Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

668 results about "Dimension measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dimension refers to measurement of areas and objects. It is a mathematical figure expressed in units of linear measurement. Dimensions are used daily in planning and designing almost everything that is built or manufactured. Measurements are classified as one dimension, two dimensions or three dimensions.

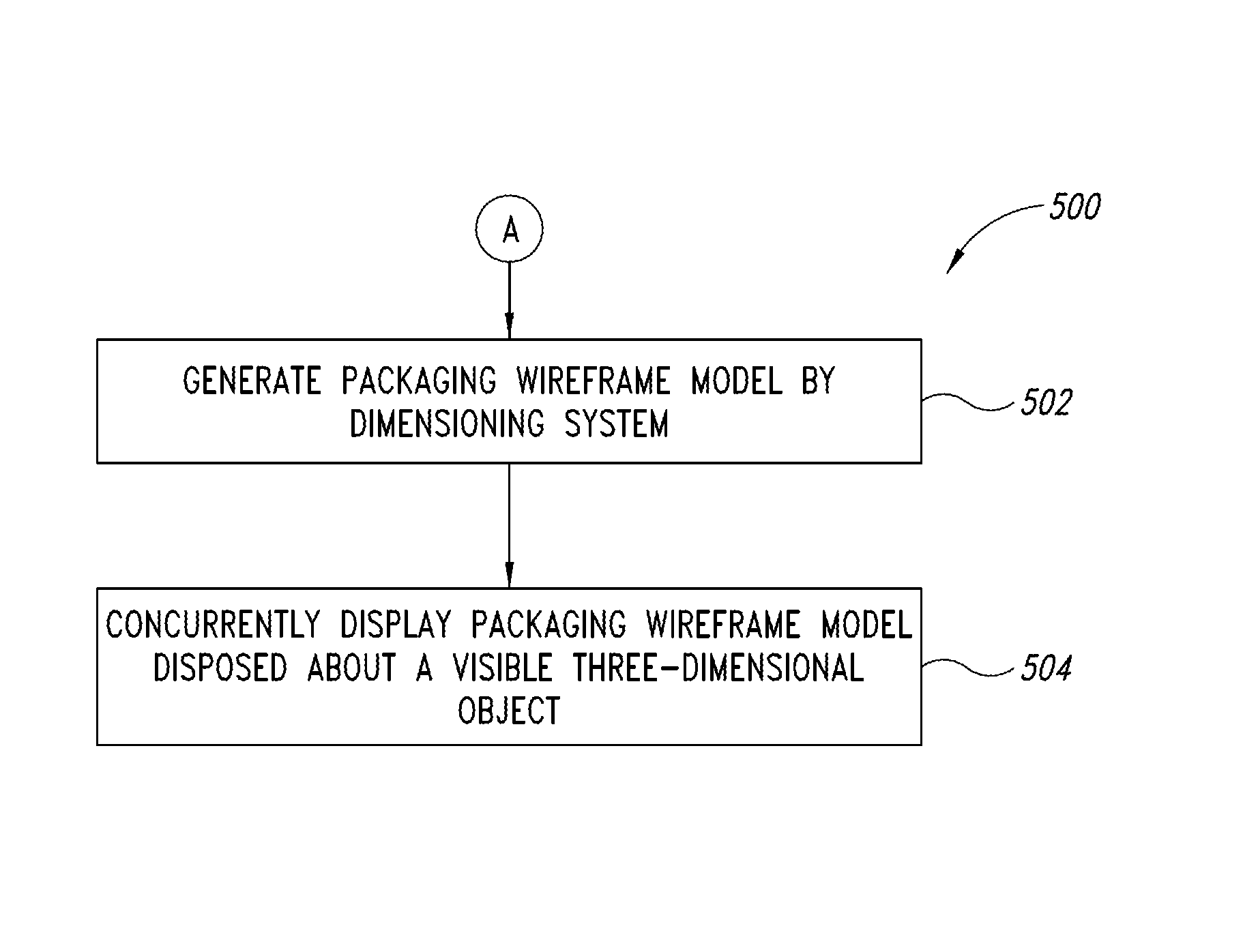

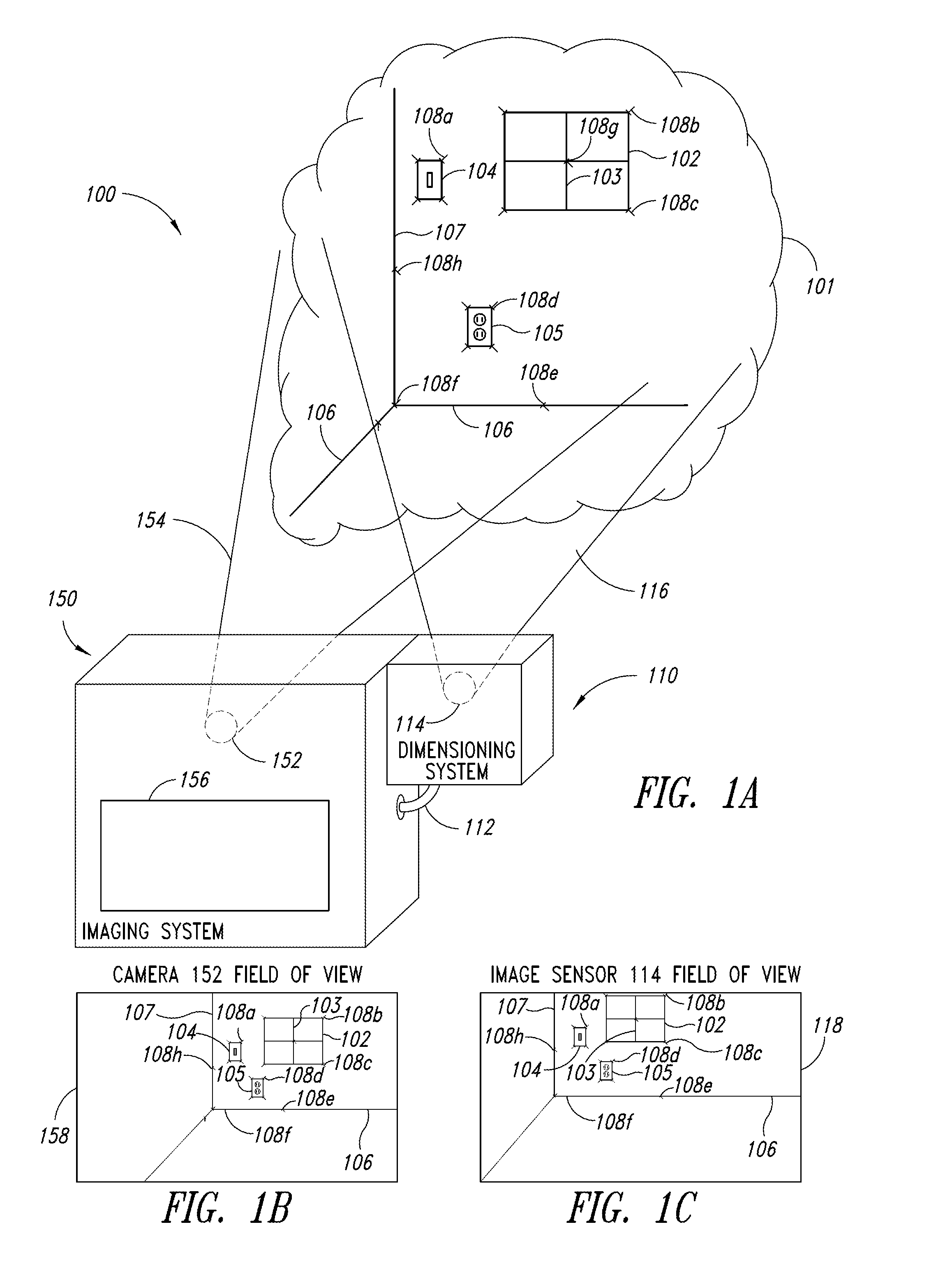

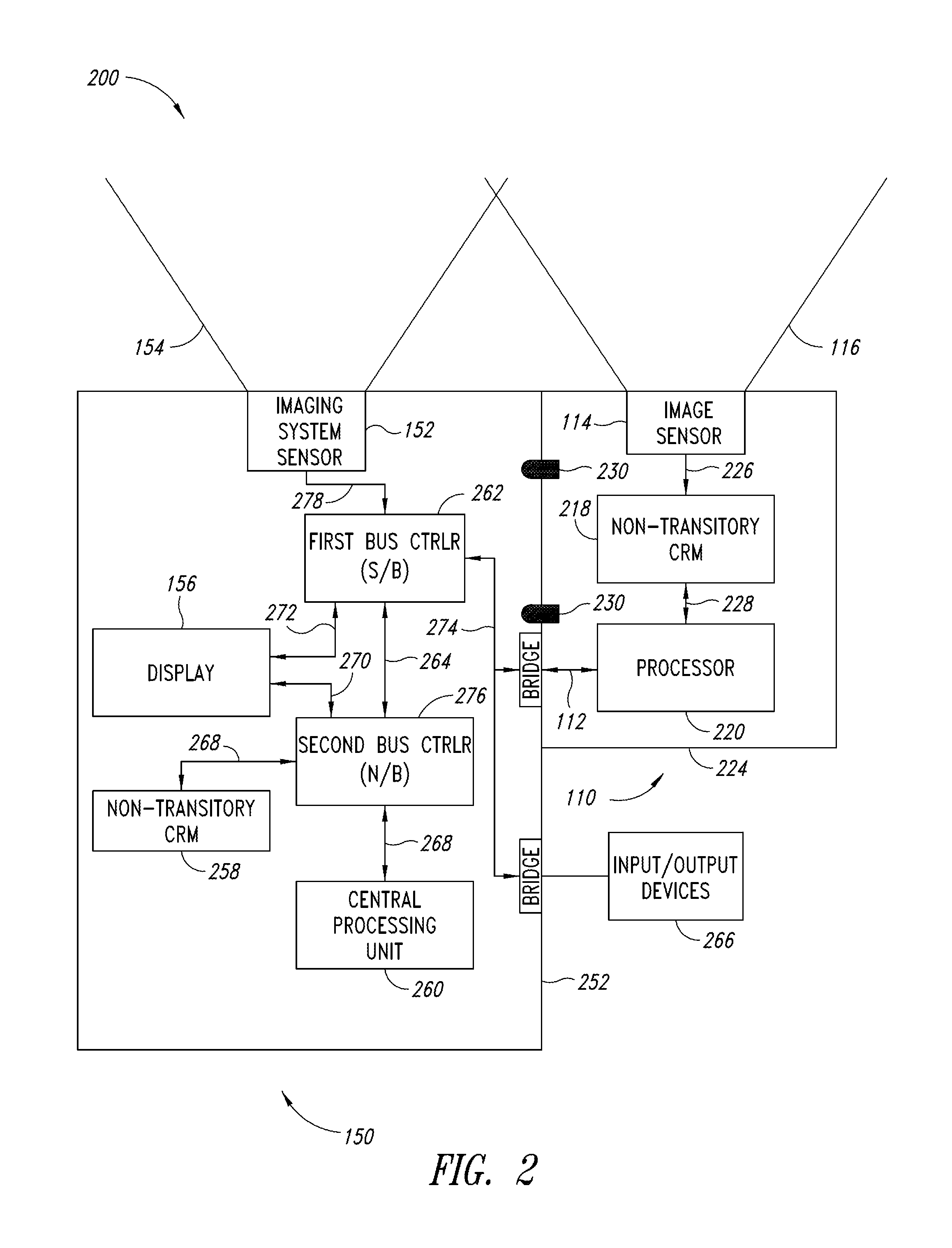

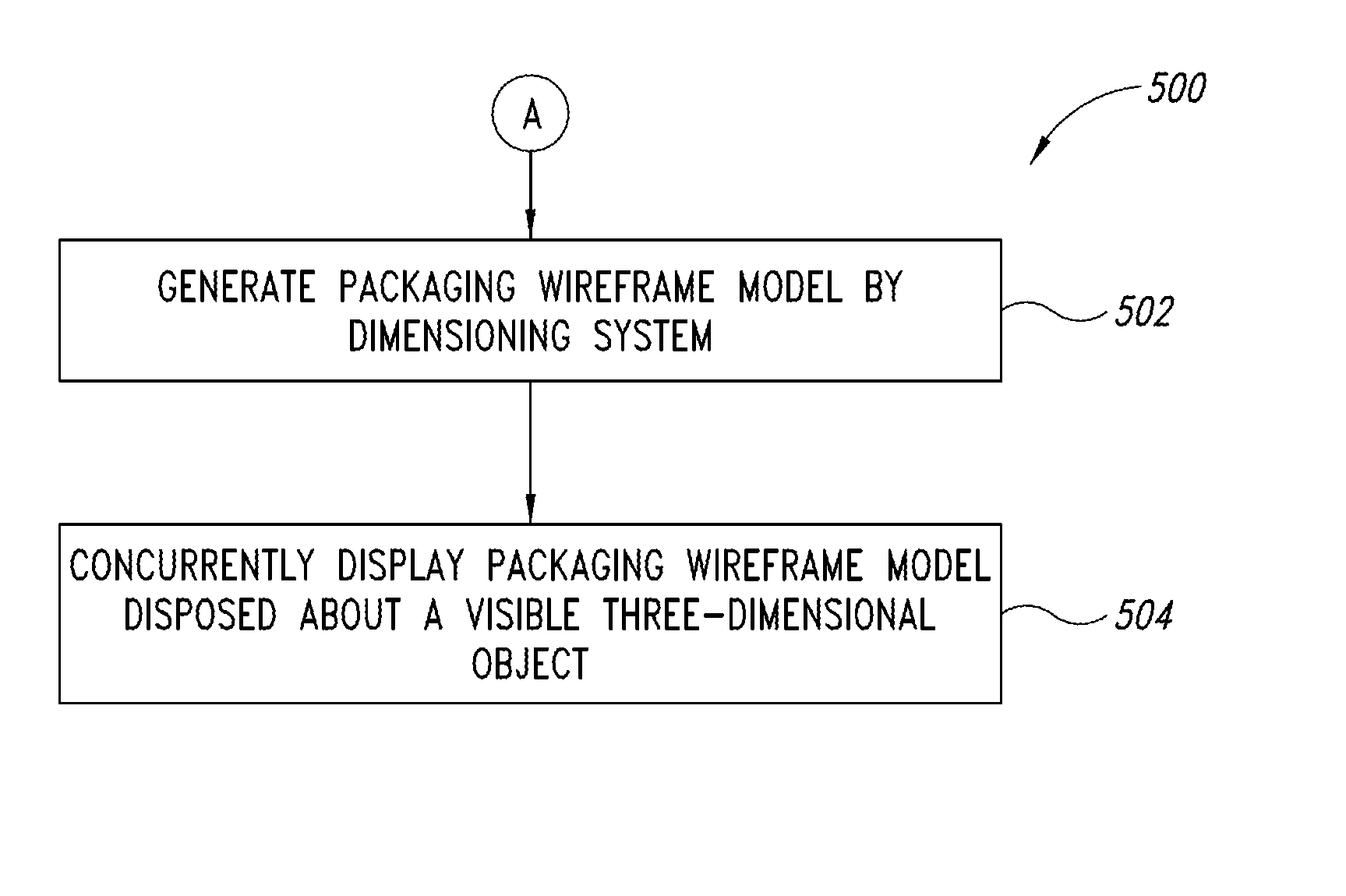

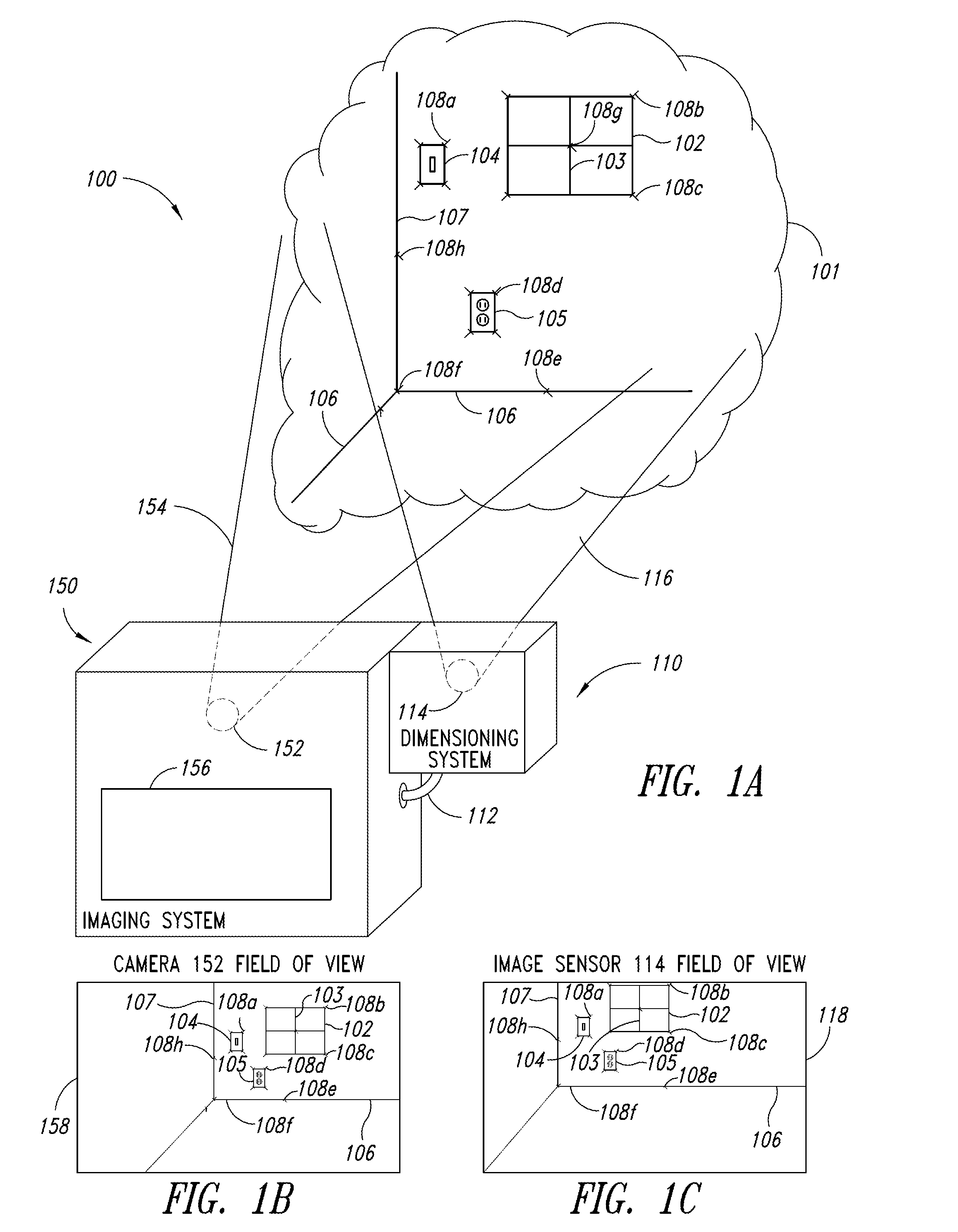

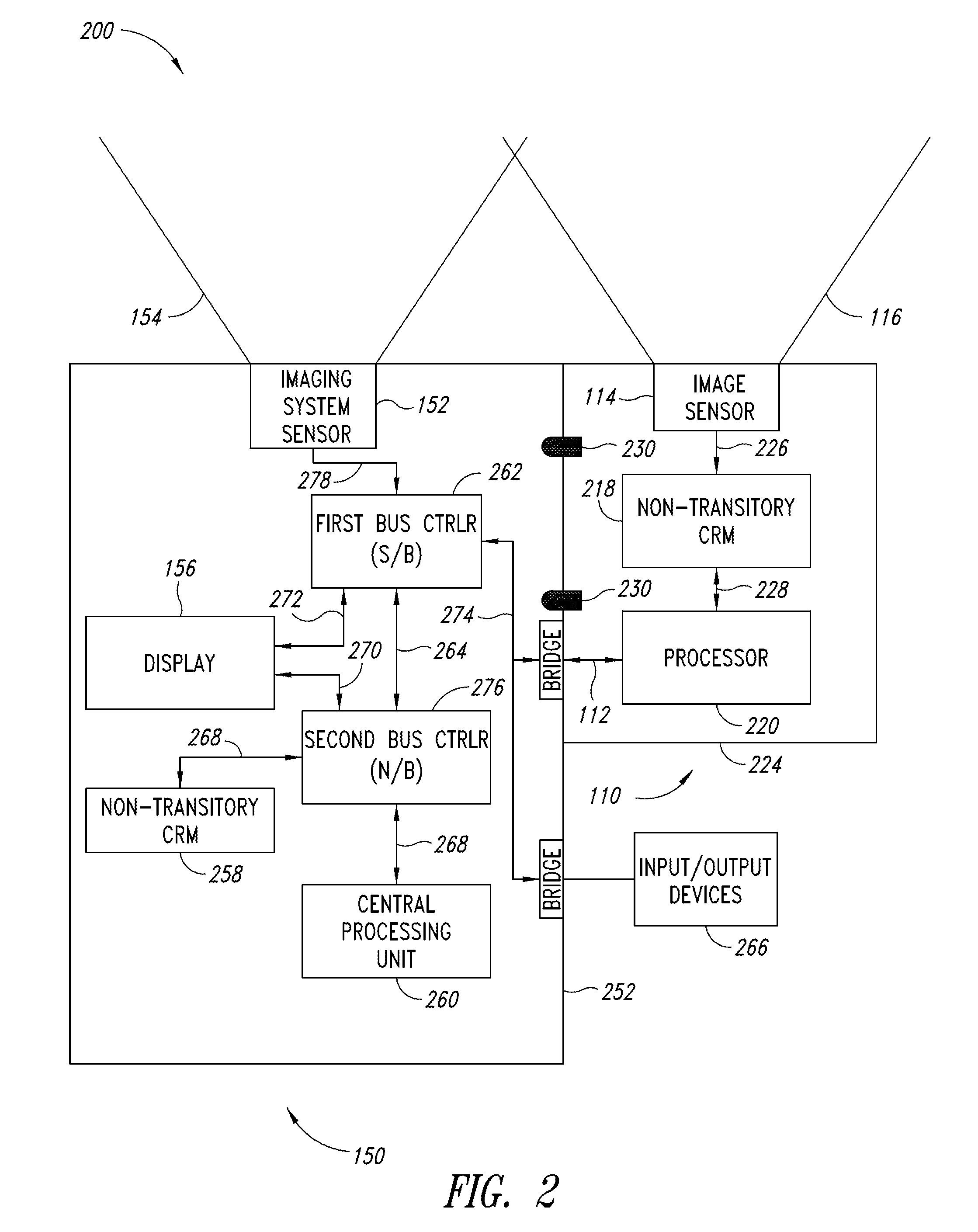

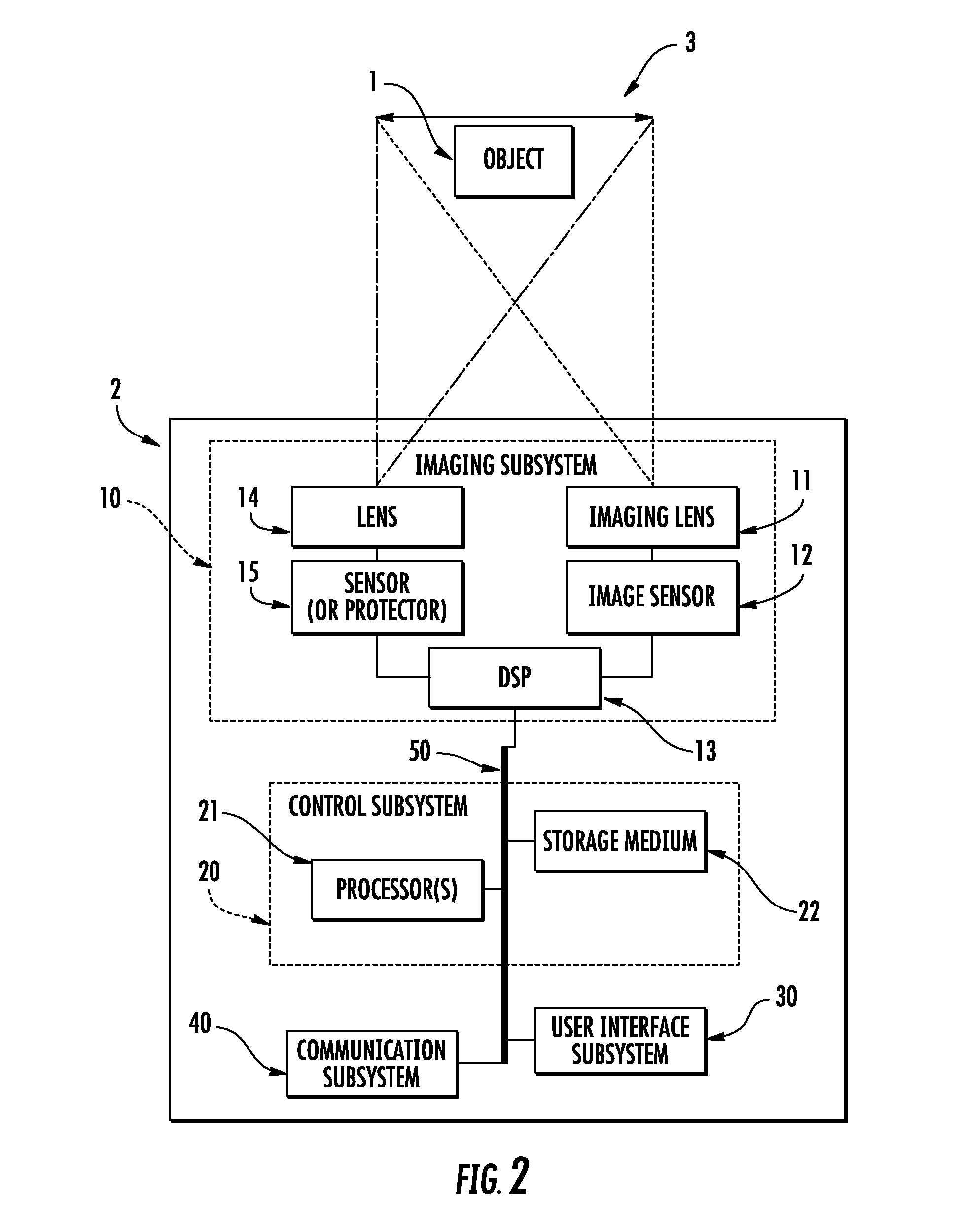

Dimensioning system calibration systems and methods

Systems and methods of determining the volume and dimensions of a three-dimensional object using a dimensioning system are provided. The dimensioning system can include an image sensor, a non-transitory, machine-readable, storage, and a processor. The dimensioning system can select and fit a three-dimensional packaging wireframe model about each three-dimensional object located within a first point of view of the image sensor. Calibration is performed to calibrate between image sensors of the dimensioning system and those of the imaging system. Calibration may occur pre-run time, in a calibration mode or period. Calibration may occur during a routine. Calibration may be automatically triggered on detection of a coupling between the dimensioning and the imaging systems.

Owner:INTERMEC IP

Dimensioning system calibration systems and methods

Systems and methods of determining the volume and dimensions of a three-dimensional object using a dimensioning system are provided. The dimensioning system can include an image sensor, a non-transitory, machine-readable, storage, and a processor. The dimensioning system can select and fit a three-dimensional packaging wireframe model about each three-dimensional object located within a first point of view of the image sensor. Calibration is performed to calibrate between image sensors of the dimensioning system and those of the imaging system. Calibration may occur pre-run time, in a calibration mode or period. Calibration may occur during a routine. Calibration may be automatically triggered on detection of a coupling between the dimensioning and the imaging systems.

Owner:INTERMEC IP

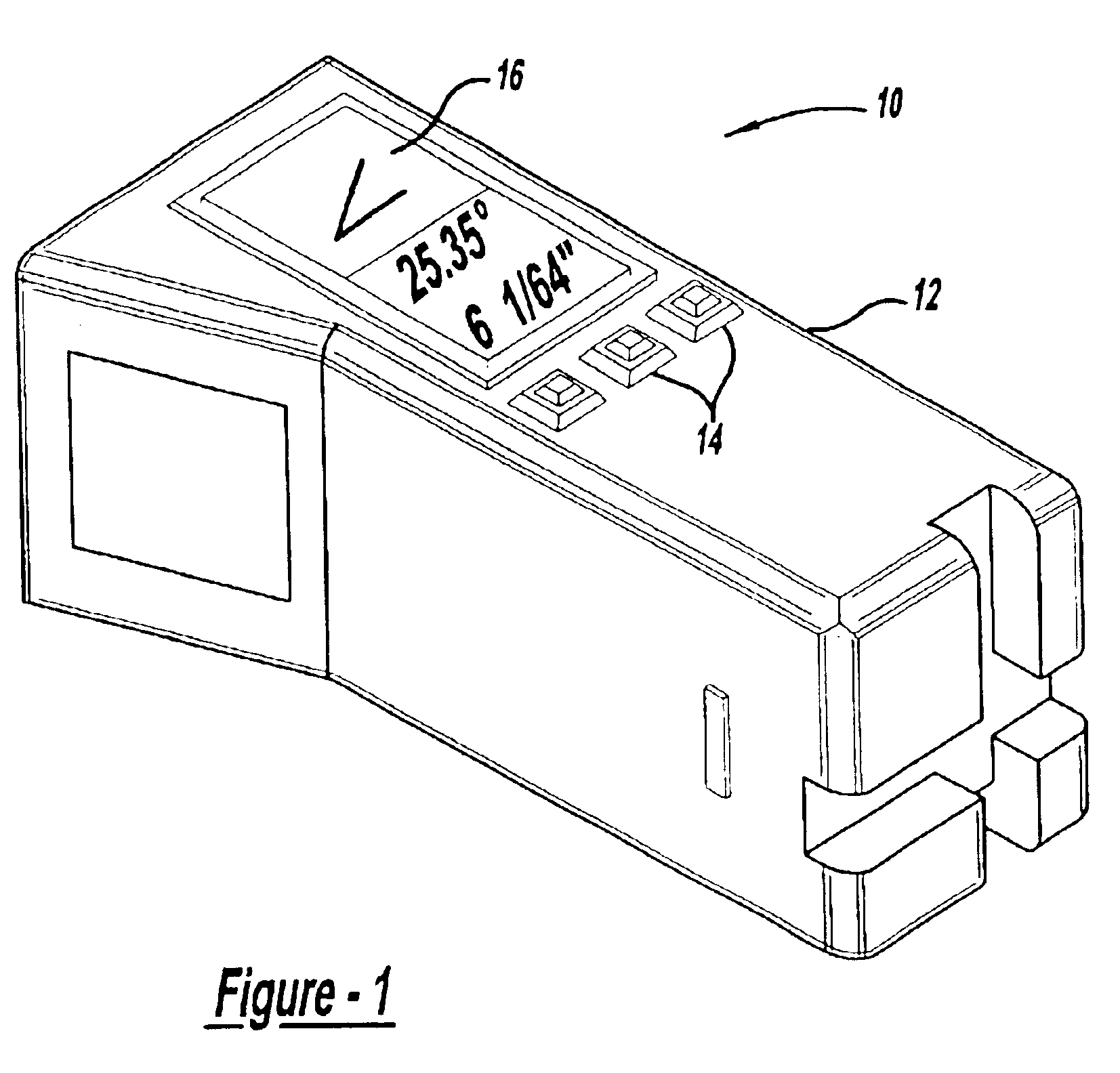

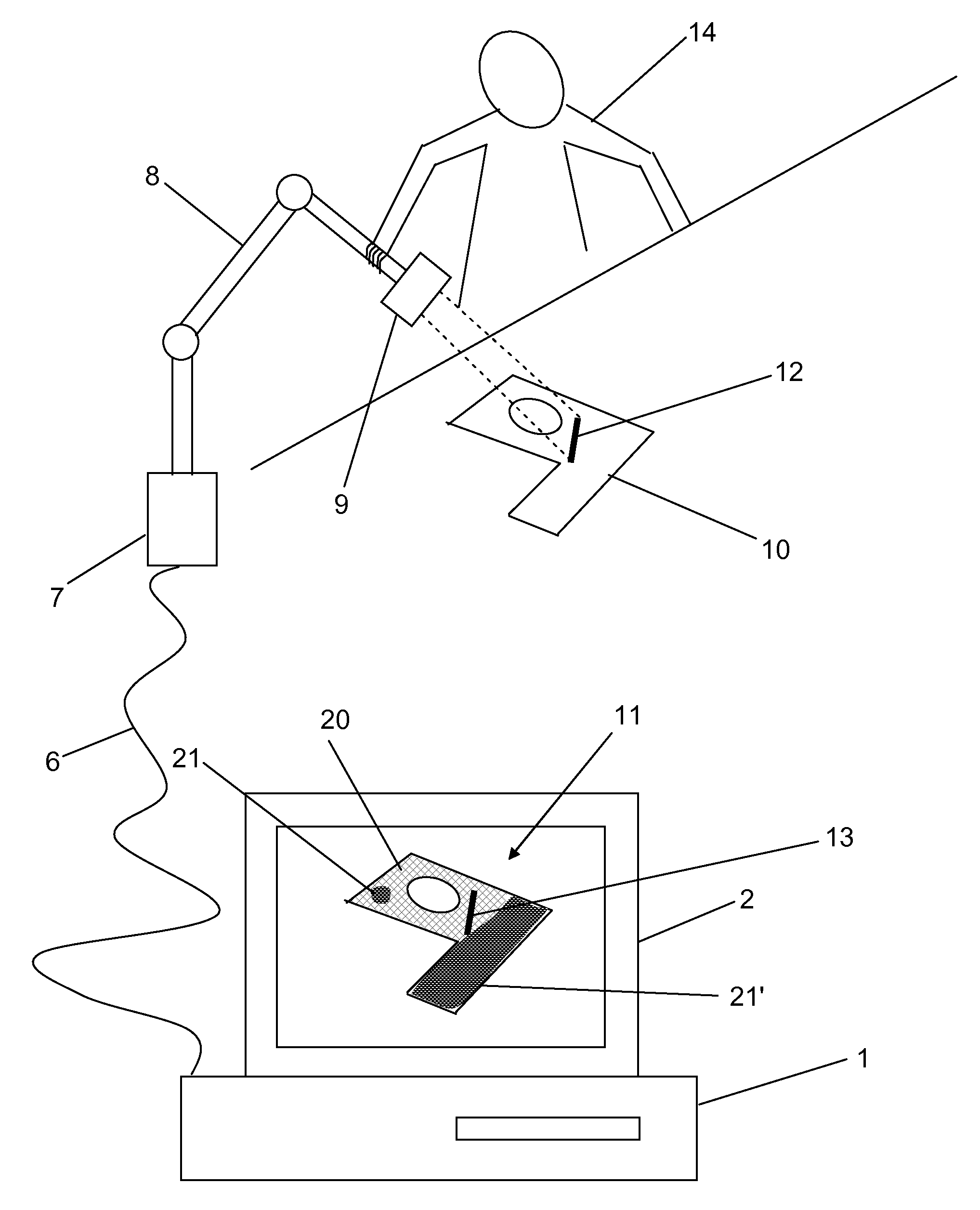

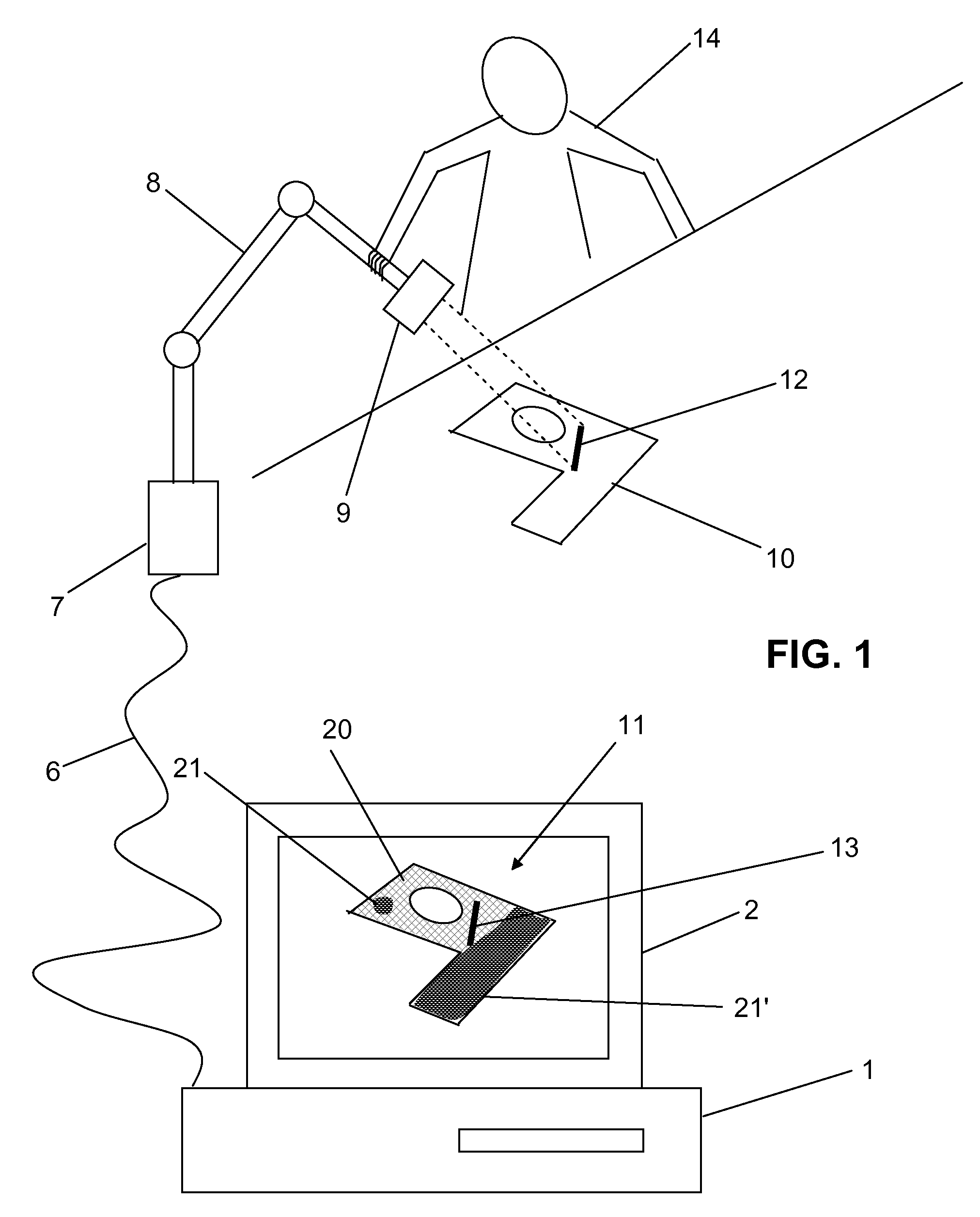

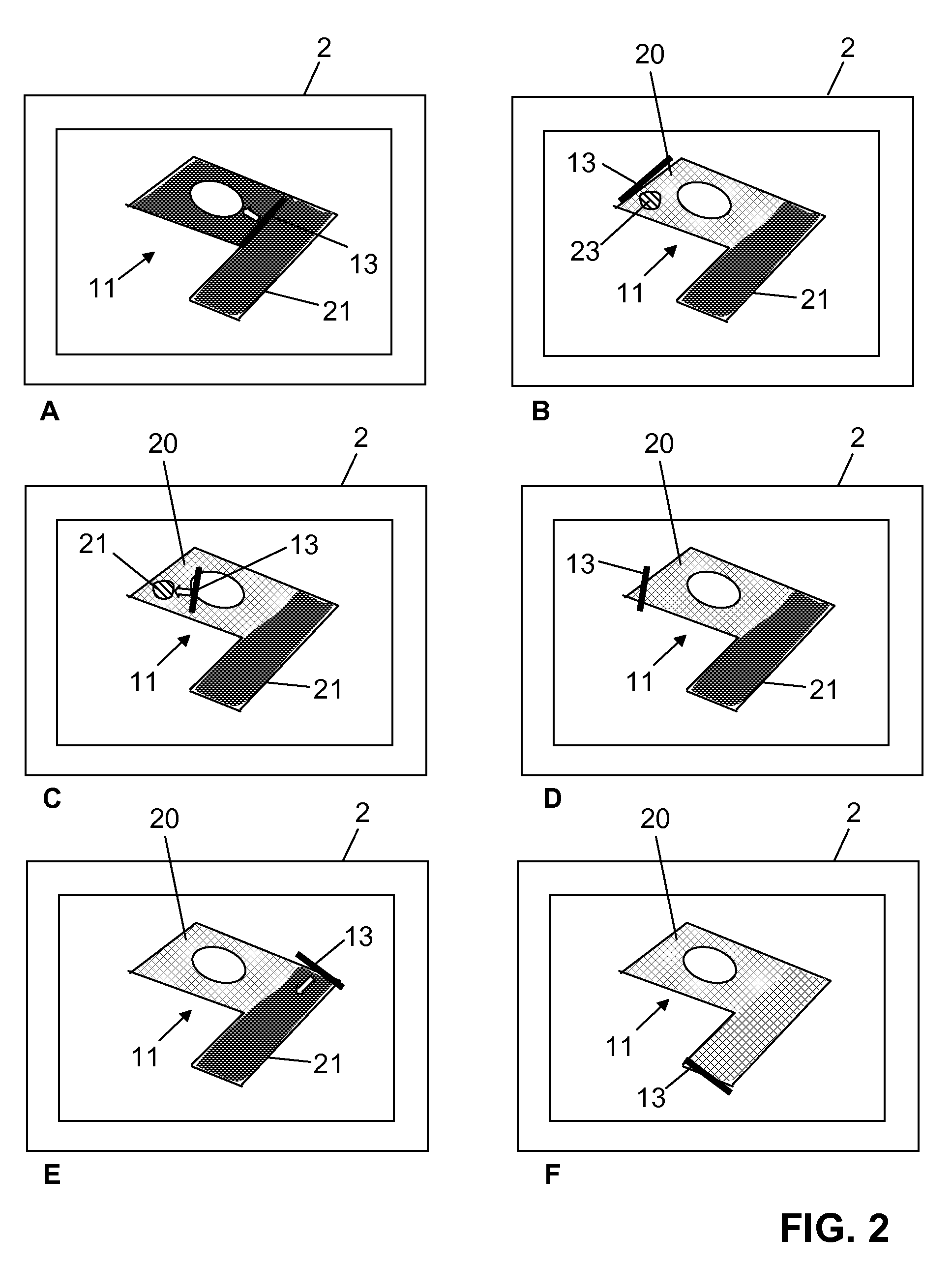

Handheld dimensioning system with measurement-conformance feedback

ActiveUS20160109219A1Color television detailsClosed circuit television systemsTechnical standardDimension measurement

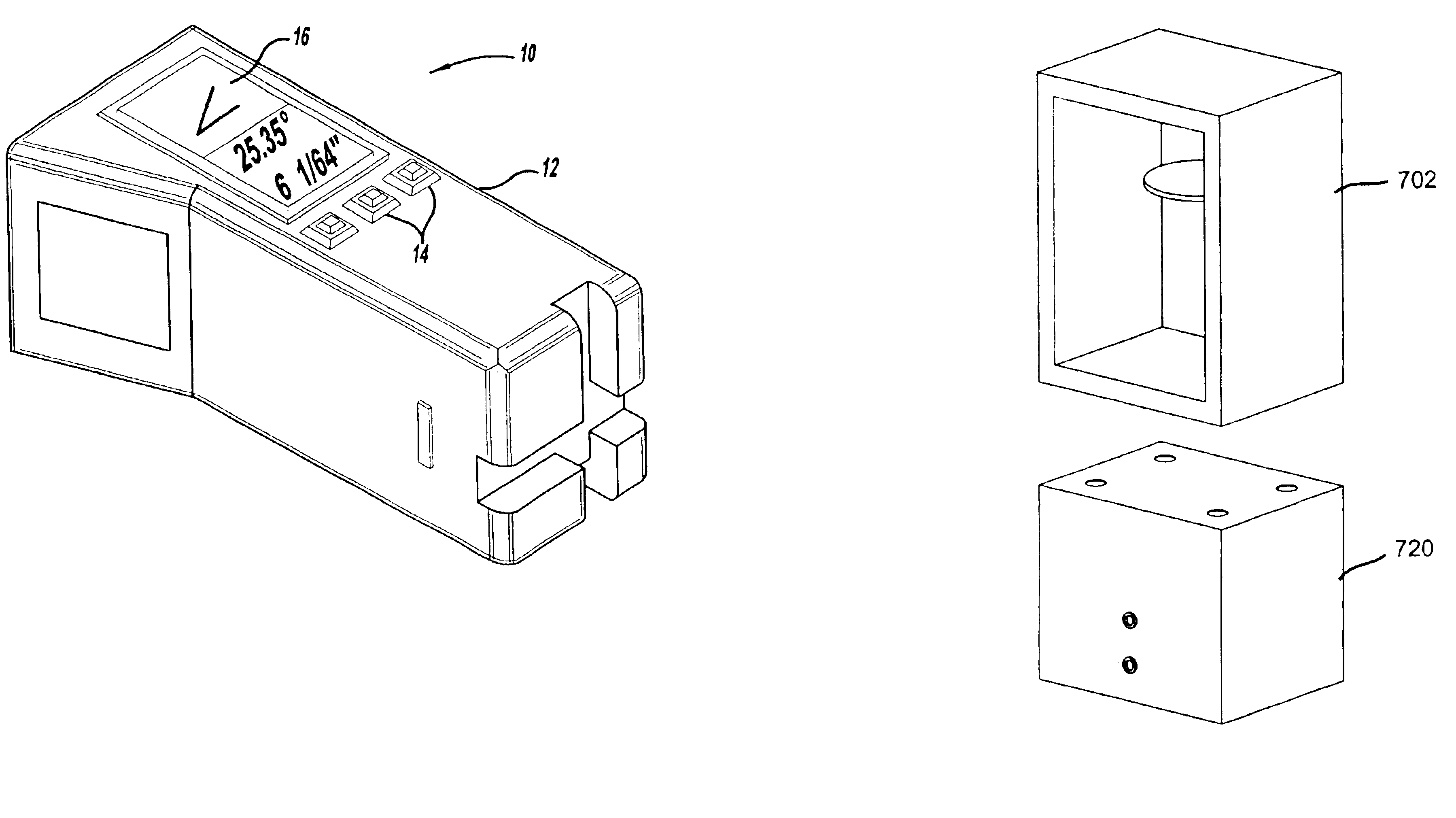

A system and method for obtaining a dimension measurement that conforms to a conformance criteria is disclosed. The dimensioning system provides either (i) feedback to confirm that the measurement complies with the criteria or (ii) information on how the measurement geometry could be adjusted in order to provide a compliant measurement in a subsequent dimension measurement.

Owner:HAND HELD PRODS

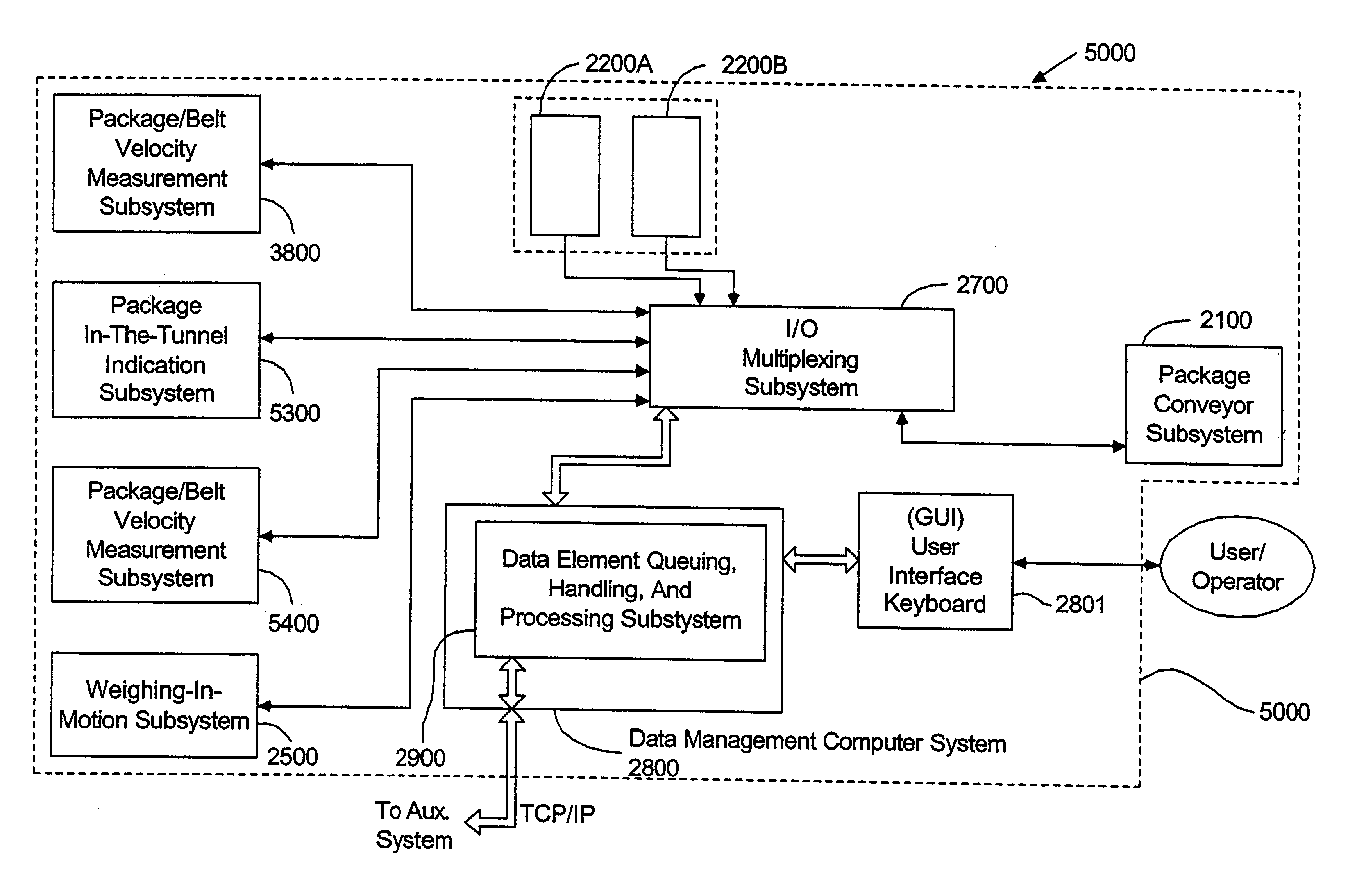

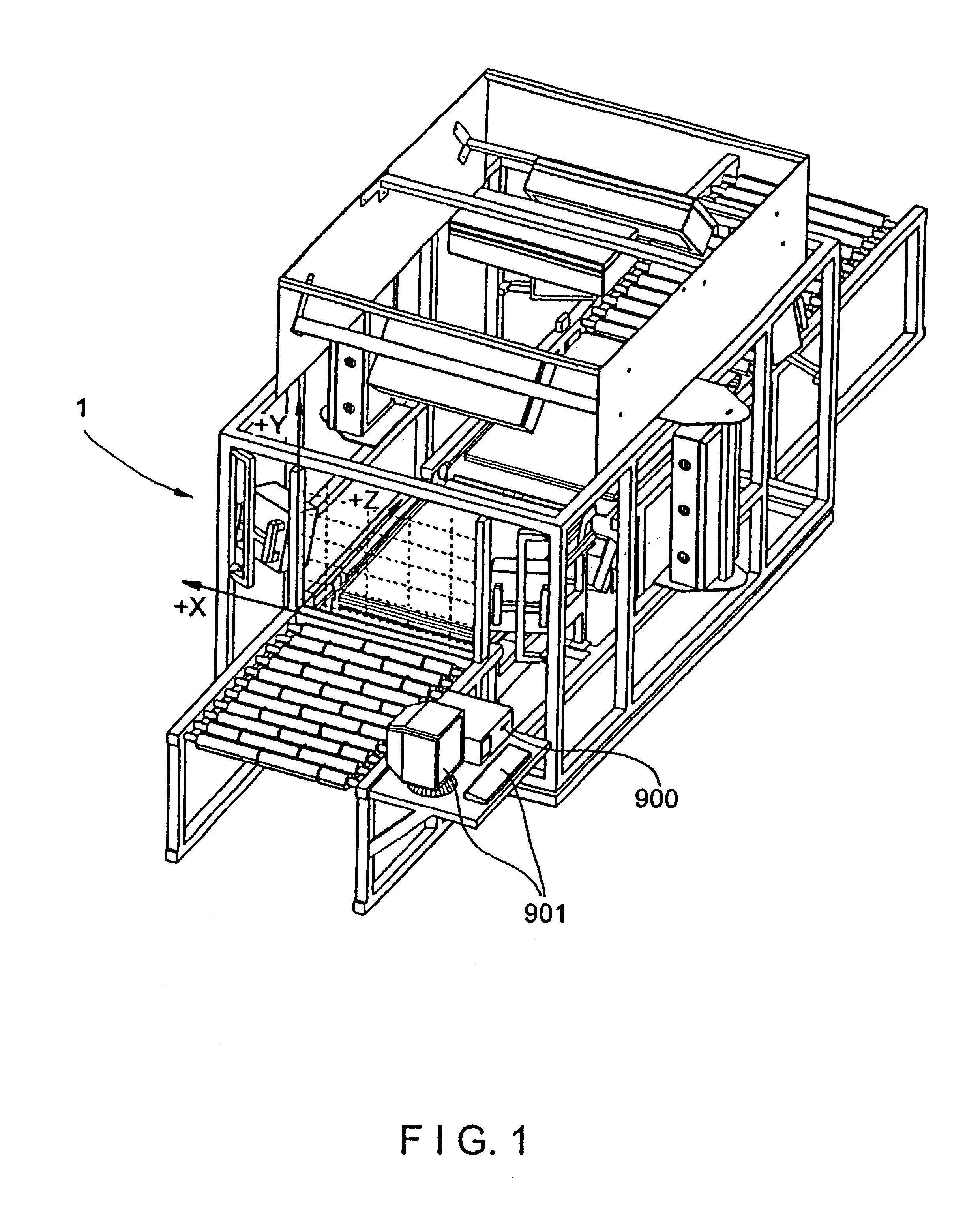

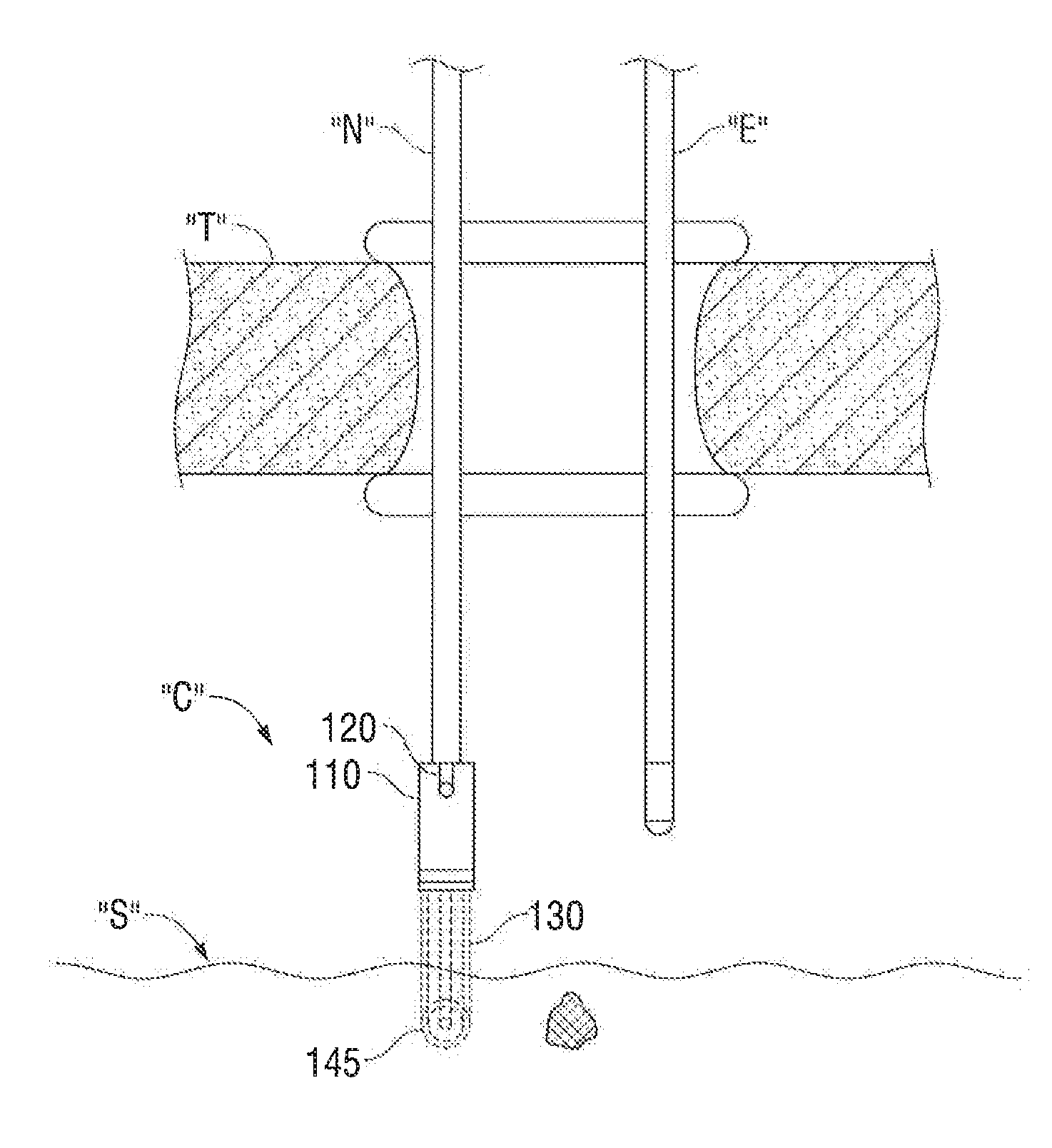

Automated method of and system for dimensioning objects transported through a work environment using contour tracing, vertice detection, corner point detection, and corner point reduction methods on two-dimensional range data maps captured by an amplitude modulated laser scanning beam

InactiveUS6705526B1Guaranteed uptimeSemiconductor/solid-state device manufacturingCo-operative working arrangementsMathematical modelLaser scanning

A fully automated package identification and measuring system, in which an omni-directional holographic scanning tunnel is used to read bar codes on packages entering the tunnel, while a package dimensioning subsystem is used to capture information about the package prior to entry into the tunnel. Mathematical models are created on a real-time basis for the geometry of the package and the position of the laser scanning beam used to read the bar code symbol thereon. The mathematical models are analyzed to determine if collected and queued package identification data is spatially and / or temporally correlated with package measurement data using vector-based ray-tracing methods, homogeneous transformations, and object-oriented decision logic so as to enable simultaneous tracking of multiple packages being transported through the scanning tunnel.

Owner:METROLOGIC INSTR

Parcel dimensioning measurement system and method

InactiveUS8132728B2Reduces cost and complexityImage analysisOptical rangefindersDimension measurementComputer science

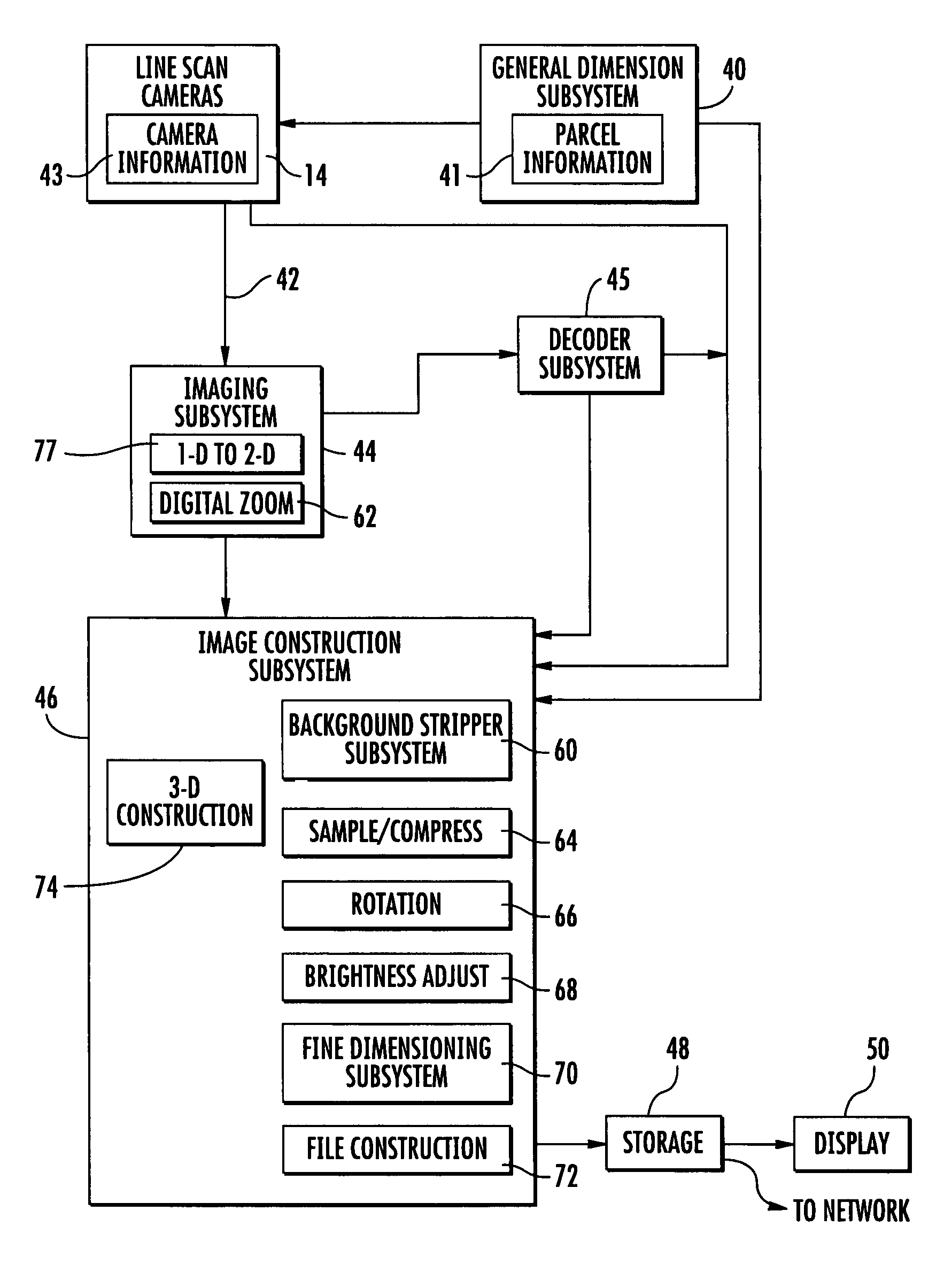

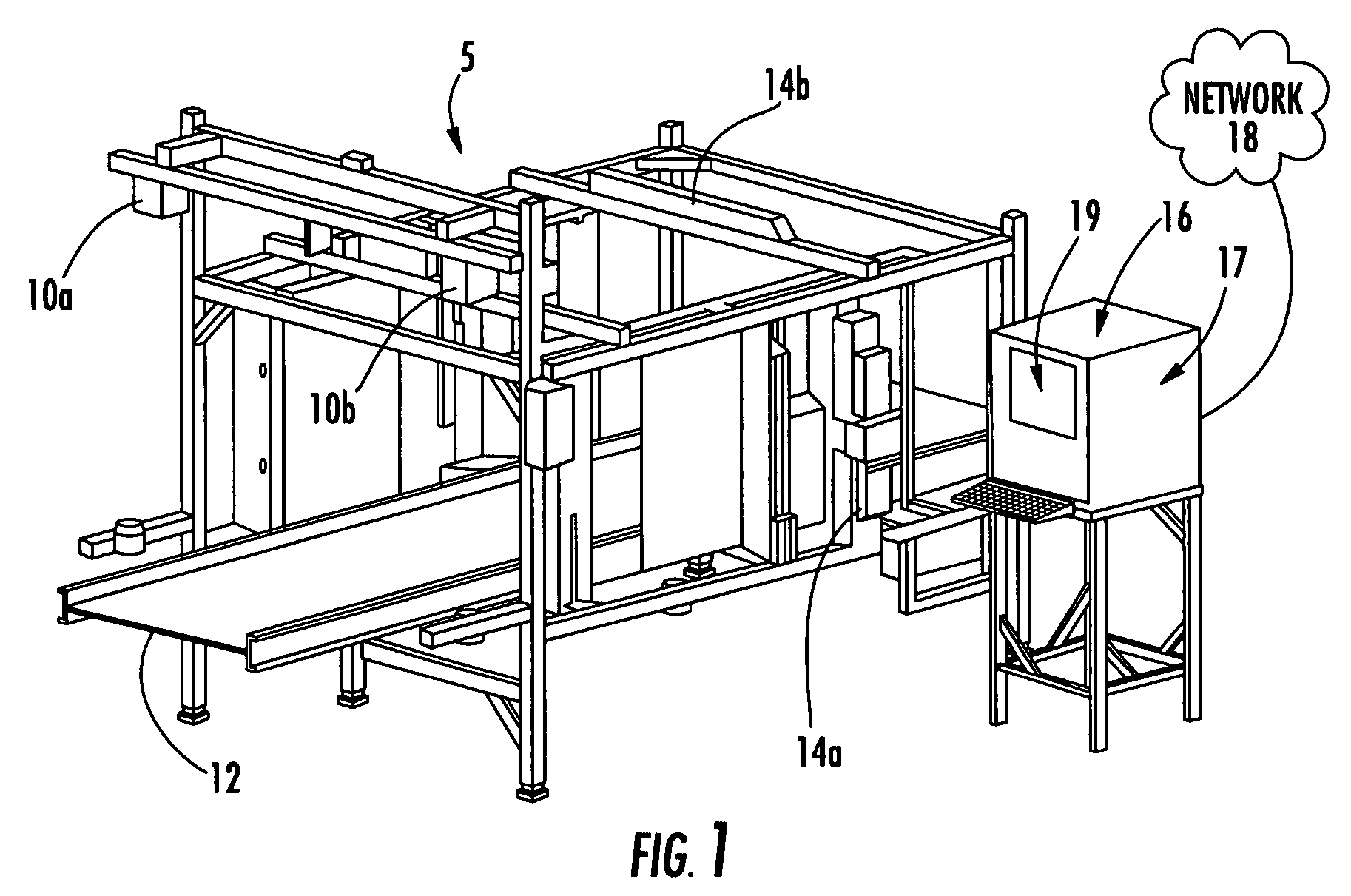

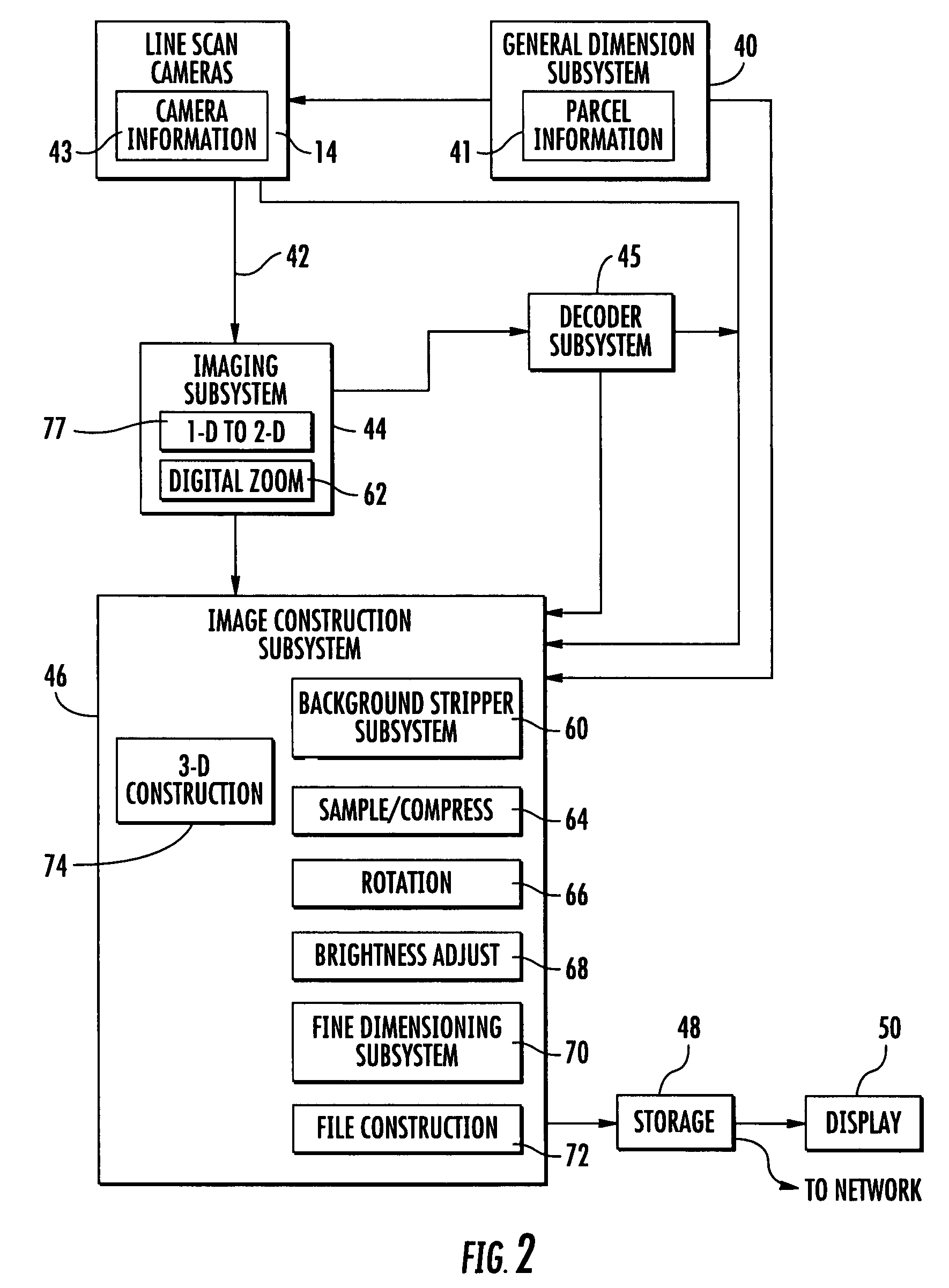

A parcel dimension measurement system includes image sensors oriented to image a parcel, an imaging subsystem configured to stitch together outputs of the image sensors to produce at least one two-dimensional image comprised of a plurality of pixels, and a general dimension subsystem including general parcel dimension information. A fine dimensioning subsystem is configured to determine dimension measurements of the parcel using the at least one two-dimensional image and the general parcel dimension information.

Owner:SICK AG

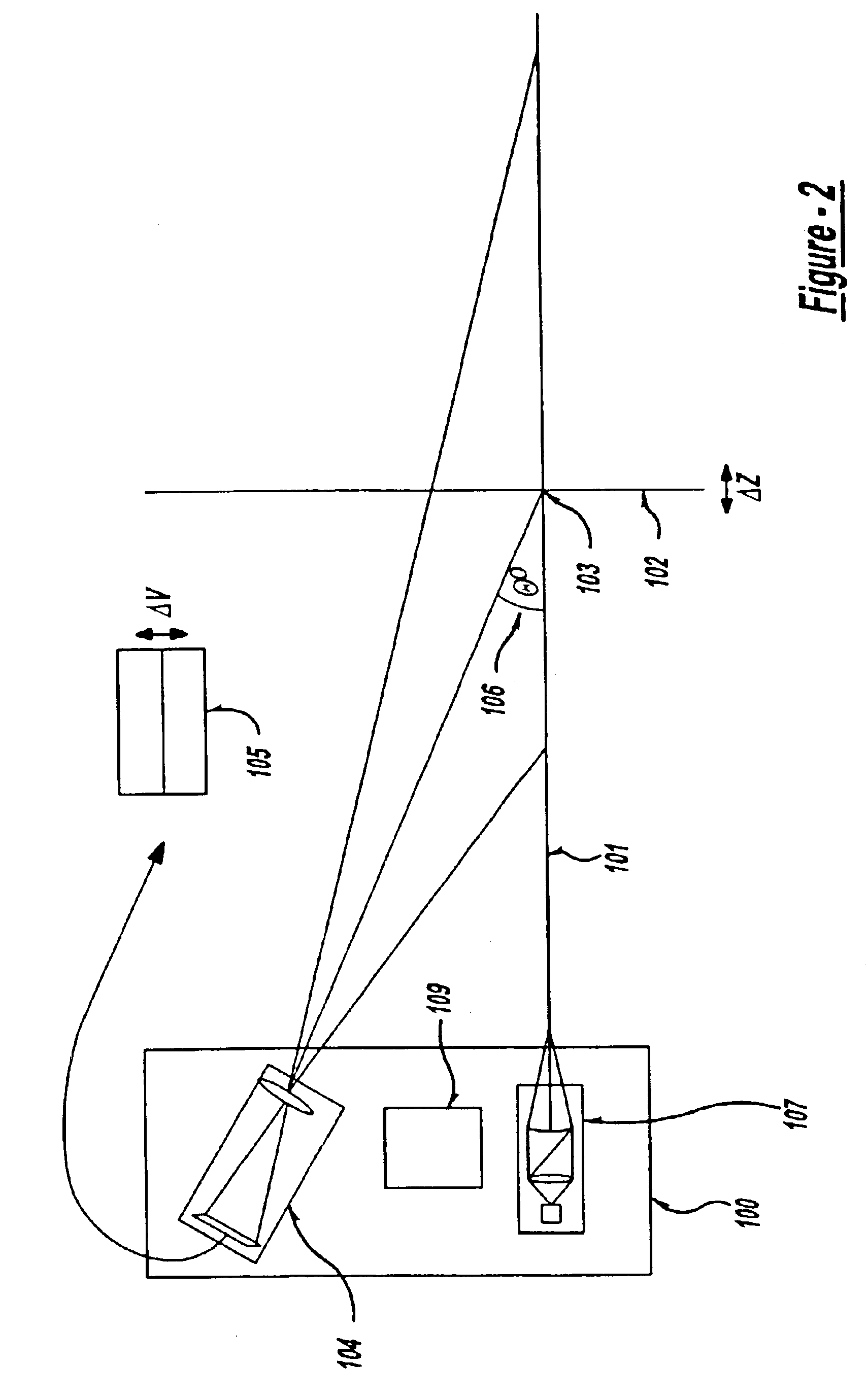

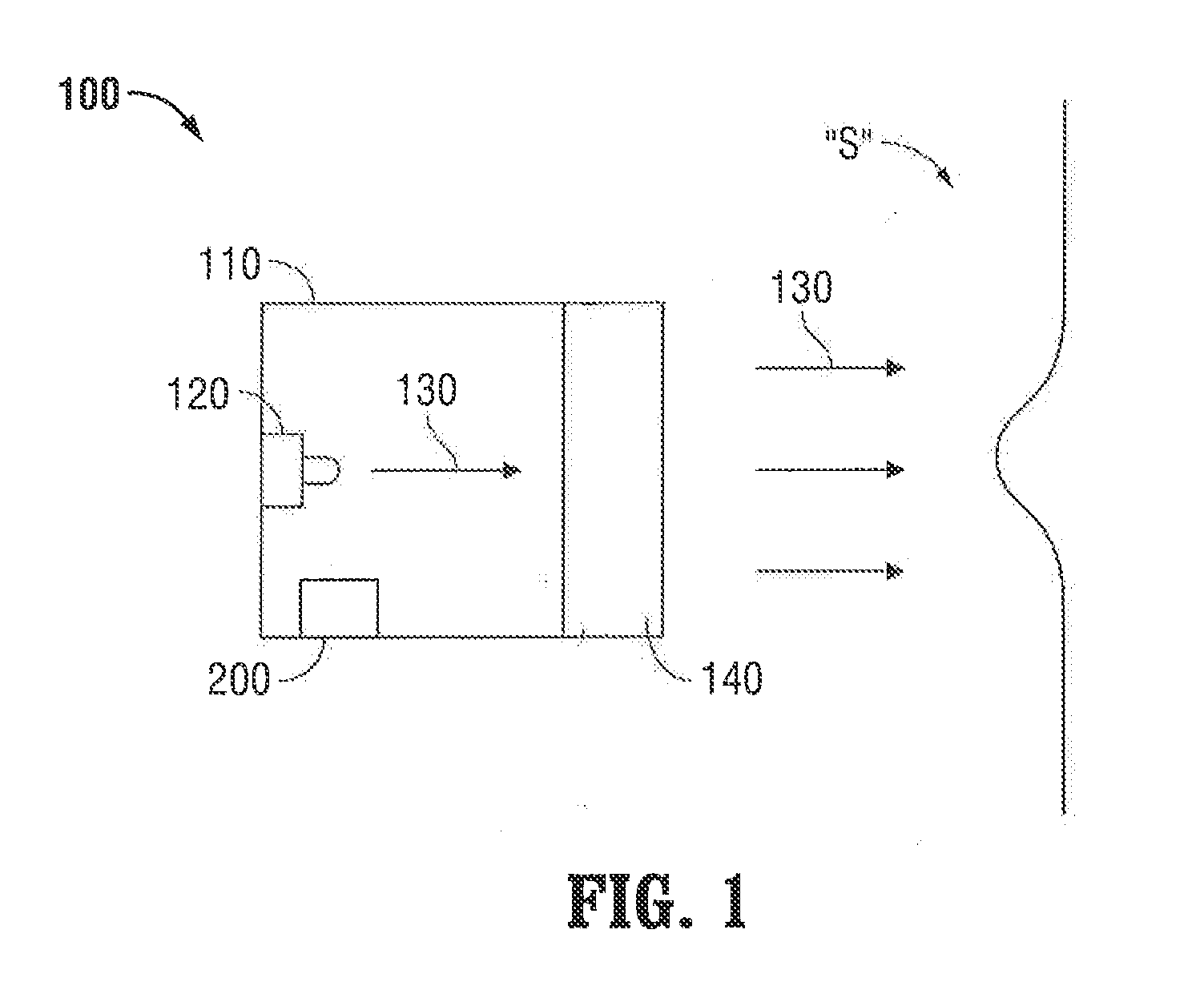

Modular non-contact measurement device for quickly and accurately obtaining dimensional measurement data

InactiveUS6858857B2Quickly and accurately performingRemove most human judgement of measurement resultsImage analysisMetal sawing accessoriesMeasurement deviceDimension measurement

A modular measurement device is provided for quickly and accurately performing non-contact measurements of various objects at different locations within a commercial or residential work area. The modular measurement device generally includes a laser base that is operable to project light onto a measured object; and a portable measurement module adapted to receive light reflected from a surface of the measured object and operable to determine dimensional measurement data for the measured object, where the portable measurement module is configured to releasably couple to the laser base. The operational components of the measurement device are partitioned between the portable measurement module and the laser base. In this way, a single portable measurement module having more expensive operational components may be used with different, less expensive laser bases, where each laser base may be adapted for a different application.

Owner:PERCEPTRON

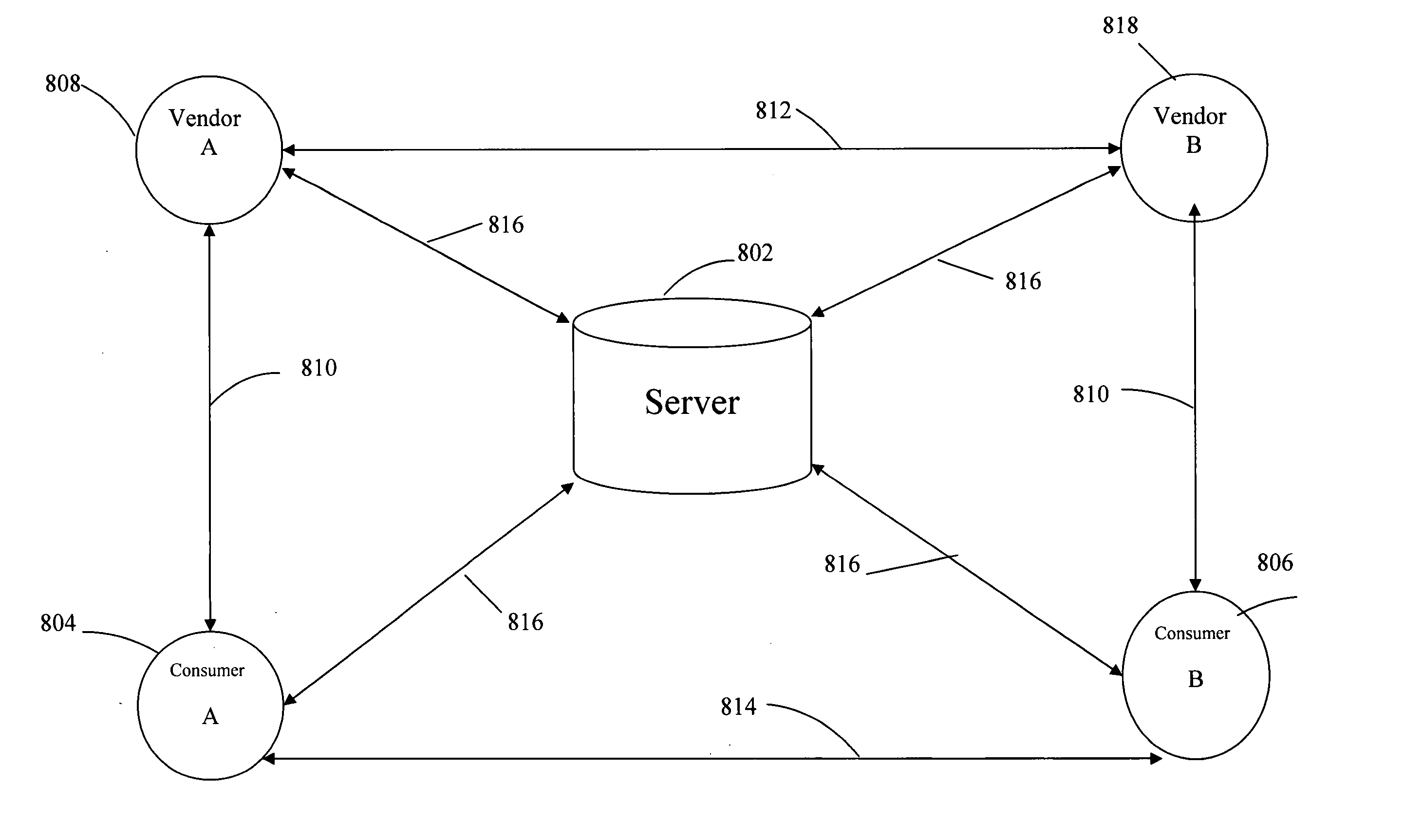

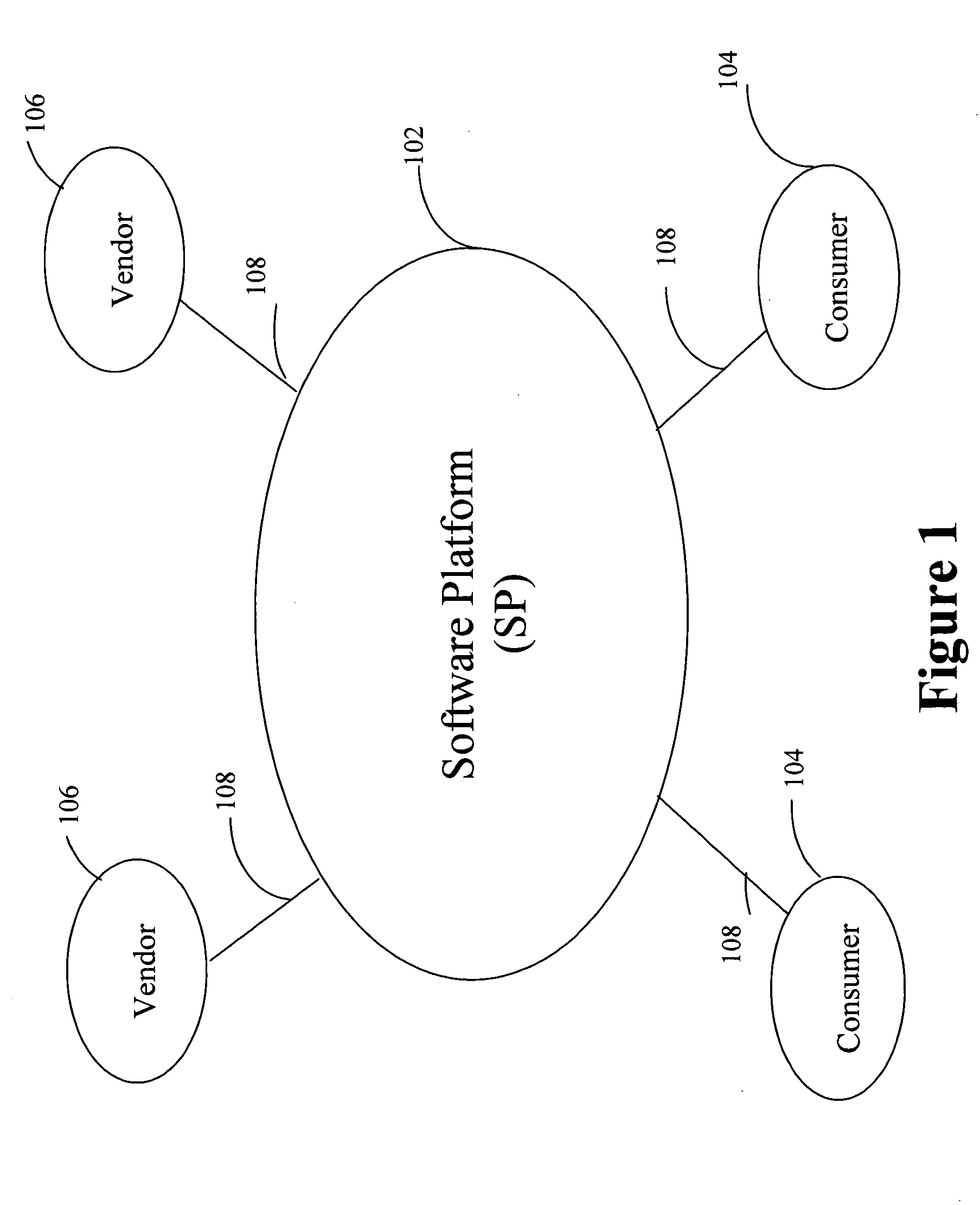

Method and system for interactive three-dimensional item display

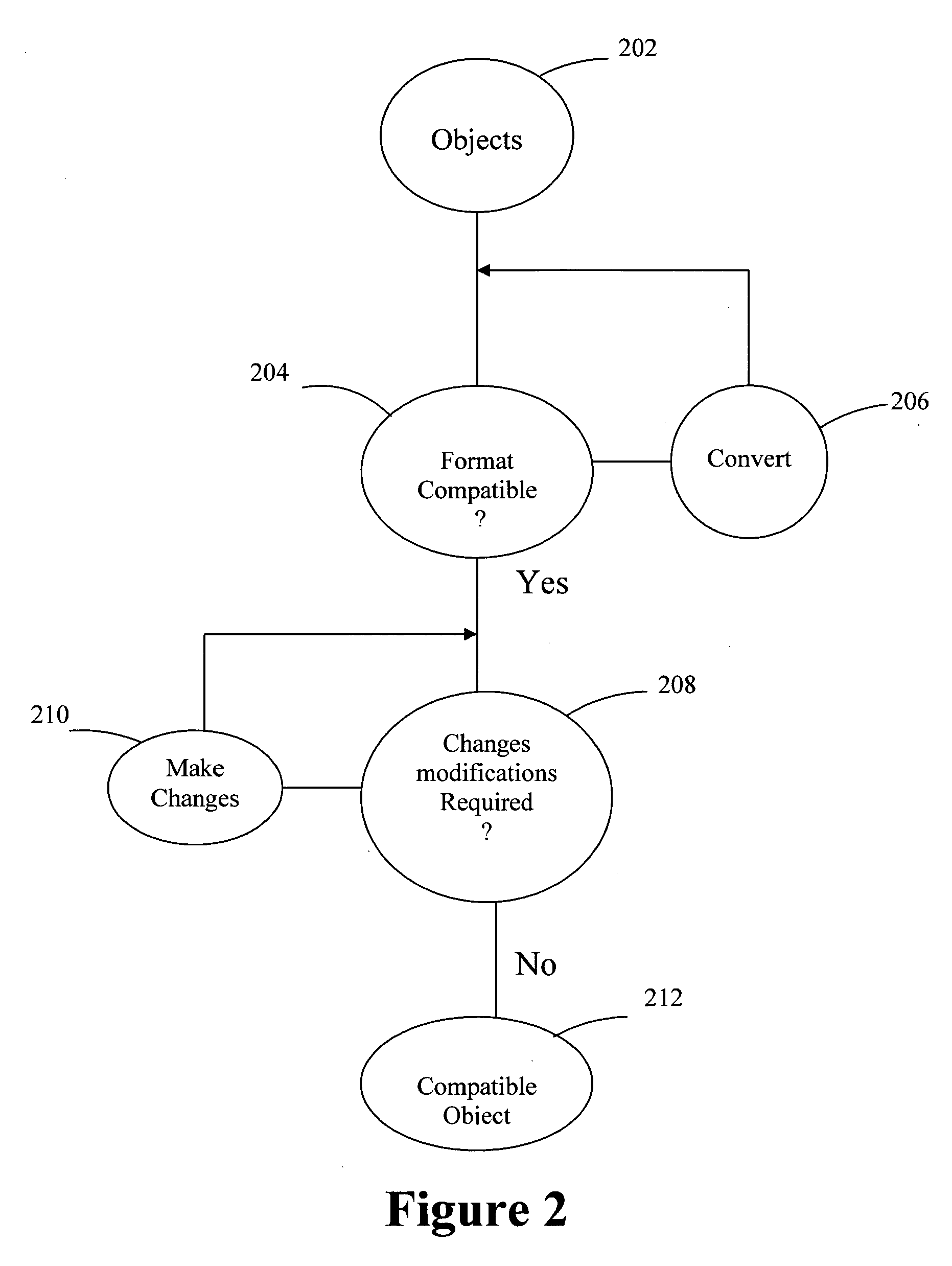

A system and method for interactive three-dimensional (3D) object simulation is provided that includes a simulated interactive 3D environment that runs locally on the user's computer, and provides automatic compatibility handling to enable vendors and consumers to place, modify, manipulate, integrate, and freely move virtual products in the 3D environment. Other embodiments may additionally include any combination of means for a vendor to create a 3D virtual store in the interactive 3D environment, and means for making the virtual object is dimensionally proportional in measurement to the dimensional measurements of the corresponding physical object.

Owner:KWON RYAN YOUNG WOOK

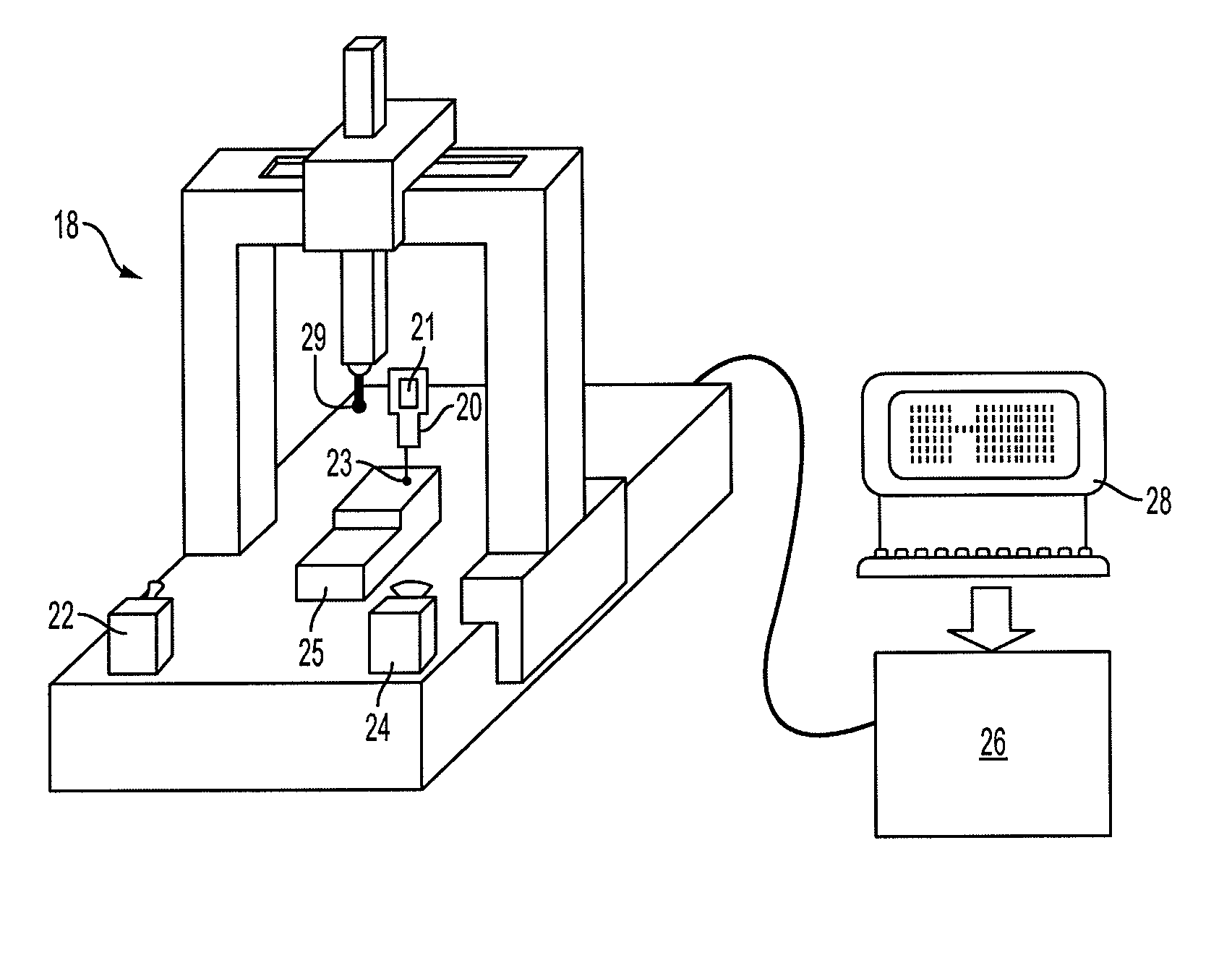

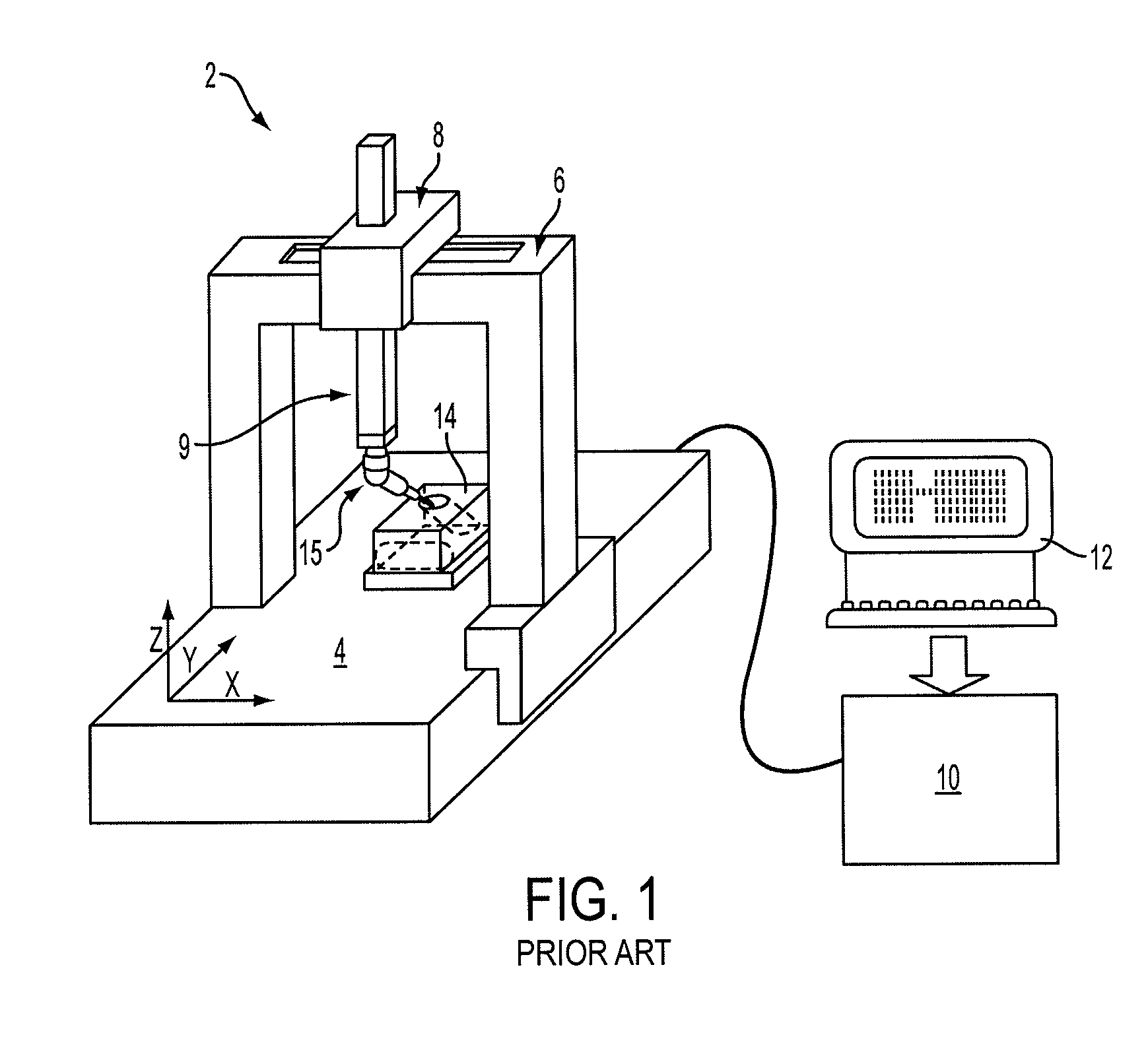

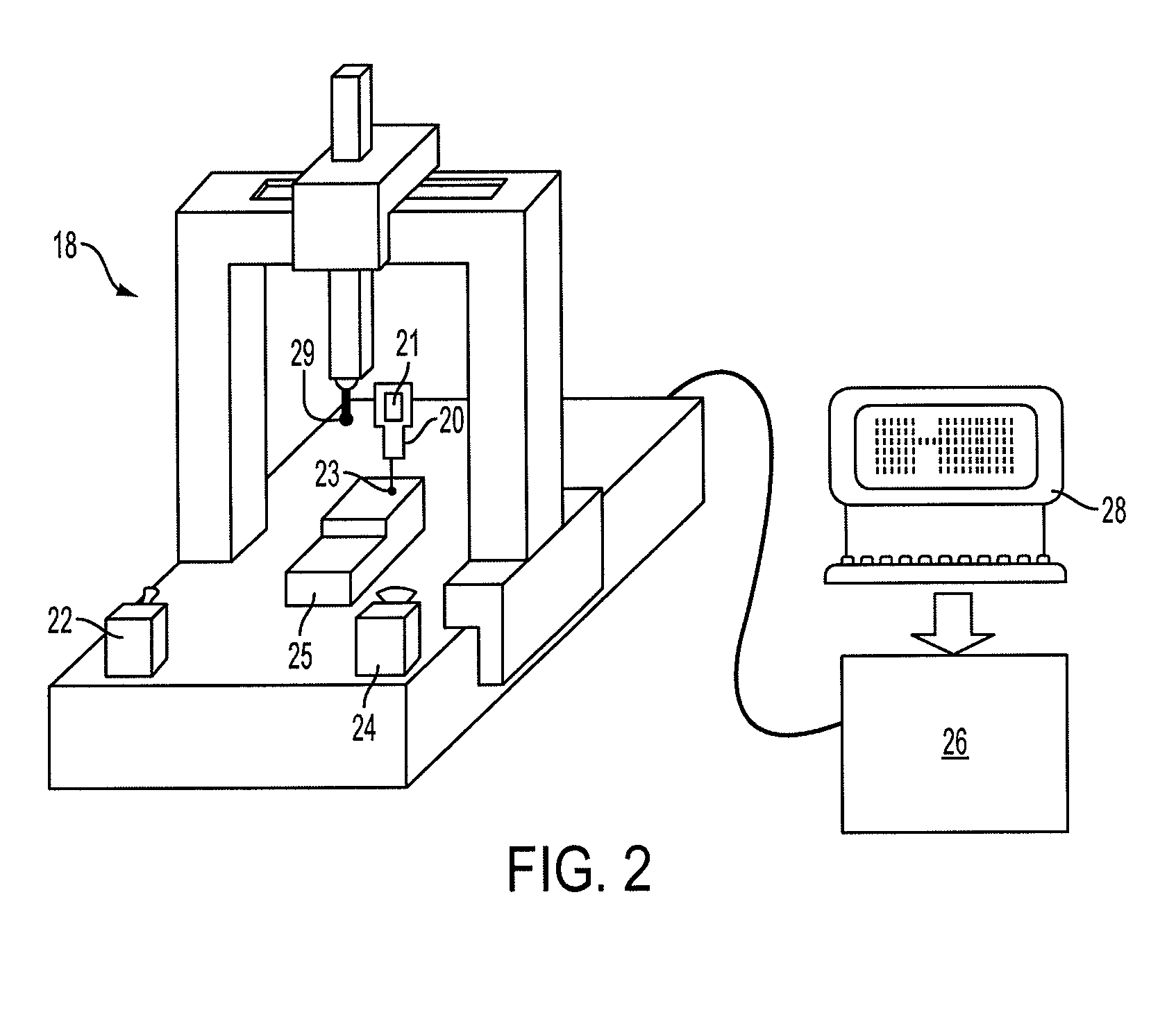

Manipulable aid for dimensional metrology

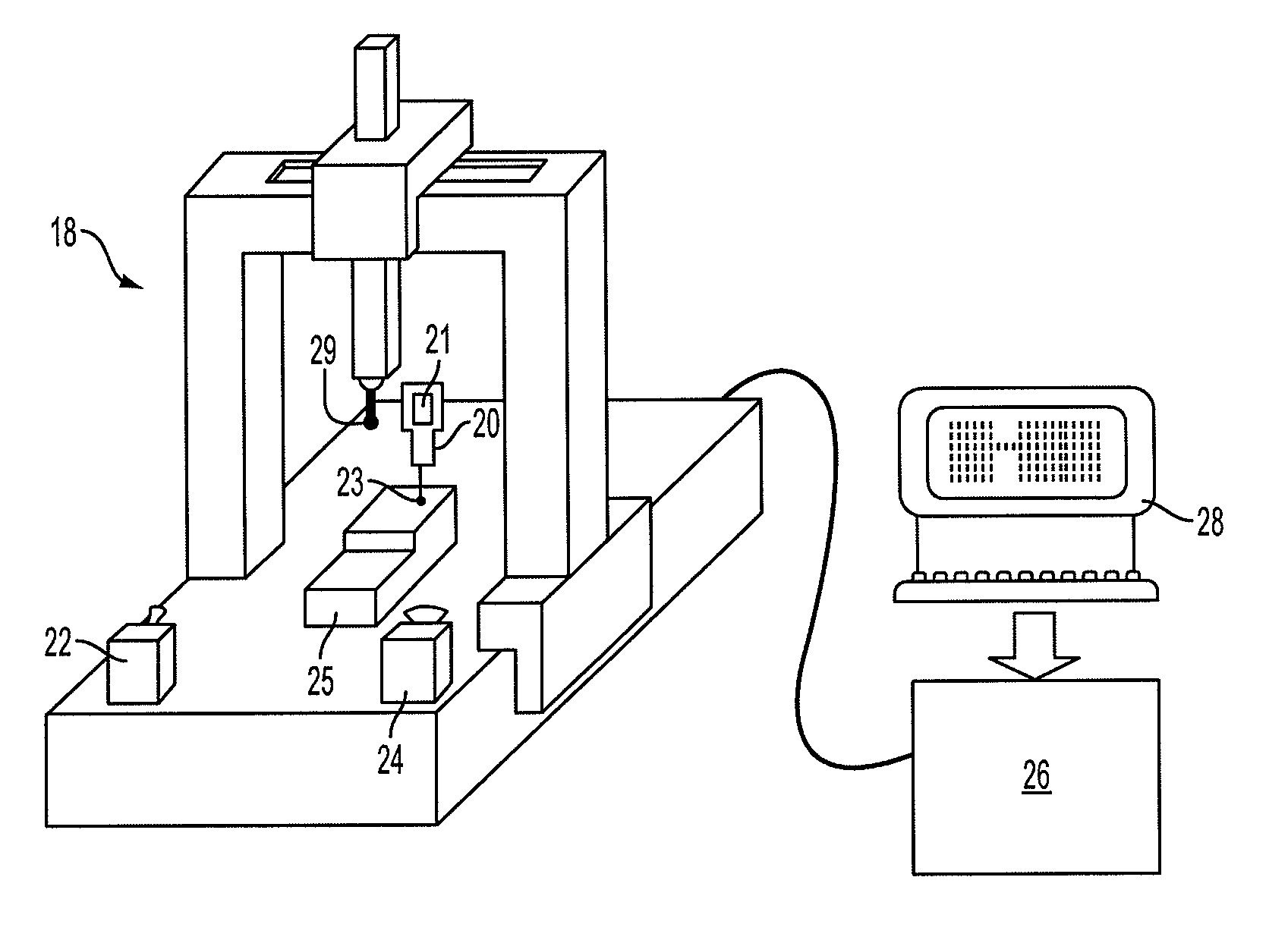

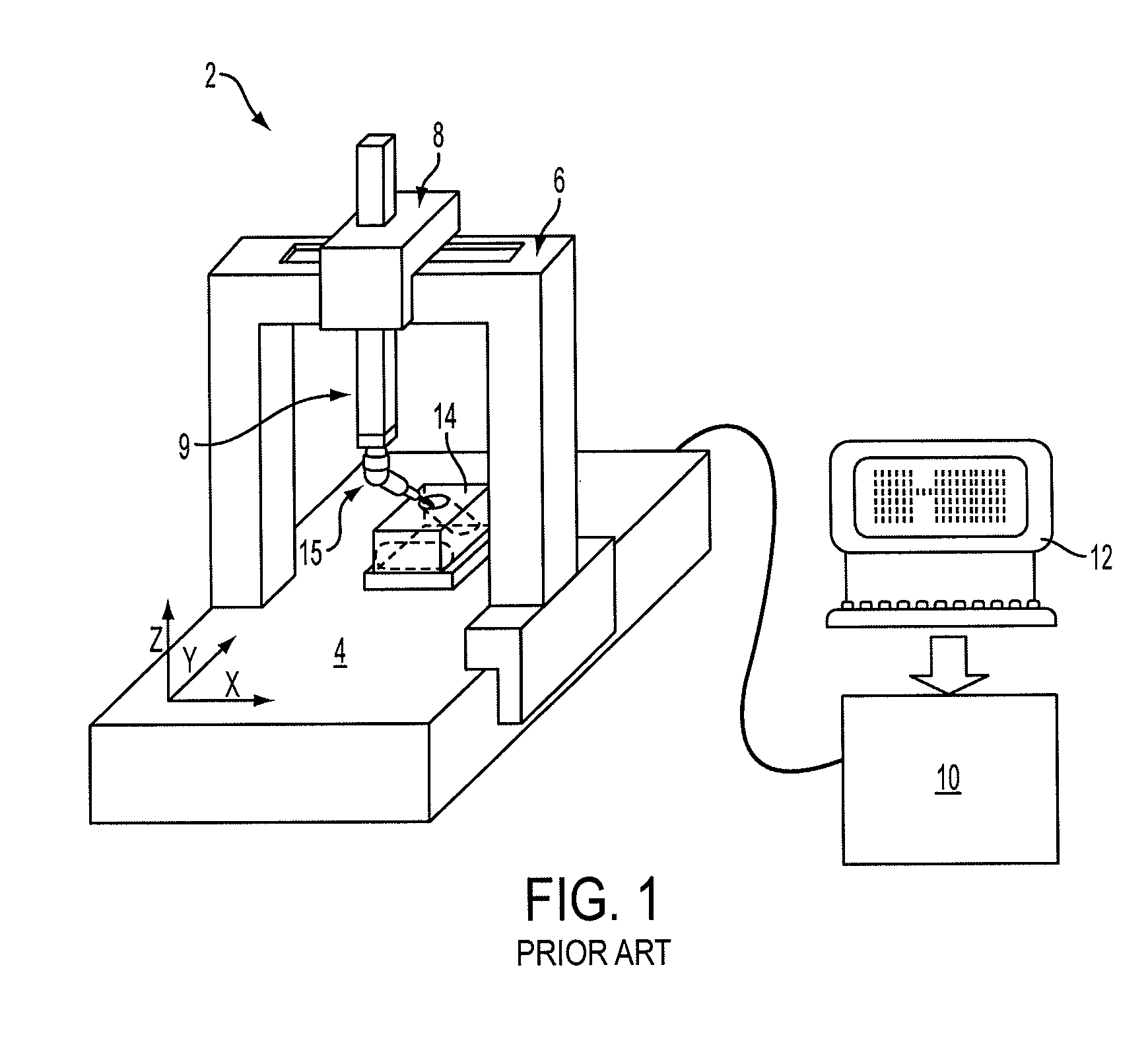

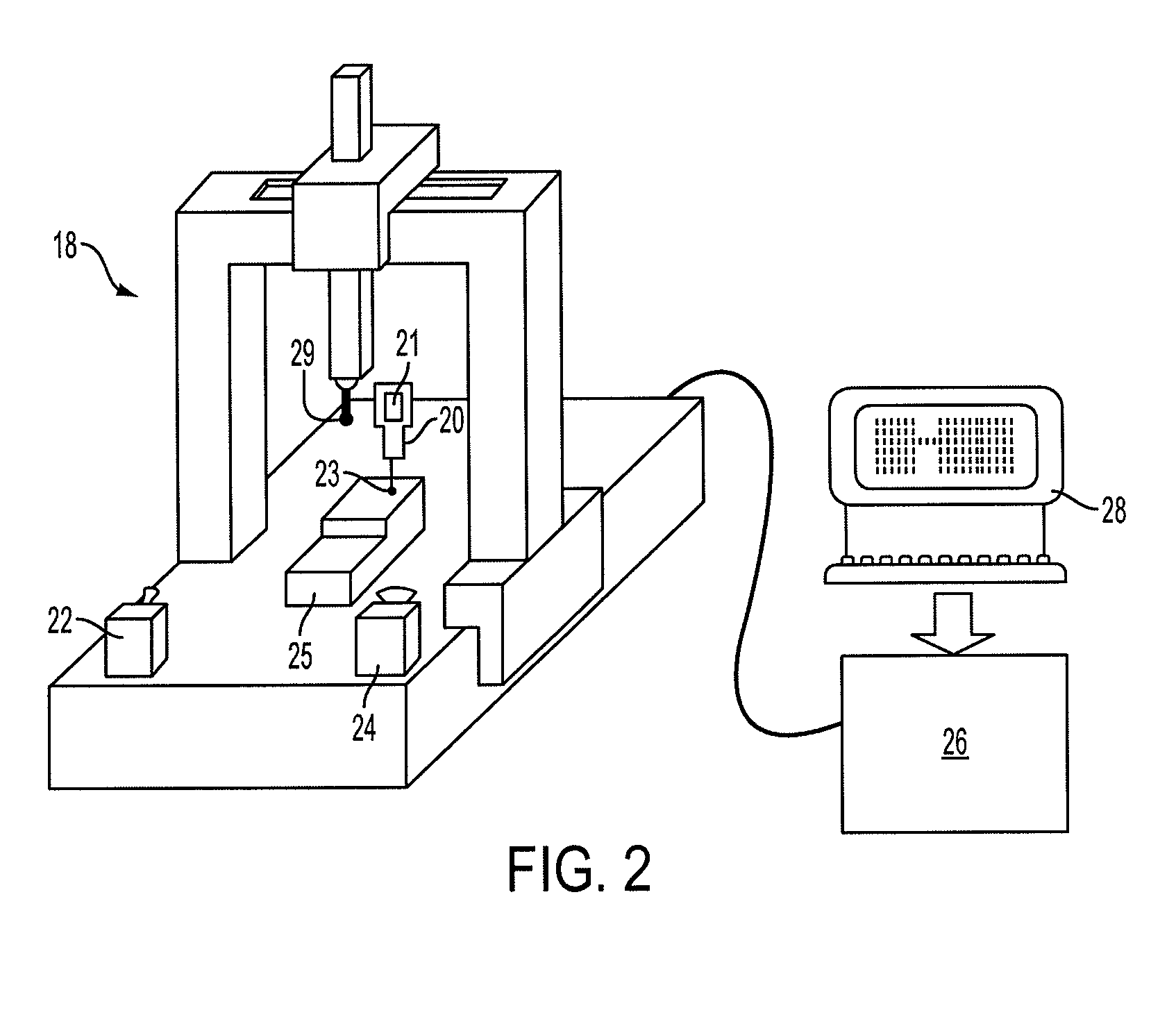

A manipulable aid which is separate and distinct from the probe of a CMM permits a CMM operator to more directly interact with a CMM measurement volume to align a workpiece, configure a measurement path, and / or program a dimensional metrology application.

Owner:HEXAGON METROLOGY INC

Method and computer program for improving the dimensional acquisition of an object

ActiveUS20110123097A1Improve accuracyIncrease speedMeasurement devicesCharacter and pattern recognitionSize measurementMeasurement device

The present invention relates to a method for improving the efficiency of dimensional acquisition of an object by a dimensional measurement device directed over the object, comprising the steps: a) directing the measurement device over the object to acquire its dimensions, b) providing an indication of the resolution of the acquired regions, c) re-directing the measurement device over at least part of the acquired regions indicating insufficient resolution according to predetermined criteria, d) updating the indication of the resolution of the acquired regions, and e) repeating steps c) and d) until sufficient resolution is indicated according to the predetermined criteria, thereby efficiently acquiring the dimensions of the object at sufficient resolution. It also relates to a computer program therefor.

Owner:3D SCANNERS LTD

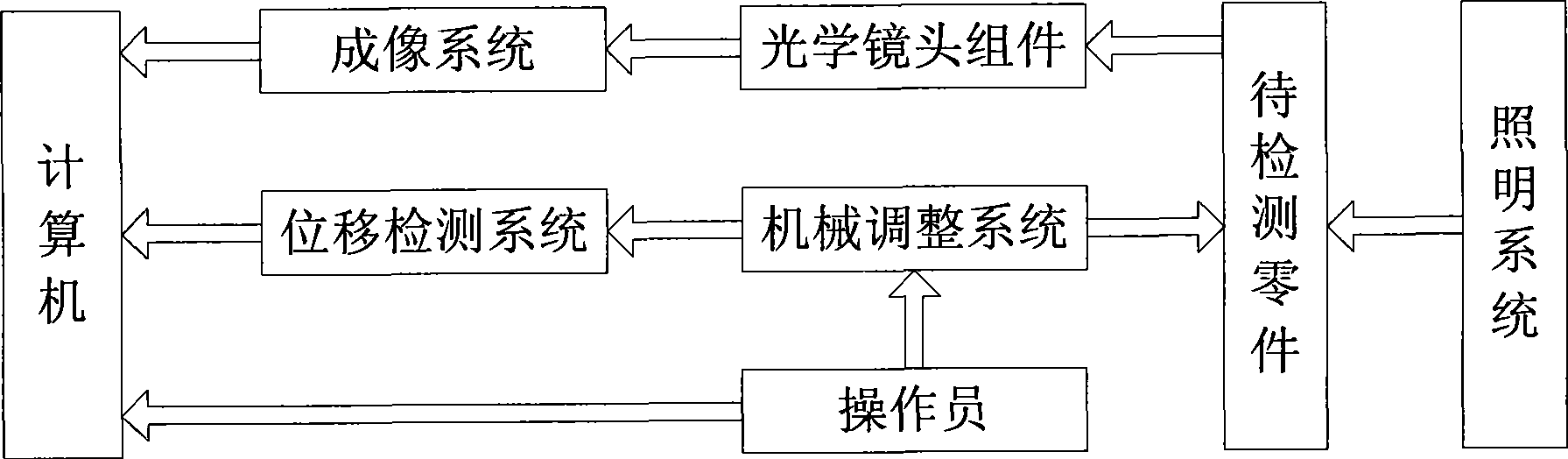

Part vision detection device

InactiveCN101509878AAvoid fatigueAvoid subjectivityMaterial analysis by optical meansUsing optical meansCamera lensDefect size

A visual detection device for parts mainly comprises an imaging system, an optical lens component, a lighting system, a mechanical adjusting system, a displacement detection system and a computer, wherein the imaging system consists of a CCD camera and an image acquisition card; the optical lens component consists of a lens body, an amplifying objective lens, and the like; the lighting system is respectively used for detecting surface defects and measuring topographic sizes; the mechanical adjusting system consists of displacement platforms used for adjusting the positions of the parts; the displacement detection system is used for recording the displacement distance of the displacement platforms; and the computer is used for recording and processing images. By shooting edge images of theparts through the imaging system and recording the displacement distance of the displacement platforms through the displacement detection system, the detection device calculates the topographic sizessuch as diameter, and the like, detects the surface defects of the whole spherical surface by the combined rotation of rotary tables, measures the defect sizes accurately, records the number of the defects and meets the two detection requirements of topography measurement and surface detection. By utilizing the visual microscopic detection technology, the device has high system resolution, good integrated performance and simple measurement process.

Owner:BEIHANG UNIV

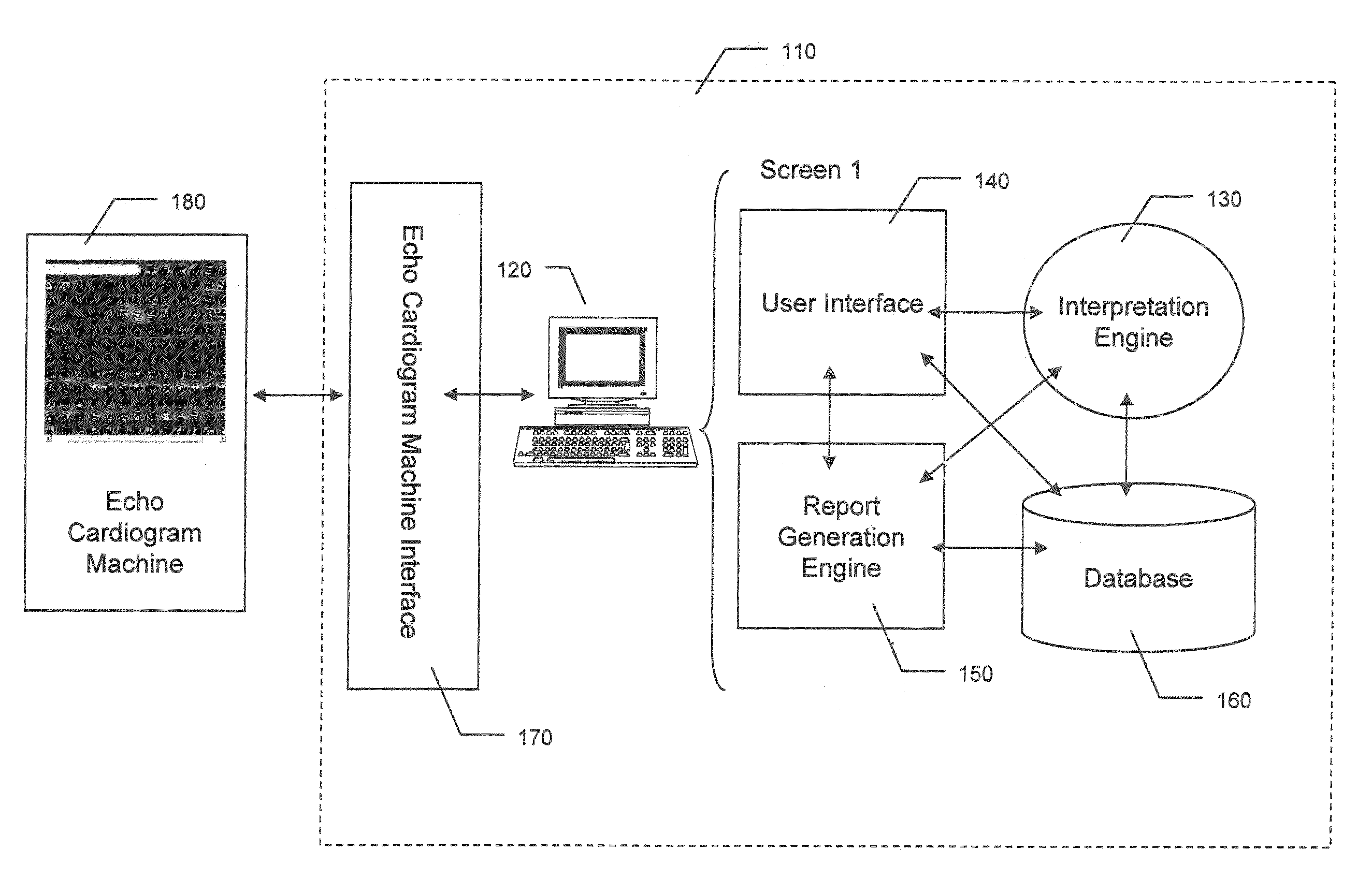

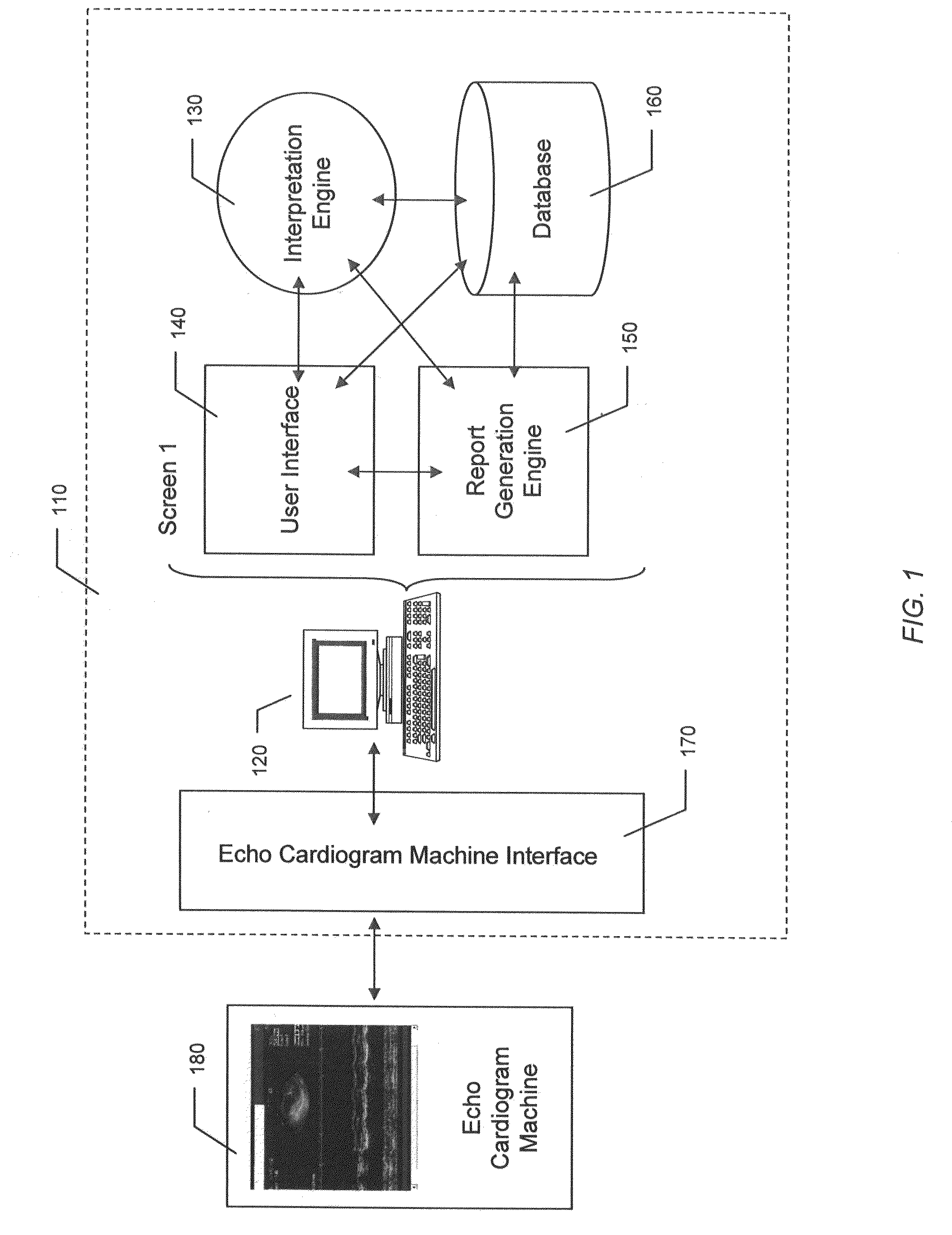

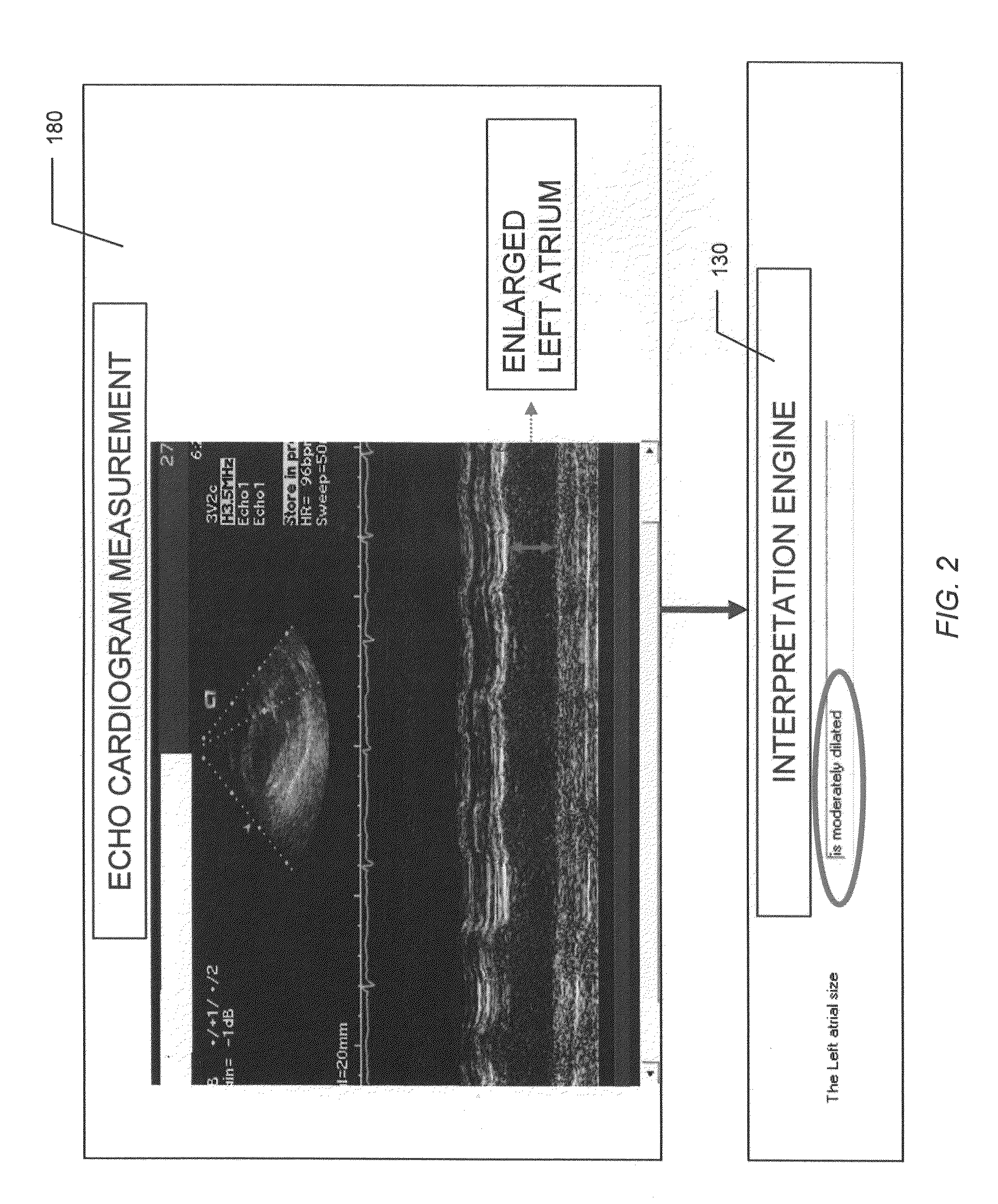

System and Method for Automated Medical Diagnostic Interpretation and Report Generation

InactiveUS20090171225A1Ultrasonic/sonic/infrasonic diagnosticsCharacter and pattern recognitionDimension measurementEngineering

Automated medical diagnostic interpretation and report generation for a non-invasive medical diagnostic test, such as an echo cardiogram, is provided. Various dimension measurements and physiological measurements from an echo cardiogram machine are transferred automatically to a computer over an echo cardiogram machine interface. The dimensions and physiological measurements are automatically interpreted by an intelligent interpretation engine running on a computer, generating various machine evaluations. The physician can approve the machine evaluations, overrule them, or make appropriate adjustments. Upon completion of the physician's review, the physician approved interpretations become diagnostic conclusions, and the report containing the results of the physician's review is generated by the report generation engine.

Owner:MEDNOVA

Manipulable aid for dimensional metrology

A manipulable aid which is separate and distinct from the probe of a CMM permits a CMM operator to more directly interact with a CMM measurement volume to align a workpiece, configure a measurement path, and / or program a dimensional metrology application.

Owner:HEXAGON METROLOGY INC

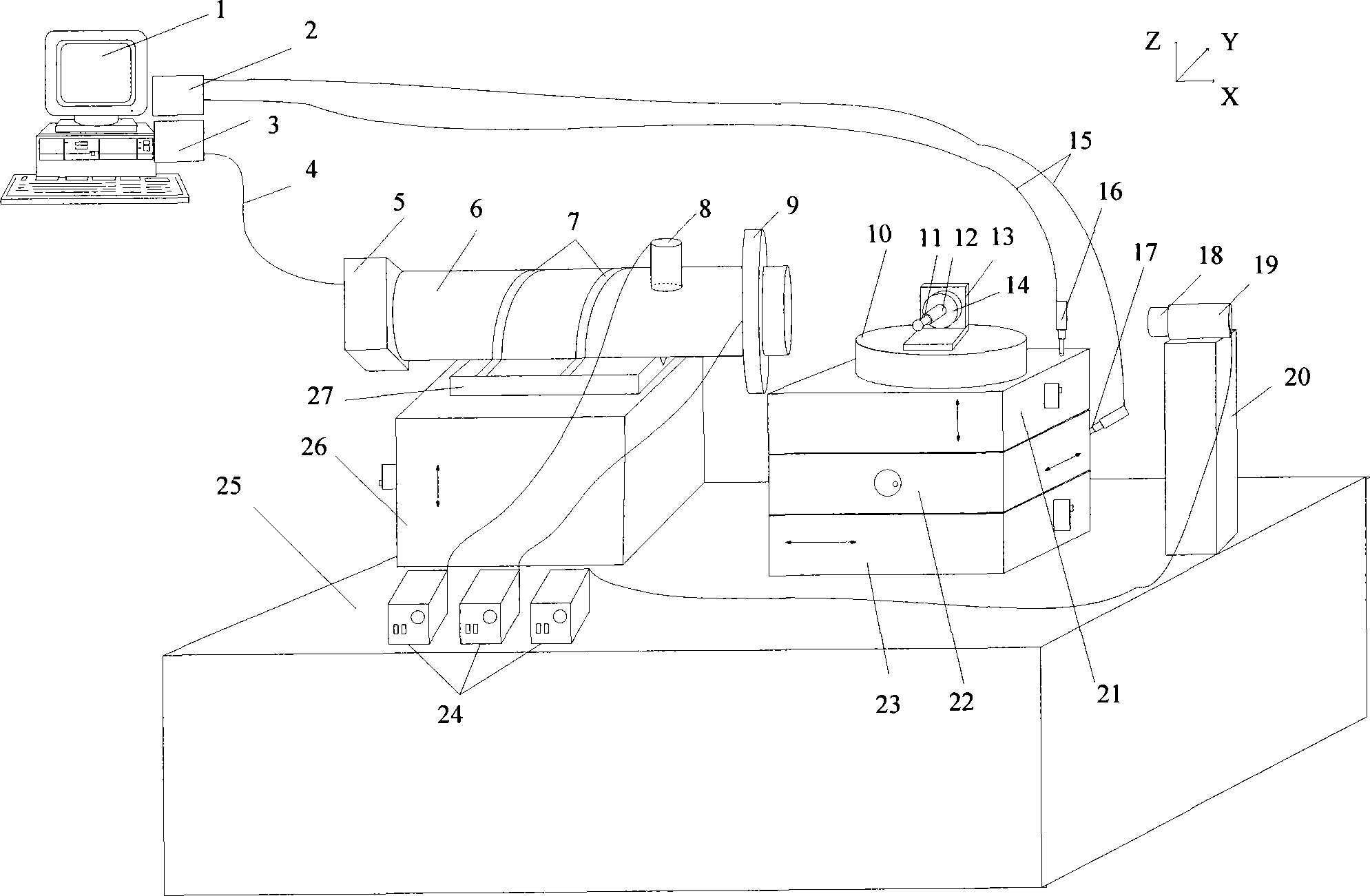

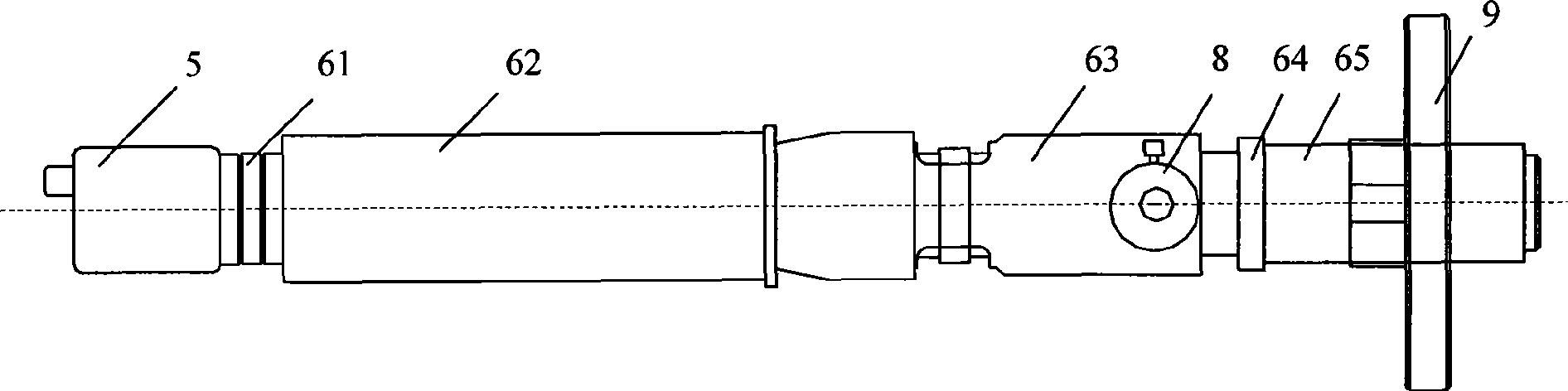

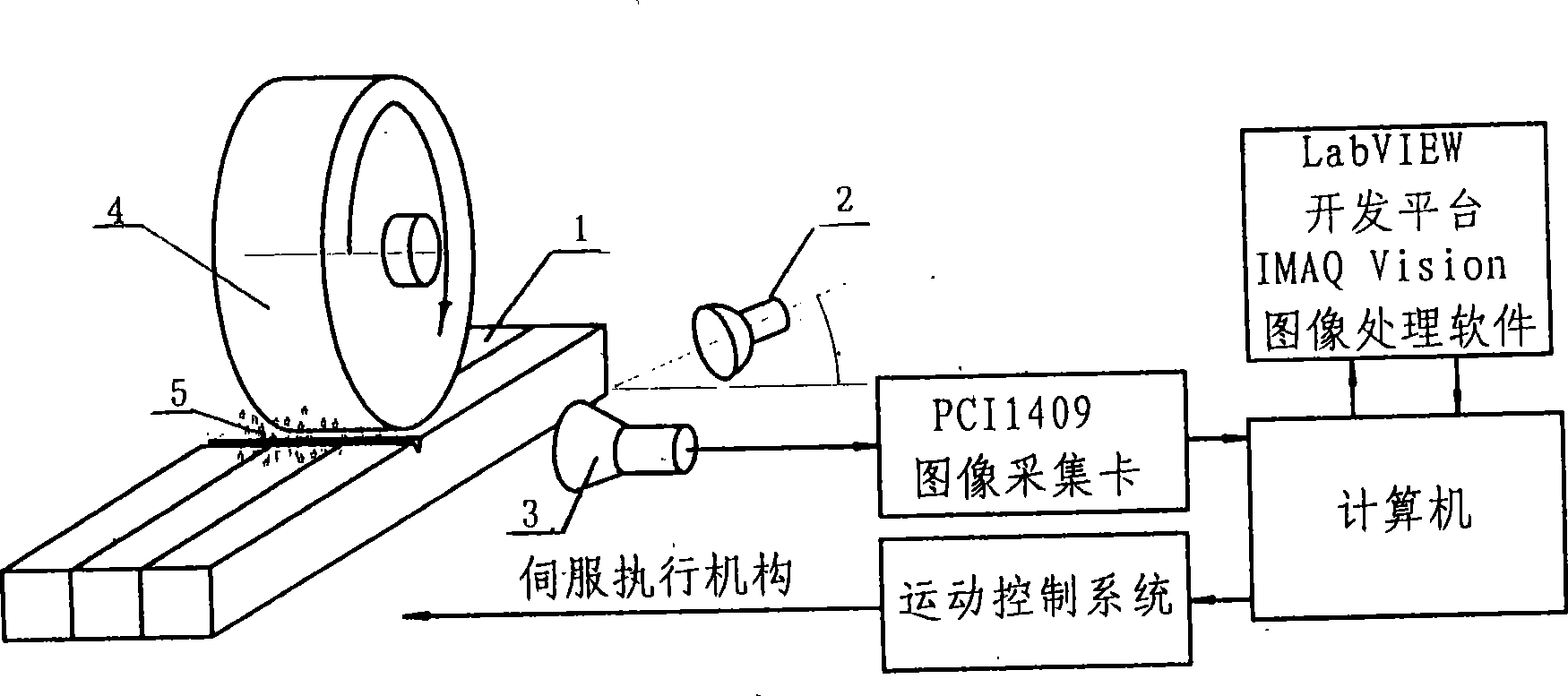

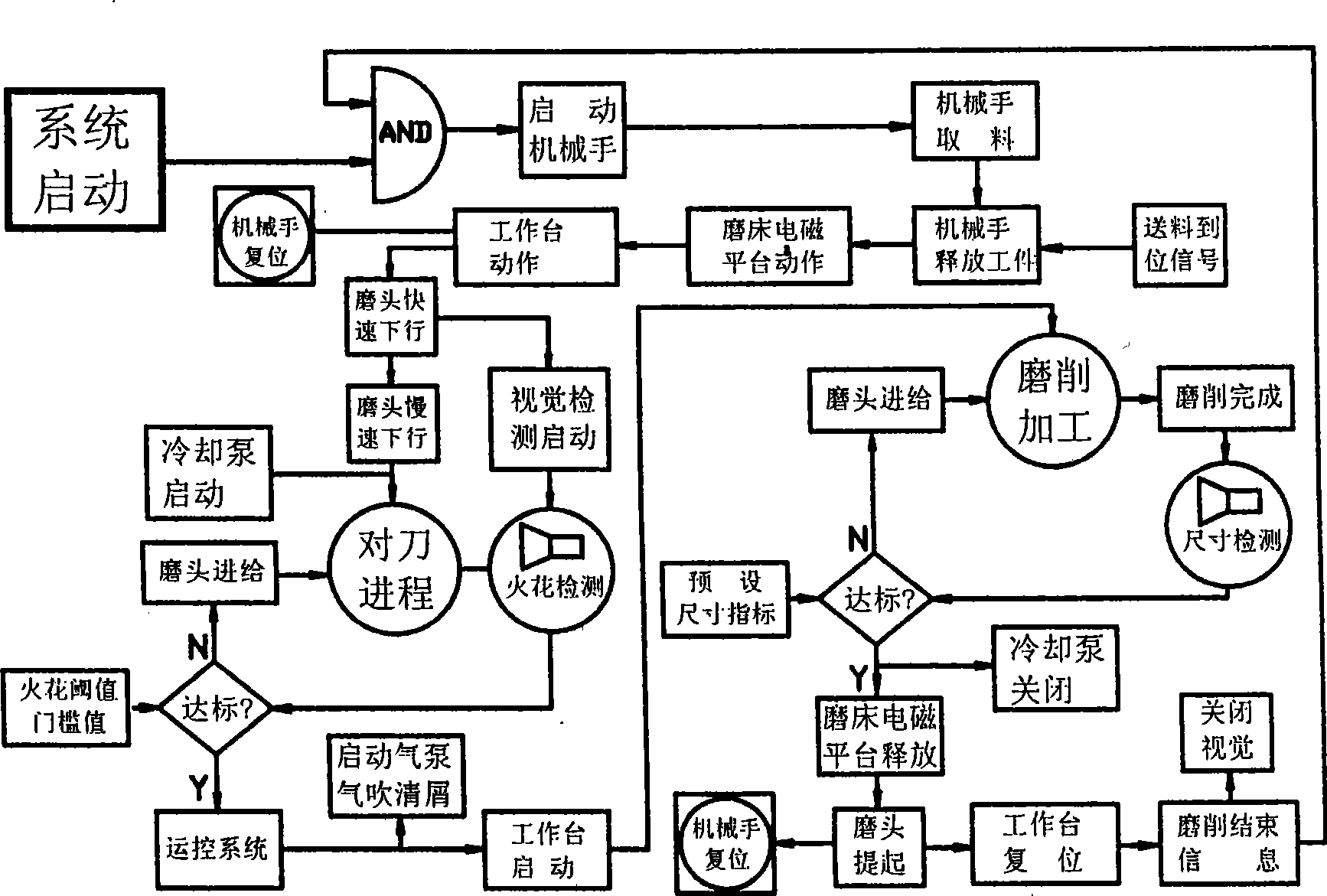

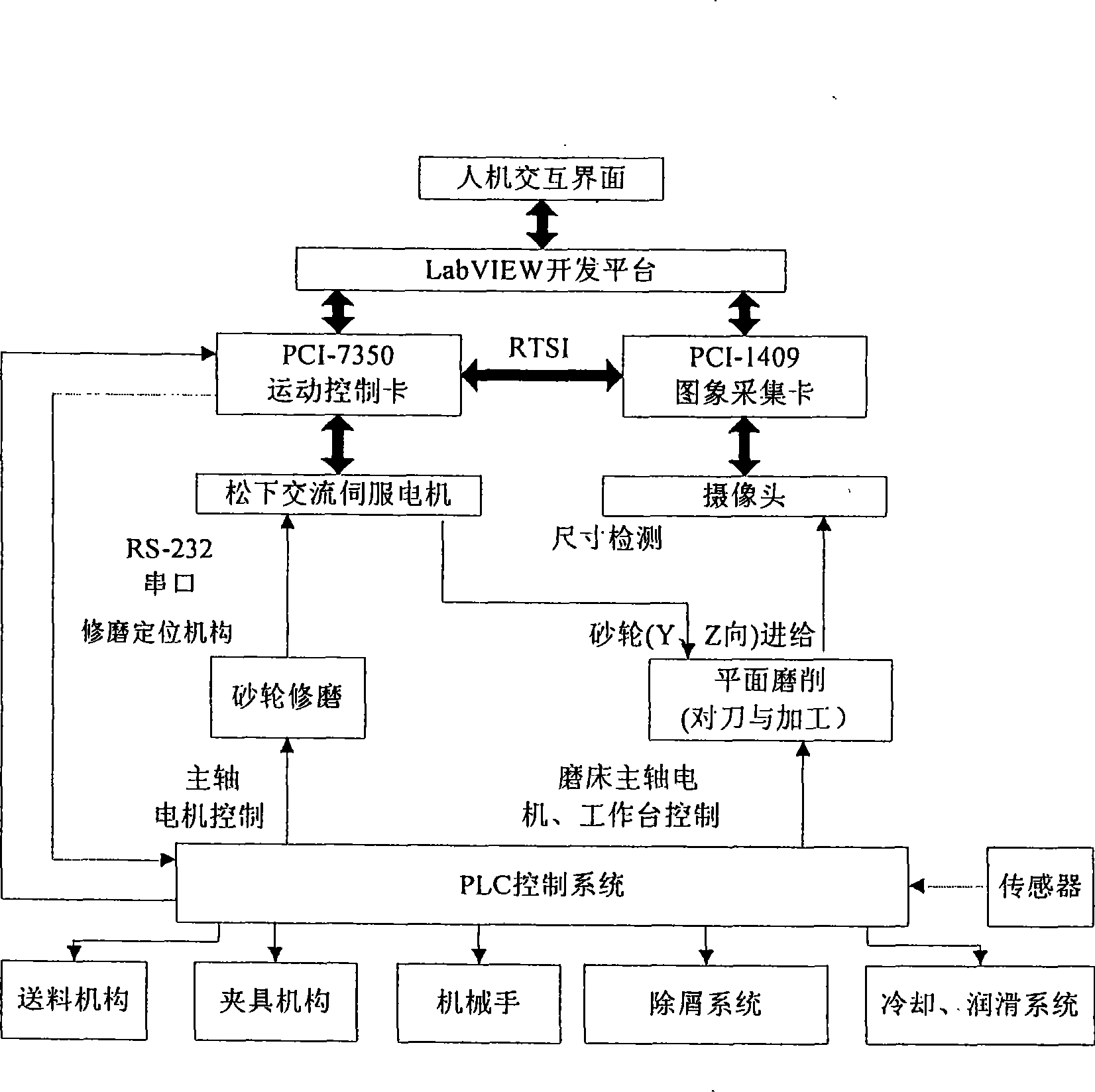

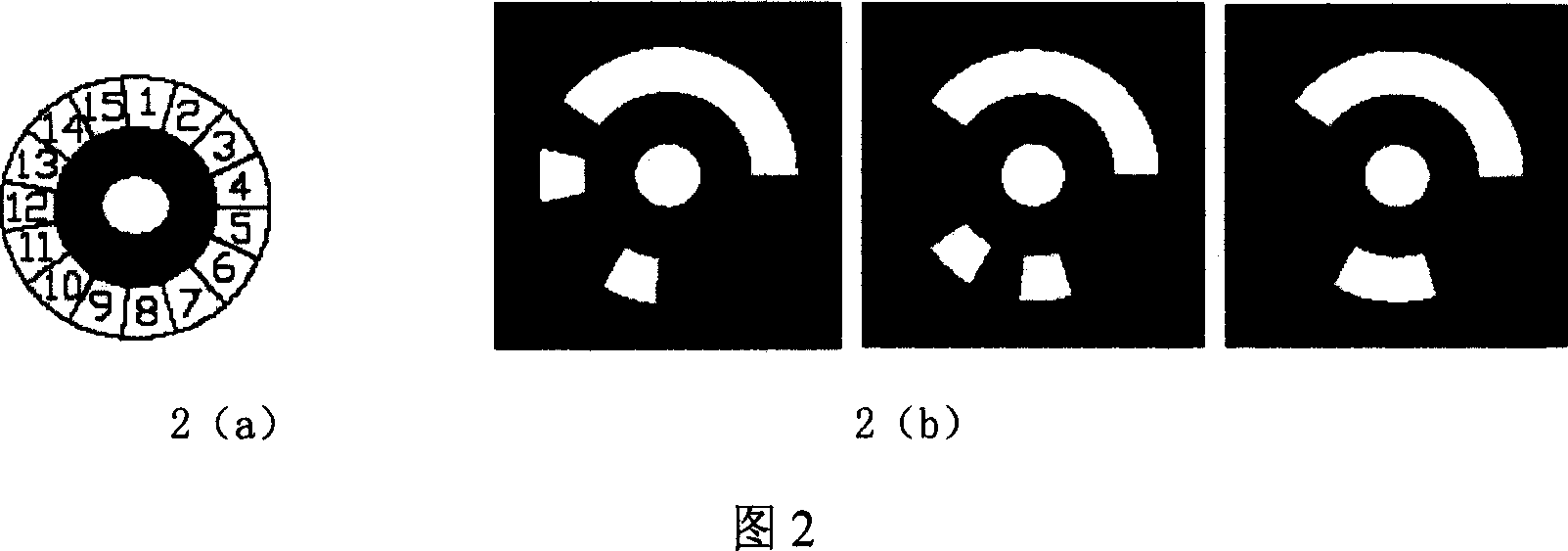

Spark identification tool-setting method and abrasive machining automatic system

The invention discloses a method for setting a tool through sparkle identification and an automatic system for grinding processing. The method and the system achieve the intelligent automatic control for the whole grinding process and accurately and reliably solve the problem of automatic tool setting, the problem of dimension compensation caused by the abrasion of a grinding wheel, and the problems of on-line dimension measurement and motion servo control in the grinding process. The method organically combines a vision technique, a PLC technique and a motion control technique, and provides a solution for solving the problems of tool setting, on-line dimension measurement and grinding wheel wear compensation by using the vision technique, and the problem of motion servo control by using the PLC technique and the motion control technique. The method makes use of the vision technique to automatically identify the operating condition contacted with a workpiece, and switch the operating condition to a grinding processing state instantly so as to solve the problem of automatic tool setting, thus the method can combine a plurality of mature correlation techniques to construct the automatic system which integrates detection and motion control. The method and the automatic system achieve the accurately automatic tool setting, solve the problems of the wear measurement and compensation of the grinding wheel, and open up a novel approach for fully automatic and intelligent control in the grinding process.

Owner:QIQIHAR HUAGONG MACHINE +1

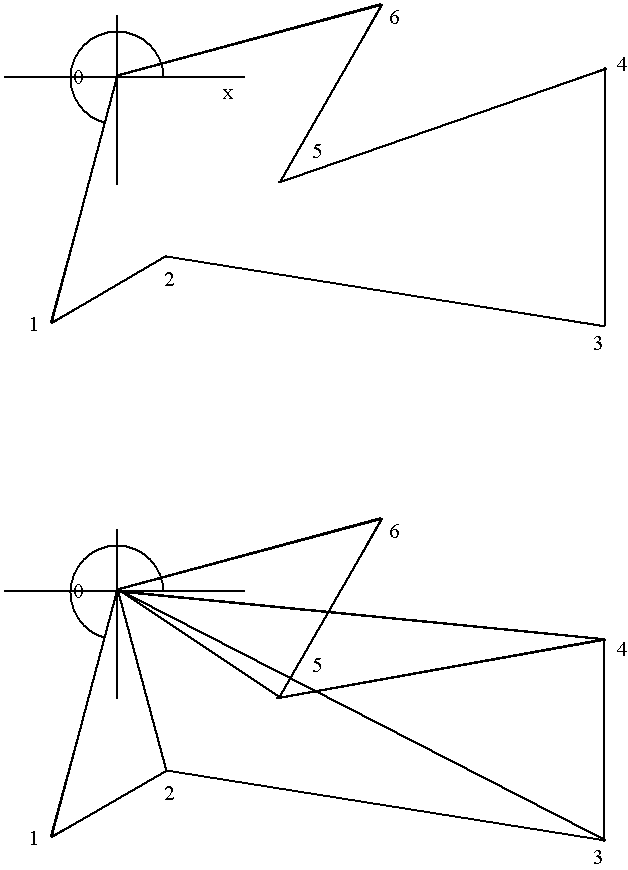

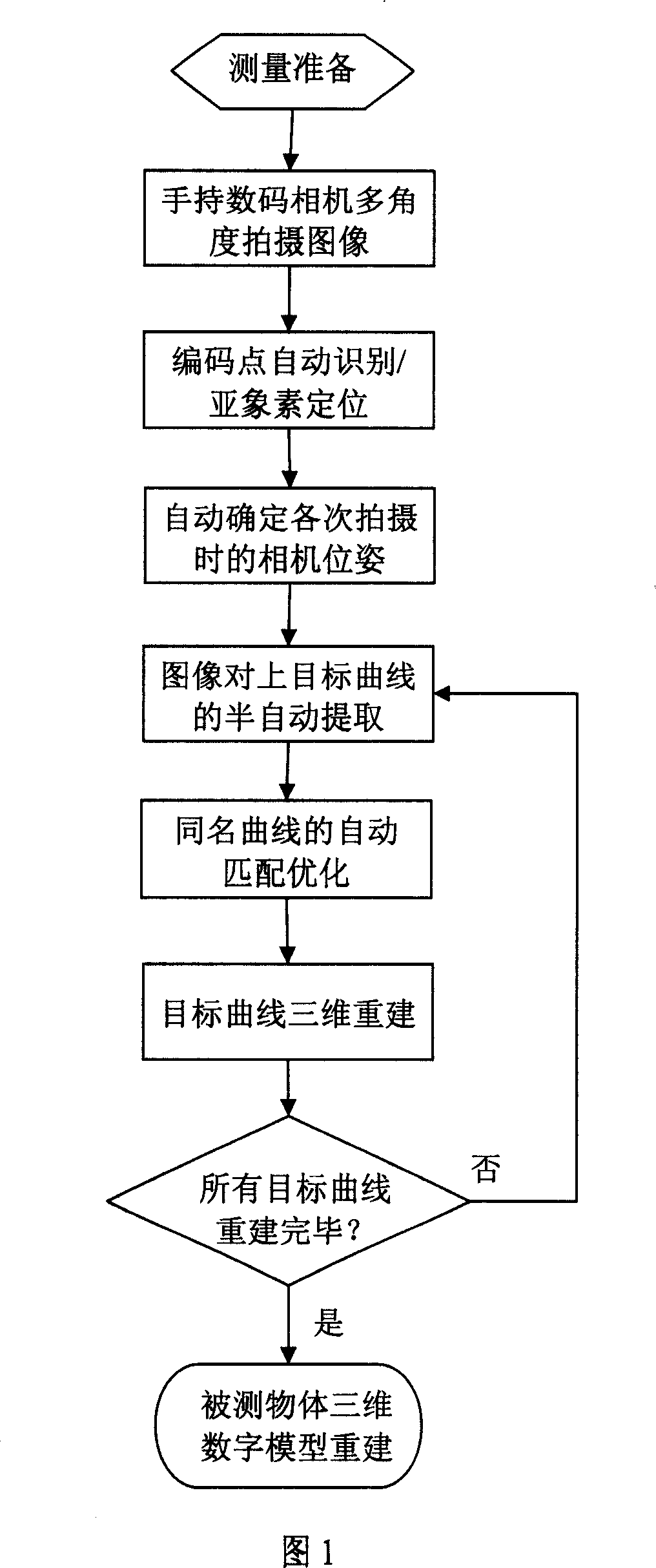

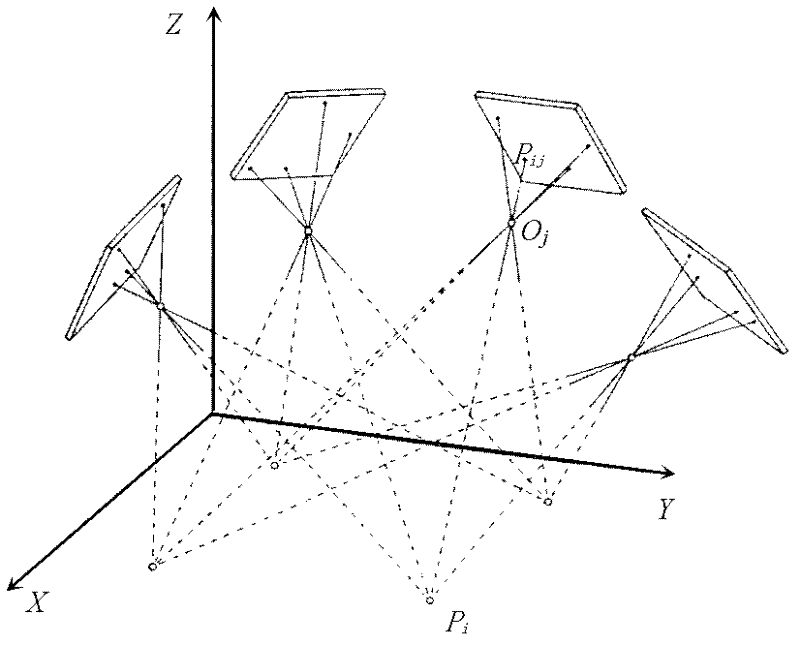

Method for making three-dimensional measurement of objects utilizing single digital camera to freely shoot

InactiveCN1975323APromote reconstructionAvoid Cumulative ErrorsUsing optical meansDimension measurementCurve matching

This invention disclosed a three-dimension measurement method which consists of preparation, picture intussusception, coding spot identification, camera location confirmation, target curve pick-up, homonymic curve matching and target curve reconstruction. It has the following characteristics: mark on the target curve before measuring to make the picture identification much more easy; place a guage and a set of coding spots around the target object; screen randomly to obtain a set of image by the camera; calculate automatically the position and gesture of the camera according to the images; pick up the marked curve and match the homonymic curve in different images so that the information of three-dimensional spot line was automatically calculated.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Integrated non-contact dimensional metrology tool

An apparatus for determining endoscopic dimensional measurements, including a light source for projecting light patterns on a surgical sight including shapes with actual dimensional measurements and fiducials, and a means for analyzing the projecting light patterns on the surgical sight by comparing the actual dimensional measurements of the projected light patterns to the surgical site. The projected light patterns may include multiple wavelengths of light for measurements of different features of tissue and may be produced using a laser in conjunction with a light shaping optical diffuser, or using a light emitting diode in conjunction with a light shaping optical diffuser, or using a special filter. The projected light patterns may take the form of concentric rings with each ring representing a radius of a given dimension and may be a collimated pattern which does not significantly change size as a function of a distance to a projected plane.

Owner:TYCO HEALTHCARE GRP LP

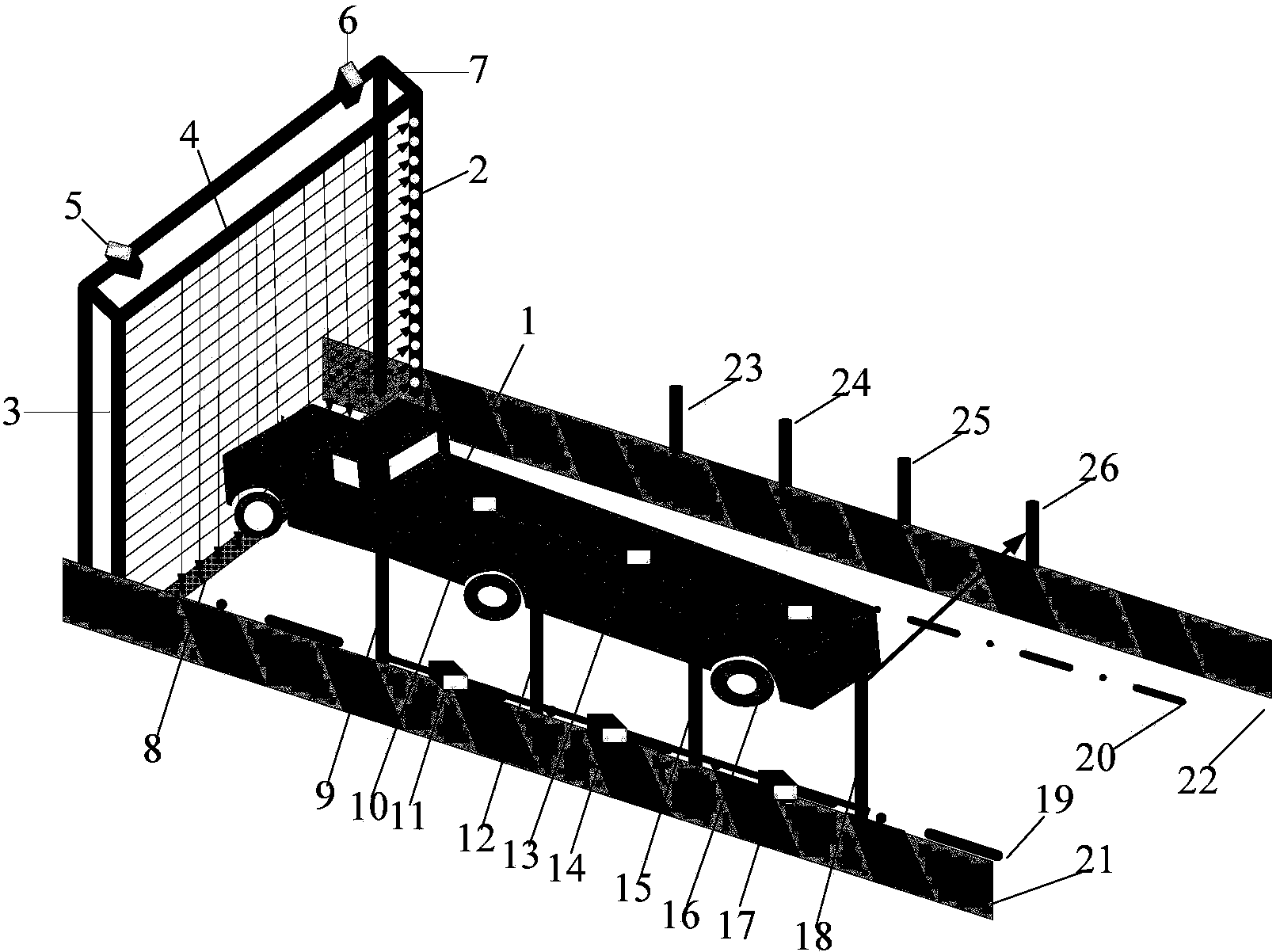

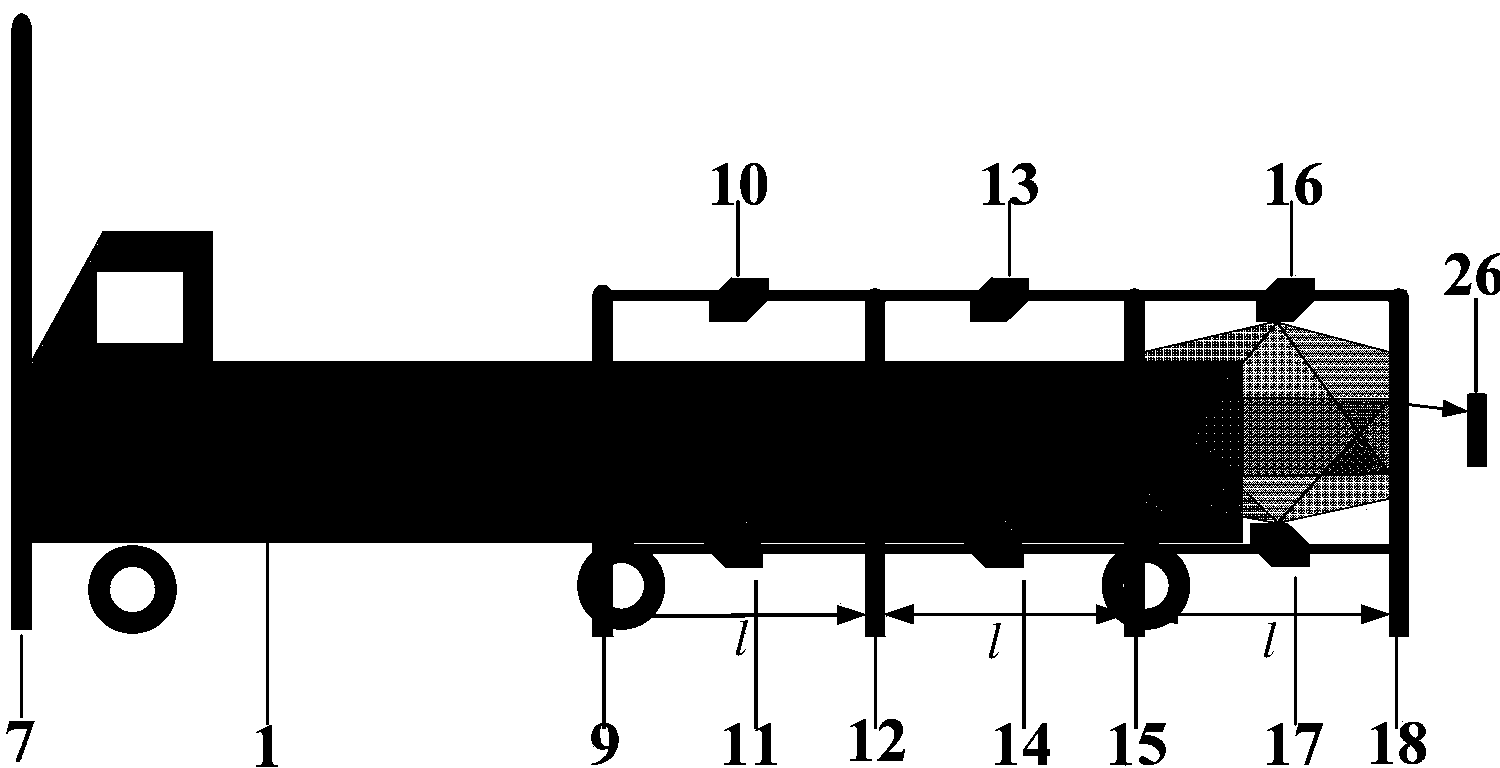

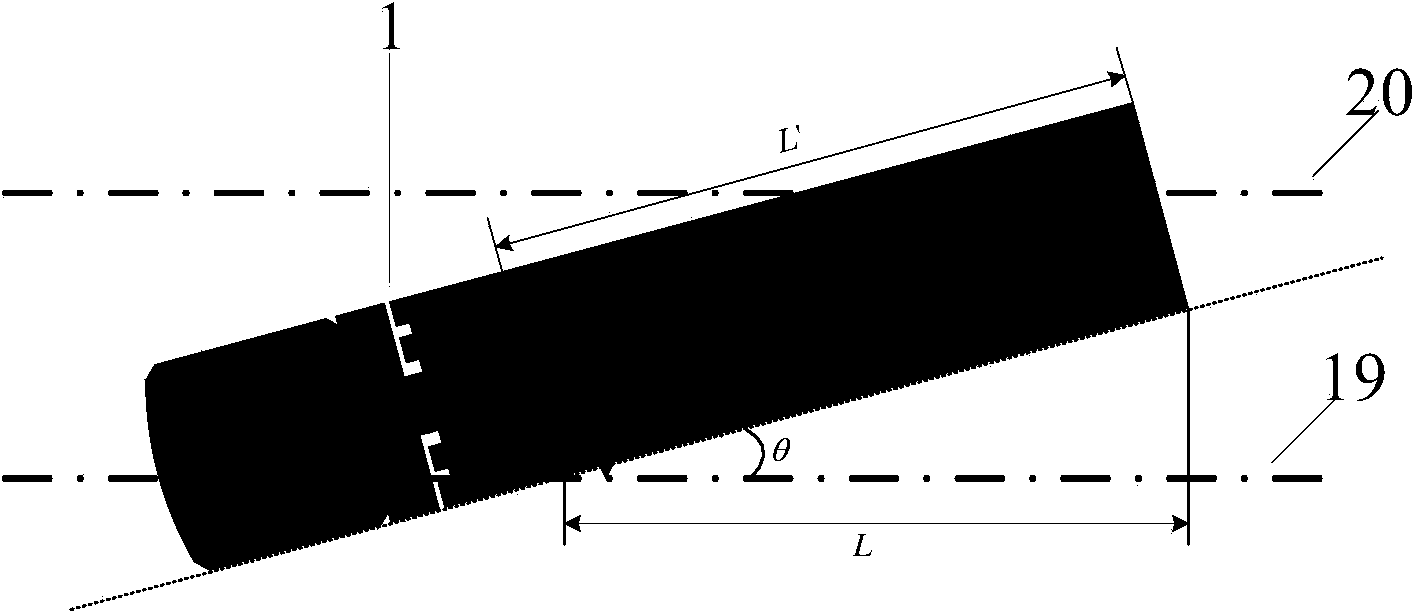

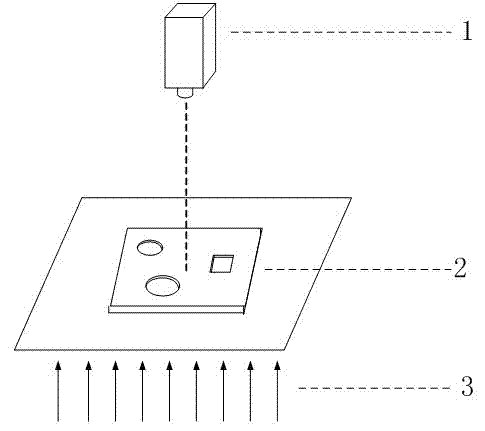

System and method for measuring vehicle outline dimensions based on machine vision and laser light curtain

The invention belongs to the technical field of test and measurement, provides a system and method for measuring vehicle outline dimensions based on machine vision and a laser light curtain, and high-precision, real-time and rapid measurement for feature sizes such as the length, width and height of a vehicle can be achieved on the premise of not influencing the normal running state of the vehicle. According to the technical scheme, the system for measuring the vehicle outline dimensions comprises a vehicle outline length dimension measuring module, a vehicle outline width dimension measuring module and a vehicle outline height dimension measuring module. Furthermore, a group of one-dimensional laser detector arrays are installed on a position, relative to the same height of the transverse laser light curtain, of the other side of a running measuring area of a vehicle to be measured, and the one-dimensional laser detector arrays are used for detecting laser beams output by the transverse laser light curtain sheltered by a vehicle which is not tested. The system and method for measuring vehicle outline dimensions based on machine vision and the laser light curtain are mainly applied to vehicle detection.

Owner:善测(天津)科技有限公司

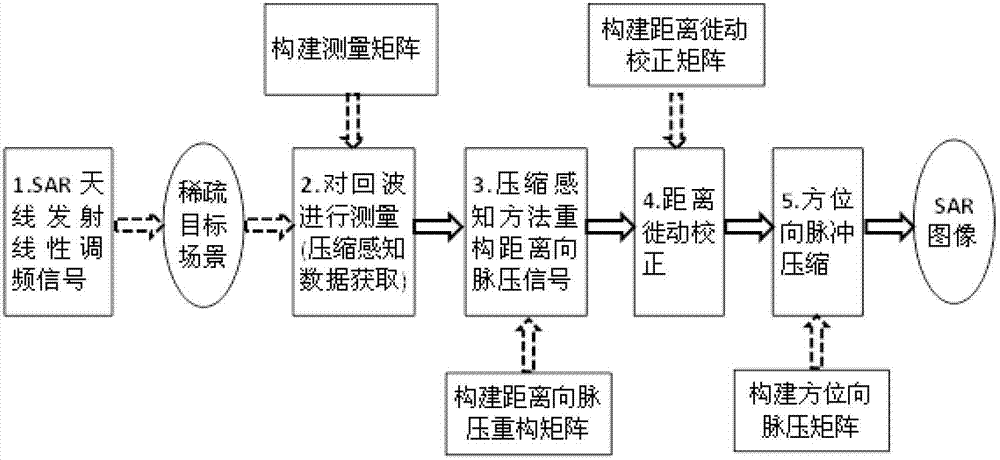

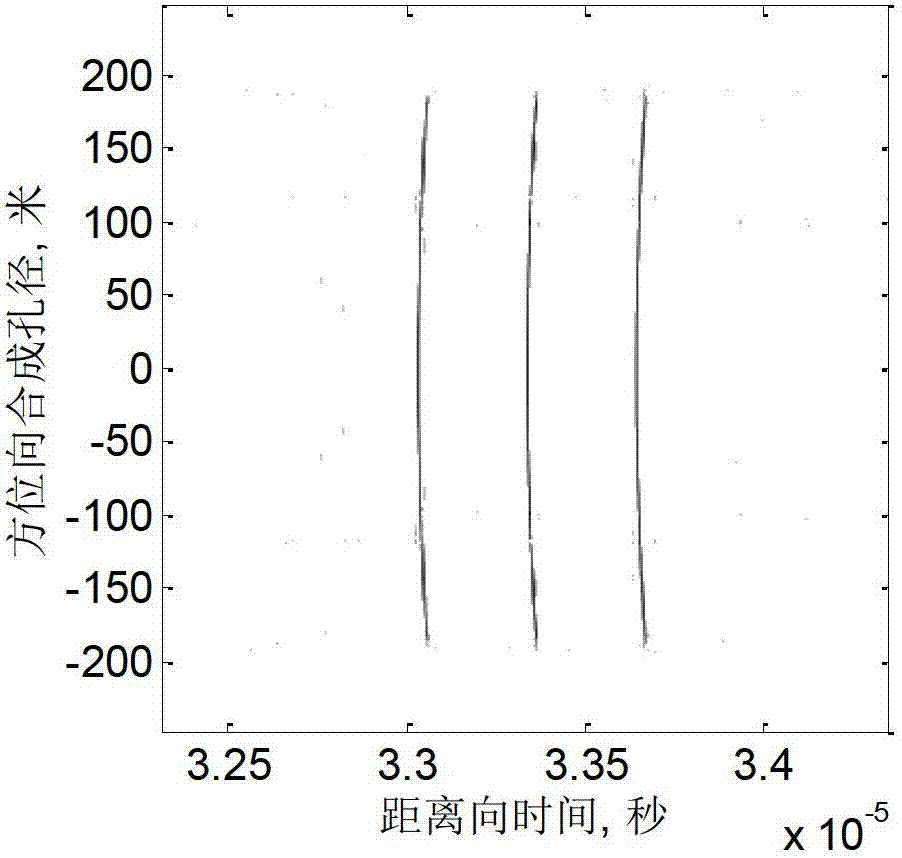

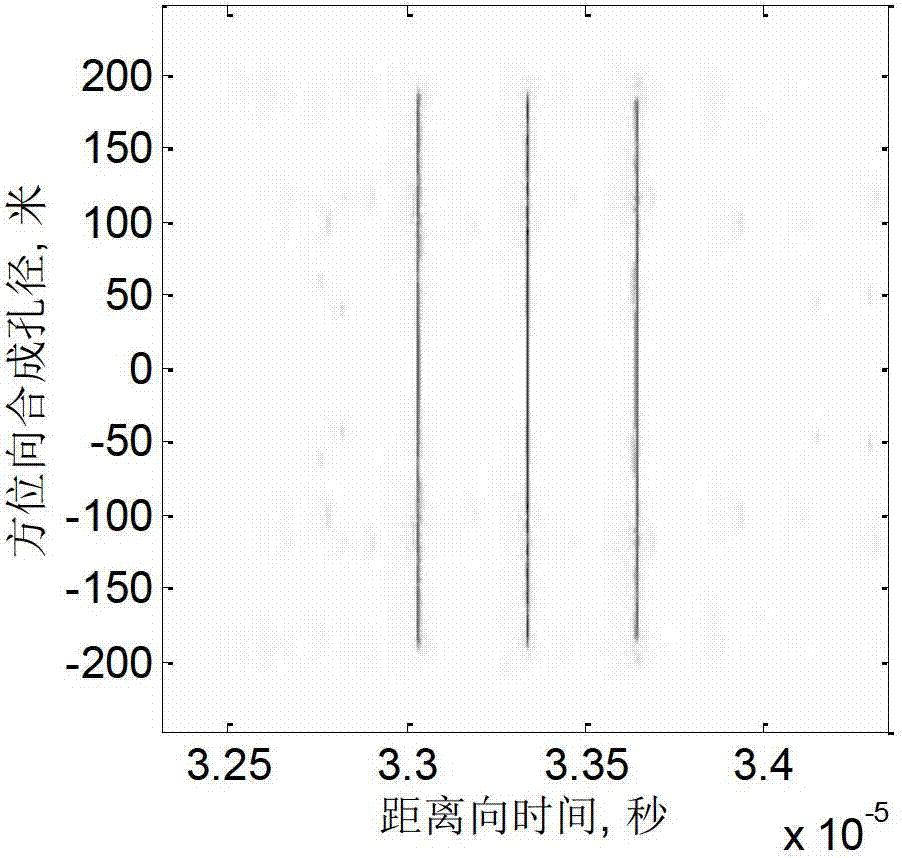

Compressed sensing synthetic aperture radar (SAR) imaging method based on fractional order fourier transformation

InactiveCN102879782AReduce the amount of measurement dataRelieve the pressure of signal storage and transmissionRadio wave reradiation/reflectionSynthetic aperture sonarDimension measurement

The invention provides a compressed sensing synthetic aperture radar (SAR) imaging method based on fractional order fourier transformation, and belongs to the technical field of microwave imaging. For a sparse target scene, a system emits a linear frequency modulation pulse signal; by adopting a method for projecting an echo signal to a low-dimension measurement matrix, measurement data which are much smaller than those required by a Nyquist sampling principle are acquired; due to the echo signal, after a reconstruction matrix is constructed by a simplified fractional order fourier transformation domain sparse mode and a data acquisition mode, a calculated distance pulse pressure result is optimized by a compressed sensing signal reconstruction method and is subjected to distance migration correction and direction pulse pressure to obtain a target scene imaging result. By the imaging method, the measurement data amount of a target scene with a sparse characteristic can be greatly reduced; and pressure on data storage and data transmission can be effectively relieved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

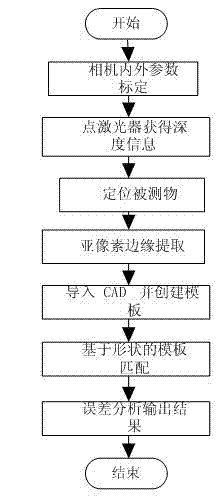

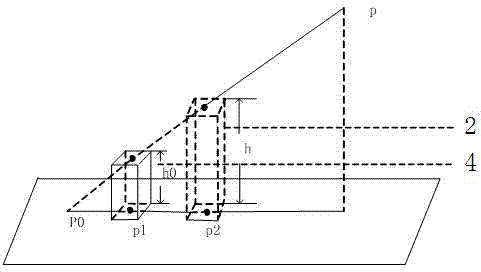

CCD (Charge Coupled Device)-based high-accuracy measuring method

ActiveCN103499297ARealize high-precision measurementHigh precisionUsing optical meansAlgorithmDimension measurement

The invention belongs to the field of vision, relates to a CCD (Charge Coupled Device)-based high-accuracy measuring method, and breaks through the limitation that the conventional CCD-based size measuring technology is mostly applied to measurement of small-sized objects. An algorithm comprises the following steps: building a camera imaging model, calibrating internal and external parameters of a camera, and correcting images according to a distortion model and internal parameter data; putting forward a method for distinguishing the edges of the upper and lower surfaces of a tested object by using neighborhood information, extracting the sub-pixel edge information of the upper surface of the tested object by using a Canny filter, building a template according to CAD (Computer Aided Design) data of a detected part, accurately locating and identifying the tested object by using a shape-based template matching algorithm, acquiring the depth information of the tested object according to a dot laser, and constraining and converting the posture of the upper surface of the tested object, wherein a profile distance is taken as the machining error measure of the tested object. The algorithm can be applied to size measurement of large-sized planar parts, and the accuracy can reach a sub-pixel grade.

Owner:爱科维申科技(天津)有限公司

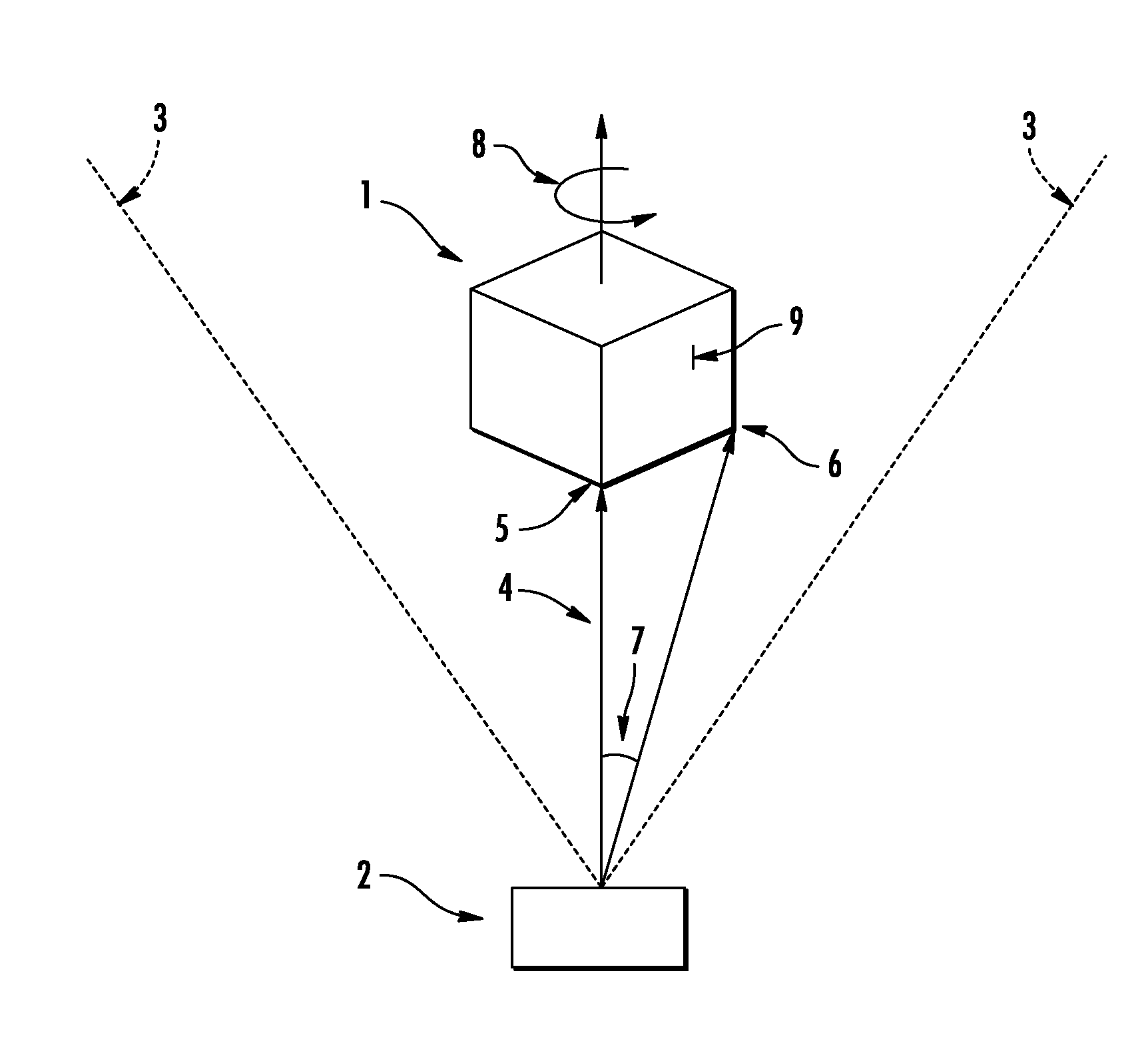

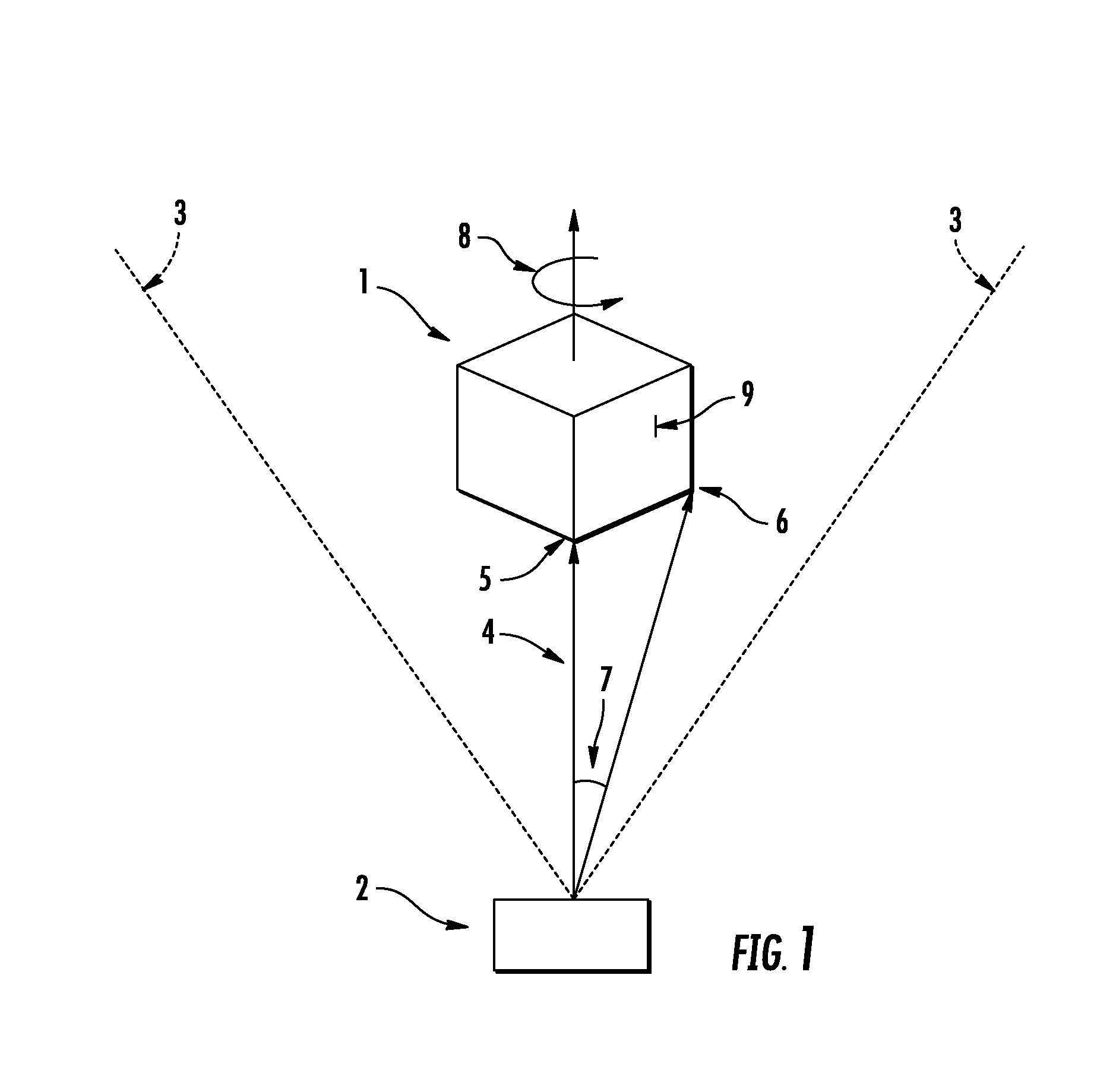

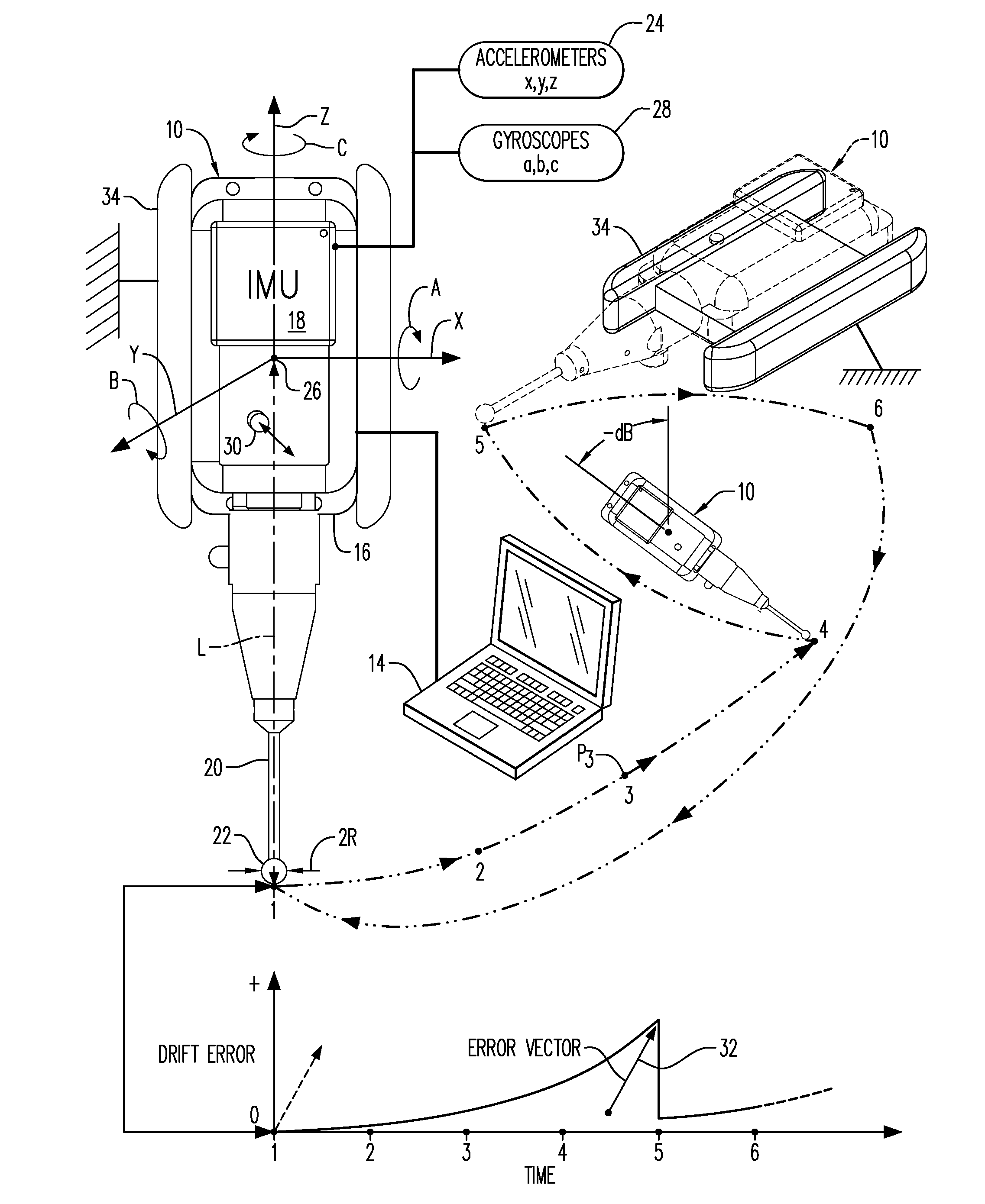

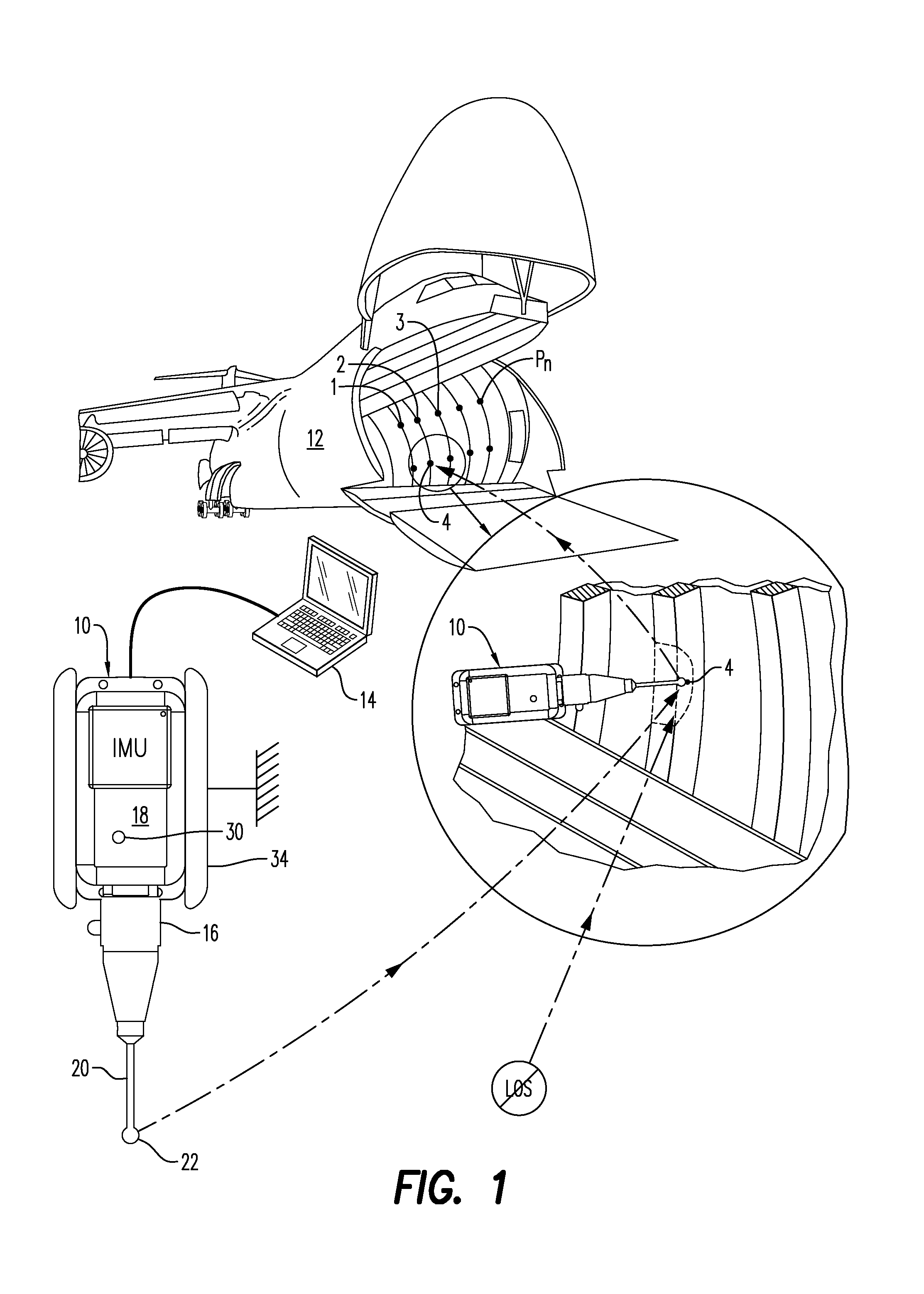

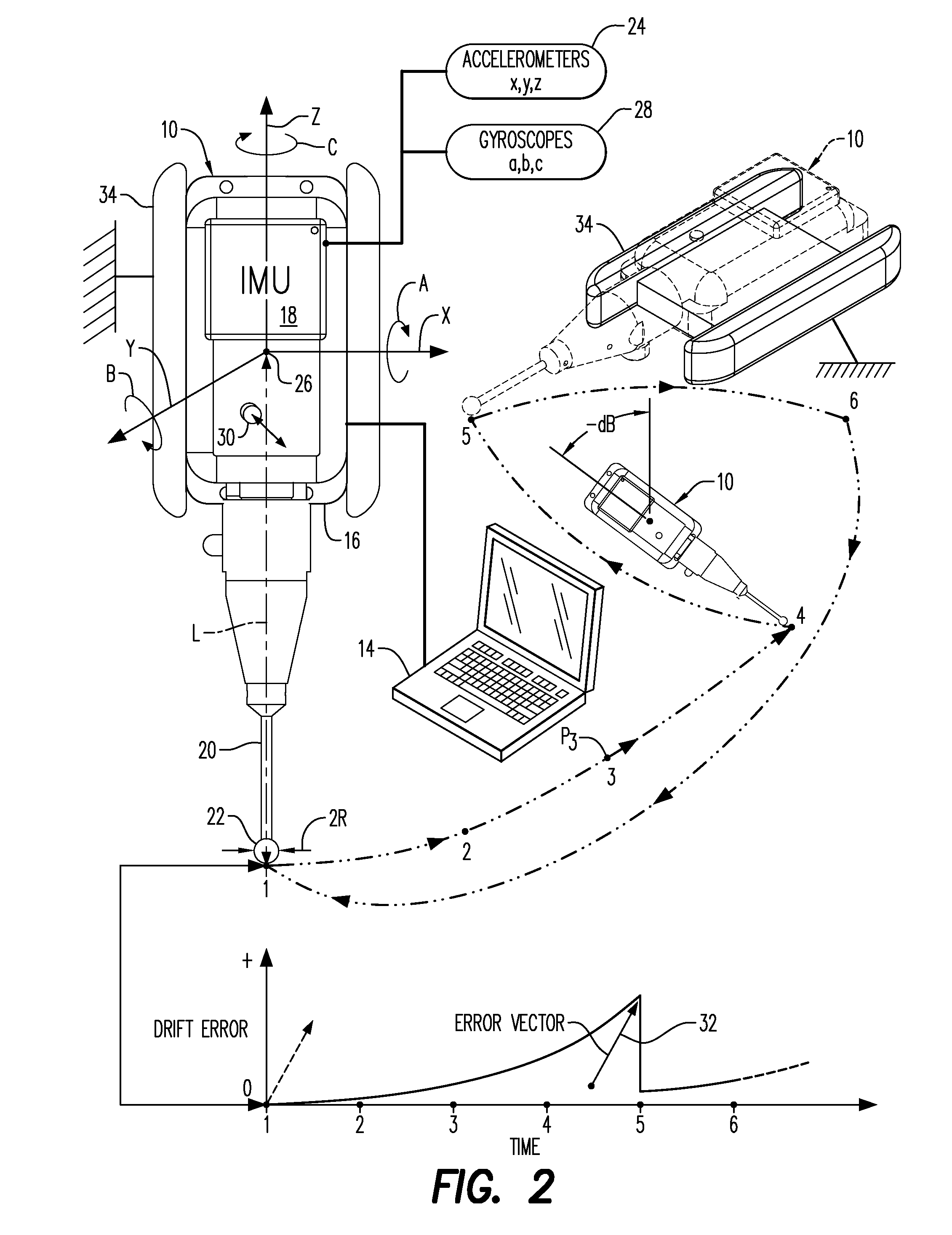

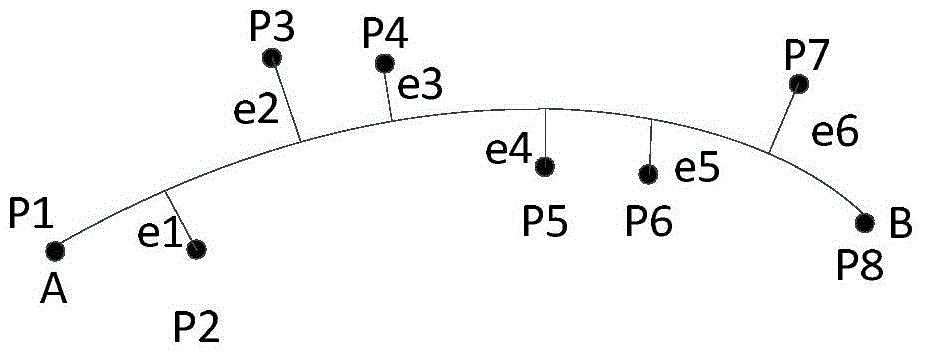

Inertial dimensional metrology

ActiveUS20160153767A1Reduce complexityLow costAcceleration measurement using interia forcesOptical rangefindersDimensional metrologyMeasurement point

A method of performing dimensional metrology of an object (12) includes incorporating an Inertial Measurement Unit (IMU-18) with an elongate probe (20) in a portable metroprobe (10). A tip (22) of the probe (20) has an offset length (L) from an origin (26) of a coordinate system in the IMU (18) and position (X,Y,Z) thereof is correlated based on attitude (A,B,C) measurement of the IMU (18). The metroprobe (10) is transported in sequence to a complement of survey points (Pn) on the object (12) for measuring corresponding coordinates (X,Y,Z) thereof based on measured attitude (A,B,C) of the IMU (18).

Owner:ADVANCED THEODOLITE TECH INC

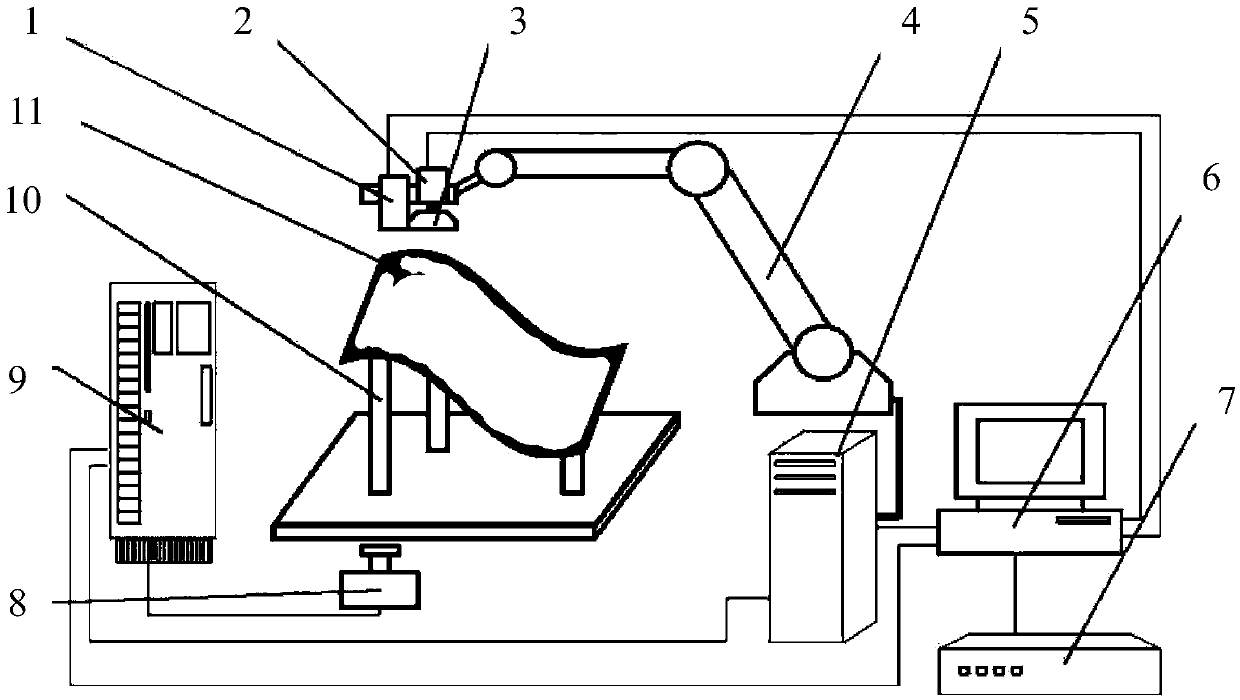

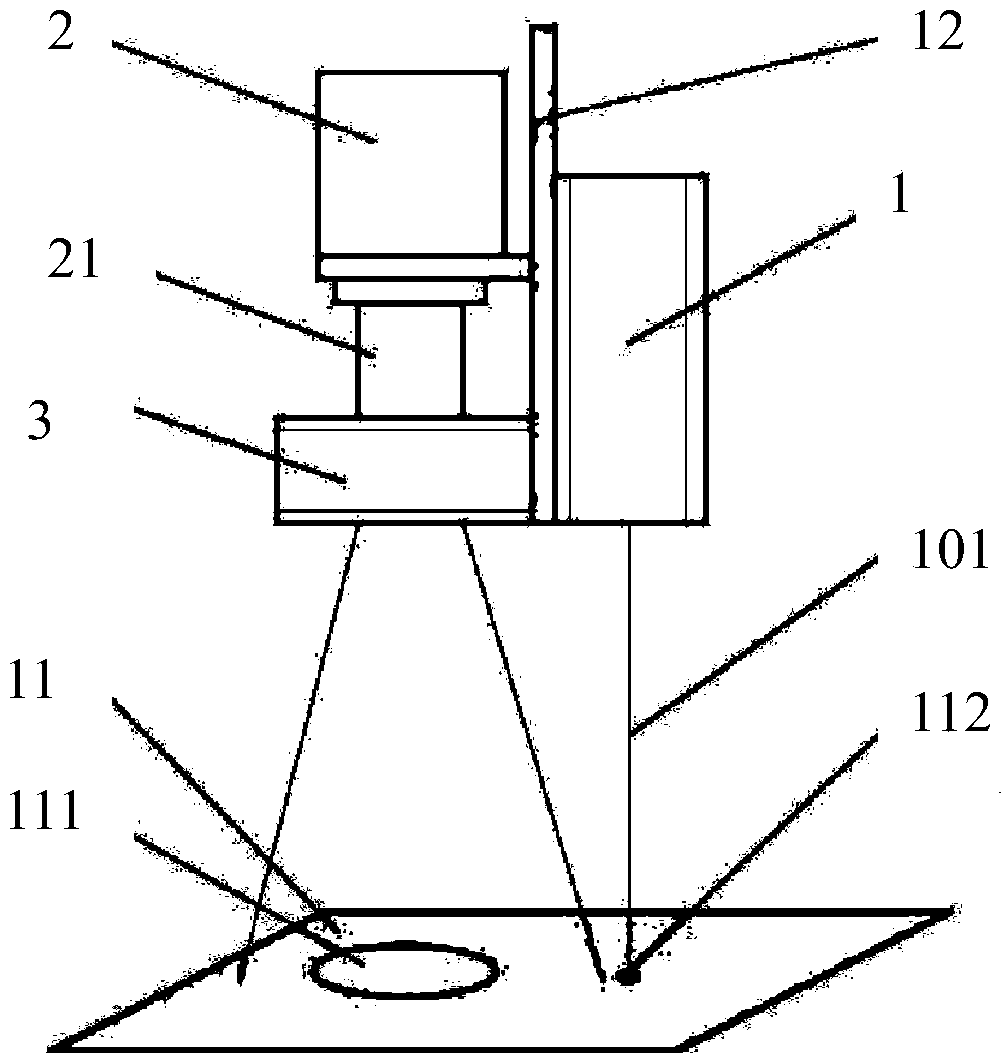

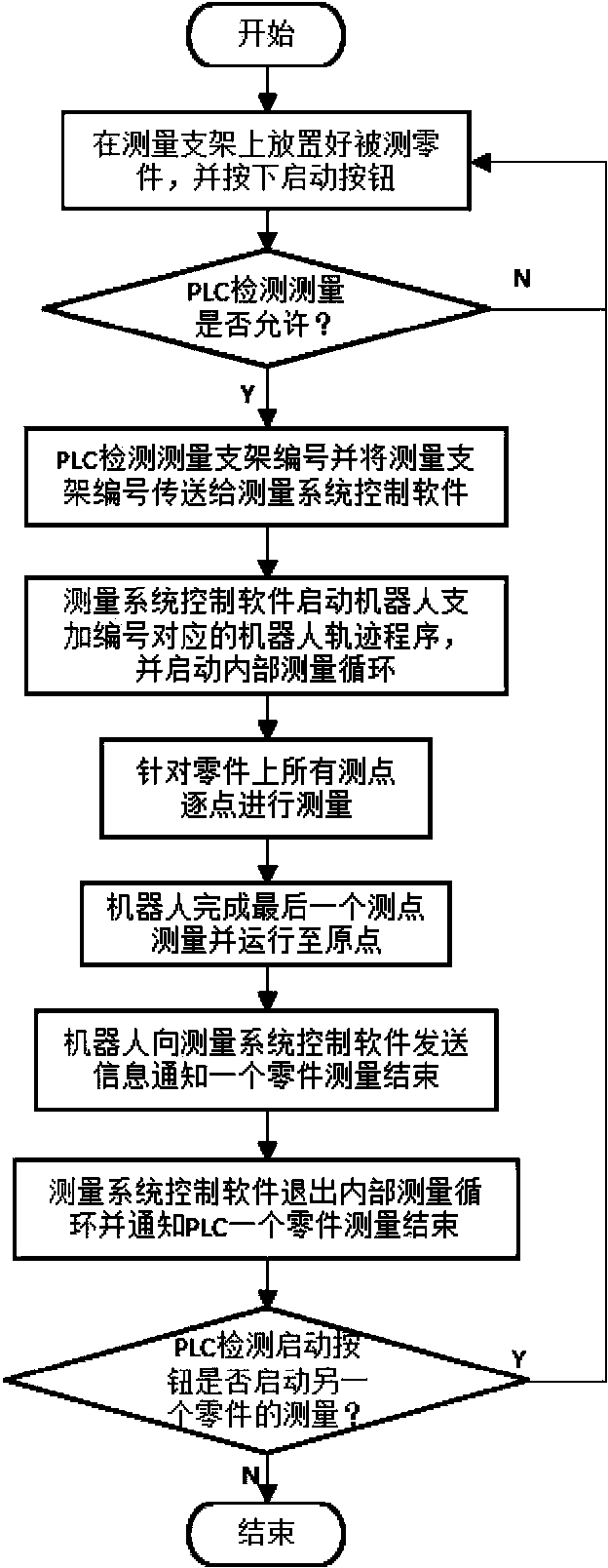

Non-contact type flexible on-line dimension measurement system

InactiveCN103776378AImprove efficiencyMultiple samplesUsing optical meansMeasurement pointControl system

Disclosed is a non-contact type flexible on-line dimension measurement system. A laser displacement sensor, an industrial camera and a power supply are fixed at the tail end of an industrial robot, and the robot saves measuring positions of workpieces to a robot moving track program through a teaching programming in advance. After the workpieces are placed on a measuring bracket and fixedly clamped, the robot drives the displacement sensor, the industrial camera and the power supply to operate to each measurement point on the workpieces for measurement according to pre-programmed programs; when the robot operates to each measurement point, the robot sends a measurement permission instruction to a measurement sensing system, a control system of the measurement sensing system performs measurement and real-timely sends measurement results to a measurement data saving and querying data base, subsequently, the control system of the measurement sensing system informs the robot of operation to the next measurement point, and the whole system repeatedly performs the above circulation to accomplish measurement work of one workpiece at all measurement points. By means of the non-contact type flexible on-line dimension measurement system, efficiency of measurement of automobile parts is improved, measurement samples are multiple, and measurement results are accurate.

Owner:上海思琢自动化科技有限公司

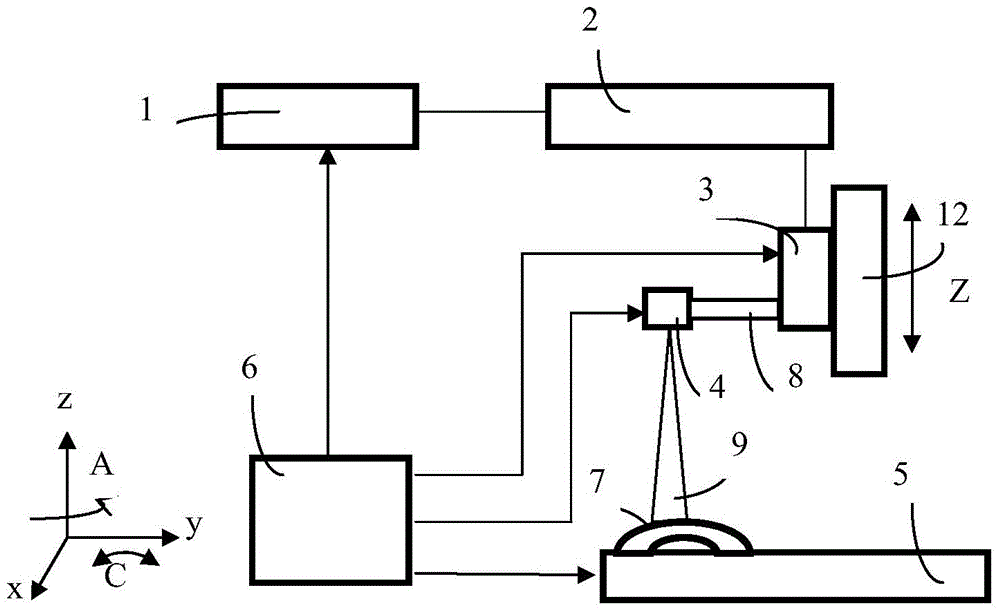

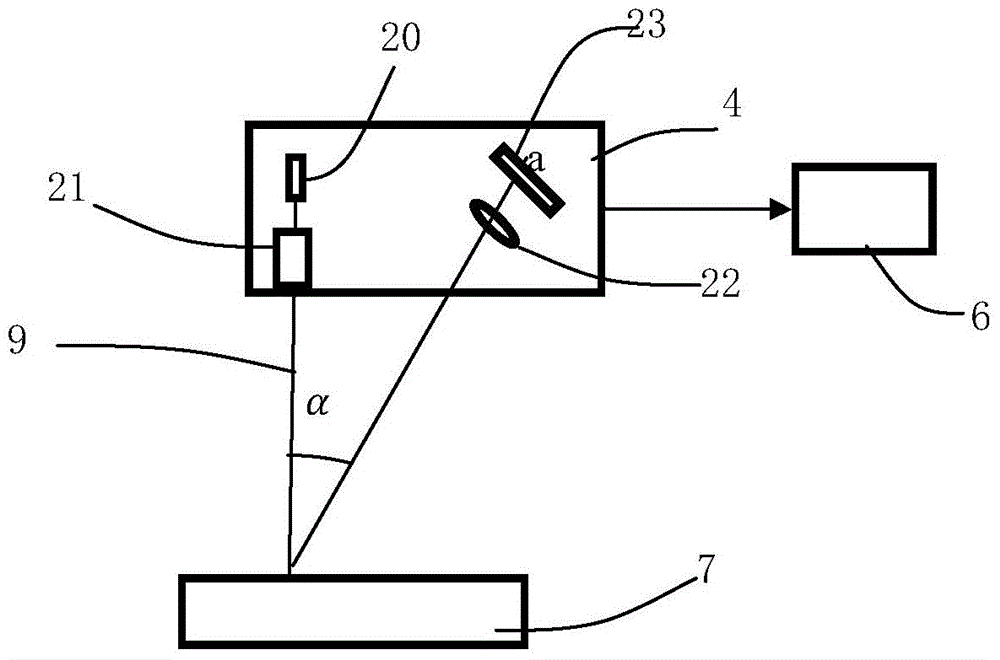

Online laser measuring, machining and detecting method and device

ActiveCN105136027AEliminate errorsHigh precisionUsing optical meansComputer control systemLaser ranging

The invention discloses an online laser measuring, machining and detecting method and a device. By integrating laser measuring, machining and detecting, the geometric dimension and shape of the planar or curved surface of a work piece to be machined can be measured online before laser machining to obtain the actual planar or spatial structure dimension and feature, the error between the work piece to be machined and a theoretical mathematical model caused by deformation or time-dependent deformation produced in early-stage machining is eliminated, and the precision and quality of laser machining are improved. The device comprises a machining laser, an optical path system, and a laser machining head which are sequentially disposed on the same optical path. The device further comprises a laser ranging system, a computer control system, a mobile component, and a workbench. The laser ranging system is used to acquire measurement data of the work piece before and after machining, including the space coordinates and the normal angle of each point of the work piece, and offer the measurement data to the computer control system. By using the device, the precision and quality of 2D platform and 3D curved surface dimension measurement and detection can be improved, and the precision and quality of laser machining can be improved.

Owner:武汉飞能达激光技术有限公司

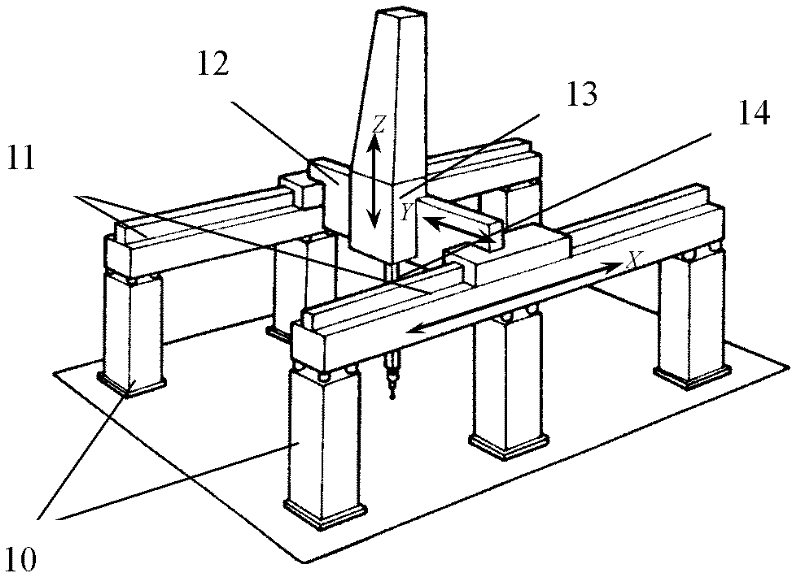

Large three-dimensional coordinate measuring method with laser tracking and device

InactiveCN102506702AMeasuring outsideMeasurement characteristicsUsing optical meansMechanical measuring arrangementsMeasurement deviceControl system

The invention relates to space coordinate measurement of large engineering and large machines and workpieces, and provides a large three-dimensional coordinate measuring system, which can be used on an engineering or production site, has high measurement accuracy, safe and reliable working and large measurement range, can detect the internal and external characteristics of a detected object and can meet the requirement for large size measurement in various engineering and production. The technical scheme adopted by the invention is as follows: the large three-dimensional coordinate measuring device with laser tracking comprises a measuring machine, a laser tracker and a calculation control system as well as a laser interferometer for measuring linear displacement, wherein the measuring machine is provided with a horizontal arm capable of doing x-direction movement and a main shaft capable of doing z-direction movement; the other end of the horizontal arm is provided with a corner prism; one end of the main shaft is provided with a measuring head rotating body which is provided with a measuring head; the other end of the main shaft is provided with a target and an angle measuring device; and a temperature measuring element which is used for carrying out temperature compensation is stuck on the main shaft. The invention is mainly applied in three-dimensional coordinate measurement.

Owner:TIANJIN UNIV

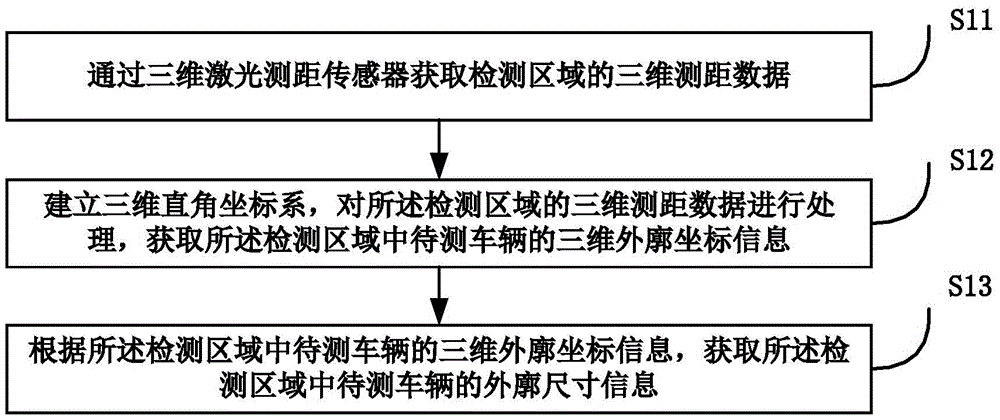

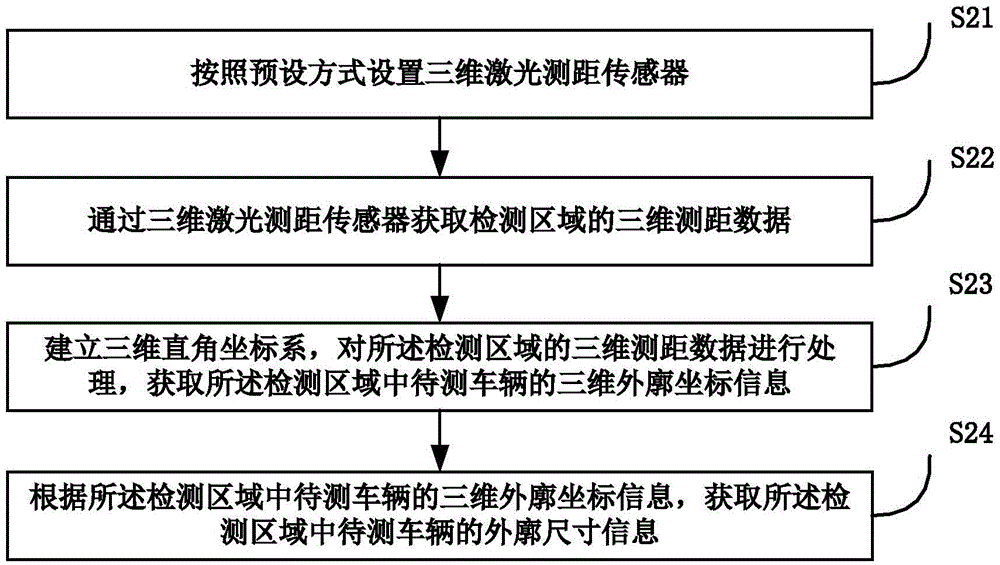

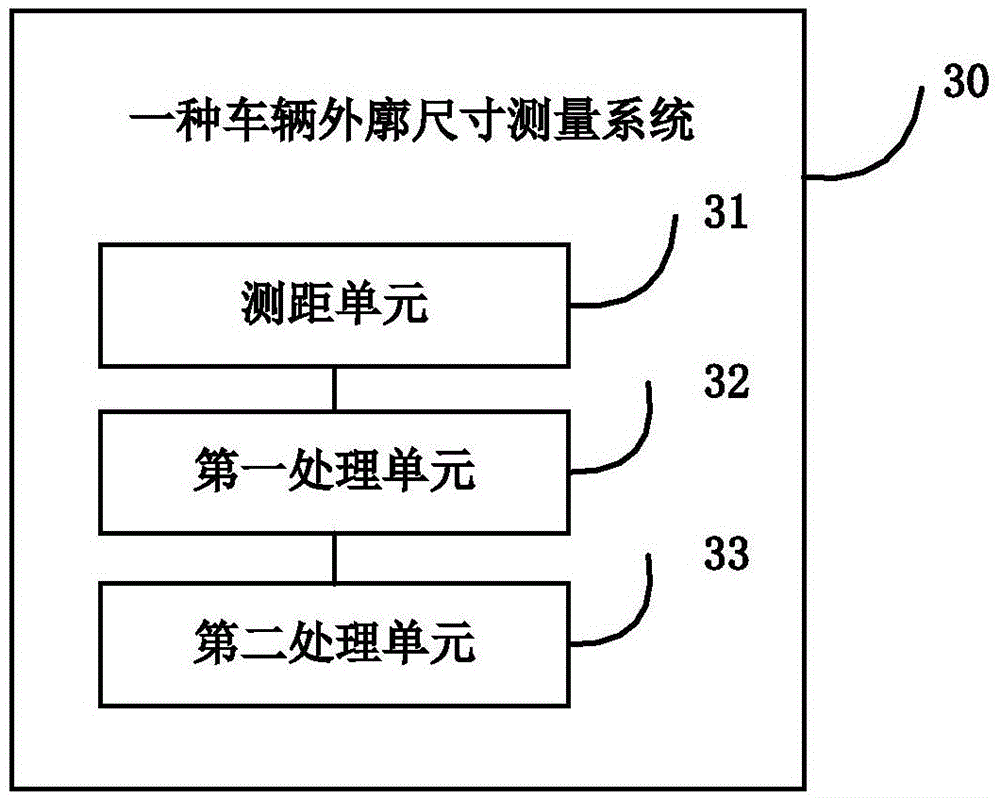

Vehicle profile dimensions measuring method and system

InactiveCN105606023ADynamic measurement of external dimensionsAvoid damageUsing optical meansRectangular coordinatesDimension measurement

The invention provides a vehicle profile dimensions measuring method, the method comprises the steps: 3D distance measuring data of a measurement area is obtained through a 3D laser distance measuring sensor; a 3D rectangular coordinate system is established to process the 3D distance measuring data of the measurement area, and 3D profile coordinate information of a to-be-measured vehicle in the measurement area is obtained; and according to the 3D profile coordinate information of the to-be-measured vehicle in the measurement area, profile dimensions information of the to-be-measured vehicle in the measurement area is obtained. The invention also provides a vehicle profile dimensions measuring system, the system comprises a distance measurement unit, a first processing unit and a second processing unit. The method can dynamically measure the profile dimensions of the vehicle, and the measurement precision is high; an enforce foundation can be provided for vehicle overloading driving detection, and the method and the system provided by the invention have advantages of real-time capability, reliability, no manual intervention and the like.

Owner:WUHAN WANJI INFORMATION TECH

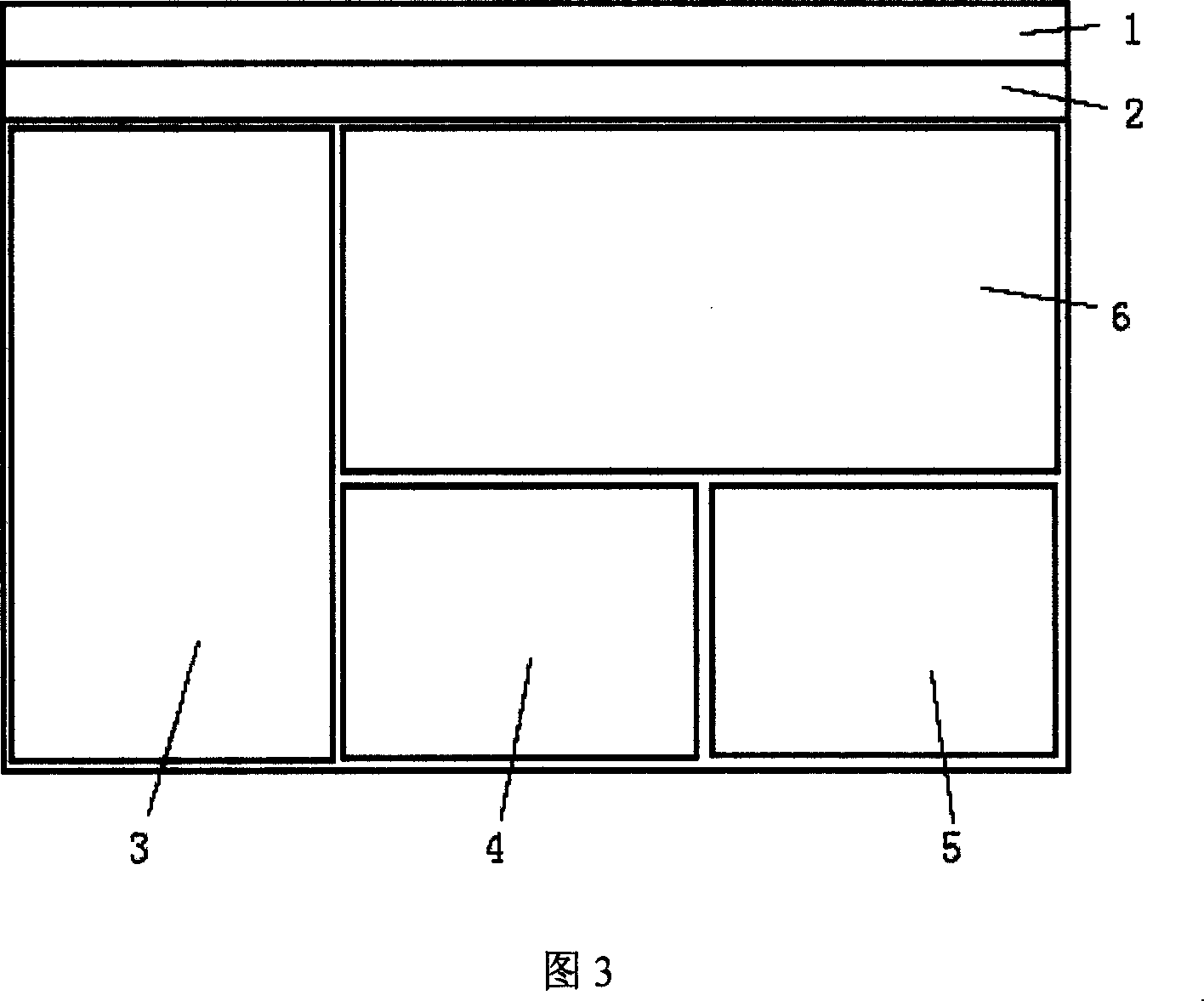

Split-screen display system and standardized methods for ultrasound image acquisition and processing for improved measurements of vascular structures

InactiveUS6979294B1Accurately and cost-effectively screenOrgan movement/changes detectionHeart/pulse rate measurement devicesSub-pixel resolutionSonification

A standardized acquisition methodology assists operators to accurately replicate high resolution B-mode ultrasound images obtained over several spaced-apart examinations. The methodology utilizes a split-screen display in which the arterial ultrasound image from an earlier examination is displayed on one side of the screen while a real-time “live” ultrasound image from a current examination is displayed next to the earlier image on the opposite side of the screen. A computerized echo edge recognition and tracking methodology automatically identifies ultrasound echo boundaries of the intima-media complex and automatically extracts IMT and arterial dimension measurements, without introducing human measurement error. Measurement accuracy is enhanced by use of sub-pixel resolution for echo edge boundary definition. Utilizing this methodology, measurement of vascular dimensions, such as carotid arterial IMT and diameter, the coefficient of variation is substantially reduced to values approximating from about 1.0% to about 1.25%. Dynamic material properties of arterial structures are measured in a standardized region in accordance with a standardized methodology in order to promote measurement repeatability.

Owner:UNIV OF SOUTHERN CALIFORNIA +1

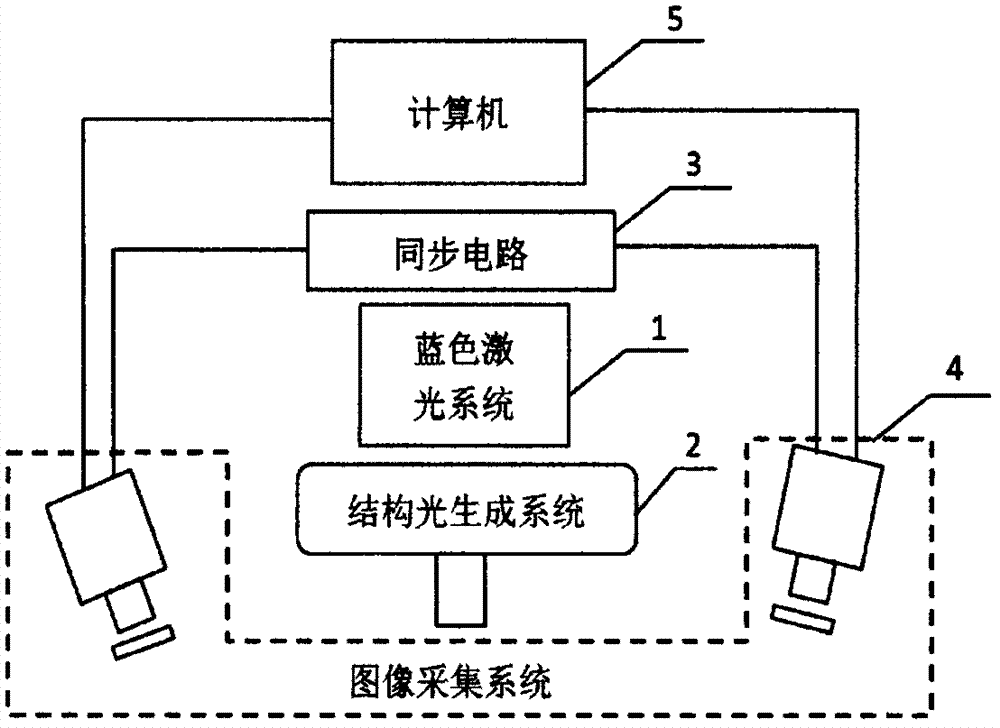

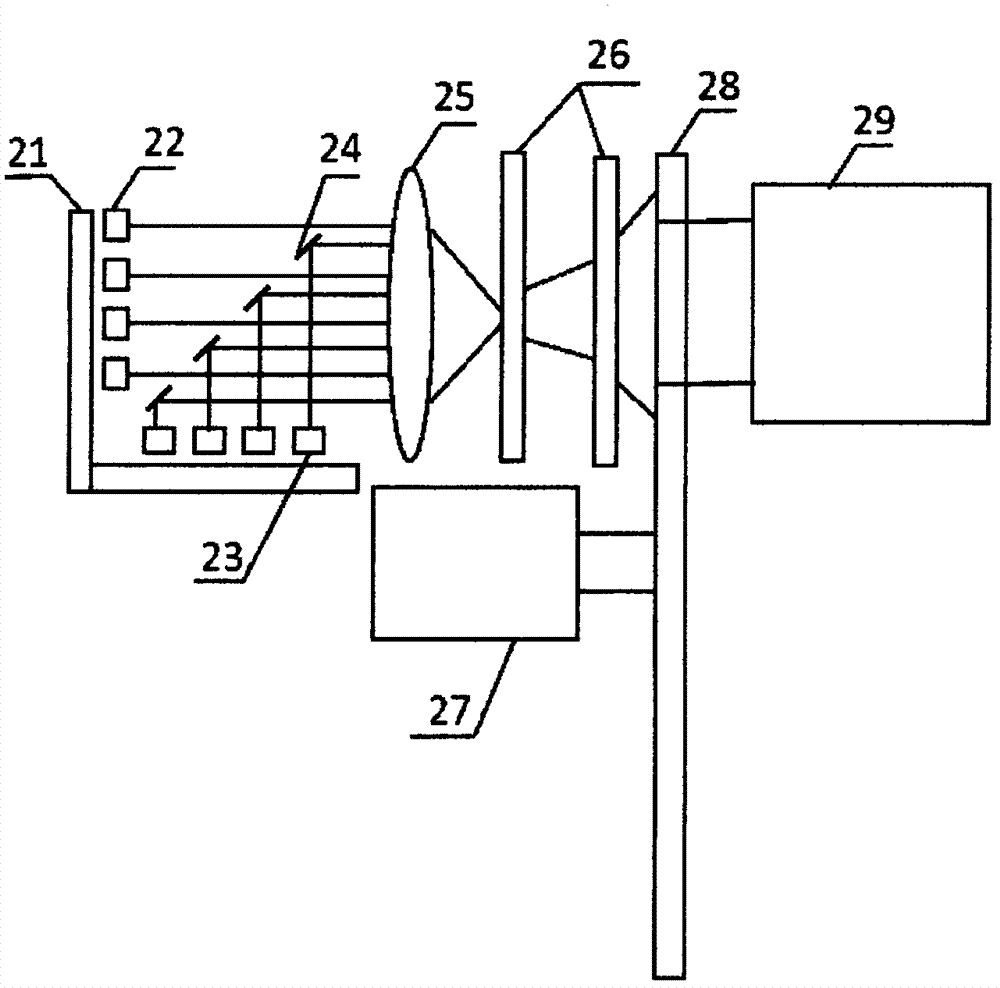

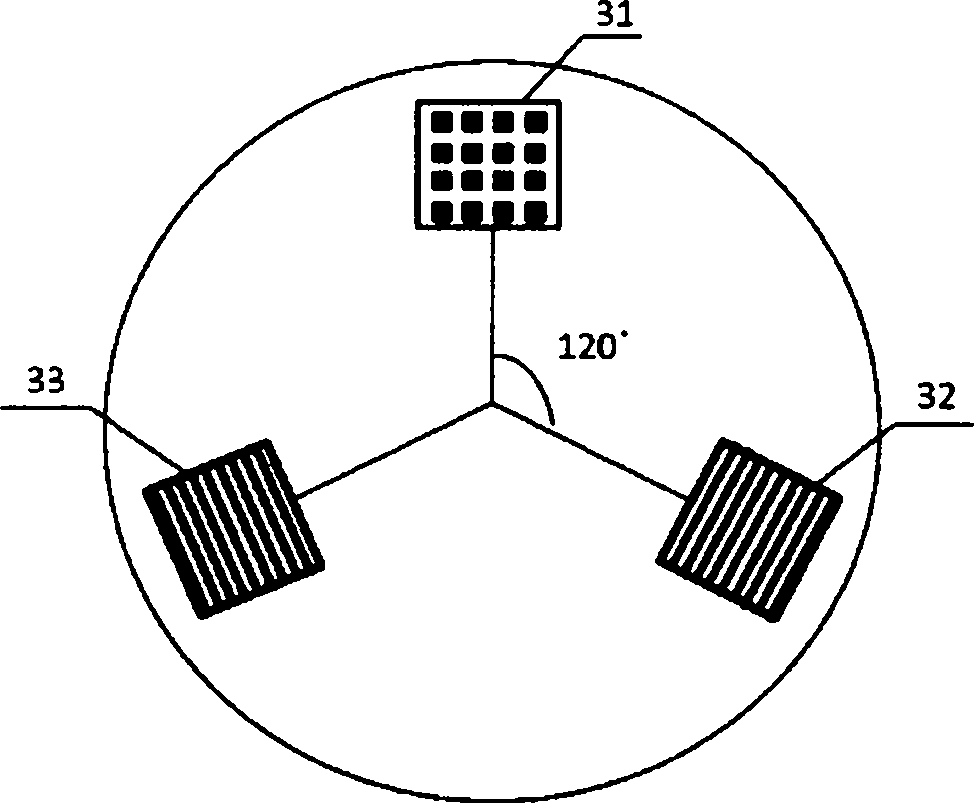

Planar structured light three dimension measuring device and method for high-reflectivity part

ActiveCN103868472ARealize measurementThere is no gamma nonlinearityUsing optical meansMeasurement deviceCollection system

A planar structured light three dimension measuring device and method for a high-reflectivity part relate to the field of three dimension optical measurement and aim to solve the problems of large size and slow measuring speed due to the complex structure of the existing device. The planar structured light three dimension measuring device comprises a blue laser source system, a structured light pattern generation system, a synchronous control circuit, an image collection system and a computer. The device has the advantages of small size, light weight, fast projecting speed and the like. The phenomena of local mirror reflection, mutual reflection and direction reflection and the like at the part surface are effectively inhibited by the projecting random or pseudo random coding patterns and two groups of periodically, forwardly and reversely changed black and white strip patterns, the sub pixel point match of two images shot by left and right cameras are fast realized, and the efficient measurement of the high-reflectivity part is finished. The planar structured light three dimension measuring device and method for the high-reflectivity part is suitable for the planar structured light three dimension measurement of the high-reflectivity part.

Owner:南京禺疆电子技术有限公司

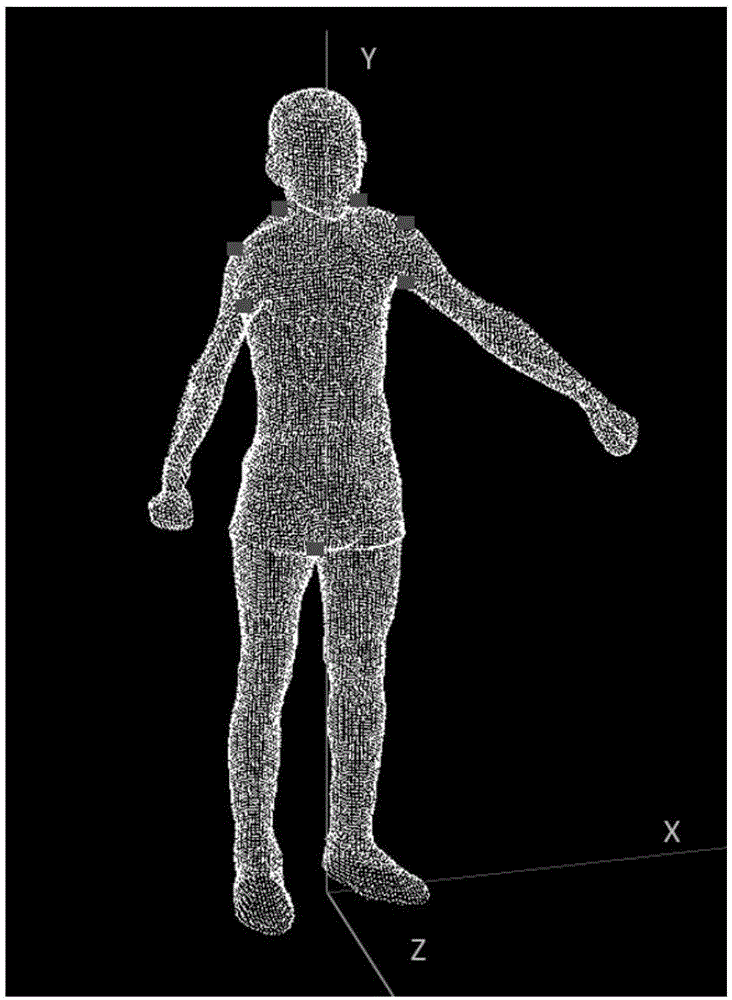

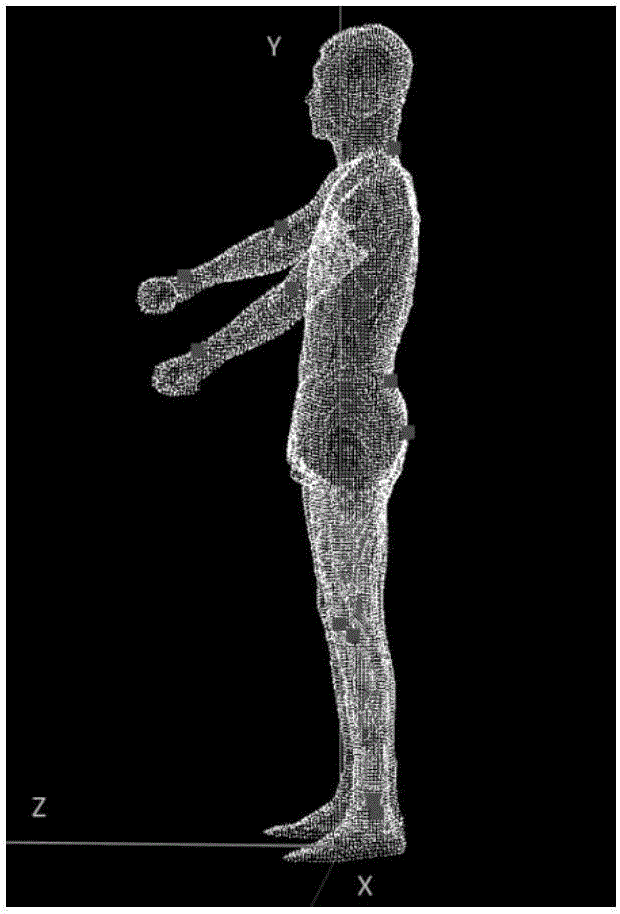

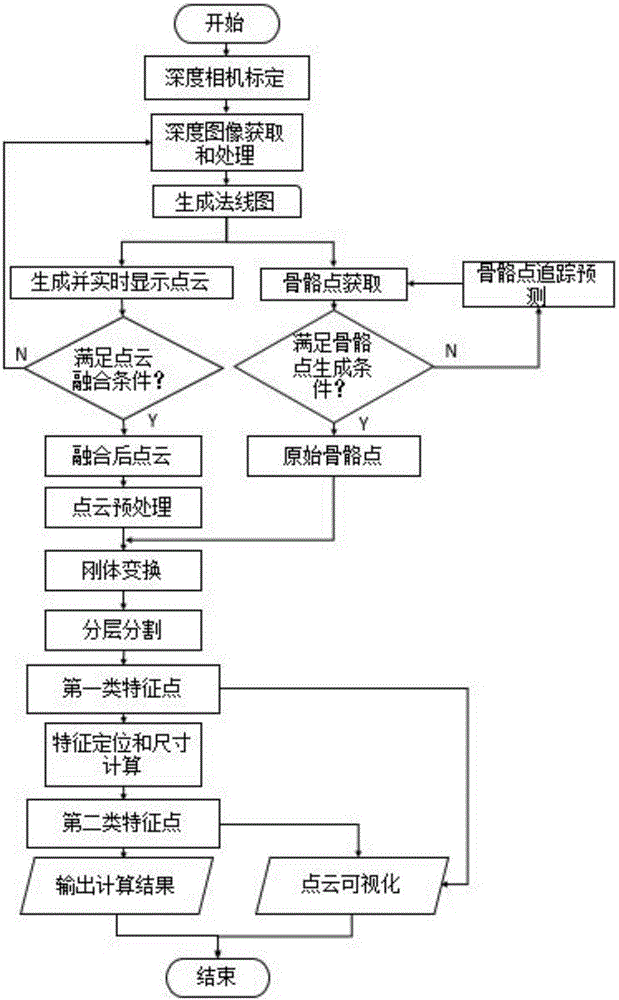

Human body dimension measurement method based on Kinect depth camera

ActiveCN106780619AImprove operational efficiencyLow costImage enhancementImage analysisColor imageSoftware system

The invention discloses a human body dimension measurement method based on a Kinect depth camera, and belongs to the technical field of machine vision. The method comprises the following steps that: (1) depth camera calibration: carrying out up-sampling on an original depth image, and automatically extracting angular point information through OpenCV (Open Source Computer Vision Library) to finish calibration; (2) depth image processing: adopting a united bilateral filtering method, and utilizing a high-resolution color image to improve the quality of the depth image and reduce noise interference in the depth image; (3) point cloud fusion and bone point information acquisition; and (4) human body dimension calculation. While system cost is lowered, the accuracy requirement of garment customization is guaranteed, the human body bone point information is used for enabling a human body characteristic identification algorithm to be simpler, and the operation efficiency of a software system is effectively improved.

Owner:QINGDAO POINT CLOUD INTELLIGENT TECH CO LTD

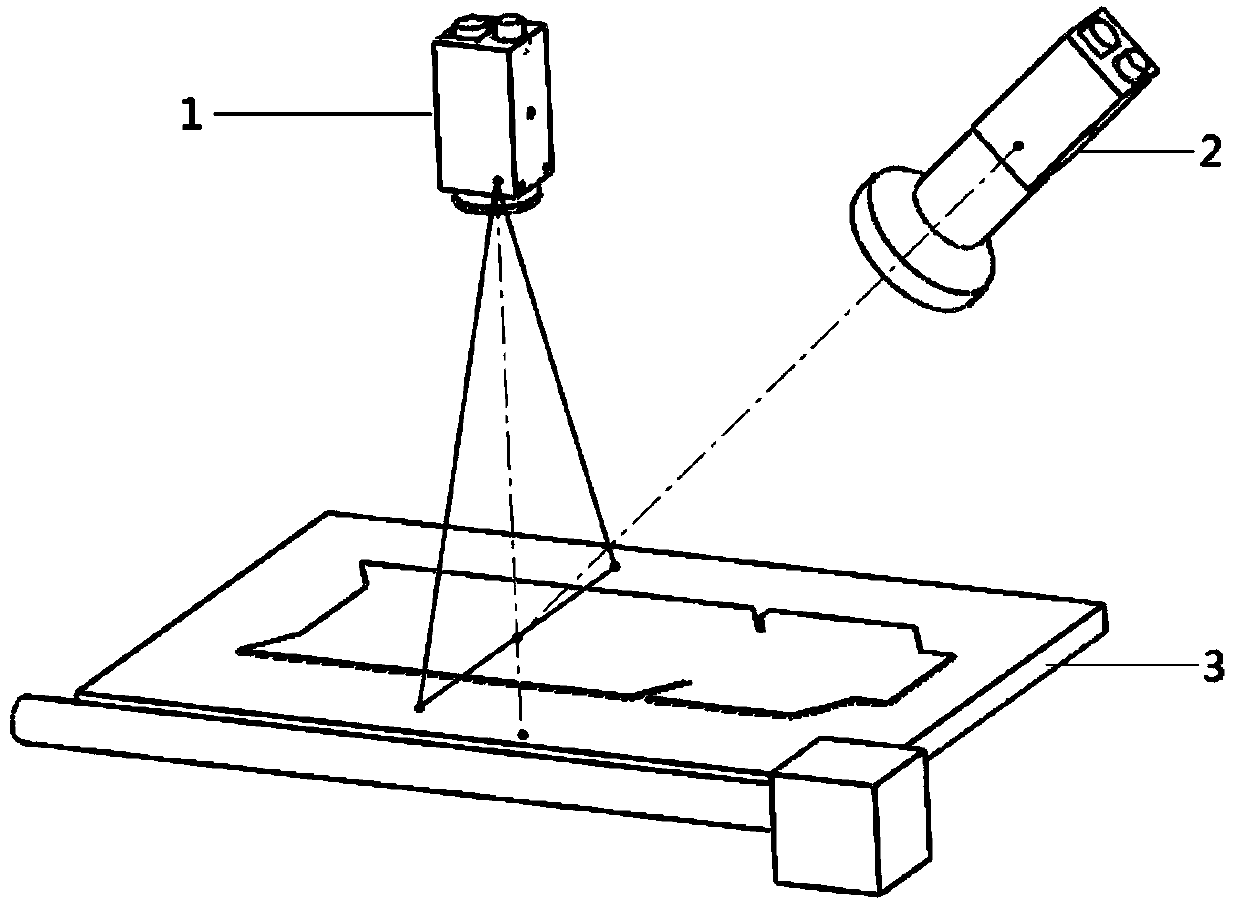

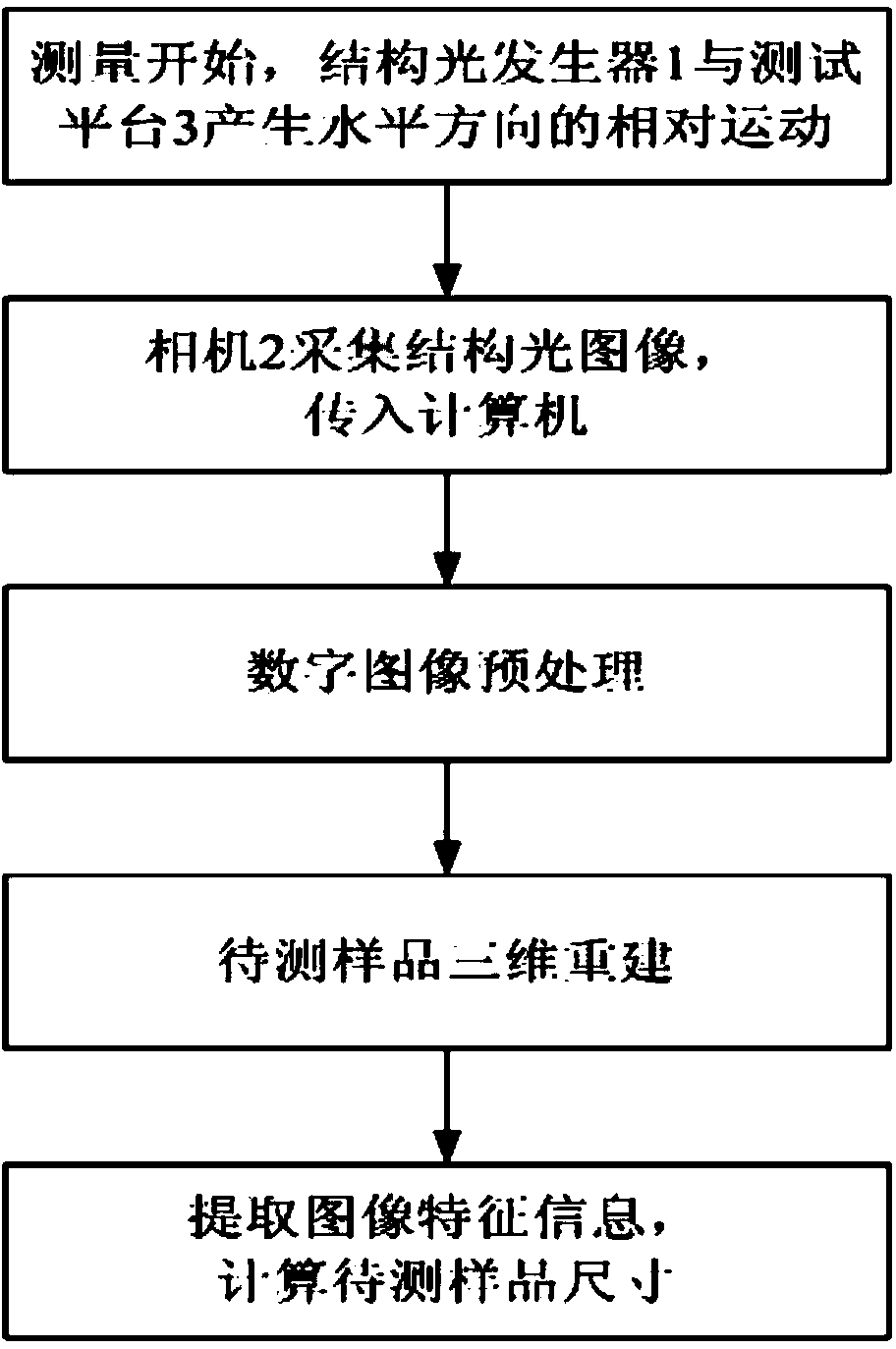

Computer vision based cigarette carton and box packing paper dimension measurement method

InactiveCN104197838ARealize automatic measurementReduce workloadUsing optical meansImaging processingVision based

The invention discloses a computer vision based cigarette carton and box packing paper dimension measurement method. The method is characterized in that structured light is projected on the surface of a measured object by the aid of a structured light generator, the structured light forms modulated structured light as being subjected to modulation of surface topography of a sample to be measured, the structured light is subjected to imaging by a camera to obtain a digital image of the measured object, three-dimensional topography and to-be-measured information of the measured object are extracted from the digital image of the measured object according to a computer vision algorithm and an image processing method, dimensional measurement of the measured object is realized, and the measured object is cigarette carton or cigarette box packing paper. By the method, contactless automatic measurement of cigarette carton and box packing paper dimensions is realized, personal error is reduced effectively, and measurement precision and efficiency are improved.

Owner:CHINA TOBACCO ANHUI IND CO LTD +1

Method for arranging at most article in finite dimension three dimensions

The invention relates to a method to arrange the most articles and goods in a container; prior container loading technologies are only limited in designing the optimum arrangement locations for the articles and goods through software calculation for a plurality of dimensions of regular articles and goods. However, for arrangement of many irregular articles and goods, both space utilization rate of containers and working efficiency are so low that fine schemes can be gained always through multiple rounds of repeated arrangement. The invention is characterized by performing dimension measurement, weighting, categorization and numbering for article and goods in different sizes, different dimensions and different properties with a weighting device, a laser scaner or a projection grate; put all the following information into a computer: All dimension measurement data, weight data, property data, category and coding data for articles and goods, and three-dimensional data of a container; the computer utilizes a pre-compiled software to calculate the optimum arrangement scheme for the articles and goods inside the container, and then, output the optimum arrangement scheme. The method can fulfill scanning for irregular articles and goods, and optimize calculation before an average space efficiency is anticipated to reach 95%.

Owner:张斌

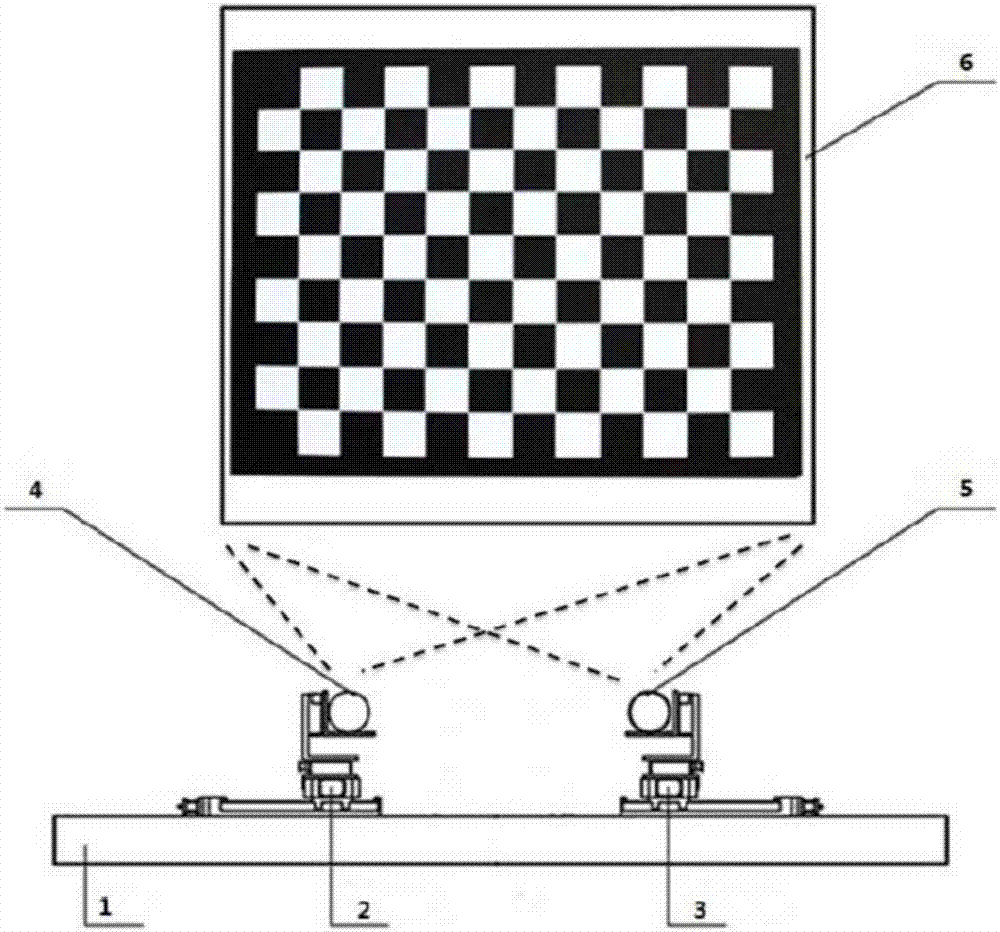

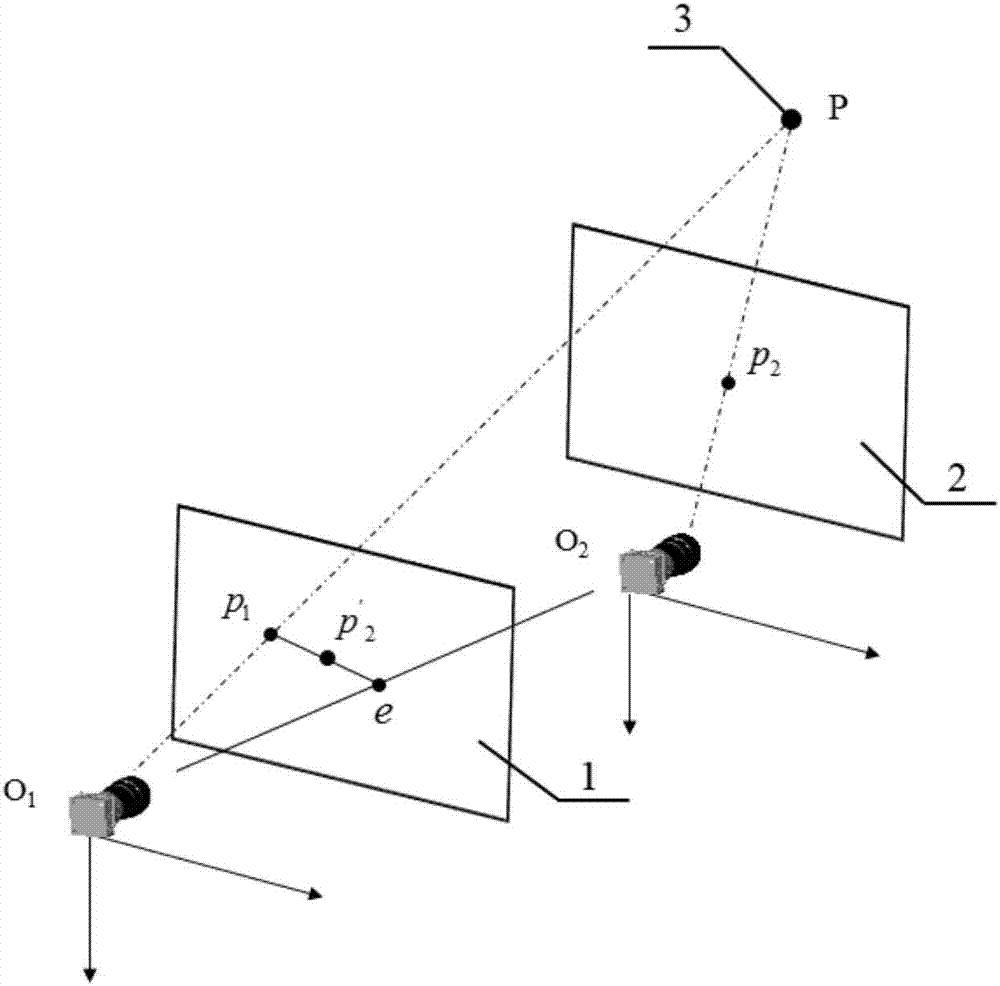

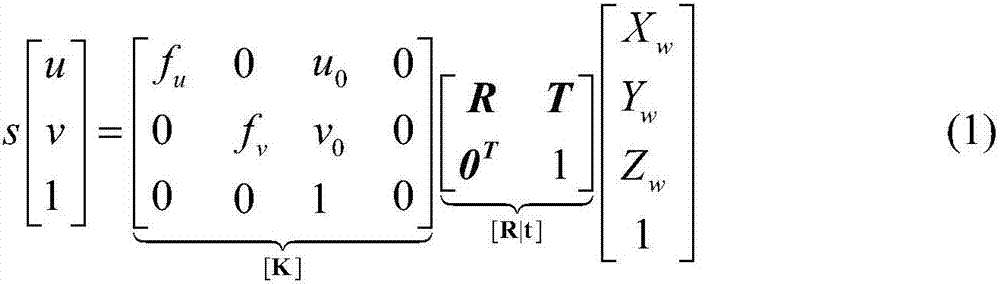

Step-by-step calibration method for camera parameters of binocular stereoscopic vision system

ActiveCN106981083AReal-time calibrationApplicable calibration requirementsImage analysisDimension measurementElectric control

The invention relates to a step-by-step calibration method for the camera parameters of a binocular stereoscopic vision system and belongs to the field of image processing and computer vision detection, which relates to a step-by-step calibration method for the camera intrinsic and external parameters of a dimension measurement system for large-scale forgings. According to the calibration method, firstly, the intrinsic parameter matrix of a camera is calibrated in the off-line manner in a laboratory, and the camera is driven to conduct two sets of mutually independent triorthogonal motions by a high-precision electric control platform. Secondly, based on the properties of FOD points, the intrinsic parameters of the camera are listed through the unique solution of a linear equation. At a forging experiment site, a basic matrix between two images is figured out through the 8-point method, and the method of decomposing of an essential matrix is conducted. In this way, the real-time on-line calibration for the external parameters of the camera is realized. Finally, based on the image information, the length of a high-precision three-dimensional scale is reconstructed, so that the solution of a camera scale factor is realized. The above method is simple and convenient in calibration process, short in calibration time and high in precision. The calibration of the camera of the binocular vision measurement system at the forging site can be precisely realized by adopting fewer images.

Owner:DALIAN UNIV OF TECH

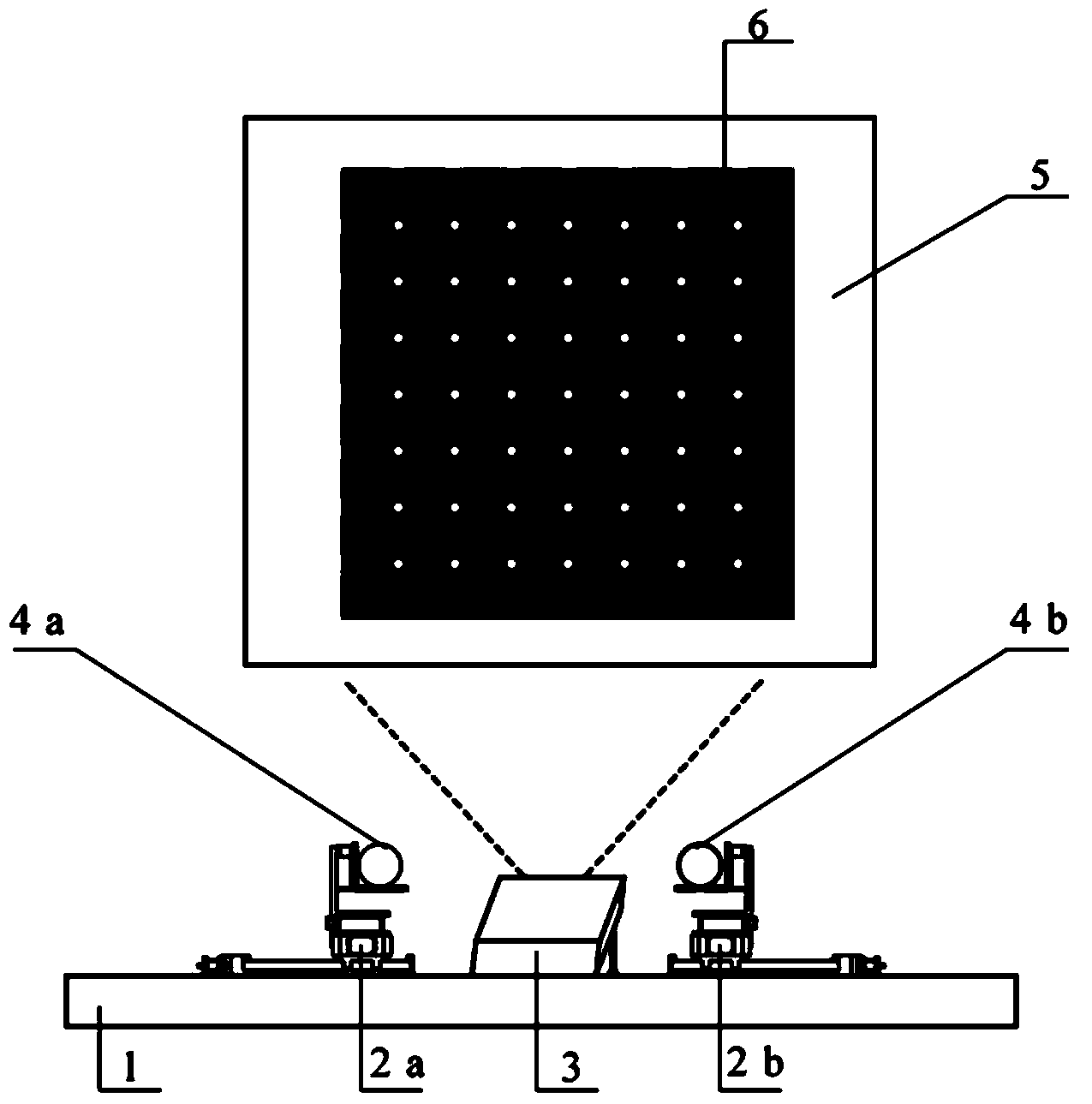

Camera calibration method based on projected Gaussian grid pattern

ActiveCN103530880AReduce usageAvoid couplingImage analysisImaging processingIntersection of a polyhedron with a line

A camera calibration method based on a projected Gaussian grid pattern, which is disclosed by the invention, belongs to the field of image processing and computer visual inspection, in particular to an on-site calibration method for the intrinsic and exterior parameters of cameras in a large forging dimension measurement system. By utilizing the characteristic of the Gaussian distribution of the widthwise grey scales of transverse and vertical light bars in the Gaussian grid pattern and fitting a Gaussian curve, the camera calibration method can accurately obtain the image coordinates of the points on the central lines of the light bars, so that a central line equation of the transverse and vertical light bars is fit out, the intersection points of the central lines of the transverse and vertical light bars are feature points for calibration, and according to the image coordinates of the feature points for calibration provided in the shot image of the Gaussian grid pattern, the intrinsic and exterior parameters of the cameras are acquired step by step. The camera calibration method has high real-timeness, robustness and high calibration precision, high-precision camera parameters can be obtained by step-by-step calibration, the problem of coupling in the simultaneous solution of all the camera parameters is avoided, and the camera calibration method is applicable to the on-line calibration of cameras on the forging site.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com