Computer vision based cigarette carton and box packing paper dimension measurement method

A technology of computer vision and measurement methods, applied in measurement devices, optical devices, instruments, etc., can solve the problems of sample deformation, inability to accurately measure paper indentation depth, flatness, and large influence, and reduce workload. , The effect of improving detection accuracy and detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

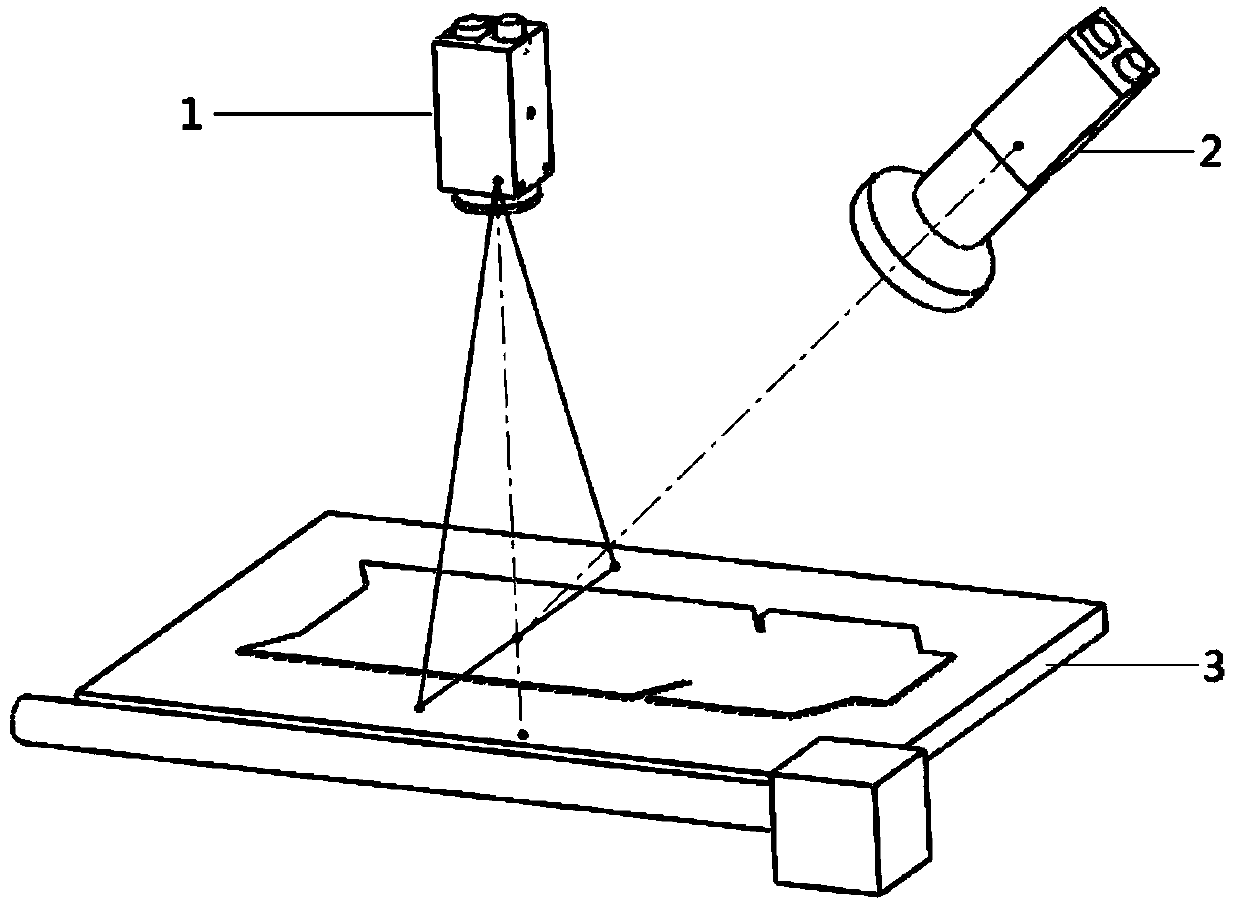

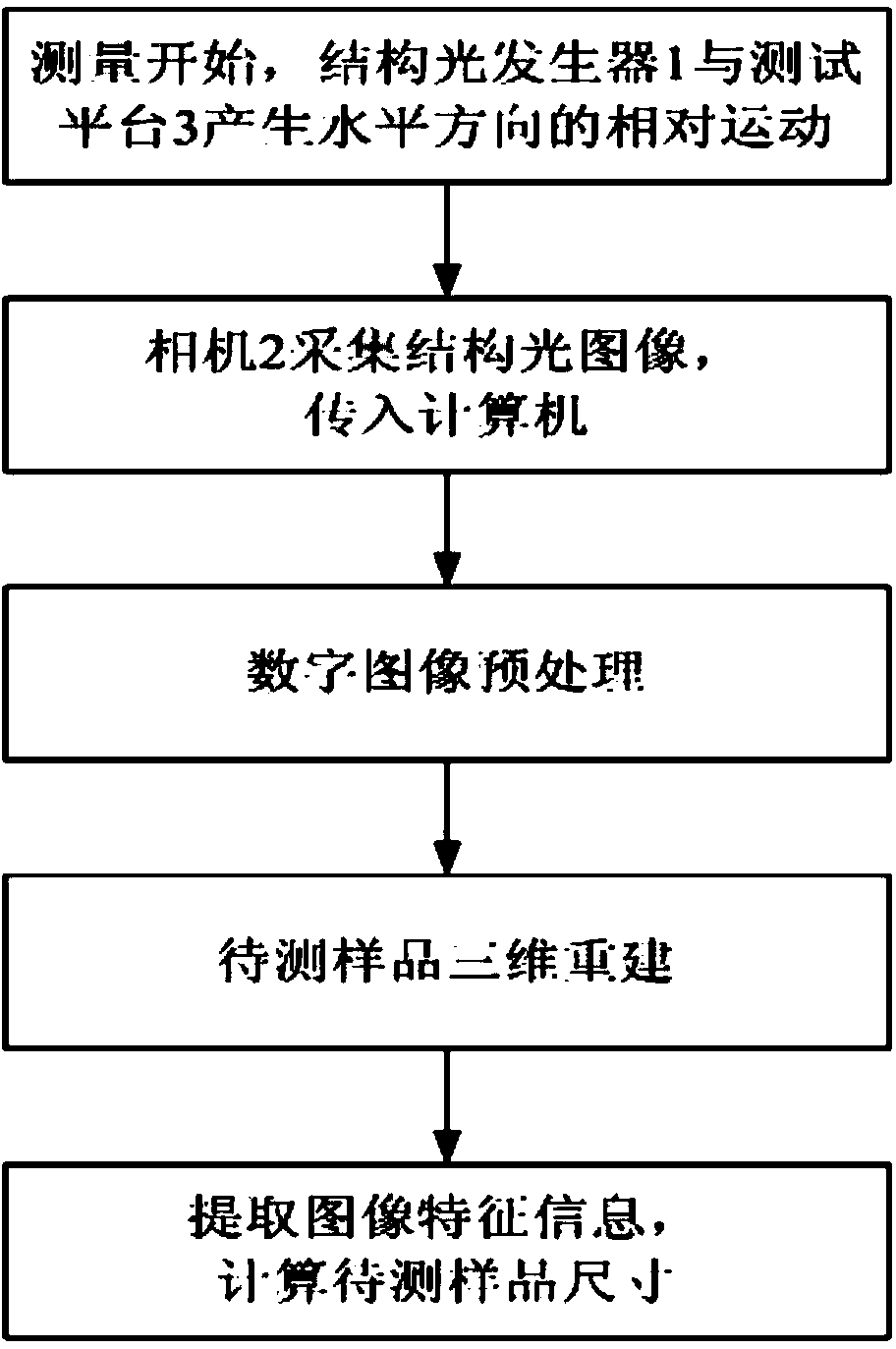

[0018] The feature of the method for measuring the size of cigarette rods and box wrappers based on computer vision in this embodiment is: using a structured light generator to project structured light on the surface of the object to be measured, and the structured light is modulated by the surface topography of the sample to be measured to form Modulated structured light, for the modulated structured light, use camera imaging to obtain the digital image of the measured object, and extract the three-dimensional shape and information of the measured object from the digital image of the measured object according to the computer vision algorithm and image processing method to realize the measured object. The size measurement of the measured object, the measured object is a cigarette rod or cigarette pack wrapping paper.

[0019] A structured light generator refers to a laser emitter or projector that projects a fixed shape feature and a regular pattern. The structured light patter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com