Portable tool wear measuring instrument and method for predicting remaining service life of tool through measuring instrument

A tool wear and measuring instrument technology, applied in the direction of measuring/indicating equipment, manufacturing tools, metal processing machinery parts, etc., can solve problems such as troublesome installation and debugging, inaccurate judgment, huge software/hardware system, etc., to reduce tool waste, The effect of accurate prediction results and saving clamping time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

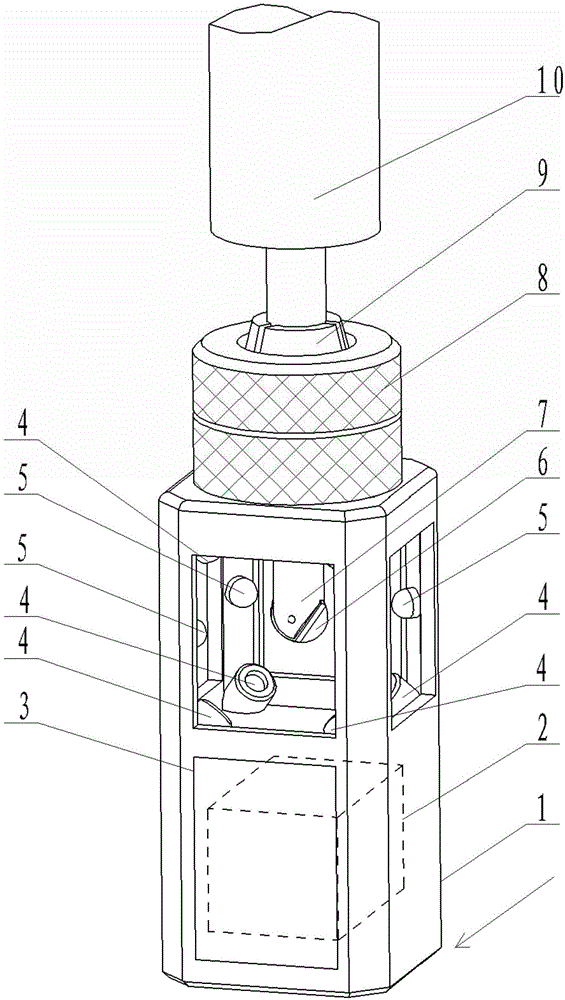

[0029] Specific implementation mode one: combine Figure 1 to Figure 6 Describe this embodiment. The portable tool wear measuring instrument described in this embodiment includes a housing 1, a data processing circuit 2, a display screen 3, one or more cameras 4, one or more light source lamps 5 and a battery 10;

[0030] The top of the housing 1 is provided with an opening, and the opening is used to insert the tool 6 installed on the machine tool into the portable tool wear measuring instrument. A camera 4 and a light source lamp 5 are arranged around the tool 6, and a data processing circuit 2 and the battery 10 are both arranged inside the casing 1, and the display screen 3 is arranged on the outer surface of the casing 1;

[0031] The battery 10 is used to provide working power for the portable tool wear measuring instrument;

[0032] The signal output end of the camera 4 is connected to the image signal input end of the data processing circuit 2 , and the data output en...

specific Embodiment approach 2

[0035] Specific implementation mode two: combination Figure 1 to Figure 3 ,as well as Figure 6 Describe this embodiment. This embodiment is a further limitation of the portable tool wear measuring instrument described in Embodiment 1. In this embodiment, the measuring instrument also includes a locking ring 8 and a tool holder 9. The locking ring 8 It is located outside the top opening of the housing 1, and one end of the locking ring 8 is fixed on the top of the housing 1, and the other end can rotate around the axis of the locking ring 8, and the tool bar clamp 9 is arranged in the central hole of the locking ring 8, The center of the tool bar clamp 9 is also provided with a hole, which is used to place the tool bar 7. When the locking ring 8 rotates, the diameter of the tool bar clamp 9 can be changed.

[0036] like figure 1 As shown, both the locking ring 8 and the tool bar clamp 9 are conventional structures, and the tool bar clamp 9 is divided into the same several p...

specific Embodiment approach 3

[0037] Specific implementation mode three: combination Figure 1 to Figure 3 This embodiment will be described. This embodiment is a further limitation of the portable tool wear measuring instrument described in Embodiment 1. In this embodiment, a window is opened on the side of the casing 1 .

[0038] The window on the side of the housing 1 can be used to observe whether the measuring instrument is installed correctly, and can observe the measurement process in real time. And because the window is opened, external light can enter the casing 1, so the brightness or quantity of the light source lamp 5 can be appropriately reduced, thereby reducing the energy consumption of the measuring instrument.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com