Planar structured light three dimension measuring device and method for high-reflectivity part

A technology of surface structured light and three-dimensional measurement, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of slow measurement speed, complex structure, large volume, etc., and achieve high measurement efficiency, small size, and high projection frequency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

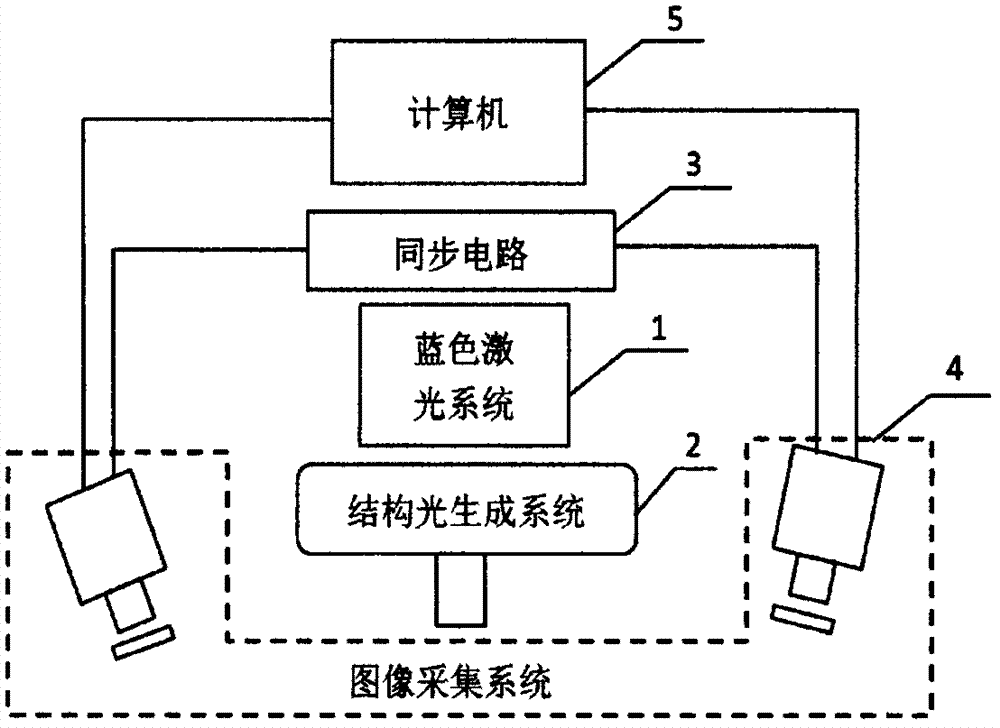

[0042] Specific implementation mode 1. Combination figure 1 Describe this specific embodiment, a surface structured light three-dimensional measurement device for high reflectivity parts, which includes a blue laser system (1), a structured light generation system (2), a synchronization circuit (3), an image acquisition system ( 4) and computer (5);

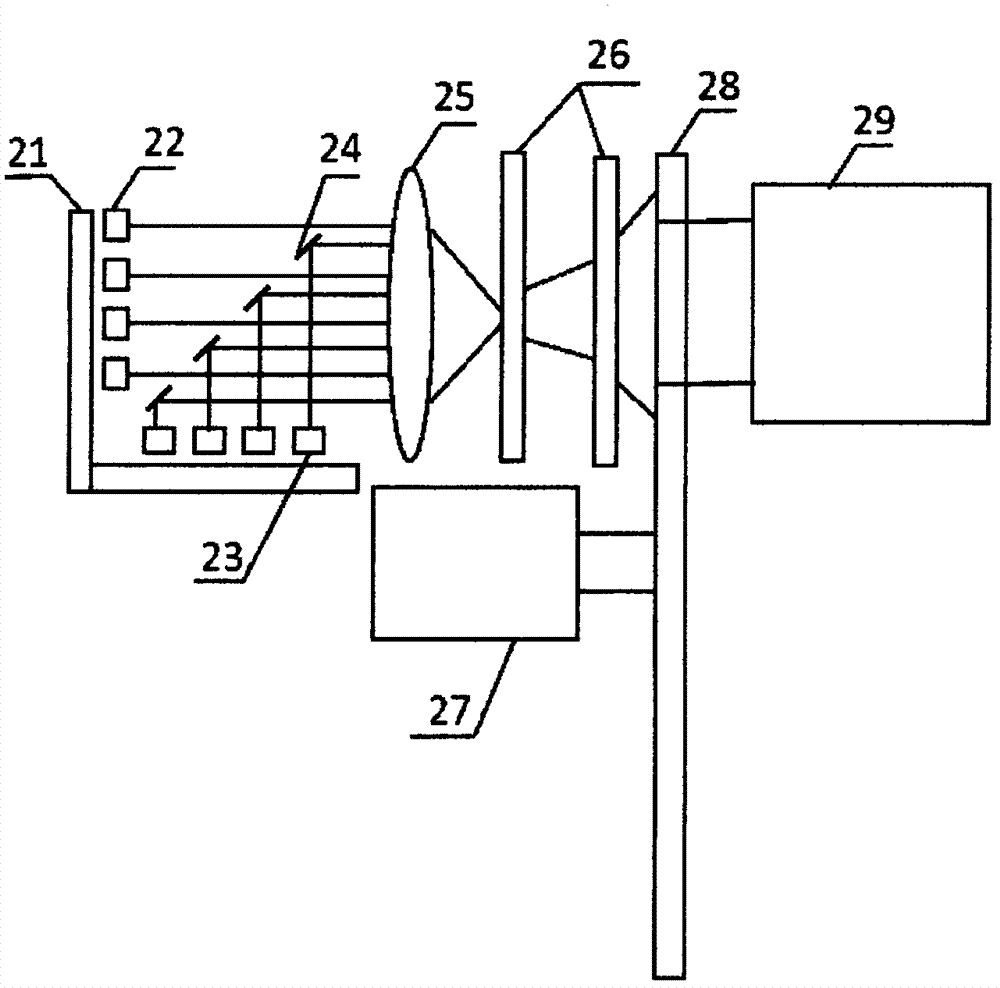

[0043] The blue laser system (1) comprises a laser diode driving circuit (21), a blue laser module No. 1 (22), a blue laser module No. 2 (23), a mirror (24), a converging lens (25) and Diffusion sheet group (26);

[0044] The structured light generation system (2) includes a servo motor (27), a circular grating sheet with a pattern (28) and a focusing lens (29);

[0045] The No. 1 blue laser module (22) is vertically set, and the No. 2 blue laser module (23) is horizontally set;

[0046] The light in the horizontal direction emitted by the blue laser system (1) through the No. 1 blue laser module (22) is incident on the conver...

specific Embodiment approach 2

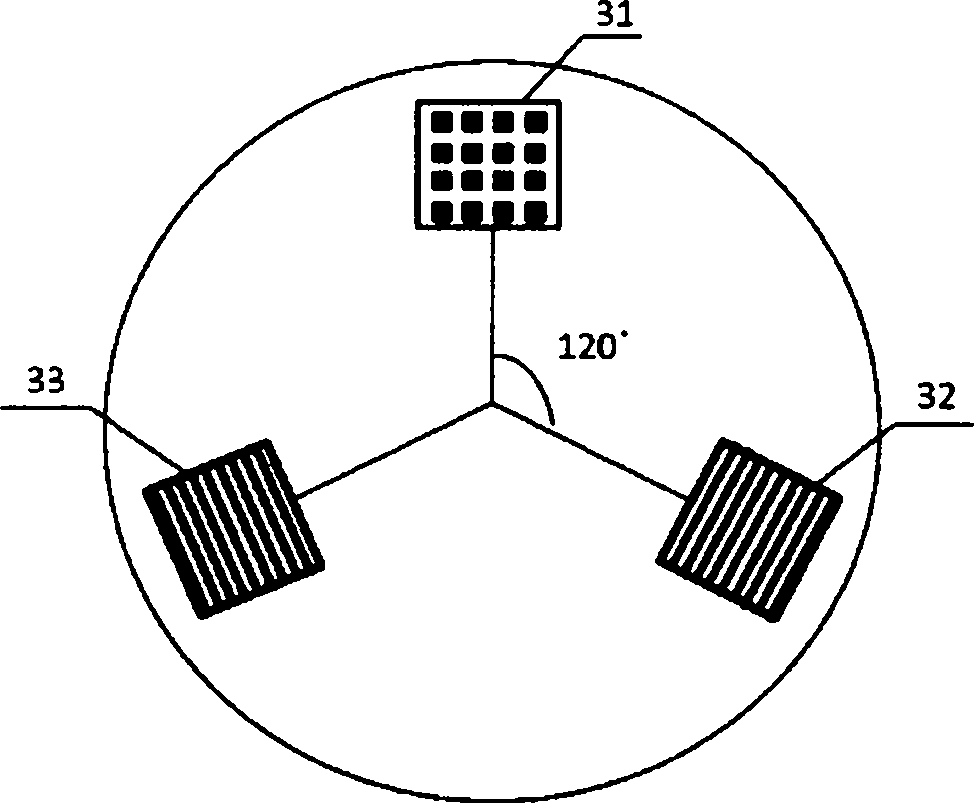

[0052] Embodiment 2. The difference between this embodiment and the surface structured light three-dimensional measurement device for high-reflectivity parts described in Embodiment 1 is that the circular grating sheet (28) with a pattern has three The first pattern is a two-dimensional random coding pattern or a two-dimensional pseudo-random coding pattern; the second pattern is a stripe pattern composed of periodic black and white stripes; the third pattern is a mirror image pattern of the second pattern.

specific Embodiment approach 3

[0053] Specific Embodiment 3. The difference between this specific embodiment and the surface structured light three-dimensional measuring device for high-reflectivity parts described in specific embodiment 2 is that the three The patterns are evenly distributed on the circumference of the circular lenticular sheet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com