Non-contact type flexible on-line dimension measurement system

A measurement system, non-contact technology, applied in the field of physics, can solve the problems of small number of samples, delay of test results, low efficiency and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

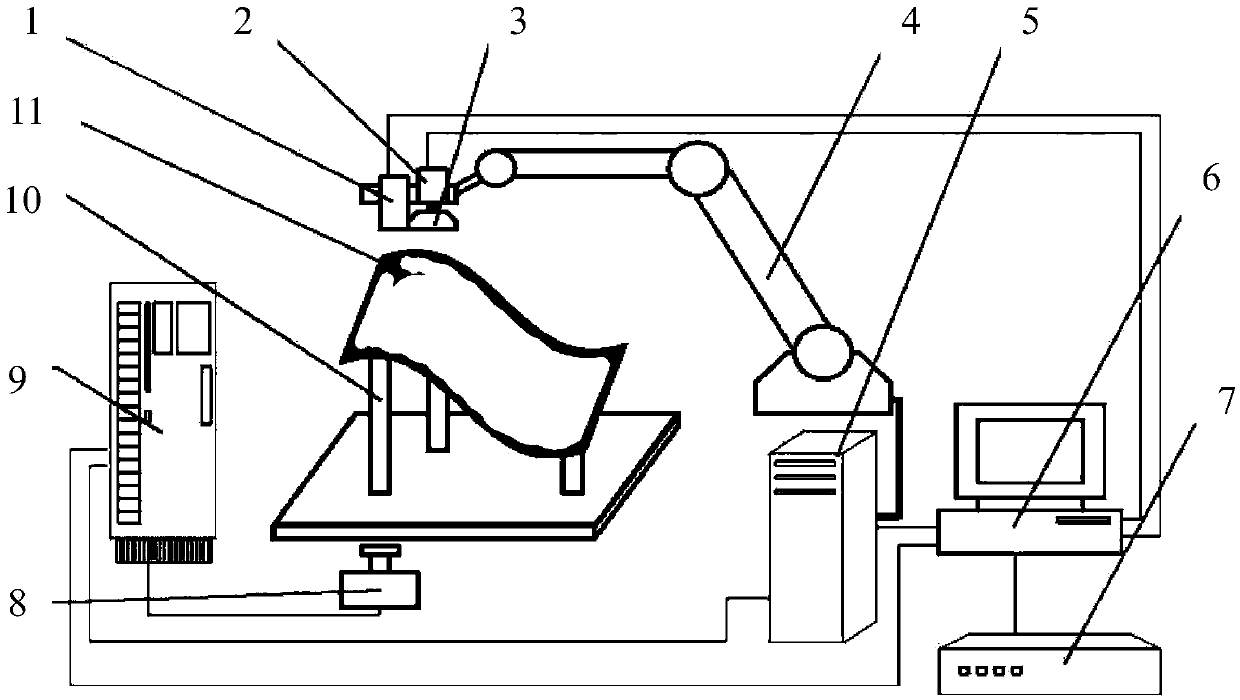

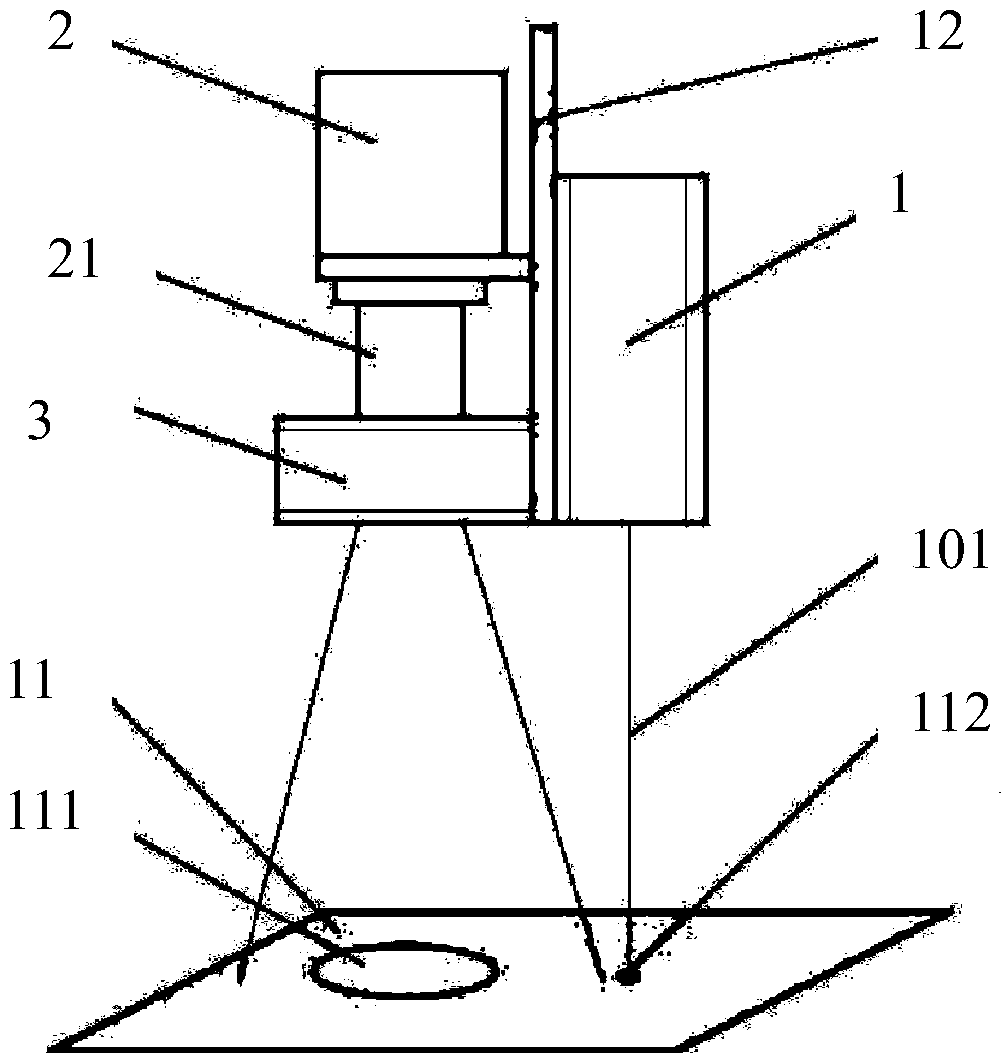

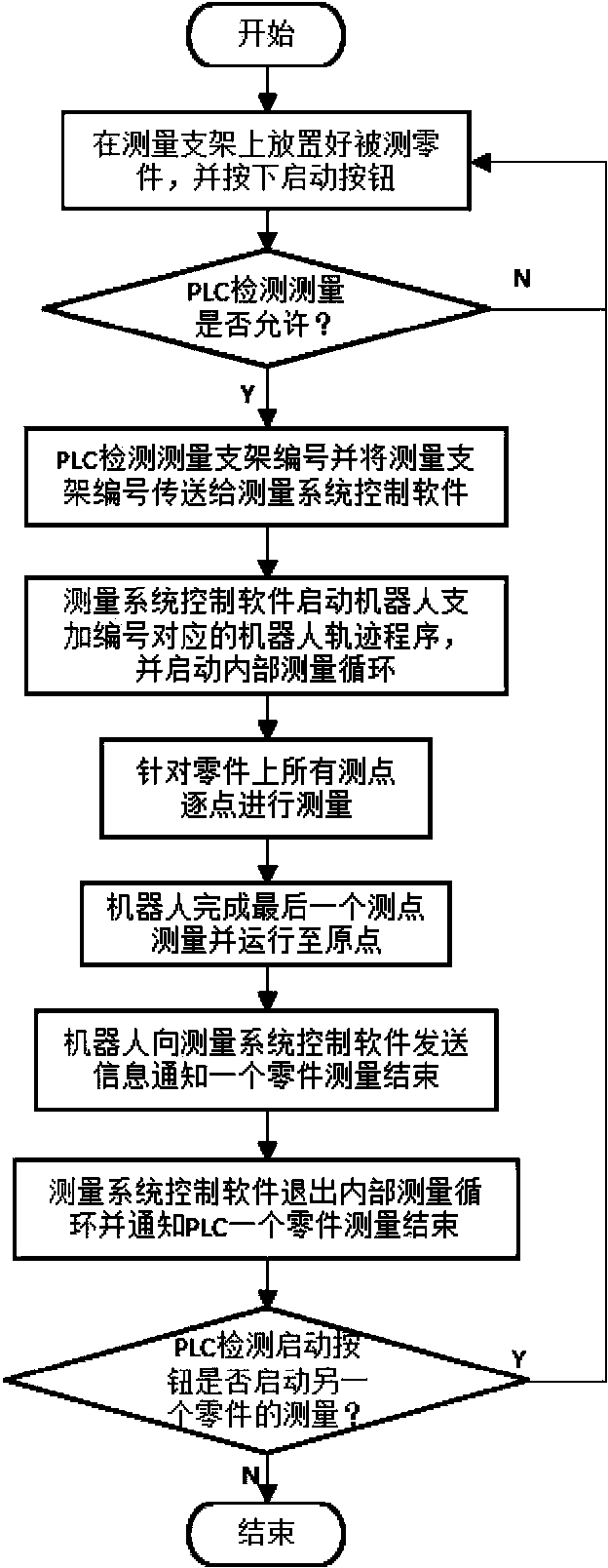

[0023] Such as figure 1 As shown, the non-contact flexible online dimension measurement system of the present invention includes a combined measurement sensor and an industrial robot 4. The industrial robot 4 includes a mechanical arm, and the combined measurement sensor is fixedly connected to On the mechanical arm of the industrial robot 4, the combined measurement sensor includes a one-dimensional laser displacement sensor 1 and an industrial camera 2. The one-dimensional laser displacement sensor 1 and the industrial camera 2 are fixedly connected, and the combined measurement sensor is The light source 3 is connected, the one-dimensional laser displacement sensor 1 includes a signal line, and the industrial camera 2 includes a video signal output line. The signal line of the one-dimensional laser displacement sensor 1 and the video signal output line of the industrial camera 2 are both connected to a computer 6 , The industrial robot 4 is connected to a robot controller 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com