Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

141 results about "Wear measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

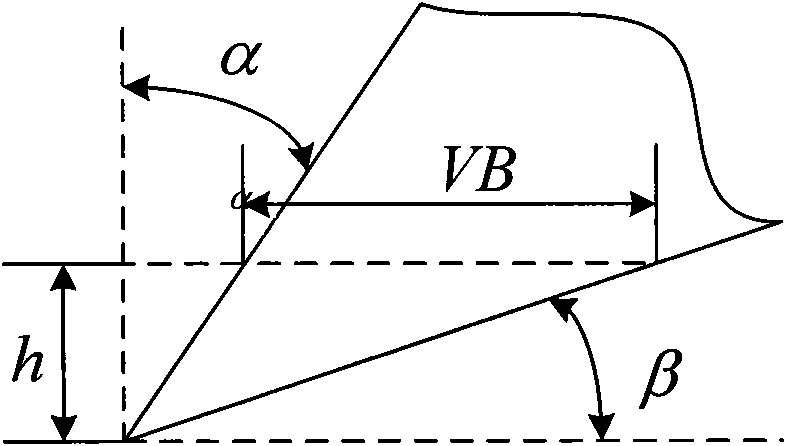

Common techniques of wear measurement include using a precision balance to measure the weight (mass) loss, profiling surfaces, or using a microscope to measure the wear depth or cross-sectional area of a wear track so as to determine the wear volume loss or linear dimensional change.

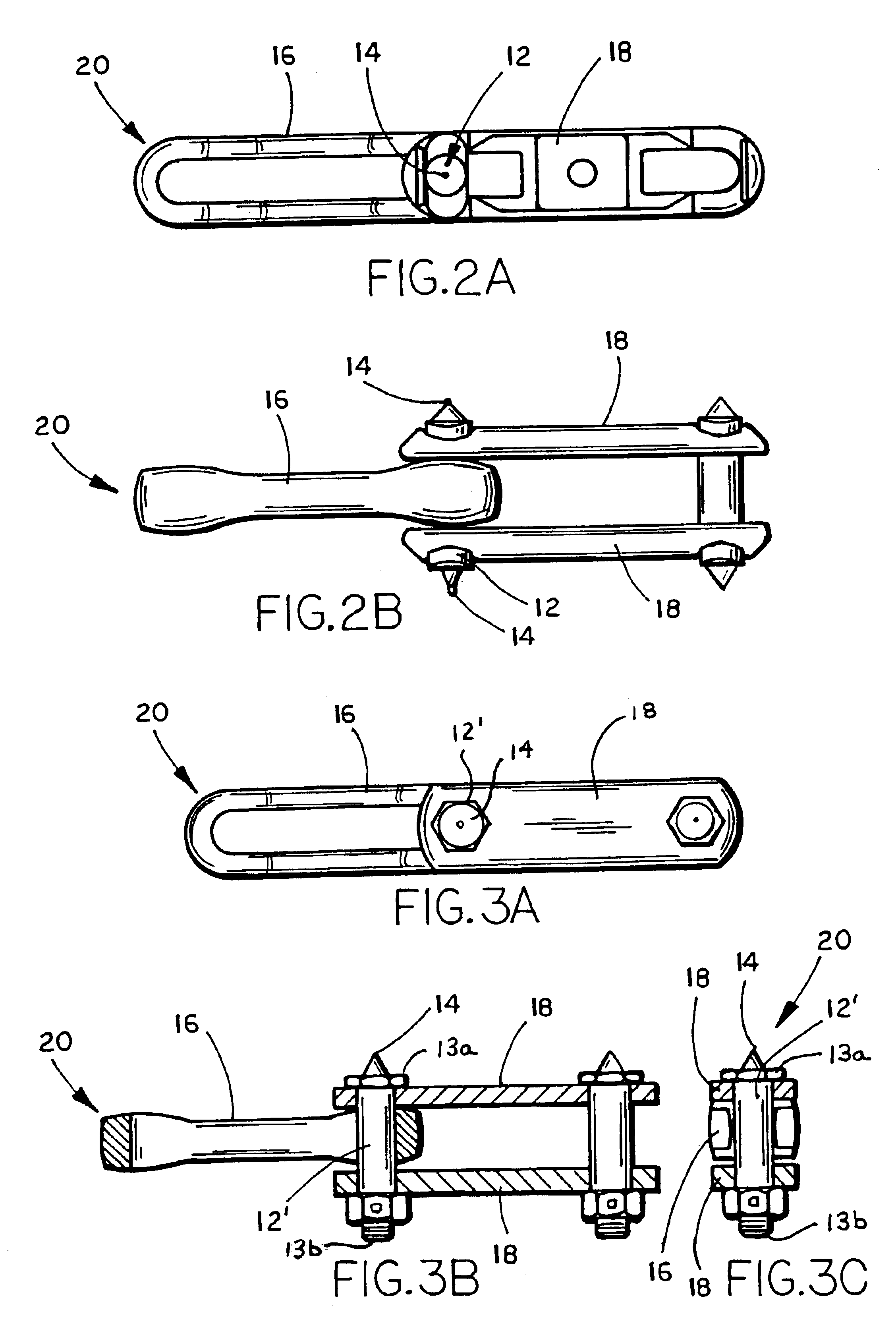

Conveyor chain

InactiveUS20050061636A1Increase flexibilityReducing and controlling wearConveyorsPackagingEngineeringChain link

A section of chain for conveying product along a material handling system includes a pin connecting a center link between two side links. The pin may be dialable or selectably positioned at the side links to control and adjust the wear surface of the pin relative to the chain links. The pin may have a rotationally non-symmetrical shaft portion to provide different wear surfaces that engage a center link of the section of chain. The different wear surfaces may be sized and shaped to accommodate wear at the wear surface of the center link. The shaft portion may include a rotationally non-symmetrical ball member or portion on the shaft portion to enhance flexibility of the section of chain. The pin may be dialed to the next position or wear surface in response to an output of a wear measurement device or system.

Owner:FROST TECH

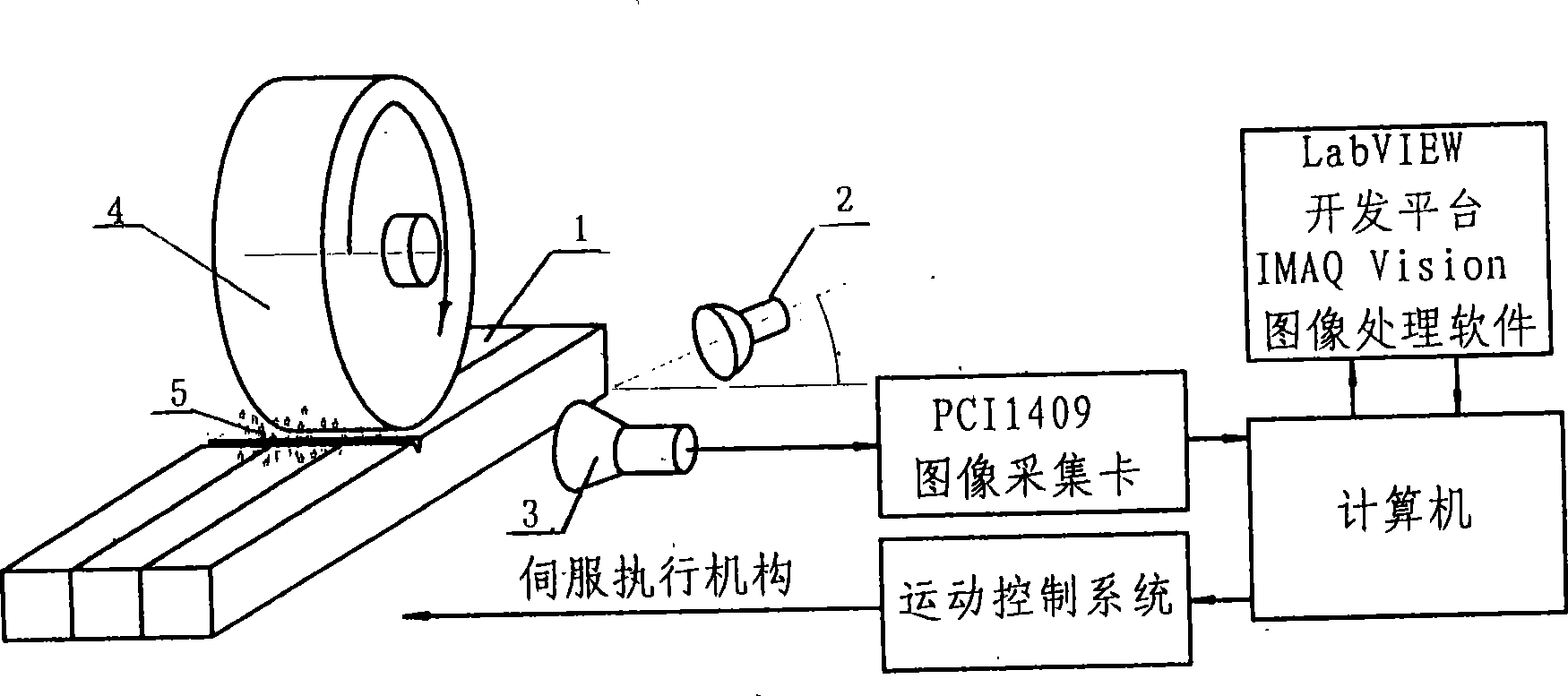

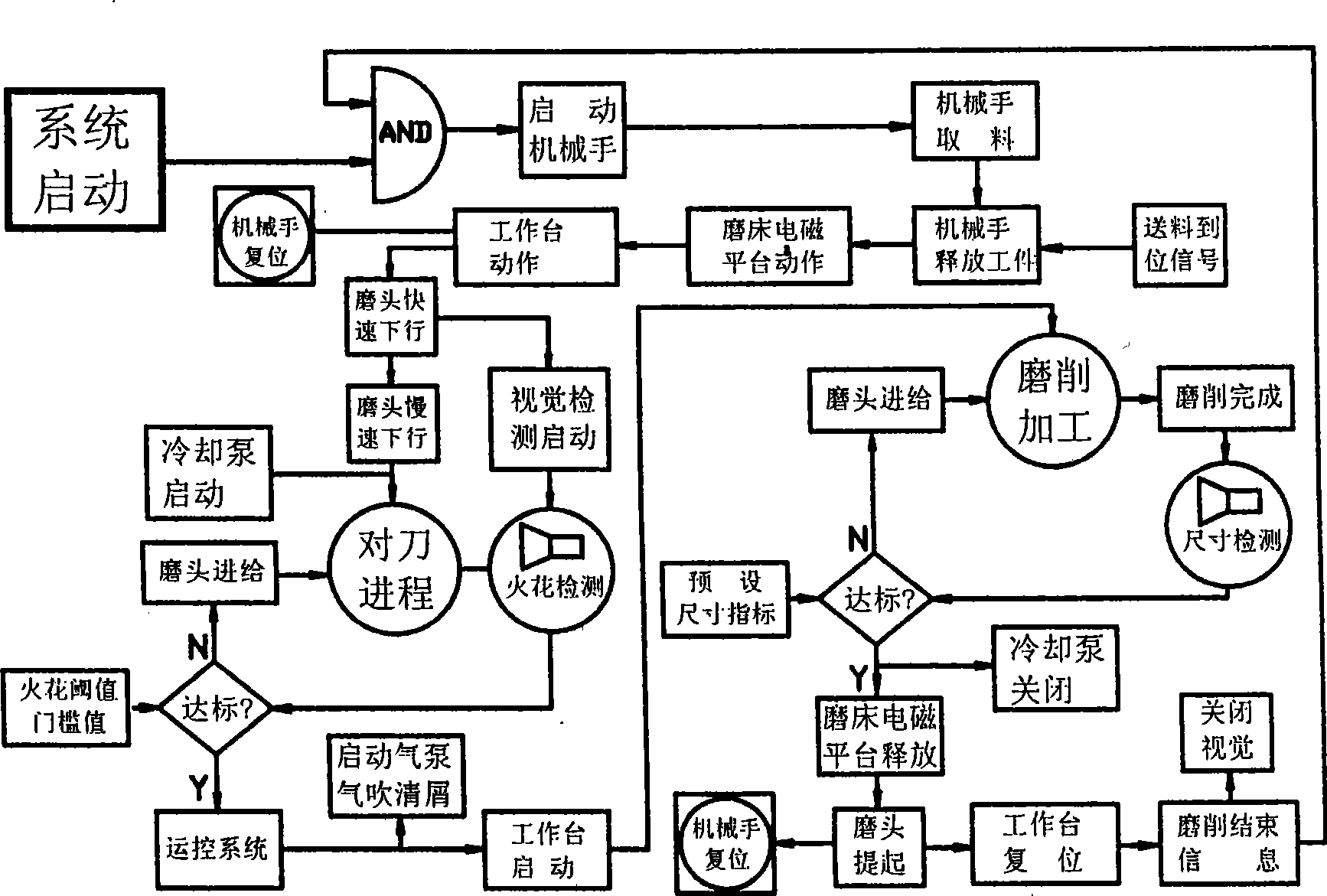

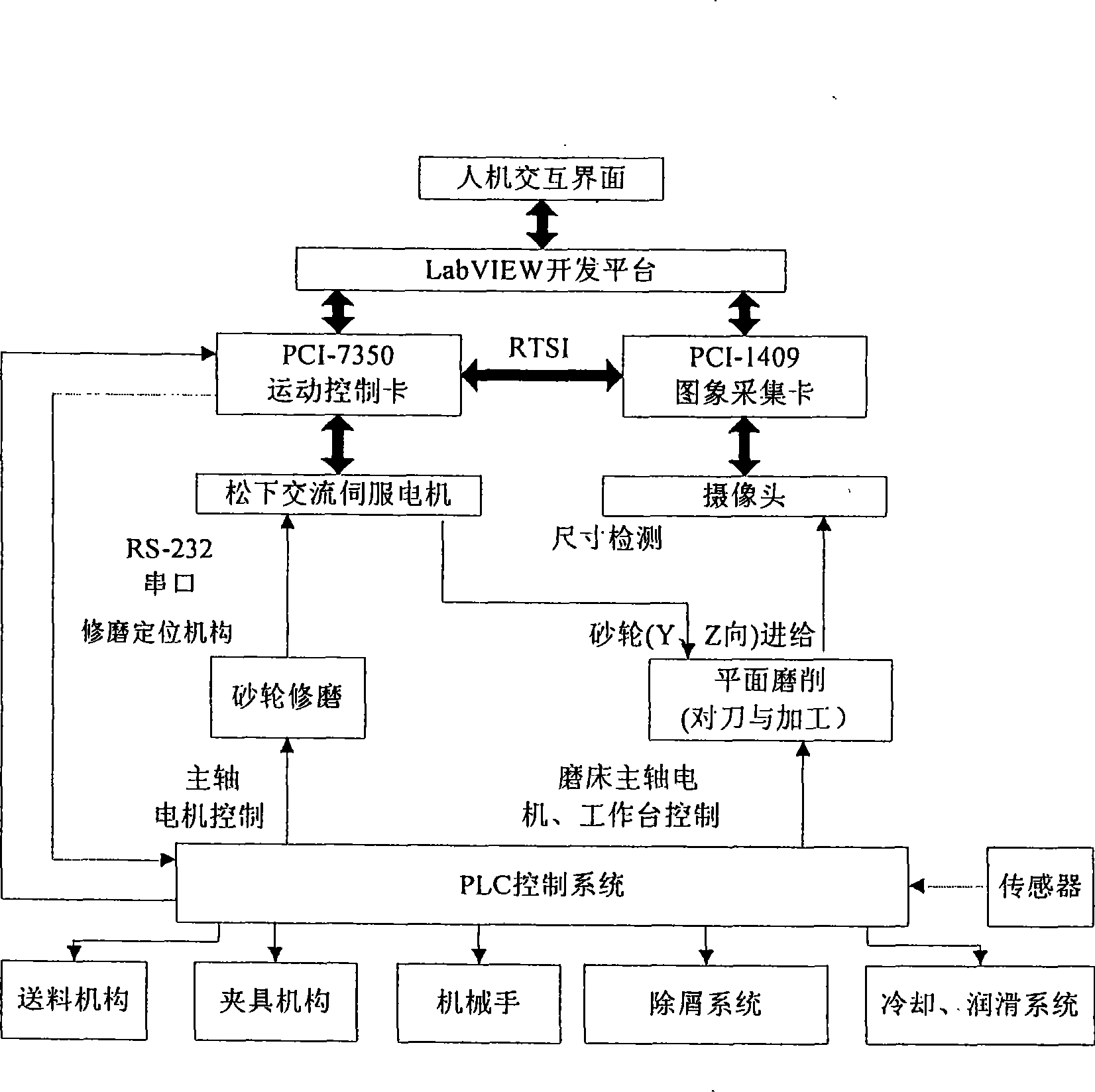

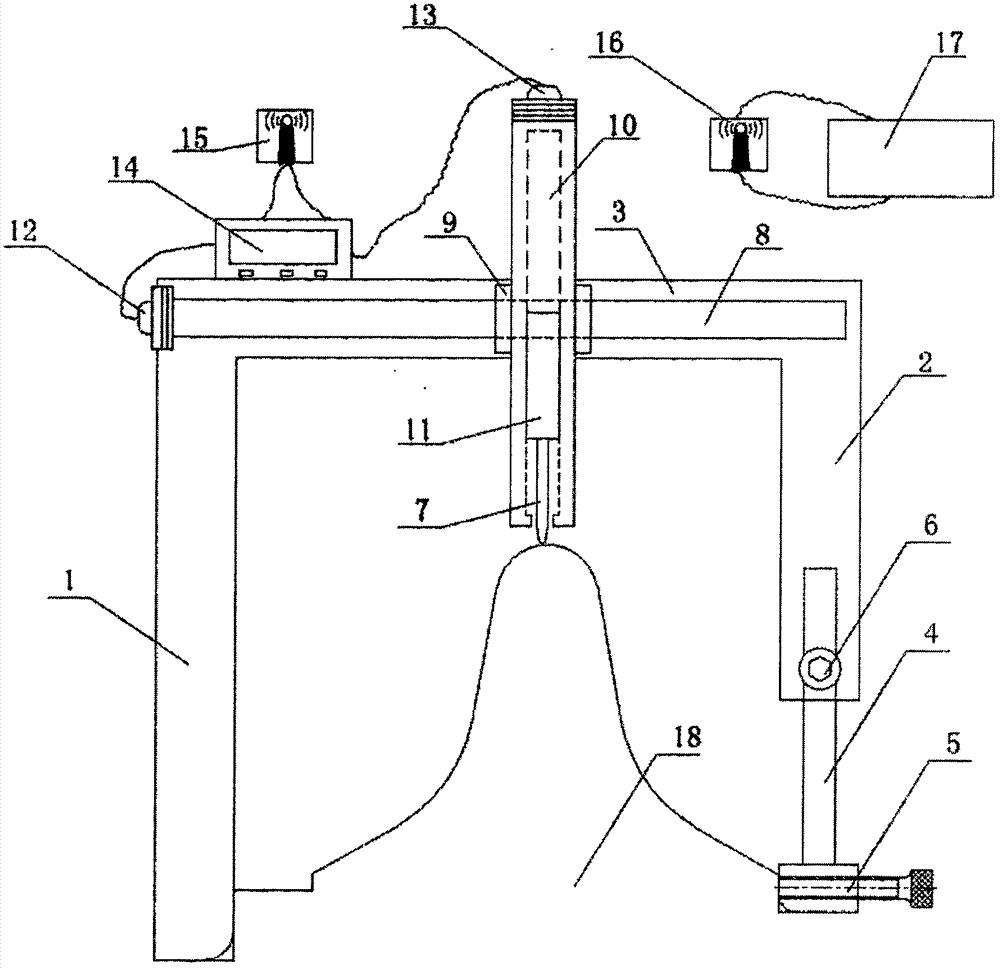

Spark identification tool-setting method and abrasive machining automatic system

The invention discloses a method for setting a tool through sparkle identification and an automatic system for grinding processing. The method and the system achieve the intelligent automatic control for the whole grinding process and accurately and reliably solve the problem of automatic tool setting, the problem of dimension compensation caused by the abrasion of a grinding wheel, and the problems of on-line dimension measurement and motion servo control in the grinding process. The method organically combines a vision technique, a PLC technique and a motion control technique, and provides a solution for solving the problems of tool setting, on-line dimension measurement and grinding wheel wear compensation by using the vision technique, and the problem of motion servo control by using the PLC technique and the motion control technique. The method makes use of the vision technique to automatically identify the operating condition contacted with a workpiece, and switch the operating condition to a grinding processing state instantly so as to solve the problem of automatic tool setting, thus the method can combine a plurality of mature correlation techniques to construct the automatic system which integrates detection and motion control. The method and the automatic system achieve the accurately automatic tool setting, solve the problems of the wear measurement and compensation of the grinding wheel, and open up a novel approach for fully automatic and intelligent control in the grinding process.

Owner:QIQIHAR HUAGONG MACHINE +1

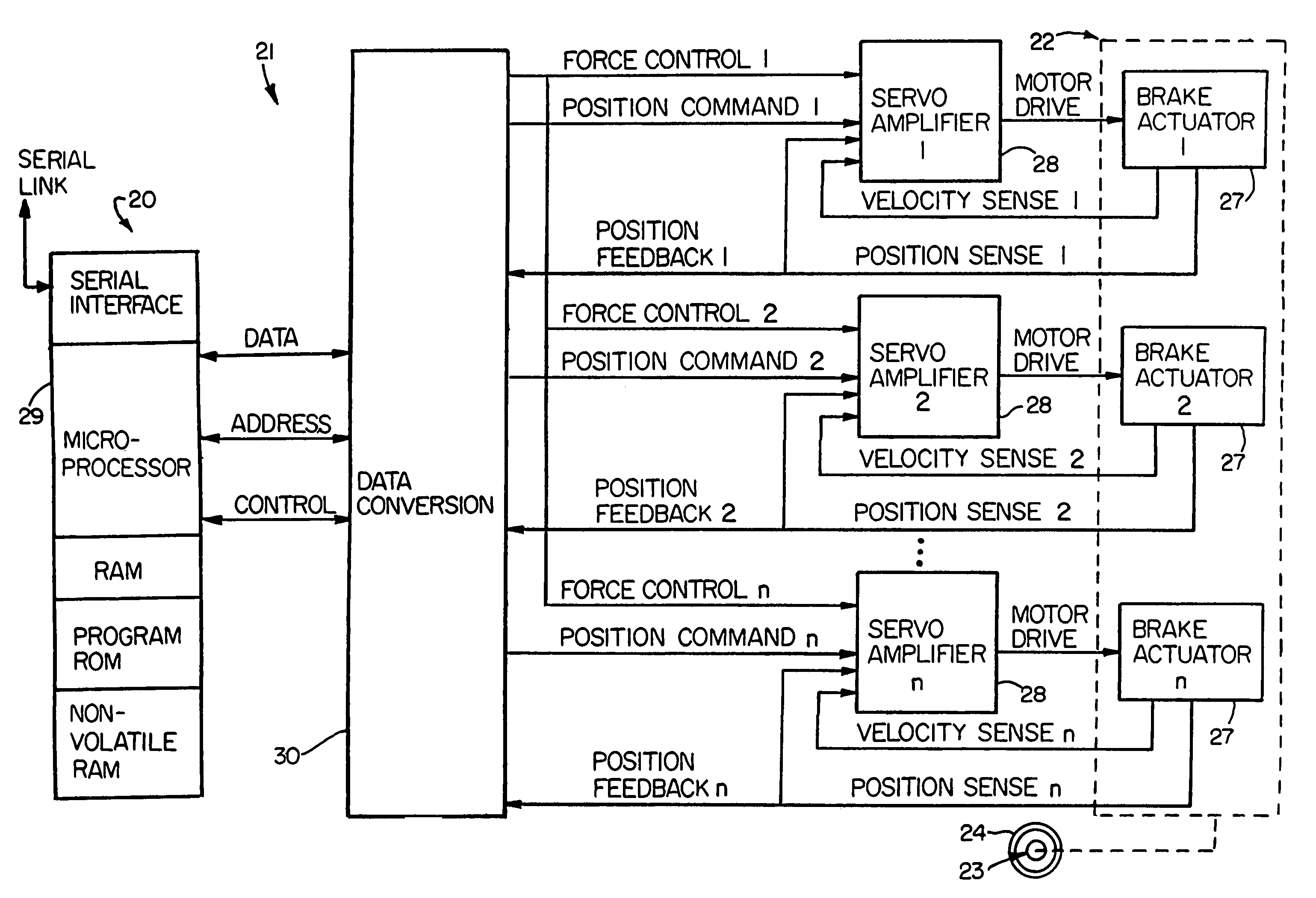

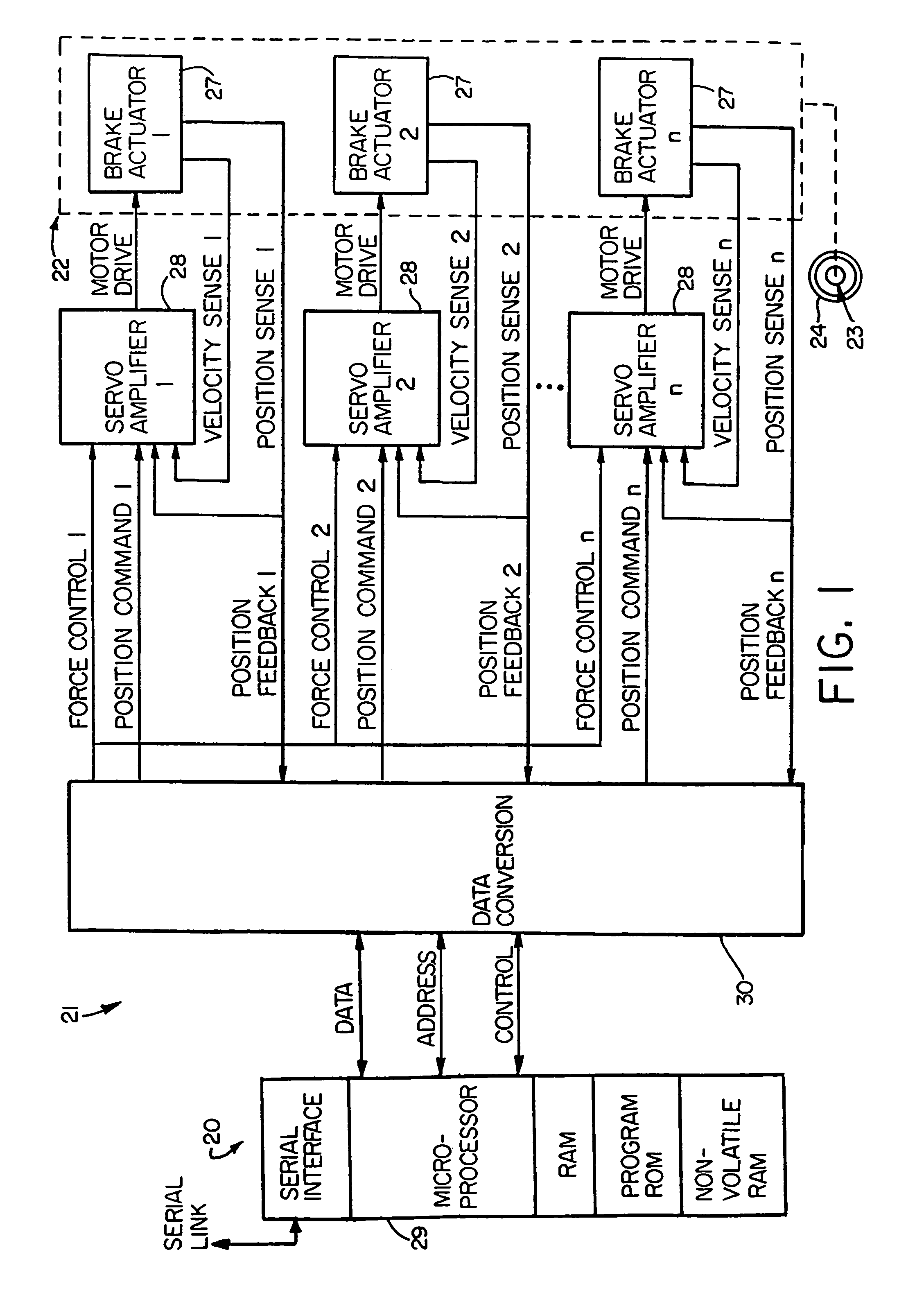

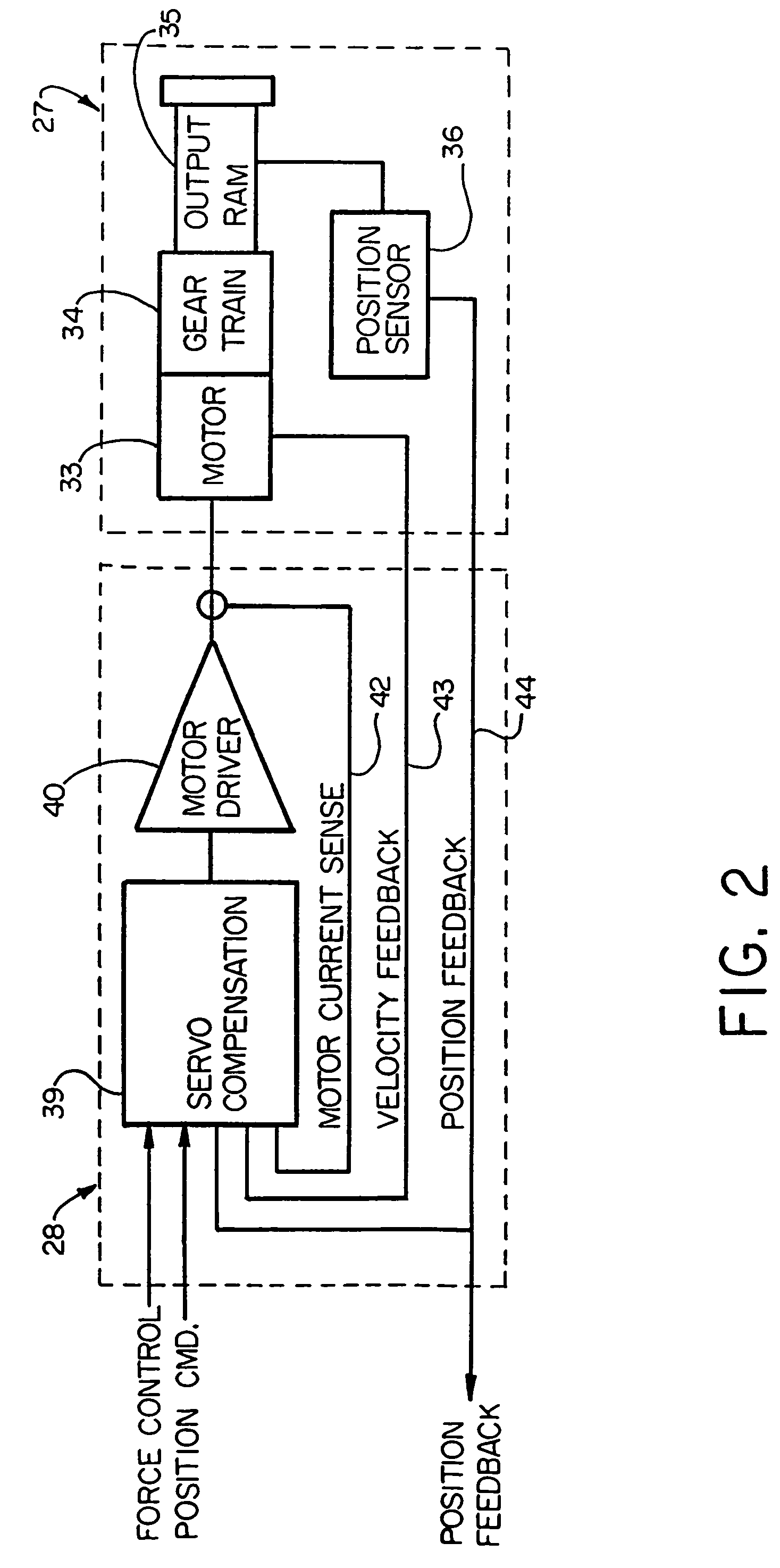

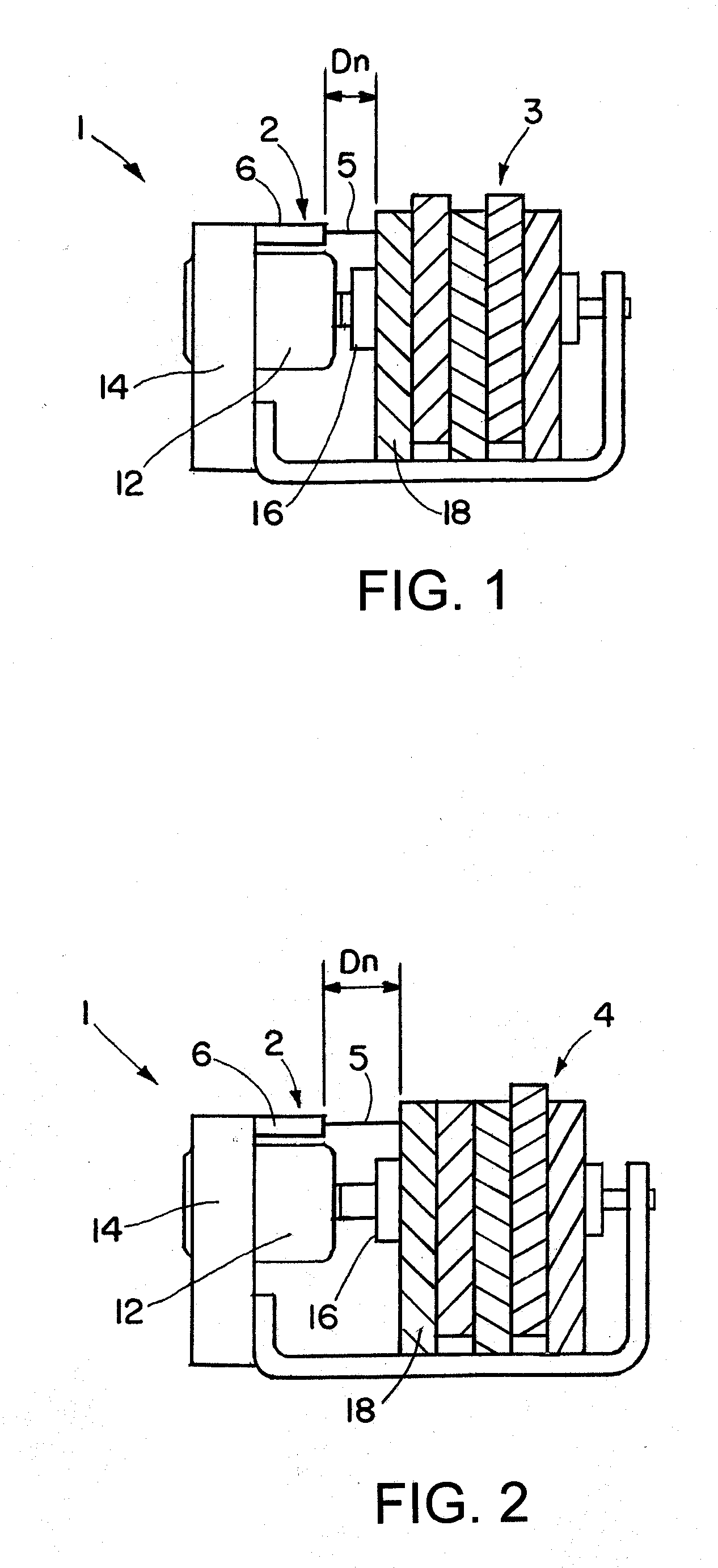

Electronic aircraft braking system with brake wear measurement, running clearance adjustment and plural electric motor-actuator ram assemblies

InactiveUS7108107B2Easy maintenanceIncrease weightAxially engaging brakesBraking action transmissionElectric aircraftActuator

An electrically actuated aircraft brake system and method which provides for brake wear measurement, brake running clearance adjustment, ram position-based control and improved construction and operation. Brake wear and running clearance measurement are obtained by analyzing the output of position sensing circuitry. The position sensing circuitry, preferably including a LVDT position sensor, is also used to determine braking load, a brake controller including circuitry for effecting displacement of one or more reciprocating rams to load a brake disk stack by a predetermined amount based on a present displacement value of the position signal obtained from the position sensor. The position sensor preferably includes a LVDT transducer connected between the reciprocating ram and a brake housing, and the motive device preferably includes a servo motor. Also provided is an actuator housing including a guideway for each ram, the guideway and ram having the same polygonal cross-section, whereby the ram nut is guided and restrained from rotation by the guideway as it is translated by a ball screw in threaded engagement with the ram nut for selective movement into and out of forceful engagement with the brake disk stack for applying and releasing braking force on a rotatable wheel. An electric motor is drivingly connected to each ball screw by a first gear integral with the ball screw, a second gear in mesh with the first gear, and a pinion on a rotating drive shaft of the electric motor.

Owner:THE BF GOODRICH CO

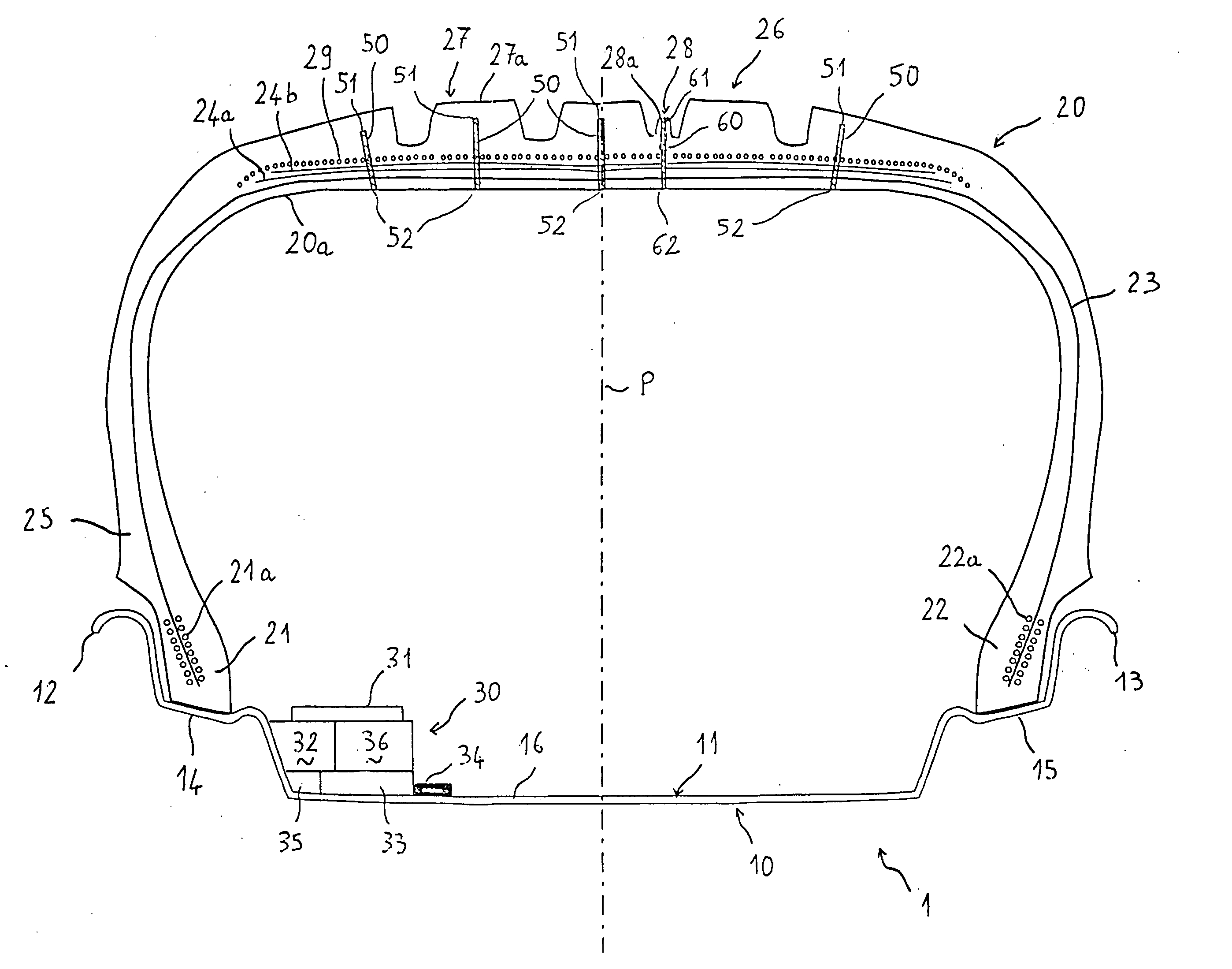

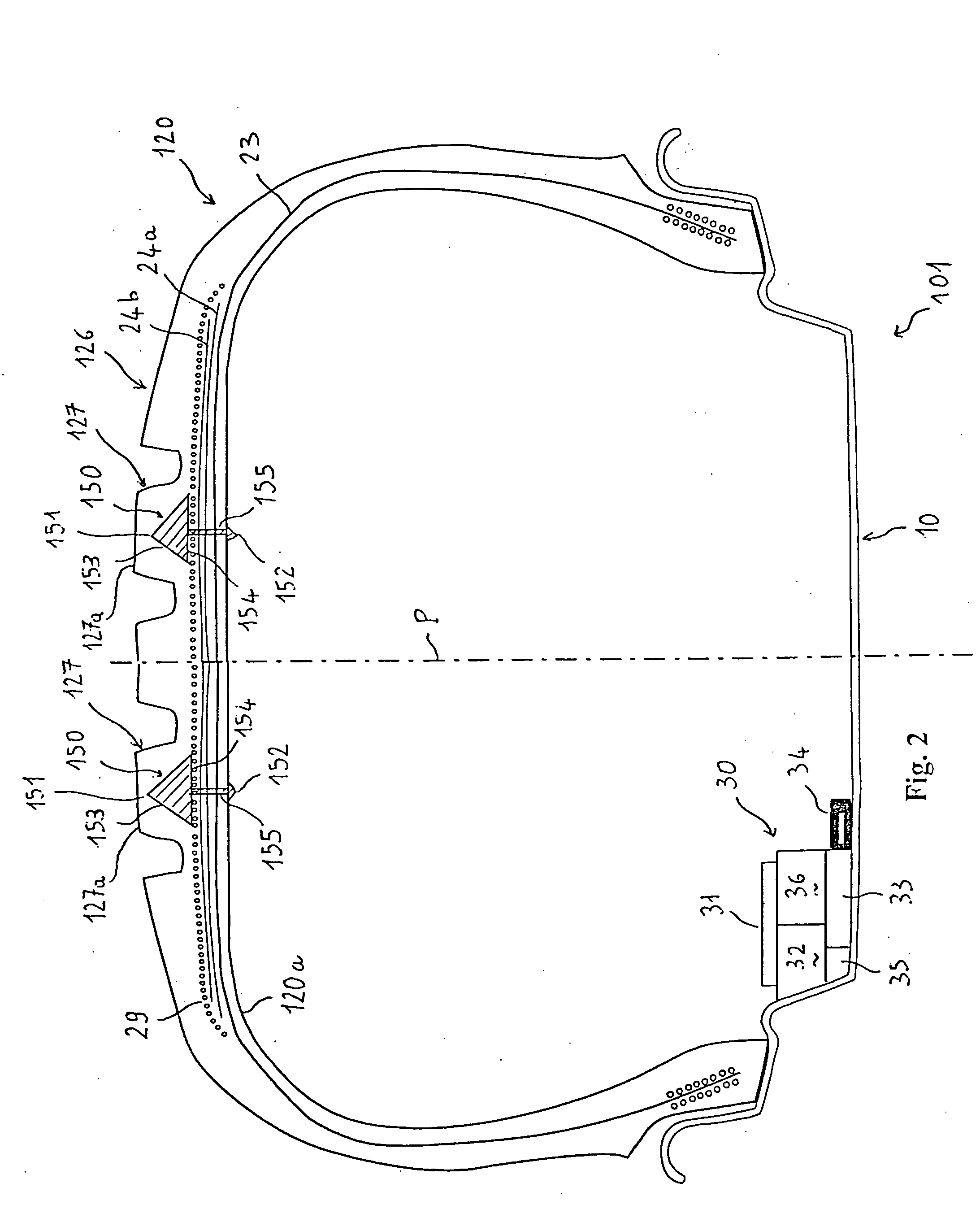

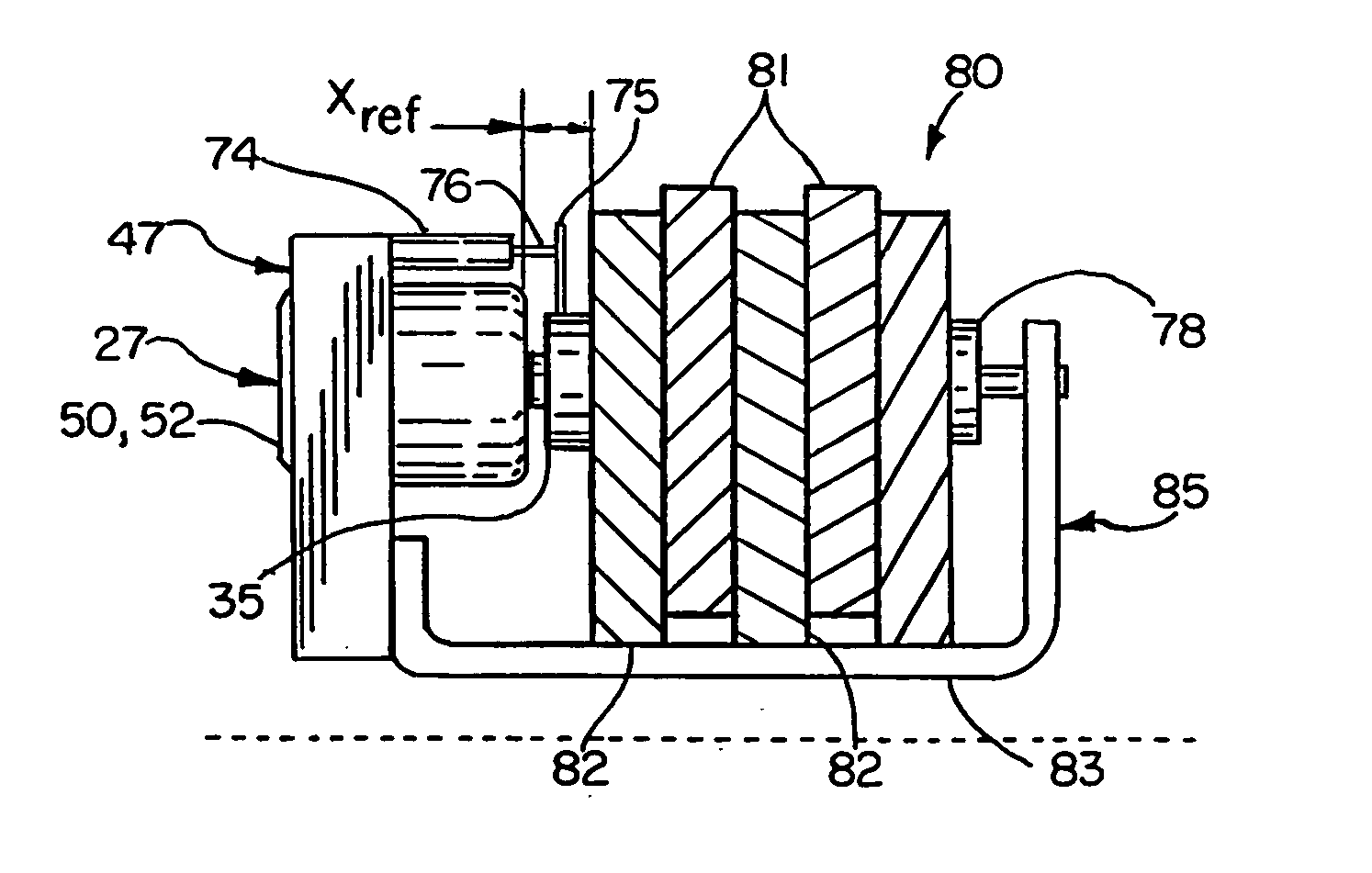

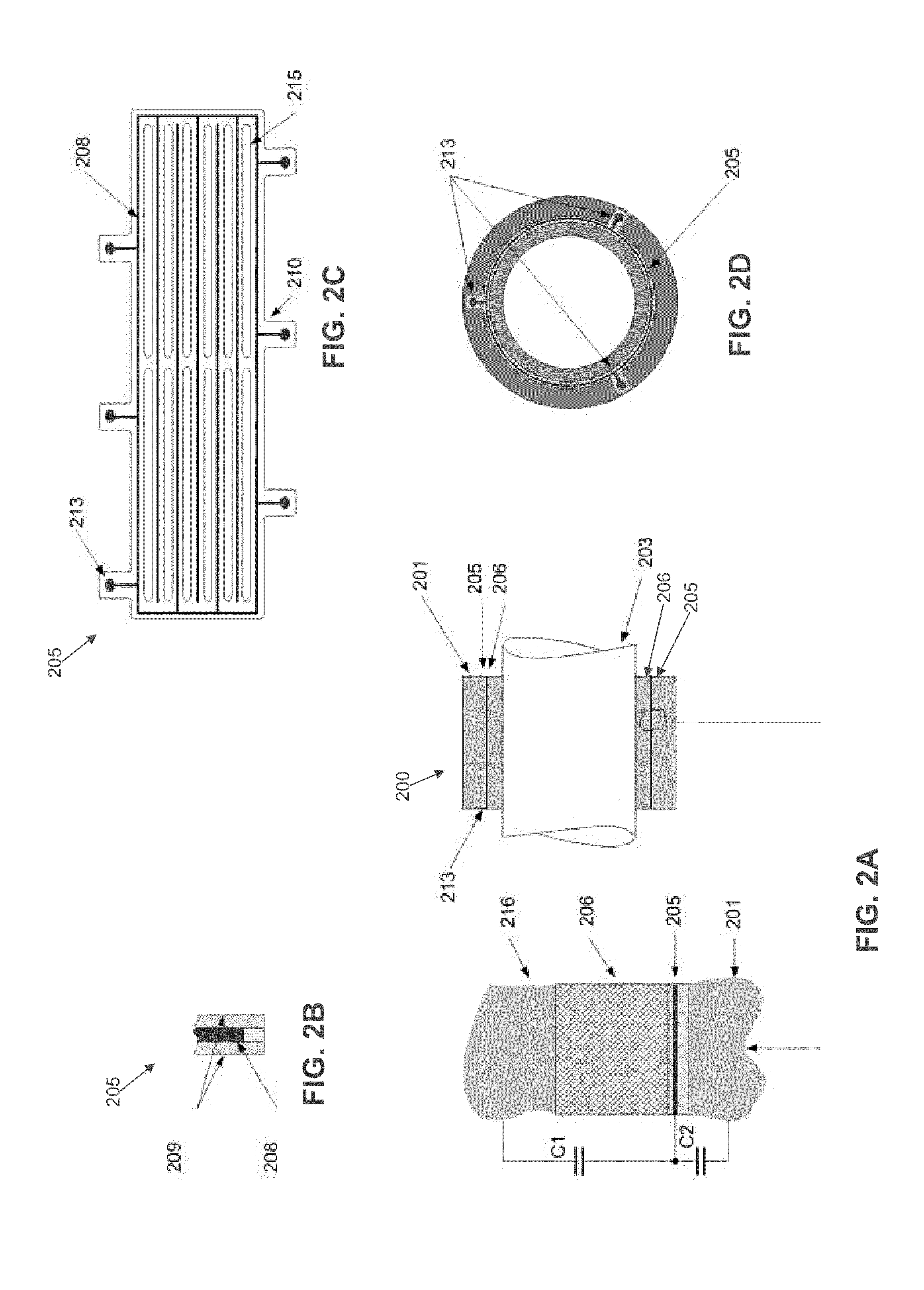

Method and systems for measuring wear on a tire

ActiveUS20050044943A1Improve the transfer coefficientLarge axial section areaMaterial analysis by optical meansUsing optical meansEngineeringElectromagnetic radiation

The present invention concerns a method of measuring the wear on at least one tire (20) mounted on a wheel (10) and comprising tread pattern elements (27, 28), and a tire (20), wheel (10), and a tire / wheel assembly (1) for implementing this method. According to the invention, the wear measurement method includes detecting electromagnetic energy transmitted through a transmission element disposed in at least one tire tread element to an internal space of the tire, the energy detected representative of a wear condition of the tread element or elements (27, 28). A tire (20) according to the invention comprises at least one device for transmitting electromagnetic radiation (50, 60), which device is disposed in at least one of tread element (27, 28) to conduct incident radiation striking the external surface to the tire (20) to the internal space, the transmission devices (50, 60) becoming exposed to the external surface upon a predetermined amount of wear of the tread element (27, 28).

Owner:MICHELIN RECH & TECH SA

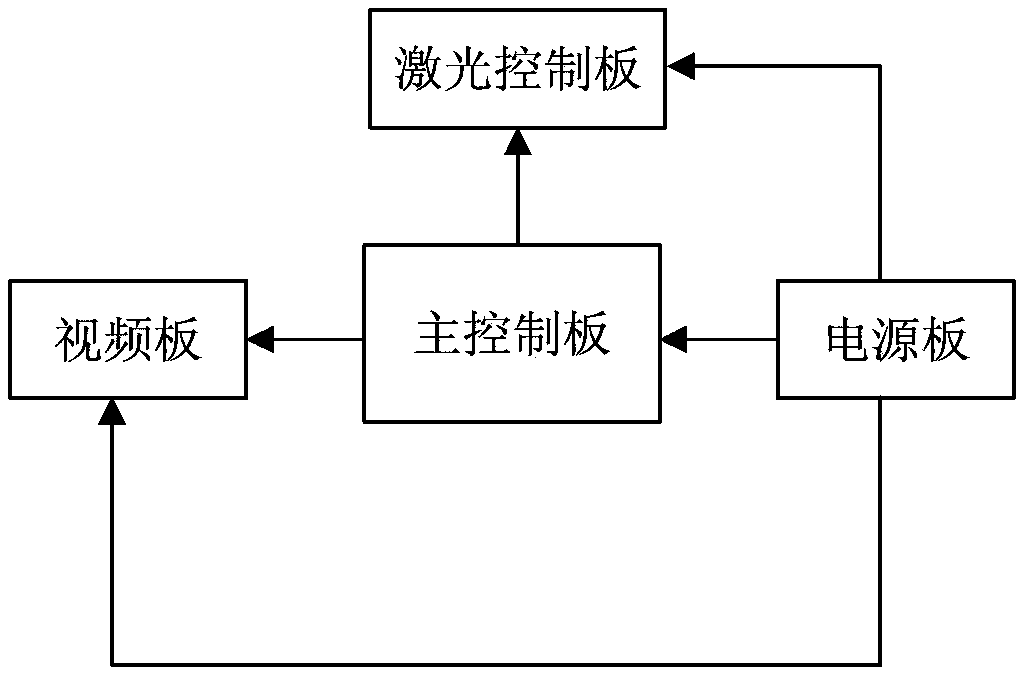

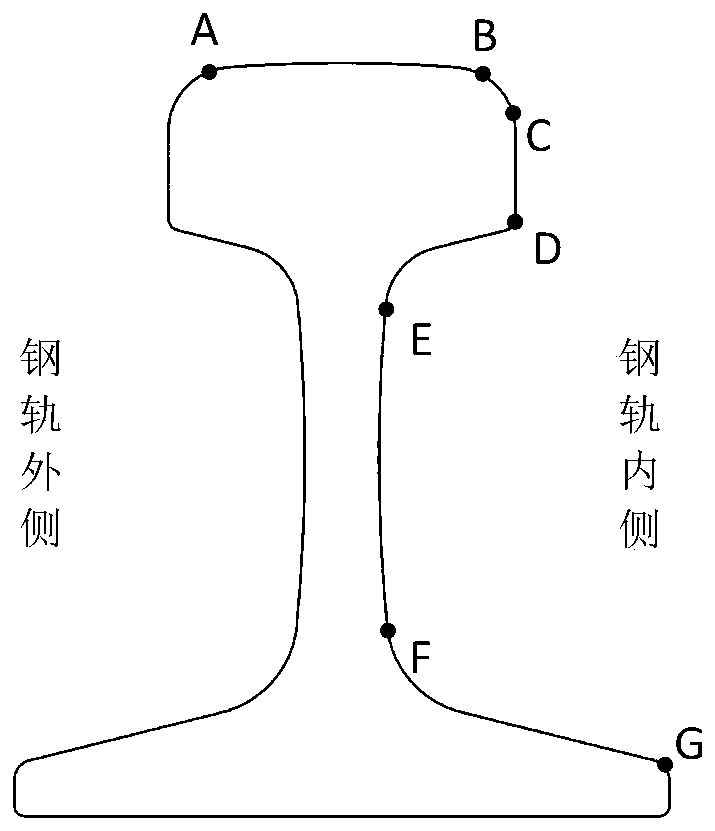

Steel-rail wear measurement device based on machine vision and grinding strategy method thereof

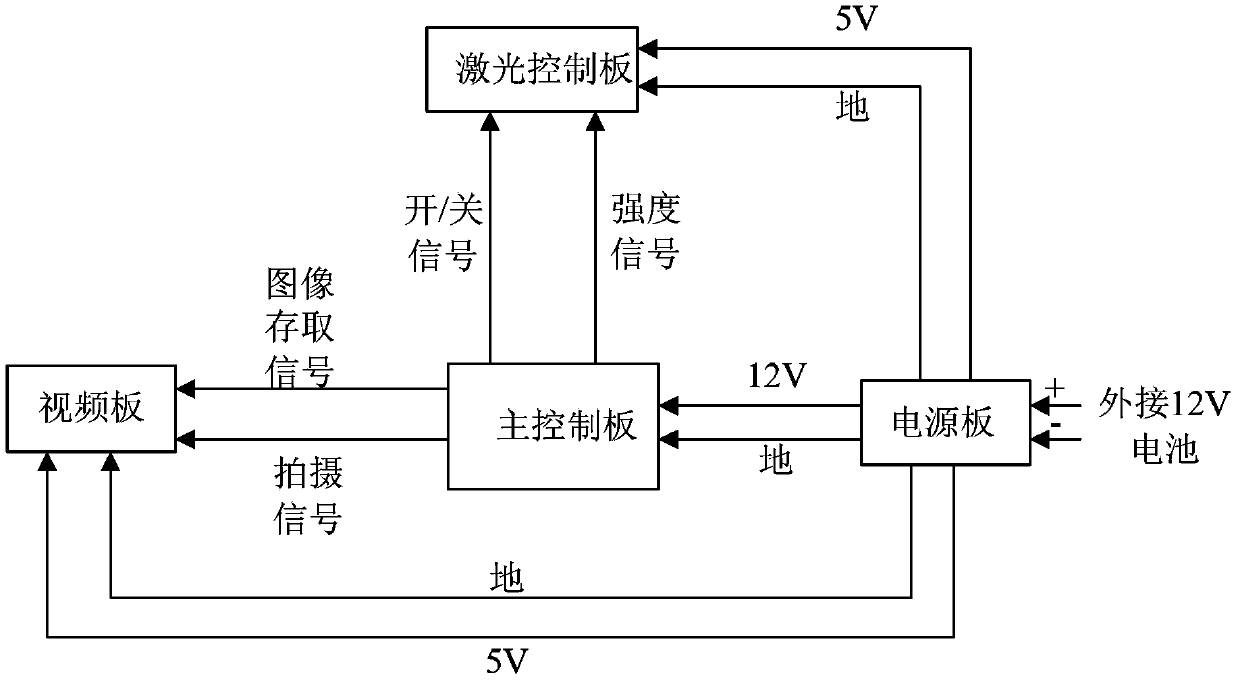

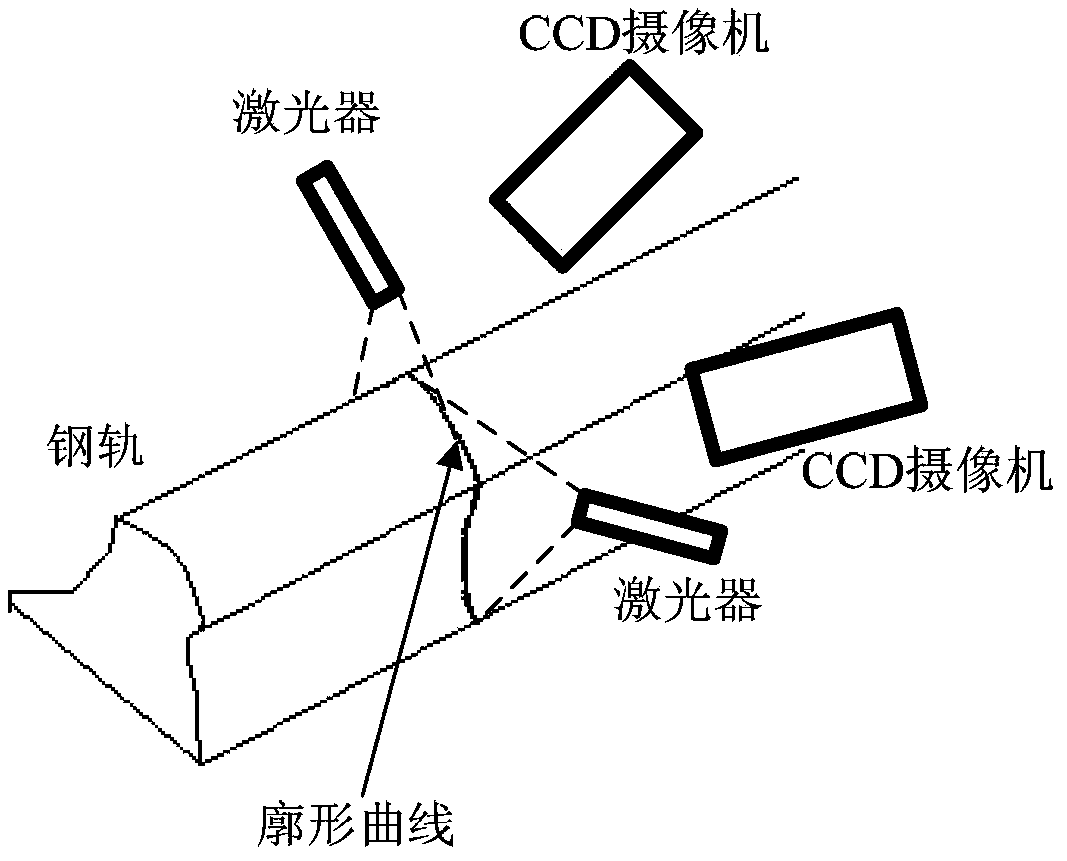

InactiveCN104180767AMeet the selection needsGrinding feed controlUsing optical meansMeasurement deviceHigh power lasers

The invention provides a steel-rail wear measurement device based on machine vision, which comprises a main control panel, a power panel, a laser control panel, and a video panel. The power panel is used for providing a stable direct-current voltage for the main control panel, the laser control panel and the video panel. The laser control panel is electrically connected with two high-power lasers. The video panel is electrically connected with two CCD cameras. The main control panel is connected with the power panel, the laser control panel, and the video panel, and used for controlling the on-off and intensities of the two high-power lasers and controlling the shooting actions of the two CCD cameras. The invention also provides a grinding strategy method for steel-rail wear according to the measurement device. According to a planned grinding quantity, a proper grinding speed of a steel-rail grinding car, the grinding power, and the motor distribution of different angles are calculated, and the steel rail is grinded. The steel-rail wear measurement device based on machine vision has the beneficial effects that the planned grinding area of the steel rail on side can be calculated according to different zones, and shortcomings of large amount of labor, poor environment, low efficiency and the like of the measurement mode of manual and mechanical contact can be overcome.

Owner:中国铁路武汉局集团有限公司武汉大型养路机械运用检修段 +1

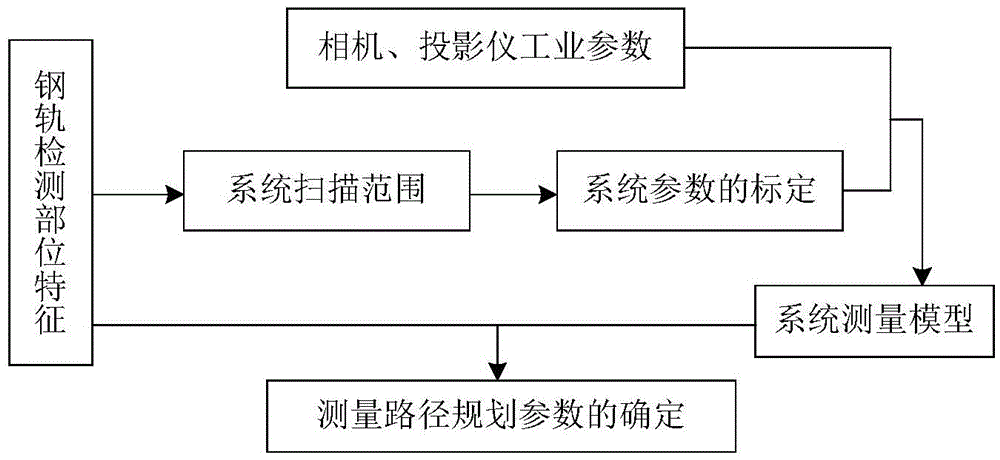

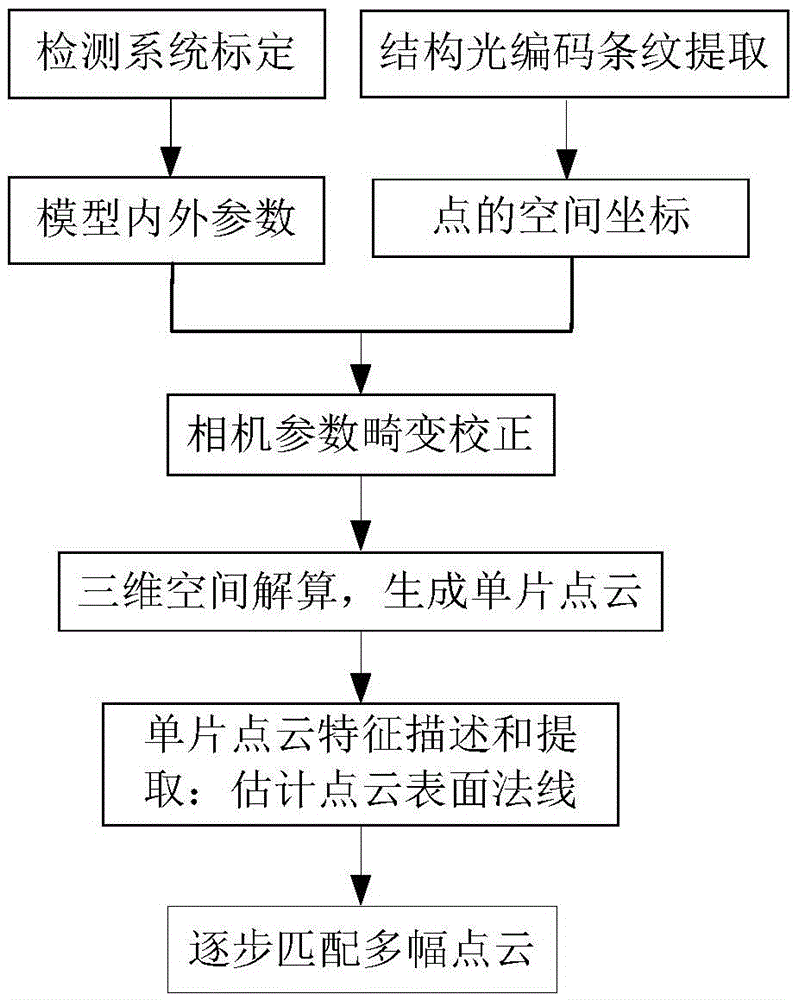

Turnout wear detection system and detection method based on structured light measurement

ActiveCN105526882AReduce mistakesReduce subjectivityUsing optical meansComputer Aided DesignPoint cloud

The invention provides a turnout wear detection system and detection method based on structured light measurement. The detection system comprises a detection system bearing platform, a support, a digital projector, an industrial camera, a computer, a turnout data measurement module, a turnout point cloud data processing module, a turnout curved plane reconstruction module and a contrast detection and data analysis module. The detection method comprises: acquiring turnout data to obtain three-dimensional point cloud data of a target turnout; simplifying and optimizing the point cloud data to reconstruct a continuous turnout three-dimensional curved plane model; and comparing the obtained turnout three-dimensional curved plane model with a same-model turnout standard CAD (Computer Aided Design) model to analyze and estimate turnout wear. By adopting the system and the method, errors caused by wear of contact measurement equipment and subjective influences caused by manual measurement are reduced; and acquired are continuous three-dimensional data, so that the turnout wear measurement is expanded from a limited section to any section, more comprehensive turnout wear information can be established, the turnout wear trend can be forecasted, and missing detection can be effectively prevented.

Owner:SOUTHWEST JIAOTONG UNIV

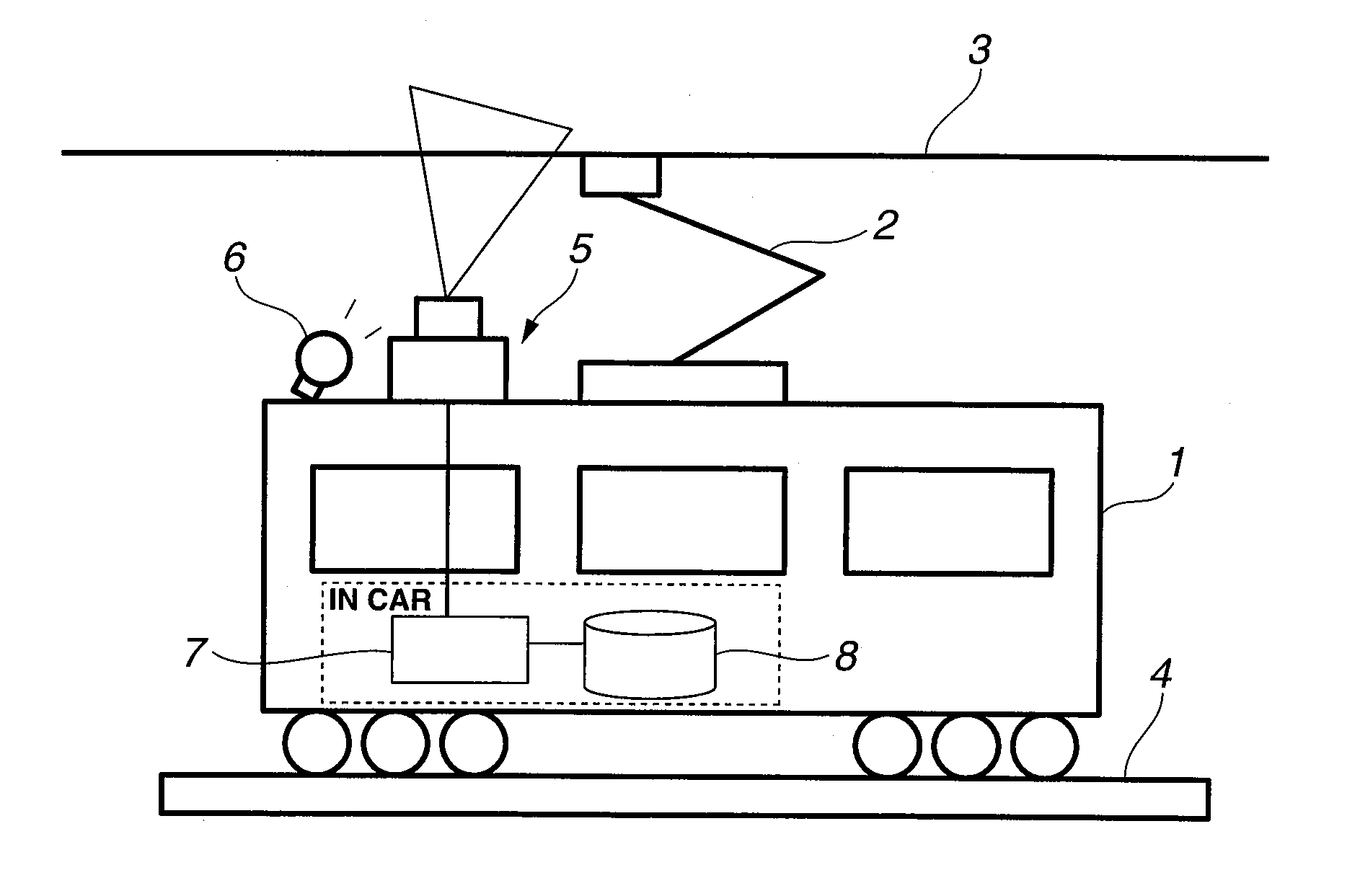

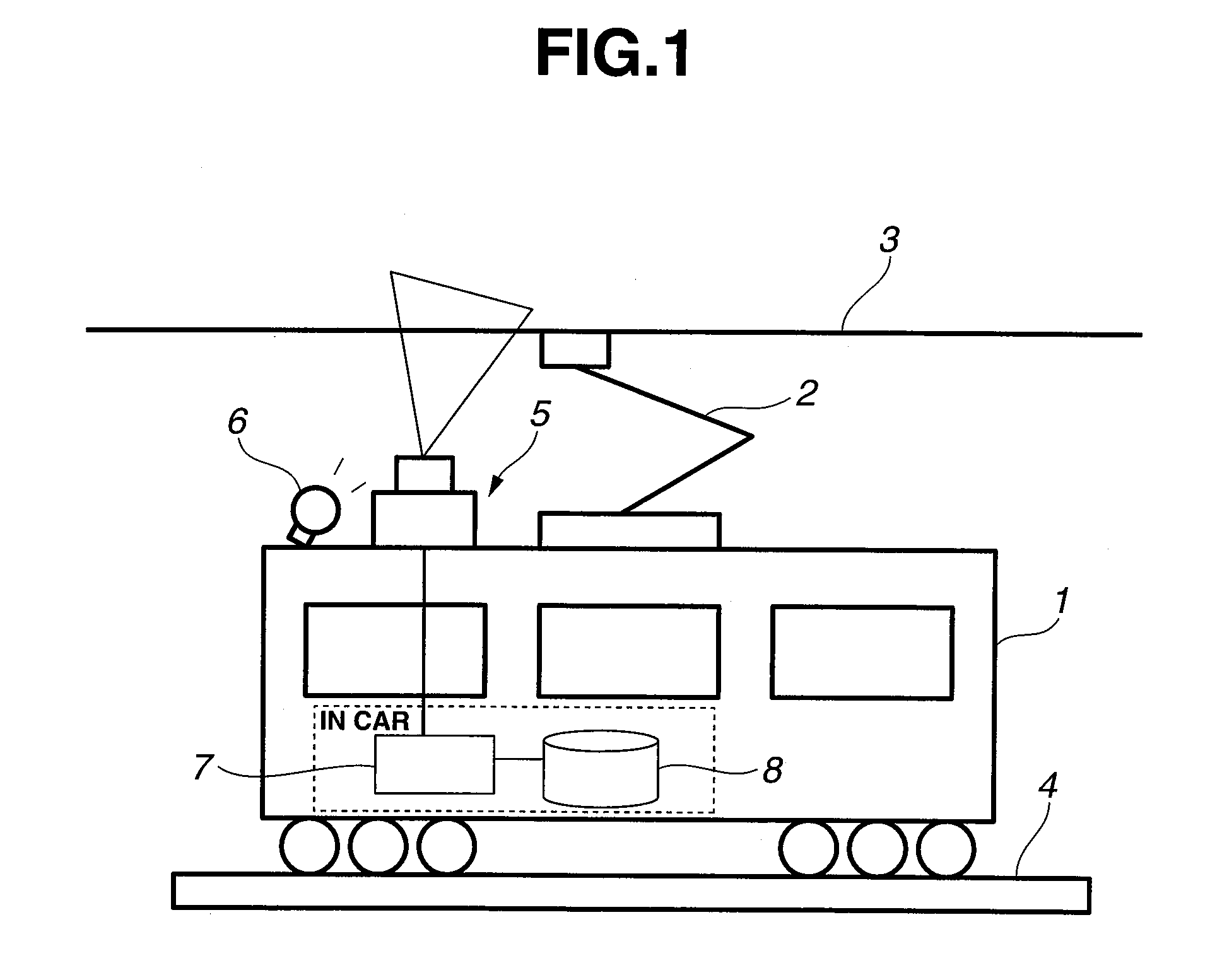

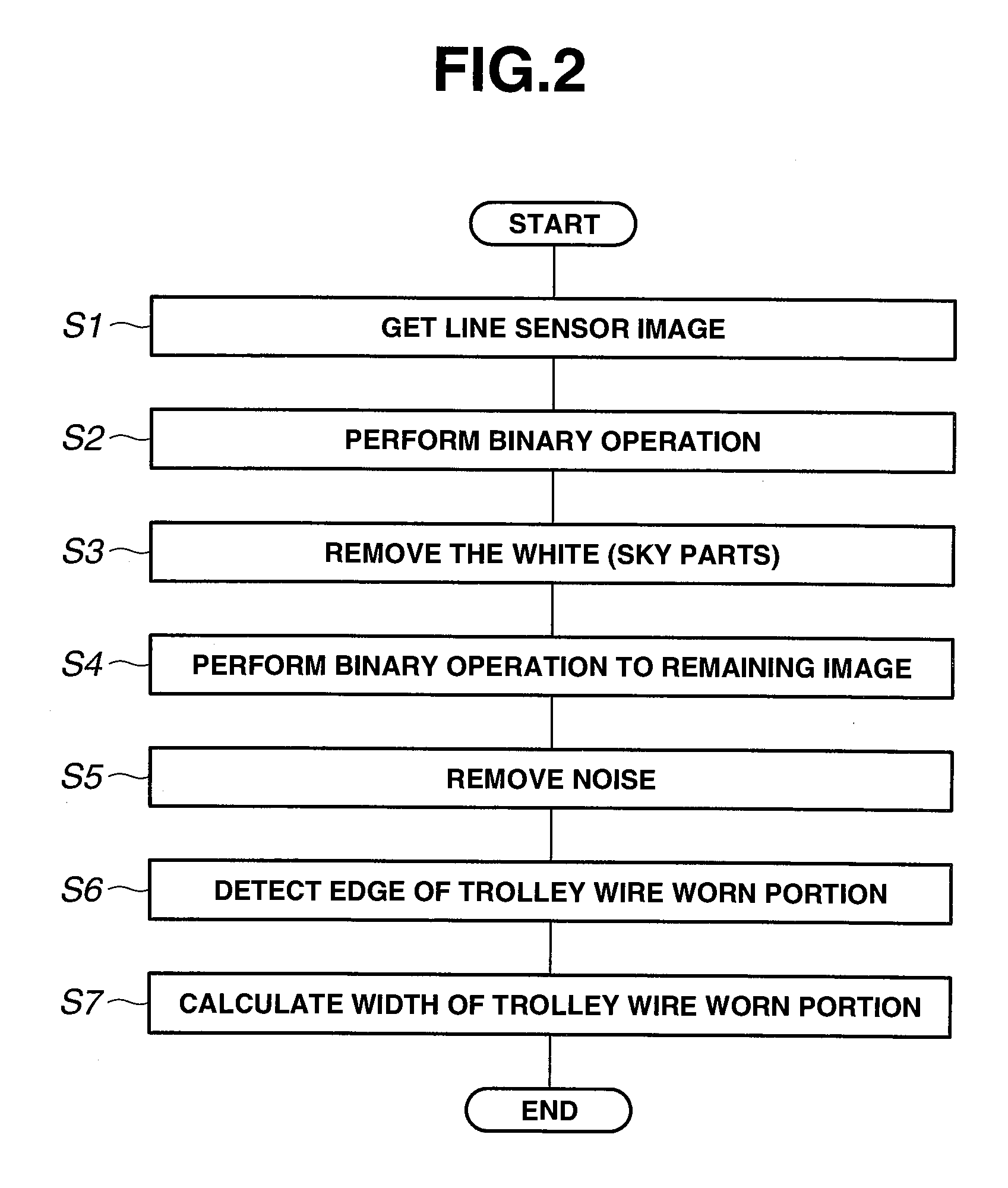

Trolley wire wear measuring device

ActiveUS20090320554A1Facilitates wear measurementMeasurement is performedSolid-state devicesInvestigating moving sheetsLine sensorSky

[Object] To ensure a wear measurement over an entire section of a trolley wire and to facilitate the wear measurement, and also to perform the measurement during daytime, without being affected by structures existing around the trolley wire.[Means to solve] A line sensor 5 and an illumination lamp 6, which are placed in a direction of a scanning line perpendicular to a laying direction of a trolley wire, are mounted on a test car 1. The line sensor 5 shoots a pantograph contact surface of the trolley wire by the running of the test car, and this image signal is saved in a recording device 8 through a measurement computer 7. The measurement computer 7 arranges luminance signals of scanning lines, obtained by the line sensor 5, in time series, and creates a line sensor image. The measurement computer 7 gets a binary operated line sensor image from this line sensor image. The measurement computer 7 further removes sky parts from this binary operated line sensor image and detects edges of a trolley wire worn portion, then determines a width of the trolley wire worn portion through an overall width of the trolley wire and a height, viewed from the line sensor, of the trolley wire.

Owner:MEIDENSHA ELECTRIC MFG CO LTD

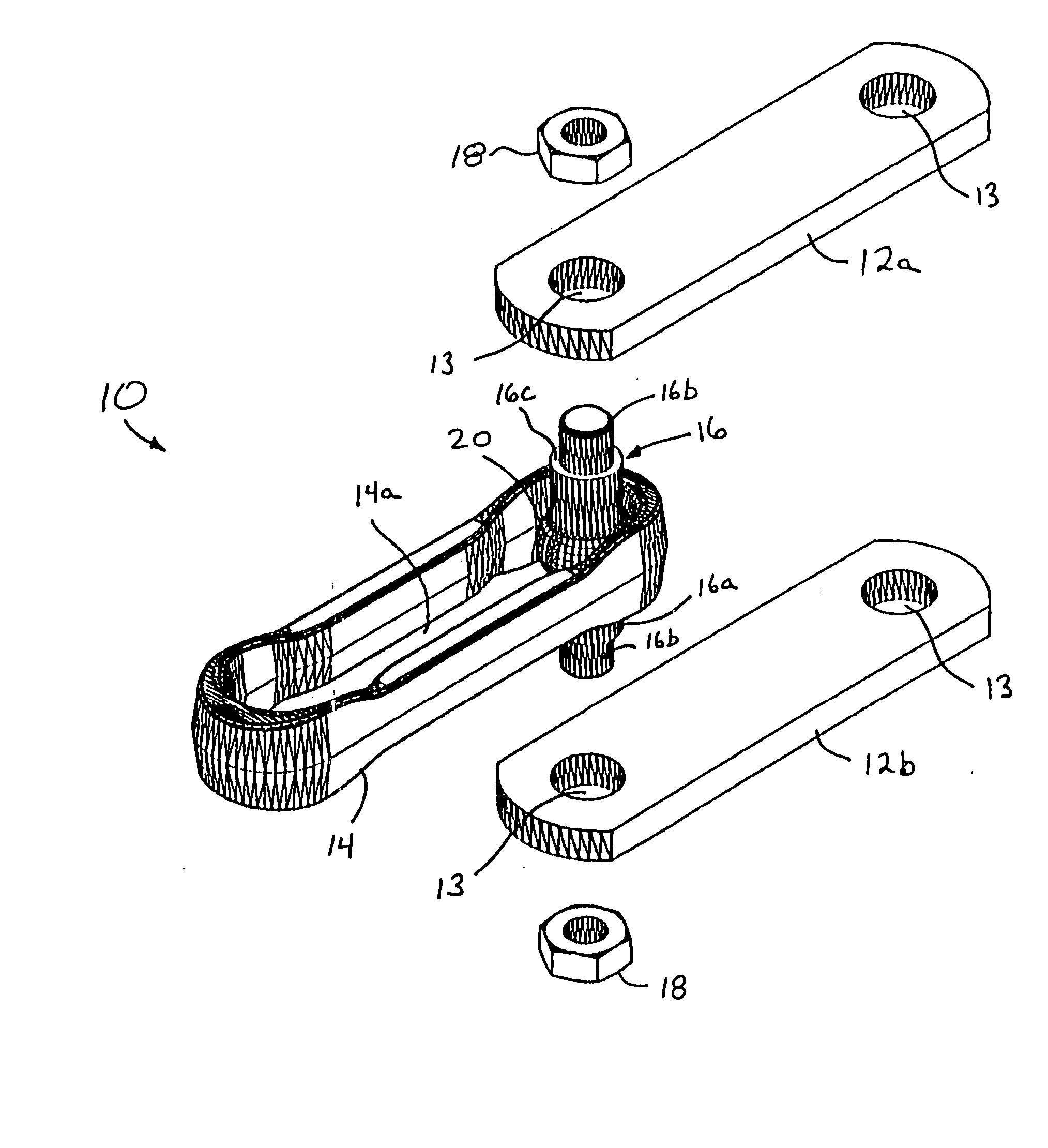

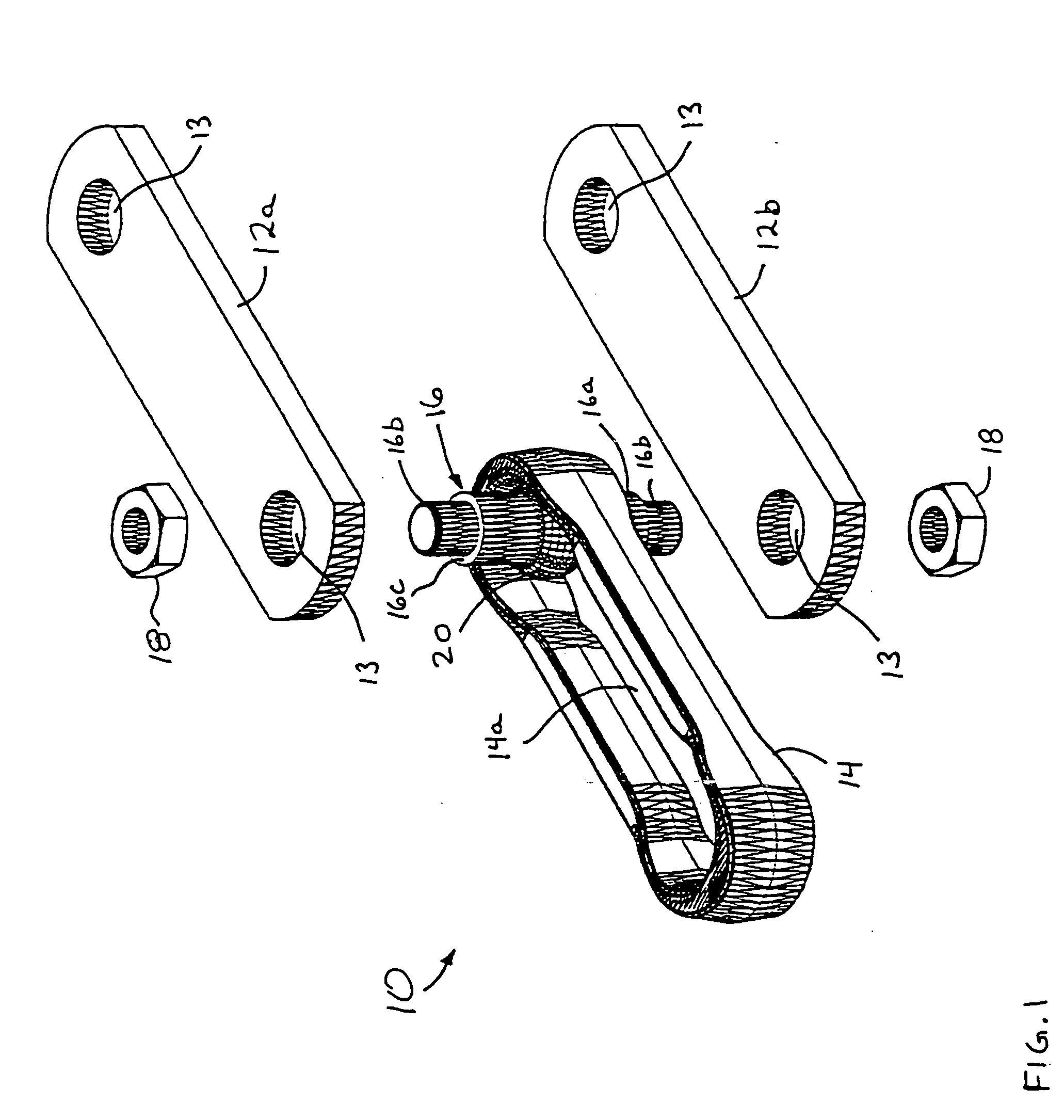

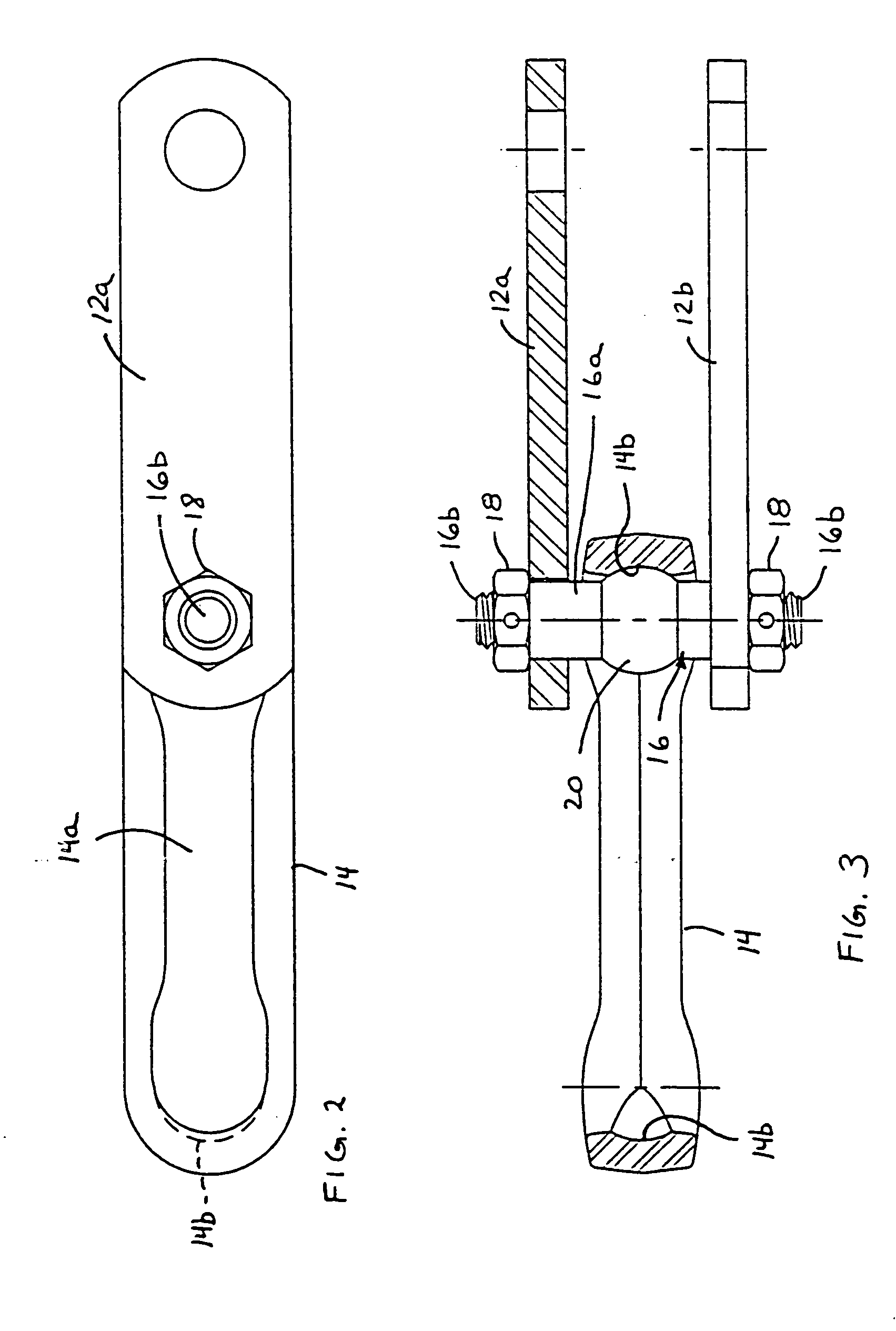

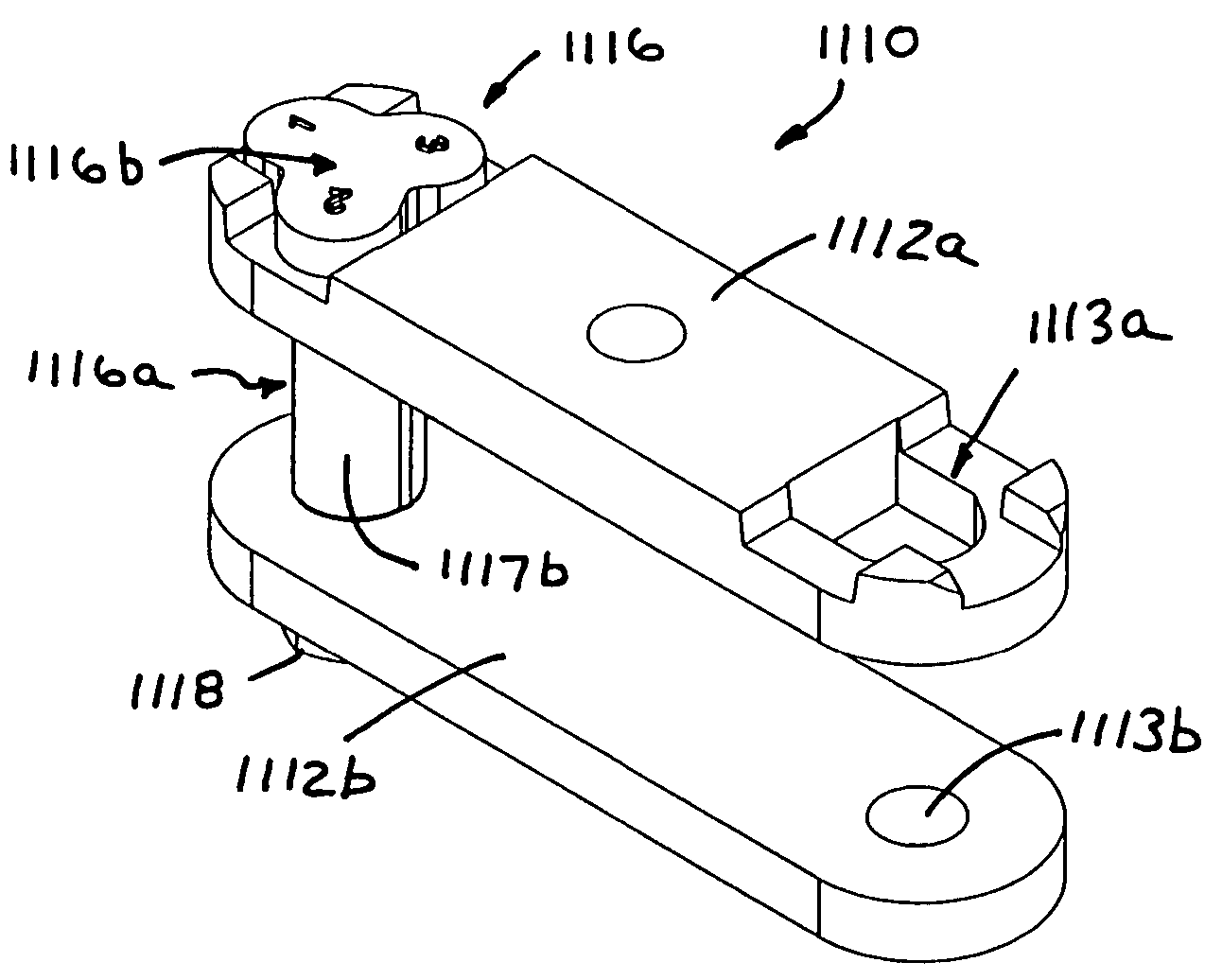

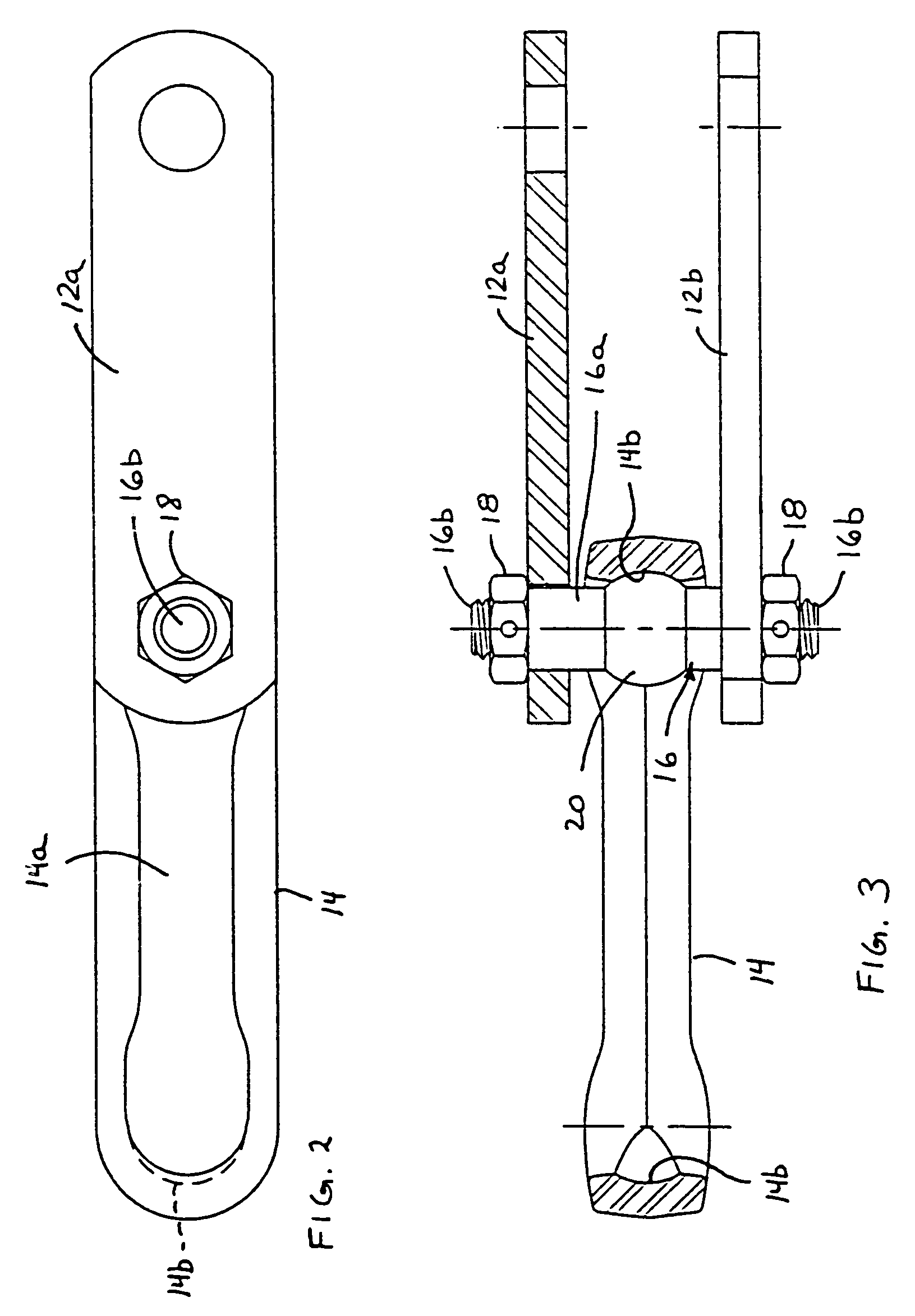

Wear measurement device

InactiveUS6862939B2Accurately determineEasy to detectMachine gearing/transmission testingMaterial strength using tensile/compressive forcesEngineeringChain link

A chain wear measurement system and / or method for determining an amount of wear in a section of chain comprises a chain or section of chain having a plurality of chain links connected together by a plurality of pins or bolts or the like. At least one end of at least one of the pins or bolts may have an extension extending longitudinally therefrom. A sensor is provided along a conveying path of the chain for sensing the presence of the pin or bolt and / or extension as the section of chain is conveyed along the conveying path. The sensor provides a signal indicative of a detection of the pin or pins or bolts. A control may be responsive to the sensor, such as to determine the degree of wear in the section of chain in response to one or more signals from the sensor.

Owner:FROST TECH

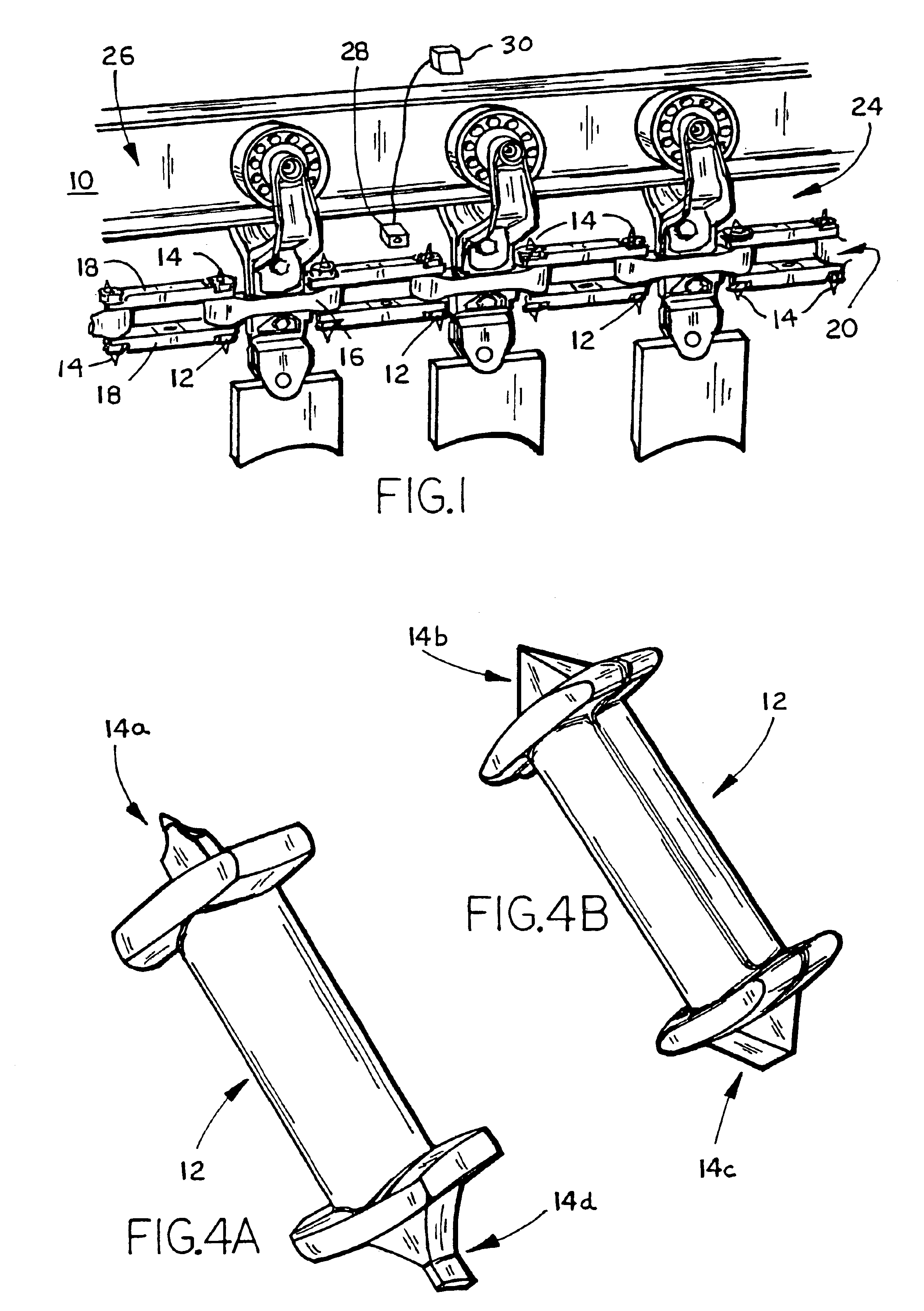

Conveyor chain

InactiveUS7246699B2Increase flexibilityReducing and controlling wearConveyorsPackagingEngineeringHandling system

A section of chain for conveying product along a material handling system includes a pin connecting a center link between two side links. The pin may be dialable or selectably positioned at the side links to control and adjust the wear surface of the pin relative to the chain links. The pin may have a rotationally non-symmetrical shaft portion to provide different wear surfaces that engage a center link of the section of chain. The different wear surfaces may be sized and shaped to accommodate wear at the wear surface of the center link. The shaft portion may include a rotationally non-symmetrical ball member or portion on the shaft portion to enhance flexibility of the section of chain. The pin may be dialed to the next position or wear surface in response to an output of a wear measurement device or system.

Owner:FROST TECH

Brake wear measurement system

ActiveUS20090205910A1Small linear displacementMechanically actuated brakesApparatus for force/torque/work measurementEngineeringLinear displacement

A brake measurement system that utilize angular and / or linear displacement sensors to measure movement of a member operatively coupled to a movable member of a brake, wherein displacement of the movable member of the brake is indicative of brake wear. The system can include a twisted spline member operatively coupled to a moveable member of a brake assembly, and an angular displacement sensor operatively coupled to the twisted spline member. Movement of the moveable member is converted by the twisted spline member into an angular displacement sensed by the angular displacement sensor.

Owner:THE BF GOODRICH CO

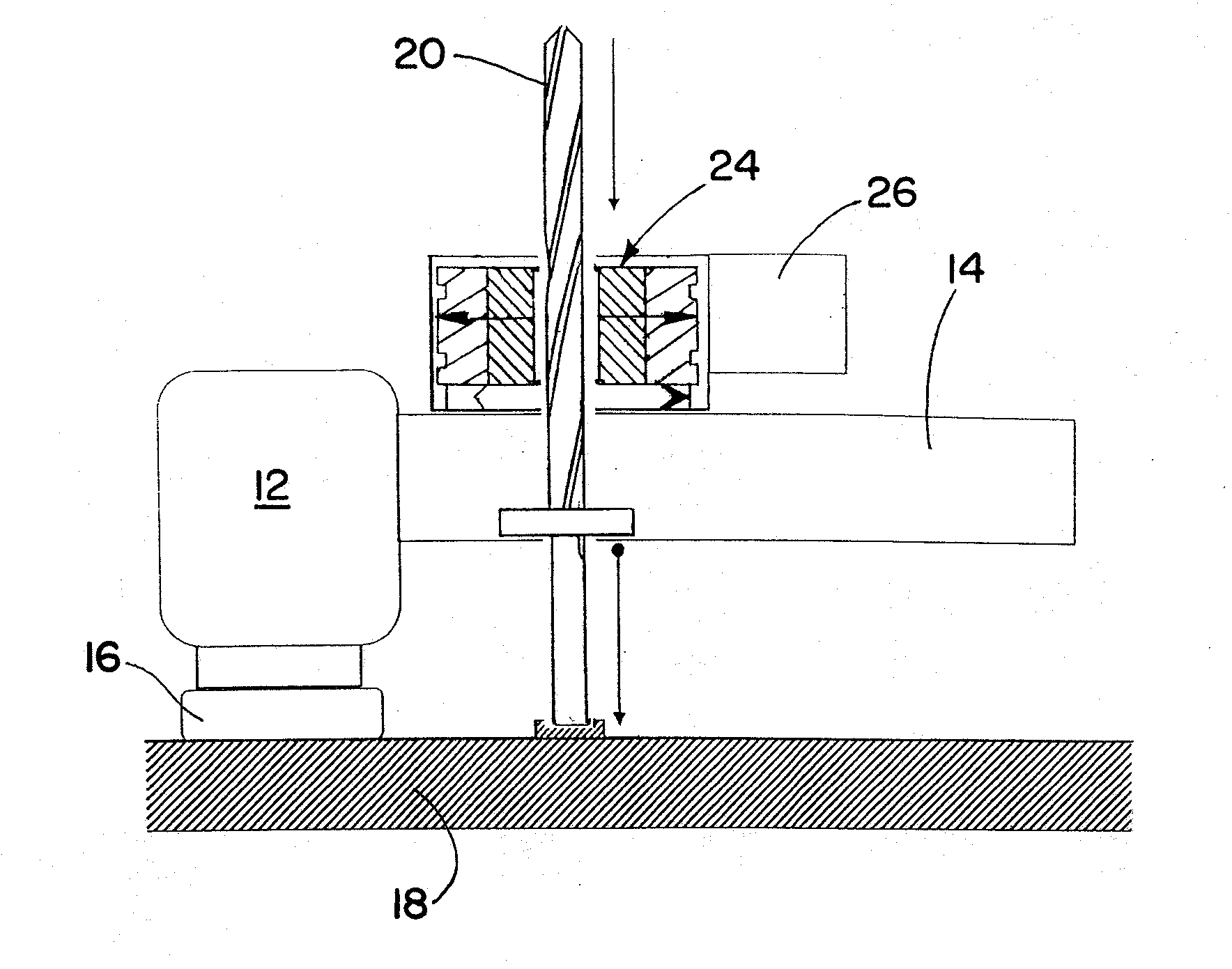

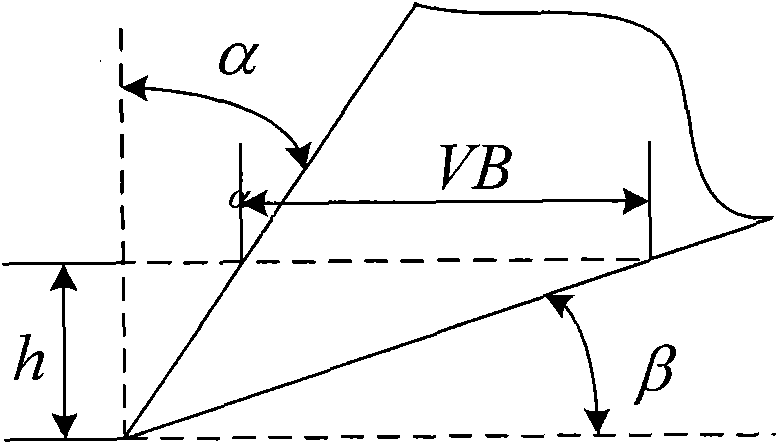

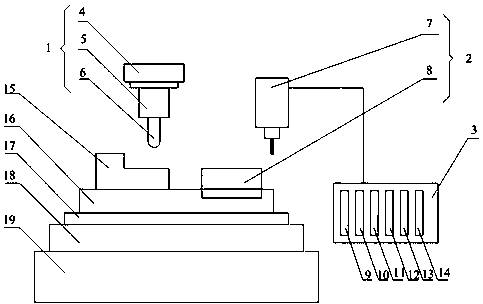

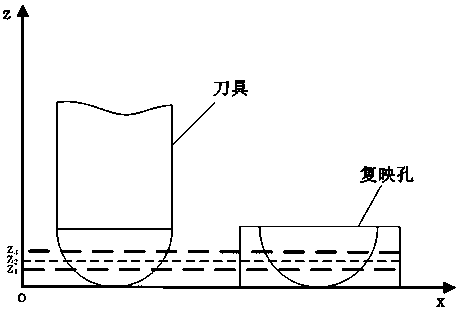

Method for measuring wear of numerical control milling cutting tool based on shape copying

InactiveCN101590614AIncrease profitLow costMeasurement/indication equipmentsNumerical controlEngineering

The invention relates to a method for measuring wear of a numerical control milling cutting tool based on shape copying, and belongs to the field of wear measurement of numerical control milling cutting tools. The method comprises the following steps that: a workpiece material and a copying material are arranged on the same numerical control machine tool worktable; the initial shape of the cutting tool is copied on the copying material before experiment, namely a preset distance of the cutting tool is fed on the copying material along the axial direction of a main shaft of a machine tool, and the shape of the cutting tool is copied on the copying material; the copying material is a material which is easy to process and ignores the wear of the cutting tool; the processing material is processed according to a designed experiment proposal; at the same time, the shape of the worn cutting tool is copied on the copying material after the processing is finished each time; and all the wear geometrical element shapes of the cutting tool on the copying material are carried out mathematical processing and measurement after all the processing process is finished. The method introduces the shape copying into the wear measurement of the cutting tool, improves the utilization rate of the machine tool, and reduces the cost and time of the numerical control processing experiment. The wear measurement of the cutting tool is easily set, and the wear extent of the cutting tool can be obtained without needing stopping the machine tool.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Wear measuring method based on profile duplication of grooving and milling cutter

InactiveCN101804583AEliminate the effects of wear measurementsEasy to set upMeasurement/indication equipmentsNumerical controlBatch processing

The invention relates to a cutter wear measuring method based on the grooving and milling profile duplication, belonging to the cutter wear measuring field. The method is characterized by comprising the following steps of: installing a workpiece material to be processed and a duplicate material on the same numerically-controlled machine workbench; firstly duplicating the initial profile of a cutter on the duplicate material before experiment, that is, feeding the cutter on the duplicate material in a grooving and milling mode for a preset distance, wherein the duplicate material is a tractable material of which the wear on the cutter can be ignored; processing the workpiece material according to the experimental scheme, and duplicating the profile of the worn cutter on the duplicate material after each processing is completed; processing the cutter wear geometric element shape on the duplicate material, extracting characteristic values, designing a measurement scheme based on the measurement requirements of the characteristic values, and measuring on three coordinates measuring machines after all experimental schemes are finished. The invention can obtain the cutter wear amount without closing down the tool, and has the advantages of simple setting for the cutter wear measurement, less measurement data, simple processing and batch processing and measurement.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

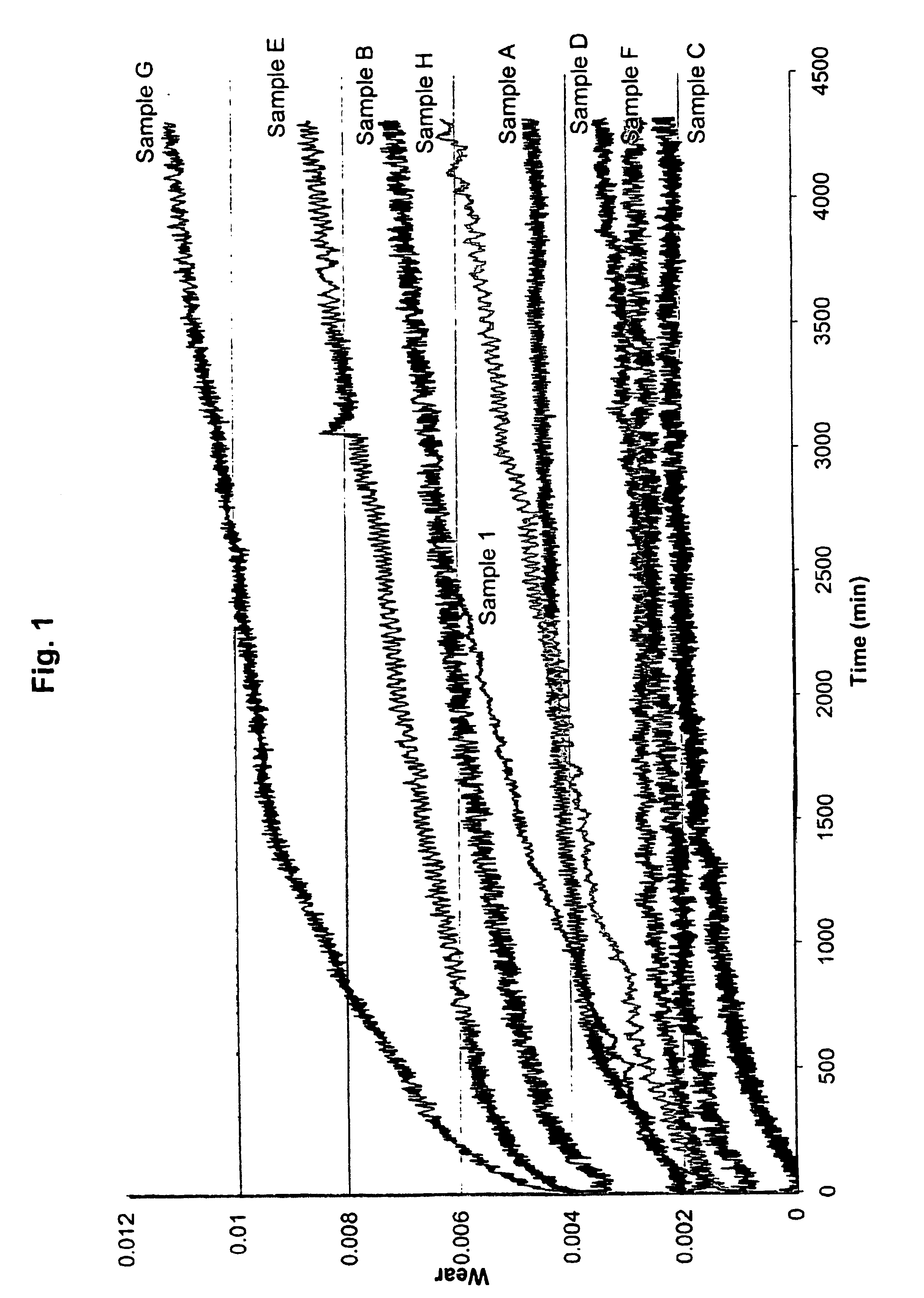

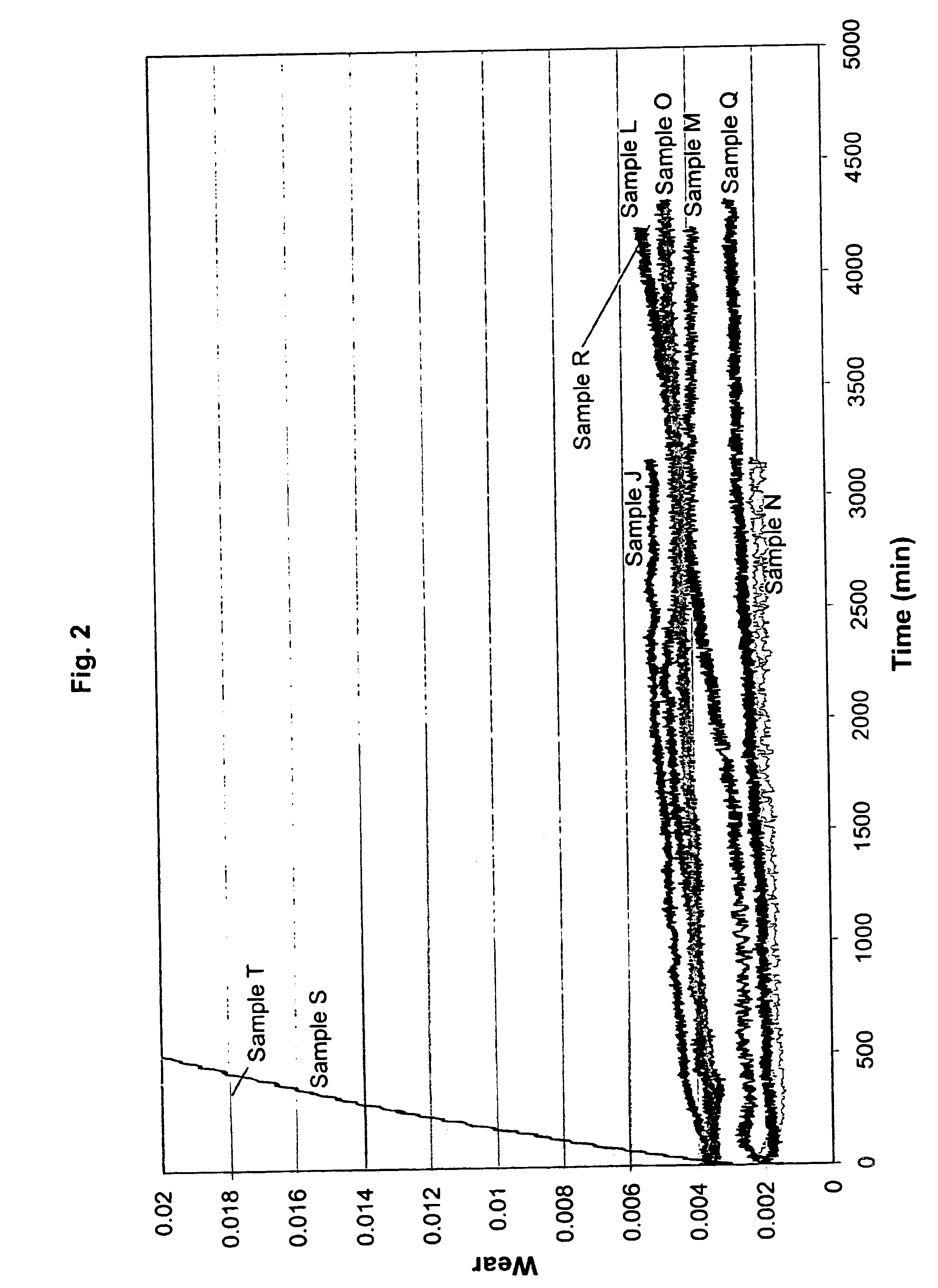

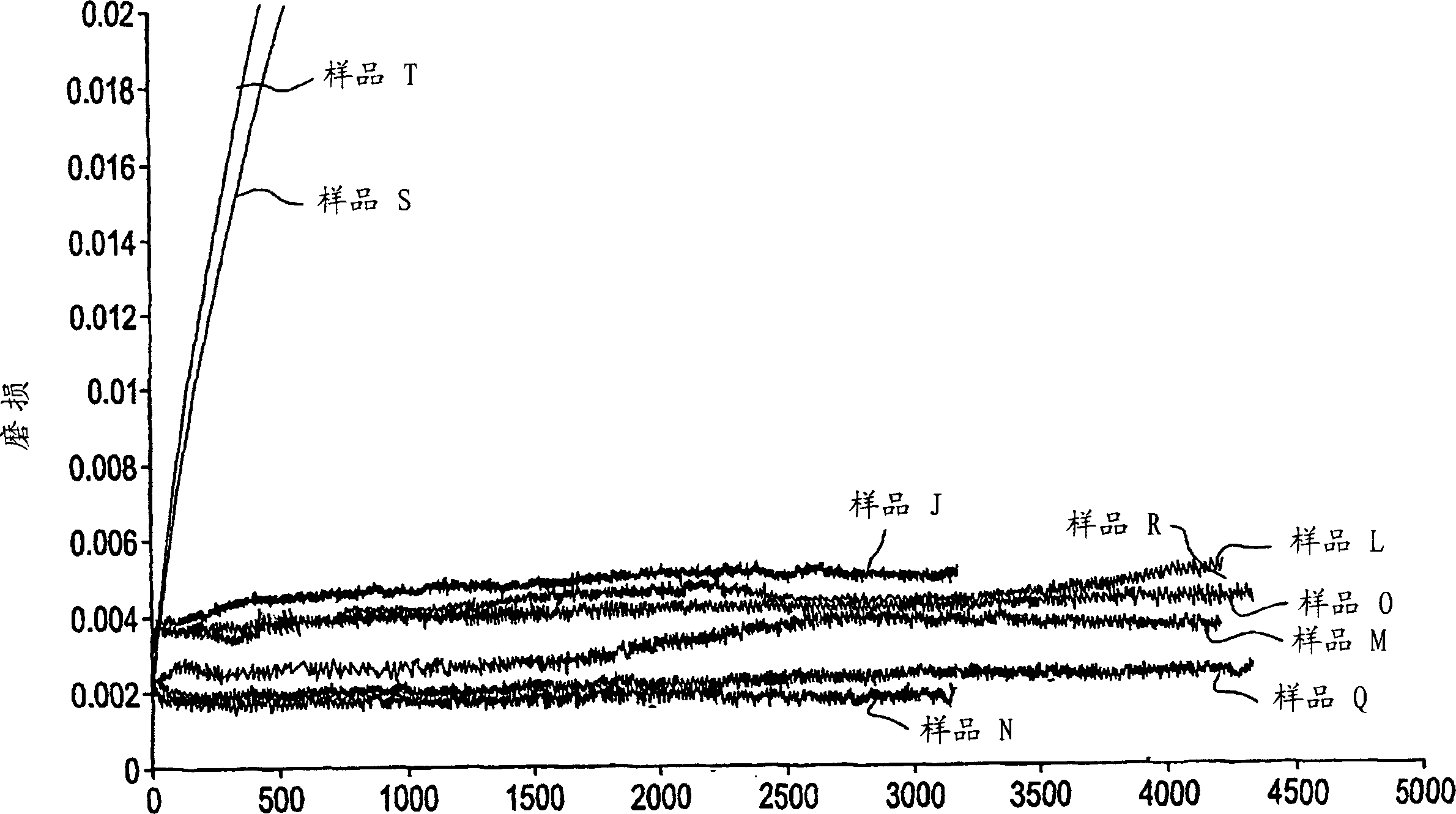

Compositions containing polyphenylene ether and/or polystyrene having improved tribological properties and methods for improving tribological properties of polyphenylene ether and/or polystyrene compositions

InactiveUS6887938B2Improve tribological propertiesImprove wear resistanceSpecial tyresOrganic dyesLinear low-density polyethylenePolystyrene

Internally lubricated polymer compositions containing a styrene- and / or polyphenylene ether-containing polymer, an olefin-containing polymer, and a compatibilizer are provided. The olefin-containing polymer, which is present in the compositions in about 3 to about 30 weight percent, provides internal lubrication and improves the tribological properties of the compositions compared with the styrene- or polyphenylene ether-containing polymer alone, as determined by wear measurements. Preferred compositions exhibit wear factors less than about 130×10−11n mm5 / Pa-m. A preferred composition includes a blend of polystyrene / polyphenylene ether, linear low density polyethylene, and styrene-ethylene-butadiene-styrene. Methods are also provided for improving tribological properties of styrene- and / or polyphenylene ether-containing base polymers by incorporating into the base polymers at least one olefin-containing polymer and at least one compatibilizer, or by incorporating at least one substantially halogen-free internal lubricant.

Owner:SHPP GLOBAL TECH BV

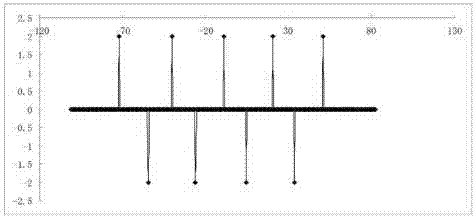

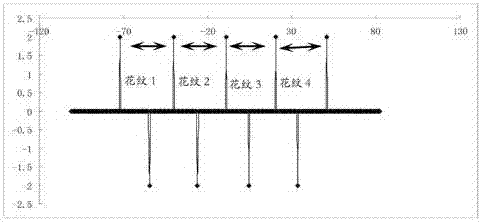

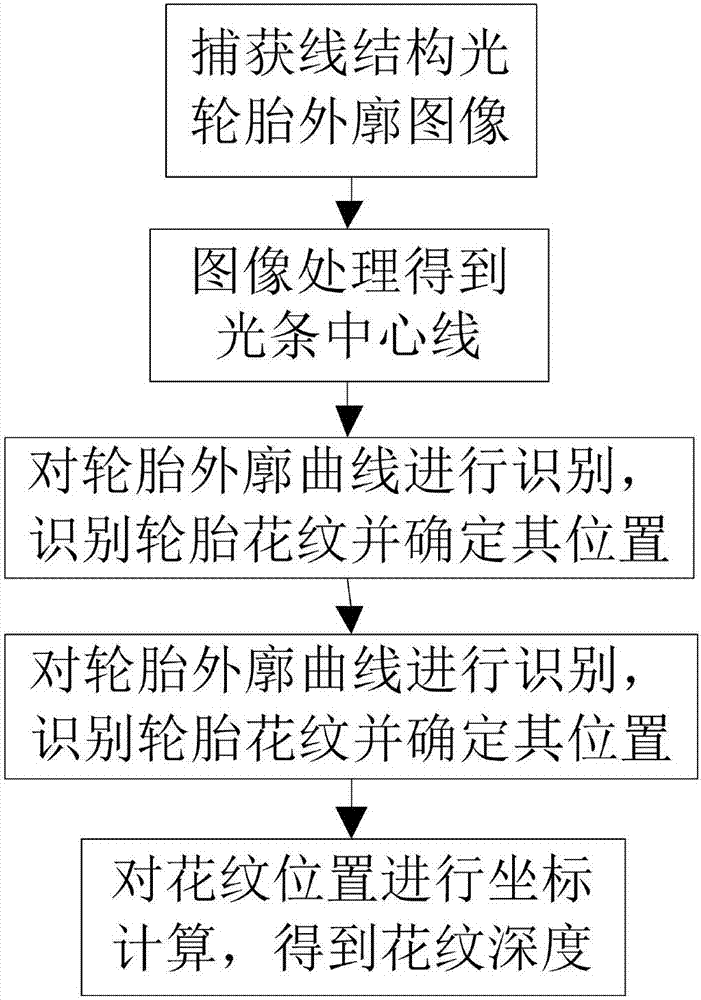

Line structured light machine vision tire abrasion measuring method

ActiveCN106918299AAids in four wheel alignmentHelp with maintenance workUsing optical meansImaging processingMachine vision

The invention discloses a line structured light machine vision tire abrasion measuring method. The method is characterized in that the method includes the following steps: capturing a tire contour image of a line structured light; subjecting the tire contour image to an image processing module and obtaining a light stripe center line; analyzing the tire contour image at the same time to identify a tire contour curve; further identifying tire pattern and the position of the tire pattern targeted at the tire contour curve; conducting coordinate computing on the pattern position to obtain a pattern depth; acquiring a laser cross-section contour light strip which is formed on the tire surface by a line laser; using a CCD camera and computing tire contour information and generating a complete contour image. By obtaining the pattern depth of the captured tire contour image, sampling of a test sensor and a to-be-tested tire are conducted in a non-contact manner during the entire test and the entire test can be conducted automatically, so that the method has excellent robustness and is conducive for future maintenance and repair of a vehicle, such as wheel positioning.

Owner:SHENZHEN ANCHE TECH

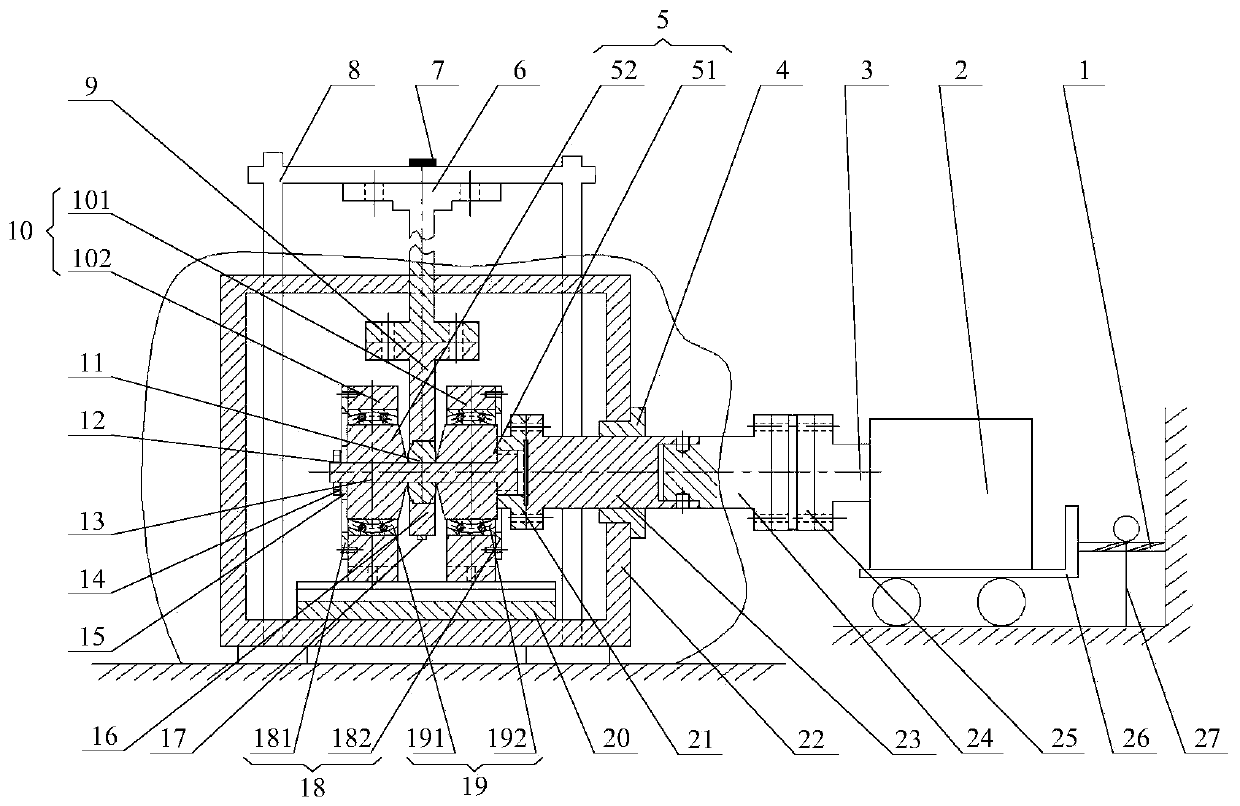

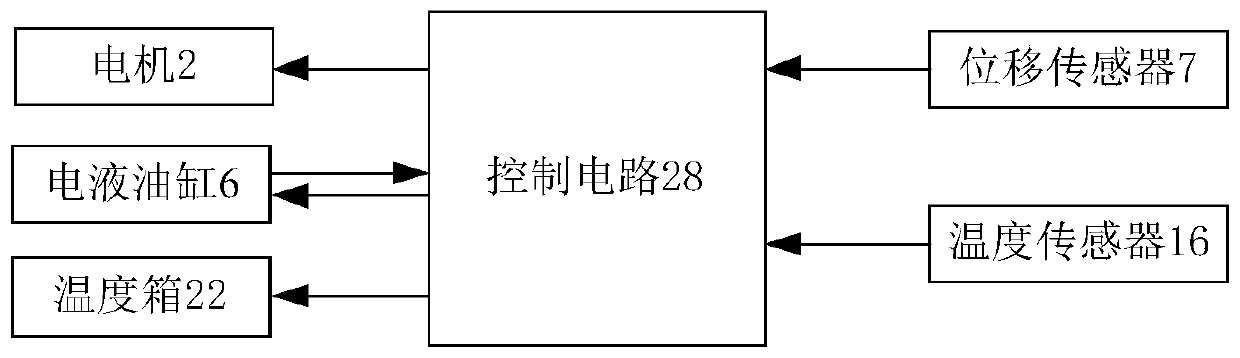

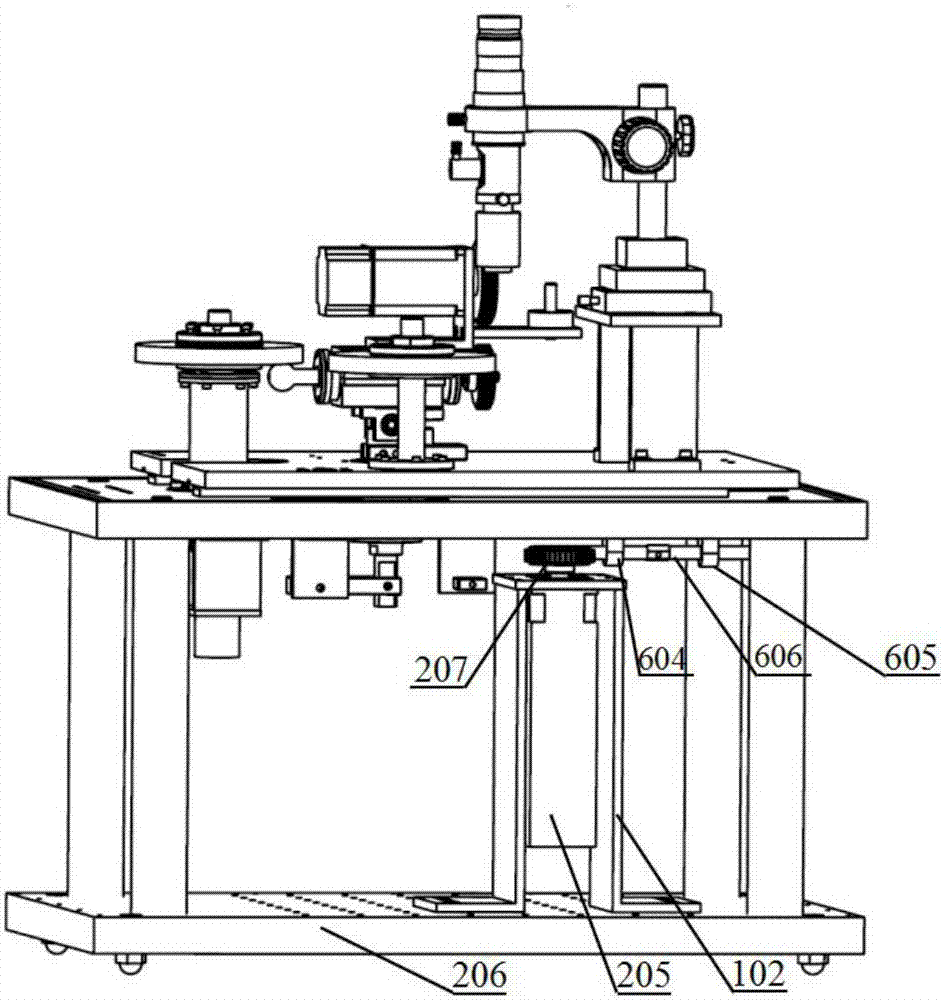

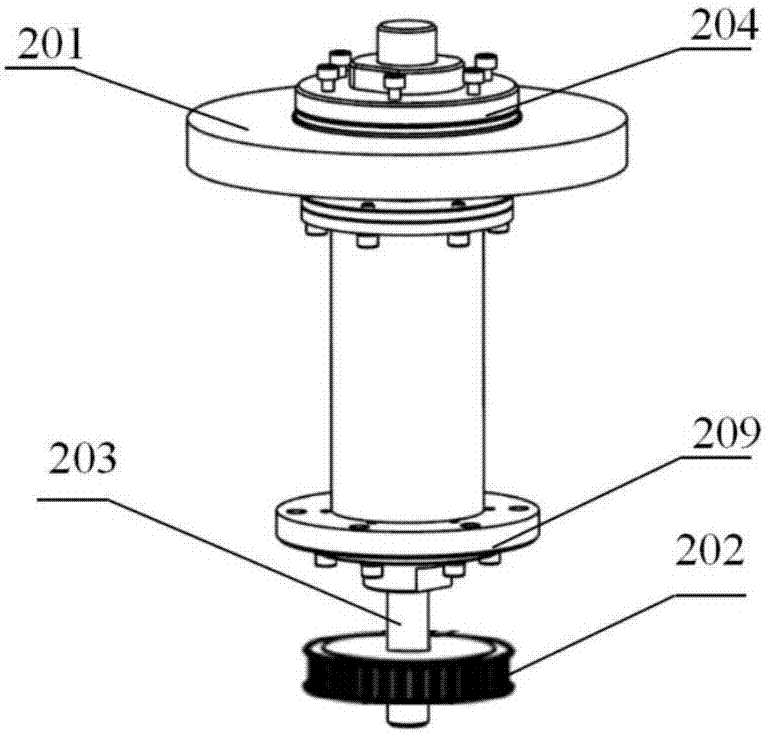

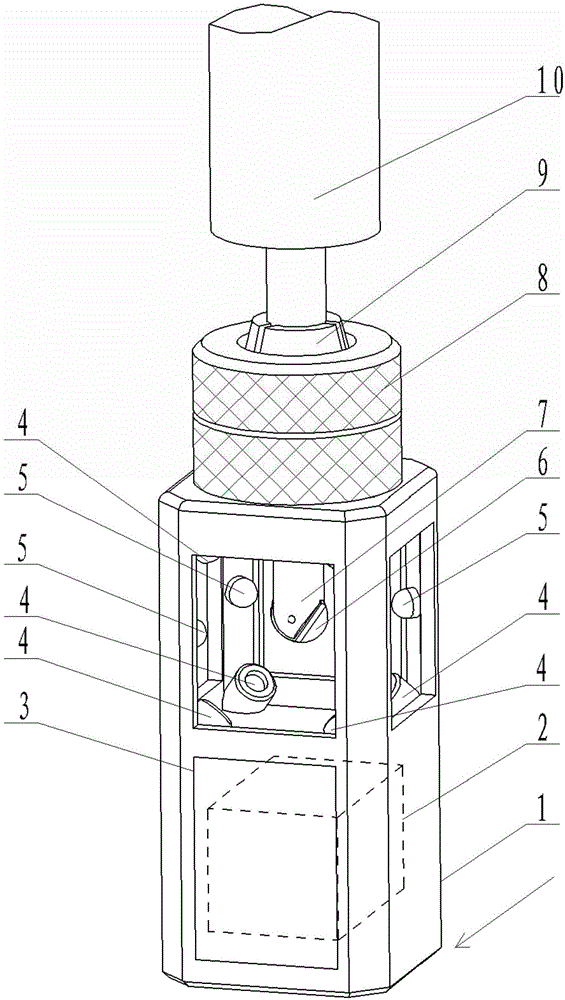

Joint bearing low-temperature wear test system and assembly method thereof

ActiveCN110243602AEasy to disassembleImprove general performanceMachine bearings testingInvestigating abrasion/wear resistanceTemperature controlRadial stress

The invention provides a joint bearing low-temperature wear test system. The system comprises a base, a temperature box, a radial stress subsystem, a power subsystem, a temperature control subsystem, a wear measurement subsystem and a clamp subsystem. The clamp subsystem comprises a pushing block, a loading plate, an accompanying test bearing seat, a mandrel, an accompanying test bearing, an end cover and a locking part, which are independent detachable parts; the mandrel, the pushing block or the loading plate can be replaced to realize clamping in a life test of joint bearings with different diameters, so that the utilization rate and the universality of a test clamp are improved; and in addition, the clamp subsystem adopts the structural design improvement that a single-side flange is added to an inner hole of the loading plate, the thickness of the pushing block is reduced, the flange and the end cover cooperatively fix the accompanying test bearing, and the like, so that the mandrel deformation or breakage easily caused in the joint bearing wear test process is effectively avoided.

Owner:CHINA AERO POLYTECH ESTAB

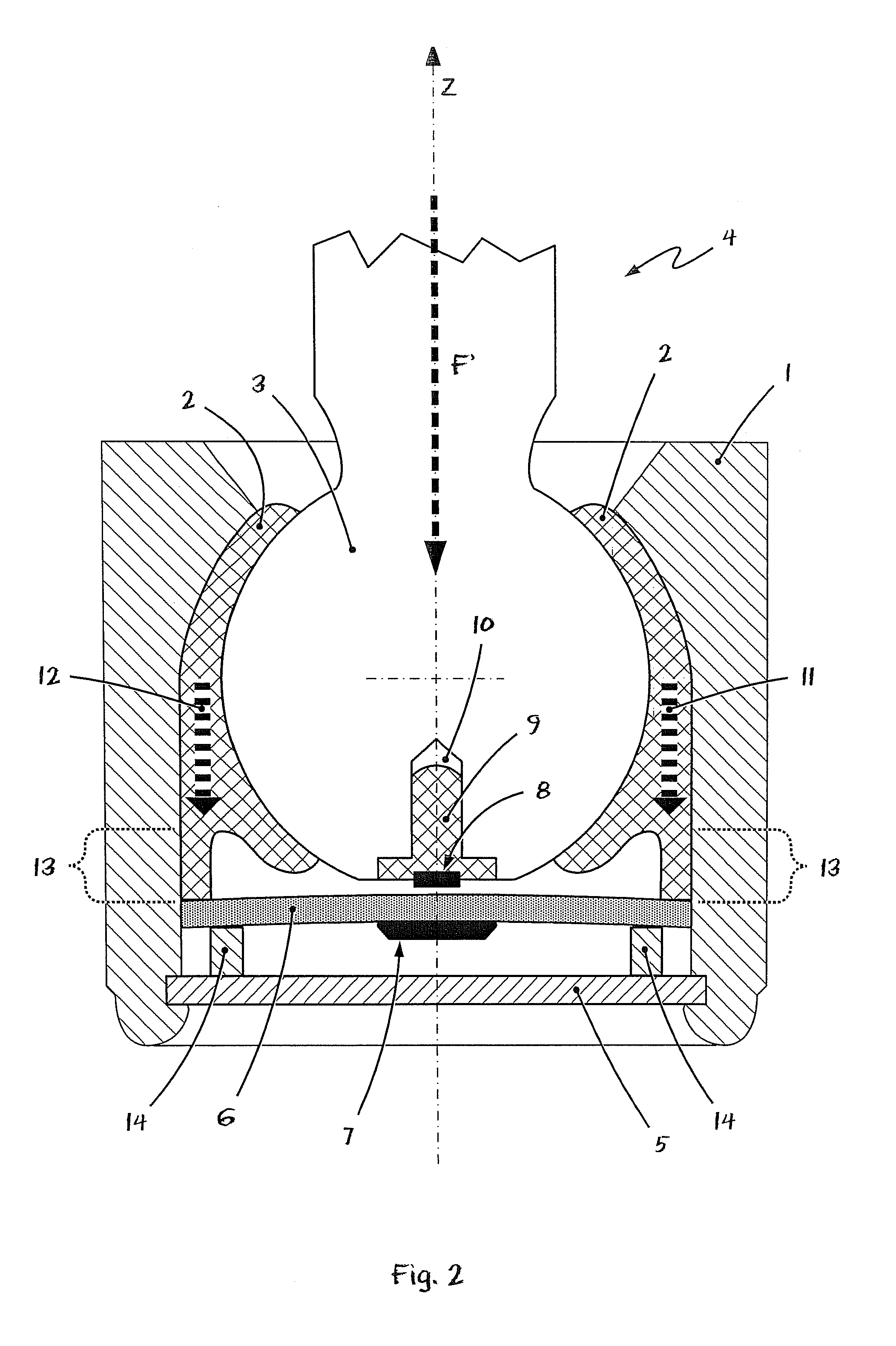

Ball-and-socket joint with sensor system and wear measurement method

The invention relates to a ball joint, eg for an axle system of a motor vehicle, and to a method for measuring wear on a ball joint. The ball and socket joint has an essentially annular or pot-shaped joint housing (1), in the essentially cylindrical interior of which a spherical bushing (2) is arranged. The ball (3) of the spherical journal (4) is slidably accommodated in the spherical bushing (2). Furthermore, the ball and socket joint has a sensor device ( 7 ) for force or load measurement. According to the invention, the ball and socket joint is distinguished in that the sensor device ( 7 ) is arranged on a flexurally elastic printed circuit board ( 6 ). The printed circuit board (6) is flexibly and movably fixed in the joint housing (1), wherein the sensor device (7) is configured to adjust the curvature or Mechanical stress is measured. In this case, the ball and socket joint includes a transmission element by means of which a force or a bending moment is introduced into the sensor printed circuit board (6) when the spherical bushing (2) deforms. The ball joint according to the invention can be produced very robustly and inexpensively and allows the measurement of forces or loads acting on the ball joint. The method according to the invention permits permanent determination of the state of wear of the ball joint by means of the measurement of the prestressing force of the spherical bushing.

Owner:ZF FRIEDRICHSHAFEN AG

Measurement device for friction force and wearing process of lubrication film on the condition of different slide-roll ratios

ActiveCN107402098APrecise designHigh resolutionApparatus for force/torque/work measurementInvestigating abrasion/wear resistanceCircular discMeasurement device

The invention belongs to the field for measuring a friction force and wearing of a higher pair contact lubrication film on the condition of different slide-roll ratios, and particularly relates to a measurement device for a friction force and a wearing process of a lubrication film on the condition of different slide-roll ratios. The main structure of the measurement device comprises a supporting platform, a disc driving device, a ball driven loading rotating device, a rotating device, a wearing measuring device, a translation device, a speed measuring device and a sensor fixing device. The rotating device is arranged below the ball driven loading rotating device and is used for supporting and driving the ball driven loading rotating device to rotate so that a steel ball on the ball driven loading rotating device rotates to a glass plate on the wearing measuring device, and then the steel ball is directly used for performing topography measurement on a wearing surface. The measurement device has advantages of ingenious integral design concept, reasonable layout between devices, multiple functions, high flexibility in switching, high convenience in use, effective measurement for the frictional force and the wearing process of an oil film, high practicability, environment-friendly application environment and wide market prosect.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

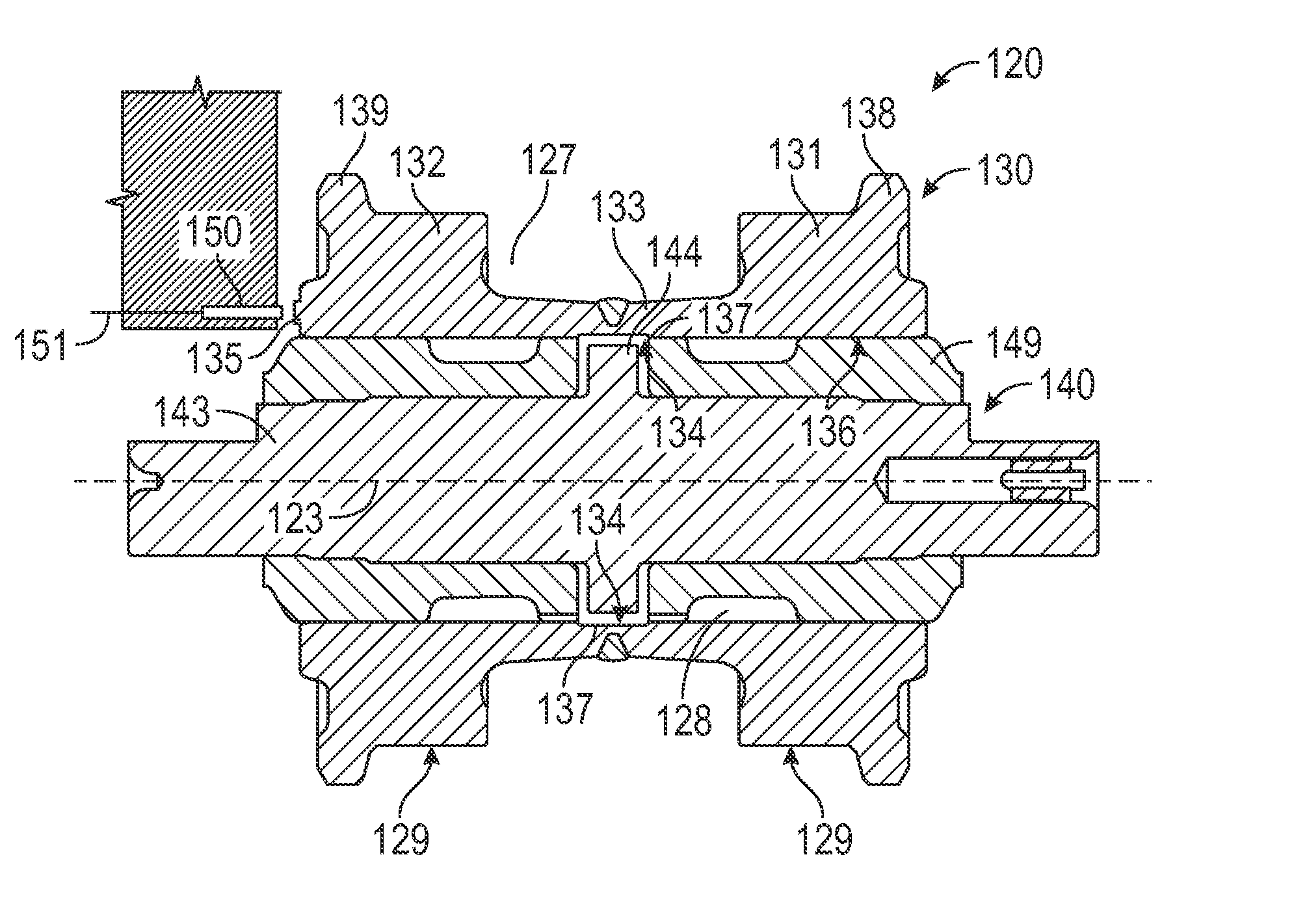

Ball and socket joint with sensor device and process for wear measurement

InactiveUS7762736B2Drawback of state can be overcomeLow costPlug gaugesBearing assemblyInterior spacePre stress

Owner:ZF FRIEDRICHSHAFEN AG

Portable tool wear measuring instrument and method for predicting remaining service life of tool through measuring instrument

InactiveCN105014481AAvoid secondary clamping errorsSimple structureMeasurement/indication equipmentsMeasuring instrumentMechanical engineering

The invention provides a portable tool wear measuring instrument and a method for predicting the remaining service life of a tool through the measuring instrument and relates to the technology of tool wear measurement. The problems that software / hardware systems of an existing tool wear measuring device is huge, installation and debugging are complex, the service life of a tool is mainly judged by human experience, and judgment is inaccurate are solved. An opening is formed in a shell and used for making the tool extend into the measuring instrument. Cameras and light source lamps are arranged on the periphery of the tool. The brand-new tool is used for cutting a workpiece multiple times according to specific cutting parameters till the tool face abrasion amount reaches the bluntness standard, and cutting time of each time and the tool face abrasion amount are recorded; and the cutting time of each time and the tool face abrasion amount are fitted into a curve through a data processing circuit, and the curve is a service life curve. The abrasion amount of the used tool is measured and compared with the service life curve, so that the service life of the tool is acquired. The portable tool wear measuring instrument is simple in structure, convenient to install and accurate in service life prediction.

Owner:HARBIN UNIV OF SCI & TECH

Ball and socket joint with sensor device and process for wear measurement

InactiveUS20090136288A1Drawback of state can be overcomeLow costPlug gaugesBearing assemblyInterior spaceEngineering

A ball and socket joint is provided for a motor vehicle that has a joint housing (1), in the interior space of which a ball shell (2) is arranged. The ball (3) of a ball pivot (4) is accommodated in the ball shell (2). A sensor device (7), for measuring forces and loads, is arranged on a flexurally elastic printed circuit board (6). The printed circuit board is fastened in the joint housing (1) in a flexurally mobile manner. The sensor device (7) measures deflections and mechanical stresses of the sensor printed circuit board (6). A transmission device introduces forces or a bending moments into the sensor printed circuit board (6) in case of a deformation of the ball shell (2). The process makes possible the permanent determination of the state of wear of the ball and socket joint via measurement of the prestressing force of the ball shell.

Owner:ZF FRIEDRICHSHAFEN AG

Electronic aircraft braking system with brake wear measurement, running clearance adjustment and plural electric motor-actuator ram assemblies

InactiveUS20050109565A1Easy maintenanceIncrease weightAxially engaging brakesBraking action transmissionEngineeringActuator

An electrically actuated aircraft brake system and method which provides for brake wear measurement, brake running clearance adjustment, ram position-based control and improved construction and operation. Brake wear and running clearance measurement are obtained by analyzing the output of position sensing circuitry. The position sensing circuitry, preferably including a LVDT position sensor, is also used to determine braking load, a brake controller including circuitry for effecting displacement of one or more reciprocating rams to load a brake disk stack by a predetermined amount based on a present displacement value of the position signal obtained from the position sensor. The position sensor preferably includes a LVDT transducer connected between the reciprocating ram and a brake housing, and the motive device preferably includes a servo motor. Also provided is an actuator housing including a guideway for each ram, the guideway and ram having the same polygonal cross-section, whereby the ram nut is guided and restrained from rotation by the guideway as it is translated by a ball screw in threaded engagement with the ram nut for selective movement into and out of forceful engagement with the brake disk stack for applying and releasing braking force on a rotatable wheel. An electric motor is drivingly connected to each ball screw by a first gear integral with the ball screw, a second gear in mesh with the first gear, and a pinion on a rotating drive shaft of the electric motor.

Owner:THE BF GOODRICH CO

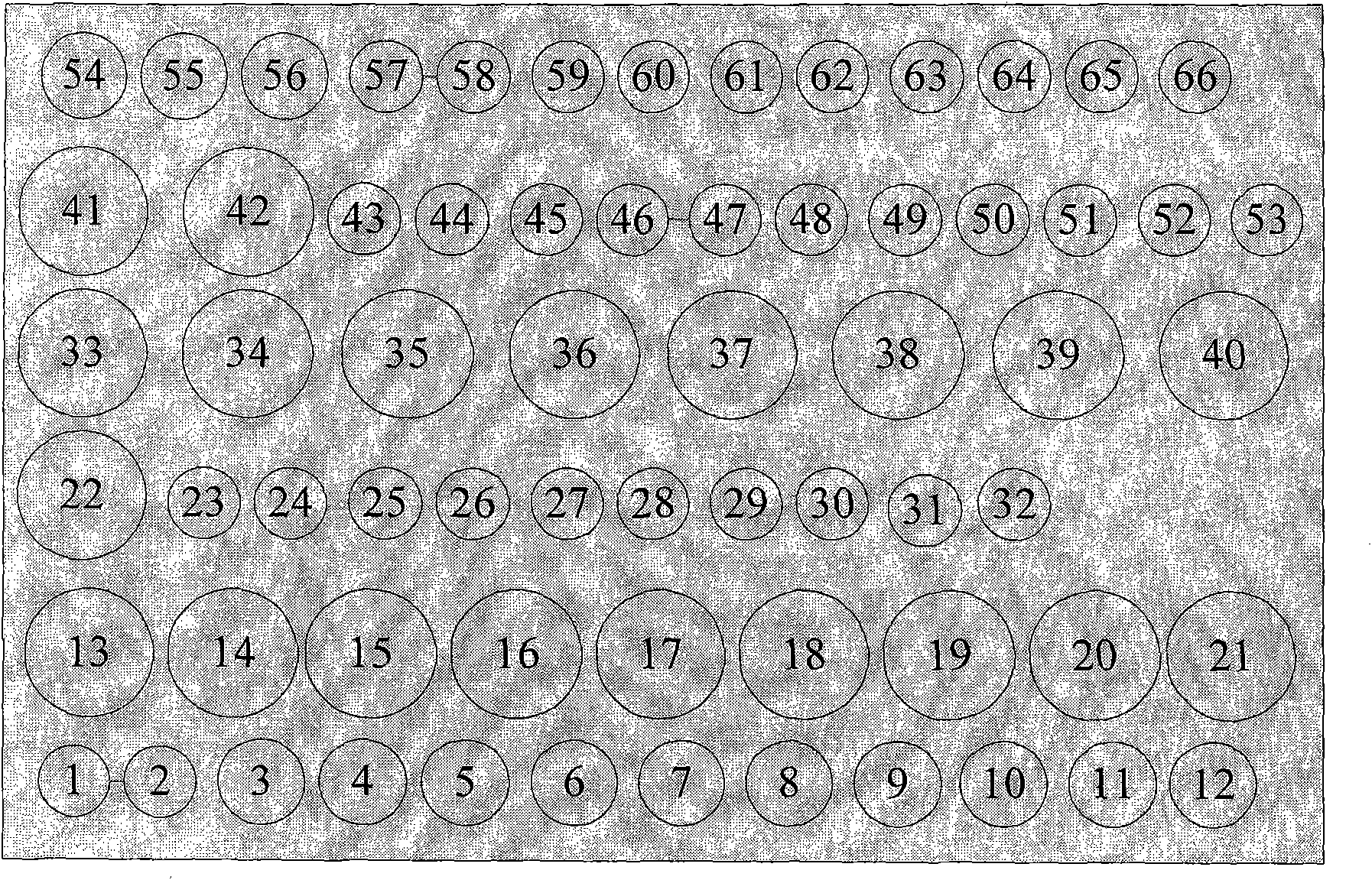

Device and method for measuring flank wear of ball end milling cutter

InactiveCN107627154AShorten the timeHigh sensitivityMeasurement/indication equipmentsTablet computerManufacturing technology

The invention relates to a device and method for measuring flank wear of a ball end milling cutter. With the progress of the machine manufacturing technology, in the milling process, the requirementsfor the machining precision of workpieces are higher increasingly. At the same time, due to the special double helix structure of the ball end milling cutter, it is necessary to study flank wear of the milling cutter so as to improve the surface machining quality. The device for measuring flank wear of the ball end milling cutter comprises two parts of hardware and software, wherein the hardware comprises a machining device (1), a double-reflection device (2) and a tablet computer (3), wherein the machining device comprises a machine frame (4). The machine frame is connected with a main shaft(5), and the main shaft is connected with a milling cutter (6), and the double-reflection device comprises a three-coordinate measuring instrument (7) and a double-reflection plate (8). The three-coordinate measuring instrument is connected with the tablet computer, and three-coordinate measuring software, tool wear measurement software and a windows system are installed on the tablet computer. The device and method are used for accurate measurement of flank wear when the milling cutter conducts milling.

Owner:HARBIN UNIV OF SCI & TECH

Compositions containing polyphenylene ether and/or polystyrene having improved tribological properties and methods for improving tribological properties of polyphenylene ether and/or polystyrene compo

Internally lubricated polymer compositions containing a styrene- and / or polyphenylene ether-containing polymer, an olefin-containing polymer, and a compatibilizer are provided. The olefin-containing polymer, which is present in the compositions in about 3 to about 30 weight percent, provides internal lubrication and improves the tribological properties of the compositions compared with the styreneor polyphenylene ether-containing polymer alone, as determined by wear measurements. Preferred compositions exhibit wear factors less than about 130 x 10<-11 >mm<5> / Pa-m. A preferred composition includes a blend of polystyrene / polyphenylene ether, linear low density polyethylene, and styreneethylene-butadiene-styrene. Methods are also provided for improving tribological properties of styrene- and / or polyphenylene ether-containing base polymers by incorporating into the base polymers at least one olefin-containing polymer and at least one compatibilizer, or by incorporating at least one substantially halogen-free internal lubricant.

Owner:SHPP GLOBAL TECH BV

Shield / TBM hob wear measuring device and measuring method thereof

ActiveCN107300369AImprove construction efficiencyEasy to analyzeMeasurement devicesHigh level techniquesMeasurement deviceHobbing

The invention discloses a shield / TBM hob wear measuring device and a measuring method thereof. The measuring device comprises a frame body, a fastening assembly and a mobile measurement assembly. The frame body comprises a crossbeam, a fixed strut and an adjustable strut respectively arranged at two ends of the crossbeam and vertically connected with the crossbeam. The fastening assembly comprises a movable leg movably connected with the adjustable strut and a fastening bolt arranged at the lower end of the movable leg. The mobile measurement assembly includes a measuring head, a horizontal guide rail for moving the measuring head, and a vertical guide rail. The fixed end of the horizontal guide rail and the upper end of the vertical guide rail are provided with a displacement sensor respectively. The measuring device of the invention has the advantages of convenient use, high measuring precision and high efficiency, avoids the reading error of the staff compared with the measuring ruler, and can acquire the horizontal and vertical position information of the abrading and further obtain the comprehensive cross section information of the hobbing ring after wear. Through the data post-processing, it is be achieved hob two-dimensional cross-section image reproduction after wear, in order to accurately determine the hob wear category.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

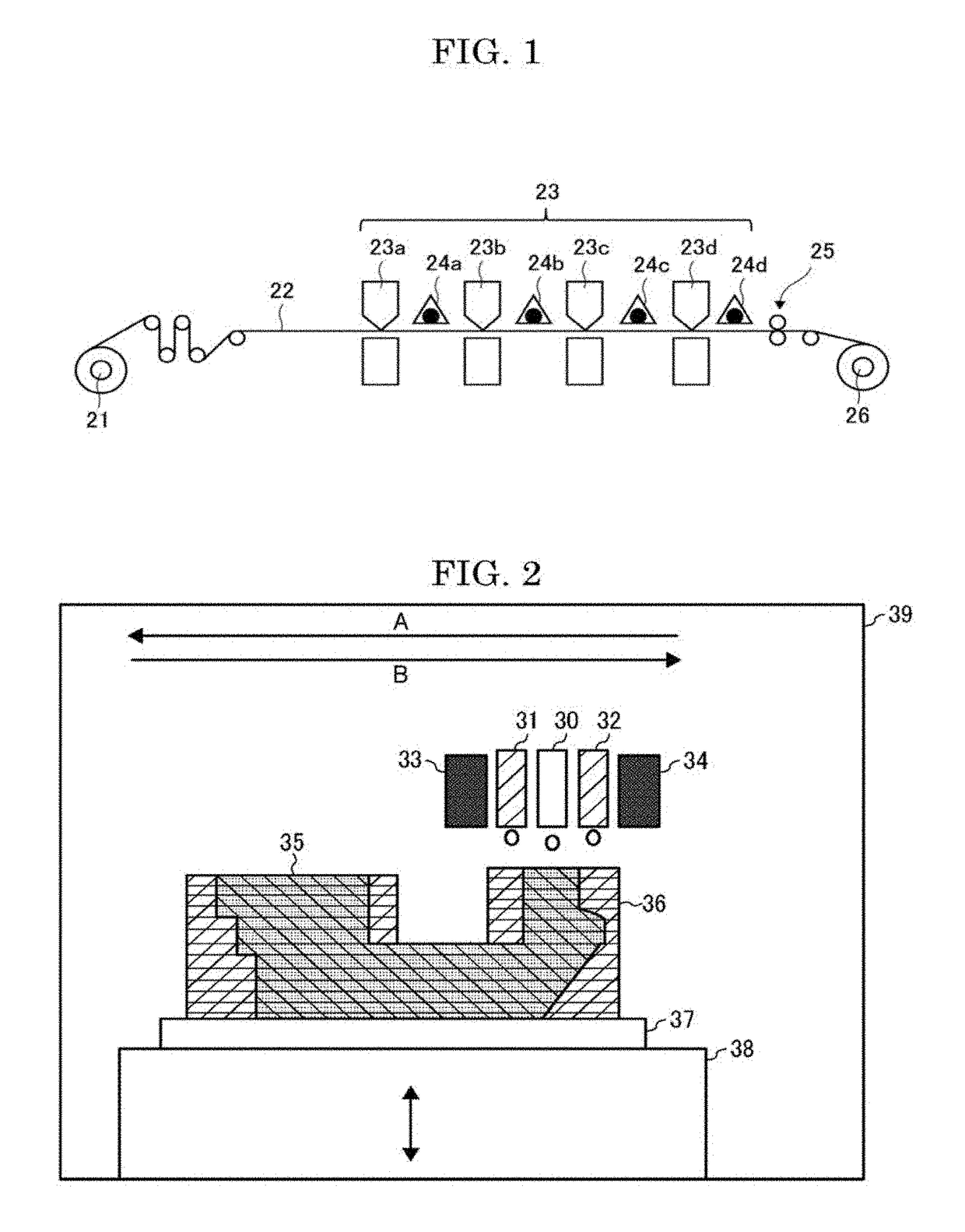

Active-energy-ray-curable composition, active-energy-ray-curable ink, two-dimensional or three-dimensional image forming method, two-dimensional or three-dimensional image forming apparatus, and cured material

An active-energy-ray-curable composition, a cured material of the active-energy-ray-curable composition satisfying a critical load of 5.0 g or more but 25.0 g or less, the critical load being obtained by a continuous loading test method using a variable normal load friction and wear measurement device, the cured material having an average thickness of 10 μm and being formed by coating the active-energy-ray-curable composition on a substrate and by irradiating and curing the active-energy-ray-curable composition with active energy rays having illuminance of 1.5 W / cm2 and an amount of irradiation of 200 mJ / cm2.

Owner:RICOH KK

Steel rail wear measurement method and device

The embodiments of the present invention provide a steel rail wear measurement method and device. The method includes the following steps that: a line scanning three-dimensional measuring sensor is adopted to continuously measure a steel rail, so that measurement data can be obtained; the measurement railhead contour, measurement rail web contour and measurement rail base contour of the steel railare obtained according to the measurement data; the measurement matching contours are matched with standard matching contours, so that the deviation parameters of the measurement matching contours and the standard matching contours are obtained; and coordinate transformation is performed on the measurement rail head contour according to the deviation parameters, the measurement rail head contourwhich has been subjected to the coordinate transformation is compared with a standard rail head contour, and the wear measurement value of the steel rail is calculated based on a comparison result. According to the steel rail wear measurement method and device provided by the embodiments of the present invention, the line scanning three-dimensional measuring sensor can quickly obtain the high-precision steel rail contours, that is, the measurement points of the steel rail contours in a cross-sectional direction and a measurement moving direction are relatively dense, and therefore, the influence of steel rail surface undulating texture on measurement results can be decreased; and the accuracy of the measurement results can be improved.

Owner:WUHAN WUDA ZOYON SCI & TECH

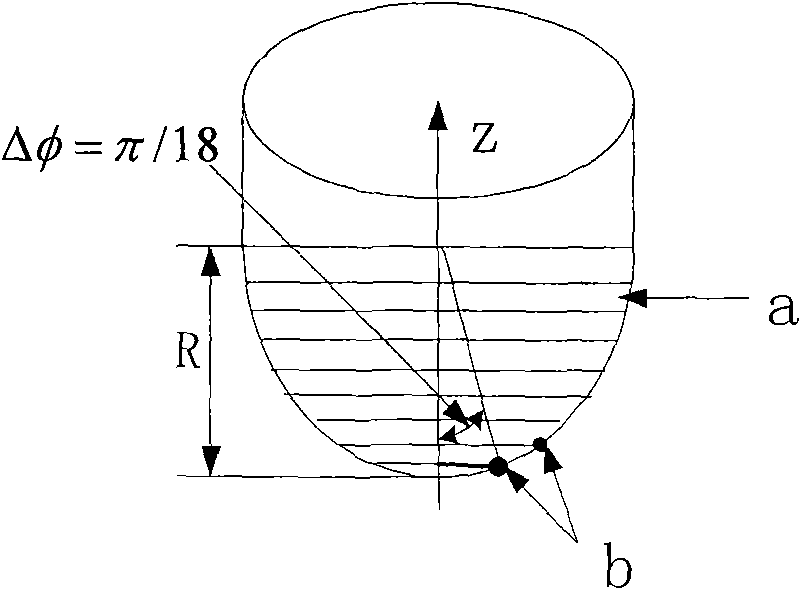

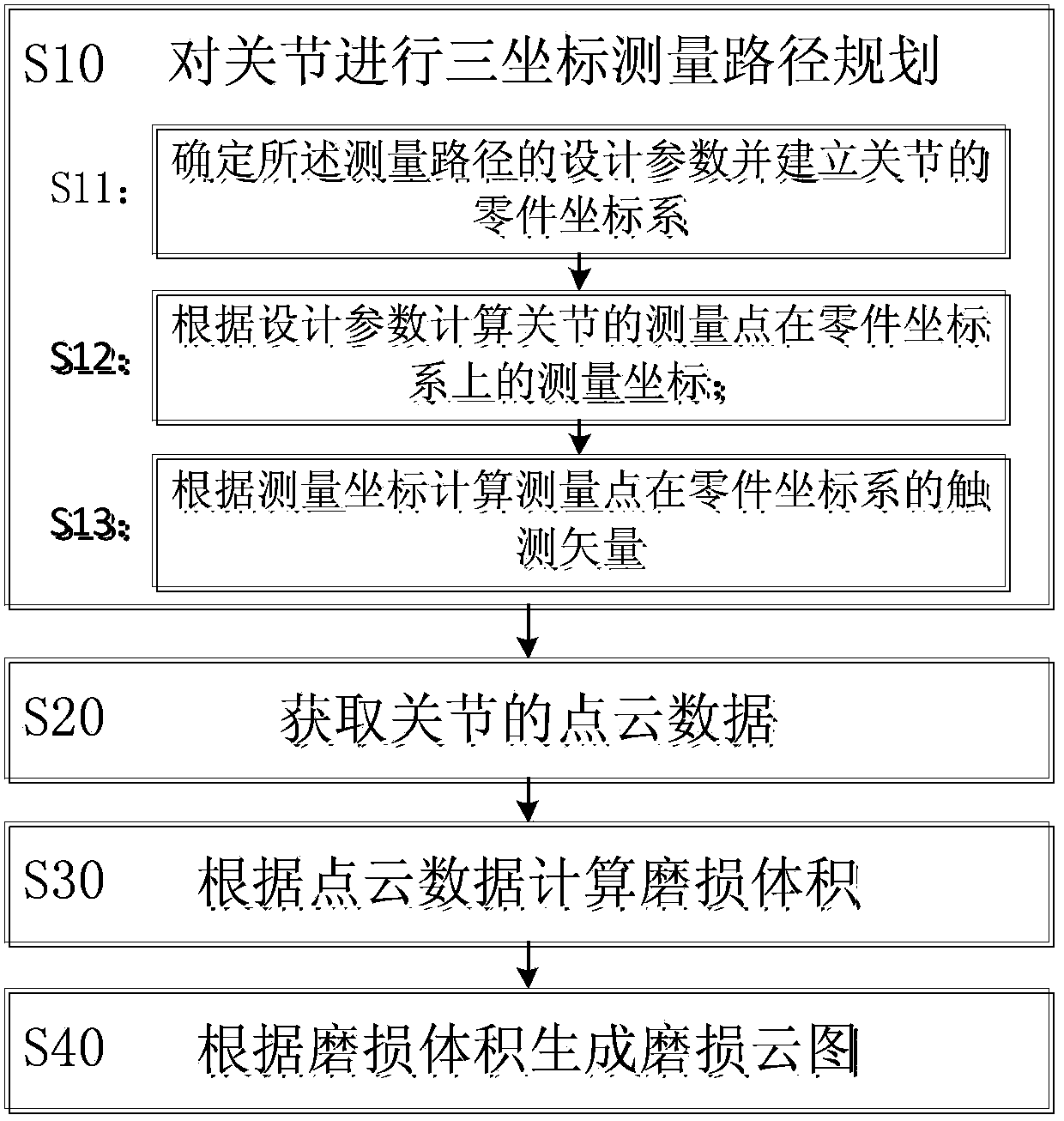

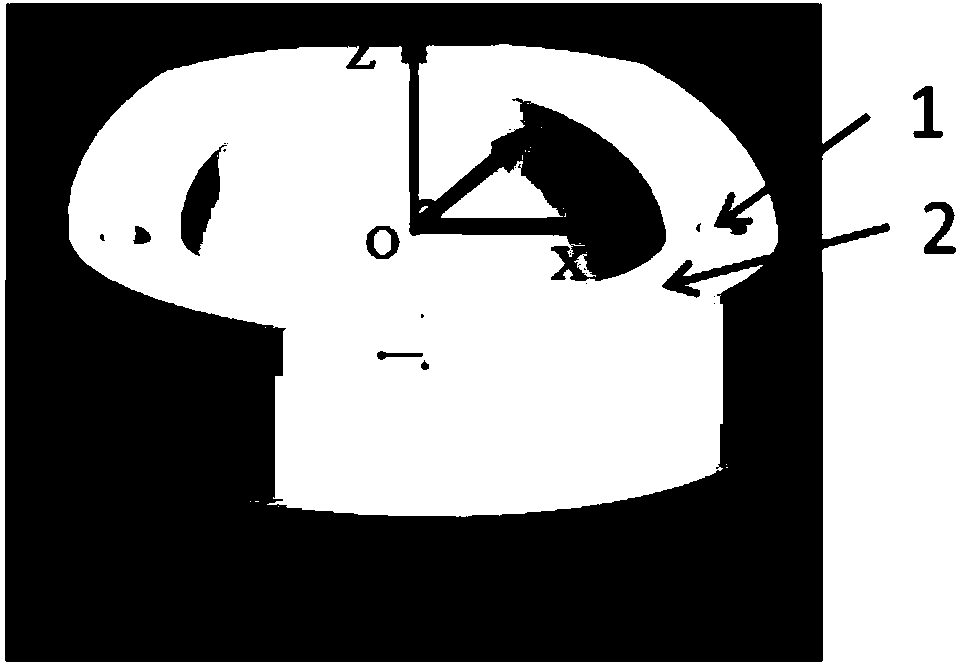

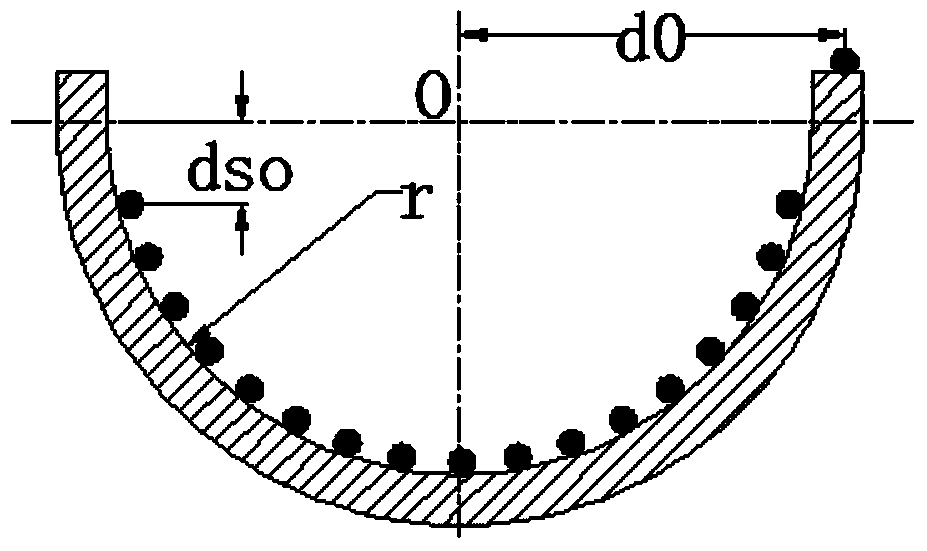

Artificial joint wear evaluation method and artificial joint wear evaluation system

The invention discloses an artificial joint wear evaluation method and an artificial joint wear evaluation system. The method includes: performing three-coordinate measuring path planning on a joint, then acquiring point cloud data of the joint, and calculating wear volume according to the point cloud data; generating a wear cloud map according to the wear volume. The artificial joint wear evaluation system comprises a measuring path planning module, a point cloud data generation module, a wear calculation module and a cloud map generation module. The three-coordinate measuring path planning is performed before cloud data acquisition, measuring path design and touch measuring vector control are performed before measurement, and precision of measured point cloud data can be controlled, so that accuracy of joint wear evaluation is improved; the problem that measuring point cloud precision is uncontrollable in the prior art is solved, and the problems of repetitive installation error and boundary measurement inaccuracy of samples in the process of joint wear measurement are solved as well.

Owner:XI AN JIAOTONG UNIV

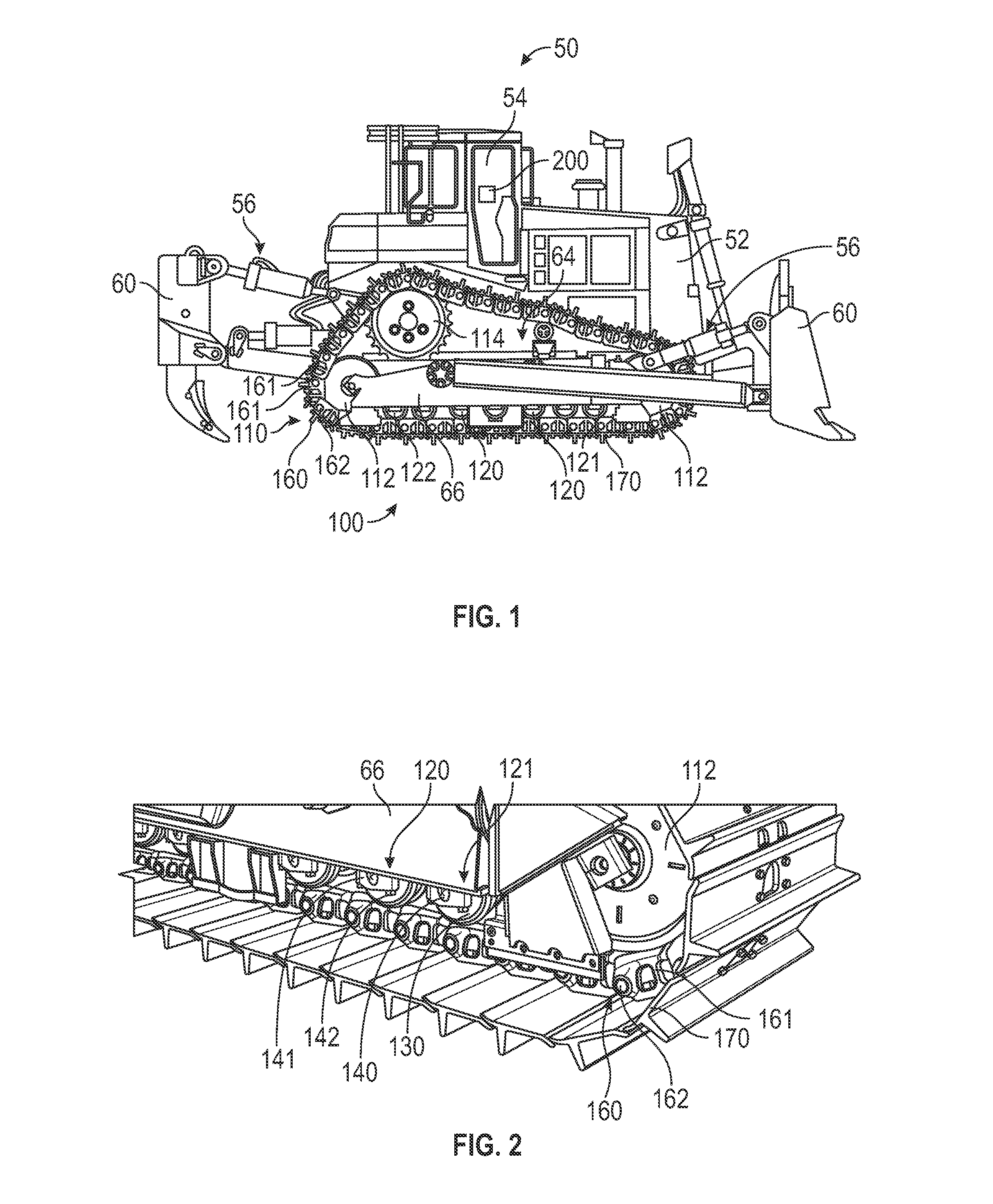

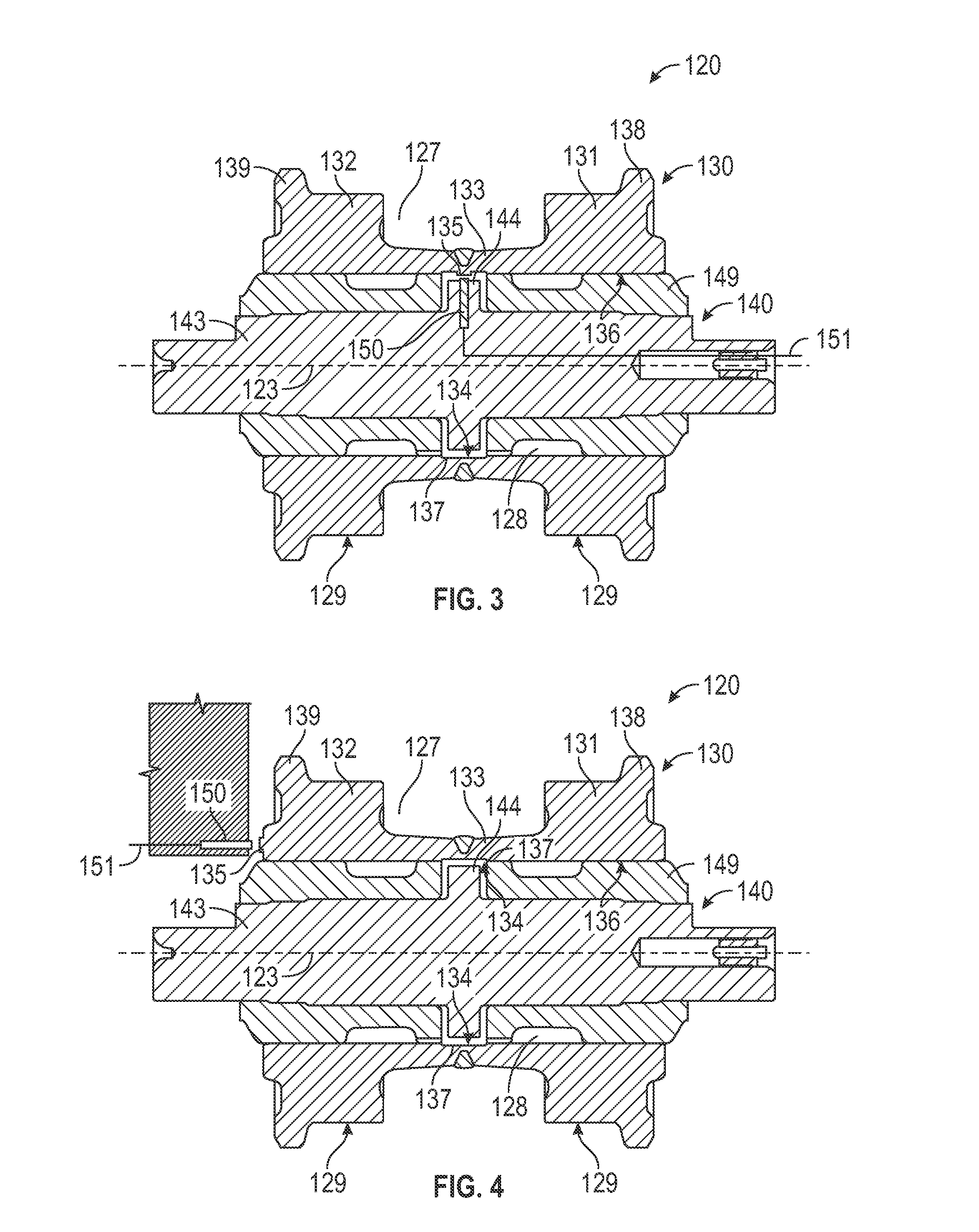

Track roller assembly with a wear measurement system

ActiveUS20160121945A1Vehicle testingRegistering/indicating working of vehiclesEngineeringWear measurement

A roller of an undercarriage track system for a machine is disclosed. The roller includes a body and a sensed feature. The body is a solid of revolution formed about a roller axis. The body includes a bore surface and a roller contact surface. The bore surface defines a bore extending through the body. The bore surface is a radially inner surface of the body. The roller contact surface is located outward from the bore surface. The sensed feature is located at the body. The sensed feature is configured to rotate with the body and to be detectable by a sensor.

Owner:CATERPILLAR INC

Sensor for wear measurement, method of making, and method of operating same

ActiveUS20140103942A1High peel strengthResistance/reactance/impedenceSliding contact bearingsAdhesiveEngineering

A wear sensor comprising:an insulating substrate having a top surface and a bottom surface;a conductive electrode formed on said top surface of said insulating substrate;an insulating wear lining material having a first side secured to said top surface of said insulating substrate and conductive electrode, an opposite second side that will be worn down by relative motion between the wear sensor and a moving component;one or more contact points where the electrical properties between the electrode and the moving component can be measured; andone or more perforations through the thickness of the substrate and electrode, through which an adhesive may flow, thereby increasing the peel strength between the wear sensor and race or between the wear sensor and the wear liner.

Owner:NEW HAMPSHIRE BALL BEARINGS

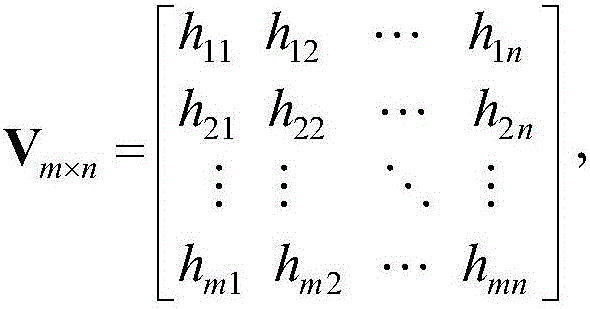

Cutting-tool wear evaluation and prediction method and system based on generalized wear extent

ActiveCN105893760AOptimizing the Wear Measurement Study ProcessGuide designInformaticsComplex mathematical operationsComputer scienceResearch process

The invention discloses a cutting-tool wear evaluation and prediction method and system based on generalized wear extent. The method and the system can be used for supplementing shortages of the existing one-dimensional and two-dimensional measurement and evaluation methods and are beneficial to the optimization of a cutting-tool wear measurement and research process and the deep understanding of a cutting-tool wear pattern and an evolutionary process thereof, and thereby better instructing the design and use of cutting tools. The method comprises the following steps: (S1) acquiring wear state data of sampling points of a cutting tool in different sampling time periods, fitting the wear state data so as to obtain a state function of the sampling points of the cutting tool, and determining the generalized wear extent according to the state function; (S2) calculating cutting-tool wear evaluating indicators and a generalized wear rate based on the generalized wear extent; (S3) evaluating cutting-tool wear conditions according to the cutting-tool wear evaluating indicators, and predicting the cutting-tool wear conditions according to the generalized wear rate.

Owner:ZHENGZHOU DIAMOND PRECISION MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com