CCD (Charge Coupled Device)-based high-accuracy measuring method

A measurement method and high-precision technology, applied in the field of image processing, can solve the problems of easy fatigue, high strength, high cost, etc., and achieve the effect of high-precision measurement and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

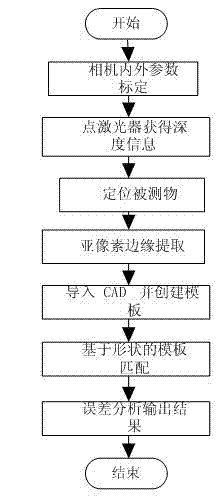

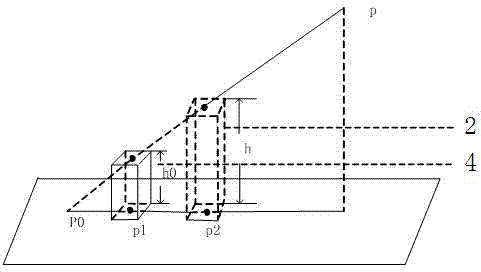

[0021] The flow chart of the present invention is as figure 1 As shown, firstly, the internal and external parameters of the camera are calibrated, using the calibrated data to correct the distortion of the image of the measured object, and then locate the measured object, distinguish the upper and lower surface edges of the measured object and extract the sub-pixel edge of the upper surface, and then create a Template, use the shape-based template matching algorithm to accurately locate and identify the measured object, obtain the depth information of the measured object according to the point laser, constrain and convert the upper surface posture of the measured object, compare the template with the measured object and perform error analysis. The specific implementation process of the technical solution of the present invention will be described below in conjunction with the accompanying drawings.

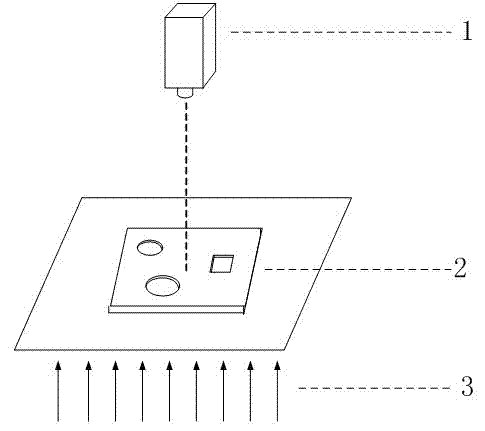

[0022] 1. System structure design

[0023] The system structure is designed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com