Online laser measuring, machining and detecting method and device

A detection method and detection device technology, applied in the field of laser measurement, to achieve the effects of saving manpower and time, expanding the range of measurement and detection dimensions, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

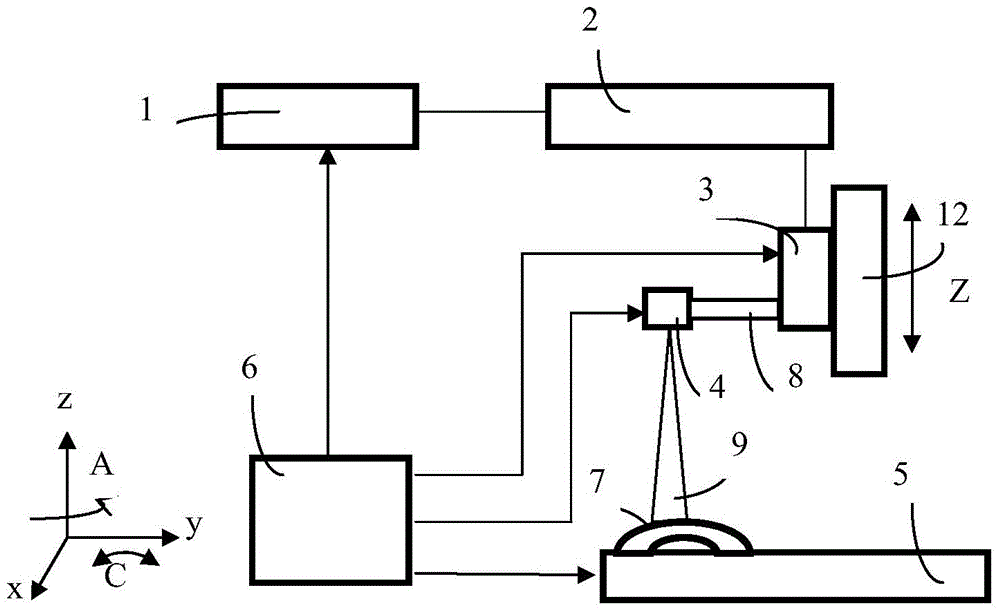

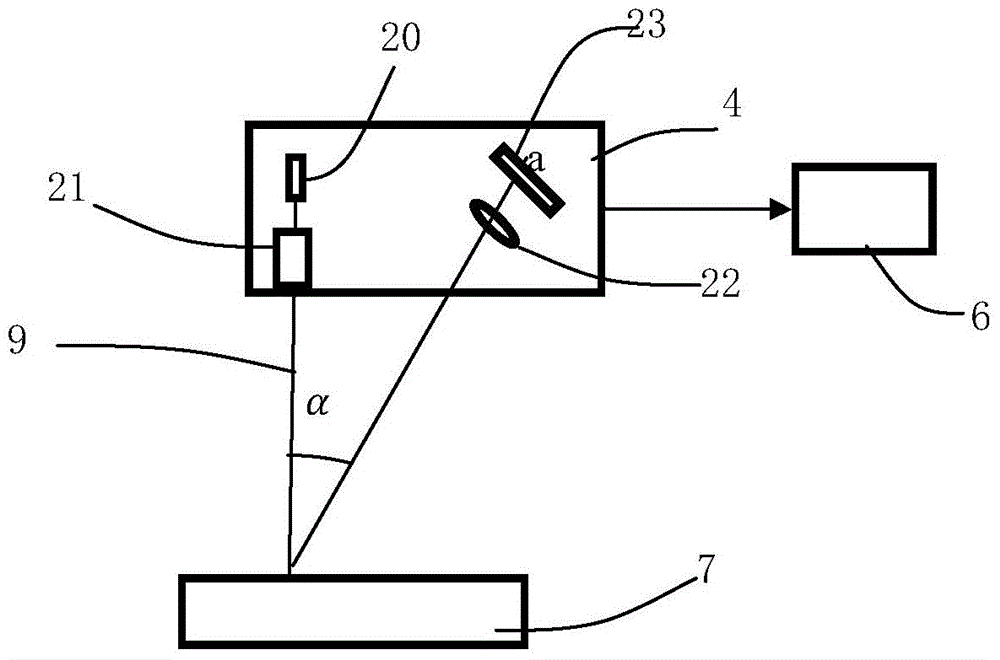

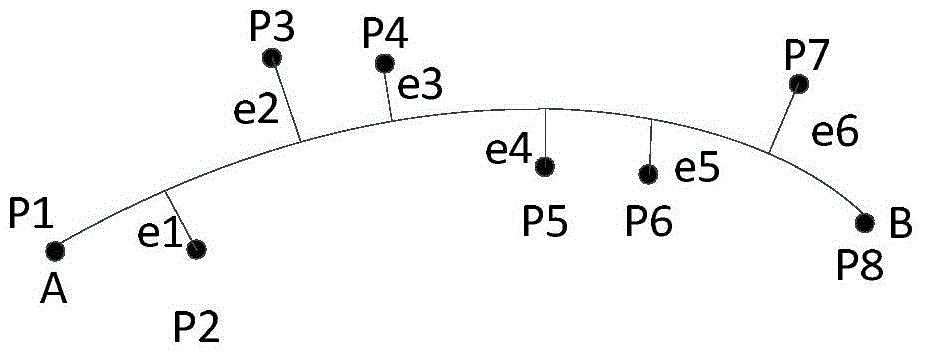

[0075] One method of the device of the present invention is used to grind the surface of the quartz ceramic device with the ultraviolet laser, and the flatness of the laser grinding surface is required to be ±0.01mm and the grinding roughness is less than 0.01mm. Before laser grinding and processing the surface of the quartz ceramic device, start the laser ranging system 4 earlier, send out the measuring laser beam 9 (the laser beam is a line beam), and move the Z-axis moving system so that the laser ranging system 4 is in contact with the quartz to be ground. The distance between the surfaces of the ceramic devices reaches within the range of measurement accuracy, and then the four-axis workbench 5 is started to carry out two-dimensional plane (workbench 5 carries out xy two-dimensional plane movement) to the surface geometry of the quartz ceramic device, and the line-by-line scanning measurement will obtain The plane three-dimensional data (x of each point, y and z coordinate...

example 2

[0077] The second method of the device of the present invention is used for fiber laser etching on the surface of a composite flexible curved aluminum film, requiring the laser to etch a circular array pattern with an inner diameter of 3mm and an outer diameter of 5mm on the aluminum film, and the accuracy of the etched rings The error is less than ±0.02mm, the center distance accuracy error between the rings is less than ±0.02mm, the thickness of the aluminum film is 0.04mm, the aluminum film of the laser etching part needs to be completely removed, but the damage to the carrier is less than 0.02mm. Before laser etching and processing the composite flexible curved surface aluminum film surface, start the laser distance measuring system 4 earlier, send out the measuring laser beam 9 (this laser beam is a point beam), move the Z axis in the motion system 13, make the laser distance measuring system 4 and When the distance between the surfaces of the composite flexible curved alu...

example 3

[0079]The third method of the device of the present invention is used for fiber laser to carry out laser etching processing on the surface of large-scale composite rigid curved copper film, requiring the laser to etch a circular array pattern with an inner width of 3mm and an outer width of 5mm on the copper film. The accuracy error of the array pattern is less than ±0.02mm, the accuracy error of the array center distance is less than ±0.02mm, the thickness of the through film is 0.012mm, the copper film of the laser etching part needs to be completely removed, but the damage to the carrier is less than 0.03mm. Before laser etching and processing the large-scale composite rigid curved copper film surface, start the laser distance measuring system 4 earlier, send out the measuring laser beam 9 (this laser beam is a line beam), and move the Z axis in the motion system 16 to make the laser distance measuring system 4 The distance between the surface of the composite flexible curve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com