Three-dimensional deformation measuring device for measured piece in high-temperature and low-temperature box

A measuring device, a technology of three-dimensional deformation, applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems such as poor measurement accuracy, and achieve the effect of overcoming the effects of additional friction and additional motion of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

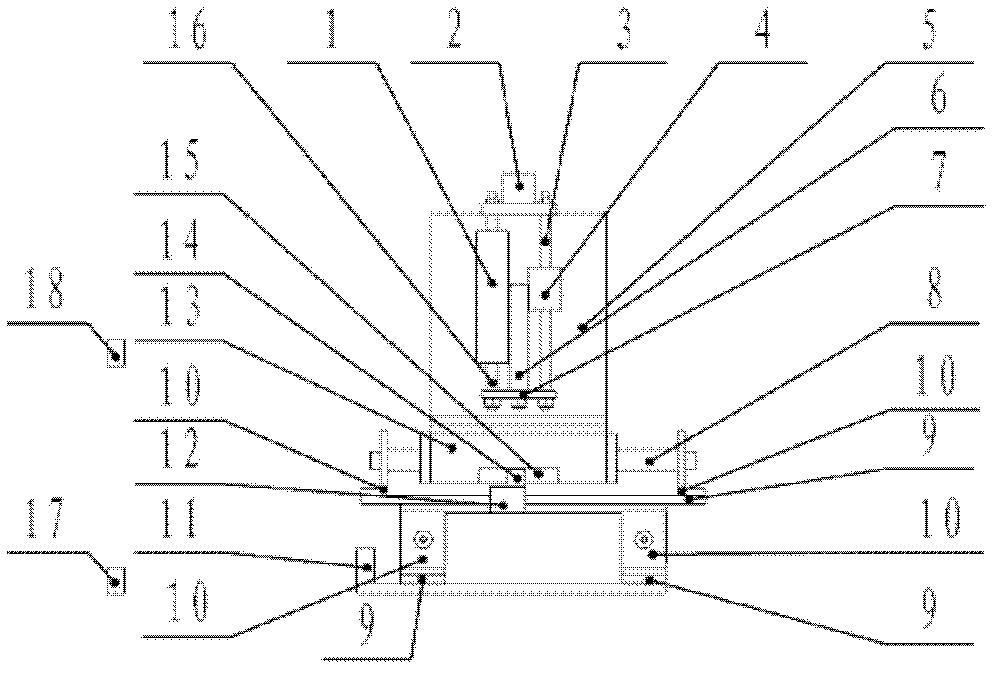

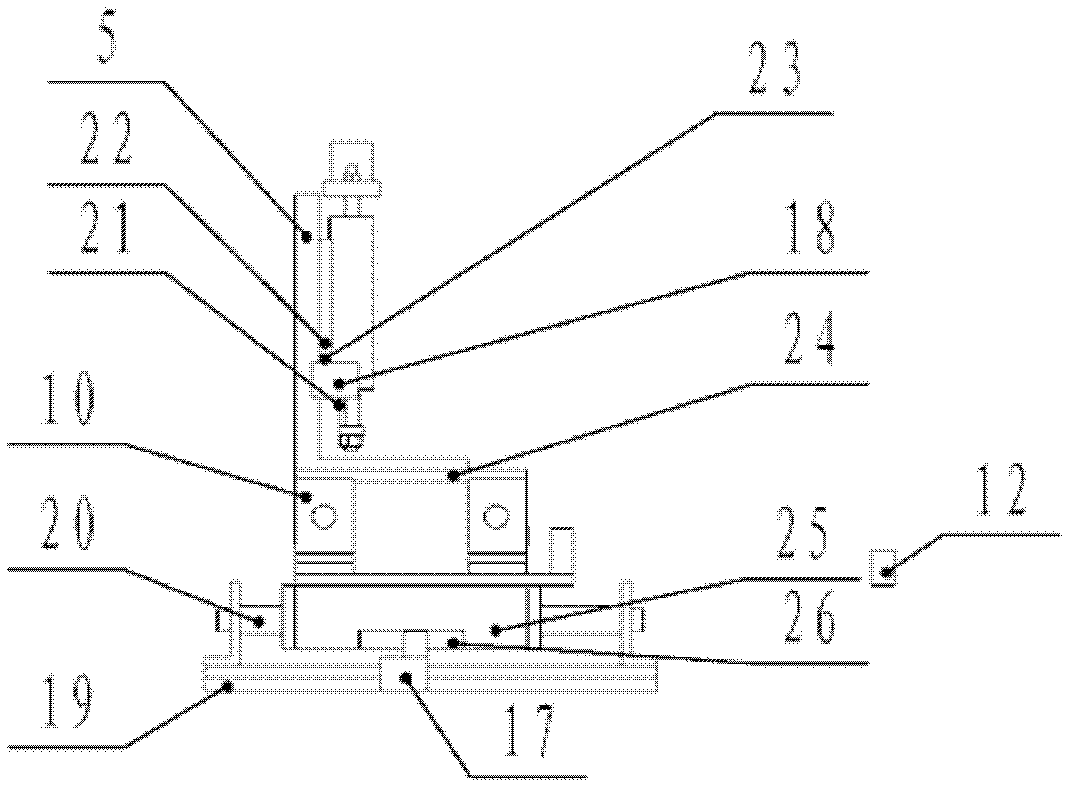

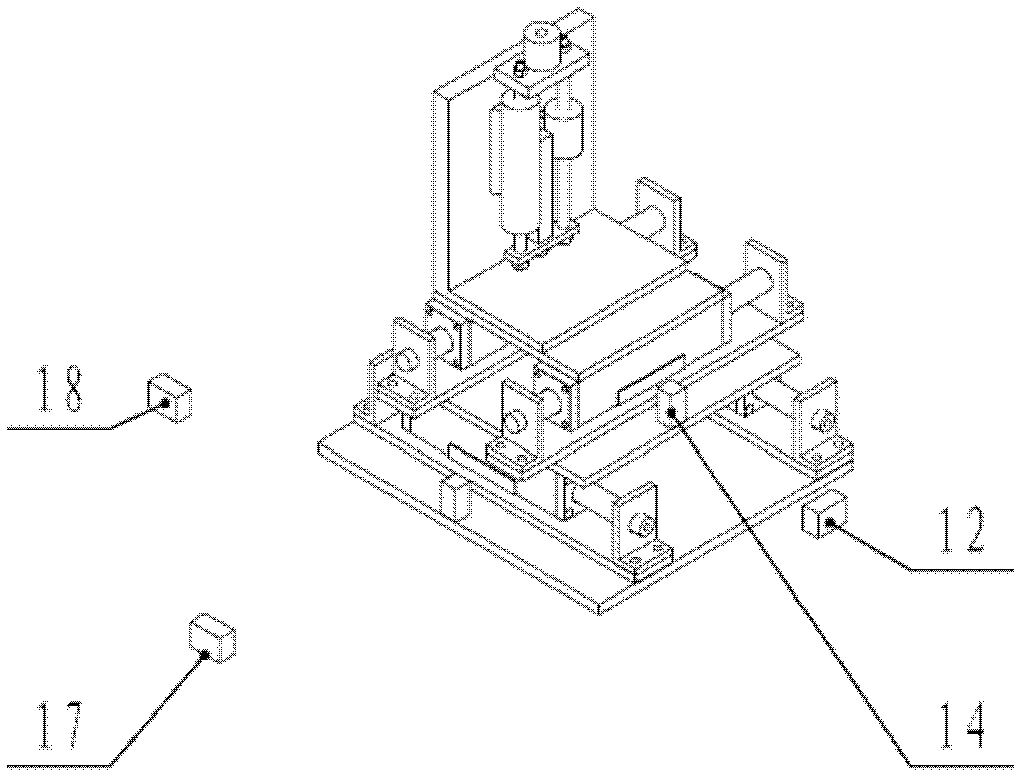

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

[0020] refer to Figure 1 ~ Figure 3 , a three-dimensional deformation measurement device for a test piece in a high-low temperature box, the measurement device includes a string, a three-dimensional air bearing assembly and a signal acquisition module with an encoder in three directions, and the three-dimensional air bearing assembly includes a fixed plate 19. The x-direction air flotation unit, the y-direction air flotation unit and the z-direction air flotation unit. Each air flotation unit includes an air flotation shaft and an air flotation sleeve. The signal acquisition modules with encoders in the three directions are respectively installed on the x to the air flotation unit, the y direction air flotation unit and the z direction air flotation unit; the x direction air flotation shaft 20 is installed on the fixed plate 19, the x direction air flotation sleeve 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com