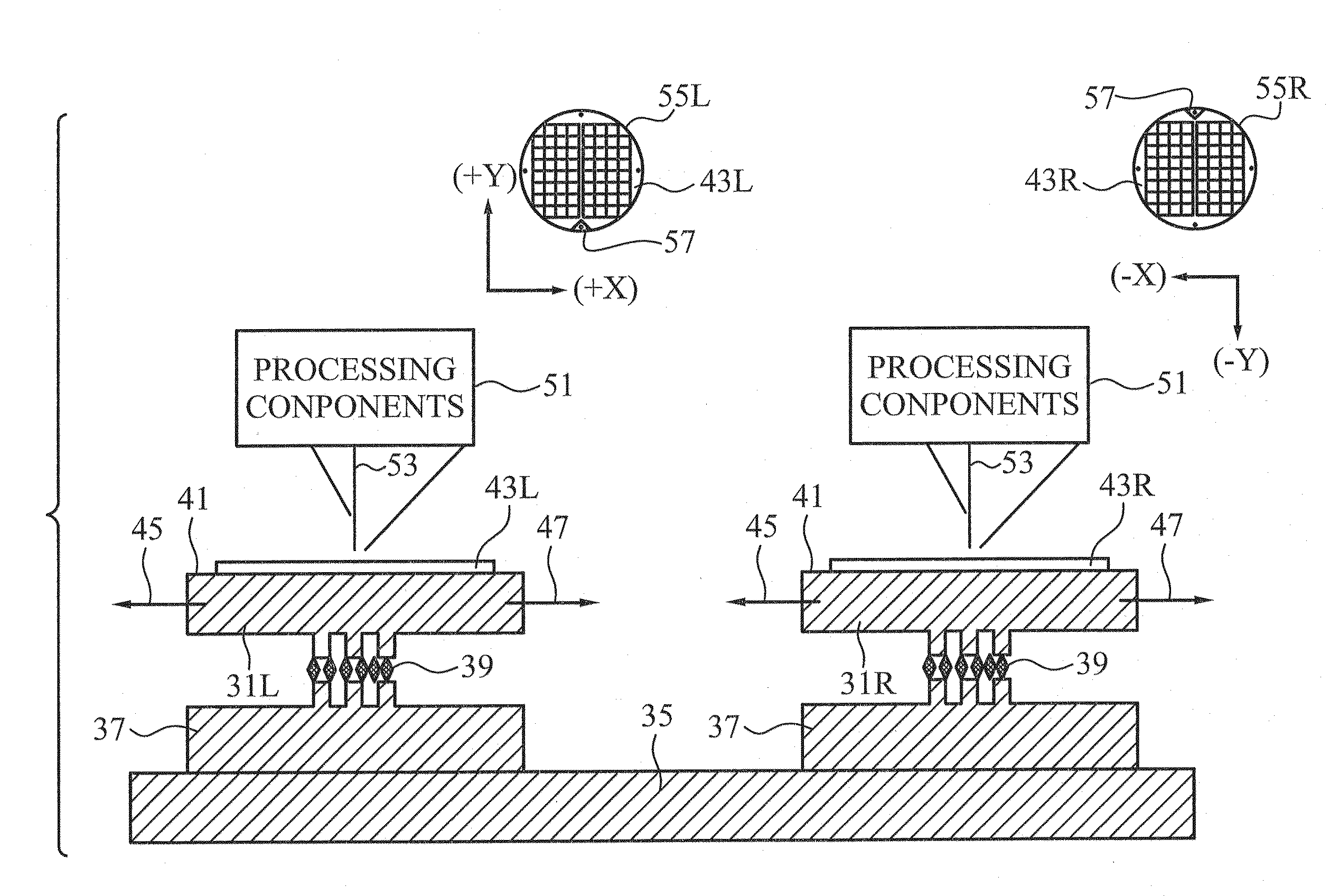

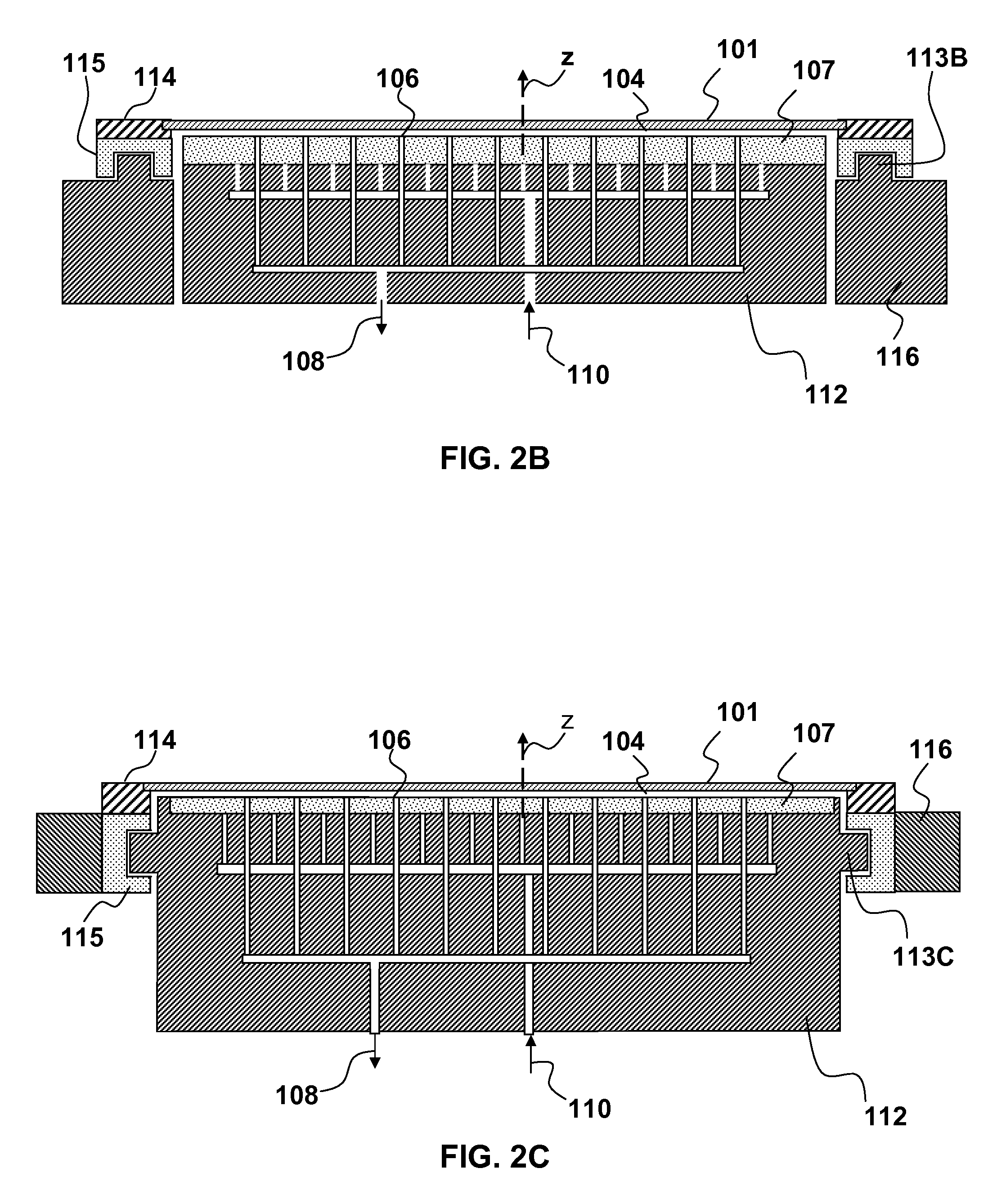

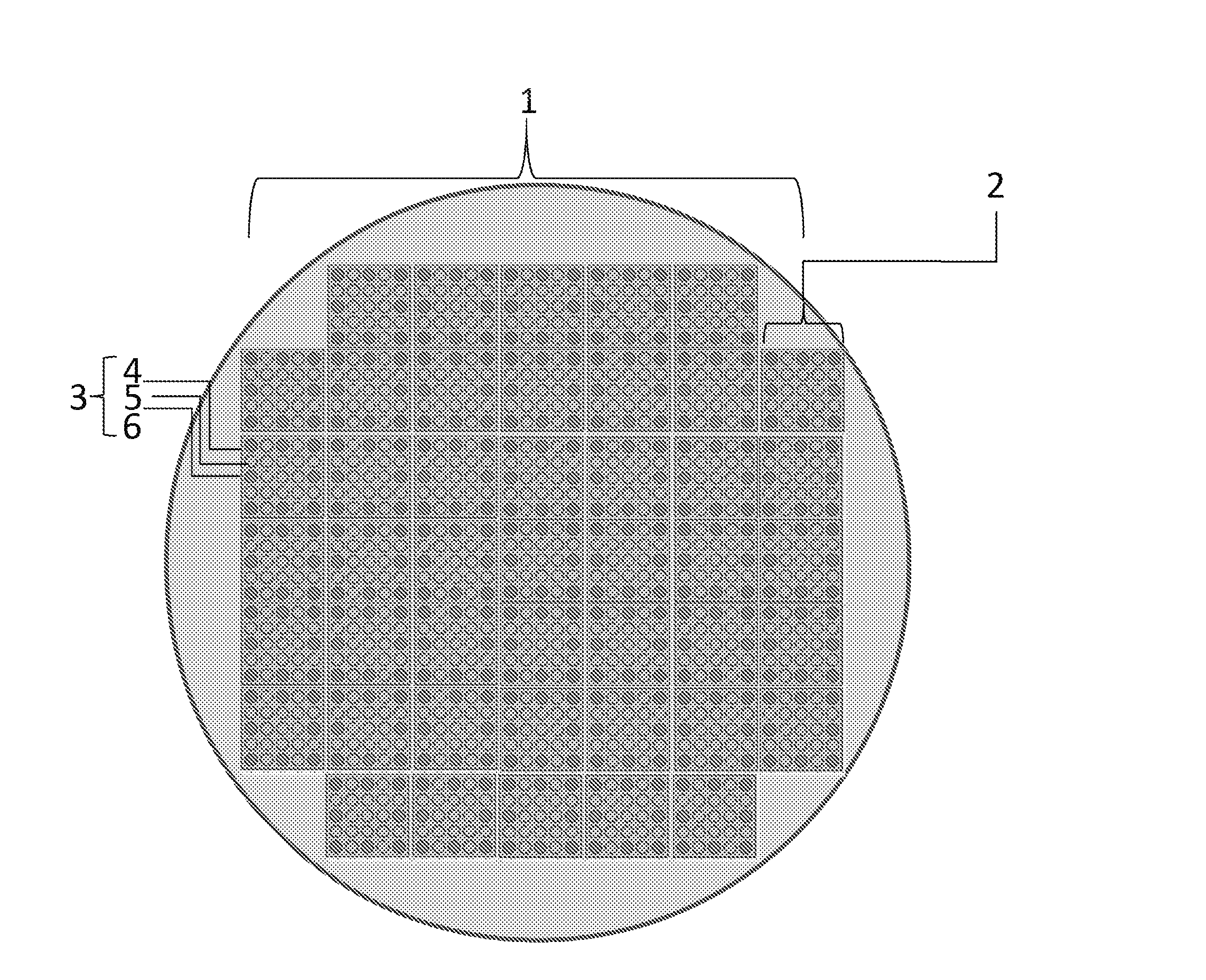

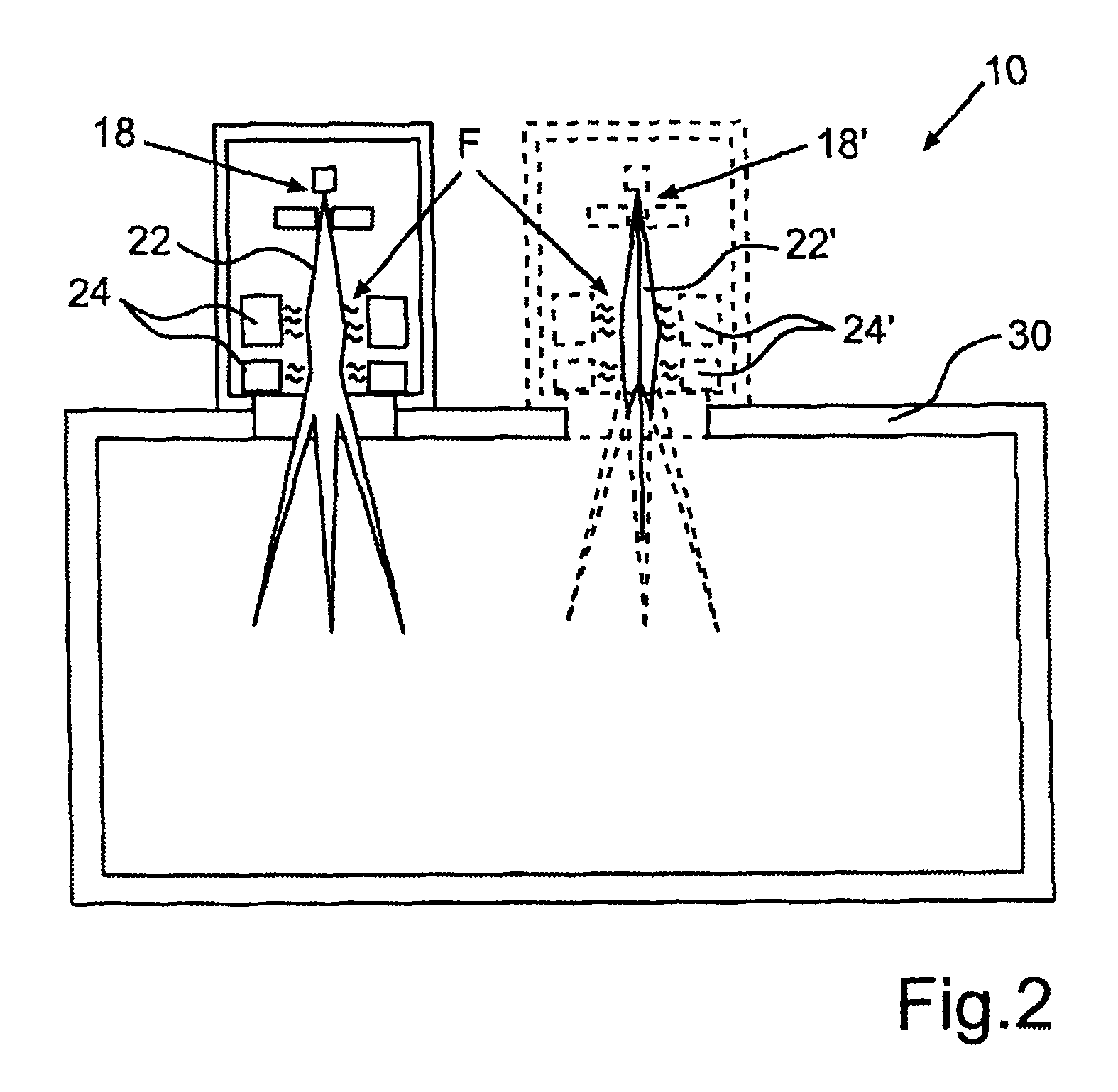

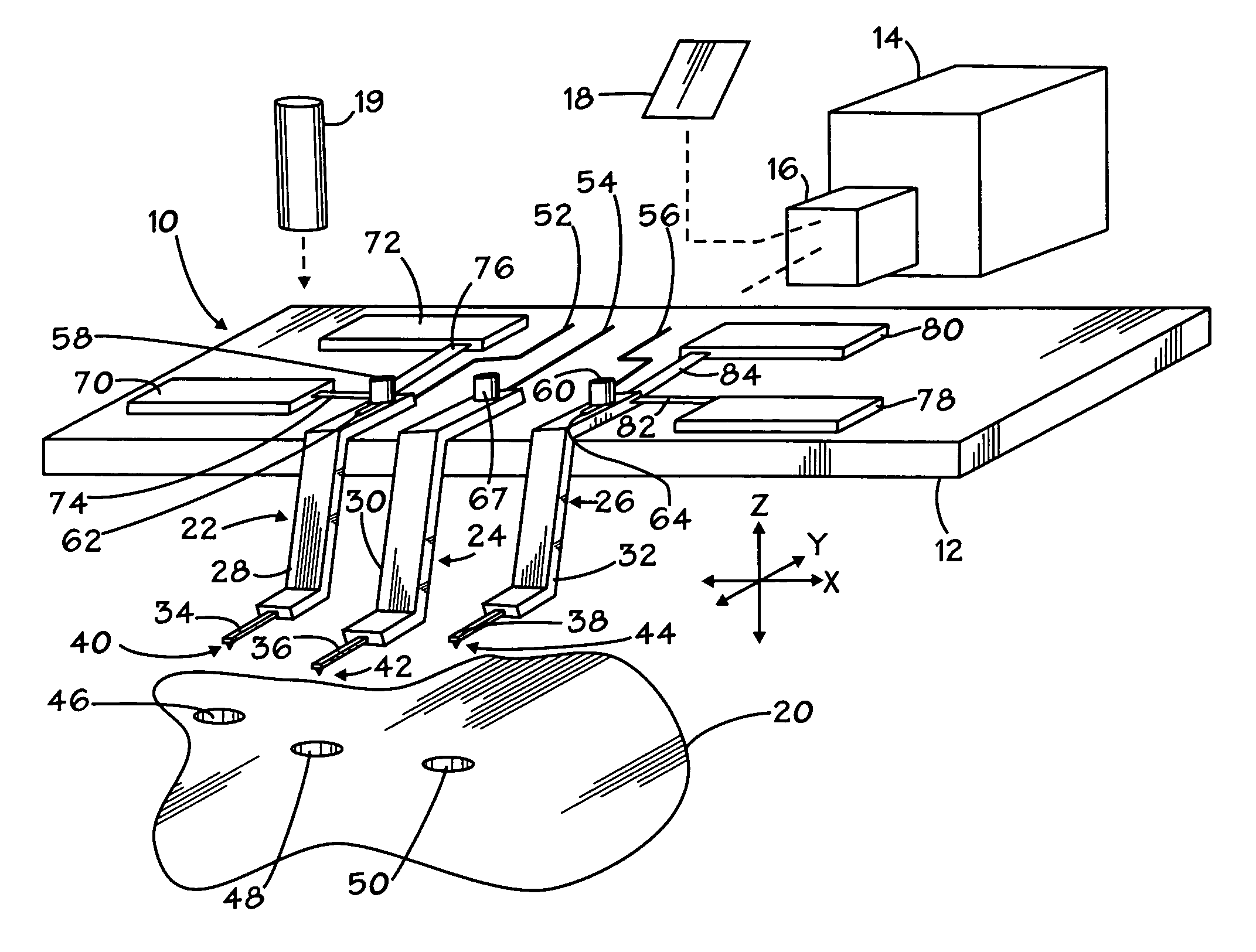

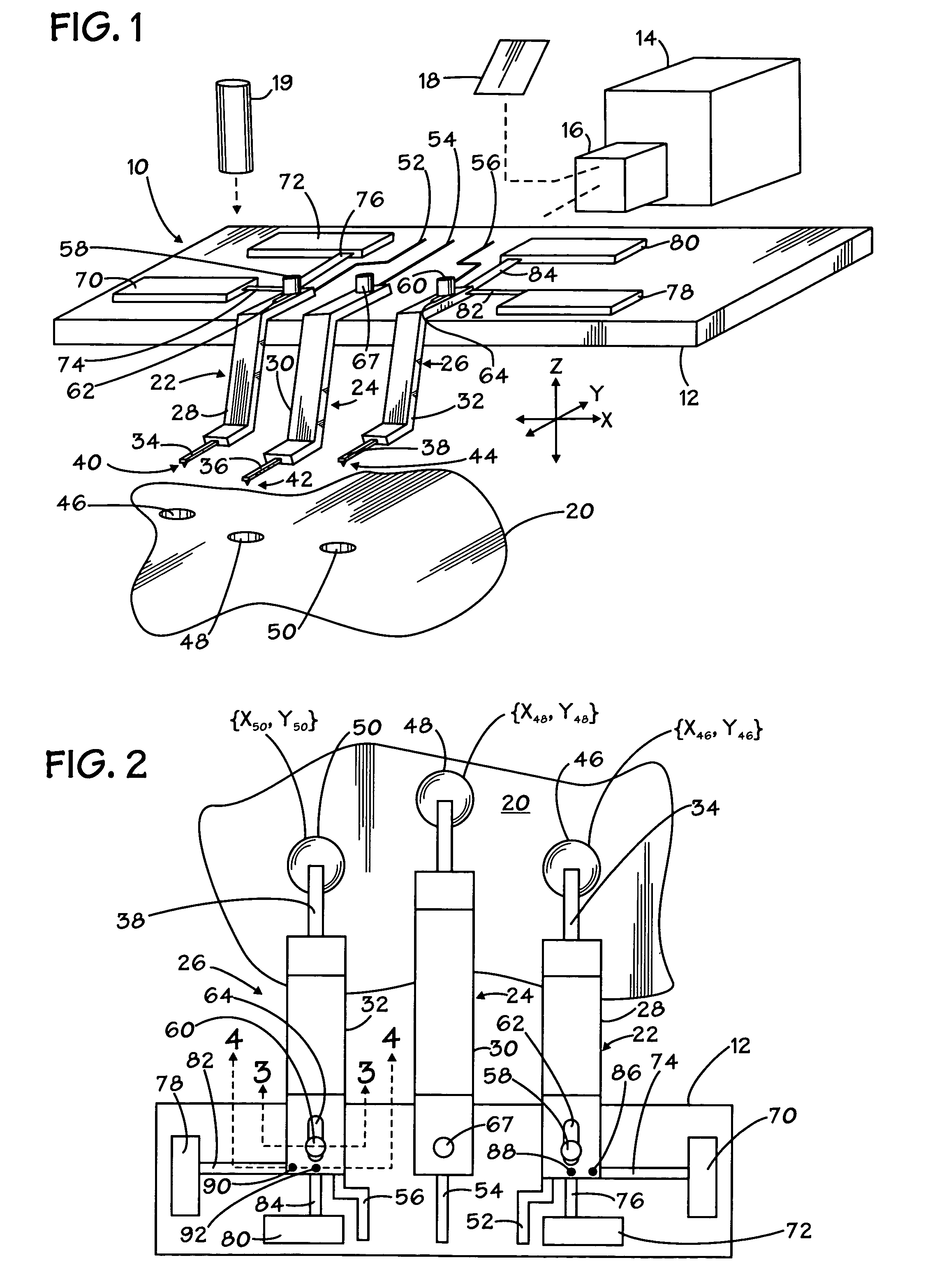

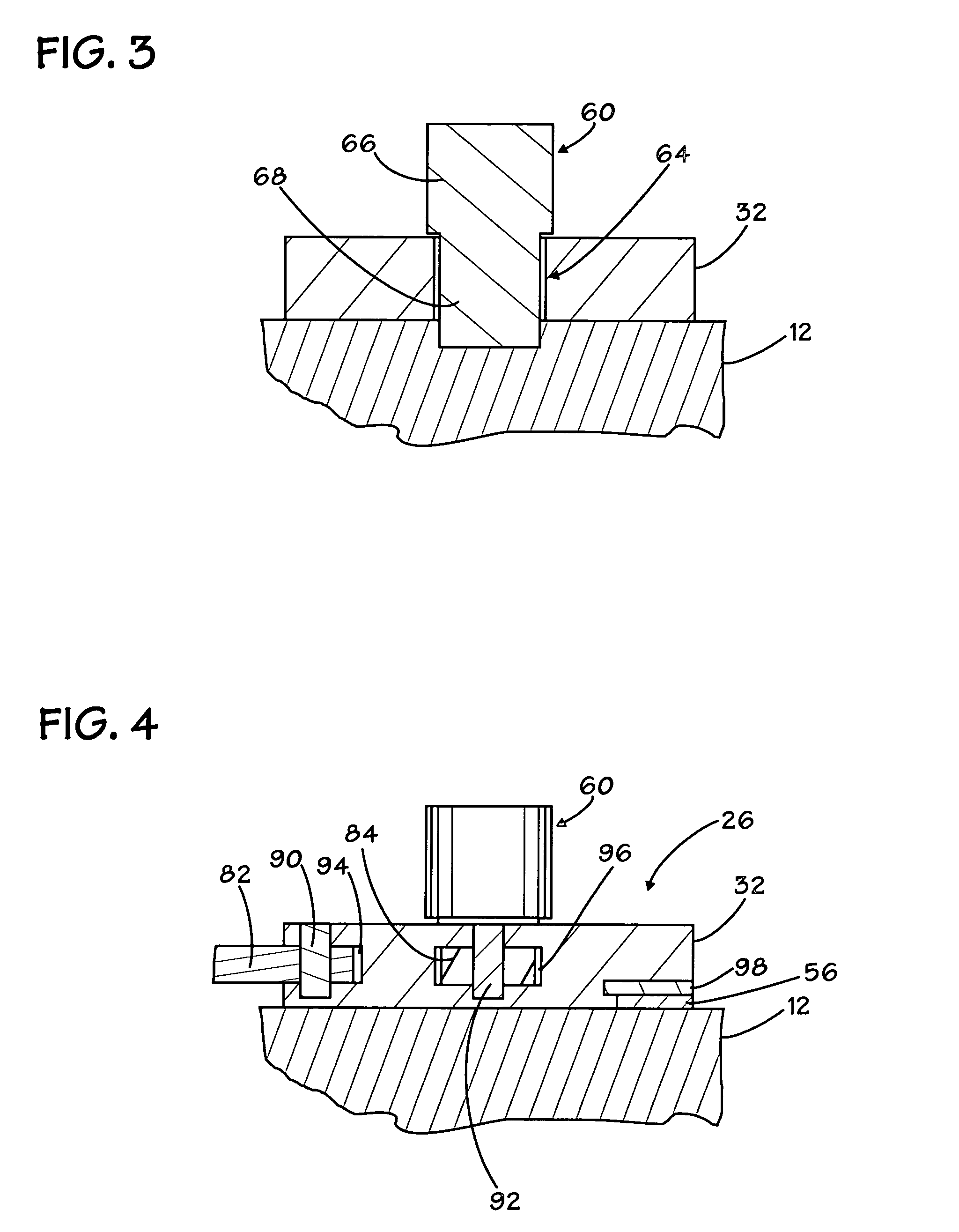

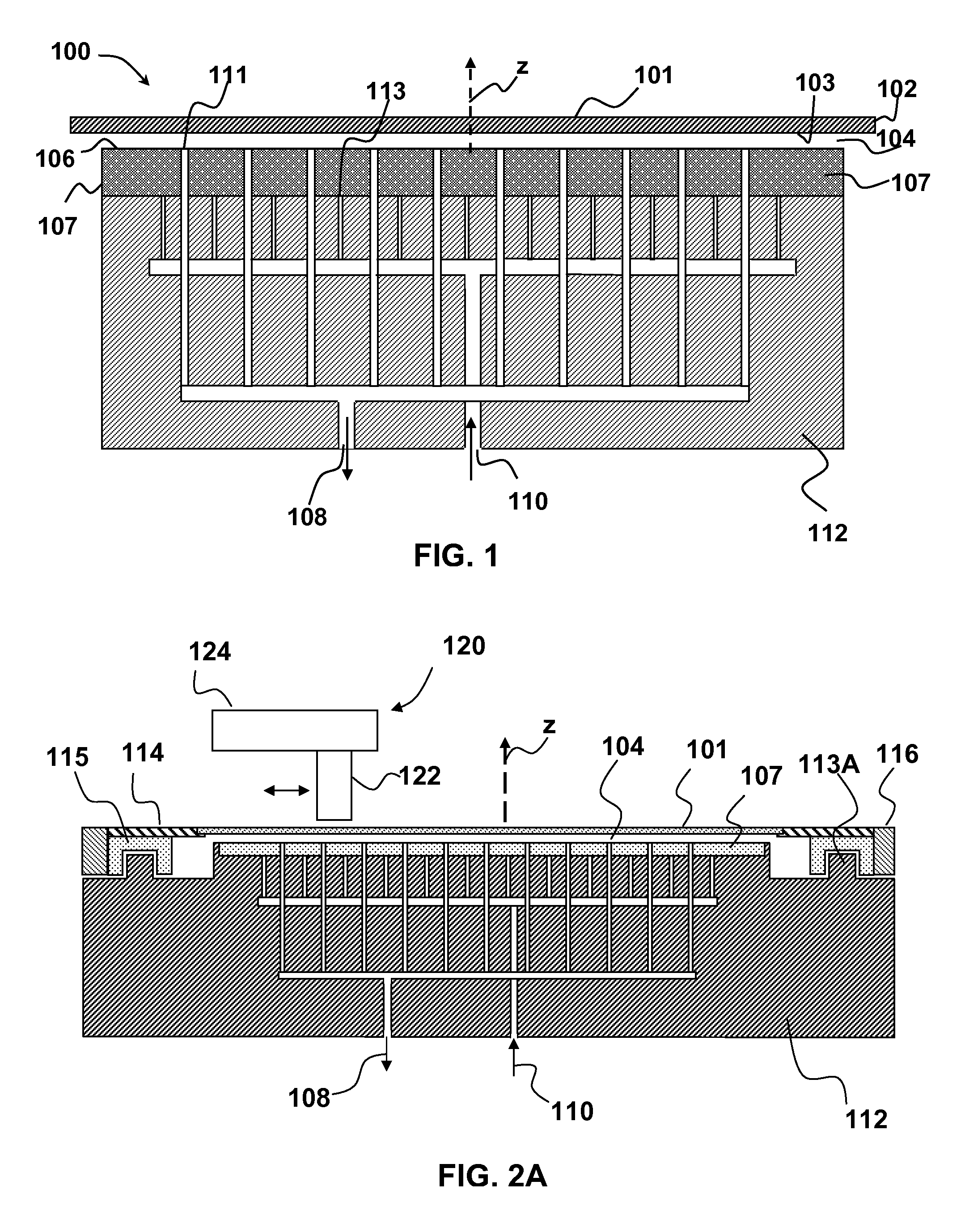

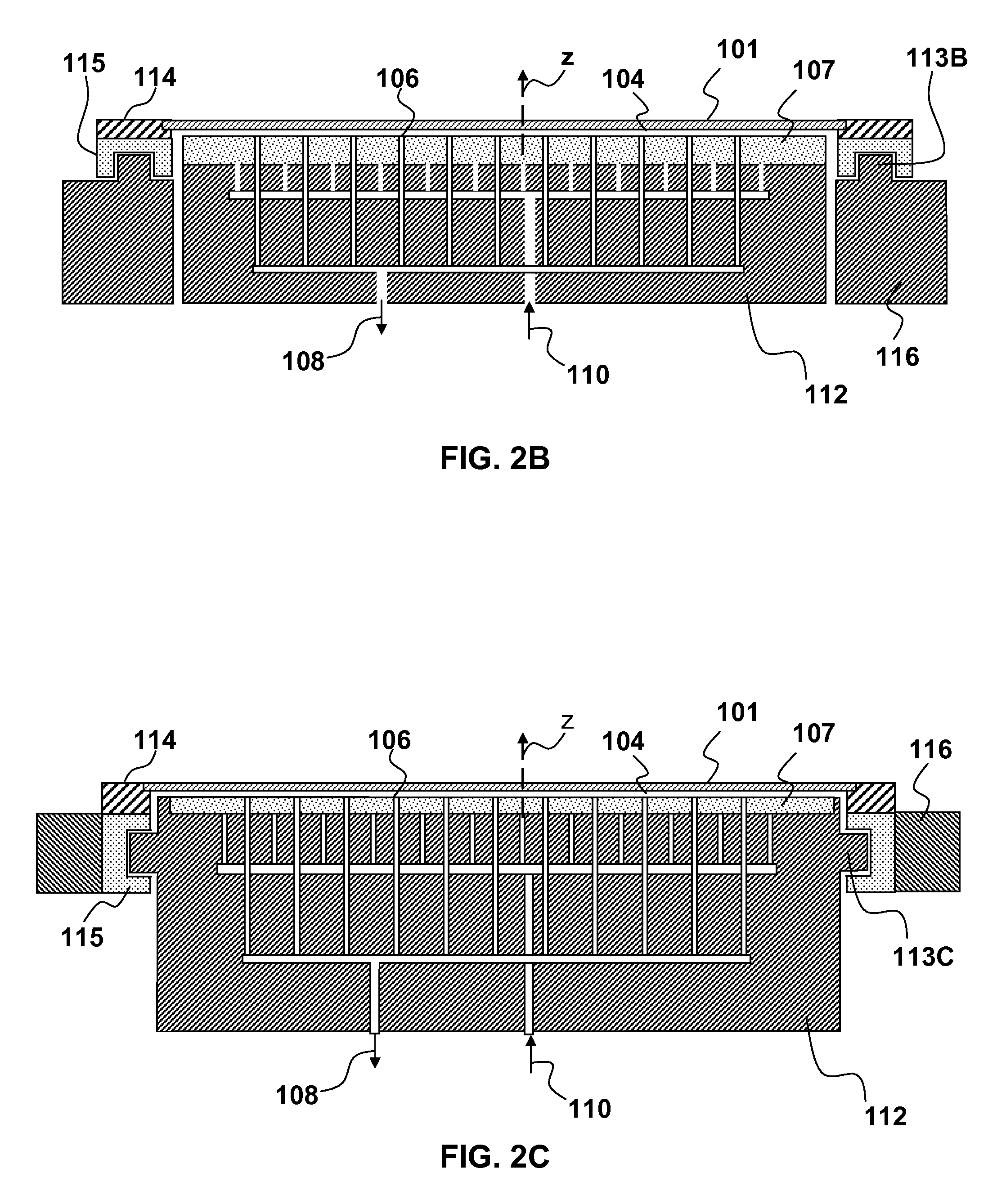

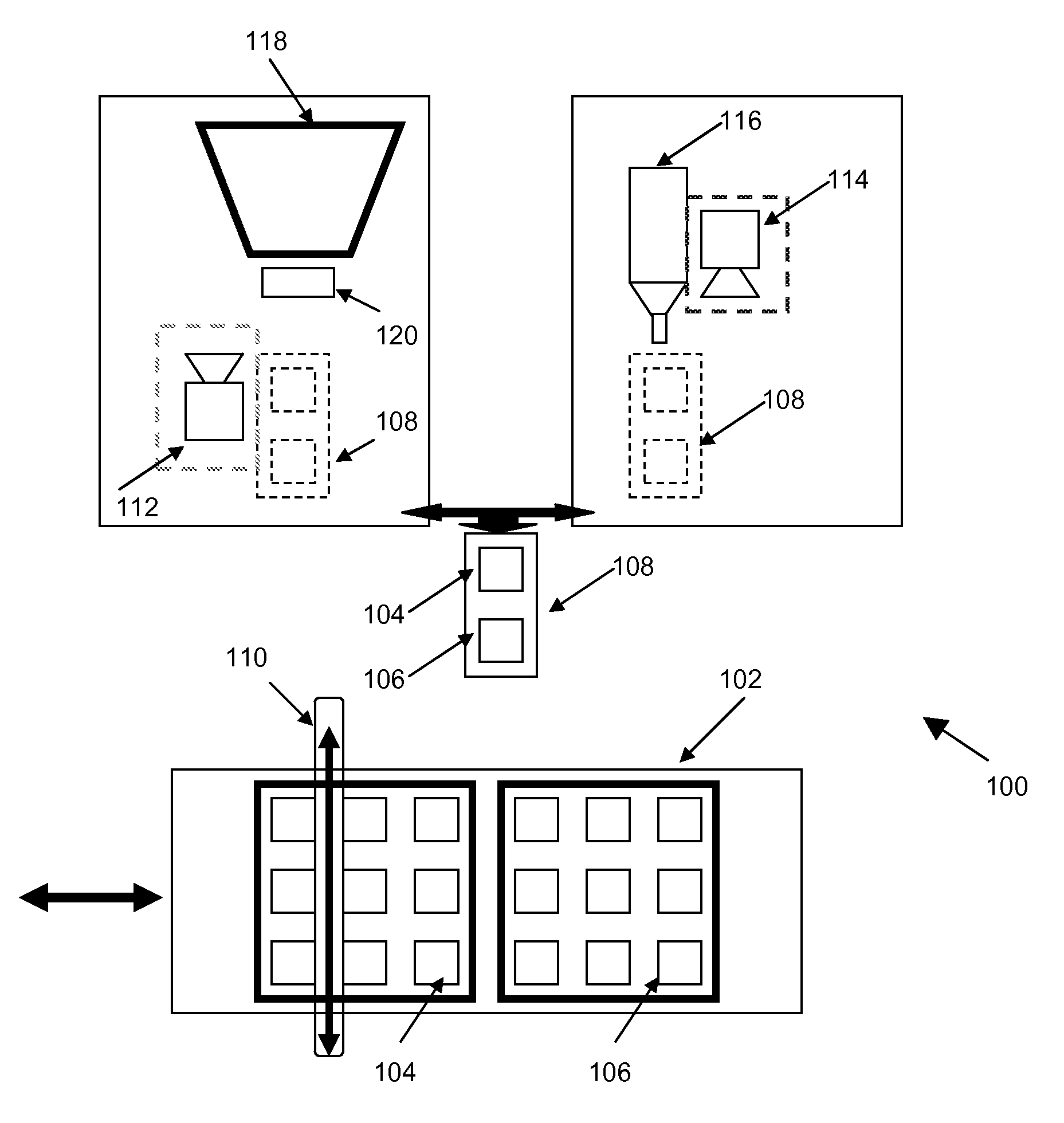

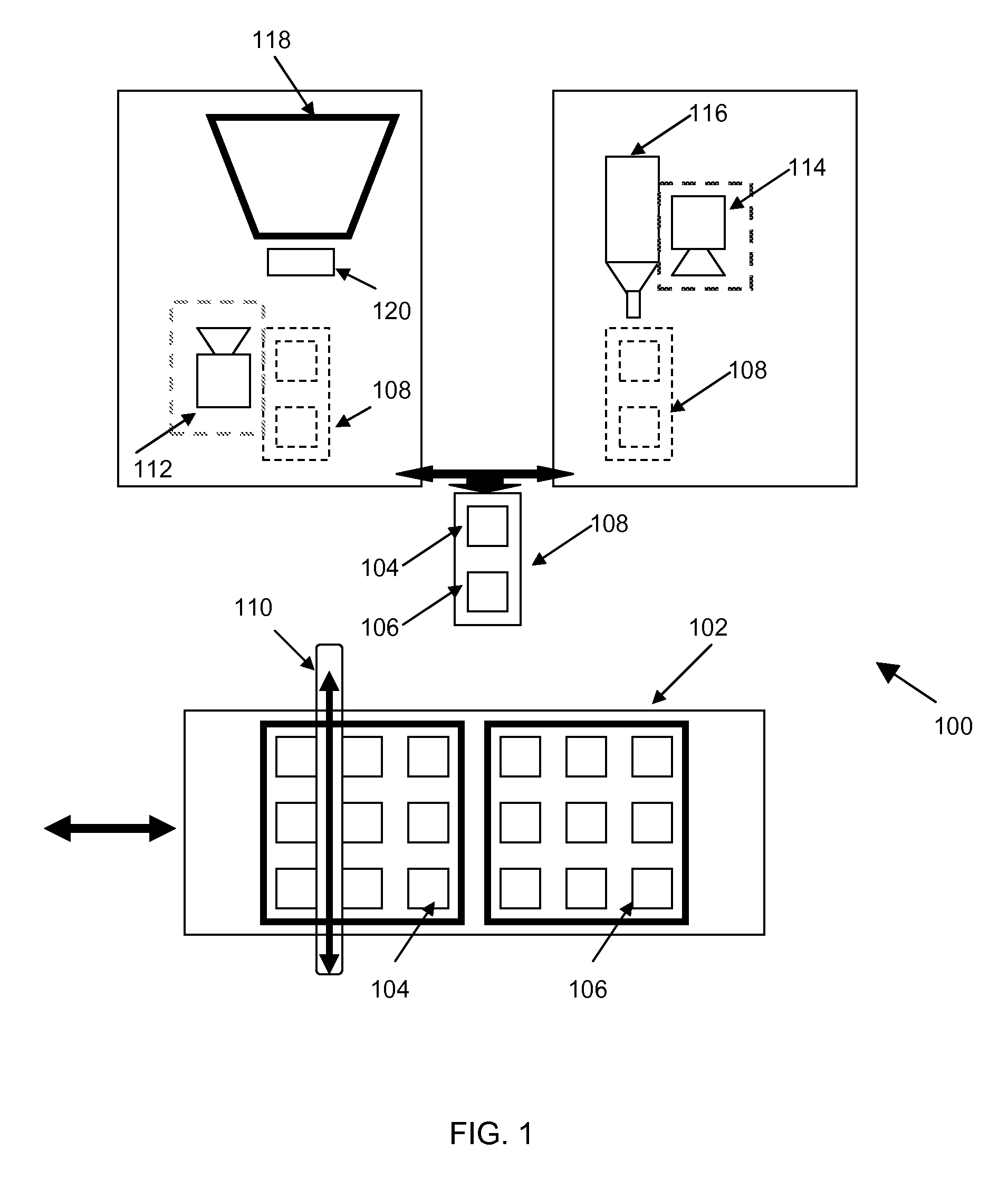

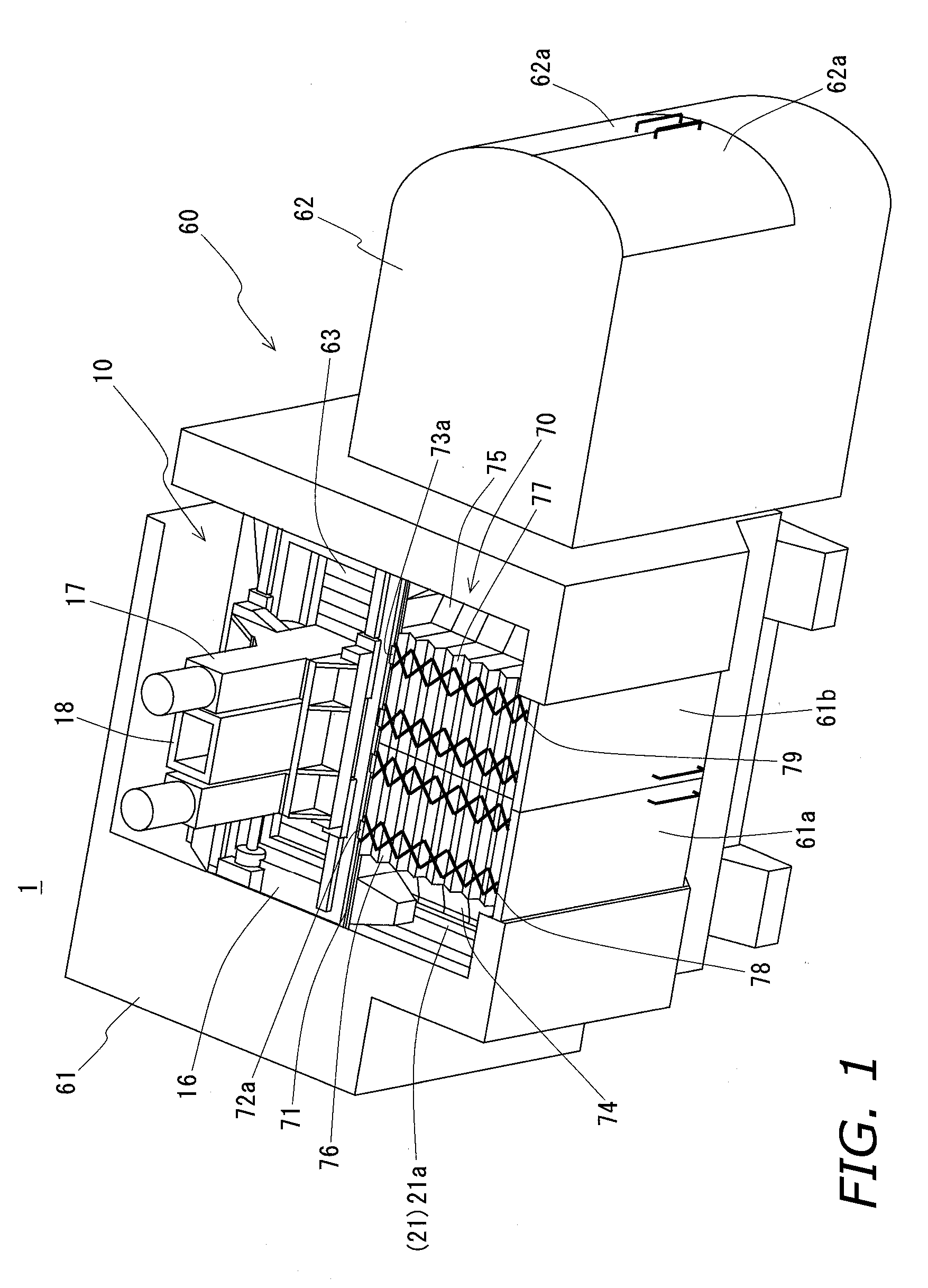

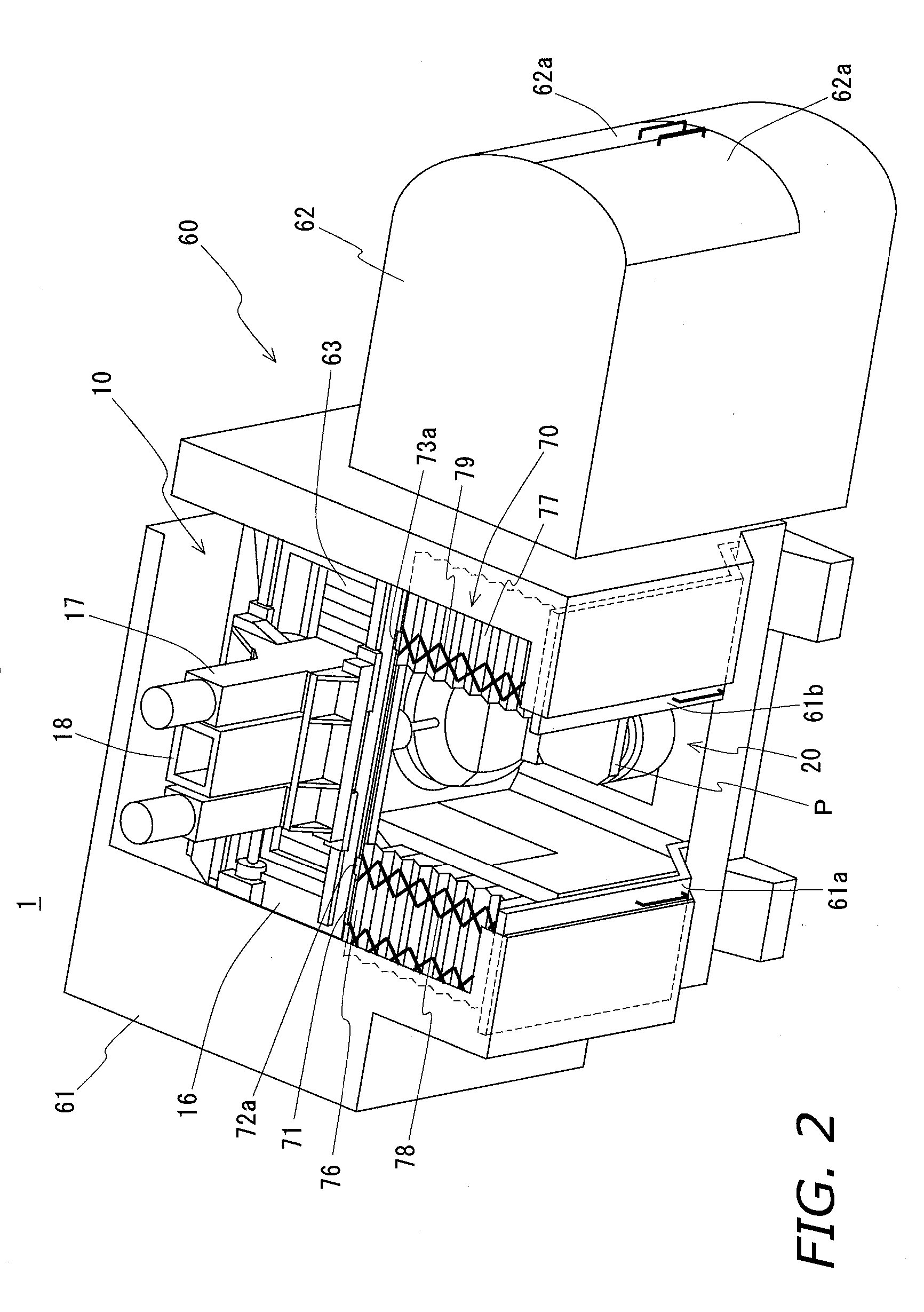

Semiconductor processing apparatus with simultaneously movable stages

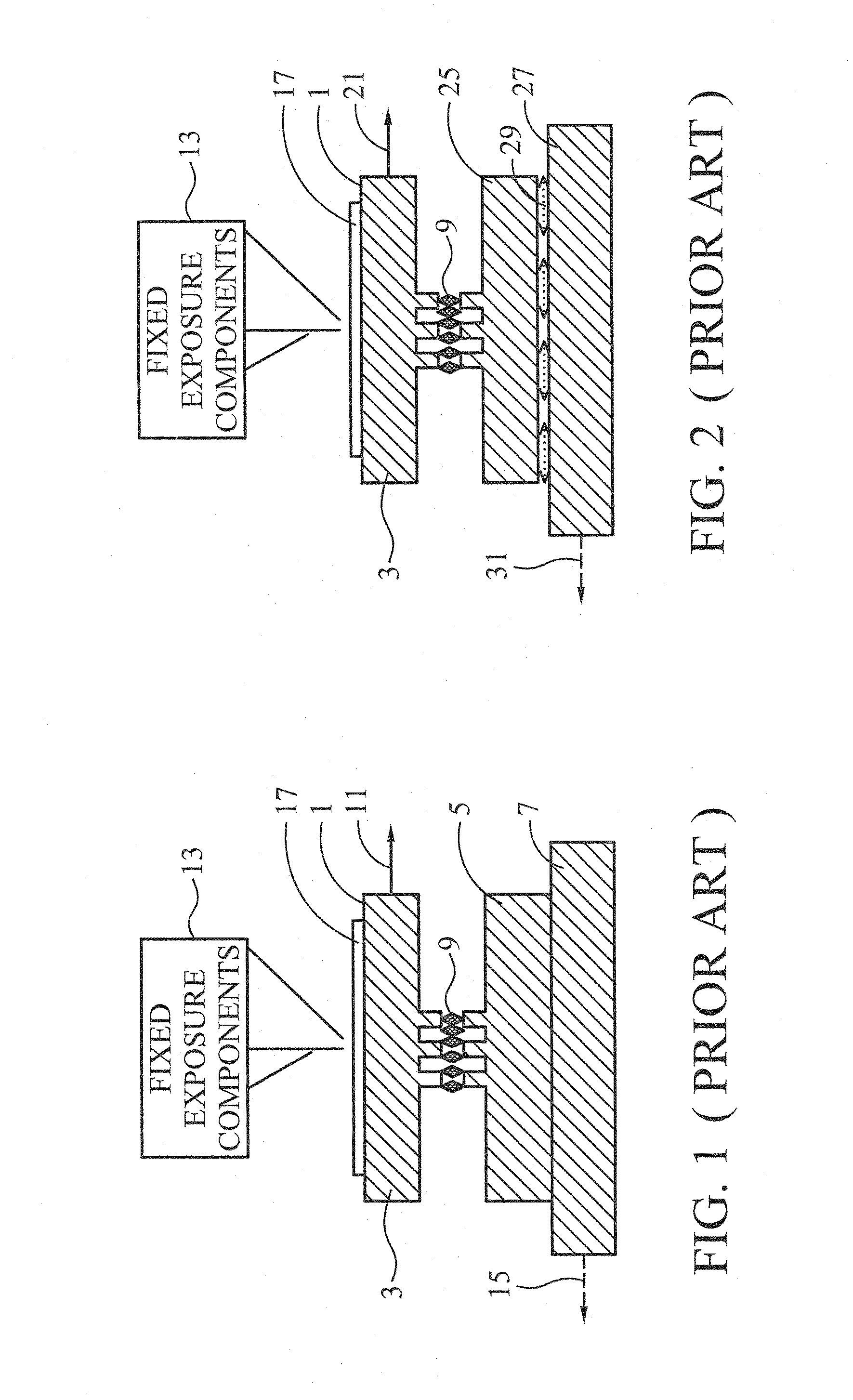

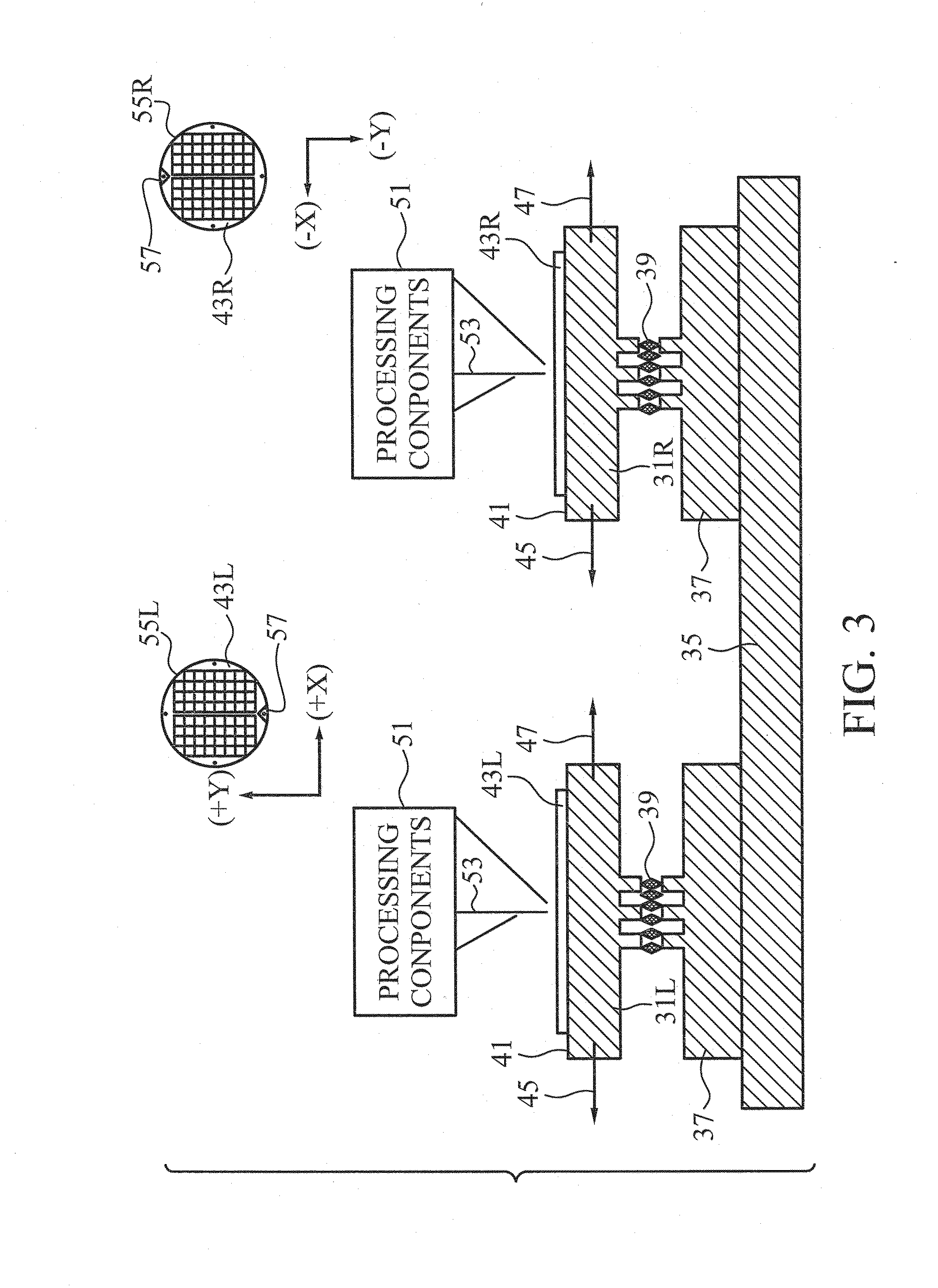

A method and apparatus provide for simultaneously moving multiple semiconductor wafers in opposite directions while simultaneously performing processing operations on each of the wafers. The semiconductor wafers are orientated in coplanar fashion and are disposed on stages that simultaneously translate in opposite directions to produce a net system momentum of zero. The die of the respective semiconductor wafers are processed in the same spatial sequence with respect to a global alignment feature of the semiconductor wafer. A balance mass is not needed to counteract the motion of a stage because the opposite motions of the respective stages cancel each other.

Owner:TAIWAN SEMICON MFG CO LTD

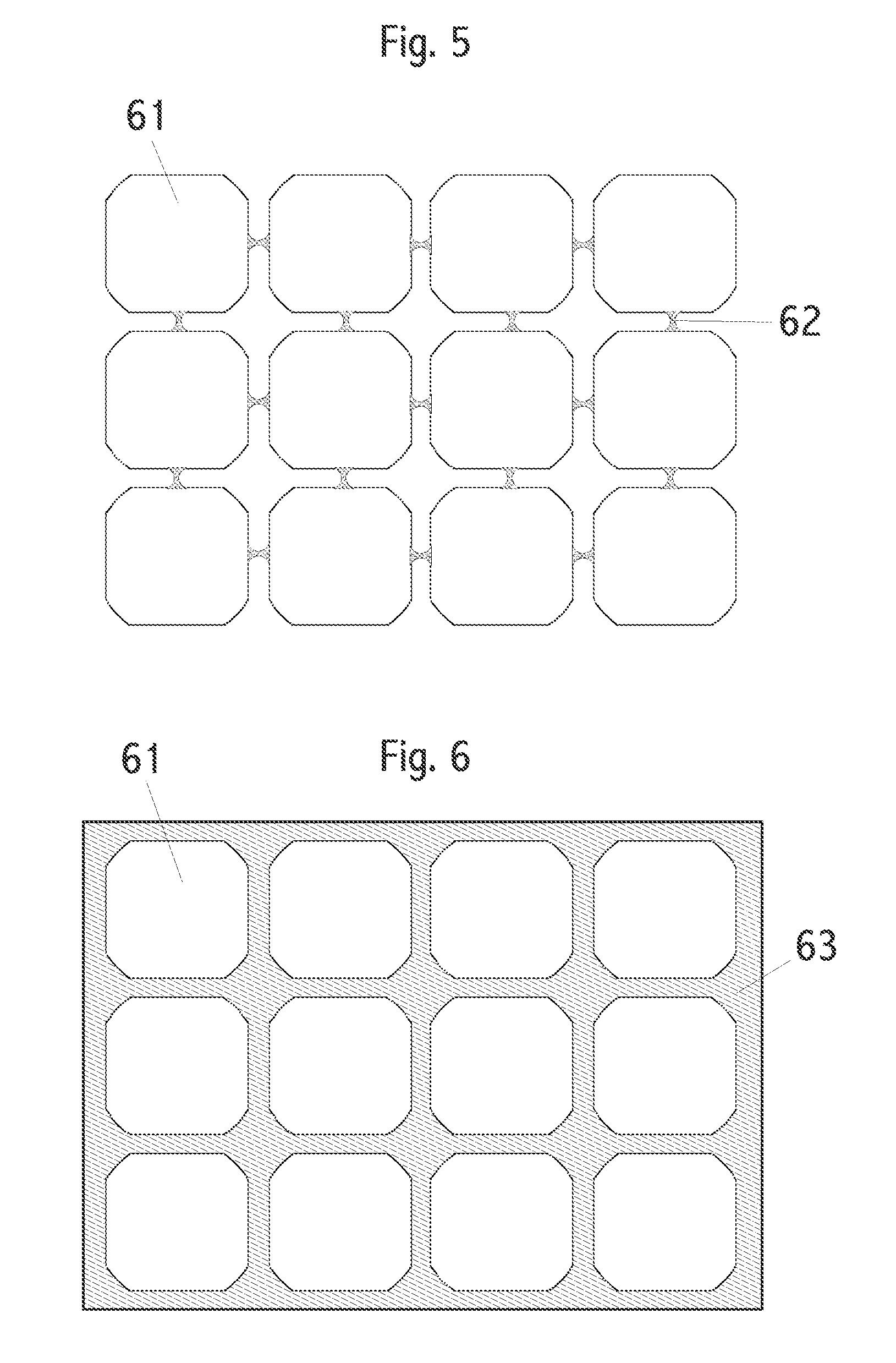

Multi-lens camera

InactiveUS20130258044A1Expand the borderLow production costTelevision system detailsMeasurement/indication equipmentsCamera lensObject based

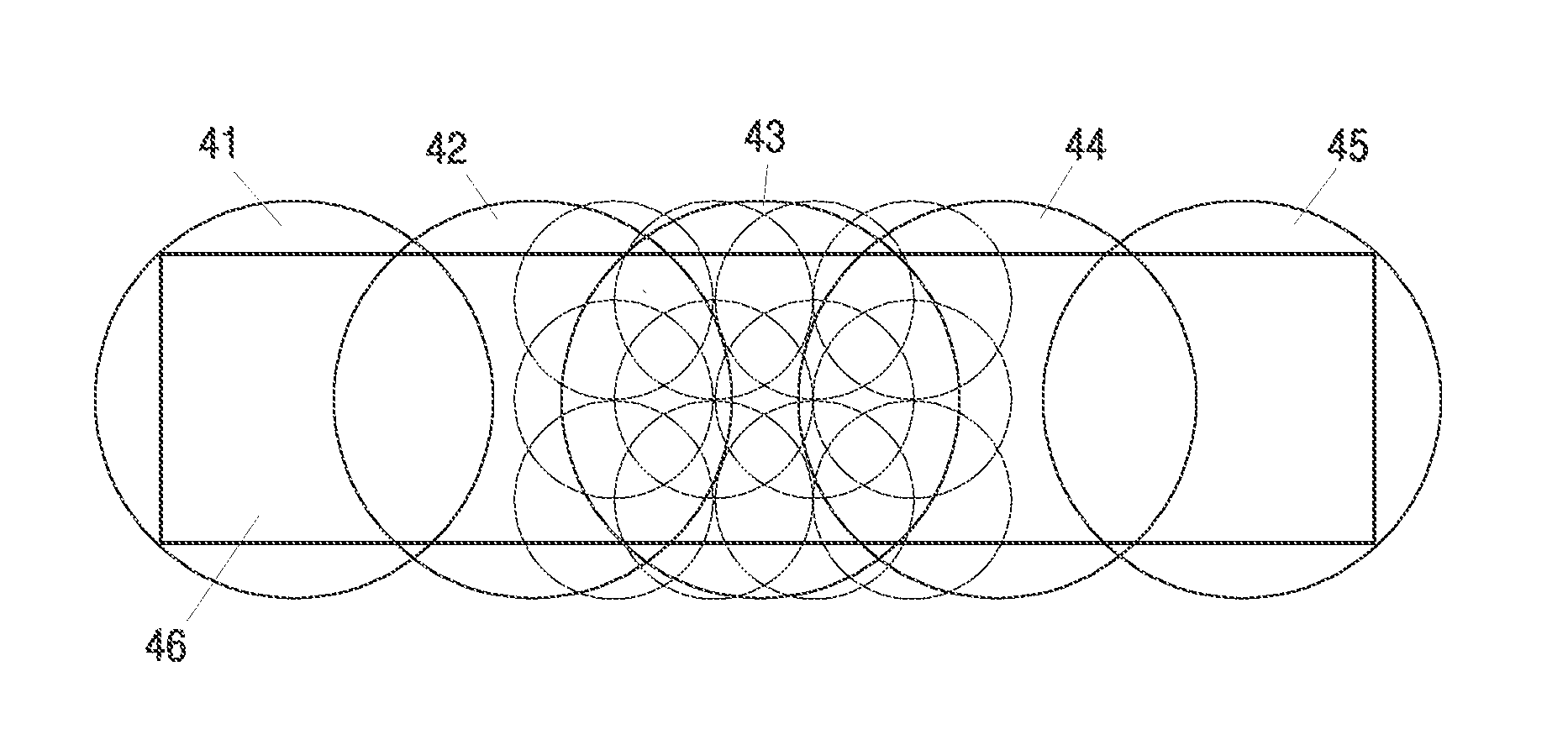

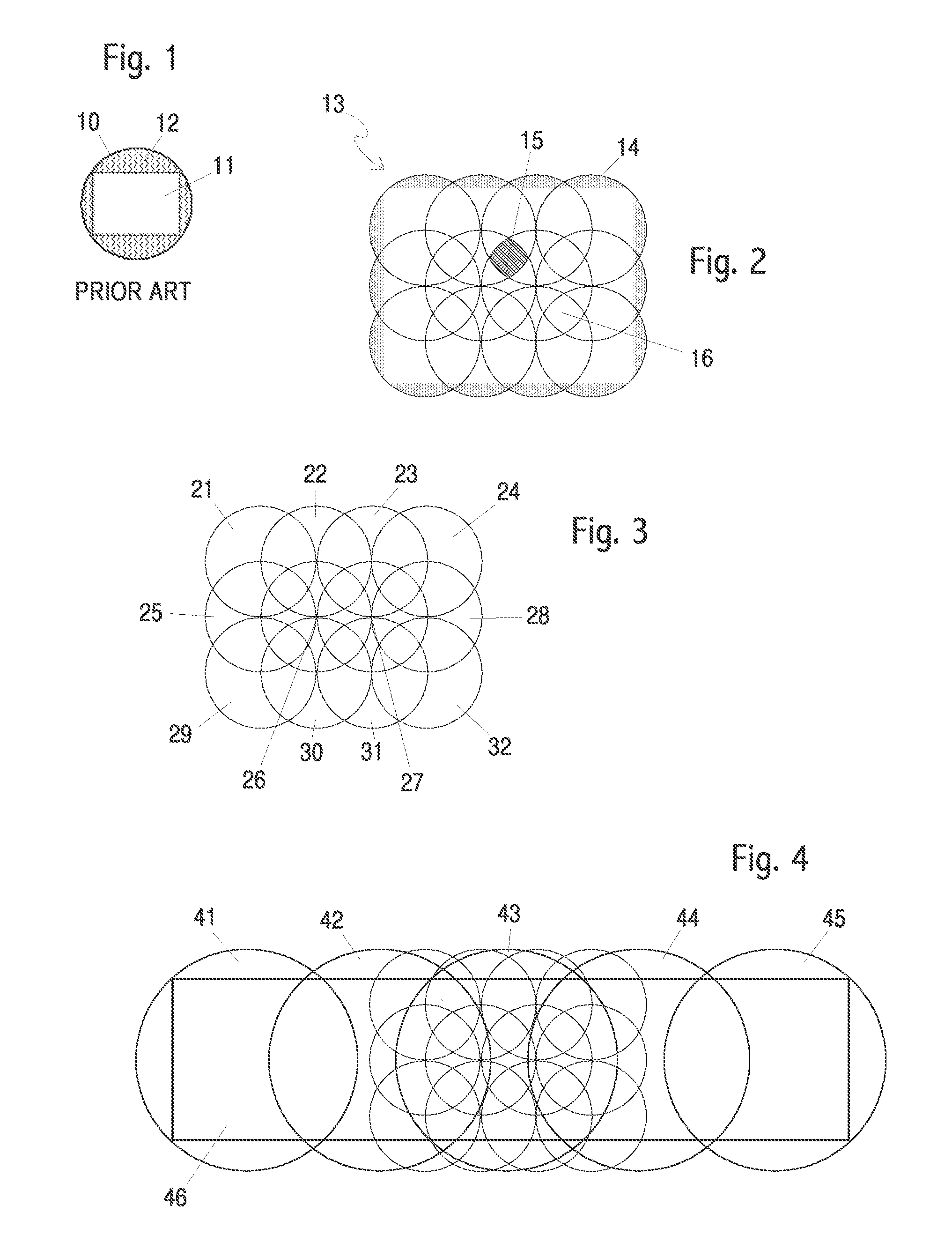

A camera with multiple lenses and multiple sensors wherein each lens / sensor pair generates a sub-image of a final photograph or video. Different embodiments include: manufacturing all lenses as a single component; manufacturing all sensors as one piece of silicon; different lenses incorporate filters for different wavelengths, including IR and UV; non-circular lenses; different lenses are different focal lengths; different lenses focus at different distances; selection of sharpest sub-image; blurring of selected sub-images; different lens / sensor pairs have different exposures; selection of optimum exposure sub-images; identification of distinct objects based on distance; stereo imaging in more than one axis; and dynamic optical center-line calibration.

Owner:ZETTA RES & DEV - FORC SERIES

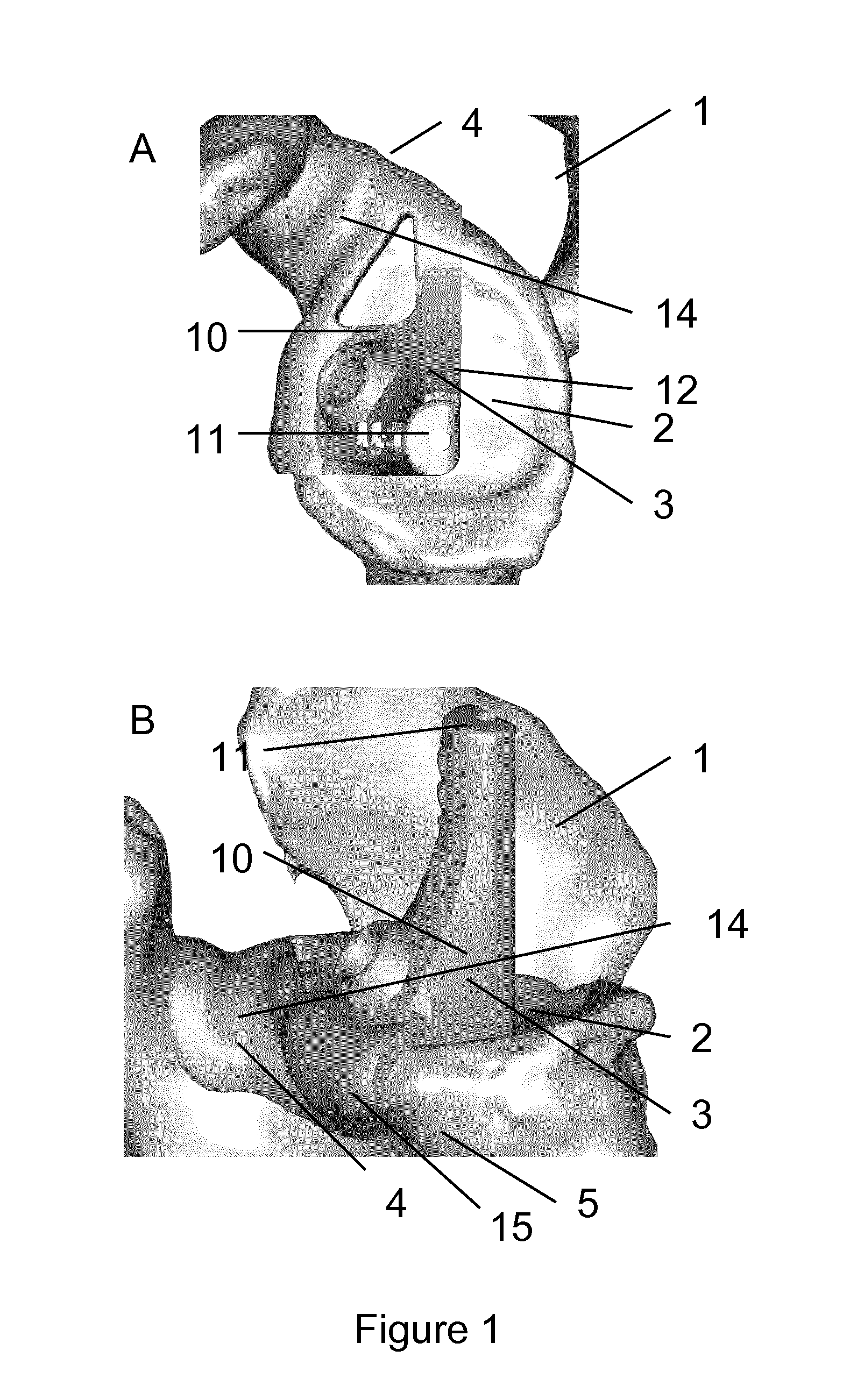

Joint Arthroplasty Devices and Surgical Tools

InactiveUS20100168754A1Accurate placementImage analysisInternal osteosythesisArticular surfacesArticular surface

Disclosed herein are methods, compositions and tools for repairing articular surfaces repair materials and for repairing an articular surface. The articular surface repairs are customizable or highly selectable by patient and geared toward providing optimal fit and function. The surgical tools are designed to be customizable or highly selectable by patient to increase the speed, accuracy and simplicity of performing total or partial arthroplasty.

Owner:CONFORMIS

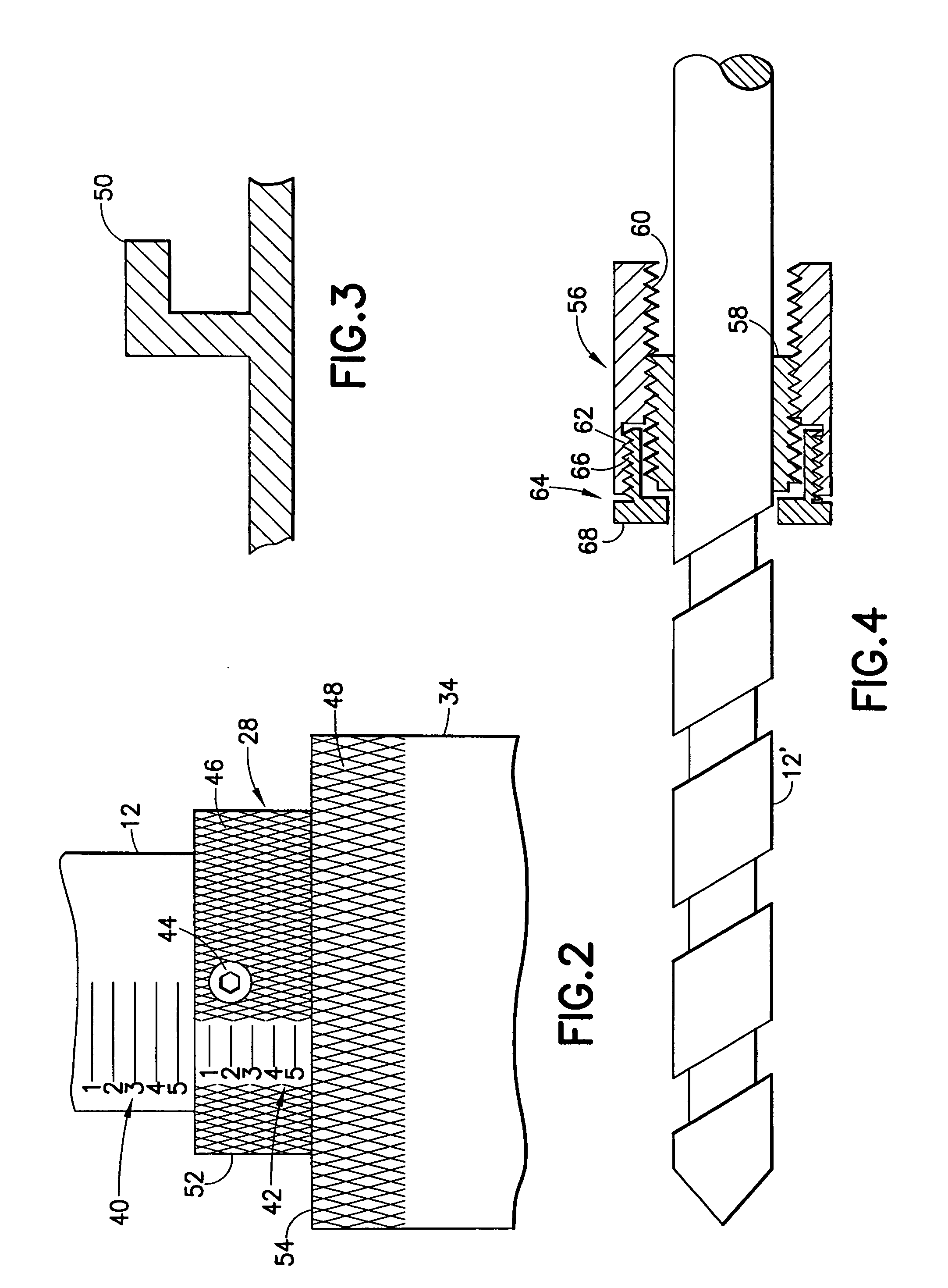

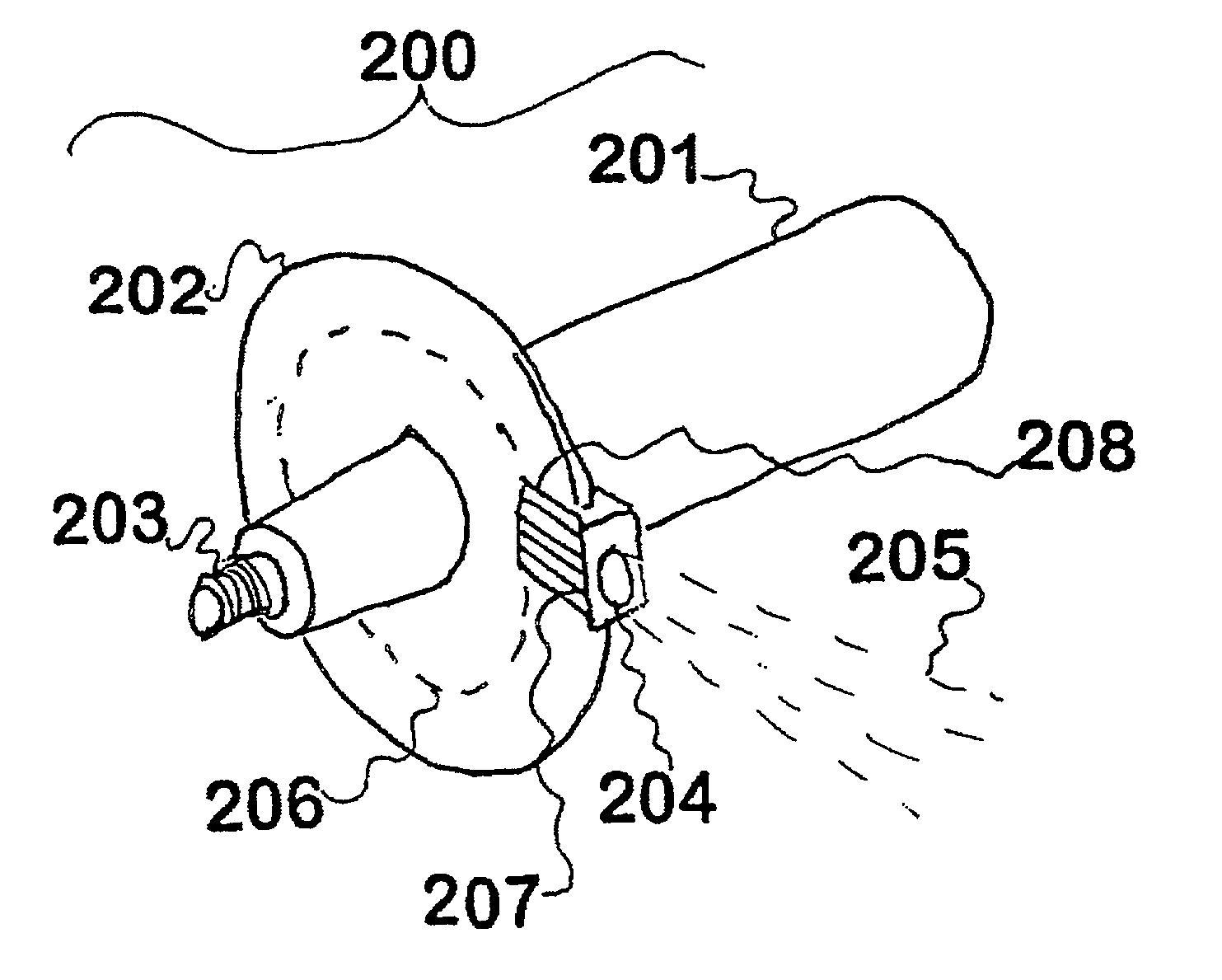

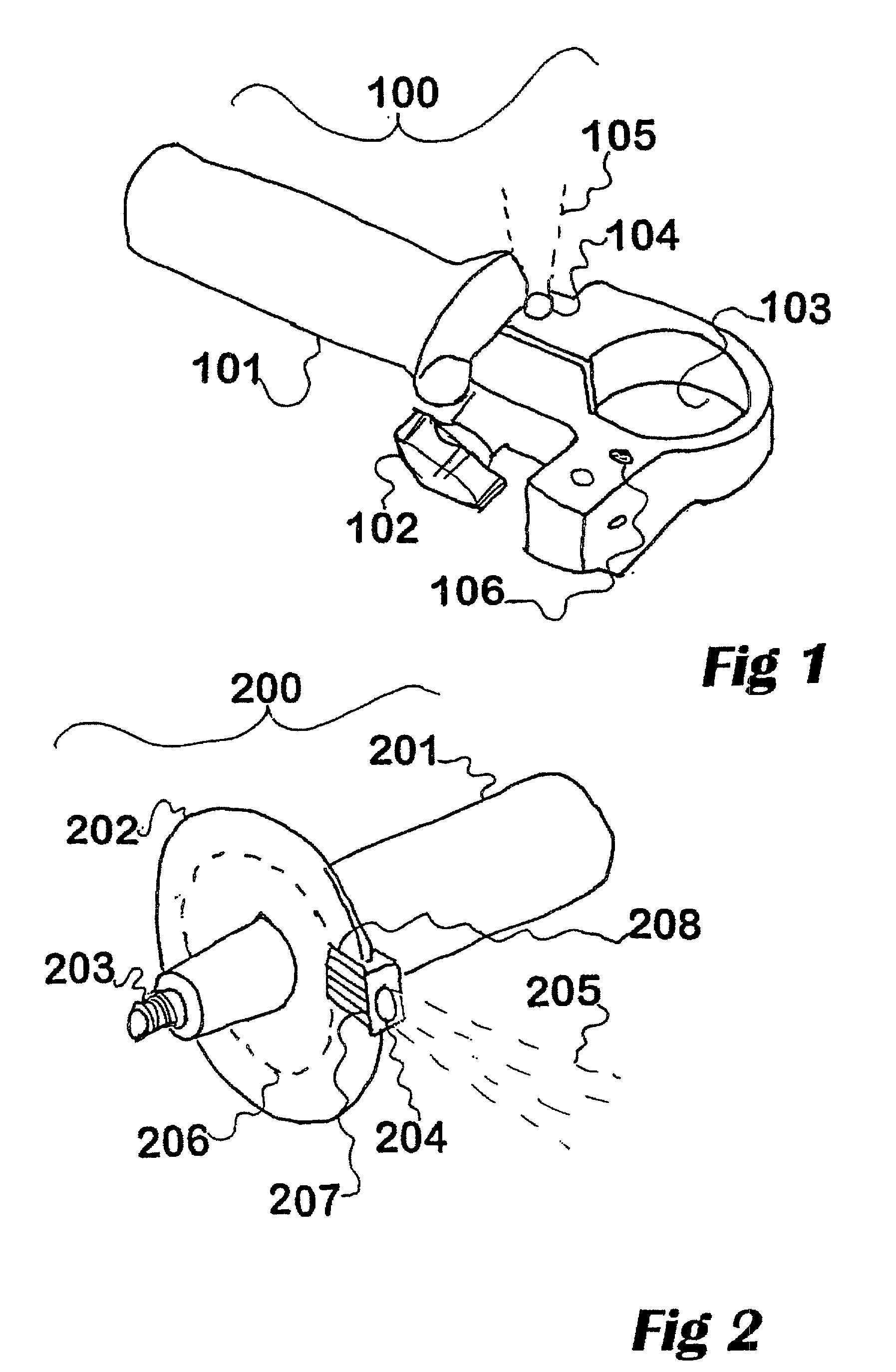

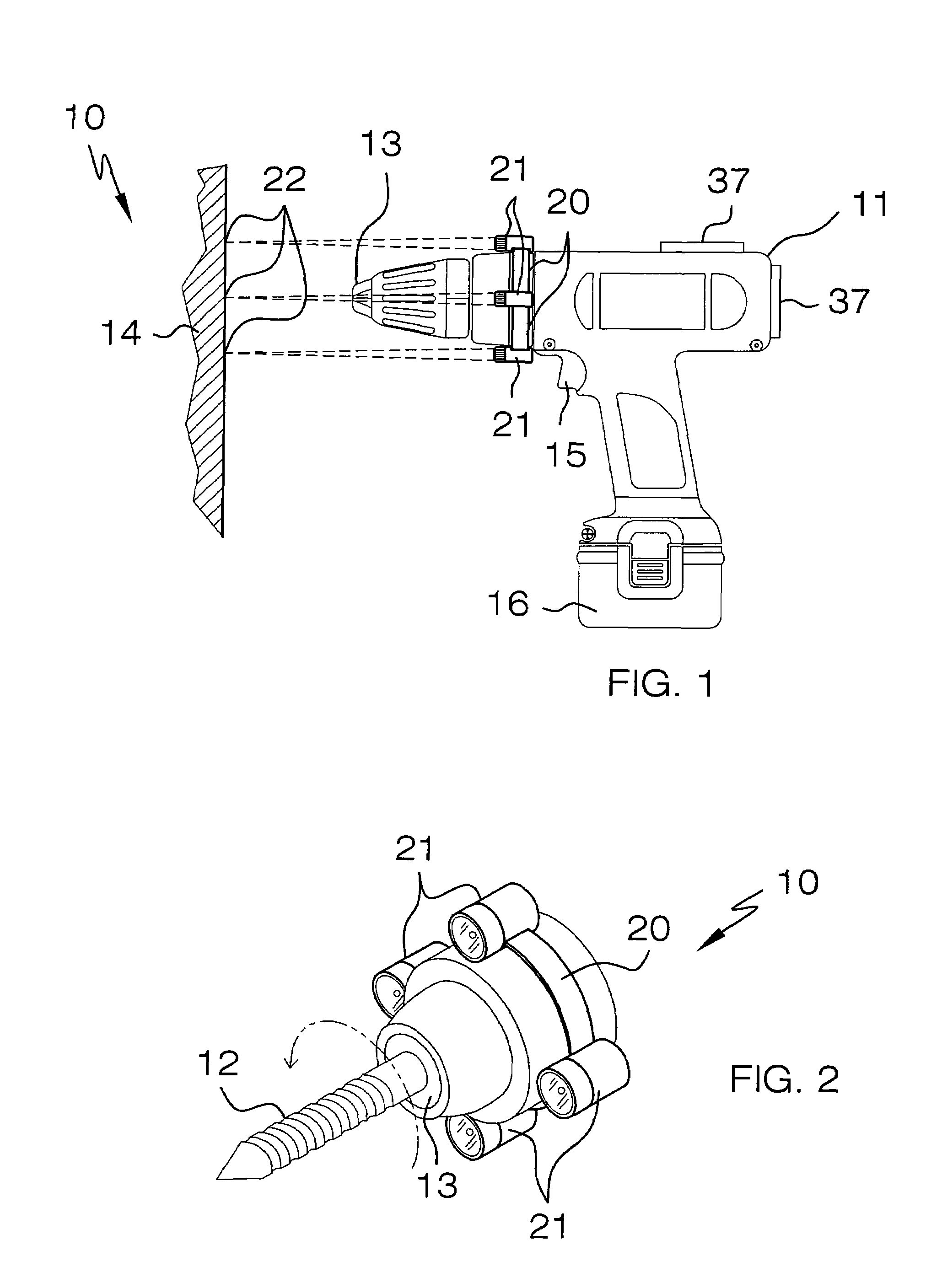

Sleeved stop for a drill bit

A stop for use with an electric drill bit, the stop having at least one threaded sleeve for positioning the stop relative to a surface into which the drill bit will extend. The stop may have both an inner and an outer sleeve. The sleeves are mounted coaxially, one inside the other about the drill bit. One of the sleeves, preferably the inner sleeve, provides coarse adjustment of the position of the shoulder relative to the tip of the bit, while the other, preferably the outer sleeve, provides fine adjustment of the position of the shoulder relative to the top of the bit.

Owner:3D SCAN GUIDE LLC

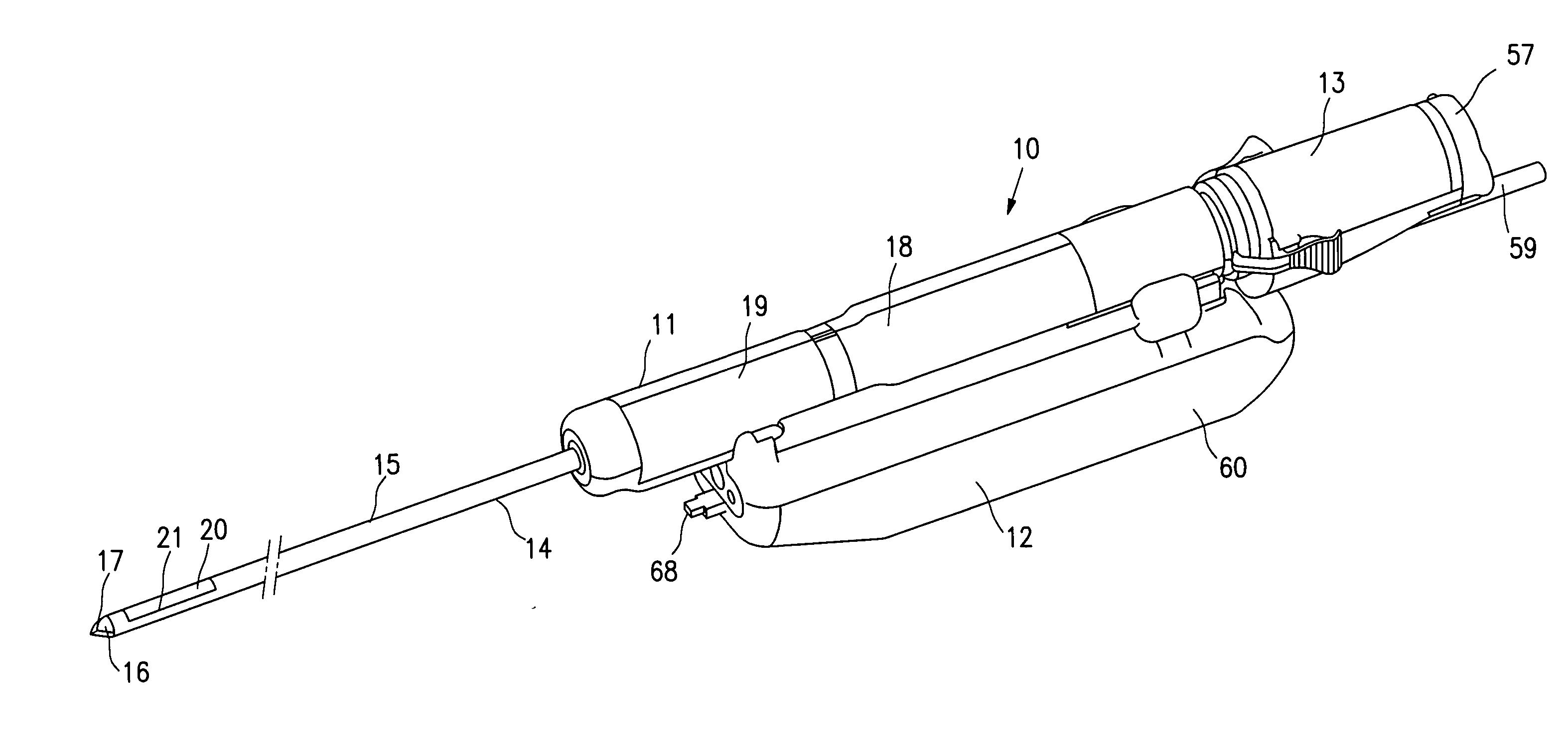

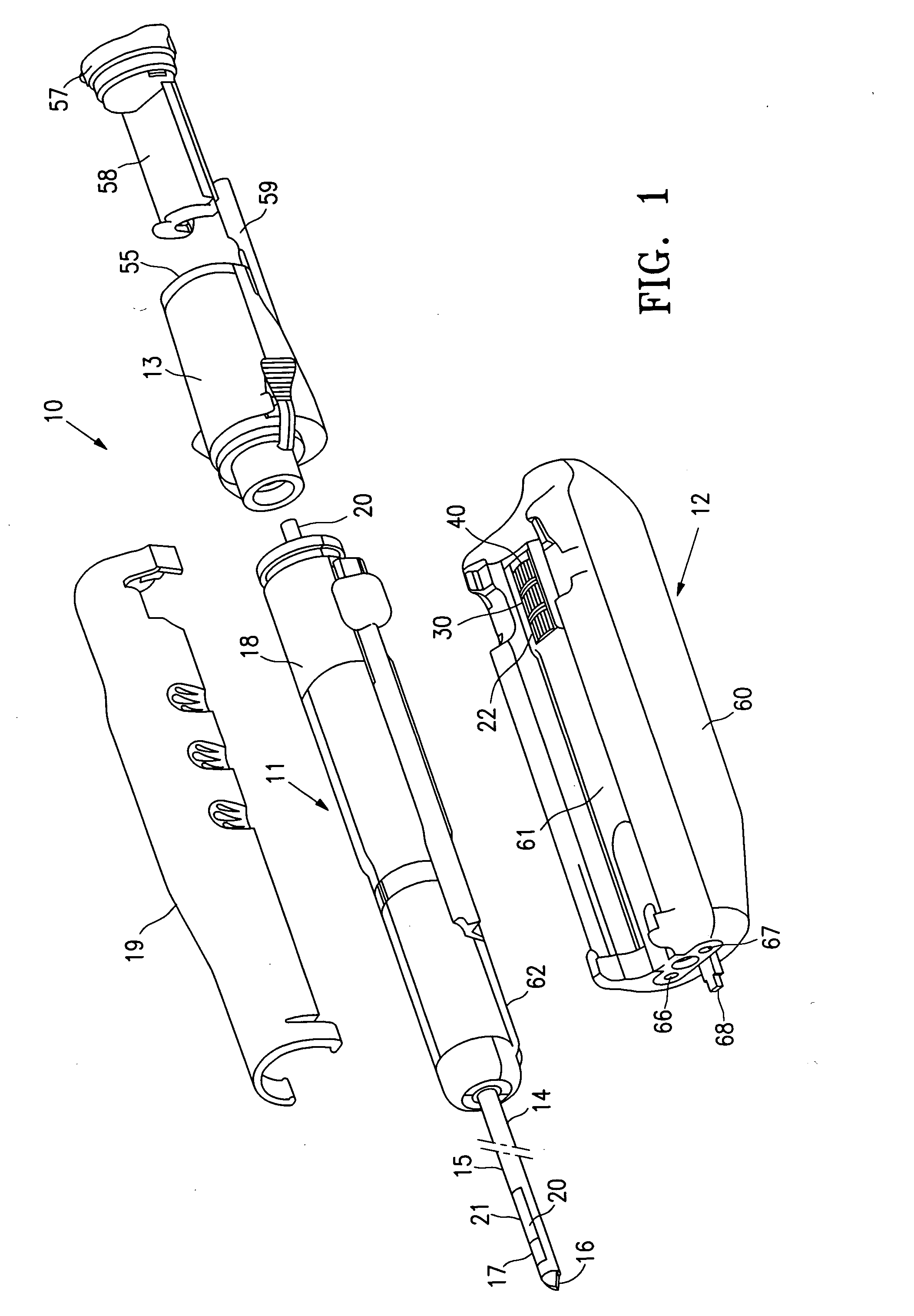

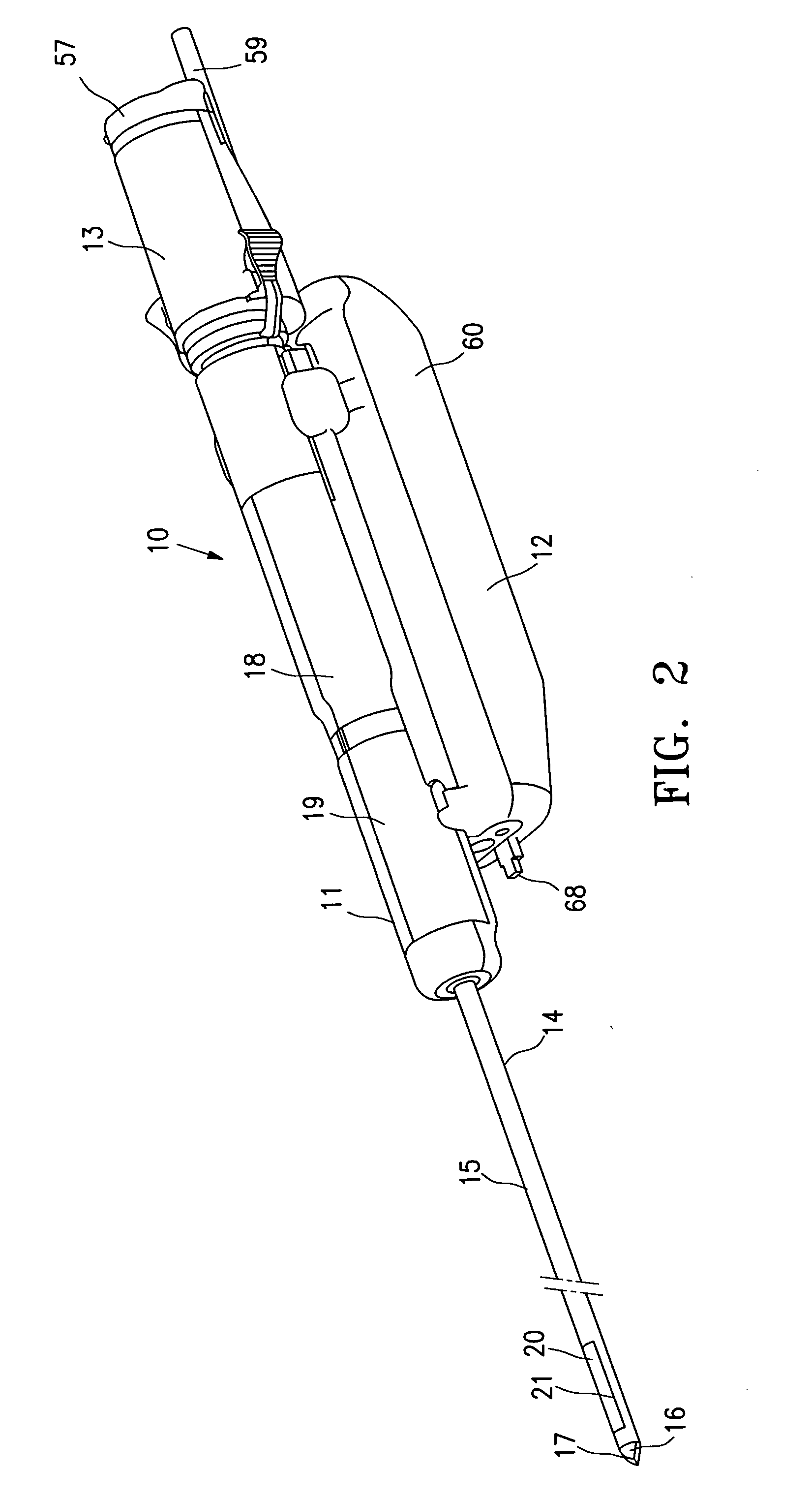

Biopsy device with selectable tissue receiving aperture orientation and site illumination

The invention is directed to a system and device for separating and collecting a tissue specimen from a target site within a patient. The device includes a probe component with an elongated tubular section, a penetrating distal tip and a tissue receiving aperture in the distal end of the tubular section proximal to the distal tip, and a tissue cutting member which is slidably disposed within the probe member to cut a tissue specimen drawn into the interior of the device through the aperture by applying a vacuum to the inner lumen of the tissue cutting member. The device also has a driver component to which the probe component is releasably secured. The driver has a drive member for adjusting the orientation of the tubular section and thus the aperture therein and one or more drive members for moving the tissue cutting member within the tubular section to sever a tissue specimen from tissue extending into the interior of the tubular section through the aperture. The motion imparted to the tissue cutter is at least longitudinal and preferably is also oscillation and / or rotational to effectively separate a tissue specimen from tissue extending through the aperture in the tubular section.

Owner:SENORX

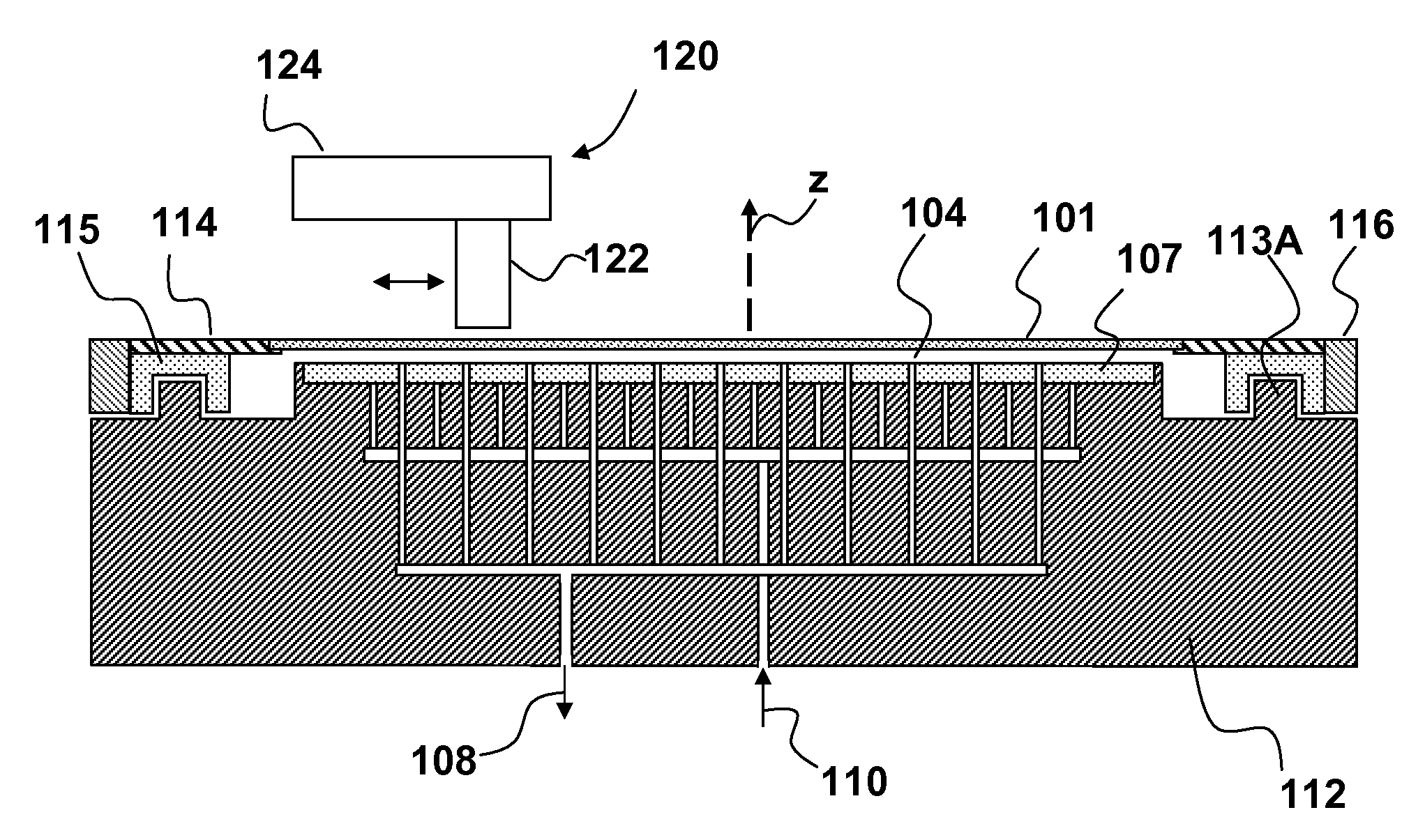

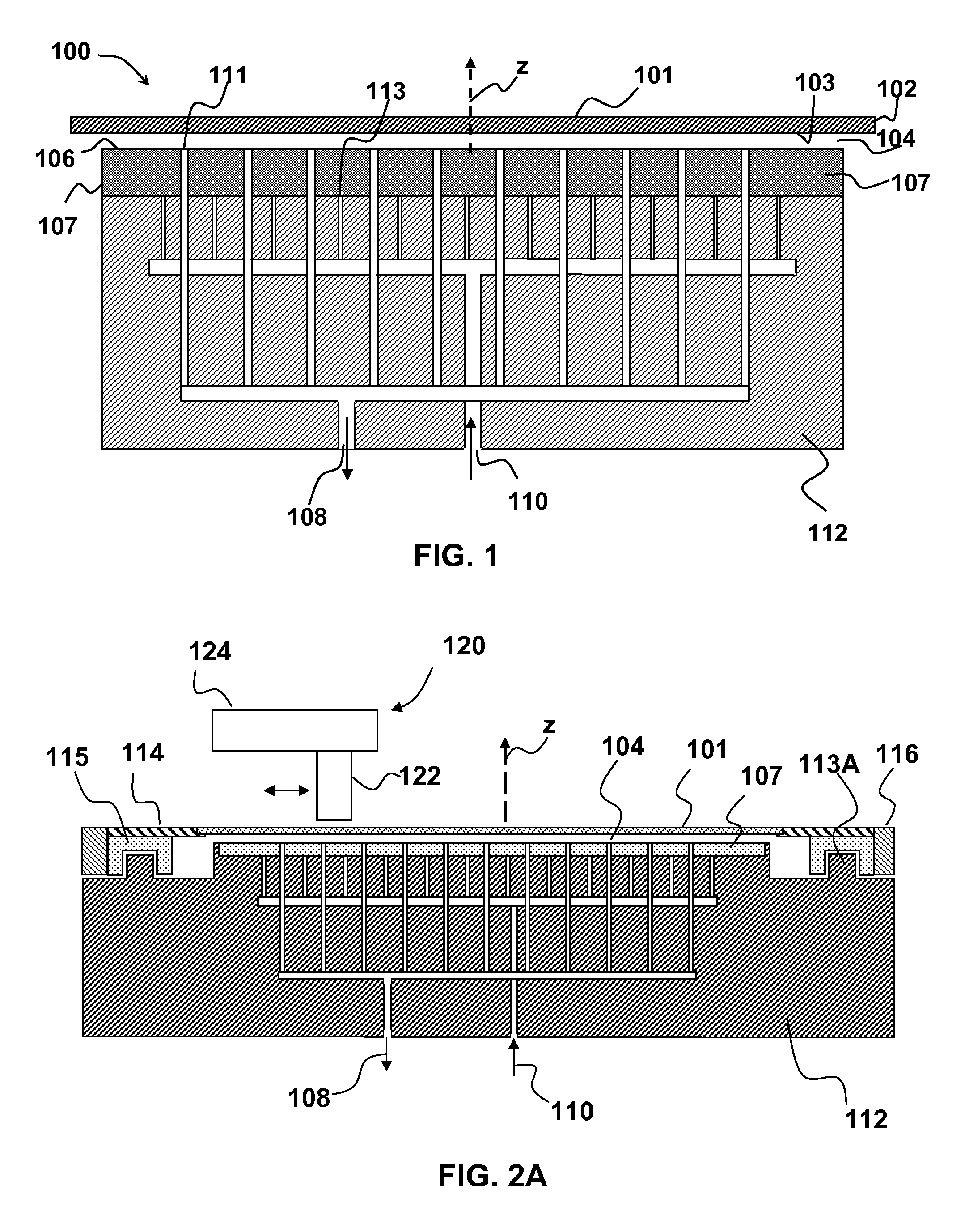

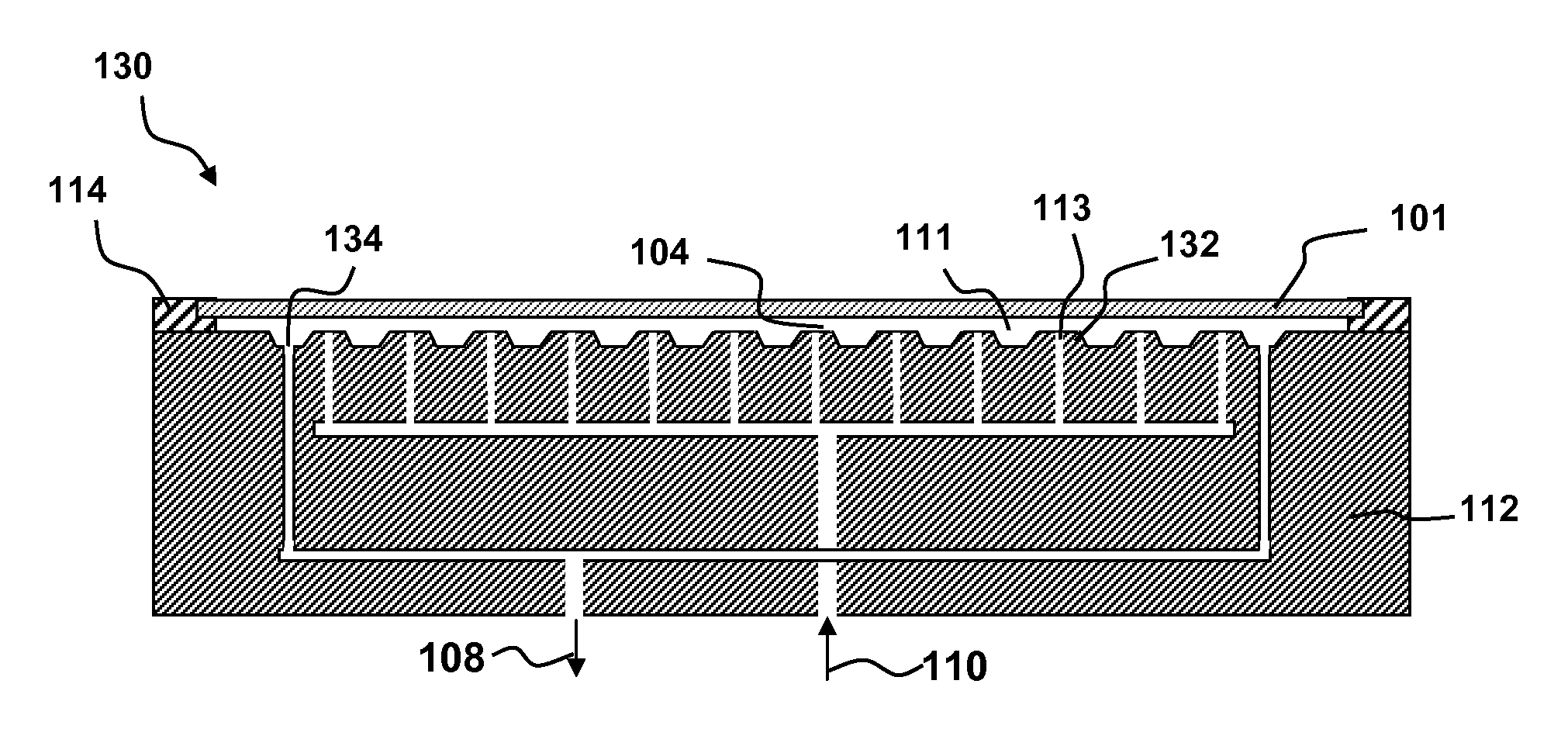

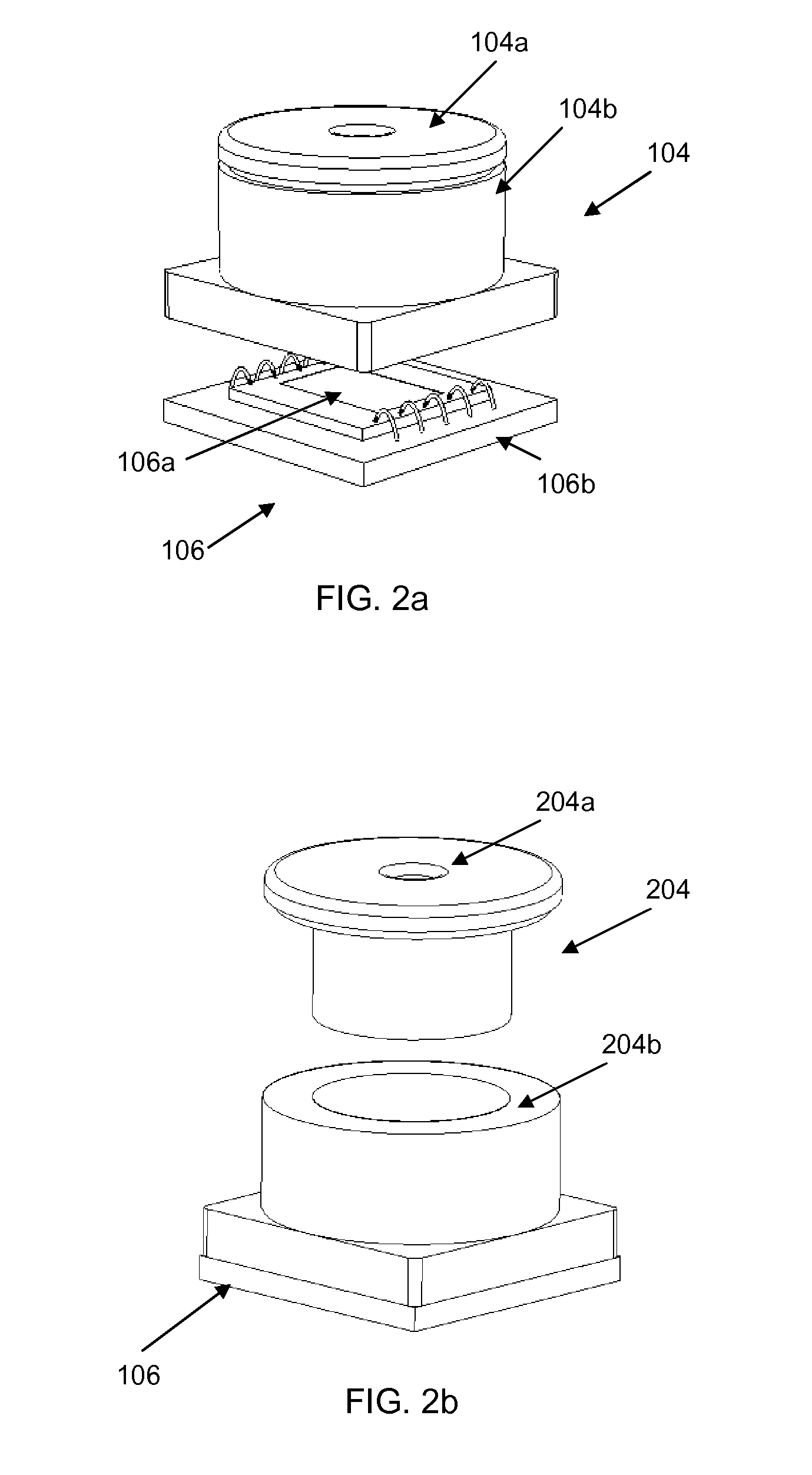

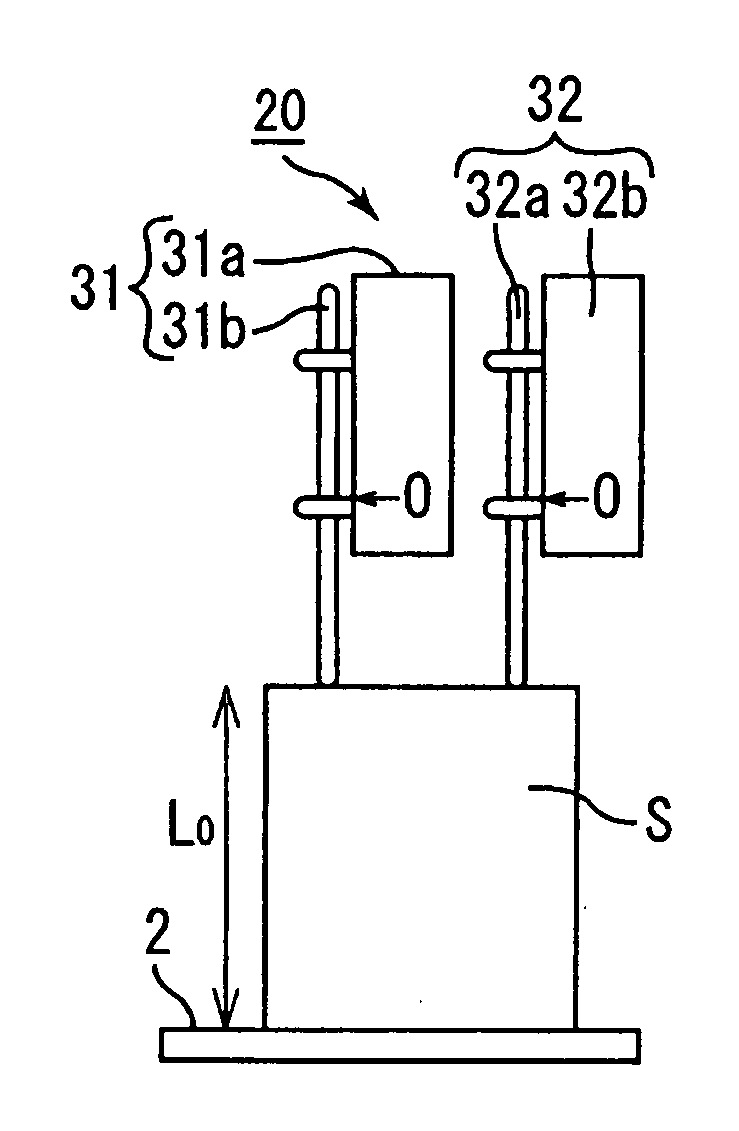

Stabilizing a substrate using a vacuum preload air bearing chuck

ActiveUS20080229811A1Improve rigidityAvoid deformationLinear bearingsGas cushion bearingsAir bearingEngineering

Substrate processing method and apparatus are disclosed. The substrate processing apparatus includes a non-contact air bearing chuck with a vacuum preload.

Owner:KLA TENCOR TECH CORP

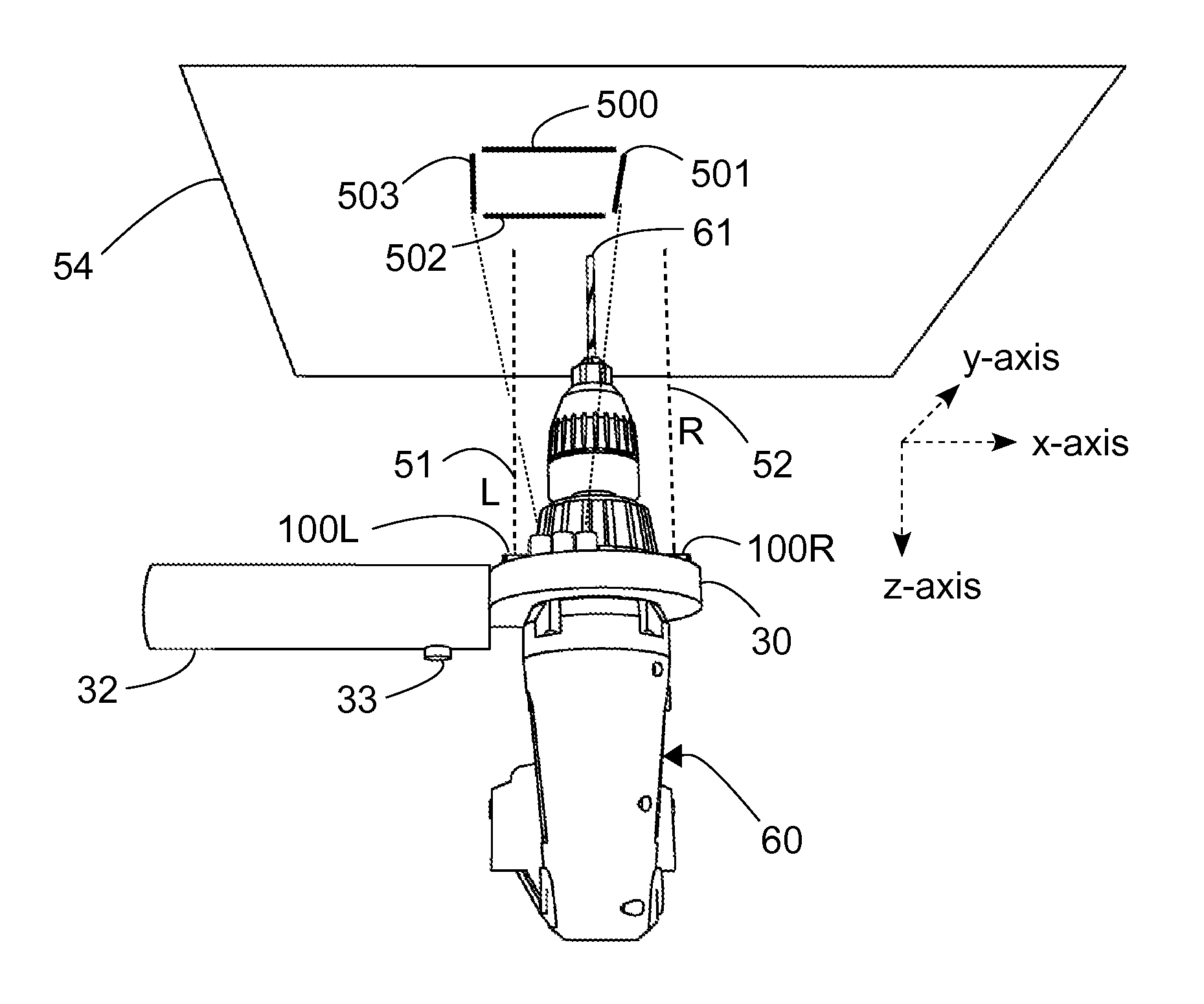

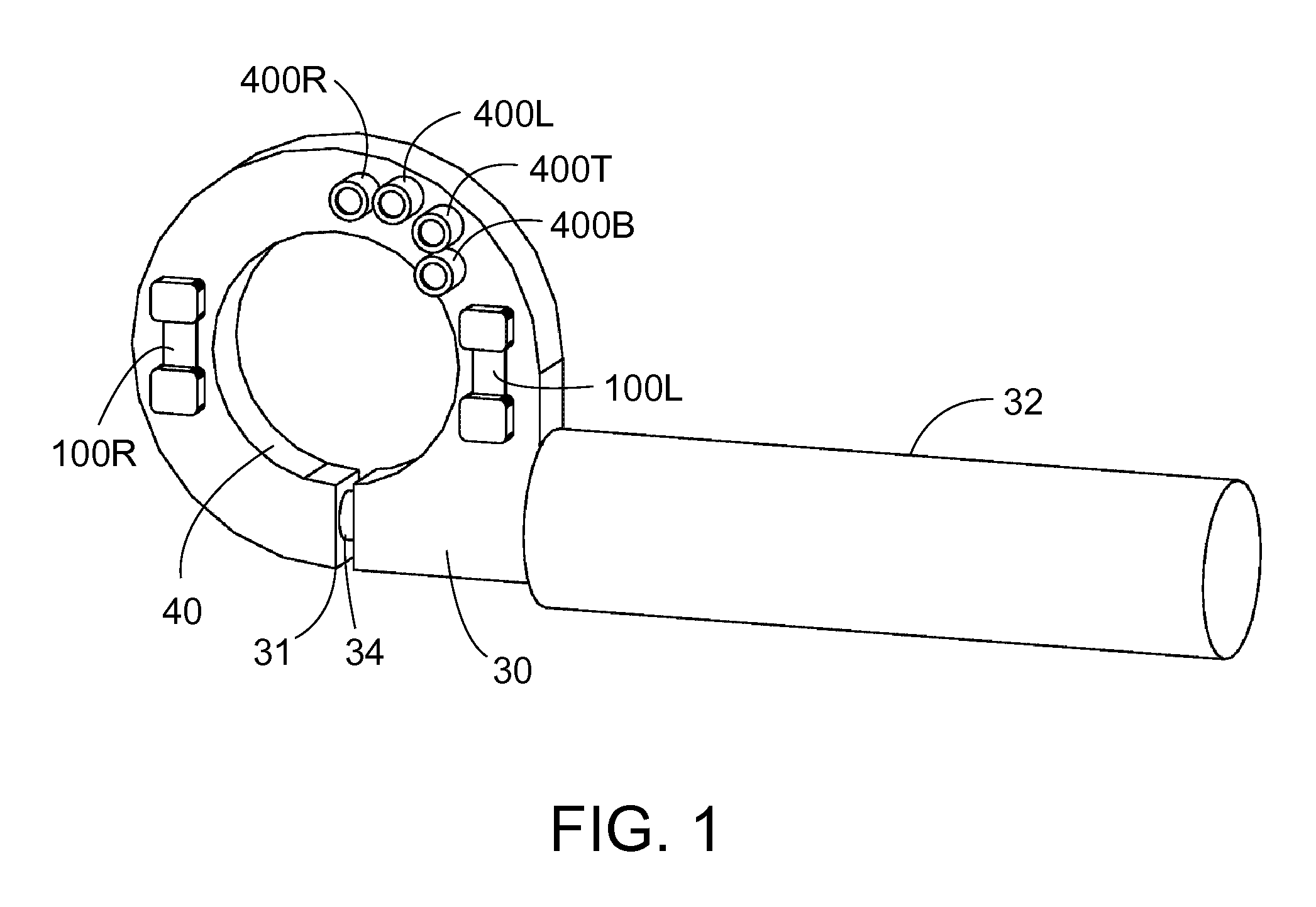

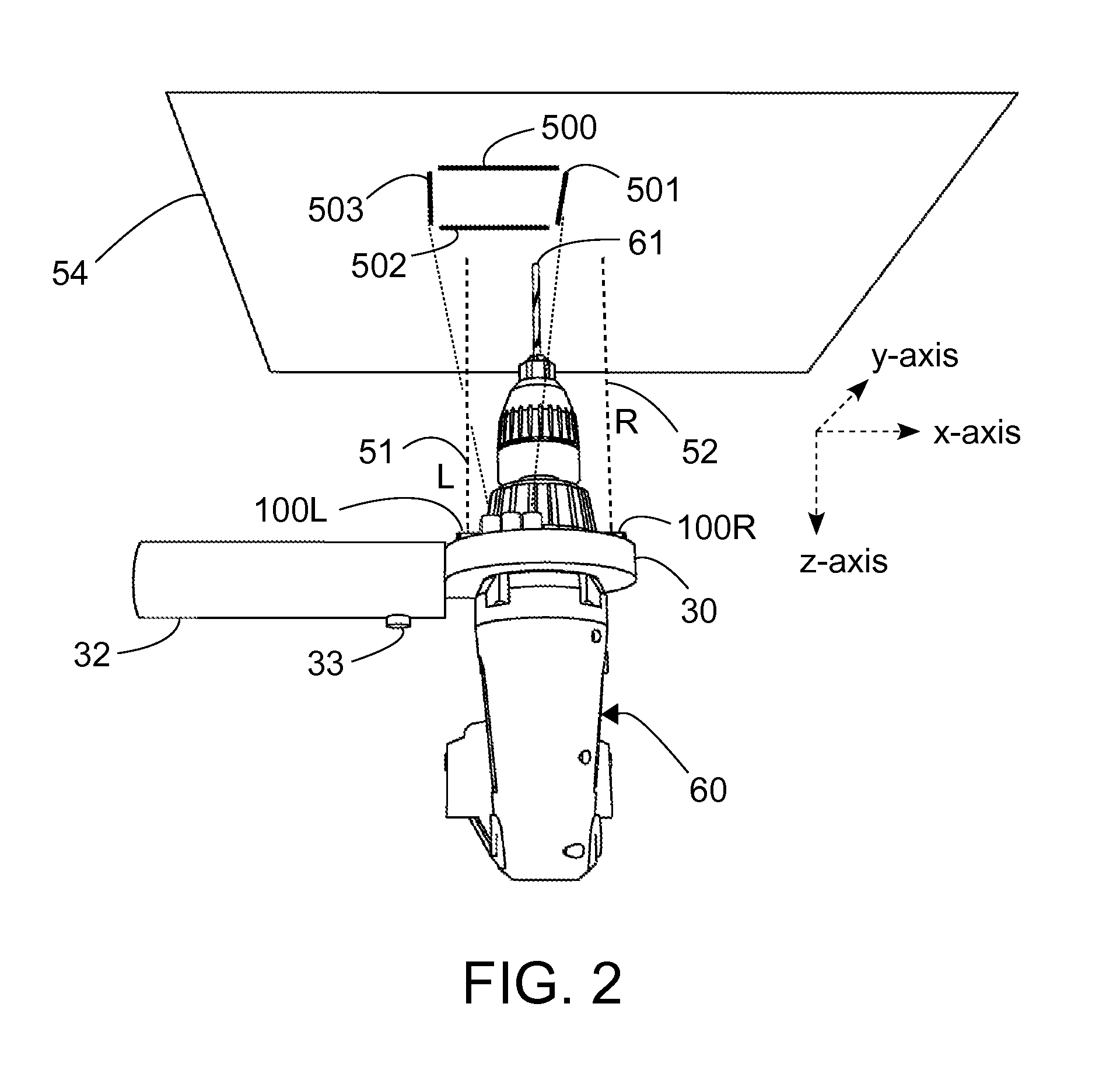

Electronic drill guide

ActiveUS9114494B1Easy to viewStapling toolsDrilling/boring measurement devicesTarget surfaceThree axis accelerometer

One embodiment of an alignment apparatus for aligning an object, such as a tool or other implement, perpendicular with respect to a horizontal or a vertical target surface, comprises a three-axis accelerometer and at least two forward-facing distance sensors and a projection display comprising four addressable laser projectors. The accelerometer and distance sensor outputs are mapped to a predefined graphic symbol representing the orientation of the tool relative to the target surface, in particular when the tool is perpendicular to the target surface. The projection display projects the predefined symbol onto the target surface where it may be easily viewed by the tool operator allowing the operator to make any necessary corrections to the tool position.

Owner:MAH KENNETH JACK

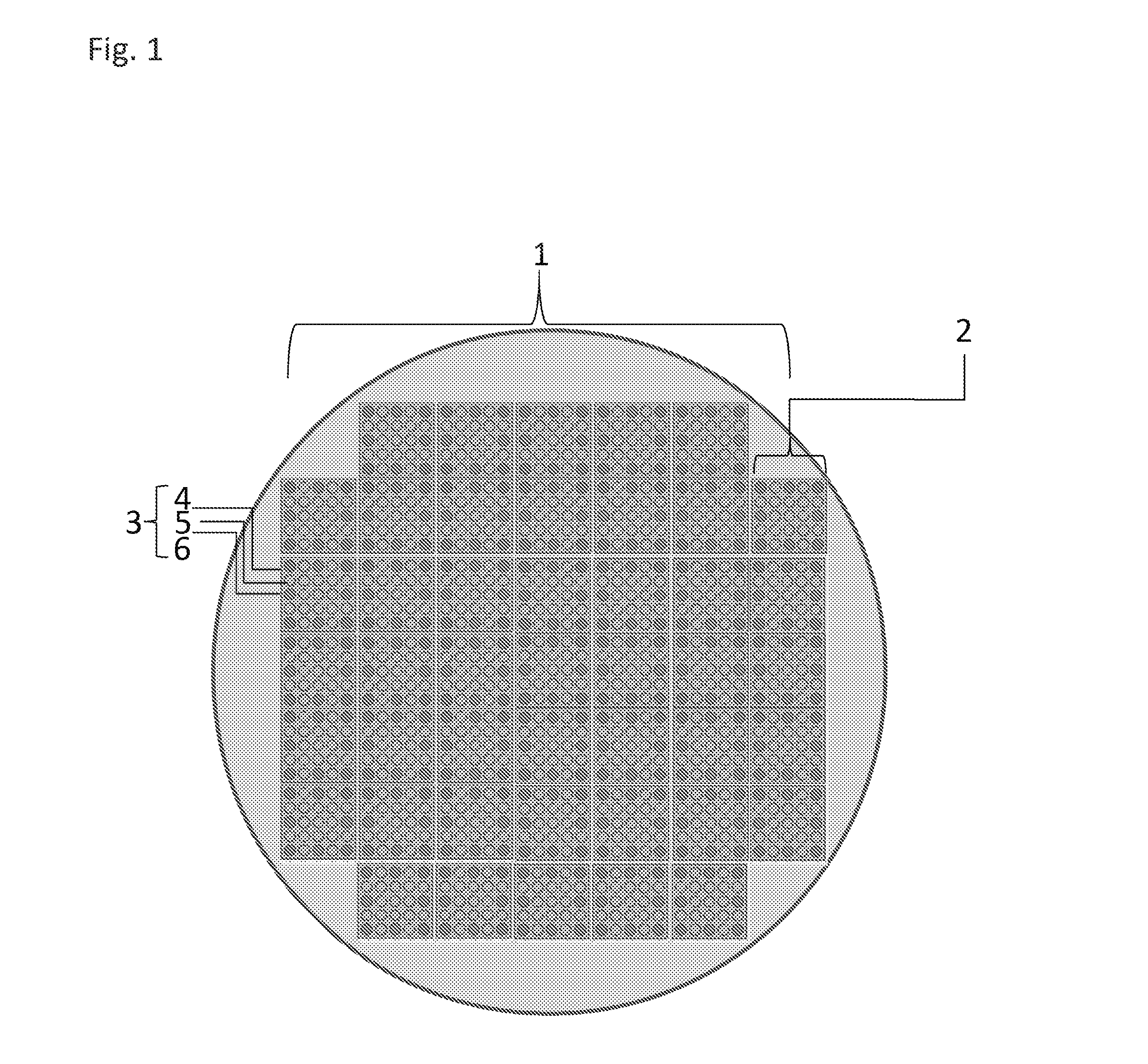

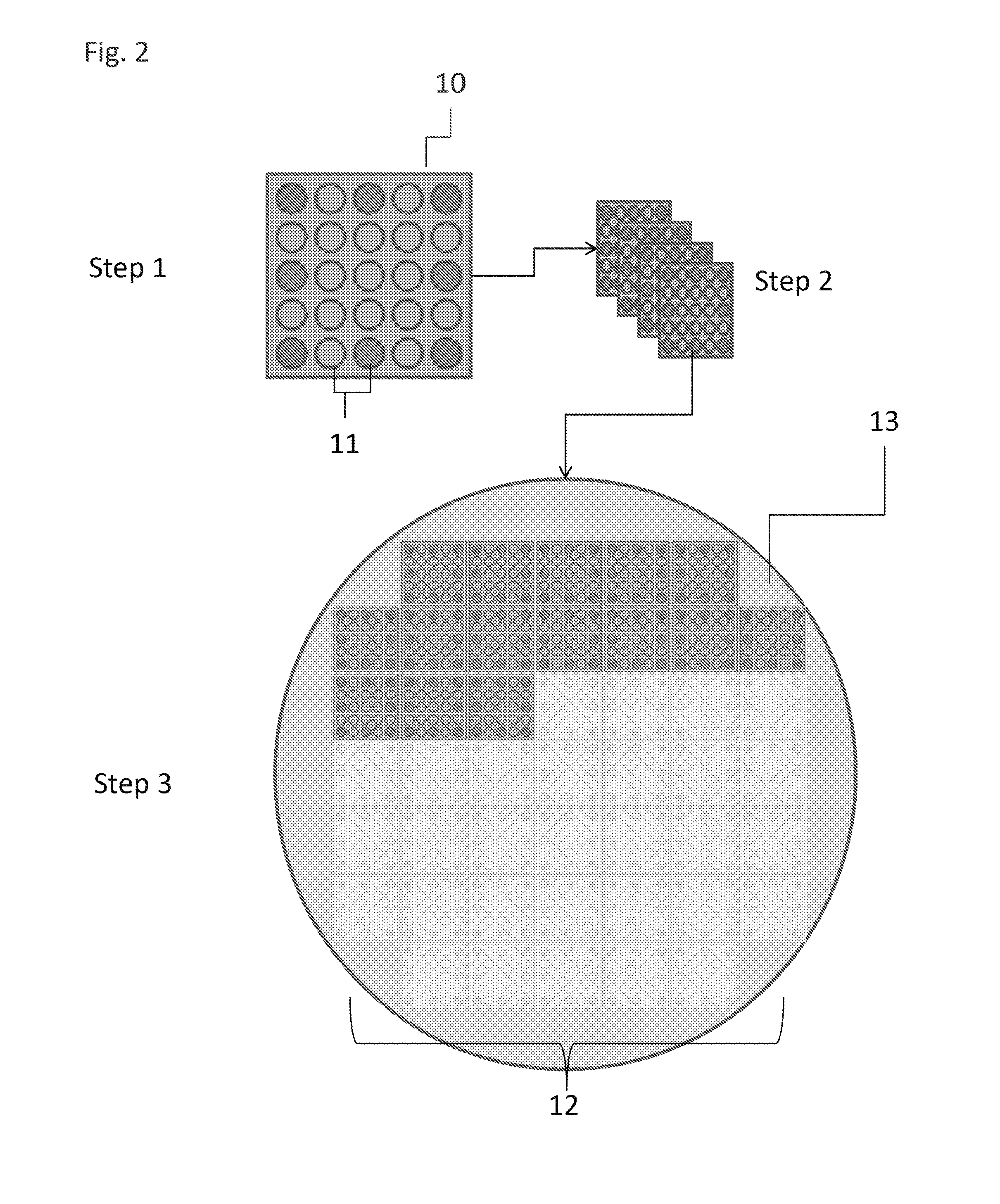

Fabrication process for mastering imaging lens arrays

Owner:FOTONATION CAYMAN LTD

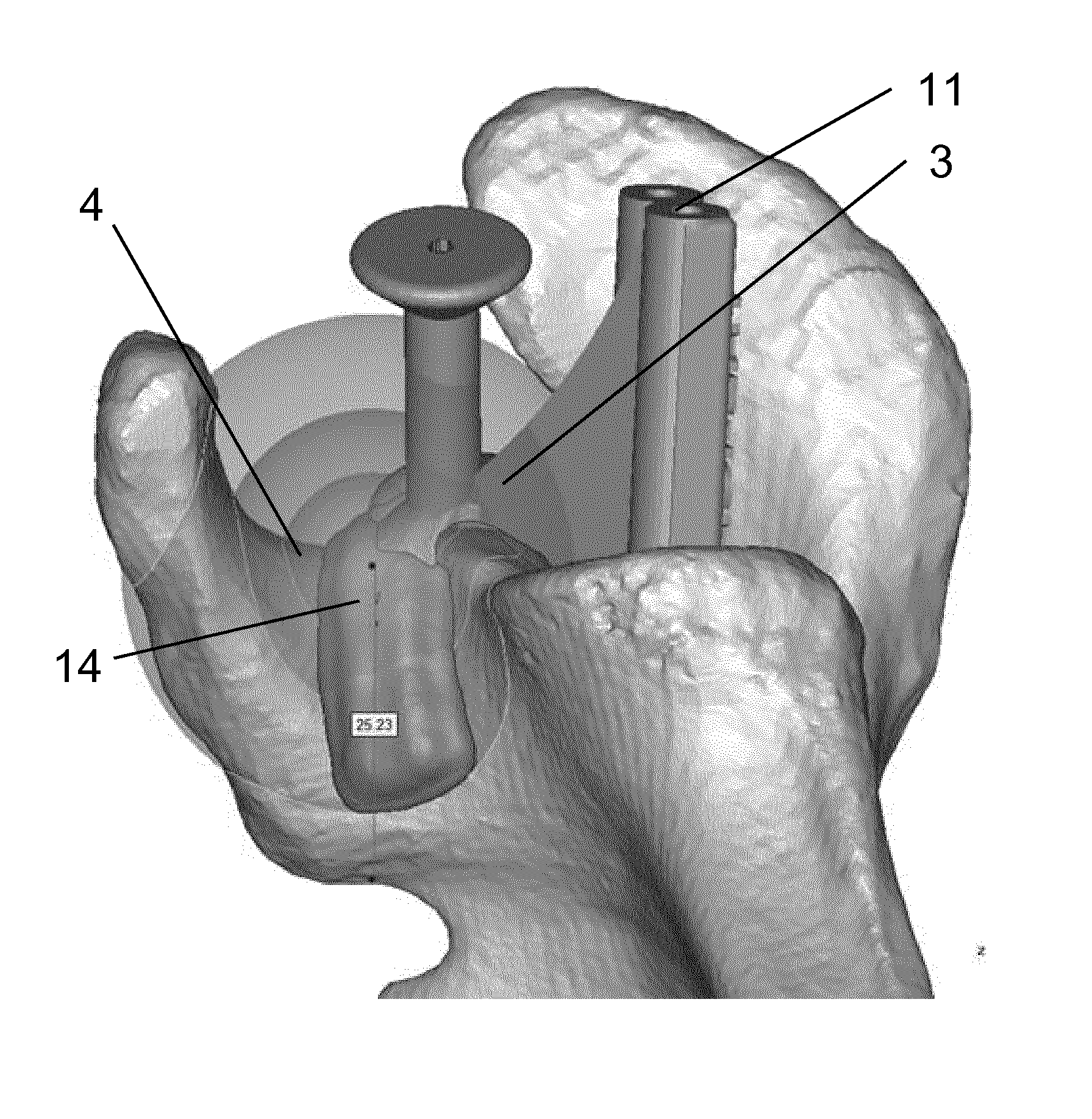

Customized surgical guides, methods for manufacturing and uses thereof

ActiveUS20120289965A1Stable guidance of the surgical instrument into the boneFixed and accurateAdditive manufacturing apparatusDiagnosticsReoperative surgerySurgical device

The invention relates to surgical guides which are of use during reconstructive bone surgery for guiding a surgical instrument or tool. More particularly, the guides are characterized in that they are fitted to the implant rather than to the bone.

Owner:MATERIALISE NV

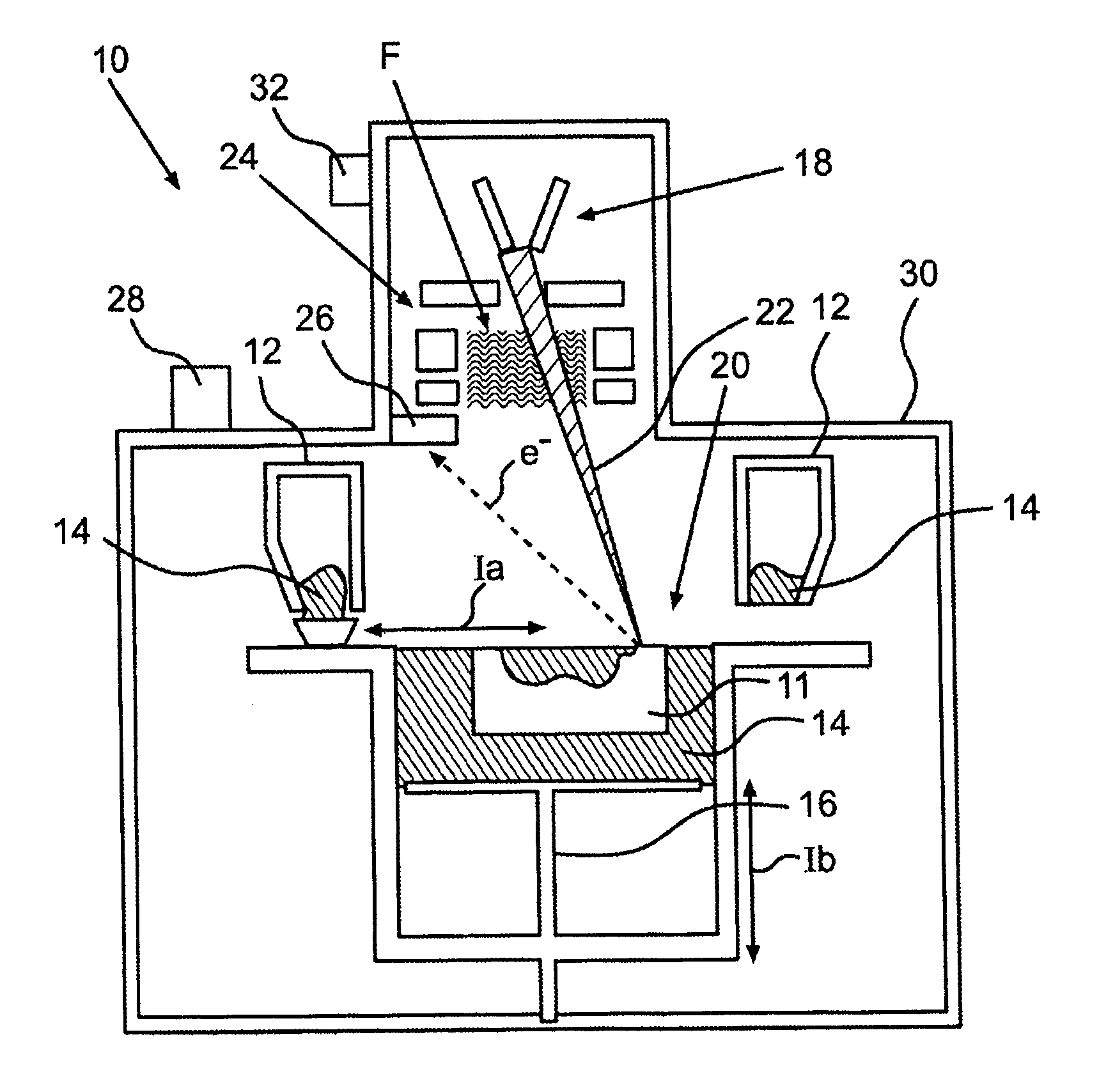

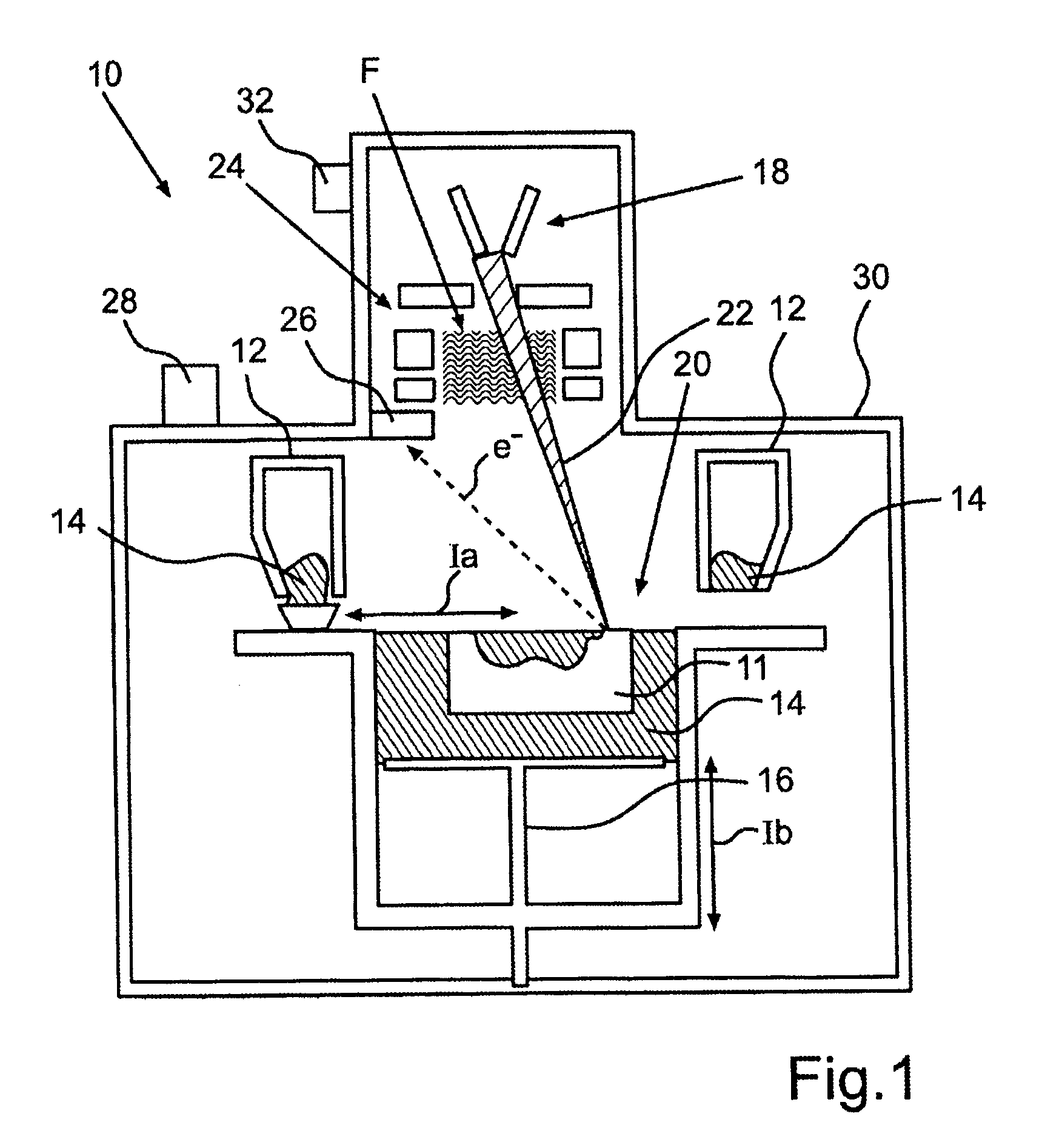

Method and device for producing a component

InactiveUS20130055568A1High build rateSpeed up preparationTurbinesAdditive manufacturing apparatusMetallurgyLayer thickness

A method for manufacturing a component, in particular a component of a turbine or a compressor, in which at least these steps are carried out: application in layers of at least one powdered component material to a component platform in the area of a buildup and joining zone; melting and / or sintering locally in layers of the component material by supplying energy with the aid of at least one electron beam in the area of the buildup and joining zone; lowering of the component platform in layers by a predefined layer thickness; and repeating steps a) through c) until completion of the component. During the manufacturing, electrons emitted due to the interaction of the electron beam with the component material are detected, after which material information, characterizing the topography of the melted and / or sintered component material, is ascertained on the basis of the emitted electrons. Alternatively or additionally, the component material is melted and / or sintered by at least two, preferably at least four electron beams.

Owner:GLOBAL BEAM TECH +1

Shoulder base plate coverage and stability

InactiveUS20130338673A1Improve stabilityAdditive manufacturing apparatusDiagnosticsSurgical departmentSurgical device

Provided herein are patient-specific surgical device that allow for a stable fitted position for use in shoulder surgery. The patient-specific surgical devices may have different functions such as a function as a guide.

Owner:MATERIALISE NV

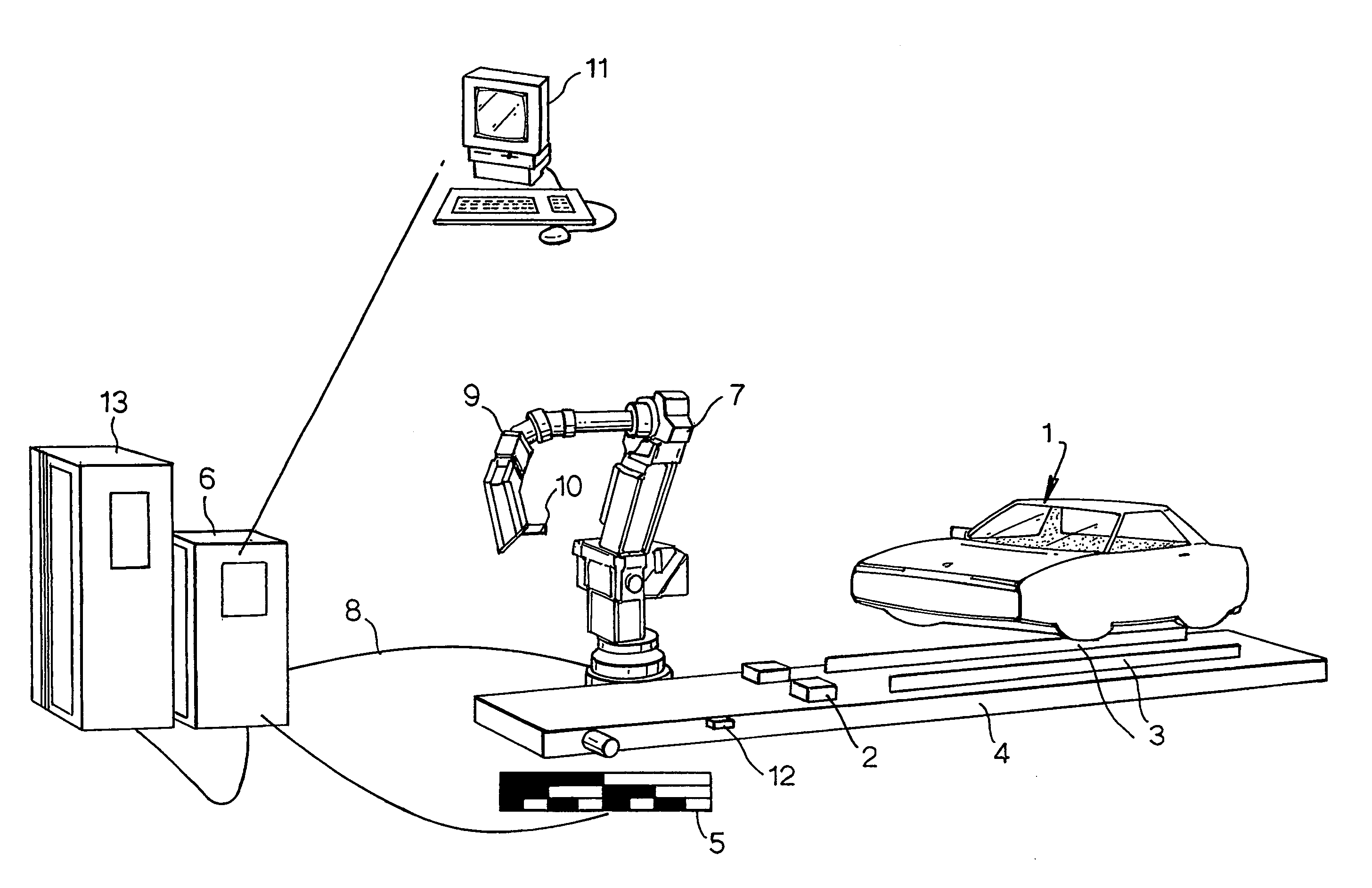

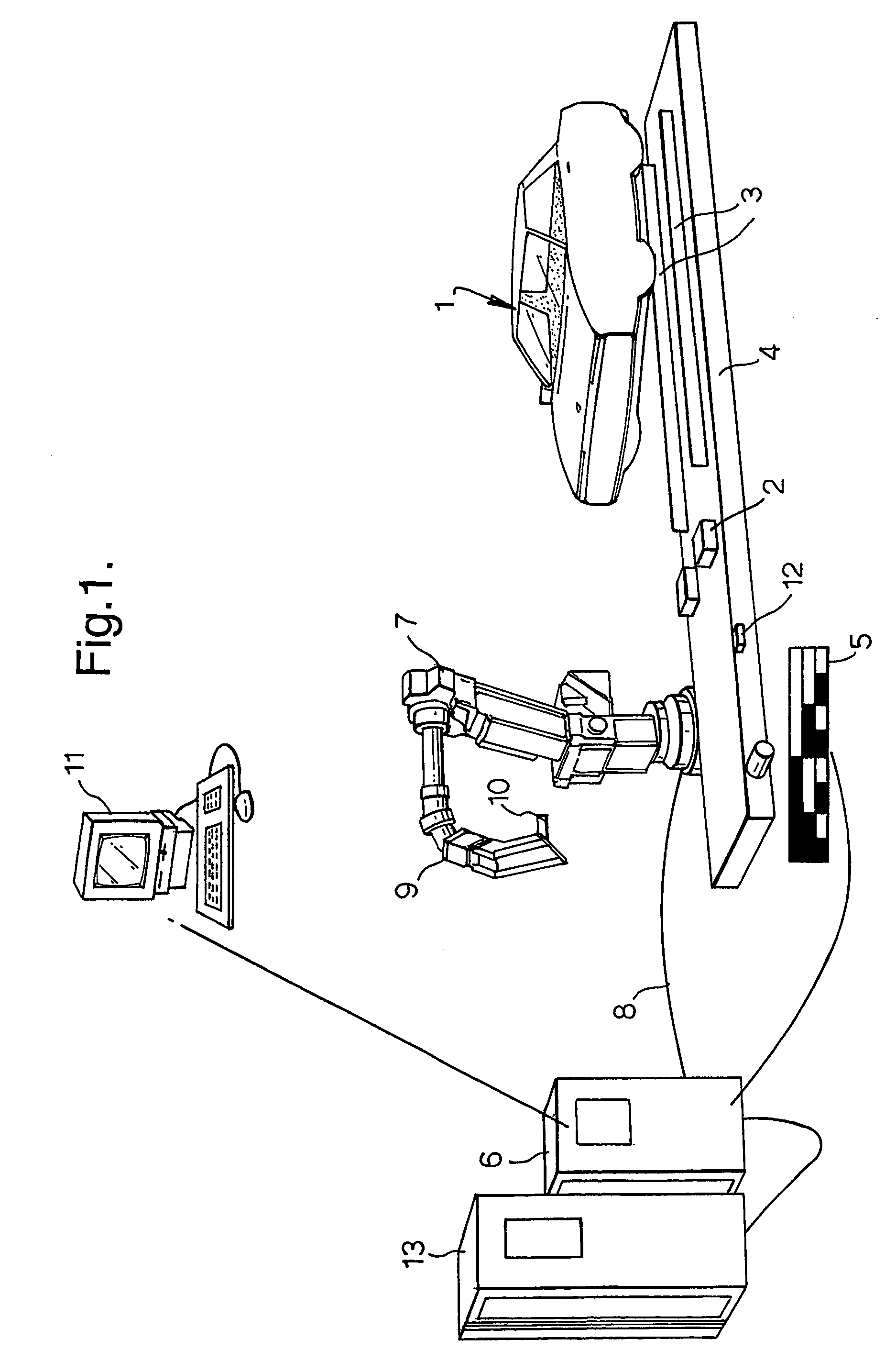

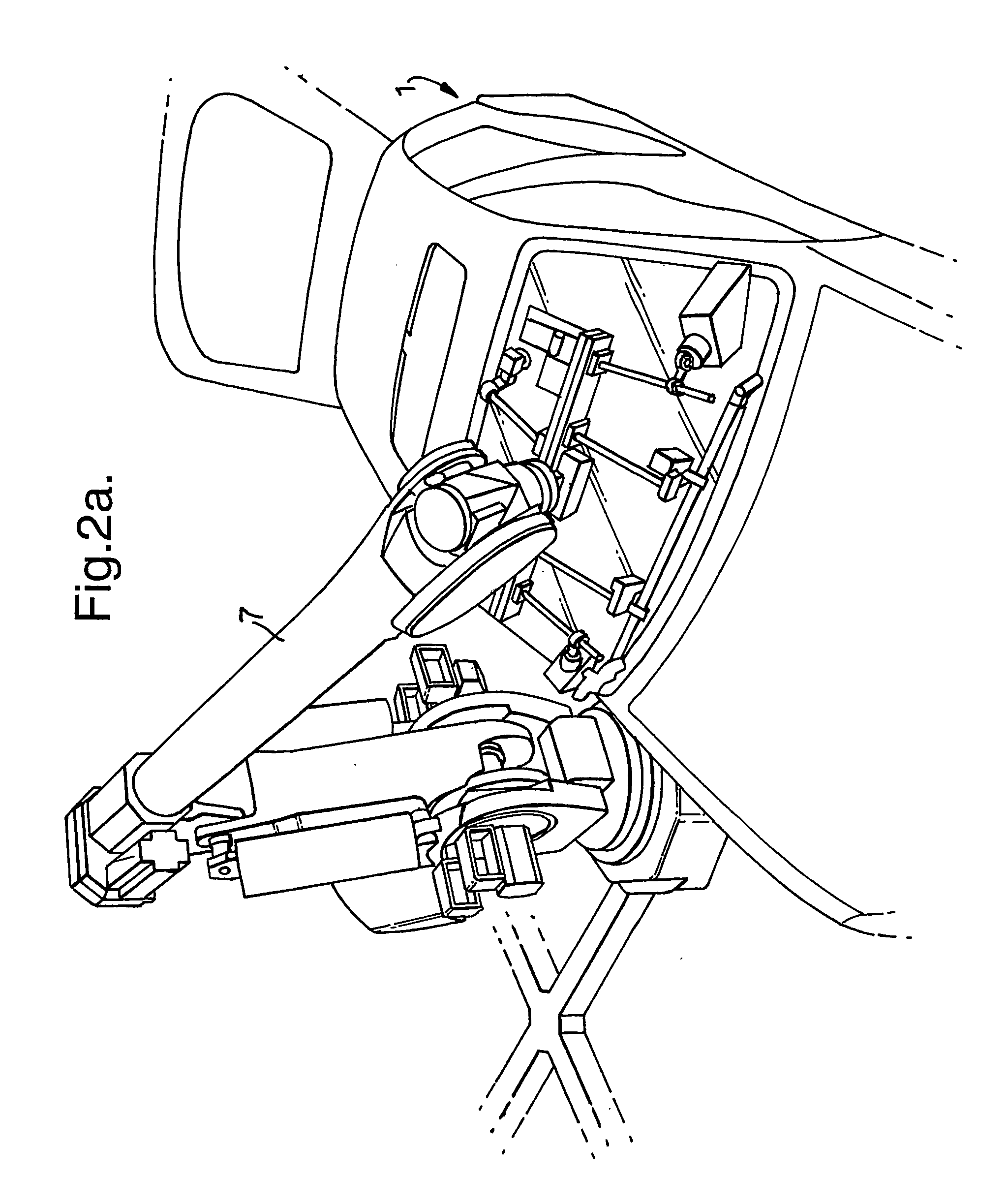

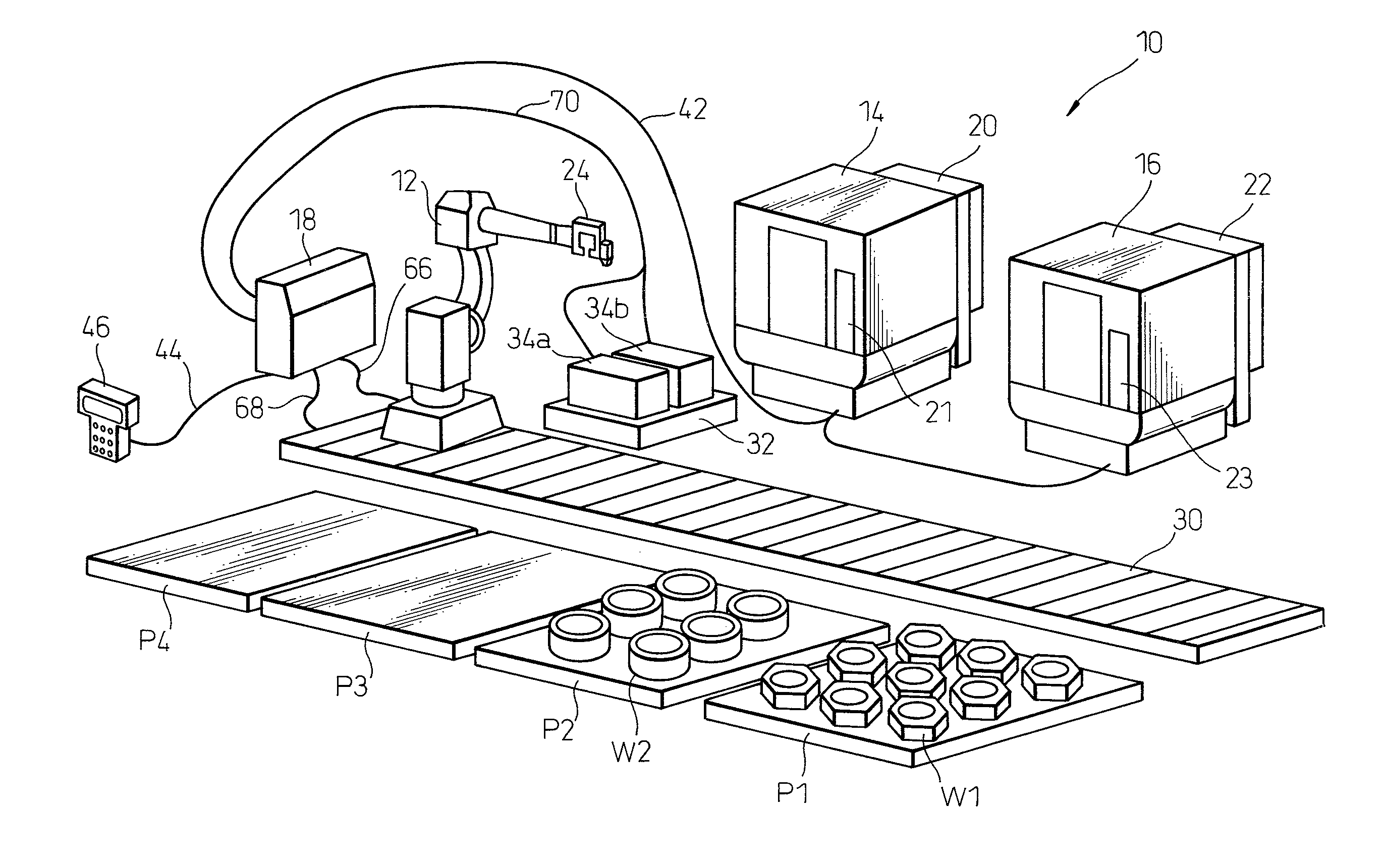

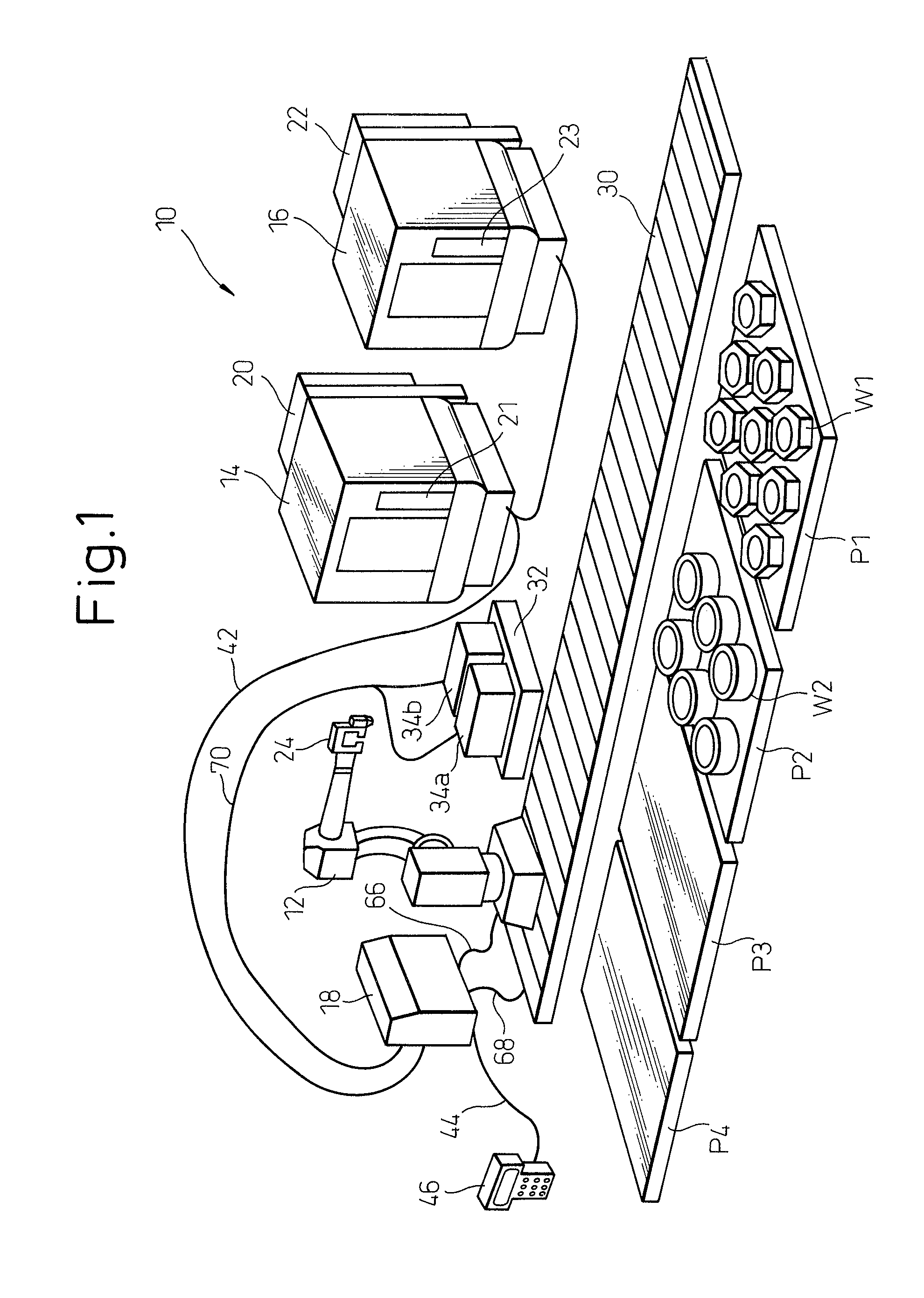

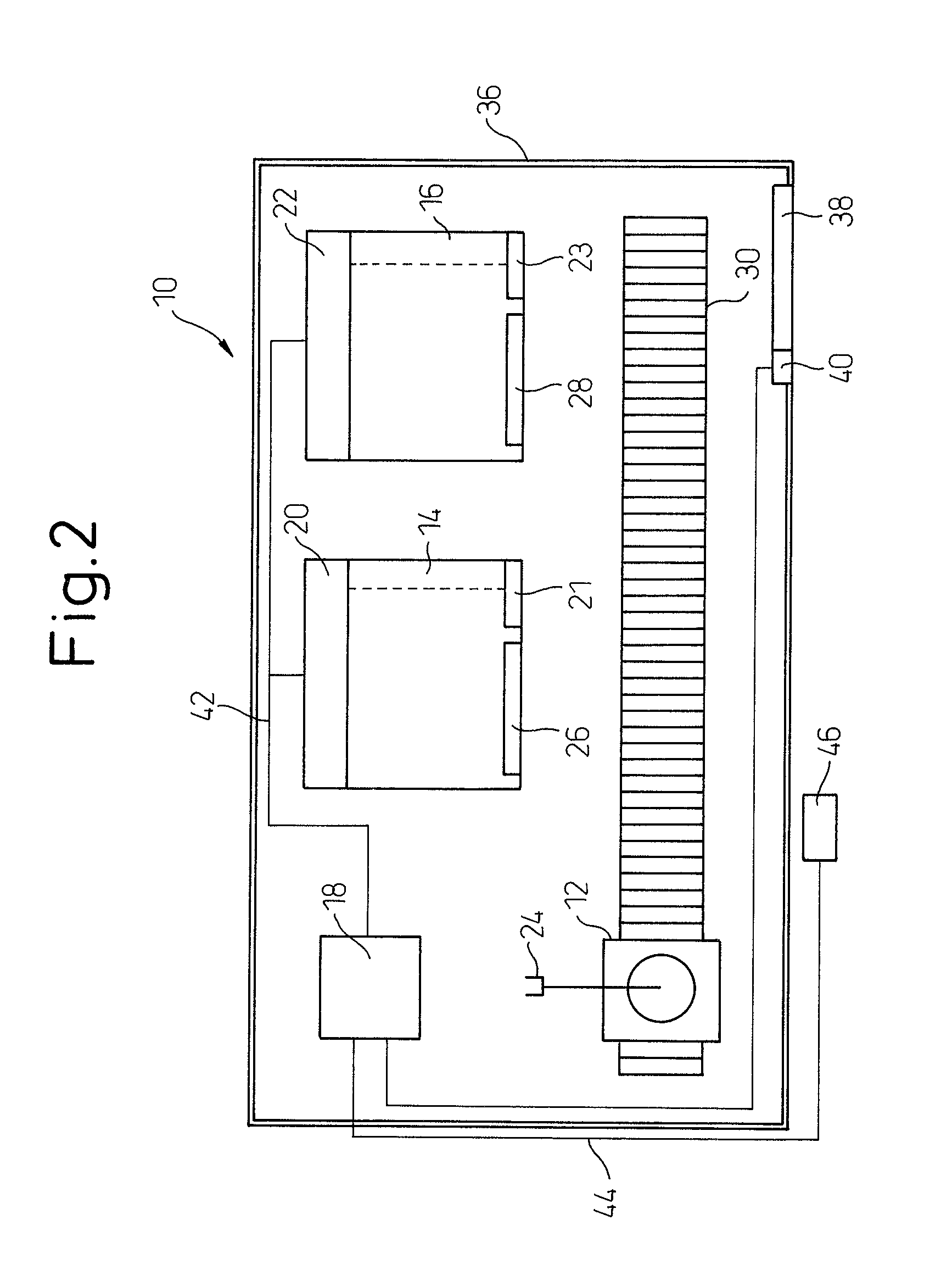

Auto Motion: Robot Guidance for Manufacturing

A robot manufacturing facility, for example for use in automobile manufacture, includes at least one robot for acting on a workpiece or intermediate product of a pre-calculated shape and dimensions at a pre-calculated position and orientation relative to a reference frame. The robot includes a body or base structure, at least one end effector movable with respect to the body or base structure for acting on workpieces, means for moving the end effector and sensing means for sensing the position of the each effector. The sensing means preferably includes a laser light source carried by the robot and means for detecting laser light, from said source, reflected from the workpiece. The movement of the end effector is controlled according to a predetermined program, modified in accordance with signals from the sending means, so that the robot is able to compensate for departures from pre-calculated values of the position and orientation and / or shape and / or dimensions of the workpiece.

Owner:READ DALE

Customized process for facilitating successful total knee arthroplasty with outcomes analysis

InactiveUS20140013565A1Address bad outcomesMedical data miningMechanical/radiation/invasive therapiesBone morphologyTotal hip arthroplasty

A method for producing a custom resection jig for a current patient scheduled to receive total knee arthroplasty using outcomes analysis comprising the steps of maintaining a database on a computer system of (1) prior patient bone morphology, (2) along with anatomical and mechanical bone alignment data and (3) data defining a custom resection jig design with a generally transverse resection window operable to guide a surgeon's transverse bone cut for prior patients that have received total knee arthroplasty and a post-surgery medically recognized scoring register greater or equal to a predetermined highly successful score value for a total knee arthroplasty procedure using prior success data to guide production of a current patient custom jig resection windows.

Owner:MACDONALD M D JAMES

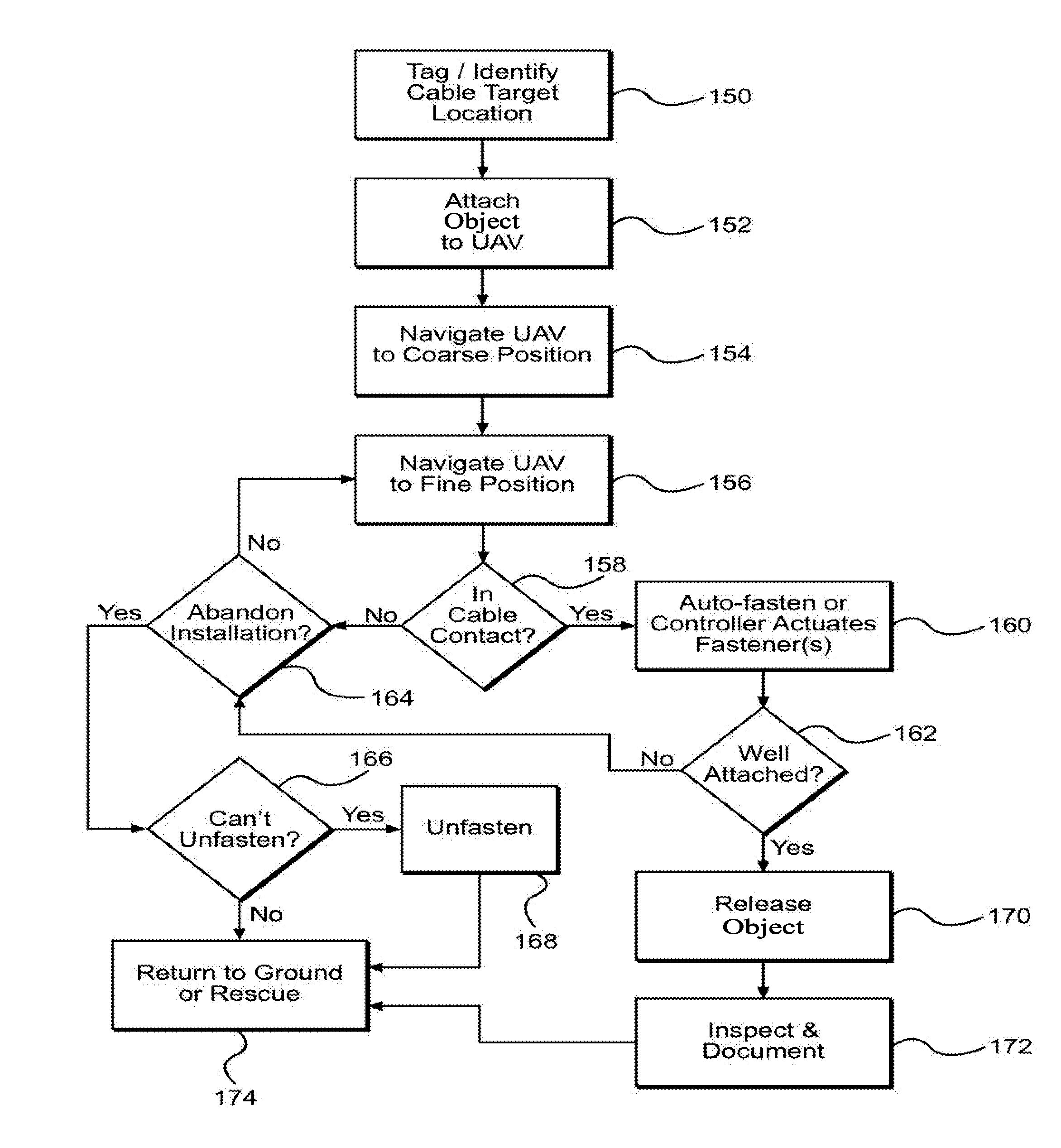

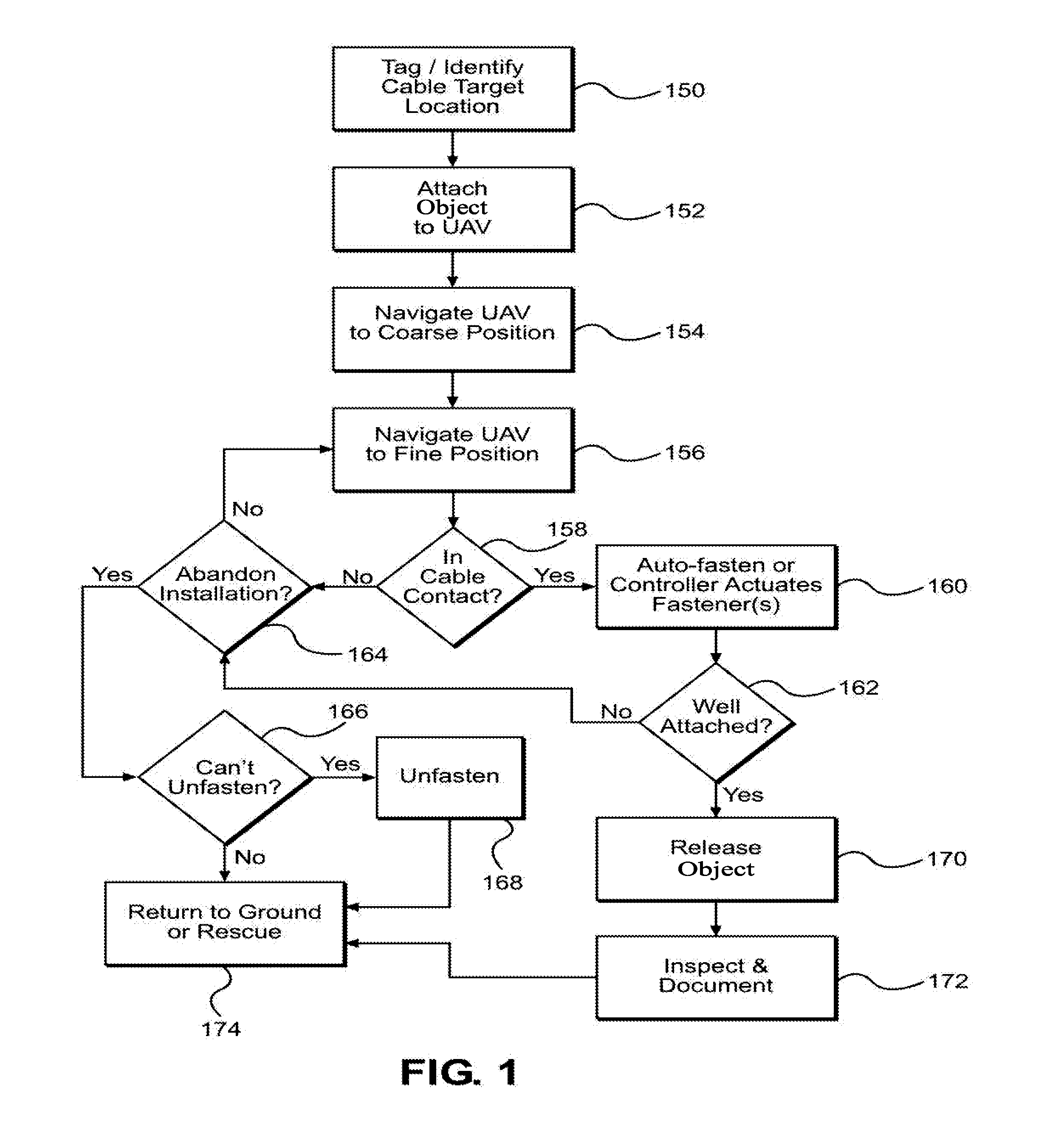

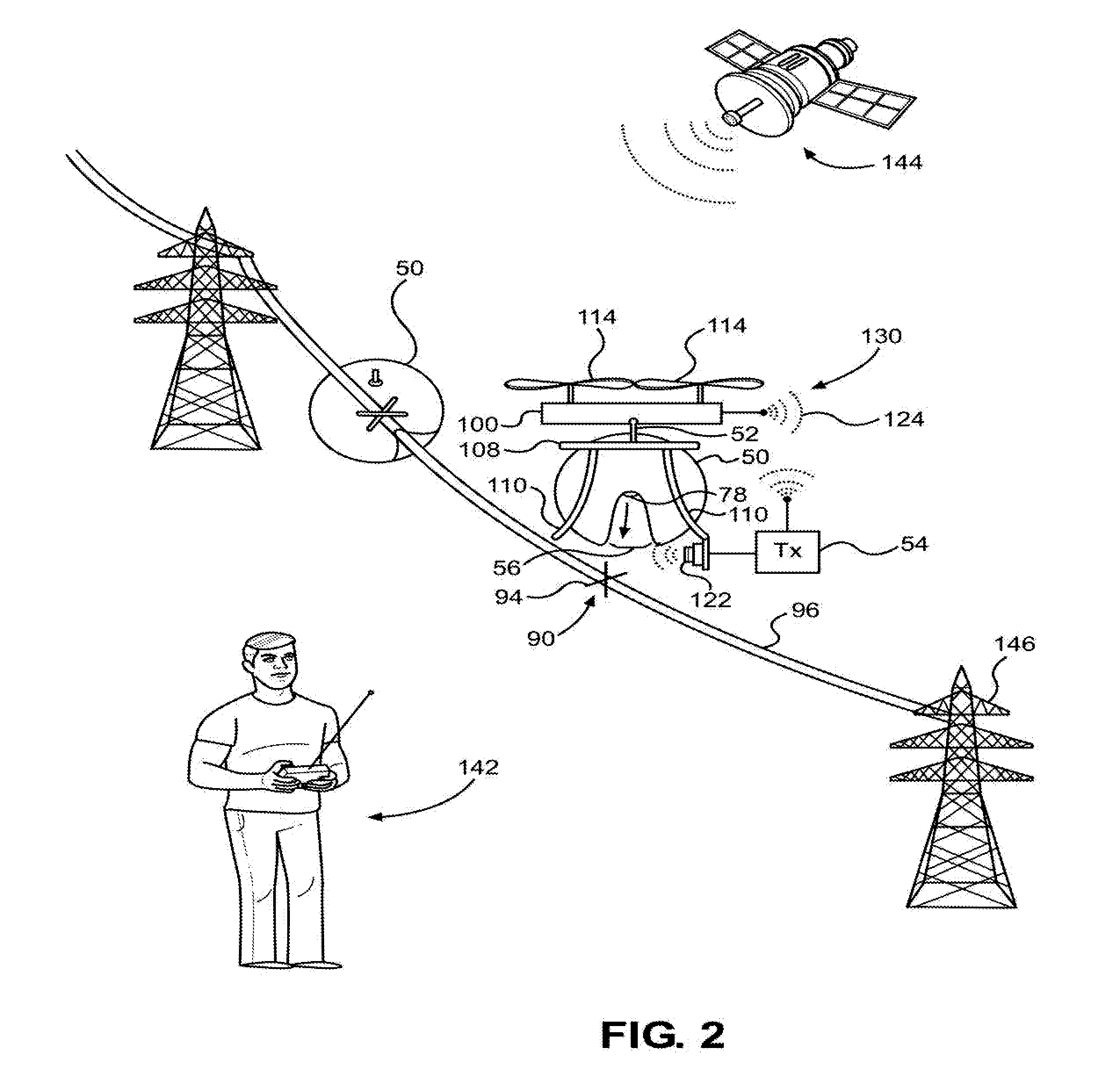

Method for installing an object using an unmanned aerial vehicle

ActiveUS20160023761A1Overhead installationUnmanned aerial vehiclesAircraft flight control systemMechanical devices

A method for using an unmanned aerial vehicle to install objects on wire and catenary structures is described. The method includes tagging the location, attaching the object to the UAV, navigating the UAV to the position, attaching the object, testing the attachment, releasing the object, inspecting the attachment, and returning the UAV to the ground. Sensors, flight control systems, means for attachment, and variations of embodiments of the methods, systems, and mechanical devices are described.

Owner:MCNALLY JONATHAN

Dynamically adjustable probe tips

ActiveUS7022976B1Beam/ray focussing/reflecting arrangementsMaterial analysis by optical meansEngineeringActuator

Various probe systems and probes are provided. In one aspect, a probe is provided that includes a base and a first member coupled to the base. The first member has a first tip for probing a circuit device. A first actuator is coupled to the first member for moving the first member relative to the base. Electrical and / or topographical probing is possible.

Owner:GLOBALFOUNDRIES US INC

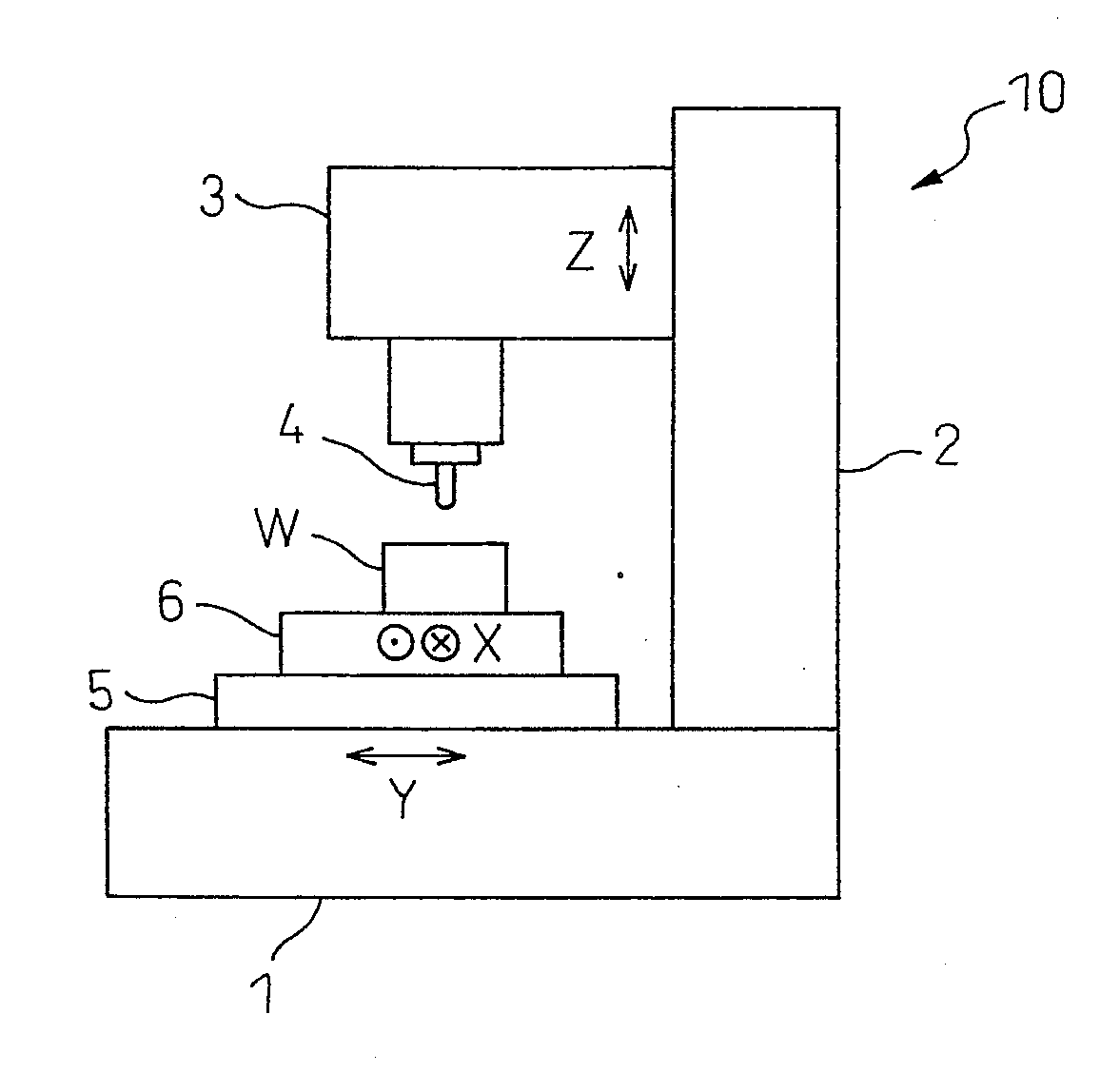

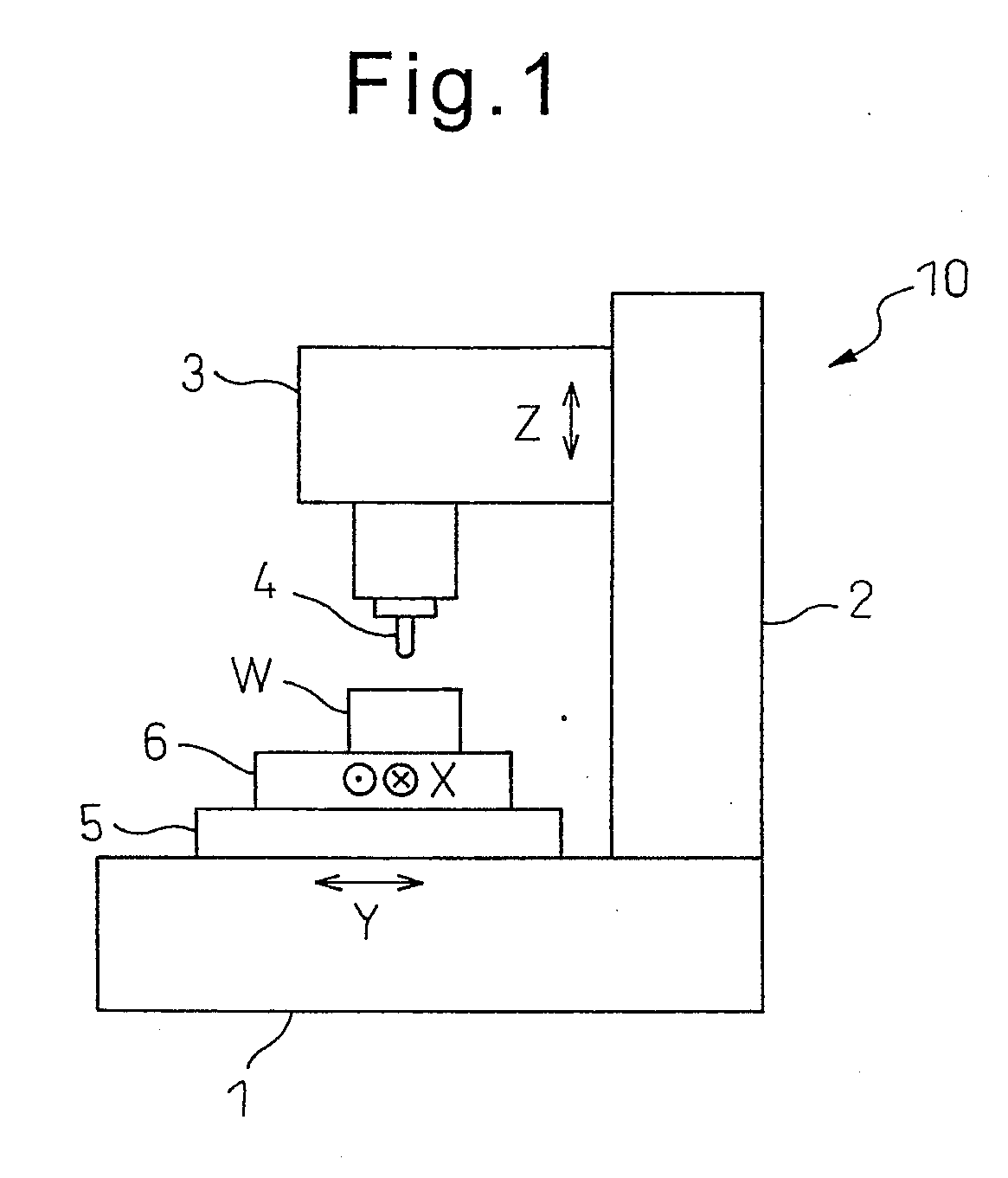

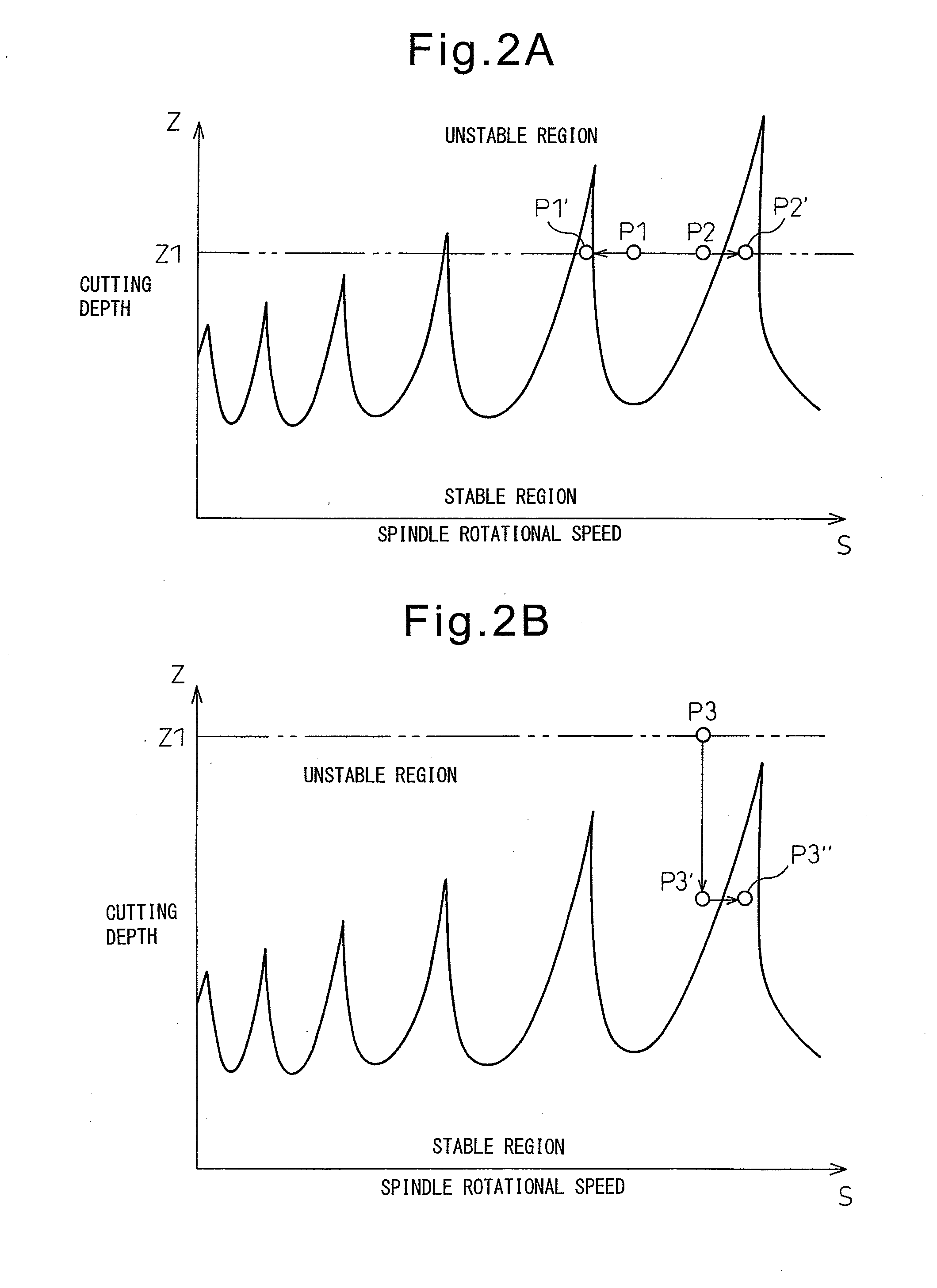

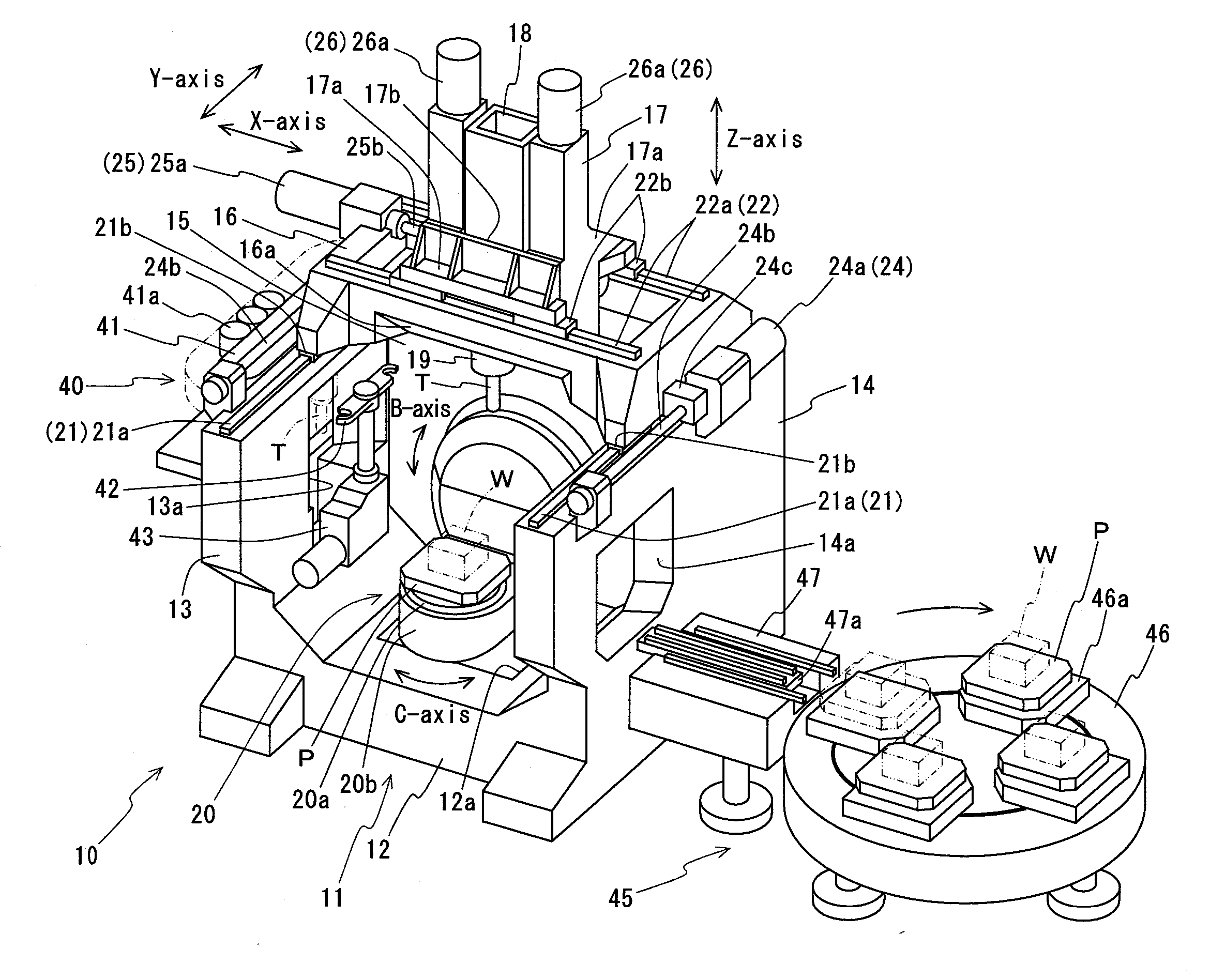

Chatter vibration detection method, chatter viberation avoidance method, and machine tool

A chatter vibration detection method includes acquiring vibration data of a tool (4) at a time of machining a workpiece at a predetermined sampling period (Δt), calculating an autocorrelation coefficient (Rxx′) corresponding to a time required for a cutting edge (4a, 4b) to contact the workpiece (W) several times based on acquired time series vibration data and calculating a period (Tx) of characteristics of the calculated autocorrelation coefficient (Rxx′), and deciding that chatter vibration occurs when a contact period (T1) at which the cutting edge (4a, 4b) contacts the workpiece (W) is not an integral multiple of the calculated period (Tx).

Owner:MAKINO MILLING MASCH CO LTD

Stabilizing a substrate using a vacuum preload air bearing chuck

ActiveUS7607647B2Improve rigidityAvoid deformationLinear bearingsGas cushion bearingsAir bearingEngineering

Substrate processing method and apparatus are disclosed. The substrate processing apparatus includes a non-contact air bearing chuck with a vacuum preload.

Owner:KLA TENCOR TECH CORP

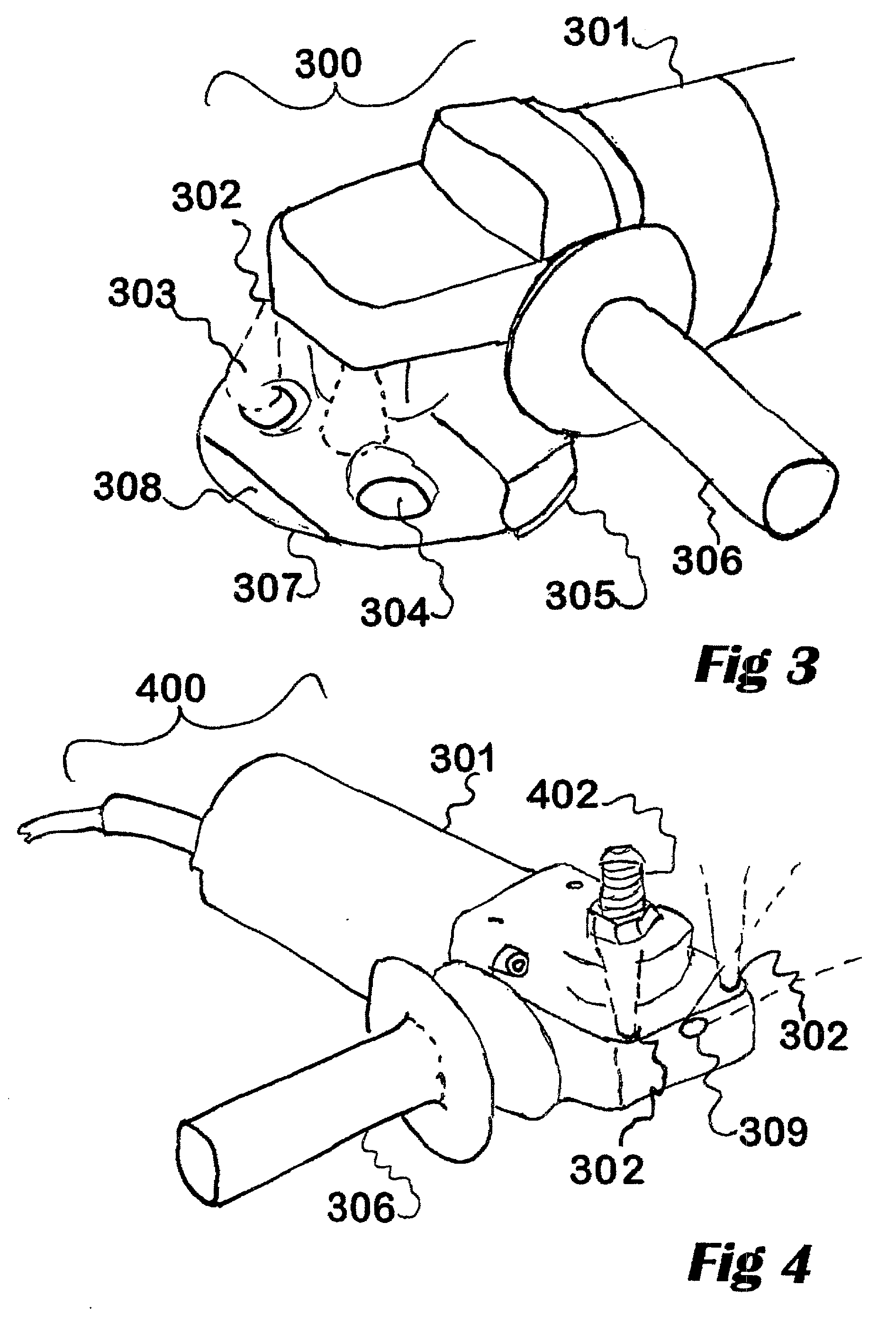

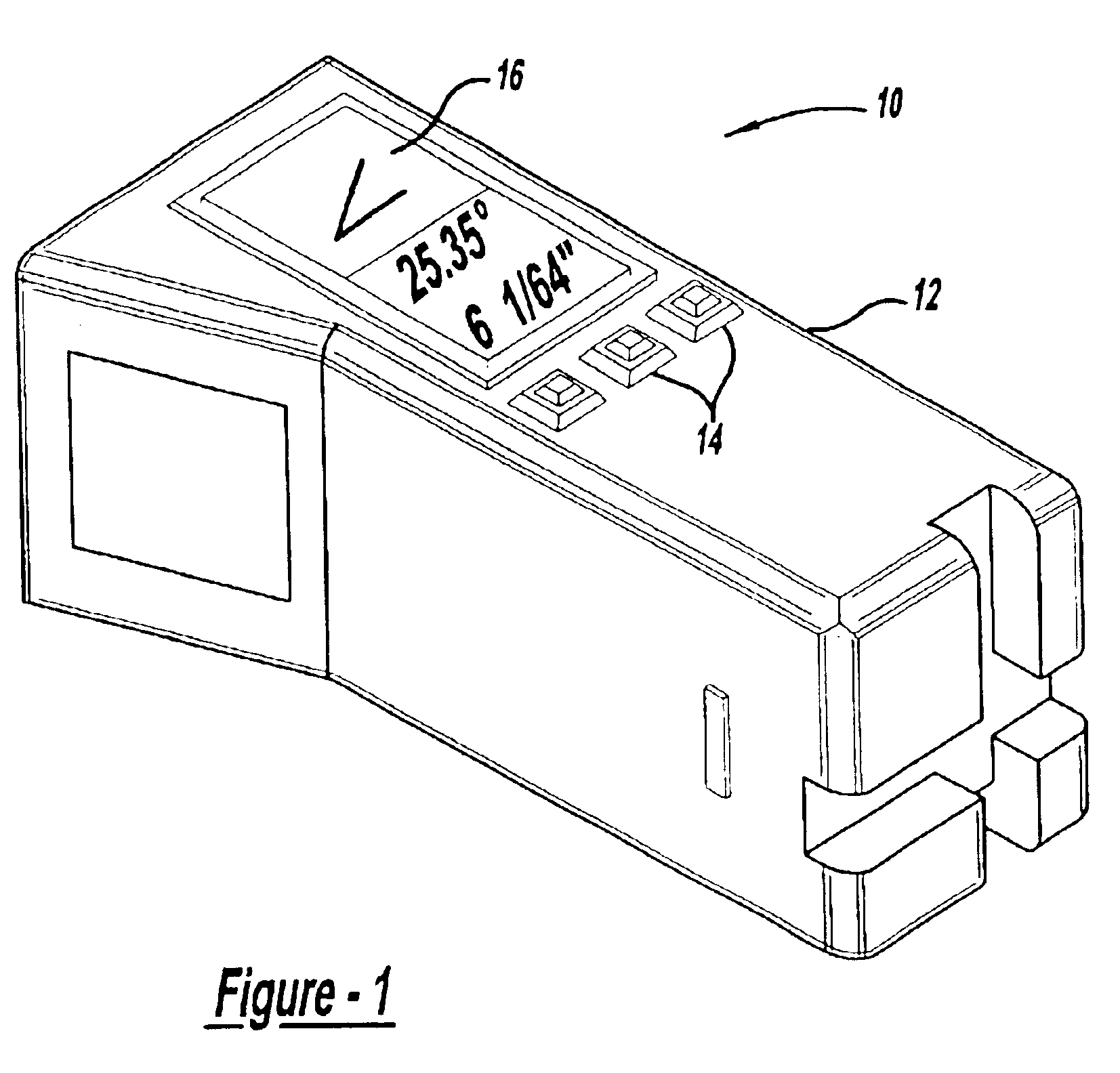

Power tool control system

InactiveUS20060076385A1Quality improvementWell formedStapling toolsDrilling/boring measurement devicesUser needsGraphics

A power tool control system allows a user to operate a power tool through a graphical user interface communicatively coupled with a non-contact measurement and alignment device. The graphical user interface correlates user engageable selectors with a logically related menu of power tool setting options displayed on a display screen in a high quality and easily readable format. The non-contact measurement and alignment device uses one or more lasers to determine power tool settings and establish proper alignment based on user needs. The power tool control system further enables stud detection and visual indication of stud location.

Owner:BLACK & DECKER INC

Illumination by hand-operated power tools

InactiveUS20020131267A1Double battery lifeConserve battery lifeMetal sawing accessoriesLighting elementsEngineeringPower tool

An illuminator adapted for use on a hand-operated tool such as a power tool (1000) comprises a low-profile, flexible, adherent laminated housing (900), including one or more lamps (906, 907) capable of illuminating a work surface beneath the power tool. This permits a user to work with the tool in conditions of poor visibility. The housing includes connectors. A battery pack (1002) may be attached to a surface of the tool or concealed within an attachable or accessory handle (1002A). Versions including lamp control are also described.

Owner:AVOS DEV

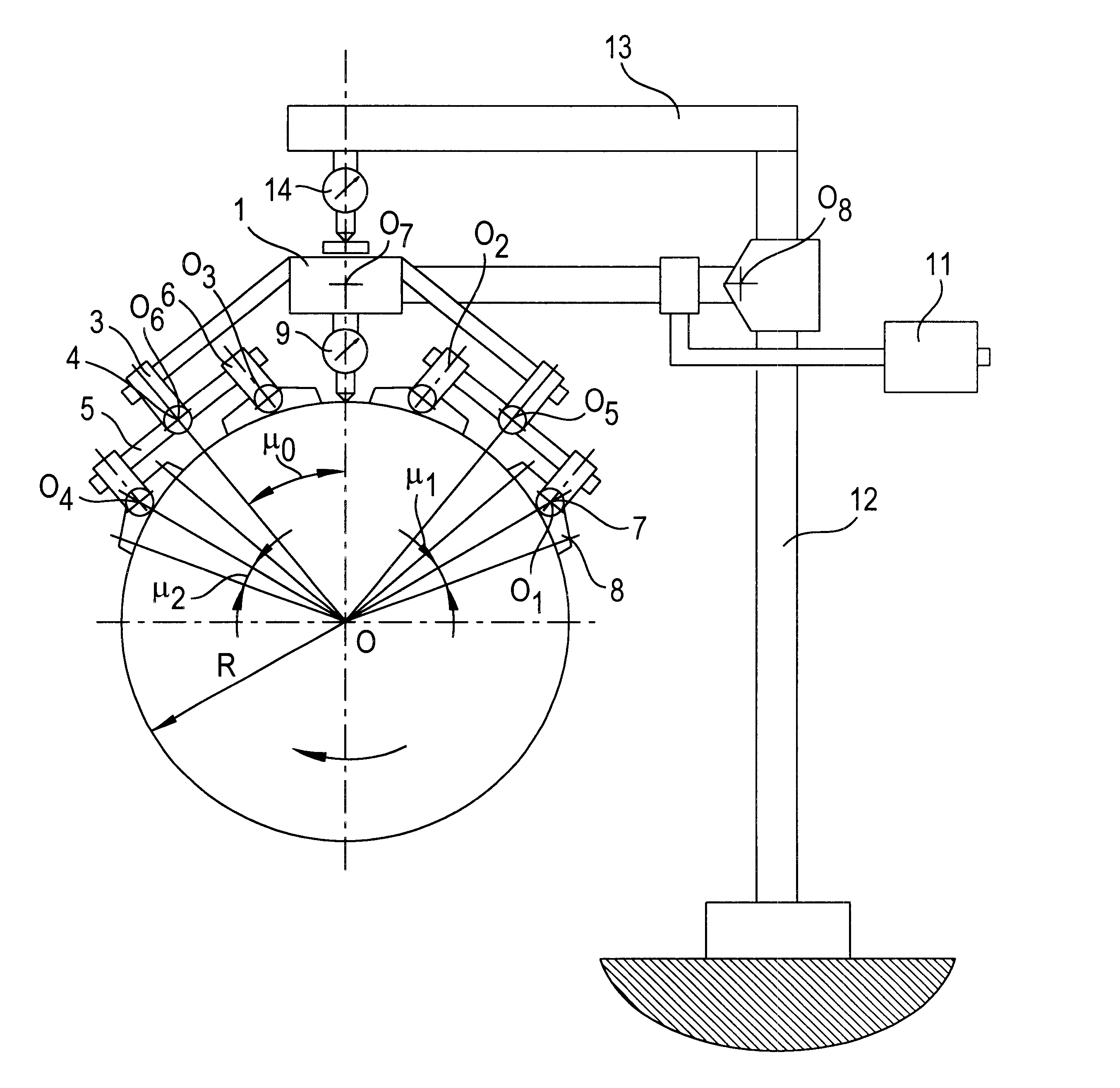

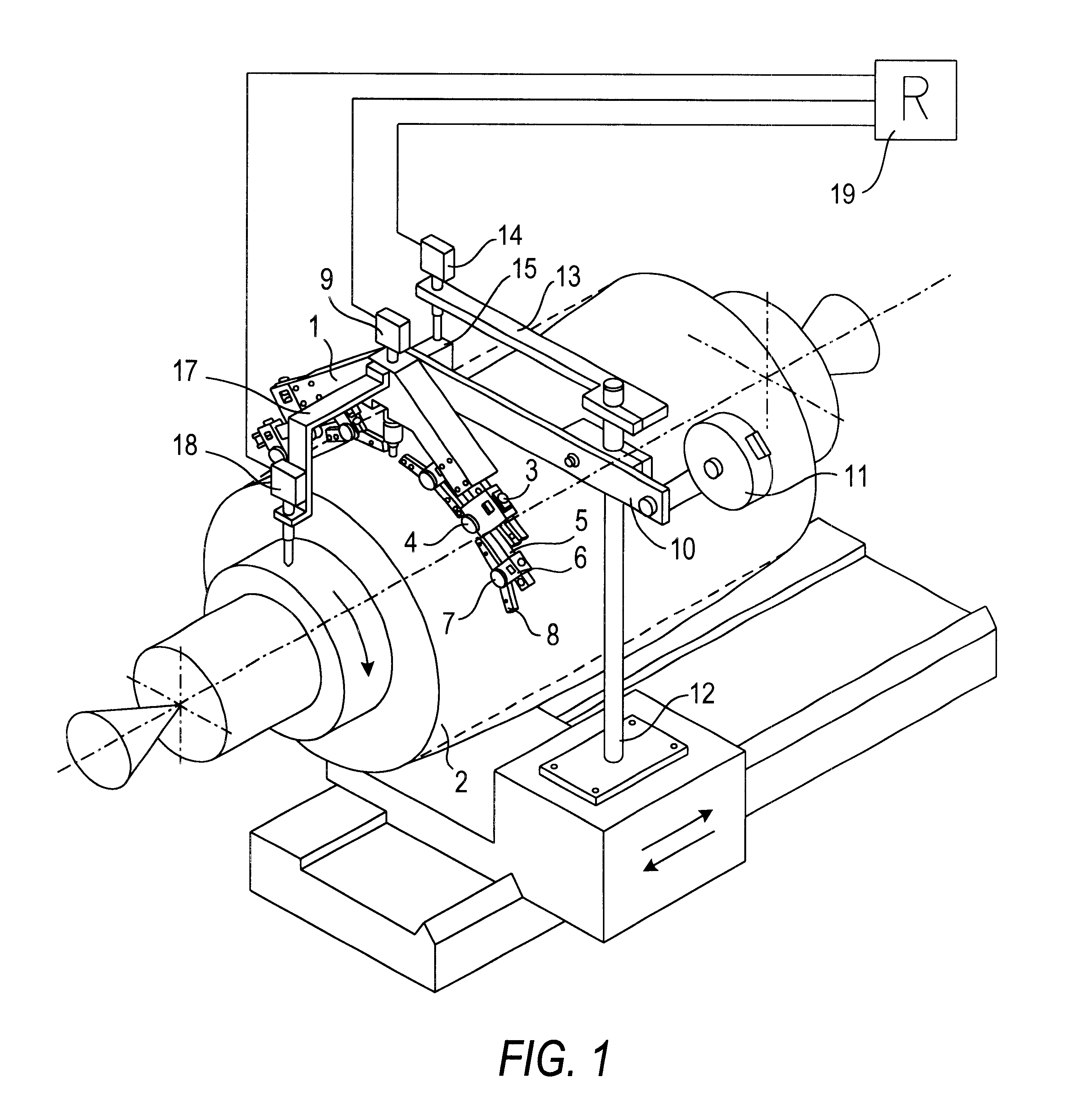

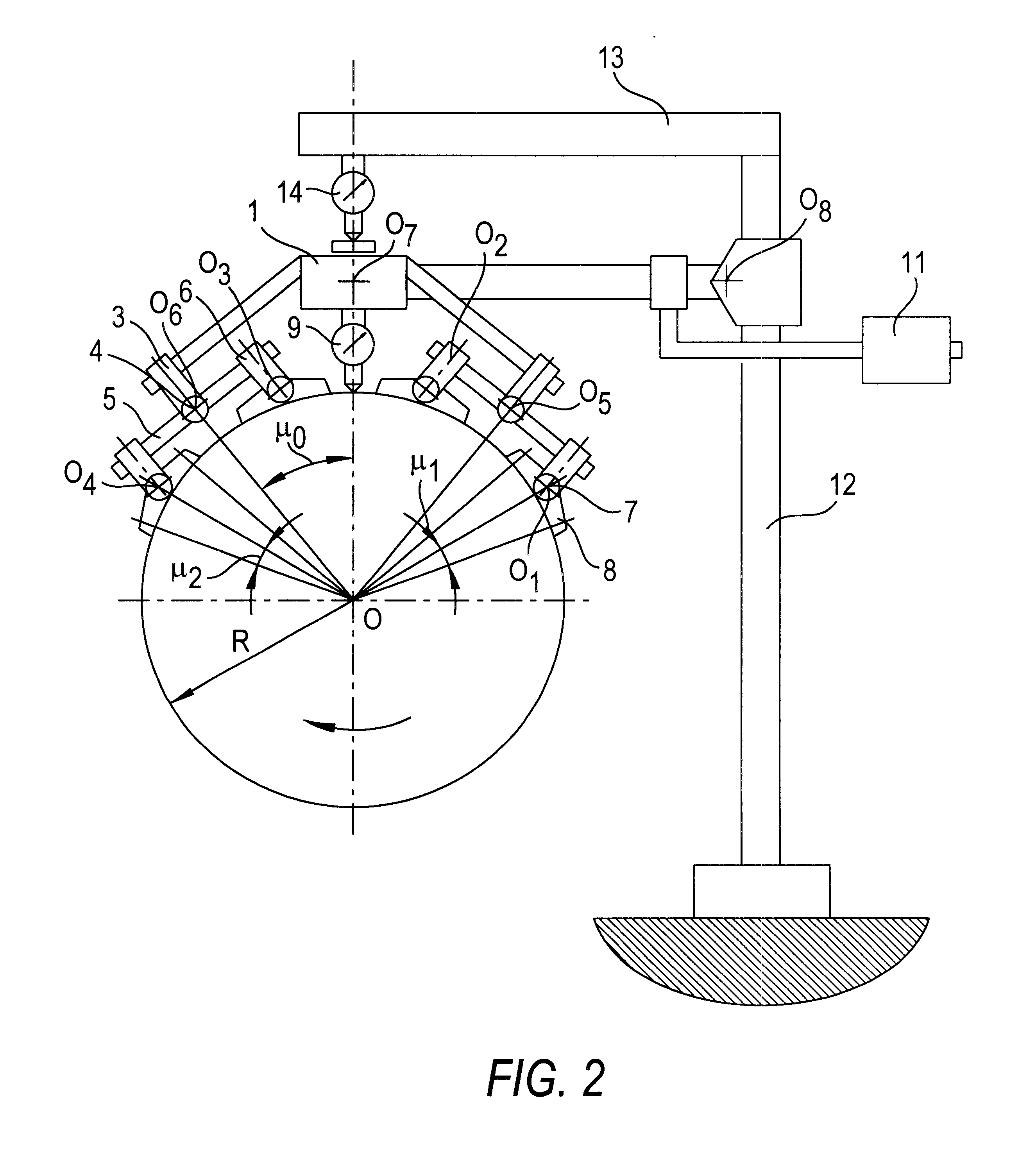

Device and method for measuring shape deviations of a cylindrical workpiece and correcting steadying element and correcting follower for use therewith

InactiveUS6568096B1Accurate measurementPrecise processingLathesAngles/taper measurementsShape deviationEngineering

A device and method for measuring deviations in shape of a generally cylindrical workpiece is disclosed. The device enables measurement of a number of shape-defining parameters while the workpiece is positioned in a machine tool, so that the workpiece does not have to be removed from the machine tool in order for the measurements to be taken. A steadying rest, for use on machine tools to hold a workpiece, especially one having a longitudinal central axis that is rotationally unsymmetrical or unstable with respect to the machining tool, in position to enable measurement of the shape defining parameters and shape deviations while the workpiece is mounted on the machine tool, is also disclosed.

Owner:OBSCHESTVO S OGRANICHENNOI OTVETABTVENNOSTIJU TEKHNOMASH

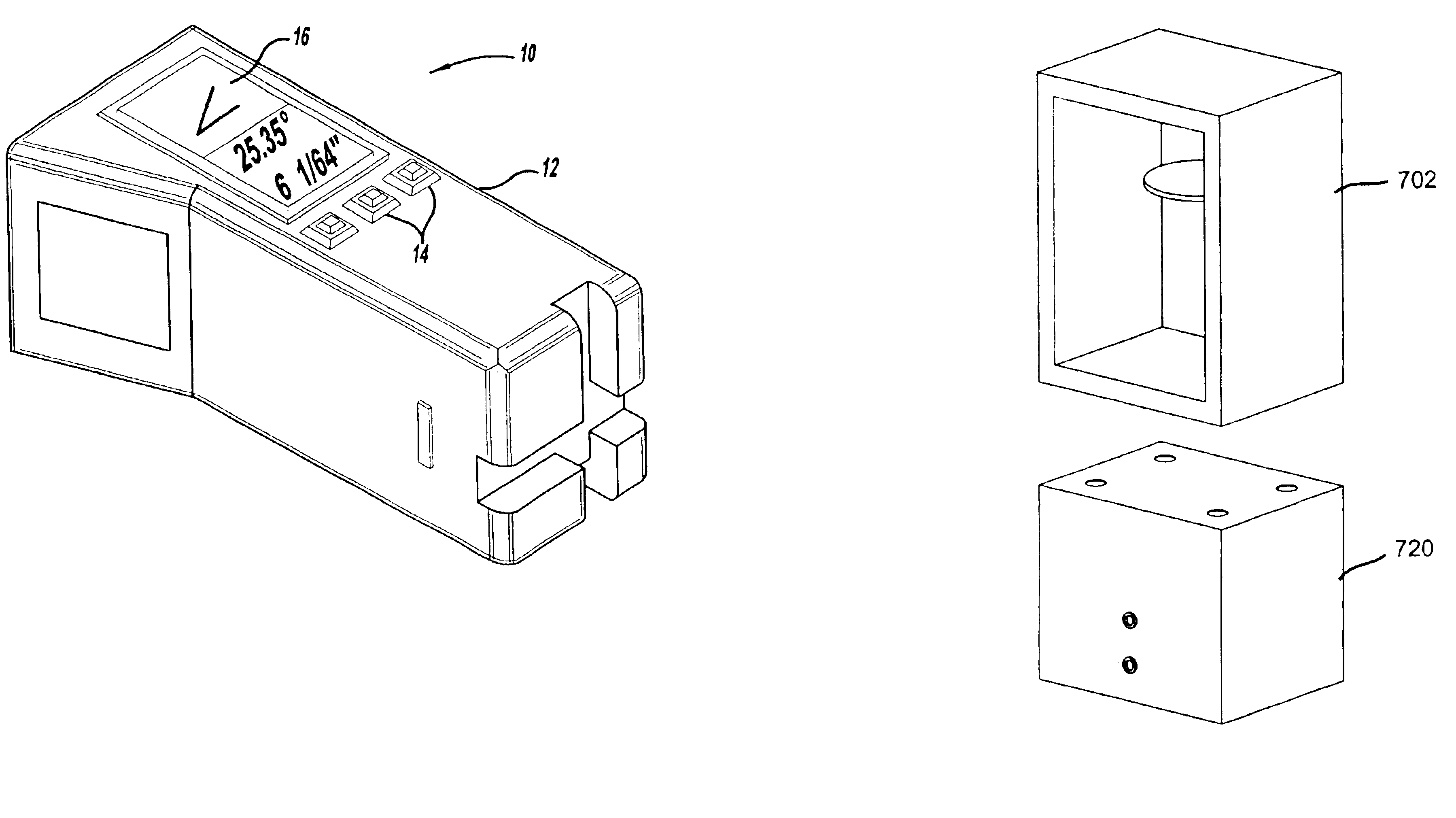

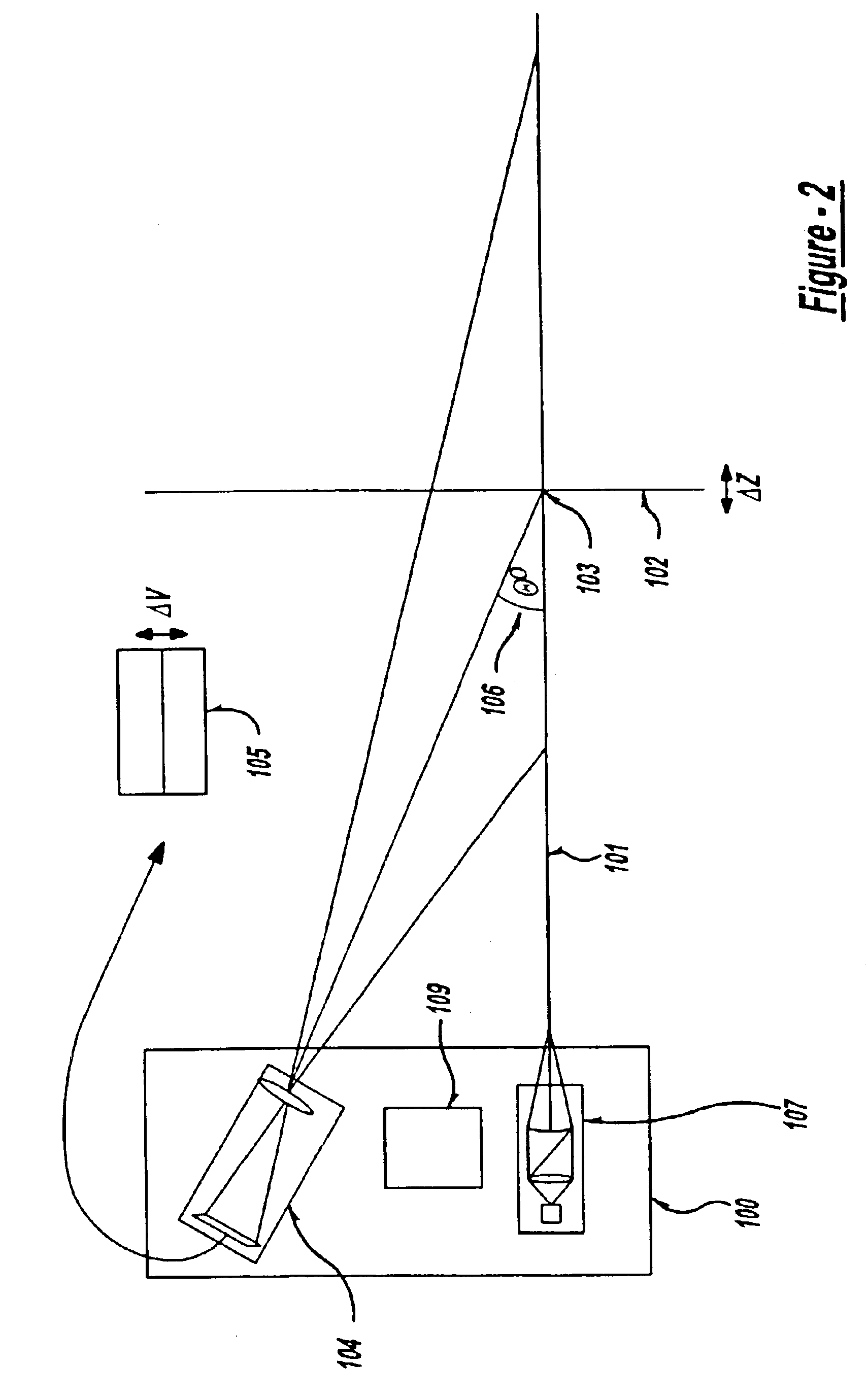

Modular non-contact measurement device for quickly and accurately obtaining dimensional measurement data

InactiveUS6858857B2Quickly and accurately performingRemove most human judgement of measurement resultsImage analysisMetal sawing accessoriesMeasurement deviceDimension measurement

A modular measurement device is provided for quickly and accurately performing non-contact measurements of various objects at different locations within a commercial or residential work area. The modular measurement device generally includes a laser base that is operable to project light onto a measured object; and a portable measurement module adapted to receive light reflected from a surface of the measured object and operable to determine dimensional measurement data for the measured object, where the portable measurement module is configured to releasably couple to the laser base. The operational components of the measurement device are partitioned between the portable measurement module and the laser base. In this way, a single portable measurement module having more expensive operational components may be used with different, less expensive laser bases, where each laser base may be adapted for a different application.

Owner:PERCEPTRON

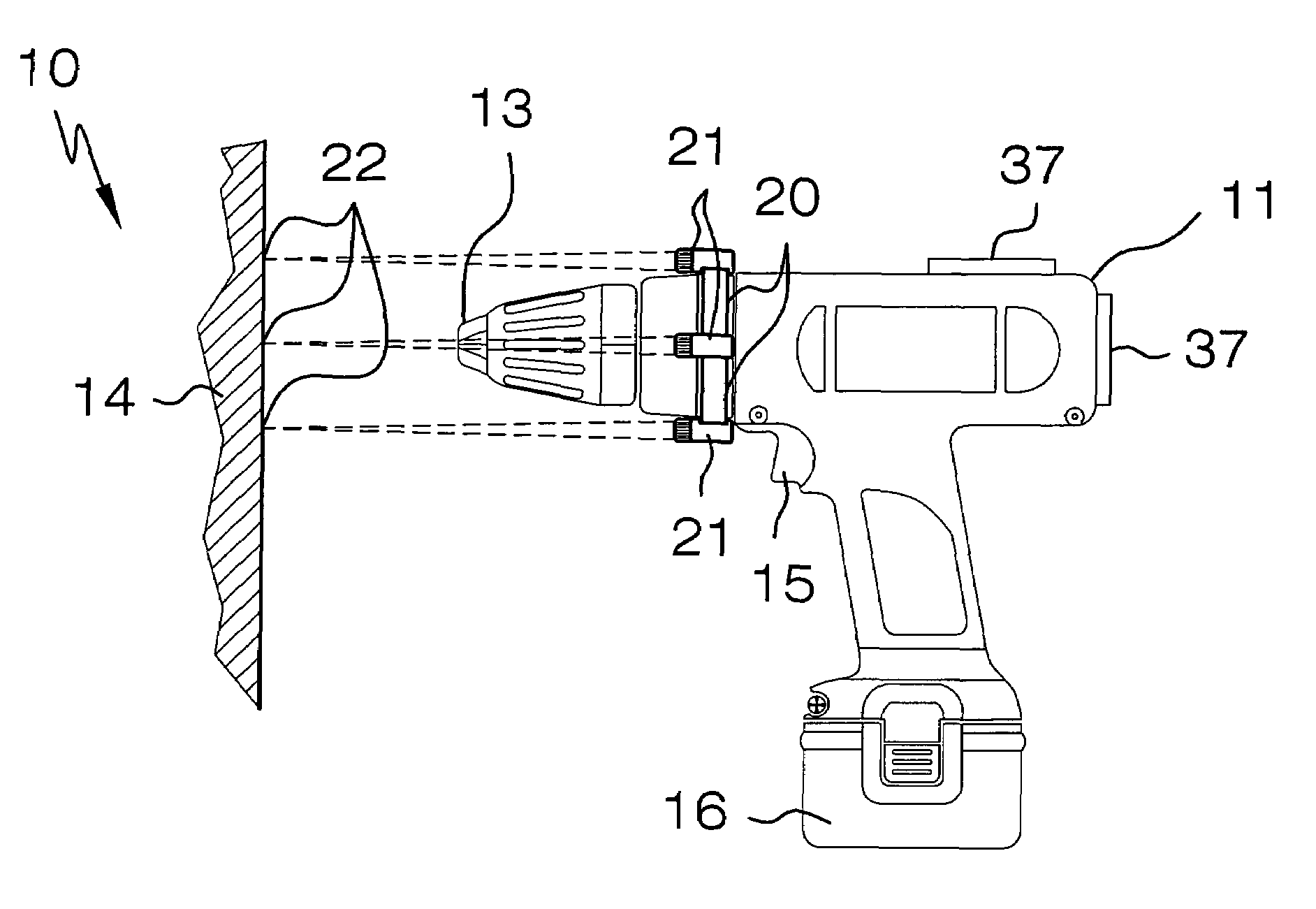

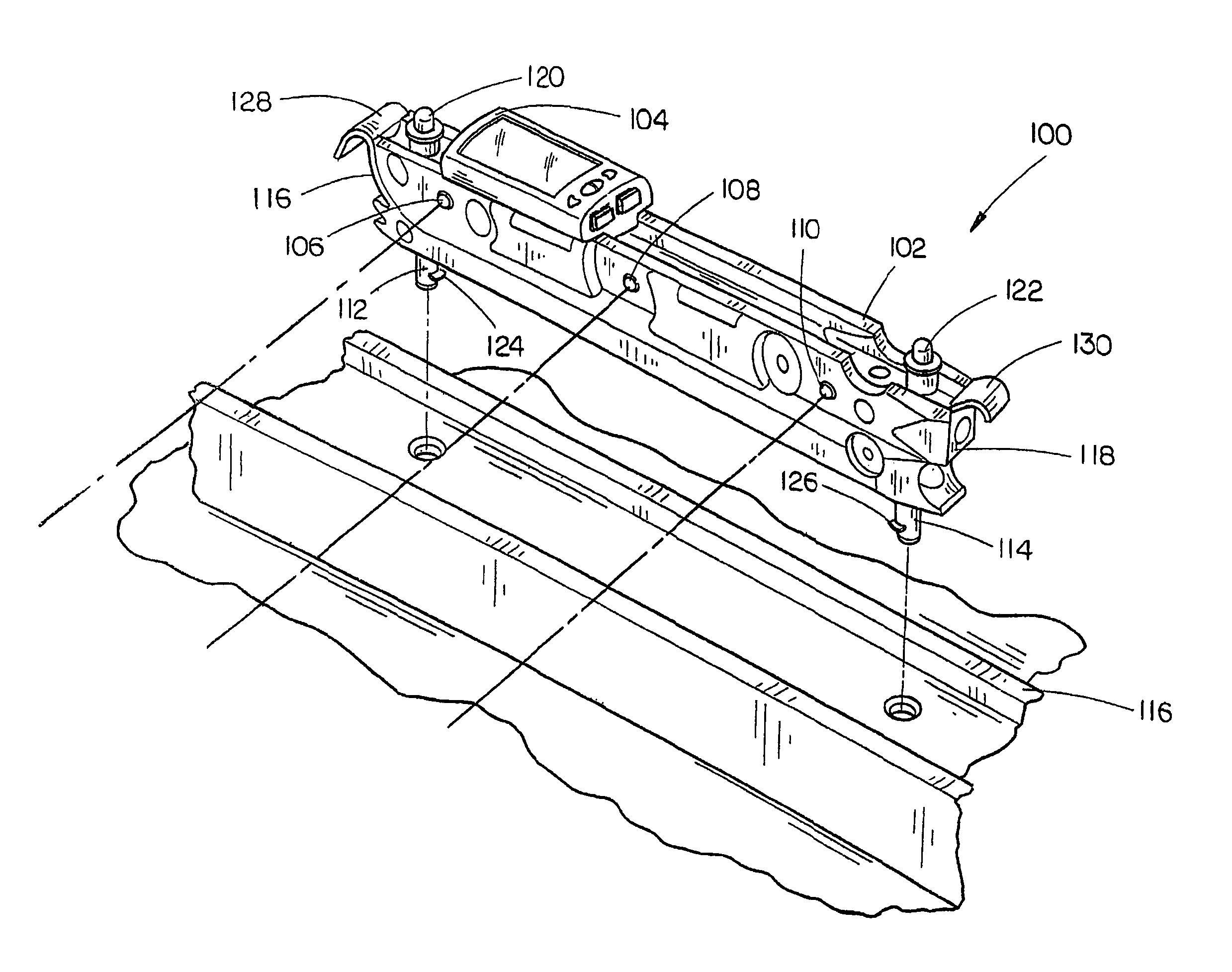

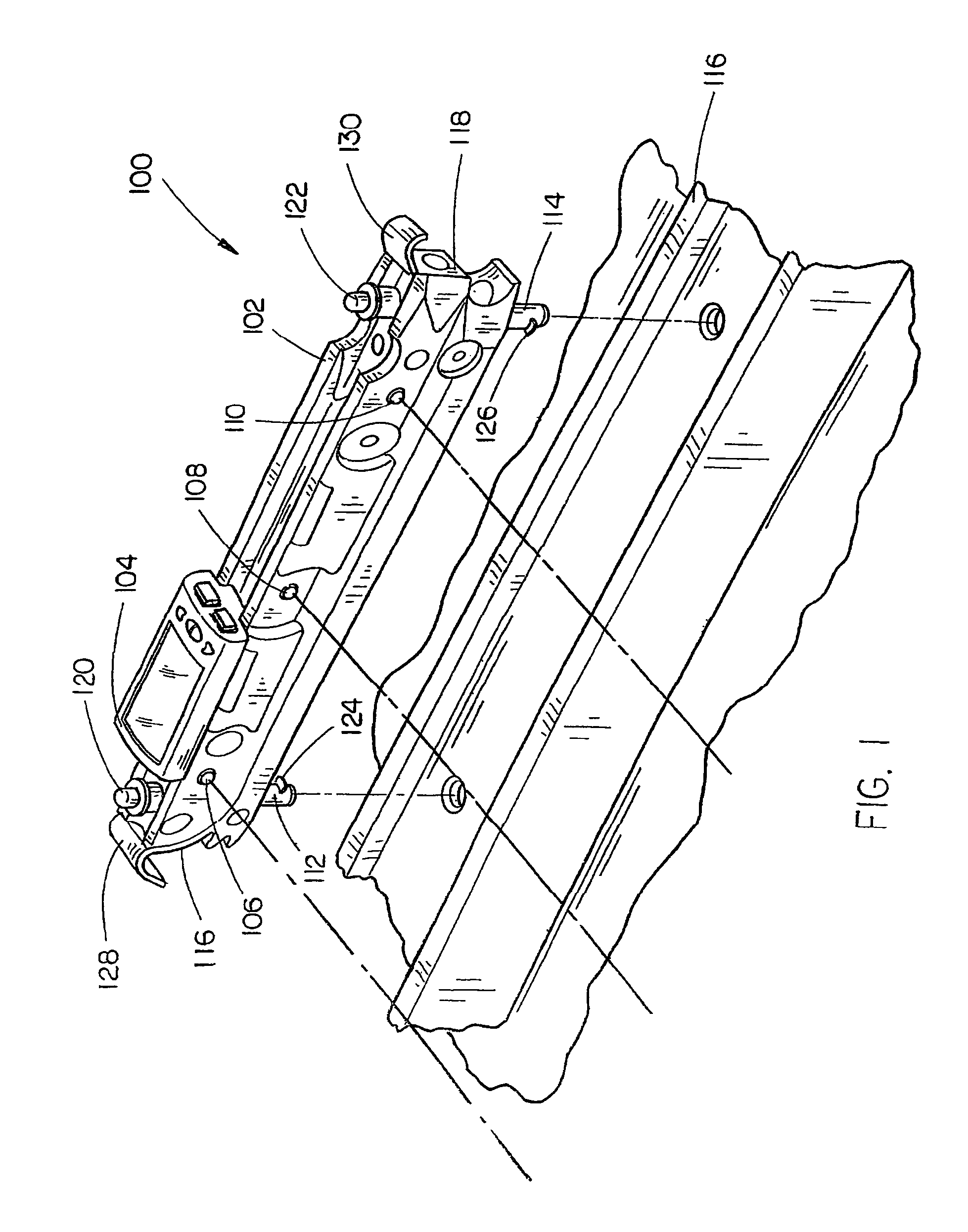

Alignment accessory for portable drills and the like

ActiveUS7200516B1Effectively and conveniently alignedQuickly and efficiently alignDrilling/boring measurement devicesWork benchesTarget surfaceOptoelectronics

An apparatus includes a strap that is positional about a drill and maintains a static relationship therewith while a drill bit and chuck rotate. The apparatus includes a plurality of light sources and sensors. The light sources and sensors face forwardly and emit corresponding light arrays aligned parallel to the drill bit and measure a linear distance to a target surface respectively. Each light source defines a reflection that has a unique diameter when the drill is not perpendicular, notifying the user to adapt the drill such that identical diameters are reflected on the work surface. A mechanism communicates an output signal to a display screen so that a visual representation of the drill bit location becomes displayed on a display screen. The drill bit is aligned perpendicular to the work surface when the light sources are equidistantly spaced from the work surface.

Owner:COWLEY BRIAN J

Apparatus for assembling a lens module and an image sensor to form a camera module, and a method of assembling the same

ActiveUS20130047396A1Improve operational performancePrecise alignmentMeasurement/indication equipmentsMetal working apparatusCamera lensCamera module

An apparatus for assembling a lens module and an image sensor to form a camera module is disclosed. The apparatus comprises i) a positioning system for adjusting a relative arrangement between the lens module and the image sensor; and ii) an inspection system operative to view fiducials of the lens modules and the image sensor. In particular, the positioning system is configured to align the lens module and the image sensor based on a relative alignment of the respective fiducials of the lens module and the image sensor as viewed by the inspection system. A method of assembling a lens module and an image sensor to form a camera module is also disclosed.

Owner:ASMPT SINGAPORE PTE LTD

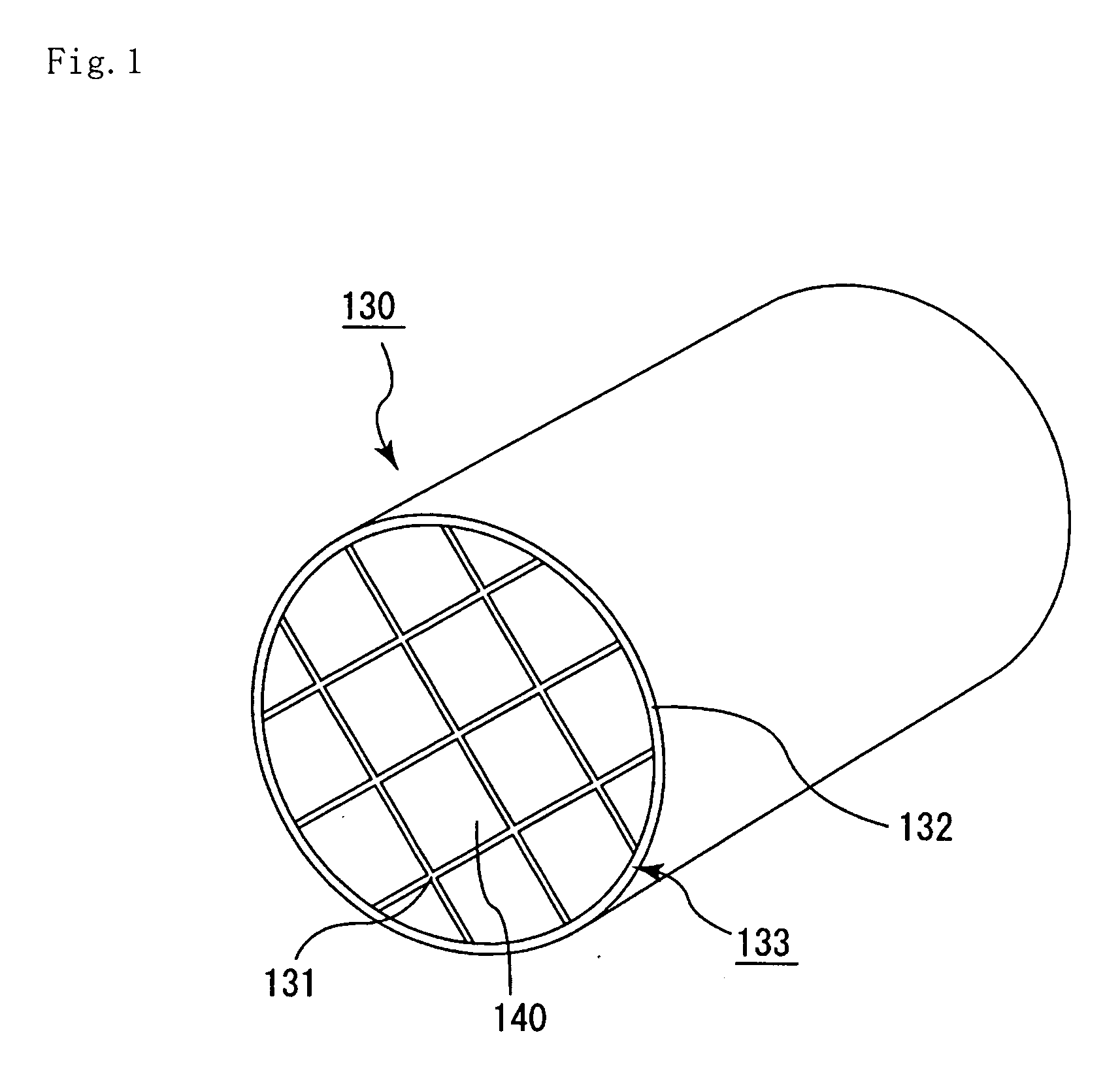

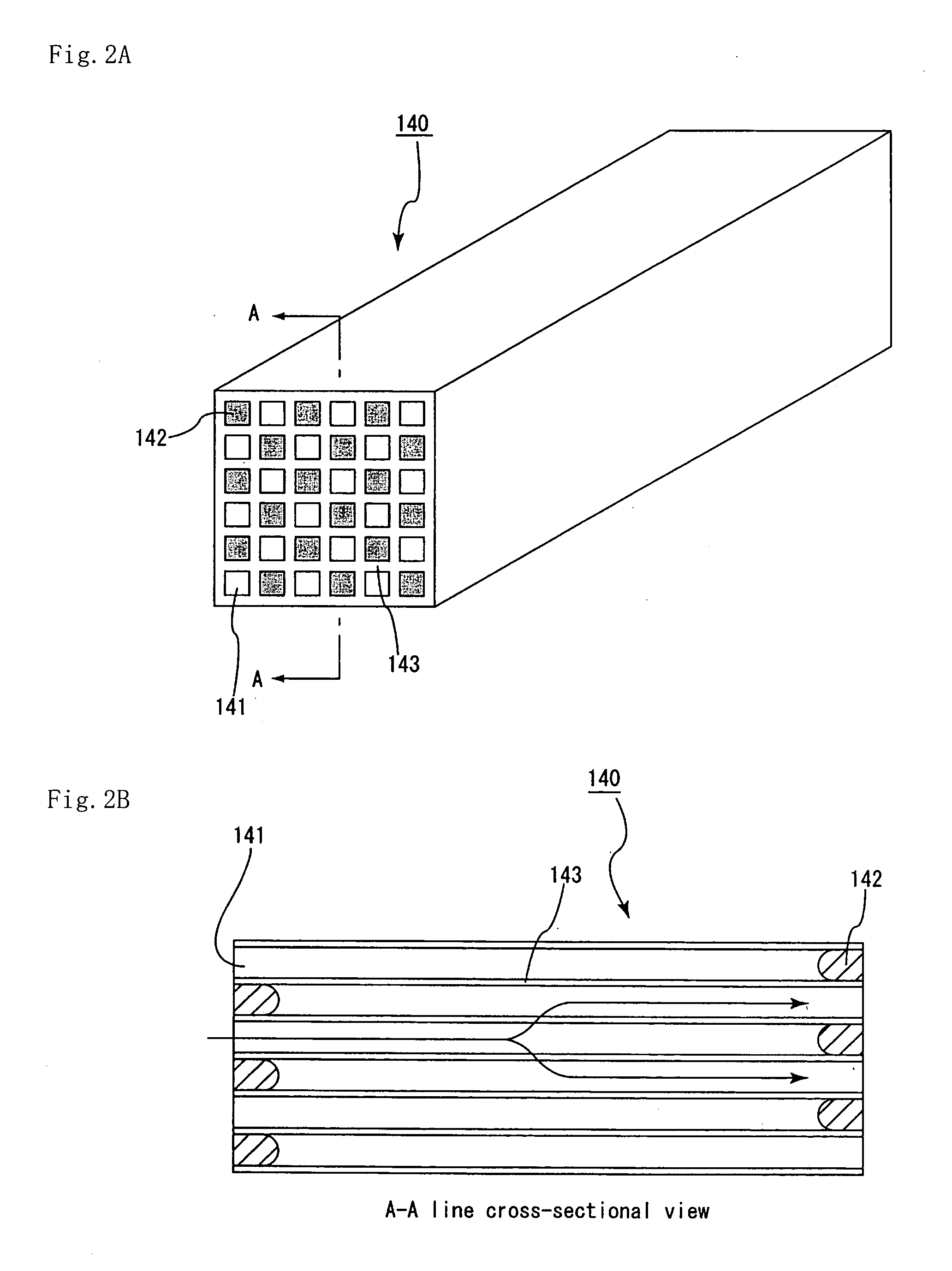

Method for inspecting honeycomb structured body and method for manufacturing honeycomb structured body

InactiveUS20070175060A1Good informationShort timeWalking sticksInternal combustion piston enginesEngineeringCell wall

Owner:IBIDEN CO LTD

Machine Tool

ActiveUS20060270540A1Easy maintenanceReduce manufacturing costPlaning/slotting machinesMilling machinesFree rotationSaddle shape

Machine tool simplifying maintenance, reducing manufacturing costs, and enabling high precision machining. The machine tool is equipped with: a bed furnished with a rectangular base, right and left sidewalls provided standing either side of the base, and a rear sidewall provided standing along the back of the base; a table disposed in the space surrounded by the three sidewalls; a first saddle shaped in the form of a rectangular frame shape, provided free to shift back and forth supported on the tops of the left and right sidewalls; a second saddle penetrated by a perpendicular through-hole and arranged free to shift sideways inside the first saddle frame; and a spindle head arranged free to shift perpendicularly inside the through-hole in the second saddle; and a main spindle arranged over the table and supported by the spindle head free to rotate centered on its axis.

Owner:DMG MORI SEIKI CO LTD

Power tool control system

InactiveUS8004664B2Quality improvementWell formedStapling toolsDrilling/boring measurement devicesGraphical user interfaceControl system

A power tool control system includes a non-contact measurement and alignment device operative with the power tool and enabled to establish various readings, such as power tool settings. A graphical user interface communicatively coupled with the non-contact measurement and alignment device enables user control over and display of the readings from the non-contact measurement and alignment device.

Owner:CHANG TYPE INDAL

Robot control system provided in machining system including robot and machine tool

ActiveUS20100305758A1Stoppage of operation can be reducedReduce needProgramme-controlled manipulatorComputer controlControl systemMachining system

A robot control system provided in a machining system including a robot and a machine tool. The robot control system includes a robot controller controlling the robot, a portable teach pendant connected to the robot controller, and a communication network adapted to connect the robot controller to a machine tool controller controlling the machine tool. The teach pendant includes a display section configured to display information relating to the robot and the machine tool. The robot controller includes a processing section configured to obtain information relating to the machine tool from the machine tool controller through the communication network, make the display section of the teach pendant display a machine tool-related screen in accordance with a given screen program, and make the machine tool-related screen of the display section of the teach pendant display the information, as obtained, relating to the machine tool.

Owner:FANUC LTD

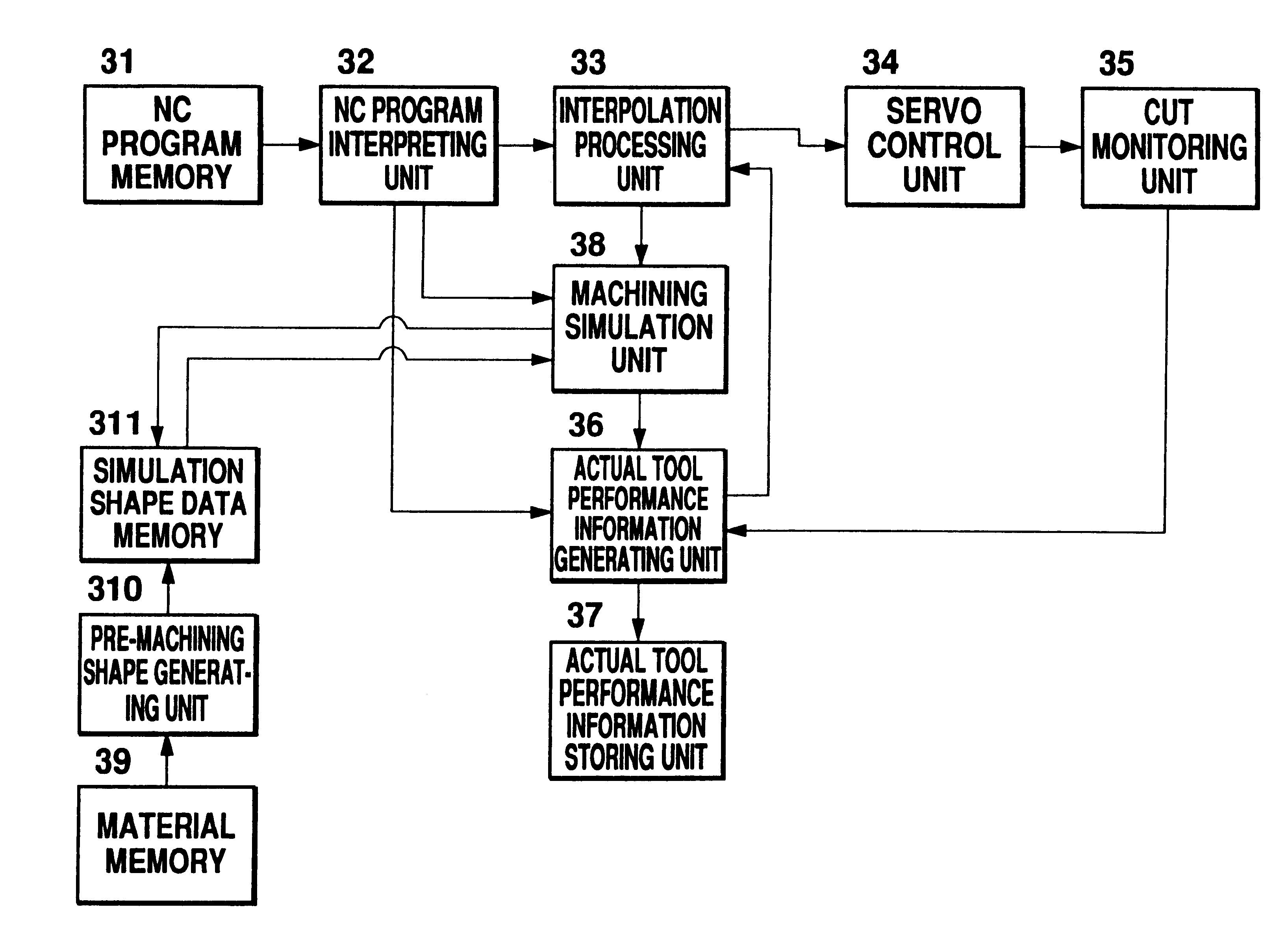

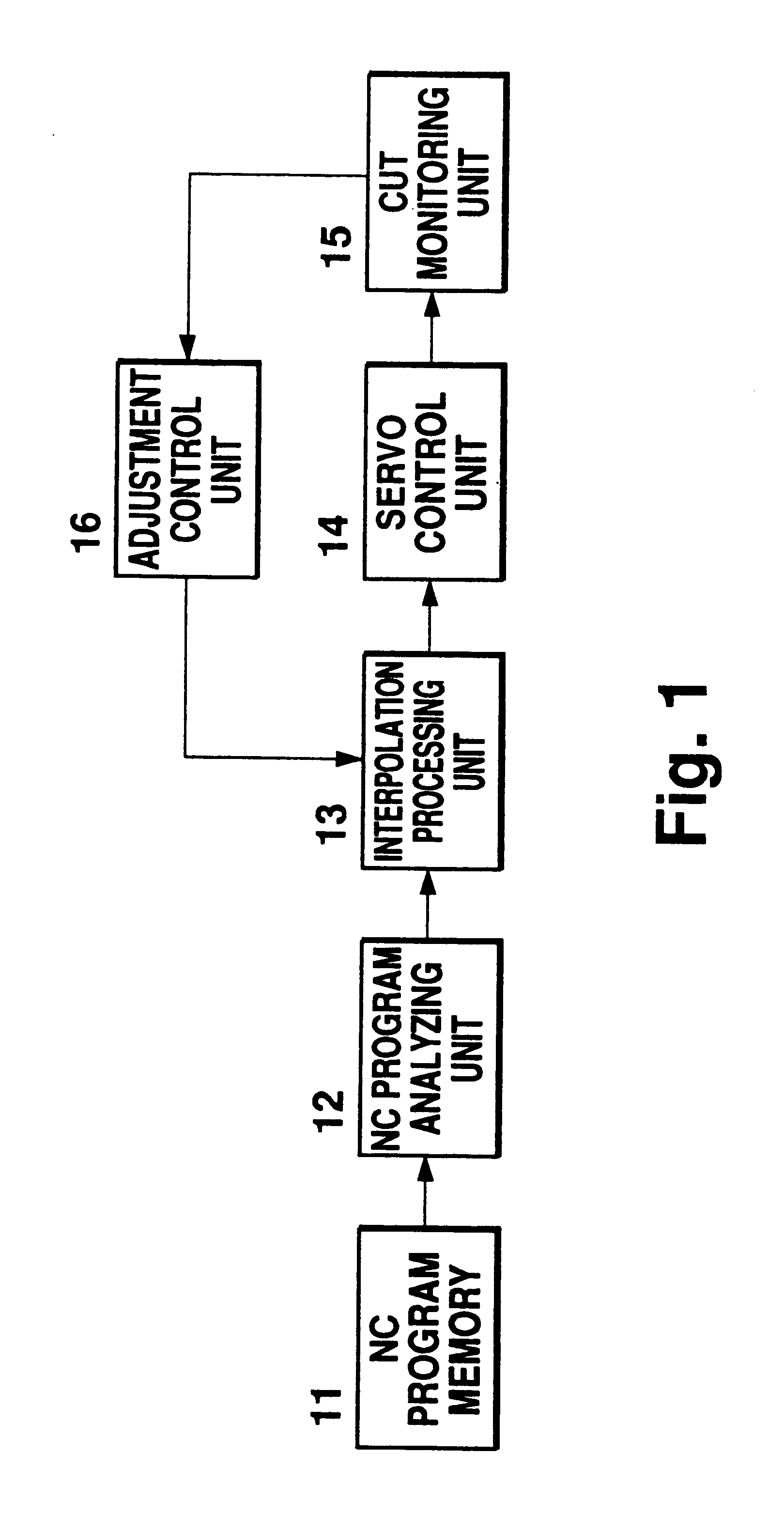

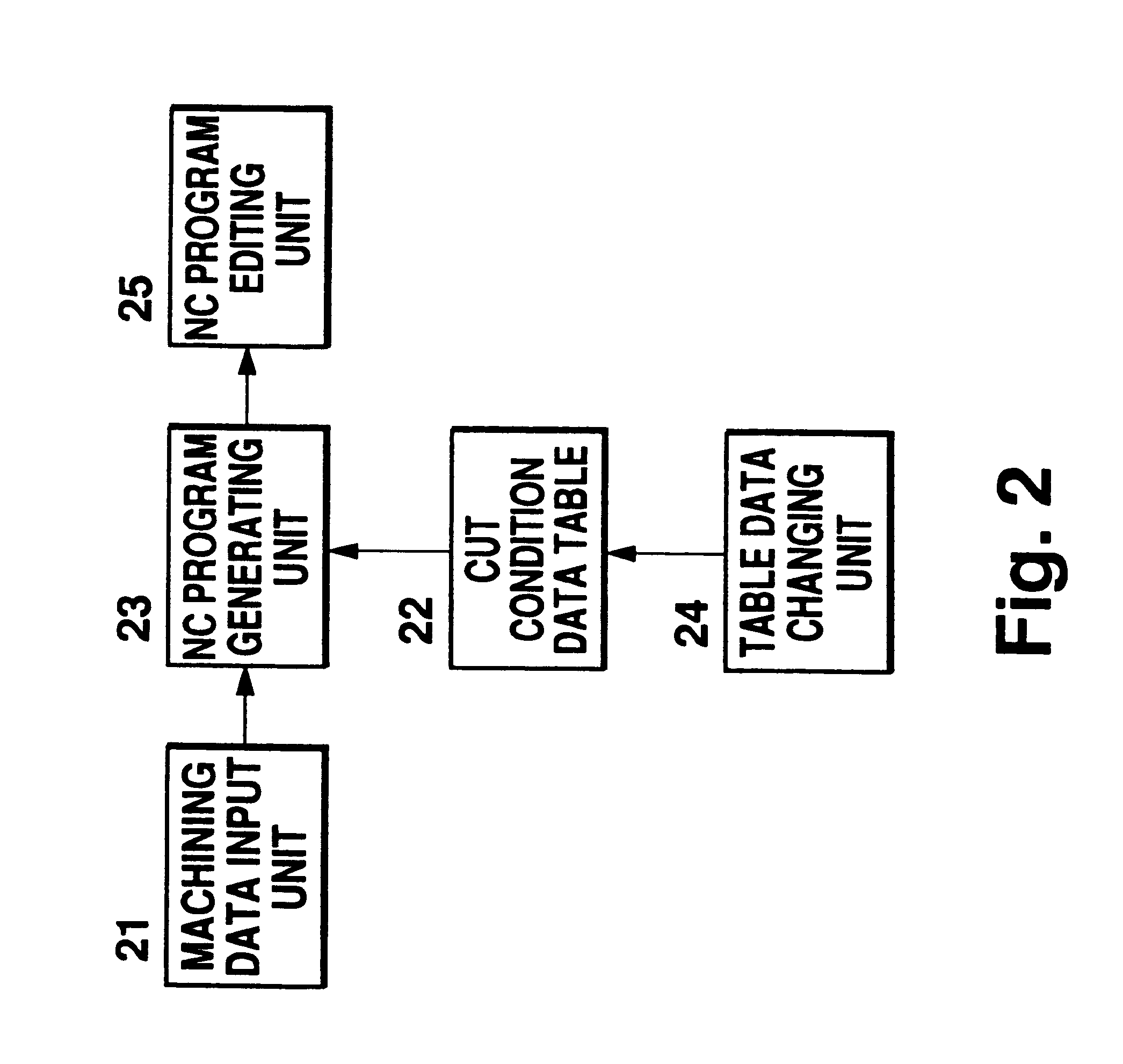

Apparatus for generating a numerical control command according to cut resistance value and cut torque value of machining simulation

InactiveUS6266572B1Solution to short lifeImprove wear resistanceProgramme controlAutomatic control devicesNumerical controlMachine simulation

A method of simulation of NC machining, wherein machining simulation is carried out according to blank shape data, tool shape data and an NC program to modify the NC program or interpolation data by feedforward control so that optimum cutting conditions can be obtained. The simulation result can be used for correcting the NC program and the interpolation data at the next stage. Further, a record of tools used can be generated on the basis of this simulation result.

Owner:OKUMA CORP +3

Optical proximity device for power tools

The present invention is directed to a power tool including a working element for performing a task. A light source is arranged to project a beam of light adjacent the working element. A detector, such as an electro-optic type detector, is communicatively coupled to the power tool such that the detector is capable of detecting the presence of a human body part in the beam of light. If a body part is detected, the detector may communicate to stop operation of the working element.

Owner:BLACK & DECKER INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com